Patents

Literature

611results about How to "The preparation process is simple and environmentally friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

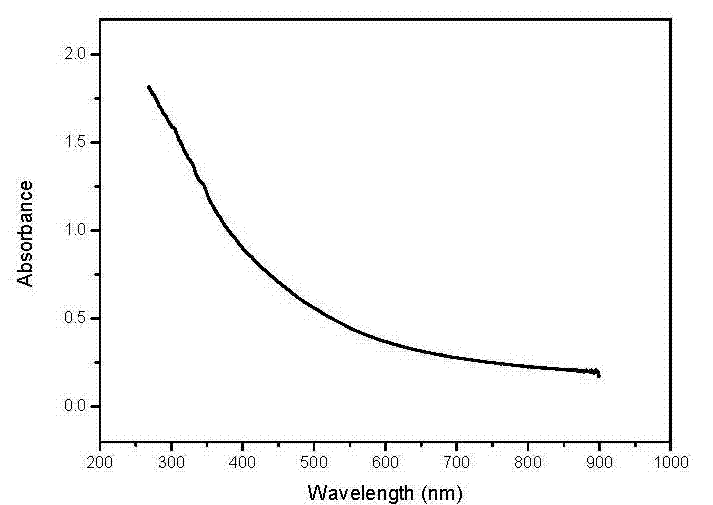

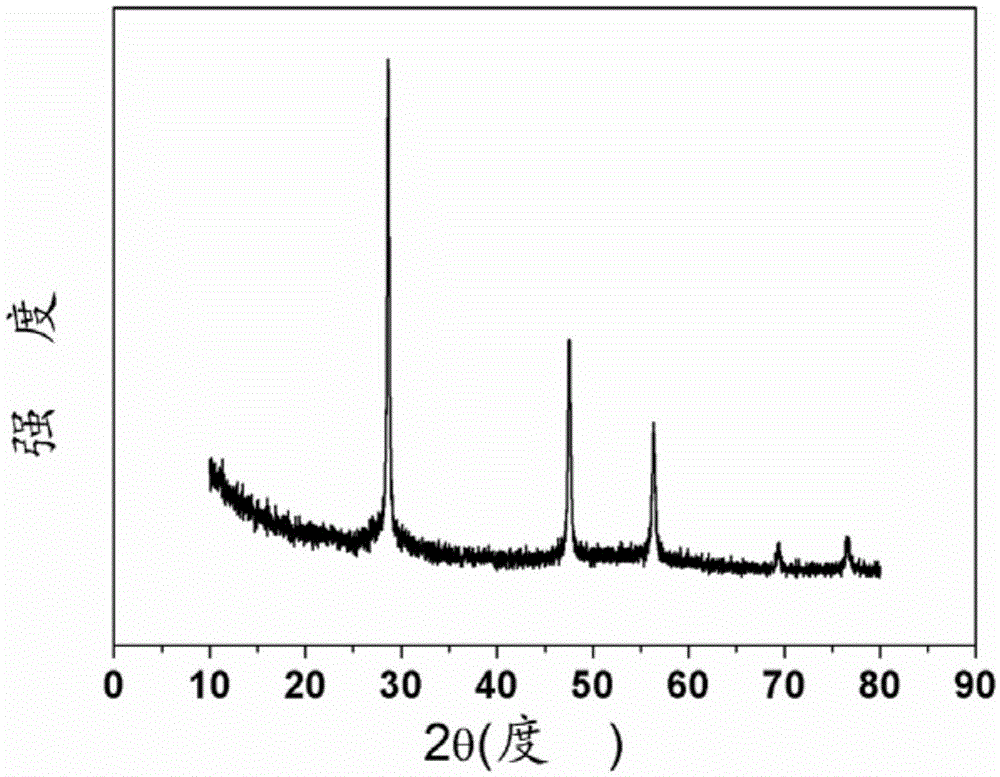

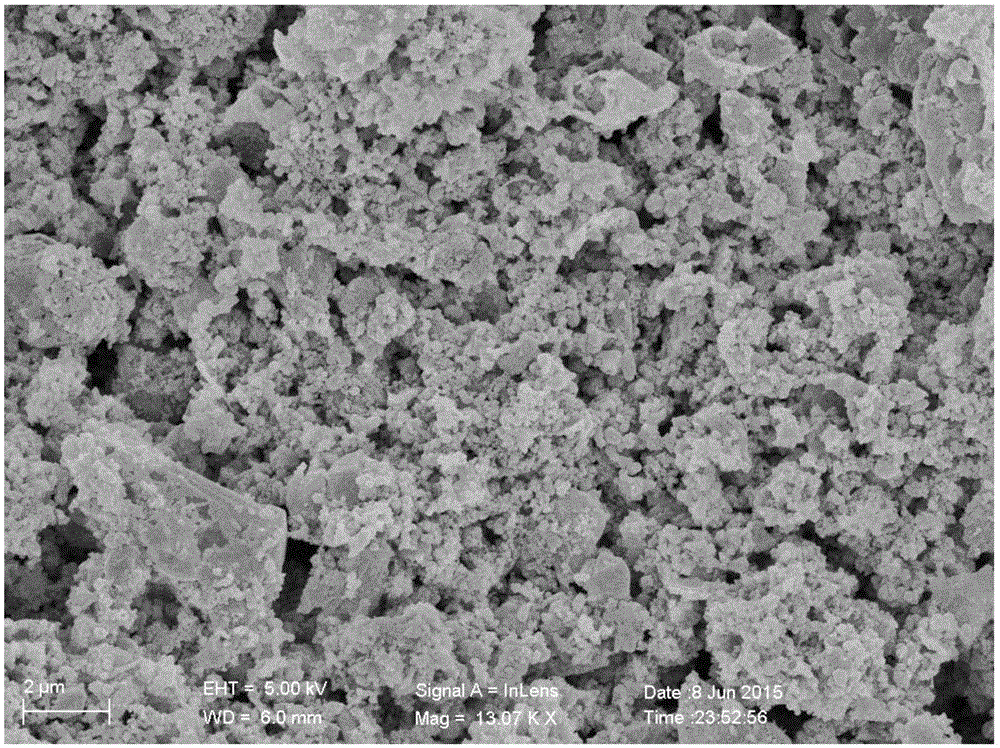

Supersonic chemical preparation method for grapheme quantum dots

InactiveCN102225758AEasy to operateSimple processNanotechnologyEnergy based chemical/physical/physico-chemical processesSolubilityUltrasound - action

A supersonic chemical preparation method for grapheme quantum dots relates to a preparation method for grapheme quantum dots, and especially relates to a method for preparing a grapheme quantum dot solution with the characteristics of good monodispersity and luminescence performance using a simple and environmentally friendly process with cheap carbon black or graphite powder as the raw material. The preparation method provided in the invention is characterized by adding a dispersant into carbon black or graphite and obtaining grapheme quantum dots under the action of supersonic wave. The grapheme quantum dot solution prepared in the invention has the characteristics of luminescence, monodispersion, water-solubility, etc.

Owner:KUNMING INST OF PHYSICS

Preparation method for silicon nano material and application

ActiveCN105084365ASave raw materialsLow reaction temperatureMaterial nanotechnologyCell electrodesOrganic solventReaction temperature

Owner:UNIV OF SCI & TECH OF CHINA

Method for preparing microcapsule red phosphorus inflaming retarding polylactic acid

ActiveCN101696319ALow costThe preparation process is simple and environmentally friendlyPigment treatment with macromolecular organic compoundsPigment physical treatmentMelamine formaldehyde resinMoisture

The invention belongs to the technical field of inflaming retarding modification of high polymer materials, and specifically relates to a method for preparing microcapsule red phosphorus inflaming retarding polylactic acid. The method comprises the following steps of: pre-treating red phosphorus, and preparing melamine formaldehyde resin prepolymer solution; adding the pretreated red phosphorus, distilled water which is 2 to 20 times of the quantity of the red phosphorus and a dispersing agent which is 0.5 to 2 percent of the quantity of the red phosphorus into a reaction vessel; stirring the mixture and heating the mixture to a temperature of between 60 and 90 DEG C to obtain a red phosphorus suspension; then adding metal salt solution into the suspension; adjusting the pH value of the system by using ammonia water; keeping the temperature and stirring the mixture; adding the mixture into the melamine formaldehyde resin prepolymer solution so that the resin content in the solution is 22 to 94 percent of quantity of the red phosphorus; adjusting the pH value of the system to between 4 and 5 by using glacial acetic acid, keeping the temperature and stirring the mixture; after the reaction is finished, cooling and filtering the suspension, washing the suspension to be neutral, and drying the suspension to obtain inorganic-organic double-layer coated microcapsule red phosphorus; grinding the obtained microcapsule red phosphorus, and drying polylactic acid to remove the moisture; and adding the obtained microcapsule red phosphorus and the polylactic acid into a drying container, mixing the obtained microcapsule red phosphorus and the polylactic acid evenly, and melting and blending the mixture to obtain the required product. In the product, the polylactic acid accounts for 65 to 75 percent and the microcapsule red phosphorus accounts for 25 to 35 percent. The method has a low cost and a simple and environment-friendly preparation process.

Owner:TONGJI UNIV

Low-temperature fast curing underfill adhesive and preparation method thereof

InactiveCN101580684ASlow down the flowLow costNon-macromolecular adhesive additivesOther chemical processesAdhesiveDiluent

The invention discloses a low-temperature fast curing underfill adhesive, which is characterized by comprising the following raw materials by weight portion: 40 to 65 portions of resin, 0.5 portion of colorant, 20 to 25 portions of curing agent, 1 to 6 portions of accelerant, 0.1 to 3 portions of coupler and 15 to 25 portions of epoxy active diluents. The preparation method comprises the following steps: firstly, uniformly mixing the resin and color paste for 20 to 40 minutes at 20 to 30 DEG C; secondly, adding the curing agent and the accelerant by three times, uniformly mixing the materials with a three-roller at 20 to 30 DEG C under a condition of chilling drying with cooling water kept at 15 DEG C for 3 times, adding the uniformly mixed materials into a reaction kettle and completely vacuumizing the reaction kettle for 15 minutes; and finally, after the resin and the curing agent are mixed uniformly, adding the coupler and the epoxy active diluents, mixing the materials in the reaction kettle, and completely vacuumizing for 30 minutes to obtain the product. The product is low in curing temperature, high in curing speed and good in storage stability, simple, easy and environmentally-friendly in preparation process, low in cost and wide in application range.

Owner:YANTAI DARBOND TECH

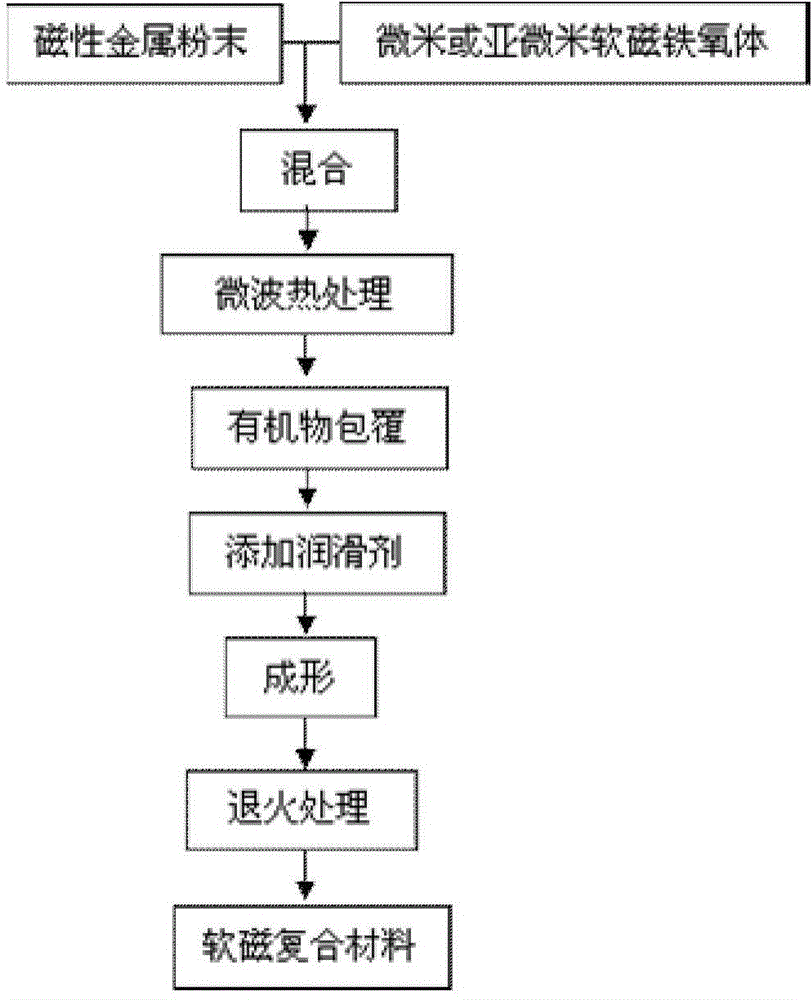

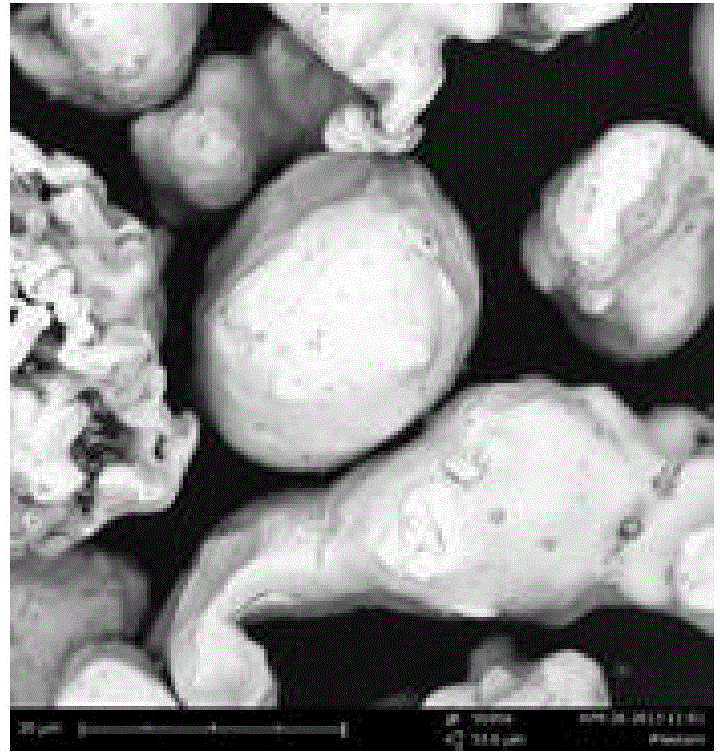

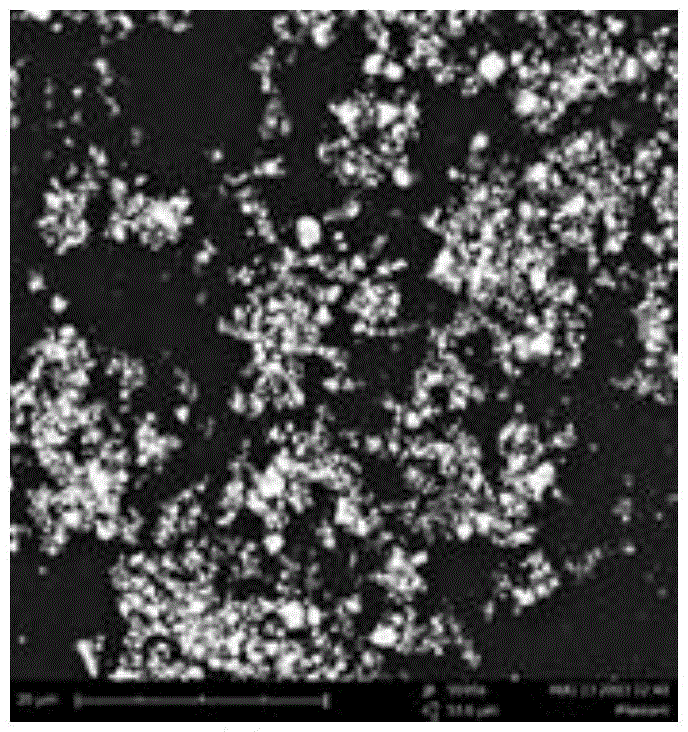

Method for coating metal magnetic powder on soft magnetic ferrites and method for preparing soft magnetic composite materials

ActiveCN104550940AConvenient sourceGood coating effectInorganic material magnetismTemperature resistanceNon magnetic

The invention provides a method for coating metal magnetic powder on soft magnetic ferrites. According to the method, the metal magnetic powder is mixed with trace micron or submicron soft magnetic ferrites, and then, a coating layer is formed through microwave high-temperature heat treatment. The invention also discloses a method for preparing the metal soft magnetic composite materials by adopting the coating powder. According to the method, the coating powder is subjected to organic matter coating, lubricating agents are added, pressing and forming are carried out, finally, annealing treatment is carried out, and the soft magnetic composite materials are obtained. The method has the advantages that the characteristics of magnetism, high electrical resistivity and high-temperature resistance of ferrite soft magnetic materials are sufficiently used, the two kinds of soft magnetic materials are compounded, non-magnetic substances are less than other kinds of soft magnetic composite materials, and in addition, a higher heat treatment temperature is realized, so that better magnetic performance is realized. The soft magnetic composite materials prepared by adopting the method provided by the invention have higher magnetic conductivity and low loss, the frequency stability is good, the magnetic loss at high frequency is low, in addition, the preparing process is simple, the environment is protected, the operation is easy, the cost is low, and the method is suitable for industrial mass and large-scale production.

Owner:NBTM NEW MATERIALS GRP

Hericium erinaceus and grape dried fruit for nourishing stomach

InactiveCN103875871AThe preparation process is simple and environmentally friendlyFull of nutritionConfectionerySweetmeatsClaviceps purpureaAdditive ingredient

A hericium erinaceus and grape dried fruit for nourishing stomach is prepared from the following raw materials in parts by weight: 400-420 parts of grape pulp, 50-60 parts of hericium erinaceus, 30-40 parts of peas, 35-40 parts of sweet potato, 30-35 parts of carrot, 60-70 parts of bayberry juice, 90-100 parts of rice wine, 30-35 parts of hawthorn, 30-35 parts of jujube, 2-25 parts of white sesameseed, 20-25 parts of purple cabbage, 10-15 parts of nori powder, 20-30 parts of milk powder, 3-5 parts of pagoda flower powder, 5-6 parts of kudzuvine root and 5-7 parts of dried orange peel. The preparation process of the hericium erinaceus and grape dried fruit for nourishing stomach is simple and environmentally friendly. By adding the ingredients of hericium erinaceus, bayberry juice, and rice wine and so on, the dried fruit has the function of nourishing stomach and promoting appetite and the nutrition of the dried fruit is enriched. In addition, extracts of Chinese medicinal materials such as pagoda flower powder, kudzuvine root, dried orange peel, prepared rehmannia root and maitake are added, so that the dried fruit has very good health care function and is recommended to most of people.

Owner:张静

Yam grape cake

InactiveCN103876048AThe preparation process is simple and environmentally friendlyGreat tasteYeast food ingredientsNatural extract food ingredientsCirsiumSalvia miltiorrhiza

The invention discloses a yam grape cake which comprises the following raw materials in parts by weight: 150-160 parts of glutinous rice flour, 100-120 parts of wheat flour, 30-40 parts of corn starch, 100-120 parts of grapes, 100-120 parts of yams, 40-50 parts of coix seeds, 50-60 parts of red beans, 6-8 parts of beer yeast powder, 4-6 parts of ganoderma lucidum spore powder, 5-7 parts of radix polygonati officinalis, 3-5 parts of cirsium setosum, 3-5 parts of perilla frutescens, 5-7 parts of astragalus membranaceus, 4-6 parts of salviae miltiorrhizae, 3-5 parts of safflower seeds and 3-5 parts of pumpkin flowers. A preparation process of the yam grape cake is simple and environmentally friendly; food materials such as the yams, the coix seeds and the red beans are added during preparation, so that the cake is good in mouth feel and rich in nutrition; extracts of Chinese herbal medicines such as the radix polygonati officinalis, the cirsium setosum, the perilla frutescens, the astragalus membranaceus and the salviae miltiorrhizae are added at the same time, so that the cake has certain health-keeping and health-care effects and is beneficial to human health.

Owner:张静

Thermal-activated adhesive film and method of producing the same

InactiveCN101402831ALow curing temperatureFast curingNatural rubber adhesivesFilm/foil adhesivesCross linkerBiological activation

The invention discloses a thermal activating glue film. The thermal activating glue film is characterized by consisting of resin, rubbers, fillings, a cross linker, a perduren compound and a promoter which are melted and mixed by a mixing mill and then calendered into a film. The thermal activation glue film is a thermal activating glue film which has the advantages of fast solidifying speed, excellent storage stability and high solidifying intensity, temperature resistance, environment protection and low cost.

Owner:YANTAI DARBOND TECH

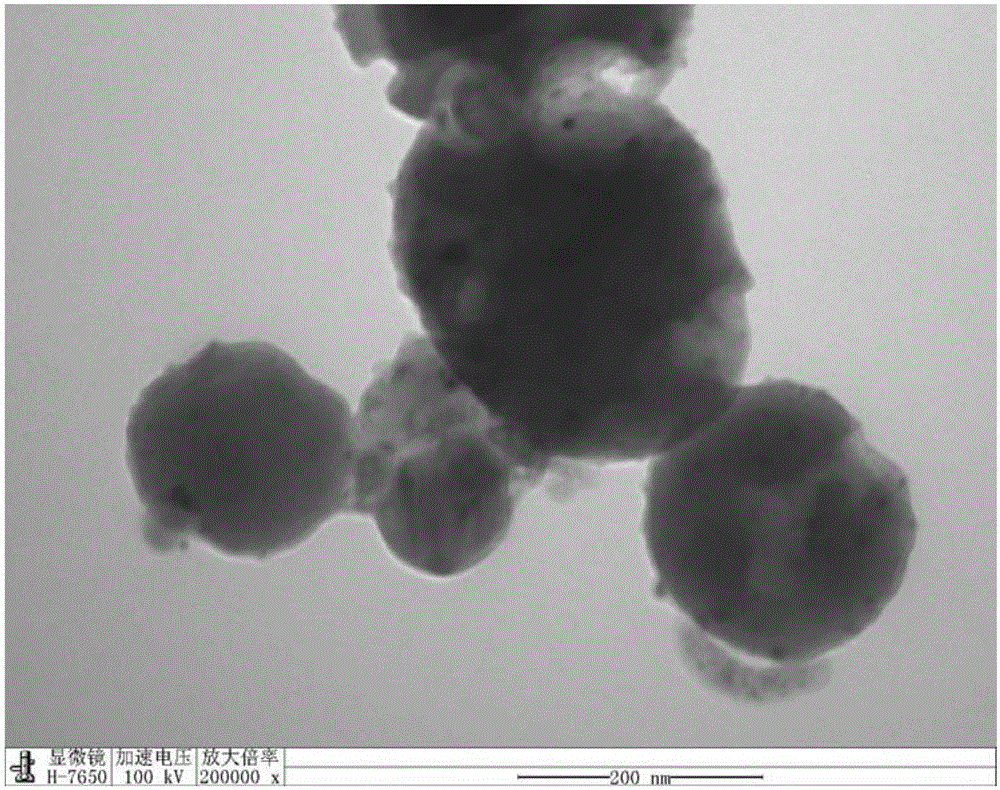

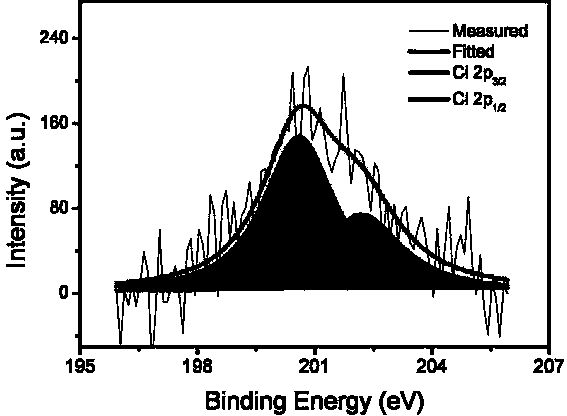

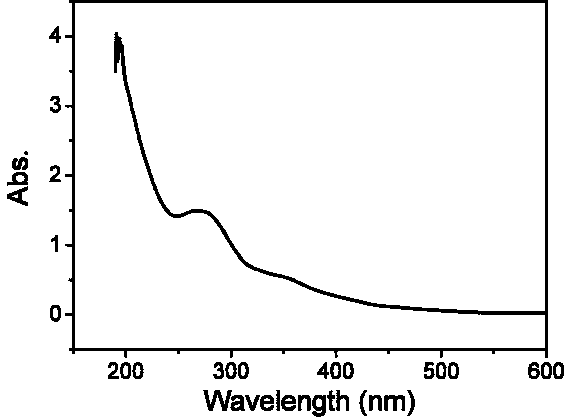

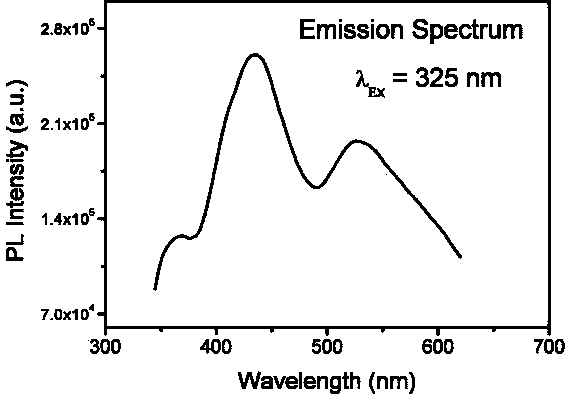

Preparation method of oxygen and chlorine co-doped graphene quantum dots

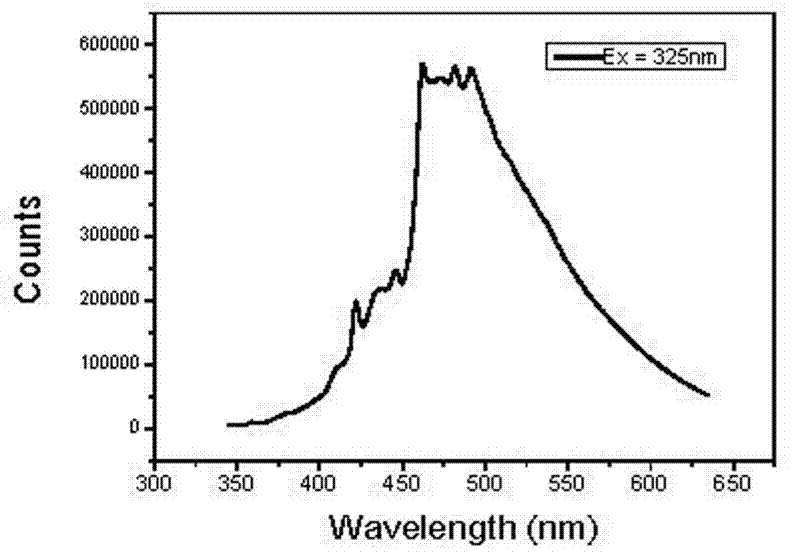

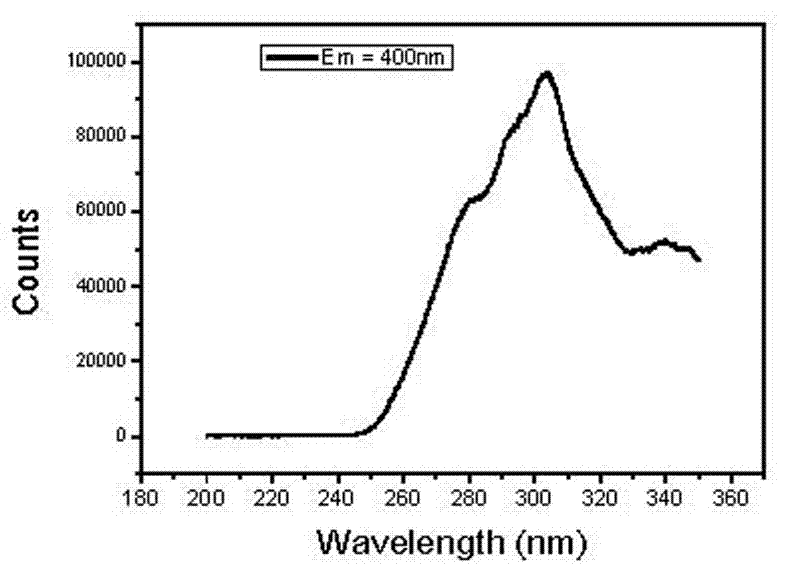

InactiveCN103359727AAverage distribution size narrowEasy to operateGrapheneDoped grapheneLuminescence

The invention discloses a preparation method of oxygen and chlorine co-doped graphene quantum dots, and relates to hydro-thermal preparation technology of the oxygen and chlorine co-doped graphene quantum dots. The hydro-thermal preparation technology of the oxygen and chlorine co-doped graphene quantum dots is characterized in that: under hydro-thermal conditions and hydrochloric acid catalysis conditions, a saccharide is used as a carbon source and an oxygen doping source, hydrochloric acid is used as a chlorine doping source, and water-soluble oxygen and chlorine co-doped graphene quantum dots are produced by water molecule-eliminating polymerization of saccharide molecules and the hydrochloric acid. The hydro-thermal preparation technology relates to simultaneous introduction of elements of oxygen and chlorine into the graphene quantum dots, so that electron transition effective energy levels in the graphene quantum dots can be increased, and furthermore the prepared oxygen and chlorine co-doped graphene quantum dots have more excellent luminescence and luminescence modulation performances.

Owner:YUNNAN NORMAL UNIV

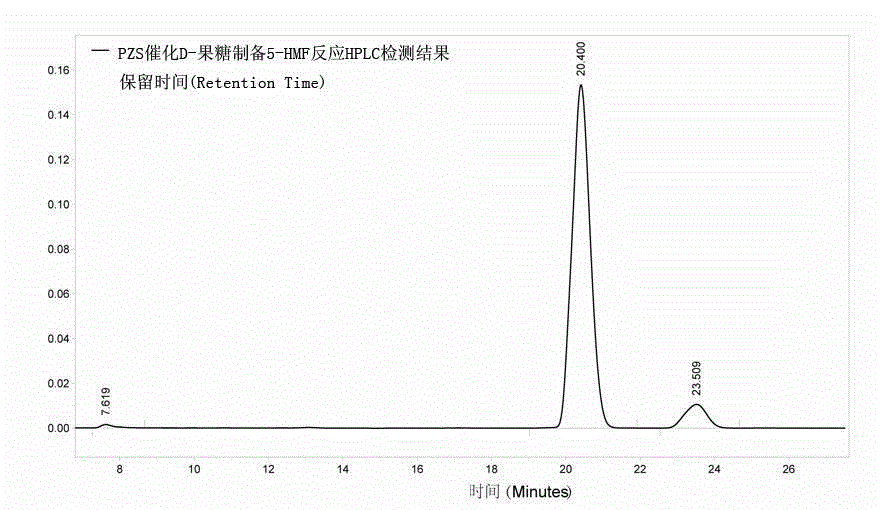

Method for preparing 5-hydroxymethylfurfural

InactiveCN102911142AImprove conversion rateHigh selectivityOrganic chemistryPtru catalystFuraldehyde

The invention belongs to the technical field of productions of chemical products, in particular to a method for preparing 5-hydroxymethylfurfural. The method includes steps of taking a macromolecular polyphosphazene polymer matrix as a solid acid type heterogeneous catalyst, taking monosaccharide, disaccharide or polysaccharide as raw materials, reacting for 5minutes to 24 hours in single-component solvent or double-component solvent such as dimethyl sulfoxide, acetonitrile, methyl isobutyl ketone, water and the like at the temperature of 25-120 DEG C under normal pressure, and finally producing the 5-hydroxymethylfurfural efficiently. The method has the advantages that conversion efficiency of raw material is high, HMF selectivity is good, operation conditions are mild, reaction speed is high, the processing is simple and environment-friendly, the catalyst is easy to prepare and the like, corrosion to equipment and environment pollution due to common liquid strong-acid homogenous catalysts are avoided, and a new way is developed for preparing commodity chemicals and substitute fuels according to regenerative biological resources.

Owner:FUDAN UNIV

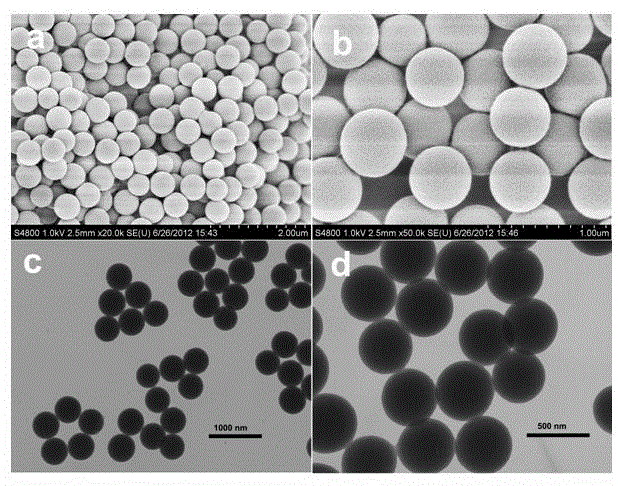

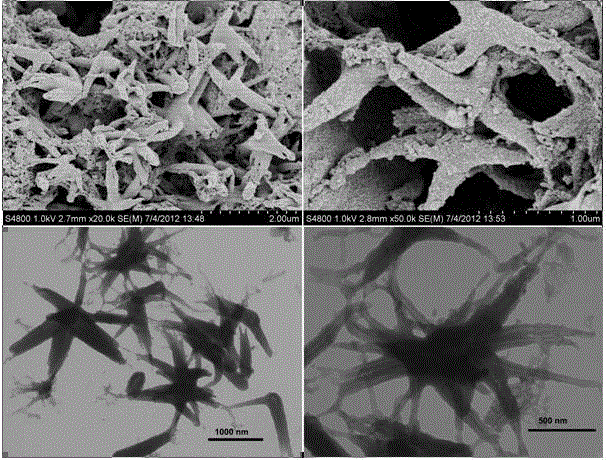

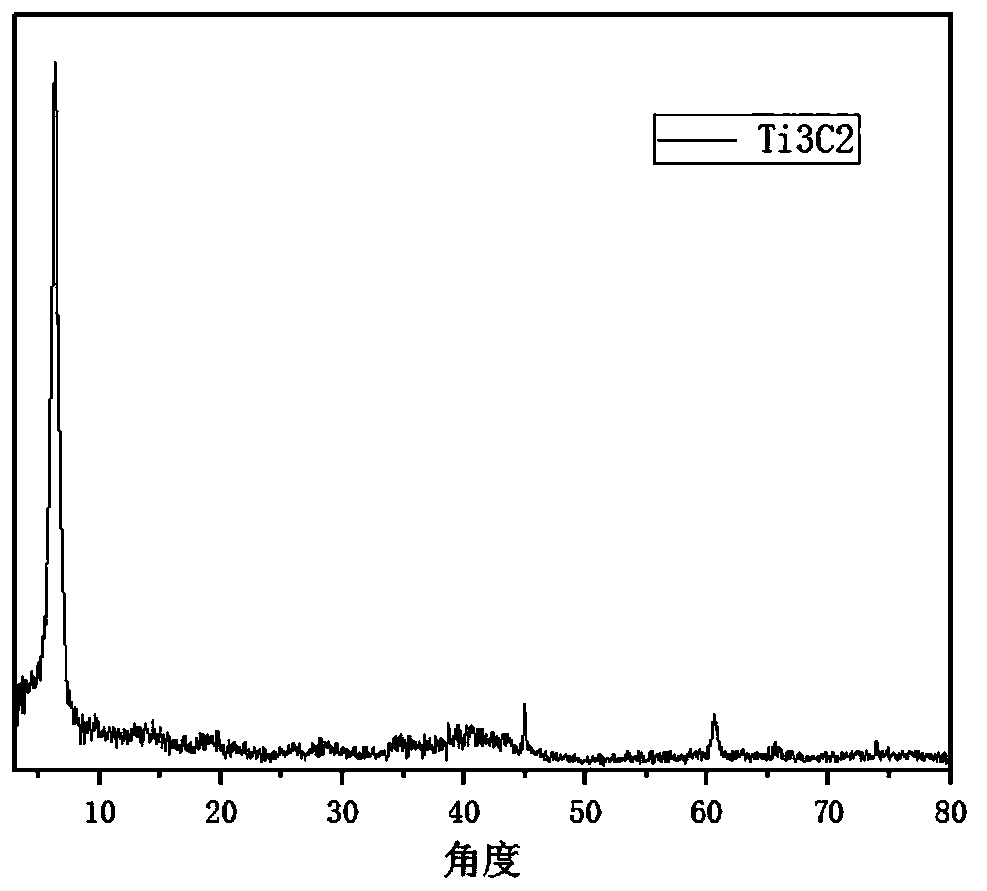

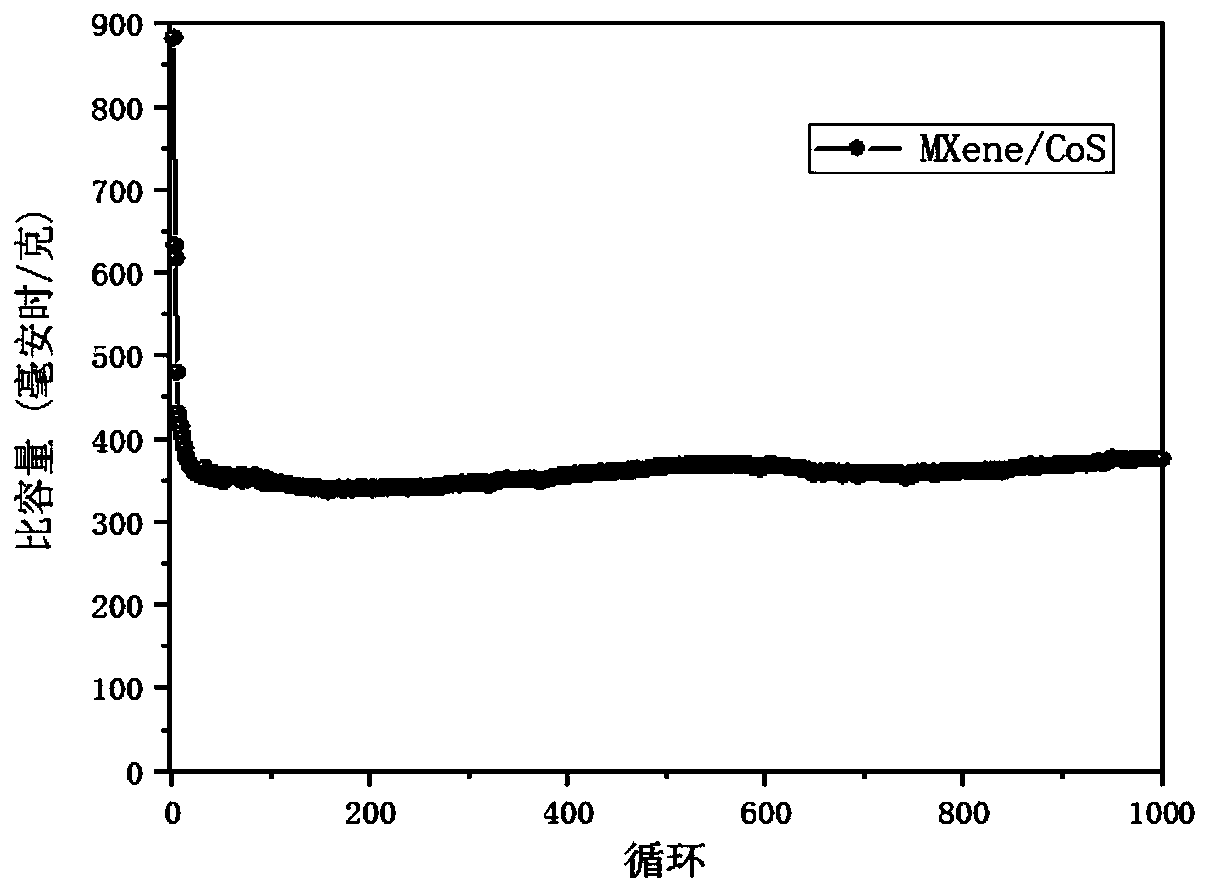

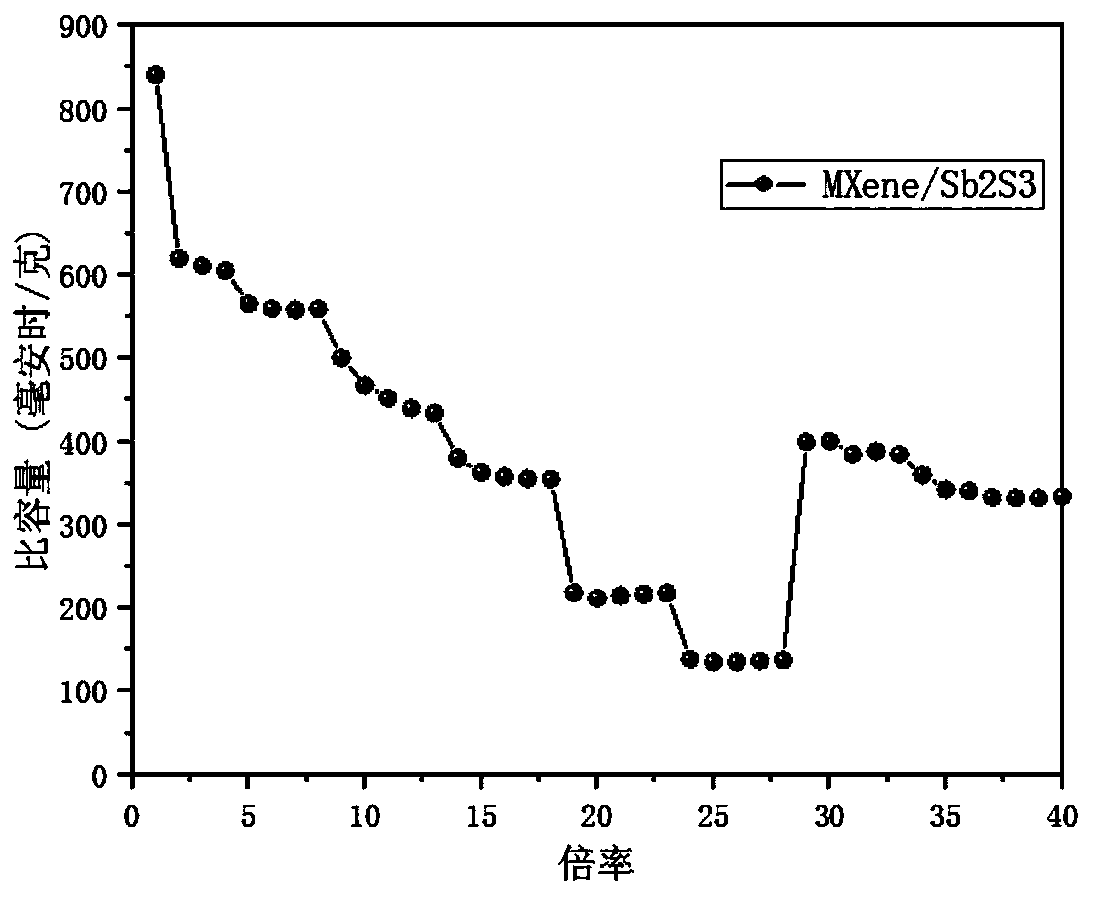

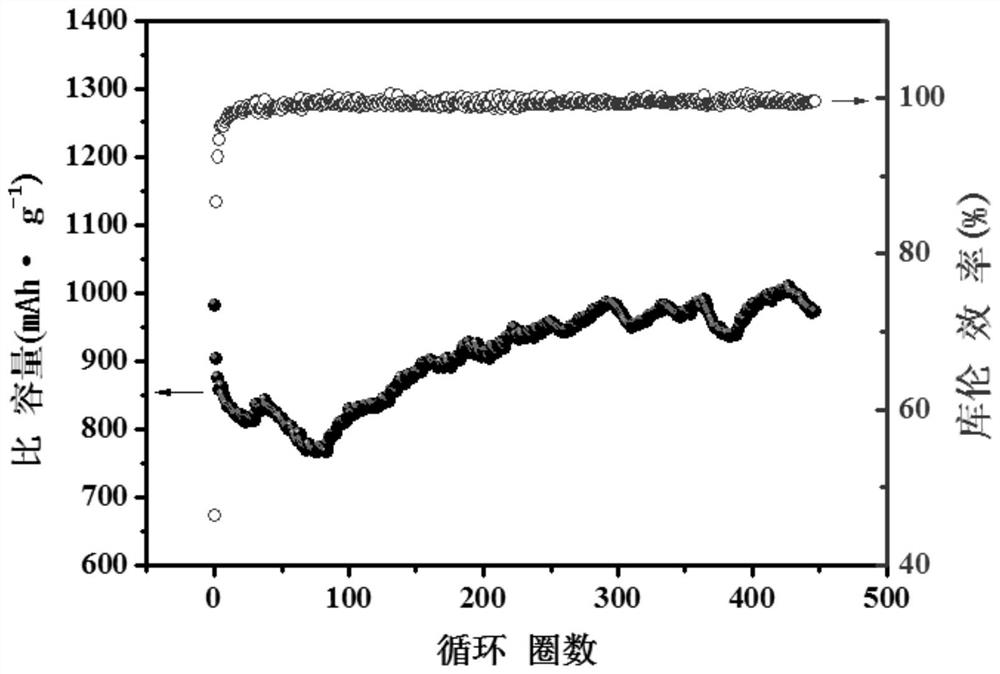

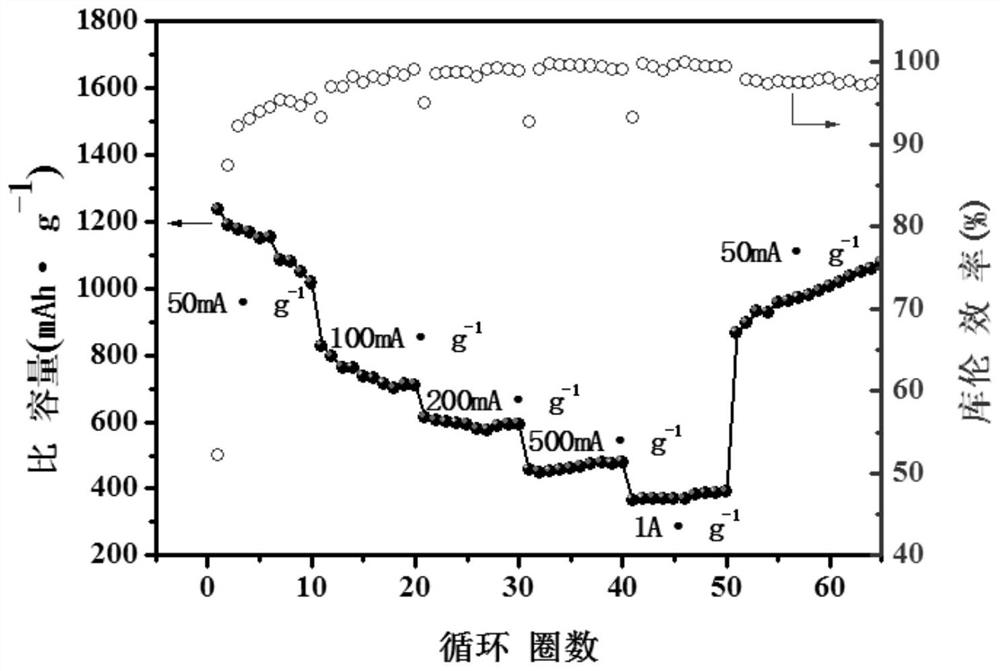

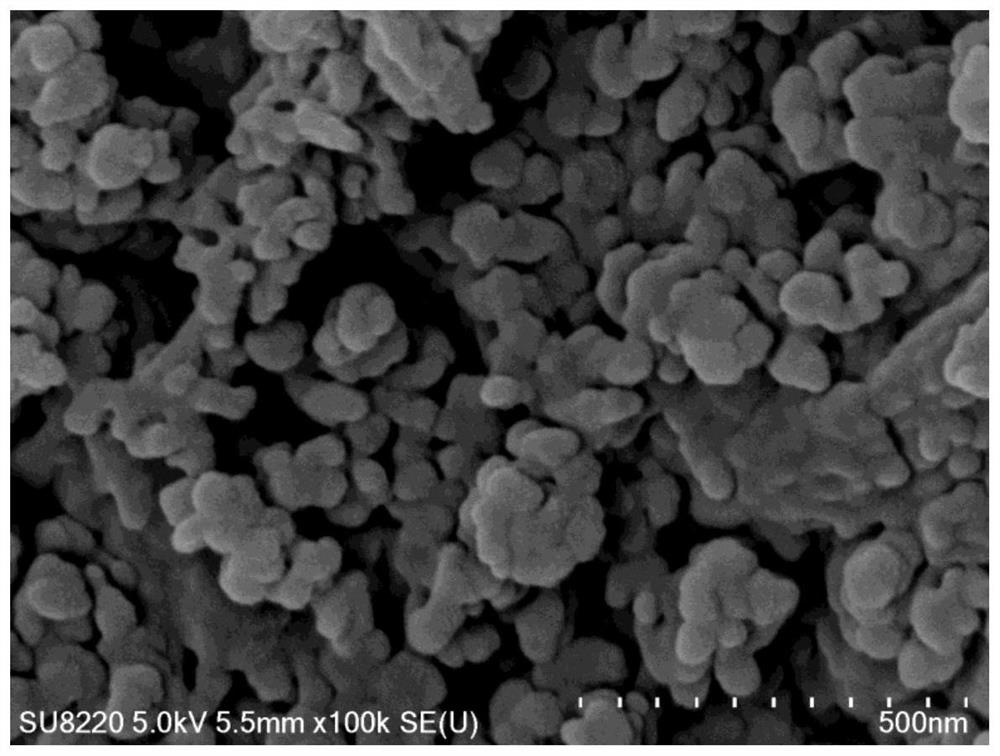

MXene/metal sulfide composite material, anode material and preparation and application

ActiveCN111180694AHigh theoretical capacityLow costNegative electrodesSecondary cellsHigh energyMetallic sulfide

The invention belongs to the technical field of high-performance / high-energy-density lithium ion battery negative electrodes, and particularly relates to an MXene / metal sulfide composite material, ananode material and preparation and application. The preparation method comprises the following steps: mixing and stirring a metal salt of a transition metal element and an MXene material, and carryingout solid-liquid separation and drying to obtain an MXene / metal salt mixture; and under a protective atmosphere, mixing the MXene / metal salt mixture with a sulfur source, and carrying out heat treatment to obtain the MXene / metal sulfide composite material. The invention also provides a sulfur-doped MXene / metal sulfide-based composite battery anode material. The anode material comprises the MXene / metal sulfide composite material. The anode material provided by the invention has good long-cycle stability, high energy density and excellent rate capability, and can be applied to various fields.

Owner:GUANGDONG UNIV OF TECH +1

Ionic crosslinking thermoplastic elastic body and preparation method thereof

ActiveCN102532770ACarboxylation transitionSimple preparation processMetal chlorideThermoplastic elastomer

The invention discloses an ionic crosslinking thermoplastic elastic body and a preparation method of the ionic crosslinking thermoplastic elastic body. The ionic crosslinking thermoplastic elastic body is prepared from the following ingredients in parts by mass: 100 parts of rubber, 2 to 20 parts of organic carboxylic acid, 0.1 to 2 parts of initiating agent and 2 to 30 parts of metallic oxide, metal hydroxide and / or metal chloride. The ionic crosslinking thermoplastic elastic body prepared by the method has good mechanical performance, the tensile strength of the ionic crosslinking thermoplastic elastic body at least reaches 6MPa, the tension fracture elongation at least reaches 700 percent, the Shore hardness (A) at least reaches 63, and the differential scanning calorimetry (DSC) glass-transition temperature can reach 10 DEG C. The preparation process of the ionic crosslinking thermoplastic elastic body is simple, and the preparation process and the product are environment-friendly, and the ionic crosslinking thermoplastic elastic body is expected to be widely applied to the fields of shoes, sealing rings, automobiles, oil transmission pipelines and the like.

Owner:FUJIAN NORMAL UNIV

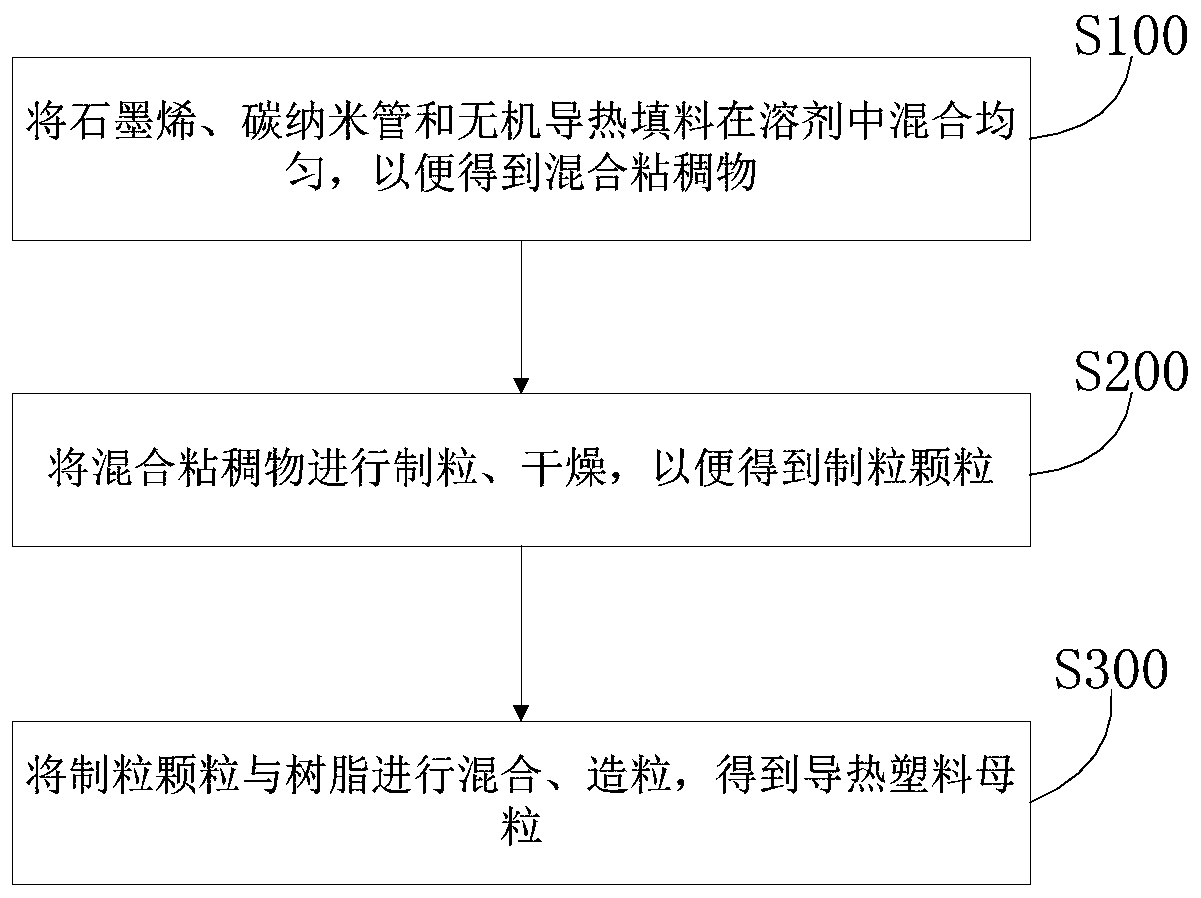

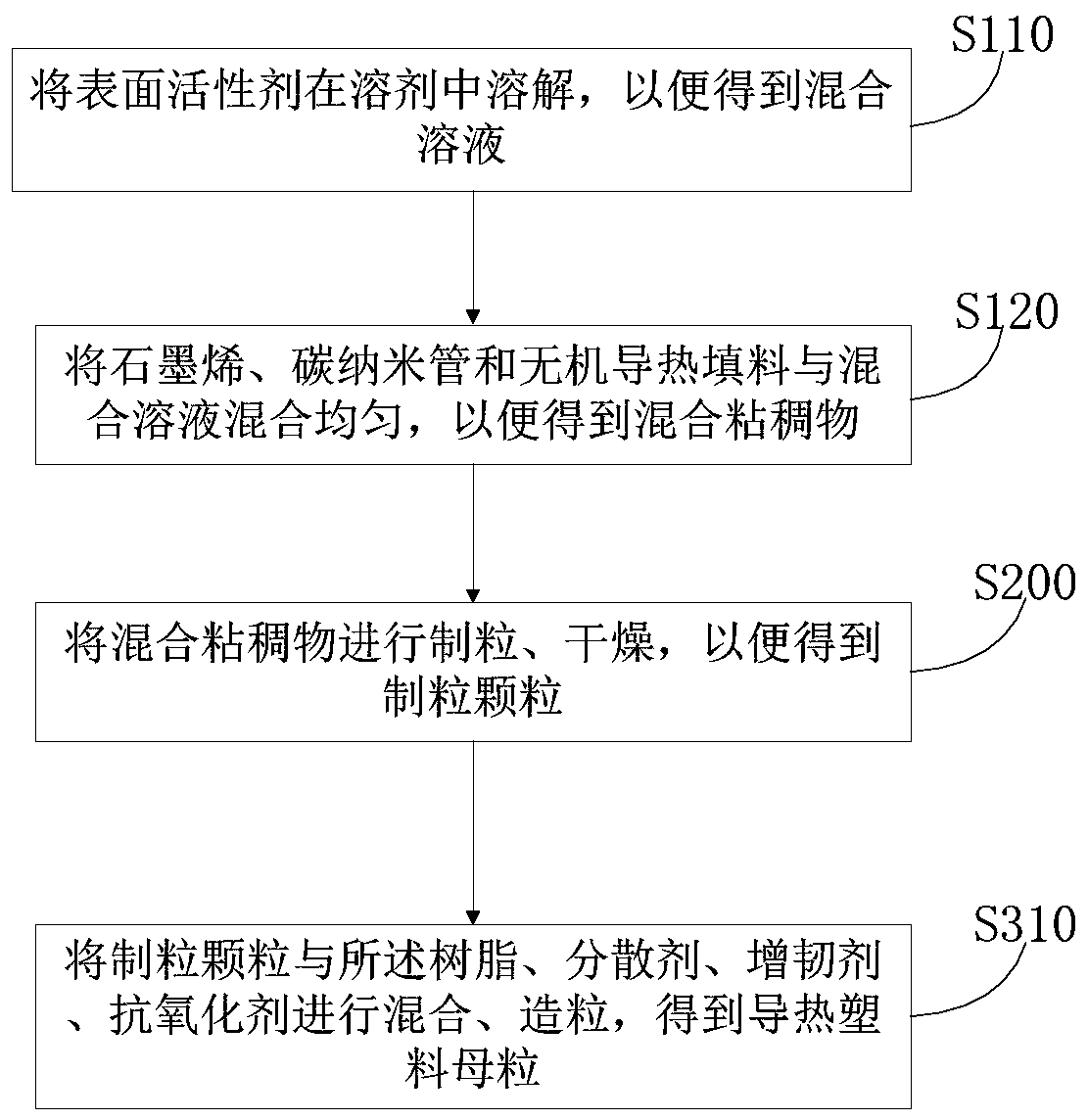

Heat-conducting plastic master batch, preparation method thereof and heat-conducting plastic

InactiveCN110172166AImprove thermal conductivityEvenly dispersedHeat-exchange elementsHeat conductingCarbon nanotube

The invention provides a heat-conducting plastic master batch, a preparation method thereof and heat-conducting plastic. The heat-conducting plastic master batch comprises resin, graphene, carbon nanotubes and a micron-sized inorganic heat-conducting filler. Thus, the nanoscale graphene and carbon nanotubes and the micron-sized inorganic heat-conducting filler complement each other in geometric dimensions and dimensions, the accordingly generated synergistic effect not only can significantly improve the heat-conducting performance of the heat-conducting plastic master batch, but also ensures the uniform dispersion of the graphene, carbon nanotubes and inorganic heat-conducting filler in the resin to obtain the heat-conducting plastic master batch with high filling density and uniformity; the mixing method can increase the filling ratio of the graphene, obtain the concentrated master batch of a network structure (heat-conducting network) formed by the graphene, the carbon nanotubes andthe inorganic heat-conducting filler in the resin, and the good construction of the heat-conducting network structure can significantly improve the heat-conducting performance of the heat-conducting plastic master batch and also improve the mechanical strength and impact toughness of the heat-conducting plastic master batch.

Owner:ENN GRAPHENE TECH CO LTD

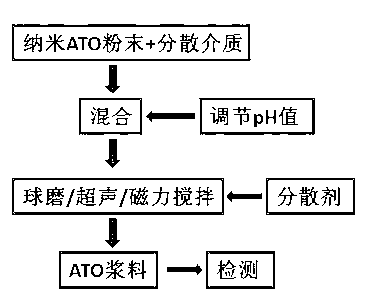

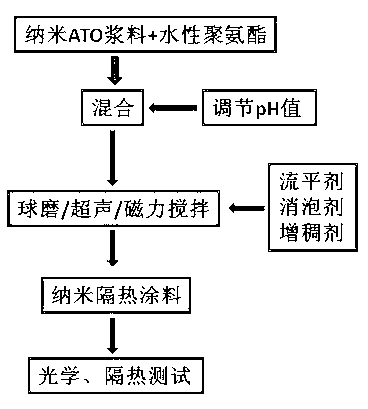

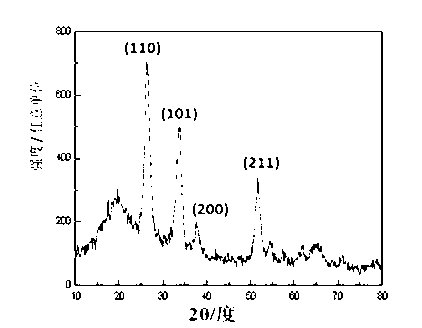

Preparation method of nano antimony tin oxide transparent insulation film

InactiveCN103102083AHigh visible light transmittanceImprove barrier propertiesPolyurea/polyurethane coatingsCzochralski methodThermal insulation

The invention discloses a preparation method of a nano antimony tin oxide (ATO) transparent insulation film. The method comprises following steps: 1) preparation of a nano ATO slurry: mixing an ATO nanopowder and a dispersant according to proportion and stirring thoroughly, and regulating a pH value to prepare the nano ATO slurry; 2) preparation of a nano ATO thermal insulation coating: mixing the nano ATO slurry and aqueous polyurethane, adjusting a pH value, adding a leveling agent, a defoaming agent and a thickener for dispersion, so as to prepare a nano thermal insulation coating; and 3) preparation of a transparent insulation film: immersing a clean glass substrate in the prepared nano thermal insulation coating liquid, and preparing a transparent film on the glass substrate by using a spin coating method / Czochralski method / bar coating method. The nano ATO transparent thermal insulation film prepared by the method provided by the invention has high visible light transmittance and infrared barrier property, and is suitable for building thermal insulation glass. The film preparation process is simple, environment-friendly, low-cost, and can form a uniform film with large area.

Owner:HANGZHOU DIANZI UNIV

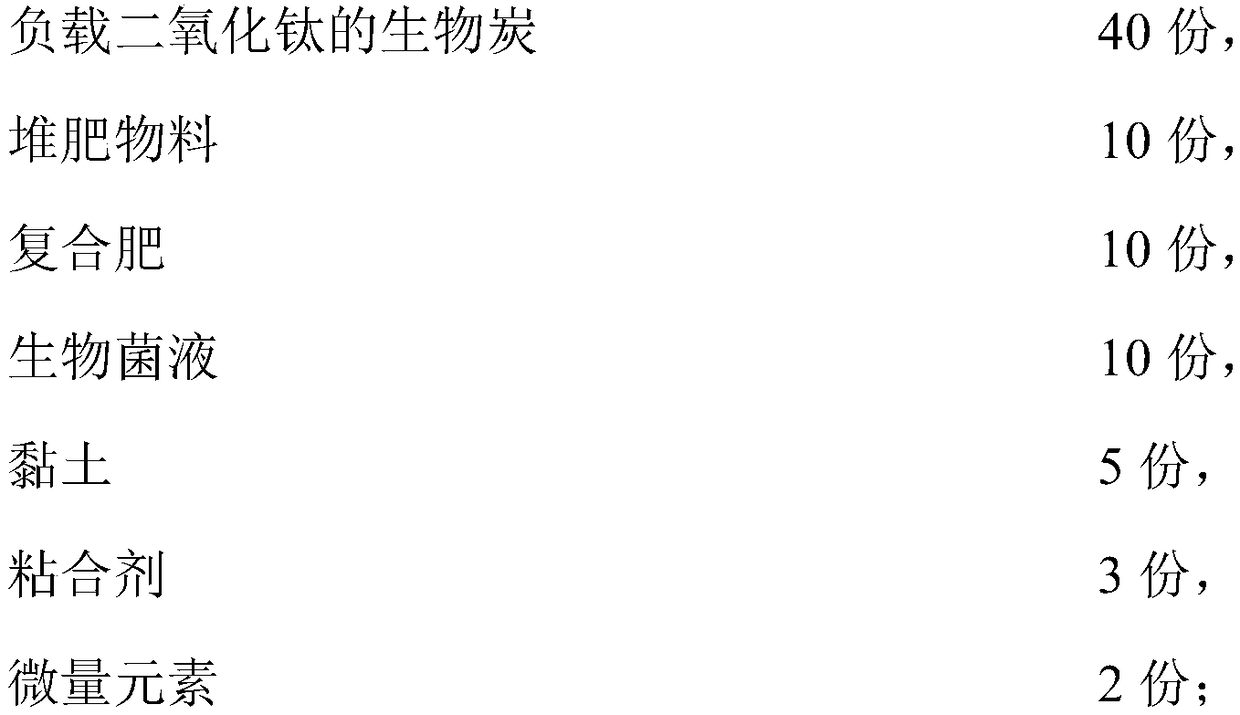

Biochar soil remediation agent and preparation method thereof

InactiveCN108640791AImprove organic matterIncrease microbial contentSuperphosphatesAlkali orthophosphate fertiliserMicroorganismSoil remediation

The invention discloses a biochar soil remediation agent and a preparation method thereof. The biochar soil remediation agent is prepared from titanium dioxide supported biochar, compost materials, compound fertilizer, a biological bacteria solution, clay, a binder and microelements; the preparation method of the biochar soil remediation agent comprises steps as follows: preparation of titanium dioxide supported biochar, preparation of the compost materials, preparation of the biological bacteria solution, preparation of the clay, preparation of a mixed material coated with biochar, pelletizing and drying. The preparation process is environmentally friendly and simple to operate, the raw materials are widely sourced, the prepared soil remediation agent not only can adsorb and degrade pollutants in soil, but also increases content of organic matter and microorganisms in the soil, and accordingly, economic benefit and environmental benefit are remarkably increased.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

Preparation method of quaternized halamine antibacterial cotton fiber

InactiveCN103276596AGood antibacterial effectThe preparation process is green and environmentally friendlyVegetal fibresCotton clothChemistry

The invention discloses a preparation method of a quaternized halamine antibacterial cotton fiber. The preparation method disclosed by the invention comprises the following steps of: taking common cotton cloth as a carrier, grafting hydrolyzed alkylsilane on cotton cloth, then carrying out quaternization between a tertiary amine functional group and an alkylhalide group on the cotton cloth to graft a halamine precursor containing the tertiary amine functional group to the cotton cloth to form the cotton cloth carrying a quaternized halamine precursor; and finally, carrying out halogenation reaction to obtain quaternized halamine antibacterial cotton cloth. The process disclosed by the invention avoids synthesizing quaternized halamine precursor silane before grafting, and the synthesis consumes time and energy and needs to use an organic solvent.

Owner:SHANGHAI NORMAL UNIVERSITY

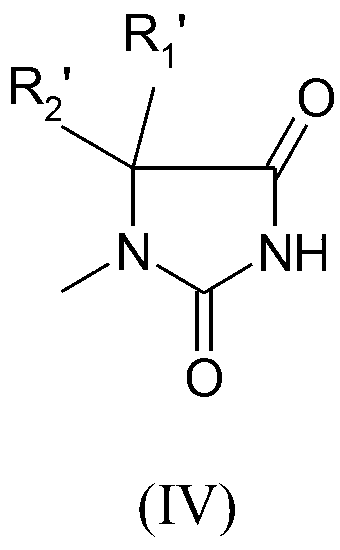

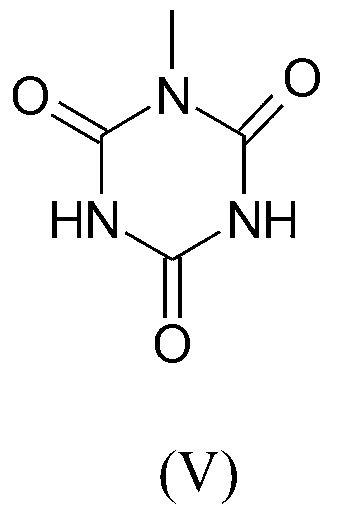

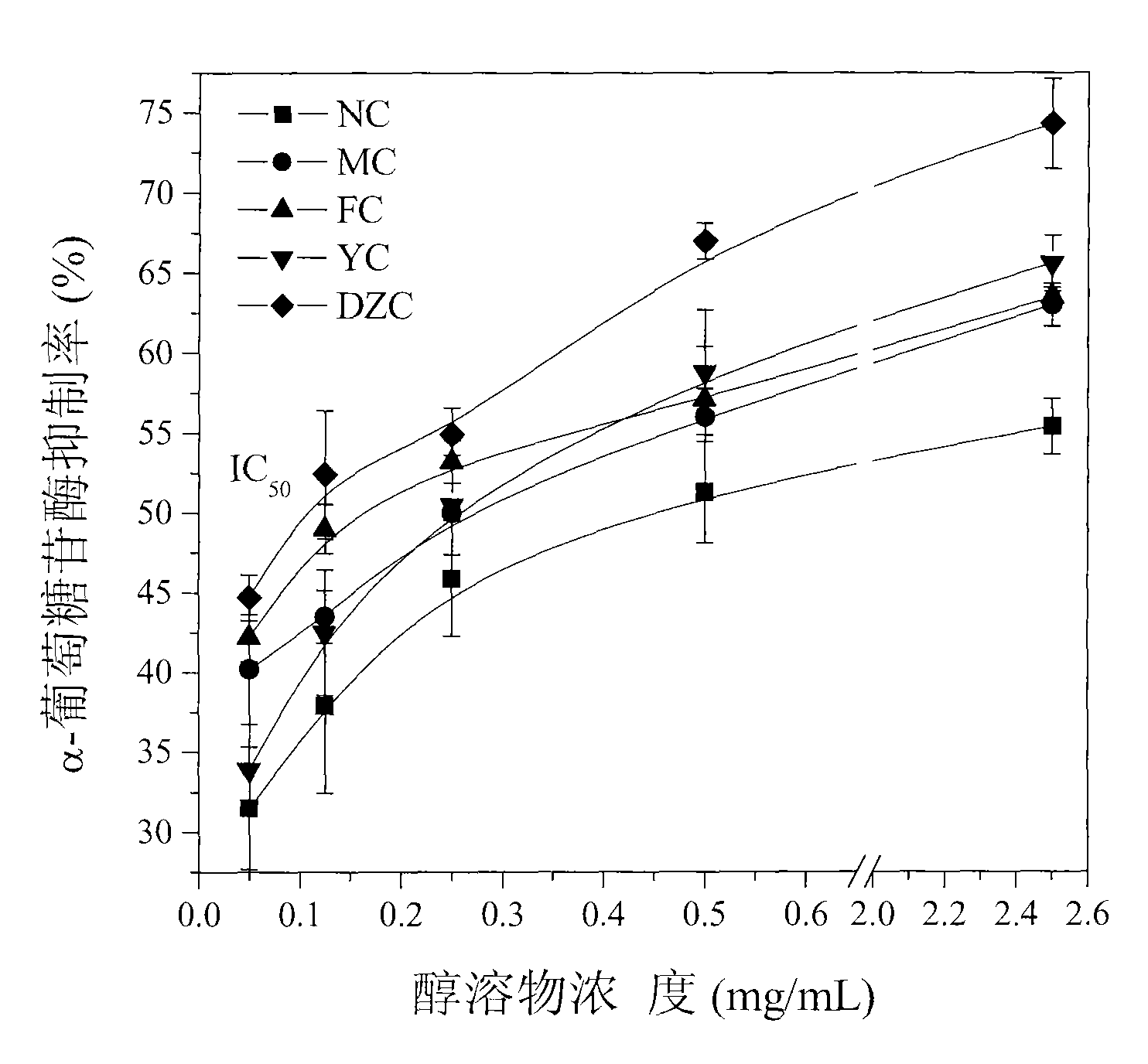

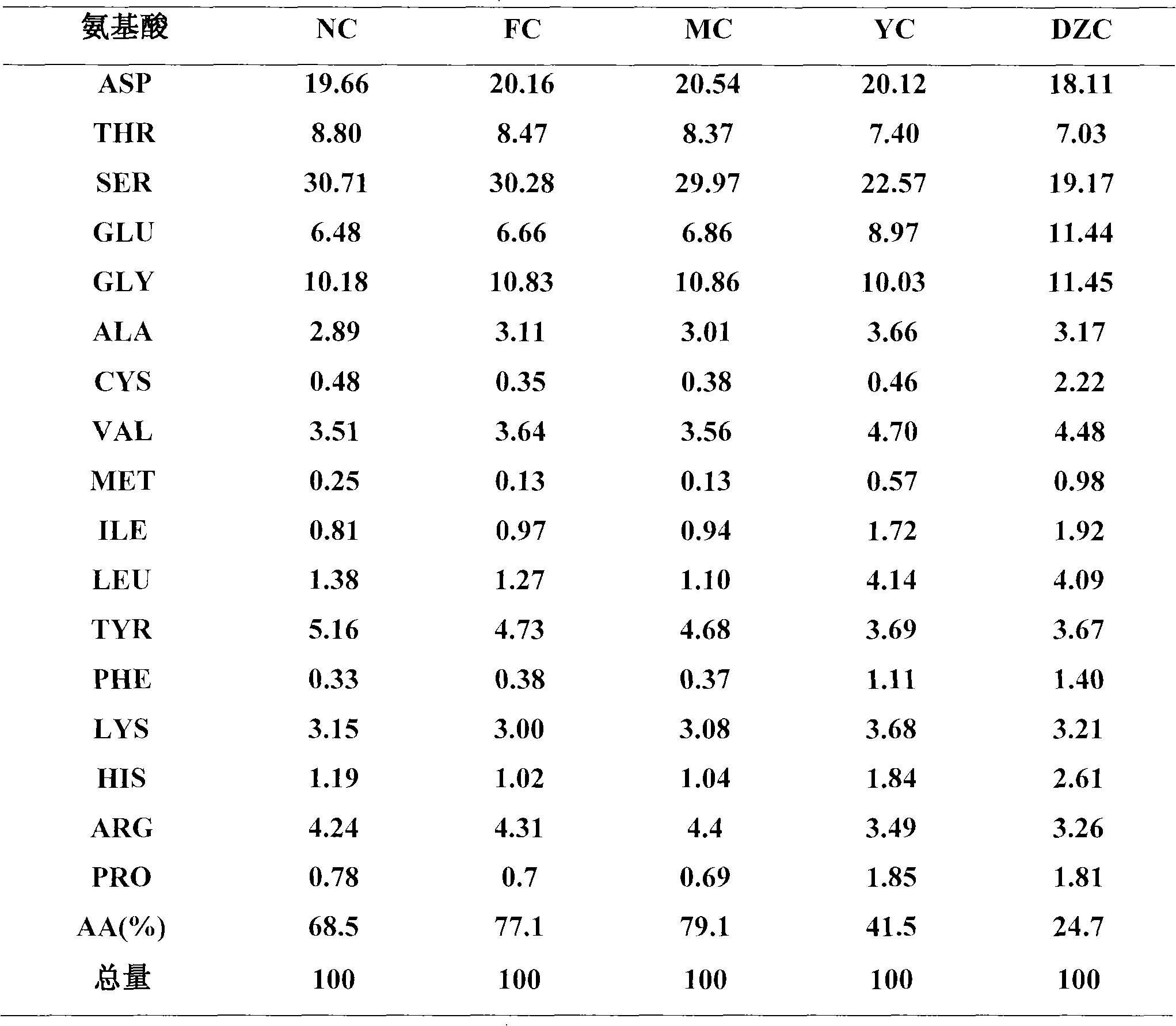

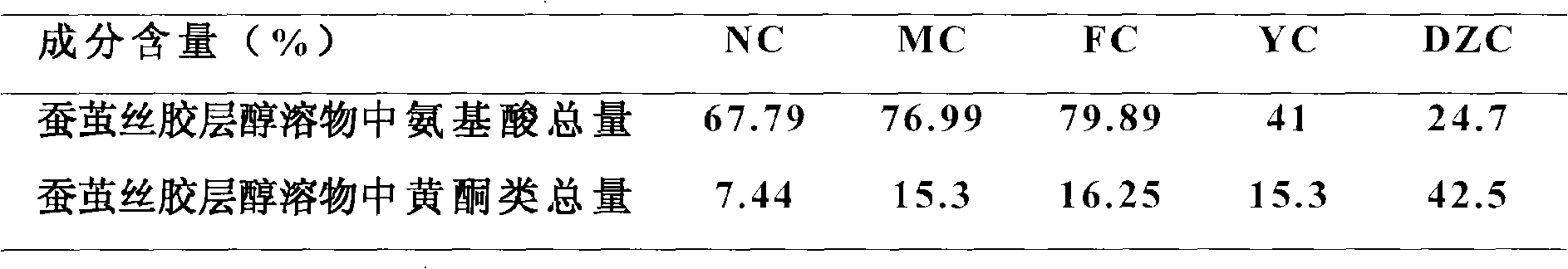

Cocoon sericin layer alcohol soluble substance and preparation method thereof

InactiveCN101601640AImprove antioxidant capacitySignificant tyrosinase inhibitory activityCosmetic preparationsAnthropod material medical ingredientsFreeze-dryingTyrosine

The invention discloses a preparation method of a cocoon sericin layer alcohol soluble substance, comprising the following steps: wetting clean cocoon shell, cocoon outer floss, waste silk or raw silk in water and carrying out degumming treatment for 1-5h under the conditions that the temperature is 110-140 DEG C and the pressure is 0.1-0.26Mpa to obtain silk degumming liquid; filtering and concentrating the silk degumming liquid to obtain concentrated sericin liquid and then adding an organic solvent for extraction; collecting supernatant and repeatedly extracting lower precipitate with the organic solvent; carrying out spray drying or vacuum freeze drying after concentrating combined supernatant to prepare powder, namely the cocoon sericin layer alcohol soluble substance; wherein, the volume ratio of the concentrated sericin liquid to the organic solvent is 1:1-9. The non-sericin component obtained by the invention has antioxidant activity, antityrosinase activity and alpha-glucosidase inhibition activity, and has wide application prospects in such aspects as cosmetics, anti-aging health care products, hypoglycemic drugs and the like.

Owner:SUZHOU UNIV

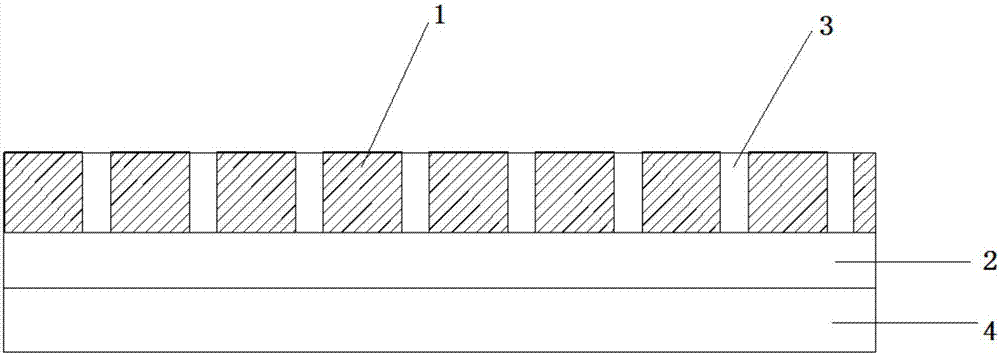

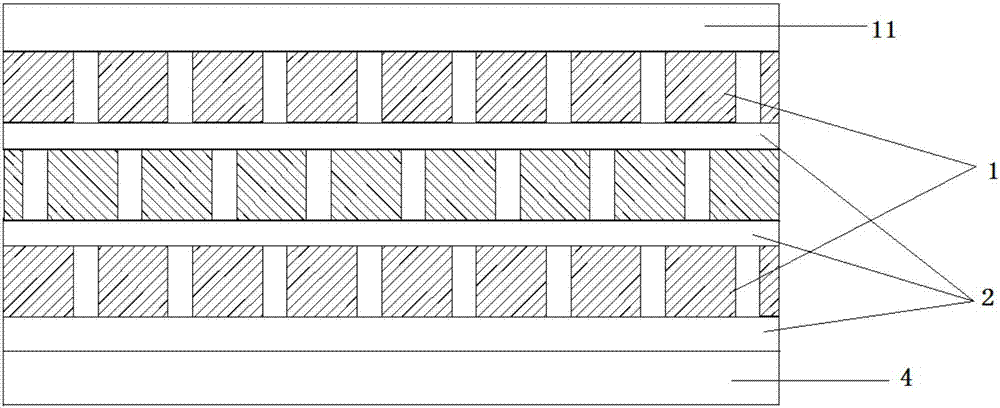

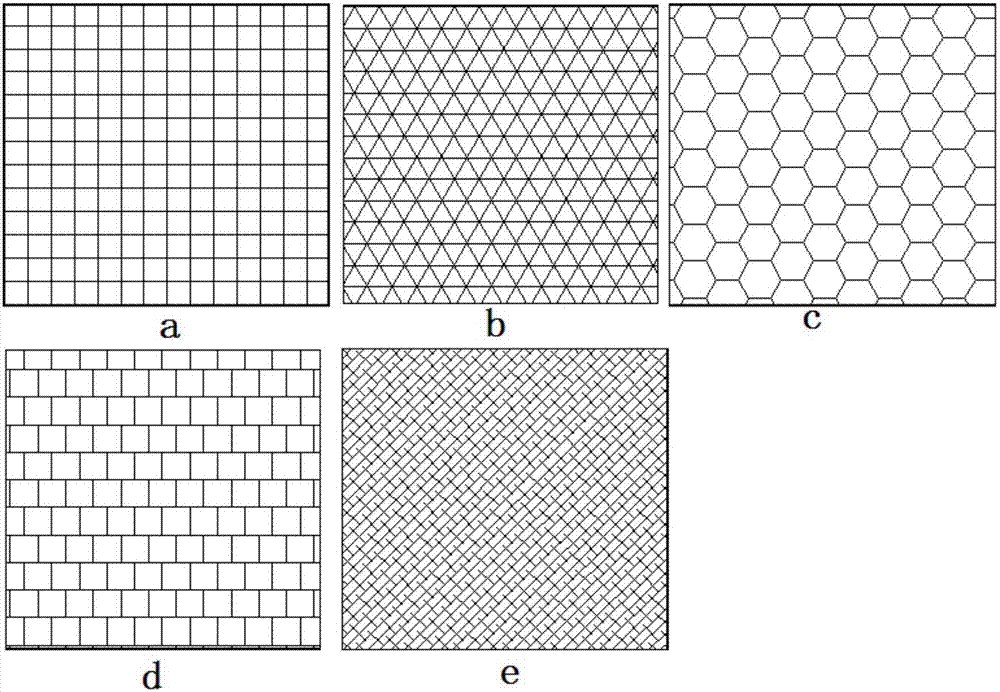

Magnetic isolation sheet applied to wireless charging and near field communication (NFC) and fabrication process of magnetic isolation sheet

InactiveCN107979966AStable working frequencyThe overall thickness is thinShielding materialsMagnetic tapeAdhesive

The invention discloses a magnetic isolation sheet applied to wireless charging and near field communication (NFC). The magnetic isolation sheet comprises at least one magnetic isolation unit, whereinthe magnetic isolation unit comprises a soft magnetic strip and a double-side adhesive tape, wherein the soft magnetic strip is of a sheet structure with two exposed surfaces, the double-side adhesive tape covers one of the exposed surfaces, and the other exposed surface of the soft magnetic strip is pressed to form a mesh-shaped line. The invention also discloses a fabrication process of the magnetic isolation sheet applied to wireless charging and NFC. The fabrication process comprises the steps of constructing a magnetic isolation unit, in which the double-side adhesive tape is pasted ontoone of the exposed surfaces of the soft magnetic strip by taking the soft magnetic strip of the sheet structure with the two exposed surfaces as an element, and the other exposed surface of the softmagnetic strip is pressed to form the mesh-shaped line; and constructing the magnetic isolation sheet. The magnetic isolation sheet applied to wireless charging and NFC, fabricated by the fabricationprocess has the advantages of thin thickness, good magnetic isolation capability, high charging efficiency, NFC working frequency stability and high product stability, and the process and the materialcost are greatly reduced.

Owner:SHANGHAI LINEPRINTING MATERIALS CO LTD

Preparation method of water dispersible granule medicinal fertilizer

The invention discloses a preparation method of a water dispersible granule medicinal fertilizer, which comprises the following steps of: firstly preparing fillers, sterilizing agents, compound activating agents, micro element fertilizers and a compound assistant which are required for preparing the medicinal fertilizers according to component proportion of different medicinal fertilizers, wherein the sterilizing agents contain liquid raw materials; then, taking a part of fillers for adsorbing the liquid raw materials, adding rest of other components and uniformly mixing to obtain a raw material mixture; carrying out air current pulverization on the raw material mixture to be below 15 microns to obtain wettable powder; controlling the granularity D98 to be less than or equal to 15 microns and the suspension ratio to be over 80 percent; taking water-borne binder solutions and mixing the water-borne binder solutions with the wettable powder, and obtaining an intermediate product through squeezing granulation-drying or boiling granulation; and finally, screening to obtain the water dispersible granule medicinal fertilizer product with the required grain size. The preparation process has the advantages of environmental friendliness, security, low cost, capability of guaranteeing product quality and the like.

Owner:湖南大方农化股份有限公司

High-reliability fast curing underfill adhesive and preparation method thereof

InactiveCN101580685AImprove reliabilityImprove temperature resistanceNon-macromolecular adhesive additivesOther chemical processesAdhesiveDiluent

The invention discloses a high-reliability fast curing underfill adhesive, which is characterized by comprising the following raw materials by weight portion: 45 to 75 portions of resin, 20 to 25 portions of specially processed silicon powder, 0.5 portion of colorant, 20 to 25 portions of curing agent, 1 to 6 portions of curing accelerant, 0.1 to 3 portions of coupler, 10 to 15 portions of cycloaliphatic epoxy resin and 15 to 25 portions of epoxy active diluents. The preparation method of the high-reliability fast curing underfill adhesive comprises the following process steps: a, pretreatment, in which the resin is roasted for one night at 70 to 75 DEG C; and b, mixing, in which the resin, the cycloaliphatic epoxy resin and the coolant are first uniformly mixed and then added with by three times the specially processed silicon powder followed by the curing agent and the curing accelerant, the uniformly mixed materials are added into a reaction kettle, the reaction kettle is completely vacuumized for 15 minutes, the coupler and the epoxy active diluents are added after the resin and the curing agent are mixed uniformly, the reaction kettle is completely vacuumized for 30 minutes, and the product is obtained. The product has the advantages of low curing temperature, high curing speed, high flowing speed, excellent storage stability, simple, easy and environmentally-friendly preparation process, low cost and wide application range.

Owner:YANTAI DARBOND TECH

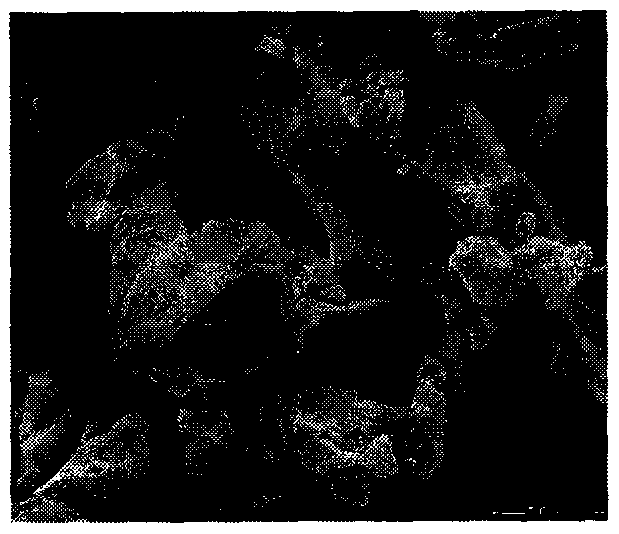

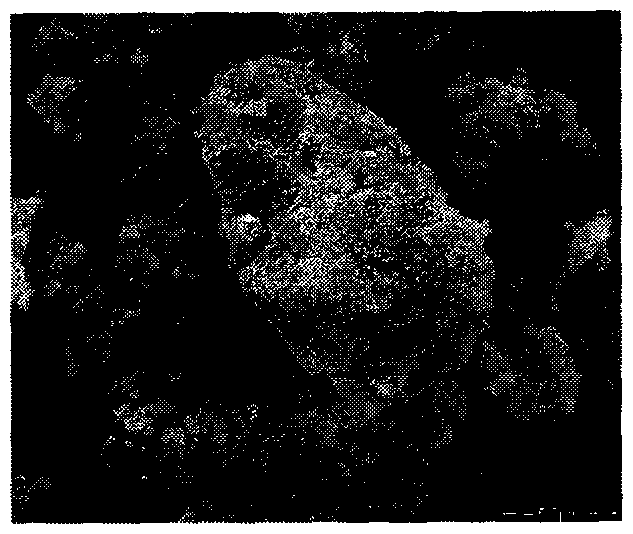

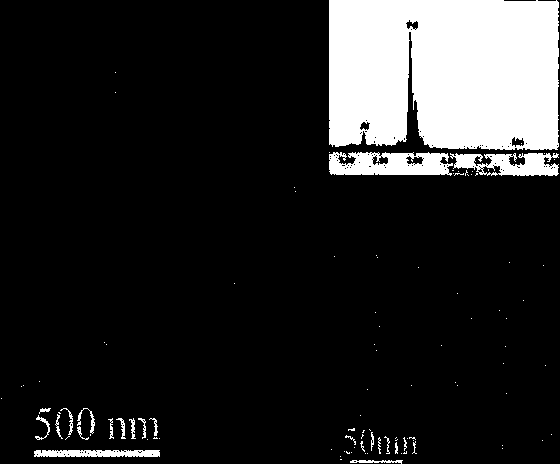

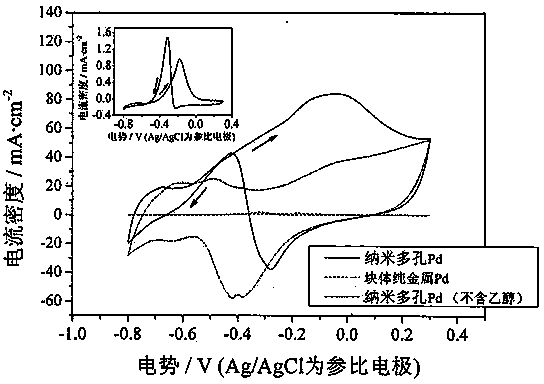

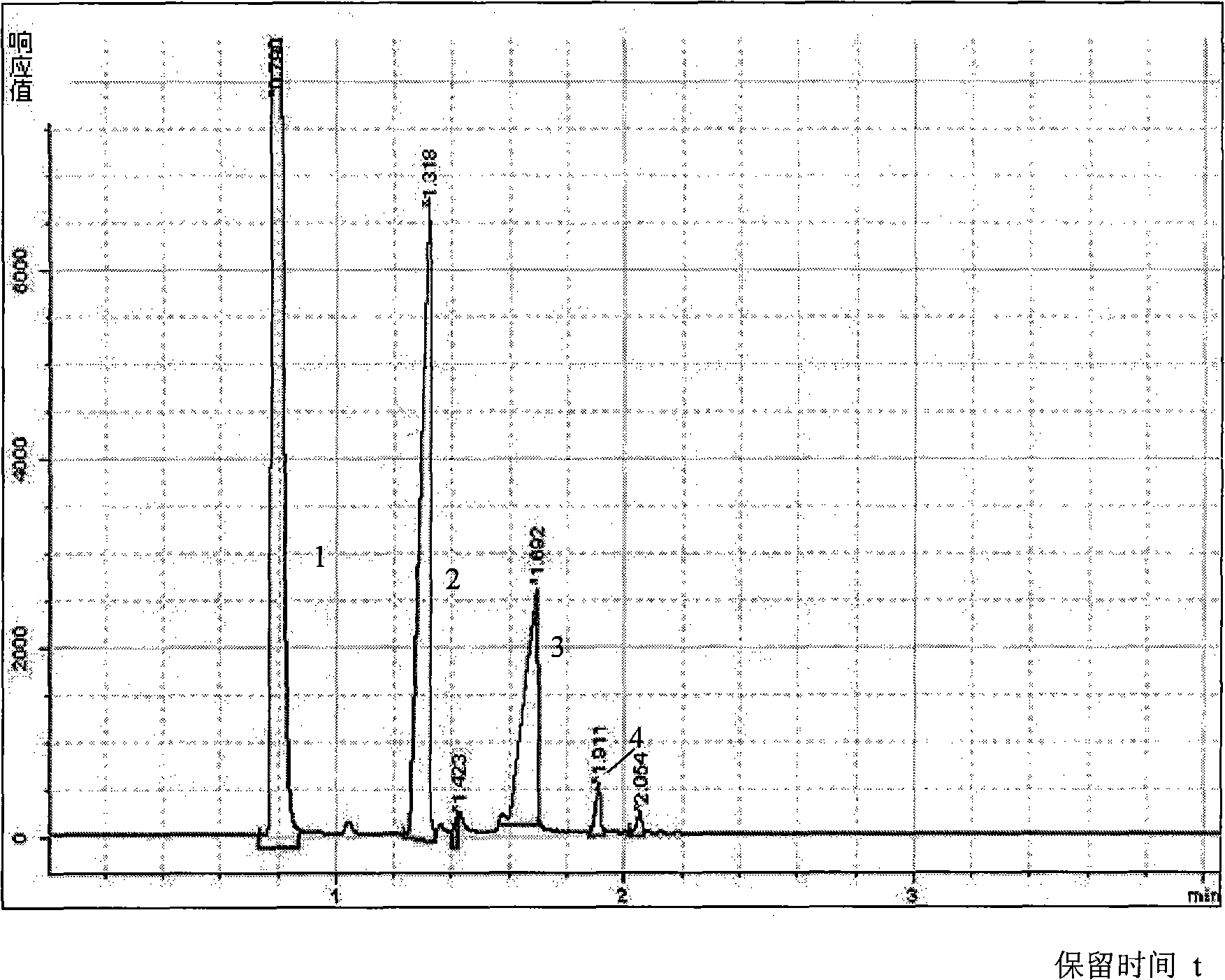

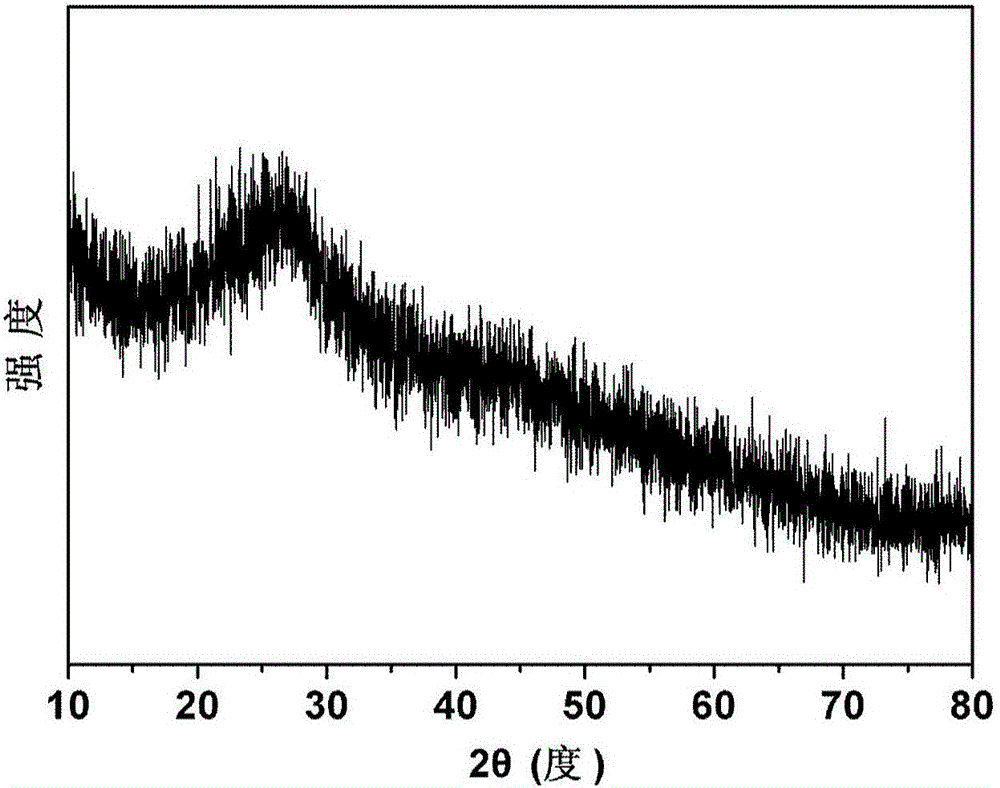

Nano-porous Pd material prepared through quasi-crystal de-alloying and preparation process of nano-porous Pd material

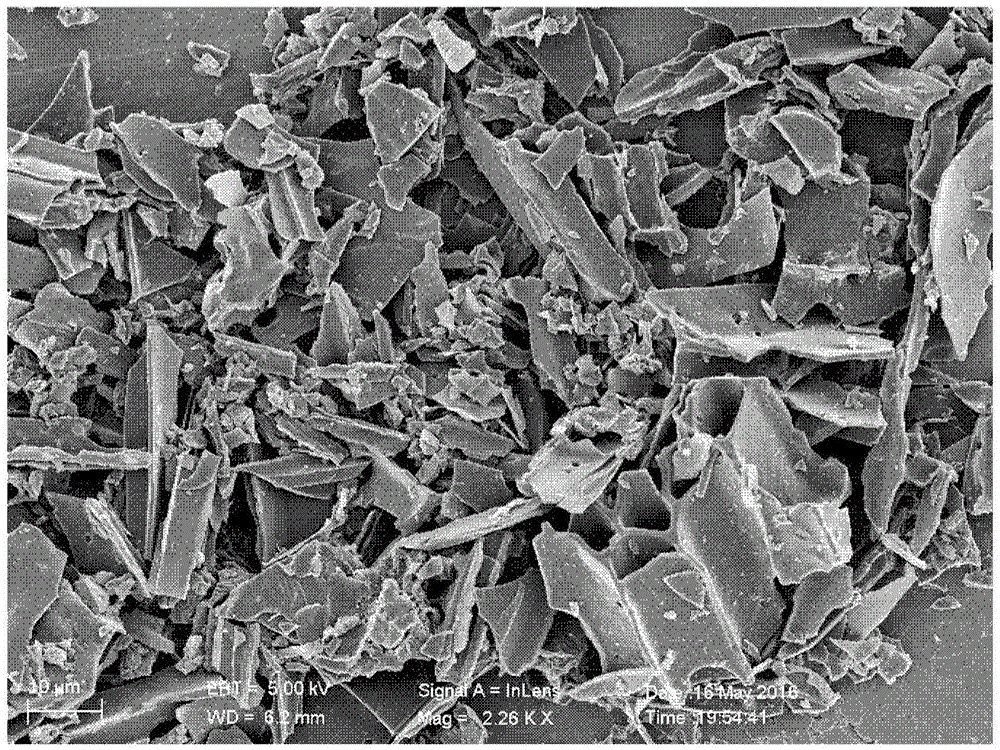

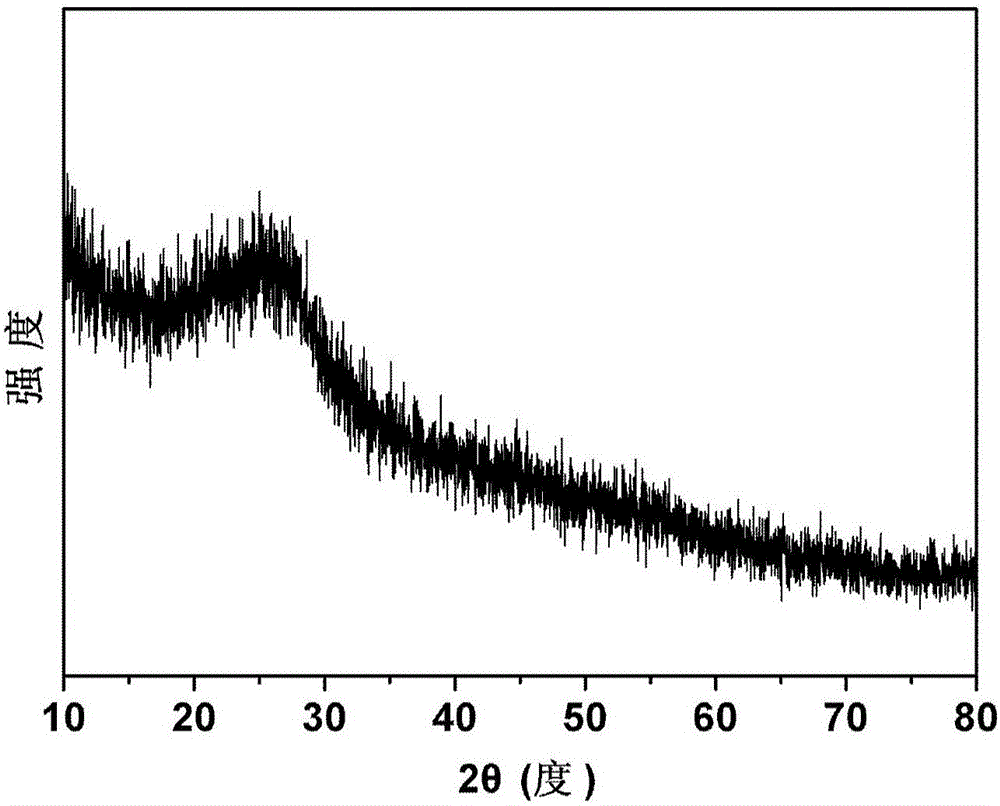

InactiveCN103938014AStructural disorderThe preparation process is simple and environmentally friendlyMaterial nanotechnologyPtru catalystFuel cells

The invention discloses a nano-porous Pd material prepared through quasi-crystal de-alloying and a preparation process of the nano-porous Pd material, belonging to the technical field of new materials. The nano-porous Pd material contains 8-12at.% of Al, less than 1at.% of TM and the balance of Pd in percentage by atom. A precursor namely a quasi-crystal alloy required for preparing the material is low in cost, and the overall technological process is environment-friendly, simple and efficient; a prepared nano-porous structure is complete. The quasi-crystal alloy with special structures is used as the precursor, and the chemical composition of the quasi-crystal alloy is Al1-x-yPdxTMy (TM is Mn, Co, Fe, Cr, V or Mg, wherein x is more than or equal to 10at.% and is less than or equal to 25at.%, and y is more than or equal to 3at.% and is less than or equal to 15at.%); by putting the quasi-crystal alloy into a dilute saline solution under room temperature, the nano-porous Pd material can be obtained through an electro-chemical de-alloying process with a constant-voltage mode in a voltage range of 0-0.2V (a reference electrode is a saturated calomel electrode). Prepared nano-porous Pd is uniform in structure, stable in pore and ligament size and unordered in crystallographic orientation, shows excellent room-temperature ethanol / methanol electro-oxidation reaction catalytic performances in alkaline solutions, can keep the high catalytic performances after being used repeatedly for many times, and can be applied to an anode catalyst of a fuel cell such as an alkaline ethanol cell and the like.

Owner:DALIAN UNIV OF TECH

Method for producing guaiacol with methanol method

InactiveCN101492353AImprove product qualityHigh yieldMolecular sieve catalystsChemical recyclingMethylating AgentGuaiacol

The invention provides a method for preparing guaiacol by a methanol method. Methanol used as a methylating agent and pyrocatechol are used for synthesizing the guaiacol under the action of a solid acid catalyst in a high pressure vessel. The solid acid catalyst used for synthesizing the guaiacol has low price, is friendly to environment and can be recycled. The invention is characterized in that the invention has simple preparation technology, mild reaction condition and short reaction time; the obtained guaiacol is light yellow clear transparent liquid and has good product quality, high yield, high selectivity and few side products; and all side products in reaction liquid can be recycled.

Owner:BEIJING UNIV OF CHEM TECH

Composition with long-acting moisturizing effect and preparation method thereof

ActiveCN107260626AStrong permeabilityPromote generationCosmetic preparationsToilet preparationsChemistryGlycerol

The invention relates to a composition with a long-acting moisturizing effect. The composition is characterized by being prepared from the following components in parts by mass: 0.5 to 2.5 parts of glue mixture, 1.0 to 3.0 parts of plant polysaccharide mixture, 0.1 to 1.0 part of collagen mixture, 0.1 to 1.0 part of amino acid mixture, 25 to 45 parts of PEG (Polyethylene Glycol) / PPG(Polypropylene Glycol) / polybutylene glycol-8 / 5- / 3 glycerin, 0.50 part of phenoxyethanol and the balance of deionized water, wherein the composition has the rotary viscosity of 800cp to 2,600cp after being subjected to high-pressure homogenization. The composition has the long-acting moisturizing effect.

Owner:PROYA COSMETICS

Silicon-carbon composite material, preparation method thereof and negative pole for lithium-ion battery

InactiveCN106058207AReduce manufacturing costImprove performanceCell electrodesSecondary cellsCarbon compositesSilicon tetrachloride

The invention provides a preparation method of a silicon-carbon composite material. The method is characterized by comprising the steps: introducing a gas mixture consisting of silicon tetrachloride gas and reducing carrier gas into a reaction chamber, in which a carbon material is placed, wherein the reducing carrier gas contains reductive gas; heating the gas mixture, so as to enable the reductive gas to reduce the silicon tetrachloride gas into elemental silicon and form the silicon-carbon composite material, in which the elemental silicon is deposited on the carbon material. The method has the advantages that the raw materials are cheap, the process is simple, and the product performance is excellent. The invention further provides the silicon-carbon composite material and a silicon-carbon composite material containing negative pole for a lithium-ion battery.

Owner:UNIV OF SCI & TECH OF CHINA

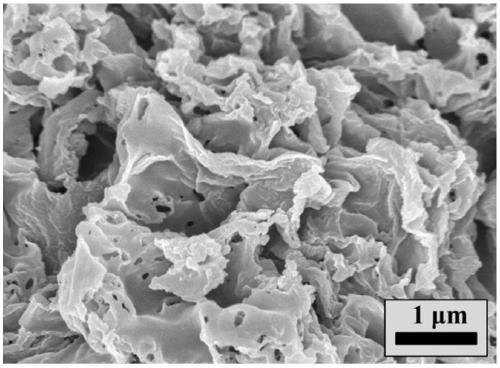

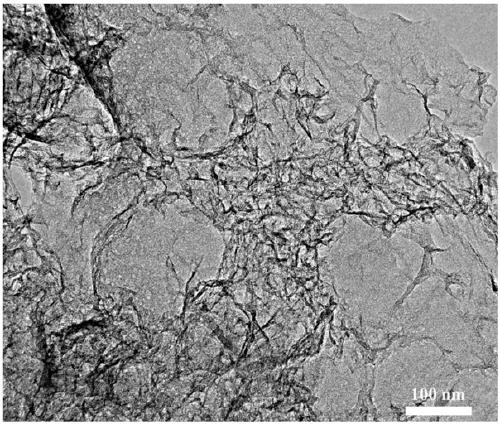

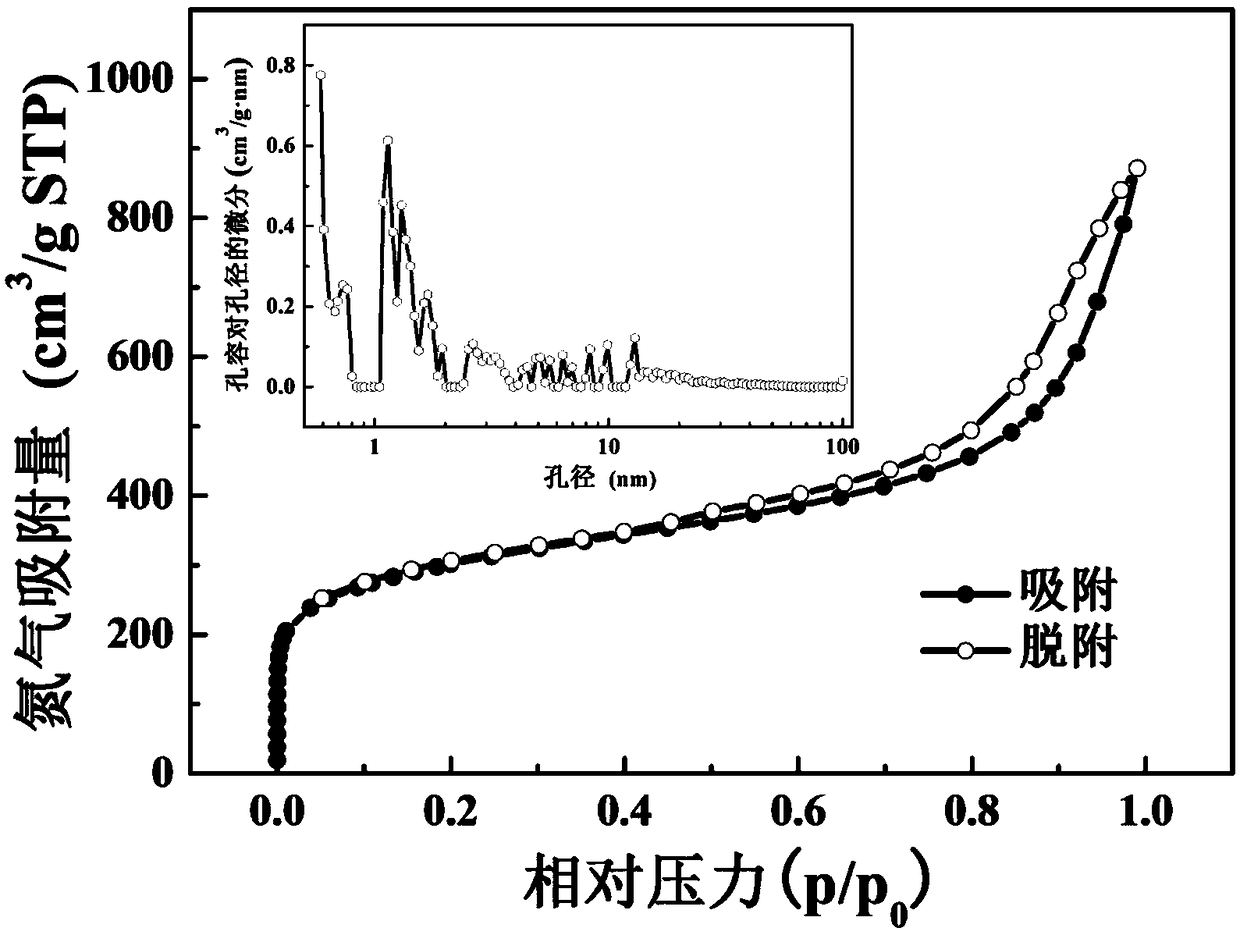

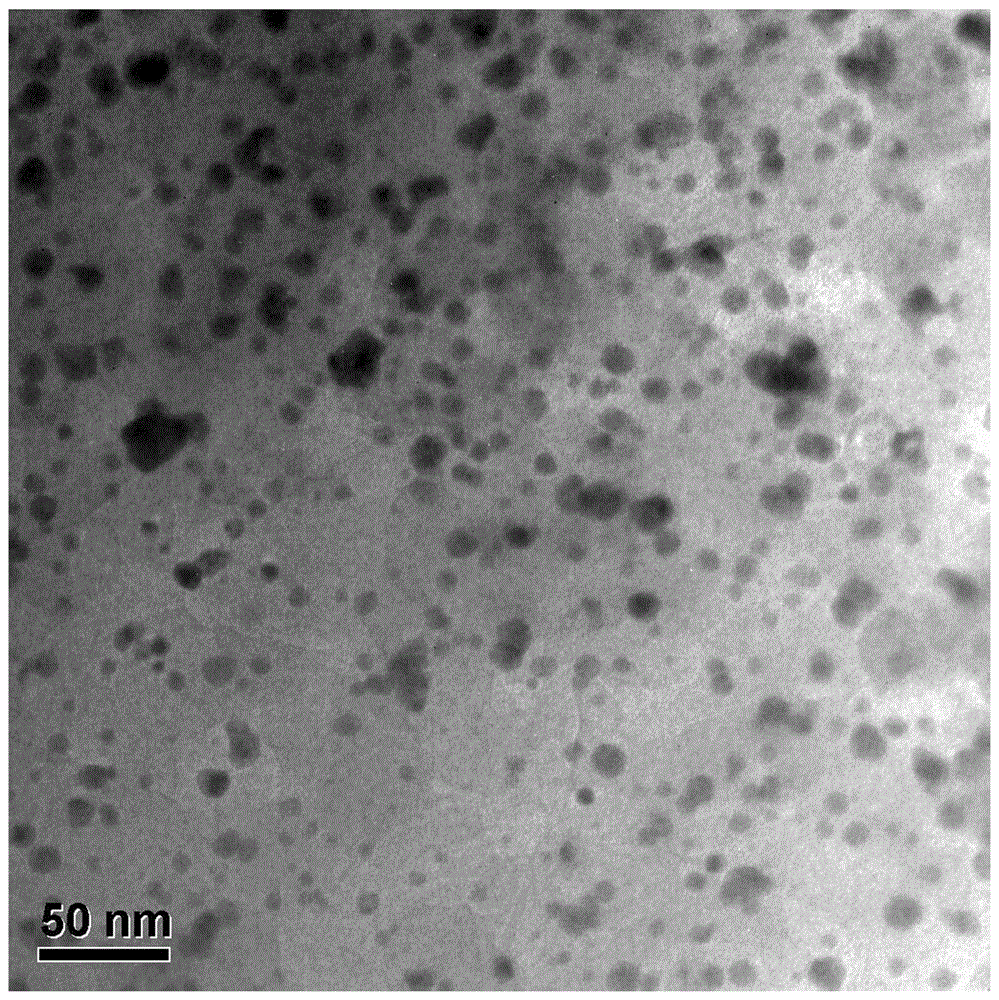

Lignin porous carbon nanosheet as well as preparation method thereof and application in supercapacitor electrode material

ActiveCN109485029ADiffusion fastFast transferHybrid capacitor electrodesNano-carbonPorous carbonSolvent

Owner:SOUTH CHINA UNIV OF TECH

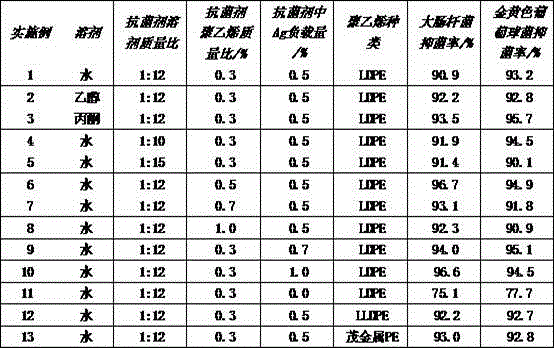

Preparation method of polyethylene antimicrobial packaging film

ActiveCN105968489AComposite uniformThe preparation process is simple and environmentally friendlyEscherichia coliEnvironmental resistance

The invention discloses a preparation method of a polyethylene antimicrobial packaging film. The preparation method is characterized by comprising the following steps of adding 0.3 to 1.0 part by weight of silver-loaded nano titania antimicrobial agent into 100 parts by weight of polyethylene resin; then adding 0.06 to 0.24 part of antioxidant 1076 and 0.04 to 0.16 part of auxiliary antioxidant 168; sufficiently mixing in a high-speed mixer, then granulating, drying and blowing film to prepare the polyethylene antimicrobial packaging film. Compared with the prior art, the preparation method disclosed by the invention has the beneficial effects that silver-ammonia ions are induced to form a strong interaction with the surface of titania by regulating a pH value; the silver-ammonia ions are reduced by using a water extract of a biomass loquat fruit, and further uniform compounding of silver and titania at the nanoscale is realized; no dispersing agent is needed, so that a preparation process is green and environmentally-friendly; the antibacterial rate of the prepared polyethylene antimicrobial packaging film to escherichia coli and staphylococcus aureus reaches 90 percent or above; the polyethylene antimicrobial packaging film is non-toxic, safe and sanitary.

Owner:SHANTOU HONGQIAO PACKAGING IND

Superhydrophobic polyvinylidene fluoride (PVDF) aerogel material and preparation method thereof

InactiveCN108192129AAvoid acid/base catalyzed hydrolysis-polymerization processNo chemical reactionPorosityOrganic solvent

The invention relates to a superhydrophobic PVDF aerogel material. The superhydrophobic PVDF aerogel material is characterized in that the material is a white opaque blocky material with a density of0.075-0.198 g / cm<3>, a porosity of 89-95.8%, a specific surface area of 256-343 m<2> / g, a water contact angle of 153-158 degrees and a thermal conductivity of 0.03531-0.04463 W / (m.K); and the materialhas a hierarchical pore structure, wherein the sizes of nanopores are in a range of 3-100 nm, and the sizes of micropores are in a range of 0.5 to 5 [mu]m. A PVDF aerogel is prepared by using a physical sol-gel process based on a phase inversion method. A preparation method for the PVDF aerogel comprises the following steps: subjecting PVDF powder and an additive to dissolving and uniform mixingin an organic solvent at a certain temperature; then adding deionized water and allowing PVDF to undergo phase inversion so as to form a PVDF gel; and subjecting the PVDF gel to solvent replacement and drying successively to prepare the PVDF aerogel. A novel preparation method is adopted in the invention to prepare the novel superhydrophobic PVDF aerogel material, and the method is simple in process and easy to realize industrial production; and the prepared PVDF aerogel material has low thermal conductivity and is a heat insulation material applicable to low-temperature humid environments.

Owner:NANJING TECH UNIV

Nanometer lignin carbon-zinc oxidecomposite material as well as preparation method and application thereof

ActiveCN112072085AInhibition of volume expansionImprove conductivityMaterial nanotechnologyHybrid capacitor electrodesCarbon layerLithium-ion battery

The invention discloses a nanometer lignin carbon-zinc oxidecomposite material as well as a preparation method and application thereof. The method comprises the following steps: (1) dissolving ligninin an alkaline solution, carrying out hydrothermal pretreatment, conducting cooling, and adjusting a pH value to 3-5 to obtain an acid-soluble lignin solution; (2) adding a mixed solution of soluble zinc salt and soluble carbonate into the acid-soluble lignin solution, conducting a hydrothermal reaction, then adding aldehydes, and continuing the hydrothermal reaction to obtain a ploycondensed lignin / zinc oxide compound; and (3) carbonizing the polycondensed lignin / zinc oxide compound to obtain the nanometer lignin carbon-zinc oxidecomposite material. In the obtained nanometer lignin carbon-zinc oxidecomposite material, lignin carbon uniformly coats the surfaces of zinc oxide particles to form a uniform carbon layer with a continuous structure, so the problems of serious volume expansion and poor conductivity of zinc oxide serving as a lithium ion negative electrode material are solved, and the specific capacity, the initial coulombic efficiency and the rate capability of a lithium ionbattery are improved.

Owner:SOUTH CHINA UNIV OF TECH +1

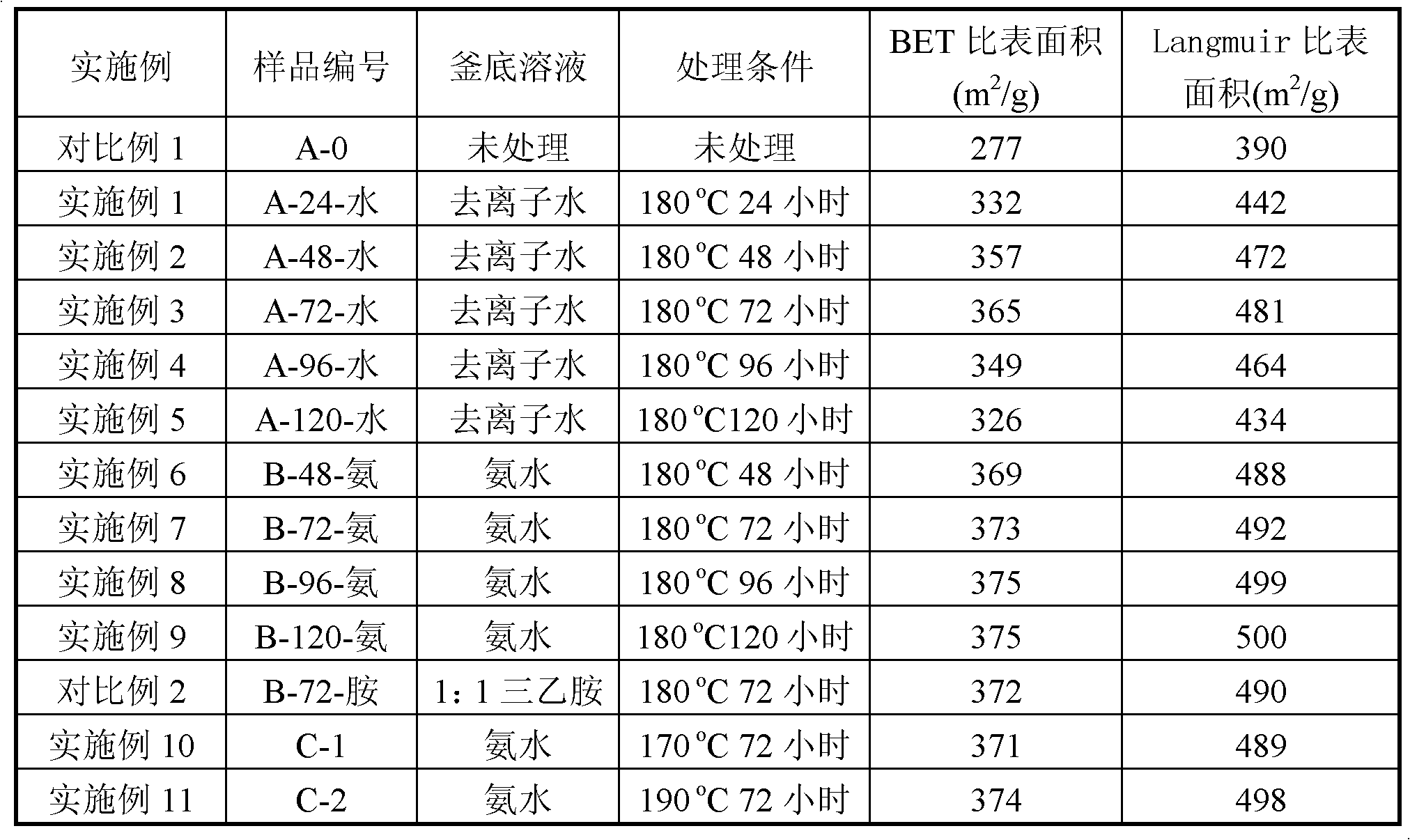

Preparation method of binderless ZSM-5 molecular sieve

ActiveCN103030156AReduce manufacturing costThe preparation process is simple and environmentally friendlyPentasil aluminosilicate zeoliteChemistryCrystallinity

The invention relates to a preparation method of a binderless ZSM-5 molecular sieve, and is mainly to solve the problem that the employment of organic amine in the production process of binderless molecular sieve leads to contaminations easily in the prior art. The preparation method of the binderless ZSM-5 molecular sieve of present invention comprises the following steps: firstly, mixing and molding the ZSM-5 molecular sieve powder and an amorphous silica binder, drying, processing by water vapor or inorganic ammonia-containing vapor to convert into the binderless ZSM-5 molecular sieve to get the binderless ZSM-5 molecular sieve, wherein the binder content is from 0 to 10%, the specific surface area of BET is from 330 to 380 m<2> / g, Langmuir specific surface area is from 440 to 500 m<2> / g, and the relative crystallinity is from 87 to 100%. The technical solution solves the problem well, and can be used for the industrial production of ZSM-5 molecular sieve catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of temperature-sensitive hollow nanofiber membrane

InactiveCN107604535AFlat surfaceUniform thicknessPhysical treatmentFibre typesSolventBiological substances

The invention relates to a preparation method of a temperature-sensitive hollow nanofiber membrane. The preparation method comprises the following steps: copolymerizing temperature-sensitive monomers,monomers capable of forming physical crossing points and monomers capable of forming chemical crossing points by heating by free radical solution polymerization to obtain a temperature-sensitive polymer; adding the temperature-sensitive polymer in a solvent and stirring to obtain a polymer solution as a shell spinning solution, taking viscous oil as a core layer spinning solution, and carrying out coaxial electro-spinning to obtain a nanofiber membrane with a core-shell structure; and carrying out heat treatment, and extracting the core layer viscous oil by an organic solvent to obtain the final product. By the coaxial electro-spinning method, the outer diameter, inner diameter and wall thickness of a product can be controlled effectively, a preparation process is environmentally friendly, and conditions are gentle. The obtained temperature-sensitive hollow nanofiber membrane can stably exist in water and cannot be dissolved, has rapid temperature sensitivity, and can be applied to atemperature sensor, a drug controlled release carrier, a cell culture substrate or a support, oil-water separation or biological substance purification film.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com