Patents

Literature

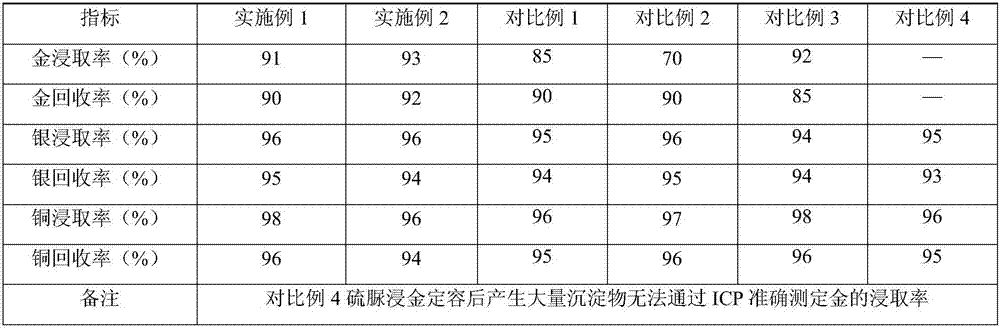

189 results about "Copper leaching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In ore leaching, on the other hand, copper is being constantly removed from the electrolyte, and the latter has to be returned to the ore for a fresh supply. It is manifest, therefore, that conditions differ essentially in the two operations and the premises seem to call for modifications of the apparatus used.

Leadless welding flux

InactiveCN1496780AAvoid leachingSmall diameterHot-dipping/immersion processesWelding/cutting media/materialsMolten stateCopper wire

lead-free solder which is significantly less susceptible to copper leaching when used in a molten state in which coil ends of copper wire are dipped comprises 1.5-8 mass % of Cu, 0.01-2 mass % of Co, optionally 0.01-1 mass % of Ni, and a remainder of Sn and has a liquidus temperature of 420 DEG C. or below. The solder may further comprise at least one oxidation-inhibiting element selected from the group consisting of P, Ge, and Ga in a total amount of 0.001-0.5 mass %, and / or Ag in an amount of 0.05-2 mass % as a wettability-improving element.

Owner:SENJU METAL IND CO LTD

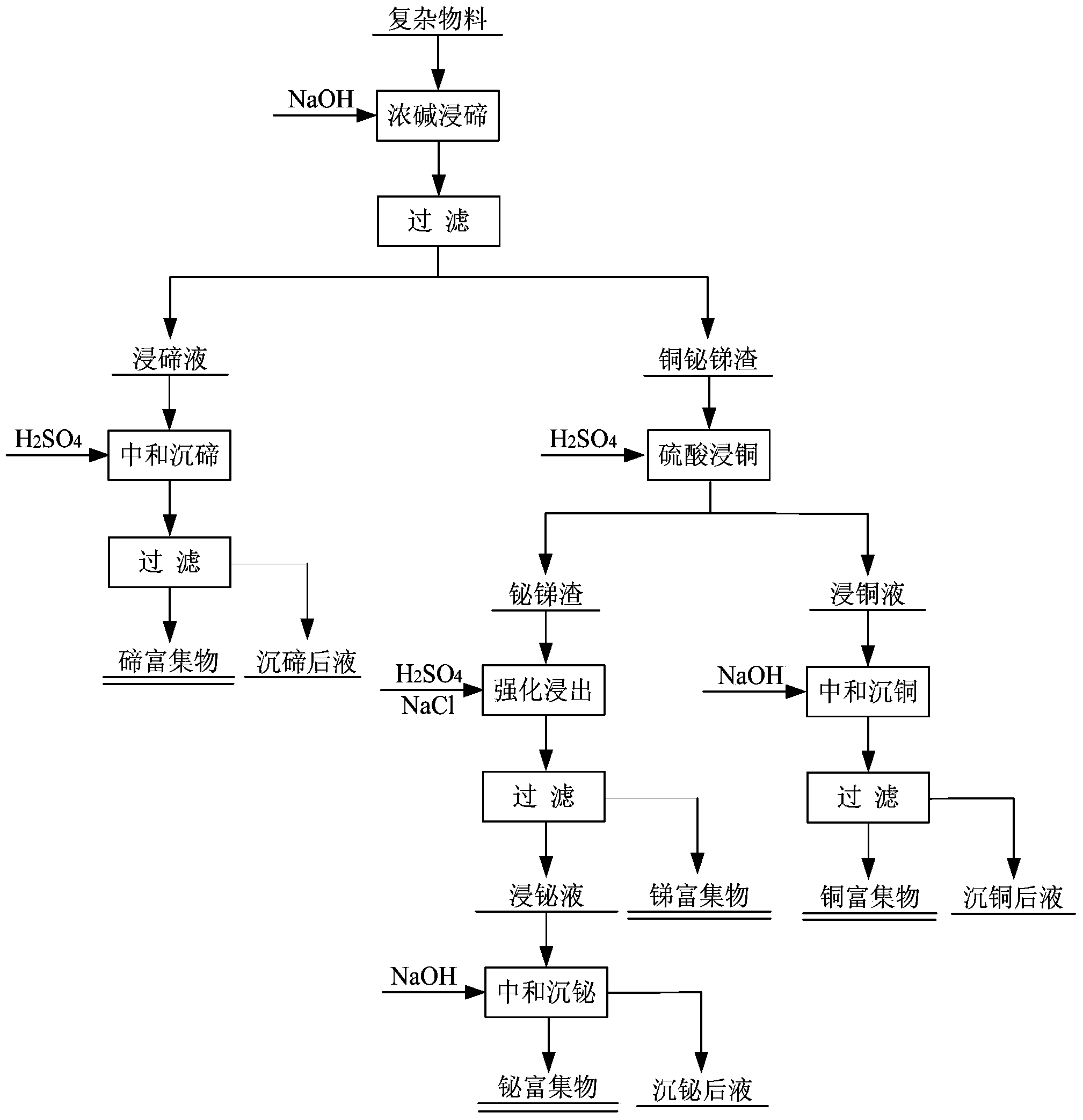

Method for recovering tellurium, bismuth, antimony, and copper from complex material

The invention aims at providing a method for recovering tellurium, bismuth, antimony, and copper from a complex material. The method comprises the steps that: the complex material is added into a sodium hydroxide solution according to a solid-liquid ratio; a temperature and a stirring time are controlled; when a reaction is finished, bismuth, antimony and copper slag and tellurium leaching liquid are obtained; the pH of the tellurium leaching liquid is regulated by adding dilute sulfuric acid; the mixture is settled and is subjected to solid-liquid separation, such that tellurium enrichment is obtained; the bismuth, antimony and copper slag is added into a dilute sulfuric acid solution according to a solid-liquid ratio; a reaction is sufficiently carried out, such that bismuth and antimony slag and copper leaching liquid are obtained; the solution temperature of the copper leaching liquid is controlled, and NaOH is added for precipitating copper; according to a solid-liquid ratio, the bismuth and antimony slag is added into a mixed solution of sulfuric acid and sodium chloride; the mixture is violently stirred, such that bismuth-antimony separation is realized; NaOH is used for regulating solution pH value and for precipitating bismuth; when the reaction is completed, bismuth enrichment and bismuth-precipitated liquid are obtained. With the technical scheme provided by the invention, tellurium, bismuth, antimony, and copper valuable metals can be comprehensively recovered from the complex material, such that waste is turned into valuable matters.

Owner:JIANGXI COPPER

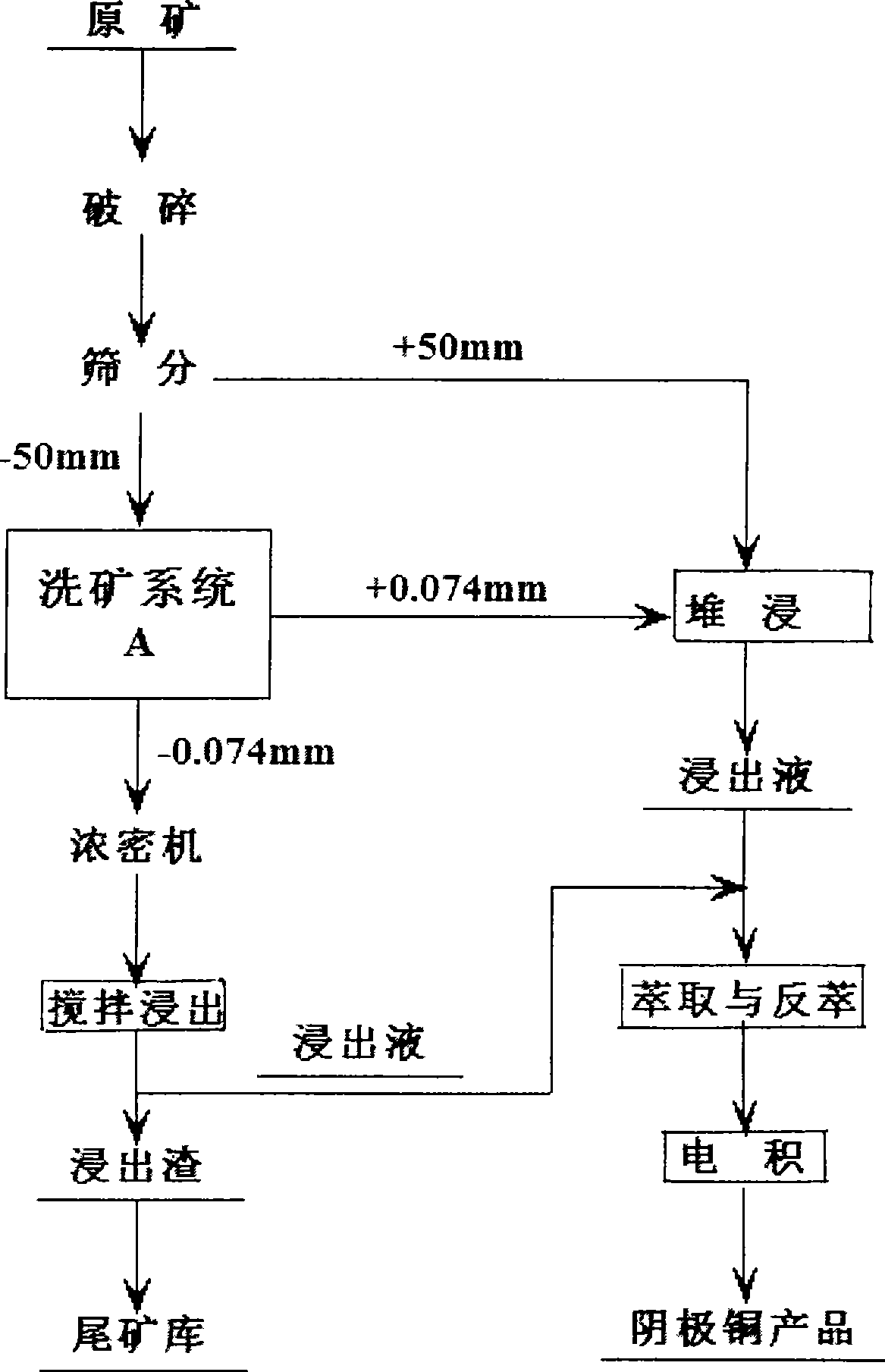

Wet processing process of high mud cupric oxide mine at high-cold area

InactiveCN101457299ASolve permeabilitySolve the problem of low copper leaching ratePhotography auxillary processesProcess efficiency improvementSlagCopper oxide

The invention provides a wet copper extraction process used in high mud-content copper oxide ores of cold areas. The process comprises the following steps: crude ores are crushed and sieved, coarse fraction ores are sent to a storage yard for piling, fine fraction ores are sent to an ore washing system for washing and grading; placer ores are sent to the storage yard for the piling after washing the ores, and mud ores are sent to an agitation tank for agitation leaching; leaching solution which is obtained from heap leaching and agitation leaching processes is sent for extraction and stripping; stripping concentration solution is sent to an electrodeposition process, and a qualified cathode copper product is obtained; leached slag from the agitation leaching is neutralized and sent to a tailings reservoir for piling. The process has good permeability, fast copper leaching rate, and greatly improved copper leaching rate and leached copper yield per day by the grading and the heap leaching of the coarse fraction ores; and the copper leaching rate is improved and the ore utilization rate is greatly improved by the agitation leaching of minus 0.074mm size fraction ores. The method is applicable to the development and the application in the wet copper extraction process used in the high mud-content copper oxide ores of the cold areas, solves the difficult technical problems of poor bing permeability and slow copper leaching rate, widens the use range of copper ore resources and improves the comprehensive utilization rate of the copper.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

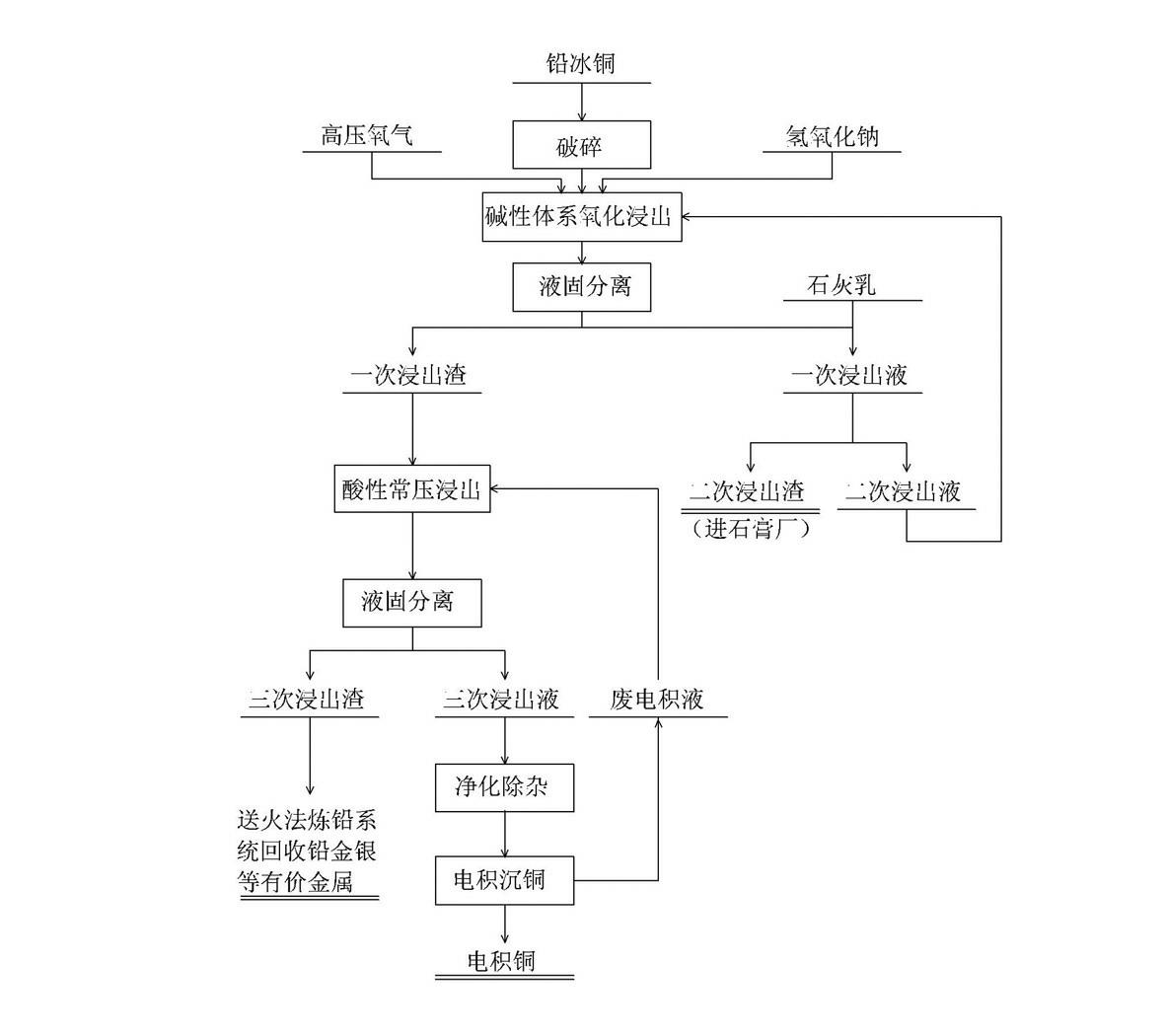

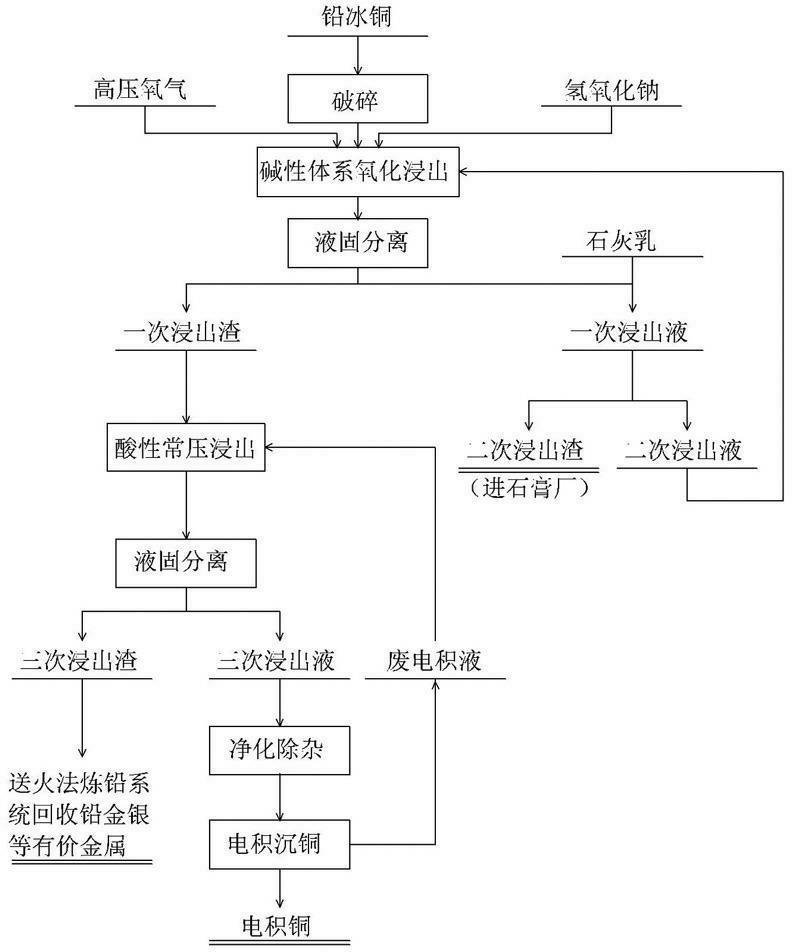

Process for recycling valuable metal from lead copper matte

ActiveCN102586600AHigh recovery rateHigh purityPhotography auxillary processesProcess efficiency improvementSulfateHydrometallurgy

The invention relates to a process for recycling valuable metal from lead copper matte, which belongs to the field of nonferrous metallurgy hydrometallurgy. The process adopts pressurization oxidation leaching in an alkalic system to convent sulfur into sulfate to be desorbed, then atmospheric pressure copper leaching is performed through diluted acid, and copper electro-deposition is further performed through purification and impurity removal to obtain cathode copper. The process is a real metallurgy cleaning process, is low in requirement for corrosion resisting conditions of device material quality, basically free of sewage discharge, free of environment pollution, short in process flow, high in comprehensive recovery rate of metal and changeable in scale, and has the advantages of having strong practical applicability and adaptability to the scale and raw materials and the like.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Method for non-cyanide copper electroplating of steel parts

The invention discloses a method for non-cyanide copper electroplating of steel parts, which relates to a method for copper electroplating of the steel parts. The method solves the problems that cyanide is easy to pollute air and water sources, can be naturally oxidized in plating baths, is oxidized on electrodes and has quick consumption and high cost. The method for the non-cyanide copper electroplating of the steel parts is realized according to the following steps of oil removal, non-cyanide copper leaching and copper electroplating, and thus the steel parts with electroplated copper are obtained. The steel parts with the electroplated copper prepared by the method have unpeeled plating layers, do not blister, and have good bonding force after high-temperature treatment. The method has simple process and convenient operation.

Owner:HARBIN TURBINE +1

Method for comprehensive recovery of valuable metals from tin anode mud

InactiveCN102787240AImprove leaching rateImprove recycling effectProcess efficiency improvementFiltrationSulfide

Belonging to the technical field of wet metallurgy, the invention especially relates to a method for comprehensive recovery of valuable metals from tin anode mud. The method comprises the following technical key points of: mixing the tin anode mud with one or more of an alkali metal hydroxide aqueous solution and an alkali metal sulfide aqueous solution, keeping the pH value of the mixed feed solution greater than 12, placing the feed solution into a sealed reactor, conducting heating to a temperature of 100-300DEG C, carrying out stirring reaction, then performing filtration, recovering valuable metals, mainly tin, from the filtrate, and recovering various valuable metals from the filter residue by means of oxidizing roasting transformation, copper leaching by sulfuric acid, silver leaching by nitric acid, bismuth leaching by hydrochloric acid. The invention is particularly suitable for treatment of tin anode mud with high antimony and low silver, and can achieve a good comprehensive recovery effect for various valuable metals. The leaching rate of tin is greater than 90%, the removal rate of antimony is greater than 85%, and silver, bismuth, copper, as well as lead are enriched over 4 times. And the method generates a relative small amount of ''three wastes'', thus being in favor of environmental protection.

Owner:云南锡业研究院有限公司研究设计院

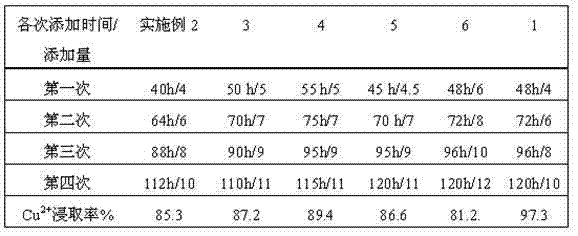

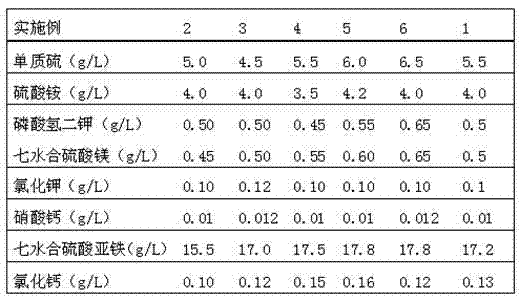

Method for leaching copper in waste printed circuit boards (PCBs) by mixed bacteria

ActiveCN103484680AEasy to addIncrease the amount addedBacteriaMicroorganism based processesPre treatmentAcidithiobacillus

The invention discloses a method for leaching copper in waste PCBs by mixed bacteria. The waste PCBs are preprocessed for standby use; acidithiobacillus ferrooxidans and acidithiobacillus thiooxidans are subjected to copper-resistant acclimation and culture respectively, and are mixed and cultured in a mixed bacteria culture solution; when the culture time reaches 40h-55h, powder of the PCBs is started to be added; then powder of the PCBs is added in additional dosage point by point at other time points; and bioleaching is performed. According to the method, when the mixed bacteria are cultured, the PH value of the culture solution is not required to be adjusted, two types of bacteria can grow in balance; at the same time, when the two types of bacteria grow, a large amount of sulfuric acid and Fe 3+ are generated and used for leaching copper in the powder of the waste PCBs in a later period; and in the whole process, the efficiency is high, and the energy is saved. A manner of low front, high rear and multipoint addition is adopted; and on the basis that the additive amount of the powder of the waste PCBs is increased, the copper leaching efficiency is improved remarkably, however, the bacteria growth inhibition degree is relatively small.

Owner:YANGZHOU NINGDA NOBLE METAL CO LTD

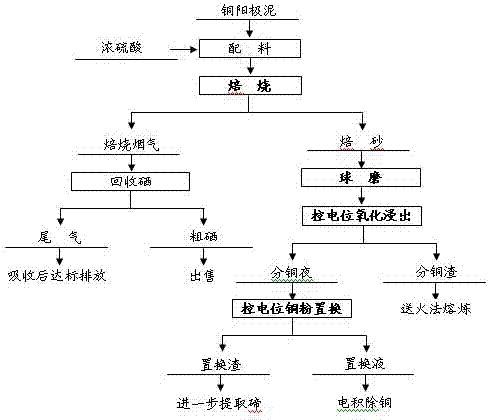

Method for potential-controlled separation and enrichment of tellurium in copper anode slime

ActiveCN107447105AEfficient enrichmentReduce consumptionProcess efficiency improvementElemental selenium/telluriumTe elementCopper anode

The invention discloses a method for potential-controlled separation and enrichment of tellurium in copper anode slime. The method comprises the steps of stirring and mixing the copper anode slime and concentrated sulfuric acid according to a center ratio, roasting under different temperature gradients, carrying out ball milling on the roasted product to a required particle size, adding hydrogen peroxide and carrying out oxidation leaching in a dilute sulfuric acid solution in the potential controlling way, adding copper powder to a copper leaching liquid and replacing in the potential controlling way, enriching the tellurium in the replacement residue and recycling copper through carrying out electrodeposition on the replaced liquid. The essence of method disclosed by the invention is that the purposes that the oxidation leaching process and the copper powder replacing process are adjustable and controllable are respectively realized in the potential controlling way; the leaching rates of the copper and the tellurium are respectively up to above 99.0% and above 80.0% in the potential-controlled oxidation leaching process; and the replacement rate of the tellurium in the potential-controlled replacing process is up to above 99.0%. The method disclosed by the invention has the advantages that the technical index in the technical processes is stable; the labour intensity is low; the production cost is low and the like.

Owner:CENT SOUTH UNIV

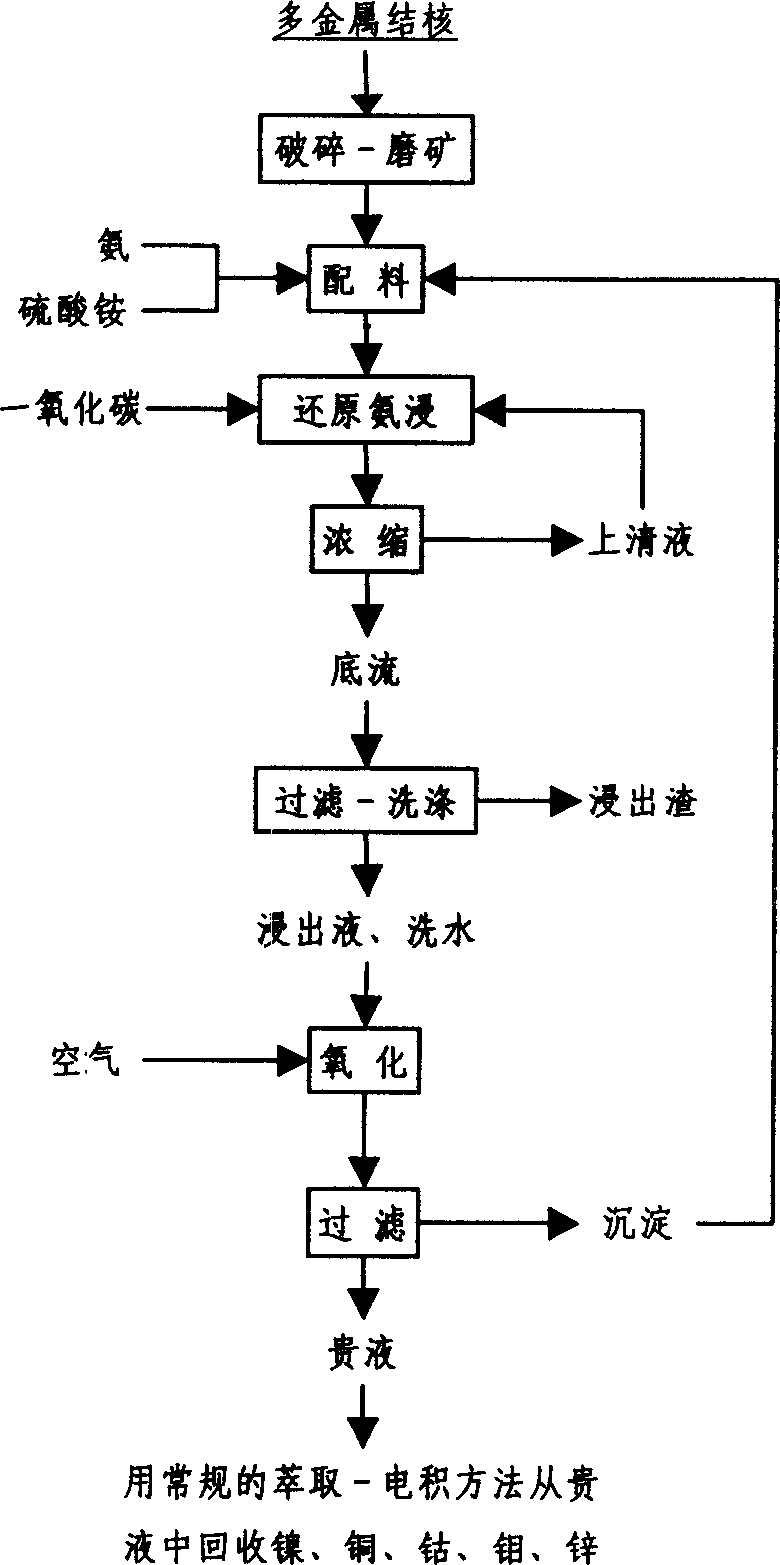

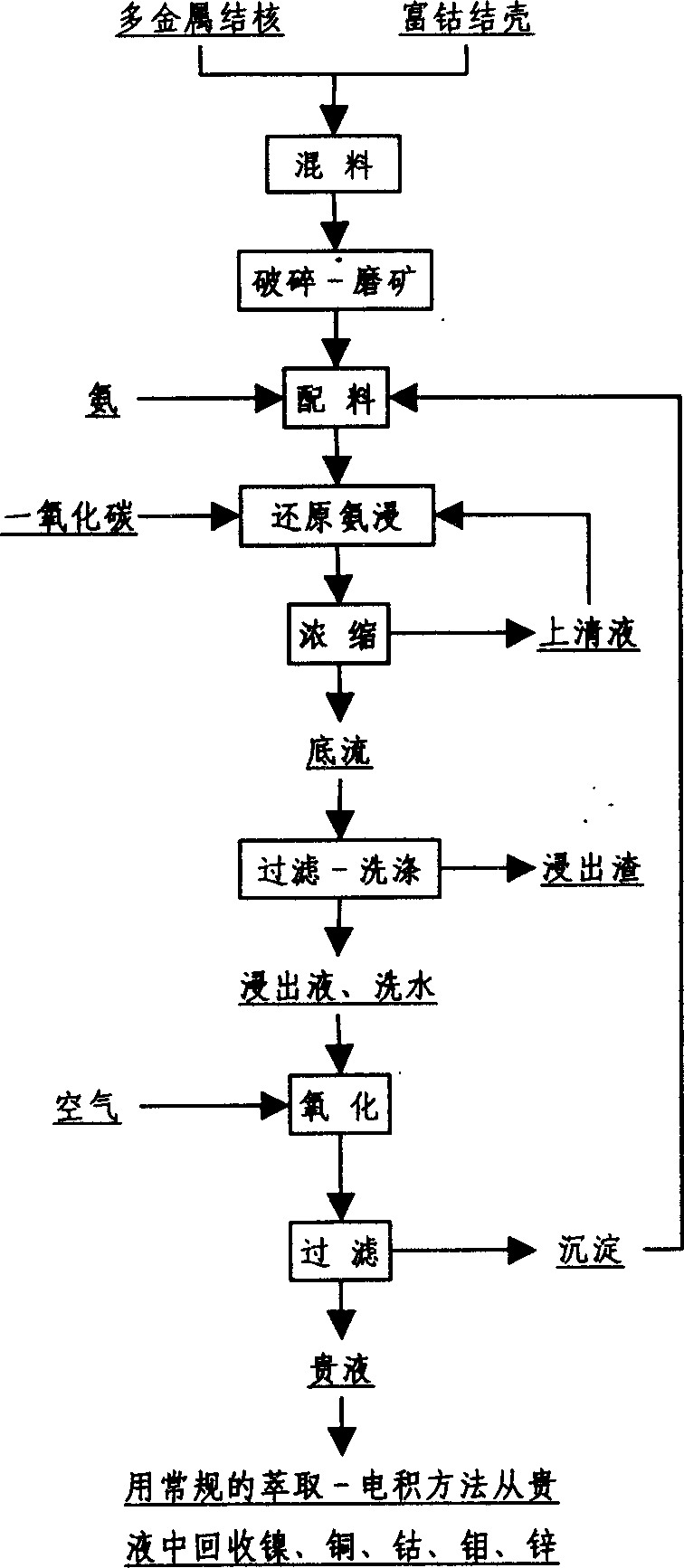

Self-catalytic reduction ammonia-leaching method for multi-metal concretion in deep sea

ActiveCN1775966AAutocatalytic reductionReduce consumptionProcess efficiency improvementWash waterConcretion

The invention relates to a method to take self-catalytic reduction ammonia leaching from deep- sea multi-metal nodule, especially uses carbon monoxide as reducer. The process includes the following steps: adding grinded material to ammonia-ammiaonia sulfate solution and adding carbon monoxide to take reducing leach; concentrating and separating, filtering to gain leaching liquid A; washing filtered cake to gain the wash water B with nickel, copper, cobalt, molybdenum, and zinc; mixing the leaching liquid A and wash water B adding air to take oxidizing, filtering to gain deposit C and solution D that contains nickel, copper, cobalt, molybdenum and zinc; deposit C returning to leach, recycling nickel, copper, cobalt; recycling the valued metal in solution D. The invention could make the cuprous ion concentration stable from the copper leaching itself.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Process for recycling copper through electrodeposition by treating scrap copper materials by adopting cyclone electrolysis technology

ActiveCN102534656ATo achieve the purpose of high efficiency and environmental protectionImprove leaching efficiencyPhotography auxillary processesProcess efficiency improvementHigh current densityCyclone

The invention provides a process for recycling copper through electrodeposition by treating scrap copper materials by adopting a cyclone electrolysis technology, belonging to the technical field of recycling copper from wastes containing copper. The process is characterized by taking various purchased wastes containing copper as raw materials, preliminarily screening and grinding the wastes, adding the materials to a dissolved copper leaching bath device to undergo continuous copper dissolving to obtain a copper sulfate solution, then filtering the solution with precision filter equipment, decoppering the obtained filtrate through cyclone electrolysis, scalding an obtained copper pipe with weak acid and then feeding the copper pipe into a product processing unit to process a standard copper plate. The process has the following beneficial effects: through portable or module assembly, the cyclone electrolysis bath and support equipment are convenient to install, dismantle and move; the solution circulates in a closed loop, thus avoiding emission of harmful gases; electrolytic deposition is carried out on the metals selectively and the copper can be better purified by applying the cyclone electrolysis technology; higher current density and current efficiency are ensured, fewer reagents are consumed, the production cost is lowered and the enterprise revenue is improved; and high efficiency and high purity electrolytic extraction is carried out on the solution, the recycled copper is the standard cathode copper and the total recycling rate is above 96%.

Owner:浙江科菲科技股份有限公司

Process for efficiently and selectively separating copper in lead copper matte

InactiveCN104017991AAdaptableHigh recovery ratePhotography auxillary processesProcess efficiency improvementPregnant leach solutionLead smelting

The invention discloses a process for efficiently and selectively separating copper in lead copper matte. The process comprises the following steps: smashing and grinding the lead copper matte taken as a raw material and screening to reach below 80 meshes; sending the lead copper matte which is ground and screened into a leaching tank and leaching by using a sulfuric acid; reacting for 3 to 5 hours at a normal pressure under the conditions that the oxidation potential of the solution is controlled within 450mV to 800mV, the concentration of sodium chlorate is controlled within 200g / L to 500g / L, the liquid-solid ratio is controlled within (5-15):1, the temperature is controlled within 70 DEG C to 100 DEG C and the concentration of the sulfuric acid is controlled within 1.0mol / L to 1.5mol / L; and leaching the copper under an acid condition by taking the sodium chlorate as an oxidizing agent. During the oxidizing and leaching process, sulfur in the lead copper matte is oxidized into elemental sulfur which is transferred into slags, wherein copper which is oxidized enters the solution in a form of copper ions while lead remains in the slags in a form of lead sulfate together with gold and silver. After the leaching process is finished, the solid-liquid separation is carried out, so that the primary separation of the copper and other valuable elements is realized; a certain amount of scrap iron is added into the leaching solution rich in the copper so as to replace the deposited copper, so that the spongy copper, which is a primary product, can be obtained; the leaching slags are sent into a pyrogenic lead smelting system, so that the valuable elements such as Pb and Ag are comprehensively recycled.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

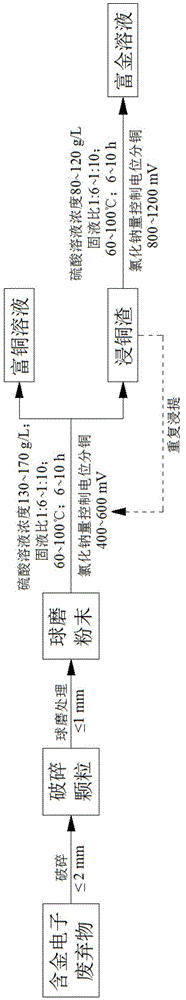

Leaching method of gold and copper in gold-contained electronic waste

InactiveCN104894383AHigh extraction rateHigh degree of resource utilizationProcess efficiency improvementSlagOxidation-Reduction Agent

The invention discloses a leaching method of gold and copper in a gold-contained electronic waste. The gold-contained electronic waste is crushed, and the particle size of crushed particles is not more than 2 mm; then, the ball-milling treatment is performed, and the particle size is not more than 1 mm after the ball-milling treatment; powder obtained by the ball-milling treatment is added in sulfuric acid solution with a concentration of 130-170 g / L for copper leaching to obtain copper-enriched solution and copper leaching slag; and finally, the chlorination gold leaching is performed for the copper leaching slag to obtain gold-enriched solution. The method realizes the separation of copper and gold; the obtained copper-enriched solution and gold-enriched solution can be deeply treated to obtain gold and copper simple substances; and in the separation process, such other metals as lead and tin can be separated through controlling the redox potential.

Owner:SHANGHAI JIAO TONG UNIV

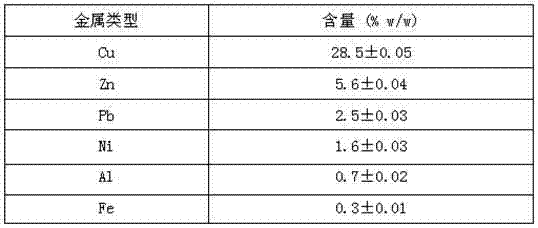

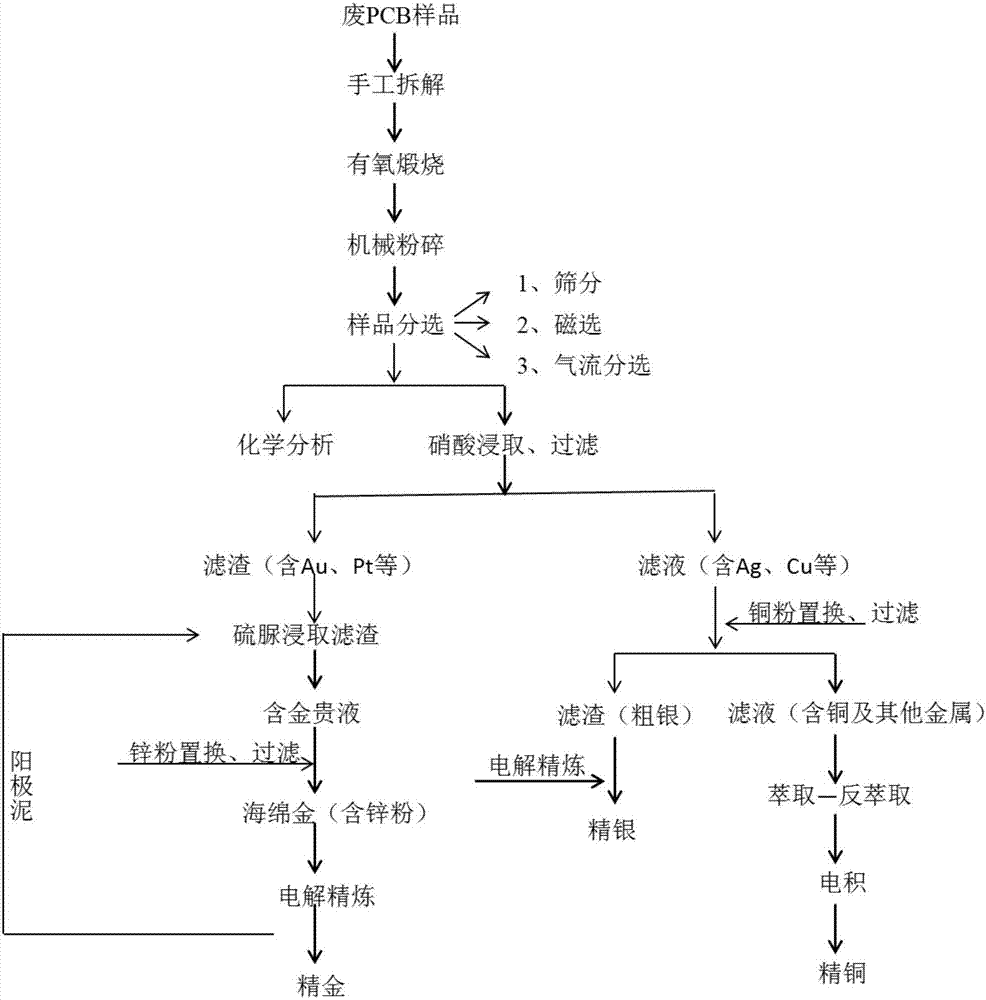

Method for extracting gold, silver and copper from mobile phone circuit board

InactiveCN107400780AHigh extraction recoveryAvoid pollutionPhotography auxillary processesProcess efficiency improvementElectrolysisThiourea

The invention discloses a method for extracting gold, silver and copper from a mobile phone circuit board. The method comprises steps as follows: step one, pretreatment of the mobile phone circuit board: the circuit board is calcined, broken, screened and subjected to magnetic separation, and metal-enriched powder and non-metal impurities are obtained through pneumatic separation; step two, metal element analysis: content of metals such as silver, copper, aluminum, zinc and the like is tested by an atomic absorption spectrometer, and content of precious metals such as gold, platinum, palladium and the like is measured by an inductively coupled plasma emission spectrometer; step three, extraction and recovery of silver and copper; step four, thiourea leaching of gold: residues obtained after silver and copper leaching with nitric acid are put in a reactor and dissolved with thiourea and ferric sulfate, and content of gold is measured; step five, gold recovery: the solution obtained after thiourea leaching of gold is transferred to a reaction container, trisodium citrate and zinc powder are added, and filter residues are subjected to electrolytic refining of gold. According to the method, extraction and recovery rate of gold, silver and copper is high, the reaction speed is high, invested cost is low, little environmental pollution is produced, and industrialization is facilitated.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

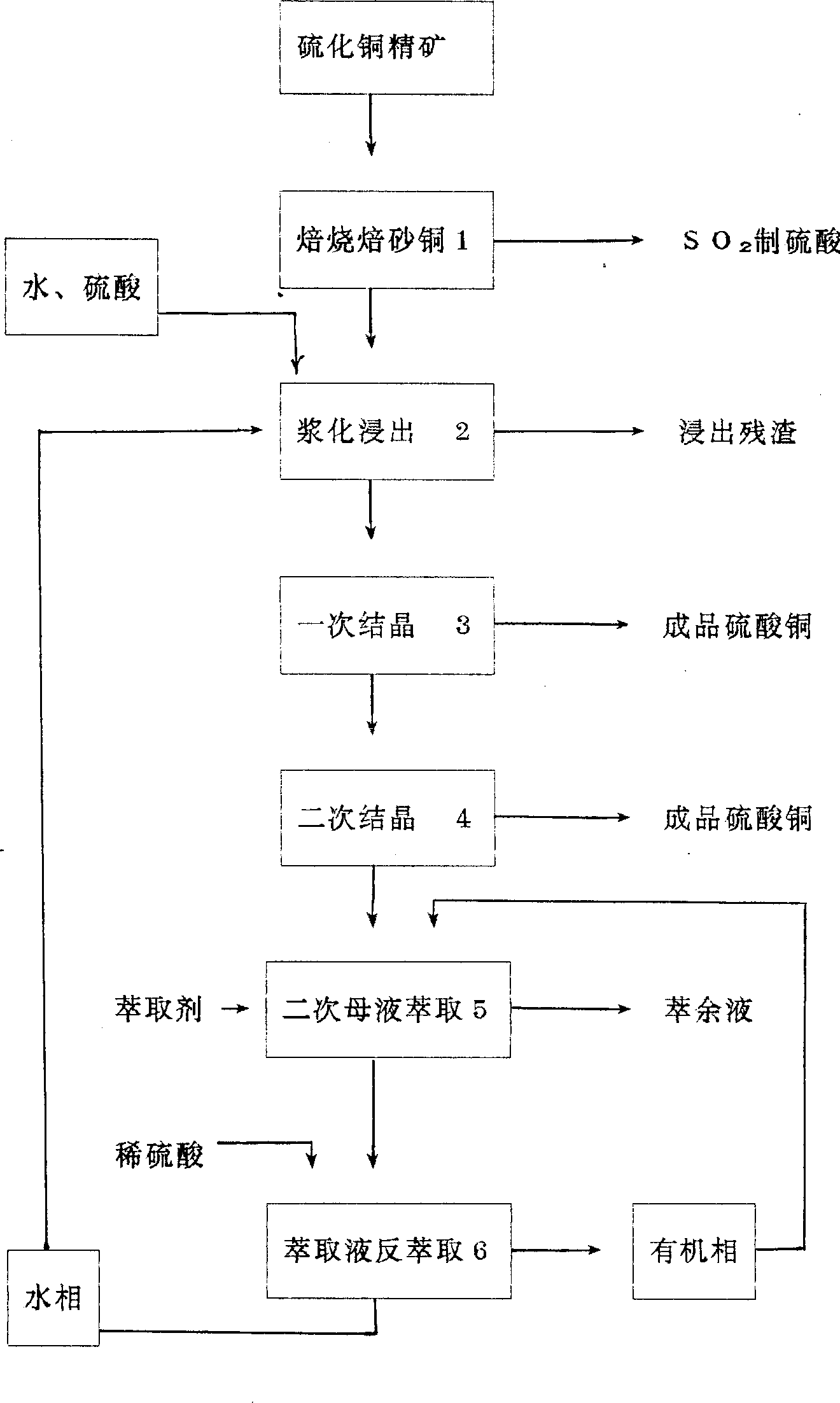

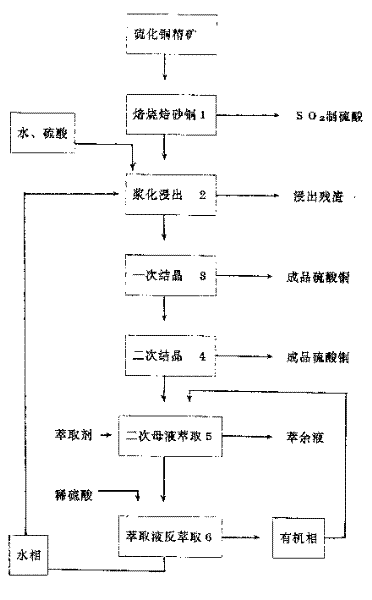

Production process of copper sulfate from copper sulfide ore

InactiveCN1370742AIncrease production capacityContact mix evenlyProcess efficiency improvementCopper sulfatesCopper sulfateCopper ore

The present invention relates to a process of producing copper sulfate from copper sulfide ore. In one Lurgi boiling bed roaster, copper sulfide ore powder is roasted at 660-710 deg.c into roasted sand copper with acid dissolving rate of 98 % and water dissolving rate of 60-70 % and the exhausted SO2 is used directly in preparing acid. Roasted sand copper is made to mix with dilute copper sulfatesolution returned from extraction step and sulfuric acid is added to regulate liquid-to-solid ratio of 1-2 and ultimate H2SO4 concentration lower than 20 g / L. The copper leaching rate is greater than98%. The crystallized secondary mother liquid is extracted and purified to recover copper sulfate. The extracting liquid is back extracted with dilute sulfuric acid, the back extracting liquid is returned to leaching step and the organic phase containing extractant is returned to secondary mother liquid.

Owner:XINTAI COPPER IND LAIWU IRON & STEEL GRP

Mixed ammonia leaching method for multi-metal concretion and cobalt-rich skull in deep sea

ActiveCN1775971AAutocatalytic reductionReduce consumptionProcess efficiency improvementWash waterCuprous ion

The invention relates to a mixture ammonia leaching method of deep sea multi-metal nodule and cobalt-bearing crust that the process includes the following steps: mixing, crashing, grinding the multi-metal nodule and cobalt-bearing crust; adding the material into ammonia salt solution and adding carbon monoxide to take reducing leaching out; concentrating and separating, the supernatant returning to leaching out and the underset taking filtering to gain leaching out liquid A; washing filtered cake to gain the wash water B with nickel, copper, cobalt, molybdenum; mixing the leaching liquid A and wash water B adding air to take oxidizing, filtering to gain deposit C and solution D that contains nickel, copper, cobalt, and molybdenum; deposit C returning to leach, recycling nickel, copper, cobalt; recycling the valued metal in solution D. The invention could make the cuprous ion concentration stable from the copper leaching itself.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

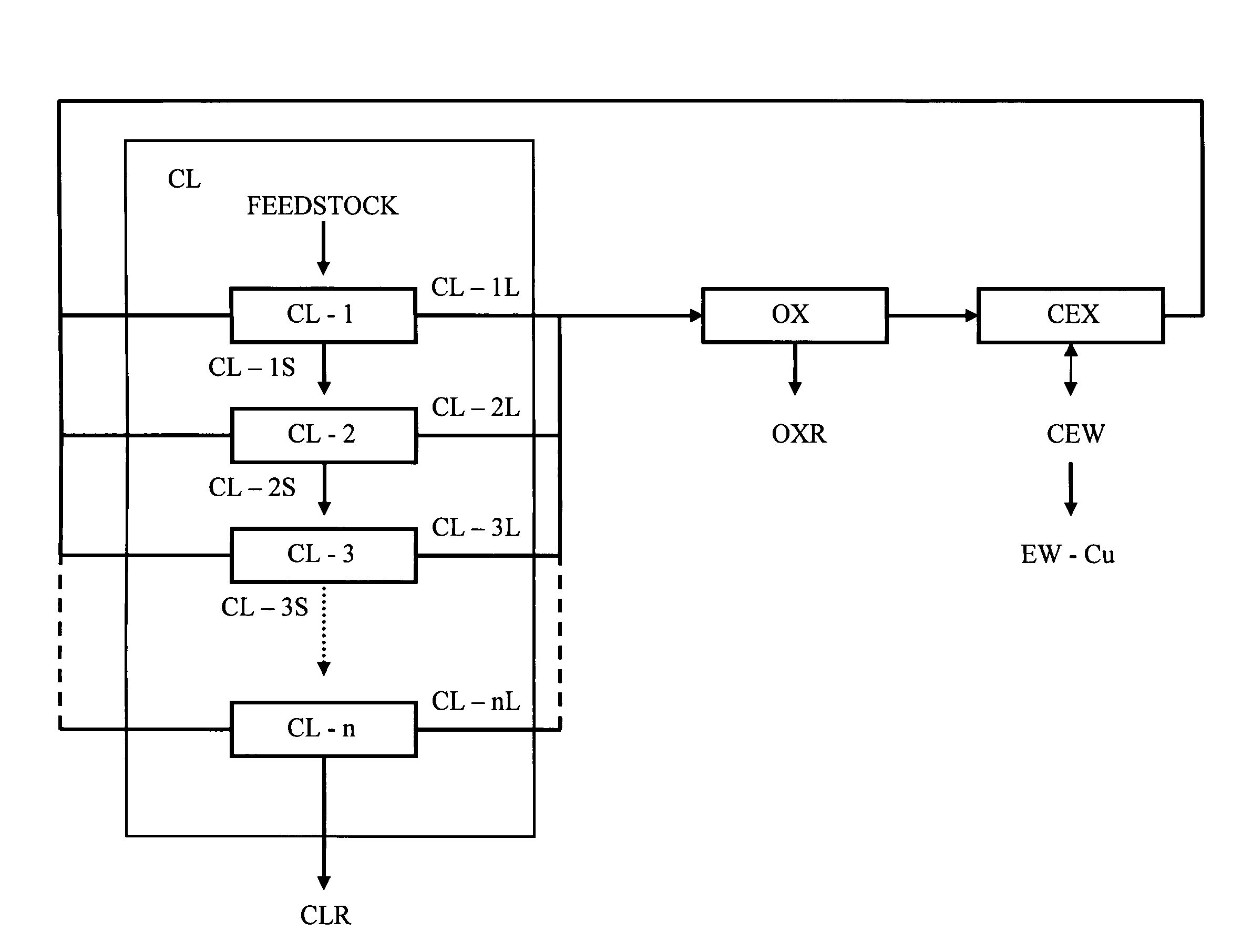

Method for recovering metal from ore

ActiveUS20090241736A1Drawback can be obviatedProcess efficiency improvementImpurityMaterials science

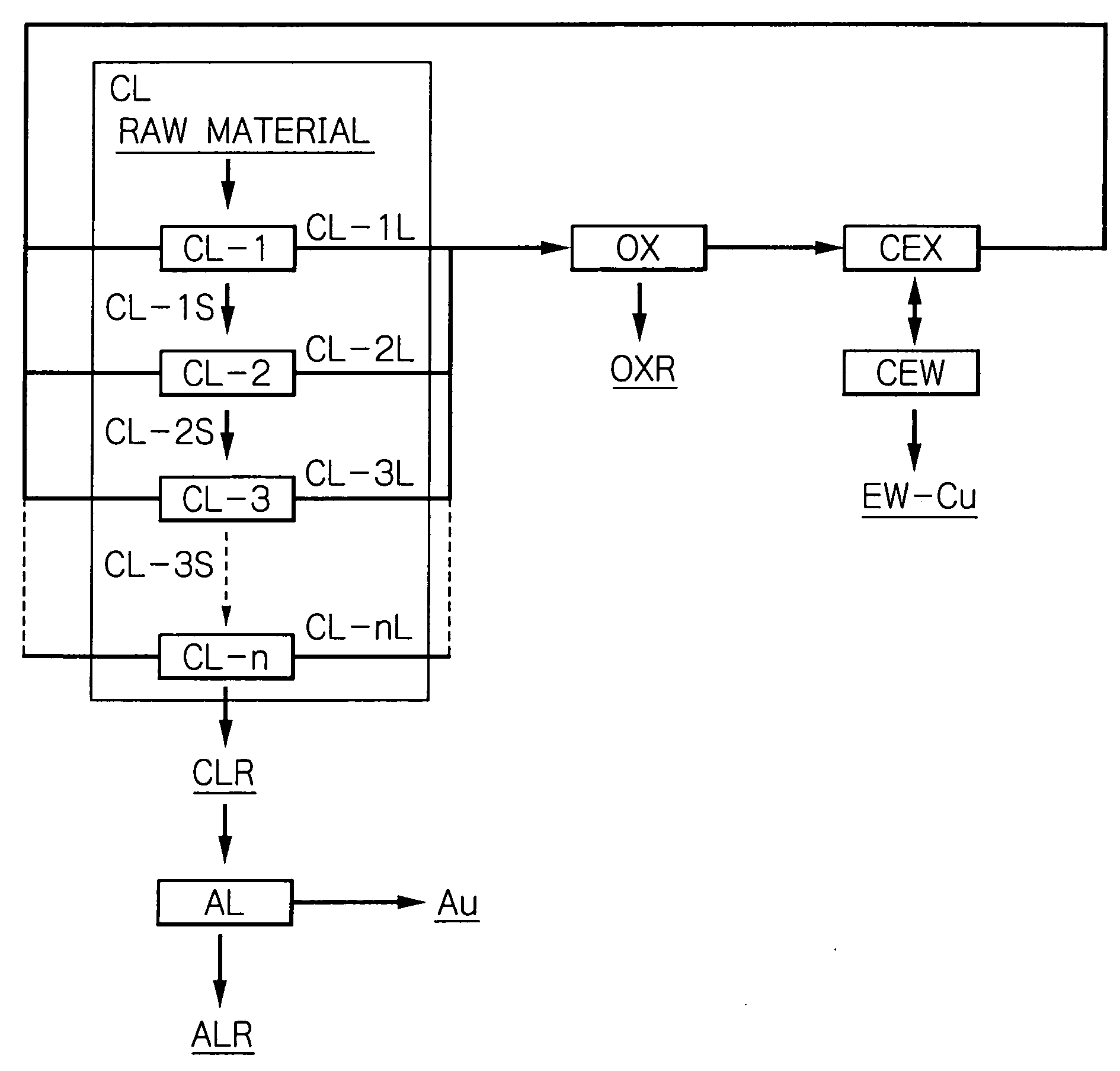

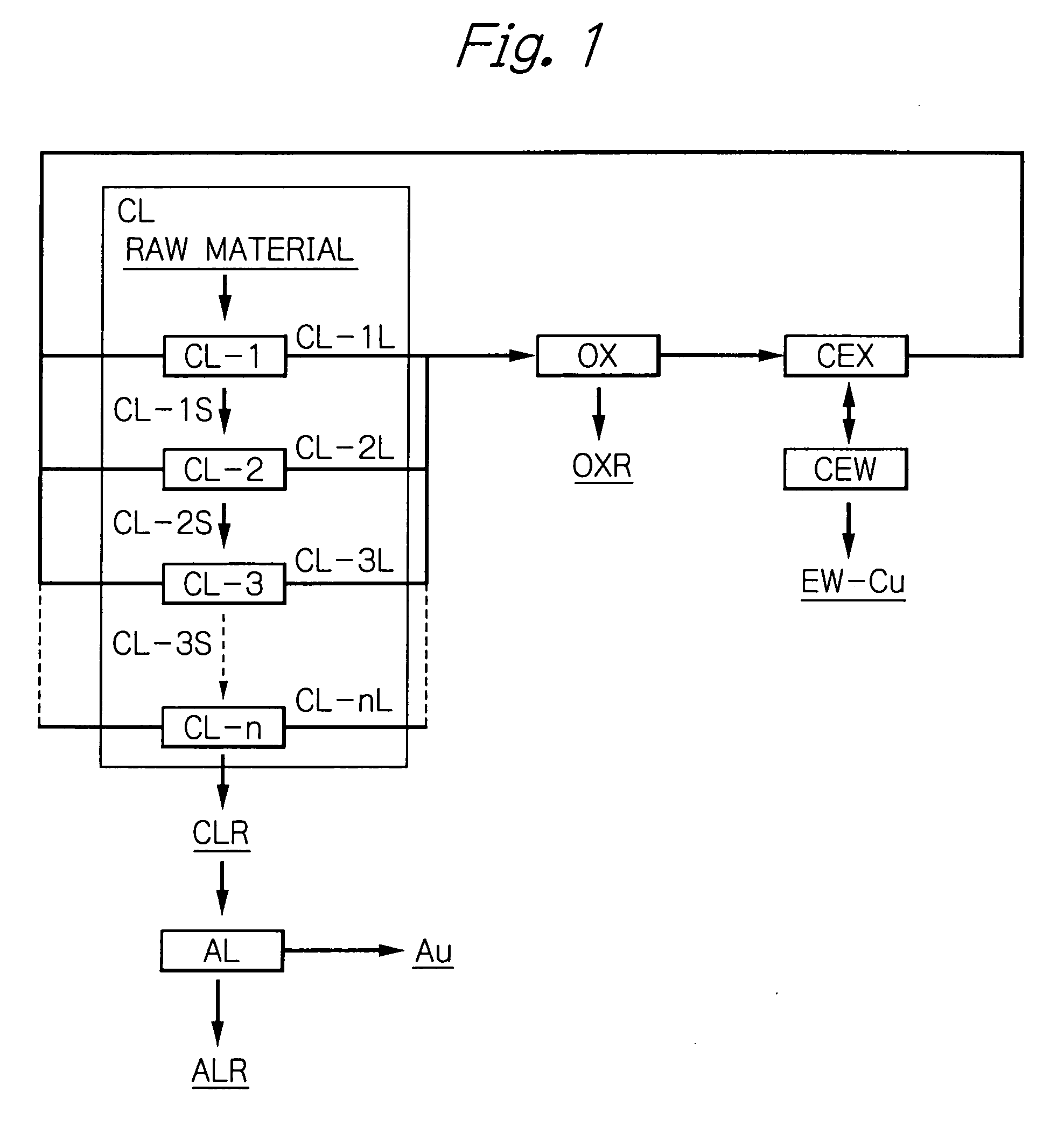

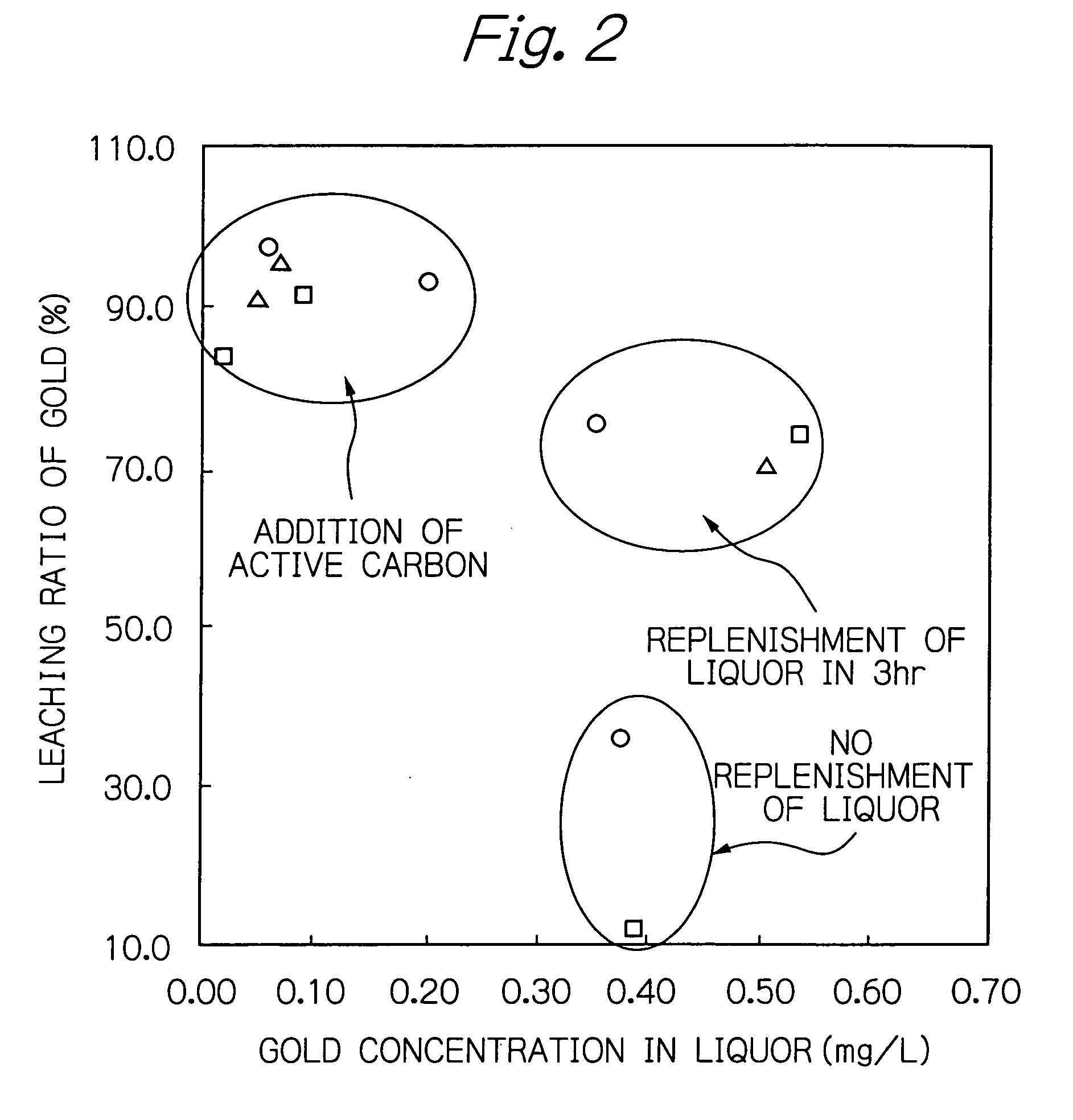

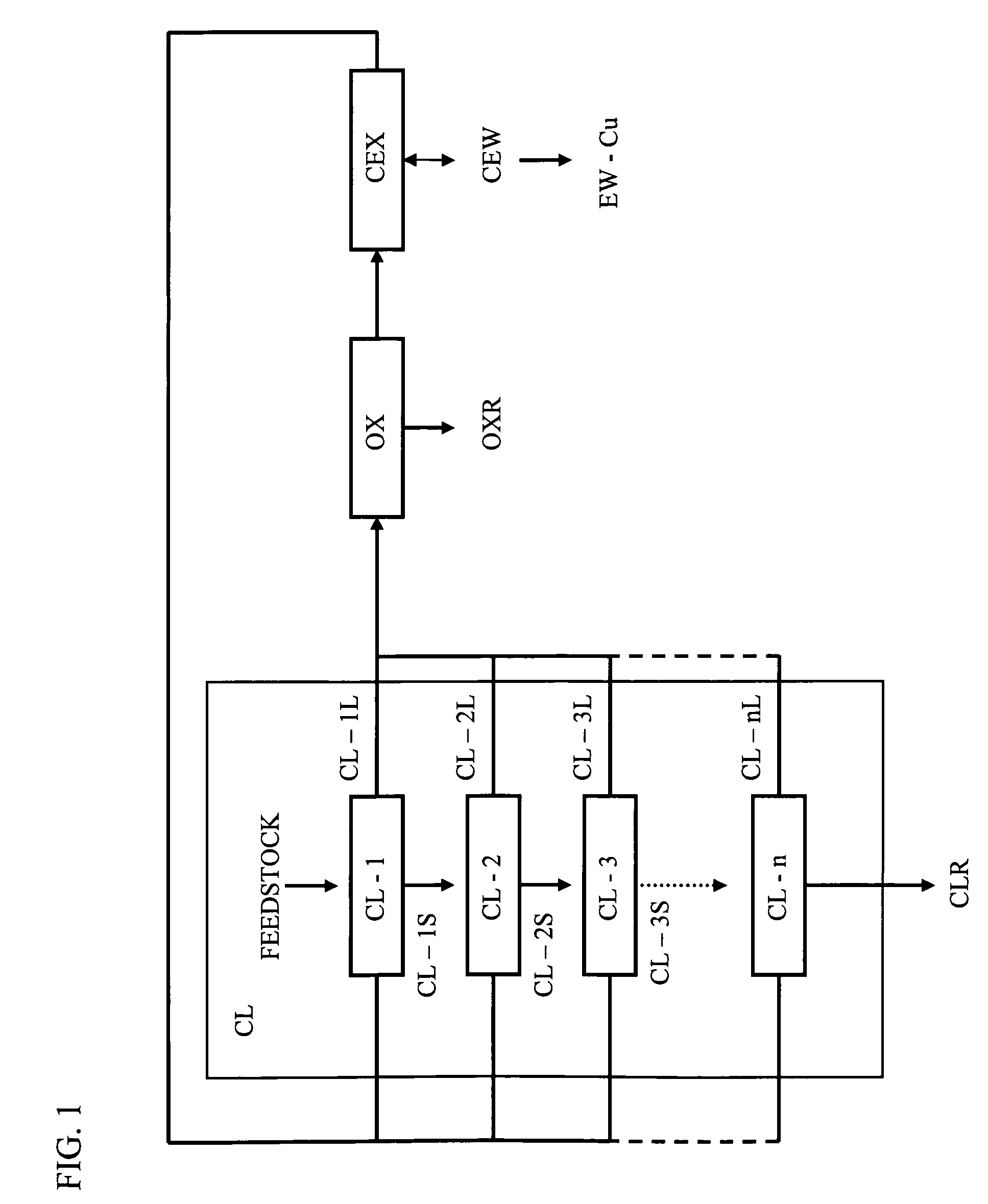

The copper sulfide ore is leached in the halide bath without using a special oxidant but with the use of only air. The copper and gold in the copper sulfide ore can be leached at high leaching ratio.The treating steps are as follows.(1) Copper leaching process (CL). The raw material is charged into the first acidic aqueous solution, which contains cupric chloride, ferric chloride, 7 g / L of hydrochloric acid, and sodium chloride. The post-leach liquor contains copper in cuprous state ions and copper in cupric state ions.(2) Solid-Liquid separation step. The resultant solid and liquid of CL step are separated.(3) Air oxidation step (OX). Air is blown into the post solid-liquid separation liquor. The copper in cuprous state ions are oxidized to the copper in cupric state ions. The iron leached in the step (1) is oxidized. Simultaneously, the impurities leached in the step (2) are precipitated.(4) Copper extracting step (CEX). The copper is recovered from the post-liquor of the step (3)(5) Gold recovering step (AL). The residue separated in the step (2) is added to the leach liquor similar to that of the step (1). The steps (1) and (5) are carried out under the atmospheric pressure and at the temperature of boiling point or lower, while blowing air into the leach liquor.

Owner:JX NIPPON MINING& METALS CORP

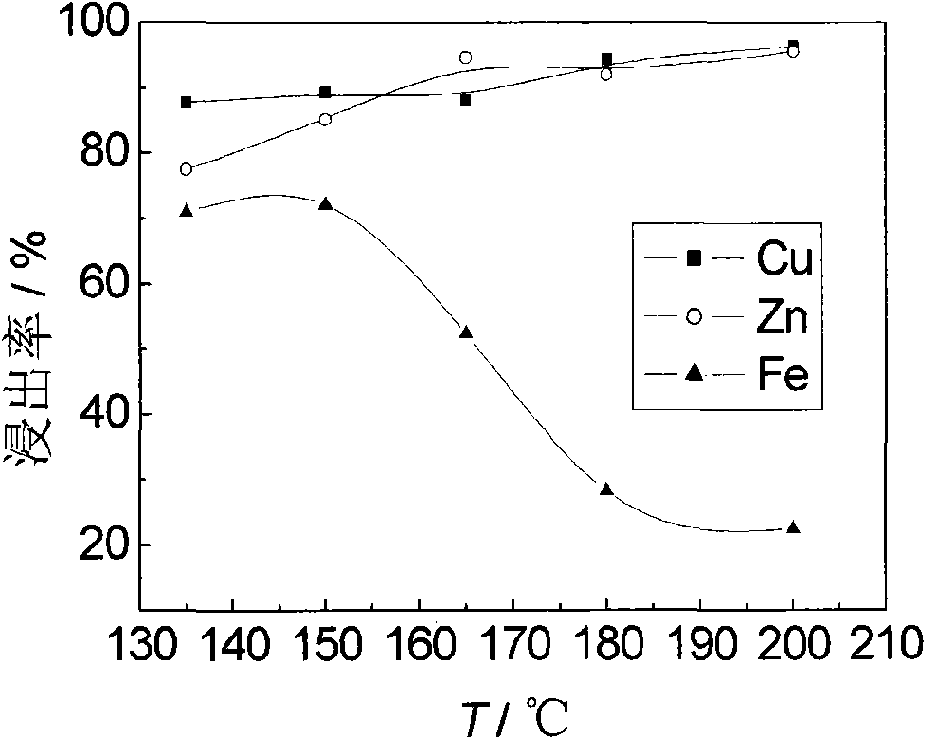

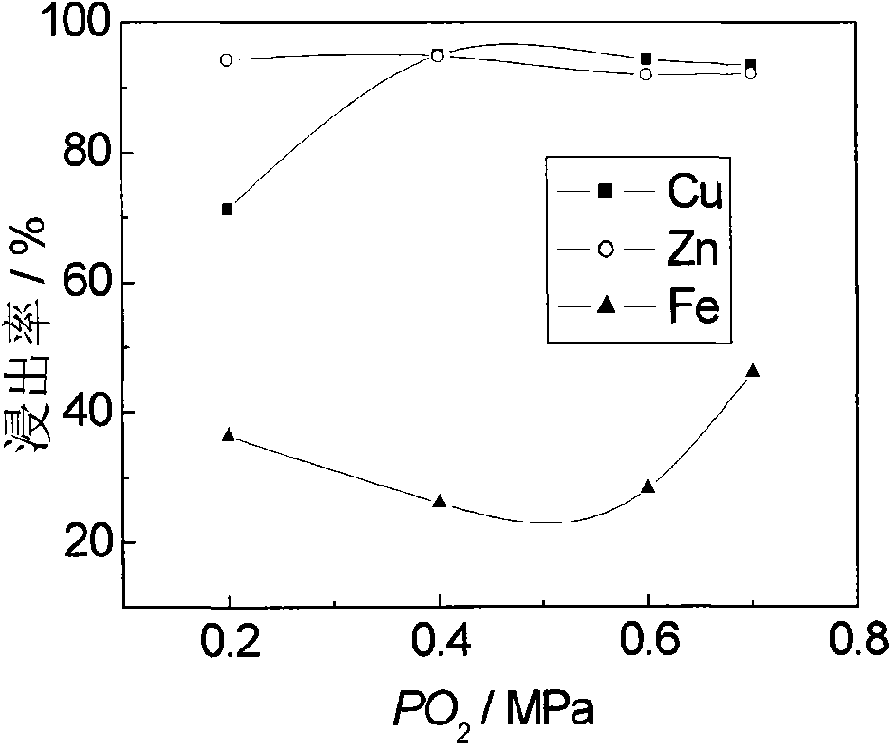

Complex copper sulphide ore thermal activating-pressure leaching technology

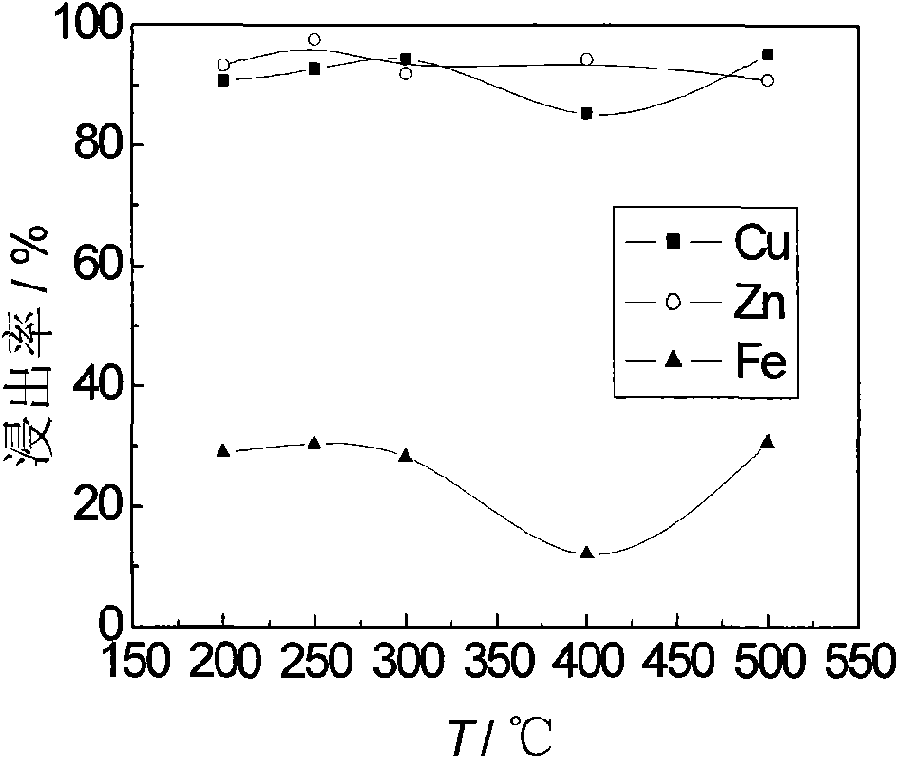

ActiveCN101643846ANo low-altitude pollution problemsEfficient leachingProcess efficiency improvementLiquid ratioCalcium lignin sulfonate

The invention relates to a wet metallurgy technology of complex copper sulphide ore, in particular to a complex copper sulphide ore thermal activating-pressure leaching technology. The technical scheme of the technology is as follows: activating time is 2.0 hours under the temperature of 300 DEG C; leaching temperature is 180 DEG C; oxygen partial pressure is 0.6 MPa; initial sulfuric acid concentration is 1.23 mol / L; solid-to-liquid ratio mL / g is 5:1; surface active agent selects calcium lignin sulfonate, wherein usage amount thereof is 1.25% of the weight of fine ore; stirring speed is 500 r / min; and leaching time is 2.0 hours. The technology can not generate toxic compounds such as SO2, and the like, to cause low-air pollution, is cleaning and environmentally friendly, improves the copper leaching ratio from original less than 70% to more than 90%, smoothly solves the difficulties of easy passivation in the process of leaching yellow copper ore and tetrahedrite, improves metal use ratio, and reduces resource waste.

Owner:JIANGXI UNIV OF SCI & TECH

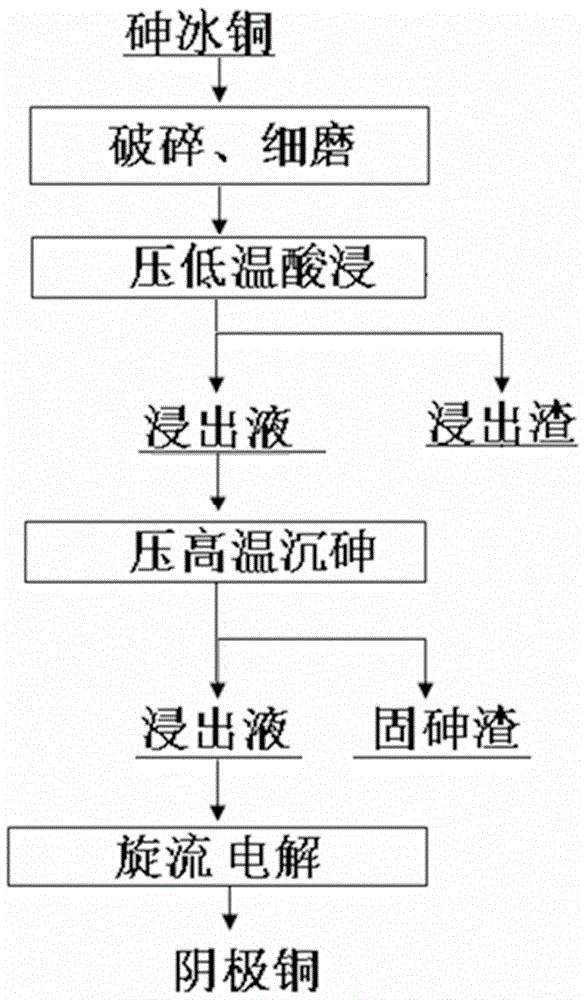

Technological method for cleaning and efficiently treating arsenic matte

ActiveCN106048251AReduce pollutionHigh recovery ratePhotography auxillary processesProcess efficiency improvementSlagEnergy consumption

The invention discloses a technological method for cleaning and efficiently treating arsenic matte. The technological method comprises steps of crushing, grinding, low-temperature acid leaching, high-temperature arsenic precipitating and the like. The technological method is a wet process, is low in energy consumption, is less in environmental pollution, is high in degree of automation and is high in production efficiency. The technological method is simple and quick in reaction process and is high in selectivity. Copper in arsenic matte can be efficiently leached, so that metal is separated completely. Compared with a current wet process for treating the arsenic matte, a copper leaching process can be quickly realized at a relatively low leaching temperature within relatively short time. The arsenic removal effect is good, and an arsenic removal rate is higher than 99%. Arsenic in the arsenic matte is recycled in the form of arsenic slag, so that secondary pollution of arsenic is avoided. The technological method has the advantages of being high in metal recovery rate, low in production cost, good in economical effect, high in adaptability to raw materials, clean, environmentally friendly and the like.

Owner:KUNMING METALLURGY INST

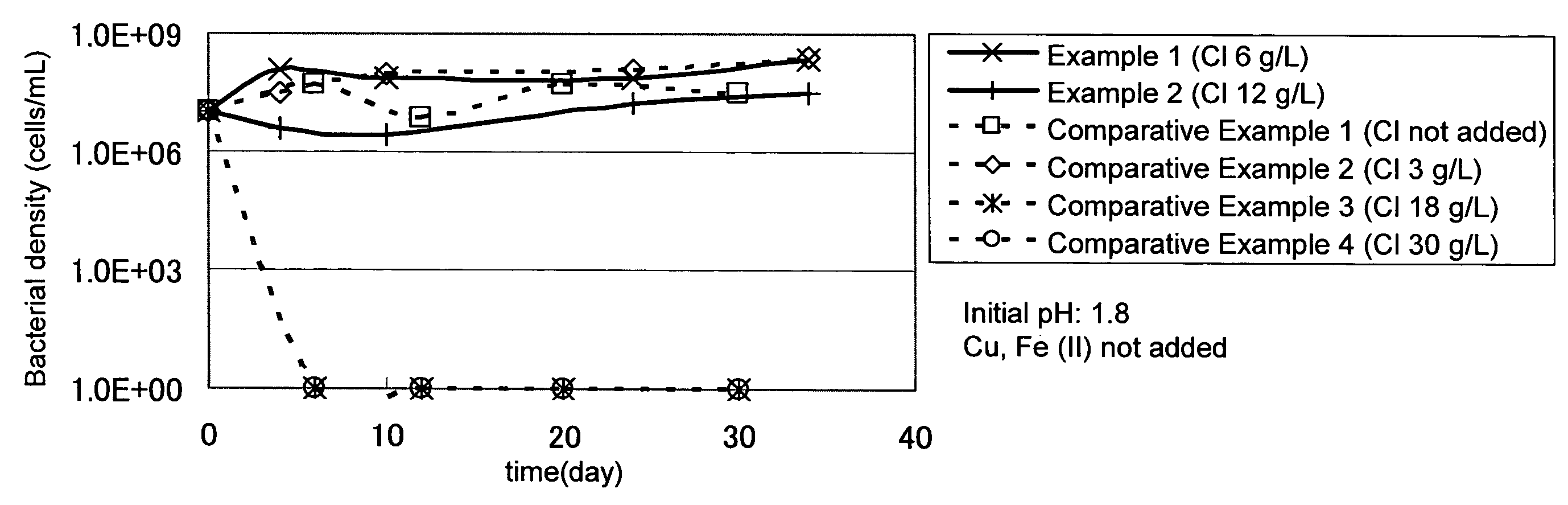

Method of leaching copper sulfide ores containing chalcopyrite

InactiveUS20080026450A1Efficient and cost-effectiveProcess efficiency improvementBiological water/sewage treatmentPregnant leach solutionChalcopyrite

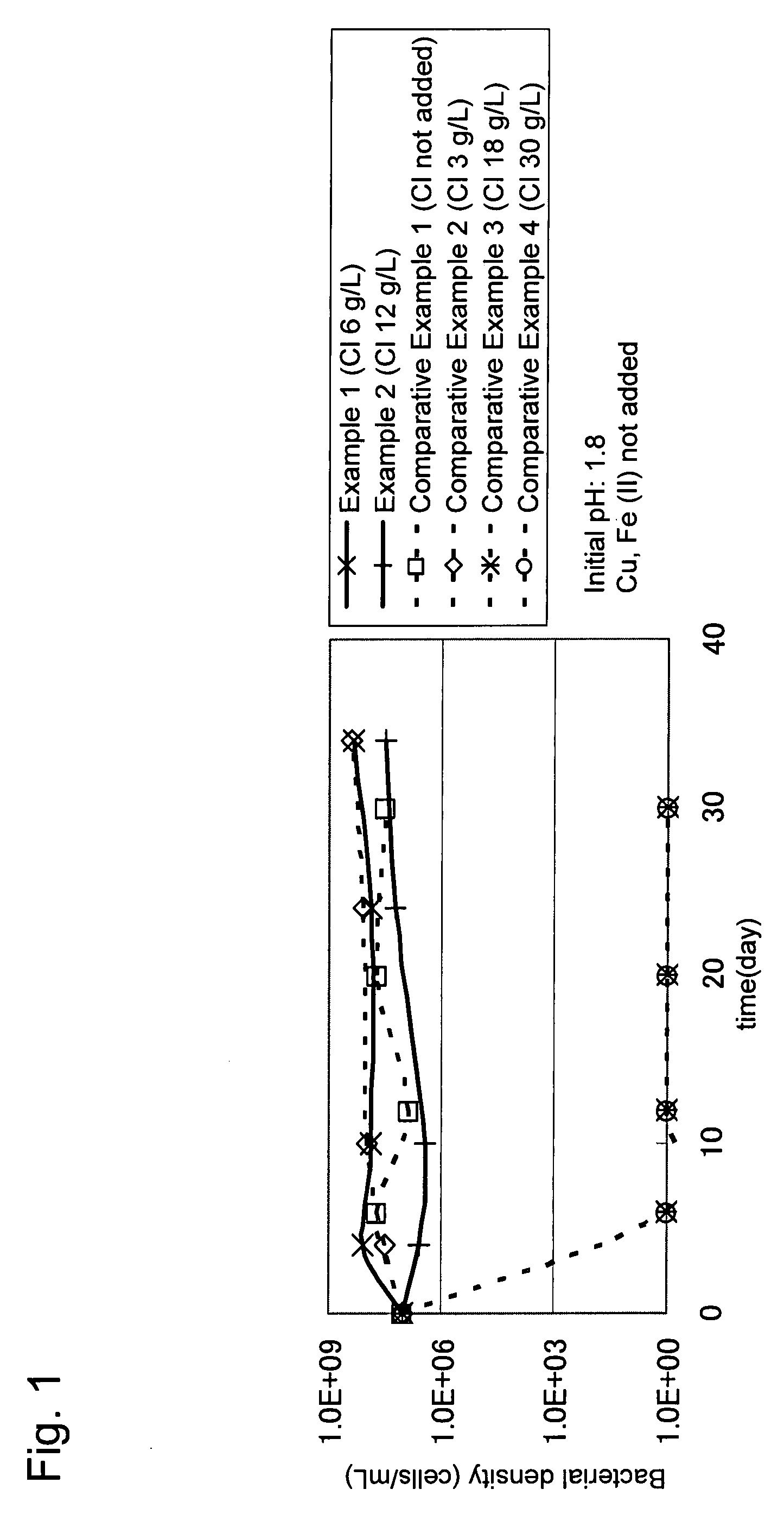

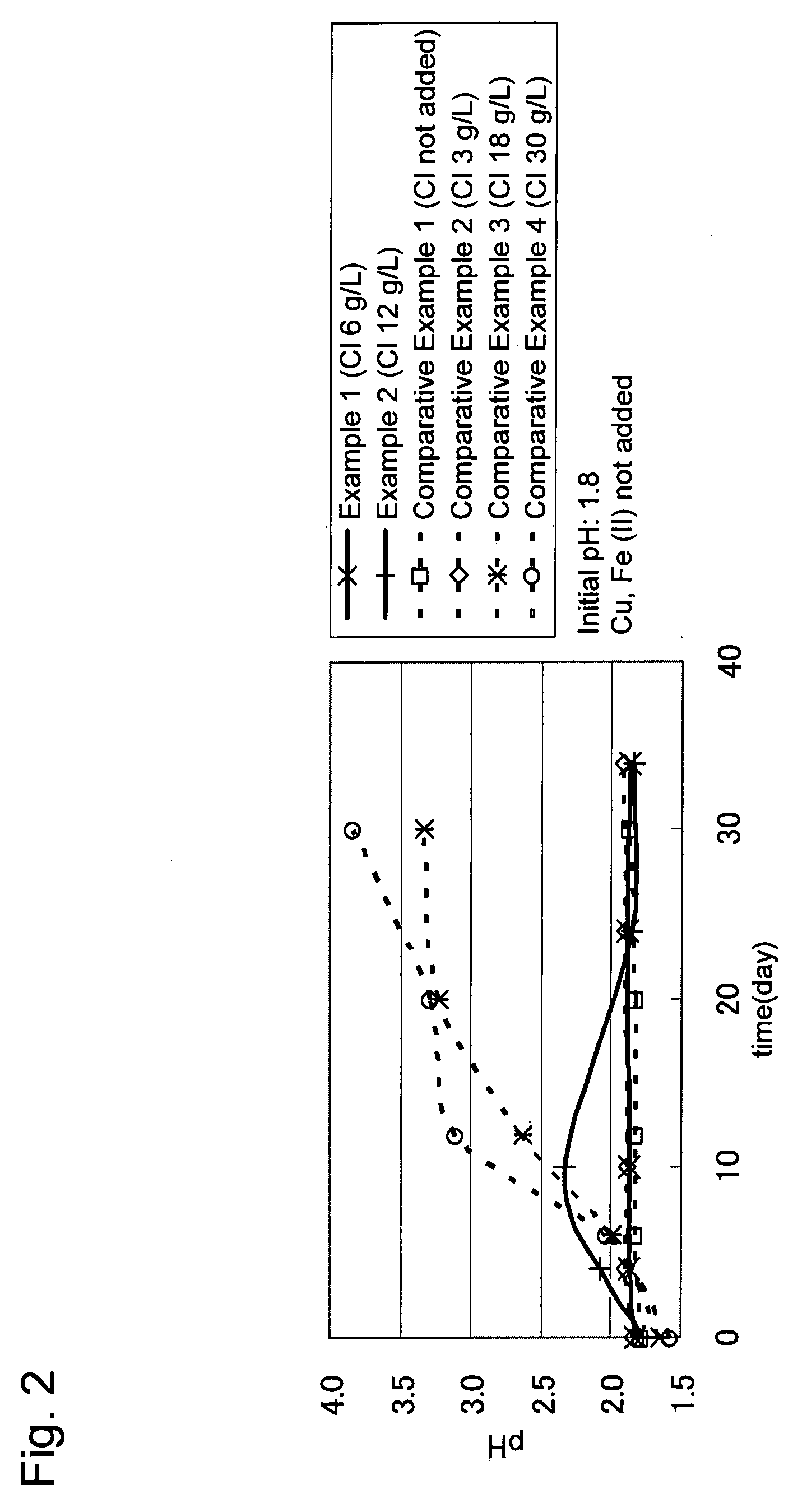

An object of the present invention is to provide a method of efficiently leaching copper from copper sulfide ores containing chalcopyrite at room temperature.A method of recovering copper from copper sulfide ores, characterized by comprising: using a sulfuric acid solution having a chloride ion concentration adjusted to 6 g / L or more but less than 18 g / L and a pH adjusted to 1.6 or more but less than 2.5 as a leaching solution; and carrying out copper leaching with the addition of a chloride ion-resistant sulfur-oxidizing bacterium to the leaching solution, when recovering copper from copper sulfide ores containing chalcopyrite, is provided.

Owner:JX NIPPON MINING& METALS CORP

Method for recovering rare and precious metal from copper anode slime copper leaching liquid

ActiveCN107746957AStrong process adaptabilityRecycling does not affectProcess efficiency improvementReduction ratePre treatment

The invention relates to a method for recovering rare and precious metal from copper anode slime copper leaching liquid. The method comprises the following steps that 1, rare and precious metal are strengthened and reduced form the copper anode slime copper leaching liquid; and 2, ultrafine particles of rare and precious metal are precipitated, and purification of the copper leaching liquid is synergistically conducted. According to the method for recovering the rare and precious metal from the copper anode slime copper leaching liquid, the copper leaching liquid is pre-treated through the process and can be effectively purified, and the impurity content is reduced, the key point is that the rare and precious metal is efficiently and synergistically recovered, so that the rare and preciousmetal which is dissolved and dispersed in the copper leaching liquid at an ionic state and ultrafine particle state are effectively reduced and enriched, and rare and precious metal concentrate is obtained; and the concentrate is high in valuable element grade and single in element state, and is a source of high quality raw materials for recovering the rare and precious metal, and the method forrecovering the rare and precious metal from the copper anode slime copper leaching liquid has the advantages of high process adaptability, high reduction rate, less impurities and high efficiency.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for leaching copper from copper oxide ore

InactiveCN102296186AIncrease productivityImprove leaching rateRotary drum furnacesCrucible furnacesSlurryCopper oxide

The invention relates to a method for leaching copper from copper oxide ore, and belongs to the field of extracting metal compounds from ores or concentrates by wet methods. The technical problem solved by the invention is to provide a method for leaching copper from copper oxide ore, which is continuous leaching, and has higher production efficiency than the existing technology. The method for leaching copper from copper oxide ore of the present invention comprises the following steps: adding the reaction amount of copper oxide ore and sulfuric acid into the reactor at a uniform speed, mixing, and reacting the copper oxide ore and sulfuric acid for 0.5 to 2 hours, and the obtained slurry is The material flows out from the reactor in a continuous discharging manner; wherein, the concentration of the sulfuric acid is 8-25wt%, and the copper oxide ore can pass through a 100-mesh sieve. The method of the invention improves the production efficiency of copper oxide ore leaching, realizes the continuous acid leaching of copper oxide ore, improves the copper leaching rate, greatly reduces production cost, and provides a new option for acid leaching of copper oxide ore ,with broadly application foreground.

Owner:PANZHIHUA QINGHONGYUAN ENVIRONMENTAL PROTECTION TECH

Method for separating copper from lead matte and comprehensively utilizing lead matte

InactiveCN104004907AReduce pollutionLow equipment requirementsProcess efficiency improvementSulfate radicalsRefining (metallurgy)

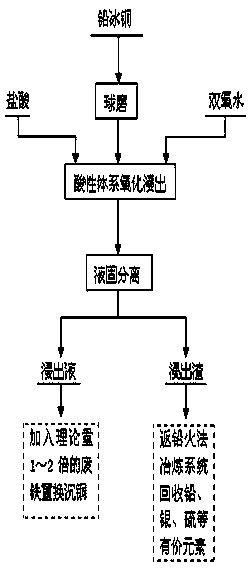

The invention relates to a method for separating copper from lead matte and comprehensively utilizing lead matte, and belongs to the field of wet metallurgy of non-ferrous metals. The process is characterized by adding hydrogen peroxide under a hydrochloric acid system for oxidization leaching. The method is as follows: ball-milling lead matte blocks until grain size is lower than 100 meshes, and feeding the ball-milled lead matte into a leaching slot for carrying out oxidization leaching, wherein HCl concentration is controlled to 1mol / L-6mol / L, concentration of hydrogen peroxide is controlled to 0.5mol / L-3.5mol / L, a liquid-solid ratio is controlled to (3-10):1, a temperature is controlled to 60-90 DEG C and reaction time is controlled to 1-2 hours. Under a hydrochloric acid condition, hydrogen peroxide is utilized and used as an oxidant for leaching sulfide; in the oxidization leaching process, sulfur in the lead matte is oxidized into elemental sulfur or sulfate radical, copper is oxidized to enter liquor in the form of ion, and lead is left in slag with gold and sliver in the form of lead chloride or lead sulfate. After the leaching process is completed, solid-liquid separation is carried out to realize preliminary separation of copper and lead. Copper-rich leachate can replace deposited copper by adding scrap iron, and leaching residue is returned to a pyrogenic process lead refining system for recycling valuable elements such as lead, sliver, elemental sulfur, and the like.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Pretreatment method for platinum palladium concentrate

ActiveCN103045849AEasy to extract and handleLow precious metal contentProcess efficiency improvementPretreatment methodSlag

The invention provides a pretreatment method for platinum palladium concentrate. The pretreatment method comprises the following steps: mixing the platinum palladium concentrate, sodium carbonate, sodium hydroxide and sodium chlorate uniformly according to a certain ratio; roasting at certain temperate; transforming impurity elements such as copper, selenium and tellurium into corresponding oxide or corresponding salt; and adding the roasting slag into water according to a certain ratio and leaching, wherein impurities such as copper, selenium and tellurium enter the alkaline leachate, and gold, platinum and palladium are enriched in the alkaline leaching slag. Compared with the traditional pretreatment method for the platinum palladium concentrate, the pretreatment method for the platinum palladium concentrate has the advantages that oxidation roasting and water leaching are adopted, so the noble metal content of the alkaline leachate is low; the leaching rate of the impurities such as copper, selenium and tellurium is high, the copper leaching rate reaches over 95 percent, the selenium leaching rate reaches over 88 percent, and the tellurium leaching rate reaches over 95 percent; the enrichment rate of the noble metal such as gold, platinum and palladium is high, so the extraction treatment on gold, platinum and palladium in the next step is promoted; and equipment is low in corrosivity, safe in operation, good in comprehensive recycling benefit and good in operating environment.

Owner:JIANGXI COPPER

Method for selectively extracting copper from iron-copper-matte materials

ActiveCN105349791AImprove electrolysis efficiencyIncrease current densityProcess efficiency improvementElectrolysisHydrometallurgy

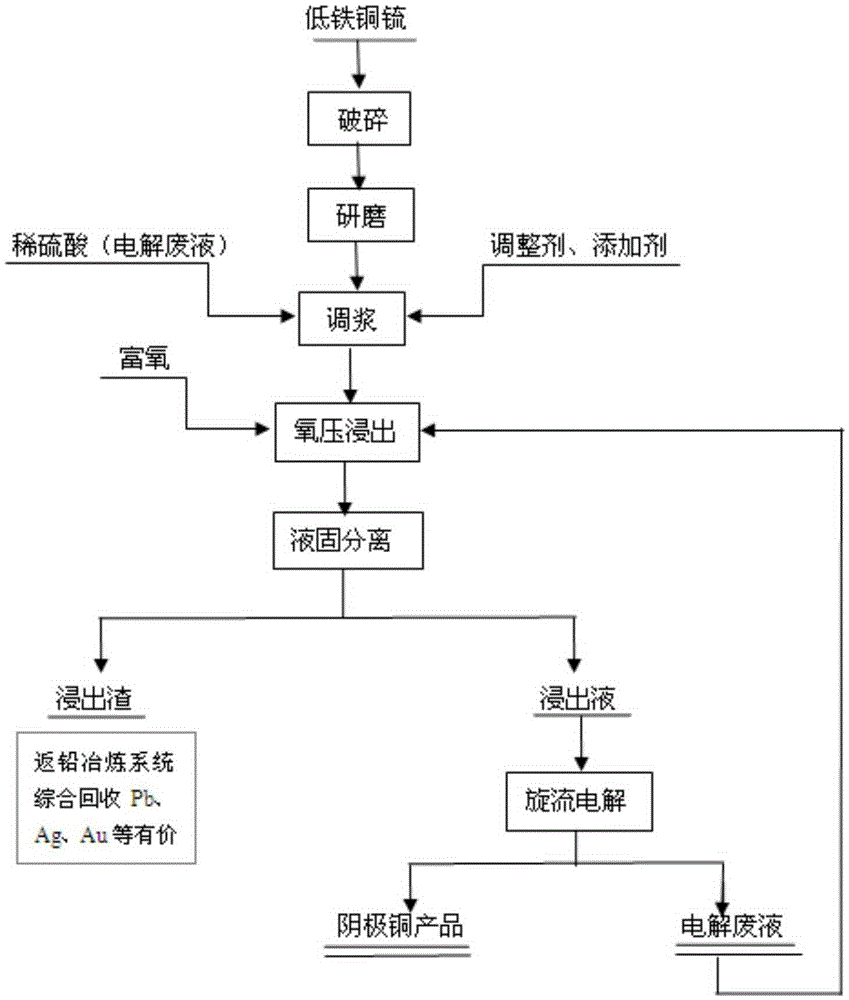

The invention relates to the field of hydrometallurgy of nonferrous metals, in particular to a method for selectively extracting copper from iron-copper-matte materials. The method for selectively extracting the copper from the iron-copper-matte materials comprises the following steps that after being subjected to crushing grinding and sulfuric acid adding size mixing, the iron-copper-matte materials are subjected to oxidizing leaching by pumping enriched oxygen into a high-pressure kettle; after oxidizing leaching of the iron-copper-matte materials is completed, solid-liquid separation is carried out to obtain leaching liquid and leaching residues; and after the leaching liquid is subjected to acid adjusting, a rotational flow electrolysis technology is adopted for obtaining a cathode copper product. The iron-copper-matte materials comprise, by weight percentage, 15%-45% of Pb, 35%-60% of Cu, 2%-18% of S, 0.2%-0.8% of Ag, 5%-20% of As and 0.05%-0.6% of Fe. The method is especially suitable for selectively extracting the copper from the iron-copper-matte materials with the low iron content, the rotational flow electrolysis technology is adopted in the copper leaching liquid for electrolysis of settled copper, the yield is higher, and the obtained cathode copper product is few in impurity and high in purity.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

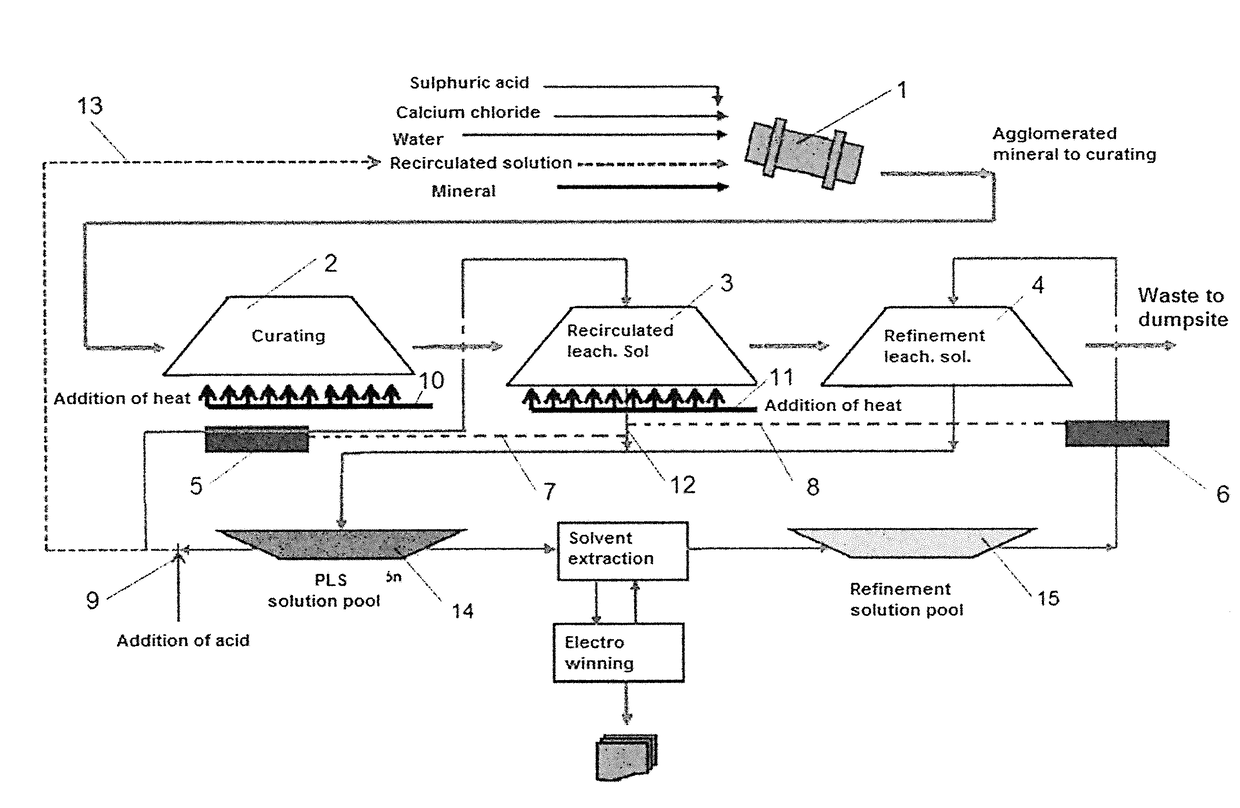

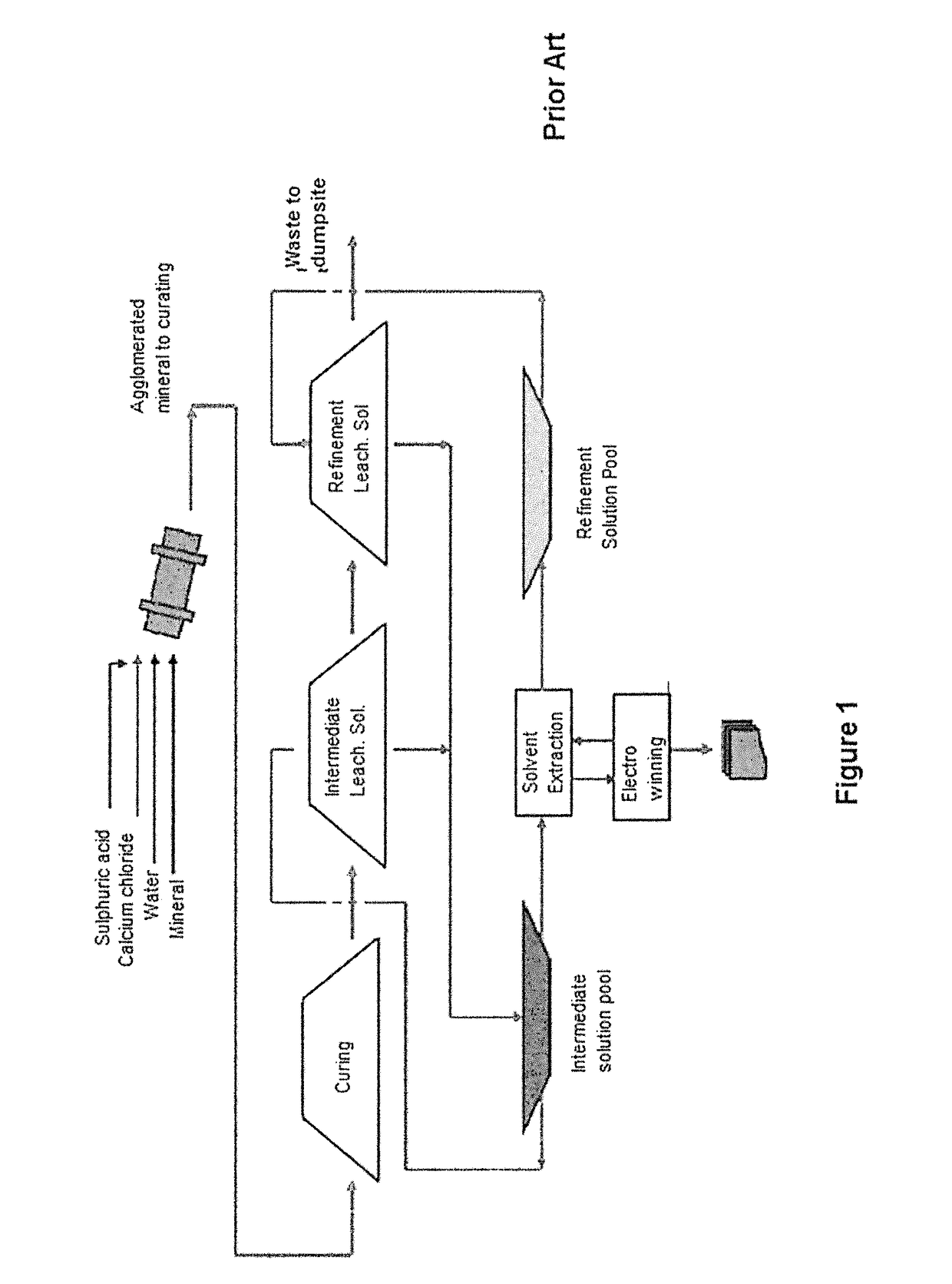

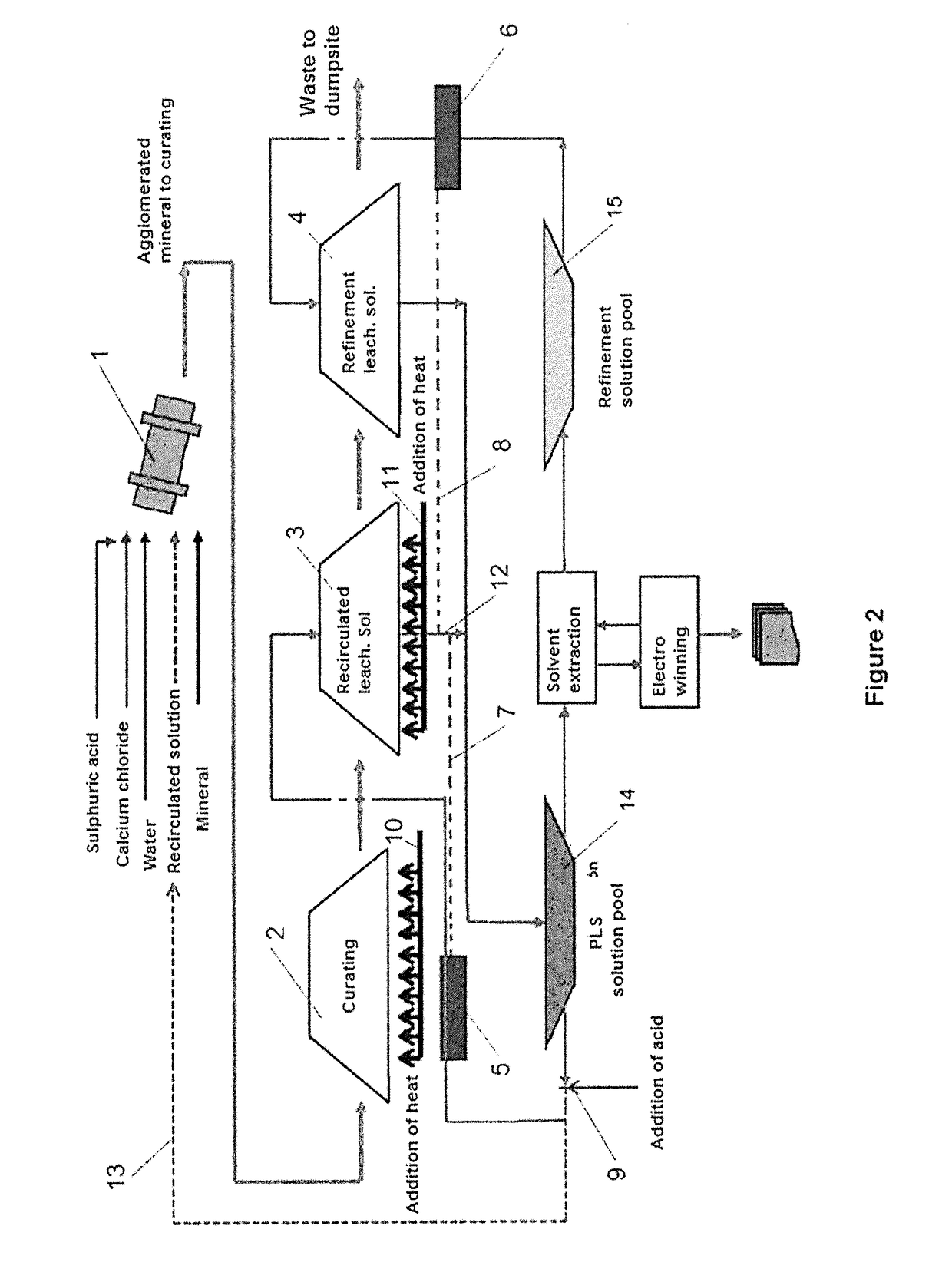

Process For the Improvement of Copper Leaching Processes Using Calcium Chloride

A process to significantly improve the copper chemical leaching process for primary and secondary minerals, using calcium chloride including the agglomeration, curing, and leaching with a high content of chloride, iron and copper stages. The mineral is then washed with a low concentration of copper and a high concentration of acid, where the impregnated copper is extracted from the pit and wherein a recirculated solution is used in the agglomeration stage.

Owner:ANTOFAGASTA MINERALS SA

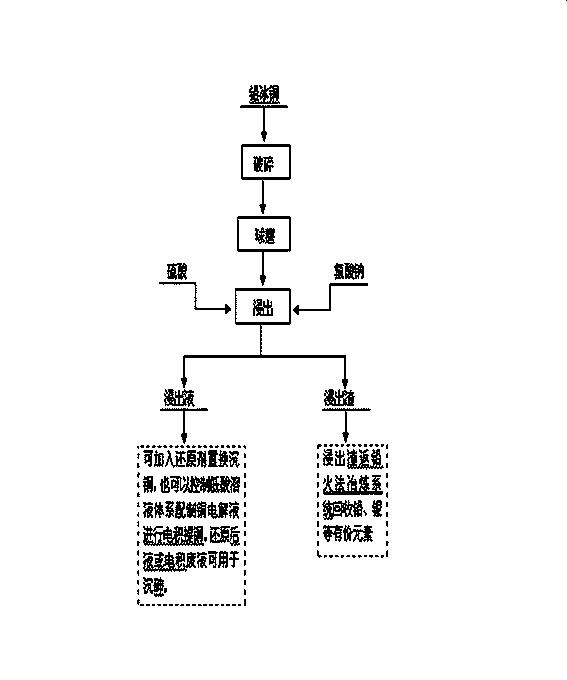

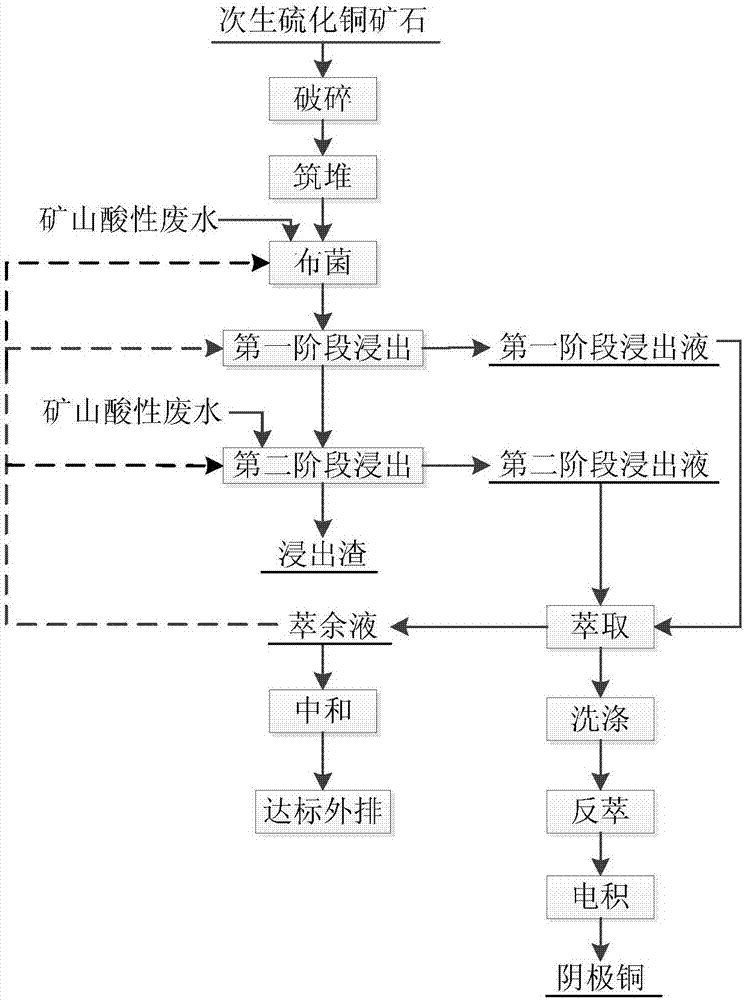

Heap bioleaching method for secondary copper sulfide ore

ActiveCN107267755ASimple process controlReduce manufacturing costProcess efficiency improvementRaffinateCopper sulfide

The invention discloses a heap bioleaching method for secondary copper sulfide ore. The heap bioleaching method for the secondary copper sulfide ore comprises the steps that after the secondary copper sulfide ore is heaped, mine acid waste water or raffinate is used for spray wetting and fungus distribution, so that microorganisms are made to grow rapidly on the surface of the ore, and rapid leaching of the secondary copper sulfide ore is achieved; and afterwards, the leaching process is conducted by two stages, specifically, in the first stage, the raffinate obtained after leach liquor is extracted is used for continuous spraying, the acid concentration is controlled to 5-15 g / L, the total iron concentration is controlled to 5-15 g / L, and the oxidation reduction potential does not need to be controlled particularly; and the second stage is started when the copper leaching rate reaches 45%-50%, the mine acid waste water or the mixed liquor of the mine acid waste water and the raffinate is used for intermittent spraying in the second stage of the leaching process, the acid concentration is controlled to 3-6 g / L, the total iron concentration is controlled to 3-6 g / L, and the oxidation reduction potential is controlled to 600-700 mV. By adoption of the heap bioleaching method for the secondary copper sulfide ore, oxidation of iron pyrite can be effectively restrained while efficient leaching of copper is achieved, technological parameters can be controlled easily, the production cost is low, and the economic benefit and the environment benefit are remarkable.

Owner:ZIJIN MINING GROUP

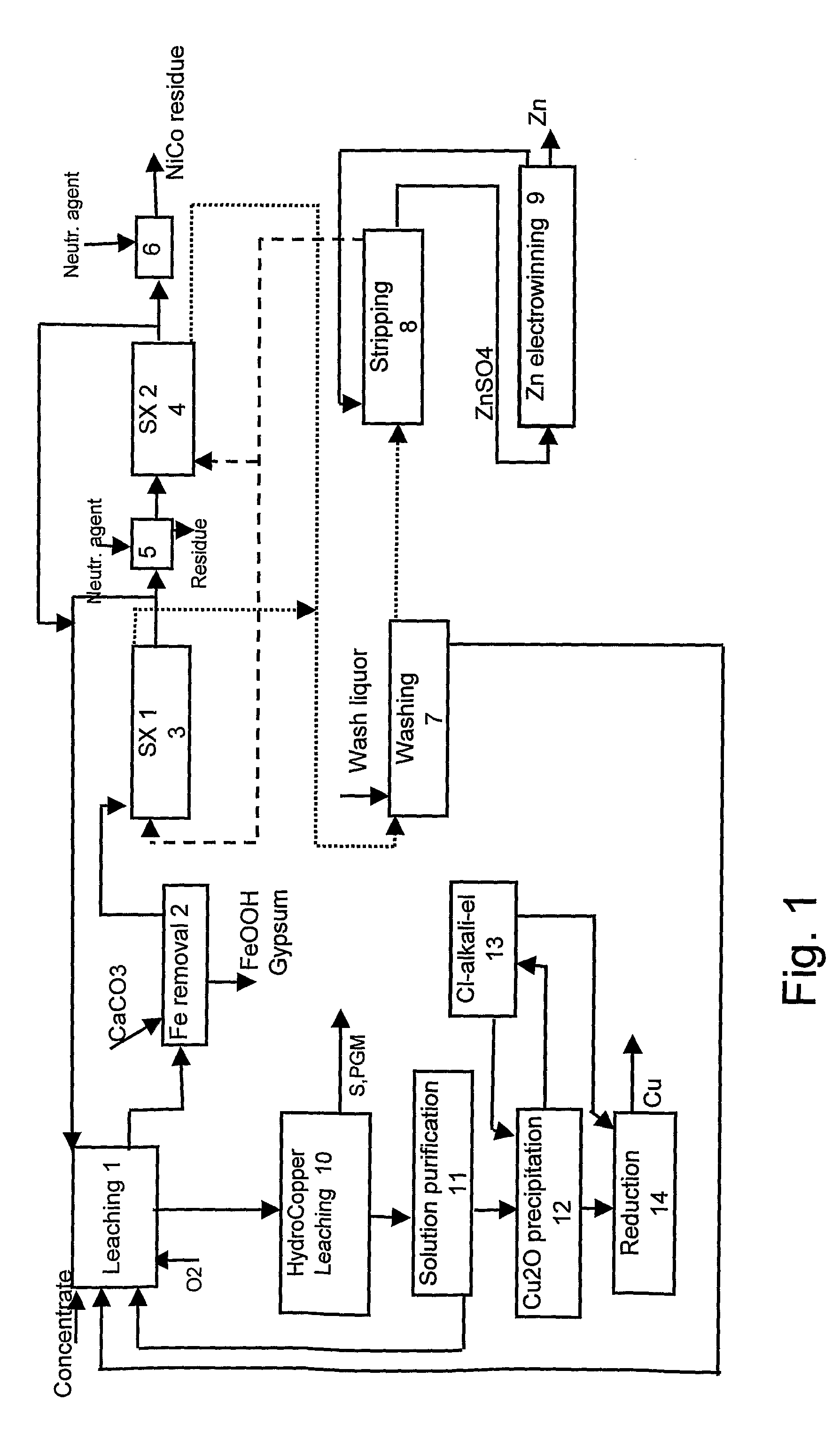

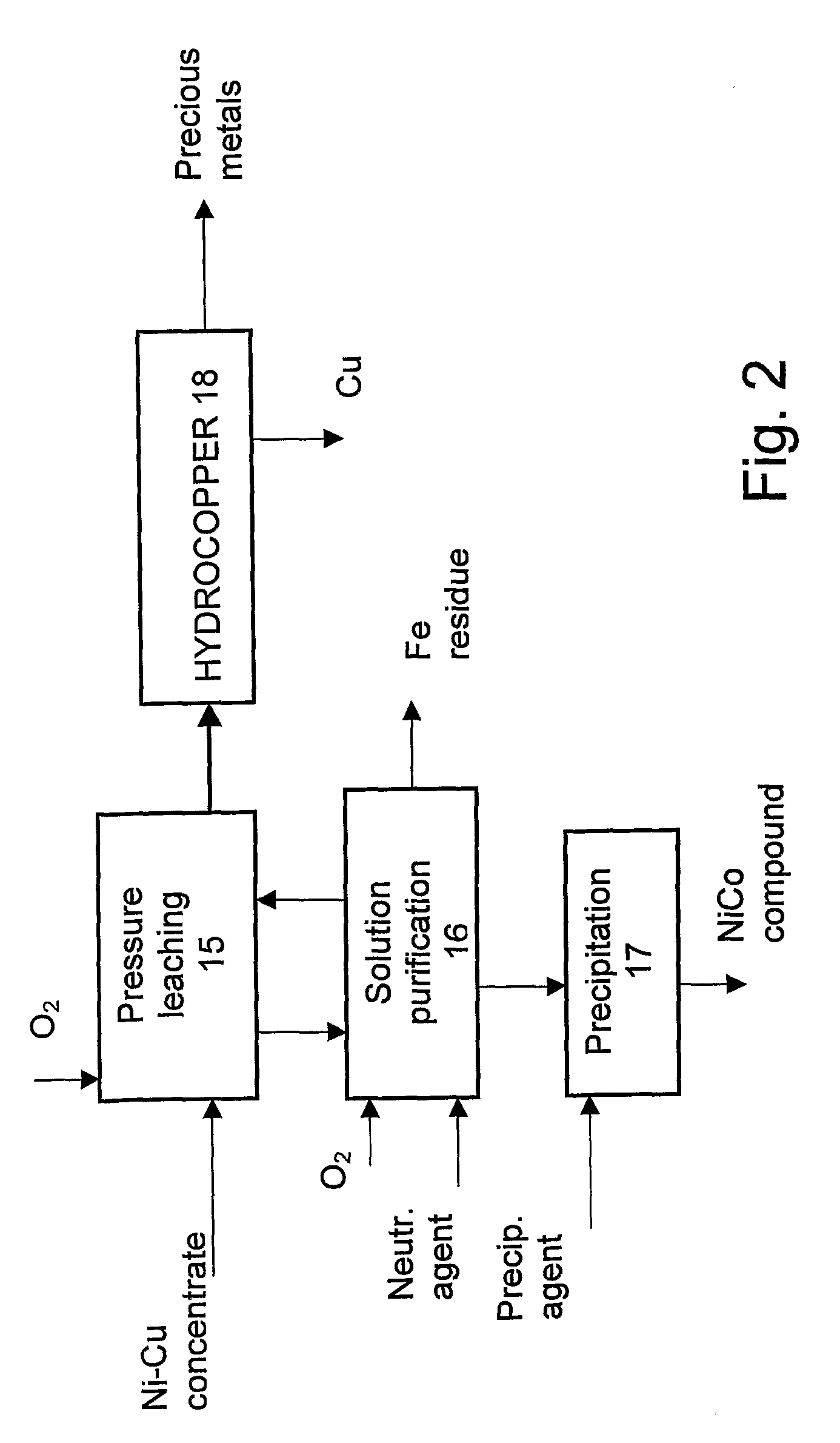

Method for the Hydrometallurgical Treatment of Sulfide Concentrate Containing Several Valuable Metals

The invention relates to a method, by means of which the valuable metals contained in a sulphidic, multicomponent concentrate are recovered using hydrometallurgical treatment. One constituent of the concentrate is copper sulphide, which is leached using an alkali chloride-copper (II) chloride solution. The sulphides of other valuable metals, such as zinc, nickel, cobalt and lead are leached before copper leaching and each is recovered as a separate product before copper recovery.

Owner:OUTOTEC OYJ

Method for efficiently extracting tungsten, molybdenum and copper from molybdenum slag

InactiveCN107345275AEfficient extractionReduce churnPhotography auxillary processesProcess efficiency improvementSlagDissolution

The invention discloses a method for efficiently extracting tungsten, molybdenum and copper from molybdenum slag. Through the technology of pretreatment removal of S2-, alkali dissolution for tungsten and molybdenum leaching, tungsten and molybdenum separation through primary amine extraction, copper leaching through inorganic acid, extraction enrichment purification through a ketoxime and aldoxime compound extraction agent, and copper electrowinnig, efficient extracting of tungsten, molybdenum and copper from molybdenum slag is achieved, losing of valuable metal can be reduced, and heavy metal diffusion in slag can be solved.

Owner:XINYANG HUARUI MOLYBRENUM NEW MATERIALS CO LTD

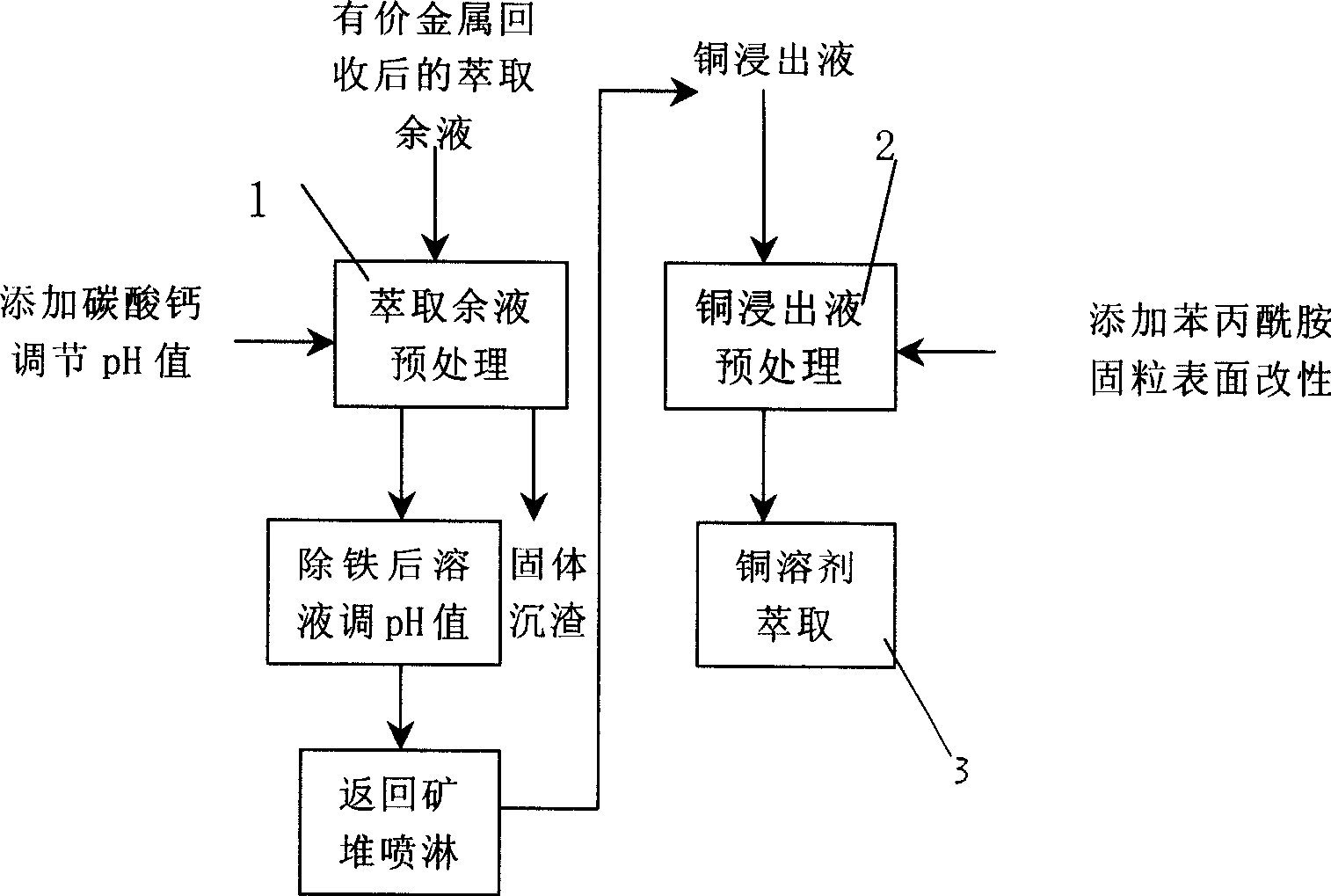

Method for eliminating interface emulsification during copper biochemical lixivium extraction process

ActiveCN101457294AImprove extraction efficiencyProcess efficiency improvementPregnant leach solutionEmulsion

The invention relates to a method for eliminating interfacial emulsion in an extraction process of copper bio-leaching solution. The method comprises the following steps: calcium carbonate is added to raffinate for sprinkling on a returned bing for precipitating ferric iron in the purification processes of the bio-leaching solution and the raffinate, a pH value of the bio-leaching solution is controlled by adjusting leaching system technological parameters, and the generation of ferric alum precipitation can be effectively controlled; a proper amount of hydrocinnamamide is added to prevent amphiphilic substances such as solid particles, and extractant degradation product and the like in the leaching solution from entering an extraction system, thus effectively eliminating the interfacial emulsion in the extraction process. The technological method is applicable to a pretreatment process of the copper leaching solution and the raffinate, has no emulsion when purified feed liquid is treated by extraction separation, reduces the consumption of raw materials such as the extractant and the like, improves the copper extraction efficiency and solves the problem of the interfacial emulsion in the extraction process.

Owner:有研资源环境技术研究院(北京)有限公司

Method of obtaining copper from ore

Owner:JX NIPPON MINING & METALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com