Casting type coke production method and apparatus system used thereof

A production method and casting type technology, which is applied in coking ovens, petroleum industry, etc., can solve the problems of uneven product size, unfavorable environmental protection, and poor coke quality, so as to reduce carbonization and coking time, benefit environmental protection, Stomatal firmness and moderate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

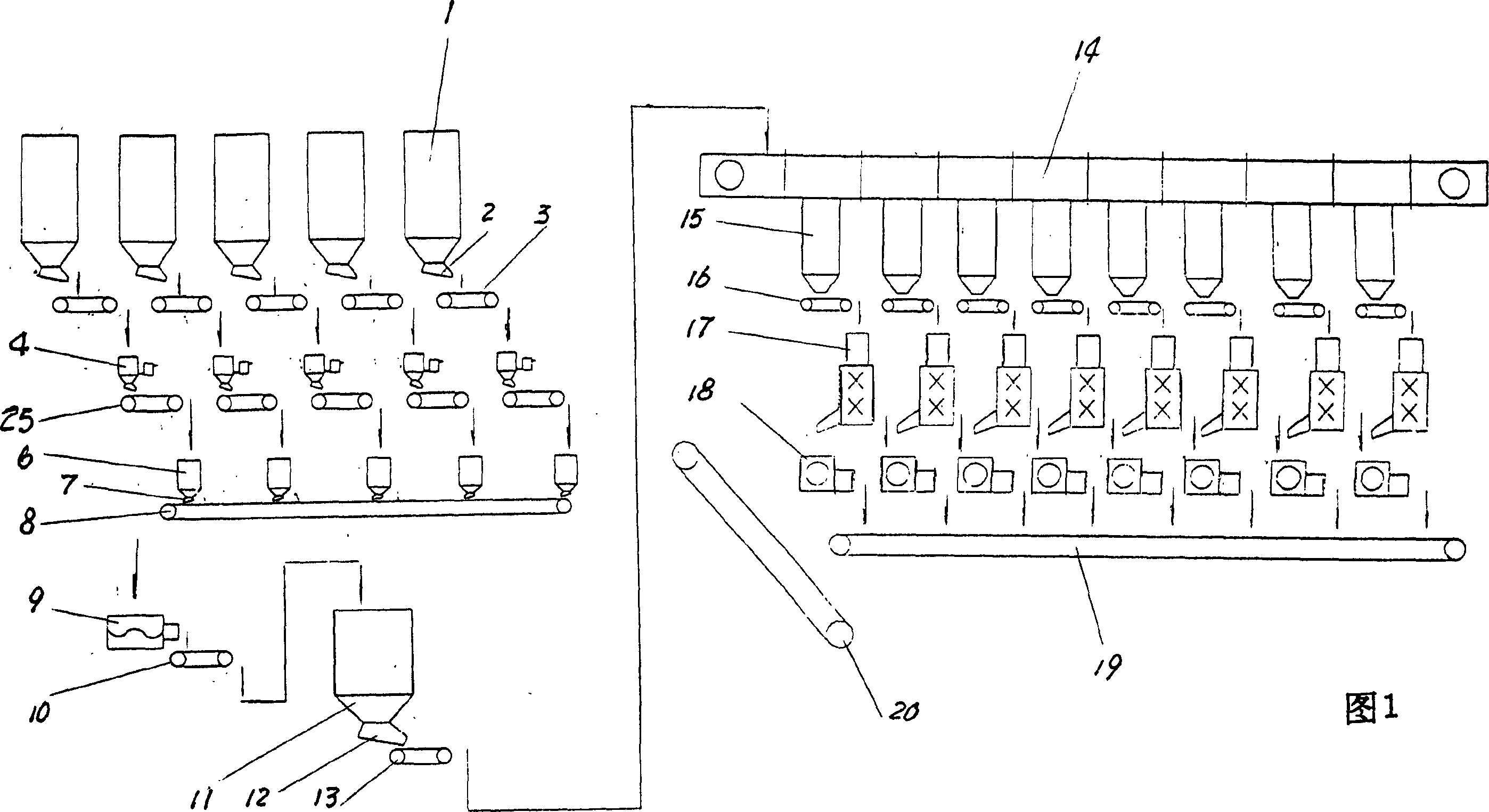

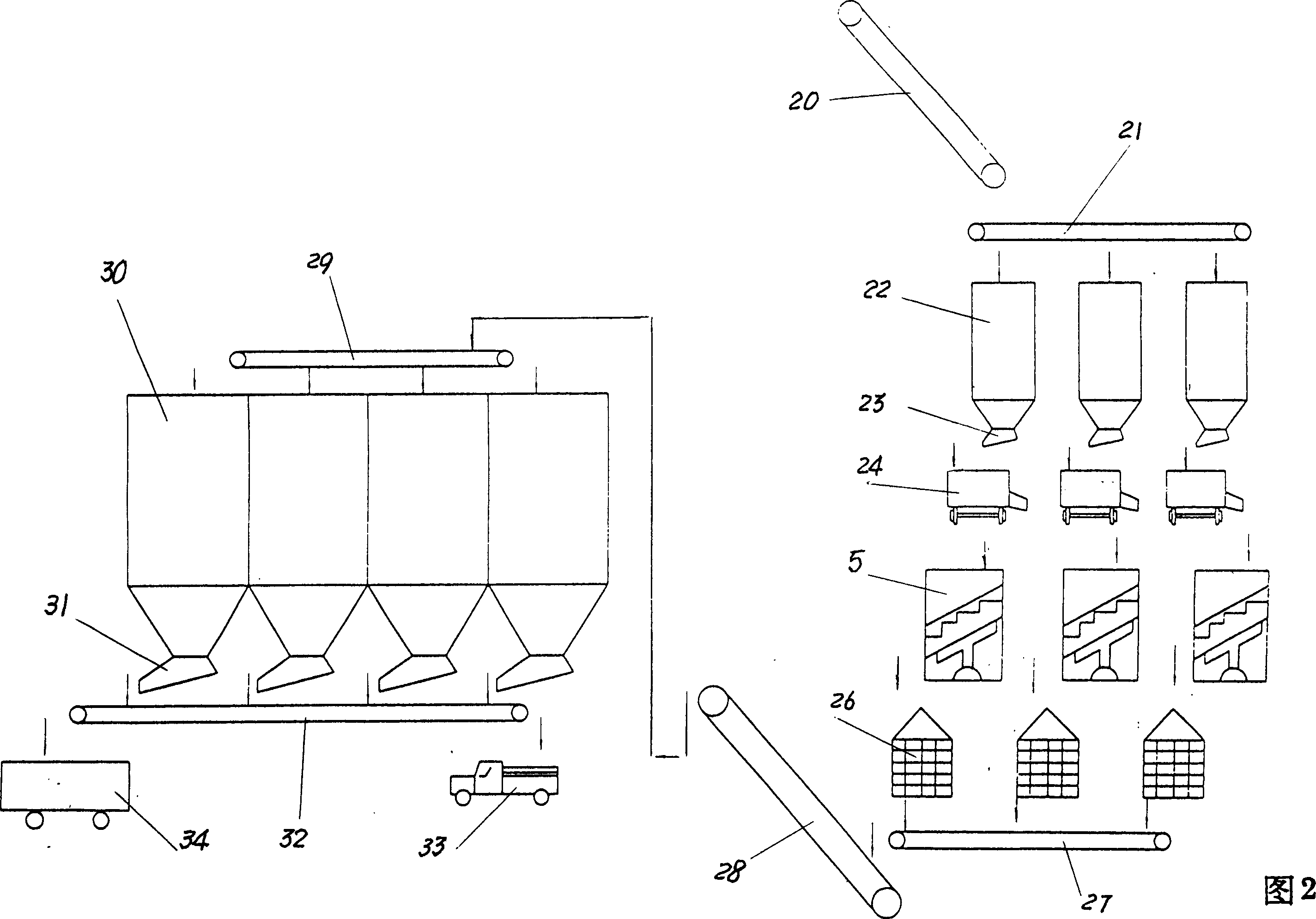

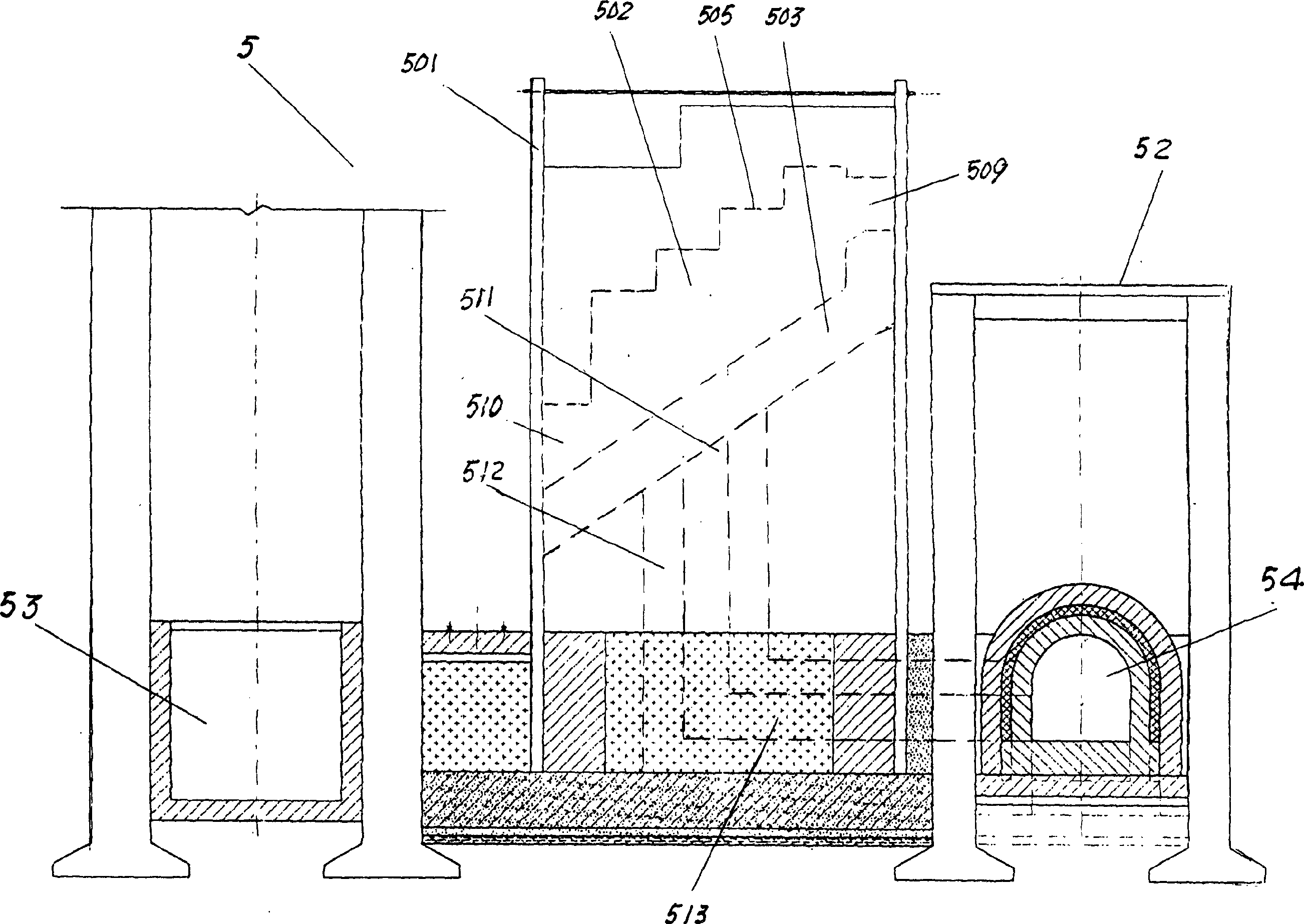

[0104] The present invention relates to a production method of casting mold coke, the method comprises batching, crushing, cold stirring, hot stirring, molding and carbonization coking;

[0105] A. The raw material components and parts by weight of the foundry coke are:

[0106] Anthracite: 45-65 parts Coke powder: 7-20 parts Petroleum coke: 8-20 parts

[0107] Coking coal or fat coal: 10-30 parts Coal tar pitch: 5-10 parts

[0108] B. Its production method comprises the following steps:

[0109] ① Grinding raw materials: Grinding anthracite, coke powder, petroleum coke, coking coal or fat coal and coal tar pitch according to the following particle size requirements:

[0110] Anthracite: ≤3mm Coke powder: 1mm Petroleum coke: ≤1mm

[0111] Coking coal or fat coal: ≤2mm Coal tar pitch: 1mm

[0112] ②Batching: Put all kinds of crushed raw materials in each storage hopper, and send them to the belt conveyor quantitatively according to the stated ratio through the feeder;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com