Activating agent for heat-stewing steel slag powder of converter as well as preparation method and application thereof

A technology of activator and steel slag powder, which is applied in the field of chemical additives, can solve the problems that the hydration activity of converter hot-simmered steel slag powder cannot be significantly improved, and the application effect is not obvious, so as to achieve significant social and economic benefits, accelerate steel slag hydration, and early The effect of increased activity in the later period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

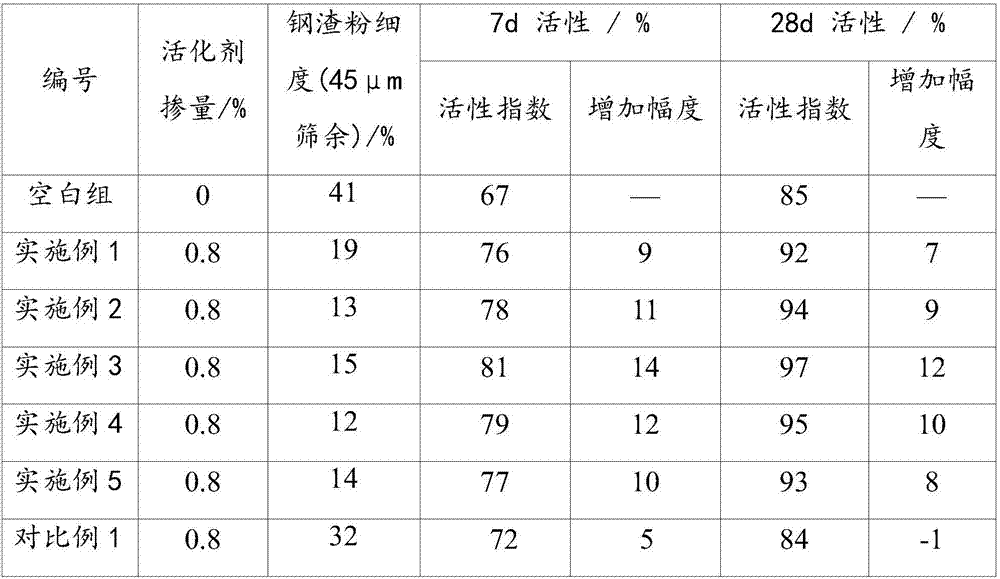

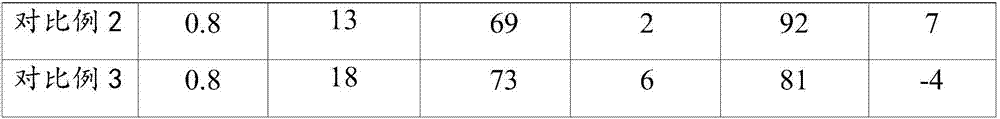

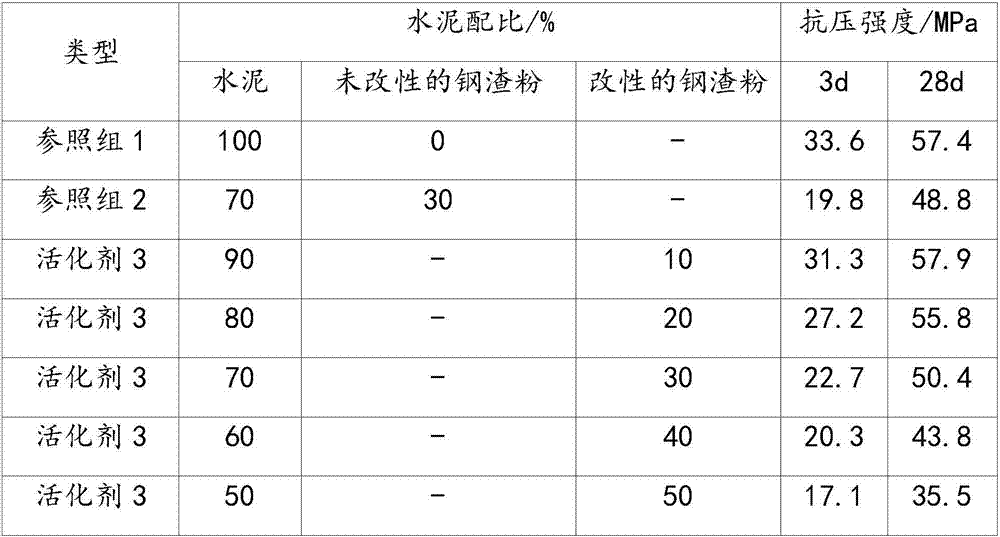

Examples

Embodiment 1

[0051] First, take 20 parts of alkali slag dry powder, 30 parts of low-alkalinity sulfoaluminate cement, 40 parts of blast furnace water-quenched slag fine powder, 10 parts of calcium formate and 0.5 part of polyvinyl ammonium phosphate to make powder, and then 0.5 part of monoethanol diisopropanolamine and 0.01 part of polydimethylsiloxane are evenly sprayed or dropped on the above powder, and mixed uniformly to prepare converter hot-steamed steel slag powder activator 1.

Embodiment 2

[0053]First, take 50 parts of alkali slag dry powder, 35 parts of low-alkalinity sulfoaluminate cement, 10 parts of blast furnace water-quenched slag micropowder, 5 parts of calcium formate and 0.8 part of polyvinyl ammonium phosphate to make powder, and then Spray or drop 2 parts of monoethanol diisopropanolamine and 0.02 parts of polydimethylsiloxane evenly on the above-mentioned powder, and finally mix them uniformly to prepare converter hot-steamed steel slag powder activator 2.

Embodiment 3

[0055] First, take 40 parts of alkali slag dry powder, 20 parts of low-alkalinity sulfoaluminate cement, 35 parts of blast furnace water-quenched slag micropowder, 5 parts of calcium formate and 0.5 part of polyvinyl ammonium phosphate to make powder, and then 1 part of monoethanol diisopropanolamine and 0.02 part of polydimethylsiloxane were evenly sprayed or dropped on the above powder, and finally mixed evenly to prepare converter hot-steamed steel slag powder activator 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com