Patents

Literature

249results about How to "Improve the first effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified composite material containing silicon-base material, preparation method thereof, and application thereof in lithium ion battery

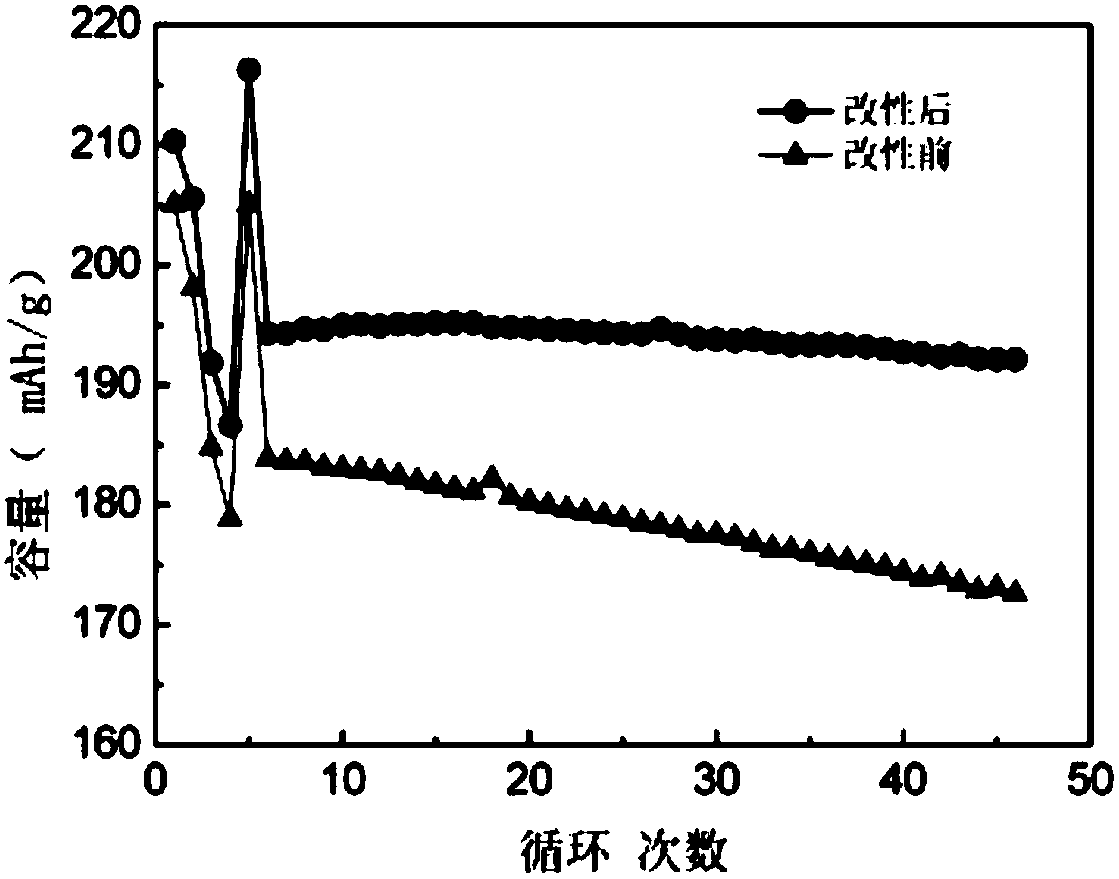

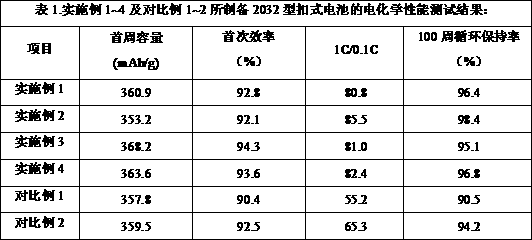

PendingCN109301184AImprove performanceEasy to crushMaterial nanotechnologyCell electrodesStructural stabilitySide reaction

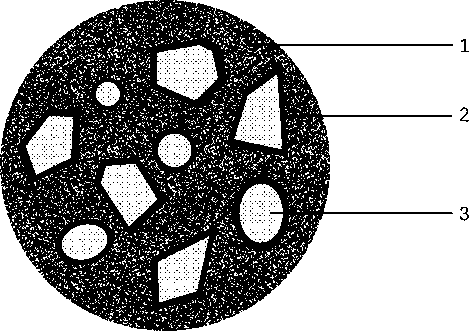

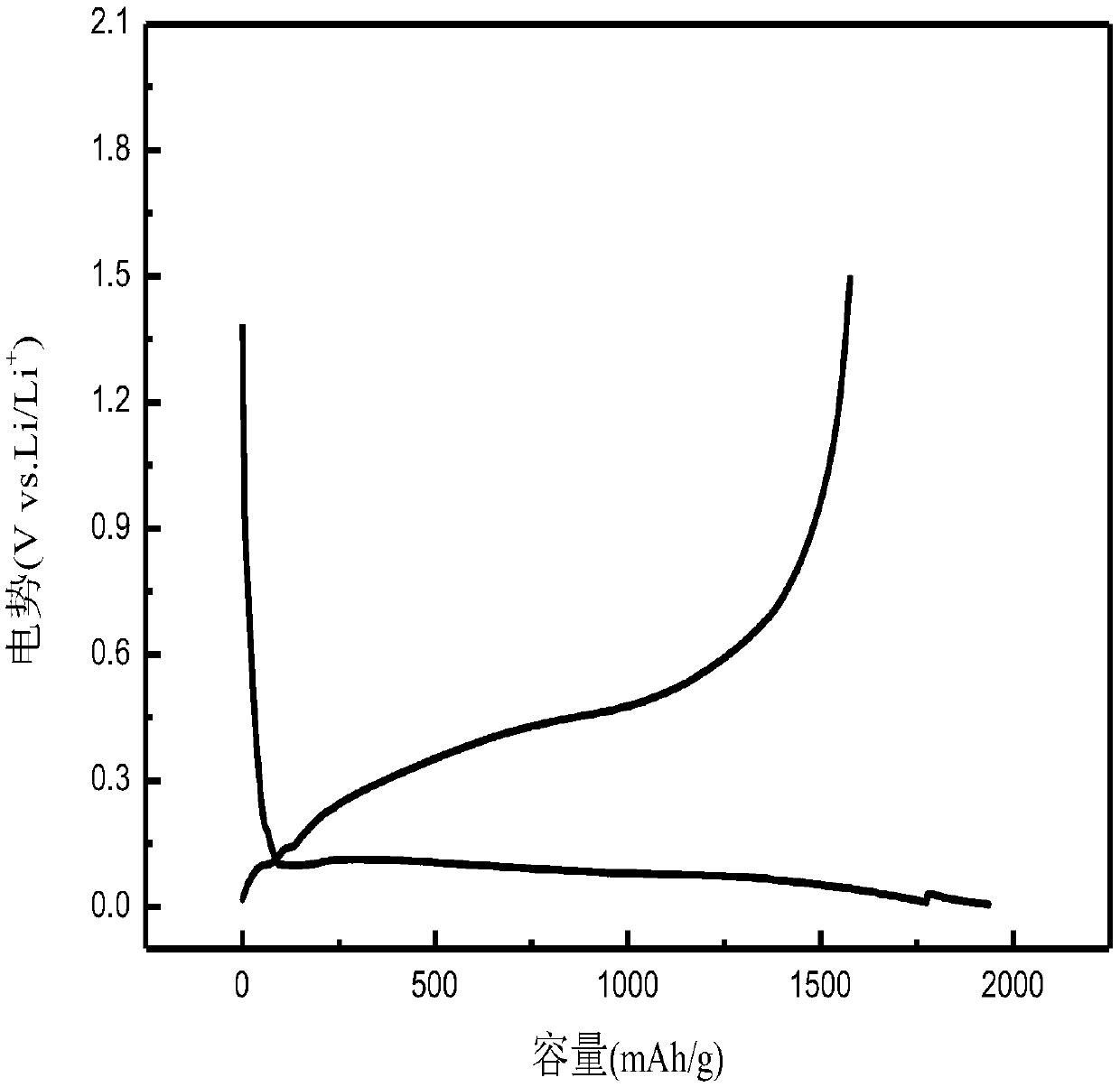

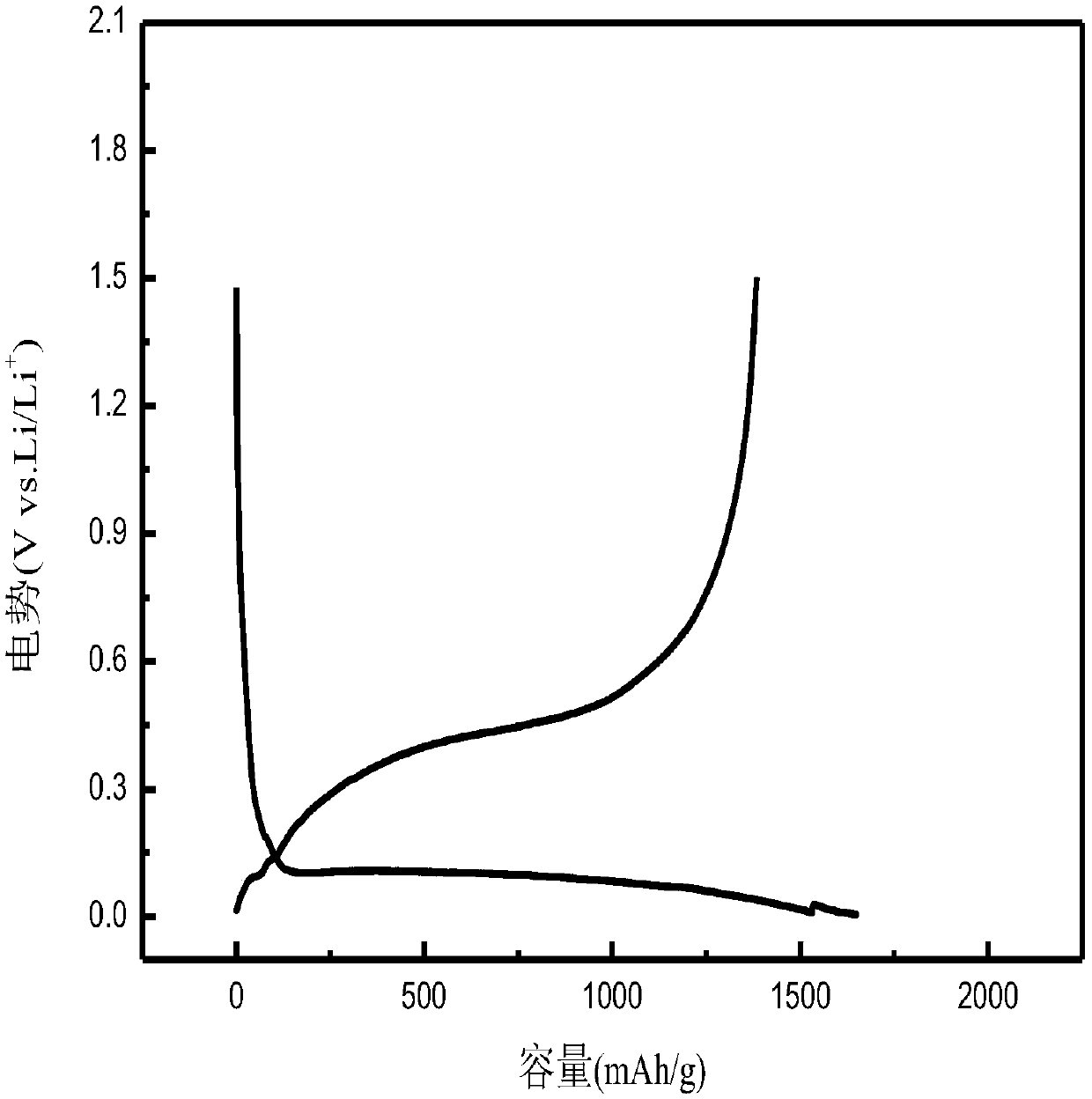

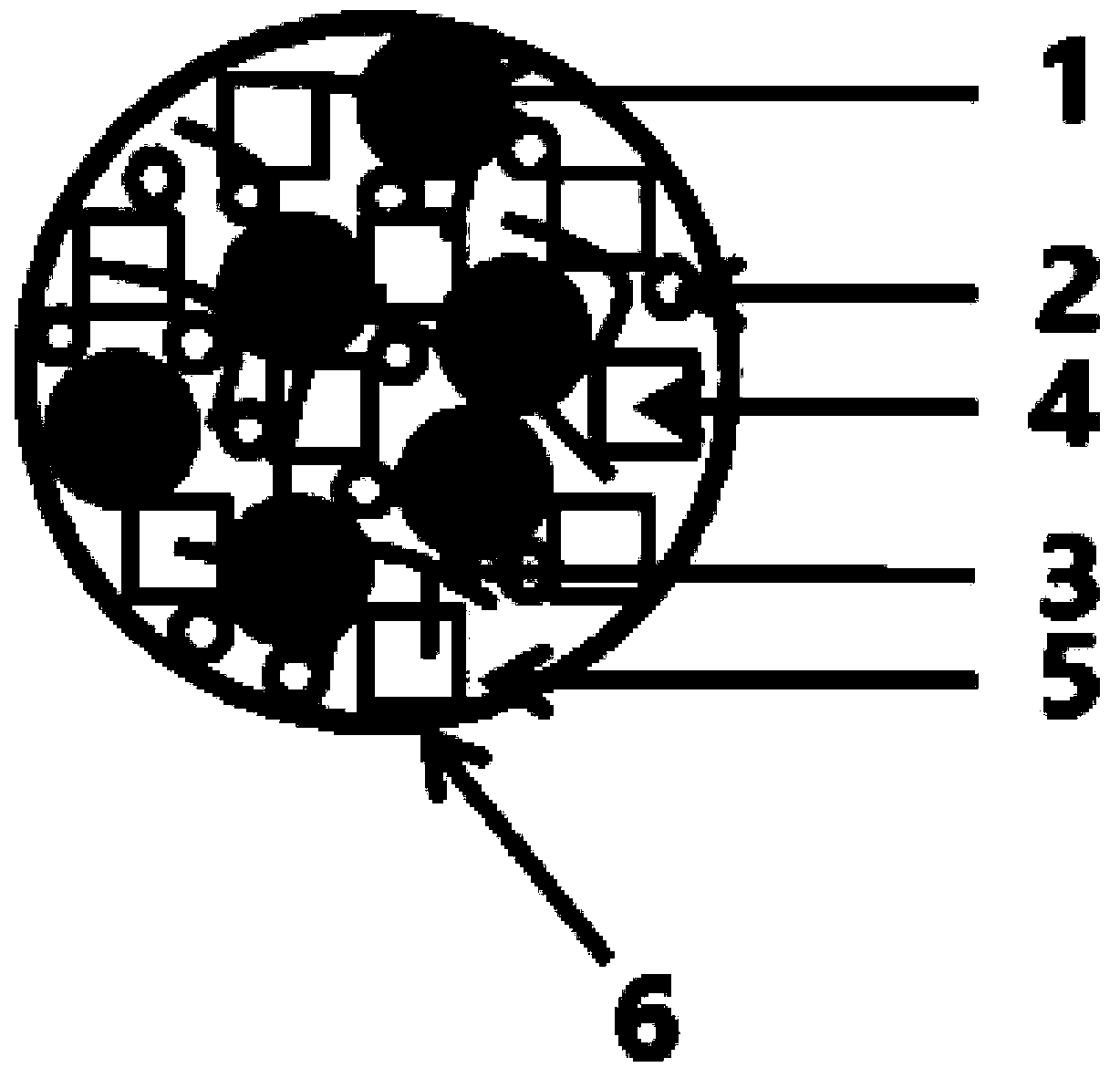

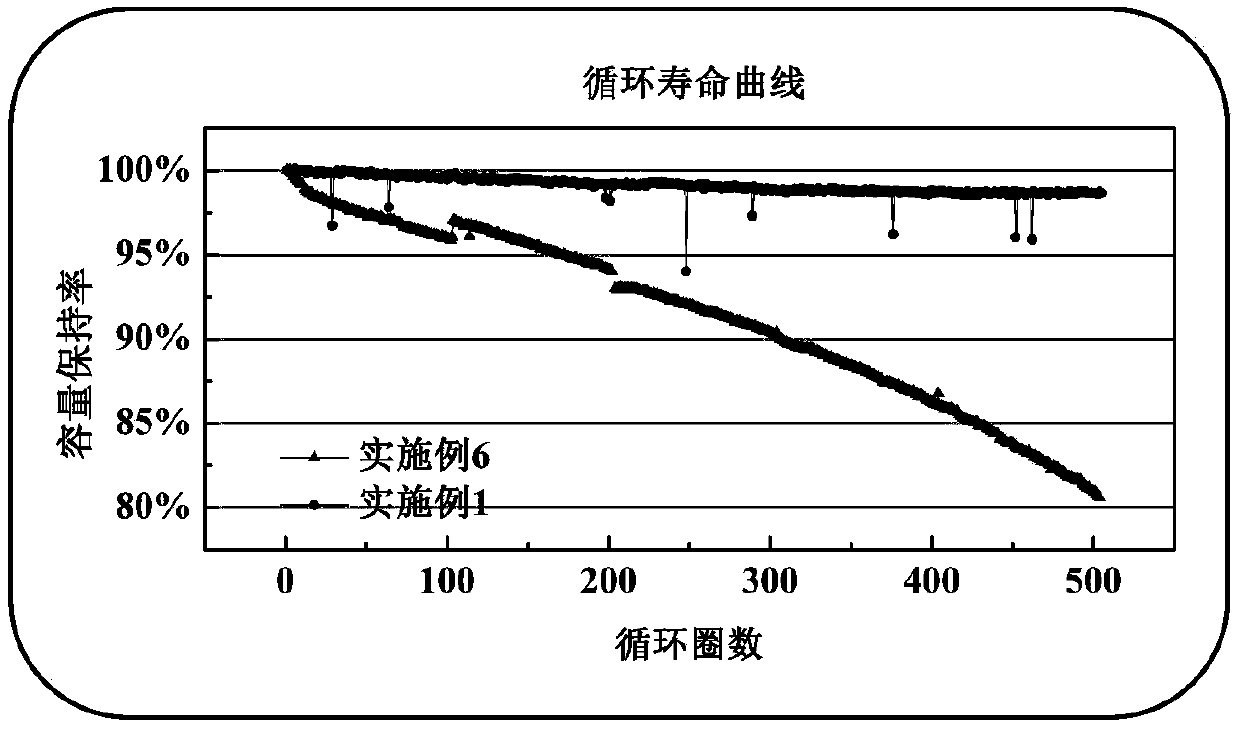

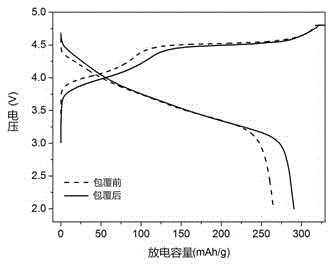

The invention discloses a modified composite material containing silicon-base material, a preparation method thereof, and an application thereof in a lithium ion battery. The composite material includes a silicon-base core and a modifying layer covering same. The modifying layer includes a polymer covering film and a nano-conductive material embedded therein. The modified composite material not only can isolate an electrolyte to inhibit side reactions of the electrolyte on the surface of the material, thus improving overall performance of the battery, but also can improve electric conductivityand improve structural stability due to the unique structure by embedding the nano-conductive material in the polymer. Tension is absorbed by means of deformation, so that problems of breaking and pulverization and stripping of the electrode during processing and use of the silicon-base negative material are solved. The problems of pulverization and stripping of the electrode due to large expansion during charge / discharge processes of the silicon-base material are solved, thus stabilizing the structure of the electrode and improving cycle performance of the cell.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

Modified composite material containing silicon-based material, preparation method thereof and use thereof in lithium ion battery

InactiveCN109103441AImprove overall performanceStable electrode structureNegative electrodesSecondary cellsSolventCharge and discharge

The invention discloses a modified composite material containing a silicon base material, which comprises a silicon base core and a polymer cladding layer covering the surface of the core, and a preparation method and use thereof in a lithium ion battery. The method comprises the steps of : 1) adding a polymer into a liquid solvent and dispersing to obtain a slurry; 2) adding a silicon-based material or a mixture of that silicon-based material and the carbon material into the slurry and mixing the solid and liquid; 3) removing the solvent to obtain a modified composite material containing a silicon-based material. As the polymer coat layer is introduced on the surface of the silicon base core, so that the electrolyte can be isolated and the side reaction of the electrolyte on the surface of the silicon base core can be prevented; the method can also improve the crushing, electrode pulverization and peeling of the silicon-based negative electrode material in the process of processing and using, and reduce the electrode crushing and peeling caused by the huge volume expansion of the silicon-based material in the process of charging and discharging, so as to achieve the purpose of stabilizing the electrode structure and improving the cell cycle performance.

Owner:JIANGSU TAFEL NEW ENERGY TECH CO LTD +2

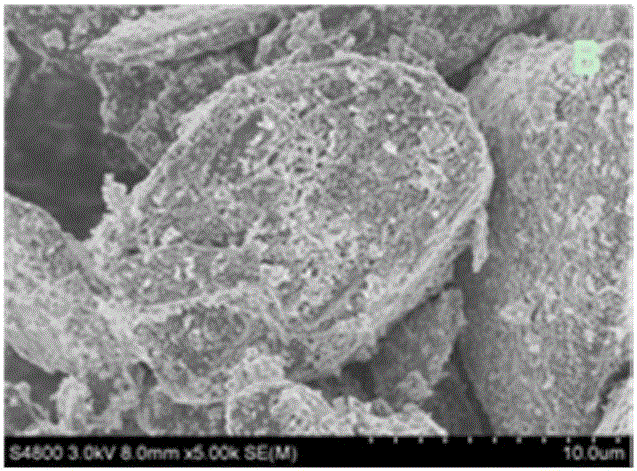

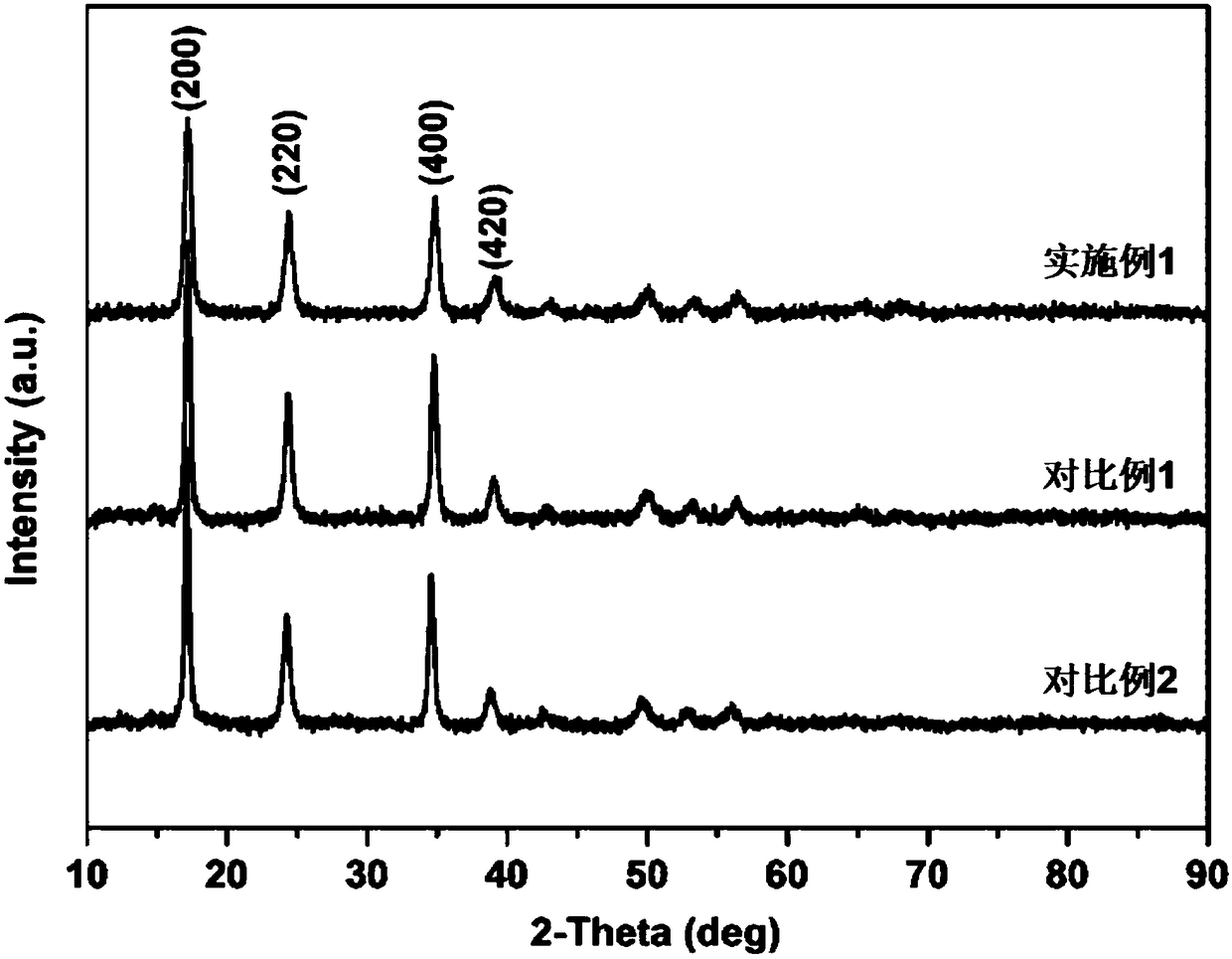

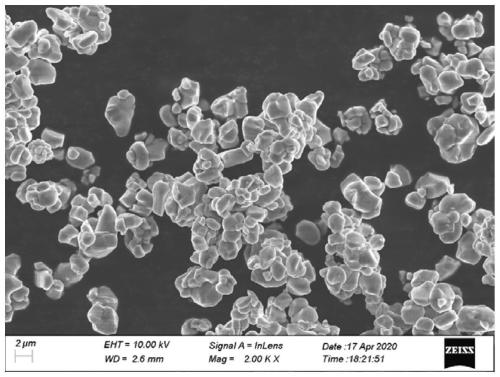

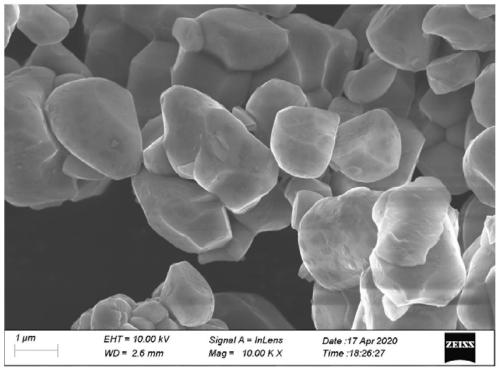

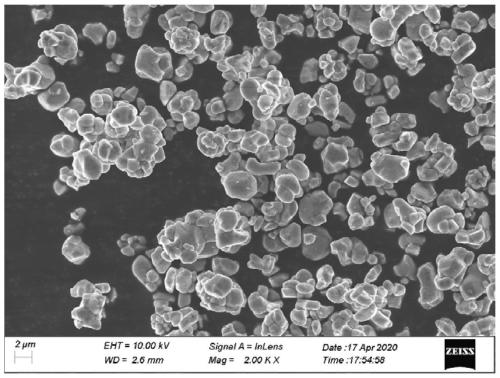

Large scale preparation method of high-nickel cobalt-free precursor and cathode material

ActiveCN109970106AExcellent electrochemical performanceConducive to large-scale market promotionCell electrodesNickel compoundsLarge capacityPrecious metal

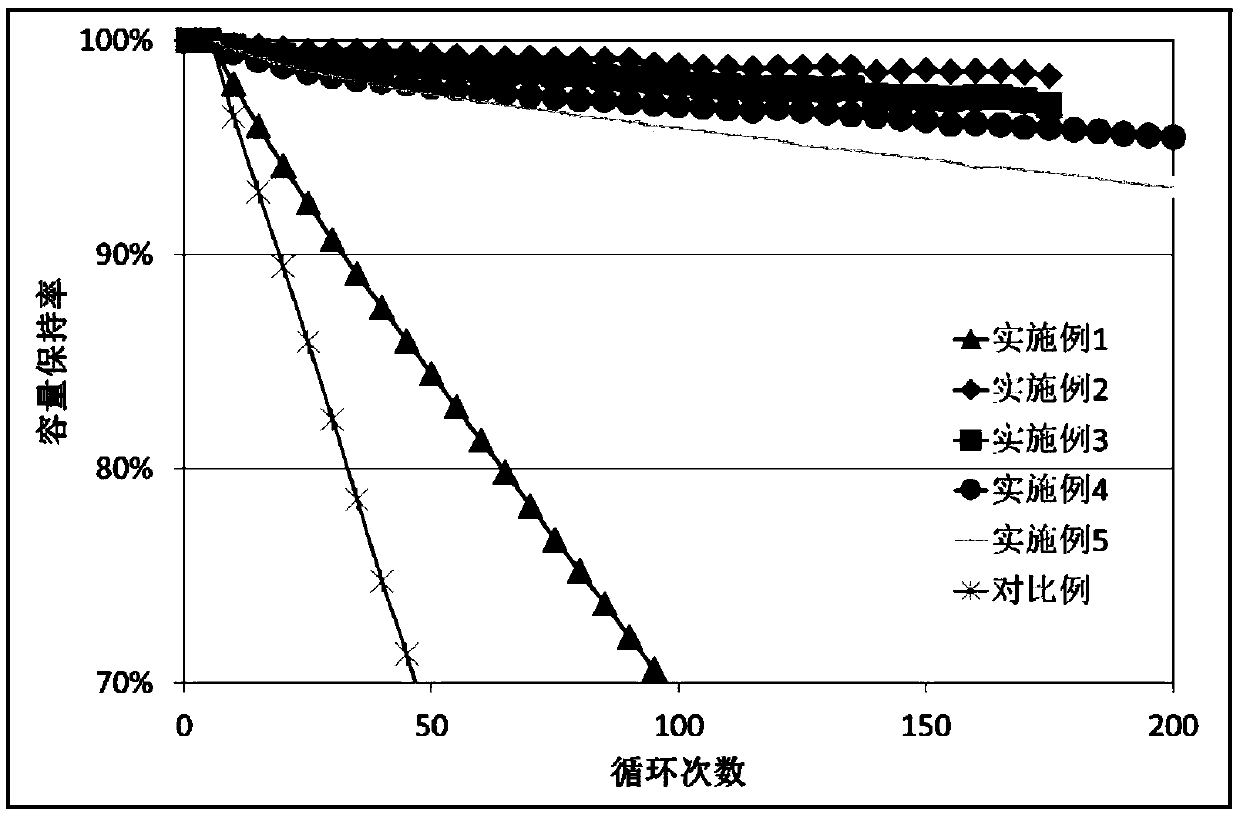

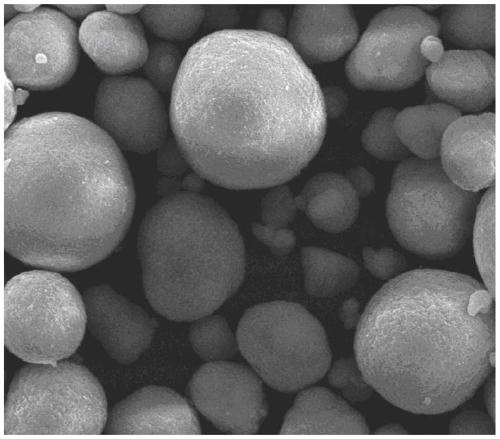

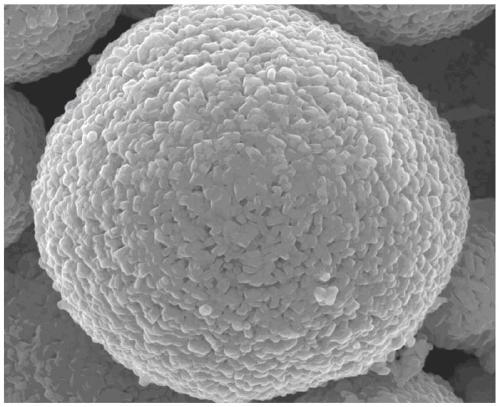

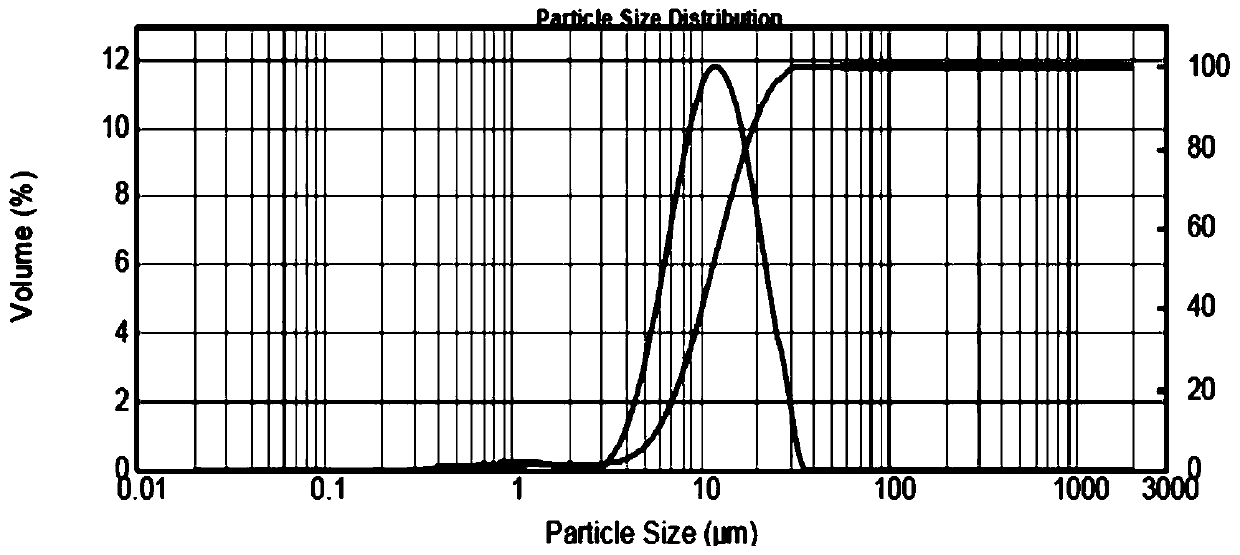

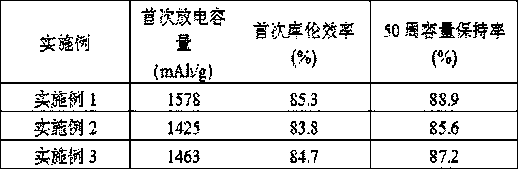

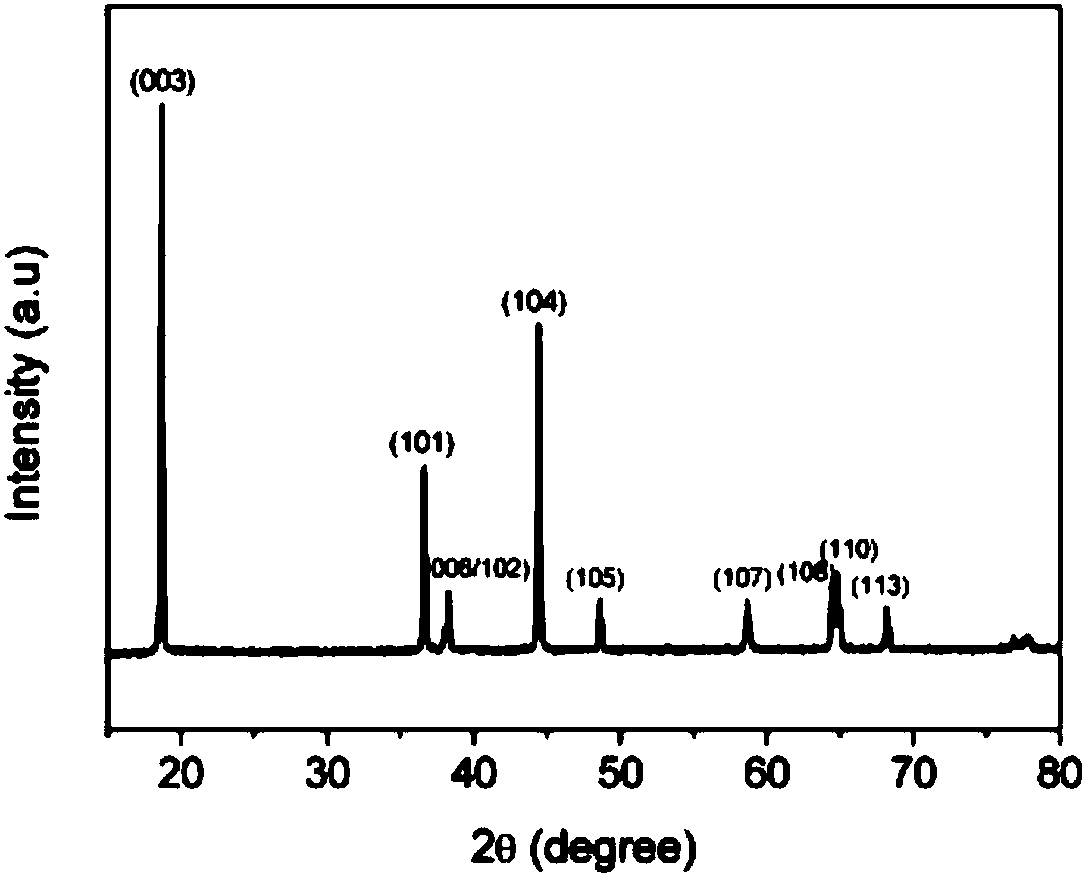

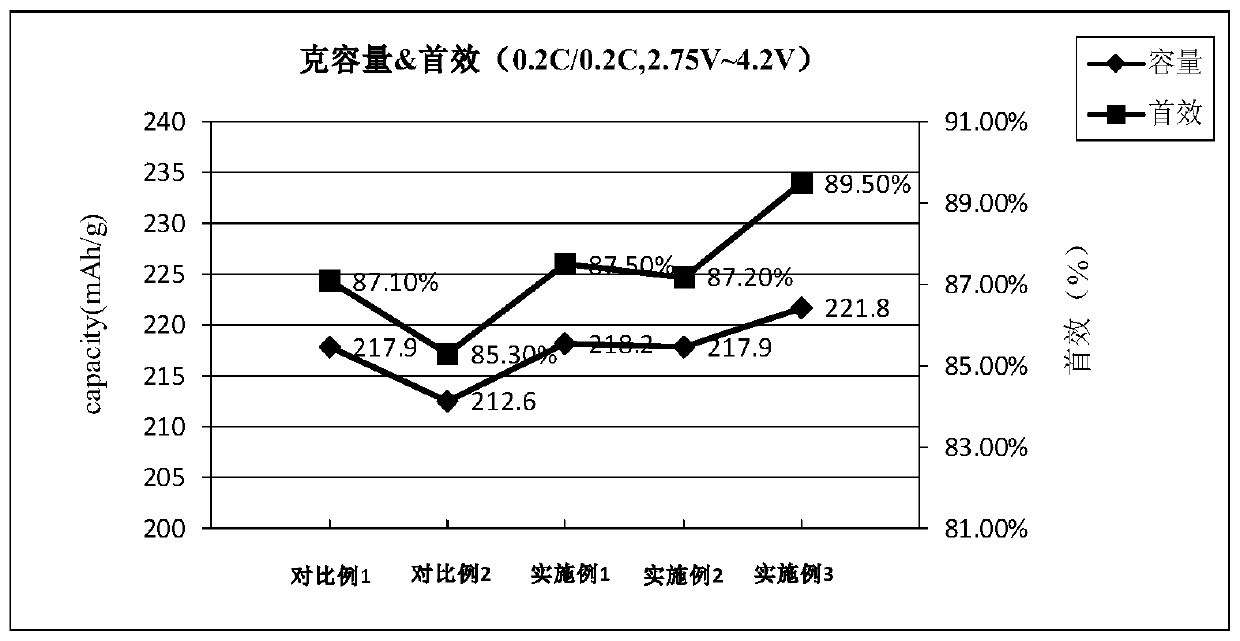

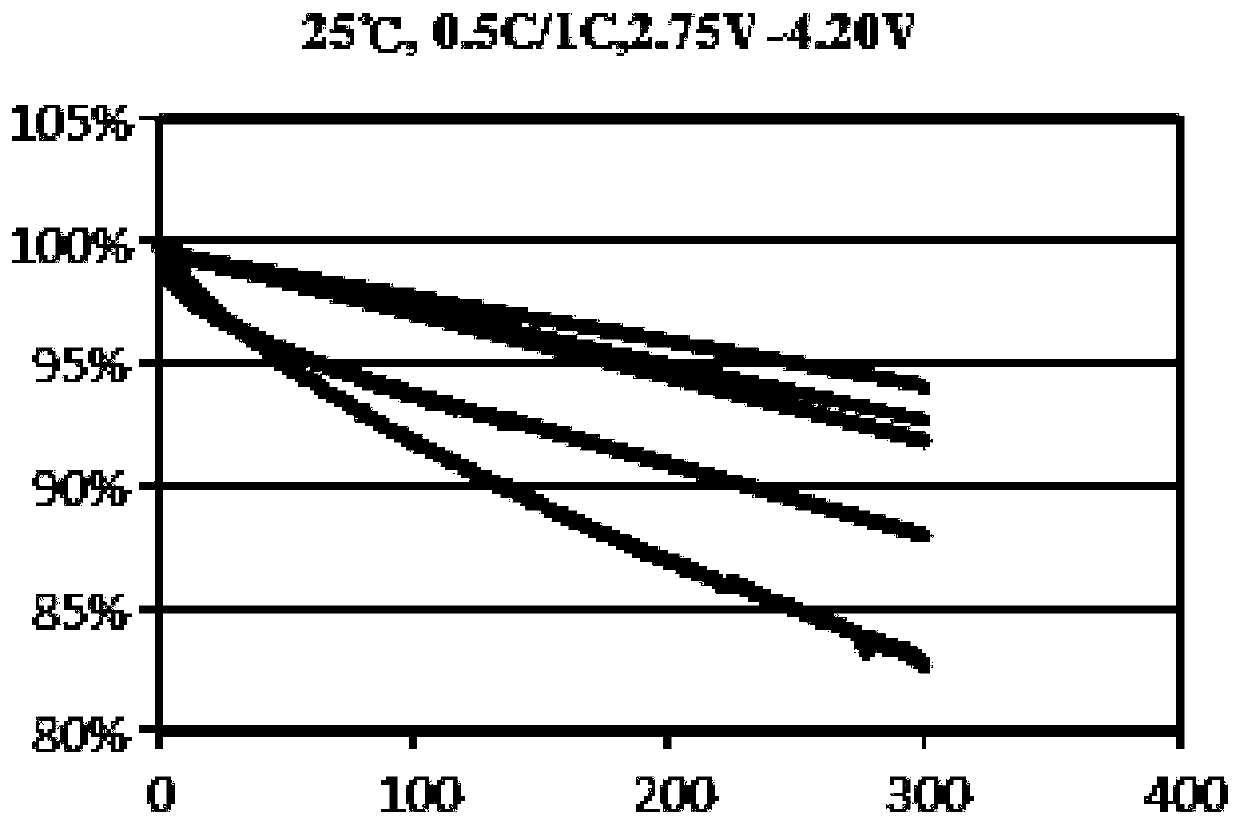

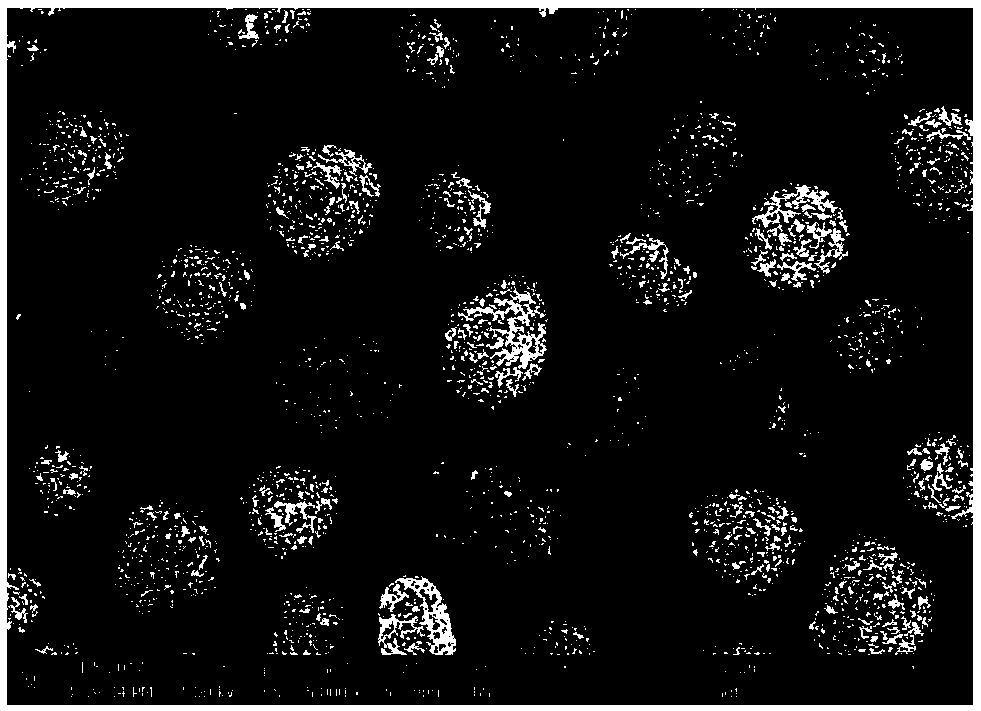

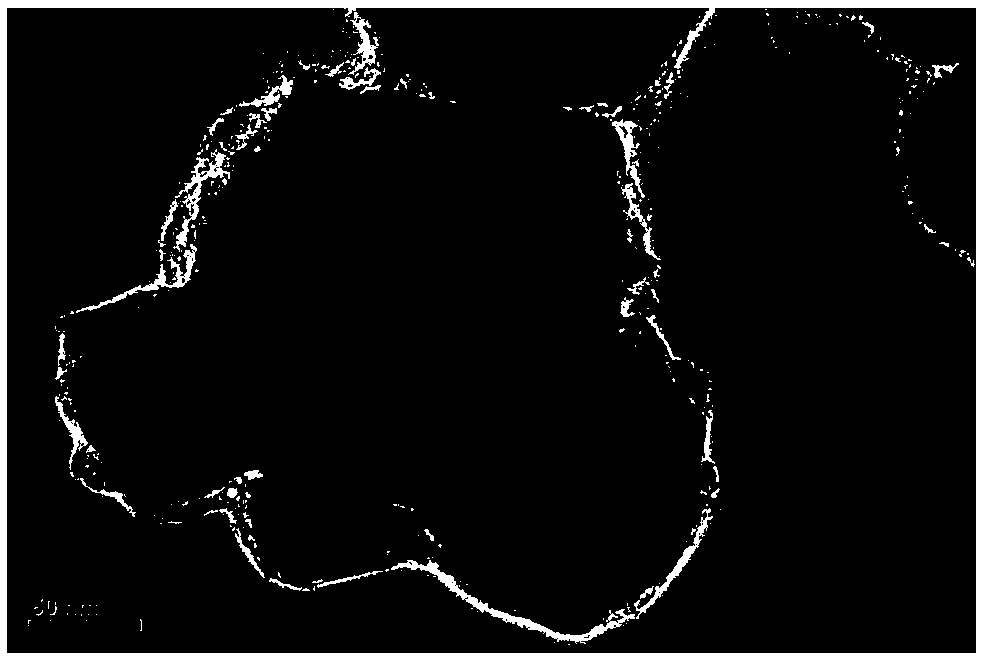

The invention discloses a large scale preparation method of a high-nickel cobalt-free precursor and a cathode material. During the co-precipitation reaction process, the key parameters are precisely controlled, thus the crystal face, morphology, and assembly arrangement mode of primary particles are regulated and controlled to obtain the high-nickel cobalt-free cathode material precursor with uniform morphology, the precursor can be used to prepare the high-nickel cobalt-free lithium battery cathode active material, which has the advantages of low residual alkali, low pH value, water absorption resistance, and good processing performance, moreover, the cathode material does not contain any precious metal and is cheap; the prepared lithium battery has the advantages of high cell primary effect, high capacity, excellent normal temperature cycle performance, good high temperature cycle performance, and excellent high temperature storage performance; moreover, the thermal stability is greatly improved through doping and coating; the preparation process is simple and efficient; and the obtained product is highly uniform, has excellent electrochemical properties, and has a wide market prospect.

Owner:姚兵

Lithium ion battery pre-lithiated silicon-carbon multilayer composite negative electrode material and preparation method thereof

ActiveCN110620223AIsolated electrolyteGood mechanical propertiesCell electrodesSecondary cellsCvd grapheneLithium electrode

The invention discloses a lithium ion battery pre-lithiated silicon-carbon multilayer composite negative electrode material and a preparation method thereof. The composite negative electrode materialcomprises an amorphous carbon matrix, pre-lithiated silicon monoxide particles and a graphene material, wherein the graphene material is uniformly coated on an outer surface of the pre-lithiated silicon monoxide to form composite particles, and the composite particles are uniformly dispersed in the amorphous carbon matrix. After the silicon monoxide is pre-lithiated, the first effect of the silicon-based negative electrode material is greatly improved, the graphene material is light in weight, high in strength and excellent in conductivity, so mechanical property and conductivity of the composite material are greatly improved, the amorphous carbon matrix plays a role in isolating electrolyte and preventing silicon from being in contact with the electrolyte to generate a large number of unstable SEI films, and experiments show that the composite negative electrode material prepared has characteristics of good mechanical property, high conductivity, high initial coulombic efficiency andstable cycle performance.

Owner:SHENZHEN XIANGFENGHUA TECH CO LTD +1

Preparation method of preoxidation modified high-nickel ternary cathode material

InactiveCN108511746AReduce mixingReduce the mixing degree of lithium and nickelSecondary cellsPositive electrodesNitrateSlurry

The invention discloses a preparation method of a preoxidation modified high-nickel ternary cathode material. The preparation method comprises the following steps of mixing a high-nickel ternary precursor material, nitrate and a solvent to obtain slurry; sequentially performing drying and presintering on the slurry to obtain a pre-oxidized high-nickel ternary precursor material, wherein a chemicalformula of the pre-oxidized high-nickel ternary precursor material is NixCoyM1-x-y(OH)2, and x is greater than or equal to 0.80; and mixing the pre-oxidized high-nickel ternary precursor material anda lithium source, and performing sintering to obtain the preoxidation modified high-nickel ternary cathode material LiNixCoyM1-x-yO2, wherein x is greater than or equal to 0.80. By adopting the preparation method of the preoxidation modified high-nickel ternary cathode material provided by the invention, a cation mixed arrangement degree in a layered structure of the high-nickel ternary cathode material is lowered, and the initial effect, the capacity and the cycle performance of the high-nickel ternary cathode material are improved at the same time.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

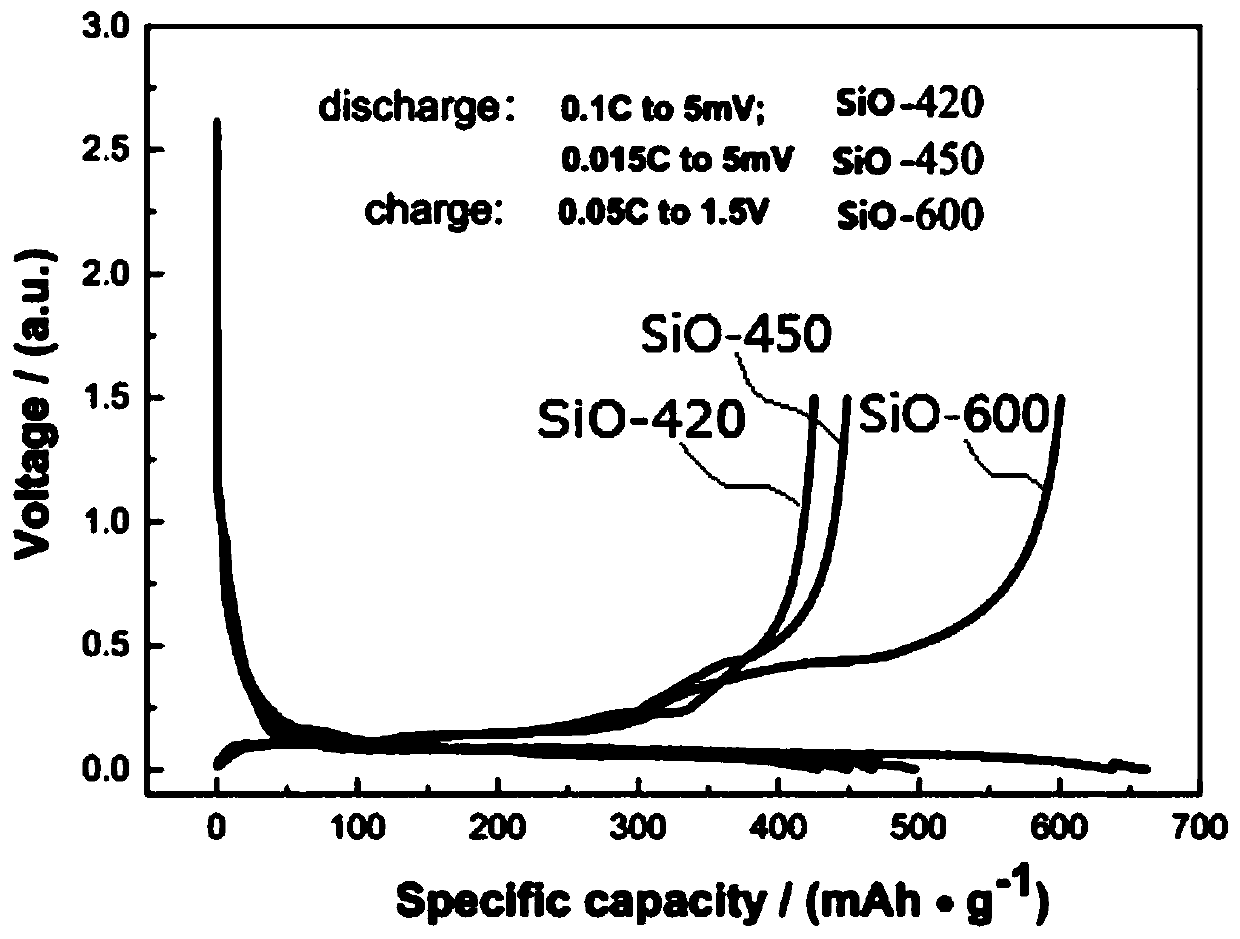

Silicon oxide composite negative electrode material for lithium ion battery and preparation method of silicon oxide composite negative electrode material

InactiveCN109524650AHigh reversible capacityImprove efficiencyCell electrodesSecondary cellsCarbon coatingElectrical battery

The invention discloses a preparation method of a silicon oxide composite negative electrode material. The preparation method comprises the following steps: mixing silicon oxide, a reactive metal anda fused salt to obtain a mixture; carrying out a roasting reaction in a protective atmosphere, cooling and pickling to remove impurities; mixing the obtained low-oxygen value silicon oxide material and a carbon coating material or adopting gas phase coating, roasting and carbonizing, cooling, crushing and screening, thereby obtaining the silicon oxide composite negative electrode material for thelithium ion battery. Compared with the prior art, the silicon oxide composite negative electrode material disclosed by the invention is prepared by taking the silicon oxide, the reactive metal, the carbon coating material and the fused salt as raw materials, mixing, performing metal hot reduction, pickling to remove impurities and grinding, the oxygen content of the finished material is low, and the first-cycle reversible capacity and efficiency of the lithium ion battery are obviously improved. Moreover, the negative electrode material is less in impurity, high in application value and smallin silicon grain size, cycle expansion of the material is effectively improved, and the cycle life of the material is obviously prolonged.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

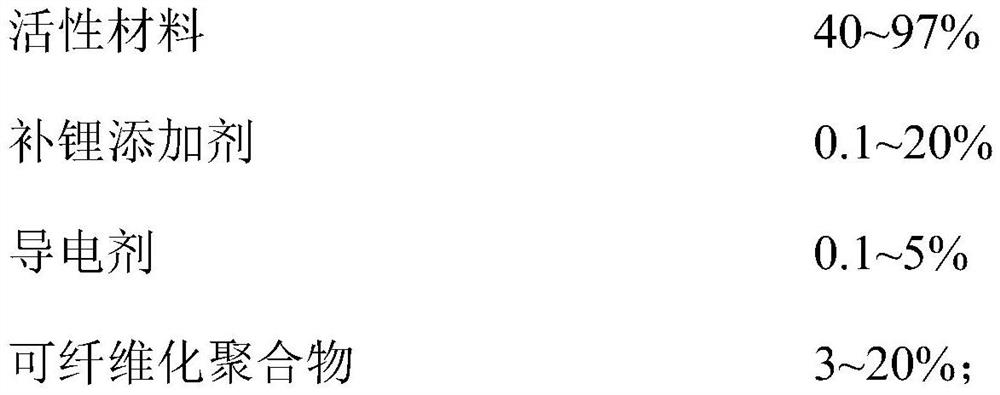

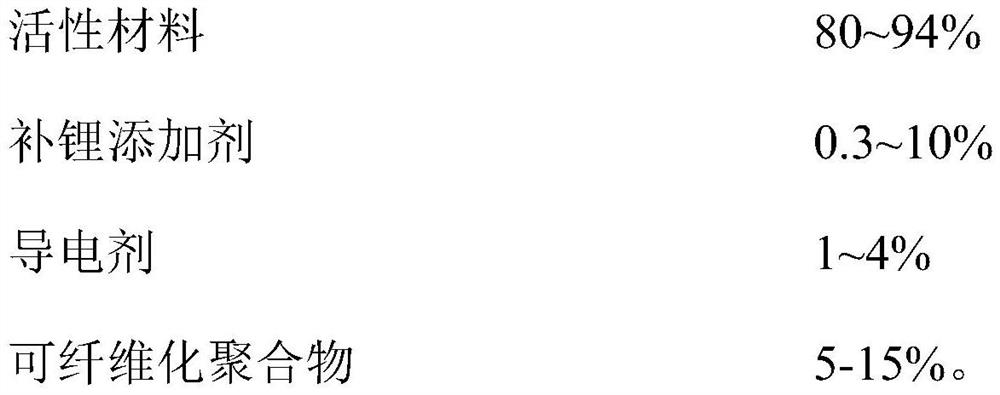

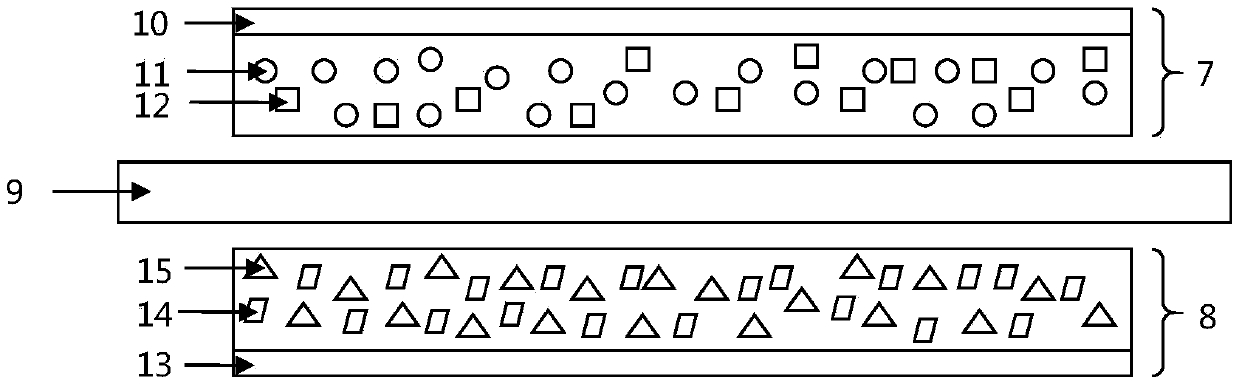

Pole piece film and preparation method and application thereof

ActiveCN112038574AImprove the first effectExcellent capacityElectrode rolling/calenderingLi-accumulatorsChemistryPolymeric surface

The invention relates to a pole piece film and a preparation method and application thereof, the pole piece film comprises a polymer with a networked structure and powder bonded to the surface of thepolymer, the powder comprises an active material and an auxiliary material, and the auxiliary material comprises a lithium supplement additive; and a battery prepared from the pole piece film has highfirst effect and capacity and excellent cycle performance. The preparation method comprises the following steps: premixing the active material, the auxiliary material and the fiberable polymer, drawing the fiberable polymer under the effect of a shearing force to form fibers, enabling the auxiliary material to contain a lithium supplementing additive, and performing hot pressing treatment to a preset thickness to obtain the pole piece film. By the adoption of the method, no solvent needs to be introduced in the whole process, the tedious processes that the lithium supplementing amount is attenuated due to existence of the solvent and the solvent needs to be removed through further baking are avoided, the lithium supplementing amount can be accurately controlled, meanwhile, the lithium supplementing additive is evenly mixed into the electrode powder through the method, more uniform lithium supplementing can be achieved, the problem of lithium supplement gradient is avoided, and the preparation method is simple to operate.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

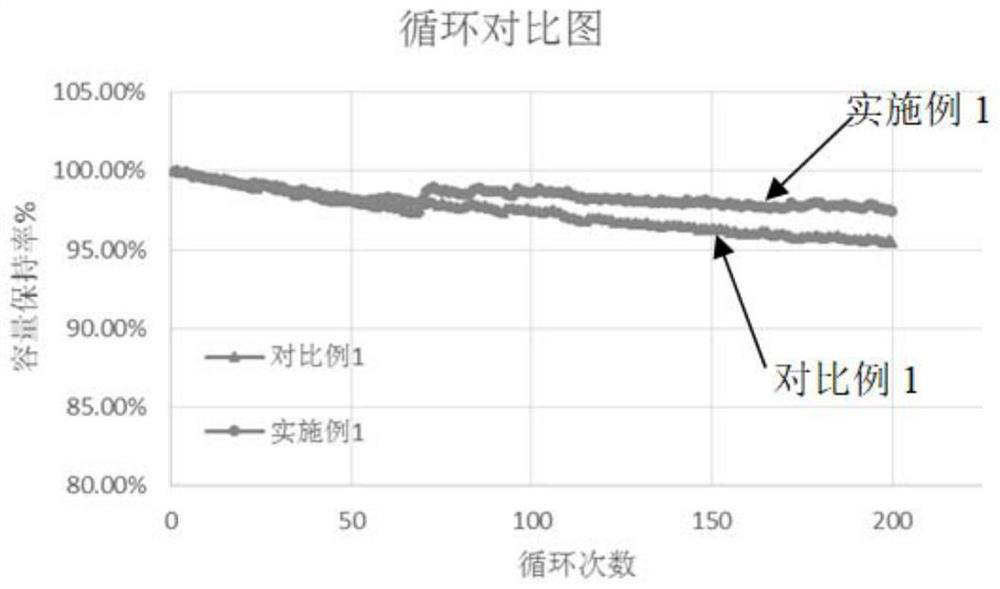

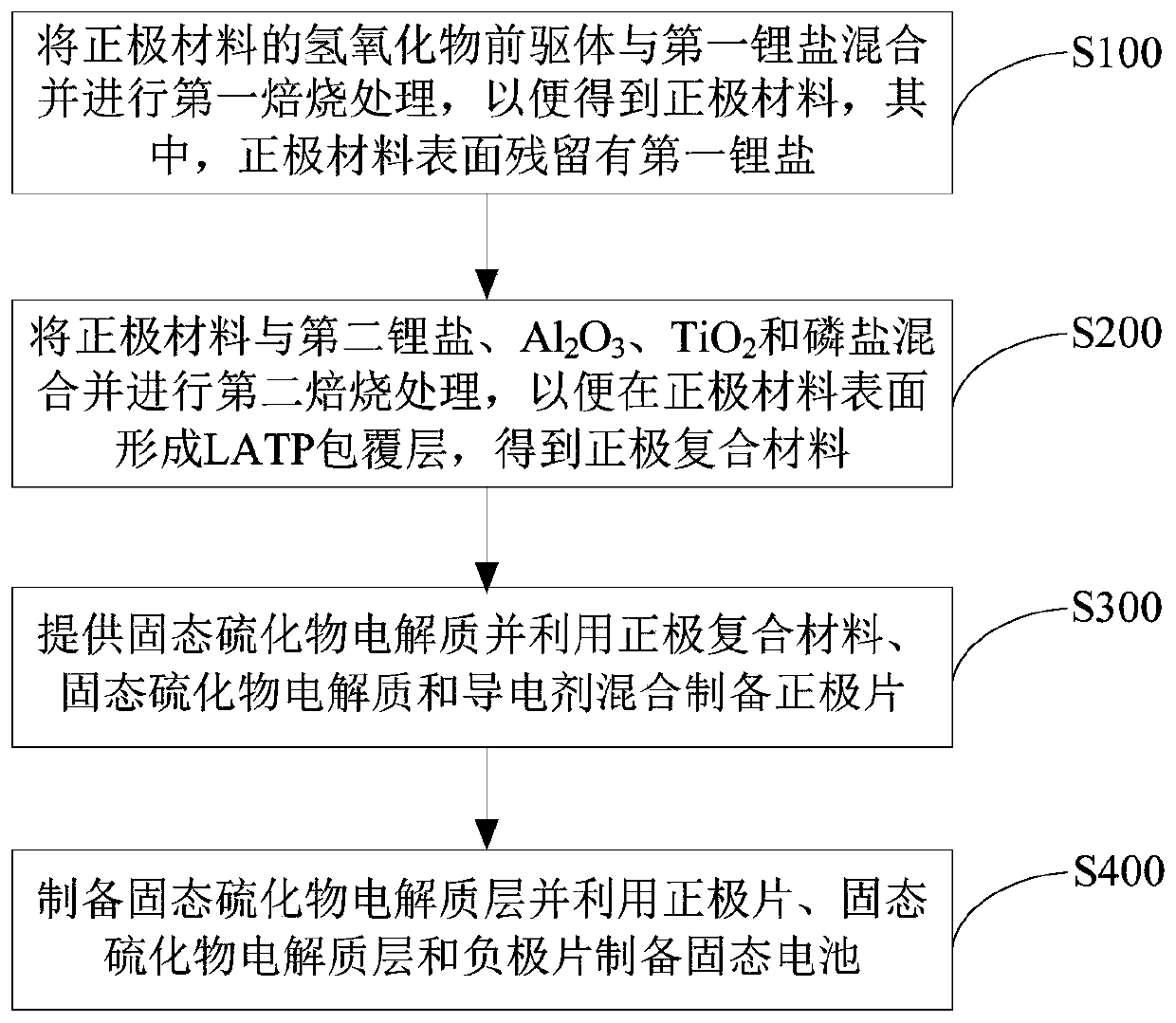

Solid-state battery and preparation method and application thereof

InactiveCN111430688AHigh charge and discharge capacityImprove the first effectSolid electrolytesCell electrodesPhysical chemistrySulfide compound

The invention discloses a solid-state battery and a preparation method and application thereof. The solid-state battery comprises a positive plate, a solid-state sulfide electrolyte layer and a negative plate. The positive plate comprises a positive composite material, a solid-state sulfide electrolyte and a conductive agent, the positive composite material comprises a positive material and an LATP coating layer formed on the surface of the positive material, and the solid sulfide electrolyte layer is arranged between the positive plate and the negative plate, wherein the LATP coating layer isobtained by taking the residual lithium salt on the surface of the positive electrode material as a guiding agent and the lithium source and inducing the lithium source, an aluminum source, a titanium source and a phosphorus source through an in-situ synthesis method. The solid-state battery has better rate capability and cycle performance at room temperature and a high temperature (70 DEG C).

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

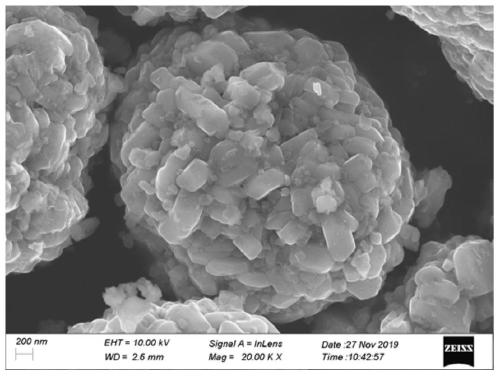

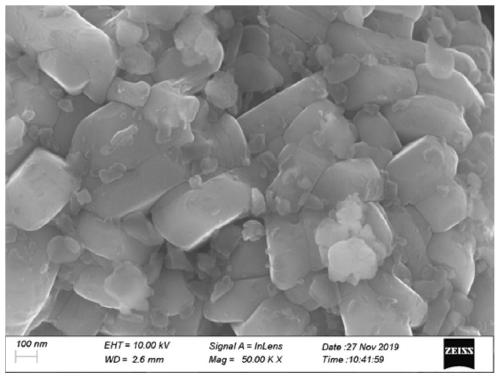

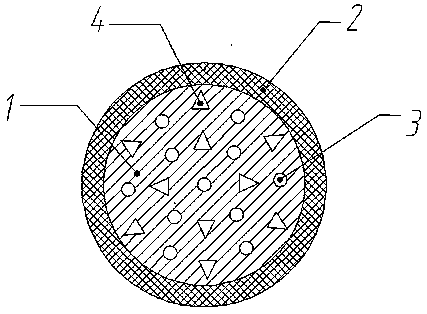

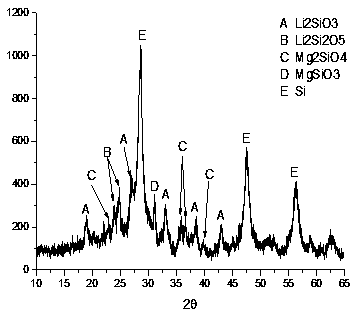

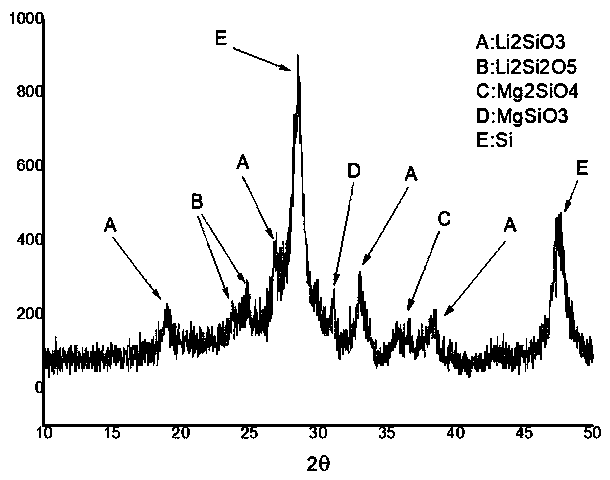

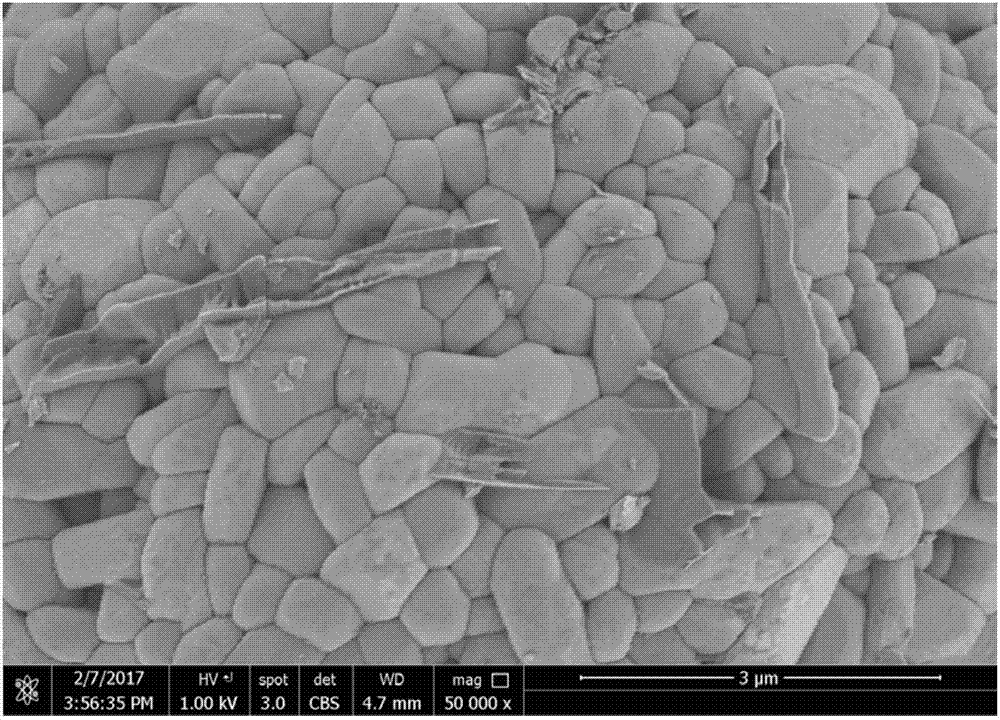

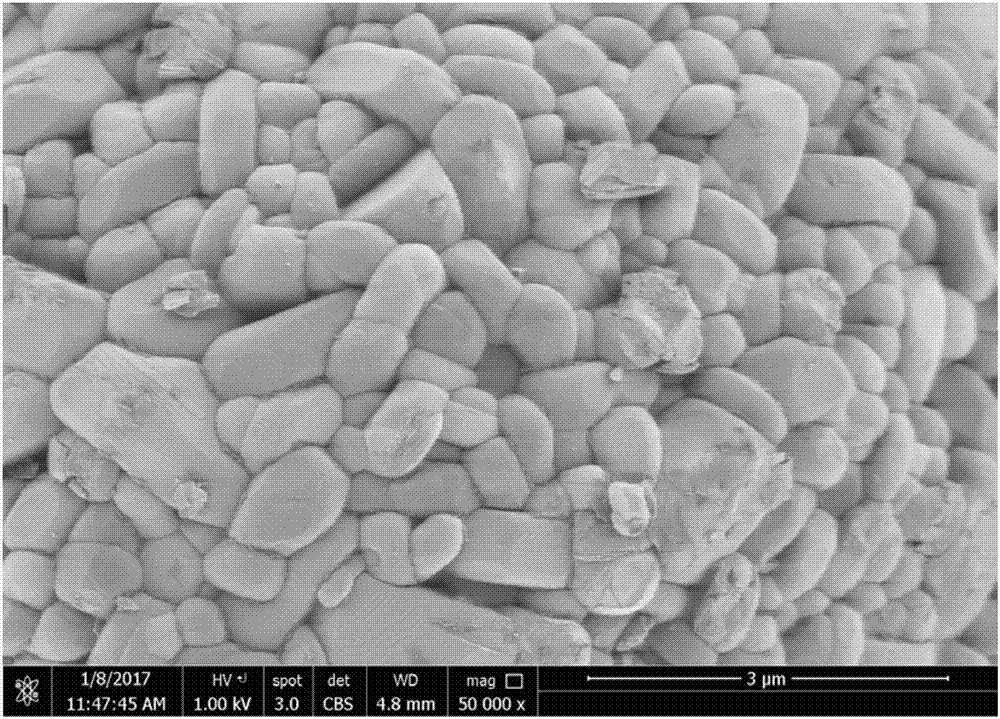

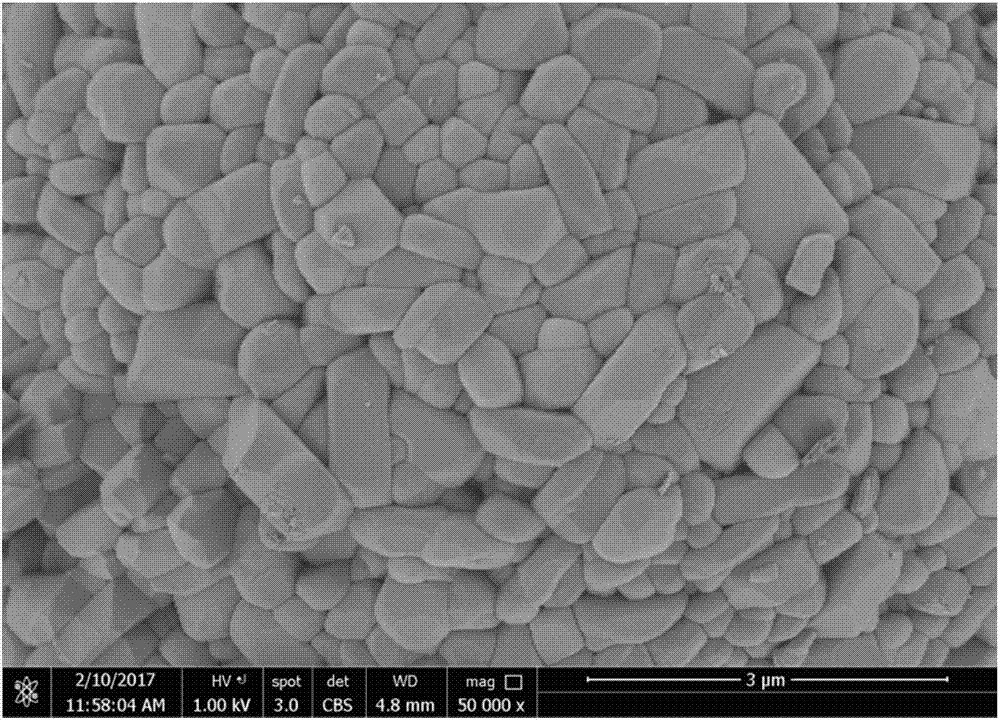

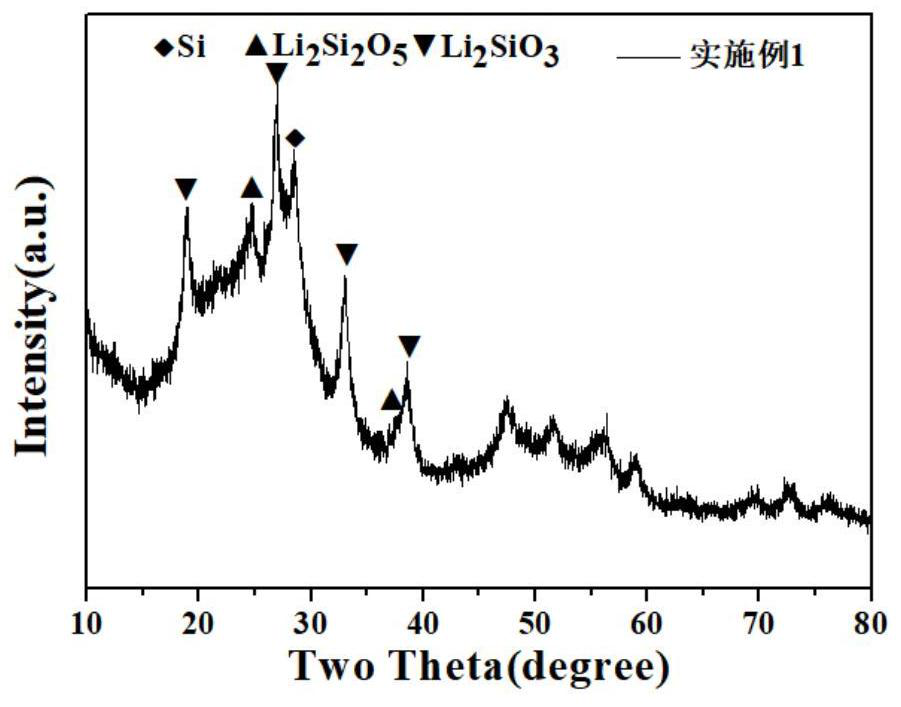

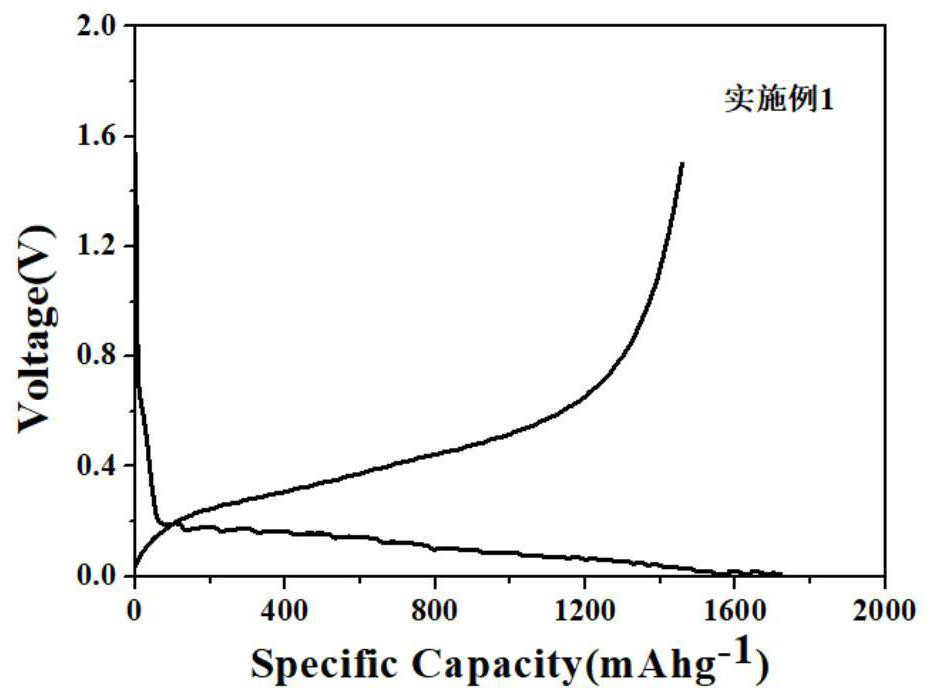

Multi-component composite high-first-effect lithium battery negative electrode material and preparation method thereof

ActiveCN111342030AImprove Coulombic efficiency and cycle performanceEasy to prepareSecondary cellsNegative electrodesElectrically conductiveMagnesium silicate

The invention relates to a multi-component composite high-first-effect lithium battery negative electrode material and a preparation method thereof. The negative electrode material forms a SiOx-lithium silicate-magnesium silicate multi-component composite system through co-doping of Li and Mg. The negative electrode material comprises silicon compound particles and a conductive layer coating the surfaces of the silicon compound particles, and further comprises lithium silicate and magnesium silicate, and the molar ratio of lithium atoms in the lithium silicate to magnesium atoms in the magnesium silicate is 0.01: 1 to 100: 1. The characteristics of high ionic conductivity of lithium silicate and high bonding strength of magnesium silicate are combined, the initial coulombic efficiency of the material is further improved, and meanwhile the cycle life is prolonged.

Owner:LANXI ZHIDE ADVANCED MATERIALS CO LTD

Modified lithium ion battery high-nickel anode material and preparation method thereof

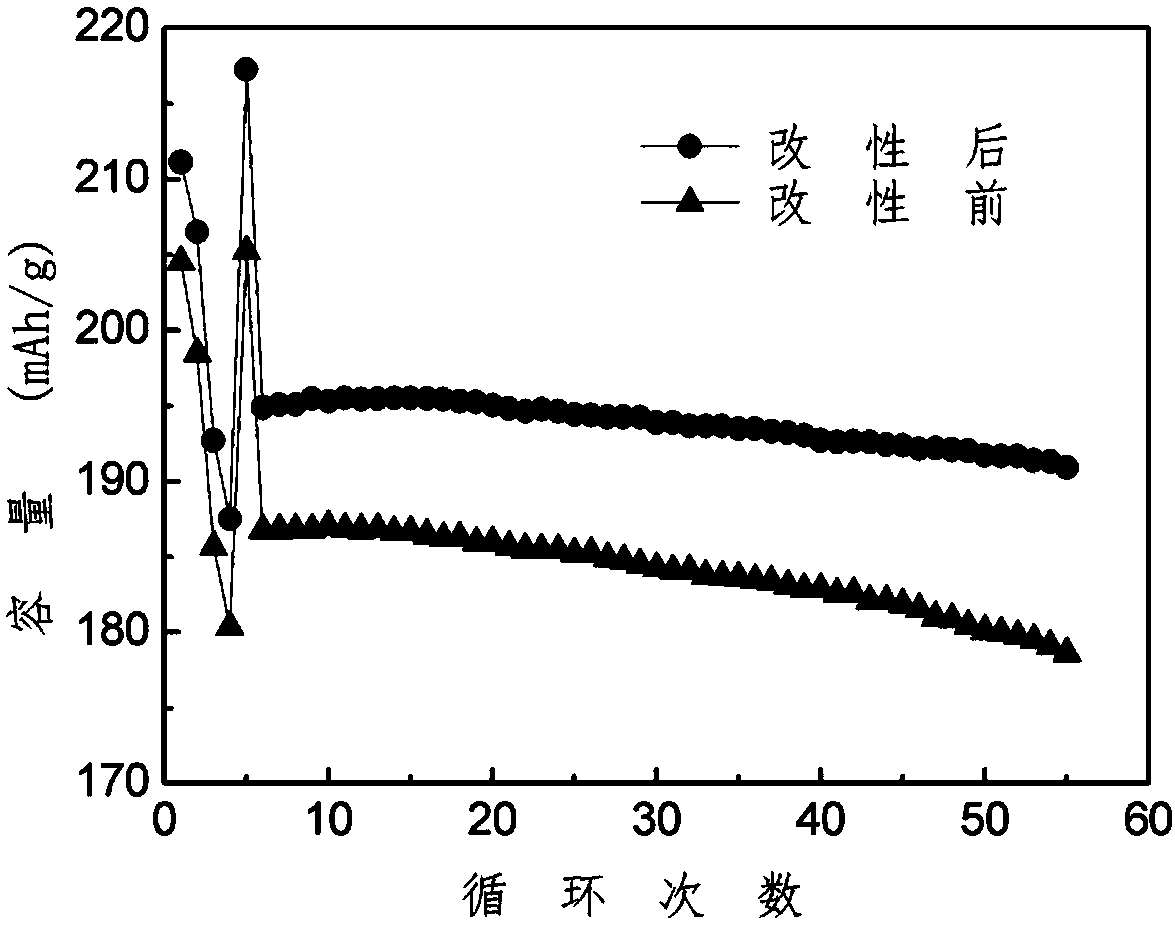

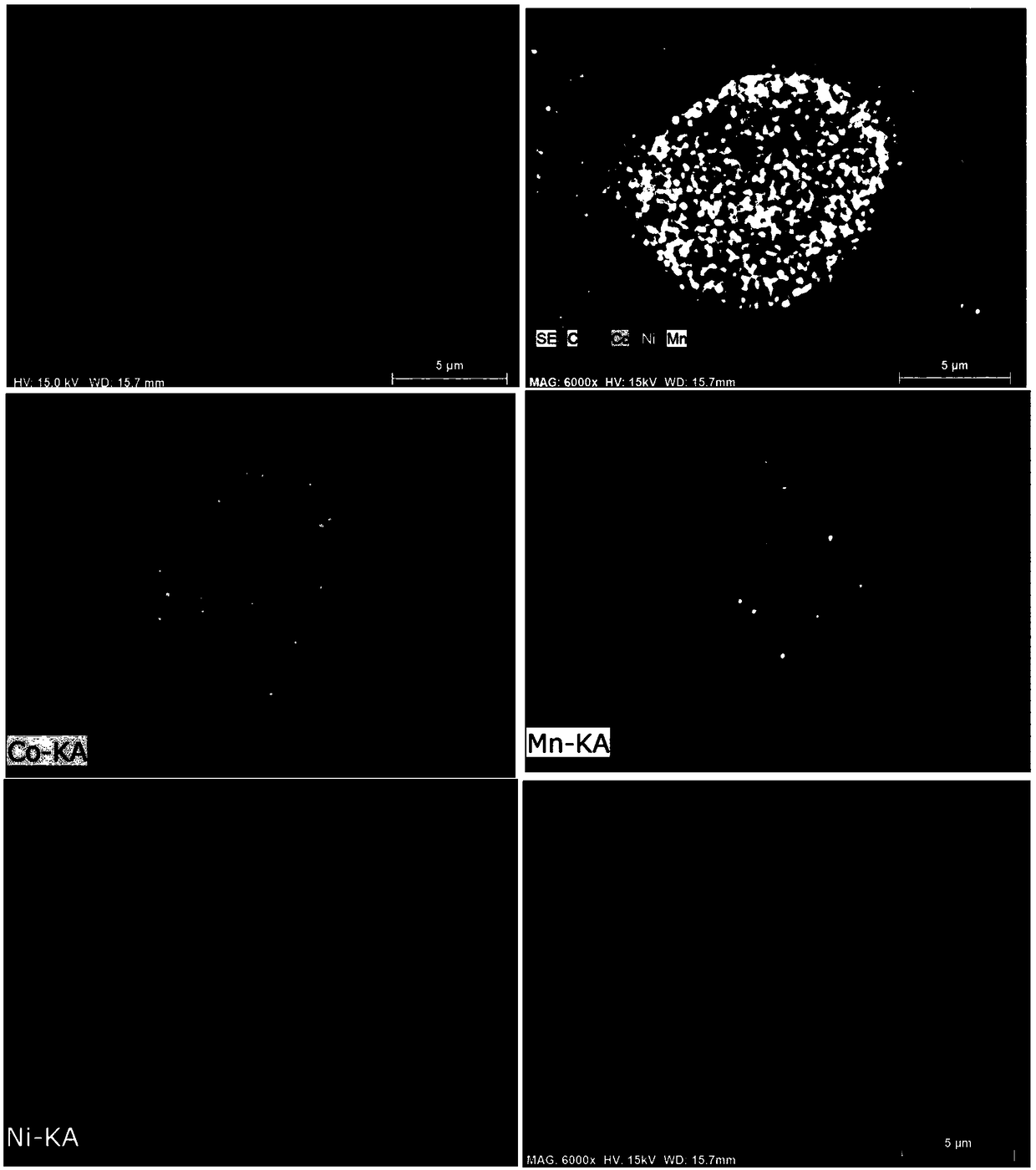

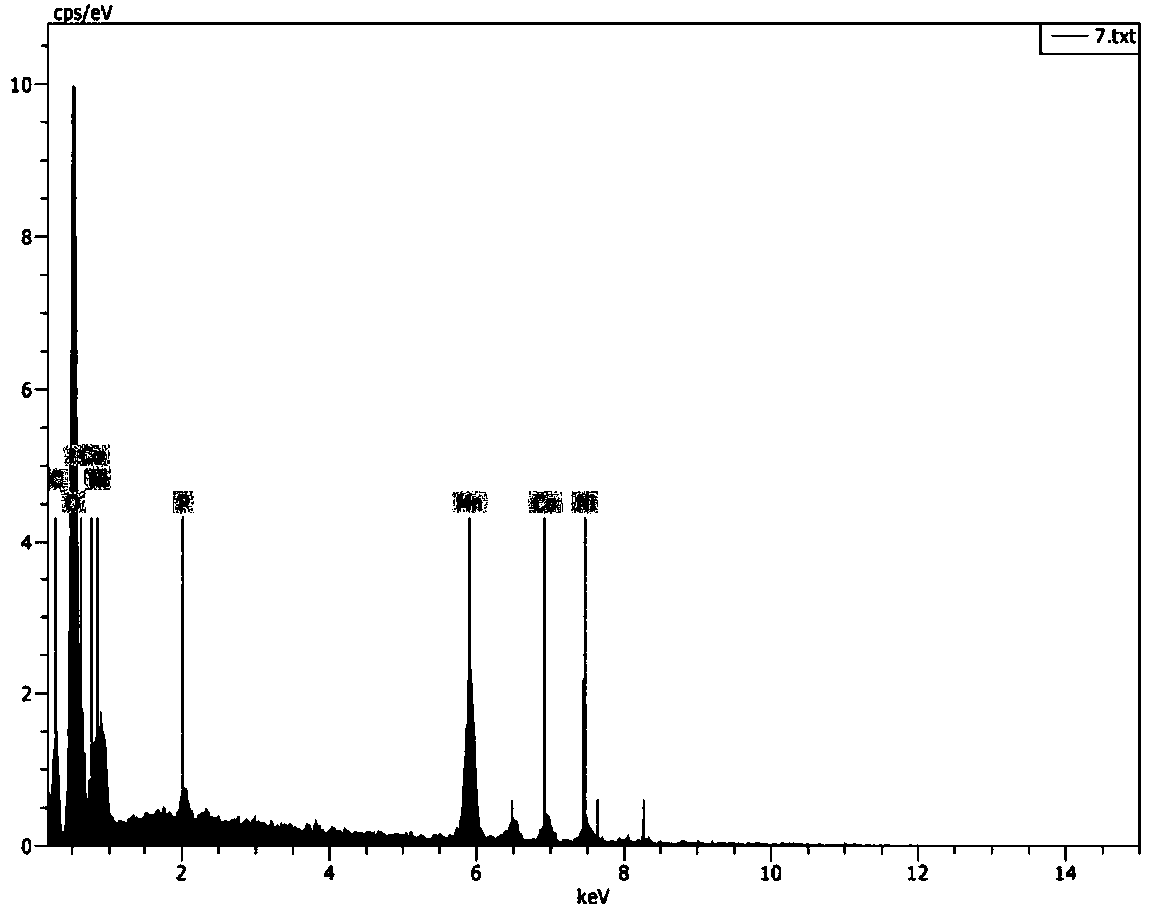

ActiveCN107256955AAvoid capacity loss phenomenonGuaranteed capacityCell electrodesSecondary cellsOxygenLithium-ion battery

The invention belongs to the technical field of lithium ion battery materials and discloses a water washing and tin coating combined modified lithium ion battery high-nickel anode material and a preparation method thereof. The preparation method includes following steps: (1), adding a high-nickel anode material into water, quickly stirring and washing for 1-20min at a rotating speed of 500-2000r / min, filtering, and drying to obtain a water-washed high-nickel anode material; (2), mixing the water-washed high-nickel anode material with a tin source well, heating to 300-700 DEG C in an oxygen-containing atmosphere at a heating rate of 1-3 DEG C / min, sintering at constant temperature for 3-10h, discharging, and breaking to obtain the modified lithium ion battery high-nickel anode material. According to the method, the high-nickel anode material is quickly washed in the water, the tin source is utilized to absorb residual lithium, and a composite coating layer of lithium stannate and tin oxide is formed on the surface of the material, so that discharging capacity and first effect of a battery are improved, and circulating performance and safety performance are improved.

Owner:GUANGDONG BRUNP RECYCLING TECH +3

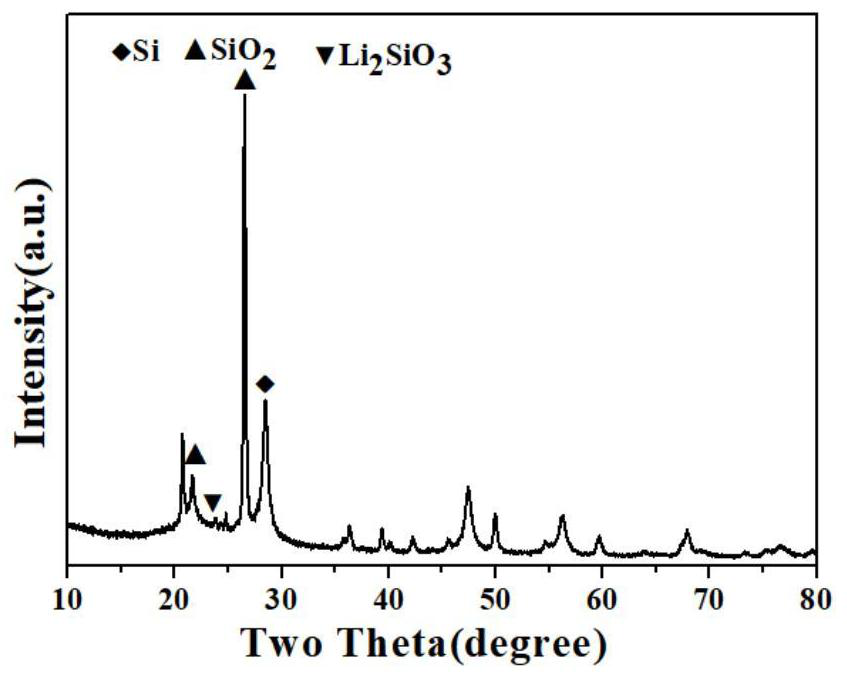

Pre-lithiated silicon monoxide/carbon composite material, and preparation method and application thereof

InactiveCN112289999AImprove electrochemical performanceAchieve lithium supplementationSecondary cellsNegative electrodesCarbon compositesMetallic lithium

The invention discloses a pre-lithiated silicon monoxide / carbon composite material, and a preparation method and application thereof, and belongs to the technical field of silicon monoxide materials.The preparation method comprises the following steps: performing vapor deposition on a silicon monoxide material to coat a carbon layer to prepare a silicon monoxide / carbon composite material; crushing a lithium salt to a proper particle size, and uniformly mixing the crushed lithium salt with silicon monoxide / carbon; and heating the mixed material to a certain temperature, and keeping the temperature for a period of time in a reducing atmosphere to obtain the pre-lithiated silicon monoxide / carbon composite material. According to the present invention, with the simple and efficient preparationmethod, a negative electrode material with characteristics of high first effect and good cycle performance can be effectively prepared, the negative electrode material can be well used for preparingthe lithium ion battery negative electrode material, and the method has advantages of low cost and easy scale-up production compared to the lithium supplementing through the metal lithium.

Owner:SHAANXI COAL & CHEM TECH INST

Fast charge graphite negative electrode material and preparation method thereof

InactiveCN107601490AIncrease charge and discharge rateImprove cycle performanceCell electrodesSecondary cellsElectrolytic agentElectrical battery

The invention discloses a fast charge graphite negative electrode material and a preparation method thereof. Through mixing of a graphite precursor and a coating material, low temperature treatment and high temperature graphitization treatment, the fast charge graphite negative electrode material for lithium ion batteries can be obtained. High temperature graphitization treatment enables conversion of the graphite precursor into high capacity graphite, at the same time the coating material converts to a structurally stable amorphous carbon coating layer, thus being conducive to rapid transmission of lithium ions in the material and electrolyte solution interface, significantly enhancing the charge-discharge rate and cycle performance of graphite material, and also ensuring high capacity and high initial coulombic efficiency. The process adopted by the invention is simple and low in energy consumption, and the fast charge graphite negative electrode material is suitable for commercial production and application in lithium ion batteries.

Owner:天津爱敏特电池材料有限公司

A preparation method of silicon-carbon negative electrode material for lithium ion battery

The invention discloses a preparation method of a silicon-carbon negative electrode material of a lithium ion battery, comprising the following steps: adding a proper amount of nano-silicon powder, adispersant, zinc nitrate hexahydrate, terephthalic acid and CNTs to a sufficient amount of N, N- A mixed solution is prepared from dimethylformamide, and then the mixed solution is uniformly dispersed; A suitable amount of triethylamine reagent is slowly and uniformly adde into that mixture prepared in the first step, aft full reaction, the precipitate is washed, filtered and dried to obtain CNTs / MOF- 5, coat that nano Si precursor; The precursor was put into a tubular furnace protected by inert gas and carbonized at high temperature to obtain silicon-carbon composites. Silicon-carbon anode materials for lithium ion batteries were prepared by mixing the prepared silicon-carbon composite and artificial graphite homogeneously. CNTs is adde into that preparation process of the silicon-carbonnegative electrode material of the lithium ion battery, and the CNTs can be use as a conductive network structure, the electronic conductivity of the silicon-carbon negative electrode is greatly improved, and the first effect and the multiplicity of the charge-discharge cycle of the silicon-carbon negative electrode are improved.

Owner:江西中汽瑞华新能源科技有限公司

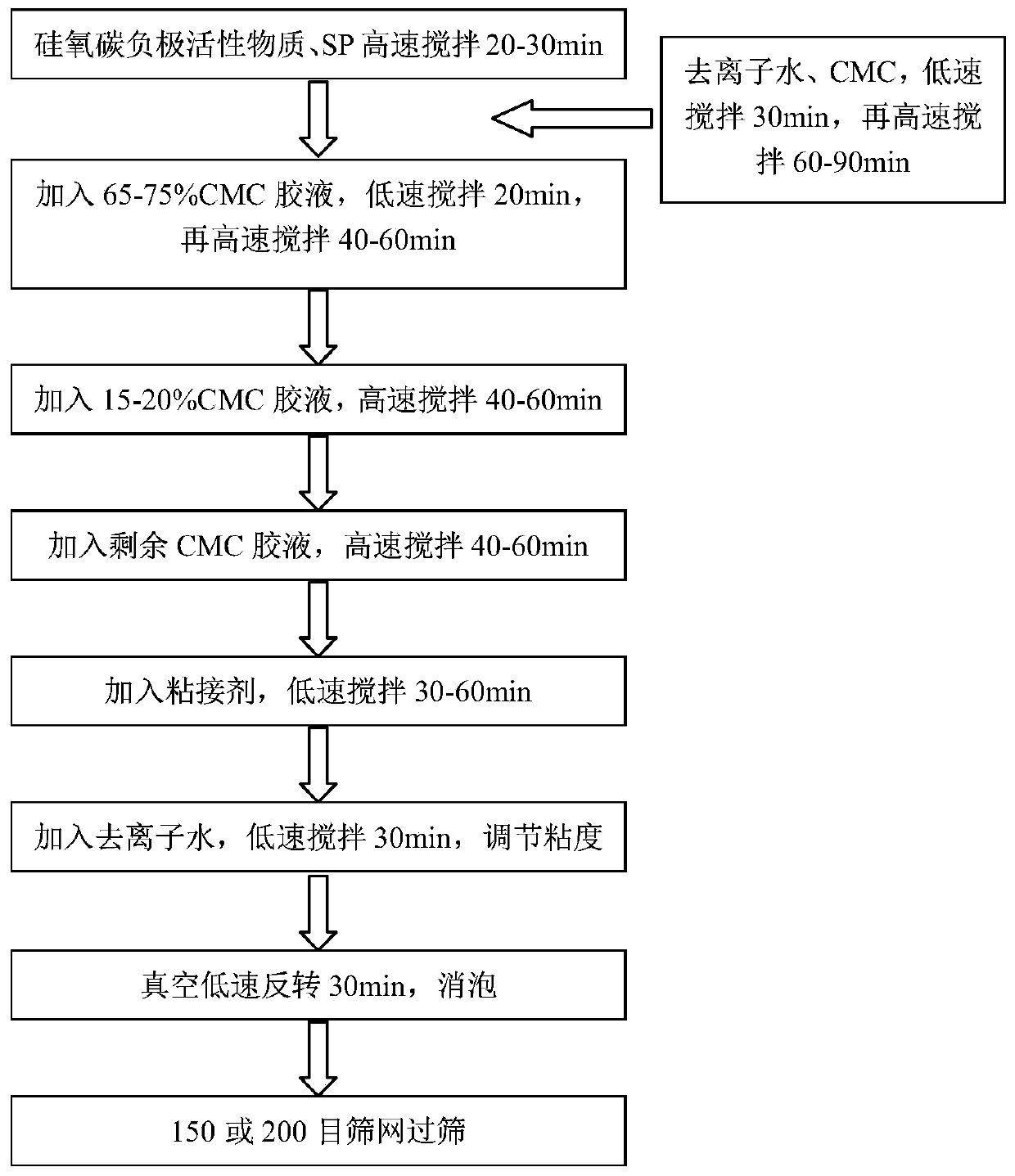

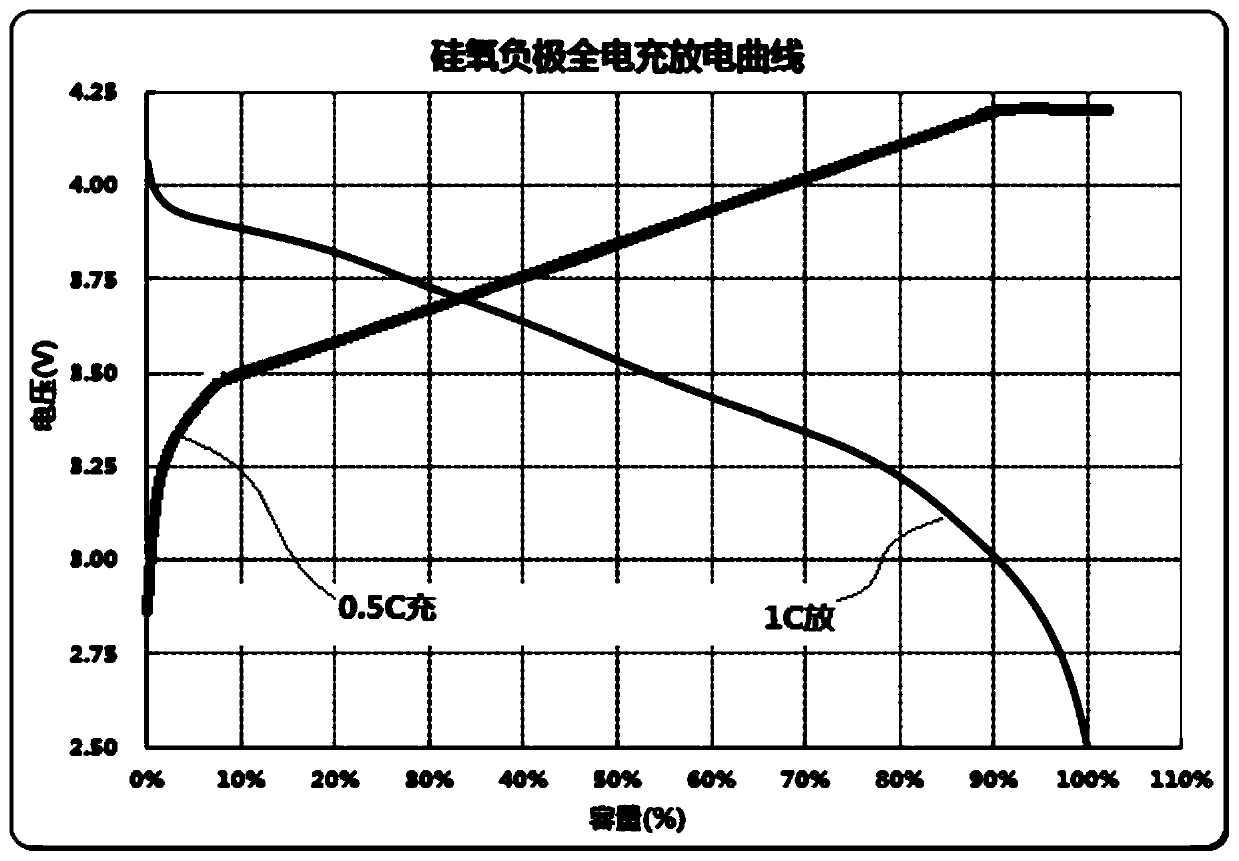

Lithium ion battery silicon oxygen anode paste, preparation method thereof, battery anode and lithium ion battery

PendingCN109950485AIncrease gram capacityImprove the first effectCell electrodesSecondary cellsGramSilicon oxygen

The invention discloses a lithium ion battery silicon oxygen anode paste, a preparation method thereof, a battery anode and a lithium ion battery, and belongs to the technical field of lithium ion battery manufacture. The lithium ion battery silicon oxygen anode paste comprises deionized water and a solid material. The solid materials comprises, with 100 total parts by weight, 93 to 97 parts of silicon-oxygen anode active material, 1 to 2 parts of CMC, binder of 1.2 to 2.0 times the CMC, and 1 to 2 parts of conductive agent SP. The solid material of the anode paste uses the 93 to 97 parts silicon-oxygen anode active material instead of the conventional graphite and the like. The prepared silicon-based anode has a much higher gram capacity than that of the graphite anode. The gram capacityof the anode active material can be greatly adjusted by adjusting the silicon content. The lithium ion battery silicon oxygen anode paste has stable later cycle stability, and high first effect.

Owner:SVOLT ENERGY TECH (MAANSHAN) CO LTD

Negative electrode piece and lithium-ion battery containing the same

InactiveCN109950510AIncrease energy densityImprove cycle lifeCell electrodesSecondary cellsElectrical batteryGraphite

The invention provides a negative electrode piece which comprises a negative electrode current collector and a negative electrode slurry applied on the negative electrode current collector. The negative electrode slurry includes a negative electrode active material, a negative electrode binder and a negative electrode conductive agent, the negative electrode active material is a mixture of Liy-SiOx and graphite, and the Li-SiOx accounts for 1% to 55% of the negative electrode active material. The invention belongs to the technical field of lithium-ion batteries, the negative electrode active material is a mixed material of Liy-SiOx and graphite, the problems of low first effect, fast cycle decay and large cycle expansion of a high-proportion mixed negative electrode can be effectively solved, therefore, the energy density and cycle life of the battery are significantly improved, and the negative electrode piece is suitable for large-scale commercial production.

Owner:ZHUHAI COSMX BATTERY CO LTD

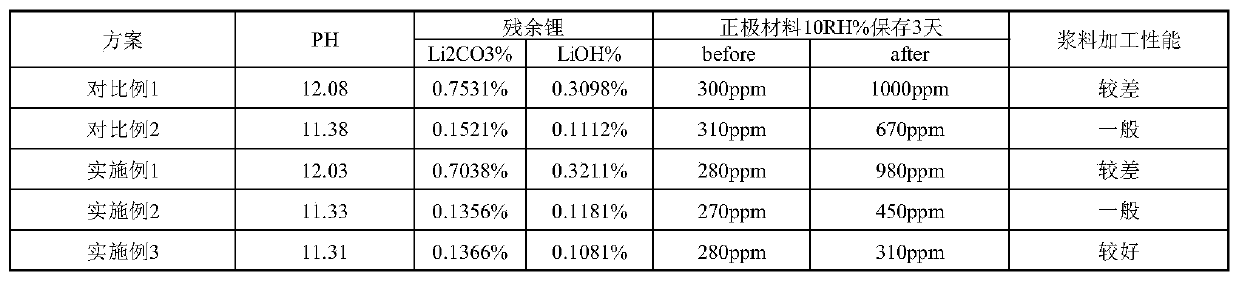

Preparation method of high-nickel positive electrode material

InactiveCN109802123AImprove high temperature stabilityImprove water absorptionCell electrodesSecondary cellsLithium hydroxideLithium carbonate

The invention discloses a preparation method of a high-nickel positive electrode material, which comprises the following steps: uniformly mixing up a Ni-containing hydroxide, a lithium-containing compound and a doping element, and calcining to obtain a base material A after the mixing operation; adding the base material A into a washing solution, controlling the temperature of the washing solution, washing away residual lithium carbonate and lithium hydroxide on the surface, adding a lithium-containing compound into the washing solution, and drying the washed base material to obtain a mixtureB; uniformly mixing the mixture B, a coating element and a lithium-containing compound, calcining, and crushing to obtain the finally modified high-nickel positive electrode material. The high-temperature stability of the nickel material is improved through doping. The residual lithium carbonate and lithium hydroxide on the surface are reduced through washing. The water absorption and processing performance of the material is improved. The damage to the surface of the material during washing can be repaired through coating. The direct contact between the positive electrode material and the electrolyte can be reduced, so that the high-temperature characteristic and long-cycle performance of the battery cell are improved.

Owner:浙江迈纳新材料有限公司

Preparation method of modified high nickel ternary cathode material

The invention discloses a preparation method of a modified high nickel ternary cathode material, which is prepared by the following steps: mixing a water washed high nickel ternary cathode material with a metal salt solution to carry out reactions, and then drying and sintering the reaction product. The provided modification method can reduce the free lithium on the surface of the high nickel ternary cathode material and pH value, and at the same time, the capacity and cycle performance of the high nickel ternary cathode material are improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

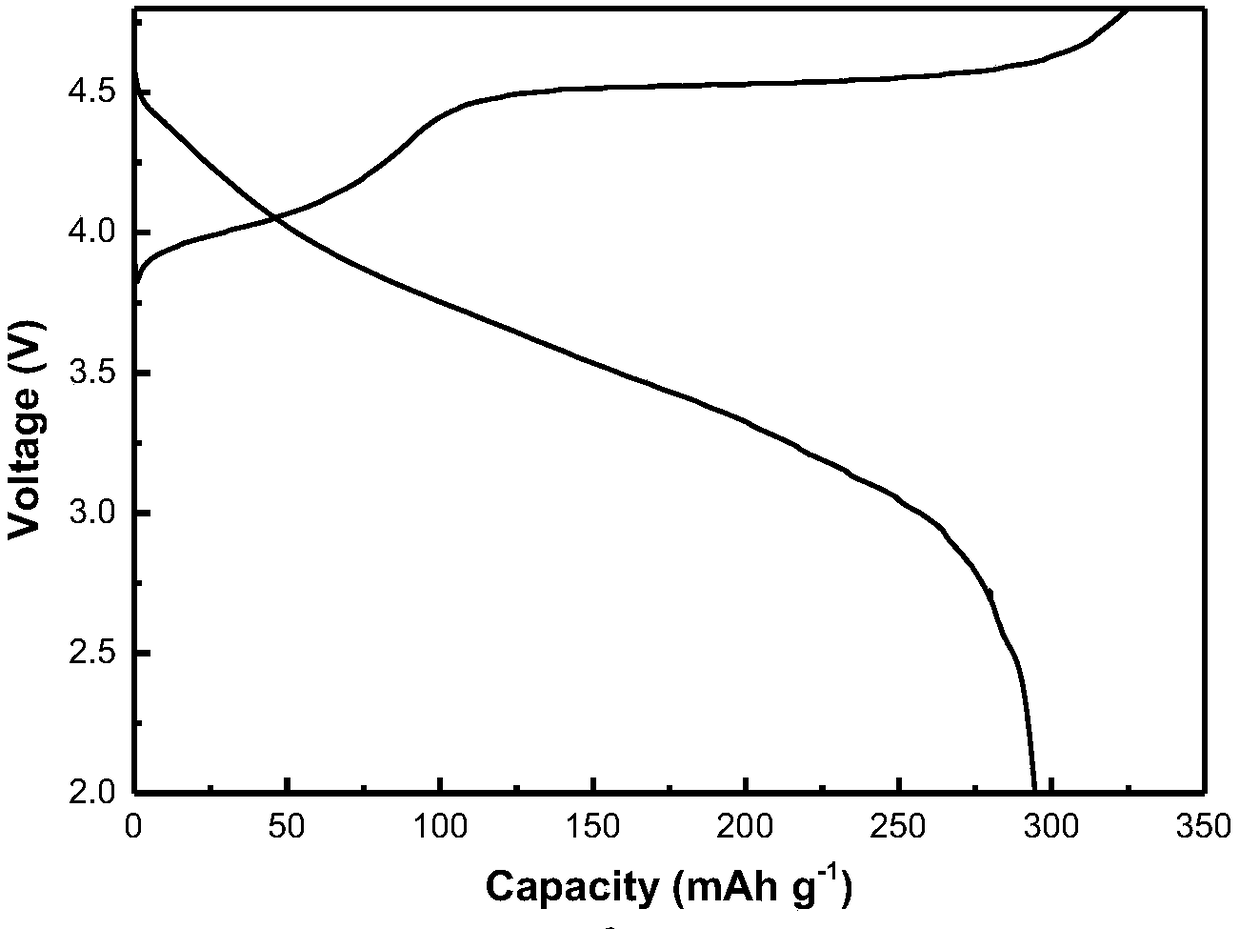

A phosphorus doped lithium-rich manganese-based cathode material for lithium ion battery and a preparation method thereof

ActiveCN109244390AImprove performanceExtended service lifeCell electrodesSecondary cellsManganeseLithium-ion battery

The invention discloses a preparation method of a phosphorus-doped lithium-rich manganese-based cathode material for a lithium ion battery, in particular comprising the steps of preparing precipitantsolution, preparing metal salt solution, preparing phosphorus-doped nickel-cobalt-manganese carbonate precursor, and preparing phosphorus-doped lithium-rich manganesebased cathode material; The precursor of phosphorus-doped Ni-Co-Mn compound can be obtained by dissolving the pyrophosphate compound as phosphorus source in precipitant solution and coprecipitating, and the phosphorus-doped lithium-rich manganesebased cathode material can be obtained by sintering at high temperature. The preparation method disclosed by the invention is simple, and the prepared cathode material is not only doped with phosphorus on the surface, but also evenly doped with phosphorus inside the material, so that the performance of the material is stable, the service life is long, and the capacity, the first effect, the ratio and the cycle stability of the material are remarkably improved.

Owner:HARBIN INST OF TECH

A composite graphite negative electrode material and a preparation method thereof, and a lithium ion battery

InactiveCN109244392ANot easy to reuniteEasy transferCell electrodesSecondary cellsElectrical conductorSodium-ion battery

The invention belongs to the technical field of lithium battery and relates to a preparation method of a composite graphite negative electrode material, comprising the steps of: 1) coating the surfaceof graphite powder with a metal oxide layer by an atomic layer deposition method; 2) uniformly mixing with that lithium salt powder, performing sintering at 300-1200 DEG C for 9-12h, reacting the metal oxide with the lithium salt to form a lithium ion conductor layer, and simultaneously allowing the metal oxide and the lithium salt to enter the graphite layered structure to form doping; 3) performing washing with water and drying. The invention also provides a composite graphite negative electrode material prepared by adopting the preparation method. The invention also provides a lithium ionbattery, wherein the negative electrode current collector surface is coated with the negative electrode material. The invention adopts ALD to coat graphite surface with the metal oxide, and then formsdense lithium ion conductor layer coating and doping of lithium ion and metal ion through high-temperature sintering, avoiding side reaction with organic electrolyte contact, facilitating lithium iontransmission, and improving lithium ion battery cycle stability and rate performance.

Owner:宁波柔创纳米科技有限公司

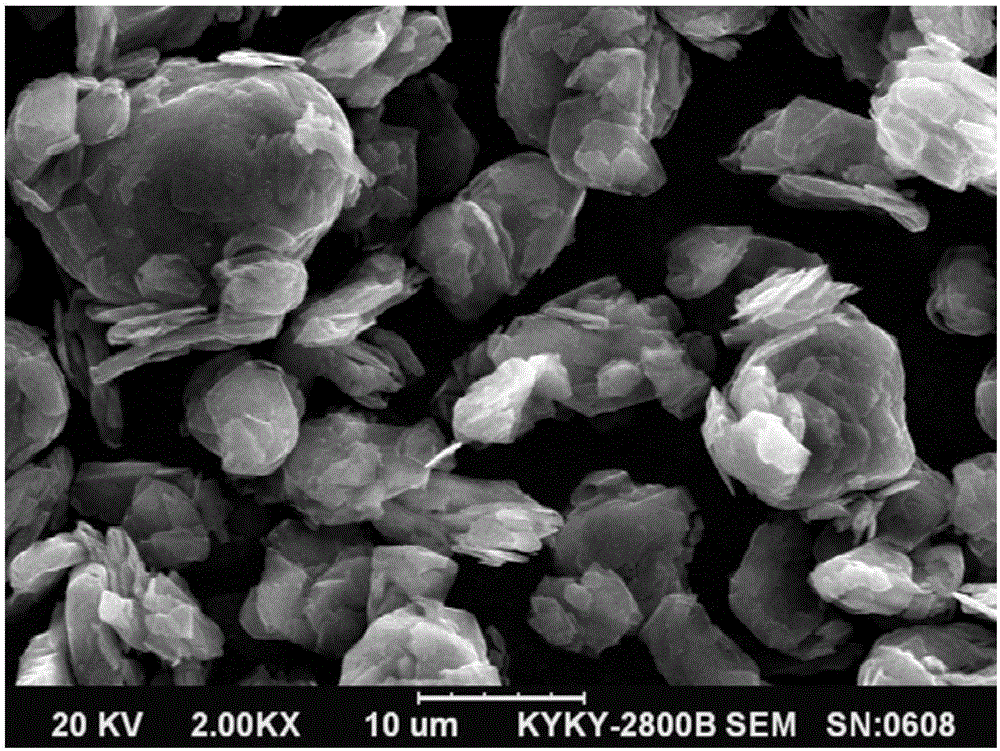

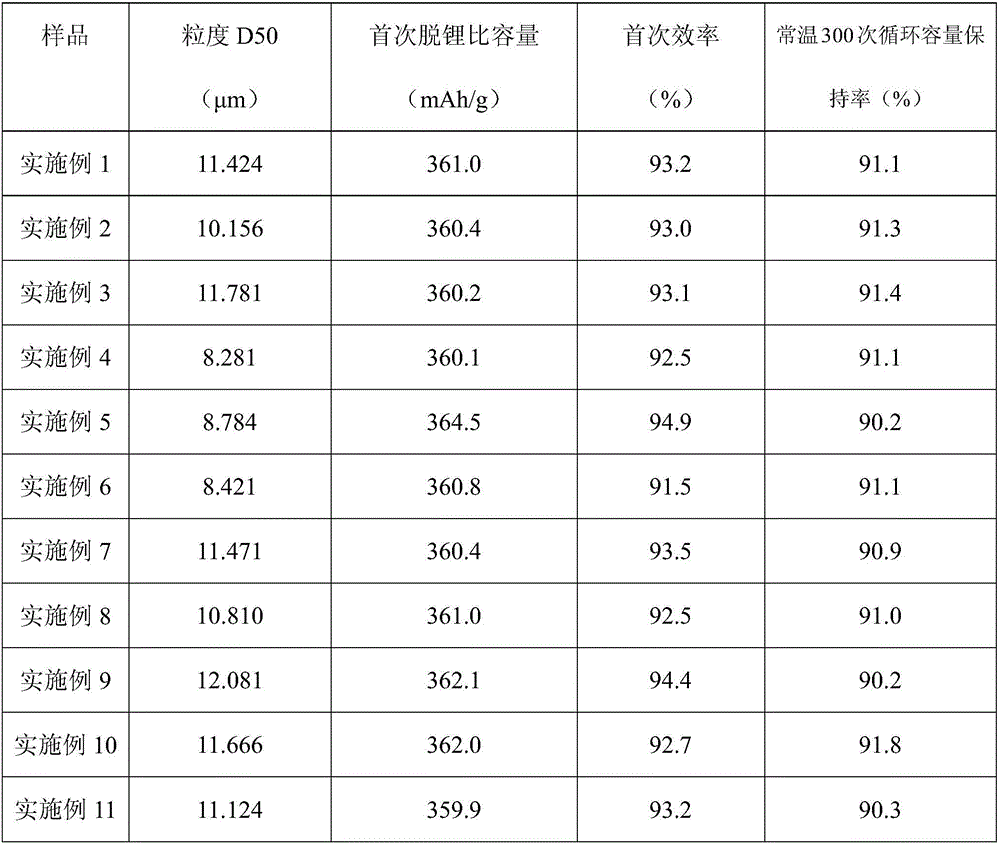

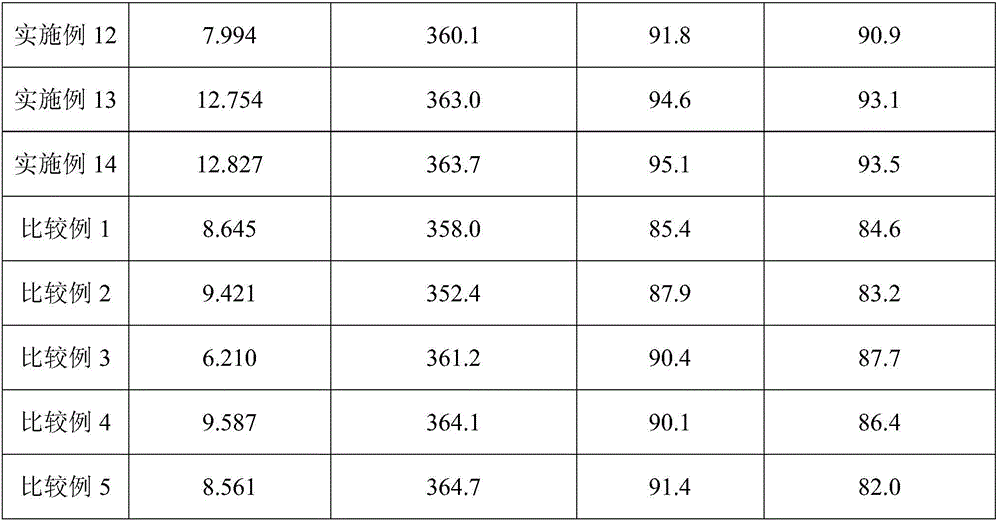

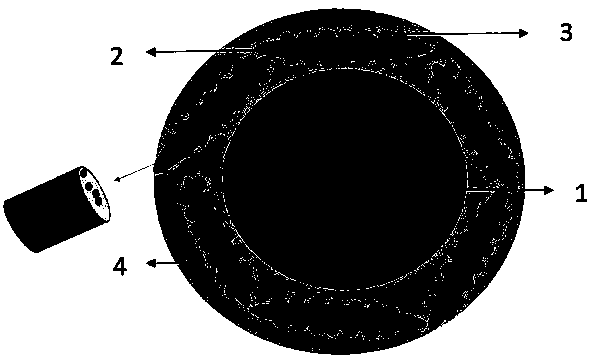

Graphite-based composite material and preparation method thereof and lithium ion battery comprising the composite material

ActiveCN106602067AHigh first efficiency andHigh specific capacityCell electrodesFinal product manufactureLithium electrodeAsphalt

The invention discloses a graphite-based composite material and a preparation method thereof and a lithium ion battery comprising the composite material. The method disclosed by the invention comprises the following steps: 1) uniformly mixing activated natural graphite and asphalt according to a proportion, adding to a fusion machine, charging inert gas and carrying out fusion and granulation under a certain temperature; and 2) carrying out carbonization treatment or graphitization treatment on a fusion and granulation product to obtain the graphite-based composite material. The battery which is assembled and whose negative electrode is prepared by adopting the graphite-based composite material has high capacity, and good rate capability and cycle performance; the initial lithium removal specific capacity is 360.1mAh / g or more, and the initial efficiency is 91.5% or more; and the room temperature charge-discharge cycles of the finished product battery is 300 weeks and the capacity retention rate is greater than 90%.

Owner:贝特瑞(江苏)新能源材料有限公司

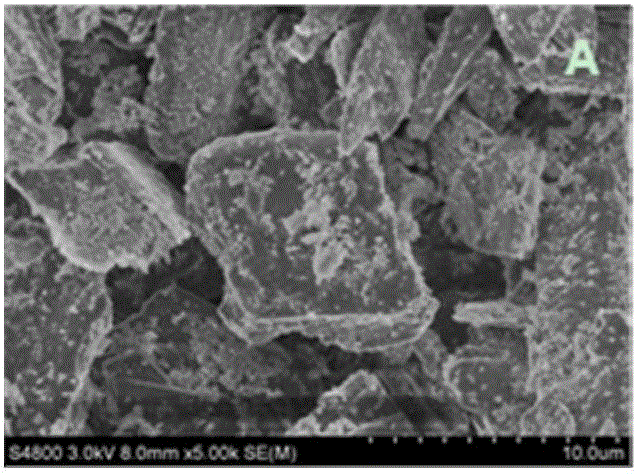

Silicon carbon composite negative electrode material and preparation method thereof

InactiveCN109713285ASimple processAlleviate volume effectCell electrodesSecondary cellsFiberCarbon composites

The invention provides a preparation method of a silicon carbon composite negative electrode material. Nano-silicon is prepared by employing a CVD method, then the nano-silicon is added to a DMF solution of polyacrylonitrile, electrostatic spinning is performed in an electric field, a silicon-carbon composite fiber is obtained, the silicon-carbon composite fiber, natural spherical graphite and asphalt are dissolved in a solvent for stirring and dispersing, then spray pyrolysis is carried out, and a high capacity silicon carbon composite material is obtained. The method is simple in equipment,is easy to operate and has good industrial application prospects. The silicon carbon composite negative electrode material prepared by the method has excellent electrochemical performance.

Owner:HUNAN SHINZOOM TECH

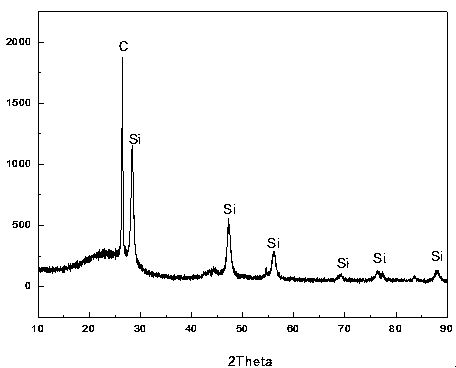

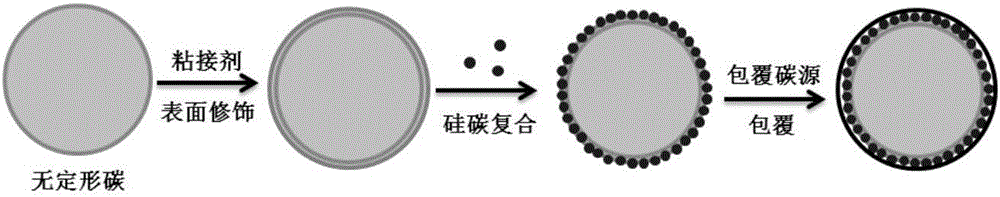

Carbon-silicon composite material and preparation method of carbon-silicon composite material as well as lithium-ion battery comprising composite material

ActiveCN106784741AEasy to operateSuitable for large-scale productionMaterial nanotechnologyCell electrodesNano siliconCharge rate

The invention discloses a carbon-silicon composite material and a preparation method of the carbon-silicon composite material as well as a lithium-ion battery comprising the composite material. The carbon-silicon composite material comprises an amorphous carbon inner core and a shell which is formed by dispersing nano silicon into a pyrolytic carbon layer. The method is simple and easy to operate, is environmental-friendly and is suitable for large-scale production; the prepared carbon-silicon composite material has a stable structure, the nano silicon has good dispersibility and the coated degree of the nano silicon is very high; the carbon-silicon composite material is used as a negative electrode material of the lithium-ion battery and has a very high lithium removing specific capacity, a good circulating performance and an excellent rapid charging property; the lithium removing specific capacity is 391.7mAh / g or more, the capacity retention rate is 95.3 percent or more after the lithium-ion battery is charged and discharged at constant current of 1.0C for 50 times, and the charging rate of 10min can reach 90.2 percent.

Owner:深圳市贝特瑞新能源技术研究院有限公司

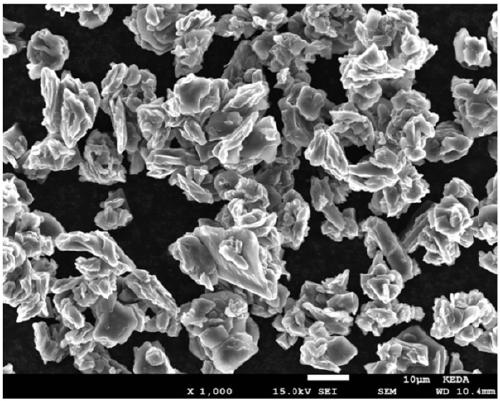

High-rate lithium ion battery graphite cathode material and preparation method thereof

InactiveCN109437184AImprove performanceIncrease charge and discharge rateCarbon compoundsHybrid capacitor electrodesHigh rateSurface oxidation

The invention belongs to the field of lithium ion batteries, and particularly relates to a high-rate lithium ion battery graphite cathode material and a preparation method thereof. The preparation method comprises the following steps: (1) pulverization and shaping of raw materials; (2) graphitization; (3) demagnetization screening; (4) liquid phase coating granulation; (5) surface oxidation treatment. According to the high-rate lithium ion battery graphite cathode material and the preparation method thereof, a liquid phase coating granulation process replaces traditional secondary granulationthrough optimized fine graphite, so as to realize uniform coating of the surface of graphite, reduce the anisotropism of the graphite and shorten the diffusion path of lithium ions; then a micro porestructure is formed on the surface of the graphite through a surface oxidization pore formation process, so that a lithium ion migration channel of a cardinal plane is added to increase the migrationspeed of lithium ions. The charging rate of the graphite obtained by the method is more than 8 C, and the capacity can be maintained at 80 percent or above under the discharging rate more than 30 C.

Owner:KEDA (ANHUI) NEW MATERIAL CO LTD

A cathode material for sodium ion battery and a preparation method thereof

ActiveCN109273682AIncrease sodium storage capacityImprove cycle stabilityCell electrodesSecondary cellsDissolved ironSodium-ion battery

The invention discloses a positive electrode material of a sodium ion battery and a preparation method thereof. cathode material of the sodium ion battery, The preparation method comprises the following steps of: dissolving iron salt in a fluorinated ionic liquid, stirring the obtained mixed solution with a carbon source, a Prussian blue sodium ion cathode material, and carrying out solvothermal reaction to obtain an iron-based fluoride and carbon in-situ coating modified Prussian blue composite sodium ion battery cathode material. The invention can effectively improve the sodium storage capacity and cycle stability of the sodium ion battery composite material, and can also increase the conductivity of the sodium ion battery composite material through a simple in-situ coating process of the iron-based fluoride and the carbon source.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

Composite positive electrode material for lithium ion battery and preparation method and application of composite positive electrode material

ActiveCN111490243AImprove ionic conductivityImprove structural stabilitySecondary cellsPositive electrodesLithium-ion batteryIonic conductivity

The invention discloses a composite positive electrode material for a lithium ion battery and a preparation method and application of the composite positive electrode material. The composite positiveelectrode material comprises a positive electrode material core and a halide coating layer coating the surface of the positive electrode material core. The halide comprises Li3YX6, and X is at least one of halogens. According to the halide-coated positive electrode material disclosed by the invention, through coating of the halide coating layer, the ionic conductivity and the structural stabilityof the positive electrode material are greatly improved, and the surface impedance of the material is reduced, so that the capacity, the first effect and the cycle performance of the material are improved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Preparation method for silicon/graphite/solid electrolyte composite negative electrode material

ActiveCN110858642AGood cycle performanceImprove conductivitySecondary cellsNegative electrodesCarbon nanofiberGraphite

The invention discloses a preparation method for a silicon / graphite / solid electrolyte composite negative electrode material. The preparation method comprises the following steps of: firstly, mixing silicon powder, graphite, a binder, a conductive agent and a solid electrolyte to prepare a dispersion liquid, and then performing spray granulation and drying; and adding asphalt for kneading, sintering at high temperature, crushing, sieving and demagnetizing to obtain the silicon / graphite / solid electrolyte composite negative electrode material. According to the material prepared by the method, a conductive network is formed by utilizing conductive agents such as carbon nanotubes, carbon nanofibers and graphene, so that the conductivity of the material is improved; a high temperature-resistantsolid electrolyte is added, the effect of partial electrolyte can be replaced, an ionic conductance medium is achieved when the electrolyte enters the active material, the use amount of the electrolyte is reduced, and when an SEI film is heated and decomposed, the solid electrolyte can still exist stably, the ionic conductance effect is achieved, and the stability and the safety performance of thesilicon / graphite / solid electrolyte composite negative electrode material are improved.

Owner:RISESUN MENGGULI NEW ENERGY SCIENCE & TECHNOLOGY CO LTD

Surface modification method of anode material of lithium ion battery

ActiveCN105576215AImprove the first effectImprove cycle performanceSecondary cellsPositive electrodesCerium nitrateElectrical battery

The invention discloses a surface modification method of an anode material of a lithium ion battery. The surface modification method comprises the following steps of adding a smashed anode material of the lithium ion battery into a mixed solution prepared from cerium nitrate and neodymium nitrate, carrying out ultrasonic stirring after mixing by adding ammonium hydroxide, evaporating water and drying; pressing a dried sample into a flaky product after grinding and smashing the dried product, putting the flaky sample into a tubular furnace in which oxygen is continuously pumped, rising the temperature, calcining in the oxygen, then calcining in argon, and obtaining a finished product. According to the surface modification method disclosed by the invention, the anode material of the lithium ion battery is coated and modified through neodymium-doped nano cerium dioxide, so that the structure stability is maintained, the first cycle efficiency is increased, oxygen deficiency caused by disembedding of lithium ions is filled, and the structure stability of the anode material is maintained; meanwhile, a coating object has higher water absorbing resistance after being subjected to surface hydrophobization treatment.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

A precharged high-efficiency liquid injection process for lithium ion batteries

InactiveCN109273662AImprove performancePlay a conductive roleFinal product manufactureSecondary cells charging/dischargingCharge ratePhysical chemistry

The invention relates to a precharged high-efficiency liquid injection technology of a lithium ion battery, comprising the following steps: first liquid injection, wherein the liquid injection amountis 20-60% of the total liquid injection amount; The batteries after the first injection are precharged with a charge rate of 0.1 C -1.7 C and a charge time of 30 -300s. 40 to 80 percent of the total liquid injection amount; High temperature activation is performed, activation temperature is 30-90DEG C, activation time is 8-15h; Formation. A first injection solution of the present invention is injected into a part of the electrolyte, then the electrostatic adsorption between the pole piece and the diaphragm is opened by precharging, the pole piece and the diaphragm are loosely separated, the electrolyte is injected into the battery for the second time, and the electrolyte can smoothly penetrate into the middle of the coil core, the electrolyte is completely absorbed by the pole piece through the high-temperature static electrolyte, and the SEI membrane is formed after the electrolyte is formed; It not only shortens the injection time and improves the injection efficiency, but also improves the first efficiency and cycle life of the battery.

Owner:江西安驰新能源科技有限公司

Silicon-oxygen composite negative electrode material, preparation method thereof and lithium ion battery

ActiveCN113066968AImprove stabilityLower pHNegative electrodesLi-accumulatorsSilicon oxygenLithium compound

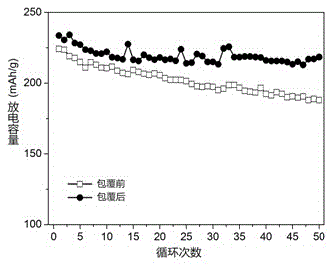

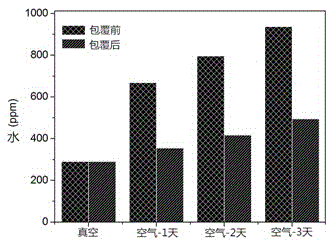

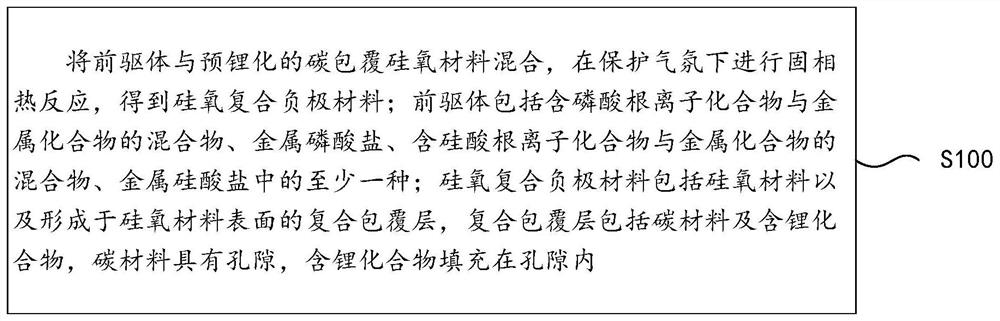

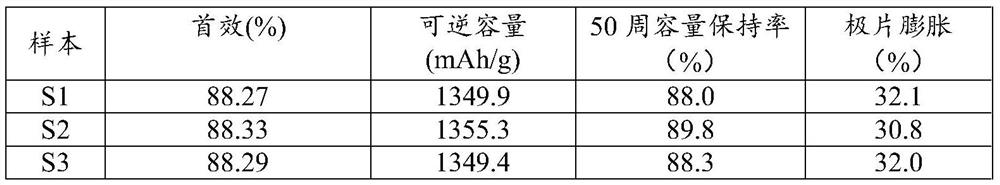

The invention relates to a silicon-oxygen composite negative electrode material, a preparation method thereof and a lithium ion battery, the silicon-oxygen composite negative electrode material comprises a silicon-oxygen material and a composite coating layer coating the surface of the silicon-oxygen material, the composite coating layer comprises a carbon material and a lithium-containing compound, the carbon material has pores, and the pores are filled with the lithium-containing compound. The silicon-oxygen composite negative electrode material and the preparation method thereof are simple and low in cost, industrial production is easy to realize, the prepared silicon-oxygen composite negative electrode material has excellent electrochemical cycle and expansion inhibition performance, and the service life of a lithium ion battery can be prolonged.

Owner:BTR NEW MATERIAL GRP CO LTD +1

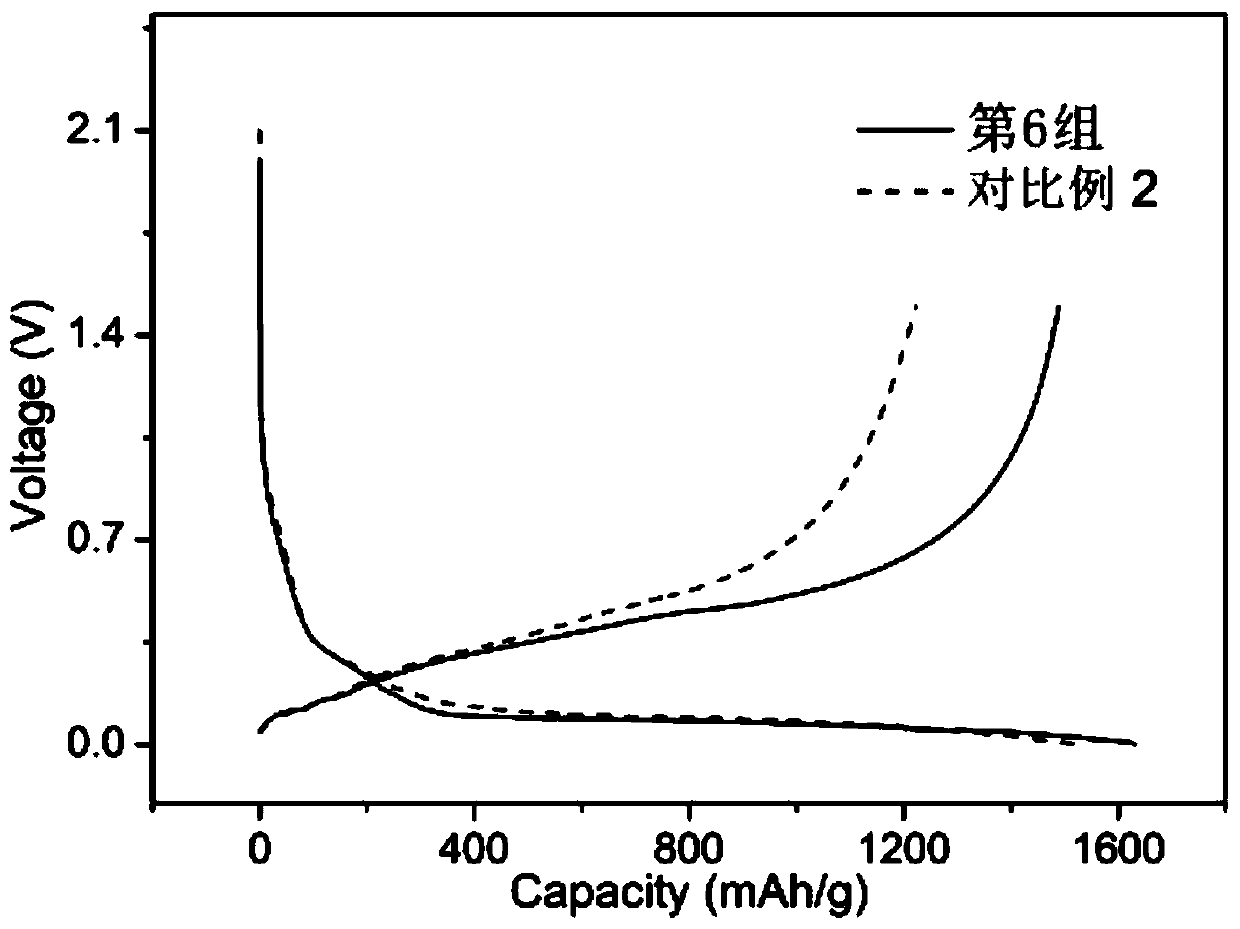

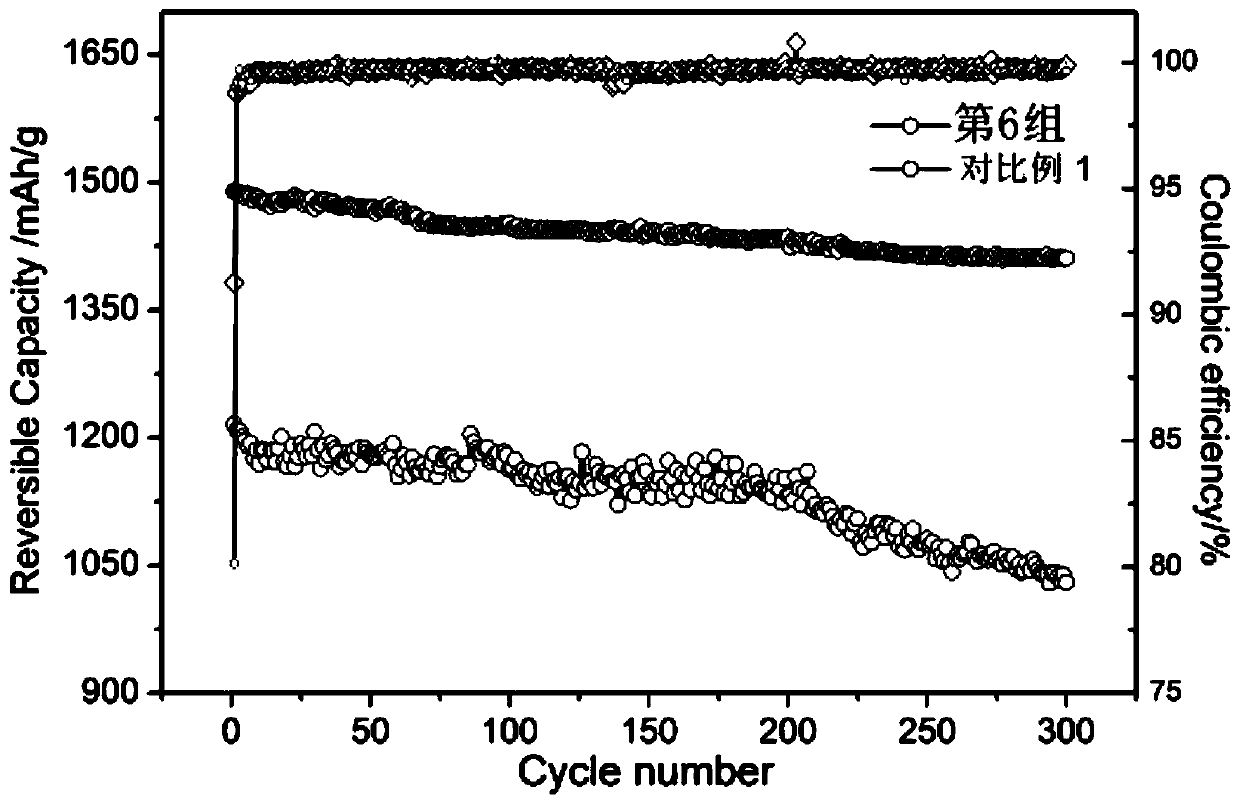

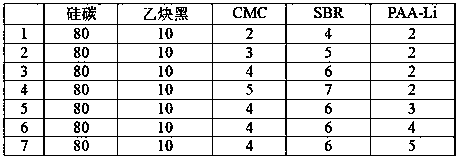

Binder for silicon-based negative electrode material and preparation method of binder

InactiveCN111326738AImprove toughnessImprove the first Coulombic efficiencyCell electrodesSecondary cellsMaterials scienceElectrode material

The invention provides a water-based binder for a silicon-based negative electrode material. The water-based binder comprises the following components in parts by weight: 1-10 parts of CMC, 6-40 partsof SBR and 4-20 parts of modified PAA. The components of the binder prepared by the method are good in intersolubility, so that agglomeration of the silicon-based negative electrode material can be reduced, and the flexibility of an electrode is improved. Meanwhile, the peeling strength and the cycle performance of the electrode are improved, and the initial Coulombic efficiency of a lithium battery is improved.

Owner:江苏载驰科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com