High strength thin steel sheet having high hydrogen embrittlement resisting property and high workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

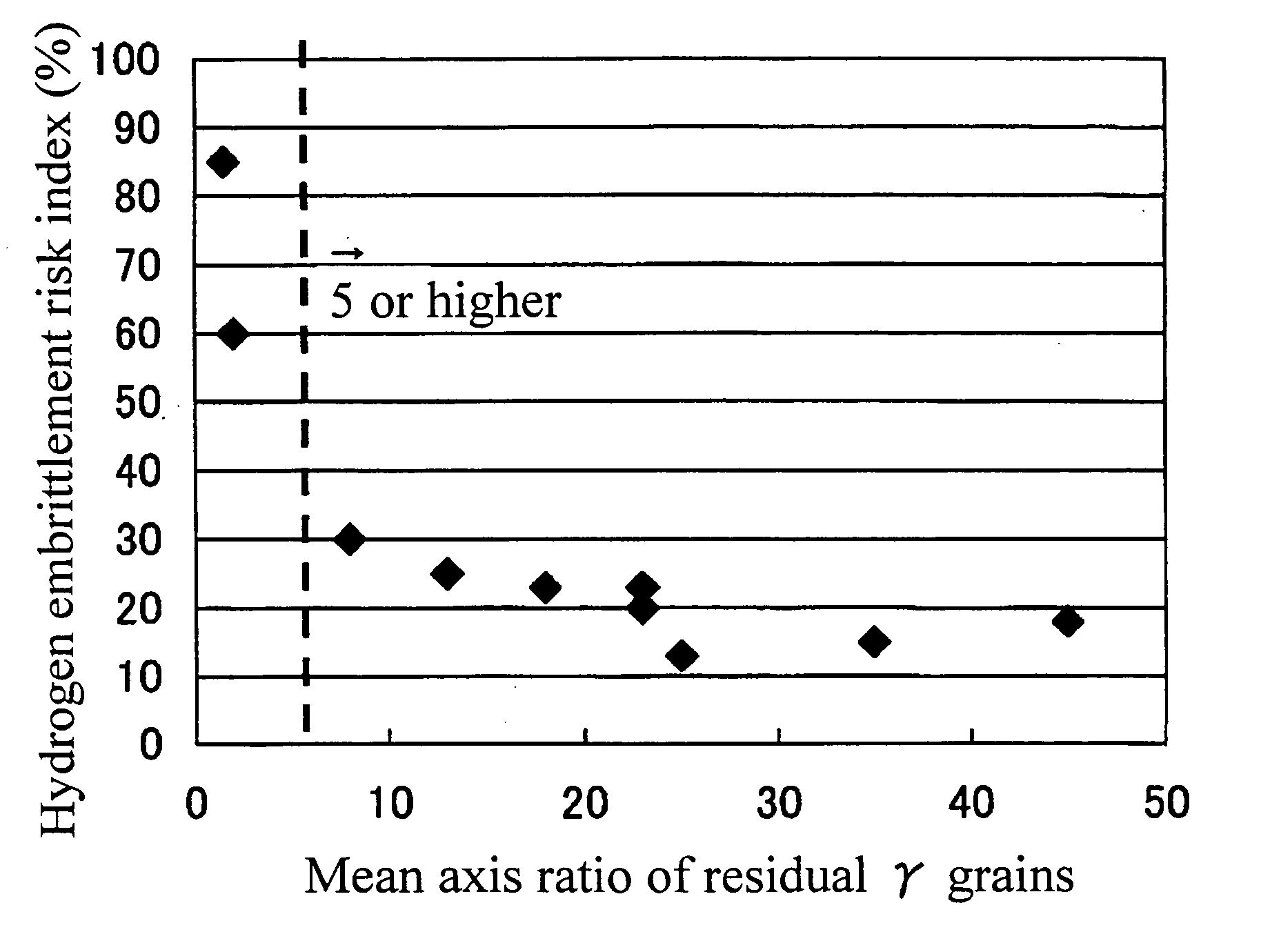

[0039] The first high strength thin steel sheet according to the present invention is constituted from higher than 0.25 and up to 0.60% of C (contents of components given in terms of percentage in this patent application all refer to percentage by weight), 1.0 to 3.0% of Si, 1.0 to 3.5% of Mn, 0.15% or less P, 0.02% or less S, 1.5% or less (higher than 0%) of Al, 1.0% or less (higher than 0%) of Mo and 0.1% or less (higher than 0%) of Nb, while iron and inevitable impurities making up the rest, and is characterized in that:

(i) the metal structure after the forming process contains: 1% or more residual austenite;

80% or more in total of bainitic ferrite and martensite; and

9% or less (may be 0%) in total of ferrite and pearlite in terms of the proportion of area to the entire structure, and

the mean axis ratio (major axis / minor axis) of the residual austenite grains is 5 or higher; and

(ii) the steel contains a specified amount of Mo and / or Nb.

[0040] The requirements described...

second embodiment

[0081] The second high strength thin steel sheet according to the present invention is constituted from higher than 0.25% and up to 0.60% of C (contents of components given in terms of percentage in this patent application all refer to percentage by weight), 1.0 to 3.0% of Si, 1.0 to 3.5% of Mn, 0.15% or less of P, 0.02% or less of S, 1.5% or less (higher than 0%) of Al while iron and inevitable impurities constitute the rest, wherein: (i) the structure after the forming process comprises:

1% or more residual austenite;

mean axis ratio (major axis / minor axis) of the residual austenite grains is 5 or higher;

80% or more in total of bainitic ferrite and martensite; and

9% or less (may be 0%) in total of ferrite and pearlite in the proportion of area to the entire structure, and

(ii) the steel contains specified amount of Cu and / or Ni.

[0082] The requirements (i) have the reasons as described above.

[0083] The requirement (ii) described above has the reason as follows.

[0084] Spec...

third embodiment

[0100] A third high strength thin steel sheet according to the present invention is constituted from higher than 0.25 and up to 0.60% of C (contents of components given in terms of percentage in this patent application all refer to percentage by weight), 1.0 to 3.0% of Si, 1.0 to 3.5% of Mn, 0.15% or less of P, 0.02% or less of S, 1.5% or less (higher than 0%) of Al, while iron and inevitable impurities making up the rest,

wherein: (iii) the structure satisfies the following requirements after forming:

1% or more residual austenite; the mean axis ratio (major axis / minor axis) of the residual austenite grains is 5 or higher;

mean length of minor axes of the residual austenite grains is 1 μm or less; and

minimum distance between residual austenite grains is 1 μm or less.

[0101] When the metal structure is controlled as described above, hydrogen embrittlement resisting property of the high strength thin steel sheet can be sufficiently improved without adding much alloy elements.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com