Patents

Literature

284 results about "Casting types" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sand casting is one of the most popular and simplest types of casting that has been used for centuries. Sand casting allows for smaller batches to be made compared to permanent mold casting and a very reasonable cost.

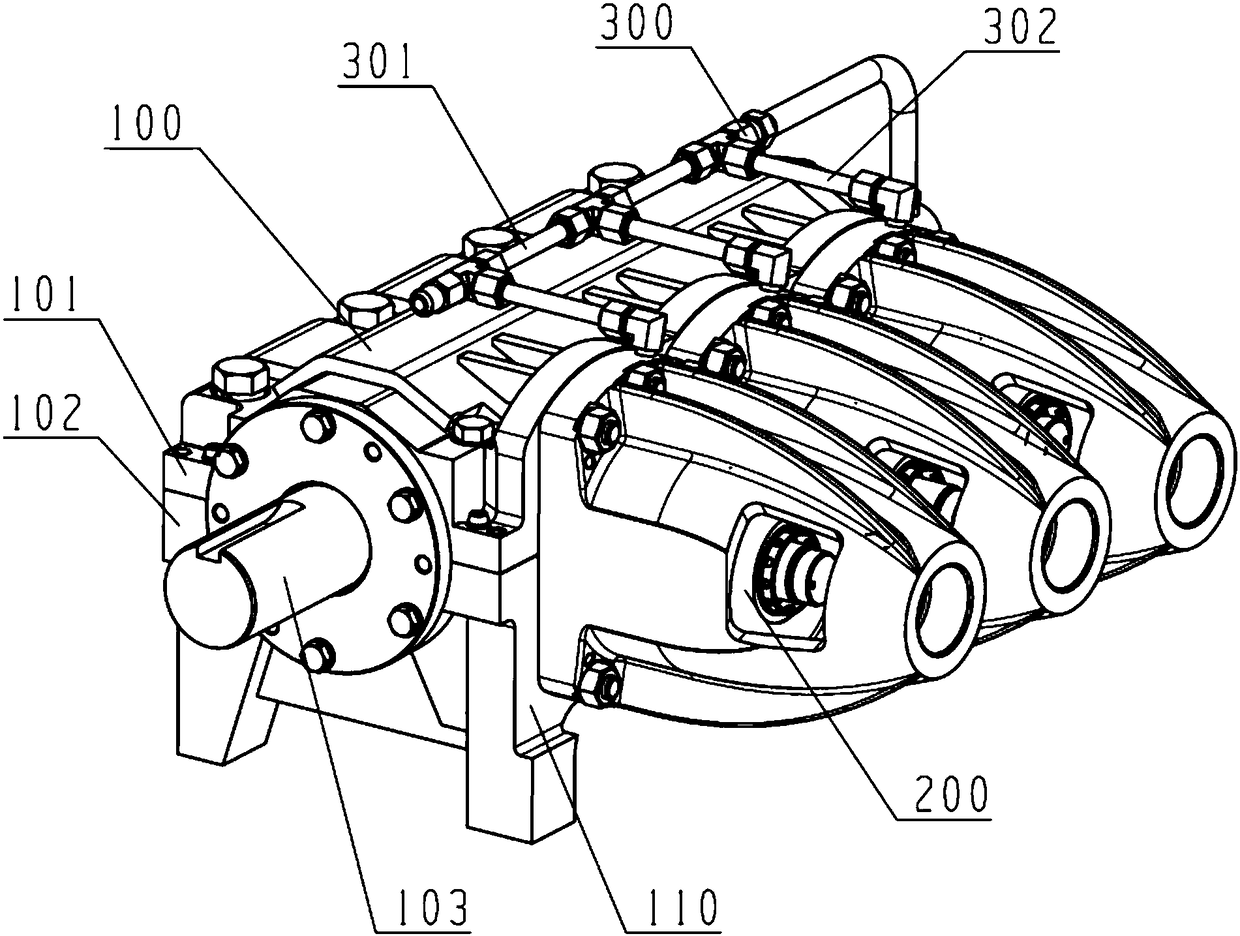

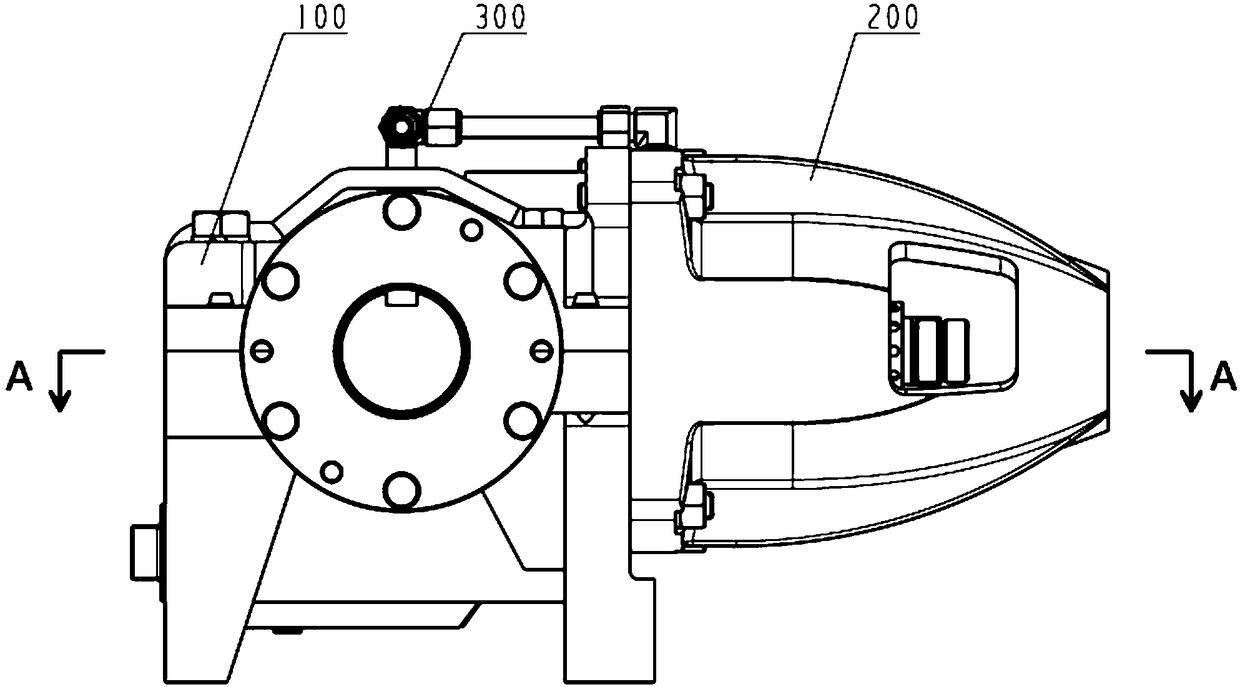

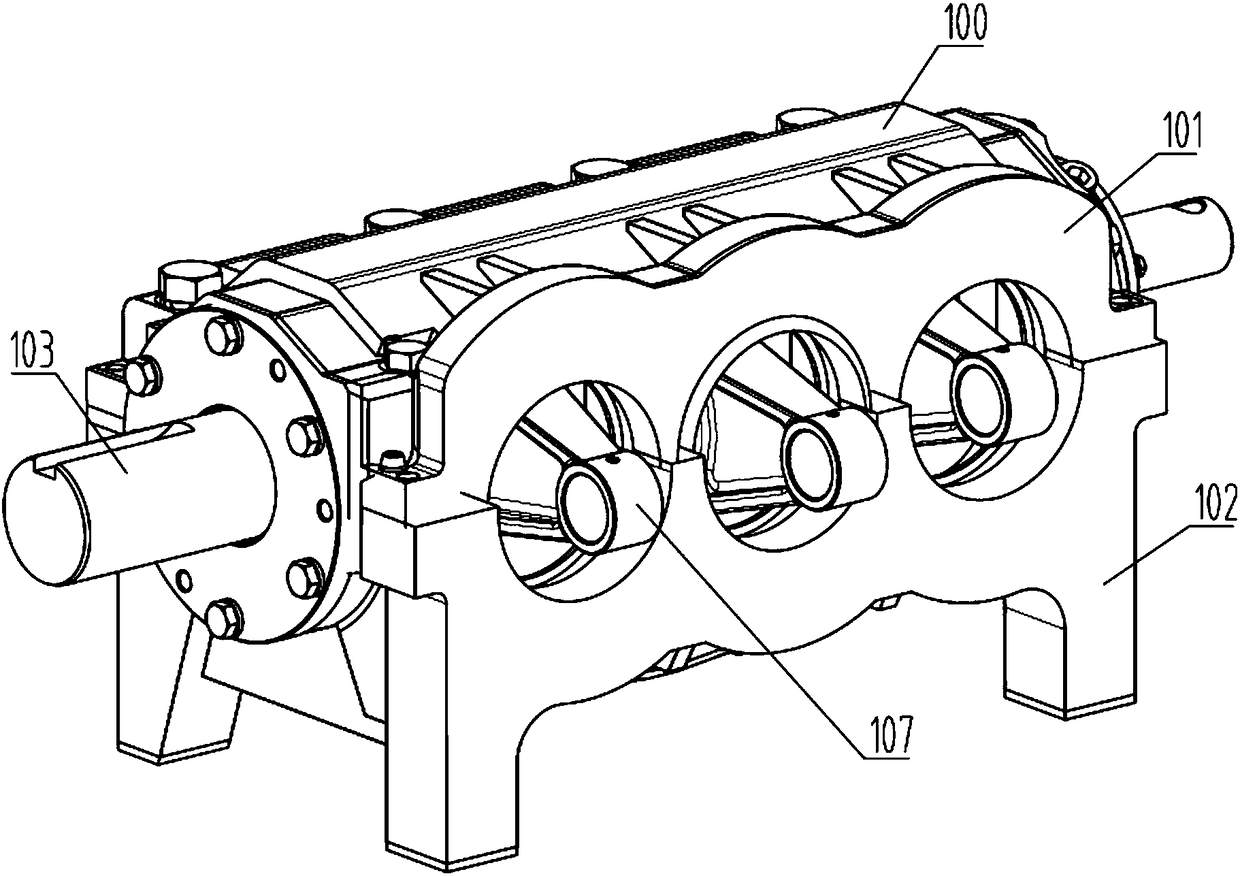

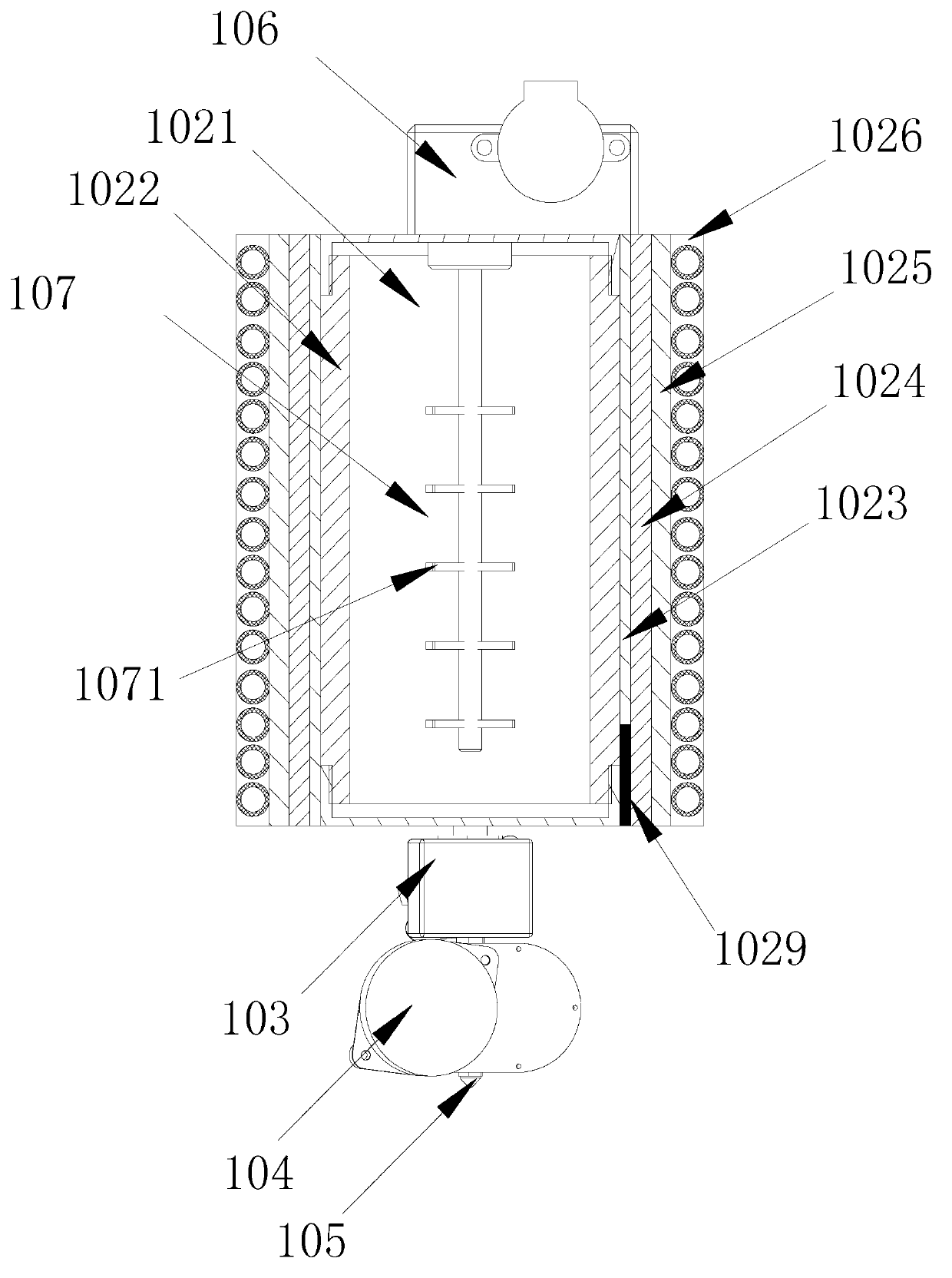

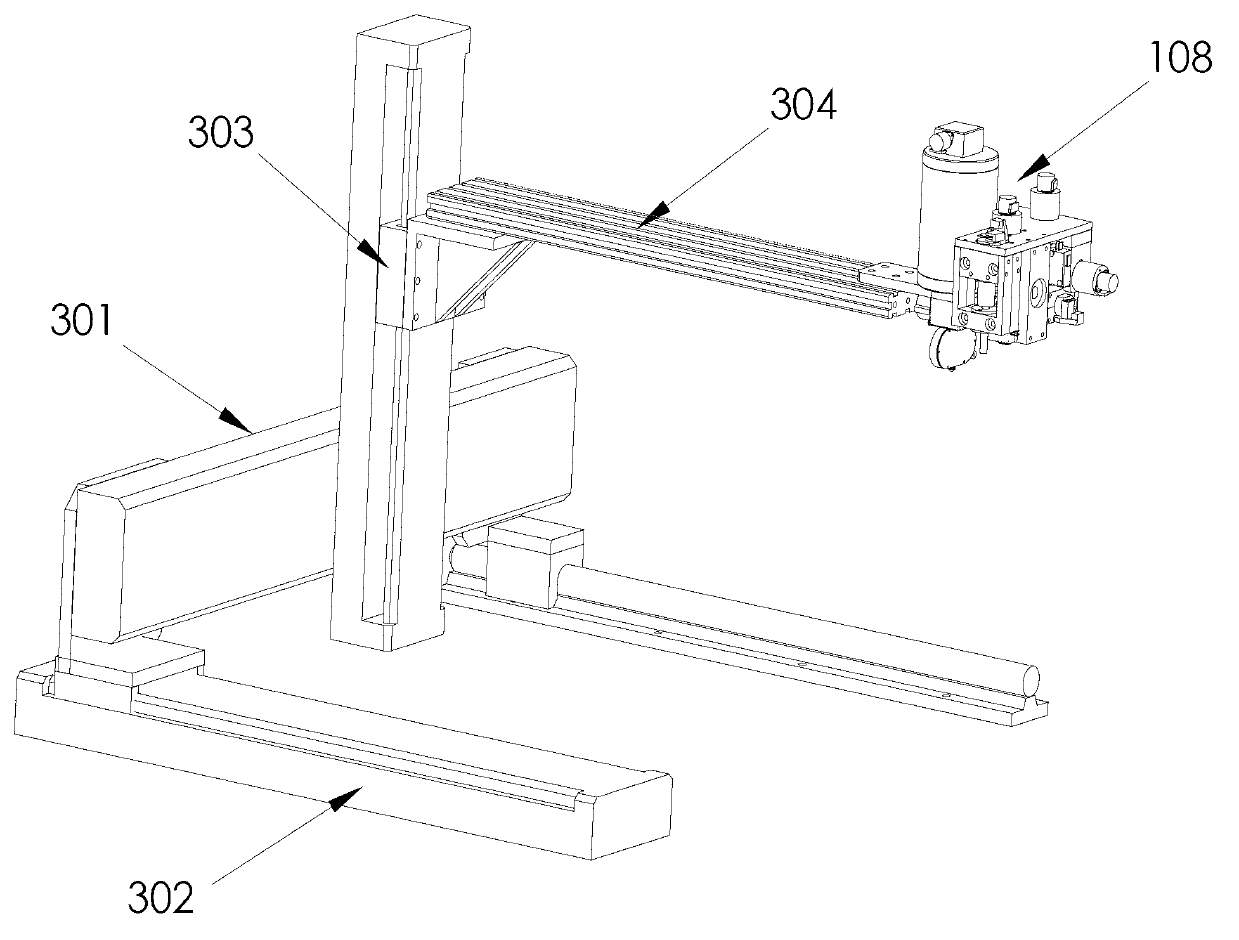

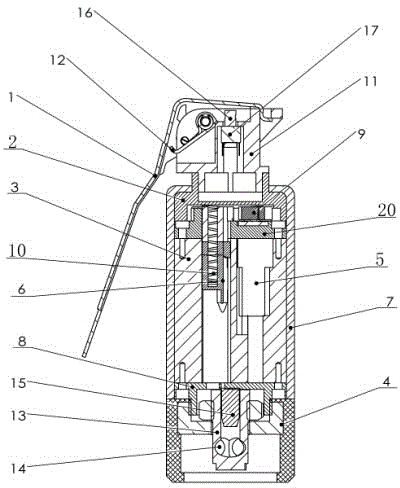

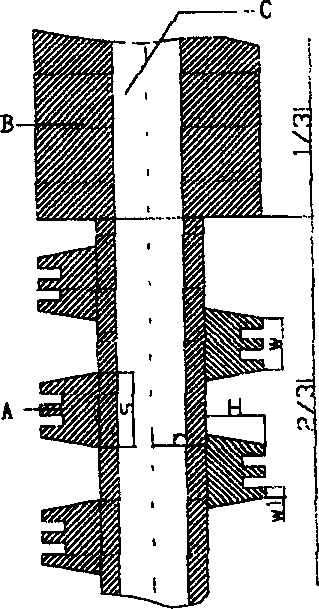

Liquid nitrogen pump power end assembly

PendingCN108547766ACompact structureEasy to processPositive displacement pump componentsPumpsTransmitted powerJackscrew

The invention provides a liquid nitrogen pump power end assembly. The liquid nitrogen pump power end assembly comprises a crankshaft box assembly. The crankshaft box assembly is correspondingly connected with crosshead shell assemblies. Lubricating systems are correspondingly arranged between the crankshaft box assembly and the crosshead shell assemblies. The liquid nitrogen pump power end assembly adopts split type module combination of the crankshaft box assembly and the crosshead shell assemblies to be assembled, a crankshaft box is designed into a welding type, crosshead shells are designed into a casting type, compared with inblock casting or overall welding, the structure is simple and compact, existing machining manners are considered, machining, manufacturing, assembling, repairingand maintaining are facilitated, crossheads are provided with threads for connection and can be connected with fluid ends with different specifications on the market to play a role in transmitting power, a crankshaft adopts a split type structure that a straight shaft and multiple eccentric wheels are connected through flat keys, the crankshaft overall machining difficulty is lowered, crosshead hinge pins are provided with jackscrew holes, by means of jackscrew fixing, axial floating of hinge pins can be eliminated, the lubricating system can protect movement members, and the service life ofeach movement member is prolonged.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

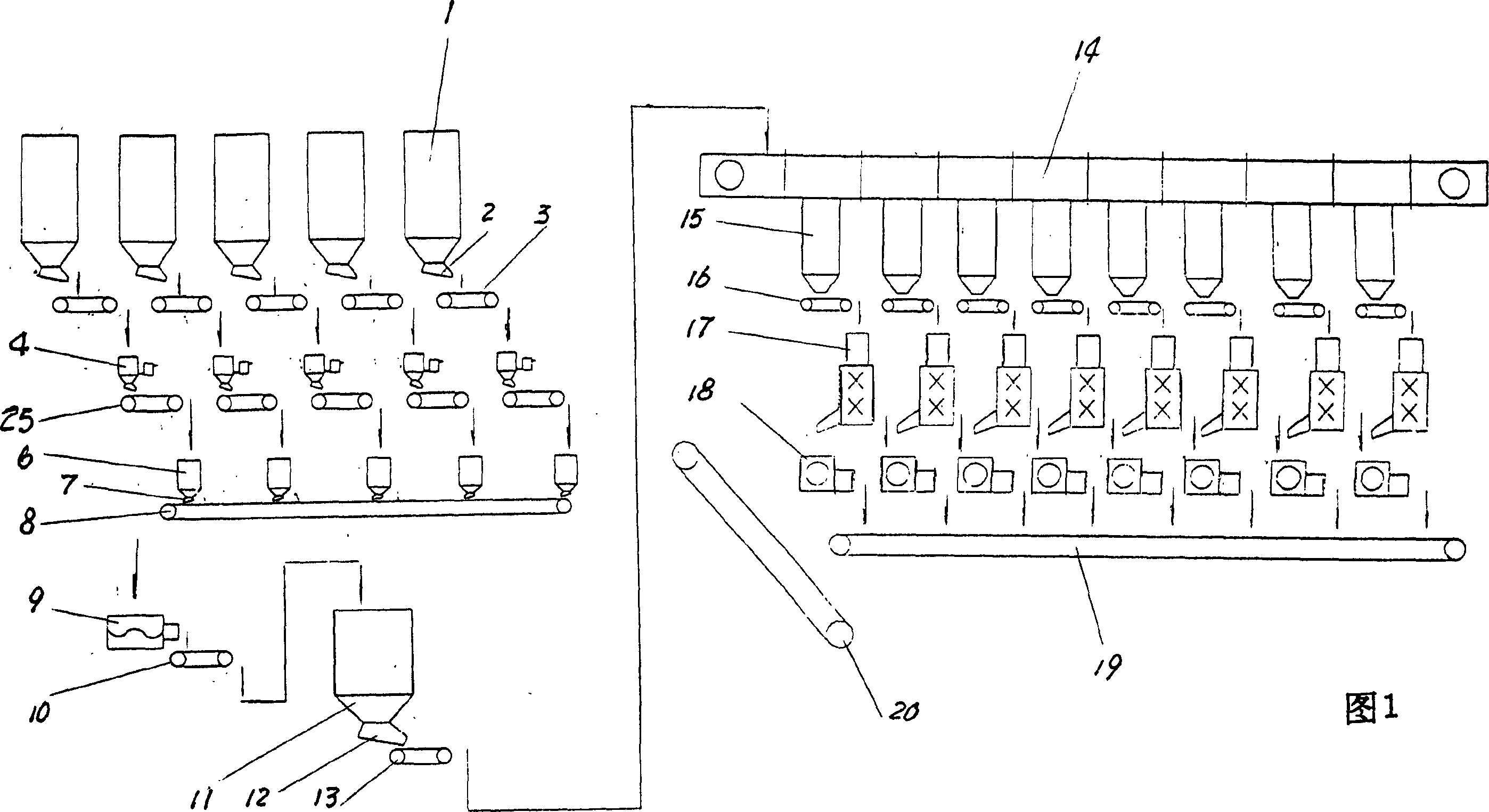

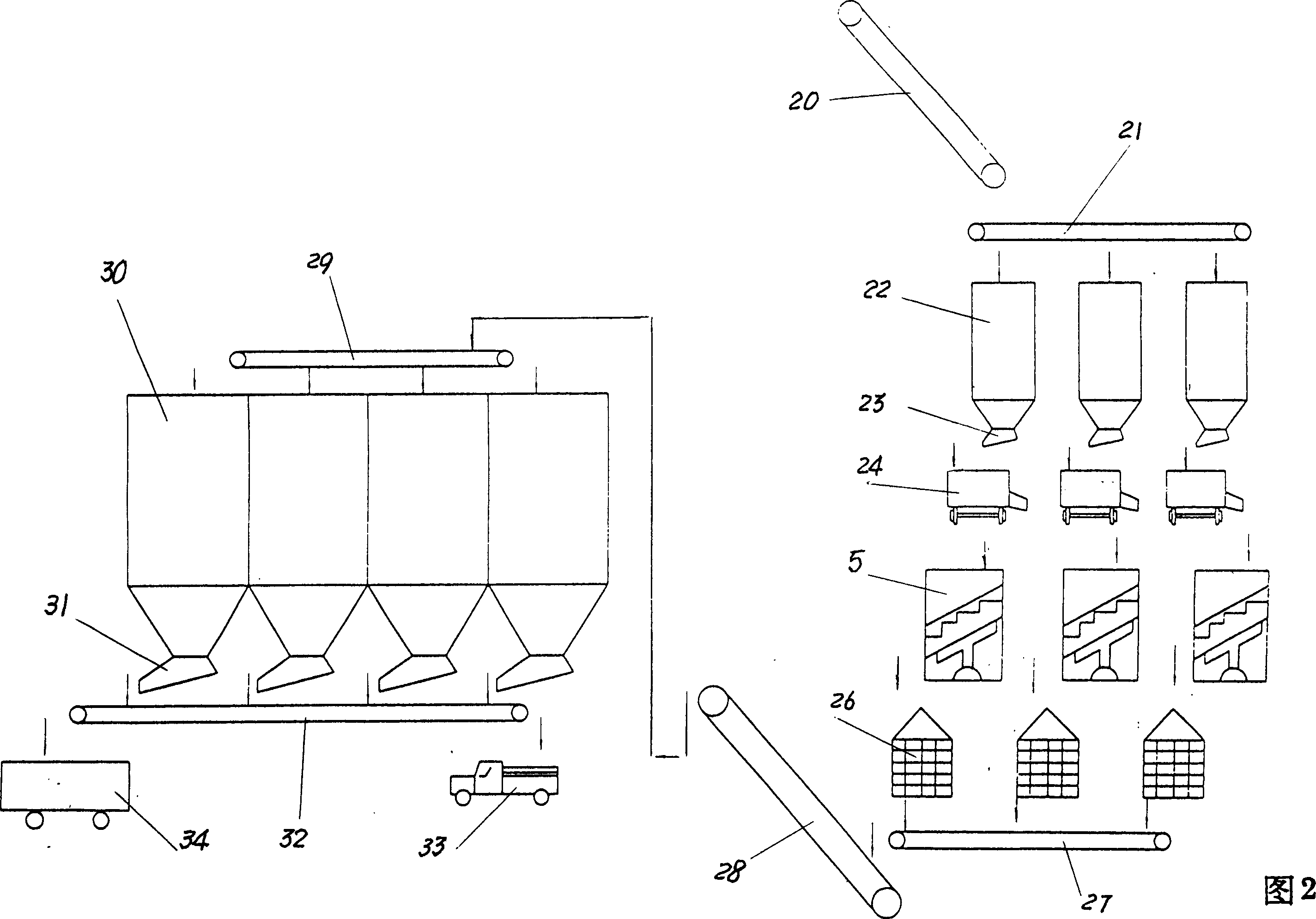

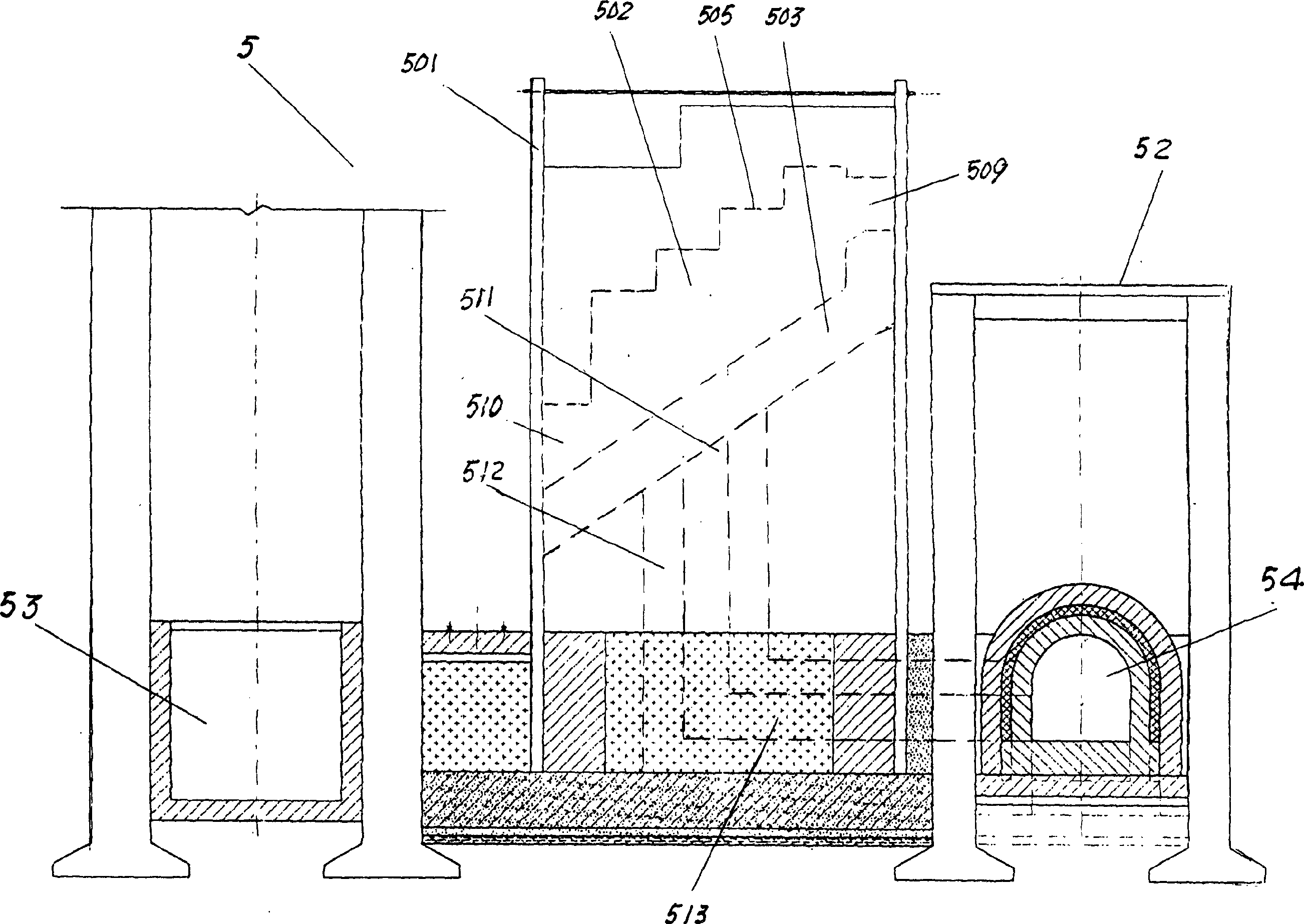

Casting type coke production method and apparatus system used thereof

The present invention relates to a production method of foundry shaped coke and its equipment system for producing said foundry shaped coke. Said method includes the procedures of preparing material,pulverizing, cold stirring, hot stirring, forming and carbonization and coking, and its equipment system includes material-preparing chamber, pulverizing machine, cold stirring machine, hot stirring machine, forming machine and carbonizing furnace, etc.

Owner:商丘市普天工贸有限公司煤化工研究所

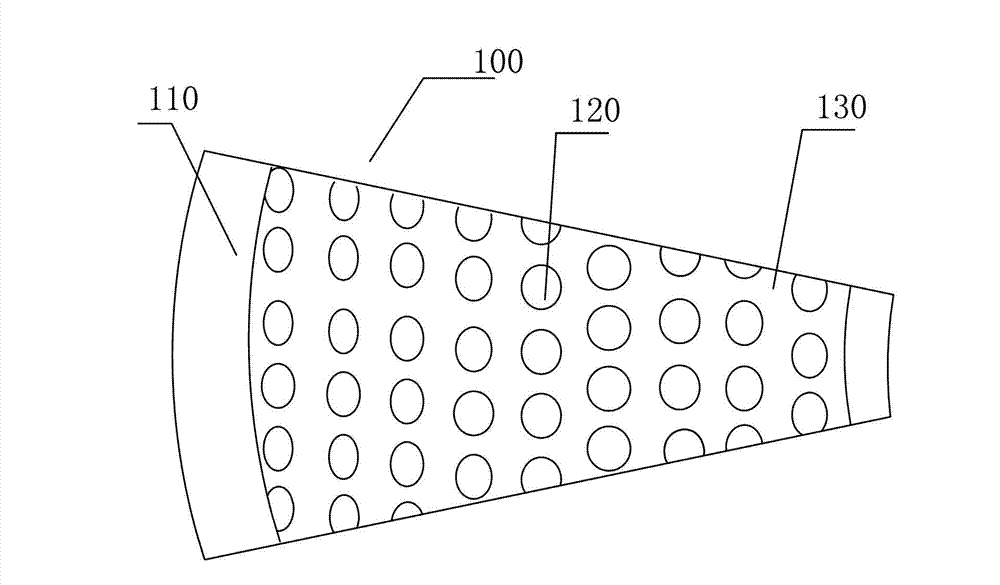

Precision-investment casting method of titanium aluminum base alloy aircraft engine blade

A precision-investment casting method of a titanium aluminum base alloy aircraft engine blade relates to a preparation method of an aircraft engine blade and solves the problems of easy deformation, complicated processing procedures and low processing efficiency caused by the thin aircraft engine blades with diverse shapes when the existing blank processing mode is adopted. The invention adopts a water jacketed copper crucible vacuum induction melting centrifugal casting method to realize the preparation of the titanium aluminum base alloy aircraft engine blade. The aluminum content of the titanium aluminum base alloy is 46-48at%. Under vacuum argon shield, the melting is implemented and the melting power is 330-350kW in the melting process. With the centrifugal casting technology adopted, the casting is carried out by adopting a bottom casting type casting system and a casting system composed of blade type shells. The preheating temperature of a casting type shell is 400-600 DEG C and the shell cools with a furnace after casting, and the oxygen content of the alloy is 0.04-0.08% after casting. The method is simple in technology, low in processing cost and is applicable to processing various aircraft engine blades.

Owner:HARBIN INST OF TECH

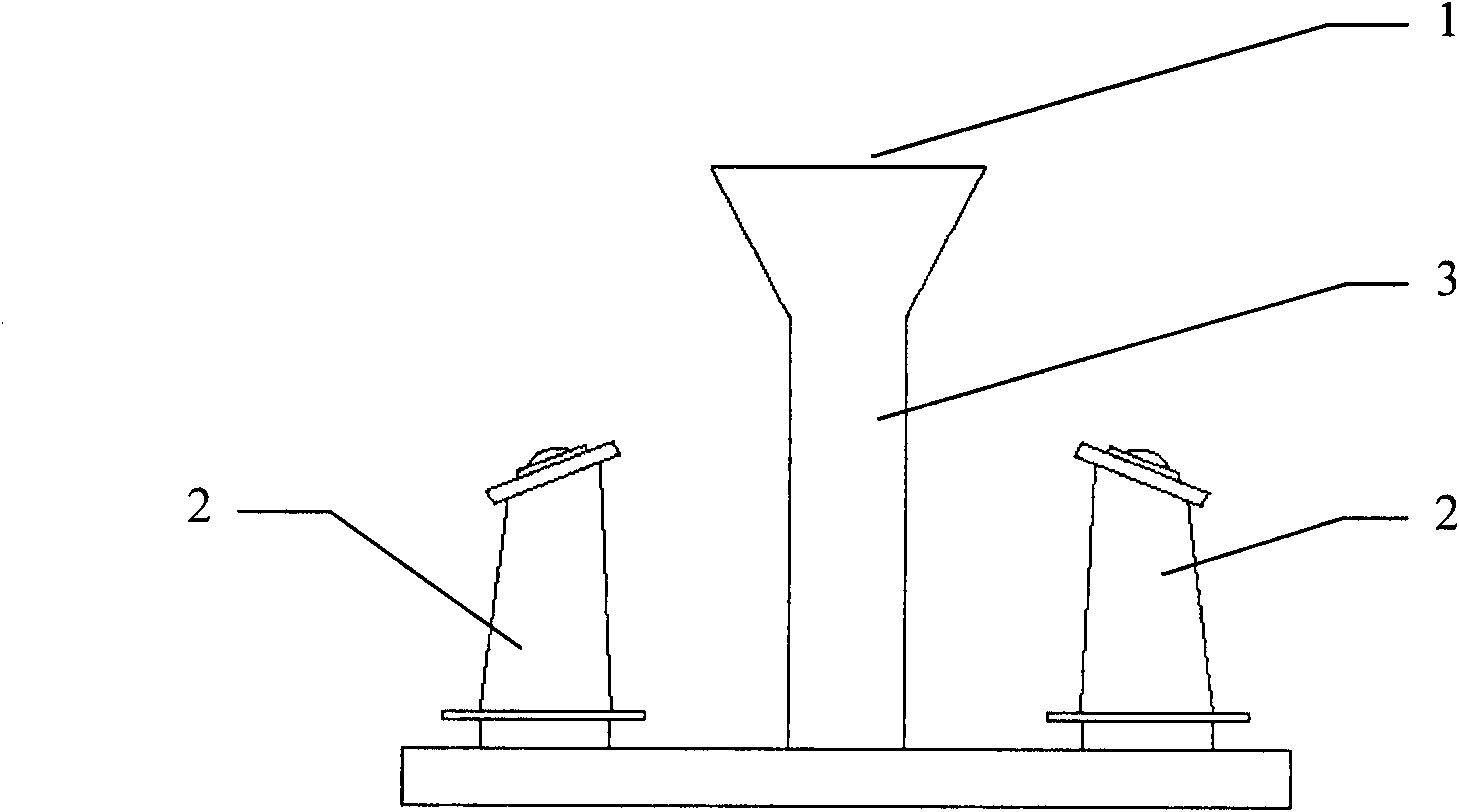

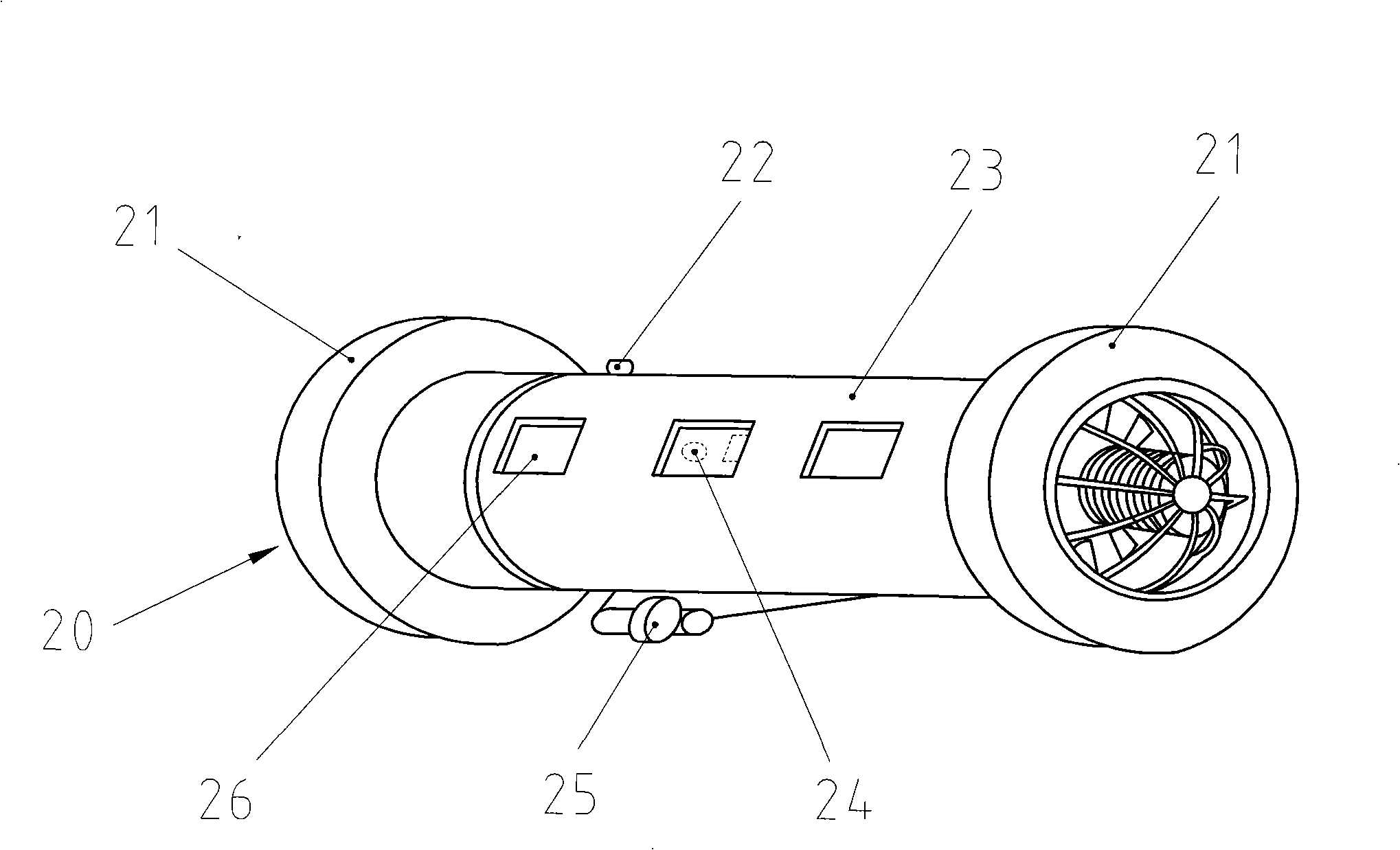

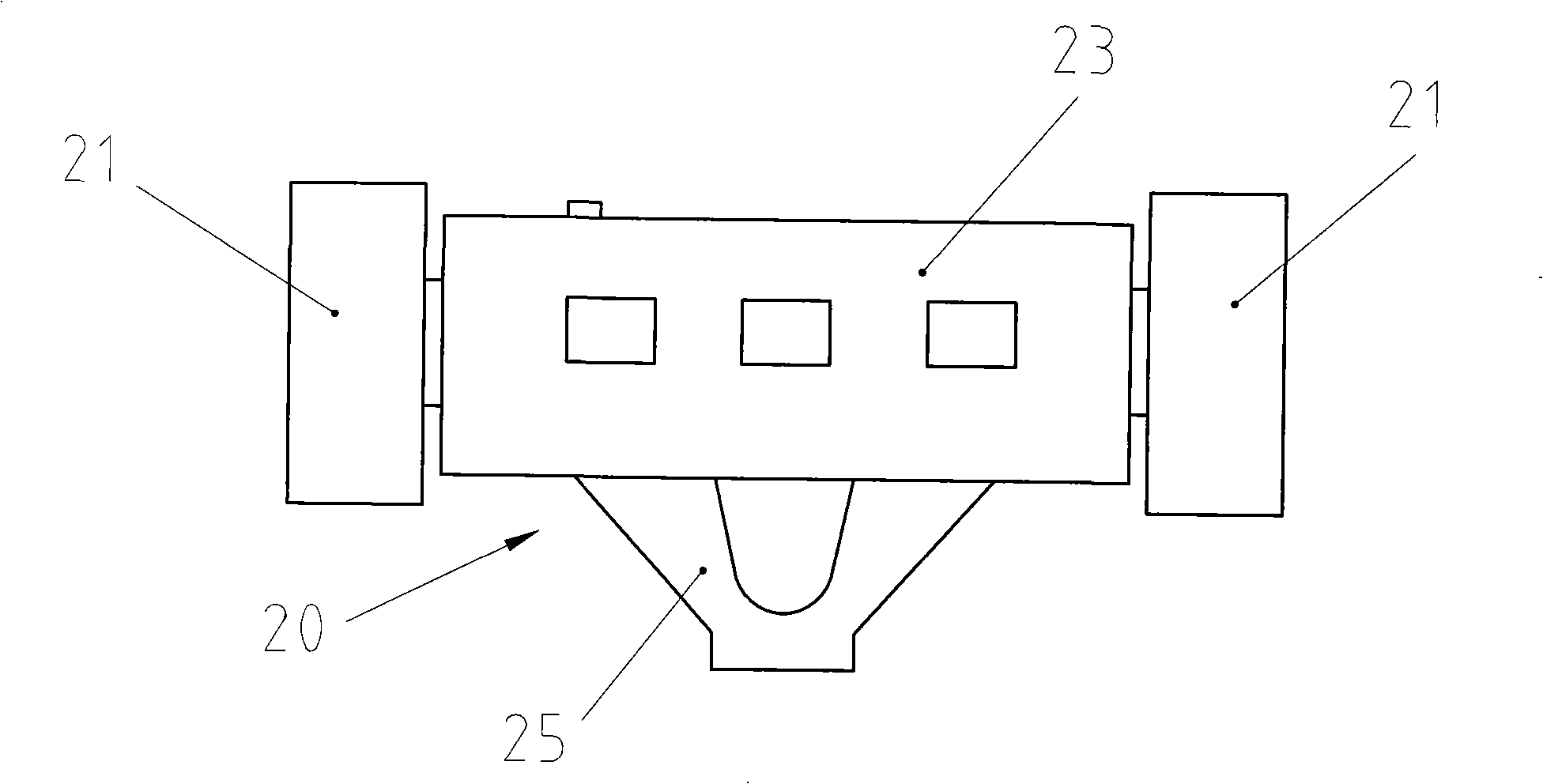

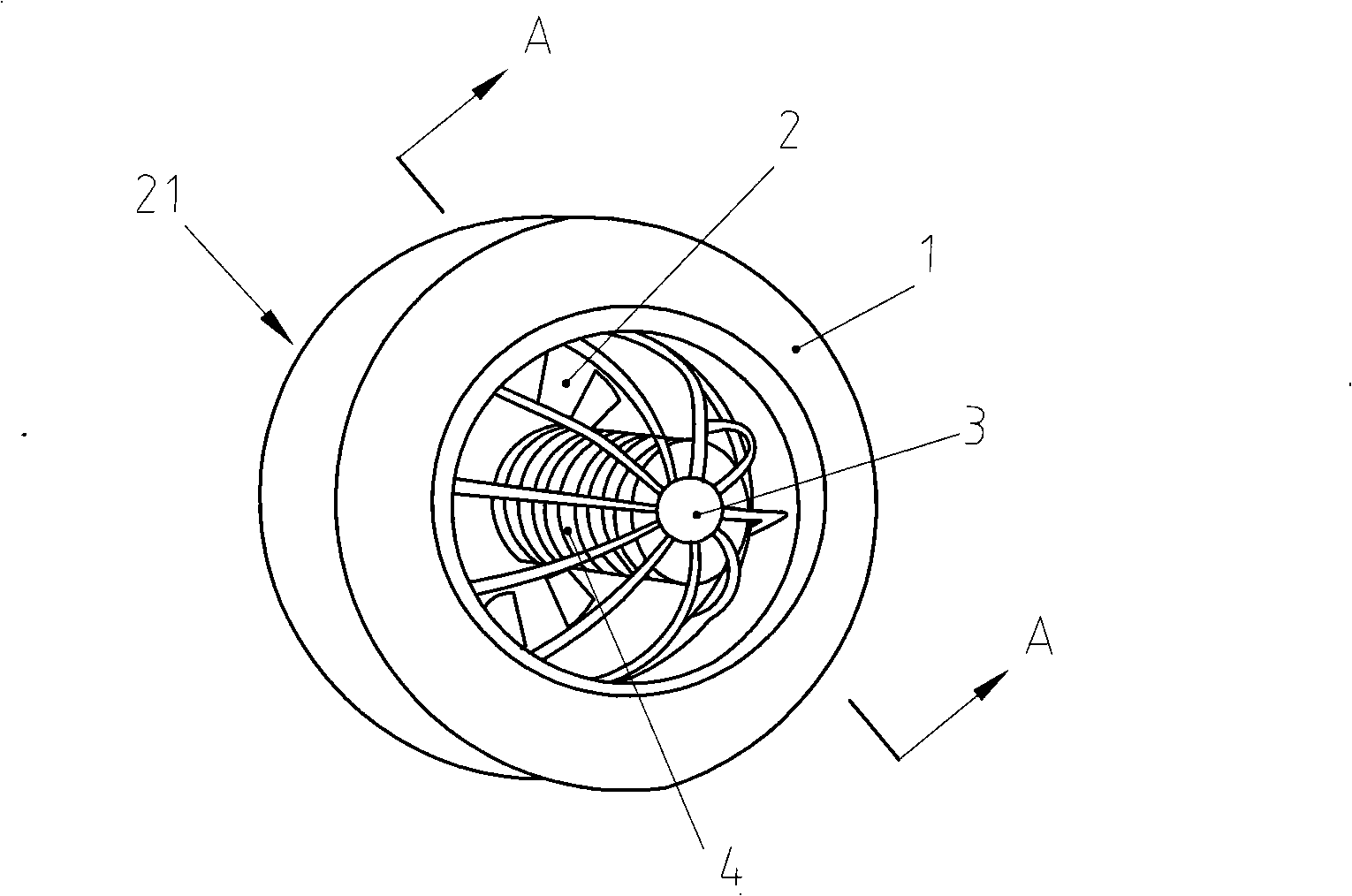

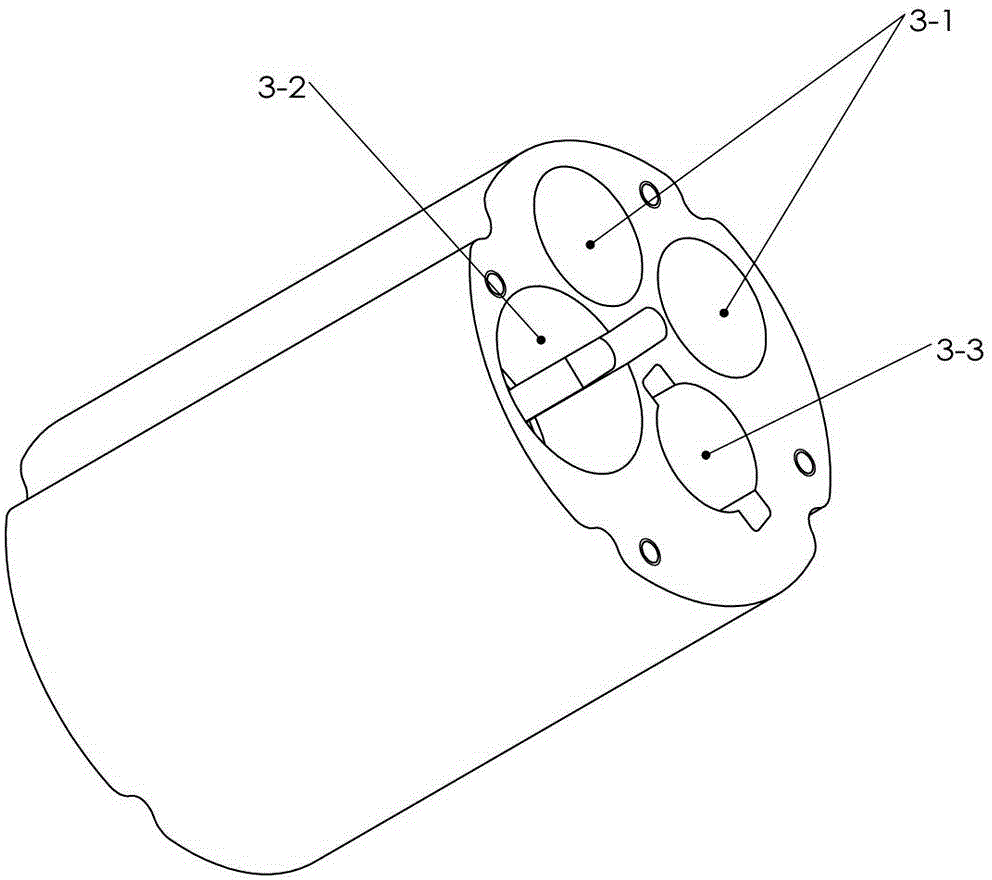

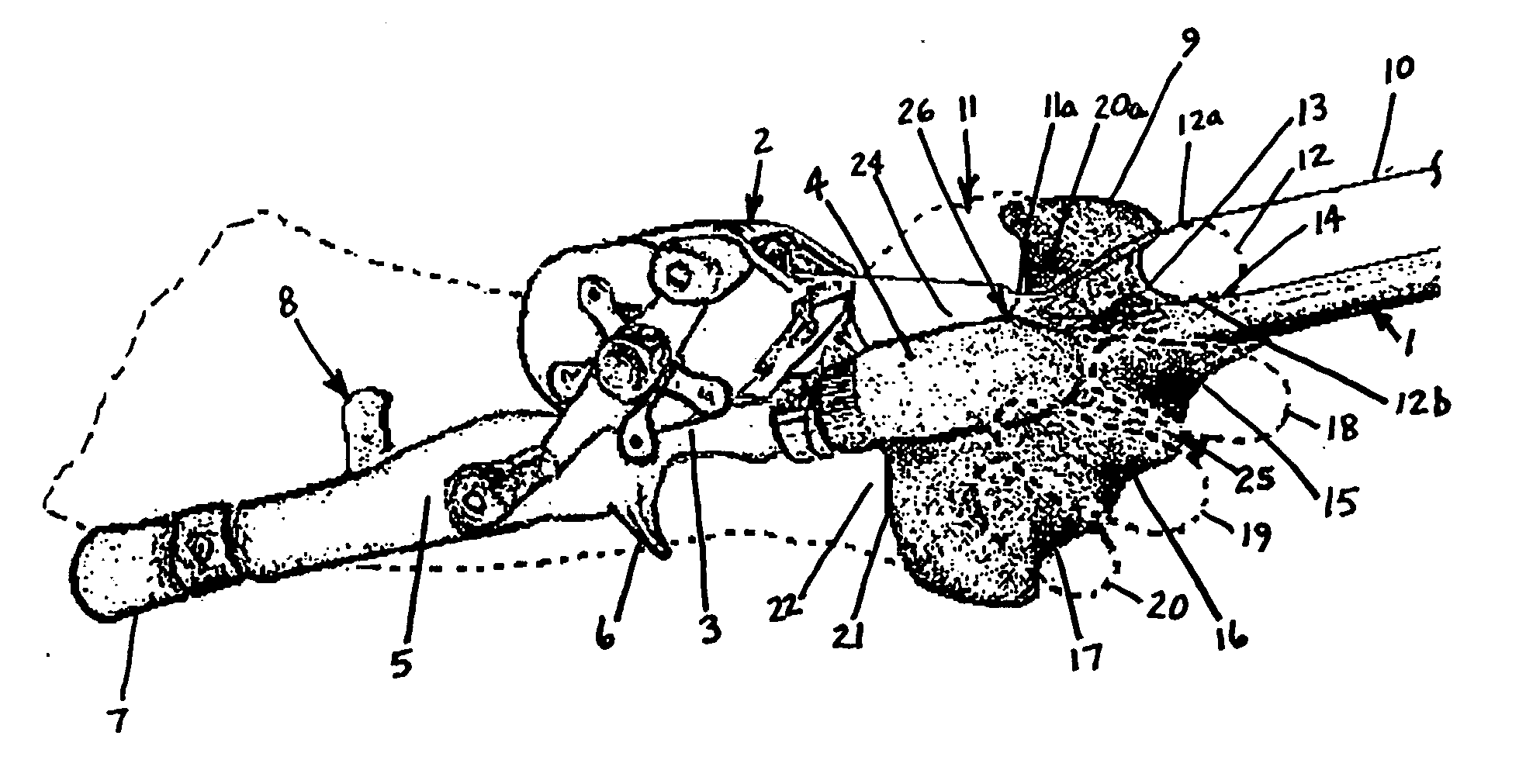

Casting type miniature robot of spring vibration reduction inflatable wheel with omnidirectional buffer capacity

InactiveCN101402198ABreak through the shortcomings of limited scope of workIntegrity guaranteedMicromanipulatorVehiclesMotor driveReduction drive

The invention discloses a throwing type microrobot with spring vibration damping inflation type wheels with omnidirectional buffering capability, which comprises a body, wheels connected on two ends of the body, and a bottom truckle arranged under the body for balancing, wherein the body is provided with an antenna, a wireless camera and a sensing module; a motor driving the two wheels to move and a speed reducer are arranged inside the body; and the wheels are the spring vibration damping inflation type wheels with the omnidirectional buffering capacity. After the microrobot is involved in a special target area and landed, the microrobot can effectively resist landing overload shock, ensure completeness of functions of the robot after the robot is landed, so that the robot can quickly enter the target area to acquire spot information and monitor important targets. The microrobot is particularly suitable for completing target monitoring and scouting tasks indoors, in caves, urban laneways and other special areas.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Casting type 3D printer

The invention relates to the field of a 3D printer, and provides the casting type 3D printer. The 3D printer comprises a 3D transmission mechanism, a Z-axis platform and a controller. The Z-axis platform is fixed on the end portion of the 3D transmission mechanism and comprises a metal or plastic smelting furnace. The metal or plastic smelting furnace comprises a feed device, a furnace body, an electric valve, a quantitative output pump and a nozzle, wherein the furnace body is used for smelting printing supplies of the 3D printer, and the controller is used for controlling the transmission of the 3D transmission mechanism, the temperature of a heating layer and the flow of the quantitative output pump. According to the technical scheme, the casting type 3D printer has the advantage of being high in printing speed.

Owner:中山科普斯特电源技术有限公司

A short-process and high-efficiency production method for brass pipes

ActiveCN102260840AReduce processHigh yieldRoll force/gap control deviceMetallic materialsCasting types

The invention belongs to the field of metal materials and relates to a short-flow efficient production method for brass tubes. The method is characterized in that: brass tube billets which have axial orientated tissue and high internal and external surface quality are produced efficiently by using the low-consumption hot and cold combination cast type continuous casting technology; the tube billets are subjected to subsequent forming directly under the condition that surfaces are not peeled, wherein intermediate annealing is not needed to be performed or only a little bit of low-temperature annealing is needed to produce the brass tubes efficiently. The hot and cold combination cast type continuous casting is characterized in that: a continuous casting crystallizer is formed by combining a hot section which is heated and a cold section which is subjected to forced cooling by circulating water, and the tube billets which are high in the quality of the surfaces and have the axial orientated tissue are prepared efficiently by controlling solidification interfaces of the tubes to be positioned nearby the junction of the hot section and the cold section. The method has the advantages of short production flow, low consumption, high yield and high production efficiency.

Owner:UNIV OF SCI & TECH BEIJING

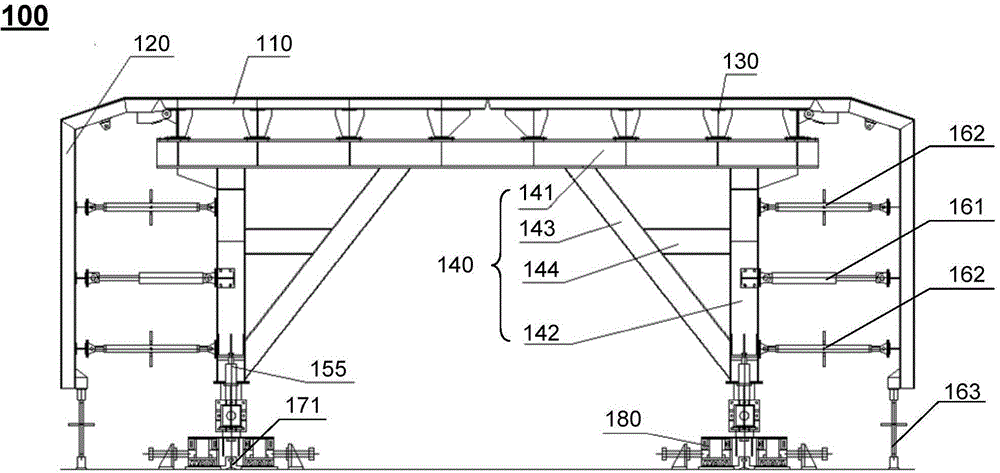

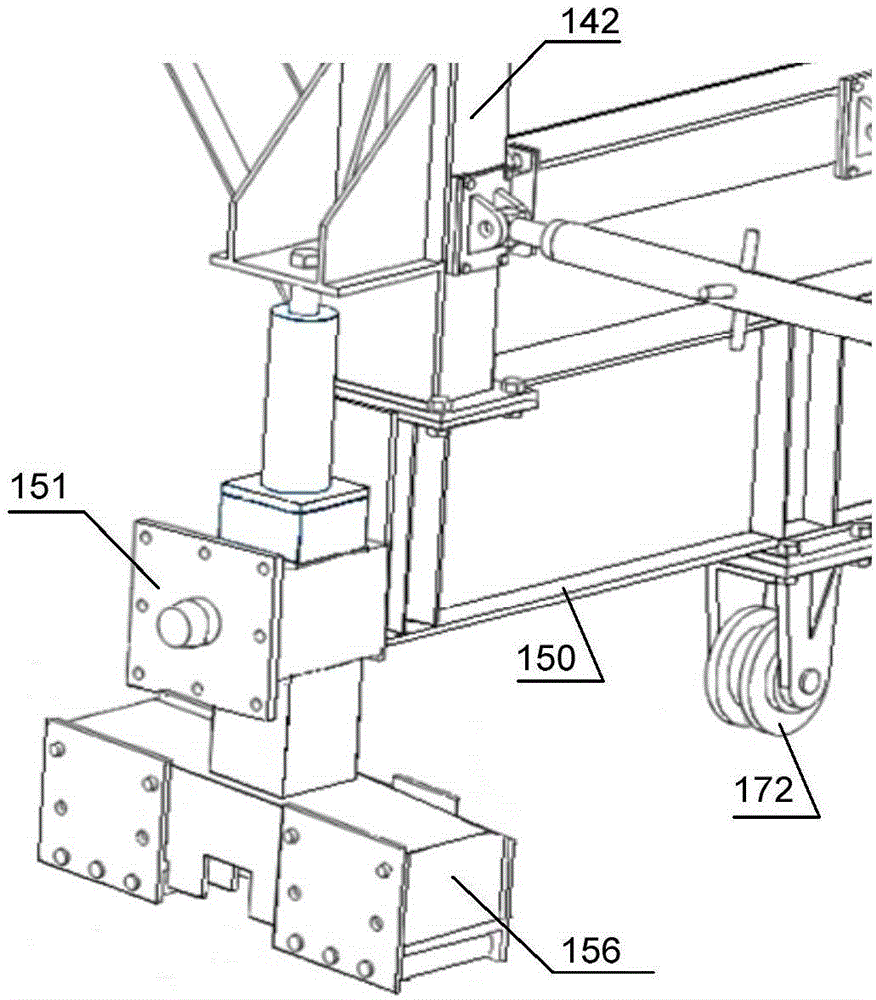

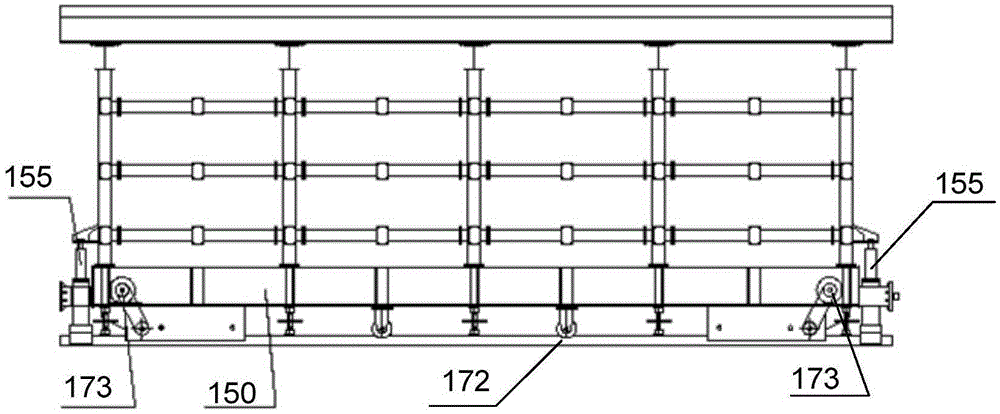

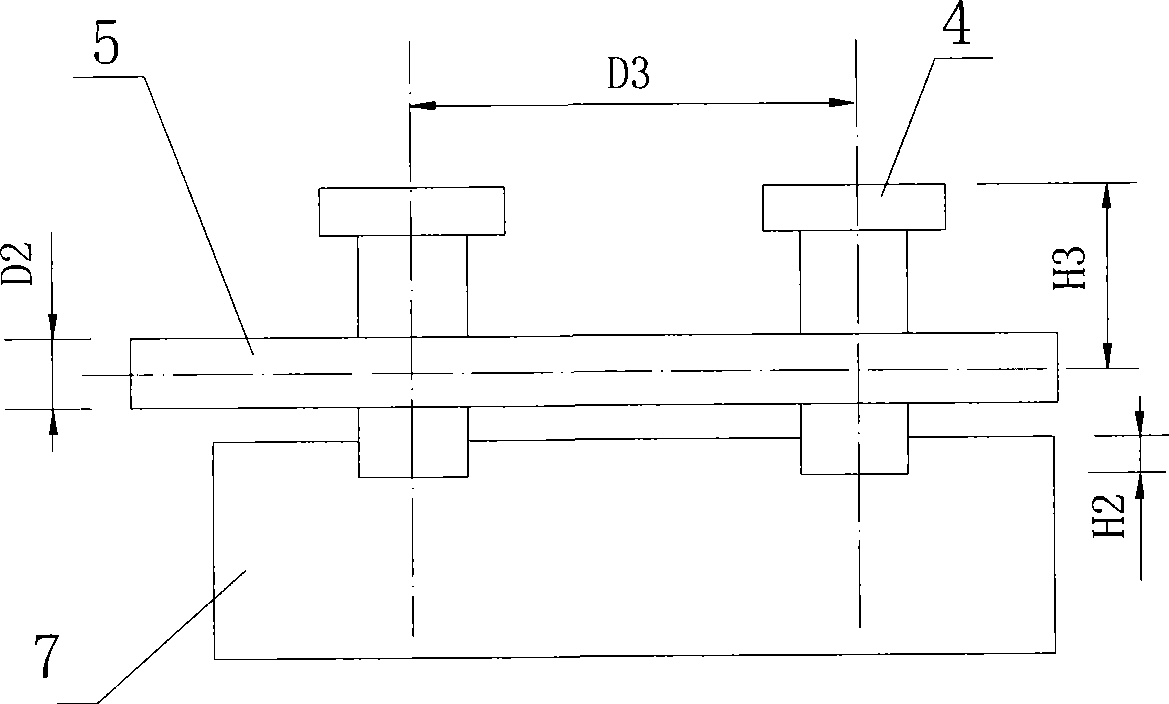

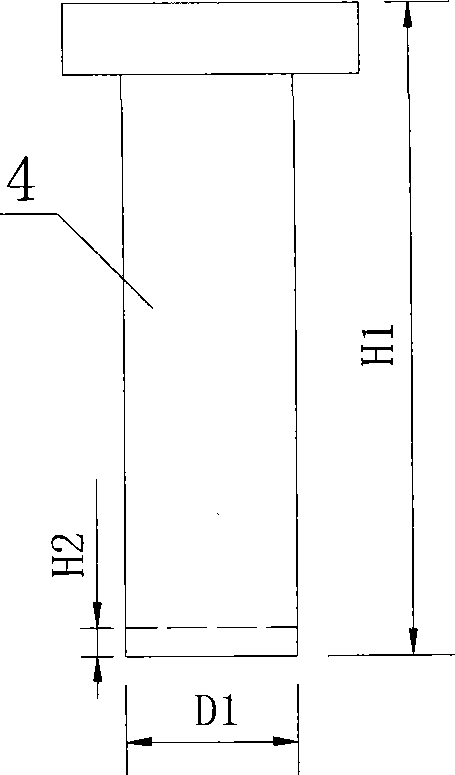

Integrally cast type mould plate trolley and construction method of concrete pouring of underground passage

InactiveCN104632251AReduce the amount of manual workReduce construction proceduresUnderground chambersTunnel liningSupporting systemMechanical equipment

The invention provides an integrally cast type mould plate trolley and a construction method of concrete pouring of an underground passage. The integrally cast type mould plate trolley adjusts a mould plate to be at a proper position through a vertical lifting device and a lateral mold release and supporting device, a mold release process and a mold supporting process are both implemented through mechanical equipment, and therefore manual workloads are greatly lightened; besides, during concrete pouring construction, a base plate and a part of side walls are formed at first to replace a supporting system below a structure roof so that the side walls and the roof of the underground passage can be formed in one shot. Therefore, construction procedures are reduced, construction efficiency is improved, and construction cost is saved.

Owner:SHANGHAI MECHANIZED CONSTR GRP

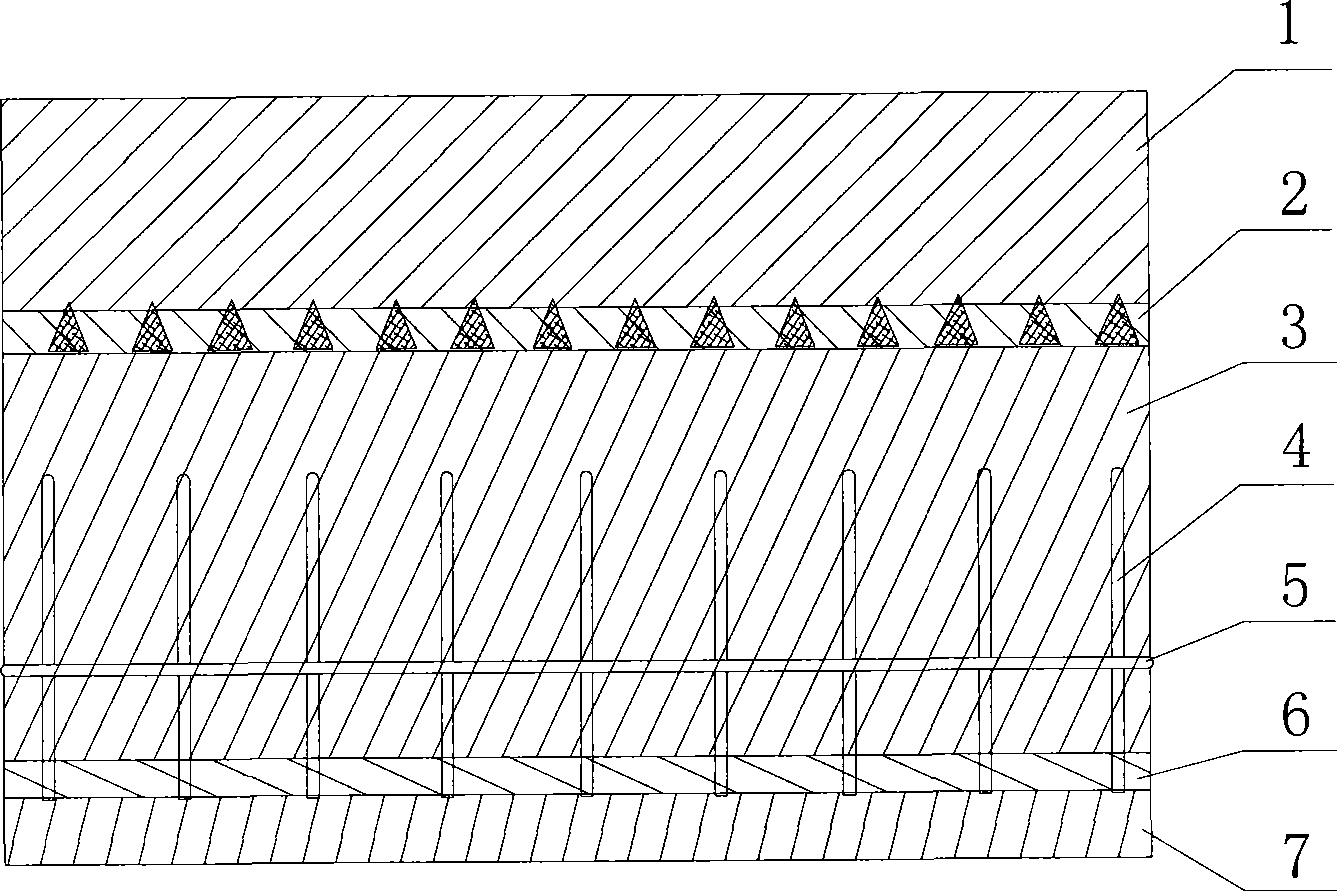

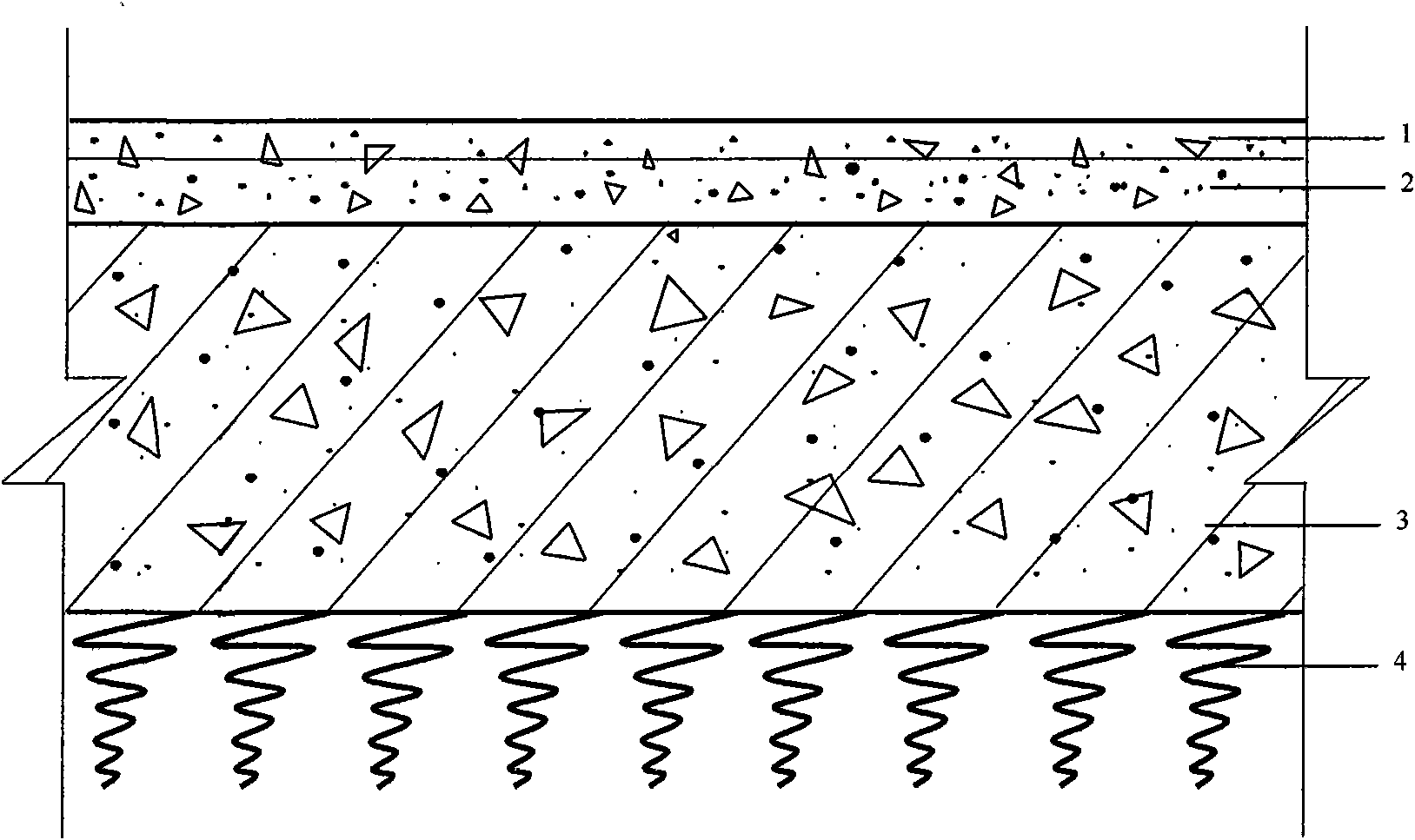

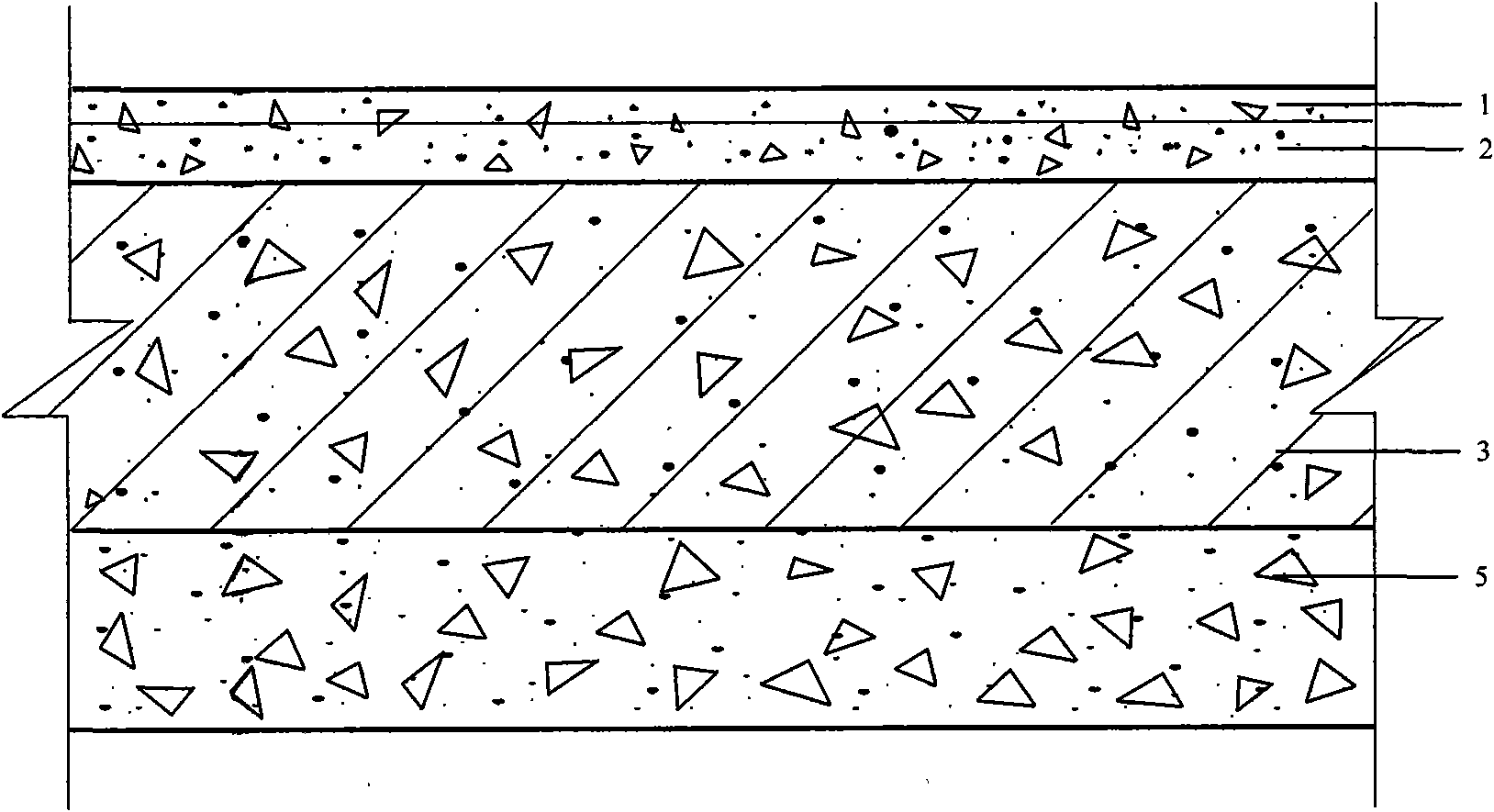

Pavement method for anti-movement composite structure of large-span steel box beam bridge deck

ActiveCN101368368AImprove bindingIncrease stiffnessIn situ pavingsBridge structural detailsSheet steelBridge deck

The invention relates to a method for paving combined anti-push structures on the surface of a large-span steel box girder bridge, including the following steps: 1) pretreating the armor plates of the large-span steel box girder bridge; 2), welding shear studs: welding shear studs on the armor plates of the large-span steel box girder bridge, with an interval at area of (35-45)cm X (35-45)cm between two shear studs; 3) colligating the reinforcement mats: fixing the reinforcement mats at specification of (95-105)cm X (95-105)cm on the shear studs; 4) mineral aggregate grading; 5)preparing and paving cast-type asphalt concrete; 6) paving a waterproof bond coat; and 7)paving anti-skid denoising wearing layer: paving a anti-skid denoising wearing layer at thickness of 3-5cm on the waterproof bond coat. The method has the advantages that cohesiveness at the interfaces is good, the paved layer and the armor plates are strong in coordinated deformability, and construction process is simple and convenient.

Owner:WUHAN MUNICIPAL CONSTR GROUP +1

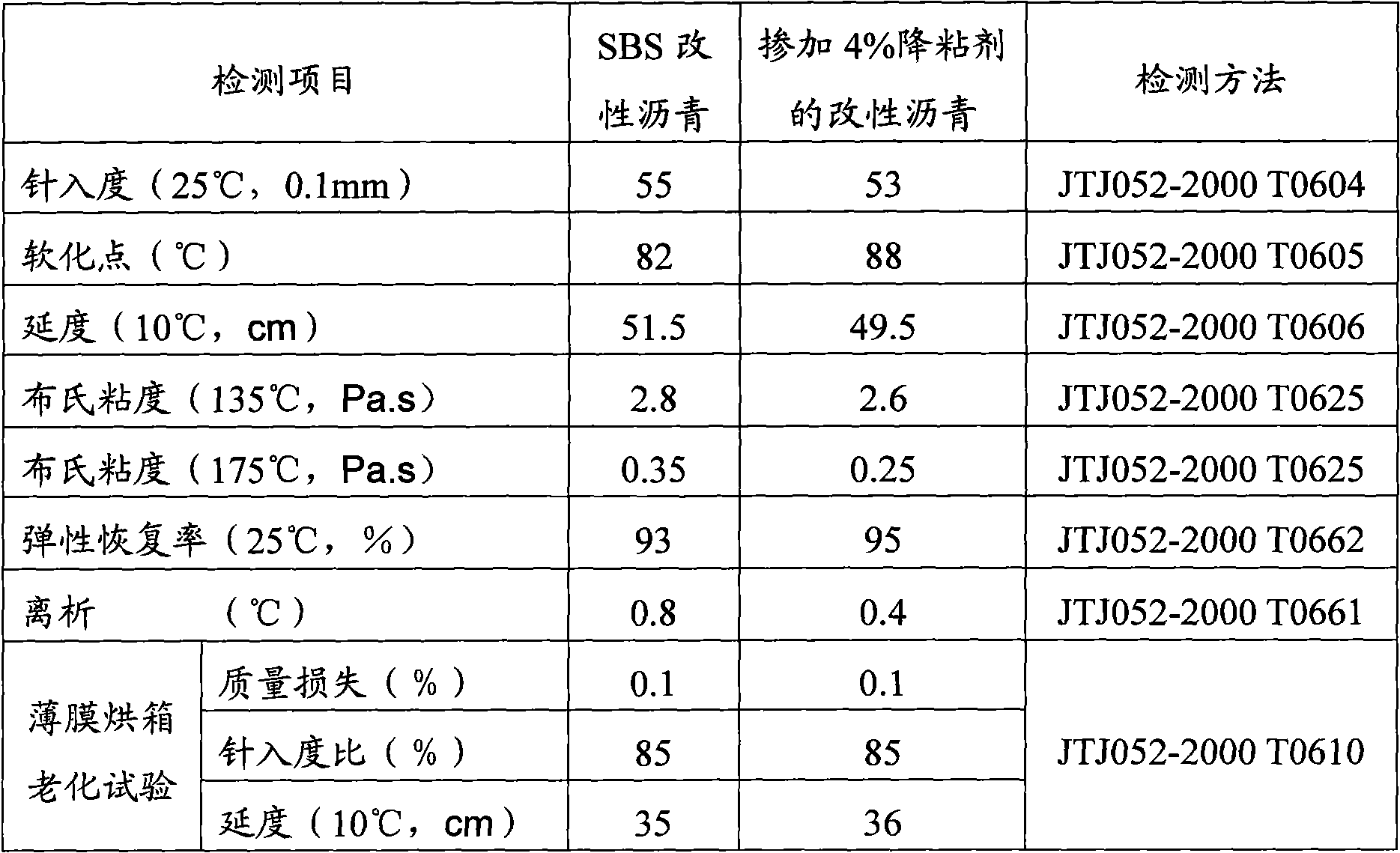

Modified asphalt viscosity decreasing agent

ActiveCN101781468AReduce high temperature viscosityImprove low temperature crack resistanceBuilding insulationsCasting typesEngineering

The invention provides a modified asphalt viscosity decreasing agent which relates to a paving material for roads, bridges and tunnels. The viscosity decreasing agent is prepared from the following components in parts by weight: 4-20 parts of organic acid, 1-30 parts of surface active agent, 5-80 parts of synthesis paraffin, and 1-30 parts of compatilizer. After the viscosity decreasing agent is doped, the high-temperature viscosity of the modified asphalt is greatly decreased, while other various indexes are not changed. Simultaneously, compared with the common modified asphalt, after the viscosity decreasing agent is doped, the concrete stirring temperature, low-temperature property and fatigue property of the casting type asphalt are greatly improved. The invention is mainly used for road petroleum asphalt and SBS modified asphalt.

Owner:重庆市智翔铺道技术工程有限公司

Cast-type concrete abrasion-resistant ground and construction method thereof

InactiveCN101654951AImprove impact resistanceHigh resistance to oil seepageFlooringReinforced concreteSurface layer

The invention relates to the field of building construction, in particular to a cast-type concrete abrasion-resistant ground and a construction method thereof. The cast-type concrete abrasion-resistant ground consists of a compacted plain soil basic layer (or an original concrete basic layer), a cast reinforced concrete layer and an abrasion-resistant ground surface layer, and is characterized inthat the cast reinforced concrete layer is covered on the compacted plain soil basic layer (or an original concrete basic layer), and the abrasion-resistant ground surface layer is covered on the castreinforced concrete layer. As far as the prior various common concrete grounds, the requirements on the strength, the flatness and the flexibility of the basic concrete are all higher than the present national construction specification standard, thereby the effect of the abrasion-resistant ground is greatly improved, and the service life of the abrasion-resistant ground is prolonged. The invention has the characteristics and advantages of high impact resistance, high oil-leakage resistance capacity, convenient construction, short period, favorable integrity, dust reduction, easy cleaning, beautiful appearance, inherent color, low cost, and the like.

Owner:魏勇

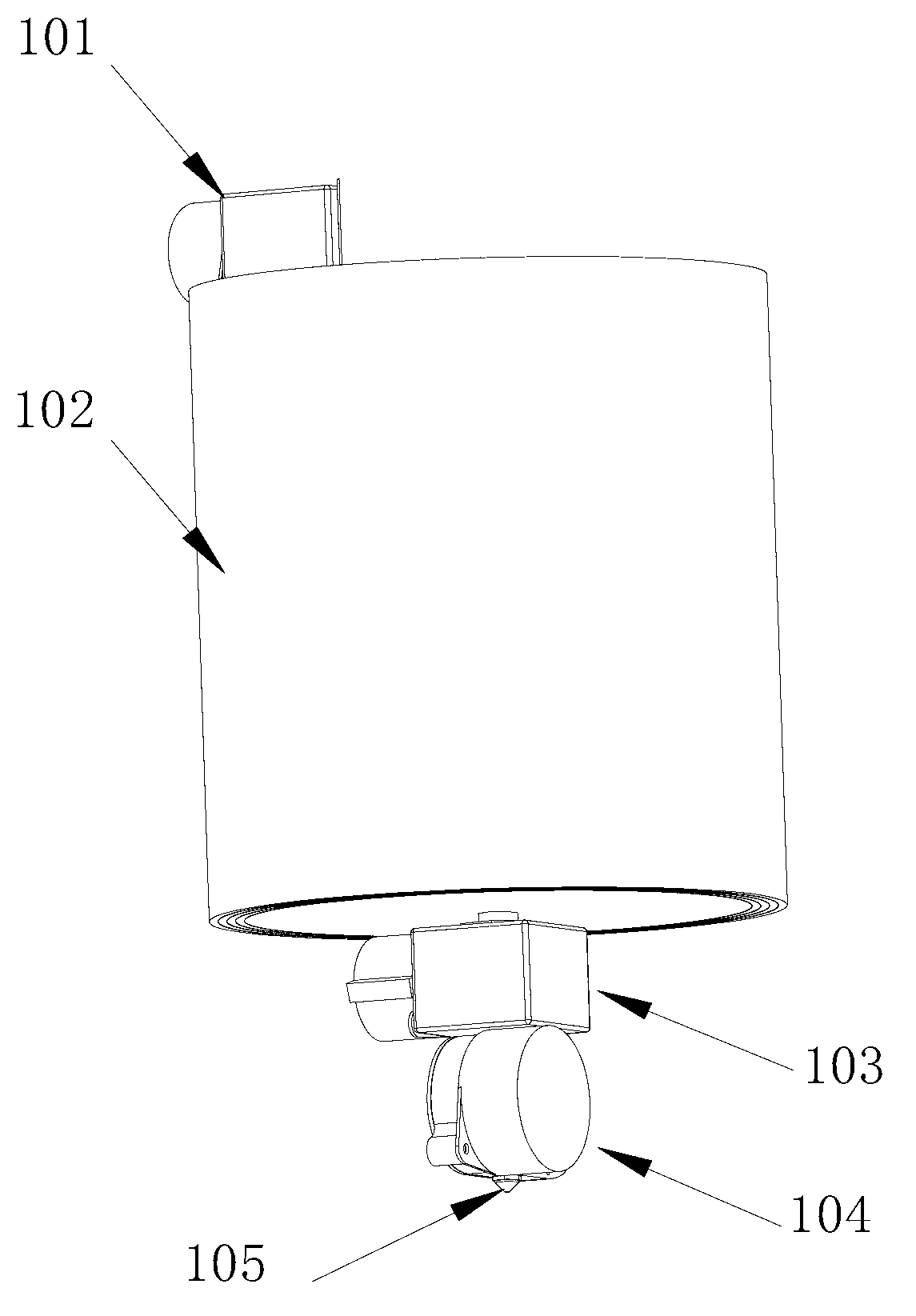

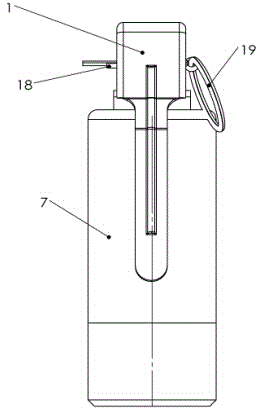

Hand casting type simulation bomb for training

InactiveCN104089545ATraining to ensureImprove training effectivenessTraining ammunitionSimulationSound production

The invention relates to a hand casting type simulation bomb for training and belongs to the field of military teaching training tools. The hand casting type simulation bomb for training comprises a simulation anti-riot bomb and a simulation hand grenade, wherein the simulation anti-riot bomb comprises a shape simulation shell, a secure structure, a delayed explosion starting mechanism and a blank cartridge, and the simulation hand grenade is composed of a shape simulation shell, a handle, a pull wire, a delayed explosion starting mechanism and a blank cartridge. The hand casting type simulation bomb for training has the advantages that live ammunition explosion starting motions and explosion starting delaying can be simulated, and the sound production, smoke production and misoperation alarming functions are achieved; furthermore, the hand casting type simulation bomb does not have the live ammunition demage effect, and the performance of the simulation anti-riot bomb (hand grenade) for teaching training is safe and reliable. The hand casting type simulation bomb for training has important application value and practical significance on ensuring military police unit training safety, improving training benefits, reducing training consumption and shortening a fighting capacity generating cycle.

Owner:亓开

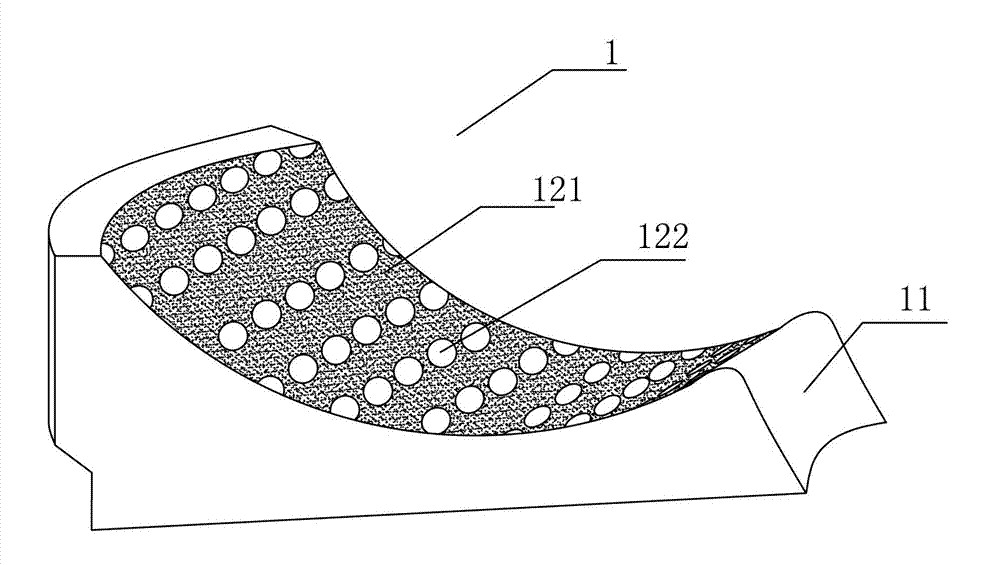

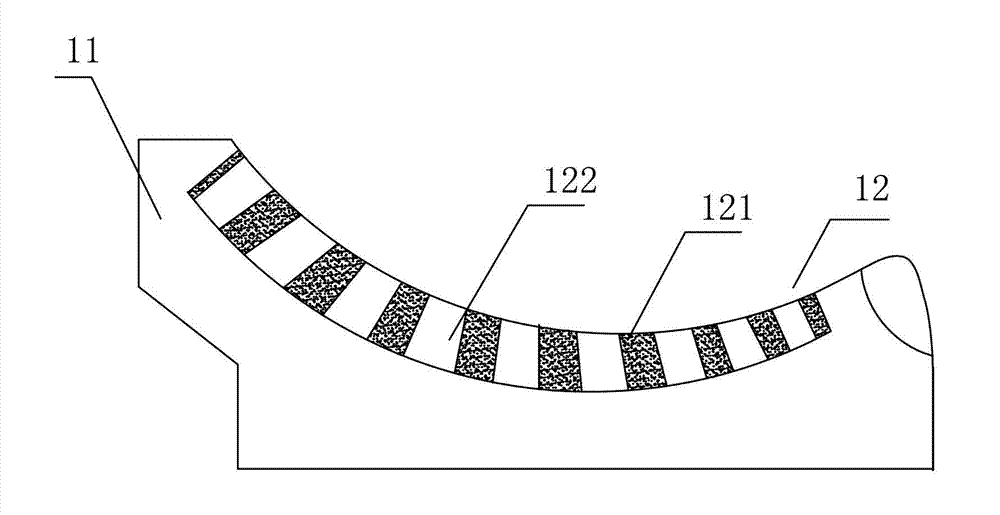

Lost foam casting type composite wear-resistant component and casting method thereof

ActiveCN103203428AAnti-wear self-protectionEvenly distributedFoundry mouldsFoundry coresWear resistantCasting types

The invention discloses a lost foam casting type composite wear-resistant component and a casting method of the lost foam casting type composite wear-resistant component. The wear-resistant component comprises a metallic substrate part and a working layer part, wherein the metallic substrate part is provided with concave part; the working layer part, the metallic substrate part are cast into a whole and the working layer part is filled into the concave part; reinforced particles are uniformly distributed on the working layer part; and the reinforced particles are wrapped with molten metal which flows around the reinforced particles during integrated casting and then is solidified, so as to be fixed on the working layer part. The composite wear-resistant component has wear-resistant and self-protective effects, and is capable of preventing possible cracks from expanding in a ceramic working layer; therefore, the wear resistance is improved, and the service life is prolonged. Compared with cast-in type reinforced particles, the reinforced particles disclosed by the invention have higher yield, are hardly influenced by the casting temperature and speed; simultaneously, the reinforced particles are distributed more uniform in the metal substrate; in addition, the casting method is simple to operate, short in production period and low in cost, and materials can be saved.

Owner:BEIJING POWER EQUIP GRP

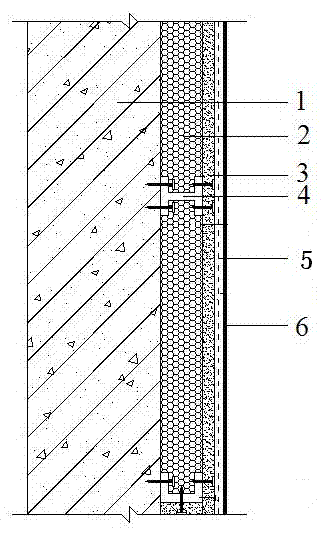

Casting type fireproof external wall insulation system and construction method thereof

ActiveCN102852332ADoes not affect the decorative effectControl construction qualityWallsBuilding material handlingCement boardCasting types

The invention discloses a casting type fireproof external wall insulation system and a construction method thereof. The casting type fireproof external wall insulation system comprises a wall base layer, a thermal insulation layer, a metal anchoring connecting piece, a fiber cement board, a flexible anti-crack layer and a finishing layer, wherein the thermal insulation layer is positioned between the wall base layer and the fiber cement board and is cast by an inorganic thermal insulation material in times; the wall base layer, the thermal insulation layer and the fiber cement board are connected into a whole through the metal anchoring connecting piece; the flexible anti-crack layer is compounded on the outer side of the fiber cement board; and the finishing layer is positioned on the outer side of the flexible anti-crack layer. The casting type fireproof external wall insulation system has the characteristics of firm and reliable structure, high fireproof performance, high wall decoration property, crack difficulty, environment friendliness, economical construction cost, convenient installation, rapid construction and the like.

Owner:CHANGZHOU ARCHITECTUAL RES INST GRP CO LTD +1

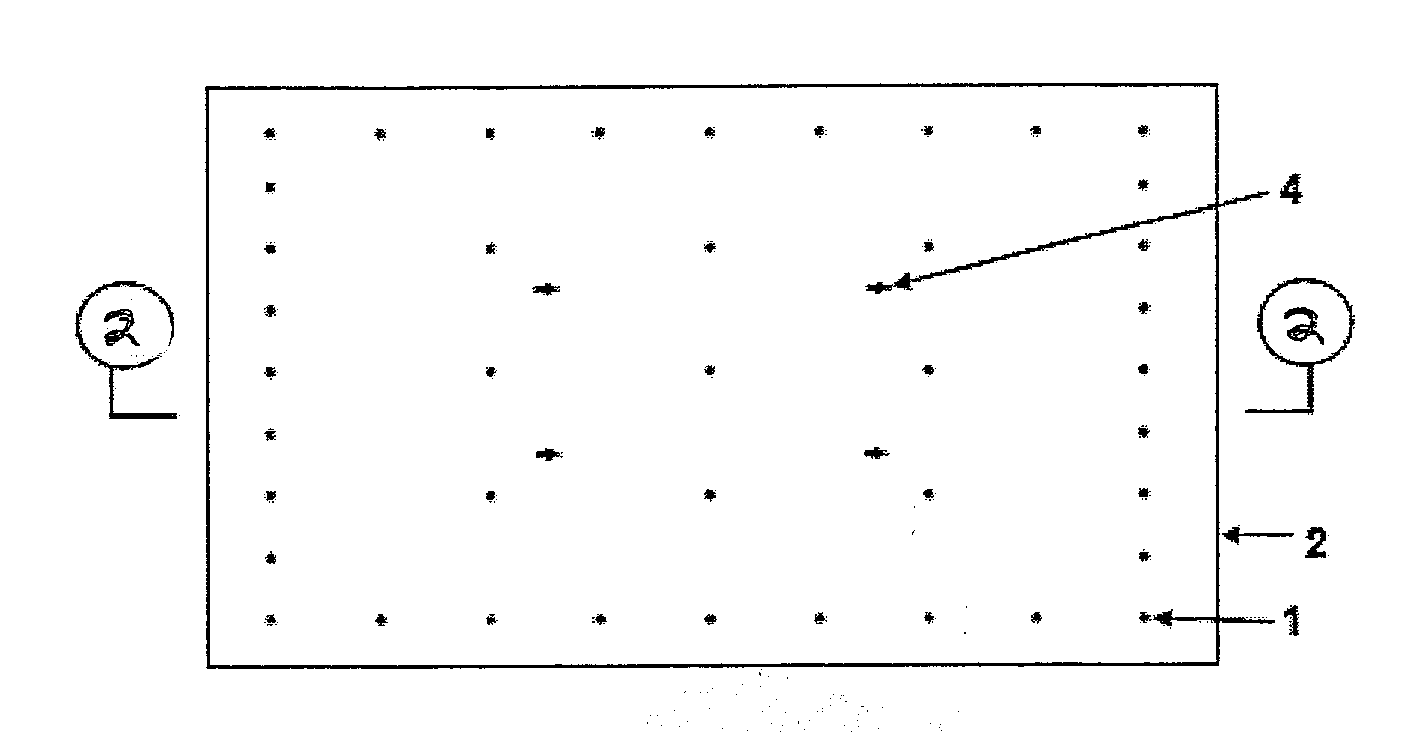

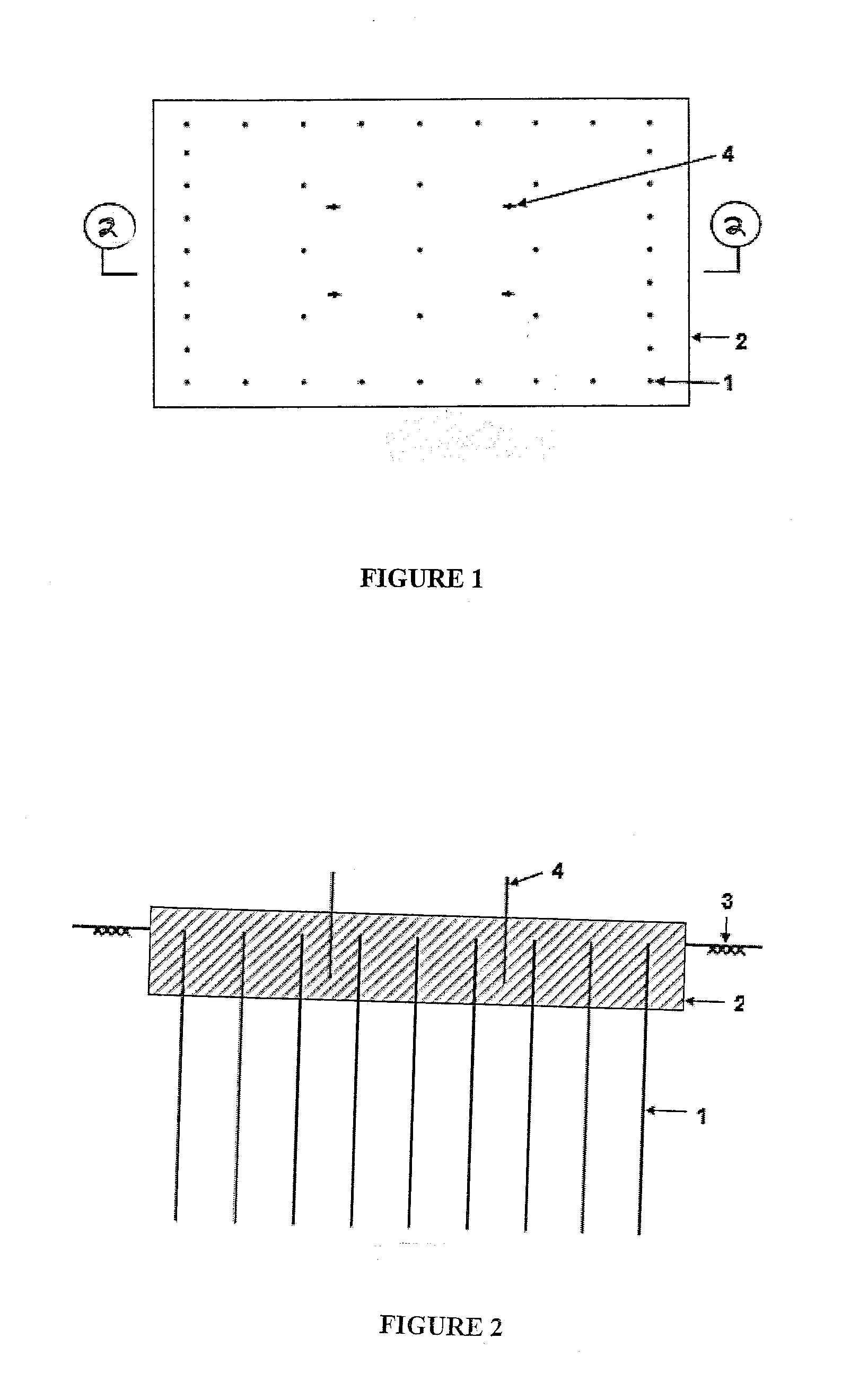

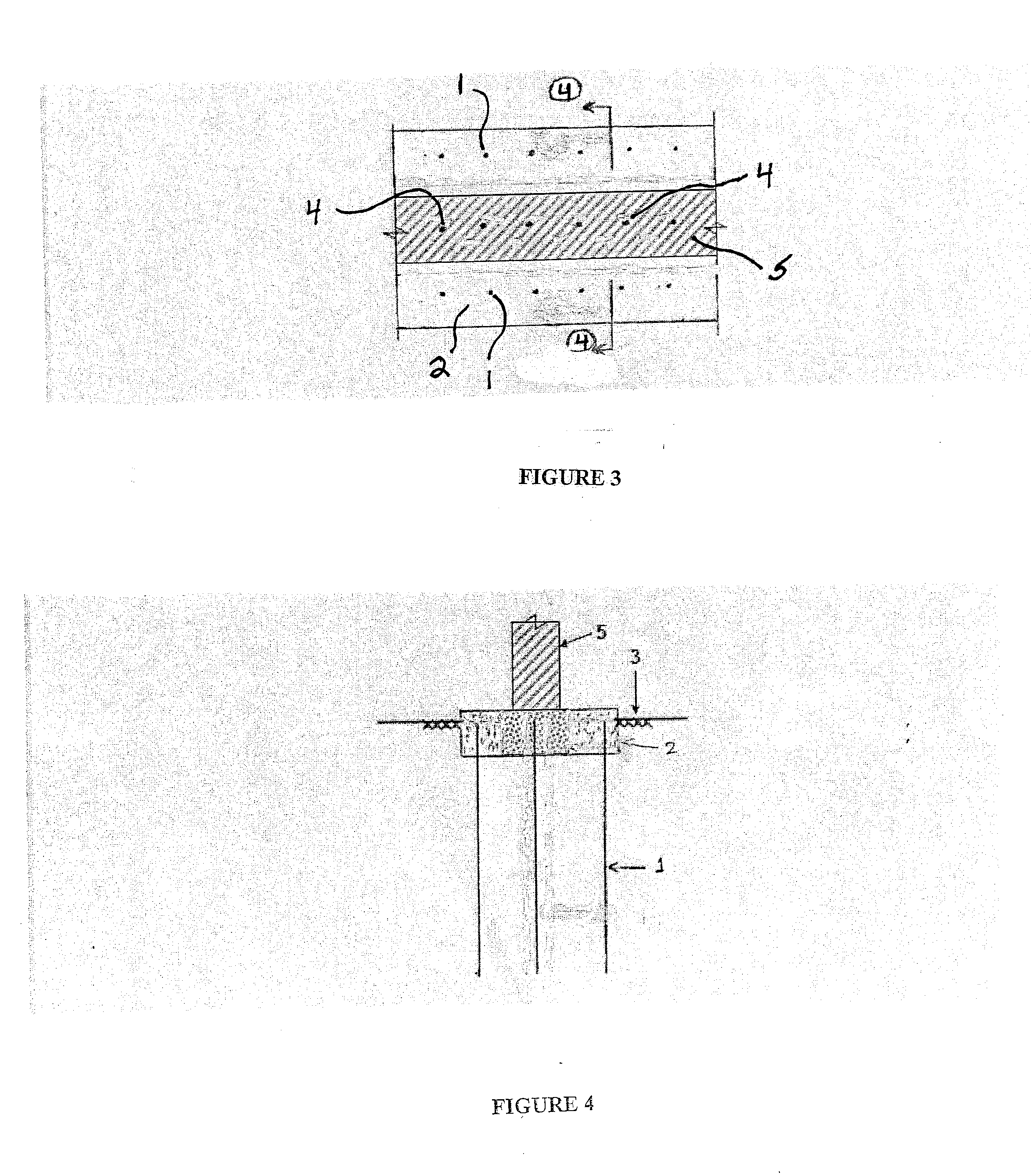

Soil anchor footing

InactiveUS20140161539A1Light weightLow production costProtective foundationBulkheads/pilesSupporting systemBrick

The present invitation relates to a soil anchor footing supporting system within the ground surface to support steel or concrete column, brick or block wall, light post, sign post, substation equipment, pre-cast panel, retaining wall etc. It comprises of a footing slab (2) made of concrete; plurality of deformed steel bars (1) or fiber reinforced polymer (FRP) bars embedded in the lower surface of the concrete slab (2) and plurality of anchor bolts (4) or reinforcing starter bars which are embedded into upper surface of concrete slab (2) to suit steel or concrete column. The bars, which act as mini piles, are configured for ground penetration and a concrete slab is cast on top to encase all the bars and is capable of holding desired loads. These footings can be cast-in-situ type where the bars are pushed into ground (3) individually or in groups and concrete is cast on top, or it can be pre-cast type where, the whole footing is pushed into ground using pile driving equipment or mobile press.

Owner:ARYA ANOOP KUMAR

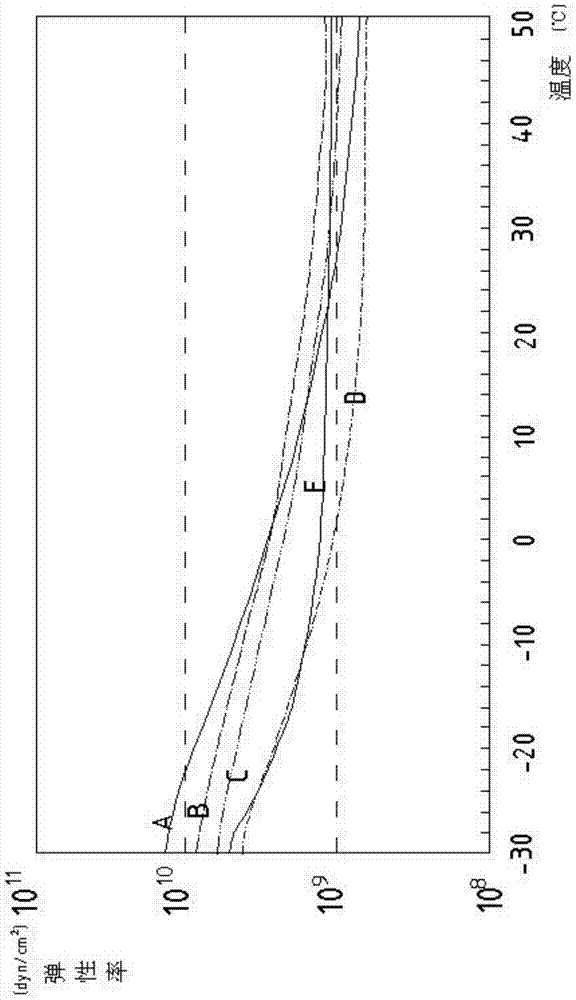

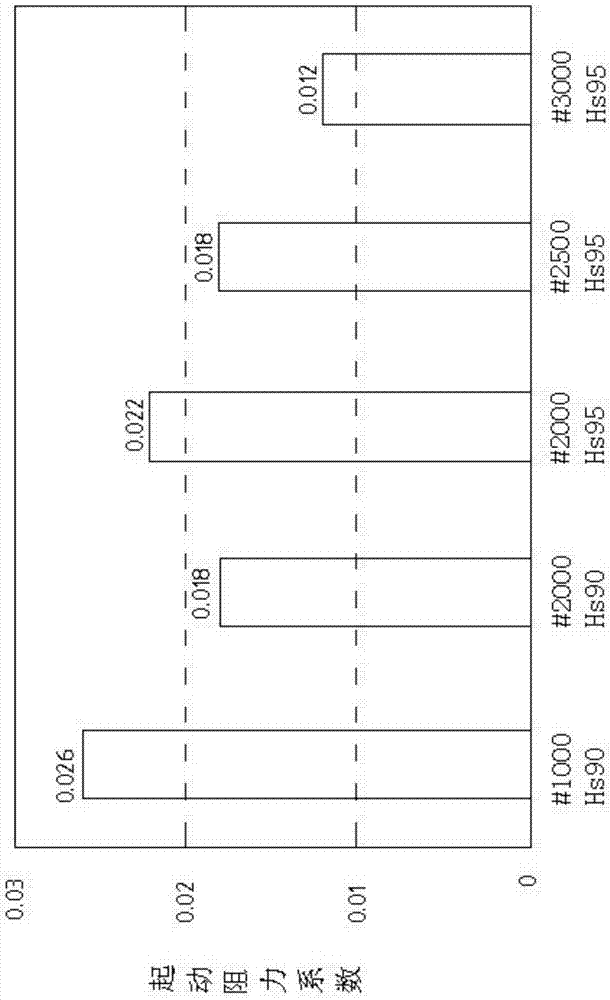

Wearing resistance enhanced pouring type urethane elastomer composition

A cast type polyurethane elastomer compound with improved abrasion resistance consists of two constituents of a prepolymer and an aroma diamine curing agent. MDI / TDI-80 cross blending diisocyanate reacts with polyester polyol at a temperature of between 70 to 90 DEG C to obtain a prepolymer containing 3 to 5 percent of isocyanic acid radical. The invention adopts the MDI / TDI-80 cross blending diisocyanate to replace TDI-80, thereby improving the abrasion resistance of a TDI-80 type polyurethane elastomer.

Owner:SHANDONG INOV POLYURETHANE

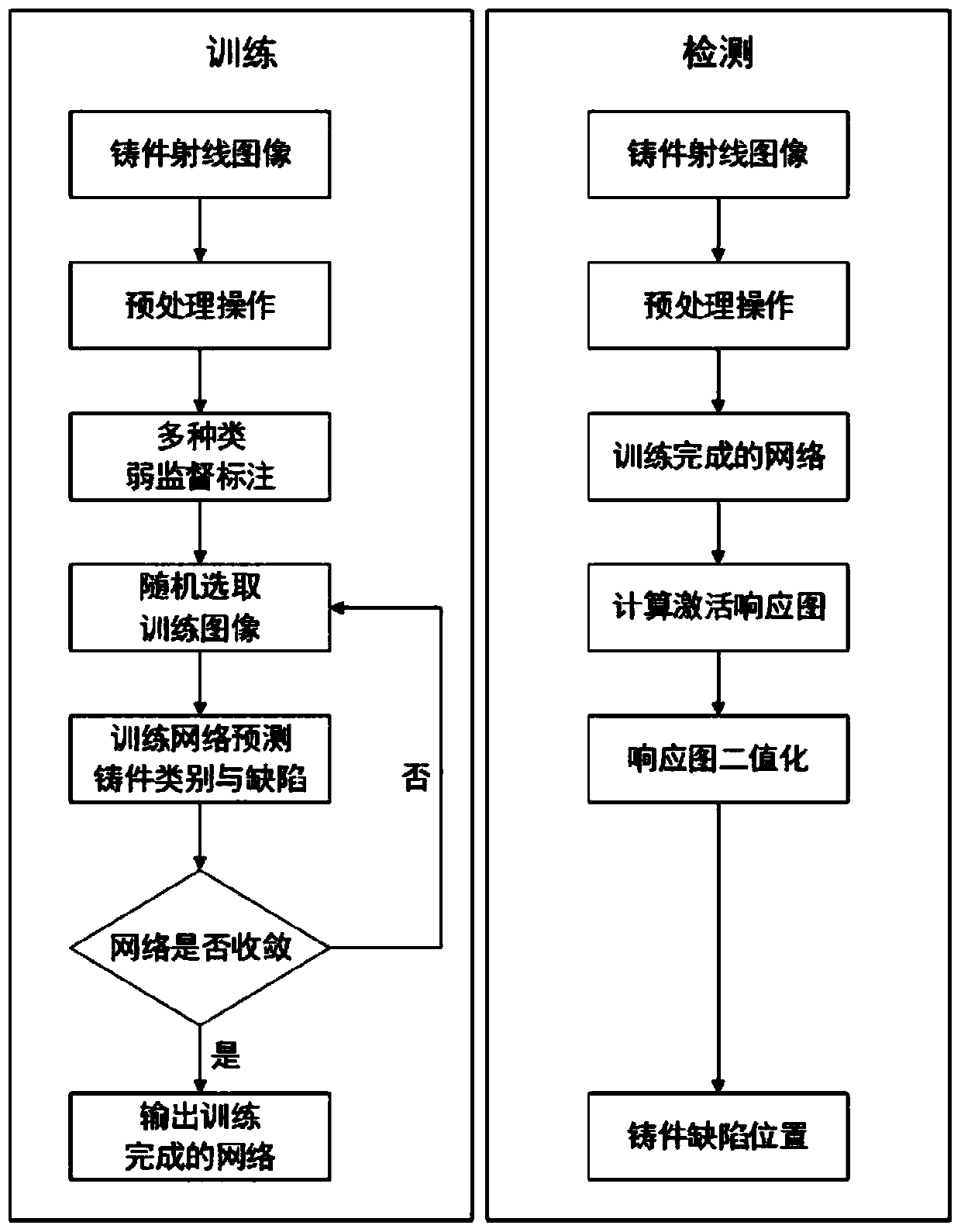

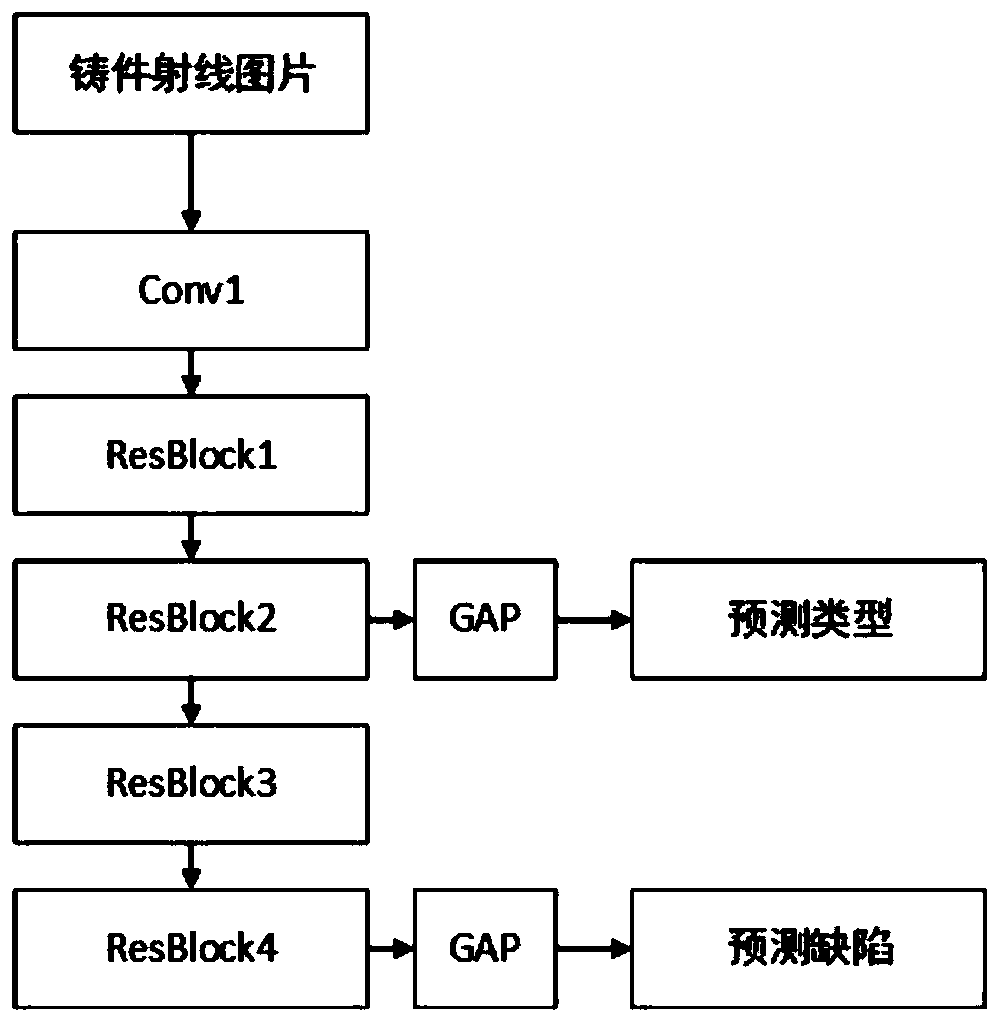

Weakly supervised casting defect recognition method based on attention mechanism

PendingCN110648310AReduce labor costsGuaranteed defect recognition rateImage enhancementImage analysisEngineeringNetwork model

The invention relates to a weak supervision casting defect recognition method based on an attention mechanism. The method comprises the following steps: firstly obtaining a ray image of a casting, carrying out the multi-label weak marking of the casting types and defects in the image, and forming a training set; and then training a ResNe-50 network model on the training sample set, forming an attention mechanism by utilizing multi-label information, enabling the model to accurately identify casting defects under the condition of weak supervision, and then calculating an activation mapping graph to obtain accurate positions of the defects. According to the method, under the condition that the casting defect recognition accuracy is guaranteed, the manpower consumption of labeling data is reduced, and finally the production cost is reduced.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

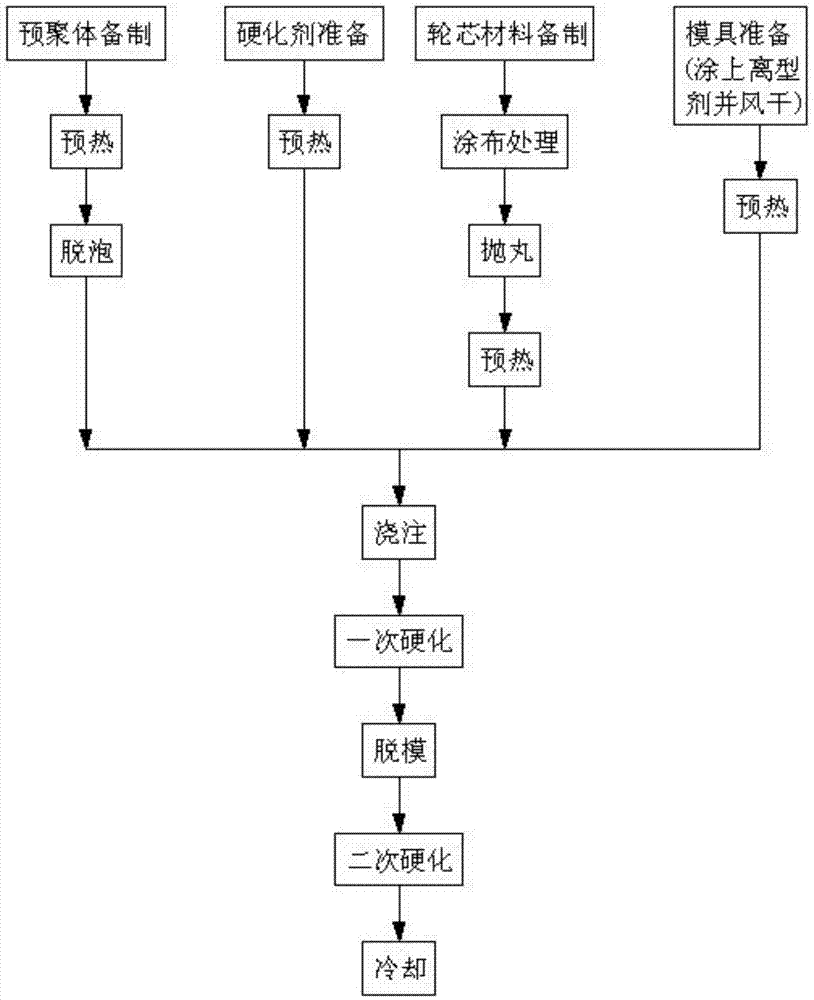

Preparation process of vacuum epoxy resin casting type mutual inductor

InactiveCN104319088AImprove permeabilityImprove compactnessTransformersInductances/transformers/magnets manufactureInductorCasting types

The invention provides a preparation process of a vacuum epoxy resin casting type mutual inductor. The preparation process comprises the following steps of (1) winding a primary winding and a secondary winding on a mutual inductor iron core; (2) fully drying a mutual inductor iron core winding and a part die; (3) mounting the dried mutual inductor part in a die, and after moving the die into a vacuum can, vacuumizing the die; (4) preheating an injection molding material, and casting the injection molding material into the die; (5) stopping and vibrating the vacuum can; (6) changing the vacuum state into a normal-pressure state; (7) taking the die out, and after performing a post curing process, opening the die. The preparation process has the beneficial effects that due to the fact that the injection molding material is preheated in advance, bubbles are prevented from being generated during product injection molding, and local discharging amount of a product is increased; due to the fact that the injection molding material in the vacuum can is vibrated by an electromagnetic vibrator, the infiltration filling property and the compaction degree of the injection molding material are greatly improved, and the electric appliance insulating property and the mechanical strength of the mutual inductor are greatly improved.

Owner:TIANJIN BINHAI NEW TECH ELECTRIC

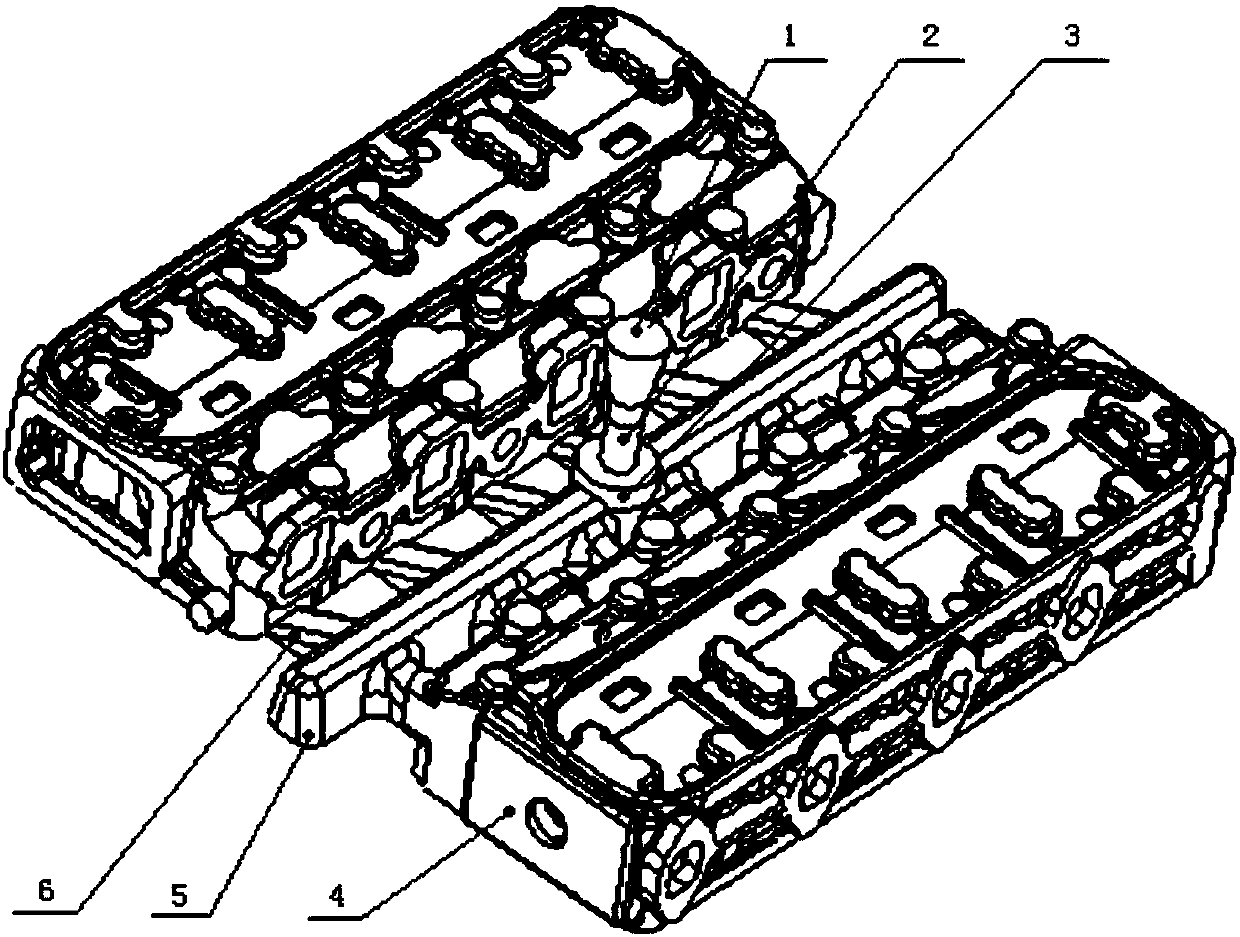

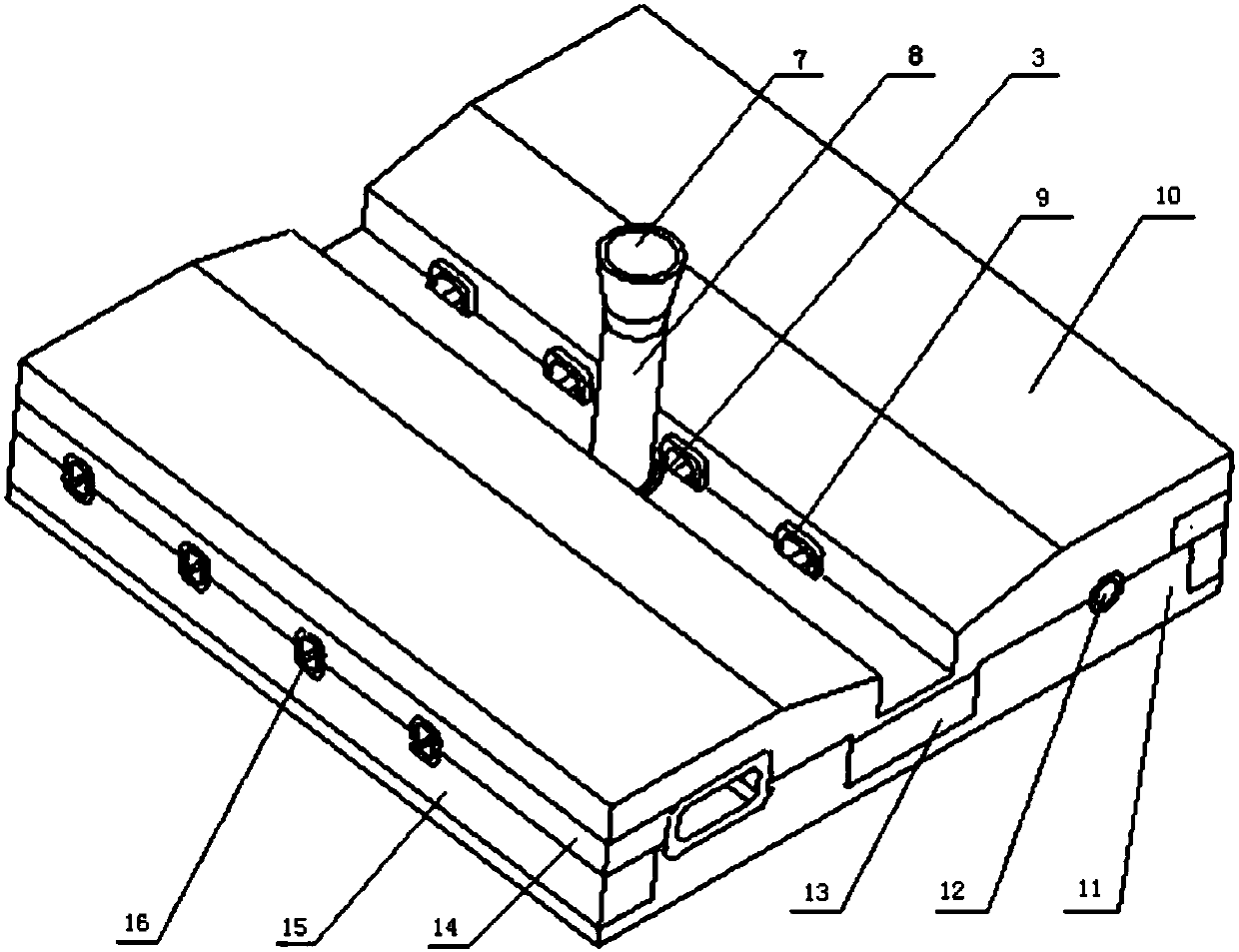

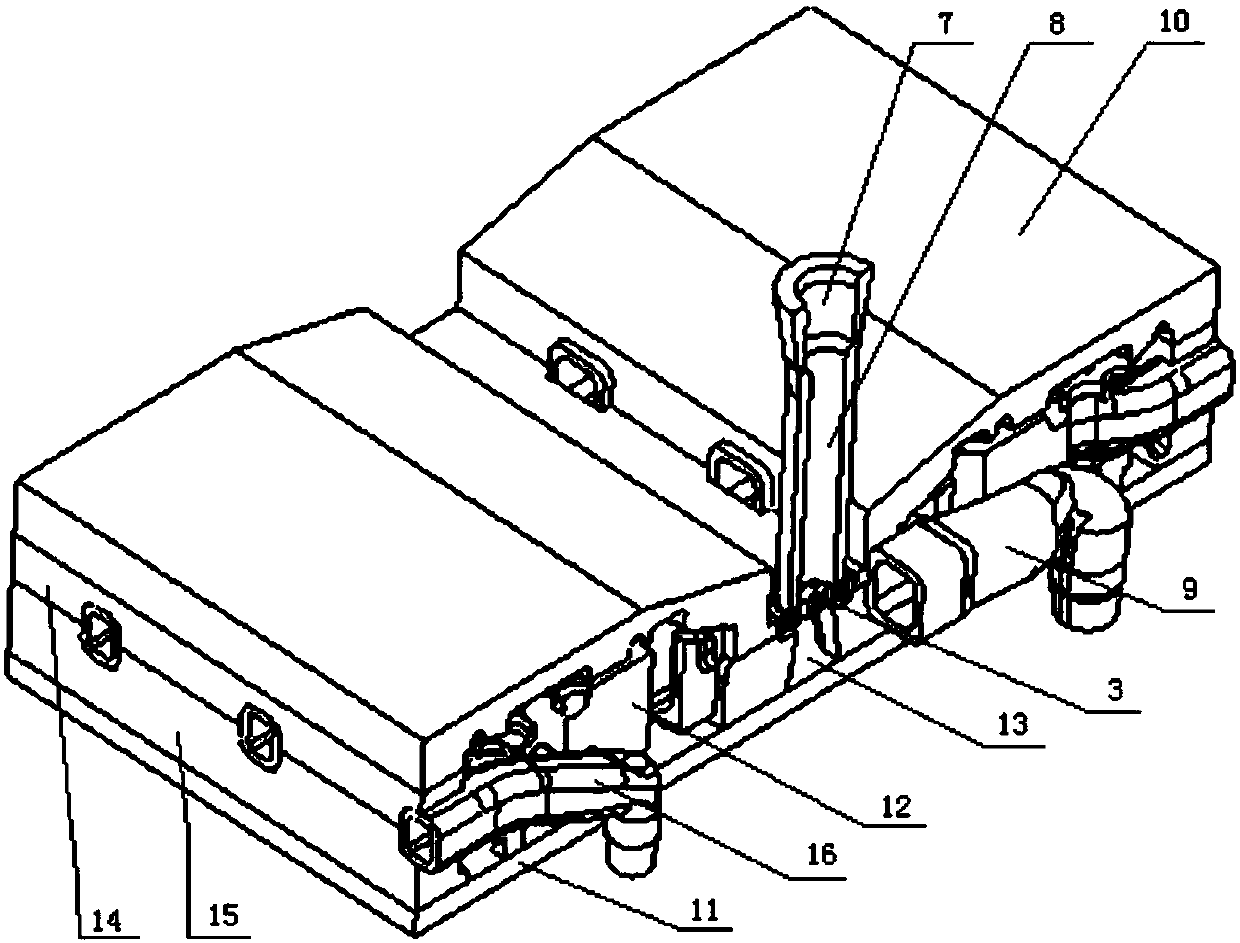

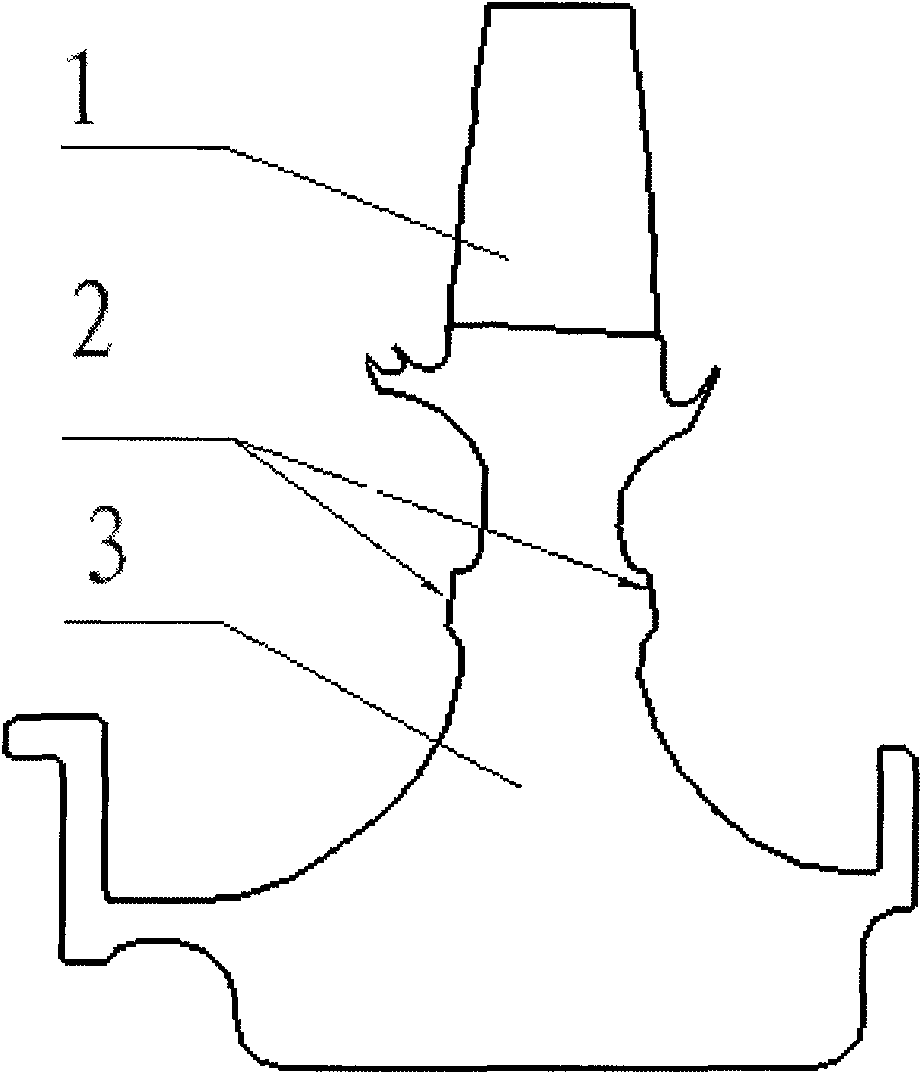

Forming method of cylinder cover

ActiveCN107900284AIncrease stiffnessSmall amount of feedFoundry mouldsFoundry coresInlet channelAlloy

The invention relates to a forming method of a cylinder cover, which is simple and convenient in process and good in effect. Manufacturing of an upper outer mold shell and a lower outer mold shell isas follows: a template is preheated to 180 to 220 DEG C, a coating film naturally falls into a forming cavity formed by the template and a sand blocking frame, the template is continuously heated to 250 to 260 DEG C and heat is preserved for 680 to 760 seconds; manufacturing of gas inlet channel shell cores and gas exhausting channel shell cores is as follows: a mold cavity is preheated to 180 to250 DEG C, film coating sand naturally falls into a core box mold cavity, the mold cavity is continuously heated to 275 to 285 DEG C and heat is preserved for 50 to 70 seconds; manufacturing of cooling water cavity solid cores, a pouring cup, a straight pouring gate, a transverse-inner pouring gate, an exhausting channel side upper core base solid core and an exhausting channel side lower core base solid core is as follows: the mold cavity is preheated to 180 to 260 DEG C, the film coating sand is blown into the mold cavity, the mold cavity is continuously heated to 280 to 290 DEG C and heat is preserved for 90 to 110 seconds; a film coating sand casting type structural component is subjected to coating, drying and assembling; a casting mold is modeled; alloy is smelted and inoculation isconducted; and gravity casting, solidification and separation are conducted. The forming method of the cylinder cover is suitable for manufacturing the cylinder cover.

Owner:贵州英吉尔机械制造有限公司

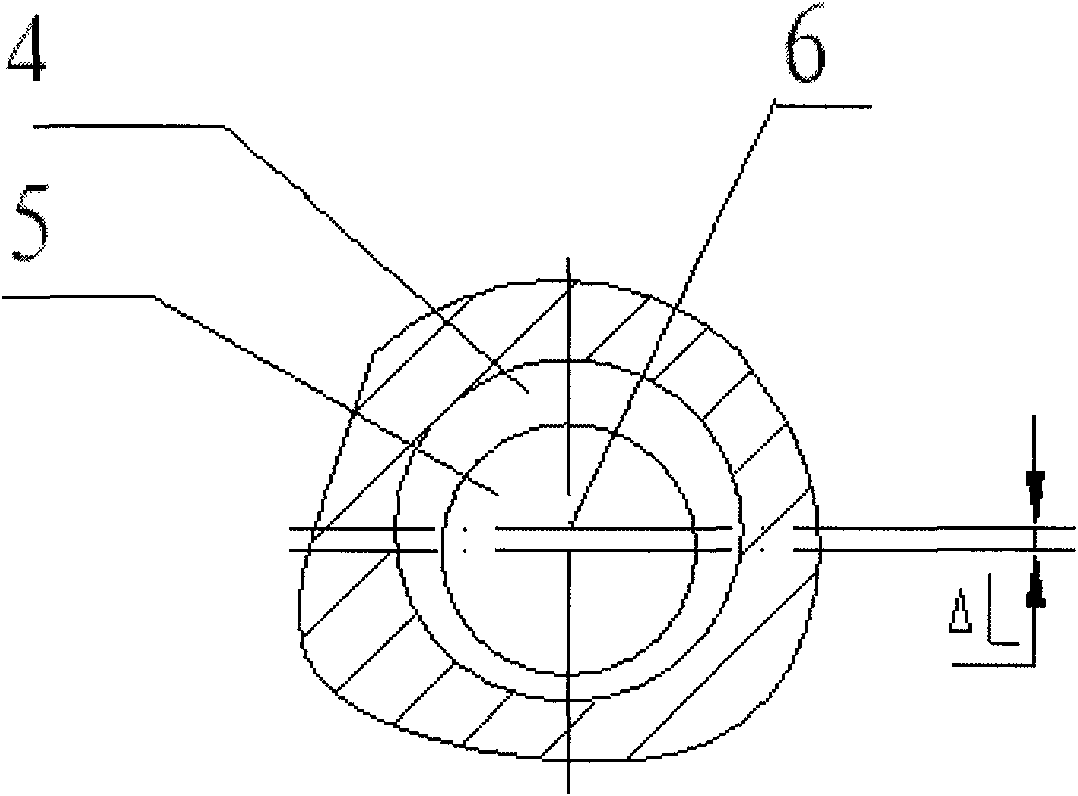

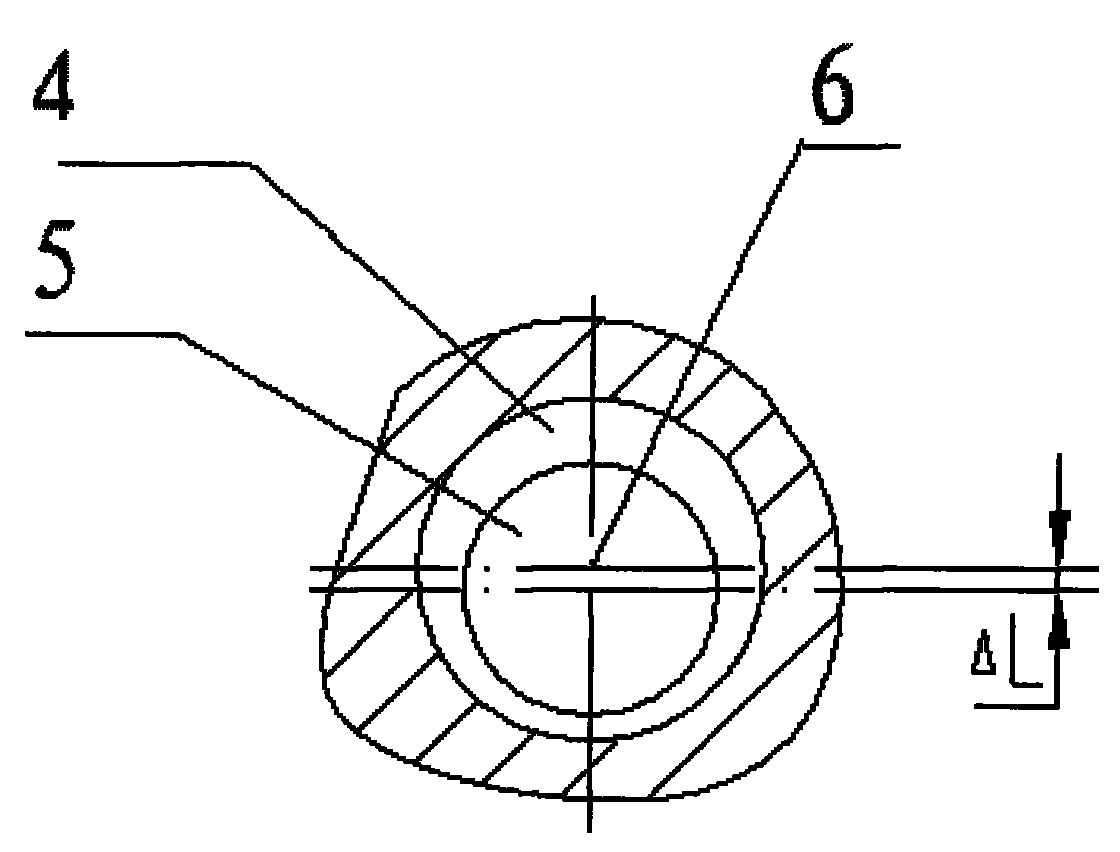

Static balancing adjusting method for cast type blisk

ActiveCN101832840AHigh balance precisionSimple structureBlade accessoriesStatic/dynamic balance measurementGravitationCasting types

The invention discloses a static balancing adjusting method for a cast type blisk. The static balancing adjusting method for the cast type blisk comprises the following steps of: firstly, machining a basic hole at the center of the disk during the primary pretreatment to the blisk; then measuring the primary unbalance of the bilsk by the basic hole and calculating the eccentric distance of the blisk according to the primary unbalance and weight of the bilsk; after that, fixing the blisk then adjusting rotation center of the disk by performing hole expansion to the basic hole according to the eccentric distance to make the rotation center of the basic hole coincide with the center of gravity thereof; then performing fine machining to the bilsk taking the adjusted basic hole as benchmark; and finally, grinding a balancing discharging belt to fulfill the requirement of static balancing. The static balancing adjusting method for the cast type blisk can get rid of relatively serious unbalance caused by uneven distribution of blade weight during casting. The method is simple and easy to implement and the precision requirement to casting is low. Characteristics such as simple structure and high reliability of blisk are reserved.

Owner:CHINA GAS TURBINE ESTAB

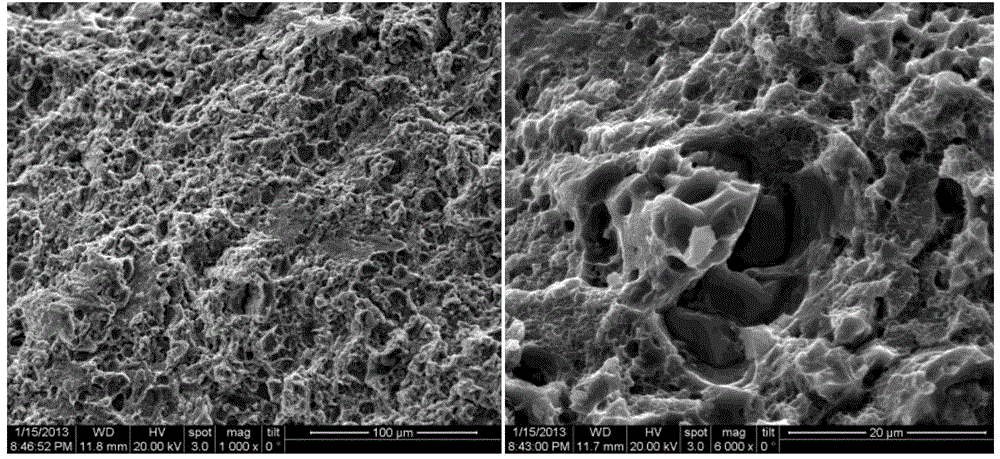

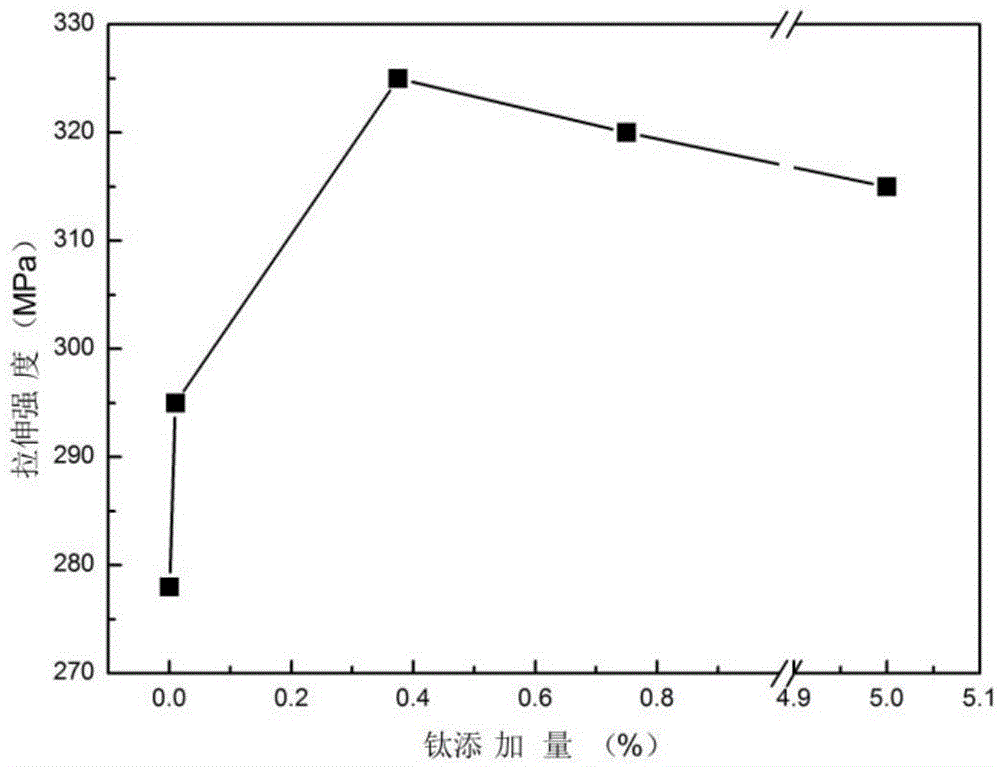

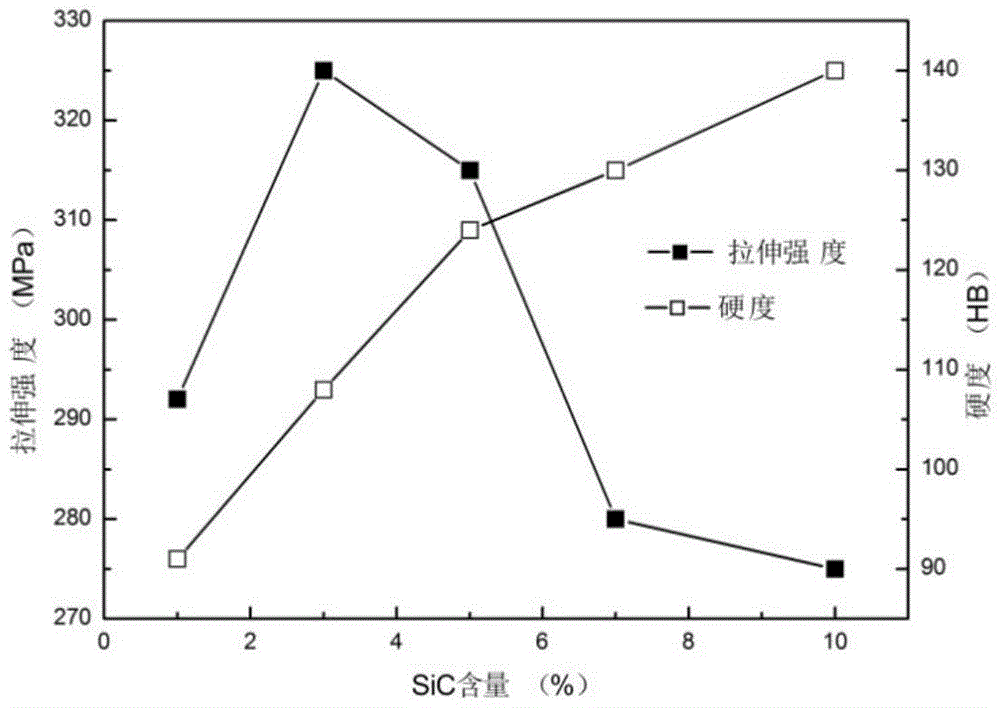

Preparation method of aluminum-based composite material

The invention relates to a preparation method of an aluminum-based composite material. The preparation method comprises steps: melting down pure aluminum or aluminum alloy, and adding a titanium-containing additive while mixing to obtain a composite aluminum alloy melt A, wherein the titanium-containing additive in the composite aluminum alloy melt A is 0.01-5 wt%; after the composite aluminum alloy melt A is subjected to degasification and slag removal treatment, cooling the composite aluminum alloy melt A rapidly to be in a semi-solid state, and adding SiC powder which is preheated and subjected to high-temperature oxidation treatment while stirring to obtain a composite aluminum alloy melt B, wherein the use level of SiC powder is 0.1-10 wt% of the composite aluminum alloy melt B; heating the composite aluminum alloy melt B to be in an overheated liquid state, casting the heated composite aluminum alloy melt B into a preheated metal mould after the heated composite aluminum alloy melt B is mixed, and demoulding to obtain a cast type product; and putting the preheated cast type product in the mould and producing a final product by virtue of a hot extrusion process. Double strengthening functions of a titanium element and hot extrusion are utilized in the invention, so that mechanical properties of the aluminum-based composite material are improved greatly; and in addition, the process is simple, the cost is low, and industrial production in batches is easy to implement.

Owner:SUZHOU ALOME SCI & TECH

Construction process for jet grouting anchor rod

ActiveCN101532292ASolve the technical problems of poor anchoring effectImprove the anchoring effectBulkheads/pilesAnchoring boltsCasting typesRock bolt

The invention relates to a construction process for jet grouting anchor rod, which comprises the following detailed steps of: 1. setting out according to design requirements; 2. positioning a drilling machine; 3. drilling; 4. guniting; 5. lifting by jet grouting; 6. drilling for a second time; 7. guniting for a second time; 8. lifting by jet grouting for a second time; 9. installing and embedding a rod body; and 10. pouring and capping. The construction process can overcome the technical problem that the anchoring effect of slip-casting type or mechanical type anchoring is poor, and breaks through the tradition, and the test demonstrates that the anchoring effect is better than that of slip-casting anchoring.

Owner:SHANGHAI FOUND ENG GRP +1

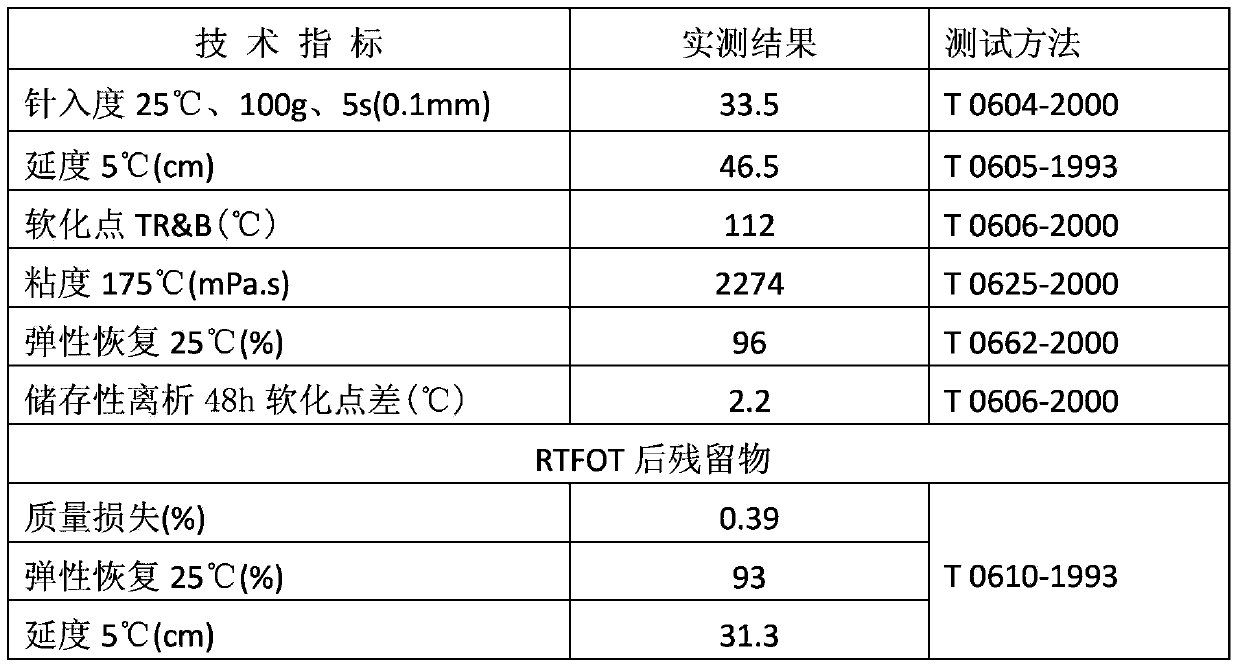

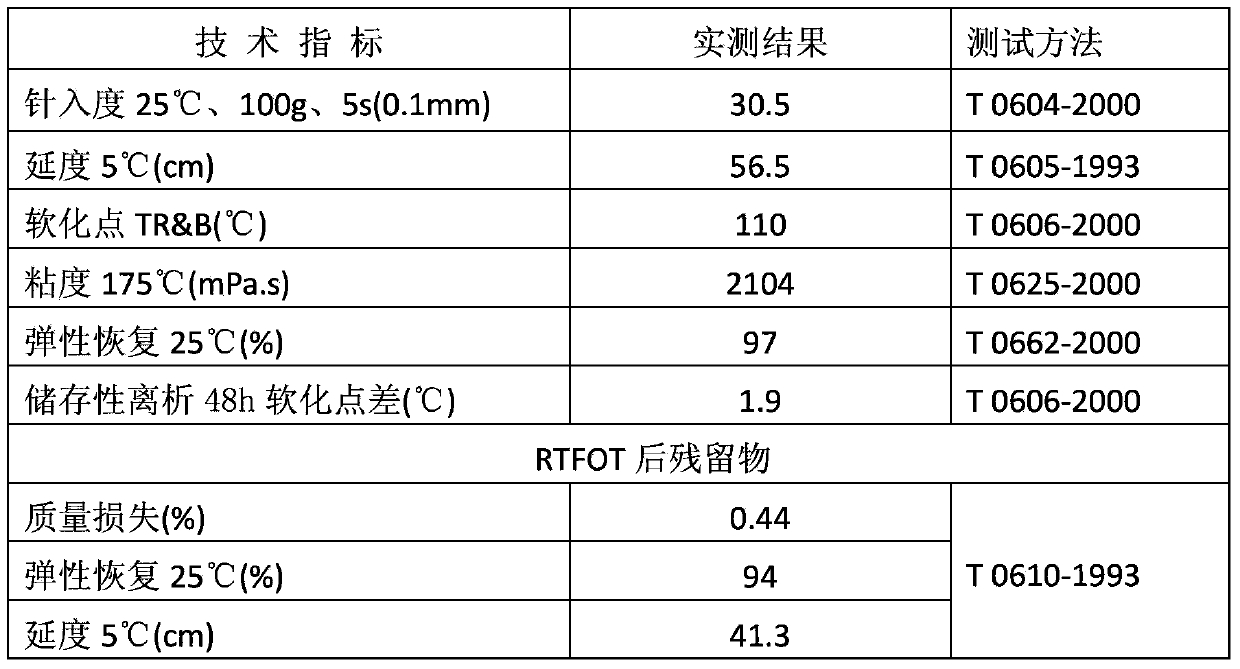

Casting type mixture asphalt material and preparation method thereof

InactiveCN104212188ANo pollution in the processWide range of applicationsBuilding insulationsCasting typesAsphalt

The invention relates to a casting type mixture asphalt material and a preparation method thereof. The casting type mixture asphalt material is composed of, by weight, 70-92 parts of matrix asphalt, 7-14 parts of an asphalt SBS modifier, 0.5-10 parts of filling oil, and 0.05-0.3 part of an accelerant. The preparation method includes: adding the modifier into 140-190DEG C matrix asphalt, performing high shear for 20-90min under 1000-5000rpm, after full swelling of the modifier, adding the filling oil, and conducting shearing for 5-30min under 1000-5000rpm, adding the accelerant into a reaction kettle, and further carrying out high shear for 90min under 1000-5000rpm. The modified asphalt has good adhesion, high elastic recovery and low temperature elongation, low high-temperature construction viscosity, good stability under hot storage conditions, no segregation, and good pavement performance under high temperature state.

Owner:PETROCHINA CO LTD +2

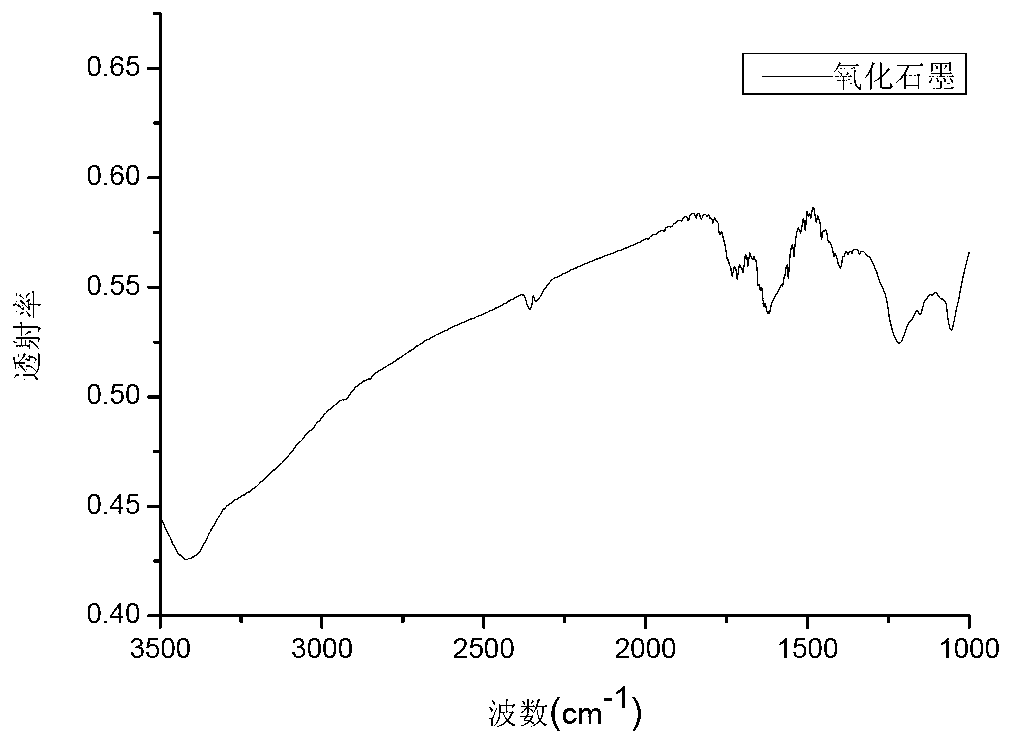

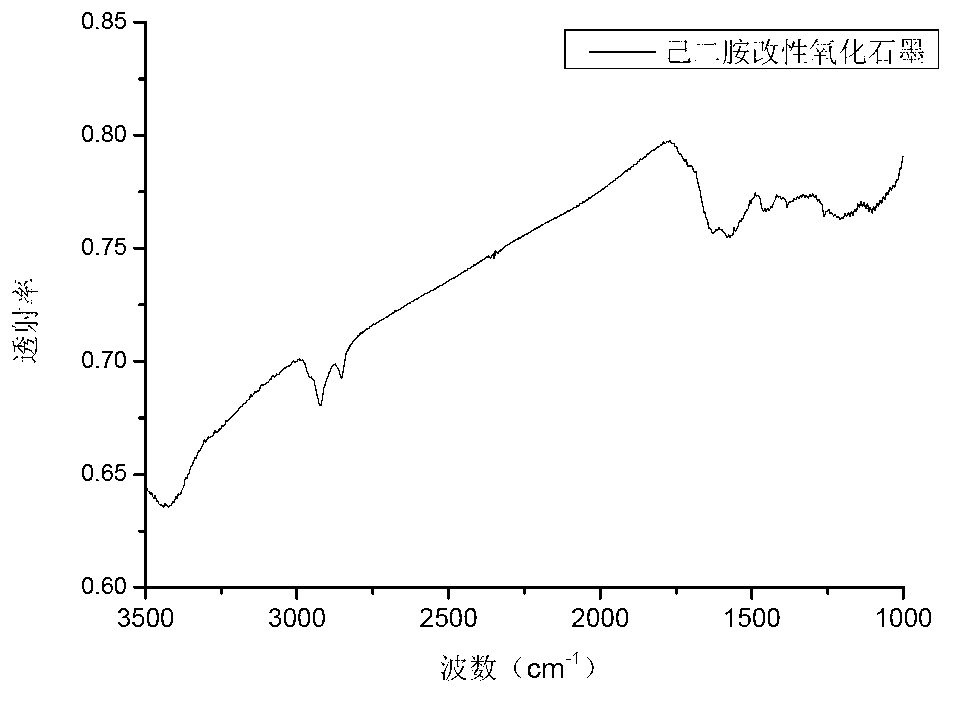

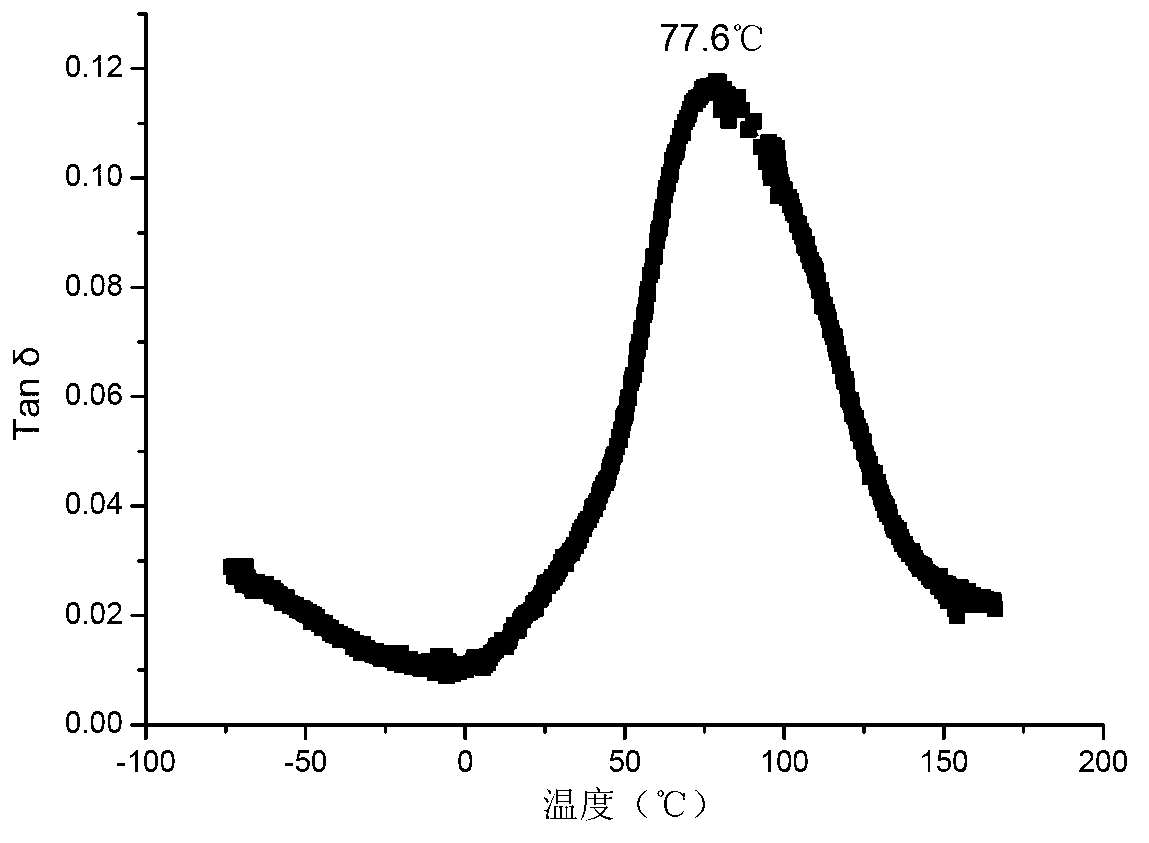

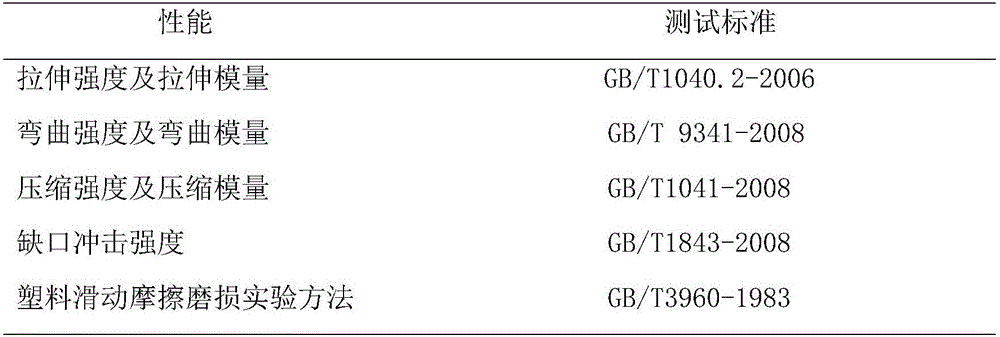

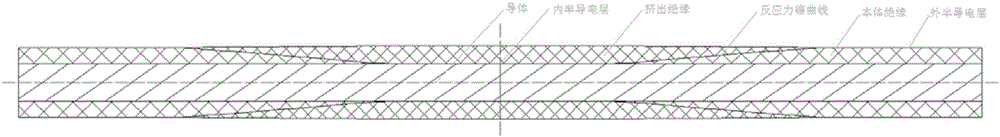

Method for preparing casting type nylon/modified graphite oxide nanocomposite

The invention discloses a method for preparing a casting type nylon / modified graphite oxide nanocomposite. According to the method, graphite oxide is modified by diamine, and amido is introduced into the graphite oxide, so that an interface action between the graphite oxide and nylon is enhanced, and the mechanical property and the heat performance of the casting nylon are comprehensively improved. The preparation technology disclosed by the invention is simple, and the cost is low; due to the little modified graphite oxide, the impact intensity of the composite is obviously improved; when the hexanediamine modified graphite oxide content is 0.1 percent, the impact intensity of the composite is improved by 62 percent than that of pure nylon, and the tensile strength of the composite is also obviously improved; the glass-transition temperature is up to 93.9 DEG C and is improved by 16.3 DEG C than that of pure nylon, and the heat performance is obviously improved.

Owner:HEBEI UNIV OF TECH

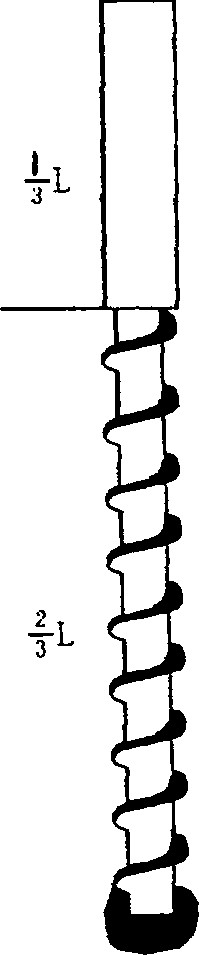

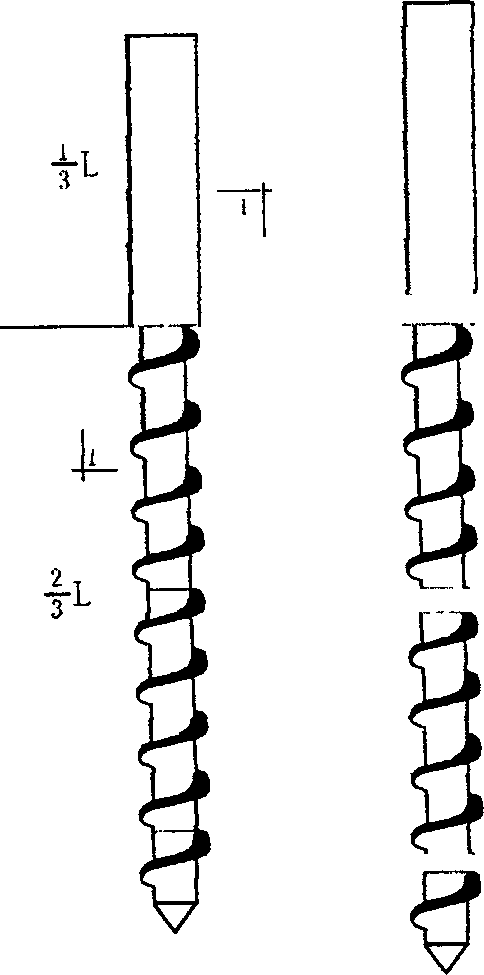

Half screw pile and its pile forming method thereof

Owner:HAINAN ZHUODIAN HIGH TECH DEV

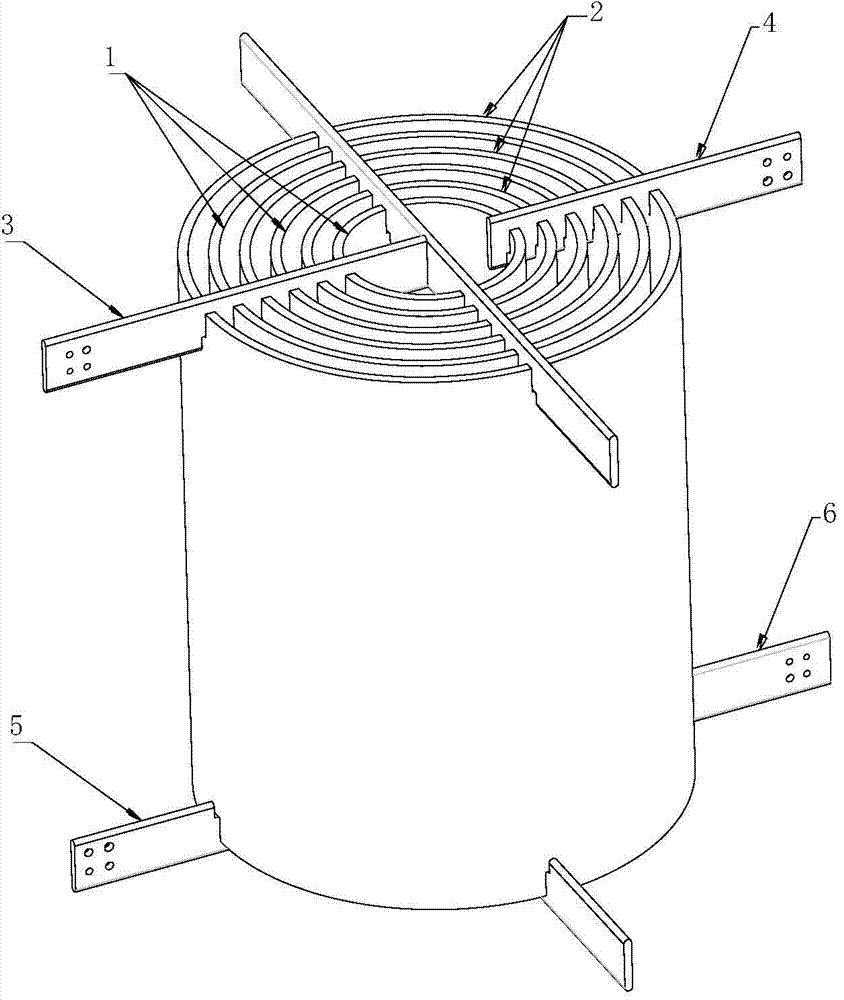

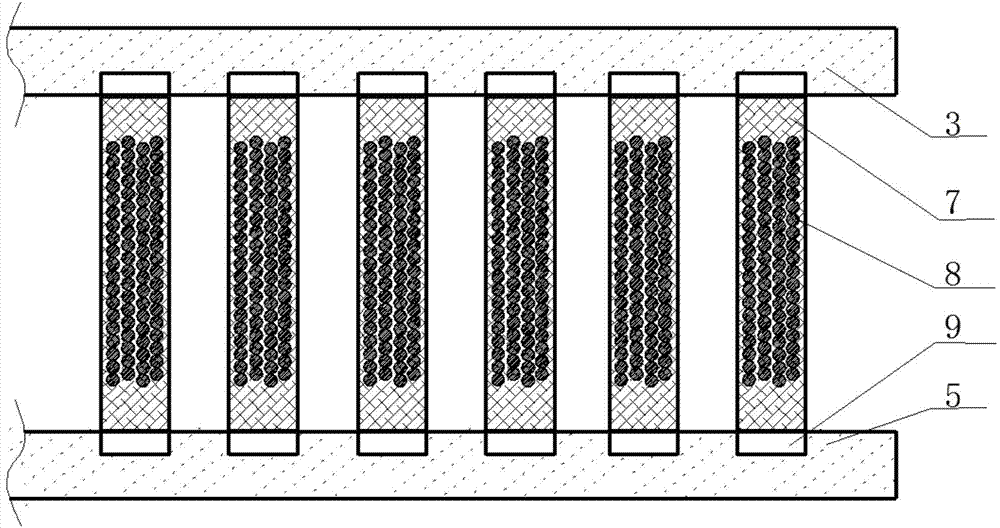

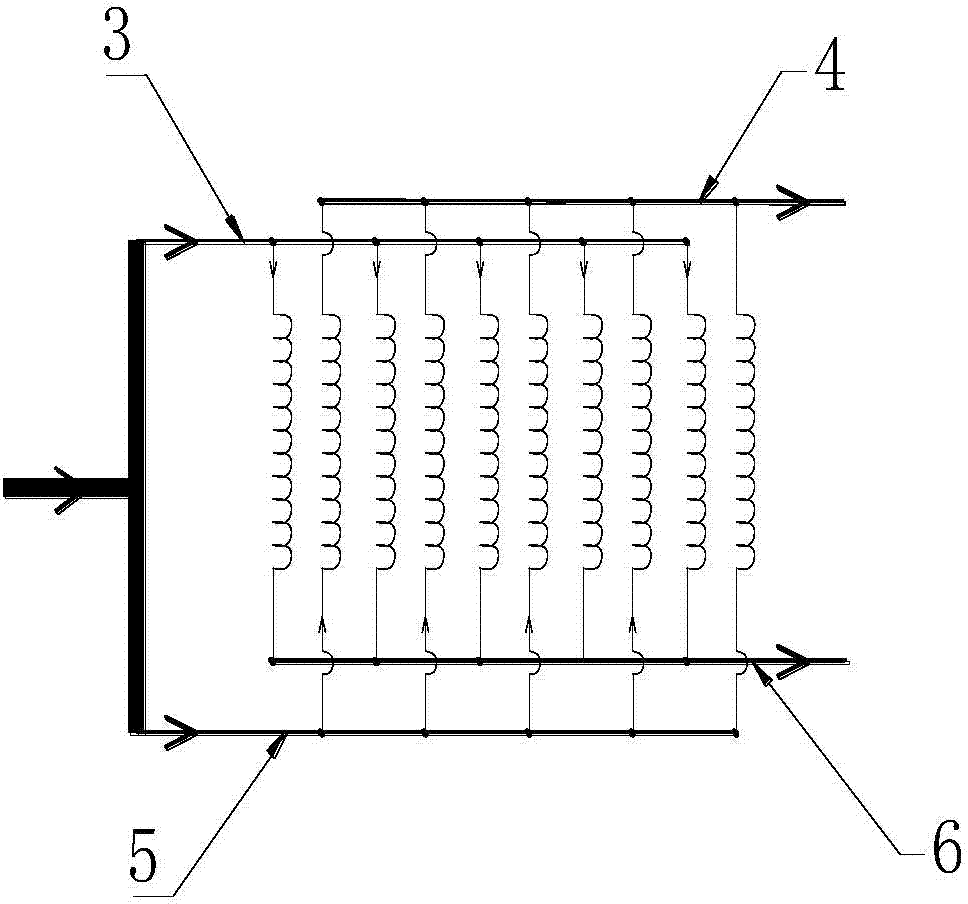

Casting type split reactor

InactiveCN104124043AEnsure consistencyAvoid uneven thicknessTransformers/inductances coils/windings/connectionsInsulation layerCasting types

The invention discloses a casting type split reactor. A coil of the casting type split reactor comprises a first winding and a second winding which are arranged coaxially, and encapsulation parts of the first winding and encapsulation parts of the second winding are arranged alternatively from inside to outside in sequence. A first wire inlet bar and a second wire outlet bar are arranged at an interval radially and fixed at the upper end of the coil, and the other first wire inlet bar and a first wire outlet bar are arranged at an interval radially, connected with a current introducing end of the second winding in a conductive mode and fixed at the lower end of the coil. Each encapsulation part comprises a conductive part formed by winding a plurality of multi-layer round leads, and an insulation part formed by casting epoxy resin in a vacuum mode is arranged outside the conductive part. According to the casting type split reactor, the encapsulation parts are formed by casting epoxy resin in the vacuum mode through a casting mould, consistency of sizes of the insulation layers can be ensured, and uneven thicknesses of the insulation layers are avoided. In addition, no bubbles exist in the windings, partial discharge is reduced, occurrence of air gaps can be avoided effectively, and therefore, insulation performance of the insulation layers can be improved.

Owner:STATE GRID CORP OF CHINA +2

Oil-containing casting type nylon/rare earth/graphene oxide composite material

The invention discloses an oil-containing casting type nylon / rare earth / graphene oxide composite material. The composite material is prepared by mixing a caprolactam suspension containing nanoparticles A and nanoparticles B according to a mass ratio of 1:1; at temperature of 120-130 DEG C, adding a catalyst, and at 120-130 DEG C, depressurizing for 4-8min; at 130-140 DEG C, adding, by mass, 3.0-5.0 parts of lubricating oil or lubricating grease, adding an activator, mixing, pouring into a mould, and maintaining 30-60min at temperature of 150-180 DEG C to obtain the composite material. The oil-containing casting type nylon / rare earth / graphene oxide composite material has excellent comprehensive performance and is especially suitable for requirements of parts of large machinery such as gears, sliders and bearings.

Owner:HEBEI UNIV OF TECH

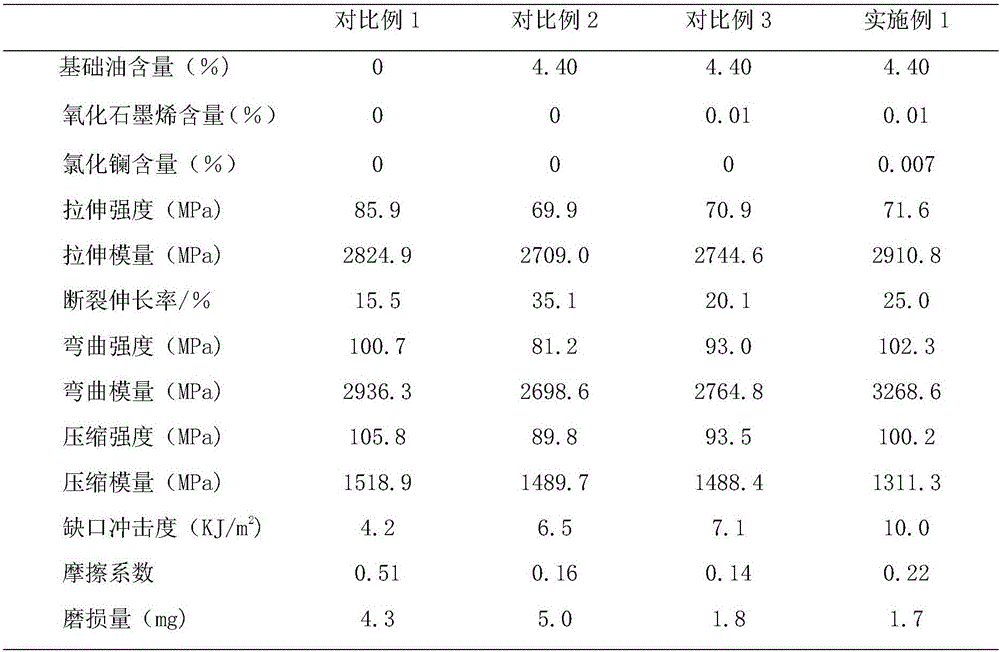

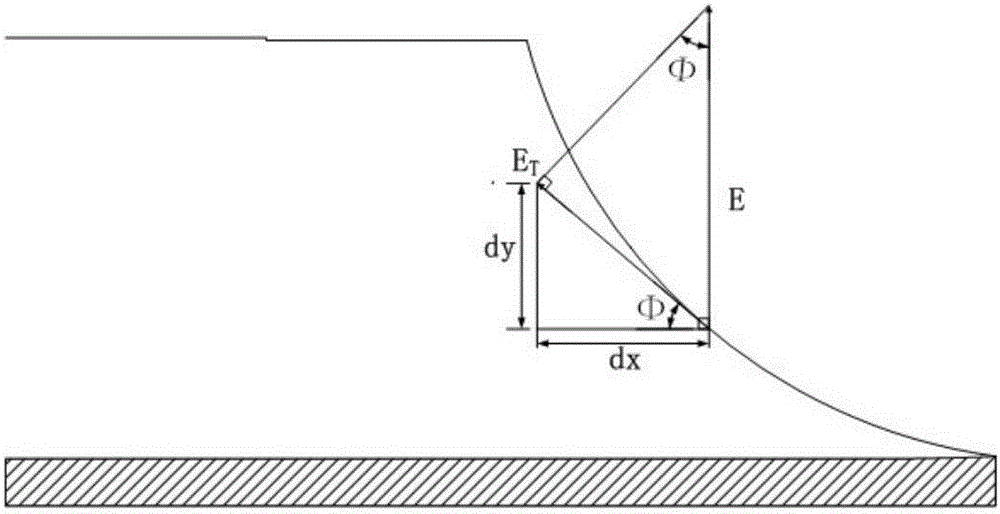

Mould casting type flexible direct-current cable soft joint reaction force cone structure designing method

InactiveCN106451316ASolve the electric field problemAvoid field strength build-upCable fittingsElectricityElectrical conductor

The invention discloses a mould casting type flexible direct-current cable soft joint reaction force cone structure designing method. The method is characterized by comprising the following steps: (I) determining the parameters of a cable conductor, and calculating the temperature difference between the insulating inner and outer surfaces of a direct-current cable body; (II) calculating the electric field intensity at the center of a direct-current cable insulation layer; (III) calculating a direct-current cable soft joint reaction force cone curve equation; and (IV) obtaining a reaction force cone structure to obtain the specific structure of the cable soft joint. The method has the following advantages: the problem of electrical resistivity mismatching between the cable body insulation material and the mould casting insulation material and consequent field intensity accumulation at the interface of the two are avoided; meanwhile, the influence of temperature and electric field factors on the electrical resistivity is considered, electric field distribution in flexible direct-current cable terminal insulation is proposed, and a theoretical basis is provided for designing a flexible direct-current cable soft joint; uniform electric field at the flexible direct-current cable soft joint is guaranteed; and the electrical property requirement of the whole flexible direct-current cable system on the joint is met, and long-term safety and reliability of the flexible direct-current cable system are guaranteed.

Owner:NANJING NARI GROUP CORP +3

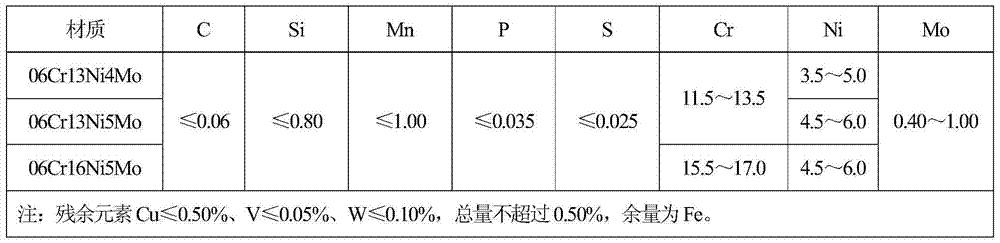

Manufacturing method for through-flow turbine continuous variable cross-section movable guide vanes through electroslag smelting casting

ActiveCN103567419AHigh purityReduce sulfur and phosphorus contentManufacturing technologyWater turbine

The invention relates to a smelting casting type manufacturing method for through-flow turbine guide vanes, in particular to a manufacturing process for high-requirement and high-performance through-flow turbine moveable guide vanes, and particularly discloses an manufacturing method for through-flow turbine continuous variable cross-section (fan-shaped) movable guide vanes through electroslag smelting casting, which can solve the technical problem that continuous variable cross-section castings cannot be produced by adopting the existing electroslag smelting casting. In order to solve the technical problem, the invention provides an electroslag smelting casting process design method and a manufacturing method for continuous variable cross-section castings, and an electroslag smelting casting process method for a through-flow hydrogenerator moveable guide vane, the cross section of the guide vane produced by adopting the electroslag smelting casting technology is continuously variable during the smelting casting process . The performance index of the moveable guide vane of the through-flow hydrogenerator, produced by the electroslag smelting casting technology is greatly improved as compared with that of the guide vane produced by the current manufacturing method. The through-flow hydrogenerator moveable guide vane is produced by the electroslag smelting casting technology instead of sand mould casting, so the utilization ratio of materials is increased by more than 20%.

Owner:沈阳市盛华特种铸造有限公司

Method for fabricating casting-type polyurethane elastomer tire

The invention relates to a method for fabricating a polyurethane tire, and discloses a method for fabricating a casting-type polyurethane elastomer tire. The method comprises the following steps: preparing materials, coating, pre-treating a mold, preheating, assembling, casting, primarily hardening and secondarily hardening. By adopting the technology disclosed by the invention, polyurethane can be tightly bonded with a wheel core surface by expanding the molecular polarity; the wheel core surface is coated; the wheel core surface is coated with a material comprising per 1kg of an adhesion agent and 1.2-1.8kg of methyl ethyl ketone (MEK) coating; the relatively great matching is generated between the polyurethane and a wheel core; the bonding strength is improved; the polyurethane and a hardening agent are cast into the mold according to the ratio of 100:(10-100):15 by weight percent in the casting process; the cast mold is hardened twice, so that the polyurethane is full in liquidity in the casting process, and air bubbles are prevented from being formed on the wheel core surface, the adhesion reduction is reduced, and the degumming is avoided.

Owner:安徽台创智能科技有限公司

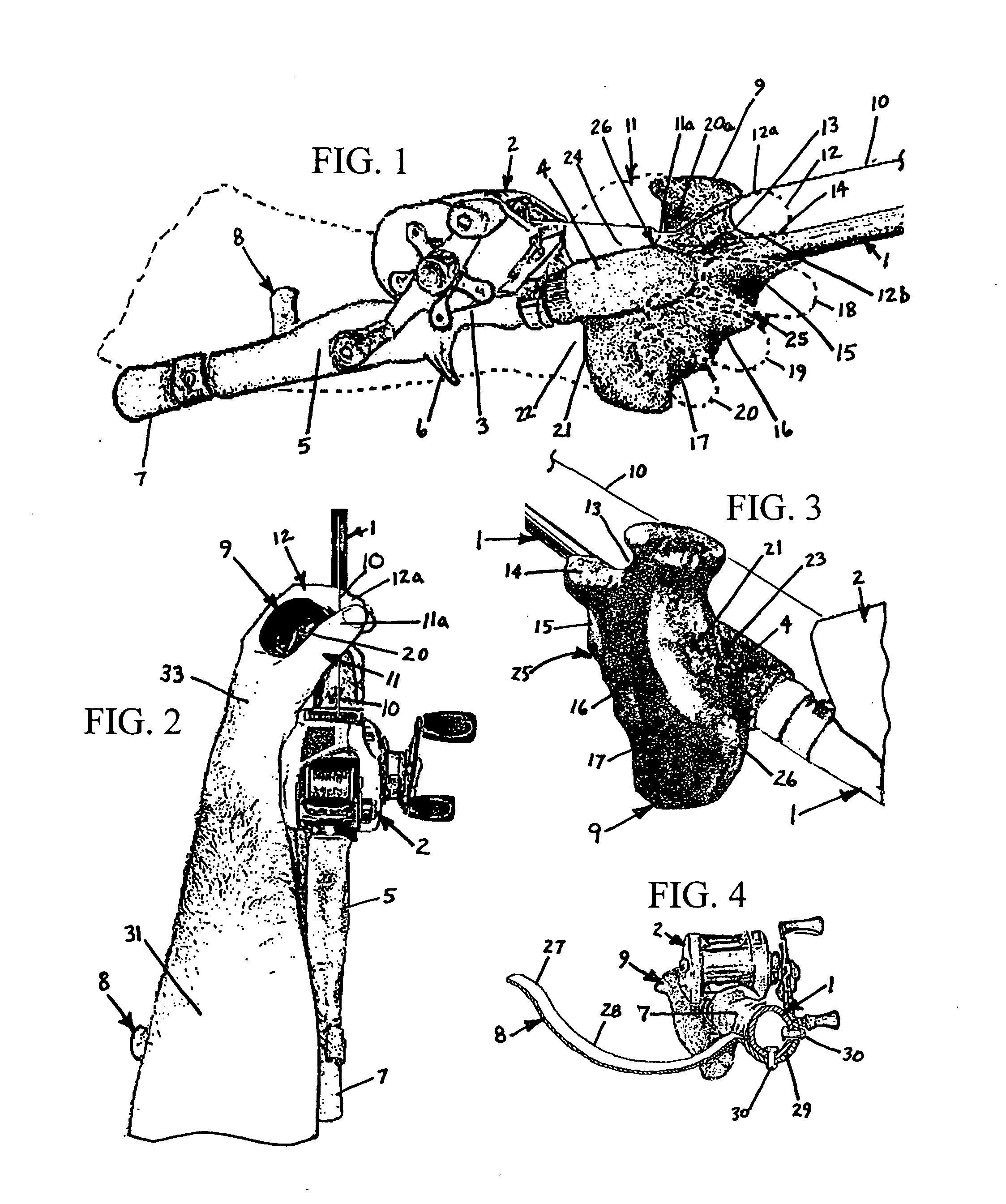

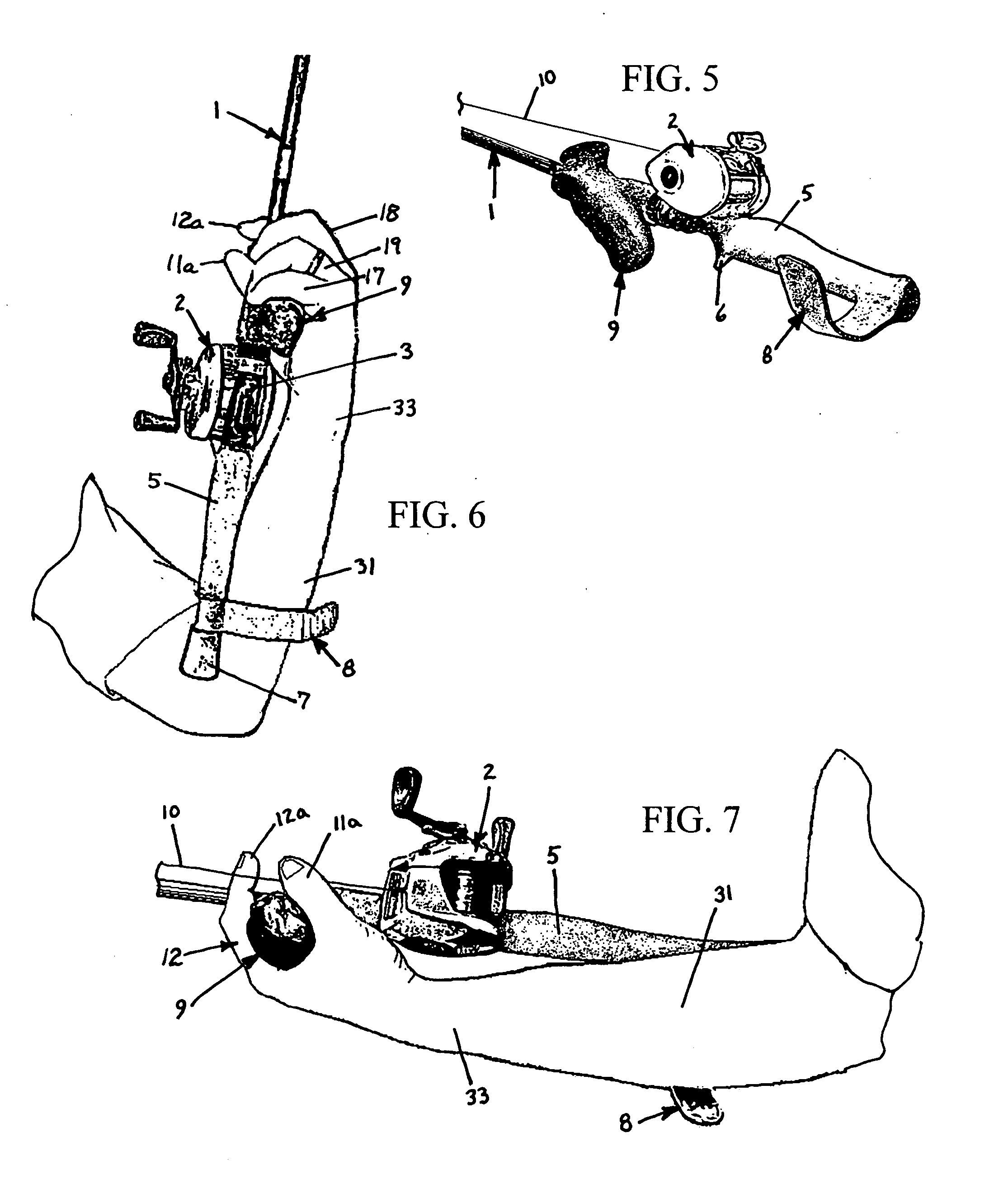

Bait-casting rod handle

InactiveUS20060101702A1Easy to controlIncreased rod leverageRodsOther angling devicesPull forceConventional casting

A handle for bait-casting type fishing rods, with a preferred embodiment including a single-piece, lightweight, contoured pistol-grip type handle located on the rod ahead of the reel to afford the user exceptional fishing sensitivity due to direct finger contact with the fishing line extending from the reel. The handle also affords good control over rod twist and facilitates a more positive grip than conventional grasping of the rod during reeling. Also included is a rear forearm cradle that acts as a lever point which, when combined with the pistol-grip type handle, provides exceptional control of rod tip motions, useful during hook sets and while counteracting the pull of a fish. A preferred embodiment includes the pistol grip handle and forearm cradle features, either or both of which can be retrofitted to or incorporated into conventional casting rod handle designs that may include trigger grips and attachment mechanisms for securing a reel in place. Because of the two control points provided by the forward pistol-grip handle and rear forearm cradle, this embodiment facilitates use of only one arm to hold and support the fishing rod during reeling.

Owner:LACOSTE BRIAN O

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com