High-strength composite steel sheet having excellent moldability and delayed fracture resistance

a composite steel sheet, high-strength technology, applied in the direction of manufacturing tools, heat treatment equipment, furniture, etc., can solve the problems of deterioration of formability, affecting the quality of steel sheets, and limiting applications, so as to achieve excellent spot wedability and good formability

Inactive Publication Date: 2010-09-02

KOBE STEEL LTD

View PDF13 Cites 34 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

[0023]According to the present invention, by specifying chemical components of the steel material as described above, particularly controlling a ratio (Si+Al) / Mn or a ratio (Si+Al) / (Mn+Cr), and constituting the metal structure with a composite structure which mainly contains bainitic ferrite (BF) and also contains polygonal ferrite (PF) and residual austenite (residual γ), it is possible to provide a composite steel sheet which has good formability (elongation-stretch flangeability) and also excellent spot-wedability and anti-delayed fraction property while ensuring a tensile strength of 980 MPa or higher class at cheap price.

Problems solved by technology

However, in the case of high-strength steel sheets having a tensile strength of 980 MPa or higher class, deterioration of formability cannot be avoided and there is restriction on applications since it is possible to apply to parts having complicated shapes.

In the case of high-strength steel sheets having a tensile strength of 980 MPa or higher class, residual stress generated upon press forming increases and thus a risk of delayed fracture enhances.

That is, delayed fracture is a phenomenon in which hydrogen in the corrosion environment or atmosphere is diffused and accumulated at dislocations, vacancies and grain boundaries in the structure of steel materials, especially high-strength steel sheets thereby causing embrittlement of the materials, leading to fracture when stress is applied.

Therefore, delayed fracture exerts a severe influence on ductility and toughness of steel materials.

However, when a tensile strength (TS) becomes a tensile strength of 980 MPa or higher class, this steel sheet shows TS×El as an indicator of the strength (TS) and ductility (El) of 9,000 to 10,300 at most and therefore it is hardly to say that the steel sheet is satisfactory.

However, under the production conditions disclosed in this document, it is required to cool to a temperature within the range from 350 to 400° C. in a salt bath after annealing at 950° C. for 1,200 seconds, and thus this method is not suited for the practical operation.

However, in this technique, the addition of expensive alloy elements such as Mo, Ni and Cu is indispensable and it leaves a room for improvement in cost.

However, in the case of reeling up at low temperature during the hot rolling step, since the structure before annealing is broken and the intended metal structure is not obtained unless the subsequent cold rolling reduction is controlled to the low value, severe restriction is added to the thickness and thickness tolerance.

When continuous annealing is performed twice, although there is no restriction on the thickness, the number of steps increases when compared with the case of a conventional method and thus cost-up cannot be avoided.

However, since a study is mainly made on steels having a tensile strength of 900 MPa class in this steel type, delayed fracture, which is caused in steels having a tensile strength of 980 MPa or higher class, is not sufficiently studied.

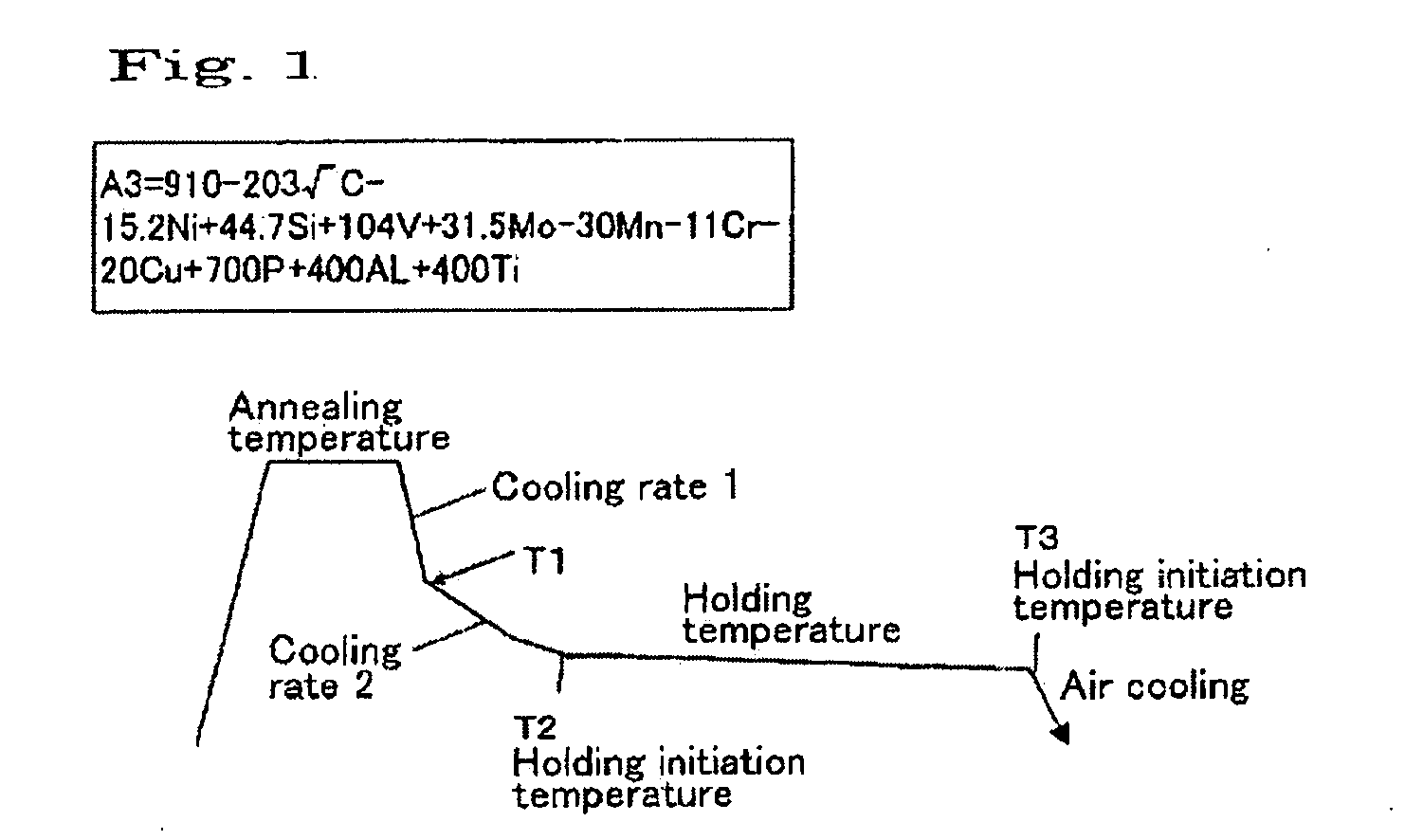

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

examples

[0060]The present invention is further illustrated by the following examples. It is to be understood that the present invention is not limited to the examples, and various design variations made in accordance with the purports described hereinbefore and hereinafter are also included in the technical scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Login to View More

Abstract

The present invention provides a high-strength composite steel sheet which has a tensile strength of 980 MPa class as well as excellent and excellent anti-delayed fraction property, and also has excellent spot-weldability. The high-strength composite steel sheet comprises a steel satisfying: C: 0.10 to 0.25% (% by mass in case of a chemical component, the same shall apply hereinafter), Si: 1.0 to 3.0%, Mn: 1.5 to 3.0%, P: 0.15% or less, S: 0.02% or less, Al: 0.4% or less, and comprising the remnant made from iron and unavoidable impurities; the contents of Si, Al, Mn and Cr satisfy the relationship of “(Si+Al) / Mn or (Si+Al) / (Mn+Cr)=0.74 to 1.26”; and microstructure is specified.

Description

TECHNICAL FIELD[0001]The present invention relates to a high-strength composite steel sheet which has a tensile strength of 980 MPa or higher class as well as excellent formability and excellent anti-delayed fraction property, and also has excellent spot-weldability and is useful as automotive structural parts (body flame members such as pillar, member and reinforcement; bumper, door guard bar, sheet parts, suspension parts, and other reinforcing members).BACKGROUND ART[0002]In recent years, for the purpose of reducing fuel consumption due to saving body weight of automobiles and ensuring safety upon collision, demands for high-strength steels have increased more and more. Accordingly, steel sheets having a tensile strength of 980 MPa or higher class have been required in place of those having a tensile strength of 590 MPa class. However, in the case of high-strength steel sheets having a tensile strength of 980 MPa or higher class, deterioration of formability cannot be avoided and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/28C22C38/06C22C38/18C22C38/02C22C38/04C22C38/00

CPCC21D9/46C22C38/04C22C38/02C22C38/08C22C38/14C22C38/16C22C38/38C22C38/58C22C38/002C22C38/005C22C38/12

Inventor NAKAYA, MICHIHARUMUKAI, YOICHISUGIMOTO, KOICHI

Owner KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com