Preparation of compost fermentation complex bacterial agent

A technology for fermenting composite bacteria and composting, which is applied in the field of preparation of composite microbial bacterial agents, which can solve the problems of complex operation, unsatisfactory deodorization effect, and heavy workload, and achieve cycle shortening, composting odor elimination, and degradation quality Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

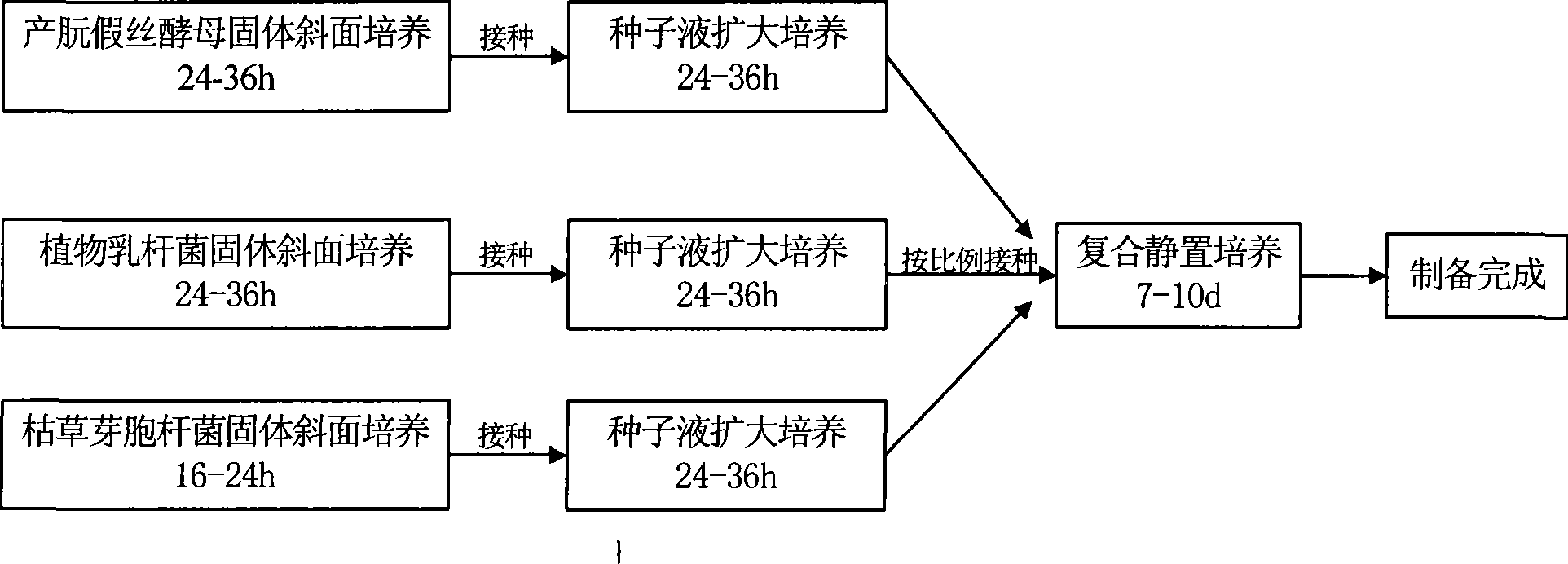

preparation example Construction

[0020] (1) Preparation of solid slope.

[0021] Lactobacillus plantarum slant medium formula: beef extract 5g, yeast extract 5g, peptone 10g, glucose 10g, lactose 5g, sodium chloride 5g, agar 15g, pH value 5.5-6.5, distilled water 1000ml.

[0022] Candida utilis adopts the formula of potato sugar agar medium: 200g of potatoes, 20g of glucose, 15-20g of agar, pH value of 7.2-7.4, and 1000ml of distilled water.

[0023] Bacillus subtilis slant medium formula: glucose 20g, peptone 15g, sodium chloride 5g, beef extract 0.5g, agar 15g, natural pH, distilled water 1000ml.

[0024] (2) Solid slant culture.

[0025] Candida utilis, Lactobacillus plantarum, and Bacillus subtilis were respectively connected to the solid inclined surface, wherein the culture temperature of Bacillus subtilis was 30-35°C, and the culture time was 16-24h; the culture of Candida utilis and Lactobacillus plantarum The temperature is 25-28°C, and the incubation time is 24-36h.

[0026] 2. Expand the cultiva...

Embodiment 1

[0035] Add 10g of sucrose, 0.5g of peptone, 1g of yeast powder, 0.5g of potassium dihydrogen phosphate, 1.0g of ammonium sulfate, 0.5g of calcium chloride, 0.36g of magnesium sulfate, 0.02g of ferrous sulfate, 1.0g of sodium acetate, and Sodium 0.5g, pH 7.0. The culture medium was sterilized at 115°C for 30 minutes. After mixing the seed liquids of Candida utilis, Lactobacillus plantarum and Bacillus subtilis at a volume ratio of 0.2:0.5:0.5, add 10% into the fermentation medium liquid after high-temperature sterilization, and statically Place the culture for 10 days; when the fermentation broth no longer produces bubbles, the fermentation is terminated. At this time, the pH value is 4.0, the taste is sour, and there are white membranes floating on the surface of the fermentation broth, and the number of living microorganisms reaches 1×10 9 Individuals / ml or more, the culture is complete.

Embodiment 2

[0037] Add 15g of sucrose, 2g of peptone, 2g of yeast powder, 0.5g of potassium dihydrogen phosphate, 1.0g of ammonium sulfate, 0.5g of calcium chloride, 0.5g of magnesium sulfate, 0.01g of ferrous sulfate, 1.0g of sodium acetate, and sodium bicarbonate in 1000ml of water 0.5g, pH 7.0. The culture medium was sterilized at 115°C for 30 minutes. After mixing the seed liquids of Candida utilis, Lactobacillus plantarum and Bacillus subtilis at a volume ratio of 0.5:1:0.8, insert them into the high-temperature sterilized fermentation medium in an amount of 5%, and statically place them at 30°C. Cultured for 7 days; when the fermentation broth no longer produces bubbles, the fermentation is terminated. At this time, the pH value is 3.8, the taste is sour, and there are white membranes floating on the surface of the fermentation broth. After shaking well, the microscopic count can reach 1×10 9 cells / ml, the culture is complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com