Production process of high-residual-stress valve spring

A residual stress, valve spring technology, applied in the direction of manufacturing springs from wire, application, wire processing, etc., can solve the problems of inability to obtain high residual stress, inability to completely remove the tension stress of coil springs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

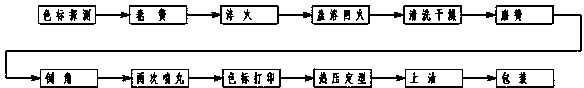

[0027] Such as figure 1 As shown, a high residual stress valve spring production process, the steps of the process are as follows:

[0028] a) coil spring: the blank is rolled into a semi-finished spring; the blank can be a spring steel wire that has not been oil-quenched; wherein the blank is a 55CrSi or 50CrVA spring steel wire material;

[0029] b) Isothermal quenching; wherein, the temperature range of quenching is 850°C to 870°C, and it is kept for a period of time to control the atmosphere in the quenching furnace to avoid decarburization exceeding the standard;

[0030] c) Salt bath tempering; wherein, the temperature of the salt bath is controlled at 400°C to 440°C, and the time is about 1 hour;

[0031] d) Cleaning and drying: After clea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com