Patents

Literature

195results about How to "Improved resistance characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

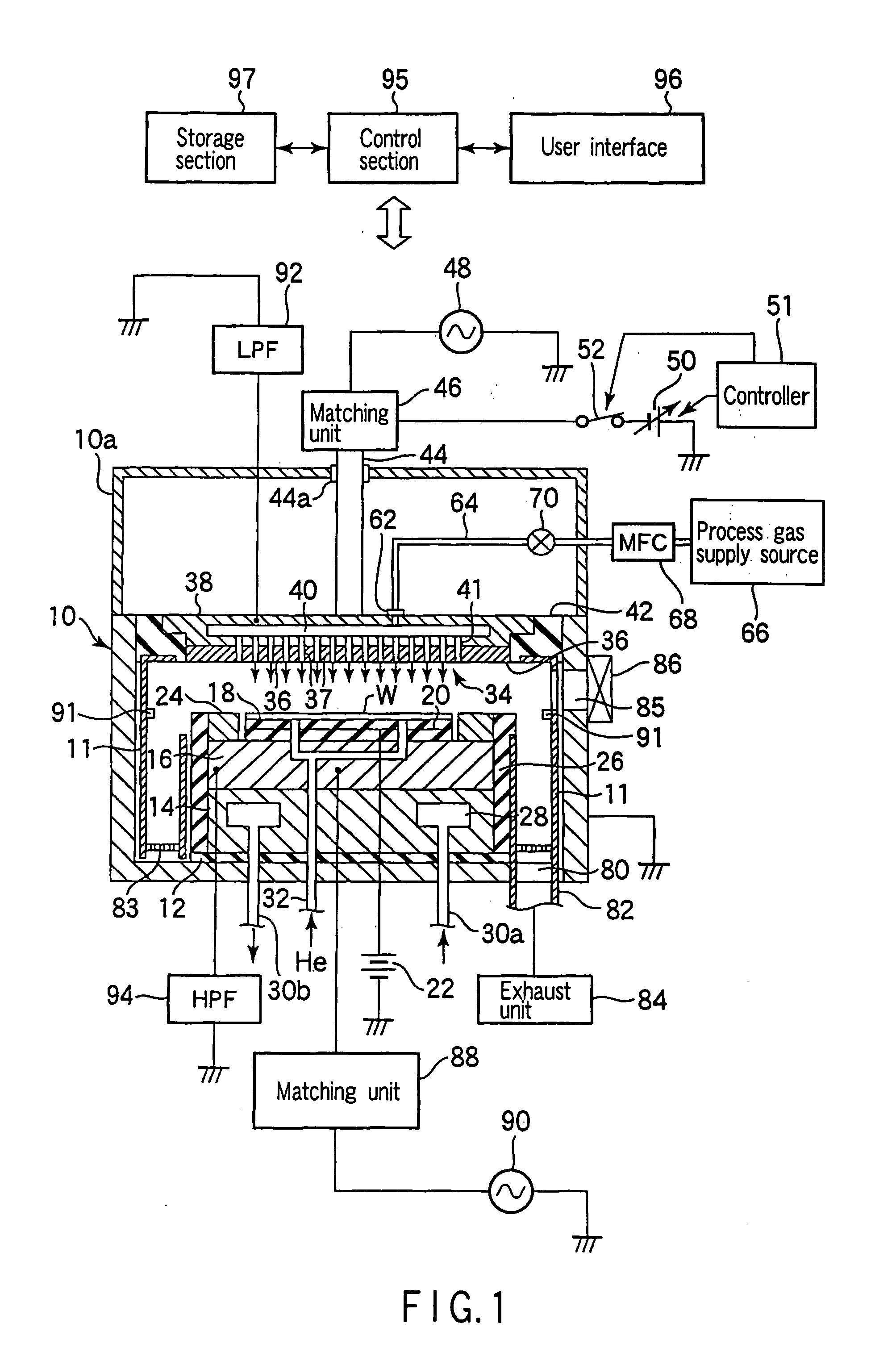

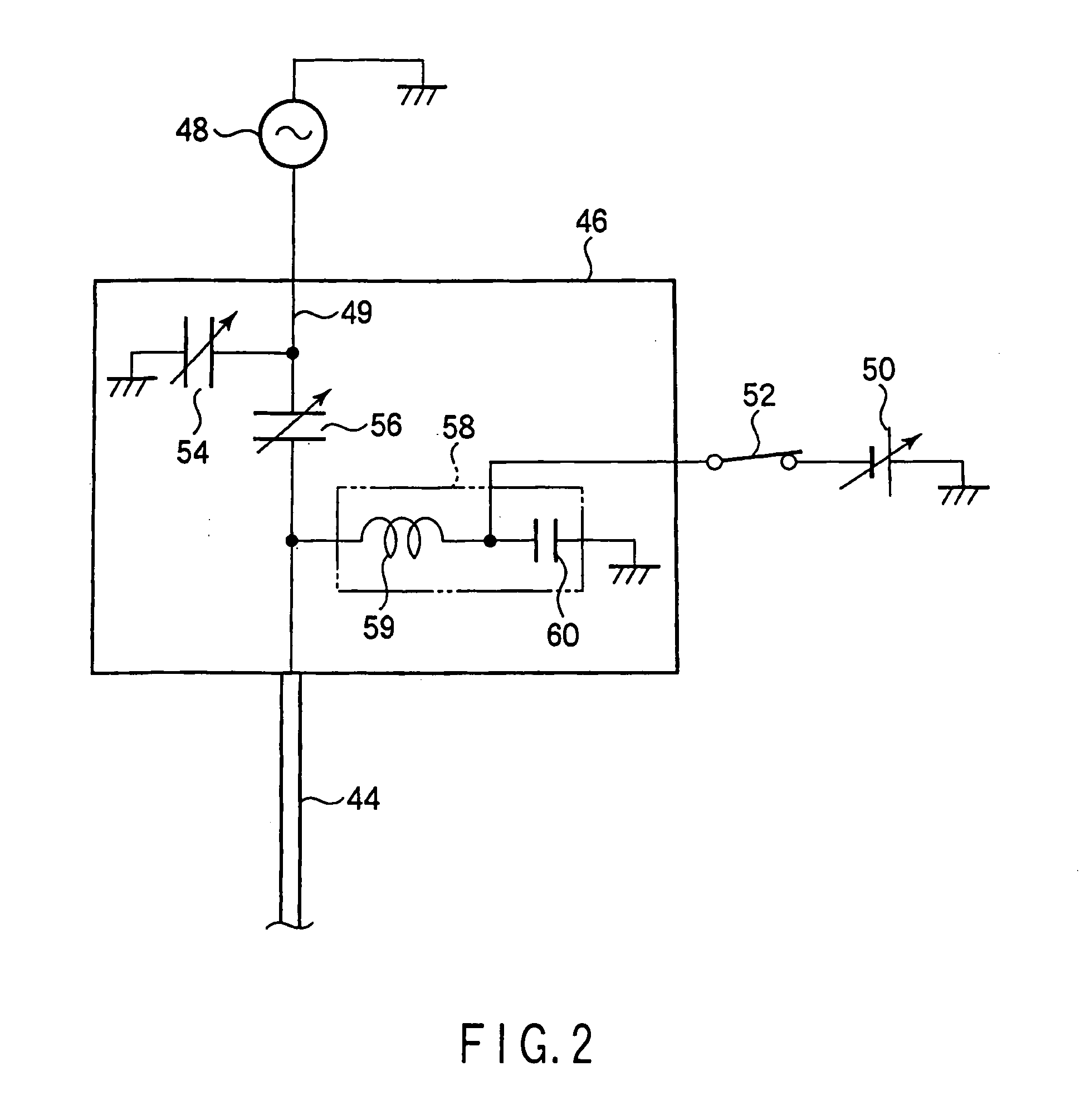

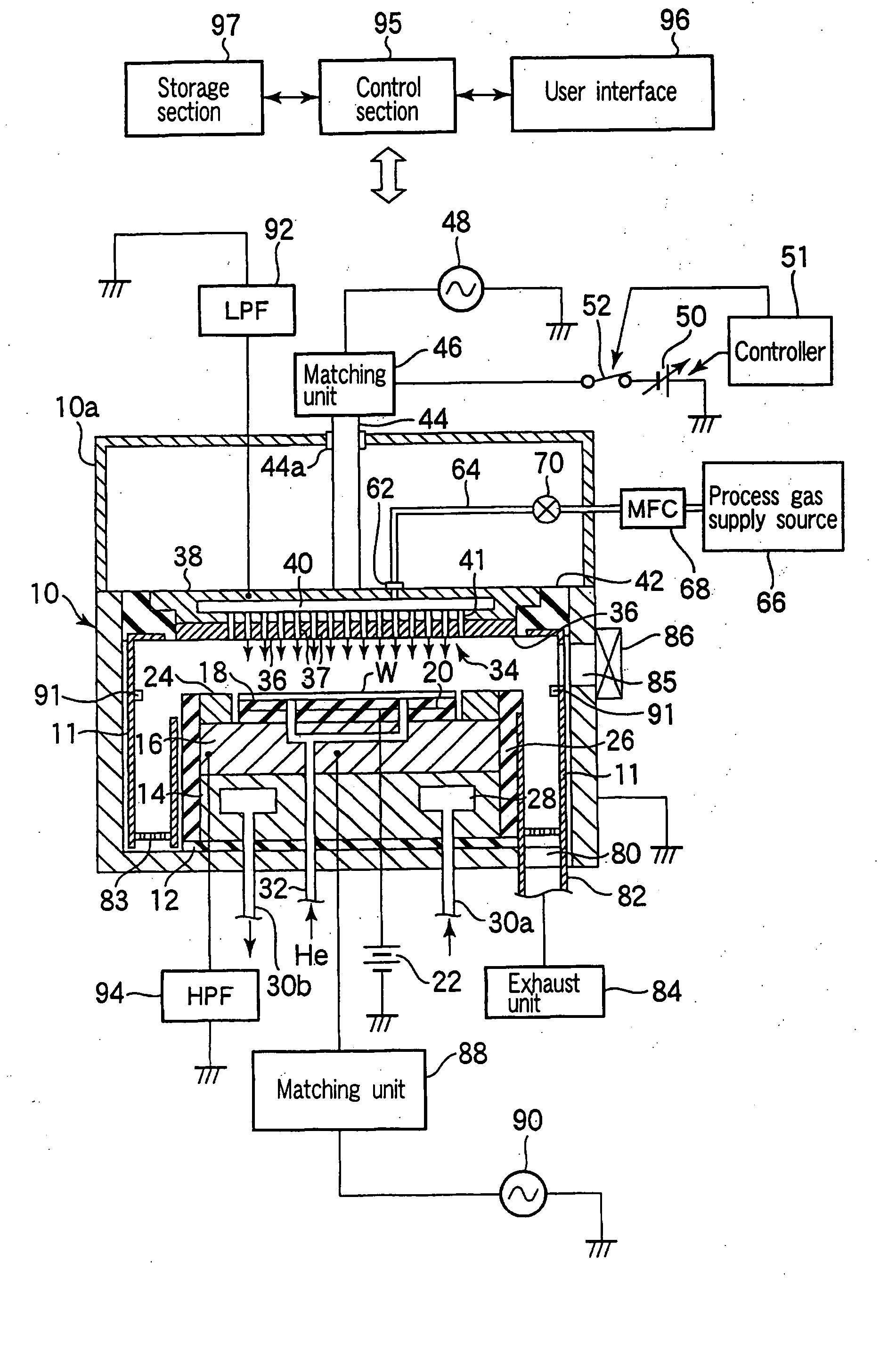

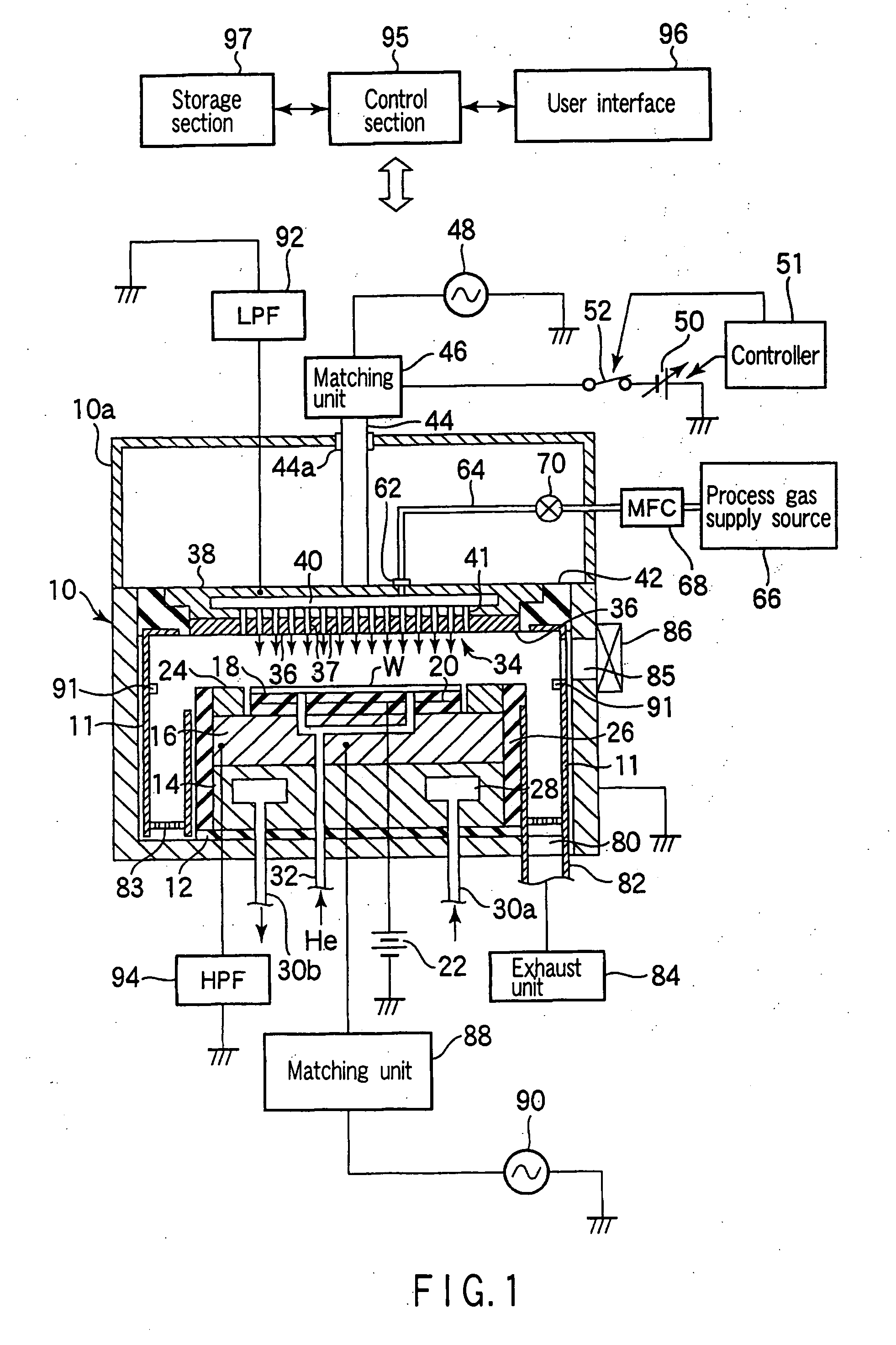

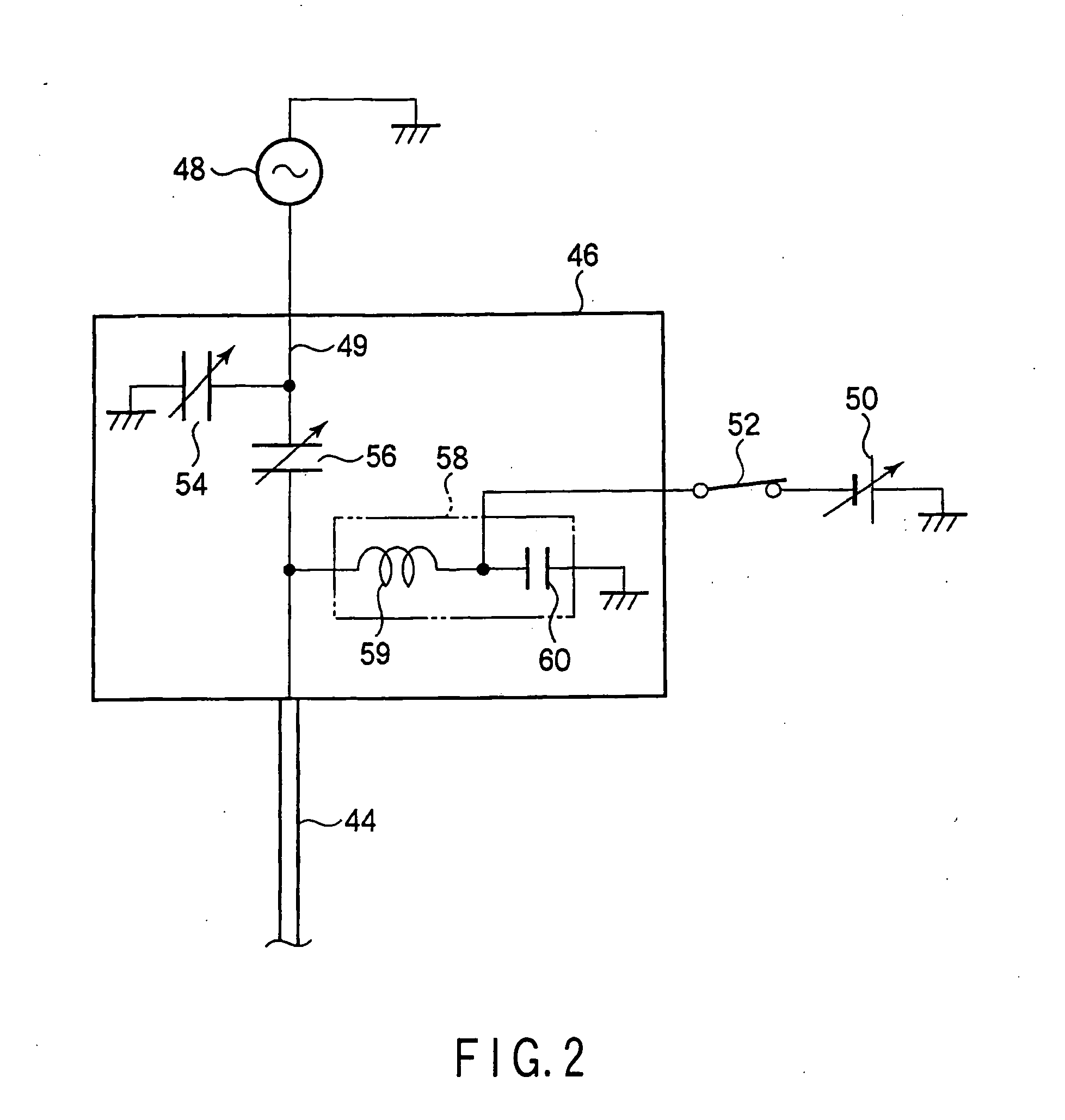

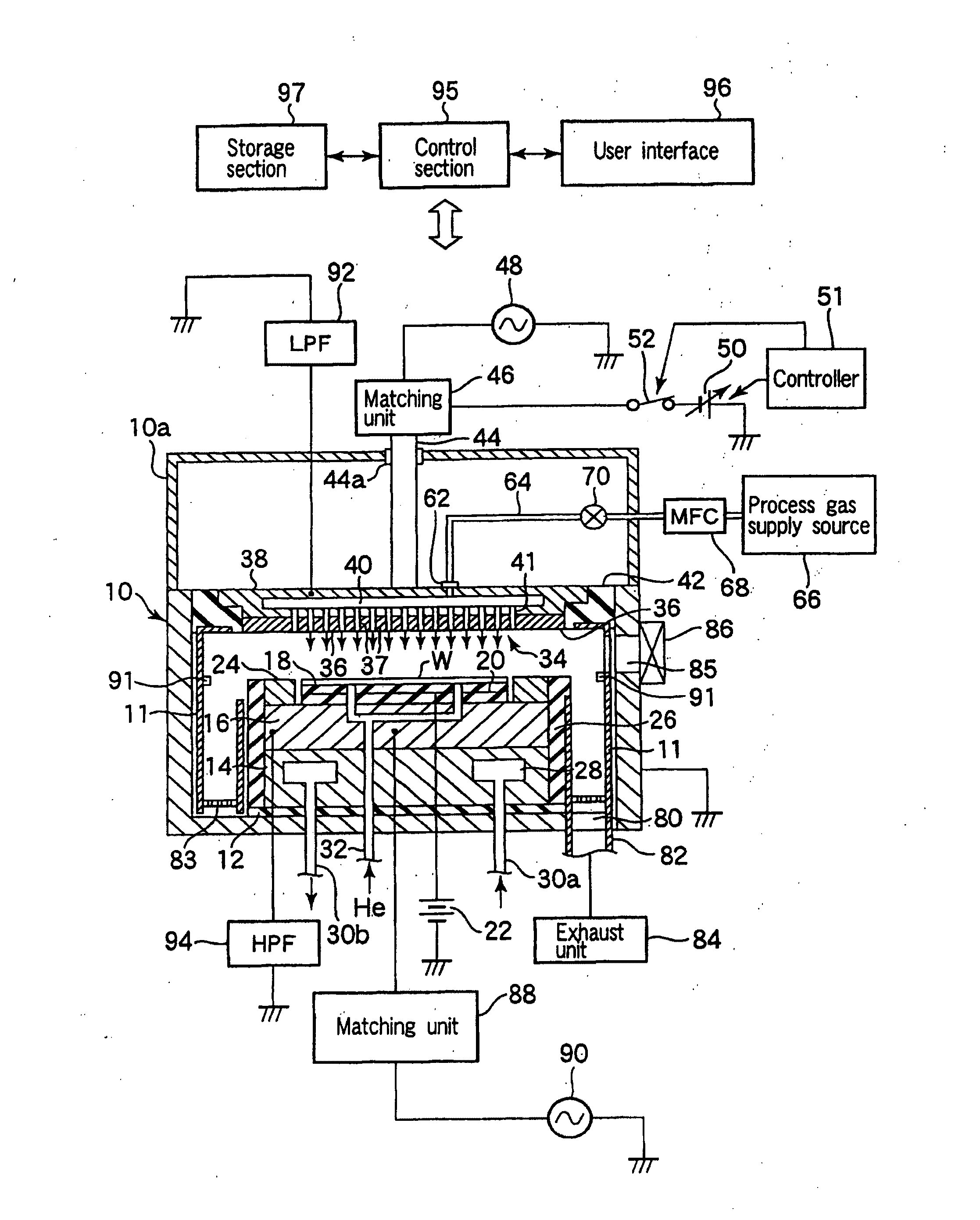

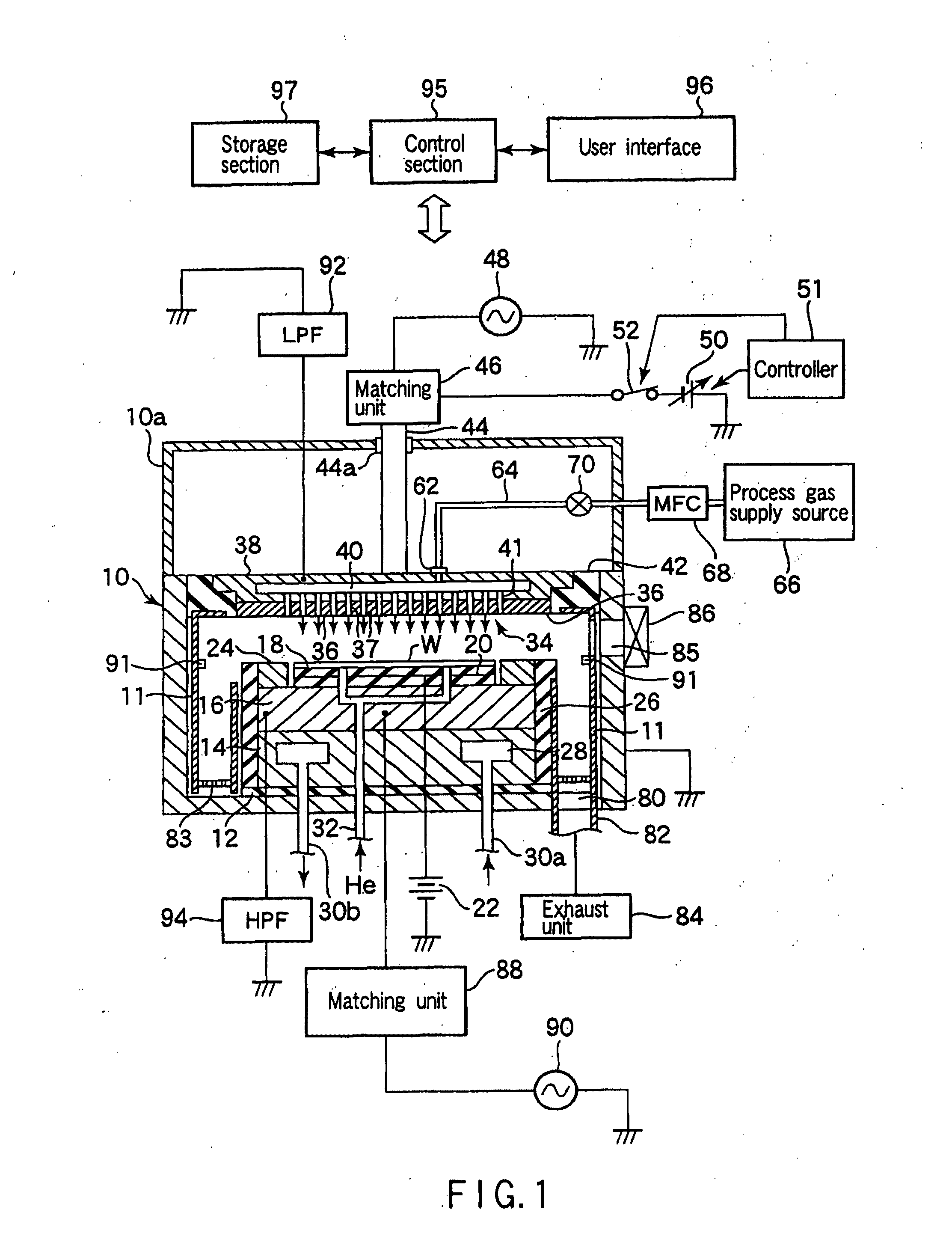

Plasma processing apparatus and method

ActiveUS7951262B2Improved resistance characteristicsIncrease chanceElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringPlasma processing

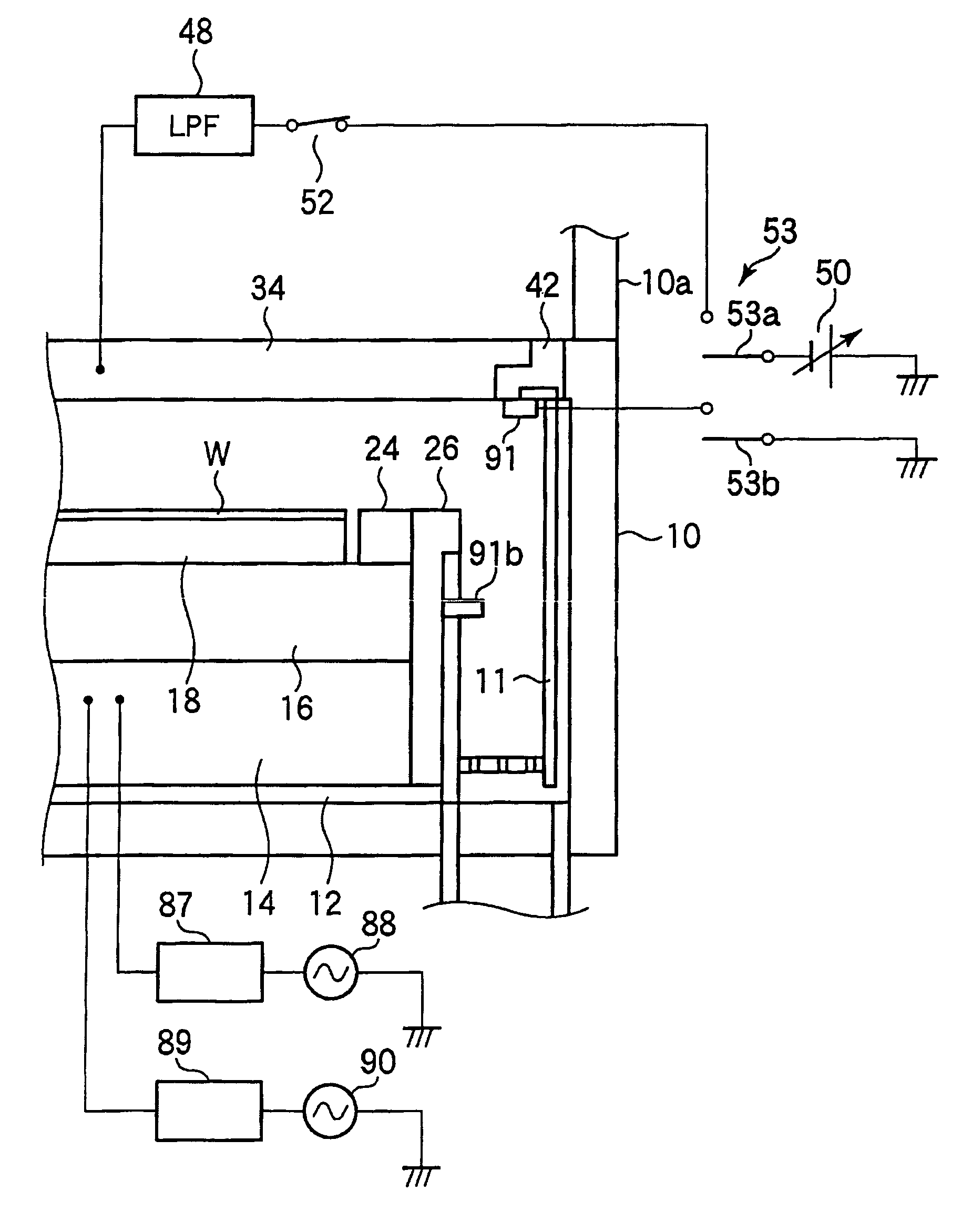

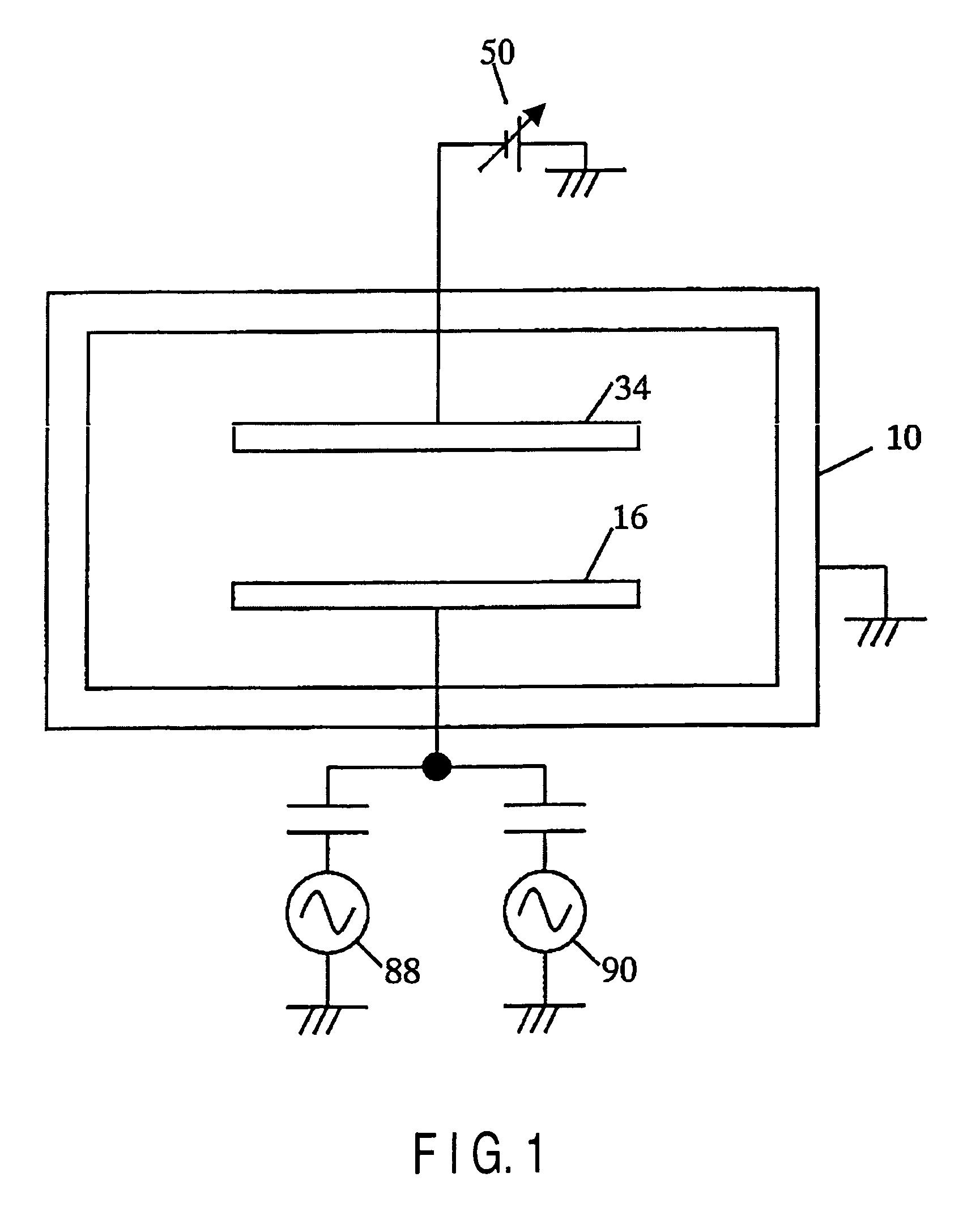

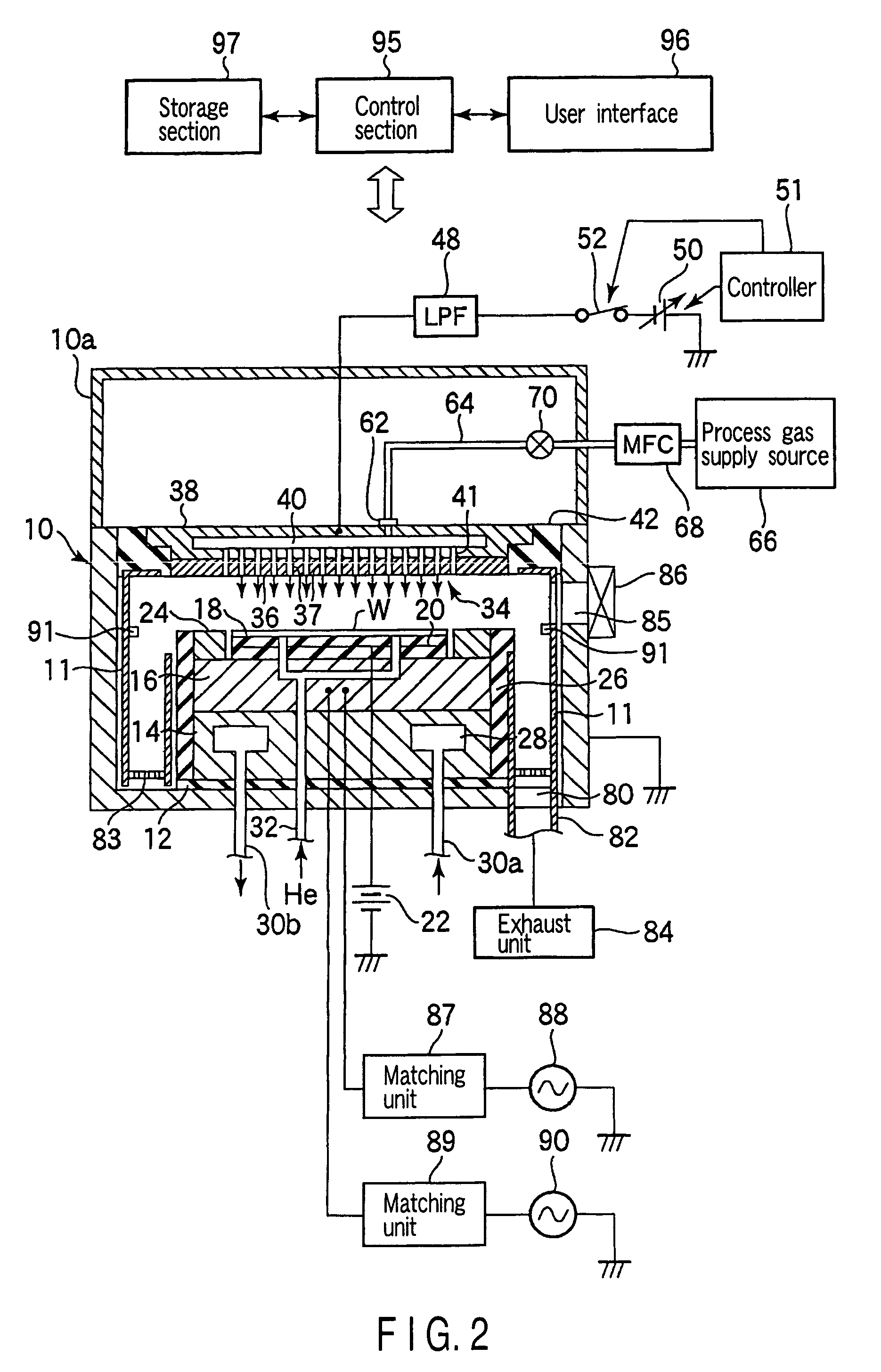

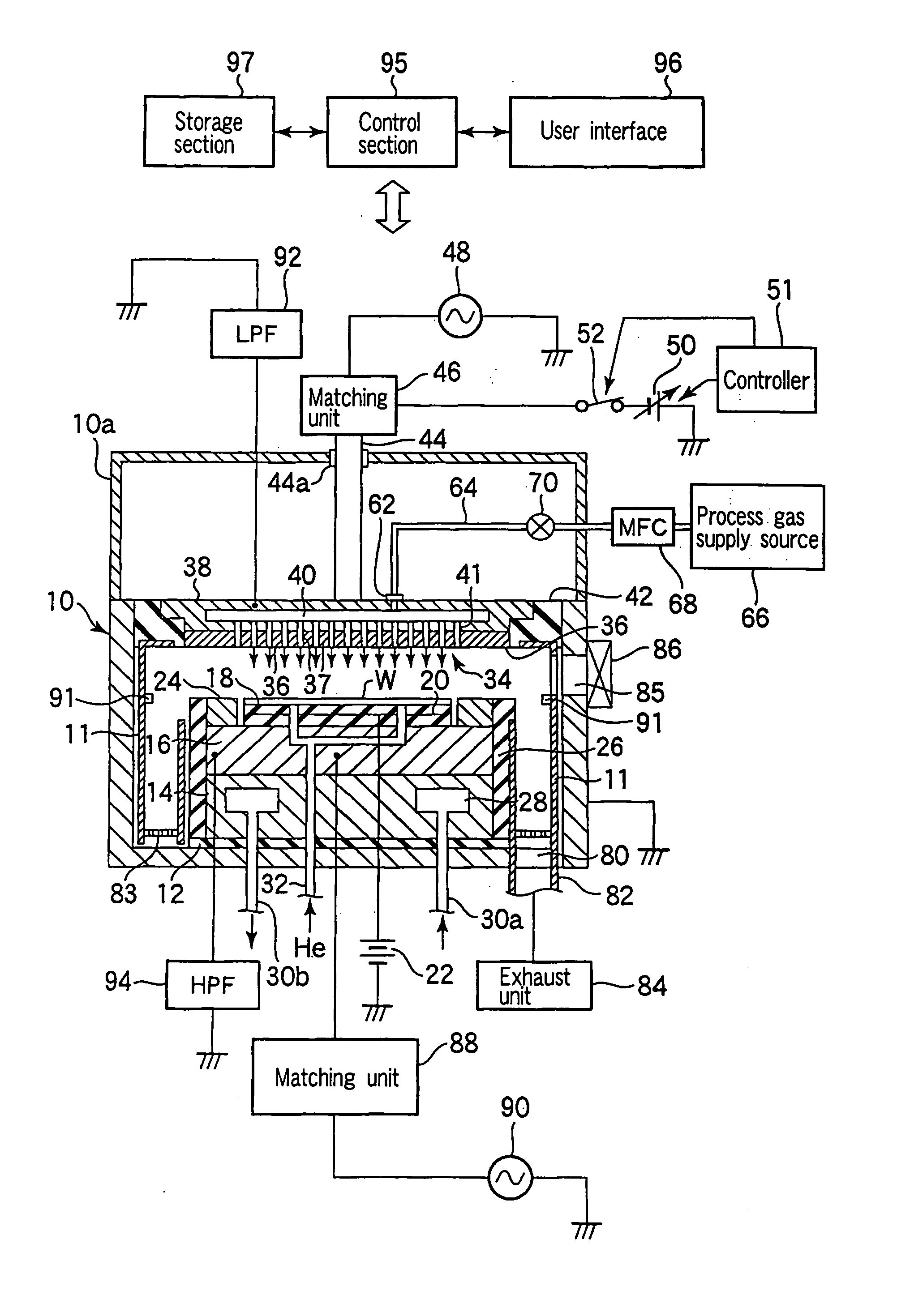

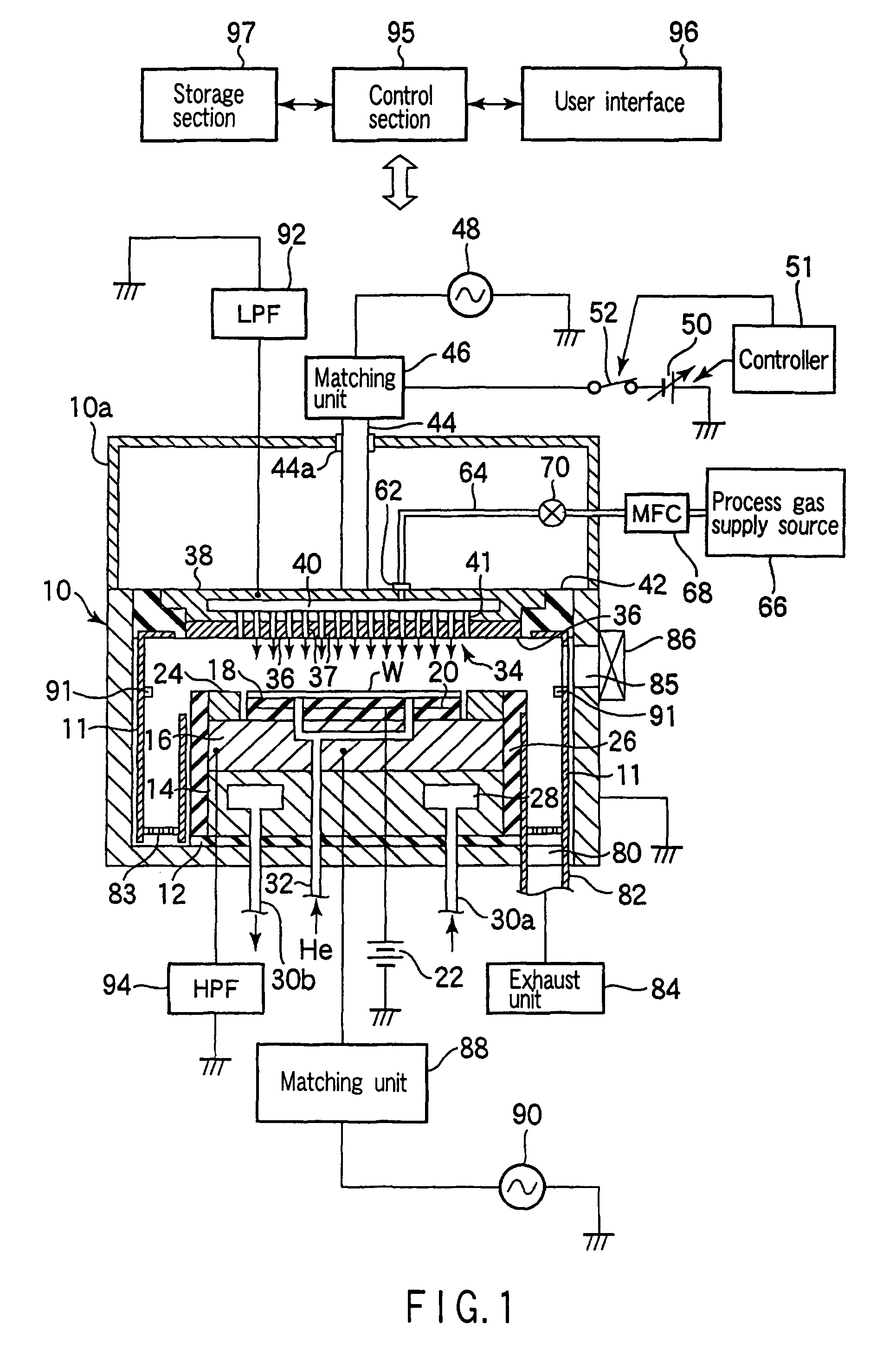

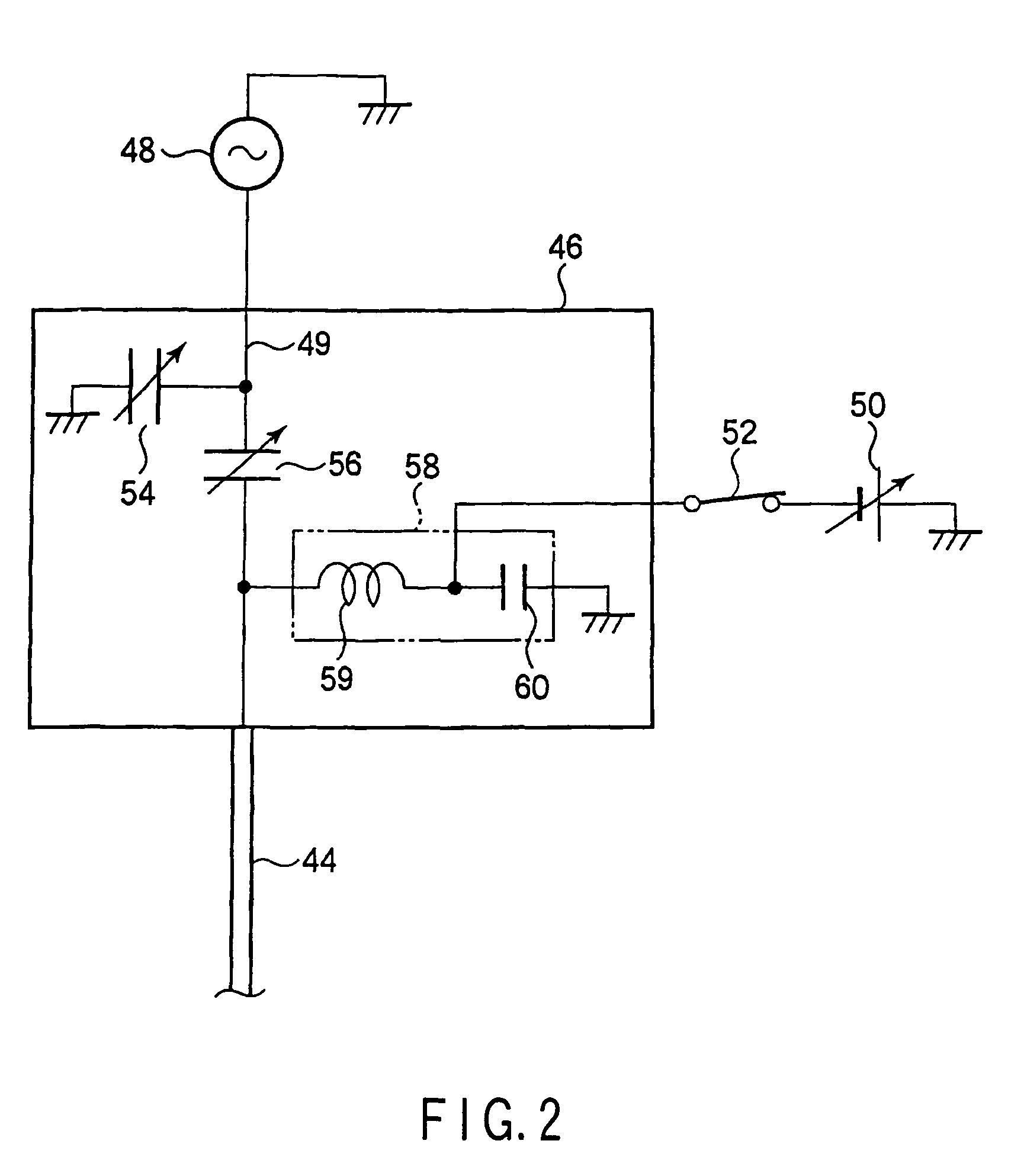

An apparatus includes an upper electrode and a lower electrode for supporting a wafer disposed opposite each other within a process chamber. A first RF power supply configured to apply a first RF power having a relatively higher frequency, and a second RF power supply configured to apply a second RF power having a relatively lower frequency is connected to the lower electrode. A variable DC power supply is connected to the upper electrode. A process gas is supplied into the process chamber to generate plasma of the process gas so as to perform plasma etching.

Owner:TOKYO ELECTRON LTD

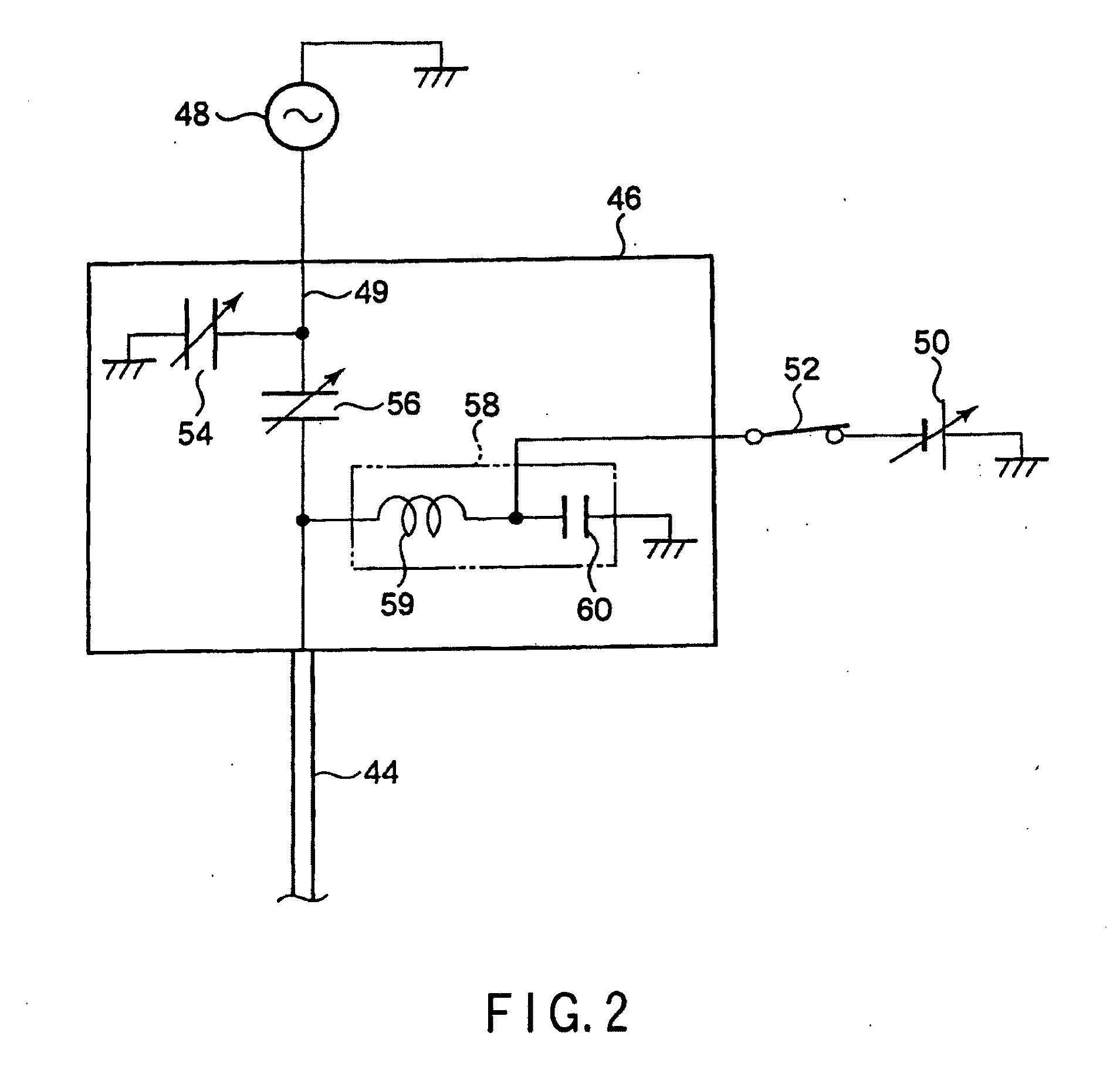

Plasma processing apparatus and method

ActiveUS20060037701A1High selectivity etchHigh rateElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma processingPower flow

An apparatus includes an upper electrode and a lower electrode for supporting a wafer disposed opposite each other within a process chamber. A first RF power supply configured to apply a first RF power having a relatively higher frequency is connected to the upper electrode. A second RF power supply configured to apply a second RF power having a relatively lower frequency is connected to the lower electrode. A variable DC power supply is connected to the upper electrode. A process gas is supplied into the process chamber while any one of application voltage, application current, and application power from the variable DC power supply to the upper electrode is controlled, to generate plasma of the process gas so as to perform plasma etching.

Owner:TOKYO ELECTRON LTD

Plasma processing apparatus and method

ActiveUS20060066247A1Improved resistance characteristicsIncrease chanceElectric discharge tubesSemiconductor/solid-state device manufacturingDc voltagePlasma processing

A plasma etching apparatus includes an upper electrode and a lower electrode, between which plasma of a process gas is generated to perform plasma etching on a wafer W. The apparatus further comprises a variable DC power supply to apply a DC voltage to the upper electrode, so as to cause the absolute value of a self-bias voltage on the surface thereof to be large enough to obtain a suitable sputtering effect on the surface, and to increase the plasma sheath length on the upper electrode side to generate predetermined pressed plasma.

Owner:TOKYO ELECTRON LTD

High temperature glass fiber insulation

Owner:GLASS

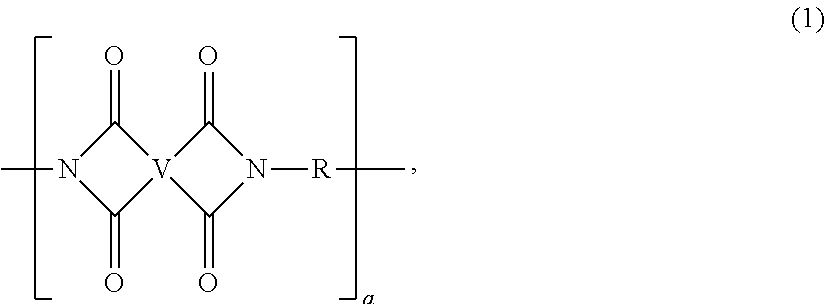

Abuse resistant opioid drug-ion exchange resin complexes having hybrid coatings

InactiveUS20120148672A1Improved resistance characteristicsPowder deliveryNervous disorderMedicineIon-exchange resin

A sustained release formulation for opioid drugs is described. The formulation contains an opioid-ion exchange resin complex having a hybrid coating. The hybrid coating contains a cured polyvinylacetate polymer and a pH-dependent enteric coating layer mixed therein. Also provided are methods of making and using same.

Owner:TRIS PHARMA

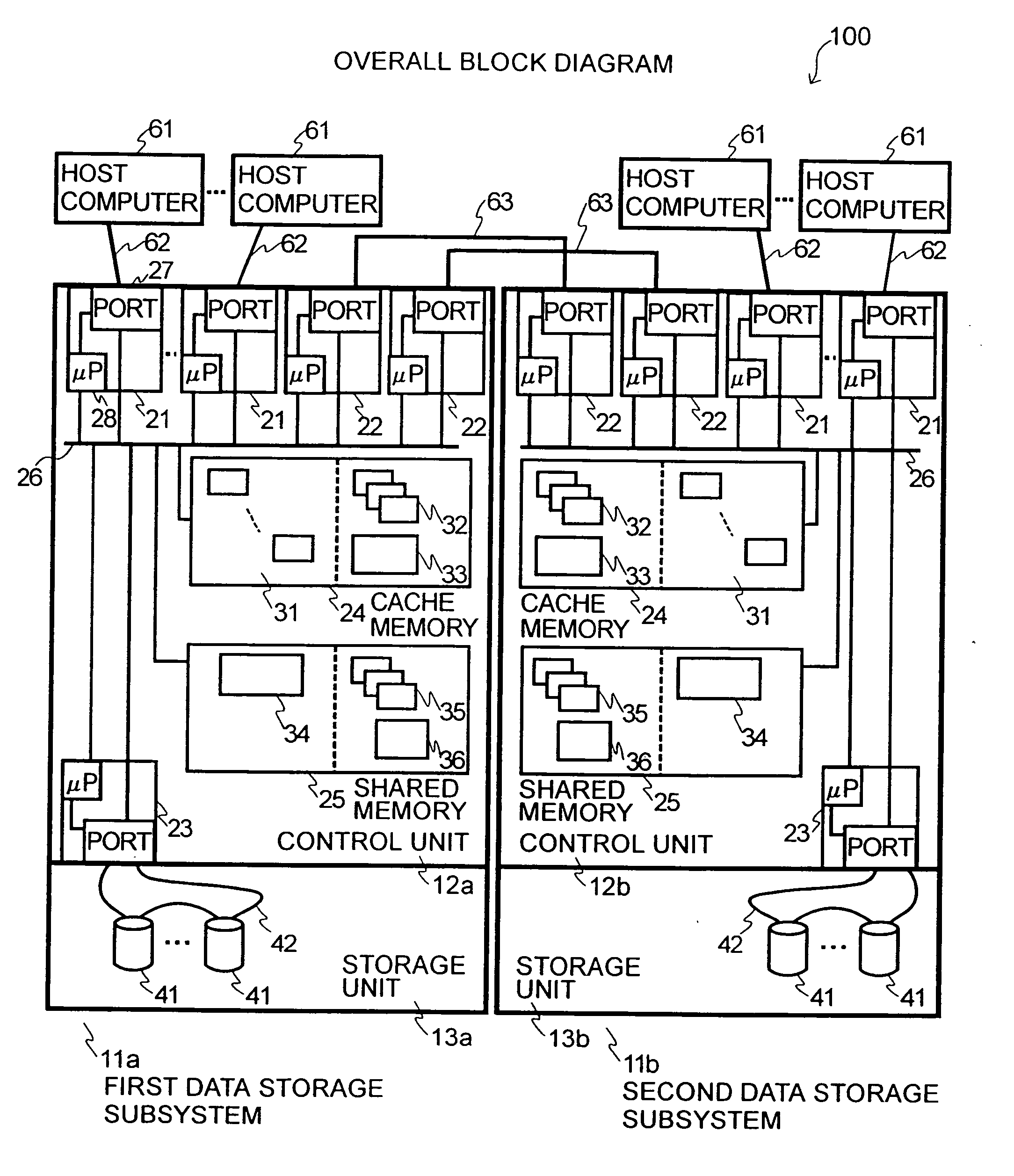

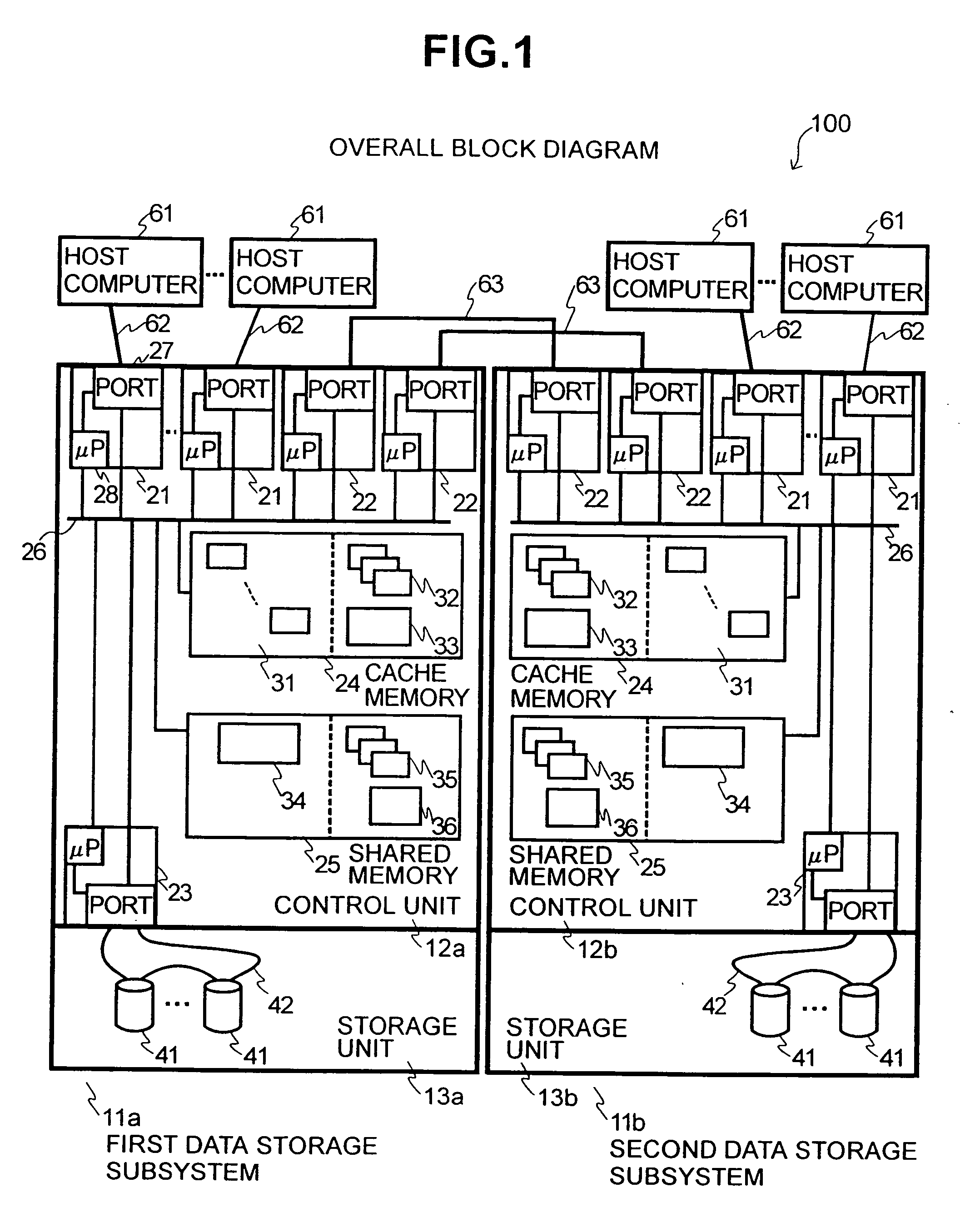

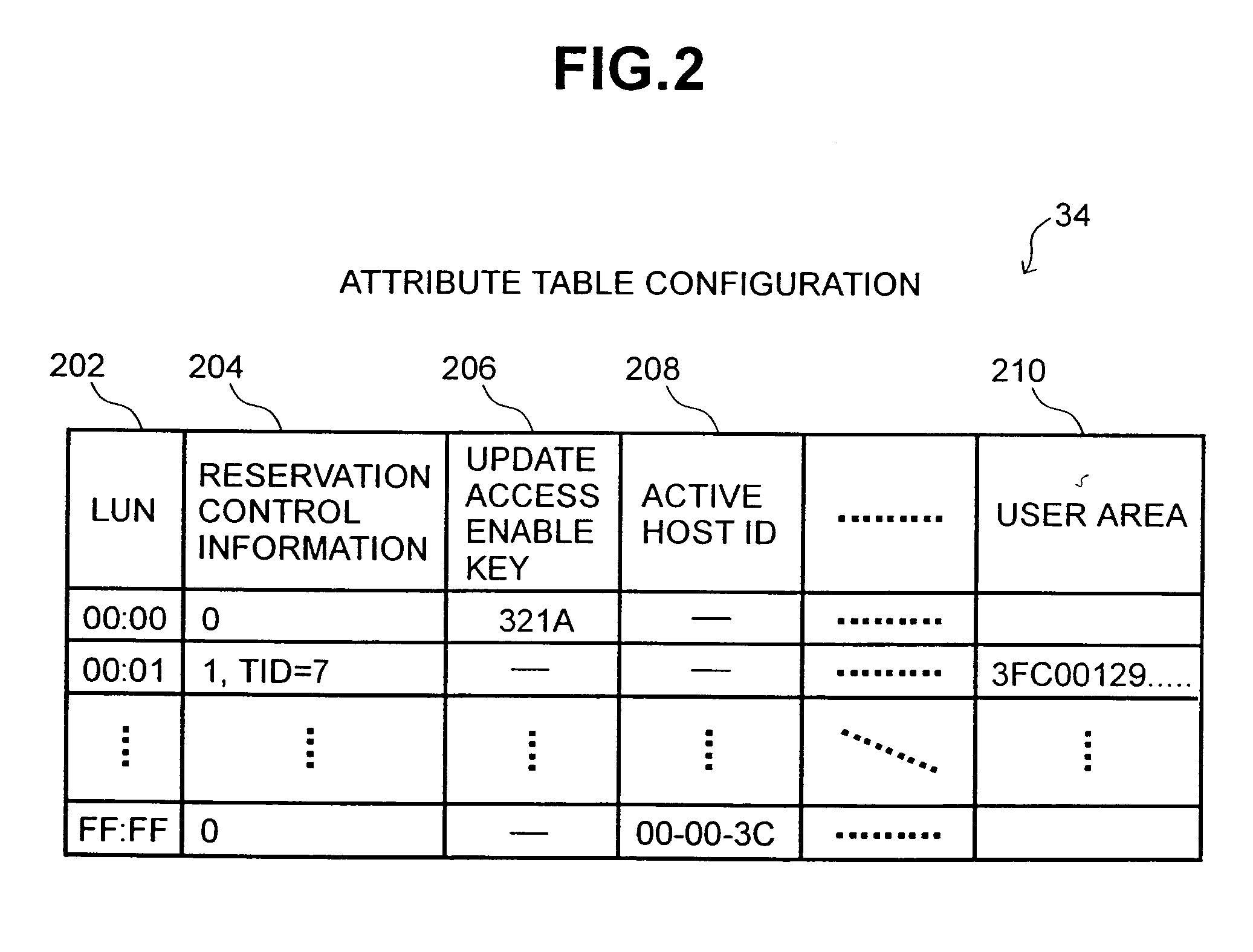

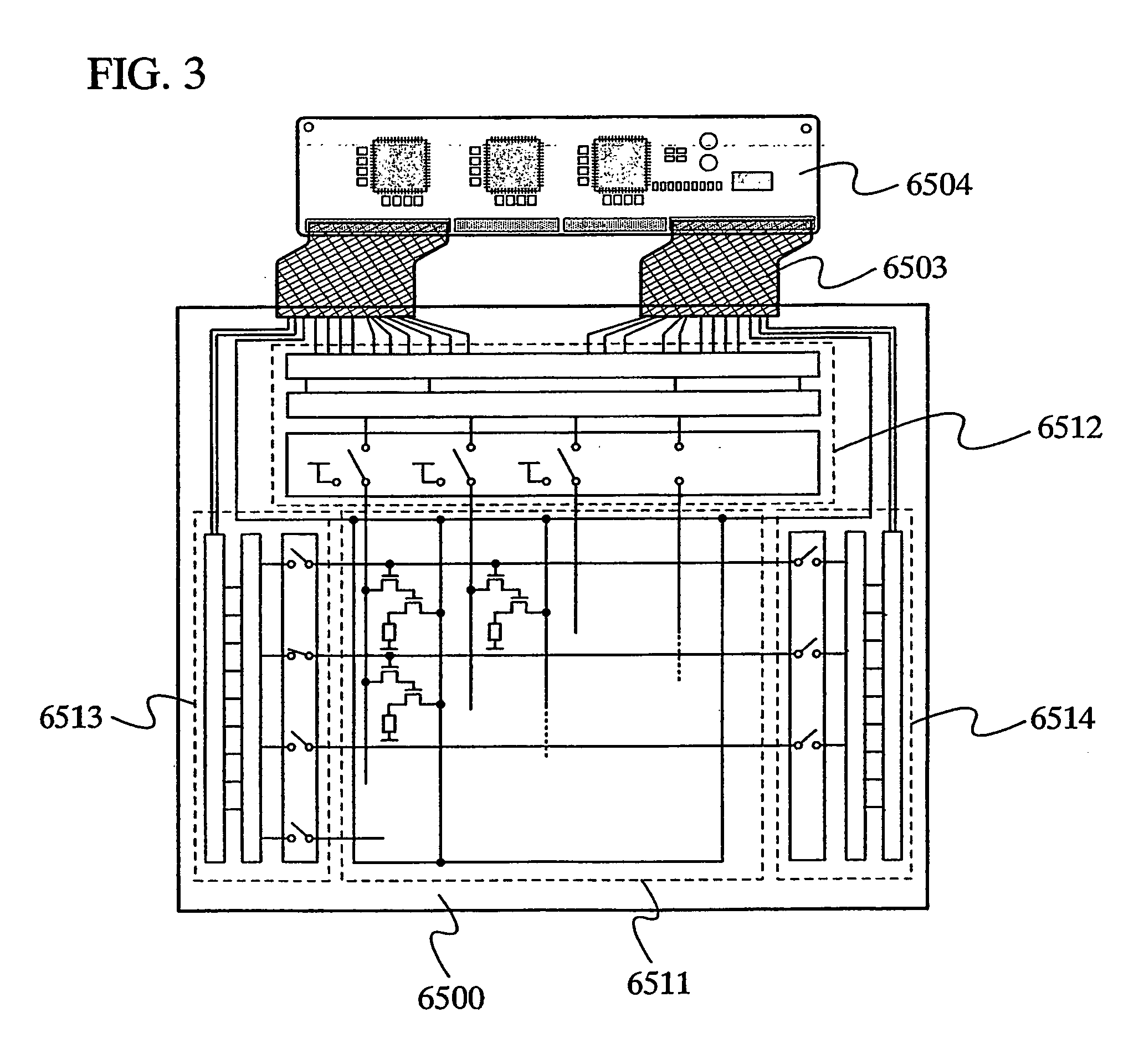

Data storage subsystem

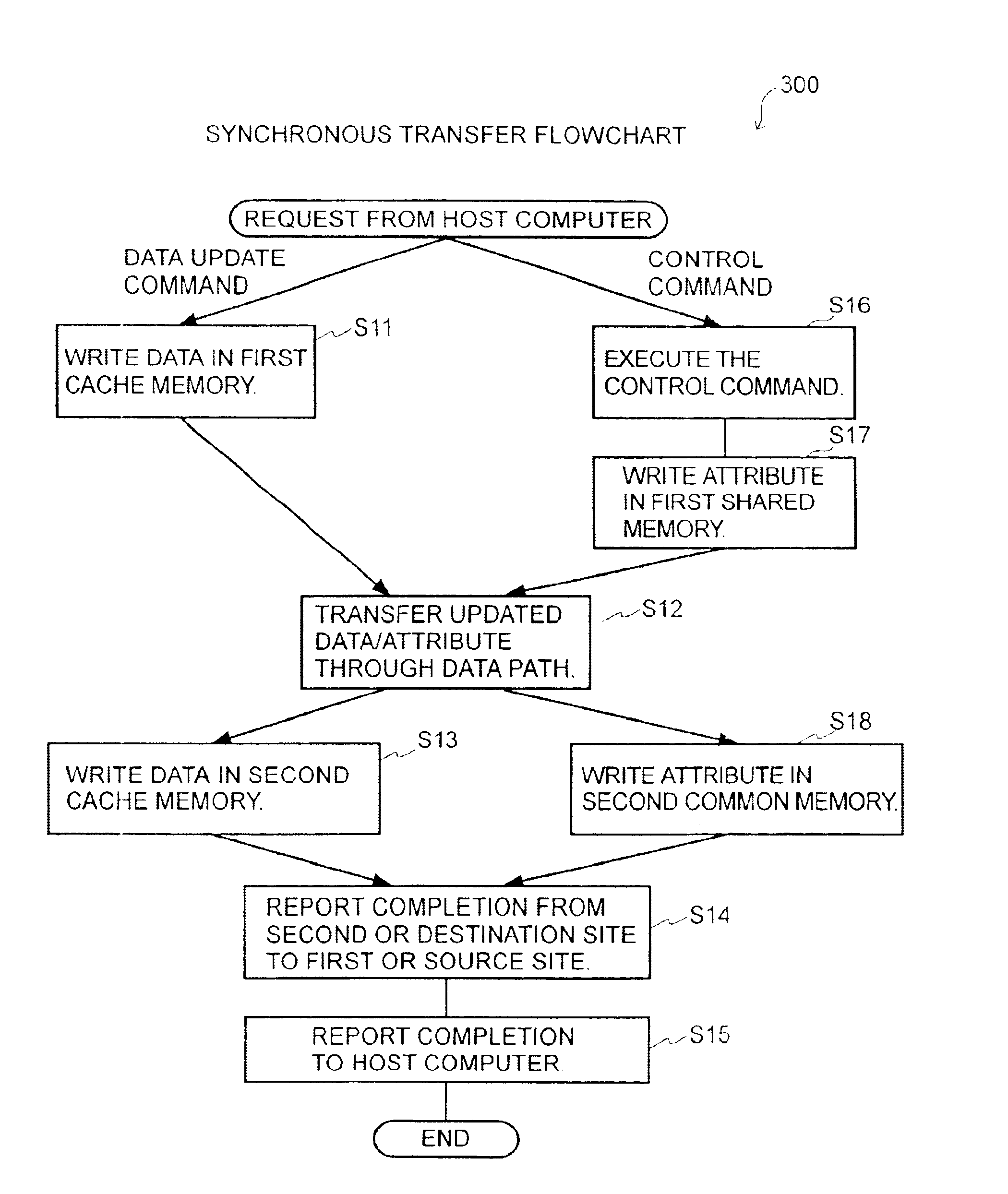

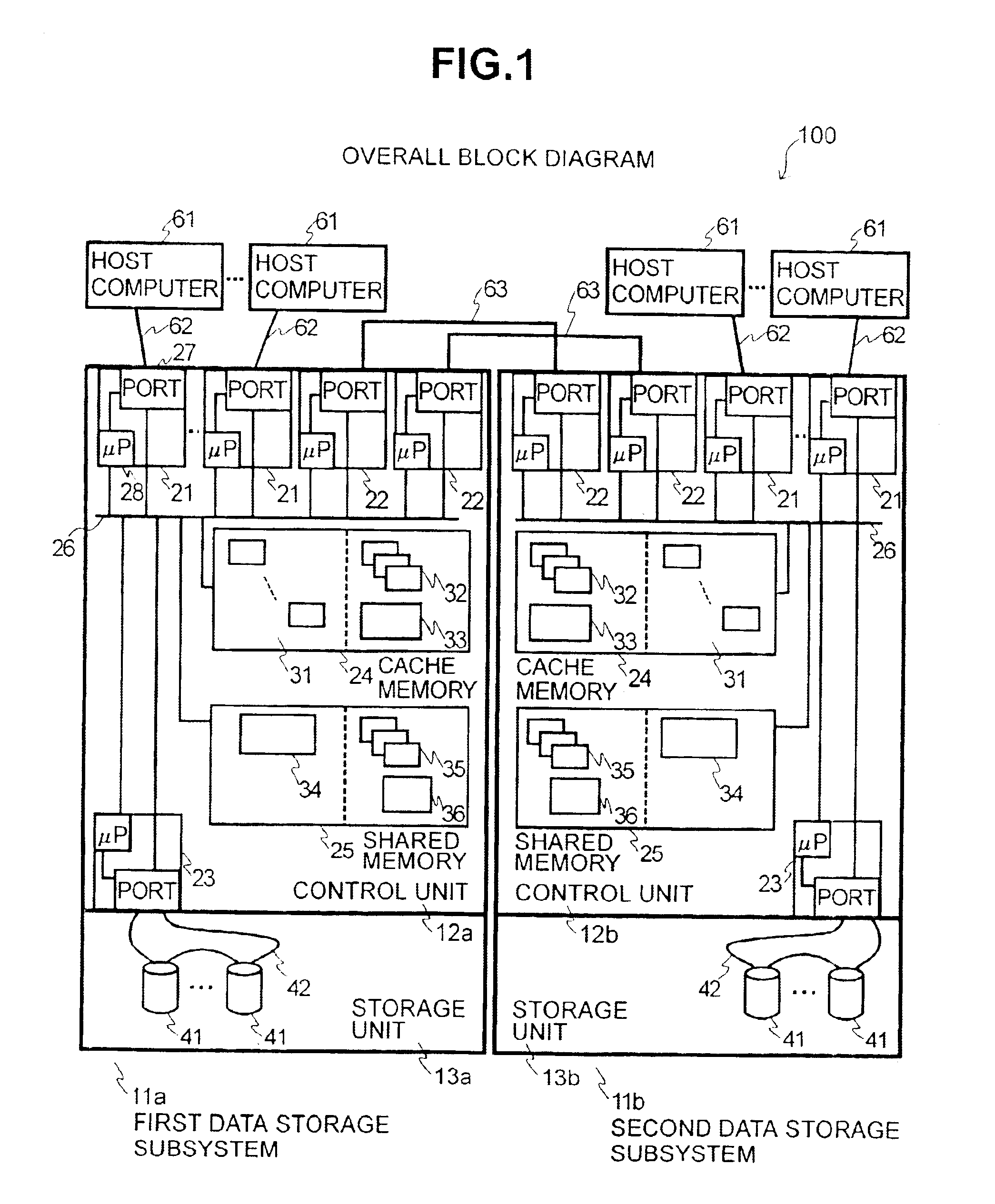

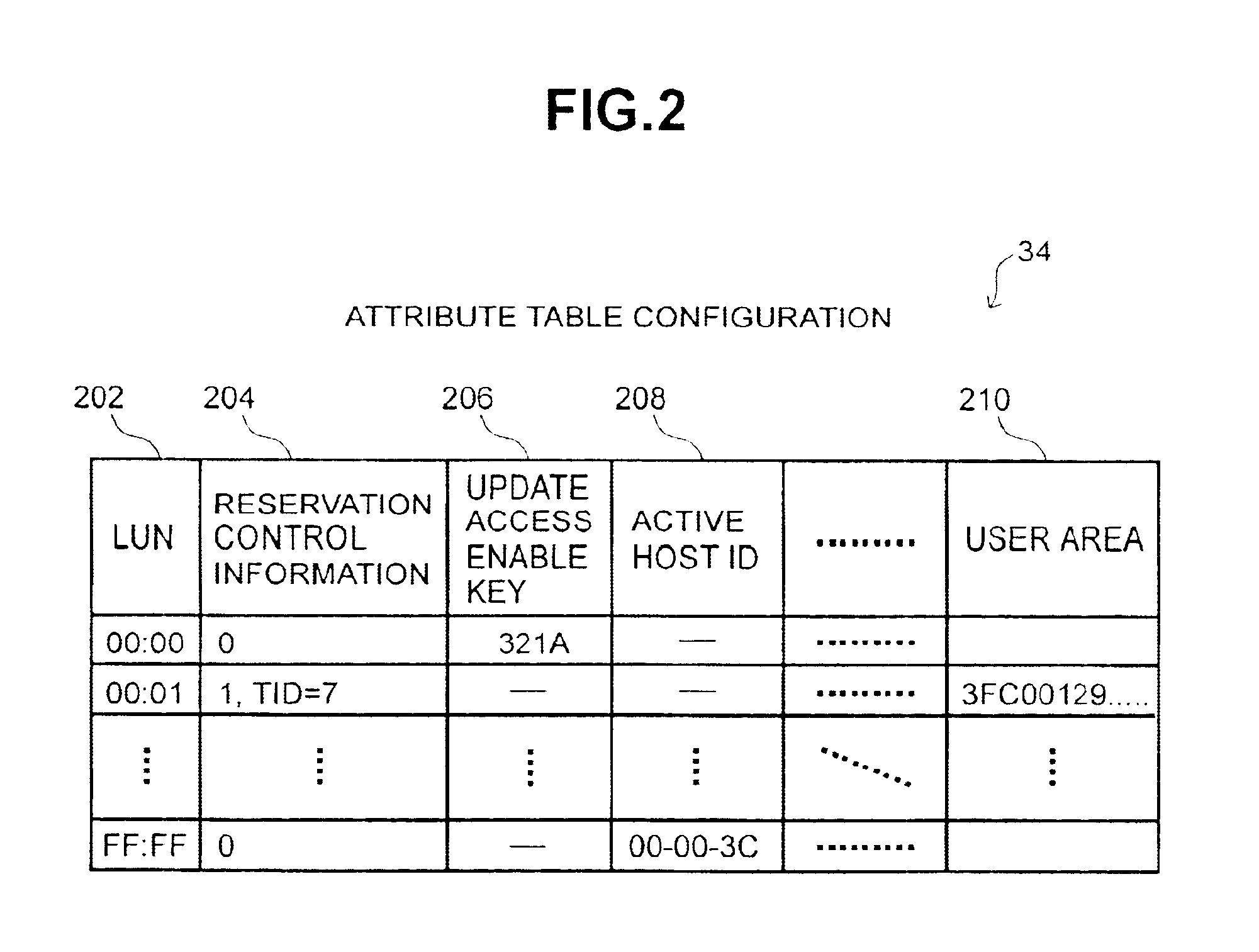

InactiveUS20050071393A1Eliminates complicated exchangeQuick updateData processing applicationsInput/output to record carriersComputer hardwareData store

A method for copying information from a first storage subsystem to a second storage subsystem is disclosed. The first and second storage subsystems are provided in a data storage system. The method comprises transmitting first data block from the first storage subsystem to the second storage subsystem, the first storage subsystem being associated with a first host computer and the second storage subsystem being associated with a second host computer; and transmitting first attribute information from the first storage subsystem to the second storage subsystem without intervention from the first host computer.

Owner:HITACHI LTD

Data storage subsystem

InactiveUS6950915B2Improve error resistanceExchange be complicateData processing applicationsInput/output to record carriersComputer hardwareData store

A method for copying information from a first storage subsystem to a second storage subsystem is disclosed. The first and second storage subsystems are provided in a data storage system. The method comprises transmitting first data block from the first storage subsystem to the second storage subsystem, the first storage subsystem being associated with a first host computer and the second storage subsystem being associated with a second host computer; and transmitting first attribute information from the first storage subsystem to the second storage subsystem without intervention from the first host computer.

Owner:HITACHI LTD

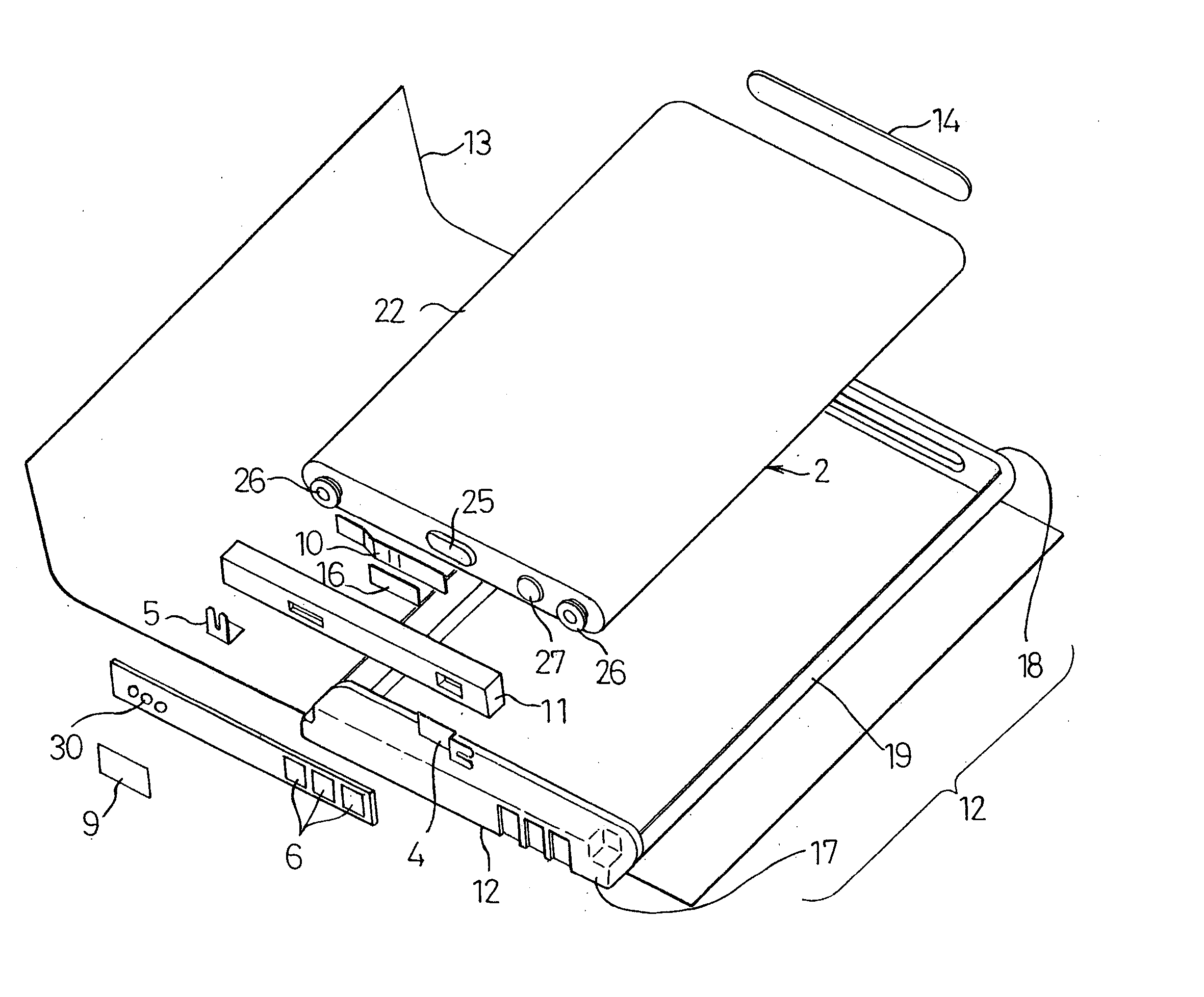

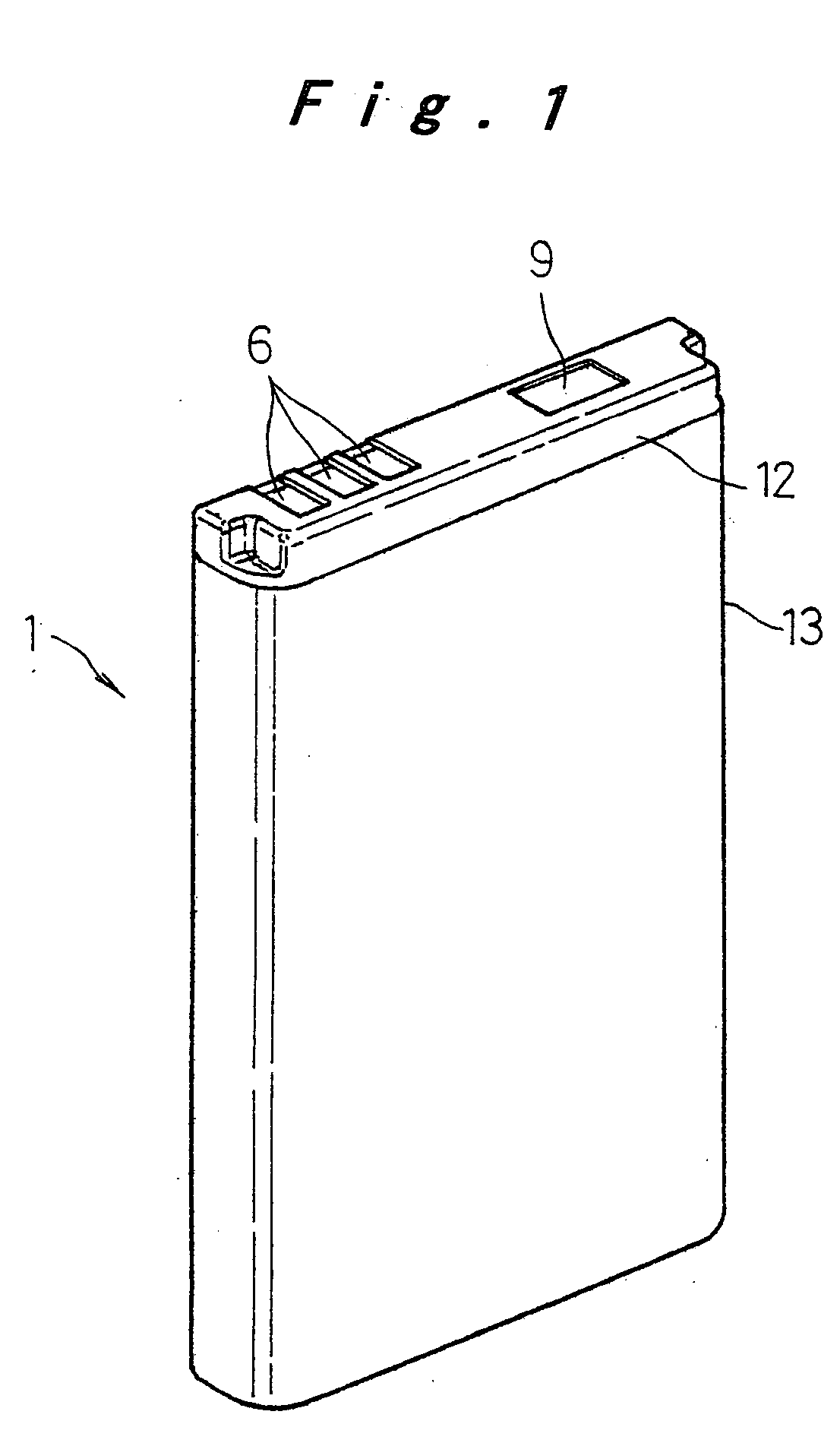

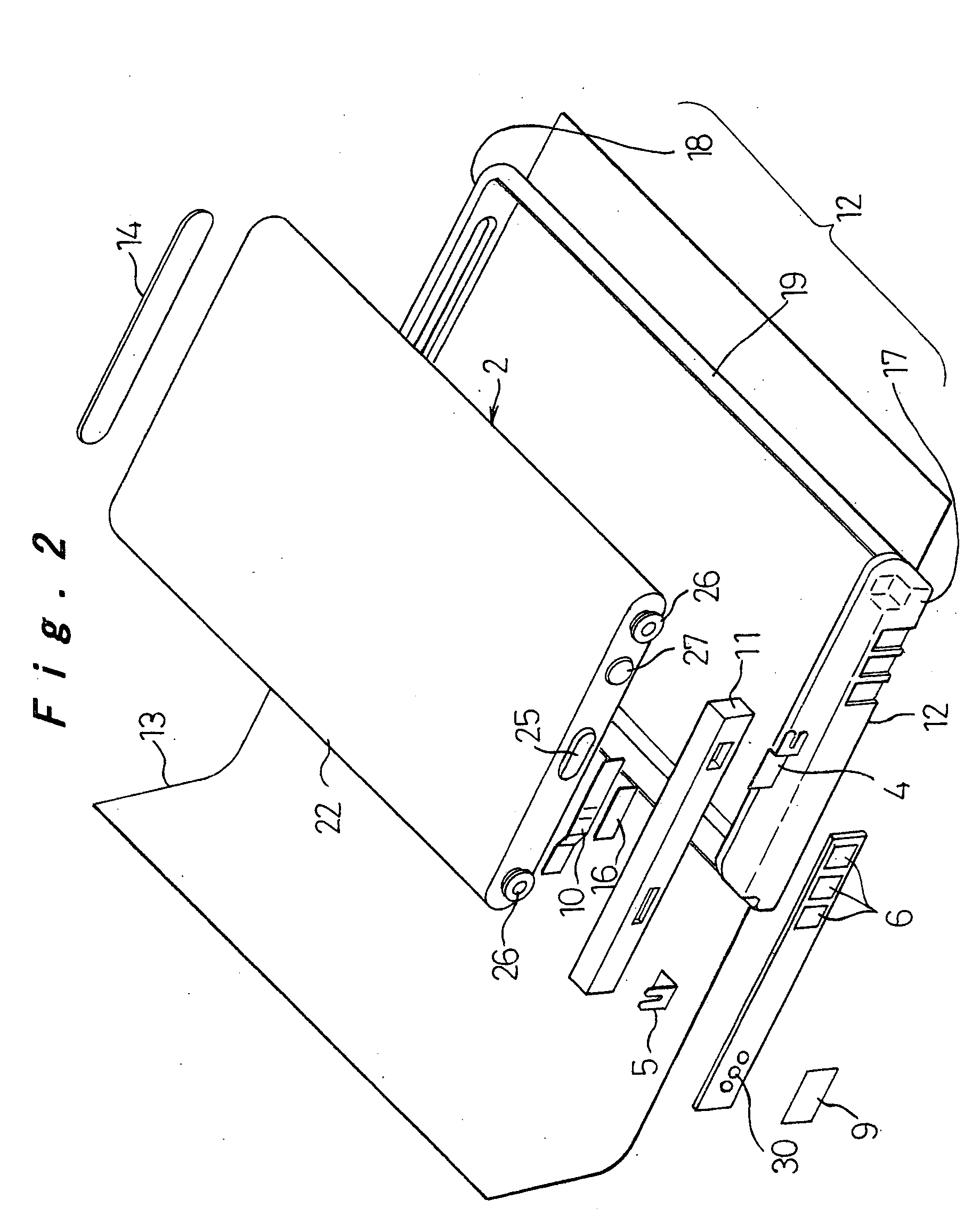

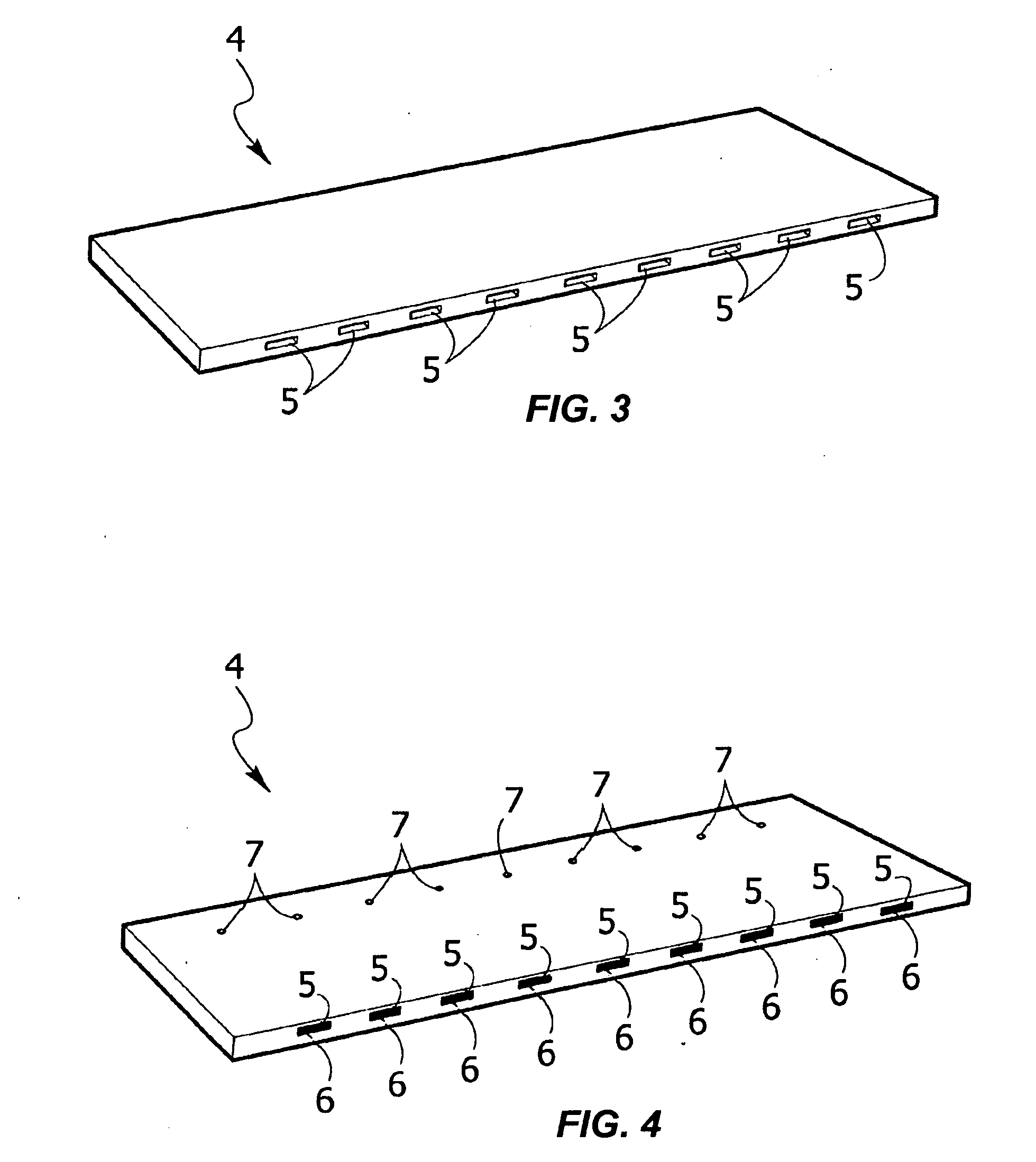

Battery pack manufacturing method

InactiveUS20050064286A1Improve rigidityIncrease in sizeFinal product manufacturePrimary cellsRechargeable cellEngineering

A rechargeable battery (2) and a circuit substrate (3) are connected by lead plates (4, 5) and united by a primary mold (11) that is formed by filling resin therebetween, after which a secondary mold (12) is formed on the outer face by filling resin at necessary locations and a winding sheet (13) is wound around the periphery, thereby forming a battery pack.

Owner:PANASONIC CORP

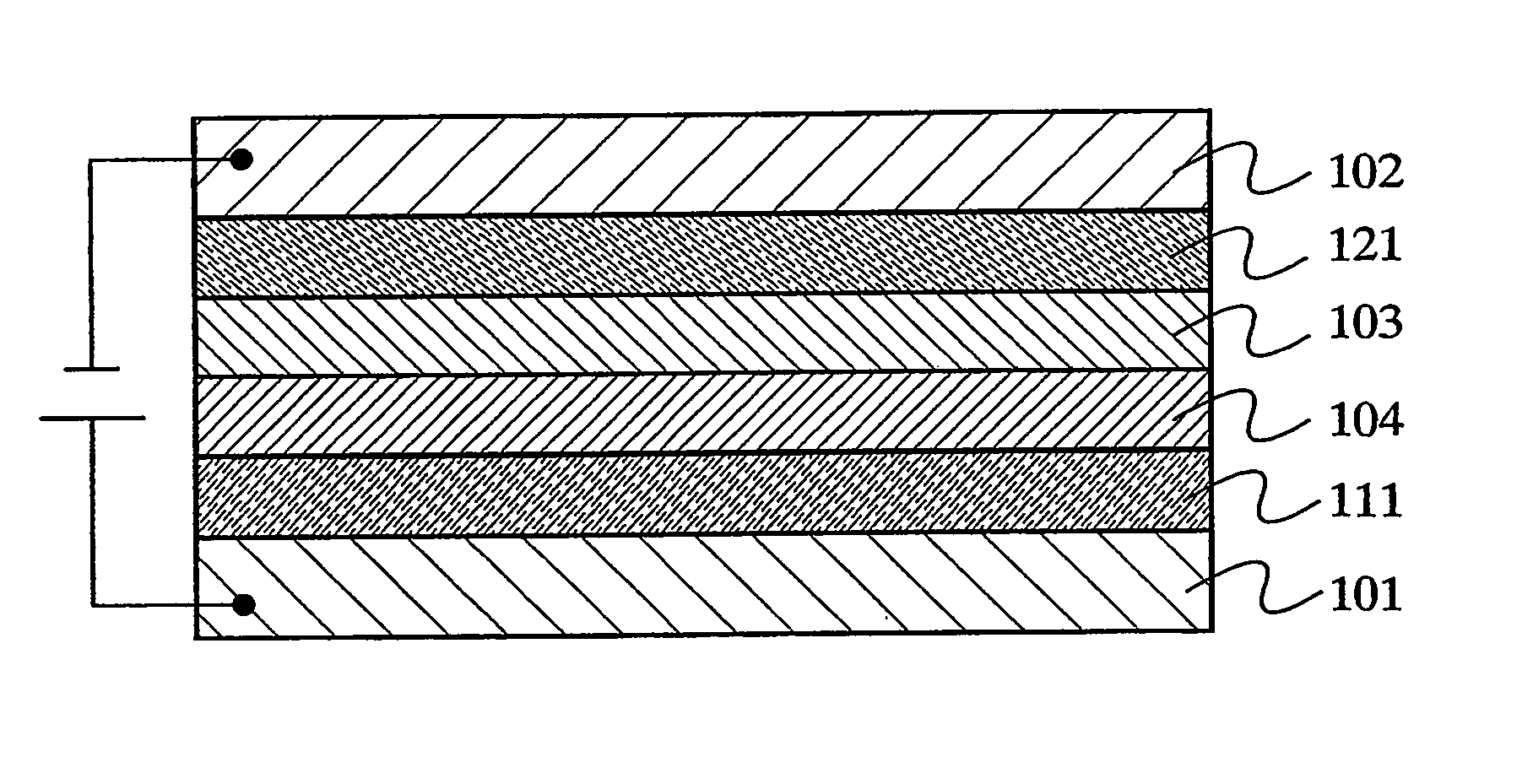

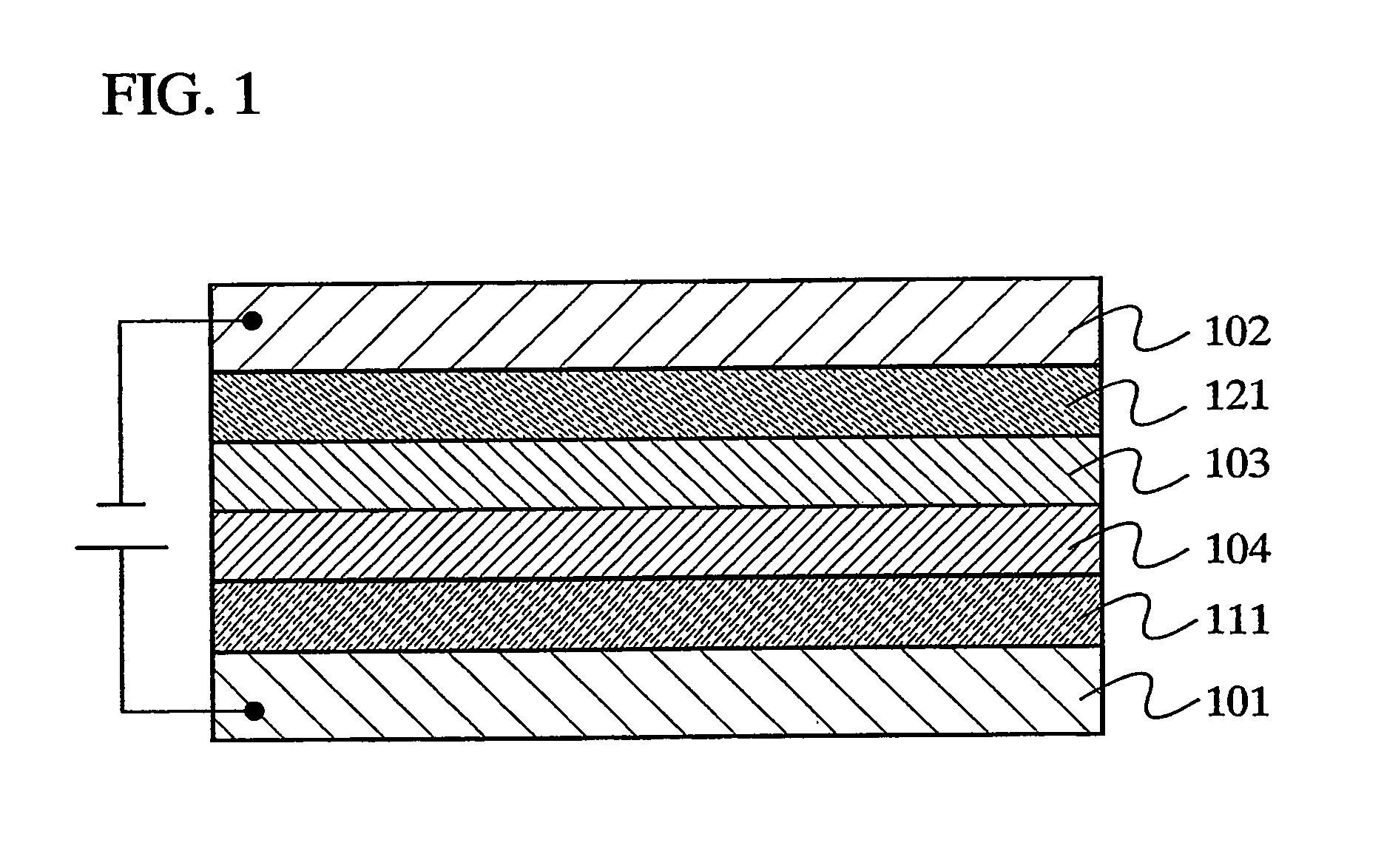

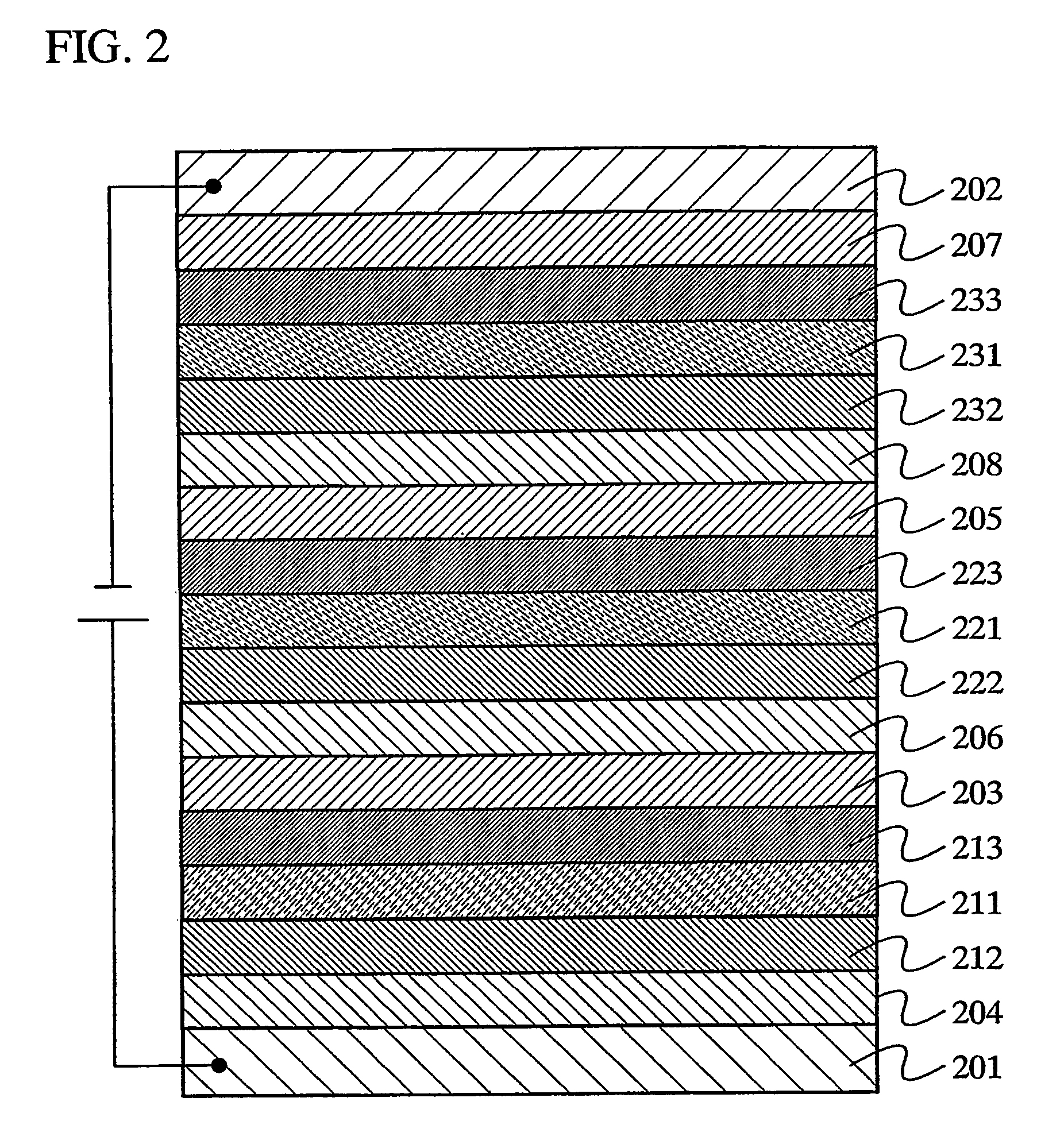

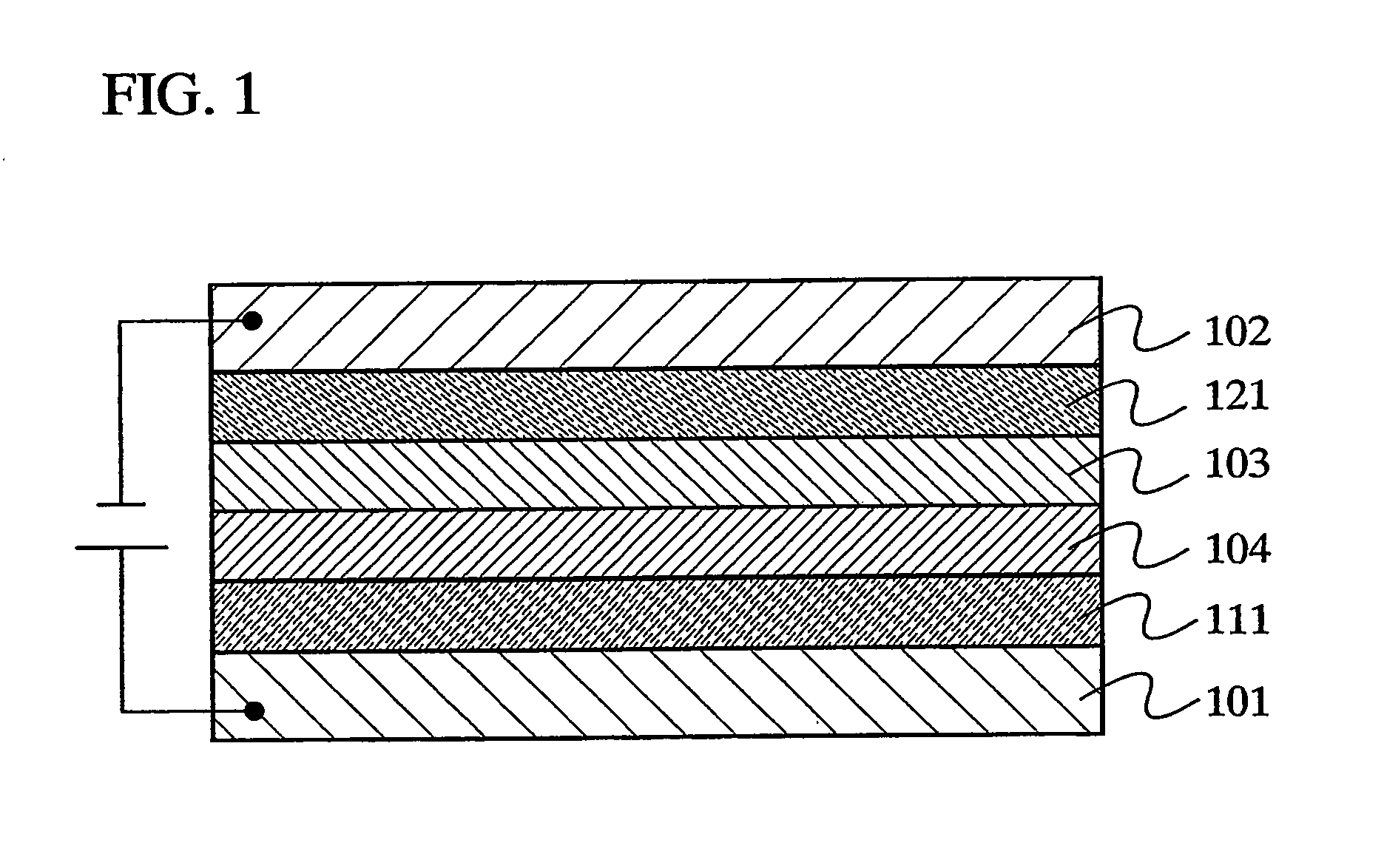

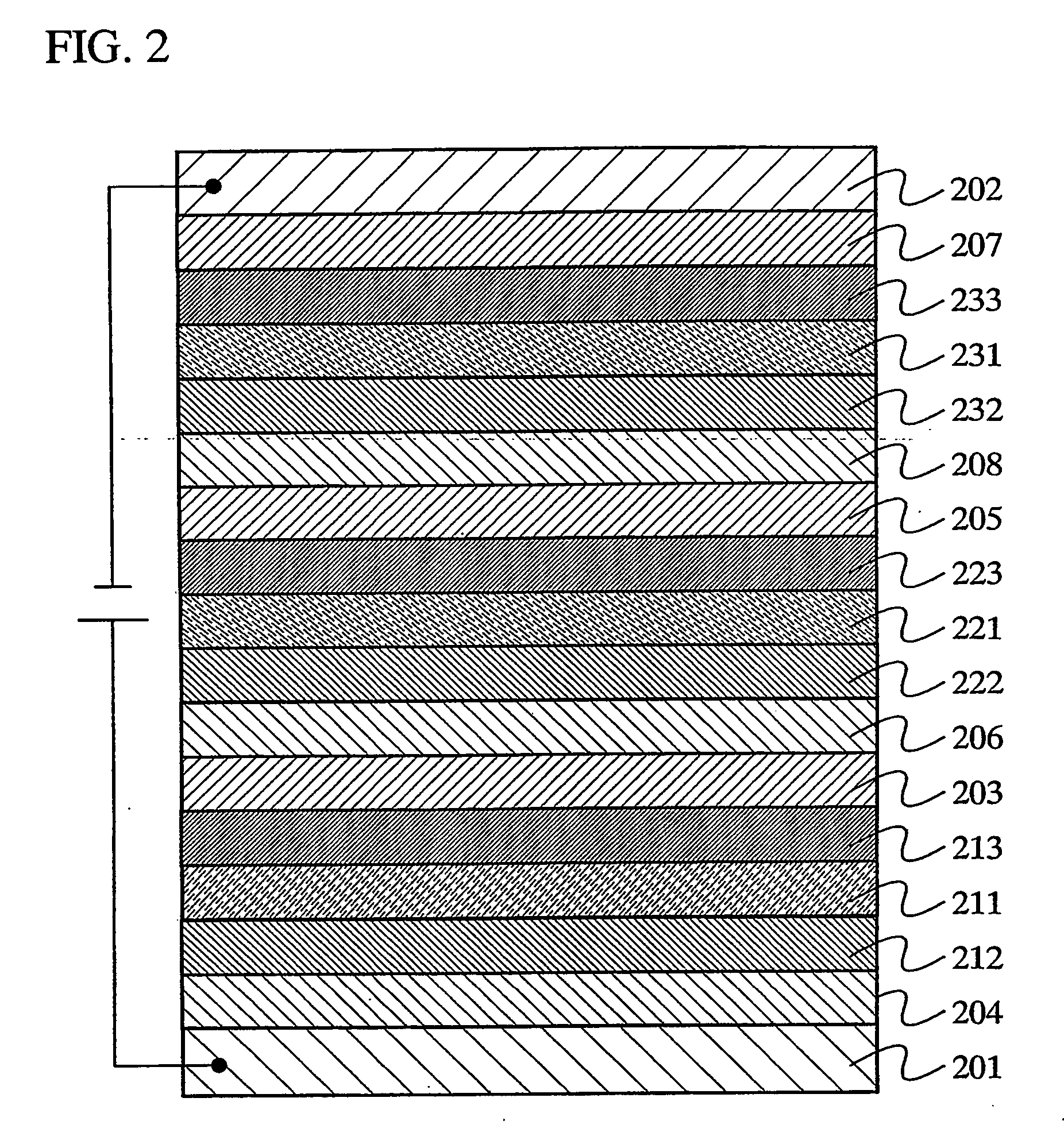

Light emitting element and light emitting device

ActiveUS7598670B2Improve moisture resistanceConvenient lightingDischarge tube luminescnet screensElectroluminescent light sourcesLight-emitting diodeLight emitting device

A light emitting element of the invention includes n pieces of light emitting layers (n is a natural number) between first and second electrodes. A first layer and a second layer are provided between the mth light emitting layer (m is a natural number of 1≦m≦n) and the m+1th light emitting layer. The first and second layers are contacted to each other. The first layer contains a substance that transports holes easily and a substance with an electron accepting property. The second layer contains a substance that transports electrons easily and a substance with an electron donating property. Molybdenum oxide is used as the substance with the electron accepting property.

Owner:SEMICON ENERGY LAB CO LTD

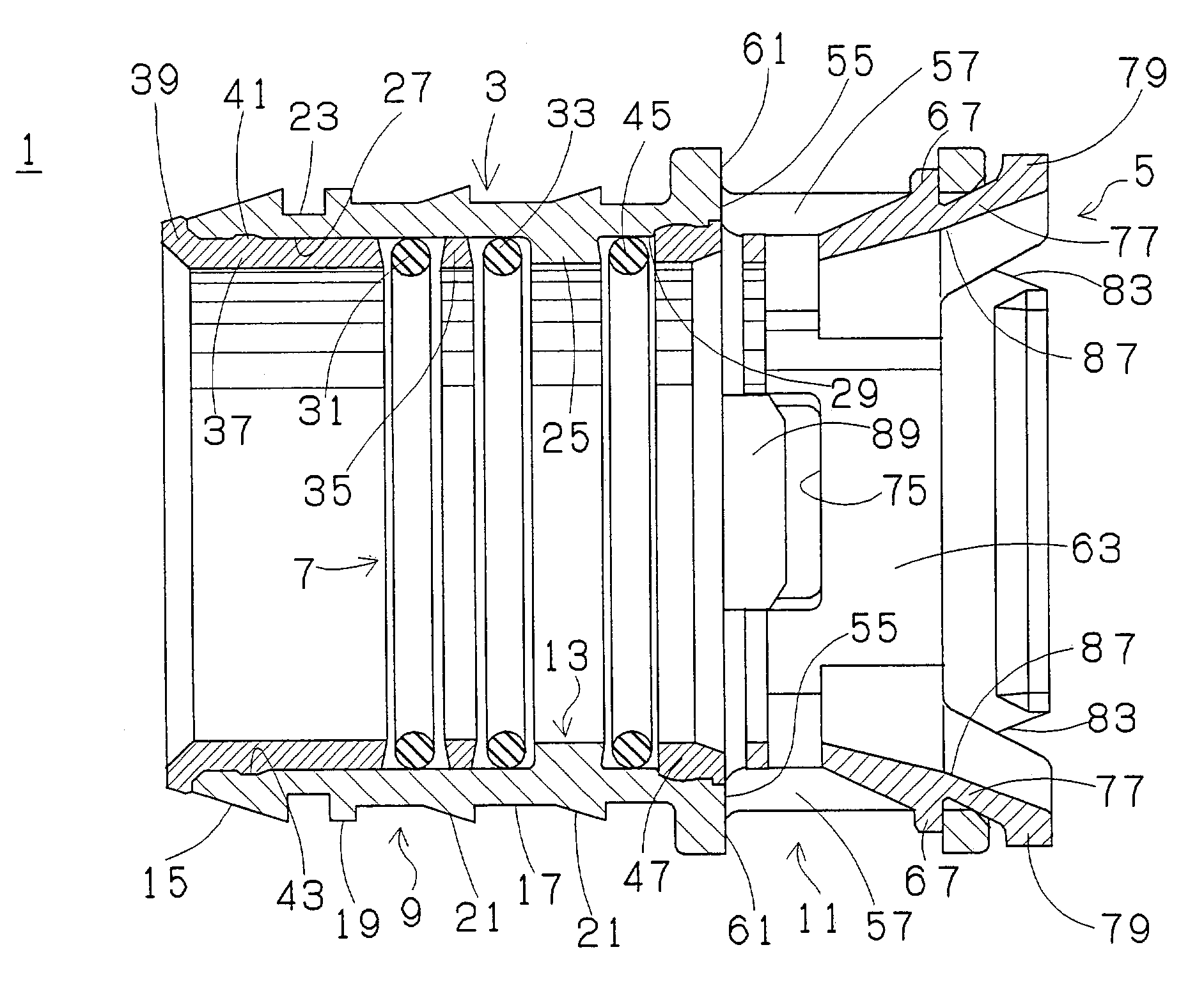

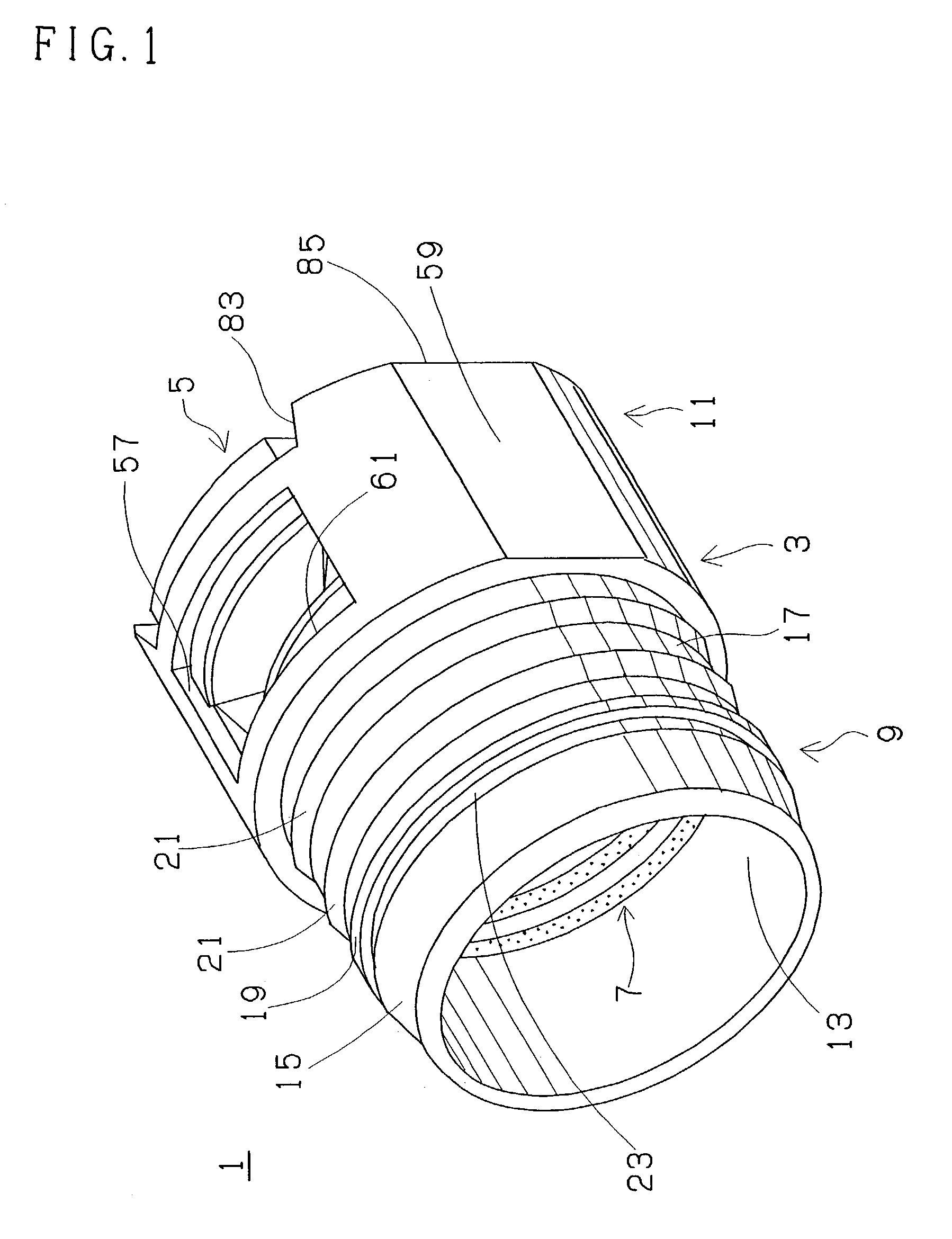

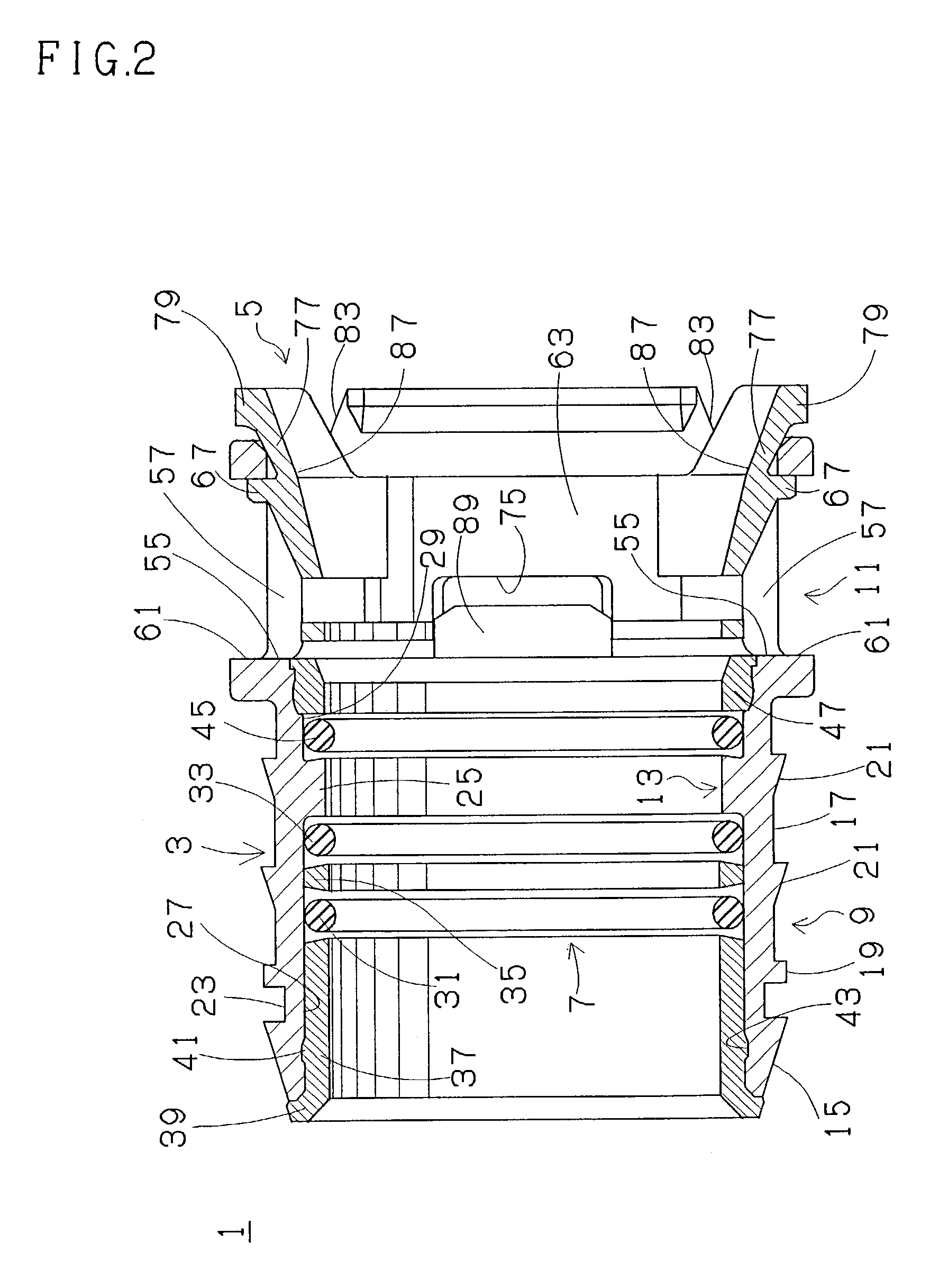

Quick connector

InactiveUS7108297B2Excellent and high gasoline fuel resistant propertyAvoid Insufficient SealingFluid pressure sealed jointsJoints with sealing surfacesEngineeringShaft collar

An inner peripheral surface of a tube connecting portion of a tubular connector housing is divided into a first receiving portion on one axial side and a second receiving portion on an opposite axial side by an inwardly directed annular parting projection. A first O-ring of one axial side and a second O-ring of an opposite axial side are disposed with intervening a collar therebetween on an opposite axial side in the first receiving portion. The first O-ring is made of FKM and the second O-ring is made of FVMQ. A third O-ring is disposed on one axial side in the second receiving portion. The third O-ring is also made of FVMQ.

Owner:SUMITOMO RIKO CO LTD

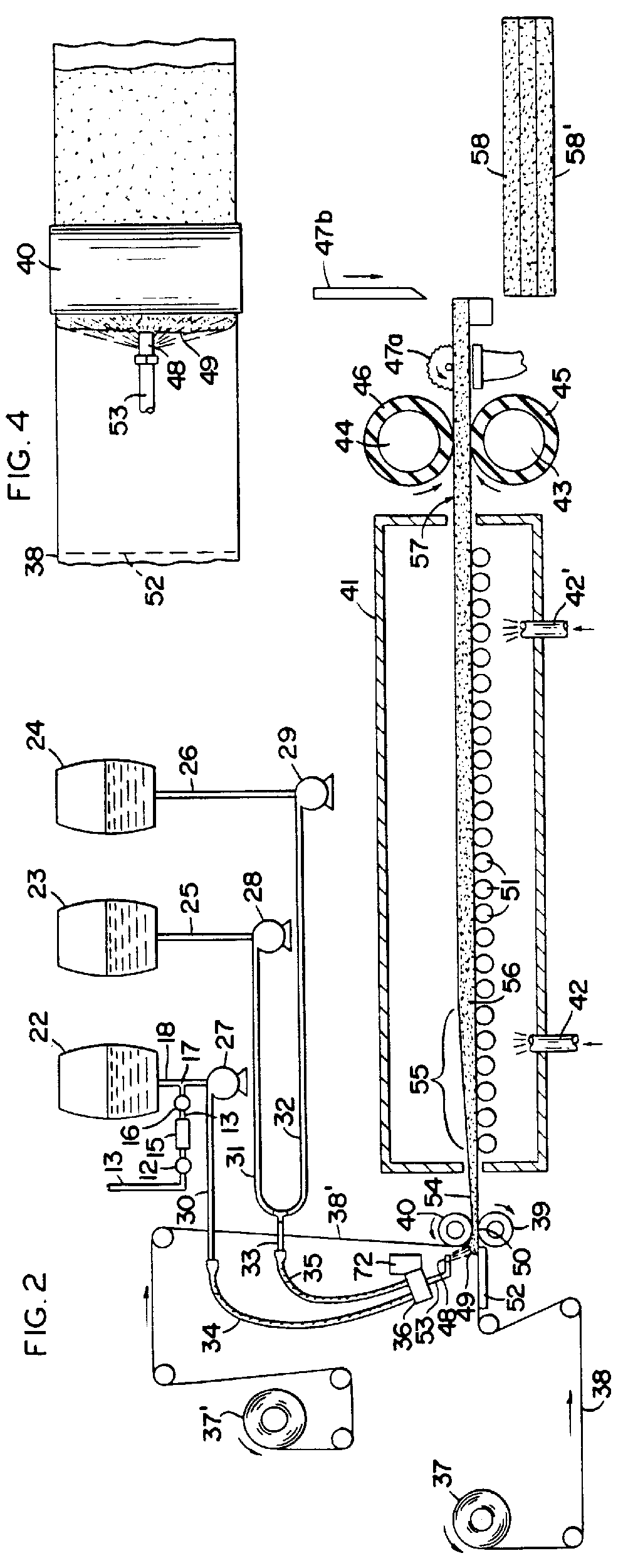

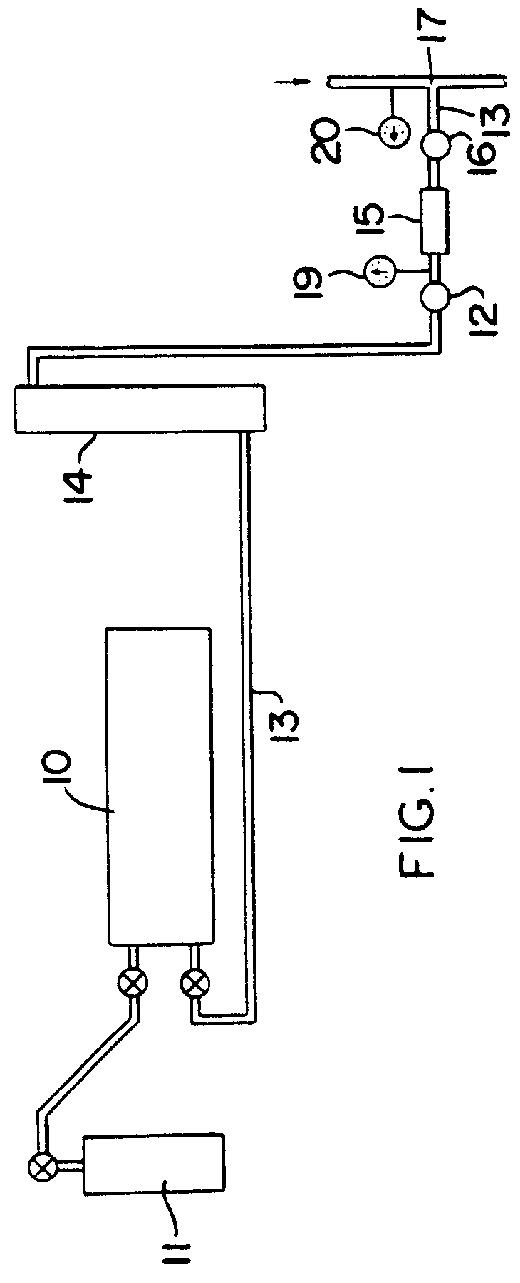

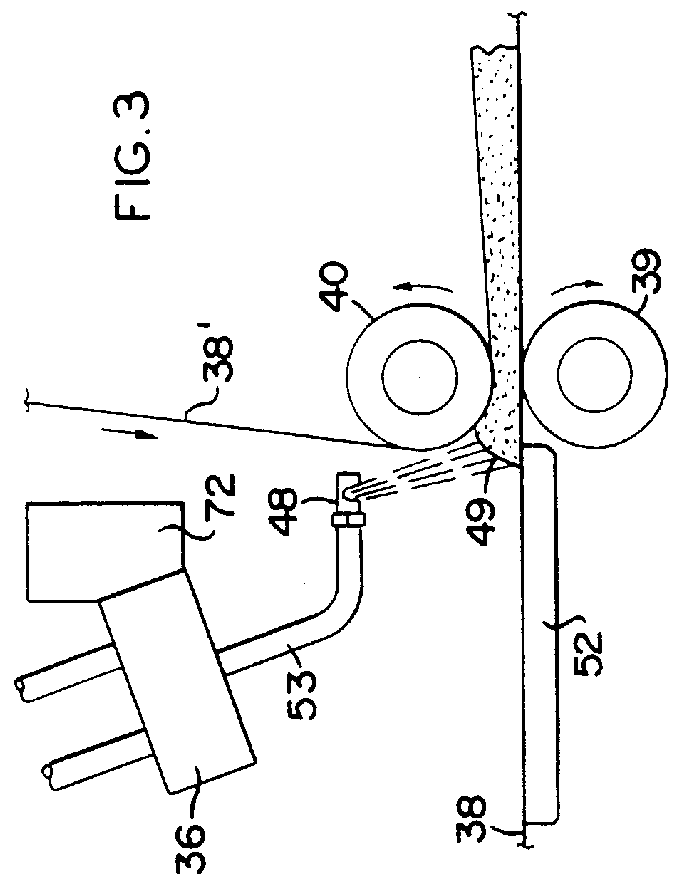

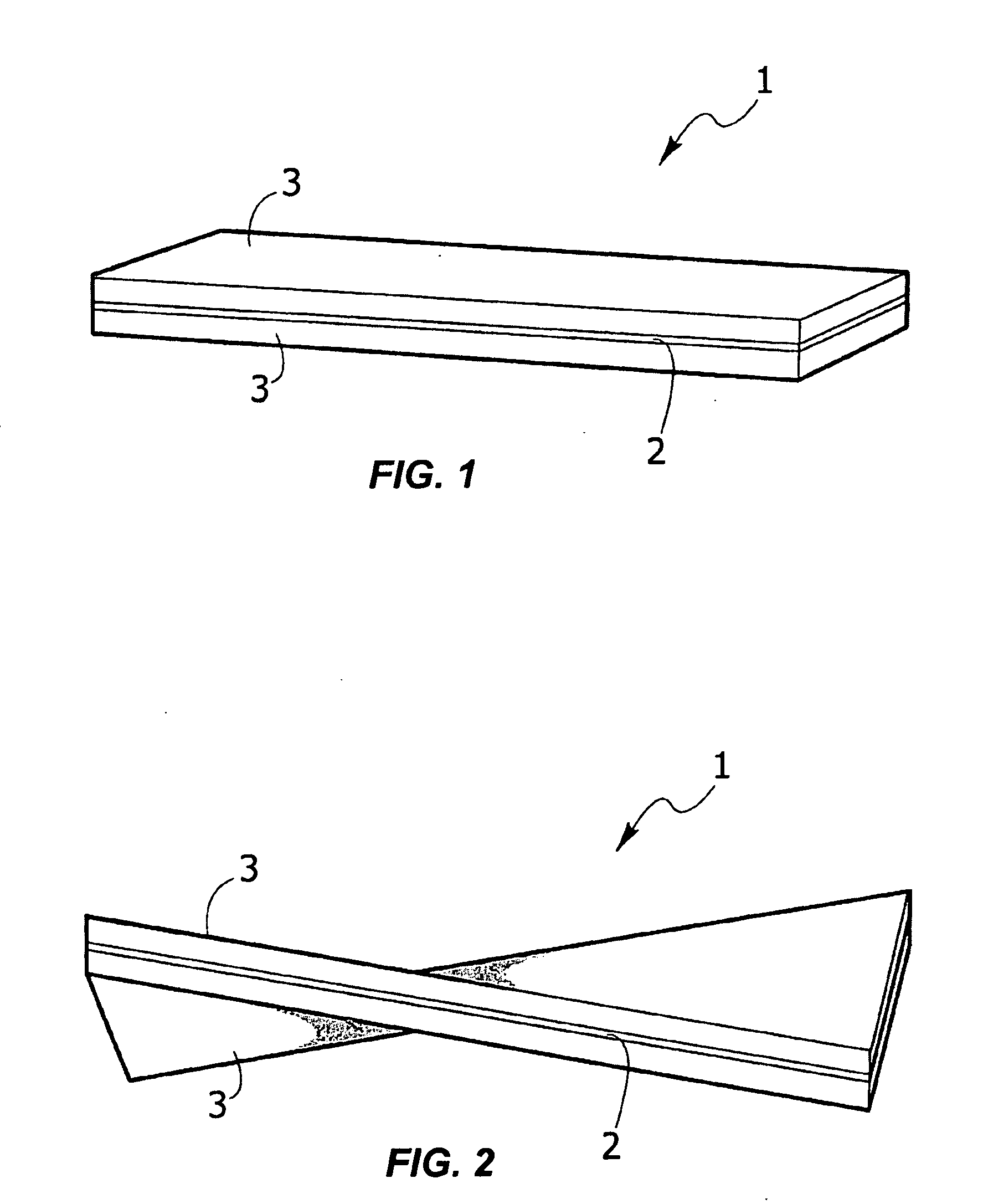

Faced foam insulation board and froth-foaming method for making same

InactiveUSRE36674E1Big lossSimple and economical mannerConfectionerySweetmeatsProduction lineEngineering

A method for continuously producing an insulation board comprising a rigid plastic foam core having two major surfaces and a facing material on one or both of the major surfaces, the method including conveying a facing material along a production line, depositing a partially expanded froth foam of a plastic mixture, which contains at least one frothing agent, on the facing material, and further expanding and curing the froth foam in contact wiht the facing material to form the insulation board. The board is particularly useful as roof insulation.

Owner:THE DOW CHEM CO

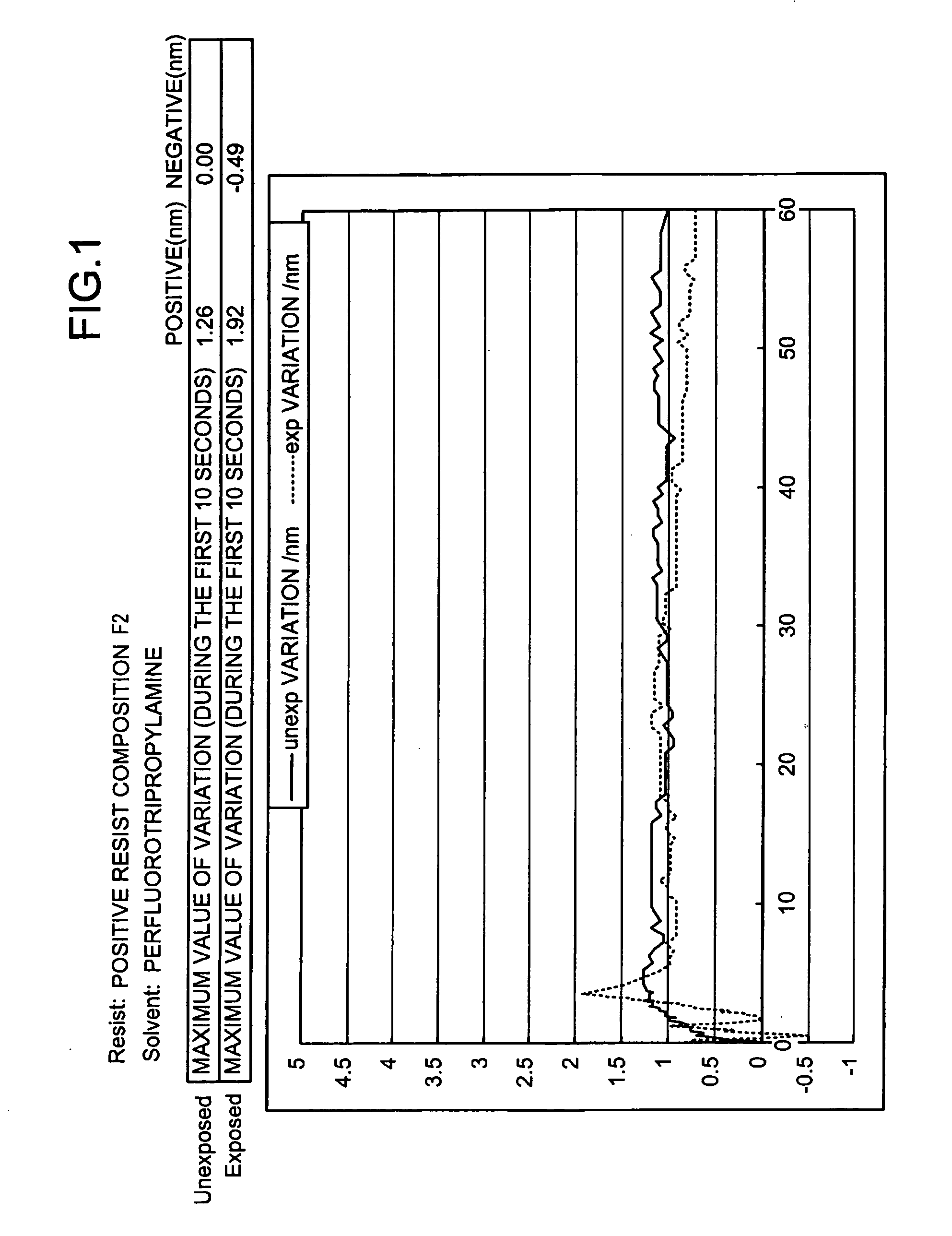

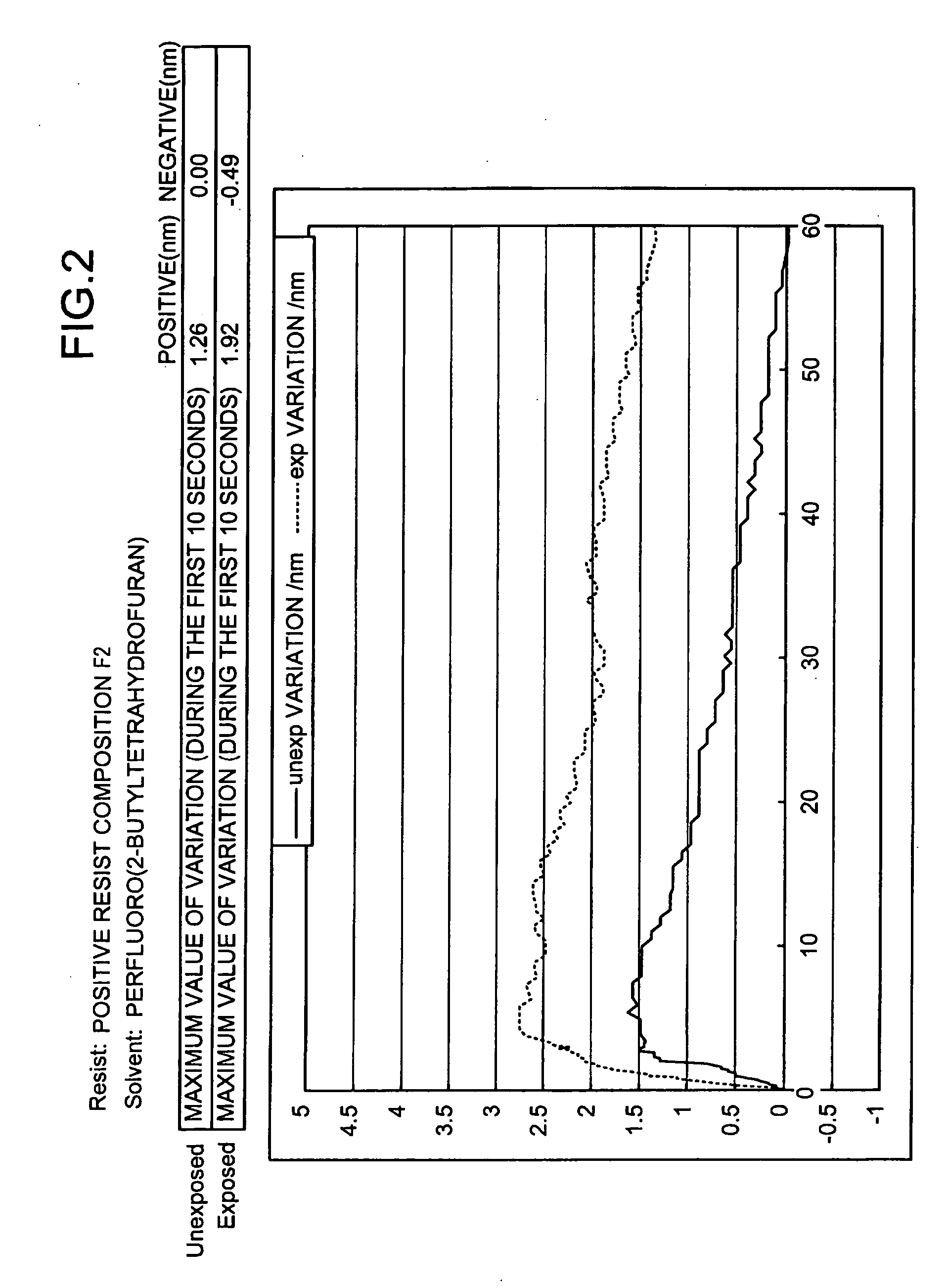

Immersion fluid for use in liquid immersion lithography and method of forming resist pattern using the immersion fluid

InactiveUS20060154188A1High resolutionHigh refractive indexPhotosensitive materialsSemiconductor/solid-state device manufacturingChemistryOptics

An immersion fluid for use in liquid immersion lithography in which a resist film is exposed to light via a fluid. The fluid is transparent to the exposure light used in the liquid immersion lithography and comprises a fluorine-based liquid having a boiling point of 70 to 270° C. A method of forming resist patter includes a step of placing the immersion fluid directly on the resist film or a protective film deposited on the resist film. The present invention prevents alteration of resist film and other films as well as alteration of the fluid during liquid immersion lithography and enables high resolution resist patterning using liquid immersion lithography.

Owner:TOKYO OHKA KOGYO CO LTD

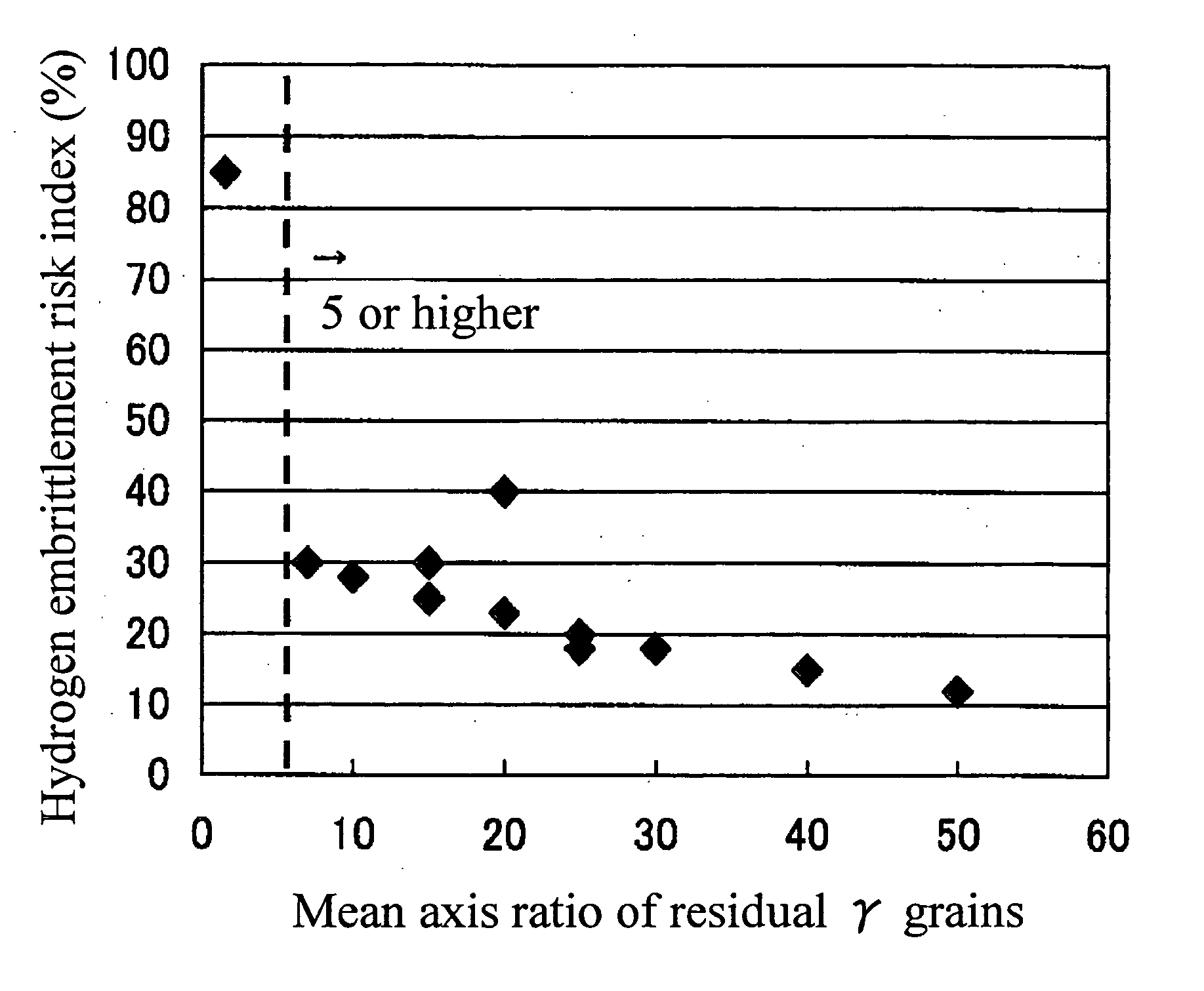

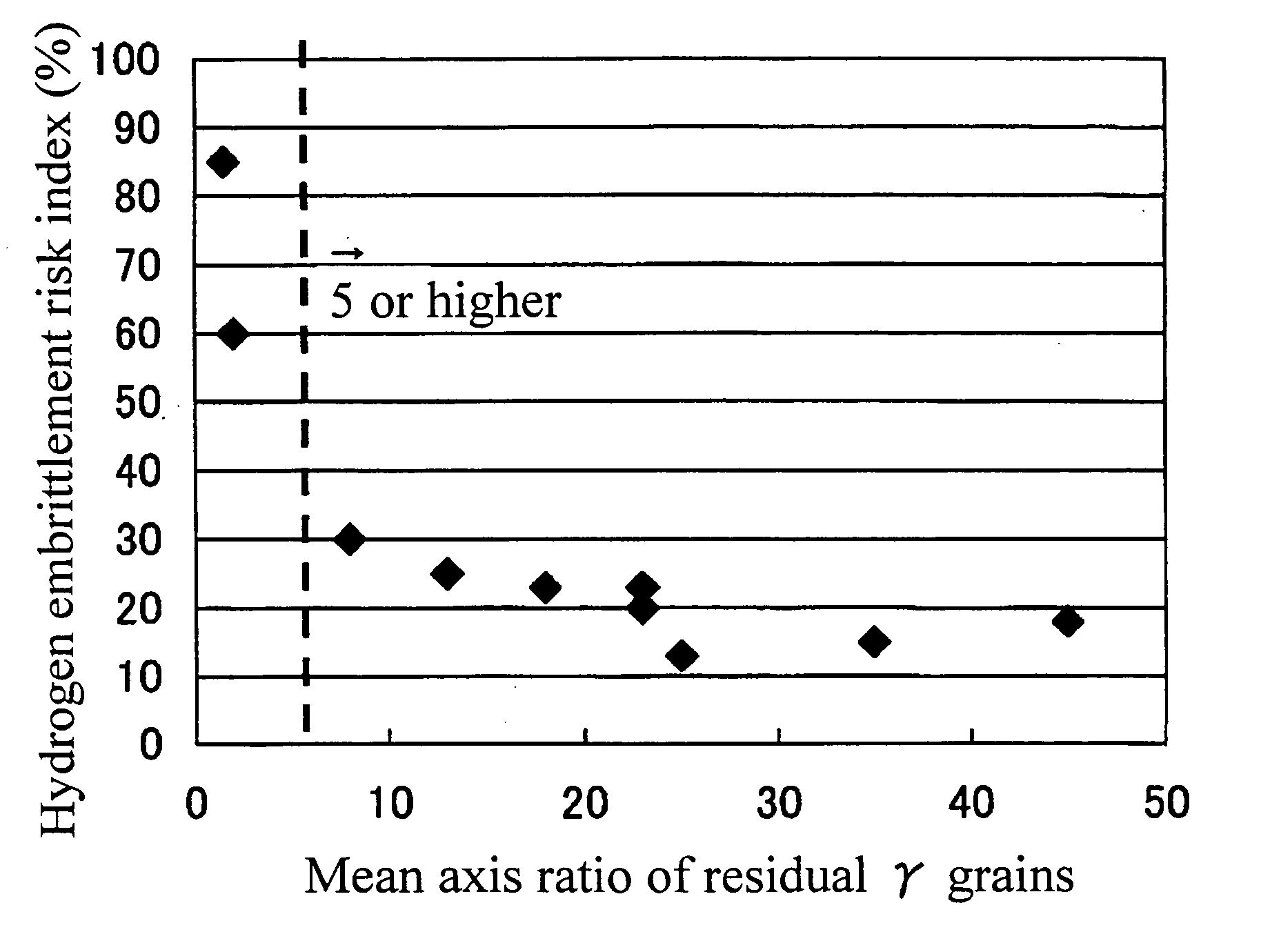

High strength thin steel sheet having high hydrogen embrittlement resisting property

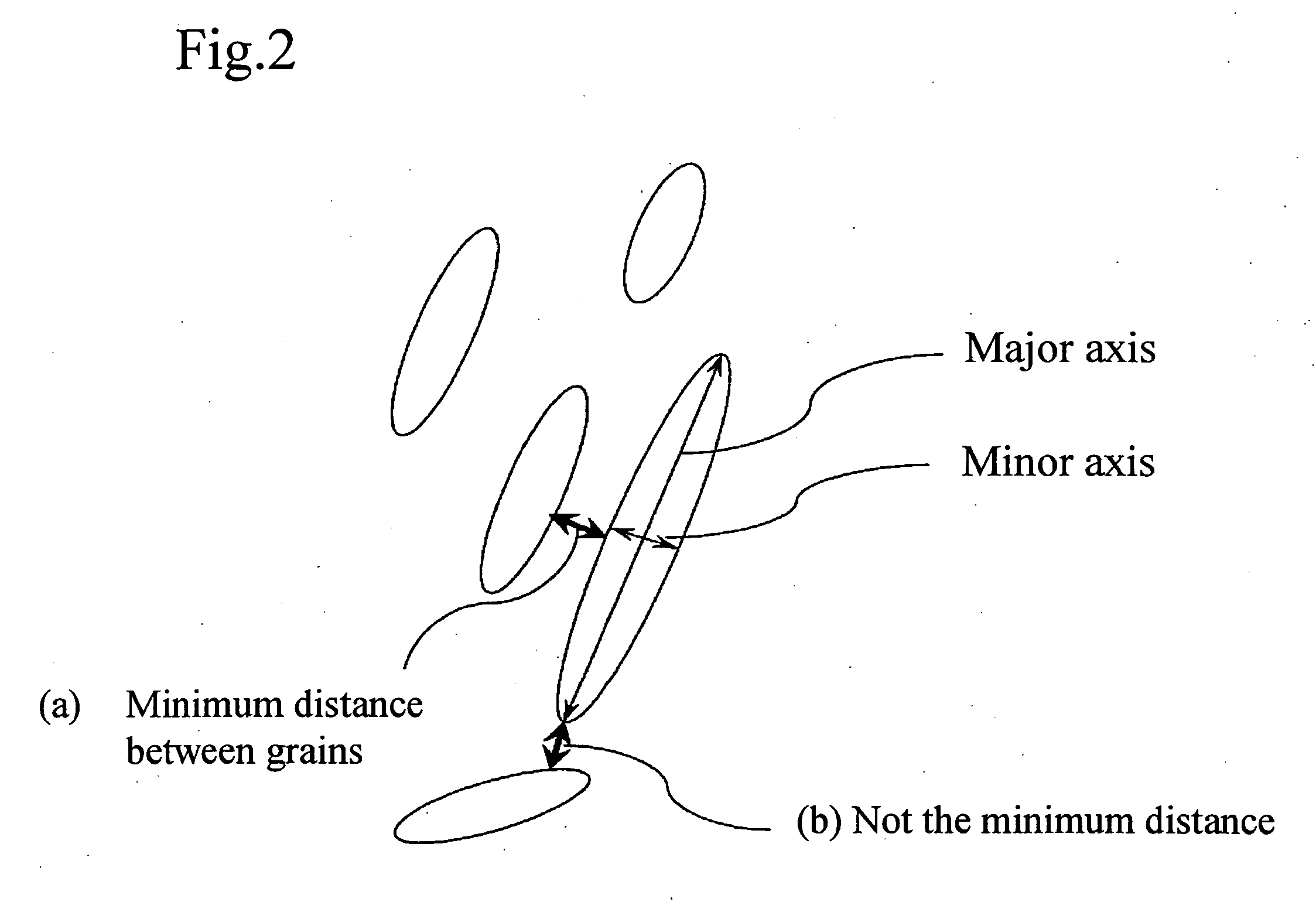

The purpose of the present invention is to provide a high strength thin steel sheet that has high hydrogen embrittlement resisting property. In order to achieve the above purpose, a high strength thin steel sheet having high hydrogen embrittlement resisting property comprises: C: 0.10 to 0.25%; Si: 1.0 to 3.0%; Mn: 1.0 to 3.5%; P: 0.15% or less; S: 0.02% or less; and Al: 1.5% or less (higher than 0%) in terms of percentage by weight, with balance of iron and inevitable impurities; and the metal structure comprises: residual austenite; 1% by area or more in proportion to the entire structure; bainitic ferrite and martensite: 80% or more in total; and ferrite and pearlite: 9% or less (may be 0%) in total, while the mean axis ratio (major axis / minor axis) of said residual austenite grains is 5 or higher, and the steel has tensile strength of 1180 MPa or higher.

Owner:KOBE STEEL LTD

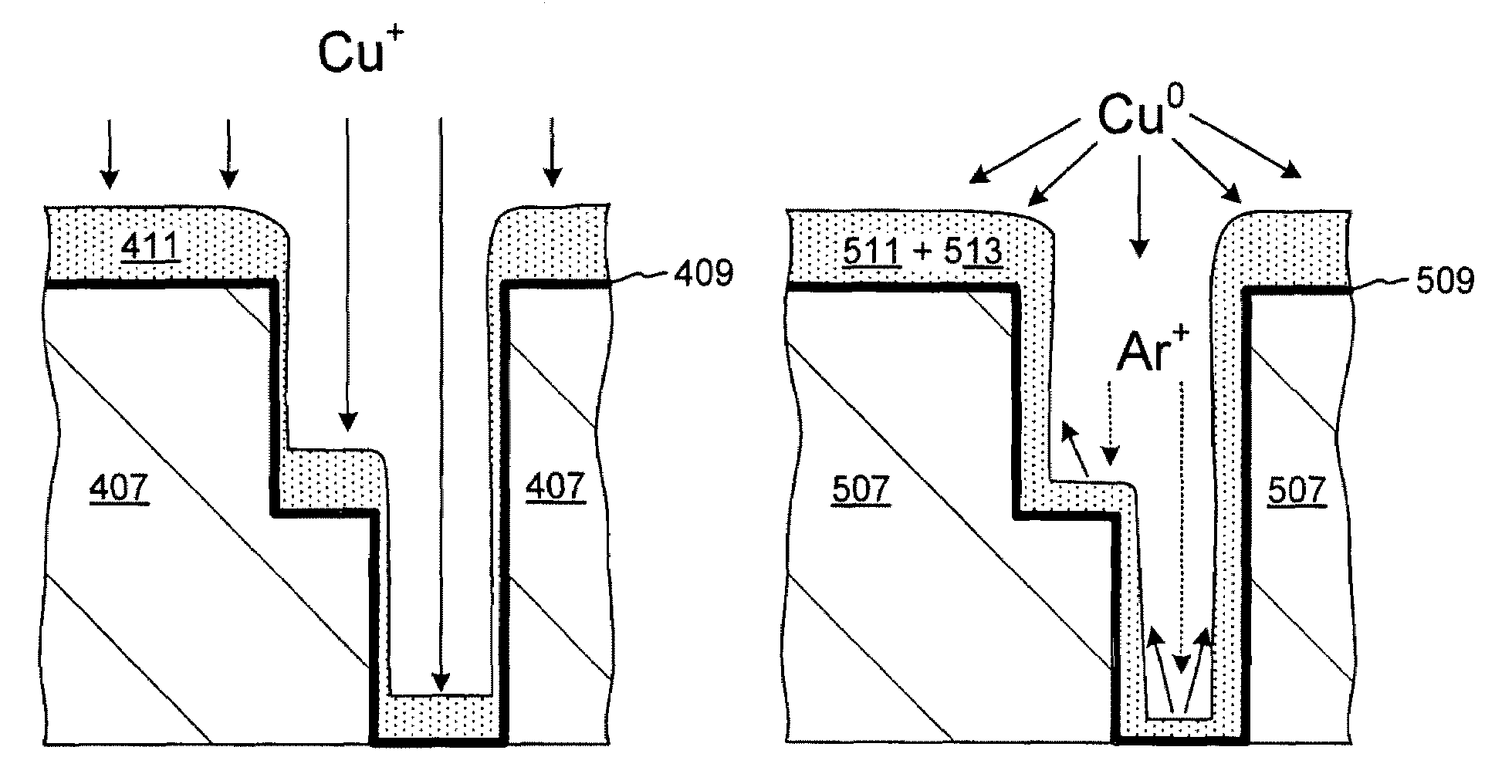

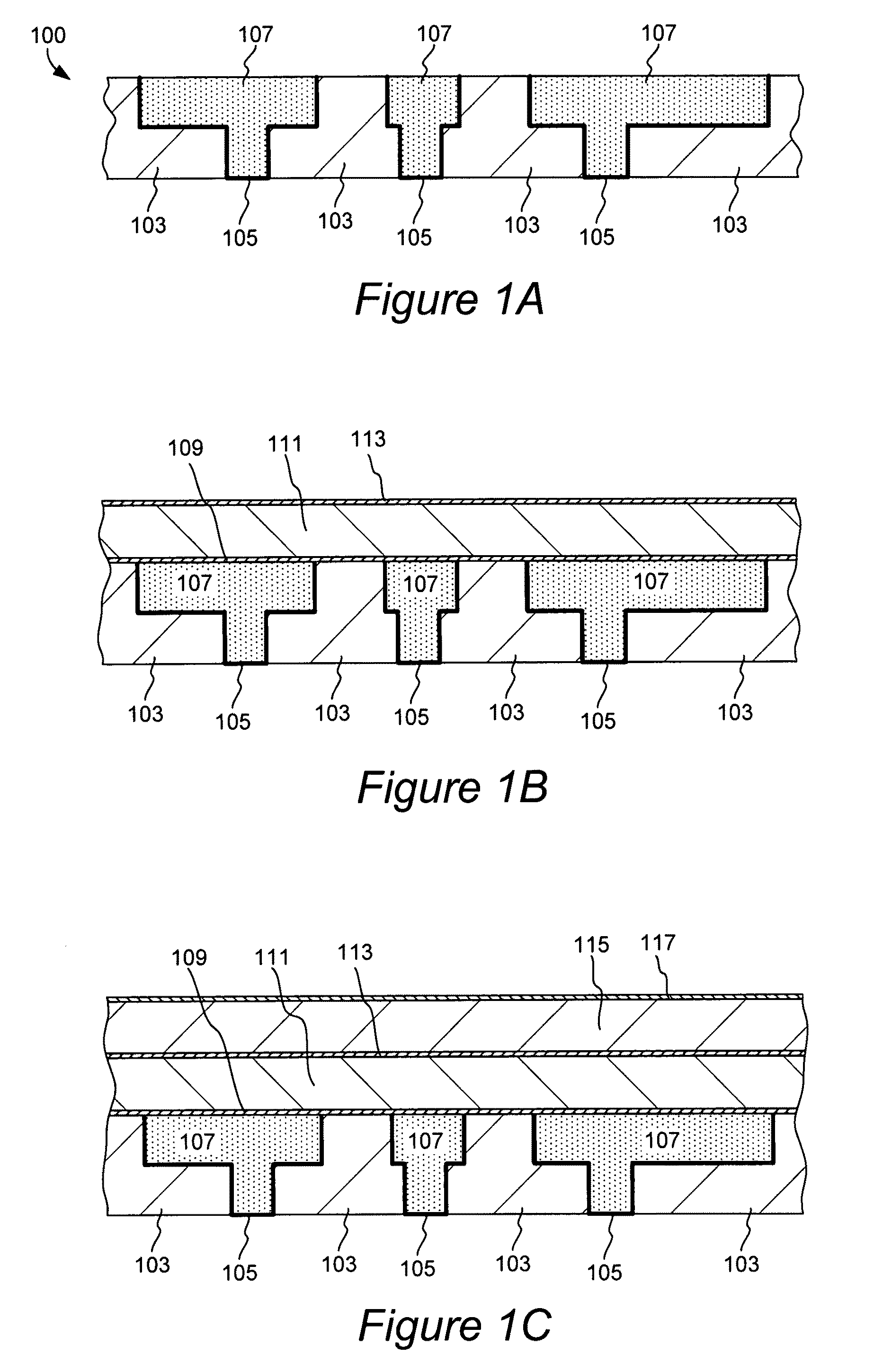

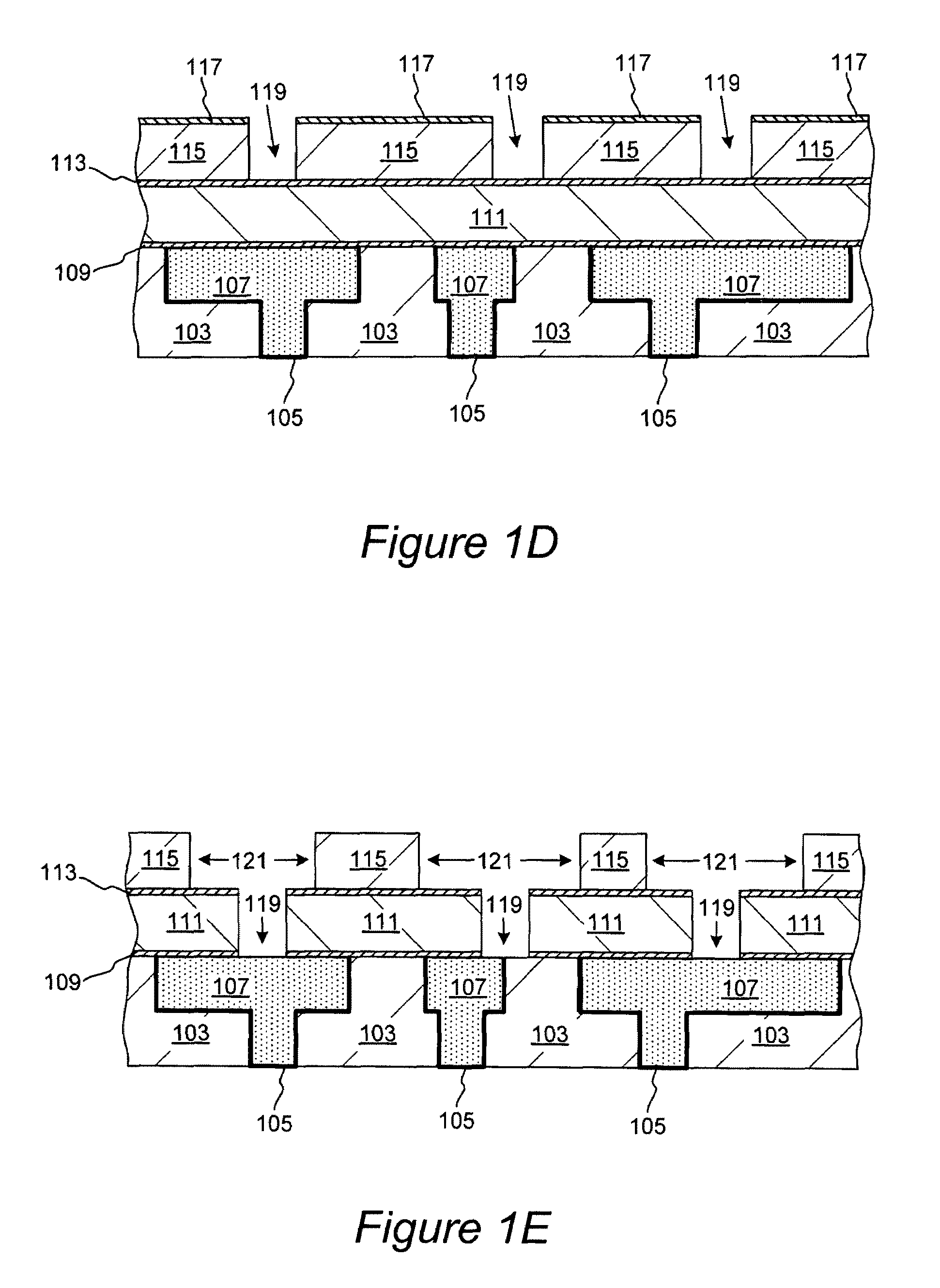

Multistep method of depositing metal seed layers

ActiveUS7682966B1Improve sidewall coverageGood step coverageSemiconductor/solid-state device detailsVacuum evaporation coatingSemiconductorMetal

Metal seed layers are deposited on a semiconductor substrate having recessed features by a method that involves at least three operations. In this method, a first layer of metal is deposited onto the substrate to cover at least the bottom portions of the recessed features. The first layer of metal is subsequently redistributed to improve sidewall coverage of the recessed features. Next, a second layer of metal is deposited on at least the field region of the substrate and on the bottom portions of the recessed features. The method can be implemented using a PVD apparatus that allows deposition and resputtering operations. This sequence of operations can afford seed layers with improved step coverage. It also leads to decreased formation of voids in interconnects, and to improved resistance characteristics of formed IC devices.

Owner:NOVELLUS SYSTEMS

Waterborne multistage polymer dispersion

InactiveUS20090143528A1Improve stabilityFine particlePretreated surfacesCoatingsEmulsionPolymer science

The invention relates to a process for the manufacture of a waterborne multistage polymer dispersion that has ethylenically unsaturated functional groups for crosslinking. The process comprises the steps of;a. making an aqueous emulsion or solution of a first stage polymer comprising carboxylic acid functionalised monomers to an amount sufficient to make the first stage polymer water soluble or dispersible,b. at least partially neutralising the first stage polymer with a base,c. forming a two-stage polymer dispersion by adding to the at least partially neutralised first stage polymer a second stage monomer mixture and emulsion polymerising said second stage monomer mixture to a second stage polymer which is less hydrophilic than the first stage polymer,d. reacting with the obtained two-stage polymer dispersion a bi-functional compound comprising an ethylenically unsaturated group and a group reactive towards the carboxylic acid in the two-stage polymer.The invention further relates to a water-borne curable multistage polymer dispersion, to coating compositions.

Owner:NUPLEX RESINS BV

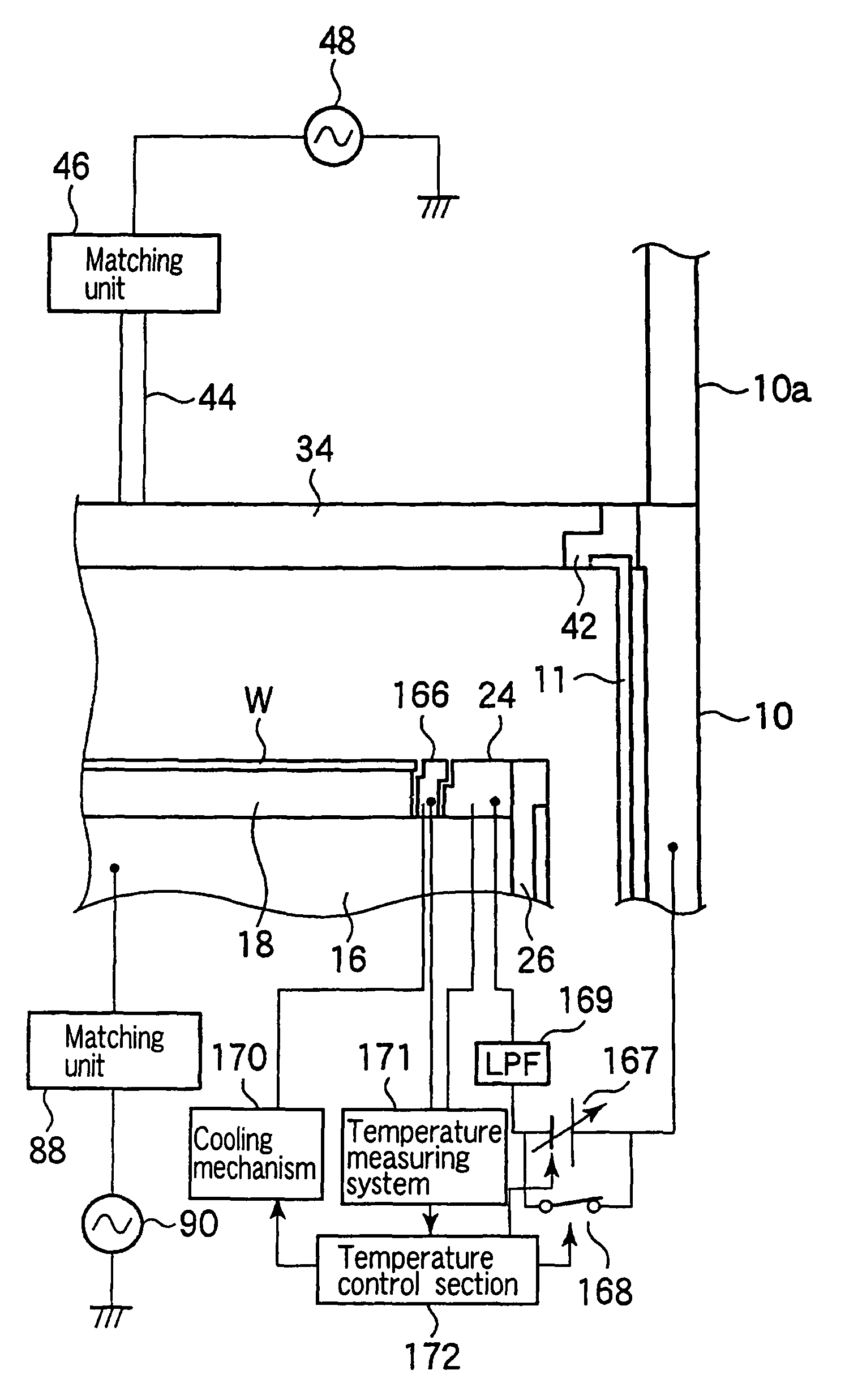

Plasma processing apparatus and method

ActiveUS7988816B2Improved resistance characteristicsIncrease chanceElectric discharge tubesElectric arc lampsNegative biasDc voltage

A plasma etching apparatus includes an upper electrode and a lower electrode, between which plasma of a process gas is generated to perform plasma etching on a wafer W. The apparatus further comprises a cooling ring disposed around the wafer, a correction ring disposed around the cooling ring, and a variable DC power supply directly connected to the correction ring, the DC voltage being preset to provide the correction ring with a negative bias, relative to ground potential, for attracting ions in the plasma and to increase temperature of the correction ring to compensate for a decrease in temperature of a space near the edge of the target substrate due to the cooling ring.

Owner:TOKYO ELECTRON LTD

Process of making dispersed polyetherimide micronized particles and process of coating and further forming of these particles products made therefrom

InactiveUS20140272430A1Improve interface adhesionImprove performanceSynthetic resin layered productsPretreated surfacesFiberPolymer science

Processes involving wetting fibers with an aqueous dispersion of micronized thermoplastic powders; processes for producing an aqueous dispersion of micronized thermoplastic powders; processes of chemically surface cross-linking micronized particles; and articles of produced therefrom.

Owner:SABIC GLOBAL TECH BV

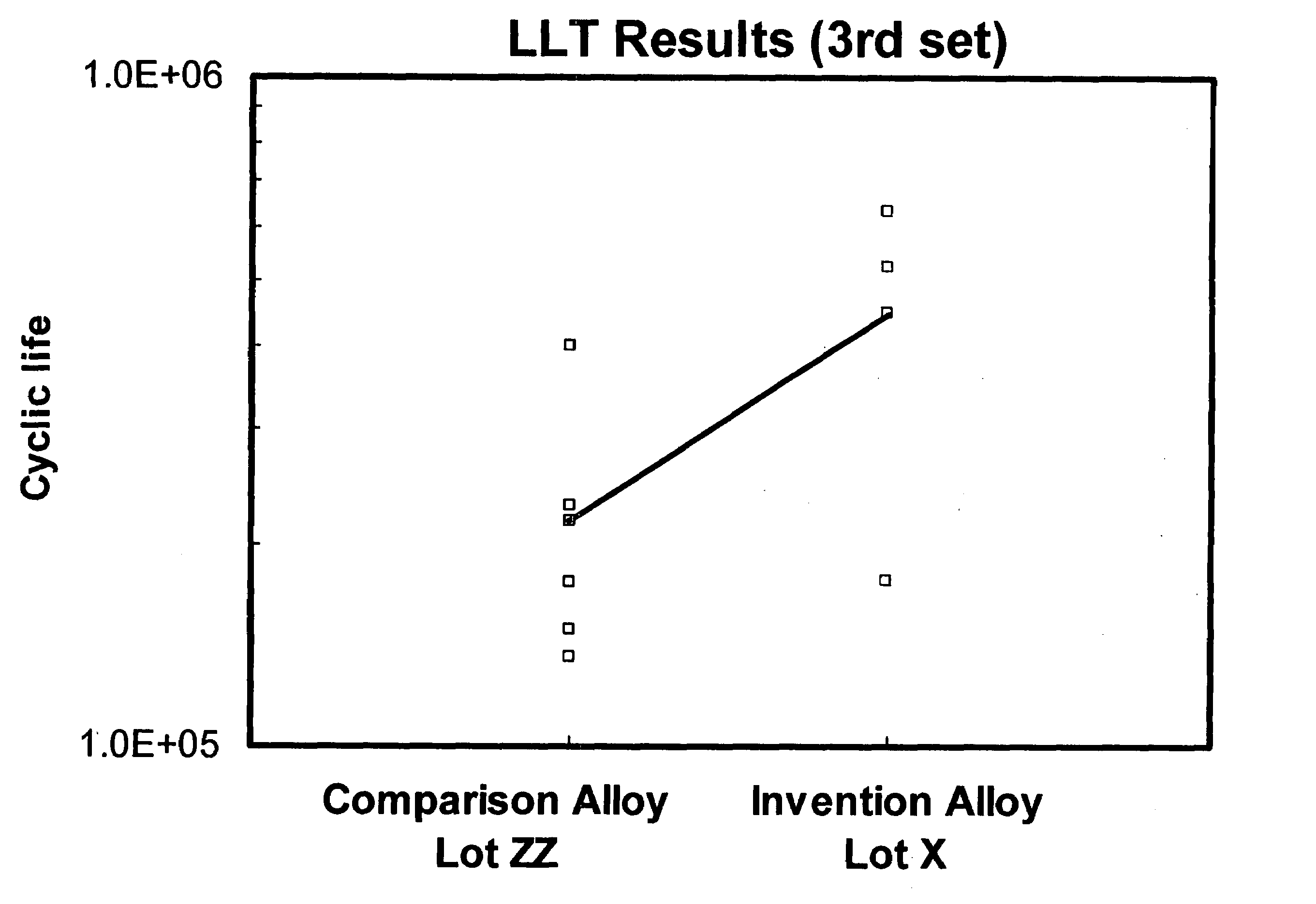

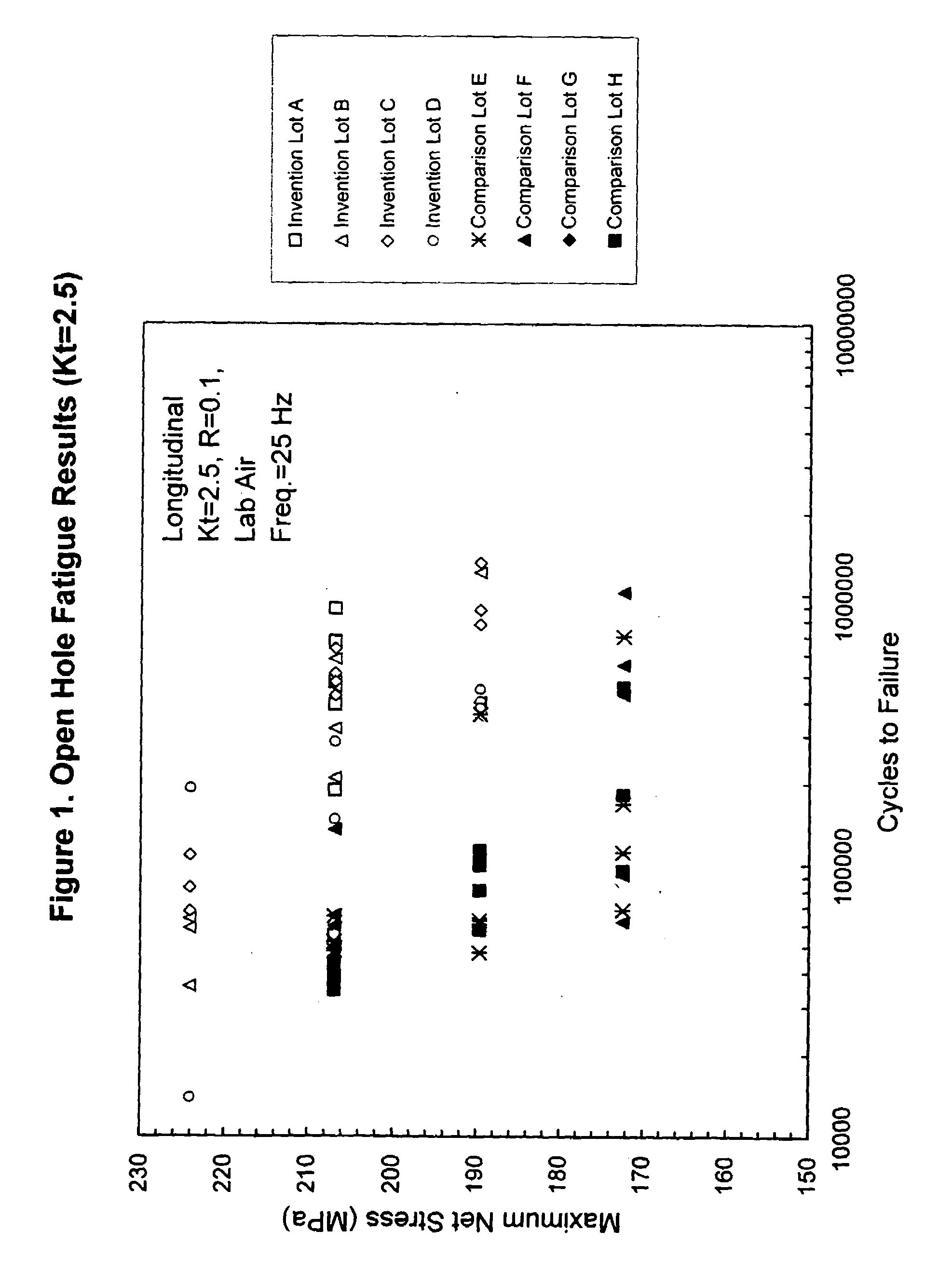

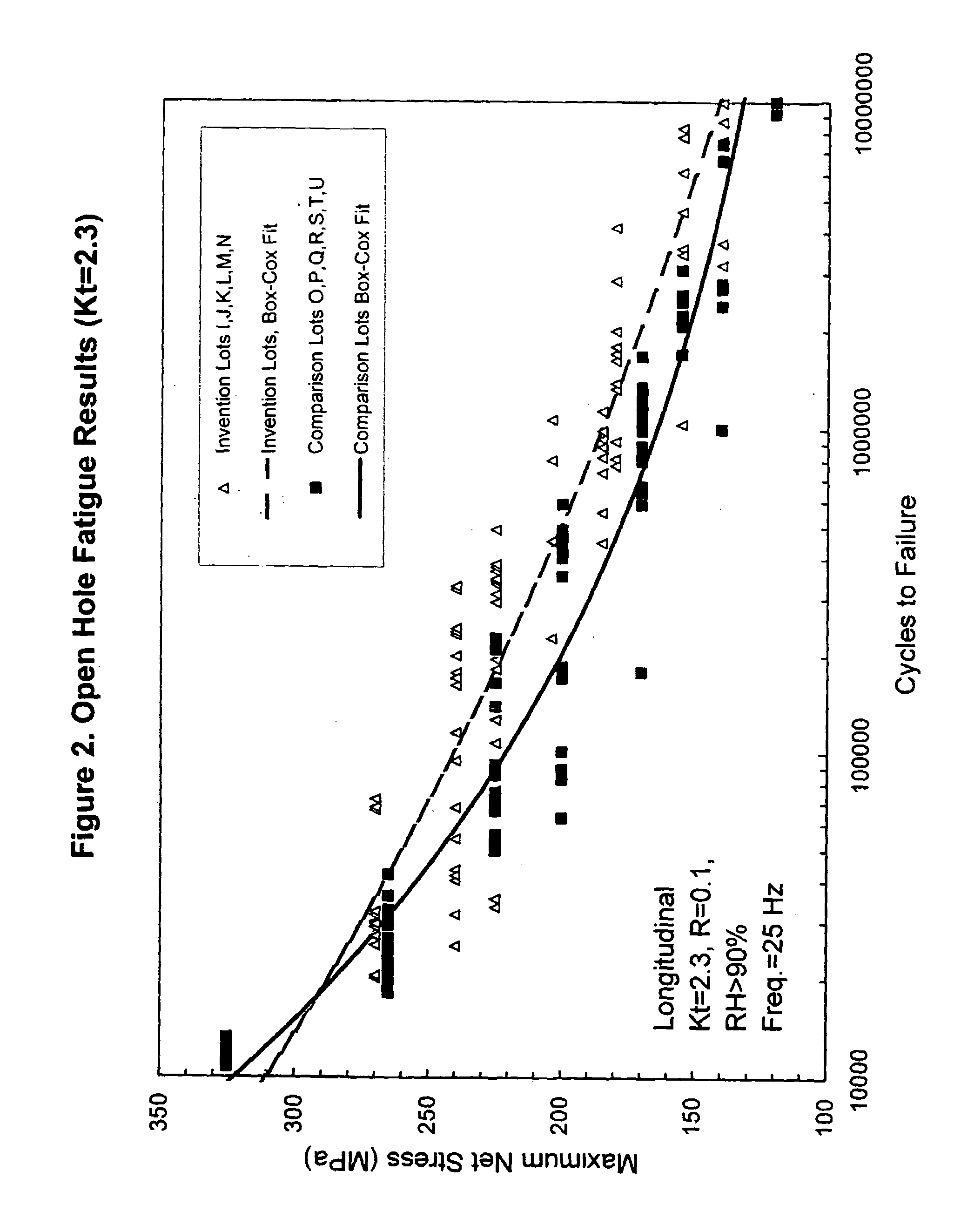

Aluminum alloy product having improved combinations of properties

An alloy product having improved fatigue failure resistance, comprising about, by weight, 7.6 to about 8.4% zinc, about 2.0 to about 2.6% copper, about 1.8 to about 2.3% magnesium, about 0.088 to about 0.25.% Zr, about 0.01 to about 0.09.% Fe, and about 0.01 to about 0.06 w % Si the balance substantially aluminum and incidental elements and impurities The alloy product, suitable for aerospace applications, exhibits improved fatigue failure resistance than its 7055 counterpart of similar size, shape, thickness and temper.

Owner:ARCONIC INC

Abuse resistant opioid drug-ion exchange resin complexes having hybrid coatings

ActiveUS20120135077A1Favorable abuse resistance propertyImproved resistance characteristicsPowder deliveryNervous disorderMedicineIon-exchange resin

A sustained release formulation for opioid drugs is described. The formulation contains an opioid-ion exchange resin complex having a hybrid coating. The hybrid coating contains a cured polyvinylacetate polymer and a pH-dependent enteric coating layer mixed therein. Also provided are methods of making and using same.

Owner:TRIS PHARMA

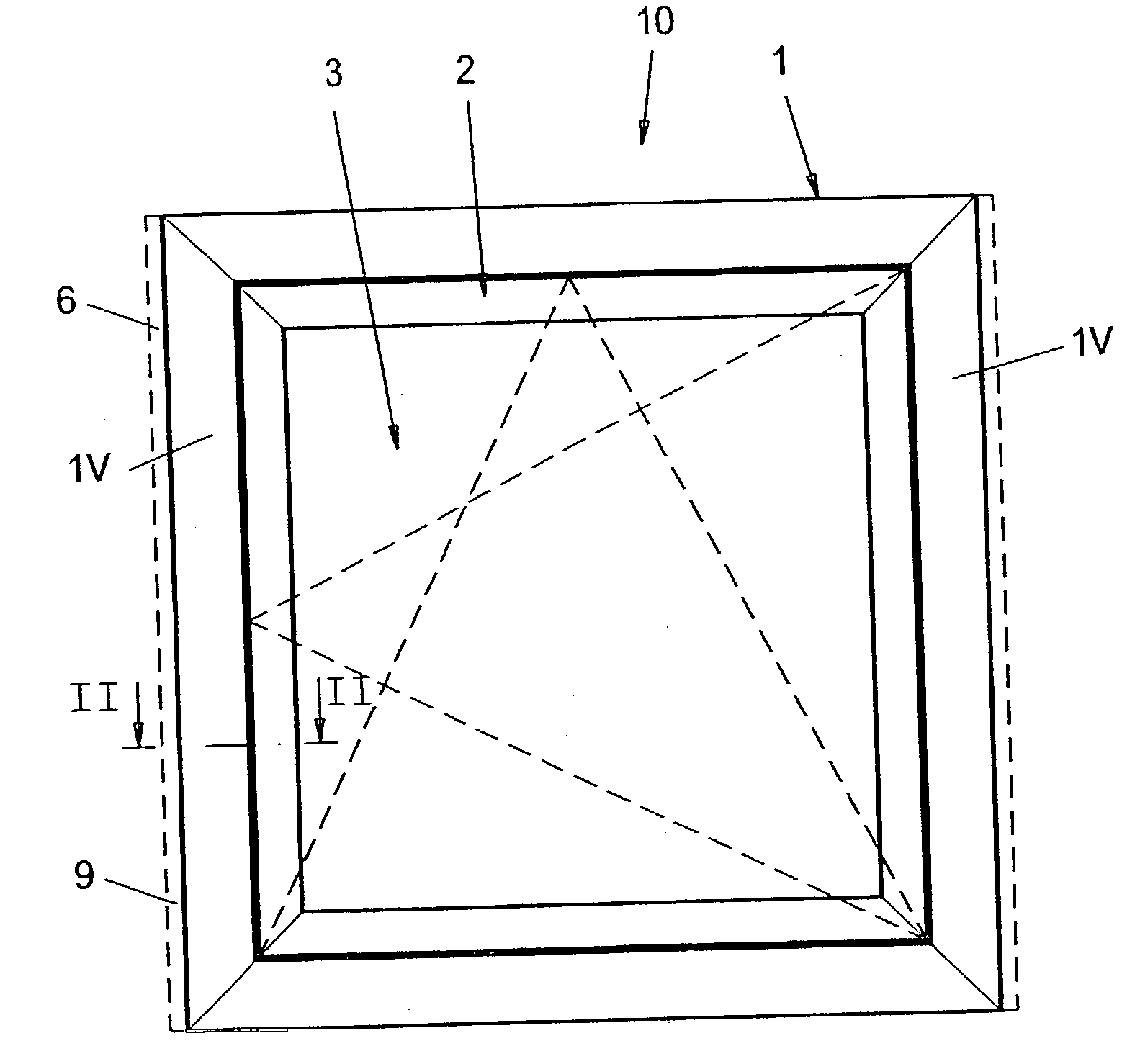

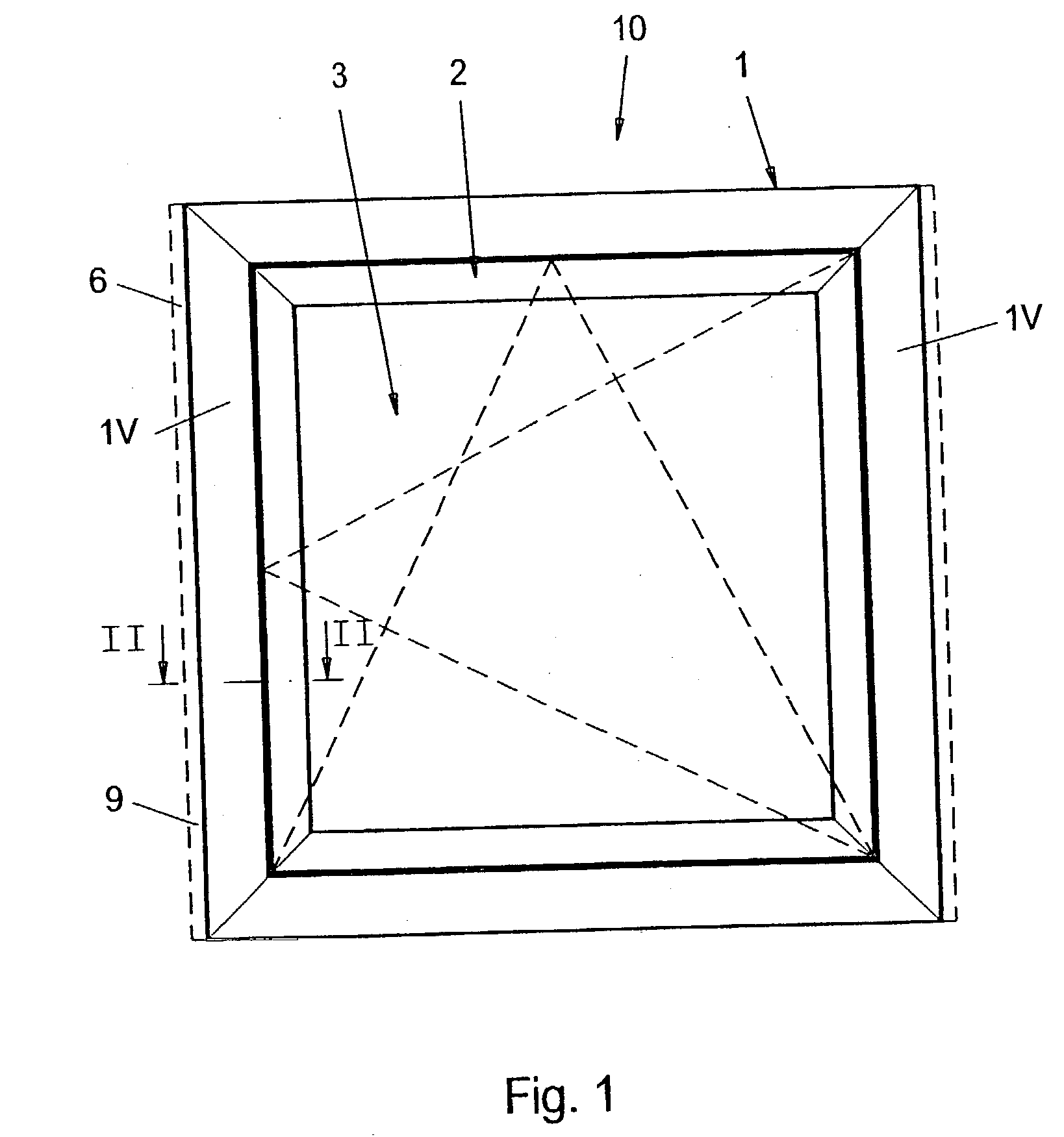

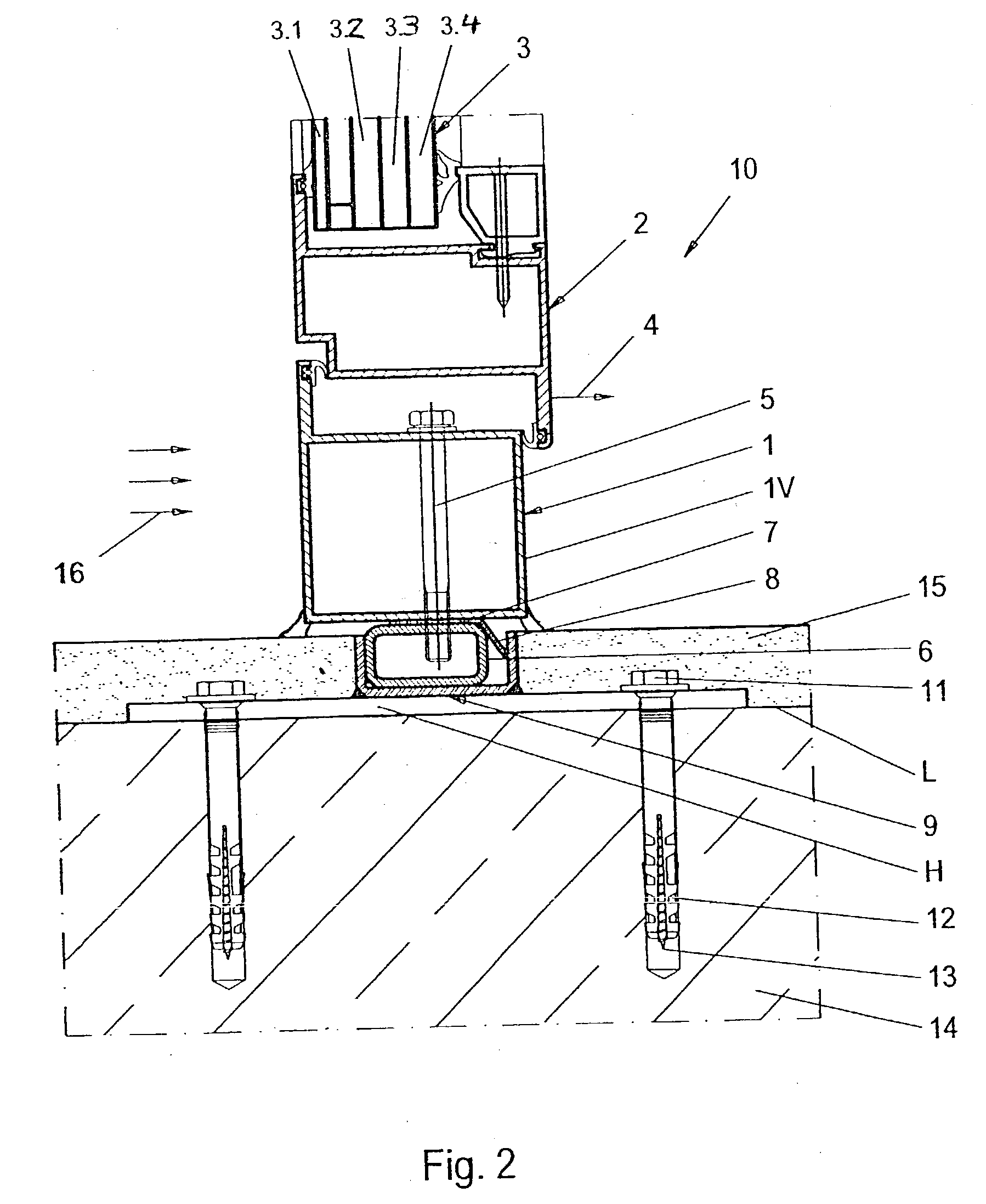

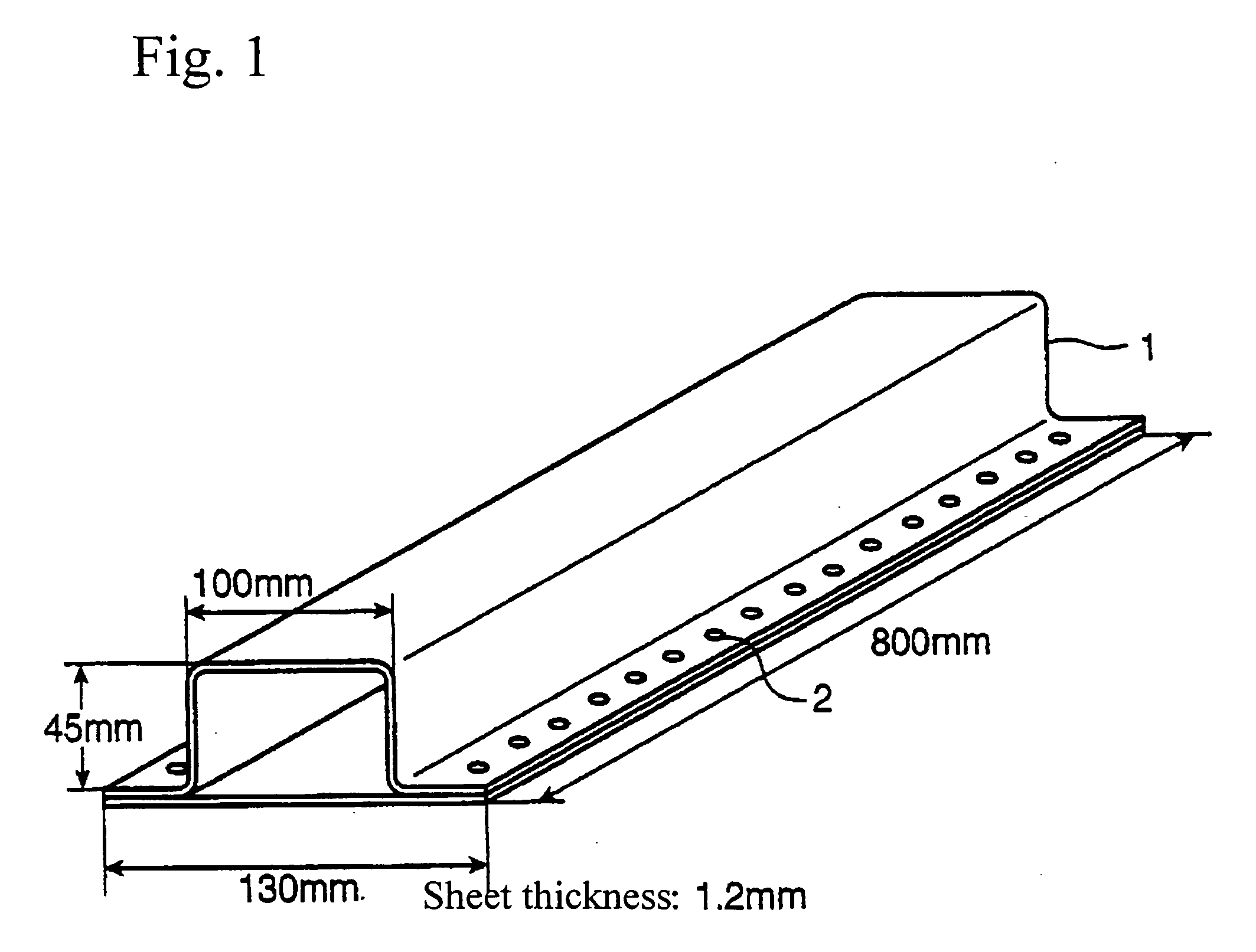

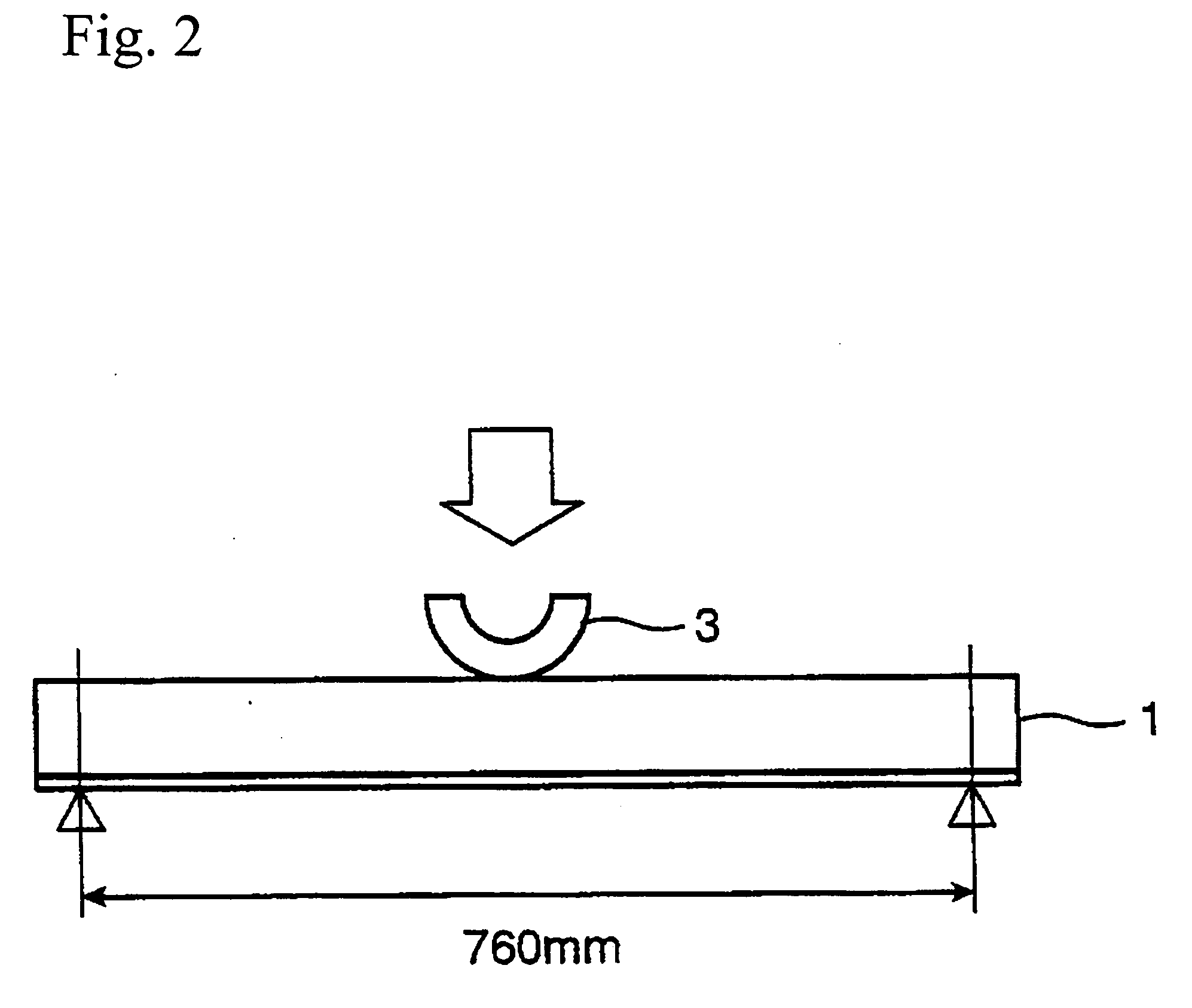

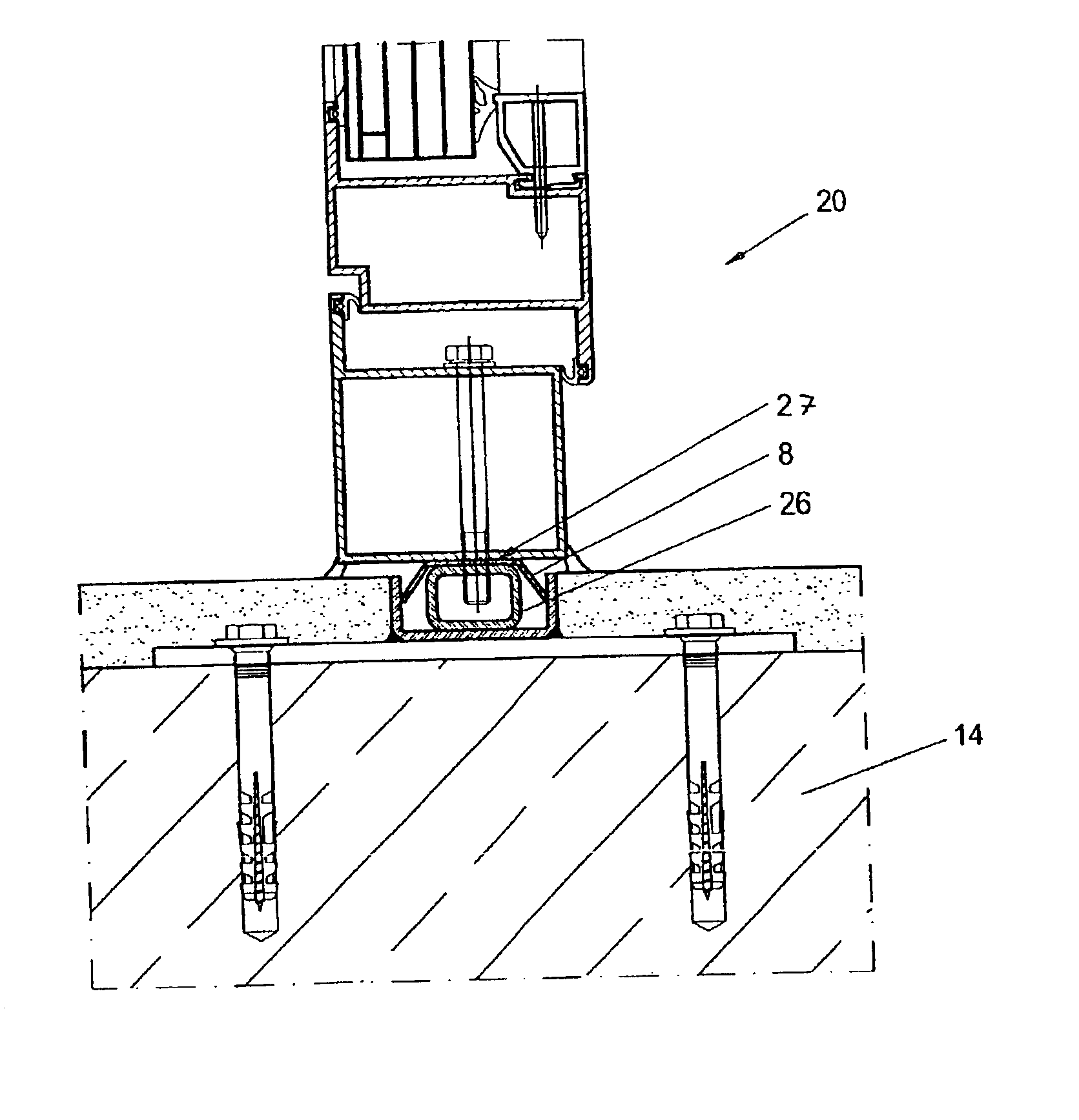

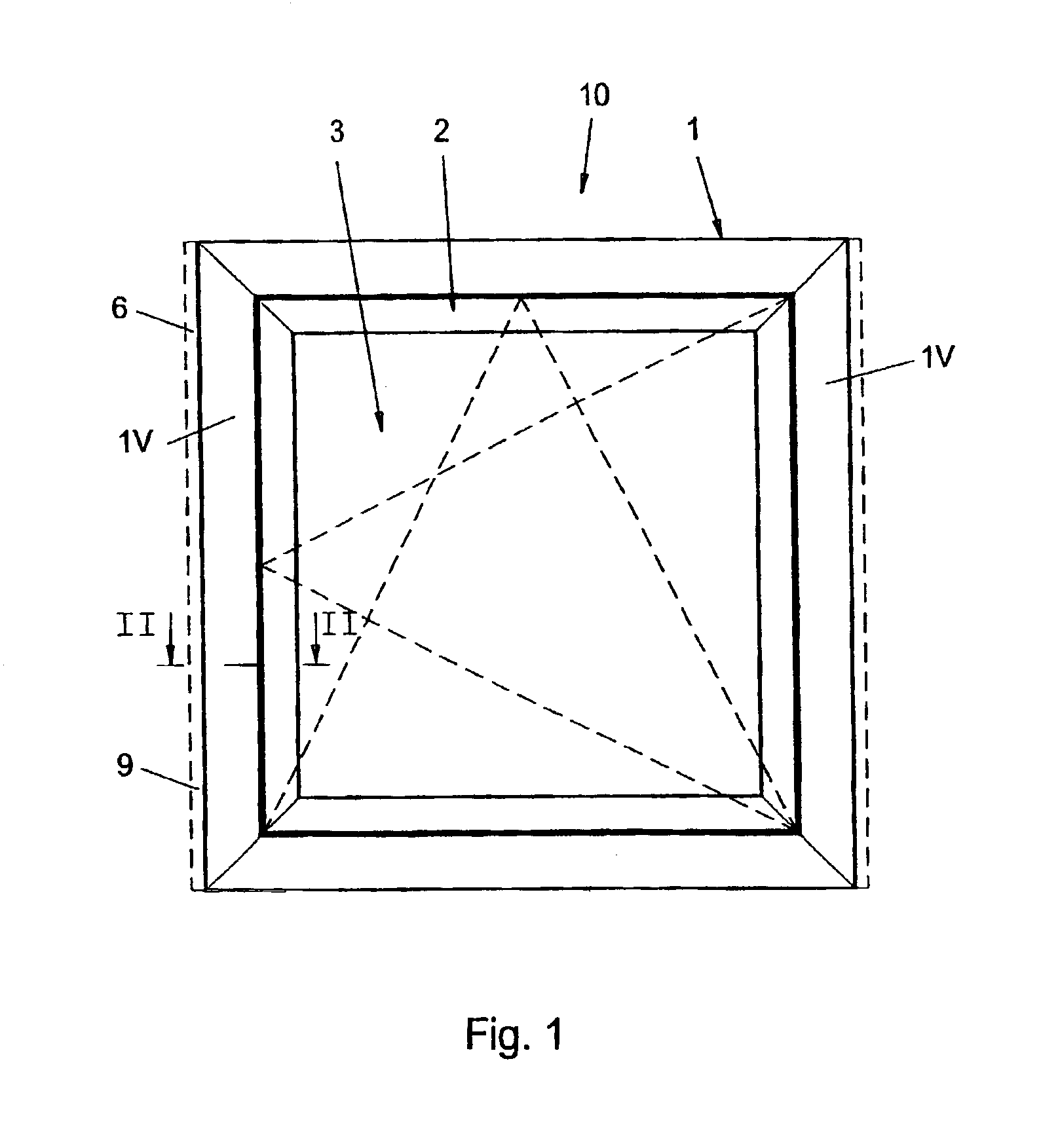

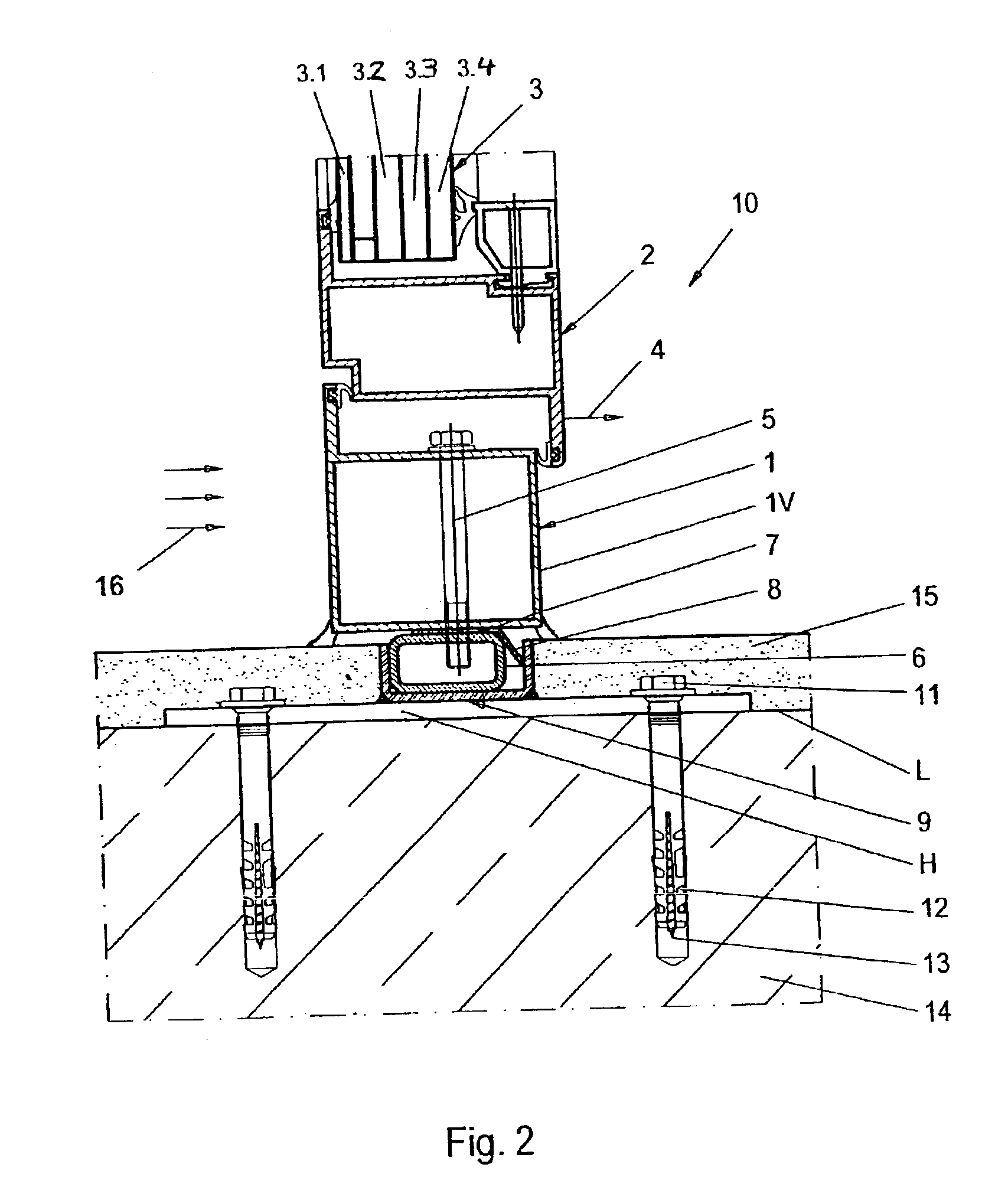

Building closure, such as a door or window, constructed to resist an explosive blast

InactiveUS20030208970A1Improved resistance characteristicsReduce complexityArtificial islandsFrame fasteningMetal stripsAbsorbed energy

An opening in a building wall is closed by a building closure such as a window or door. A mounting part of the closure arrangement is received in a space between two countersupport surfaces formed by a U-channel or opposite L-members that protrude perpendicularly from the sill or jamb surface of the wall bounding the opening. Mounting brackets secure the U-channel or L-members to the wall. On one or both sides, a respective damping element is interposed between the mounting part and the respective adjacent countersupport surface. The damping element may be a plastically deformable metal strip. When an explosion force acts on the closure arrangement, the damping element is first plastically deformed to absorb energy, before the remaining force is transmitted into the building wall. The two damping elements on opposite sides damp forces from the positive and negative pressure waves of the explosion.

Owner:SALZER SICHERHEITSTECHN

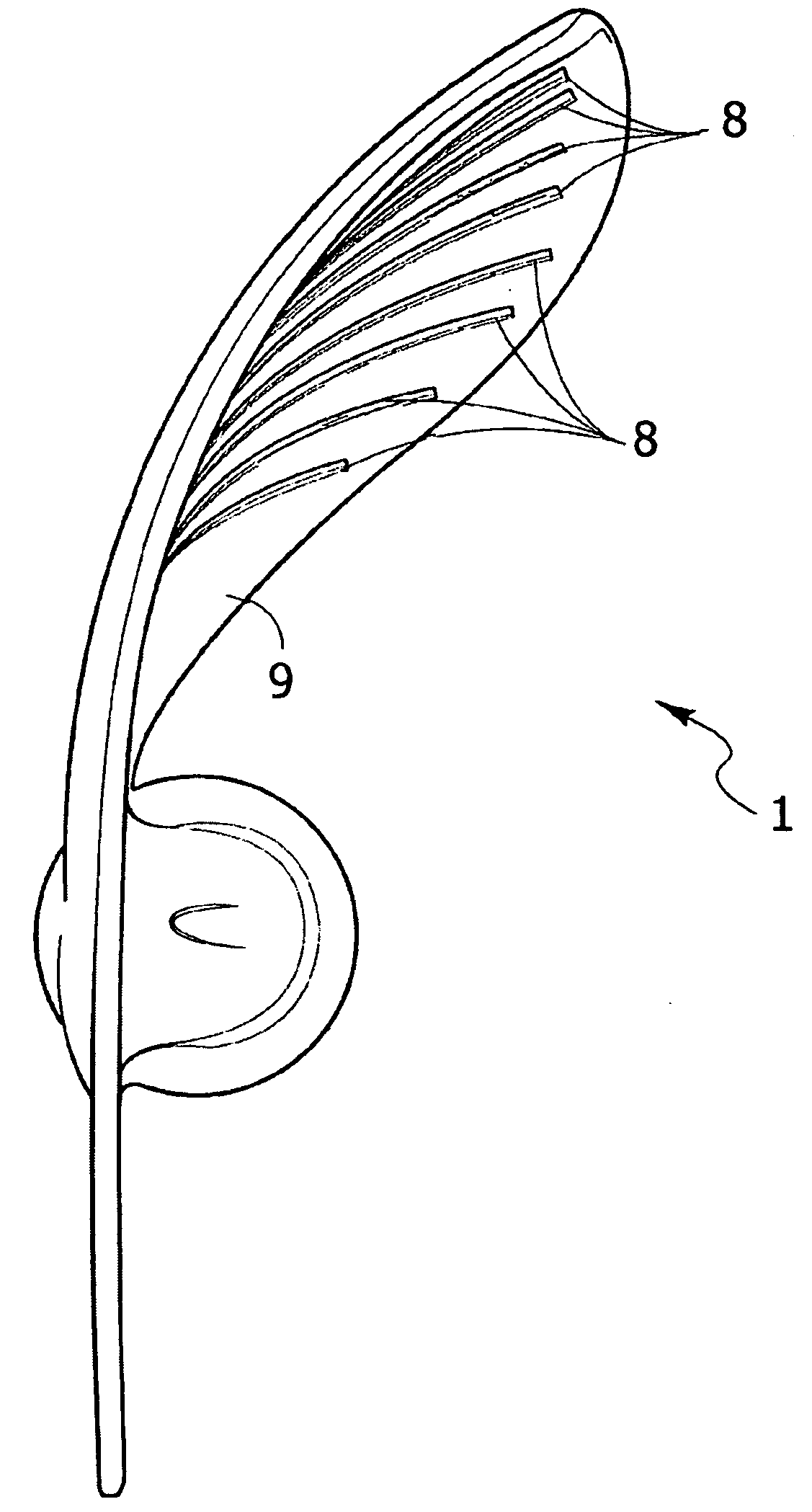

Variable geometry fan and method for manufacturing the blades thereof

InactiveUS20090175726A1High mechanical resistance propertyImproved resistance characteristicsPropellersRotary propellersComposite structureEngineering

A fan, particularly for cooling internal combustion engines for earth moving machines, whose blades have an elastically deformable composite structure including at least one shape memory alloy foil adapted to be heated by means of electric current to vary the geometry of the blade.

Owner:ROSATI FRAT

Waterborne multistage polymer dispersion

InactiveUS8013050B2Easy to operateImproved resistance characteristicsCoatingsVibration suppression adjustmentsPolymer scienceEmulsion

Owner:NUPLEX RESINS BV

Polyester resin composition

InactiveUS6326435B1Easy to prepareEasy to processTin organic compoundsConductive materialPolymer modifiedCarboxylic acid

Owner:POLYPLASTICS CO LTD

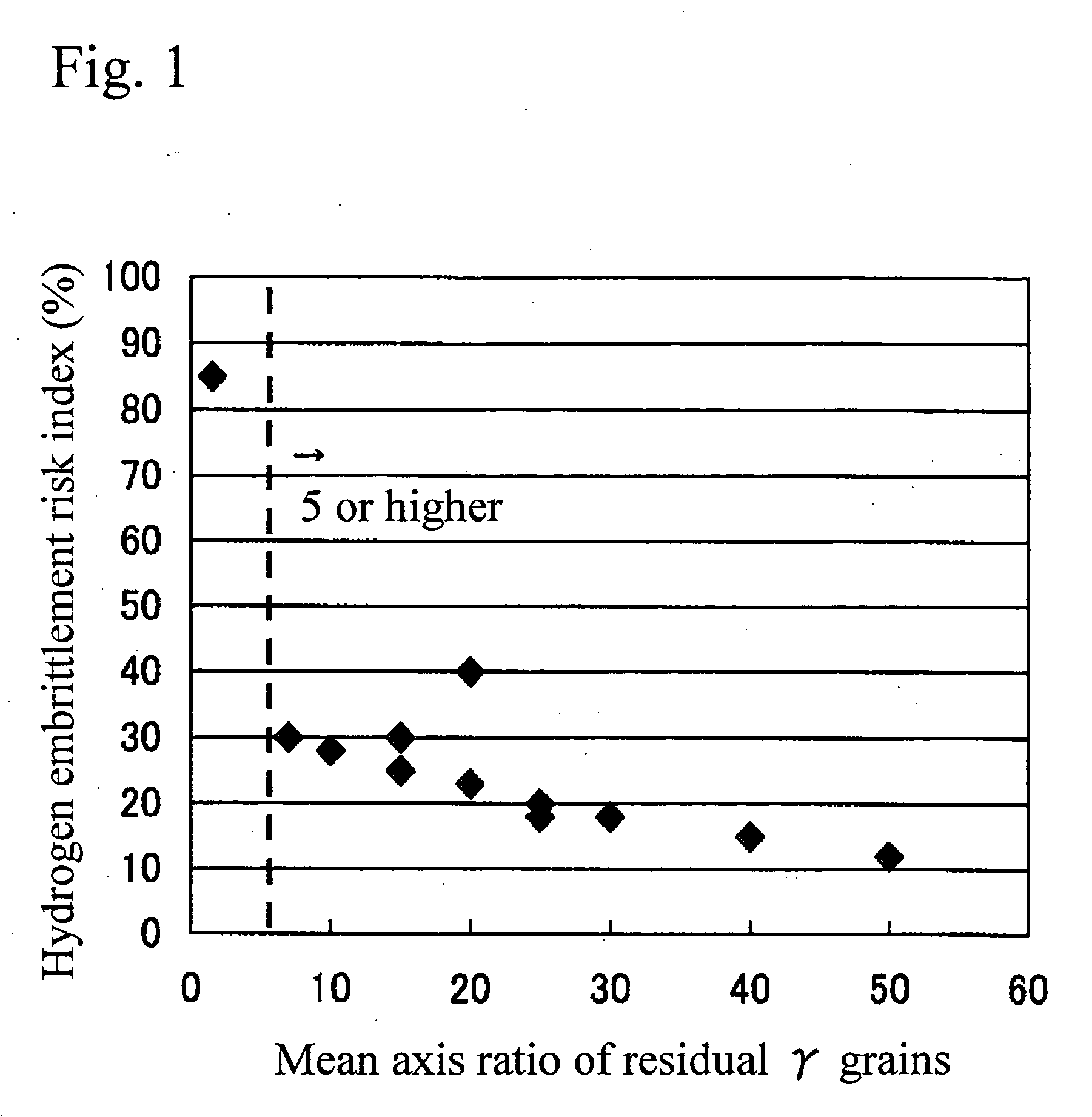

High strength thin steel sheet having high hydrogen embrittlement resisting property and high workability

The present invention provides a high strength thin steel sheet that has high hydrogen embrittlement resisting property and high workability. The high strength thin steel sheet having high hydrogen embrittlement resisting property has a metallurgical structure after stretch forming process to elongate 3% comprises: (i) 1% or more residual austenite; 80% or more in total of bainitic ferrite and martensite; and 9% or less (may be 0%) in total of ferrite and pearlite in terms of proportion of area to the entire structure, wherein the mean axis ratio (major axis / minor axis) of the residual austenite grains is 5 or higher, or (ii) 1% or more residual austenite in terms of proportion of area to the entire structure; mean axis ratio (major axis / minor axis) of the residual austenite grains is 5 or higher; mean length of minor axes of the residual austenite grains is 1 μm or less; minimum distance between the residual austenite grains is 1 μm or less; and the steel has tensile strength of 1180 MPa or higher.

Owner:KOBE STEEL LTD

Light emitting element and light emitting device

ActiveUS20070182318A1Easily reflects lightEasy to transportDischarge tube luminescnet screensElectroluminescent light sourcesSecondary layerAmount of substance

A light emitting element of the invention includes n pieces of light emitting layers (n is a natural number) between first and second electrodes. A first layer and a second layer are provided between the mth light emitting layer (m is a natural number of 1≦m≦n) and the m+1th light emitting layer. The first and second layers are contacted to each other. The first layer contains a substance that transports holes easily and a substance with an electron accepting property. The second layer contains a substance that transports electrons easily and a substance with an electron donating property. Molybdenum oxide is used as the substance with the electron accepting property.

Owner:SEMICON ENERGY LAB CO LTD

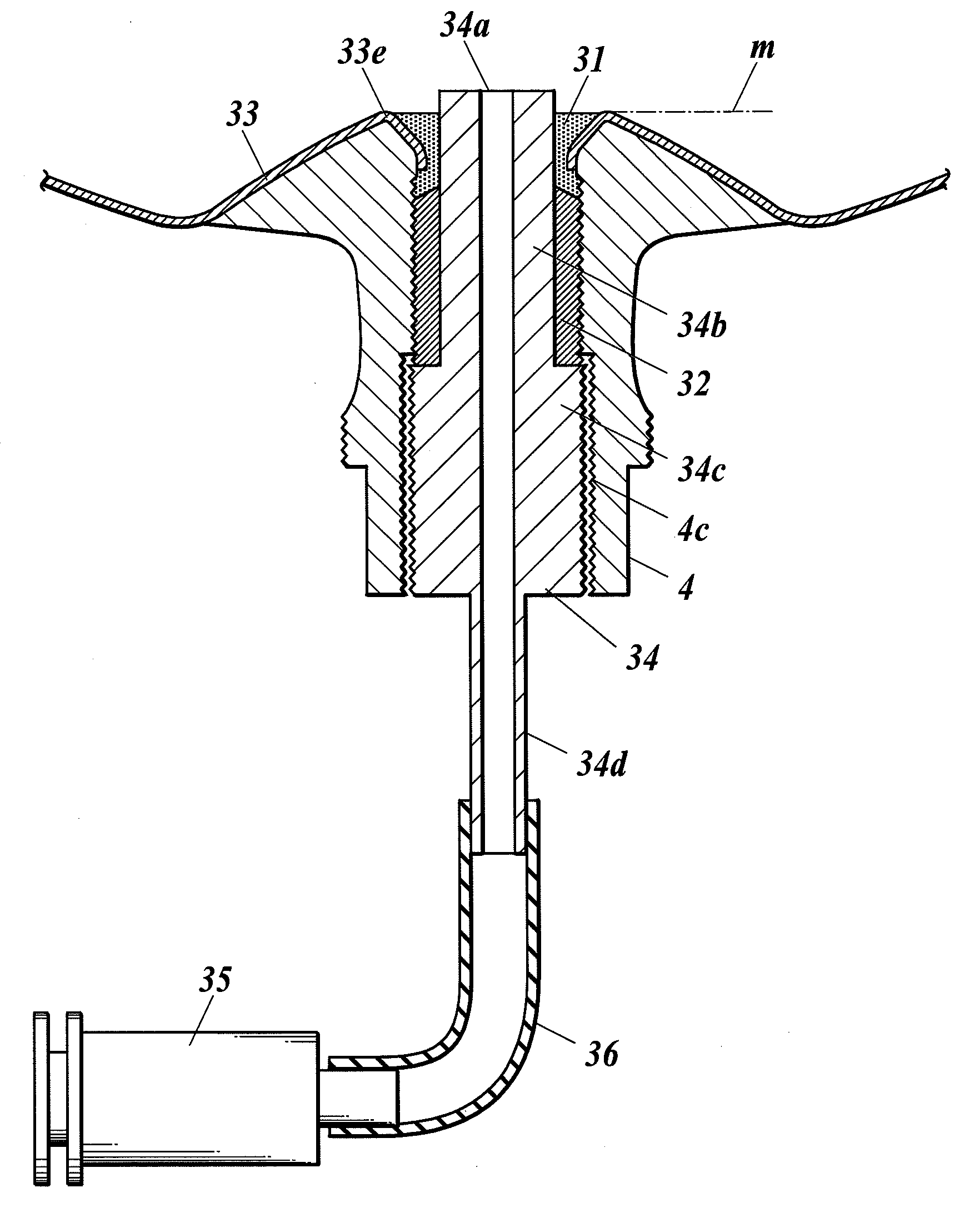

Plasma processing apparatus and method

ActiveUS20110272097A1Improved resistance characteristicsIncrease chanceElectric discharge tubesSemiconductor/solid-state device manufacturingNegative biasDc voltage

A plasma etching apparatus includes an upper electrode and a lower electrode, between which plasma of a process gas is generated to perform plasma etching on a wafer W. The apparatus further comprises a cooling ring disposed around the wafer, a correction ring disposed around the cooling ring, and a variable DC power supply directly connected to the correction ring, the DC voltage being preset to provide the correction ring with a negative bias, relative to ground potential, for attracting ions in the plasma and to increase temperature of the correction ring to compensate for a decrease in temperature of a space near the edge of the target substrate due to the cooling ring.

Owner:TOKYO ELECTRON LTD

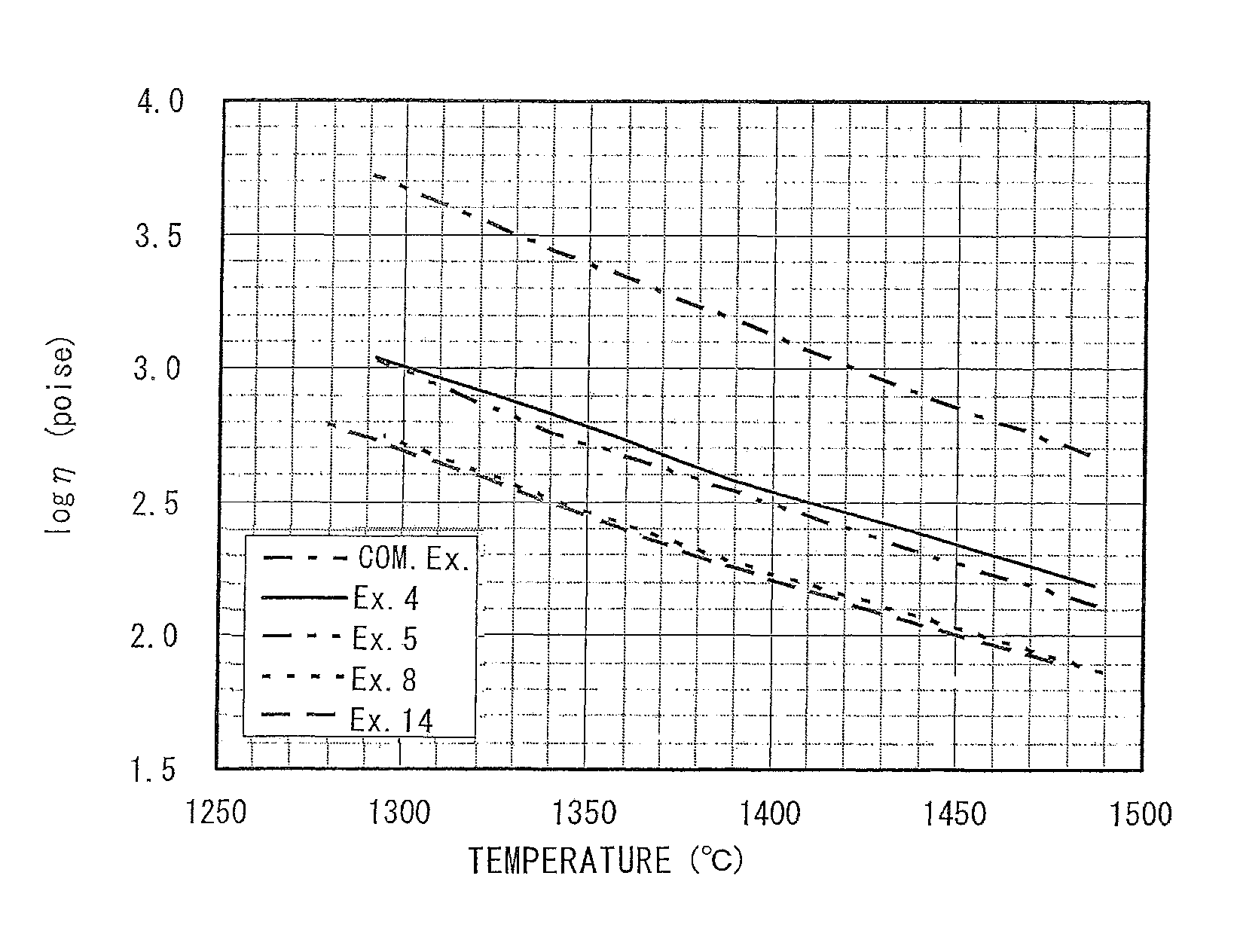

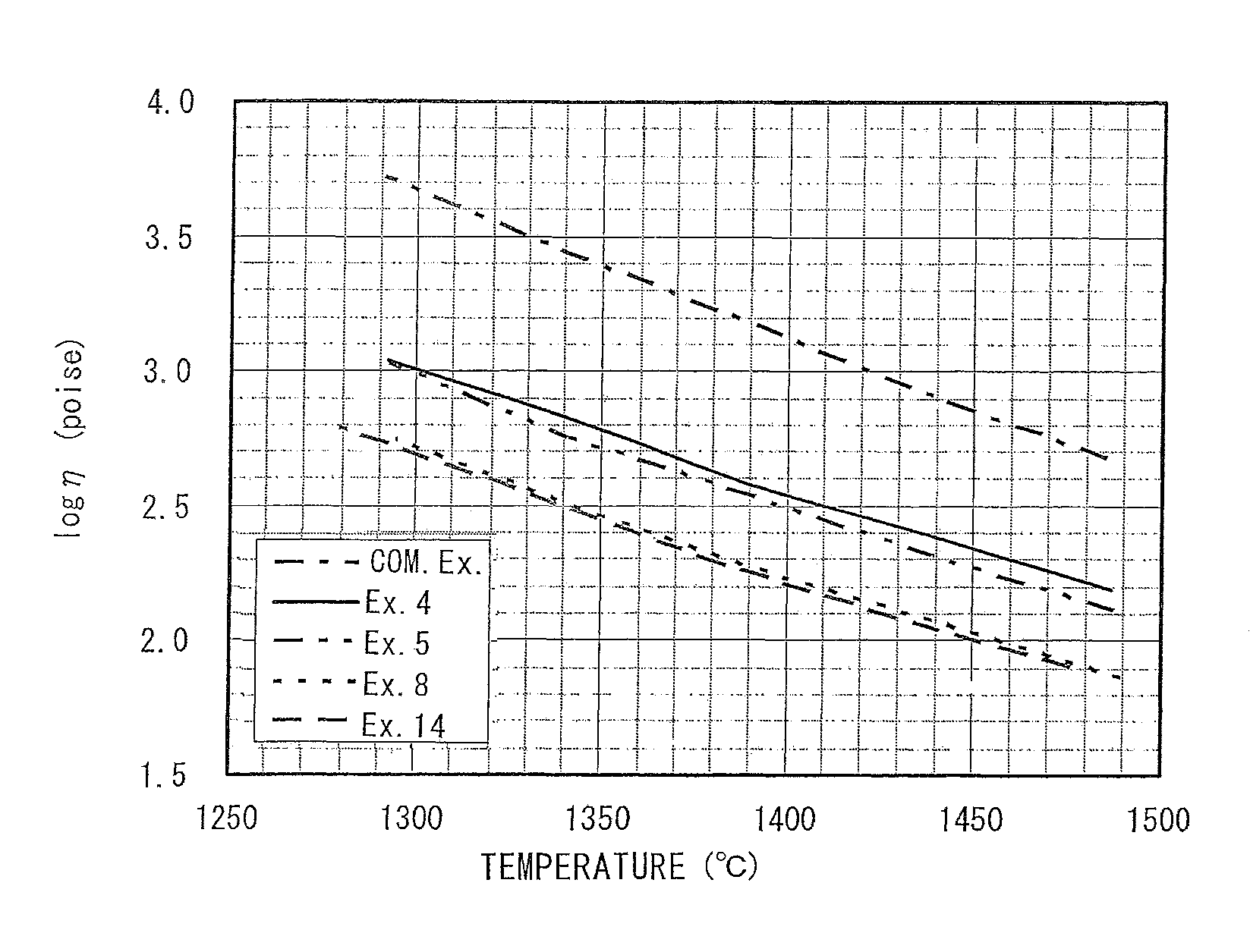

Glass-ceramics

InactiveUS8257831B2High strengthEasy to adaptMagnetic materials for record carriersRecord information storageSolid solutionGlass-ceramic

Glass-ceramics include SiO2, Al2O3 and Li2O on oxide basis. In the glass-ceramics, total amount in mass % of SiO2 and Al2O3 is less than 77% and Li2O / (SiO2+Al2O3) which is the ratio in mass % of the amount of Li2O to the total amount of SiO2 and Al2O3 is 0.064 or over. The glass-ceramics include at least one crystal phase selected from the group consisting of β-quartz, β-quartz solid solution, β-eucryptite, β-eucryptite solid solution, β-spodumene and β-spodumene solid solution.

Owner:OHARA

Building closure, such as a door or window, constructed to resist an explosive blast

InactiveUS6922957B2Improved resistance characteristicsReduce complexityFrame fasteningWindow/door framesMetal stripsAbsorbed energy

An opening in a building wall is closed by a building closure such as a window or door. A mounting part of the closure arrangement is received in a space between two countersupport surfaces formed by a U-channel or opposite L-members that protrude perpendicularly from the sill or jamb surface of the wall bounding the opening. Mounting brackets secure the U-channel or L-members to the wall. On one or both sides, a respective damping element is interposed between the mounting part and the respective adjacent countersupport surface. The damping element may be a plastically deformable metal strip. When an explosion force acts on the closure arrangement, the damping element is first plastically deformed to absorb energy, before the remaining force is transmitted into the building wall. The two damping elements on opposite sides damp forces from the positive and negative pressure waves of the explosion.

Owner:SALZER SICHERHEITSTECHN

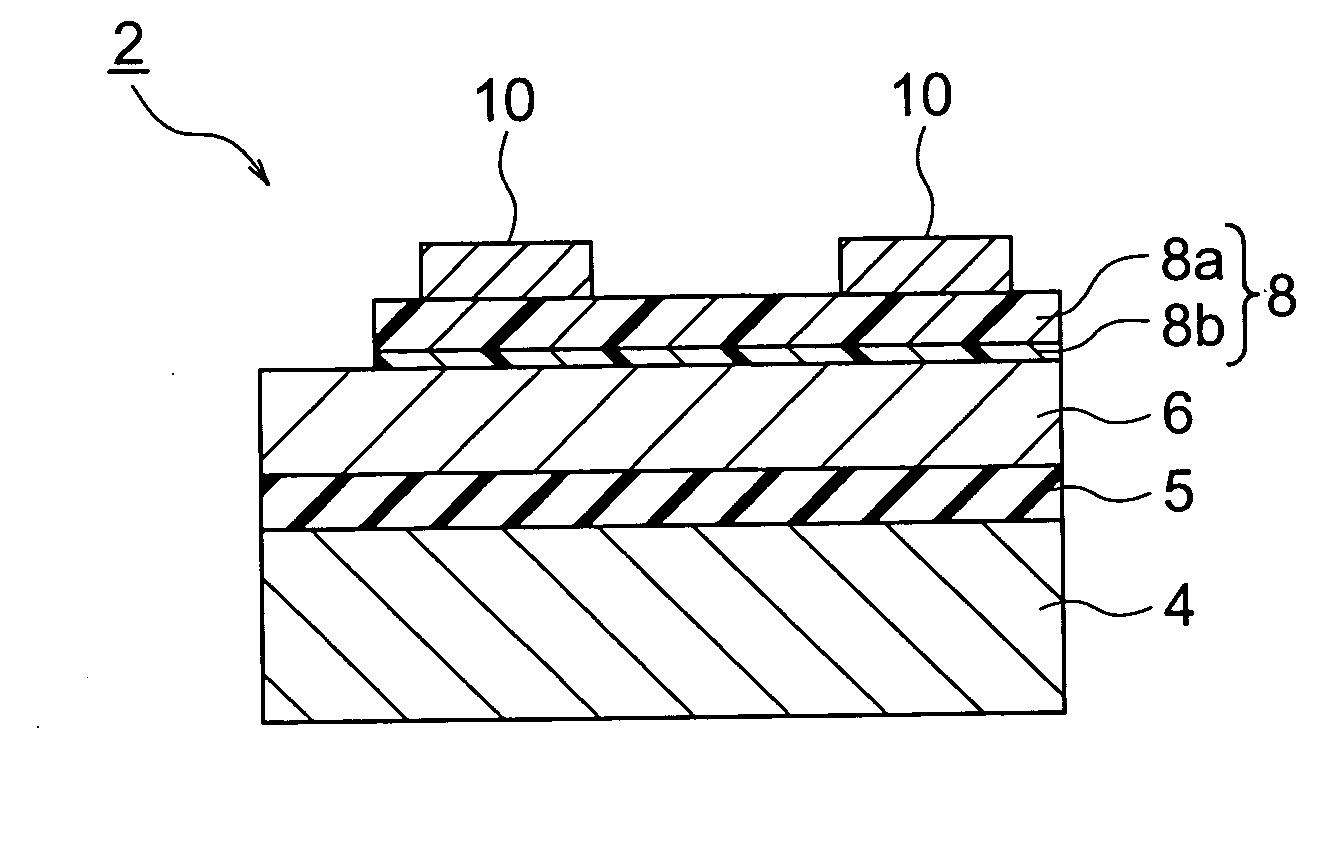

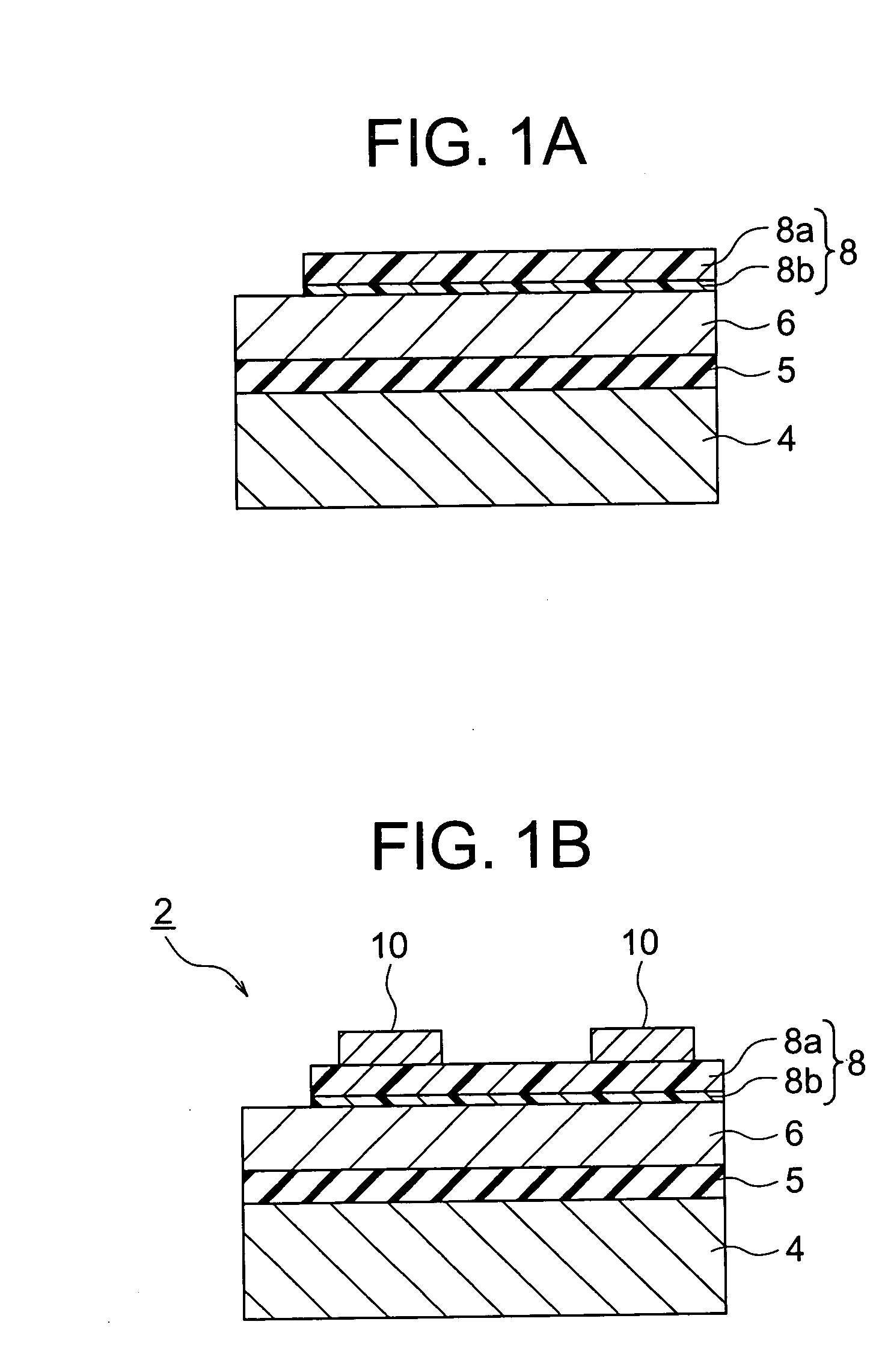

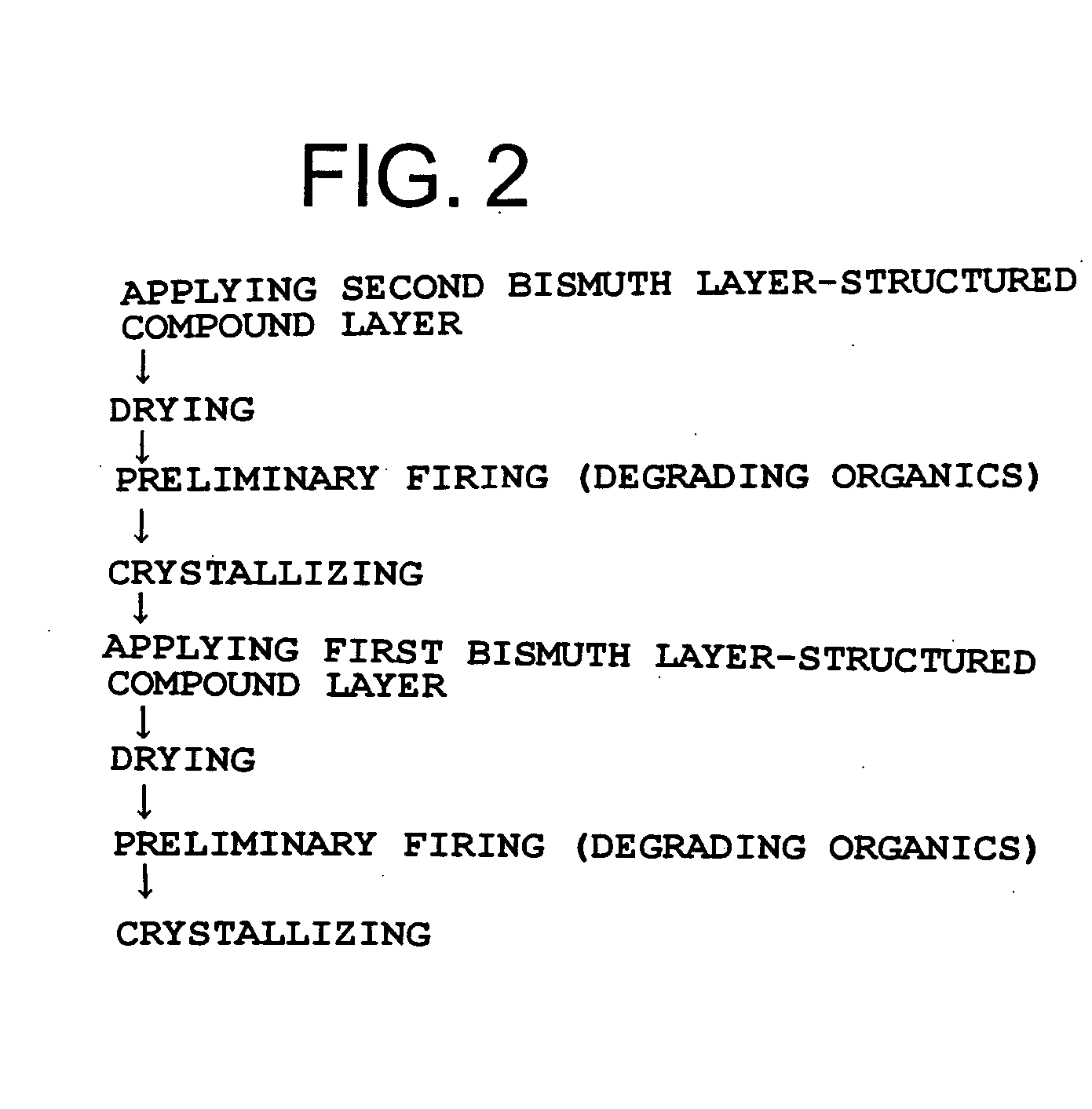

High-permittivity insulation film, thin film capacity element, thin film multilayer capacitor, and production method of thin film capacity element

ActiveUS20060091494A1Good effectImprove leak propertyThin/thick film capacitorFixed capacitor dielectricOptoelectronicsPermittivity

A dielectric thin film 8, comprising a first bismuth layer-structured compound layer 8a expressed by a composition formula of (Bi2O2)2+(Am−1 Bm O3m+1)2− or Bi2 Am−1 Bm O3m+3, wherein “m” is a positive number, “A” is at least one element selected from Na, K, Pb, Ba, Sr, Ca and Bi, and “B” is at least one element selected from Fe, Co, Cr, Ga, Ti, Nb, Ta, Sb, V, Mo and W. Between the first bismuth layer-structured compound layer 8a and a lower portion electrode 6, a second bismuth layer-structured compound layer 8b including bismuth in excess of that in the composition formula of said first bismuth layer-structured compound layer 8a.

Owner:TDK CORPARATION

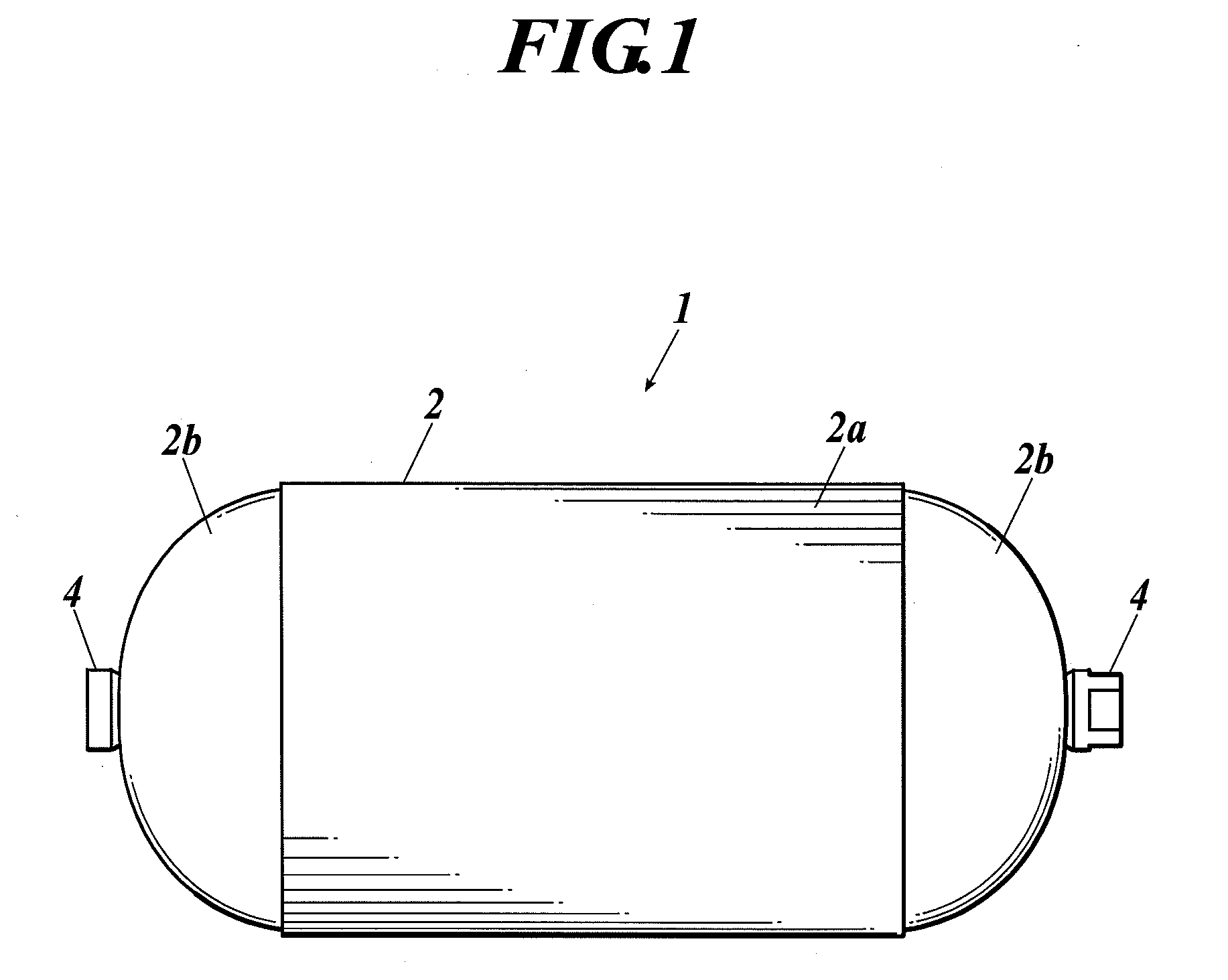

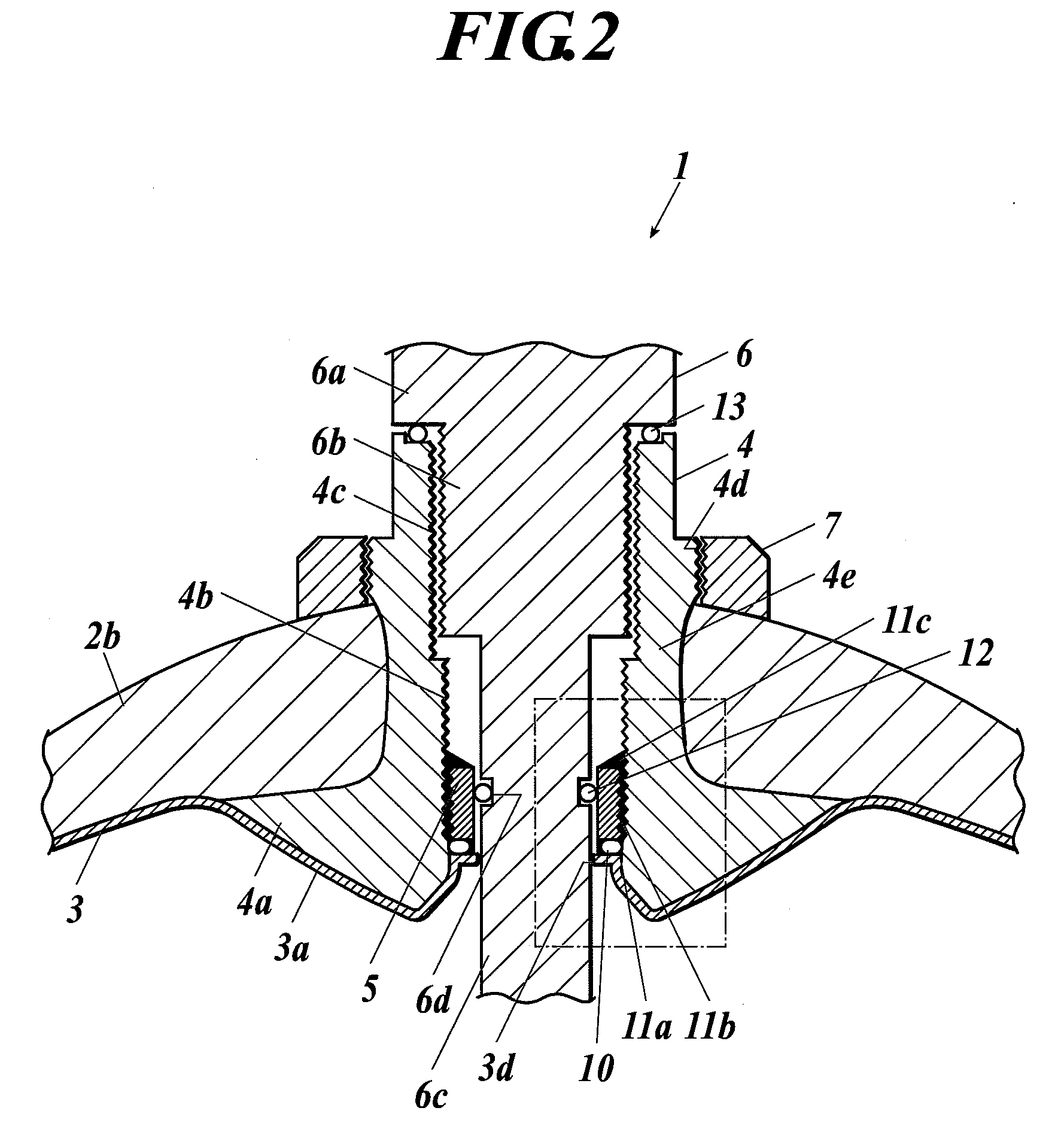

Pressure-Resistant Container

ActiveUS20100163565A1High pressure resistance propertyImprove pressure resistanceVessel mounting detailsVessel manufacturingEngineeringSealant

In a pressure-resistant container 1, a peripheral part 3a of an opening 3d of an inner shell 3 is attached to an end surface of a mouth ring 4 at an inside of the container so as to cover thereof. Further, the pressure-resistant container 1 comprises a cylindrical pressing member 5 which is screwed into an inner peripheral surface 4b of the mount ring 4, an inner peripheral surface b (FIG. 3) of the mouth ring 4 which exposes between the inner shell 3 and the pressing member 5, a first seal (an O-ring 10 and an liquid sealant 11a) which peripherally contacts with the inner shell and the pressing member, a valve 6 having a screw part 6b which screws into an inner periphery 4c of the mouth ring at outside of the container than the pressing member and an inner end part 6c which is inserted in the hole part of the pressing member and a second seal (an O-ring 12) to seal between an outer peripheral surface of the inner end part 6c and an inner peripheral surface of the pressing member. Further, the pressure-resistant container 1 comprises a third seal (an O-ring 13).

Owner:SUBARU CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com