Carbon-silicon composite material and preparation method of carbon-silicon composite material as well as lithium-ion battery comprising composite material

A composite material and carbon-silicon composite technology are applied in the fields of its preparation, carbon-silicon composite material, electrochemical and lithium-ion battery anode materials, and can solve the problems of high first efficiency, difficult to guarantee, and low value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] The specific preparation method of the cylindrical battery is as follows: the negative electrode material, the conductive agent and the binder are dissolved and mixed in the solvent according to the mass percentage of 94:1:5, and the solid content is controlled at 50%, and coated on the copper foil current collector Then, the ternary positive pole piece prepared by traditional mature technology, 1mol / L LiPF6 / EC+DMC+EMC (v / v=1:1:1) electrolyte, Celgard 2400 separators and casings are assembled with 18650 cylindrical single cells using conventional production processes.

[0089] Test the charging and discharging performance and first effect of the battery under the test conditions of charging and charging: Among them, the charging and charging test conditions are: first discharge in the way of CC+CV (that is, first constant current and then constant voltage), and then charge in the way of CC (constant current), and the constant current rate during charging and discharging...

Embodiment 1

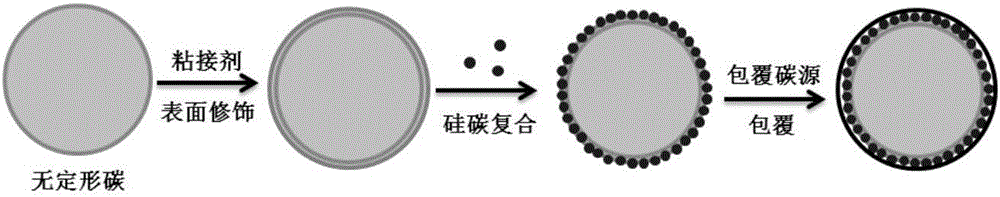

[0093] (1) Surface modification: Use a binder to modify the surface of amorphous carbon by solid-phase modification. Specifically, accurately weigh 47.6g of high-temperature pitch and 456.4g of soft carbon, and mix them in a VC mixer for 30 minutes , The speed of the VC mixer is 3000r / min. Then, put the obtained material into the fusion machine, and fuse it for 45 minutes. The rotation speed of the fusion machine is 3000r / min, and obtain the soft carbon modified by high temperature pitch, which is marked as SC@LQ;

[0094] (2) Composite: adding nano-silica powder and dispersant to isopropanol, high-energy ball milling, the ball milling condition is 300r / min, ball milling 24h, to obtain silicon slurry. Accurately weigh the silicon slurry (converted to 2.8 g of silicon, the solvent is isopropanol), ultrasonically disperse for 30 min, and set aside. Under the condition of stirring at room temperature, 36.0 g of high-temperature pitch-modified soft carbon (SC@LQ) was added to the...

Embodiment 2

[0108] (1) Surface modification: Use a binder to modify the surface of amorphous carbon by the liquid phase modification method, accurately weigh 3.4g of high-temperature pitch, and add the high-temperature pitch to 100mL of tetrahydrofuran (THF) solution under the condition of magnetic stirring at room temperature , and stirred for 1 hour to obtain a THF solution of asphalt. Add 32.6 g of soft carbon to the THF solution of asphalt, heat and evaporate the solvent to obtain a soft carbon modified with high-temperature pitch.

[0109] (2) Composite: adding nano-silica powder and dispersant to isopropanol, high-energy ball milling, the ball milling condition is 300r / min, ball milling 24h, and silicon slurry solution is obtained. Add the high-temperature pitch-modified soft carbon obtained in step (1) and the silicon slurry after ultrasonic dispersion for 1 hour (converted to 2.8 g of silicon, and the solvent is isopropanol) into 80 mL of isopropanol solvent, and stir at room tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com