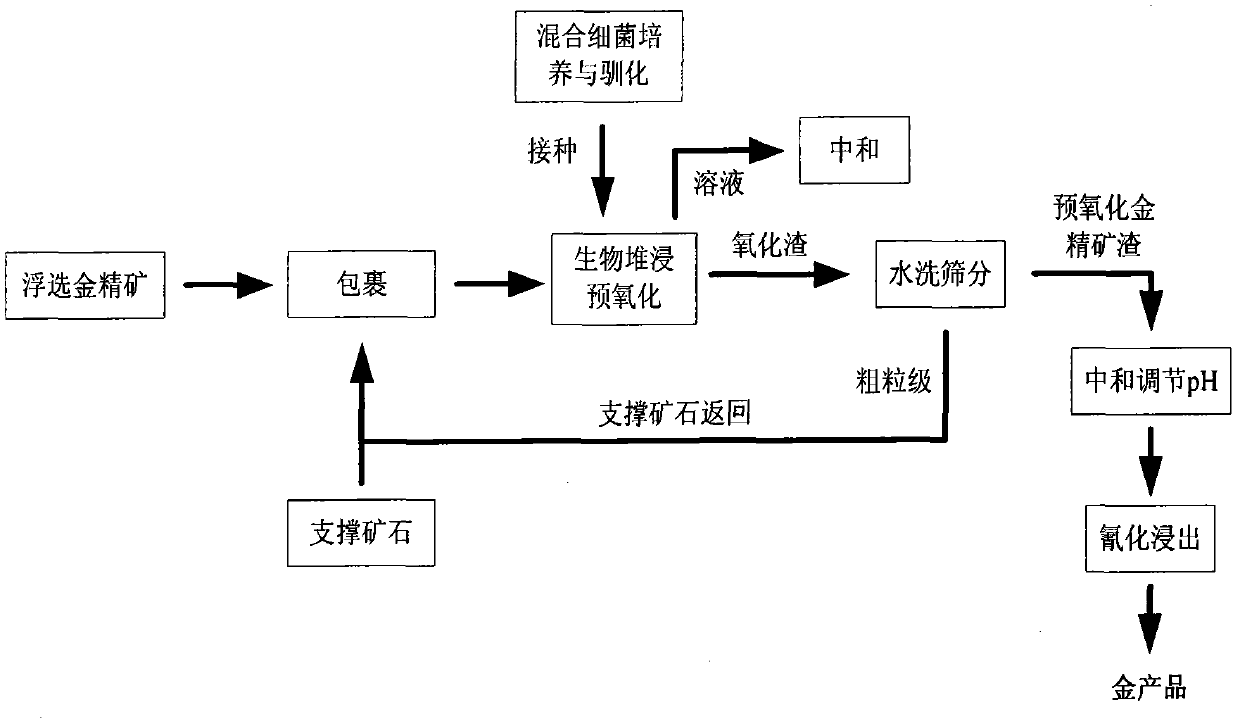

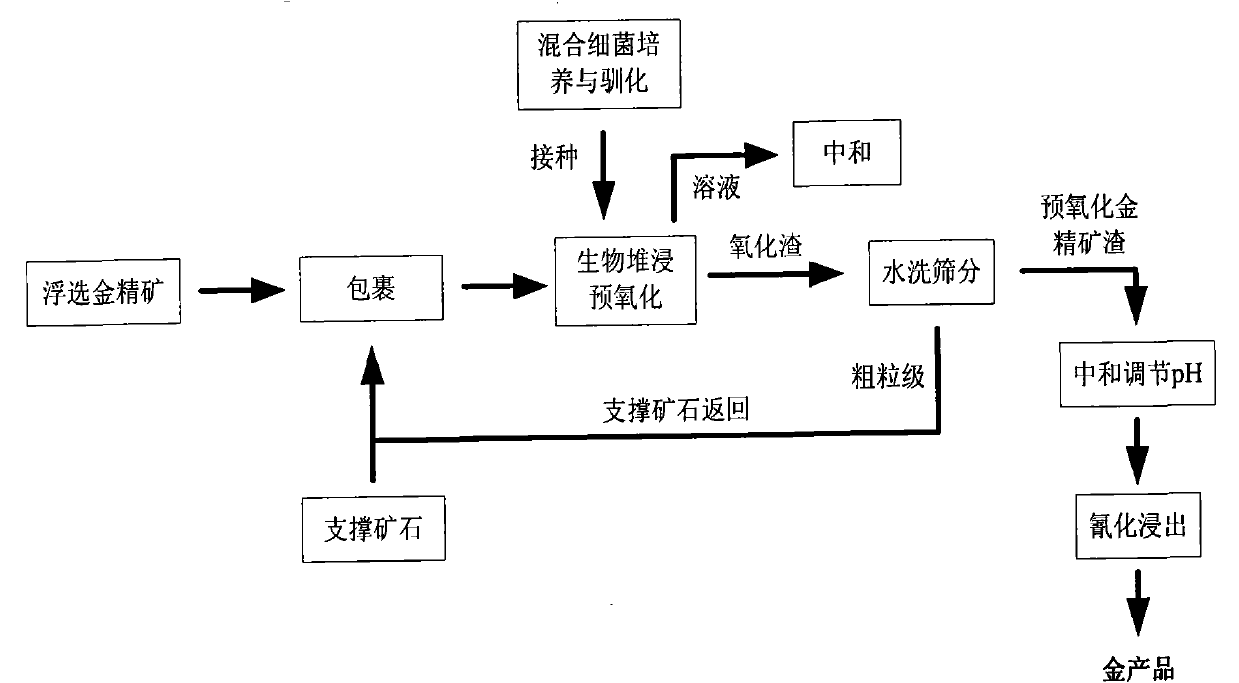

Biological pre-oxidation treatment process of low-grade refractory gold ores or ore concentrate

A low-grade, gold concentrate technology, applied in the direction of improving process efficiency, etc., can solve the problems of long biological pre-oxidation period, insufficient exposure of gold particles, low arsenic and sulfur oxidation rate, etc., achieve no harmful gas emissions, improve comprehensive Effect of low recycling rate and operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The main type of ore in a domestic gold mine is sulfide carbonaceous fine particle disseminated refractory gold ore, the gold grade is 2.98g / t, the sulfur content is 9.5%, and the sulfide content is 25-30%. The ore is a sulfide ore with pyrite as the matrix mineral. The gold particle size is very fine, the largest gold particle is less than 8μm, and most of the others are below 5μm. Most of them are disseminated in sulfide, accounting for 90% of the total gold content. Most of the iron and sulfur in the ore form sulfide minerals - pyrite, marcasite and arsenopyrite, a small part of iron forms iron oxide minerals - magnetite, hematite, limonite, and some iron Distributed in carbonate minerals and aluminosilicate minerals in the form of impurities; gangue minerals mainly include quartz, feldspar, chlorite, sericite and carbonate minerals. Pyrite is the main sulfide mineral, mostly in colloidal structure, high degree of crystallization, fine particle size, more than 50% of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com