Patents

Literature

555results about "Ingot casting plants" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anodizing Aluminum and Alloys Thereof

This invention encompasses methods of producing a colored oxide layer on an aluminum material by anodizing the aluminum material in an electrolyte comprising water, sulfuric acid and oxalic acid. The anodizing step comprises passing at least two sequential current densities through the electrolyte. Methods of making and using article with a colored oxide layer on an aluminum material make by the methods disclosed herein are also disclosed.

Owner:DURACOUCHE INT

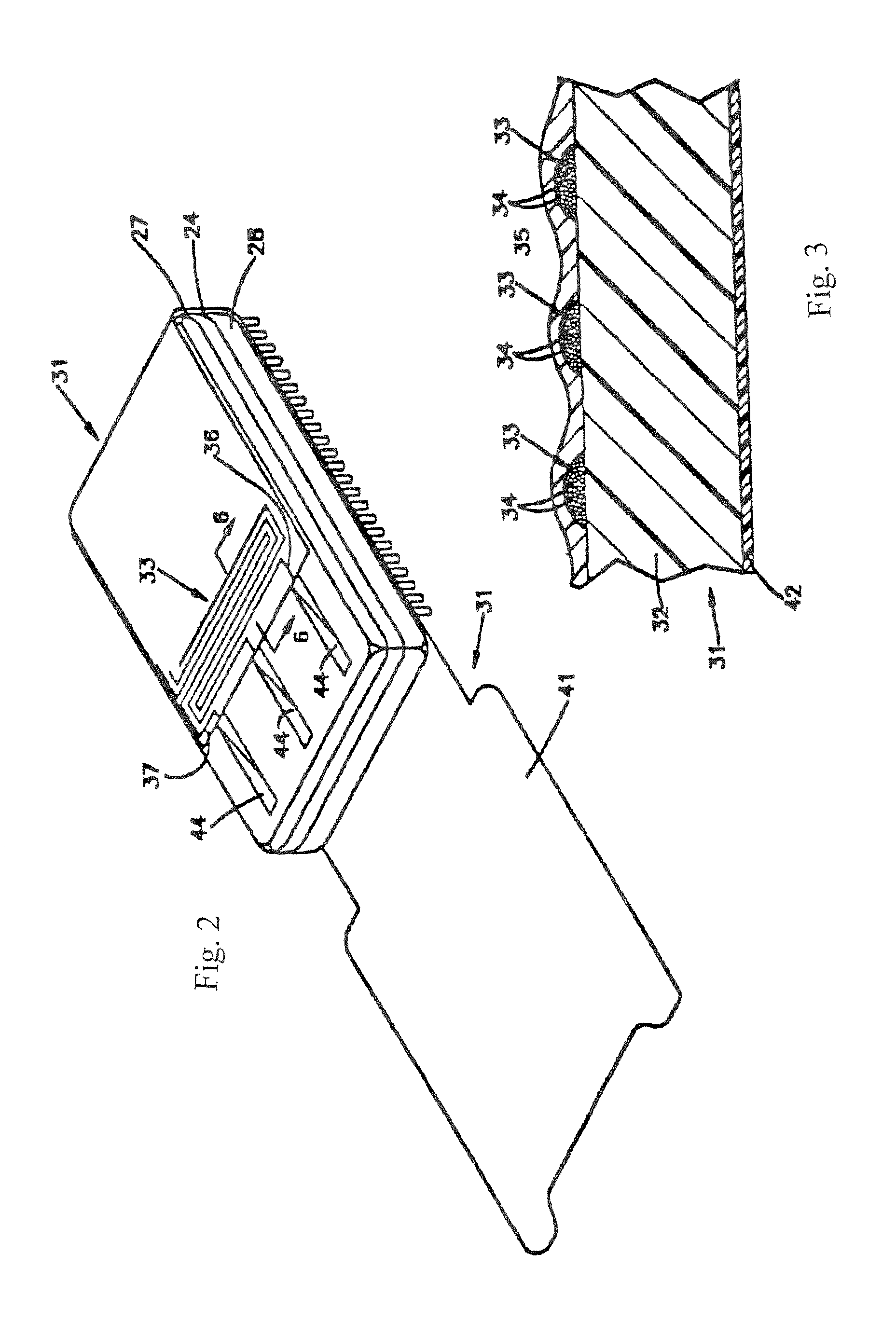

Data protection by detection of intrusion into electronic assemblies

InactiveUS7901977B1Improve adhesionImprove thermal stabilityPig casting plantsPrinted electric component incorporationResistFilling materials

Electronic assemblies, especially one containing volatile memory, used a flexible membrane with conducting lines which acts as an intrusion sensor against chemical and mechanical attacks. The lines are fabricated from inherently conducting polymers which are solution processed and directly patterned. The material was applied to a flexible polymer film by spin coating and patterned by application of a resist, followed by exposure / development of the resist and transferring the image into the polyaniline by reactive ion etching techniques. The conducting lines have high conductivity, tranparency properties which made them difficult to detect and possess excellent adhesion to the substrate film, as well as to the potting material which enclosed the structure. They also offered lightweight advantages over conventionally filled materials. These materials can also be used in conjunction with conventional conductor materials to further enhance protection against intrusion by sophisticated mechanical means.

Owner:IBM CORP

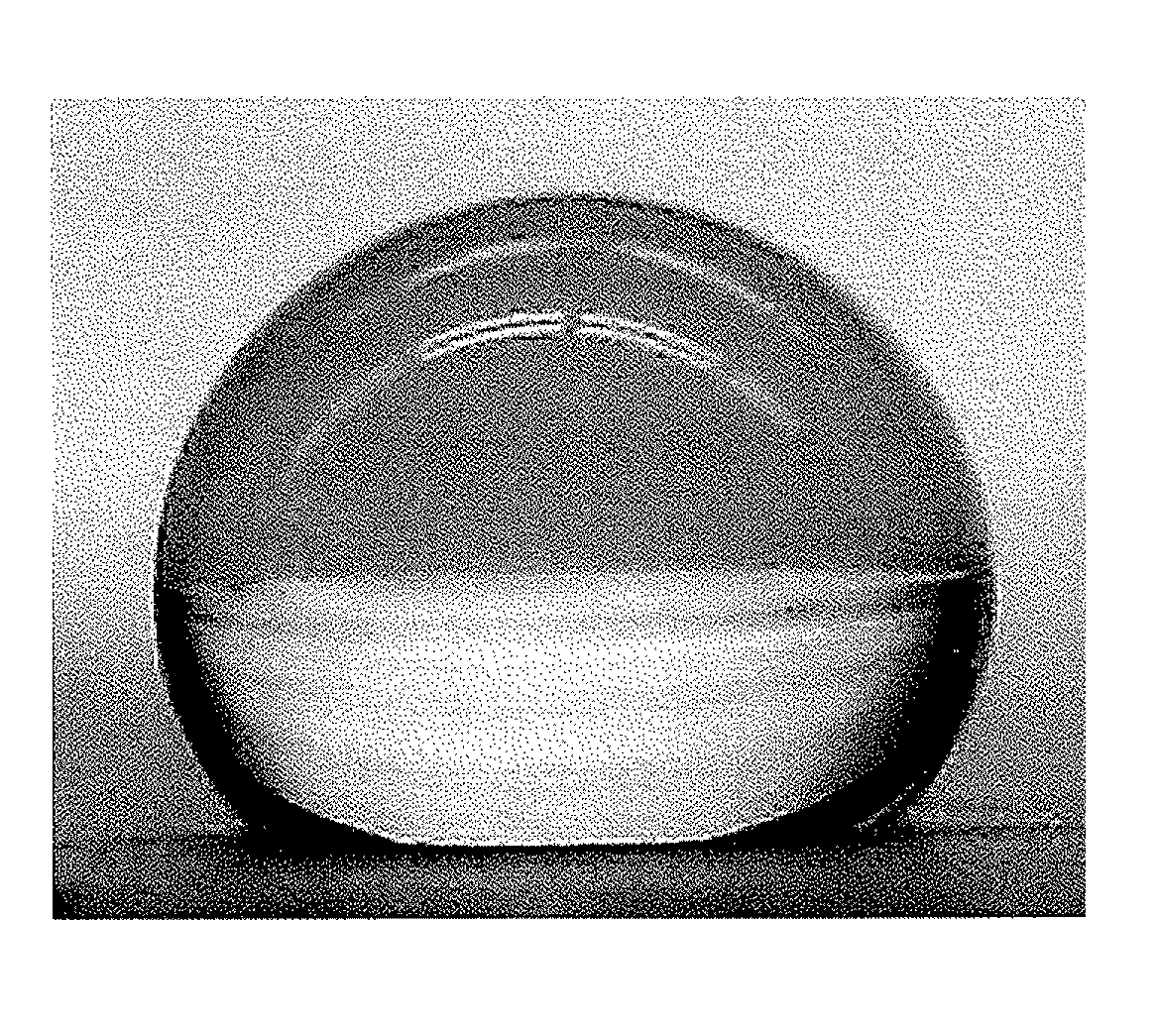

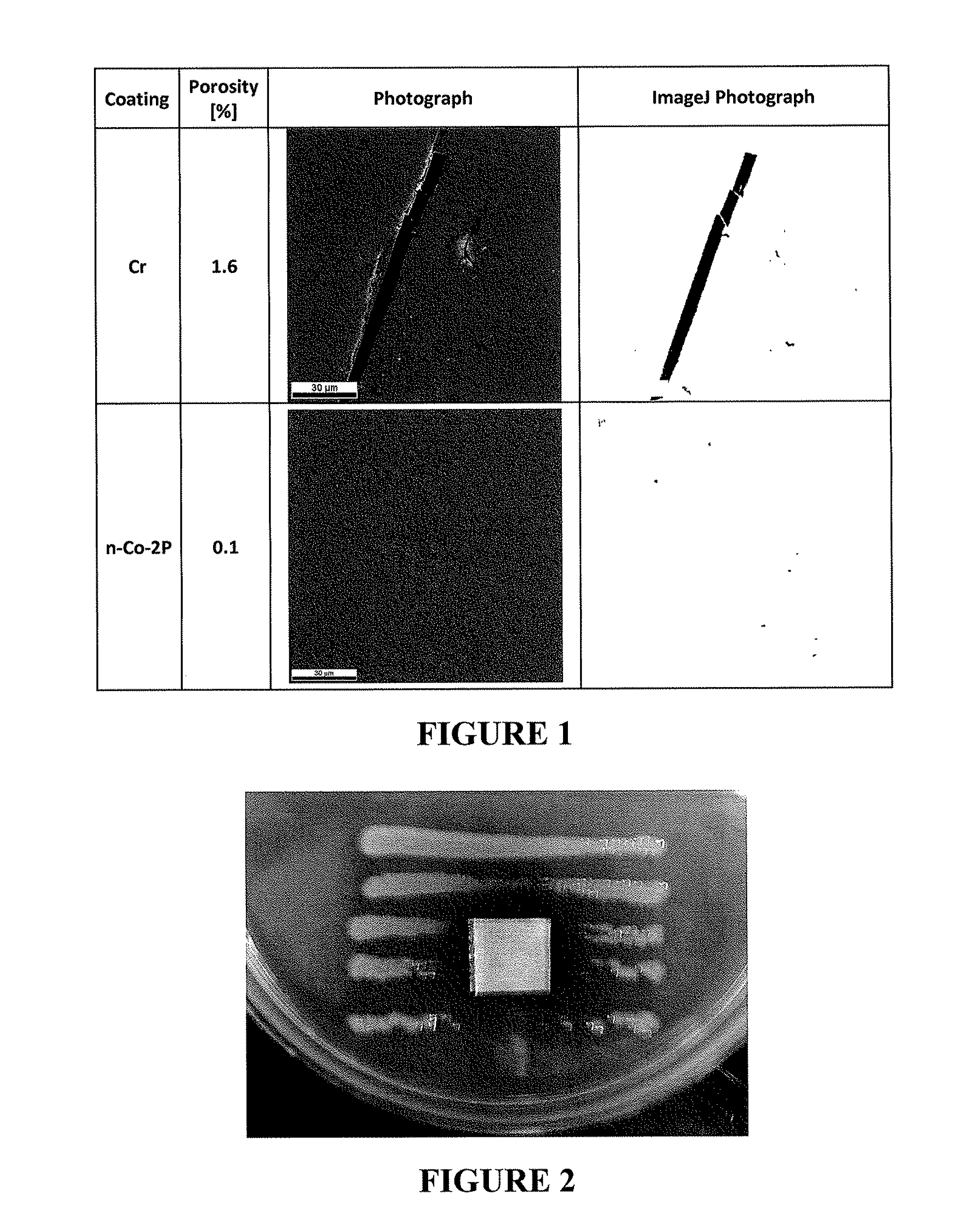

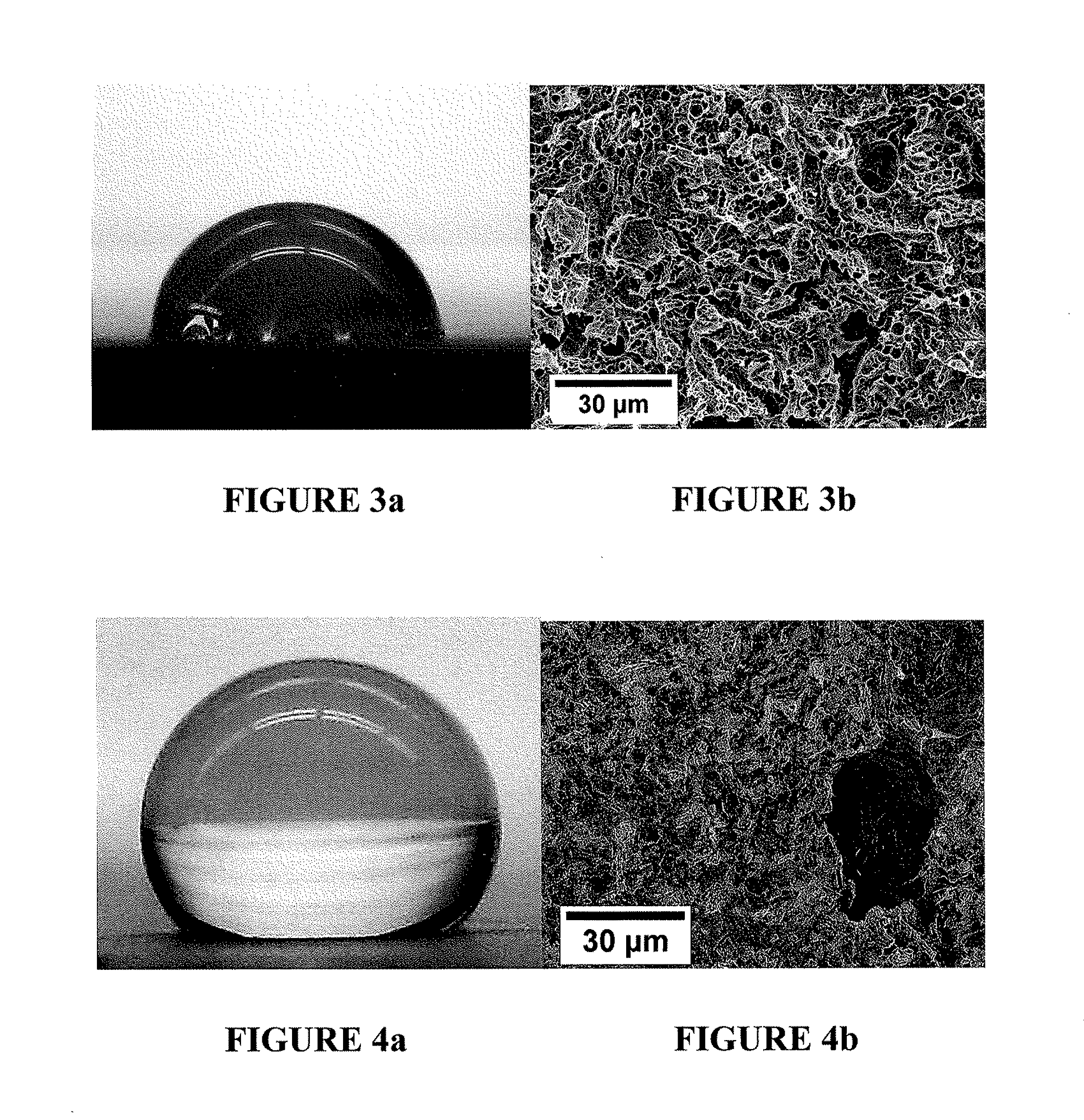

Electrodeposited metallic materials comprising cobalt

ActiveUS20100304179A1Reduce resistanceEliminate security concernsPig casting plantsElectrolytic coatingsMetal coatingMetallic materials

Free standing articles or articles at least partially coated with substantially porosity free, fine-grained and / or amorphous Co-bearing metallic materials optionally containing solid particulates dispersed therein, are disclosed. The electrodeposited metallic layers and / or patches comprising Co provide, enhance or restore strength, wear and / or lubricity of substrates without reducing the fatigue performance compared to either uncoated or equivalent thickness Cr coated substrate. The fine-grained and / or amorphous metallic coatings comprising Co are particularly suited for articles exposed to thermal cycling, fatigue and other stresses and / or in applications requiring anti-microbial and hydrophobic properties.

Owner:INTEGRAN TECH

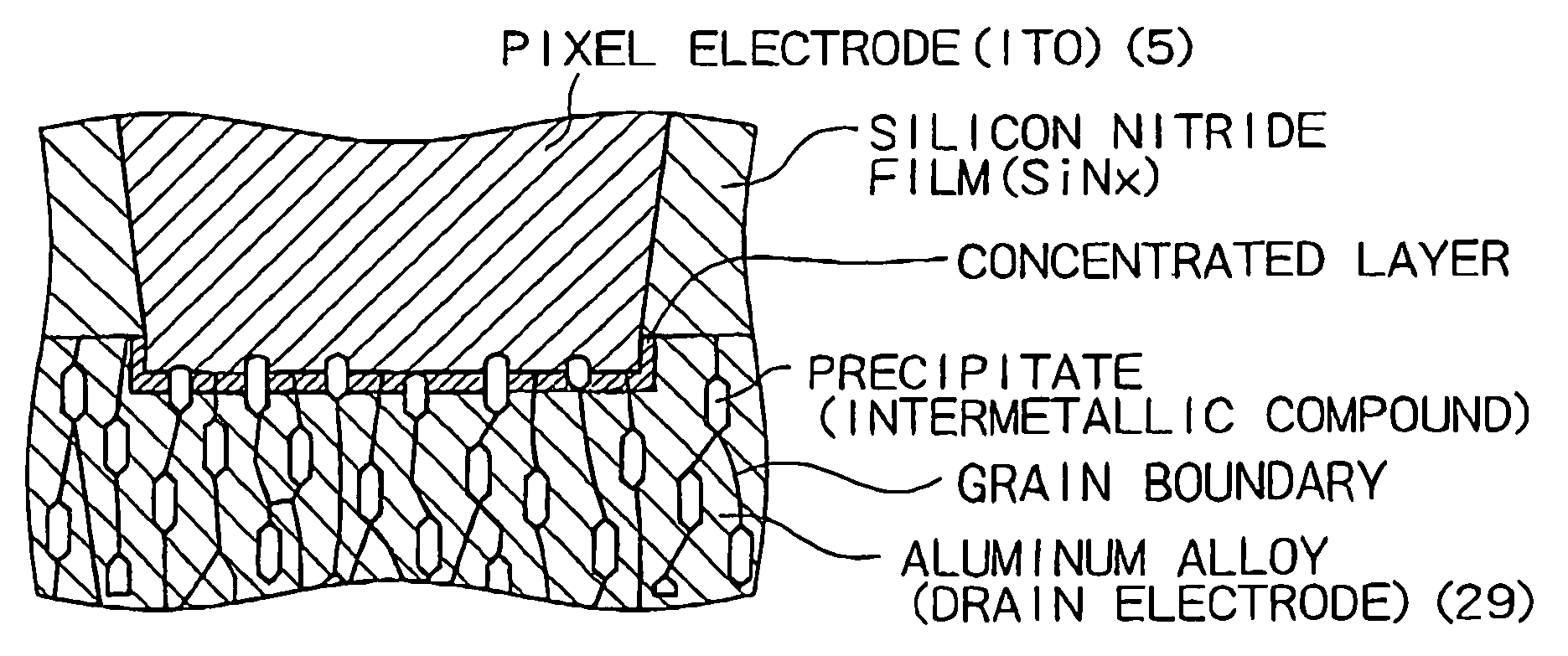

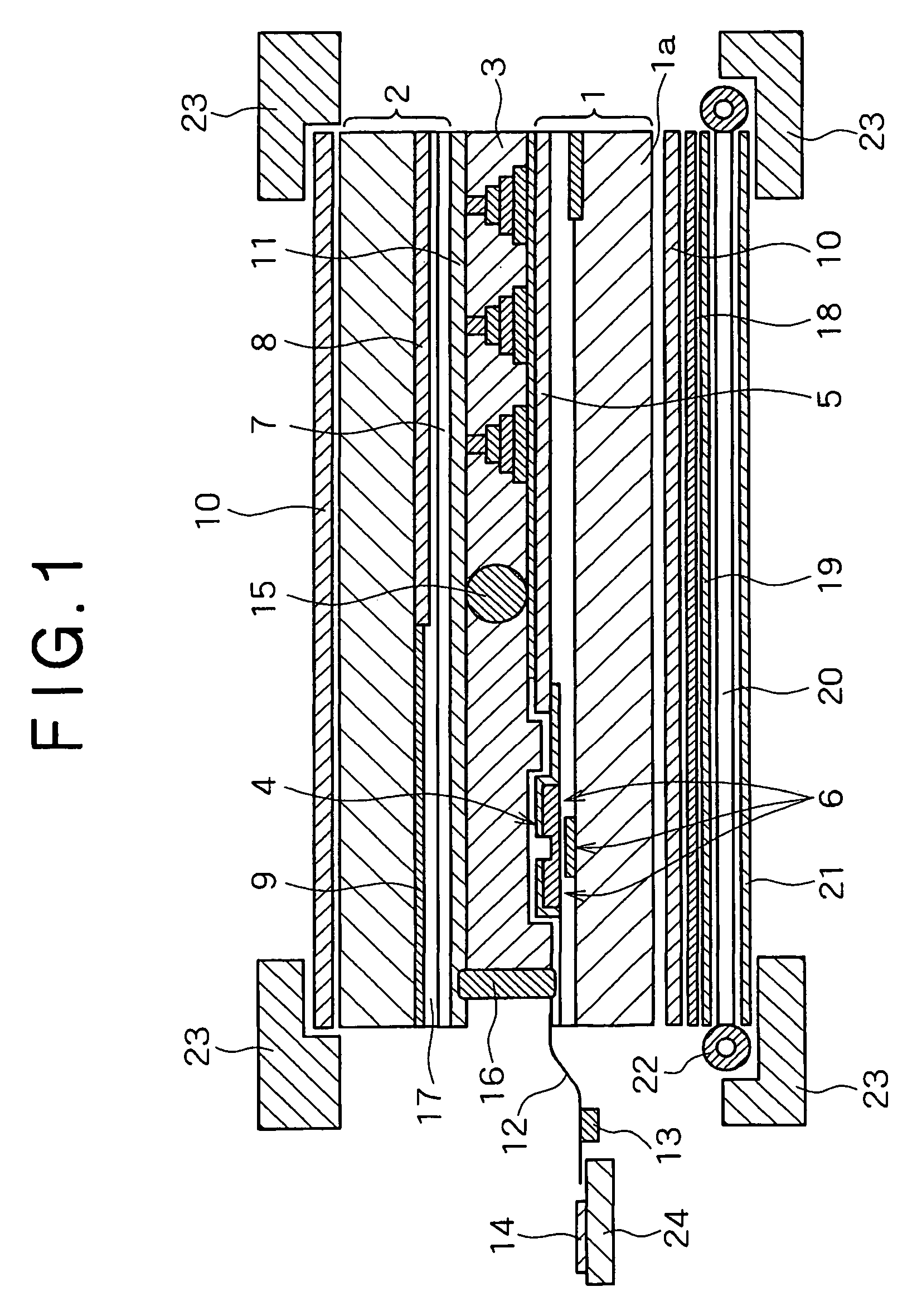

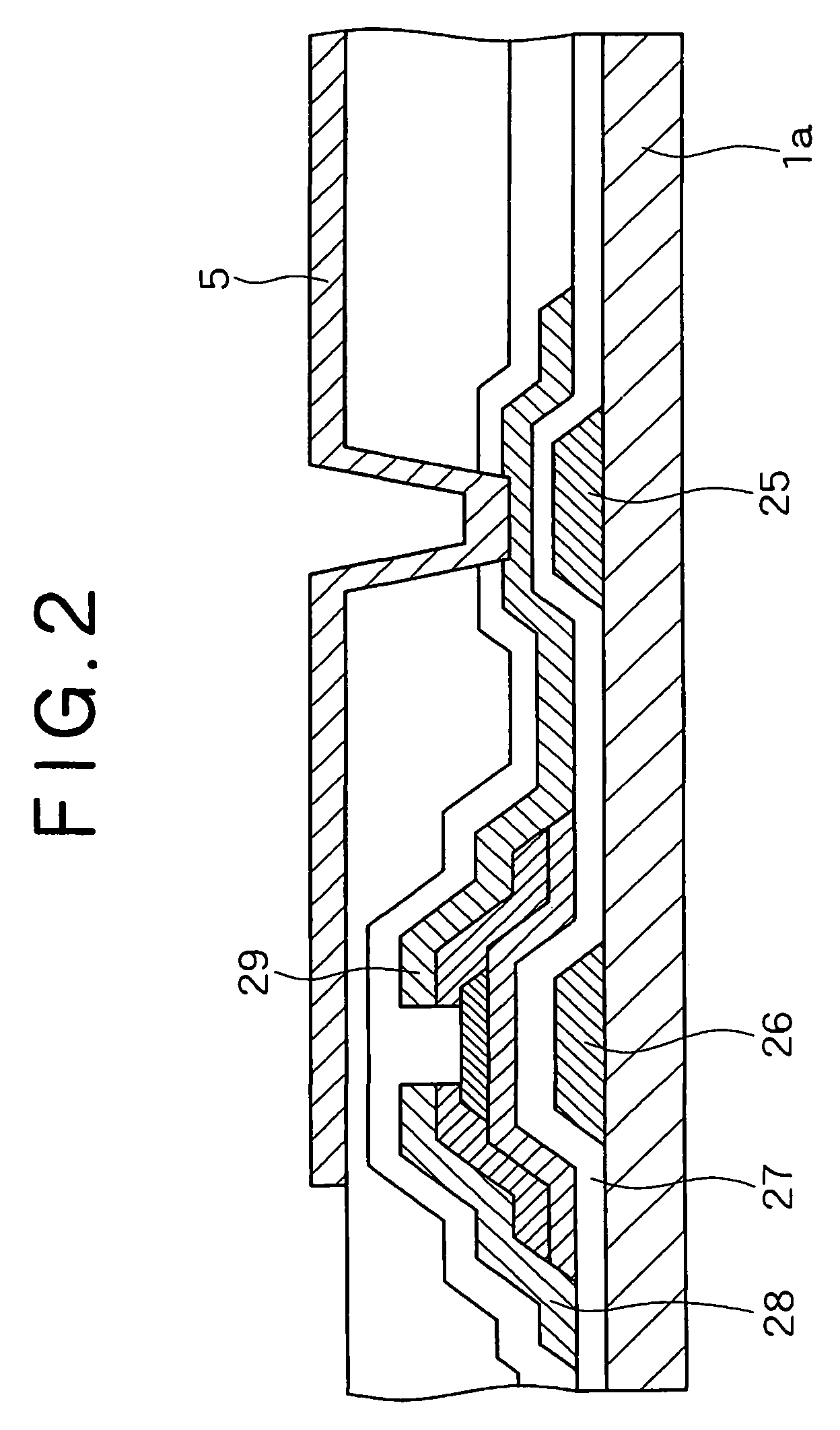

Electronic device, method of manufacture of the same, and sputtering target

InactiveUS7098539B2Simplification of processImprove electrical performancePig casting plantsSemiconductor/solid-state device detailsManufacturing technologyMetal

In an electronic device comprising a first electrodes consisting of a metal oxide and a second electrode consisting of an aluminum alloy film directly contacted and electrically connected to the first electrode, the contact interface between the aluminum alloy film and the first electrode is constructed so that at least a part of alloy components constituting the aluminum alloy film exist as a precipitate or concentrated layer. This construction enables direct contact between the aluminum alloy film and the electrode consisting of a metallic oxide and allows elimination of a barrier metal in such an electronic device, and manufacturing technology therefor.

Owner:KOBE STEEL LTD

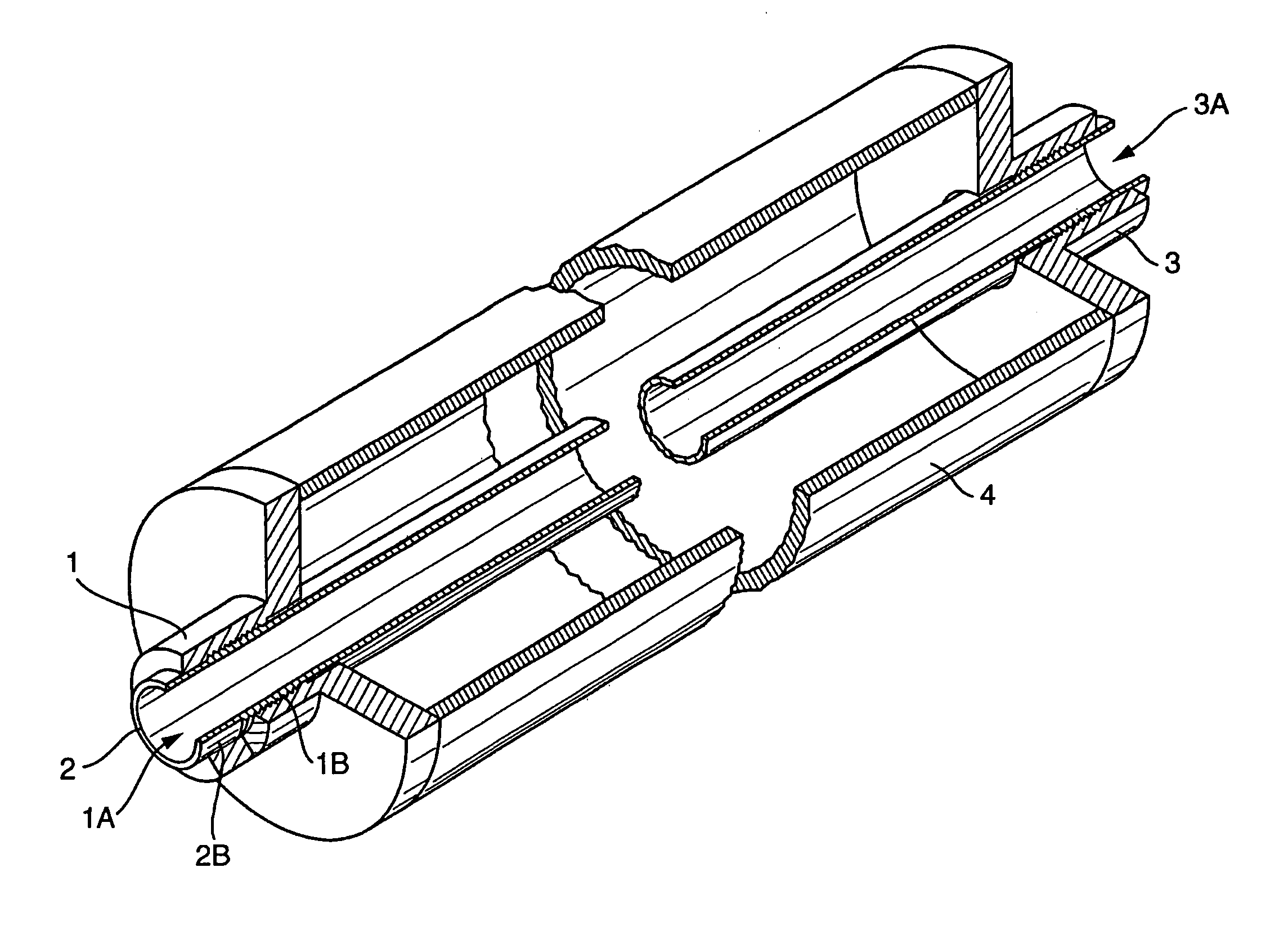

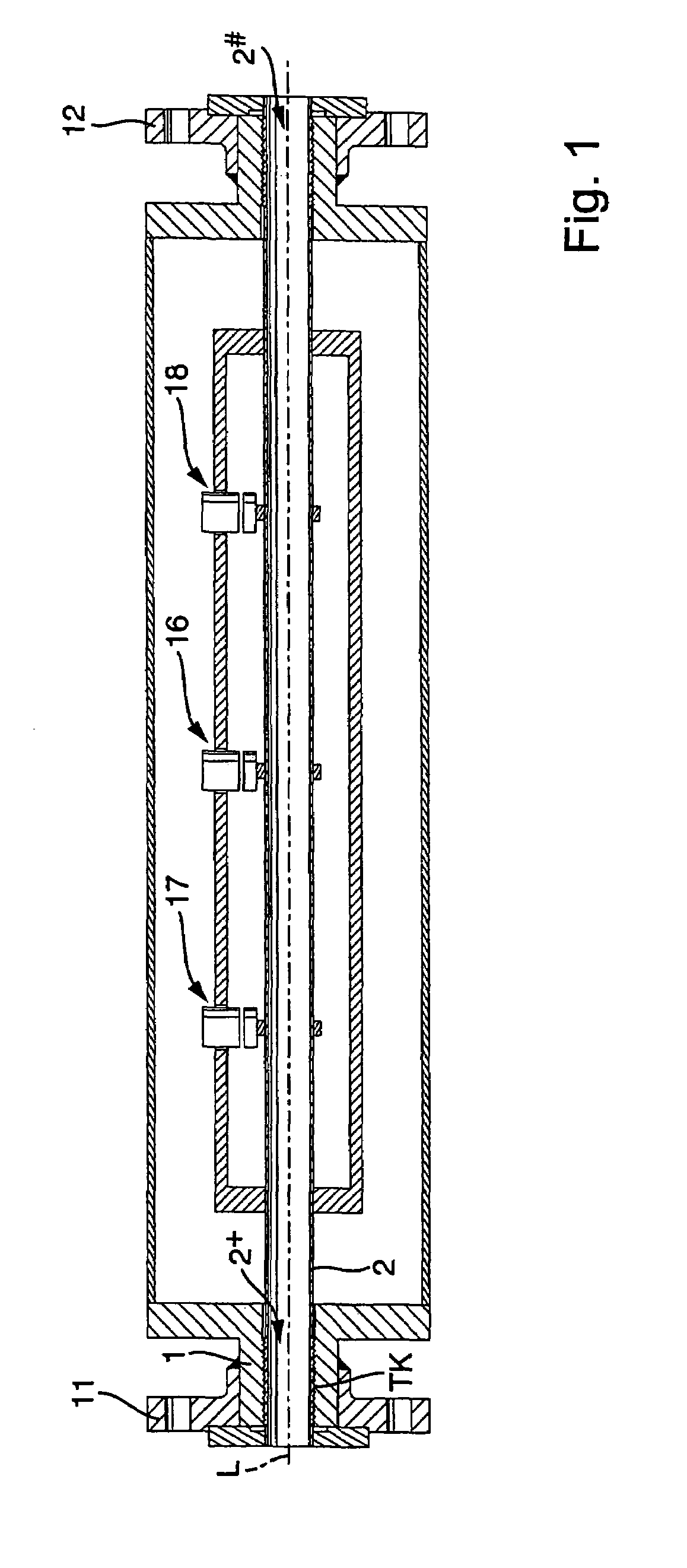

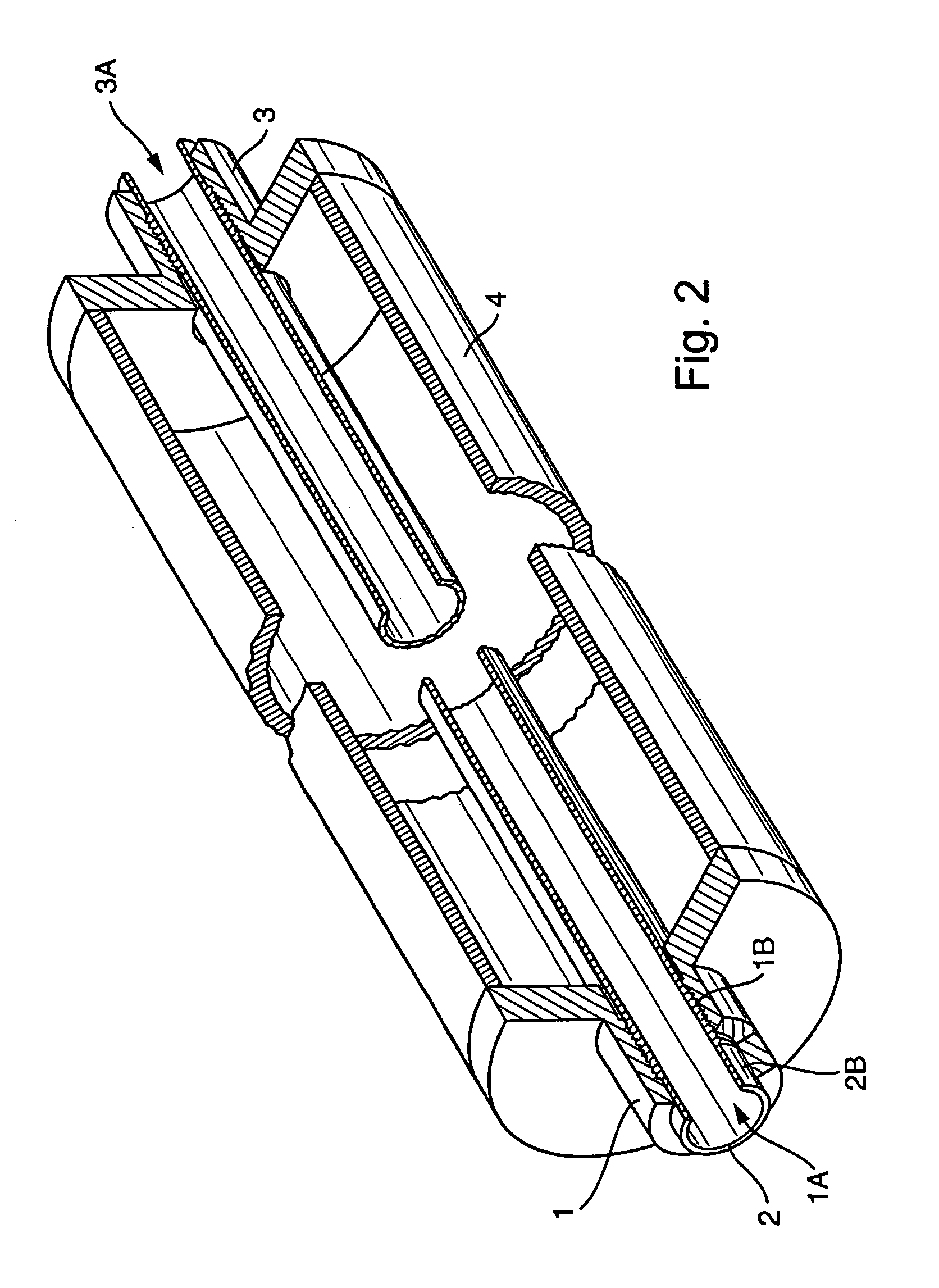

Composite system, method for its manufacture, and measurement pickup using such a composite system

ActiveUS7299699B2Stable, high-strength and lasting,Increased pull-out strengthMaterial analysis using sonic/ultrasonic/infrasonic wavesPig casting plantsEngineeringCompound system

A composite system includes a first component, for instance of metal, and a second component extending at least partly through the first component along an imaginary longitudinal axis of the composite system. The second component contacts, with an at least partially curved, especially cylindrical, outer surface, an inner surface of the first component flushly such that the first component at least sectionally, at least partly, grips around the second component. Joining surfaces of the composite system, which are formed by the mutually contacting surfaces of the two components, are formed in such a manner that the two components exhibit contour portions in the area of these joining surfaces embodied as self-closing, peripheral surfaces. The contour portions fit at least partly into one another, to form a mechanical interference locking effective, at least in part, likewise in the direction of the longitudinal axis. Additionally, the second component, with its outer surface, contacts the inner surface of the first component flushly, such that the two components are mechanically tightly connected together also by means of a frictional locking effective at least partly in the direction of the longitudinal axis. Alternatively, or in supplementation thereof, at least one of the components is subjected at least partly to lastingly elastic, especially mixed plastic-elastic, deformations. The composite system is distinguished by a high pull-out strength, even in the presence of repeatedly arising vibrations in one of the components and is, therefore, especially suited also for use in a vibration-type measurement pickup.

Owner:ENDRESS HAUSER FLOWTEC AG

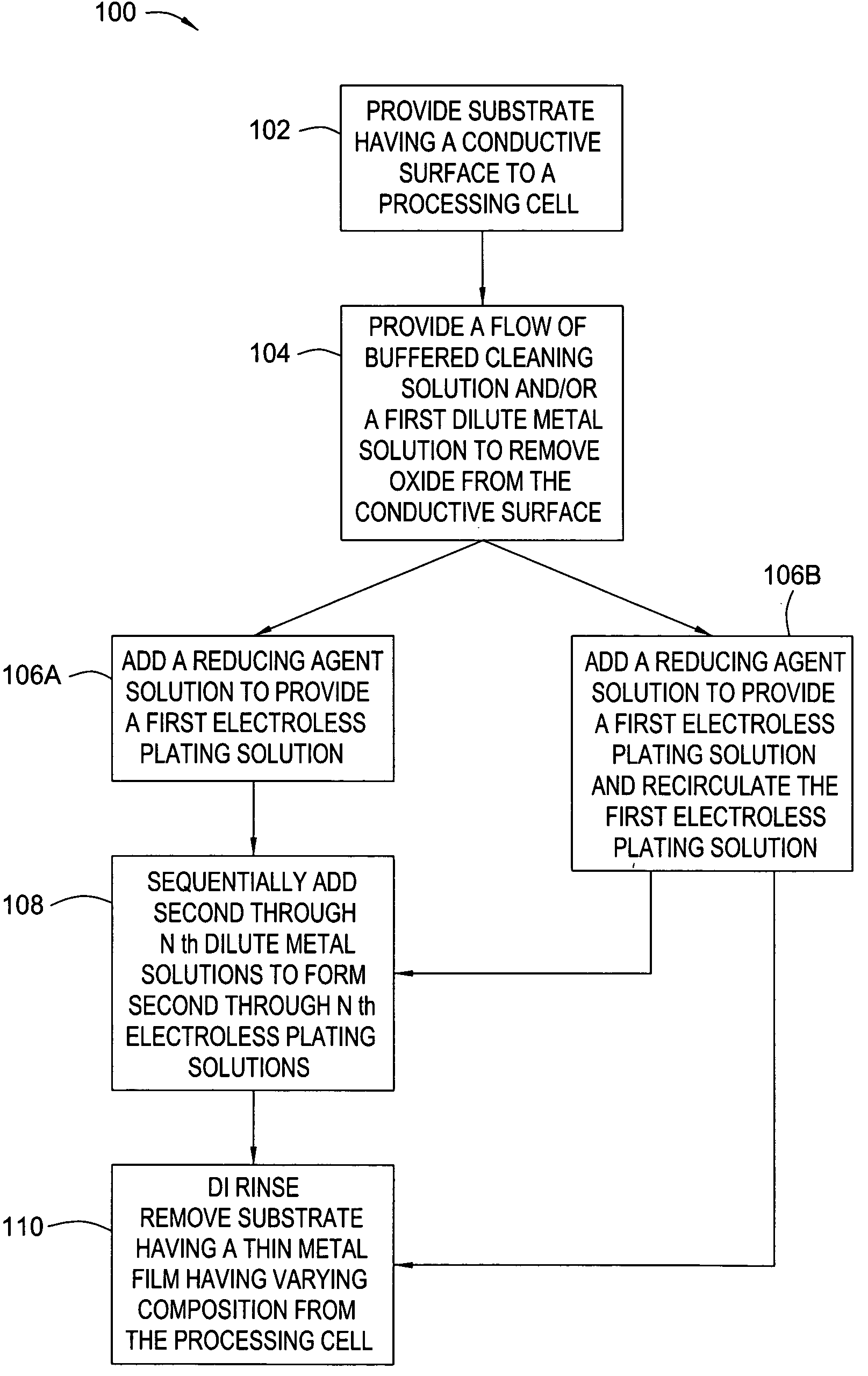

Method and apparatus for selectively changing thin film composition during electroless deposition in a single chamber

Owner:APPLIED MATERIALS INC

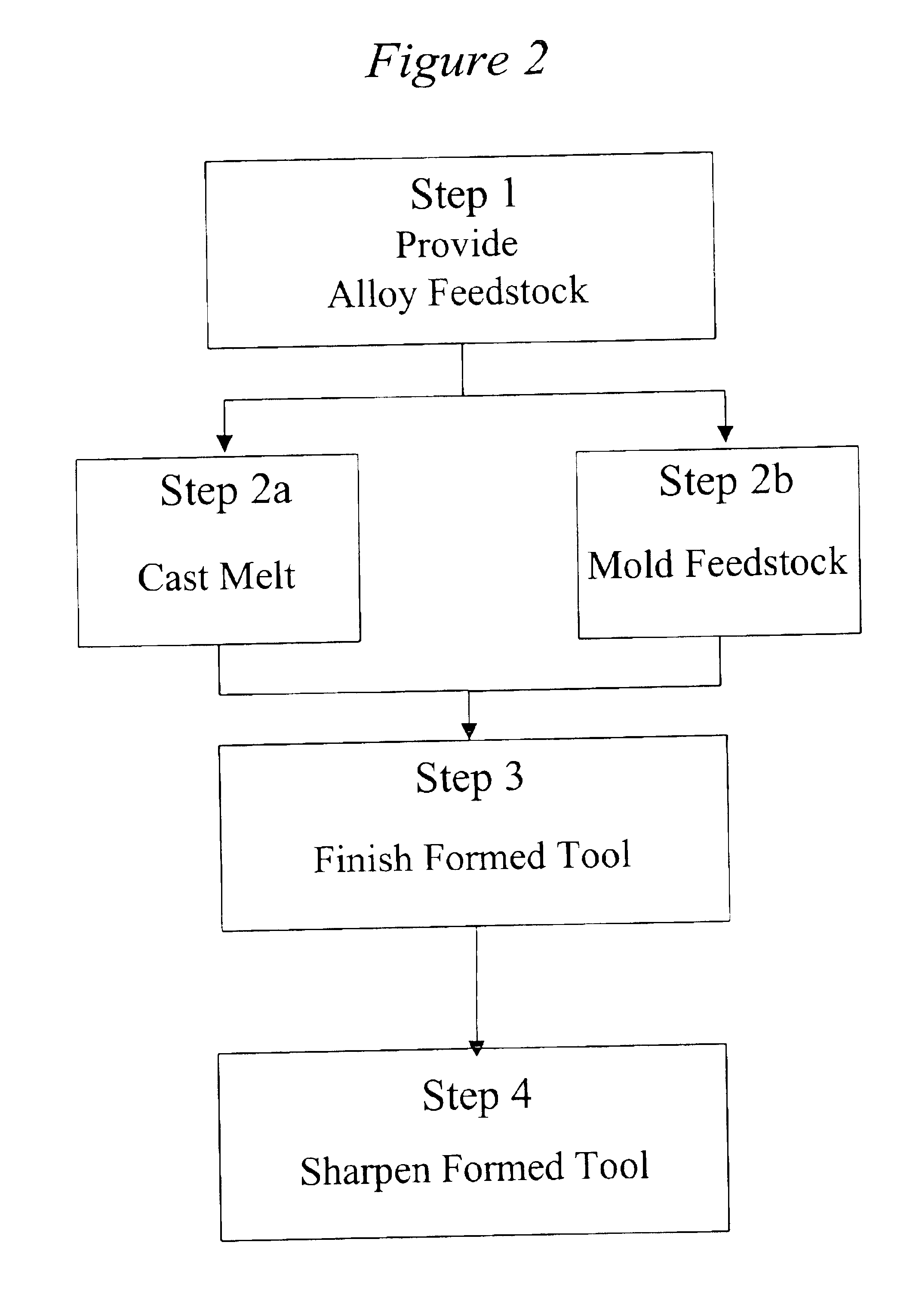

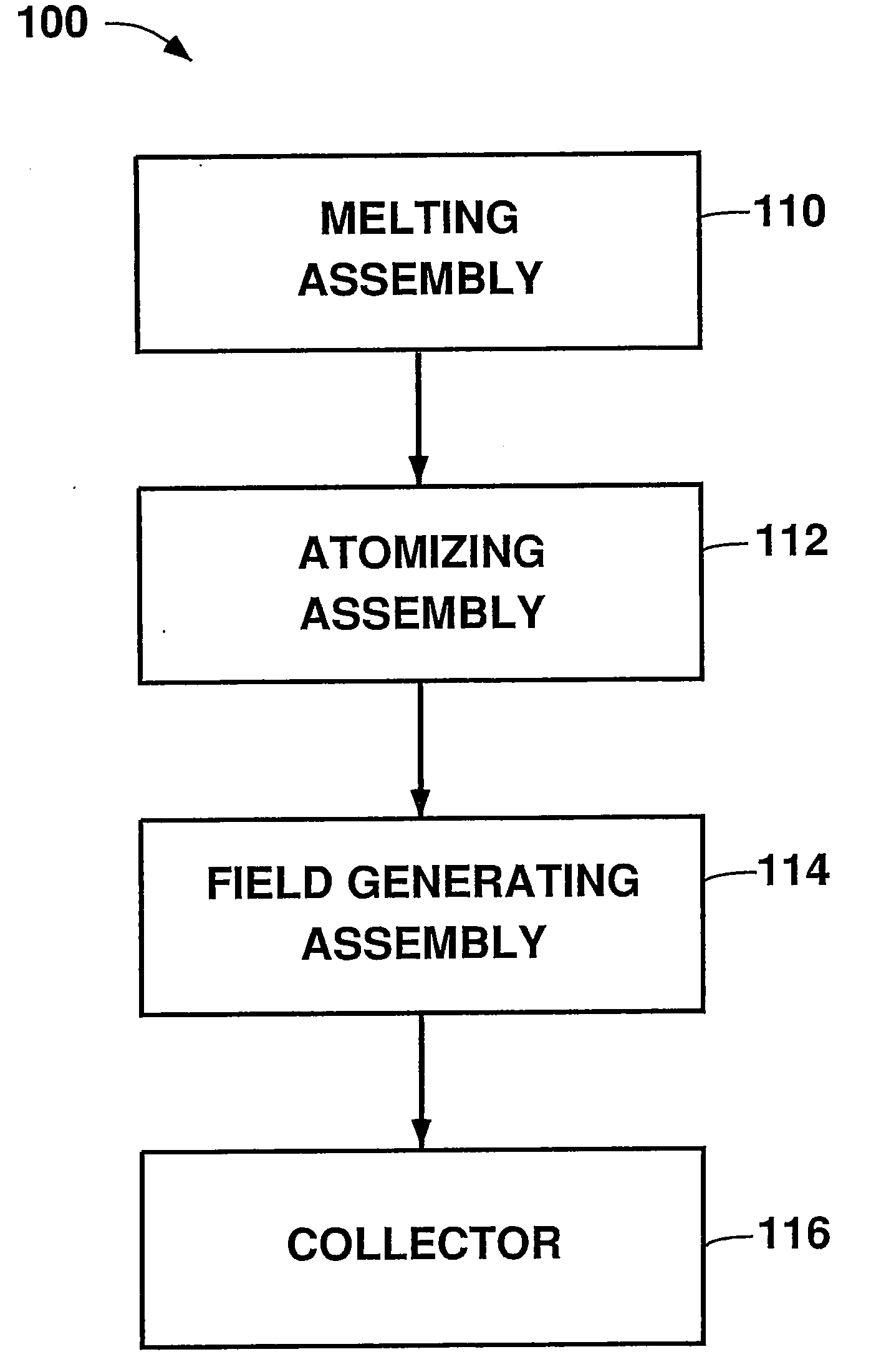

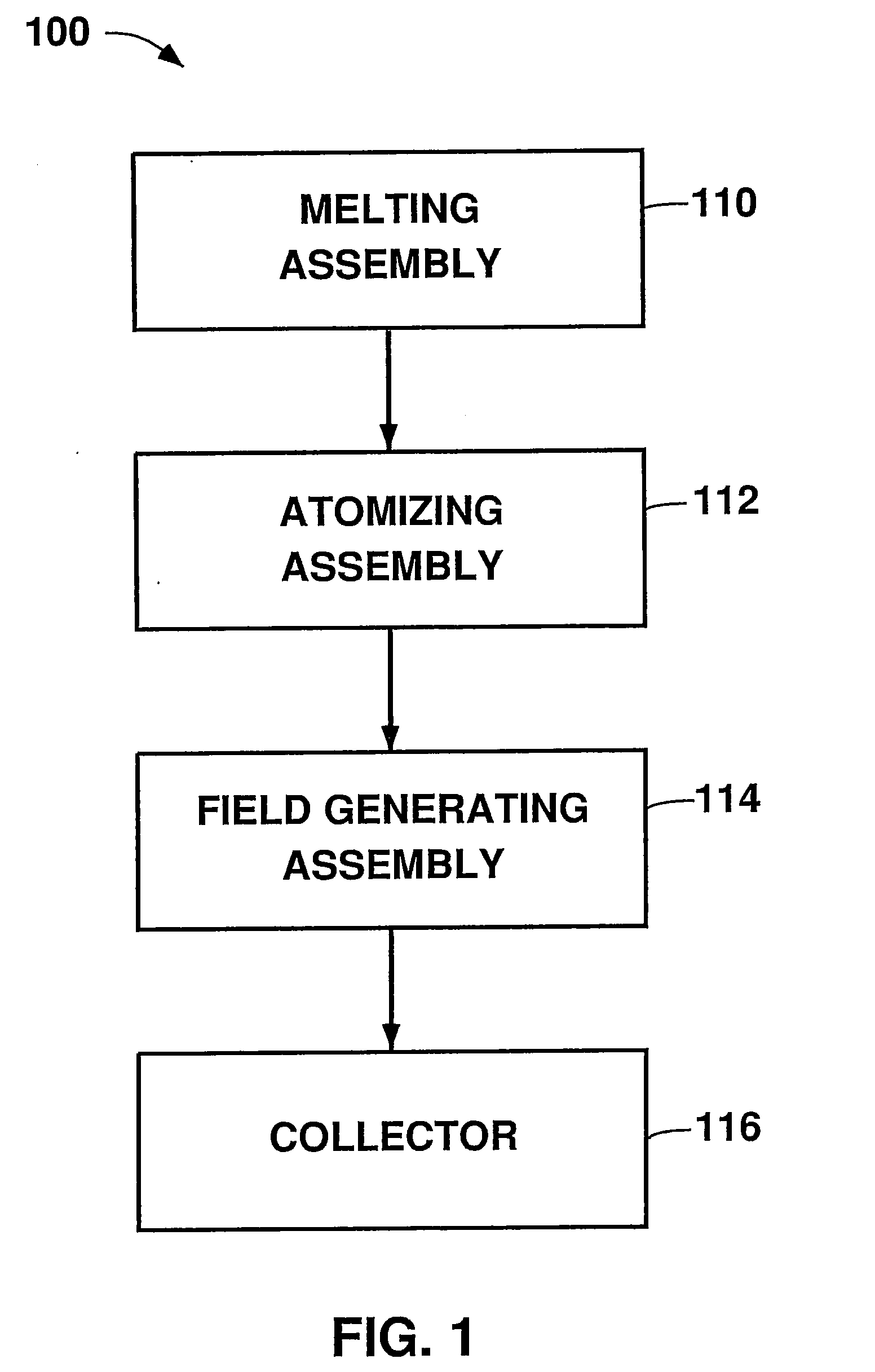

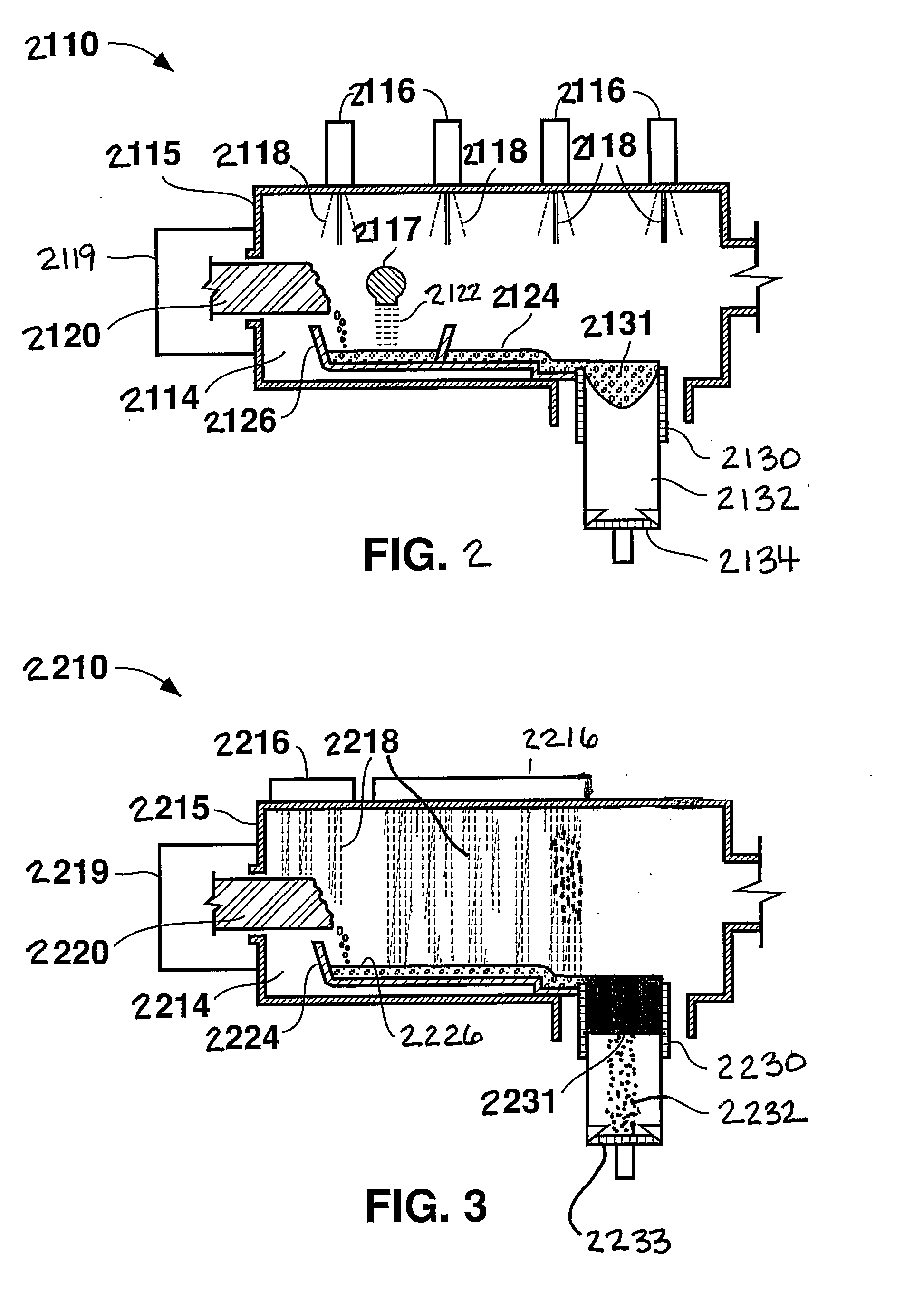

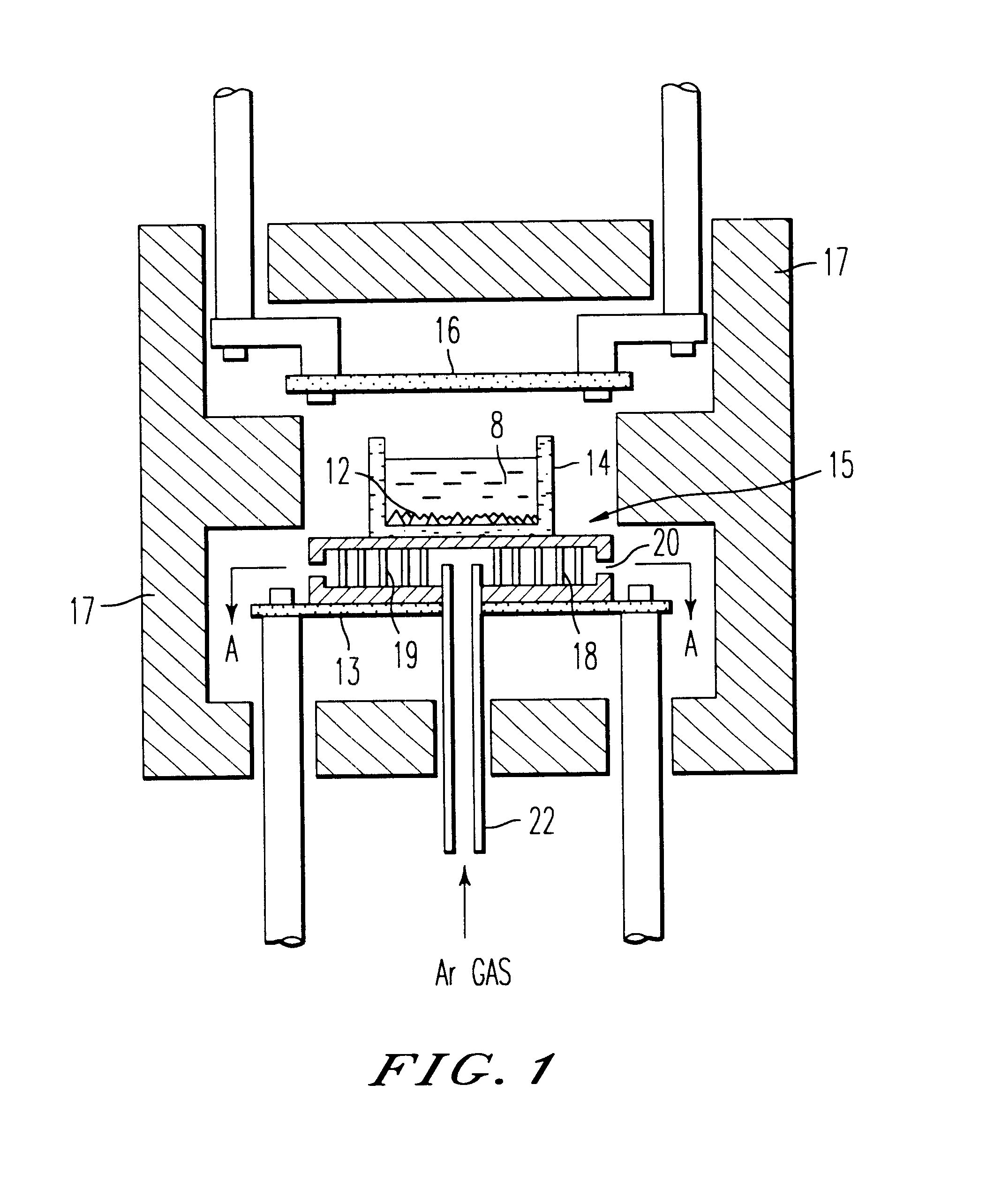

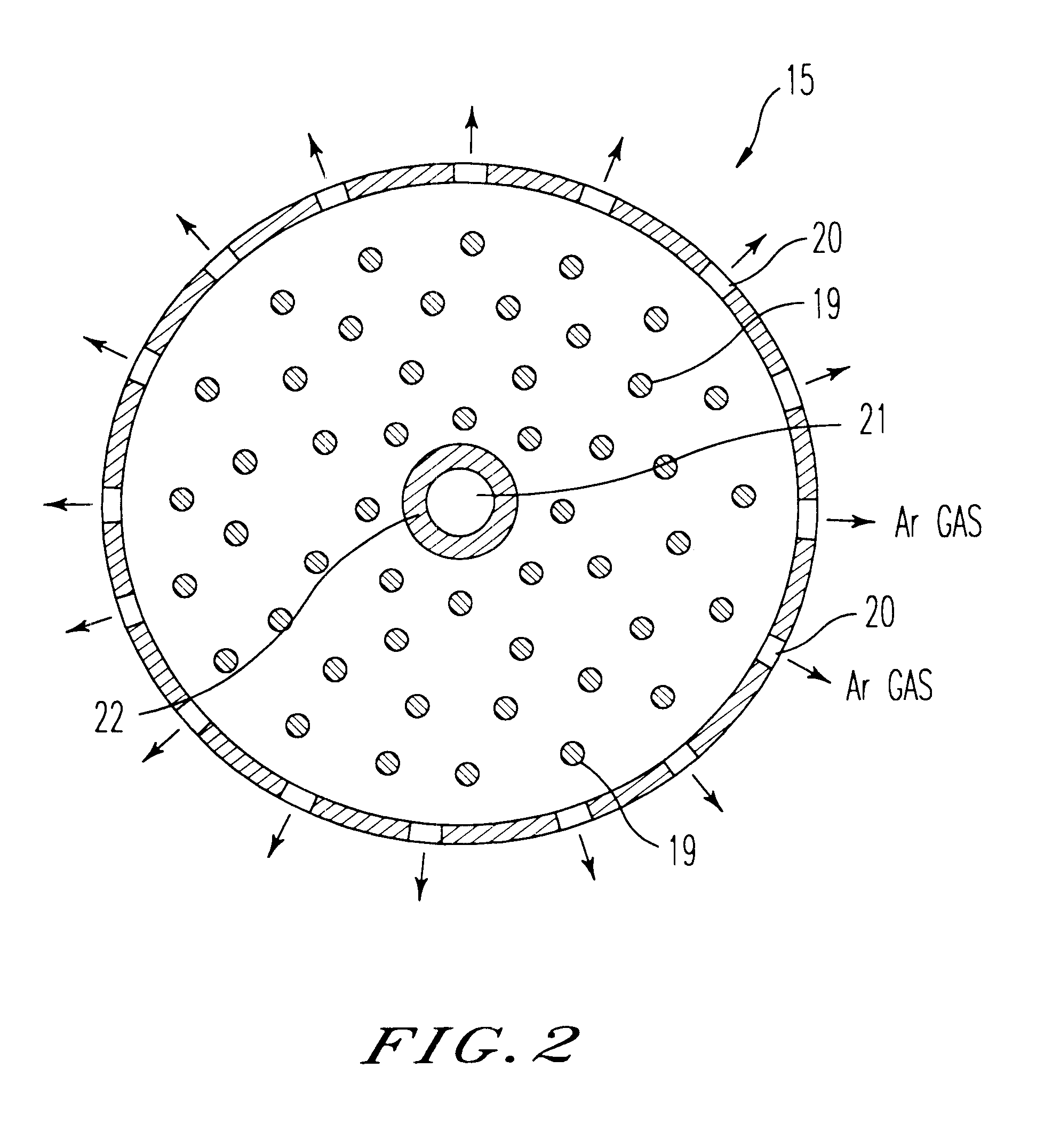

Method and apparatus for producing large diameter superalloy ingots

Methods and apparatus for producing large diameter superalloy ingots are disclosed. A material comprising at least one of a metal and a metallic alloy is introduced into a pressure-regulated chamber in a melting assembly. The material is subjected to a wide-area electron field within the pressure-regulated chamber to heat the material to a temperature above the melting temperature of the material to form a molten alloy. At least one stream of molten alloy from the pressure-regulated chamber is provided from the melting assembly and is fed into an atomizing assembly, where particles of the molten alloy are generated by impinging electrons on the molten alloy to atomize the molten alloy. At least one of an electrostatic field and an electromagnetic field are produced to influence the particles of the molten alloy. The particles of the molten alloy are deposited onto a collector in a spray forming operation to form an alloy ingot.

Owner:ATI PROPERTIES

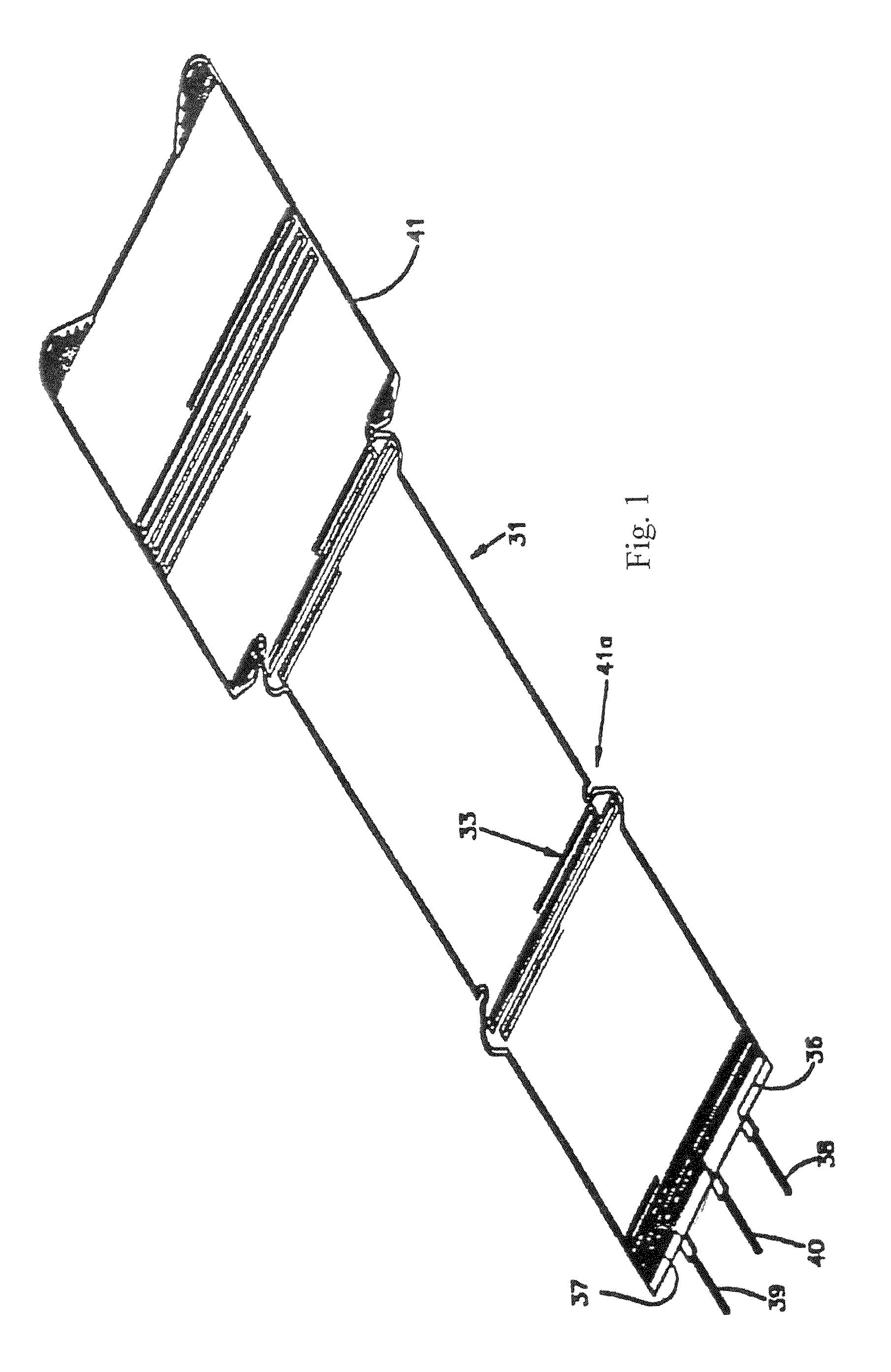

Method of manufacture of particles with controlled dimensions

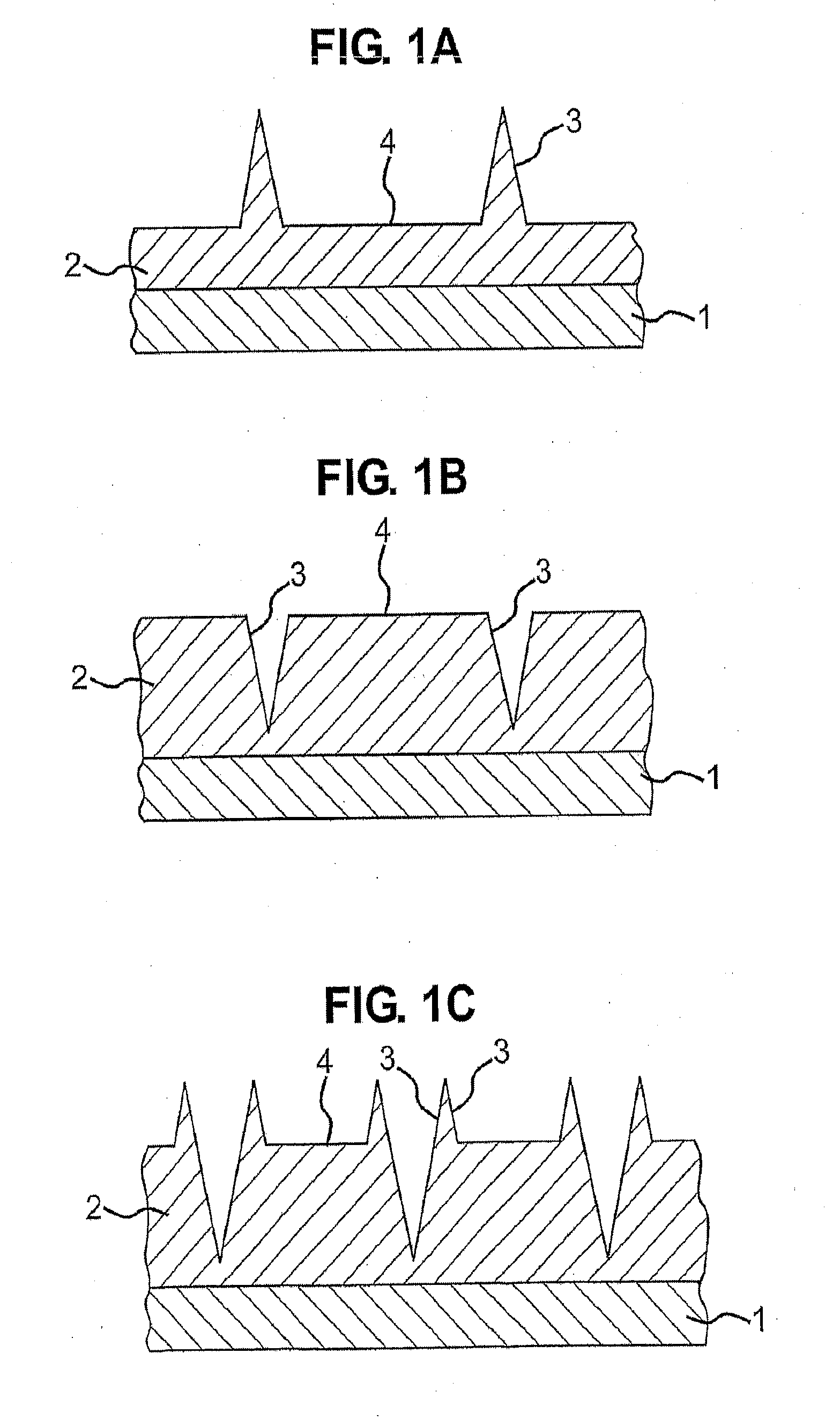

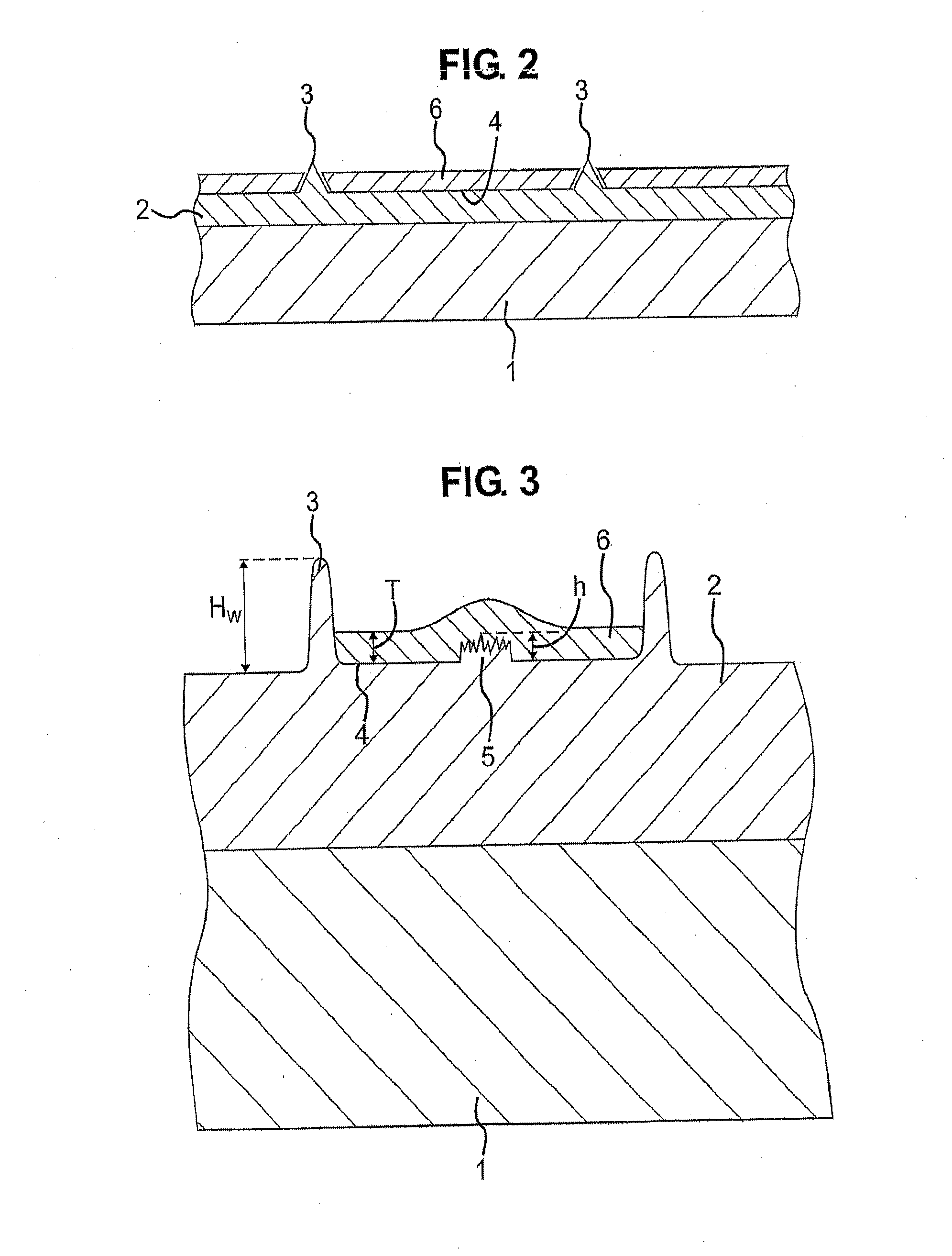

ActiveUS20150337137A1Reduce risk of damageEfficient conversionPigmenting treatmentPig casting plantsRepeat patternMaterials science

A process for the preparation of particles with controlled dimensions comprising the steps of: (i) providing a laminar substrate having a patterned surface comprising a micro-relief repeat pattern comprising one or more discrete cells, each cell consisting of a floor portion and walls having a height (HW); (ii) depositing organic or inorganic material onto the patterned surface and into the cells to provide a thickness (T) of the deposited material wherein T≦HW (iii) stripping the deposited organic or inorganic material from the surface of the substrate; and (iv) collecting the particles formed from said organic or inorganic material; and a composition obtainable from said process comprising a plurality of particles (P), wherein the number (n) of particles in said composition is at least 10, wherein said particles (P) are platelets exhibiting a planar geometry which is circular or which is made up of a number (x) of planar (y)-sided polygon(s), wherein x is from 1 to 20 and y is at least 3 wherein if x is greater than 1 then said planar (y)-sided polygons are fused along one or more sides thereof, wherein the width (WP) of the platelets (P) at their widest point is no more than about 250 pm and the thickness of the platelets (P) is in the range of 10 nm to 50 nm.

Owner:SZUSCIK MACHNICKI ANDREW HENRY

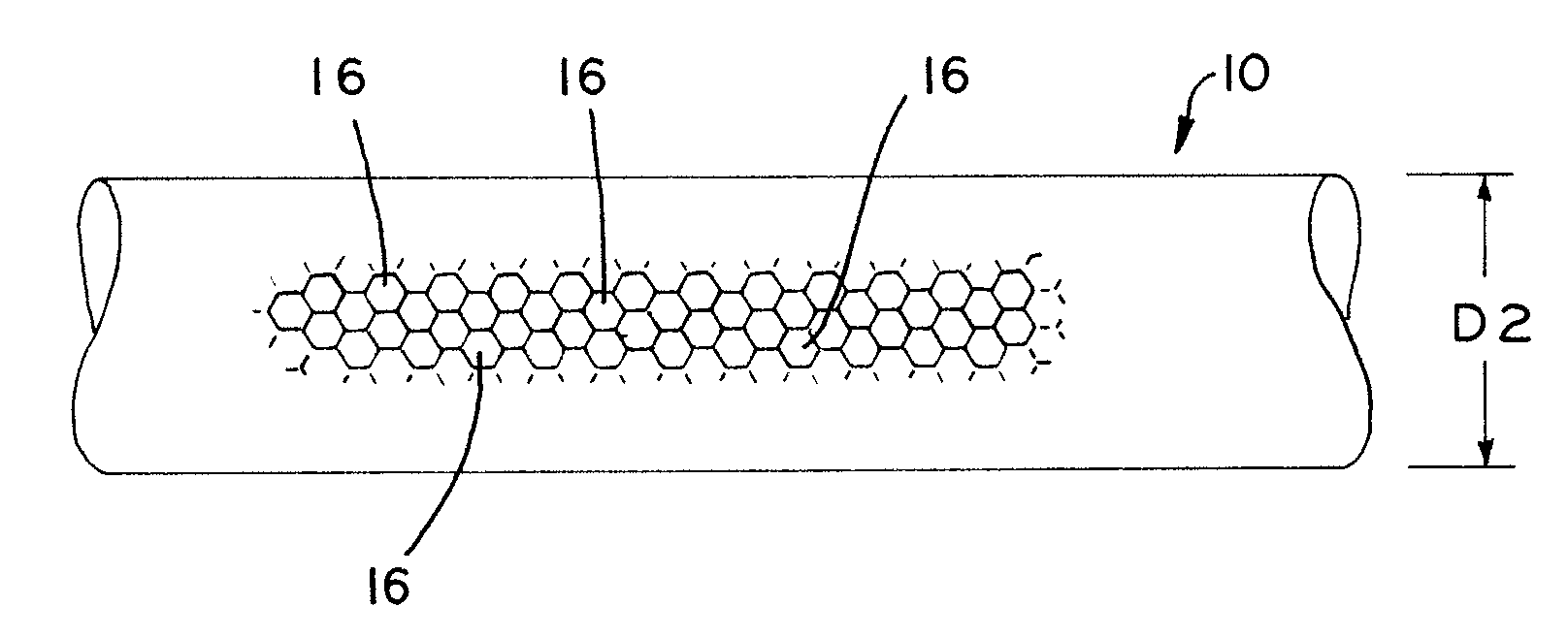

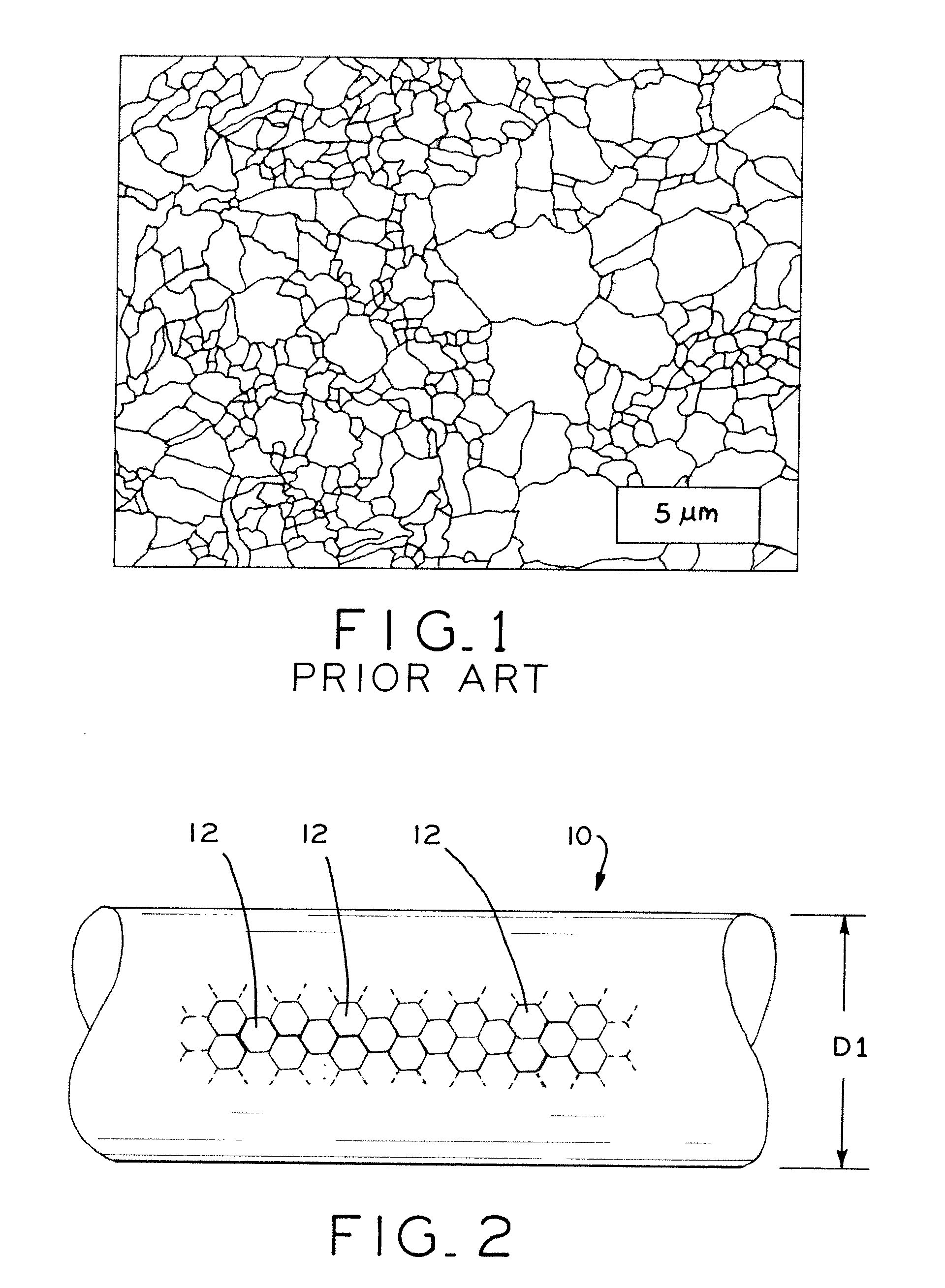

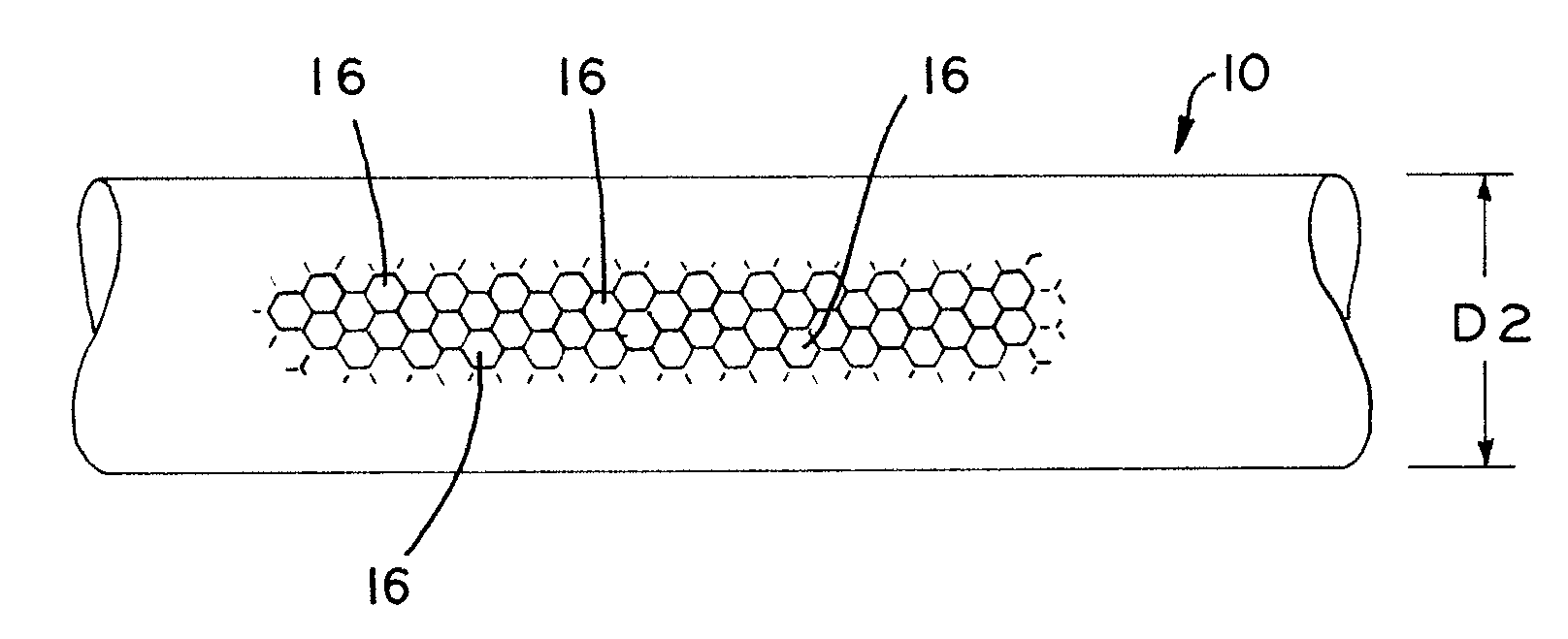

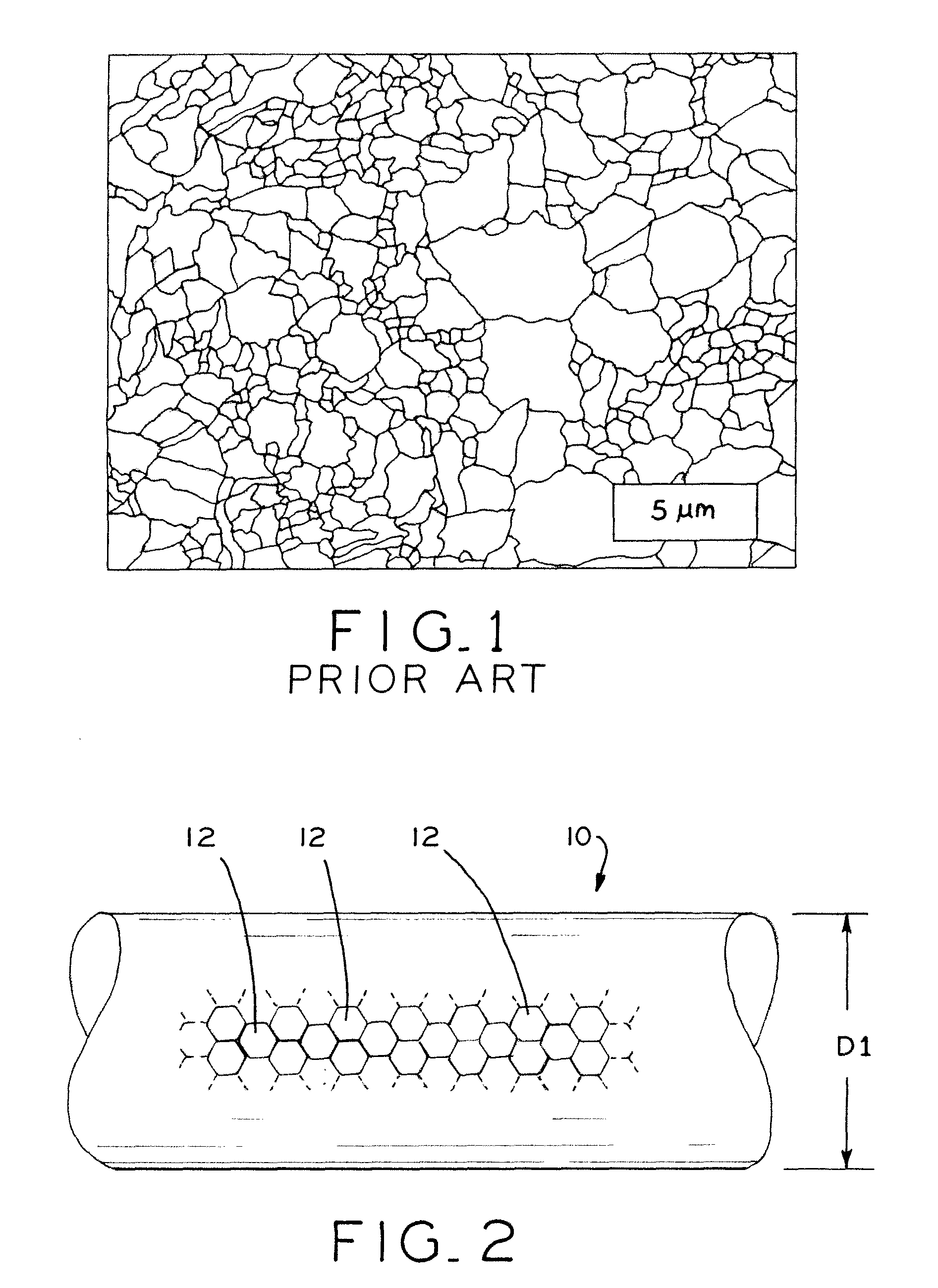

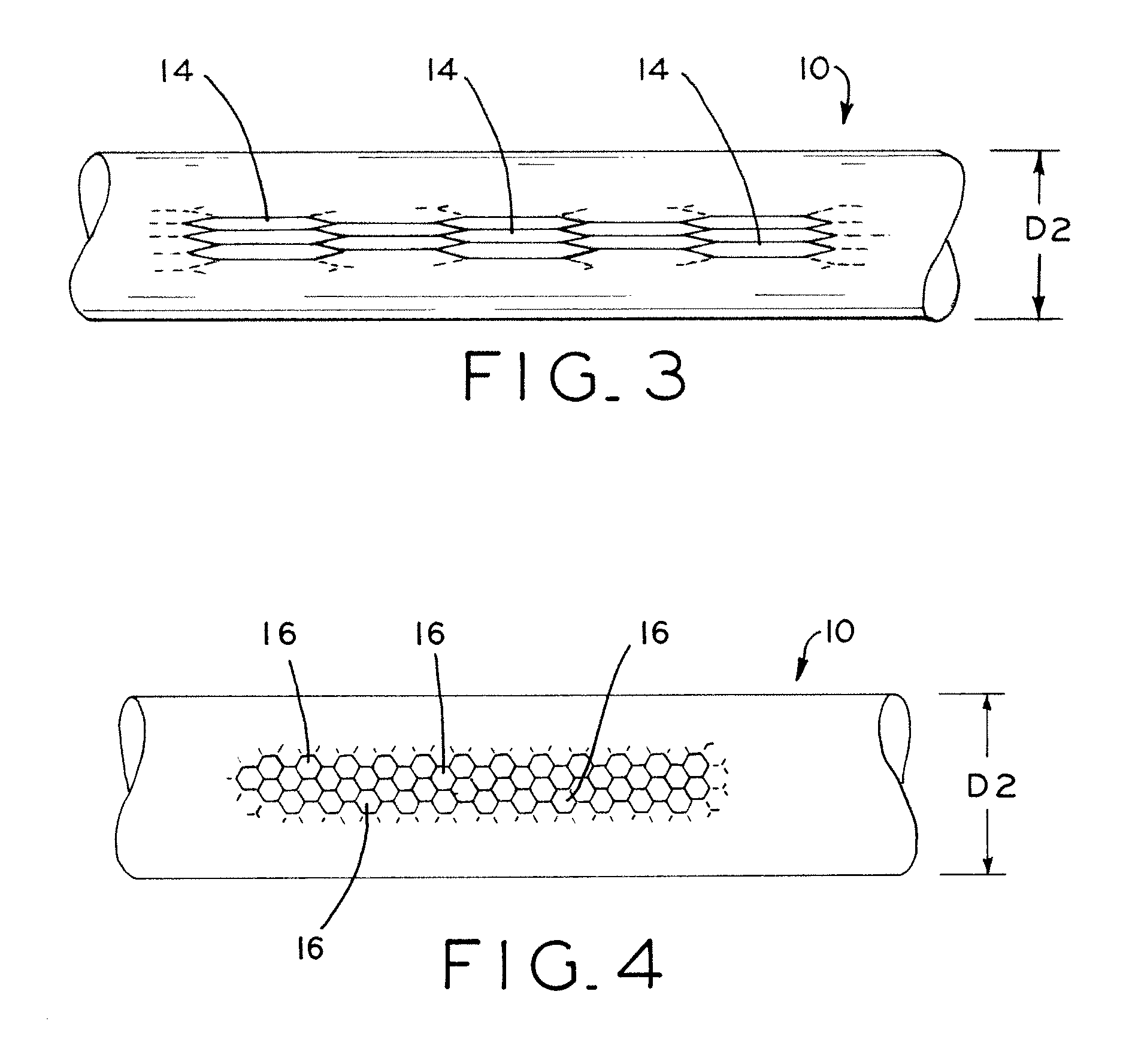

Fatigue damage resistant wire and method of production thereof

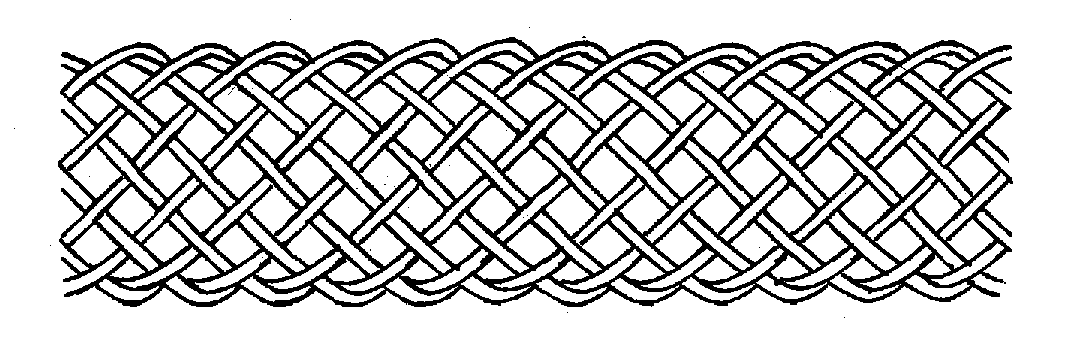

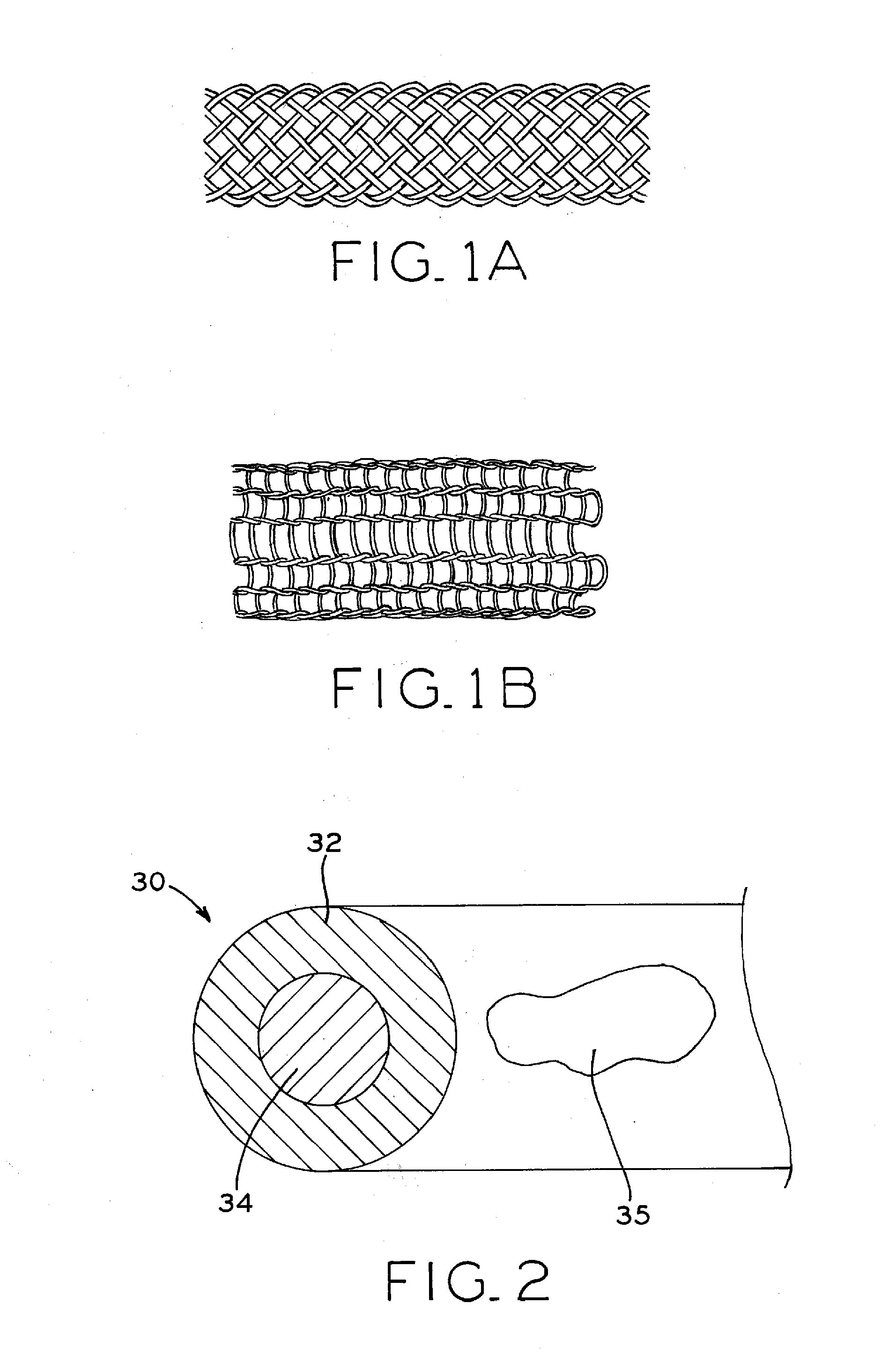

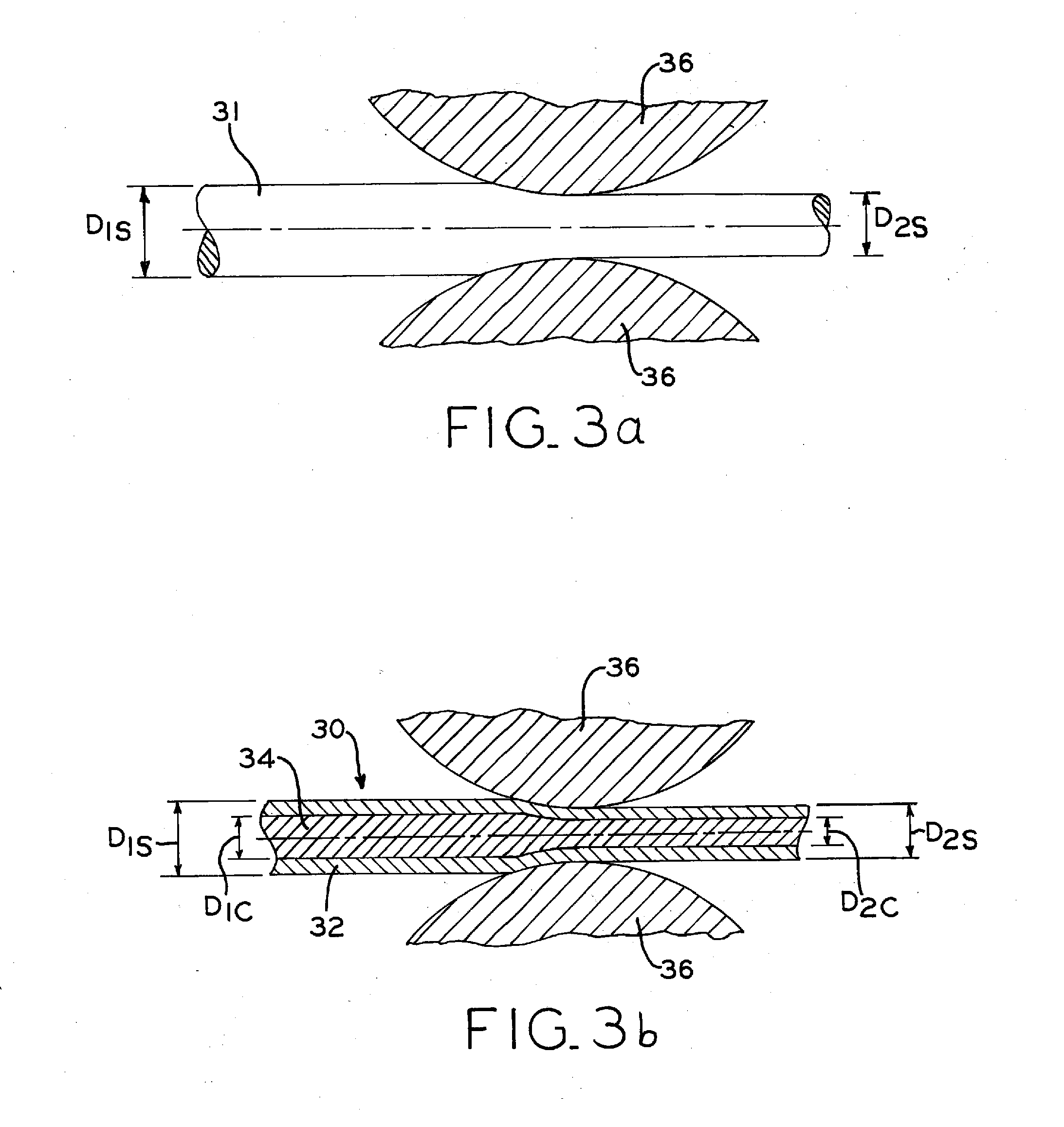

ActiveUS20100075168A1Improve resistance to fatigue damageImprove material performanceStentsPig casting plantsFatigue damageWire rod

Fatigue damage resistant metal or metal alloy wires have a submicron-scale or nanograin microstructure that demonstrates improved fatigue damage resistance properties, and methods for manufacturing such wires. The present method may be used to form a wire having a nanograin microstructure characterized by a mean grain size that is 500 nm or less, in which the wire demonstrates improved fatigue damage resistance. Wire manufactured in accordance with the present process may show improvement in one or more other material properties, such as ultimate strength, unloading plateau strength, permanent set, ductility, and recoverable strain, for example. Wire manufactured in accordance with the present process is suitable for use in a medical device, or other high end application.

Owner:FORT WAYNE METALS RES PROD LLC

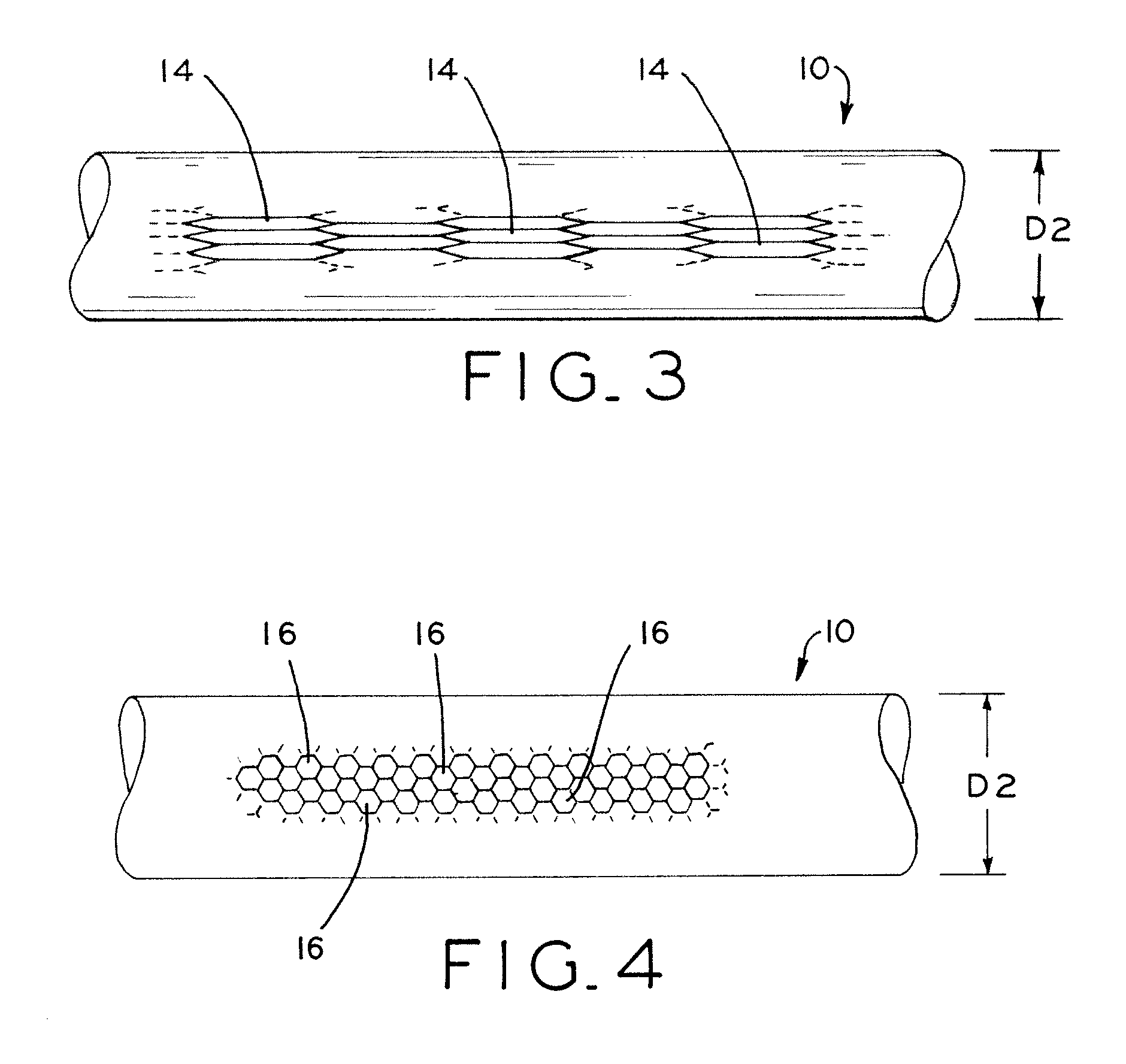

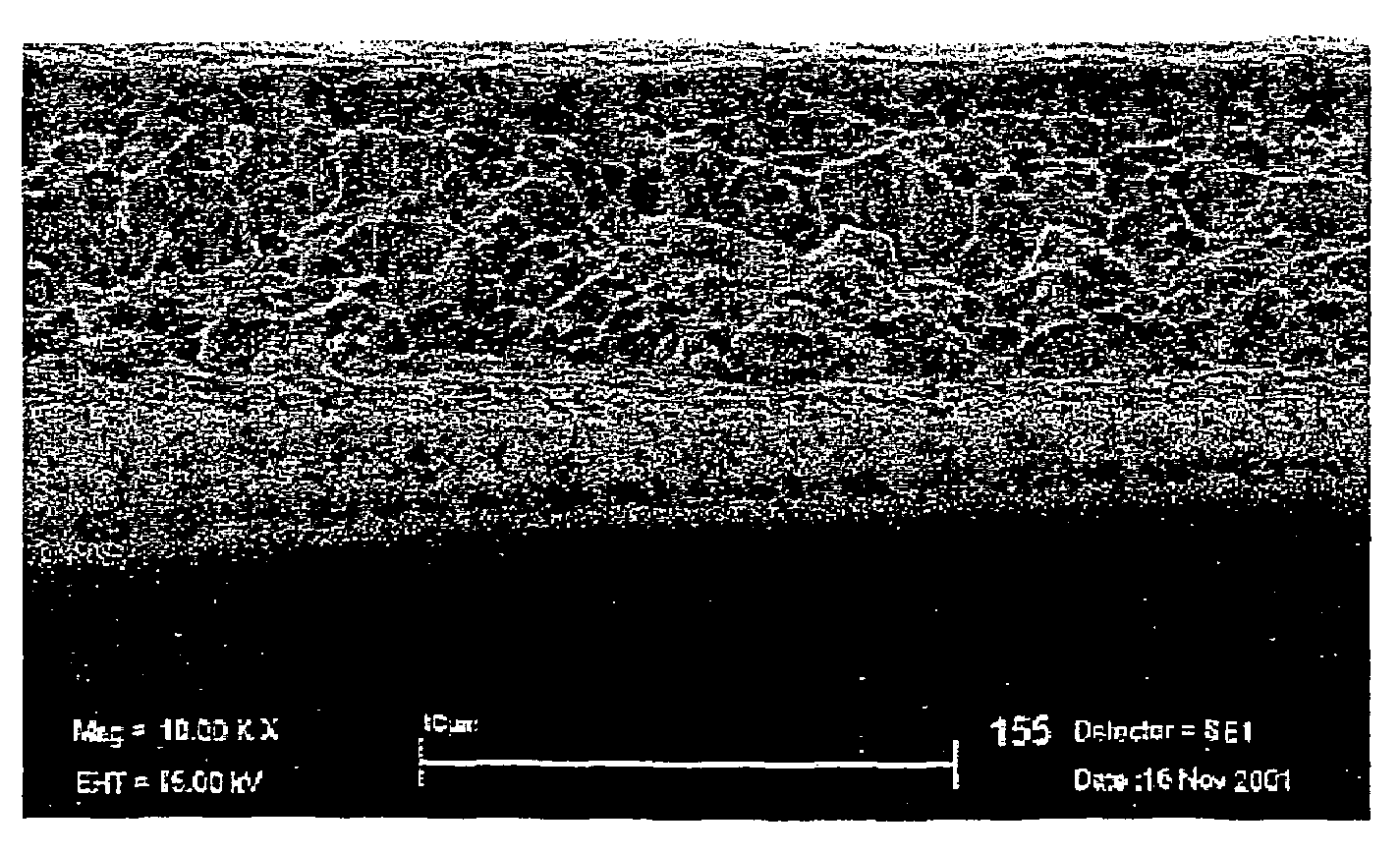

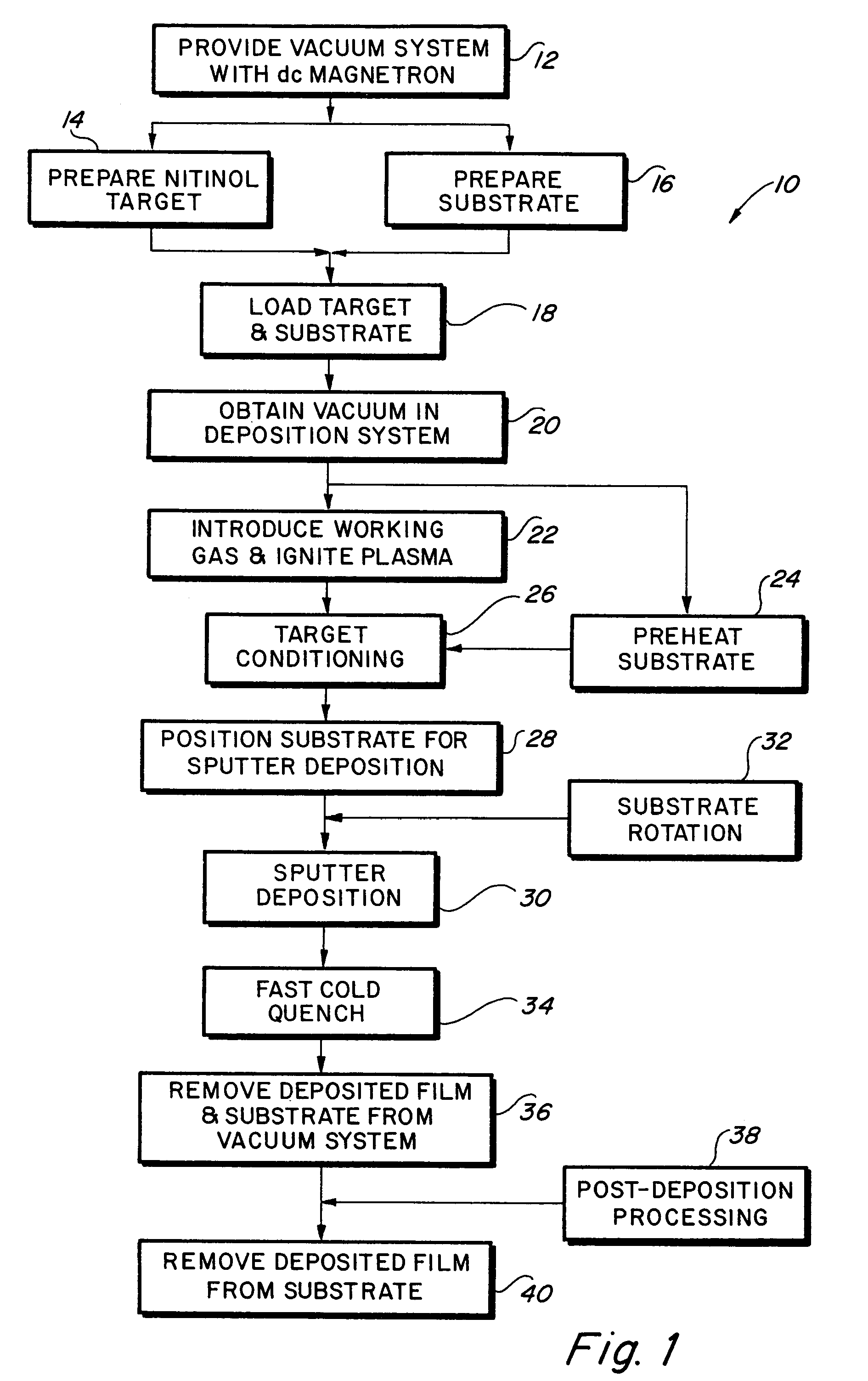

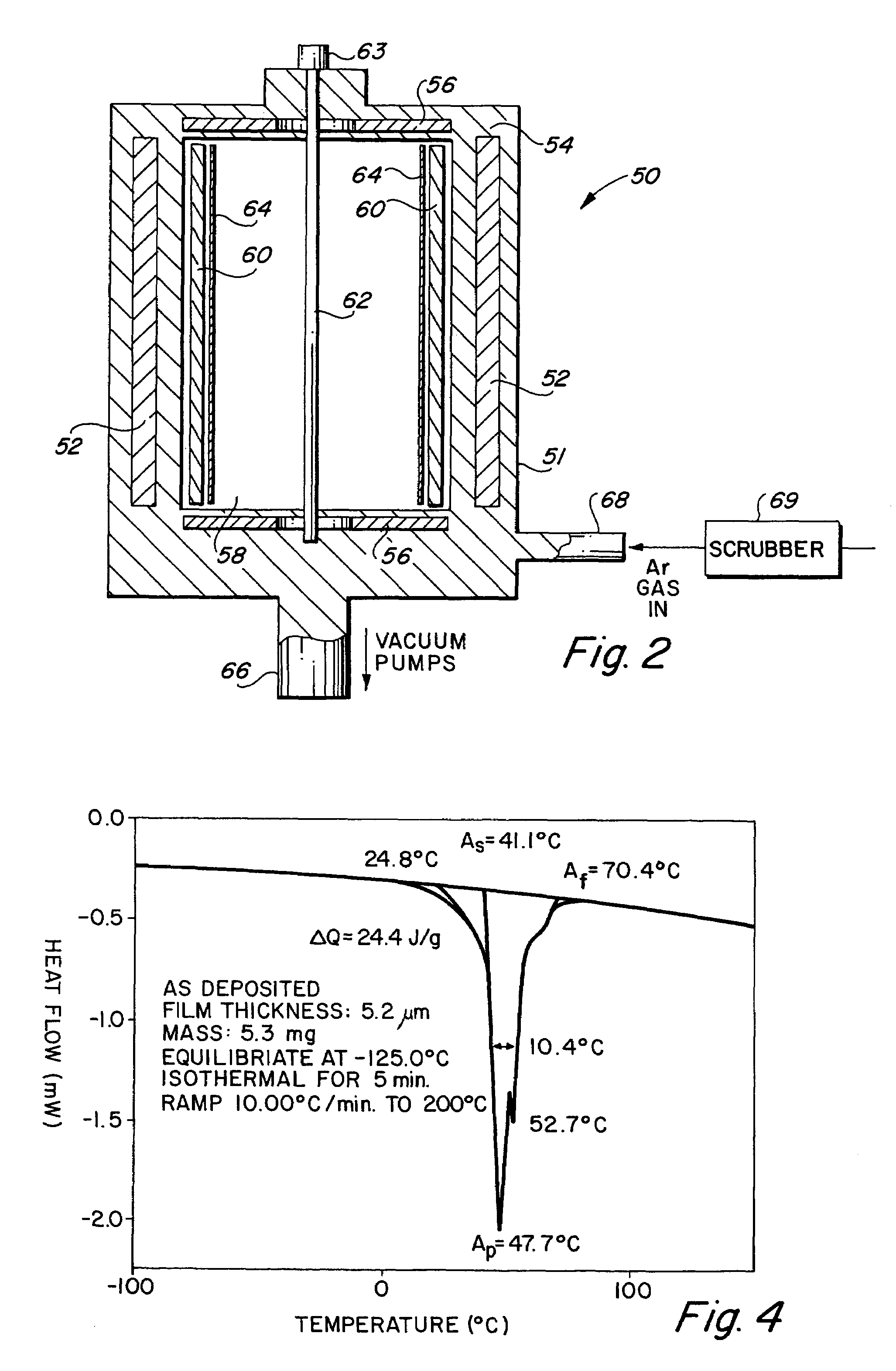

High strength vacuum deposited nitinol alloy films and method of making same

InactiveUS7335426B2Minimise scatteringControlled surface roughnessPig casting plantsThermometers using material expansion/contactionThin membraneTitanium

A vacuum deposition method for fabricating high-strength nitinol films by sputter depositing nickel and titanium from a heated sputtering target, and controlling the sputter deposition process parameters in order to create high-strength nitinol films that exhibit shape memory and / or superelastic properties without the need for precipitation annealing to attenuate the transition conditions of the deposited material. A vacuum deposited nitinol film having high-strength properties equal to or better than wrought nitinol films and which are characterized by having non-columnar crystal grain structures.

Owner:VACTRONIX SCI LLC

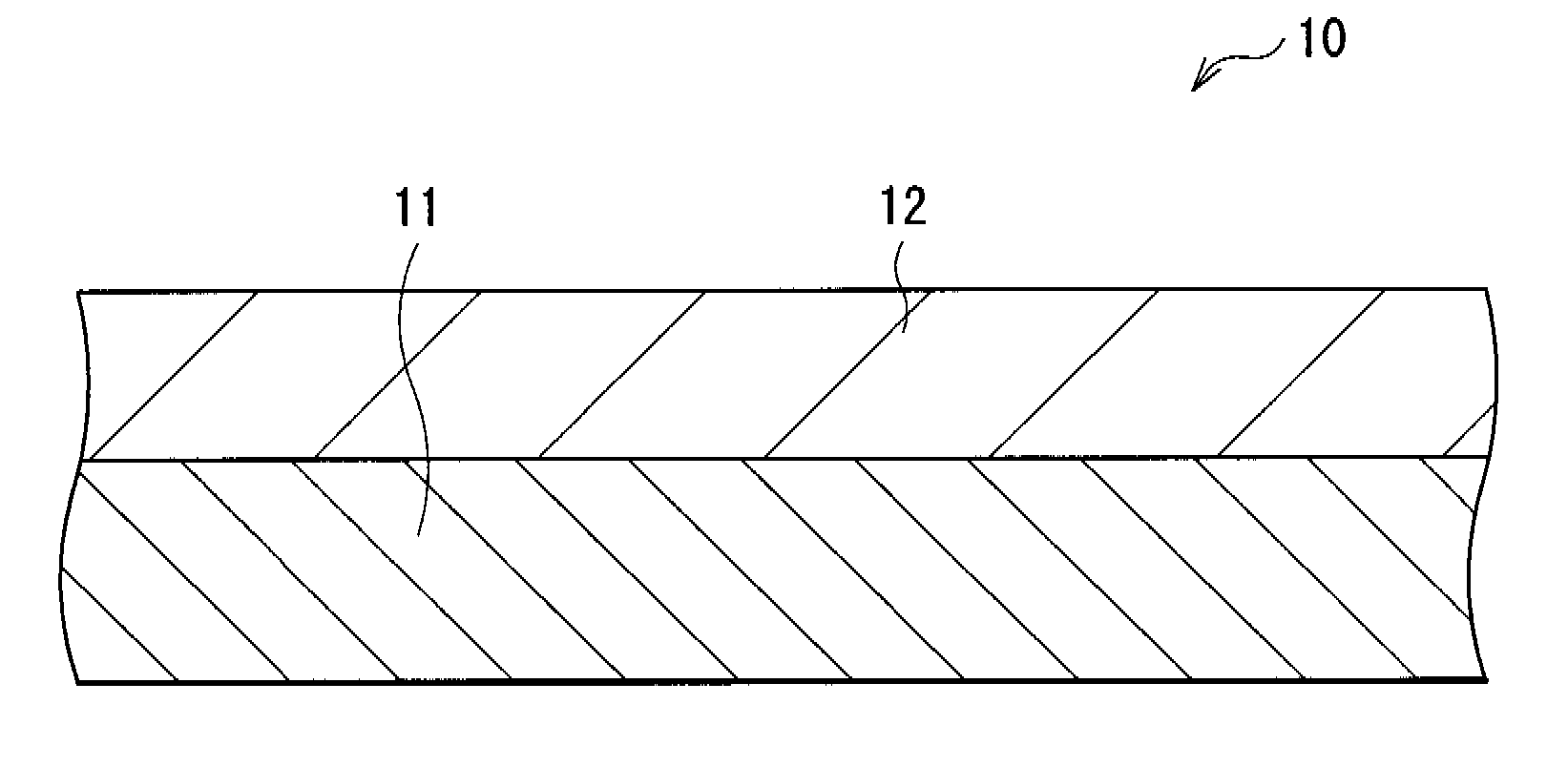

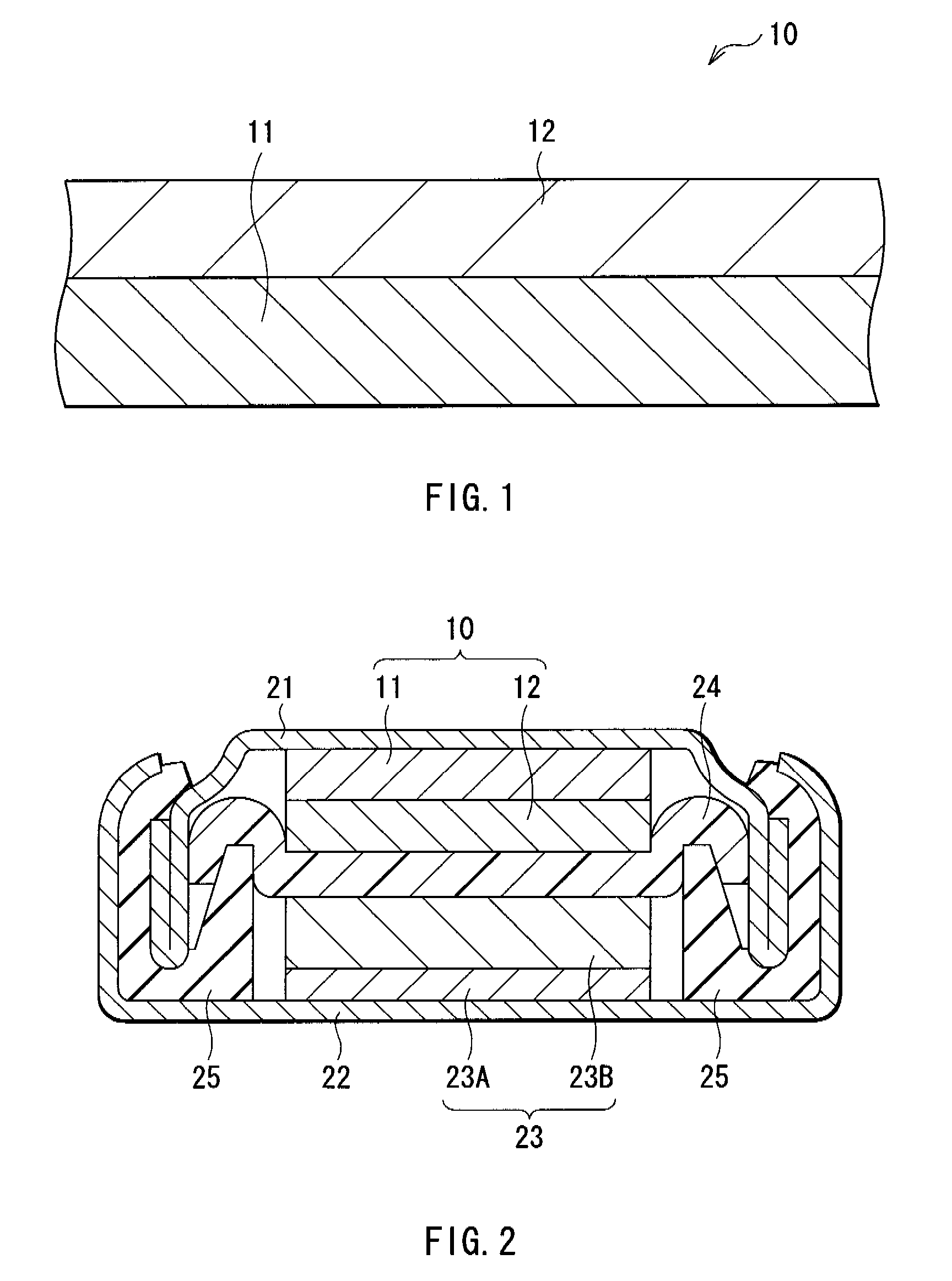

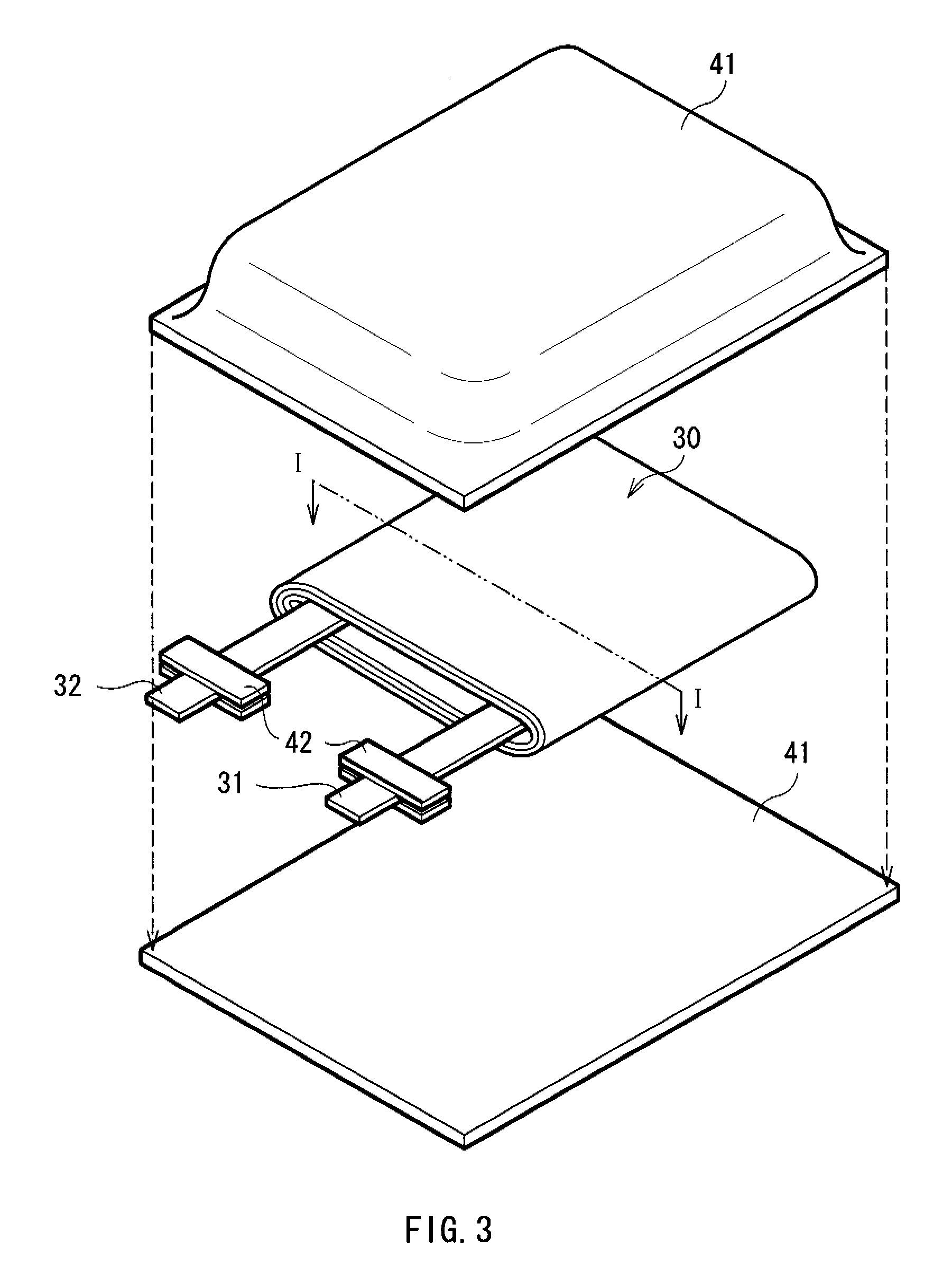

Current collector, anode, and battery

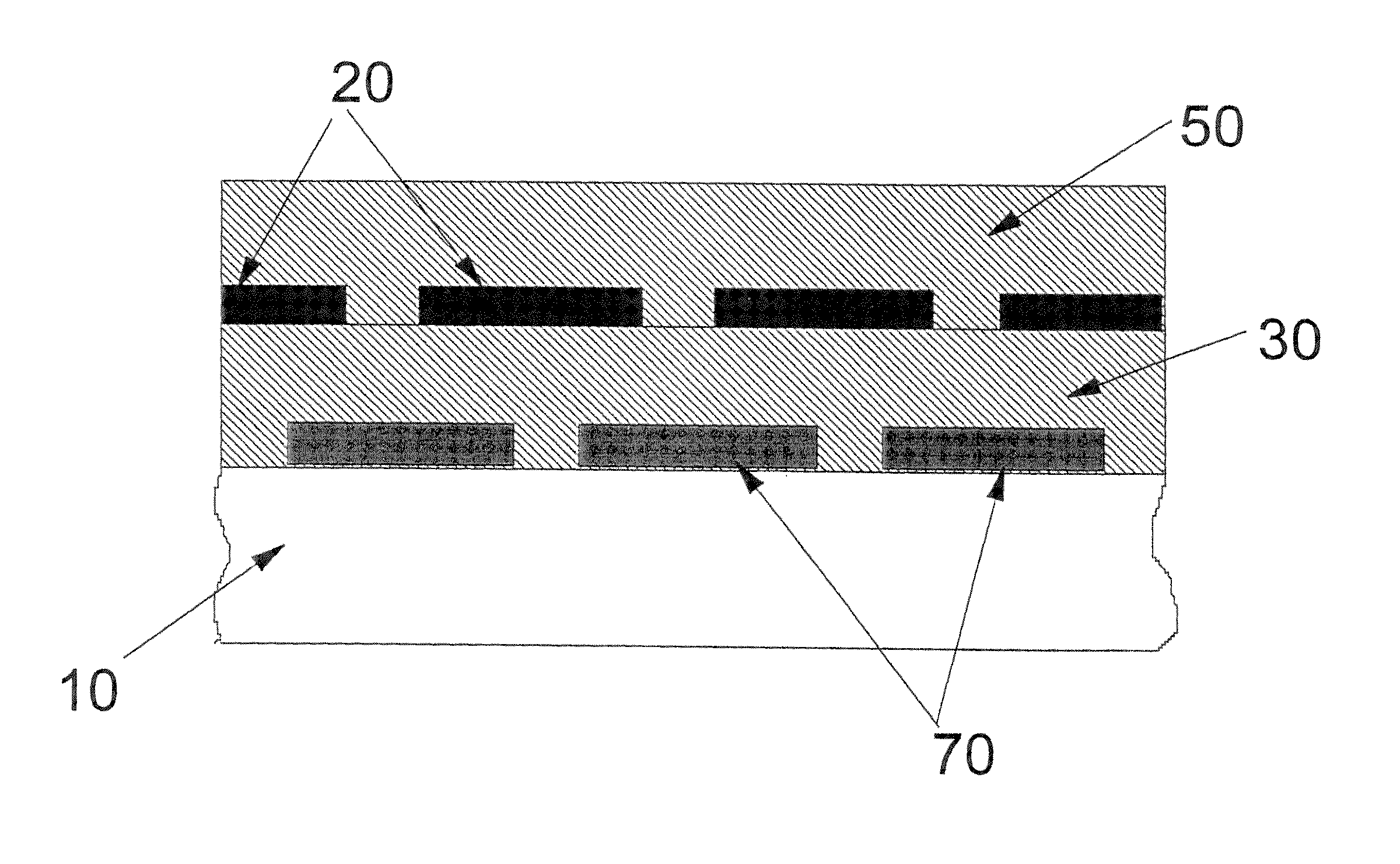

InactiveUS20070111103A1Stress to expansion be relaxedStress to shrinkage be relaxedPig casting plantsNon-aqueous electrolyte accumulatorsX-rayEngineering

A current collector capable of relaxing stress and of improving charcteristics, an anode using the current collector, and a battery using the current collector are provided. An active material layer containing Si is provided on a current collector. The current collector contains Cu. Where a peak area resulting from (220) crystal face of Cu obtained by X-ray diffraction is I220, and a peak area resulting from (200) crystal face of Cu obtained by X-ray diffraction is I200, ratio I220 / I200 as a ratio of the peak area I200 to the peak area I200 is 2.5 or less. Thereby, even when the active material layer is expanded and shrunk due to charge and discharge, the stress can be relaxed, and separation or the like of the active material layer can be prevented.

Owner:SONY CORP

Steel Sheet for Hot Press Forming Having Excellent Heat Treatment and Impact Property, Hot Press Parts Made of It and the Method for Manufacturing Thereof

InactiveUS20080286603A1High strengthHigh yield strengthHot-dipping/immersion processesPig casting plantsSheet steelUltimate tensile strength

Disclosed is a steel sheet that exhibits an ultra-high strength after hot press forming followed by rapid cooling, and an enhanced yield strength after painting. The steel sheet has a composition comprising 0.1% to 0.5% by weight of C, 0.01% to 1.0% by weight of Si, 0.5% to 4.0% by weight of Mn, 0.1% by weight or less of P, 0.03% by weight or less of S, 0.1% by weight of soluble Al, 0.01% to 0.1% by weight of N, 0.3% by weight or less of W, and the balance Fe and other inevitable impurities. Further disclosed are a hot-pressed part made of the steel sheet and a method for manufacturing the hot-pressed part. The hot-pressed part achieves a high increment in yield strength after heat treatment for painting while ensuring an ultra-high tensile strength. Furthermore, the hot-pressed part exhibits superior adhesion to a coating layer, good surface appearance and improved corrosion resistance after painting.

Owner:POHANG IRON & STEEL CO LTD

Sintering electrode

InactiveUS6218025B1Reduce instabilityReduce stepsPig casting plantsLamp incadescent bodiesMetal powderTungsten

A sintered electrode of high-melting metal (for example tungsten) is produced from spherical metal powder having a well defined particle size. The mean particle size is from 5 to 70 mum. The particle size distribution covers a range from at most 20% below to at most 20% above the mean particle size.

Owner:PATENT TREUHAND GESELLSCHAFT FUR ELECTRIC GLUEHLAMPEN MBH

Aircraft structure element made of an Al-Cu-Mg alloy

InactiveUS6569542B2Pig casting plantsSemiconductor/solid-state device detailsAlloyStructuring element

The purpose of the invention is a structure element, particularly an lower wing element of an aircraft, manufactured from a rolled, extruded or forged product made of an alloy with composition (% by weight):Cu=4.6-5.3, Mg=0.10-0.50, Mn=0.15-0.45, Si <0.10, Fe<0.15, Zn<0.20, Cr<0.10, other elements <0.05 each and <0.15 total, the remainder being Al treated by solution heat treating, quenching, controlled tension to more than 1.5% permanent deformation and aging.

Owner:RHENALU PECHINEY

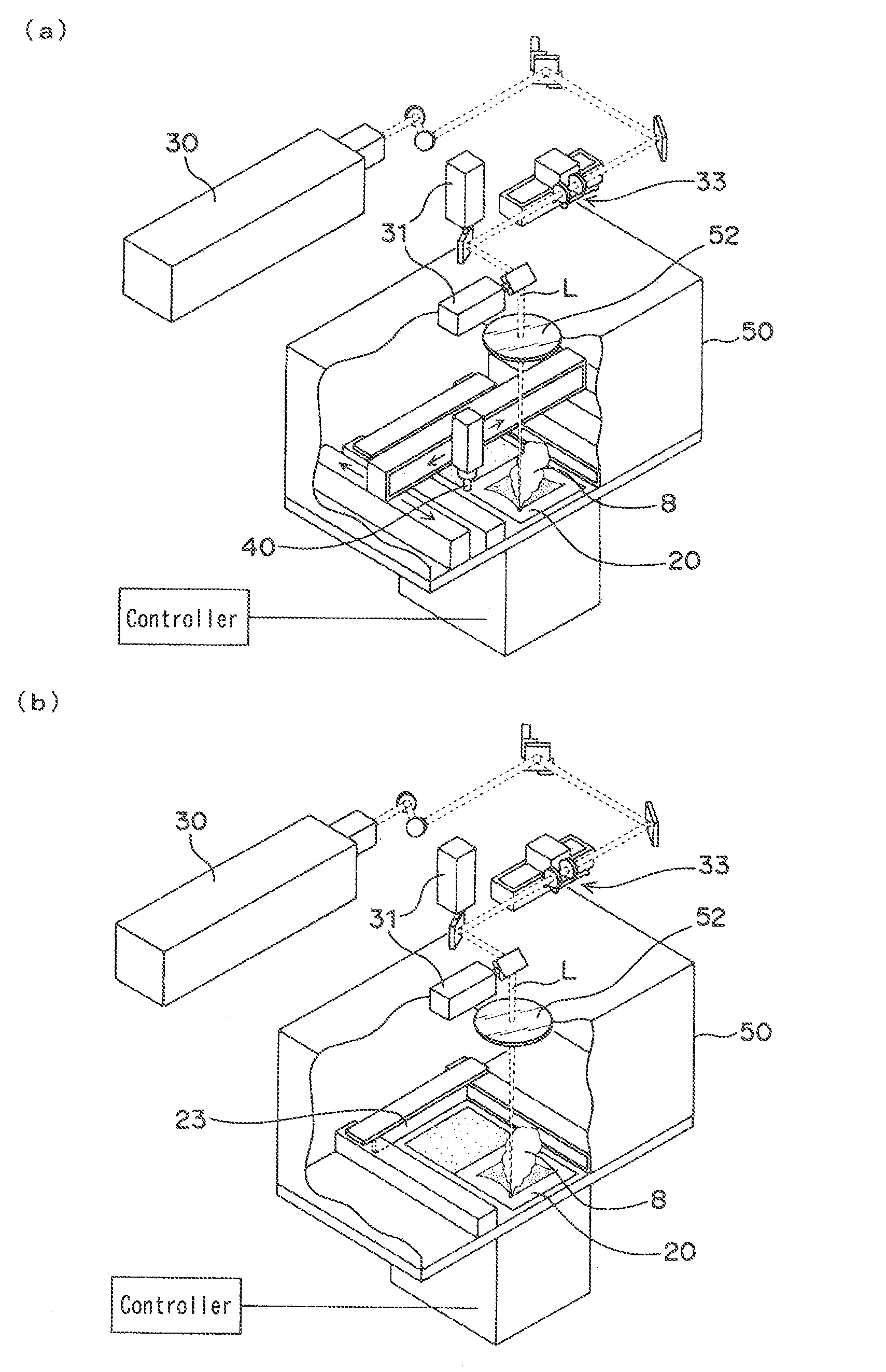

Metal powder for selective laser sintering, method for manufacturing three-dimensional shaped object by using the same, and three-dimensional shaped object obtained therefrom

InactiveUS20130065073A1Reduce warpingReduce deformationAdditive manufacturing apparatusPig casting plantsSelective laser sinteringPowder mixture

There is provided a metal powder for use in a selective laser sintering method for producing a three-dimensional shaped object, wherein the metal powder comprises a powder mixture of a precipitation-hardening metal composition. In particular, the metal powder of the present invention is configured to have a Fe-based component powder and a Ni-based component powder which are individually included in the powder mixture wherein a powder made of an alloy of Fe-based and Ni-based components is not included as a main powder in the powder mixture.

Owner:PANASONIC CORP

Fatigue damage resistant wire and method of production thereof

Fatigue damage resistant metal or metal alloy wires have a submicron-scale or nanograin microstructure that demonstrates improved fatigue damage resistance properties, and methods for manufacturing such wires. The present method may be used to form a wire having a nanograin microstructure characterized by a mean grain size that is 500 nm or less, in which the wire demonstrates improved fatigue damage resistance. Wire manufactured in accordance with the present process may show improvement in one or more other material properties, such as ultimate strength, unloading plateau strength, permanent set, ductility, and recoverable strain, for example. Wire manufactured in accordance with the present process is suitable for use in a medical device, or other high end application.

Owner:FORT WAYNE METALS RES PROD CORP

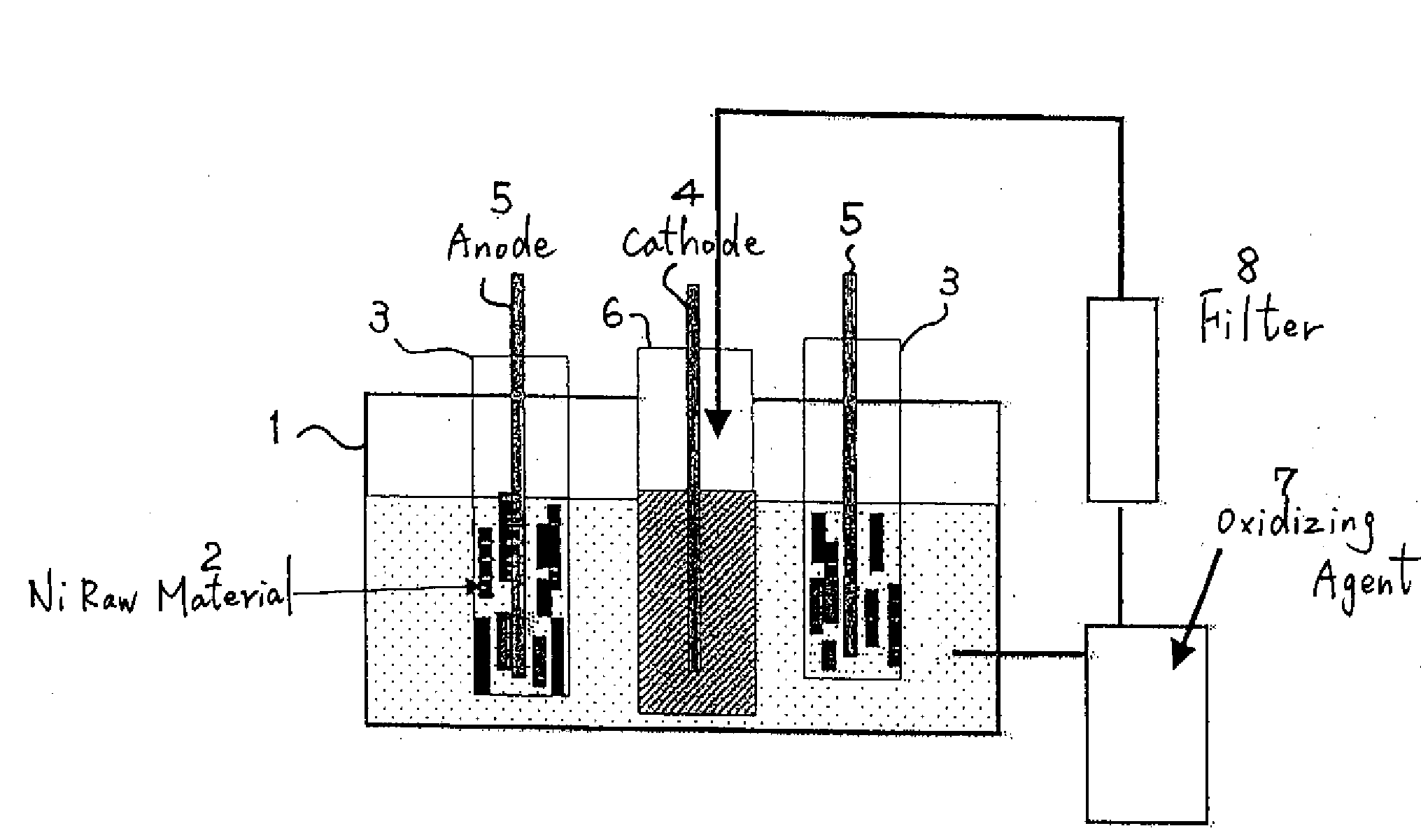

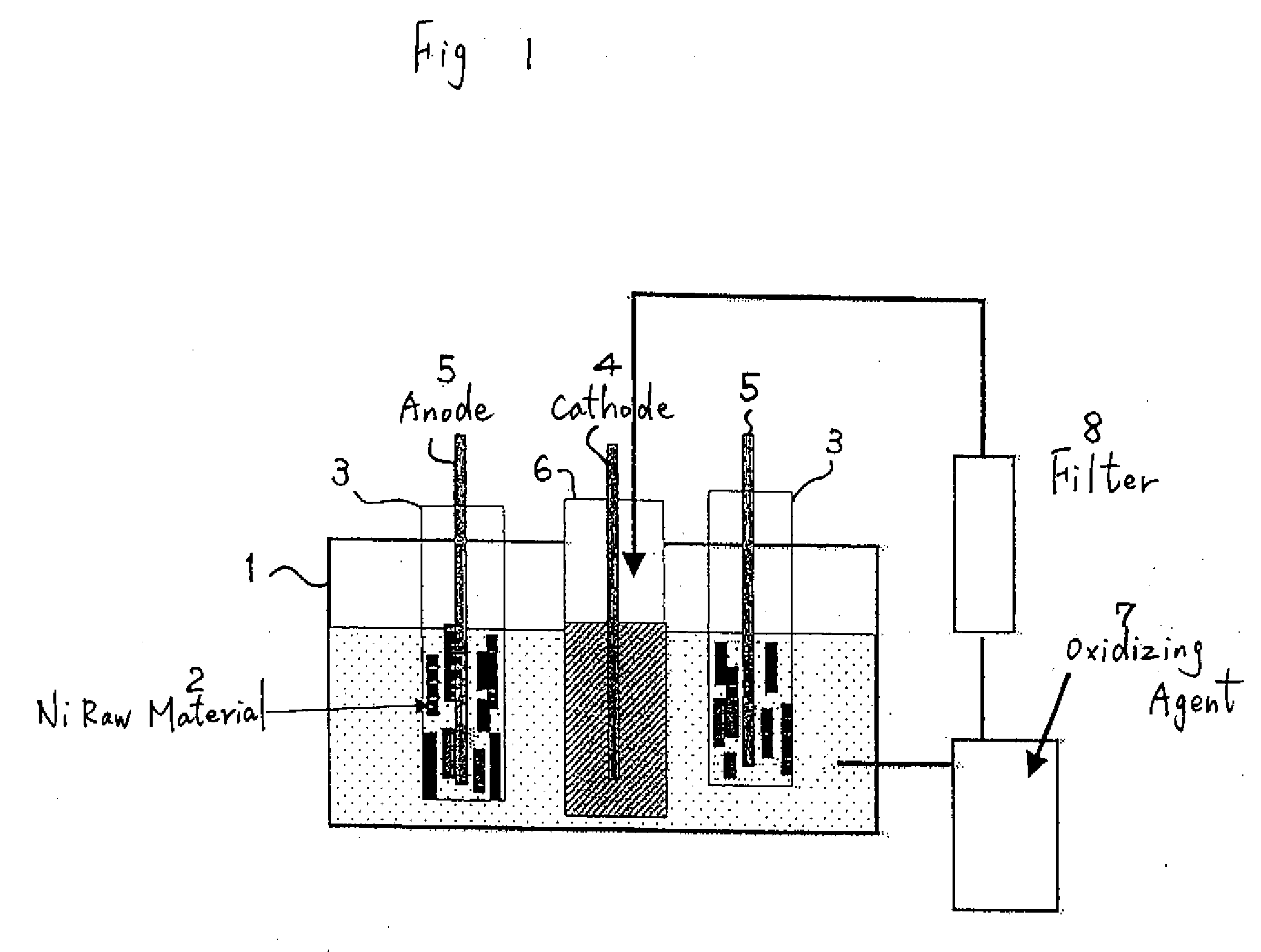

Manufacturing Method of High Purity Nickel, High Purity Nickel, Sputtering Target formed from said High Purity Nickel, and Thin Film formed with said Sputtering Target

InactiveUS20090004498A1Simple methodEfficient preparationPhotography auxillary processesPig casting plantsElectrolysisDisplacement reactions

Upon performing electrolysis with a solution containing nickel as the electrolytic solution, anolyte is adjusted to pH 2 to 5; impurities such as iron, cobalt and copper contained in the anolyte are eliminated by combining any one or two or more of the methods among adding an oxidizing agent and precipitating and eliminating the impurities as hydroxide, eliminating the impurities through preliminary electrolysis, or adding Ni foil and eliminating the impurities through displacement reaction; impurities are thereafter further eliminated with a filter; and the impurity-free solution is employed as catholyte to perform the electrolysis. The present invention relates to a simple method of performing electrolytic refining employing a solution containing nickel from nickel raw material containing a substantial amount of impurities, and provides technology on efficiently manufacturing high purity nickel having a purity of 5N (99.999 wt %) or more.

Owner:JX NIPPON MINING & METALS CORP

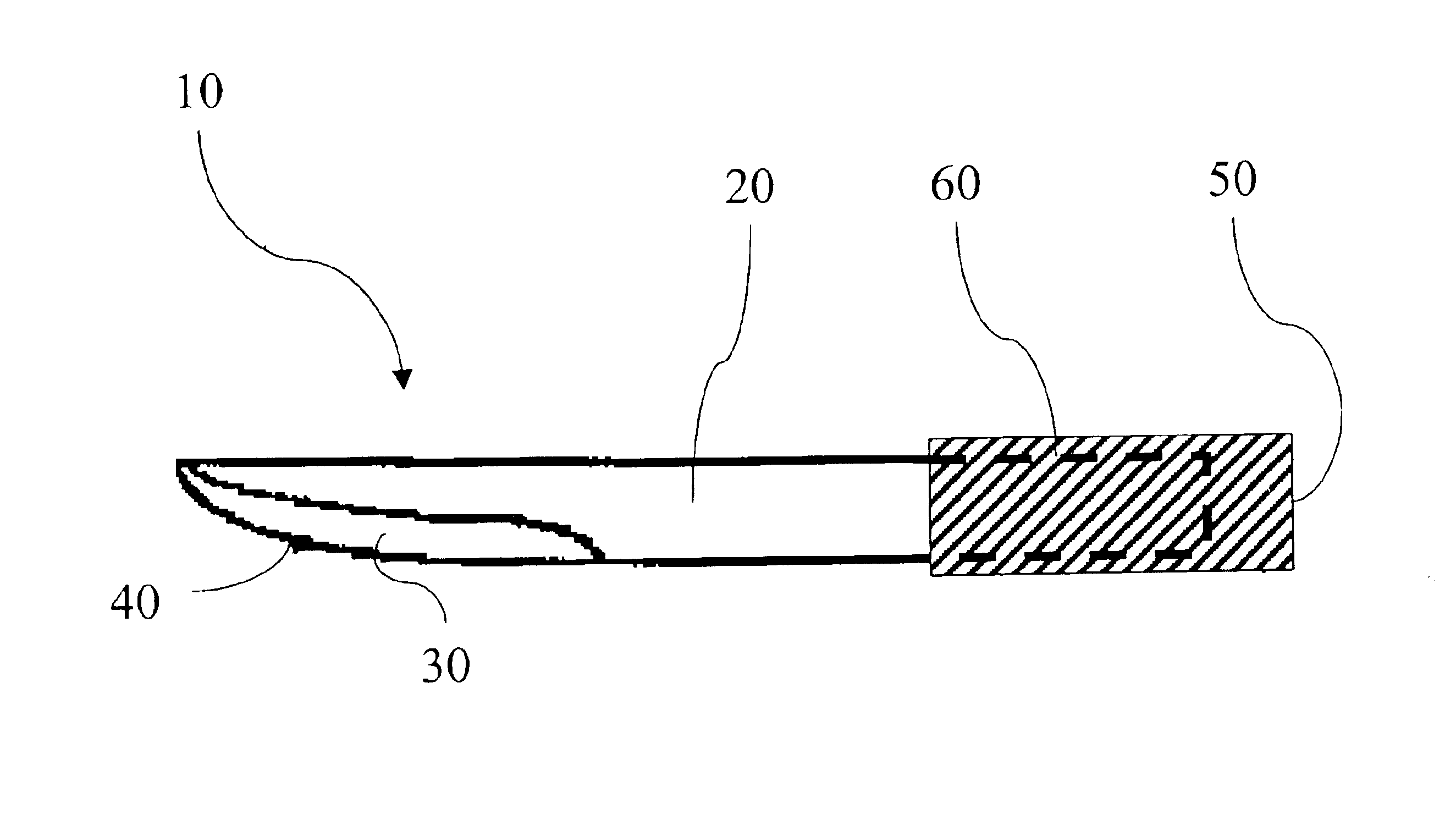

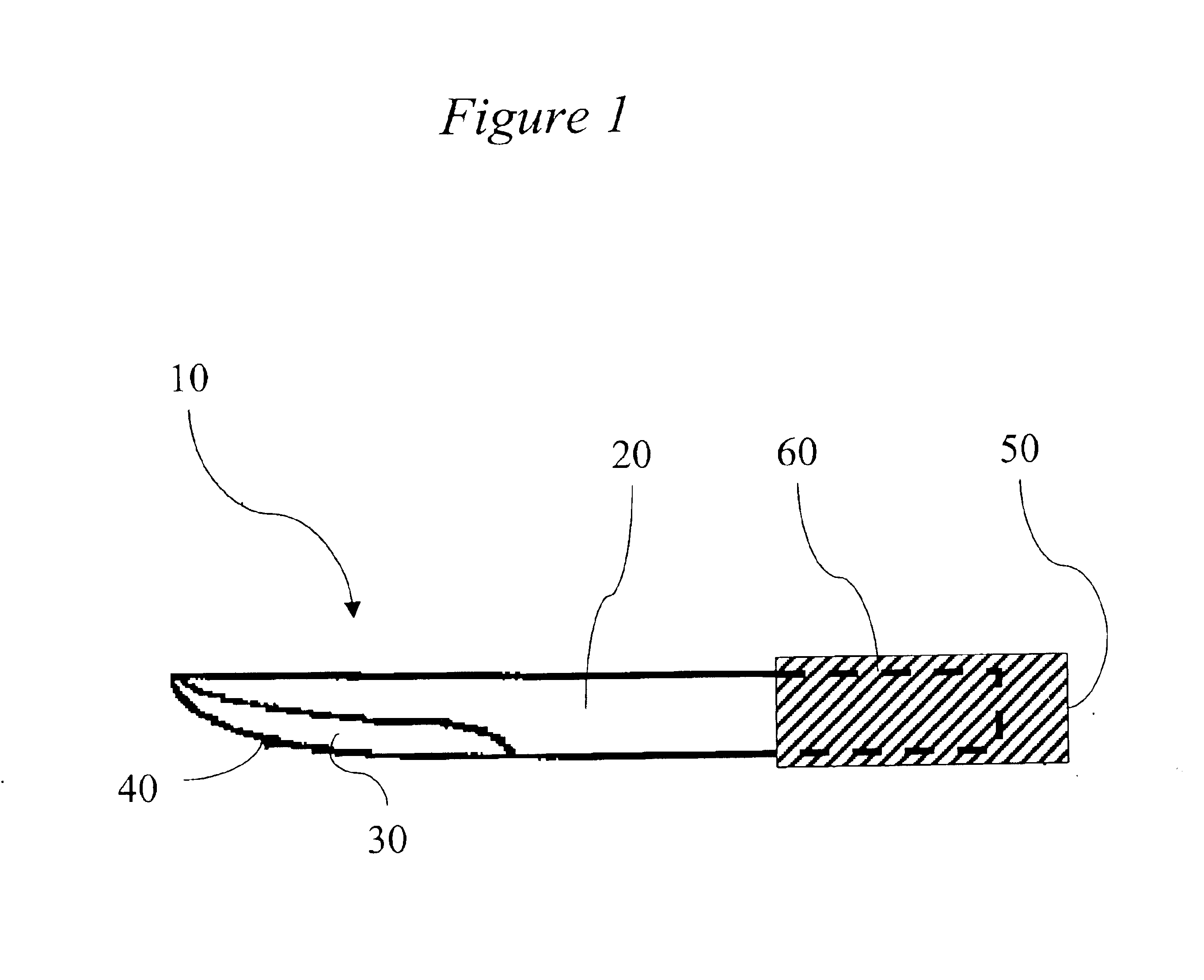

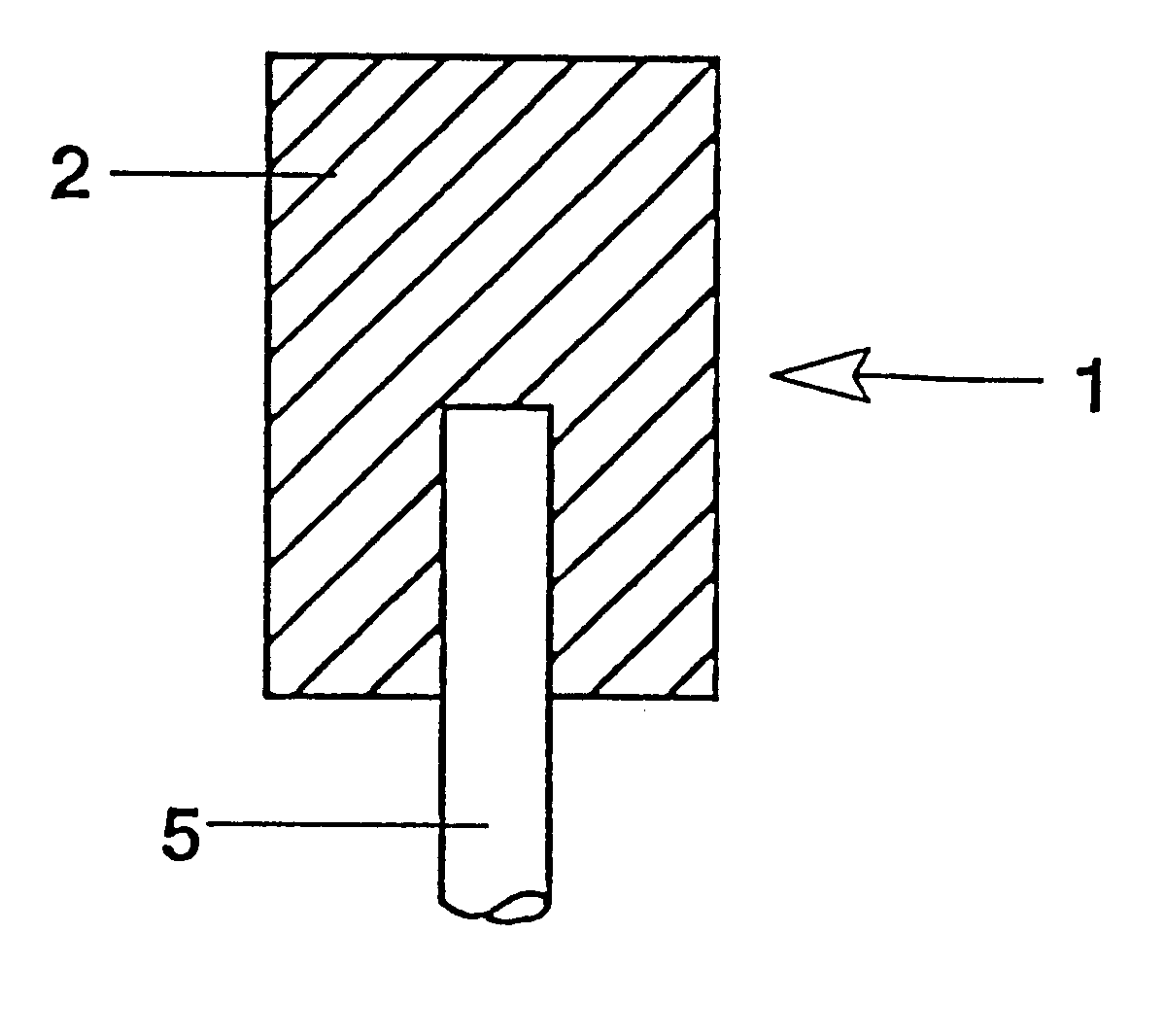

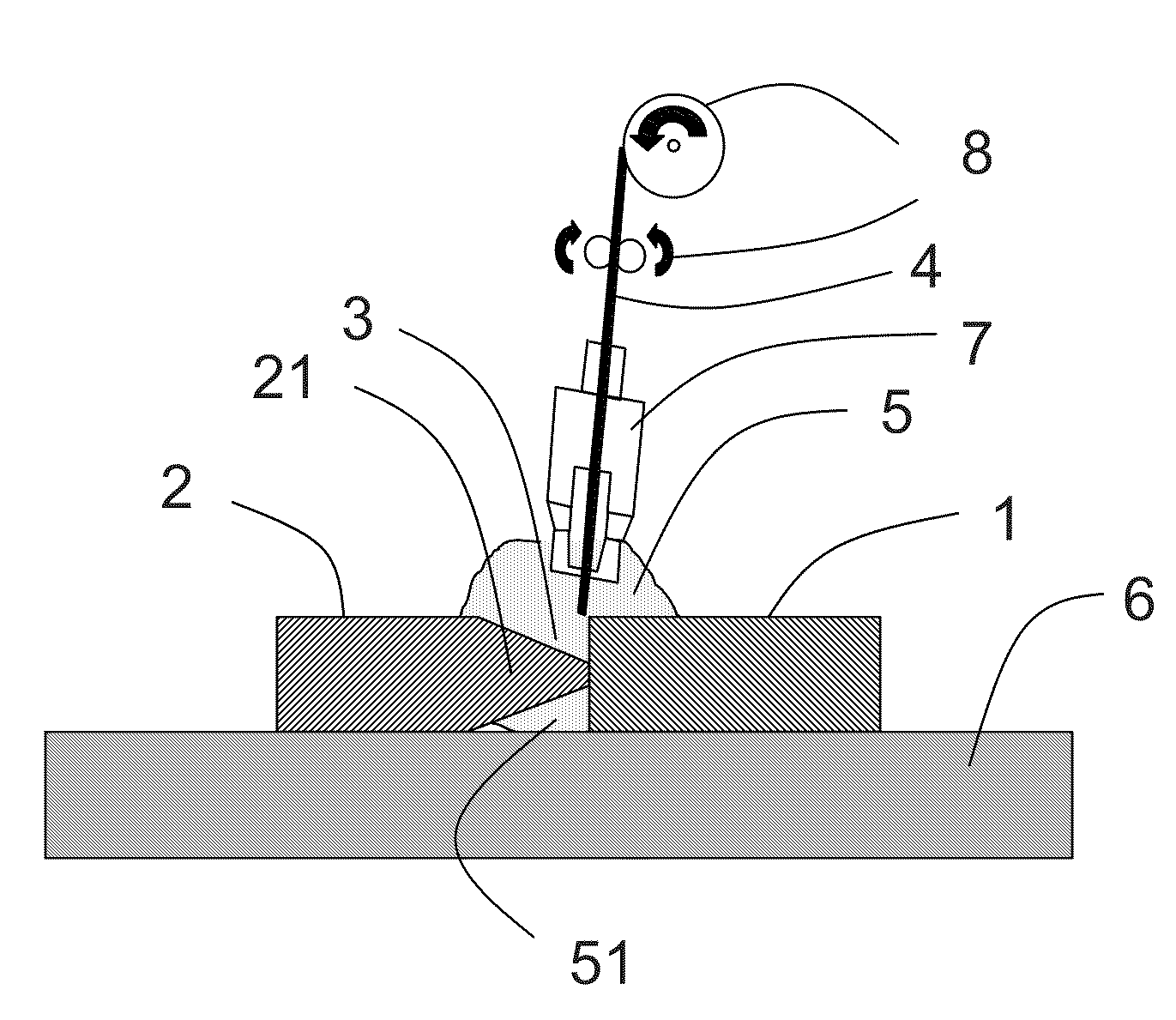

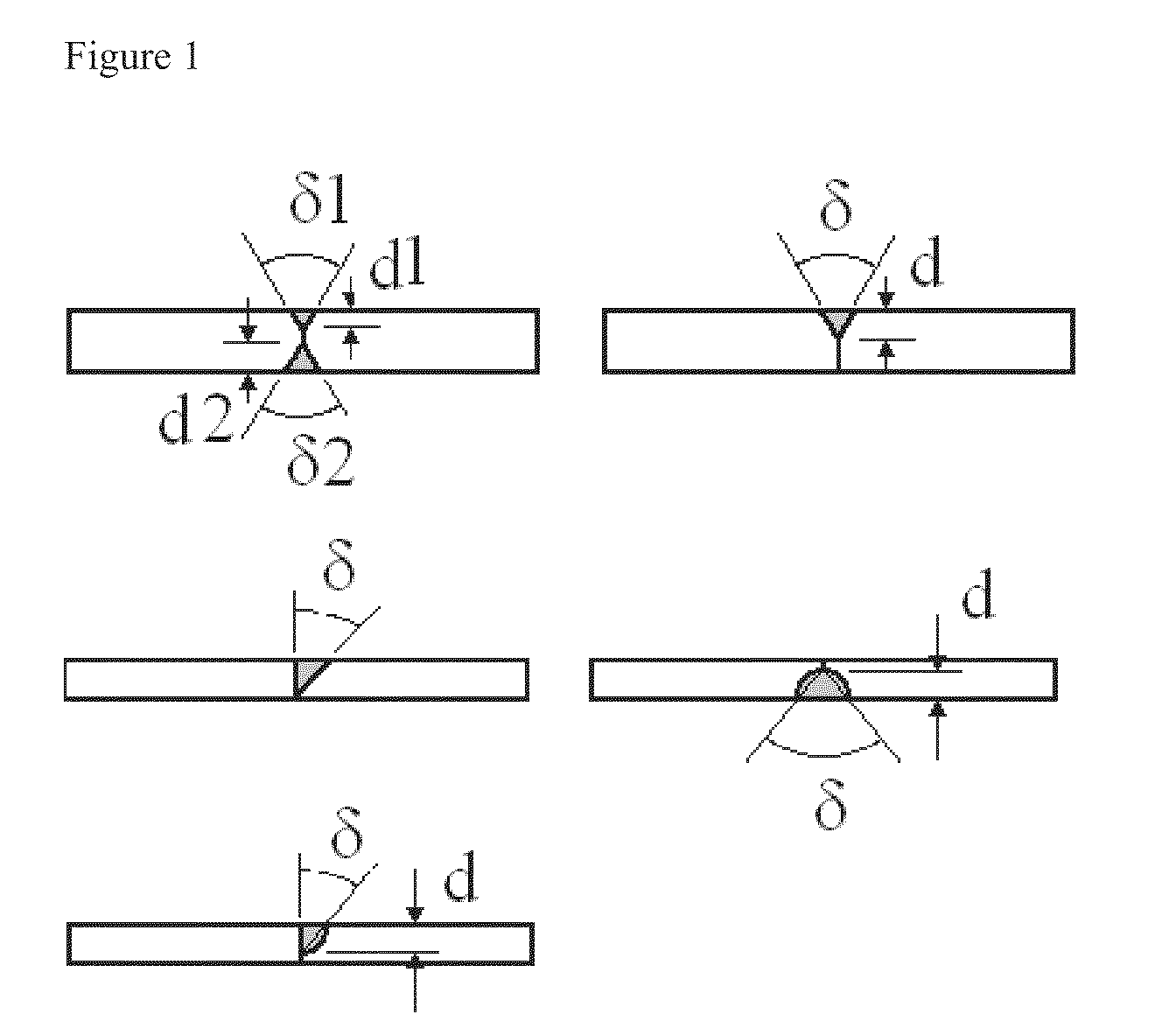

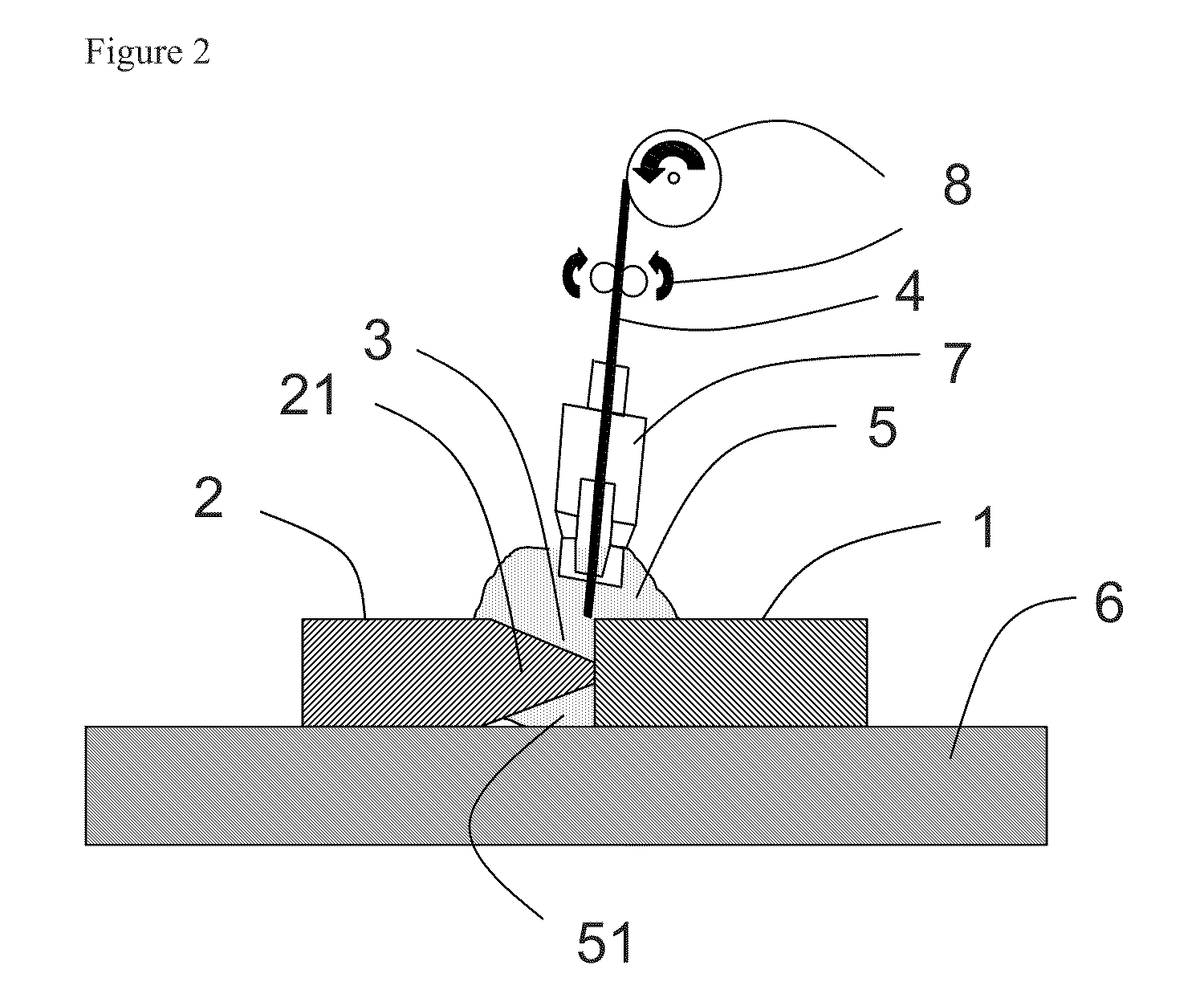

Fusion Welding Process To Join Aluminium and Titanium

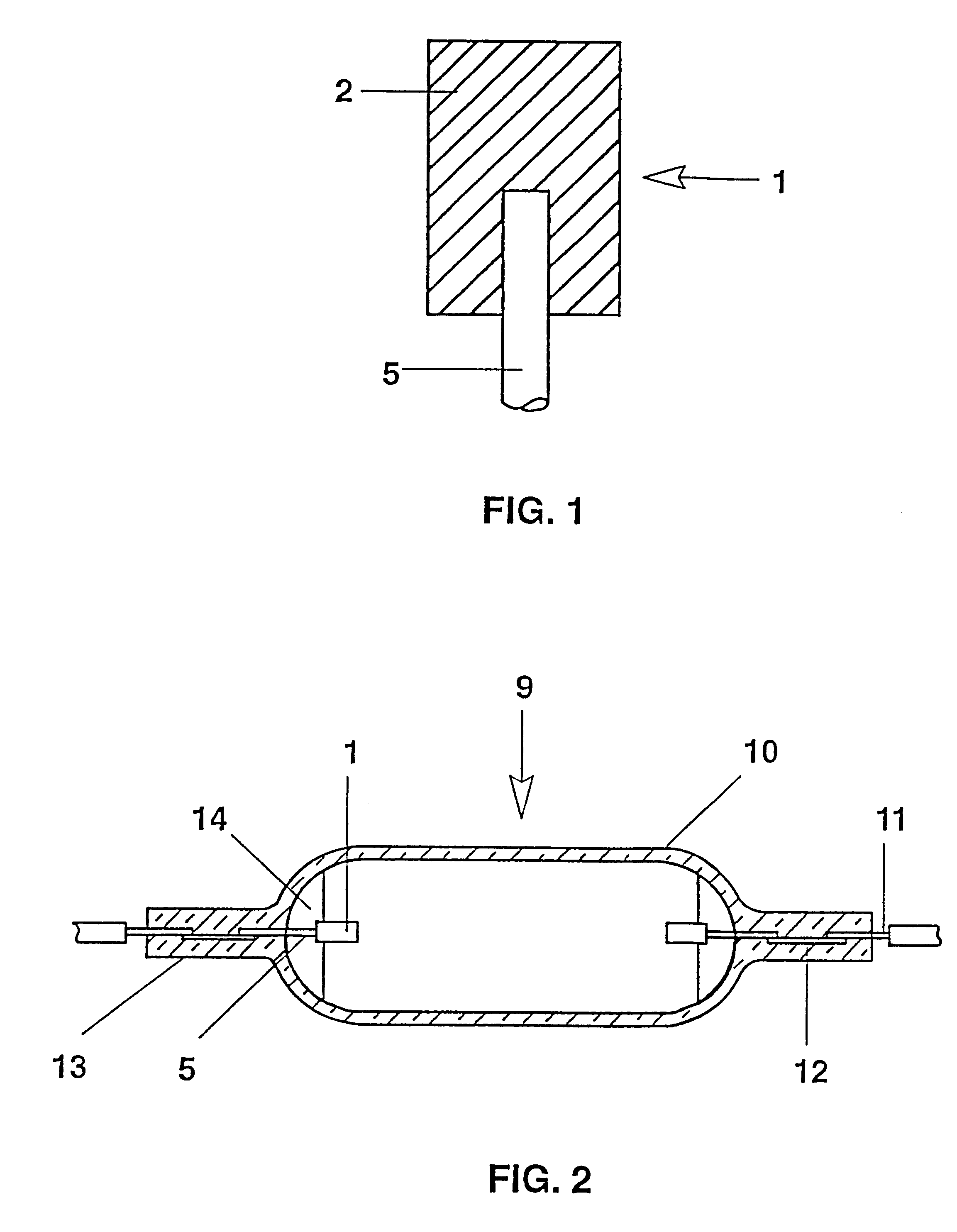

The invention concerns a process for joining a first member (1) comprising an aluminum alloy to a second member (2) comprising a titanium alloy and having at least one edge with a thickness e,comprising the steps of(i) chamfering said edge of said second member into a tapered truncated shape having on a first side a first tapering angle α1, on a second side a second tapering angle α2 and a minimum thickness t, wherein α1 and α2 are greater than or equal to zero, the sum of α1 and α2 is between 10° and 50° and t is between 0.05 e and 0.3 e,(ii) placing said first member and said chamfered edge of said second member (21) in an abutting relationship defining a geometry to be weld-brazed (3),(iii) heating the surface areas of said members adjacent the abutment to a temperature above the melting temperature of said aluminum alloy and below the melting temperature of said titanium alloy, in the presence of an inert gas (5) and of a filler metal (4) to obtain a weld-brazed joint.The process of the invention is particularly useful for obtaining high strength weld-brazed joints between aluminum and titanium with a high process output.

Owner:CONSTELLIUM SWITZERLAND

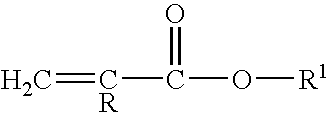

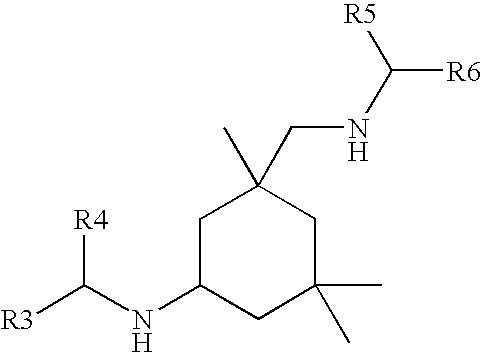

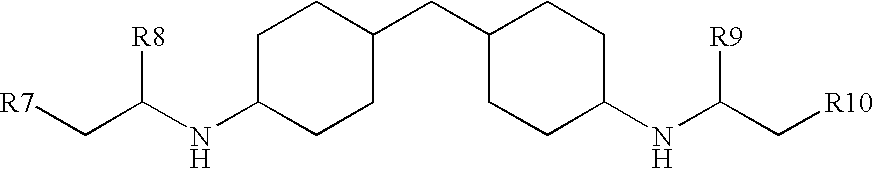

(METH)acrylate/aspartate amine curatives and coatings and articles comprising the same

(Meth)acrylate / aspartate amine curatives comprising the reaction product of a polyamine, a dialkyl maleate and / or dialkyl fumarate, and a (meth)acrylate are disclosed, as are methods for making the same. A polyurea comprising the reaction product of the acrylate / aspartate amine curative and isocyanate is also disclosed, as are coatings comprising such a polyurea and substrates coated with the same.

Owner:PPG IND OHIO INC

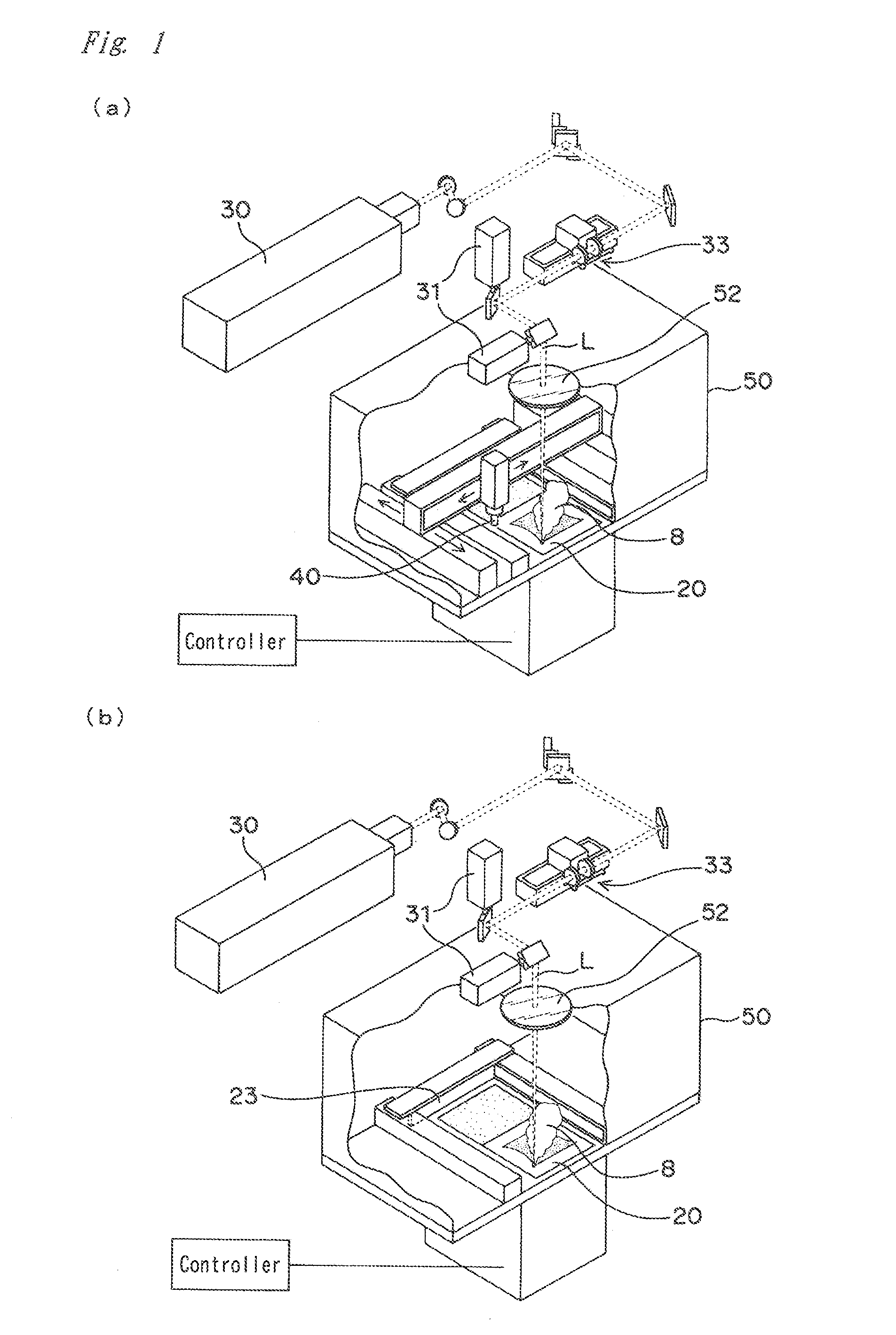

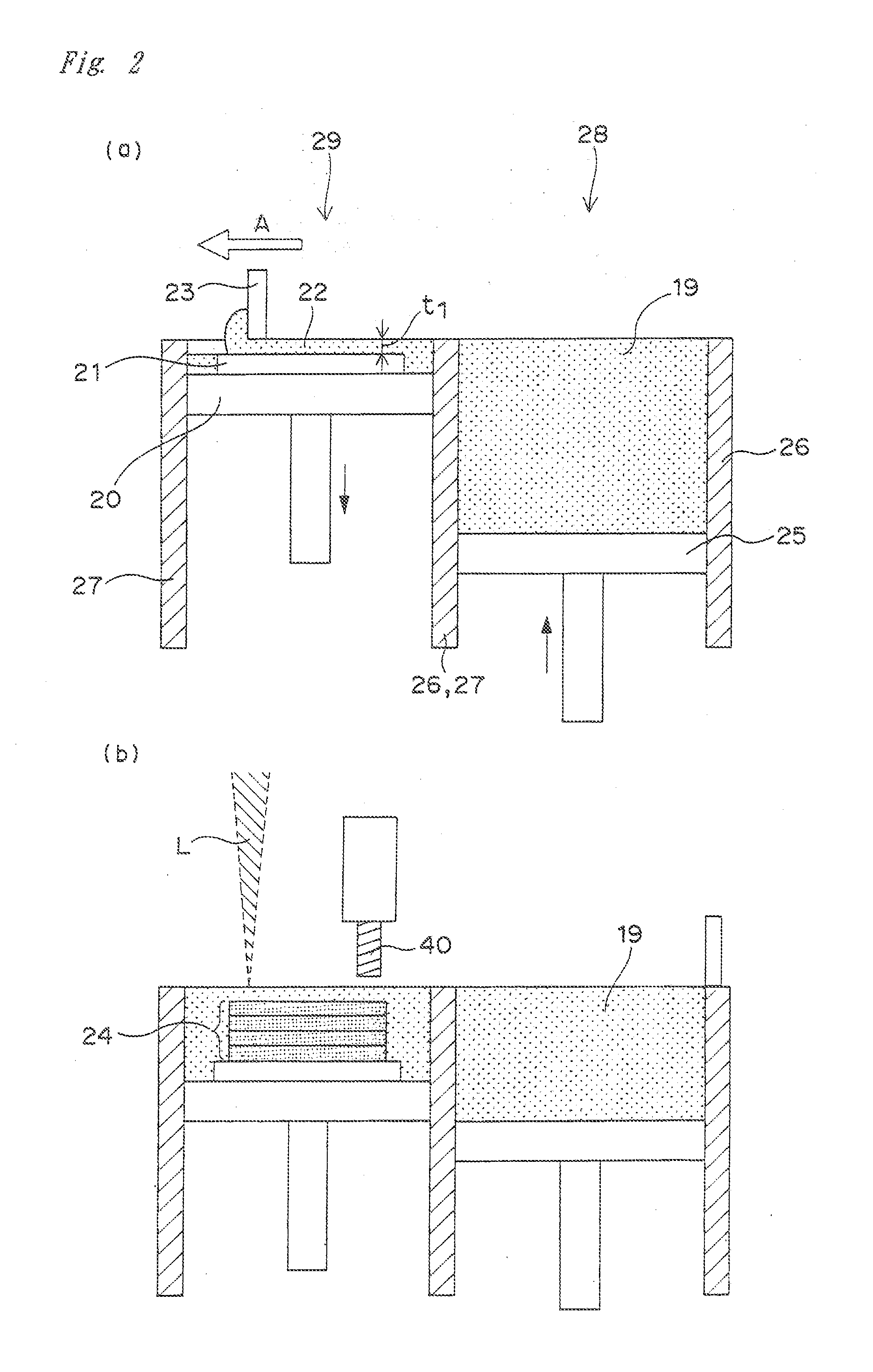

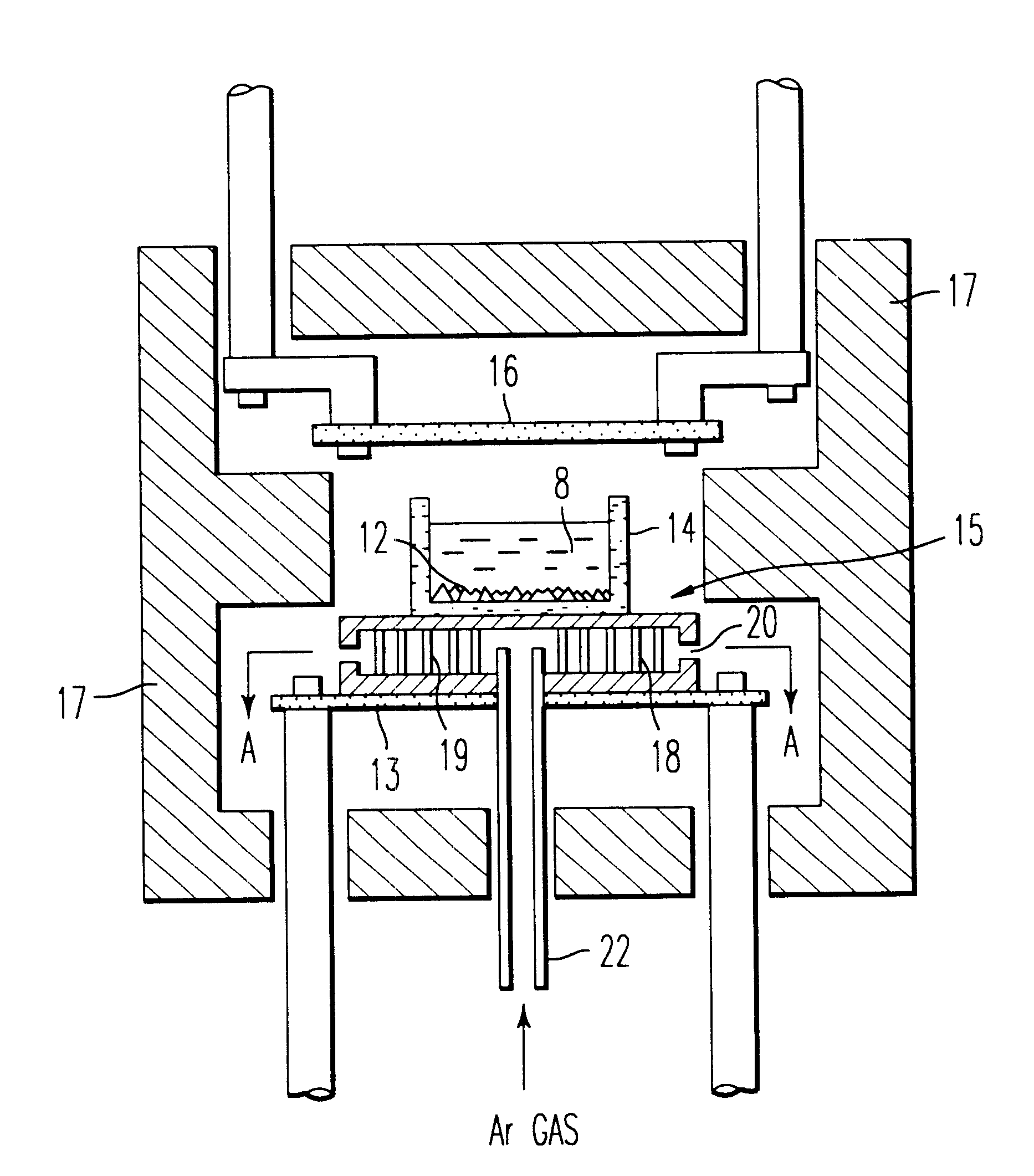

Method for producing silicon ingot having directional solidification structure and apparatus for producing the same

A method for producing a silicon ingot having a directional solidification structure comprising the steps of: placing a silicon raw material into a crucible of a melting device constructed by mounting a chill plate on an underfloor heater, mounting a crucible with a large cross-sectional area on the chill plate, providing an overhead heater over the crucible, and surrounding the circumference of the crucible with a heat insulator; heat-melting the silicon raw material by flowing an electric current through the underfloor heater and overhead heater; chilling the bottom of the crucible by halting the electric current through the underfloor heater after the silicon raw material has been completely melted to form a molten silicon; chilling the bottom of the crucible by flowing an inert gas through the chill plate; and intermittently or continuously lowering the temperature of the overhead heater by intermittently or continuously decreasing the electric current through the overhead heater, and an apparatus for producing the silicon ingot.

Owner:MITSUBISHI MATERIALS CORP

Aircraft structure element made of an Al-Cu-Mg alloy

InactiveUS20010006082A1Lower wing skin panelsEasy to weldPig casting plantsSemiconductor/solid-state device detailsAlloyStructuring element

The purpose of the invention is a structure element, particularly an lower wing element of an aircraft, manufactured from a rolled, extruded or forged product made of an alloy with composition (% by weight): Cu=4.6-5.3, Mg=0.10-0.50, Mn=0.15-0.45, Si <0.10, Fe<0.15, Zn<0.20, Cr<0.10, other elements <0.05 each and <0.15 total, the remainder being Al treated by solution heat treating, quenching, controlled tension to more than 1.5% permanent deformation and aging.

Owner:RHENALU PECHINEY

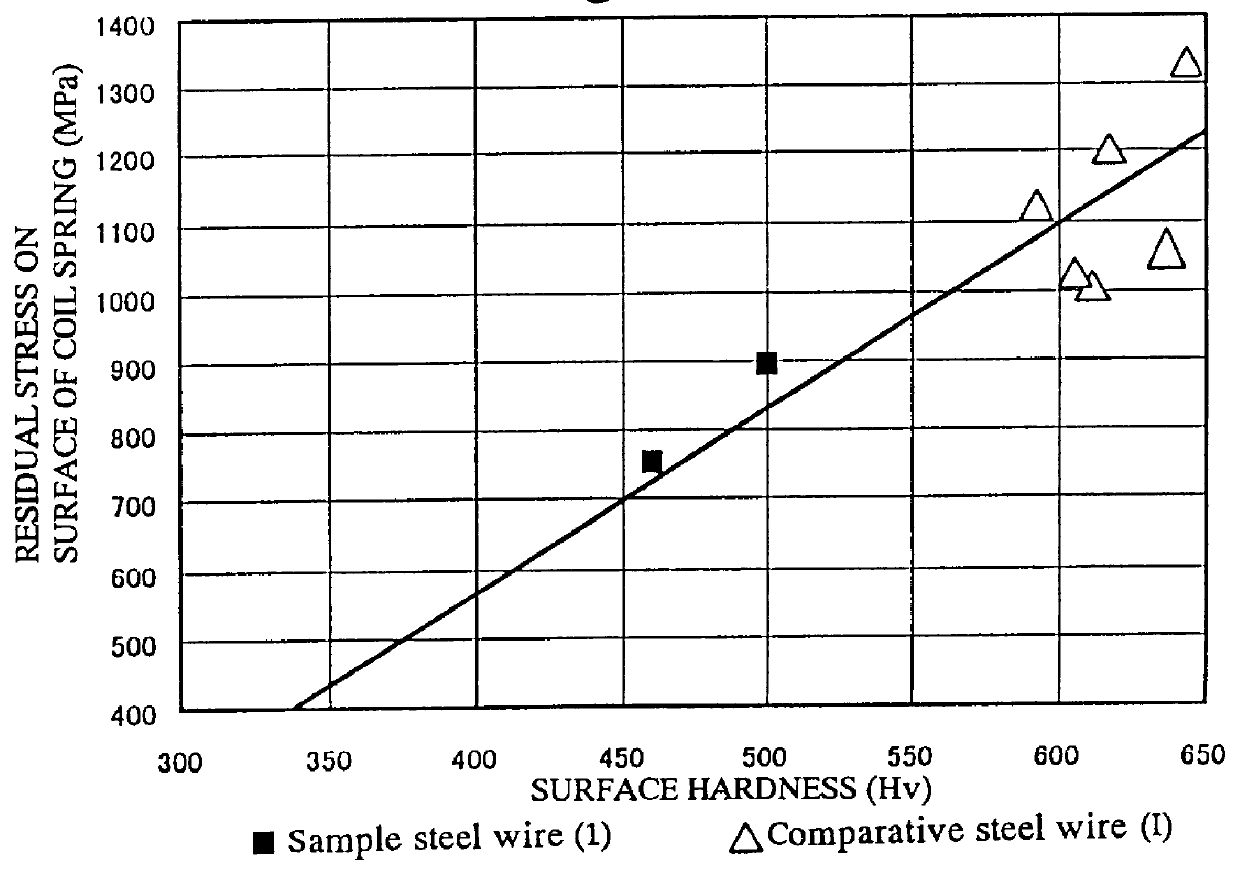

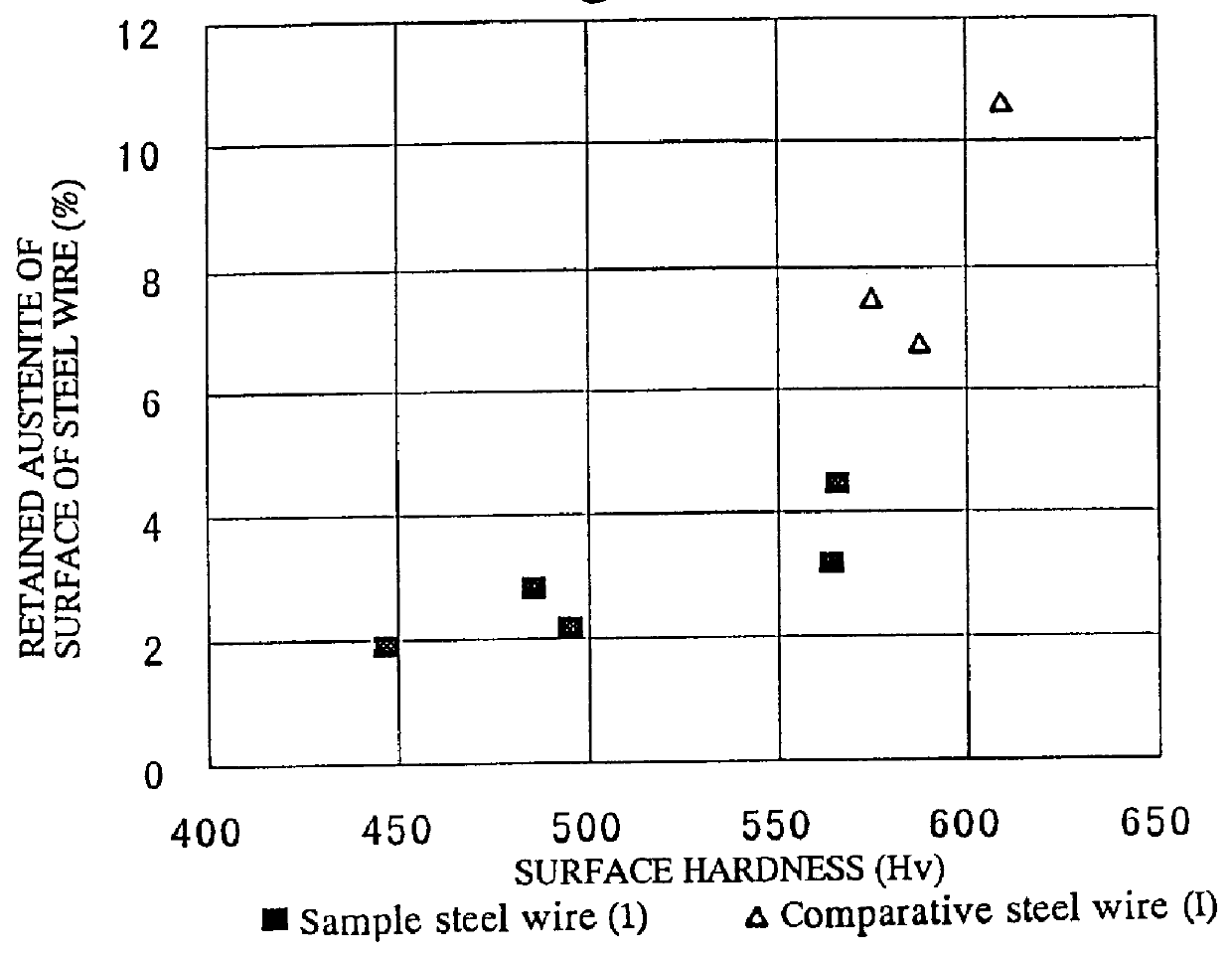

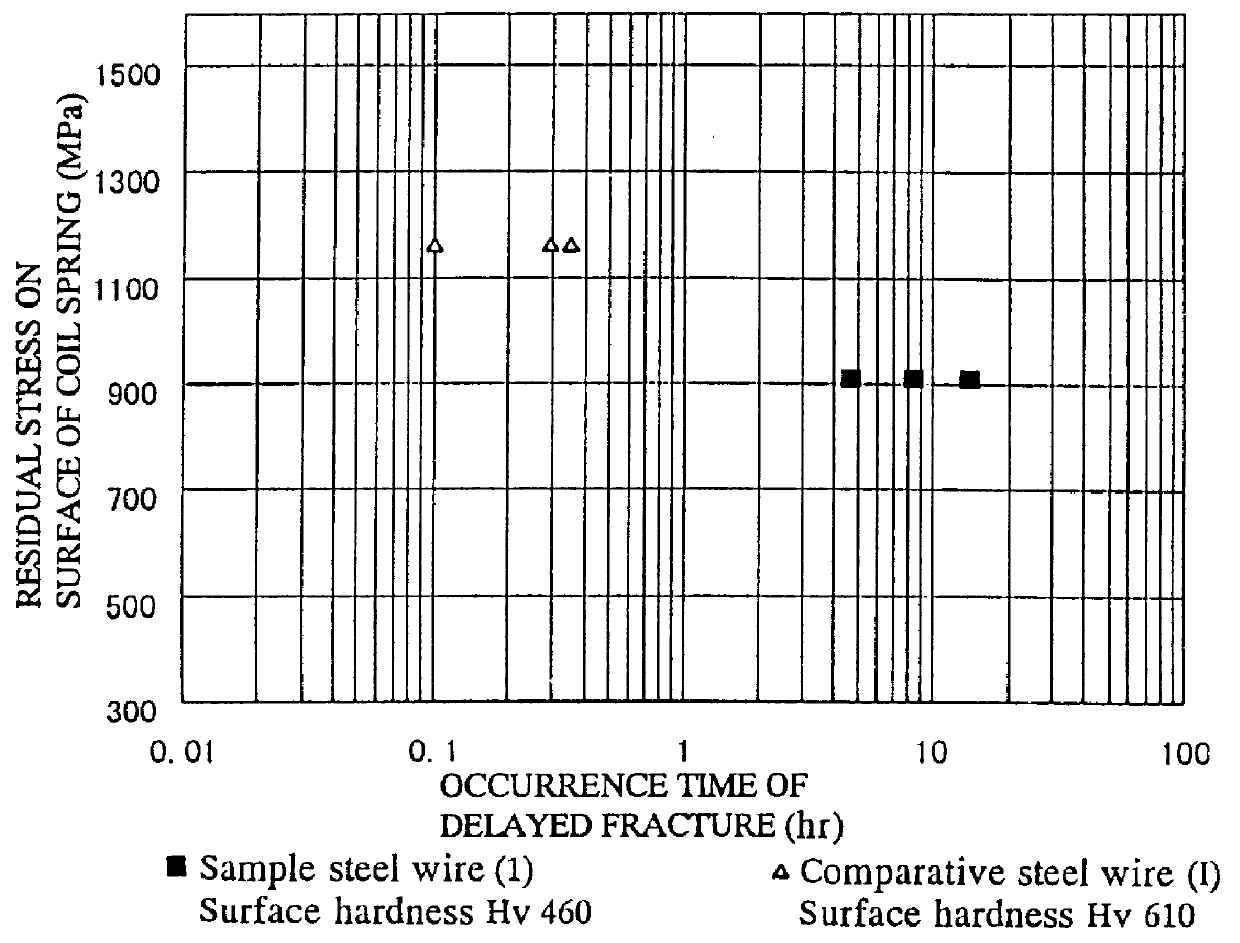

Coil spring resistive to delayed fracture and manufacturing method of the same

A coil spring made of an oil-tempered steel wire with internal hardness of more than Hv 550 in cross-section, the surface hardness of the oil-tempered steel wire being determined in an extent between Hv 420 in a minimum value and hardness defined by subtraction of Hv 50 from the internal hardness in a maximum value.

Owner:CHUO SPRING +1

Biodegradable composite wire for medical devices

A bioabsorbable wire material includes manganese (Mn) and iron (Fe). One or more additional constituent materials (X) are added to control corrosion in an in vivo environment and, in particular, to prevent and / or substantially reduce the potential for pitting corrosion. For example, the (X) element in the Fe—Mn—X system may include nitrogen (N), molybdenum (Mo) or chromium (Cr), or a combination of these. This promotes controlled degradation of the wire material, such that a high percentage loss of material the overall material mass and volume may occur without fracture of the wire material into multiple wire fragments. In some embodiments, the wire material may have retained cold work for enhanced strength, such as for medical applications. In some applications, the wire material may be a fine wire suitable for use in resorbable in vivo structures such as stents.

Owner:FORT WAYNE METALS RES PROD CORP

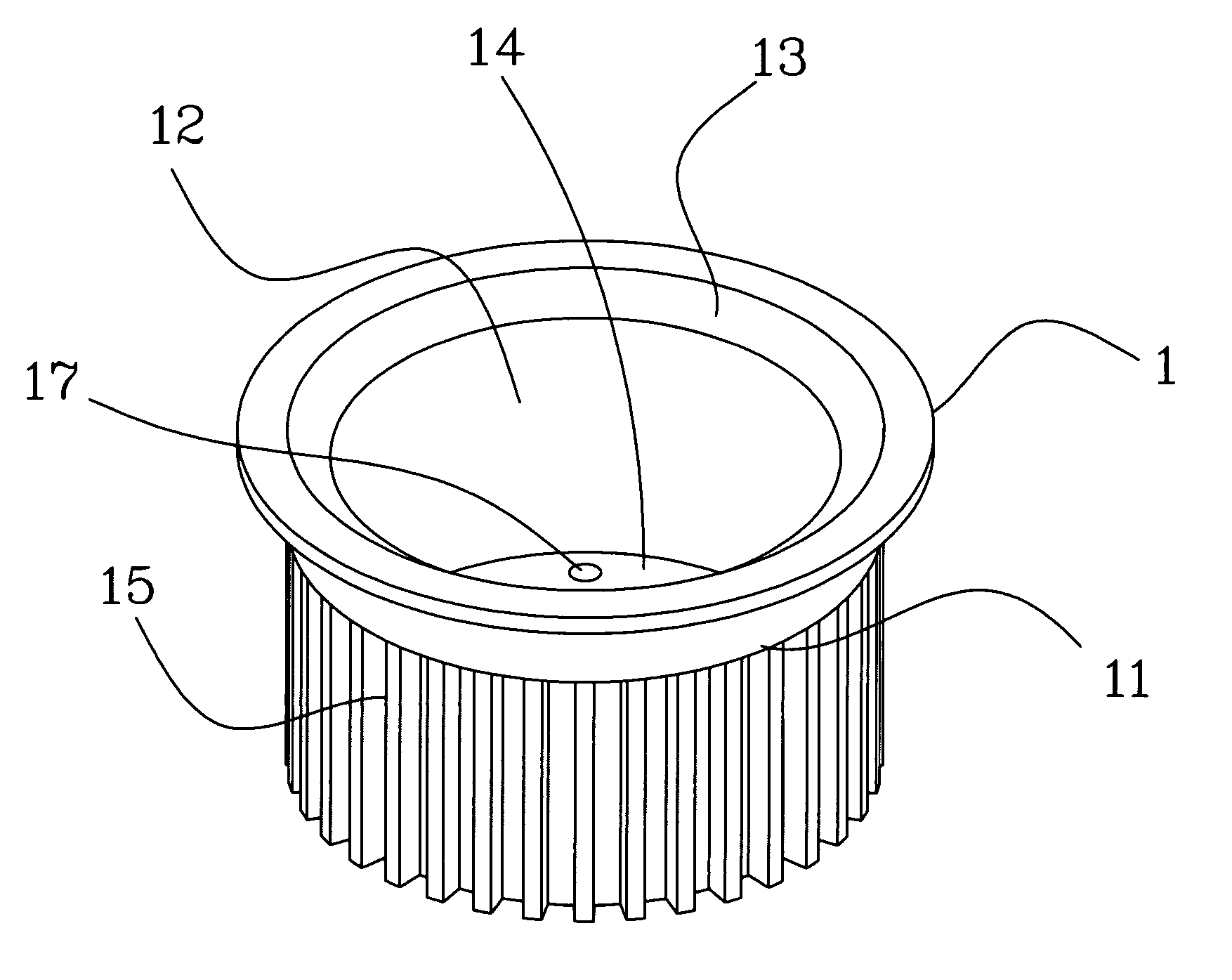

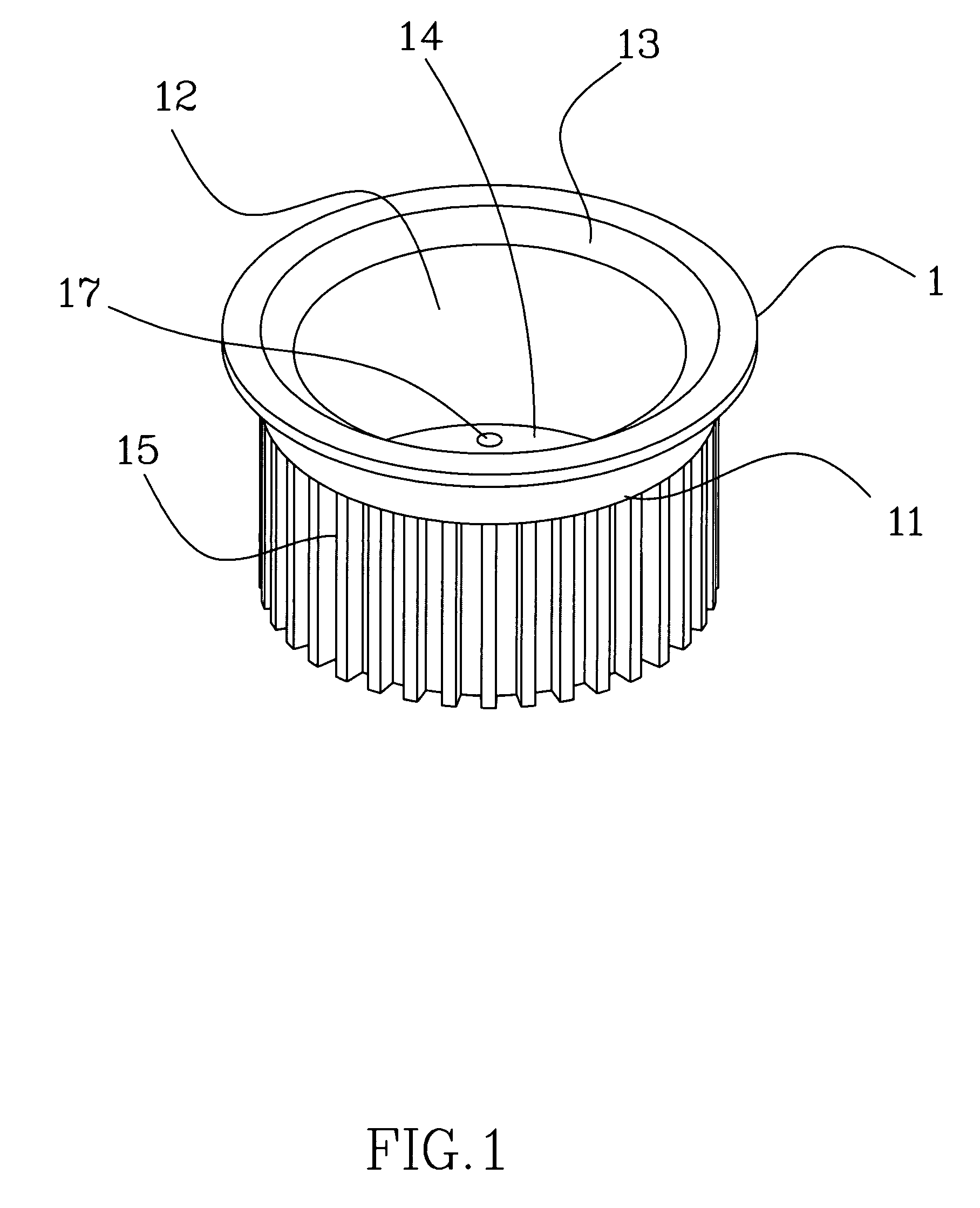

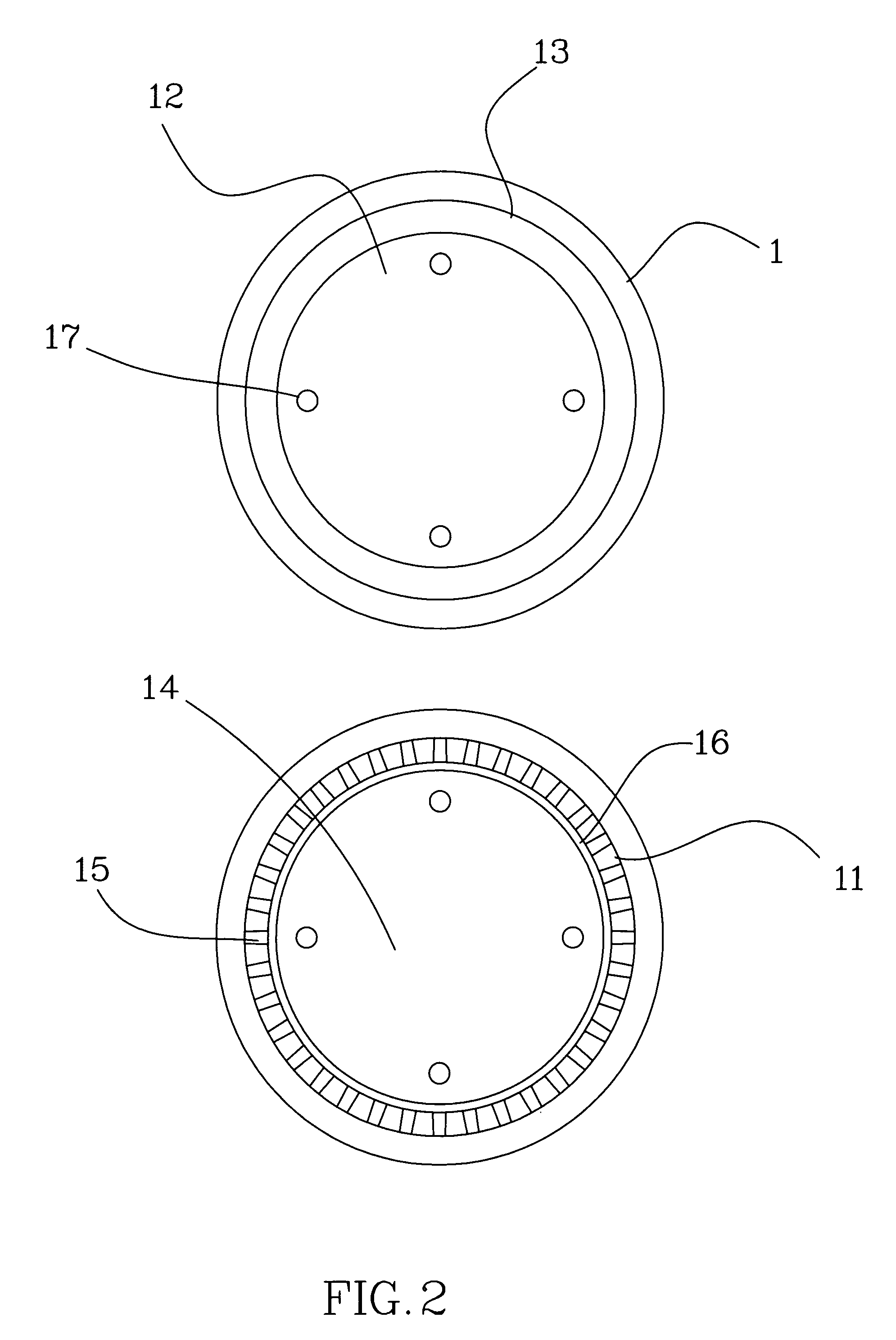

Thermal module

InactiveUS7914902B2Uniform and tight crystal phase structureImprove cooling efficiencyPig casting plantsLayered productsMagnesium alloy

A thermal module directly press-forged from magnesium alloy is disclosed having a peripheral wall, a recessed chamber surrounded by the peripheral wall. The body is made of magnesium alloy by means of softening magnesium alloy with heat and then press forging softened magnesium alloy into the desired shape.

Owner:JIING TUNG TEC METAL

High strength gray cast iron

A gray cast iron alloy is disclosed. The gray cast iron alloy includes carbon from about 3.05 to about 3.40 weight percent, niobium from about 0.05 to about 0.3 weight percent, and silicon from about 1.75 to about 2.3 weight percent. The gray cast iron alloy also includes nickel less than or equal to about 0.06 weight percent.

Owner:CATERPILLAR INC

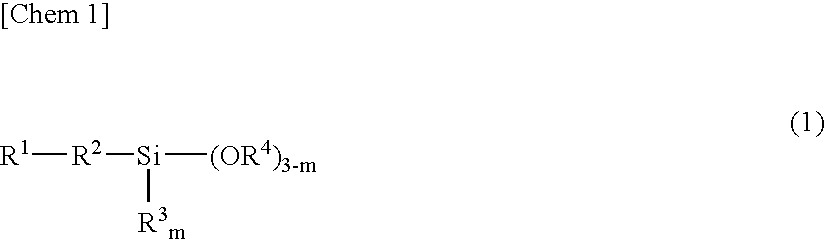

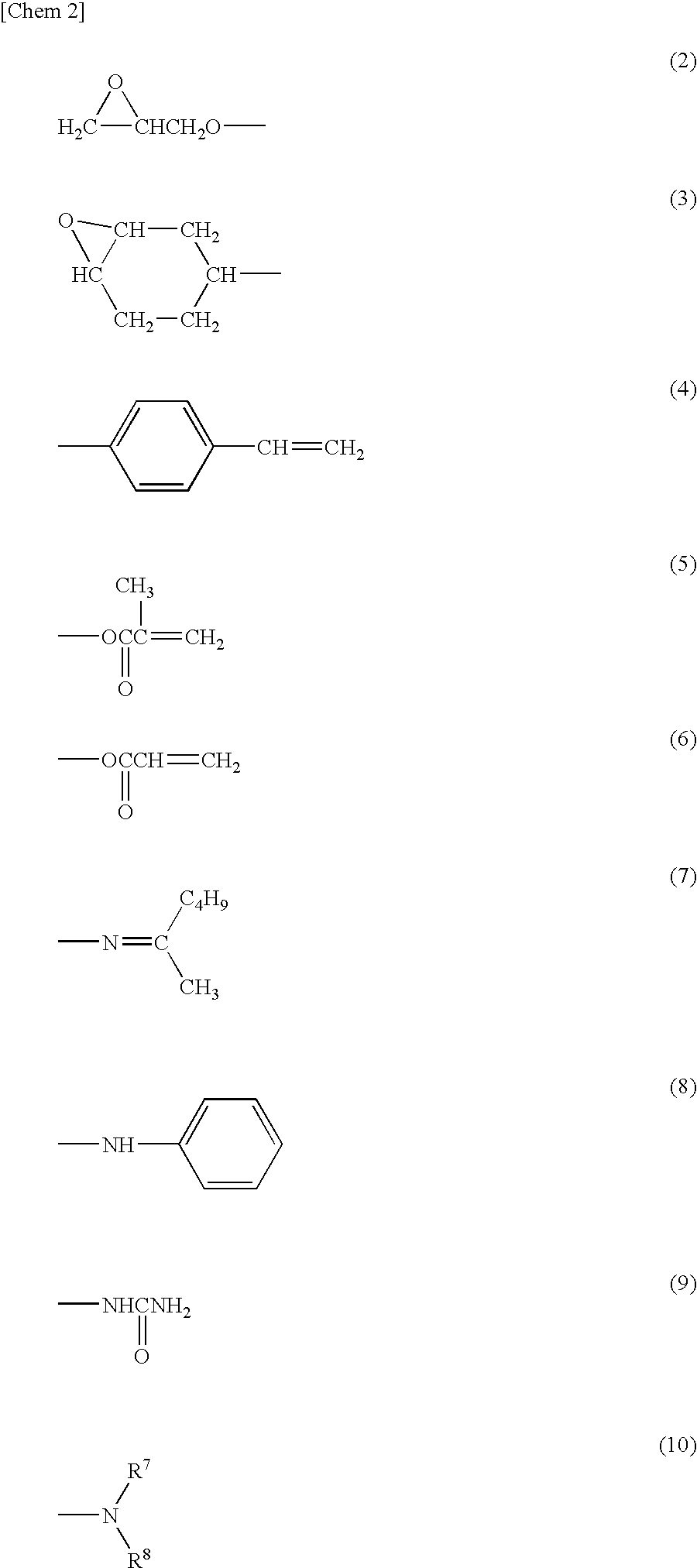

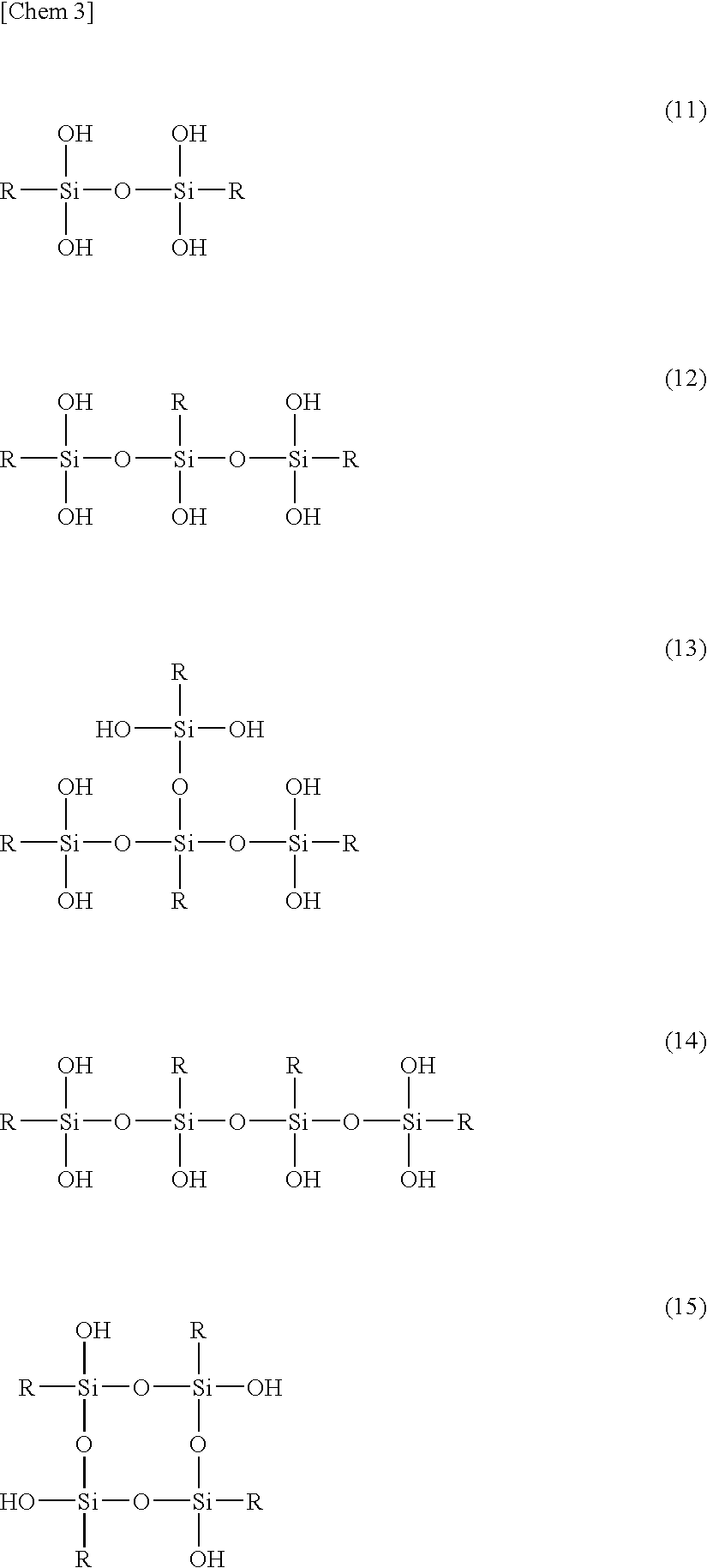

Metal surface treatment composition, metal surface treatment method, and metal material

ActiveUS20080081212A1Good storage stabilityImprove propertiesPig casting plantsPretreated surfacesTitaniumSilicon

A metal surface treatment composition including at least one compound selected from the group consisting of a zirconium compound and a titanium compound, and an organosiloxane, which is a polycondensate of organosilane and has in a molecule thereof of at least two amino groups, in which the Degree of polycondensation of the organosiloxane is at least 40%, the content of at least one compound selected from the group consisting of the zirconium compound and the titanium compound is predetermined content, the content of the organosiloxane in the metal surface treatment composition is predetermined content, and the mass ratio of at least one element selected from the group consisting of the zirconium element and the titanium element contained in the zirconium compound and the titanium compound, respectively, to the silicon element contained in the organosiloxane is a predetermined ratio.

Owner:NIPPON PAINT SURF CHEM +1

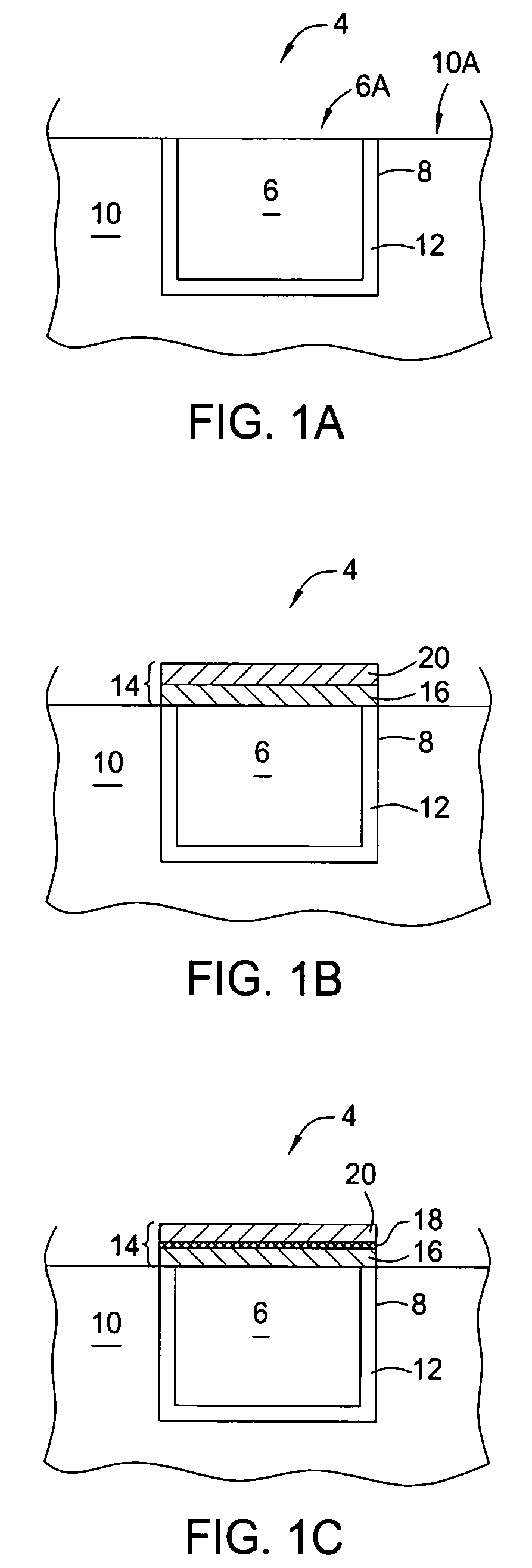

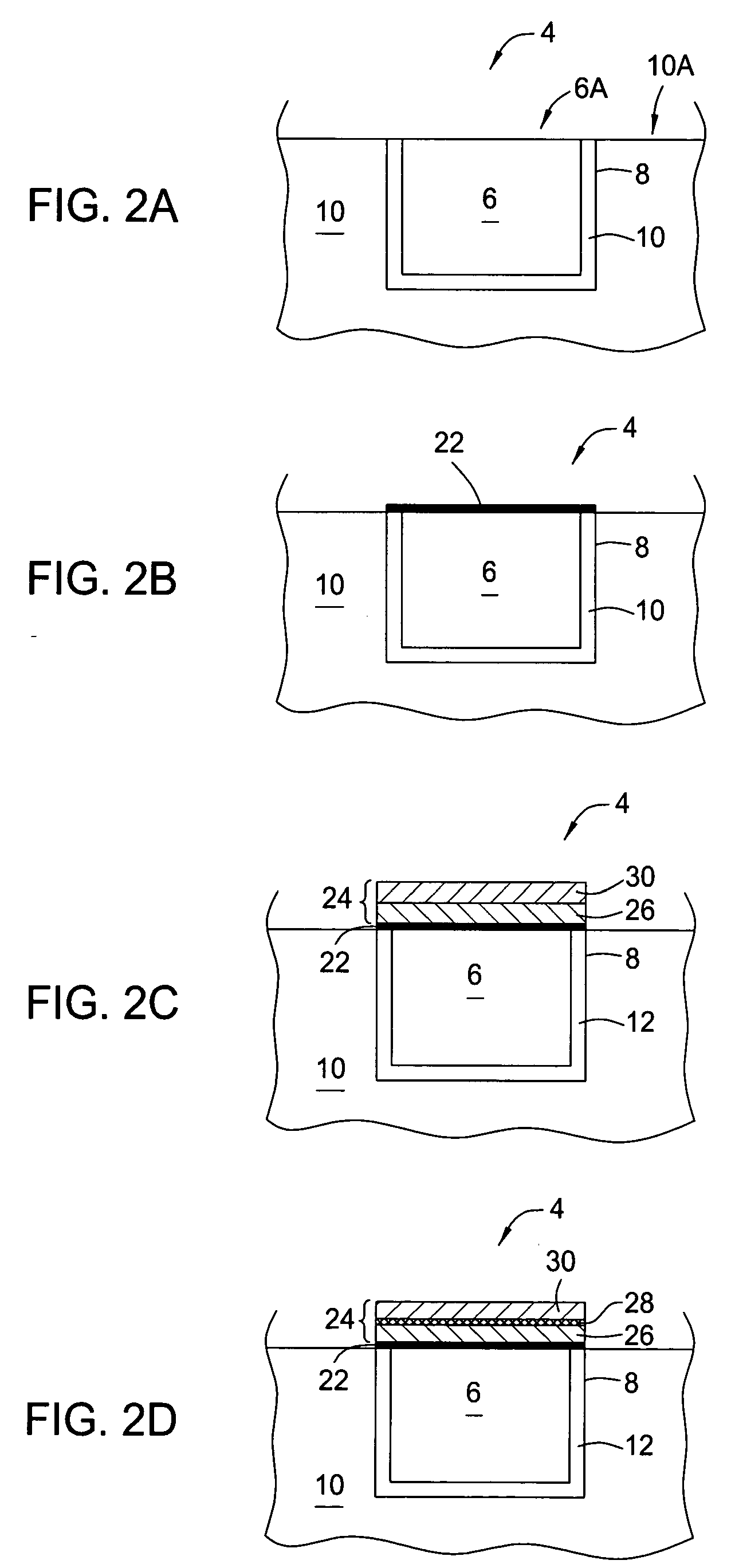

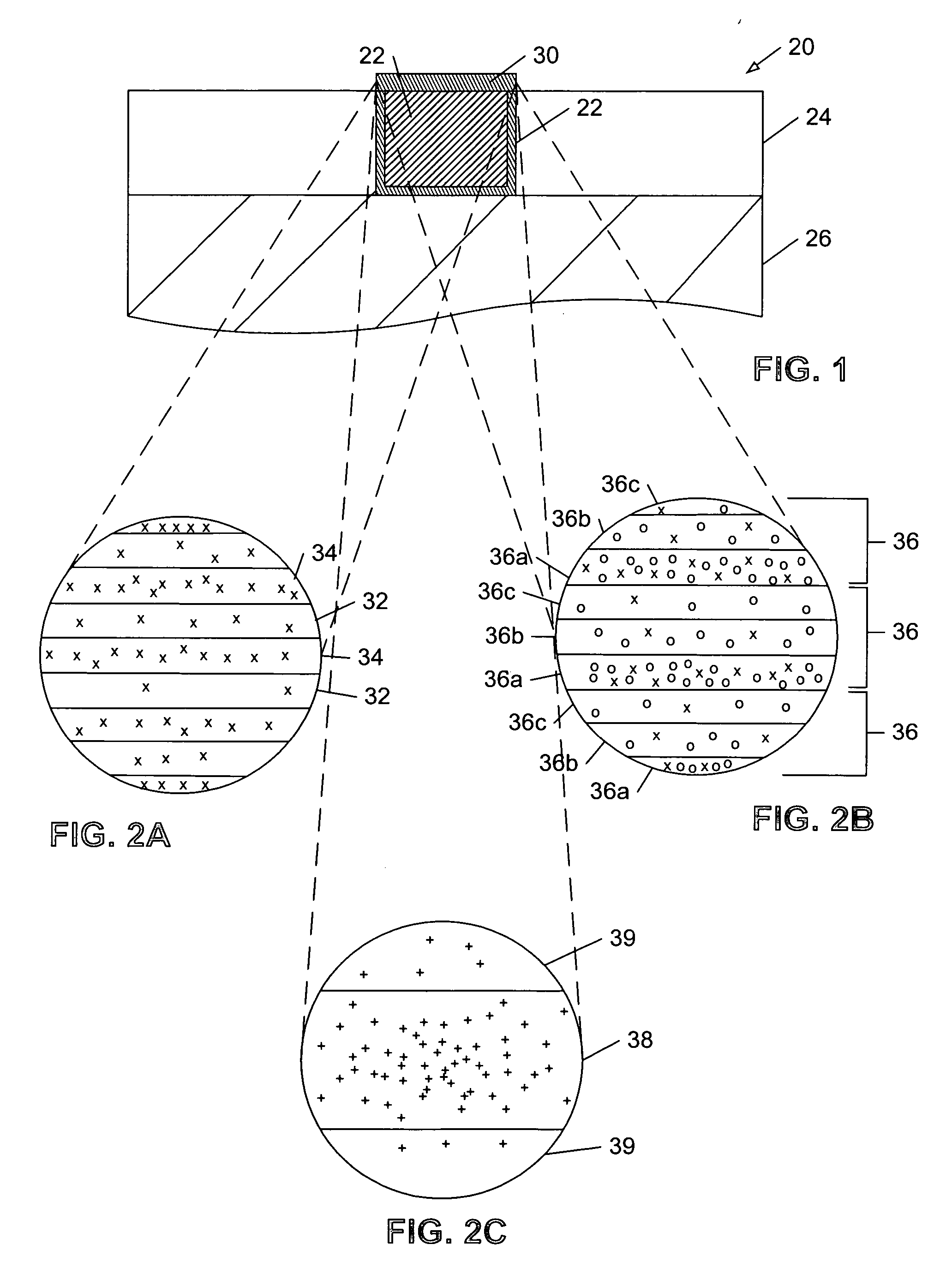

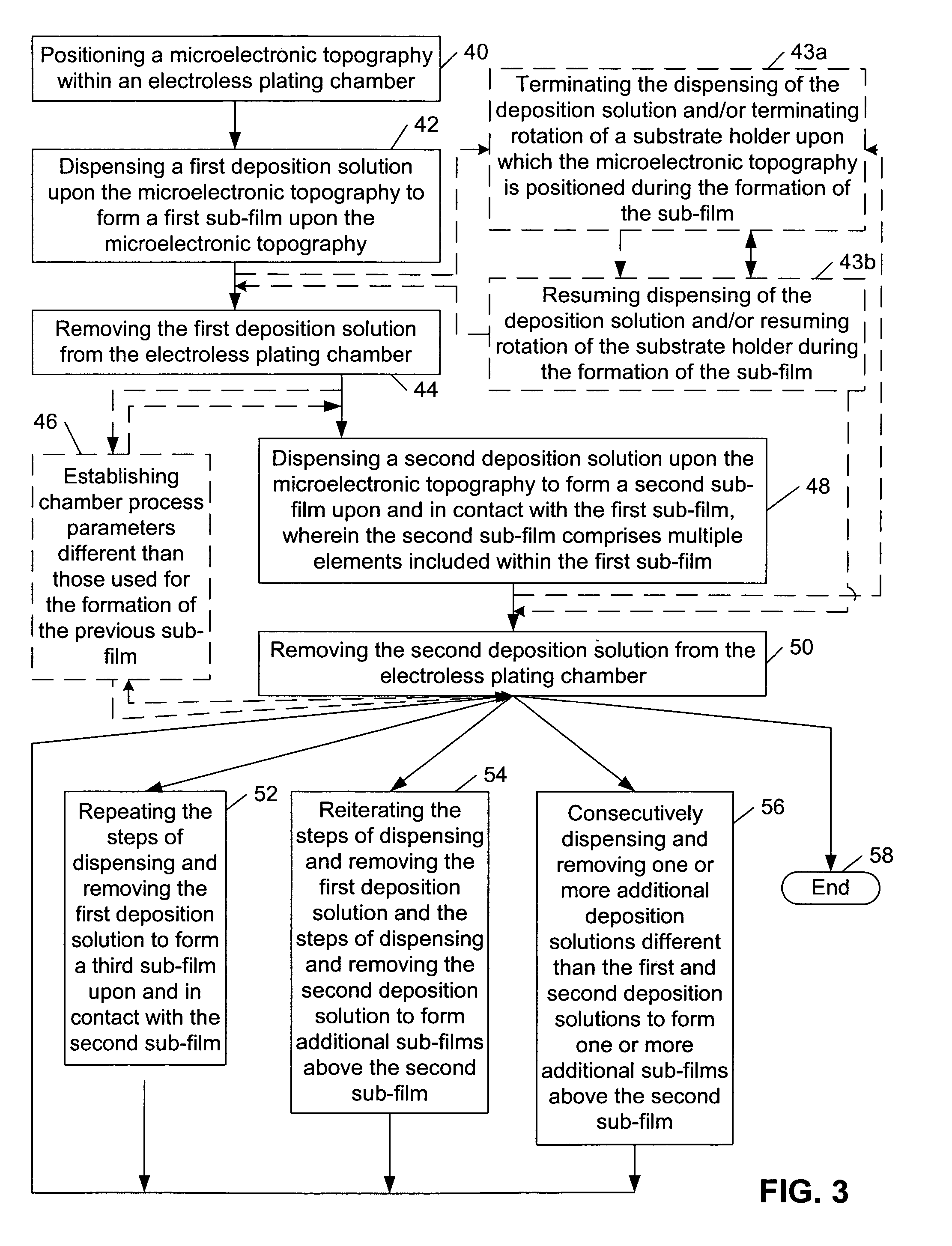

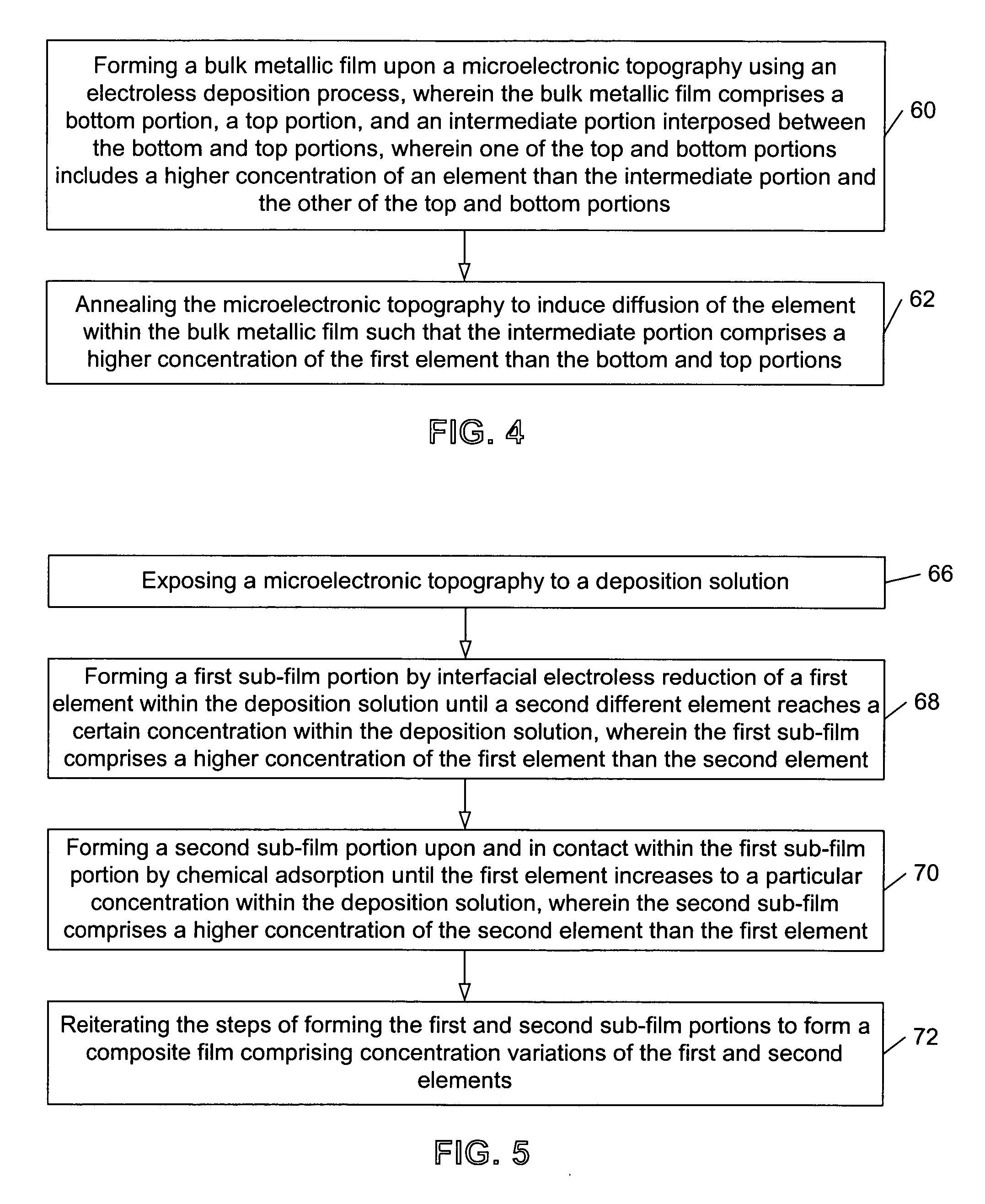

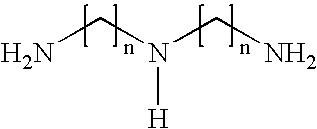

Methods for forming a barrier layer with periodic concentrations of elements and structures resulting therefrom

InactiveUS20060029833A1Increase concentrationMaterial nanotechnologyLiquid surface applicatorsDiffusionChemical adsorption

A method is provided which includes dispensing and removing different deposition solutions during an electroless deposition process to form different sub-films of a composite layer. Another method includes forming a film by an electroless deposition process and subsequently annealing the microelectronic topography to induce diffusion of an element within the film. Yet another method includes reiterating different mechanisms of deposition growth, namely interfacial electroless reduction and chemical adsorption, from a single deposition solution to form different sub-films of a composite layer. A microelectronic topography resulting from one or more of the methods includes a film formed in contact with a structure having a bulk concentration of a first element. The film has periodic successions of regions each comprising a region with a concentration of a second element greater than a set amount and a region with a concentration of the second element less than the set amount.

Owner:LAM RES CORP

Triamine/aspartate curative and coatings comprising the same

The reaction product of a triamine and a dialkyl maleate and / or dialkyl fumarate, wherein the reaction product has a viscosity of less than 2000 cPs is disclosed. Polyurea coatings comprising this reaction product are also disclosed, as are substrates coated with the same.

Owner:PPG IND OHIO INC

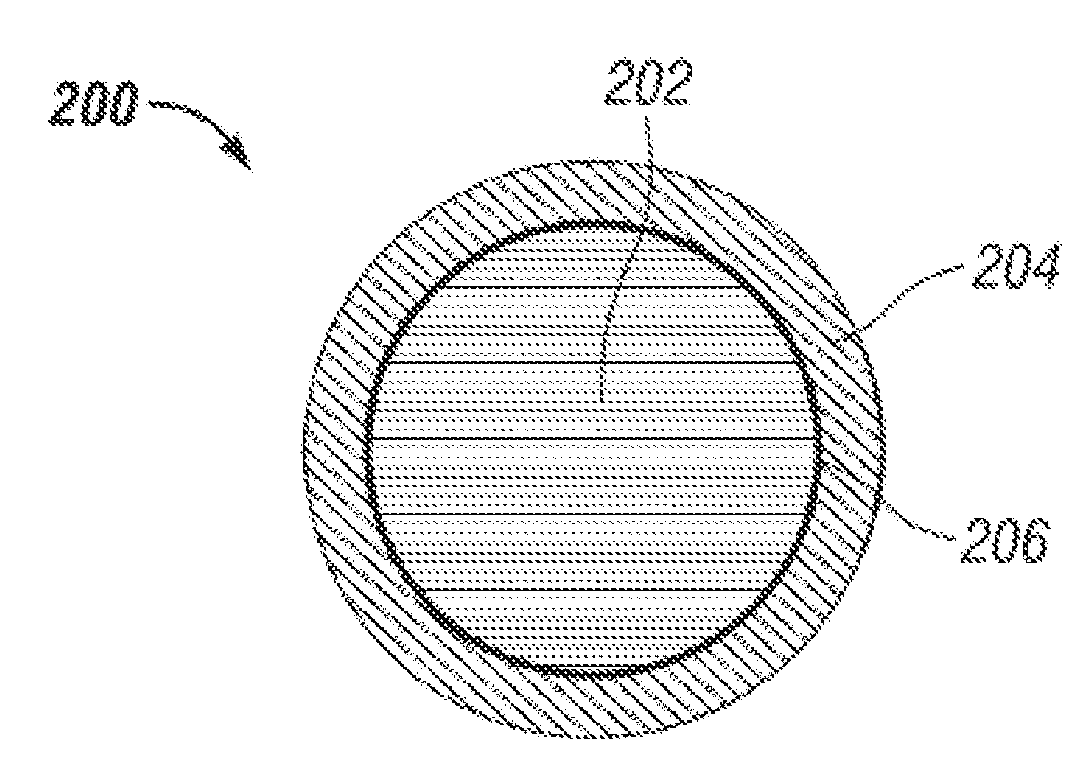

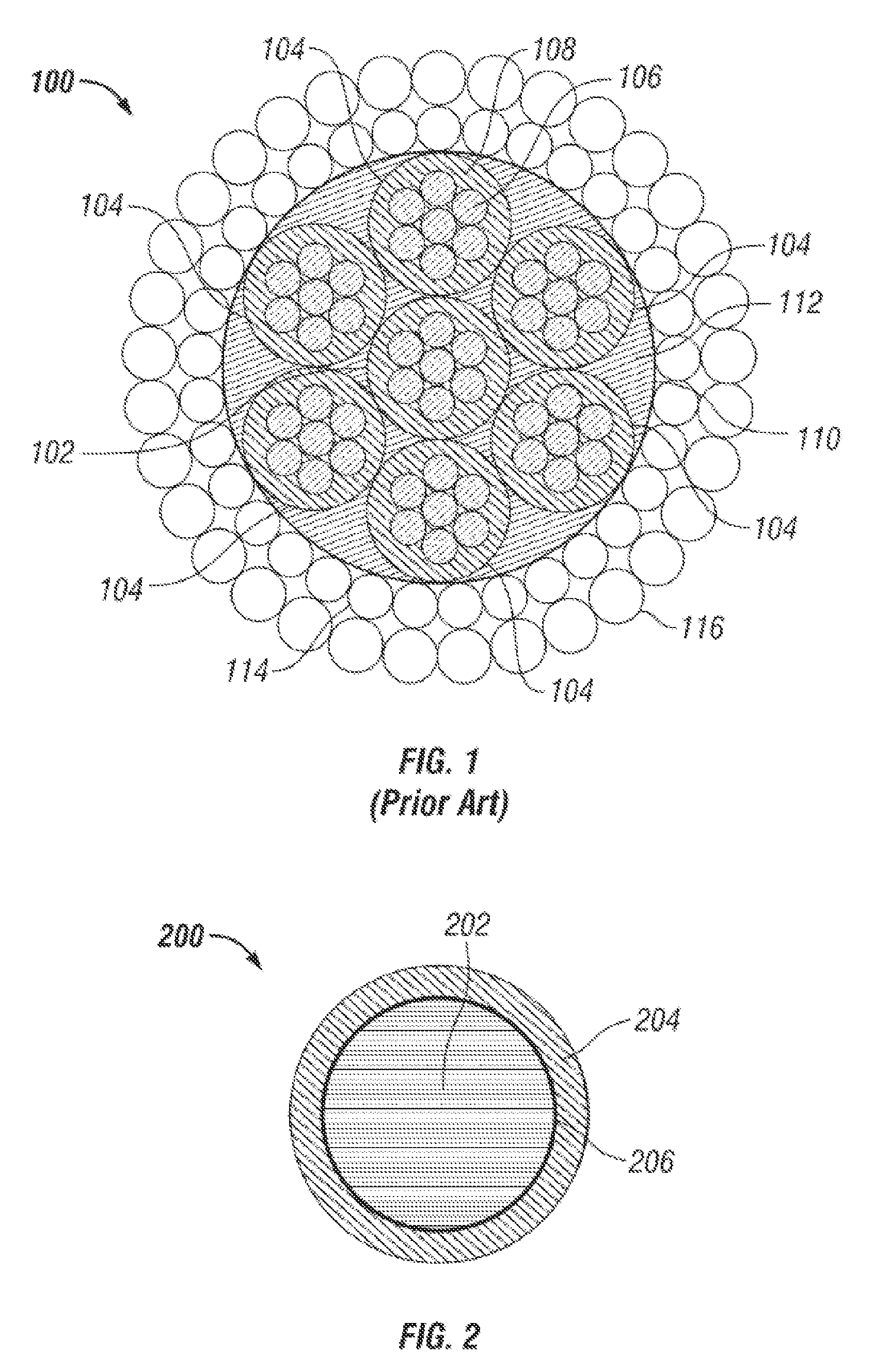

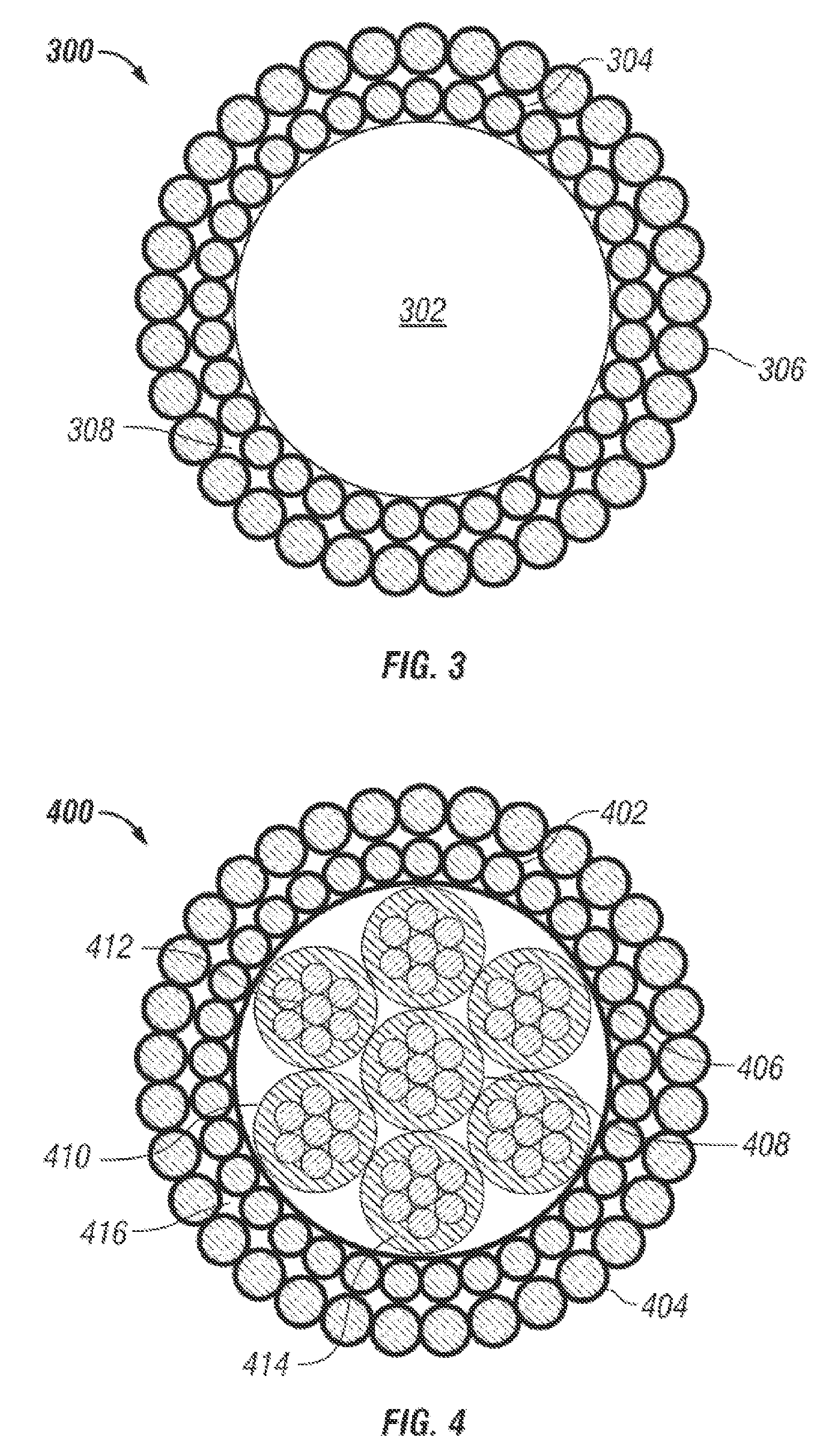

Bimetallic materials for oilfield applications

Corrosion resistant and / or lightweight bimetallic cylinders used in tools and electric cables, including core surrounded by corrosion resistant alloy outer cladding materials, where the alloy clad may include such alloys as beryllium-copper based alloys, nickel-chromium based alloys, superaustenitic stainless steel alloys, nickel-cobalt based alloys, nickel-molybdenum-chromium based alloys, and the like. The core may be a low density core based substantially upon titanium or titanium alloys.

Owner:SCHLUMBERGER TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com