Patents

Literature

667 results about "Salt bath" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An Epsom salt bath is a simple but very effective natural remedy. When correctly prepared, an Epsom salt bath eases stress and relaxes the body, relieves pain and muscle cramps, and it eliminates toxins from the body.

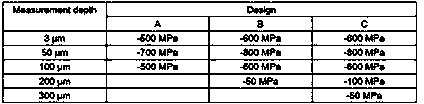

Method for producing tempered glass with plurality of surface stress layers and tempered glass product

The invention discloses a method for producing tempered glass with a plurality of surface stress layers and a tempered glass product and particularly relates to a method for producing tempered lithium glass with a plurality of surface stress layers. The method comprises that a mixed salt bath is used for conducting ion exchange in a step, or various mixed salt baths are used for conducting several ion exchange in a plurality of steps. By the aid of the novel chemical tempered lithium aluminosilicate glass and the treatment method of relative glass products, glass with the plurality of surface stress layers and products of the glass are obtained, and the product serves as a high-strength cover plate in electronic devices, household appliances and vehicles. Compared with the prior art, the tempered glass with the plurality of surface stress layers can protect electronic devices, household appliances and vehicles reliably.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

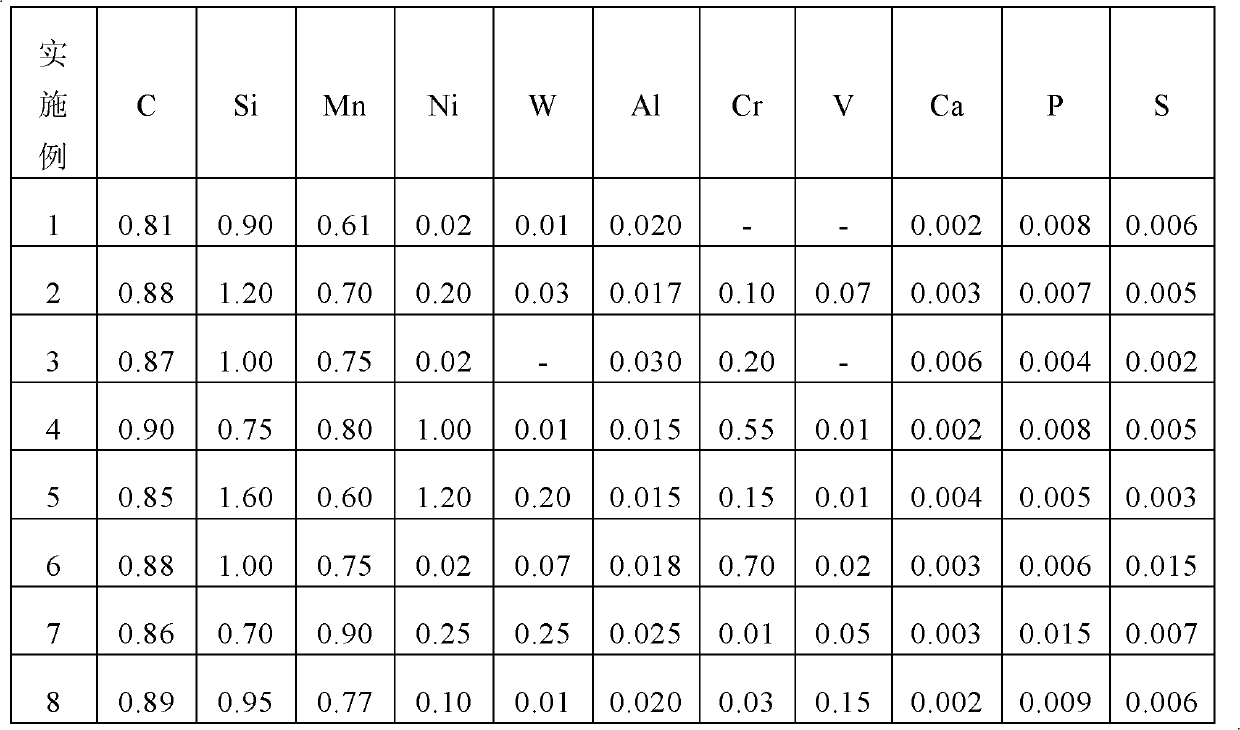

Steel wire rod for 1860MPa-level bridge cable galvanized steel wire and manufacturing method thereof

The invention relates to a steel wire rod for an 1860MPa-level bridge cable galvanized steel wire and a manufacturing method of the steel wire rod. The steel wire rod for the 1860MPa-level bridge cable galvanized steel wire comprises the following raw materials by weight percent: 0.81-0.90% of C, 0.70-1.60% of Si, 0.60-0.90% of Mn, 0.02-1.20% of Ni, 0.00-0.25% of W, 0.015-0.030 of Al, 0.00-0.70% of Cr, 0.00-0.15% of V, 0.002-0.006% of Ca, less than or equal to 0.015% of P, less than or equal to 0.015% of S and the balance of Fe and inevitable impurities, wherein the total quantity of the impurity elements is lower than 0.05%. For the steel wire rod and the preparation method of the steel wire rod, the steel wire rod is not required for salt bath processing, and can be produced by adopting conventional drawing technique, the finished steel wire after being drawn and galvanized has the strength higher than 1860MPa, has 14 times of torsion values, and can be applicable to the need for construction of extra big span bridge.

Owner:BAOSHAN IRON & STEEL CO LTD

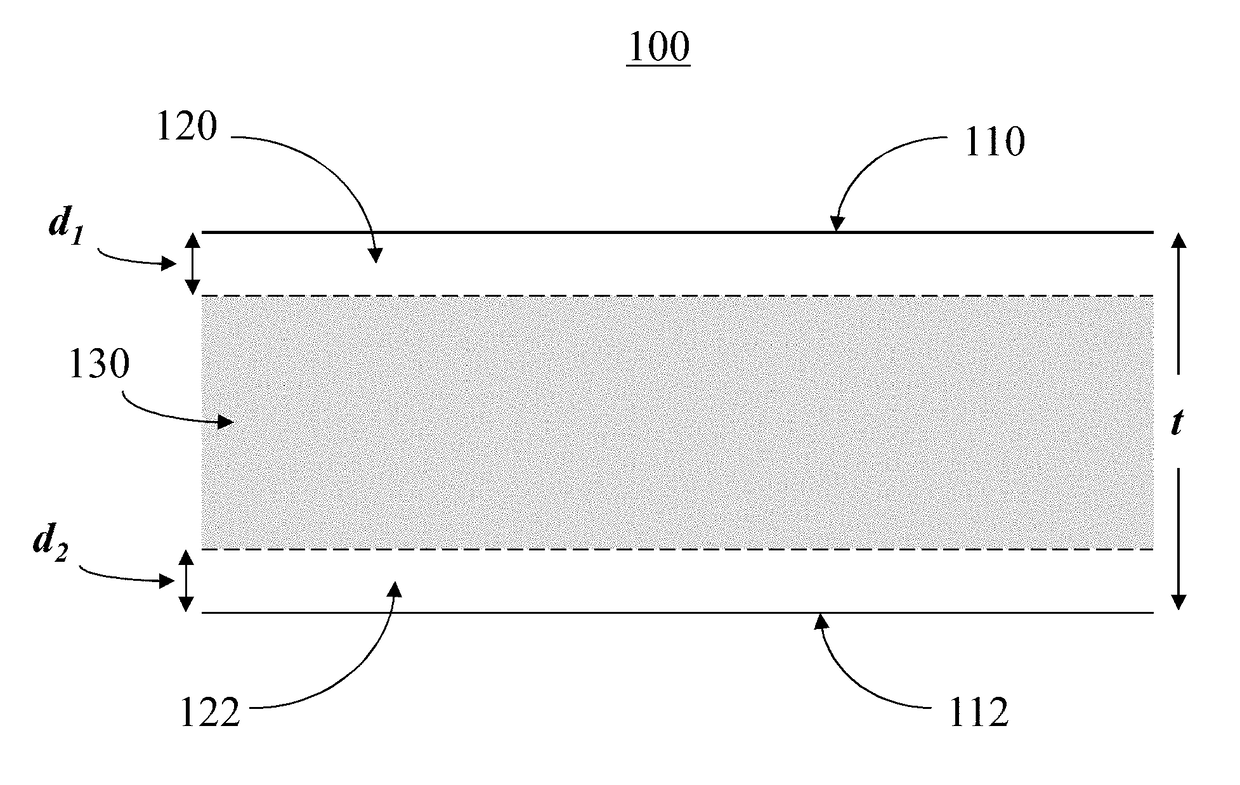

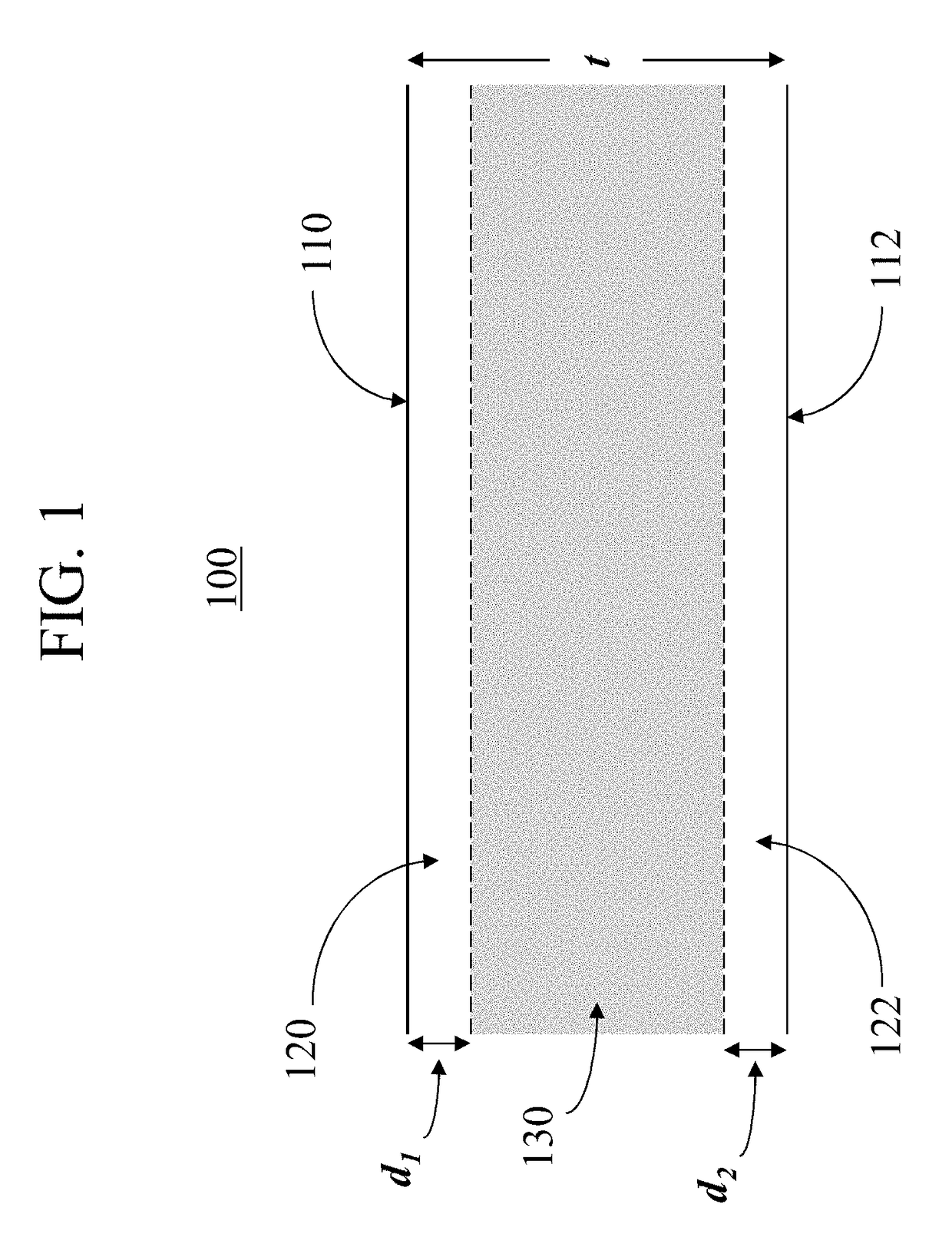

Damage resistant glass with high coefficient of thermal expansion

ActiveUS20150064472A1Fast ion exchangeGlass/slag layered productsThin material handlingIon exchangeThermal expansion

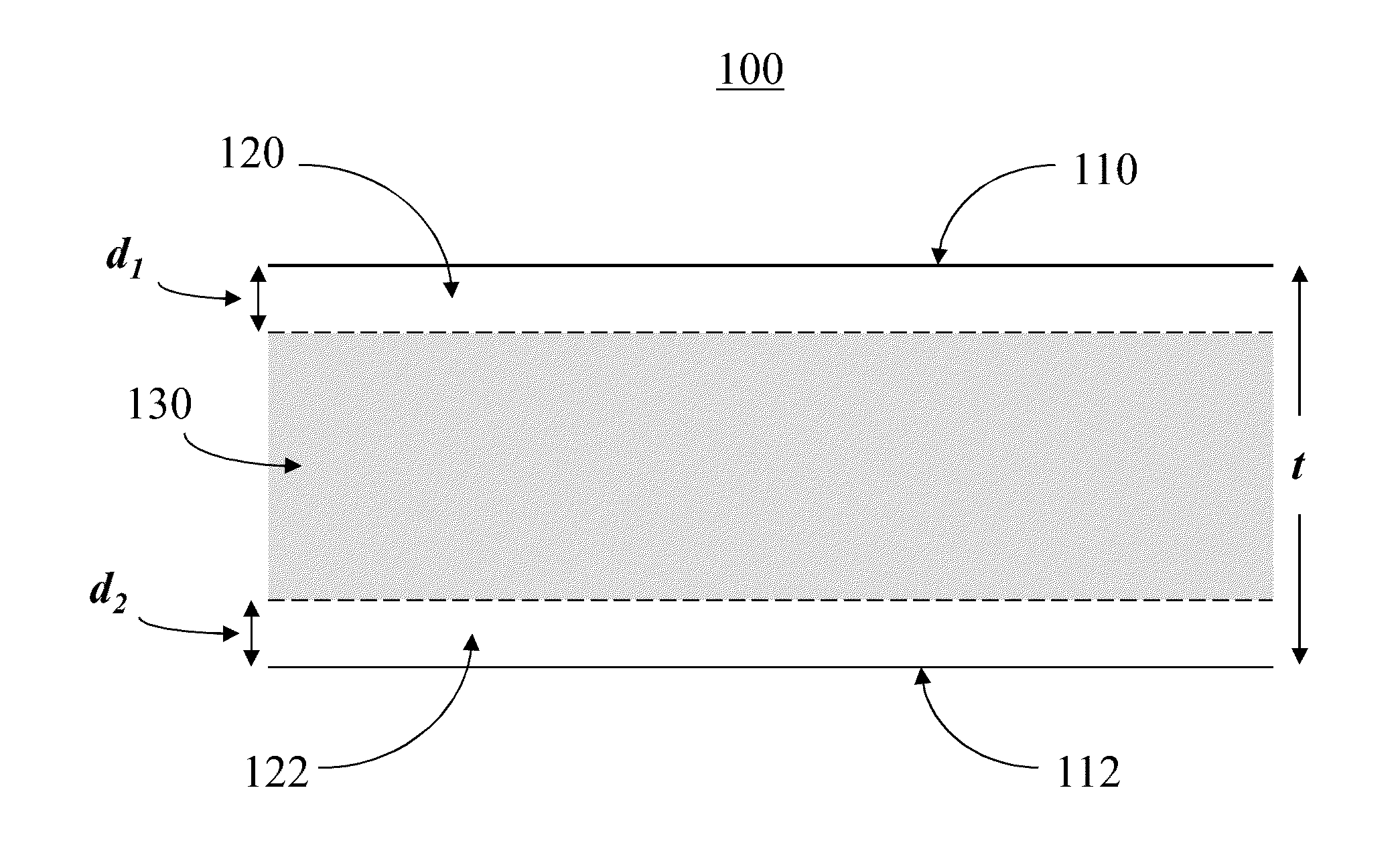

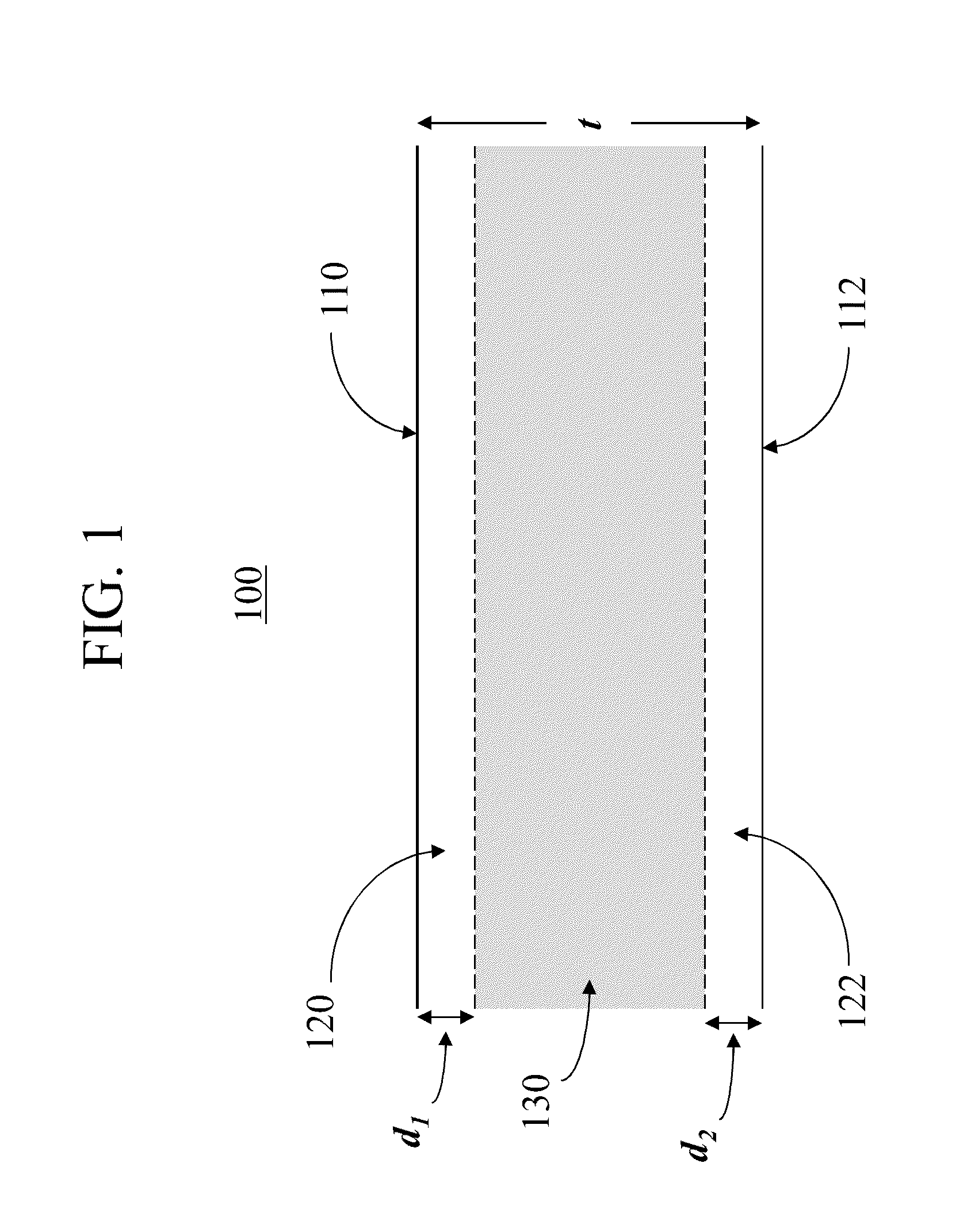

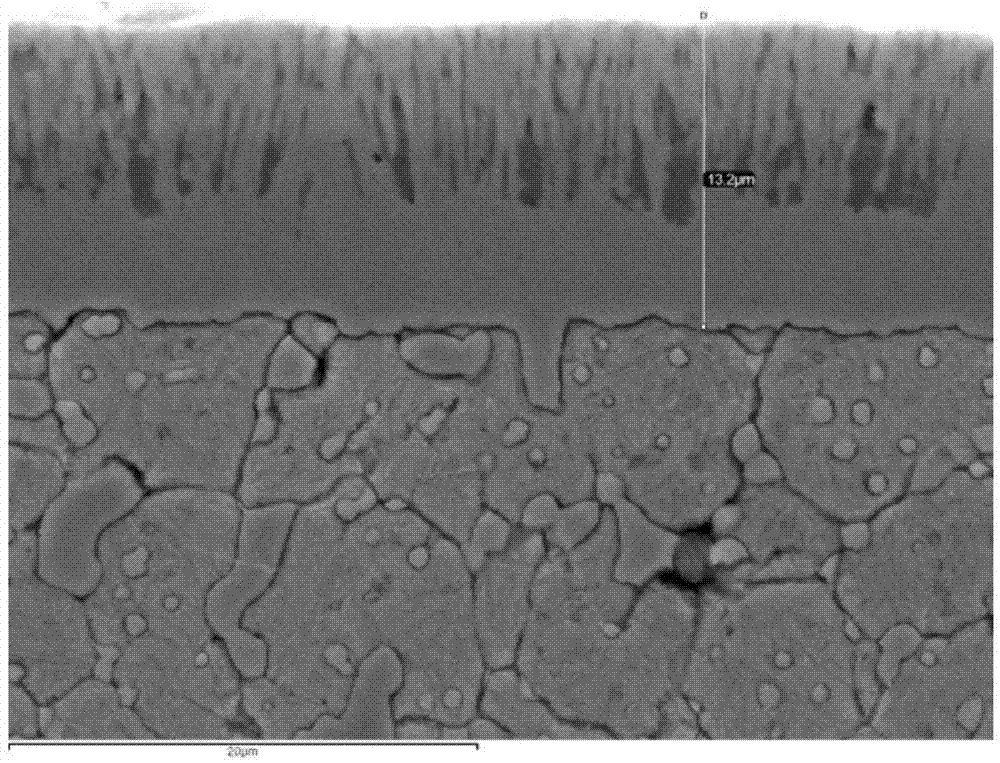

Ion exchangeable glasses having coefficients of thermal expansion (CTE) at least about 90×10−7 ° C.−1. The glasses undergo rapid ion exchange, for example, in a molten KNO3 salt bath to a depth of layer of greater than 30 microns in less than 2 hours at temperatures of 370° C. to 390° C. When ion-exchanged to a depth of layer between 30 to 50 microns, the glasses exhibit a Vickers median / radial crack initiation threshold exceeding 30 kilograms force (kgf). The glasses are fusion formable and, in some embodiments, compatible with zircon.

Owner:CORNING INC

High-boron low-carbon abrasion resistant cast steel and heat treatment method thereof

InactiveCN101260501ARich sourcesReduce manufacturing costProcess efficiency improvementElectric furnaceChemical compositionRoom temperature

The invention relates to high-boron low-carbon wearproof cast steel and a heat treatment method thereof, which belongs to the steel material technical field. The cast steel comprises the following chemical compositions in percentage by weight (wt percent): 0.15 to 0.30 percent of C, 1.5 to 2.5 percent of B, 2.6 to 3.0 percent of Si, 1.4 to 1.8 percent of Cr, 0.5 to 0.8 percent of Mn, 0.05 to 0.12 percent of Ce, 0.03 to 0.15 percent of V, 0.03 to 0.15 percent of Ti, less than 0.05 percent of P, less than 0.05 percent of S, the balance being Fe, the content of v and Ti is more than 0.01 and less than 0.25. In the invention, a casting is kept between 880 DEG C and 920 DEG C for 1h to 3h, treated by isothermal quench in an isothermal salt bath furnace with the temperature between 250 DEG C and 300 DEG C, is kept for 2h to 4h and later cooled in the air to room temperature, thereby obtaining the high-boron low-carbon wearproof cast steel. Compared with the prior art, the cast steel and the technology of the invention have the advantages of good plasticity and toughness, high wear resistance , low cost, etc.

Owner:BEIJING UNIV OF TECH

Salt bath nitrogenization heat treatment method for metal surface

InactiveCN101144148ASolve heat treatment problemsReduce distortionSolid state diffusion coatingPotassiumHeat treating

The present invention relates to a metal surface salt bath nitride nitriding heat treatment method which belongs to the metal part surface heat treatment technology field. The method is performed in the following technical process: first, loading and clamping: the metal part is hung and arranged in a charging basket; second, nitriding: the metal part hung and arranged in the charging basket is positioned in a nitriding furnace, heated and charged with nitriding salt for salt bath and nitriding, and heat is preserved for 30-80 minutes in the condition that the temperature is 540-570 DEG C; third, cleaning: the nitrided metal part is cleaned, and the water temperature is controlled at 60-80 DEG C; the nitriding salt in the nitriding working process comprises carbamide, potassium chloride or barium chloride, sodium carbonate, and K 2 S, etc., according to the weight percentage, the composition of each component is respectively: 30-40 percent of carbamide, 20-28 percent of potassium chloride or barium chloride, 38-44 percent of sodium carbonate, and 0.0001-0.1 percent of K 2 S, and the sum of the weight percentage of each component is 100 percent. The present invention has the advantages of smaller deformability, short time, high efficiency, and wide application range; and also can achieve the effect of reducing the cost obviously.

Owner:孙国飞

Surface enhancing and lubricating process for long-life bearing

InactiveCN1818140AExtended service lifeBearing componentsSolid state diffusion coatingQuenchingPeening

The invention is about the surface peening and greasing process of a long life shafting bearing. It can solve the shot life of the GCr15 steel rolling shafting bearing by the process of the traditional quenching and lonnealing. It includes: put the collar and the rolling element into the salt-bath furnace with the C-N seeping agent to treat for 2-4h in 600DEG C; Put the washed parts into the salt-bath hardening furnace to heat to 830-850DEG C, then to oil cooling, next to lonneal for 2h in 160-180DEG C; Polish. The invention can improve the antisticking, seizure resistance and the using life.

Owner:陈治贵

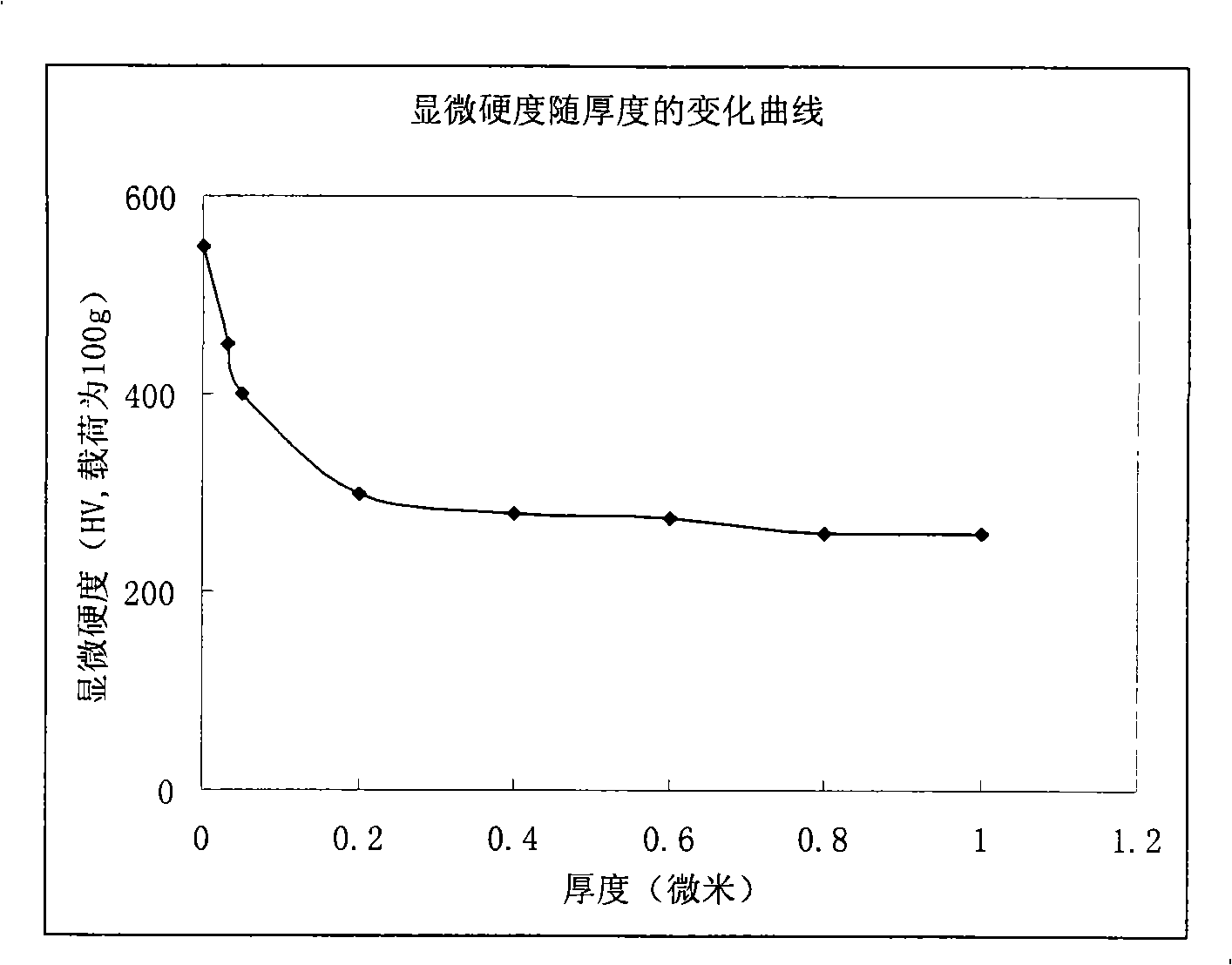

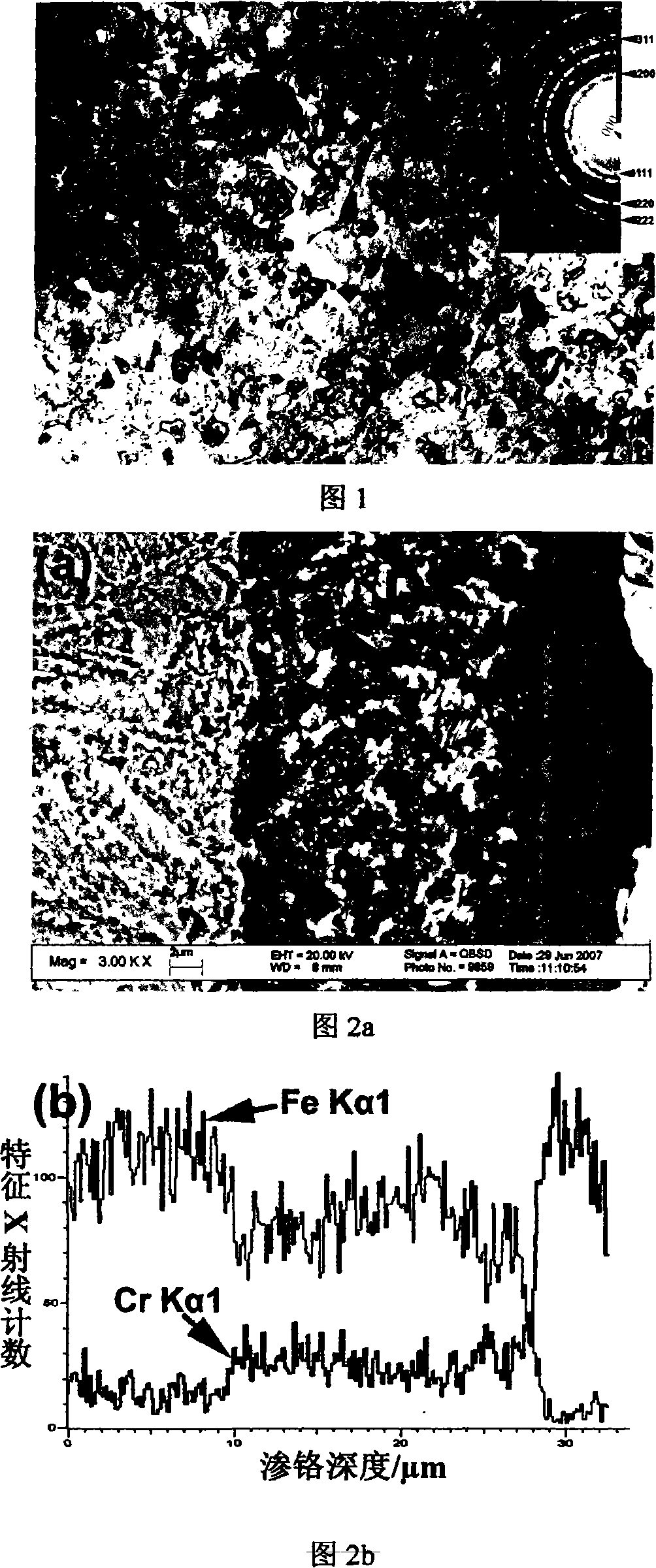

Chrome alum rare earth multicomponent cementation borax salt bath penetration metal penetrating agent and application method thereof

InactiveCN103526154AThe chemical heat treatment process is acceleratedPlay a tragic roleSolid state diffusion coatingAl powderRare earth

The invention provides a chrome alum rare earth multicomponent cementation borax salt bath penetration metal penetrating agent, and belongs to the surface strengthening technology of parts such as moulds. The chrome alum rare earth multicomponent cementation borax salt bath penetration metal penetrating agent is suitable for parts with surface abraded easily and strained easily, such as metal moulds. According to the chrome alum rare earth multicomponent cementation borax salt bath penetration metal penetrating agent, borax serves as basic salt, a vanadium supplying agent is V205 or V-Fe alloy, a chromium supplying agent is Cr2O3 or Cr powder, a reducing agent is Al powder or Si-Ca powder, activating agent is NaF or CaF, rear earth is Ce or Ce alloy, and the chrome alum rare earth multicomponent cementation borax salt bath penetration metal penetrating agent comprises, by weight, 65-80% of the basic salt, 5-10% of the chromium supplying agent, 5-10% of the vanadium supplying agent, 3-9% of the reducing agent, 3-9% of the activating agent, and 0.5-8% of the rear earth. Compared with a traditional vanadinizing process, under the conditions that the thickness is the same while the hardness is approximate, the coating can be prepared at lower temperature and within short time through a preparation method of the chrome alum rare earth multicomponent cementation borax salt bath penetration metal penetrating agent, and the chrome alum rare earth multicomponent cementation borax salt bath penetration metal penetrating agent has the advantages of being high in quality of the coating, long in service life, environmentally friendly, capable of saving energy, short in production cycle and the like.

Owner:CHONGQING UNIV OF TECH +1

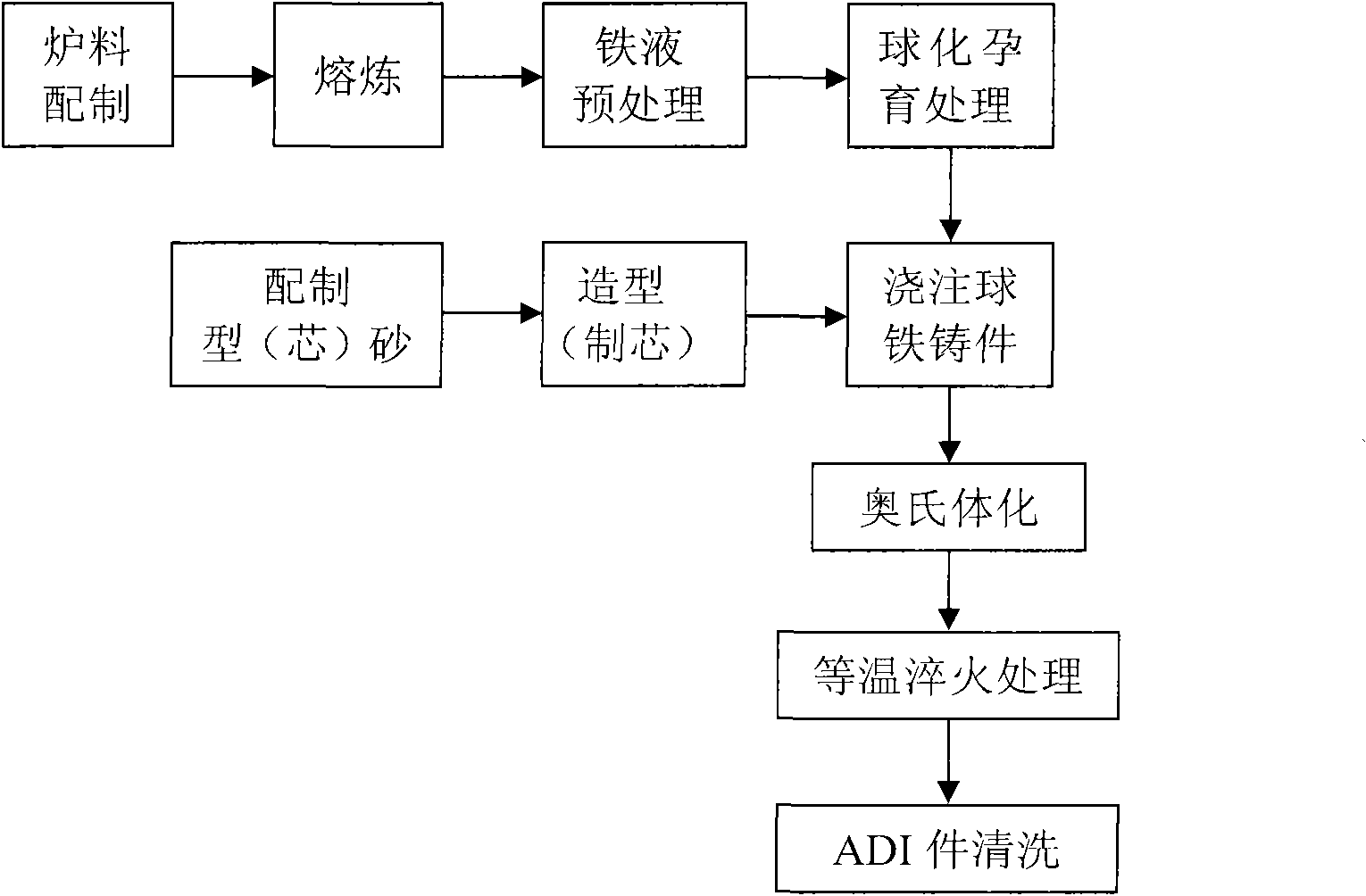

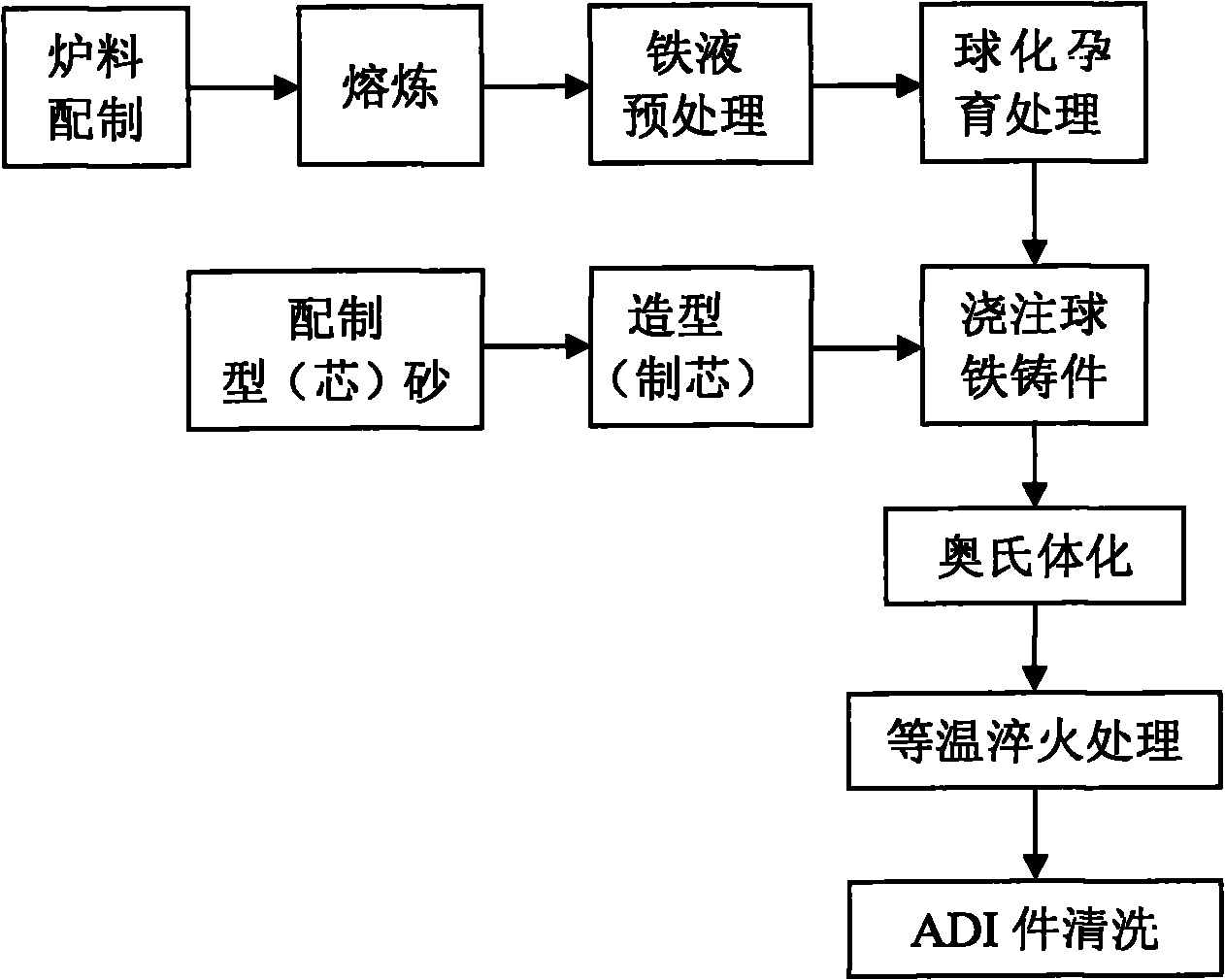

ADI (Austempered Ductile Iron) piece with high toughness and high strength and manufacturing method thereof

InactiveCN101876026ALess gasLess inclusionsProcess efficiency improvementIntermediate frequencyHigh intensity

The invention discloses an ADI piece with high toughness and high strength and a manufacturing method thereof. The ADI piece comprises the following elements by mass percent: 3.6% to 3.9% of C, 2.5% to 2.7% of Si, 0.2% to 0.3% of Mn, smaller than or equal to 0.03% of P, smaller than or equal to 0.012% of S, 0.2% to 0.25% of Mo, 0.6% to 0.8% of Cu, 0.5% to 0.8% of Ni and the balance of Fe. The ADI piece has the elongation of 12.5% to 14.5%, the impact toughness of 125 to 140J / cm2, and the tensile strength of 990 to 1080MPa. The manufacturing method comprises the steps of: smelting burden in an intermediate frequency electric furnace; pretreating melted iron for desulfuration and dephosphorization and then pouring into a casting mould to obtain a raw casting; preserving the temperature of 905 DEG C to 915 DEG C for 1.5 to 2 hours for austenitizing the raw casting; quickly quenching in a salt bath at 350 DEG C to 370 DEG C for isothermal quenching for 1 to 1.5 hours; cooling and washing to obtain the ADI piece. The ADI piece of the invention has high elongation, high impact toughness and higher tensile strength. In the pretreatment of melted iron, no new equipment is added. The technological parameter is reasonably designed and the manufacturing cost is low.

Owner:WUHAN TEXTILE UNIV

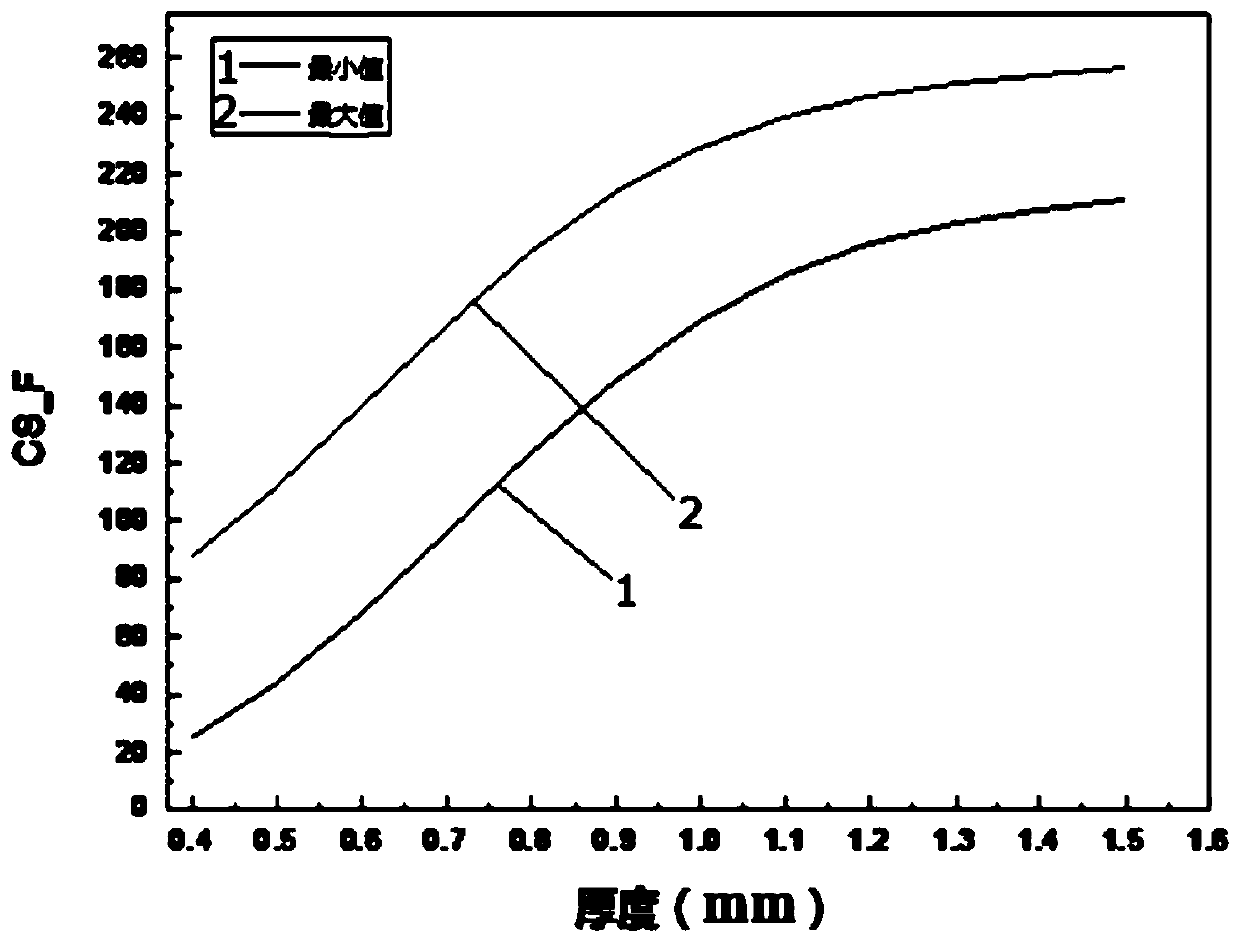

Chemical tempered glass with combined stress advantage as well as preparation method and application thereof

The invention discloses chemical tempered glass with a combined stress advantage as well as a preparation method and application thereof. When the chemical tempered glass is 0.4-1.5mm in thickness specification, and the planar pressure stress CS_F at an area which is 50 mu m below a surface depth meets: CS_F is greater than or equal to 215.24-230.61 / (1+EXP((T-0.715) / 0.203)). The chemical temperedglass disclosed by the invention has high-level deep layer stress and high drop-resistant strength, and is high in mechanical strength. The chemical tempered glass further has relatively low dielectric constant and dielectric loss. As the chemical tempered glass has the advantages, the application of the chemical tempered glass is effectively expanded. The chemical tempered glass is obtained by adopting a single binary ion exchange processing method, the chemical reinforcing method of the chemical tempered glass can effectively save the usage amount of salt bath, the reinforcing treatment process is simplified, the stability of chemical tempered glass performance is guaranteed, and the cost of production is lowered.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

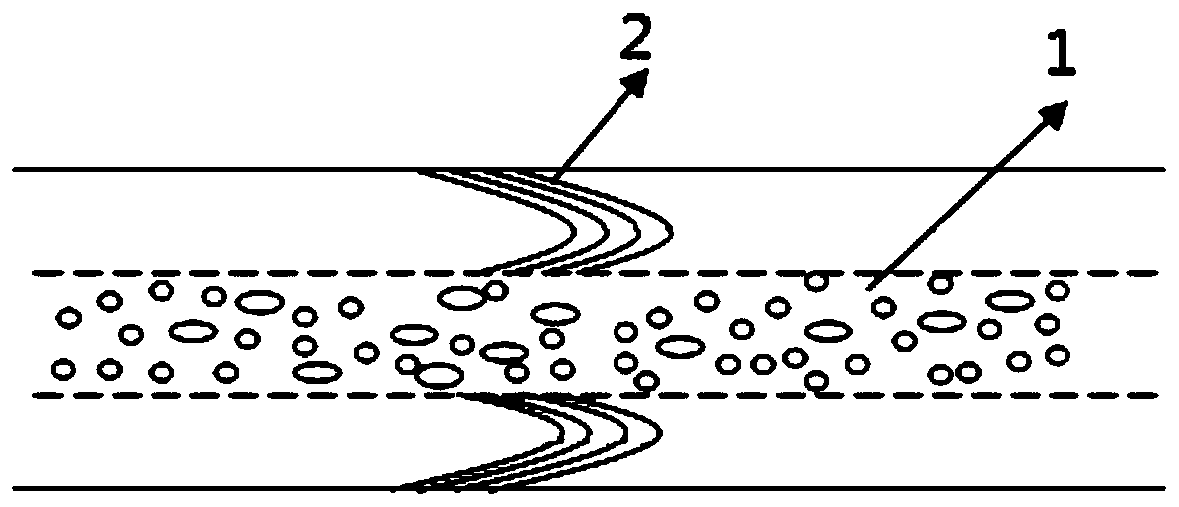

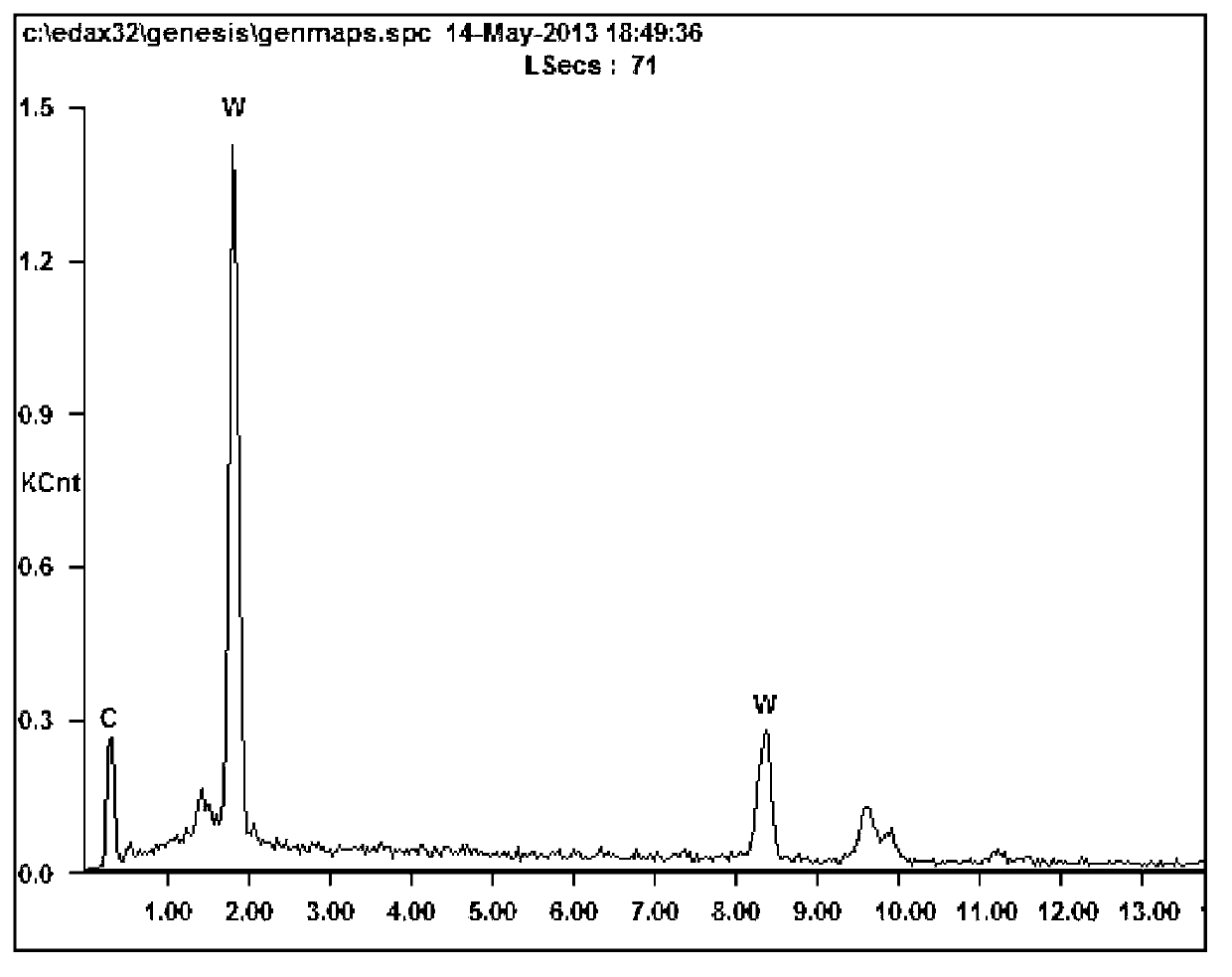

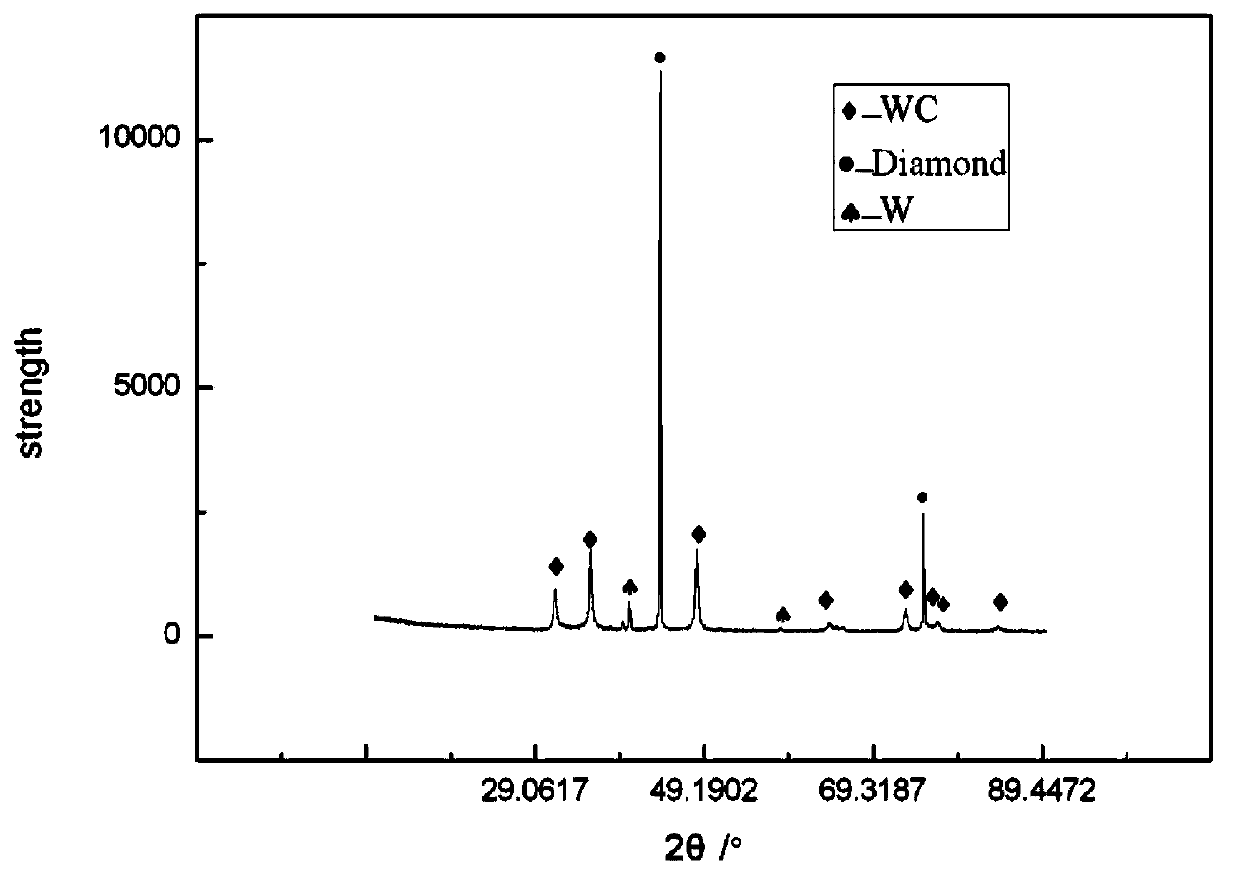

Method for plating tungsten on diamond surface

InactiveCN103388142AImprove adsorption capacityFacilitate depositionHeat inorganic powder coatingCarbideUltrasonic oscillation

The invention relates to a method for plating tungsten on a diamond surface. In the invention, a salt-bath tungsten plating method is adopted. The method comprises the following steps of removing greasy dirt on the surface of a diamond particle, mixing with tungsten powder in a crucible after coarsening and carrying out sensitization-activation treatment; carrying out high-temperature salt-bath tungsten plating in a fused salt environment; and then cleaning and drying through a clear water boiling method to obtain an finished product, wherein the method for removing greasy dirt and coarsening is as follows: placing the diamond particle in diluted alkaline and carrying out ultrasonic oscillation cleaning, and cleaning by deionized water; soaking and cleaning by diluted acid; washing to neutral by water; adding into a nitric acid solution for boiling for 3-10 minutes, carrying out coarsening treatment and washing to neutral by deionized water, and carrying out sensitization-activation treatment; and cleaning by deoionized water and drying after cleaning by alcohol for acetone, wherein the salt-bath tungsten plating is carried out in a vacuum furnace. The method for plating tungsten on the diamond surface can be used for effectively plating a layer of compact and uniform coating on the surface of the diamond particle; the phase is mainly composed of WC (Wolfram Carbide) and W (Wolfram), so that toxic substances are not generated in the process. Moreover, the process is simple and the cost is low.

Owner:SOUTHEAST UNIV

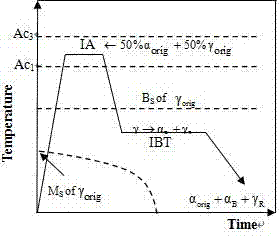

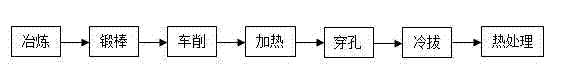

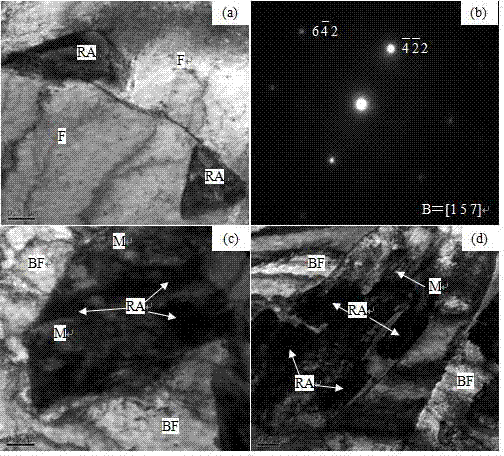

Method for producing transformation induced plasticity (TRIP) seamless tube

InactiveCN102407245AAustempering achievedReduce contentFurnace typesHeat treatment furnacesAustemperingChemical composition

The invention belongs to the field of preparation of steel tubes, and in particular relates to a method for producing a transformation induced plasticity (TRIP) seamless tube. The method comprises the following steps that: a smelted ingot is forged into a rod, turned, heated, punched and subjected to cold drawing to obtain a seamless cold drawing steel tube, and the seamless cold drawing steel tube is placed in a resistor furnace for critical region isothermal annealing for 180-1200 seconds at the temperature of 780-850 DEG C, and then is rapidly placed in a salt bath furnace for bainite region isothermal annealing for 120-1800 seconds at the temperature of 380-470 DEG C so as to obtain the TRIP seamless tube. According to the technical scheme in the invention, the chemical components of common low carbon steel can be used for producing the TRIP seamless tube with good comprehensive mechanical properties, high yield strength up to 580MPa, high tensile strength up to 763MPa and high product of strength and elongation up to 22029MPa.%. The method is easy to realize in industrialized production, has the advantages of relatively stable process and relatively low cost, and is suitable for producing TRIP seamless steel tubes with different chemical components and sizes.

Owner:NORTHEASTERN UNIV LIAONING

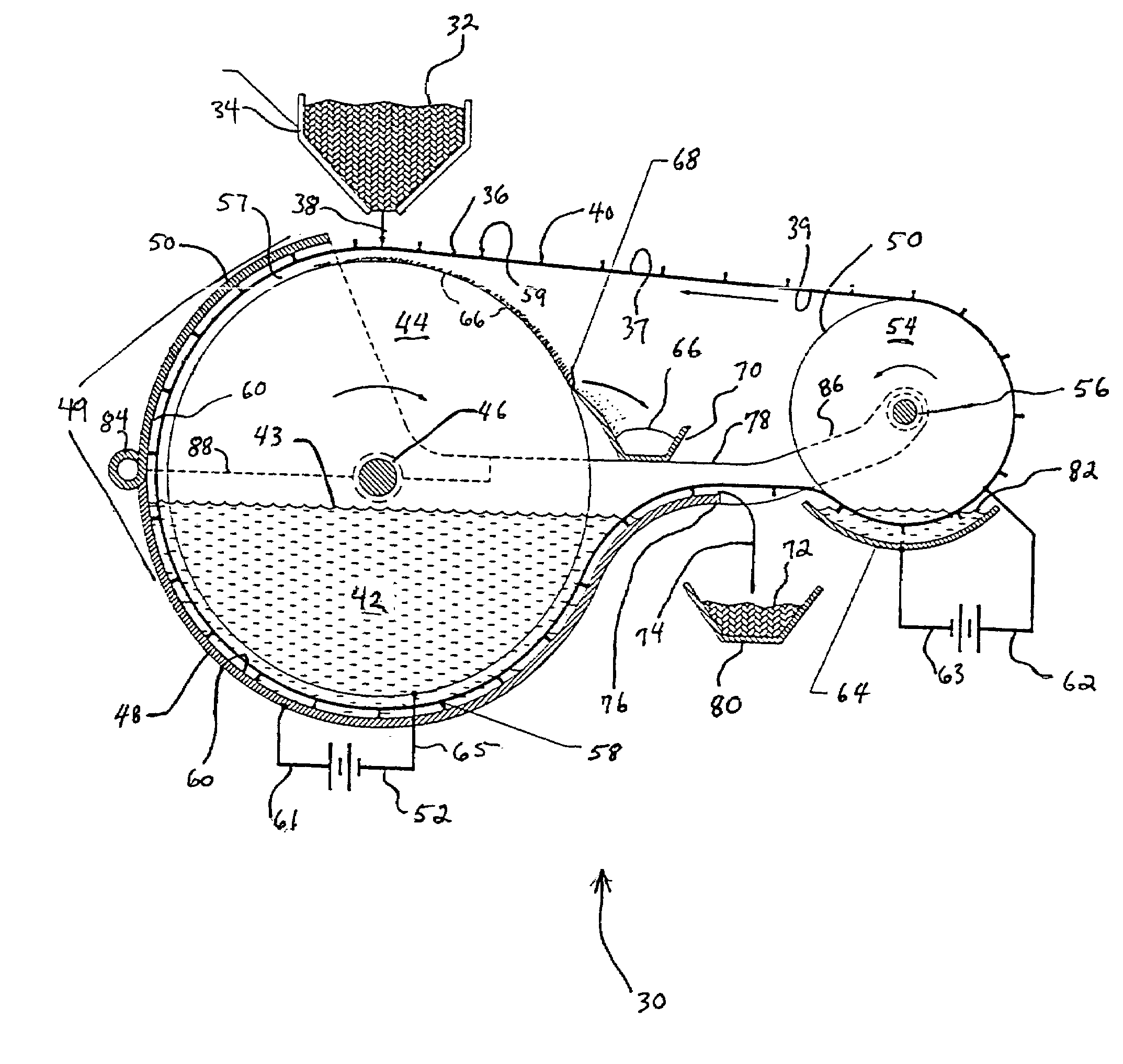

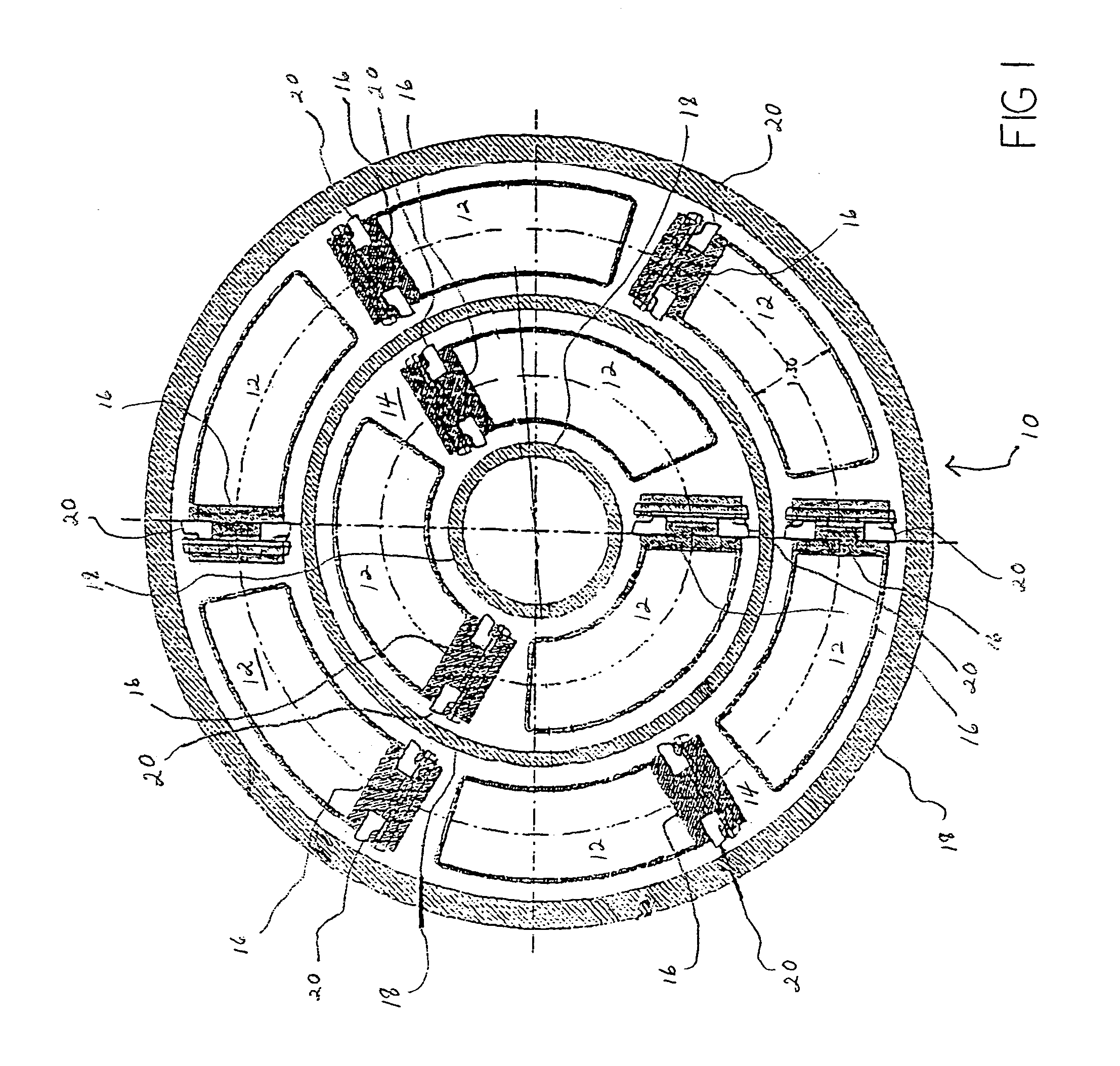

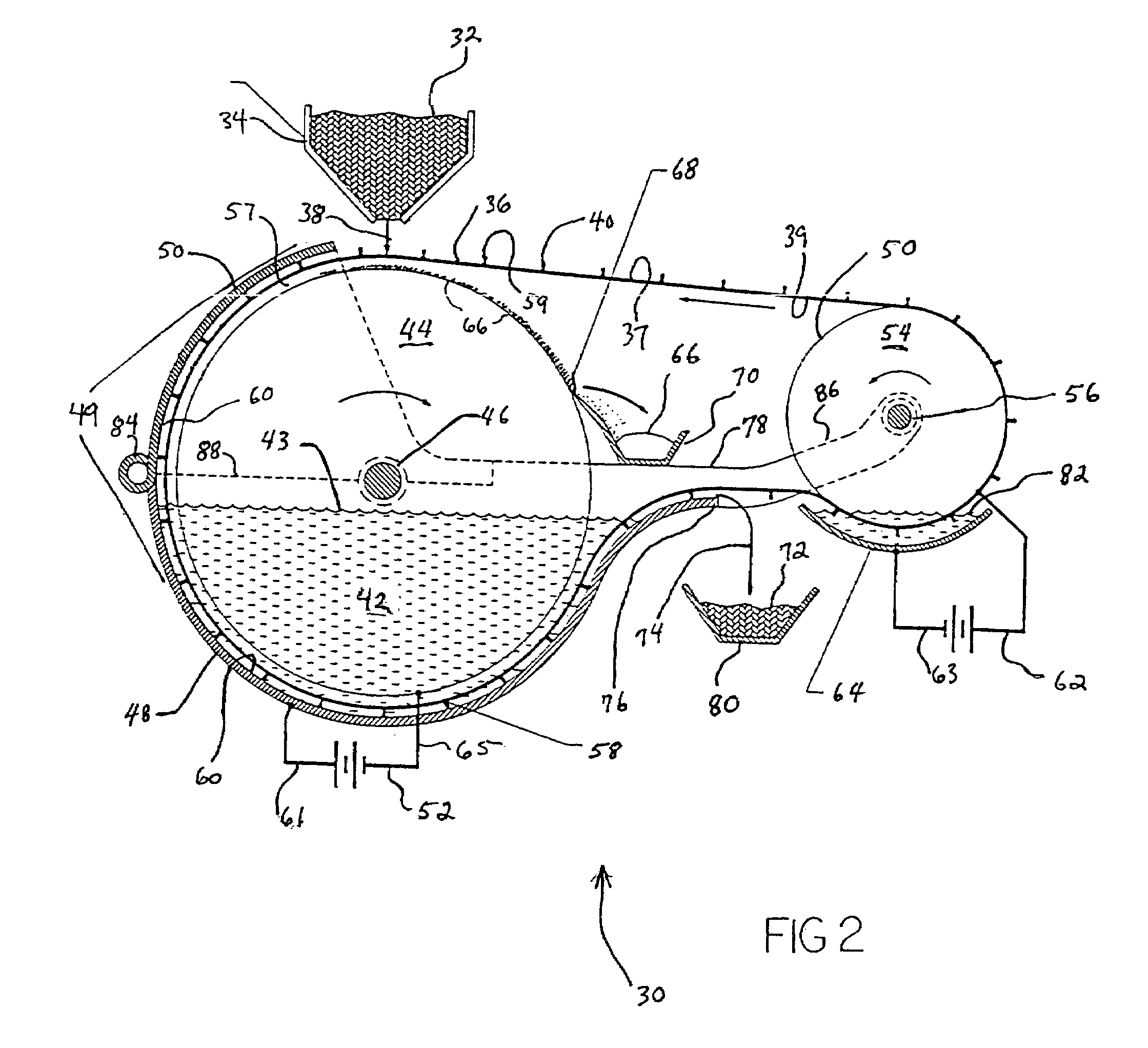

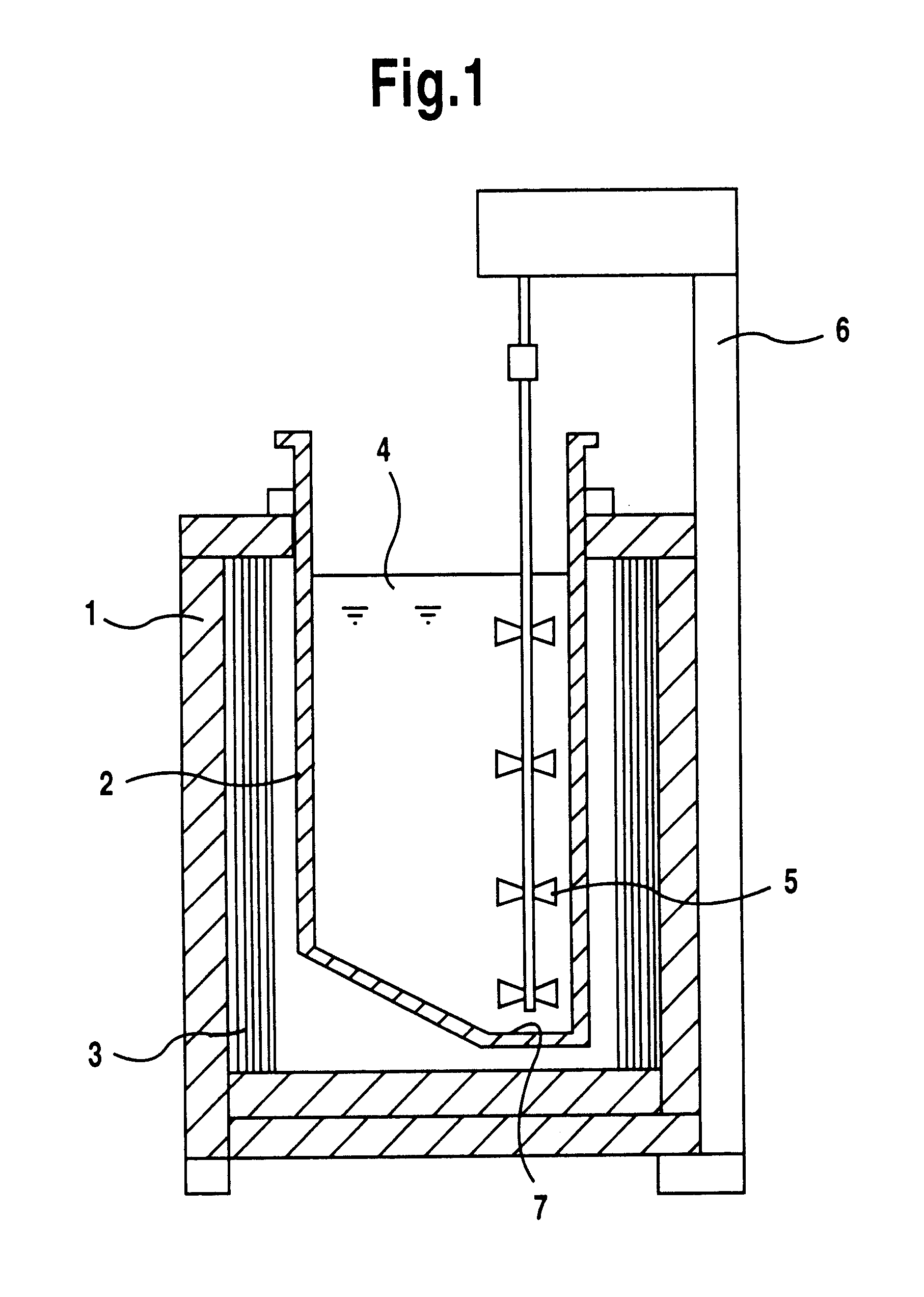

Continuous process electrorefiner

A new device is provided for the electrorefining of uranium in spent metallic nuclear fuels by the separation of unreacted zirconium, noble metal fission products, transuranic elements, and uranium from spent fuel rods. The process comprises an electrorefiner cell. The cell includes a drum-shaped cathode horizontally immersed about half-way into an electrolyte salt bath. A conveyor belt comprising segmented perforated metal plates transports spent fuel into the salt bath. The anode comprises the conveyor belt, the containment vessel, and the spent fuel. Uranium and transuranic elements such as plutonium (Pu) are oxidized at the anode, and, subsequently, the uranium is reduced to uranium metal at the cathode. A mechanical cutter above the surface of the salt bath removes the deposited uranium metal from the cathode.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

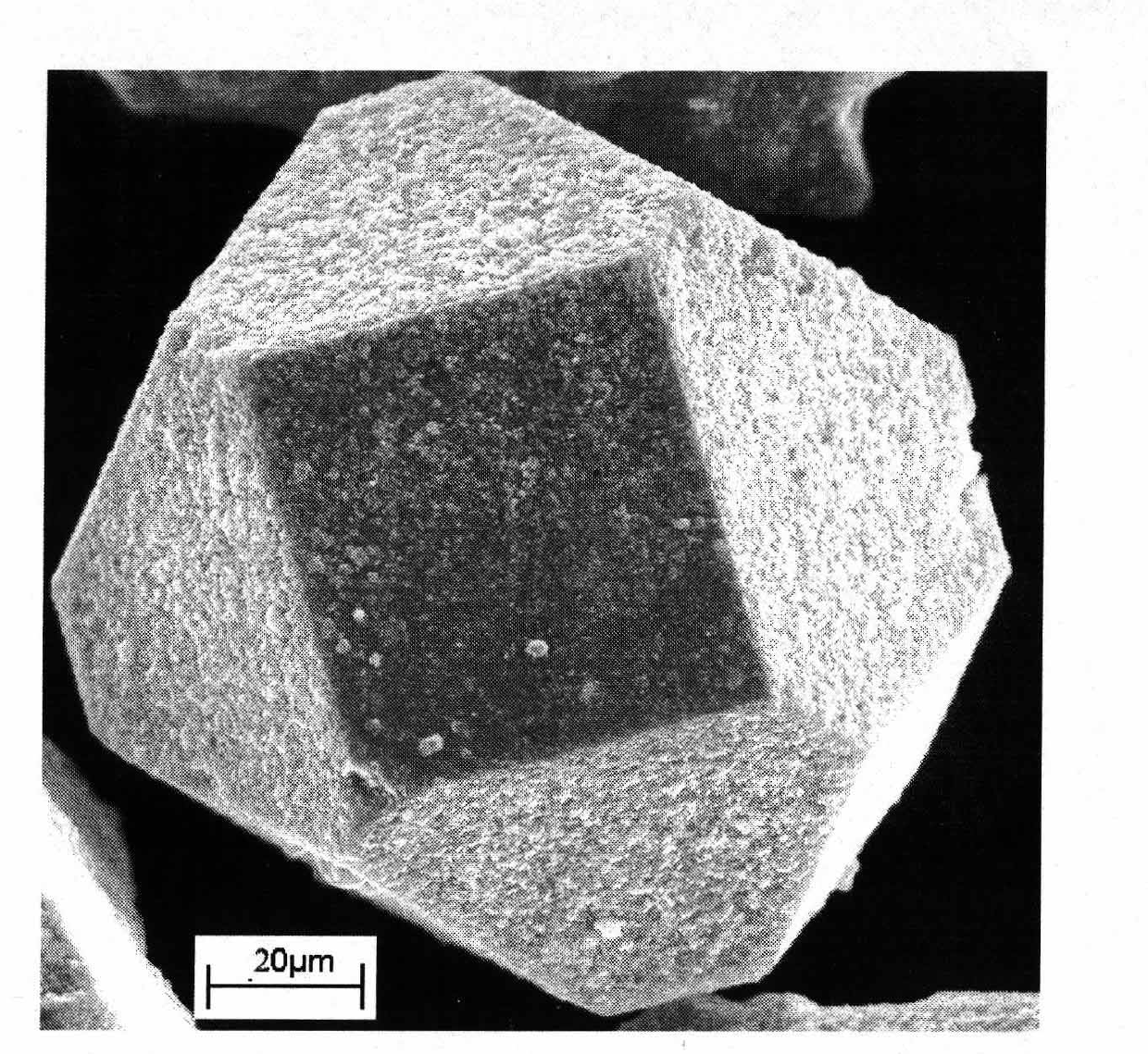

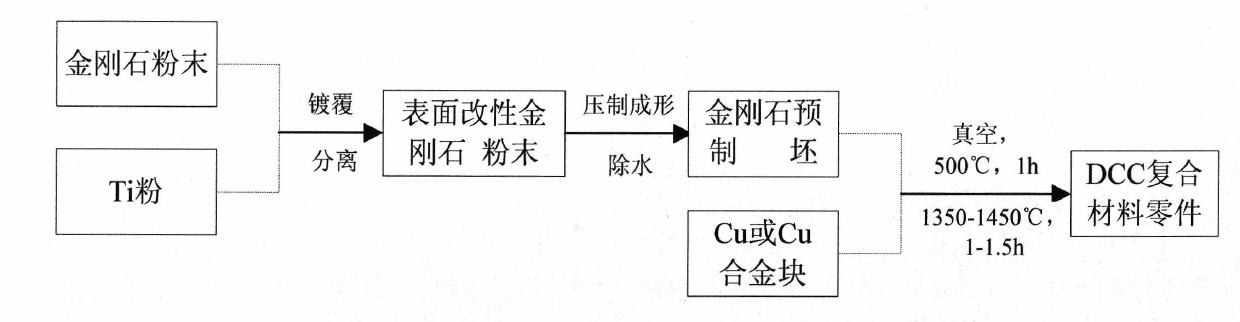

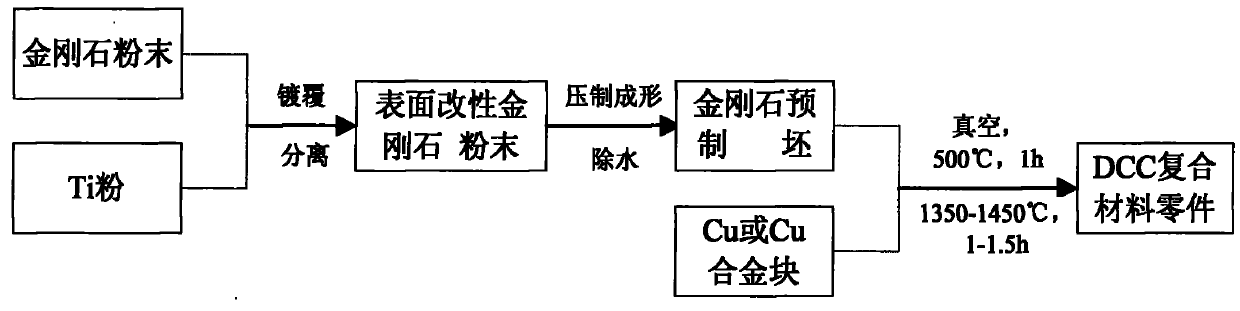

Preparation method of diamond particle reinforced copper-based composite material parts with high volume fraction

InactiveCN101768706AImprove wettabilityImprove the interface binding forceLayered productsHigh densityHigh volume manufacturing

The invention relates to a preparation method of diamond particle reinforced copper-based composite material parts with high volume fraction, belonging to the field of metal materials. The preparation method is characterized in that the composite material comprises copper or copper alloy, diamond particles and an intermediate layer, wherein the volume fraction of the copper or the copper alloy is 32-45 percent, and the volume fraction of the diamond particles and the intermediate layer is 55-68 percent. The preparation method comprises the following steps of: firstly forming a TiC-Ti composite thin plating layer on the surface of the diamond by adopting a vacuum salt bath plating method, then adding an appropriate amount of caking agent into modified diamond powder and pressing into a porous prefabricated blank according to the shape of the parts; and finally putting the porous prefabricated blank and the copper or the copper alloy into a vacuum condition together for carrying out pressureless infiltration treatment to obtain the diamond-copper composite material parts with high volume fraction and high density. The invention has the advantages that the diamond-copper composite material parts with high volume fraction and the complex shape can be directly prepared, and the composite material parts have high density, even tissue distribution and low production cost, and can realize large-batch production.

Owner:UNIV OF SCI & TECH BEIJING

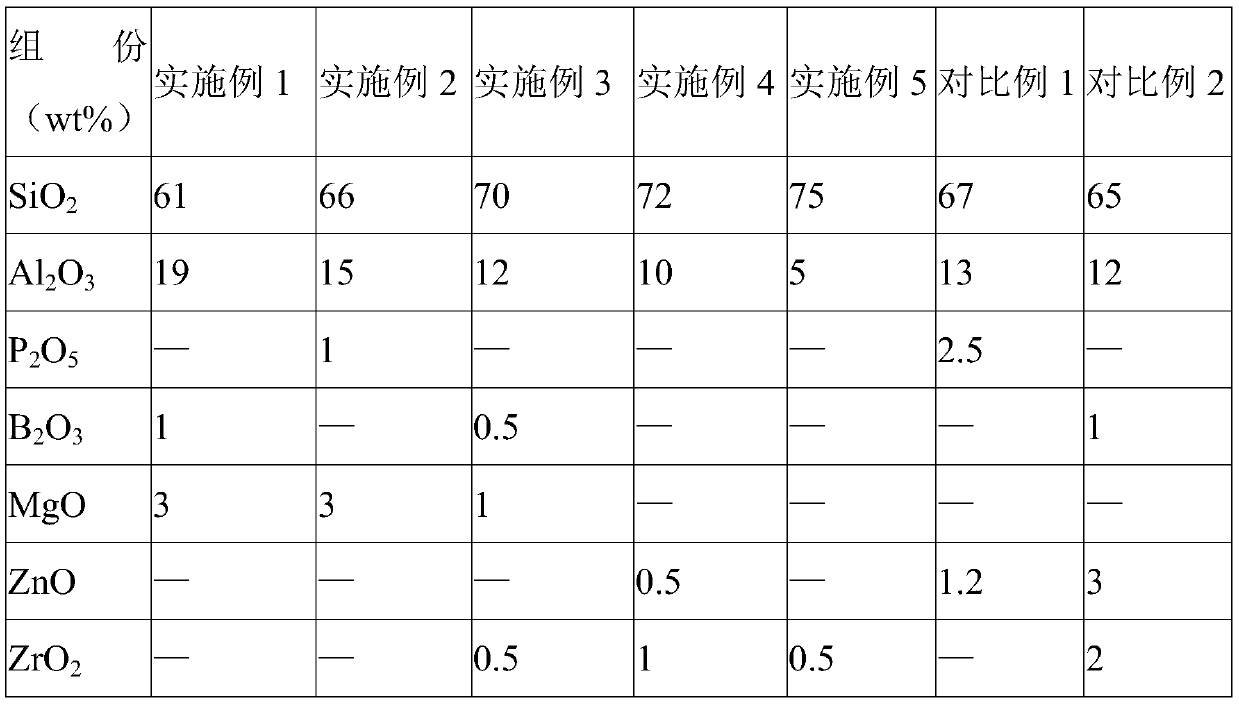

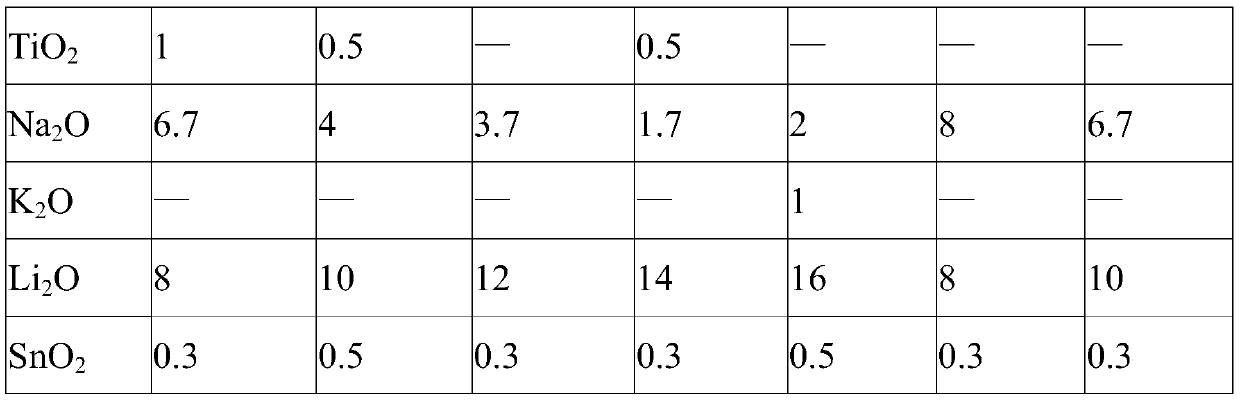

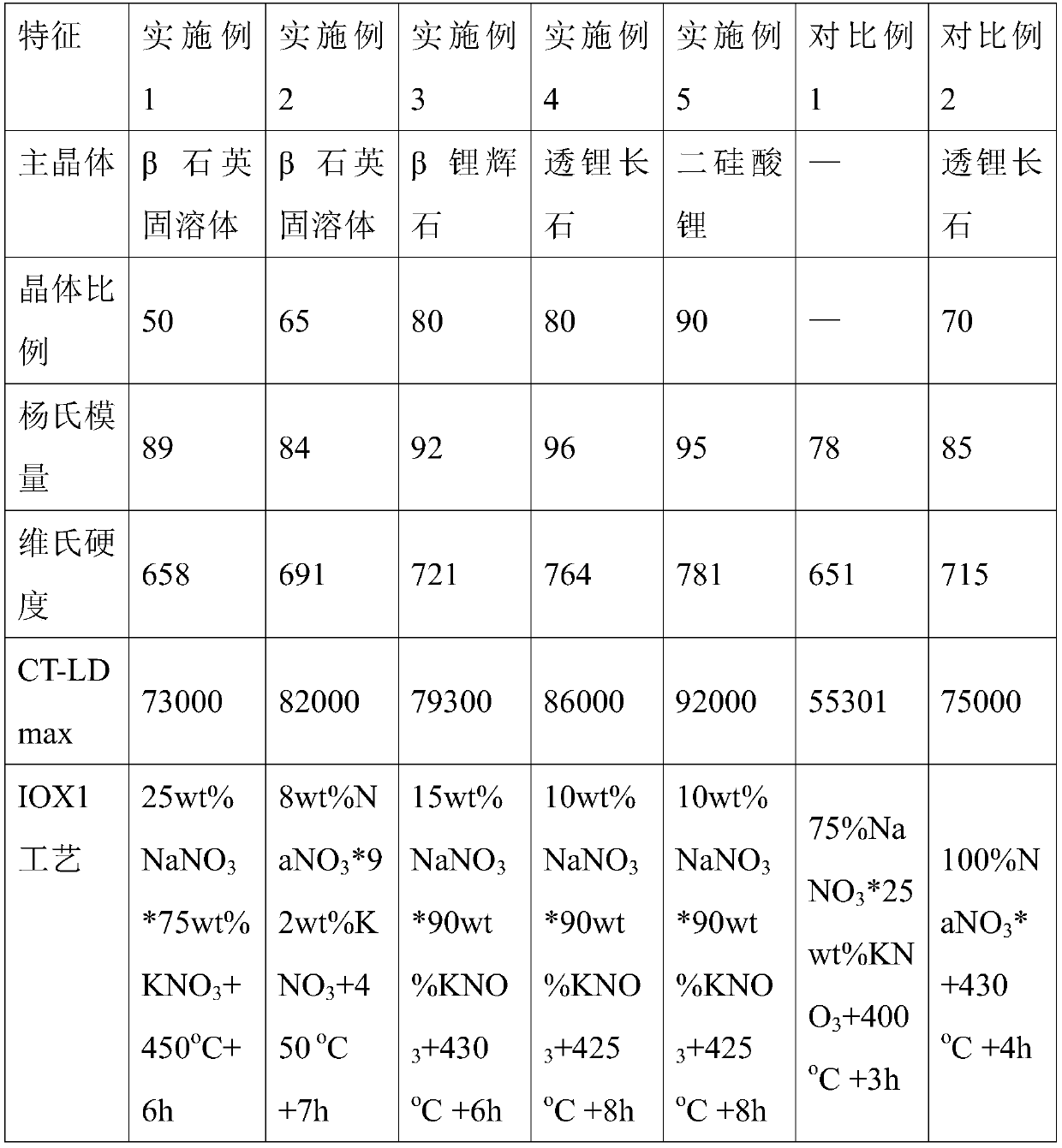

Strengthened microcrystalline glass with high-pressure stress layer depth and preparation method thereof

ActiveCN110845153AImprove structural strengthSufficient surface compressive stressIon exchangeStress relaxation

The invention discloses strengthened microcrystalline glass with high stress layer depth and a preparation method of the strengthened microcrystalline glass. The strengthened microcrystalline glass isformed by carrying out chemical ion exchange on the microcrystalline glass in a salt bath for one time or multiple times; a pressure stress layer and a tensile stress layer corresponding to the pressure stress layer are sequentially formed on the two opposite sides of the strengthened microcrystalline glass from the surface to the interior respectively, and the depth of the single-face pressure stress layer of the strengthened microcrystalline glass is 18%-25% of the total thickness of the strengthened microcrystalline glass. The high crystallinity of the strengthened microcrystalline glass improves the intrinsic network structure strength of the strengthened microcrystalline glass, so that the microcrystalline glass can accommodate higher compressive stress, and the stress relaxation amount at high temperature is small; the exchange depth of the microcrystalline glass can be increased by adopting a lithium-containing salt bath, so that the depth of the pressure stress layer is remarkably increased; the depth of the stress layer of the strengthened microcrystalline glass accounts for more than 18% of the total thickness of the glass, and the strengthened microcrystalline glass hasvery high anti-falling strength; wide field of application.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

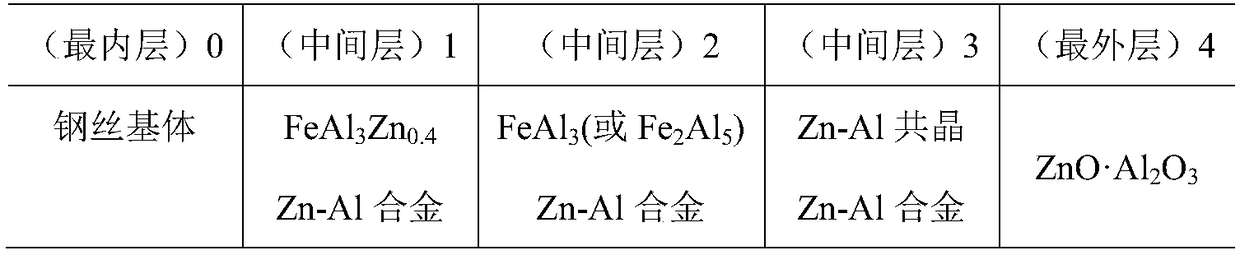

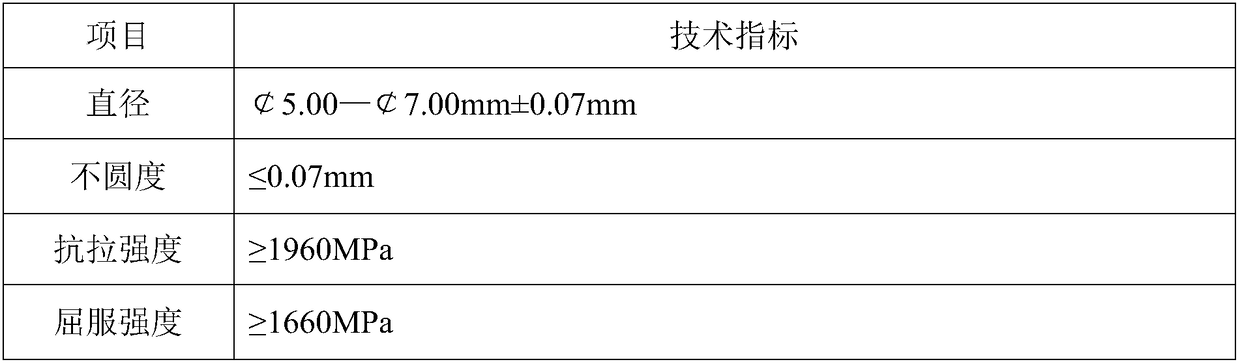

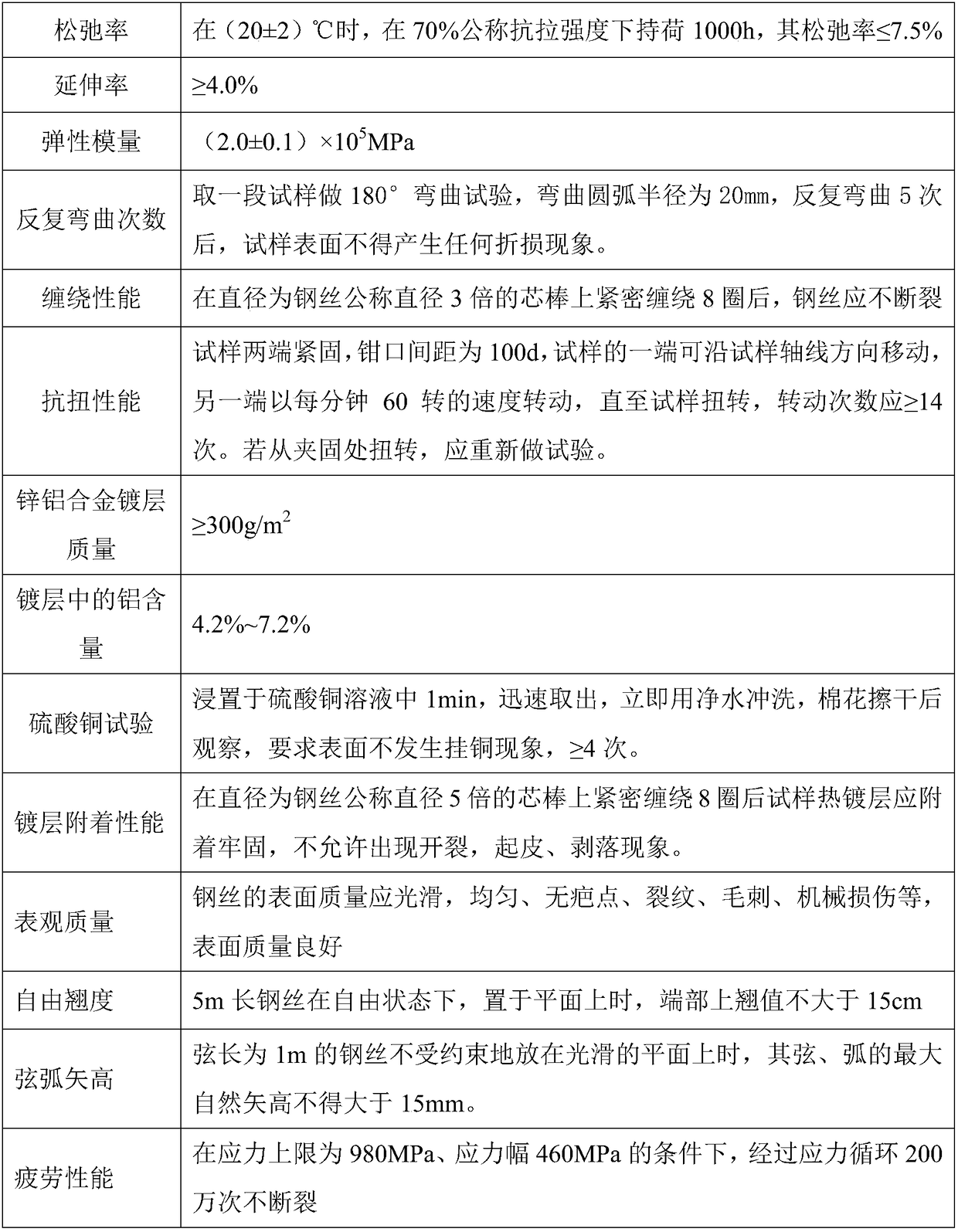

High-strength and ductility durable type large-diameter 1960 MPa stage zinc-aluminum alloy coating steel wire for bridge cable

InactiveCN108239735AHigh strengthIncreased durabilityHot-dipping/immersion processesWater bathsHigh carbon

The invention relates to a high-strength and ductility durable type large-diameter 1960 MPa stage zinc-aluminum alloy coating steel wire for a bridge cable. A steel wire rod is an ultra-pure hyper-eutectoid steel high-carbon steel wire rod obtained after sorbite treatment (water bath, lead bath and salt bath), the strength of extension is larger than or equal to 1290 MPa, the area reduction rate is larger than or equal to 30%, and the elongation is larger than or equal to 10%; and the steel wire rod is drawn into a bright steel wire with the diameter ranging from 4.90 mm to 6.90 mm, then hot galvanizing zinc-aluminum alloy coating is carried out, and technological processes include lead bath degreasing, hot water washing, chlorohydric acid pickling, hot water washing, weak base washing, hot water washing, ammonium chloride and zinc chloride solvent plating assisting, hot-dip galvanizing-nitrogen smearing, zinc-aluminum alloy hot galvanizing, nitrogen smearing and wire collecting. The steel wire rod is subject to stabilization treatment, and the strength, the linearity, the relaxation rate and the steel wire axial homogeneity of the large-diameter ultrahigh-strength Zn95Al5 alloy coating steel wire are guaranteed.

Owner:JIANGSU FASTEN STEEL CABLE CO LTD +1

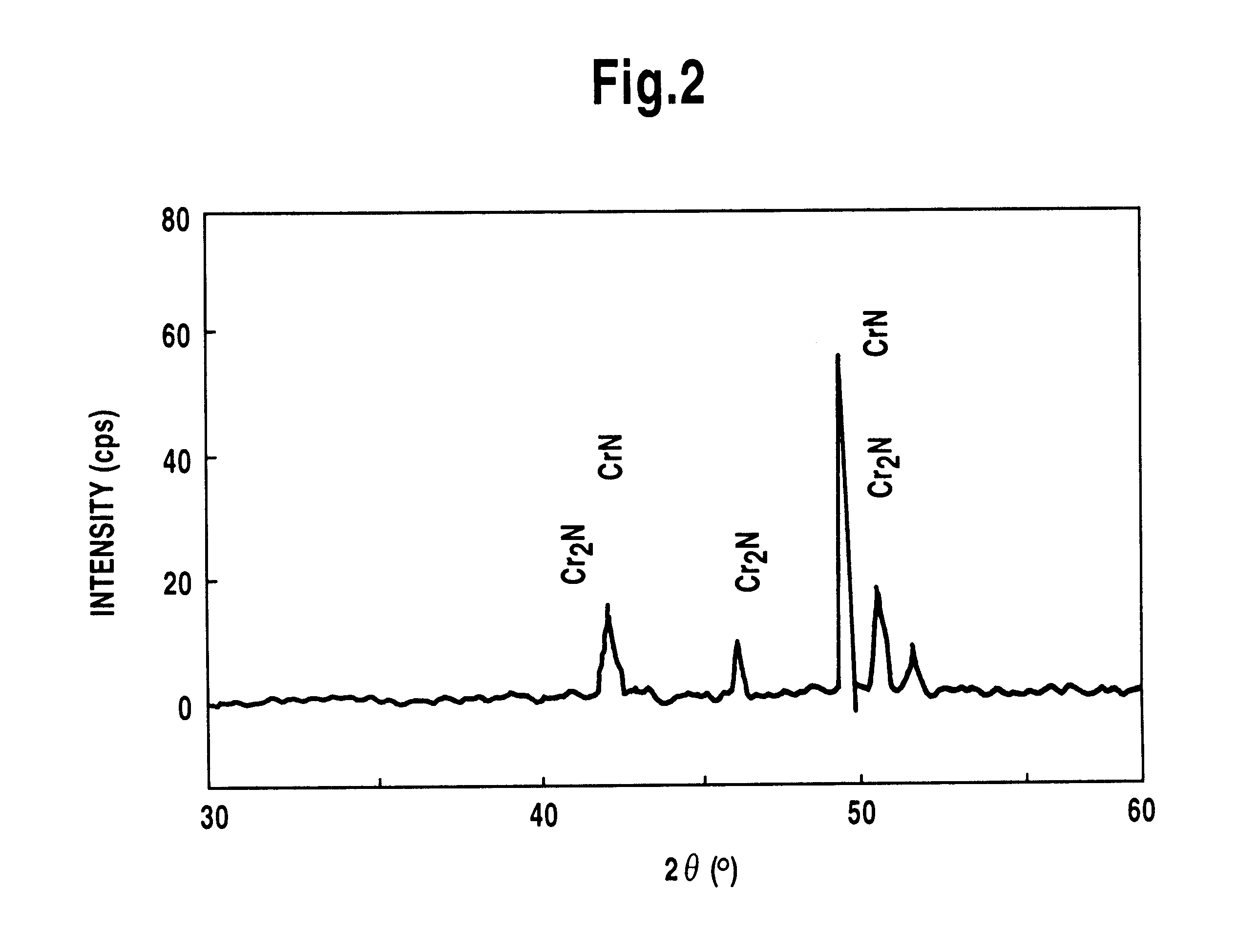

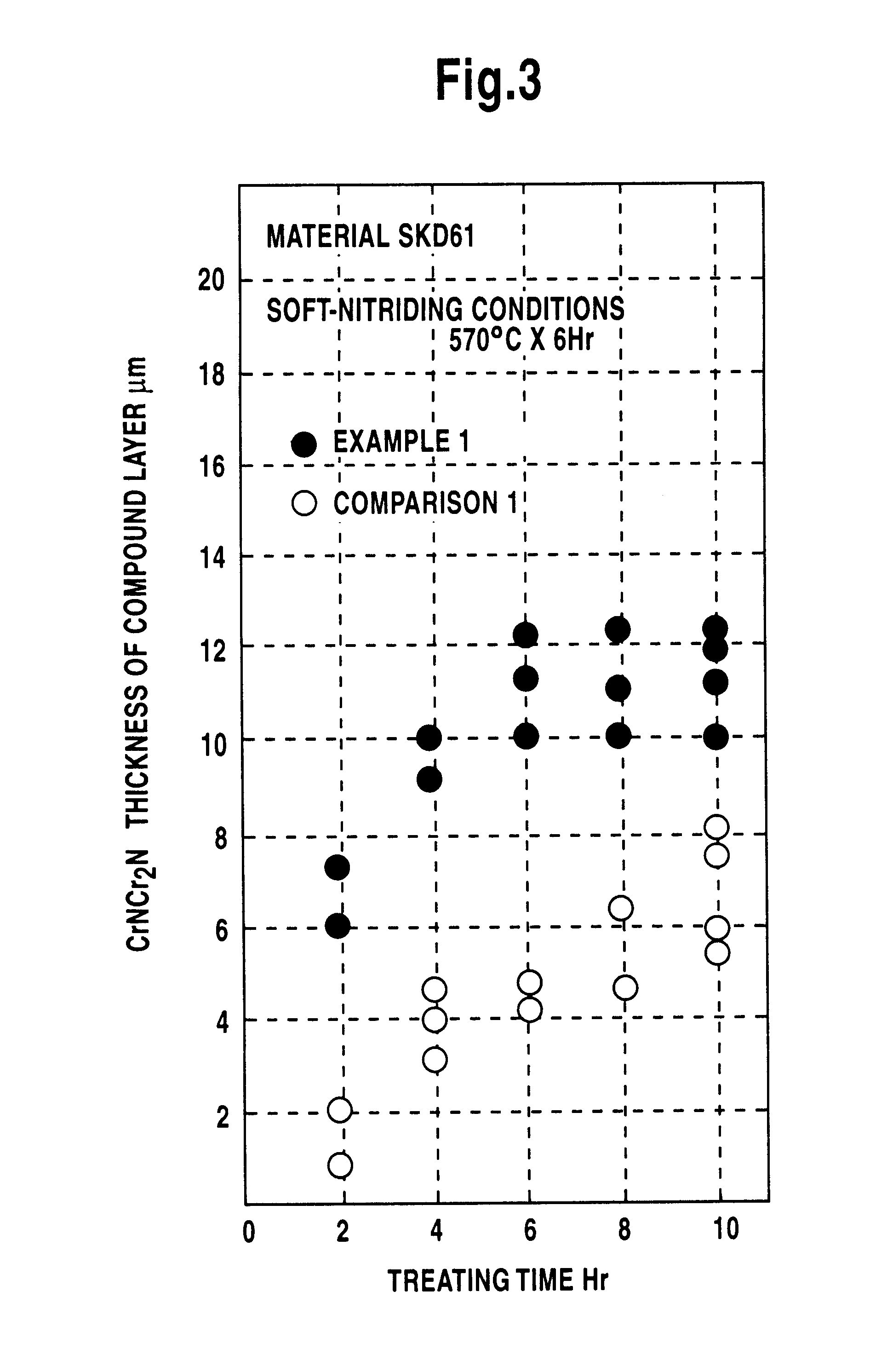

Method for treating surface of ferrous material and salt bath furnace used therefor

The present invention features nitriding-treating the ferrous material to form a nitrided layer composed of at least one of iron nitride and iron carbide nitride on the surface thereof, and heating to maintain the ferrous material at a temperature of 500 to 700° C. in a treating agent (A), whereby chromium is diffused into the nitrided layer to form a compound layer composed of at least one of chromium nitride and chromium carbide nitride,wherein the treating agent (A) contains the following (a) as a main component and containing the following (b) and (c):(a) at least one of alkali metal chloride and alkaline earth metal chloride;(b) glass having silicone oxide as a main component; and(c) chromium.

Owner:SANSHU

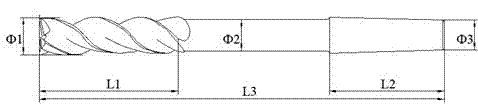

One-time heat treatment method of integral high-speed steel cutter

ActiveCN102453797AReduce distortionShorten quenching timeFurnace typesHeat treatment furnacesHeating timeQuenching

The invention discloses a one-time heat treatment method of an integral high-speed steel cutter. The method comprises the following steps of: (1) removing oil; (2) baking: the cutter is uniformly baked at a temperature of between 150 and 250 DEG C; (3) preheating; (4) quenching: after the cutter is preheated, the edge is quickly immersed in a salt bath to perform quenching heating, wherein the salt bath heating temperature of a W18 cutter is 1,280+ / -10 DEG C, the salt bath heating temperature of an M2 cutter is 1,220+ / -10 DEG C, the quenching insulating time is calculated according to tz which equals to 40 plus delta D, after insulation is completed, the cutter is completely immersed in the salt bath to quickly heat the handle of the cutter, and the heating time depends on the size of the cutter; (5) cooling; (6) cleaning; (7) annealing; and (8) subsequently processing. According to the method, the requirements for the edge part and the handle part of the cutter can be simultaneously fulfilled only by one-time heat treatment, secondary heat treatment to the handle part is not required, so that the process period can be shortened, the production efficiency can be improved, and the energy consumption can be reduced.

Owner:ZUNYI FENGHUA ELECTROMECHANICAL FITTINGS CO LTD

Anti-corrosion and heat tinting composite surface treating method for steel

InactiveCN101353801AImprove wear resistanceImprove corrosion resistancePolishing machinesSolid state diffusion coatingComposite filmSodium nitrite

The invention relates to a method for treating the anti-corrosion and oxidized and colored composite surface of steel, and pertains to the metal material surface treatment technical field. Derusting and polishing are first carried out to a steel material so as to lead the roughness degree of the material surface to reach the requirement, and pre-oxidation is carried out to the treated blank; the pre-oxidated blank is put into a salt bath furnace to react and then a carburizing salt residual on the surface is washed off, or the pre-heated blank is put into an atmosphere of ammonia and ethanol to react, the blank for carburizing treatment is vibrantly polished, and polishing wax or grease residual on the surface is cleaned; the polished blank is put into tempering atmosphere for coloring, or immersed in the water solution of sodium hydroxide and sodium nitrite to be colored, and finally, sealing treatment is carried out. The method of the invention can cause that the colored composite film of the steel surface has the excellent performances of wear resistance and anti-corrosion, and the products prepared by the steel material of the invention have good ornamental performance. The method of the invention has simple technology process, low product cost, and no environmental pollution, does not change external dimension of the products, and can be used for coloring treatment of various carbon steels and alloy steels.

Owner:余煌

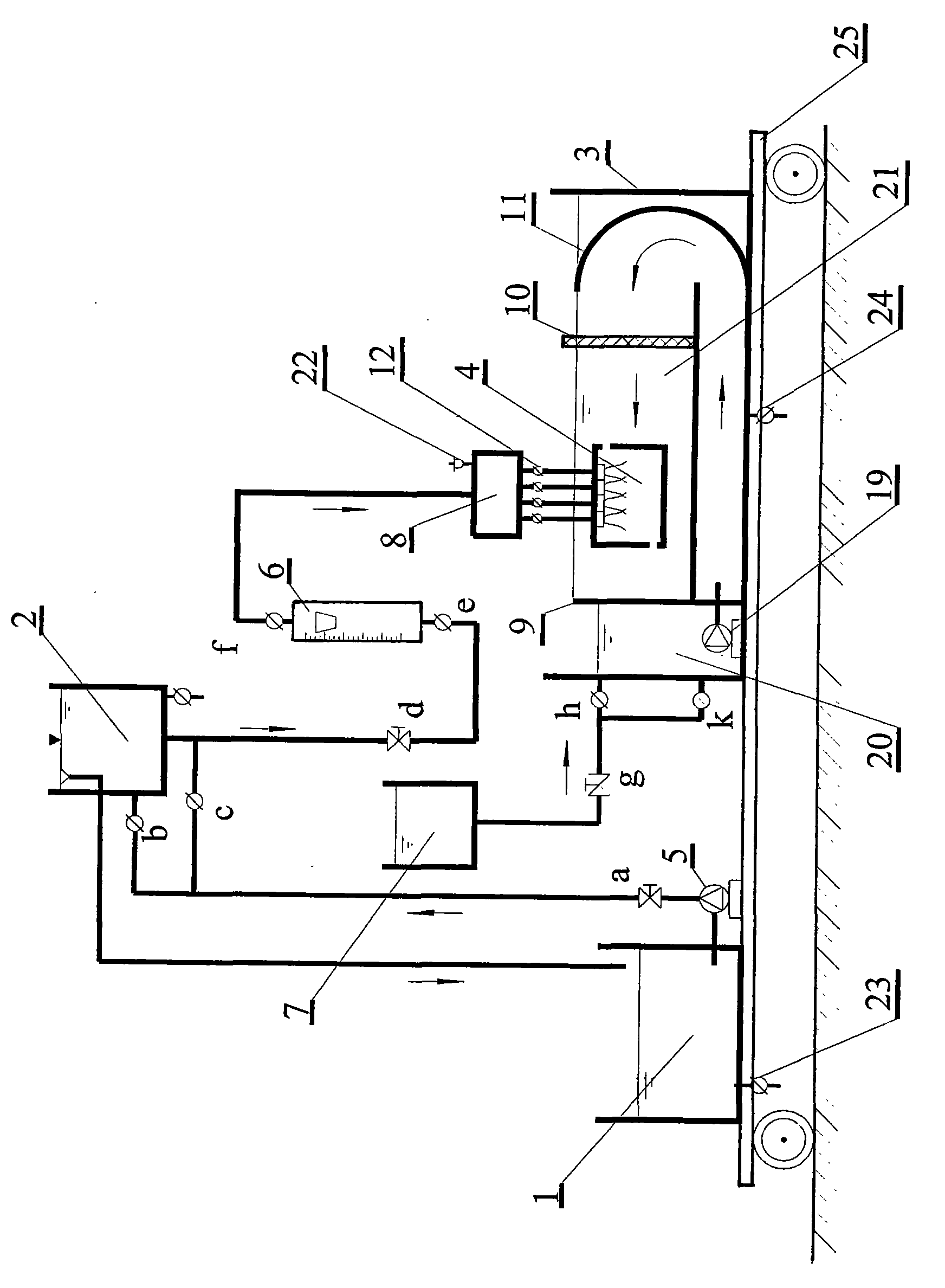

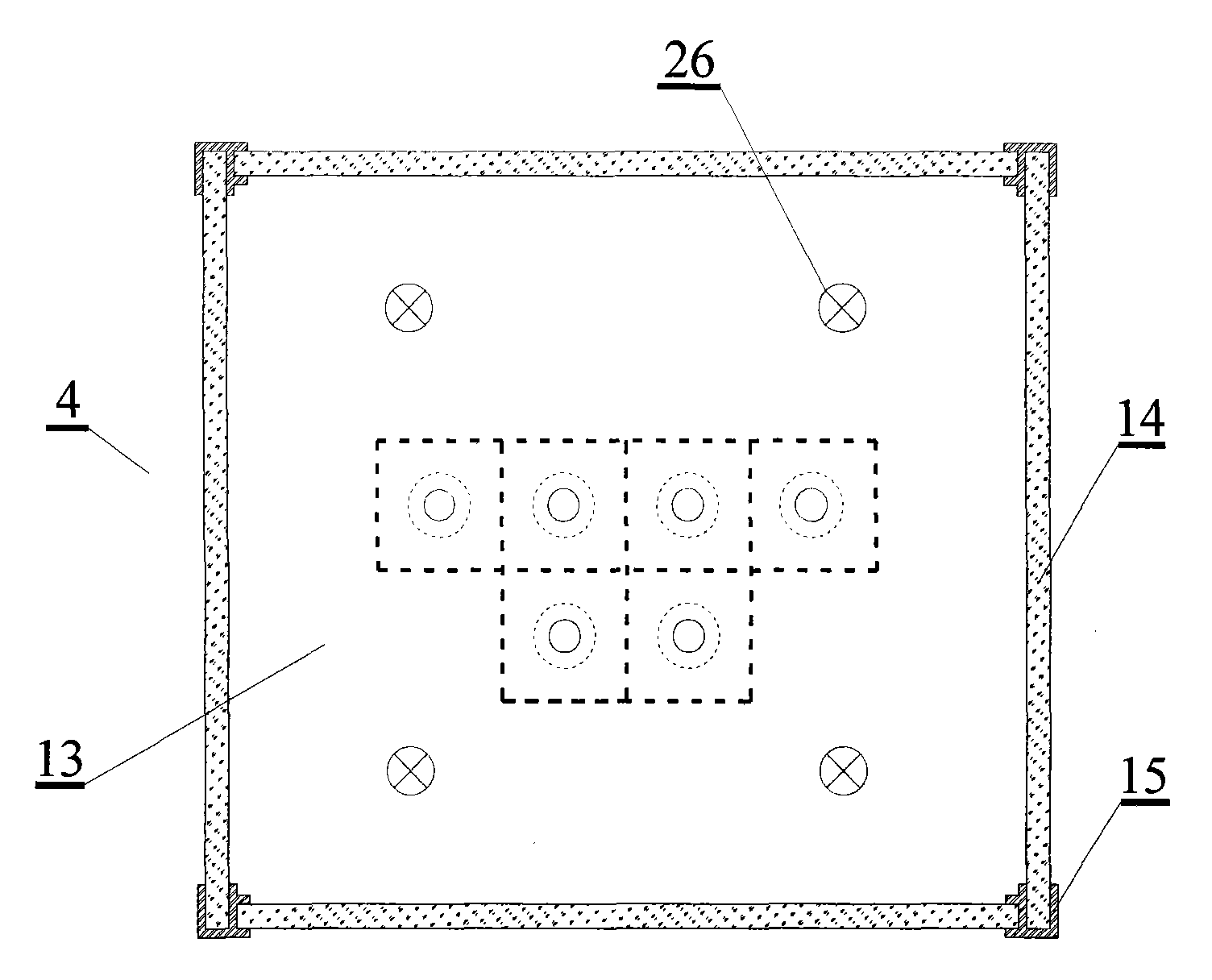

Natural ventilation salt-bath scaled model experimental device

InactiveCN101561343AReal display of temperature fieldLow costAerodynamic testingScale modelEngineering

The invention relates to a natural ventilation salt-bath scaled model experimental device, which is characterized in that: the natural ventilation salt-bath scaled model experimental device is provided with a salt water storage tank, a clear water tank and a high order salt water tank; the high order salt water tank is connected with the salt water storage tank; a model building is arranged in a model building sink arranged in the clear water tank; a dispenser arranged above the model building is communicated with a salt water inlet corresponding to the model building through a brake valve on the dispenser, and is communicated with the high order salt water tank through a brake valve of a pipe, a flowmeter and a regulating valve; and a built-in submerged pump in a header tank is communicated with the clear water tank. The experimental device can simulate upward movement of hot air under buoyancy driving by using downward movement of salt water under gravity driving in a scale-model test, simulate a temperature field in an actual building by using the density difference generated by the salt water and clear water, and utilize the clear water to compare cold air of the ambient environment and the salt water to compare an internal heat source of a room. If the scaling of corresponding variables in the model building and the actual building is known, the temperature field and the ventilation quantity in the actual building can be predicted through model experiments, so that a simulated result is similar to an actual condition, and the cost is low.

Owner:HARBIN INST OF TECH

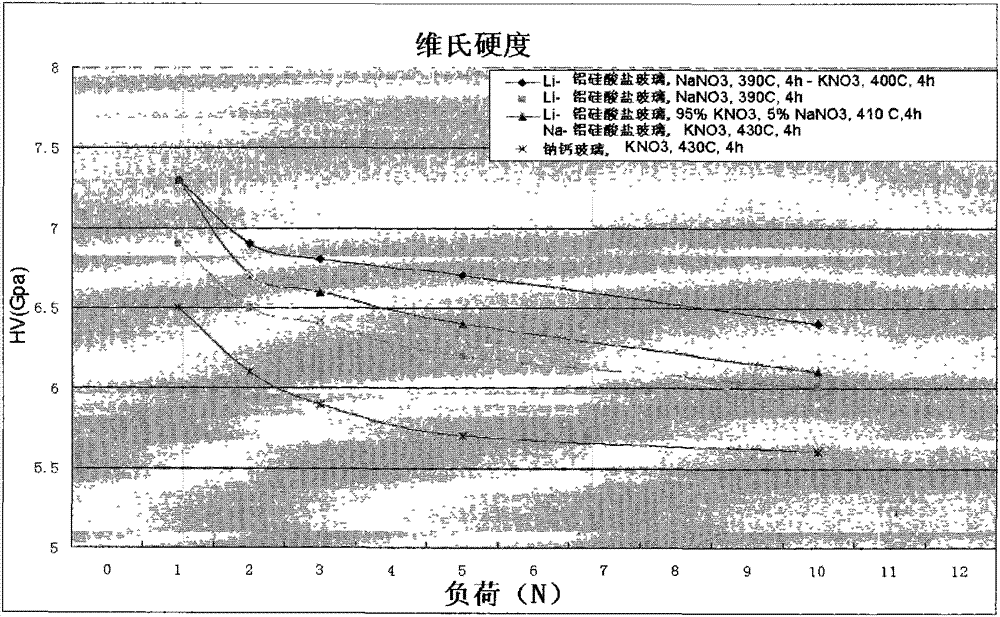

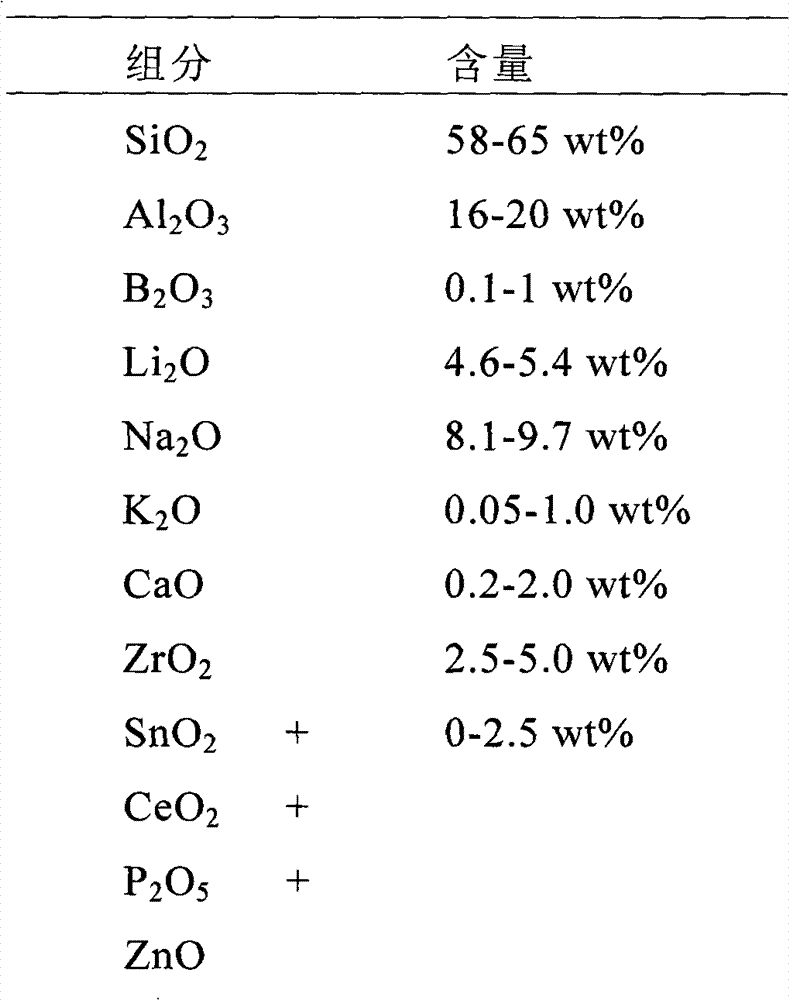

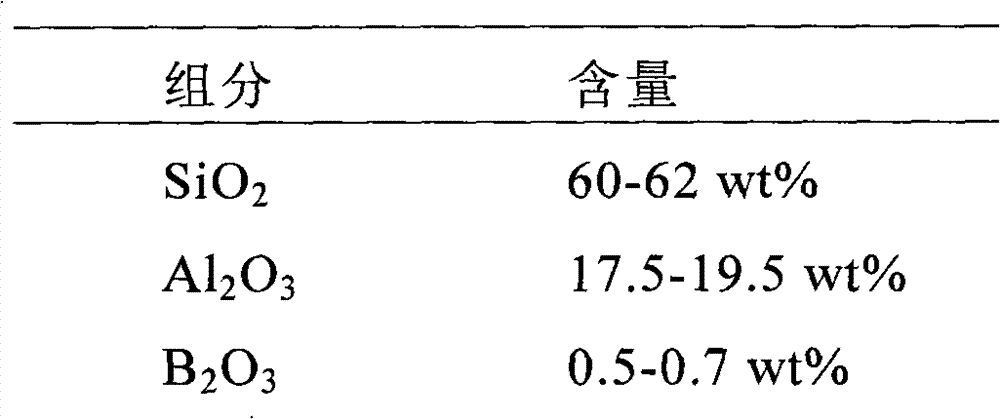

Damage resistant glass with high coefficient of thermal expansion

Ion exchangeable glasses having coefficients of thermal expansion (CTE) at least about 90×10−7° C.−1. The glasses undergo rapid ion exchange, for example, in a molten KNO3 salt bath to a depth of layer of greater than 30 microns in less than 2 hours at temperatures of 370° C. to 390° C. When ion-exchanged to a depth of layer between 30 to 50 microns, the glasses exhibit a Vickers median / radial crack initiation threshold exceeding 30 kilograms force (kgf). The glasses are fusion formable and, in some embodiments, compatible with zircon.

Owner:CORNING INC

Cu-P based amorphous brazing filler metal and method for manufacturing the same

InactiveCN101367159AFlat surfaceImprove toughnessWelding/cutting media/materialsSoldering mediaUltimate tensile strengthFiller metal

The invention relates to the technical field of the brazing of amorphous filler metal, copper and copper alloy, and relates to Cu-P based amorphous filler metal and a preparation method thereof. The Cu-P based amorphous filler metal comprises the following compositions with the content in percentage by mass: 7.0 to 8.0 percent of P, 14.0 percent of Ni, 5.0 percent of Sn, 0.02 to 0.06 percent of Zr, 0.2 percent of Si, and the balance being Cu. The preparation of the Cu-P based amorphous filler metal adopts a fast solidification technology, and the prepared filler metal has bright and clean surface, smooth two sides, and good toughness. The melting temperature range of the filler metal is between 590 and 635 DEG C, and the temperature of the brazing is between 650 and 685 DEG C. The filler metal is applicable to the brazing of the copper and the copper alloy, and applicable brazing techniques comprise flame brazing, furnace brazing, gas-shielded brazing, salt bath brazing and the like. When the filler metal is adopted to perform the flame brazing to red copper, the wettability of the filler metal is apparently better than that of filler metals which has the same compositions and are prepared by the prior melting technology, and the shearing strength of a brazed joint is larger than 92MPa, so the filler metal has good application prospect.

Owner:JIANGSU UNIV OF SCI & TECH

Metal surface salt bath nitrocarburizing method

ActiveCN102899604AReduce contentImprove regenerative abilitySolid state diffusion coatingCyanideNitrogen

The invention discloses a metal surface salt bath nitrocarburizing method which comprises the following steps: (1) workpiece cleaning; (2) workpiece clamping; (3) workpiece preheating; (4) nitrocarburizing: transferring the workpieces preheated by the step (3) into a salt bath furnace, immersing the workpieces in the salt bath, and keeping the workpieces in the 535-585 DEG C salt bath for 30-180 minutes to complete nitrocarburizing, wherein when starting from the treatment of the first batch of workpieces to be nitrocarburized, taking salt samples from the salt bath furnace every 12-24 hours, determining the concentrations of cyanides and cyanates in the salt bath, and adding sulfur-containing compounds for lowering the cyanide content and regenerated salt into the salt bath furnace when the mass percent of the cyanides in the salt bath exceeds 3 wt%; and after completing the nitrocarburizing, cooling the workpieces, cleaning, drying, and carrying out oil immersion. According to the metal surface salt bath nitrocarburizing method disclosed by the invention, the sulfur-containing compounds are added into the salt bath composition in the nitrocarburizing process to lower the content of cyanides and enhance the regeneration capacity of the regenerated salt.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

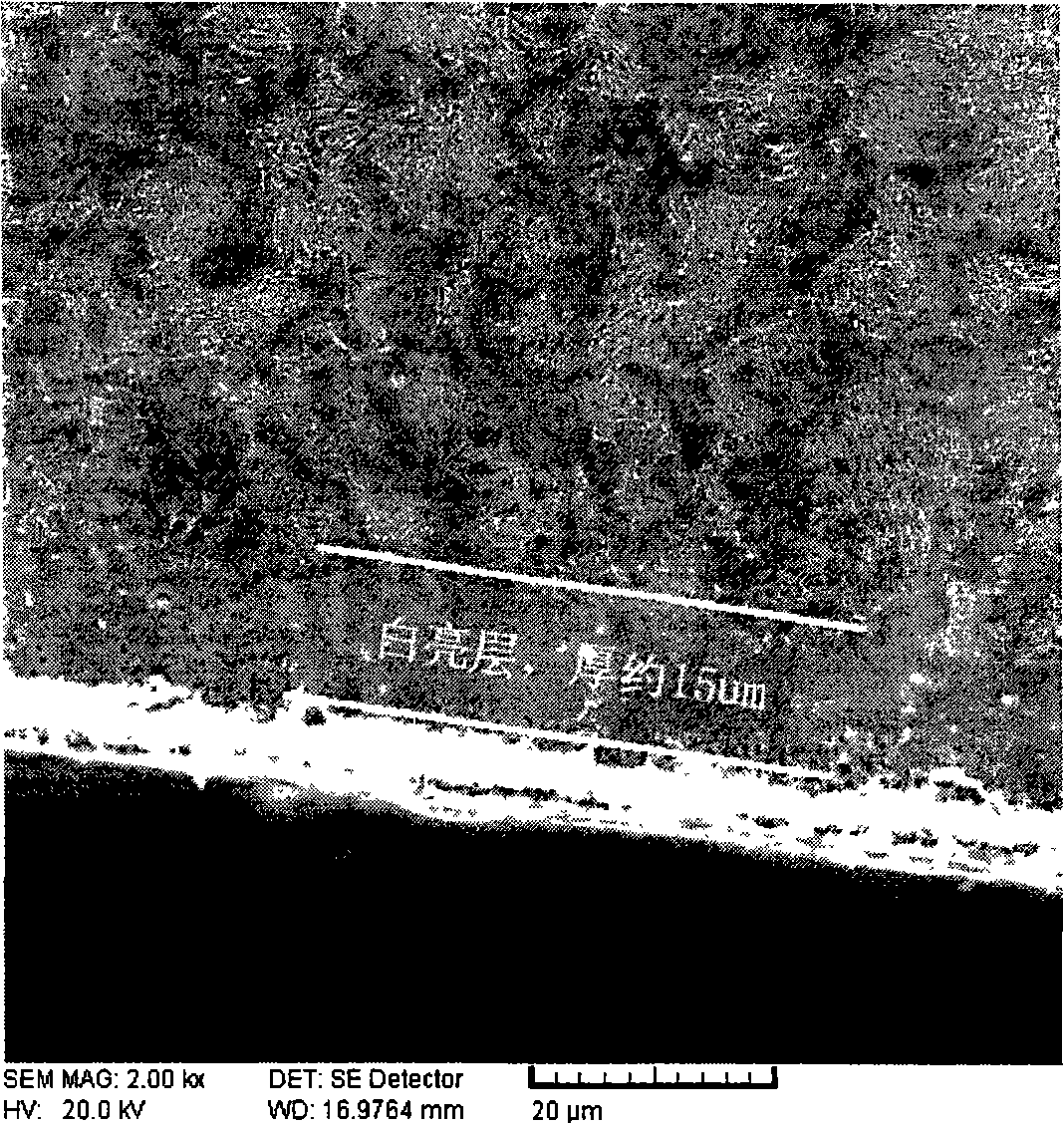

Surface treatment technique for coal winning machine cutting bit

InactiveCN101191230AExtended service lifeImprove work efficiencySolid state diffusion coatingHeat treatment bathsHardnessCoal

The invention discloses a surface treatment technology for a cutting bit of a coal winning machine. The cutting bit is made of the 35 chrome molybdenum vanadium alloy structural steel; the surface treatment technology includes the carburizing treatment, the boronizing, molybdenum permeating and chromizing treatment in which the optimal proportioning of the ingredients in a permeating box is that the boronizing agent is 80.6 percent, the molybdenum powder is 3 percent and the chrome powder is 16.4 percent, the salt bath treatment in which the optimization proportioning of the ingredients in a salt bath furnace is that the baryta is 73 percent, the non-iodized refined salt is 22 percent and the salt bath deoxidizing agent is 5 percent and the annealing and tempering treatment. The cutting bit which is treated according to the technology of the invention has the Rockwell hardness higher than HRC62 and the service life more than 400 hours.

Owner:李明

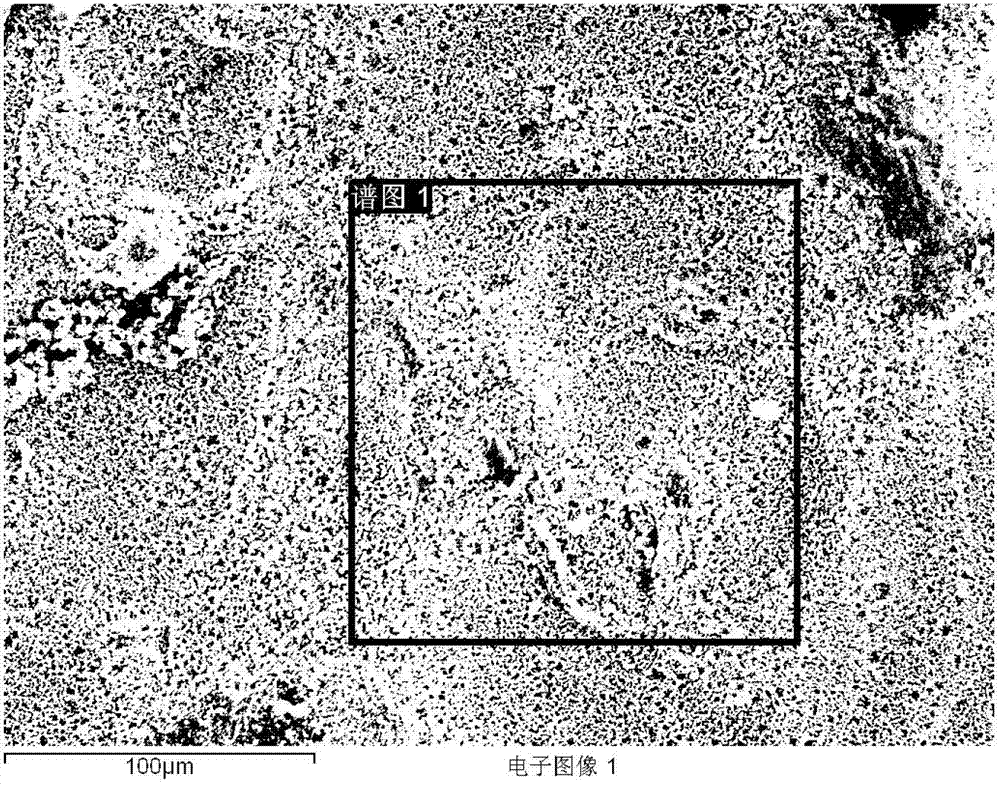

Method for directly growing nano-crystal chromium nitride film on steel products

InactiveCN101148769AReduce coefficient of frictionImprove bindingSolid state diffusion coatingRoom temperatureNanocrystal

The process of growing nanometer crystalline chromium nitride film directly on steel includes the first nitriding and the salt bath chromizing of the nitrided steel at 500-650 deg.c after being cooled to room temperature and surface washing. The salt bath fluid for salt bath chromizing has base salt comprising NaC l20-25 wt%,BaCl2 30-35 wt% and CaCl2 40-50 wt%; and effective components including Cr powder 10-20 wt% of the base salt, Fe powder 5-10 wt% of the base salt, CrCl3.6H2O 25-50 wt% of the base salt, and Si powder 5-10 wt% of the base salt. The process grows nanometer crystalline CrN film directly on steel, and the film has great base bonding force, effect of reducing friction, fast growing speed and high suitability of steel types.

Owner:SOUTH CHINA UNIV OF TECH

Salt bath tuff-triding treatment for high speed steel (W6Mo5Cr4V2) slide vane (or vane)

ActiveCN1616705AImprove wear resistanceExtended service lifeSolid state diffusion coatingKeroseneCleansing Agents

The present invention relates to the salt bath tufftriding treatment of high speed steel slide vane or blade. The tufftriding treating liquid consists of: NaCNO 40-60 wt%, KCNO 5-15 wt%, Li2CO3 3-10 wt% and K2CO3 25-40 wt%. The salt bath tufftriding treatment of the high speed steel slide vane or blade with the tufftriding treating liquid includes the following steps: cleaning with aviation kerosene or alcohol; mounting vertically on proper steel wire net; pre-heating at 350-420 deg.c for 10-20 min; treating at 550-590 deeg.c for 15-60 min while introducing ammonia or compressed air; 100-160 deg.c hot oil cooling for 30-120 sec; water washing and cleaning for 5-10 min; eliminating oil via soaking in water containing detergent for 2-5 min and soaking in water for 1-2 min for cleaning; and polishing in a vibrating polishing machine for 40-80 min. The present invention can raise the antiwear performance and prolong the service life of slide vane or blade of compressor.

Owner:浙江百达精工股份有限公司

Boron-containing high-silicon bainite wear-resistant corrosion-resistant alloy and manufacturing method thereof

The invention relates to a boron-containing high-silicon bainite wear-resistant corrosion-resistant alloy and a manufacturing method thereof. The alloy comprises the following chemical components in percentage by weight: 0.3-0.6% of C, 1.6-2.6% of Si, 0.6-1.0% of Mn, 0.6-4.0% of Cr, 0.3-0.5% of Mo, 0.3-0.5% of Ni, 0.3-0.5% of Cu, 0.1-0.3% of Ti, 0.05-0.1% of B, 0.05-0.15% of Ce, 0.05-0.15% of Nb, less than 0.04% of P, less than 0.04% of S and the balance of Fe. The manufacturing method comprises the following steps: carrying out electric-furnace smelting, carrying out secondary aluminum insertion deoxidization, putting on the bottom of a casting ladle to form a casting, austenizing the casting at 850-950 DEG C, keeping the temperature for some time, putting in a salt bath at 200-260 DEG C to carry out primary isothermal quenching, keeping the temperature for 5-10 minutes, carrying out secondary isothermal quenching in a salt bath at 260-400 DEG C, keeping the temperature for 0.5-4 hours, and cooling in air to obtain the wear-resistant corrosion-resistant alloy of which the austenite-bainite base is distributed with boride. The alloy is low in preparation cost and suitable for marine silt erosion and corrosion environments, has favorable comprehensive properties of toughness, wear resistance and corrosion resistance, and can be used for dredger cutter teeth, slurry pipelines, centrifugal-pump impellers, blades and the like.

Owner:CHANGXING DETIAN ENG MACHINERY

Salt bath formula for treating high-speed steel air conditioning compressor blade by salt bath nitriding treatment and treatment method

ActiveCN101871087ARaise the concentration ratioLow melting pointSolid state diffusion coatingAir conditioningSodium cyanate

The invention relates to a salt bath formula for treating a high-speed steel air conditioning compressor blade by salt bath nitriding treatment and a treatment method. The salt bath formula comprises the following compositions in percentage by weight: 15-25 percent of potassium cyanate, 5-20 percent of sodium cyanate, 3-10 percent of lithium carbonate, 8-20 percent of sodium carbonate, 10-40 percent of potassium carbonate and 1-10 percent of sodium chloride. The invention has the advantages that because Li ions and Cl ions are added in the formula, the melting point of salt bath is lowered, and nitridation can be carried out under lower temperature; the activity is favorable, and good appearance and good diffusion layer thickness can be achieved without introducing ammonia; and the K / Na concentration proportion is enhanced, and a white layer is not easy to form on the surface of a workpiece.

Owner:SHANGHAI JIANGKAI METAL SURFACE TREATMENT TECH +1

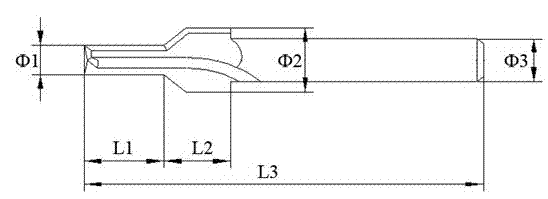

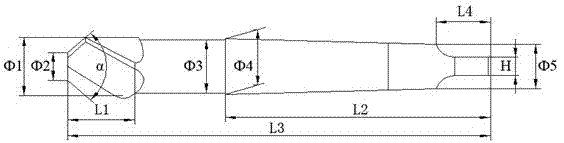

Technology for manufacturing cutting tooth for mining coal and minerals

ActiveCN101994512ASmall overall deformationLittle thermal impactSlitting machinesCutting machinesWear resistantHardness

The invention relates to technology for manufacturing a cutting tooth for mining coal and minerals. The cutting tooth comprises a tooth body and a tooth tip, and the technology is characterized by comprising the following steps of: (1) pre-manufacturing the tooth body; (2) pre-manufacturing the tooth tip; (3) assembling the tooth tip and the tooth body; (4) cladding a wear-resistant layer on the surface of the tooth body of the assembled cutting tooth; (5) performing salt bath treatment and quenching treatment on the product in the step (4); (6) performing low-temperature tempering treatment on the quenched product; and (7) performing post-treatment on the tempered product so as to obtain the finished cutting tooth. The deformation and thermal effect of the cutting tooth treated by the treatment technology are extremely low, and the service life is prolonged by 5 to 6 times. Compared with the traditional cutting teeth, the cutting tooth with the wear-resistant layer on the surface of the tooth body has higher Vickers hardness, and through detection, the hardness is more than 1,800 and is far greater than the Vickers hardness of the traditional cutting teeth. Due to higher hardness, the service life of the cutting tooth is greatly prolonged.

Owner:HUNAN LIANSHAO CONSTR ENG GRP

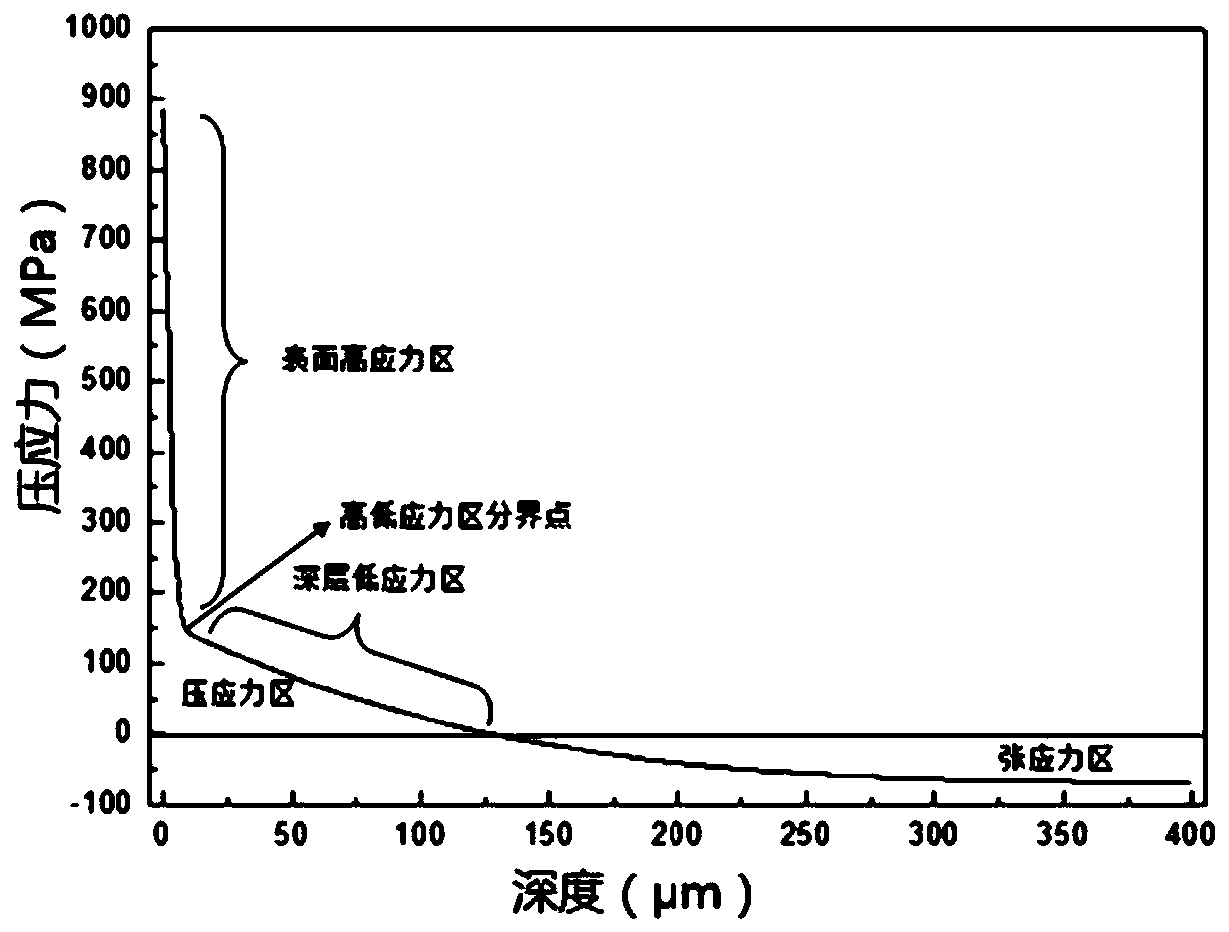

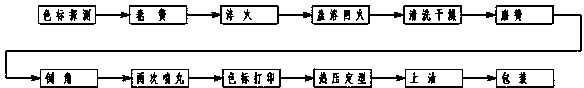

Production process of high-residual-stress valve spring

ActiveCN104190828AImprove residual stressHigh and deep residual stressWire springsMiniaturizationWork in process

The invention discloses a production process of a high-residual-stress valve spring. The process comprises the following steps of spring rolling, wherein 55CrSi or 50CrVA spring steel wire materials are adopted as a blank; isothermal quenching; salt bath tempering, wherein the temperature of a salt pool is controlled between 400 DEG C and 440 DEG C, and heat preservation is carried out for a period; cleaning and drying; spring grinding; chamfering, wherein the two ends of a semi-finished spring obtained after spring grinding treatment are chamfered, burrs are removed, and the assembling requirements of customers are met; shot blasting of two times, wherein rough blasting is carried for the first time, a high residual stress value is obtained, fine blasting is carried out for the second time, and a deep residual stress value is obtained; hot press shaping; subsequent settling. Therefore, the high-residual-stress valve spring is manufactured. According to the production process, residual tension in the spring rolling process can be eliminated, the original mechanical performance of the materials can be kept, the high and deep residual stress can be obtained in the shot blasting process, the valve spring can be applied to high-stress-amplitude occasions, and the miniaturization requirement of an engine is met.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

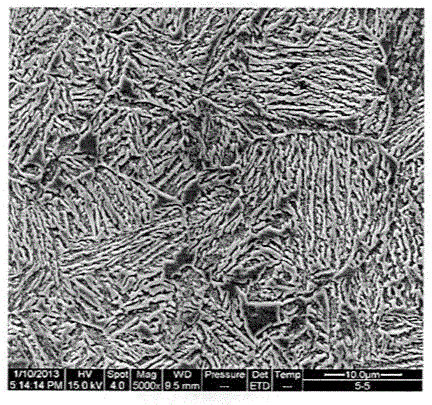

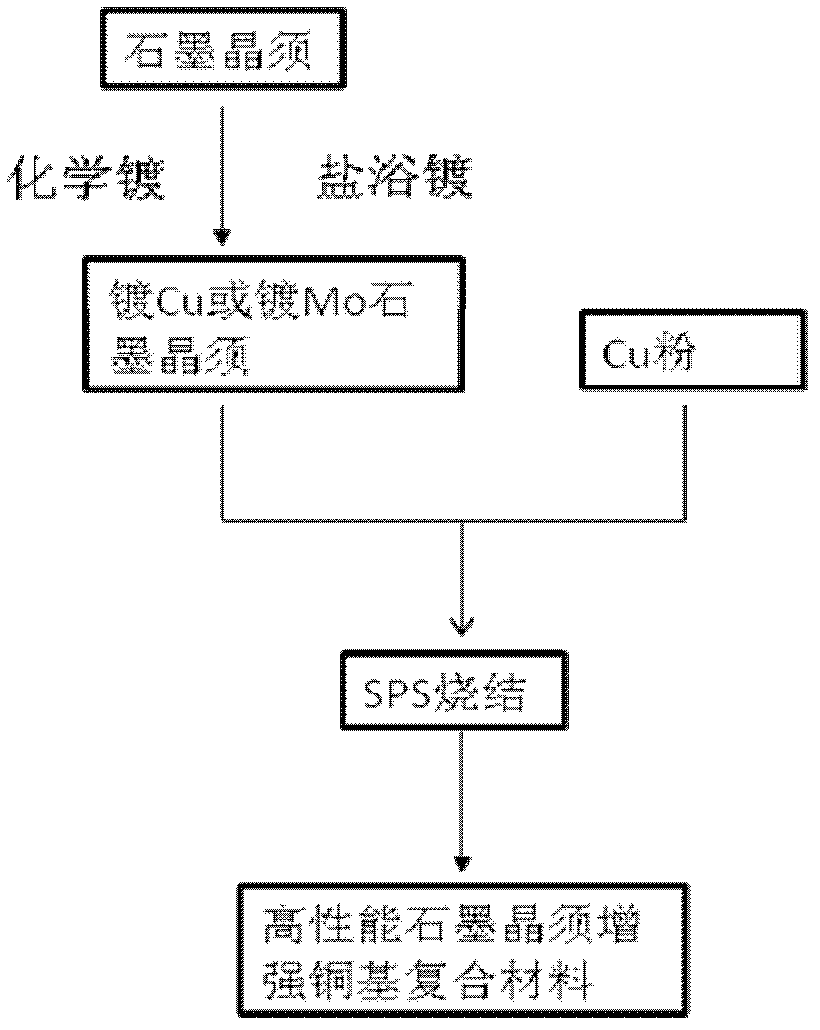

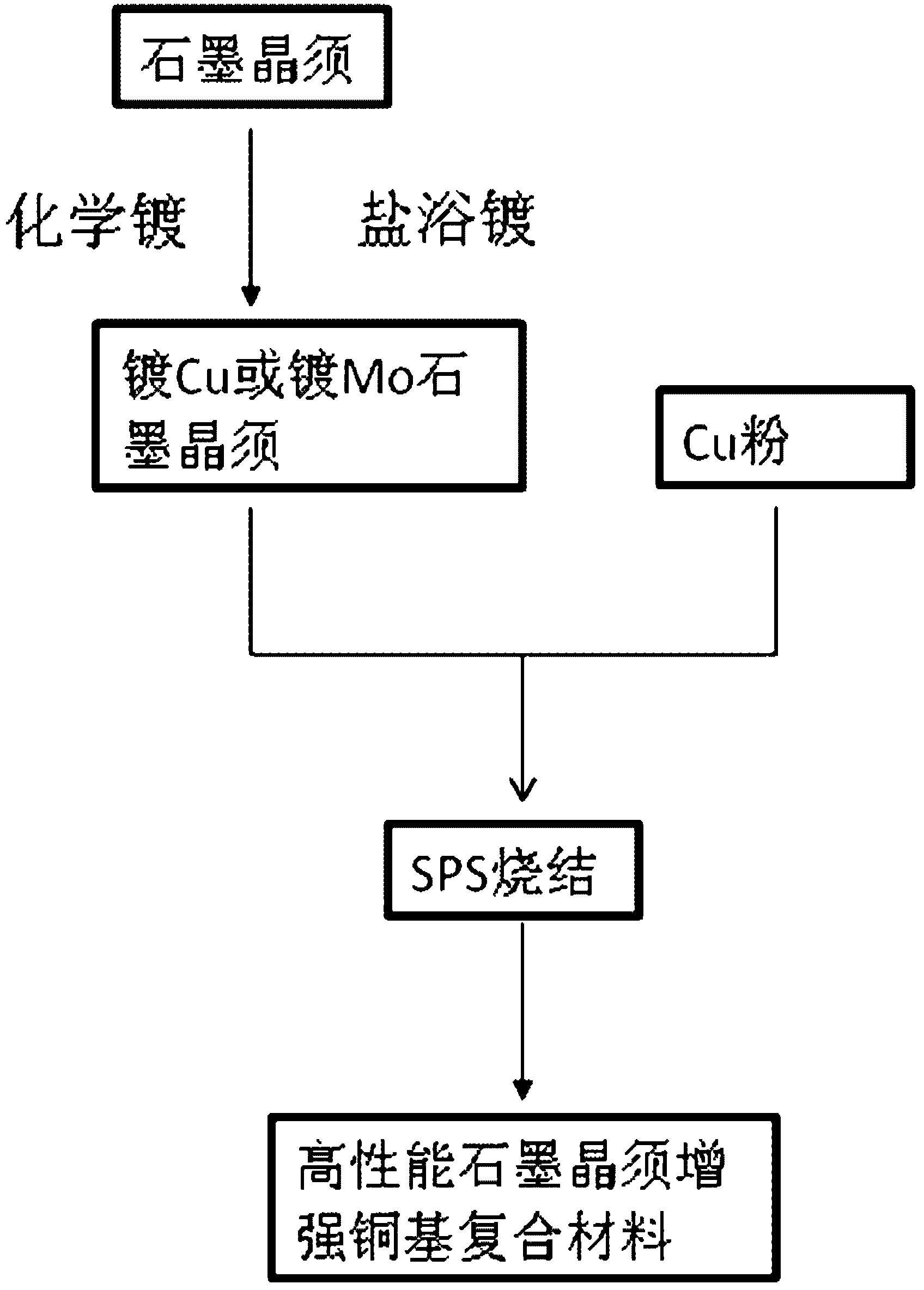

High thermal conductivity graphite whisker/copper composite and preparation method thereof

InactiveCN102586704AControllable coefficient of thermal expansionImprove wettabilityThermal dilatationChemical plating

The invention belongs to the research field of metal matrix composites and relates to a high thermal conductivity graphite whisker / copper composite and a preparation method thereof. The composite comprises two parts, namely matrix pure copper and plated reinforced phase high thermal conductivity graphite whisker, wherein the volume fraction of the pure copper is 40 to 70 percent, and the volume fraction of the plated graphite whisker is 30 to 60 percent. The composite adopts the following production process steps: firstly, the surface of graphite whisker is plated with copper or molybdenum byadopting a chemical plating or salt bath plating method, so as to form a plating with the thickness of 1 to 2 Mum; and secondly, the plated graphite whisker and copper powder are uniformly mixed in the proportion of (30 to 60) to (70 to 40), and then the mixture is sintered at 820 to 980 DEG C by adopting an SPS Spark Plasma Sintering powder metallurgic method, so as to prepare the graphite whisker / copper composite. The invention provides the preparation method of the graphite whisker / copper composite used in the electronic packaging field, and the graphite whisker / copper composite has the advantages of high thermal conductivity, controllable thermal expansion coefficient, high density, easiness in processing and the like, thereby meeting requirements in the modern electronic packaging field.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com