Device for degrading organic pollutants through catalytic oxidation

A technology of organic pollutants and catalytic oxidation, applied in water pollutants, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problems of low mass transfer efficiency, low catalytic efficiency, uncontrollable wastewater concentration, etc. Improve mass transfer efficiency, easy operation, process controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

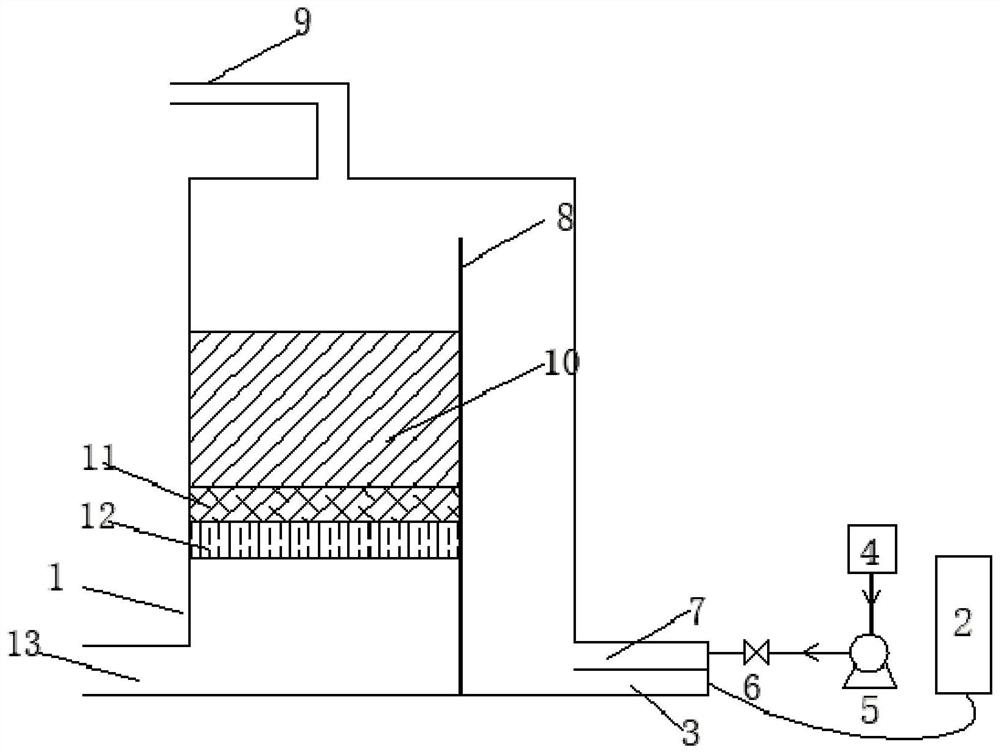

[0026] A device for catalytic oxidation degradation of organic pollutants of the present invention comprises a reactor 1 and an ozone microbubble generator 2, the reactor is divided into left and right chambers by a partition 8 in the reactor, the left chamber A water outlet 13 is set on the side wall of the chamber, an air inlet 3 and a water inlet 7 are arranged on the side wall of the right chamber, the ozone microbubble generator is communicated with the air inlet, and the water inlet passes through the valve 6, the peristaltic pump 5 and the waste water The water storage tank 4 is connected; in the left chamber, a catalytic material layer 10, a catalyst cushion layer 11 and a catalyst support grid 12 are arranged sequentially from top to bottom, and an air outlet 9 is arranged on the top of the reactor.

[0027] The process of wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com