Patents

Literature

1193results about "Wire springs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

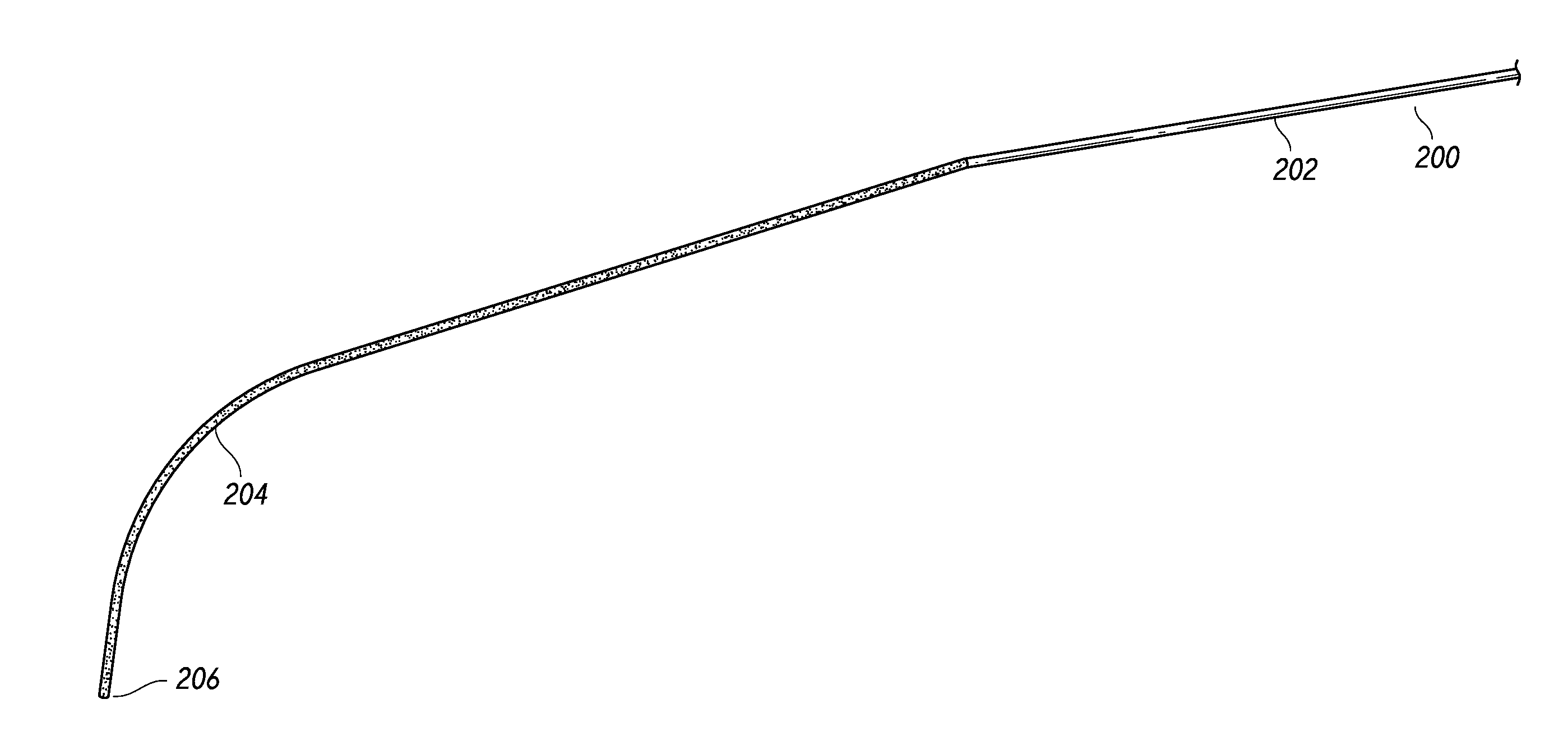

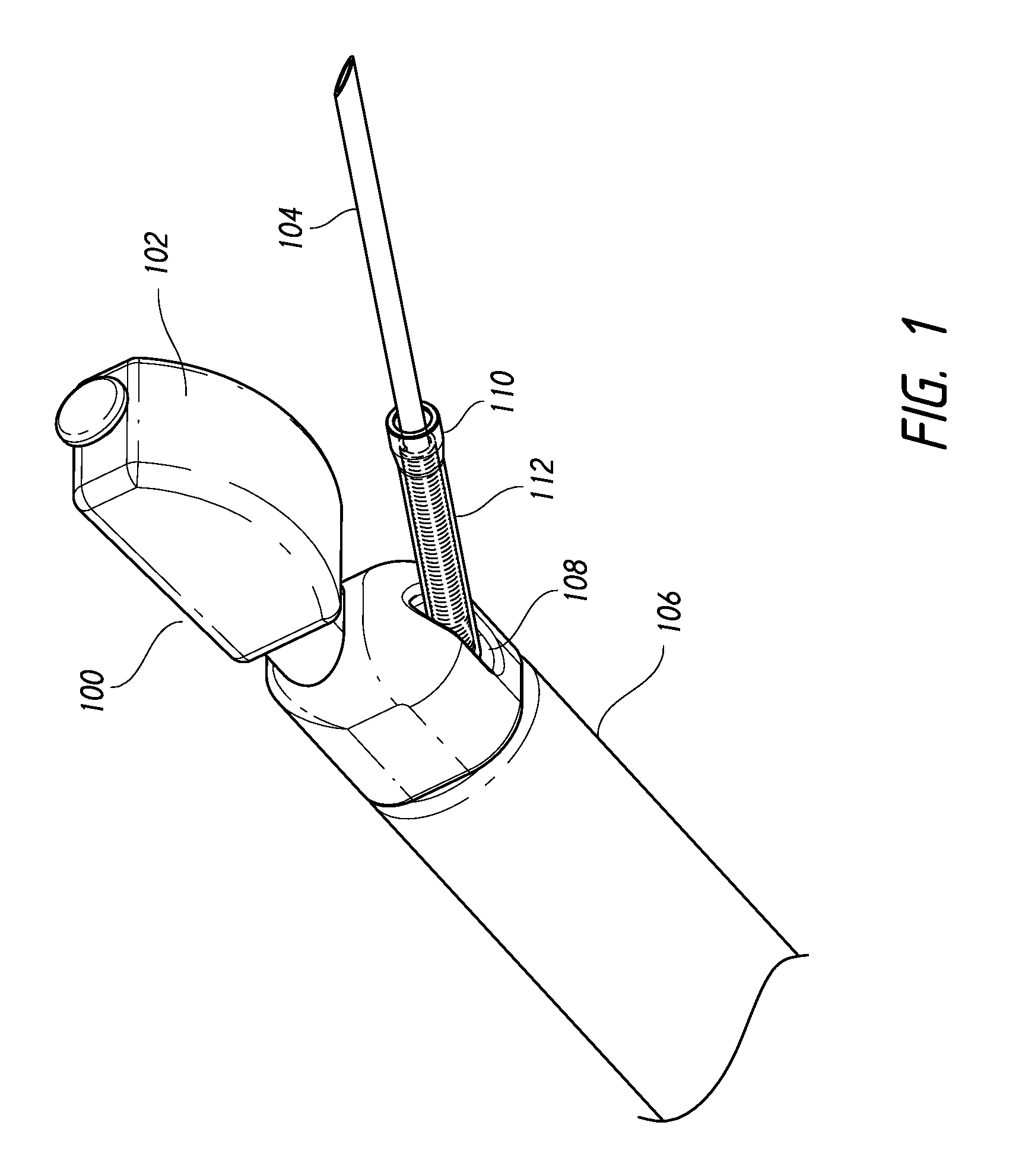

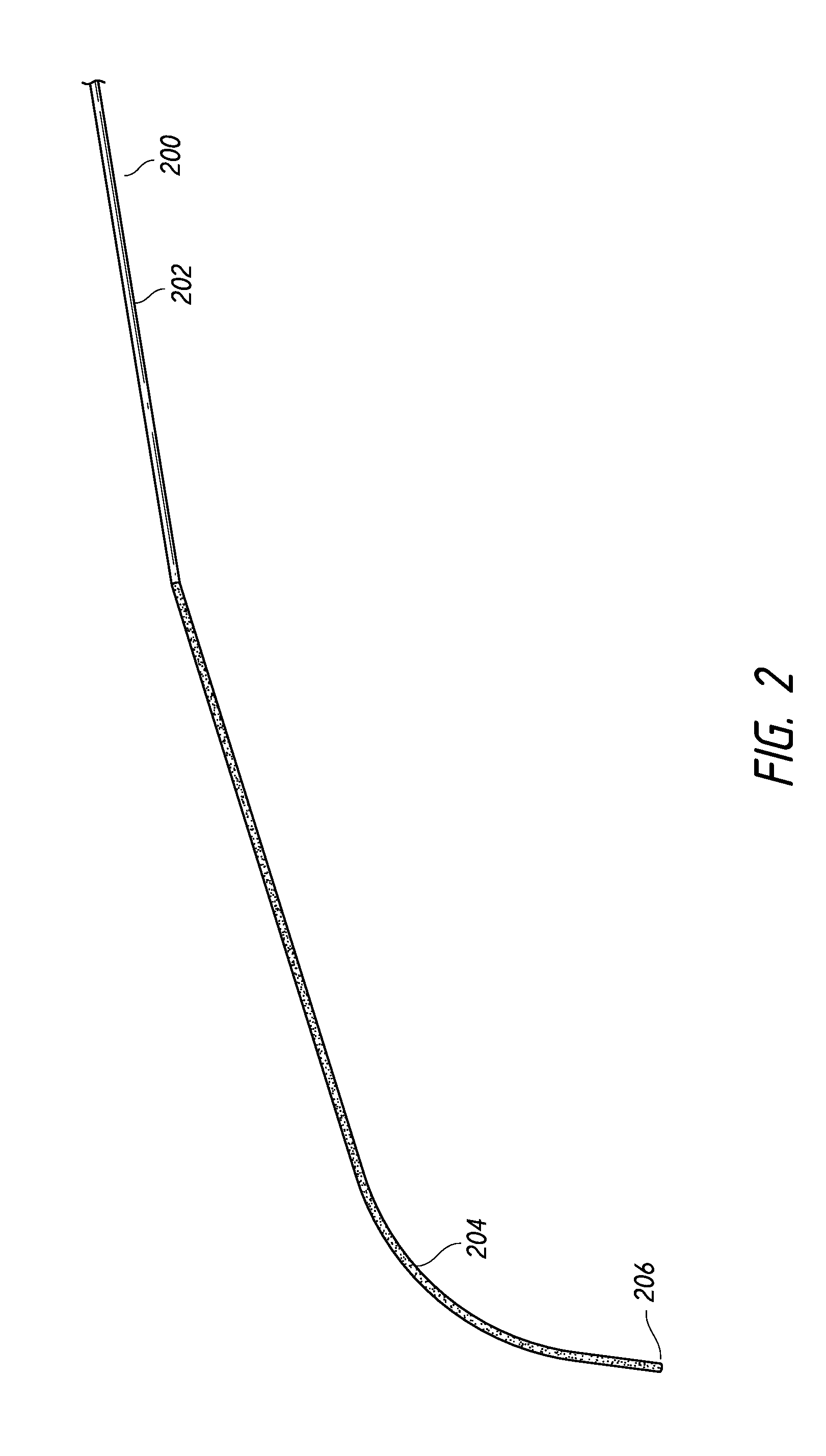

Lung biopsy needle

InactiveUS20130225997A1Add featureUltrasonic/sonic/infrasonic diagnosticsSurgical needlesLung biopsyPulmonary nodule

Systems, methods, and devices for biopsying tissue, in particular lung nodules, with a flexible needle are described herein. Preferably, the flexible needle is able to articulate or bend so as to provide access to areas previously difficult or impossible to biopsy. Further embodiments provide for steering and navigating the flexible needle to a region to be biopsied.

Owner:GYRUS ACMI INC (D B A OLYMPUS SURGICAL TECH AMERICA)

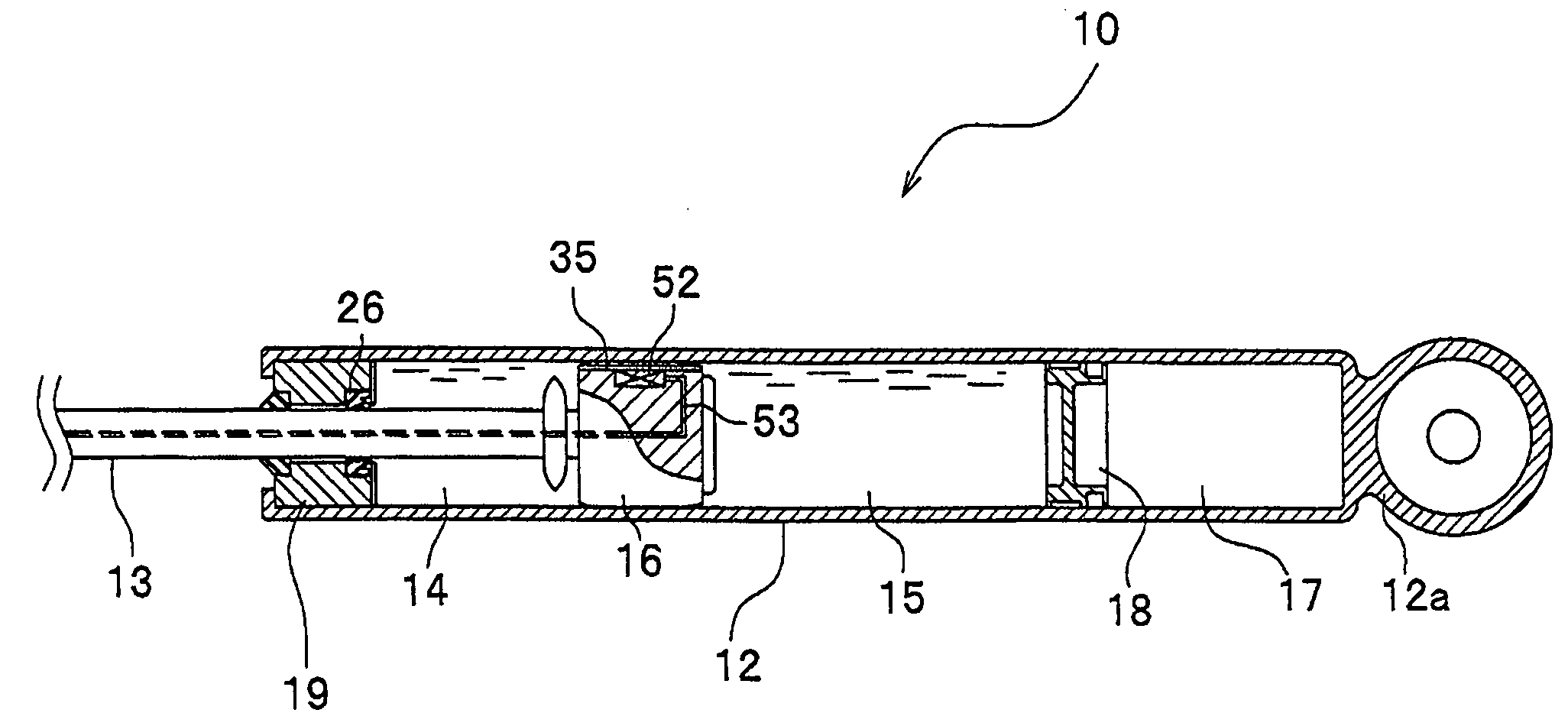

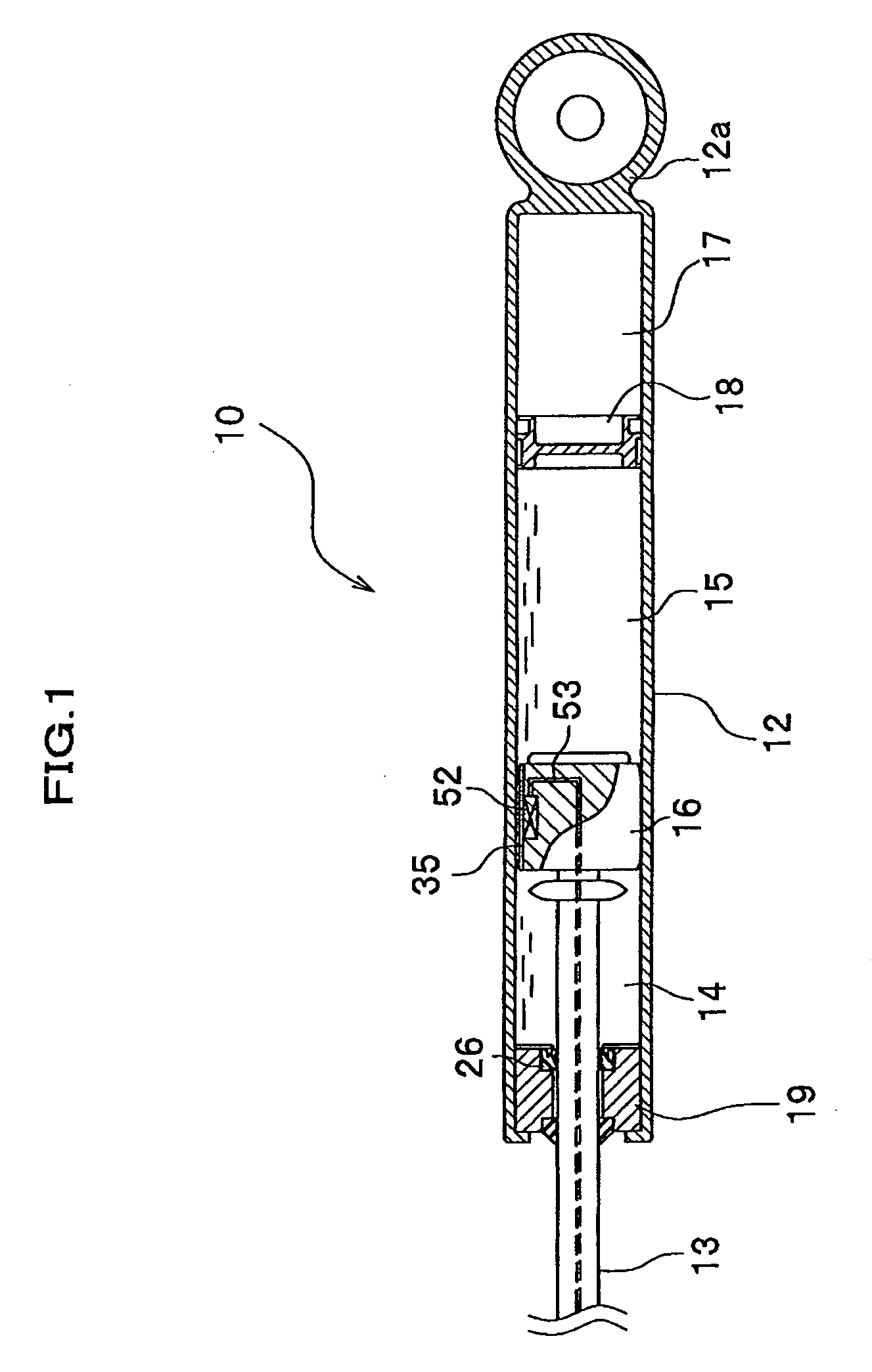

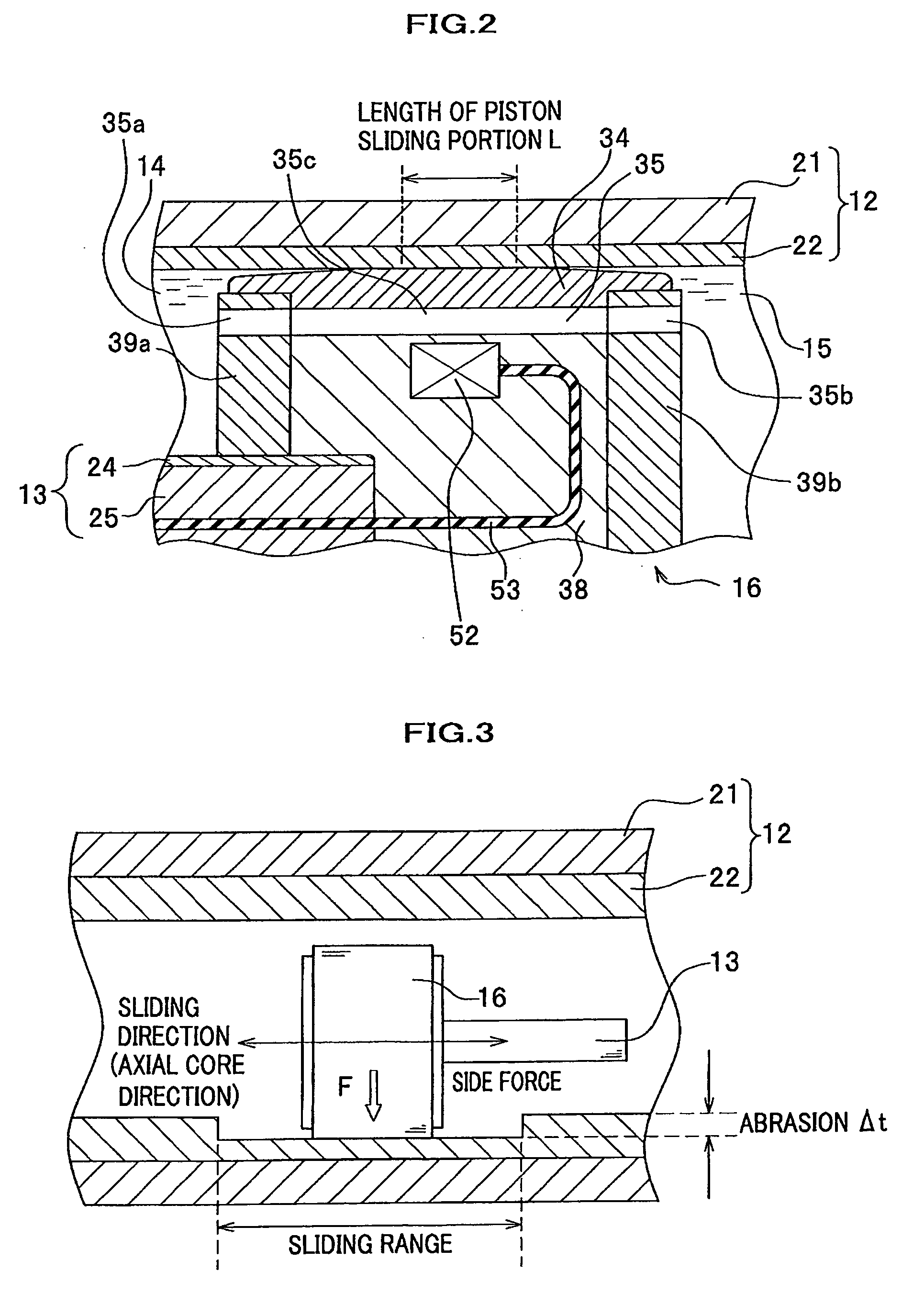

Variable damping-force damper and manufacturing method of the same

InactiveUS20090200126A1Reduced sliding resistanceIncreased durabilitySpringsNon-rotating vibration suppressionEngineeringHardness

A variable damping-force damper includes a cylinder tube filled with magnetic particles (MRF), a piston that is slidably disposed within the cylinder tube, a piston rod connected with the piston and is disposed so as to protrude out of one end of the cylinder tube and a rod guide that closes one end of the cylinder tube and slidably supports the piston rod. The cylinder tube has a Ni plating film whose Vickers hardness is 800 VHN or more on its inner peripheral surface and the piston slides relative to the Ni plating film. The rod guide has a structure having a predetermined base material portion and a fluorine resin contained Ni plating film that is treated by heat and is provided on the surface of the base material portion. The piston rod slides relative to the fluorine resin contained Ni plating film.

Owner:HONDA MOTOR CO LTD

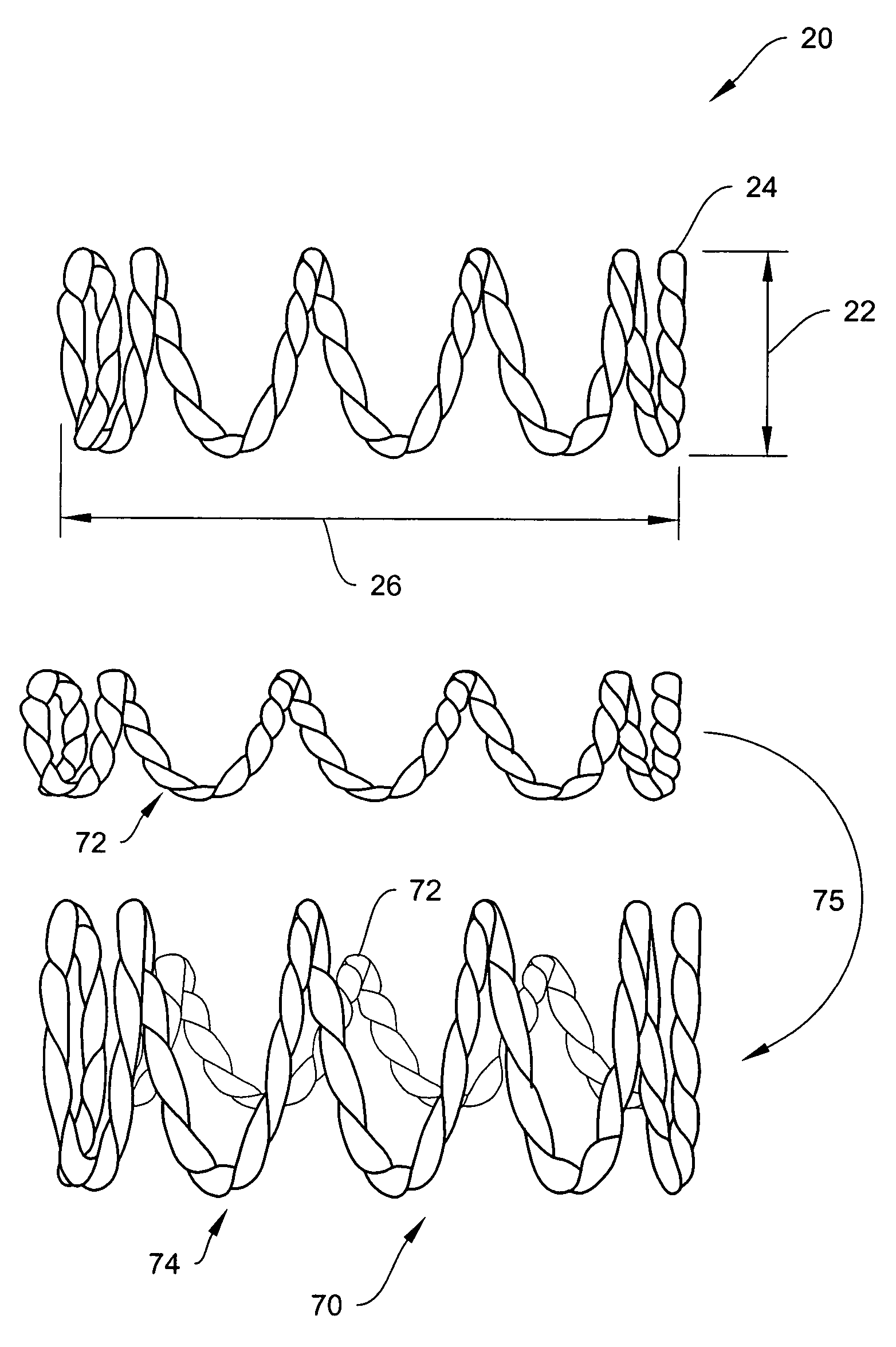

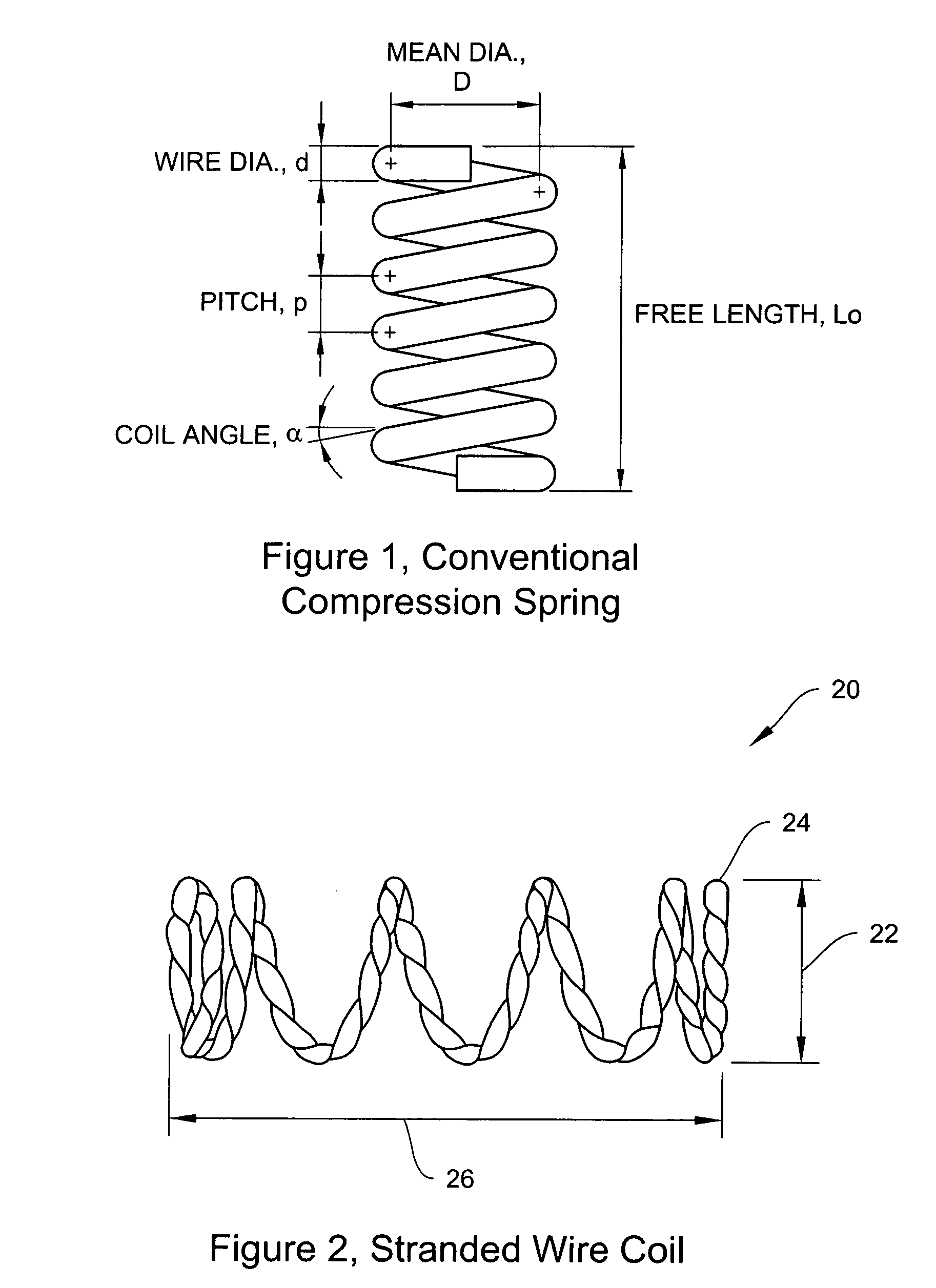

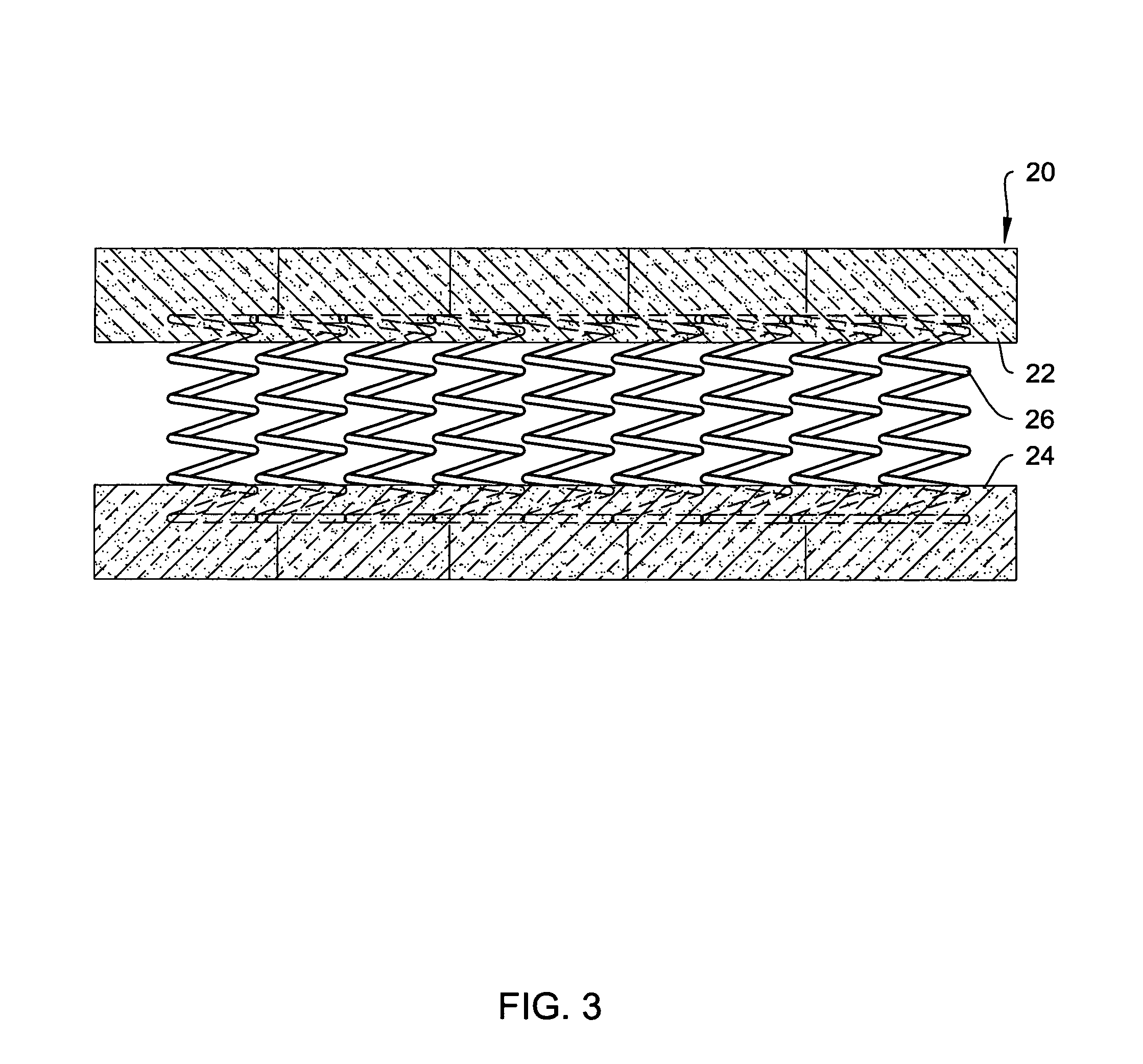

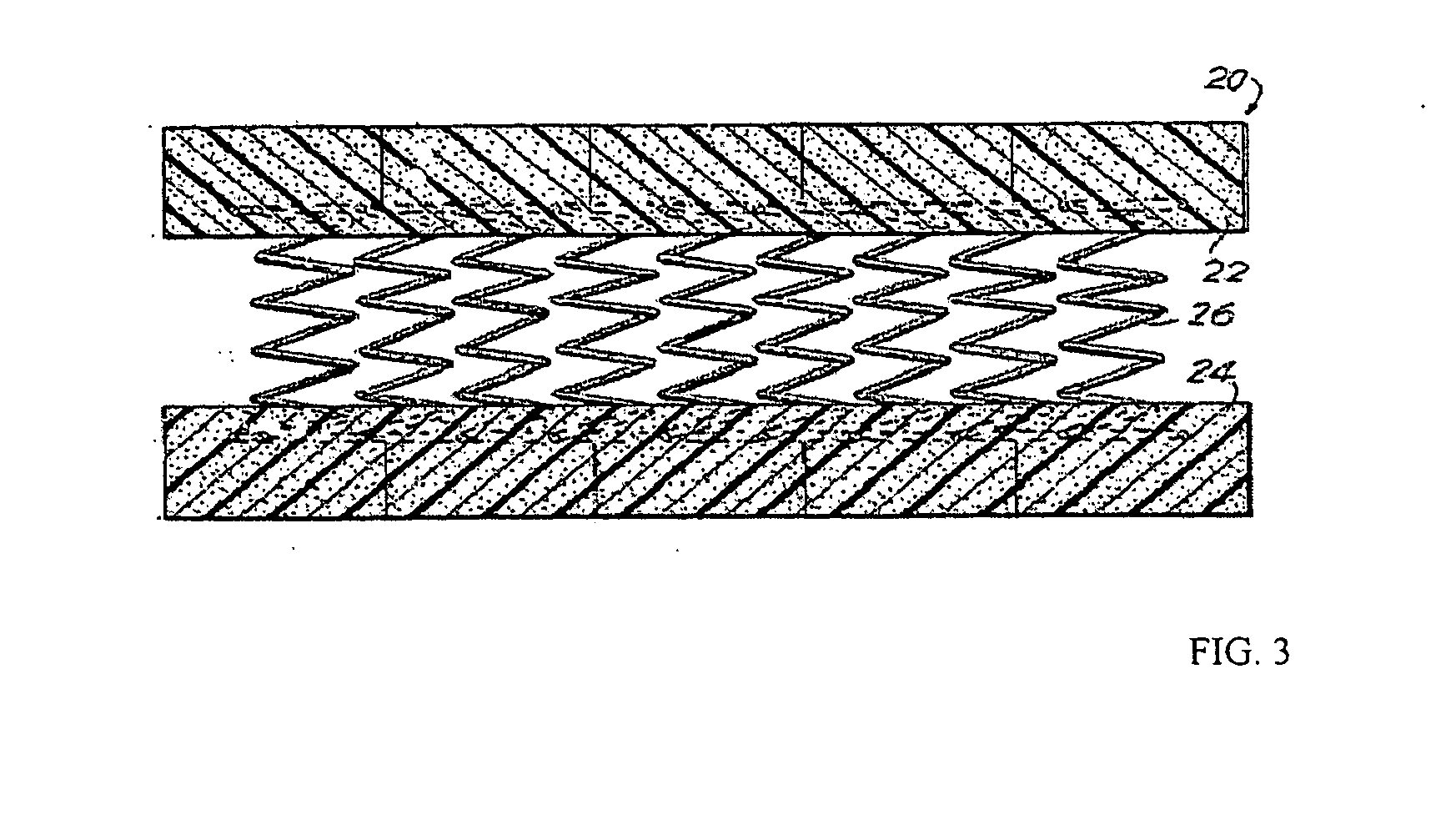

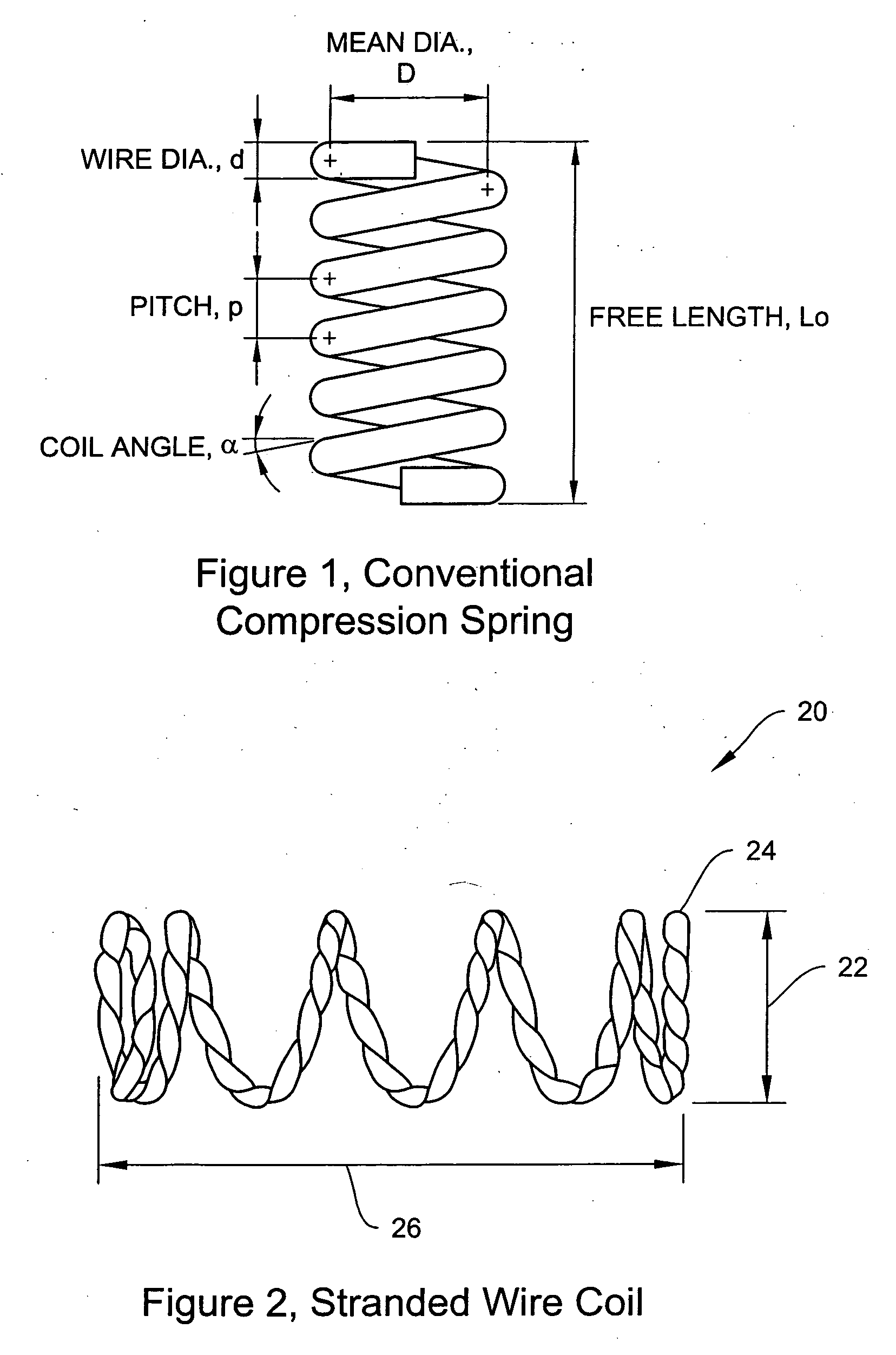

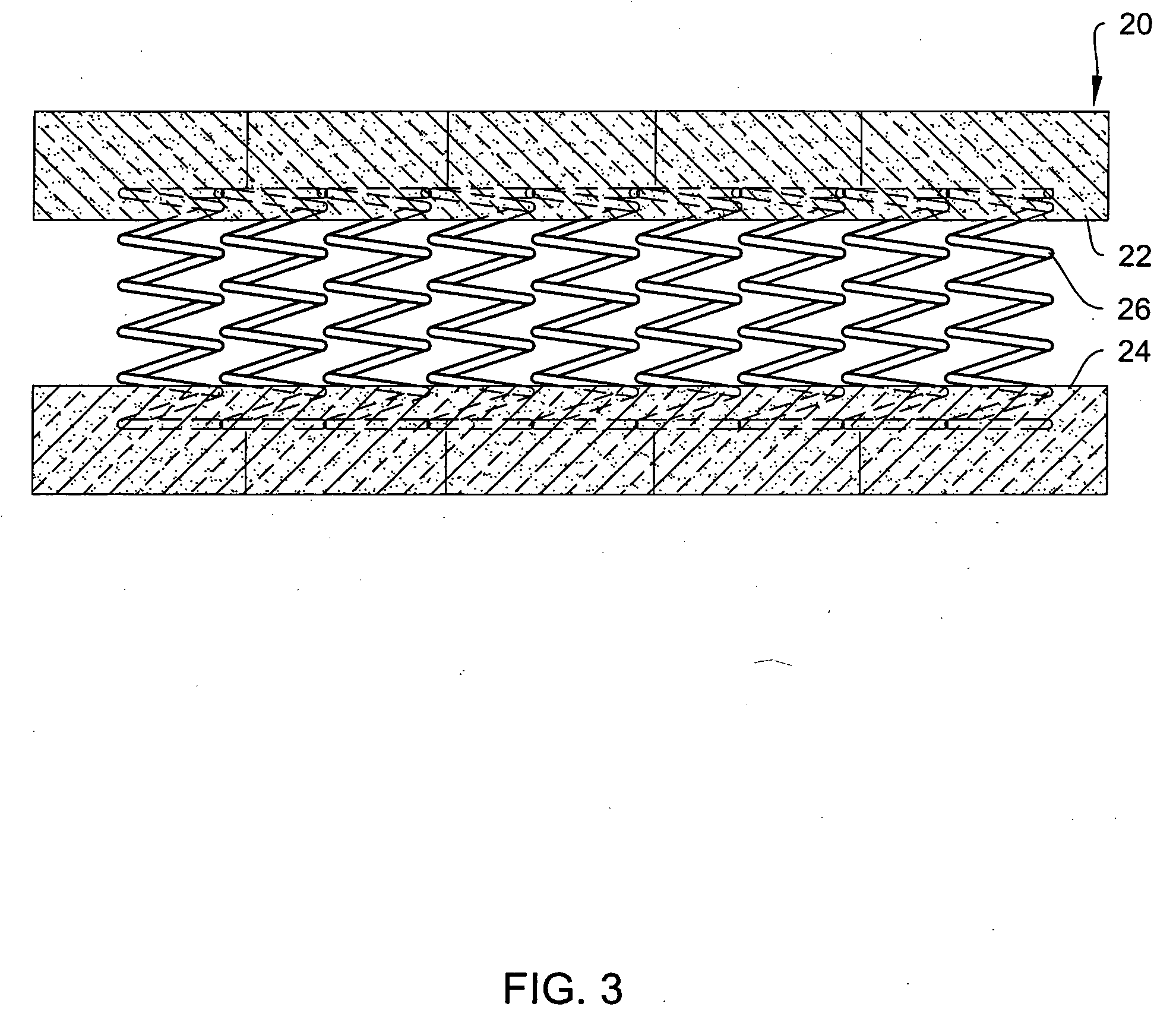

Multi-stranded coil spring

InactiveUS7168117B2Reduce adverse effectsStuffed mattressesMultiple spring combinationsCoil springHelical coil

Owner:SIMMONS CO +1

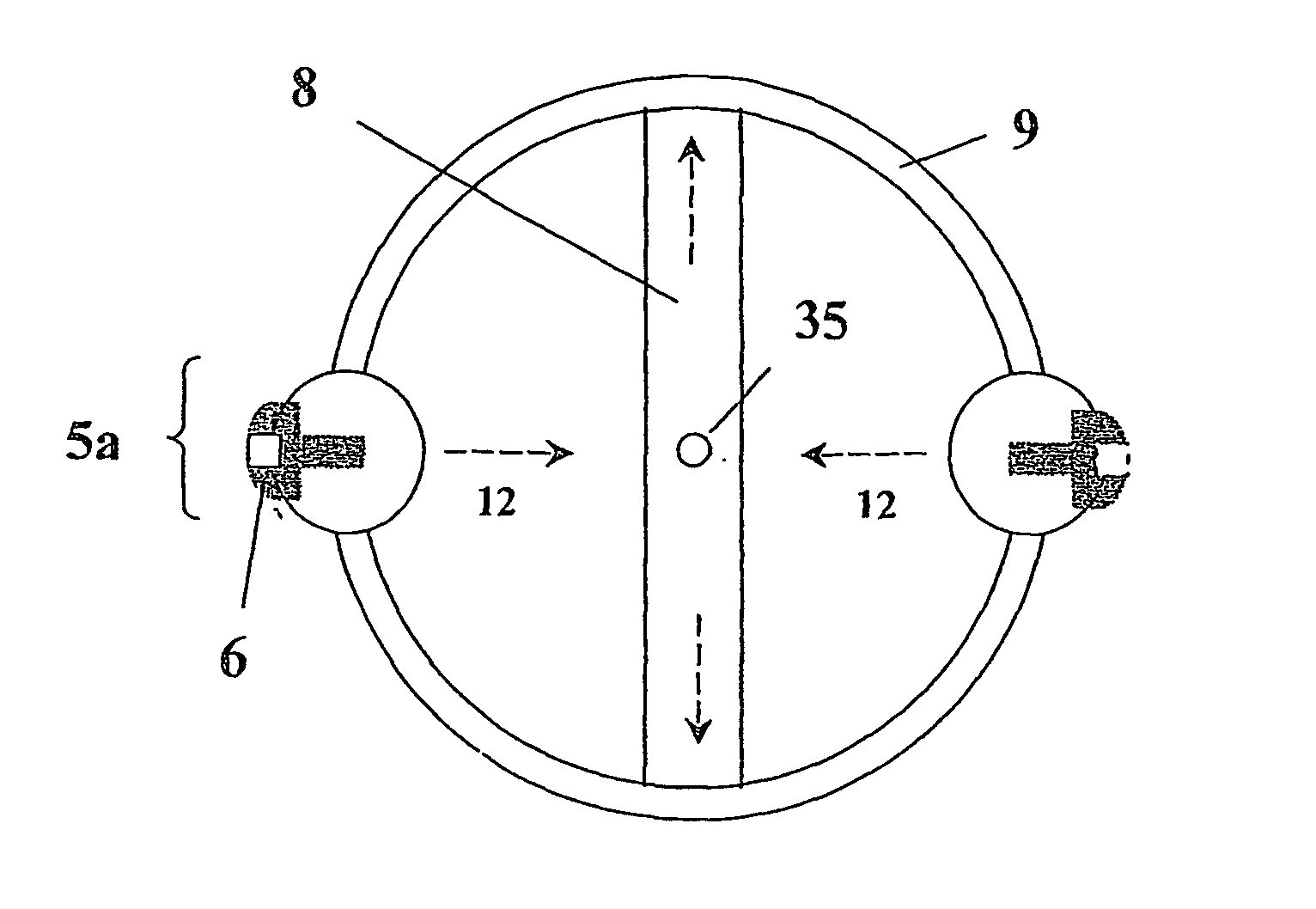

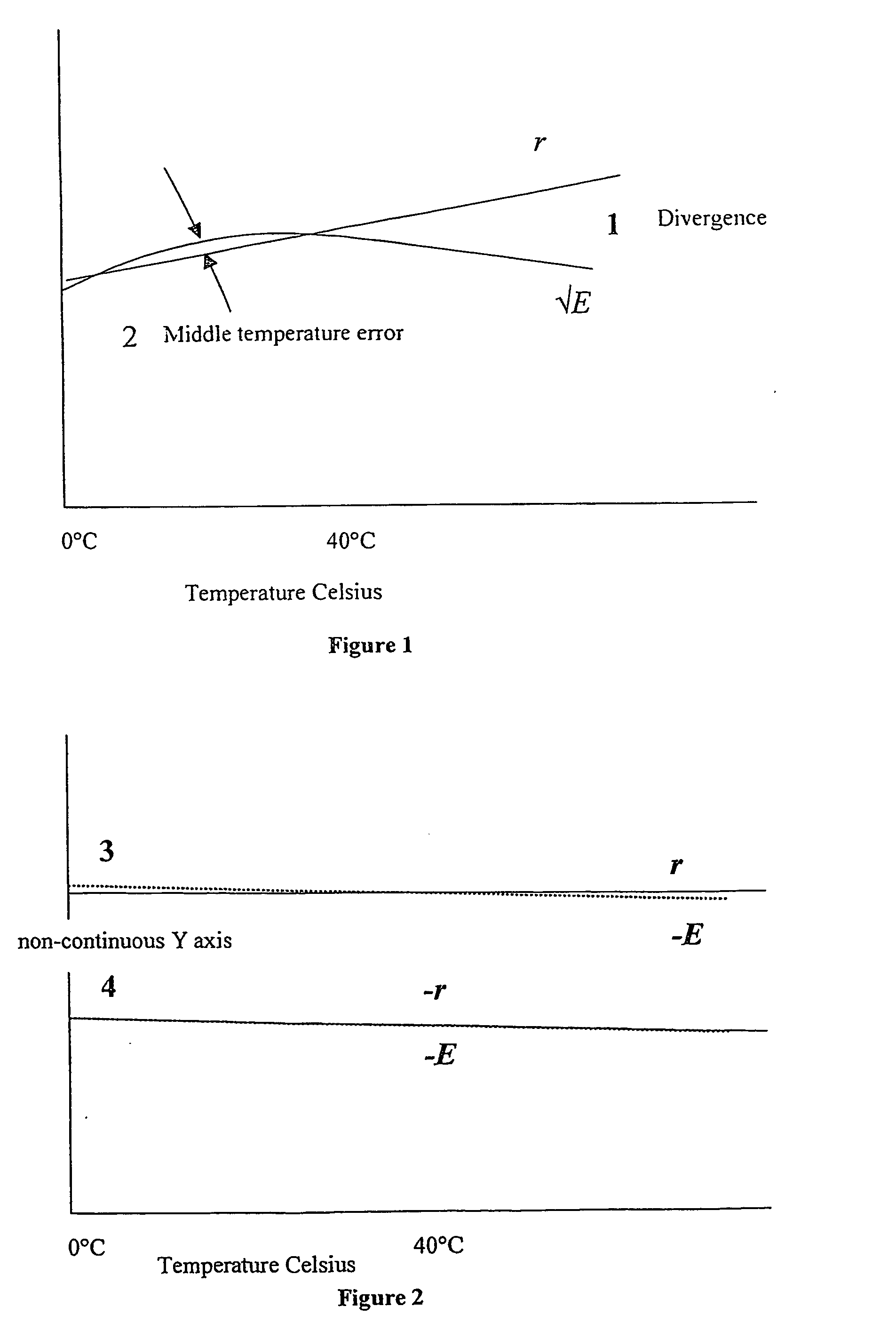

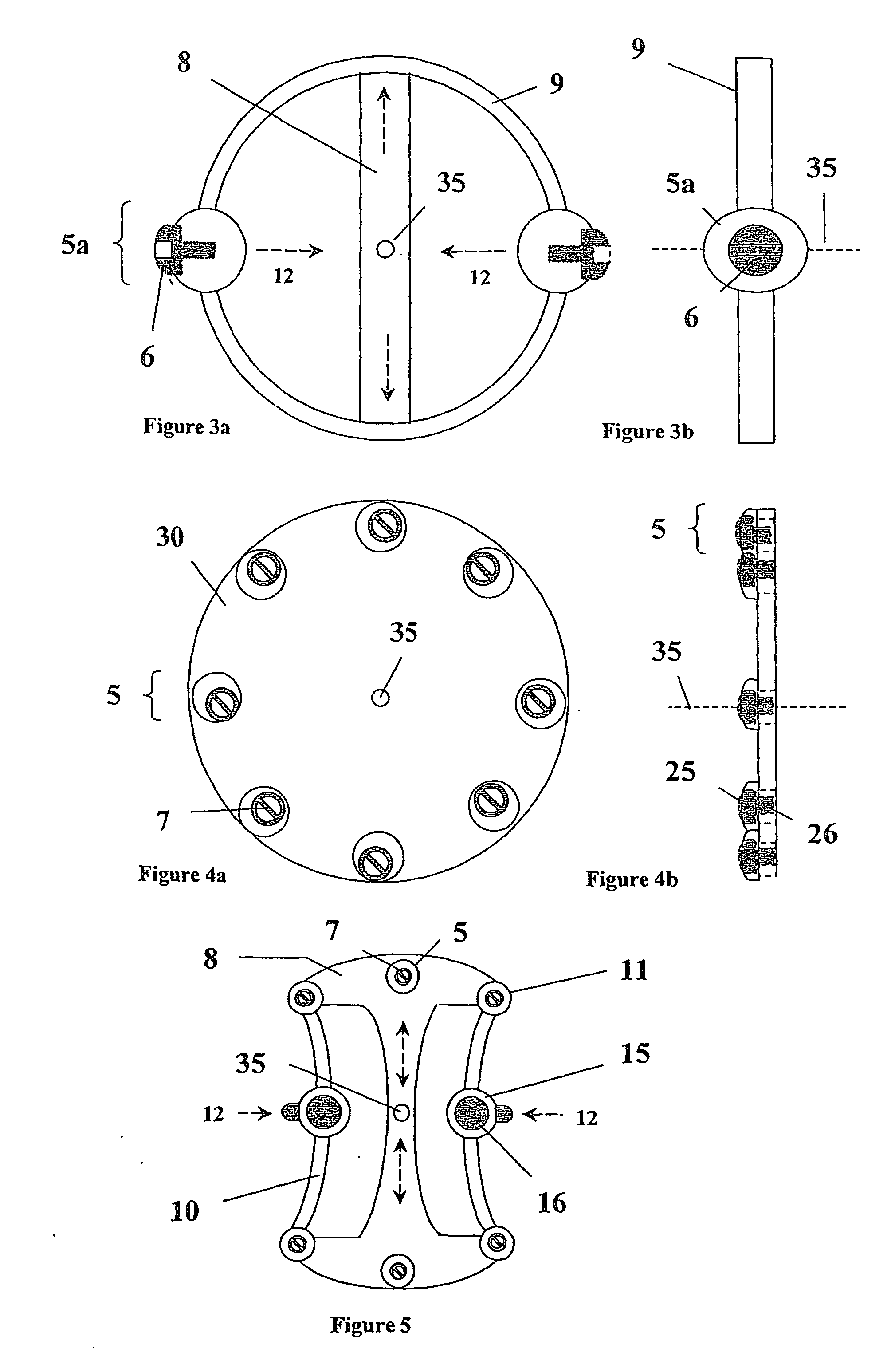

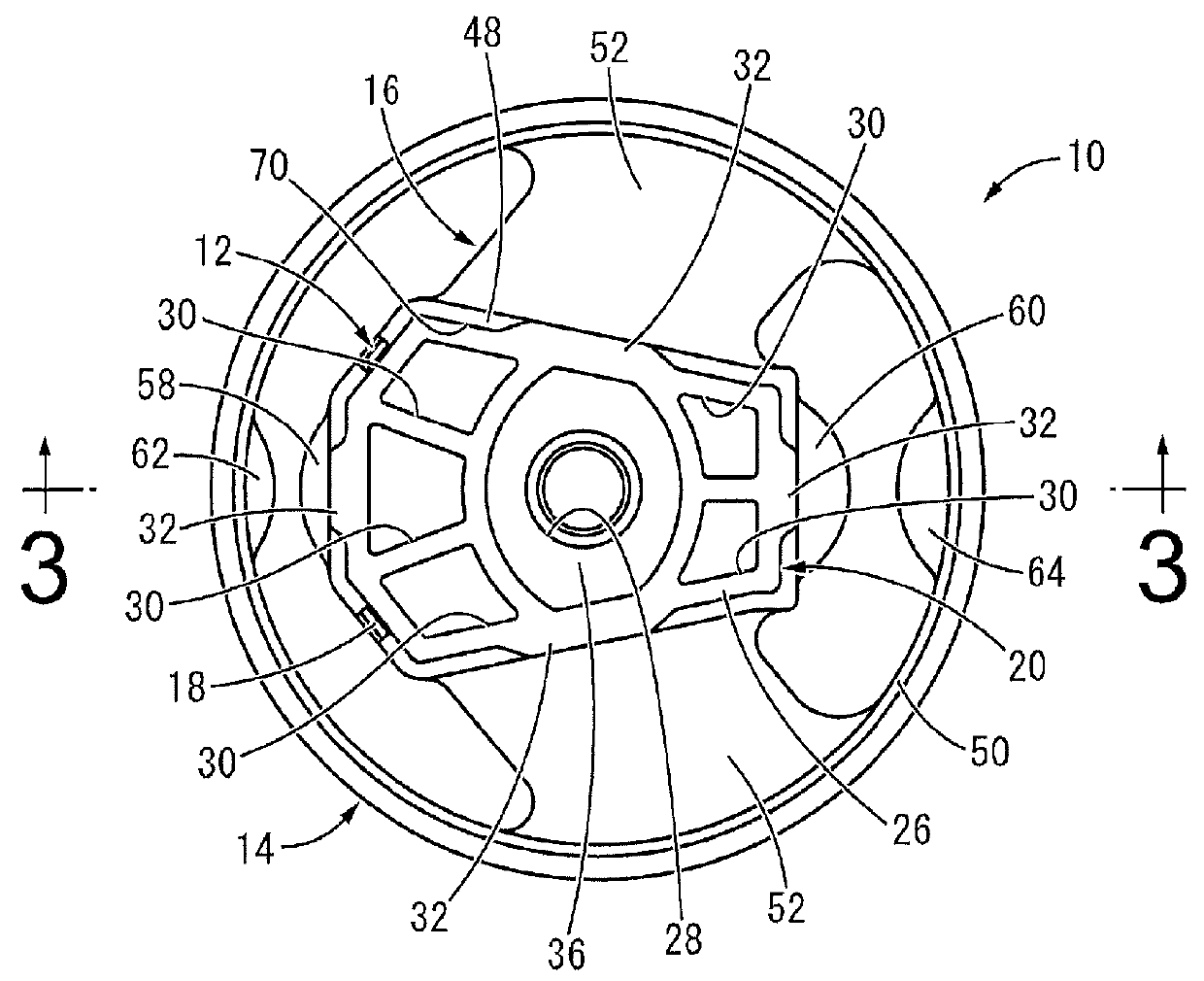

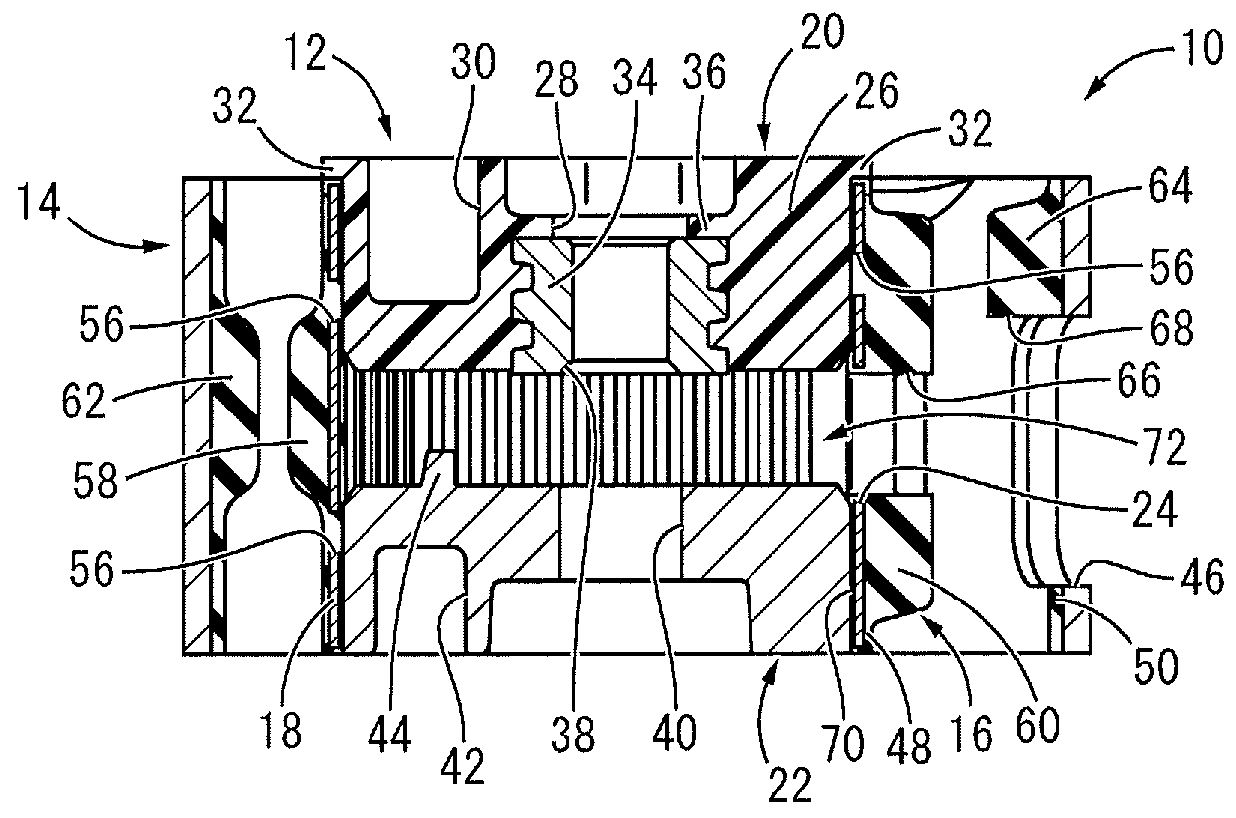

Balance wheel, balance spring and other components and assemblies for a mechanical oscillator system and methods of manufacture

The application discloses a method of making a balance spring (100) from continuous fibres or ceramic by winding them around a cylindrical former (90), interspaced with a releasing agent (110). Also disclosed is a method of making a balance spring, preferably of a ceramic material (60), by applying it to a rotating former (70) mandrel or plate and subsequently heat treating. Balance wheels (30) having a moment of inertia which decreases with a rise in temperature due to a special arrangement of components (8, 9, 10) having different coefficients of thermal expansion are also disclosed. A mechanical oscillator system comprising a non-magnetic ceramic or continuous fibre balance spring (50) and a non-magnetic balance wheel (30) formed of a material having a coefficient of thermal expansion of less than 6×10−6K−1 and having a plurality of non-magnetic poising or timing appendages (5) is also disclosed.

Owner:CARBONTIME

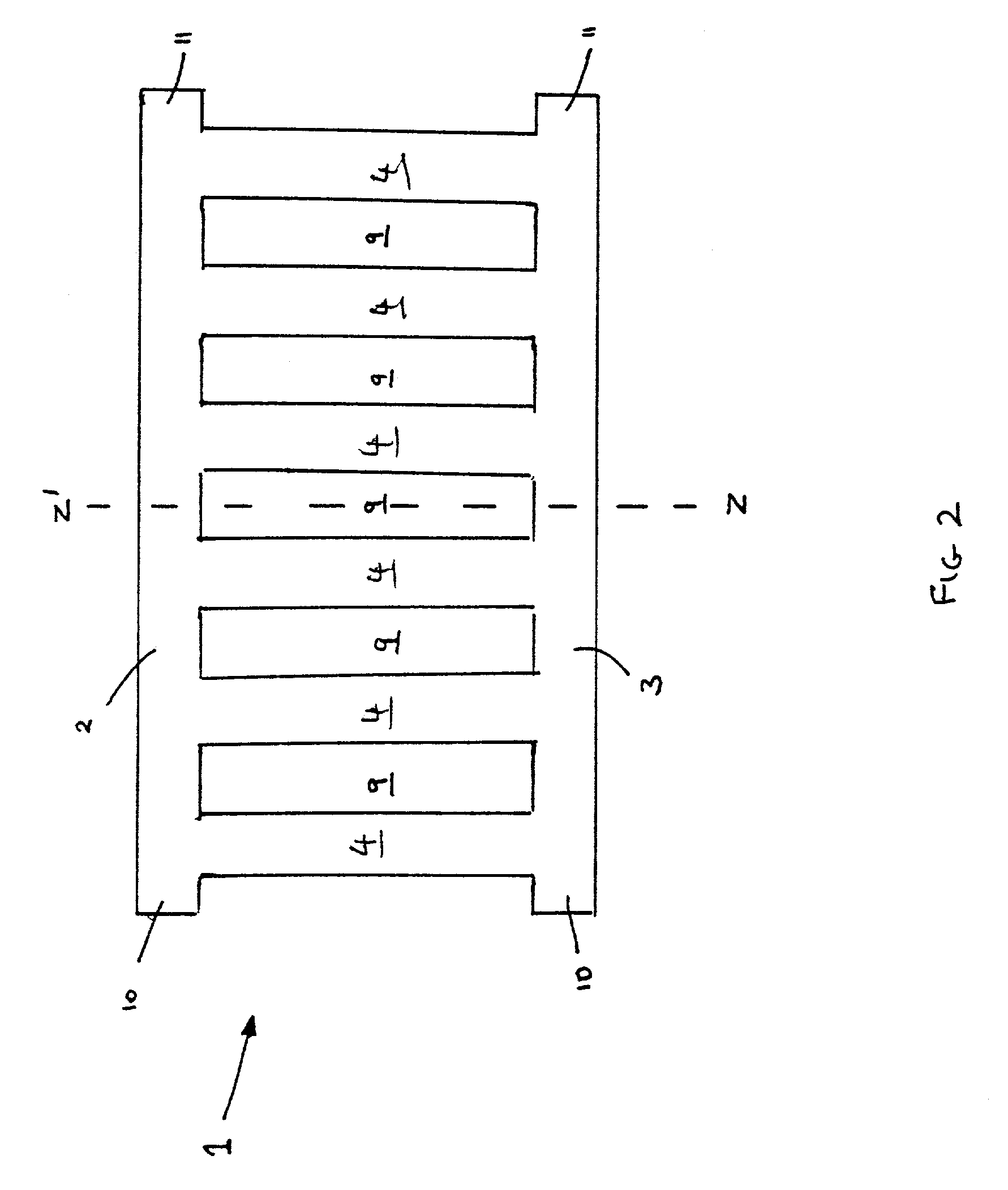

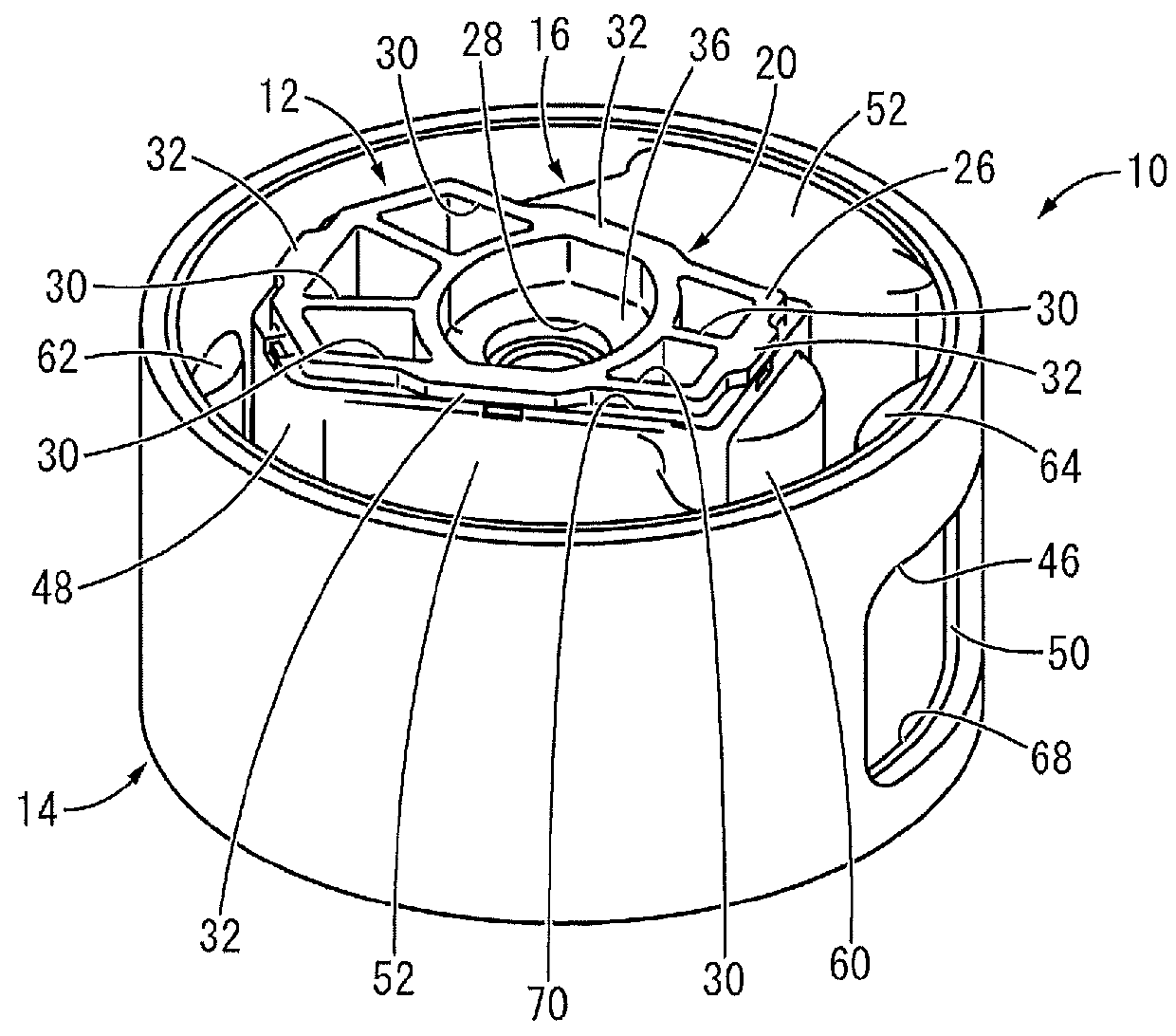

Method of making a centering device and centering device formed by that method

A spring centralizer device for supporting a tubular member spaced from the wall of a bore is made from a single piece of boron steel material. The spring centralizer device has first and second collars spaced apart along a longitudinal axis. Spring bow portions extend between the collars. As the device is made from a single piece of material, the material extends seamlessly from each collar portion through the bow portions so that there are no joins or points of weakness. Use of boron steel means that the device can be made by cold forming.

Owner:CENTEK

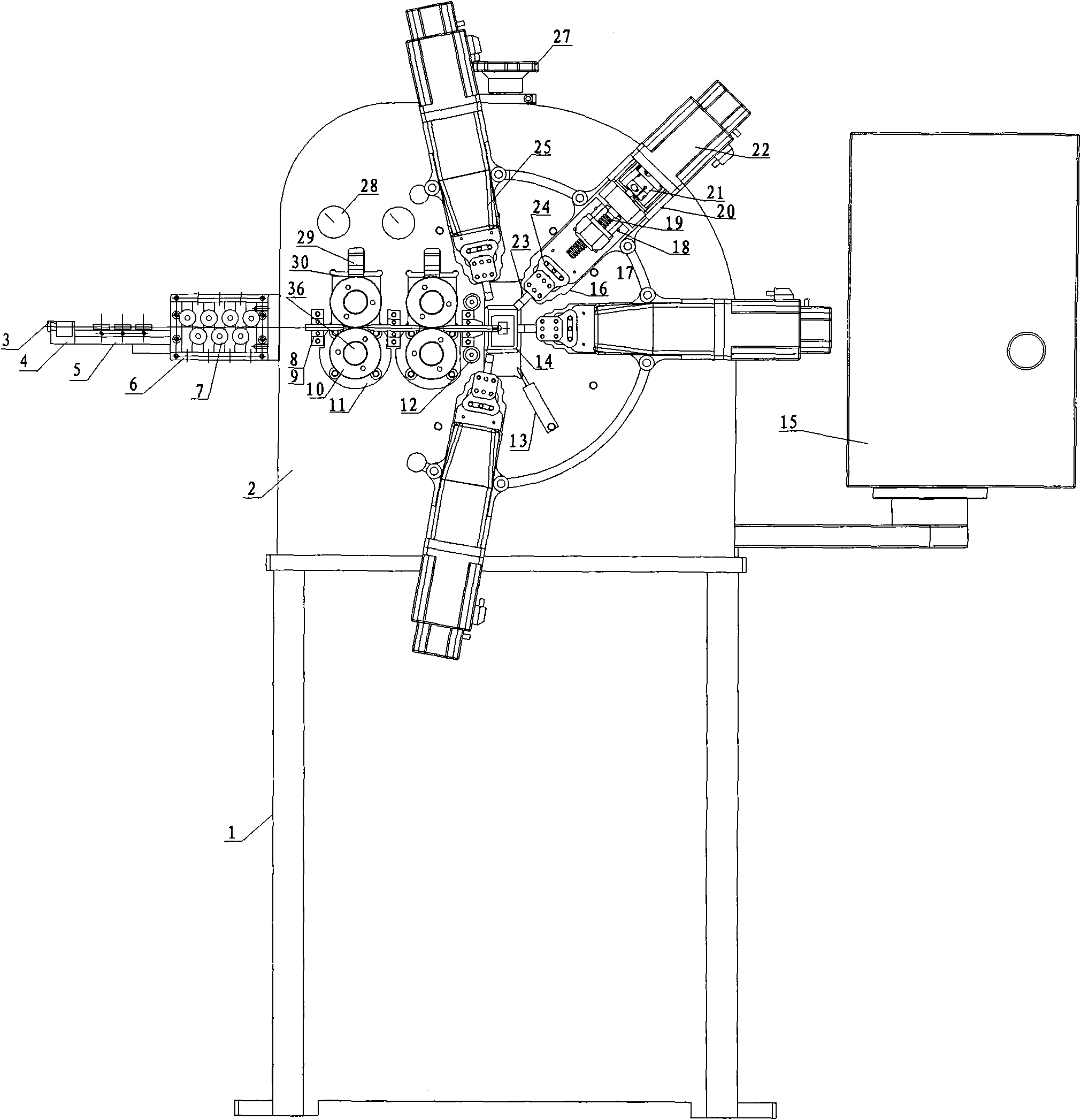

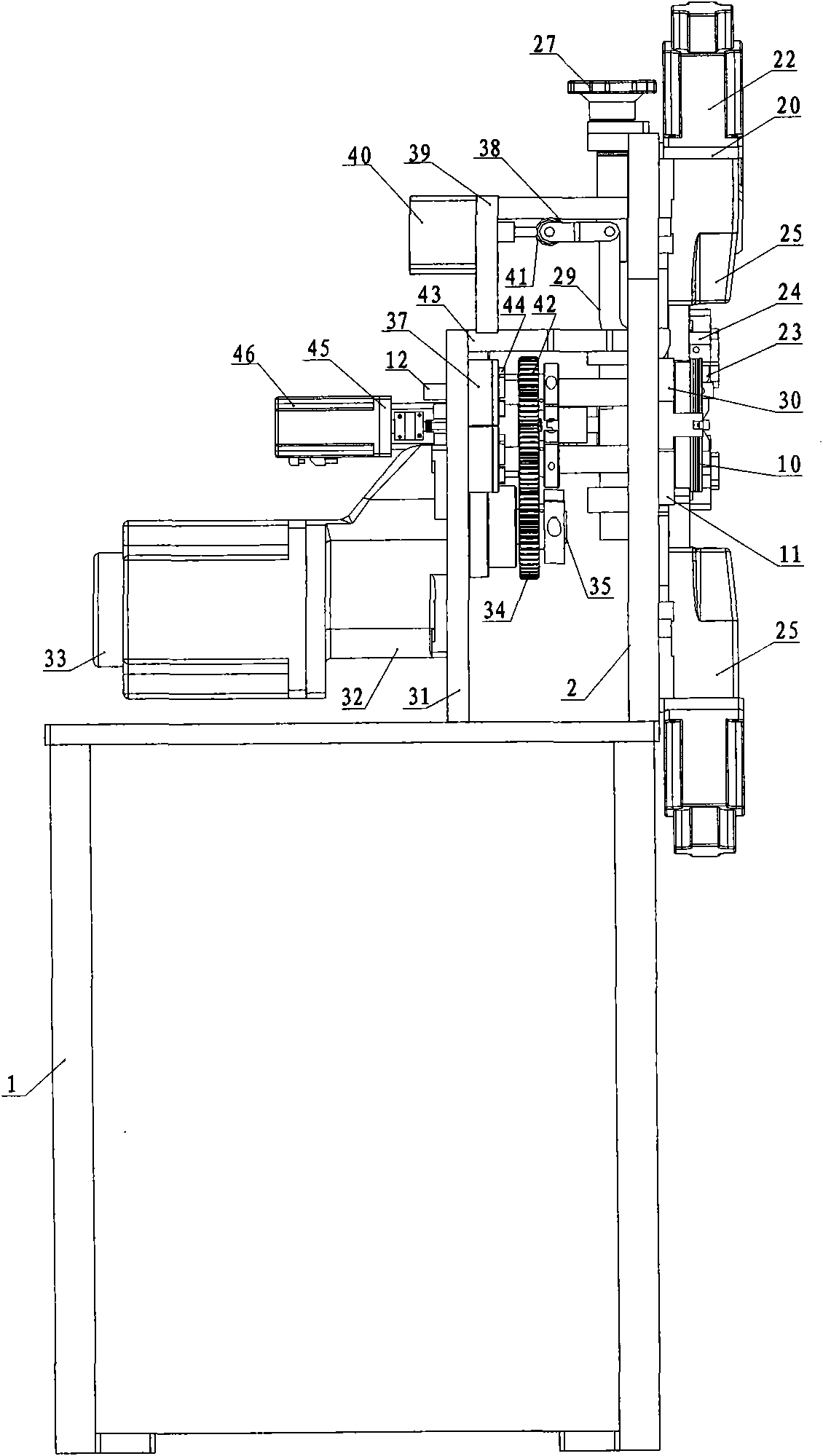

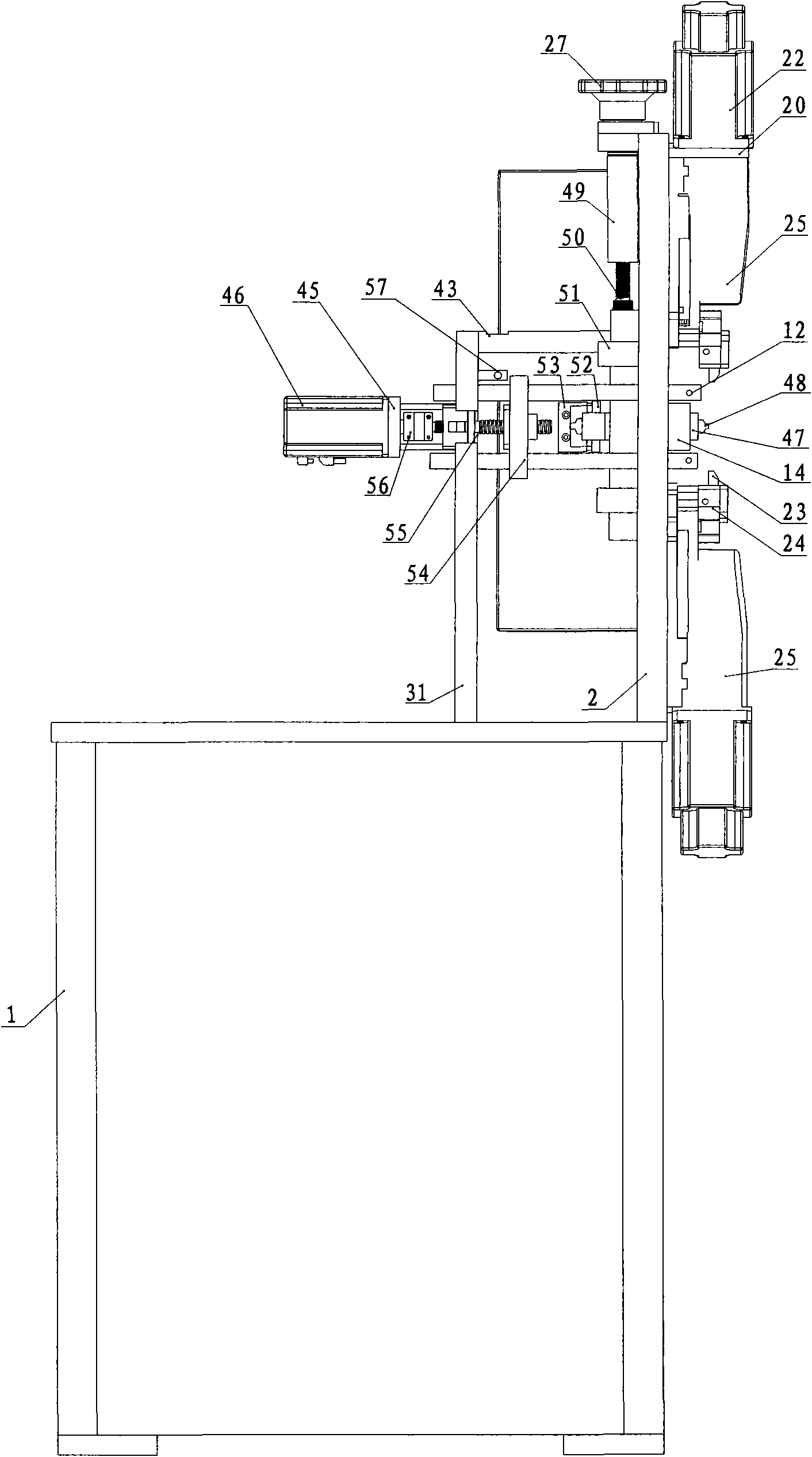

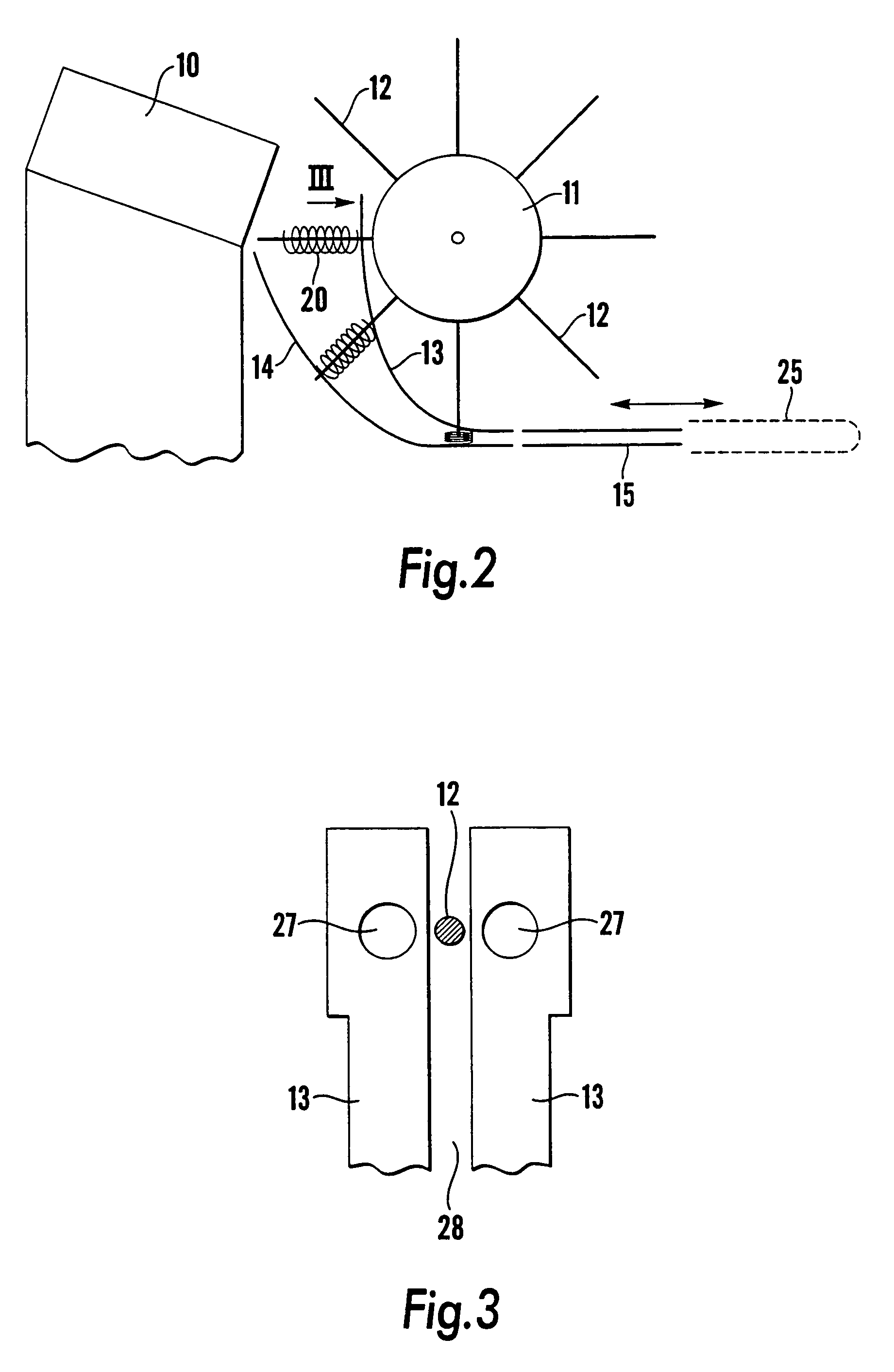

Intelligent computerized numerical control (CNC) spring machine

ActiveCN101559463AReduce scrap rateReasonable structural designWire springsComputer control systemNumerical control

The invention discloses an intelligent CNC spring machine used for processing extension springs, compression springs, torsion springs, spiral springs and the like. The intelligent CNC spring machine comprises a straightening mechanism, a wire feeding mechanism, a pitch mechanism, a core seat mechanism, a knife seat mechanism and a computer control system. The pitch mechanism comprises a pitch servo motor and a pitch ball screw pair driving a pitch shaft to move; the core seat mechanism comprises a core seat lifting mechanism and a core rod core-pulling mechanism; and the knife seat mechanism comprises a plurality of sliding knife seats and knife seat driving mechanisms and can move along an arc-shaped track in a radial direction. The spring machine is provided with five sections including a straightening section, a wire feeding section, a pitch section, a core seat section and a knife seat section according to the principle of spring formation, and has reasonable structure design and is driven by a full servo and controlled by a computer so as to realize fully closed loop control and be capable of reducing the rejection rate of finished products. The intelligent CNC spring machine can be widely applied to the production of various extension springs, compression springs, torsion springs, spiral springs and the like, with simple operation, high processing precision and high production efficiency.

Owner:湖北伟斯科技有限公司

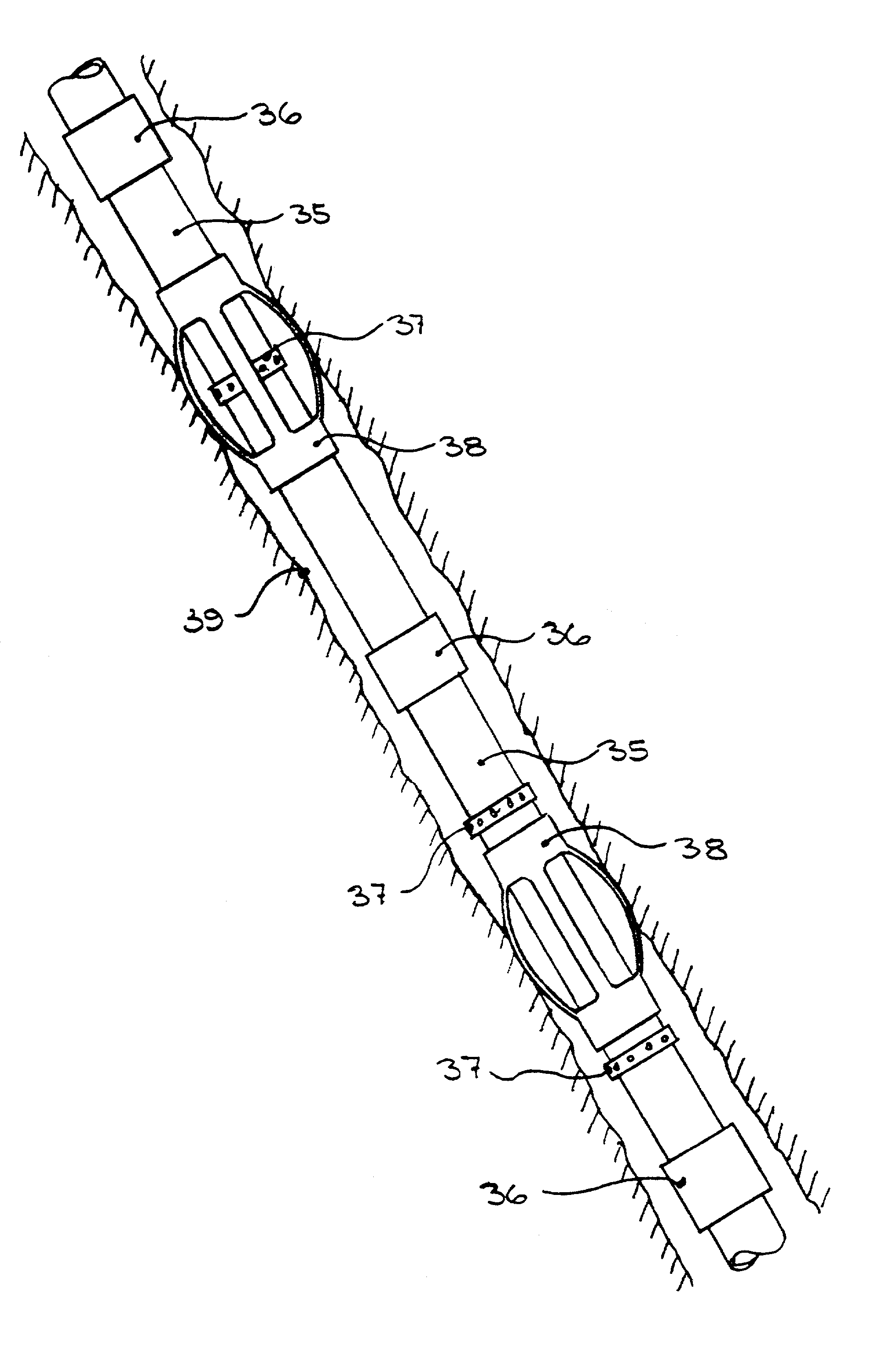

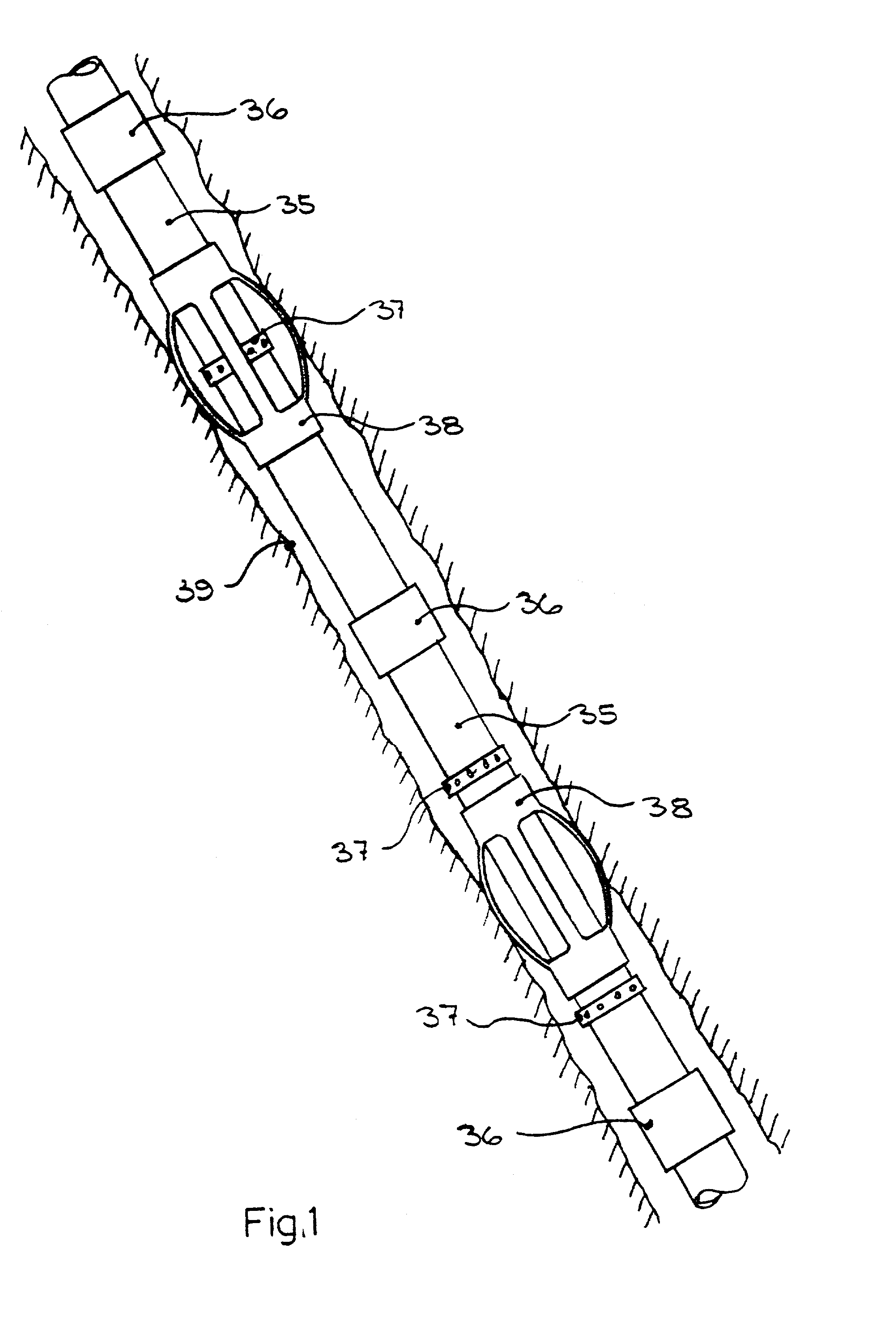

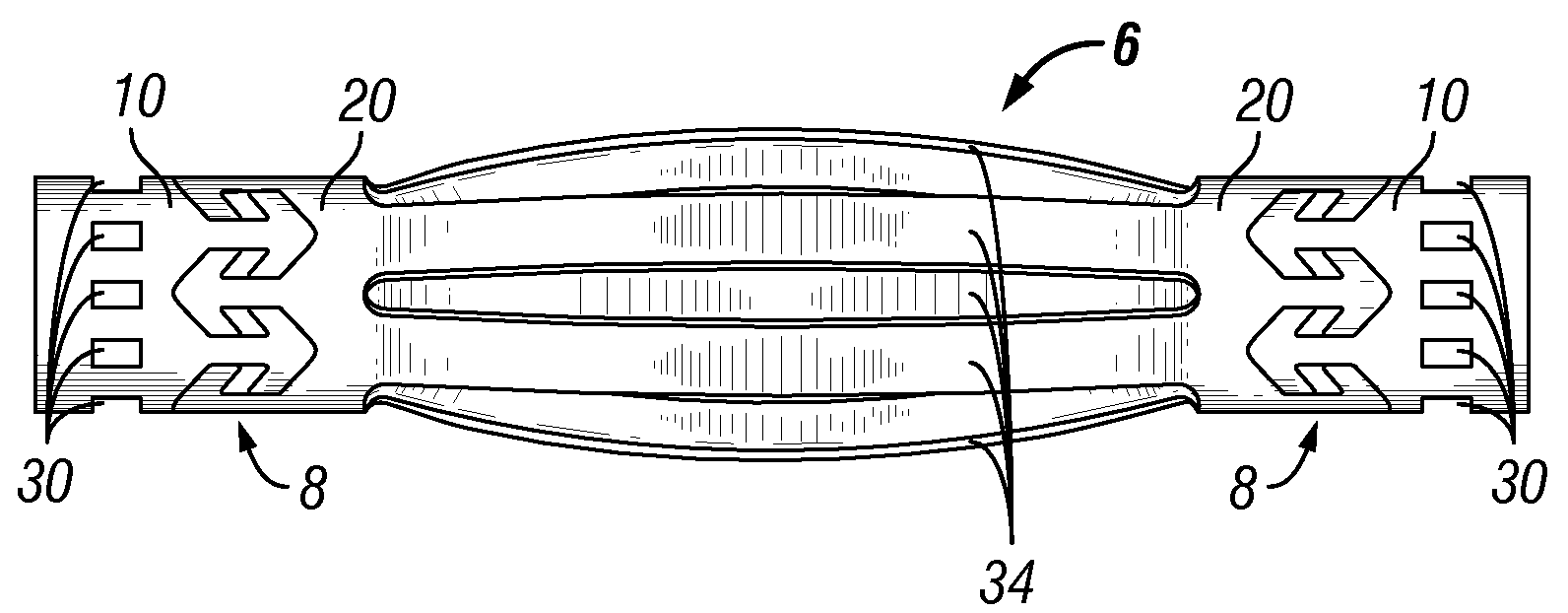

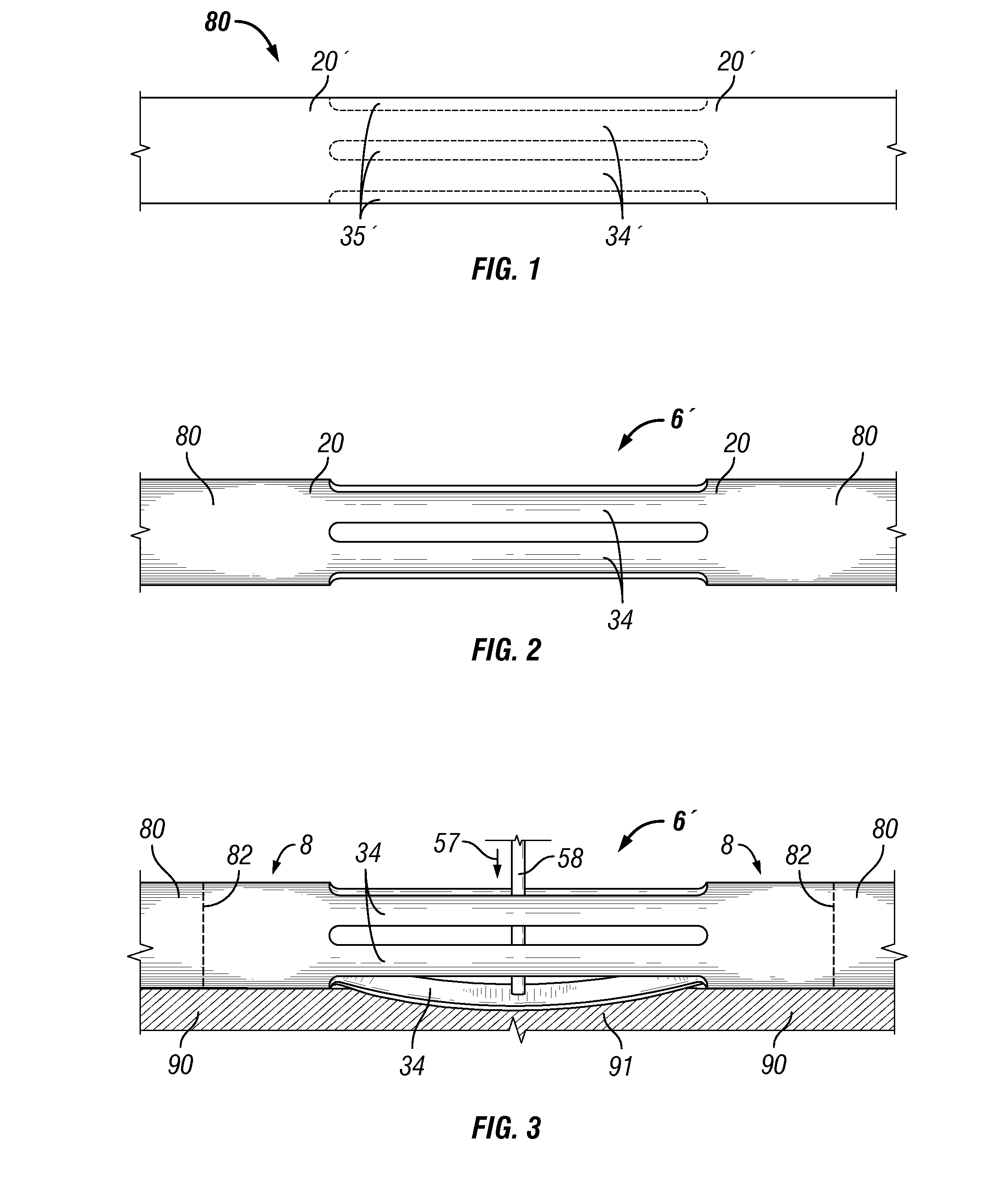

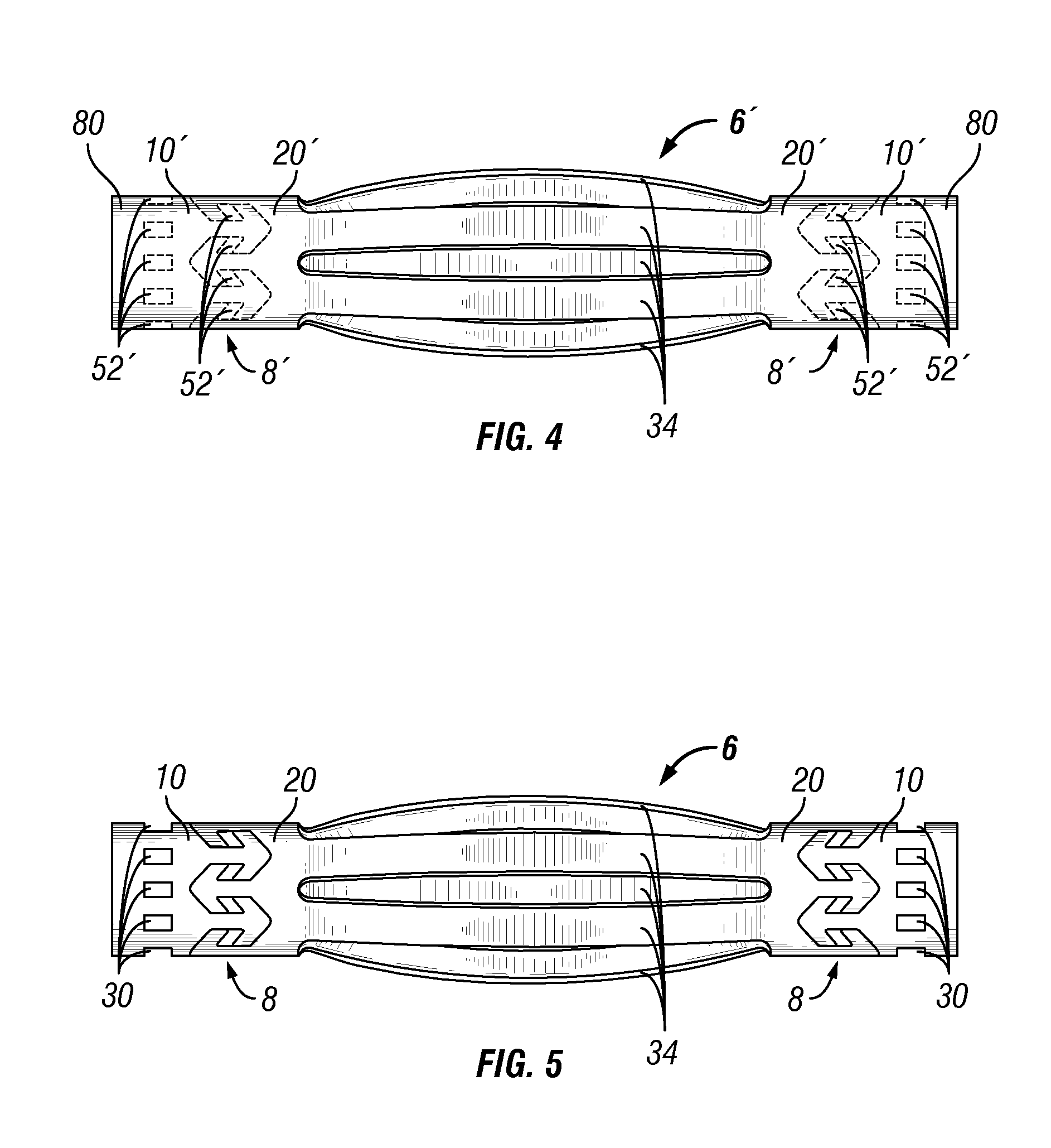

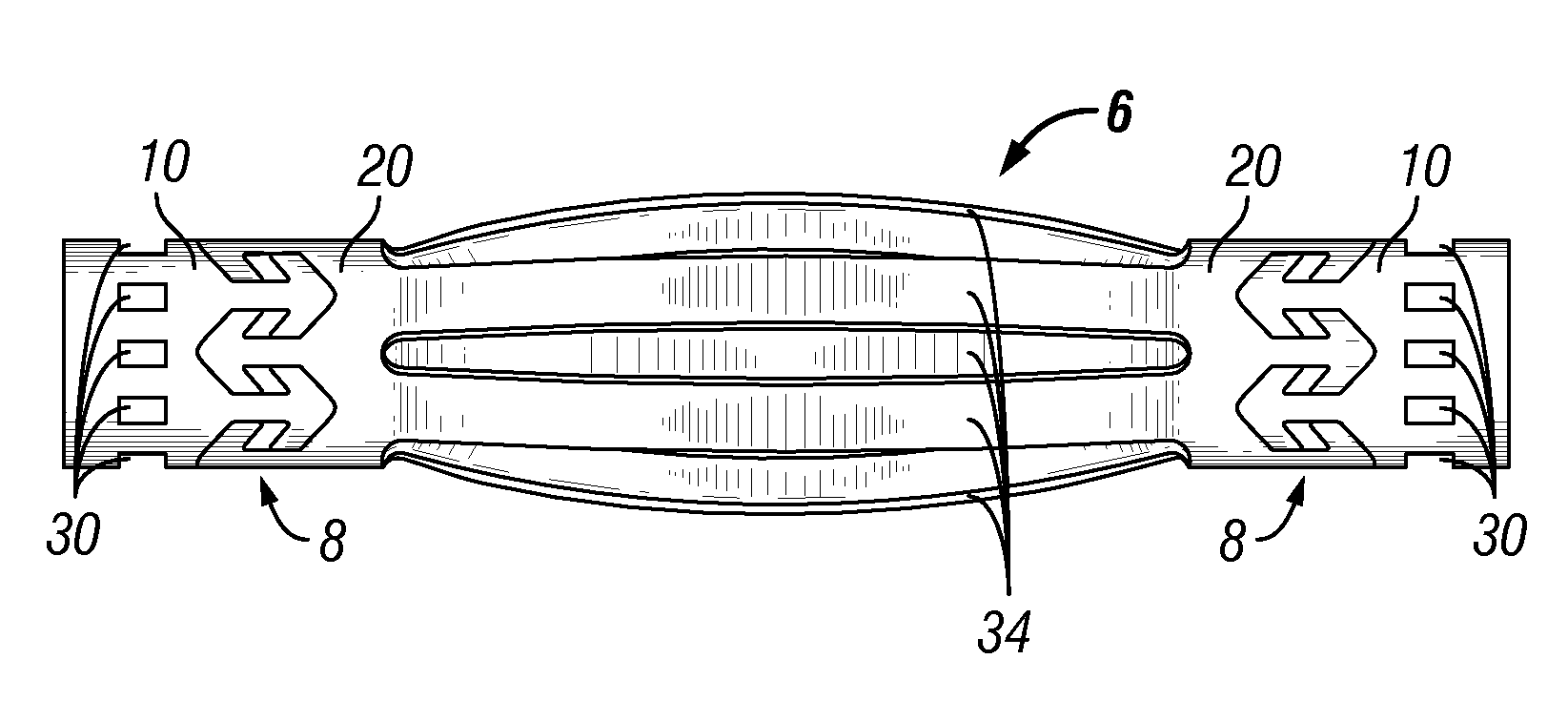

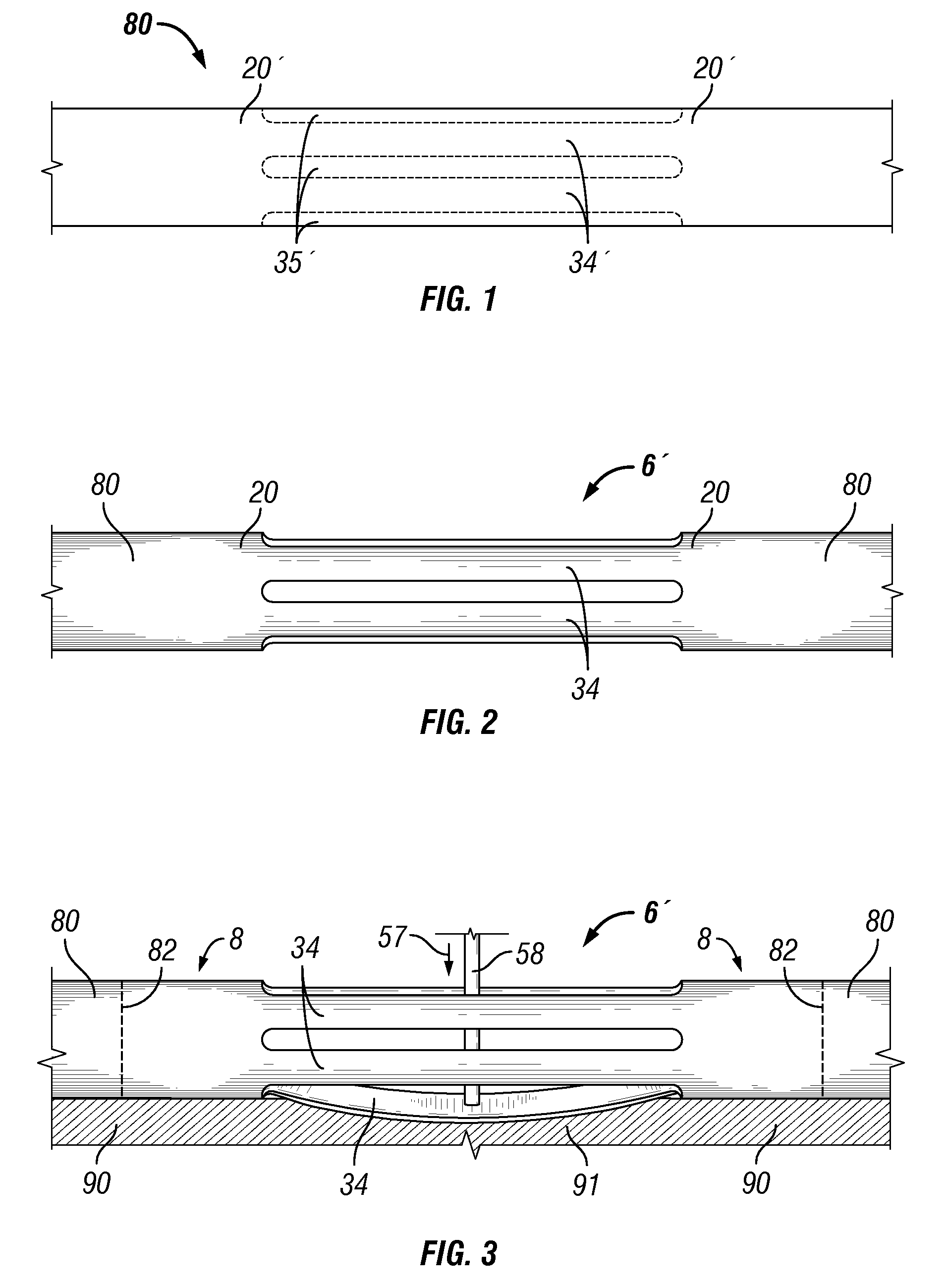

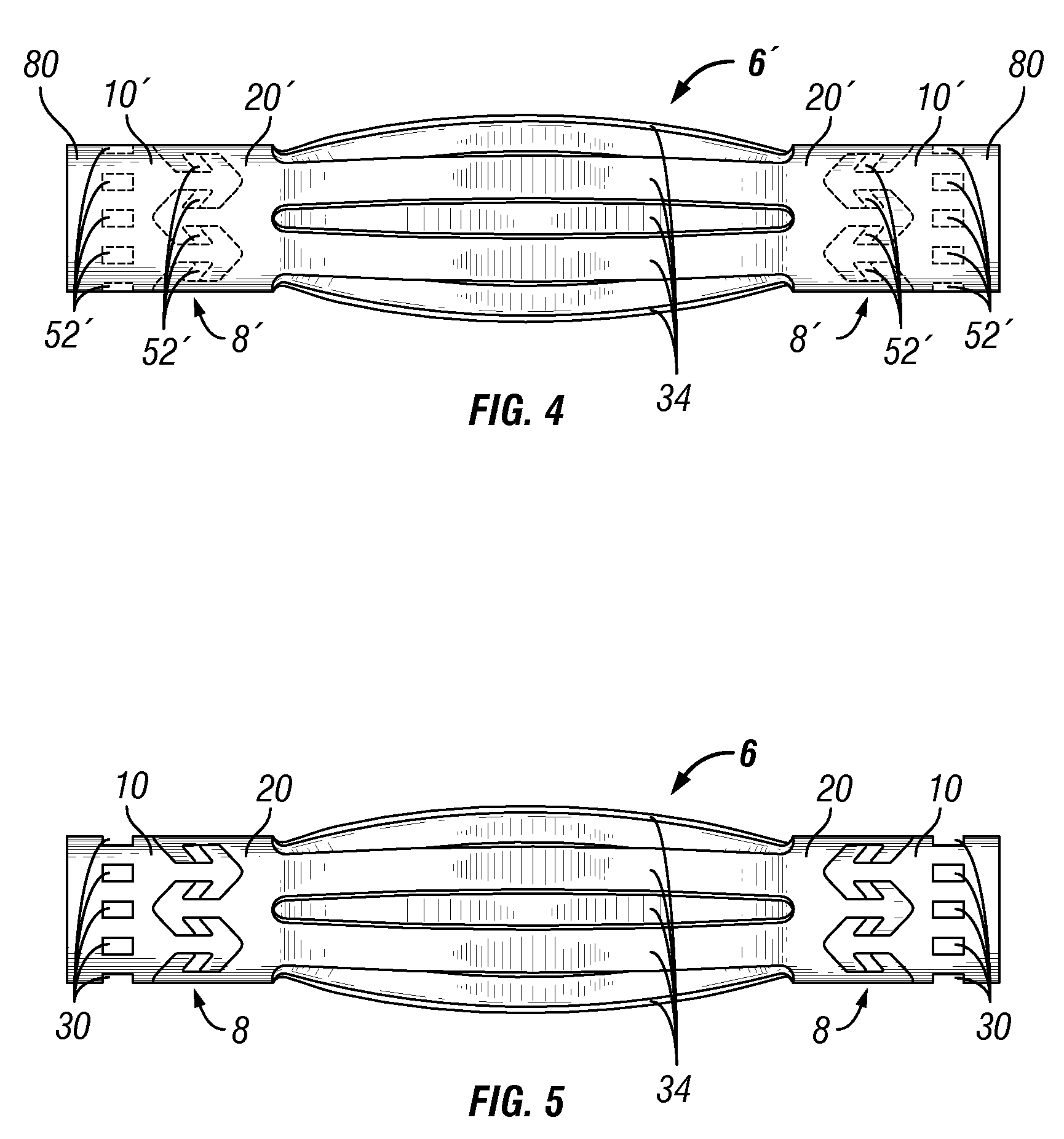

Low Clearance Centralizer and Method of Making Centralizer

ActiveUS20080283237A1Efficient preparationDrilling rodsFluid removalShaft collarMechanical engineering

A bow-spring centralizer includes a center assembly having a plurality of bow springs and a pair of generally tubular moving collars secured one to each end of each bow spring, the center assembly formed intermediate a pair of generally tubular stop collars. Each moving collar / stop collar combination forms an interlocking and axially extendable collar. The centralizer is formed from a single tube. The tube is cut using a laser according to a cut pattern that creates interlocked stop collar / moving collar combinations that are rotatably locked but axially movable one relative to the other. Each of the interlocked stop collars and moving collars includes a plurality of circumferentially spaced heads, each head integrally formed on one of a plurality of circumferentially spaced extensions protruding from the stop collar or moving collar. The heads may have a variety of projected shapes, such as a rectangular, arrow or a teardrop shaped. Each head is axially slidably captured within one of a plurality of chambers on the other tubular member (stop collar or moving collar) to which the first member is coupled. The extensions of each interlocked tubular member define the outer walls of the chamber in which a head of the opposing tubular member is slidably captured.

Owner:INNOVEX DOWNHOLE SOLUTIONS INC

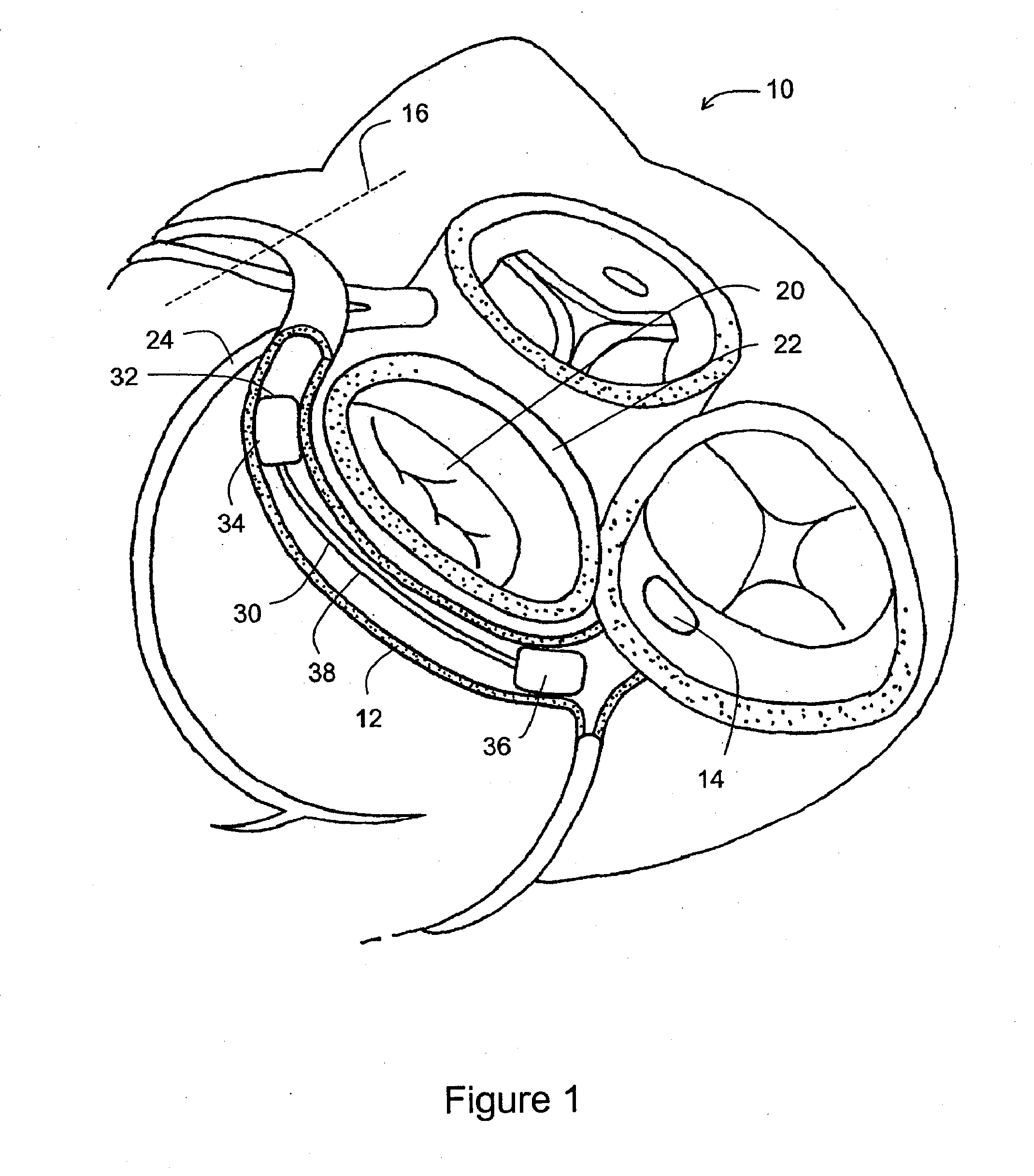

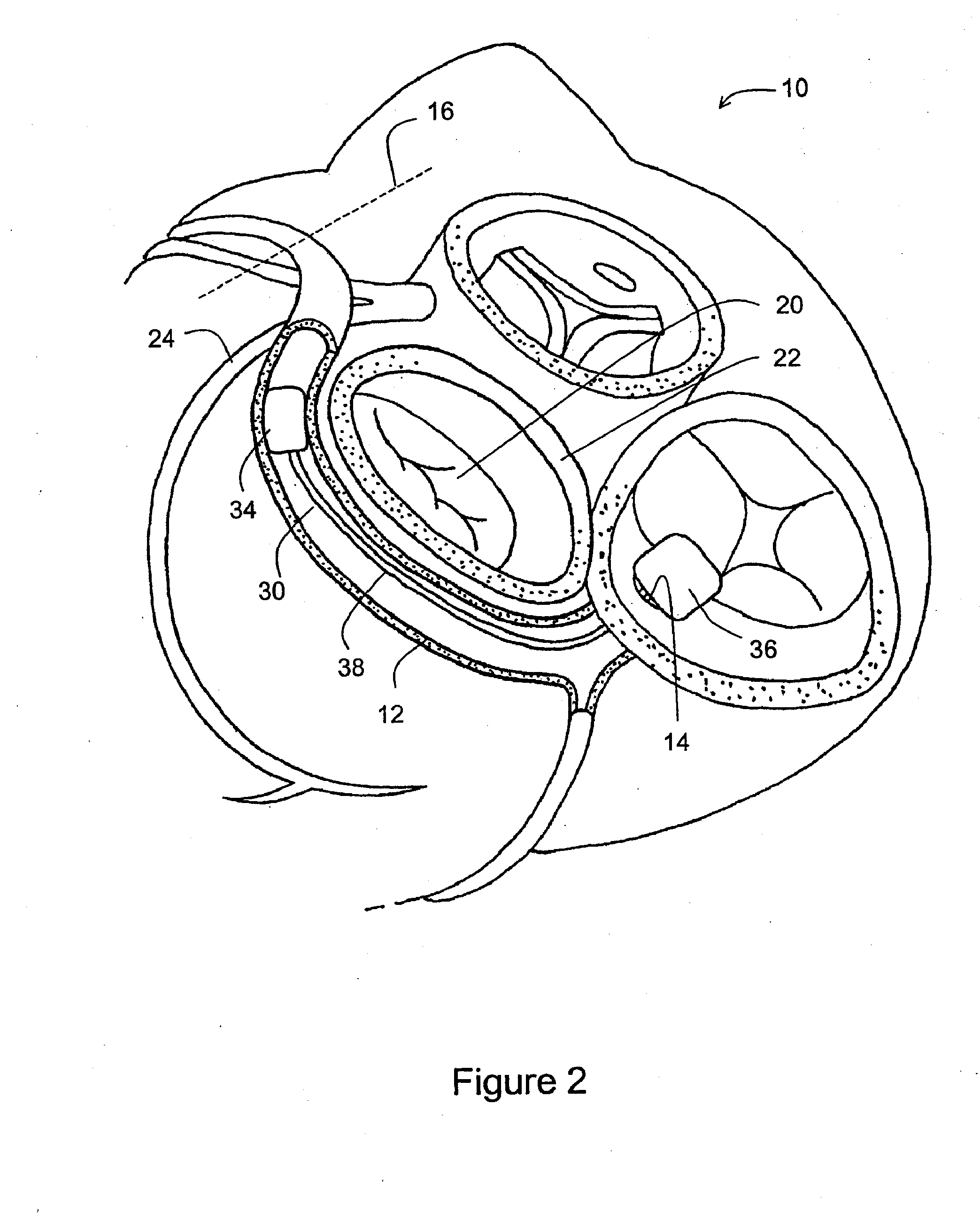

Tissue Shaping Device with Integral Connector and Crimp

ActiveUS20060191121A1Maximize the effect of treatmentReduce regurgitationHeart valvesWire springsBiomedical engineeringBlood vessel

Owner:CARDIAC DIMENSIONS

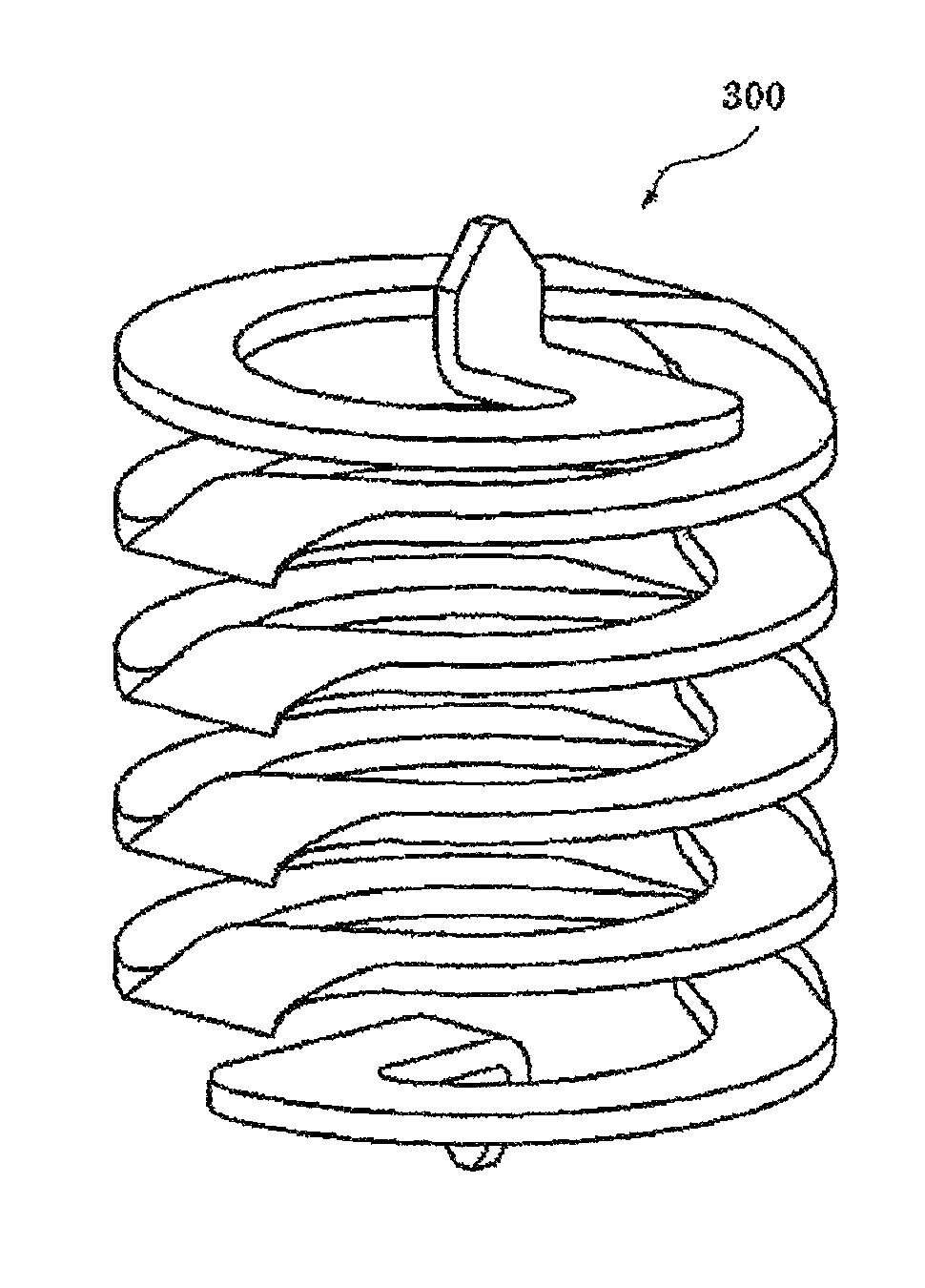

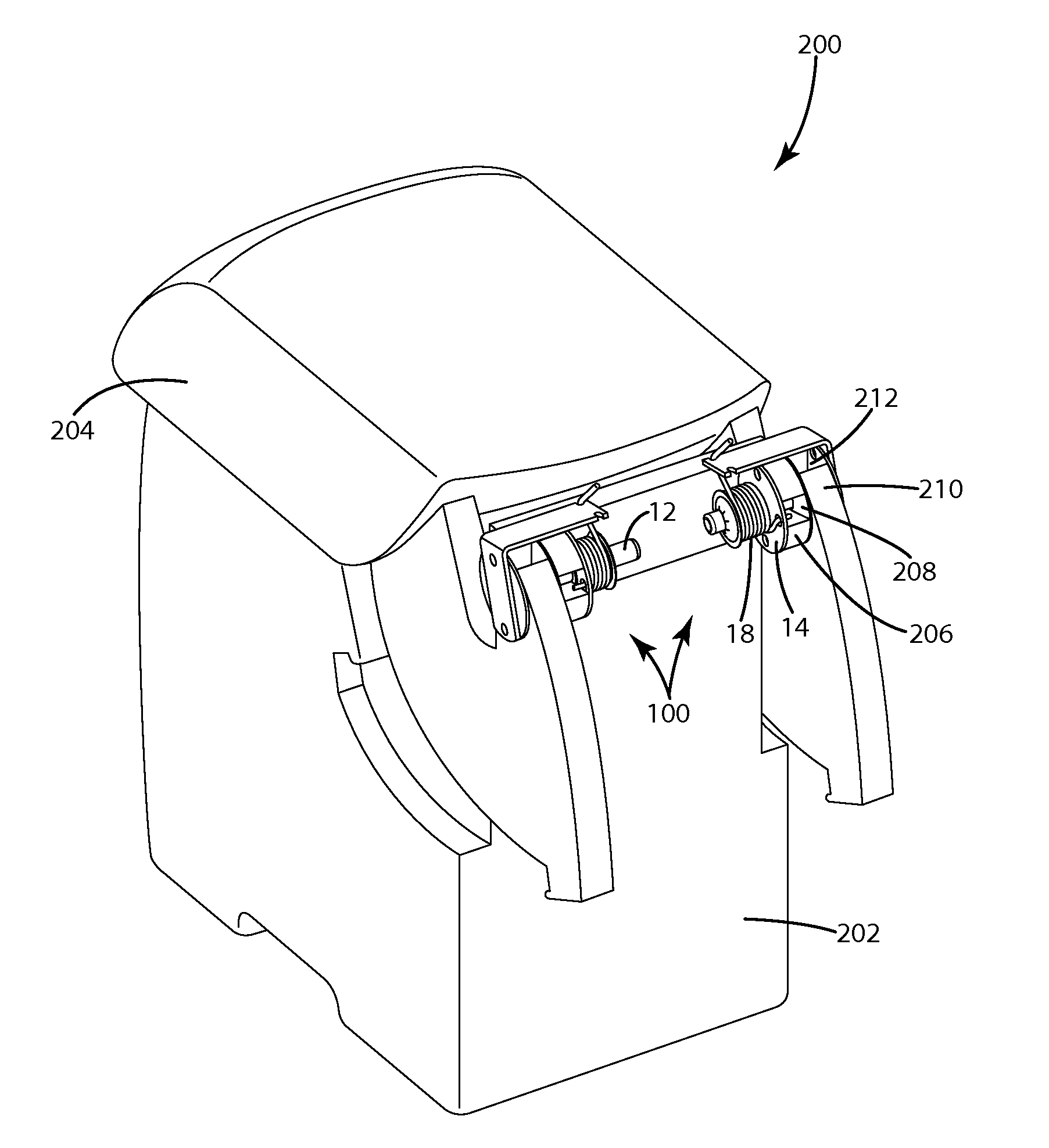

Shock absorbing mechanism with feet protection for vehicle and aircraft seats

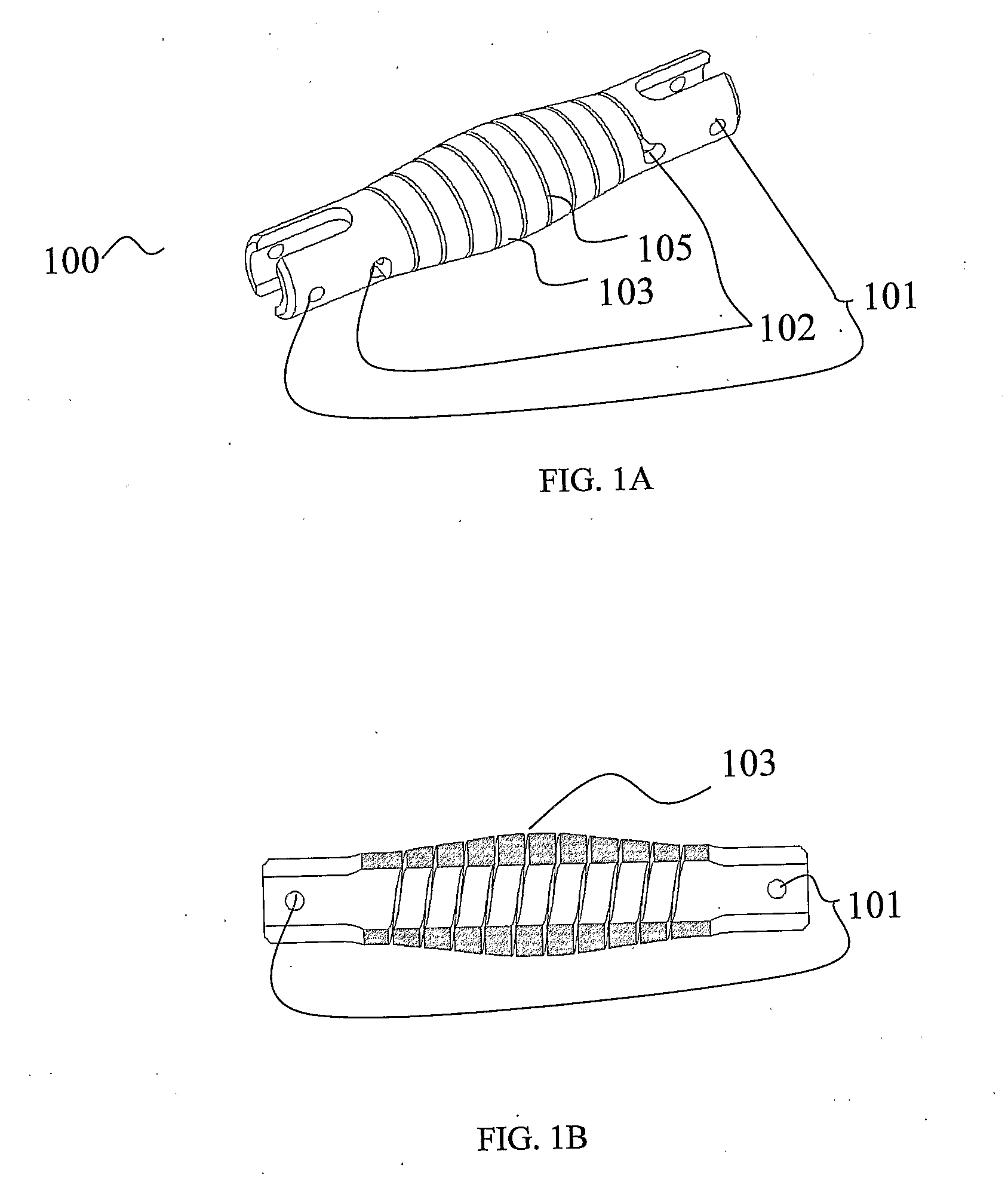

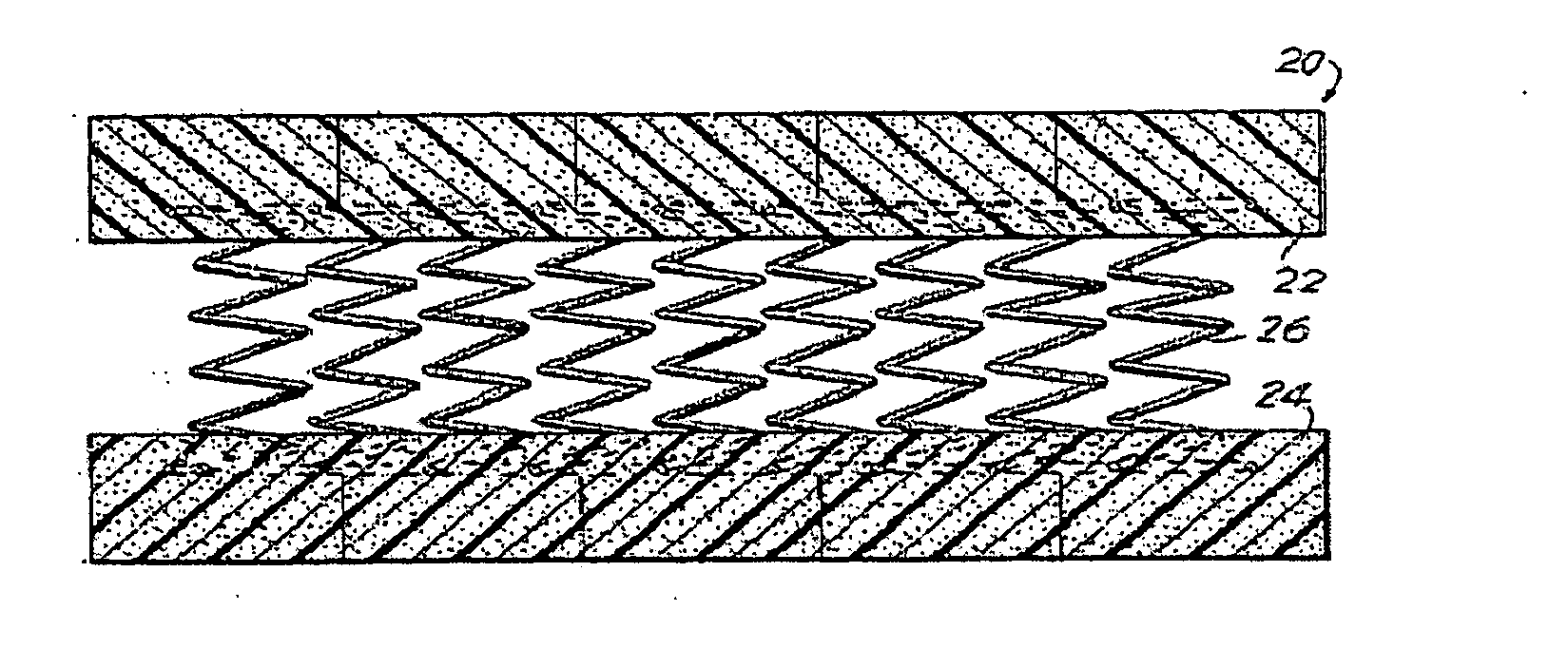

ActiveUS20110233975A1Increase stiffnessMinimizing accelerationPedestrian/occupant safety arrangementWire springsJet aeroplaneStress–strain curve

The present invention discloses a method and apparatus for minimizing accelerations during impacts such as those encountered in motor vehicle accidents, helicopter and airplane crashes, explosions, and the like. The preferred embodiment takes the form of a helical spring-like member (100), designed to experience plastic deformation over a desired deformation length, under a given impact load threshold. The spring-like member is preferably installed in a mechanical linkage that is flattened under impact, straining the spring-like member in a predictable fashion. The operating characteristics of this system [namely the stress-strain curve, and thus the deformation length, impact load threshold, and acceptable load range for the system to be protected] can be easily controlled by varying the device dimensions and installation configuration.

Owner:MOBIUS PROTECTION SYST

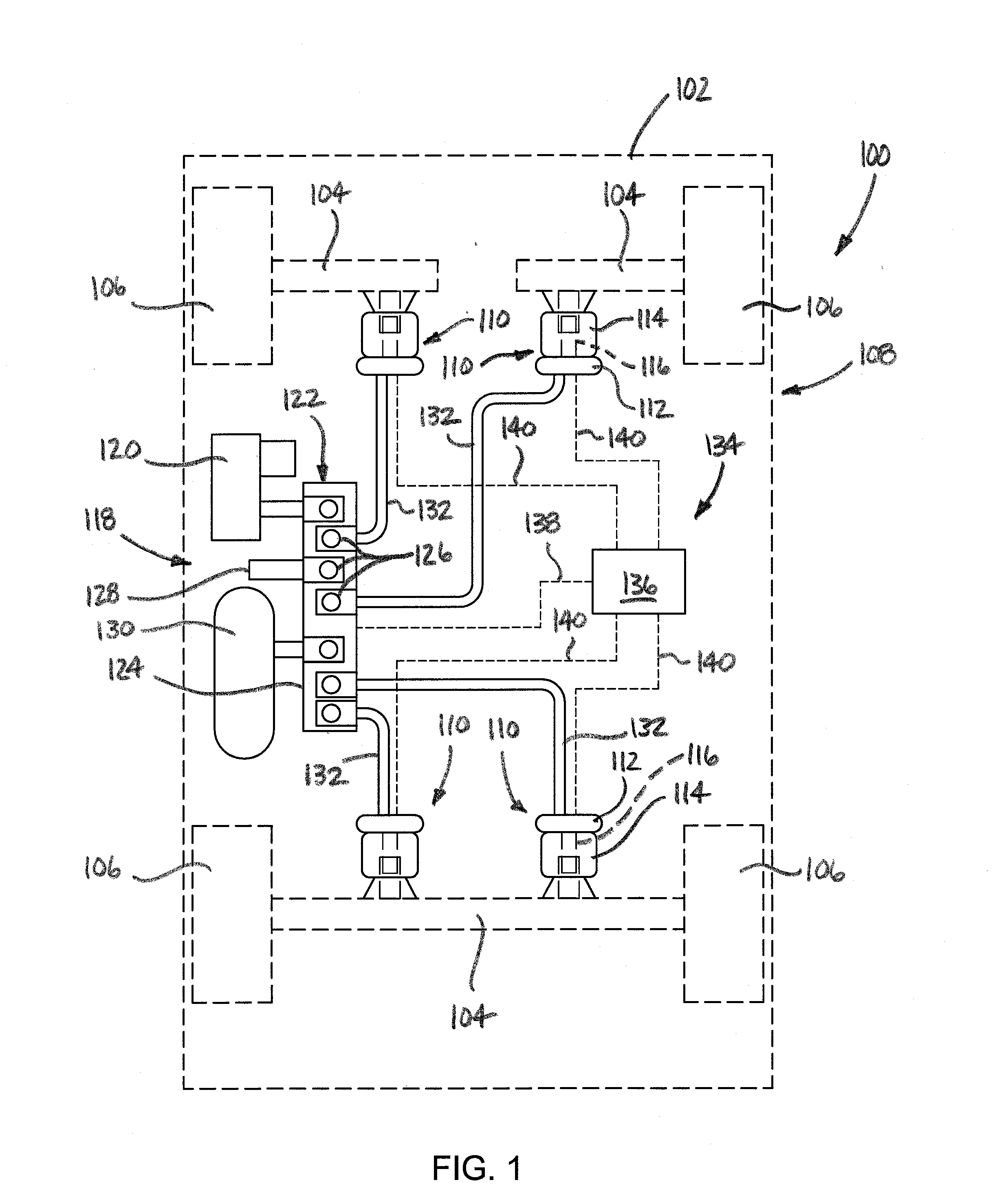

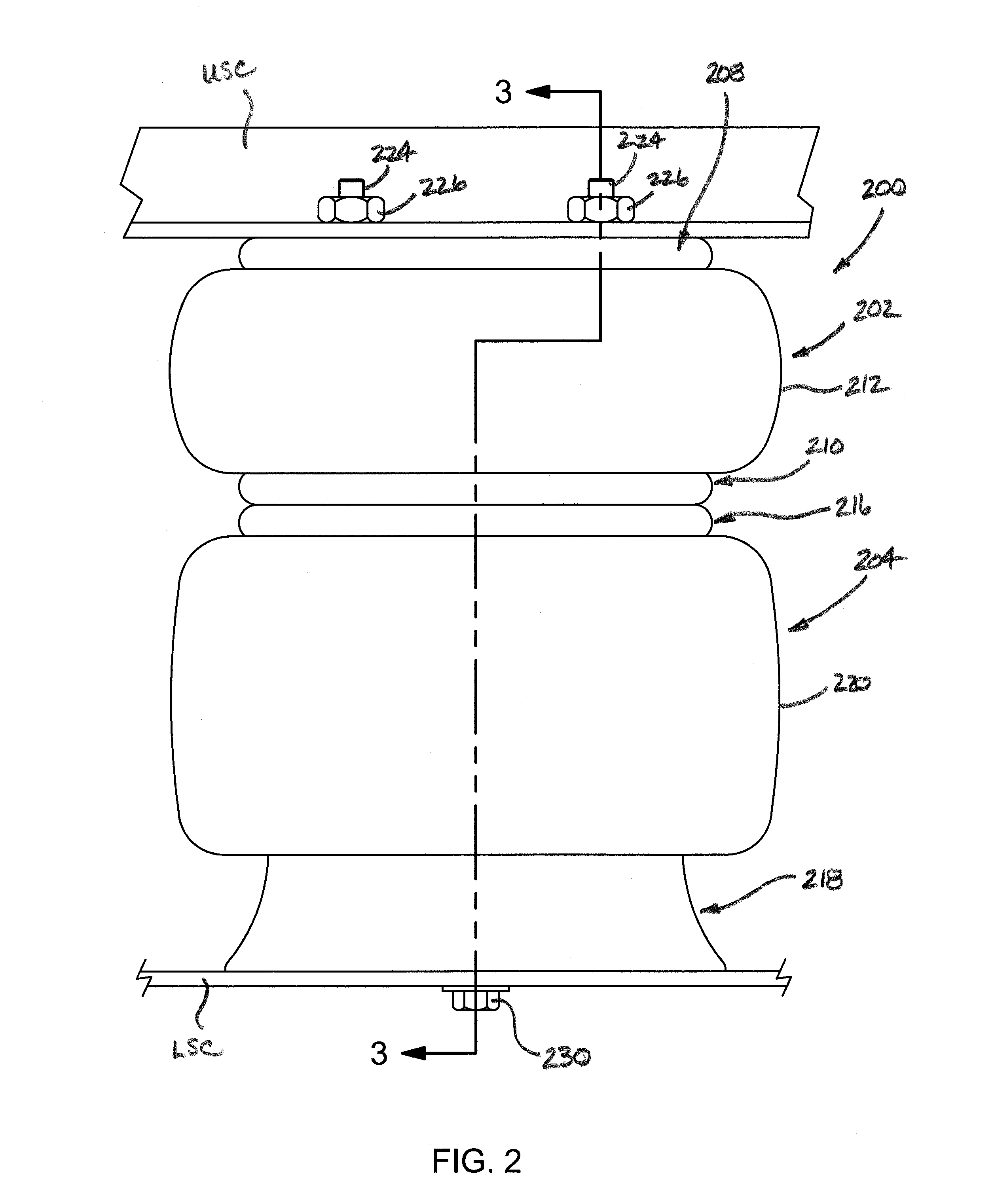

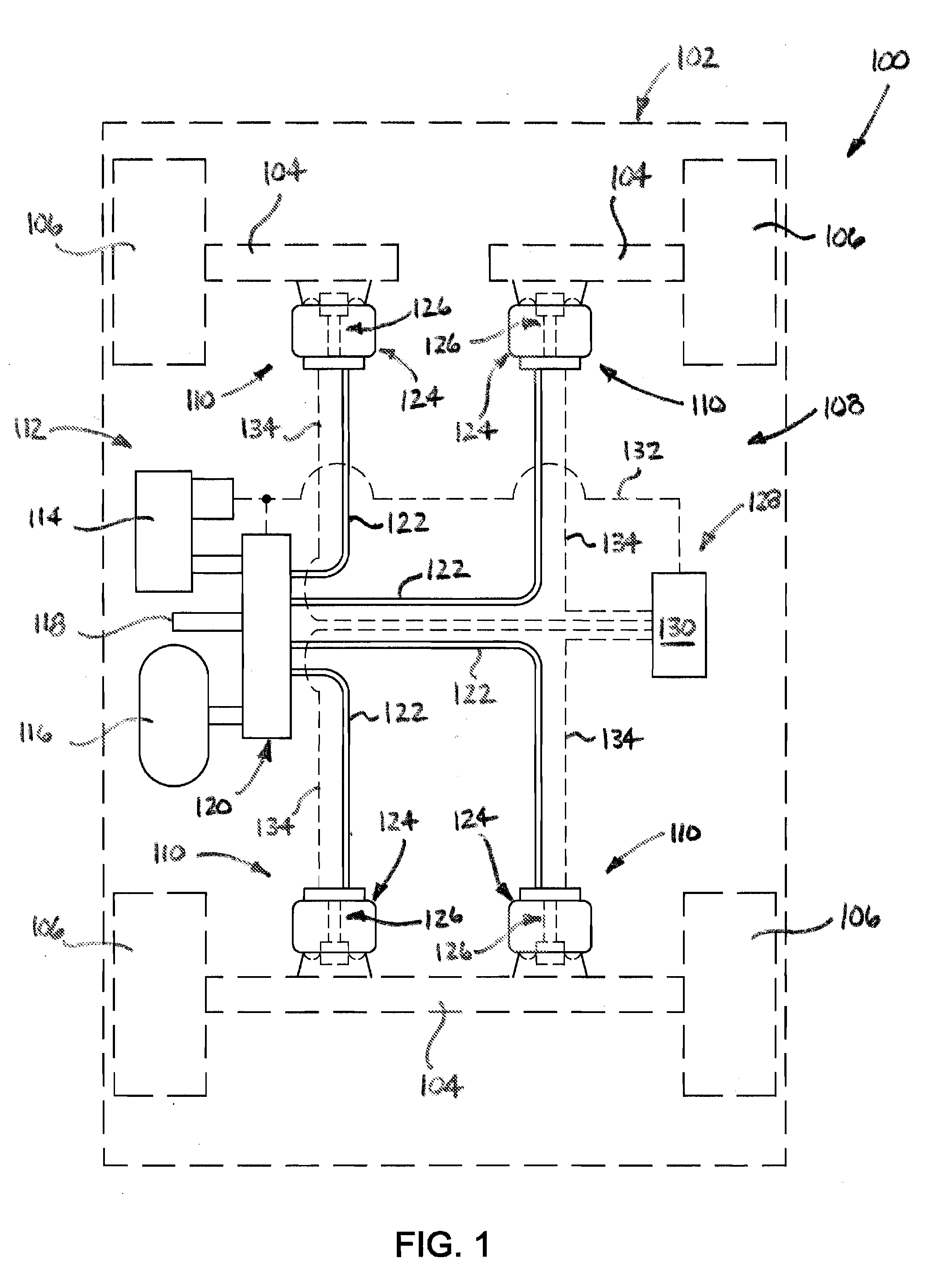

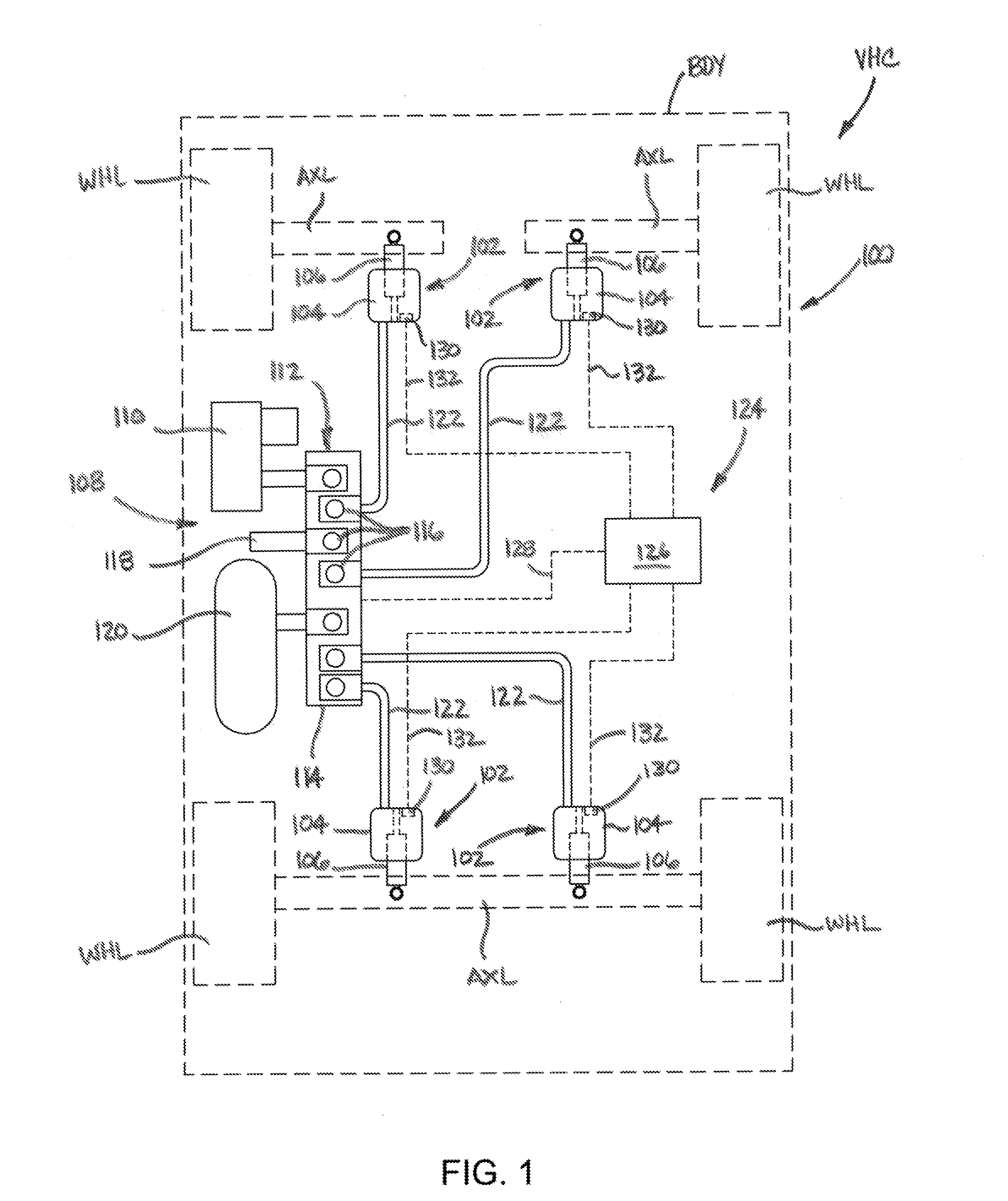

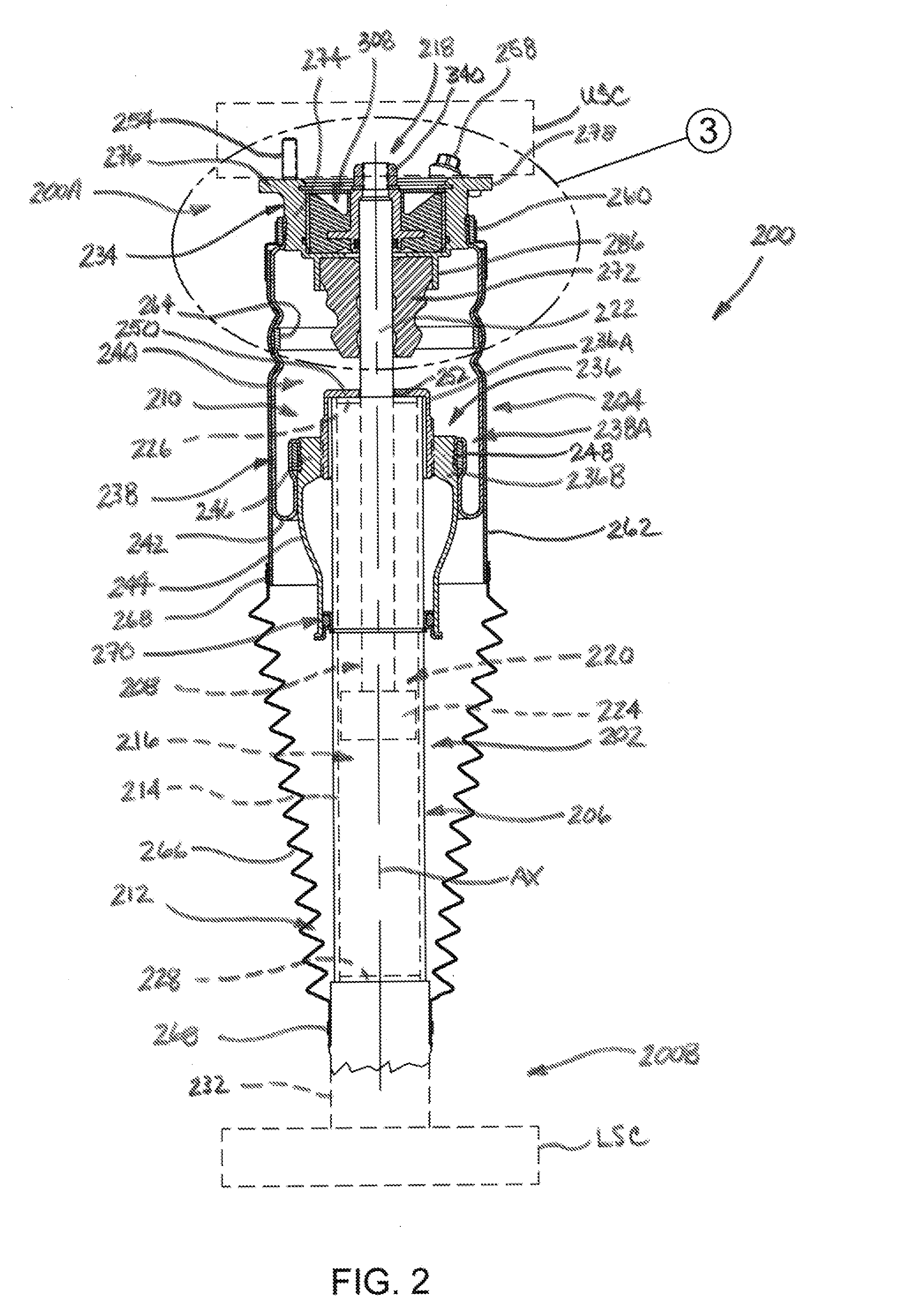

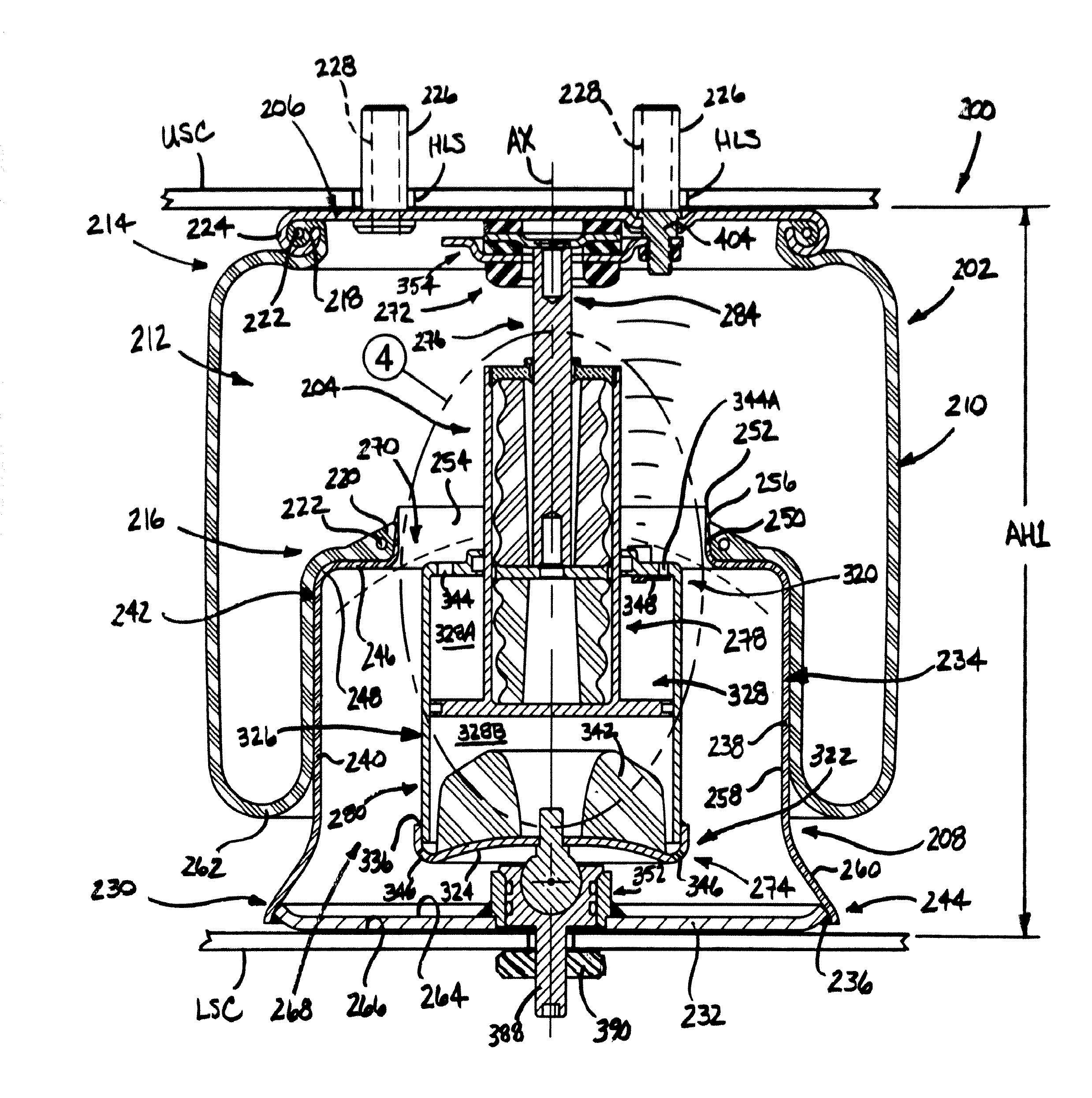

Gas spring and damper assemblies and methods

A gas spring and damper assembly can include a first gas spring having a first spring rate and a second gas spring connected in series with the first gas spring. The second gas spring can have a second spring rate that is at least two times the first spring rate of the first gas spring. A damper can be operatively connected with at least one of the first and second gas springs. A suspension system including one or more of such gas spring and damper assemblies and a method of assembly are also included.

Owner:FIRESTONE IND PROD COMPANY

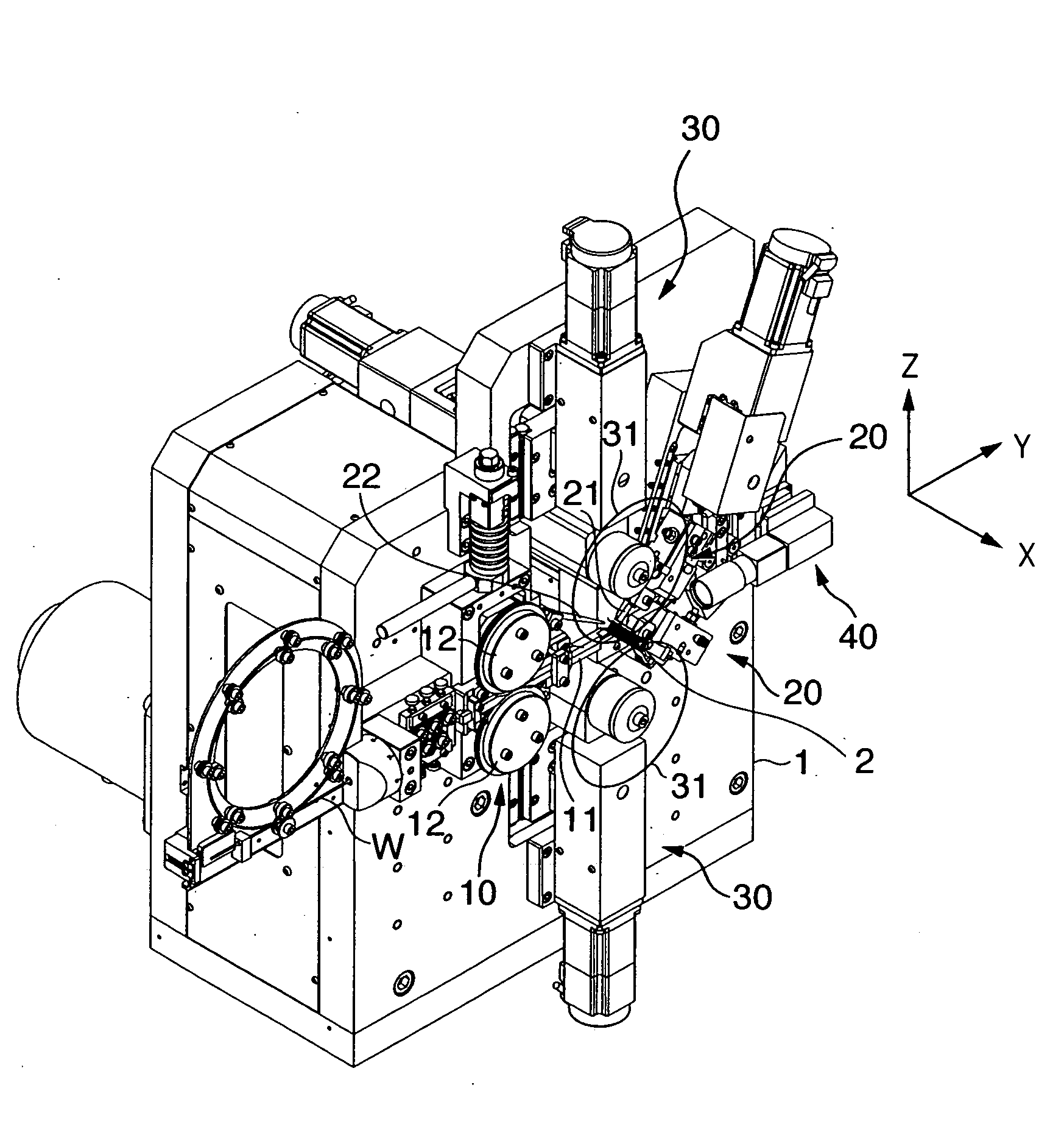

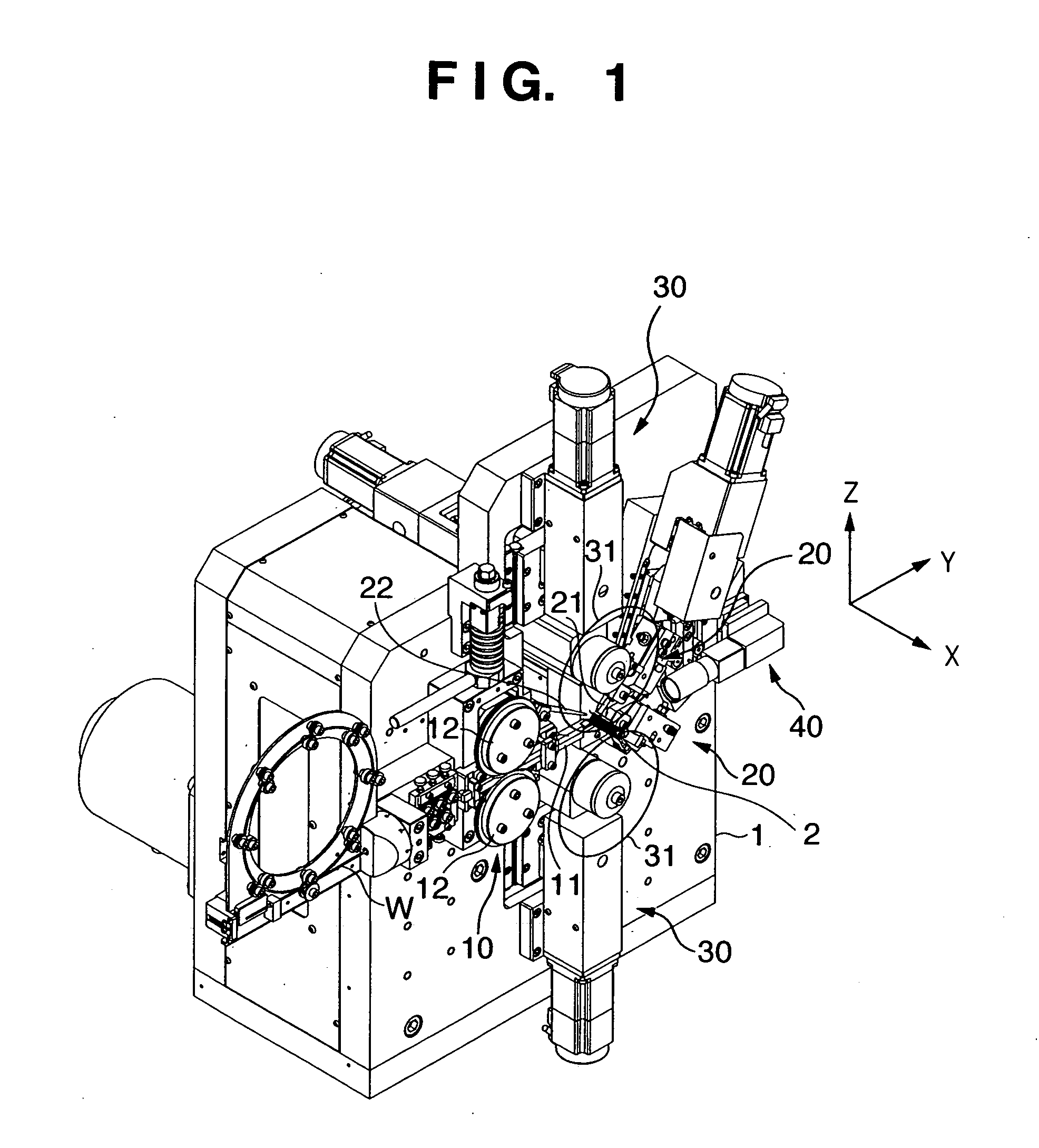

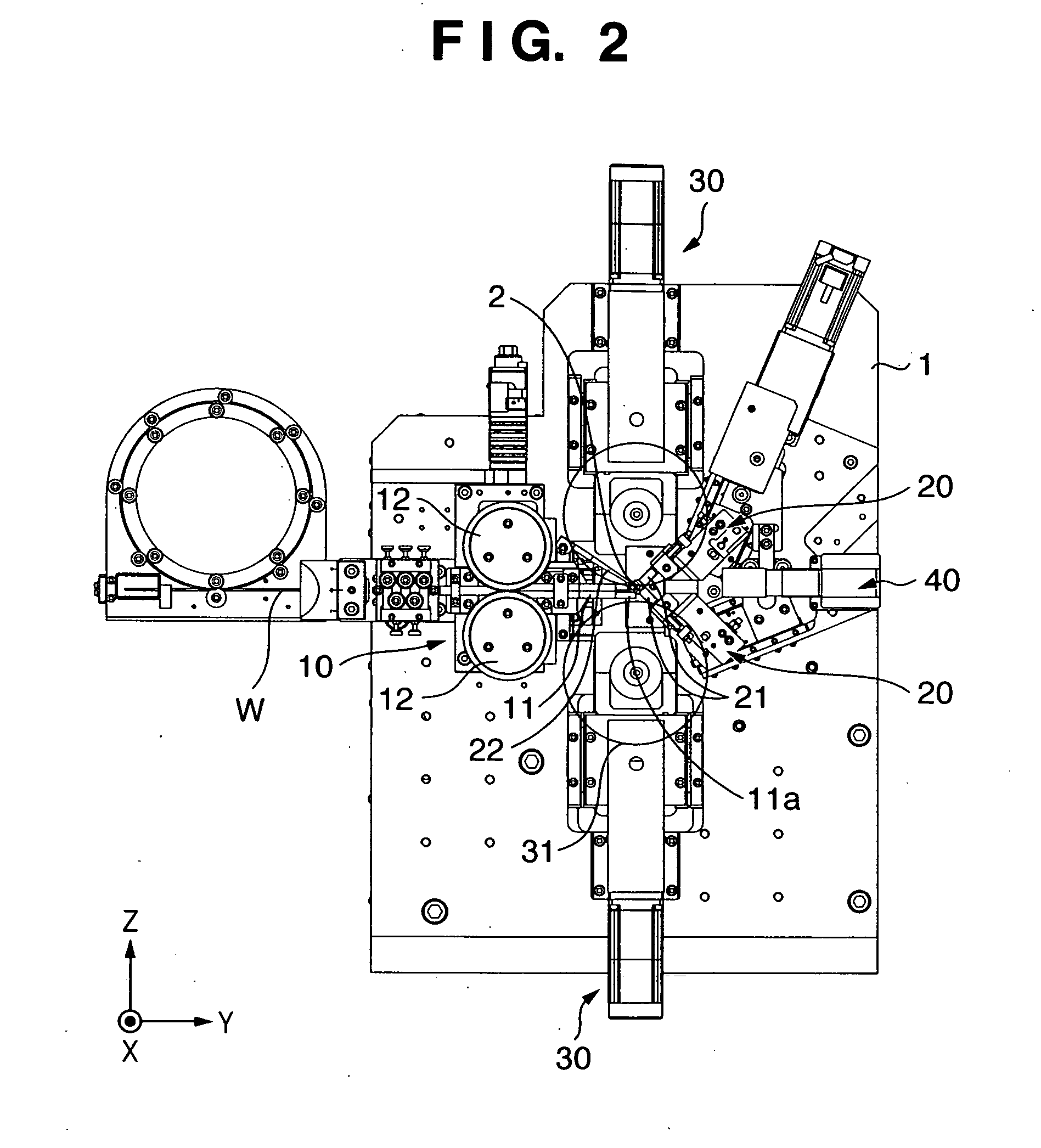

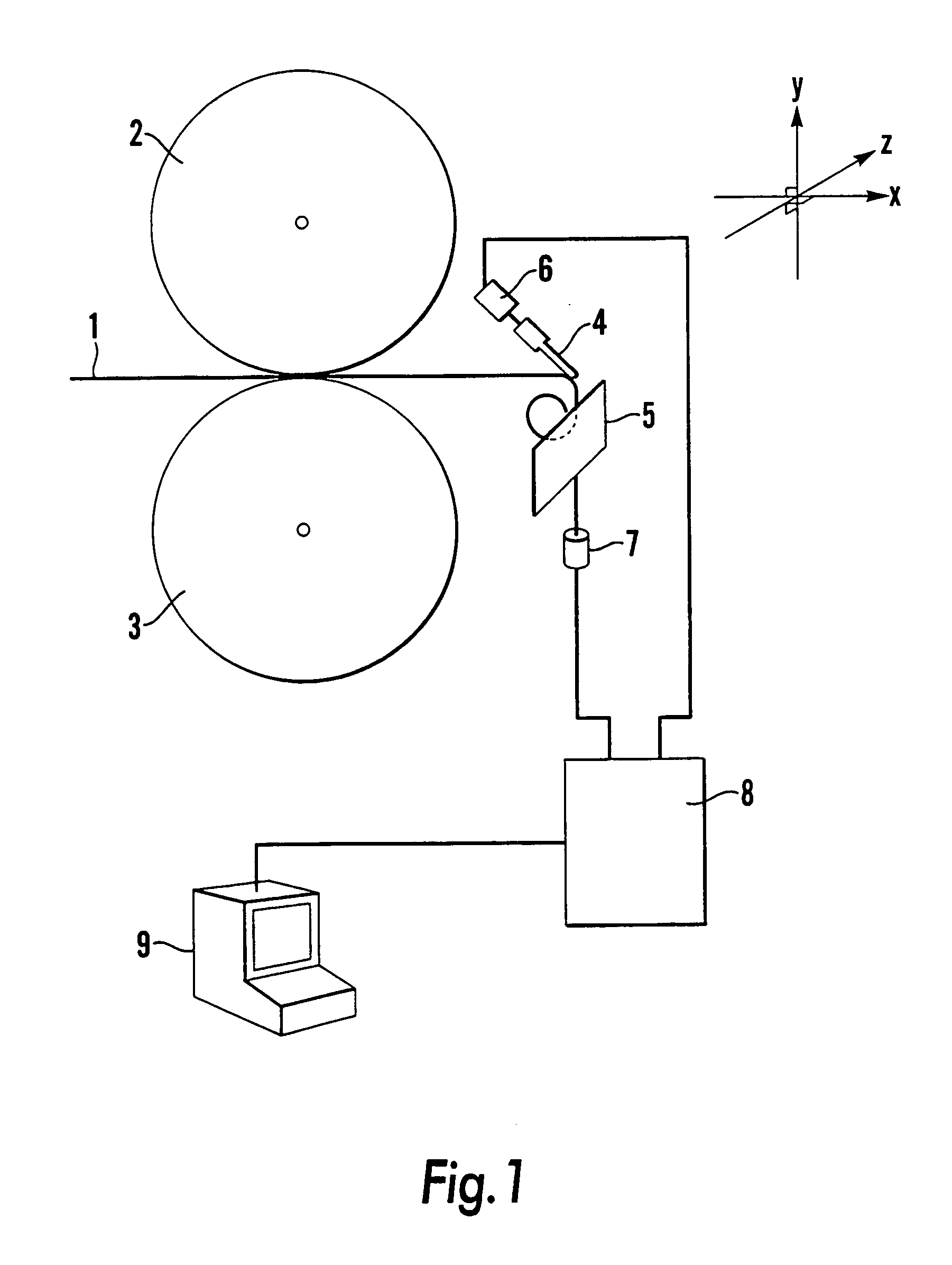

Helical part manufacturing apparatus and control method thereof

InactiveUS20080302156A1Easy to processIncrease productivityShaping safety devicesGrinding feed controlManufactured apparatusEngineering

This invention provides an apparatus for manufacturing a helical part by feeding a wire W toward a pointing tool 21 and pushing the wire W against the pointing tool 21 to forcibly wind the wire. The apparatus comprises: a feed roller 12 for feeding the wire W toward the pointing tool 21; a wire feeding motor 111 for rotatably driving the feed roller; a grindstone tool unit 30, which holds a discoid grindstone 31 rotatable and movable, for cutting the wire W by the rotating discoid-grindstone 31; and a CPU 100 for controlling the wire feeding motor 111 and grindstone tool unit 30 to move the discoid grindstone 31 on a plane which is substantially perpendicular to a coil growing direction of the helical part and to cut the wire W in a direction which is substantially perpendicular to the coil growing direction.

Owner:ITAYA SEISAKUSHO

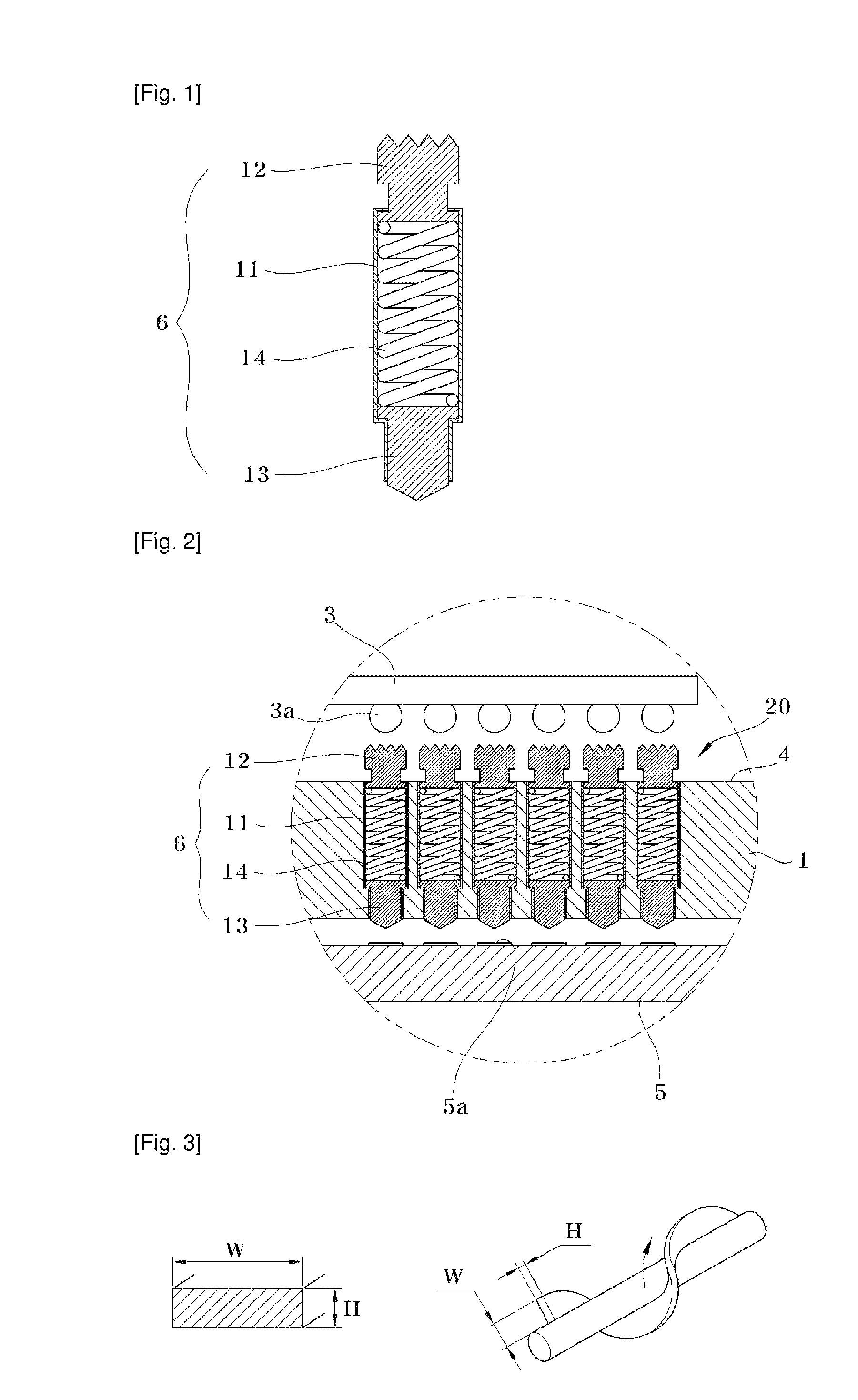

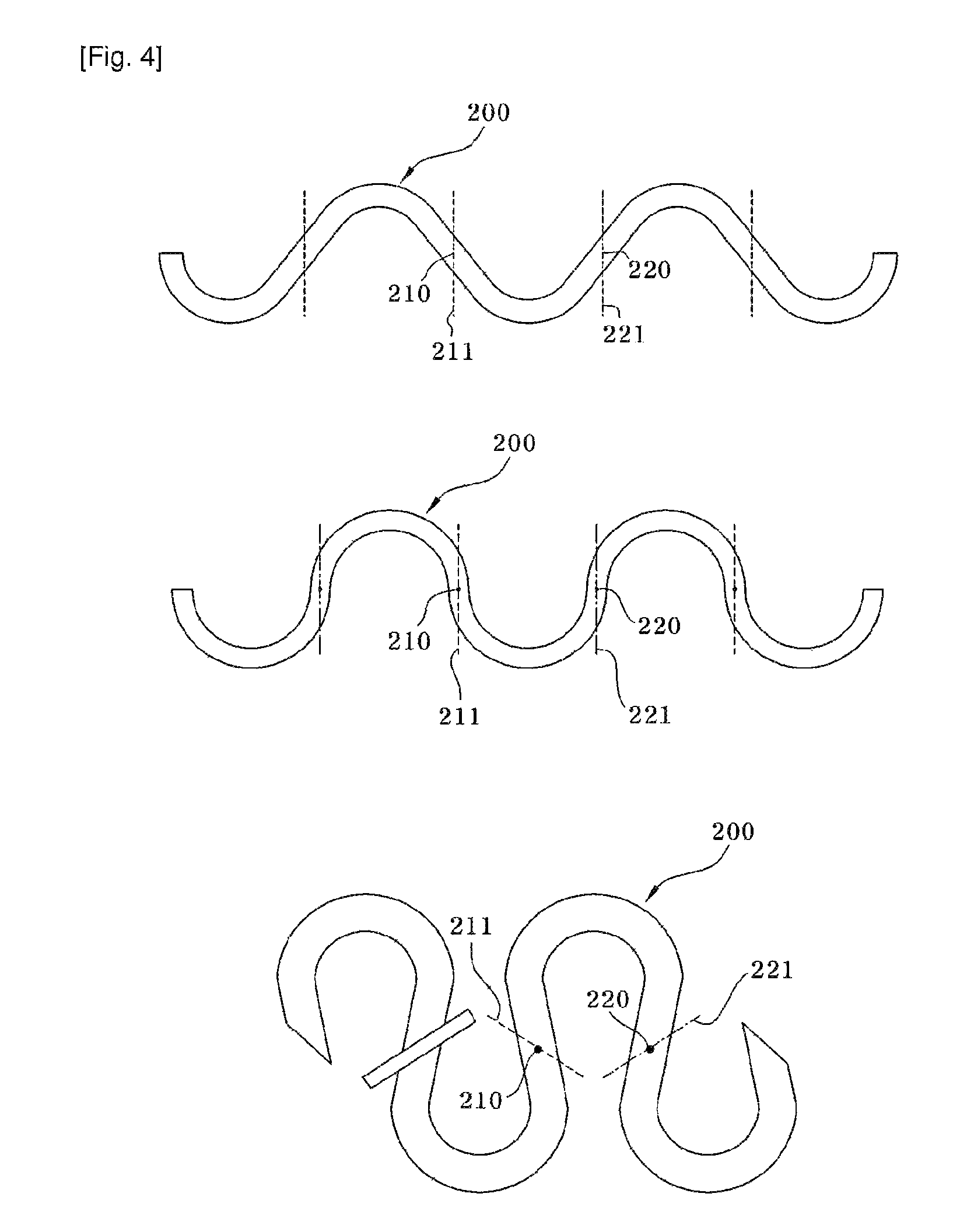

Flat plate folding type coil spring, pogo pin and manufacturing method

ActiveUS8029291B2Sufficient range of motionIncrease widthElectrical measurement instrument detailsWire springsMetal stripsRange of motion

A coil spring, a pogo pin having the coil spring, and manufacturing methods thereof are provided. The method for manufacturing a coil spring includes i) preparing a metal strip 200 with a periodically repeated U- or S-shape pattern, and ii) bending the metal strip 200 at one or more inward bending points 210 and at one or more outward bending point 220, which are formed on the metal strip 200, in opposite directions, the inward bending point and the outward bending point being spaced apart from each other. The coil spring and the pogo pin may be manufactured to be small in size and low in manufacturing costs as compared with conventional ones. Further, the coil spring and the pogo pin may provide a sufficient maximum range of motion and spring force of a probe.

Owner:PARK SANG YANG

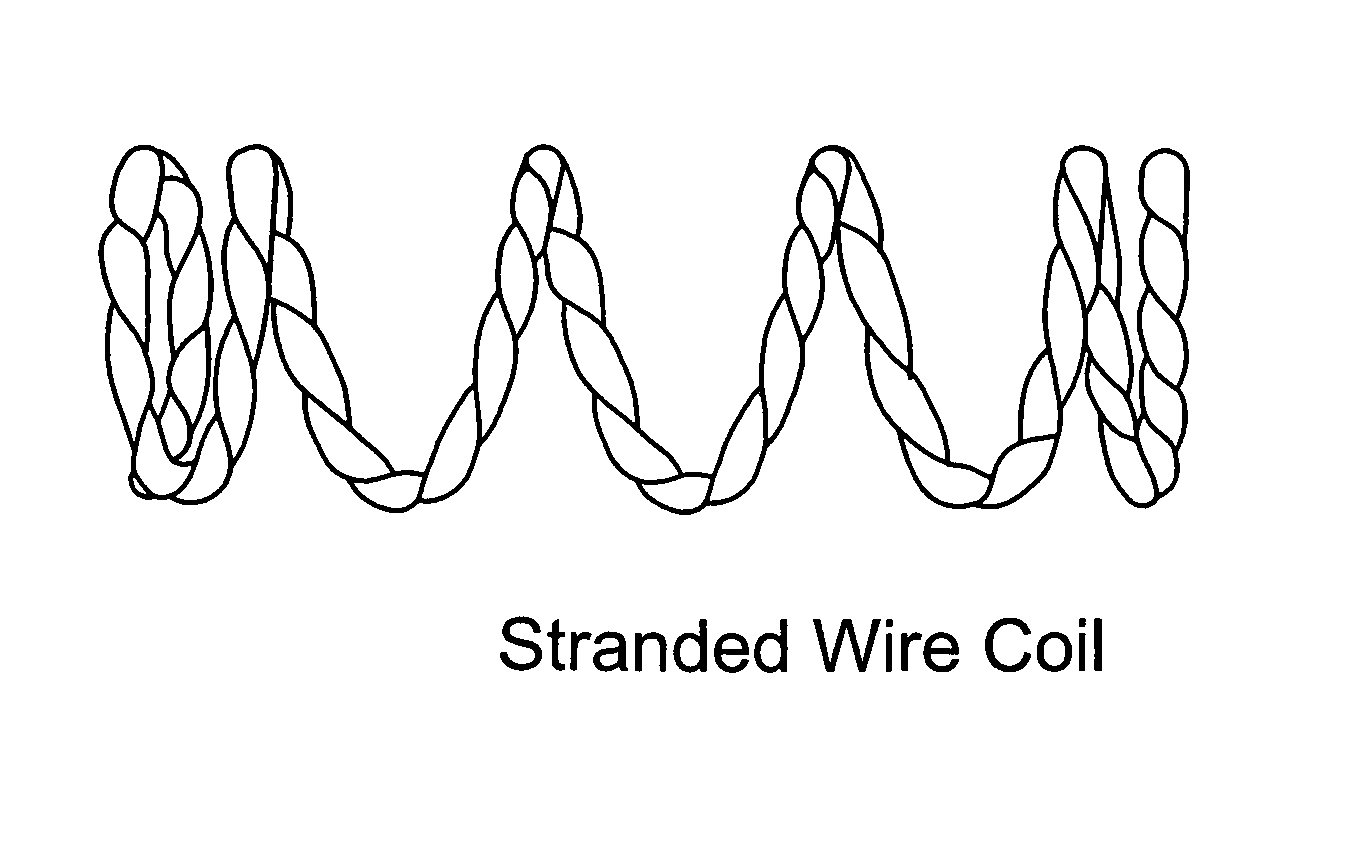

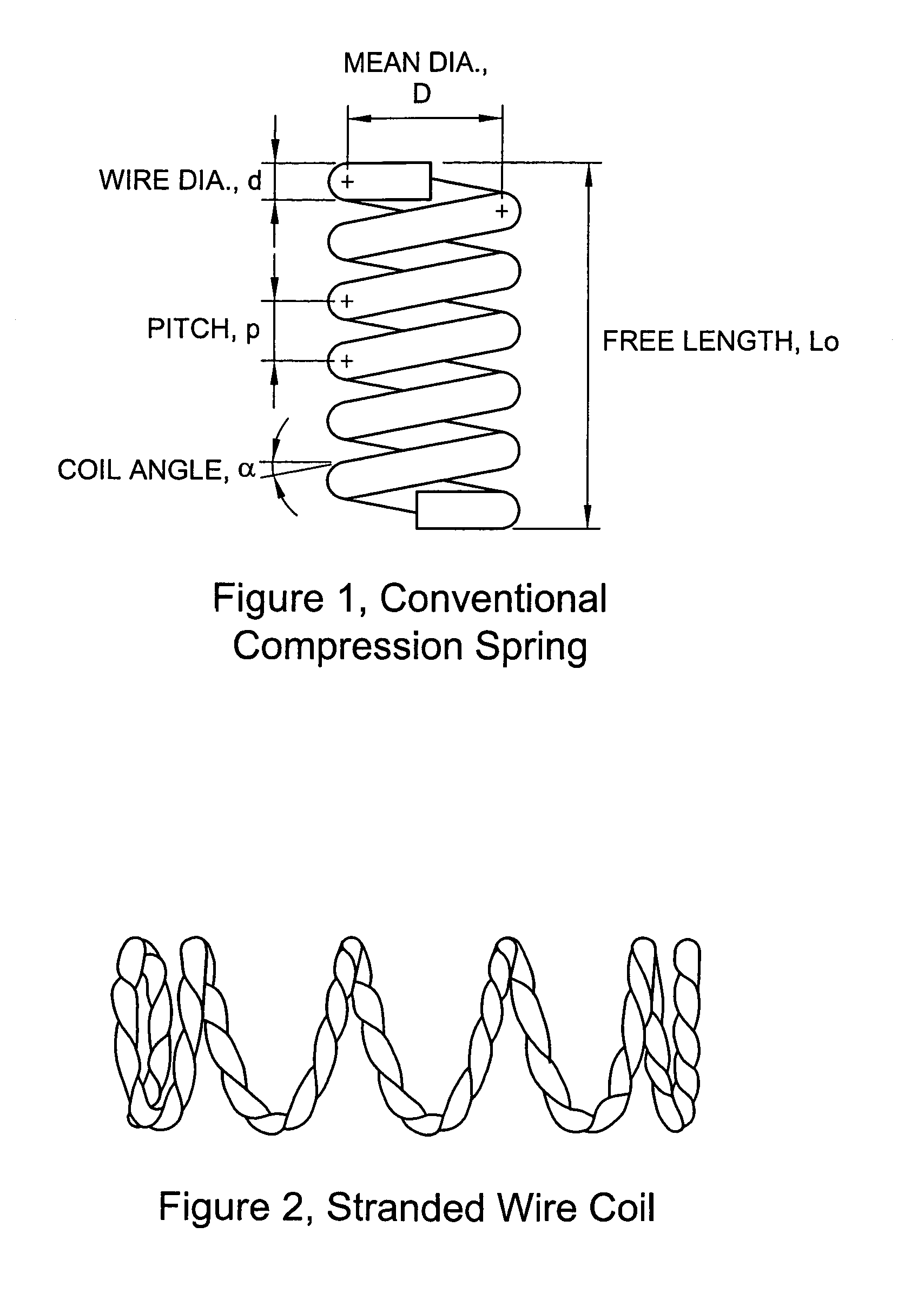

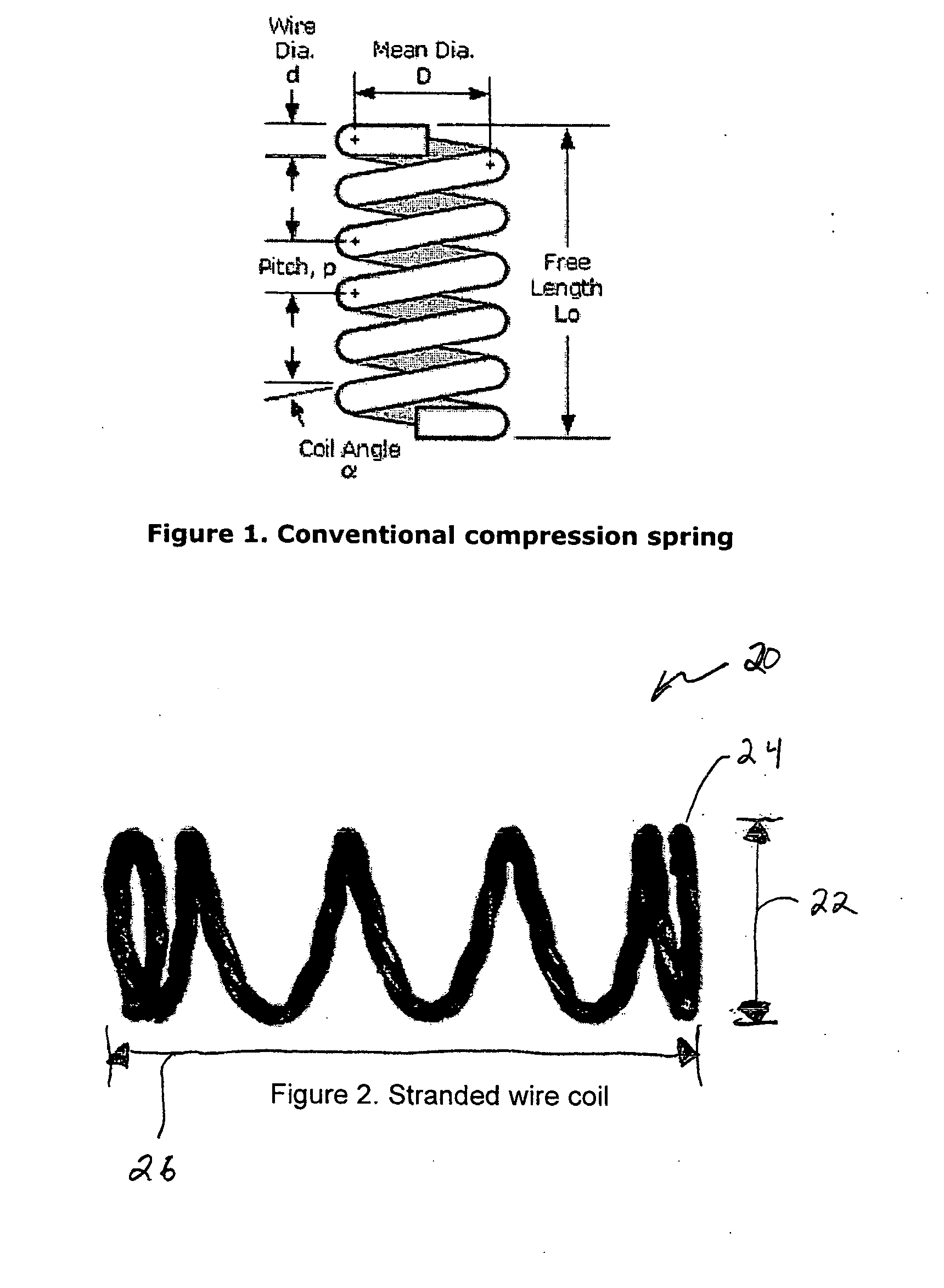

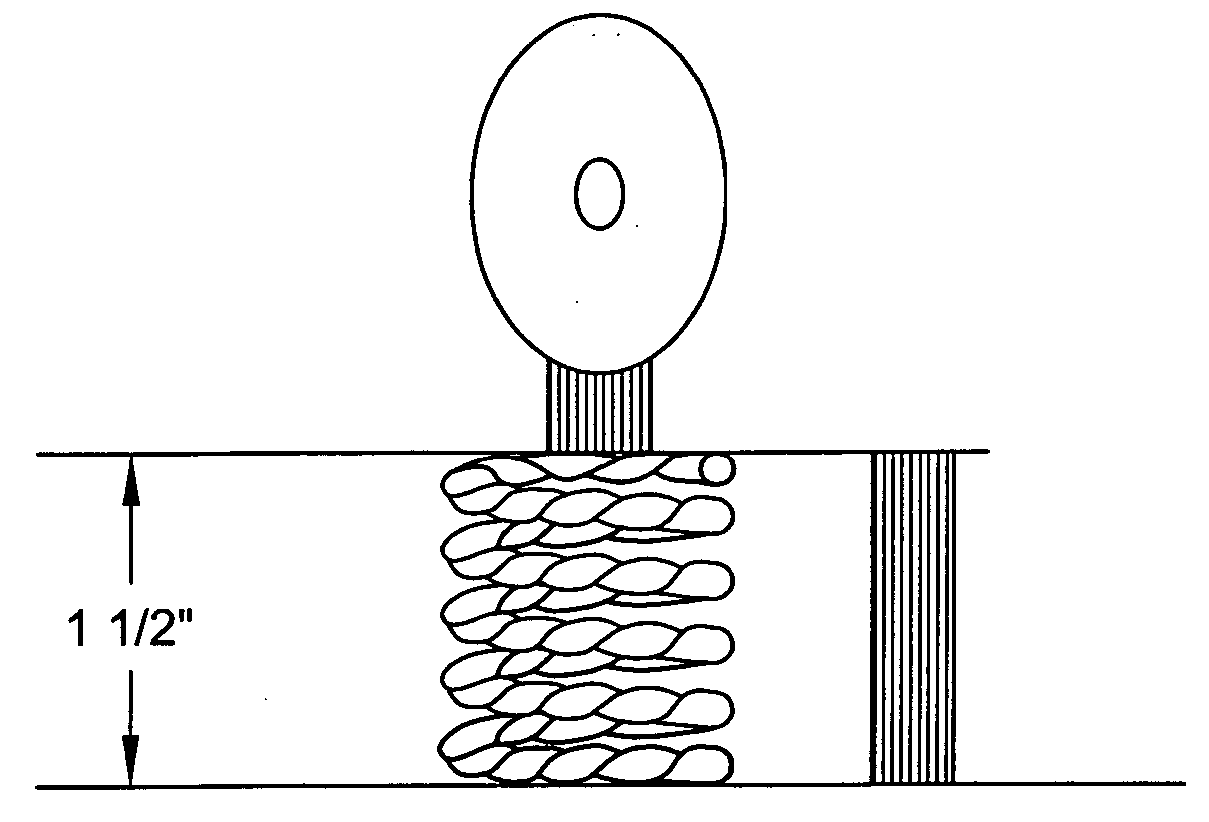

Stranded mattress spring

InactiveUS7047581B2Prevent looseningReduce adverse effectsUpholstery manufactureStuffed mattressesCoil springEngineering

A mattress construction with a stranded wire spring is disclosed. The stranded wire spring can be designed with the same performance characteristic as a conventional single strand coil spring, but at a lower manufacturing and material cost.

Owner:DREAMWELL

Multi-stranded coil spring

InactiveUS20050005354A1Reduce adverse effectsStuffed mattressesSpring mattressesCoil springHelical coil

Owner:SIMMONS CO +1

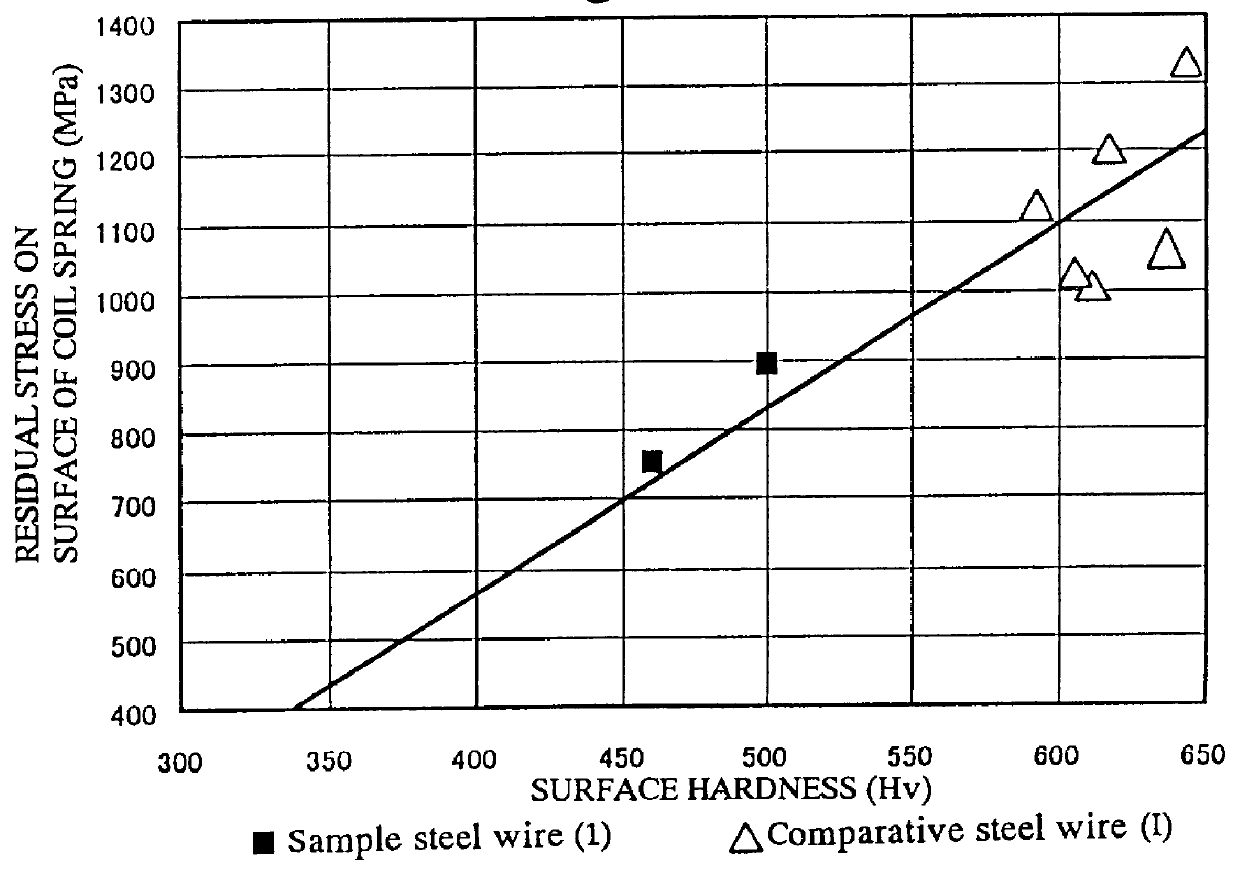

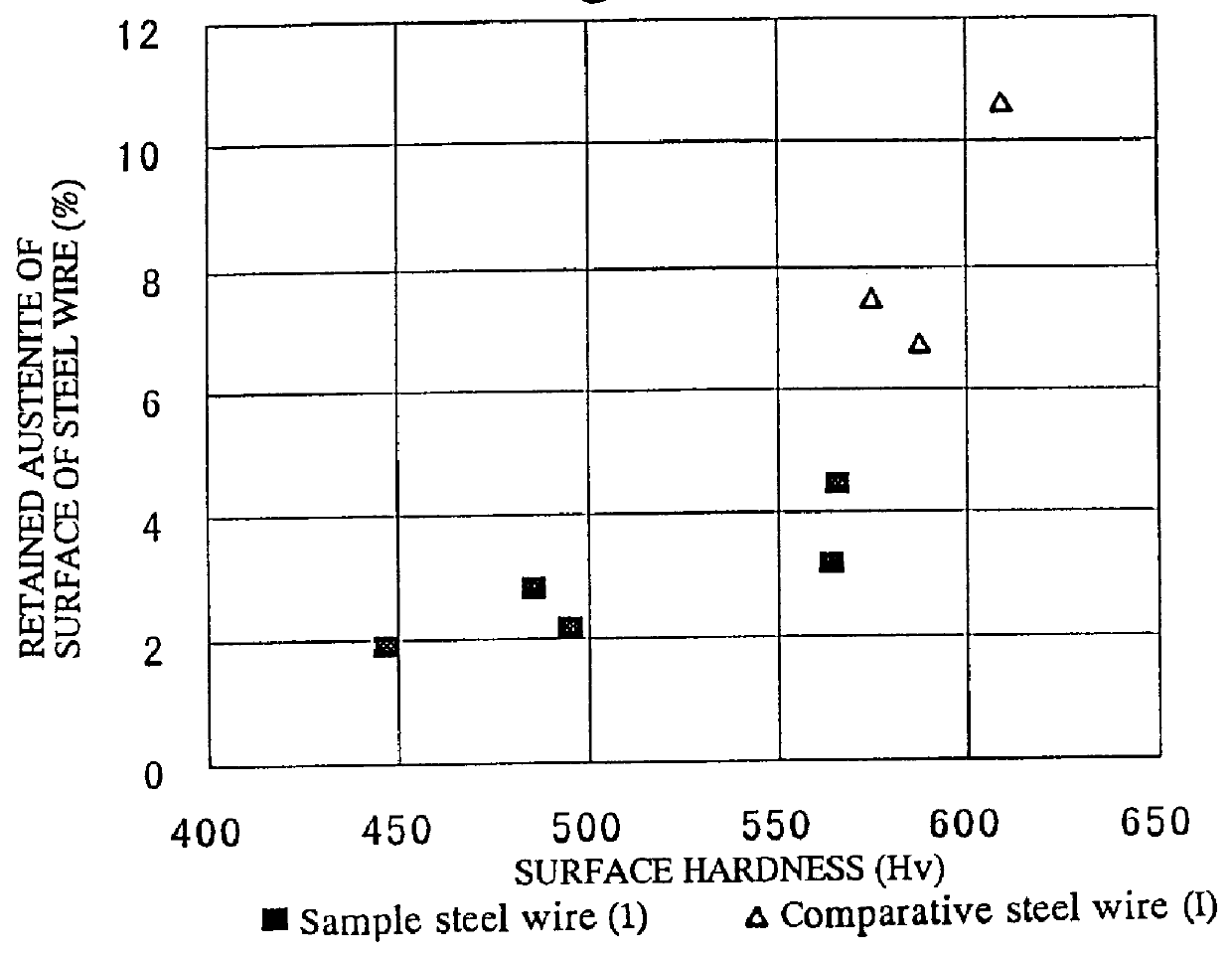

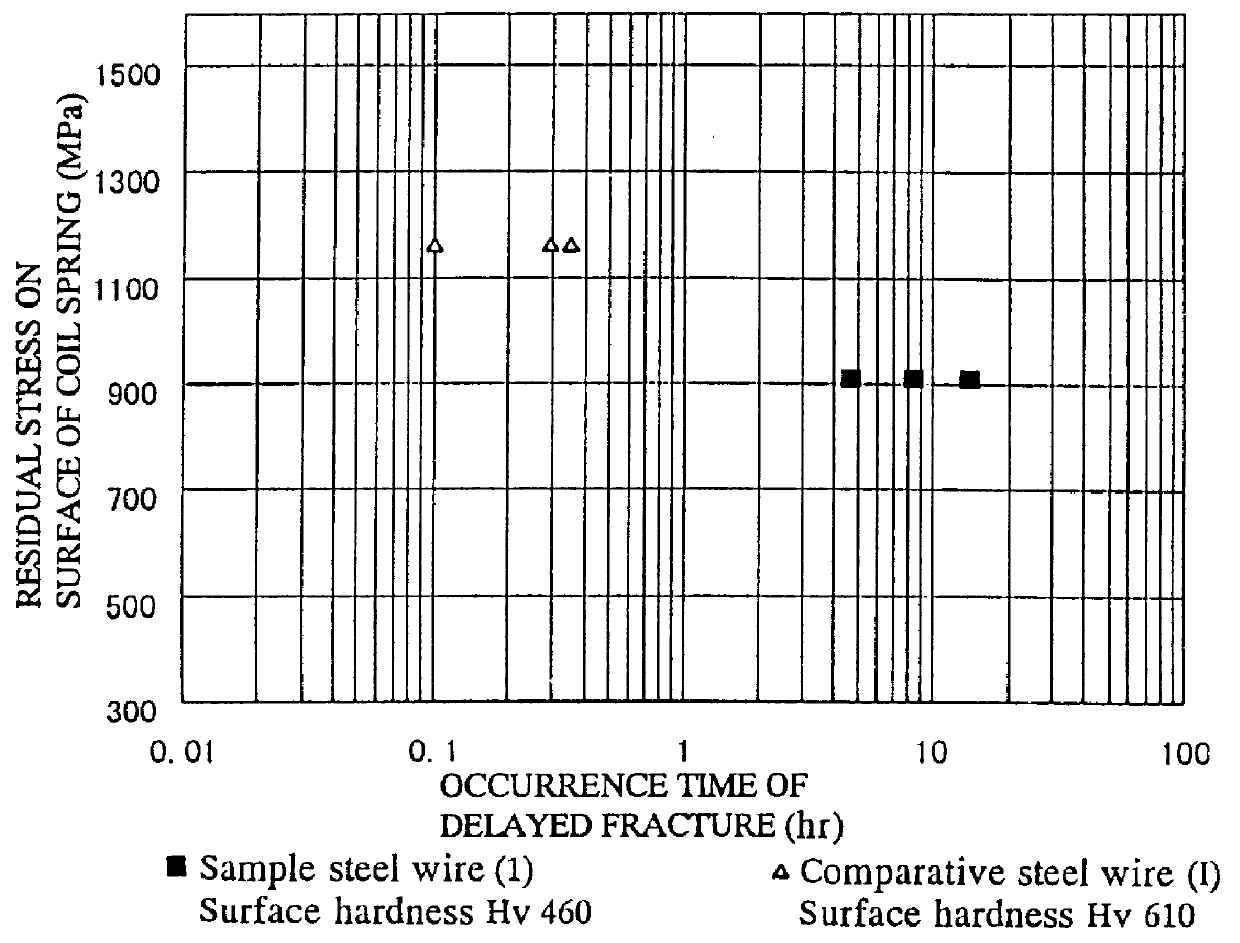

Coil spring resistive to delayed fracture and manufacturing method of the same

A coil spring made of an oil-tempered steel wire with internal hardness of more than Hv 550 in cross-section, the surface hardness of the oil-tempered steel wire being determined in an extent between Hv 420 in a minimum value and hardness defined by subtraction of Hv 50 from the internal hardness in a maximum value.

Owner:CHUO SPRING +1

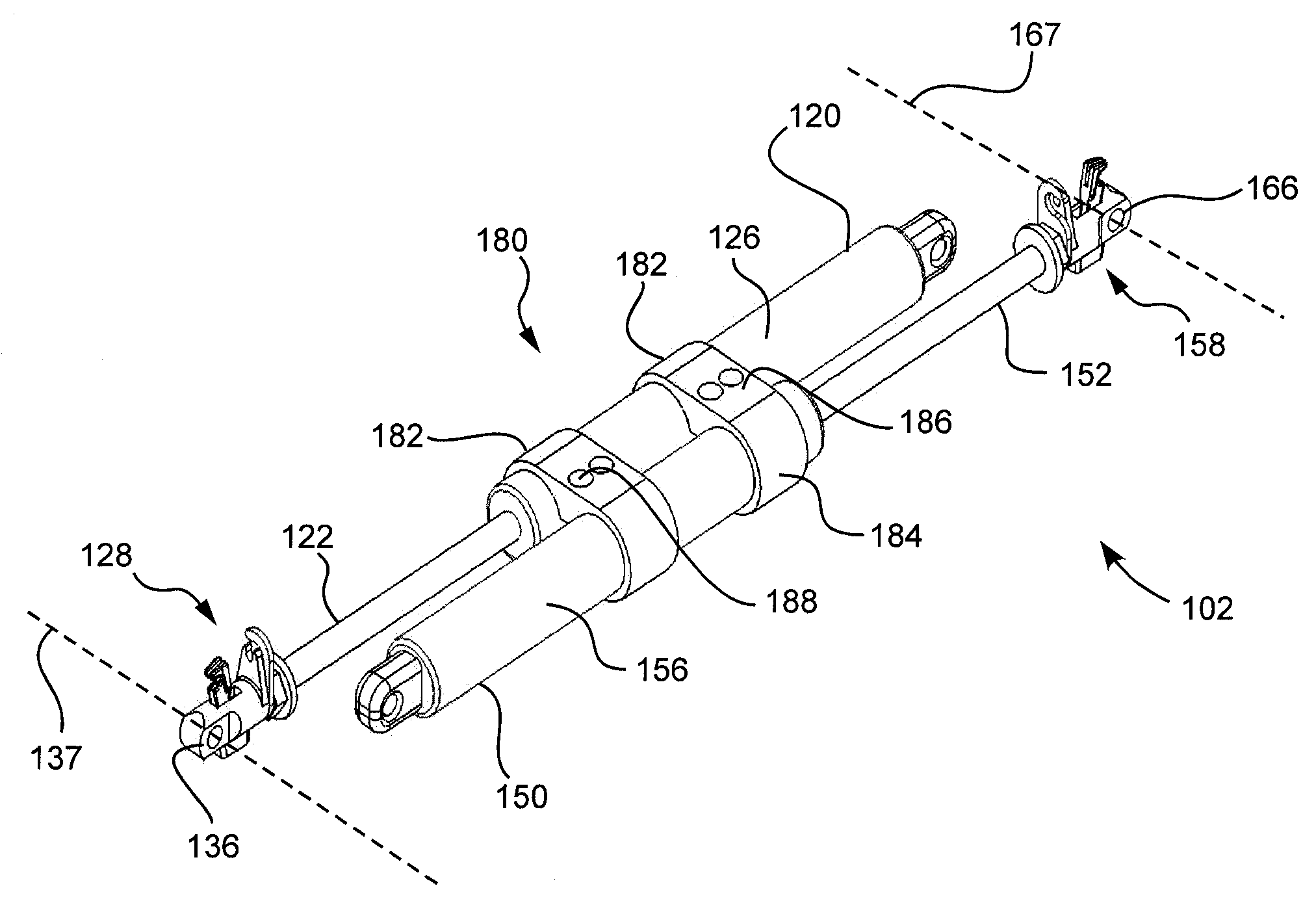

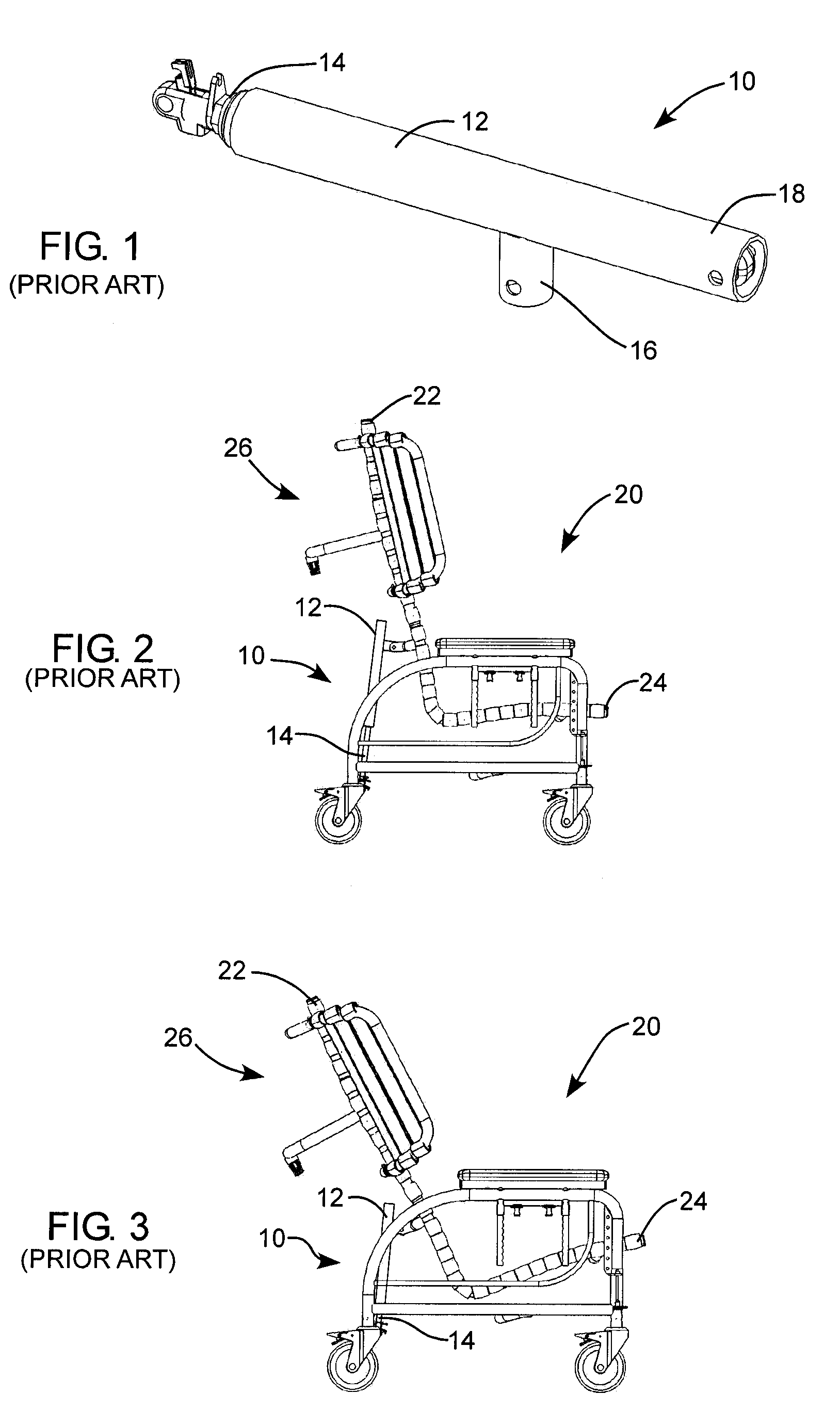

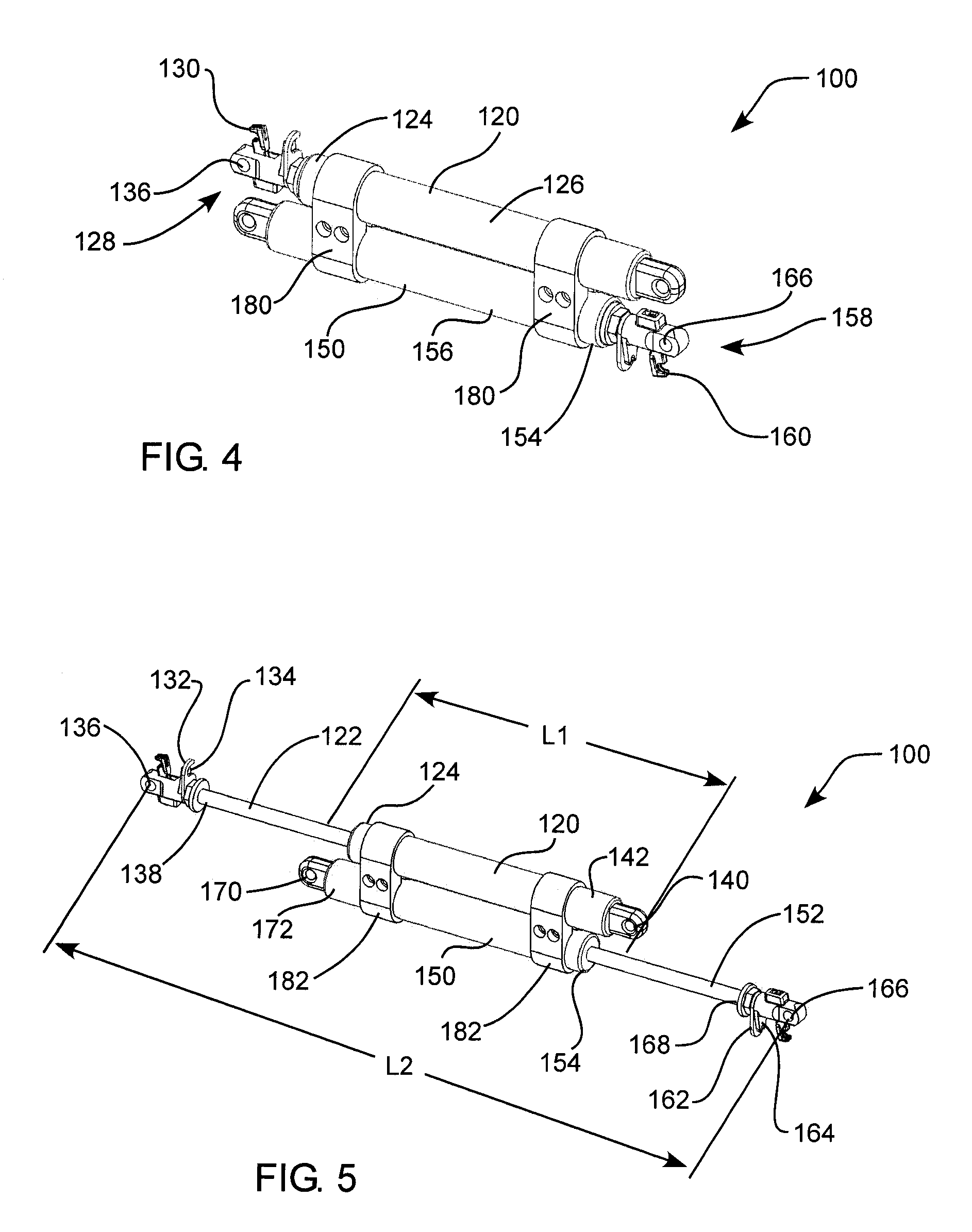

Reclinable chair with adjustable parallel locking gas spring device

InactiveUS20090315376A1Increase effective lengthSpringsWheelchairs/patient conveyanceCouplingGas spring

A gas spring device includes a pair of gas springs disposed parallel and adjacent one another. Each of the gas springs has a piston extendable in an opposite direction from the piston of the other gas spring. An adjustable coupling joins the pair of gas springs together and is adjustable to selectively position one of the gas springs along a longitudinal length of the other gas spring in order to adjust the overall piston-to-piston length of the gas spring device. Additionally, an inclinable chair can include the gas spring device to allow a chair frame to be selectively positioned at a desired angle of inclination with respect to a base frame.

Owner:BRODA ENTERPRISES

Apparatus for the production of pocketed coil springs

InactiveUS6922895B1Easy to createEasy to modifyStuffed mattressesSpring mattressesCoil springEngineering

Owner:SPRINGFORM TECH

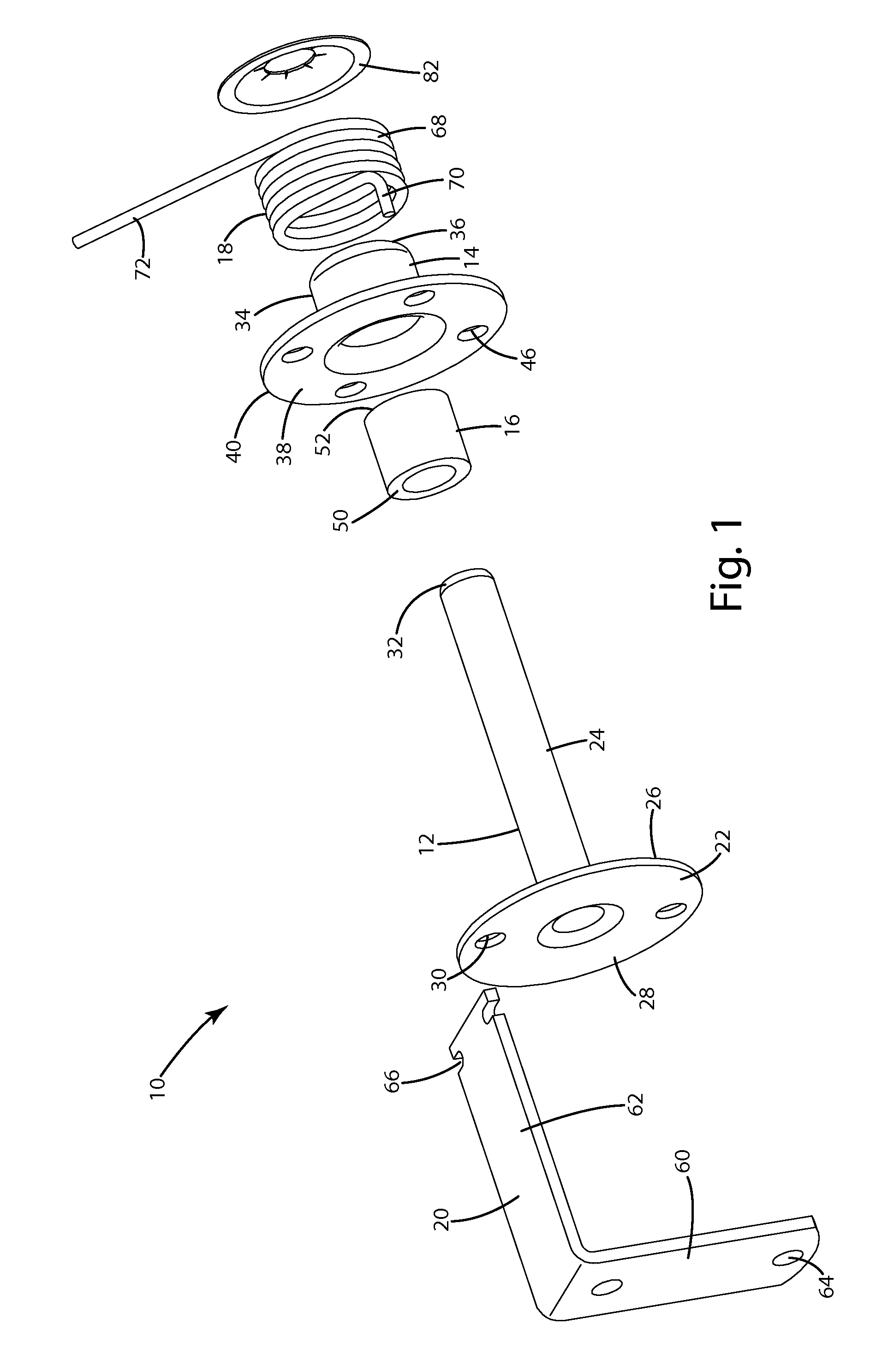

Torque assembly and method of manufacture

A torque assembly includes a spindle, a cap mounted on the spindle for rotation about the spindle, and a work-hardened, plastic sleeve inserted between the cap and the spindle for constant rotation of the sleeve and cap with respect to the spindle. The torque assembly may be installed onto a hinged object and fixed object with movement along a single axis. The torque assembly may be formed by: (a) providing a spindle having a base and a rod extending from the base; (b) providing a cap member with an annular section defining an inner diameter; (c) providing an annular plastic sleeve having an inner diameter and an outer diameter; (d) work-hardening the sleeve for a predetermined time period; (e) changing the inner diameter of the sleeve; and (f) inserting the spindle rod through the inner diameter of the sleeve.

Owner:VENTURESOURCE SOLUTIONS

Low clearance centralizer and method of making centralizer

Owner:INNOVEX DOWNHOLE SOLUTIONS INC

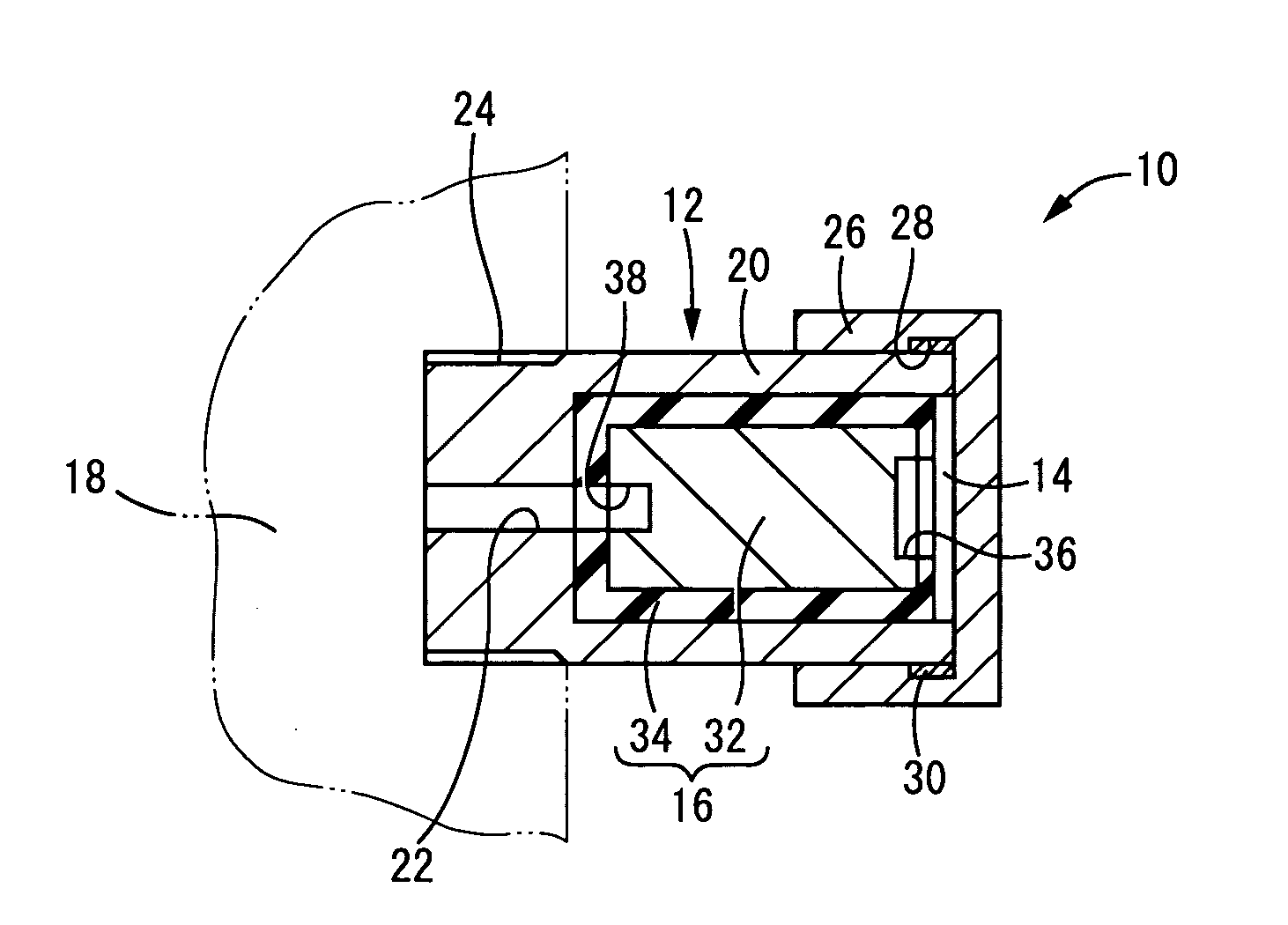

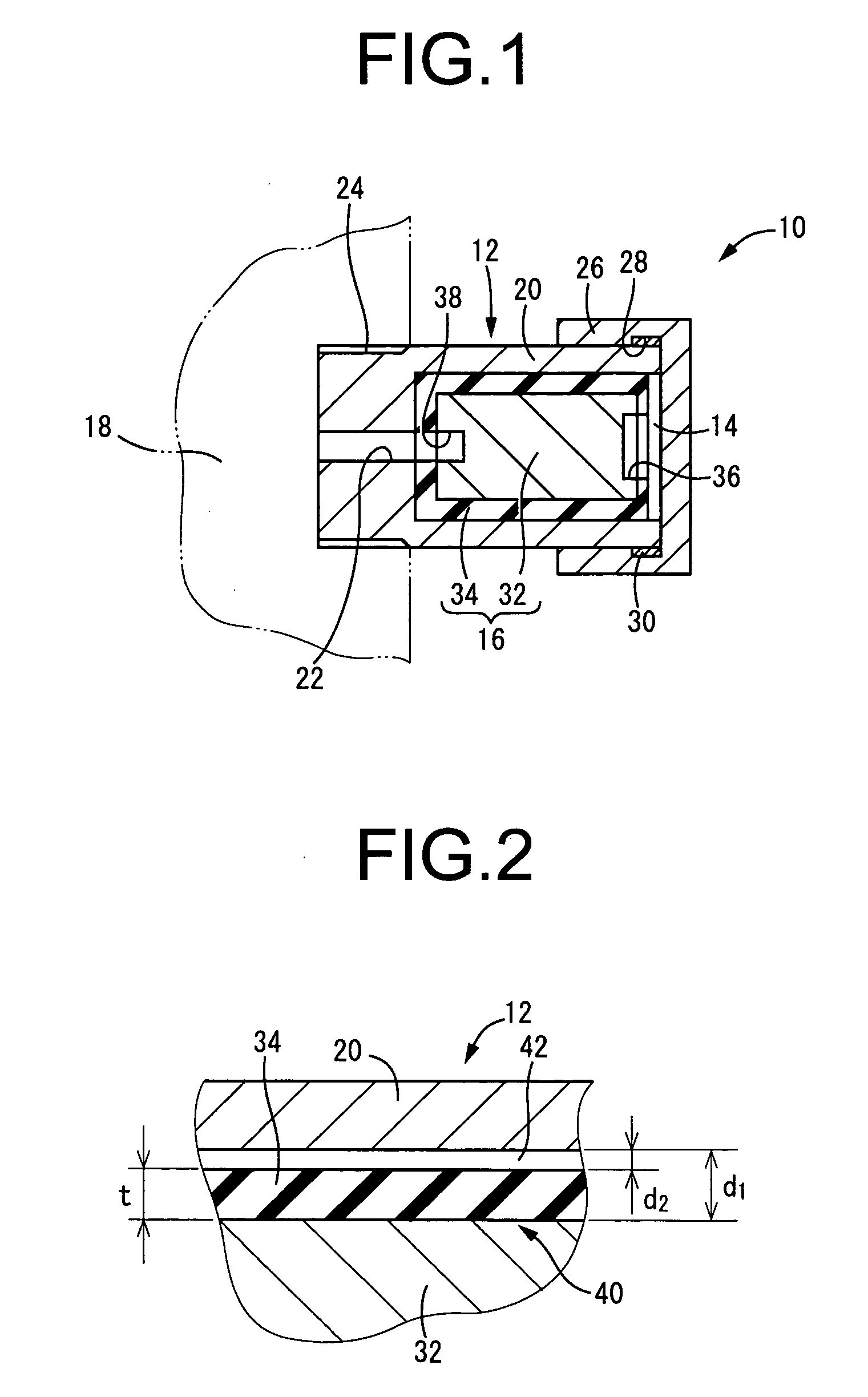

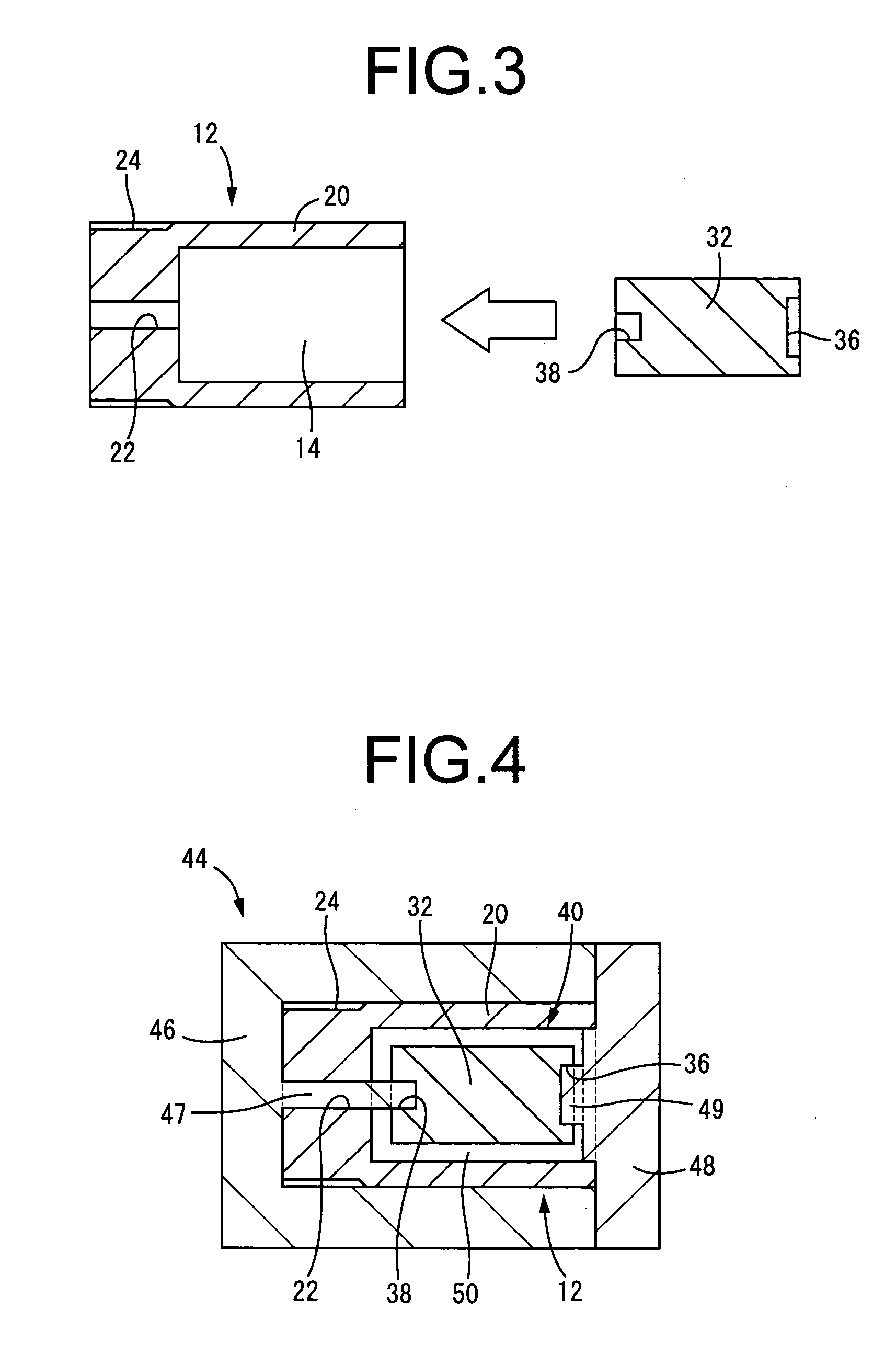

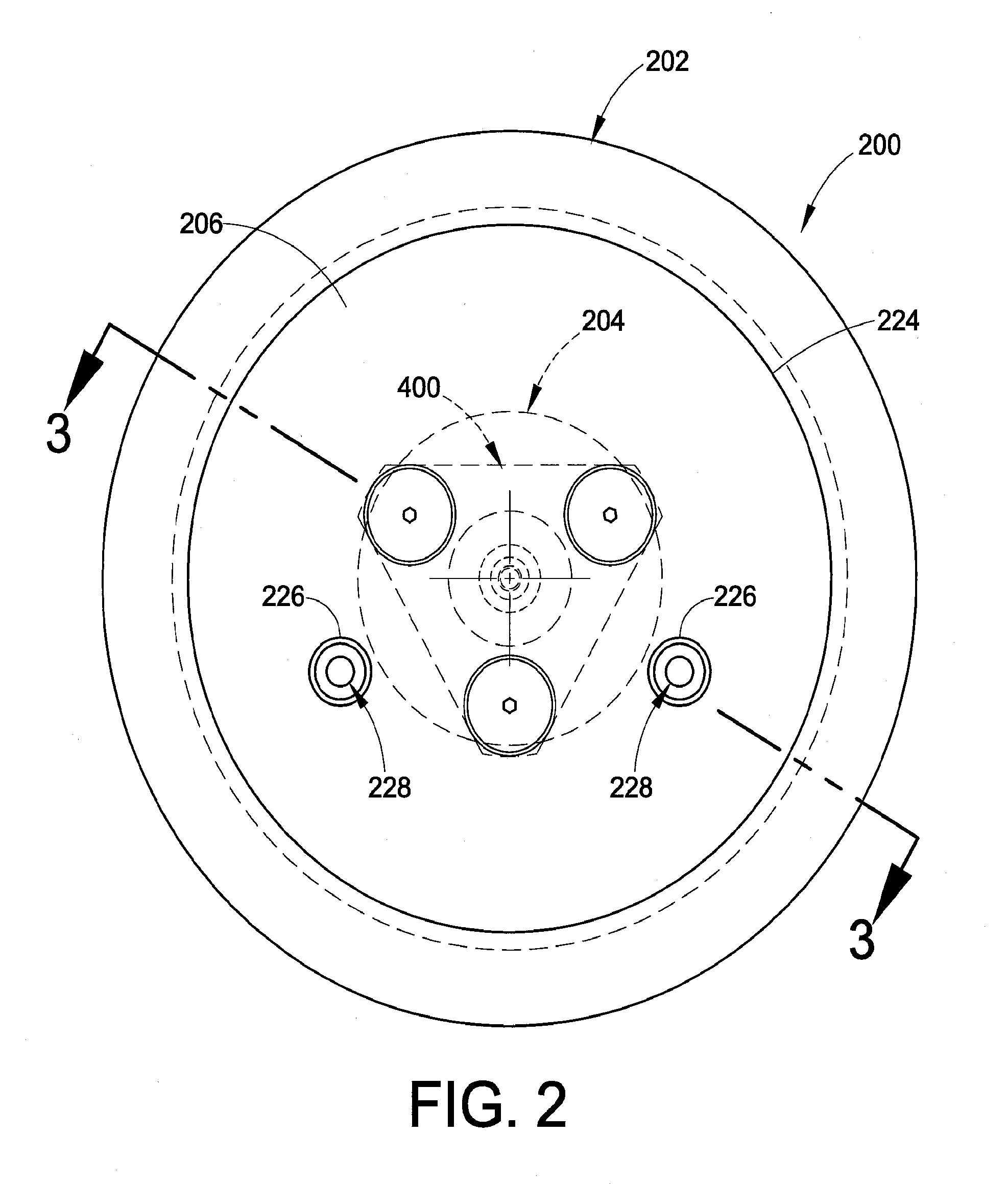

Vibration-damping device for vehicles and method of manufacturing the same

InactiveUS20050253317A1Novel structureReduce exerciseMachine framesNon-rotating vibration suppressionRubber materialVulcanization

A vehicle vibration-damping device including a rigid housing and an independent mass member housed in the housing and having a metallic mass of circular shape in section and a rubber elastic body layer adhered to the metallic mass. A distance of a gap between opposing surfaces of the housing and the metallic mass in the radial direction, with the housing and metallic mass disposed coaxially, is set to between 0.5 and 2 mm. The rubber elastic body layer is formed around an entire outer peripheral surface of the metallic mass by a vulcanization molding of a rubber material filling the gap, and thermal contraction is used both to cause the rubber elastic body layer to peel from the housing and to cause it to adhere onto the outer peripheral surface of the metallic mass to thereby fabricate a small gap of no more than 0.1 mm. A method of manufacturing the same is also disclosed.

Owner:SUMITOMO RIKO CO LTD

Multi-stranded coil spring

InactiveUS20070118987A1Reduce adverse effectsStuffed mattressesSpring mattressesCoil springHelical coil

Owner:DREAMWELL LTD

Compression spring processing process

InactiveCN102248097AShorten the lengthGuaranteed straightnessFurnace typesWire springsSand blastingMechanical property

The invention relates to a compression spring processing process. The compression spring processing process is characterized by comprising the following process steps of: rolling, cutting into rings, reducing diameters, quenching, performing primary tempering, inspecting mechanical properties, setting, grinding end faces, correcting the length and the concentricity of springs, performing secondary tempering, setting, performing primary heating and loading aging treatment, grinding the end faces, detecting, performing sand blasting, performing magnetic powder inspection, performing sand blasting, performing surface treatment, performing secondary heating and loading aging treatment, and detecting finished products. By the process, the deformation of the springs in the processing process can be reduced, the geometric dimension of the springs is ensured, and production efficiency is greatly improved.

Owner:SHENYANG AIRCRAFT CORP

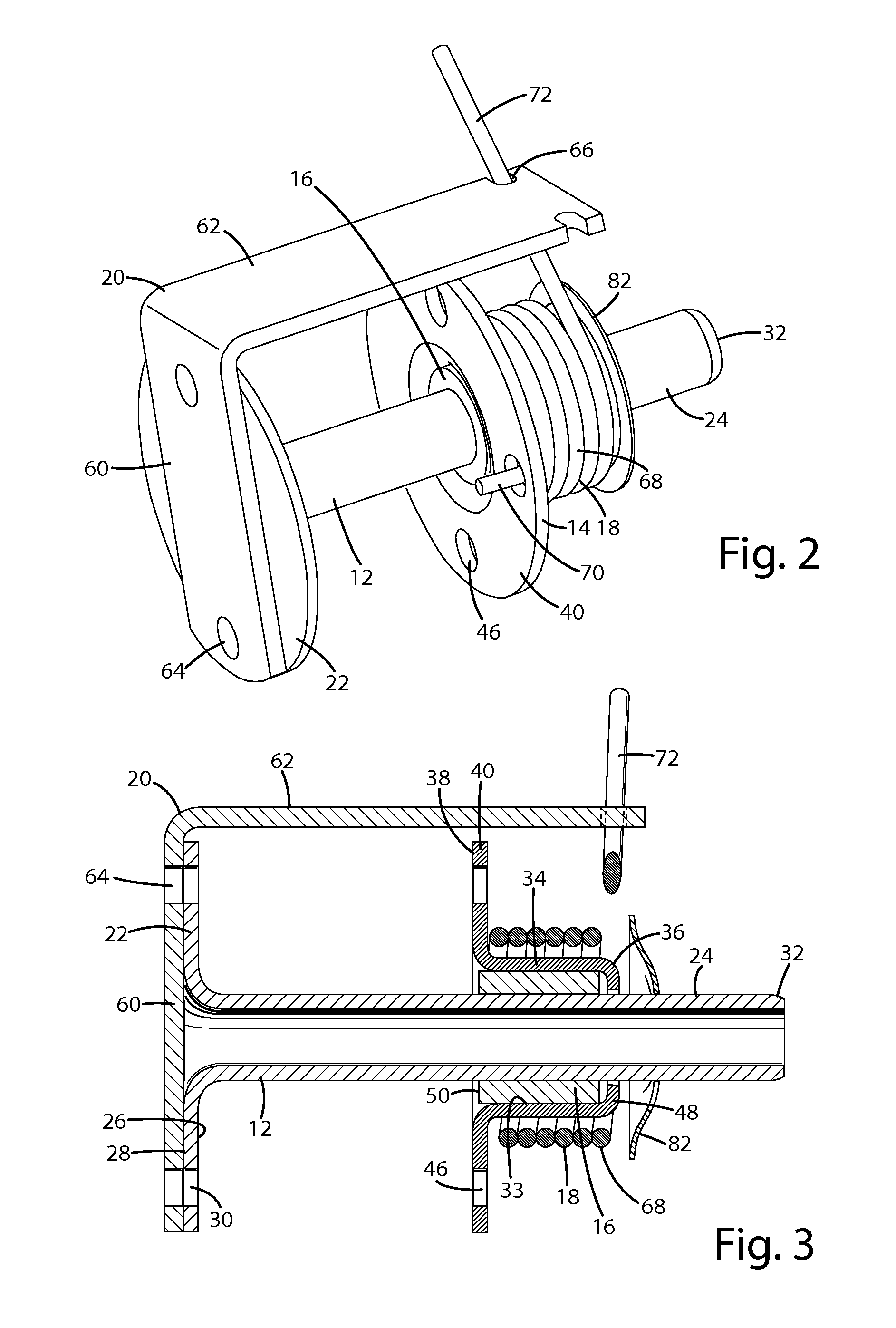

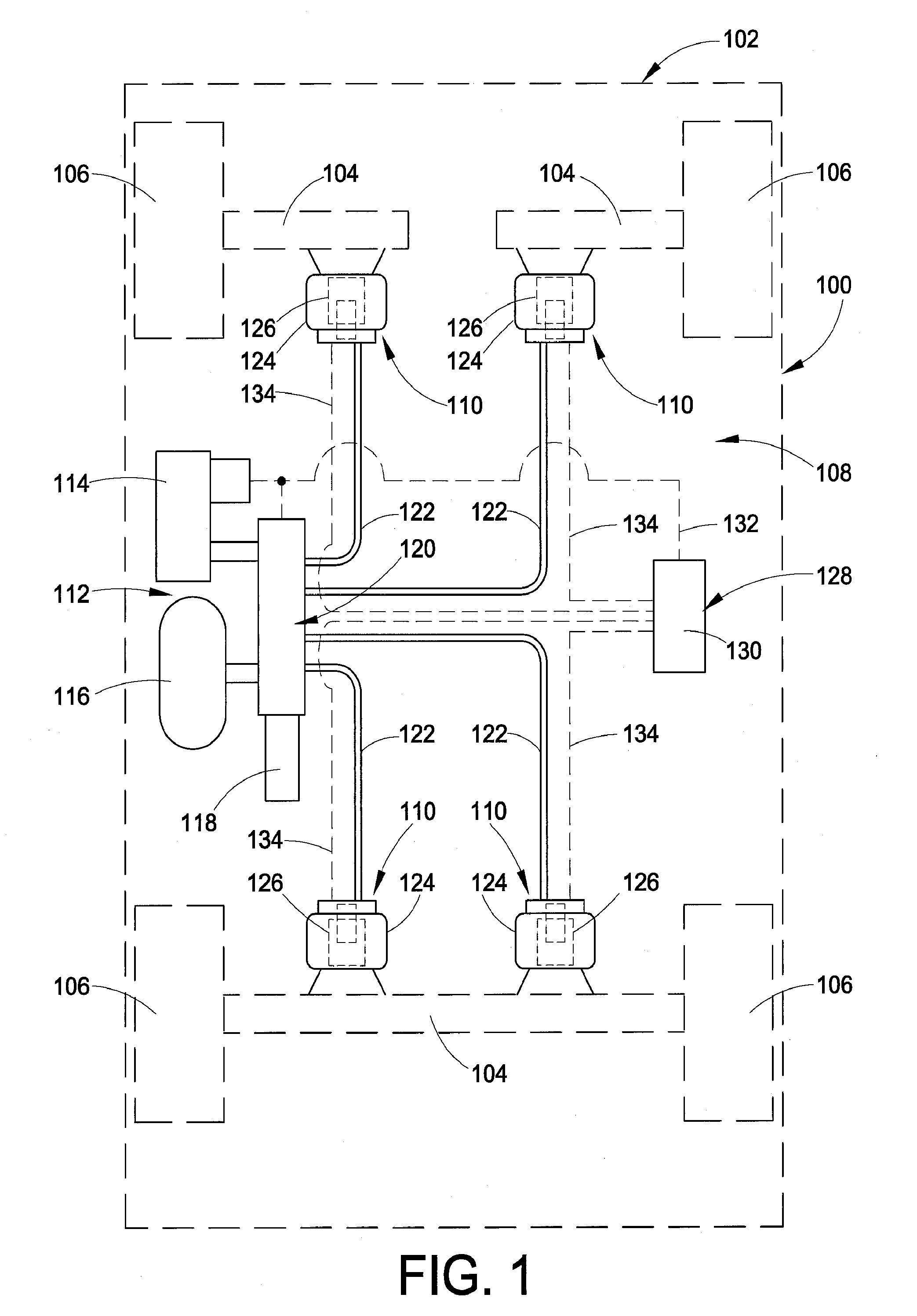

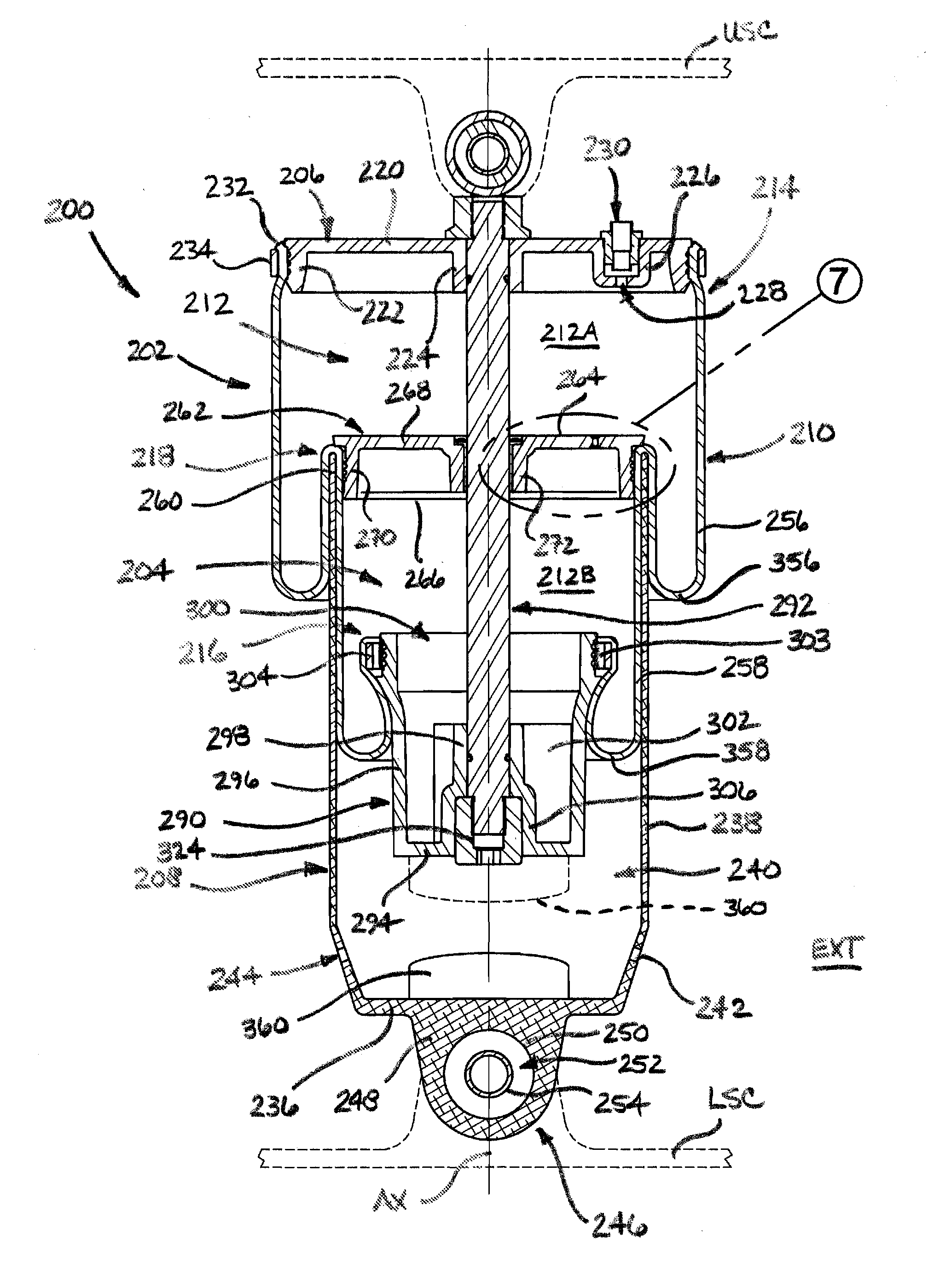

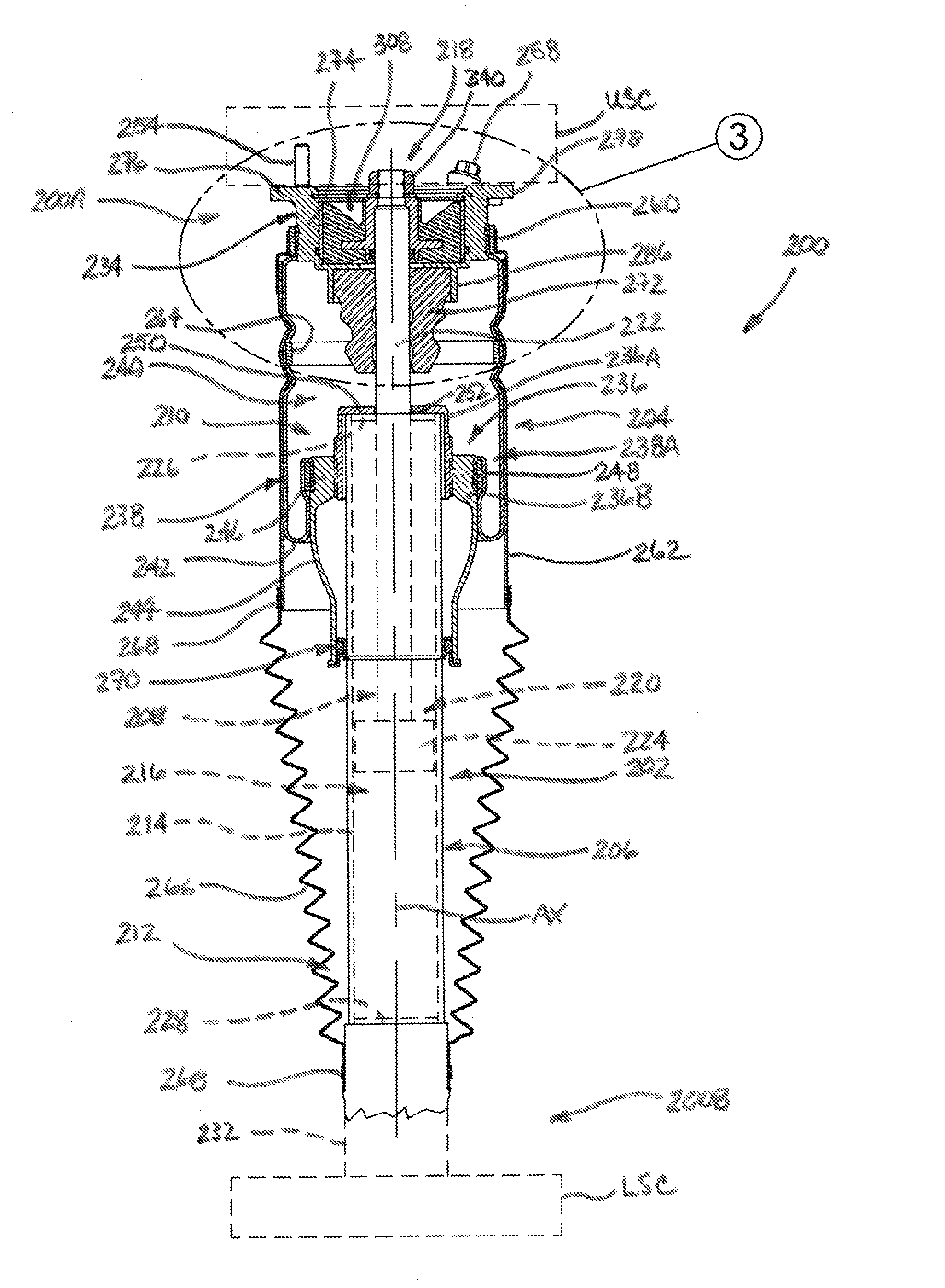

Axial clutch assembly as well as gas spring and gas damper assembly and method including same

A gas spring and gas damper assembly can include a gas spring and a gas damper. The gas spring can include a first end member, a second end member and a flexible wall that at least partially form a spring chamber. The gas damper can include first, second and third damper elements that are telescopically interconnected with one another. The first and third damper elements can be operatively connected to respective ones of the first and second end members. The third damper element includes damper piston having an axial clutch. The second damper element is suspended between the first and third damper elements by biasing elements that engaging the damper piston.

Owner:FIRESTONE IND PROD COMPANY

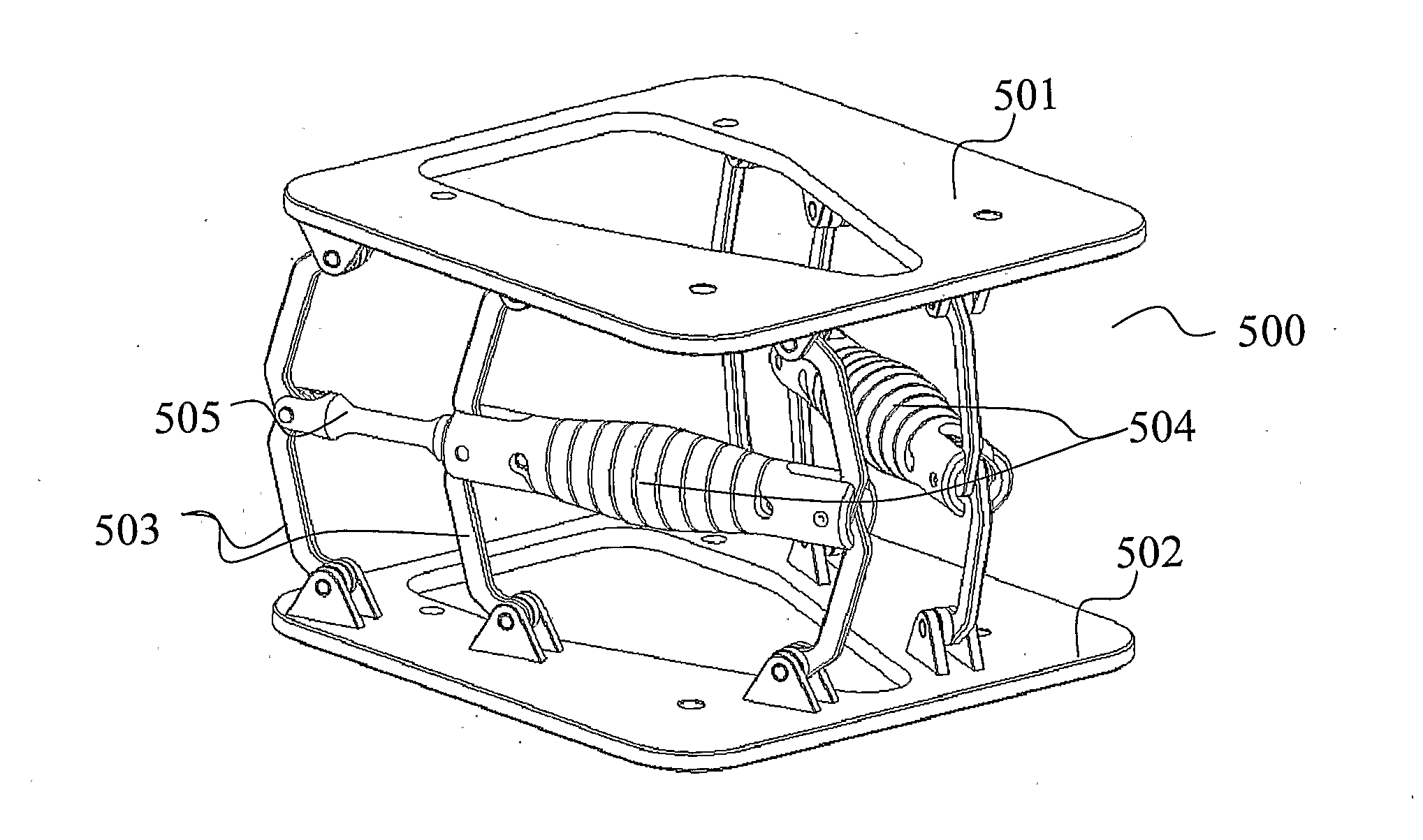

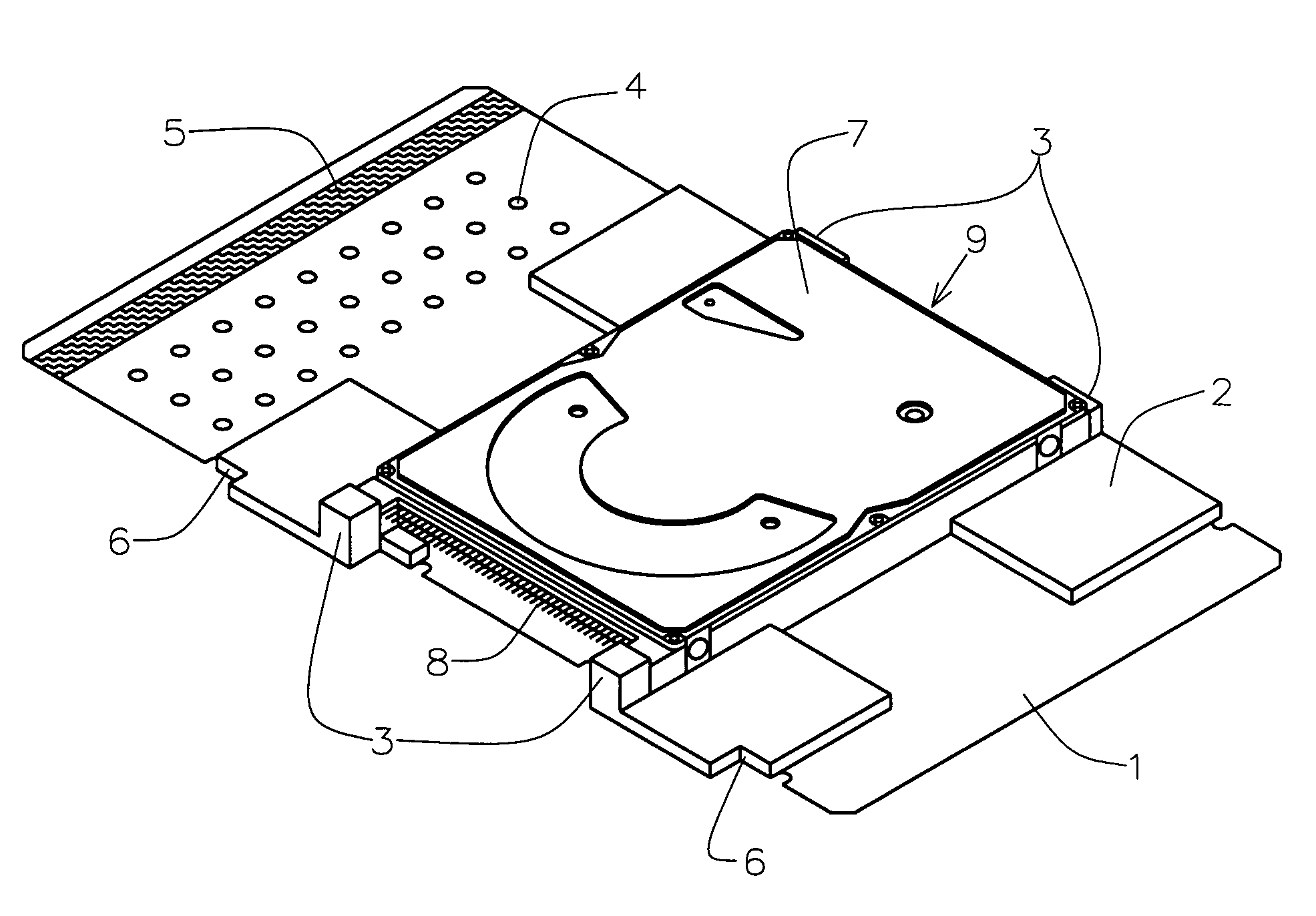

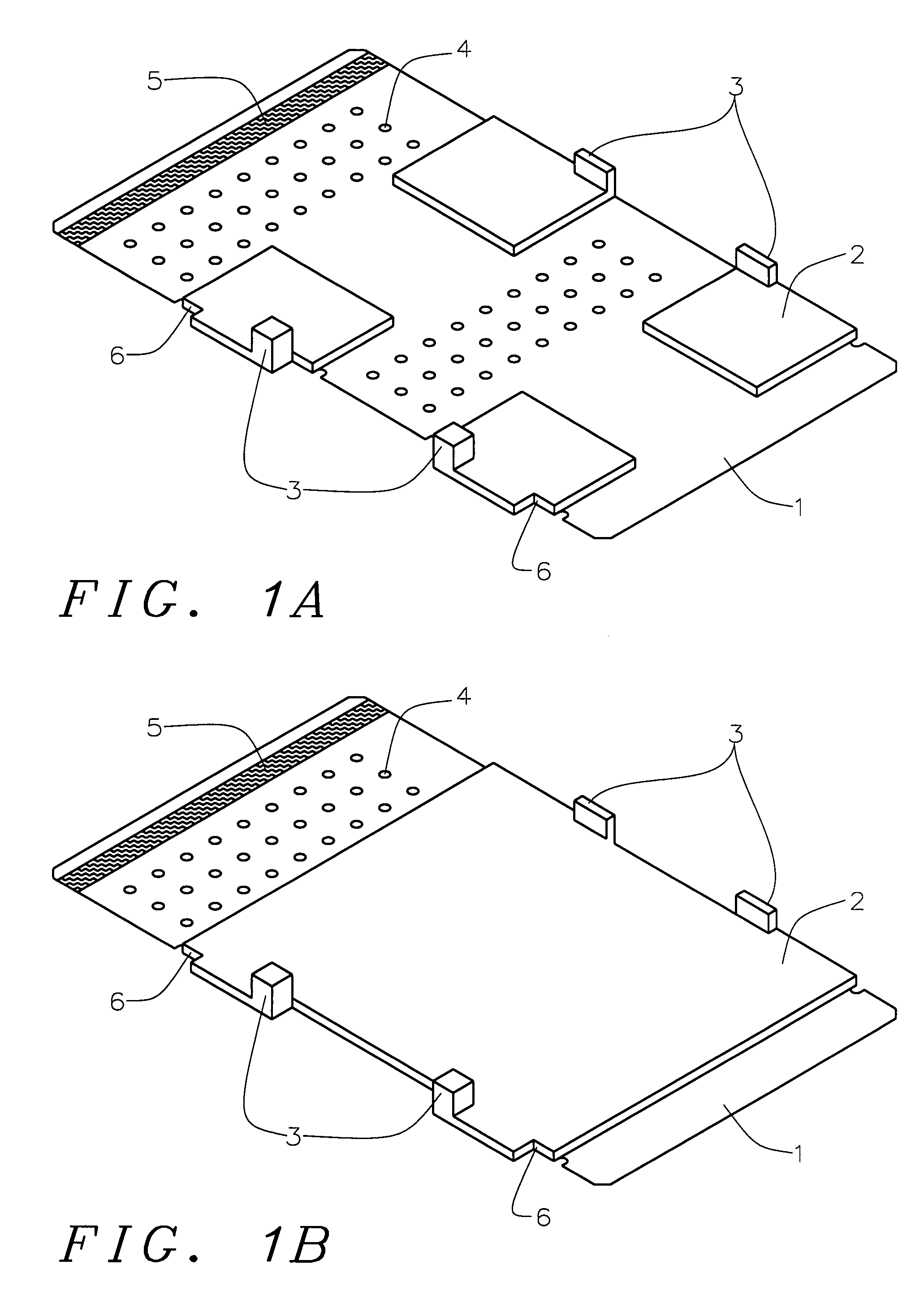

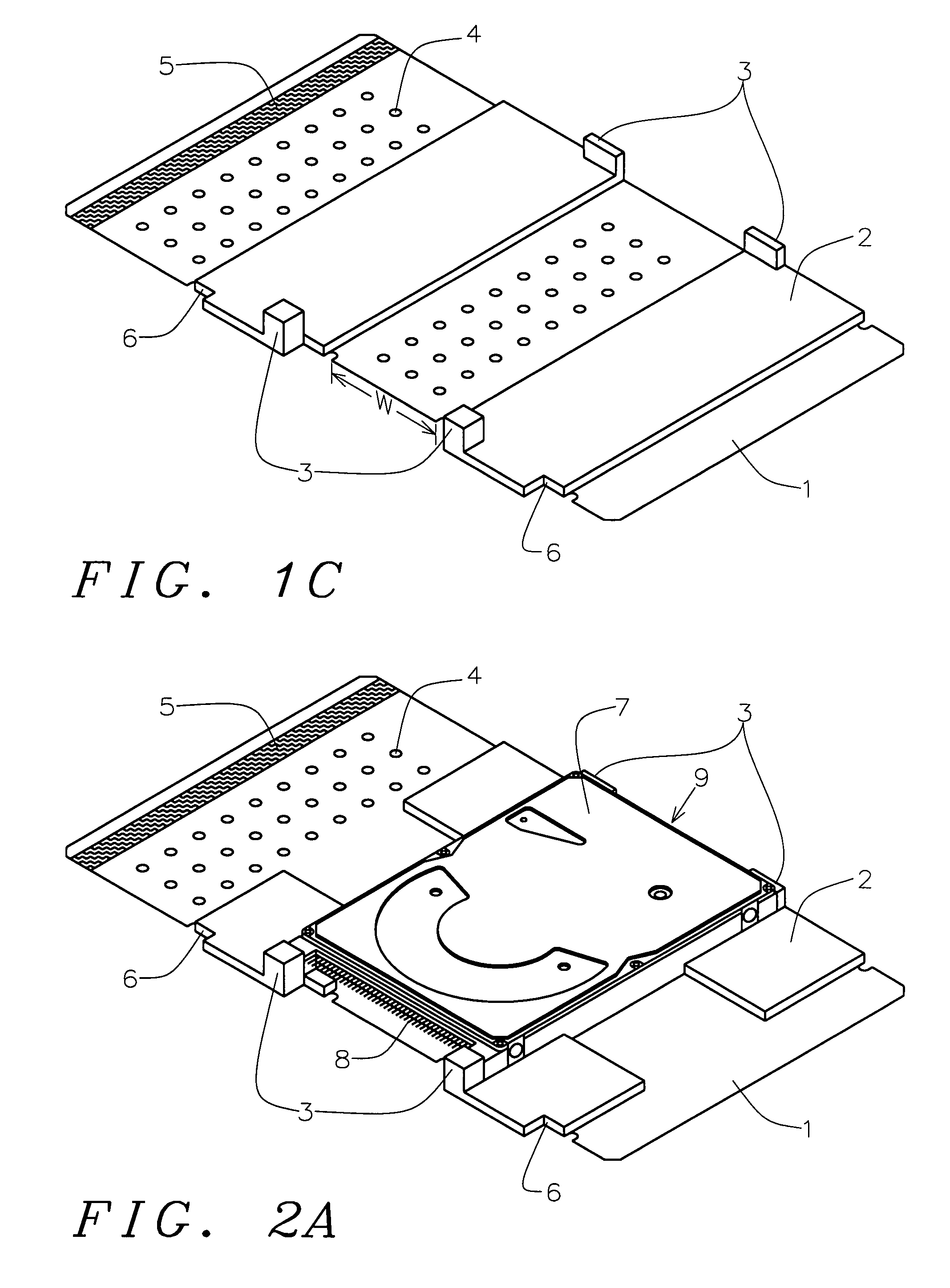

HDD anti-shock and anti-vibration device

Owner:ESGW HLDG

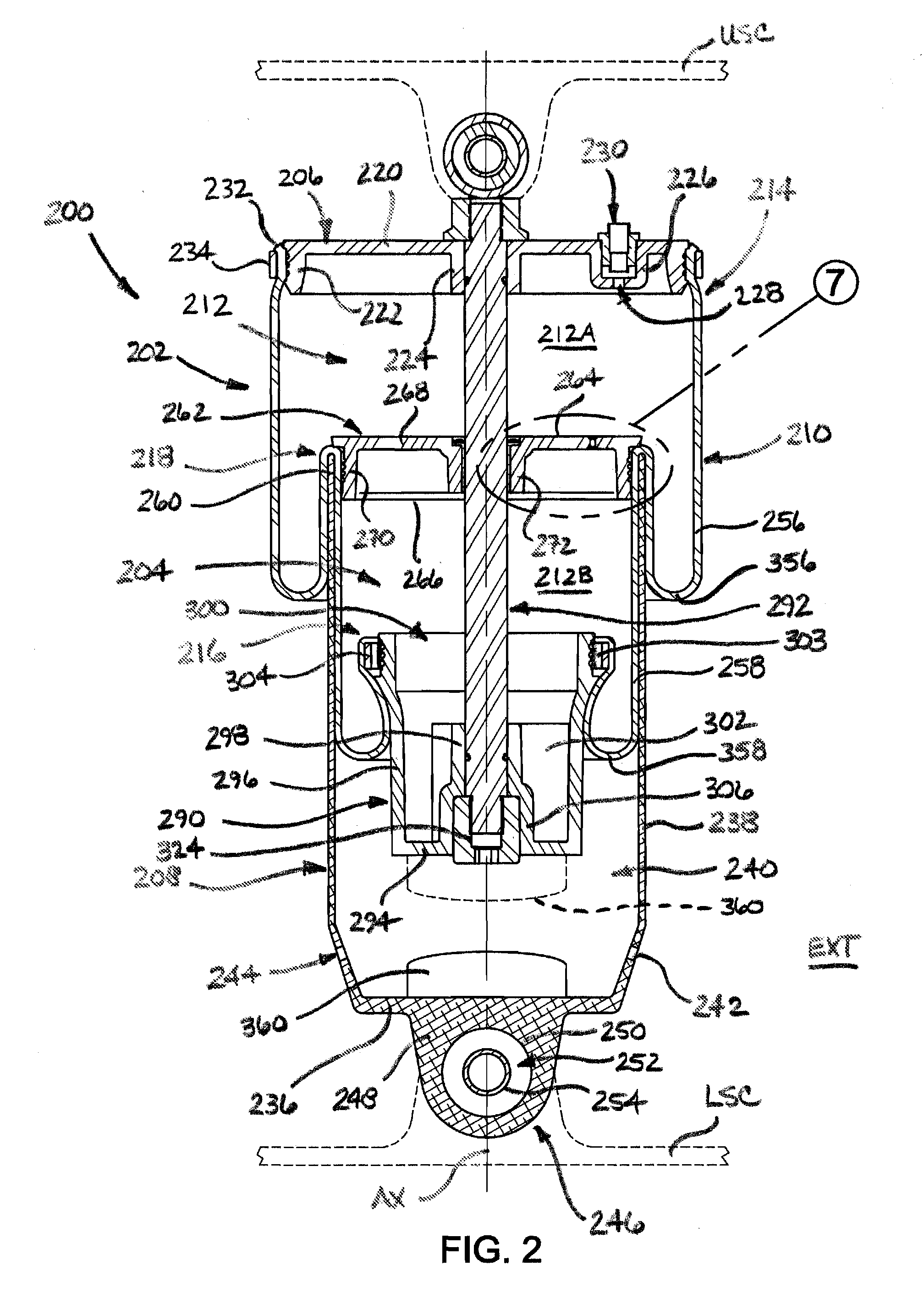

Gas spring and gas damper assembly and method

A gas spring and gas damper assembly (1000) includes a gas spring assembly (1002) and a gas damper assembly (1004). The gas spring assembly (1002) includes a first wall portion (1006), a second wall portion (1008) disposed in spaced relation to the first wall portion (1006), and a flexible wall section (1010) connected therebetween. The gas damper assembly (1004) includes a third wall portion (1094) disposed in longitudinally-spaced relation to the first wall portion (1006), and a second flexible wall section (1104) connected between the second wall portion (1008) and the third wall portion (1094). A fourth wall portion (1070) is disposed between the first (1006) and second (1008) wall sections to define two pressurized gas chambers (1012, 1004). A damper rod (1130) connects at least the first (1006) and third (1094) wall portions. Methods are also included.

Owner:FIRESTONE IND PROD COMPANY

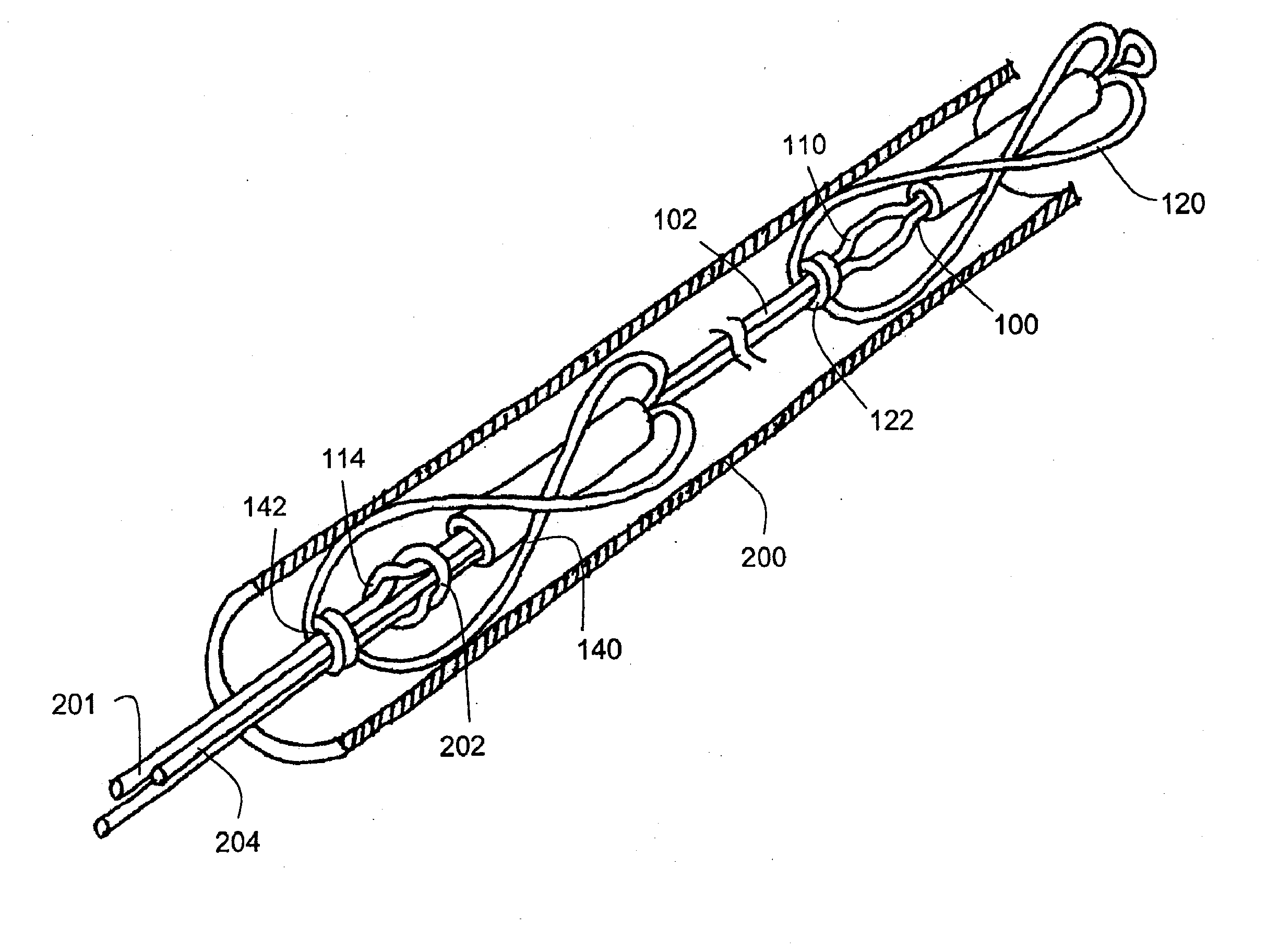

Tubular vibration-damping device used for vibration-damping connecting rod, vibration-damping connecting rod using the same, and method of manufacturing vibration-damping connecting rod

ActiveUS20160053848A1Easy to handleImprove degree of tuning freedomNon-rotating vibration suppressionWire springsElastomerEngineering

Provided are a tubular vibration-damping device for a vibration-damping connecting rod, a vibration-damping connecting rod using the same and a method of manufacturing the vibration-damping connecting rod. The device including an inner shaft member and an outer tubular member being connected by a main rubber elastic body, the inner shaft member having a structure wherein first and second connecting members are inserted into a sleeve member bonded to the main rubber elastic body, the connecting members being axially overlapped with and spaced from each other to provide a rod-end insertion space communicated with outside via rod insertion holes that open through peripheral walls of the sleeve member and the outer tubular member, one end of a rod main body being inserted via the rod insertion holes into the rod-end insertion space and fixed to the first and second connecting members by a fastening member.

Owner:SUMITOMO RIKO CO LTD

Damper rod bushings as well as gas spring and damper assemblies and methods including same

A damper rod bushing operatively connects an end member of a gas spring and a damper rod of a damper to at least partially form a gas spring and damper assembly. The damper rod bushing is constructed for exposure to gas pressure within a spring chamber of a gas spring and damper assembly such that pre-load forces due to gas pressure within said spring chamber act on said damper rod bushing. The damper rod bushing can include an outer support element, an inner support element and an elastomeric connector element operatively connected between the outer and inner support elements such that a substantially fluid-tight seal is formed therebetween. A gas spring and damper assembly including such a damper rod bushing, as well as a suspension system including one or more of such gas spring and damper assemblies and a method of assembly are also included.

Owner:FIRESTONE IND PROD COMPANY

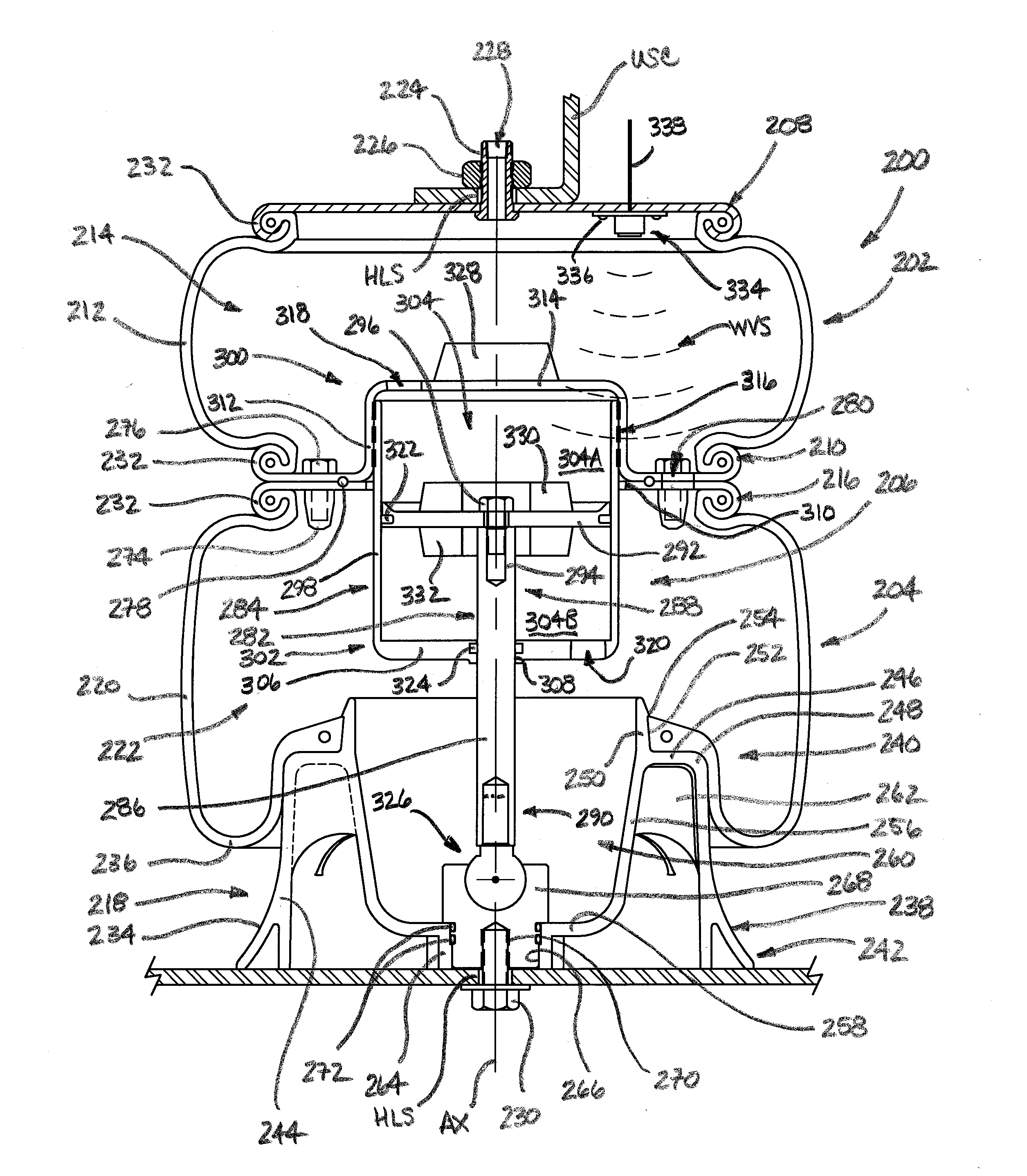

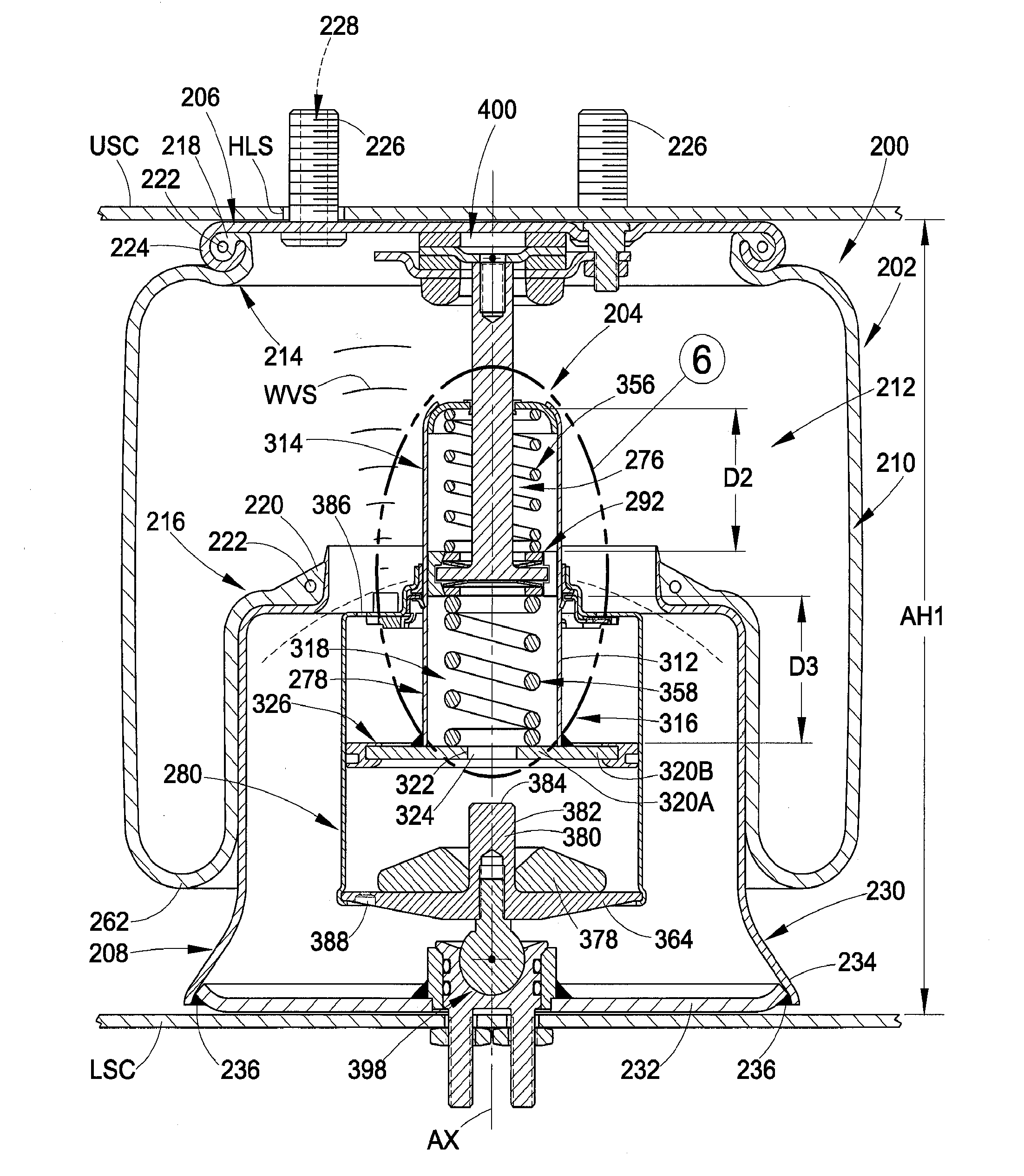

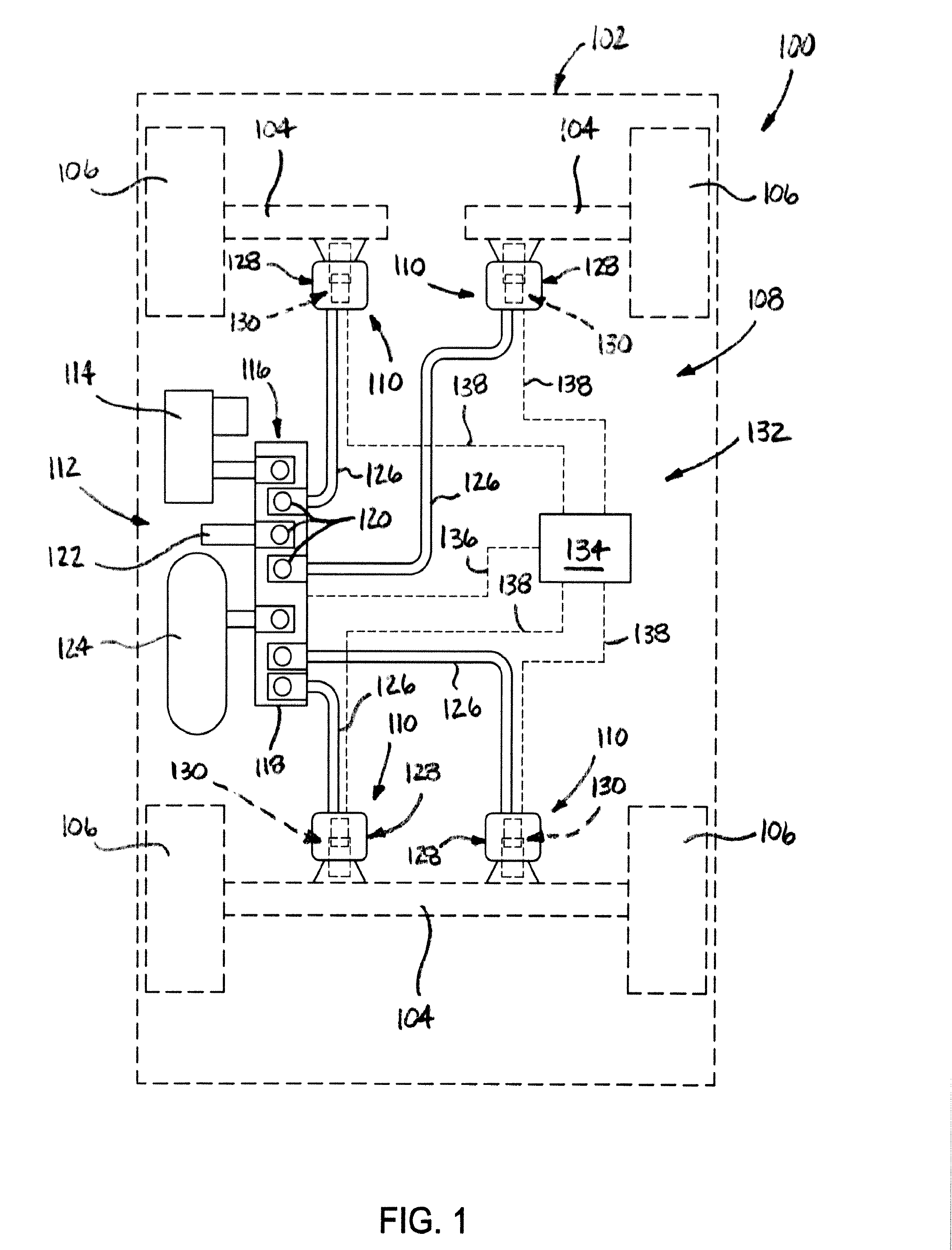

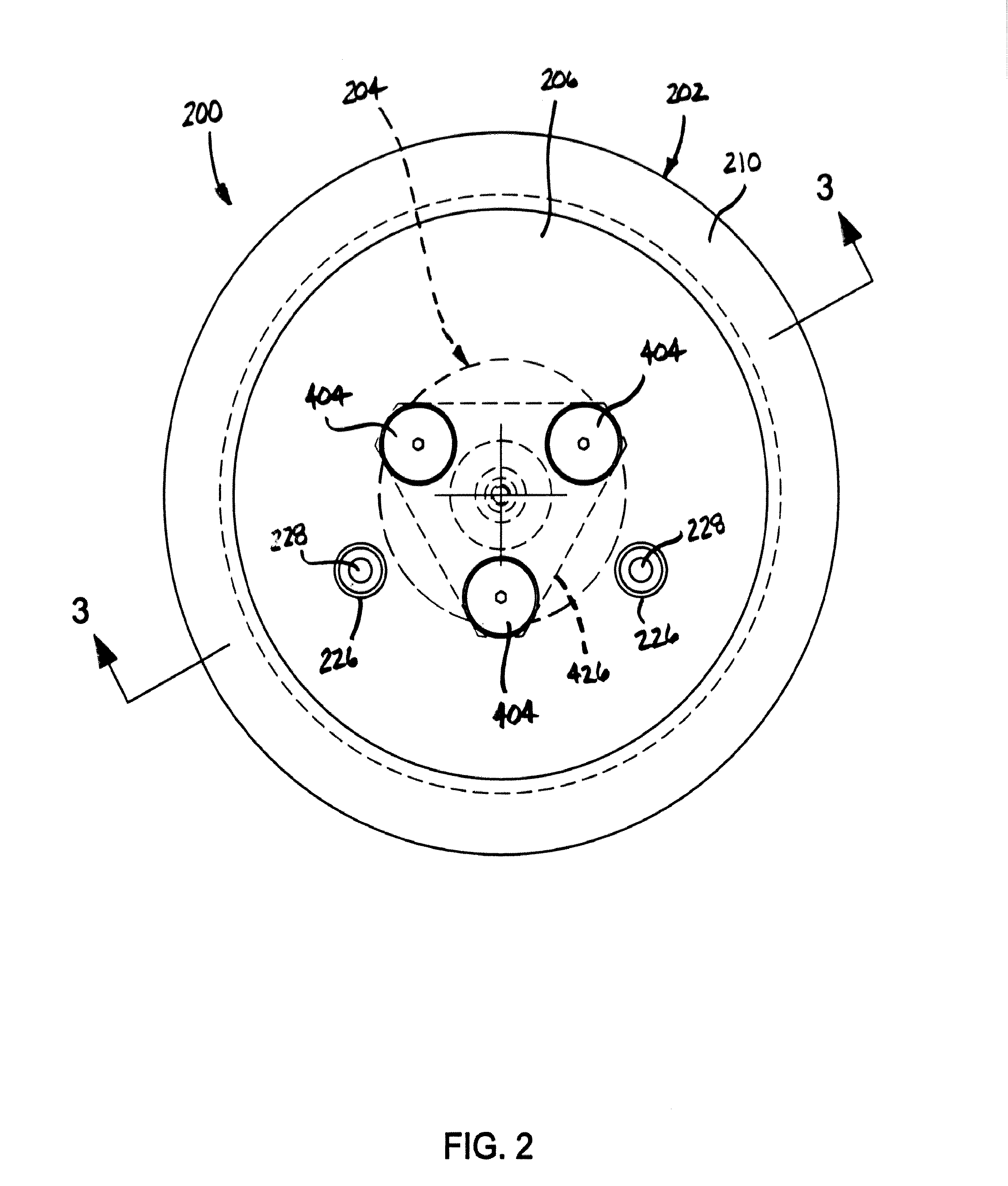

Gas spring and gas damper assemblies and methods of assembly

A gas spring and gas damper assembly (200) can include a gas spring and a gas damper. The gas spring can include a first end member, a second end member and a flexible wall that at least partially forms a spring chamber. The gas damper can include first and second damper elements (278, 280) as well as a damper element assembly that are telescopically interconnected with one another. The damper element assembly can include an outer side wall portion that at least partially defines a cavity and a biasing element extending into the cavity. A suspension system and a method of assembly are also included.

Owner:FIRESTONE IND PROD COMPANY

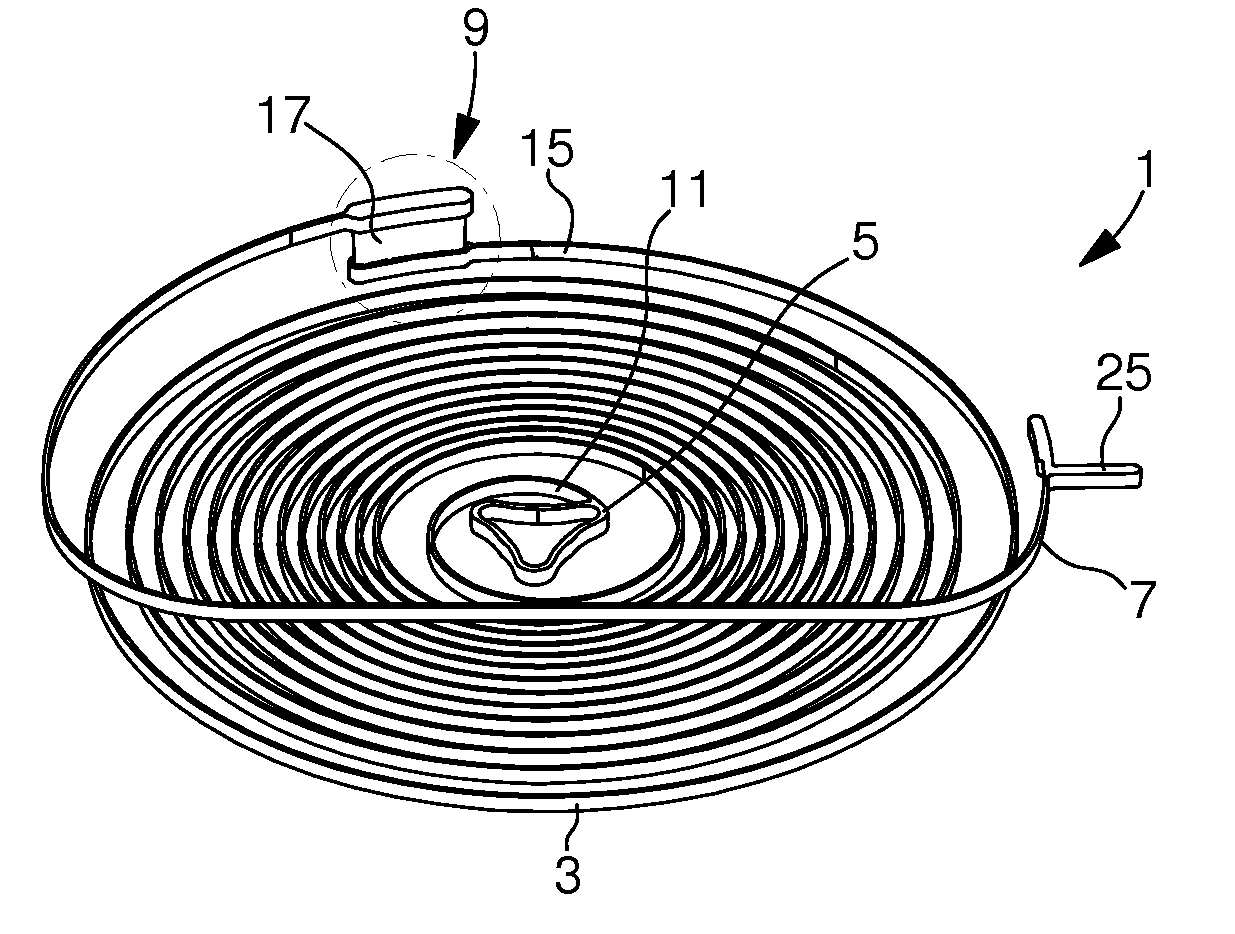

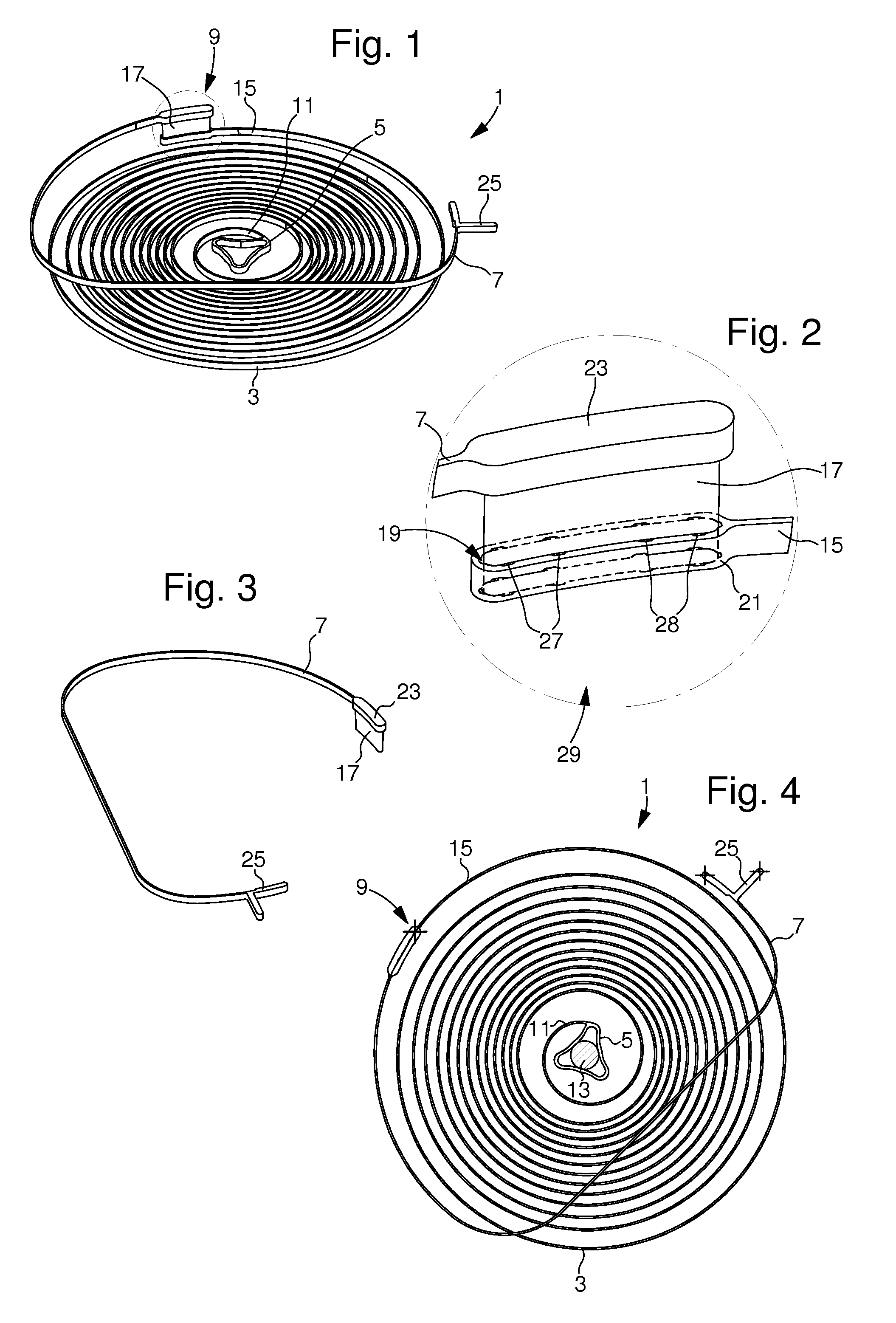

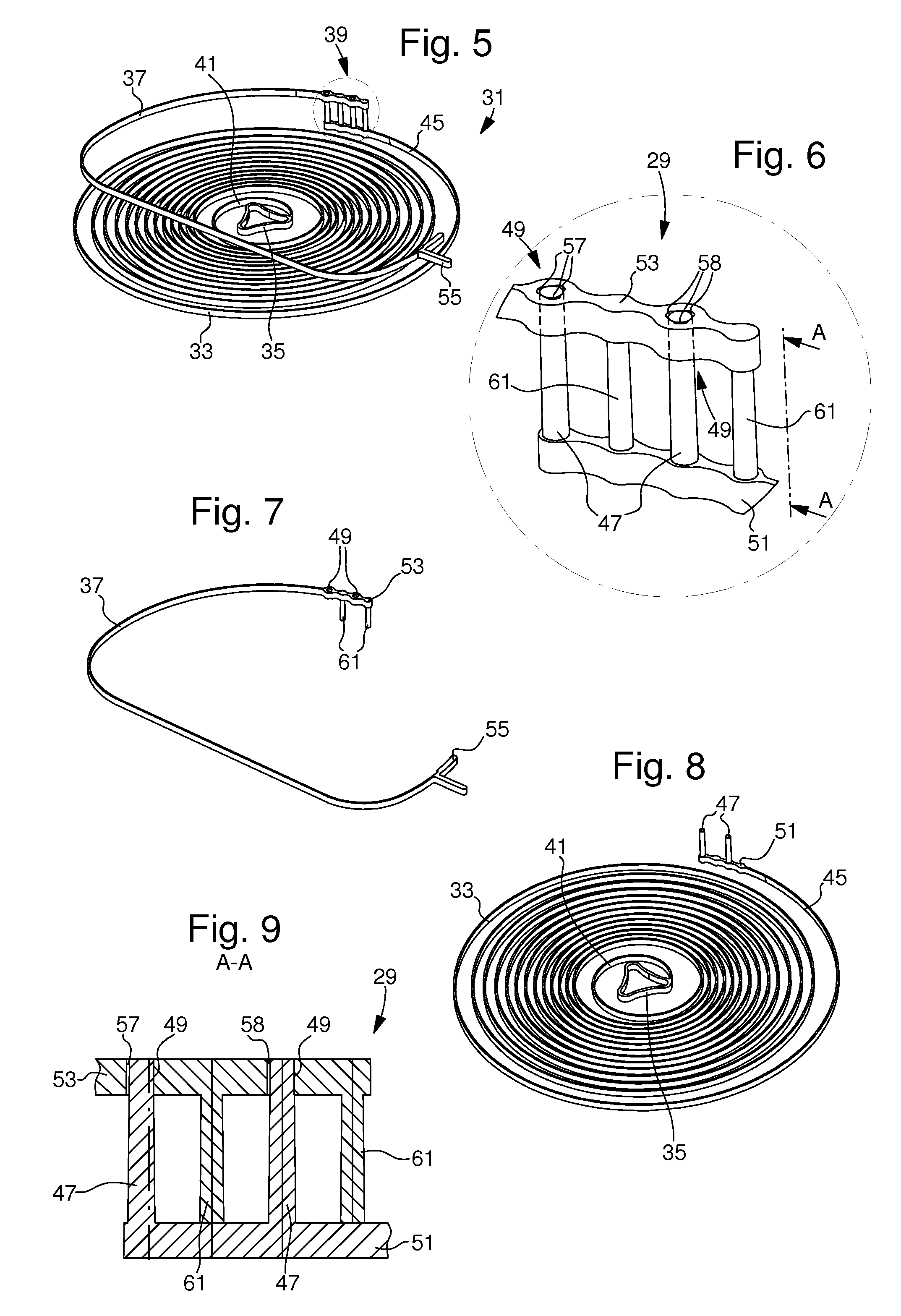

Breguet overcoil balance spring made of silicon-based material

ActiveUS20100149927A1Easy to manufactureReduce variationFrequency stabilisation mechanismWire springsEngineeringMechanical engineering

The invention relates to a silicon-based Breguet overcoil balance spring (1, 31) that includes a hairspring (3, 33) made integral coaxially with a collet (5, 35), a terminal curve (7, 37) and an elevation device (9, 39) between the outer coil (15, 45) of the hairspring and the terminal curve. According to the invention, the balance spring has two single parts secured to each other to increase the development precision of the balance spring. The invention also relates to the method of manufacturing the balance spring. The invention concerns the field of timepiece movements.

Owner:MONTRES BREGUET

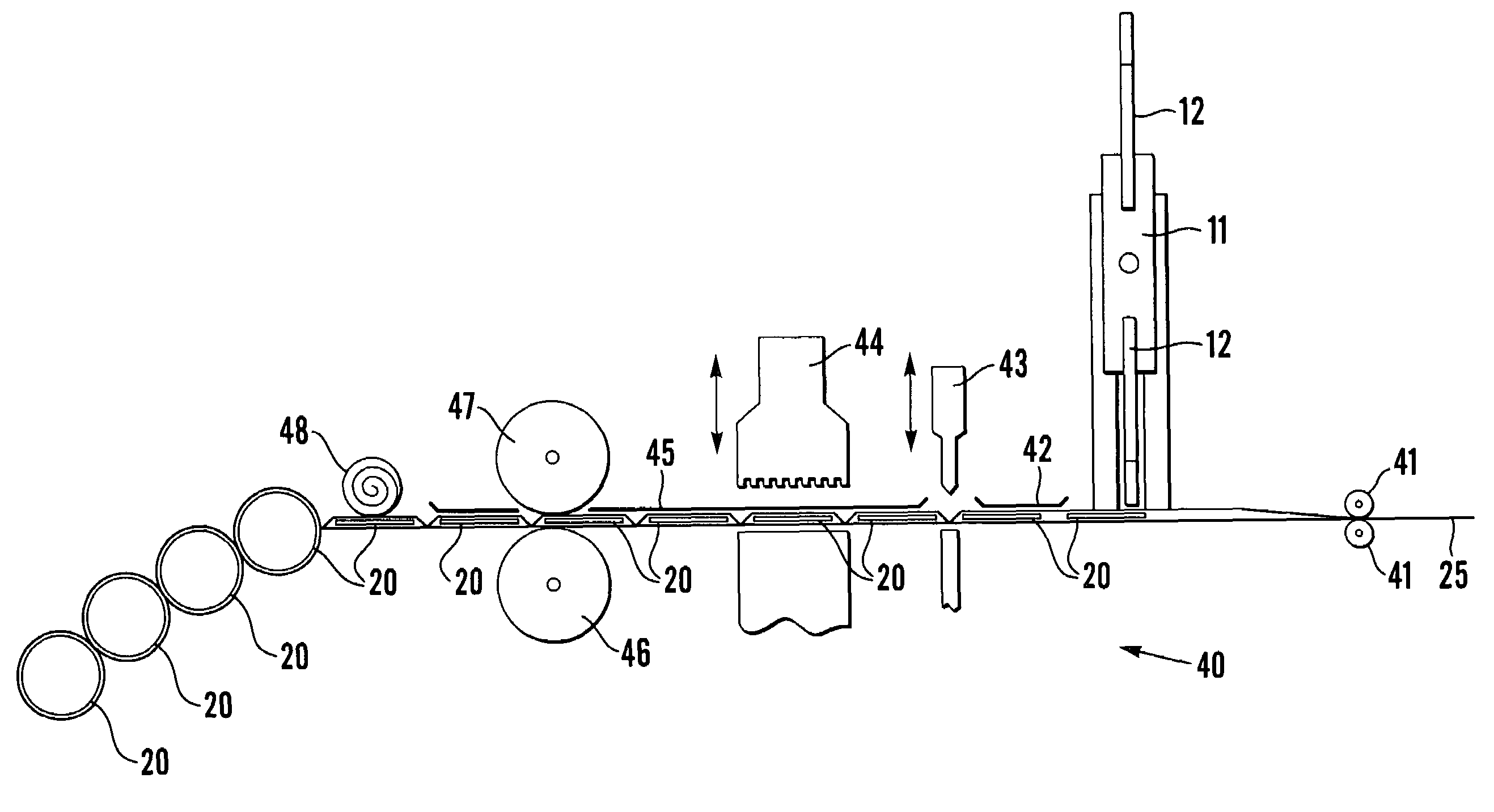

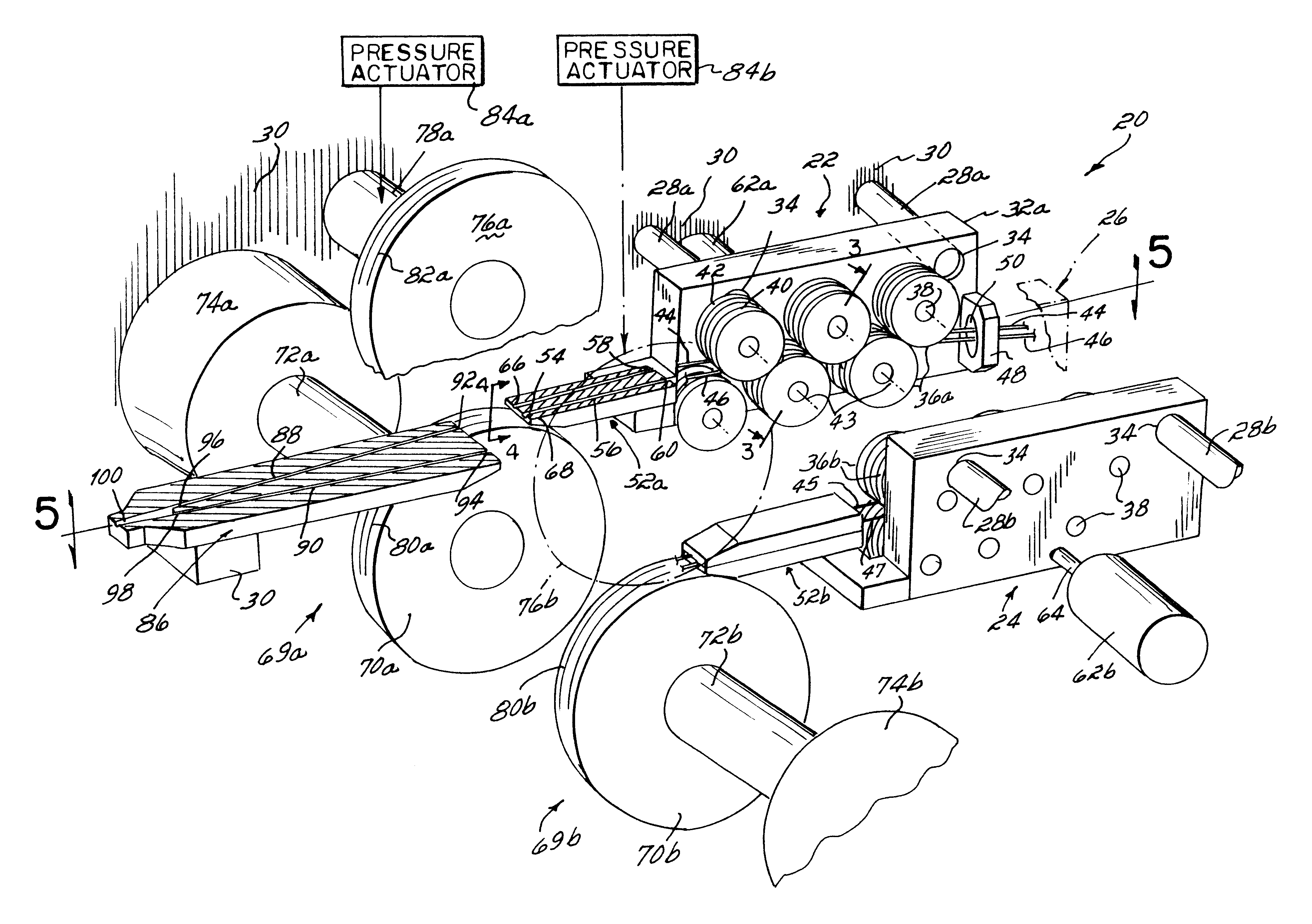

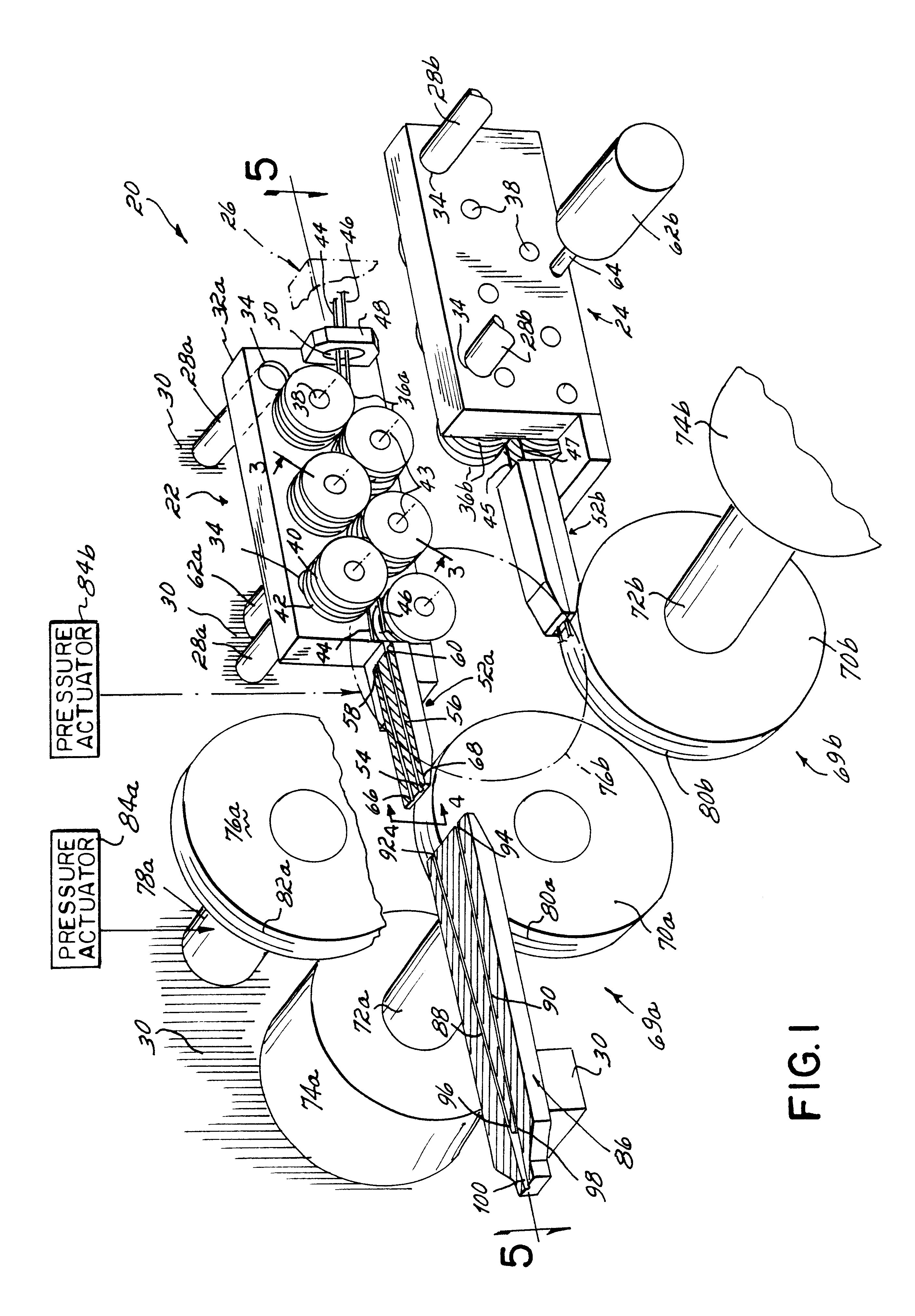

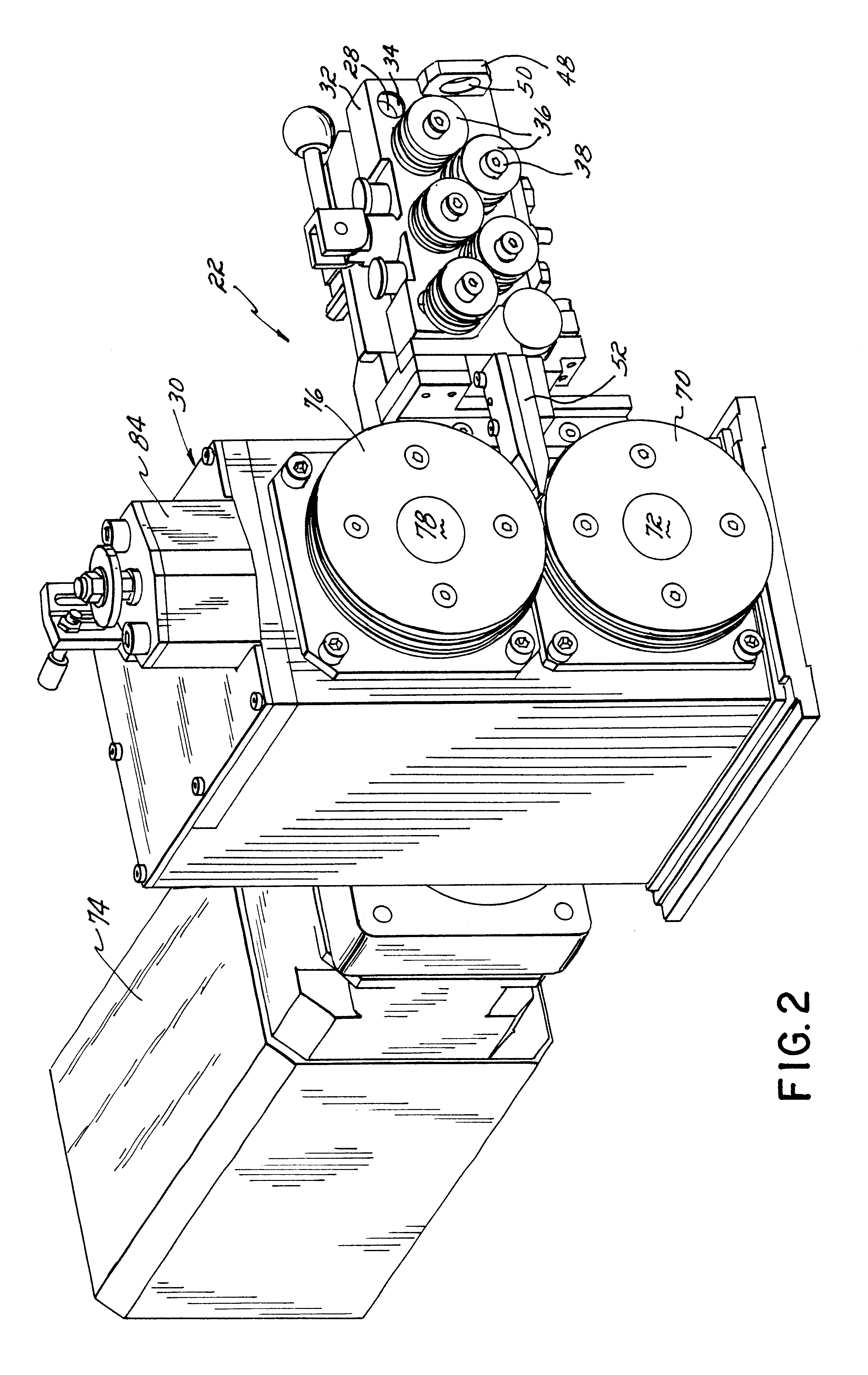

Multiple wire feed for spring coiling machine and method

InactiveUS6910360B2Saving on needLow costMetal-working apparatusWire networkEngineeringMechanical engineering

An apparatus for making mattress and upholstery spring coils. The apparatus has a wire feeding device and a wire guide adapted to support first and second wires of different diameters. The wire guide is movable to first and second positions to align the first and second wires, respectively, with the wire feeding device. A spring coiling machine is positioned adjacent the wire feeding device. When the wire guide is in the first position, the spring coiling machine receives the first wire of one diameter from the wire feeding device; and the spring coiling machine bends the first wire into a spring coil of a desired diameter and pitch and having a first stiffness. When the wire guide is in the second position, the spring coiling machine receives the second wire of another diameter from the wire feeding device; and the spring coiling machine bends the second wire into a spring coil of the desired diameter and pitch but having a second stiffness.

Owner:L & P PROPERTY MANAGEMENT CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com