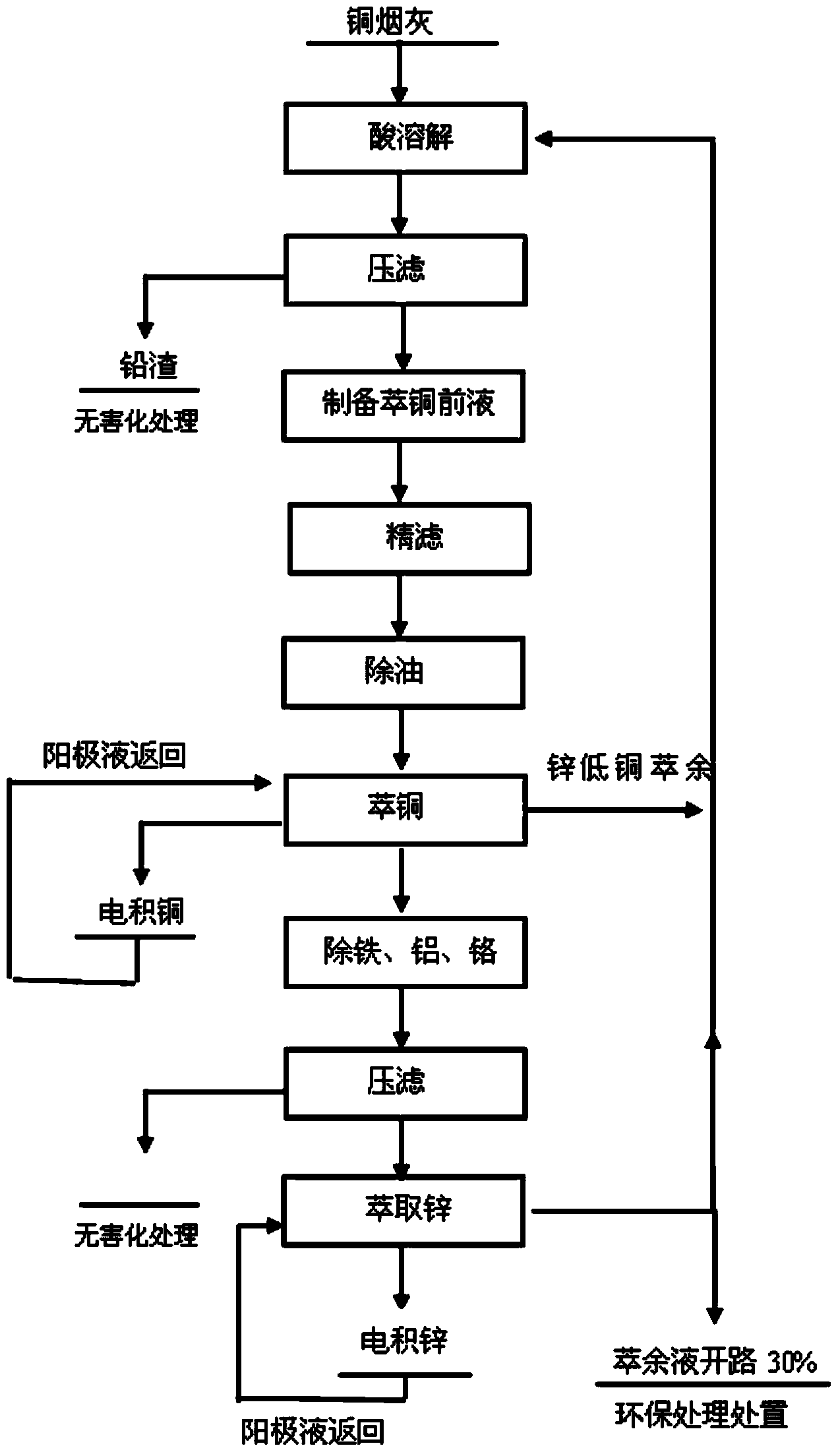

Technology for directly extracting copper and zinc by using copper dust wet method

A copper soot and copper extraction technology, applied in the direction of improving process efficiency, etc., can solve the problems of low added value of products, high price of zinc powder, and large damage to the furnace body, etc., and achieve high added value of products, low cost, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Copper soot Cu6.27%, Zn12.39%. Normal temperature 20°C, sulfuric acid leaching, solid-liquid ratio 1:2.5, leaching process beating for 30 minutes, reaction time 2 hours, sulfuric acid dosage by weight is 0.18 times the weight of copper soot. Vacuum suction filtration is performed after leaching, and the filter residue is washed with warm water at 30-40°C. The copper leaching rate was 62.94%, the zinc leaching rate was 90.55%, and the slag rate was 32.5%. The filtrate was adjusted to pH 3.0 with 15% soda ash, and vacuum-filtered twice with two layers of filter paper to obtain a clear and transparent solution. Take 100ml of N902 and 400ml of 260# kerosene, mix them evenly, and prepare the extracted organic phase. Use a 125ml separatory funnel as a reactor for single-stage copper extraction. The flow ratio of the organic phase to the liquid is 2:1. The extraction mixing time is 5 minutes, and the extraction and clarification time is 3 minutes. Pre-extraction solution Cu...

Embodiment 2

[0042] Copper soot Cu6.27%, Zn12.39%. Temperature 44°C, sulfuric acid leaching, adding oxidant sodium chlorate, solid-to-liquid ratio 1:2.5, beating for 30 minutes during leaching, reaction time 2 hours, the amount of sulfuric acid by weight is 0.24 times the weight of copper soot, chloric acid by weight The amount of sodium used is 0.007 times the weight of copper soot. Vacuum suction filtration is performed after leaching, and the filter residue is washed with warm water at 30-40°C. The copper leaching rate is 98.01%, and the slag rate is 13.25%. The filtrate was adjusted to pH 3.0 with 15% soda ash, and vacuum-filtered twice with two layers of filter paper to obtain a clear and transparent solution. Take 75ml of N902 and 425ml of 260# kerosene, mix them evenly, and prepare the extracted organic phase. Use a 125ml separatory funnel as a reactor for single-stage copper extraction. The flow ratio of the organic phase to the liquid is 3:1. The extraction mixing time is 5 min...

Embodiment 3

[0044]Copper soot Cu6.27%, Zn12.39%. Temperature 50°C, sulfuric acid leaching, add oxidant sodium chlorate, solid-to-liquid ratio 1:2, leaching process beating for 30 minutes, reaction time 4 hours, the amount of sulfuric acid by weight is 0.23 times the weight of copper soot, chloric acid by weight The dosage of sodium is 0.01 times of the weight of copper soot. Vacuum suction filtration is performed after leaching, and the filter residue is washed with warm water at 35-40°C. The copper leaching rate was 97.02%, and the slag rate was 19.11%. The filtrate was adjusted to pH 3.5 with 15% soda ash, and vacuum-filtered twice with two layers of filter paper to obtain a clear and transparent solution. Take 100ml of N902 and 400ml of 260# kerosene, mix them evenly, and prepare the extracted organic phase. Use a 125ml separatory funnel as a reactor for single-stage copper extraction. The flow ratio of the organic phase to the liquid is 2:1. The extraction mixing time is 5 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com