Patents

Literature

2271results about "Pigment physical treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Use of nanoparticulate organic pigments in paints and coatings

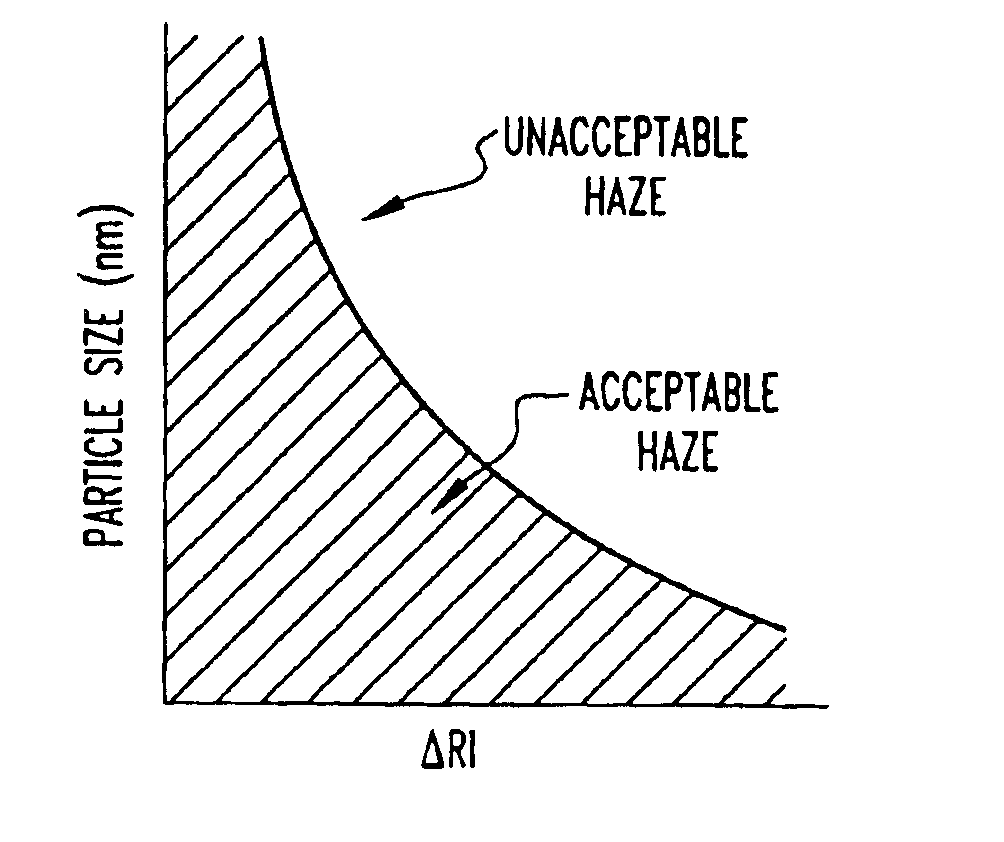

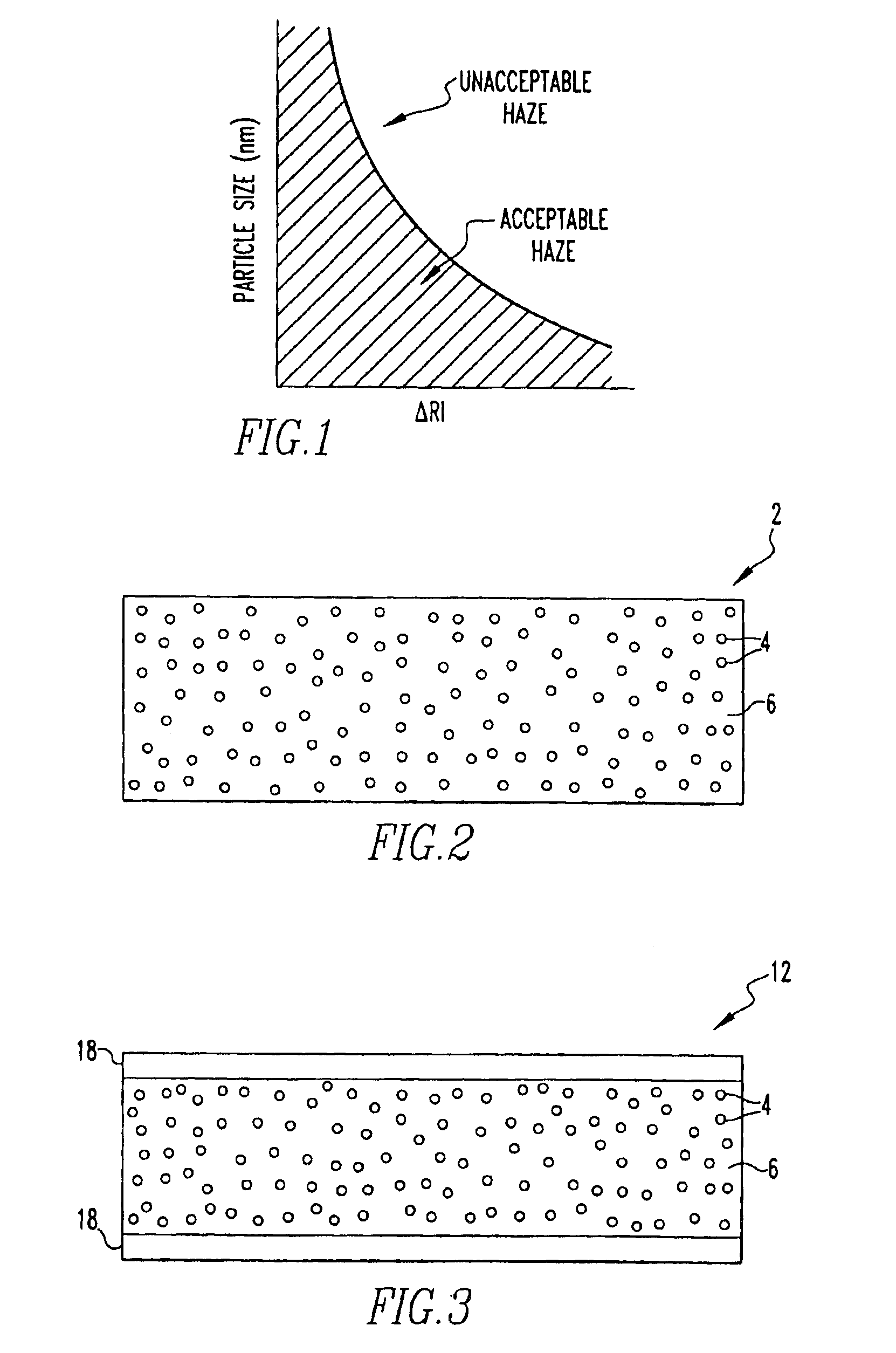

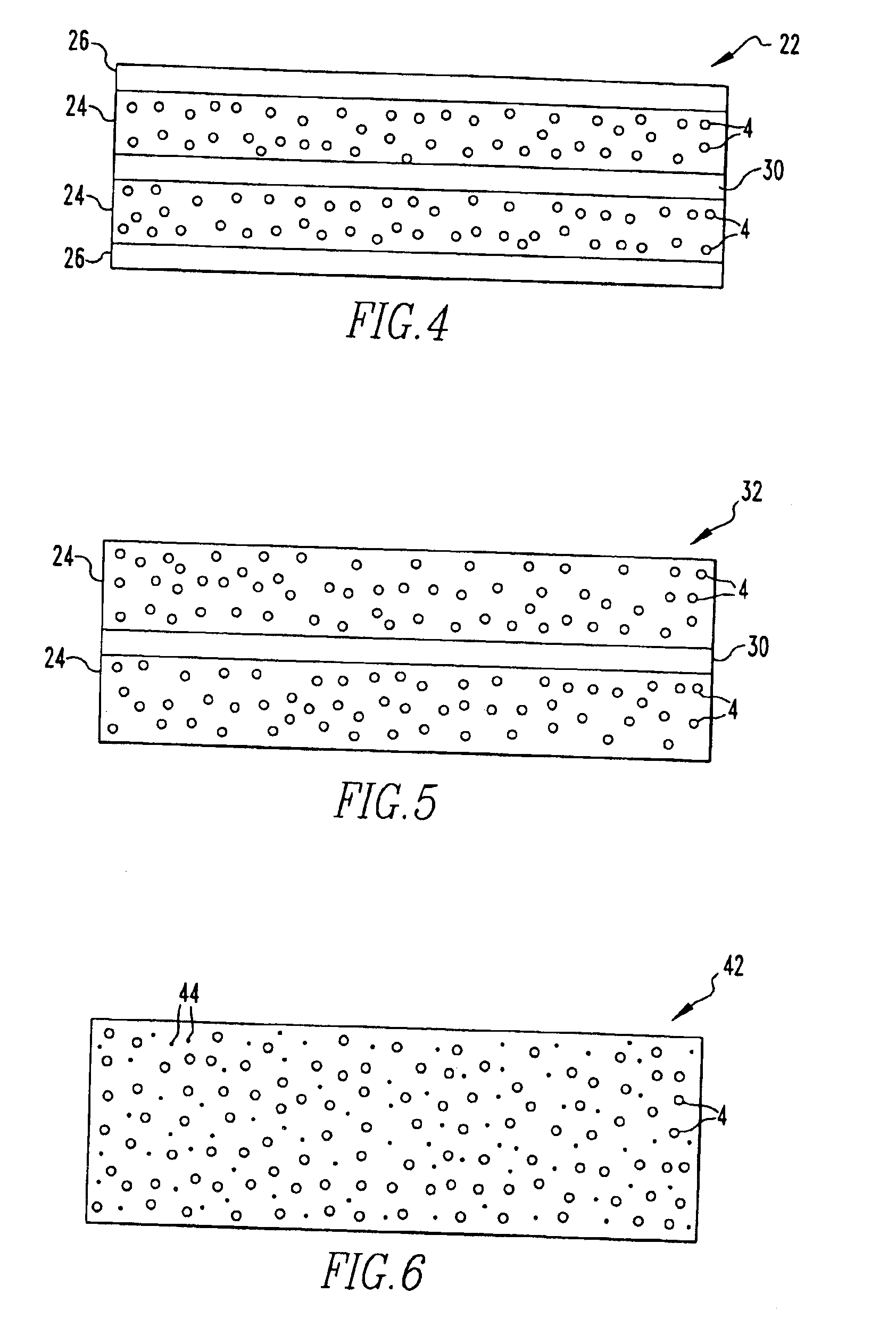

A protective and decorative coating composition including about 2 to 10 different colorants which in combination with a resinous composition produce a desired visible coating. A majority of the colorants has a maximum haze of about 10% and exhibits an absorbance peak in the visible spectrum wherein at least about 50% of the total absorbance in the visible spectrum occurs at wavelengths within about 50 nm of the wavelength of the peak absorbance.

Owner:PPG IND OHIO INC

Aluminum phosphate or polyphosphate particles for use as pigments in paints and method of making same

InactiveUS20060045831A1PhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAluminium sulfateOrganic acid

An aluminum phosphate or polyphosphate-based pigment product is made by a process comprising contacting phosphoric acid with aluminum sulfate and an alkaline solution to produce an aluminum phosphate based product; and optionally calcining the aluminum phosphate based product at an elevated temperature, wherein the process is substantially free of an organic acid. The aluminum phosphate or polyphosphate-based pigment is amorphous. The amorphous aluminum phosphate or polyphosphate characterized by a bulk density of less than 2.30 grams per cubic centimeter and a phosphorus to aluminum mole ratio of greater than 0.8. The composition is useful in paints and as a substitute for titanium dioxide.

Owner:BUNGE AMORPHIC SOLUTIONS +1

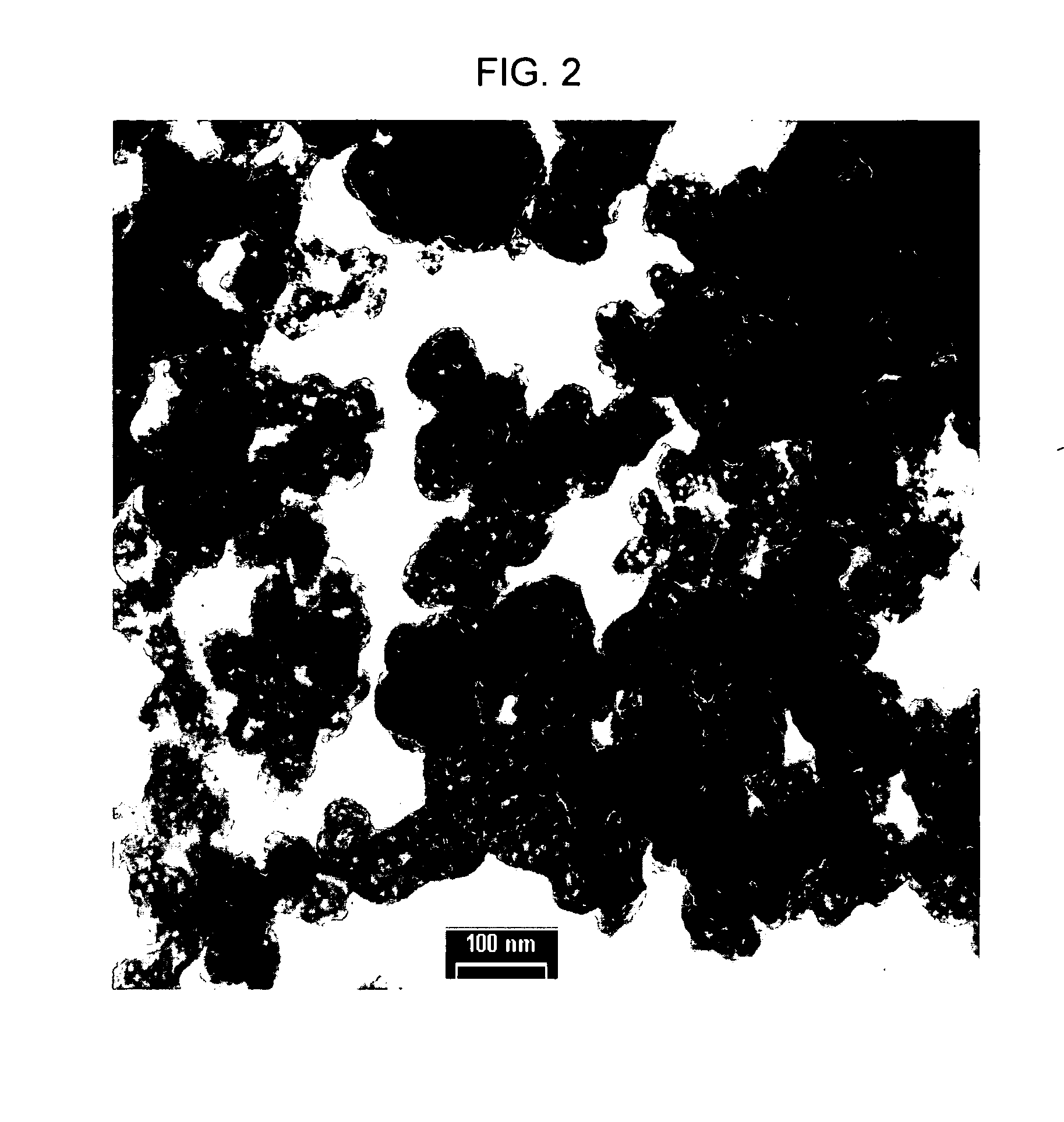

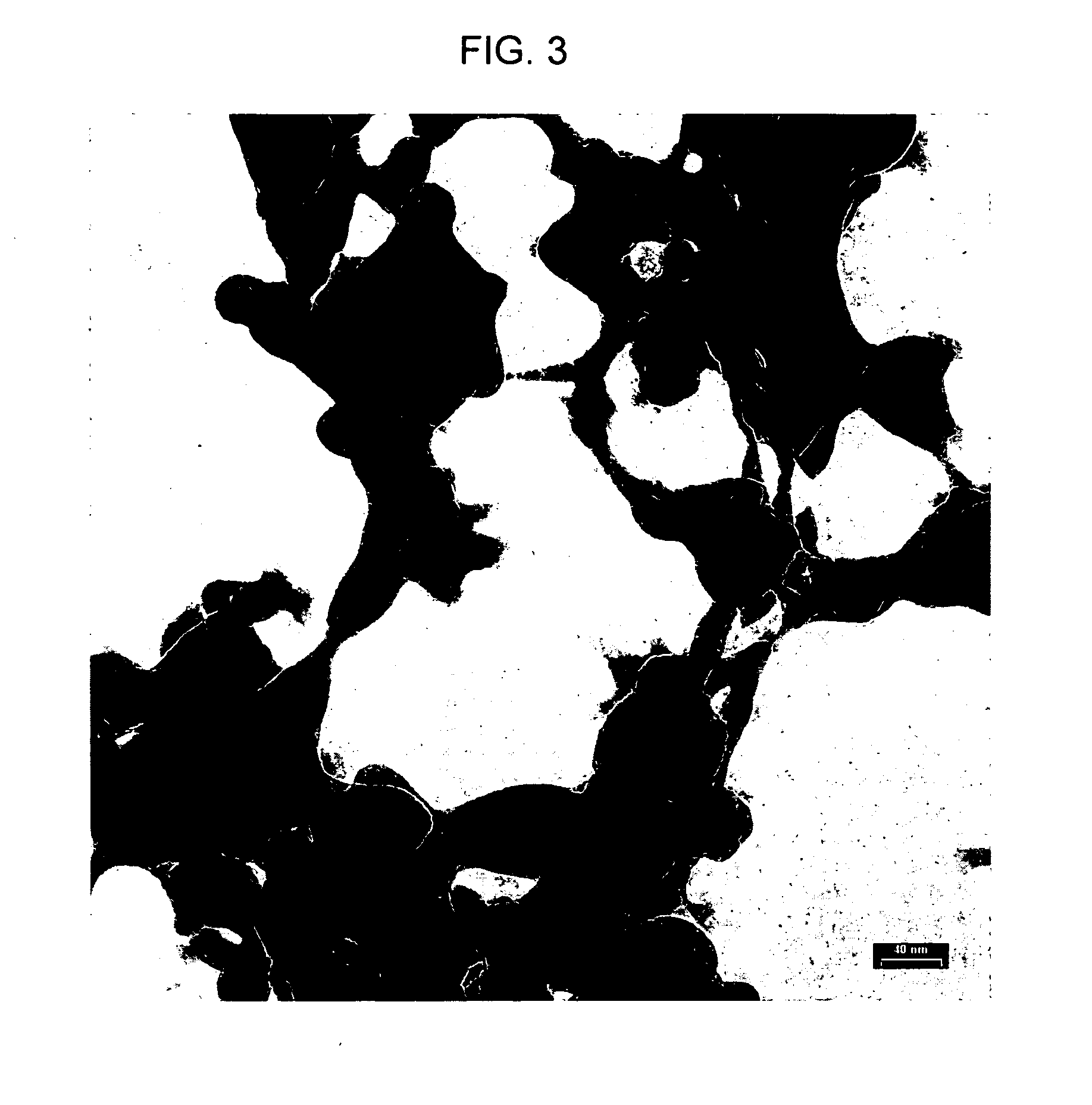

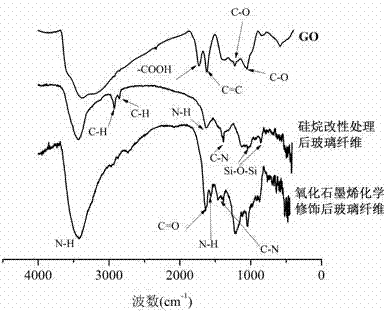

Method for chemically modifying inorganic filler with graphene oxide, product and application

InactiveCN103788413AImprove adhesionHigh mechanical strengthPigment treatment with organosilicon compoundsPigment physical treatmentEpoxySilanes

The invention discloses a method for chemically modifying inorganic filler with graphene oxide and a product. The method comprises the following steps: performing surface hydroxylation treatment and silane coupling agent treatment on the inorganic filler; maintaining the pH of a graphene oxide solution at 5.8-6.0 with an MES buffer solution; sequentially adding EDC and NHS, and performing ultrasonic treatment for 1-3 hours; adding the treated inorganic filler, and performing an amidation reaction at room temperature; and after the reaction, filtering, washing and drying to obtain the graphene oxide modified inorganic filler. The invention also discloses a method for preparing an inorganic filler / epoxy resin composite by use of the product. The process flow of the method disclosed by the invention is simple and environmentally friendly; the GO is connected to the surface of the inorganic filler by a chemical modification process, and the firm covalent bond combination between the GO and inorganic particles is generated, so that the interface adhesiveness and mechanical strength between the inorganic filler and the polymer are enhanced, and a new idea is provided to the modification of an inorganic filler surface and the preparation of a high-performance composite.

Owner:UNIV OF JINAN

Aqueous dispersion, a process for the preparation and the use thereof

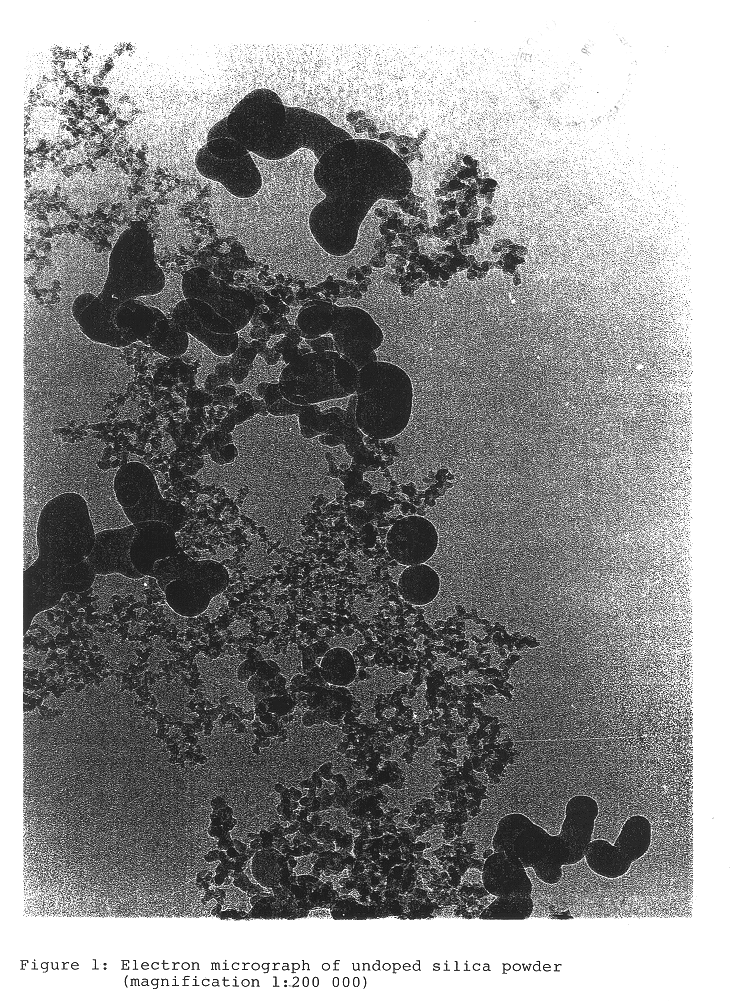

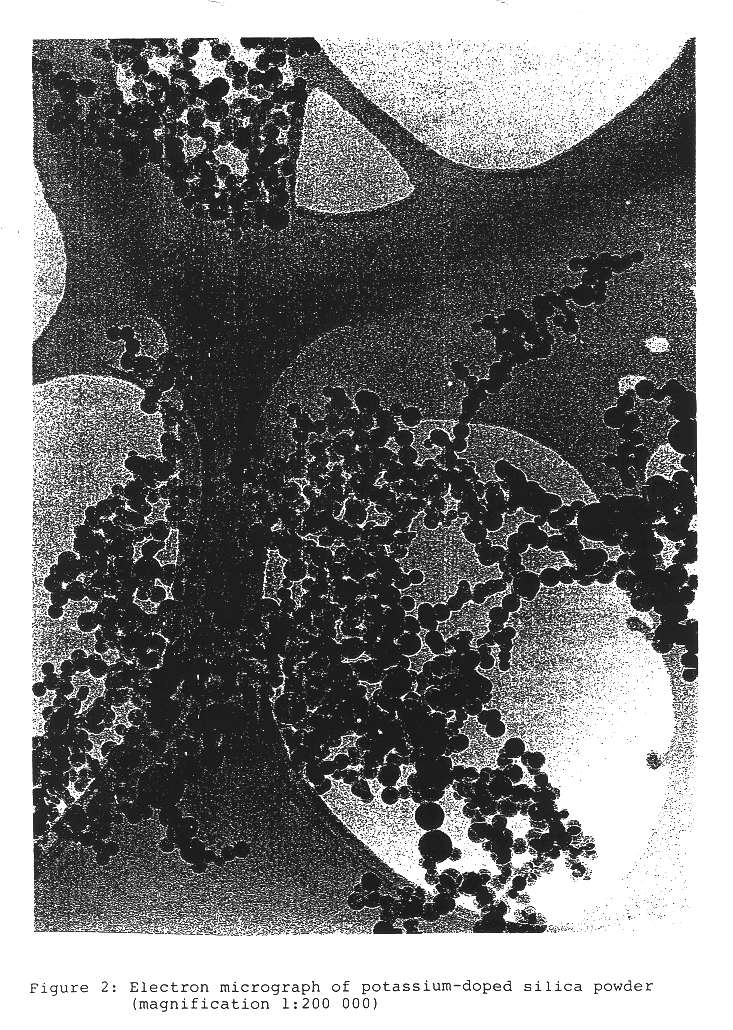

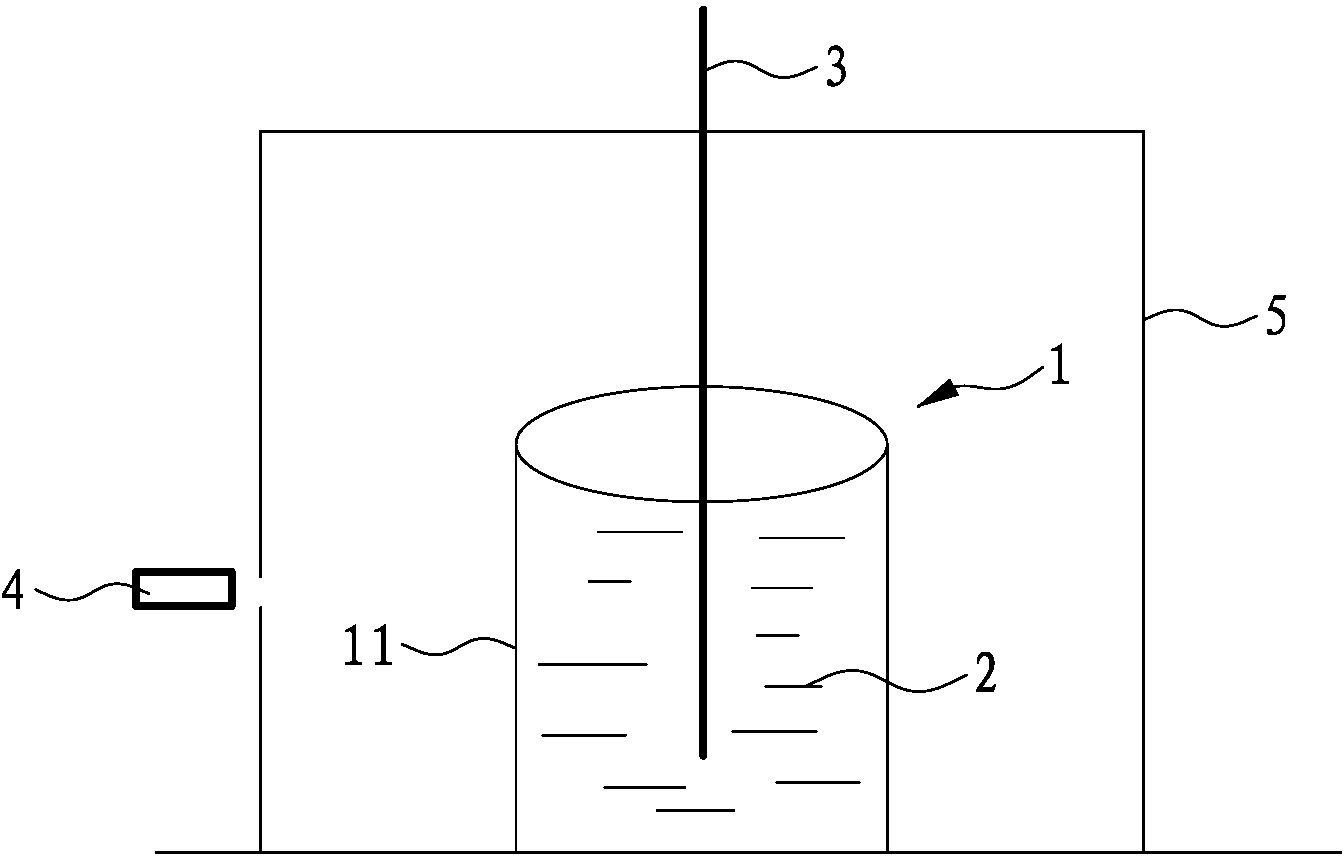

InactiveUS6676719B2Improve stabilityTrend downCosmetic preparationsNon-fibrous pulp additionSilica particleSilicon dioxide

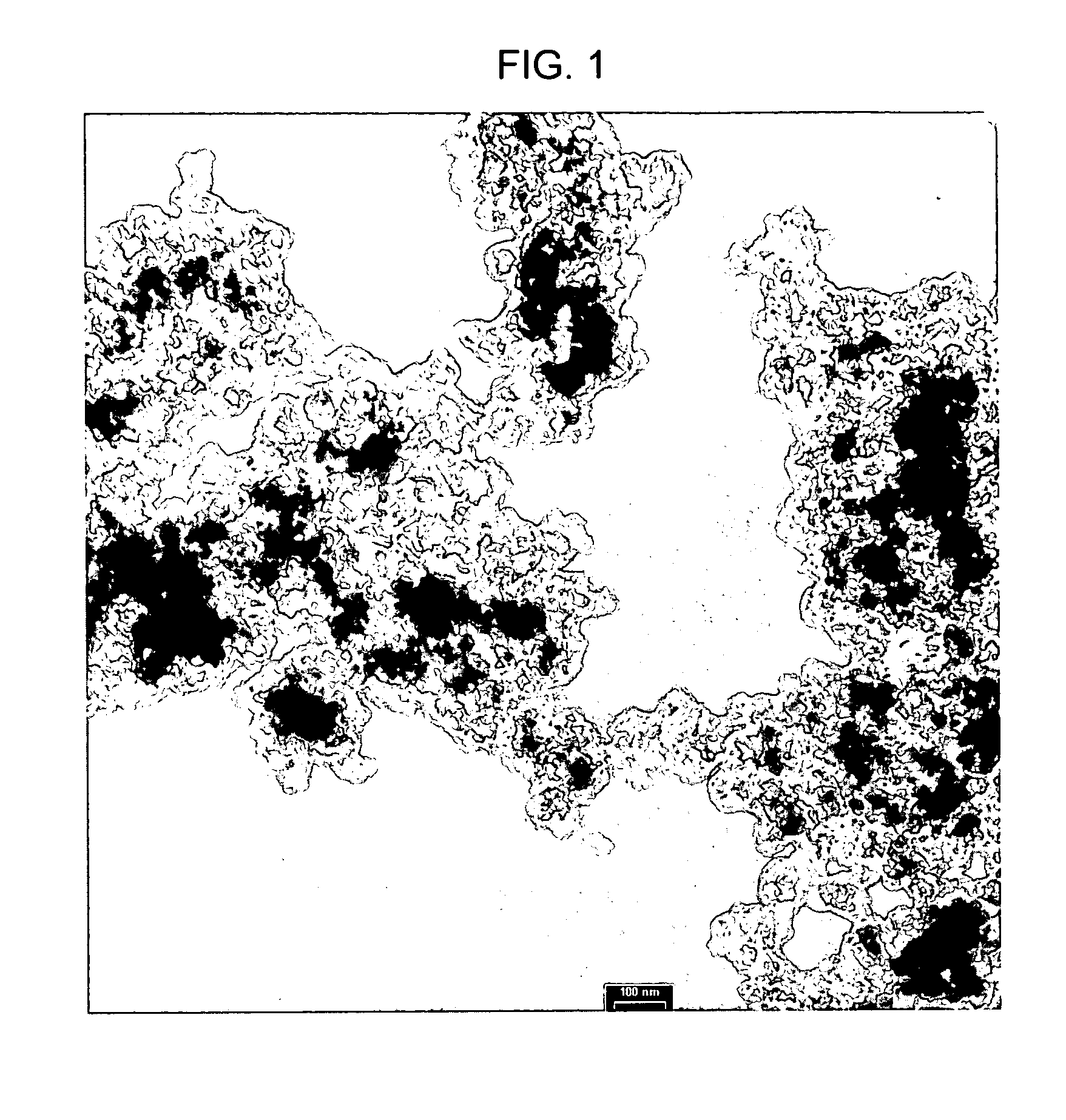

A pyrogenic process is used to prepare alkali-doped silica particles. Particles produced by this process exhibit homogeneous doping, reduced agglomeration, greater stability and higher removal rates. Aqueous dispersions containing alkali-doped pyrogenic silica with average particle size less than 100 nm are used for polishing surfaces (CMP).

Owner:EVONIK DEGUSSA GMBH

Graphene-containing insulated radiating composition and preparation and application thereof

ActiveCN103804942AHigh thermal conductivityImprove mechanical propertiesCoatingsPigment treatment with organosilicon compoundsHeat conductingGraphene

The invention discloses a graphene-containing insulated radiating composition and preparation and application thereof. The composition comprises the components of silica-coating graphene, insulated heat-conducting filler, a surface treating agent, and a function additive. The preparation method comprises the following steps of: hydrolyzing ethyl silicate on the graphene surface by the sol-gel method to obtain graphene coated with a silica film on the surface; adding the surface treating agent to a mixture of the insulated heat-conducting filler and modified graphene; uniformly agitating; then adding the function additive; and uniformly dispersing to obtain the insulated radiating composition. The composition has the advantages that the graphene is processed by insulating and coating, and the insulated heat-conducting filler and additive of other forms are coordinately added, thus the composition shows high radiating improvement effect in the plastic cement and coating fields; and the composition can be widely applied to a heating element and a radiating facility of various electronic products and electrical equipment, and can greatly improve the radiating effect as well as prolong the service life of devices.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

TiO2 material and the coating methods thereof

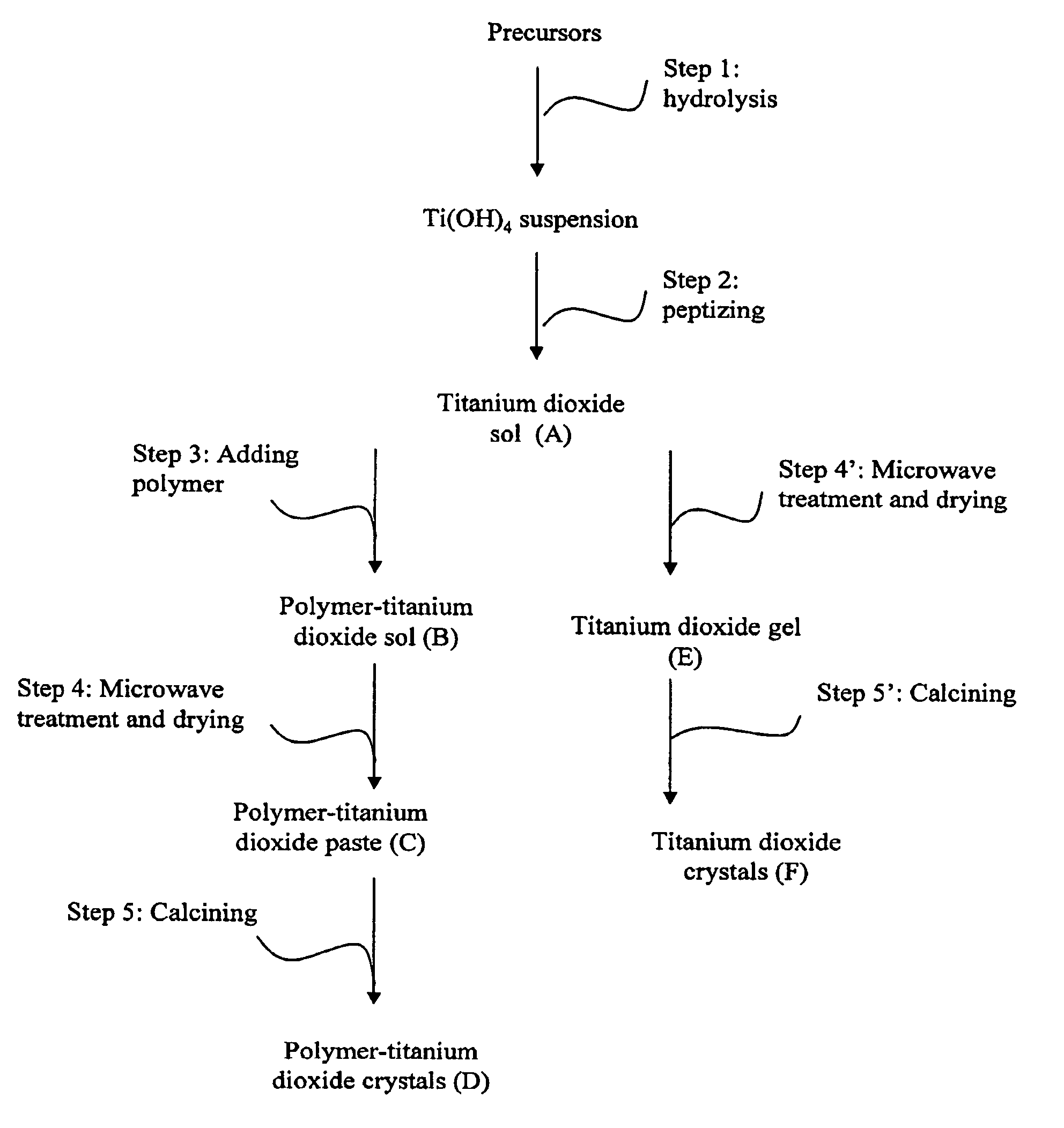

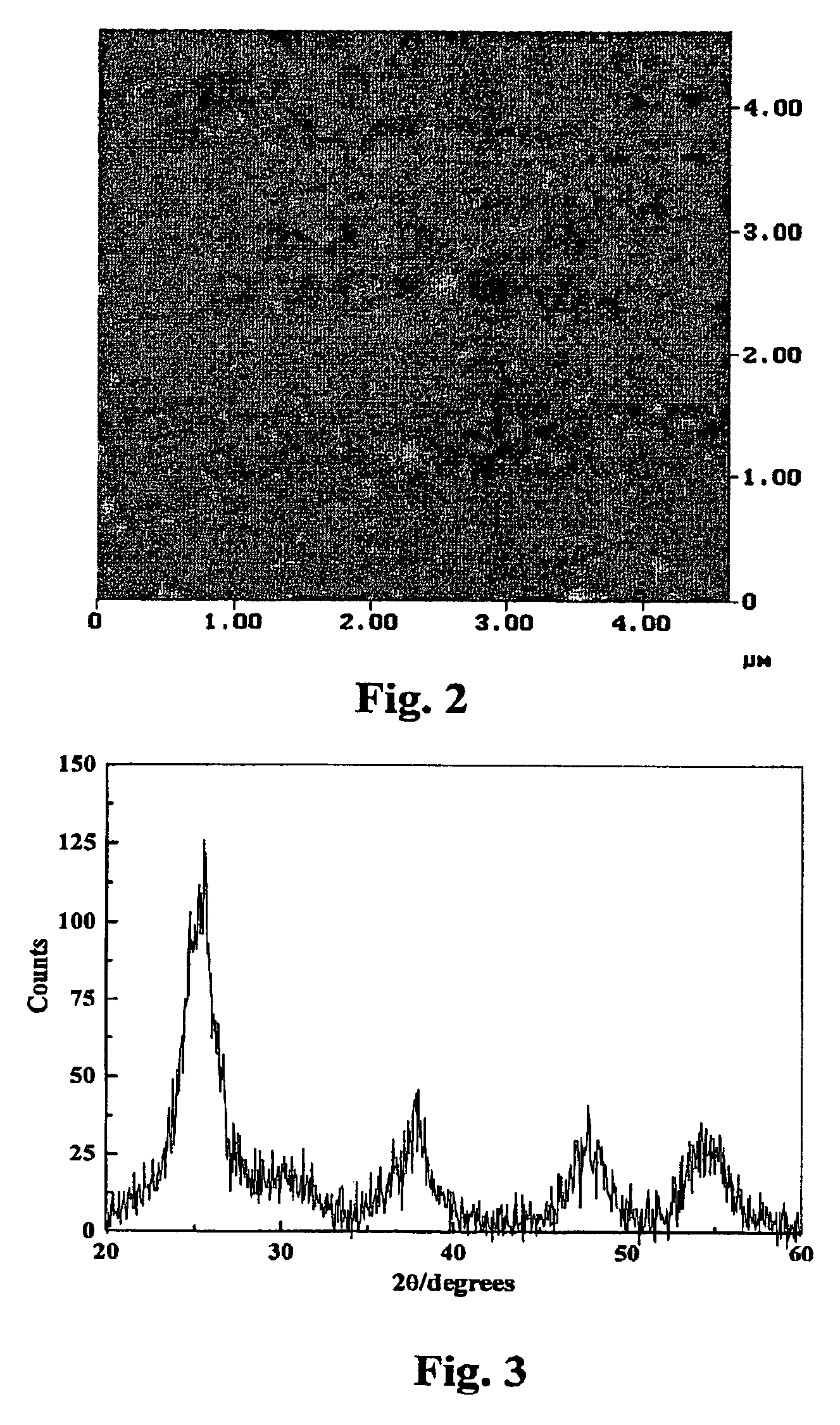

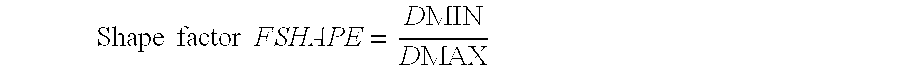

ActiveUS7144840B2Reduce moistureInhibit aggregationMaterial nanotechnologyLiquid surface applicatorsAir purificationTitanium dioxide

The present invention relates to a titanium dioxide material for coating on a substrate and method of making the same. The coated material is resistant to delamination and can be used for air-purification purposes.

Owner:THE HONG KONG UNIV OF SCI & TECH

Production process of super strength interference pearlylustre pigment

The invention relates to a production process for ultra-strong interferential golden pearl pigment of a multi-coating two-dimensional structural slice base object, which is obtained by coating mica with four layers. The golden pearl pigment product prepared by the production process of the invention has the effect of 24K gold, low price, and extremely-large economic value.

Owner:河北欧克新型材料股份有限公司

Silane-modified oxidic or siliceous filler, process for its production and its use

InactiveUS20030200900A1Avoid problemsCosmetic preparationsSilicon organic compoundsPolymer scienceSilanes

Silane-modified oxidic or siliceous filler with a bead fraction below 75 mum of less than 15 wt. % and a median particle size distribution between of 150 to 500 mum, which is produced by the reaction of at least one microbeaded or microgranular, oxidic or siliceous filler in a compressed gas with at least one silane. The silane-modified oxidic or siliceous fillers are used in rubber compounds.

Owner:EVONIK DEGUSSA GMBH

Silane-modified oxidic or siliceous filler, process for its production and its use

Silane-modified oxidic or siliceous filler with a bead fraction below 75 μm of less than 15 wt. % and a median particle size distribution between of 150 to 500 μm, which is produced by the reaction of at least one microbeaded or microgranular, oxidic or siliceous filler in a compressed gas with at least one silane. The silane-modified oxidic or siliceous fillers are used in rubber compounds.

Owner:EVONIK DEGUSSA GMBH

Method for producing special rutile type titanium white powder for power coating

ActiveCN101880479ALattice stabilizationGood dispersionPigment treatment with organosilicon compoundsPigment physical treatmentSlurryZircon

The invention discloses a method for producing special rutile type titanium white powder for power coating, which comprises the following steps of: preparing slurry of which titanium dioxide concentration is 300 to 400g / l by using bleached metatitanic acid, and adding a calcining auxiliary agent into the slurry; filtering the obtained metatitanic acid, then calcining solid, and grinding the solidto obtain a primary product; preparing titanium dioxide slurry of which titanium dioxide concentration is 650 to 850g / l by using the obtained primary product, adding a wetting agent into the titaniumdioxide slurry, and performing dispersion and grinding; heating the obtained titanium dioxide slurry to between 40 and 90 DEG C, adding dispersant, zircon salt or titanium salt, silicon salt and aluminum salt into the slurry in turn, adjusting the pH value to between 5 and 9, ageing the mixture, and adjusting the pH value to between 7 and 8; and then filtering, washing and drying the mixture, treating the dried product by an organic surface treatment agent, and vaporizing the product to obtain the rutile type titanium white powder. Compared with the prior art, the rutile type titanium white powder obtained by the method has the properties of stable crystal lattice, good dispersion, heat and yellowing resistance, and good oily whiteness, reducing power, covering power and weather resistance and the like; the appearance and properties of the rutile type titanium white powder are close to that of the rutile type titanium white powder prepared by a chlorination process; and the productionmethod has the advantages of easily obtained process raw materials and stable process control.

Owner:NINGBO XINFU TITANIUM DIOXIDE

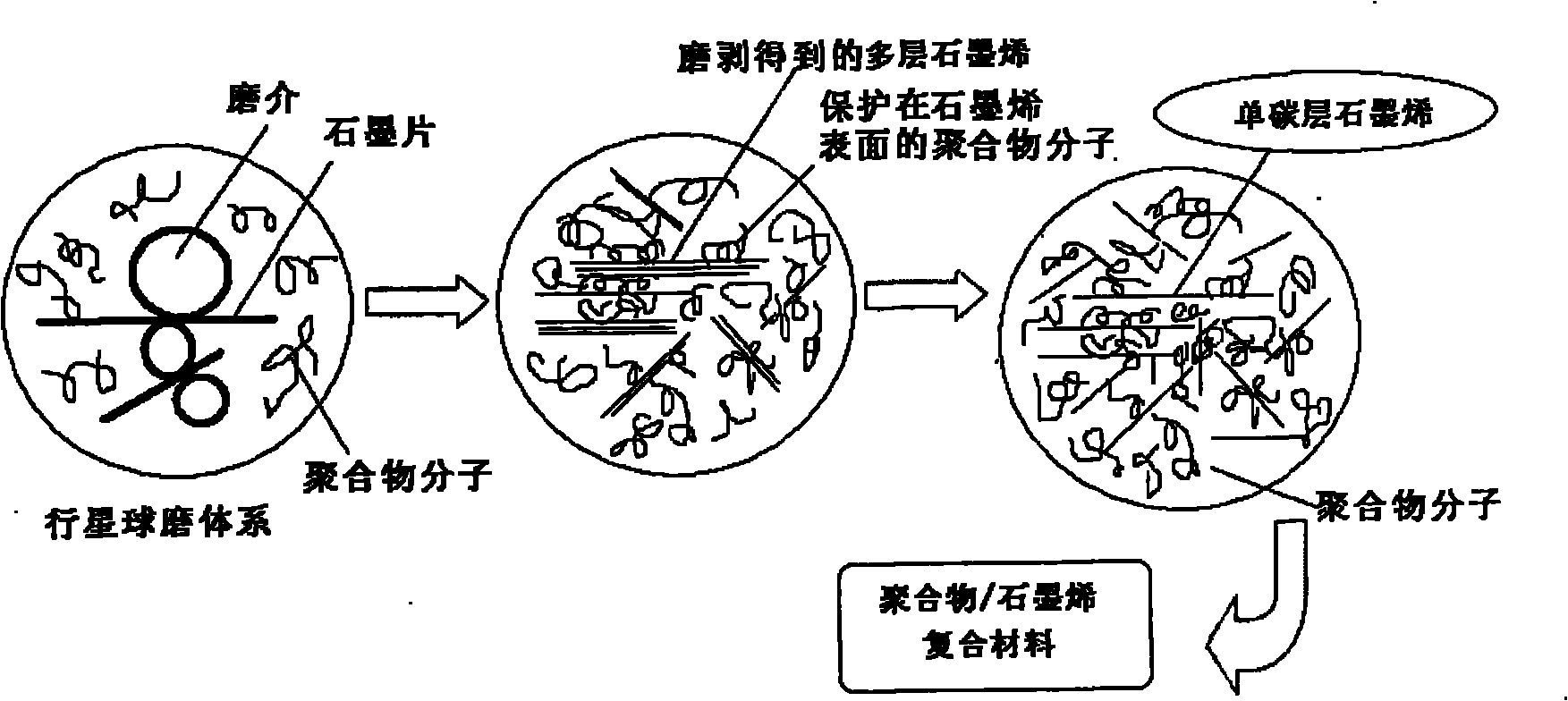

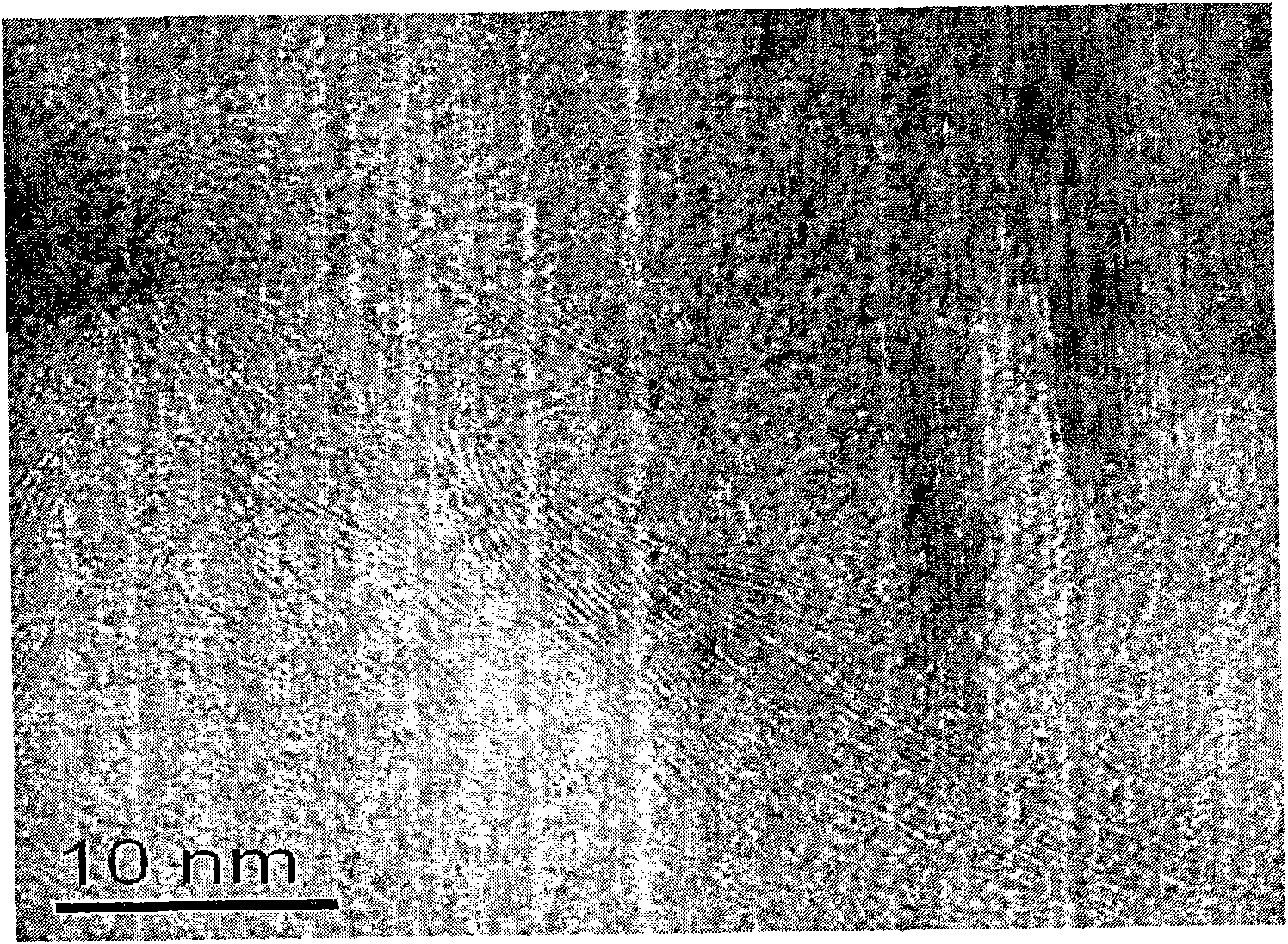

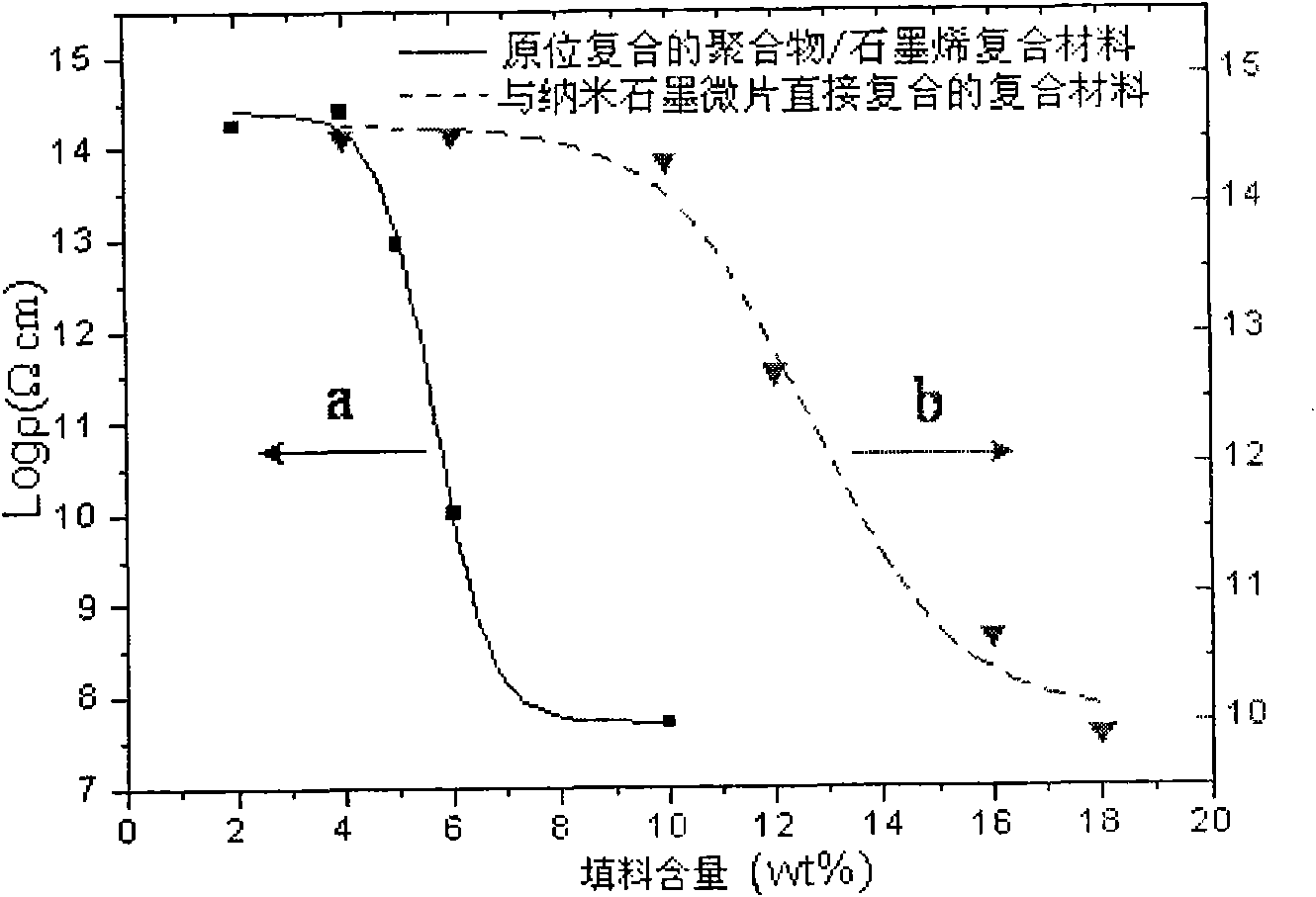

Method for preparing polymer/graphene composite material

ActiveCN101864005AChemical bond breakdownAvoid self reunionPigment physical treatmentPolymer scienceLiquid medium

The invention discloses a method for preparing a polymer / graphene composite material, which comprises: firstly, uniformly dispersing graphite powder in a polymer liquid medium, and grinding and stripping the graphite by using grinding balls to obtain polymer / graphene suspension; and secondly, obtaining the polymer / graphene composite material by adopting a method of adding a precipitator into the polymer / graphene suspension to precipitate the polymer and graphene from the solution, or a method of directly initiating the polymerization of a polymer monomer or a method of curing a prepolymer of the polymer. The method is a new in-situ graphene preparation and compounding method. Once generated, the graphene is enveloped and isolated by polymer molecules or the prepolymer monomer, so the self-agglomeration of the graphene is prevented effectively. In addition, the mechanical grinding in the polymer liquid medium ensures the full mixing of the filler and the polymer, so that the graphene can disperse in a polymer substrate more effectively. And the mechanical ball grinding process makes scale expansion and the realization of industrial production easier.

Owner:HUAQIAO UNIVERSITY +1

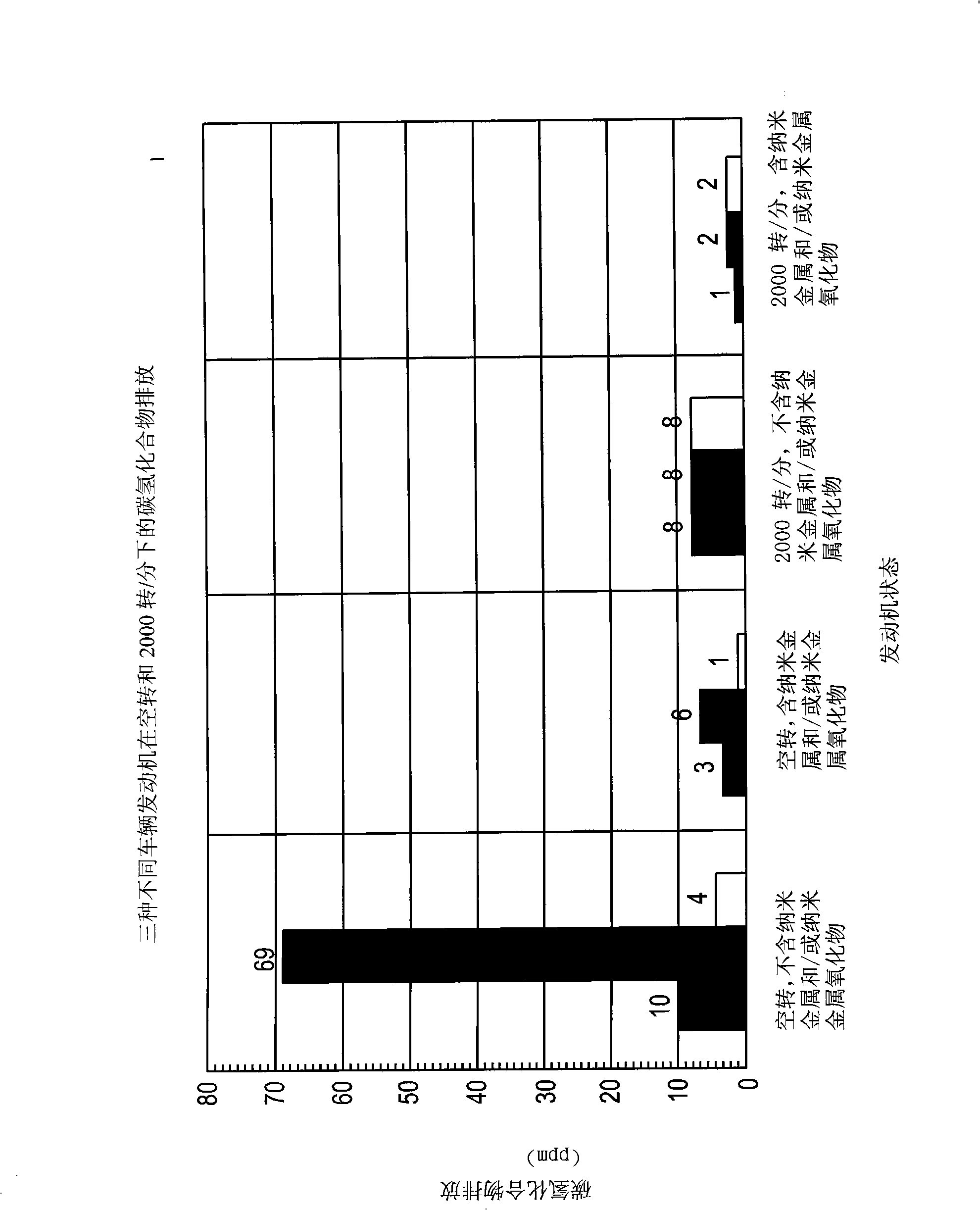

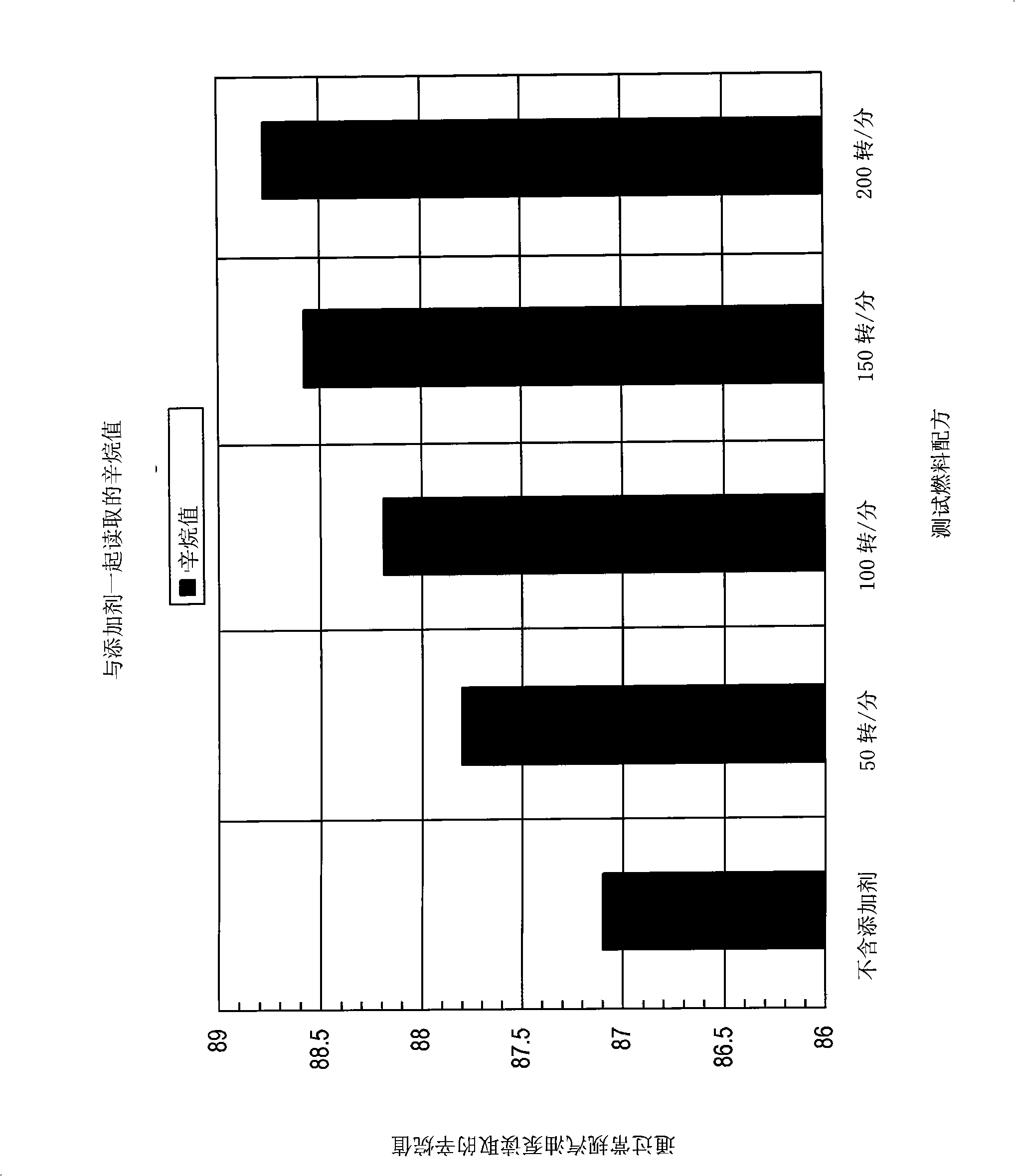

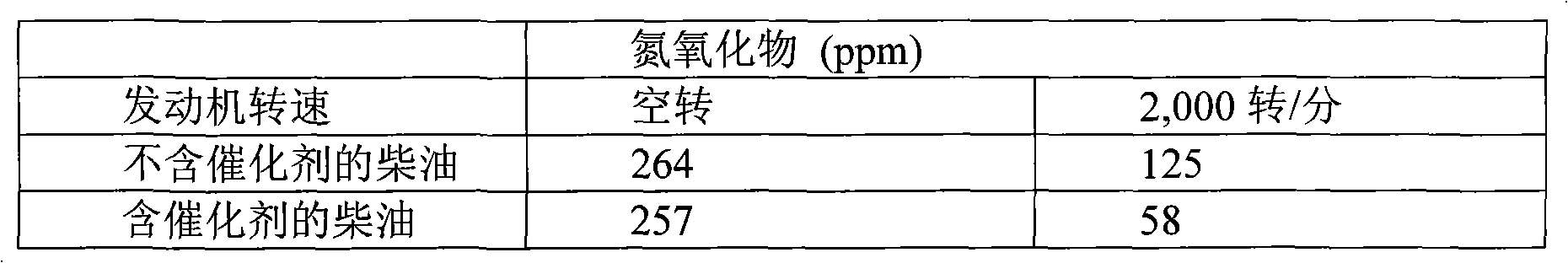

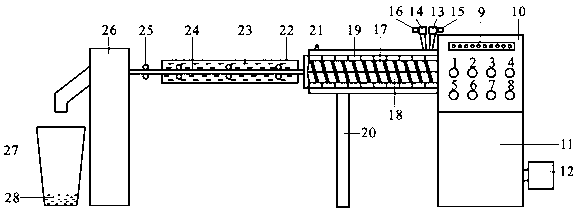

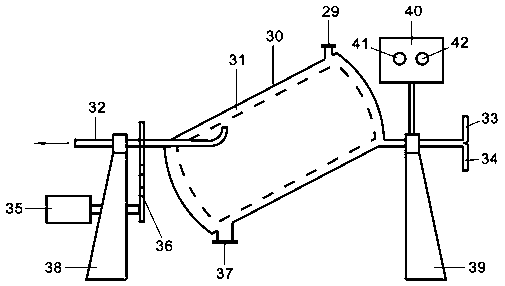

Nano-sized metal and metal oxide particles for more complete fuel combustion

InactiveCN101333467ACombustion-air/fuel-air treatmentLiquid carbonaceous fuelsCatalytic oxidationLiquid fuel

Owner:詹姆士·肯尼思·桑德斯

Preparation method for heat-resisting polylactic acid fiber

InactiveCN102839443AImprove heat resistanceEnsuring environmental friendlinessSpinning head liquid feederMelt spinning methodsPolymer scienceTriethoxysilane

The invention relates to a preparation method for a heat-resisting polylactic acid fiber, which comprises the following steps: drying polylactic acid grains in a vacuum drum; modifying the surface of nanometer silicon dioxide by using a silane coupling agent, namely, gamma-aminopropyl triethoxy silane; mixing the dry polylactic acid grains with the modified nanometer silicon dioxide; preparing into polylactic acid plus silicon dioxide master batches by utilizing a double-screw extruding machine; uniformly mixing the master batches and the polylactic acid grains at weight ratio; pouring the mixture into a melt spinning machine for spinning; and drafting through two areas, thereby obtaining polylactic acid plus silicon dioxide fibers. The process of the preparation method is advanced; the data is full and accurate; the preparation method is suitable for mass production; the prepared polylactic acid filament is excellent in heat resistance and mechanical property; the problem of poor heat resistance of the polylactic acid fiber is effectively solved; and the application scope of the polylactic acid fiber is widened.

Owner:TAIYUAN UNIV OF TECH

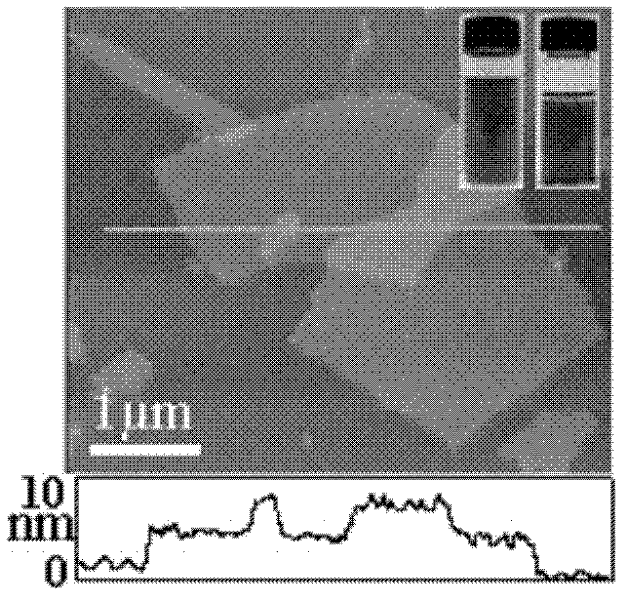

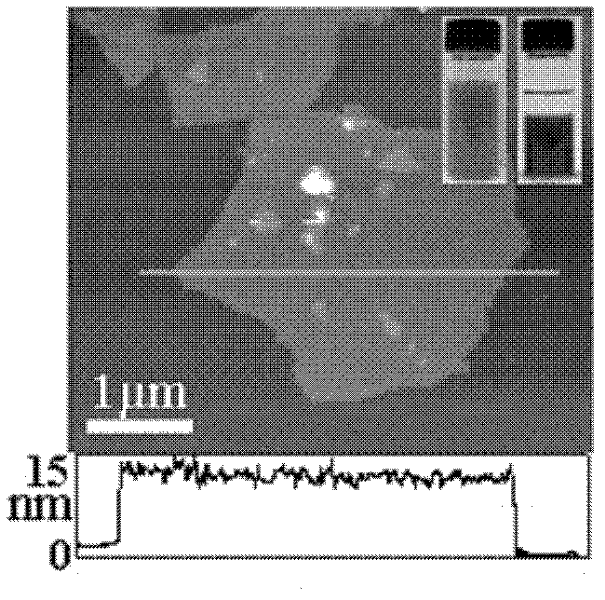

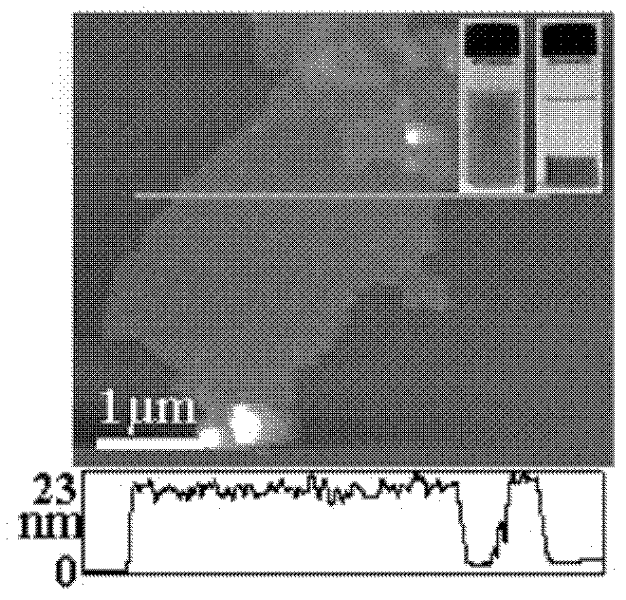

Titanium dioxide and graphene oxide composite nano-grade sheet material and preparation method thereof

ActiveCN102492313AThickness is continuously controllableMeet different requirements of thicknessPigment physical treatmentOxide compositeVacuum drying

The invention relates to a titanium dioxide and graphene oxide composite nano-grade sheet material and a preparation method thereof. A structural layer of the titanium dioxide and graphene oxide composite nano-grade sheet comprises a graphene oxide layer, and two titanium dioxide layers respectively positioned on the upper and lower sides of the graphene oxide layer. The preparation method comprises steps that: step 1, graphene oxide is subject to ultrasonic oscillation under a normal temperature, such that graphene oxide is uniformly dispersed in distilled water, and a graphene oxide dispersed liquid is obtained; step 2, the graphene oxide dispersed liquid is diluted by using absolute alcohol; step 3, a proper amount of tetrabutyl titanate is dissolved in absolute alcohol, such that an alcohol solution of tetrabutyl titanate is obtained; step 4, the alcohol solution of tetrabutyl titanate with a different concentration is gradually dropped into the alcohol diluent of graphene oxide with a temperature of 20-60 DEG C while stirring; step 5, a reaction is carried out, such that a dispersed liquid of an amorphous titanium dioxide and graphene oxide composite nano-grade sheet materialis obtained; step 6, the dispersed liquid is subject to centrifugal washing by using distilled water and absolute alcohol, and is subject to normal-temperature vacuum drying, such that powder is obtained. The powder is the amorphous titanium dioxide and graphene oxide composite nano-grade sheet material obtained with the initial reaction.

Owner:SICHUAN UNIV +1

Method for preparing multifunctional titanium dioxide pigment with chlorination method

ActiveCN102079885AGood weather resistanceGood light fastnessPigment physical treatmentPhosphatePapermaking

The invention relates to a method for preparing multifunctional titanium dioxide pigment with a chlorination method, which comprises the following steps of: blending a titanium dioxide primary product into titanium dioxide slurry by adopting a chlorination method and adjusting a pH value between 9.0 and 11.0; adding a phosphate dispersing agent and carrying out grinding treatment; removing a grinding medium from the slurry and heating; adding a water-soluble silicate solution for curing; adjusting the pH value of the slurry for forming amorphous silica and curing for forming a first coating layer; cooling the slurry to 50-70 DEG C; adding a sodium metaaluminate solution and curing; adjusting the pH value of the slurry between 8.0 and 9.0, curing and forming an amorphous alumina coating layer on the first coating layer; adding an aluminum salt solution, maintaining the pH of the slurry between 7.0 and 9.0 and curing; adjusting the pH value of the slurry between 6.0 and 7.0 and curing; and washing the slurry with deionized water till the conductivity of a filter cake is larger than 15,000 ohm.cm, and carrying out drying and steaming pulverizing treatment to obtain a finished product. The multifunctional titanium dioxide pigment prepared with the method has higher weather resistance, whiteness, covering capability, opacity and dispersibility and excellent processing performance in the fields of coating, plastics, papermaking, and the like.

Owner:中信钛业股份有限公司

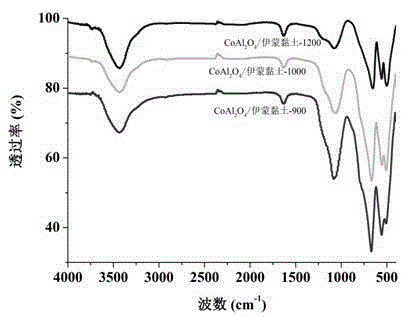

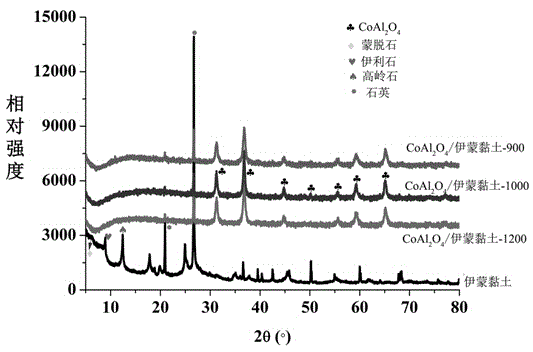

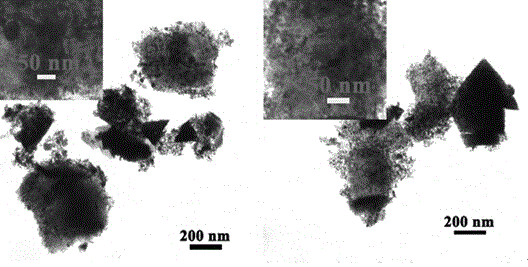

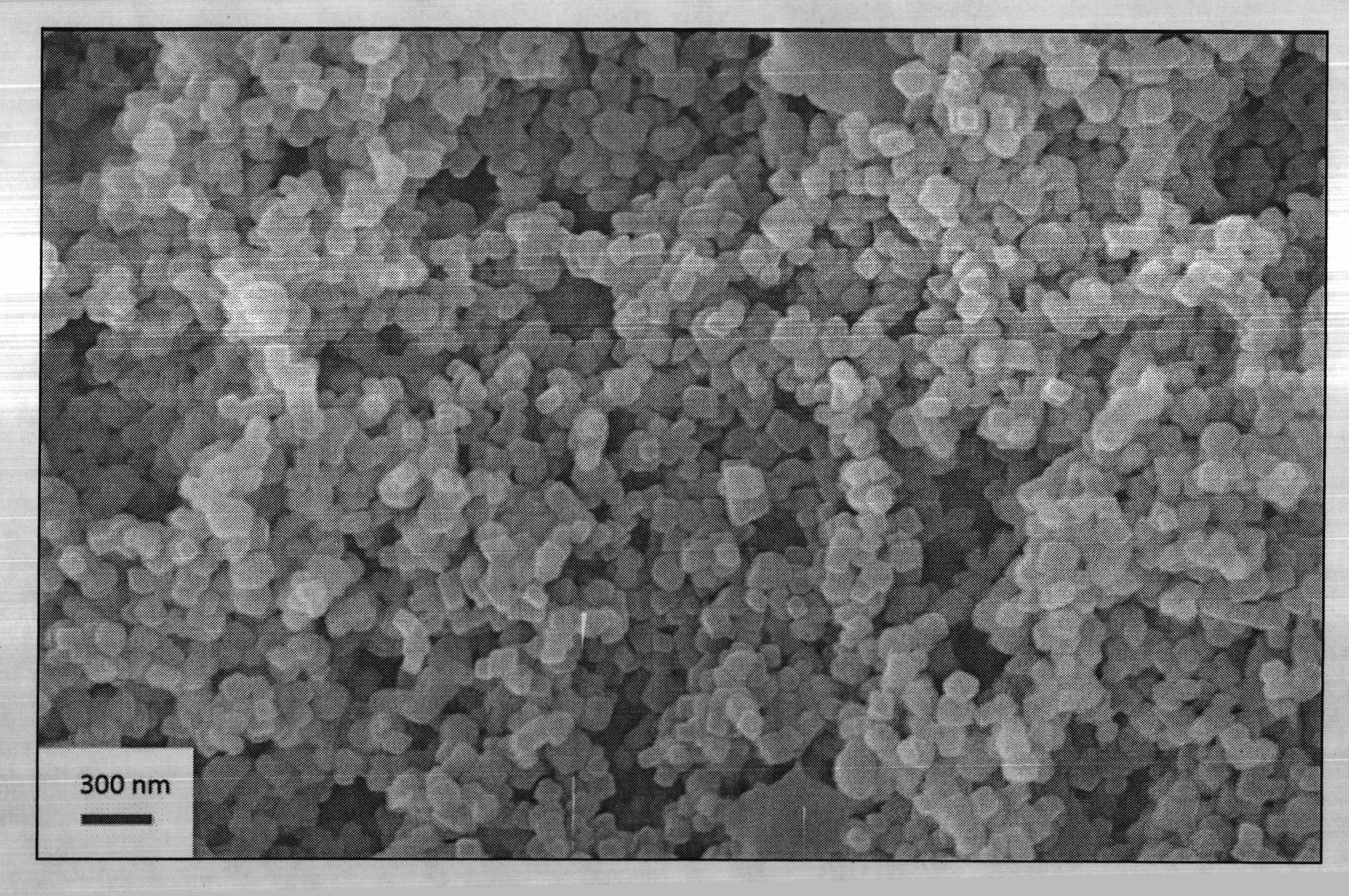

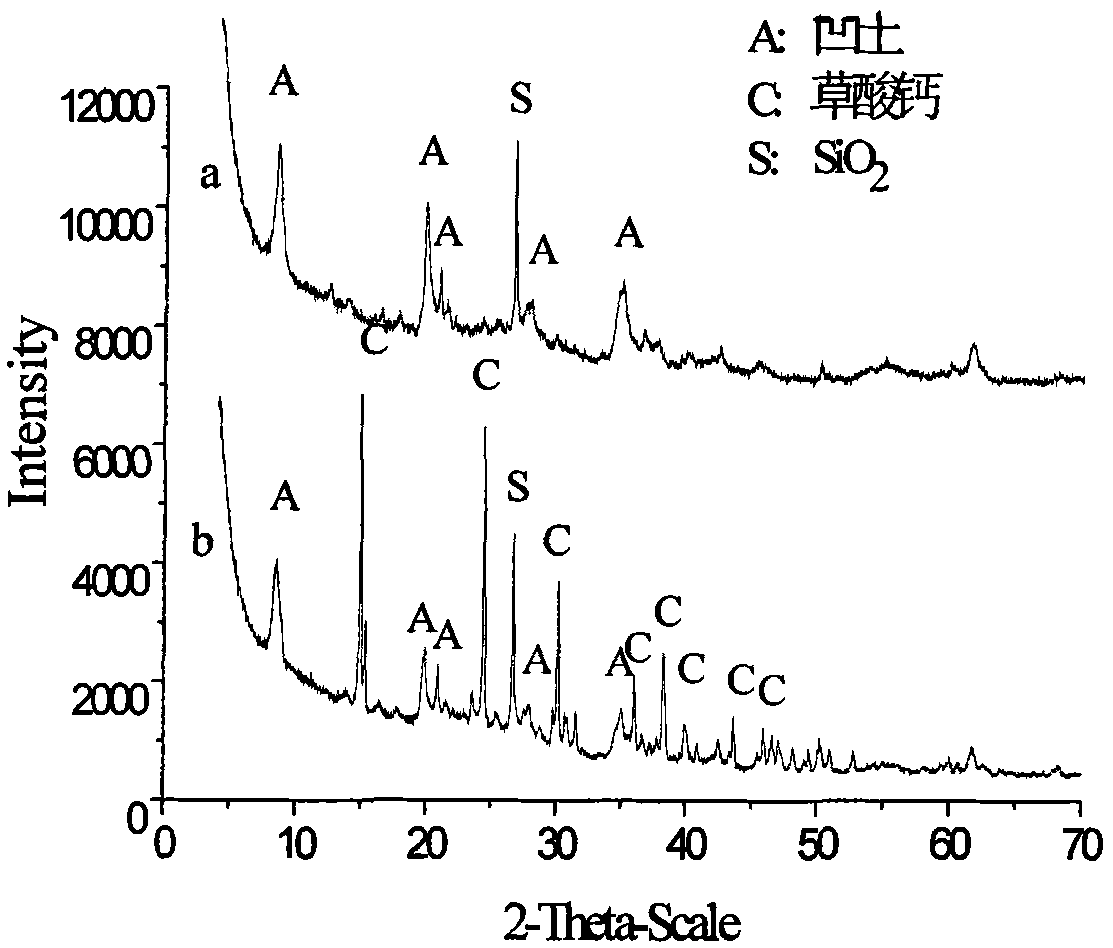

Preparation method of cobalt blue and clay mineral hybrid pigment

ActiveCN105199435ALow costReduce manufacturing costPigment physical treatmentClay mineralsCobalt blue

The invention relates to a preparation method of a cobalt blue and clay mineral hybrid pigment and belongs to the technical field of preparation of nano-spinel hybrid pigments. A hybridization precursor is prepared with a co-precipitation technique with Co(III) salt and Al(III) salt as raw materials and inorganic clay minerals as filler, and the cobalt blue and clay mineral hybrid pigment is prepared through high-temperature crystallization. With the adoption of the clay minerals, the preparation cost of the cobalt blue pigment can be reduced, cobalt blue nanoparticles can be effectively prevented from aggregating and enlarging in the following high-temperature crystallization process, the particle diameter of the nanoparticles ranges from 10 nm to 20 nm, and the prepared cobalt and clay mineral hybrid pigment has a bright color and can meet requirements of durable coatings, neutral ink, CRT (cathode ray tube) fluorescent powder coating pigment products and the like in the cobalt blue market. Besides, the preparation process is simple, the cost of the raw materials is low, and large-scale production is facilitated.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Surface modification method for nano calcium carbonate

ActiveCN102174275AOvercome the disadvantage of being difficult to disperseGood dispersionPigment physical treatmentPigment treatment with non-polymer organic compoundsPolyvinyl chlorideSlurry

The invention discloses a surface modification method for nano calcium carbonate, which is characterized by comprising the following steps of: adding inorganic alkali into nano calcium carbonate slurry, uniformly stirring, heating the slurry, adding fatty acid and performing surface modification. The method comprises the following specific steps of: adding a certain amount of nano calcium carbonate slurry into a reaction kettle, adding 0.00004 to 0.00040mol of inorganic alkali into 1g of CaCO3, and uniformly stirring; heating to the temperature of between 75.0 and 90.0 DEG C, adding 0.00005 to 0.00035mol of fatty acid or fatty acid salt into 1g of nano calcium carbonate (CaCO3) slurry, reacting, and continuously stirring for 30 to 120 minutes; and after surface modification reaction is finished, cooling, filtering, washing, drying and grinding the slurry to obtain the nano calcium carbonate subjected to surface modification. The method is simple and practicable, a modifier can form a uniform and complete coating layer on the surface of the nano calcium carbonate, and the modified product has a good application effect in polymer such as silicone sealant, polyvinyl chloride (PVC) paste resin and the like.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

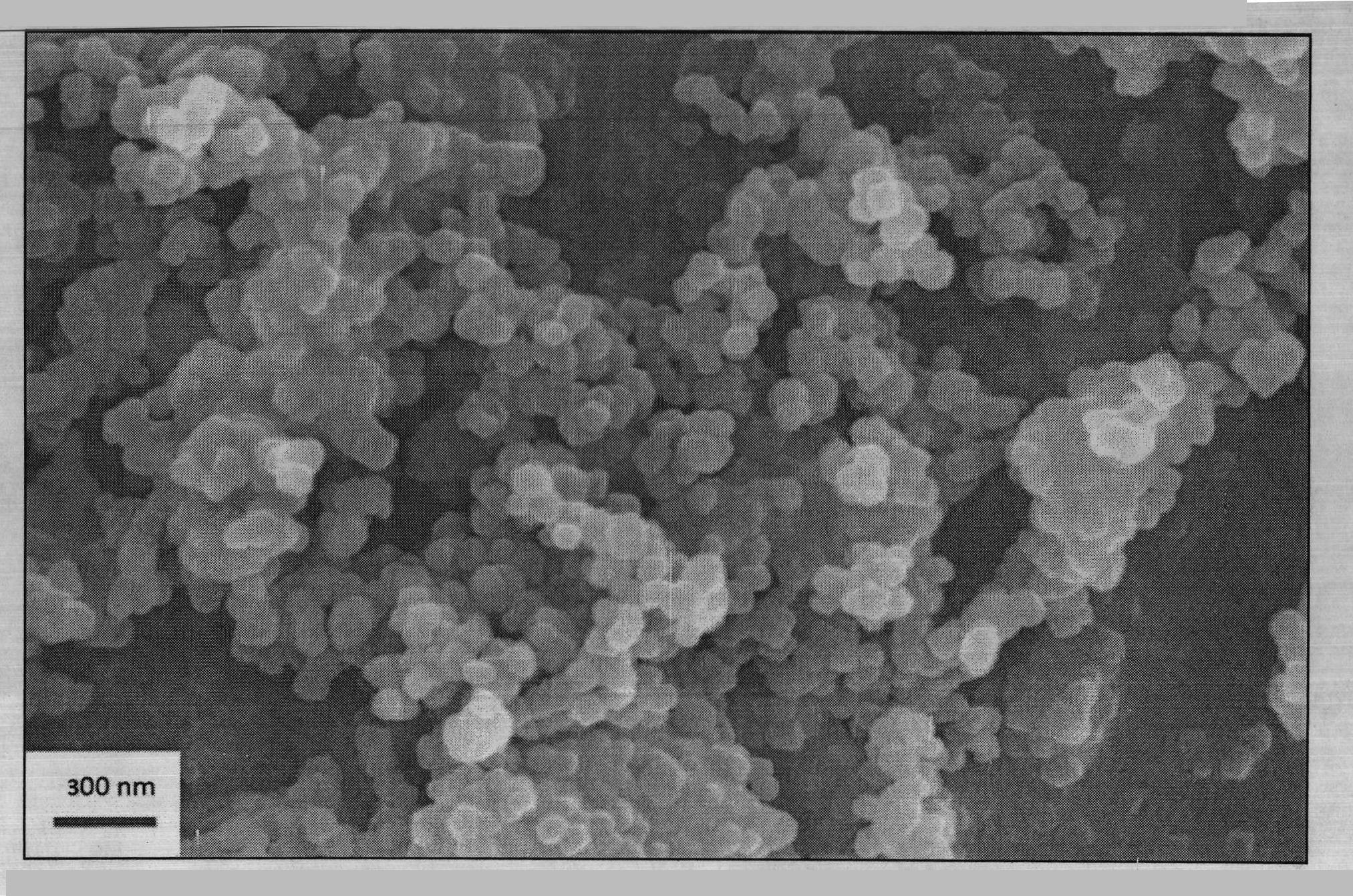

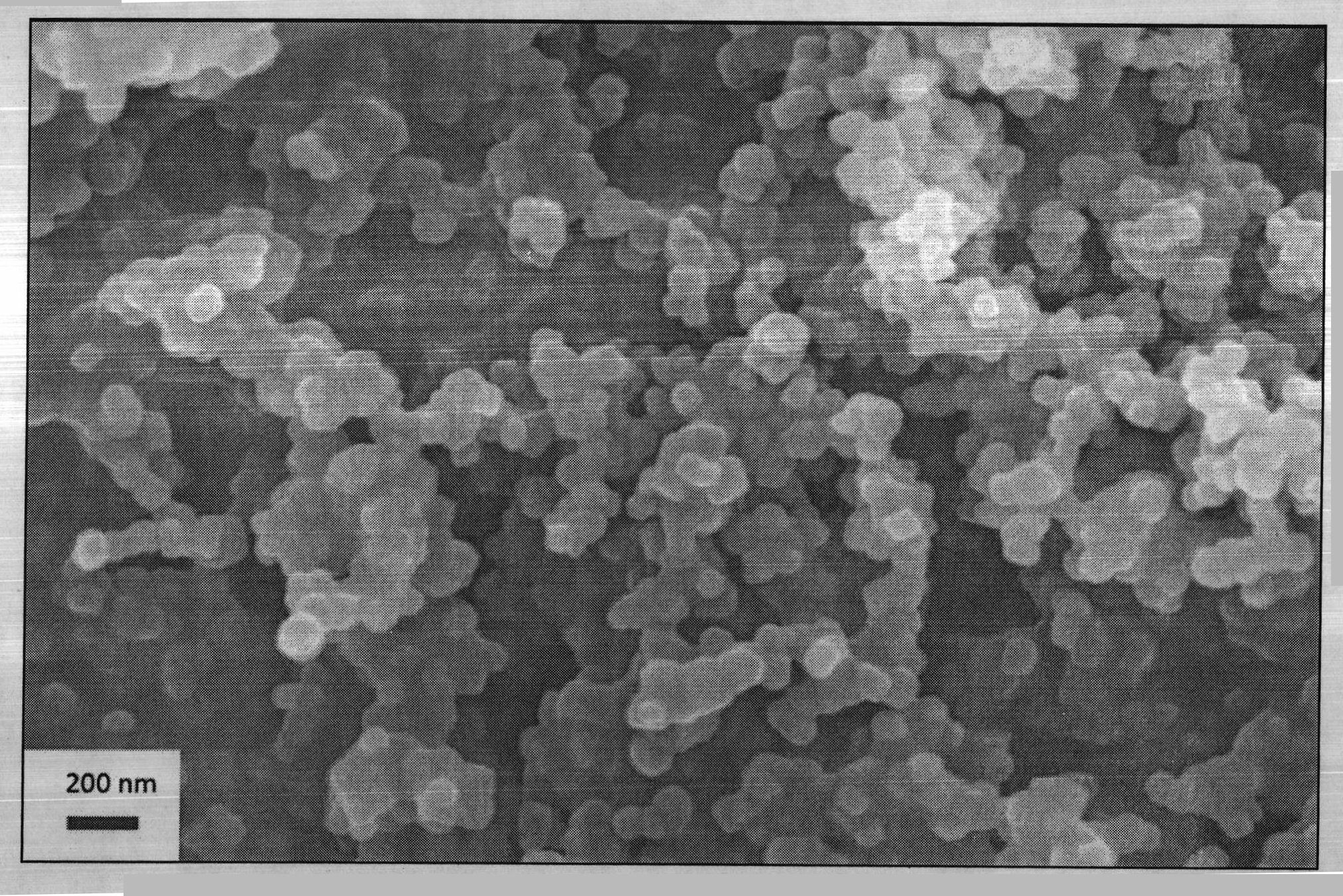

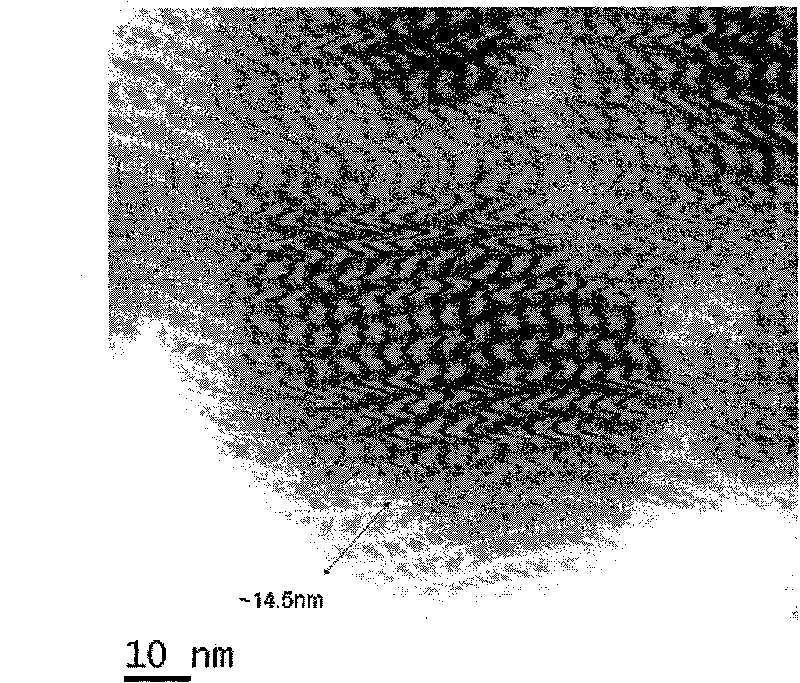

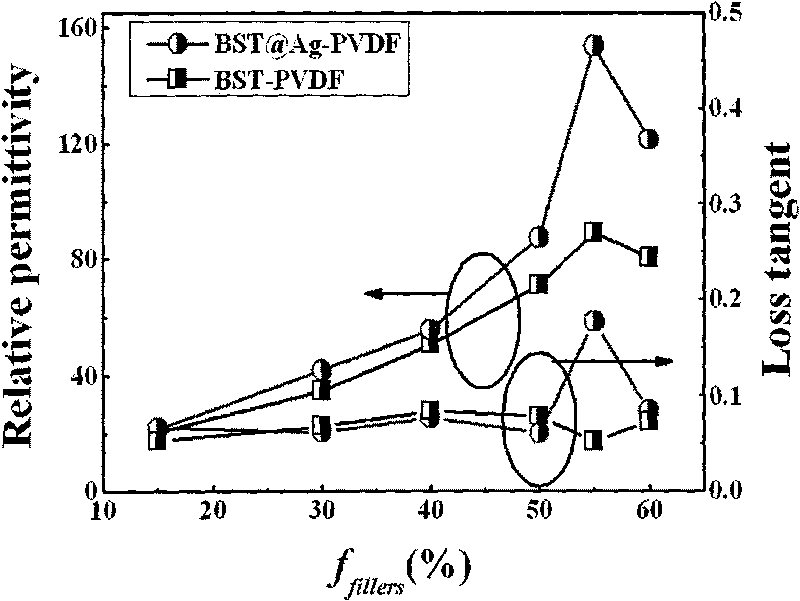

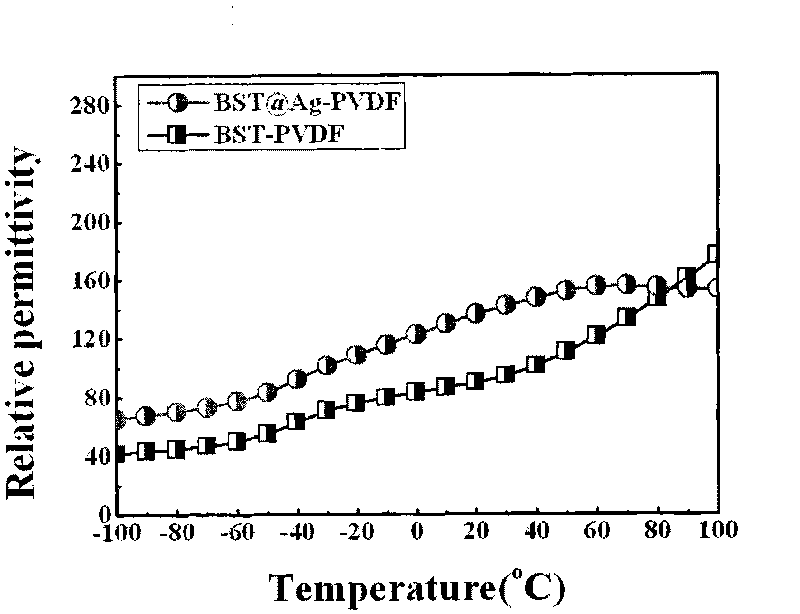

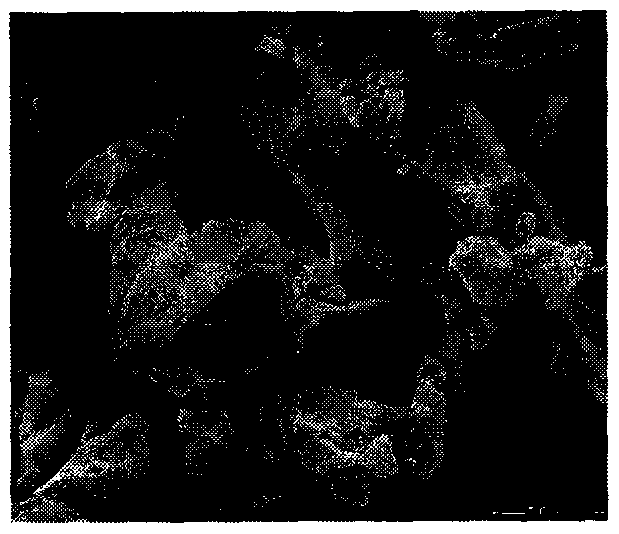

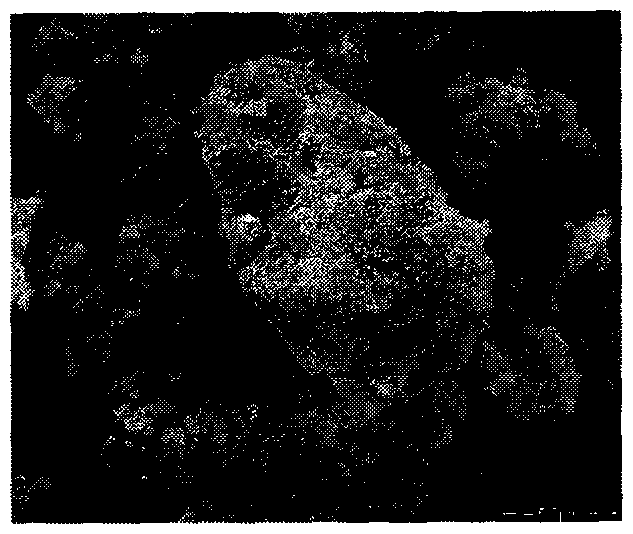

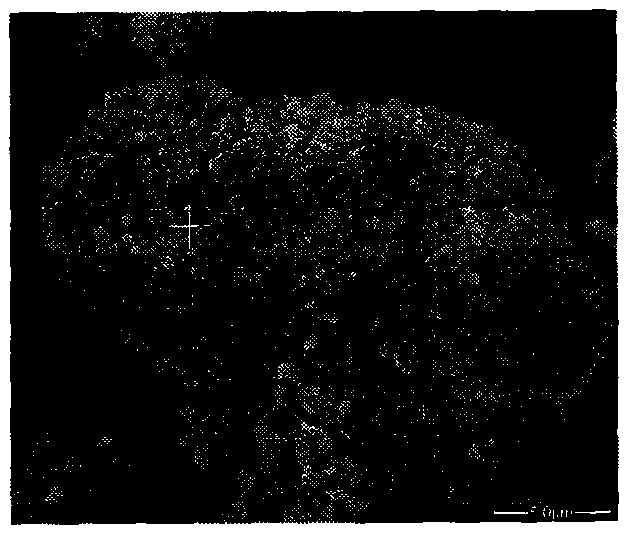

Nuclear shell structured packing/polymer-based composite material and preparation method thereof

InactiveCN101712784AHigh dielectric constantExcellent dielectric propertiesPigment physical treatmentPigment treatment with non-polymer organic compoundsDielectric lossThermal treatment

The invention relates to a nuclear shell structured packing / polymer-based composite material and a preparation method thereof. The nuclear shell structured packing / polymer-based composite material comprises a nuclear shell structured packing and a polymer formed by coating ceramic particles with metal, wherein the nuclear shell structured packing is coated by the polymer completely. The nuclear shell structured packing / polymer based composite material prepared by the method has the advantages of high dielectric constant, low dielectric loss, excellent dielectric property and temperature stability and the like, and the preparation method has the characteristics of simple operation, low thermal treatment temperature, low cost, suitability for industrial production, environmental protection and the like.

Owner:XI AN JIAOTONG UNIV

Method for preparing microcapsule red phosphorus inflaming retarding polylactic acid

ActiveCN101696319ALow costThe preparation process is simple and environmentally friendlyPigment treatment with macromolecular organic compoundsPigment physical treatmentMelamine formaldehyde resinMoisture

The invention belongs to the technical field of inflaming retarding modification of high polymer materials, and specifically relates to a method for preparing microcapsule red phosphorus inflaming retarding polylactic acid. The method comprises the following steps of: pre-treating red phosphorus, and preparing melamine formaldehyde resin prepolymer solution; adding the pretreated red phosphorus, distilled water which is 2 to 20 times of the quantity of the red phosphorus and a dispersing agent which is 0.5 to 2 percent of the quantity of the red phosphorus into a reaction vessel; stirring the mixture and heating the mixture to a temperature of between 60 and 90 DEG C to obtain a red phosphorus suspension; then adding metal salt solution into the suspension; adjusting the pH value of the system by using ammonia water; keeping the temperature and stirring the mixture; adding the mixture into the melamine formaldehyde resin prepolymer solution so that the resin content in the solution is 22 to 94 percent of quantity of the red phosphorus; adjusting the pH value of the system to between 4 and 5 by using glacial acetic acid, keeping the temperature and stirring the mixture; after the reaction is finished, cooling and filtering the suspension, washing the suspension to be neutral, and drying the suspension to obtain inorganic-organic double-layer coated microcapsule red phosphorus; grinding the obtained microcapsule red phosphorus, and drying polylactic acid to remove the moisture; and adding the obtained microcapsule red phosphorus and the polylactic acid into a drying container, mixing the obtained microcapsule red phosphorus and the polylactic acid evenly, and melting and blending the mixture to obtain the required product. In the product, the polylactic acid accounts for 65 to 75 percent and the microcapsule red phosphorus accounts for 25 to 35 percent. The method has a low cost and a simple and environment-friendly preparation process.

Owner:TONGJI UNIV

Inorganic material in particles form

InactiveUS6165510ADoes not affect strengthPowder deliveryCosmetic preparationsInorganic materialsMaterials science

PCT No. PCT / EP97 / 00202 Sec. 371 Date Aug. 11, 1998 Sec. 102(e) Date Aug. 11, 1998 PCT Filed Jan. 15, 1997 PCT Pub. No. WO97 / 30126 PCT Pub. Date Aug. 21, 1997A cosmetic composition includes an inorganic material in granular form which, under condition of use of the cosmetic composition, breaks down to a particle size wherein less than 5% by weight, preferably less than 2% by weight, most preferably less than 1% by weight is above 45 microns, as measured by wet sieve analysis.

Owner:PQ SILICAS UK

Method for preparing silicate nano-clay/urea resin composite adhesive

ActiveCN101818036AGood dispersionHigh reactivityNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesAdhesiveDeep processing

The invention provides a method for preparing a silicate nano-clay / urea resin composite adhesive, and belongs to the field of deep processing of non-metallic mine and high polymer materials. The technical scheme of the method comprises the following steps of: first, performing surface activating treatment on the silicate clay; then, inorganically and organically modifying the nano-clay by using soluble silicate solution and a silane coupling agent respectively; and finally, adding the modified nano-clay in a process of synthesizing the urea resin so as to prepare the silicate nano-clay / urea resin composite adhesive. The raw materials of the composite adhesive have rich sources and low price; and the method has a simple process, can effectively reduce the free formaldehyde content of the urea resin, and simultaneously improve the mechanical performance of the urea resin.

Owner:溧阳常大技术转移中心有限公司

Ultrasonic method for the production of inorganic/organic hybrid nanocomposite

InactiveUS20030148042A1High priceBetter rheological behaviorMaterial nanotechnologyNanostructure manufactureBiologyNanocomposite

The present invention provides a method for producing organic / inorganic hybrid nanocomposites by use of ultrasonic agitation.

Owner:UCB SA

PET (polyethylene glycol terephthalate) fiber/teflon fiber composite sound absorbing cotton and preparation method of PET fiber/teflon fiber composite sound absorbing cotton

InactiveCN102965843AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsNon-woven fabricsDiphenyl phosphatePolymer science

The invention discloses PET (polyethylene glycol terephthalate) fiber / teflon fiber composite sound absorbing cotton, which is prepared from the following ingredients in parts by weight: 70 to 80 parts of PET fibers, 40 to 50 parts of teflon fibers, 10 to 15 parts of emulsifying agents OP-30, 5 to 10 parts of peregal O-20, 80 to 100 parts of PP (propene polymer), 30 to 40 parts of HIPS (high impact polystyrene), 15 to 20 parts of activated clay, 10 to 15 parts of modified kieselguhr, 2 to 3 parts of stearic acid, 5 to 8 parts of dioctyl adipate, 4 to 6 parts of cresyl diphenyl phosphate, 2 to 3 parts of liquid paraffin, 1 to 2 parts of 3-aminopropyltrimethoxysilane, 2 to 3 parts of calcium stearate, 1 to 2 parts of barium stearate, 0.5 to 1.5 parts of anti-aging agents RD and 1 to 2 parts of antioxidants DLTP (dilauryl thiodipropionate). The sound absorbing cotton prepared by the invention has the advantages that the appearance evenness is good, the thickness is uniform, the hand feeling is soft, the product bonding degree is good, the tensile performance is high, the sound absorbing performance is excellent, the flame retardant effect is good, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

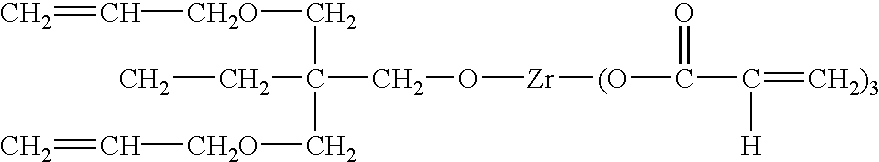

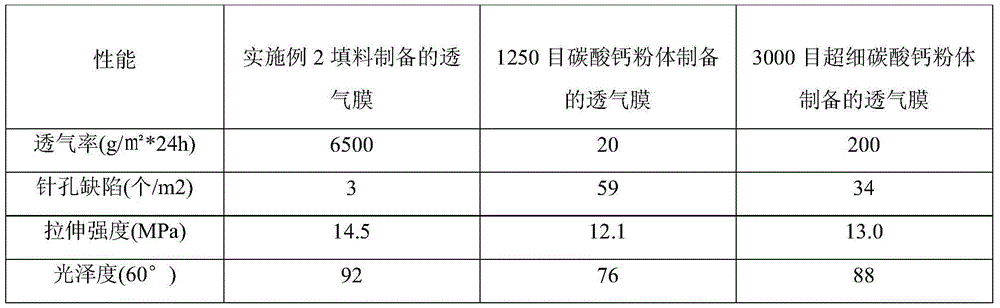

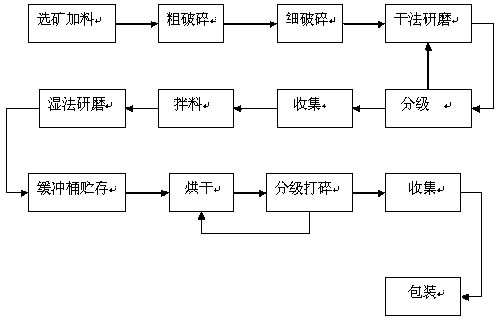

Coarse whiting filler for gas-permeable membrane and preparation method of coarse whiting filler

ActiveCN104530768AGood sphericityNo edges and cornersPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsMicrometerSURFACTANT BLEND

The invention belongs to the field of deep processing and utilization of nonmetal minerals, composite materials and functional materials, and particularly relates to coarse whiting filler for a gas-permeable membrane and a preparation method of the coarse whiting filler. The invention aims to provide the preparation method of the coarse whiting filler for the gas-permeable membrane. The preparation method comprises the following steps: crushing marble until the diameter is 40 to 70 micrometers; uniformly mixing marble powder, water and a high-molecular surfactant at a weight ratio of 1:(0.2-1.5):(0.001-0.1); ball-milling and filtering; dehydrating until the water content is not larger than 1%; dismissing gathered powder; drying until the water content is not larger than 0.2%; adding an activating agent of which the weight is 0.5% to 3% of the total weight of the dried powder material; fully reacting at the temperature of 110 to 140 DEG C; and cooling, uniformly mixing and packaging. The coarse whiting filler prepared by the method disclosed by the invention is good in performance and can be well applied to preparation of the gas-permeable membranes and relevant products.

Owner:SICHUAN SHIMIAN JUFENG POWDER

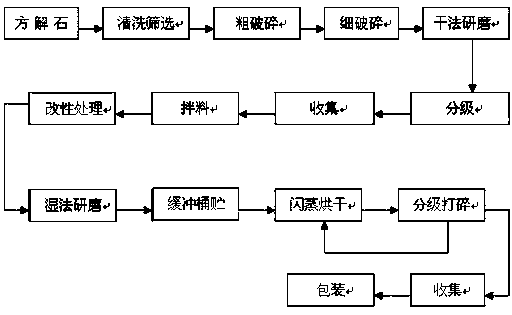

Preparation process of wet-process superfine modified calcium carbonate

InactiveCN104744971AIncrease productivityHigh activityInorganic compound additionPigment treatment with macromolecular organic compoundsSodium stearateMicrosphere

The invention discloses a preparation process of wet-process superfine modified calcium carbonate. The preparation process comprises the following steps: performing cleaning and screening, rough crushing, fine crushing, dry grinding and grading on calcite ores; collecting fine powder of 600 meshes and preparing slurry with water in such a manner that the solid content is 70%-80%; adding a modifier sodium stearate to the slurry for modification treatment and then performing wet grinding, and adding a grinding medium zirconium oxide microspheres and a dispersant sodium polyacrylate during grinding, wherein the volume ratio of the grinding medium to the slurry is 1: 1.5, and the dosage of the modifier is 0.6%-1.2% of the solid content; and putting the slurry obtained after the wet grinding through a vibrating screen, collecting the obtained wet-process superfine modified calcium carbonate slurry into a slurry barrel for flashing drying, collecting the finished product and packaging. The new preparation process is adopted; the wet grinding-modifying integrated technique and the flashing drying technique are adopted so that the production efficiency is high and the production cost is low; the product has the advantages of small particle size, low oil absorption value, high activity and the like; and the major product quality indices are at the international leading level.

Owner:江西科越科技有限公司

Preparation method of aqueous self-dispersing nanometer carbon black

ActiveCN106634059AGood dispersionSmall particle sizePigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsDouble bondSolvent

The invention discloses a preparation method of aqueous self-dispersing nanometer carbon black, and belongs to the field of fine chemical engineering. Silane coupling agents containing carbon-carbon double bonds are grafted on the surface of carbon black; polymerizable groups of the silane coupling agents are used for being copolymerized with other aqueous monomers; a layer of polymers with duplex effects of dispersion and stabilization coats the surface of the carbon black particles, so that the goal of self dispersion in an aqueous solvent is achieved.

Owner:JIANGNAN UNIV

Method for preparing plastic filler from waste residue in crystal industry

InactiveCN102391694ASmall particle sizeReduce miningPigment treatment with organosilicon compoundsPigment physical treatmentSocial benefitsEngineering

The invention discloses a method for preparing a plastic filler from waste residue in the crystal industry. The method comprises the following steps of: (1) primarily screening the waste residue by using screening equipment to remove impurities and large particles; (2) grinding the waste residue by using grinding equipment, and finely screening; (3) dehydrating and drying particles of the waste residue; and (4) performing surface coating treatment on the particles of the waste residue by using a surfactant to obtain a highly activated inorganic filler capable of being directly filled in plastics. The waste residue is properly treated to form the filler applied to the plastics; and by the method, a great amount of waste residue generated in the crystal industry can be recycled, the pollution of the waste residue on the environment is lightened, the exploitation of inorganic minerals is saved, and good social benefit is achieved.

Owner:JINHUA GUANHUA CRYSTAL +1

Method for grinding superfine heavy calcium carbonate in dry method

ActiveCN101768378AReduce reunionIncrease the degree of ultra-refinementPigment physical treatmentMetallurgySURFACTANT BLEND

The invention provides a method for grinding superfine heavy calcium carbonate by a dry method. The method comprises the following steps of: adding coarse heavy calcium carbonate powder into a grinding device, adding a grinding assistant and a surfactant, grinding by adopting the dry method in a grinding medium, and simultaneously adding a wetting agent in the grinding process to obtain the superfine heavy calcium carbonate, wherein the weight of the superfine heavy calcium carbonate with the grain diameter being less than 2mum accounts for 35 to 55 percent relative to the total weight thereof.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

PET (polyethylene glycol terephthalate) fiber/aramid fiber composite sound absorbing cotton and preparation method of PET fiber/aramid fiber composite sound absorbing cotton

InactiveCN102965839AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsSound producing devicesEpoxyPolymer science

Owner:芜湖跃飞新型吸音材料股份有限公司

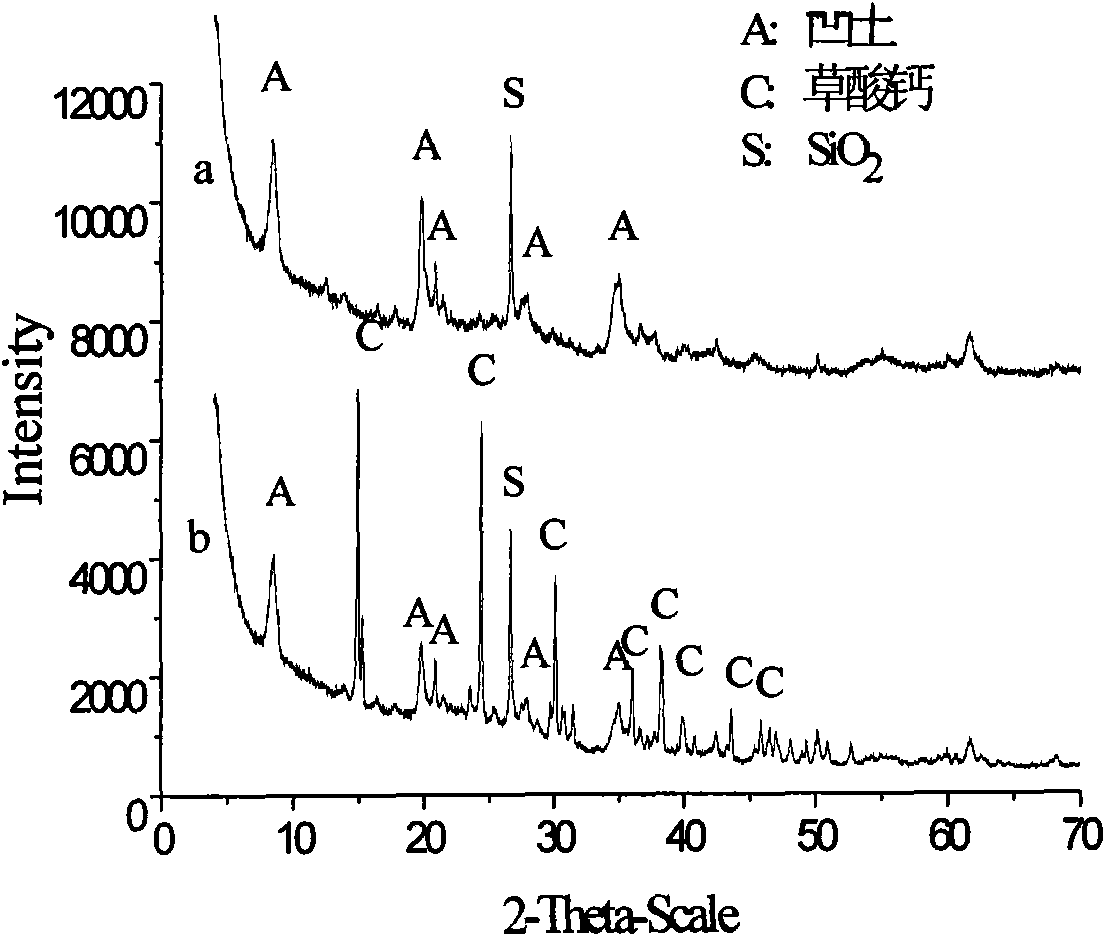

Method for removing iron and whitening for iron-containing attapulgite clay

InactiveCN101818000AEfficient removalIntensified collisionPigment physical treatmentDistilled waterSlurry

The invention relates to a method for removing iron and whitening for iron-containing attapulgite clay, comprising the following steps of: (1) selecting ore the content of attapulgite of which is more than 40%, crashing the attapulgite clay, and screening the attapulgite clay by a 100-mesh sieve, roasting and activating the attapulgite clay for 1 hour at the temperature of 300 to 700 DEG C; (2) acidulating the attapulgite clay after roasting treatment by 3 to 8% sulfuric acid , wherein the mass ratio of the sulfuric acid solution to the attapulgite clay is 8:1; placing the attapulgite clay in the sulfuric acid, stirring and soaking for 4 hours at the temperature of 60 DEG C, then washing for many times by utilizing distilled water, controlling the pH value to be 6.0 to 7.0, drying at the temperature of 105 DEG C, and then grinding, screening by a 80 to 120 mesh sieve; and (3) preparing the attapulgite clay after acidification to 10 to 30% ore slurry, placing the ore slurry into a reaction vessel, adding oxalic acid with the concentration of 0.5 to 1.5 mol / L and 3 to 5% titanium trichloride, heating reaction vessel for 8 to 150 minutes, acidulating for 40 to 50 minutes, and centrifuging, washing and filtering after reaction, and drying at the temperature of 105 DEG C to obtain the white attapulgite clay.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com