Novel martensitic wear resistant steel and production technology for steel casting thereof

A production process, martensitic technology, applied in the field of wear-resistant steel, can solve the problems of low toughness, difficult to meet the use requirements, fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

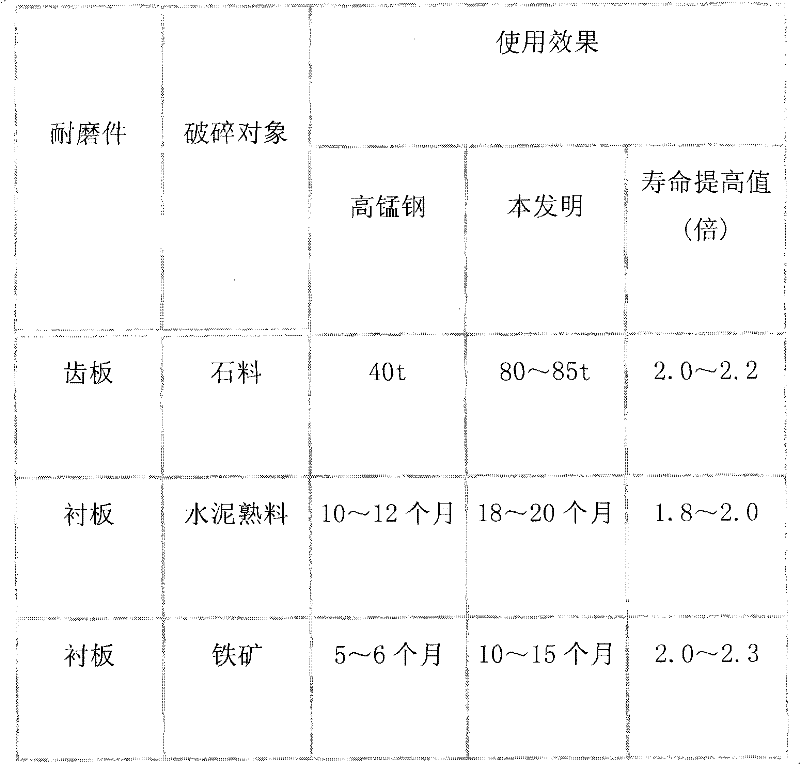

Examples

Embodiment

[0031] The chemical composition measured by weight percentage is preferably: C: 0.35% to 0.45%, Si: 0.8% to 1.5%, Cr: 2.1% to 2.5%, Mn: 0.8% to 1.2%, Ni: 0.7% to 1.0% %, Mo: 0.6%-1.0%, Nb: 0.1%-0.3%, Ti: 0.1%-0.15%, Re: 0.04%-0.05%, P, S≤0.04, and the balance is iron.

[0032] A production process of the martensitic wear-resistant steel casting is characterized in that it includes a smelting process, a casting process, a heat treatment process, and a quality inspection.

[0033] The smelting process adopts the oxidation method. Firstly, scrap steel is added for melting, then Mo iron and copper are added, and oxygen blowing is carried out when melting 68-72%. After melting, test the composition, then remove the slag, and then make new slag, enter the reduction period, add Cr iron, Mn iron, Ni iron and Nb iron successively, and carry out the full composition analysis test after the alloy material added is fully melted, according to the test results Adjust each element, after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com