Patents

Literature

8304 results about "Ion-exchange resin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An ion-exchange resin or ion-exchange polymer is a resin or polymer that acts as a medium for ion exchange. It is an insoluble matrix (or support structure) normally in the form of small (0.25–0.5 mm radius) microbeads, usually white or yellowish, fabricated from an organic polymer substrate. The beads are typically porous, providing a large surface area on and inside them. The trapping of ions occurs along with the accompanying release of other ions, and thus the process is called ion exchange. There are multiple types of ion-exchange resin. Most commercial resins are made of polystyrene sulfonate.

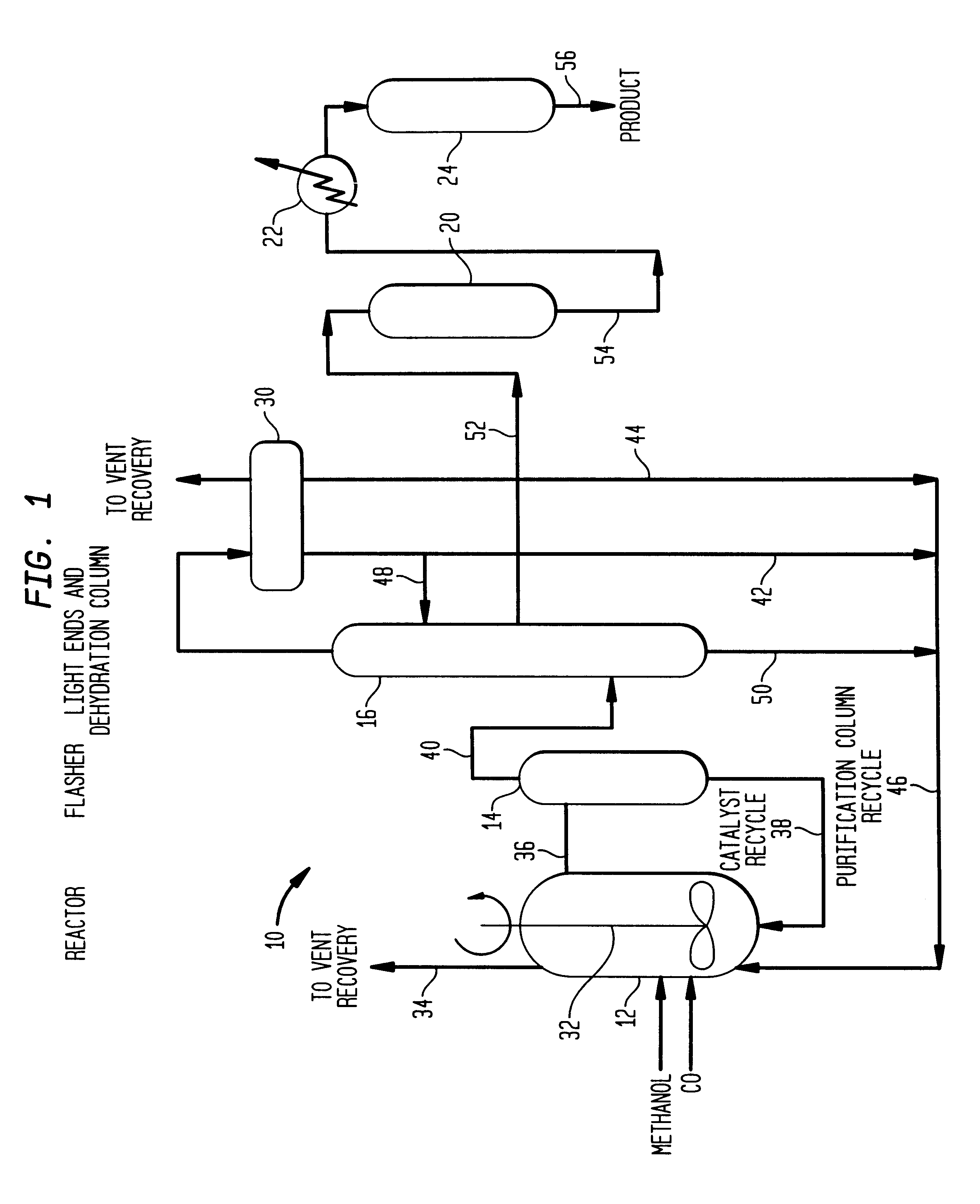

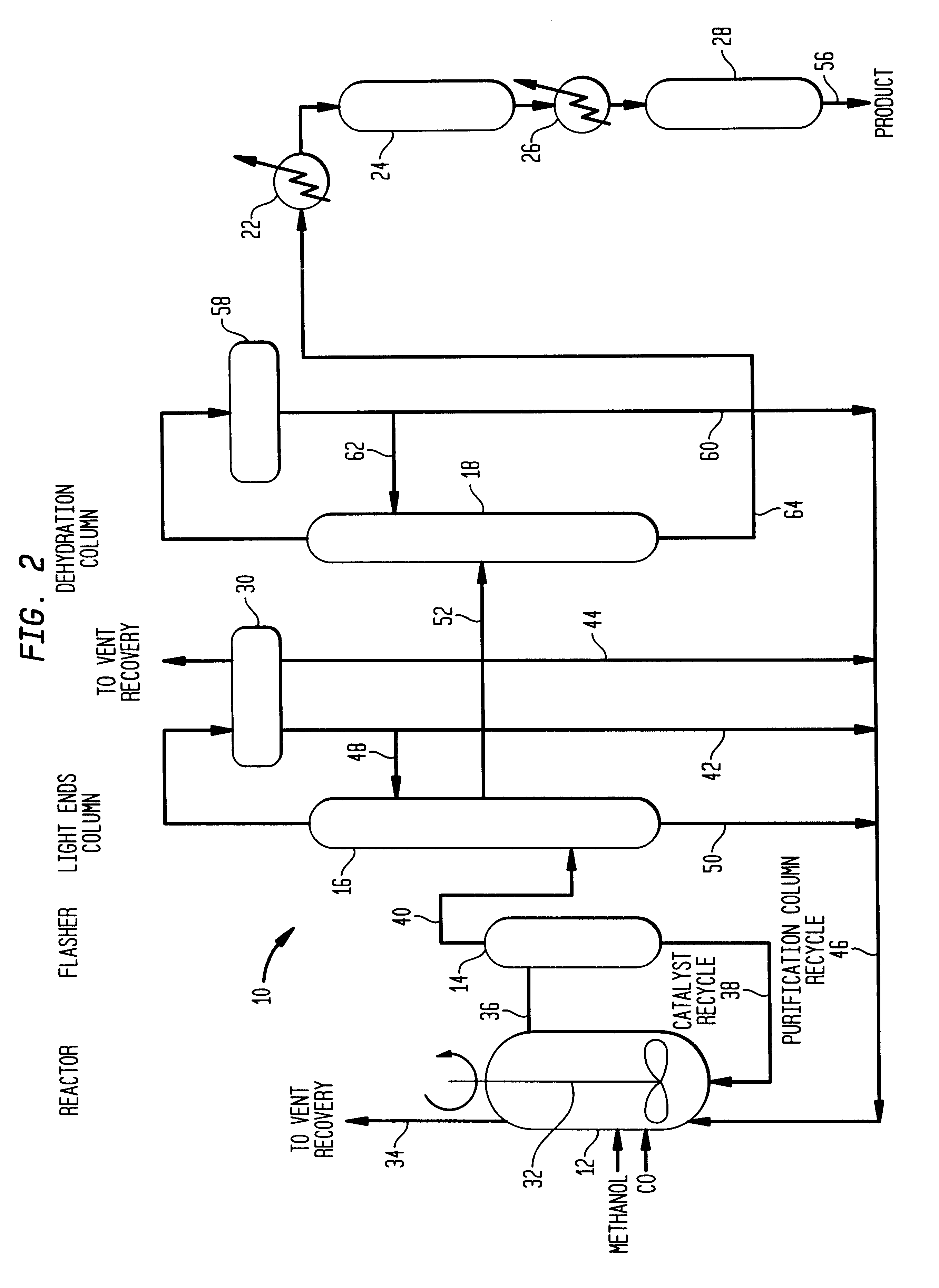

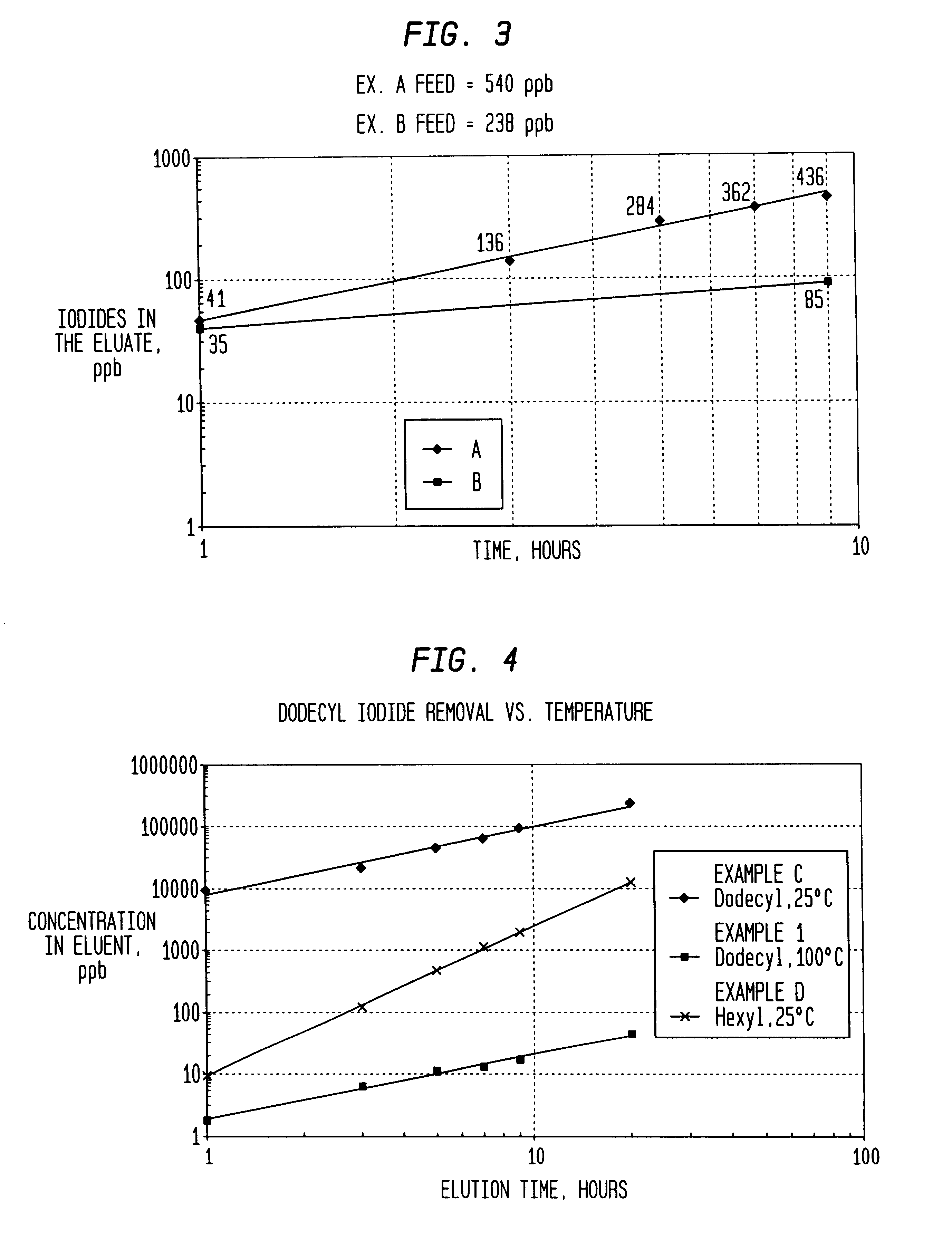

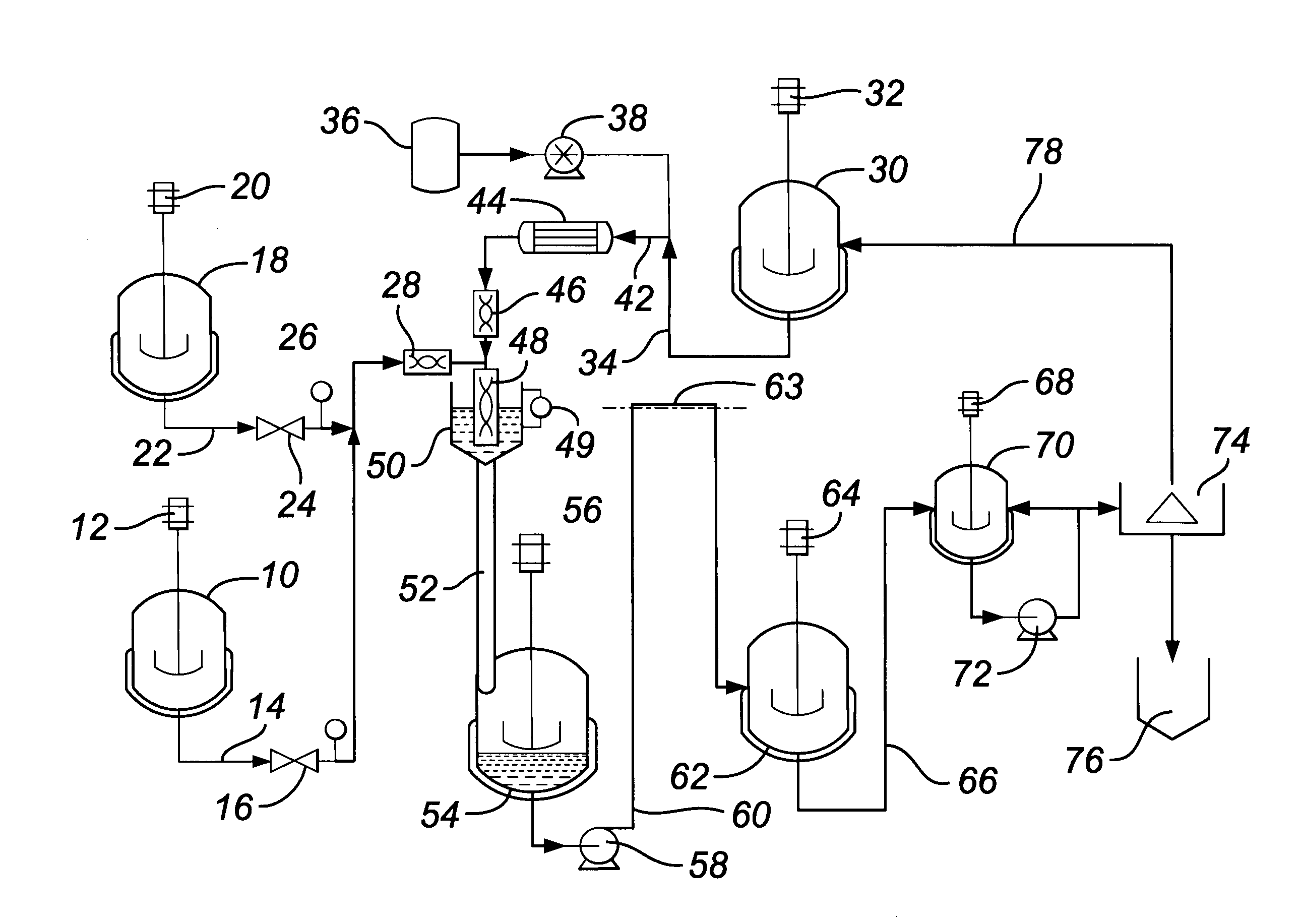

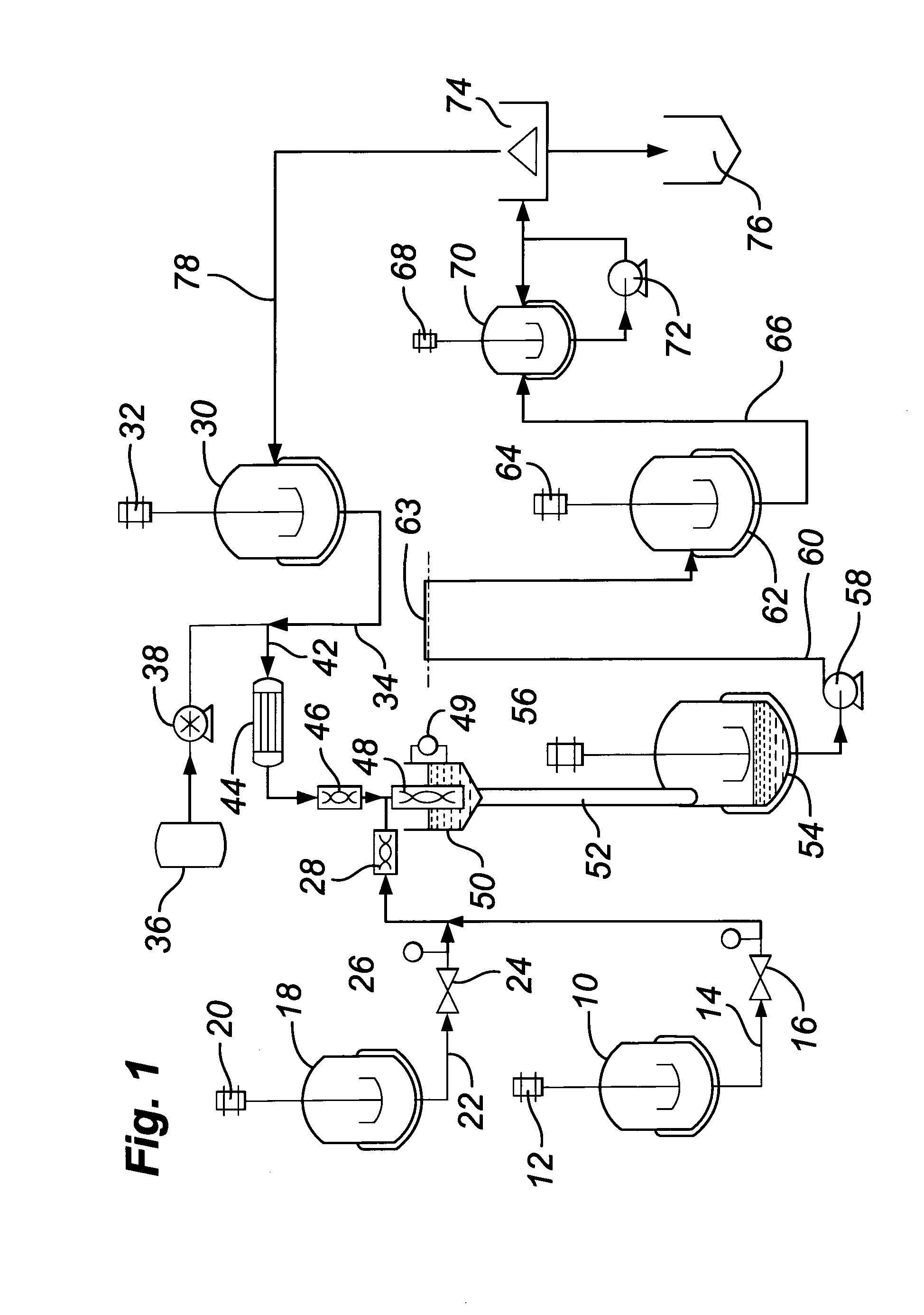

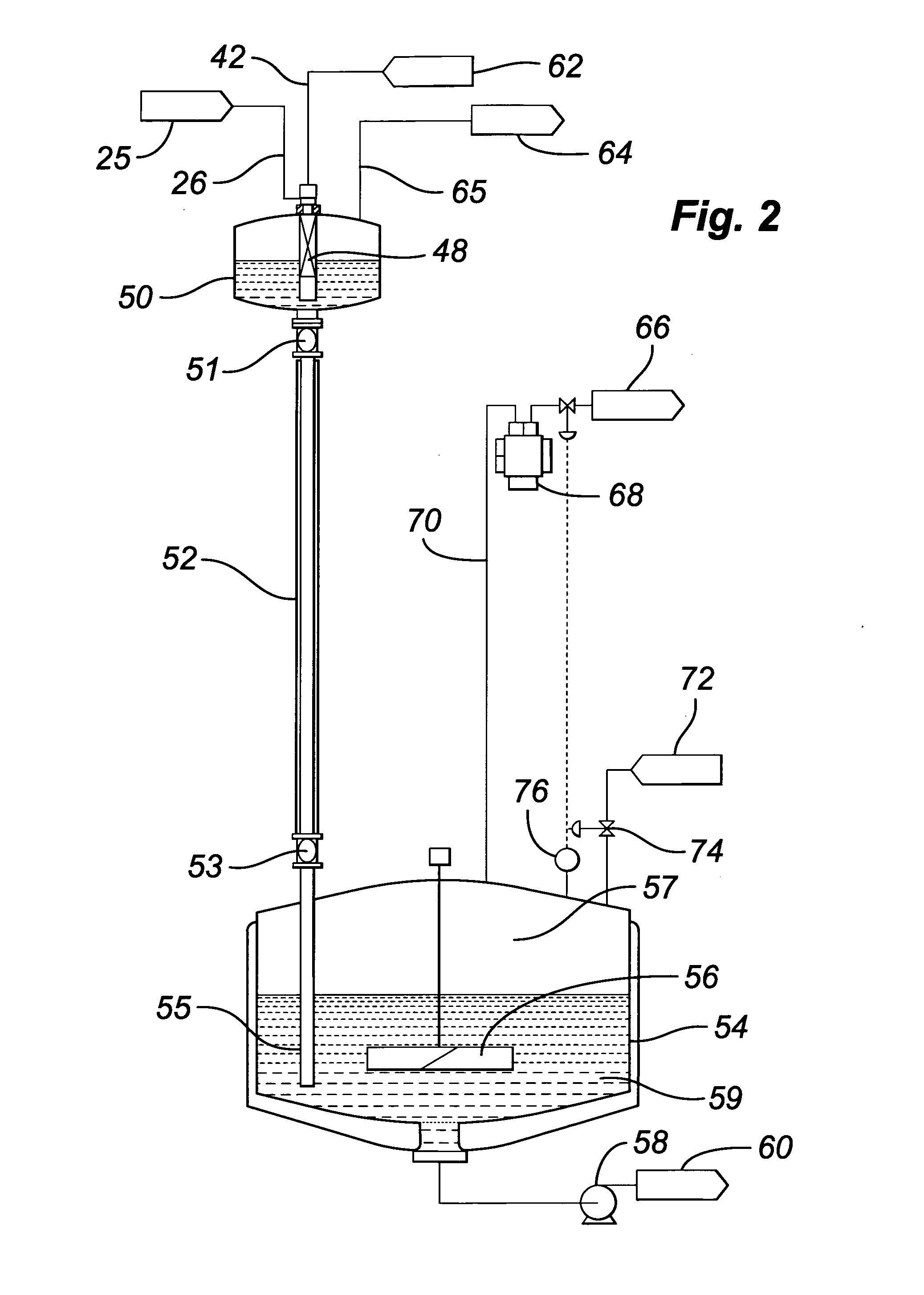

Low energy carbonylation process

InactiveUS6657078B2Weaken energyHigh purityOrganic compound preparationOrganic chemistry methodsPropanoic acidIodide

A low energy process for producing acetic acid by the carbonylation of methanol is disclosed. The process involves a rhodium-catalyzed system operated at less than about 14% water utilizing up to 2 distillation columns. The process is preferably controlled such that the product stream has a low level of propionic acid impurity and the level of aldehyde impurities is minimized by way of aldehyde removal or minimizing aldehyde generation. The level of iodides is controlled by contacting the product, at elevated temperatures, with ion exchange resins. In preferred embodiments, at least one silver or mercury exchanged macroreticular strong acid ion exchange resin is used to purify the product. The high temperature treatment provides the added benefit of controlling the Color Value (Pt-Co units) of the product stream.

Owner:CELANESE INT CORP

Abuse-resistant sustained-release opioid formulation

InactiveUS20050163856A1Prevent extractionDissuades abuseBiocidePowder deliveryCompound (substance)Solvent

A method for reducing the abuse potential of an oral dosage form of an opioid extractable by commonly available household solvents said method comprising combining a therapeutically effective amount of the opioid compound, or a salt thereof, a matrix-forming polymer and an ionic exchange resin.

Owner:BOEHRINGER INGELHEIM ROXANE

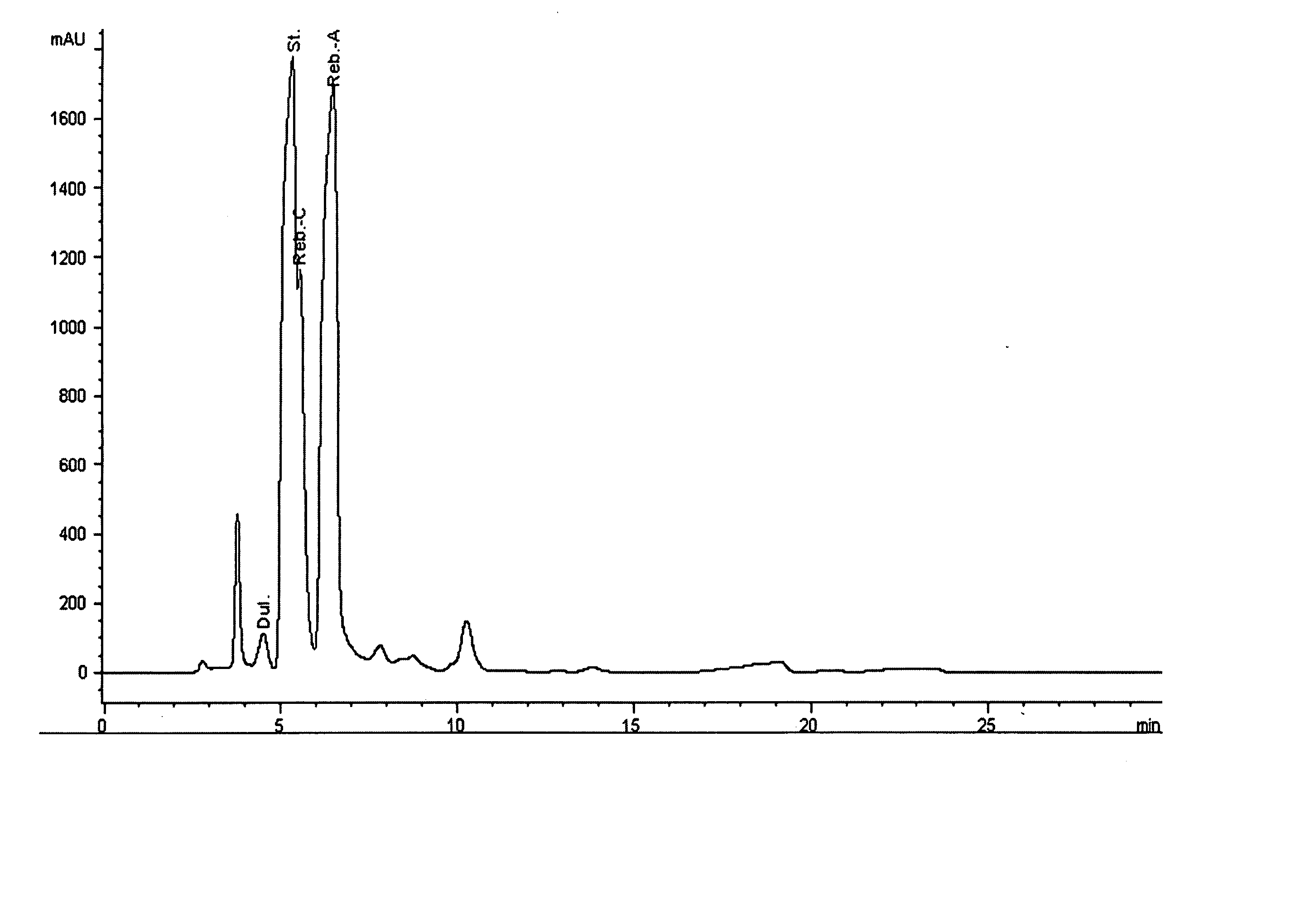

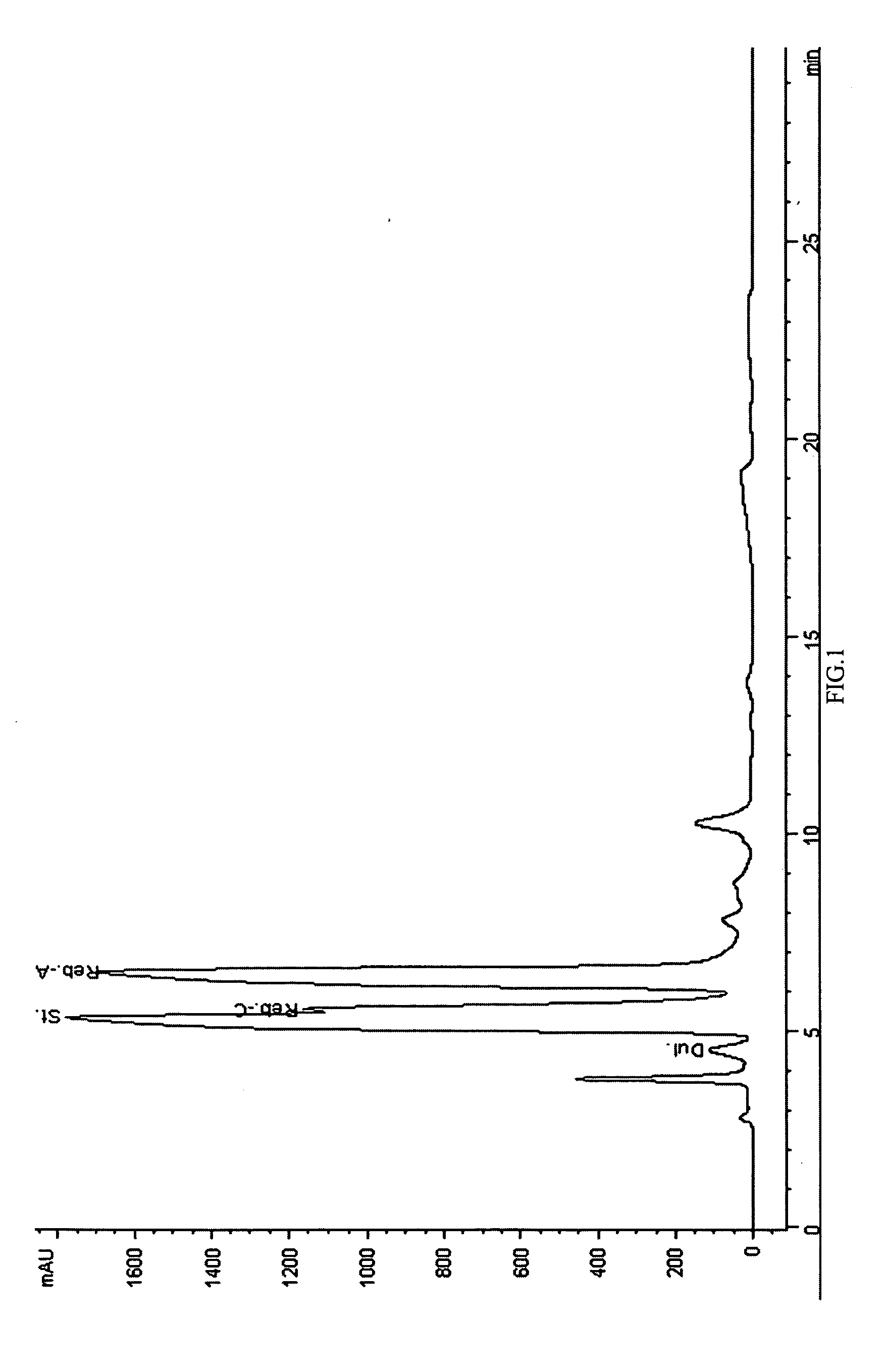

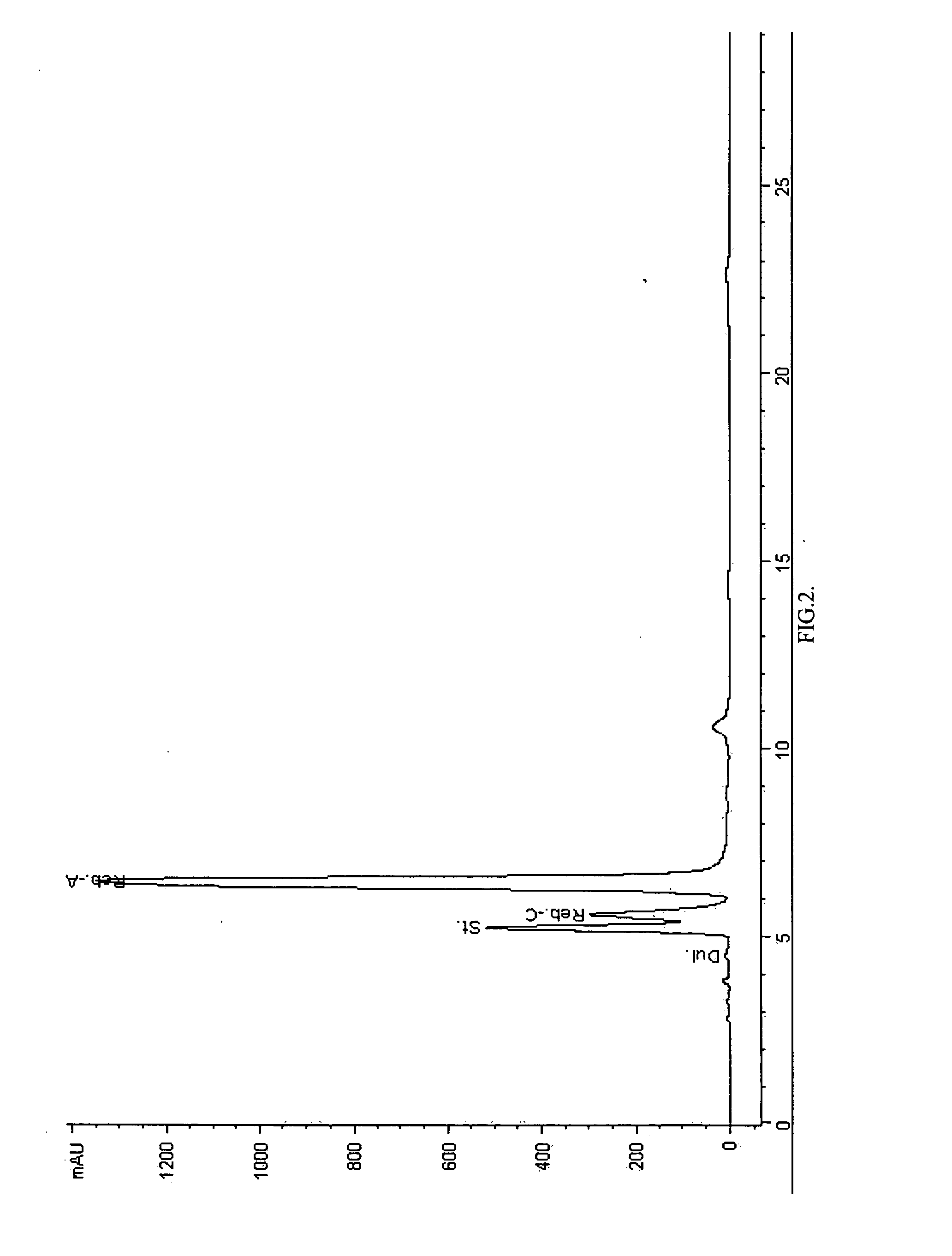

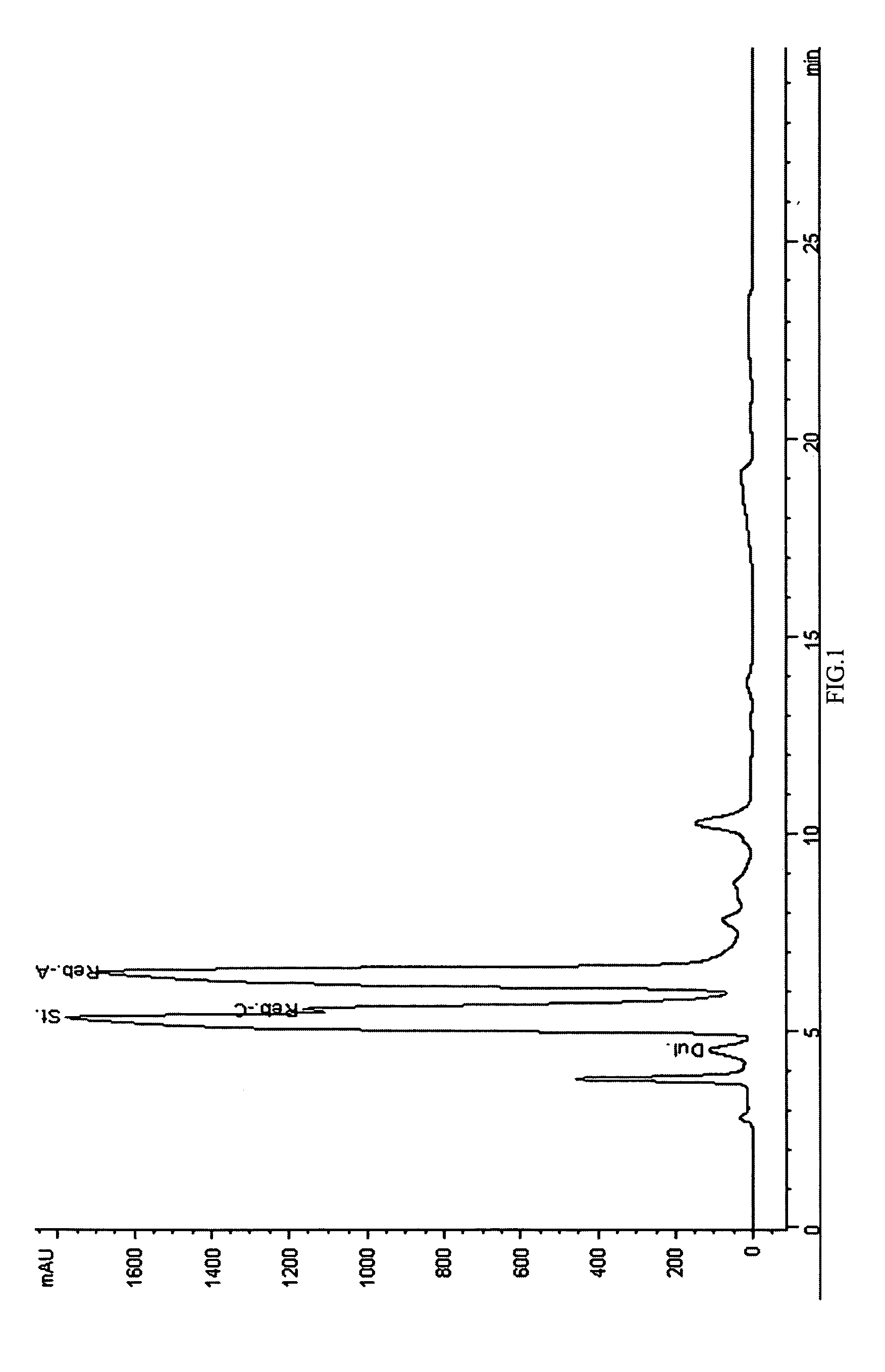

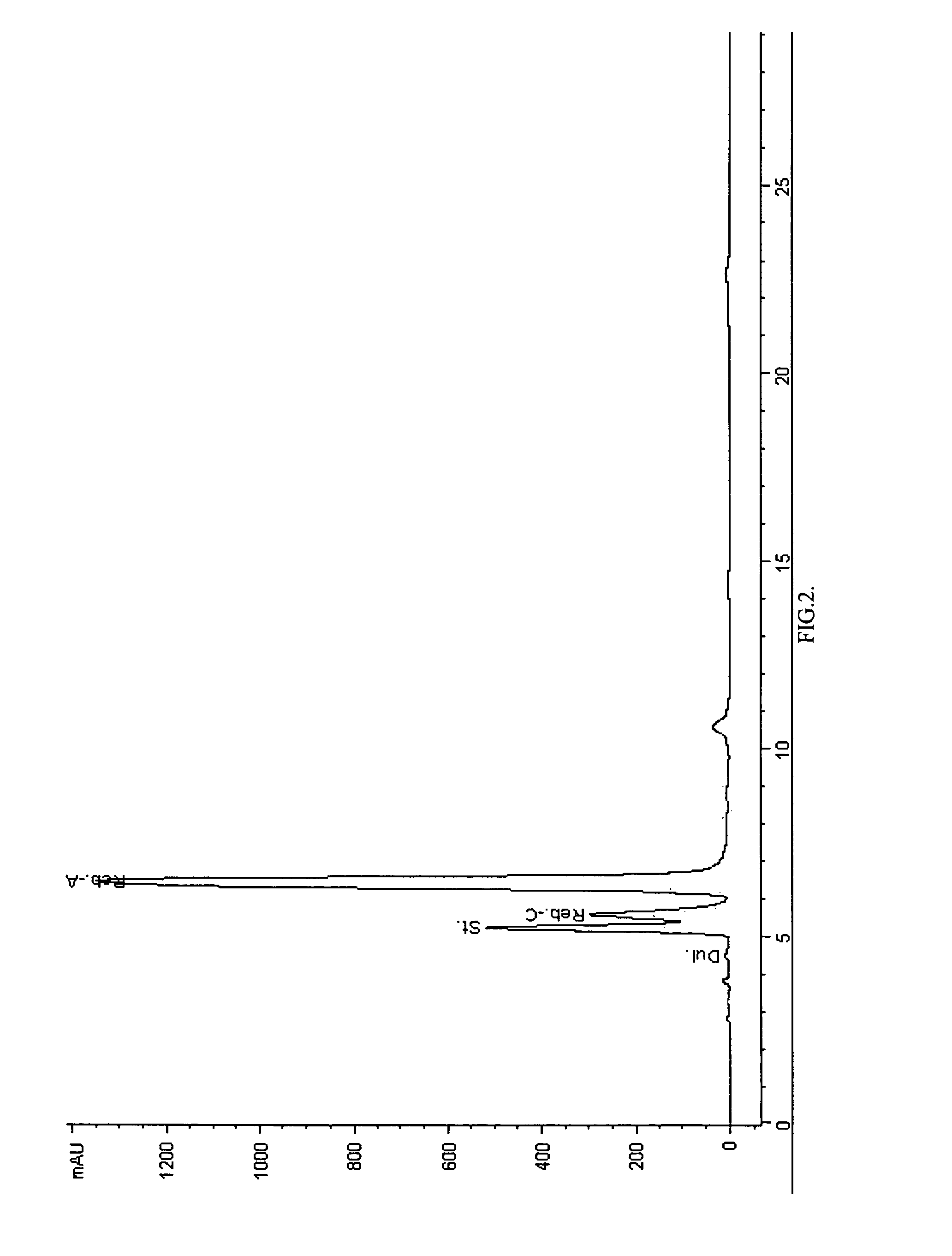

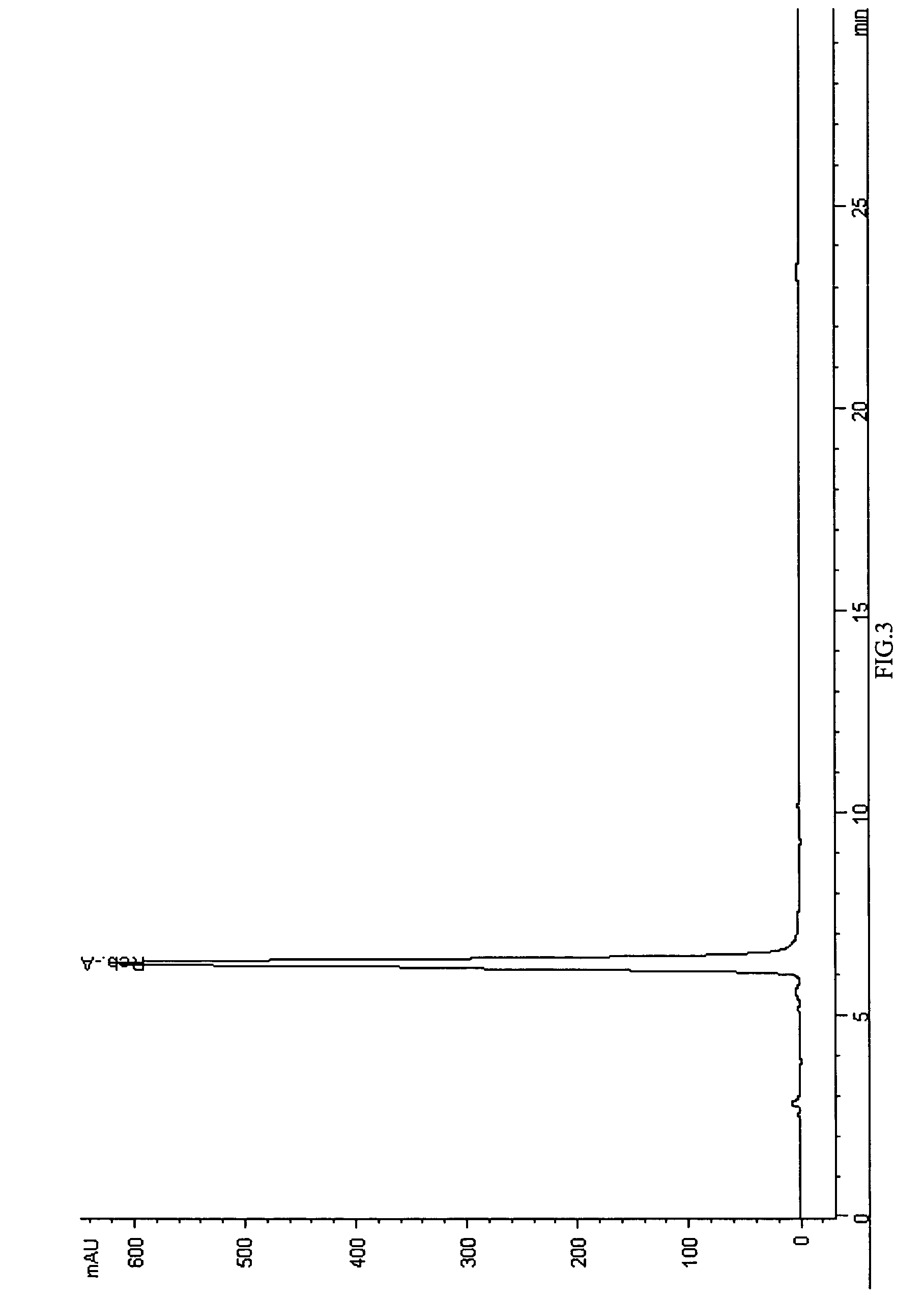

Extraction, separation and modification of sweet glycosides from the stevia rebaudiana plant

ActiveUS20060134292A1Increasing of degree of transglycosylationDelayed reaction timeBiocideAnimal repellantsPectinaseSodium Bentonite

The invention disclosed relates to a method for the extraction of sweet glycosides from the Stevia rebaudiana Bertoni plant and recovery of individual rebaudioside A and stevioside. The extraction is developed in the presence of pectinase, and the extract is purified using cyclodextrin and bentonite. High purity rebaudioside A is obtained by crystallization and recrystallization from ethanol. High purity stevioside is prepared from the filtrate by purification with cyclodextrin, bentonit, and ion exchange resins. The enzymatic modification of the rebaudioside A, stevioside and the purified extract is carried out using the transferring enzymes derived from Thermoactinomyces vilgaris and Bacillus halophilus.

Owner:PURECIRCLE SDN BHD

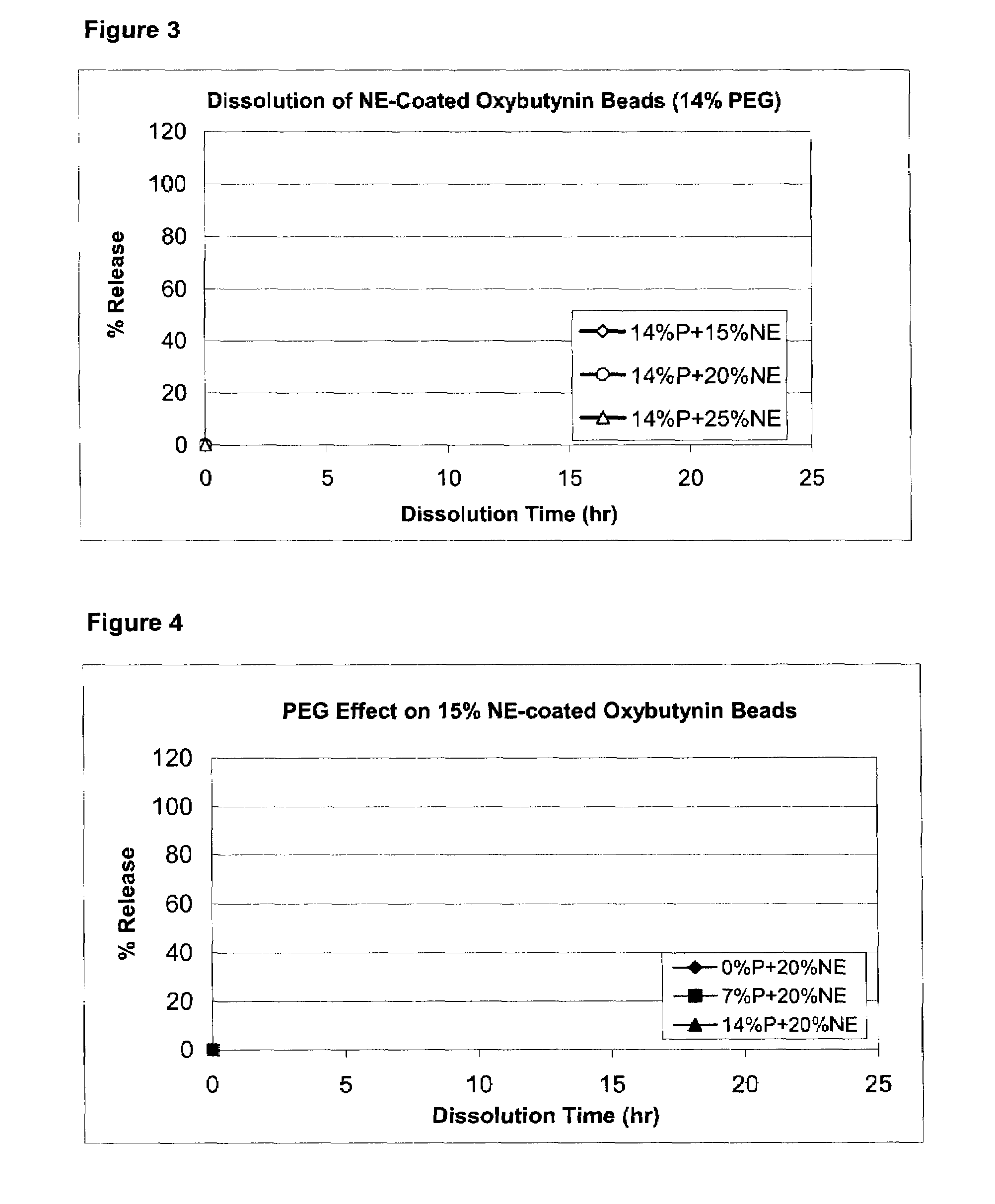

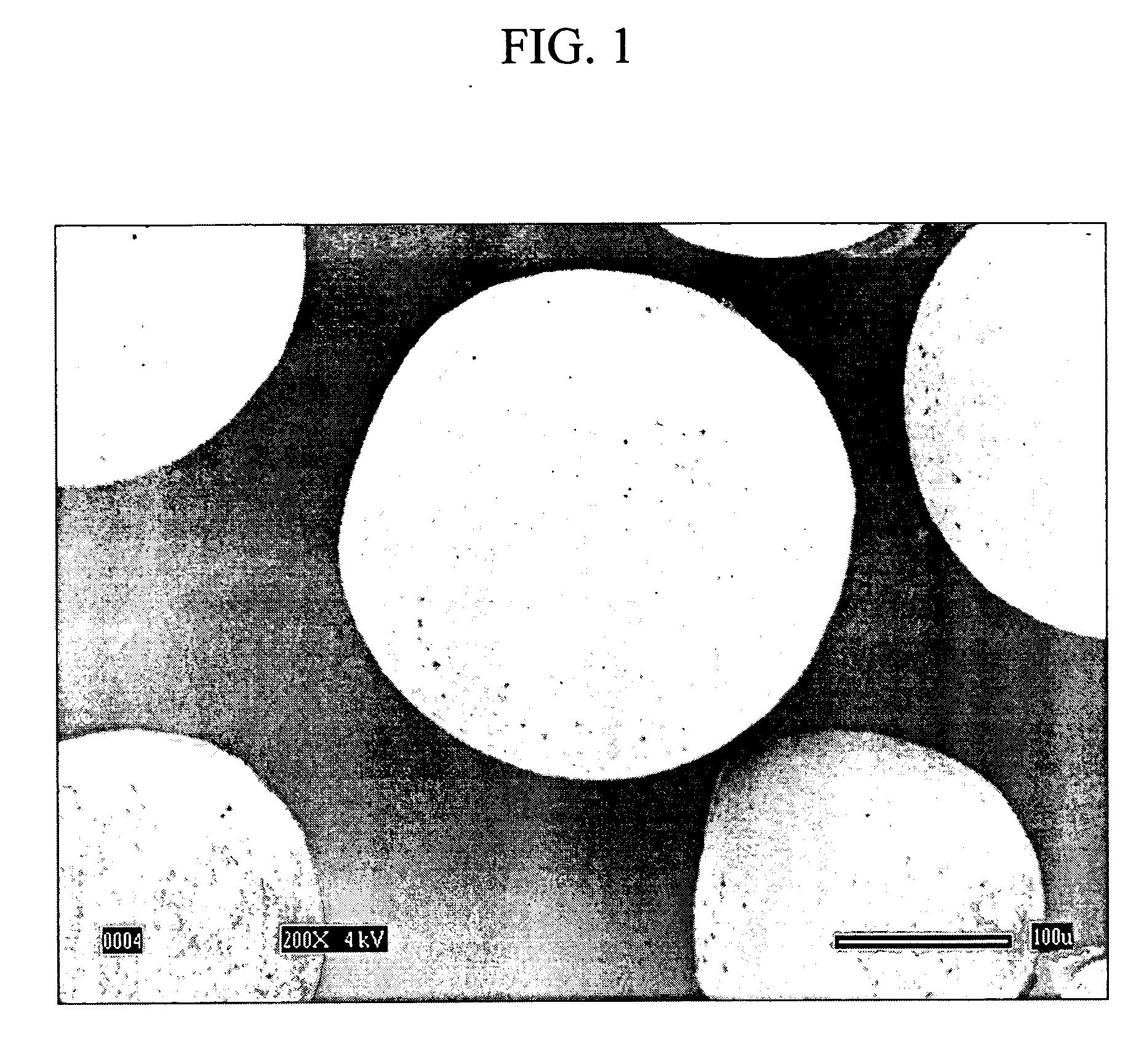

Dosage forms using drug-loaded ion exchange resins

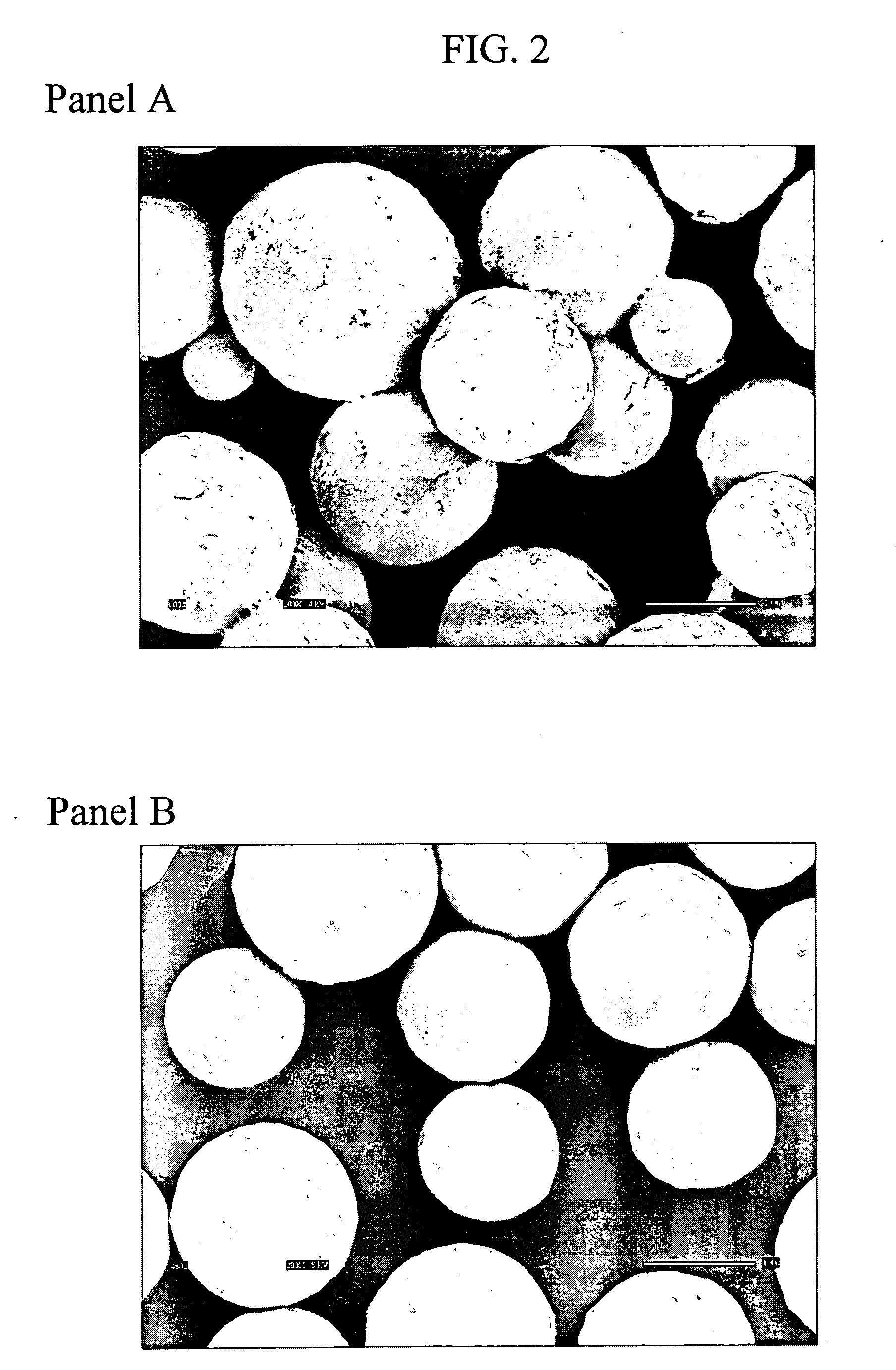

InactiveUS20050181050A1Avoid breakingPharmaceutical non-active ingredientsPill deliveryOral medicationImmediate release

A multiparticulate, modified release composition for oral administration has been developed. The formulation is made by complexing a drug with an ion-exchange resin in the form of small particles, typically less than 150 microns. The present invention provides novel extended release coated ion exchange particles comprising drug-resin complexes, produced by binding the salt form of the drug, that do not require impregnating agents to insure the integrity of the extended release coat. To prepare a modified release formulation, one or more of the following types of particles are formulated into a final dosage form: (a) Immediate release particles, (b) Enteric coated particles, (c) Extended release particles, (d) Enteric coated-extended release particles; and (e) Delayed release particles. The various drug-containing particles described above can be further formulated into a number of different easy-to-swallow final dosage forms including, but not limited to, a liquid suspension, gel, chewable tablet, crushable tablet, rapidly dissolving tablet, or unit of use sachet or capsule for reconstitution

Owner:COLLEGIUM PHARMA INC

Process for production of steviosides from stevia rebaudiana bertoni

A process for the production of steviosides from Stevia rebaudiana Bertoni includes extraction of comminuted plant material by directly injecting steam into the extractor followed by filtration to get aqueous extract and alkali treatment to remove unwanted compounds in the form of precipitate. The treated aqueous extracted was filtered and the filtrate was first treated with gel or macroporous strong acid cation exchange resin and then with gel or macroporous weak base anion exchange resin. The aqueous eluant containing steviosides was concentrated to obtain purified steviosides.

Owner:COUNCIL OF SCI & IND RES

Sprayable formulations for the treatment of acute inflammatory skin conditions

A topical spray or foam, methods of making the formulation, and methods of use thereof, has been developed. In one preferred embodiment, the composition includes one or more active agents and exhibits both antibacterial activity and antifungal activity. Excipients such as chemical disinfectants, anti-pruritic agents to minimize itching, and skin protective compounds may be added. The composition may be formulated to be dispensed as a spray or foam and the spray or foam may be administered either by a hand pump or by an aerosolizing propellant. A second single phase formulation has also been developed. The formulation comprises a first drug which is water soluble or hydrophilic and a second drug which is lipid soluble or hydrophobic, wherein at least one of the drugs is bound to an ion-exchange resin. The use of binding resins, such as ion-exchange resins, allows drugs with incompatible solvent requirements to be prepared in a single-phase formulation.

Owner:COLLEGIUM PHARMA INC

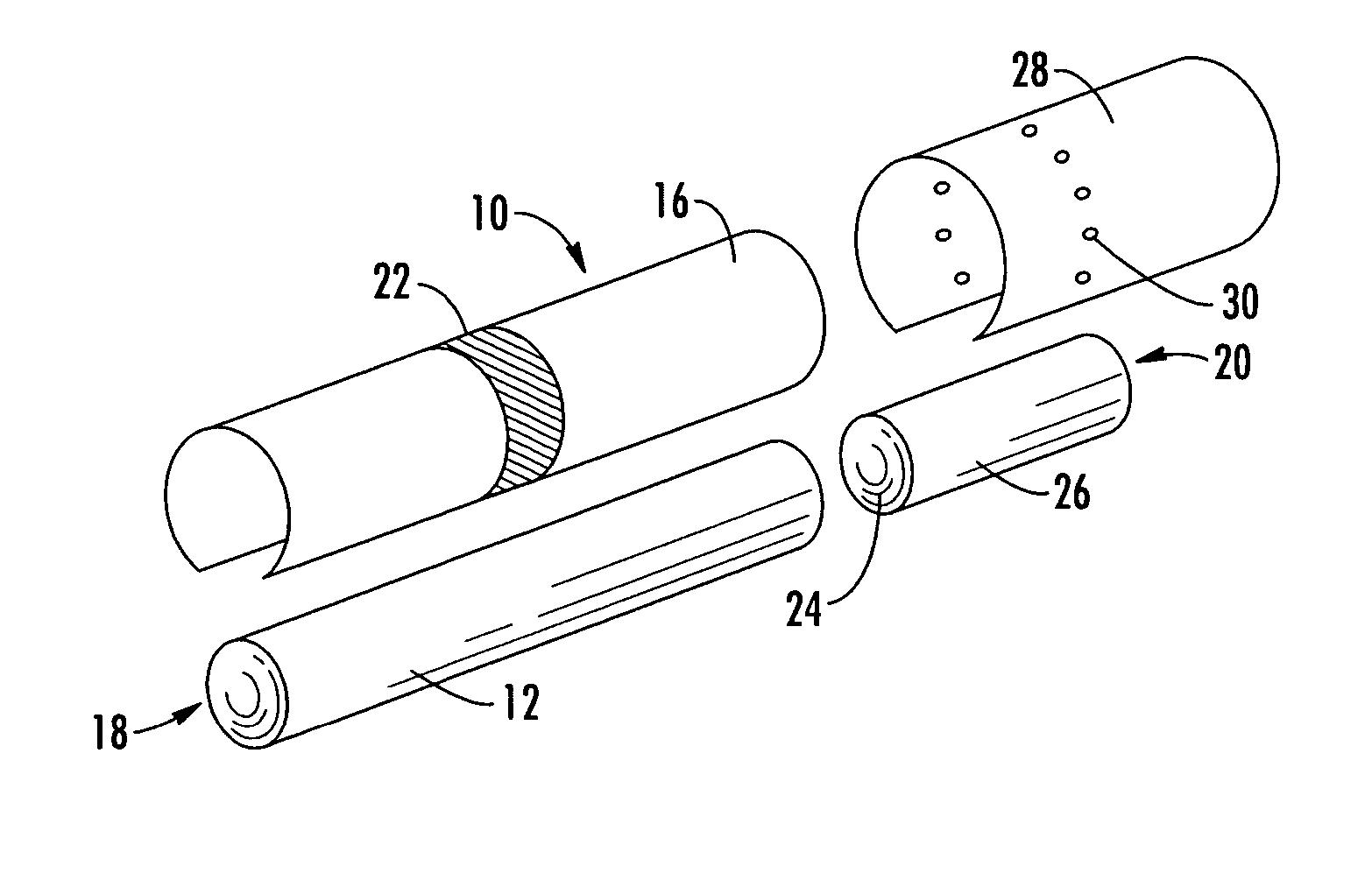

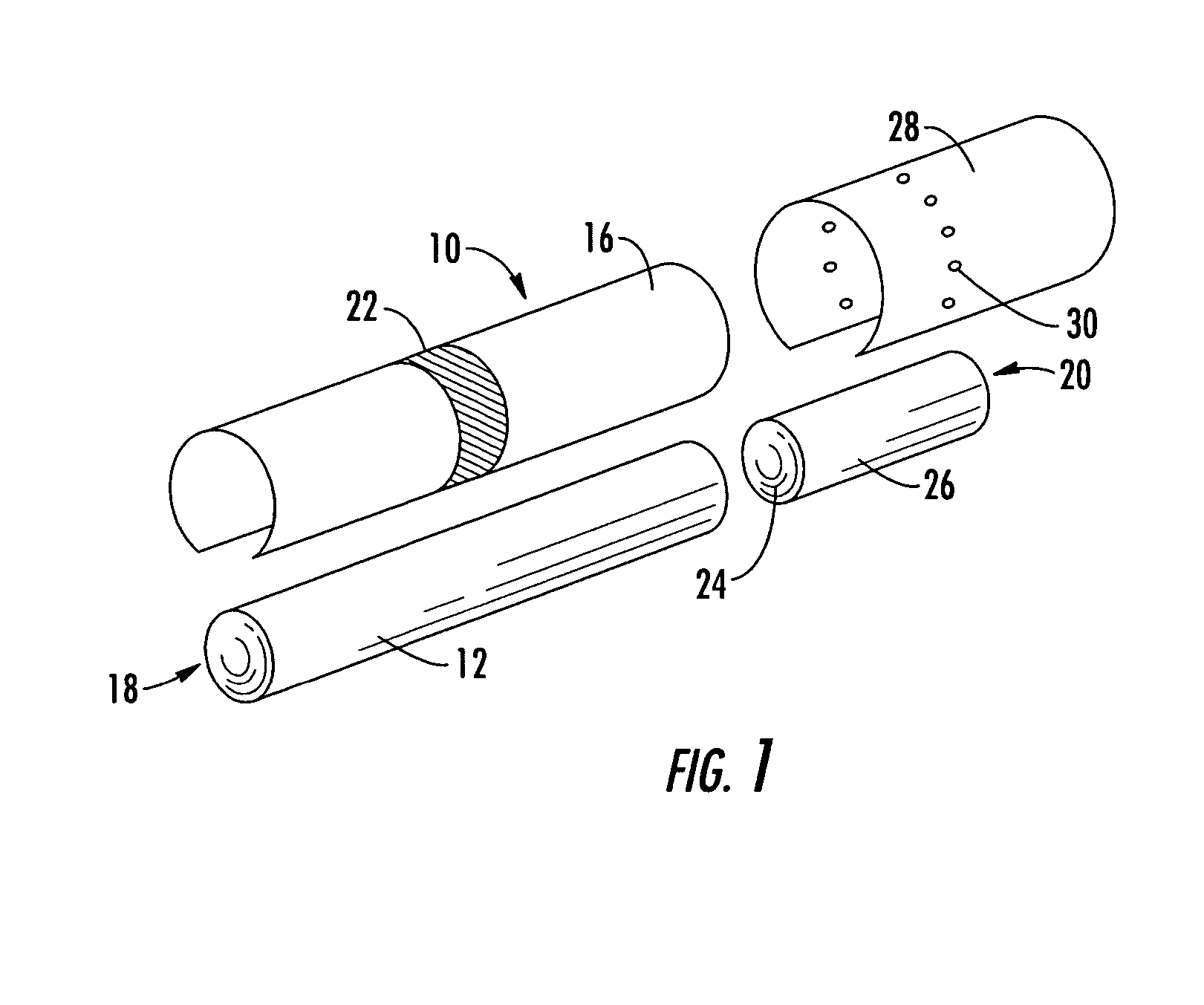

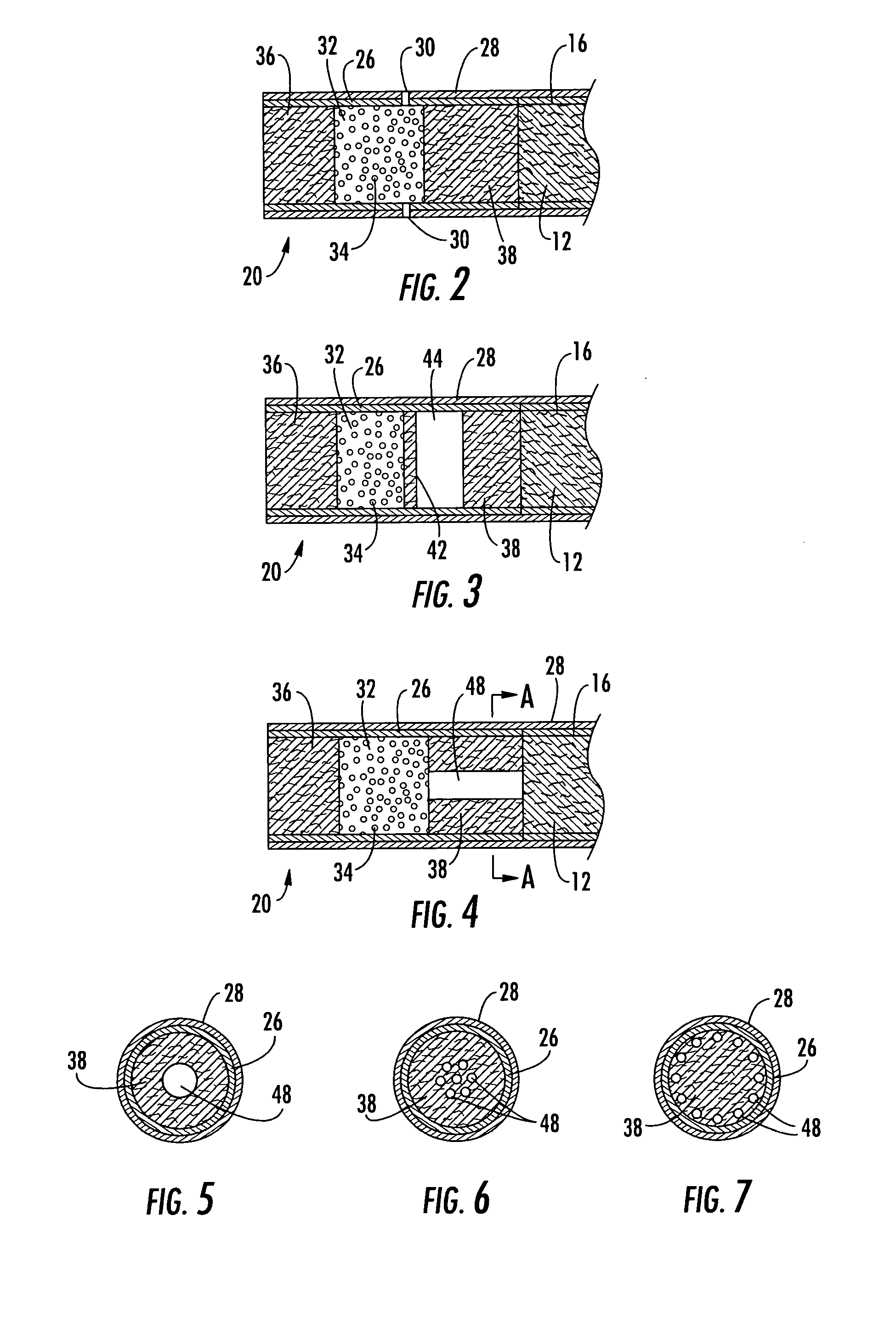

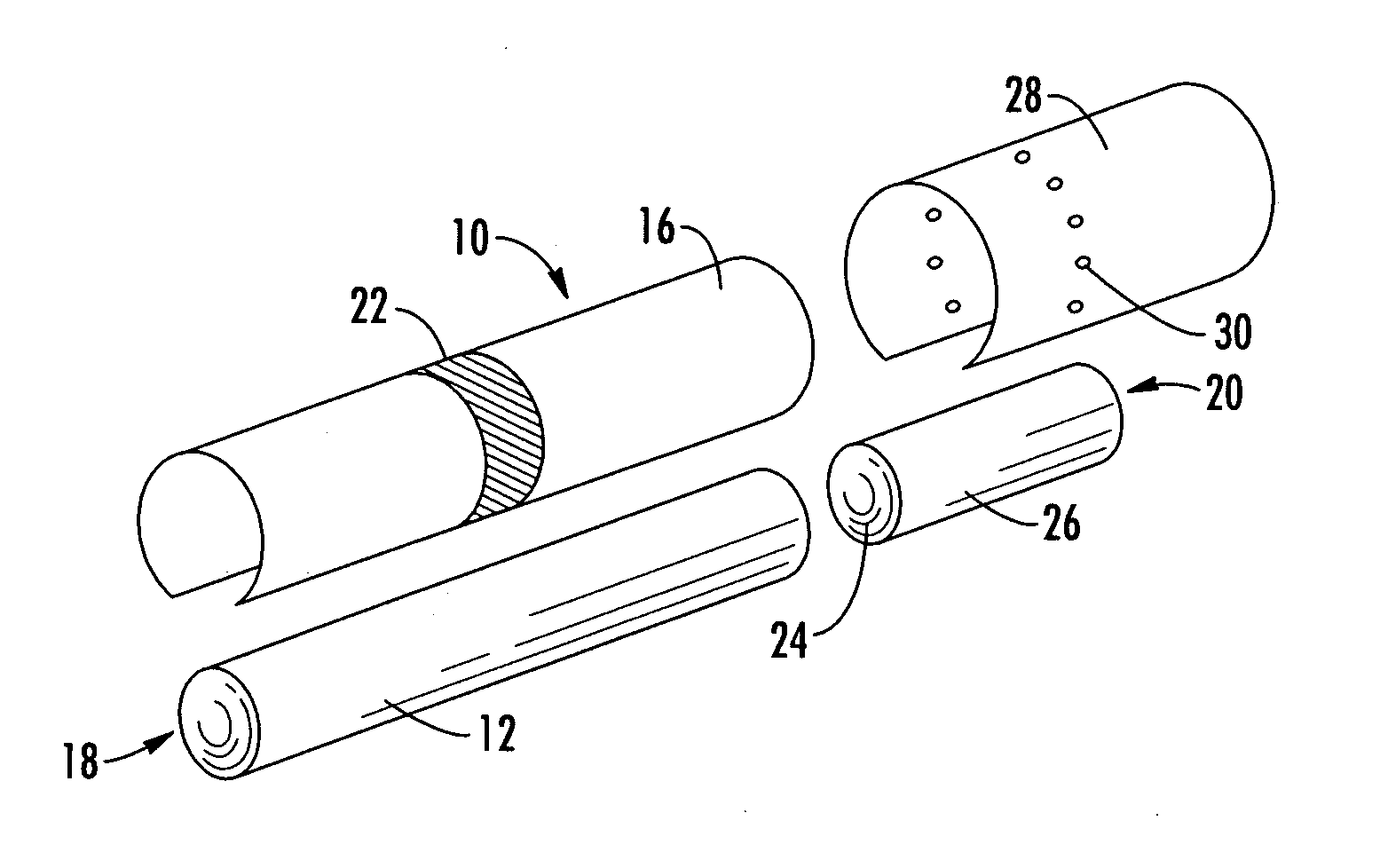

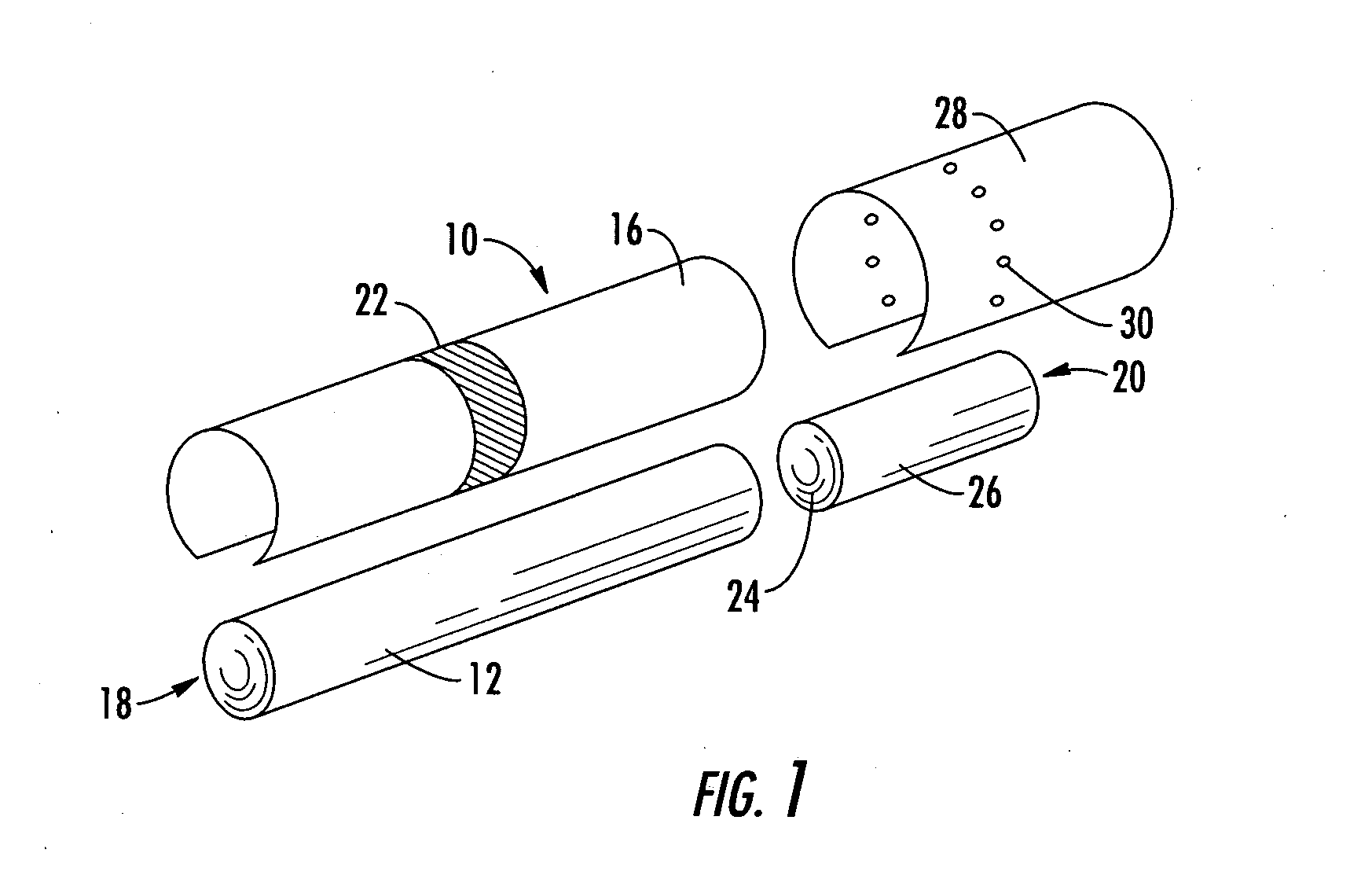

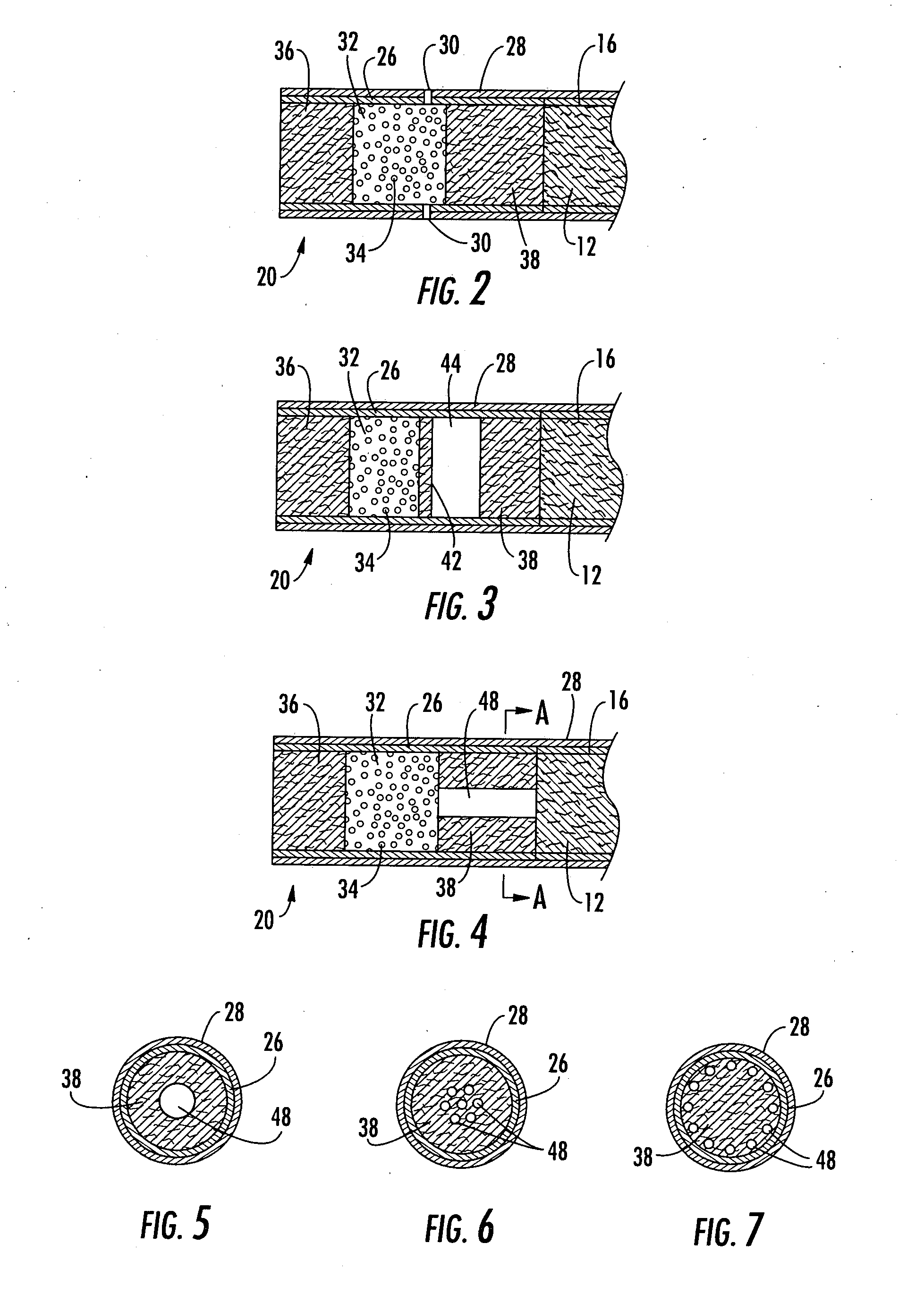

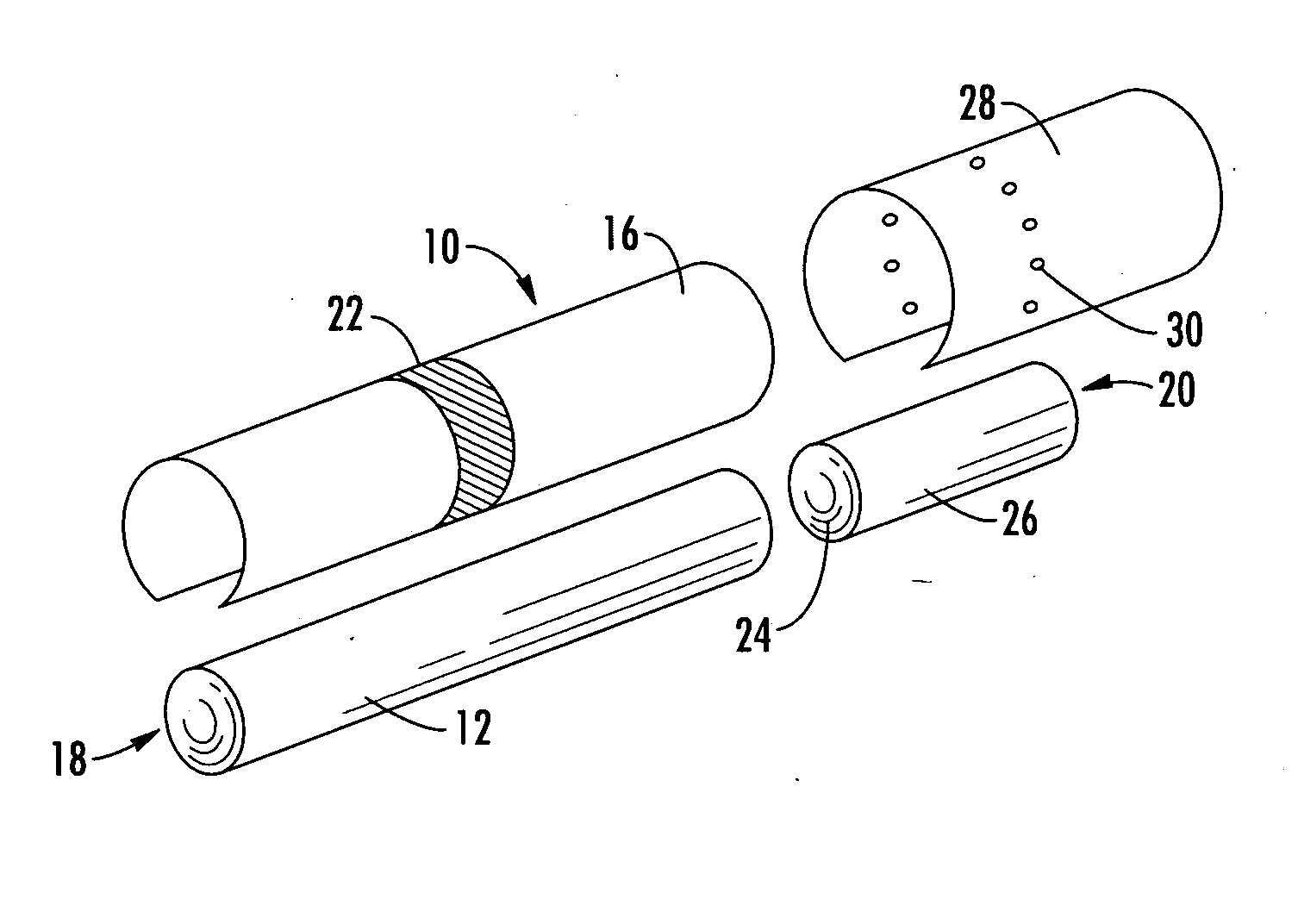

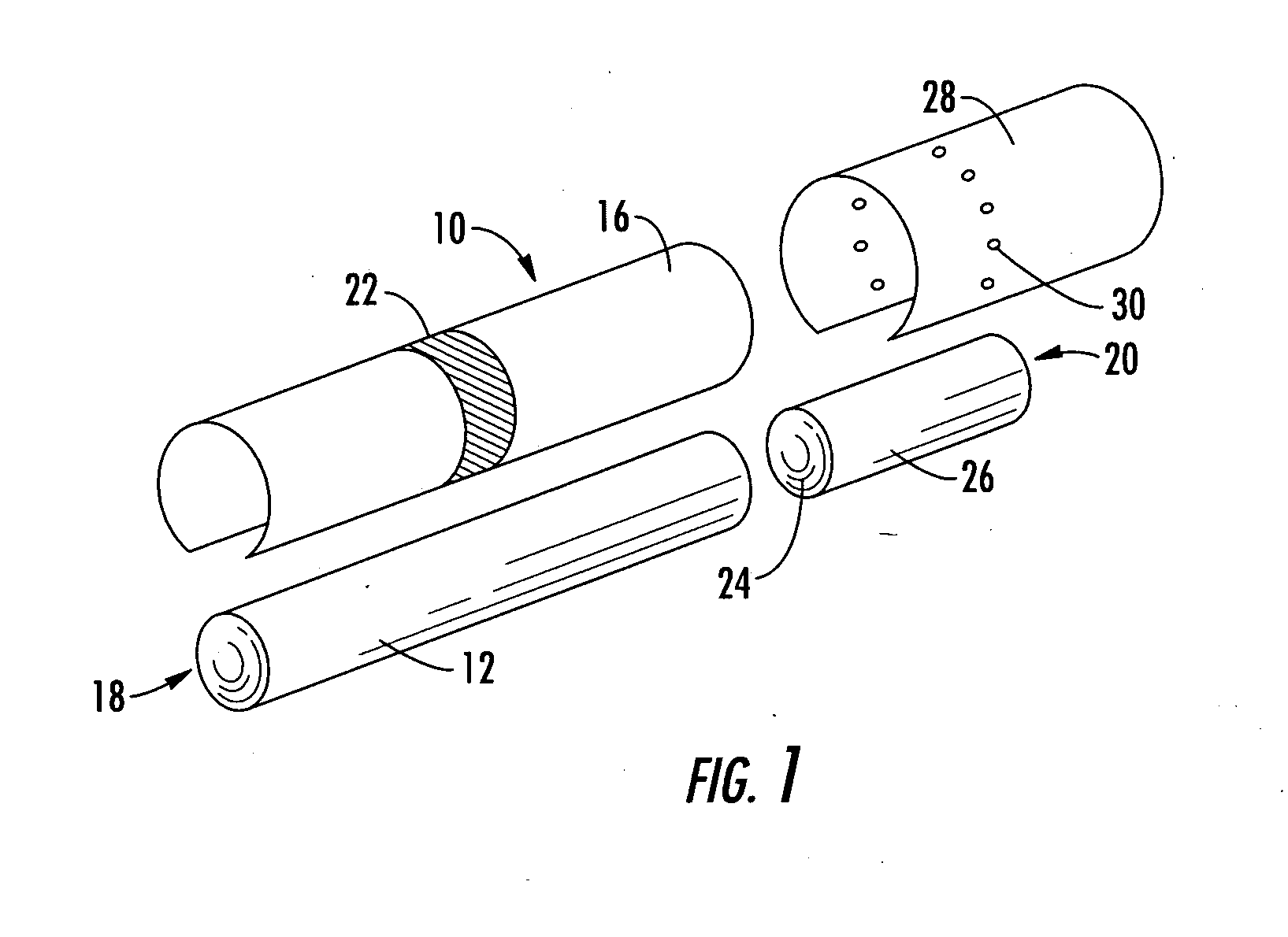

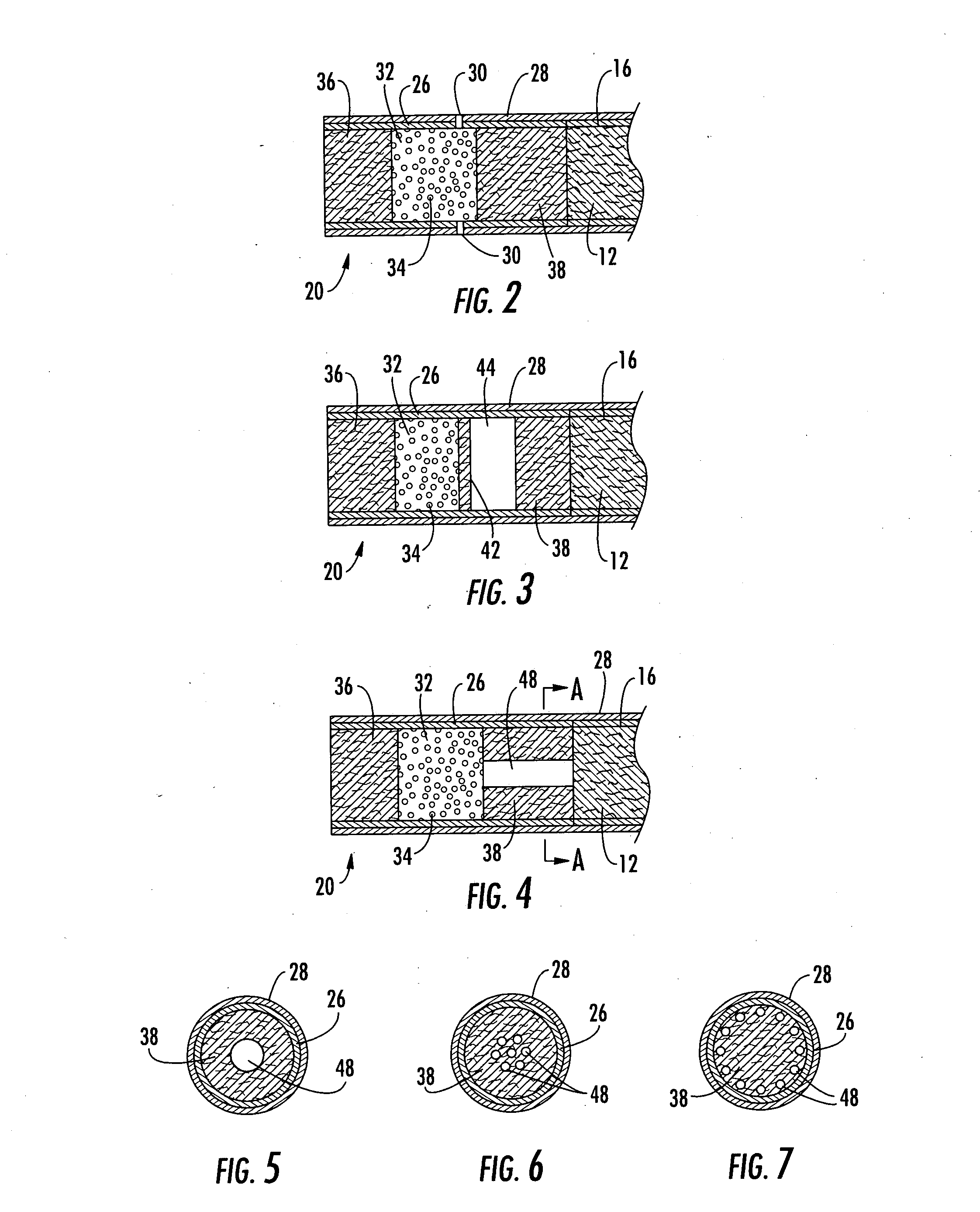

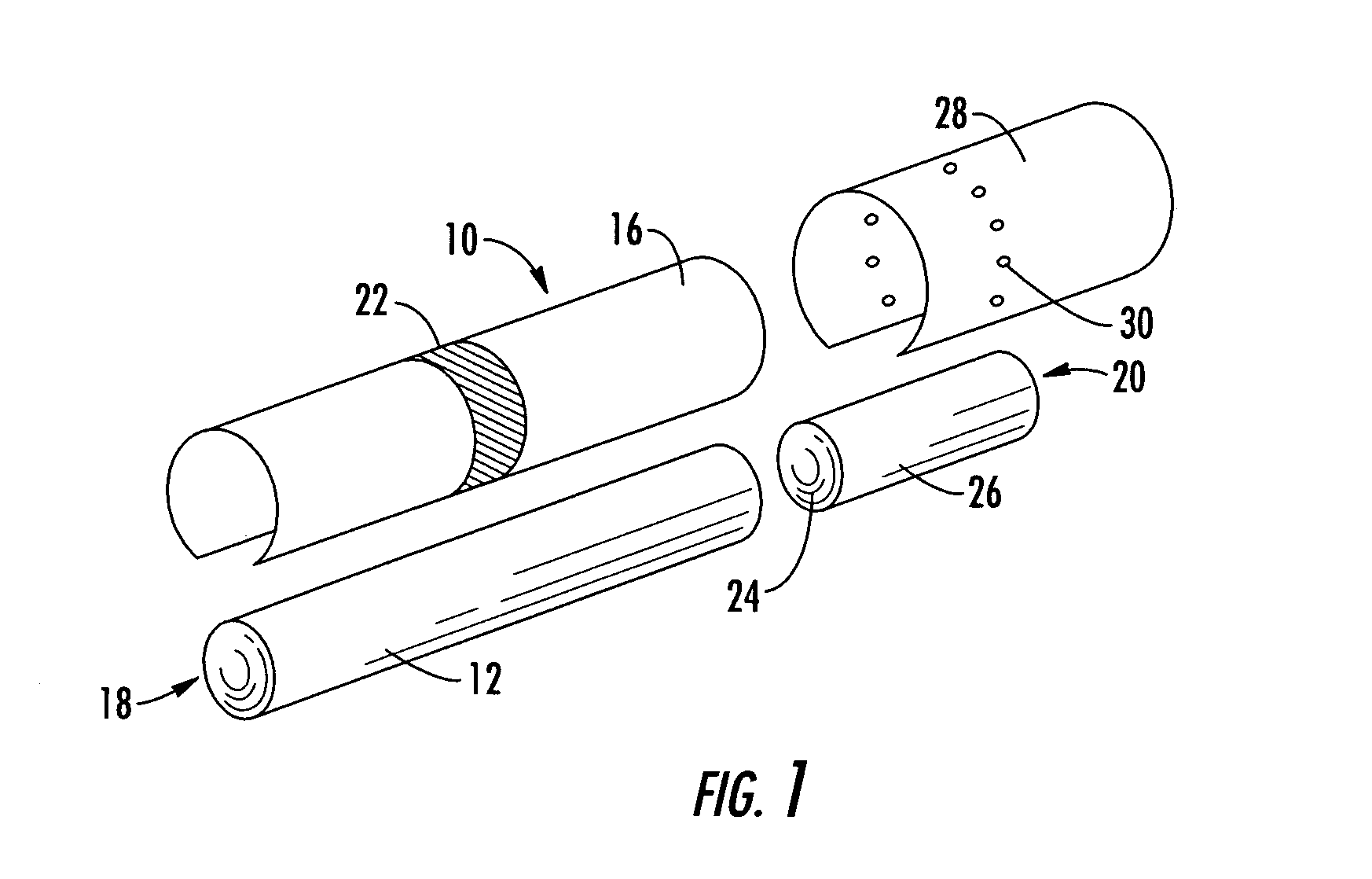

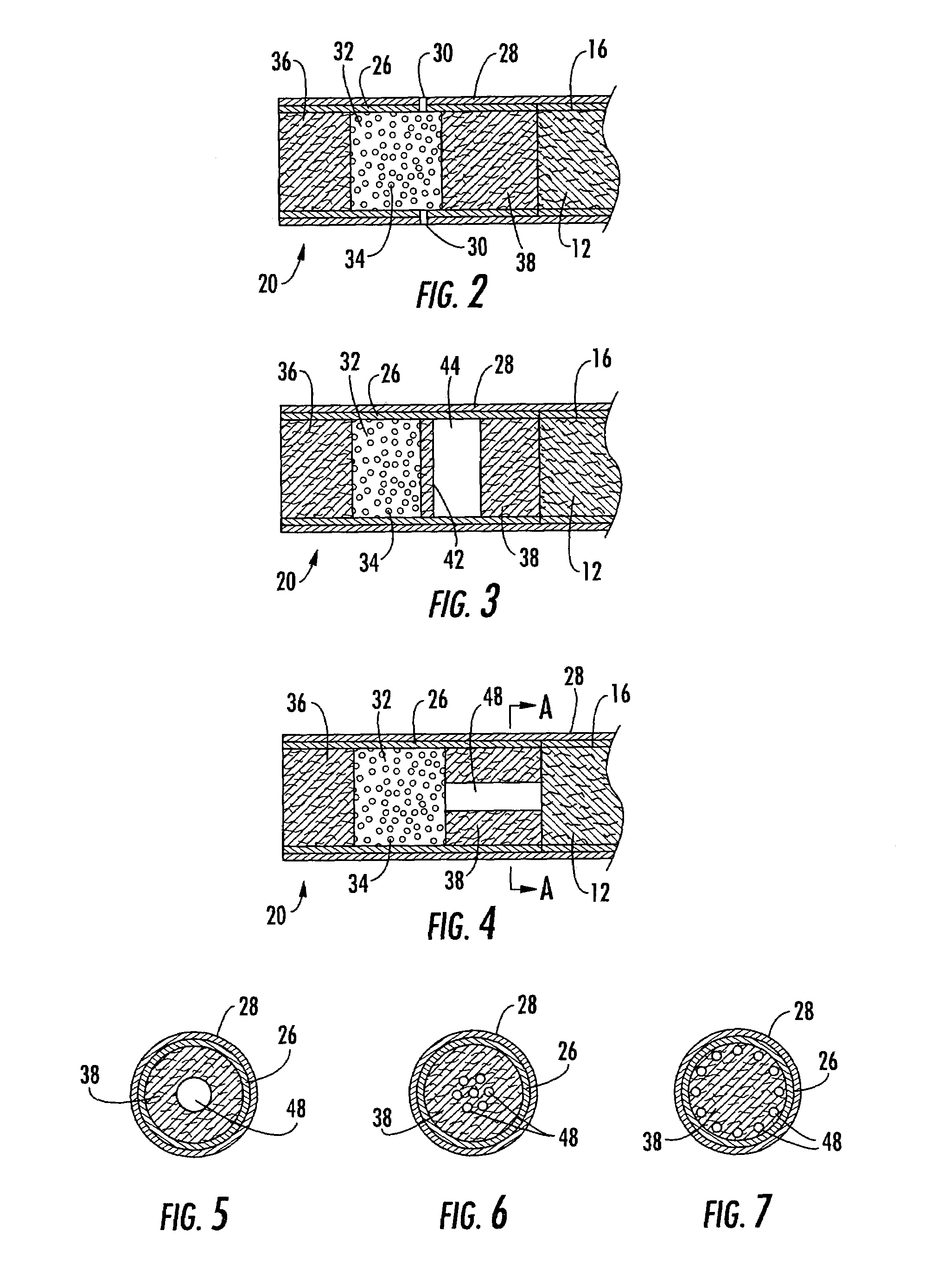

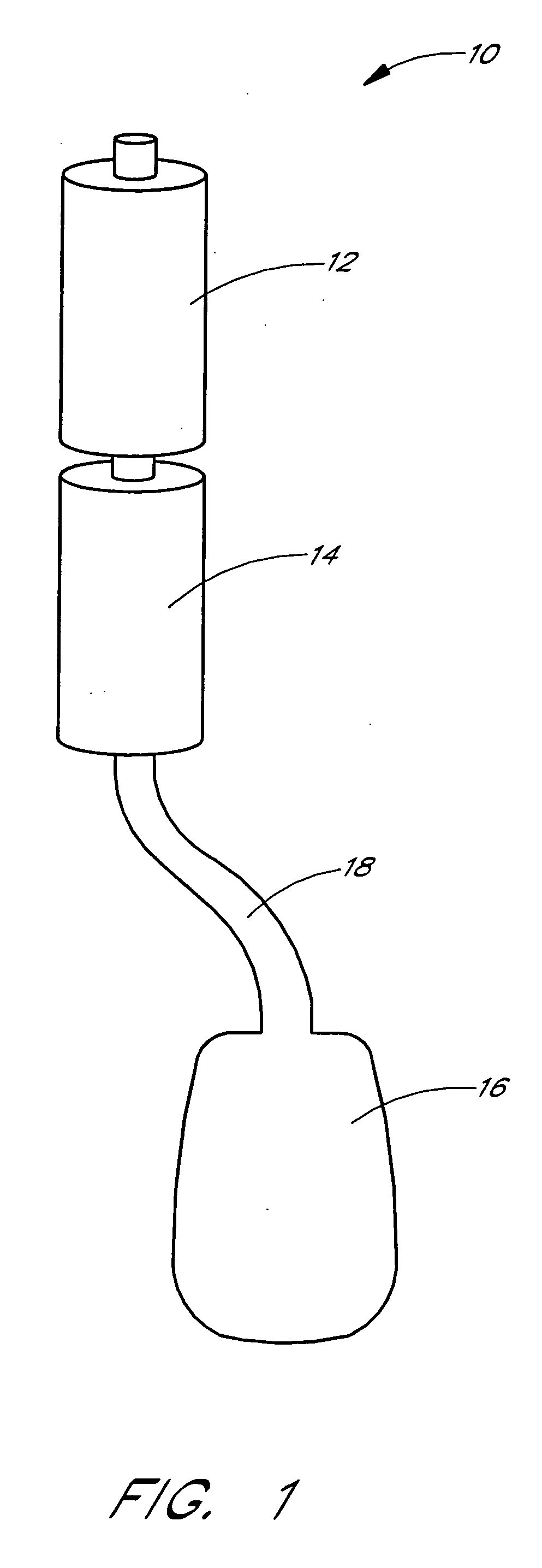

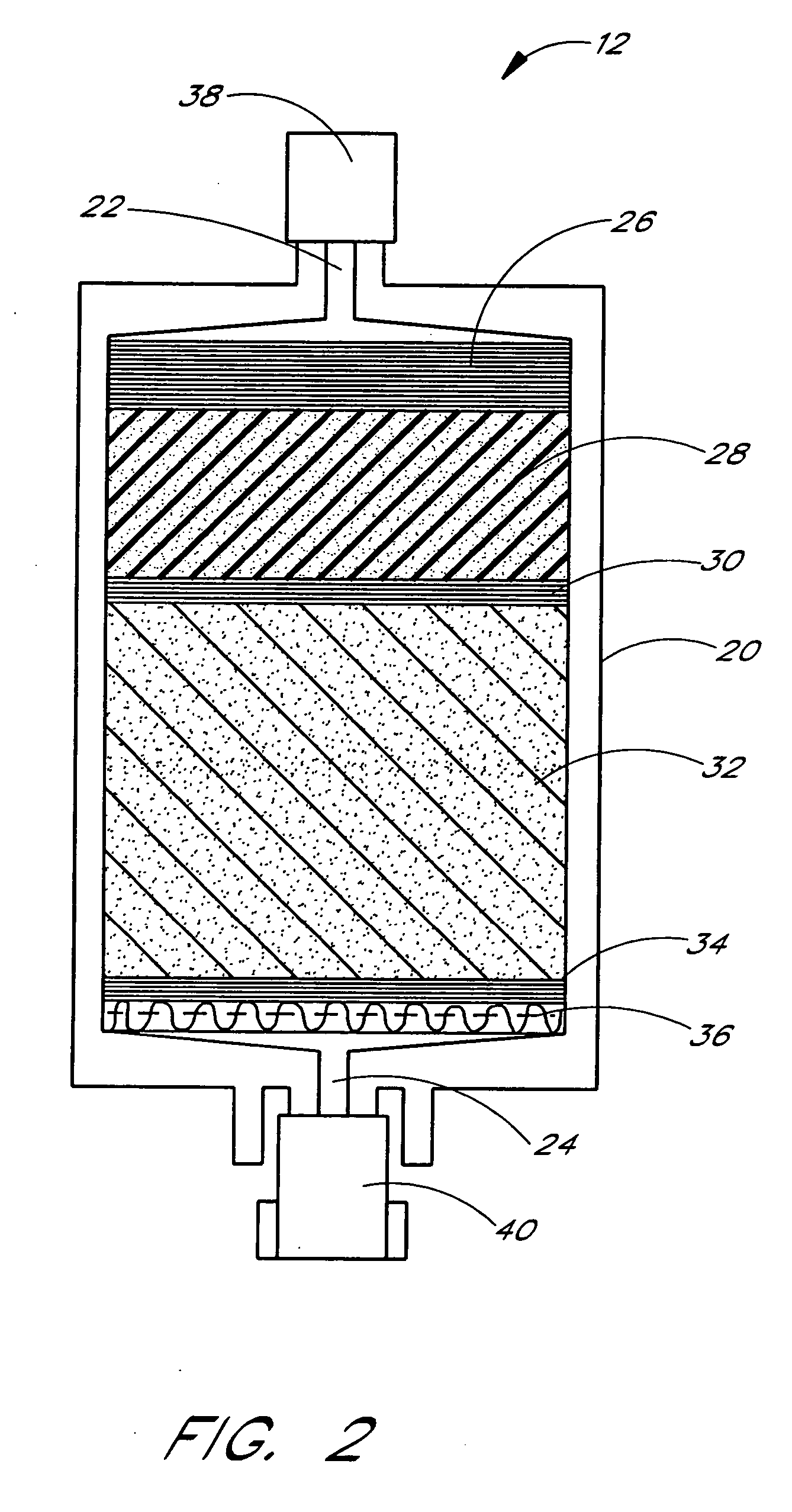

Filtered cigarette incorporating an adsorbent material

ActiveUS20050066984A1Enhanced mixing processTobacco treatmentTobacco smoke filtersFilter materialIon-exchange resin

A filter element incorporating an adsorbent material is provided. The filter element may comprise a first section of filter material and a second section of filter material spaced apart to form a compartment therebetween. The compartment may be filled with one or more adsorbents or the compartment may be divided into two regions, wherein one compartment region is filled with an adsorbent and the other compartment region is either filled with an ion-exchange resin or remains empty. The section of filter material adjacent to the tobacco rod may include one or more channels therethrough for passaging smoke directly from the tobacco rod into the adsorbent-filled compartment. The mouth end section of filter material may contain a breakable capsule, wherein the breakable capsule is filled with a flavoring agent capable of altering the taste characteristics of mainstream smoke.

Owner:R J REYNOLDS TOBACCO COMPANY

Filtered cigarette incorporating an adsorbent material

ActiveUS20050066981A1Enhanced mixing processCigar manufactureTobacco smoke filtersFilter materialIon-exchange resin

A filter element incorporating an adsorbent material is provided. The filter element may comprise a first section of filter material and a second section of filter material spaced apart to form a compartment therebetween. The compartment may be filled with one or more adsorbents or the compartment may be divided into two regions, wherein one compartment region is filled with an adsorbent and the other compartment region is either filled with an ion-exchange resin or remains empty. The section of filter material adjacent to the tobacco rod may include one or more channels therethrough for passaging smoke directly from the tobacco rod into the adsorbent-filled compartment. The mouth end section of filter material may contain a breakable capsule, wherein the breakable capsule is filled with a flavoring agent capable of altering the taste characteristics of mainstream smoke.

Owner:R J REYNOLDS TOBACCO COMPANY

Extraction, separation and modification of sweet glycosides from the Stevia rebaudiana plant

ActiveUS7838044B2High extraction rateSimple processBiocideAnimal repellantsPectinaseSodium Bentonite

The invention disclosed relates to a method for the extraction of sweet glycosides from the Stevia rebaudiana Bertoni plant and recovery of individual rebaudioside A and stevioside. The extraction is developed in the presence of pectinase, and the extract is purified using cyclodextrin and bentonite. High purity rebaudioside A is obtained by crystallization and recrystallization from ethanol. High purity stevioside is prepared from the filtrate by purification with cyclodextrin, bentonit, and ion exchange resins. The enzymatic modification of the rebaudioside A, stevioside and the purified extract is carried out using the transferring enzymes derived from Thermoactinomyces vulgaris and Bacillus halophilus.

Owner:PURECIRCLE SDN BHD

Filtered cigarette incorporating an adsorbent material

ActiveUS20050066982A1Enhanced mixing processTobacco treatmentTobacco smoke filtersEngineeringFilter material

A filter element incorporating an adsorbent material is provided. The filter element may comprise a first section of filter material and a second section of filter material spaced apart to form a compartment therebetween. The compartment may be filled with one or more adsorbents or the compartment may be divided into two regions, wherein one compartment region is filled with an adsorbent and the other compartment region is either filled with an ion-exchange resin or remains empty. The section of filter material adjacent to the tobacco rod may include one or more channels therethrough for passaging smoke directly from the tobacco rod into the adsorbent-filled compartment. The mouth end section of filter material may contain a breakable capsule, wherein the breakable capsule is filled with a flavoring agent capable of altering the taste characteristics of mainstream smoke.

Owner:R J REYNOLDS TOBACCO COMPANY

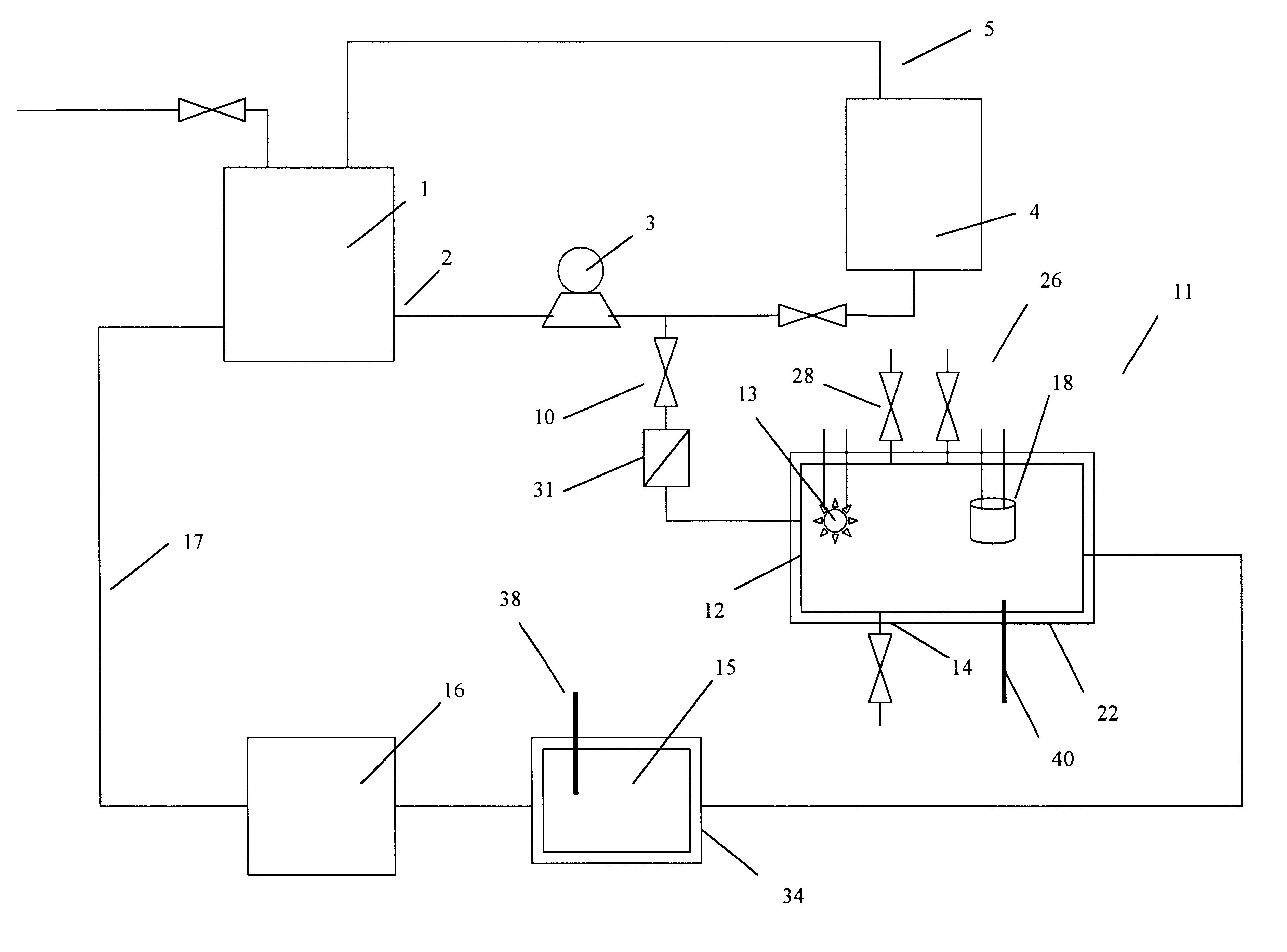

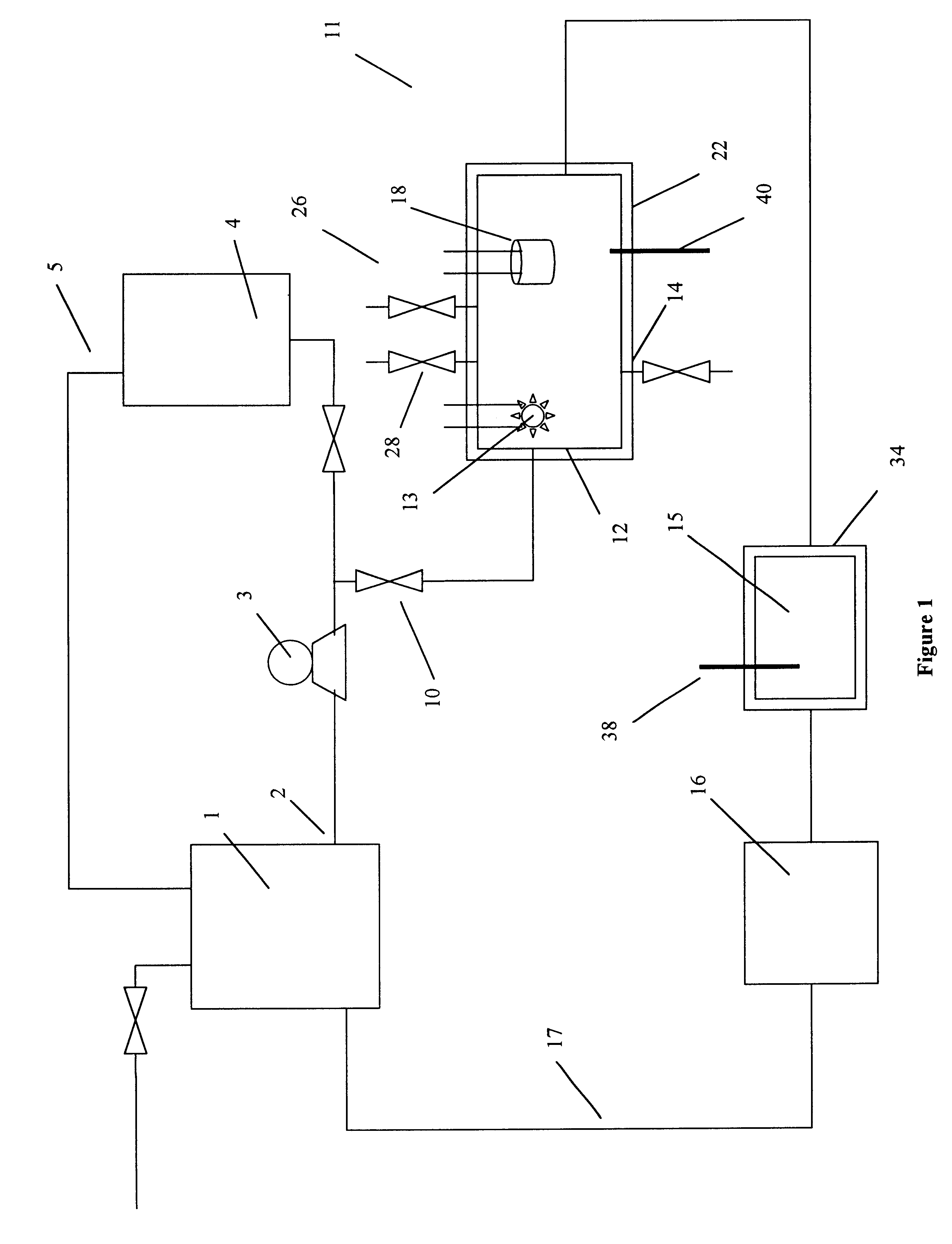

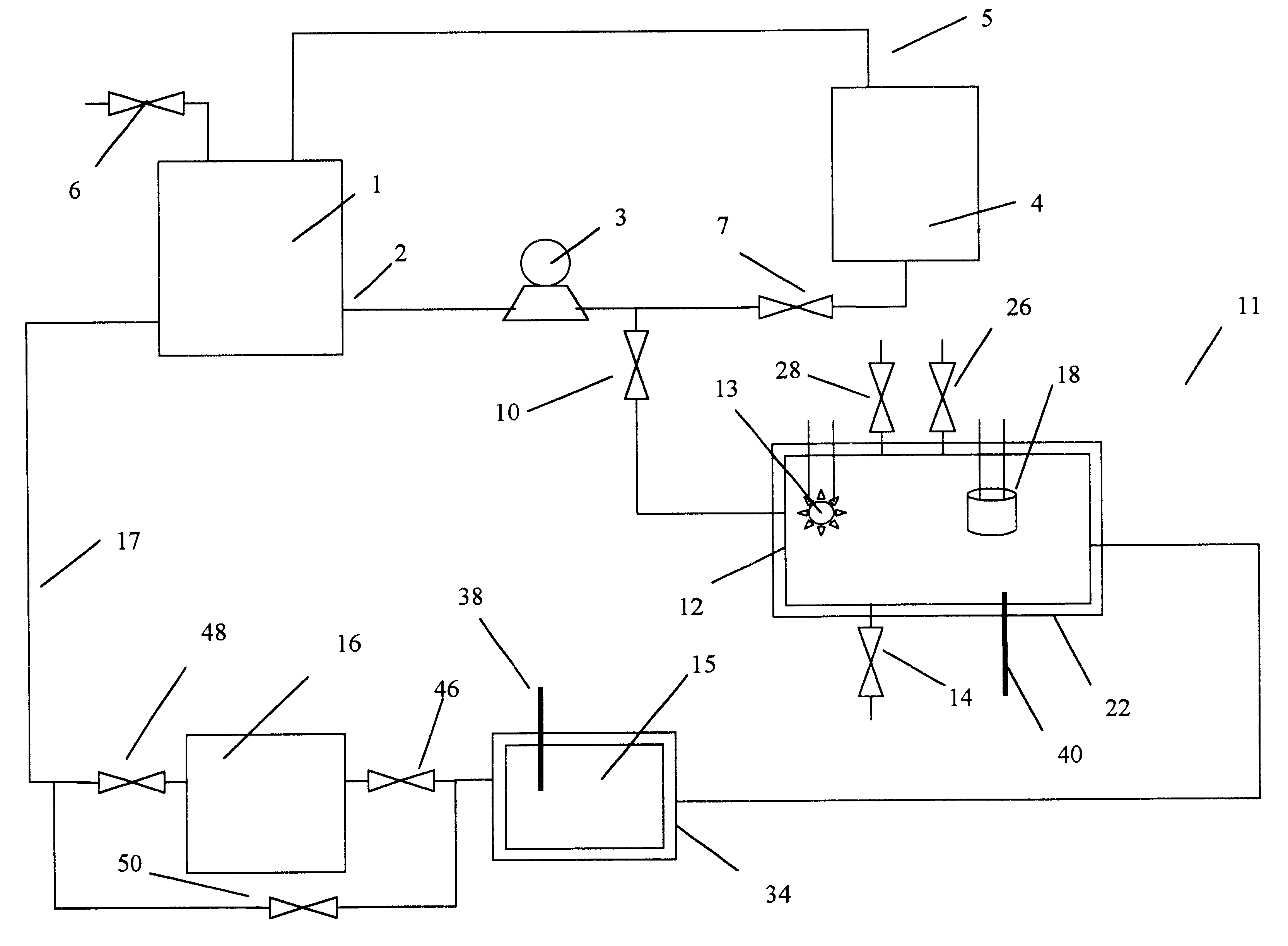

Regeneration of plating baths

InactiveUS6391209B1Maximize gasLower Level RequirementsDialysis systemsCell componentsParticulatesFiltration

The present invention provides a system and method for selectively removing organic and inorganic contaminants from plating baths. More particularly, the invented method relates to the use of a source of energy in combination with chemical oxidants, alone or in conjunction with a catalyst to oxidize organic contaminants in the plating bath to a level such that the electroplating bath can be recovered and reused after appropriate chemical adjustment. The oxidative treatment method may be a continuous process or a batch process that is performed in a single pass and the endpoint of the oxidative process detected by a sensor. Residual organics, and chloride ions in the bath are removed from the solution by a chemisorption or physisorption treatment. Inorganic contaminants are removed from the electroplating bath by selective ion exchange resins or electrodialysis, while particulate and suspended colloidal particles are removed by filtration before the treated plating bath is recycled.

Owner:ENTEGRIS INC

Filtered cigarette incorporating an adsorbent material

ActiveUS7240678B2Enhanced mixing processCigar manufactureTobacco smoke filtersFilter materialIon-exchange resin

A filter element incorporating an adsorbent material is provided. The filter element may comprise a first section of filter material and a second section of filter material spaced apart to form a compartment therebetween. The compartment may be filled with one or more adsorbents or the compartment may be divided into two regions, wherein one compartment region is filled with an adsorbent and the other compartment region is either filled with an ion-exchange resin or remains empty. The section of filter material adjacent to the tobacco rod may include one or more channels therethrough for passaging smoke directly from the tobacco rod into the adsorbent-filled compartment. The mouth end section of filter material may contain a breakable capsule, wherein the breakable capsule is filled with a flavoring agent capable of altering the taste characteristics of mainstream smoke.

Owner:R J REYNOLDS TOBACCO COMPANY

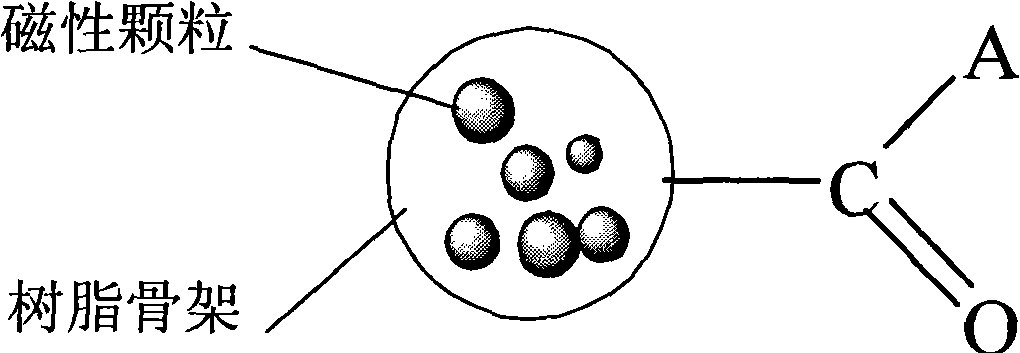

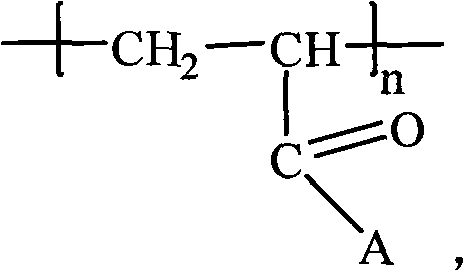

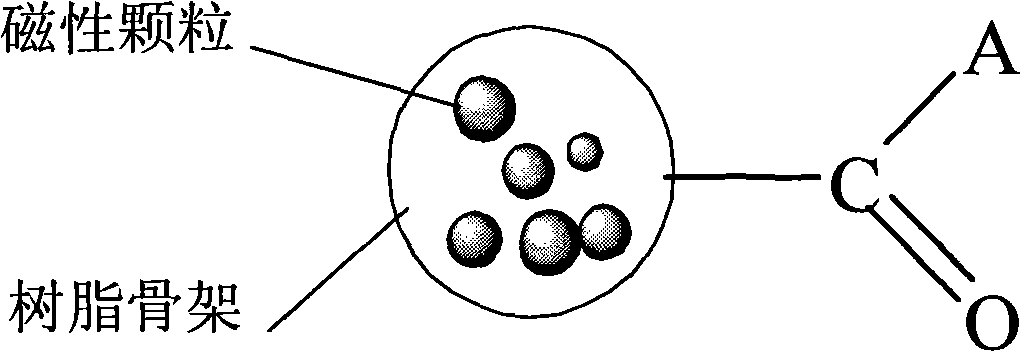

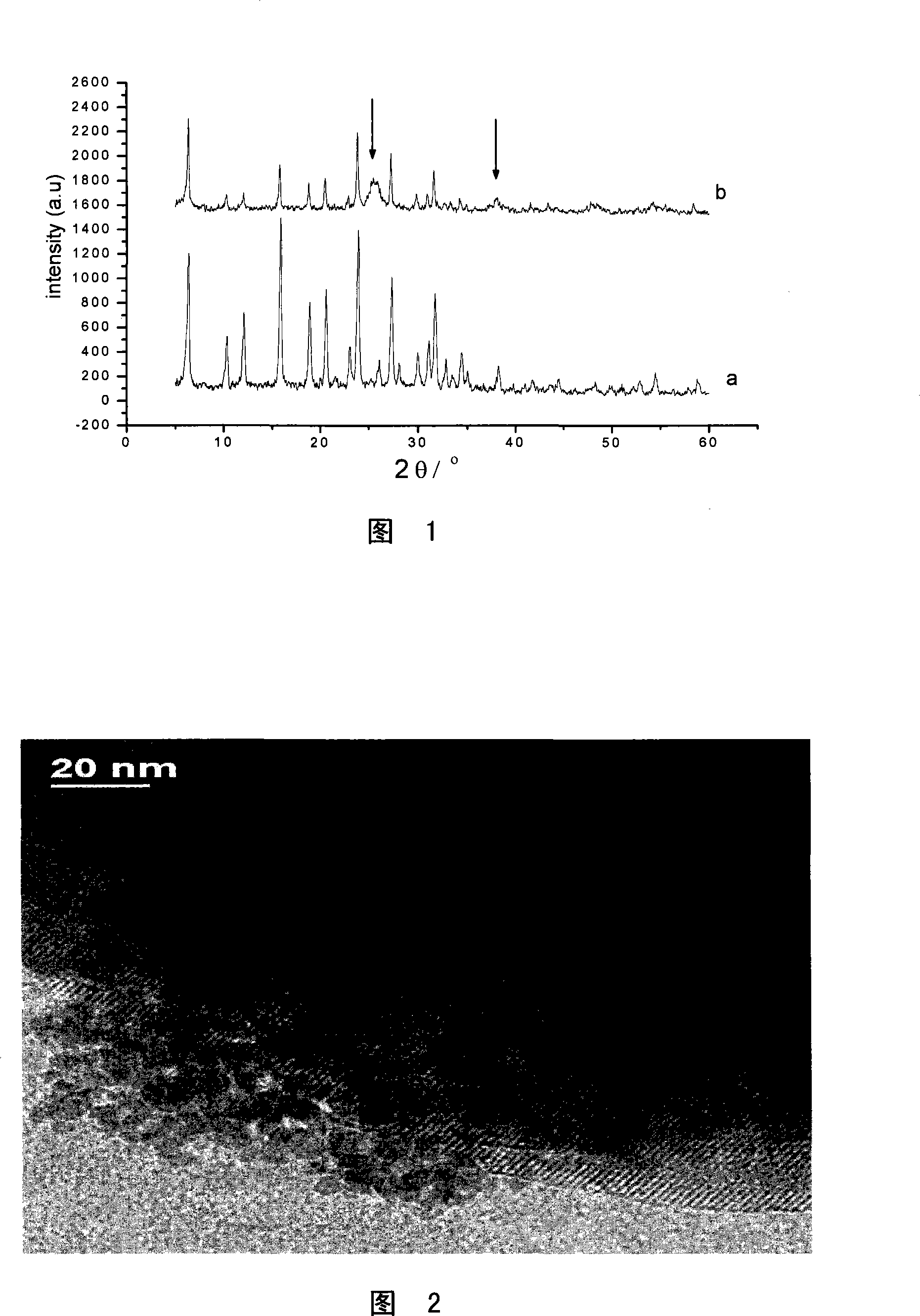

Magnetic acrylic acid series strongly basic anion exchange microballoon resin and preparation method thereof

ActiveCN101781437AIncrease switching capacityHigh base exchange capacityInorganic material magnetismAnion exchangersCross-linkIon exchange

The invention discloses a magnetic acrylic acid series strongly basic anion exchange microballoon resin and a preparation method thereof. The microballoon resin has the following structure: the resin skeleton is internally provided with magnetic particles, wherein A stands for a radical containing quaternary ammonium salt. The preparation method comprises the following steps: acrylic acid series substances serve as a monomer, the monomer is mixed with cross-linking agent and pore-forming agent to form oil phase; the oil phase is uniformly mixed with the magnetic particles and then suspension polymerization is carried out on the mixture; after going through amination and alkylation reaction, the polymerized magnetic polymer particles form the quaternary ammonium salt, namely the magnetic acrylic acid series strongly basic anion exchange microballoon resin. Exchange capacity of the resin is higher than any magnetic acrylic acid series strongly basic anion exchange microballoon resin ever found in existing literatures and reports and domestic market as well as foreign markets and can replace the traditional strongly basic anion exchange resin, thus being capable of being used for separating and removing soluble organisms in various water bodies, especially disinfection by-product precursor and multiple negative ions such as nitrate and phosphate.

Owner:NANJING INNOVATION CENT FOR ENVIRONMENTAL PROTECTION IND

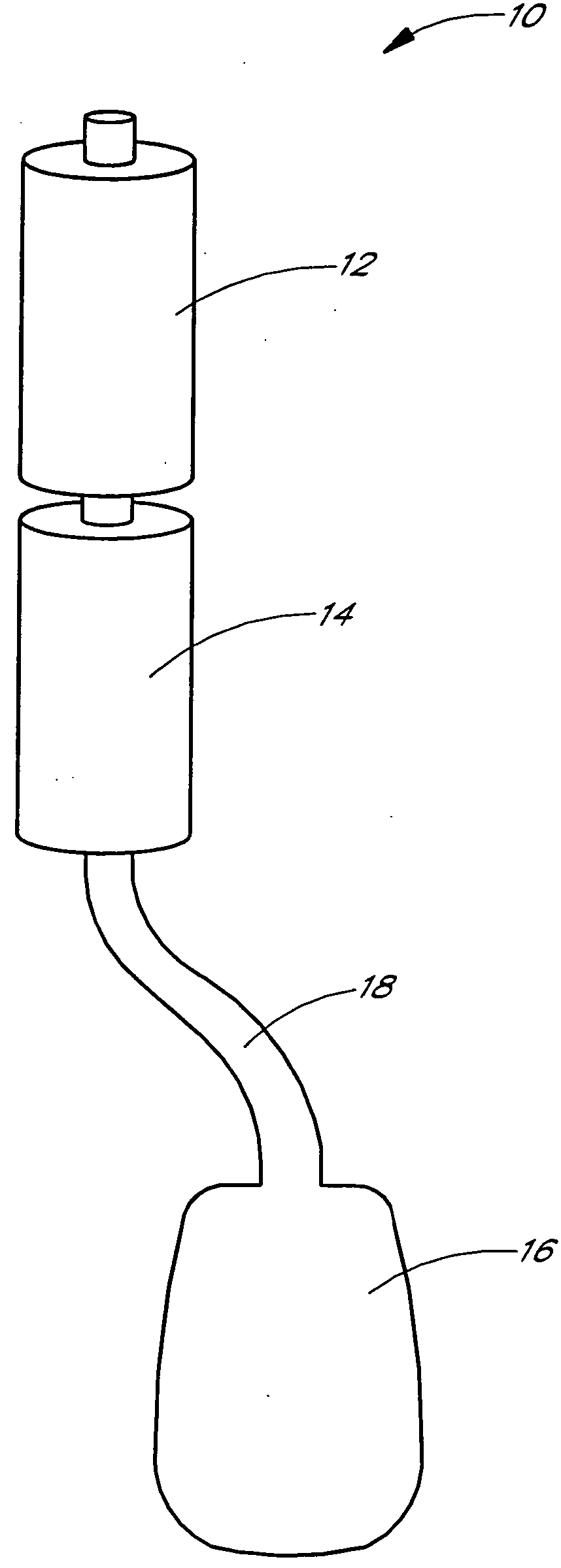

Water purification pack

InactiveUS20050113796A1General water supply conservationTransportation and packagingHuman bodyQuality level

An apparatus and methods are disclosed for purifying fluid, such as potable water, to quality levels suitable for medical application, particularly to applications involving injection of the fluid into a human body. The apparatus comprises a portable purification pack constructed for a single use. The pack houses depth filtration, activated carbon, mixed bed ion exchange resins and terminal filtration stages in series. The terminal filter comprises a fine (microfiltration or ultrafiltration), permeable membrane, treated with an endotoxin-binding chemistry. In contrast with semi-permeable osmotic membranes, the permeable membrane produces high flow rates at relatively low pressures, while still safely purifying fluid to injection quality.

Owner:TAYLOR MICHAEL A

Process for reducing the amount of fluorinated surfactant in aqueous fluoropolymer dispersions

InactiveUS6825250B2Easy dischargeWashed quickly and effectivelyFibre treatmentPolymer scienceFluoropolymer

The present invention provides a process of reducing the amount of fluorinated emulsifier in an aqueous fluoropolymer dispersion by contacting the aqueous fluoropolymer dispersion with an anion exchange resin in a non-fixed resin bed, the process comprising:(a) mixing the aqueous fluoropolymer dispersion with an effective amount of a surfactant so as to stabilize the fluoropolymer dispersion while being contacted with the anion exchange resin;(b) contacting the aqueous fluoropolyrner dispersion with an anion exchange resin by agitating the aqueous fluoropolymer dispersion with an effective amount of anion exchange resin for a time of less than 4 hours to reduce the amount of fluorinated emulsifier in the aqueous fluoropolymer dispersion to a desired level; and(c) separating the anion exchange resin from the aqueous fluoropolymer dispersion.

Owner:3M INNOVATIVE PROPERTIES CO

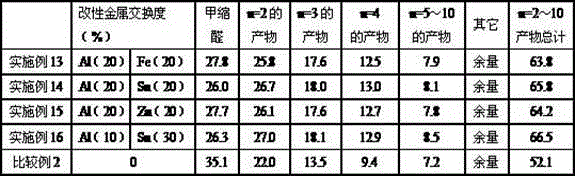

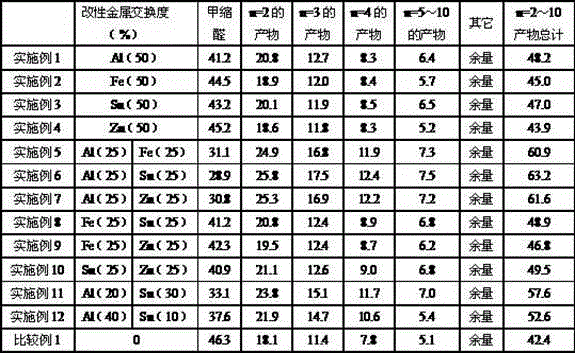

Catalyst for synthesis of polyoxymethylene dimethyl ether and application of catalyst

ActiveCN104549502AHigh yieldEasy to separateOrganic chemistryOrganic compound preparationIon exchangeStrong acids

The invention relates to a catalyst for synthesis of polyoxymethylene dimethyl ether, application of the catalyst in synthesis of polyoxymethylene dimethyl ether and a method for synthesizing polyoxymethylene dimethyl ether, and mainly aims to solve the problem that the catalyst has low selectivity and low yield for polyoxymethylene dimethyl ether which has a polymierization degree n of 2-10 in the prior art. The technical problem can be well solved by adopting a technical scheme that the catalyst is a metal ion modified hydrogenous strong-acid ion exchange resin, wherein the modifying metal is at least one of Al, Fe, Sn and Zn; and the ion exchange degree of the modifying metal in the catalyst is more than zero and less than or equal to 50 percent. The catalyst can be used in industrial production of polyoxymethylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

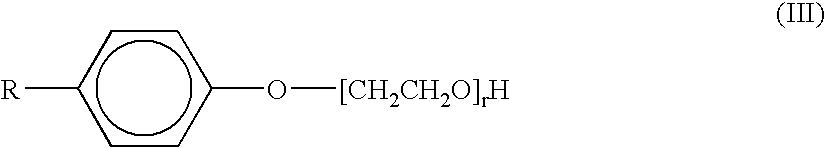

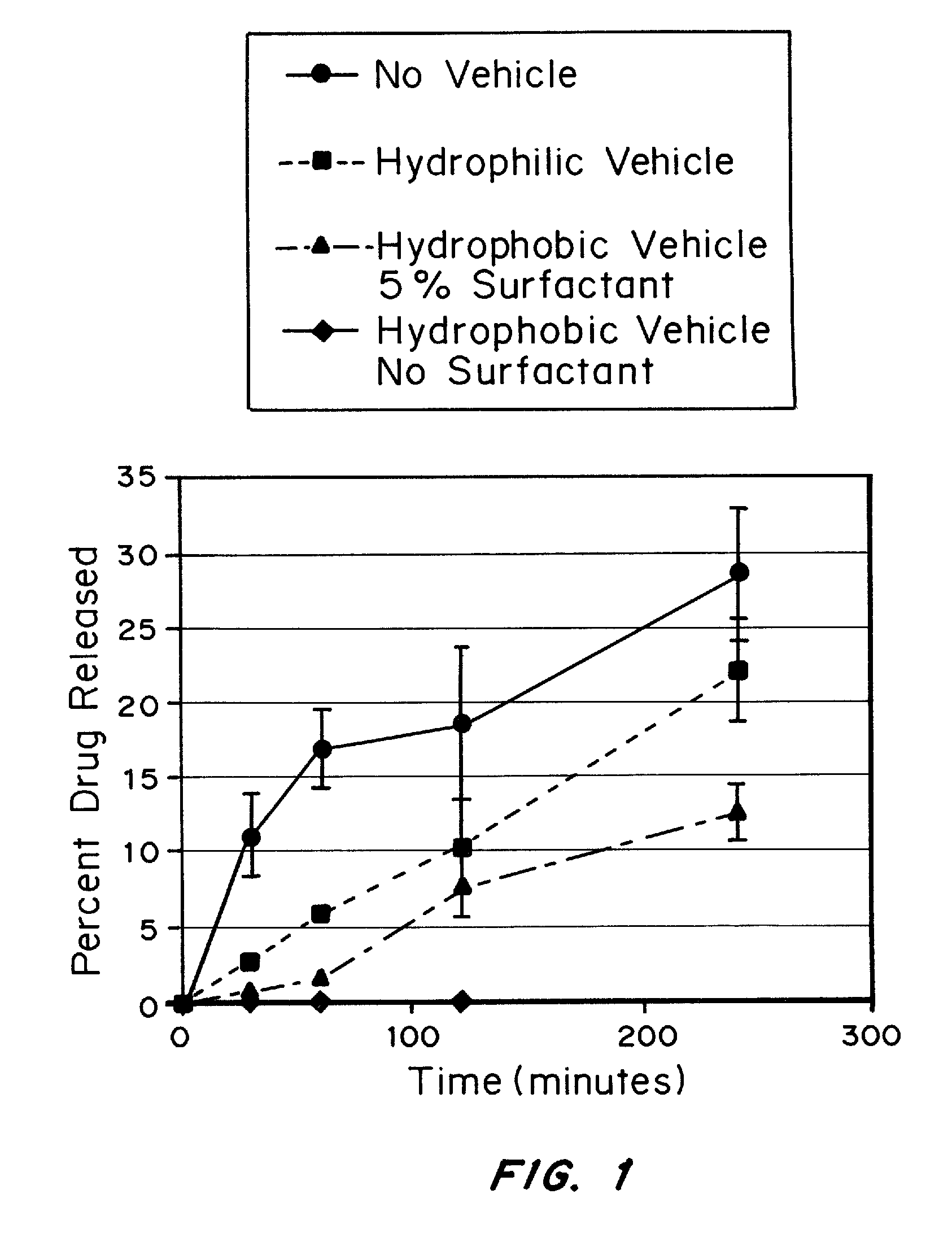

Non-ionic non-aqueous vehicles for topical and oral administration of carrier-complexed active agents

InactiveUS20070036843A1Control releaseLow costOrganic active ingredientsPharmaceutical non-active ingredientsActive agentNon ionic

An improved controlled release composition for non-parenteral administration of active agents and other therapeutics, particularly for oral or topical administration, has been developed. The composition is made by dispersing a complex formed of an active agent bound to an ion-exchange resin or to another form of resin or carrier, in a non-ionic non-aqueous (“NINA”) vehicle. The complexes are optionally coated with one or more layers of coating material to provide a controlled pattern of release of active agent from the carrier. Replacing the usual aqueous vehicle with a NINA vehicle, such as an oil or an ointment, allows the active agent-carrier complexes, with or without coatings, to be both orally and topically administered. The compositions can be formulated as powders, liquids, liquid suspensions, gels, capsules, soft gelatin capsules, tablets, chewable tablets, topical ointments, lotions, pourable or pumpable fluids, semisolid, crushable tablets, and unit-of-use sachets or capsules for reconstitution or direct application. The combination of multiple active agents is possible with this system, in which one or more active agents are bound to particles and one or more active agents are dissolved or dispersed in the NINA vehicle. This allows the combination of two or more active agents, which are otherwise incompatible, into a single dosage form.

Owner:COLLEGIUM PHARMA INC

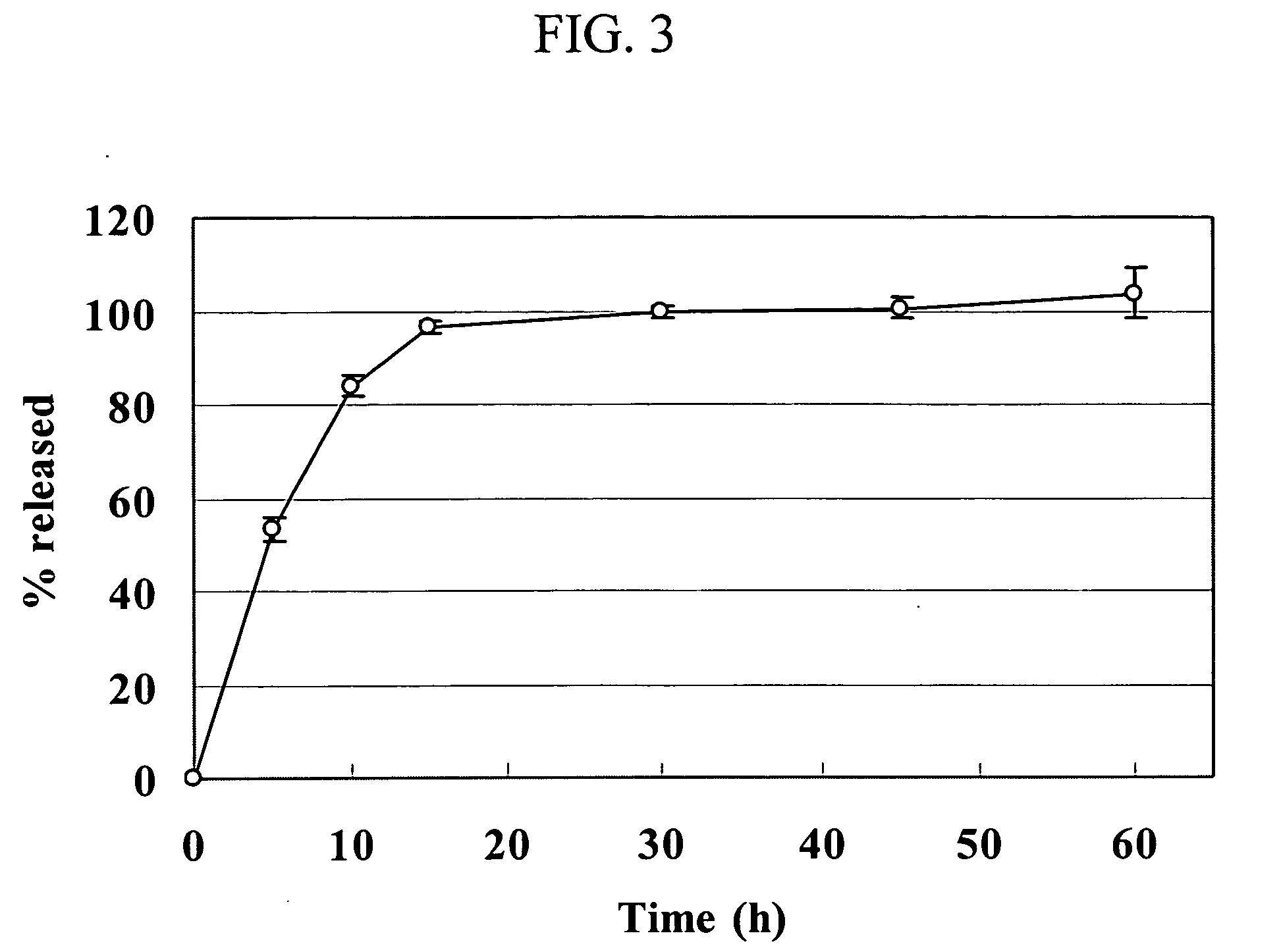

Polymer coated drug-ion exchange resins and methods

Included are compositions, and methods of making, coated controlled-release drug and ion exchange resin form complexes. Methacrylate coatings, which can be free of plasticizers particularly with Eudragit® NE type polymer, are preferred to enhance the control of drug release from the drug-resin complexes. Liquid formulations including the coated resin forms and a chelating agent to inhibit degradation are also included.

Owner:WOCKHARDT EU OPERATIONS SWISS

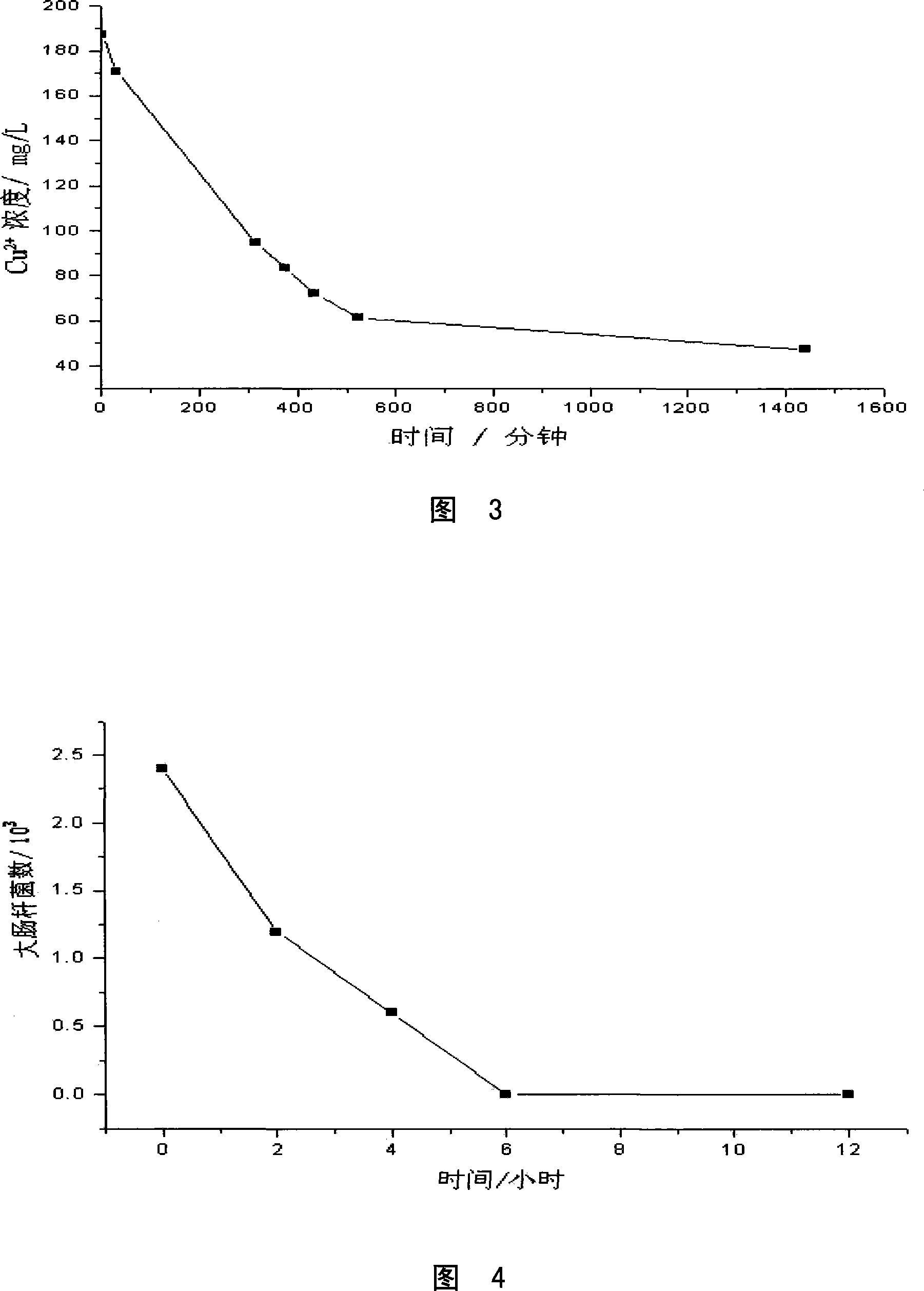

Zeolite base composite antibiotic material and its preparation method

InactiveCN101167451APrevent seepageImprove thermal stabilityBiocideDisinfectantsIon exchangeSilver ion

The invention relates to zeolite-based composite antibiotic material and a process for preparation, the material of which is low-silicon-aluminum-ratio zeolite molecular sieve which is used as the base and carrier, the outer surface of the invention is covered with nanometer titanium dioxide particles, and the pore passages or cages of the invention are provided with metallic ions which have antibiotic effect. The process for preparing the material is that low-silicon-aluminum-ratio zeolite molecular sieve absorbs organic amine to saturation and then is dipped into soluble titanates for roasting to generate nanometer titanium dioxide on the outer surface of zeolite, and metallic ions such as silver ions, copper ions and the like which have antibiotic effect are exchanged to zeolite by the ion exchange process to form the novel composite antibiotic material. The composite antibiotic material not only has the antibiotic effect of metallic ions but also has the antibiotic effect of nanometer titanium dioxide, and thereby the antibiotic effect is strengthened. The composite antibiotic material is easy to prepare, low in price and suitable for industrial production.

Owner:SUZHOU UNIV OF SCI & TECH

Fast-melting tablets having taste-masking and sustained release properties

Fast-melting tablets contain particles of an active ingredient and ion-exchange resin complex to mask unpleasant taste associated with the active ingredient. The resin complex particles can be coated or uncoated to impart sustained release properties to the active ingredient. A fast-melting tablet also comprises a dry binder and bulk diluent to form highly plastic granules that are subsequently compressed into tablets.

Owner:AKINA INC

High density magnetic recording compositions and processes thereof

InactiveUS6451220B1NanomagnetismMagnetic materials for record carriersHigh densityCobalt ferrite nanoparticles

A magnetic composition comprised of cobalt ferrite nanoparticles dispersed in an ionic exchange resin.

Owner:XEROX CORP

Method of separating anionic fluorochemical surfactant

InactiveUS20040010156A1Short elution timeHigh recovery rateFatty oils/acids recovery from wasteIon-exchanger regenerationOrganic solventIon-exchange resin

Separation of an anionic fluorochemical surfactant from an aqueous solution containing the anionic fluorochemical surfactant is carried out by i) contacting the aqueous solution with a basic anion-exchange resin so that the anionic fluorochemical surfactant is adsorbed on the resin, and ii) eluting the anionic fluorochemical surfactant adsorbed on the resin with an eluent which is an alkaline solution containing water and an organic solvent.

Owner:DAIKIN IND LTD

Sustained release preparations

Disclosed are sustained release drug particles suitable for forming sustained release oral pharmaceutical compositions. The sustained release drug particles comprise a drug-ion exchange resin complex and a water-permeable, diffusion barrier surrounding at least a portion of the drug-ion exchange resin complex. The diffusion barrier comprises a film-forming polymer and is free or contains no substantial traces of organic solvent. Also disclosed are oral pharmaceutical compositions, for example, oral suspensions, comprising the sustained release drug particles, a method for the controlled administration of a drug to a patient, and a method for manufacturing the sustained release drug particles. The method of manufacturing involves the use of an aqueous coating composition comprising a water-permeable film-forming polymer such as ethylcellulose.

Owner:MALLINCKRODT INC

Abuse resistant opioid drug-ion exchange resin complexes having hybrid coatings

InactiveUS20120148672A1Improved resistance characteristicsPowder deliveryNervous disorderMedicineIon-exchange resin

A sustained release formulation for opioid drugs is described. The formulation contains an opioid-ion exchange resin complex having a hybrid coating. The hybrid coating contains a cured polyvinylacetate polymer and a pH-dependent enteric coating layer mixed therein. Also provided are methods of making and using same.

Owner:TRIS PHARMA

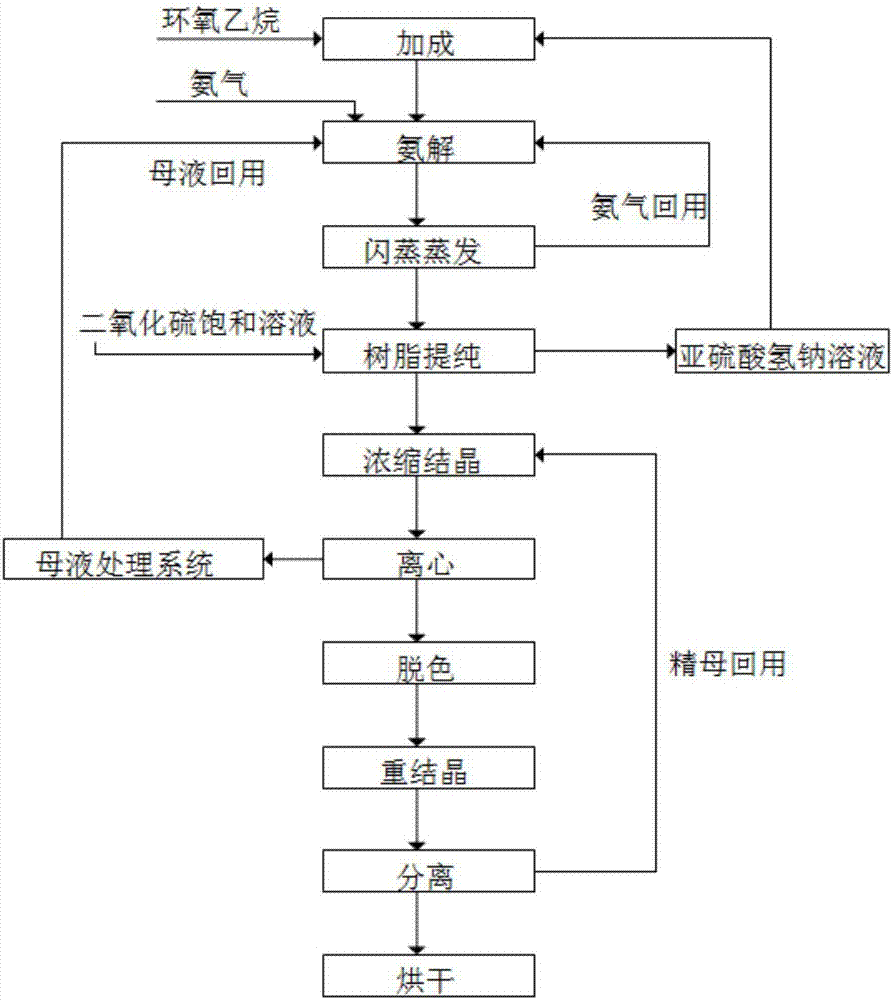

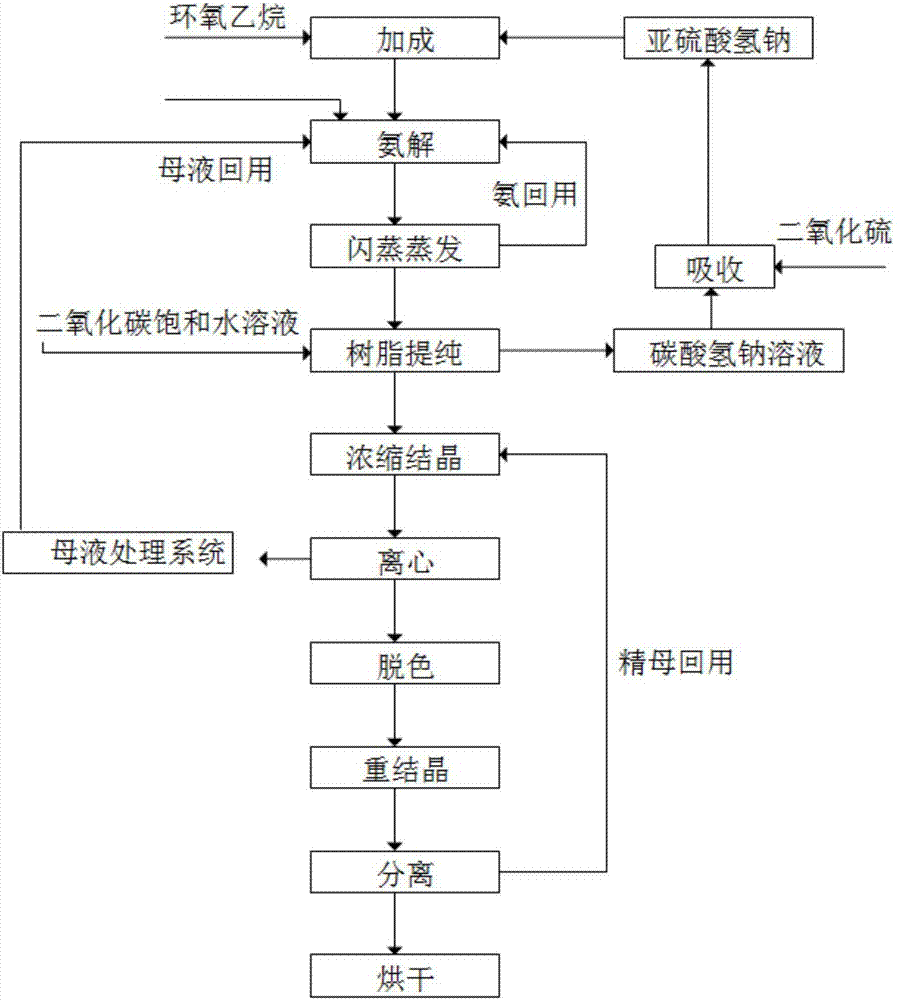

Method for cyclically producing taurine at high yield

ActiveCN107056659AReduce productionEfficient recyclingPhysical/chemical process catalystsOrganic compound preparationAfter treatmentHydrogen

The invention relates to a method for cyclically producing taurine at a high yield. The method includes the following steps that S1, ethylene oxide reacts with a sodium hydrogen sulfite solution to generate sodium hydroxyethyl sulfonate; S2, sodium hydroxyethyl sulfonate obtained in S1 is subjected to an ammonolysis reaction in ammonium hydroxide, flashing is carried out after the reaction is completed, and ammonia gas is recycled; S3, taurine-containing feed liquid of reaction liquid obtained after flashing in S2 is collected through an acid cation exchange resin column, the resin column is regenerated with a sulfur dioxide or carbon dioxide water solution after being inactivated, and eluant obtained during regeneration can be directly reused or reused after being treated with sulfur dioxide; S4, the feed liquid collected in S3 is subjected to after-treatment, and taurine is obtained. The method has the advantages that the generation amount of waste liquid in the whole process is small, part of substances are effectively and cyclically utilized in the process, the cost is reduced, the yield of taurine can reach 90% or above, meanwhile, the production process is relatively simple, and large-scale production is easy.

Owner:QIANGJIANG YONGAN PHARMA

Carbonising and/or Activating Carbonaceous Material

A method is provided for carbonizing and activating carbonaceous material, which comprises supplying the material to an externally fired rotary kiln maintained at carbonizing and activating temperatures, the kiln having a downward slope to progress the material as it rotates, the kiln having an atmosphere substantially free of oxygen provided by a counter-current of steam or carbon dioxide, and annular weirs being provided at intervals along the kiln to control progress of the material. There may further be provided an externally fired rotary kiln for carbonizing and activating carbonaceous material having a hollow rotary body that has a downward slope towards a discharge end thereof, and which is provided at intervals along its length with annular weirs for controlling progress of the carbonaceous material. In embodiments, there is also provided a process is for producing discrete solid beads of polymeric material e.g. phenolic resin beads having a mesoporous structure, which may be useful as feedstock for the above mentioned carbonization / activation process or which may have other utility e.g. as ion exchange resins. The process may produce resin beads on an industrial scale without aggregates of resin building up speedily and interrupting production. The process comprises the steps of: (a) combining a stream of a polymerizable liquid precursor e.g. a novolac and hexamine as cross-linking agent dissolved in a first polar organic liquid e.g. ethylene glycol with a stream of a liquid suspension medium which is a second non-polar organic liquid with which the liquid precursor is substantially or completely immiscible e.g. transformer oil containing a drying oil; (b) mixing the combined stream to disperse the polymerizable liquid precursor as droplets in the suspension medium e.g. using an in-line static mixer; (c) allowing the droplets to polymerise in a laminar flow of the suspension medium so as to form discrete solid beads that cannot agglomerate; and (d) recovering the beads from the suspension medium. There is also provided apparatus for forming discrete solid beads of polymeric material, said apparatus comprising: a first line for conveying s stream of a polymerizable liquid precursor; a second line for conveying a stream of a dispersion medium with which the polymerizable liquid precursor is substantially or completely immiscible; an in-line mixer configured to receive a combined flow from the first and second lines and to disperse the polymerizable liquid precursor as droplets in the dispersion medium; a vertical polymerization column configured to receive the dispersion medium with the droplets dispersed therein and to permit the polymerizable liquid precursor polymerize while descending the column in a descending flow of polymerization medium; and a vessel at the base of the column for receiving the descending flow of dispersion medium and collecting polymerized solid beads.

Owner:BRITISH AMERICAN TOBACCO (INVESTMENTS) LTD

Process for synthesizing weakly alkaline anionic exchange resin with double functions and superhigh cross-linking

A series of ultrahigh-cross-linked weakly alkaline-anionic exchange resin with both adsorption and exchange functions, which has different specific surface areas and exchange capacities, is prepared from low-cross-linked macroporous polystyrene through chloromethylation, cross-linking reaction, where the nitrobenzene or substituted nitrobenzene is used as solvent and the Lewis acid is used as catalyst, and amination by dimethylamine.

Owner:南京大学环境学院

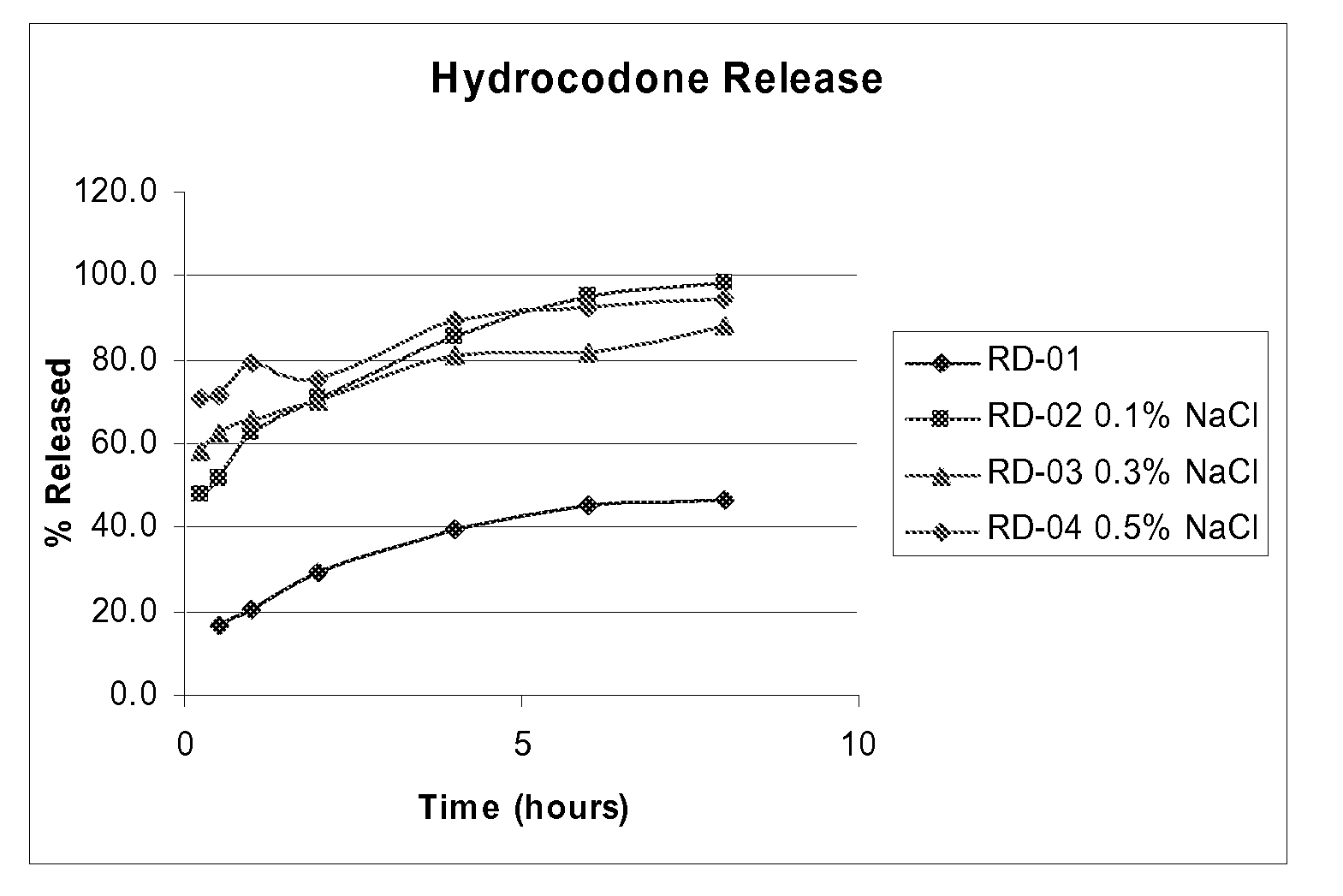

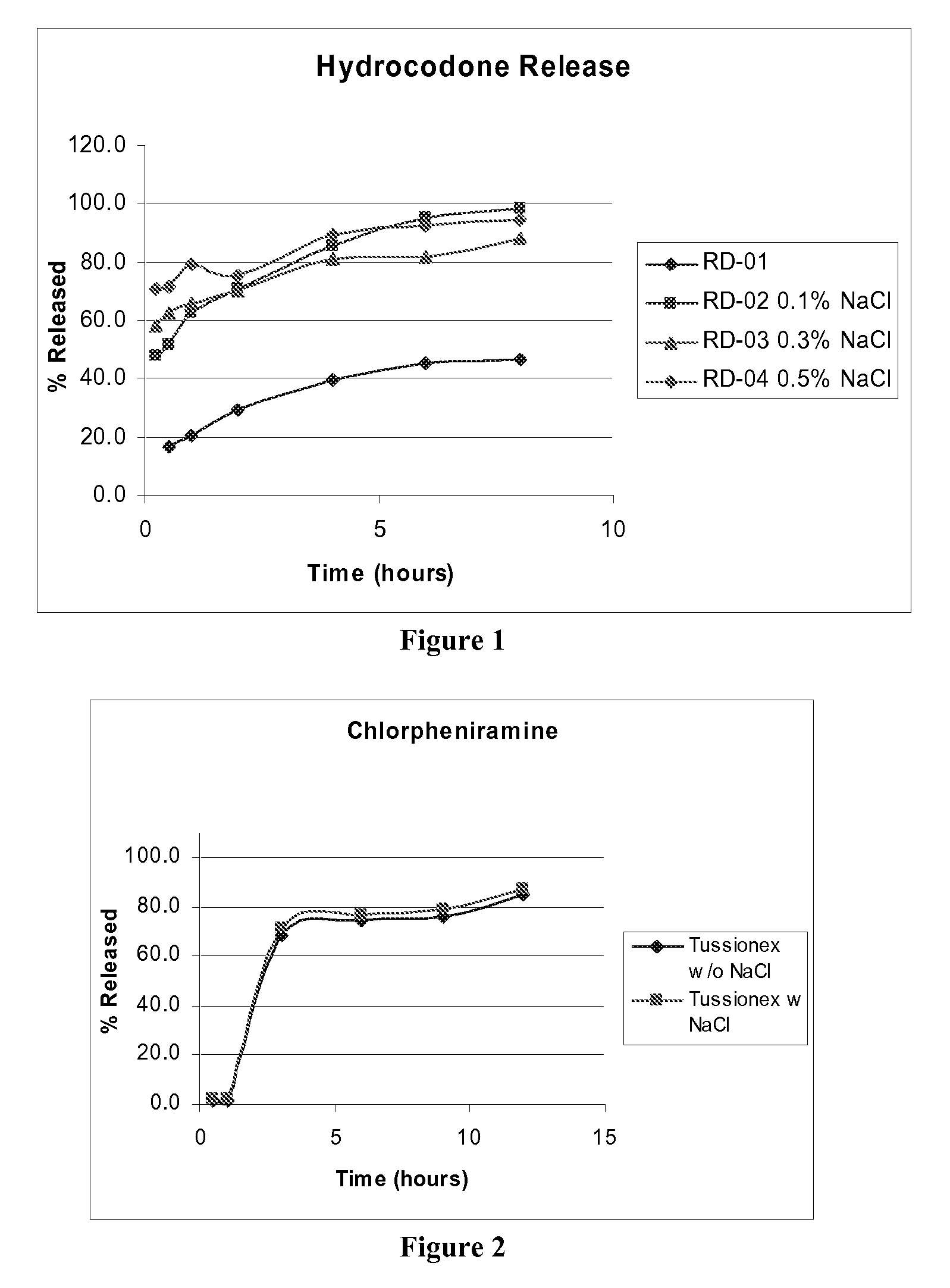

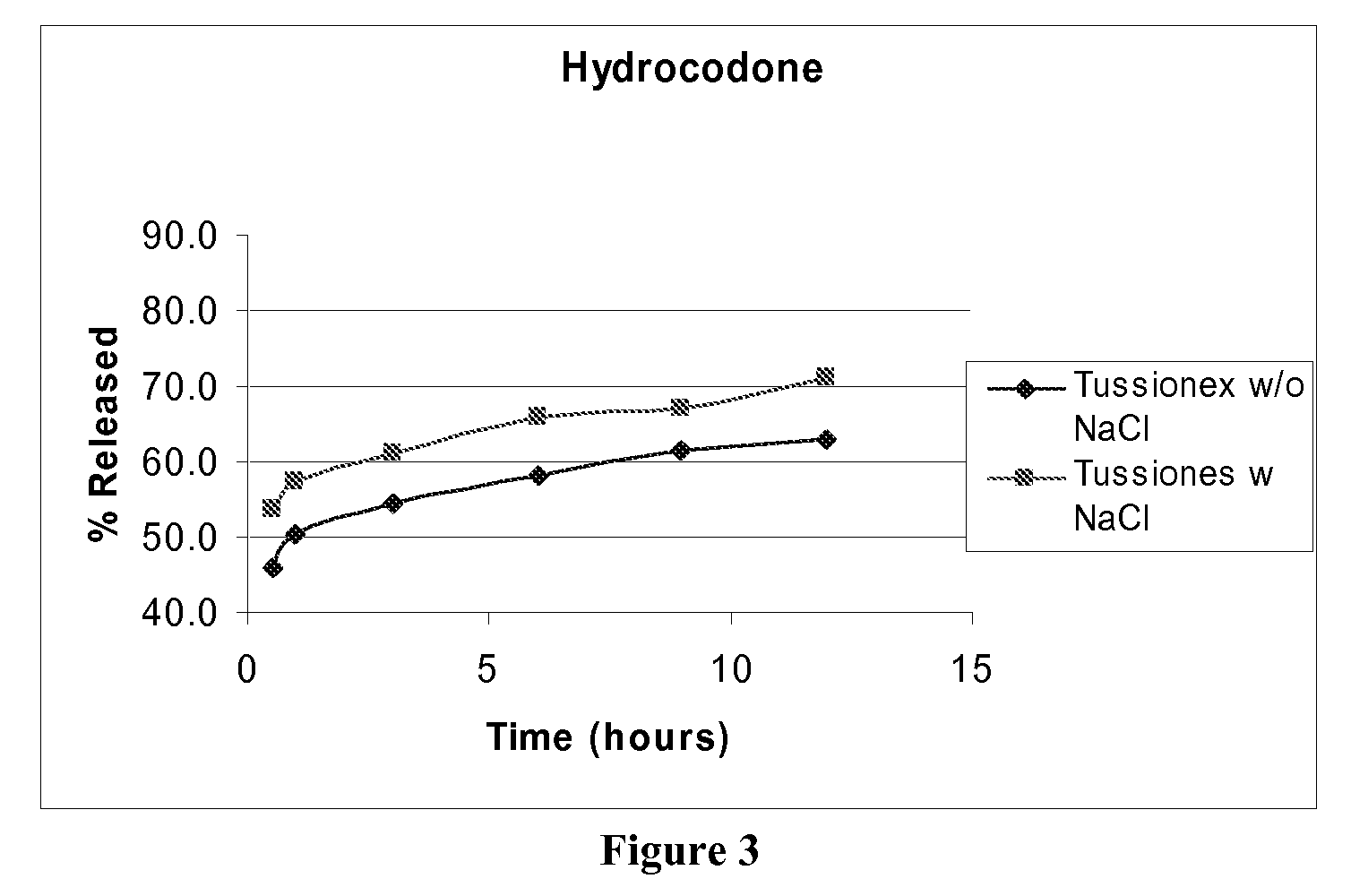

Modifying Drug Release in Suspensions of Ionic Resin Systems

ActiveUS20090011027A1Improve consistencyReduce releasePowder deliveryDispersion deliveryActive agentDrug release

The present invention includes compositions and methods for delivering one or more unit dosage units by modifying the release profile of an optionally coated drug-resin complex suspended in an ionic salt solution, wherein the optionally coated drug-resin complex includes one or more active agents loaded on to one or more ion-exchange resin particles, and wherein the release of the one or more active agents is modulated by the one or more ionic salts in solution.

Owner:NEOS THERAPEUTICS LP

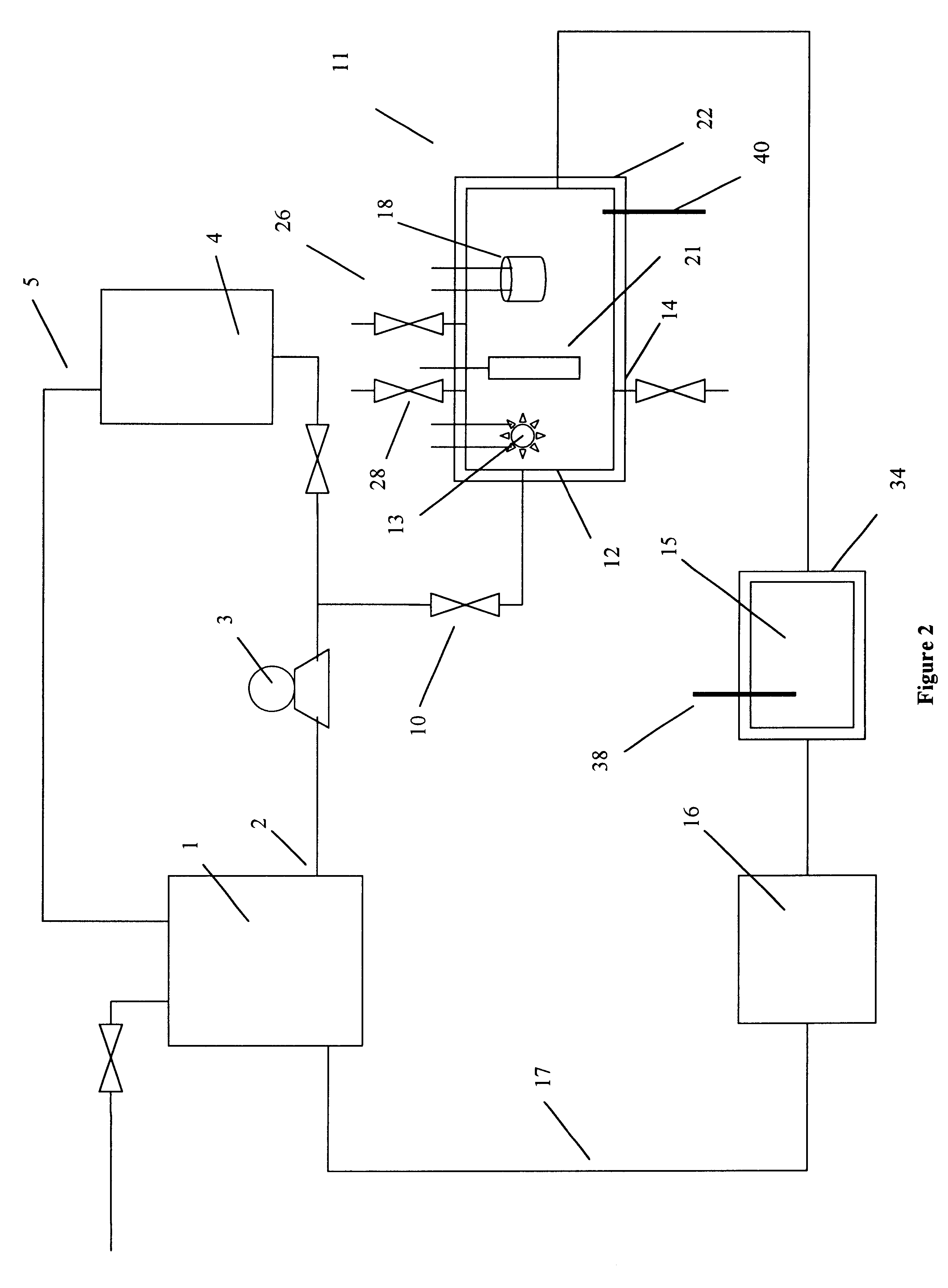

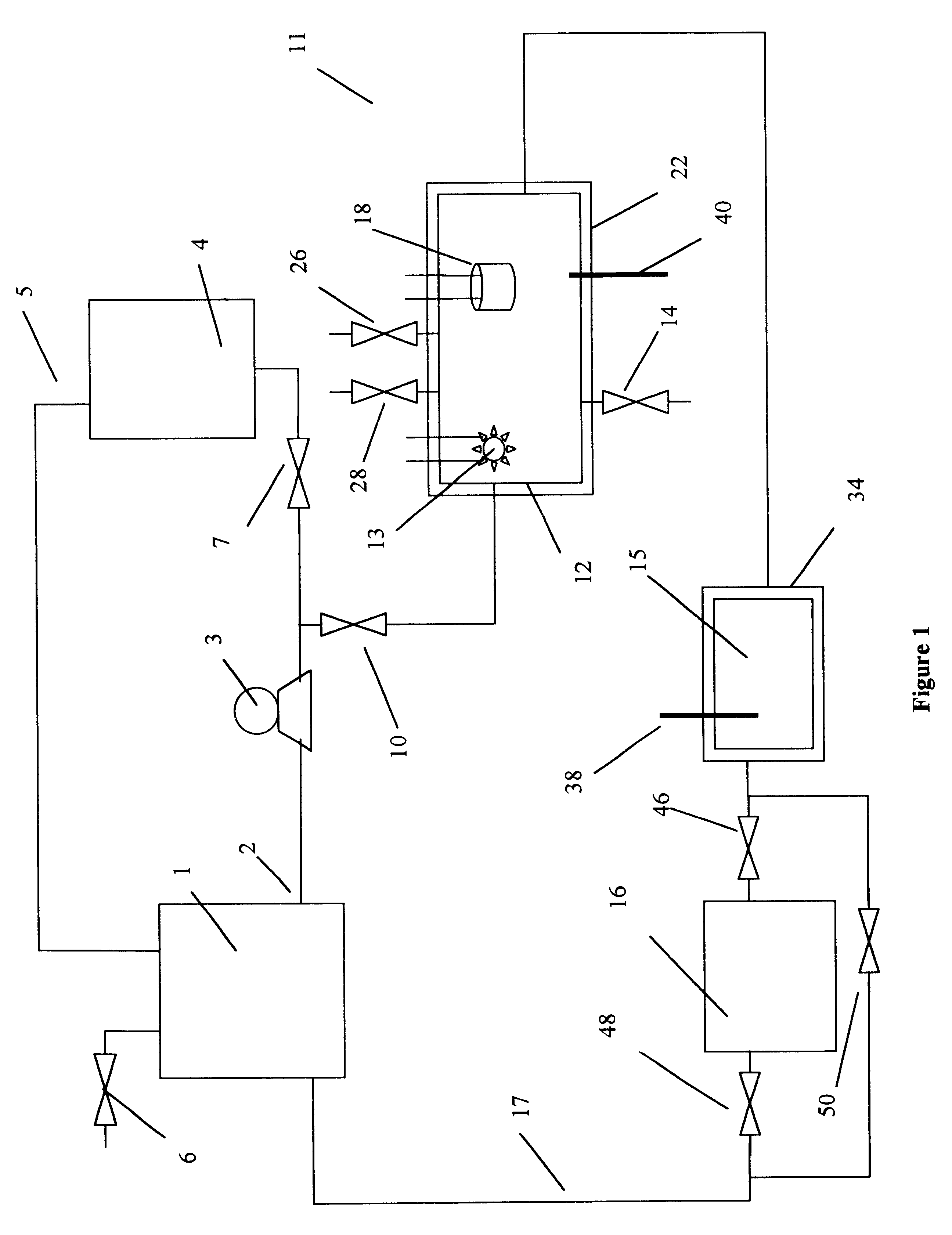

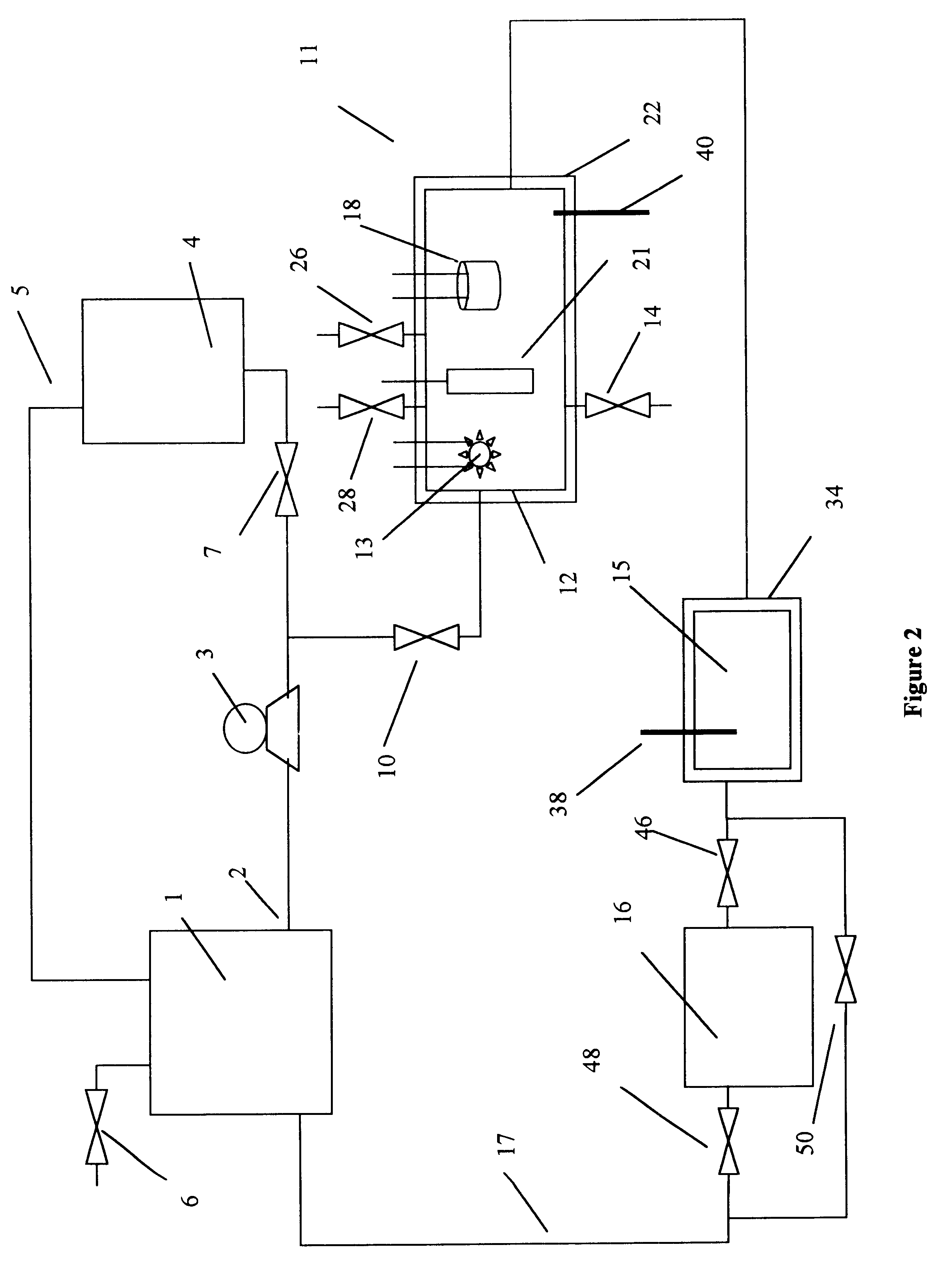

Regeneration of plating baths and system therefore

InactiveUS6596148B1Maximize gasLower Level RequirementsDialysis systemsCell componentsParticulatesFiltration

The present invention provides a system and method for selectively removing one or more organic and also preferably one or more inorganic contaminants from plating baths. More particularly, the invented method relates to the use of a source of energy in combination with chemical oxidants, alone or in conjunction with a catalyst to oxidize organic contaminants in the plating bath to a level such that the electroplating bath can be recovered and reused after appropriate chemical adjustment. The oxidative treatment method may be a continuous process or a batch process that is performed in a single pass and the endpoint of the oxidative process detected by a sensor. Residual organics, if desired, and chloride ions in the bath are removed from the solution by a chemisorption or physisorption treatment. Inorganic contaminants are removed from the electroplating bath by selective ion exchange resins or electrodialysis, while particulate and suspended colloidal particles are removed by filtration before the treated plating bath is recycled.

Owner:ENTEGRIS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com