Device and method for testing relation between residual stress and surface hardness of metal component

A technology of residual stress and surface hardness, which is applied in the field of test devices for the relationship between residual stress and surface hardness of metal components, can solve the problems of complex operation, low test efficiency, and low test accuracy, and achieve simple processing and production, simple structure, and low investment costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

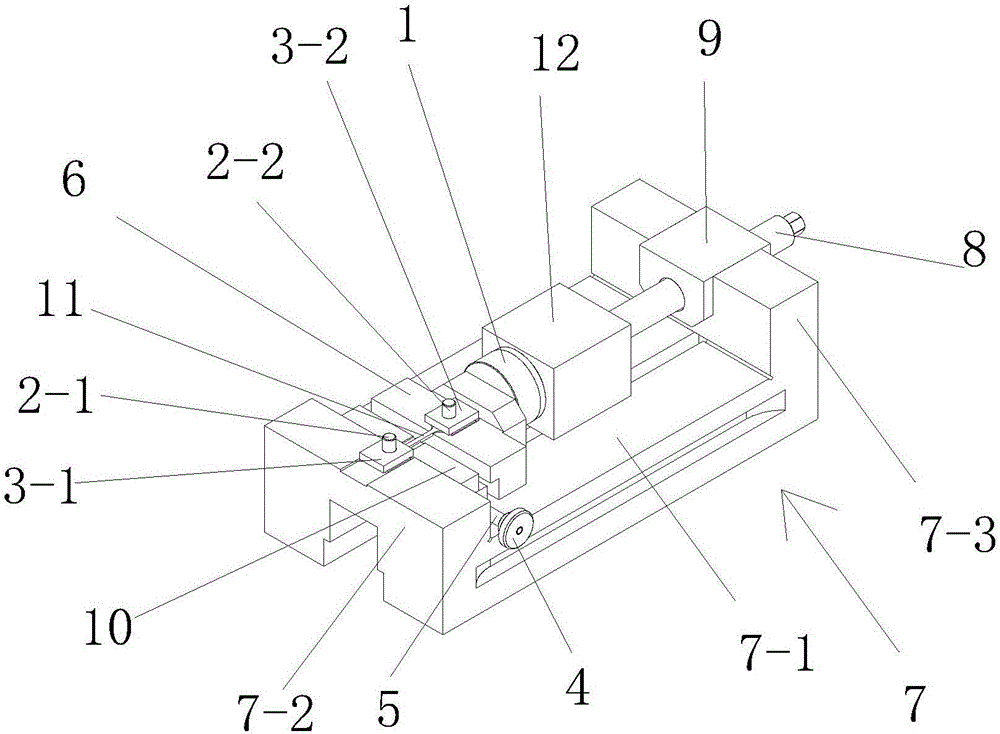

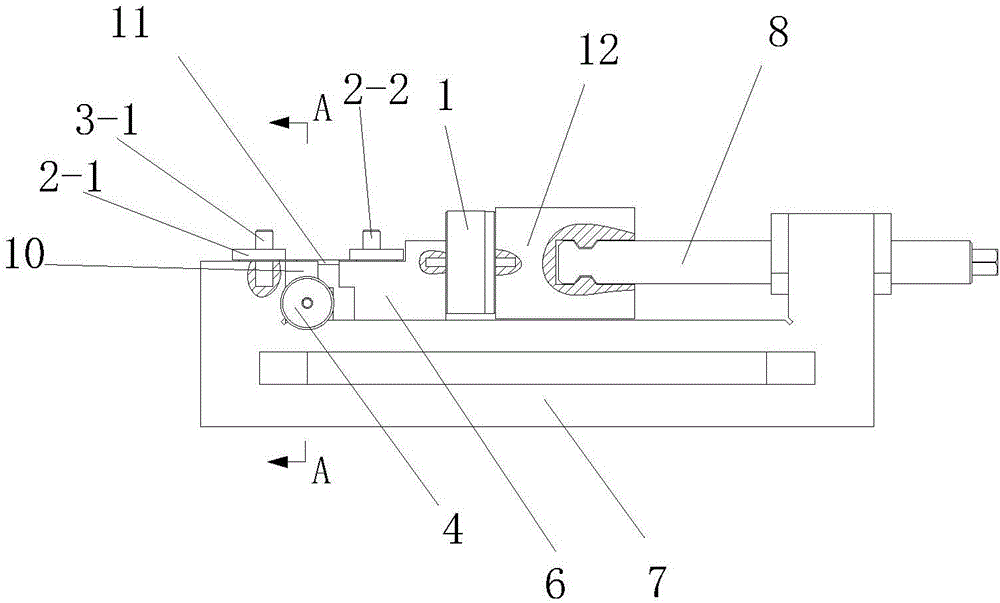

[0062] Such as figure 1 , figure 2 , image 3 with Image 6 The shown test device for the relationship between residual stress and surface hardness of a metal component includes a test frame 2, a residual stress simulation test device installed on the test frame 2 and performing a residual stress simulation test on the tested component 11, an installation The hardness detection module 3 that is above the residual stress simulation test device and tests the surface hardness of the tested member 11 and the monitoring device that monitors the residual stress simulation test device and the hardness detection module 3, the tested The component 11 is a metal component, and the tested component 11 is arranged horizontally;

[0063] The residual stress simulation test device includes a base 7 installed on the test frame 2, a positioning mechanism installed on the base 7 and positioning the tested component 11, and carries out residual stress simulation loading on the tested compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com