In-situ uranium leaching and mining treatment method by adding O2 into CO2

A technology of in-situ leaching and treatment method, which is applied in the fields of mining fluids, earth-moving drilling, wellbore/well components, etc. It can solve the problems of clogging of underground ore-bearing aquifers and groundwater pollution, and improve the salinity and desorption rate. Improved, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The ground hydration composition type of a uranium-bearing aquifer is HCO 3 -Na and HCO 3 ·Cl-Na type is the main type, and the top and bottom of the uranium-bearing layer are mainly mudstone, with relatively stable thickness and good water resistance. Salinity 3.5g / L, water temperature 15℃, pH value 6.8, Eh: 150mv, HCO 3 - :2000mg / L, O 2 <2mg / L, the hydrogeochemical environment is in the state of weak oxidation-reduction transition zone.

[0023] Using the uranium CO of the present invention 2 Add O 2 The in-situ leaching mining treatment method includes the following steps:

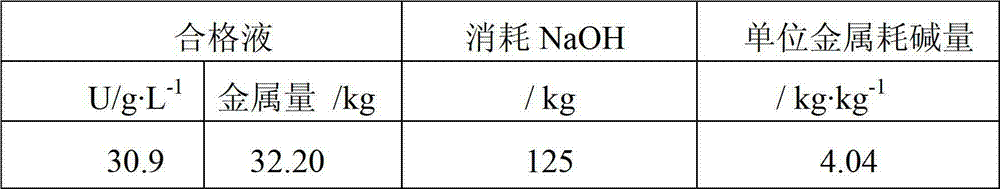

[0024] (1) The leaching liquid is natural bicarbonate-type groundwater (HCO 3 - The content is 2000mg / L, the pH value is 6.8), add O to the leaching solution 2 Then, the underground ore-bearing aquifer is injected through the injection pipeline, and the injection pressure of the leaching solution is controlled at 1.6Mp, O 2 The adding pressure is higher than the injection pressure of the leaching solut...

Embodiment 2

[0046] 108m of water inflow in a uranium-bearing aquifer 3 / d, the permeability coefficient is 0.23m / d. The top and bottom of the uranium-bearing layer are mainly mudstone, with relatively stable thickness and good water resistance. HCO 3 -Na and HCO 3 ·Cl-Na type, salinity 5.7g / L, water temperature 16℃, pH value 8.4, Eh: 400mv, HCO 3 - : 2600mg / L, the hydrogeochemical environment is in the state of weak oxidation-reduction transition zone.

[0047] Using the uranium CO of the present invention 2 Add O 2 The in-situ leaching mining treatment method includes the following steps:

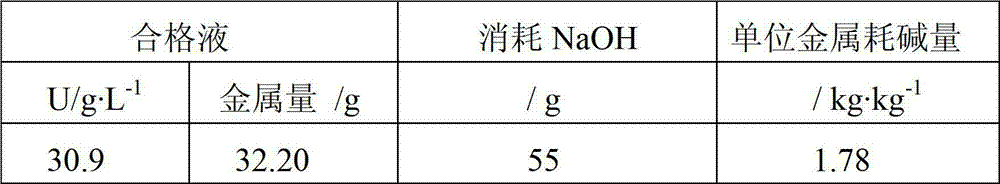

[0048] (1) The leaching liquid is natural bicarbonate-type groundwater (HCO 3 - The content is 2600mg / L, the pH value is 6.8), add O to the leaching solution 2 Then, the underground ore-bearing aquifer is injected through the injection pipeline, and the injection pressure of the leaching solution is controlled at 1.5Mp, O 2 The adding pressure is 0.1Mpa higher than the injection pressure of the leaching so...

Embodiment 3

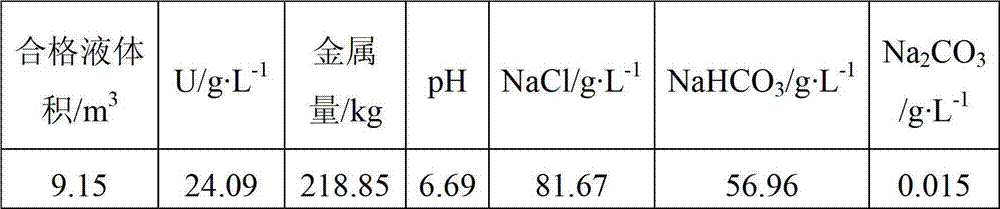

[0074] In a certain uranium mining area, the bicarbonate-type groundwater in-situ leaching uranium mining process of the present invention is adopted. The water inflow from the ore-bearing aquifer in the mining area is 90m 3 / d, the permeability coefficient is 0.12m / d. The top and bottom of the uranium-bearing layer are mainly mudstone, with relatively stable thickness and good water resistance. HCO 3 -Na and HCO 3 ·Cl-Na type mainly, pH value 7, Eh: 300mv, HCO 3 - : 2100mg / L, the hydrogeochemical environment is in the state of weak oxidation-reduction transition zone.

[0075] Using the uranium CO of the present invention 2 Add O 2 The in-situ leaching mining treatment method includes the following steps:

[0076] (1) The leaching liquid is natural bicarbonate-type groundwater (HCO 3 - The content is 2100mg / L, the pH value is 7), add O to the leaching solution 2 Then, the underground ore-bearing aquifer is injected through the injection pipeline, and the injection pressure of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com