Preparation method of modified high nickel ternary cathode material

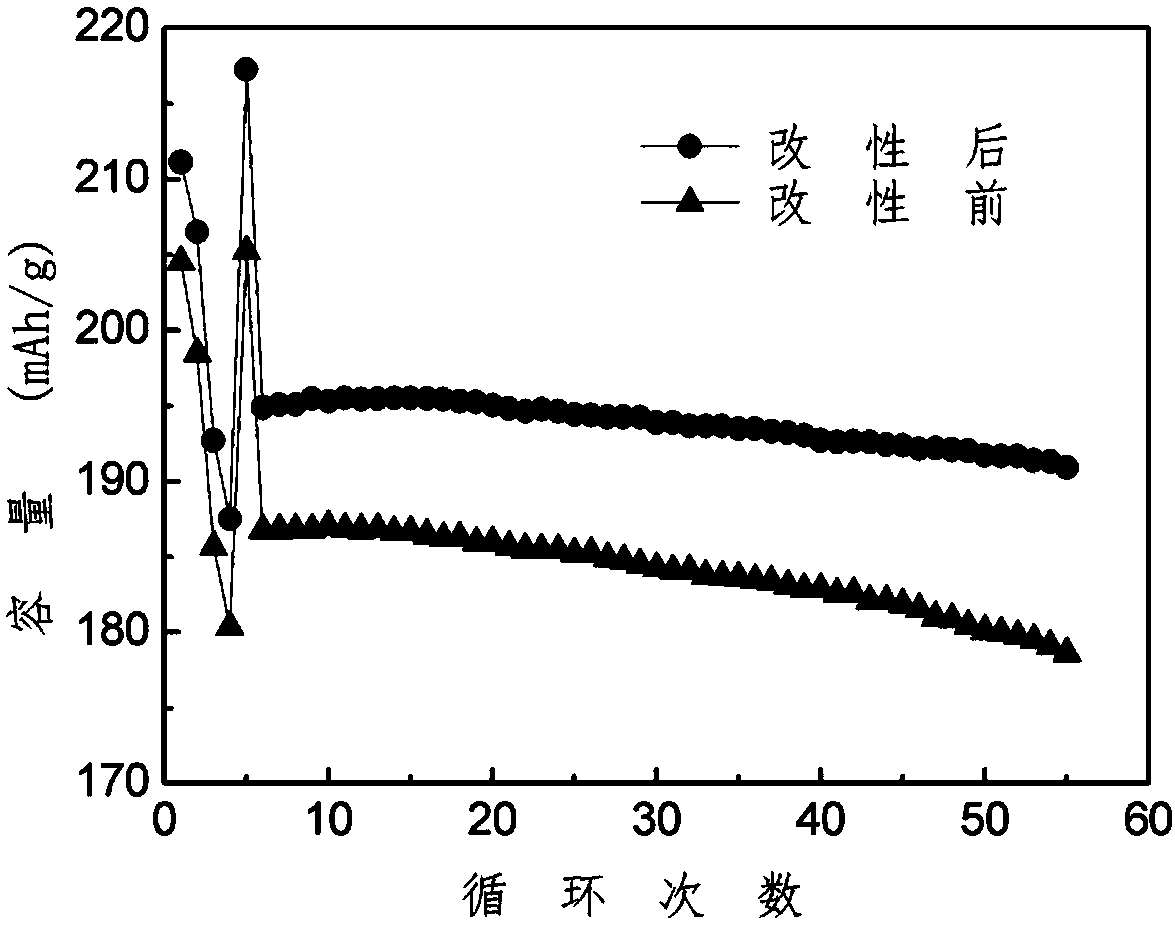

A positive electrode material, high-nickel technology, applied in the field of preparation of modified high-nickel ternary positive electrode materials, can solve the problems of increased residual alkali content, increased pH value, high requirements, etc., to inhibit reaction, improve processing performance, and increase magnification performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

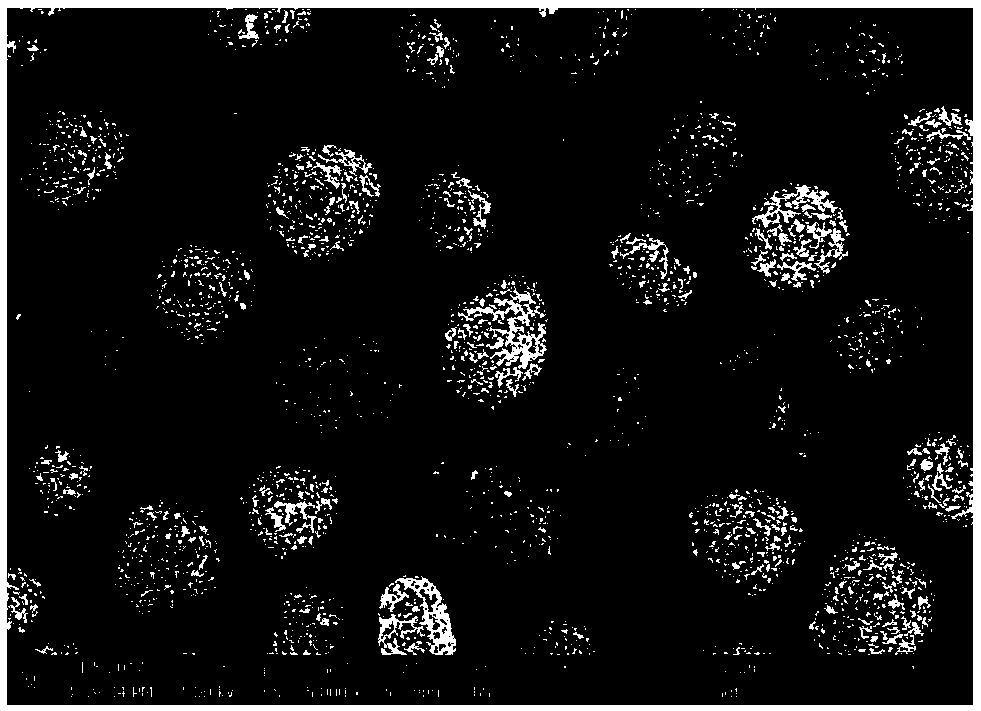

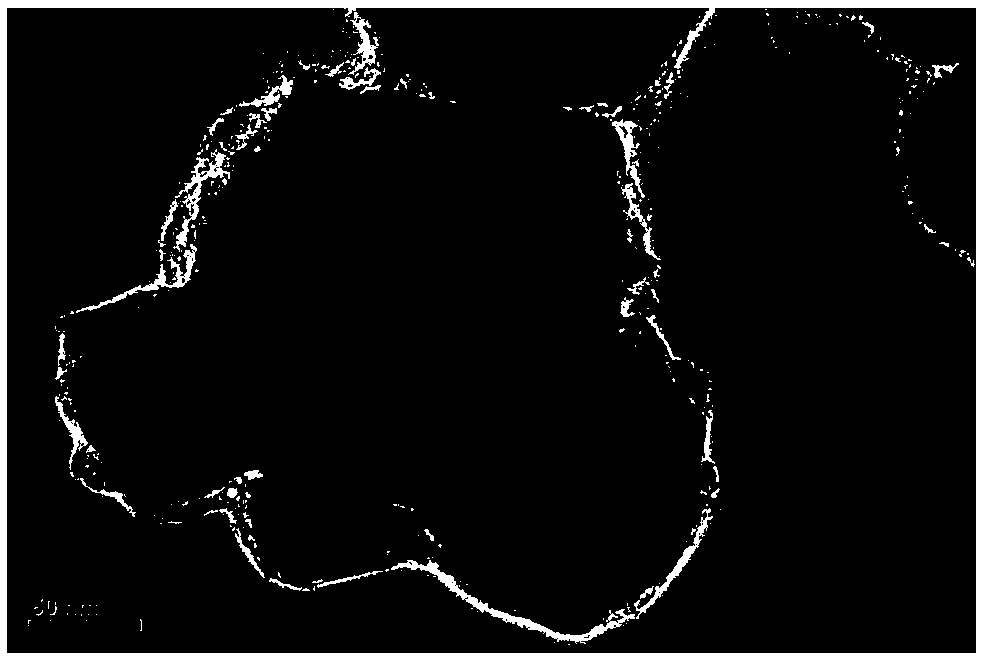

[0033] A method for preparing a modified high-nickel ternary positive electrode material, comprising the steps of: mixing and reacting the washed high-nickel ternary positive electrode material with a metal salt solution, followed by drying and sintering to obtain the modified high-nickel ternary positive electrode material .

Embodiment 2

[0035] A method for preparing a modified high-nickel ternary positive electrode material, comprising the steps of: mixing 100 g of high-nickel ternary positive electrode material with deionized water, stirring, centrifuging, and drying in sequence to obtain a high-nickel ternary positive electrode material washed with water Positive electrode material: After mixing the washed high-nickel ternary positive electrode material with the metal salt solution, stirring continuously for 2 hours to obtain a slurry, drying and sintering the slurry in sequence to obtain a modified high-nickel ternary positive electrode material;

[0036] Wherein, the high-nickel ternary positive electrode material is LiNi 0.85 co 0.1 mn 0.05 o 2 ;

[0037] The drying equipment is a rotary evaporator;

[0038] The sintering is carried out in an atmosphere of pure oxygen;

[0039] The temperature of the sintering is 500°C, and the time is 8h;

[0040] The weight ratio of the high-nickel ternary positi...

Embodiment 3

[0050] A method for preparing a modified high-nickel ternary positive electrode material, comprising the steps of: mixing 100 g of high-nickel ternary positive electrode material with deionized water, stirring, centrifuging, and drying in sequence to obtain a high-nickel ternary positive electrode material washed with water Positive electrode material: After mixing the washed high-nickel ternary positive electrode material with the metal salt solution, stirring continuously for 2 hours to obtain a slurry, drying and sintering the slurry in sequence to obtain a modified high-nickel ternary positive electrode material;

[0051] Wherein, the high-nickel ternary positive electrode material is LiNi 0.8 co 0.1 mn 0.1 o 2 ;

[0052] The drying equipment is a rotary evaporator;

[0053] The sintering is carried out in an atmosphere of pure oxygen;

[0054] The temperature of the sintering is 600°C, and the time is 5h;

[0055] The weight ratio of the high-nickel ternary positive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com