Patents

Literature

358 results about "Delayed fracture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

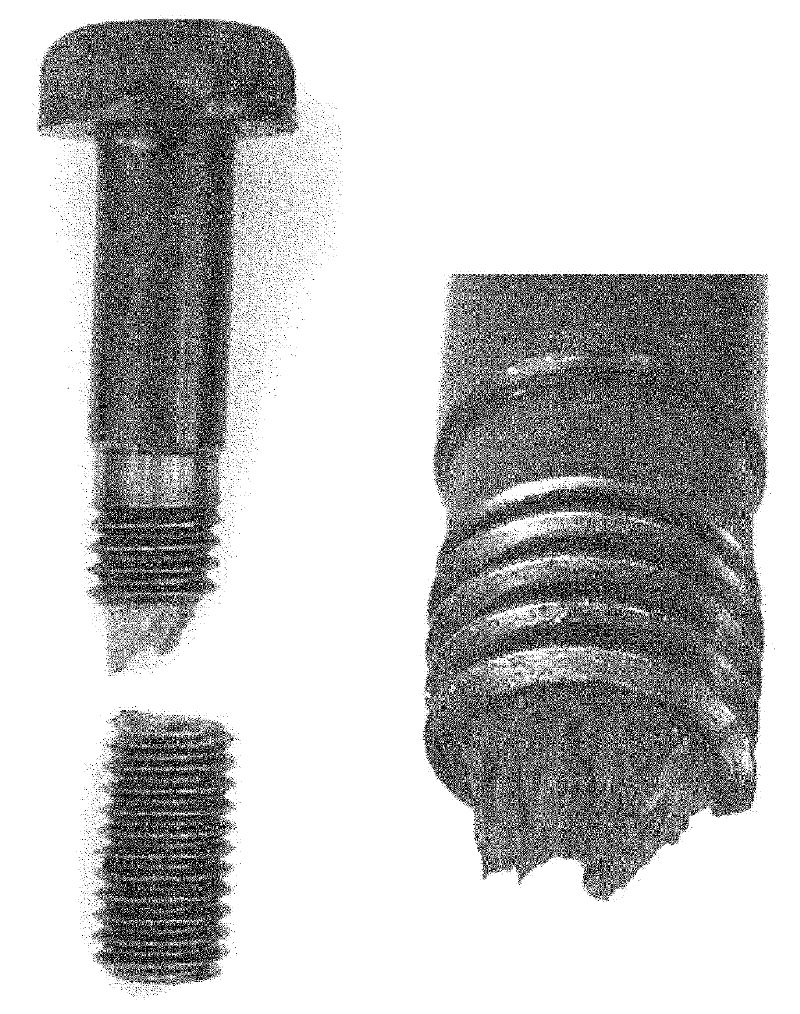

Processing method of high-strength bolts

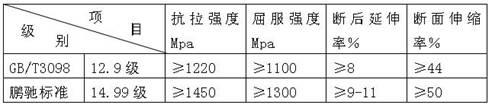

The invention relates to a processing method of bolts, in particular to a processing method of high-strength bolts. SCM440 and 42CrMoVNb materials are adopted for producing the high-strength bolts. The method is characterized by selecting materials, spheroidizing the materials, acid cleaning the materials and drawing wires from the materials until the materials retract to the required diameter, carrying out extrusion molding on the materials 3-4 times on a multi-station cold forging machine to form the required bolt heads and shanks, carrying out rolling to obtain the required threads and thread length and realizing the required hardness and strength through thermal processing and quench tempering. The processing method in which the cold extruding process of the invention is adopted improves the strength of the bolts, achieves the hardness and strength required by the 12.9-class and 14.9-class high-strength bolts, solves the problems of delayed fracture and fatigue fracture of the bolts under high strength, ensures the bolts to be reliably connected and not to be easily fractured during use, prolongs the lives of the bolts and meets the use requirements of various industries in the society for the high-strength bolts.

Owner:EAGLE METALWARE

Hotforming martensitic steel

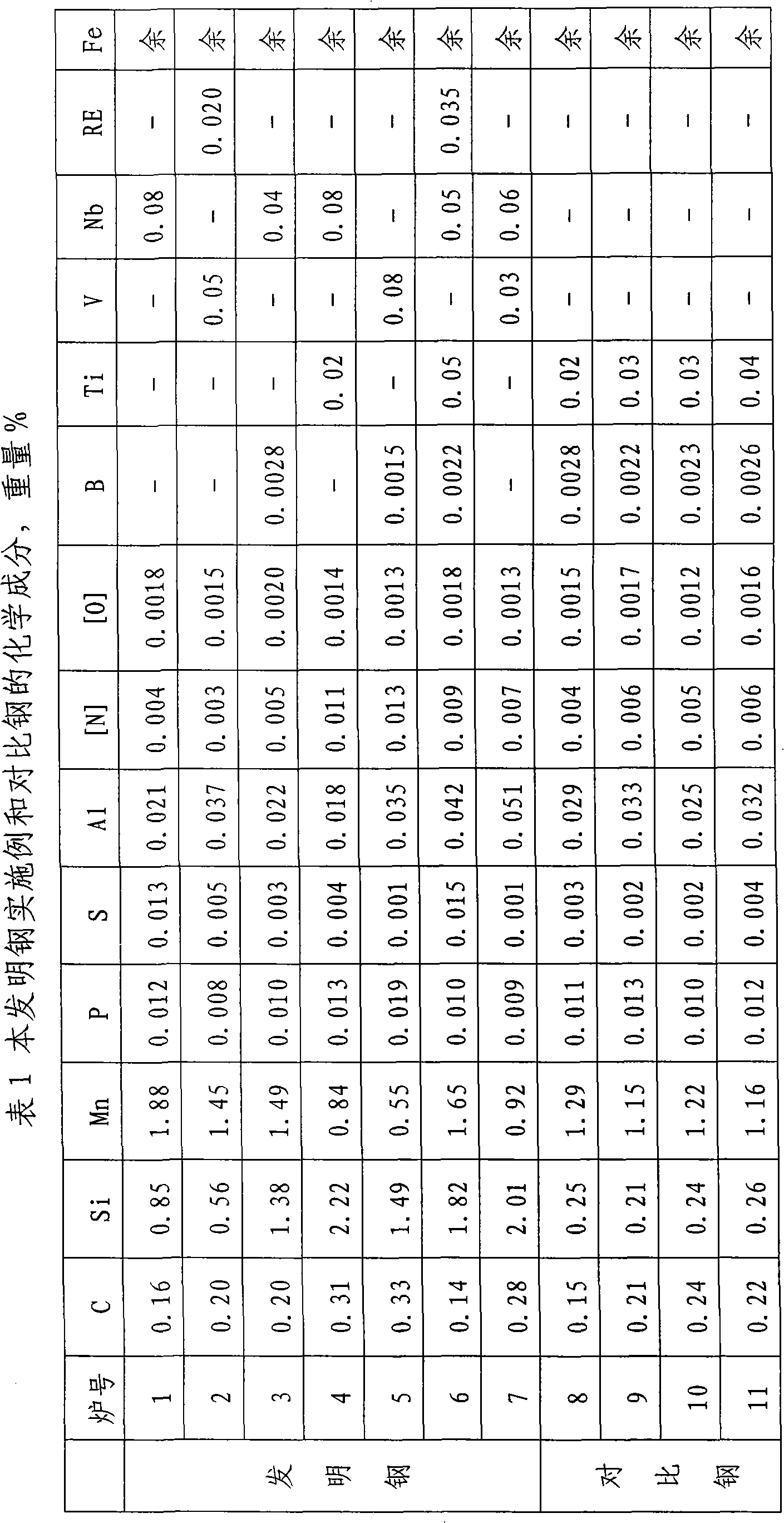

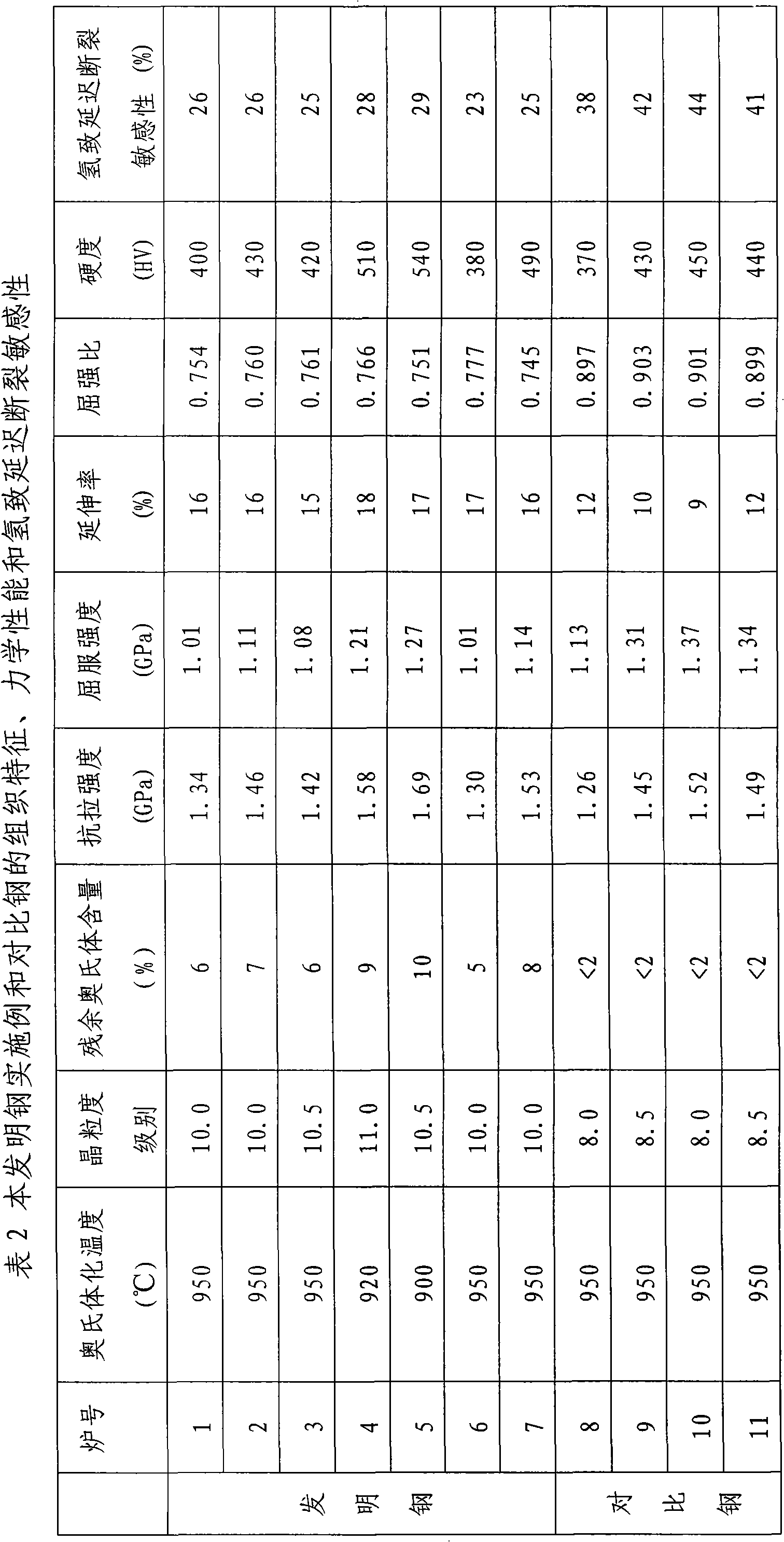

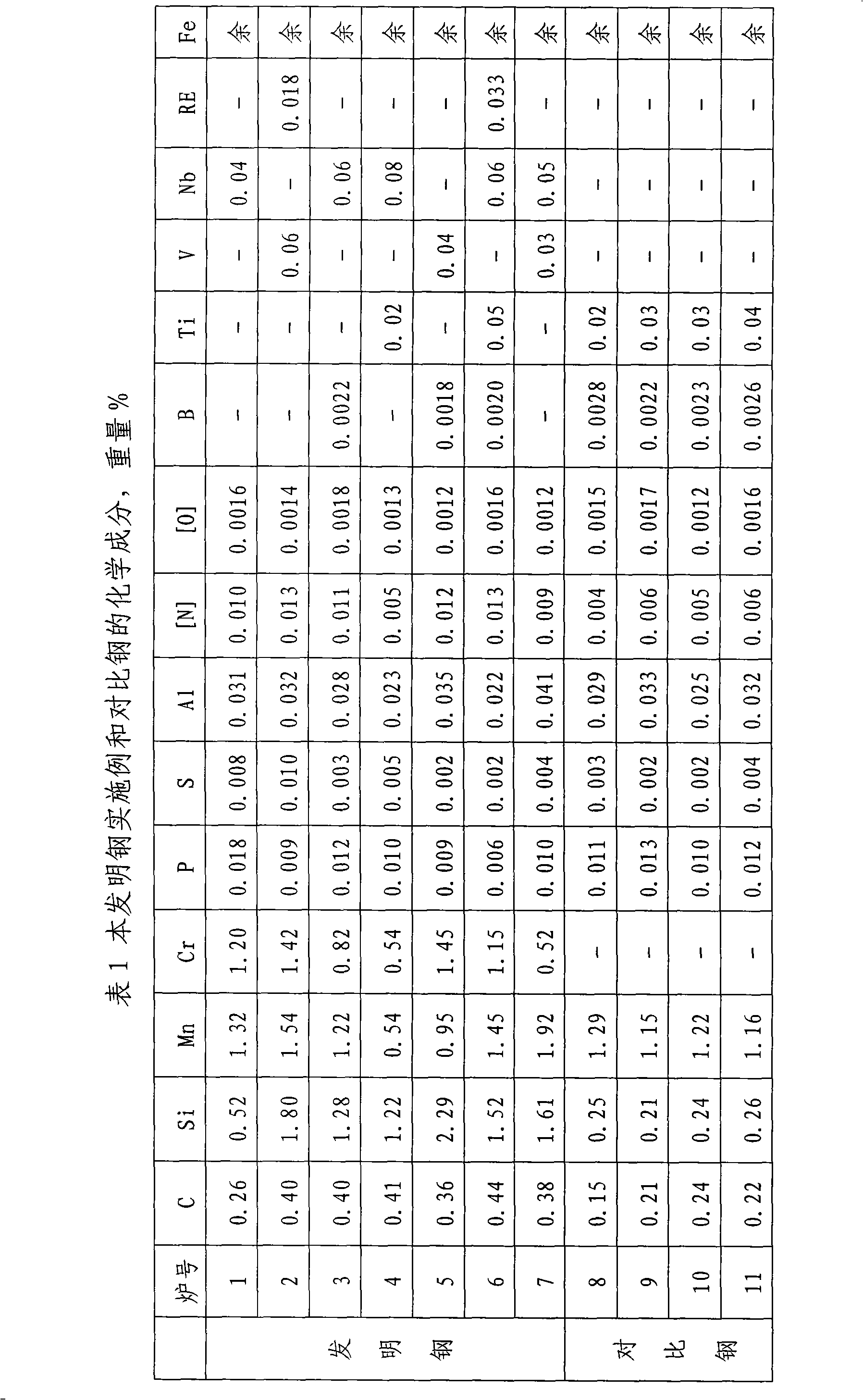

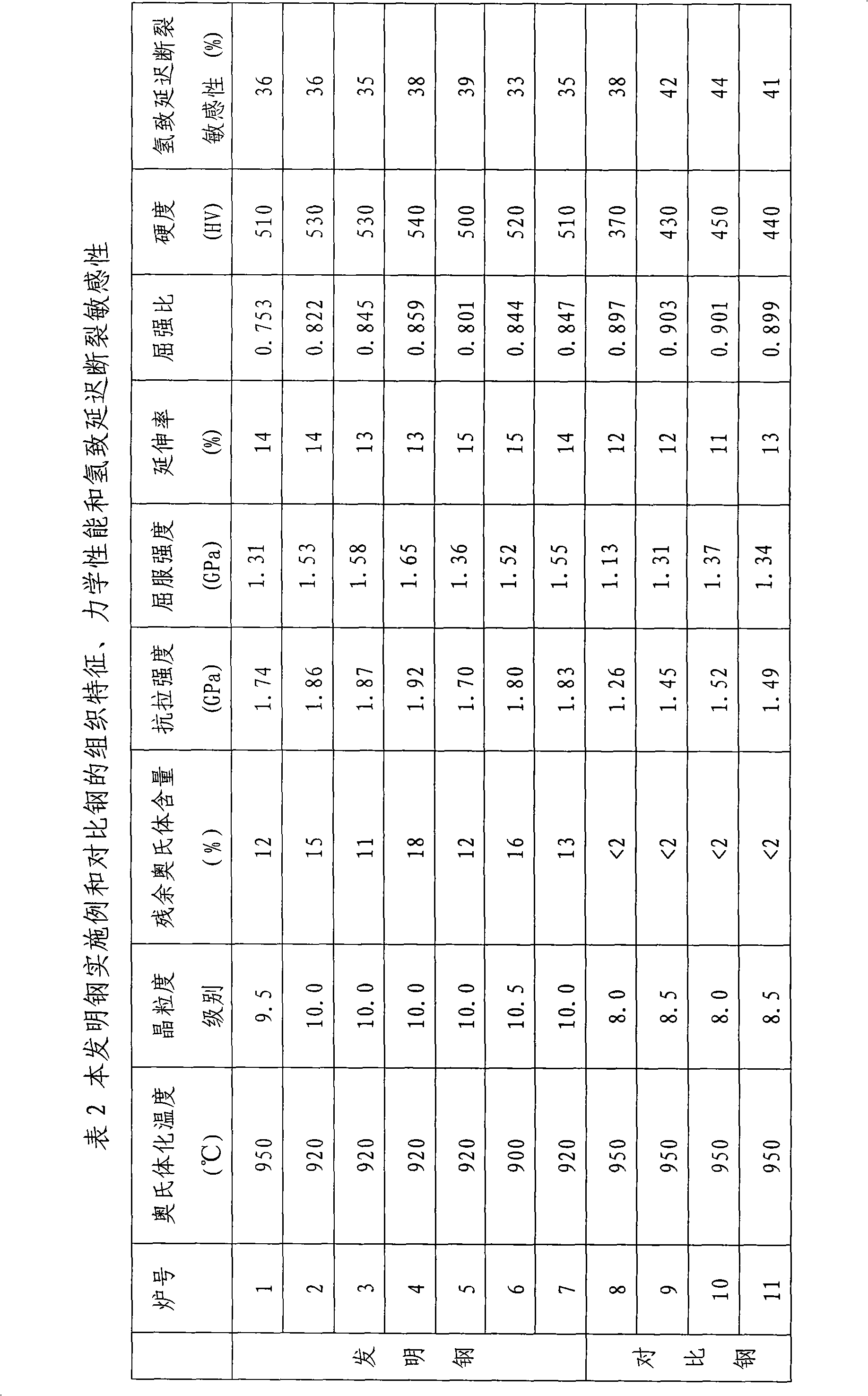

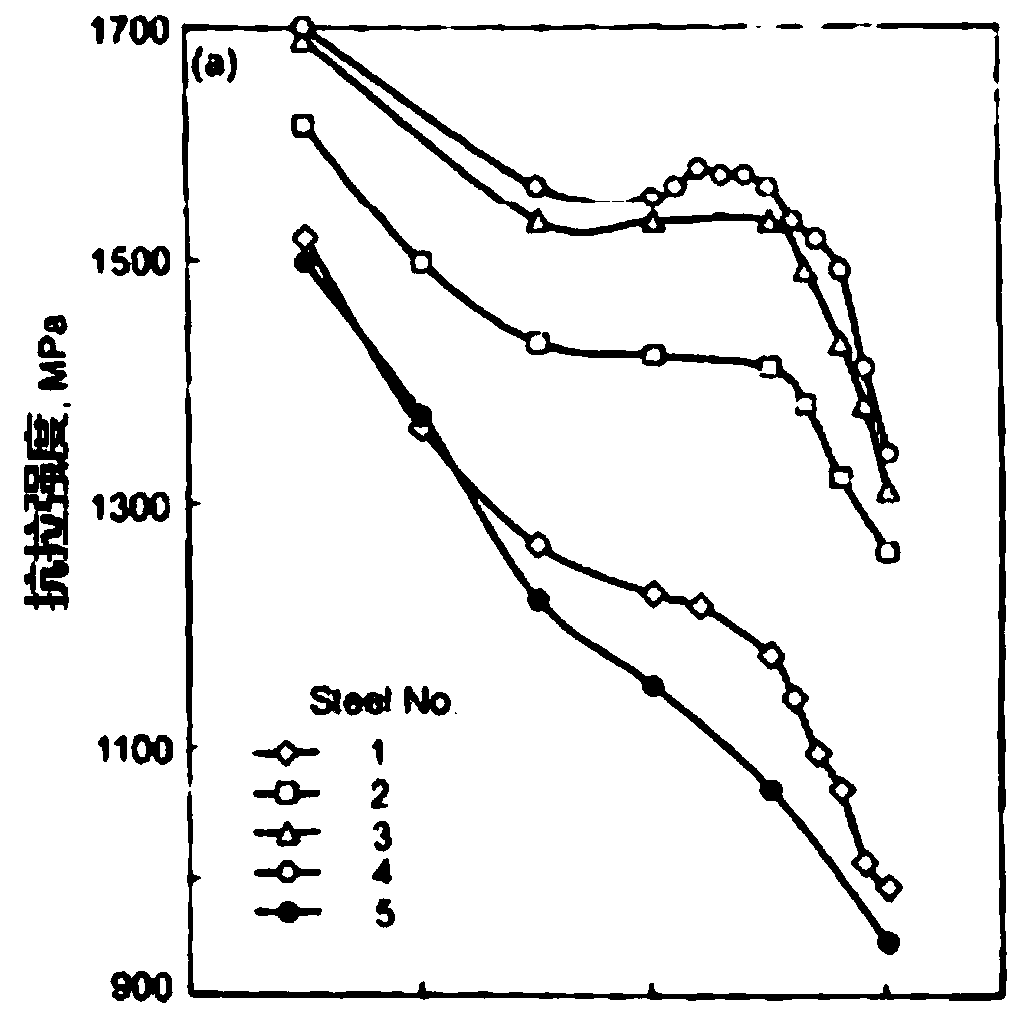

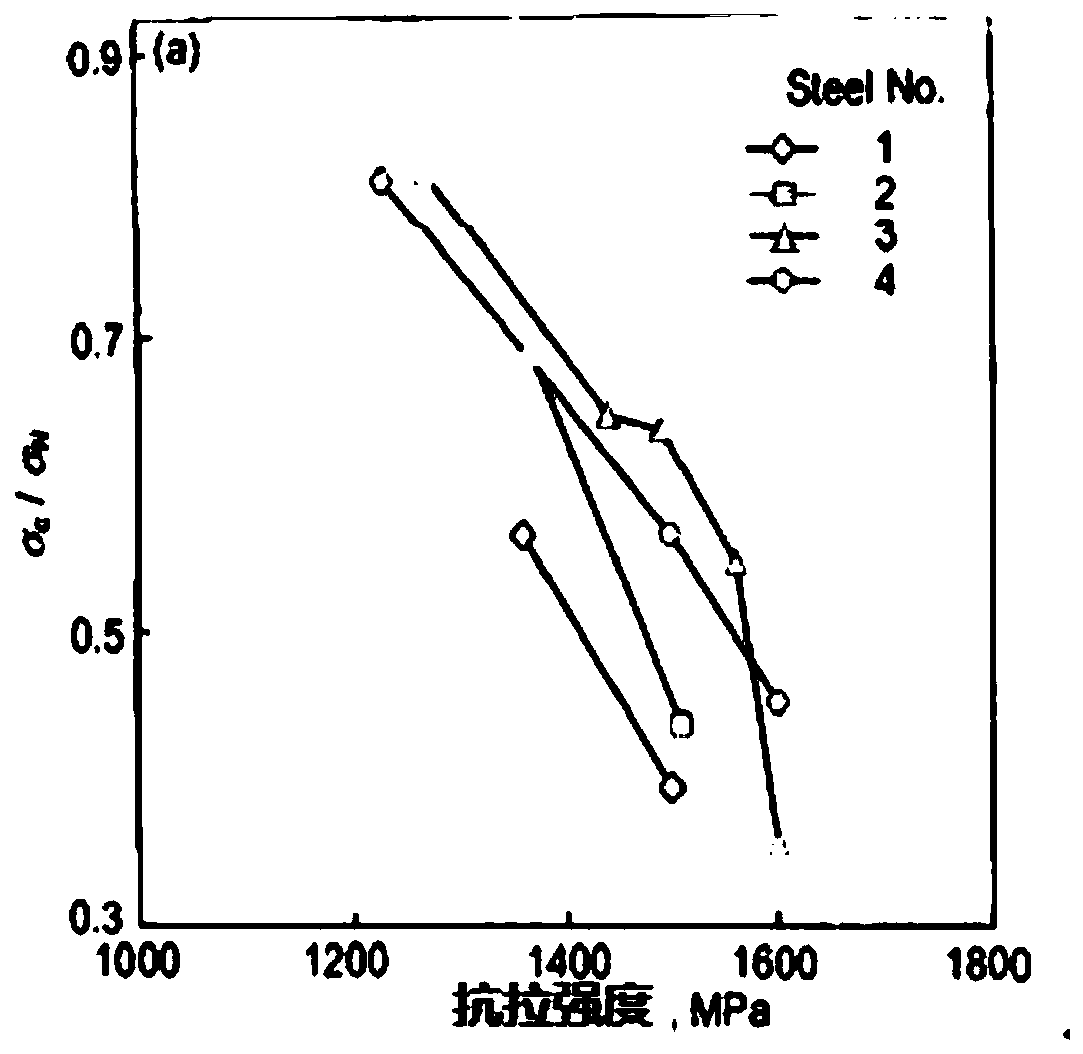

The invention belongs to the field of alloy steel, more particularly relates to thermal forming martensitic steel, which is mainly suitable for the steel for thermal punching forming accessory with thin thickness whose tensile strength ranges from 1.3 to 1.7GPa. The mainly chemical ingredients (weight %) of the steel are: C 0.10-0.33%, Si, 0.50-2.30%, Mn 0.50-2.00%, P <= 0.020%, S <= 0.015%, Al 0.015-0.060%, [O] <= 0.002%, [N] 0.002-0.015%, the rests are Fe and unavoidable impurities. In addition, the steel is also added with any or more than one of the group consisting of B 0.0005-0.0050%, Ti 0.02-0.10%, Nb 0.02-0.10%, V 0.02-0.15% and RE 0.001-0.050%. Compared with the current thermal forming martensitic steel 22MnB5, the steel of the invention not only has the tensile strength enhanced from 1.0-1.5GPa to 1.3 to 1.7GPa, but also has good plasticity, the coefficient of extension is more than 15%, and hydrogen-induced delayed fracture sensitivity is obviously reduced, thus making the vehicle having lighter weight and higher secure performances become true.

Owner:CENT IRON & STEEL RES INST

High strength bainitic steel rail and heat treatment process thereof

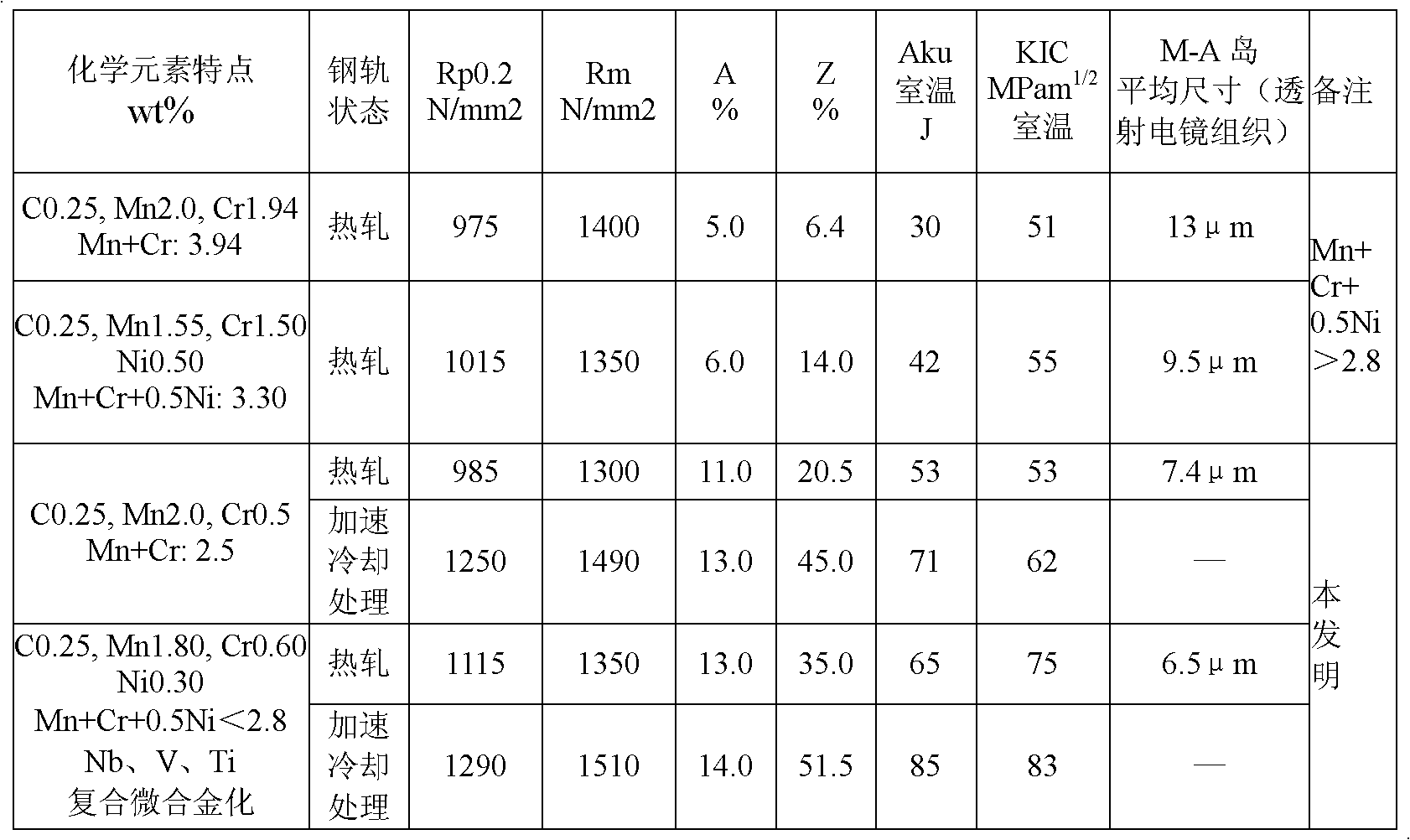

ActiveCN103160736AImprove wear resistanceImprove impact toughnessFurnace typesHeat treatment furnacesImpurityHeat treated

The invention provides a high strength bainitic steel rail and a heat treatment process thereof. The steel rail comprises the following chemical compositions by weight percentage: 0.10%-0.32% of C, 0.80%-2.00% of Si, 0.80%-2.80% of Mn, Cr less than 1.50%, 0.10%-0.40% of Mo, 0-0.5% of Ni, wherein Mn, Cr and Ni satisfy the relation of: Mn+Cr+0.5Ni<=2.8%, and the balance of Fe and unavoidable impurities. The process is as below: conducting hot rolling on the steel rail or air cooling on the steel rail to room temperature, then reheating to 850-1000 DEG C for austenization; cooling the steel rail head to 620-570 DEG C with a cooling rate of 0.3-15 DEG C / s; when the temperature is lower than 620-570 DEG C, cooling to 350-200 DEG C with a cooling rate of 0.5-5 DEG C / s; and then conducting air cooling to room temperature. The invention avoids generation of excessive unstable thick M-A islands in granular bainite during air cooling to room temperature in hot rolling, reduces the risk of straightening fracture (or delayed fracture)of hot-rolled steel rail, and improves the adaptability of steel production process. The steel rail has tensile strength higher than 1400MPa, and realizes optimum matching of strength, toughness and ductility, and excellent rolling contact fatigue resistance and wear resistance.

Owner:ANGANG STEEL CO LTD

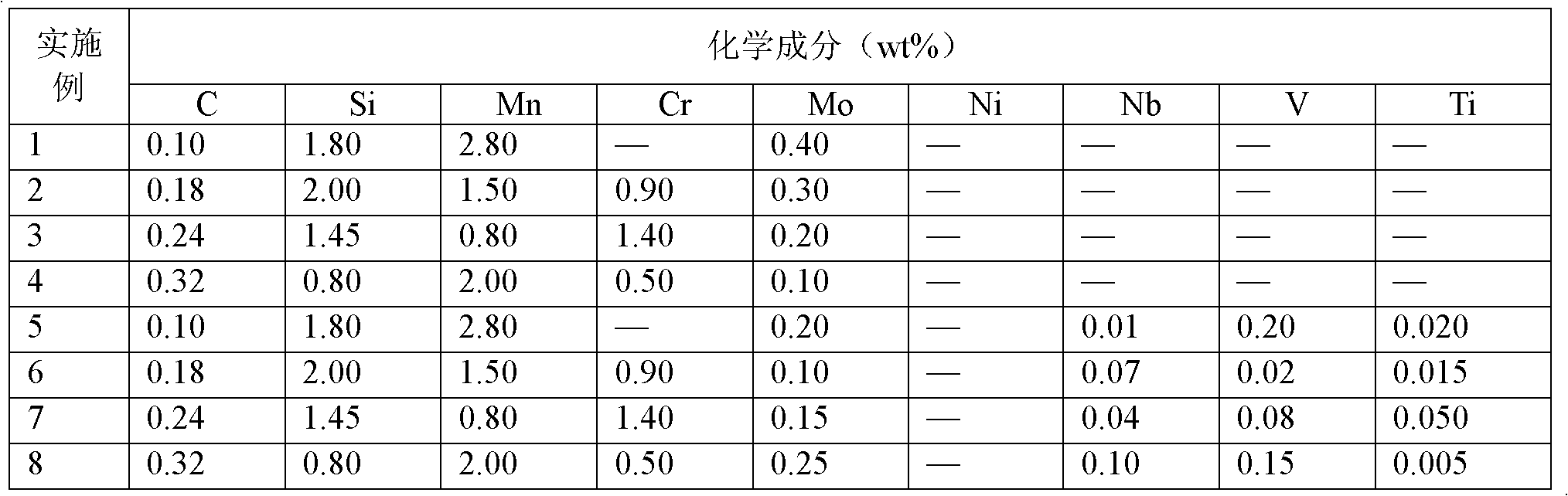

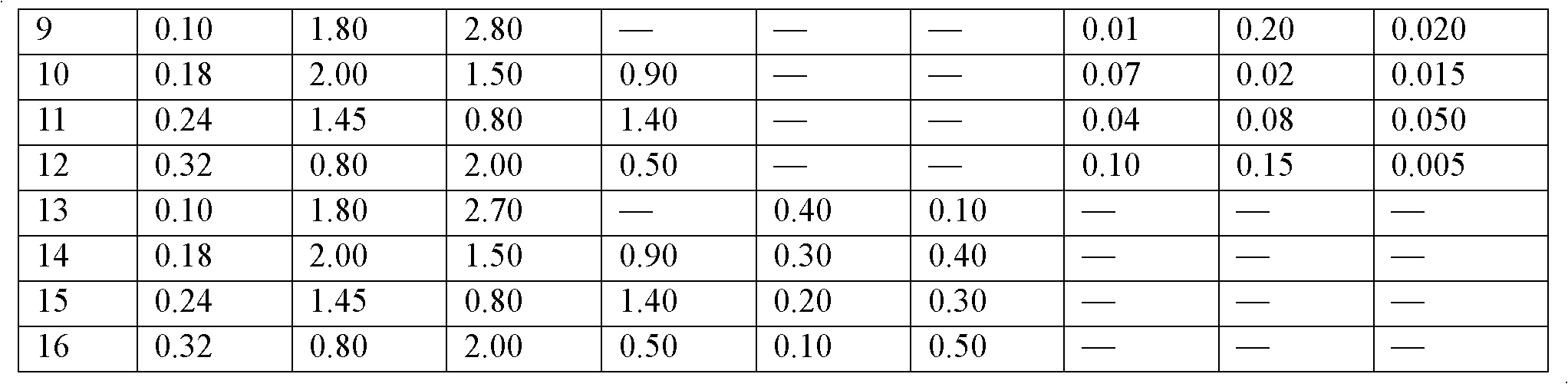

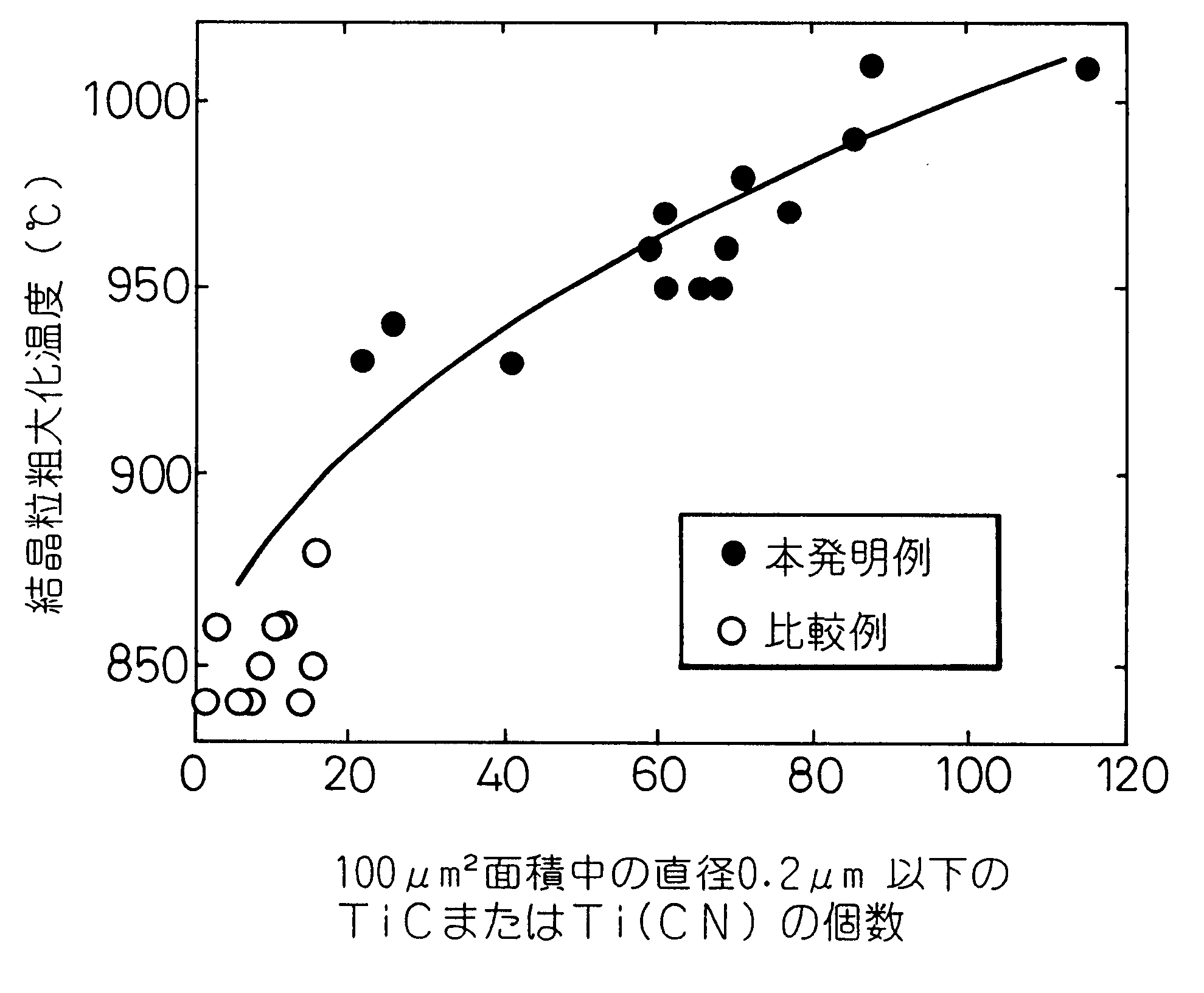

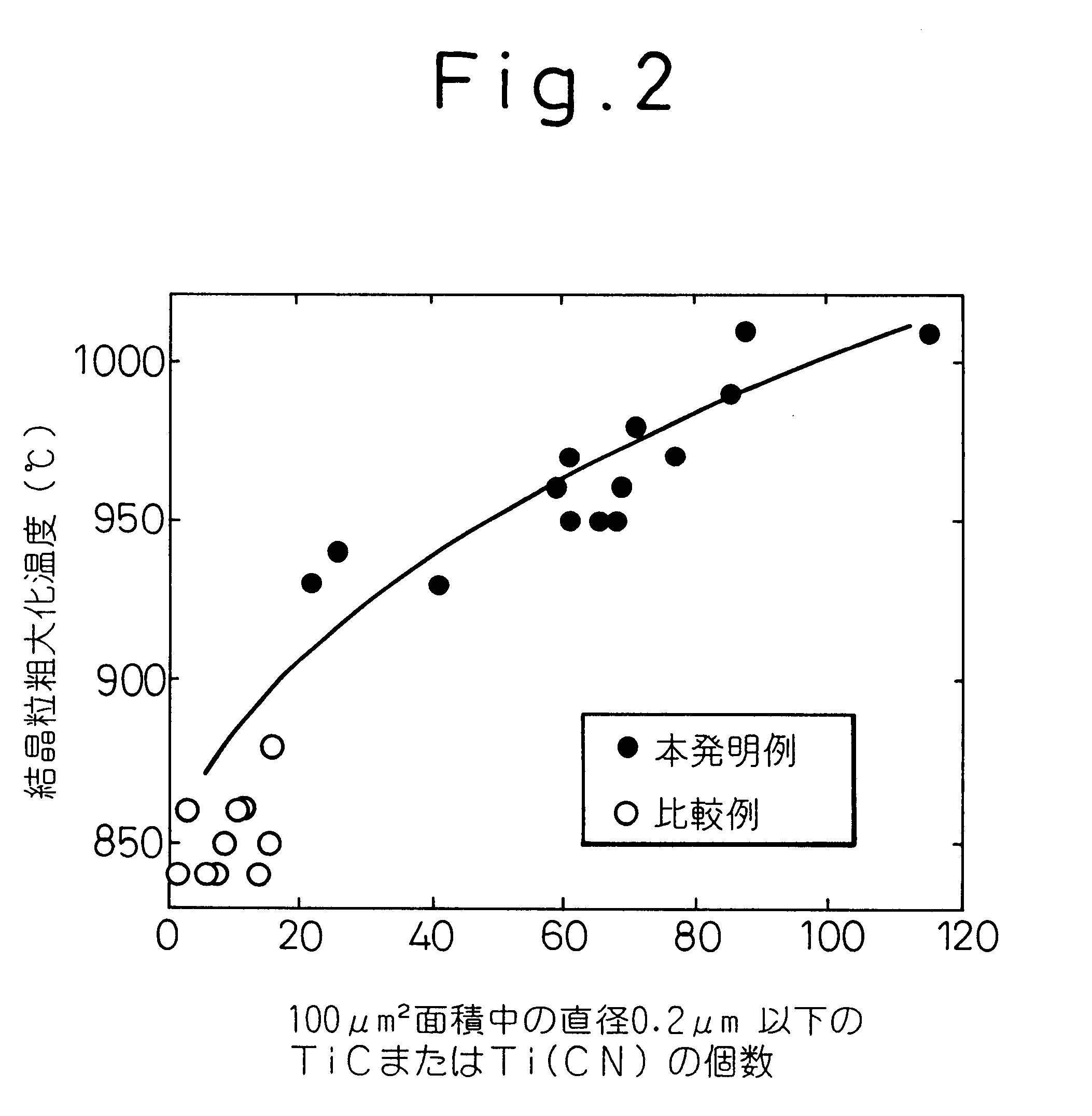

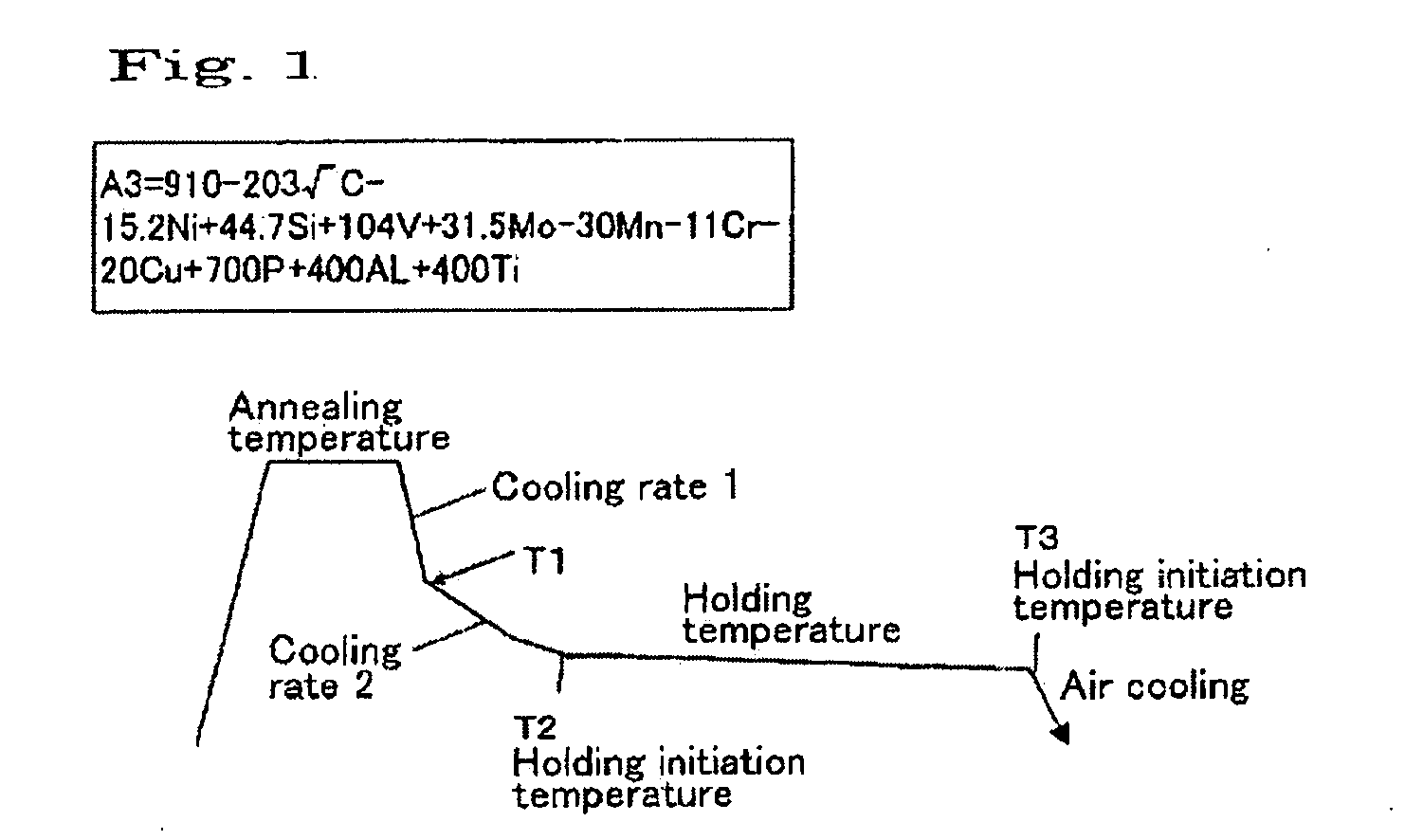

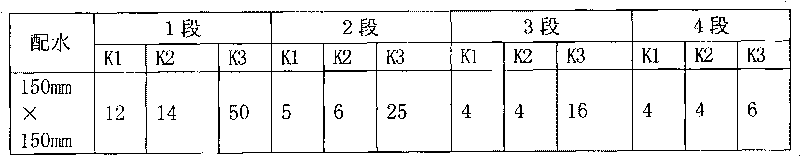

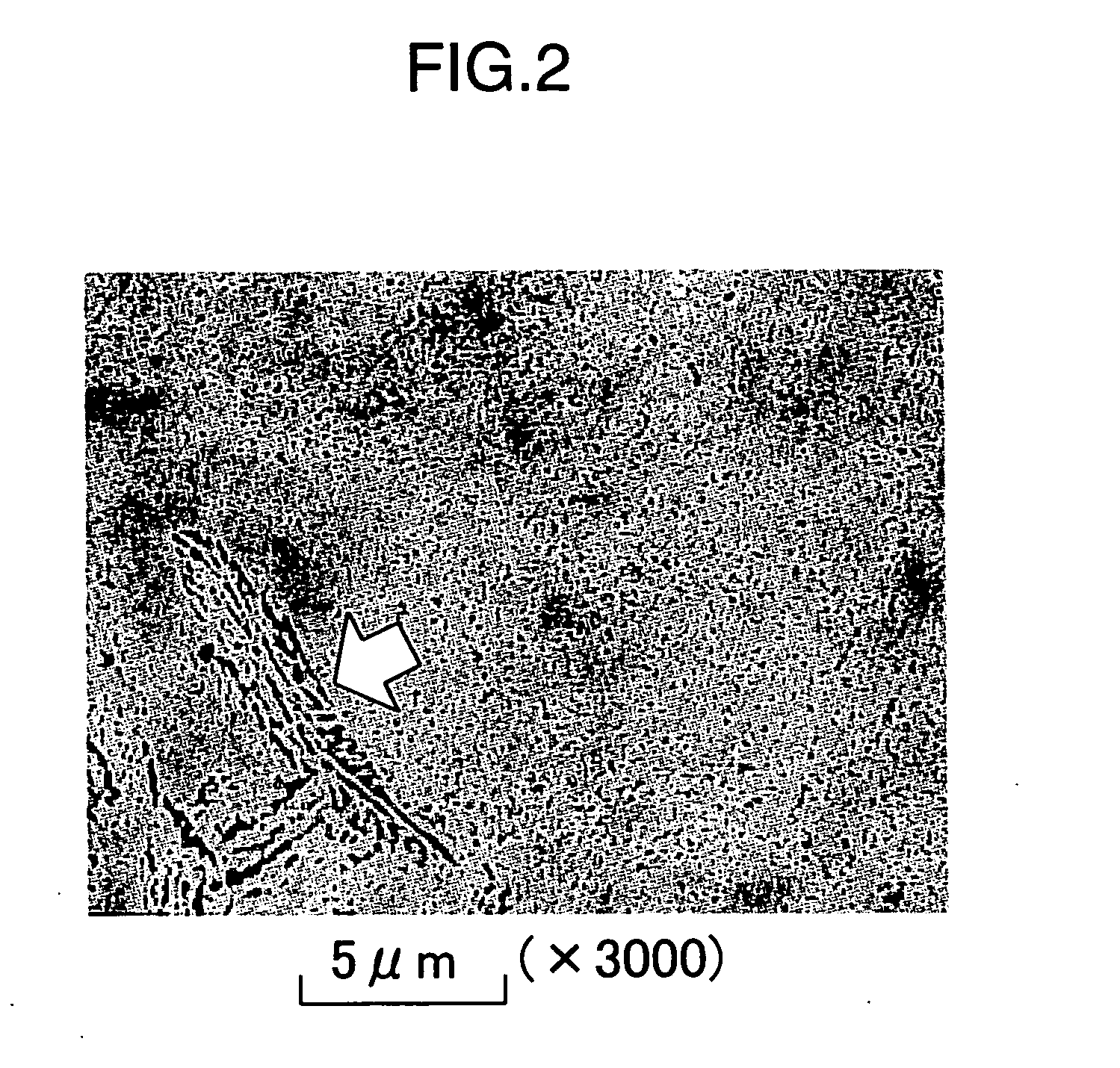

Cold forging steel having improved resistance to grain coarsening and delayed fracture and process for producing same

InactiveUS6261388B1Reduce the amount requiredSurface of therefore becomes dullFurnace typesHeat treatment furnacesHigh intensitySteel bar

A cold forging steel excellent in grain coarsening prevention and delayed fracture resistance and method of producing the same are provided that enable omission of a step of annealing or spheroidization annealing before cold forging and improvement of delayed fracture resistance of a high-strength component used with a heat-treated surface. The cold forging steel is a steel of a specified composition having dispersed in the matrix thereof particles of not greater than 0.2 mum diameter of one or more of TiC, Ti(CN), NbC, Nb(CN) and (Nb, Ti)(CN) in a total number of not less than 20 / 100 mum2. The method of producing a cold forging steel includes the steps of heating this steel to not lower than 1050° C., hot-rolling the steel into steel wire or steel bar, and slowly cooling the steel at a cooling rate of not greater than 2 C. / s during cooling to a temperature not higher than 600° C. to obtain a steel having dispersed in the matrix thereof particles of not greater than 0.2 mum diameter of one or more of TiC, Ti(CN), NbC, Nb(CN) and (Nb, Ti)(CN) in a total number of not less than 20 / 100 mum2.

Owner:NIPPON STEEL CORP +1

Petroleum casing pipe with high strength and high toughness and preparing method thereof

InactiveCN101586450ALow alloy contentLow costDrilling rodsProcess efficiency improvementAlloyMechanical property

The present invention provides a petroleum casing pipe with high strength and high toughness, wherein the weight of the component element of the casing pipe steel is characterized proportionally. The invention also provides a preparing method for preparing the petroleum casing pipe with high strength and high toughness, wherein the method comprises the following steps: 1. smelting the ingredients and casting the tube blank; 2. punching and tandem rolling of the steel tube; and 3. heat treating. The invention has the following beneficial effects: the performance of the petroleum casing pipe obtained by the method is the performance of the steel with lower content of alloy and the cost is low; a low carbon content is adopted so that the lath martensite tissue is obtained after heat treatment, the high toughness is provided after tempering and a delayed fracture resistance is provided; the complex micro-alloying processing techniques of V, Nb, Ti, B, etc. are adopted for strengthening the matrix, strengthening the grain-boundary strength, increasing the tempering resistance, reducing the content of manganese element, reducing the content of the impurity elements and improving the shape of the inclusion. The rolling ratio is optimized so that the aeolotropism of the material is remarkably reduced and the horizontal and vertical impact toughness of the material is larger than 0.8. The casing pipe of the invention far exceeds the prior highest steel grade requirement of the API standard.

Owner:TIANJIN PIPE GROUP CORP

High-strength composite steel sheet having excellent moldability and delayed fracture resistance

InactiveUS20100221138A1Good molding effectExcellent spot-wedabilityFurnace typesHeat treatment furnacesChemical compositionCompound (substance)

The present invention provides a high-strength composite steel sheet which has a tensile strength of 980 MPa class as well as excellent and excellent anti-delayed fraction property, and also has excellent spot-weldability. The high-strength composite steel sheet comprises a steel satisfying: C: 0.10 to 0.25% (% by mass in case of a chemical component, the same shall apply hereinafter), Si: 1.0 to 3.0%, Mn: 1.5 to 3.0%, P: 0.15% or less, S: 0.02% or less, Al: 0.4% or less, and comprising the remnant made from iron and unavoidable impurities; the contents of Si, Al, Mn and Cr satisfy the relationship of “(Si+Al) / Mn or (Si+Al) / (Mn+Cr)=0.74 to 1.26”; and microstructure is specified.

Owner:KOBE STEEL LTD

55Si2MnVNbN spring steel and production process thereof

InactiveCN101717893AHigh strengthHigh tensile strengthTemperature control deviceMetal rolling arrangementsWorking environmentSpring steel

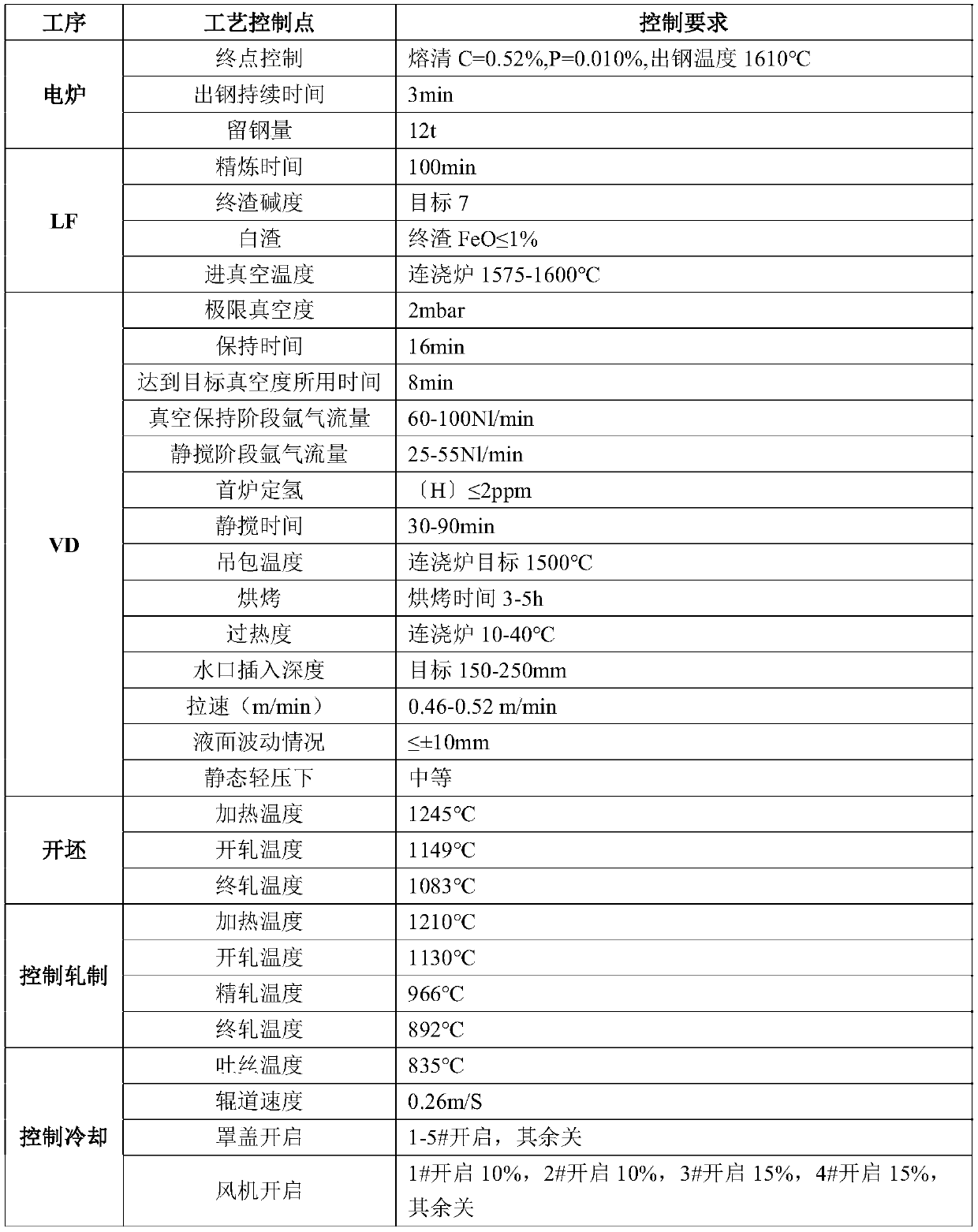

The invention relates to spring steel and a production process thereof, in particular to 55Si2MnVNbN spring steel and a production process thereof. The 55Si2MnVNbN spring steel comprises the following components in percentage by weight: 0.52 to 0.60 percent of C, 1.60 to 1.90 percent of Si, 0.60 to 0.80 percent of Mn, 0.15 to 0.35 percent of Cr, 0.06 to 0.12 percent of V, 0.015 to 0.025 percent of Nb, 0.80 to 1.50 percent of N, less than or equal to 0.0035 of P, less than or equal to 0.0035 percent of S and the balance of Fe and inevitable impurities. The process comprises electric furnace electrosmelting, LF refining, VD furnace vacuum degassing, continuous casting and rolling. The spring steel can meet the requirements of springs on various severe working environments, high strength and long service life and has high tensile strength, high delayed fracture resistance, high corrosion resistance, high fatigue resistance and high elasticity attenuation resistance.

Owner:NANJING IRON & STEEL CO LTD

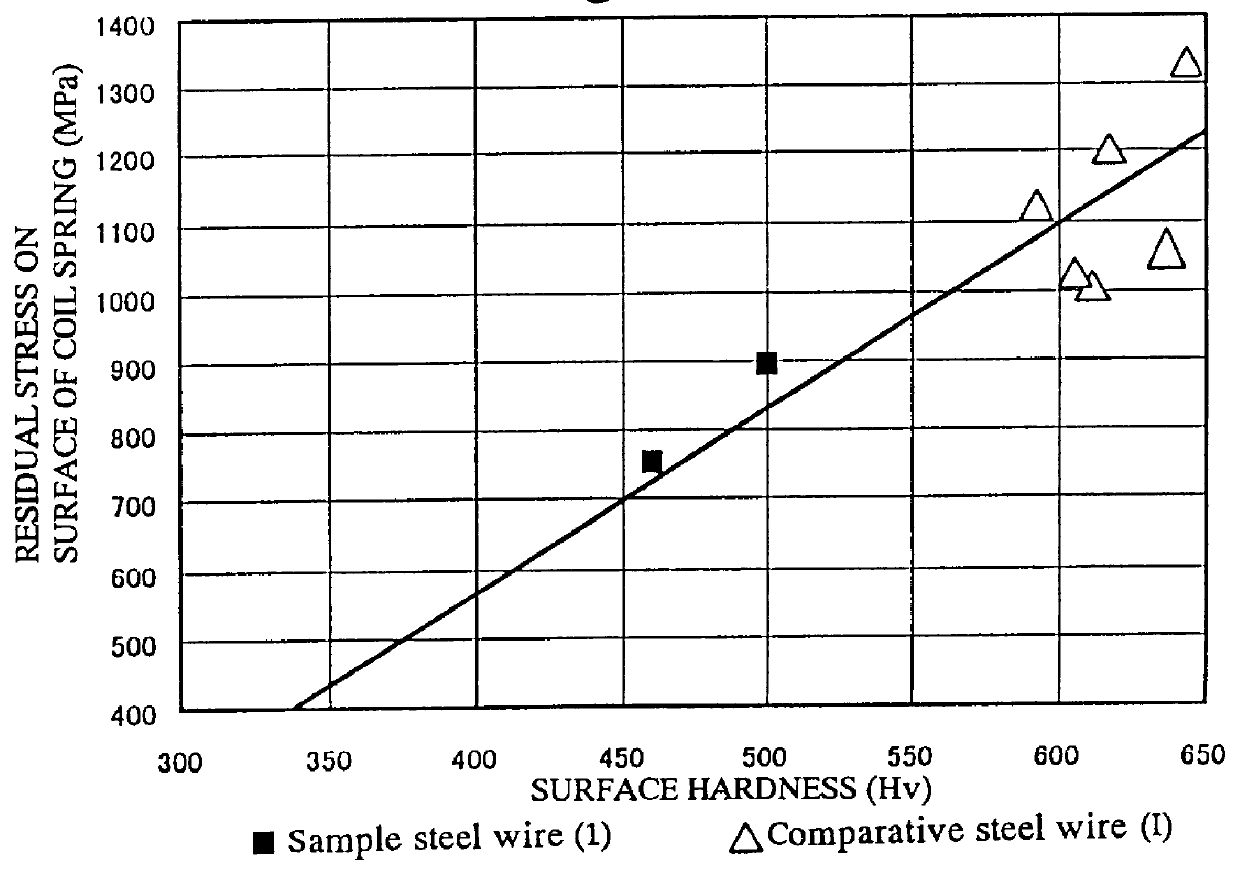

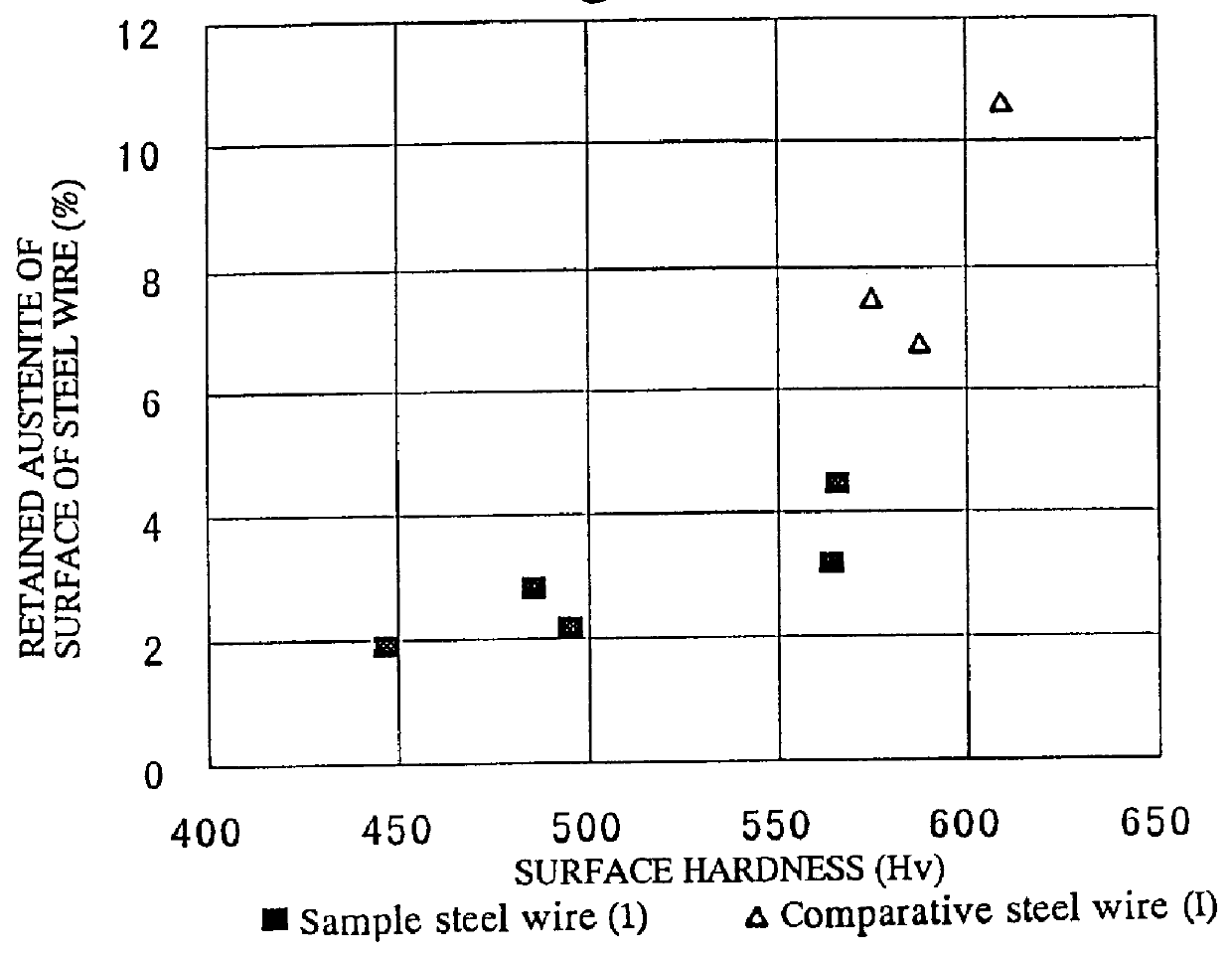

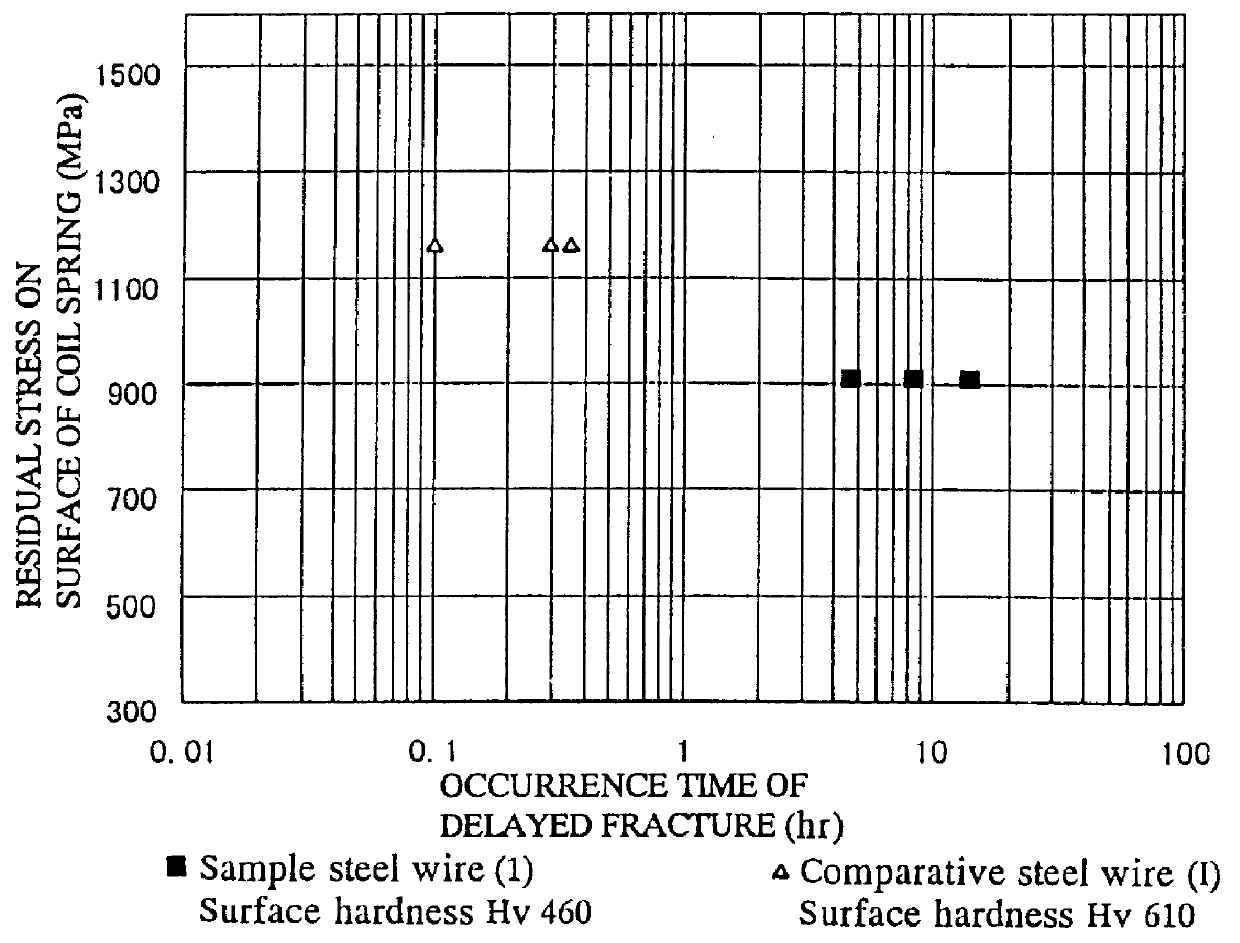

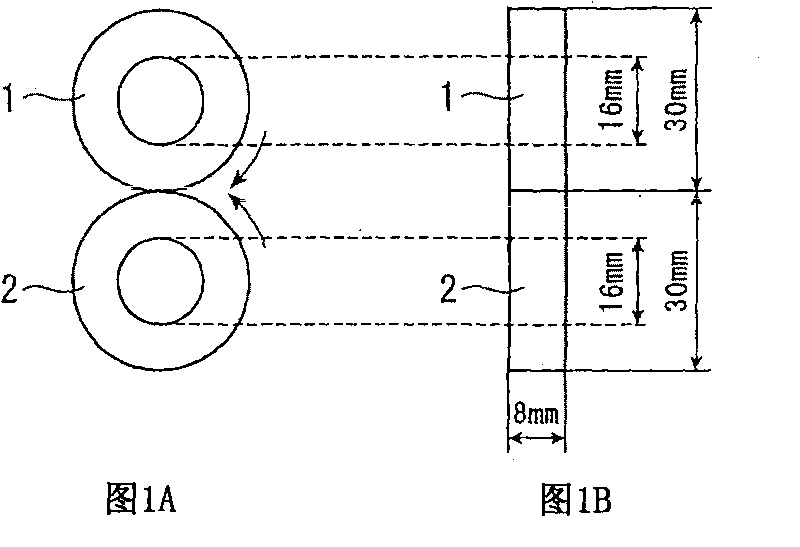

Coil spring resistive to delayed fracture and manufacturing method of the same

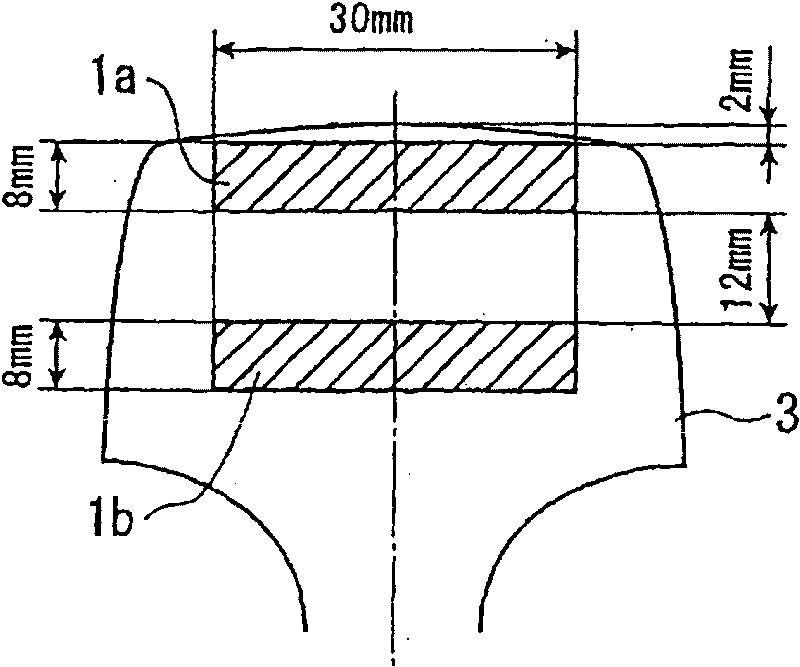

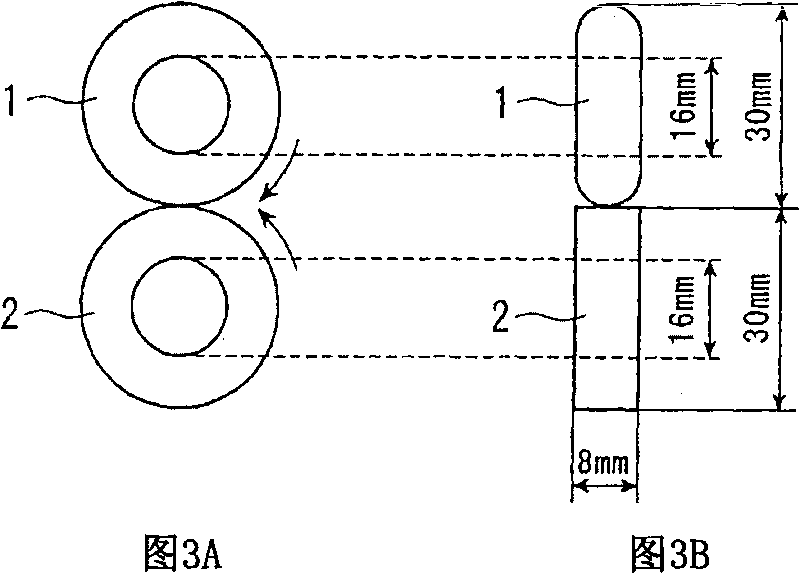

A coil spring made of an oil-tempered steel wire with internal hardness of more than Hv 550 in cross-section, the surface hardness of the oil-tempered steel wire being determined in an extent between Hv 420 in a minimum value and hardness defined by subtraction of Hv 50 from the internal hardness in a maximum value.

Owner:CHUO SPRING +1

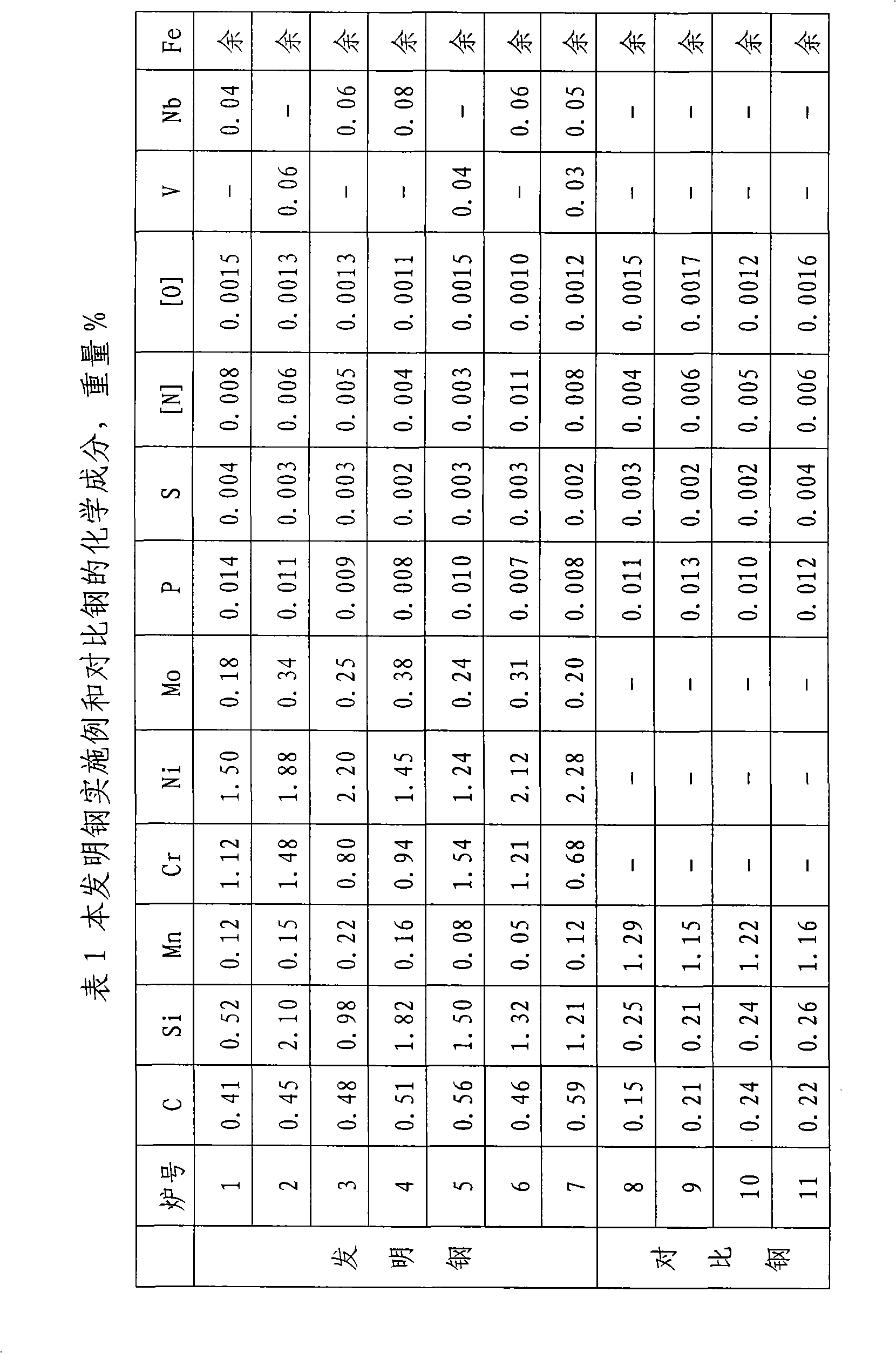

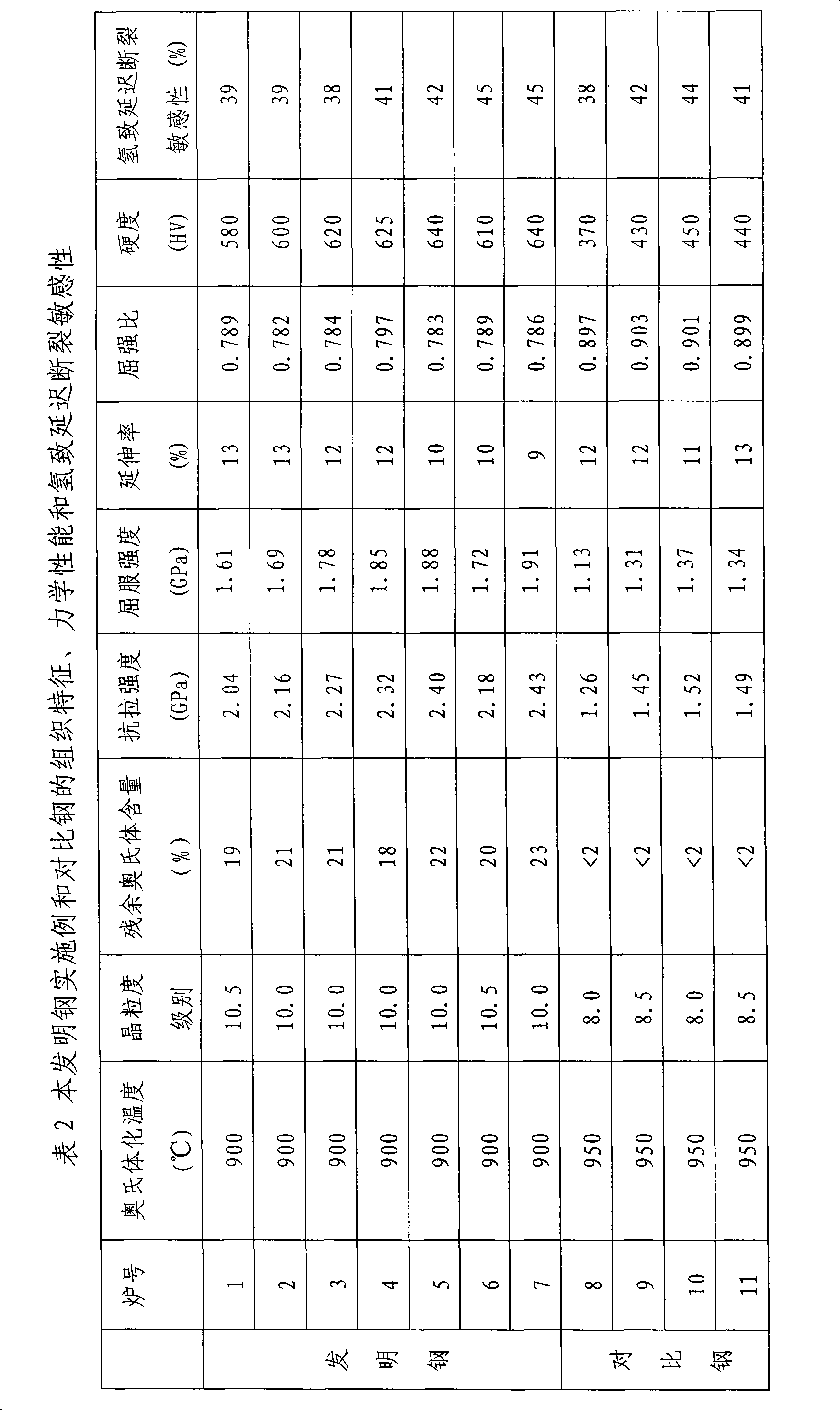

Ultrahigh-strength thermal forming martensitic steel

The invention belongs to the field of alloy steel, in particular to a high intensity hotforming martensite steel which is mainly applied to a thin part with the anti-tension intensity of 1.9 to 2.5GPa that is formed by hot punching. The main chemical components (weight percentage)of the steel are: 0.40 to 0.60 percent of C, 0.50 to 2.30 percent of Si, equal to or less than 0.25 percent of Mn, 0.50 to 1.50 percent of Cr, 0.80 to 3.00 percent of Ni, 0.15 to 0.40 percent of Mo, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, equal to or less than 0.003 percent of [O], 0.002 to 0.015 percent of [N] and the rest are Fe as well as other unavoidable impurities. Besides, any one of or two of 0.02 to 0.10 percent of Nb as well as 0.02 to 0.15 percent of V are added. Compared with the 22MnB5 steel of the existing hotforming martensite steel, the anti-tension intensity of the steel of the invention is improved from 1.0-1.5GPa to 1.9-2.5GPa; besides, the steel has excellent plasticity (percentage of elongtation is larger than 8 percent) and the sensitivity to hydrogen induced delayed fracture is reduced remarkably; thereby providing foundation for vehicle light weight and high safety performance.

Owner:CENT IRON & STEEL RES INST

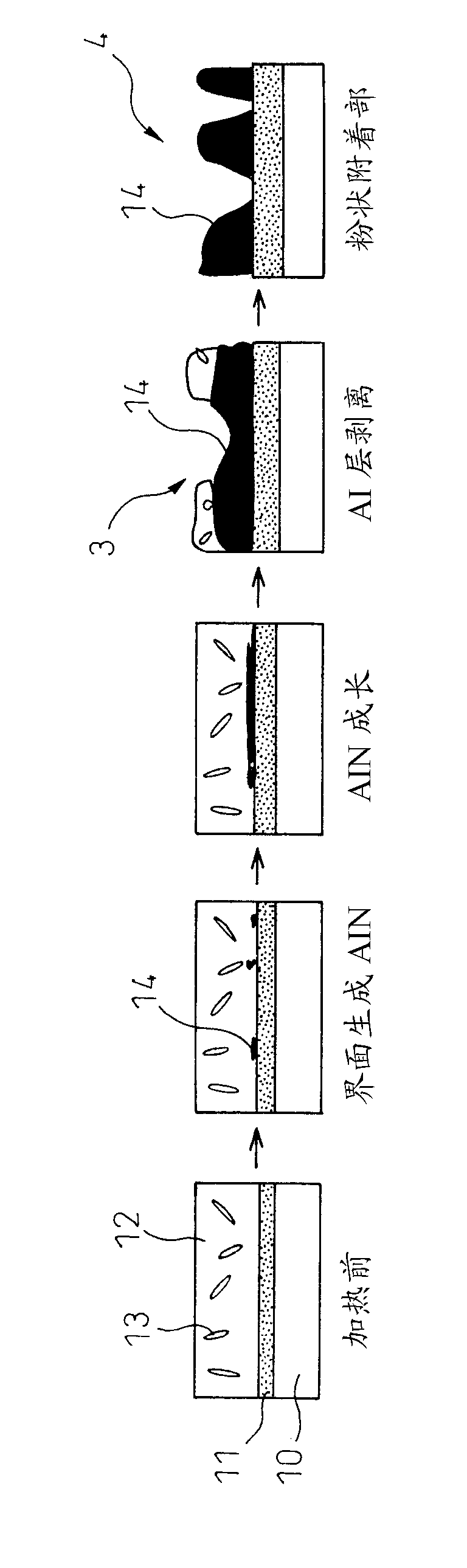

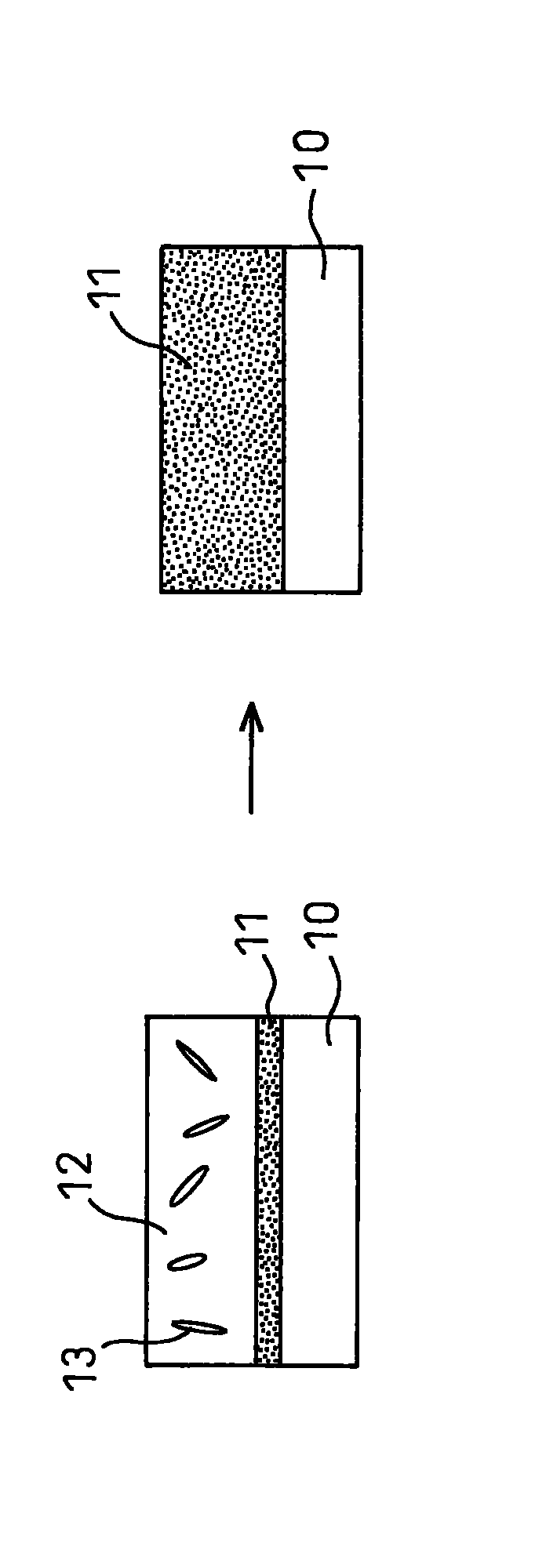

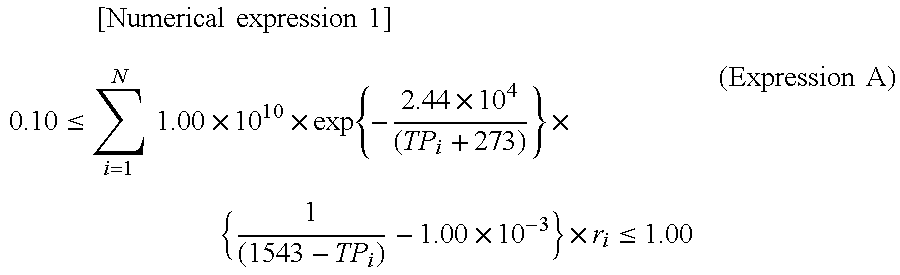

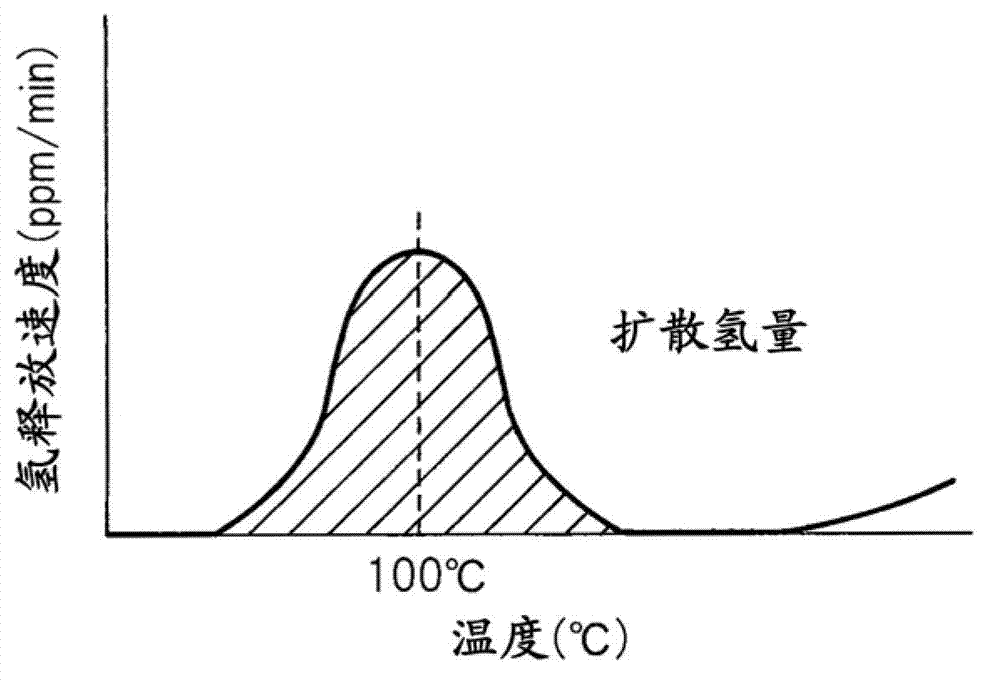

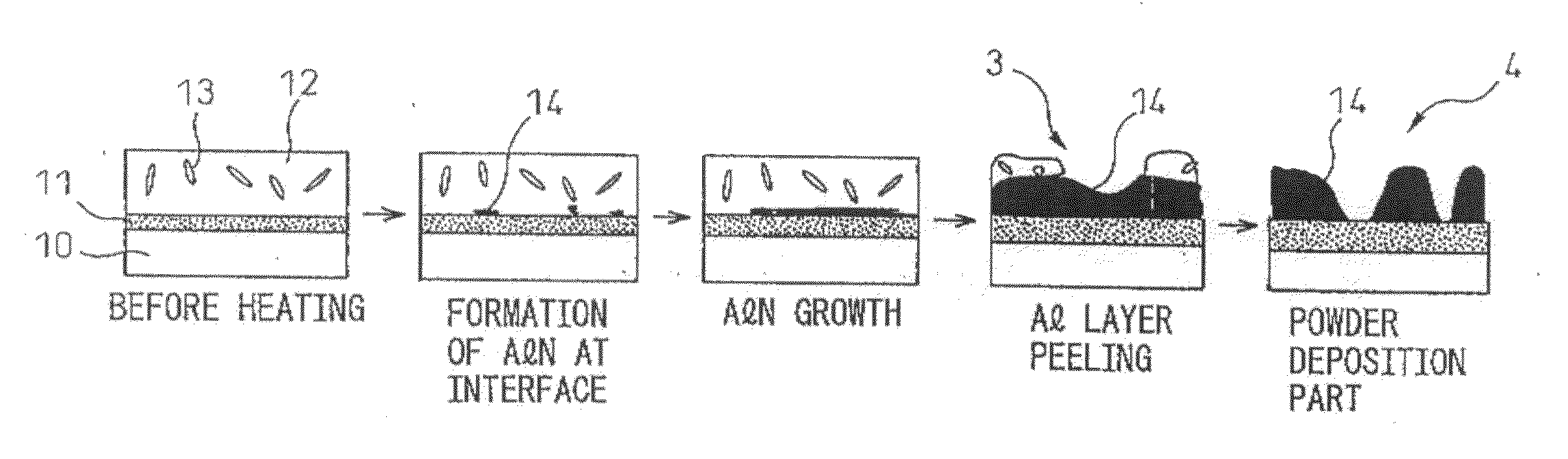

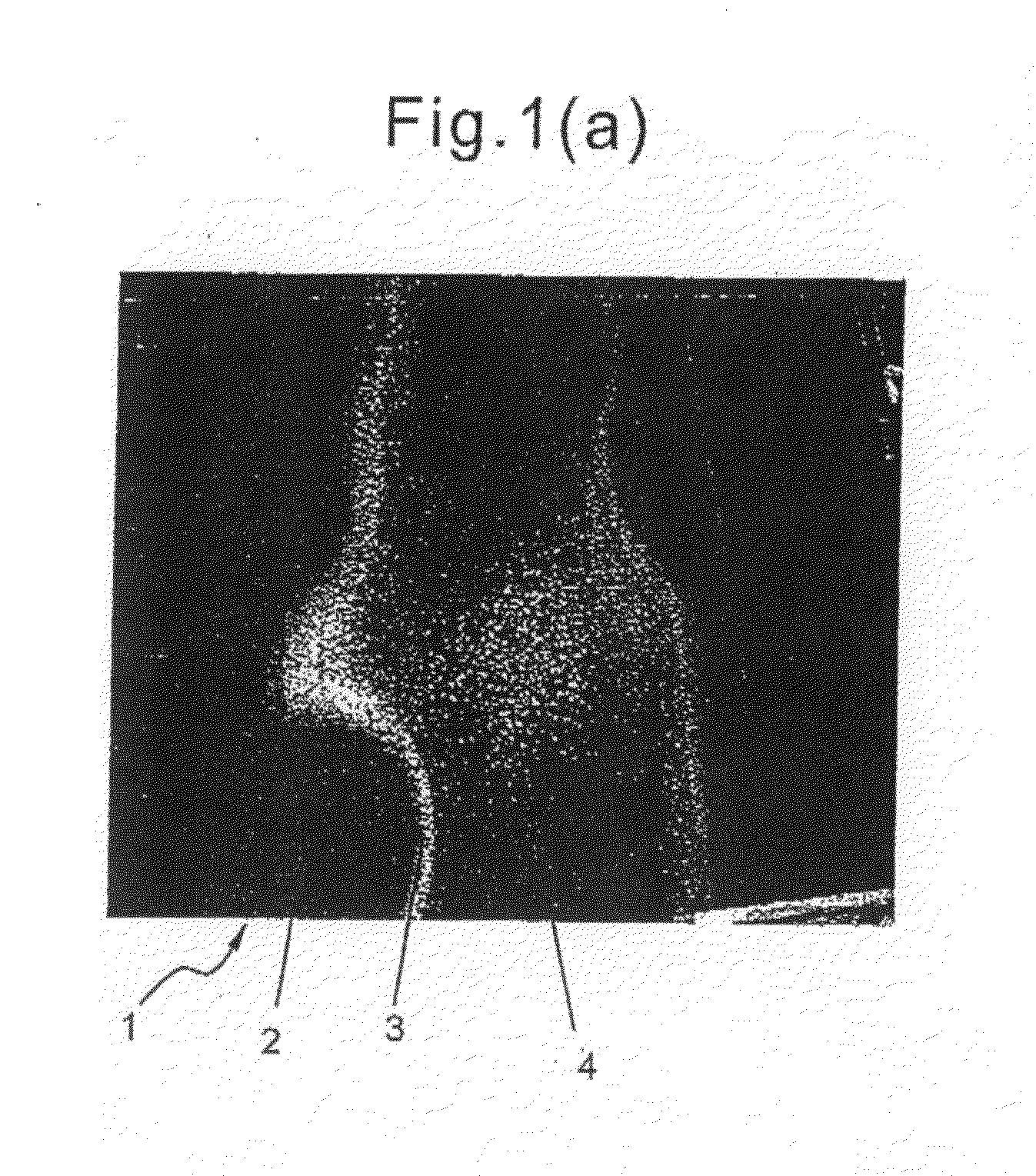

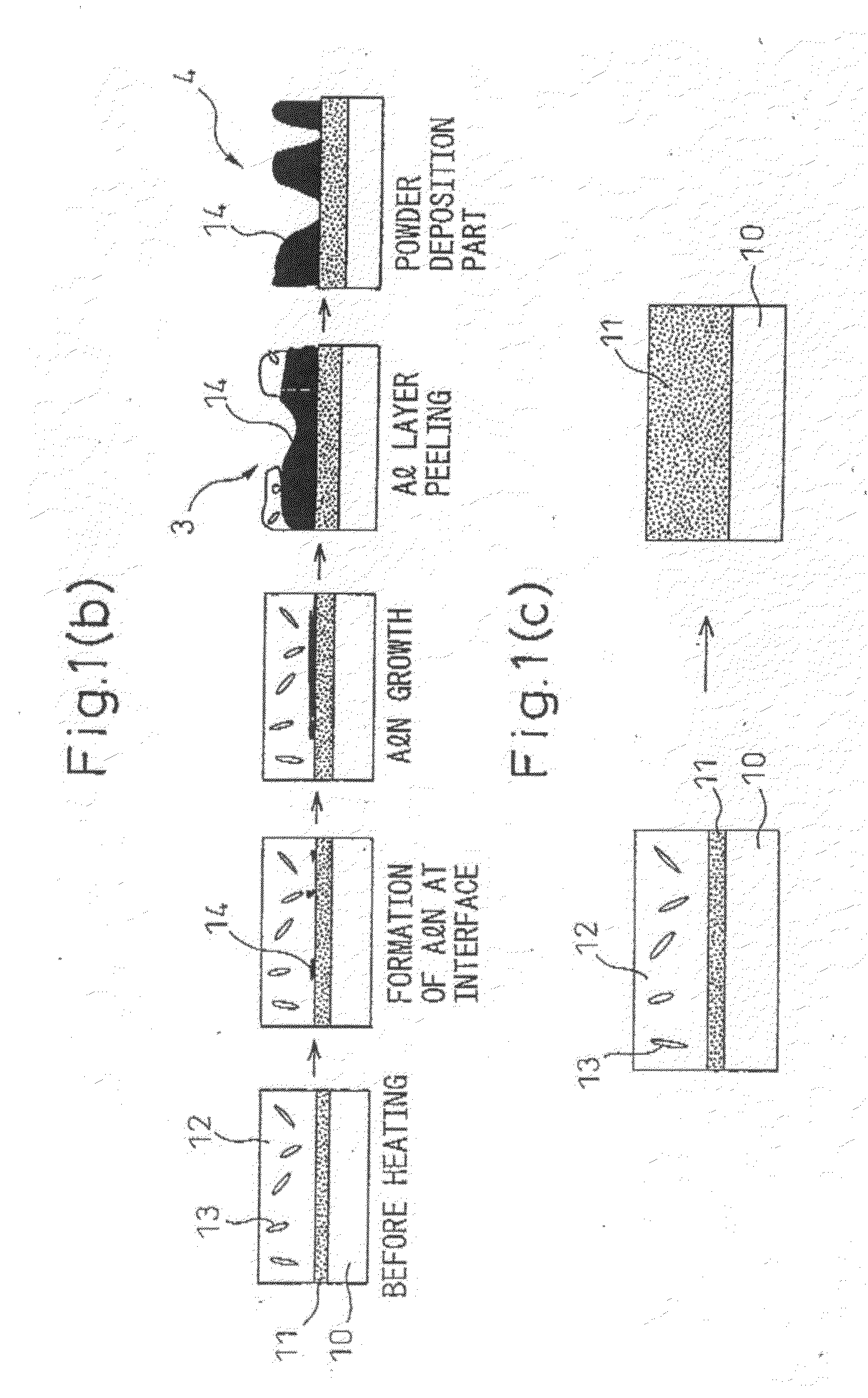

Aluminum-plated steel sheet for hot pressing with rapid heating, process for producing same, and method of hot-pressing same with rapid heating

ActiveCN102089451AIncrease production capacityPrevent saggingHot-dipping/immersion processesBell type furnacesHydrogenSheet steel

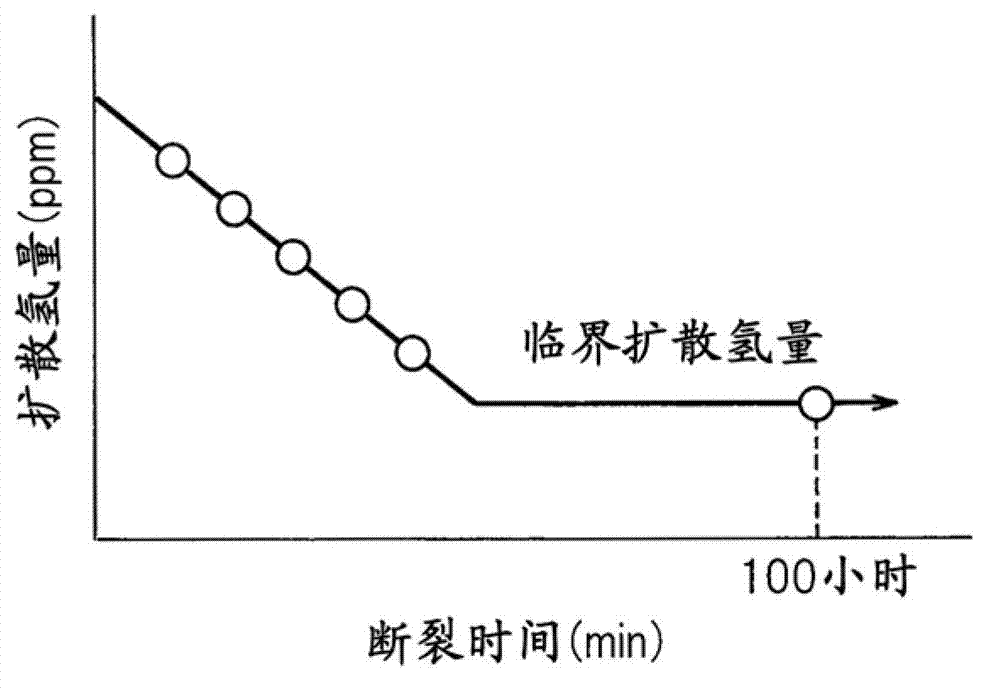

An aluminum-plated steel sheet for hot pressing is provided which is free from the conventional problem that an aluminum-plated steel sheet, when applied to hot pressing, suffers aluminum melting during preheating for the hot pressing. The steel sheet is further free from the problem concerning delayed fracture caused by residual hydrogen. Also provided are: a process for producing the aluminum-plated steel sheet; and a method of hot pressing with rapid heating in which the aluminum-plated steel sheet is used. The aluminum-plated steel sheet for hot pressing is produced by annealing an aluminum-plated steel sheet in a coiled state in an annealing box furnace under holding-time and temperature conditions which are within the range shown in Fig 5, whereby the aluminum deposit is alloyed with the steel sheet. The method of hot pressing with rapid heating is characterized in that a blank cut out of the aluminum-plated steel sheet for hot pressing is preheated at a heating rate of 40 DEG C / sec or higher on the average so that the time period over which the blank is exposed to an environment of 700 DEG C or higher is 20 seconds or shorter, and the preheated blank is hot-pressed.

Owner:NIPPON STEEL CORP

High-strength hot-dip galvanized steel sheet having excellent delayed fracture resistance and manufacturing method thereof

ActiveUS20140234659A1Improve fracture resistanceSmall anisotropyHot-dipping/immersion processesFurnace typesDiameter ratioMaterials science

A hot-dip galvanizing layer or an alloyed hot dip galvanizing layer is formed on the surface of a base steel sheet in which in volume fraction, 40 to 90% of a ferrite phase and 5% or less of a retained austenite phase are contained, and a ratio of non-recrystallized ferrite to the entire ferrite phase is 50% or less in volume fraction, and further a grain diameter ratio being a value of, of crystal grains in the ferrite phase, an average grain diameter in the rolling direction divided by an average grain diameter in the sheet width direction is 0.75 to 1.33, a length ratio being a value of, of hard structures dispersed in island shapes, an average length in the rolling direction divided by an average length in the sheet width direction is 0.75 to 1.33, and an average aspect ratio of inclusions is 5.0 or less.

Owner:NIPPON STEEL CORP

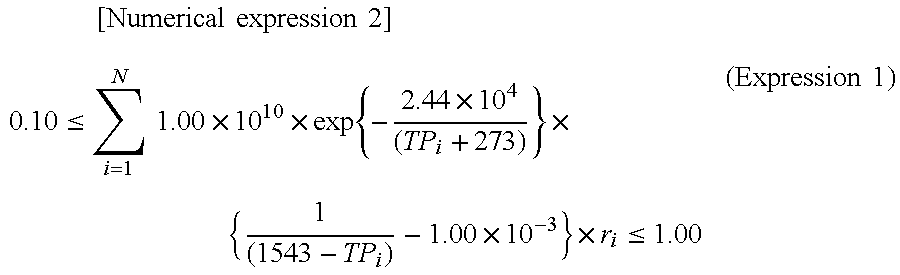

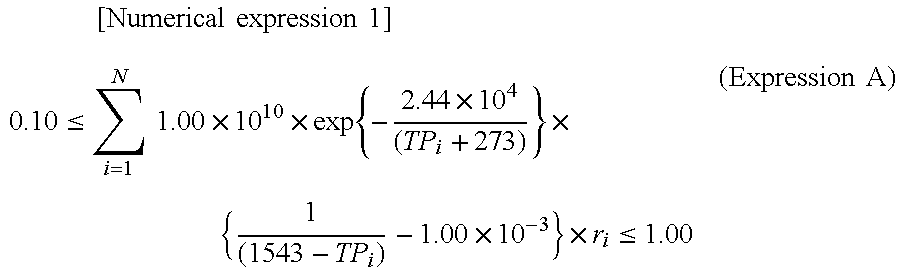

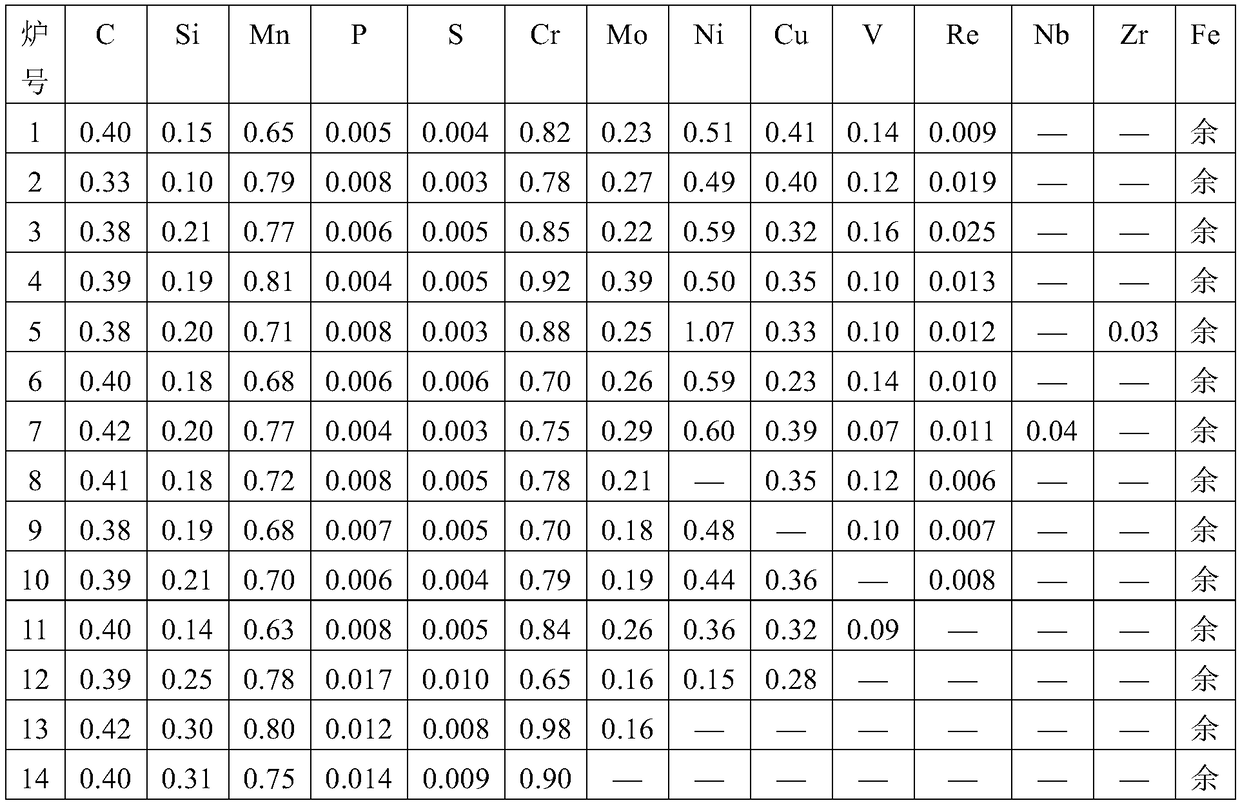

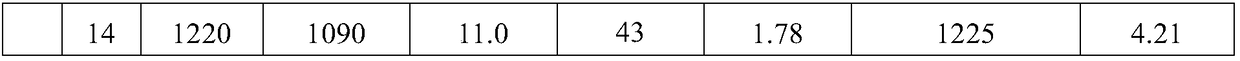

High-strength bolt steel with excellent resistance to atmospheric corrosion and delayed fracture

PendingCN108754303AAccelerated corrosionImproved delayed fracture resistanceAtmospheric corrosionDelayed fracture

The invention discloses a high-strength bolt steel with excellent resistance to atmospheric corrosion and delayed fracture. The high-strength bolt steel with excellent resistance to atmospheric corrosion and delayed fracture comprises, by mass, 0.30-0.45% of C, below 0.25% of Si, 0.40-1.40% of Mn, below 0.012% of P, below 0.008% of S, 0.40-1.20% of Cr, 0.15-0.50% of Mo, 0.30-1.20% of Ni, 0.20-0.60% of Cu, 0.05-0.20% of V, 0.005-0.030% of Re, and the balance of Fe and inevitable impurity elements. Compared with steels in the prior art, the high-strength bolt steel with excellent resistance to atmospheric corrosion and delayed fracture has the advantages of high strength, excellent resistance to atmospheric corrosion and delayed fracture, and low cost, and can be used to 12.9 level high-strength bolts for bridges and other steel structures.

Owner:BEIJING JIAOTONG UNIV

High strength thin steel sheet excellent in resistance to delayed fracture after forming and method for preparation thereof , and automobile parts requiring strength manufactured from high strength thin steel sheet

InactiveUS20070006948A1Improve the immunityDelayed-fracture resistanceFurnace typesHeat treatment furnacesSheet steelHigh intensity

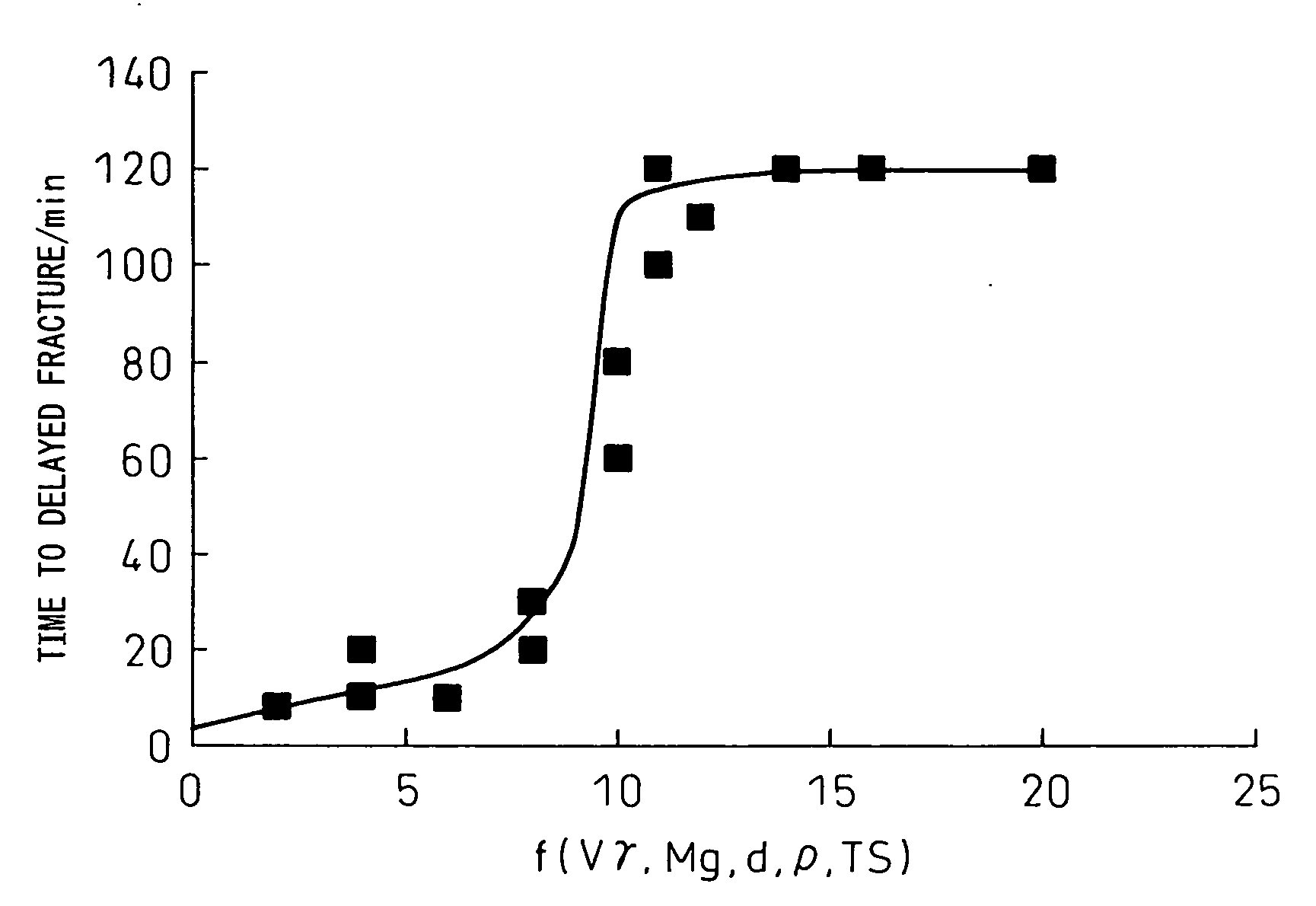

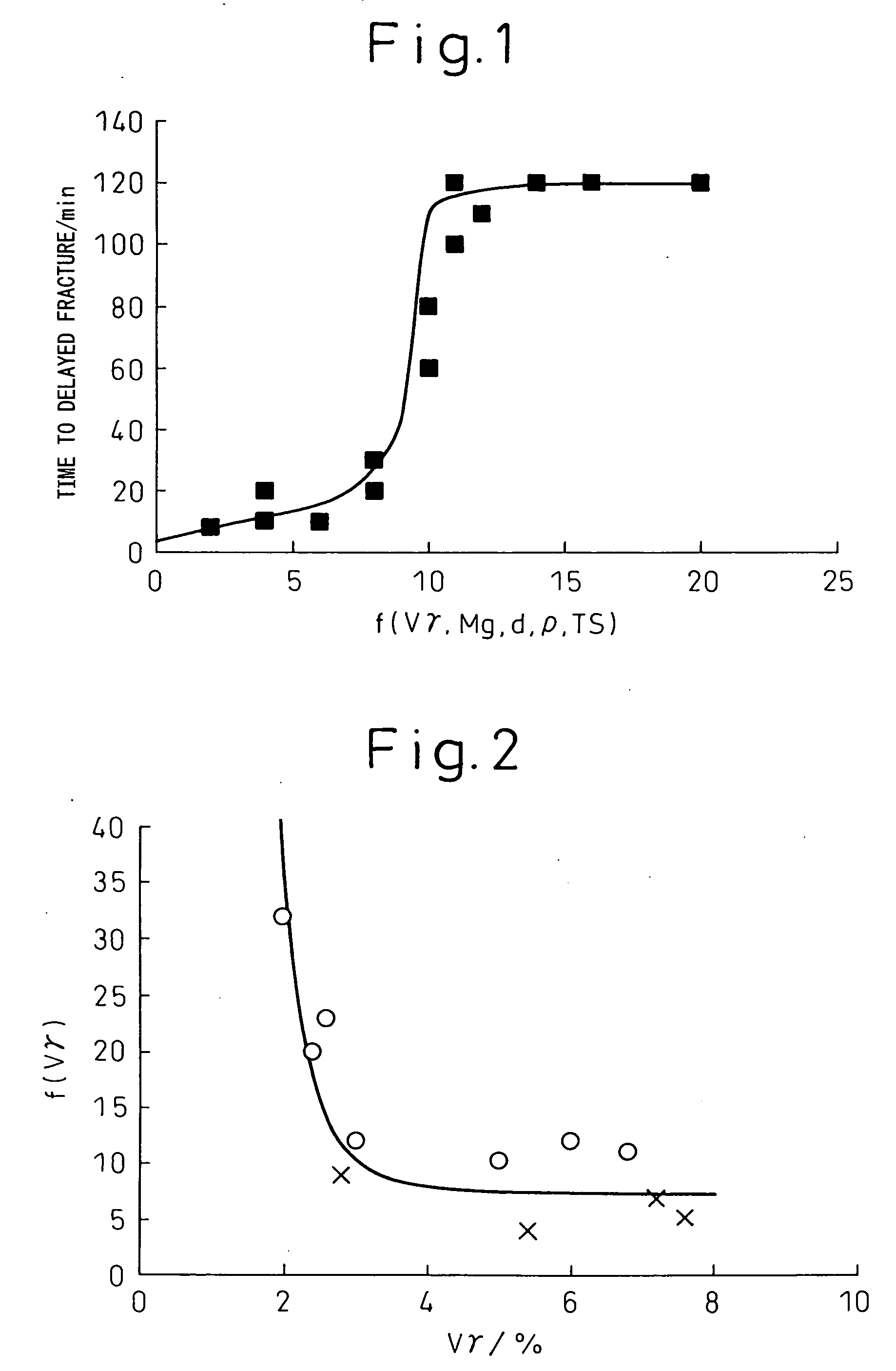

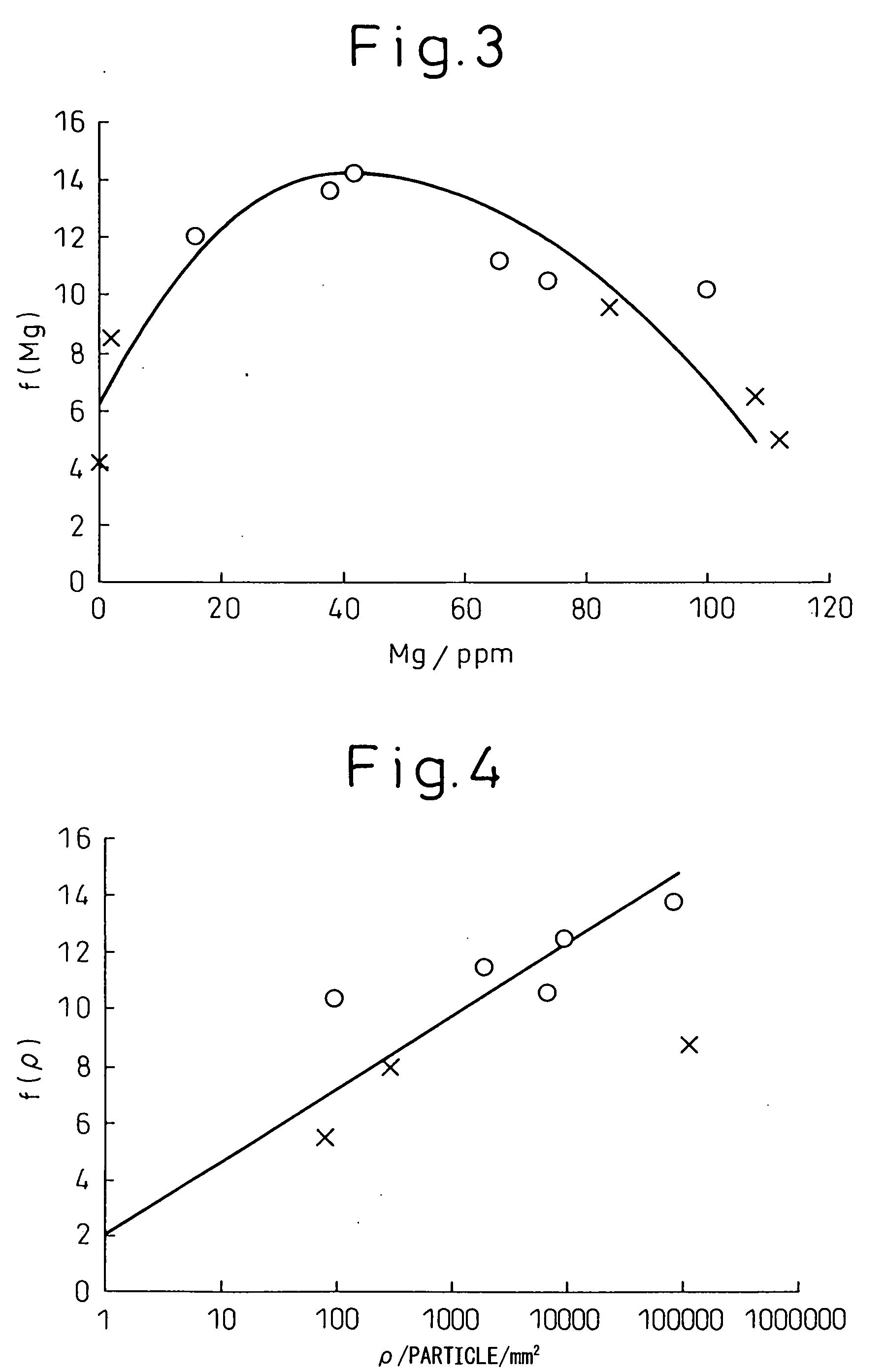

Steel sheets containing residual austenite of not more than 7 vol.%, crystallized and / or precipitated compounds with particle diameters of 0.01 to 5.0 μm of 100 to 100000 particle / mm2 and C of 0.05 to 0.3 mass %, Si of not more than 3.0 mass %, Mn of 0.01 to 3.0 mass %, P of not more than 0.02 mass %, S of not more than 0.02 mass %, Al of 0.01 to 3.0 mass %, N of not more than 0.01 mass % and Mg of 0.0002 to 0.01 mass %, with the remainder comprising iron and unavoidable impurities.

Owner:NIPPON STEEL CORP

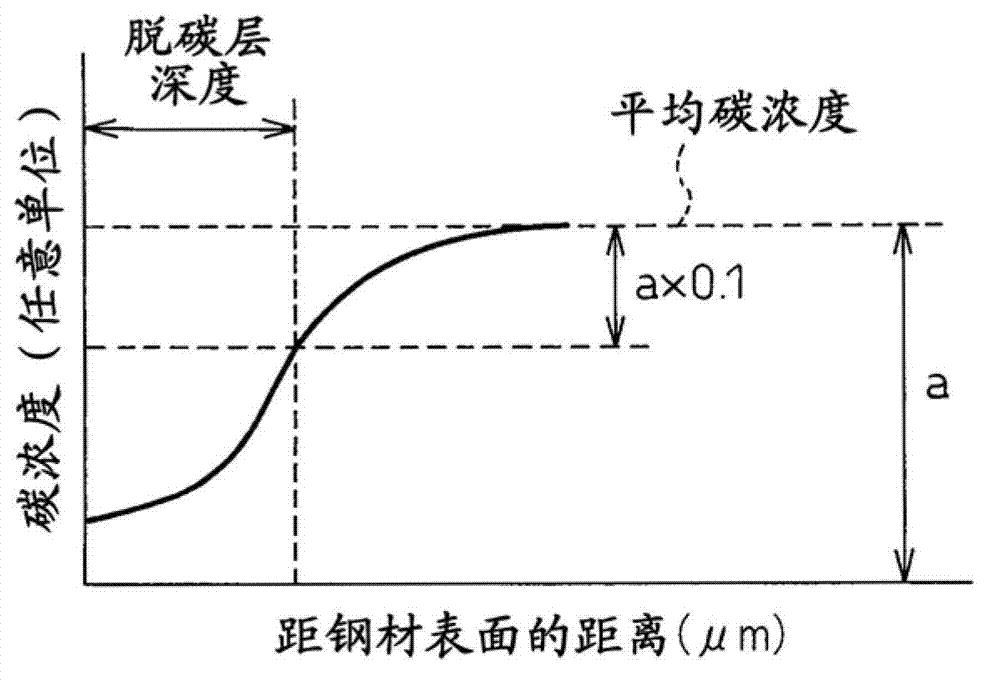

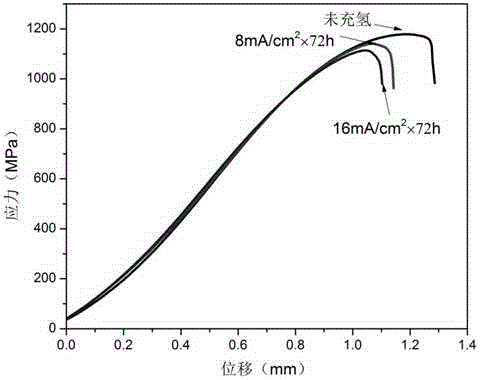

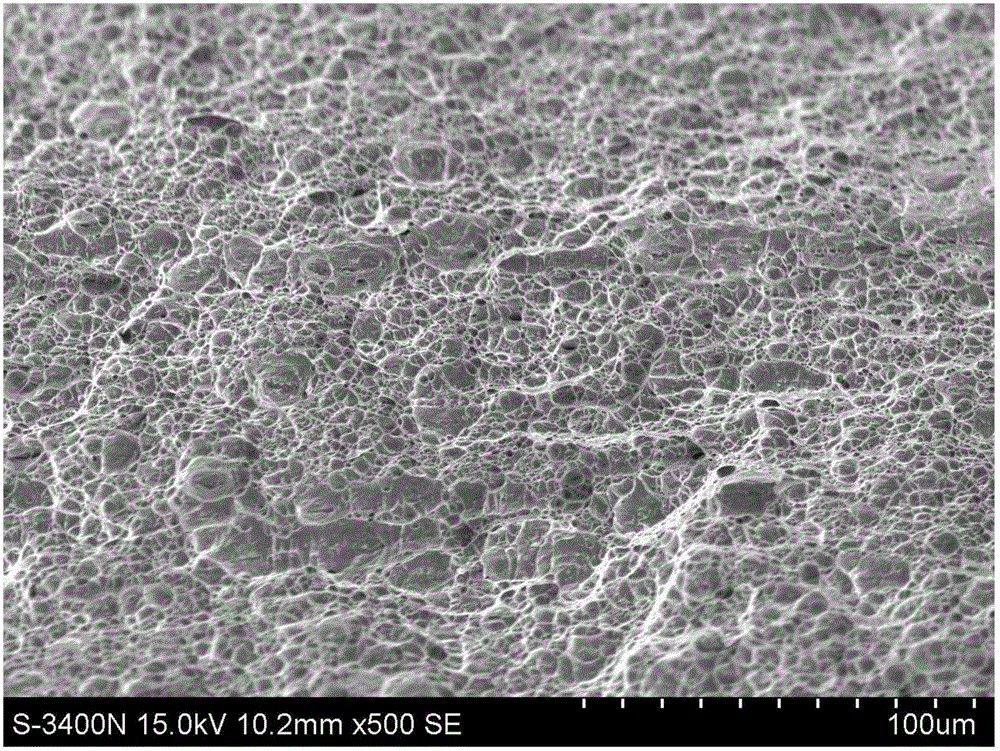

High-strength steel and high-strength bolt with excellent resistance to delayed fracture, and manufacturing method therefor

InactiveCN102791898AExcellent resistance to delayed fractureCheap manufacturingSolid state diffusion coatingFurnace typesNiobiumManganese

The disclosed steel contains, by mass, 0.10-0.55% carbon, 0.01-3% silicon, and 0.1-2% manganese. Said steel also contains one or more of the following: 0.05-1.5% chromium; 0.05-0.2% vanadium; 0.05-0.40% molybdenum; 0.001-0.05% niobium; 0.01-4% copper; 0.01-4% nickel; and 0.0001-0.005% boron. The remainder comprises iron and unavoidable impurities. The structure of the disclosed steel is primarily tempered martensite. Said steel, which is a high-strength steel that exhibits excellent resistance to delayed fracture, is characterized by the following being formed in a surface layer thereof: (a) a nitrided layer with a thickness of at least 200 [mu]m from the surface of the steel and a nitrogen concentration by mass that is at least 0.02% higher than that of the steel and no greater than 12.0%; and (b) a low-carbon region, at a depth between 100 [mu]m and 1000 [mu]m from the surface of the steel, with a carbon concentration by mass that is at most 0.9 times that of the steel and no less than 0.05%.

Owner:NIPPON STEEL CORP

Aluminum plated steel sheet for rapid heating hot-stamping, production method of the same and rapid heating hot-stamping method by using this steel sheet

ActiveUS20110174418A1Eliminate generationReduce riskShaping toolsHot-dipping/immersion processesHot stampingHydrogen

The present invention solves the problem of melting of Al in heating before hot-stamping, which had been a problem in the past in applying hot-stamping to Al-plated steel sheet, and provides Al-plated steel sheet for hot-stamping and a method of hot-stamping using that Al-plated steel sheet to solve the problem of delayed fracture due to residual hydrogen, and, furthermore, a method of a rapid heating hot-stamping using that Al-plated steel sheet.The Al-plated steel sheet of the present invention is produced by annealing the Al-plated steel sheet as coiled in a box-anneal furnace for the time and at the temperature indicated in FIG. 5, and alloying of a plated Al and a steel sheet.Further, a method of rapid heating hot-stamping in the present invention is characterized by cutting out a stamping blank of an Al-plated steel sheet, and heating that blank in heating before hot-stamping by an average temperature with a rising rate of 40° C. / sec or more and a time of exposure to an environment of 700° C. or more of 20 seconds or less, and then hot-stamping it.

Owner:NIPPON STEEL CORP

High strength bolting steel with excellent delayed fracture resistance and cold working performance

The name in religion belongs to the alloy steel domain, mainly is suitable above tensile strength 1200MOa, has good bears the detention break and cold finishing the performance high strength bolt steel. The steel concrete chemical composition (weight %) is: C0.25~~0.4%, Si is smaller than is equal to 0.1%, Mn0.4~~1.4%, P is smaller than is equal to 0.01%, S is smaller than is equal to 0.008%, Cr0.1-0.5%, Mo0.15~~0.35%, B0.0005~~0.003%, Ti0.01~~0.1%, RE0.005~~0.04%, Al0.005~~0.05%, N0.004~~0.01%, -odd is Fe. The steel concrete chemical composition (weight %) center also may join 0.01~~0.1% Nb, in Zr any a kind of or two kind of sums. The invention and the existing technology compare, this steel not only tensile strength very high, moreover bears the detention break and cold finishing the performance fine, the cost is low.

Owner:CENT IRON & STEEL RES INST

High-strength thermal forming martensitic steel

The invention belongs to the field of alloy steel, in particular to a high intensity hotforming martensite steel which is mainly applied to a thin part with the anti-tension intensity of 1.7 to 2.0GPa that is formed by hot punching. The main chemical components (weight percentage)of the steel are: 0.26 to 0.45 percent of C, 0.50 to 2.30 percent of Si, 0.50 to 2.00 percent of Mn, 0.50 to 1.50 percent of Cr, less than or equal to 0.018 percent of P, less than or equal to 0.010 percent of S, 0.015 to 0.060 percent of Al, equal to or less than 0.003 percent of [O], 0.002 to 0.015 percent of [N] and the rest are Fe as well as other unavoidable impurities. Besides, any one of or more than of 0.0005 to 0.0050 percent of B, 0.02 to 0.10 percent of Ti, 0.02 to 0.10 percent of Nb, 0.02 to 0.15 percent of V and 0.001 to 0.050 percent of RE are added. Compared with the 22MnB5 steel of the existing hotforming martensite steel, the anti-tension intensity of the steel of the invention is improved from 1.0-1.5GPa to 1.7-2.0GPa; besides, the steel has excellent plasticity (percentage of elongtation is larger than 12 percent) and the sensitivity to hydrogen induced delayed fracture is reduced remarkably; thereby providing foundation for vehicle light weight and high safety performance.

Owner:CENT IRON & STEEL RES INST

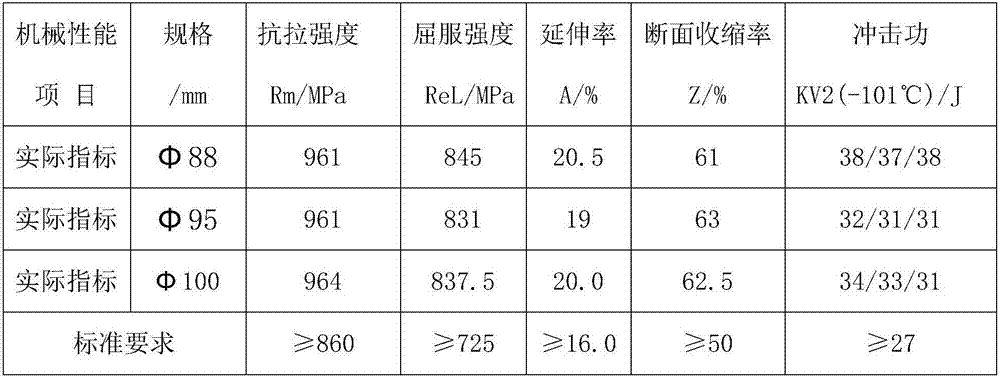

Manufacturing method of ultralow-temperature-impact resistant steel for high-intensity bolt of wind turbine generator set

ActiveCN107299278AImprove uniformityImprove performance indicatorsManufacturing convertersProcess efficiency improvementElectricityPerformance index

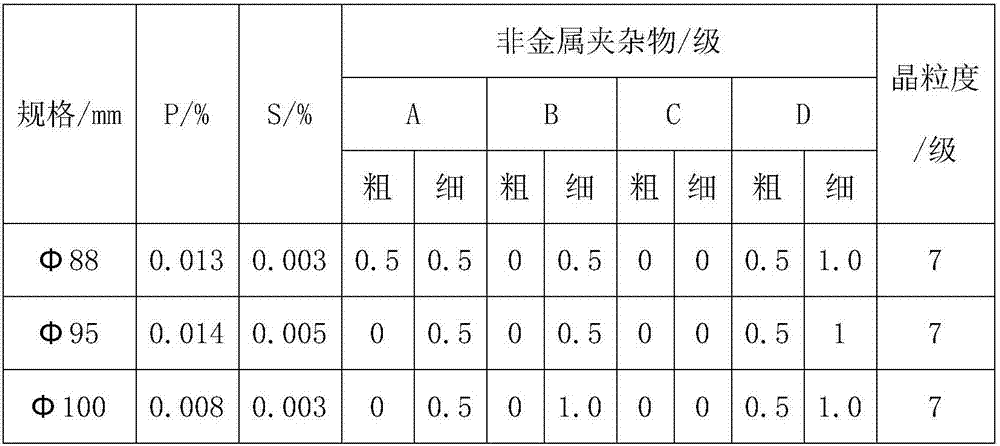

A manufacturing method of ultralow-temperature-impact resistant steel for a high-intensity bolt of a wind turbine generator set comprises the following steps: primarily melting by a top-bottom combined blowing basic converter; refining by an LF refining furnace; degassing by a VD vacuum furnace; continuously casting by a round billet arc-shaped continuous casting machine; heating rolled steel; dephosphorizing and oxidizing iron scales; rolling; and drawing into a pit and slowly cooling. According to the method, the development and design are on the basis of three aspects, namely, high toughness, delayed fracture resistance and cold deformability; after the whole round steel is thermally processed, the performance indexes reach that Rm is not less than 950Mpa, Re is not less than 830Mpa, A is not less than 20%, Z is not less than 60%, and KV2 (-101 DEG C) is not less than 30J.

Owner:山东寿光巨能特钢有限公司

High-strength steel and high-strength bolt with excellent resistance to delayed fracture, and manufacturing method therefor

InactiveCN102812145AExcellent resistance to delayed fractureCheap manufacturingSolid state diffusion coatingFurnace typesNiobiumManganese

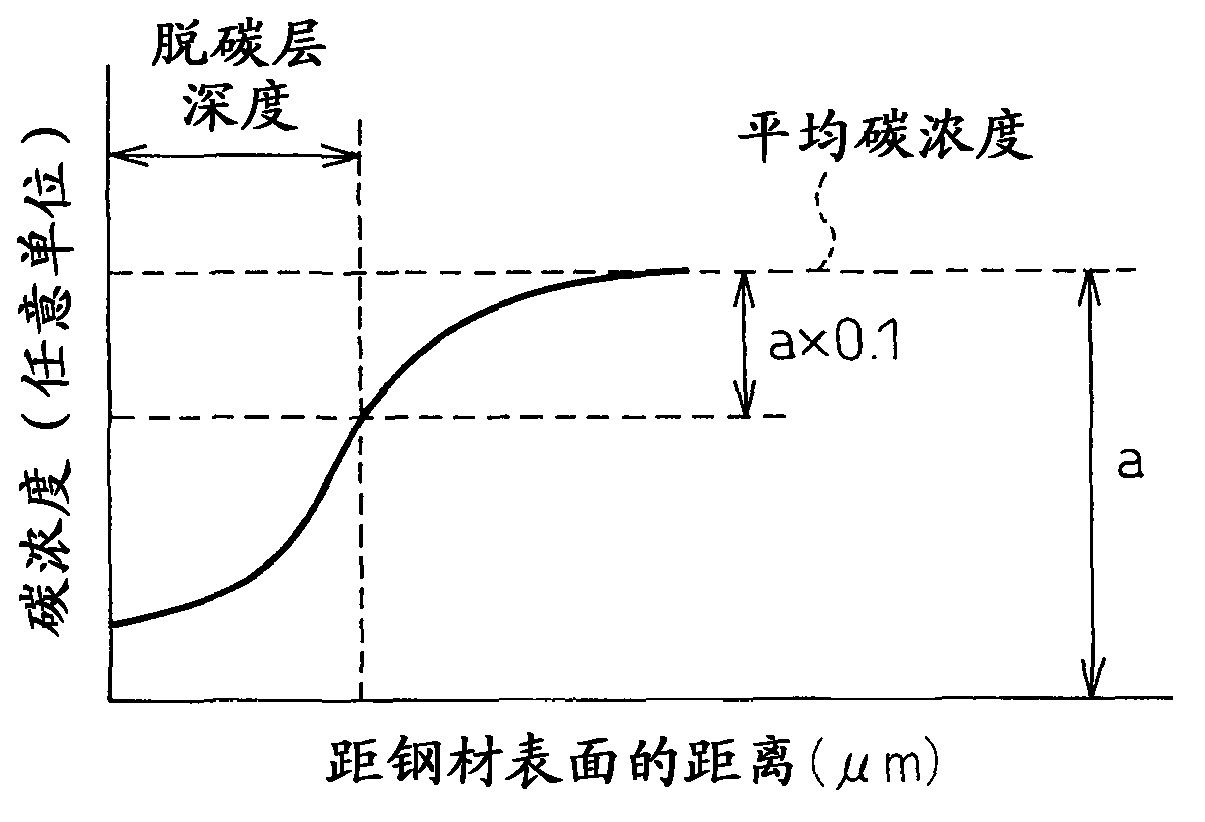

The disclosed steel contains, by mass: 0.10-0.55% carbon; 0.01-3% silicon; 0.1-2% manganese; and up to 1.5% vanadium and / or up to 3.0% molybdenum, with the vanadium content (V) and the molybdenum content (Mo) satisfying the relation V+ 1 / 2 Mo > 0.4%. Said steel also contains one or more of the following: 0.05-1.5% chromium; 0.001-0.05% niobium; 0.01-4% copper; 0.01-4% nickel; and 0.0001-0.005% boron. The remainder comprises iron and unavoidable impurities. The structure of the disclosed steel is primarily tempered martensite. Said steel, which is a high-strength steel that exhibits excellent resistance to delayed fracture, is characterized by the following being formed in a surface layer thereof: (a) a nitrided layer with a thickness of at least 200 [mu]m from the surface of the steel and a nitrogen concentration by mass that is at least 0.02% higher than that of the steel and no greater than 12.0%; and (b) a low-carbon region, at a depth between 100 [mu]m and 1000 [mu]m from the surface of the steel, with a carbon concentration by mass that is at most 0.9 times that of the steel and no less than 0.05%.

Owner:NIPPON STEEL CORP

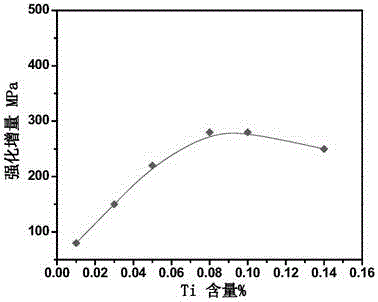

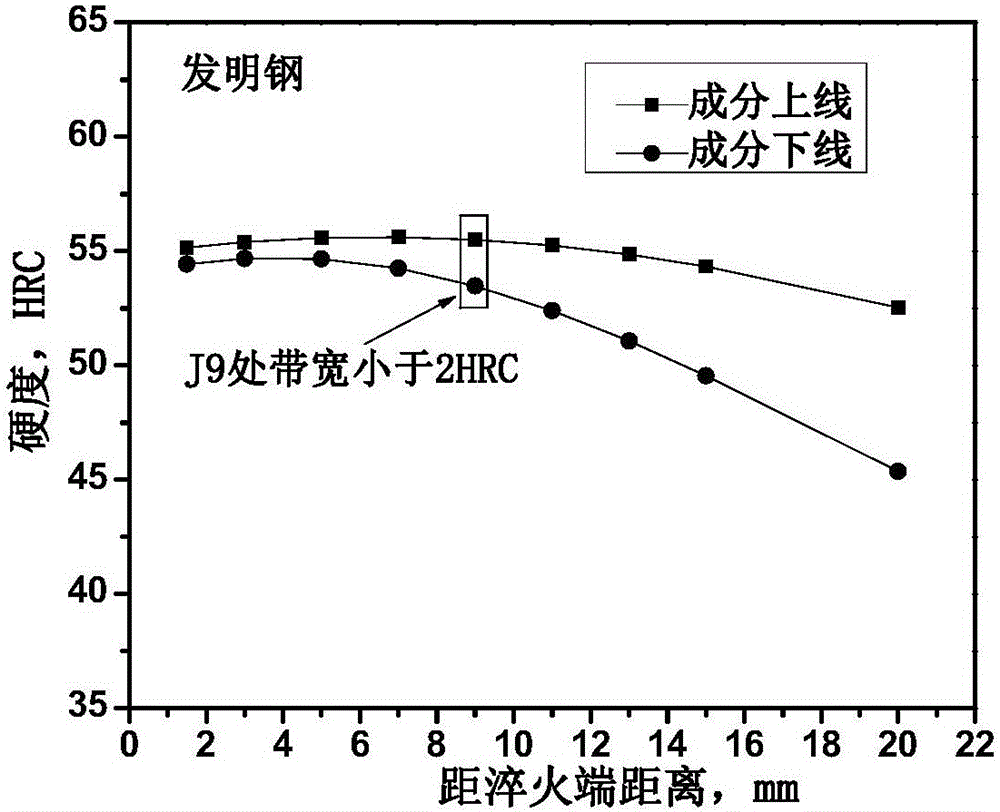

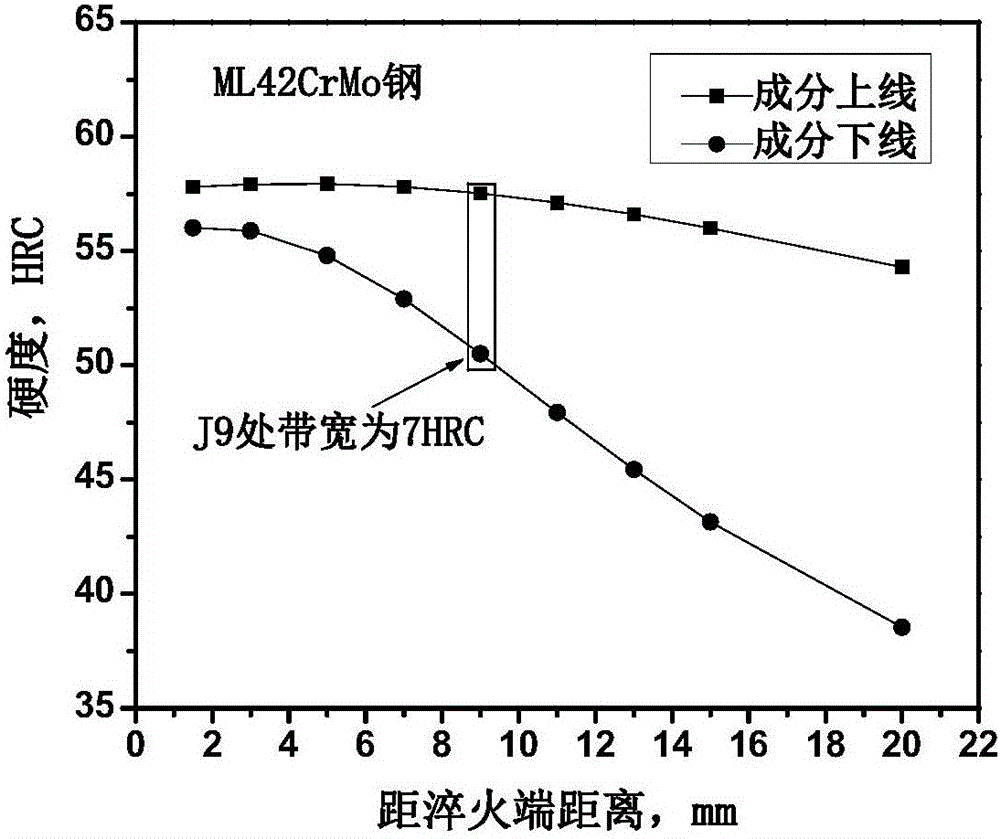

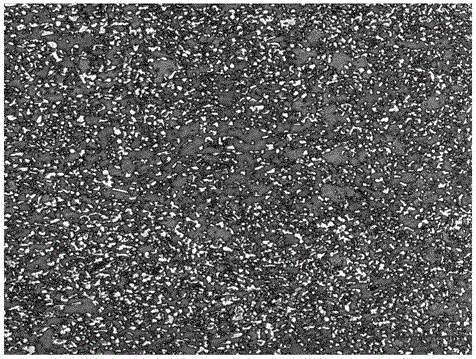

Industrial stable high-performance bolt steel and manufacturing method thereof

ActiveCN105002427AImprove high temperature tempering strengthReduce carbon contentChemical compositionAustenite grain

The invention discloses industrial stable high-performance bolt steel and a manufacturing method thereof and belongs to the technical field of high-strength bolt steel. The chemical components of the steel comprise, by mass, 0.28-0.37% of C, equal to or less than 0.10% of Si, 0.15-0.30% of Mn, equal to or less than 0.010% of P, equal to or less than 0.005% of S, 1.10-1.20% of Cr, 0.15-0.40% of Mo, 0.0005-0.003% of B, 0.03-0.08% of Ti, 0.015-0.030% of Al and equal to or less than 0.005% of N, and the balance is Fe, on the basis, 0.15-0.30% of V or 0.02-0.04% of Nb can be added. Through the adoption of a reasonable controlled rolling and controlled cooling technology, the original austenite grain size of the steel after phase change is further refined by 1-2 grades, 3-8 um superfine austenite grains and precipitated phase with the size of 1-20 nm are obtained, and therefore the high-temperature tempering strength of the steel is improved. The industrial stable high-performance bolt steel and the manufacturing method thereof have the advantages that compared with the prior art, the carbon content of the steel in the same strength grade is reduced, the hardness fluctuation after quenching+tempering is small, the strength after high-temperature tempering is high, the stability of batch quality is high, the cost is low, and the delayed fracture resistance is excellent.

Owner:CENT IRON & STEEL RES INST

Dual phase steel with tensile strength of 1000 MPa and production method thereof

The invention discloses a dual phase steel with tensile strength of 1000 MPa and a production method thereof. The dual phase steel is composed of the following chemical components in percentage by weight: 0.08%-0.11% of C, 0.2%-0.6% of Si, 2.0%-2.5% of Mn, at most 0.01% of P, at most 0.01% of S, 0.02%-0.06% of Al, 0.4%-0.6% of Cr, 0.02%-0.05% of Ti, at most 0.003% of N, and the balance of Fe and inevitable impurities. The method solves the technical problem of how to lower the alloy cost and enhance the reaming property and delayed fracture resistance of the material on the premise of satisfying the strength requirement.

Owner:SHOUGANG CORPORATION

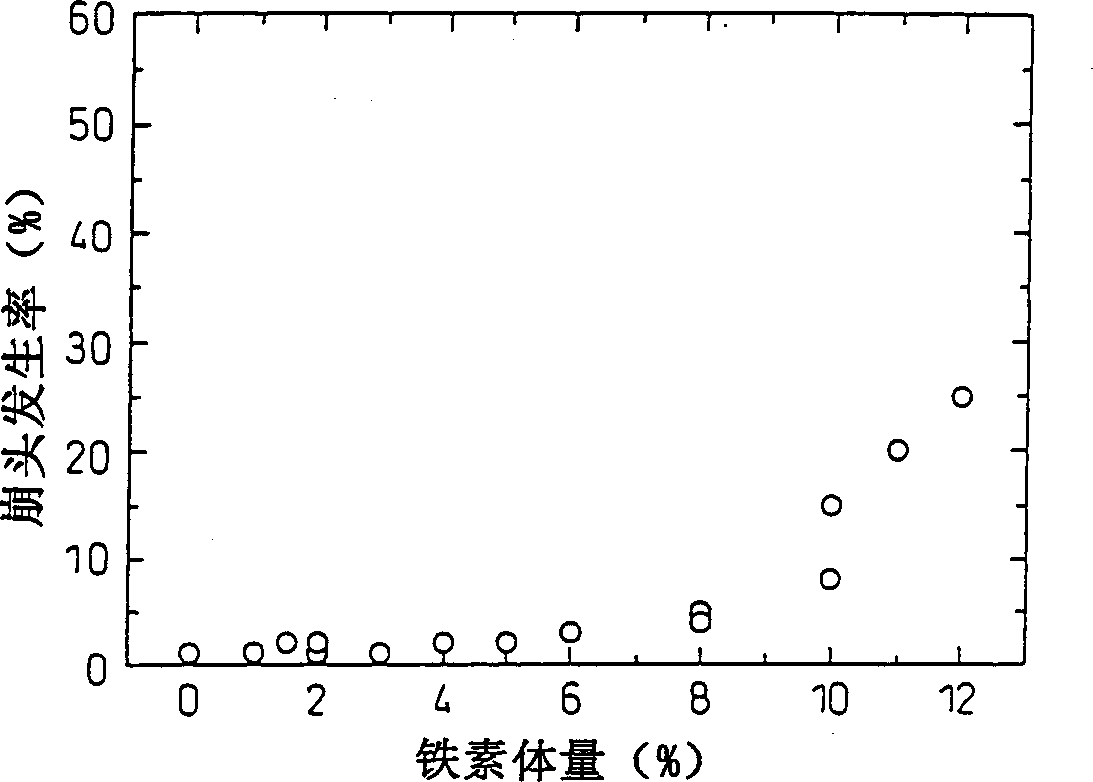

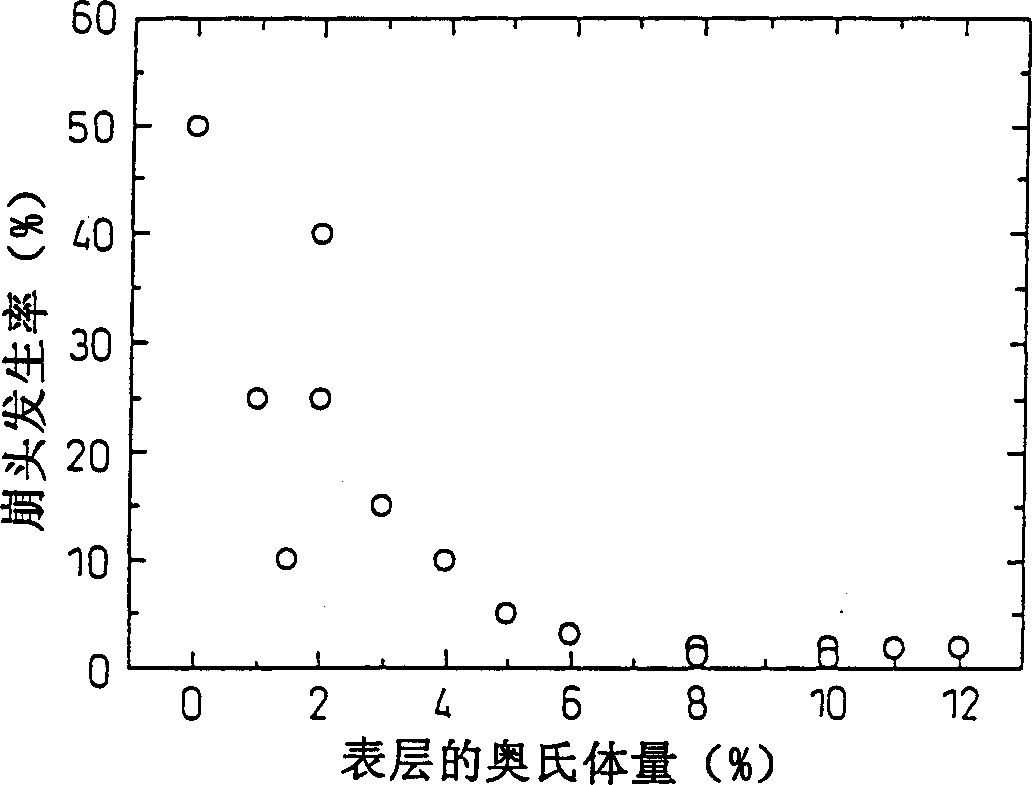

High-strength, high-toughness stainless steel excellent in resistance to delayed fracture

InactiveCN1334883ACheap and stableImprove toughnessSolid state diffusion coatingFurnace typesSurface layerChemical composition

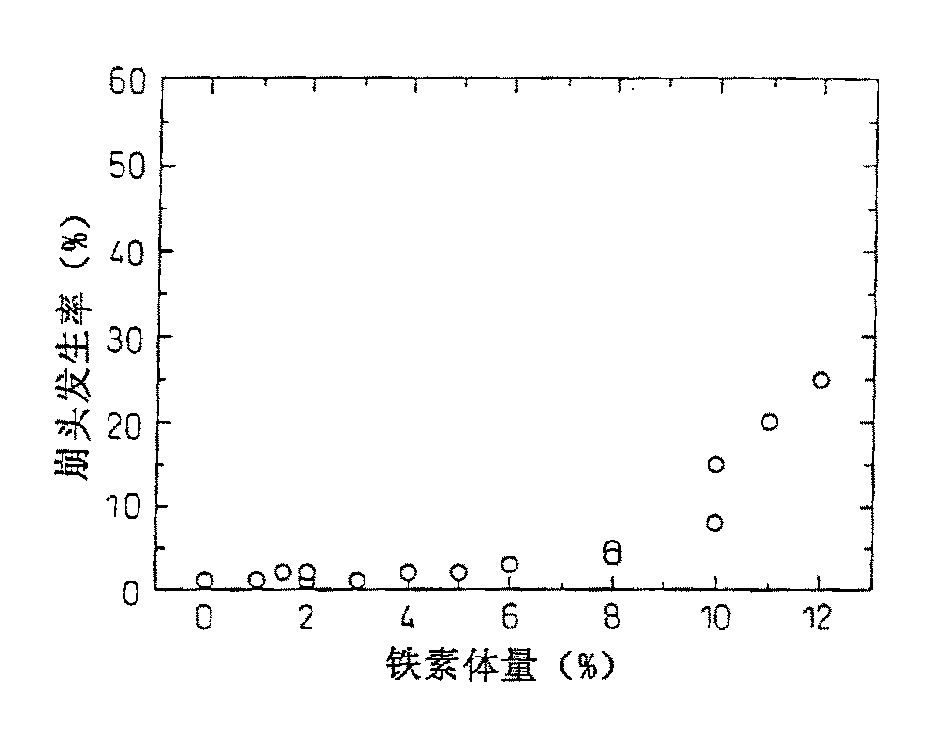

The present invention makes the best use of a low-cost chemical composition in providing a high strength and high corrosion resistance stainless steel, which has improved delayed fracture resistance and toughness in particular, for building and construction uses, and as, for example, a stainless steel tapping screw. The present invention is, specifically, a stainless steel and a stainless steel screw with high strength and high toughness and excellent in delayed fracture resistance, characterized by: comprising, by mass, 0.01 to 0.25% of C, 0.05 to 1.0% of Si, 0.1 to 2.0% of Mn, 0.1 to 3.0% of Ni, 11.0 to 16.0% of Cr, 0.01 to 0.15% of N, and 0.01 to 3.0% of Mo; containing, optionally, 0.001 to 0.005% of B and / or one or more of 0.05 to 0.5% of Ti, 0.05 to 0.5% of Nb, and 0.05 to 0.5% of W; having less than 10% of ferrite in the center portion of the material; and having a mixed structure of martensite and 3 to 30% of austenite in the surface layer from the outermost surface to the depth of at least 1 mum, and a method to produce the same.

Owner:NIPPON STEEL & SUMIKIN STAINLESS STEEL CORP

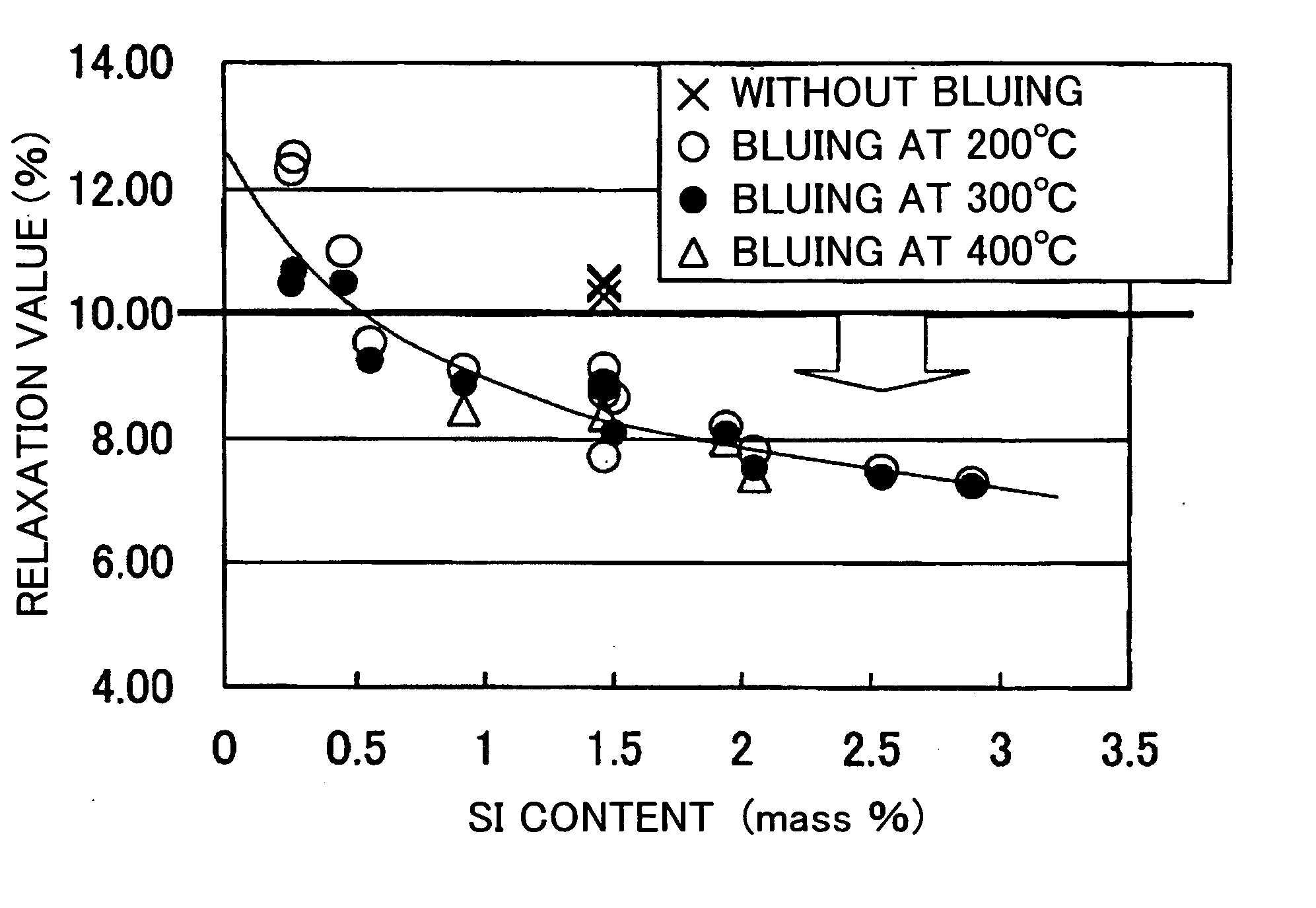

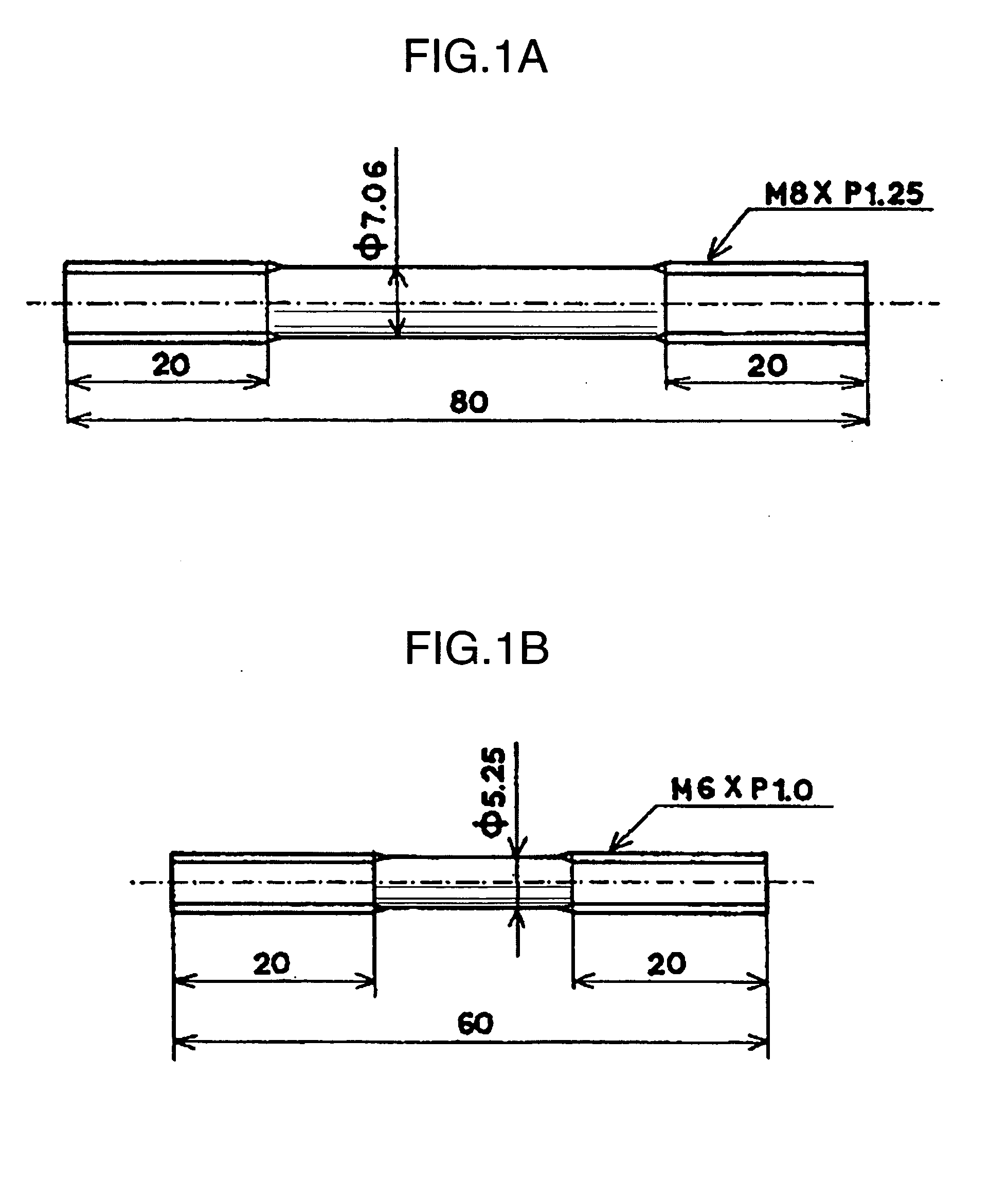

High-strength bolt superior in delayed fracture and resistance and relaxation resistance

Disclosed is a high-strength bolt having a tensile strength of 1,200 N / mm2 or more and superior in delayed fracture resistance and relaxation resistance, prepared by wire-drawing a bolt steel containing the following elements: C: 0.5 to 1.0% (mass %, the same shall apply hereinafter), Si: 0.55 to 3%, Mn: 0.2 to 2%, P: 0.03% or less (but not 0%), S: 0.03% or less (but not 0%), and Al: 0.3% or less (but not 0%), and containing proeutectoid ferrite, proeutectoid cementite, bainite and martensite at a total areal rate of less than 20% and pearlite in balance; cold-heading the wire into a bolt shape; and then bluing the bolt in a temperature range of 100 to 500° C.

Owner:HONDA MOTOR CO LTD +2

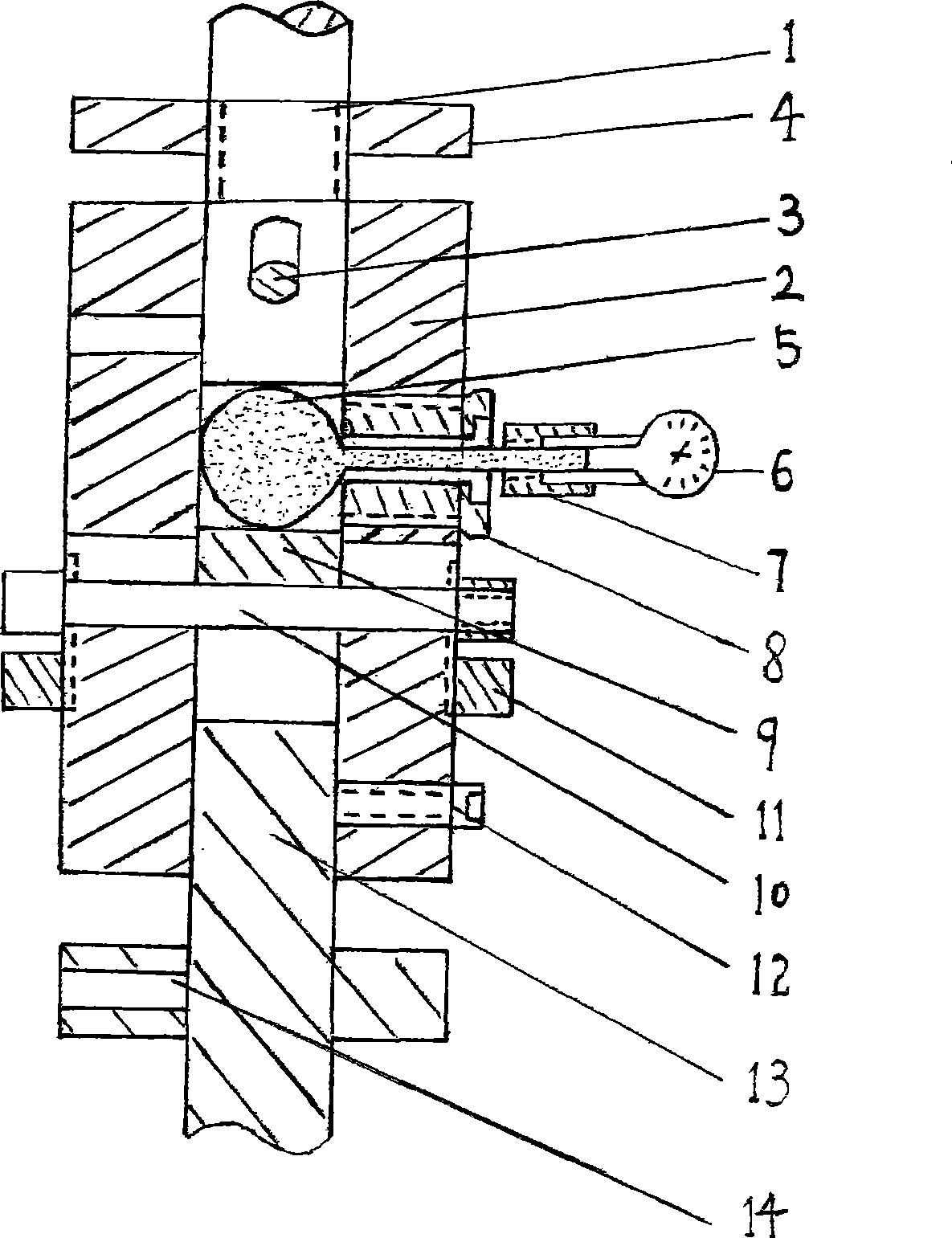

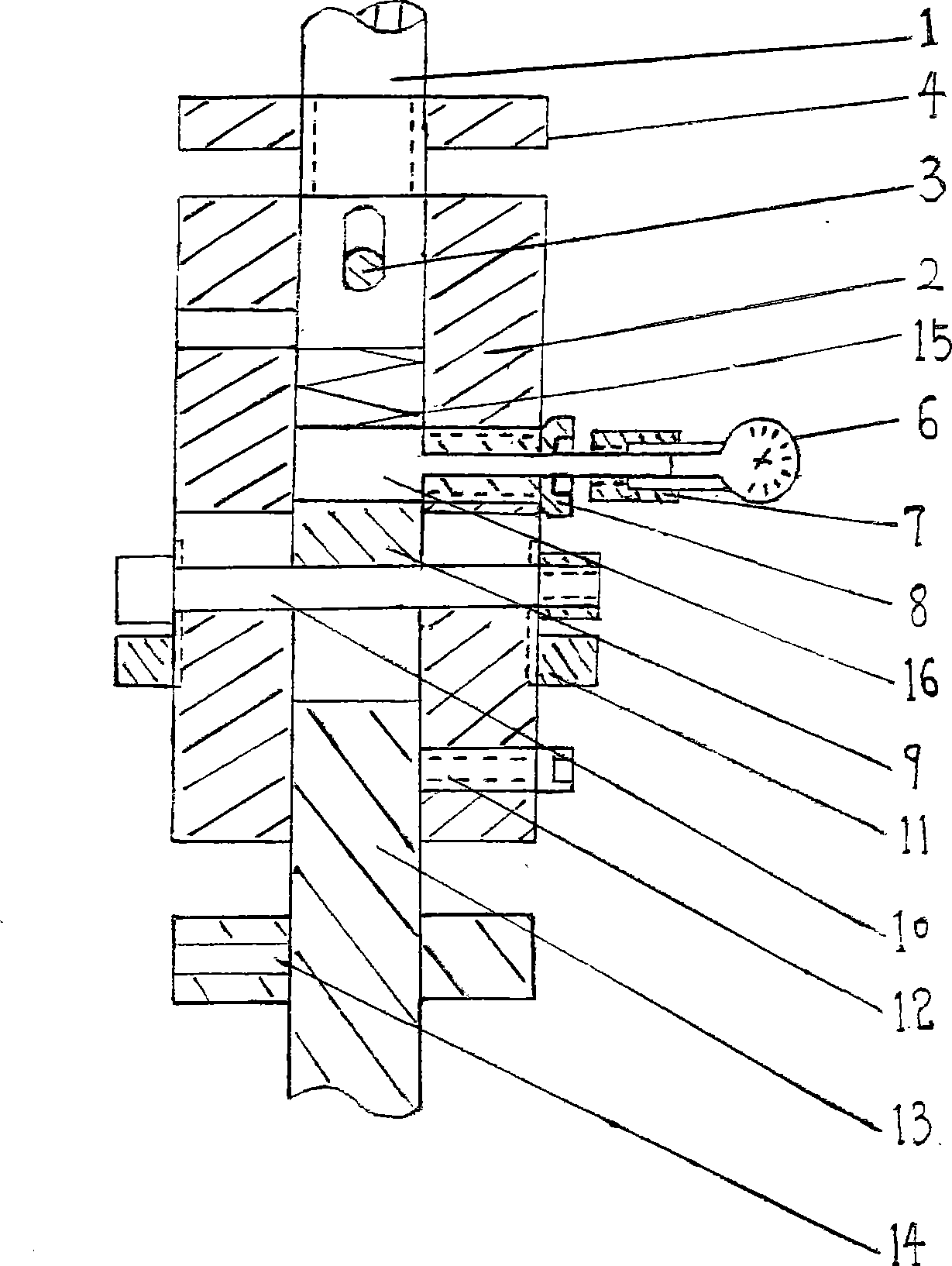

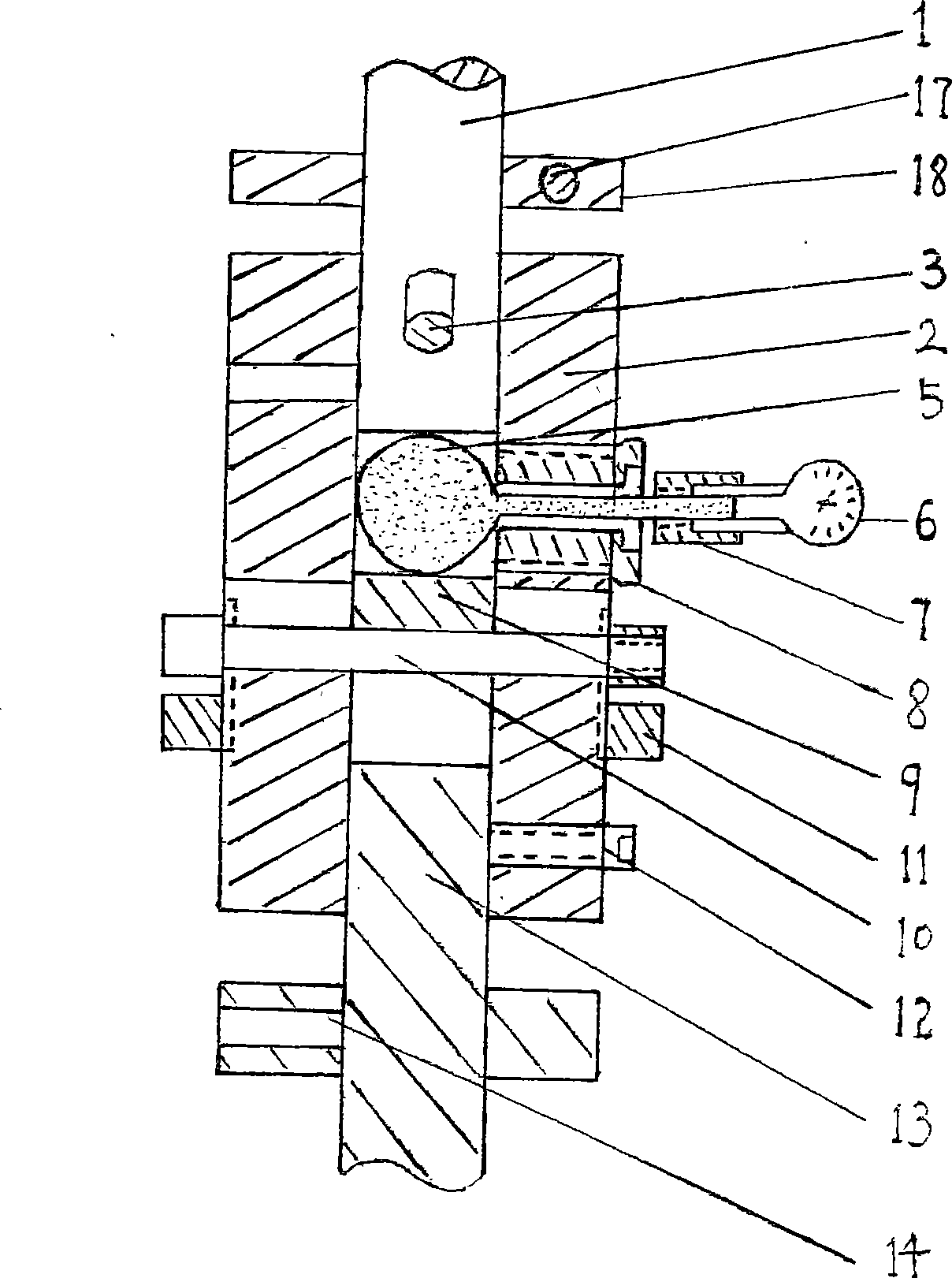

External fixation rack elasticity device

The invention discloses a resilient device of an external fixator in the clinical application of orthopaedics. The resilient device consists of a cylinder, a sliding axle in the cylinder, a flexible apparatus, a sliding nail body and a sliding axle stopper. An anti-spin rivet, a pressure regulation rivet, a pressure regulation nut, a tightening jack bolt, a hollow screw on the cylinder wall and a pressurization hole are arranged in the radial direction on the cylinder wall, wherein, the sliding axle stopper can be provided with a stop jack bolt in the radial direction on the cylinder wall, or a stop nut or a stop fixture block can be arranged on the sliding axle; the cylinder wall can be designed to have equal inner diameters at the upper and lower parts or have the inner diameter of the upper part at the corresponding position of the sliding axle larger than that of the lower part; the flexible device can be made into a flexible capsule or a spring; and the sliding nail body is connected with the cylinder in a sliding manner. The resilient device can match with external fixators of different shapes and structures to form external flexible fixators. When a limb with a fracture suffers axial pressure, the external flexible fixator can have a slight axial movement so that an interaction force can be generated due to the slight movement at the end of fracture so as to stimulate callus to grow at the end of fracture. The resilient device can avoid osteoporosis due to stress shielding of the external fixator, quicken the fracture healing, increase the strength of healed bone and effectively prevent delayed fracture healing or nonunion.

Owner:河南科科生物科技有限公司

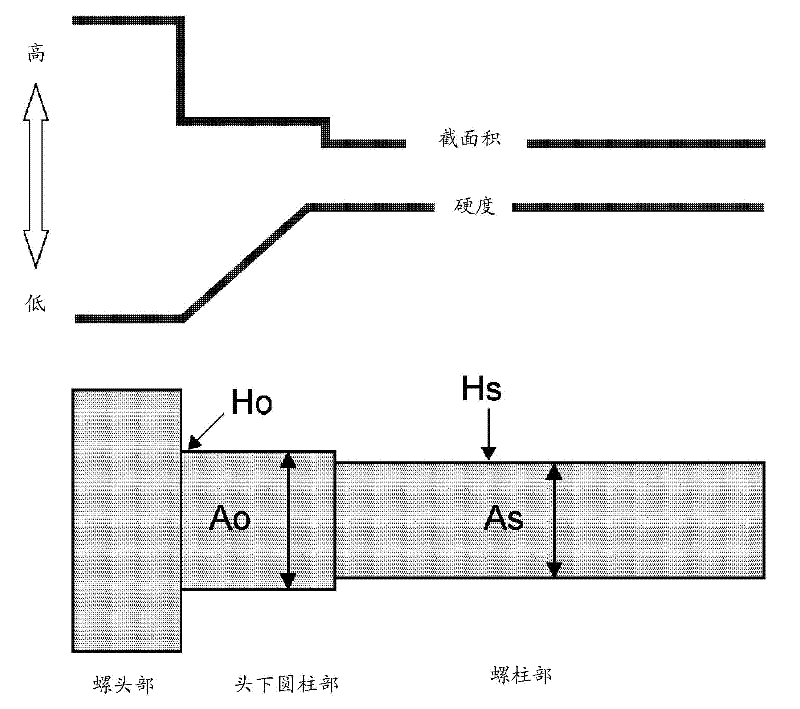

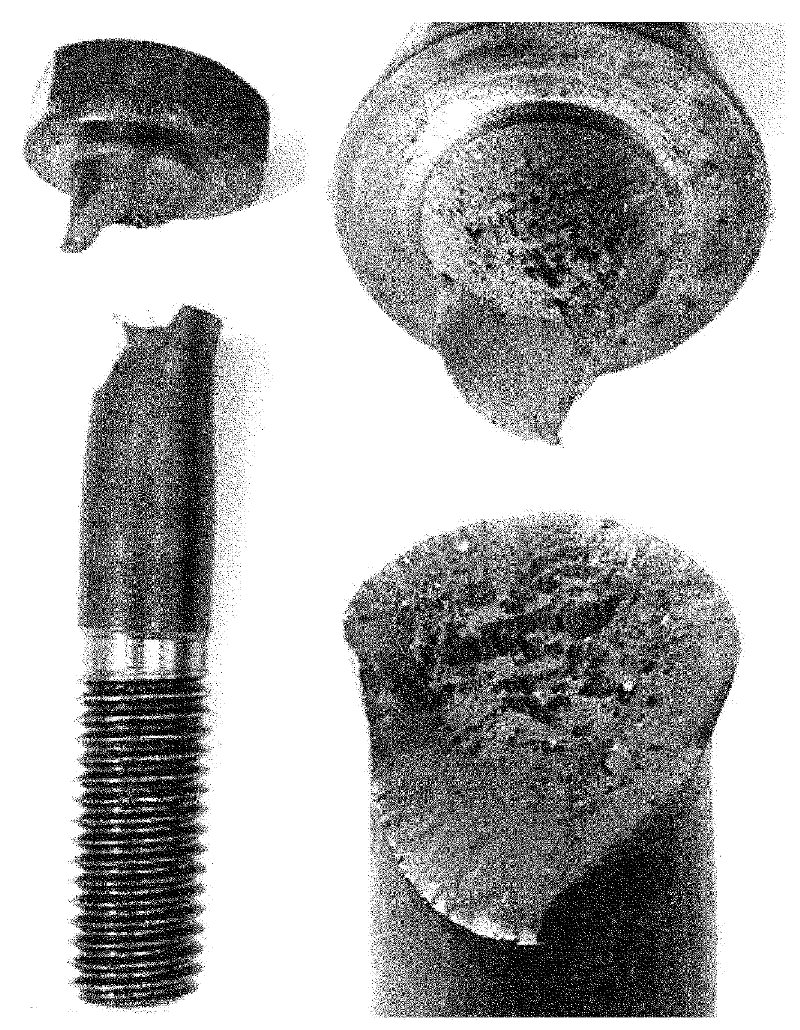

High-strength bolt

ActiveCN102597543ADelayed Fracture PropertiesImprove impact resistanceScrewsFurnace typesMaterials scienceImpact resistance

Provided is a high-strength bolt having a tensile strength of 1200 MPa or more, which further has excellent ductility and delayed fracture property, and excellent impact resistance which could not be obtained before. The high-strength bolt has a tensile strength of 1.2 GPa or more, and has a threaded portion and a neck cylindrical portion. In the high-strength bolt, if the effective section area of the neck cylindrical portion having a diameter larger than that of the threaded portion is represented by Ao, the hardness of a portion at which Ao is measured is represented by Ho, the effective section area of the threaded portion is represented by As, and the hardness of the threaded portion is represented by Hs, K=(Ao * Ho) / (As * Hs) is 0.8 or more, and Ho < Hs is satisfied.

Owner:NAT INST FOR MATERIALS SCI +2

High-strength hot-formed steel sheet member

ActiveUS20170096724A1High strengthDelayed fracture resistanceHot-dipping/immersion processesFurnace typesChemical compositionCarbide

A high-strength hot-formed steel sheet member exhibiting both a consistent hardness and delayed-fracture resistance, and is characterized in that: the high-strength hot-formed steel sheet member has a prescribed chemical composition; the degree of Mn segregation α (=[maximum Mn concentration (mass %) at the sheet center in the thickness direction] / [average Mn concentration (mass %) at a depth of ¼ of the total thickness of the sheet from the surface]) is less than or equal to 1.6; the steel purity value as defined in JIS G 0555 (2003) is less than or equal to 0.08%; the average grain size for prior γ grains is less than or equal to 10 μm; and the number density of the residual carbides is less than or equal to 4×103 particles / mm2.

Owner:NIPPON STEEL CORP

Internal high hardness type pearlitic rail with excellent wear resistance, rolling contact fatigue resistance, and delayed fracture property and method for producing same

ActiveCN101743334AImprove wear resistanceExcellent resistance to fatigue damageFurnace typesMetal rolling arrangementsFatigue damageSurface layer

An internal high hardness type pearlitic rail has a composition containing 0.73% to 0.85% by mass C, 0.5% to 0.75% by mass Si, 0.3% to 1.0% by mass Mn, 0.035% by mass or less P, 0.0005% to 0.012% by mass S, 0.2% to 1.3% by mass Cr, 0.005% to 0.12% by mass V, 0.0015% to 0.0060% by mass N, and the balance being Fe and incidental impurities, wherein the value of ¢% Mn! / ¢% Cr! is greater than or equal to 0.3 and less than 1.0, where ¢% Mn! represents the Mn content, and ¢% Cr! represents the Cr content, and the value of ¢% V! / ¢% N! is in the range of 8.0 to 30.0, where ¢% V! represents the V content, and ¢% N! represents the N content, and wherein the internal hardness of a rail head is defined by the Vickers hardness of a portion located from a surface layer of the rail head to a depth of at least 25 mm and is greater than or equal to 380 Hv and less than 480 Hv.

Owner:JFE STEEL CORP

Steel plate strip for 14.9-grade high-strength fastener and preparation method of steel plate strip

The invention discloses a steel plate strip for a 14.9-grade high-strength fastener and a preparation method of the steel plate strip. The steel plate strip is prepared from the chemical components inpercentage by mass: 0.44-0.48% of C, smaller than or equal to 0.20% of Si, 0.40-0.80% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.010% of S, 1.0-1.5% of Cr, 0.6-0.8% of Mo, 0.03-0.06% of Nb, 0.2-0.5% of V, 0.03-0.06% of Ti, smaller than or equal to 0.20% of Ni, smaller than or equal to 0.20% of Cu, 0.010-0.050% of Alt, 0.0080-0.0160% of N, smaller than or equal to 0.00015% of H, smaller than or equal to 0.0015% of O, and the balance of Fe and impurities. According to the steel plate strip for the 14.9-grade high-strength fastener, the tensile strength of a finishedbolt can be improved, and the excellent delayed fracture resistance is achieved.

Owner:NANJING IRON & STEEL CO LTD

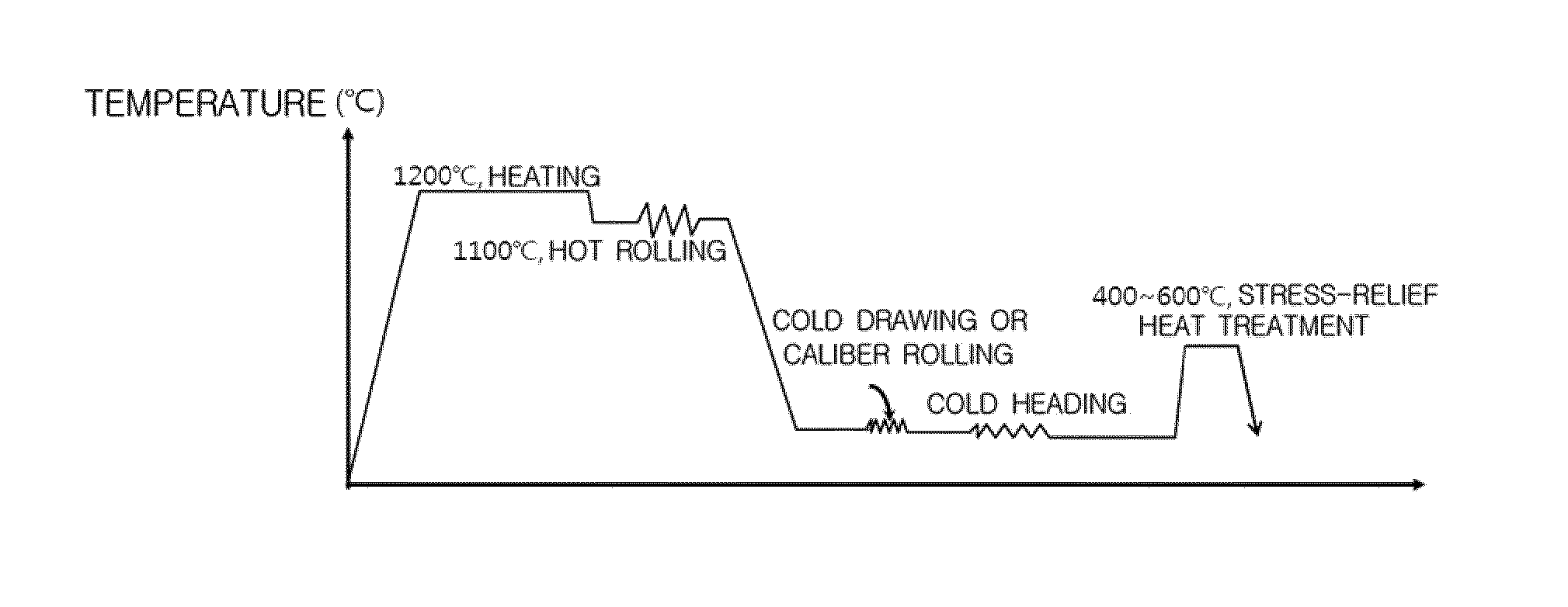

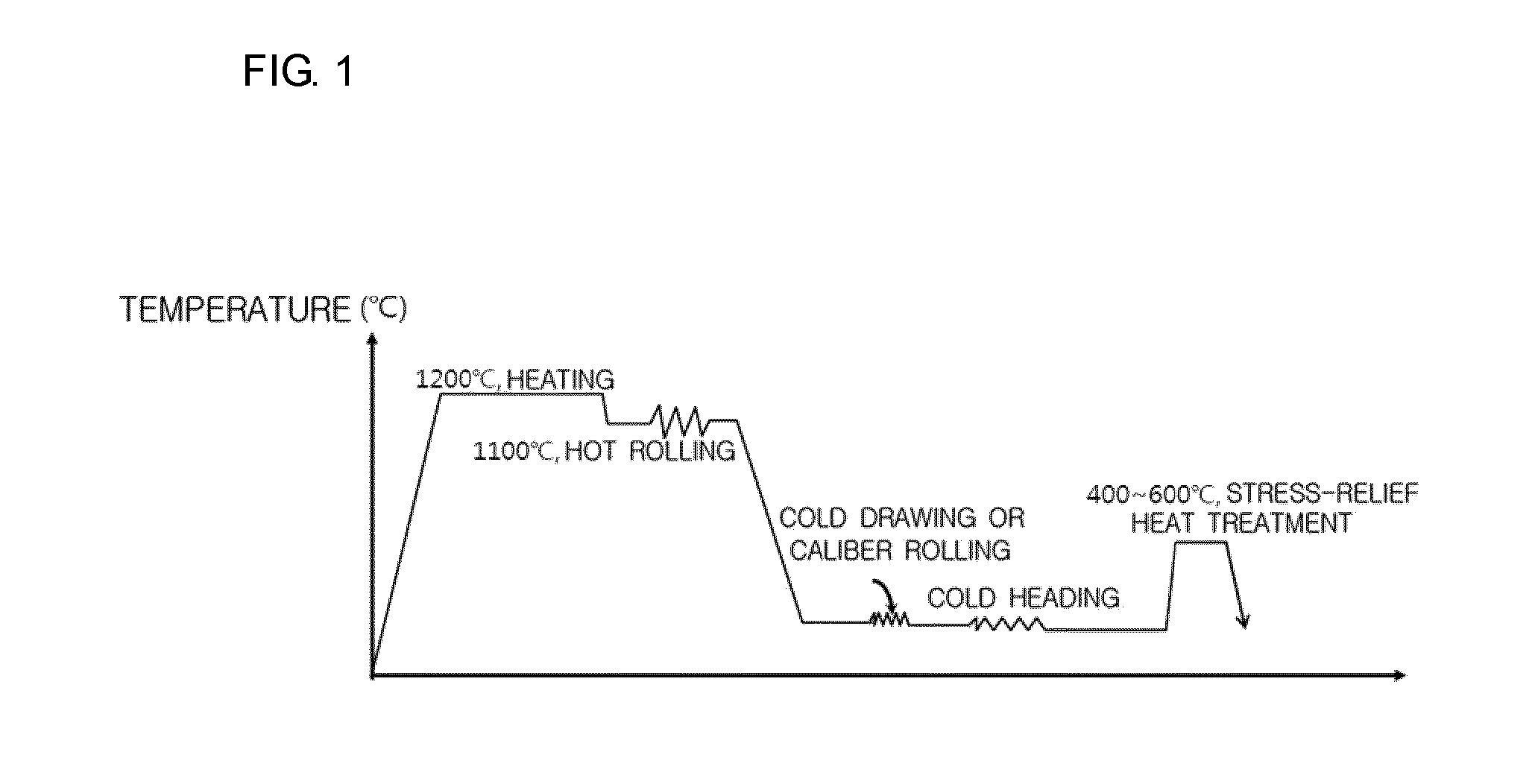

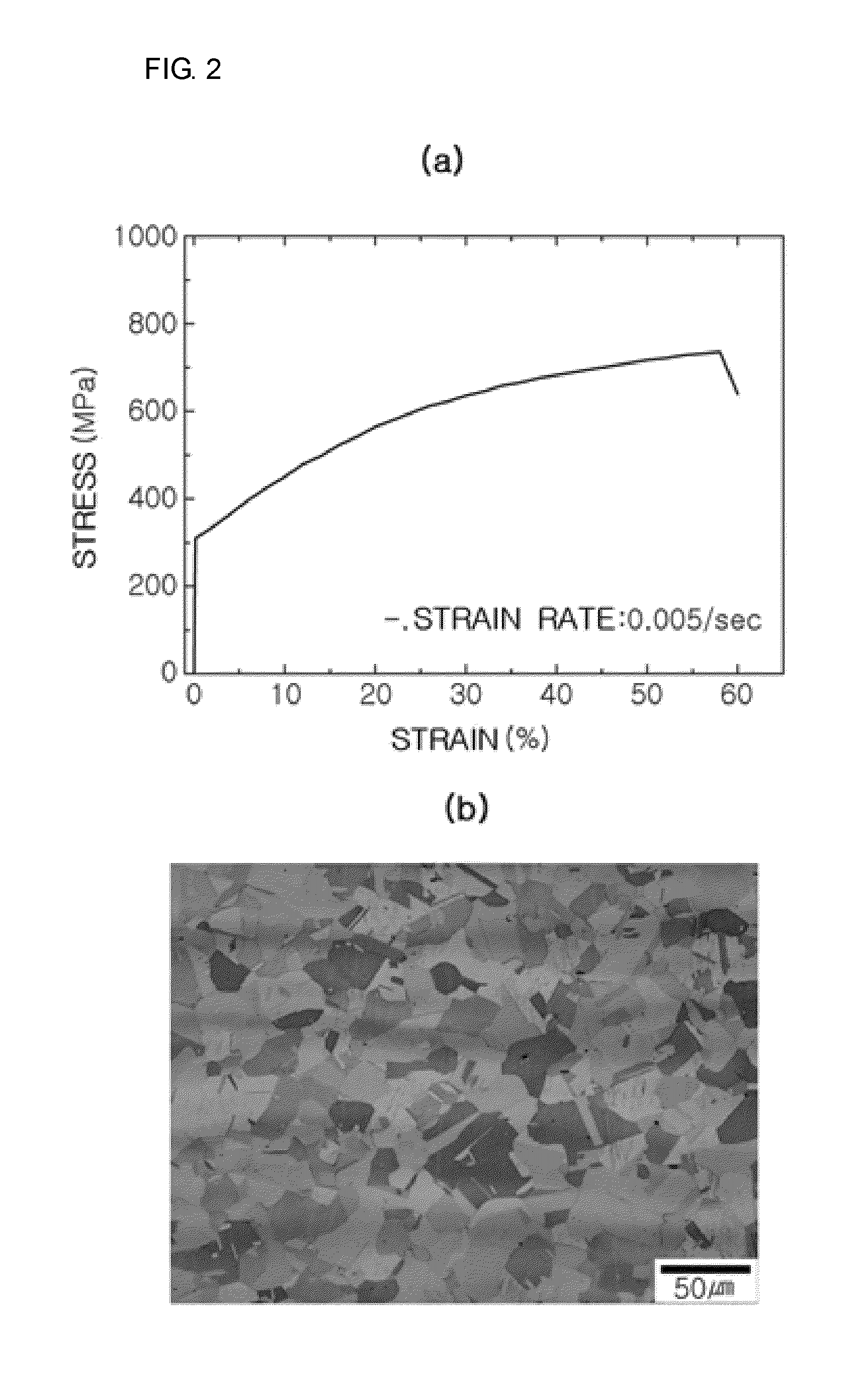

Steel wire rod having excellent cold heading quality and hydrogen delayed fracture resistance, method of manufacturing the same, and mehod of manufacturing bolt using the same

InactiveUS20120128524A1Excellent hydrogen delayed fracture resistanceExcellent cold heading qualityFurnace typesHeat treatment furnacesWire rodHydrogen

Provided are a high-strength, high-manganese steel wire rod having excellent cold heading quality and not requiring spheroidizing and quenching-tempering treatments during manufacturing a bolt and a method of manufacturing a bolt using the steel wire rod. The method of manufacturing a steel wire rod includes heating a steel containing 12 to 25 wt % of Mn within a temperature range of 1100° C. to 1250° C., hot rolling the heated steel within a temperature range of 700° C. to 1100° C., and cooling the hot rolled steel to a temperature of 200° C. or less and cold caliber rolling or drawing to manufacture a steel wire rod.

Owner:POSTECH ACAD IND FOUND

Method of manufacturing hot-press-formed steel member

ActiveUS20140144560A1High strengthImprove ductilityFurnace typesHeat treatment furnacesChemical compositionHigh intensity

To establish a method for obtaining a hot-press-formed steel member, which exhibits high strength, high tensile elongation (ductility) and high bendability, thereby having excellent deformation characteristics at the time of collision crush (crashworthiness), and which is capable of ensuring excellent delayed fracture resistance. A method for producing a hot-press-formed steel member by heating a steel sheet, which has a chemical component composition containing 0.10% (% by mass, and hereinafter the same shall apply) to 0.30% (inclusive) of C, 1.0% to 2.5% (inclusive) of Si, 1.0% to 3.0% (inclusive) of Si and Al in total and 1.5% to 3.0% (inclusive) of Mn, with the balance consisting of iron and unavoidable impurities, and hot press forming the steel sheet one or more times. The method for producing a hot-press-formed steel member is characterized in that: the heating temperature is set to not less than the Ac3 transformation point; the starting temperature of the hot pressing is set to not more than the heating temperature but not less than the Ms point; and the average cooling rate from (the Ms point−150° C. to 40° C. is set to 5° C. / s or less.

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com