Patents

Literature

177 results about "Free solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

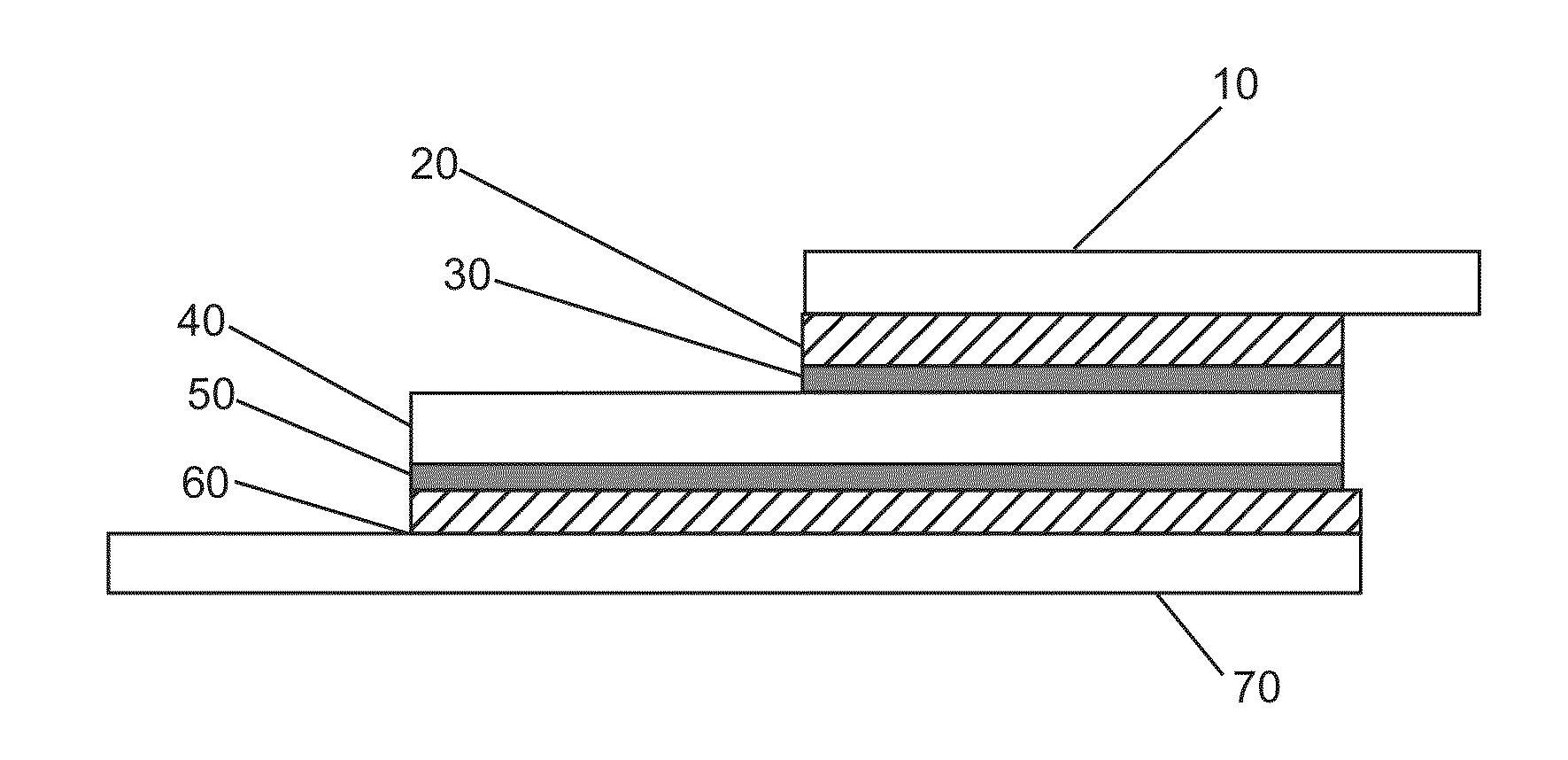

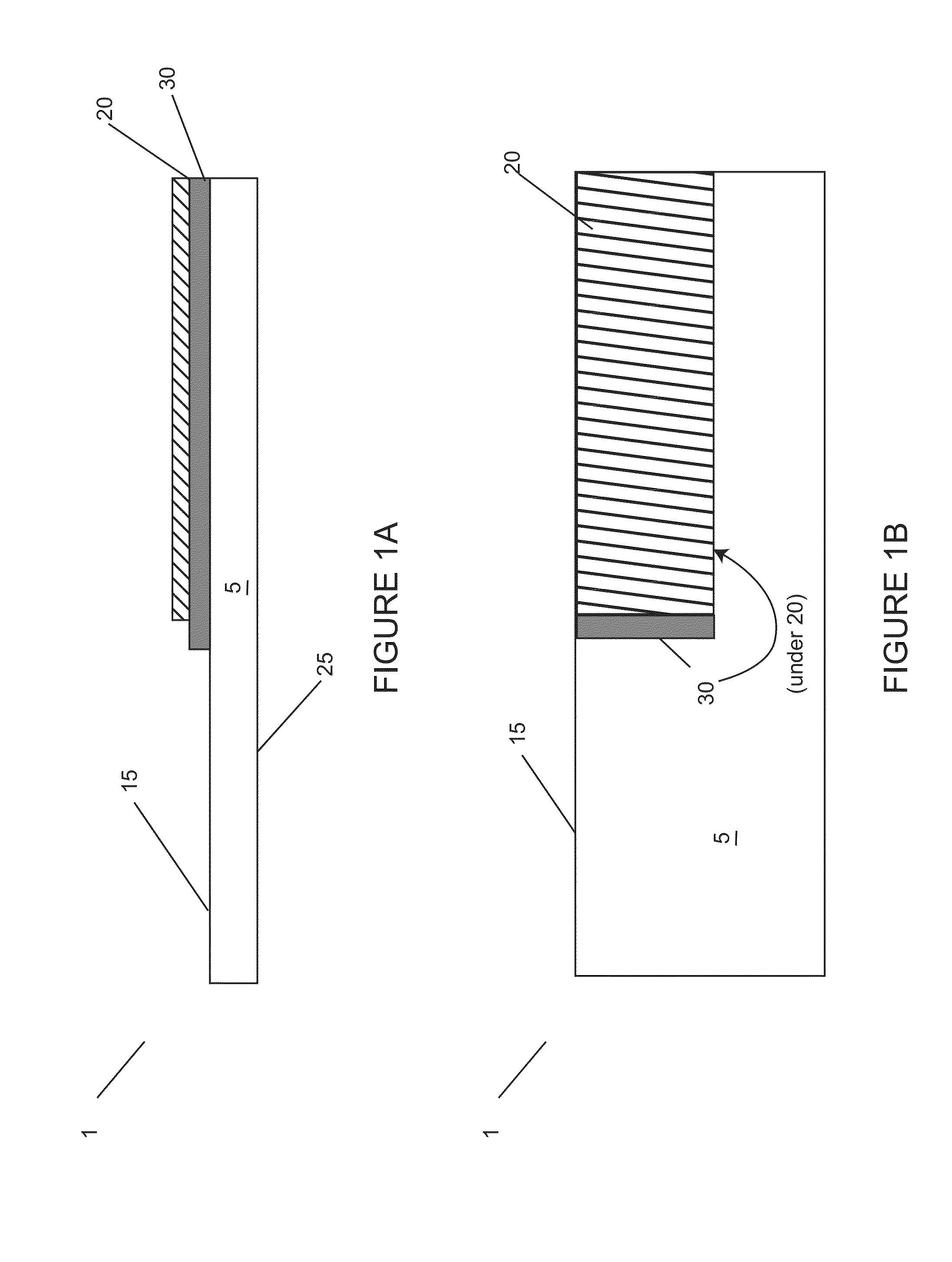

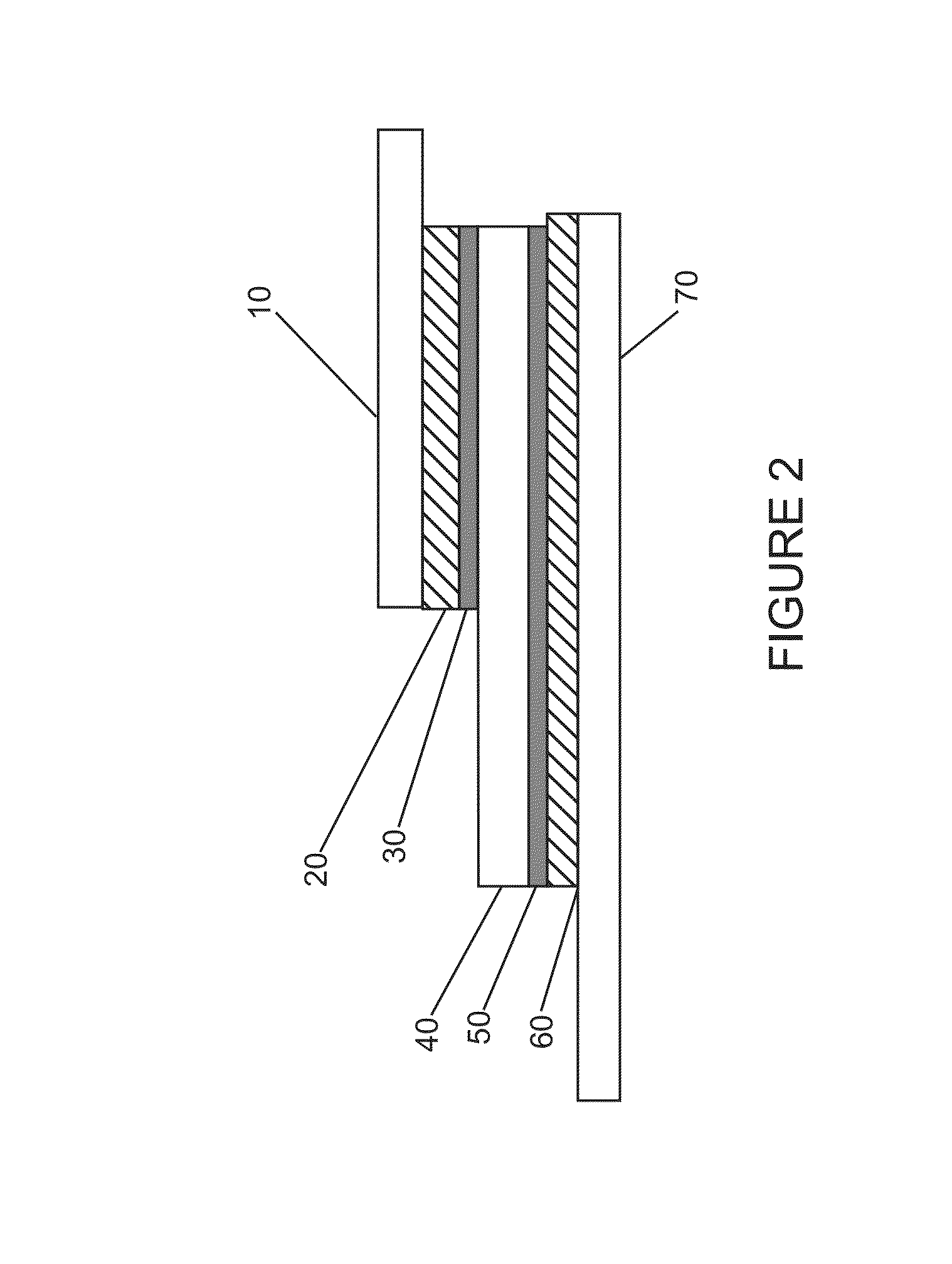

Semiconductor packaging containing sintering die-attach material

ActiveUS20140131898A1Semiconductor/solid-state device detailsSolid-state devicesState of artMetallurgy

Sintering die-attach materials provide a lead-free solution for semiconductor packages with superior electrical, thermal and mechanical performance to prior art alternatives. Wafer-applied sintering materials form a metallurgical bond to both semiconductor die and adherends as well as throughout the die-attach joint and do not remelt at the original process temperature. Application to either one or both sides of the wafer, as well as paste a film application are disclosed.

Owner:ORMET CIRCUITS

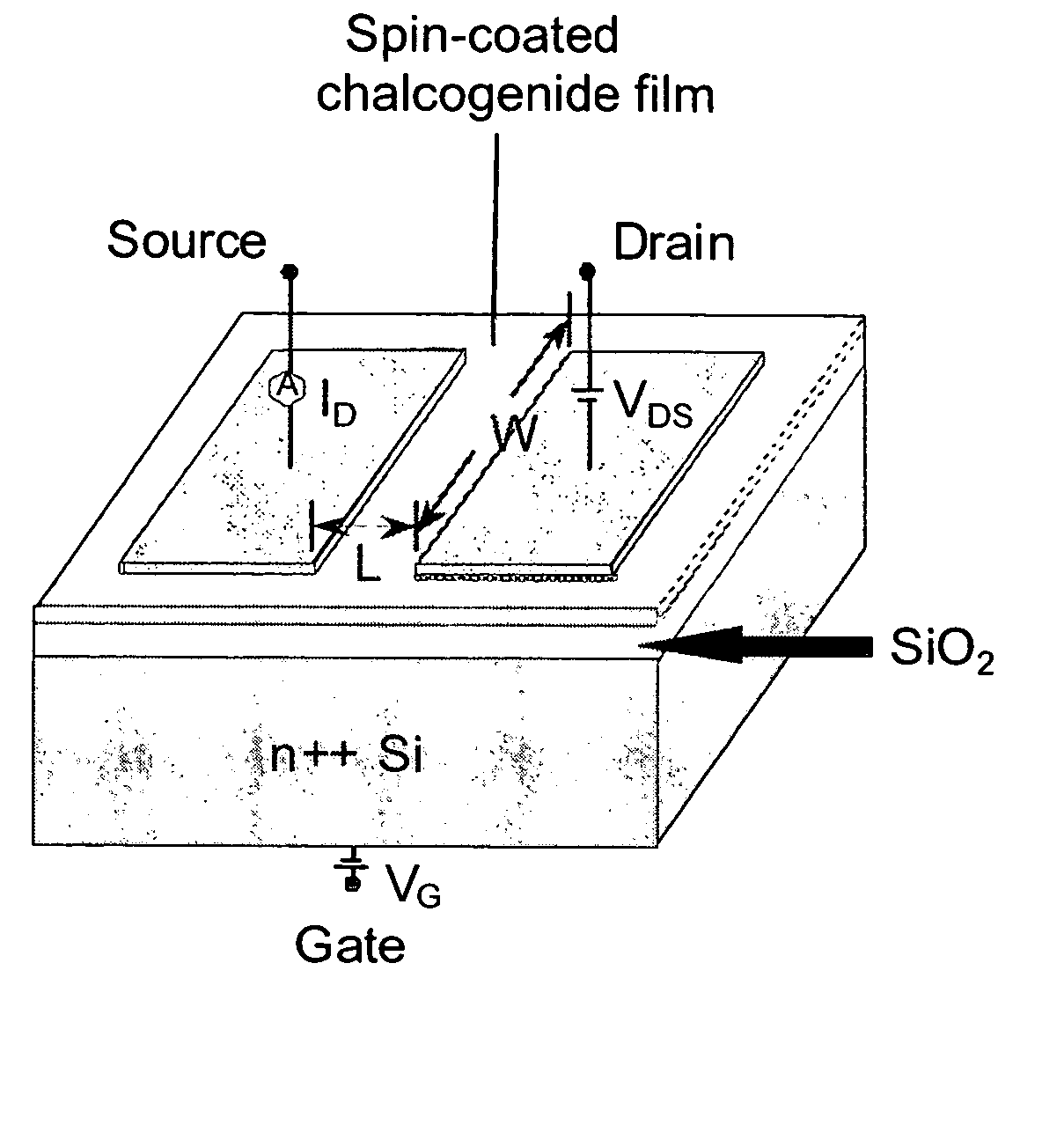

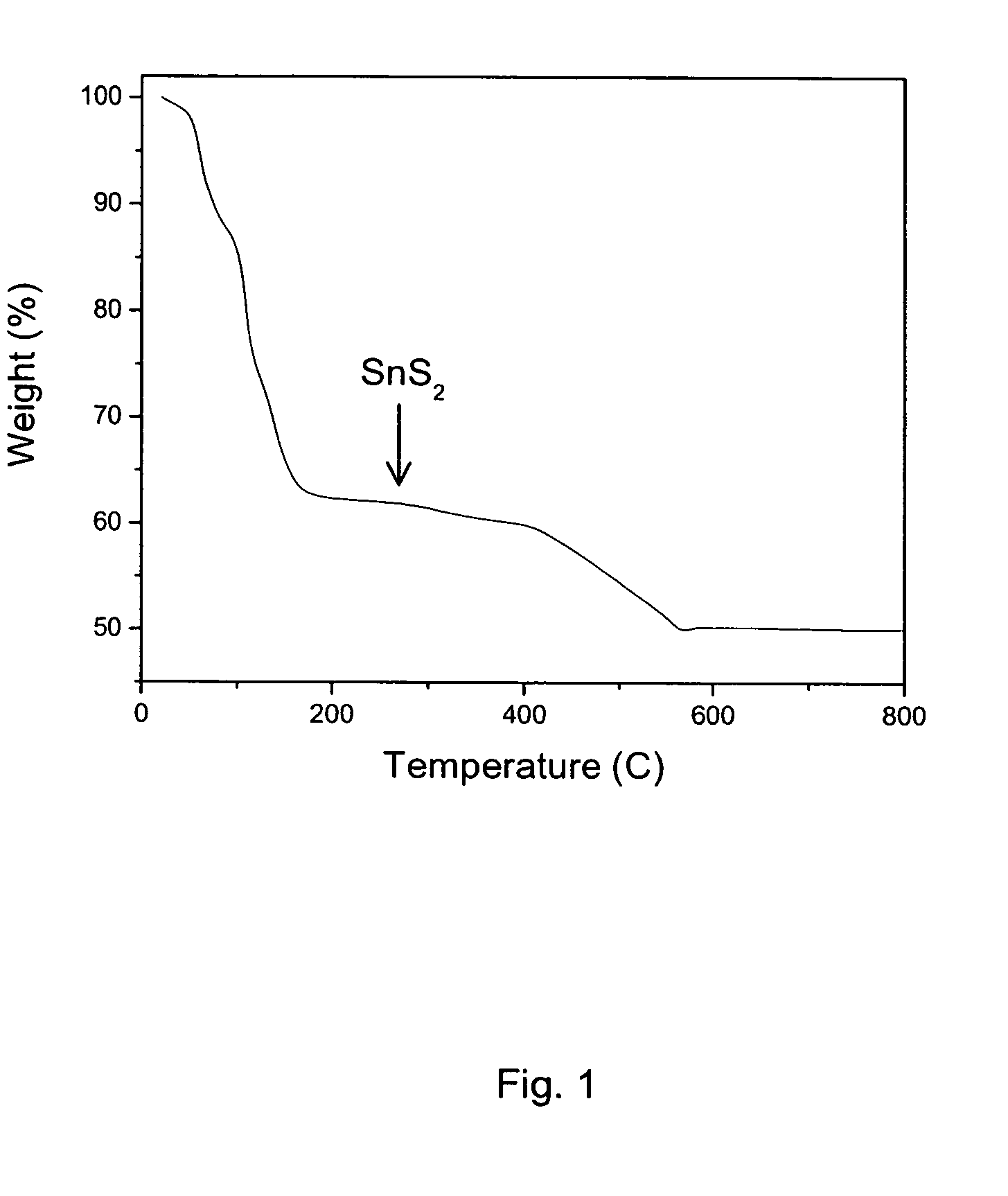

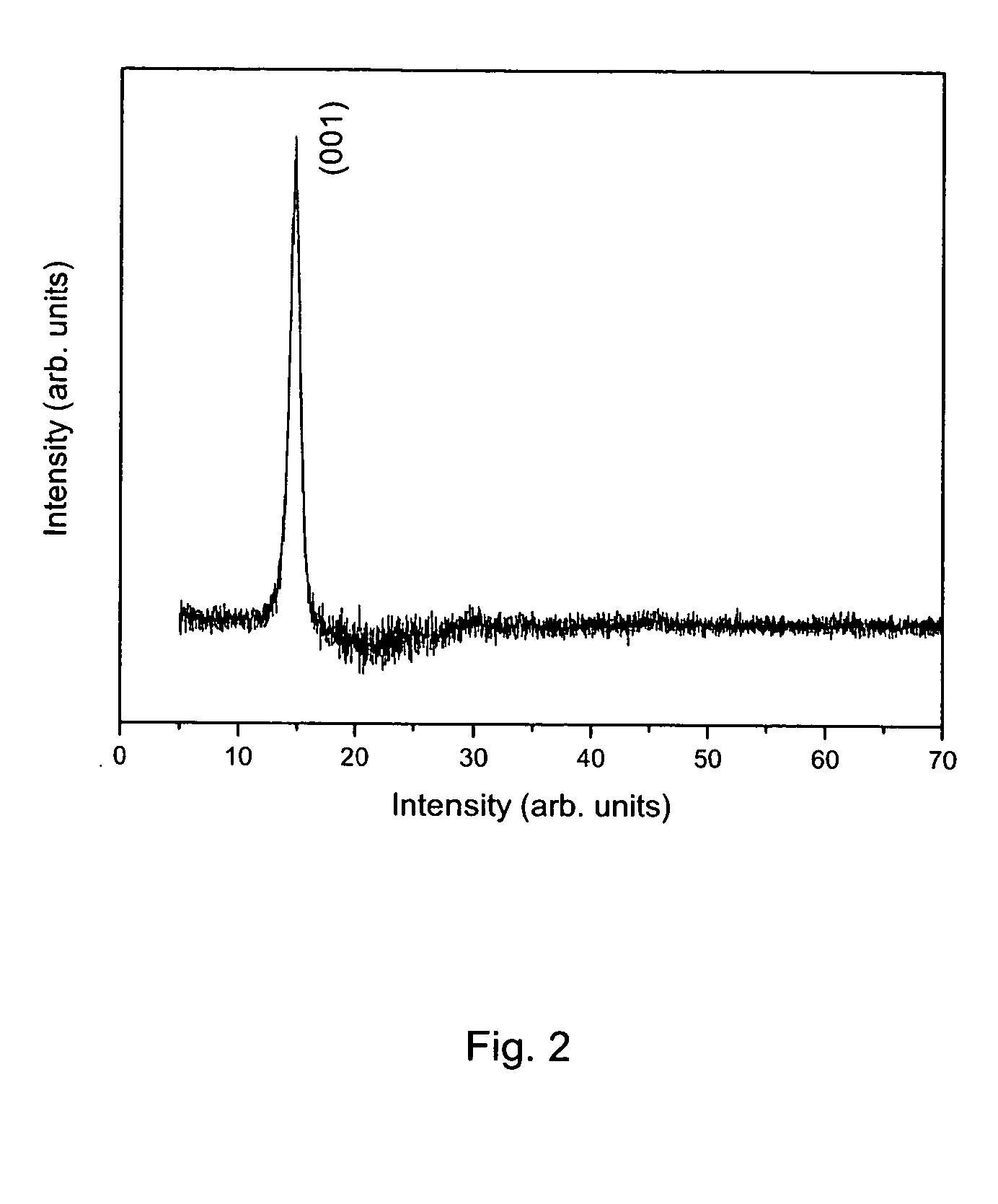

Hydrazine-free solution deposition of chalcogenide films

InactiveUS20050009225A1Efficient preparationLow costTransistorFrom solid stateHydrazine compoundSulfur

A method of depositing a film of a metal chalcogenide including the steps of: contacting an isolated hydrazinium-based precursor of a metal chalcogenide and a solvent having therein a solubilizing additive to form a solution of a complex thereof; applying the solution of the complex onto a substrate to produce a coating of the solution on the substrate; removing the solvent from the coating to produce a film of the complex on the substrate; and thereafter annealing the film of the complex to produce a metal chalcogenide film on the substrate. Also provided is a process for preparing an isolated hydrazinium-based precursor of a metal chalcogenide as well as a thin-film field-effect transistor device using the metal chalcogenides as the channel layer.

Owner:GLOBALFOUNDRIES US INC

Highly concentrated stable meloxicam solutions for needleless injection

Aqueous cyclodextrin-free solution of meloxicam suitable for administration by needleless injection, containing a pharmacologically acceptable meloxicam salt of an organic or inorganic base and one or more suitable excipients, the content of dissolved meloxicam salt being from 35 to 100 mg / ml. The formulation according to the invention has a shelf-life of up to 24 months or more.

Owner:FOLGER MARTIN ANDREAS +3

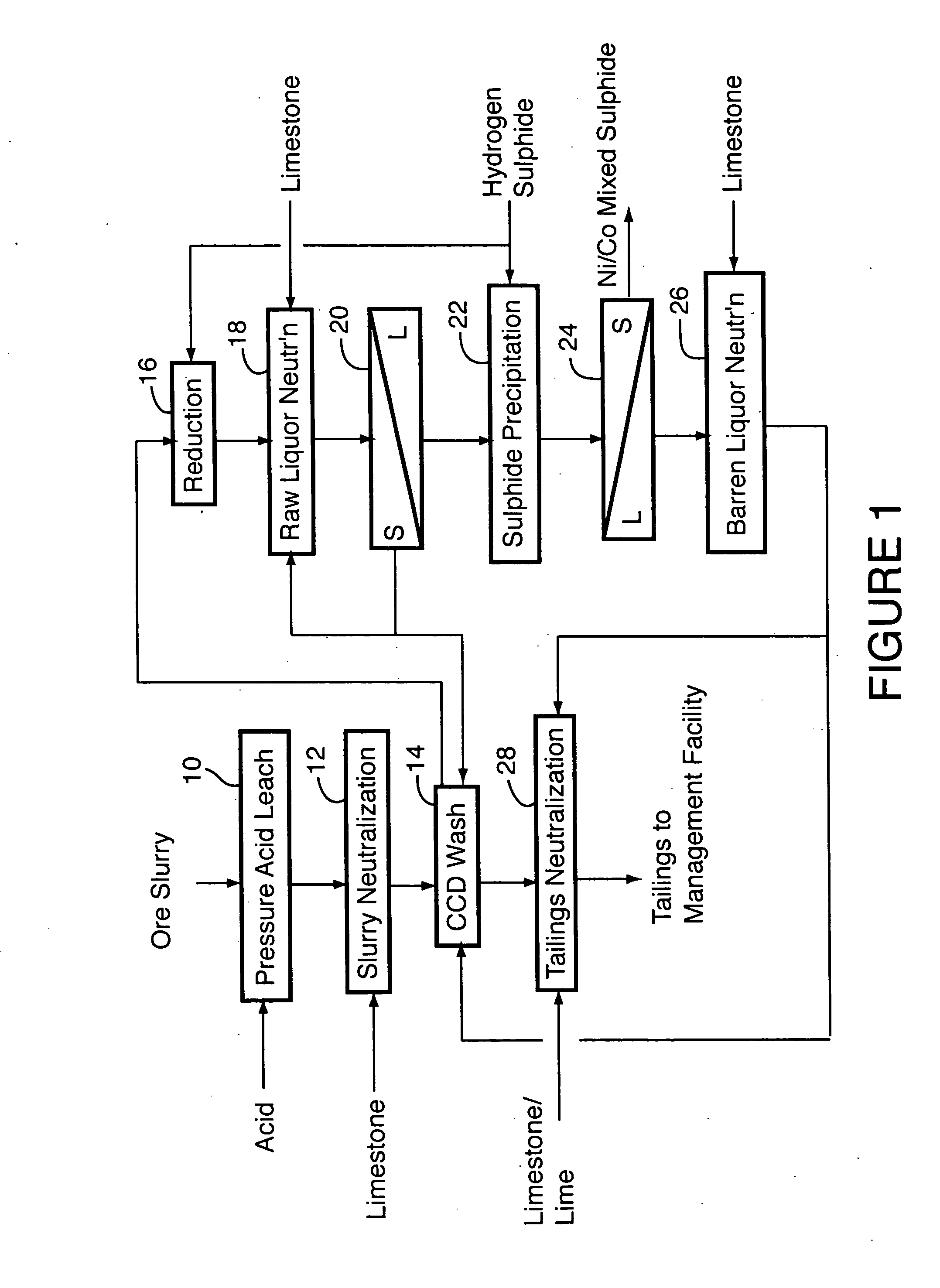

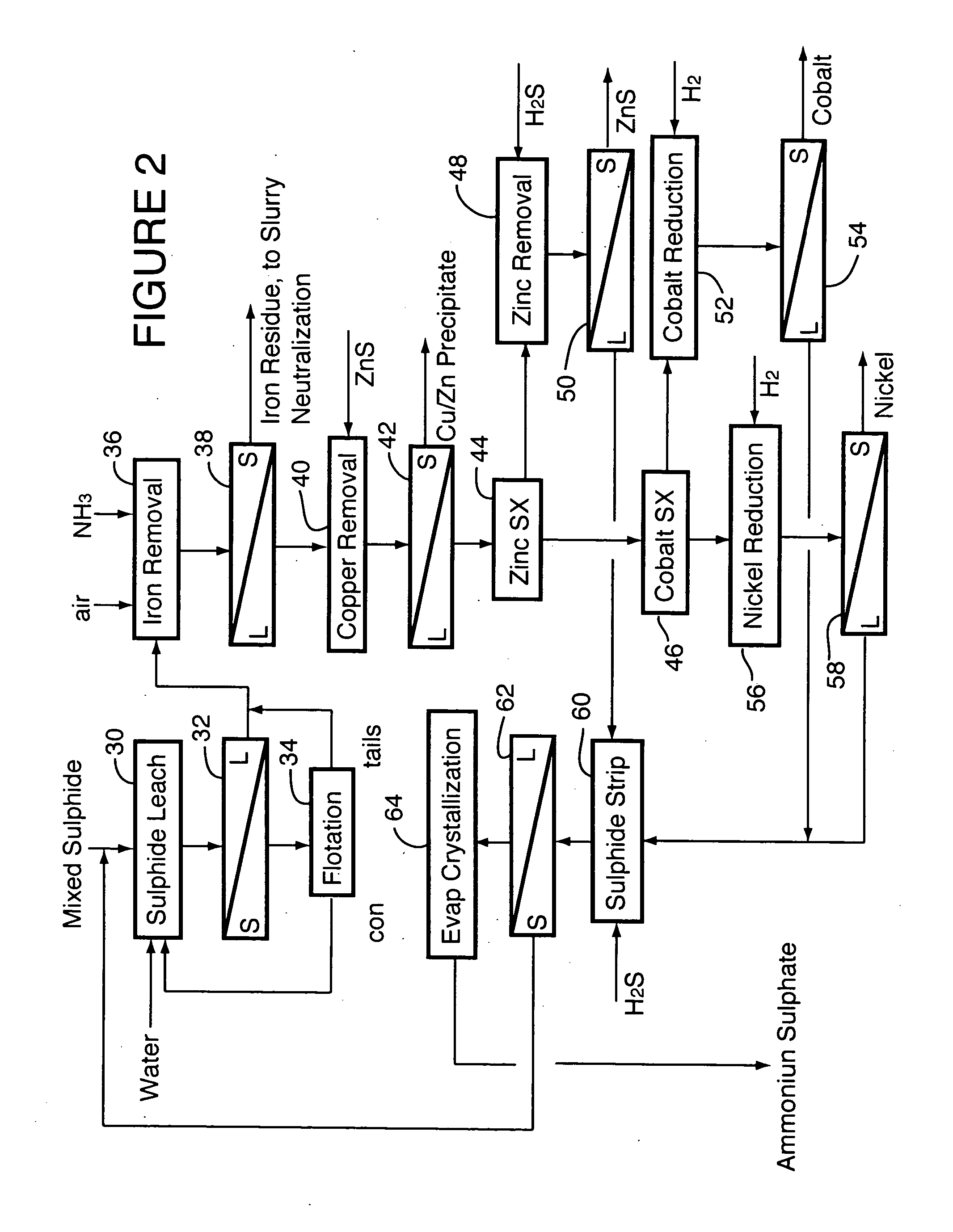

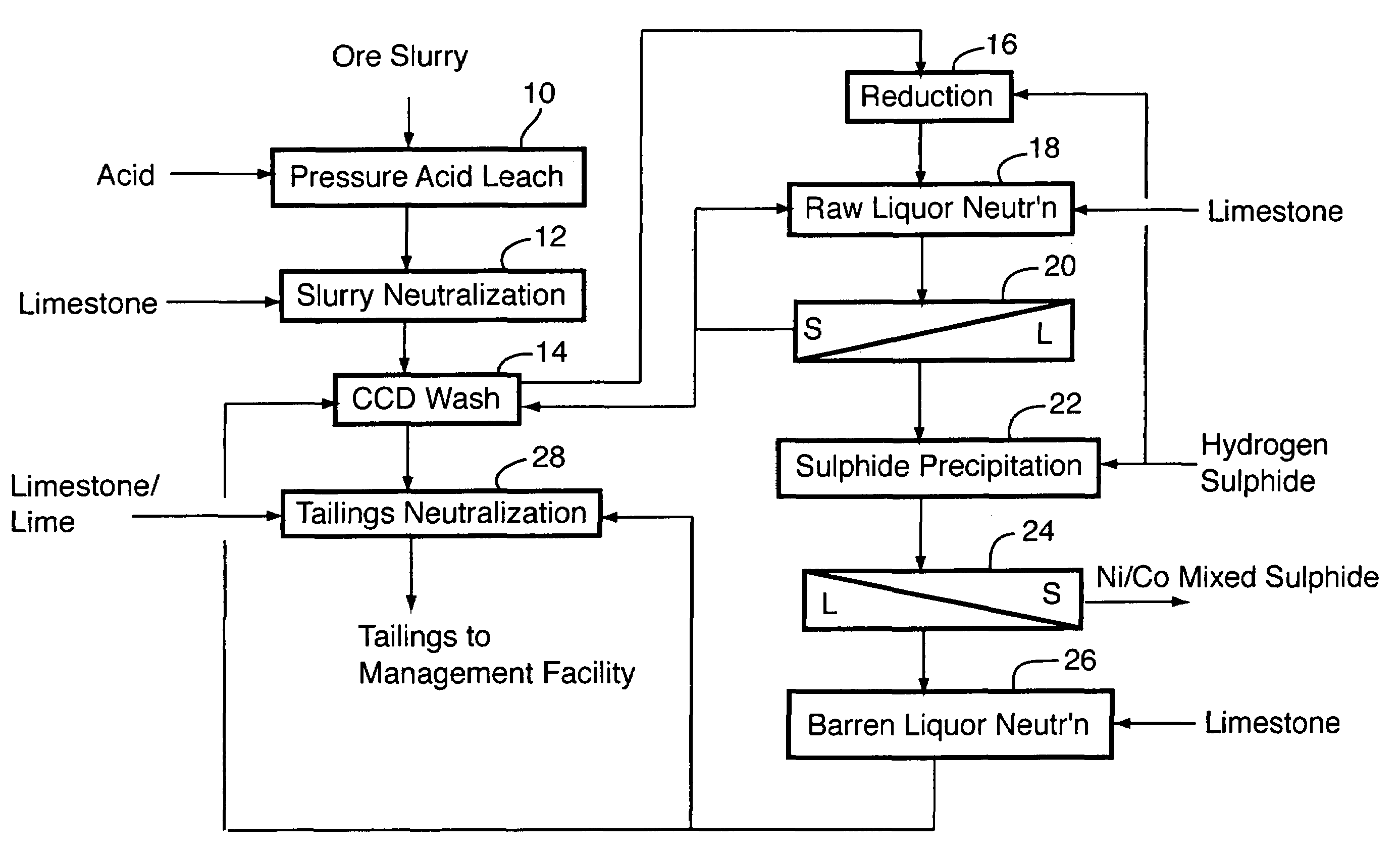

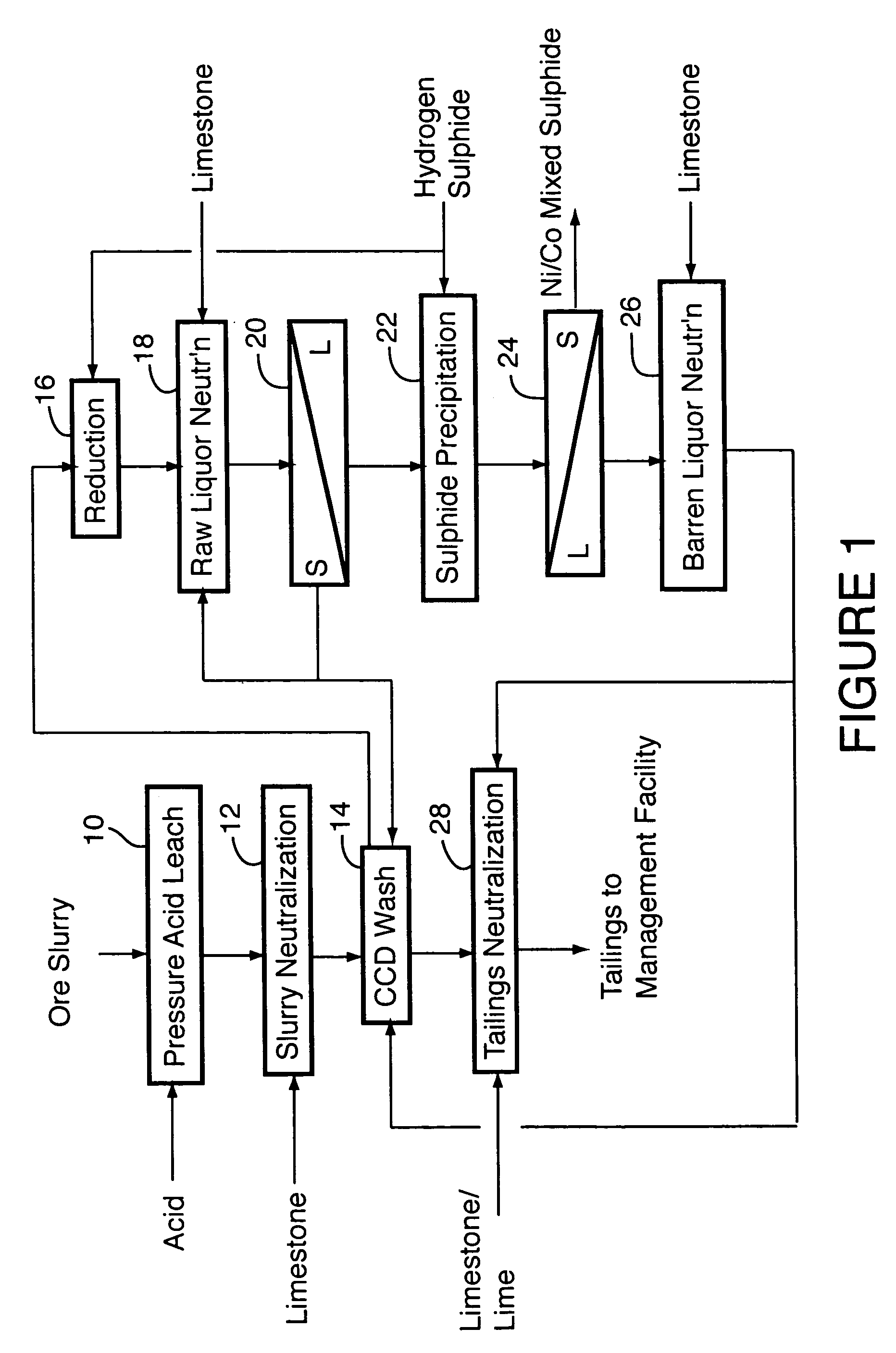

Process for recovery of nickel and cobalt from laterite ore

ActiveUS20060228279A1Efficient separation and recoveryHigh purityCobalt sulfidesSolvent extractionFree solutionSlurry

A process for recovering nickel and cobalt values from nickel- and cobalt-containing laterite ores as an enriched mixed nickel and cobalt sulphide intermediate and for producing nickel and cobalt metal from the nickel and cobalt sulphide intermediate. The laterite ore is leached as a slurry in a pressure acid leach containing an excess of aqueous sulphuric acid at high pressure and temperature, excess free acid in the leach slurry is partially neutralized to a range of 5 to 10 g / L residual free H2SO4 and washed to yield a nickel- and cobalt-containing product liquor, the product liquor is subjected to a reductant to reduce any Cr(VI) in solution to Cr(III), the reduced product liquor is neutralized to precipitate ferric iron and silicon at a pH of about 3.5 to 4.0, and the neutralized and reduced product liquor is contacted with hydrogen sulphide gas to precipitate nickel and cobalt sulphides. The precipitated nickel and cobalt sulphides can be leached in a water slurry in a pressure oxidation leach, the leach solution subjected to iron hydrolysis and precipitation, the iron-free solution contacted with zinc sulphide to precipitate copper, the iron- and copper-free solution subjected to zinc and cobalt extraction by solvent extraction to produce a nickel raffinate, the nickel raffinate contacted with hydrogen gas to produce nickel powder and the cobalt strip solution from the solvent extraction step contacted with hydrogen gas to produce cobalt powder.

Owner:SHERRITT INTERNATIONAL

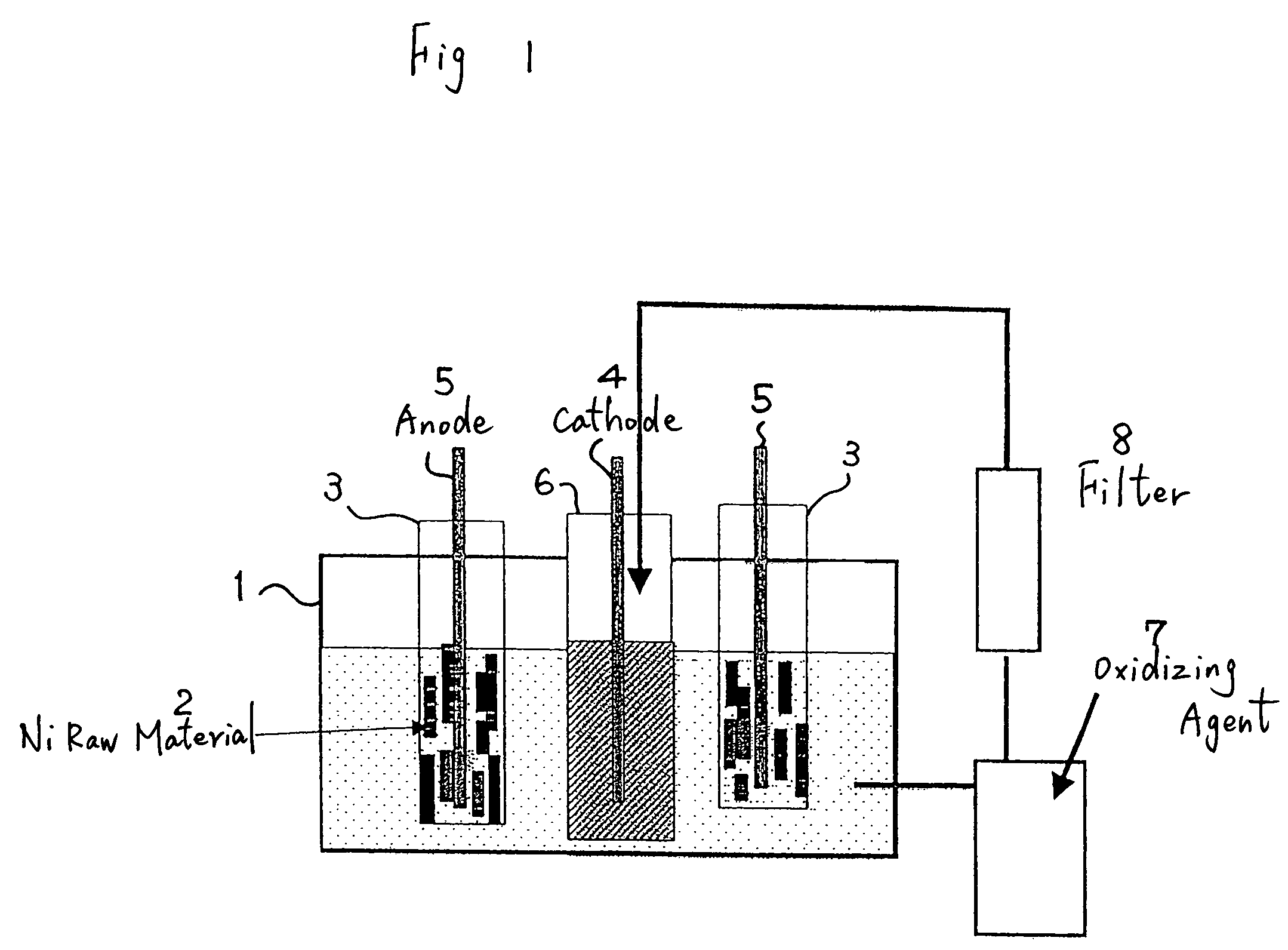

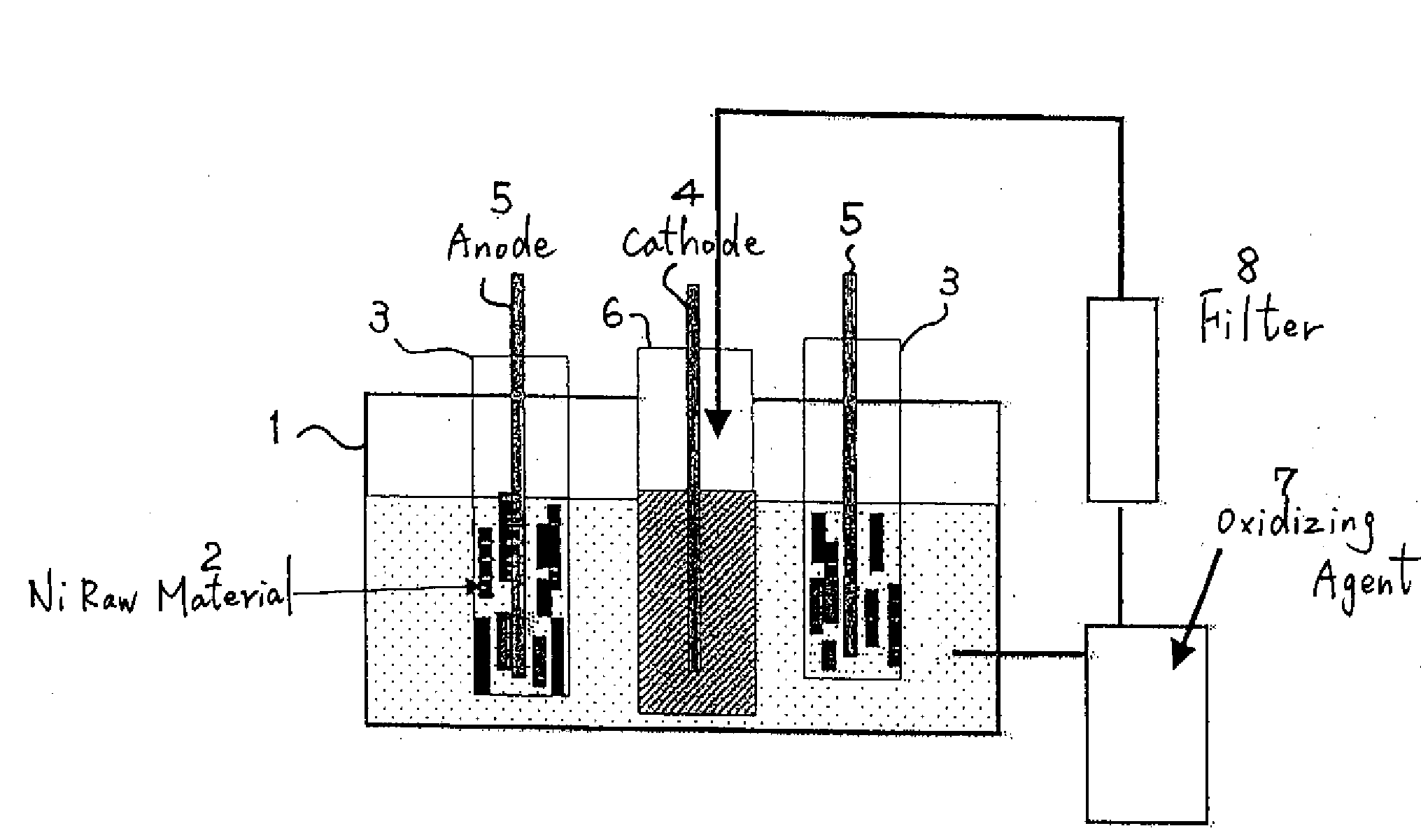

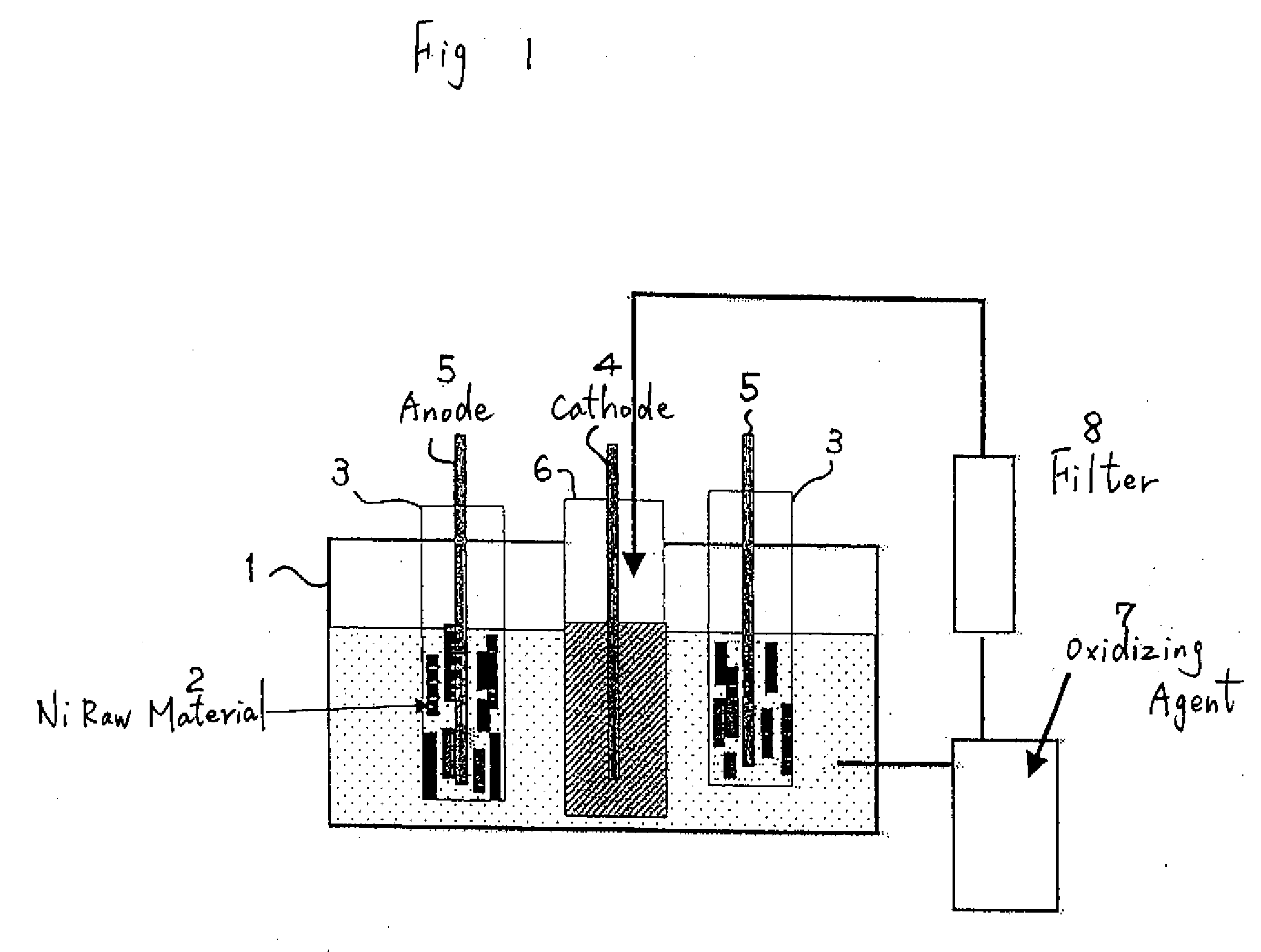

Method for producing high purity nickle, high purity nickle, sputtering target comprising the high purity nickel, and thin film formed by using said spattering target

InactiveUS7435325B2Efficient preparationSimple methodPhotography auxillary processesVacuum evaporation coatingElectrolysisDisplacement reactions

Upon performing electrolysis with a solution containing nickel as the electrolytic solution, anolyte is adjusted to pH 2 to 5; impurities such as iron, cobalt and copper contained in the anolyte are eliminated by combining any one or two or more of the methods among adding an oxidizing agent and precipitating and eliminating the impurities as hydroxide, eliminating the impurities through preliminary electrolysis, or adding Ni foil and eliminating the impurities through displacement reaction; impurities are thereafter further eliminated with a filter; and the impurity-free solution is employed as catholyte to perform the electrolysis. The present invention relates to a simple method of performing electrolytic refining employing a solution containing nickel from nickel raw material containing a substantial amount of impurities, and provides technology on efficiently manufacturing high purity nickel having a purity of 5N (99.999 wt %) or more.

Owner:JX NIPPON MINING& METALS CORP

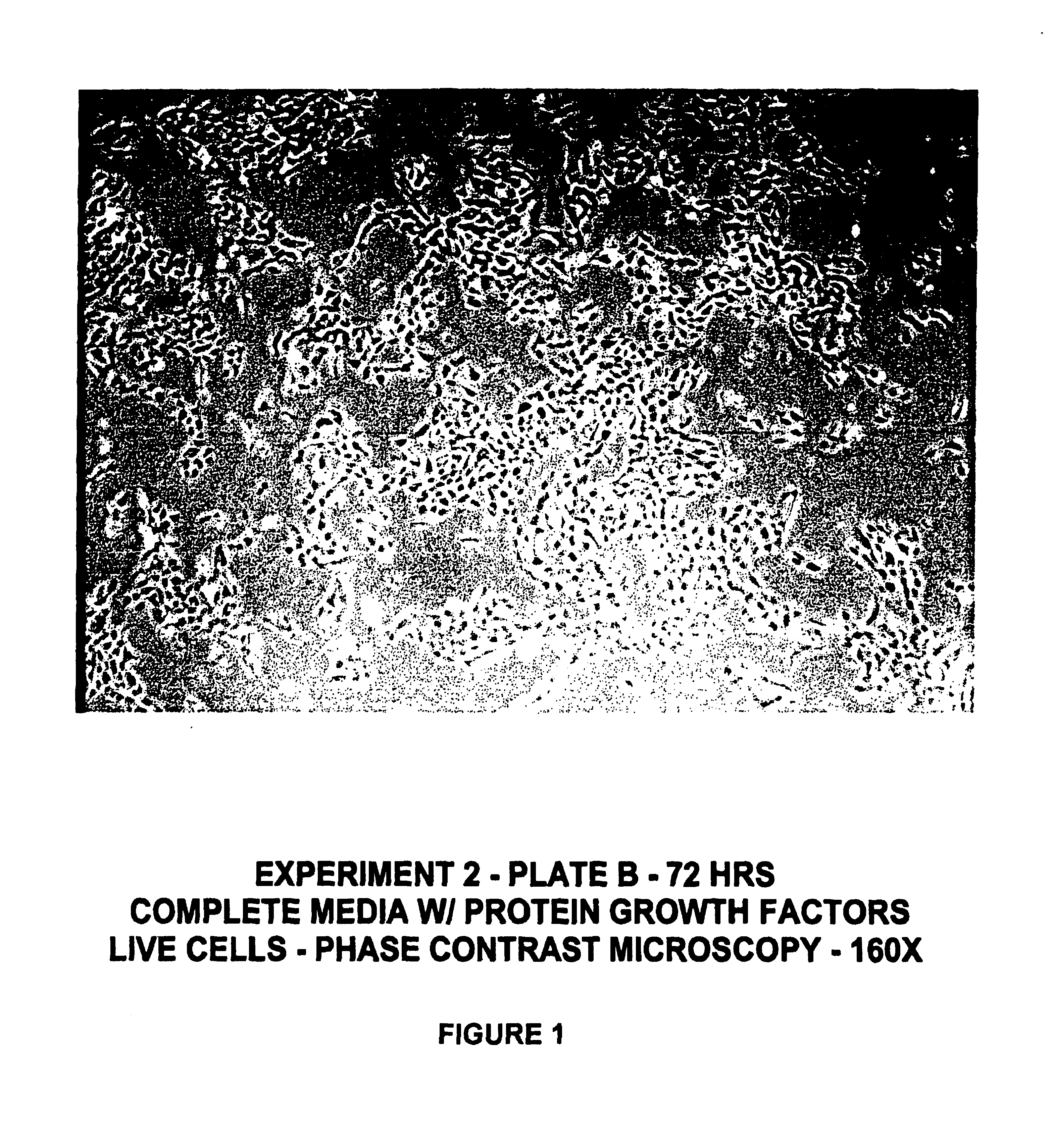

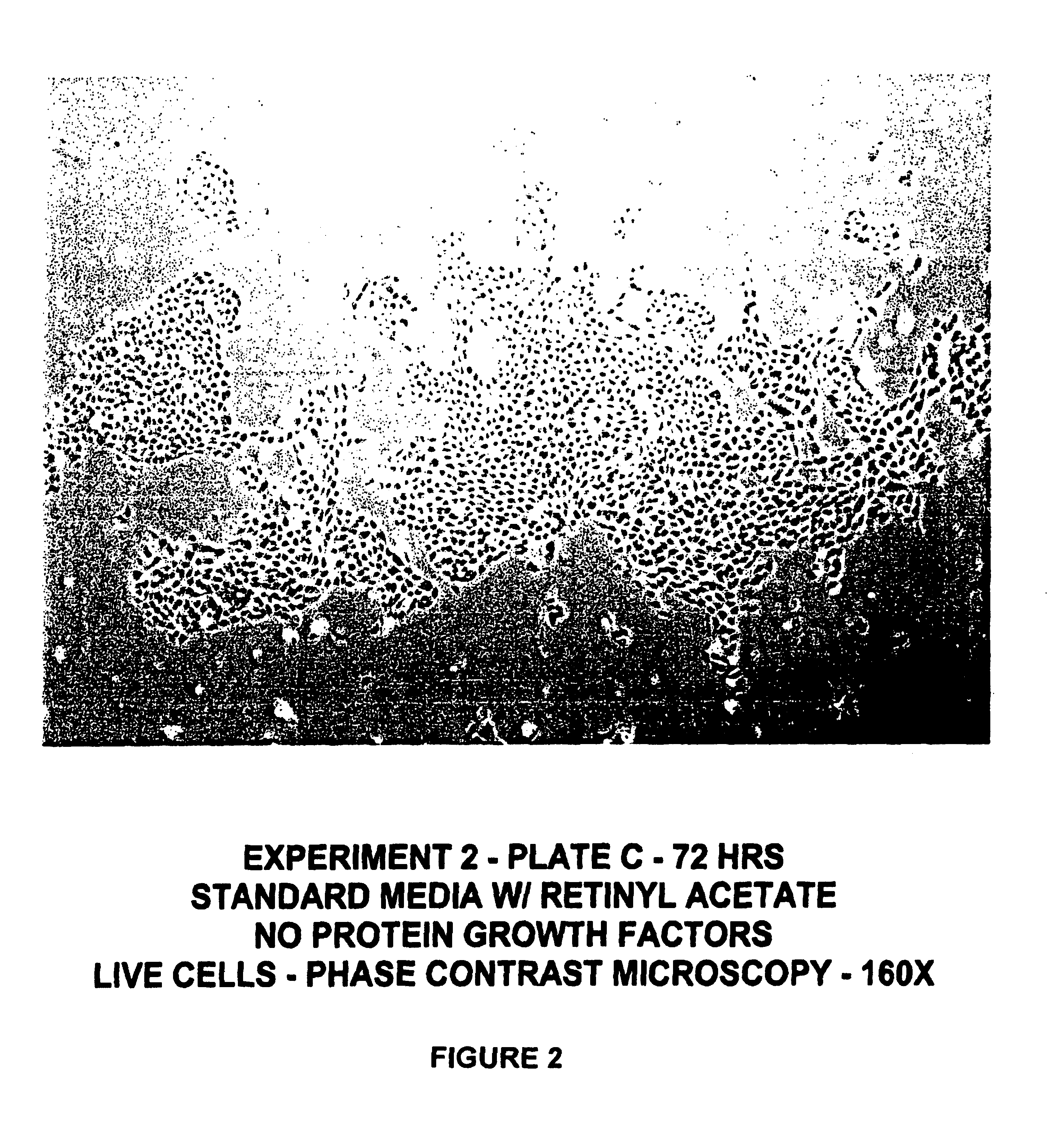

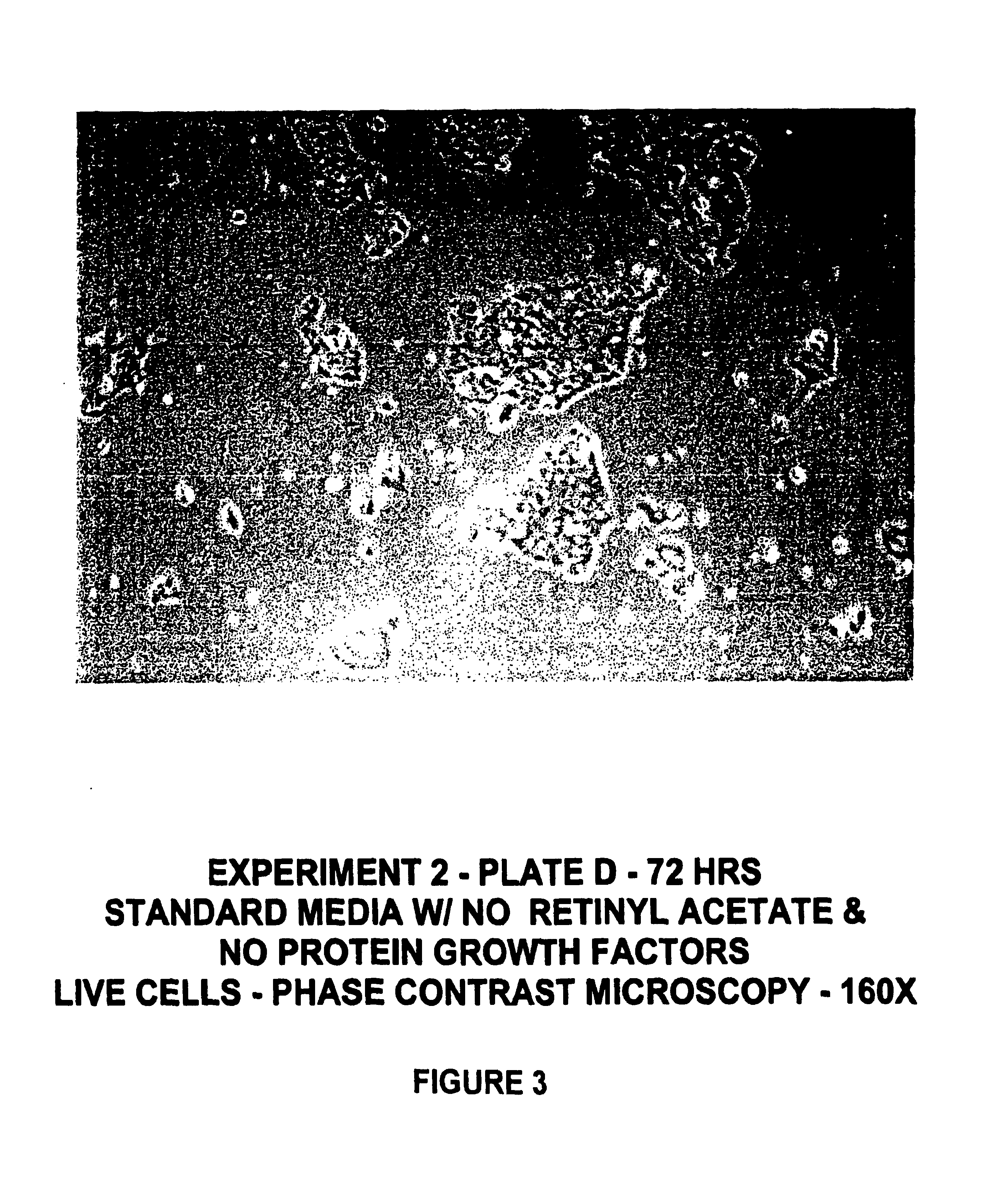

Protein-free defined media for the growth of normal human keratinocytes

Improvements are made to a novel media that replace the requirement for all protein growth factors by the addition to the medium of physiological concentrations of retinyl acetate. The media are serum-free, companion cell or feeder layer-free and organotypic, matrix free solutions for the cultivation of clonally competent basal keratinocytes. The media and methods are useful in the production of epidermal epithelial tissue that is suitable for skin grafting.

Owner:BIOPLAST MEDICAL

Manufacturing Method of High Purity Nickel, High Purity Nickel, Sputtering Target formed from said High Purity Nickel, and Thin Film formed with said Sputtering Target

InactiveUS20090004498A1Simple methodEfficient preparationPhotography auxillary processesPig casting plantsElectrolysisDisplacement reactions

Upon performing electrolysis with a solution containing nickel as the electrolytic solution, anolyte is adjusted to pH 2 to 5; impurities such as iron, cobalt and copper contained in the anolyte are eliminated by combining any one or two or more of the methods among adding an oxidizing agent and precipitating and eliminating the impurities as hydroxide, eliminating the impurities through preliminary electrolysis, or adding Ni foil and eliminating the impurities through displacement reaction; impurities are thereafter further eliminated with a filter; and the impurity-free solution is employed as catholyte to perform the electrolysis. The present invention relates to a simple method of performing electrolytic refining employing a solution containing nickel from nickel raw material containing a substantial amount of impurities, and provides technology on efficiently manufacturing high purity nickel having a purity of 5N (99.999 wt %) or more.

Owner:JX NIPPON MINING & METALS CORP

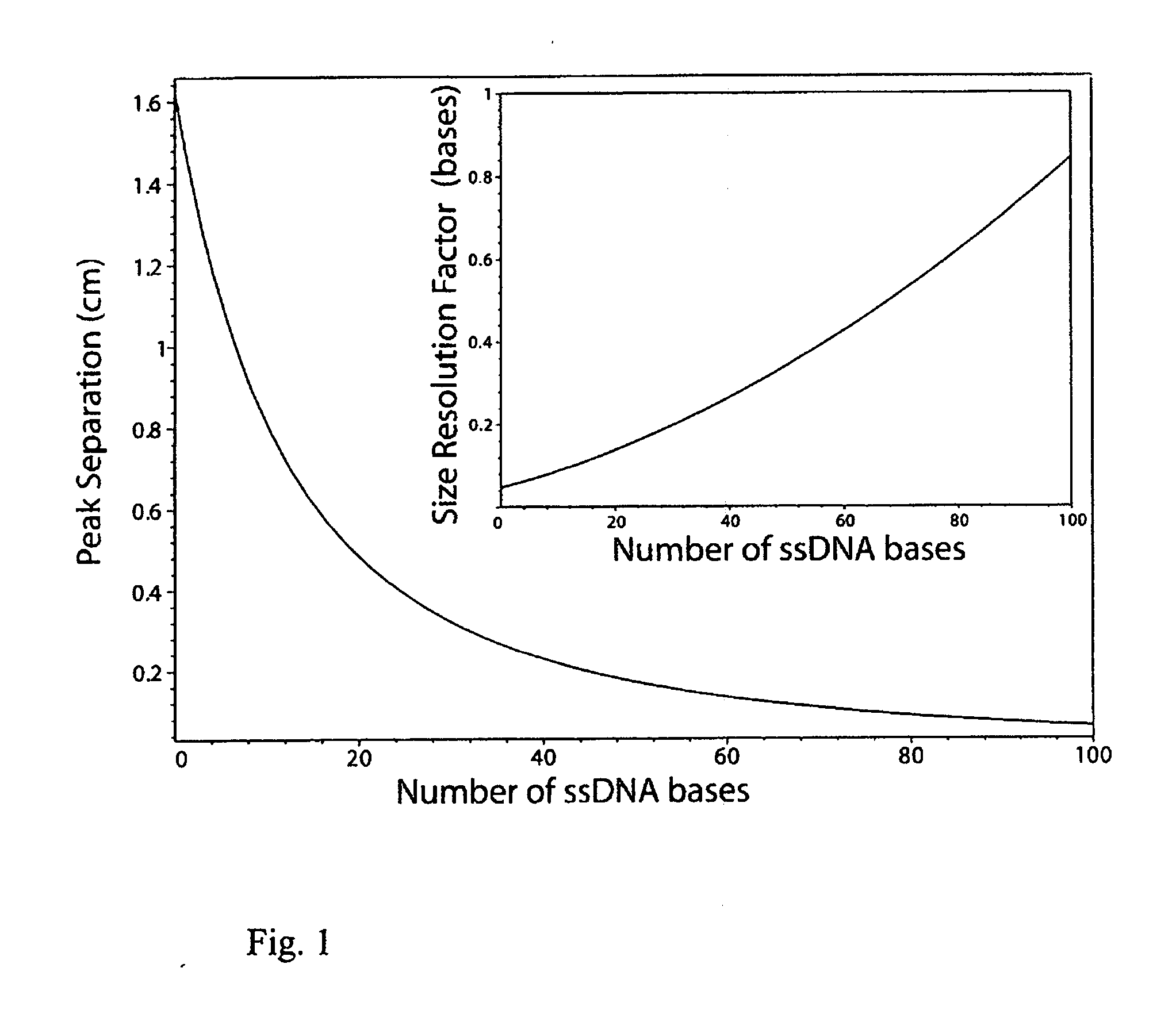

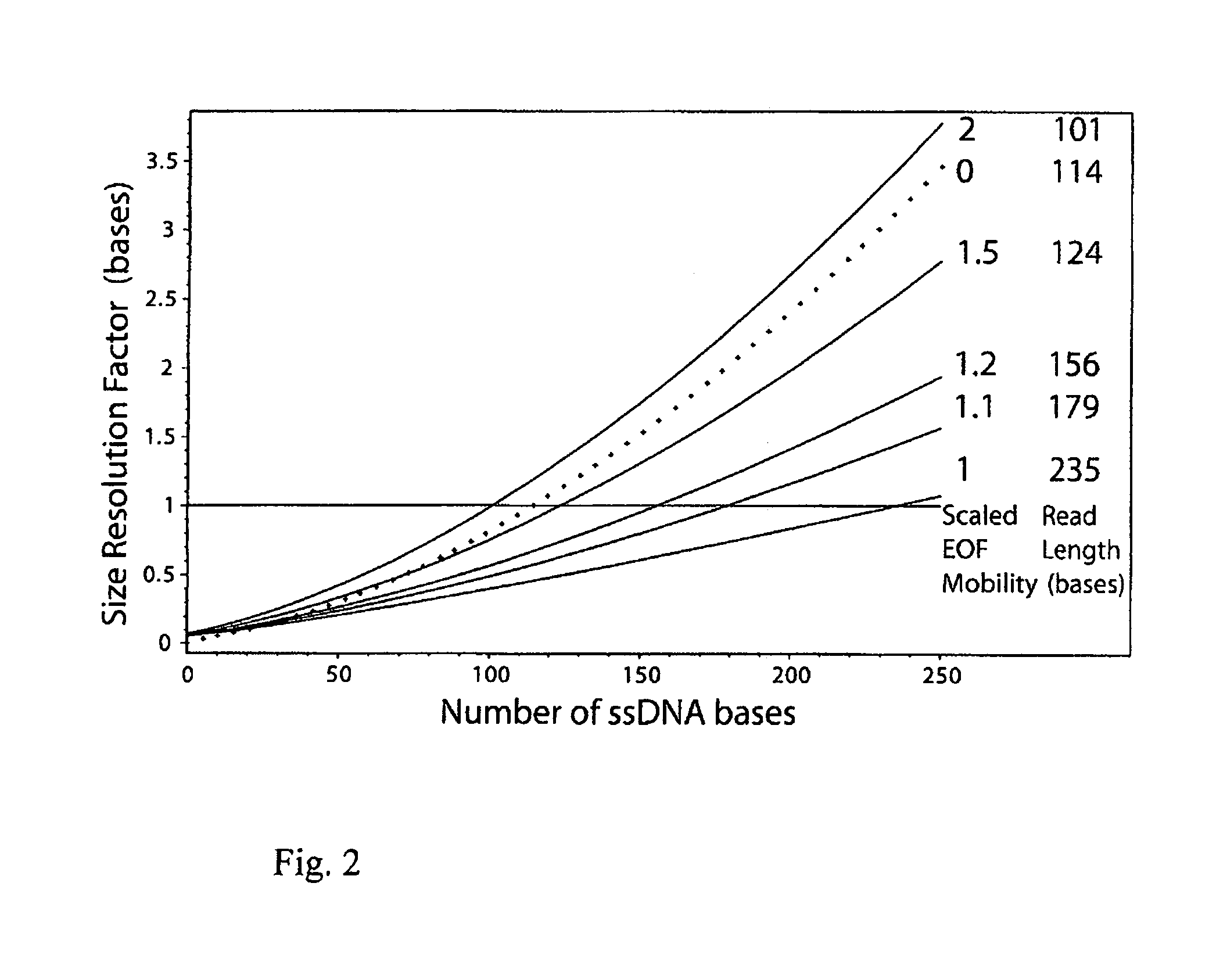

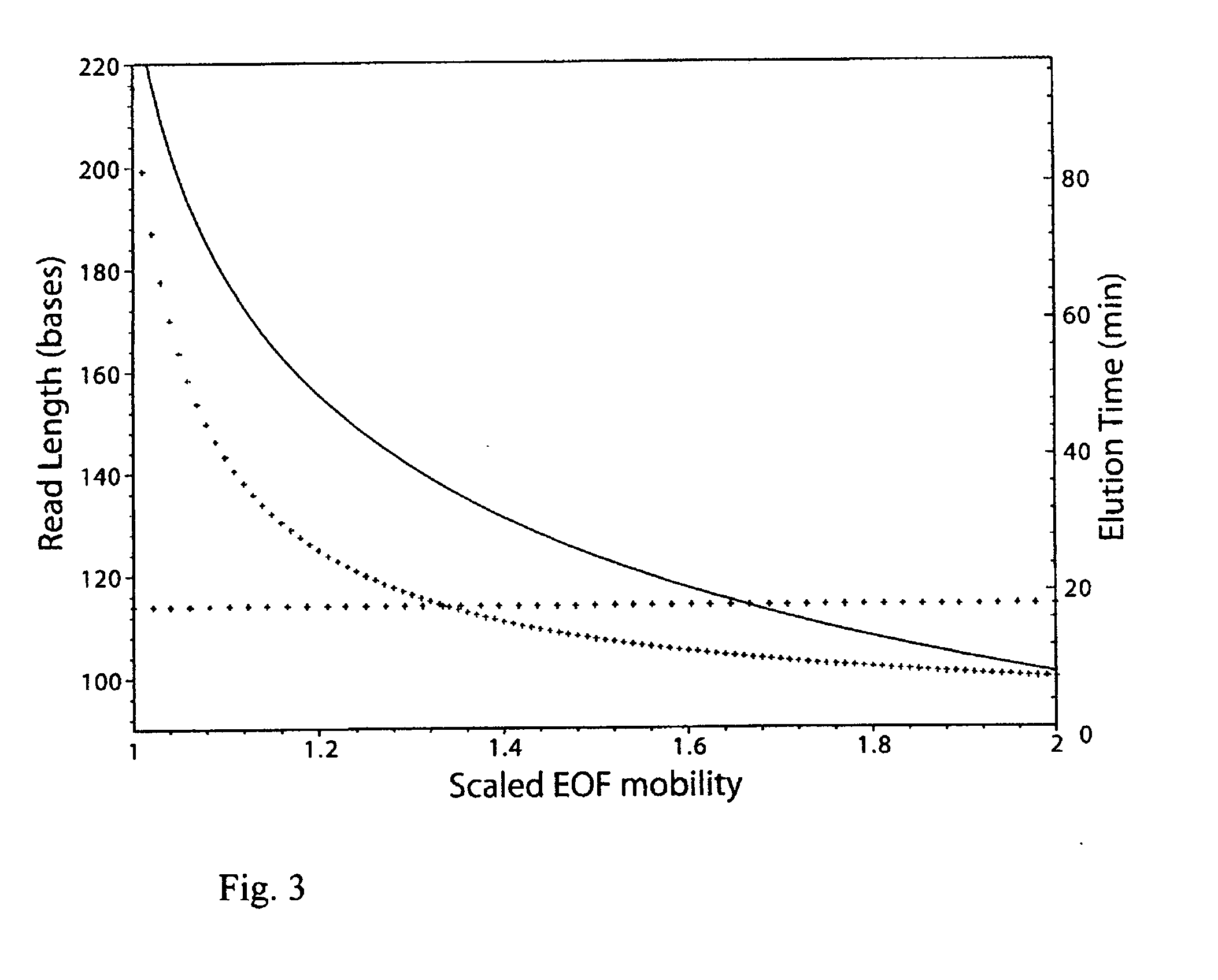

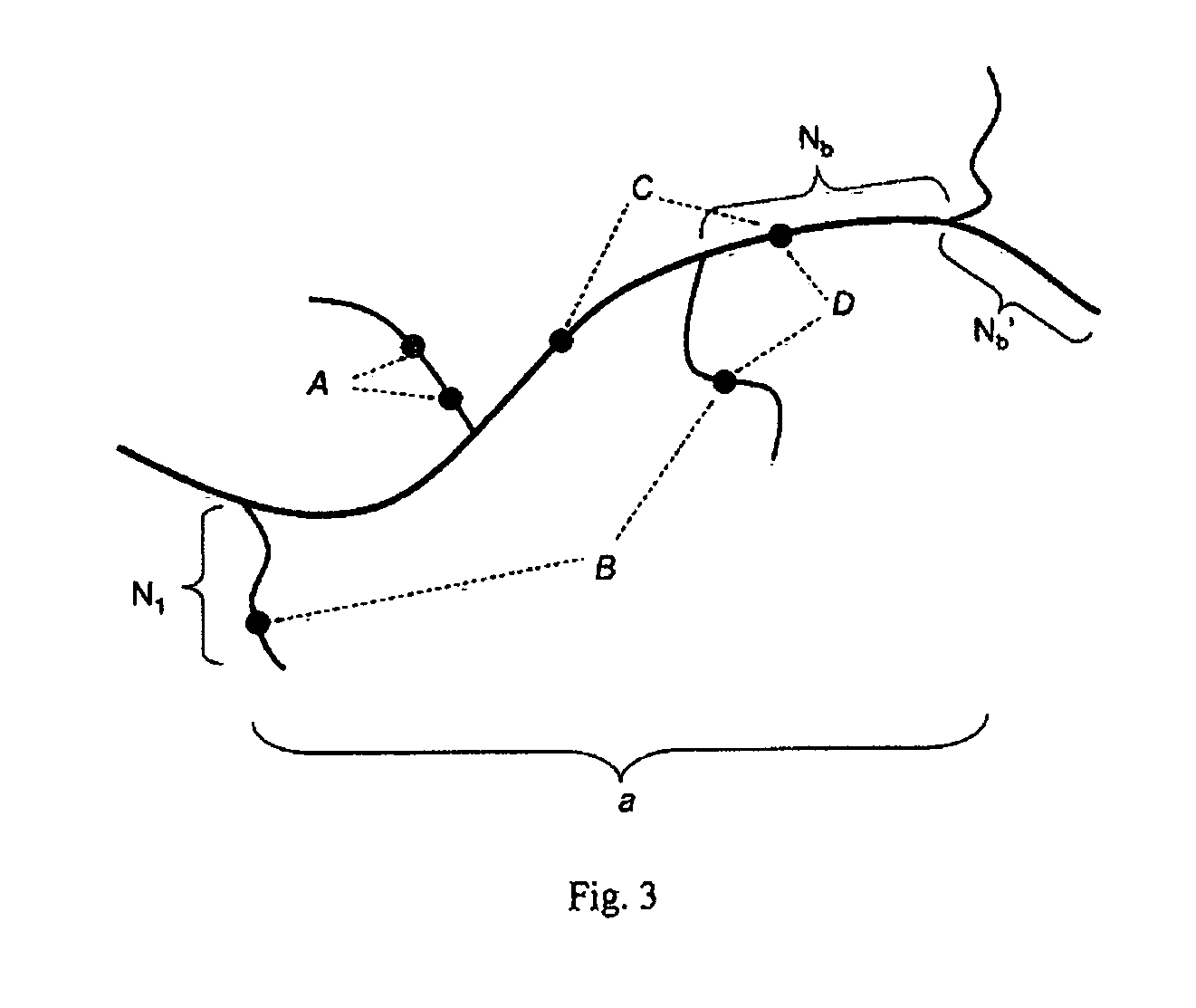

Electroosmotic flow for end labelled free solution electrophoresis

InactiveUS20070215472A1Easy to separateIncreased hydrodynamic frictionSludge treatmentVolume/mass flow measurementElectricityElectrophoresis

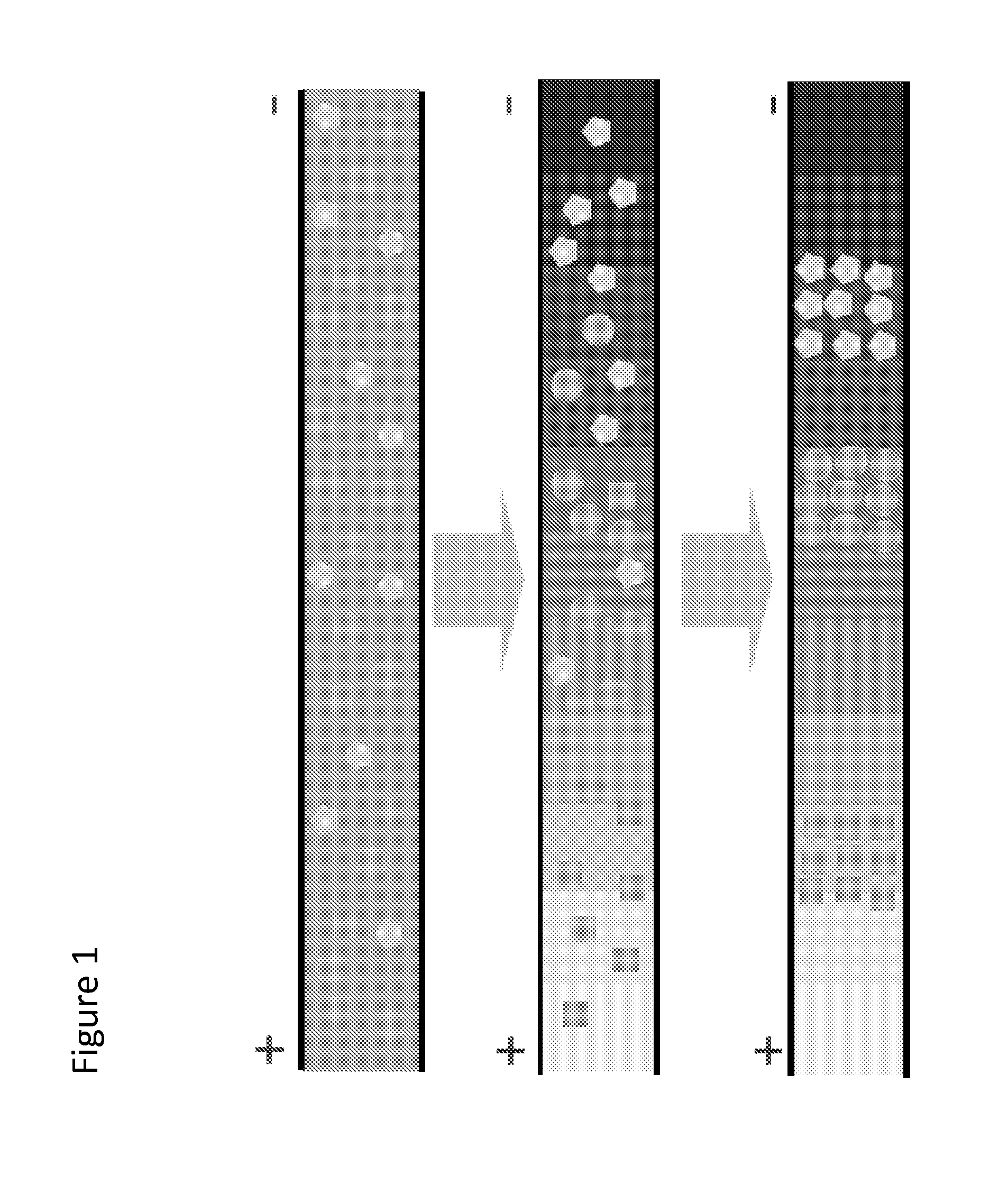

End Labelled Free Solution Electrophoresis (ELFSE) provides a means of separating polymer molecules such as ssDNA according to their size, via free solution electrophoresis, thus eliminating the need for polymer separation via gels or polymer matrices. Here, significant improvements in ELFSE are disclosed via concurrent exposure of the polymer molecules to an electroosmotic flow. When the methods are applied to DNA sequencing by ELFSE, significant improvements in read length are observed.

Owner:UNIVERSITY OF OTTAWA

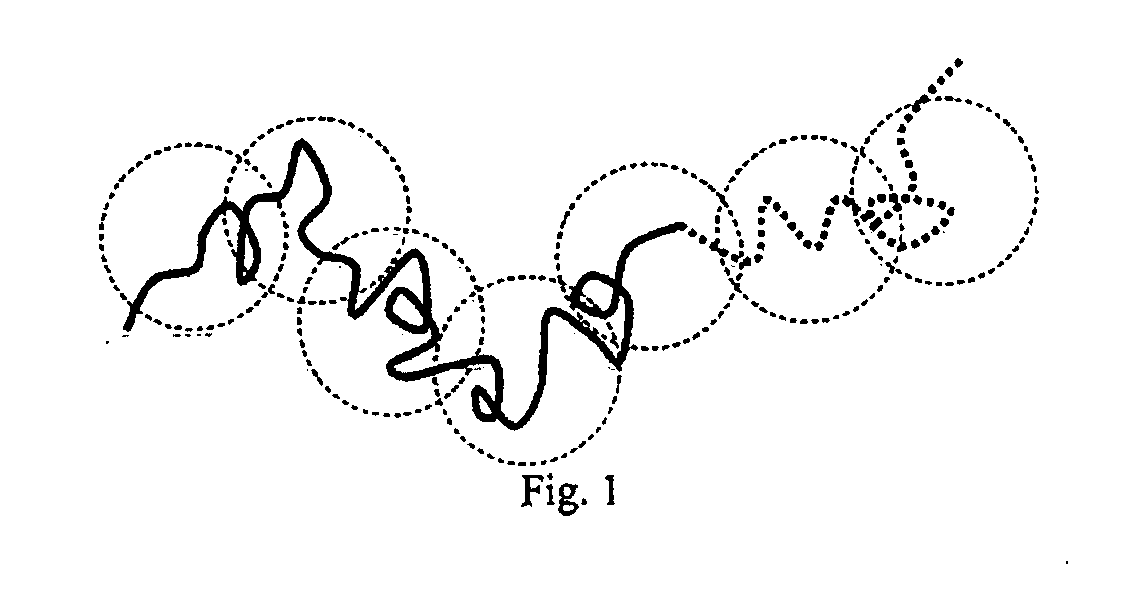

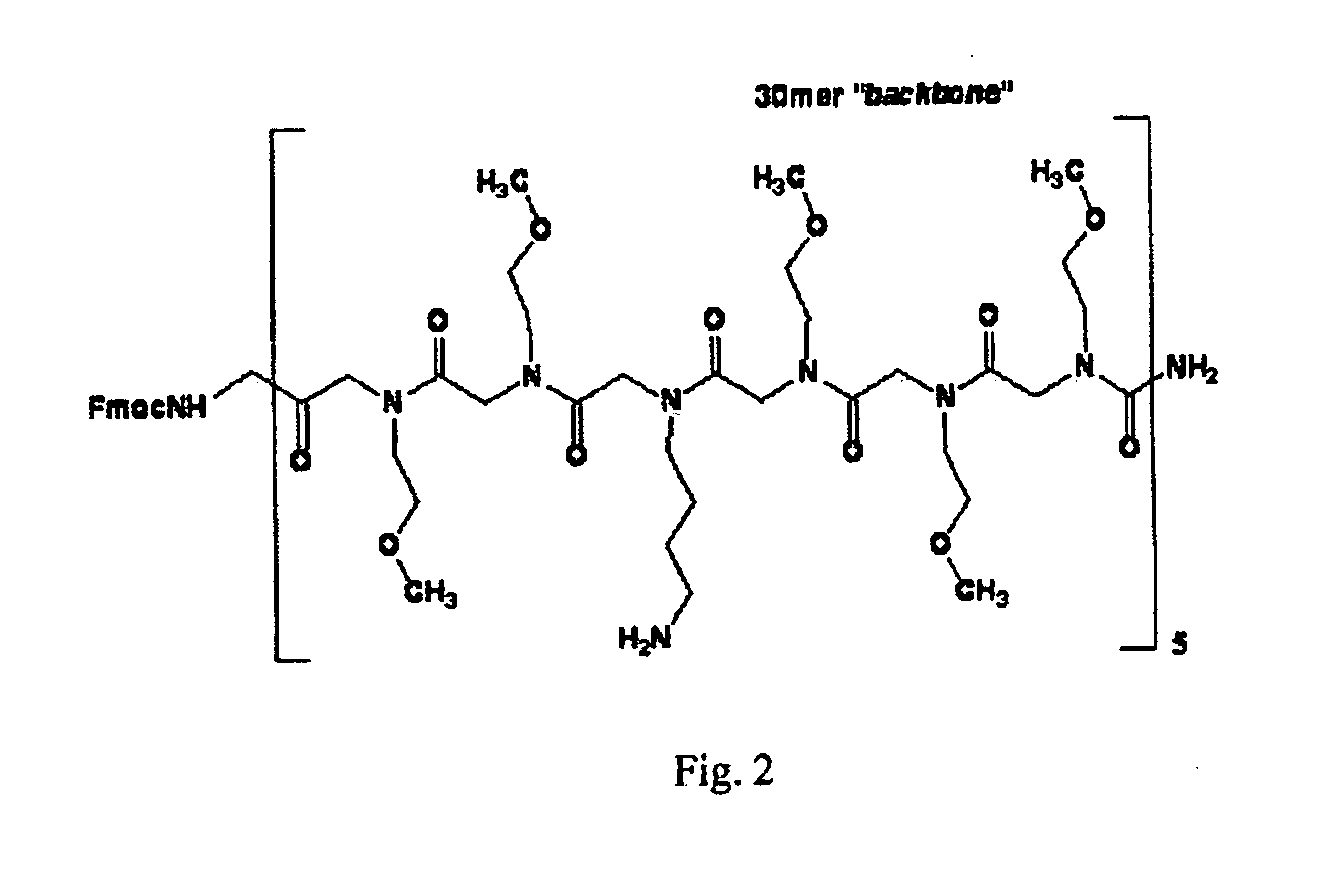

Branched polymer lables as drag-tags in free solution electrophoresis

InactiveUS20070218494A1Easy to separateIncreased hydrodynamic frictionMicrobiological testing/measurementElectrophoresisFree solution

End Labelled Free Solution Electrophoresis (ELFSE) provides a means of separating polymer molecules such as ssDNA according to their size, via free solution electrophoresis, thus eliminating the need for polymer separation via gels or polymer matrices. Here, end labels are provided that optimize branching architecture to increase hydrodynamic drag of the end label, and improve separation of polymer molecules by ELFSE.

Owner:UNIVERSITY OF OTTAWA

Highly concentrated stable meloxicam solutions

Aqueous cyclodextrin-free solution of meloxicam for administration by oral or parenteral route, containing a pharmacologically acceptable meloxicam salt of an organic or inorganic base and one or more suitable excipients, the content of dissolved meloxicam salt being more than 10 mg / mL. The formulation according to the invention has a shelf-life of up to 24 months or more.

Owner:BOEHRINGER LNGELHEIM VETMEDICA GMBH

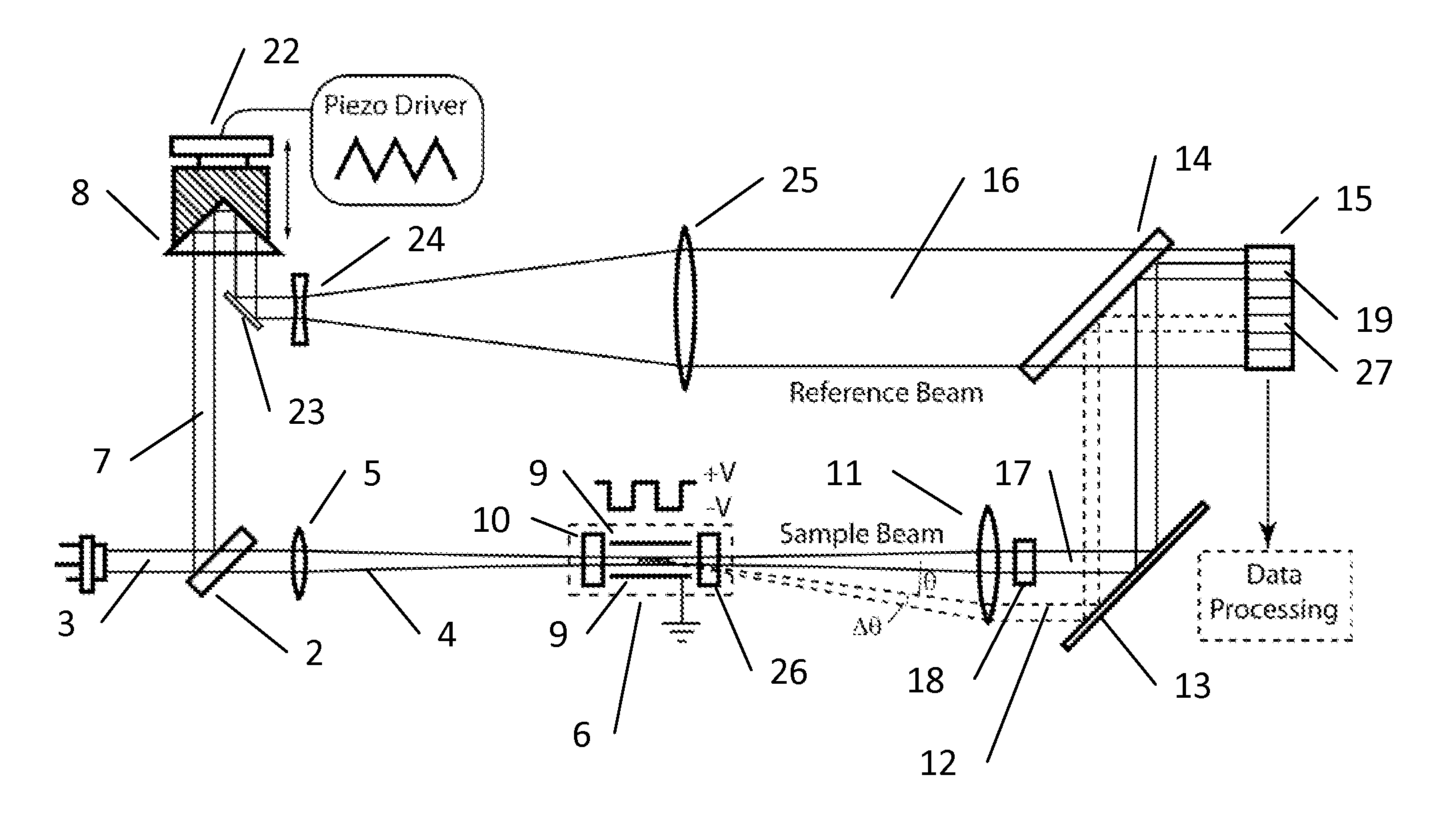

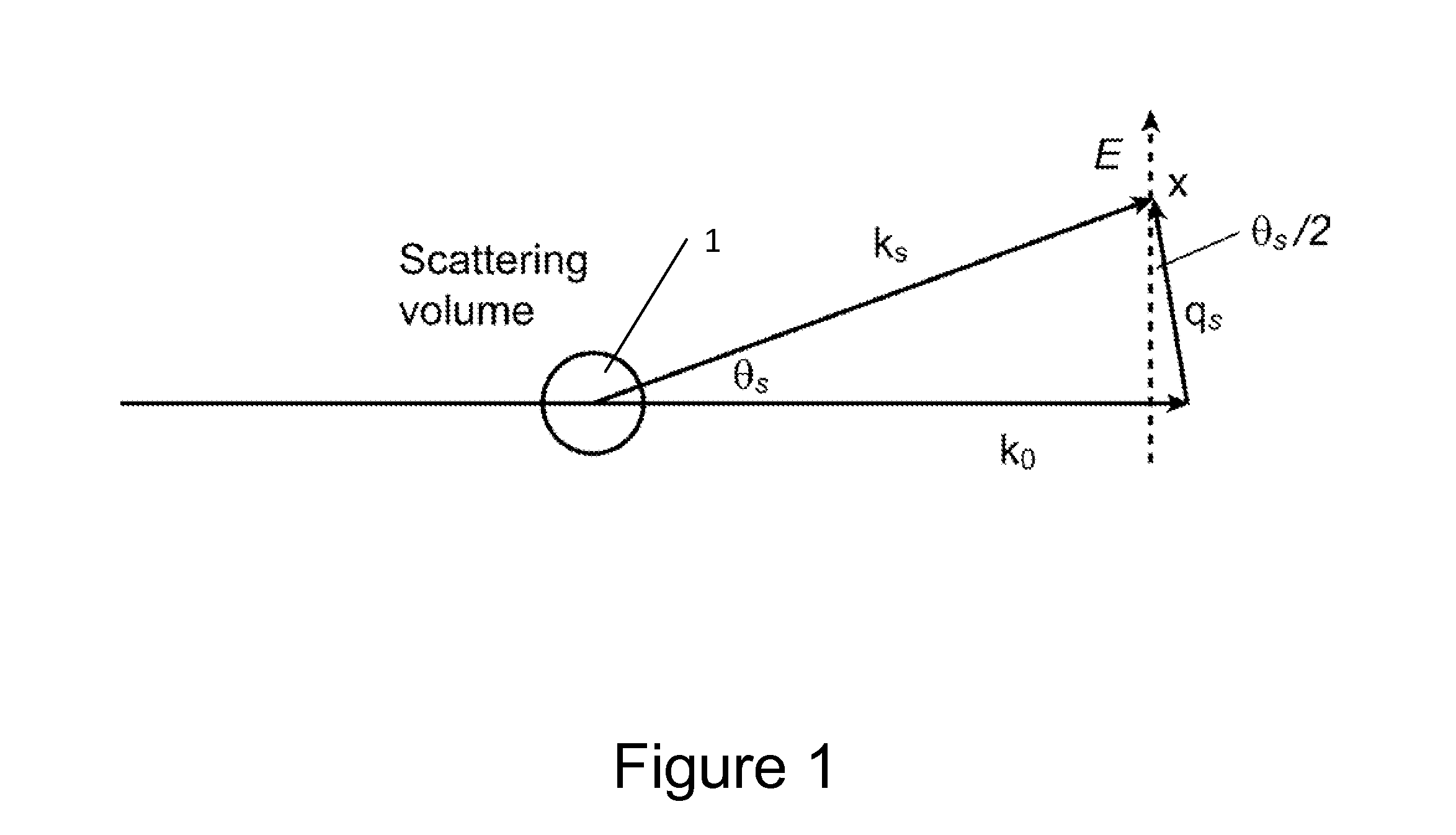

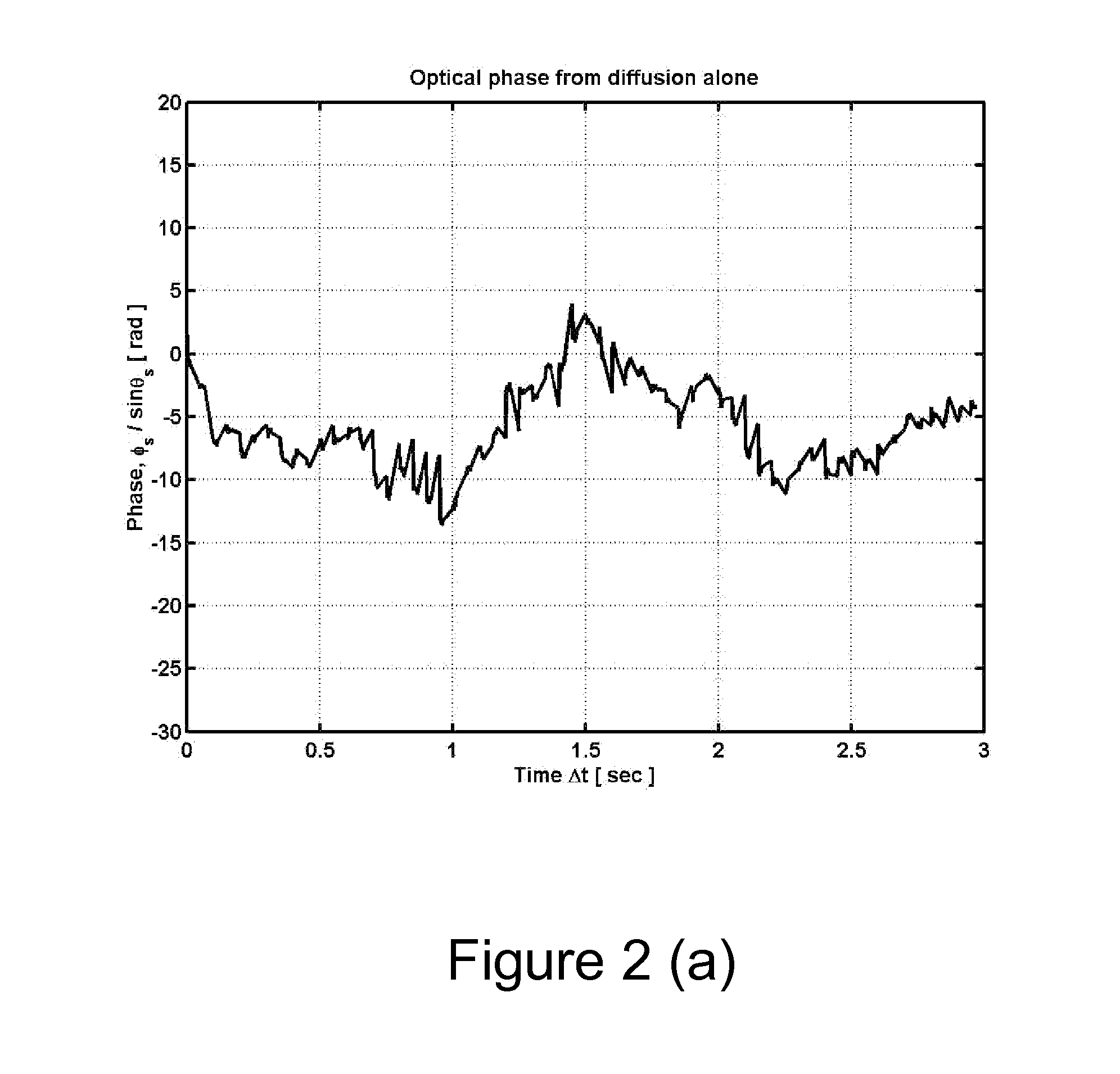

Method and apparatus to measure particle mobility in solution

ActiveUS20110210002A1Reduce harmMinimizing electrochemical degradationSludge treatmentVolume/mass flow measurementPhotodetectorFree solution

A method and apparatus is disclosed for measurement of the electrophoretic mobility of particles and molecules in solution. A sample of particles is placed in a cell containing two electrodes that apply an alternating electric field. A monochromatic light beam passes through the sample. Light scattered by the particles, along with the unscattered beam, is collected and collimated as it exits the cell. This beam is combined in free space with a phase modulated reference beam. The interference forms a frequency modulated speckle pattern, which is detected by a photodetector array. Each array element collects a narrow range of well-defined scattering angles. The signal from each is demodulated to extract the optical phase information providing a first-principle measurement of the electrophoretic mobility of the scattering particles. Each detector element provides a simultaneous independent measurement. This inherent parallelism drastically increases the amount of information available in a given time. The resulting increased sensitivity extends the mobility measurement to particles below one nanometer, reduces the required concentration and electric field compared to previous methods. This minimizes damage to fragile samples, increases the electrode useful life, and reduces joule heating. Electrophoretic mobility is a critically important parameter for predicting the stability of nanoparticle suspensions and pharmaceutical formulations such as protein therapeutics. This invention enables reliable free-solution phase measurement of these samples.

Owner:WYATT TECH

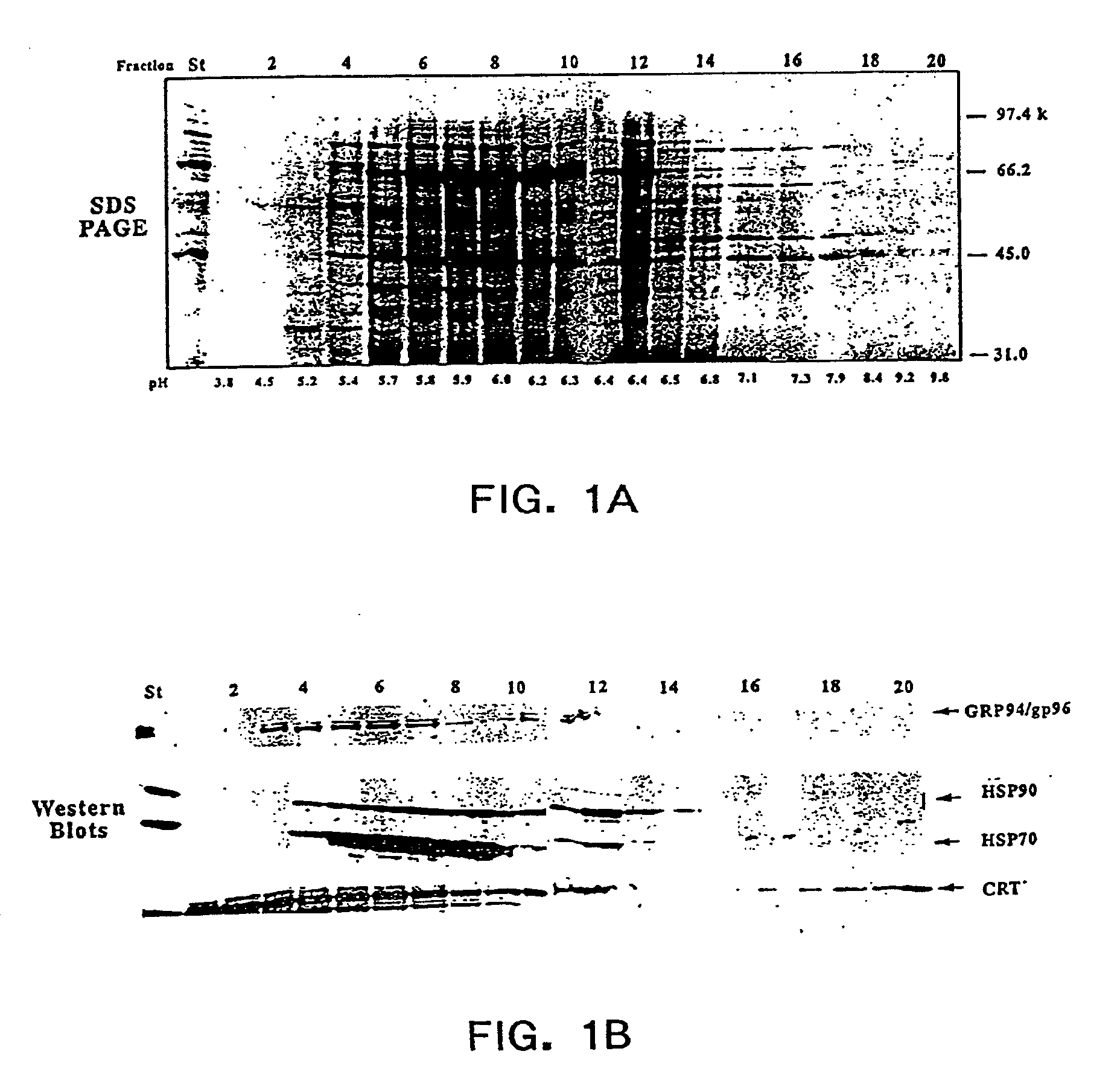

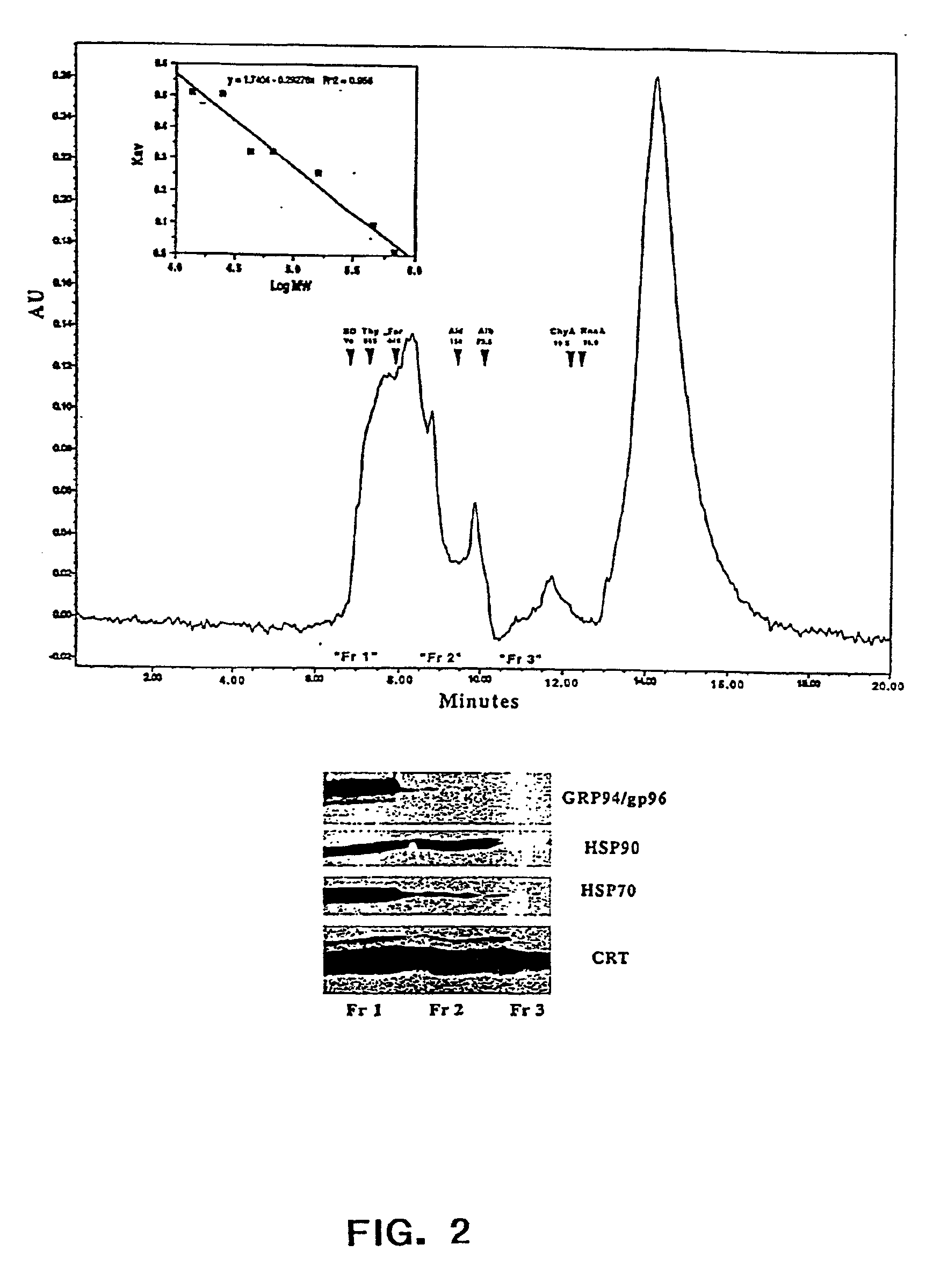

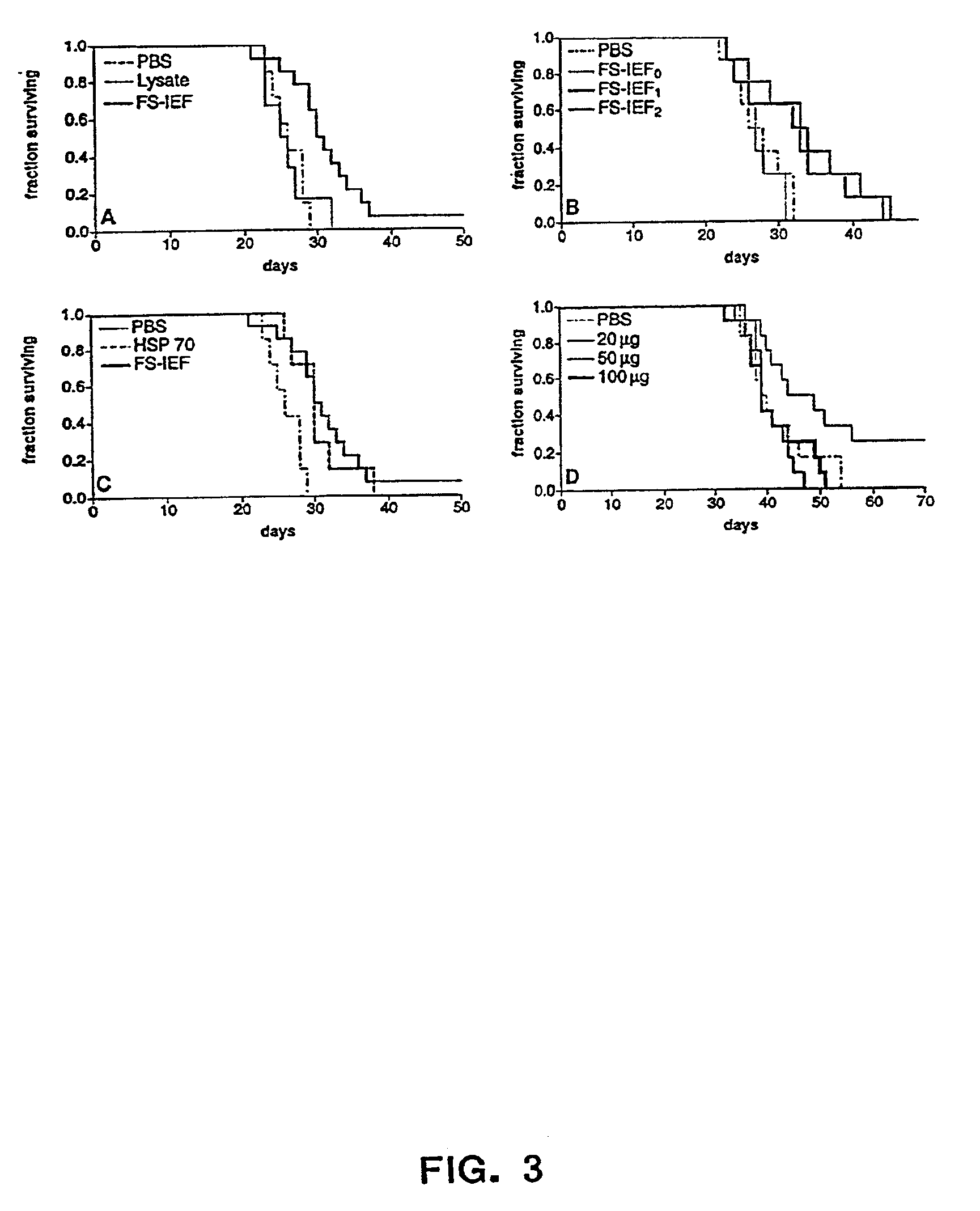

Methods of recovering chaperone proteins and complexes thereof

The present invention provides methods for efficient and concomitant recovery of multiple chaperone proteins and / or chaperone protein complexes from a limited sample source. Disclosed are methods involving the use of Free Solution Iso-Electric Focusing (FS-IEF) which can enrich samples containing chaperone proteins and / or chaperone protein complexes from a given sample. The chaperone proteins can be, but are not restricted to calreticulin, gp96, hsp86, hsp84, hsp70, hsp60 and hsp40. The invention also provides methods of recovering chaperone protein complexes for the preparation of vaccines containing chaperone complexes.

Owner:ARIZONA BOARD OF REGRENTS ON BEHALF OF THE UNIV OF ARIZONA THE

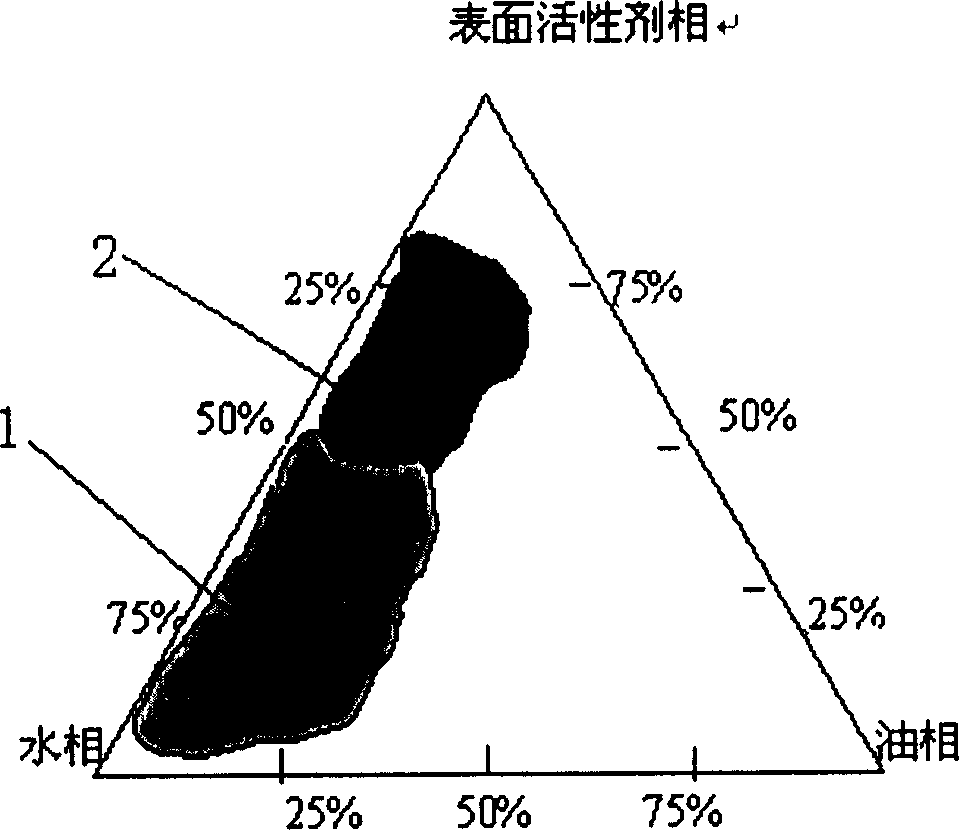

Chinese medicine volatoile oil self-mciro emulsifying nano composition and preparing method

InactiveCN1748777ALess irritatingLow toxicityEmulsion deliveryPlant ingredientsIrritationCurative effect

The Chinese medicine volatile oil self micro emulsifying nanometer composition consists of Chinese medicine volatile oil 0.2-40 wt%, surfactant 0.4-80 wt%, co-surfactant 0-40 wt%, and water 0-99.40 wt%. The present invention applies self micro emulsifying technology in Chinese medicine volatile oil to make medicine, such as soft capsule and oral liquid, self micro emulsified in body to nanometer size, or make medicine, such as injection and inhalant, existing in bacteria-free solution. The prepared self micro emulsifying nanometer composition has reduced irritation and toxicity, raised absorption rate and mucous membrane penetrating capacity, raised bioavailability, raised curative effect and improved patientí»s compliance.

Owner:SHANGHAI INST OF PHARMA IND CO LTD

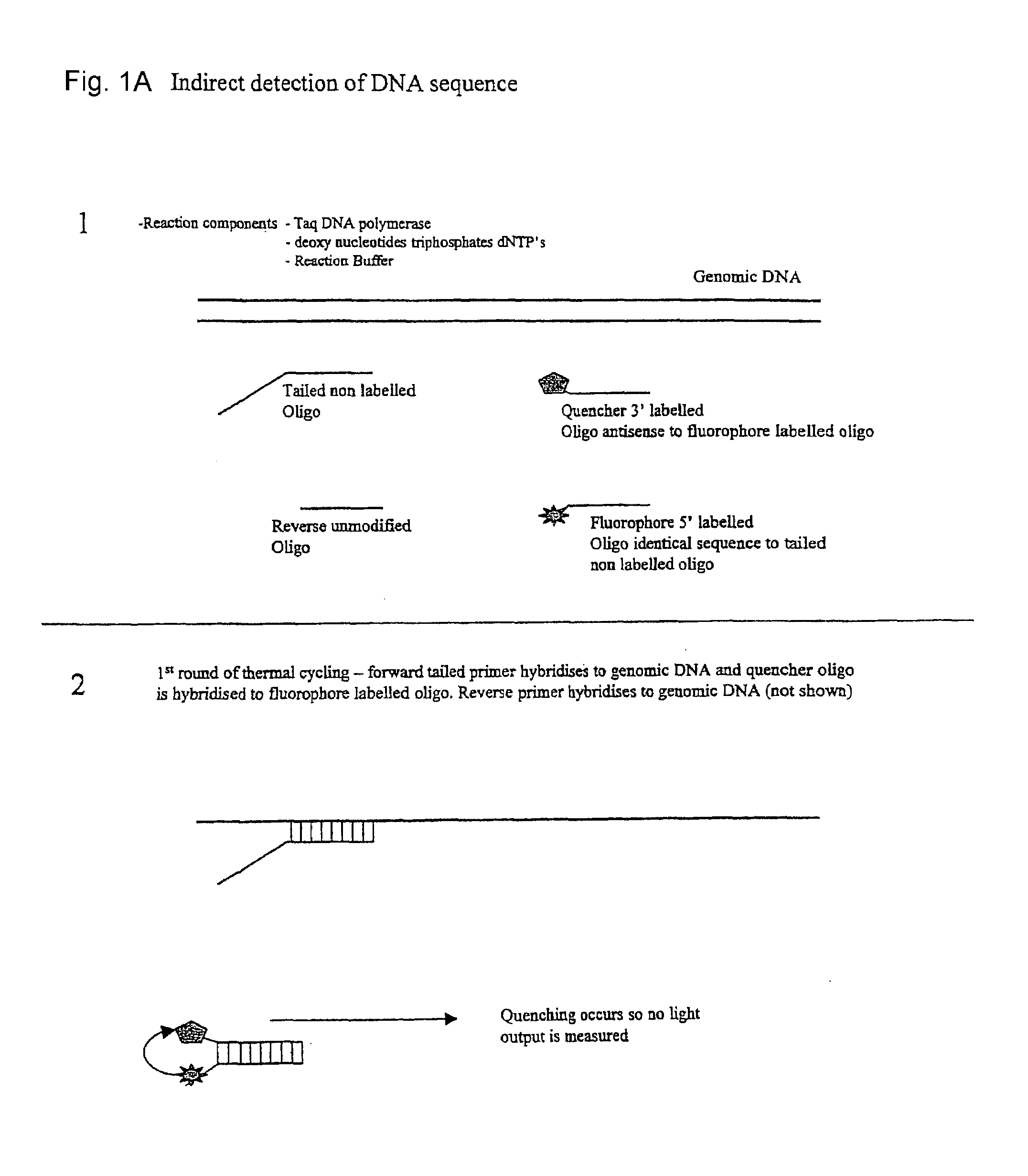

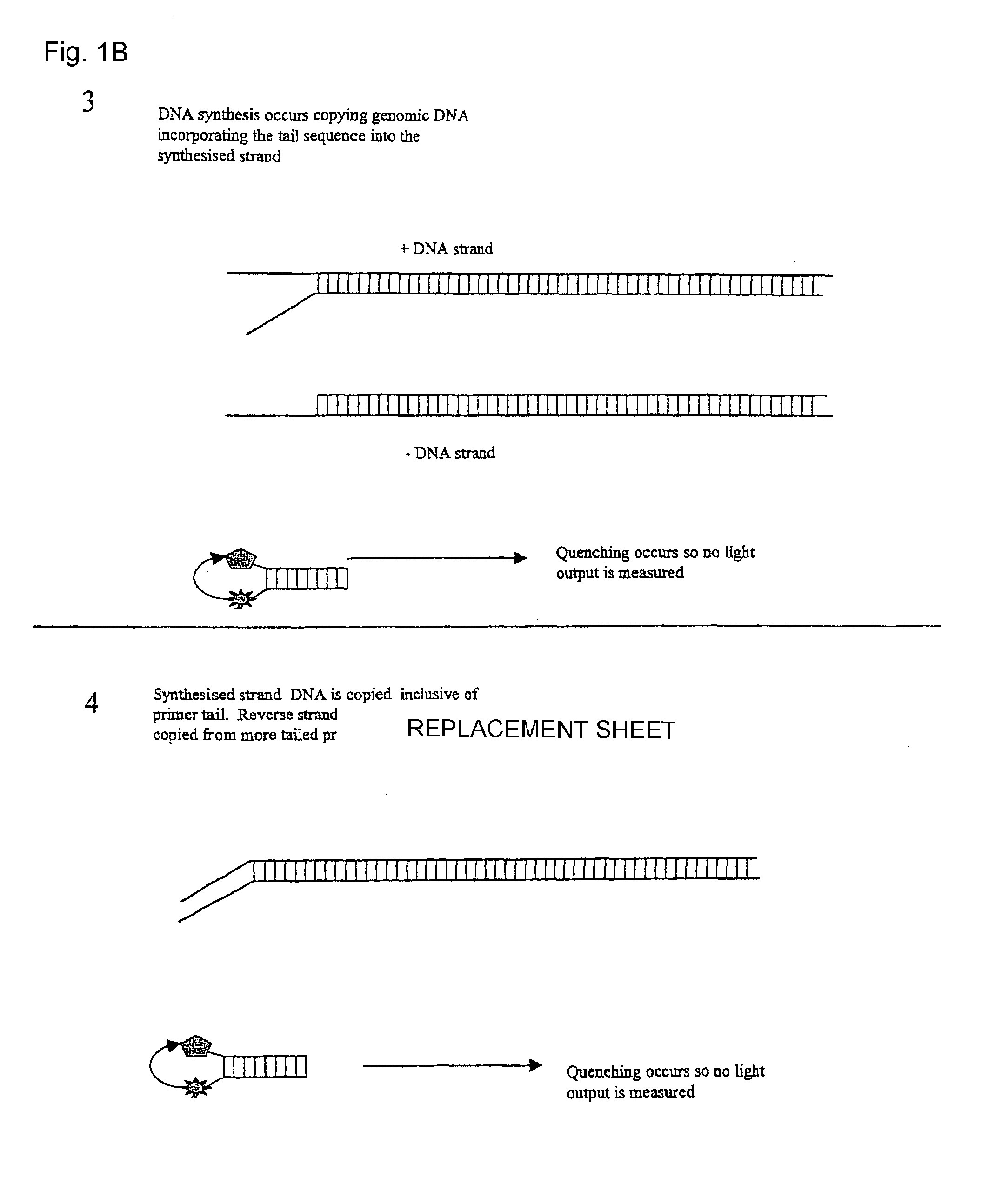

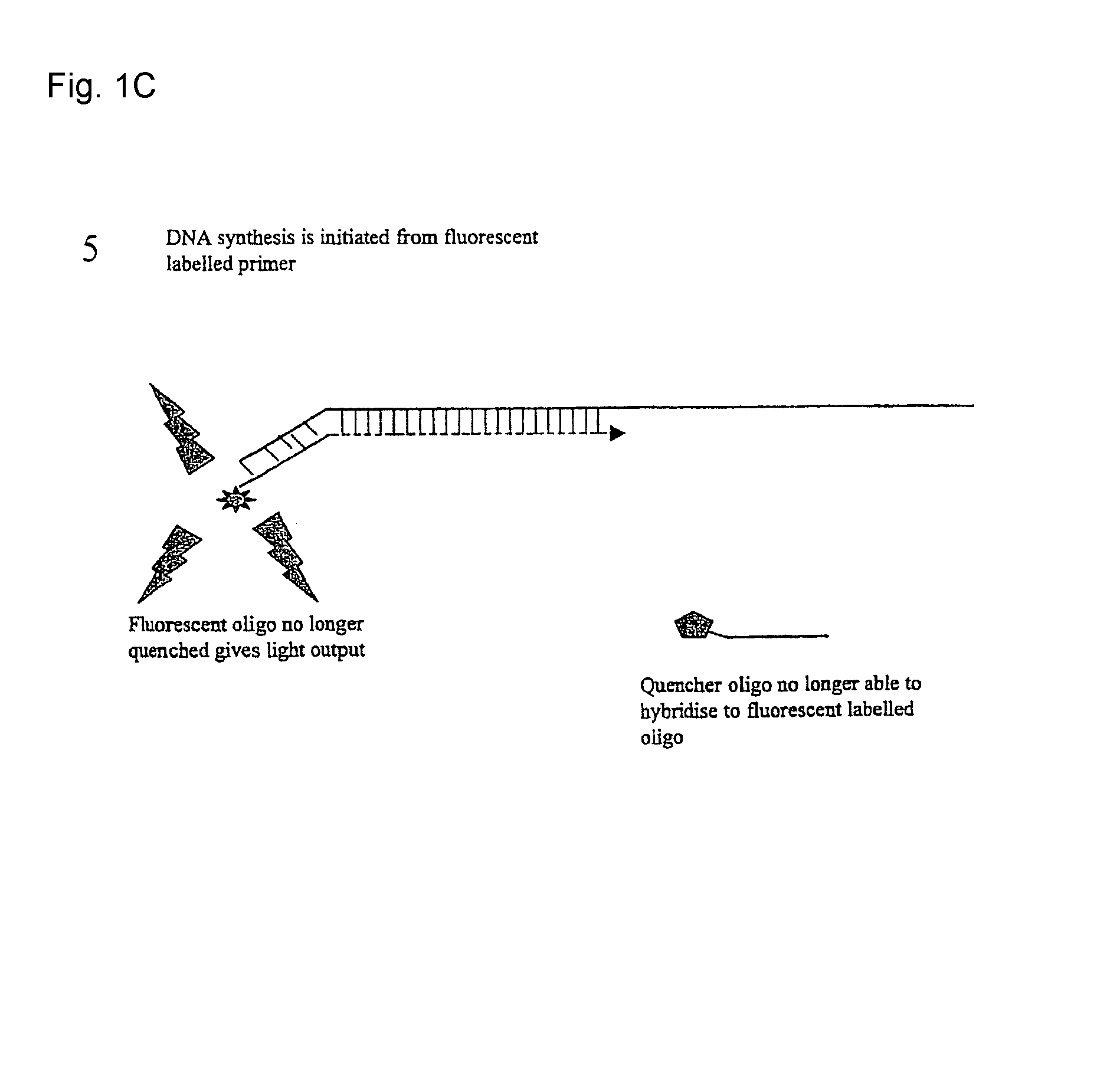

Detection system for PCR assay

ActiveUS7615620B2High of synthesisImprove throughputSugar derivativesMicrobiological testing/measurementPcr assayFluorescence

Owner:LGC GENOMICS

Fast dissolving water-soluble fertilizer formulations and methods and uses thereof

ActiveUS20100186471A1Fast preparationReadily and rapidly compoundBiocideAmmonium nitratesFree solutionWater soluble

Improved, solid water-soluble fertilizer (WSF) compositions are presented which comprise at least one acid (optionally nutritive) and at least one basic fertilizer component. In one or more embodiments of the present invention, the WSF compositions demonstrate improved solubility of one or more nutrients or additives in solution, do not require additional dissolution aids or anti-caking agents, demonstrate fast dissolution times, produce precipitate free solutions, are readily compounded without intermediate wetting or drying steps, do not generate gas, and demonstrate improved stability under typical usage conditions. Finally, the WSF compositions may be used in improved processes for the creation of stock solutions, optionally with cold water, and / or delivery of nutrients to plants.

Owner:EVERRIS INT

Pharmaceutical formulations of meloxicam

This invention is a novel pharmaceutical formulation of aqueous EDTA (Ethylene diamine tetraacetic acid) free solution of meloxicam in combination with meglumin for administration by oral or parenteral route, comprising one or more pharmaceutically acceptable excipients which is comprising N,N dimethylacetamide and propylene glycol for treating mammals, preferably animals.

Owner:SANOVEL ILAC SANAYI & TICARET ANONIM SIRKETI +1

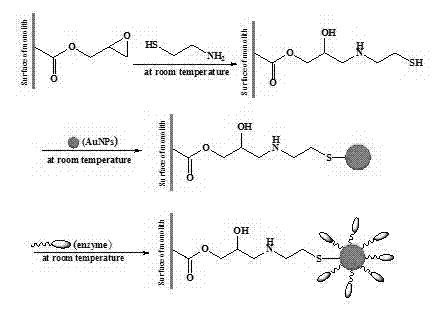

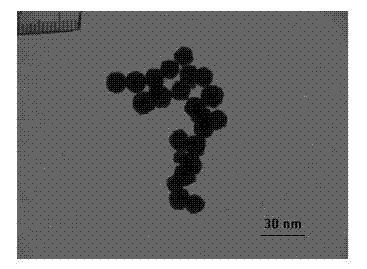

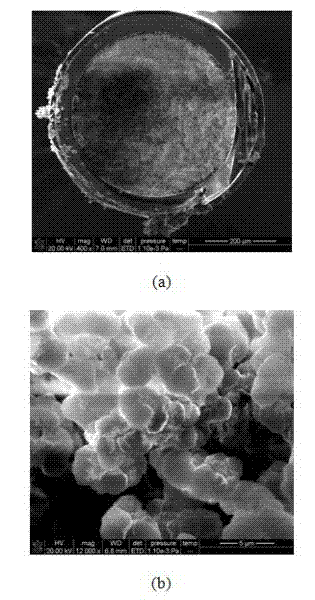

Preparation method for porous monolithic column immobilized enzyme micro-reactor

InactiveCN102391947AEasy to makeImprove permeabilityEnzyme production/based bioreactorsOn/in organic carrierCysteamineMicroreactor

The invention discloses a preparation method for a porous monolithic column immobilized enzyme micro-reactor. The porous monolithic column immobilized enzyme micro-reactor is prepared according to the preparation method as follows: firstly, a poly (GMA-co-EDMA) monolithic column is prepared; and then the poly (GMA-co-EDMA) monolithic column is modified by cysteamine and gold nanoparticles so as to obtain a porous polymer monolithic column, wherein, the gold nanoparticles are immobilized on the surface of the porous polymer monolithic column. Enzyme is immobilized to the hole surfaces of the porous monolithic column modified by the gold nanoparticles by utilizing the action of Au-NH2 bond, and then the porous monolithic column immobilized enzyme micro-reactor can be obtained. The preparation method has the advantages as follows: the preparation method is simple; enzyme immobilization reaction conditions are moderate; the permeability of the enzyme micro-reactor is good; large immobilized enzyme quantity can be achieved; the activity, the service life and the stability of enzyme are high in comparison with free solution enzymolysis, and enzyme can be used repeatedly.

Owner:GUANGXI NORMAL UNIV

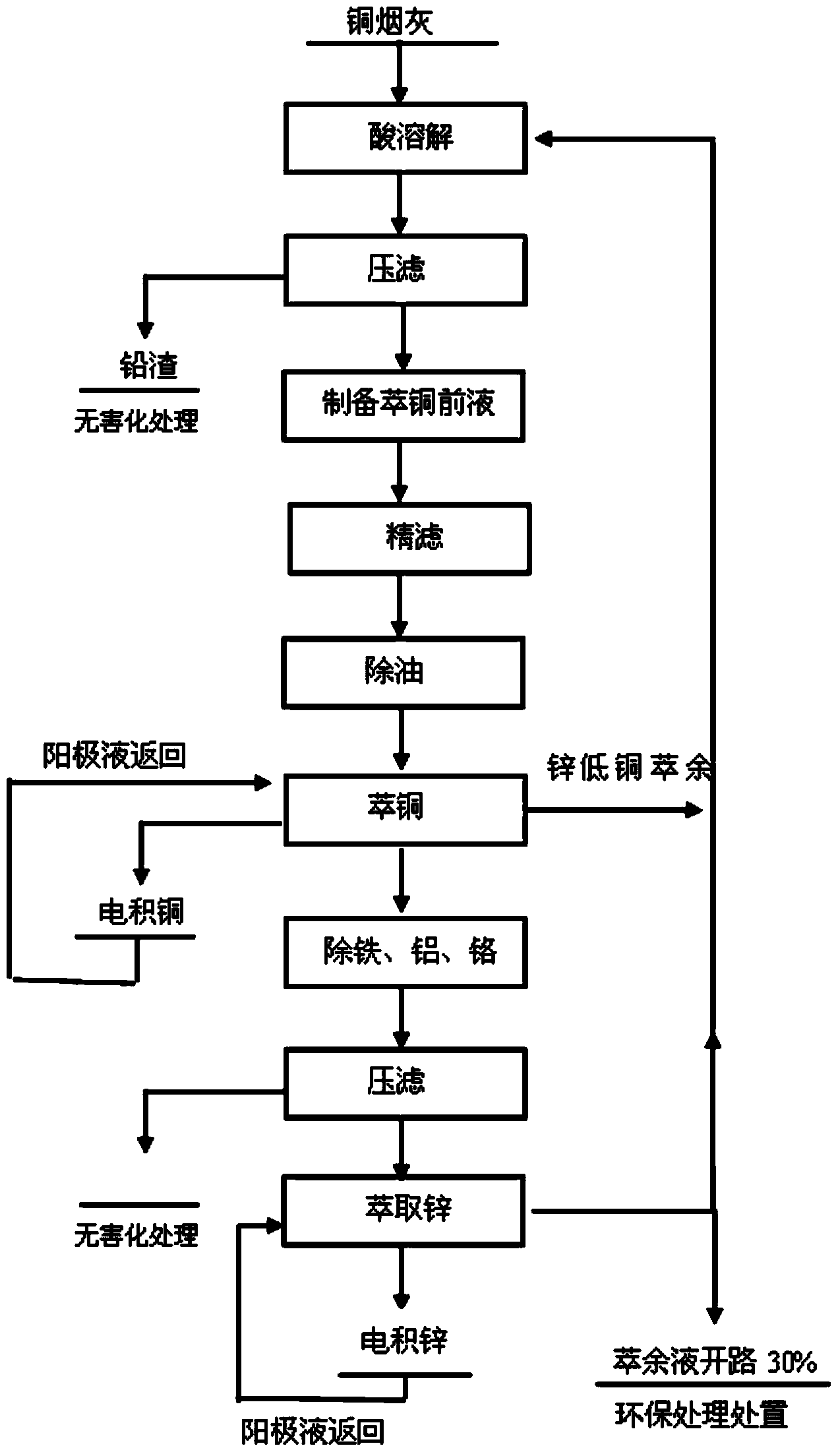

Technology for directly extracting copper and zinc by using copper dust wet method

ActiveCN103643044AReduce the amount requiredThorough recyclingProcess efficiency improvementFree solutionLower grade

The invention discloses a technology for directly extracting copper and zinc by using a copper dust wet method for carrying out high-activity processing on a low-grade copper dust material. The technology provided by the invention comprises the following steps of leaching, removing organic matters, extracting copper, removing iron, aluminum and chromium, extracting zinc, and leaching a zinc-free solution (20-30% of open loop can be achieved during the process). The technology provided by the invention has the advantages that a direct extracting operation technology is adopted, more low-grade copper dust can be recycled, the total amount of environment waste is reduced, meanwhile, the product percent conversion is high, the added value of a product is high, the cost is low, the technology has energy-saving and an environment-friendly properties, the low-grade high-impurity dust material which is generated by smelting crude copper through a pyrogenic process and is hard to process at present can be processed, and the valuable metal of the low-grade copper-zinc dust is fully recycled.

Owner:温贵能

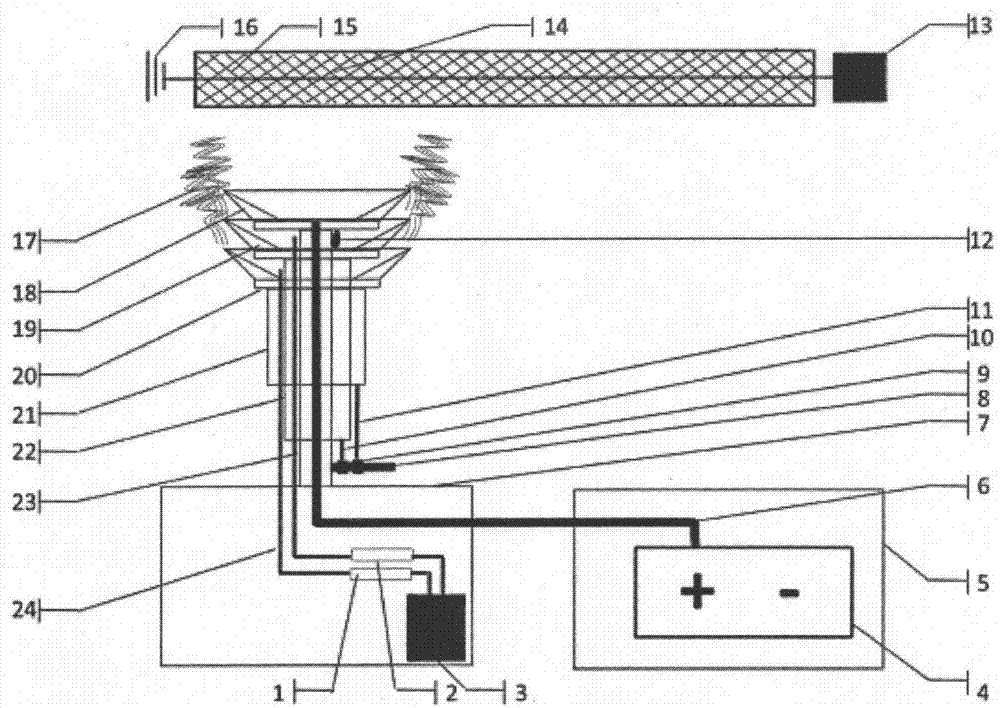

Electrospinning device for dynamically controlling curvature of spinning solution and application method for electrospinning device

ActiveCN107475785ALower threshold voltageStable and controllable productionElectro-spinningFiberElectrospinning

The invention discloses an electrospinning device for dynamically controlling the curvature of a spinning solution and an application method for the electrospinning device. The electrospinning device comprises a solution supply system, an electric field control system, a spinning solution curvature regulating system and a nanofiber collecting system. The application method for the electrospinning device comprises the steps of adopting a first electrospinning method to regulate the curvature of the spinning solution to a constant value so as to produce a narrowly distributed nanofiber product, adopting a second electrospinning method to regulate the dynamic change of the curvature of the spinning solution so as to produce a multistage narrowly distributed nanofiber product, or adopting a third electrospinning method to control an electric field and regulate the curvature of the spinning solution so as to produce the narrowly distributed nanofiber product simultaneously. According to the electrospinning device for dynamically controlling the curvature of the spinning solution and the application method for the electrospinning device, since the spinning solution curvature regulating system is adopted, precise control over the curvature of the edge of the spinning solution can be achieved, the regulation of a batch free solution level spinning process can be achieved, and the critical voltage required for the free liquid surface for electrospinning can be reduced; besides, batch, stable and controllable production of the nanofiber products can be achieved, the curvature of the edge of the spinning solution can be dynamically regulated, and one-step production of aggregation of the multistage narrowly distributed nanofiber product is achieved.

Owner:DONGHUA UNIV

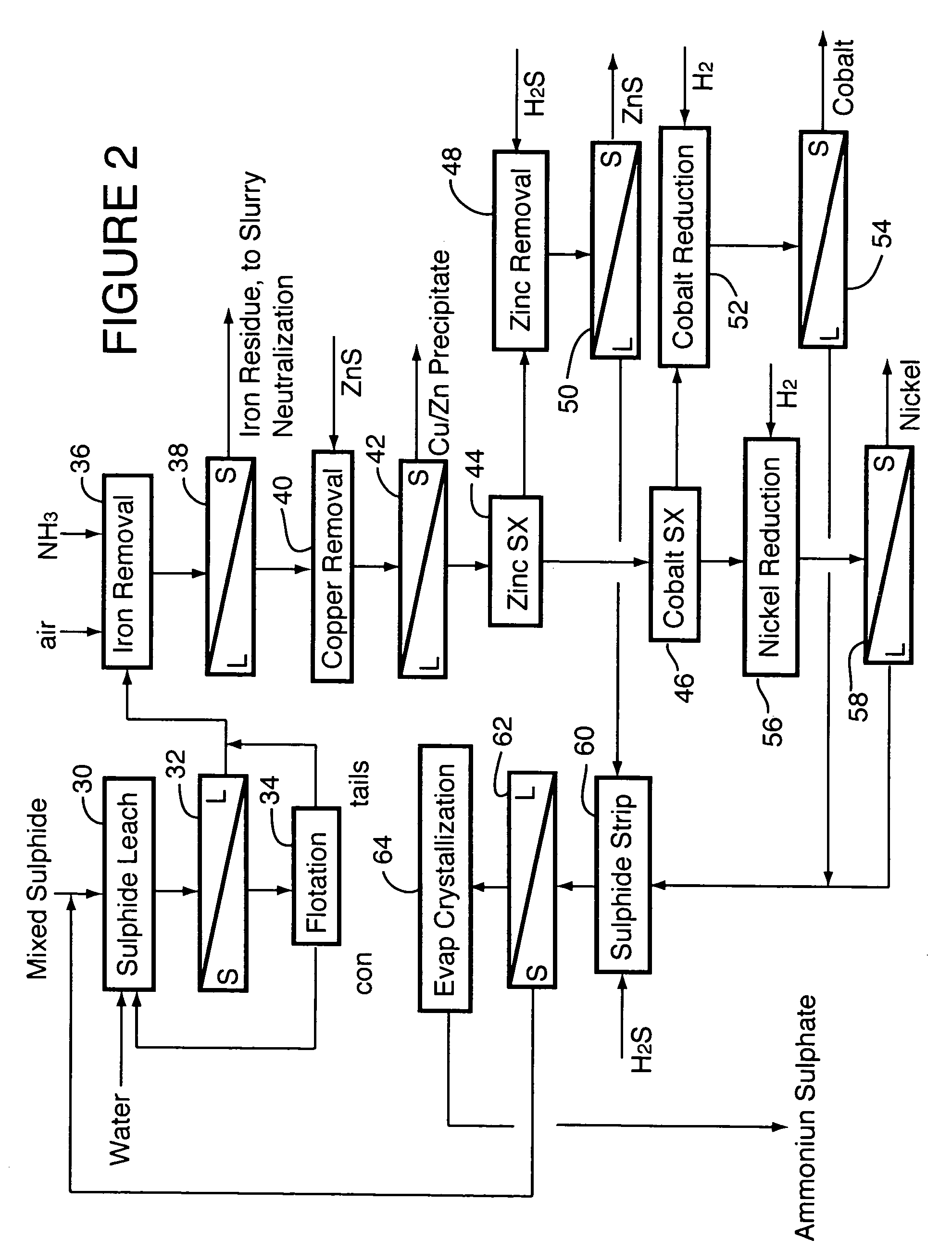

Recovery of nickel, cobalt, iron, silica, zinc and copper from laterite ore by sulfuric acid leaching

ActiveUS7387767B2Efficient separation and recoveryHigh purityCobalt sulfidesSolvent extractionFree solutionSlurry

A process for recovering nickel and cobalt values from nickel- and cobalt-containing laterite ores as an enriched mixed nickel and cobalt sulphide intermediate and for producing nickel and cobalt metal from the nickel and cobalt sulphide intermediate. The laterite ore is leached as a slurry in a pressure acid leach containing an excess of aqueous sulphuric acid at high pressure and temperature, excess free acid in the leach slurry is partially neutralized to a range of 5 to 10 g / L residual free H2SO4 and washed to yield a nickel- and cobalt-containing product liquor, the product liquor is subjected to a reductant to reduce any Cr(VI) in solution to Cr(III), the reduced product liquor is neutralized to precipitate ferric iron and silicon at a pH of about 3.5 to 4.0, and the neutralized and reduced product liquor is contacted with hydrogen sulphide gas to precipitate nickel and cobalt sulphides. The precipitated nickel and cobalt sulphides can be leached in a water slurry in a pressure oxidation leach, the leach solution subjected to iron hydrolysis and precipitation, the iron-free solution contacted with zinc sulphide to precipitate copper, the iron- and copper-free solution subjected to zinc and cobalt extraction by solvent extraction to produce a nickel raffinate, the nickel raffinate contacted with hydrogen gas to produce nickel powder and the cobalt strip solution from the solvent extraction step contacted with hydrogen gas to produce cobalt powder.

Owner:SHERRITT INC

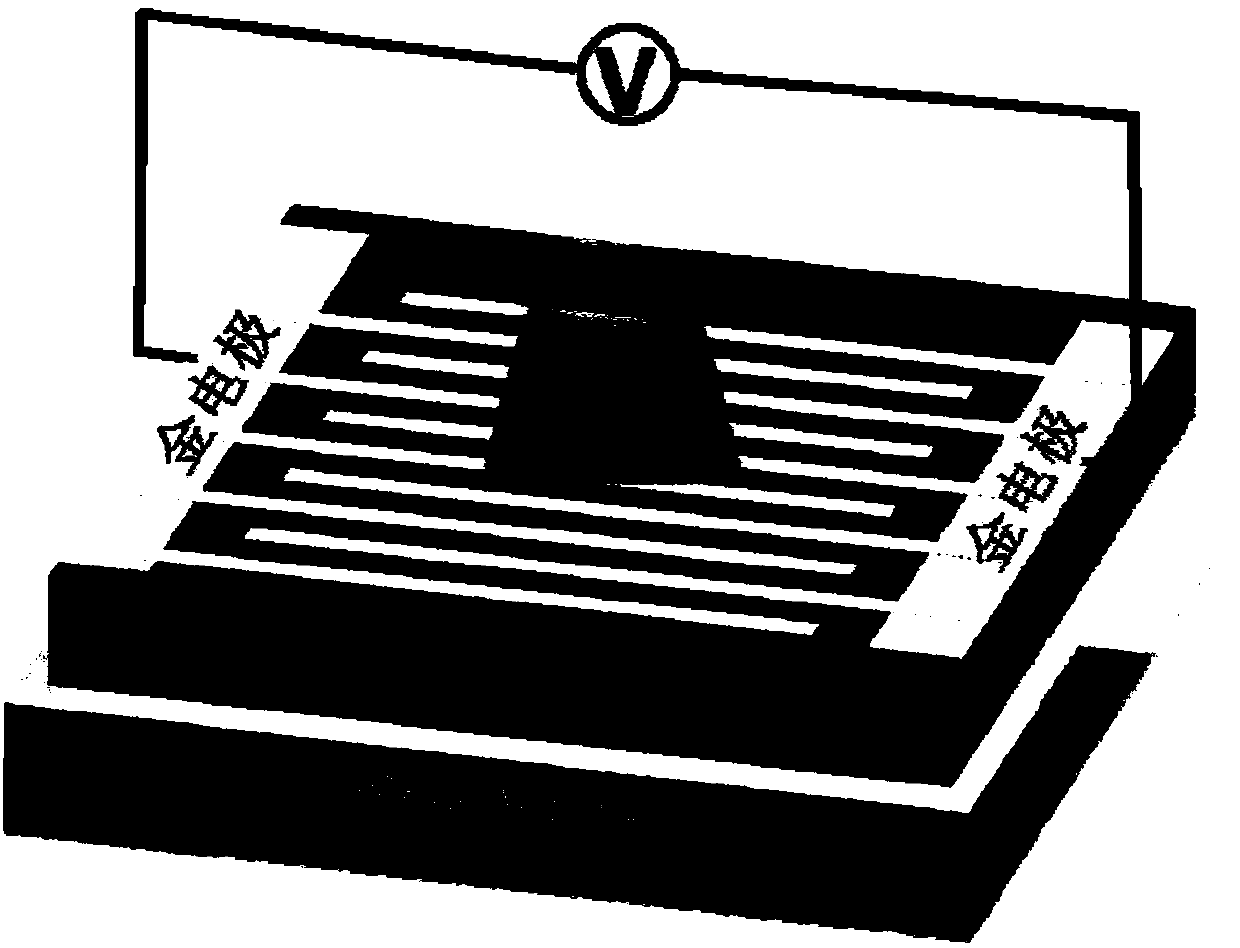

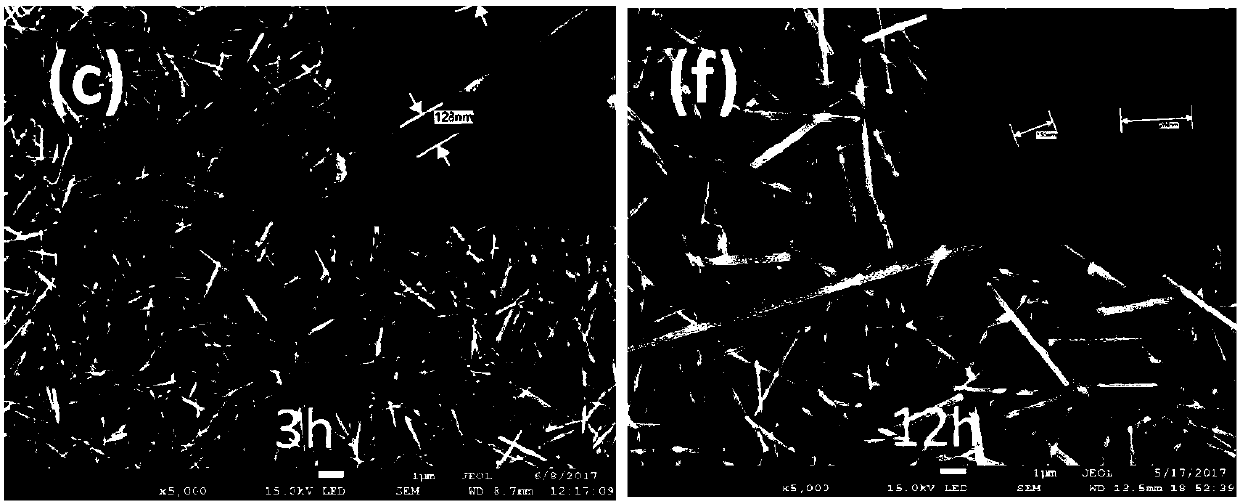

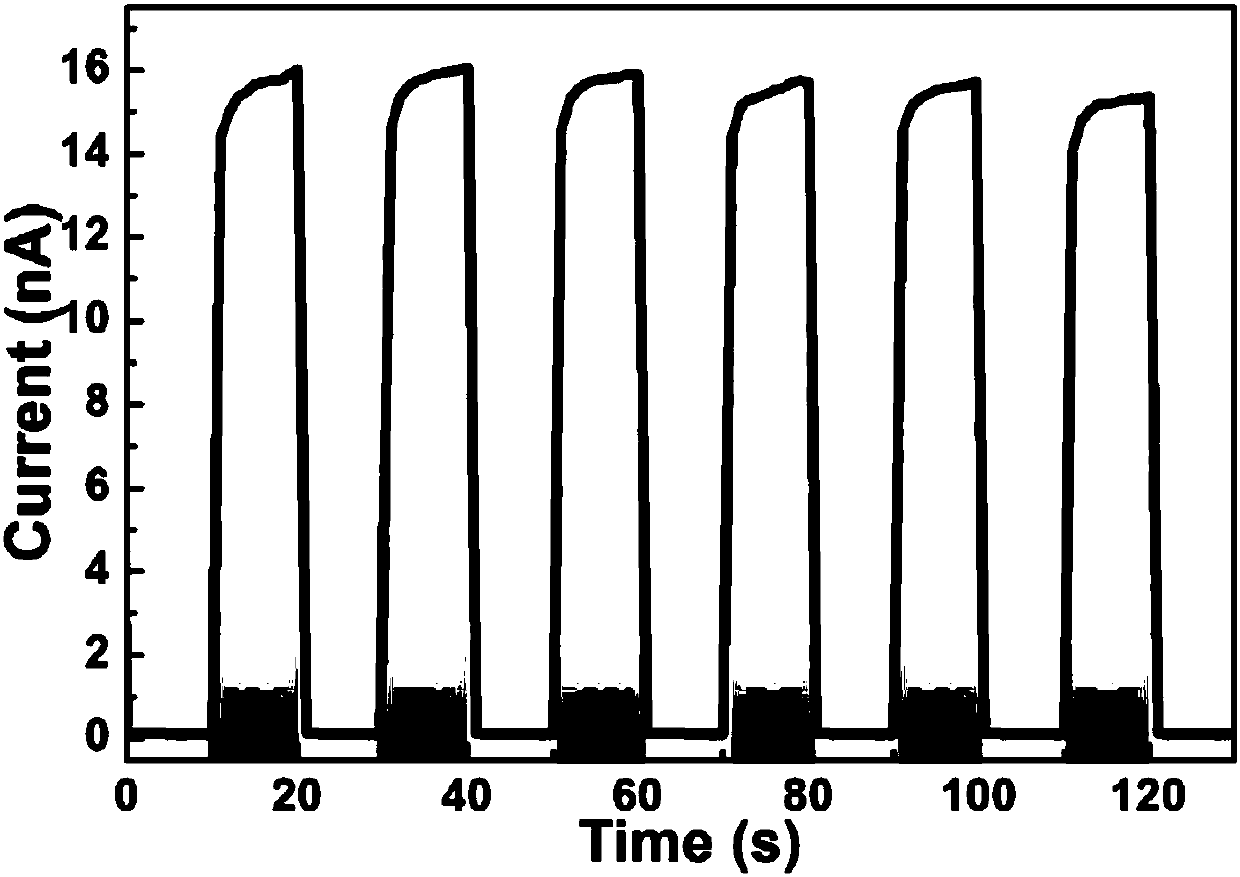

CsPbBr3 fully-inorganic perovskite nano wire based visible light photoelectric detector and preparation method thereof

InactiveCN107919409AStrong water and oxygen stabilityAttenuation of light and dark currentFinal product manufactureSemiconductor devicesManufacturing technologyIon exchange

The invention provides a CsPbBr3 fully-inorganic perovskite nano wire based visible light photoelectric detector and a preparation method thereof. The detector structurally comprises transparent glass, a CsPbBr3 perovskite nano wire film and Au, and the CsPbBr3 perovskite nano wire film synthesized in a soap-free solution method and an ion exchange method serves as a perovskite light absorption layer. The detector is high in on / off ratio and water and oxygen stability, and the photoelectric current attenuation amplitude is lower than 4.9% when the detector is placed in the atmospheric environment at the average temperature of 32 DEG C and the average relative humidity of 75% for 200h; light-dark current of the detector is not attenuated obviously after that the detector is irradiated continuously for 10000s by ultraviolet light in the intensity of 2.2mW cm<-2>; and the detector can detect visible light within the detection range of 300-540nm. The detector is simple in manufacturing technology, low in cost, and suitable for batch and industrialized production. The dark current of the detector is as low as 100pA, and energy can be saved. The prepared detector has higher responsibility and detection sensitivity.

Owner:HUBEI UNIV

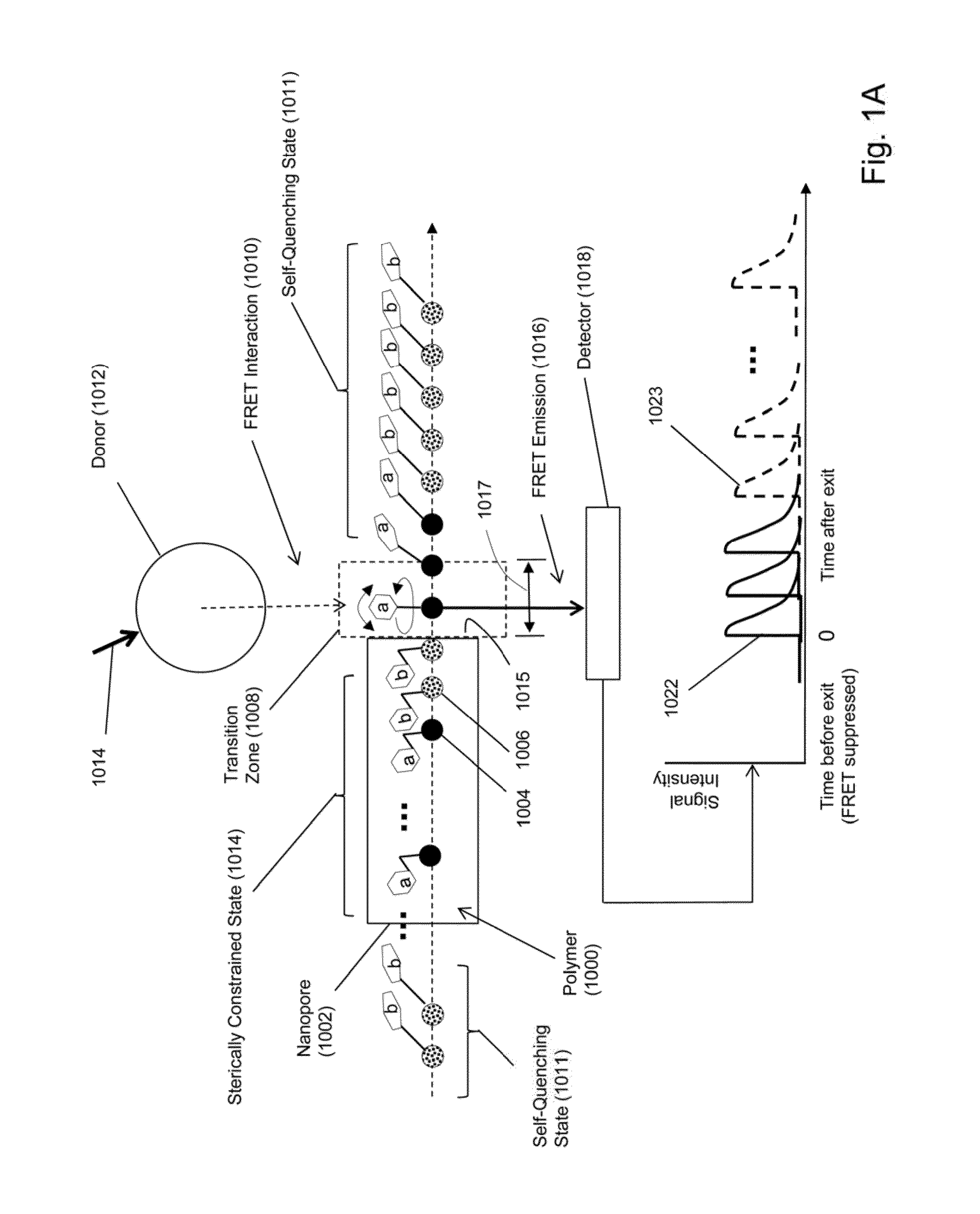

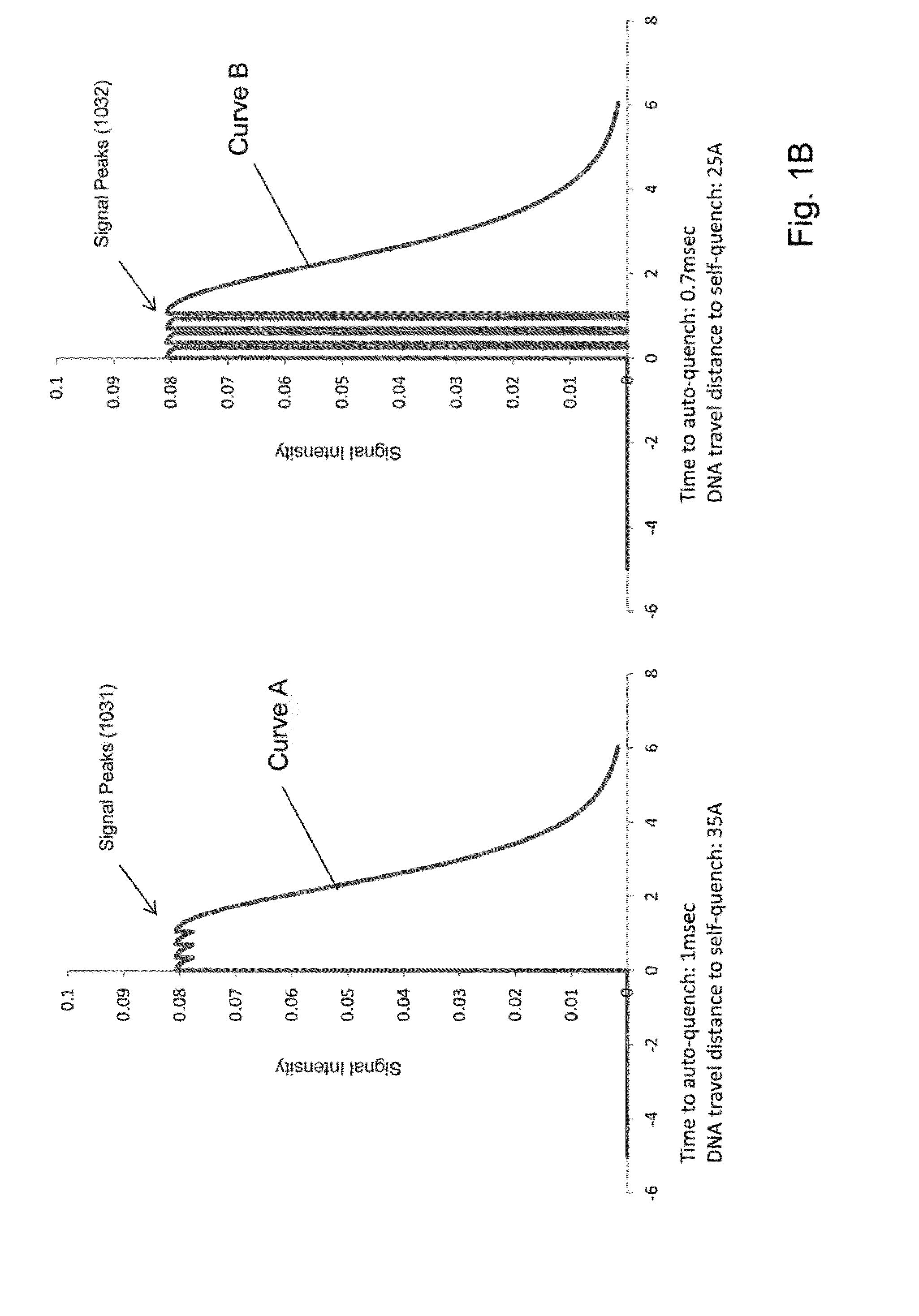

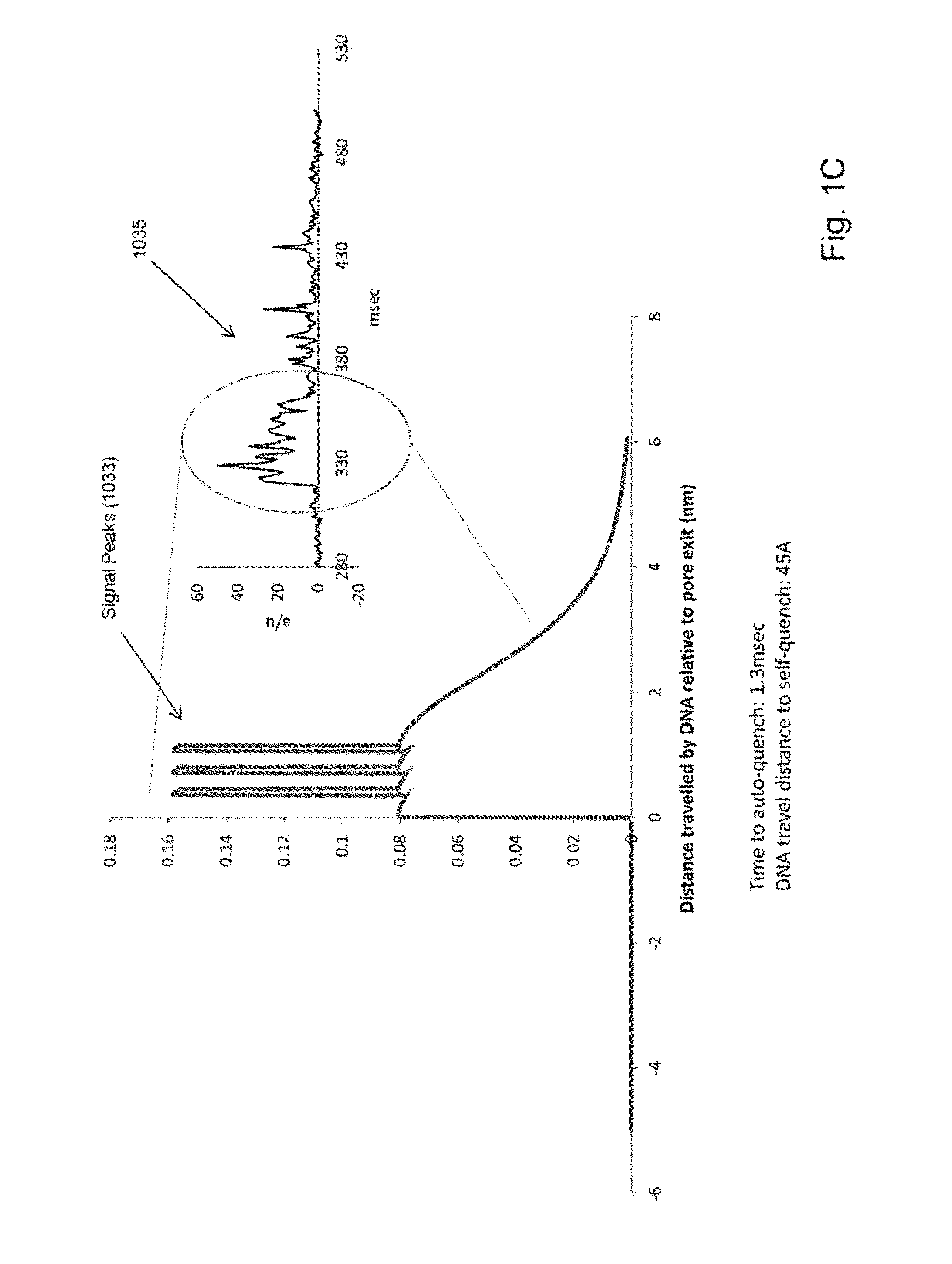

Nanopore-based polymer analysis with mutally-quenching fluorescent labels

ActiveUS20160122812A1Microbiological testing/measurementLibrary member identificationFluorescenceFree solution

The invention is directed to a method for determining a monomer sequence of a polymer that is translocated through a nanopore. Monomers of the polymer are labeled with fluorescent labels such that in free solution fluorescent labels of adjacent monomers substantially quench each other and wherein the nanopore constrains fluorescent labels within its bore into a constrained state wherein no detectable fluorescent signal can be generated. By exciting the fluorescent label of each monomer as it exits the nanopore and transitions from a constrained state to a quenched state with an adjacent fluorescent label, a fluorescent signal can be generated by the exiting fluorescent label that allows its monomer to be identified, thereby permitting a monomer sequence to be determined from a sequence of fluorescent signals as the polymer translocates through the nanopore.

Owner:QUANTAPORE

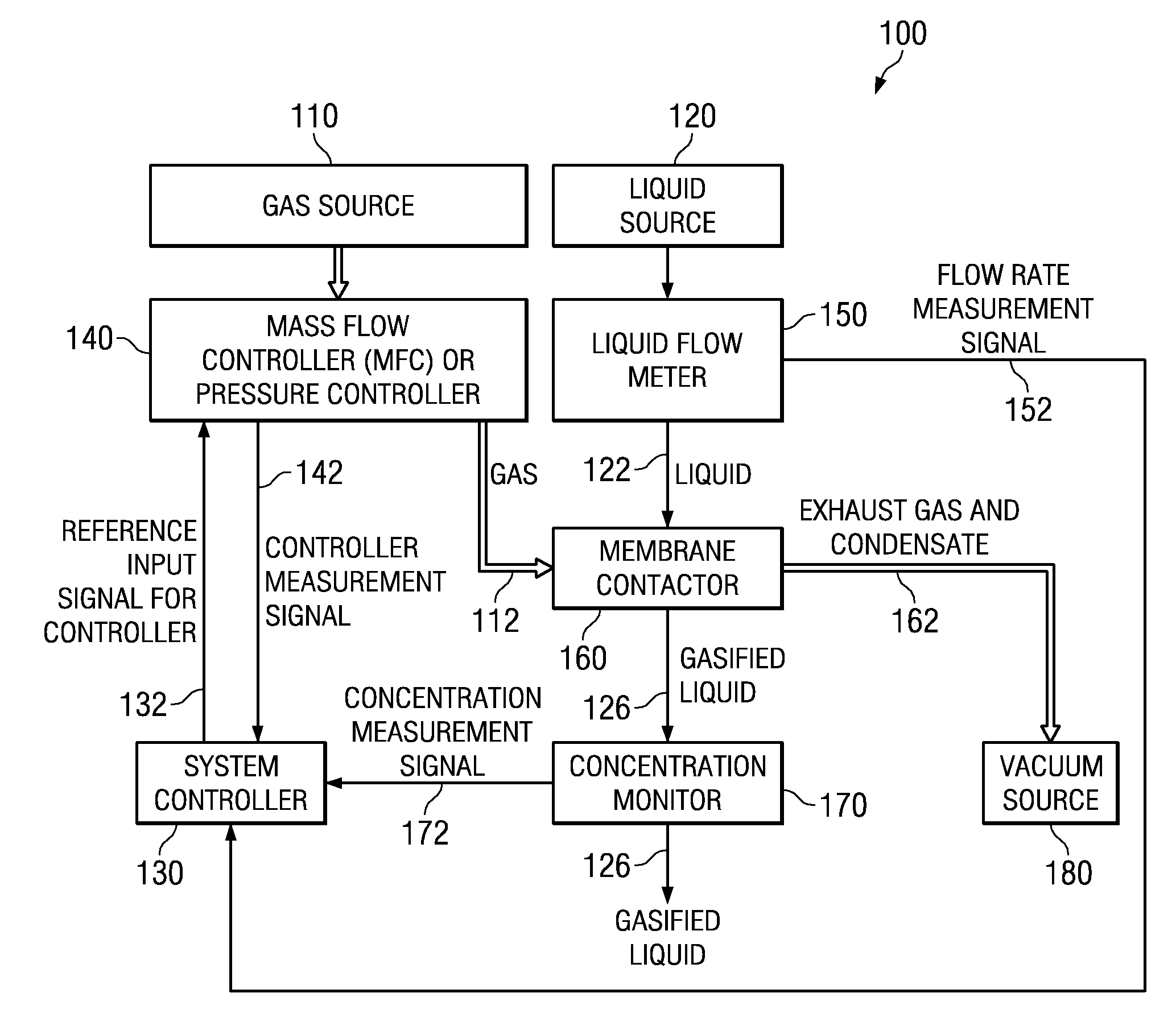

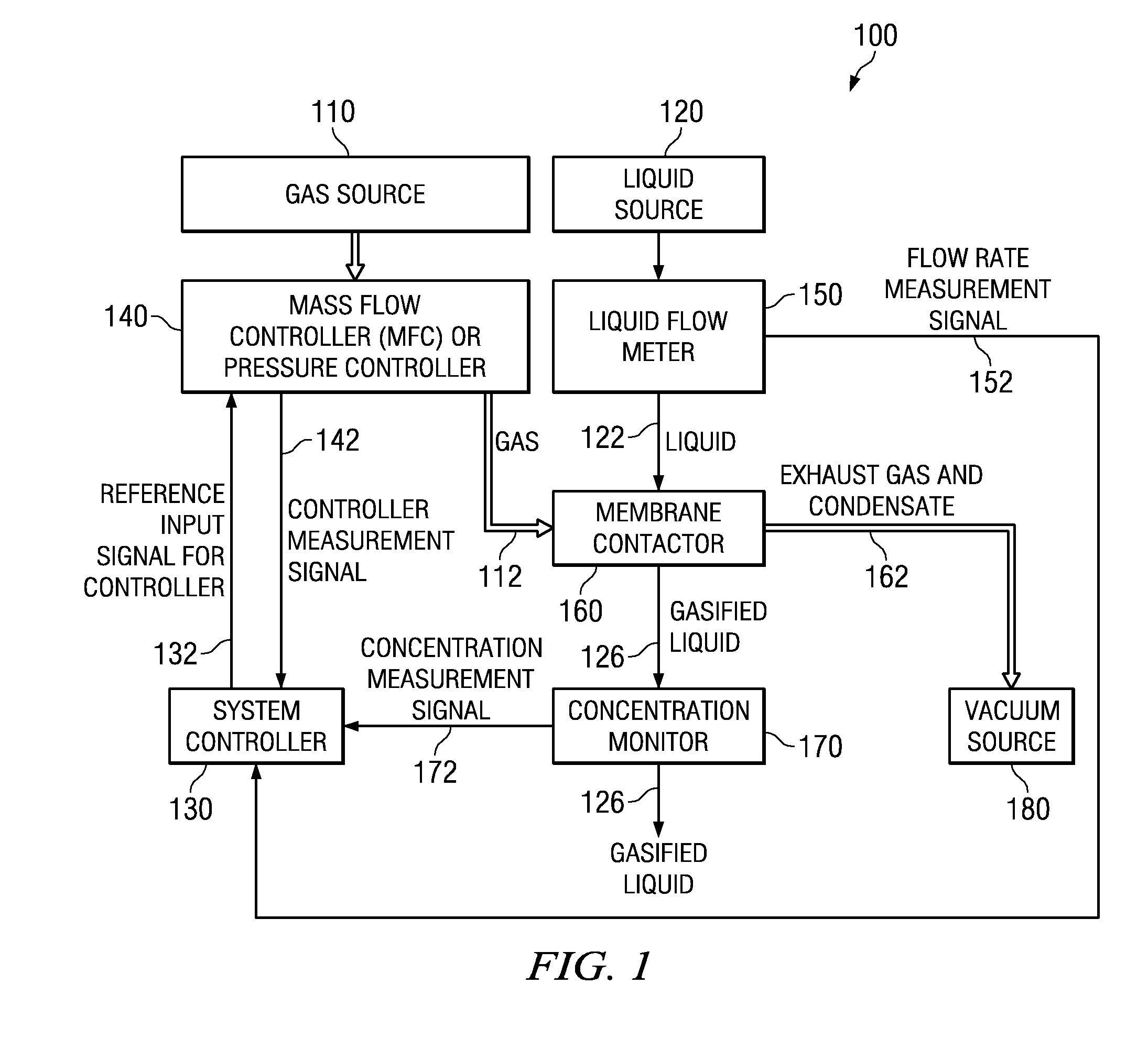

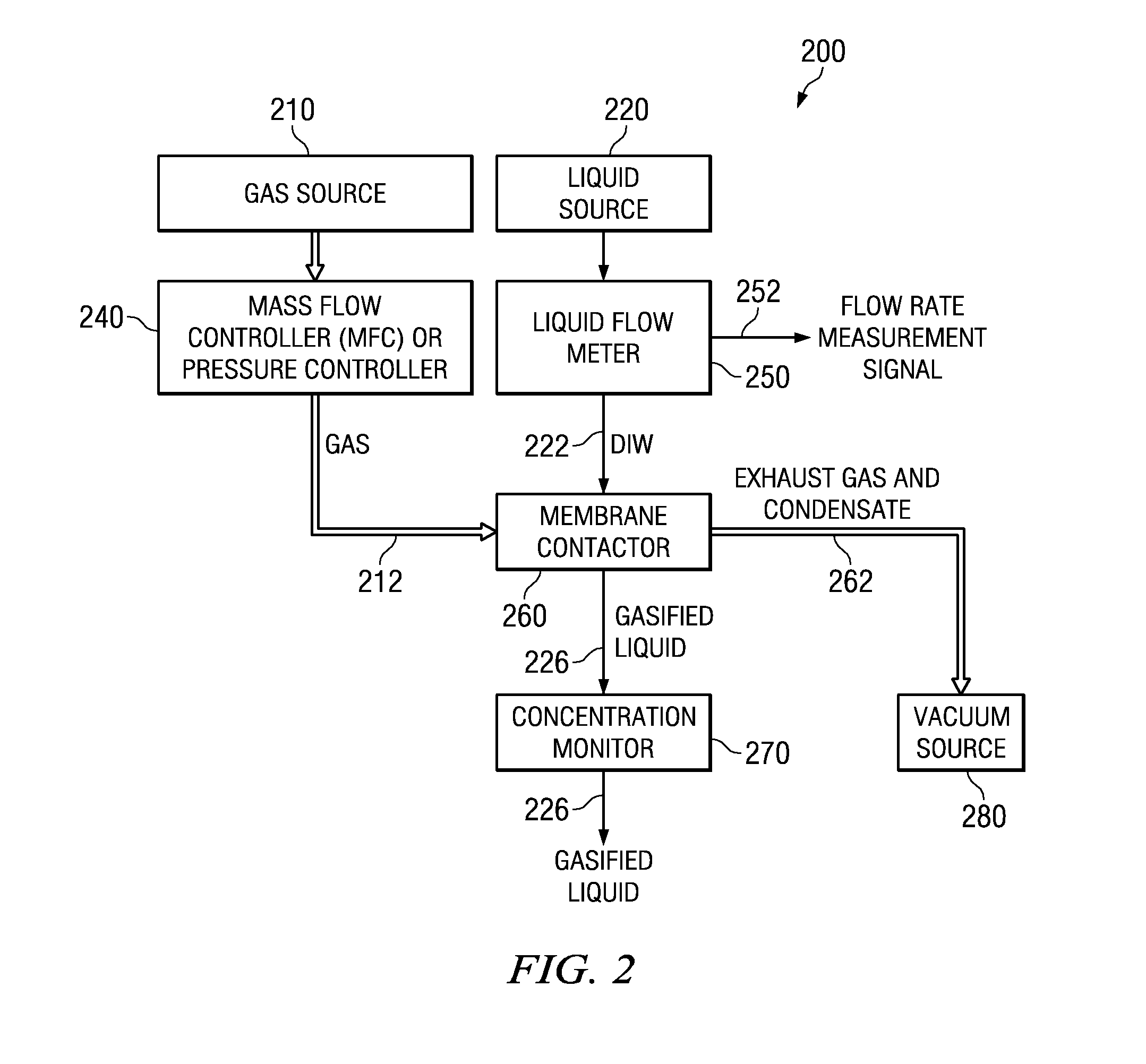

Gasification systems and methods for making bubble free solutions of gas in liquid

InactiveUS20110180148A1Low gas consumptionEliminate needLighting and heating apparatusMixing methodsFree solutionProduct gas

Embodiments disclosed herein can introduce low amounts of gas in a liquid with fast response time and low variation in concentration. In one embodiment, a gas is directed into an inlet on a gas contacting side of a porous element of a contactor and a liquid is directed into an inlet on a liquid contacting side of the porous element of the contactor. The liquid contacting side and the gas contacting side are separated by the porous element and a housing. The gas is removed from an outlet on the gas contacting side of the porous element at a reduced pressure compared to the pressure of the gas flowing into the inlet of the contactor. A liquid containing a portion of the gas transferred into the liquid is removed from an outlet on the liquid contacting side of the porous element, producing a dilute bubble free solution.

Owner:ENTEGRIS INC

Chromium-free solution for treating metal surfaces

InactiveUS20080254315A1Lower resistanceImprove corrosion resistancePretreated surfacesAnti-corrosive paintsChromium freeOrganic acid

An acidic chromium-free solution for treating a metal surface containing: a vanadium cation source and / or a vanadyl cation source; an organic acid as an anion source; and at least one oxoacid as another anion source is provided. The oxoacid is selected from oxoacids of nitrogen, sulfur, phosphorus, boron, and chlorine. A metal component composed of, for example, aluminum or magnesium is brought into contact with the chromium-free solution to form a vanadium coating film of a surface of the metal component. A surface treating process using this chromium-free solution is useful for formation of a coating film having low corrosion resistance and low electric resistance.

Owner:NIPPON HYOMEN KAGAKU KK

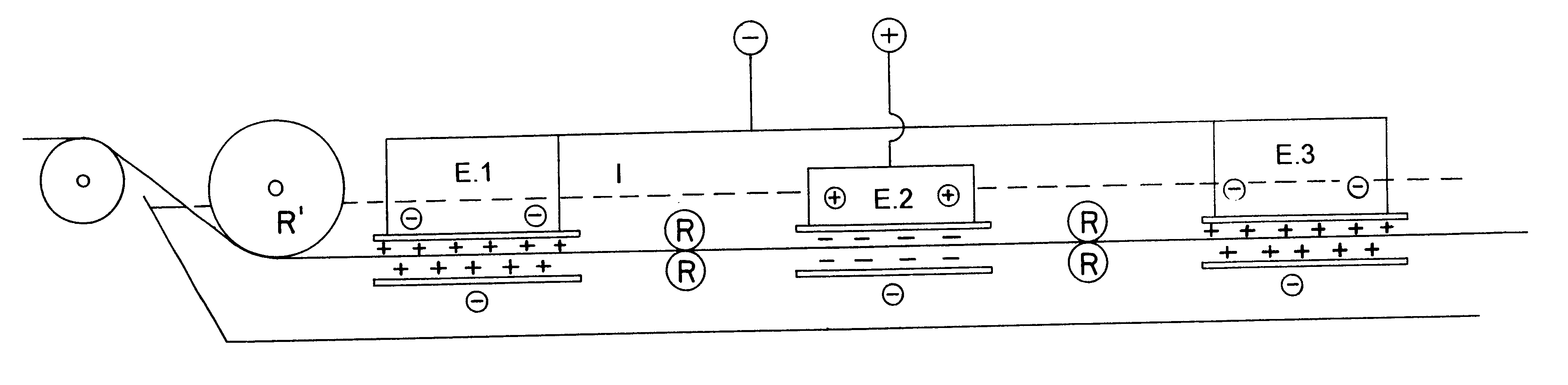

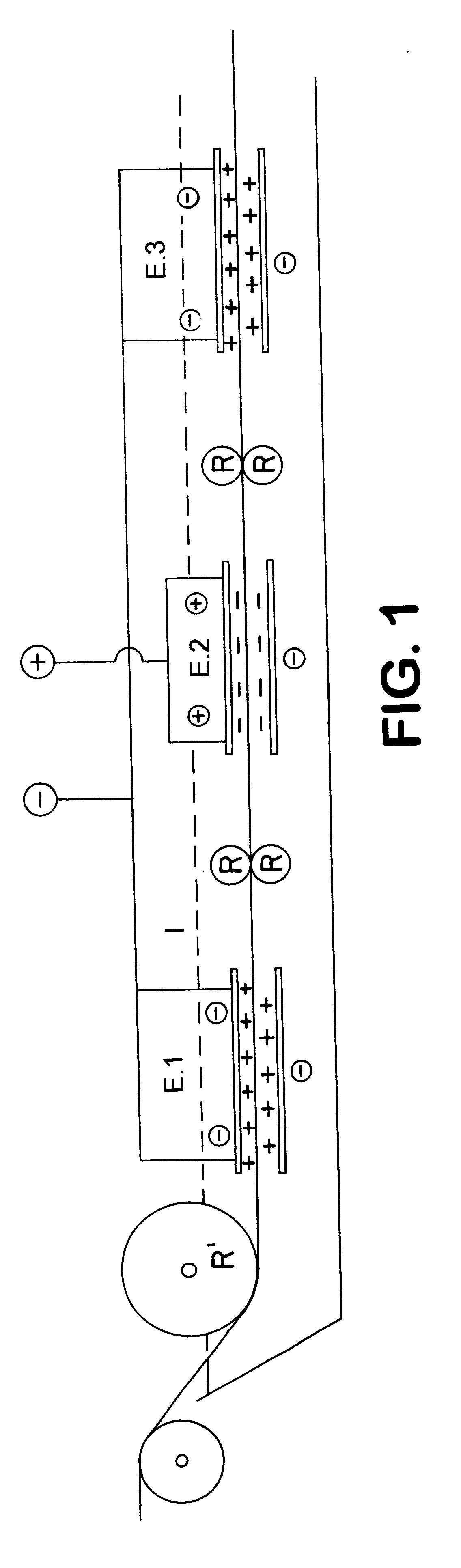

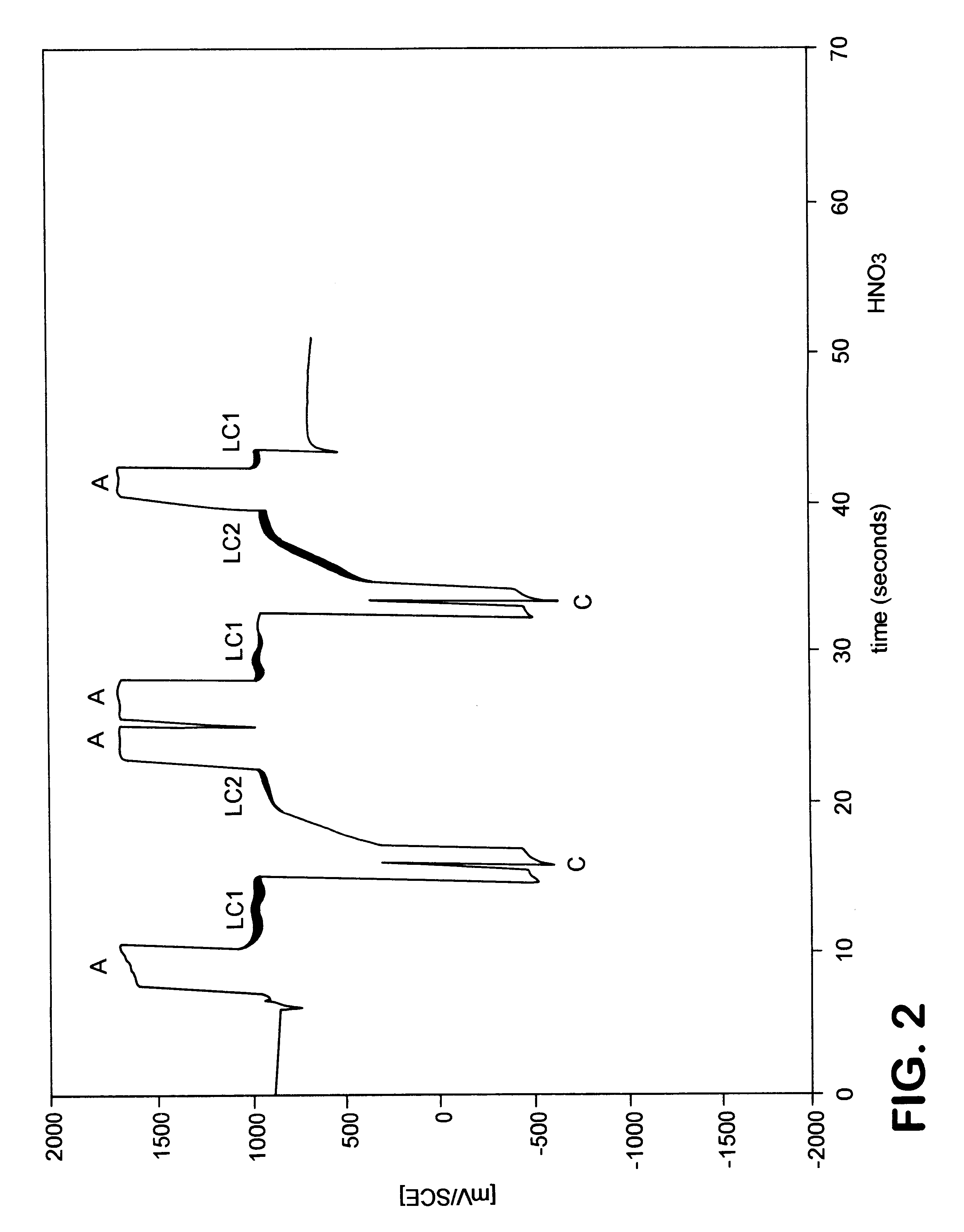

Process for electrolytic pickling using nitric acid-free solutions

A process for electrolytic pickling of stainless steel of the ferritic, martensitic, austenitic and duplex series as well as superaustenitic and superferritic steels, nickel or Ni / Cr-based super alloys, and titanium and its alloys is provided. The process utilizes an electrolytic pickling solution containing H2SO4 in a concentration of from 20 to 140 g / l and Fe3+ ions in a concentration of from 15 to 80 g / l, the Fe2+ ions being present a quantity corresponding to a Fe3+ / Fe2+ ratio of >1 and preferably >3.

Owner:ACCIAI SPECIALI TERNI SPA +1

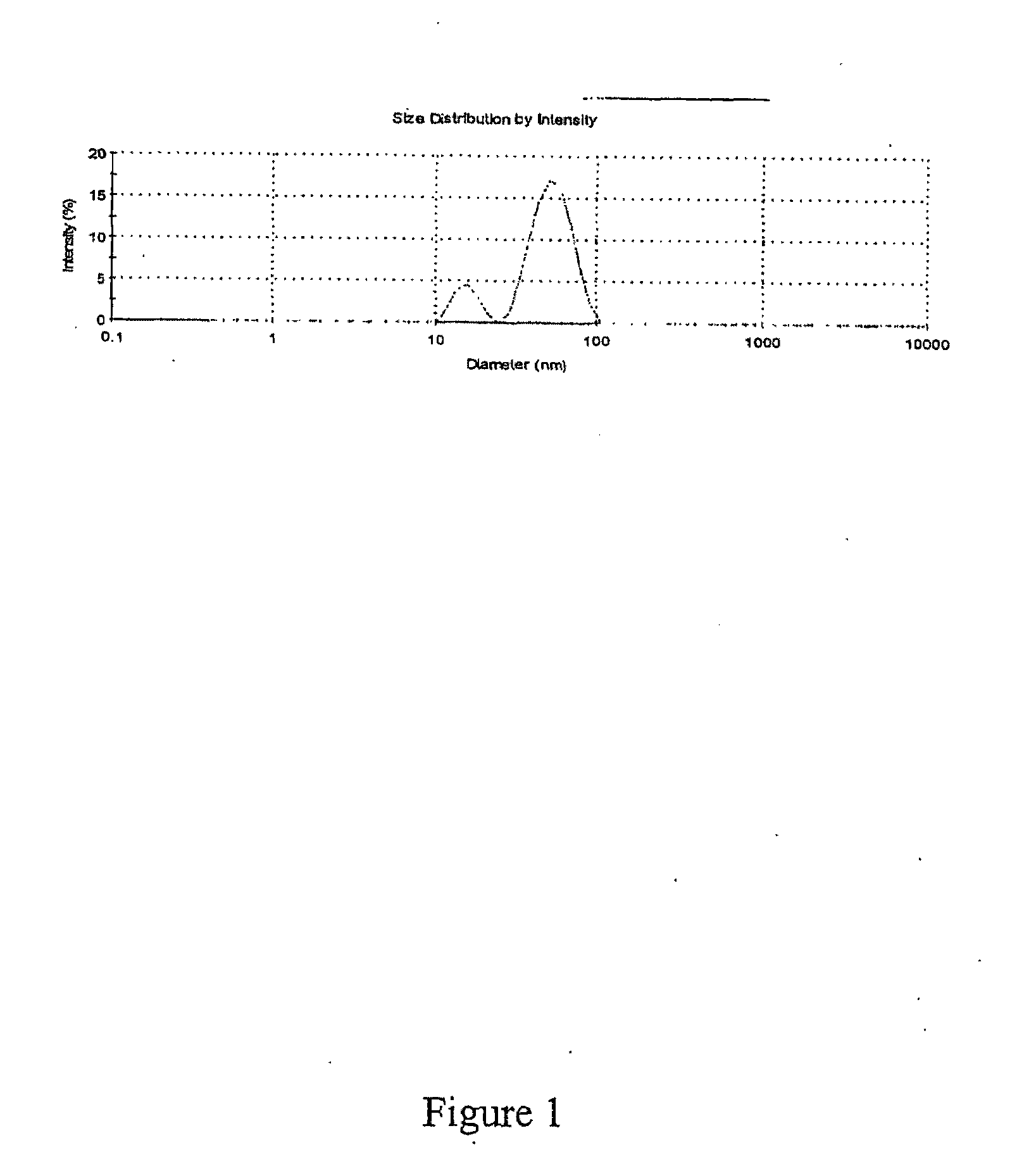

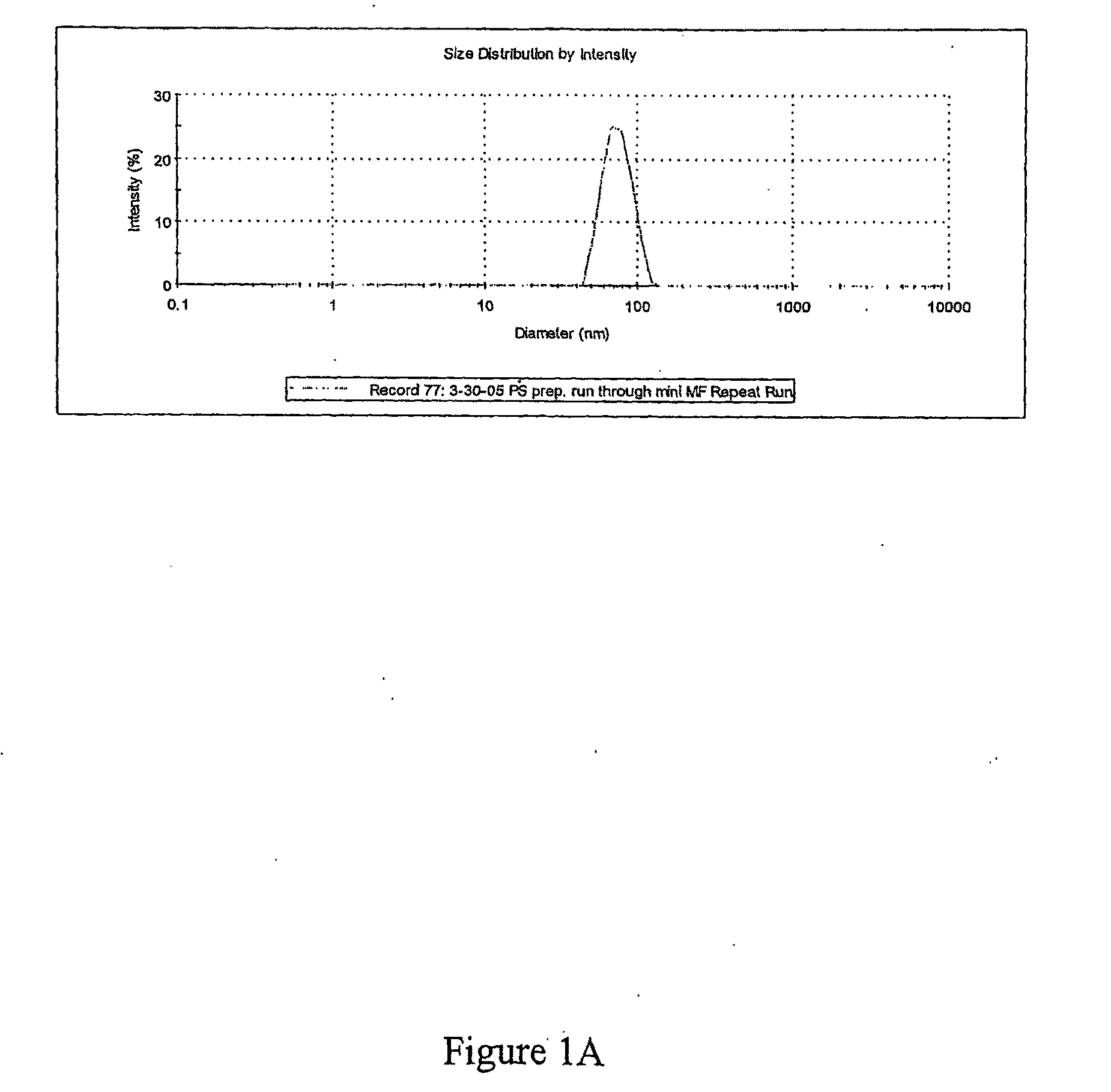

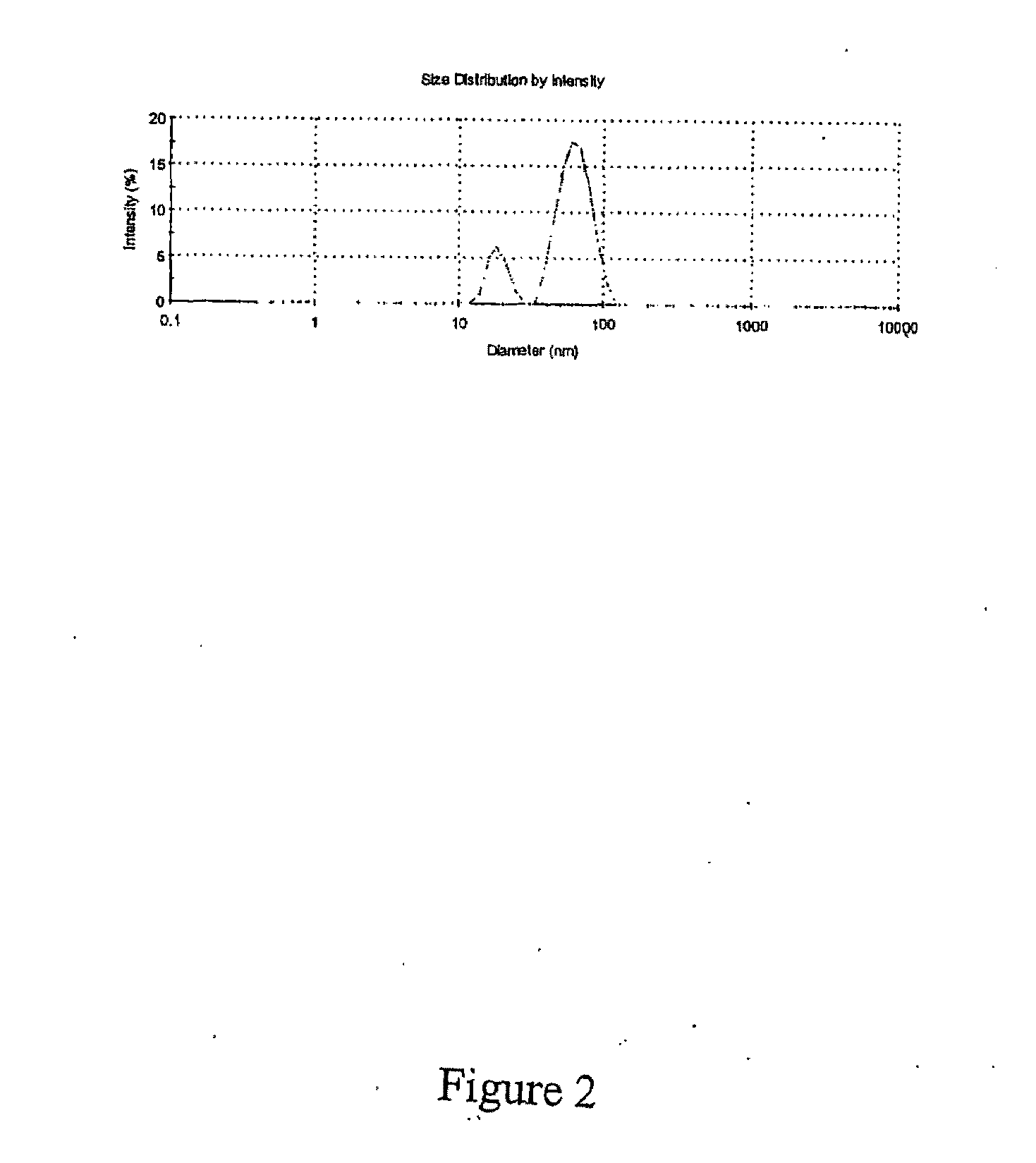

Anti-Oxidant Synergy Formulation Nanoemulsions to Treat Caner

A uniform microfluidized nanoemulsion is disclosed containing a synergistic combination of two antioxidants and a cell membrane stabilizer phospholipid (i.e., an anti-oxidant synergy formulation; ASF). The microfluidized nanoemulsion improves the combination's cell membrane permeability by at least four-fold over conventional nanoemulsion compositions, which significantly increases the intracellular concentration of typically cell-impermeant antioxidants (i.e., for example, tocopherol) and / or systemic bioavailability. As a nanoemulsion, synergistic combination has greater anticancer efficacy than the same combination applied as a free solution.

Owner:UNIV OF MASSACHUSETTS

Highly Concentrated Stable Meloxicam Solutions for Needleless Injection

A method for treating pain, inflammation, fever and respiratory complaints in mammals comprising administering by needleless injection to a mammal in need of such treatment an aqueous cyclodextrin-free solution of meloxicam containing a pharmacologically acceptable meloxicam salt of an organic or inorganic base.

Owner:BOEHRINGER LNGELHEIM VETMEDICA GMBH

Highly concentrated stable meloxicam solutions

Aqueous cyclodextrin-free solution of meloxicam for administration by oral or parenteral route, containing a pharmacologically acceptable meloxicam salt of an organic or inorganic base and one or more suitable excipients, the content of dissolved meloxicam salt being more than 10 mg / mL. The formulation according to the invention has a shelf-life of up to 24 months or more.

Owner:BOEHRINGER LNGELHEIM VETMEDICA GMBH

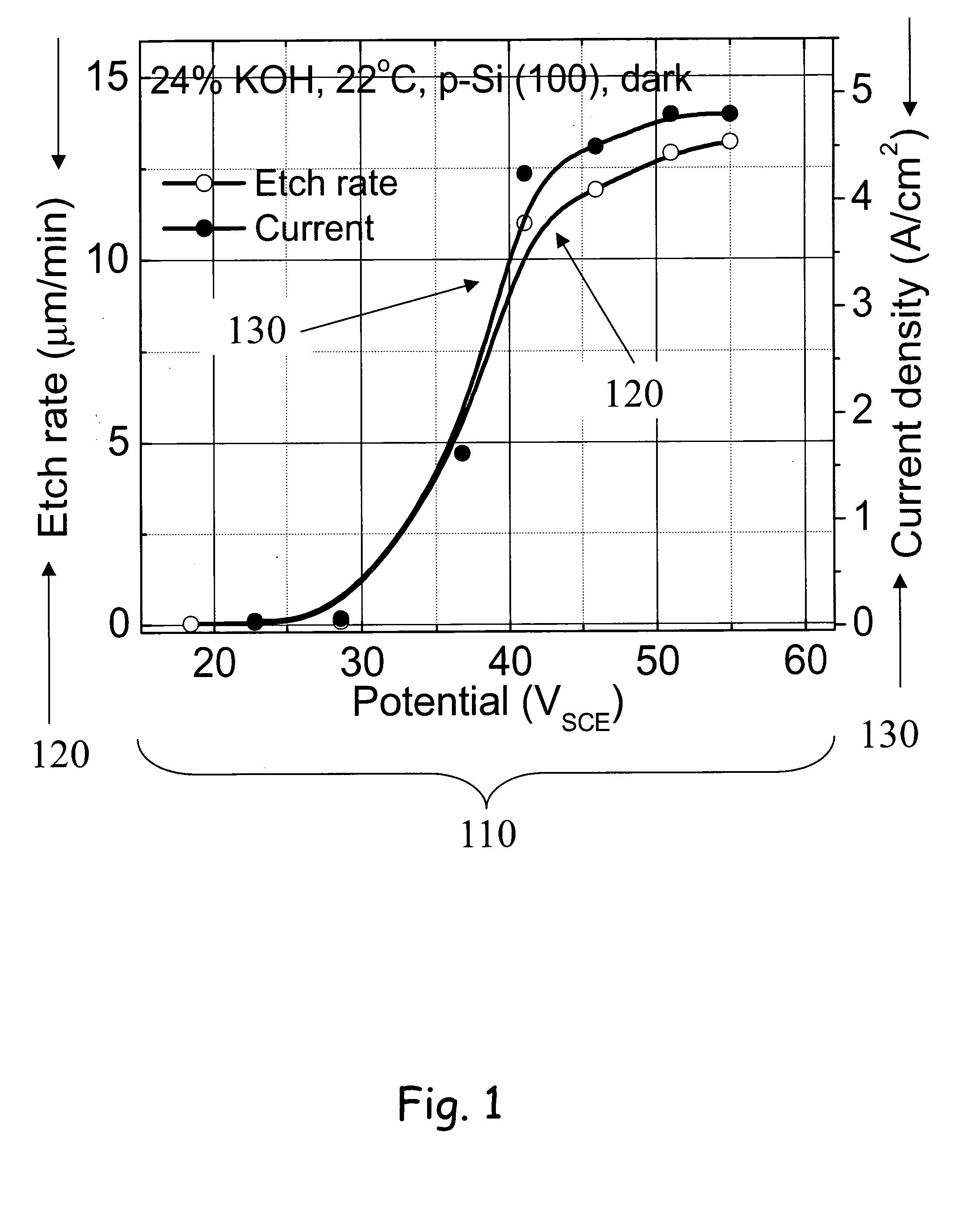

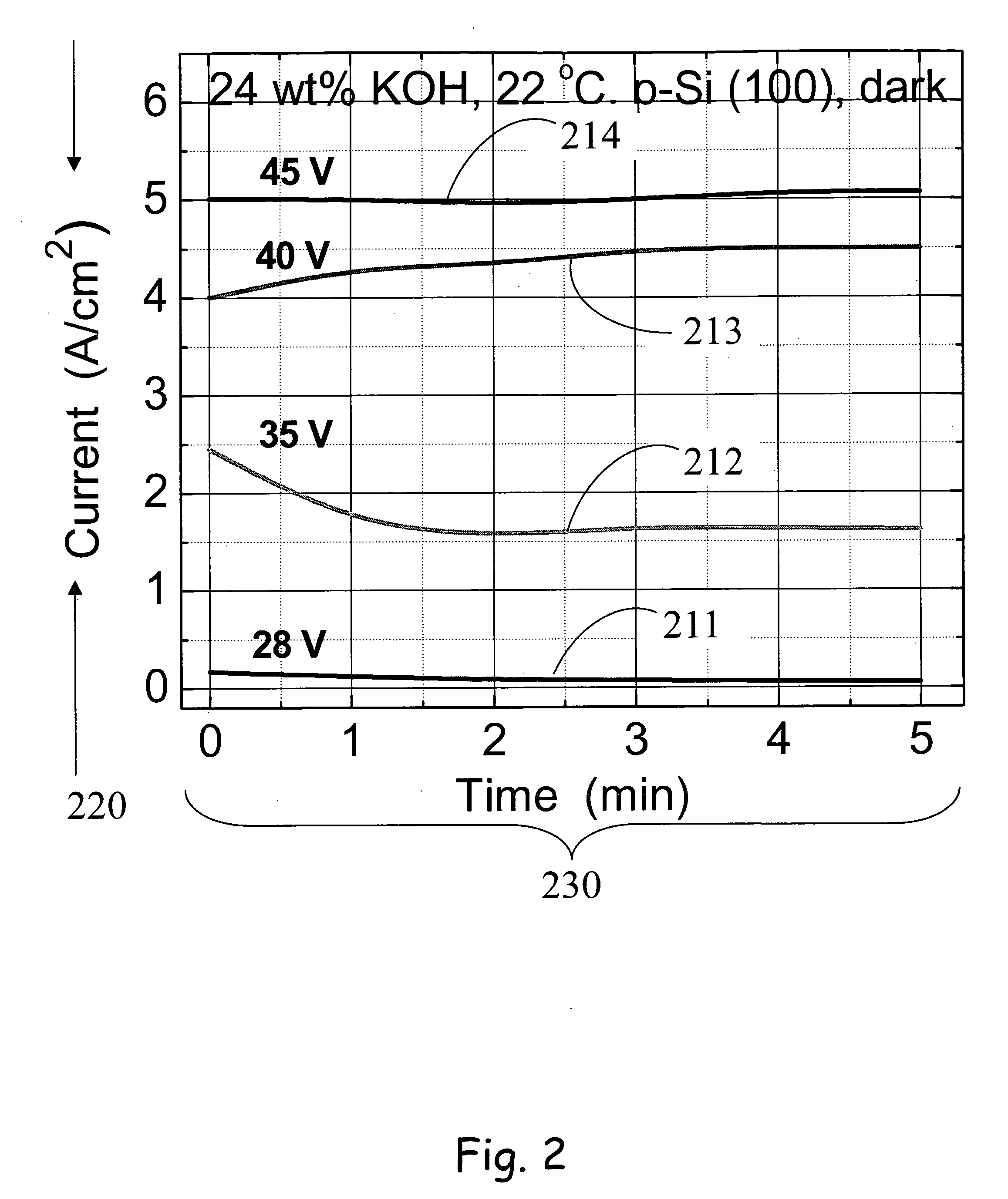

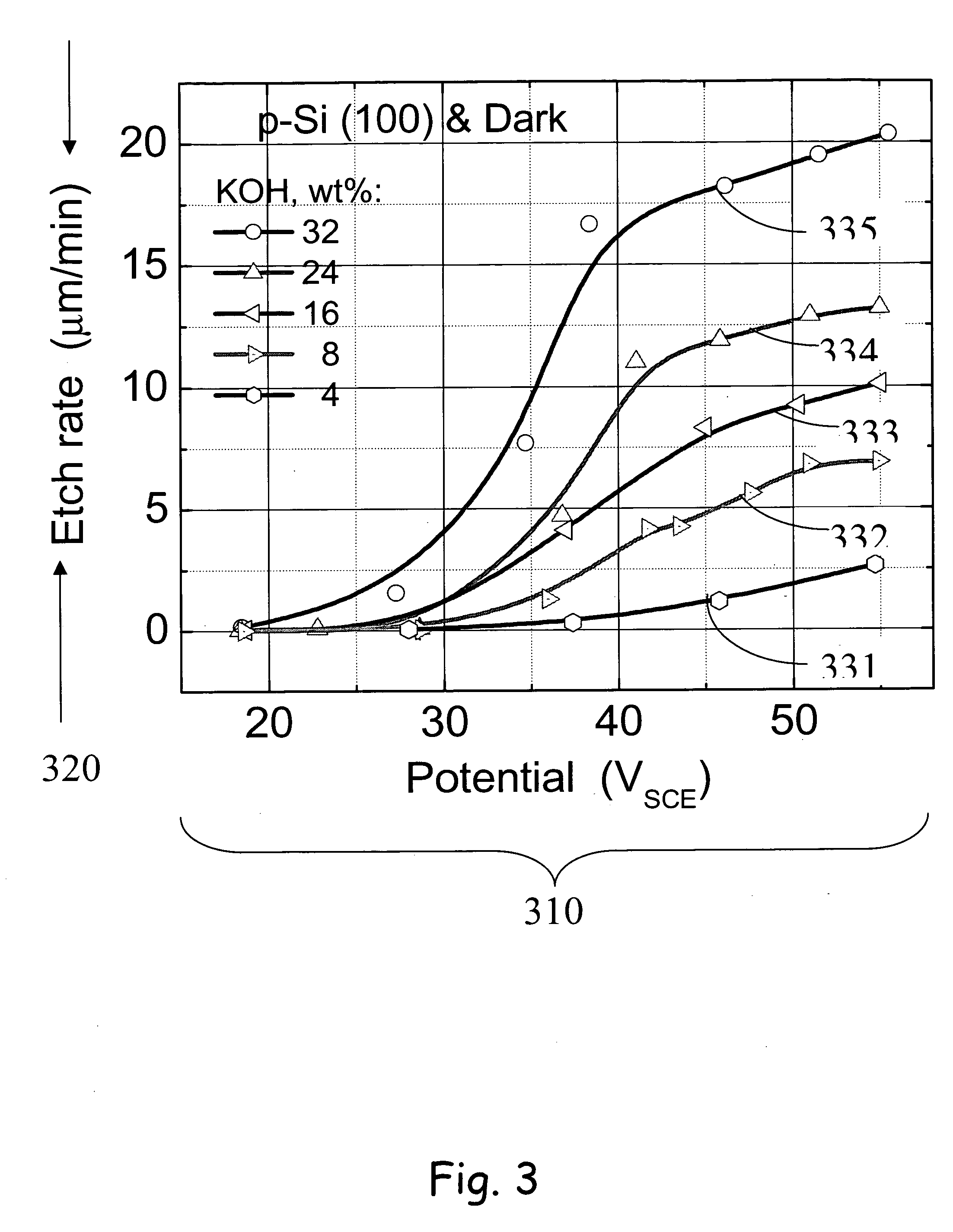

Method for electrochemical etching of semiconductor material using positive potential dissolution (PPD) in HF-free solutions

InactiveUS20060254928A1Fast etchSimple and inexpensive stepCellsSemiconductor/solid-state device manufacturingHydrofluoric acidSemiconductor materials

A method for electrochemical etching of a semiconductor material using positive potential dissolution (PPD) in hydrofluoride (HF)-free solutions. The method includes subjecting one of: a polished material; and an as-cut semiconductor material to an etching solution. The method also includes positive biasing at atypically highly positive (anodic) potentials. The specifically controlled and directed illumination of the positively biased semiconductor material surface contacted and wetted by the etching solution significantly increases the value of the anodic current density (A / cm2) of the semiconductor material. The application of positive biasing at atypically highly positive (anodic) potentials, is combined with specifically controlling and directing illumination by light of the semiconductor material surface contacted and wetted by the etching solution. This is done for a necessary and sufficient period of time to enable a positive synergistic effect on the rate and extent of etching of the semiconductor material, and that formed therefrom.

Owner:TECHNION RES & DEV FOUND LTD

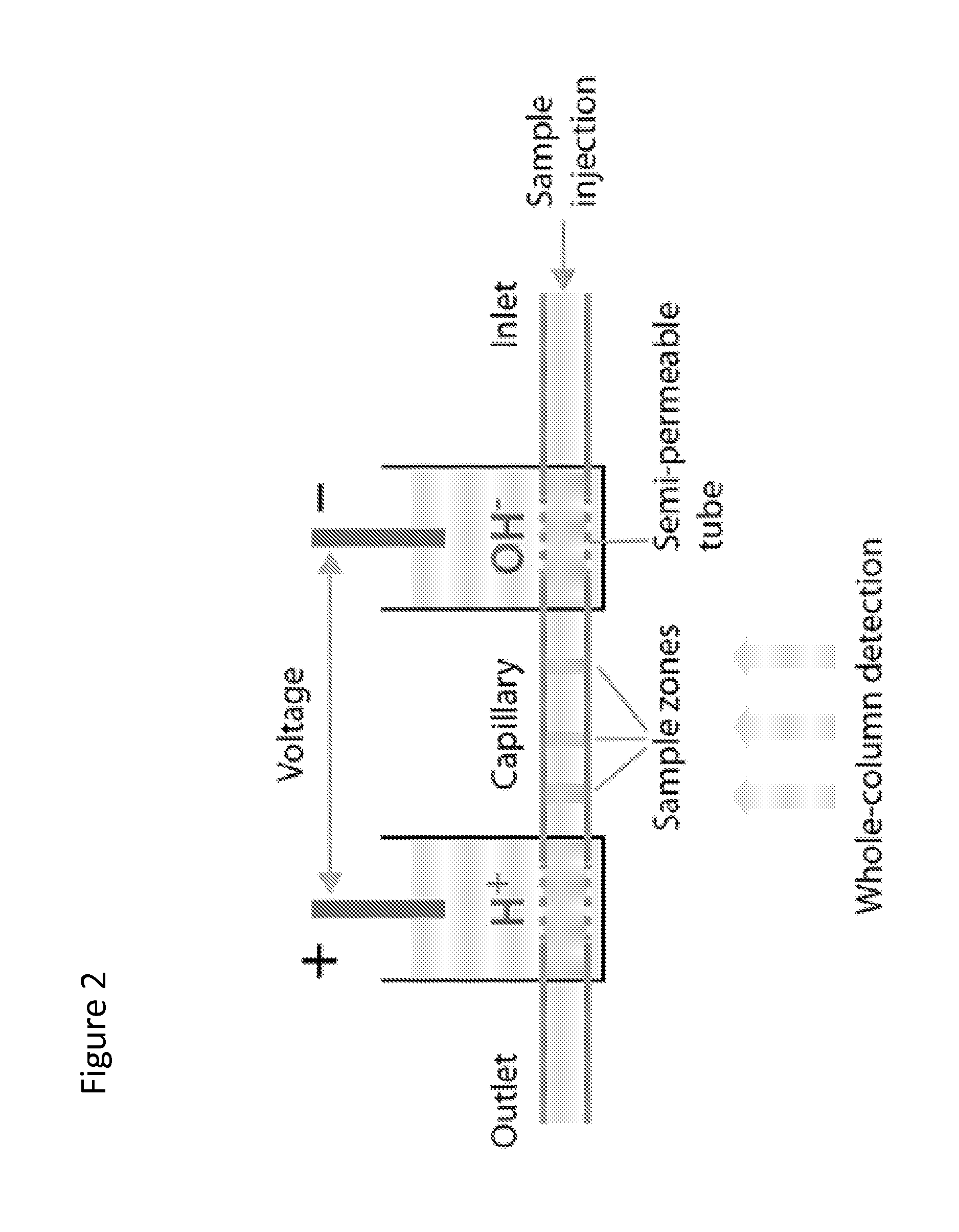

Dual wavelength isoelectric focusing for determining drug load in antibody drug conjugates

ActiveUS20130280815A1High net chargePharmaceutical non-active ingredientsColor/spectral properties measurementsFree solutionLength wave

Provided herein are IEF focusing methods for determining the number of drug molecules present in at least one antibody-drug conjugate (ADC) species subpopulation. In one embodiment, the method comprises performing free solution isoelectric focusing on a sample comprising at least one ADC species, to obtain a focused sample. The absorbance of the sample at two different wavelengths is then measured, for example, over a range of pI values. Absorbance values at the two different wavelengths are compared at at least one corresponding pI value, where the at least one corresponding pI value is the pI of the ADC subpopulation. The number of drug molecules in the at least one ADC species subpopulation is then determined based on the comparison. The methods provided herein can also be used to determine the number of specific binding pair members bound to its target specific binding pair member.

Owner:PROTEINSIMPLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com