Static balancing adjusting method for cast type blisk

An adjustment method, the technology of the whole blisk, applied in the static/dynamic balance test, the supporting element of the blade, the measuring device, etc., can solve the problems of low reliability, small range, complex structure, etc., and achieve high reliability and operation Simple, high-balanced precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

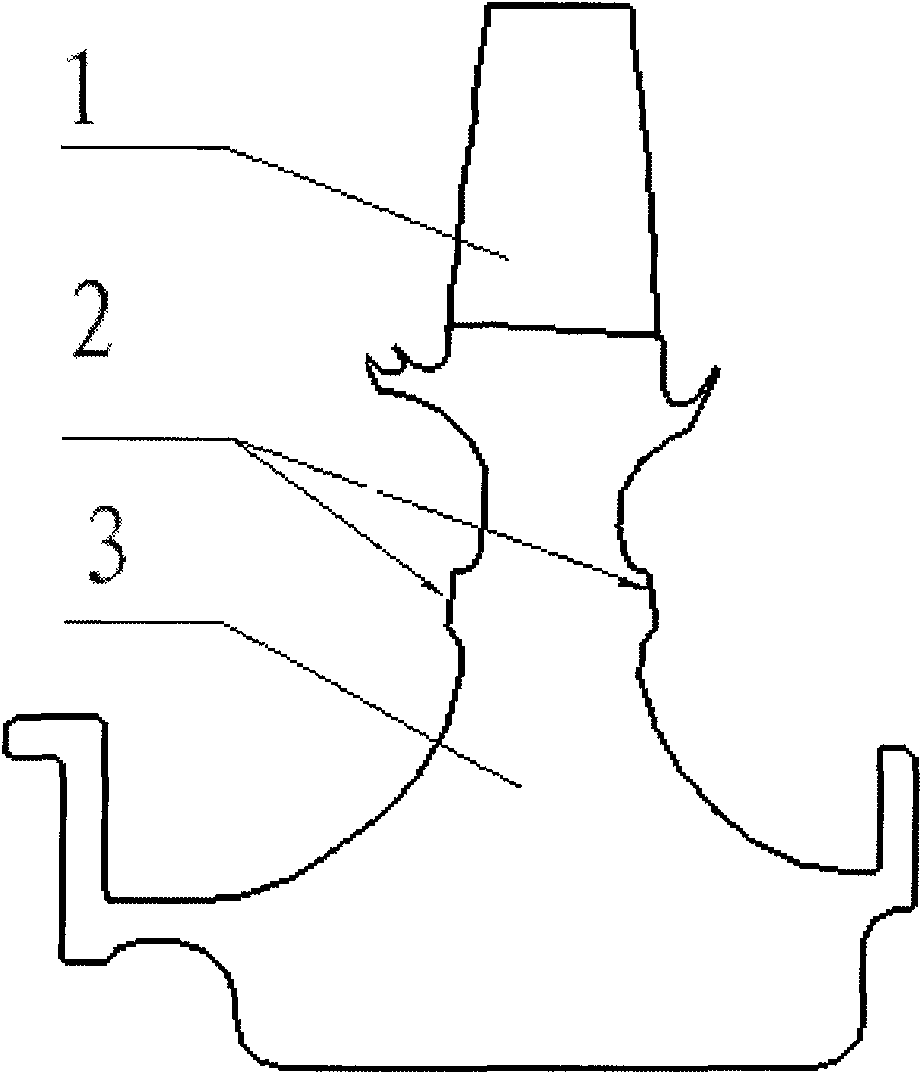

[0018] see figure 1 , which is a structural schematic diagram of the blisk in the method for adjusting the static balance of the cast blisk according to the present invention. The blisk is composed of a blade 1 and a disc 3, wherein a balance removal belt 2 is provided at the place where the disc 3 is connected to the blade 1 . The balance strip 2 is a ring of protrusions surrounding the blisk, used for grinding and stripping to adjust the balance.

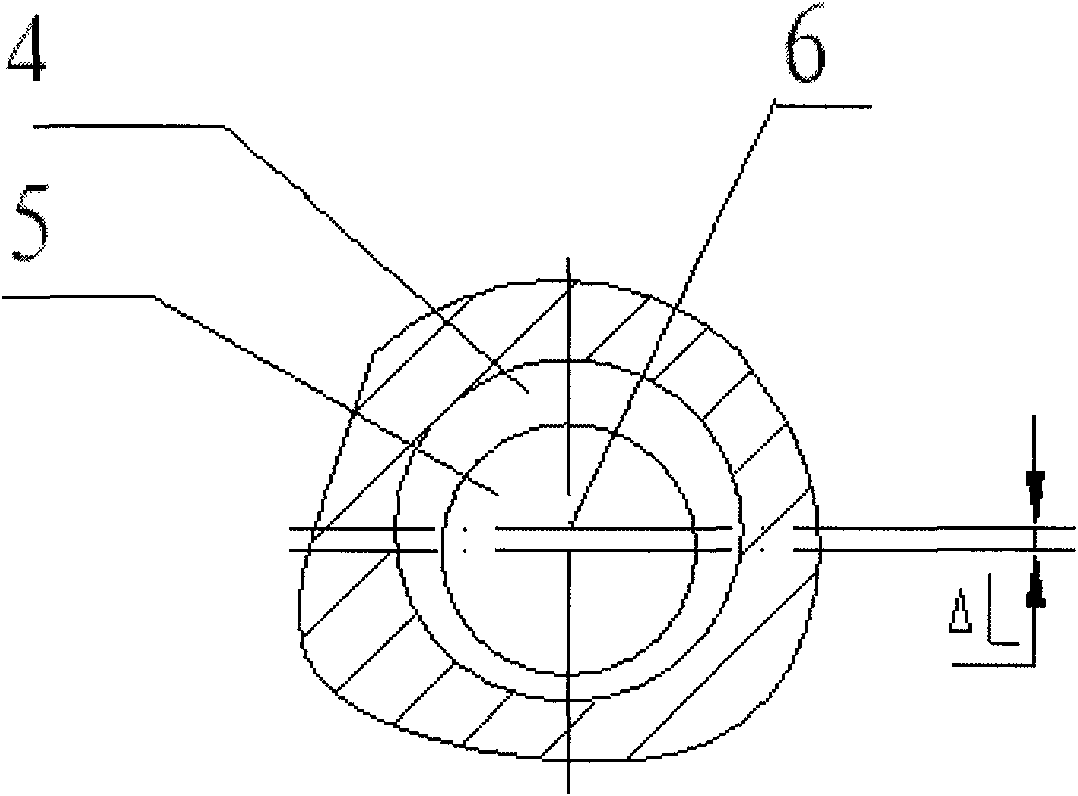

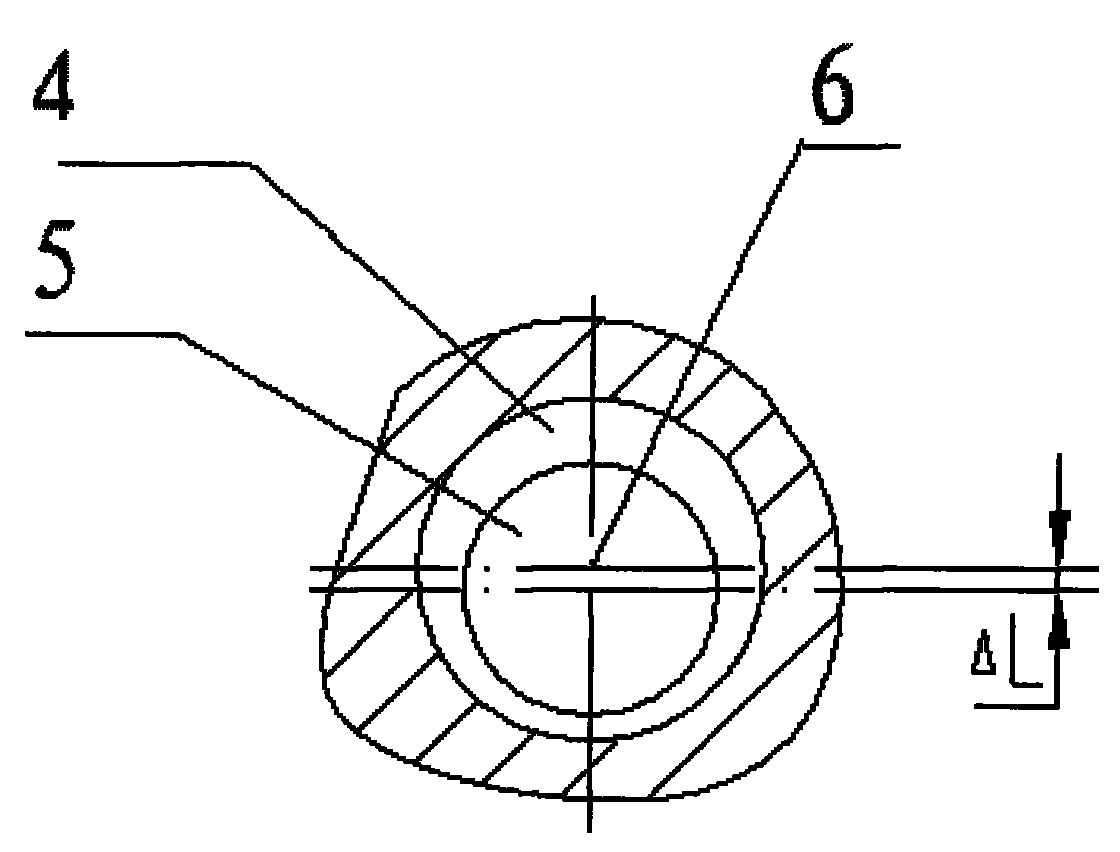

[0019] According to the principle of balance, if the center of gravity of the blisk does not coincide with the center of rotation, an eccentricity will occur. At this time, when the blisk rotates at a high speed, it will cause large vibrations. When the actual cast-type blisk is just cast, it is easy to have uneven mass distribution among the blades, so there is a serious imbalance. The method for adjusting the static bala...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com