Preparation method of polyethylene antimicrobial packaging film

A technology of packaging film and polyethylene, which is applied in the field of preparation of polyethylene antibacterial packaging film, can solve the problems of strong specificity, poor broad spectrum, poor heat resistance, etc., and achieve the effect of green and environmental protection in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

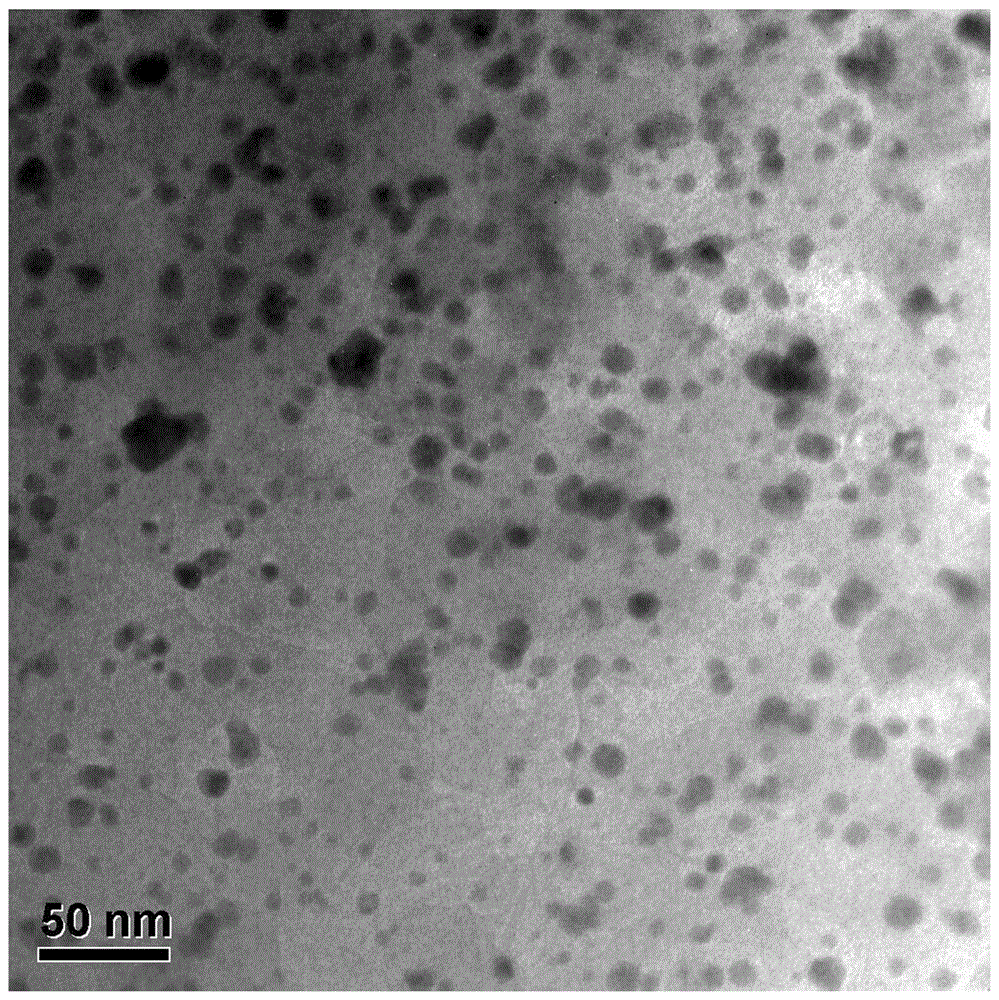

Image

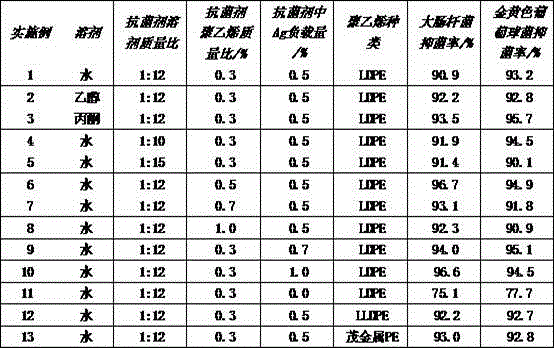

Examples

Embodiment 1

[0030] The preparation method of silver-loaded nano-titanium dioxide antibacterial agent was carried out according to the following steps: (1) After drying and crushing loquat leaves, add them to deionized water (the ratio of dry powder of loquat leaves to deionized water is 1 g:100 mL), shake Filtrate the water extract of loquat leaves; (2) Slowly drop 0.3 mol / L ammonia water into 0.1 mol / L AgNO 3 In the aqueous solution, prepare a 0.05 mol / L silver ammonia solution; (3) Add nano-titanium dioxide P25 into the silver ammonia solution (silver loading 0.5%), stir well, add 0.3 mol / L ammonia water to adjust the pH of the solution to 10. Prepare the mixed solution; (4) Add the water extract of loquat leaves obtained in step (1) to the mixed solution obtained in step (3) for reduction, suction filter and wash the obtained mixed solution, and dry the filter cake to obtain Silver-loaded nano-titanium dioxide. (5) Silver-loaded nano-titanium dioxide needs to be modified before it is ...

Embodiment 2

[0033] The preparation method of silver-loaded nano-titanium dioxide antibacterial agent was carried out according to the following steps: (1) After drying and crushing loquat leaves, add them to deionized water (the ratio of dry powder of loquat leaves to deionized water is 1 g:100 mL), shake Filtrate the water extract of loquat leaves; (2) Slowly drop 0.3 mol / L ammonia water into 0.1 mol / L AgNO 3 In the aqueous solution, prepare a 0.05 mol / L silver ammonia solution; (3) Add nano-titanium dioxide P25 into the silver ammonia solution (silver loading 0.5%), stir well, add 0.3 mol / L ammonia water to adjust the pH of the solution to 10. Prepare the mixed solution; (4) Add the water extract of loquat leaves obtained in step (1) to the mixed solution obtained in step (3) for reduction, suction filter and wash the obtained mixed solution, and dry the filter cake to obtain Silver-loaded nano-titanium dioxide. (5) Silver-loaded nano-titanium dioxide needs to be modified before it is ...

Embodiment 3

[0036] The preparation method of silver-loaded nano-titanium dioxide antibacterial agent was carried out according to the following steps: (1) After drying and crushing loquat leaves, add them to deionized water (the ratio of dry powder of loquat leaves to deionized water is 1 g:100 mL), shake Filtrate the water extract of loquat leaves; (2) Slowly drop 0.3 mol / L ammonia water into 0.1 mol / L AgNO 3 In the aqueous solution, prepare a 0.05 mol / L silver ammonia solution; (3) Add nano-titanium dioxide P25 into the silver ammonia solution (silver loading 0.5%), stir well, add 0.3 mol / L ammonia water to adjust the pH of the solution to 10. Prepare the mixed solution; (4) Add the water extract of loquat leaves obtained in step (1) to the mixed solution obtained in step (3) for reduction, suction filter and wash the obtained mixed solution, and dry the filter cake to obtain Silver-loaded nano-titanium dioxide. (5) Silver-loaded nano-titanium dioxide needs to be modified before it can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com