Patents

Literature

317 results about "Gold deposit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

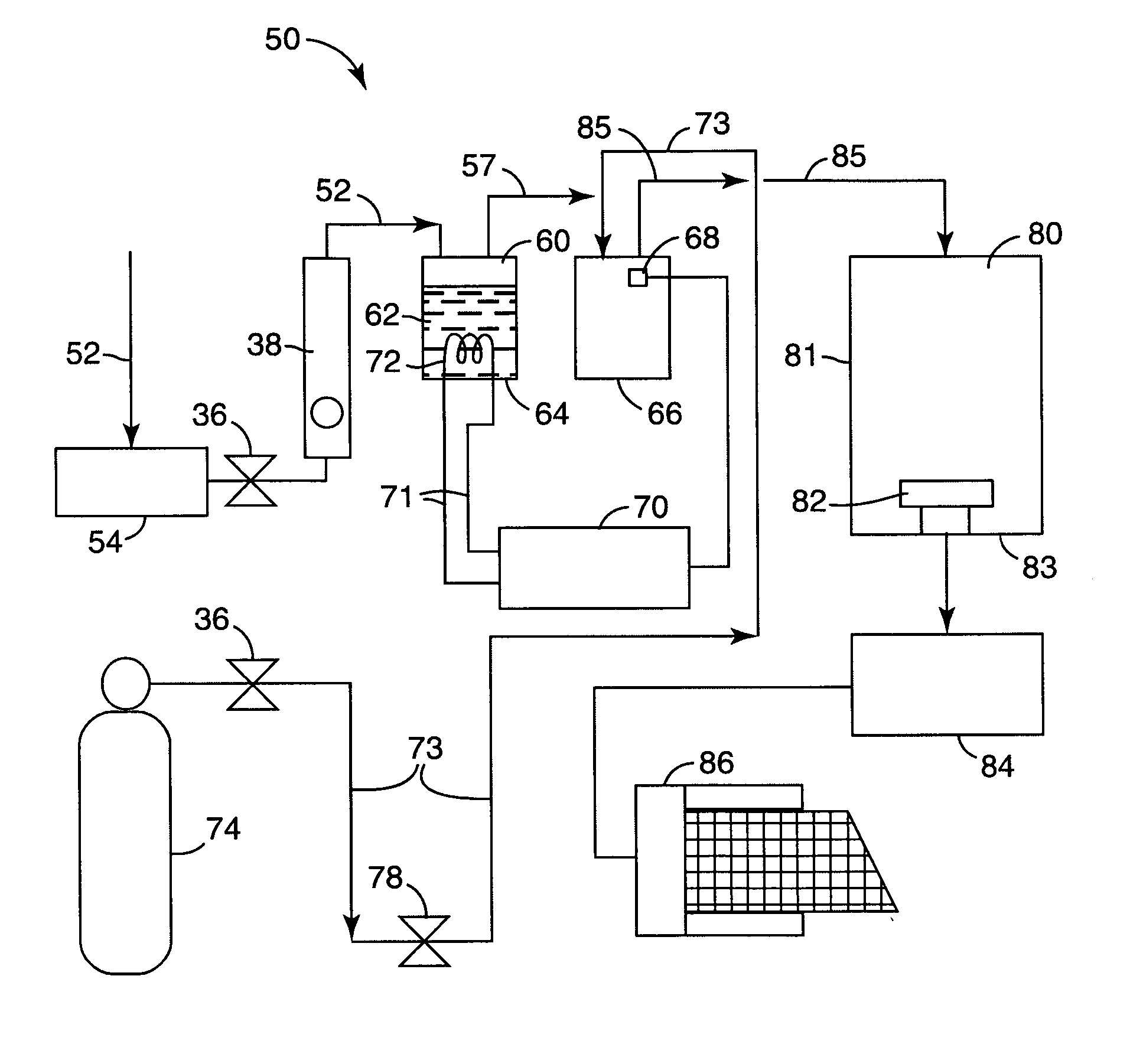

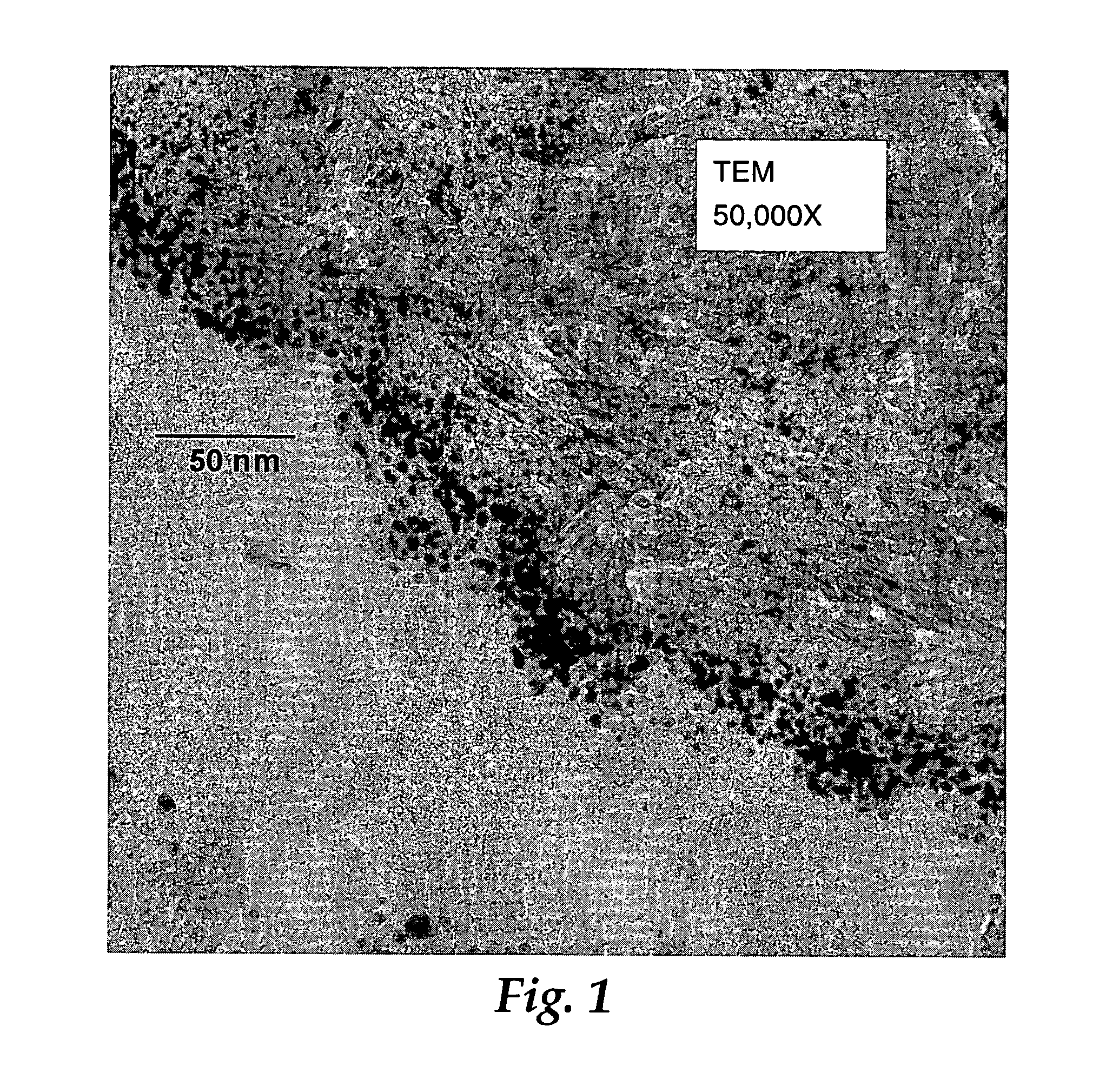

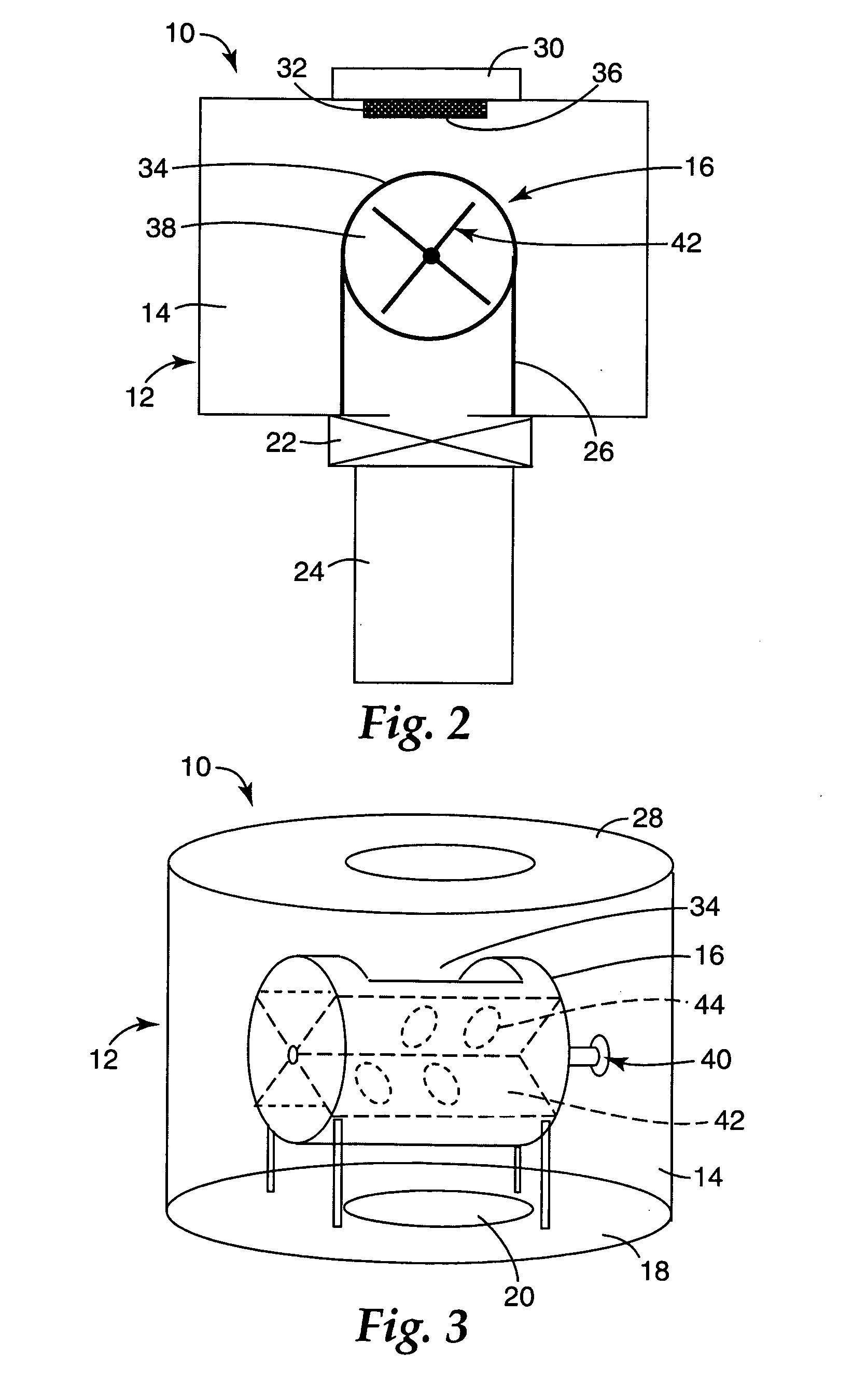

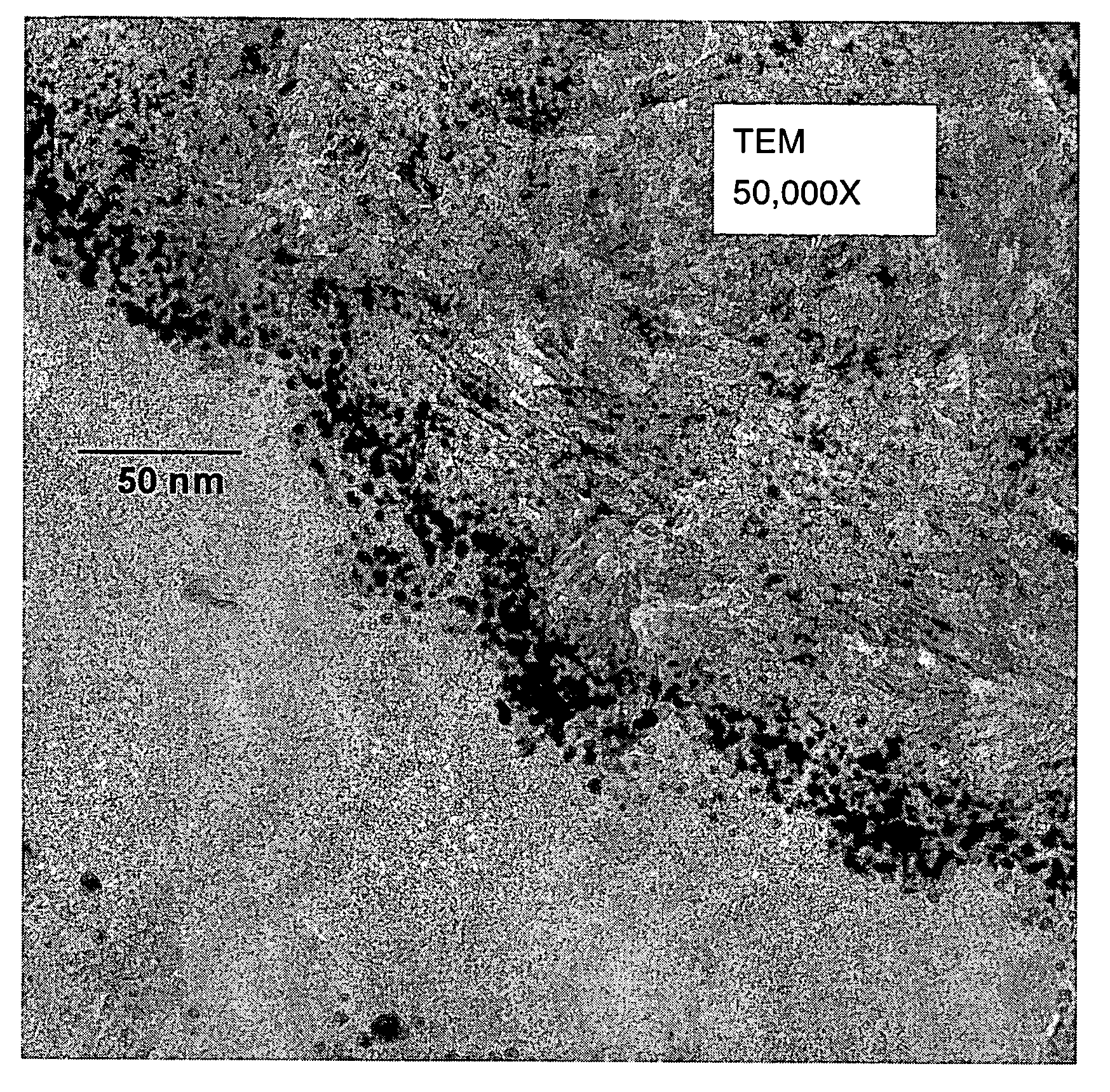

Catalysts, activating agents, support media, and related methodologies useful for making catalyst systems especially when the catalyst is deposited onto the support media using physical vapor deposition

InactiveUS20050095189A1Improve performanceEasy to useMaterial nanotechnologyInternal combustion piston enginesGas phaseAdditive ingredient

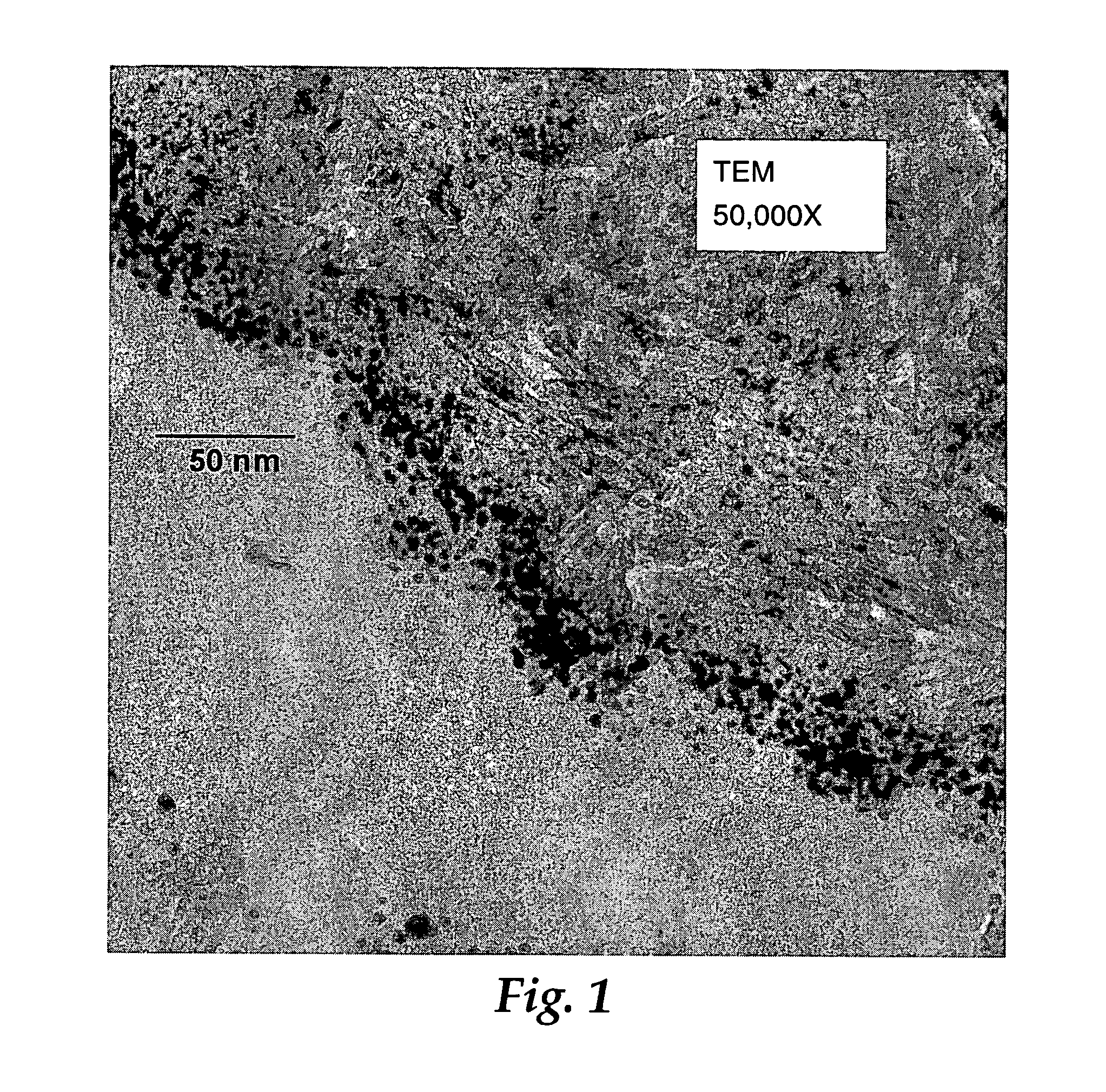

Use of physical vapor deposition methodologies to deposit nanoscale gold on activating support media makes the use of catalytically active gold dramatically easier and opens the door to significant improvements associated with developing, making, and using gold-based, catalytic systems. The present invention, therefore, relates to novel features, ingredients, and formulations of gold-based, heterogeneous catalyst systems generally comprising nanoscale gold deposited onto a nanoporous support.

Owner:3M INNOVATIVE PROPERTIES CO

Catalysts, activating agents, support media, and related methodologies useful for making catalyst systems especially when the catalyst is deposited onto the support media using physical vapor deposition

InactiveUS7727931B2High catalytic activityTendency increaseMaterial nanotechnologyInternal combustion piston enginesGas phasePhysical chemistry

Use of physical vapor deposition methodologies to deposit nanoscale gold on activating support media makes the use of catalytically active gold dramatically easier and opens the door to significant improvements associated with developing, making, and using gold-based, catalytic systems. The present invention, therefore, relates to novel features, ingredients, and formulations of gold-based, heterogeneous catalyst systems generally comprising nanoscale gold deposited onto a nanoporous support.

Owner:3M INNOVATIVE PROPERTIES CO

Non-electrolytic gold plating liquid and non-electrolytic gold plating method using same

InactiveUS6287371B1Improve adhesionInhibits excess local etching or corrosionAnti-corrosive paintsLiquid/solution decomposition chemical coatingEtchingCobalt

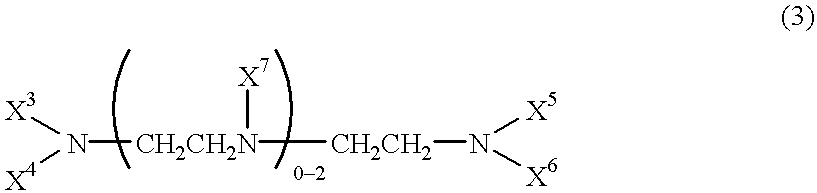

The present invention provides an excellent non-electrolytic gold plating liquid which produces a gold plating layer firmly adhered to a surface selected from the group consisting of nickel, cobalt, palladium or a metal alloy containing nickel, cobalt or palladium, as well as a method for performing a non-electrolytic gold plating method using the non-electrolytic gold plating liquid. The non-electrolytic gold plating liquid comprises:(1) a water-soluble gold compound;(2) a complexation agent which stabilizes a gold ion in the plating liquid, but does not substantially dissolve nickel, cobalt or palladium; and(3) an anti-gold deposit agent which inhibits excess local etching or corrosion by substitution reaction between the metal surface and gold during the gold plating.

Owner:LEARONAL JAPAN

Process for extracting gold from low-grade difficultly-treatable gold ore containing arsenic and carbon

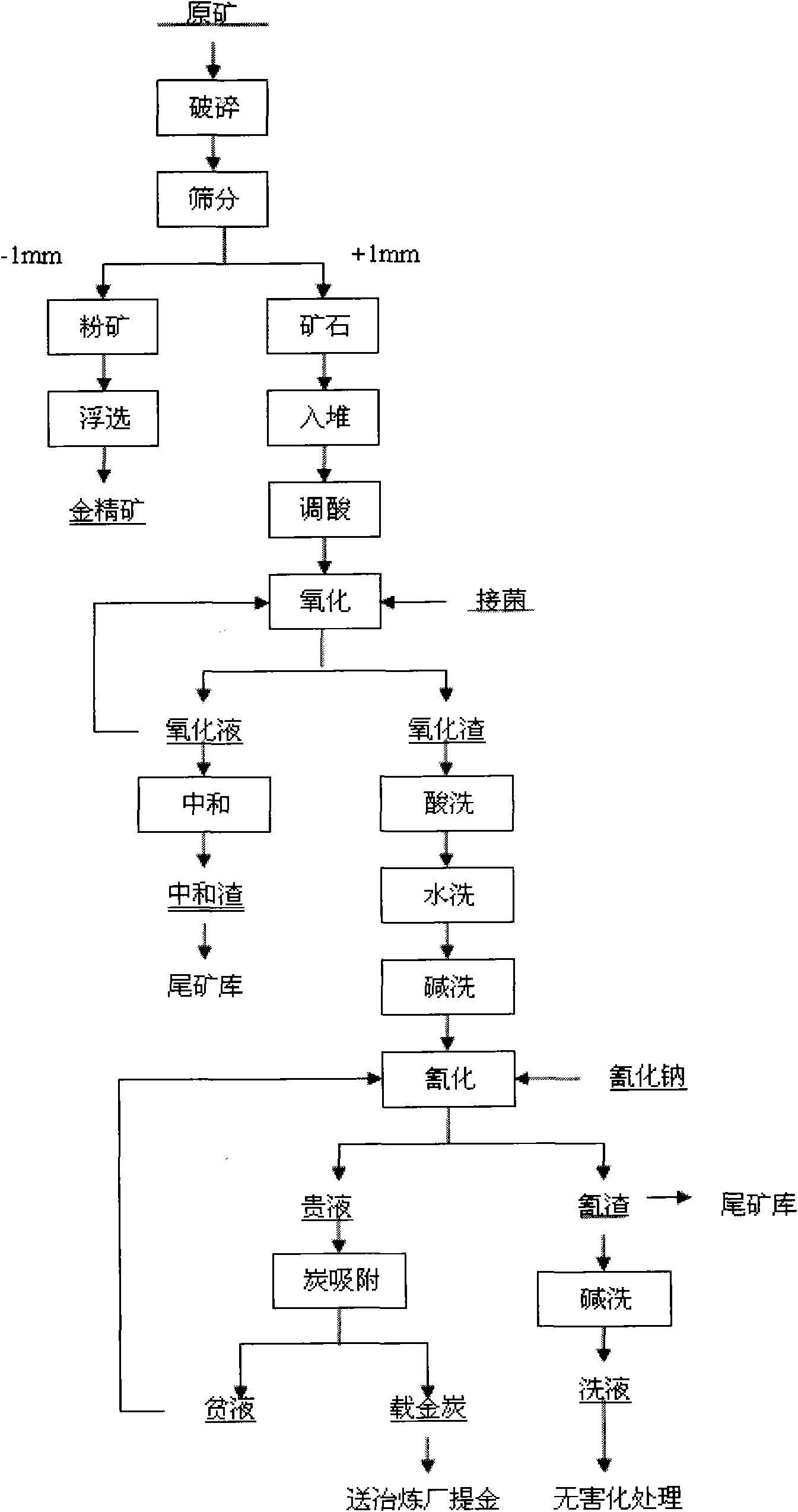

The invention relates to a process for extracting gold from low-grade difficultly-treatable gold ore containing arsenic and carbon. The process is characterized in that: the gold ore has the characteristics of high clay mineral content, large fine ore amount after grinding, and the like. The process comprises the following steps of: grinding raw ore to 10 to -30 millimeters; sieving ore through a sample sieve of 1 to -2 millimeters or washing the ore with water so as to separate fine ore from the ore; floating gold concentrate by using the obtained fine ore; performing direct heap leaching on ore of +2 millimeter and performing biological oxidation; performing medium transformation such as acid washing, water washing, alkali washing and the like on the biologically-oxidized ore and cyaniding directly so as to extract gold, wherein gold is extracted from the floated gold concentrate by biological oxidation-cyaniding and carbon soaking-pressure oxidation-cyaniding and gold extraction or baking, oxidation and cyaniding. Due to the adoption of the process, the problem of permeability of gold ore is solved and the gold extracting rate is effectively increased from 2 to 5 percent during direct heap leaching and cyaniding to 55 to 65 percent. The process has the advantages of simple process, high gold extracting rate, low pollution, high benefit and the like.

Owner:ZIJIN MINING GROUP

Preparation method for manufacturing building board by utilizing mine tailing residue

The invention discloses a preparation method for manufacturing building board by utilizing mine tailing residue. The following raw materials are used by weight ratio: 30-75% of tailing residue and 25-70% of additive; brine with the weight percent concentration of 25-28% is utilized to stir the material into paste, the paste is placed into a mould to be rolled and moulded, and the tailing residue is one or more than one of gold slag, copper slag and ferrum slag. The invention utilizes tailing residue to produce building board, massive tailing residue is consumed, pollution harm of tailing discharge is solved, the produced building board has low cost and high strength, tailing residue can be made into various building boards by utilizing the technology, and various building section bars, stone pillar, brick and lattice prism used for historic building restoration as well as modern city sculpture, roman column pendant, external decorative wall, leisure chair, rail and sidewalk lattice brick can be cast.

Owner:王琦 +3

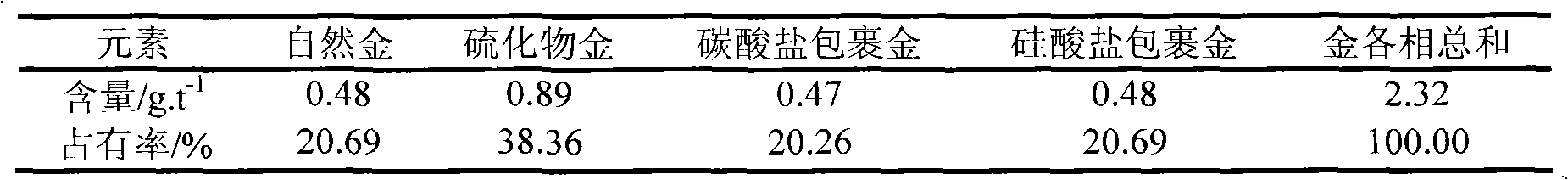

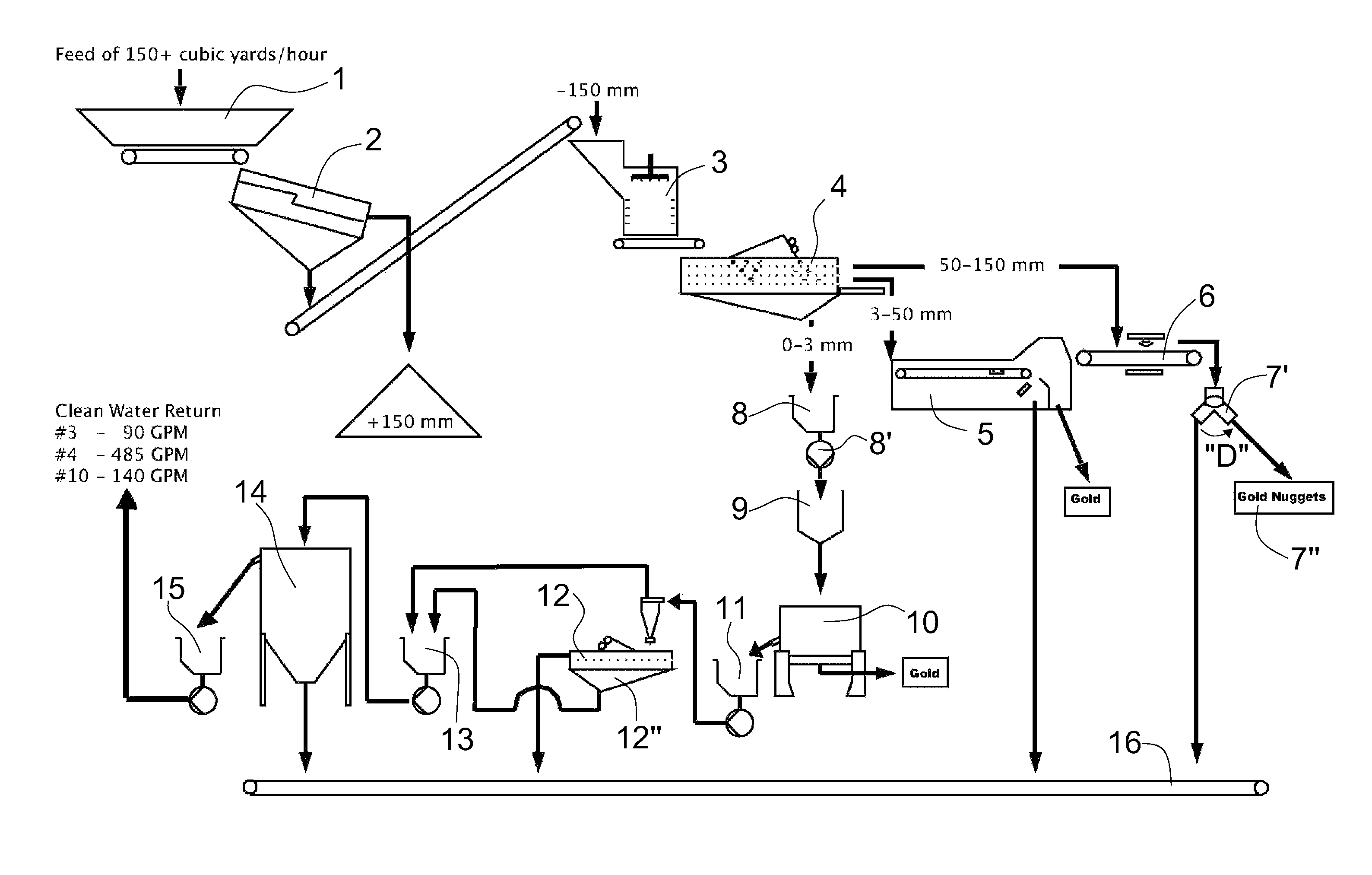

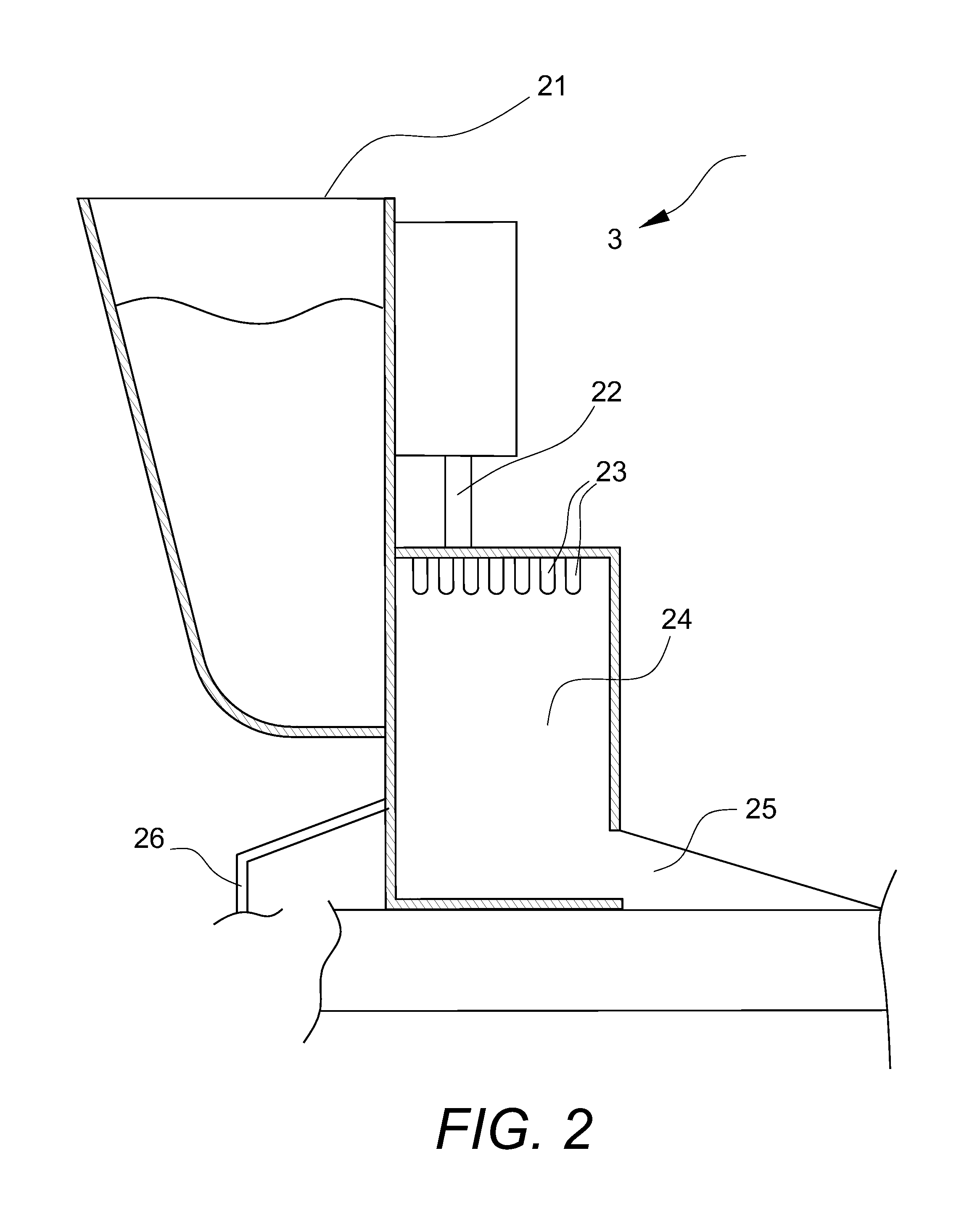

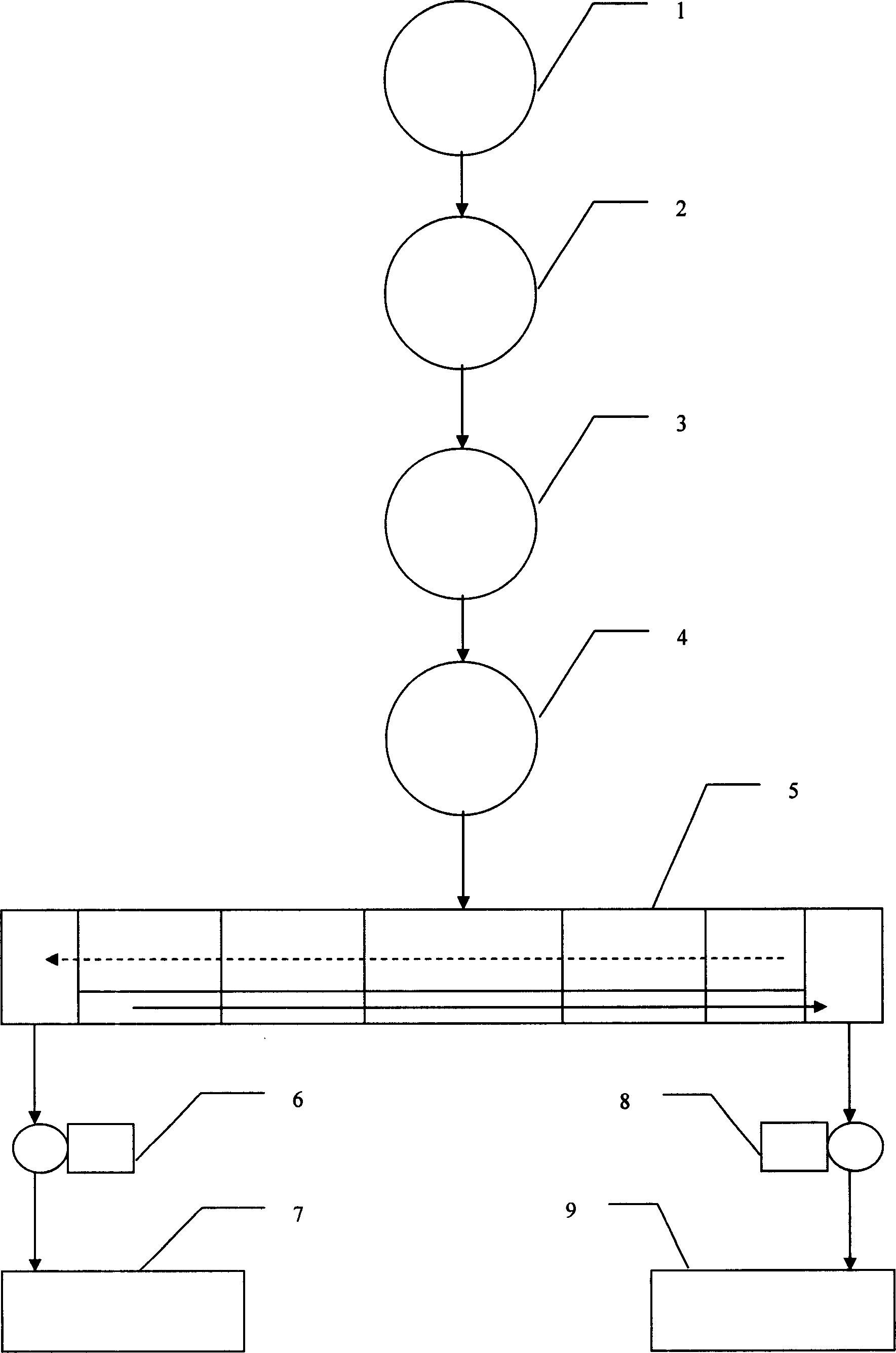

Methods and systems for recovering alluvial gold

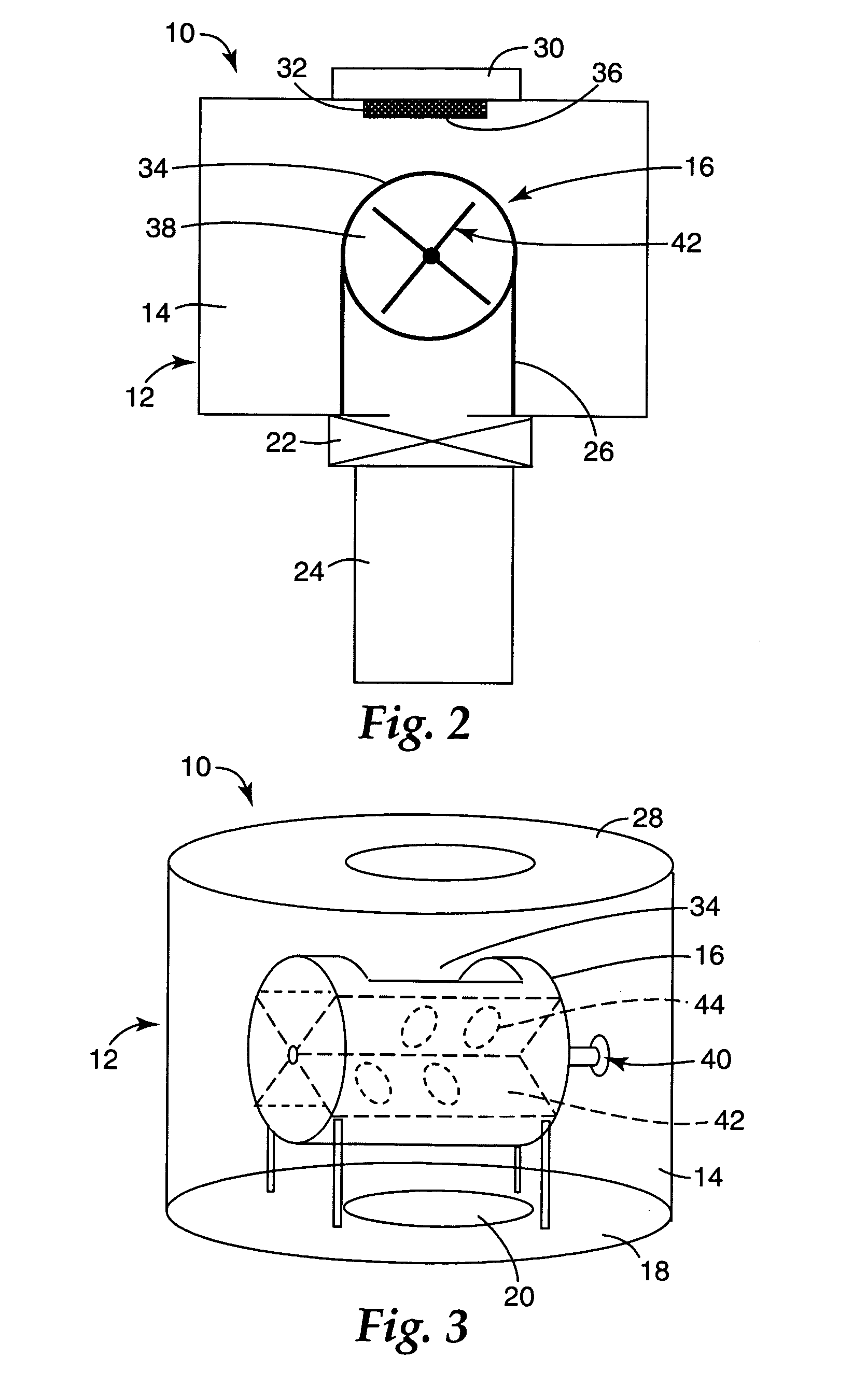

Various embodiments of methods and systems are provided for mining alluvial gold deposits. The methods can comprise collecting feed from alluvium and washing the feed at high pressure. The feed can be separated into a plurality of separate fractions. At least one fraction is transferred to a metal sensor system using a conveyer, wherein when gold is detected in a piece of the fraction, an air blast can be targeted and delivered at the piece, with the air blast diverting the piece to a receiving container.

Owner:QUINCY FROST INVESTMENTS INC

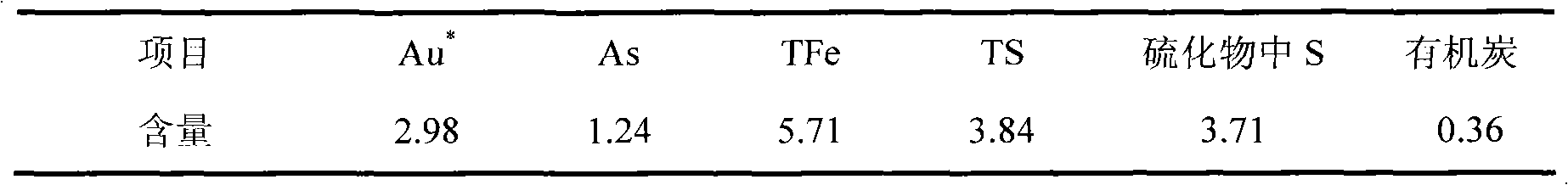

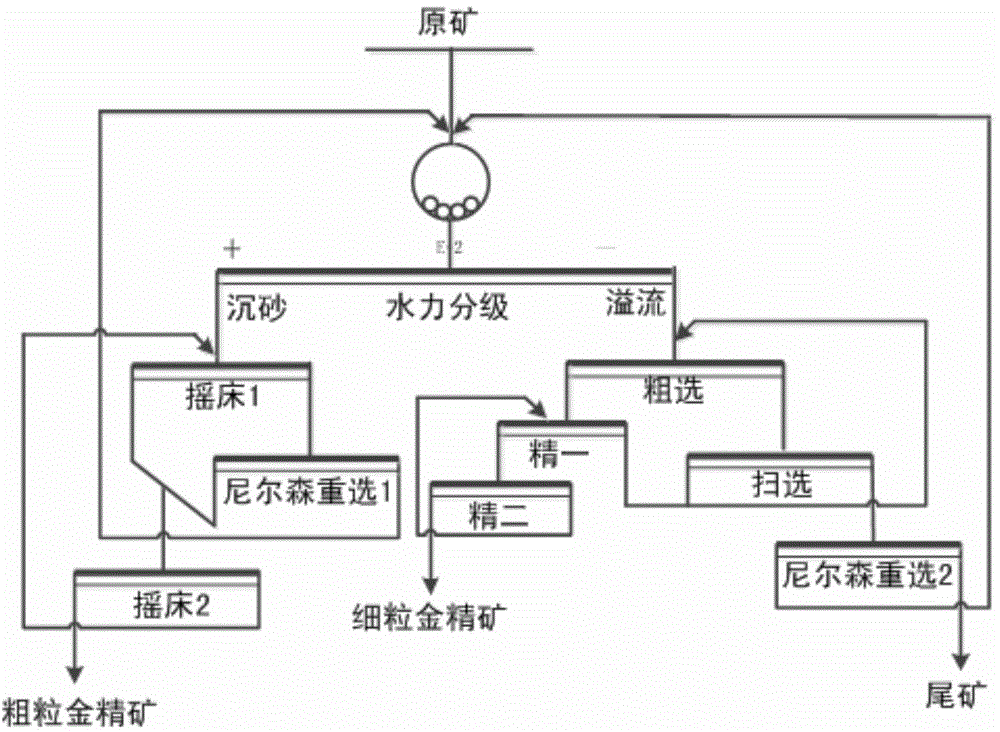

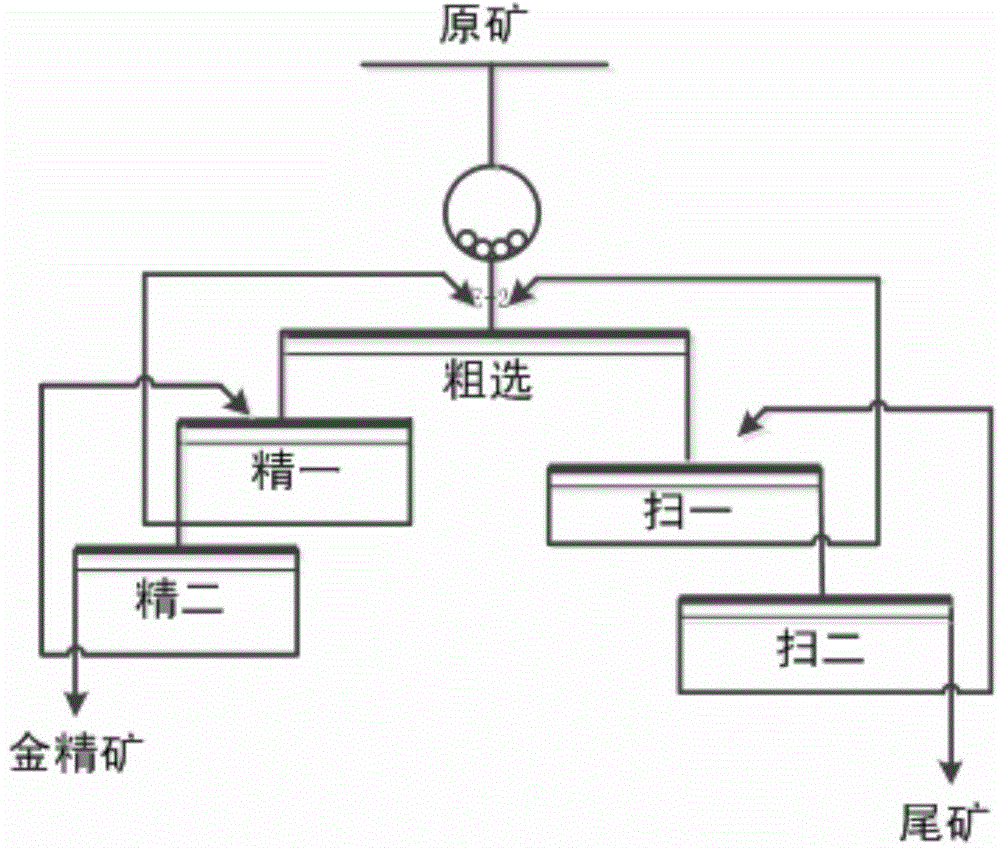

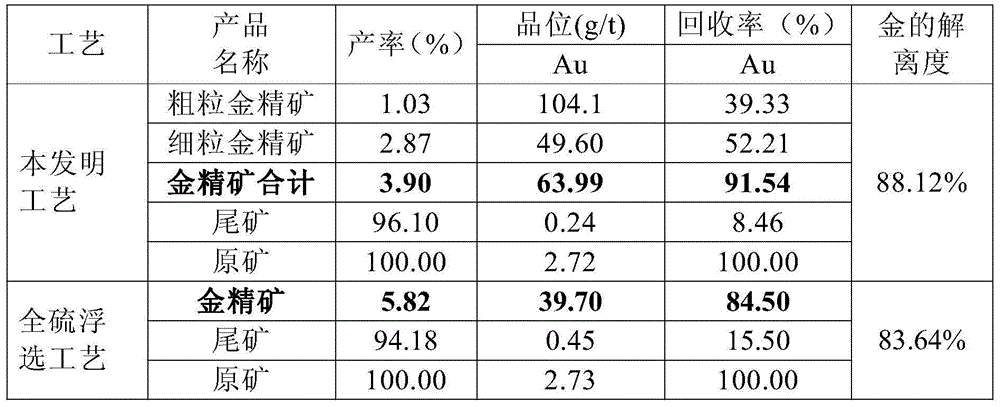

Beneficiation process for increasing recovery rate of gold of refractory gold ores

The invention relates to a beneficiation process for increasing the recovery rate of gold of refractory gold ores. According to the process, a reselection-floatation-reselection combined procedure is adopted to increase the recovery rate of the gold, and in other words, ores are ground till the particle size is -0.074 mm(60-80)%; a hydraulic power classifier is firstly utilized for classification, coarse gold concentrate is obtained from classified setting sand through a reselection method, and reselected tailings return to a ball mill to be ground gain; and classified overflow adopts a total-sulfur flotation method to recycle the gold, mustard gold concentrate is obtained, flotation tailings are reselected through a Nilson centrifugal ore separator, and obtained reselected concentrate returns to the ball mill to be ground gain. Early recovery and much recovery of the gold can be achieved through the process, gold which cannot be recycled because the particle size is too large or too small in total-sulfur flotation is effectively recycled, the purpose of selective ore grinding is achieved through reselection-ball mill closed cycle, the dissociation degree of the ores can be improved easily, the grade of the gold concentrate is remarkably improved, the metal recovery rate is remarkably increased, and good economic benefits can be brought to enterprises.

Owner:有研资源环境技术研究院(北京)有限公司

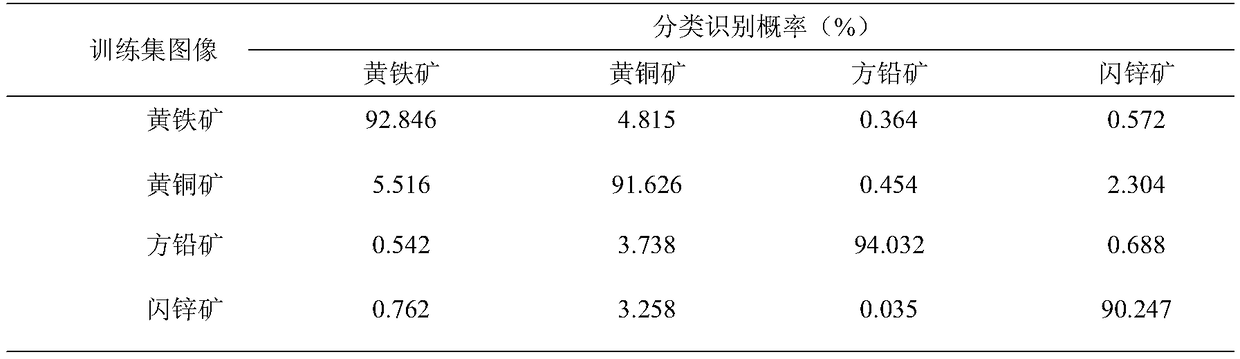

Automatic recognition and classification of ore and mineral images

InactiveCN109284780AImprove work efficiencyReduce subjectivityCharacter and pattern recognitionNeural architecturesIronstoneVisual technology

An automatic recognition and classification of ore and mineral images are disclosed in the invention. the invention utilizes the computer vision technology and the depth convolution neural network theory, Based on the big data platform Tensorflow, the convolution artificial neural network model is established, and the image data input model is trained according to the microscopic photographs of yellow iron ore from Jiapigou Gold Mine in Jilin Province, so as to realize the automatic recognition and classification of different ore minerals in the microscopic photographs of yellow iron ore. Theinvention can assist geologists to identify and classify the microscopic photographs of ore minerals and improve the working efficiency of geologists.

Owner:SUN YAT SEN UNIV

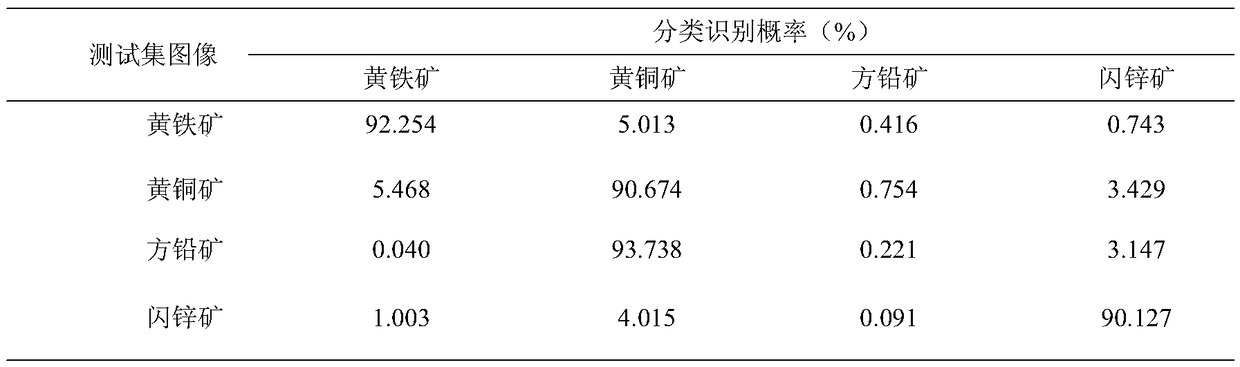

Novel martensitic wear resistant steel and production technology for steel casting thereof

The invention particularly relates to novel martensitic wear resistant steel and a production technology for steel casting thereof, belonging to the technical field of wear resistant steel in iron and metal metallurgy and foundry industry. Chemical components in the novel martensitic wear resistant steel comprise, by weight, C 0.3% to 0.5%, Si 0.8% to 1.5%, Cr 2.1% to 2.5%, Mn 0.8% to 1.5%, Ni 0.7% to 1.2%, Mo, 0.6% to 1.0%, Nb 0.1% to 0.3%, Ti 0.1% to 0.5%, Re 0.04% to 0.05%, and P and S no more than 0.04, with the balance being Fe. The production technology for steel casting comprises a smelting process, a casting process, a heat treatment process and quality inspection. The novel martensitic wear resistant steel provided in the invention can be used for liner plates of ball mills, hammerheads of hammer mills or the like used in metallurgic mines under the condition of low impact, is applicable to wear resistant products used in various mines like gold mines, iron mines and cement quarries, and is a novel wear resistant material capable of substituting conventional high manganese steel. According to results of utilization in ore dressing factories for iron ore and cement, the novel martensitic wear resistant steel has an improved service life 2 to 2.3 times longer than the high manganese steel.

Owner:ANSTEEL GRP MINING CO LTD

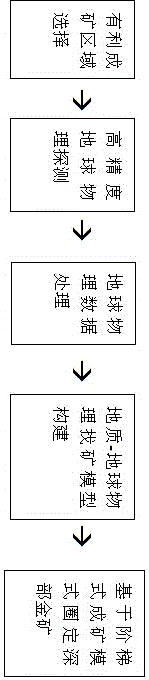

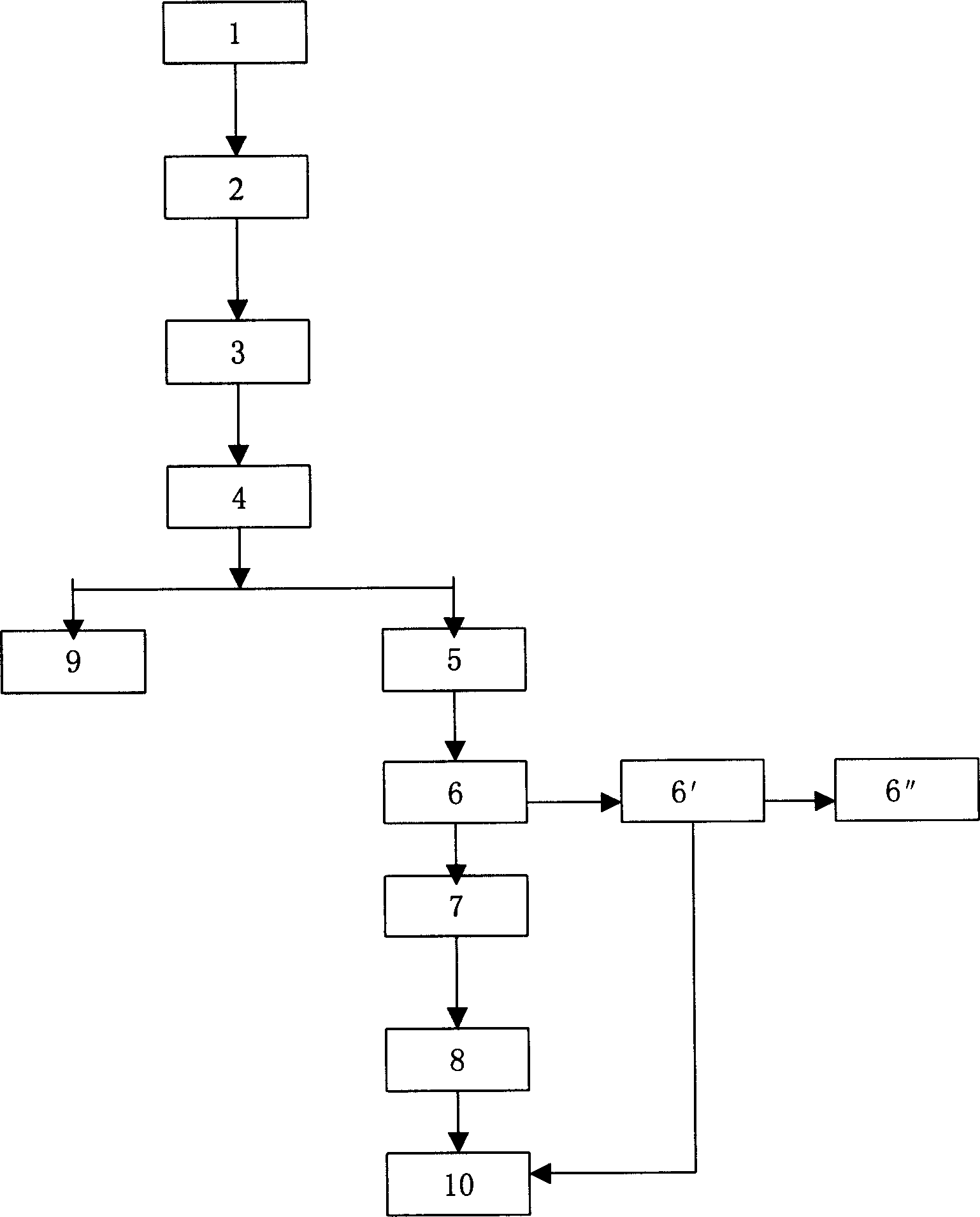

Deep gold mine stepwise prospecting method

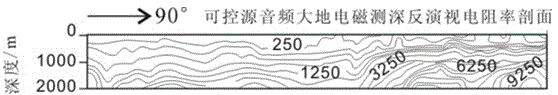

ActiveCN104597519AHigh positioning accuracyRealize human-computer interactionGeological measurementsChange positionsGold deposit

The invention discloses a deep gold mine stepwise prospecting method. The method includes the steps of (1) selecting a favorable metallogenic region; (2) arranging geophysical exploration lines in a certain distance in the selected region, and performing high-accuracy geophysical exploration to obtain exploration data of each exploration point; (3) performing geophysical data processing to form a contour map; (4) building a deep gold mine geological-geophysical prospecting model; (5) determining an ore-controlling fault deep dip angle stepwise change position in accordance with a deep gold mine stepwise metallogenic mode and the geological-geophysical prospecting model to delineate the position, shape and size of a deep gold mine.

Owner:SHANDONG INST OF GEOPHYSICAL & GEOCHEM EXPLORATION

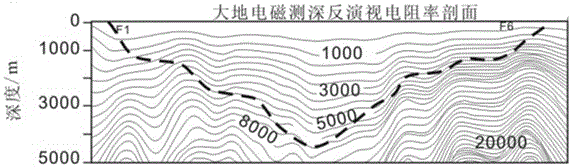

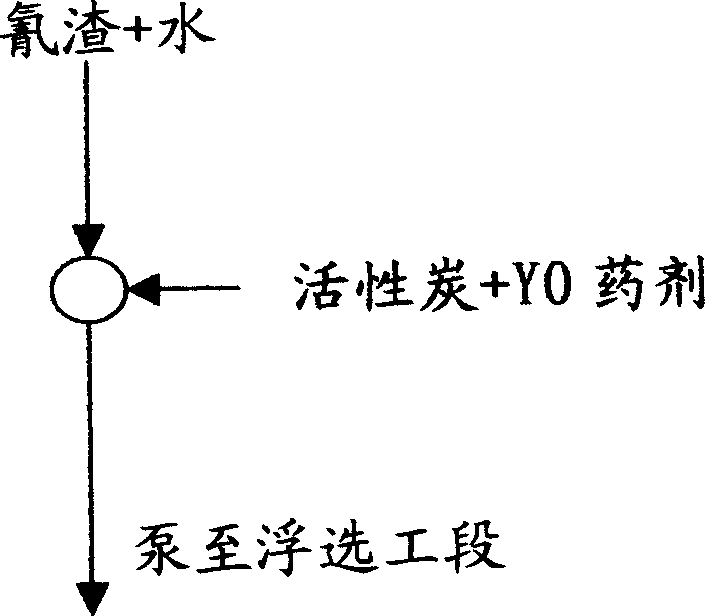

Method for floatation and recovery of lead zinc mixed concentrate from gold mine cyaniding slag tails

InactiveCN1865461AHigh recovery rateNo emissionsFlotationProcess efficiency improvementChlorinated limeSlag

The invention discloses a lead-zinc floating recycling method from gold ore cyanation tailings, which comprises the following steps: (1) predisposing: adding water in the cyanation tailings; stirring to form ore paste; adding active carbon, Y0 agent, FeSO4+ammonium persulphate in the ore paste; (2) asynchronous mixing-selecting: sending the predisposed ore paste to the floater group I to proceed first roughing separation; adding Y0 agent, limestone, butyl airpotato yam to float galena; sending the tailings in the first roughing separation to floater group II; adding Y0 agent, limestone, cupric sulfate, butyl airpotato yam to float zincblende; (3) recycling and purifying tailing water: adding chlorinated lime in the tailing water to decompose CN- less than 0.5 mg per L; recycling the tailing water.

Owner:青岛黄金铅锌开发有限公司

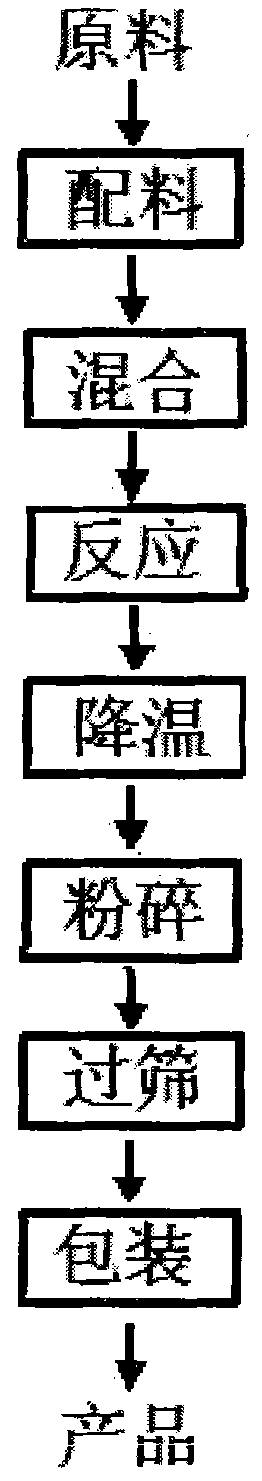

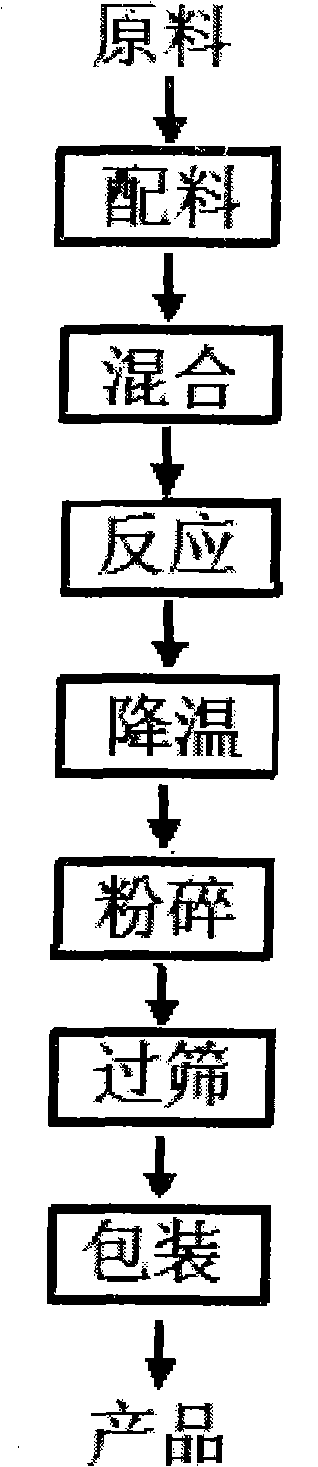

Mineral dressing additive for gold mine and preparation method thereof

The invention discloses a mineral dressing additive for a gold mine, which is prepared by taking inorganic substances as raw materials, and reacting at high temperature of 600-950 DEG C for 1-3 hours and pulverizing. The mineral dressing additive for a gold mine comprises the following components in parts by weight: 20-50 parts of urea, 5-10 parts of sodium hexametaphosphate, 5-10 parts of sodium sulfide, 0-10 parts of sodium bromide, 0-30 parts of sodium ferrocyanide, 20-50 parts of soda and 5-10 parts of sodium hydroxide. The product is free of virulent compounds, can not injure human and animals during production and use, can not cause significant pollution, and is environment-friendly. Proven by industrial trial, the product has the advantages of better mineral dressing effect, high recovery rate, simple production method, short process flow, easy technological operation, abundant and cheap raw materials for production, low production cost and better economic benefit and social benefit.

Owner:GUANGXI SENHE HIGH TECH CO LTD

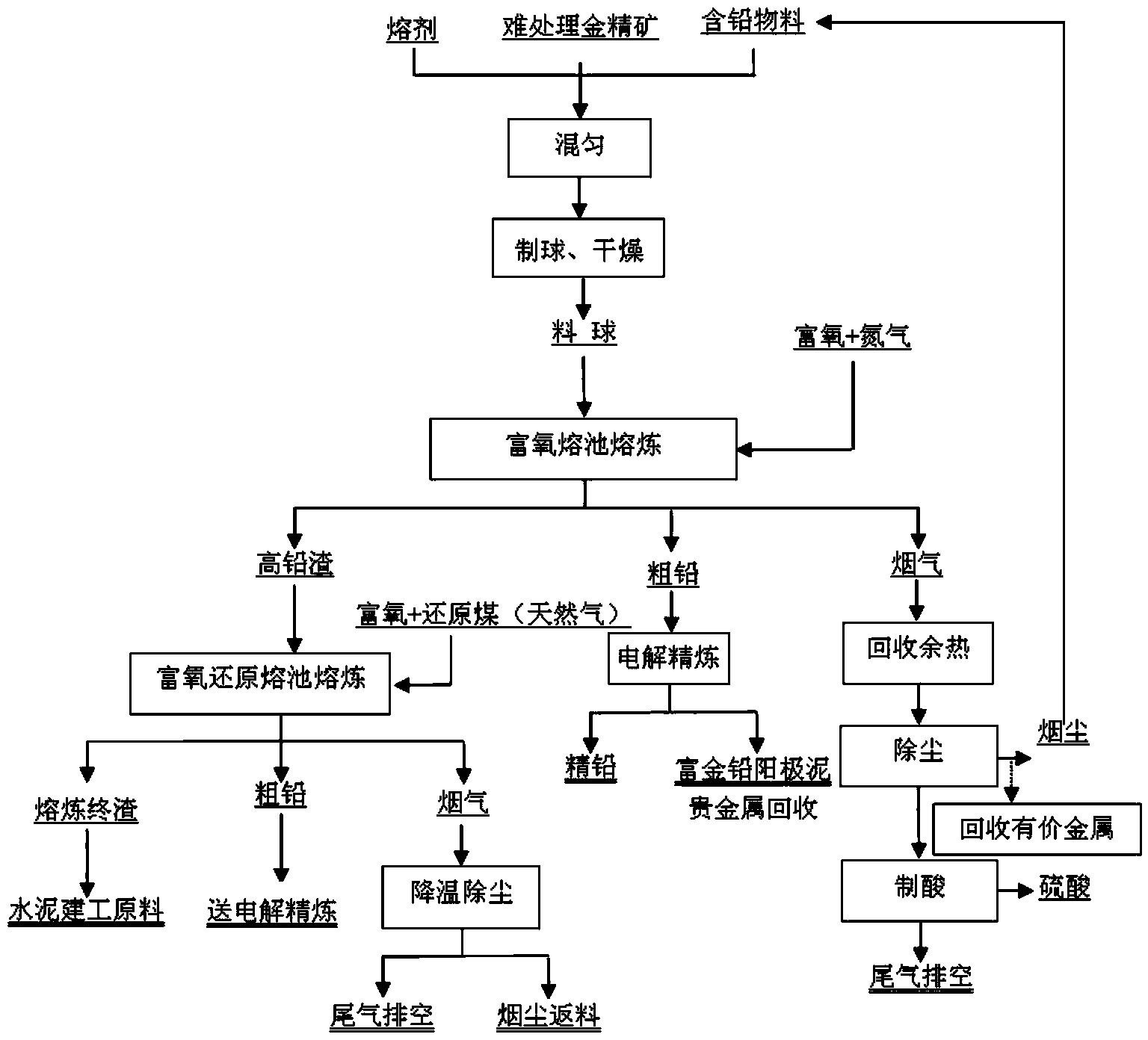

Method for recovering gold and lead by smelting refractory gold ore and lead-containing waste residue raw materials through oxygen enrichment molten pool

ActiveCN104263965AAchieve recyclingSimple processPhotography auxillary processesProcess efficiency improvementElectrolysisSlag

The invention discloses a method for recovering gold and lead by smelting refractory gold ore and lead-containing waste residue raw materials through an oxygen enrichment molten pool. The method comprises the following steps: uniformly mixing the refractory gold ore, lead-containing materials and a fusing agent, pelleting and drying, so as to obtain granular materials; performing oxidizing smelting on the obtained granular materials through an oxygen bottom blowing furnace to obtain sulphur dioxide smoke gas, lead bullion and high lead skim, and performing reduction smelting on the high lead skim in a reduction furnace to obtain slag and lead bullion; and performing electrolytic refining on the lead bullion to obtain refined lead and gold-bearing anode slime, wherein the gold recovering rate is larger than 99%, the lead recovering rate is larger than 95%, sulphur is removed in the form of the sulphur dioxide smoke gas, and the removing rate reaches 95% above. The slag is used as high-silicon mixed ingredients for cement or construction, after the sulphur dioxide smoke gas is subjected to dust removal to recycle valuable metals, the sulphur dioxide smoke gas is used for preparing acid, resources are sufficiently and comprehensively recycled, and the environmental protection and economy are achieved. The method is simple in operation and low in cost, and the method can be applied to large-scale industrial production.

Owner:湖南锐异资环科技有限公司

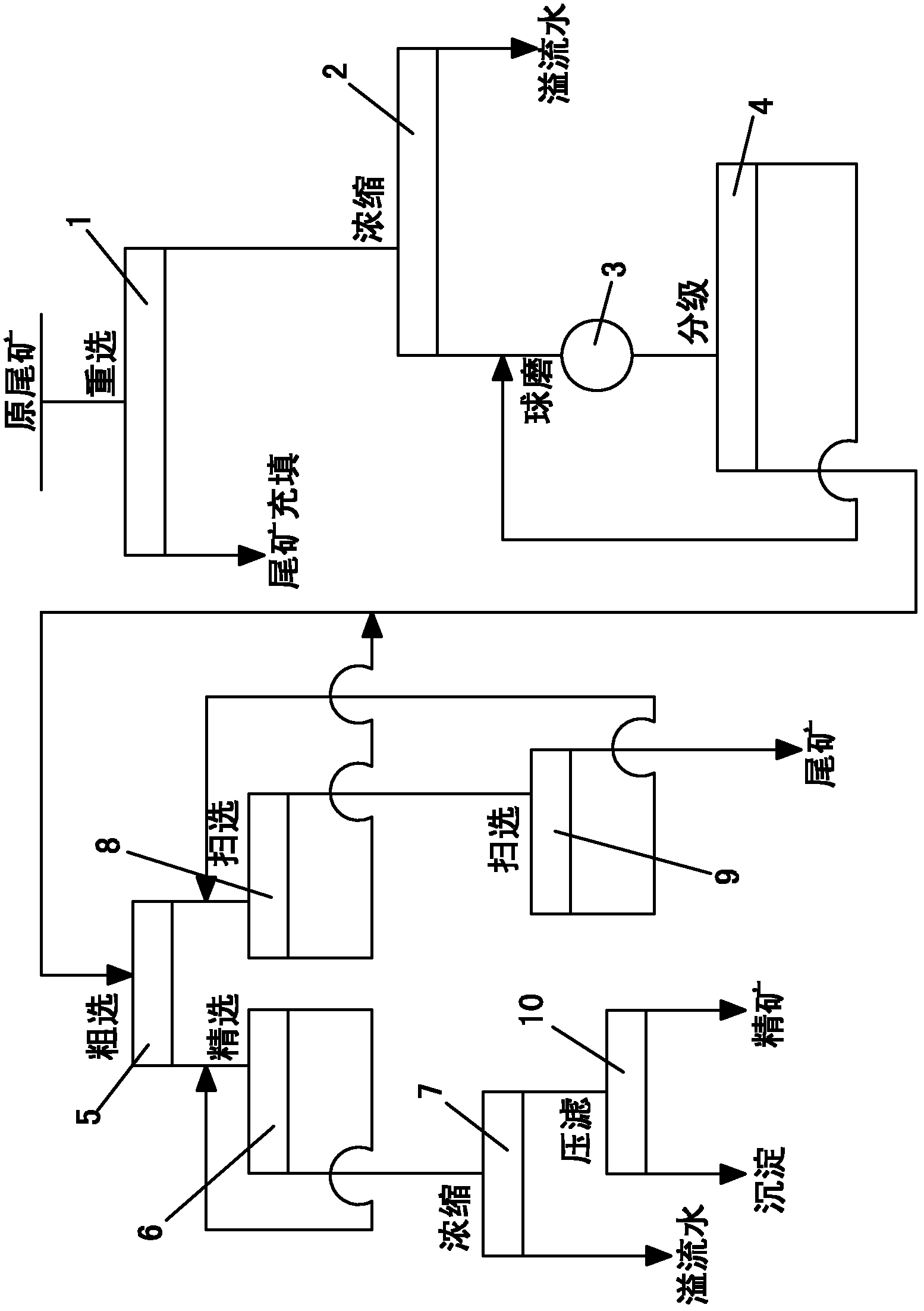

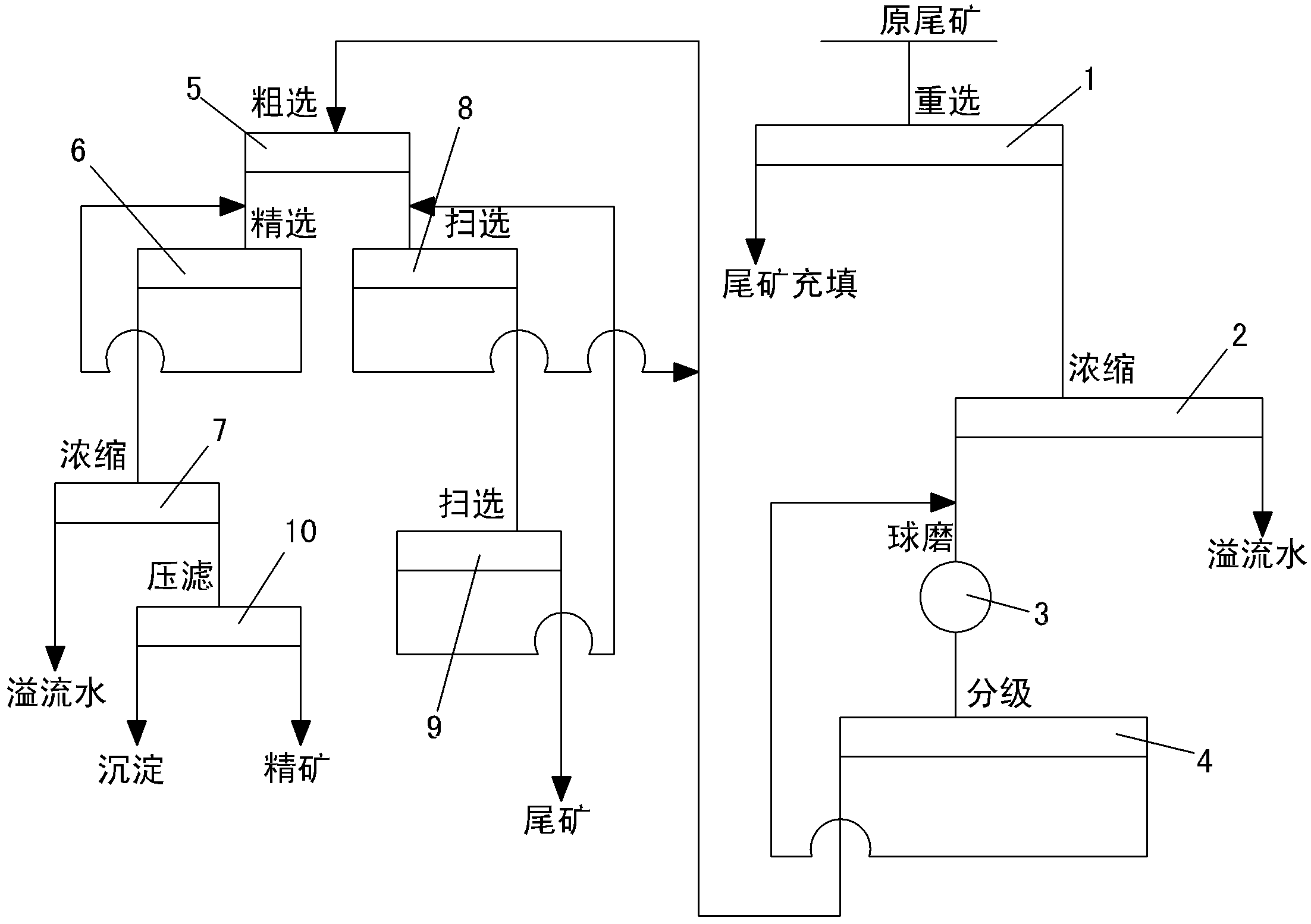

Gold tailing treatment process

The invention relates to a gold tailing treatment process, which comprises the steps of: conducting gravity separation for original tailing pulp through a spiral chute, recovering large particles of pulp within the width of 8-9CM, and using fine-grains of pulp outside the width of 8-9CM as tailing filling; then, conducting water and ore separation for the recovered pulp through a fist single-layer thickener, and draining away the separated water; finely grinding the obtained ore through a ball grinder, with the grinding fineness being 55+ / -2% of ore grains passing a screen of 200 holes / square inch and the pulp density being 33+ / -2%; sending the processed ore into a classifier for fractionating, making the ore meeting the dimensional requirement enter a flotation process, and making the ore not meeting the granular size returning to the ball grinder for circular treatment; and finally recovering the obtained fine ore through treatment, and transporting the obtained tailings through treatment to an ore district through a water isolation pump to be used for tailing filling. The gold tailing treatment process can comprehensively recover gold and valuable elements in the tailings, so that the utilization ratio of resources can be enhanced, and the economic benefit of enterprises can be increased.

Owner:中矿金业股份有限公司

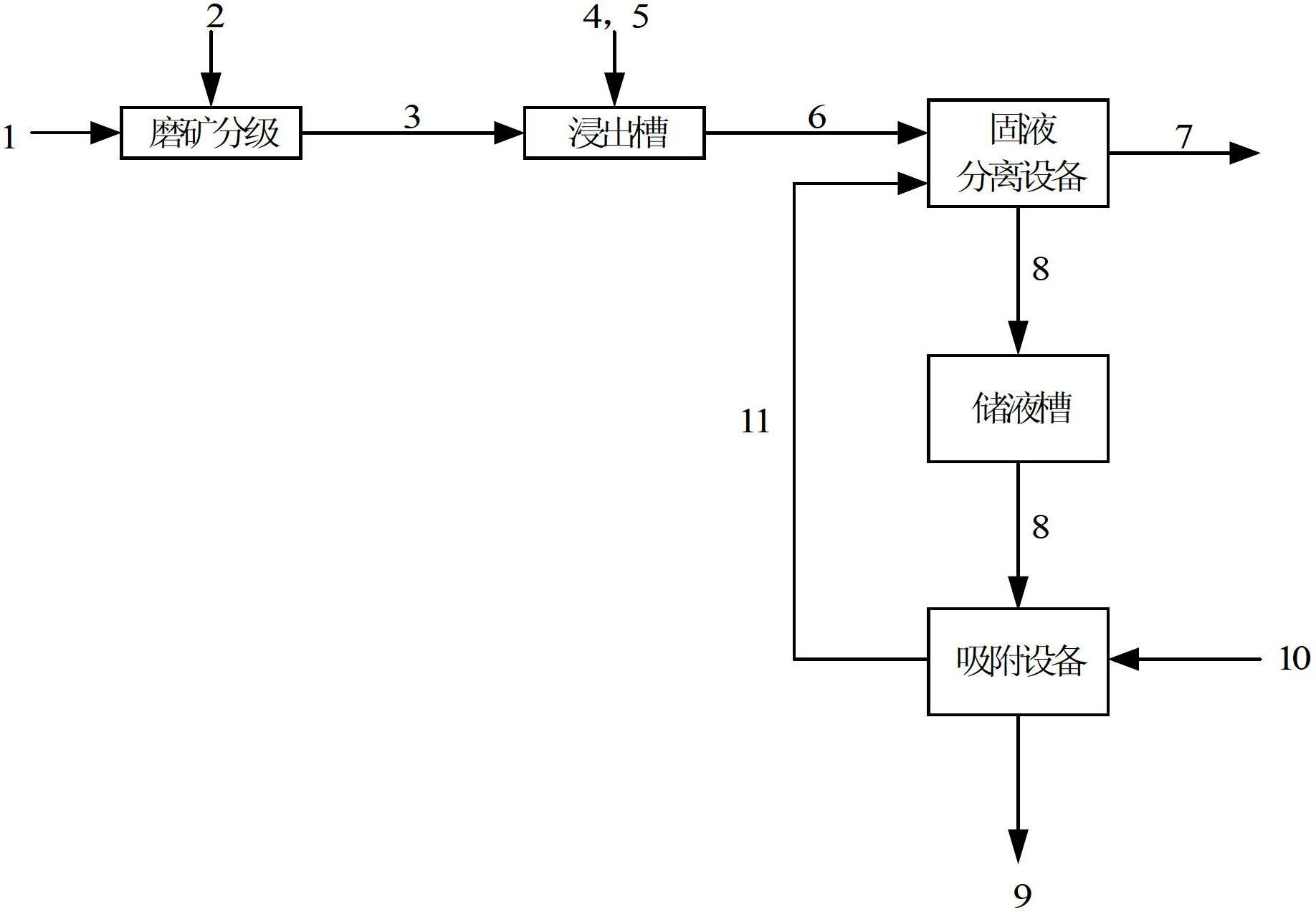

Selective heap leaching gold extraction process for gold mine containing copper

ActiveCN101818247AReduce consumptionImprove leaching rateProcess efficiency improvementSelective leachingHydrometallurgy

The invention discloses a selective heap leaching gold extraction process for gold mine containing copper, belonging to the field of hydrometallurgy. The process comprises the steps of: smashing and heaping gold mine containing copper; carrying out alkali treatment on the mine; then adding ammonium salt and sodium cyanide according to a certain proportion to realize the selective leaching of the gold and the restriction to the leaching of the copper; and finally absorbing and extracting the gold from leaching solution by conventional active carbon. The invention has the advantages of simple process method, short procedure, simple equipment, easy implementation, high gold leaching efficiency, low consumption of sodium cyanide, low energy consumption, little investment and low cost, and is the gold extraction method with easy realization of industrialized production and favorable economical benefit.

Owner:ZIJIN MINING GROUP

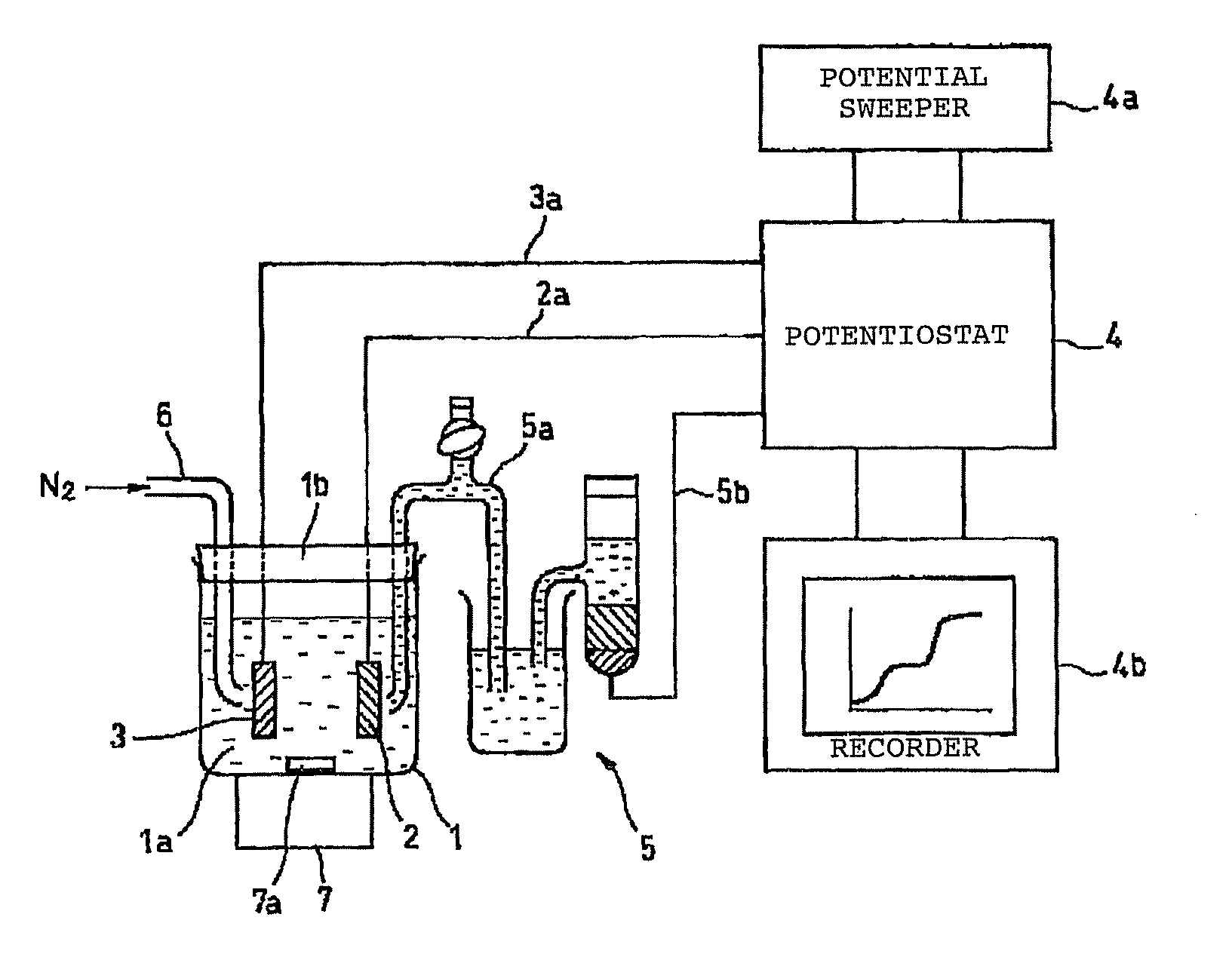

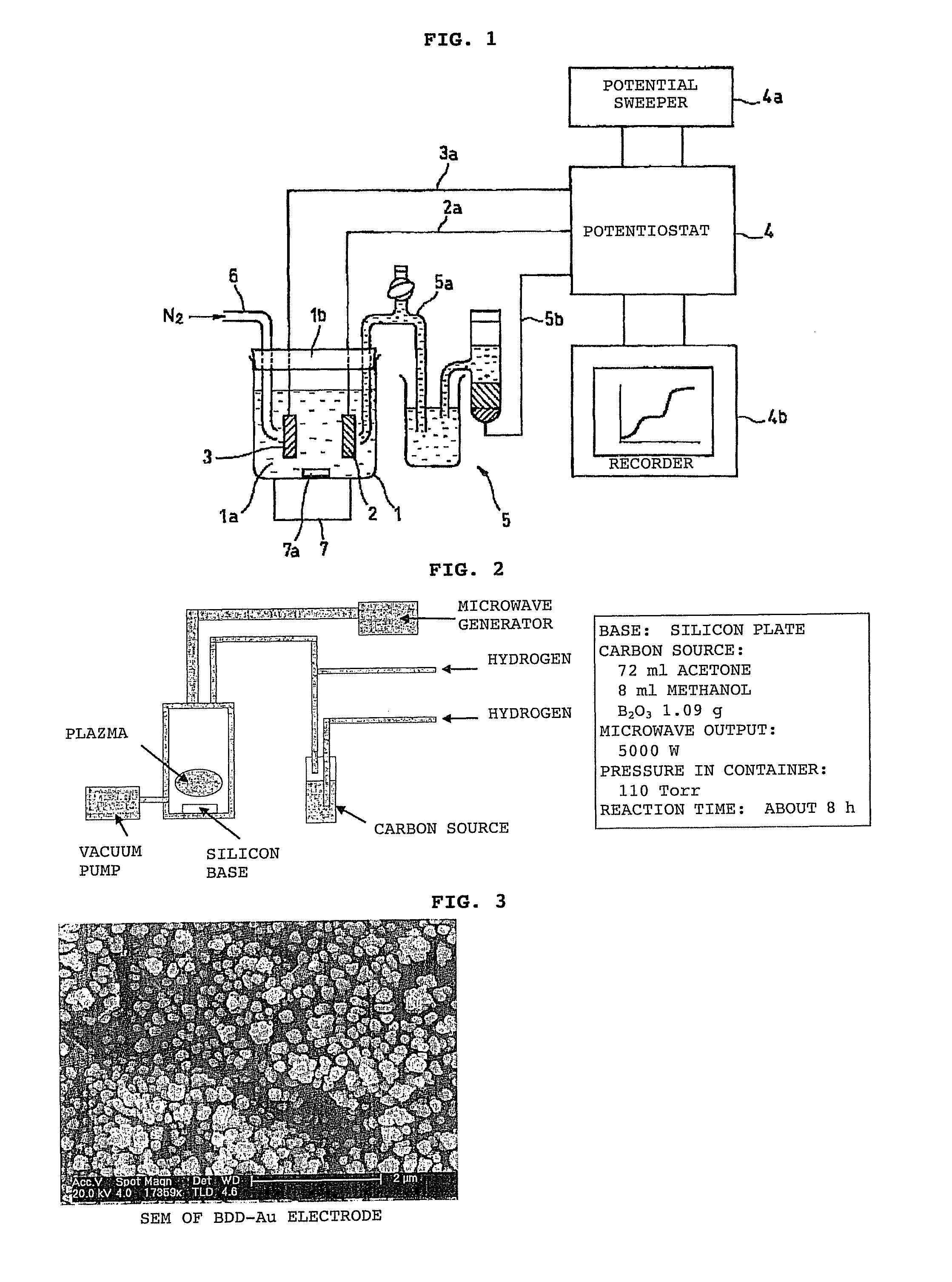

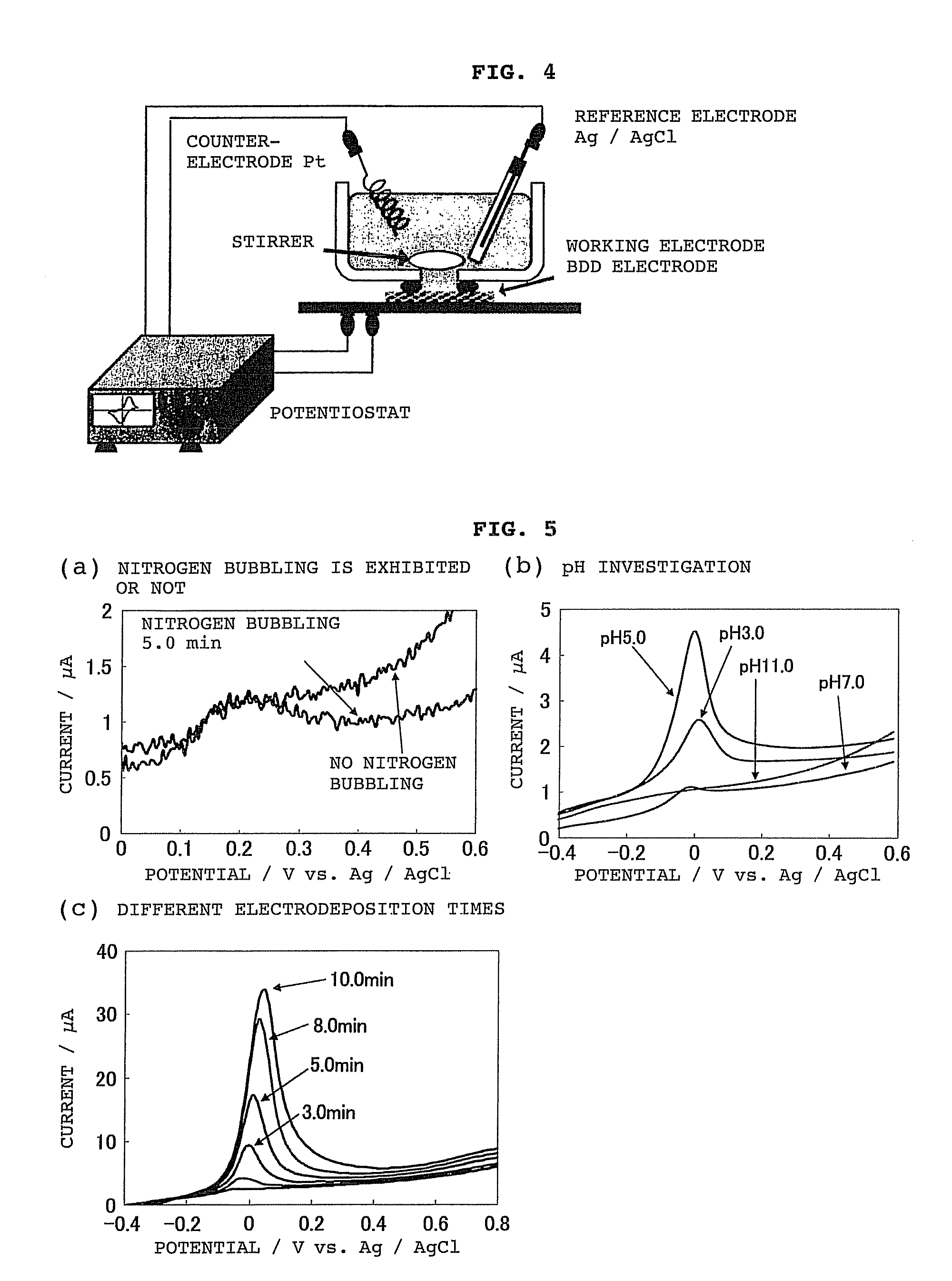

Electrochemical analysis method using boron-doped electroconductive diamond electrode

InactiveUS7883617B2Easy for quantitative analysisMaximum accuracyCellsWeather/light/corrosion resistanceElectrolytic agentPotential change

Owner:KEIO UNIV

Ultrahigh molecular weight polyethylene abrasion-proof pipe

InactiveCN101344198AImprove wear resistanceImprove scratch resistanceRigid pipesWear resistantTemperature resistance

The invention discloses an ultra-high molecular weight polyethylene wear-resistant pipe which is characterized in that: calculating by quality percentage, the raw materials comprise ultra-high molecular weight polyethylene resin of 70 to 90 percent, glass fiber or glass bead of 3 to 20 percent, silane coupling agent of 0.1 to 1 percent, graphite of 0.5 to 3 percent, and polyethylene wax of 1 to 7 percent. According to the using requirement, the raw materials also comprise needle-shaped wollastonite of 5 to 20 percent. As for different technical requirements, different environmental conditions and different delivery media, the ultra-high molecular weight polyethylene wear-resistant pipe can adjust the compositions so as to obtain desirable results. After the ultra-high molecular weight polyethylene wear-resistant pipe undertakes scientific compatibility and processing, the wear resistance thereof is greatly improved, and the high temperature resistance performance is also enhanced by more than 30 percent; when in trial use in such industries as gold mine, molybdenum mine, electricity and other industries, the effect thereof is significant.

Owner:SHANDONG DIHAO WEAR RESISTING PIPE

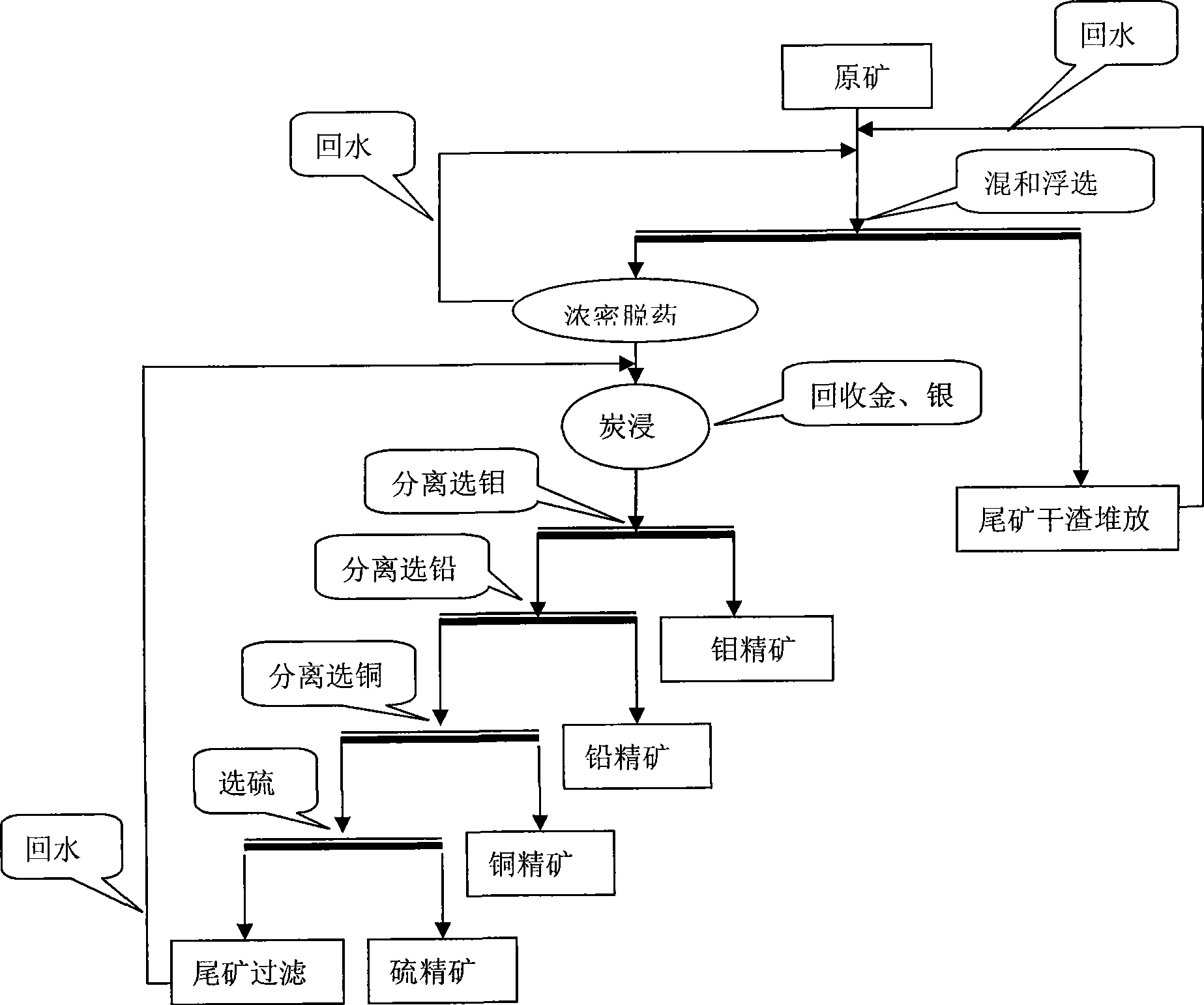

Comprehensive recovery method of gold ore resource containing molybdenum multi-metal

ActiveCN101451187AHigh Filtration AutomationReduce labor intensityFlotationProcess efficiency improvementRecovery methodFiltration

The invention discloses a method for comprehensively recovering molybdenum-containing polymetallic gold ore resources, which comprises the following steps: firstly, crushing and grinding molybdenum-containing gold ores first, performing floatation on useful metallic elements to obtain bulk concentrate by a complete mixing floatation method, and discarding tailings; secondly, leaching out and recovering gold and silver from the bulk concentrate by CCL carbon paste wet-method gold leaching technology, and using tailings after gold leaching for preferred selection of molybdenum in the next step; thirdly, performing preferred separation and floatation of the molybdenum on the gold leaching tailings to obtain qualified molybdenum concentrate; fourthly, activating molybdenum-selecting tailings, and performing separation and floatation of lead to obtain lead concentrate; fifthly, performing separation and floatation of copper on lead-selecting tailings to obtain copper concentrate; and sixthly, performing floatation of sulfur on copper-selecting tailings to obtain sulfur concentrate, performing filtration and backwater circulation on sulfur-selecting tailings, and applying the sulfur-selecting tailings to the carbon paste wet-method gold leaching technology for recovery of the gold and the silver. The method greatly improves the grade of separated metals. The following products can be obtained by utilization of the method: more than or equal to 95 percent of alloyed gold, more than or equal to 45 percent of the molybdenum concentrate, more than or equal to 40 percent of the lead concentrate and more than or equal to 35 percent of the sulfur concentrate. The tailings after floatation are filtered by a ceramic filter (the moisture content is less than or equal to 15 percent), subjected to dry-type stacking, and used for soil sealing and land rehabilitation in late stage.

Owner:LINGBAO CITY JINYUAN MINING

Process for extracting gold, platinum and palladium from goldmine

InactiveCN1635168AReduce productionImprove protectionProcess efficiency improvementLiquid wastePlatinum

The invention relates to a method for extracting gold, platinum and palladium from infusible gold ore, comprising: disintegrating infusible gold ore, pre-processing them by roasting, leaching out the roasted product by salt water, filtrating and separating, adsorbing filter liquor by active carbon and extracting gold, separating platinum and palladium from the remain filter liquor by extraction. The invention is a cyanogens-less leaching method with advantages of high extraction ratio of gold, platinum and palladium, less environmental pollution and good economic returns.

Owner:邹贵田

Floating process for enriching Cu, Ag, Au, etc from gold sulfide ore cyanizing gold extraction tailing

Owner:SHANDONG GUODA GOLD

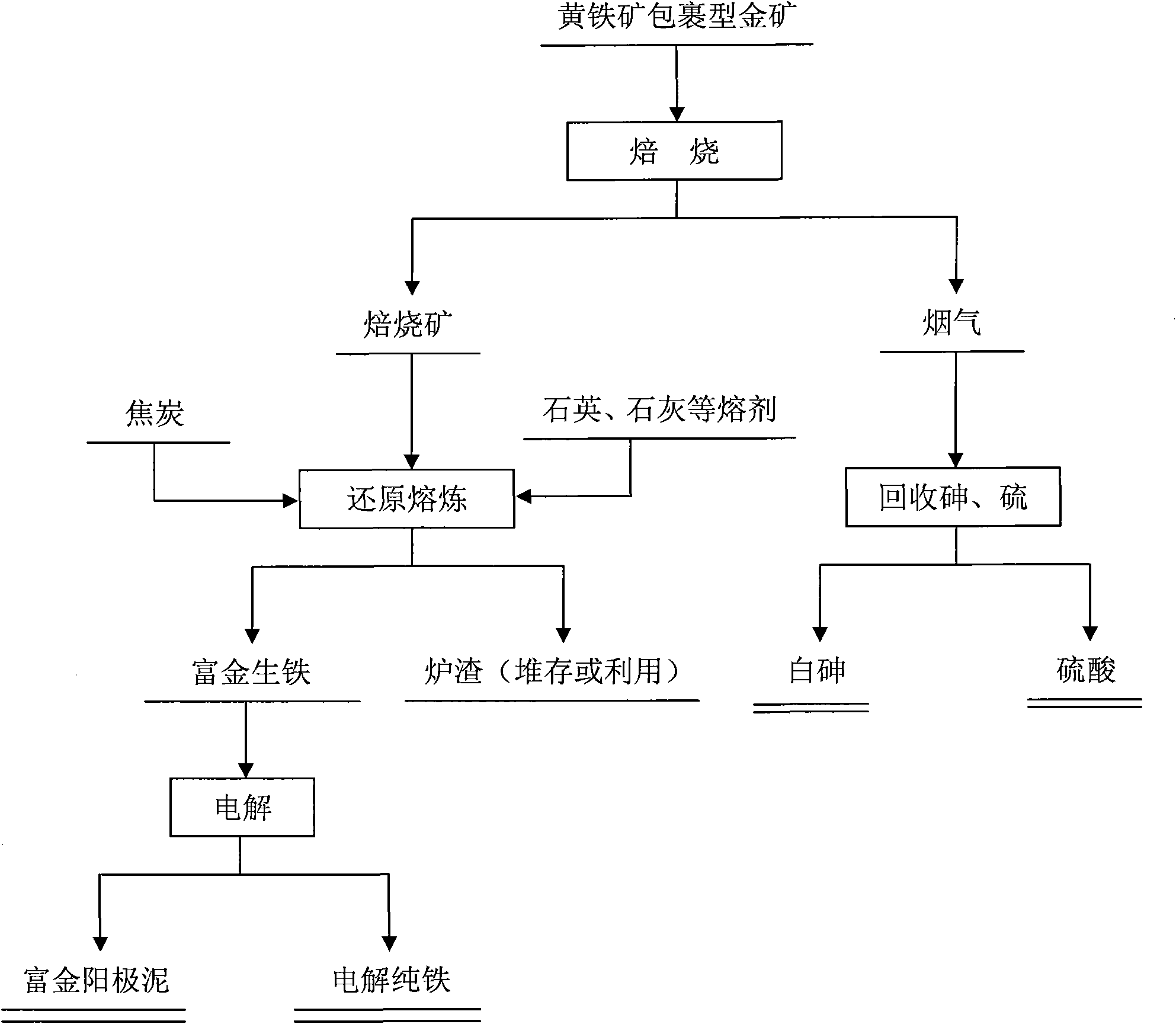

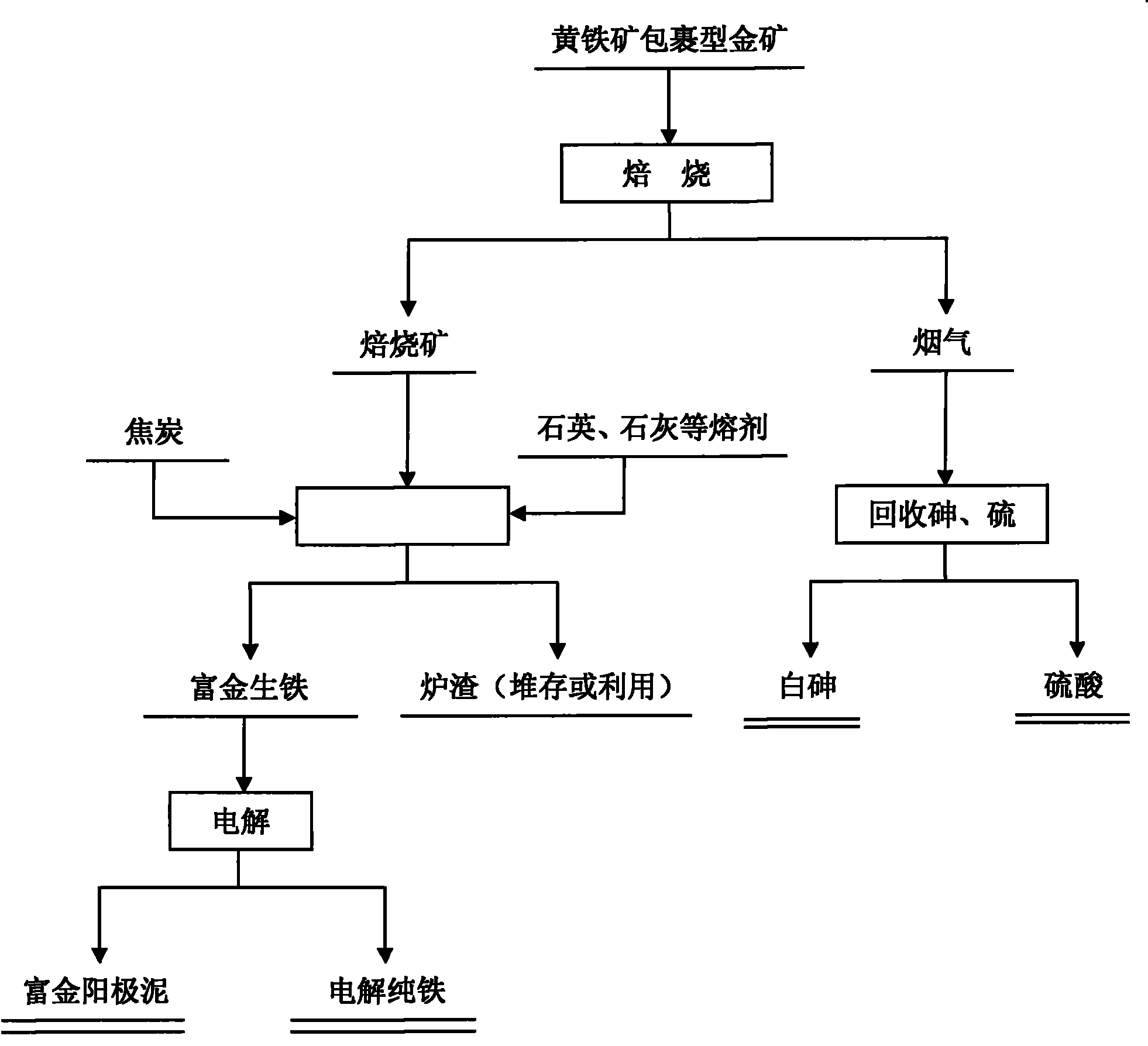

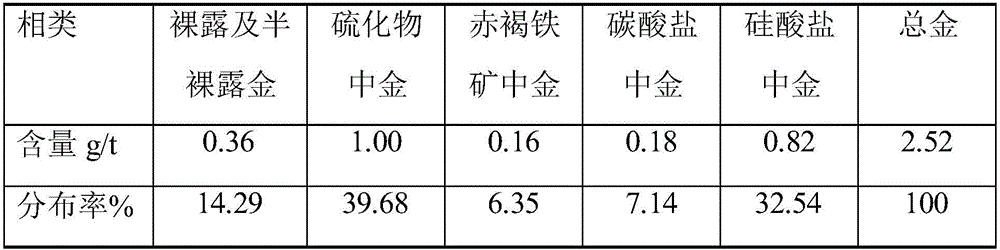

Method for concentrating gold from pyrite inclusion-type gold ore

The invention relates to a method for concentrating gold from pyrite inclusion-type gold ore. The pyrite inclusion-type gold ore is gold-containing sulfur ore with high recovery value. The roasted ore of pyrite inclusion-type gold ore is used as raw material and proportionally mixed with charred coal, lime and quartz; and the resulting mixture is fed into a smelting furnace and undergoes the reduction smelting at a temperature ranging from 1450 DEG C to 1600 DEG C, so as to produce gold-rich pig iron. The gold-rich pig iron as an anode plate is electrolyzed by the diaphragm electrolysis technique in an electrolysis system containing ferrous sulfate or ammonium sulfate aqueous solution, so as to produce electrolytic iron and gold-rich anode mud. The method increases the resource utilization rate and is environment-friendly.

Owner:CENT SOUTH UNIV +1

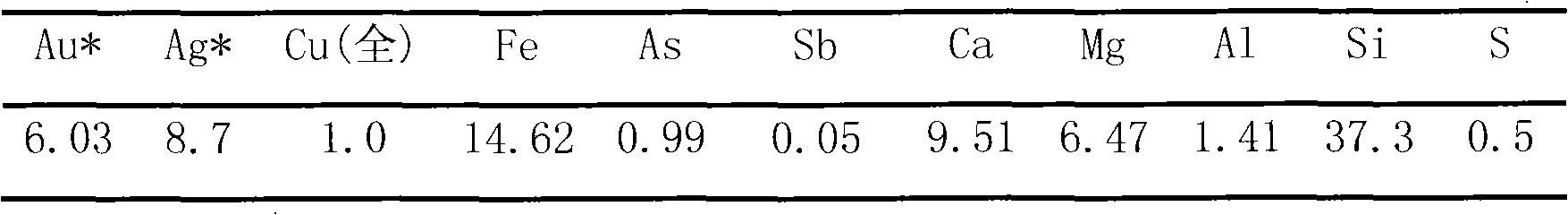

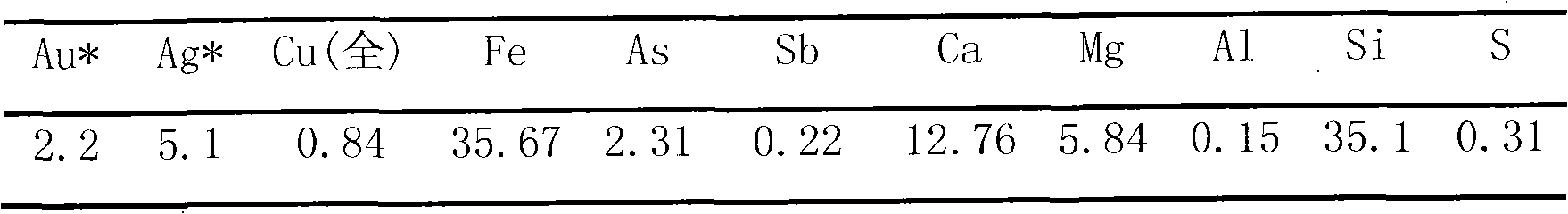

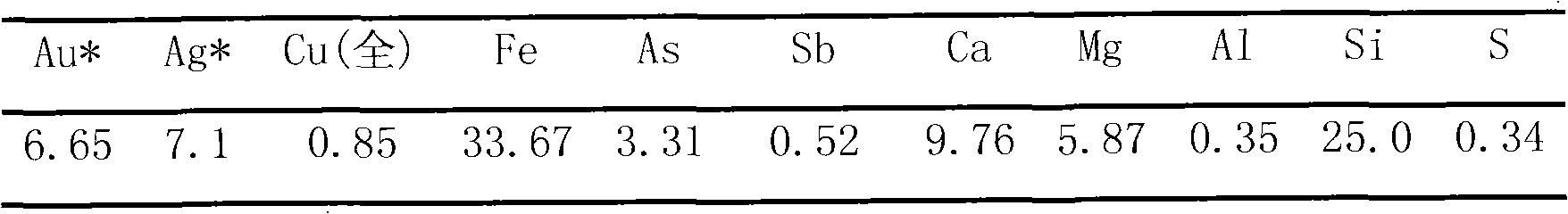

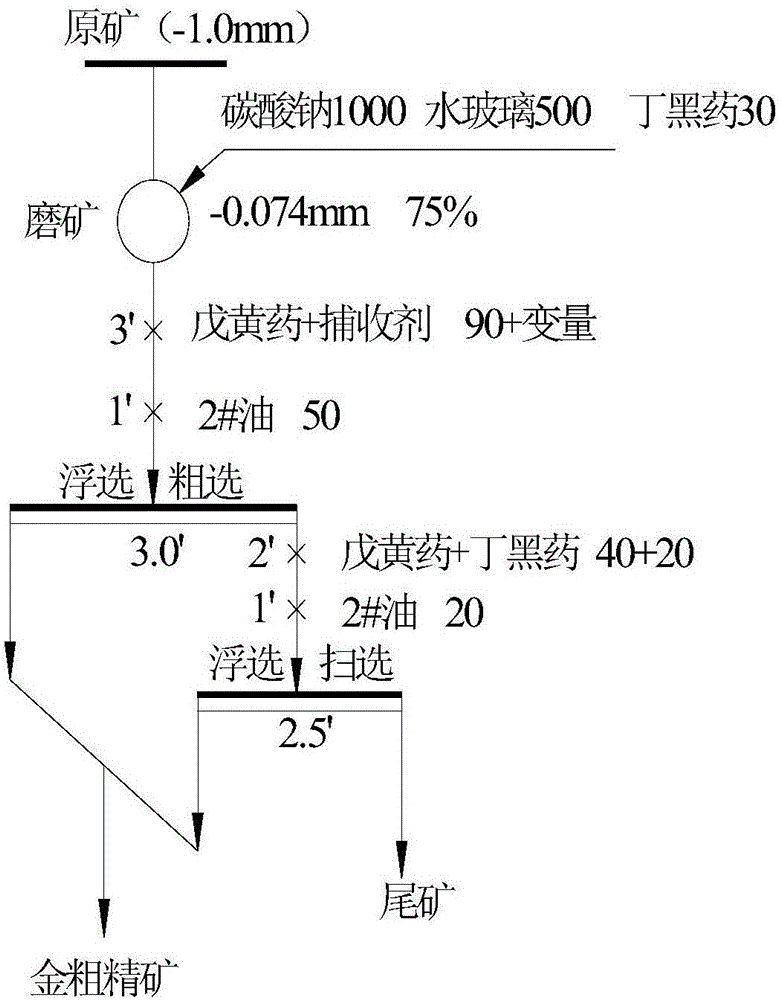

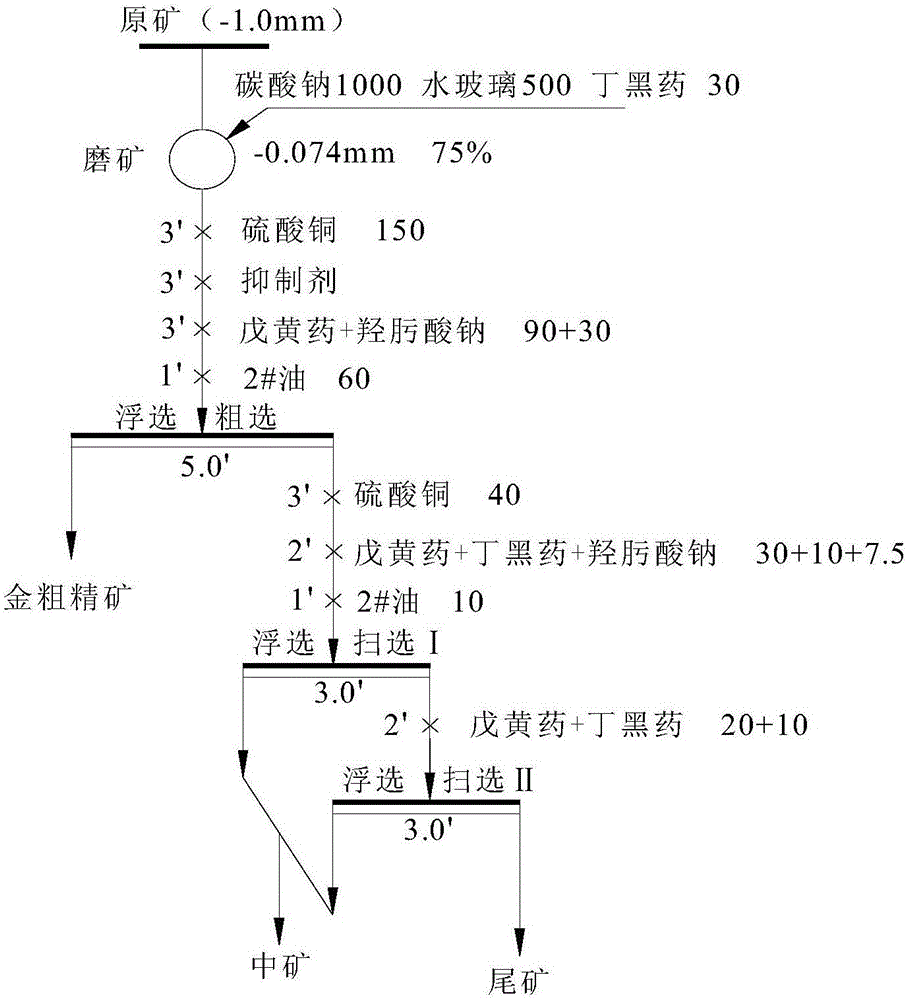

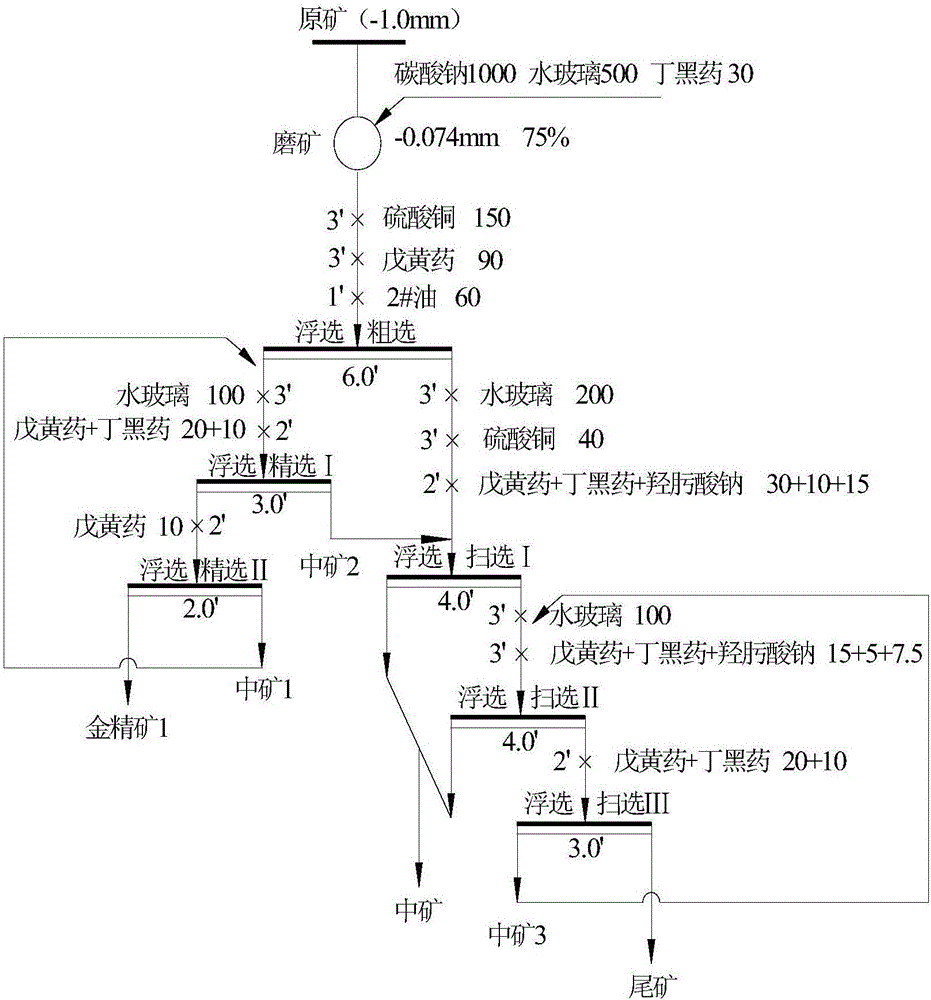

Beneficiation process for gold ores containing high arsenic and antimony content easily argillized minerals

InactiveCN106179722AHigh recovery rateFew influencing factorsFlotationWet separationDibutyl dithiophosphateFoaming agent

The invention relates to a beneficiation process for gold ores containing high arsenic and antimony content easily argillized minerals. By taking sodium carbonate as a flotation pulp regulator, water glass and sodium hexametaphosphate as an inhibitor and a dispersant for argillized minerals, copper sulfate as an activator for gold ores, pentyl xanthate and ammonium dibutyl dithiophosphate as a collecting agent for gold-bearing vulcanized minerals, sodium hydroxamate as a collecting agent for gold-bearing oxide minerals, and oil #2as a foaming agent, the process comprises the following steps: performing one stage grinding on raw ores; performing fast grading of one-stage roughing and one-stage concentrating on the ground minerals to obtain gold concentrate 1, and performing scavenging three times on the roughed tailings to obtain middlings; desliming the obtained middlings, and performing two-stage re-grinding on the deslimed pulp; and performing a strengthened collecting process of roughing at two times and concentrating at one time on the reground pulp to obtain gold concentrate 2. The process provided by the invention is high in recovery rate of the obtained gold concentrate, the affecting factors of the argillized minerals on gold grading are reduced, and through flow grading, the gold grade of obtained mixed gold concentrate is 52.84g / t and the gold recovery rate is 71.01%.

Owner:青海省地质矿产测试应用中心

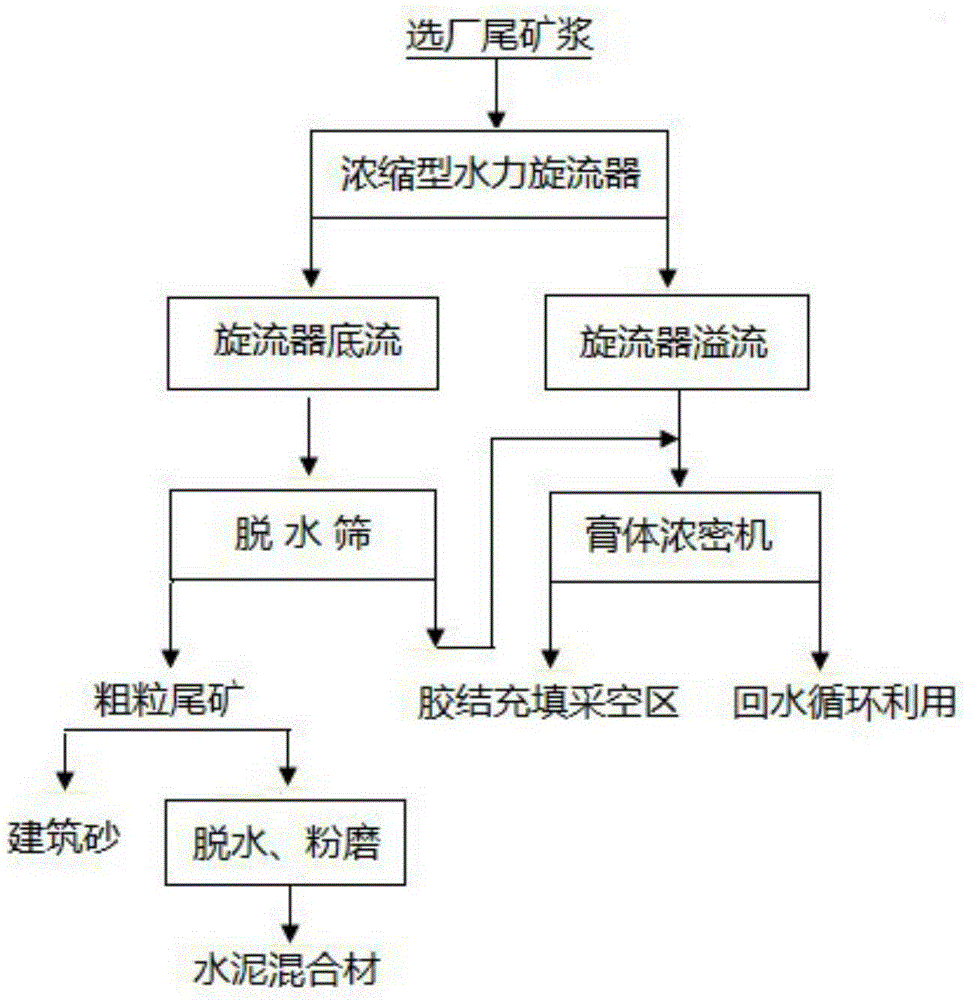

Method for zero emission production of gold mine tailings

InactiveCN105399354AAchieving zero emissionsAchieve emissionsSolid waste managementMaterial fill-upCycloneCement composites

The invention provides a method for zero emission production of gold mine tailings. The method comprises a first step of separating tailing pulp discharged by a mine plant and separating coarse grain tailings and fine grain tailing paste; a second step of airing the coarse grain tailings into building sand or performing drying dehydration and then grinding the coarse grain tailings to prepare a cement composite material; and mixing a cementing material into the fine grain tailing paste and then filling a goaf. According to the method for zero emission production of gold mine tailings, after the tailings of gold mine dressing plant are graded through a cyclone, bottom flow products are dehydrated through a high-frequency vibrating screen to prepare the building sand or are dehydrated and ground to prepare the cement composite material, overflow is concentrated through an efficient thickener and then fills the underground goaf or is used for producing building materials such as a concrete block, and clear water of the overflow of the thickener is recycled. Industrial production and organization are balanced by adjusting the quantity of the prepared building sand tailings, the quantity of the cement composite material tailings, the quantity of the goaf filling tailings and the quantity of the tailings for building material production, and the zero emission production of the gold mine tailings is achieved.

Owner:SHANDONG UNIV OF SCI & TECH

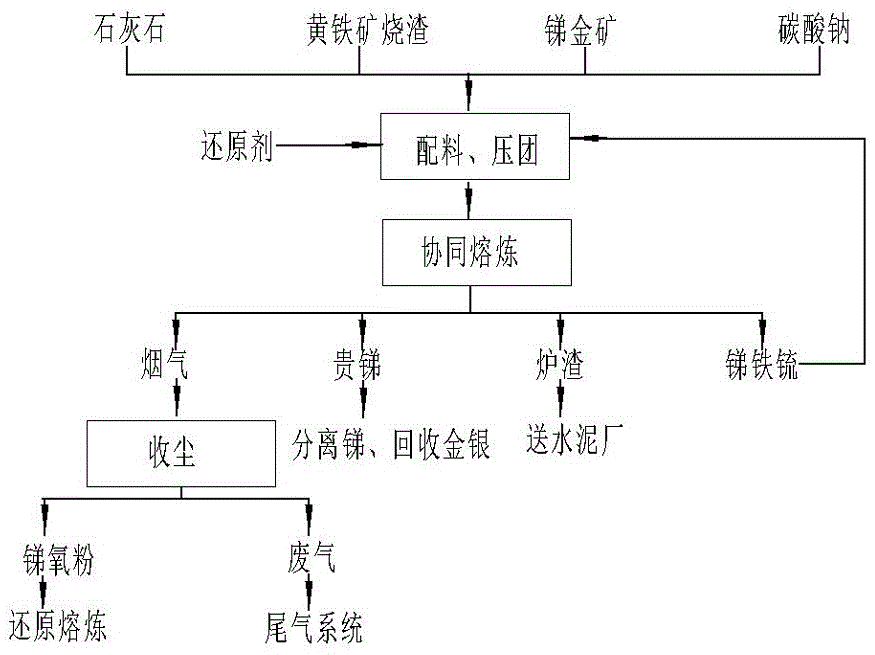

Method of enriching valuable metals through collaborative smelting of gold-antimony deposit and auriferous pyrite cinder

The invention discloses a method of enriching valuable metals through collaborative smelting of a gold-antimony deposit and auriferous pyrite cinder. According to the method, in a smelting burdening process of the gold-antimony deposit, auriferous pyrite cinder replaces the original flux iron ore concentrate, the gold-antimony deposit and the auriferous pyrite cinder are subjected to collaborative smelting together, and a given amount of sodium carbonate is added for reducing a melting point of slag and improving the flowability of a melt, so that the smelting temperature is reduced effectively, the valuable metals like gold and silver in the auriferous pyrite cinder and antimony concentrate can be enriched in crude metallic antimony more, and the probability of oxygenation volatilization of antimony is reduced. The method has the outstanding advantages as follows: firstly, one-step smelting allows antimony to generate metallic antimony more, and the scattering problem of antimony in crude metal, flue gas and iron-antimony matte in the traditional technology is solved; secondly, difficult-to-treat solid waste, namely the auriferous pyrite cinder is used comprehensively, the iron ore concentrate is replaced, the consumption of primary resources is reduced and the industrial solid waste is treated collaboratively; finally, the valuable metals, namely gold and silver in the concentrate and the auriferous pyrite cinder are enriched and recovered, the energy consumption is reduced, and the collaborative smelting effects of comprehensive recovery, low carbon cleaning and production process centralization are exerted.

Owner:合肥龙之韵医药技术有限公司

Method for strengthening gold extraction of iron gold concentrate roasted product containing sulphur and arsenic

The invention discloses a method for strengthening gold extraction of an iron gold concentrate roasted product containing sulphur and arsenic. The high-iron gold concentrate containing sulphur and arsenic, especially high sulphur and high arsenic, hinders the subsequent chemical gold leaching process after being subjected to oxidation roasting pretreatment because of the problem that iron oxide is inevitably generated to wrap gold in a high-temperature reaction process. The invention proposes a new method for strengthening gold extraction of the iron gold concentrate roasted product containing sulphur and arsenic by a flow of 'metallized reduction roasting-acid leaching-gold leaching', namely a method for strengthening gold extraction of the iron gold concentrate roasted product containing sulphur and arsenic aiming at the problem. The method comprises the steps of firstly, carrying out metallized reduction roasting on the iron gold concentrate roasted product containing sulphur and arsenic with a reducing agent, carrying out acid leaching on the metalized roasted product, and finally carrying out chemical leaching with an acid slag. By adopting the method disclosed by the invention, the leaching rate of the iron gold concentrate roasted product containing sulphur and arsenic is higher than 95%; and important theory and technical guidance are provided for effective gold extraction of the gold roasted product.

Owner:CENT SOUTH UNIV

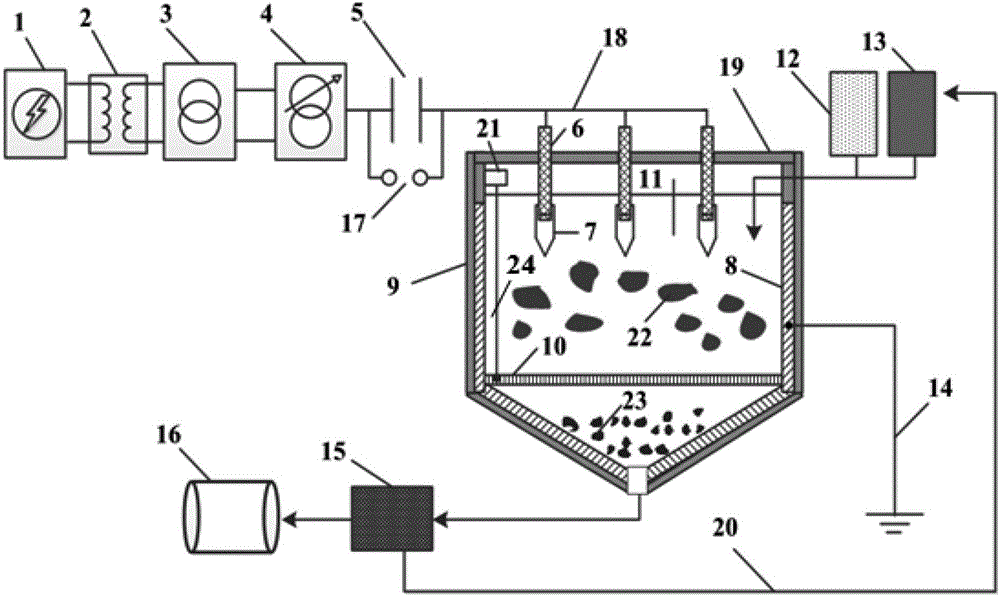

High-voltage electric pulse pretreatment method for intensifying leaching of difficult-to-treat gold ore

ActiveCN106824454AIncrease the content of useful mineralsIncrease monomer dissociationGrain treatmentsPretreatment methodMineral particles

The invention discloses a high-voltage electric pulse pretreatment method for intensifying the leaching of difficult-to-treat gold ore, and belongs to the technical field of the processing of minerals of gold ore. According to the method, the high-voltage electric pulse crushing pretreatment is realized by utilizing the differences of the dielectric properties of different minerals in ore; a high-voltage electric pulse discharge crushing device is used for carrying out selective crushing on gold-containing ore; gold and a gangue mineral in a gold-containing material are prompted to generate a micro crack and a running crack at an interface; a crystal of a gold-containing mineral is completely dissociated into monomer mineral particles; in this way, the exposed surface area of the gold is increased; therefore, the contact probability of cyanide and a gold grain is increased, so that the sufficient improvement of the leaching rate of the gold is facilitated.

Owner:NORTHEASTERN UNIV

Method for extracting gold from copper-containing gold oxide ore

The invention discloses a method for extracting gold from copper-containing gold oxide ore, belonging to a wet metallurgy technology. The method comprises the steps of: firstly, crushing, grinding and classifying copper-containing gold oxide ore; then carrying out alkali treatment on the copper-containing gold oxide ore; adding a certain proportion of chelant and sodium cyanide for realizing the purposes of inhibiting copper extraction and selective extraction of gold; and finally, extracting gold from the extract solution through adsorption by using conventional active carbon. The method has the advantages of simple process, simple equipment, easy implementation, high gold extraction rate, less chemical consumption, less investment of capital construction, and low cost, easily realizes industrialized production and has better economic benefit.

Owner:ZIJIN MINING GROUP

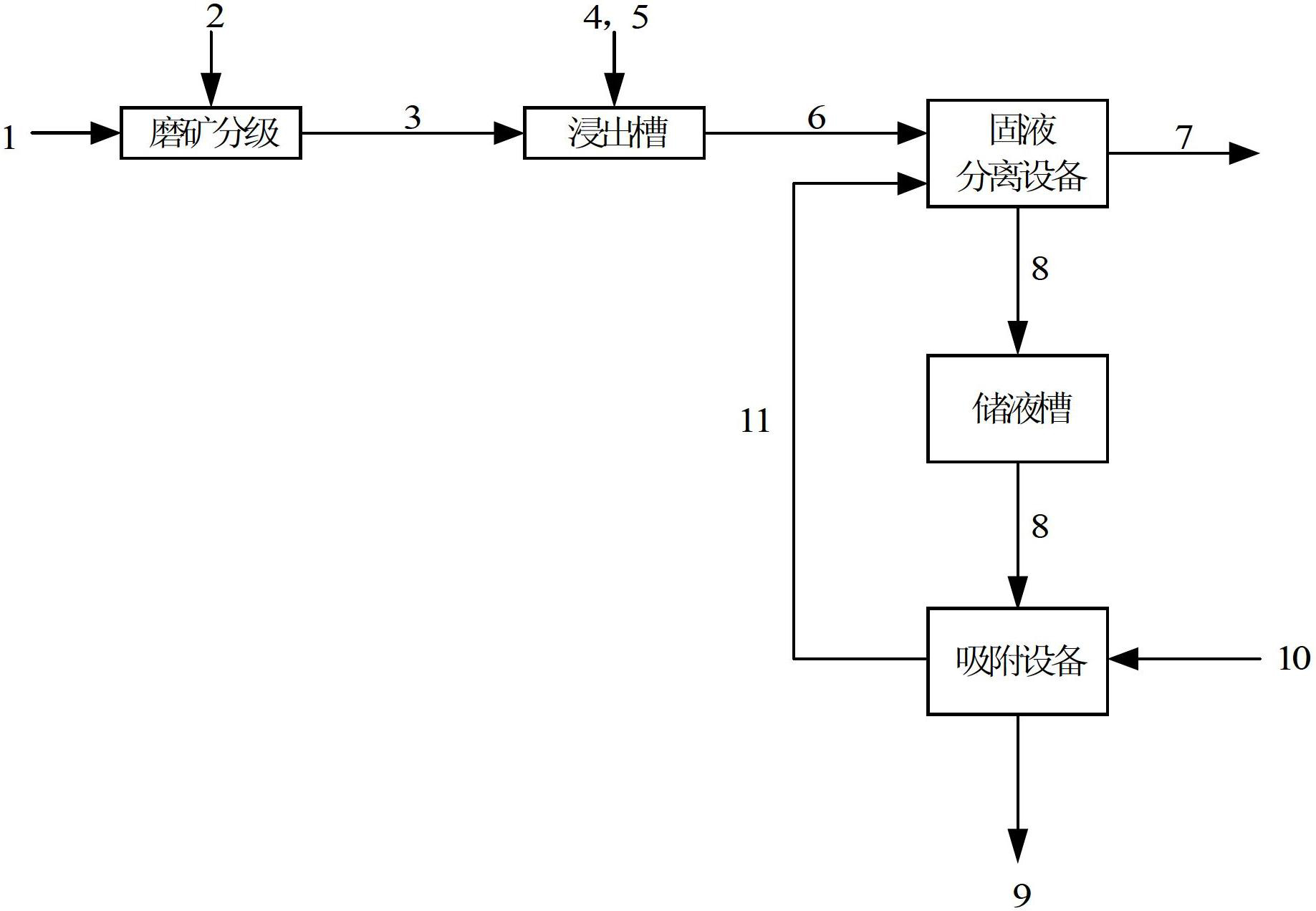

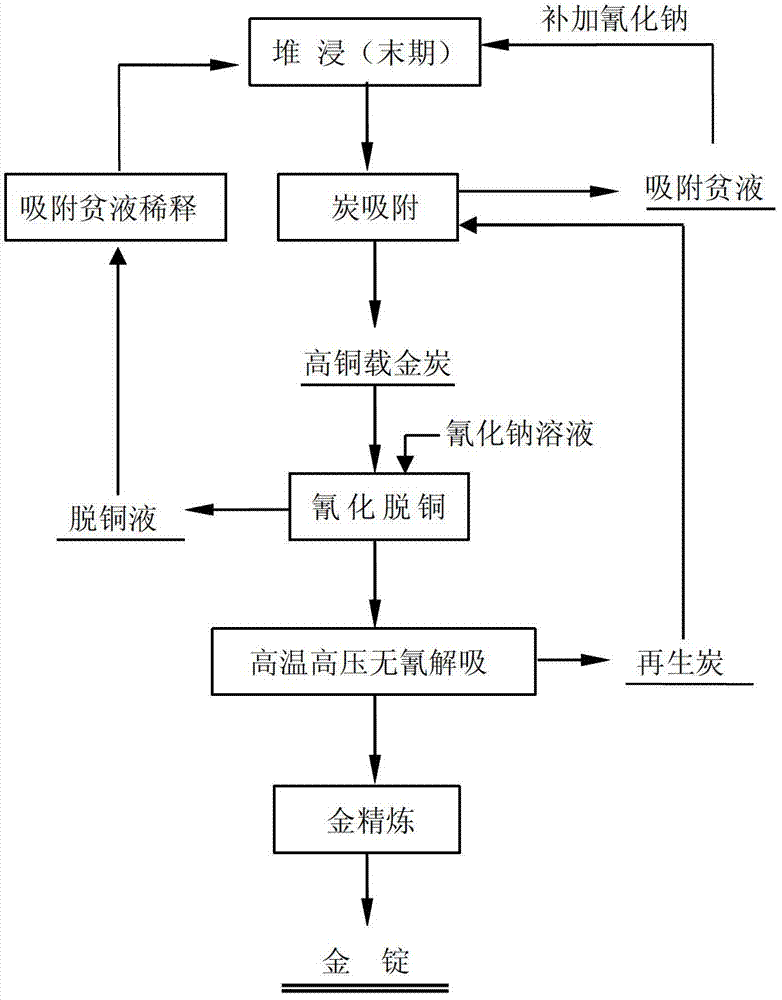

Low-grade copper-bearing gold ore dump leaching-carbon adsorption production method

ActiveCN103194614ASimple processLess investmentPhotography auxillary processesDesorptionDump leaching

The invention relates to a low-grade copper-bearing gold ore dump leaching-carbon adsorption production method. Copper contained in high-copper gold-carried carbon obtained through a low-grade copper-bearing gold ore dump leaching-carbon adsorption procedure is partially removed by adopting a cyaniding decoppering process, a decoppering solution is diluted by utilizing an adsorption barren solution to be used as a spray solution at the late stage of dump leaching, and decoppering carbon is conveyed to a high-temperature high-pressure cyanide-free desorption-electrodeposition system for treatment. The low-grade copper-bearing gold ore dump leaching-carbon adsorption production method disclosed by the invention has the advantages of simple process flow, small investment, no other original paving material addition, low production cost and the like, and is easy to industrially implement; according to the invention, after the high-copper gold-carried carbon is subjected to cyaniding decoppering, the gold desorption rate of the high-copper gold-carried carbon can be enhanced, and the adsorption property of regenerated carbon is enhanced, so that the adsorption rate of gold is enhanced, and the production technology index is optimized; and a part of copper contained in the decoppering solution and the adsorption barren solution can be deposited in a stock dump again by adopting a copper deposition process at the late stage of the dump leaching, the gold can be leached by utilizing sodium cyanide generated through copper deposition reaction, so that the concentration of copper contained in the dump leaching-carbon adsorption system can be effectively controlled, and the production system can be in a good operating environment all the time.

Owner:ZIJIN MINING GROUP

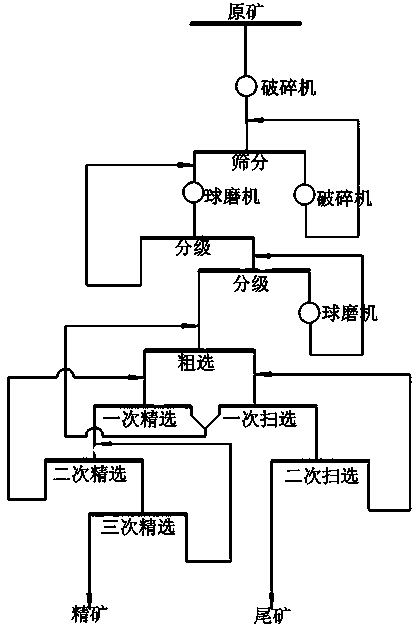

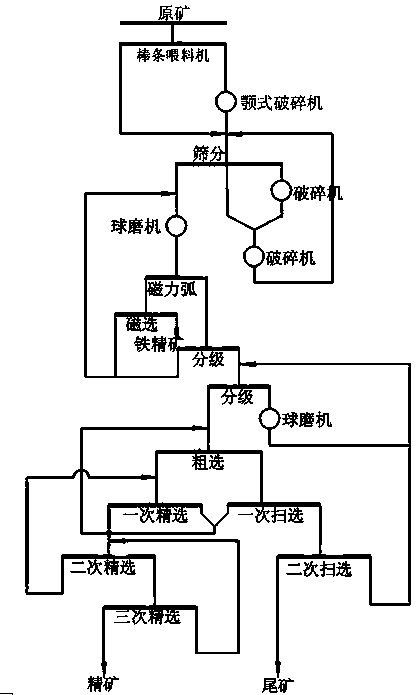

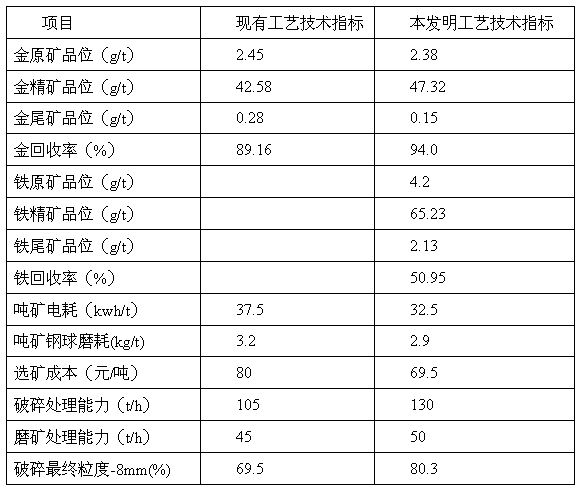

Beneficiation method and device for quartz vein type gold deposit

ActiveCN103464275AReduce wearIncreased crushing capacity efficiencyWet separationSteel ballNon magnetic

The invention discloses a beneficiation method for quartz vein type gold deposit. The beneficiation method for the quartz vein type gold deposit includes the steps of using a jaw crusher to crush raw ore, sending crushed mineral material into a double layer circular vibrating screen to be sieved, putting sieved and qualified mineral material into a grid type ball mill for single stage grinding, returning unqualified mineral material after two stage crushing back to the double layer circular vibrating screen, separating magnetic and non-magnetic minerals after discharging material from single stage grinding passing a magnetic arc, making magnetic minerals for magnetic separation to obtain iron ore concentrate and putting the non-magnetic minerals separated through the magnetic arc into a sorting system after twice classification. Compared with the prior art, with beneficiation method for quartz vein type gold deposit, the content of fine particles of a crushed final product is mostly of 80.3%, crushing efficiency is improved, wear rate of a steel ball is decreased by 9%, ferrous metals can be recycled, synchronous improvement of ore dressing recovery percentage and concentrate grade is realized with the recovery percentage increased by 4.2% and the concentrate grade increased by 3.5 grams per ton, power consumption rate is reduced by 13.86%, and cost is reduced by 15.0%.

Owner:阿勒泰正元国际矿业有限公司

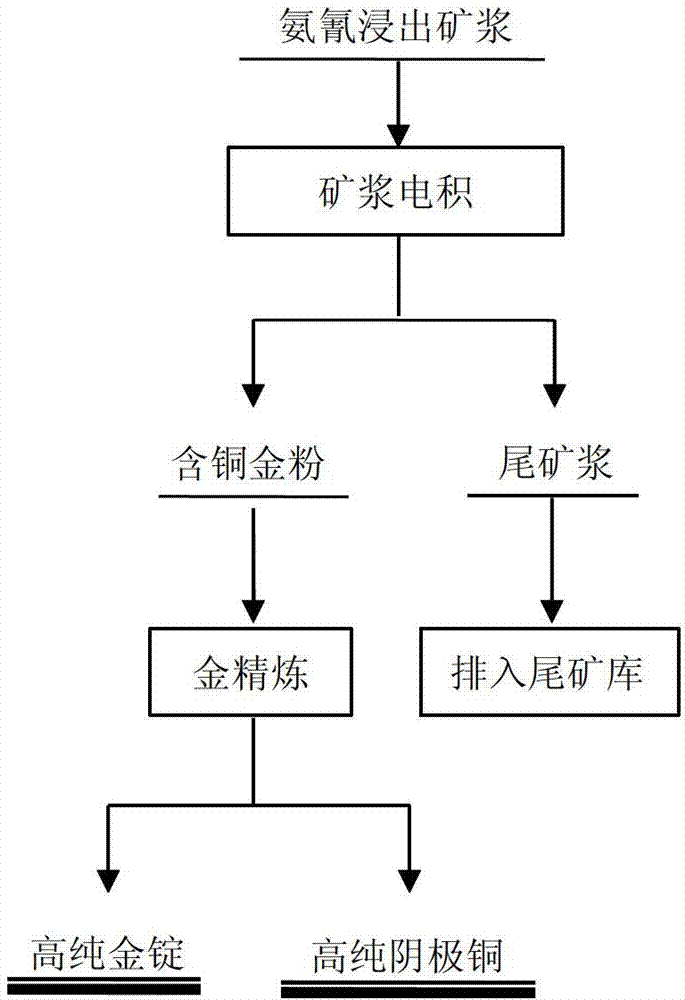

Process for extracting gold from low-grade, copper-containing and difficultly-treated goldmine ammonia cyanide leaching pulp via electrodeposition

ActiveCN103194770AHigh recovery rateShort processPhotography auxillary processesDesorptionCyanide leaching

The invention relates to a process for extracting gold from a low-grade, copper-containing and difficultly-treated goldmine ammonia cyanide leaching pulp via electrodeposition. The process comprises the following steps: diluting the low-grade, copper-containing and difficultly-treated goldmine ammonia cyanide leaching pulp to the proper pulp concentration; leading the pulp into an electrodeposition tank and performing the electrodeposition on the pulp; refining the copper-containing gold powder obtained from a cathode, thereby obtaining a high-purity gold ingot and high-purity cathode copper; and discharging the pulp after the electrodeposition into a tailings pond. The process has the advantages that the technological process is short; the gold recovery rate is high; the production cost is low; the comprehensive recovery of copper is realized; the steps of countercurrent washing, carbon adsorption, gold-carrying carbon desorption-electrodeposition and the like in the conventional gold leaching process are omitted; the investment cost is lowered greatly; and the like.

Owner:ZIJIN MINING GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com