Patents

Literature

305 results about "Heap leaching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heap leaching is an industrial mining process used to extract precious metals, copper, uranium, and other compounds from ore using a series of chemical reactions that absorb specific minerals and re-separate them after their division from other earth materials. Similar to in situ mining, heap leach mining differs in that it places ore on a liner, then adds the chemicals via drip systems to the ore, whereas in situ mining lacks these liners and pulls pregnant solution up to obtain the minerals. Most mining companies favor the economic feasibility of heap leaching, considering that heap leaching is a better alternative to conventional processing methods such as flotation, agitation, and vat leaching.

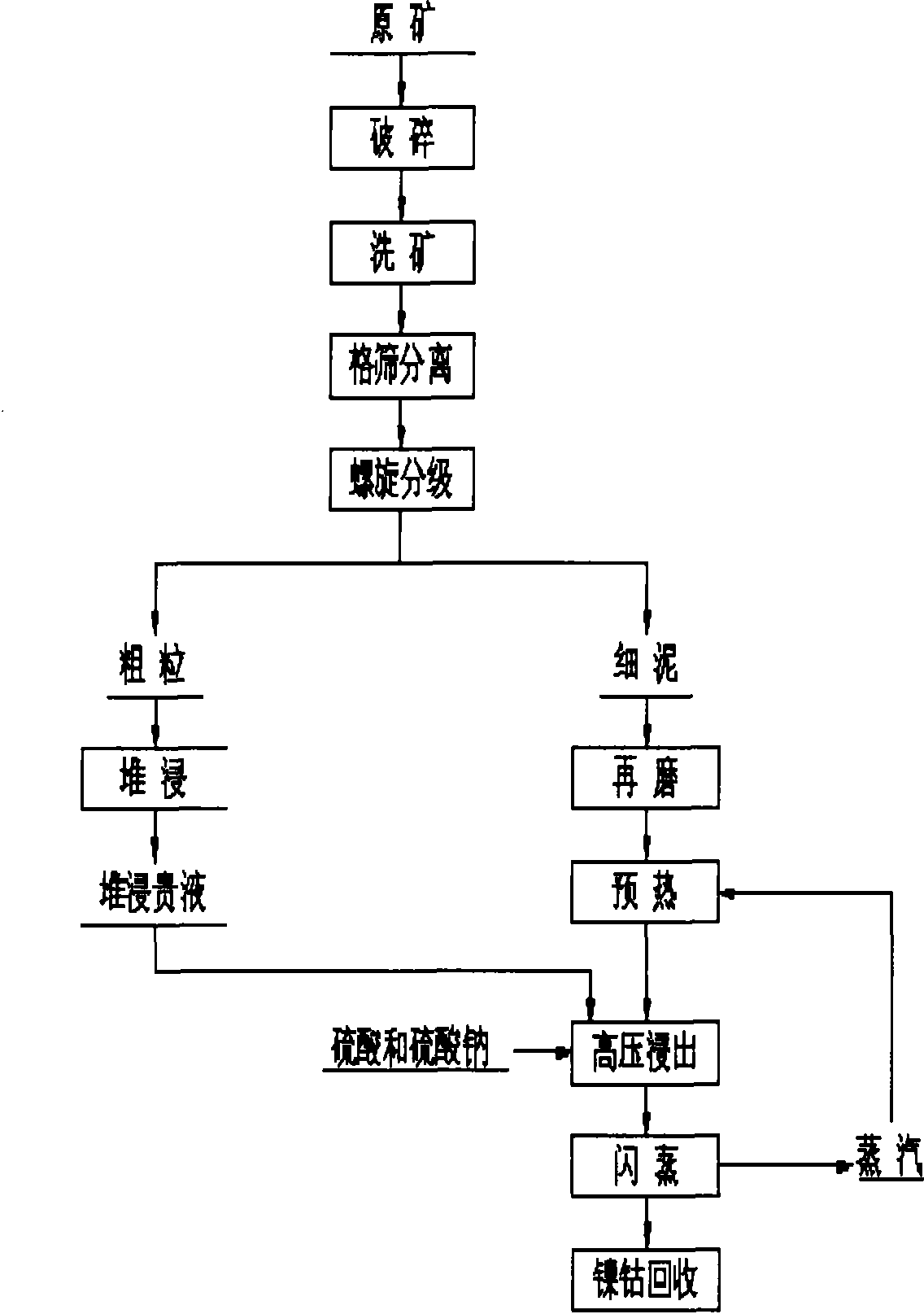

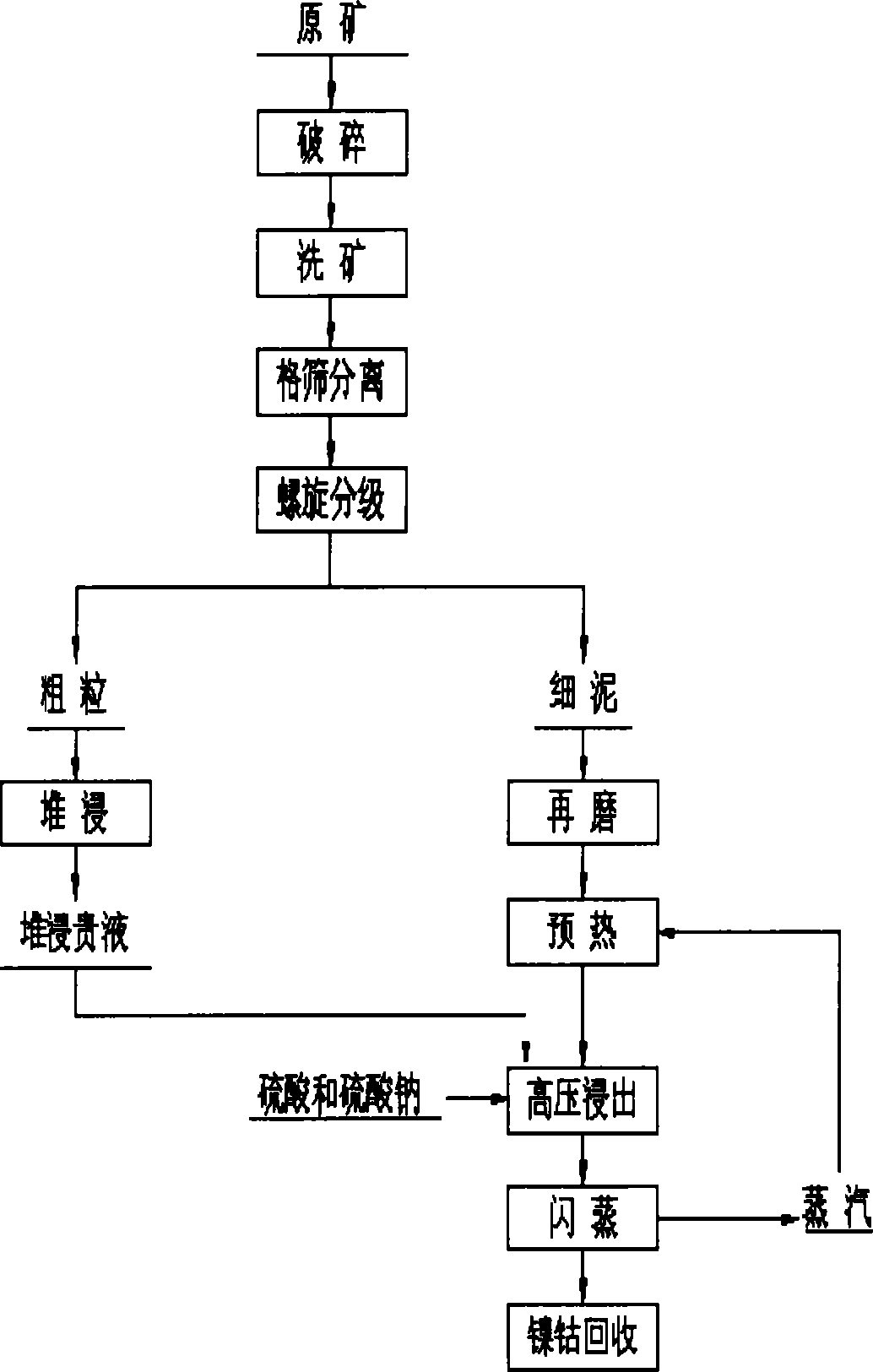

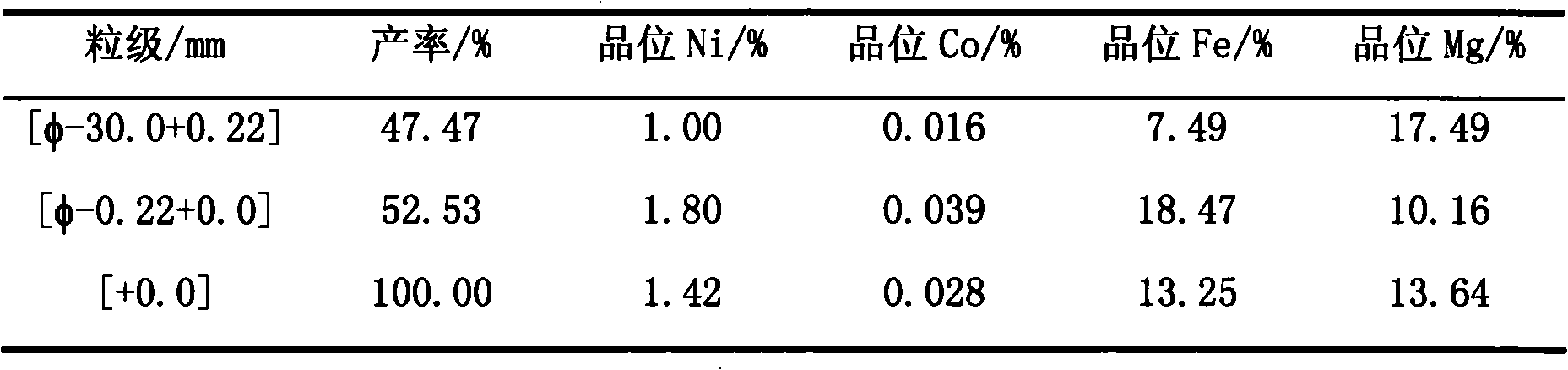

Method for reducing acid consumption during heap leaching and high-pressure leaching of nickel laterite ore

InactiveCN101768665AReduce acid consumptionReduce consumptionProcess efficiency improvementHigh pressureLaterite

The invention discloses a method for reducing acid consumption during heap leaching and high-pressure leaching of nickel laterite ore, which combines the heap leaching technology with the high-pressure leaching technology to reduce acid consumption during the treatment of nickel laterite ore; residual sulfuric acid in coarse particle immersion of limonite heap is sufficiently utilized and sodium sulfate is added during the stage of high-pressure leaching so that sulfuric acid is generated while yellow natrojarosite is formed, thereby further reducing the consumption of sulfuric acid during the stage of high-pressure leaching.

Owner:厦门紫金矿冶技术有限公司

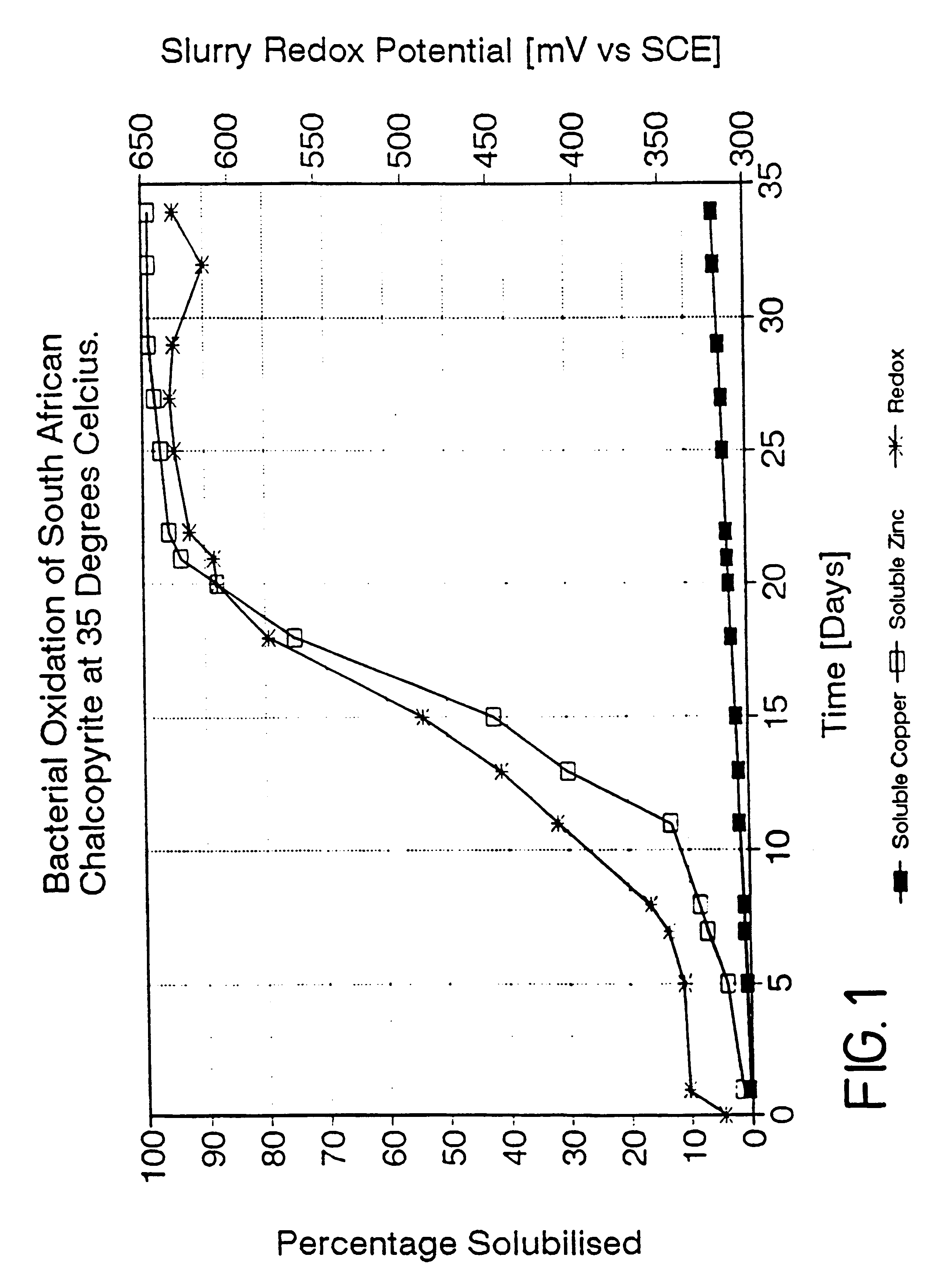

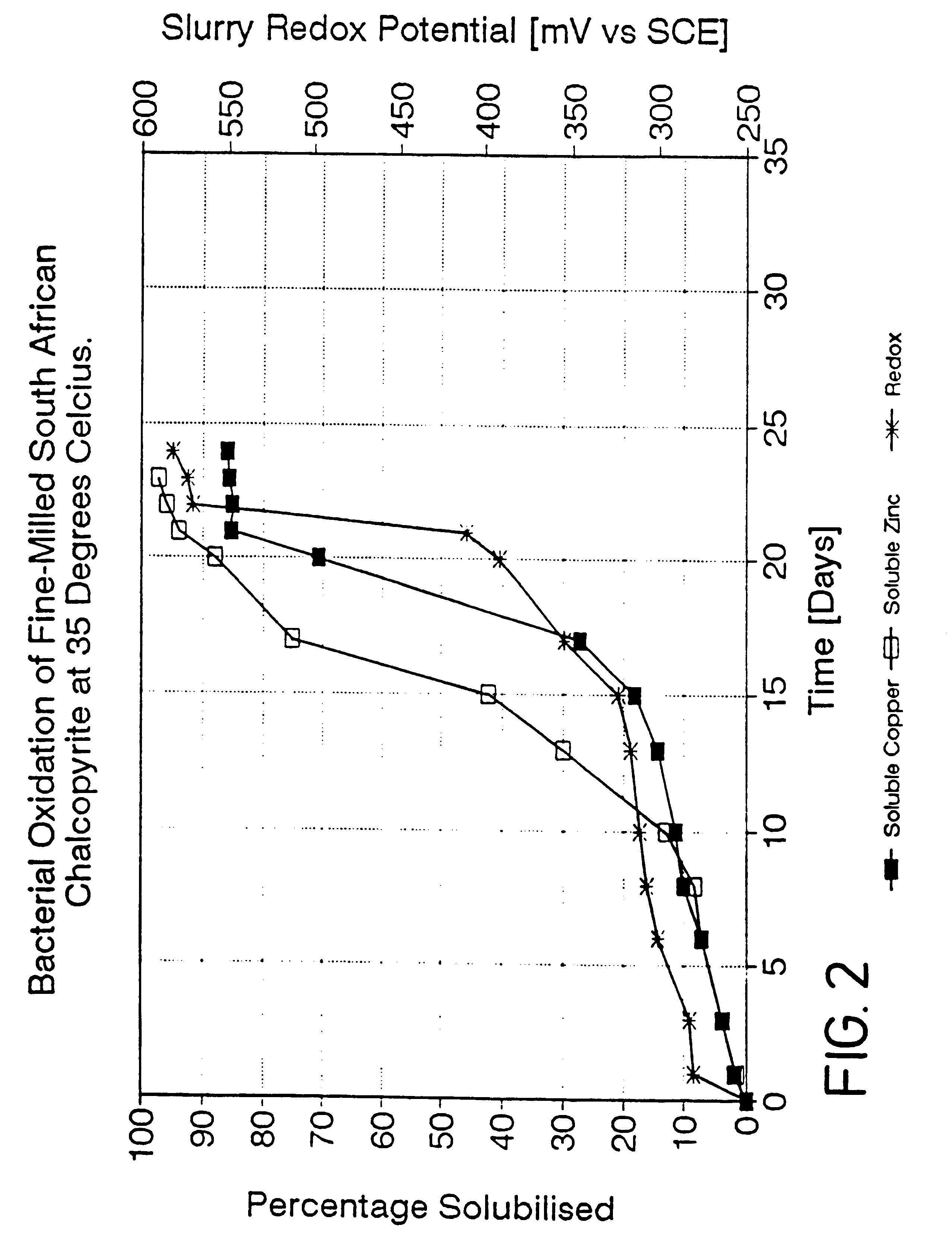

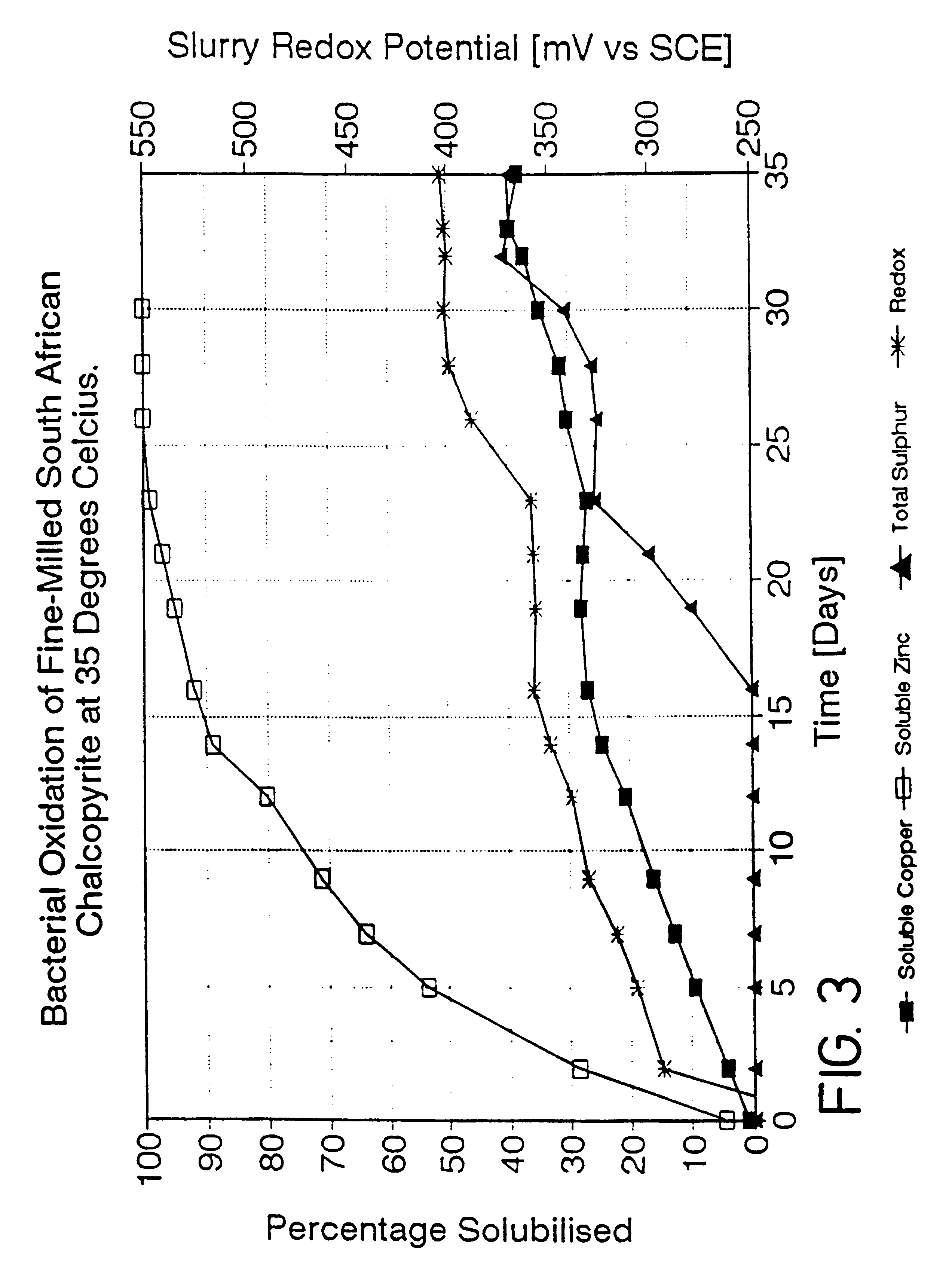

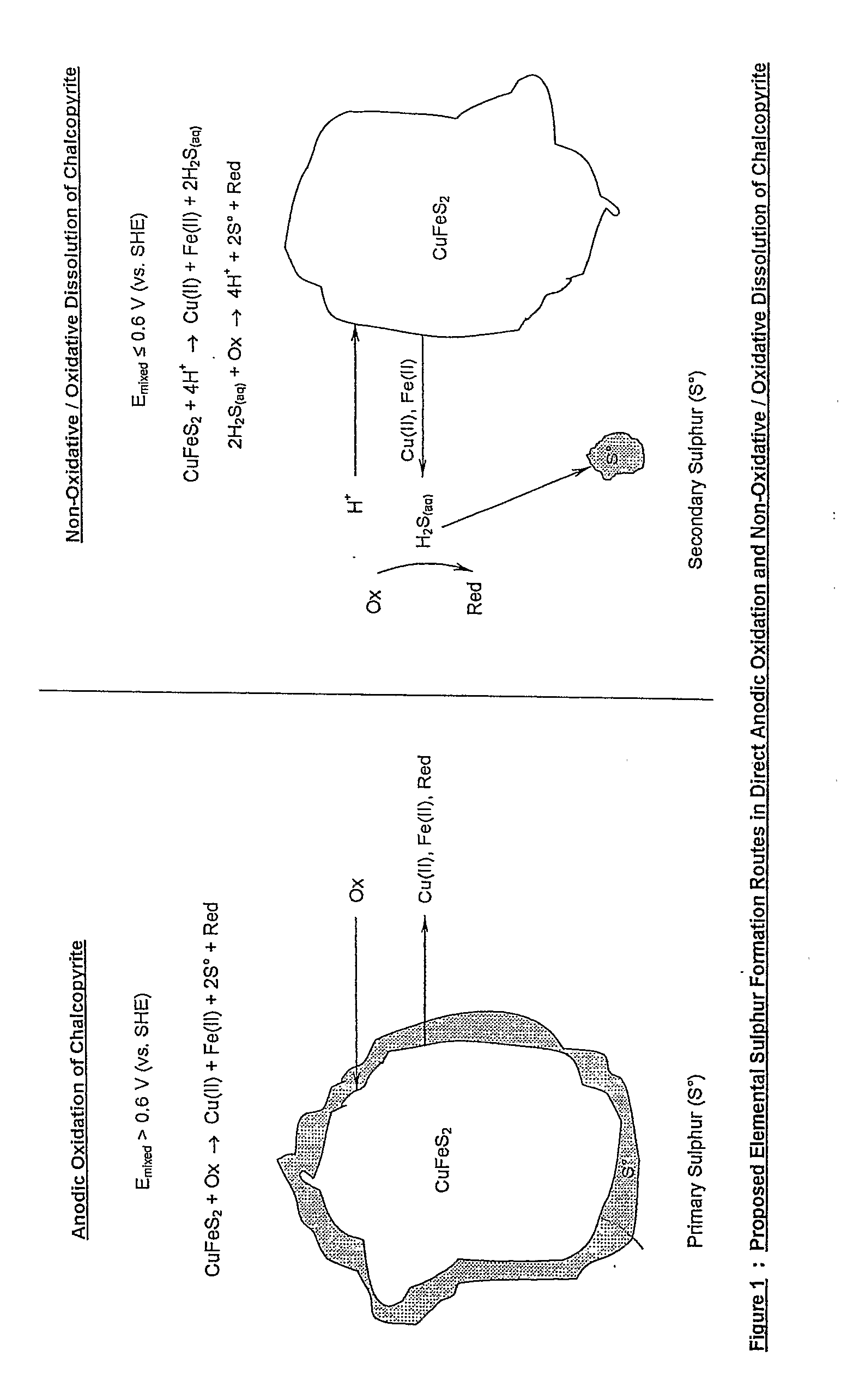

Process for the rapid leaching of chalcopyrite in the absence of catalysts

InactiveUS6277341B1Increase surface areaImprove misalignmentSolvent extractionGold compoundsPregnant leach solutionChalcopyrite

Owner:MINTEK

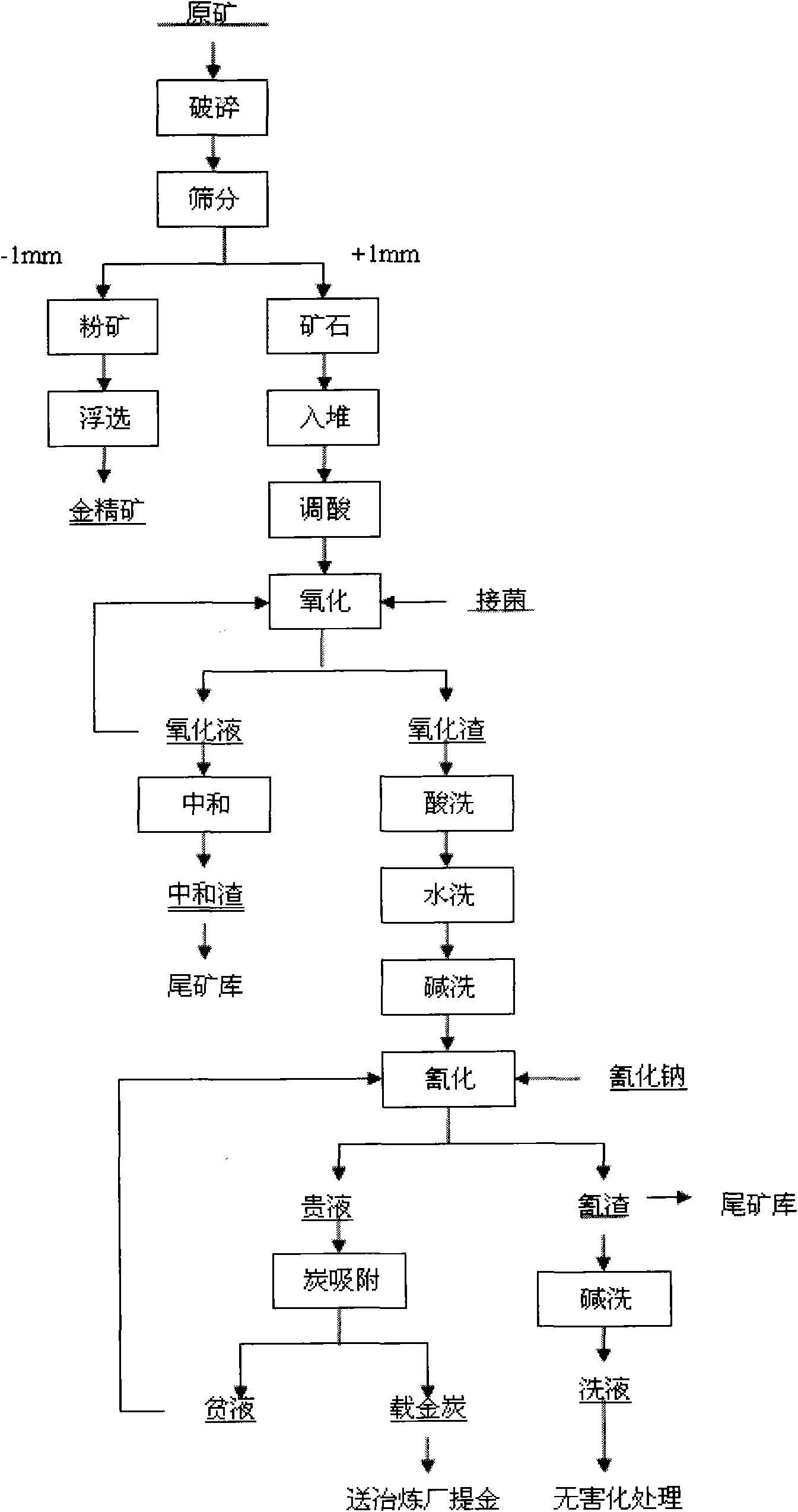

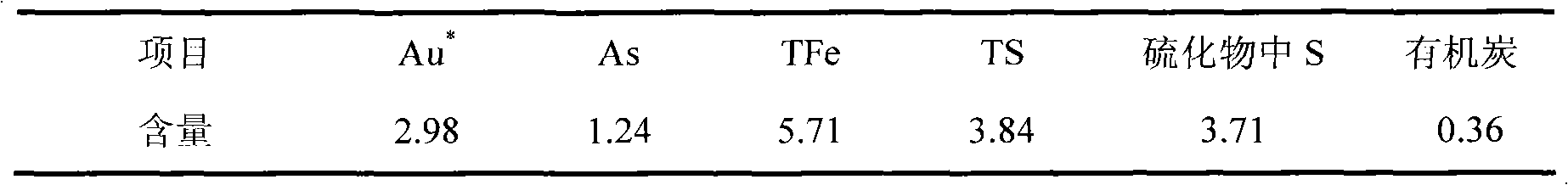

Process for extracting gold from low-grade difficultly-treatable gold ore containing arsenic and carbon

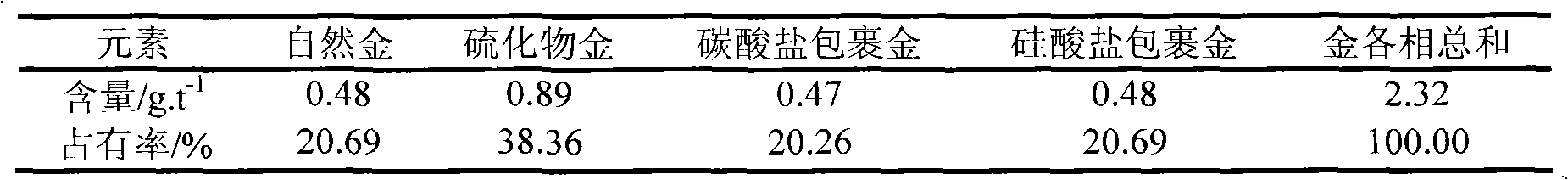

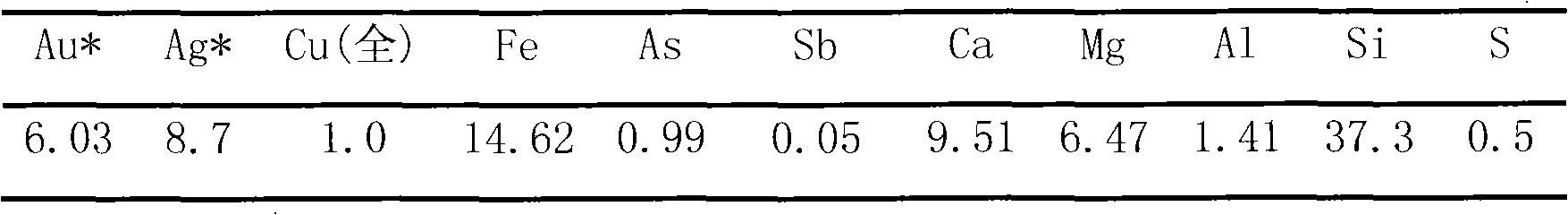

The invention relates to a process for extracting gold from low-grade difficultly-treatable gold ore containing arsenic and carbon. The process is characterized in that: the gold ore has the characteristics of high clay mineral content, large fine ore amount after grinding, and the like. The process comprises the following steps of: grinding raw ore to 10 to -30 millimeters; sieving ore through a sample sieve of 1 to -2 millimeters or washing the ore with water so as to separate fine ore from the ore; floating gold concentrate by using the obtained fine ore; performing direct heap leaching on ore of +2 millimeter and performing biological oxidation; performing medium transformation such as acid washing, water washing, alkali washing and the like on the biologically-oxidized ore and cyaniding directly so as to extract gold, wherein gold is extracted from the floated gold concentrate by biological oxidation-cyaniding and carbon soaking-pressure oxidation-cyaniding and gold extraction or baking, oxidation and cyaniding. Due to the adoption of the process, the problem of permeability of gold ore is solved and the gold extracting rate is effectively increased from 2 to 5 percent during direct heap leaching and cyaniding to 55 to 65 percent. The process has the advantages of simple process, high gold extracting rate, low pollution, high benefit and the like.

Owner:ZIJIN MINING GROUP

Heap-leaching method for separating copper and tin from tin-plated copper wires

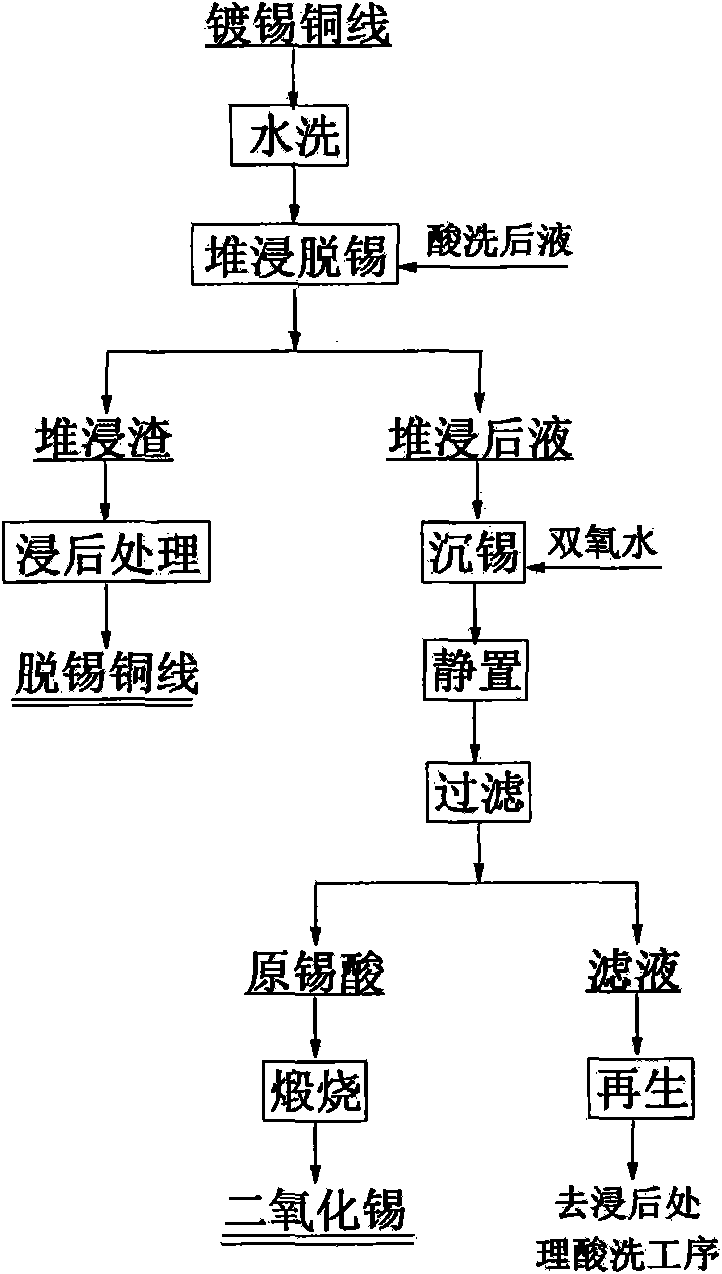

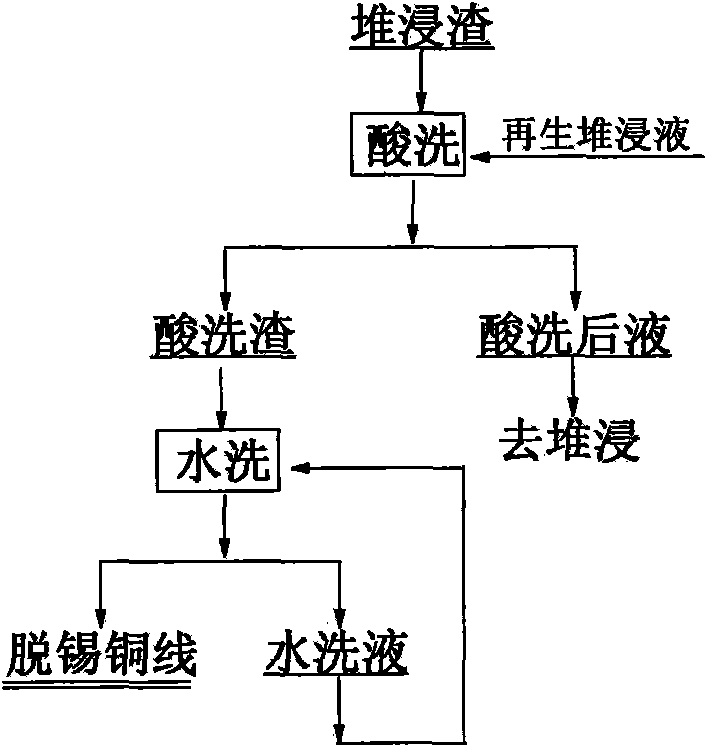

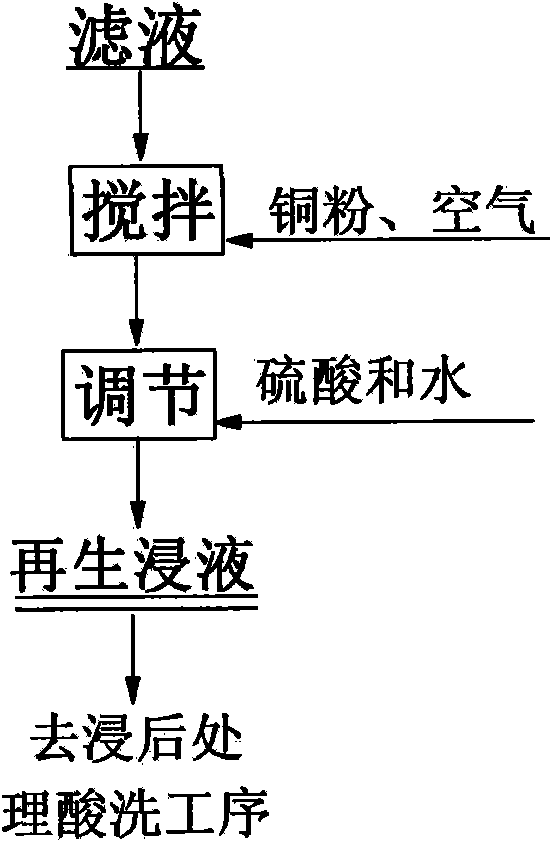

ActiveCN101643852ASolve the problem of difficult mixingSimple processProcess efficiency improvementTinningHydrogen

The invention provides a heap-leaching method for separating copper and tin from tin-plated copper wires, belonging to the recovery processing of waste tin-plated copper wires. The method adopting thecopper sulfate replacement / heap-leaching method comprises the following steps: washing and stacking peeled waste tin-plated copper wires on an acid-proof and alkali-proof heap-leaching platform for heap-leaching; pickling the heap-leaching residue with recycling heap-leaching solution, and further washing the pickled heap-leaching residue to obtain detinned copper wires; adding hydrogen peroxideto the heap-leaching solution until no white precipitation is generated, heating the reaction solution until the reaction solution is boiling, standing, filtering, and drying to obtain original stannic acid, and further calcining the original stannic acid to obtain stannic oxide; adding a proper amount of copper powder and blowing air to the filtrate, wherein the addition amount of the copper power is the copper amount required by copper sulfate in the recycling heap-leaching solution; and controlling the temperature and time of the reaction and adjusting the concentrations of copper sulfate and sulfuric acid of the solution by sulfuric acid and water. The method has the advantages that the process is simple and easy-to-operate, the materials and devices are common and cheap, the tin-plated copper wires dispense with stirring in the heap-leaching process, the heap-leaching solution is recyclable and pollution-free, the removal rate of tin is higher than 95%, and the recovery rate of hydrogen peroxide immersion tin is higher than 98%.

Owner:UNIV OF SCI & TECH BEIJING +1

Moderate thermophilic enriched substance used for mineral leaching of copper pyrites

InactiveCN101560485APromote leachingReduce inhibitionBacteriaMicroorganism based processesHigh concentrationFerroplasma thermophilum

The invention discloses a moderate thermophilic enriched substance used for mineral leaching of copper pyrites, comprising five mineral leaching microorganisms: acidithiobacillus caldus S2, leptospirillum ferriphilum YSK, sulfobacillus acidophilus ZW-1, sulfobacillus thermosulfidooxidans YN22 and ferroplasma thermophilum L1; the pH value and the temperature which are most suitable for the growth of the enriched substance are respectively 1.4-2.0 and 45-48 DEG C. Compared with the existing microorganisms used for brass bio-heap leaching, the enriched substance not only improves the leaching reaction kinetics and shortens the leaching period, but also reduces the passivation inhibition phenomenon and increases the bioleaching speed and the leaching rate of the copper pyrites; furthermore, the enriched substance can endure high concentration metallic ion at the late stage of bioleaching.

Owner:CENT SOUTH UNIV

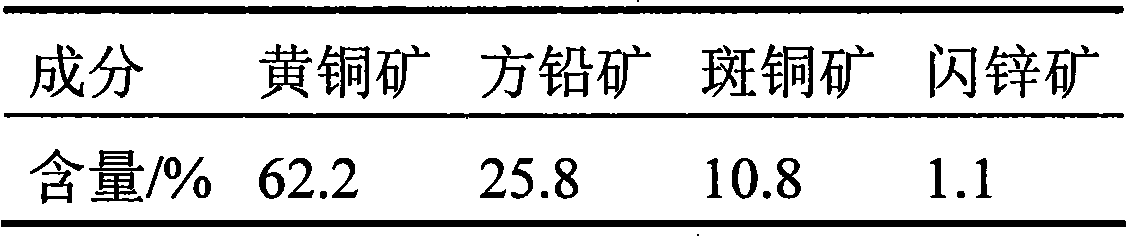

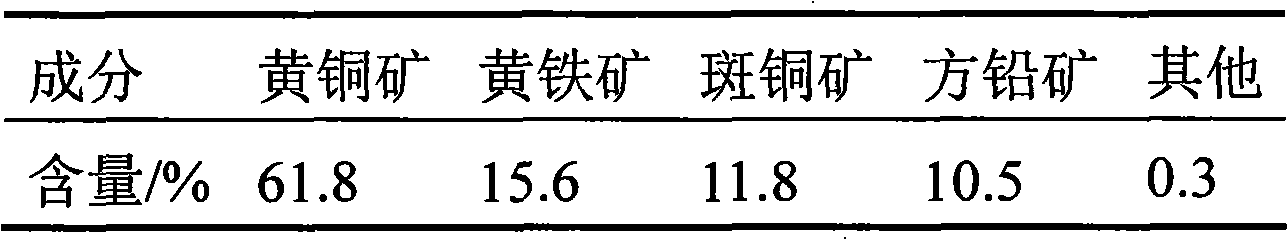

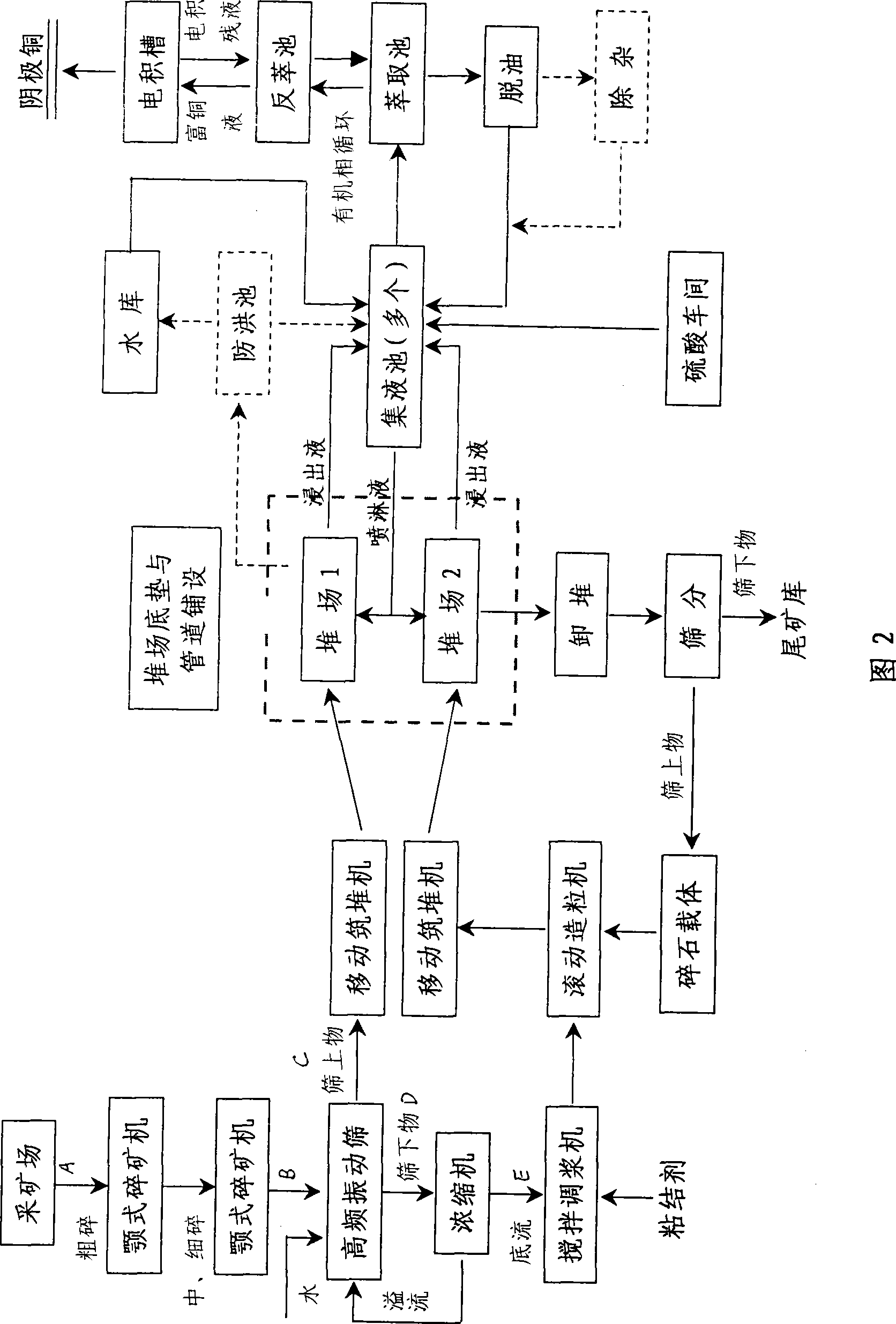

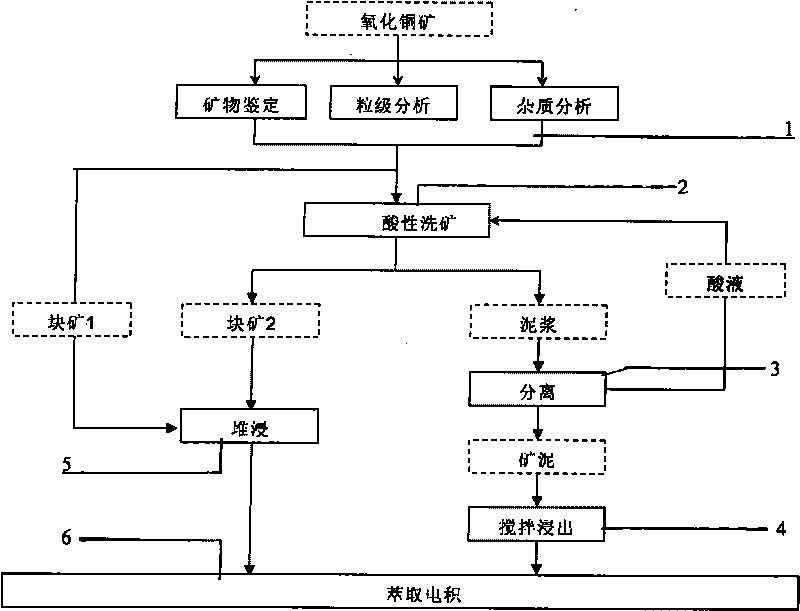

Wet processing process of high mud cupric oxide mine at high-cold area

InactiveCN101457299ASolve permeabilitySolve the problem of low copper leaching ratePhotography auxillary processesProcess efficiency improvementSlagCopper oxide

The invention provides a wet copper extraction process used in high mud-content copper oxide ores of cold areas. The process comprises the following steps: crude ores are crushed and sieved, coarse fraction ores are sent to a storage yard for piling, fine fraction ores are sent to an ore washing system for washing and grading; placer ores are sent to the storage yard for the piling after washing the ores, and mud ores are sent to an agitation tank for agitation leaching; leaching solution which is obtained from heap leaching and agitation leaching processes is sent for extraction and stripping; stripping concentration solution is sent to an electrodeposition process, and a qualified cathode copper product is obtained; leached slag from the agitation leaching is neutralized and sent to a tailings reservoir for piling. The process has good permeability, fast copper leaching rate, and greatly improved copper leaching rate and leached copper yield per day by the grading and the heap leaching of the coarse fraction ores; and the copper leaching rate is improved and the ore utilization rate is greatly improved by the agitation leaching of minus 0.074mm size fraction ores. The method is applicable to the development and the application in the wet copper extraction process used in the high mud-content copper oxide ores of the cold areas, solves the difficult technical problems of poor bing permeability and slow copper leaching rate, widens the use range of copper ore resources and improves the comprehensive utilization rate of the copper.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

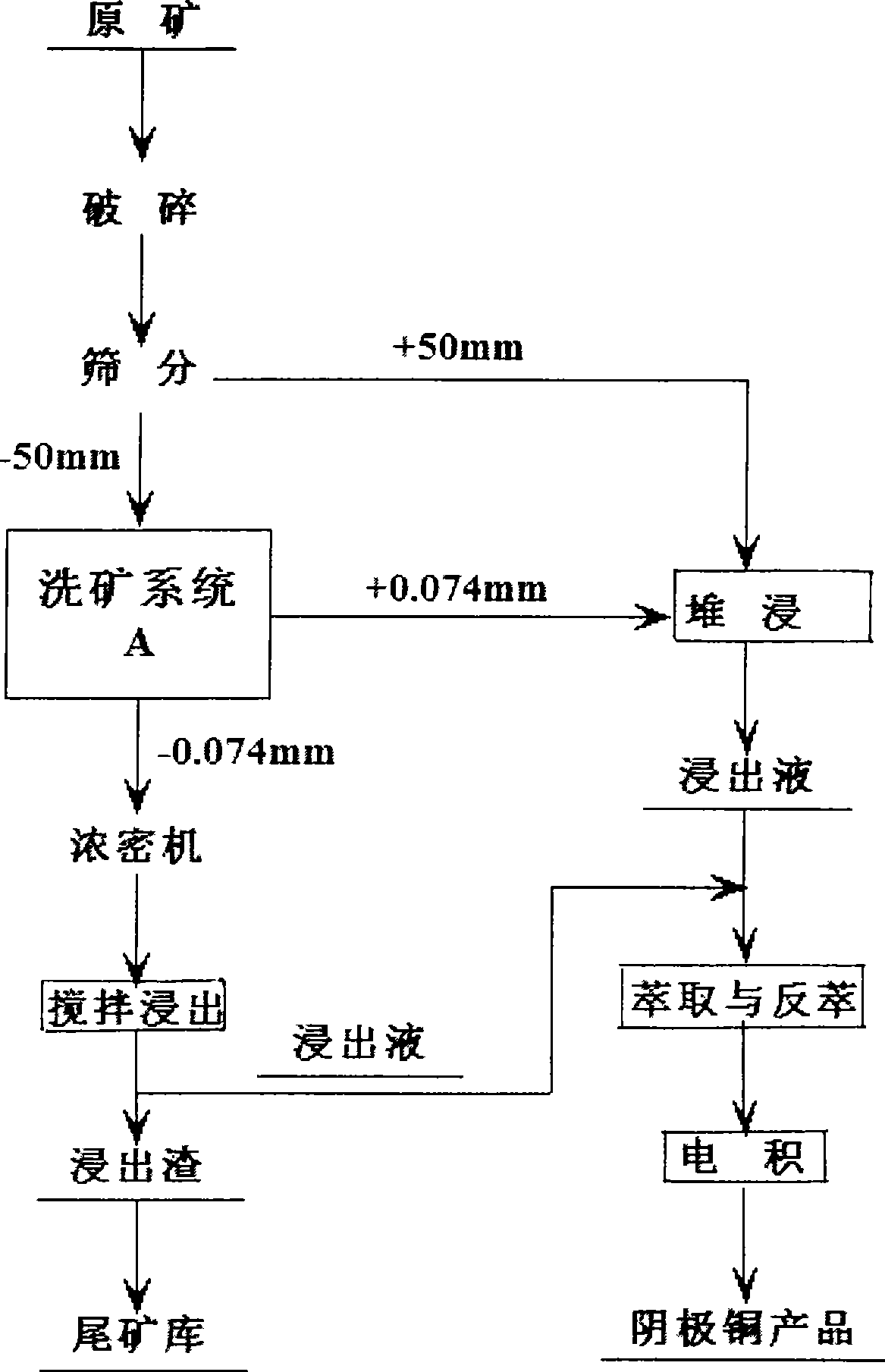

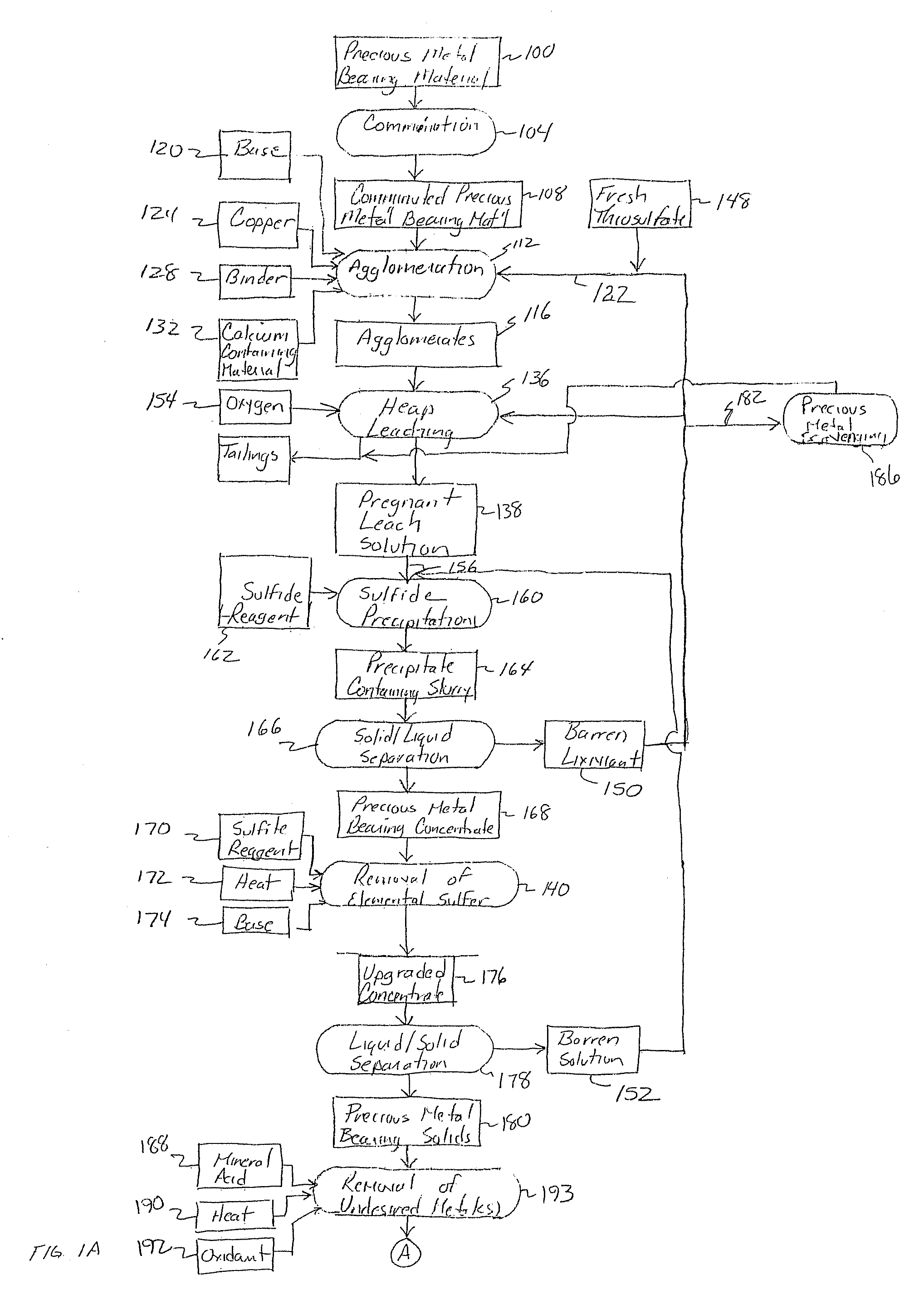

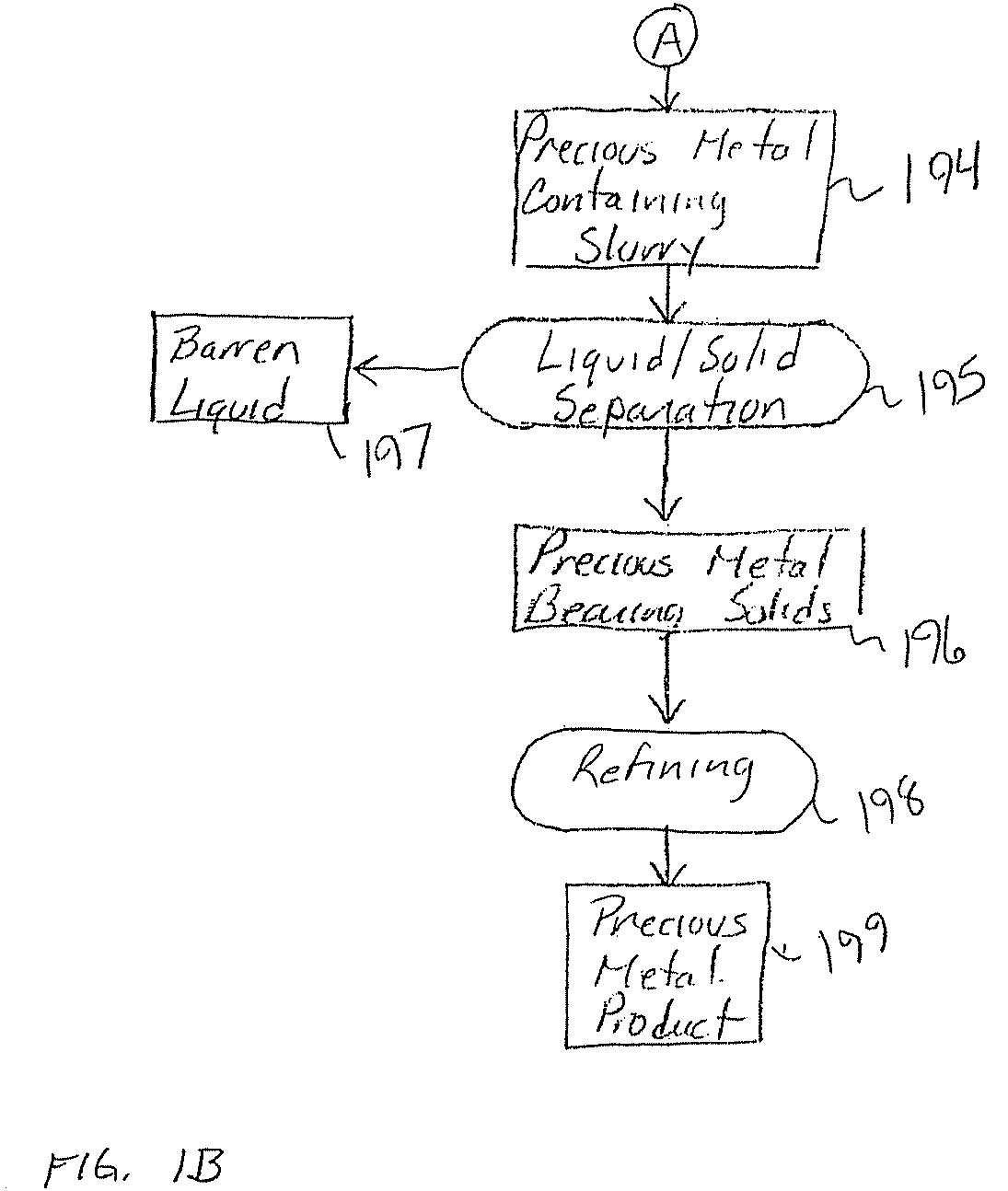

Method for thiosulfate leaching of precious metal-containing materials

InactiveUS7544232B2Avoid the needLow costCopper sulfidesProcess efficiency improvementLixiviantRefractory

Processes are provided for recovering precious metals from refractory materials using thiosulfate lixiviants. The processes can employ heap leaching or lixiviants that include one or more blinding agents.

Owner:PLACER DOME TECHN SERVICES

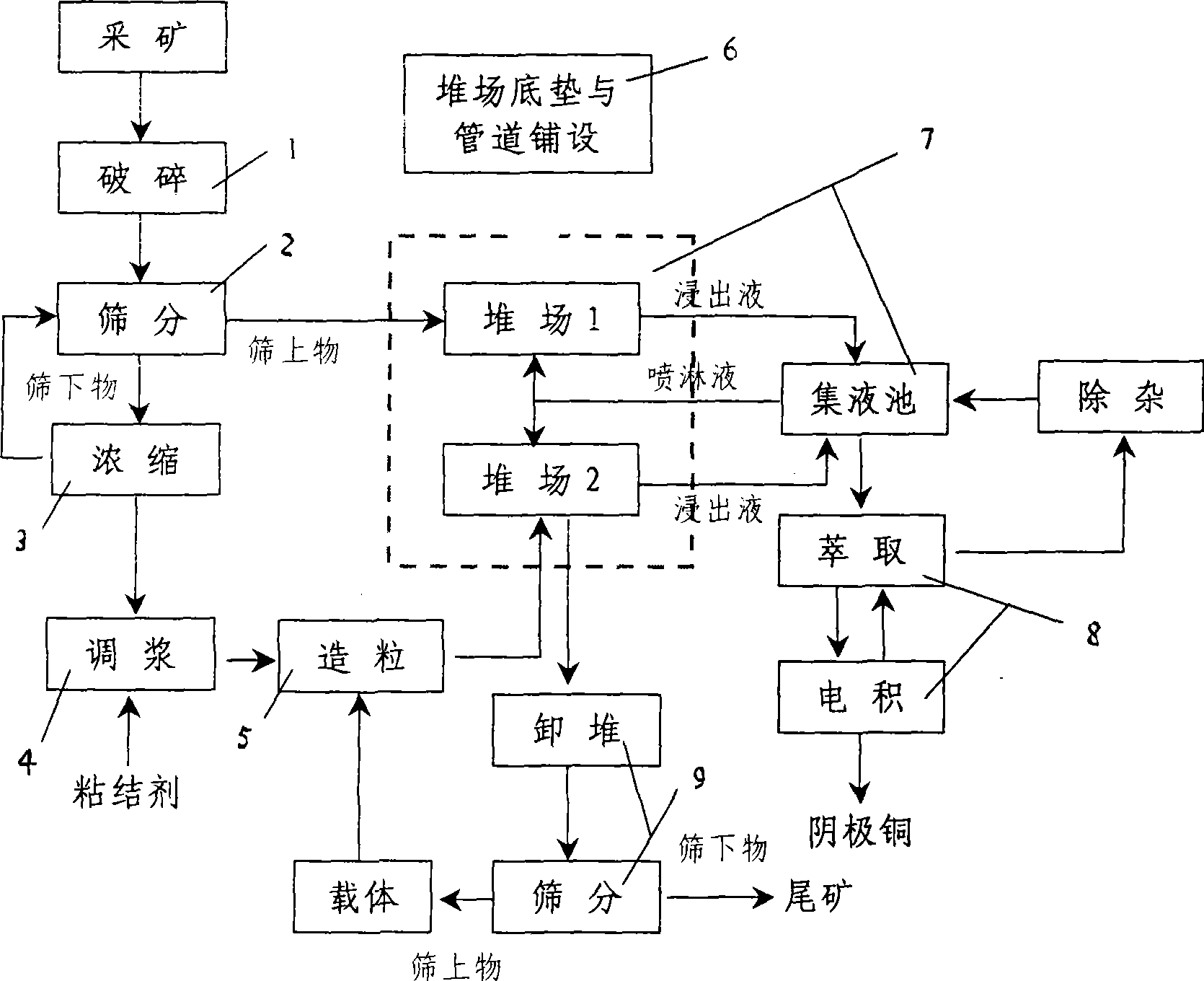

Acid heap leaching process for cupric oxide ore

InactiveCN101435021AImprove the level of comprehensive utilizationReduce pollutionPhotography auxillary processesProcess efficiency improvementPregnant leach solutionClay minerals

The invention provides a new technique of acid heap leaching of copper oxide ore. The copper oxide ore is crushed and screened, then materials on a screen are carried out conventional acid heap leaching operation and the materials under the screen carry out concentration, size mixing and granulation and then are piled and leached; and leachate rich in copper ions is treated by the procedures of extraction, electrodeposition and the like so as to obtain cathode copper sold on the market. After the materials under the screen are concentrated, a binding agent needs to be added for size mixing; after size mixing, ore pulp and prepared acid-proof gravel with the granularity of 5mm to 25mm are mixed for granulation; in the granulation and heap leaching process, the pile height is 3 to 5m, in the heap leaching process, the concentration of dilute sulphuric acid is 0.1 to 2mol / L, the spraying strength is 0.2 to 0.5L / (min.m<2>) and the leaching period is 1 to 2 months. The technique can fully utilize copper oxide ore resource which is hard to be utilized in the past time, contains a large amount of clay mineral and is easy to argillization, improves the level of comprehensive utilization of mines, saves cost and increases profit. The invention is particularly suitable for being applied to the development of copper ore resources, mainly the copper oxide ore, which are hard to treat in all regions of China, in particular to remote regions of the western highlands.

Owner:有研资源环境技术研究院(北京)有限公司

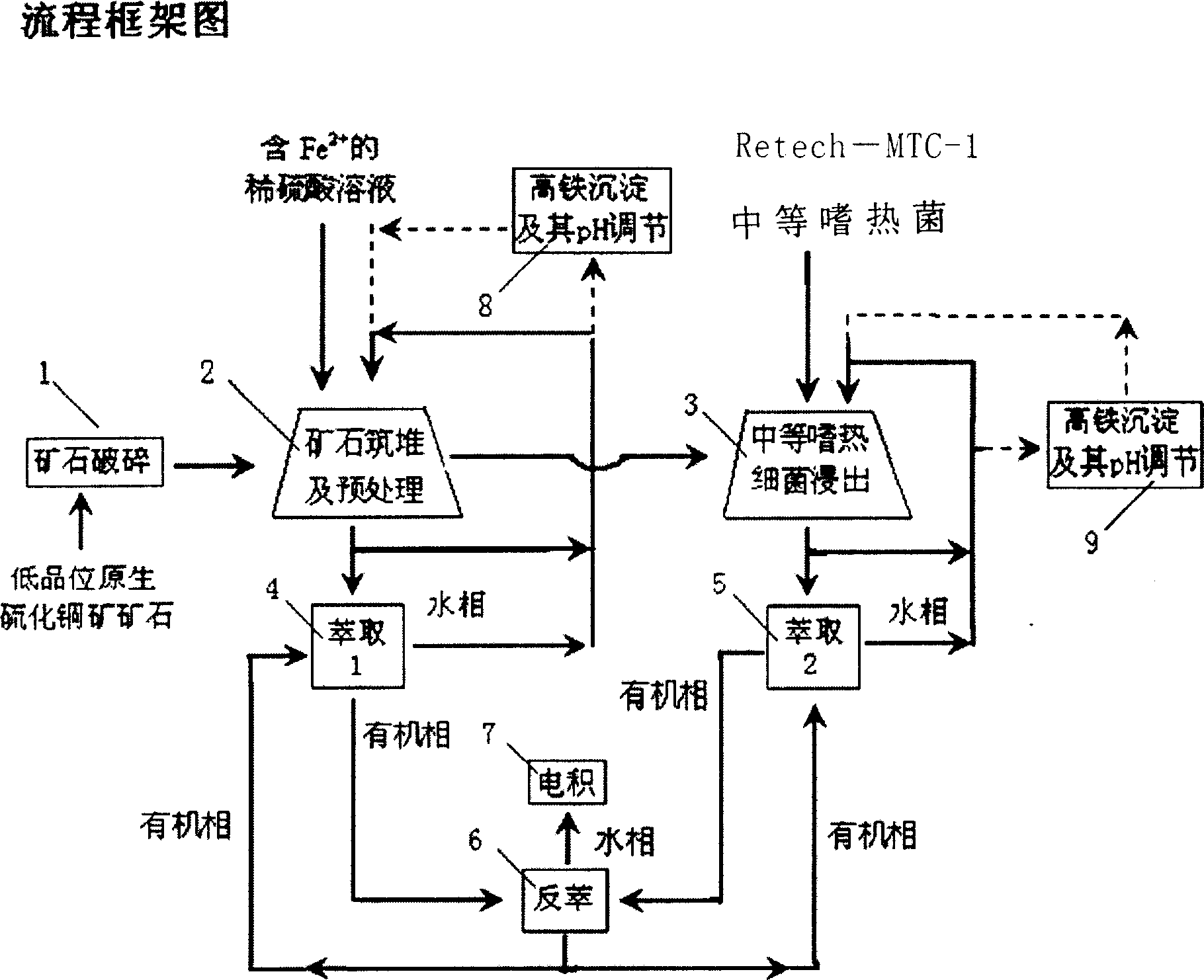

Middle thermophilic bacteria and chemical and biological combined heap leaching technique for low-grade primary copper ore

The invention discloses a chemical and biological combining push soak craft of middle grade thermophile and low-grade primary cupric sulfide ore, which comprises the following steps: utilizing diluted sulfate liquor with Fe2+ ion; pre-processing low-grade primary cupric sulfide ore; choosing domestic middle grade thermophile (Sulfobacillus thermosulfidooxidans Retech-MTC-1) with reinforced sulfur oxidability; leaching primary cupric sulfide ore; reclaiming the copper; extracting leachate in pretreating step; entering organic phase into downstream back extraction process; extracting eligible leachate in middle grade thermophile step; backing the water phase to soaking pile; merging organic phase and the organic phase in pretreating step; entering into downstream back extraction process. This craft possesses short flow process, simple device, low coat and high reclaiming ratio, which can increase the reclaiming ratio of copper.

Owner:有研资源环境技术研究院(北京)有限公司

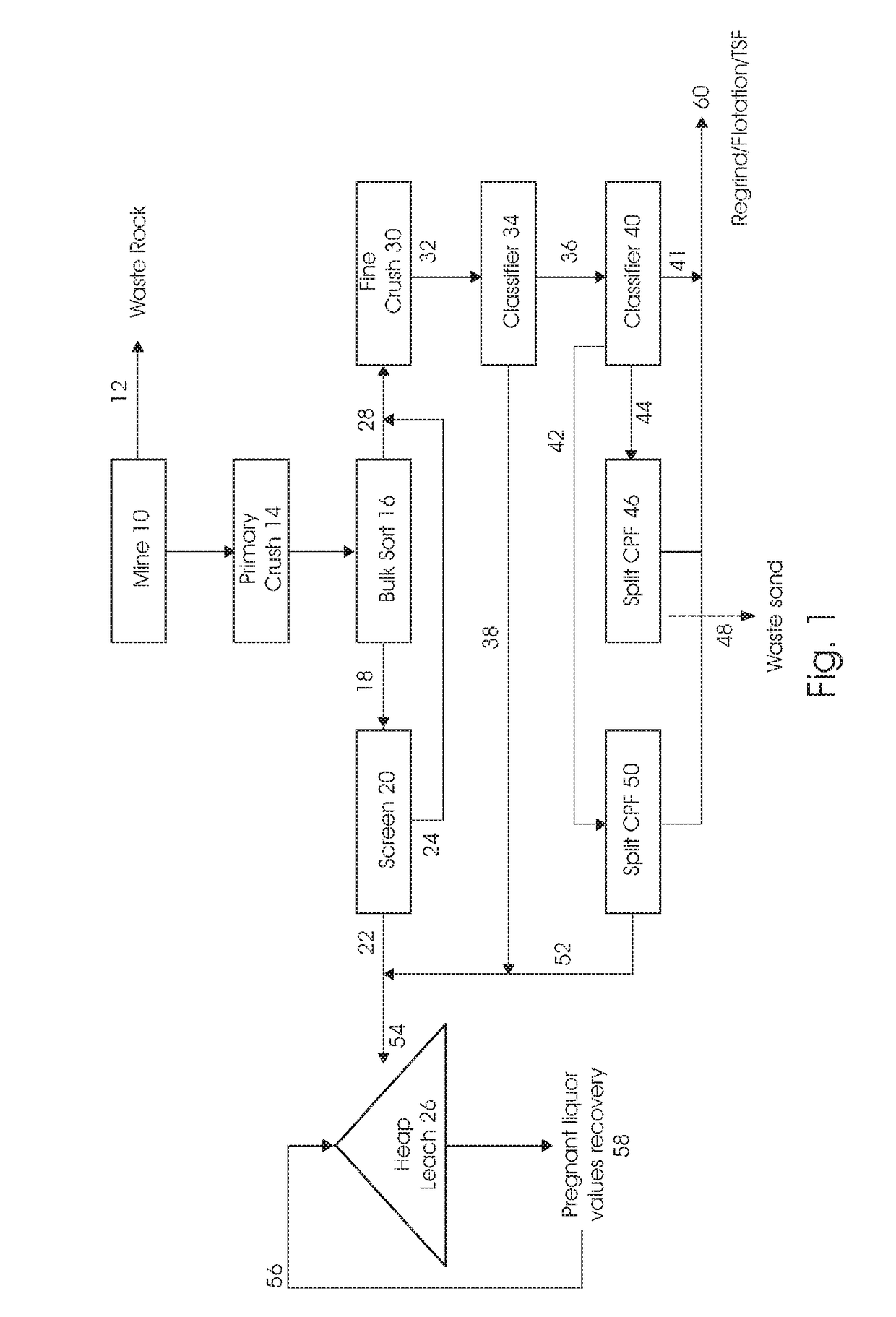

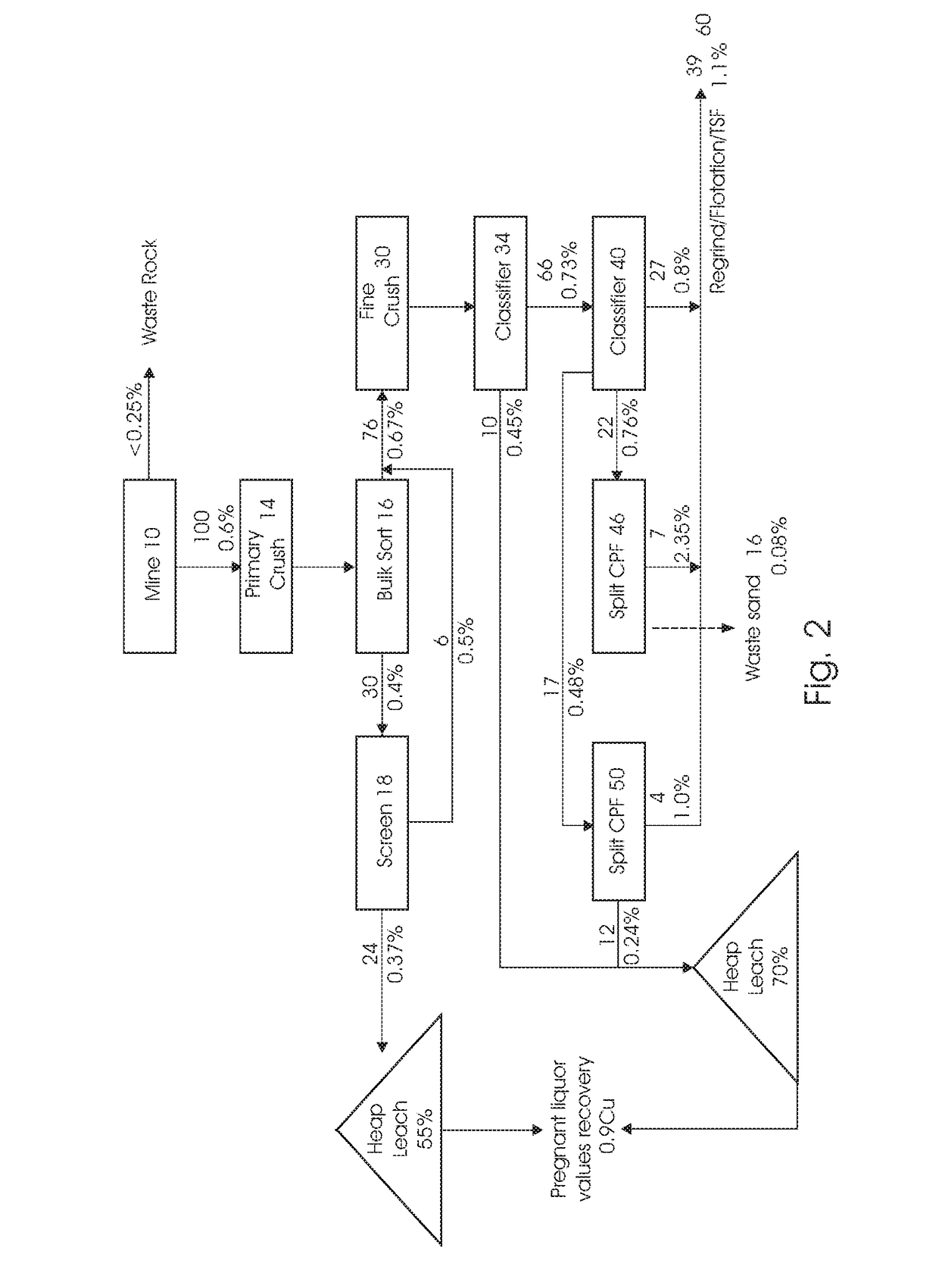

Beneficiation of Values from Ores with a Heap Leach Process

This invention relates to a process for recovering value metals from sulphide ore, including steps of crushing ore in a primary crusher (14) to a size of about 40 cm and less, passing the crushed ore through one or more of the following pre-beneficiation processes such as bulk sorting (16) and screening (20) followed by coarse floatation (46 / 50), or gravity separation or magnetic separation. A waste stream (54) from the pre-beneficiation process / es with a particle size greater than 100 μm is stacked in a heap (26) and subjected to a heap leach. This integrated process utilises the pre-beneficiation techniques best suited to the characteristics of a particular orebody; and during the pre-beneficiation simultaneously creating a low grade stream that yields significantly higher recoveries than achievable by normal heap leaching of low grade run of mine ore.

Owner:ANGLO AMERICAN TECH & SUSTAINABILITY SERVICES LTD

Selective heap leaching gold extraction process for gold mine containing copper

ActiveCN101818247AReduce consumptionImprove leaching rateProcess efficiency improvementSelective leachingHydrometallurgy

The invention discloses a selective heap leaching gold extraction process for gold mine containing copper, belonging to the field of hydrometallurgy. The process comprises the steps of: smashing and heaping gold mine containing copper; carrying out alkali treatment on the mine; then adding ammonium salt and sodium cyanide according to a certain proportion to realize the selective leaching of the gold and the restriction to the leaching of the copper; and finally absorbing and extracting the gold from leaching solution by conventional active carbon. The invention has the advantages of simple process method, short procedure, simple equipment, easy implementation, high gold leaching efficiency, low consumption of sodium cyanide, low energy consumption, little investment and low cost, and is the gold extraction method with easy realization of industrialized production and favorable economical benefit.

Owner:ZIJIN MINING GROUP

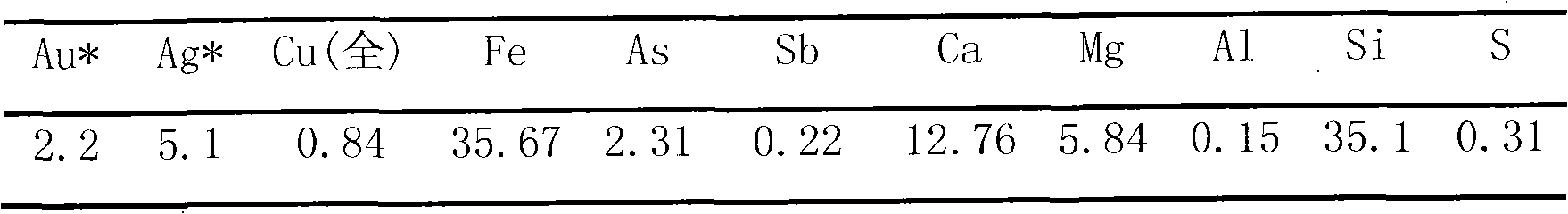

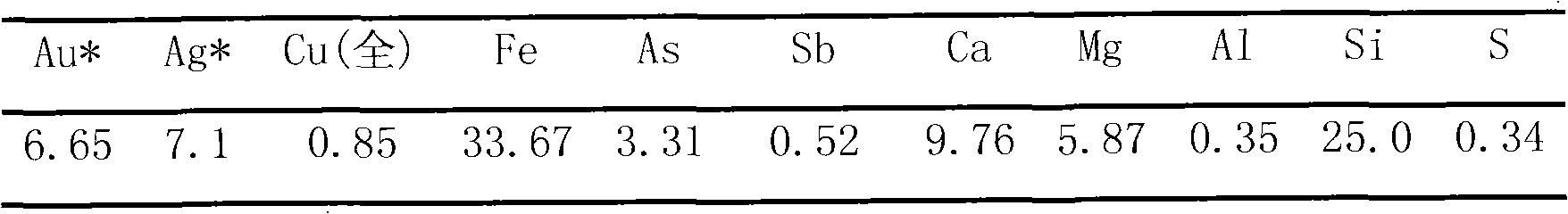

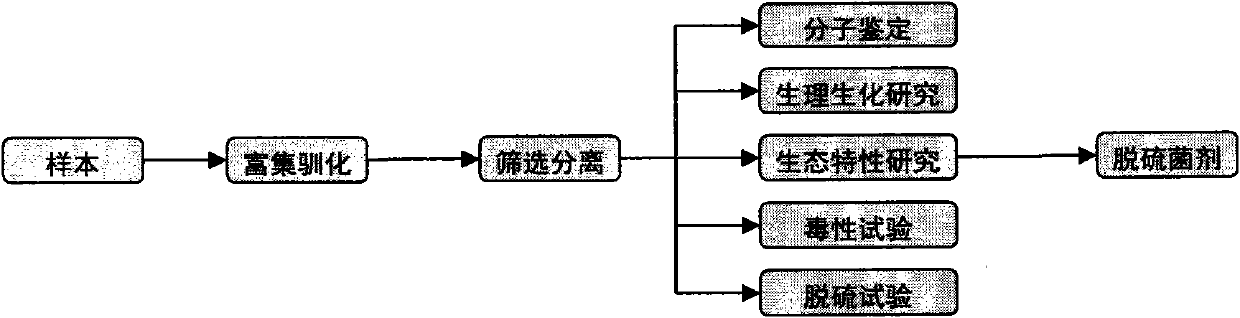

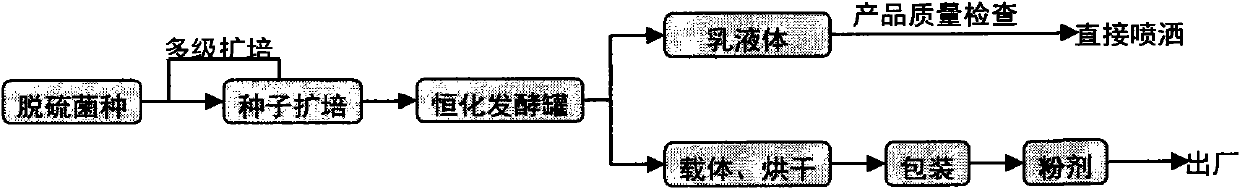

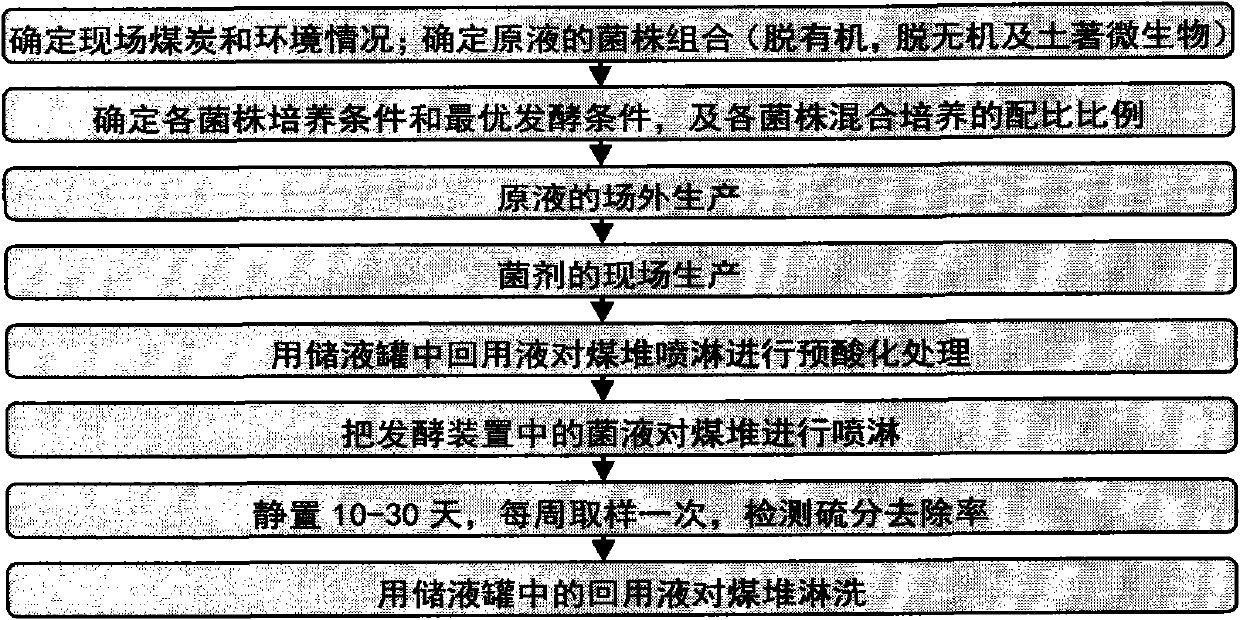

Combined microbial desulfurization method and its technology for coal

A combined desulfurization idea and process for coal removal, including the combination of high-efficiency core desulfurization bacteria agent and indigenous bacteria agent, as well as the combination of inorganic sulfur removal and organic sulfur removal technology, perfects the type and level of desulfurization, and can improve the desulfurization speed and efficiency. This invention considers and analyzes the differences in the state and content of sulfur in different coals, screens the indigenous microbial communities in the treated coal, and increases the local microbial populations’ influence on the core desulfurizing bacteria when the desulfurizing agents are expanded and applied in batches. Ecological support to form a combined desulfurization bacteria agent that is really suitable for the coal to be treated; at the same time, through the design and transformation of the traditional heap leaching method, the inorganic sulfur (mainly pyrite sulfur and elemental sulfur) and organic sulfur ( Dibenzothiophenes) are oxidized and decomposed into sulfuric acid by stage microorganisms and collected, so as to achieve the purpose of desulfurization. The combined microbial desulfurization method adopted in the present invention is a new technology pioneered at home and abroad.

Owner:上海彤微环保科技有限公司

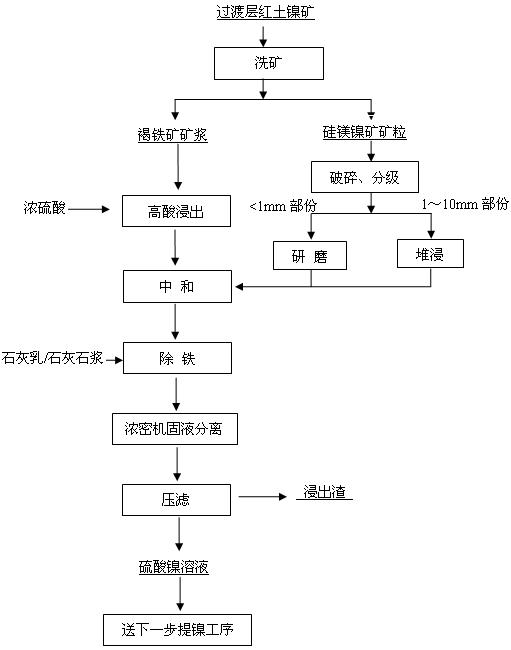

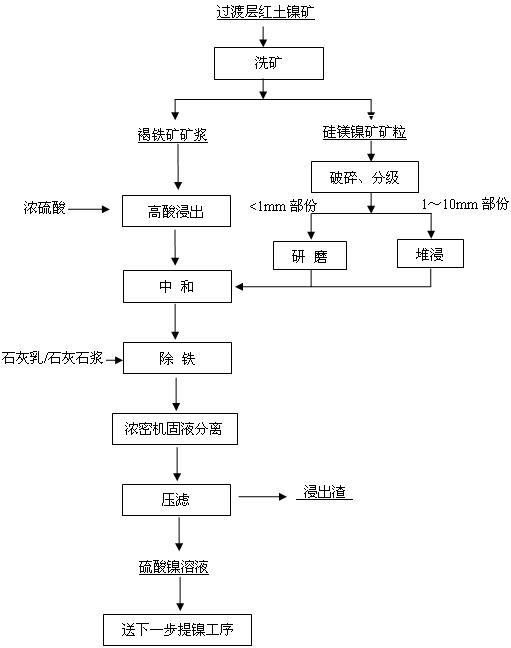

Method for wet-leaching lateritic-nickel ore at transition layer

ActiveCN102212684AImprove leaching rateReduce consumptionProcess efficiency improvementSlurryImpurity

The invention discloses a method for wet-leaching lateritic-nickel ore at a transition layer. The method comprises the following steps: firstly washing lateritic-nickel ore at a transition layer so as to separate out limonite type lateritic-nickel ore and garnierite type lateritic-nickel ore; crushing and grading garnierite, sorting out ore with size fraction of 1-10mm for heap leaching to lixiviate metallic nickel, and mechanically grinding ore with particle size of less than 1mm into garnierite pulp with particle size of -100 meshes; adding concentrated sulfuric acid to limonite pulp for high-acid leaching under normal pressure; adding the garnierite pulp and nickel-containing solution subjected to heap leaching to the high-acid leaching pulp so as to neutralize residual acid; adding lime milk or limestone slurry for removing iron; and carrying out preliminary solid-liquid separation on the slurry without iron by utilizing a thickener, then finely filtering the slurry by utilizing apress filter, and further treating the obtained nickel-containing solution. The method has the advantages of simple flow, no need of ore pretreatment, the adoption of conventional leaching equipment,low acid consumption, good impurity removal effect, high nickel recovery rate and the like.

Owner:广西银亿新材料有限公司

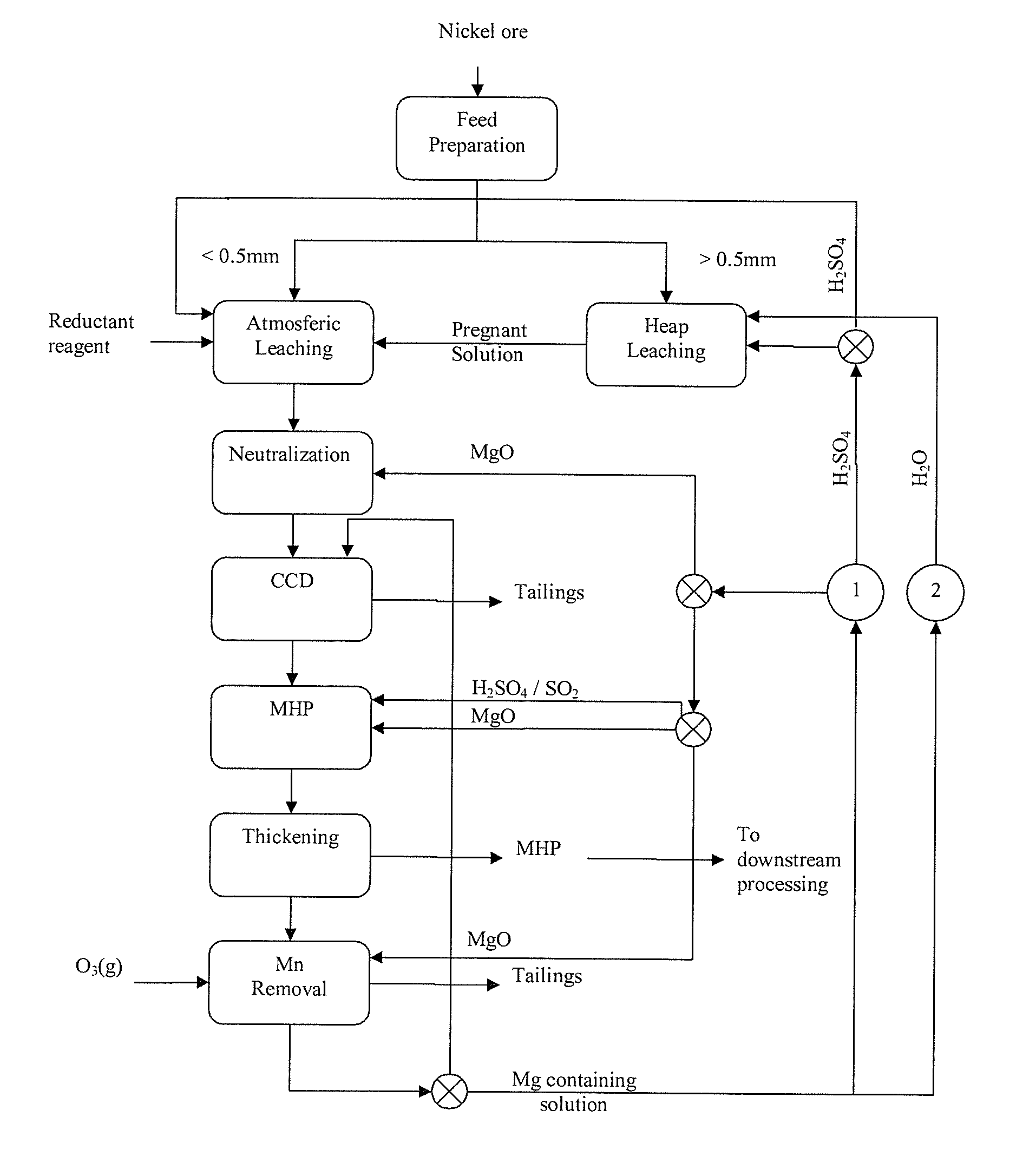

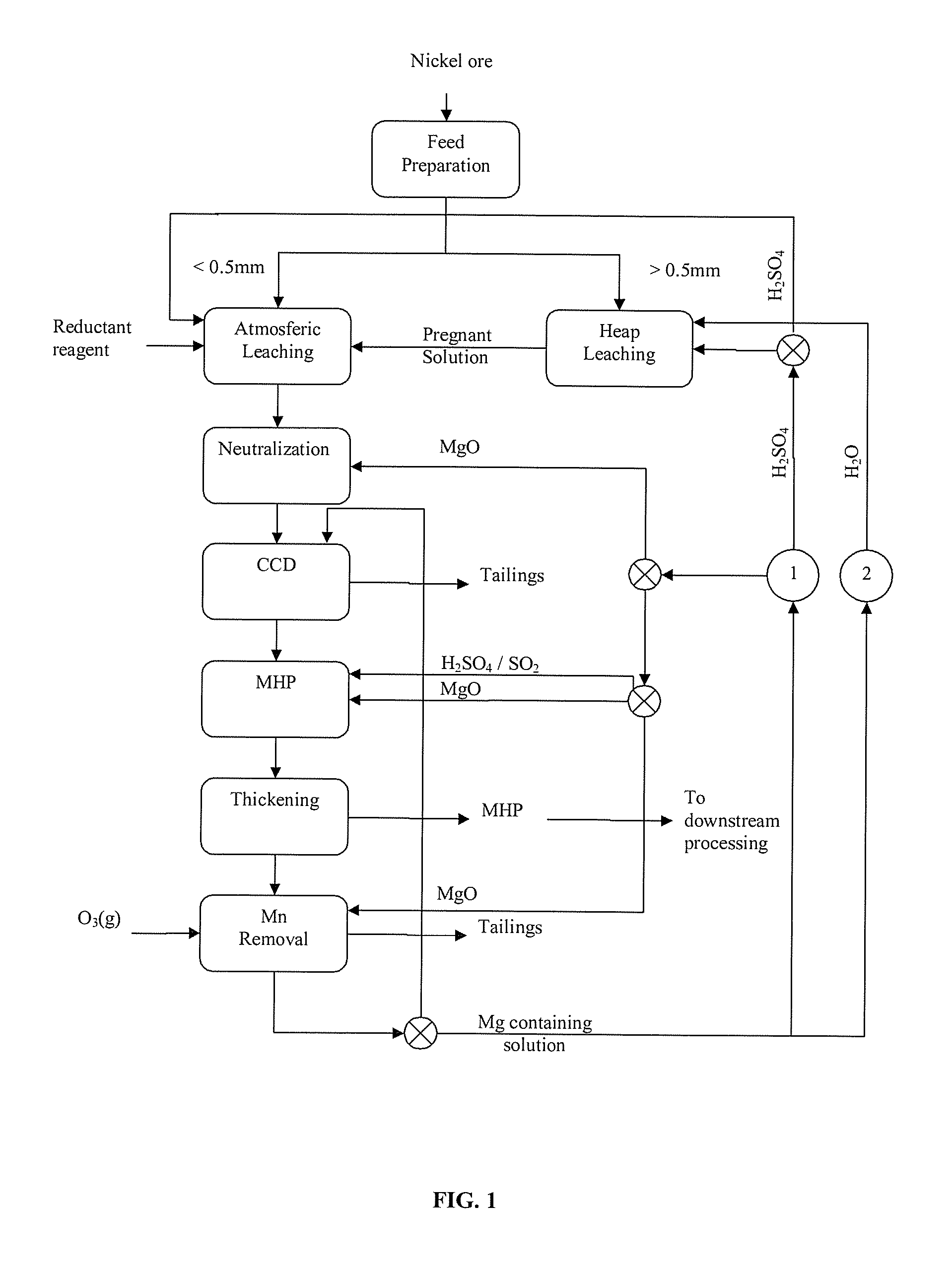

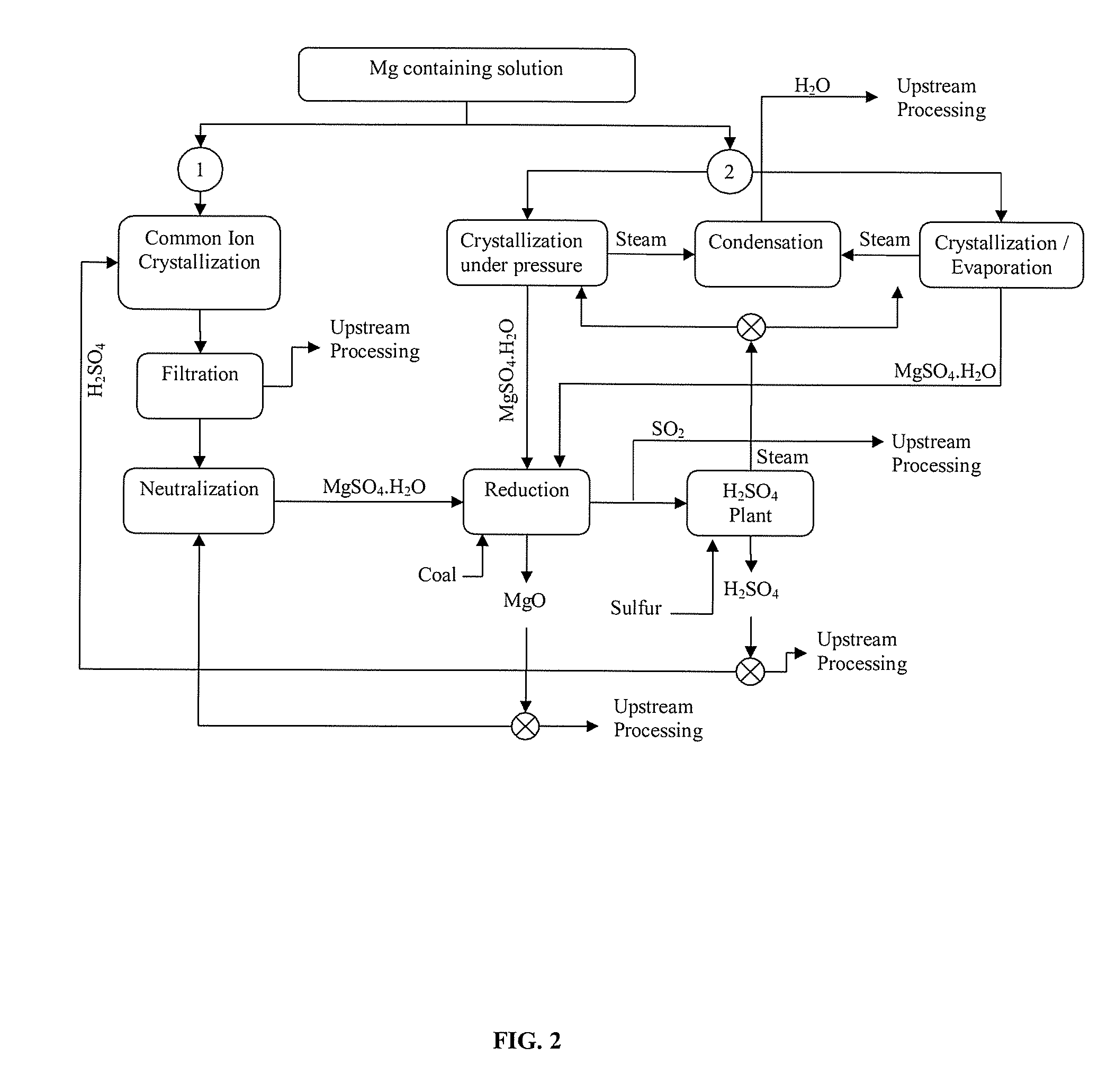

Magnesium recycling and sulphur recovery in leaching of lateritic nickel ores

ActiveUS20110110832A1Simplified logisticsReduce the amount requiredCalcium/strontium/barium sulfatesMagnesium sulfatesHigh magnesiumSulfur

The present invention resides in a process of recovering nickel and cobalt, regenerating the main raw materials, said process including the steps of: granulometric separation; leaching; neutralization; MHP production in only one stage and the pressure crystallization of magnesium sulphite.The process proposes a way to recovery nickel and cobalt from laterite ores through the atmospheric and heap leaching with staged addition of ore—by size separation—and H2SO4, decreasing the nickel losses and simplifying the neutralization circuit and producing a more purified MHP.The present process route is employed for nickel extraction, including the one from high magnesium containing lateritic ores.

Owner:VALE LIMITED

Ore separating method for low-grade oxide gold ore

InactiveCN1440837AHigh recovery rateImprove permeabilityProcess efficiency improvementWet separationLower gradeLow graded

The ore separating method for raising the recovering rate of low-grade oxide gold and with high mud content and containnig coarse gold grain has the three kinds of technological process of heap leaching, gravitational separation and charcoal leaching combined. After crushing, washing ore, sieving, secondary crushing and twice grading, the coarse one grains enter heap leaching system directly white the fine ore grains enter the charcoal leaching system; preliminary vibration chute is set before the grading machine to retain coarse gold grains via gravitational separation. The said method has gold core recovering rate obviously higher than that of single heap leaching method and can utilize the precious resource fully.

Owner:ZIJIN MINING GROUP

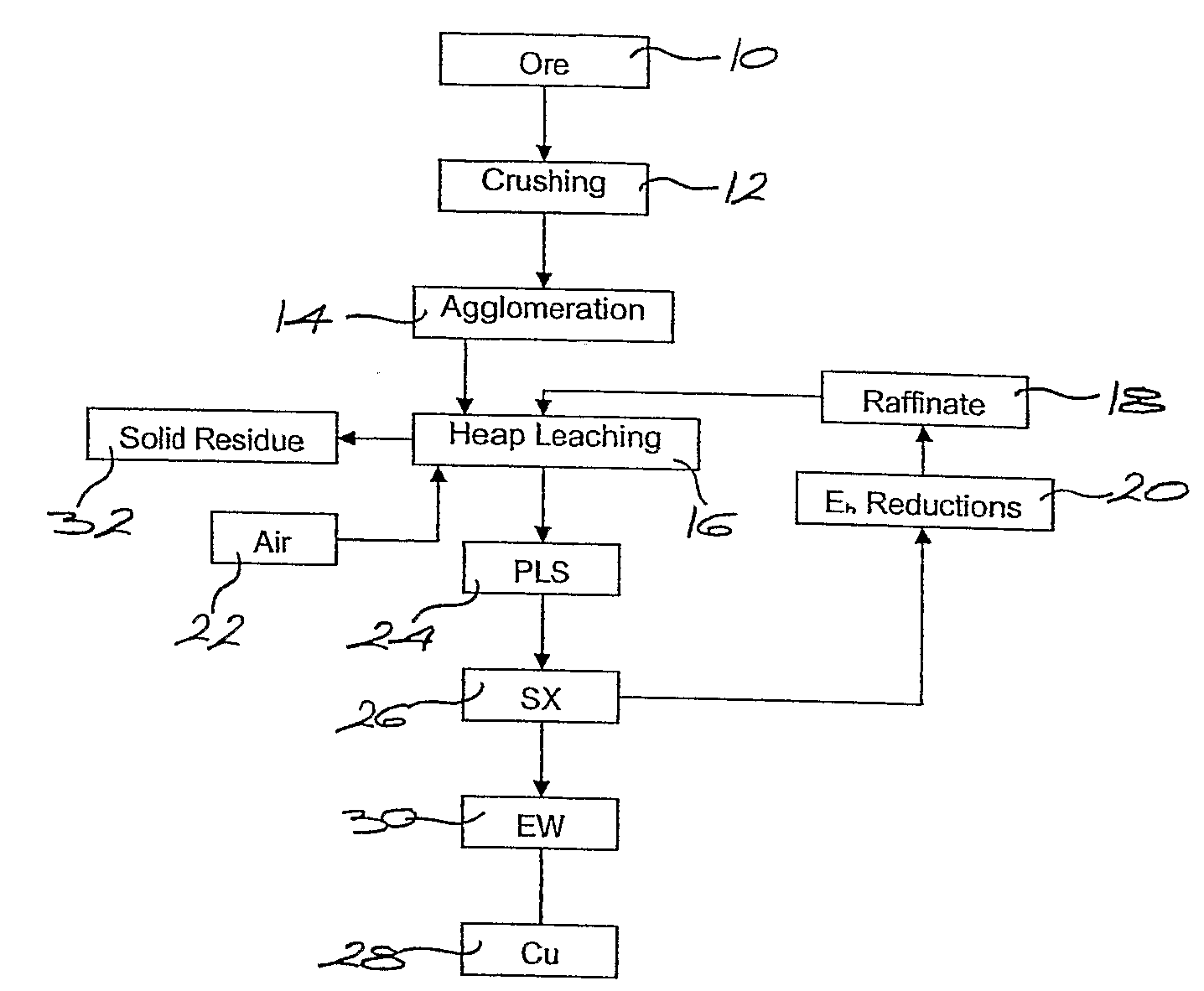

Chloride Heap Leaching

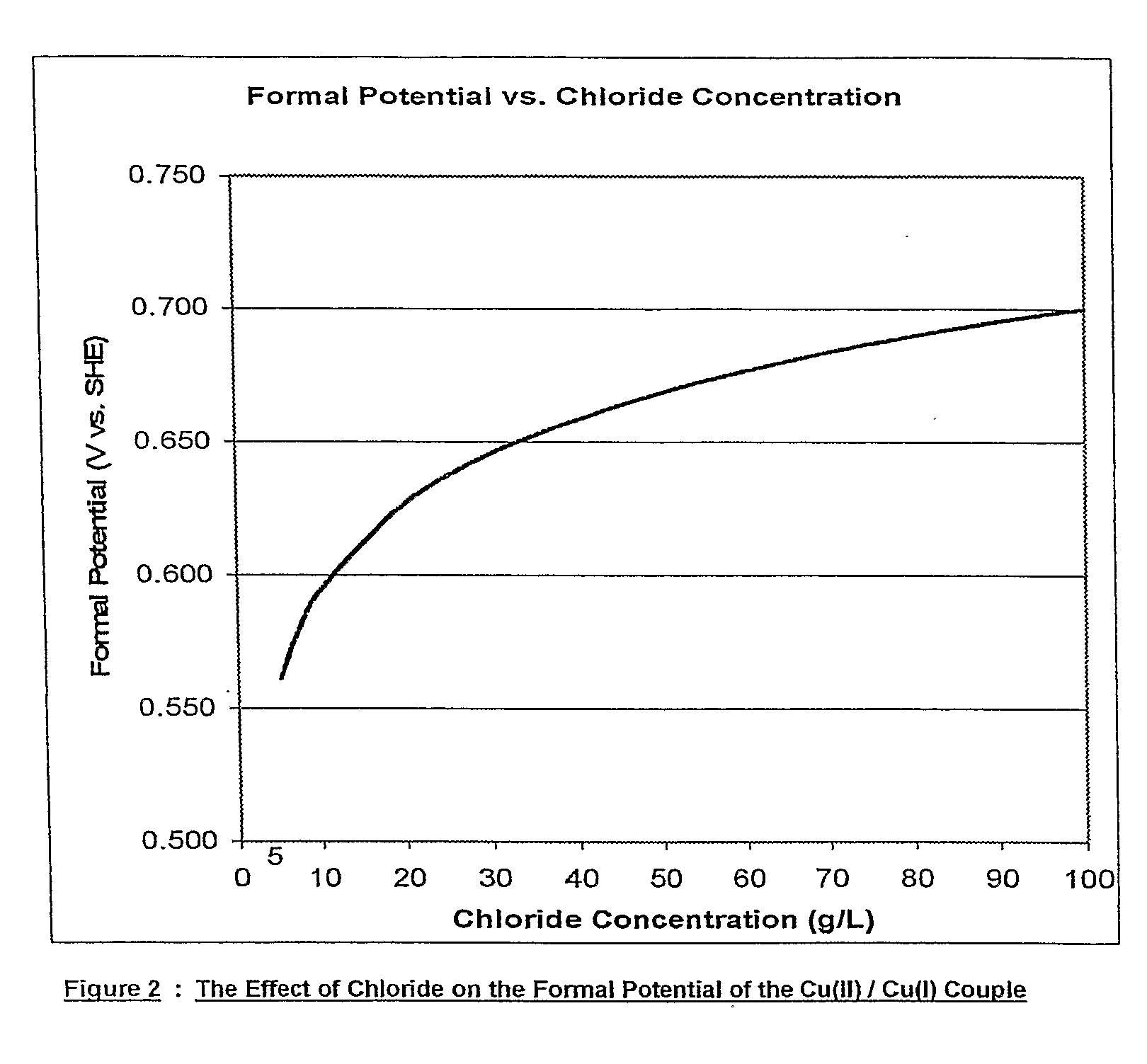

ActiveUS20090173188A1Lower potentialRaise the potentialSolvent extractionGold compoundsSulfateChloride

A heap leaching method to recover copper from a primary copper sulphide mineral wherein the mineral is leached in an acidic chloride / sulphate solution in the presence of oxygen with the surface potential of the mineral below 600 mV (vs. SHE) to cause dissolution of the copper sulphide.

Owner:CONSOL NOMINEES

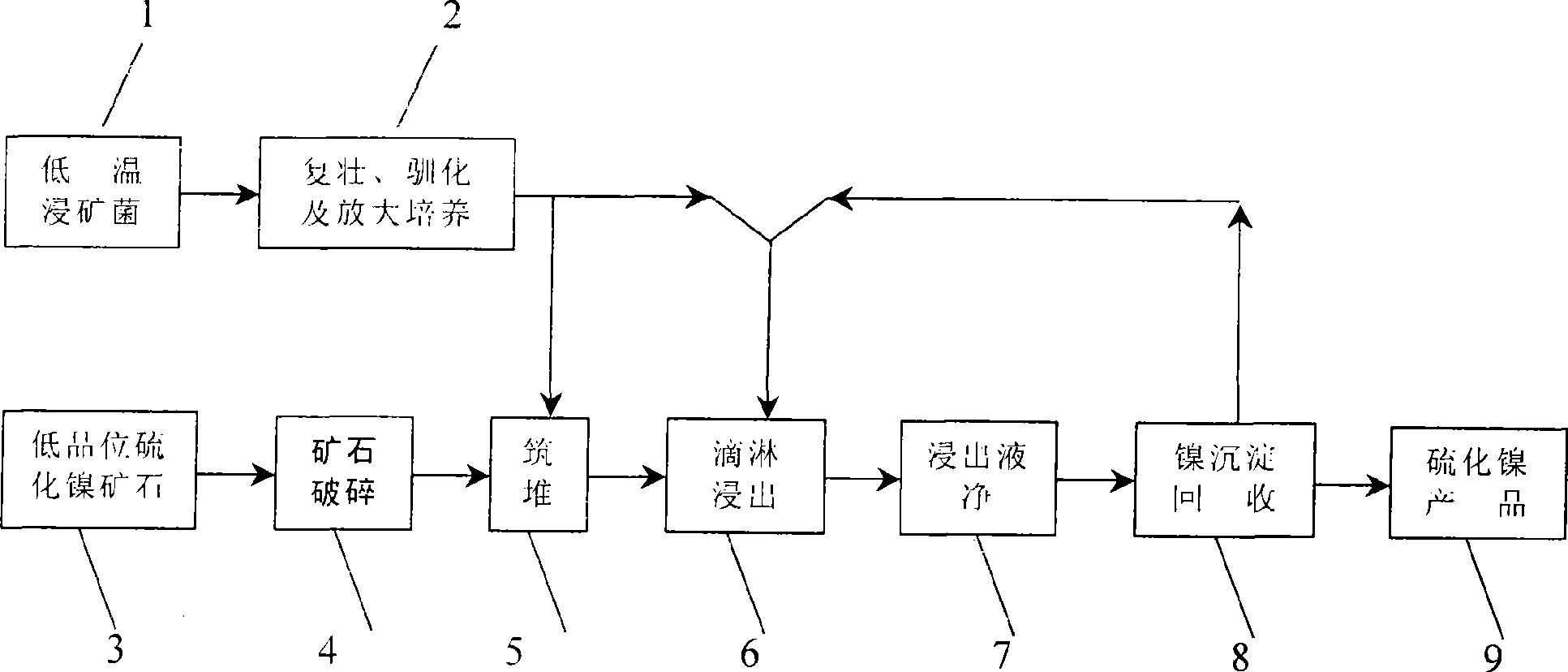

An strain of low temperature leaching-ore bacteria and process for using the same for low temperature heap leaching of nickel sulfide ore

ActiveCN101434920AGuaranteed leaching efficiency conditionsHigh recovery rateBacteriaProcess efficiency improvementThiobacillus ferrooxidansNickel sulfide

The invention provides a low-temperature mineral leaching bacterium and a low-temperature heap leaching technique of nickel sulfide ore that uses the low-temperature mineral leaching bacterium. The name of the low-temperature mineral leaching bacterium is Thiobacillus ferrooxidans Retech-L-I, the preservation registration number is CCTCC No. of M207157, the preservation date is October 16th, 2007, and the preservation unit is China Center for Type Culture Collection in Wuhan University. The low-temperature heap leaching technique of nickel sulfide ore comprises the working procedures of low-temperature mineral leaching bacterium rejuvenation, domestication and amplified cultivation, ore stacking, and spraying with a liquid containing the low-temperature mineral leaching bacterium, and a leaching liquid that is obtained by a leaching procedure is sent to working procedures of iron removing, arsenic removing and metal recycling. The low-temperature heap leaching technique of nickel sulfide ore that uses the low-temperature leaching bacterium has the advantages that the technique not only is environment-friendly, but also can be used for exploiting low-grade nickel ore resources that cannot be utilized by traditional picking metallurgy techniques, and the technique is particularly applicable to the exploit of nickel sulfide ore resources in highly cold low-temperature areas that cannot realize the engineering of biological normal temperature and high temperature heap leaching, enlarges the utilization range of nickel ore resources, and raises the synthetic nickel utilization rate.

Owner:有研资源环境技术研究院(北京)有限公司

Metal ore heap leaching, anaerobic enrichment transformation and biological leaching extraction process

InactiveCN102534210ALow concentration requirementEliminate pollutionProcess efficiency improvementLiquid wasteHigh concentration

The invention relates to a metal ore heap leaching, anaerobic enrichment transformation and biological leaching extraction process, which comprises the following steps: utilizing metal sulphate solution with low concentration obtained in the open-air heap leaching operation and treating through a sulfate reduction bacteria process (anaerobic bioreactor) to obtain a metal sulfide precipitate (solid); and obtaining metal sulphate solution with high concentration through bio-leaching (bio-leaching reactor). The invention has the beneficial effects that the environmental risk of external leakage of leaching solution is reduced, the heap leaching period is shortened, the storage capacity of a heap leaching field is greatly reduced, the environmental risk caused by accidental leakage is reduced, and the concentration of metal ions in treated waste liquid is kept below dozens of micrograms per liter so as to be lower than the current environment protection standard requirements.

Owner:JIANGXI UNIV OF SCI & TECH

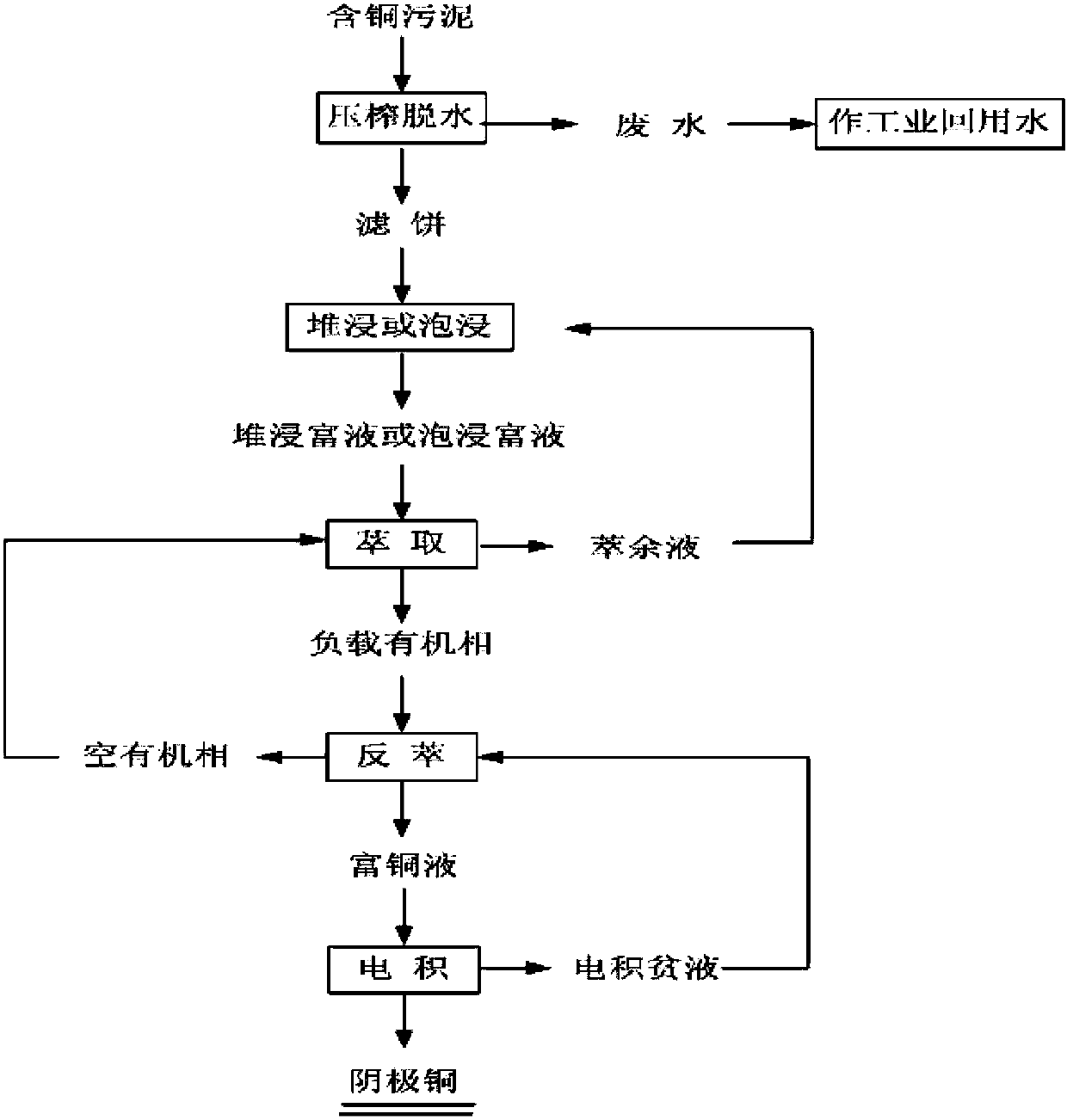

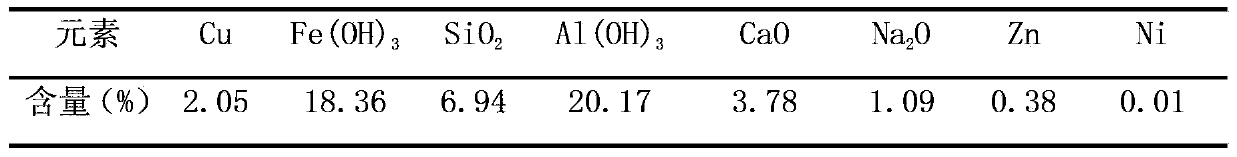

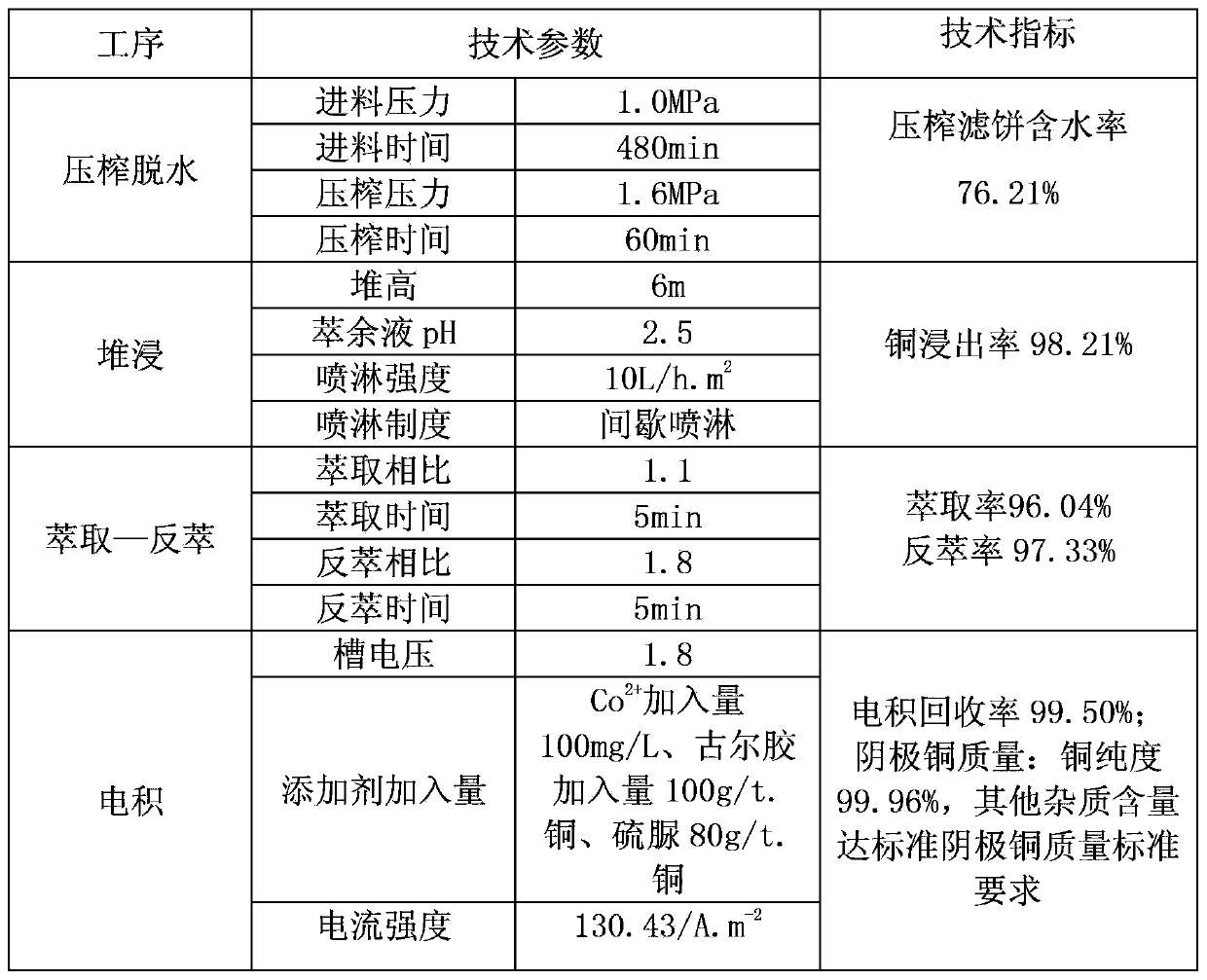

Method for producing tough cathode with cupric sludge

ActiveCN103422119AImprove leaching rateGood washing rateSludge treatment by de-watering/drying/thickeningPhotography auxillary processesSludgeMature technology

The invention relates to a method for producing tough cathode with cupric sludge. The method comprises the following processing steps: step 1, squeezing and dewatering: squeezing and dewatering cupric sewage; step 2, heap leaching or pickling: sprinkling acid solution on a columnar heap and feeding obtained heap leaching pregnant solution to an extraction system, or feeding squeezed and dewatered lump sludge to a pickling pool to pickle the squeezed and dewatered lump sludge with acid solution and feeding obtained pickling pregnant solution to the extraction system; step 3, extraction-reverse extraction: performing extraction on the heap leaching pregnant solution or the pickling pregnant solution obtained in the step 2, and performing reverse extraction on obtained loaded organic phase to obtain copper pregnant solution; step 4, electro-deposition: performing electro-deposition on the copper pregnant solution obtained in the step 3 under a copper condition to obtain tough cathode. The method has the advantages of low energy consumption, environmental friendliness, applicability to sludge with a low copper content, easiness in solid-liquid separation, high washing rate, high total recovery rate of copper, mature technology and the like and is applicable to industrial fields such as heavy mineral mining, non-ferrous metal smelting, machining and electroplating.

Owner:ZIJIN MINING GROUP

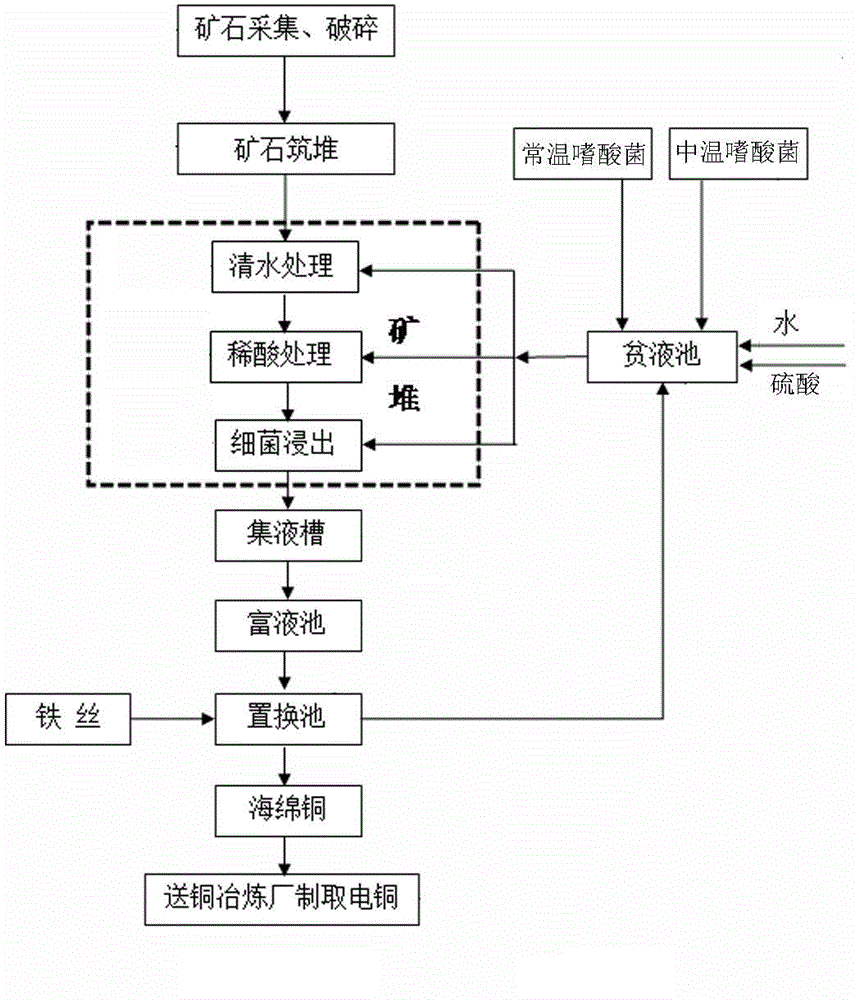

Biological heap leaching technology for stripmining copper sulfide mines

ActiveCN104152691ASimple processShort processProcess efficiency improvementPregnant leach solutionSulfidation

The invention provides a biological heap leaching technology for stripmining copper sulfide mines. The technology comprises the following steps: the copper sulfide mines with a low copper grade and high oxidizability are crushed, sieved and heaped, water and dilute sulphuric acids are dripped and sprinkled successively, a pH value is adjusted, then normal-temperature acidophile and middle-temperature acidophile are dripped and sprinkled successively according to temperature changes, and copper in leach liquor is displaced. The technology has the advantages that the technology is simple, the technological process is short, the pollution is small, the copper sulfide mines with a lower grade can be processed, and the like. Mineral leaching bacteria which are adopted are widely distributed, so that the mineral leaching bacteria are easy to obtain.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

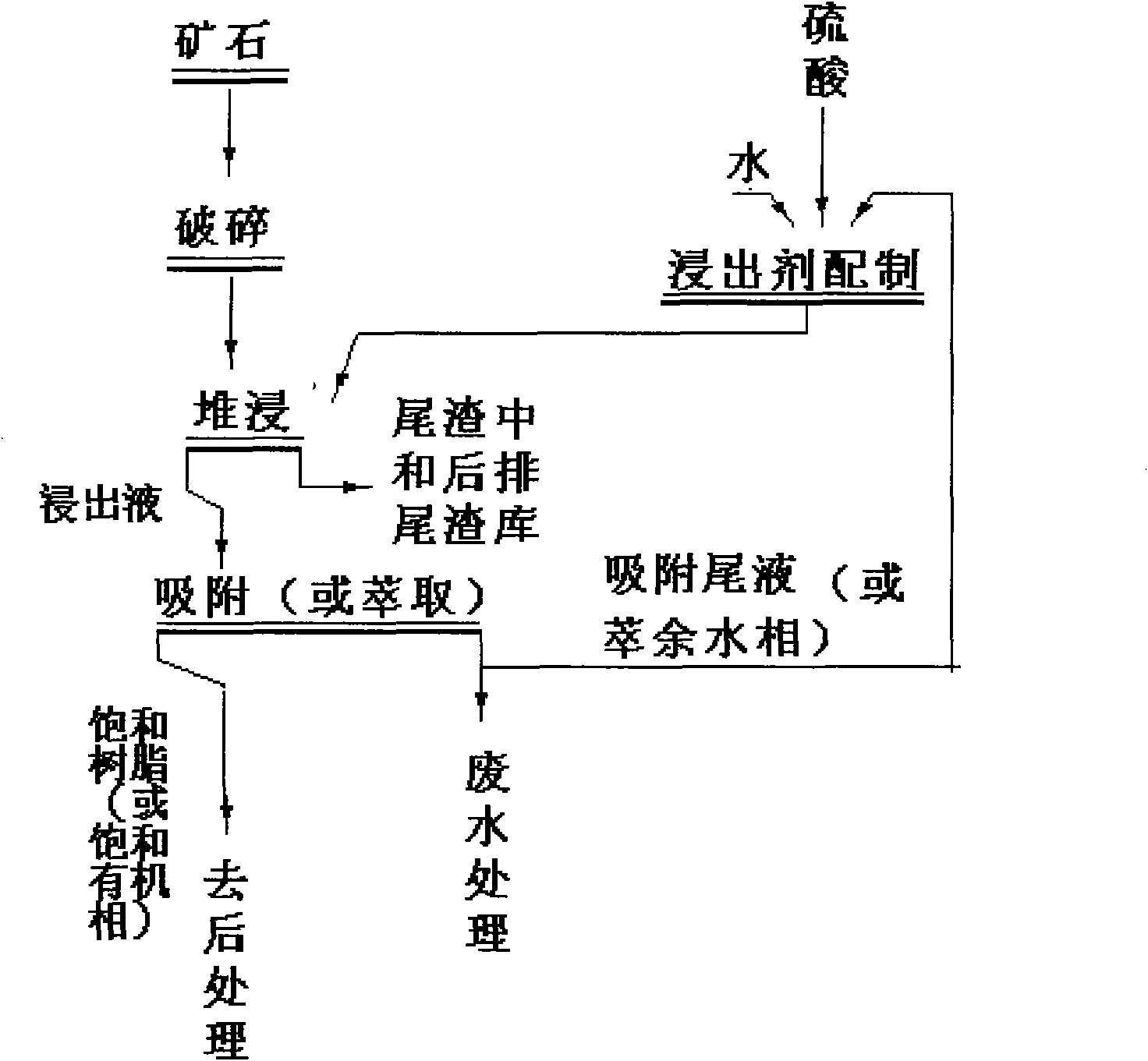

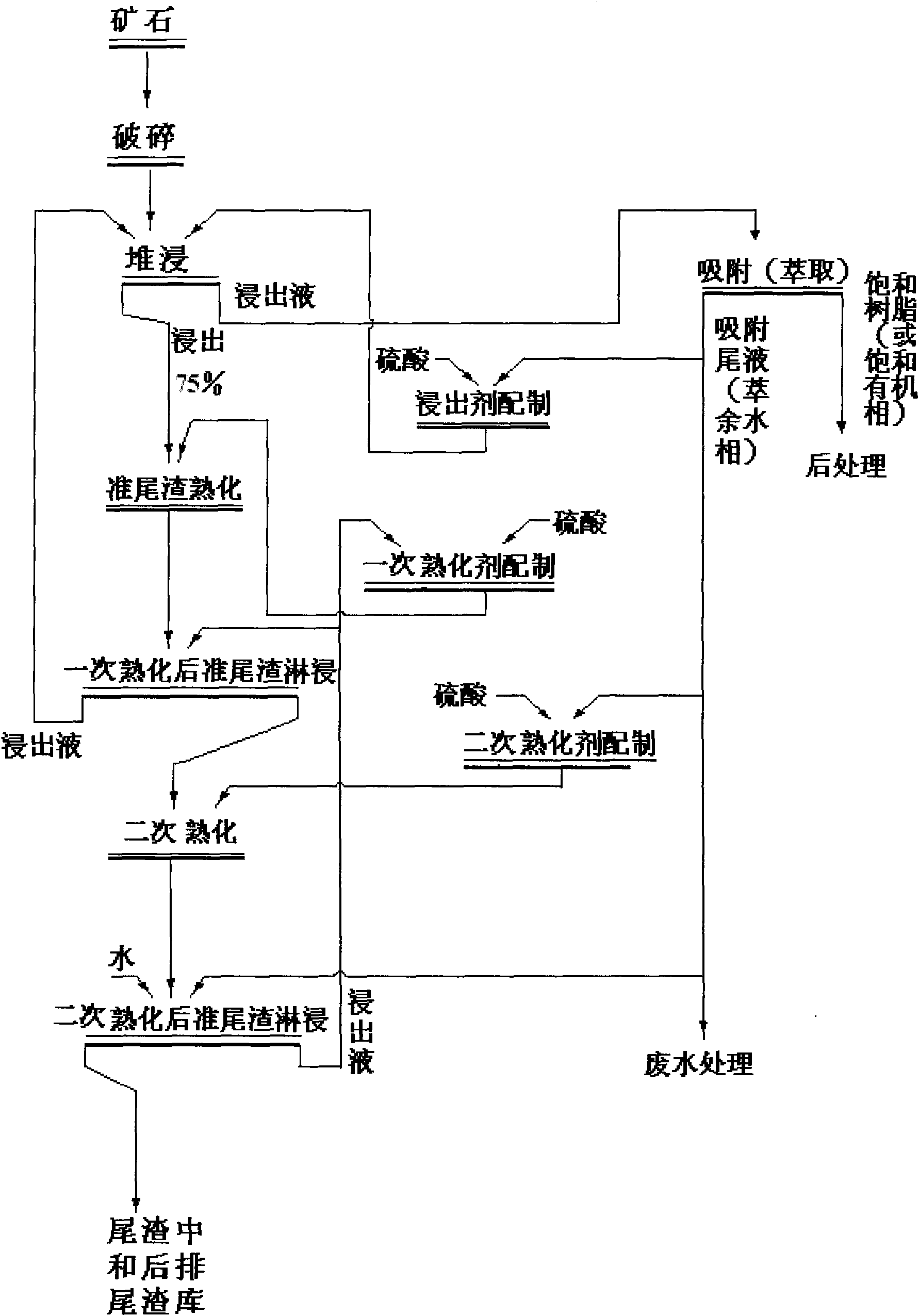

Intensified uranium ore heap leaching method

ActiveCN101560613AShorten the leaching timeDowngradeProcess efficiency improvementPregnant leach solutionUranium ore

The invention provides an intensified uranium ore heap leaching method, which comprises the following steps: (1) uranium ores are crushed firstly and then transported to a heap leaching field for heaping; (2) a leaching agent is sprayed on stock heap for leaching; (3) leachate obtained from step (2) is absorbed or extracted. Saturated resin containing metallic uranium or saturated organic phase goes through a post treatment process, and absorption tailing solution or raffinate water phase is added with acid and then returned for being used as a leaching agent for the next heap; when the leaching agent is sprayed in step (2), the leaching agent spraying is called off if the leaching ratio of the metallic uranium reaches 70 percent to 80 percent. After prospective tailings are dried and heaped for a plurality of days, a curing agent with a weight of 0.08 to 0.12 time of that of the prospective tailings is used for curing and the prospective tailings are cured for a plurality of days and then leached in a sprayed manner. The leachate obtained from sprayed leaching can return and be used as the leaching agent for the next heap. After the neutralization, the tailings are discharged into a tailing tank. The uranium ores are heap leached by the method so that the grade of the tailings can be reduced and leaching time can be shortened.

Owner:中核赣州金瑞铀业有限公司

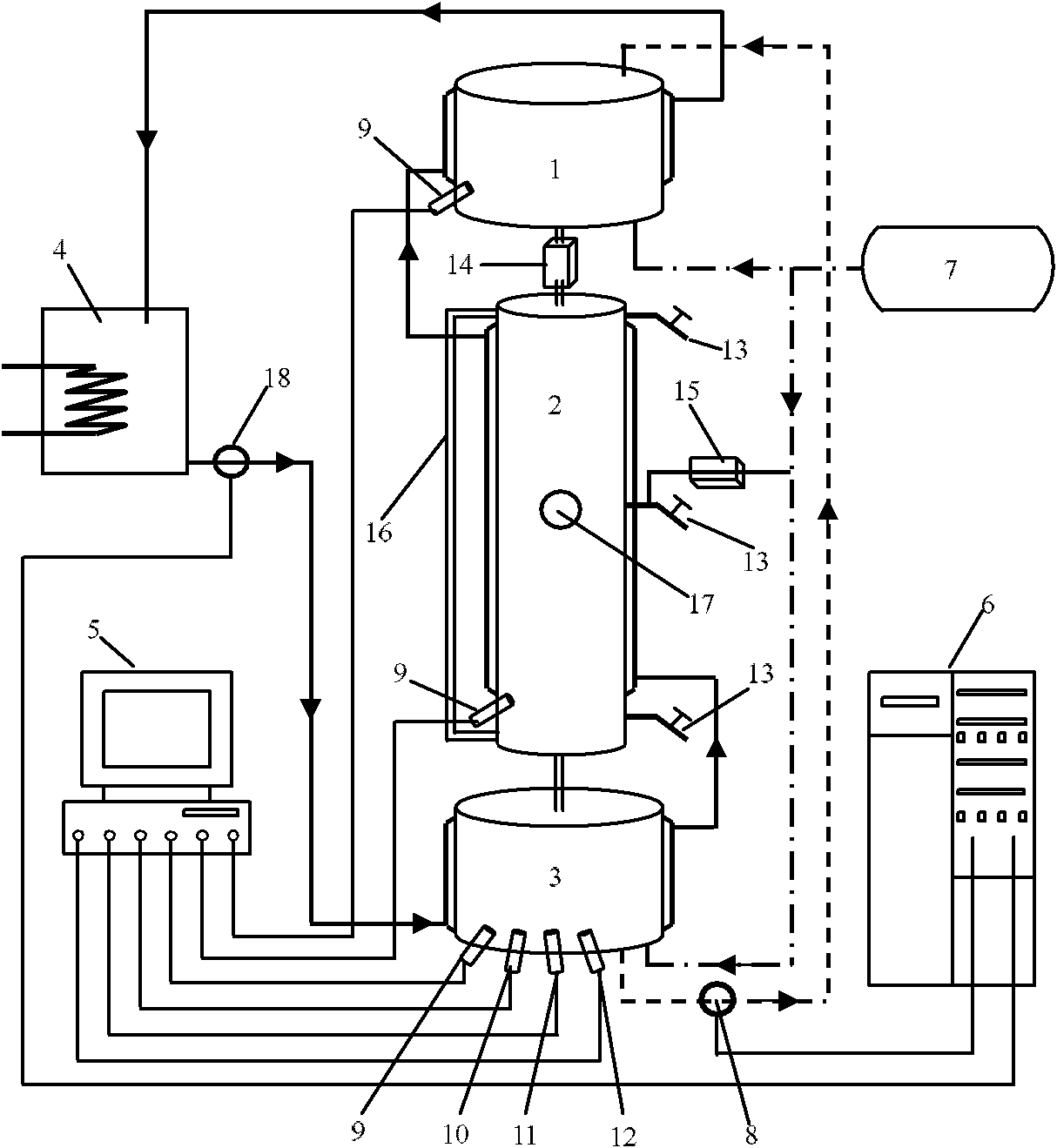

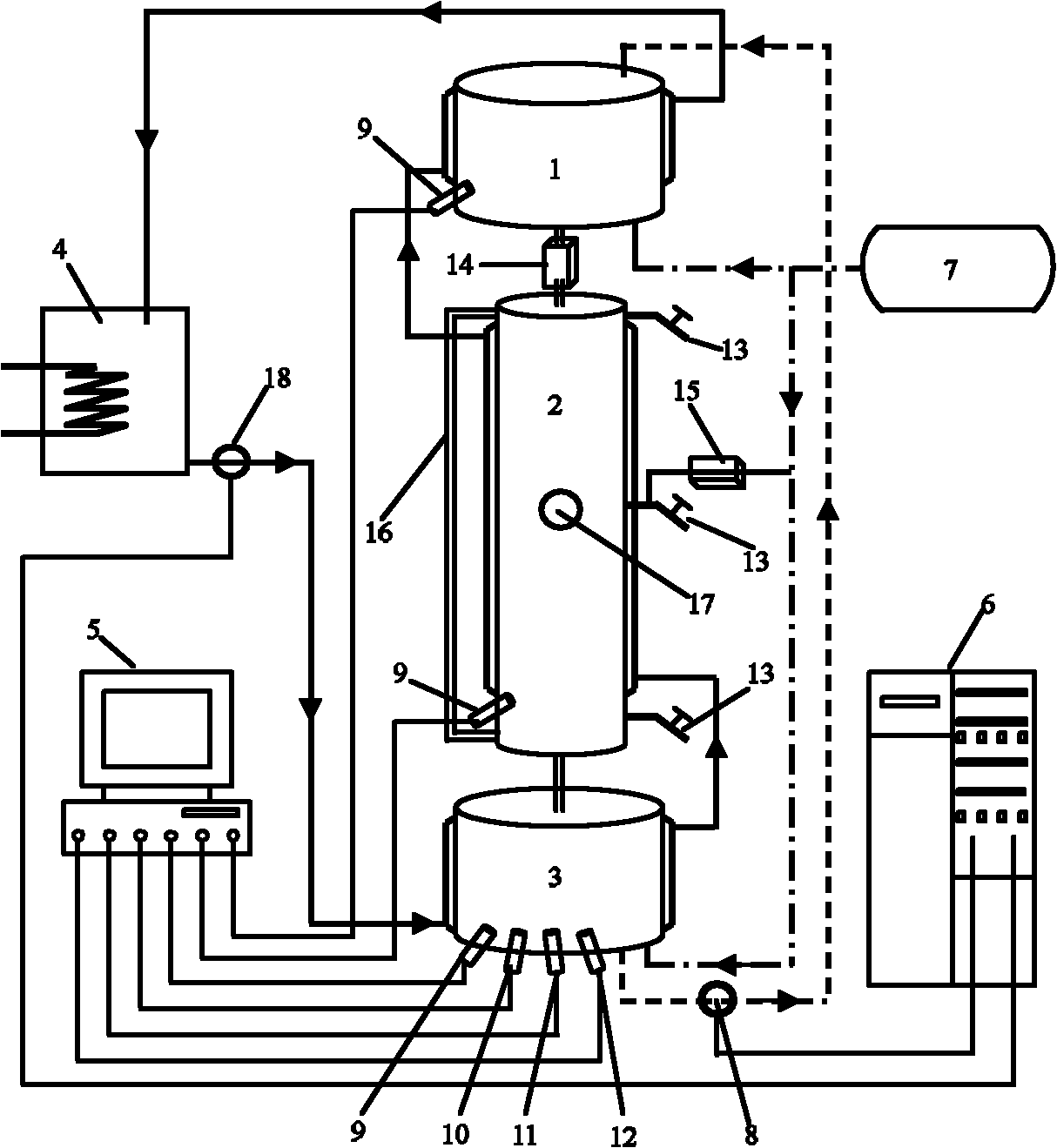

Multifunctional automatic control column leaching experimental facility

InactiveCN102253099AMonitor temperatureMonitor pHMaterial analysis by electric/magnetic meansAutomatic controlSolenoid valve

The invention discloses a multifunctional automatic control column leaching experimental facility, belonging to the field of leaching mining. The experimental facility mainly comprises a liquid circulation system, a water circulation system, an air circulation system, an automatic control system and a data collection system. The liquid circulation system is composed of a reaction column, a high-level tank and a liquid receiving tank; the water circulation system is composed of a hot water tank, a solenoid valve, a liquid receiving tank jacket, a reaction column jacket and a high-level tank jacket; the air circulation system is composed of an air compressor, an air flowmeter and a control valve; the automatic control system is used for automatically regulating and controlling the temperature of the leaching system, oxygen solubility and solution flowing; the data collection system can be used for automatically collecting and storing the solution pH value, the oxygen solubility, electric potential, the temperature and other parameters in real time. The experimental facility can be used for performing indoor simulation experiments and semi-industrial scale pilot plant experiments according to heap-leaching field conditions and actual size of mineral particles, effectively simulating the multiphase and multilevel seepage state of ore bulk and a microbiological leaching and biochemical process, and providing basic data for heap-leaching production practice and technological parameter optimization.

Owner:UNIV OF SCI & TECH BEIJING

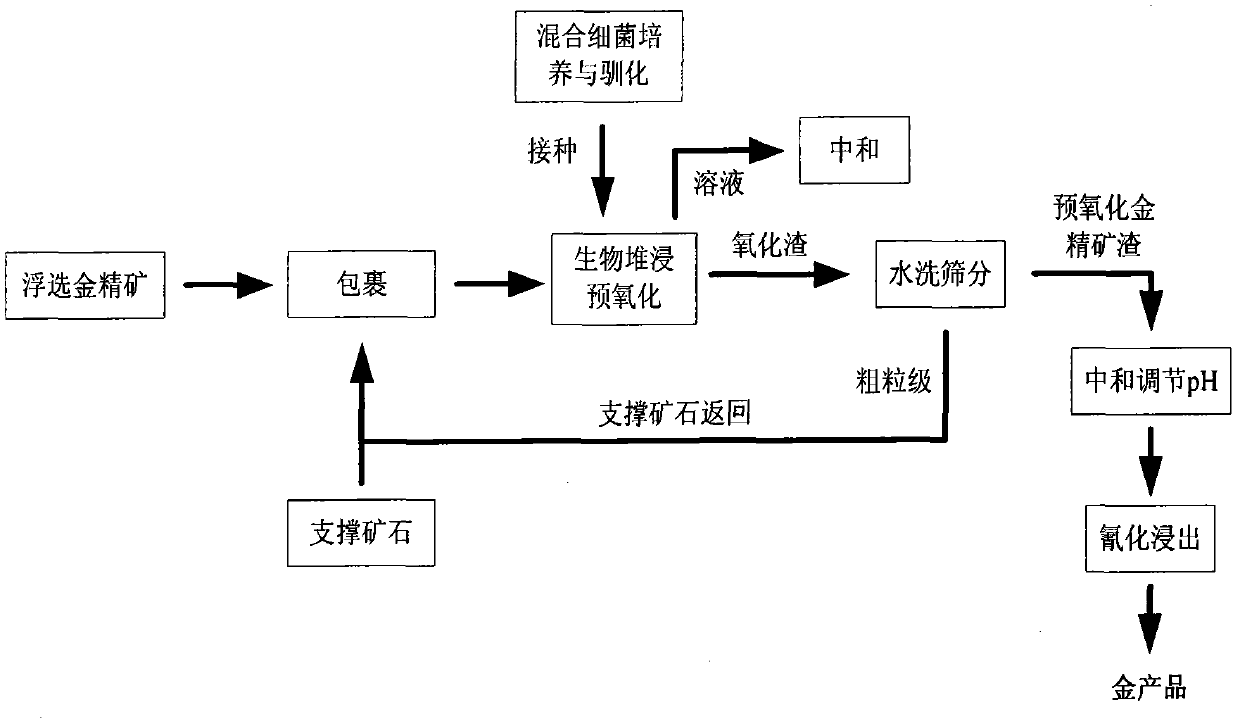

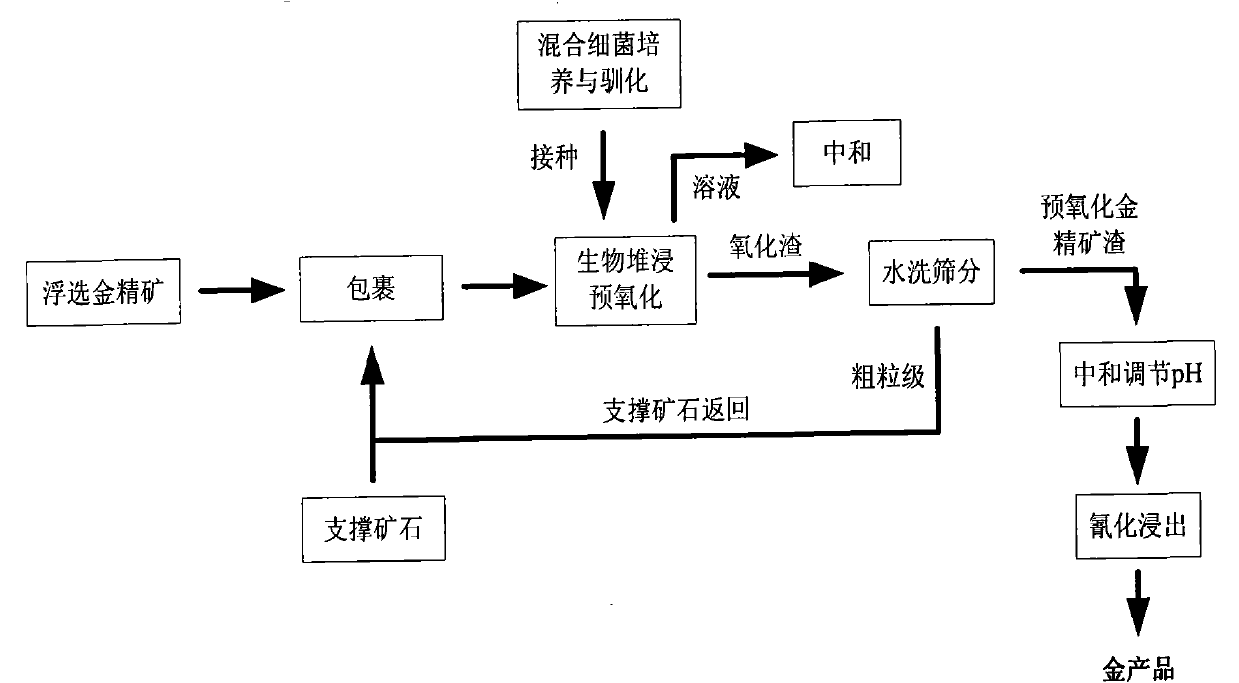

Biological pre-oxidation treatment process of low-grade refractory gold ores or ore concentrate

InactiveCN102560110AFully oxidizedImprove pre-oxidation rateProcess efficiency improvementThiobacillus ferrooxidansSlag

The invention provides a biological pre-oxidation treatment process of low-grade refractory gold ores or ore concentrate, which is a new process comprising the following steps: wrapping low-grade refractory ore concentrate on the surface of supporting ore particles, performing biological heap leaching preoxidation, washing and screening the slag, returning large particles to supplement supporting materials, and extracting gold from the gold ore concentrate-wrapped and pre-oxidized slag by cyanation. Bacteria are mixed bacteria mainly comprising Thiobacillus ferrooxidans, Thiobacillus thioxidans and Leptospirillum ferrooxidans, and the temperature is 30-45 DEG C; the particle sizes of the ore concentrate and the supporting ore are respectively 80-400 meshes and 10-30mm, and the wrapping thickness of the ore concentrate is less than 2mm; and the preoxidation period is 30-90 days, the preoxidation rate is increased to 50-70%, and the recovery rate of gold is up to 80-95%. Compared with biological stirring preoxidation and complete heap leaching preoxidation, the preoxidation treatment process provided by the invention solves the problems of long preoxidation period and low gold recovery rate, and has remarkable economic benefits. The process of the invention is especially suitable for gold ores with high content of pyrite, is environment-friendly, and is in line with the development of low-carbon economy in nonferrous metallurgy industry.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

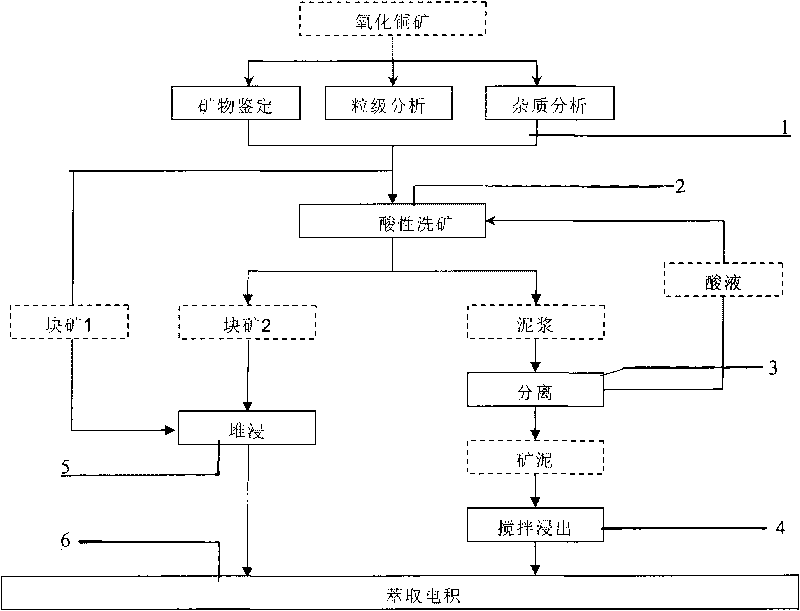

Acid washed ore leaching process for low-grade copper oxide ores with high mud content

InactiveCN101736152AReduce pollutionLow permeabilityProcess efficiency improvementCopper oxideDissolution

The invention provides an acid washed ore leaching process for low-grade copper oxide ores with high mud content, which comprises the following steps: after the raw ores are crushed and sieved, conveying the ores of +50mm size fraction to a storage yard for stacking, and carrying out acid washed ore treatment on the ores of -50mm size fraction; by adding sulfuric acid into the washing liquid, rewashing the ores to remove partial basic gangue; after the washing liquid is separated and deposited, recycling the acid liquid; after the ores are treated by an acid washed ore system, conveying the sand ores of +0.074mm size fraction to the storage yard for stacking, and stirring and leaching the mud ores of -0.074mm size fraction; after the leaching liquid generated by stirring and the leaching liquid generated by heap leaching are mixed, carrying out extracting and electrodepositing processes; and finally, obtaining cathode copper products. The process of the invention has the advantages of short procedures, simple equipment, small investment, low cost and little pollution to the environment, further solves the problems of poor heap leaching penetrability, low copper leaching rate and the like caused by existence of mud ores and dissolution and deposition of basic gangue, improves the recovery rate of copper, and comprehensively utilizes the mineral resources of the low-grade copper oxide with high mud content.

Owner:有研资源环境技术研究院(北京)有限公司

Method for microorganism-pelleting heap leaching of earthy oxide copper ores

InactiveCN101781705AIncrease throughputReduce ore washingProcess efficiency improvementThiobacillus ferrooxidansHydrometallurgy

The invention relates to a method for leaching earthy oxide copper ores, in particular to a method for microorganism-pelleting heap leaching, and belongs to the technical field of hydrometallurgy. The method is characterized in that: the earthy ores are directly screened, and fine ores with the granularity of 1.5mm are added with strain acid water and cement to prepare ore pellets with the diameter between 10 and 20 mm for heap leaching, wherein the mass concentration of sulphuric acid in the strain acid water is 3 to 10 percent, strains are mixed strains of Thiobacillus ferrooxidans, Thiobacillus thiooxidans and Leptospirillum ferrooxidans, the mass ratio of the three is 4.0-5.5:2.5-3.5:1.5-2.5, the bacterial load ratio is 105 and 108 / ml, the cement amount is 15 to 30kg / ton of ores; and leachate in the leaching is sprayed for closed cycle production. The method has the advantages of low investment, low energy consumption, good leaching effect, and no discharge of closed cycle, solves the problem of leaching the low-grade earthy oxide copper ores (including sulphide and oxide blend ores) by microorganism heap leaching, and overcomes the defects of long flow and high cost of agitation leaching.

Owner:王宣明

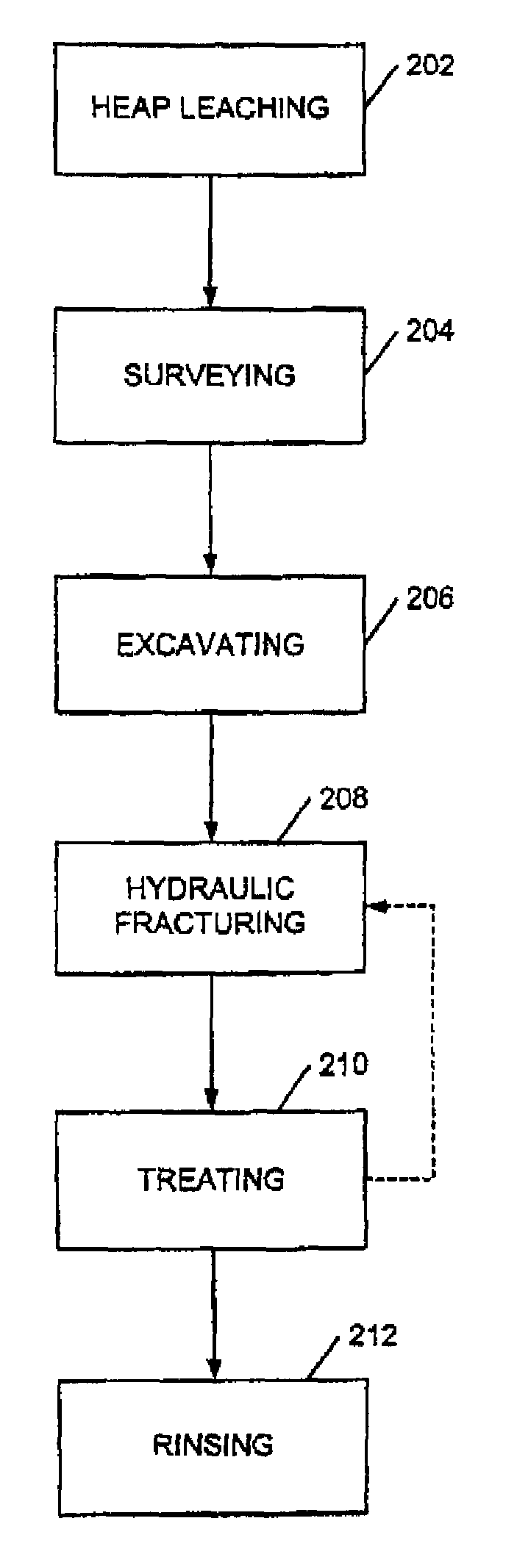

Remedial heap treatment

ActiveUS8021461B2Improve mobilityPromote sportsConstructionsGold compoundsMining engineeringHydraulic fracturing

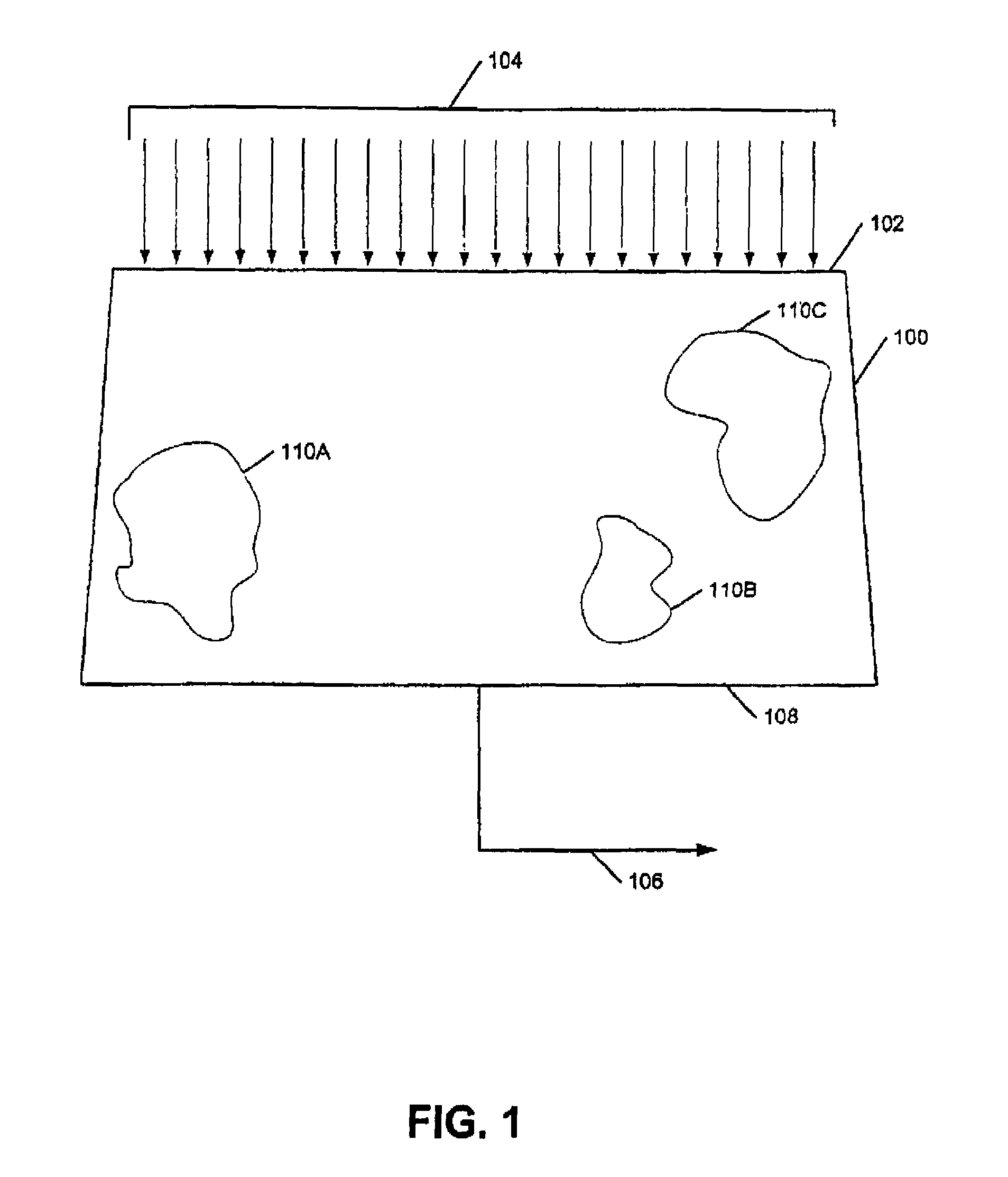

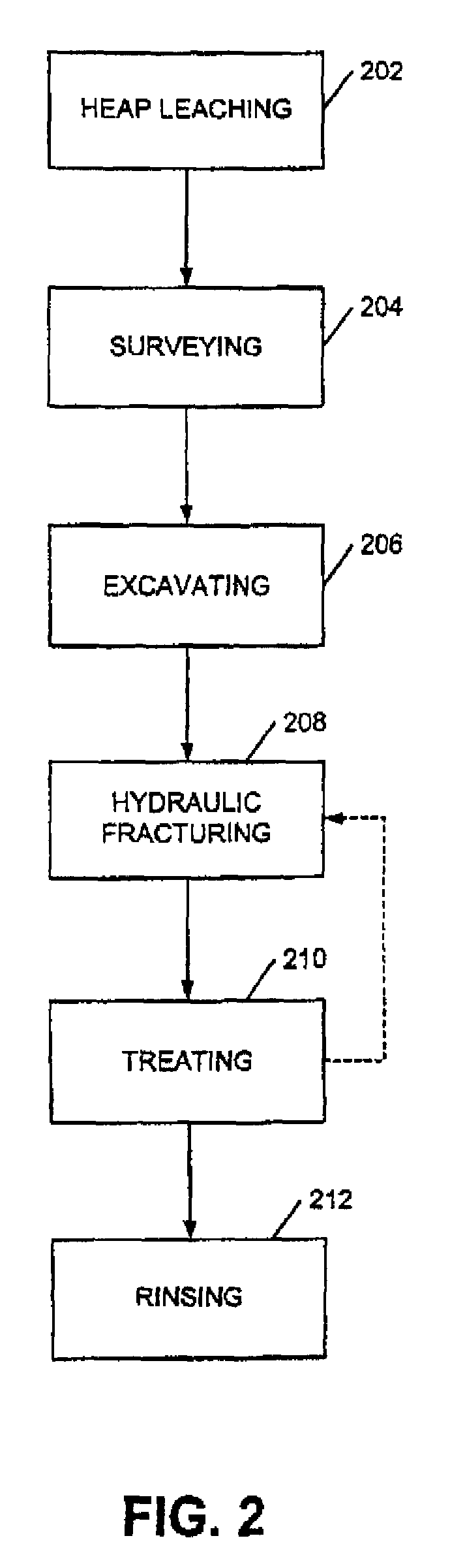

A system and method are disclosed for improving component extraction from heap leach operations. Following heap leaching for some time, portions of the heap deficient in component extraction are identified, and treatment wells are drilled and remedial treatments are selectively performed on the identified portions of the heap. The remedial treatment can include hydraulically fracturing the identified portions of the heap followed by selective treatment with leach solution of the area impacted by the fracturing.

Owner:NEWMONT USA LTD

Method for extracting nickel and/or cobalt

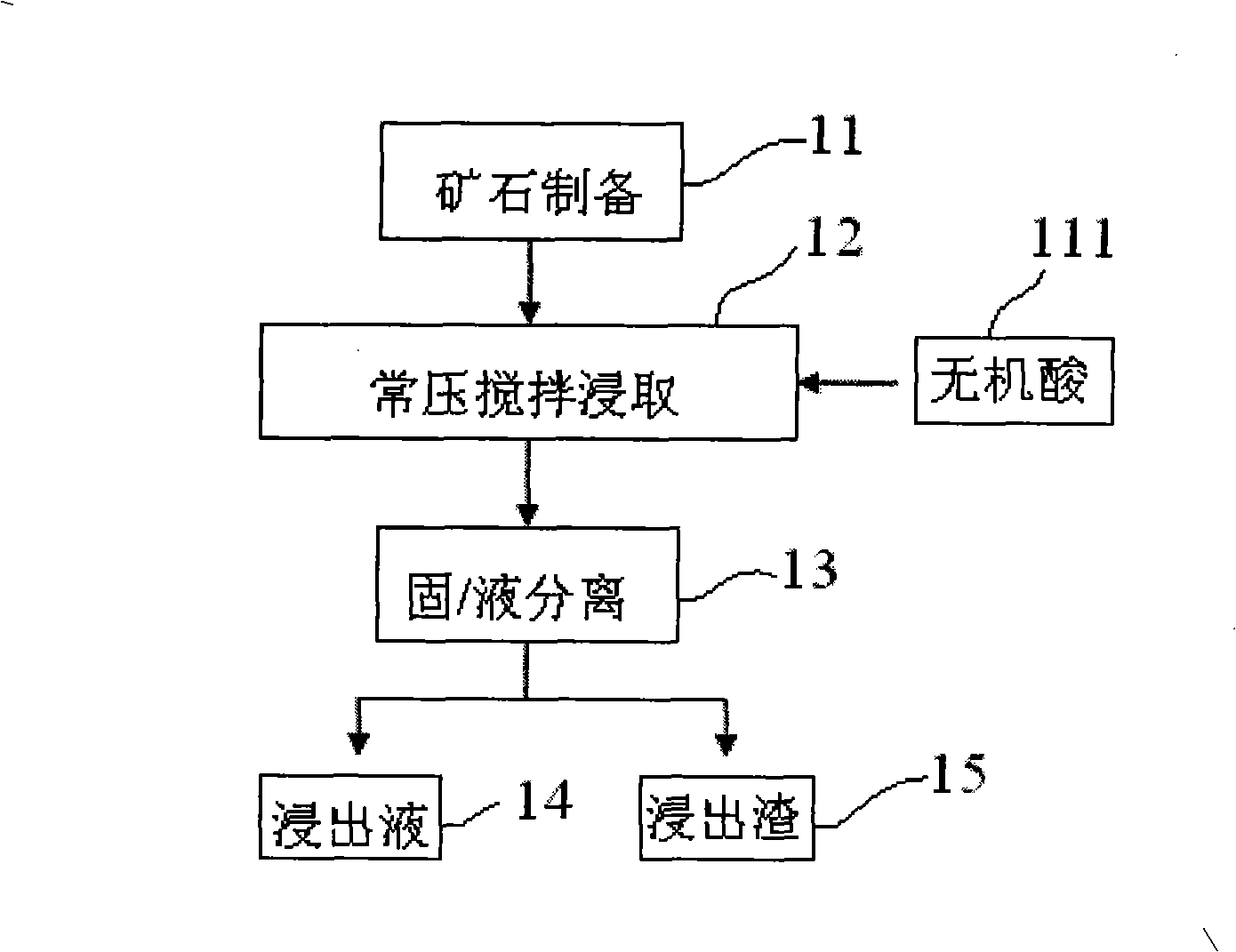

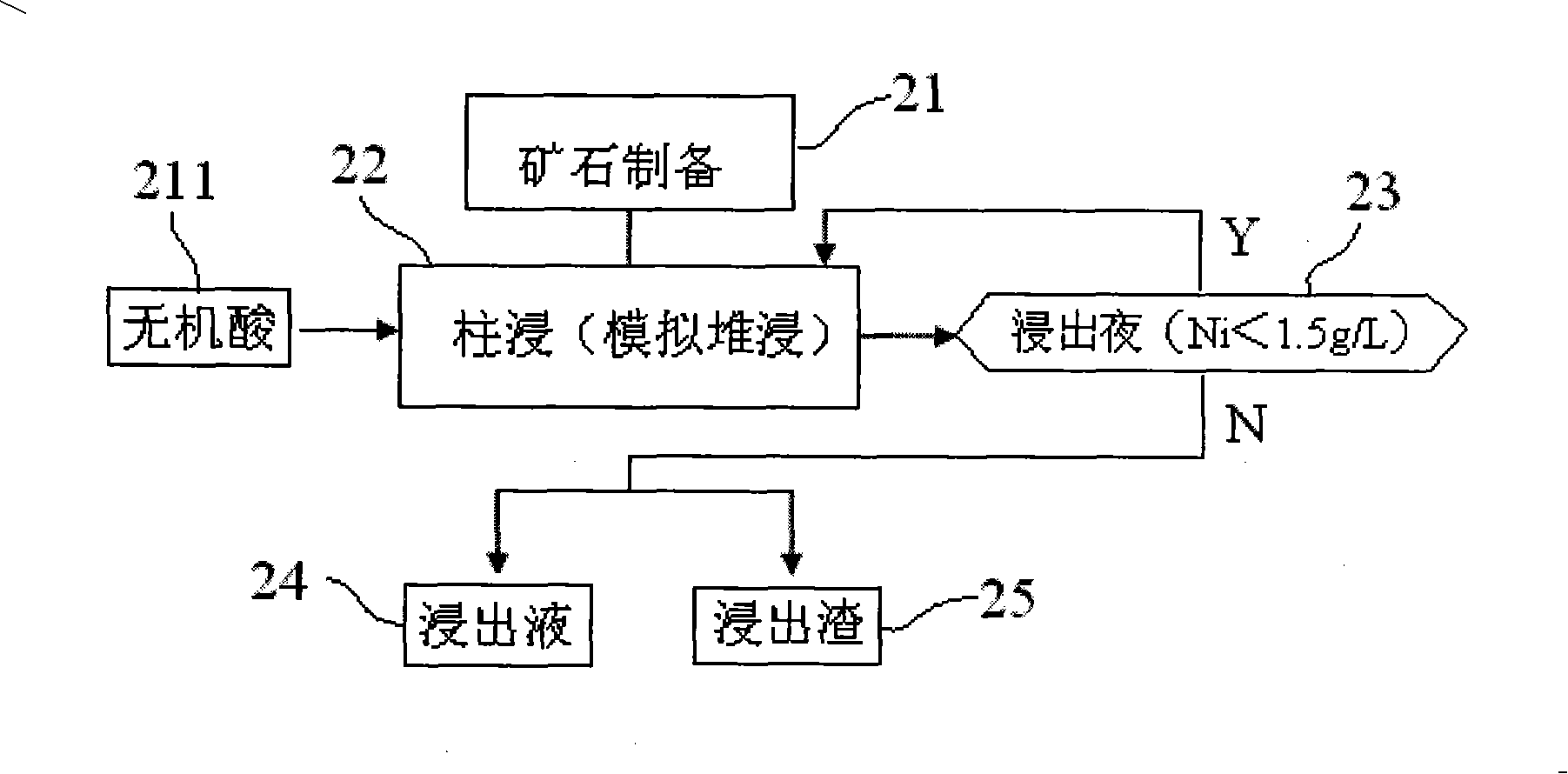

An extraction method of Nickel and / or Cobalt comprises a heap leaching technology and a technology of atmospheric heating, mixing and leaching, which is characterized in that limonite type ore is leached by using the atmospheric heating and mixing, and serpentine type ore is leached by heap leaching technology. According to the invention, different leaching technology are adopted for the serpentine type ore and the limonite type ore in laterite-nickel ore, the serpentine type ore is leached by using the heap leaching technology to obtain the faster leaching speed, and the limonite type ore is leached by using the atmospheric heating and mixing technology for avoiding the problem of the extreme low leaching speed and the long leaching period.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP

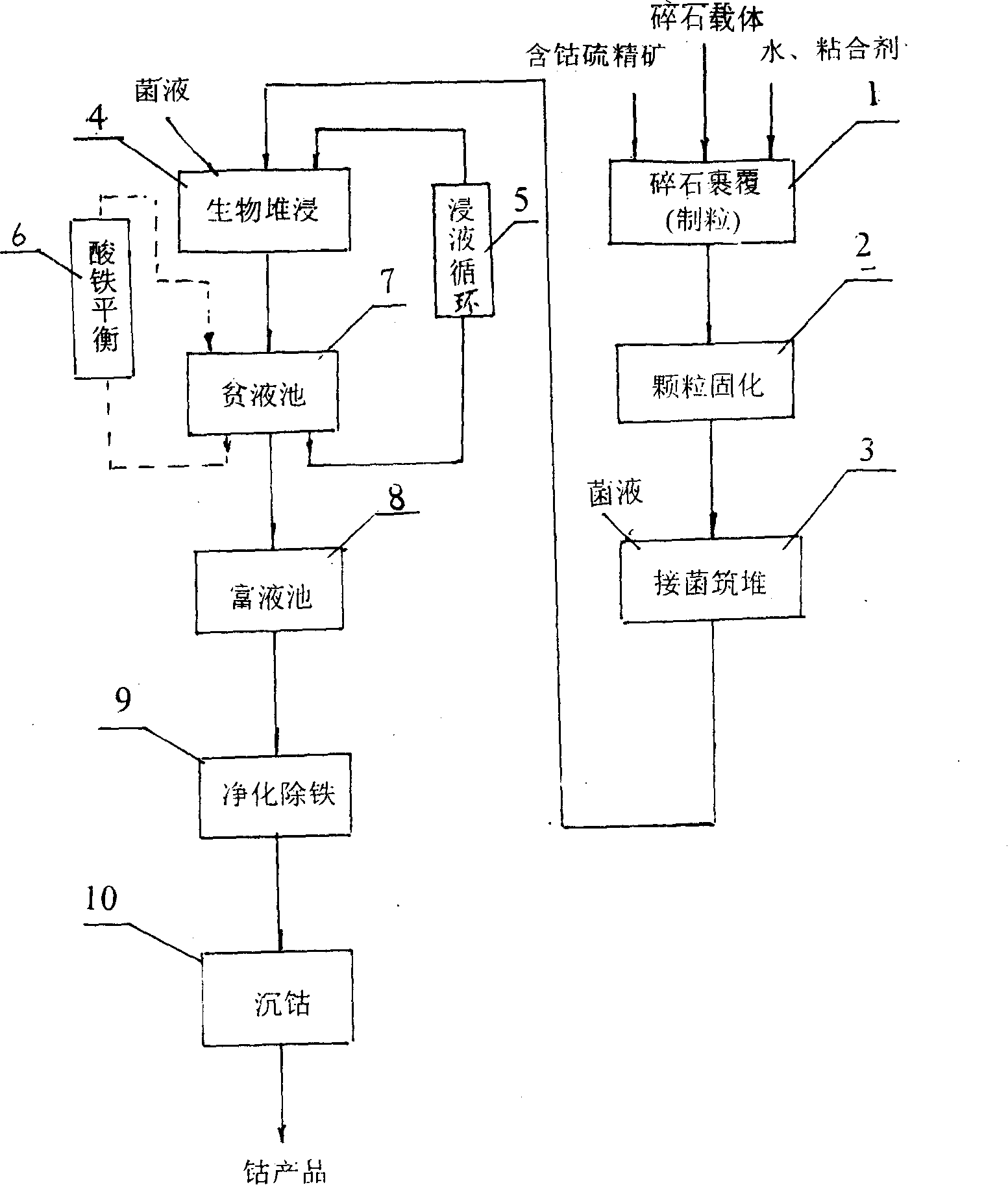

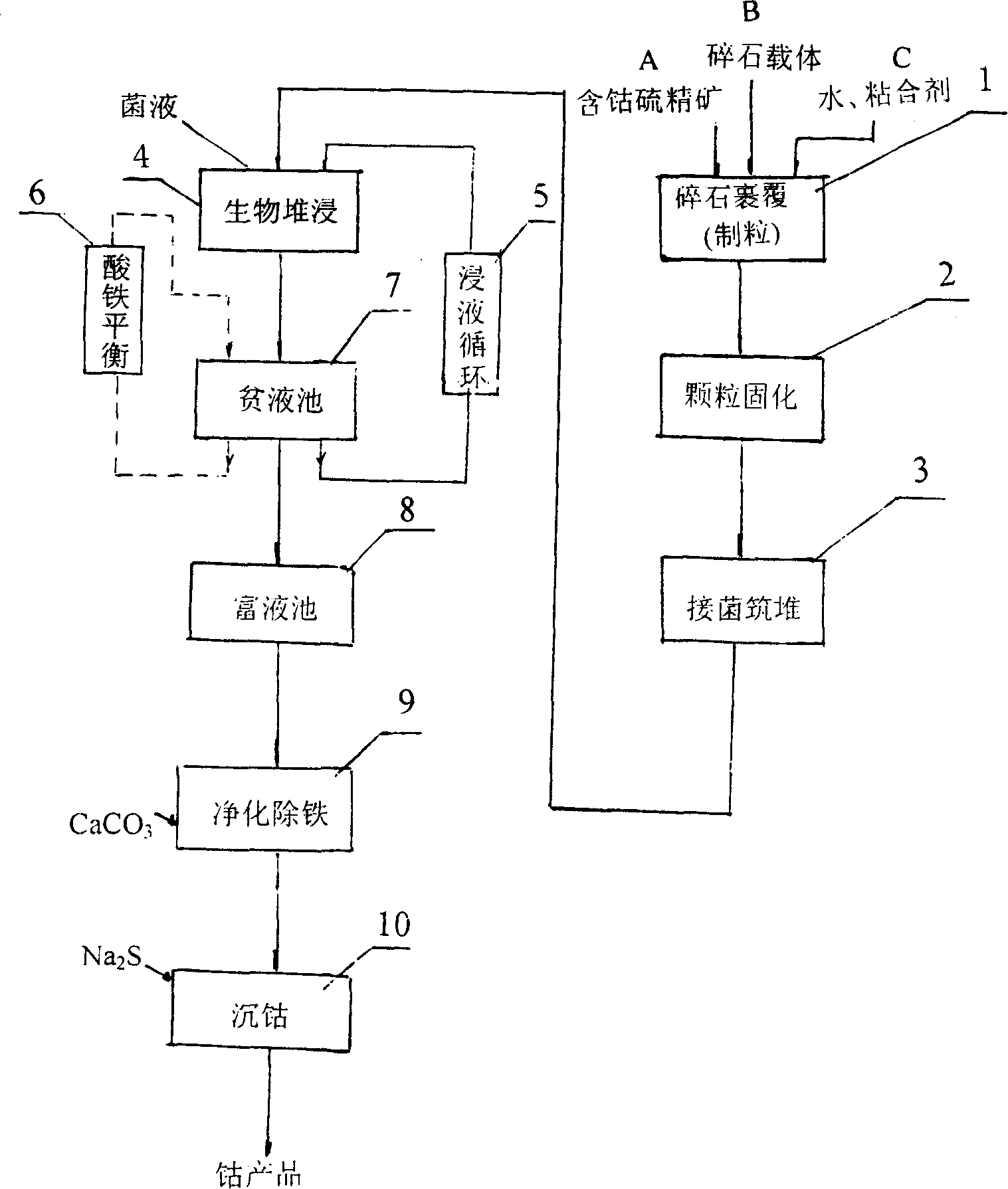

Mesophilic acidophilic bacteria and biological heap leaching technique for low-grade cobalt-containing sulfur concentrate

InactiveCN101191122AEfficient recyclingLow investment costBacteriaProcess efficiency improvementThiobacillus ferrooxidansCobalt sulphate

The invention relates to mesophilic acidophilic bacteria and a biological heap leaching technology for low-grade cobaltiferous sulfide ore concentrates. The mesophilic acidophilic bacteria have a name of Thiobacillus ferrooxidans Retech V and a collection registration number of CCTCC NO: M202039, and has been stored and collected in China Center for Type Culture Collection (in Wuhan University). The biological heap leaching technology is that: mineral grains which are suitable for biological heap leaching are obtained after coating of crushed stones and solidification of the mineral grains of the low-grade cobaltiferous sulfur-bearing ore concentrates. Cobalt sulphates are obtained through procedures of embankment, heap leaching and trickling by adoption of bacteria with two different growth temperatures, lixivium circulation, purification and deferrization of cobalt pregnant solution, cobalt settlement and so on of the mineral grains. The temperature of 10 to 55 DEG C, the PH value of 1.2 to 1.8 and the adequate Fe concentration of a storage yard in a heap leaching system during the leaching out process are favorable for activity of leaching bacteria. The invention has the advantages of capability of fully utilizing low-grade cobaltiferous sulfide ore resources in old mines, improvement of comprehensive utilization level of mines, conservation of cost, and improvement of profit. The invention is applied in developing cobaltiferous sulfide ore resources in remote areas.

Owner:有研资源环境技术研究院(北京)有限公司

A method for extracting vanadium by heap leaching of vanadium-containing stone coal with concentrated sulfuric acid and additives

ActiveCN102260792ASave and reduce grinding costsLow recovery rateProcess efficiency improvementIon exchangeCoal

The invention provides a method for extracting vanadium by heap leaching and adding concentrated sulfuric acid and an additive in vanadium-containing stone coal. The method comprises the following specific steps: smashing stone coal ore; proportioning based on weight part, evenly mixing proportioned stone coal ore powder, concentrated sulfuric acid and an additive aqueous solution through mechanical stirring until small pellets are generated and piled to be in a cone shape, and reacting for 2-5 days; feeding the stone coal ore powder subjected to complete heap leaching reaction to an agitation leaching reaction kettle, adding water in a solid-liquid ratio of 1: (0.8-1.2) for mechanical agitation leaching; adding a reducer sodium thiosulfate for reduction, adding calcium carbonate to regulate the PH value, and carrying out solid-liquid separation in a belt filter or a plate-and-frame filter press so as to obtain a blue mother liquid containing vanadium; and extracting the mother liquidwith a solvent or carrying out ion exchange, vanadium precipitation, drying and forging on the mother liquid so as to obtain vanadium pentoxide. By using the method, the grinding cost of the ore is saved and reduced, and grinding equipment and capital construction installation investments are reduced.

Owner:张国茂

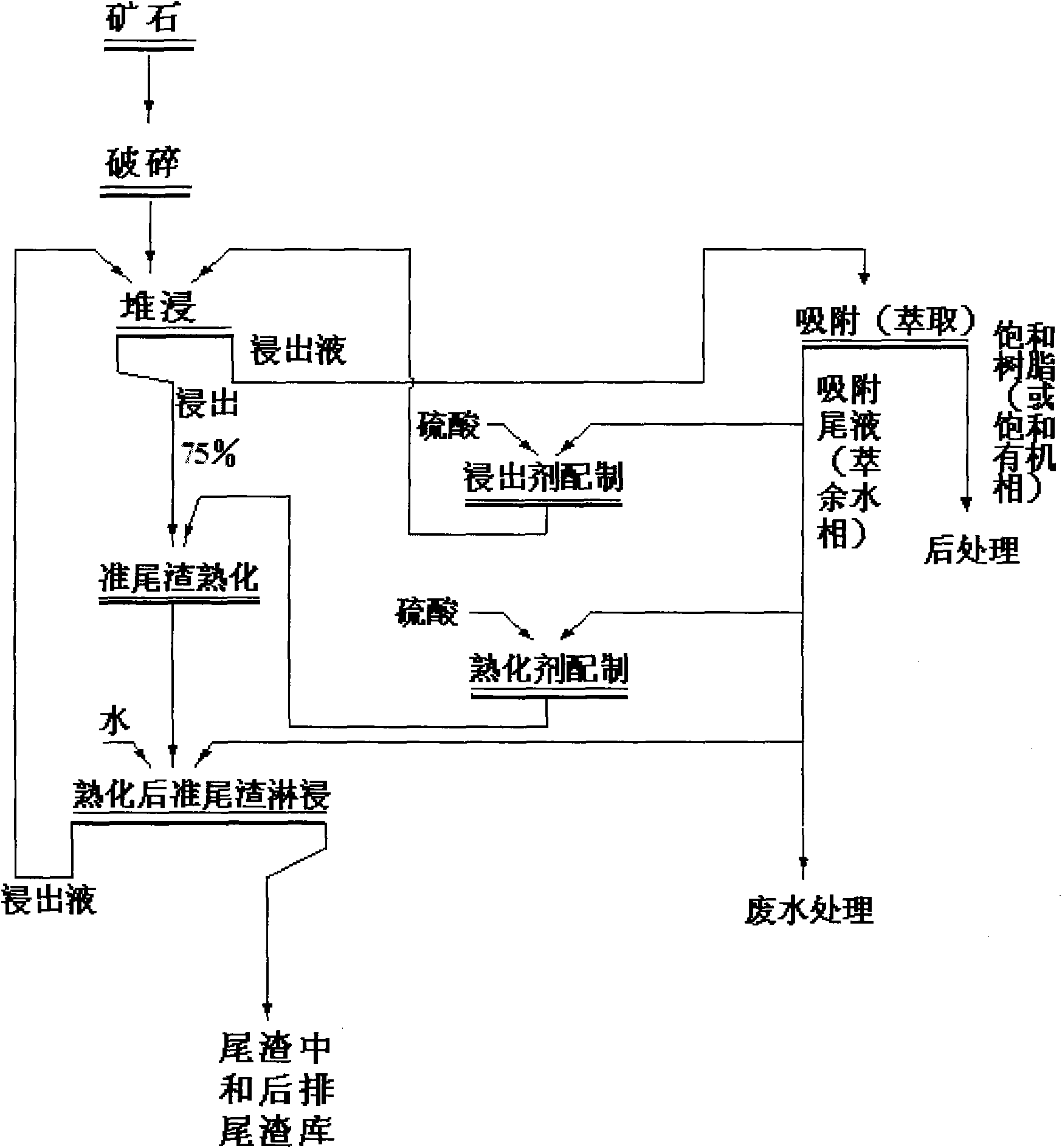

High intensity leaching method in initial heap leaching

InactiveCN104928505AReduce in quantityReduce generationProcess efficiency improvementPregnant leach solutionUranium ore

The present invention provides a high intensity leaching method in initial heap leaching. The method comprises the steps of: first crushing uranium ore, separating fine fraction and transferring to a leaching field for heap construction; (2) leaching an ore heap by spray leaching agents; employing a leaching agent with high acidity in the initial leaching agent stage namely acidification stage, and spraying continuously 24 hours a day by high spray intensity; (3) adsorbing the leaching liquid obtained in step (2) to recover uranium, adding acid in the absorption tail liquid and returning to be reused as the leaching agent, and sending the saturated resin into a posttreatment process; (4) when the uranium concentration in the leaching liquid is less than 50mg / L or liquid metered leaching rate reaches 85%, conducting quasi tailings acid curing for a few days, washing the heap, returning the washing liquid to be used as leaching agent for the next heap, neutralizing the tailings and discharged the into a tailings storage. The heap leaching method provided by the invention can prevent the phenomena of ore wrapping by precipitates and leaching channel clogging in the acidification stage of ore heap, shorten leaching time and reduce tailings grade.

Owner:中核赣州金瑞铀业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com