High-speed flexible rotor dynamic balance method

A technology of flexible rotors and rotors, which is applied in the field of dynamic balance and high-speed flexible rotor dynamic balance, can solve problems such as incorrect corrections, achieve the effects of reducing the number of starts, improving balancing efficiency and balancing accuracy, and eliminating the need for balancing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

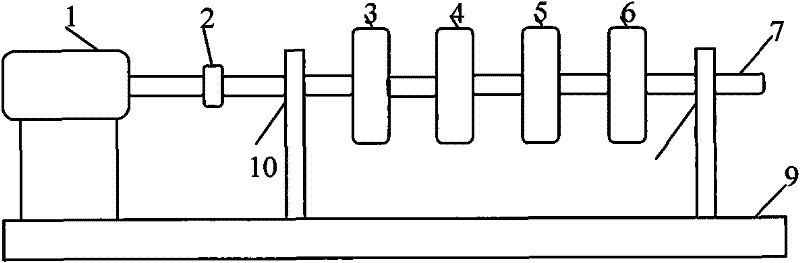

[0035] Next, a four-disk rotor is dynamically balanced in three planes by using the dynamic balancing method for a high-speed flexible rotor proposed by the present invention, and the effectiveness and applicability of the method of the present invention for balancing a high-speed flexible rotor are illustrated.

[0036] Refer to attached figure 1 , the structure diagram of the four-disk rotor is shown in figure 1 As shown, the rotor is directly driven by the motor through the coupling, and the maximum speed driven by the motor is 10000rpm.

[0037] First, determine the reference position of the rotor.

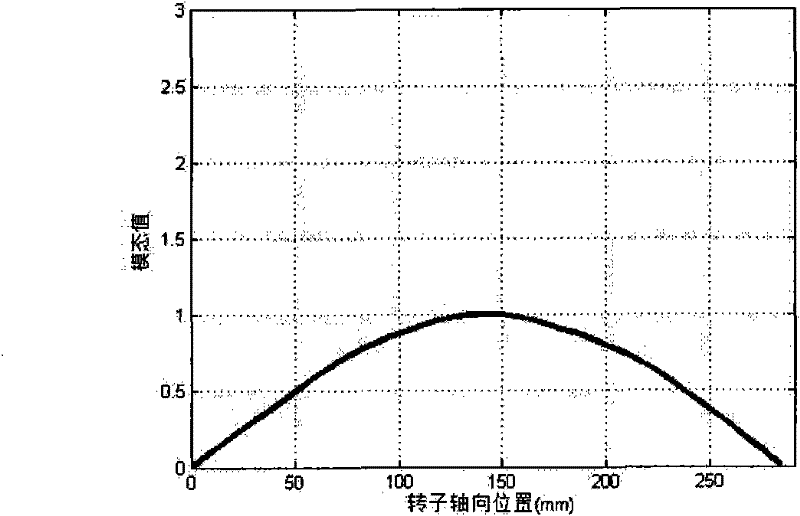

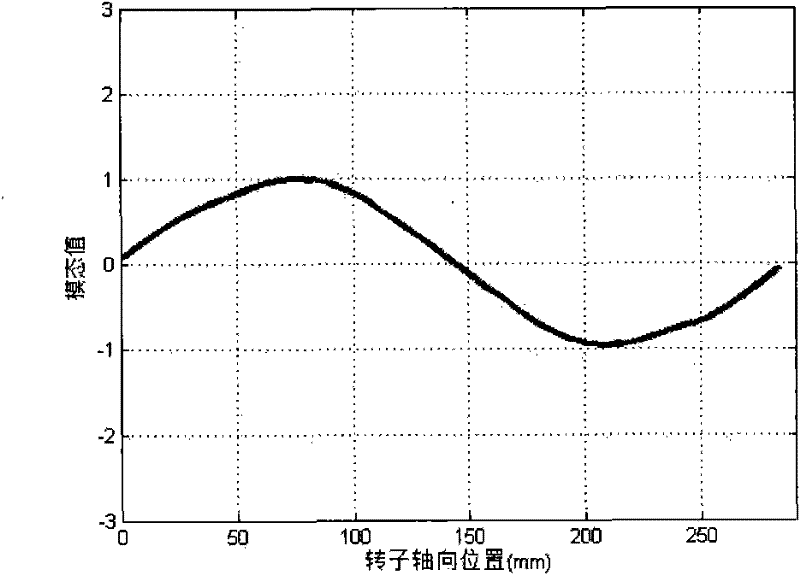

[0038] Established by ANSYS finite element numerical simulation software figure 1 The finite element model of the four-disc rotor is shown, and the 1st to nth order modal values and the rth order critical speed of the rotor are obtained from the numerical simulation results of the rotor finite element model. Since the rotor is dynamically balanced in three planes in this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com