Method for preparing casting type nylon/modified graphite oxide nanocomposite

A technology of nano-composite material and cast nylon, which is applied in the field of polymer composite material preparation, can solve the problem that tensile strength, impact strength and heat resistance cannot be improved at the same time, and achieve the increase of tensile strength and impact strength, and the preparation process. Simple, promising results for industrial applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

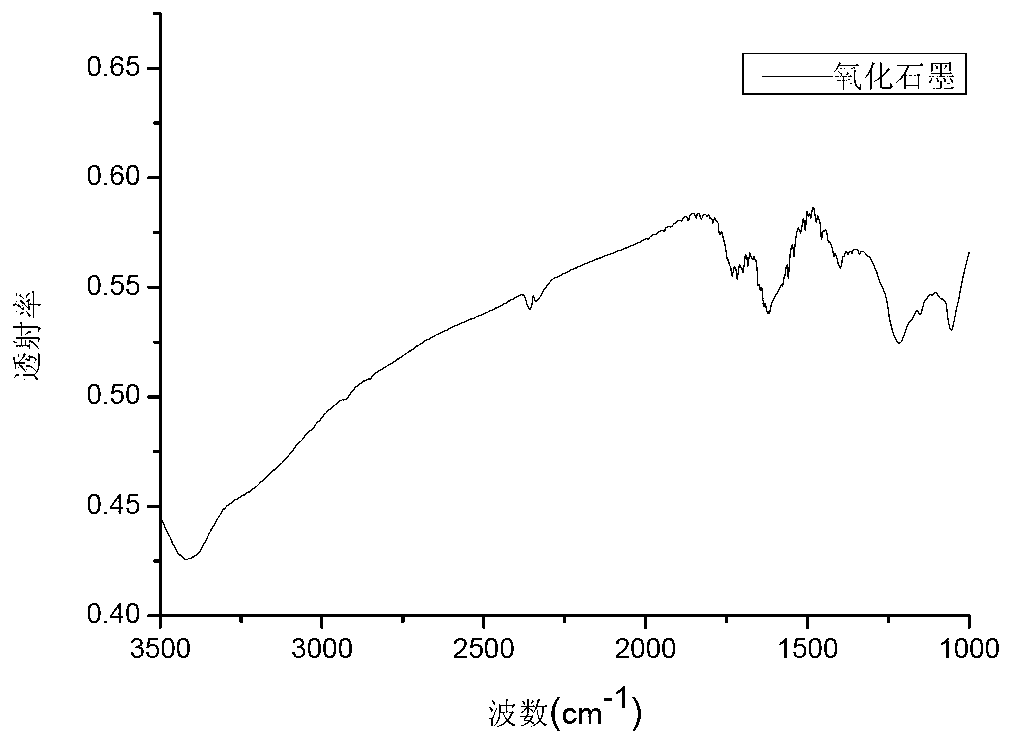

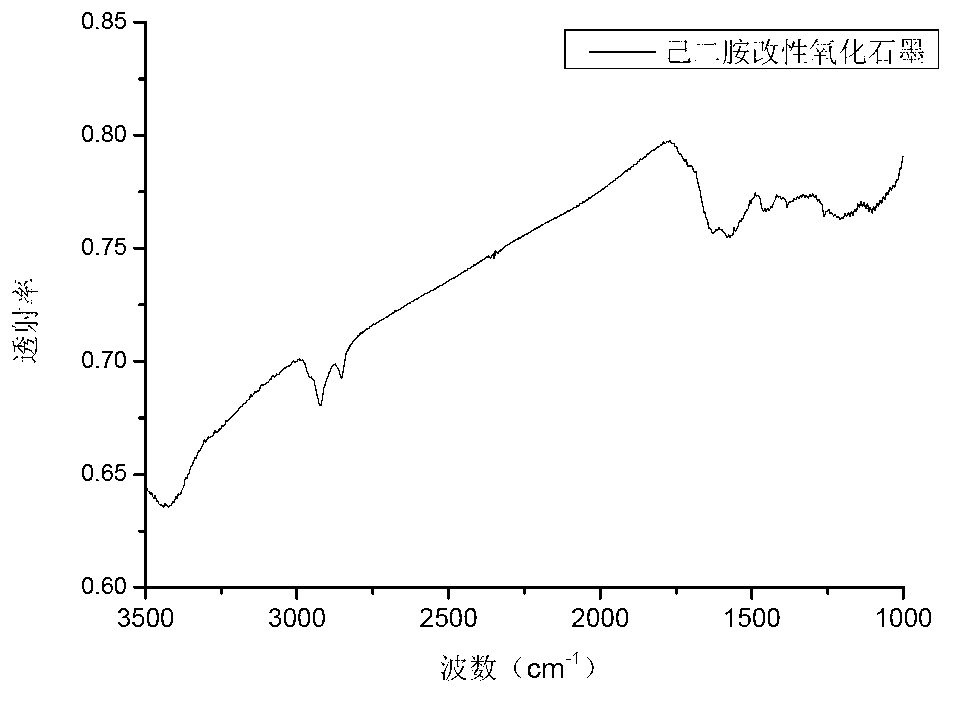

[0022] (1) Put 0.5g of graphite oxide prepared according to the Hummers method into 200ml of ethanol, ultrasonically disperse for 20 minutes, add 0.5g of hexamethylenediamine, control the temperature at 70°C to 80°C, and protect it with nitrogen. After 3h, filter, wash, Modified graphite oxide was obtained after drying.

[0023] (2) Heat and melt 100g of caprolactam at 70°C to 80°C. Under the protection of nitrogen, take 0.01g of the modified graphite oxide obtained in step (1) and put it into the melt of caprolactam, heat at 70°C to 80°C and ultrasonically After 30 minutes, a suspension of modified graphite oxide caprolactam with good dispersibility was obtained.

[0024] (3) Add all the graphite oxide caprolactam suspension obtained in step (2) into a three-necked flask, distill off water under reduced pressure at 90°C (vacuum degree is 0.9-0.95MPa), add 0.2g of sodium hydroxide, and ℃ under reduced pressure (vacuum degree 0.9-0.95MPa) to distill for half an hour to remove ...

Embodiment 2

[0028] Basically the same as Example 1, only changing the amount of modified graphite oxide in step (2) to 0.05g.

[0029] The performance of the composite material obtained is shown in attached table 2

Embodiment 3

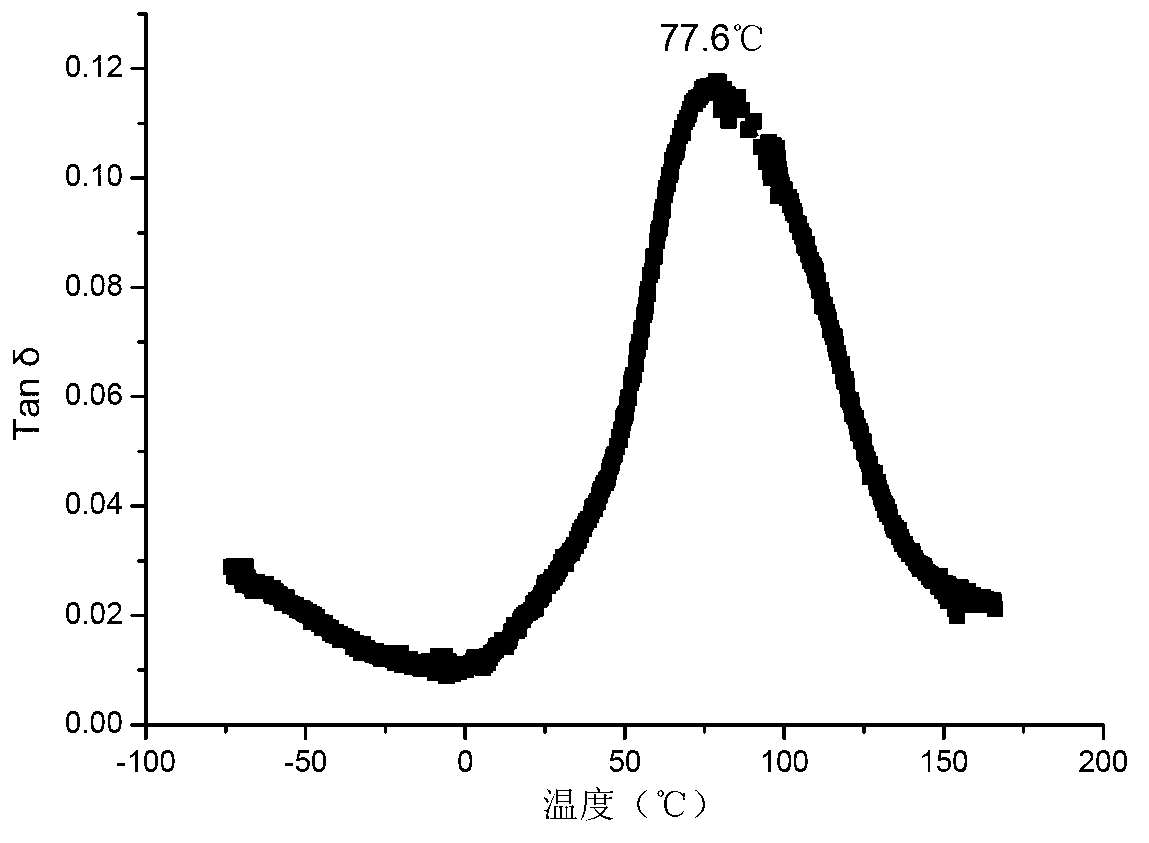

[0031] Basically the same as in Example 1, only changing the amount of modified graphite oxide in step (2) to 0.1 g. attached Figure 4 The test results of the medium dynamic thermomechanical analyzer show that the glass transition temperature is 93.9°C, which is higher than figure 2 The 77.6°C of medium pure nylon increased by 16.3°C.

[0032] The performance of the composite material obtained is shown in attached table 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com