Patents

Literature

113results about How to "High balance precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

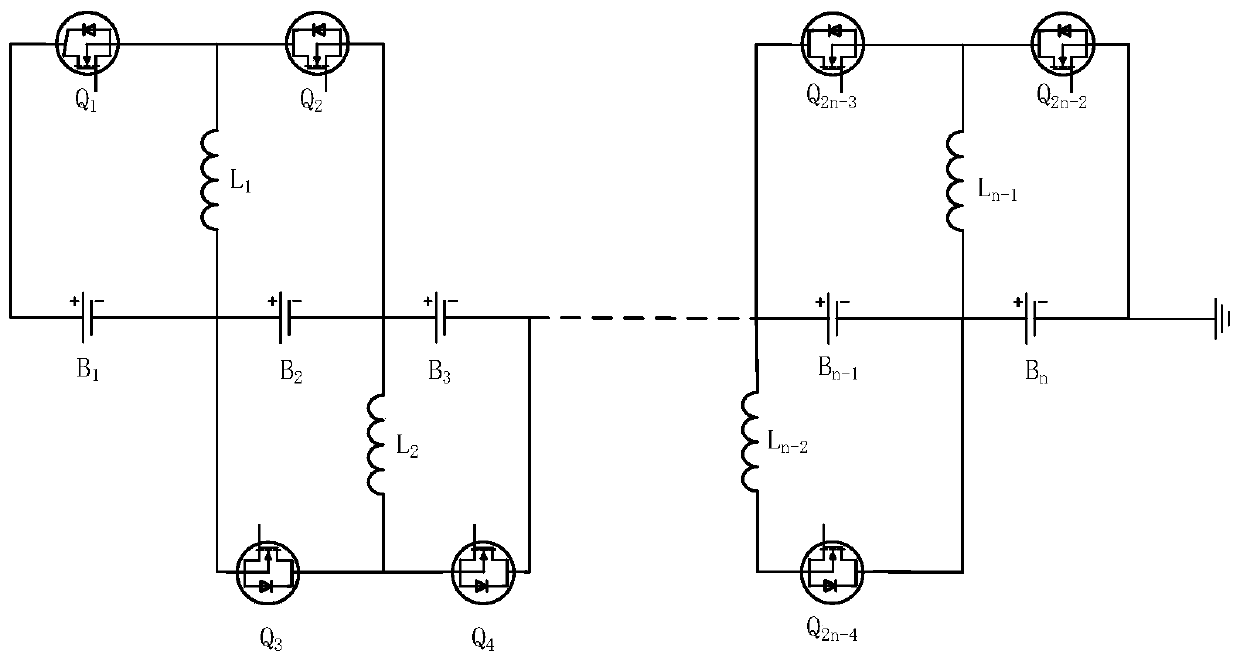

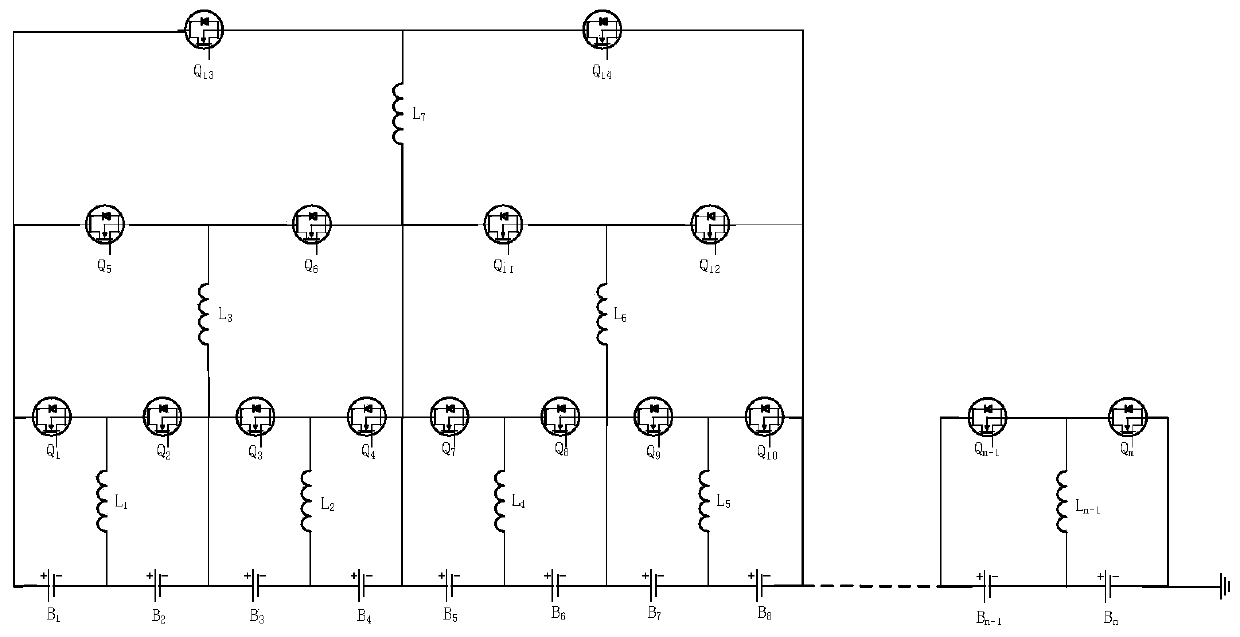

Composite automatic synchronous energy transfer equalization circuit and equalization method for series battery pack

InactiveCN102437609AHigh speedImprove efficiencyBatteries circuit arrangementsElectric powerCapacitanceMode control

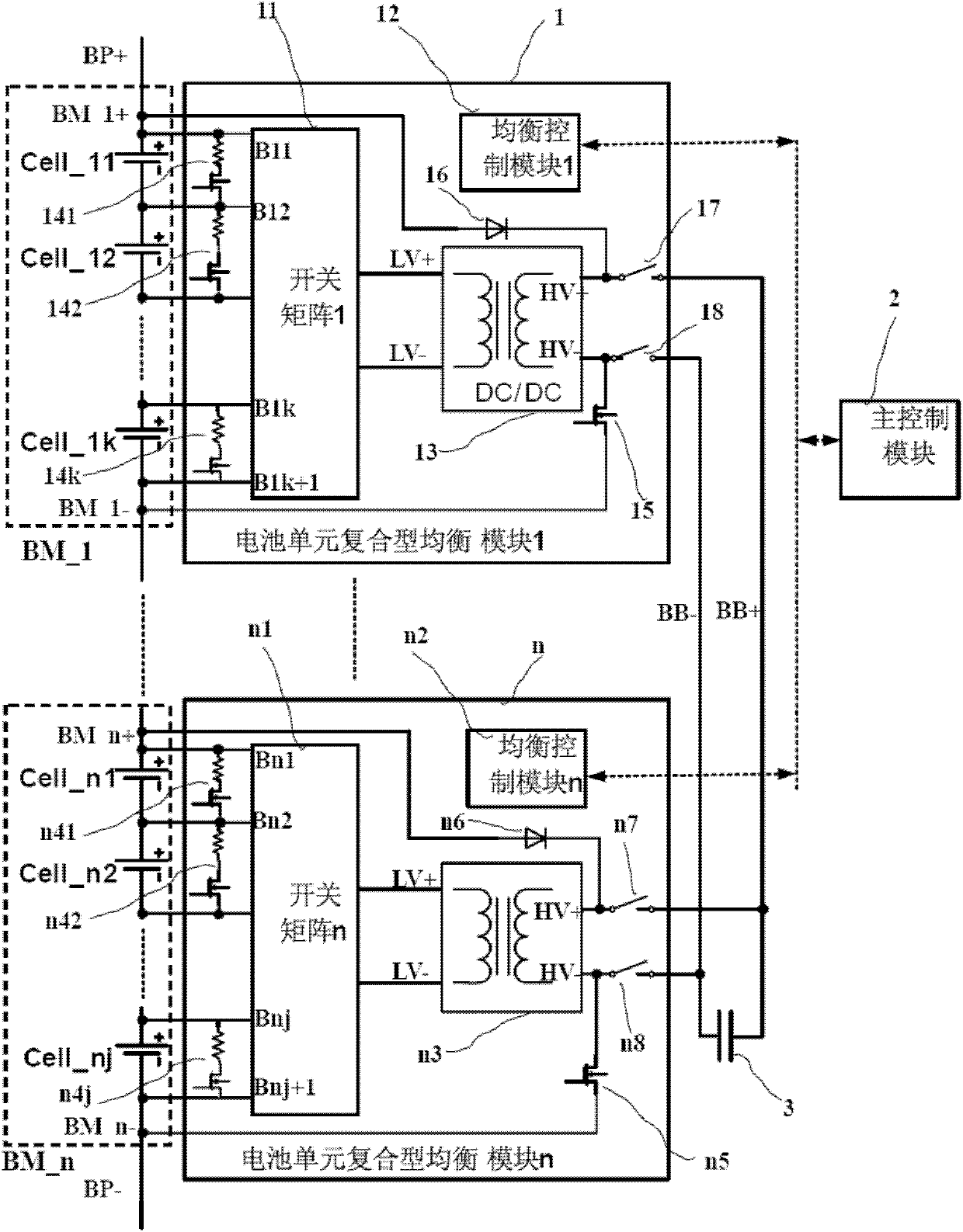

The invention discloses a composite automatic synchronous energy transfer equalization circuit and an equalization method for a series battery pack. The circuit comprises n composite two-way battery unit energy transfer equalization modules, a master control module and equalization buses, wherein the composite two-way battery unit energy transfer equalization modules are arranged according to the number of battery units in the series battery pack; n is more than or equal to 1; the composite two-way battery unit energy transfer equalization module corresponds to a battery module consisting of k battery units which are connected in series; k is more than 1; and the composite two-way battery unit energy transfer equalization module consists of a switch matrix, an equalization control module, a two-way direct current (DC)-DC module, k discharge equalization circuits and a mode control switch. The composite automatic synchronous energy transfer equalization circuit and the equalization method for the series battery pack are high in reliability, low in cost, small in volume, light in weight, functionally comprehensive and easy to manufacture and use in large scale, and can be applied in the fields of electric vehicles, rail transit, wind-driven power generation and the like by which the series battery pack and a series capacitor bank are required.

Owner:SHANGHAI 01 POWER TECH

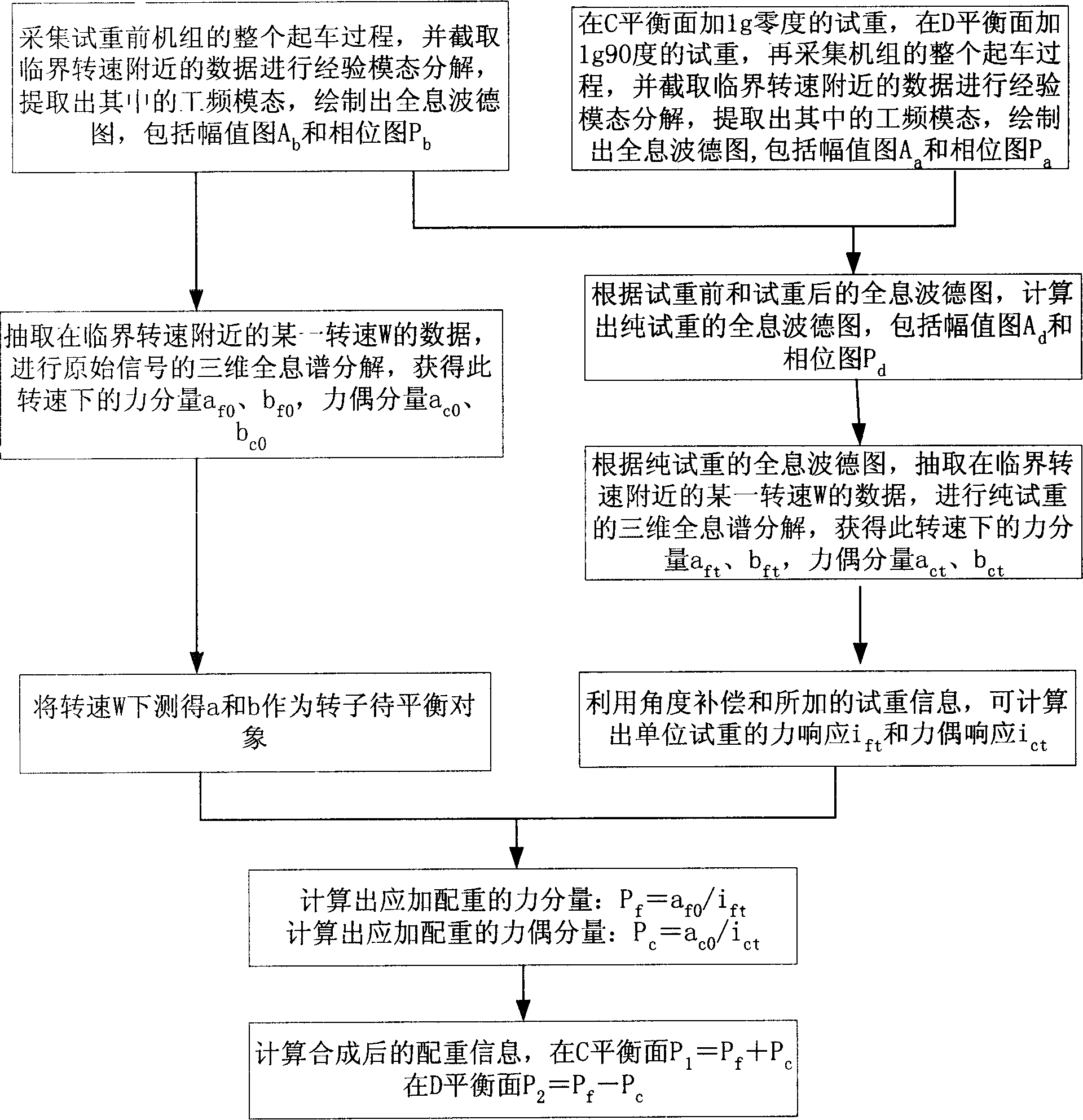

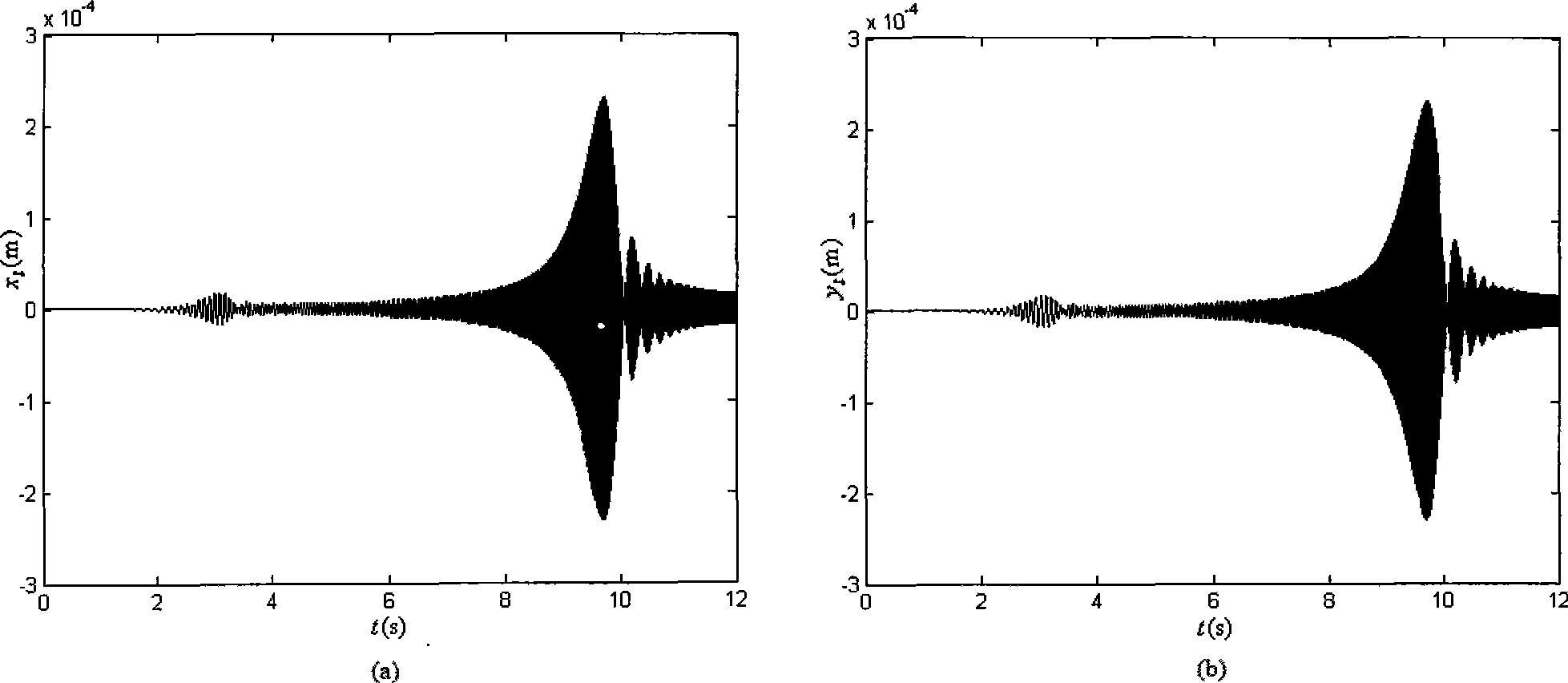

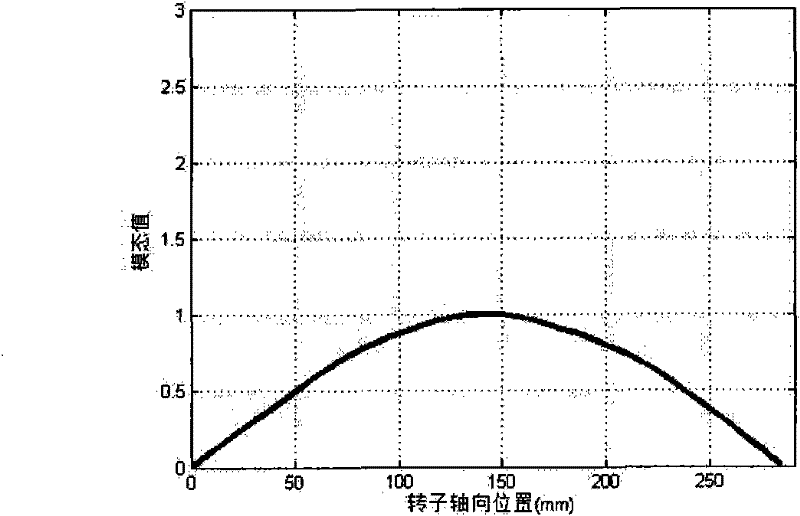

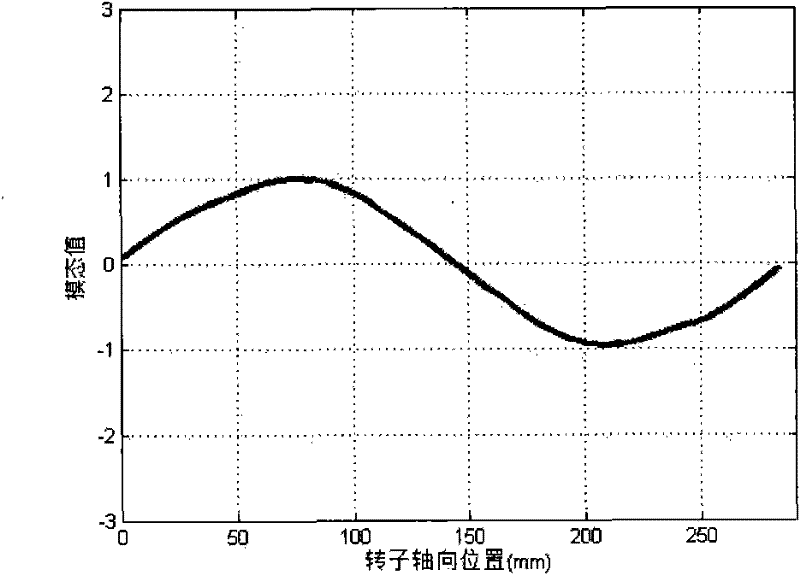

Flexible rotor holographic dynamic balancing method based on empirical mode decomposition

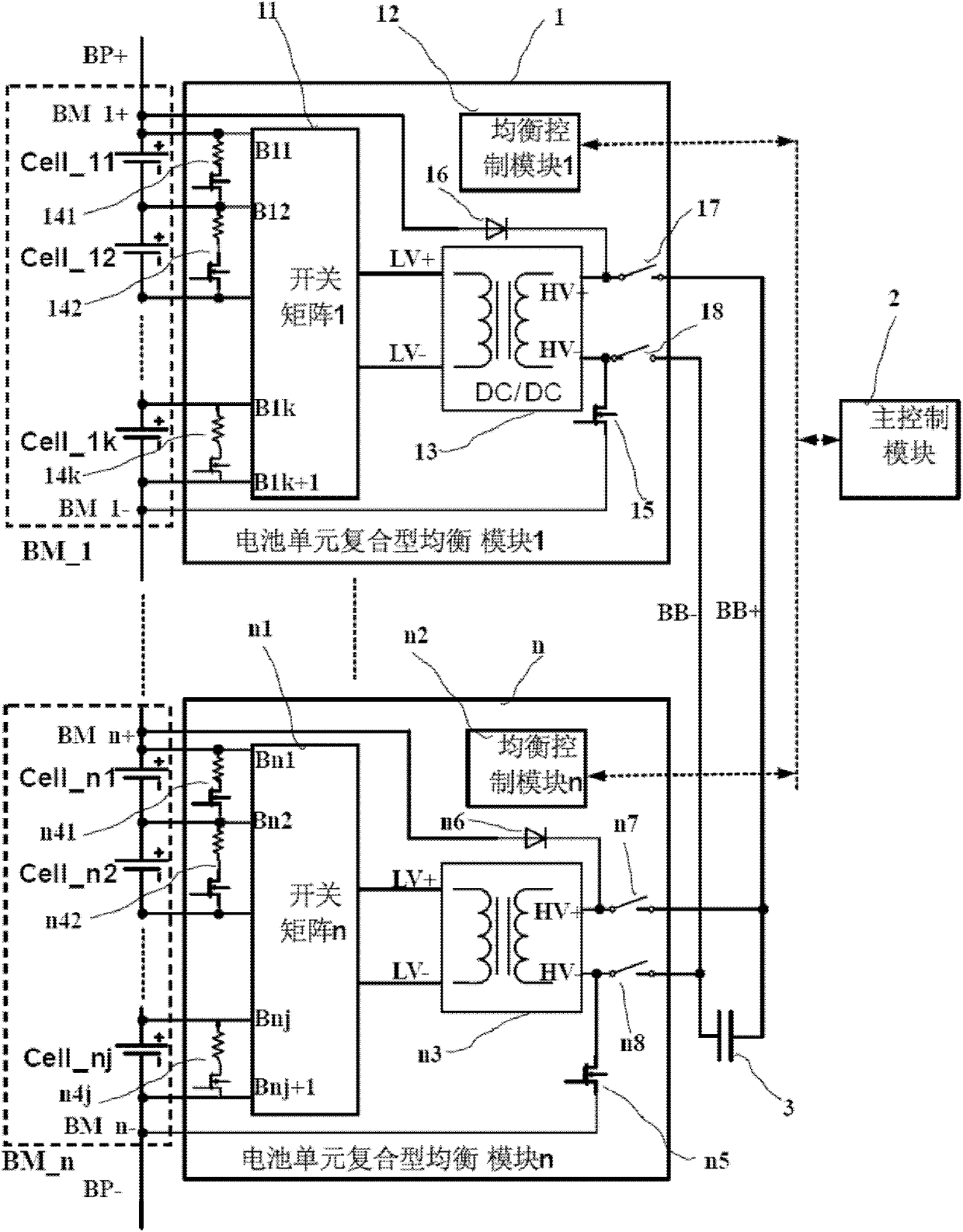

InactiveCN1789942AImplementing the Modal Balance MethodTaking into account factors such as different rigidityStatic/dynamic balance measurementDecompositionDynamic balance

The invention discloses a holographic dynamic balance method based on empirical modal breakdown flexible rotor, which is characterized by the following: resolving the data of rotor in the whole speed raising course through empirical modal breakdown advantage based on holographic spectrum information integral elementary and system theory; extracting the industrial frequency component; drawing the holographic baud graph; calculating the weight quality and orientation of different rotary speeds, especially near the weight information of critical rotary speed. The invention breaks through the limitation of traditional stable data and reduces the risk, which can reach the better balancing effect.

Owner:XI AN JIAOTONG UNIV

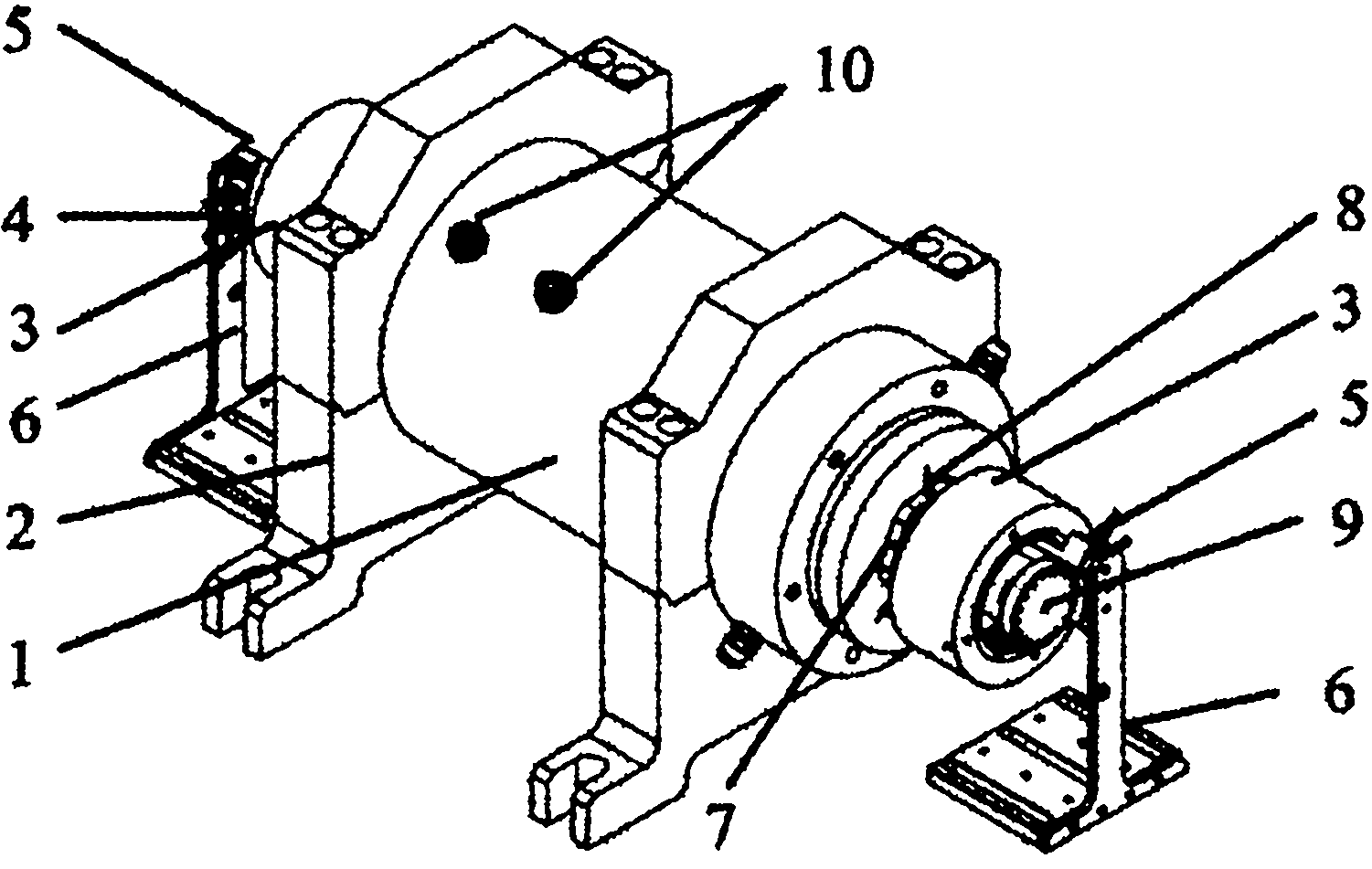

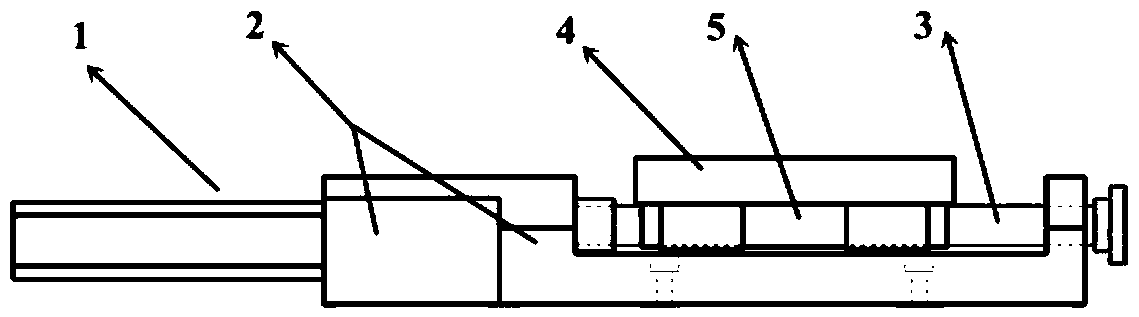

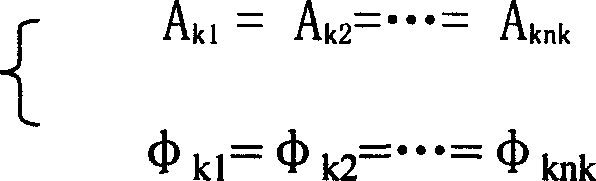

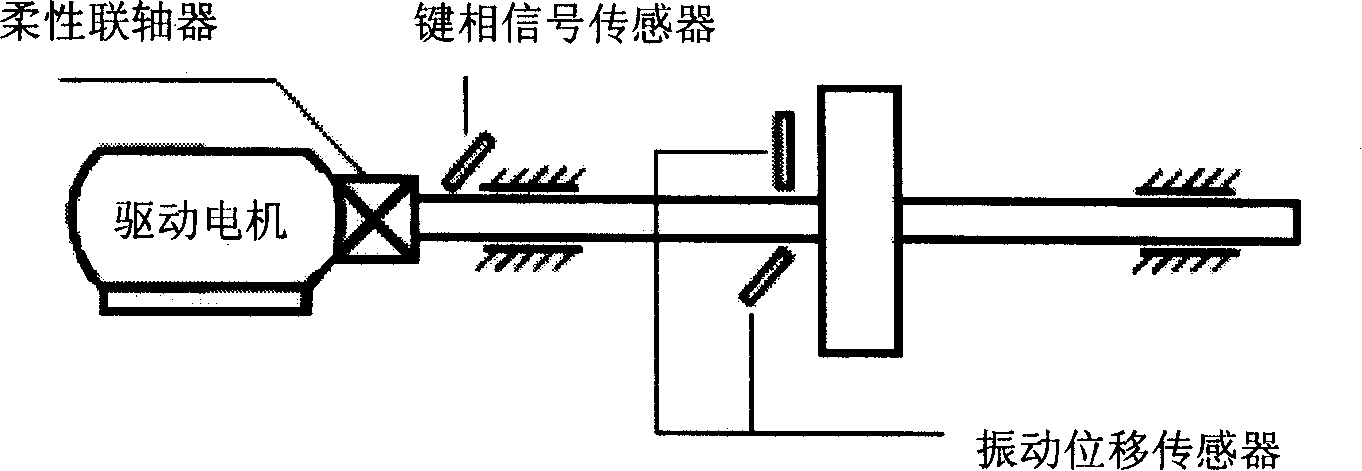

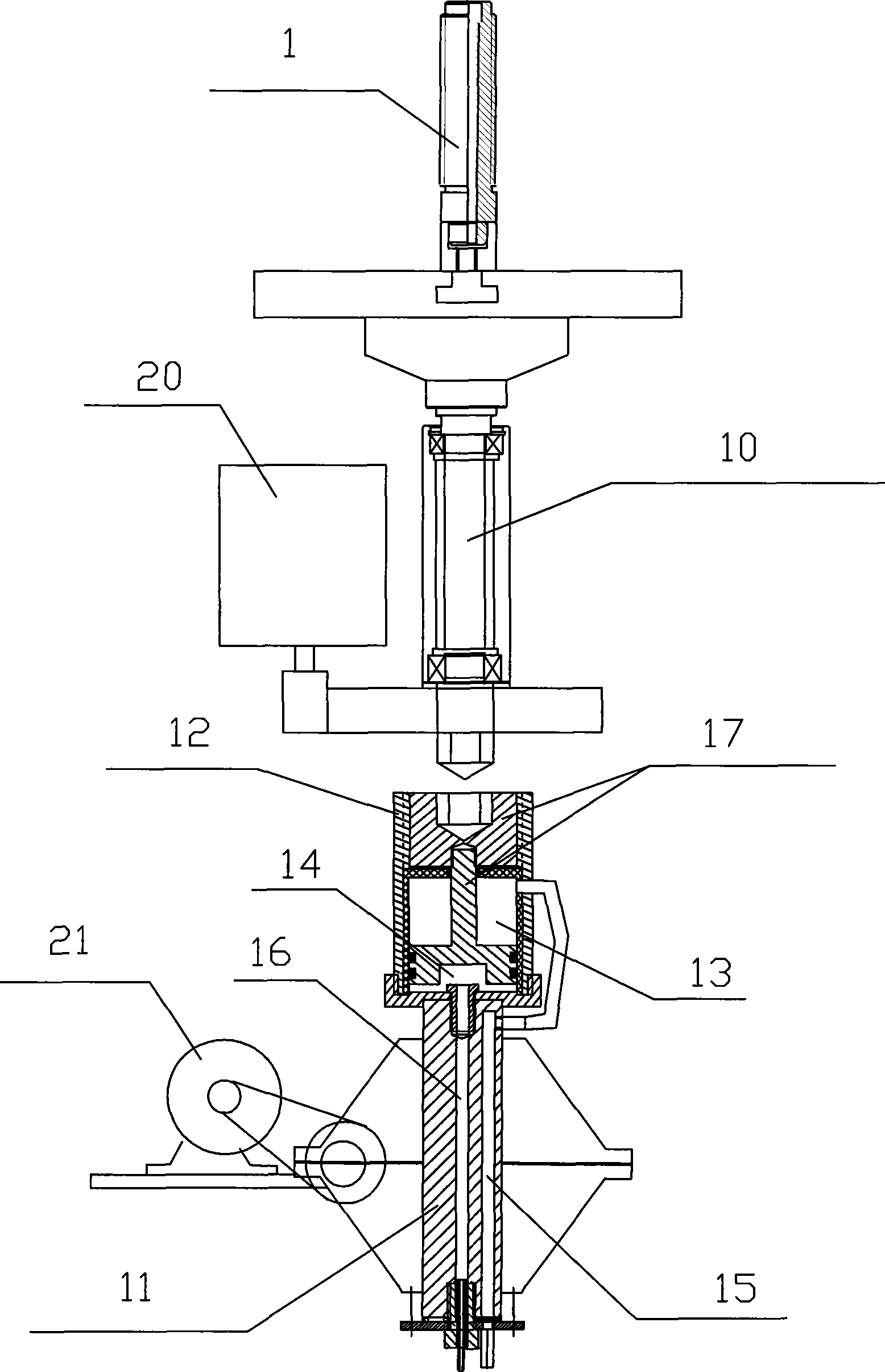

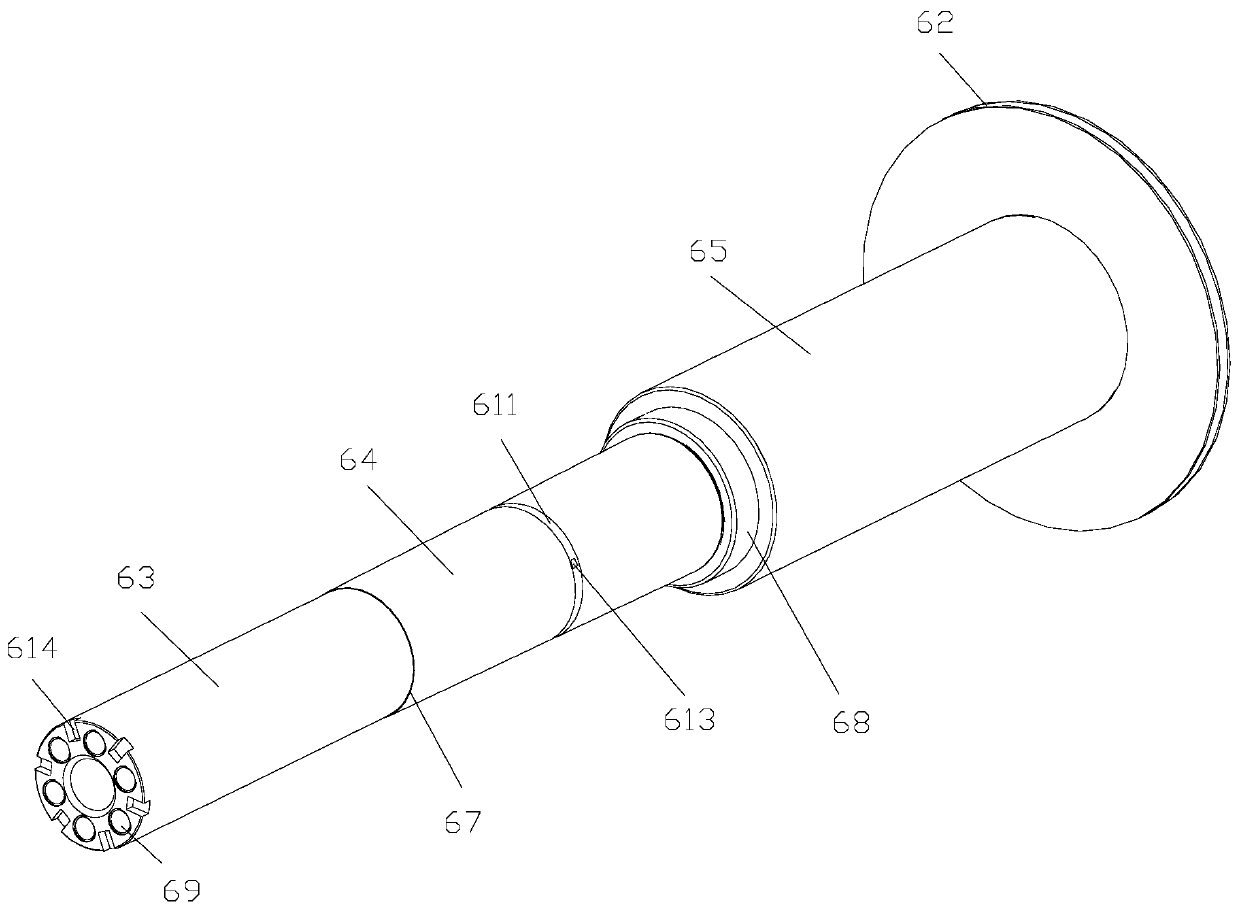

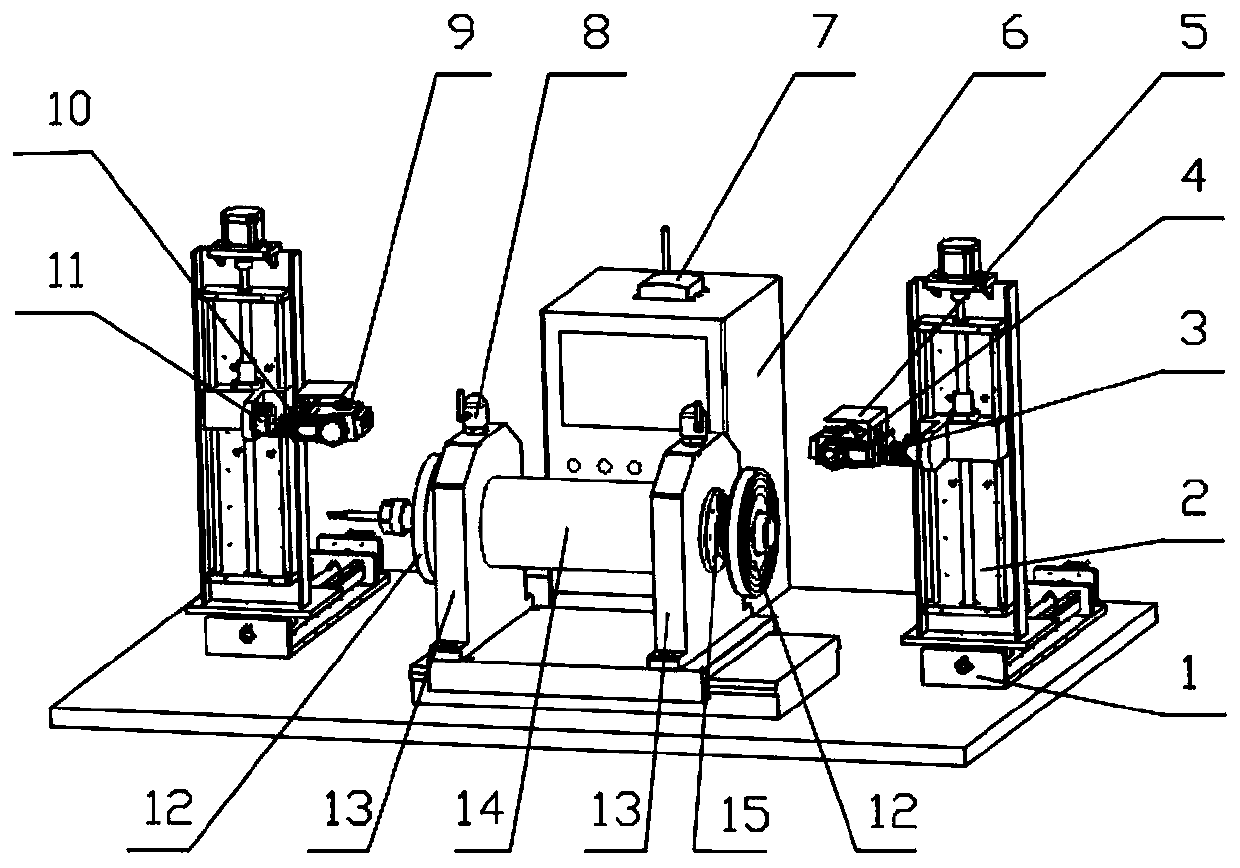

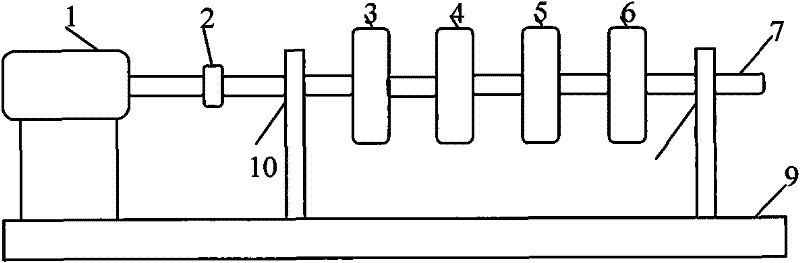

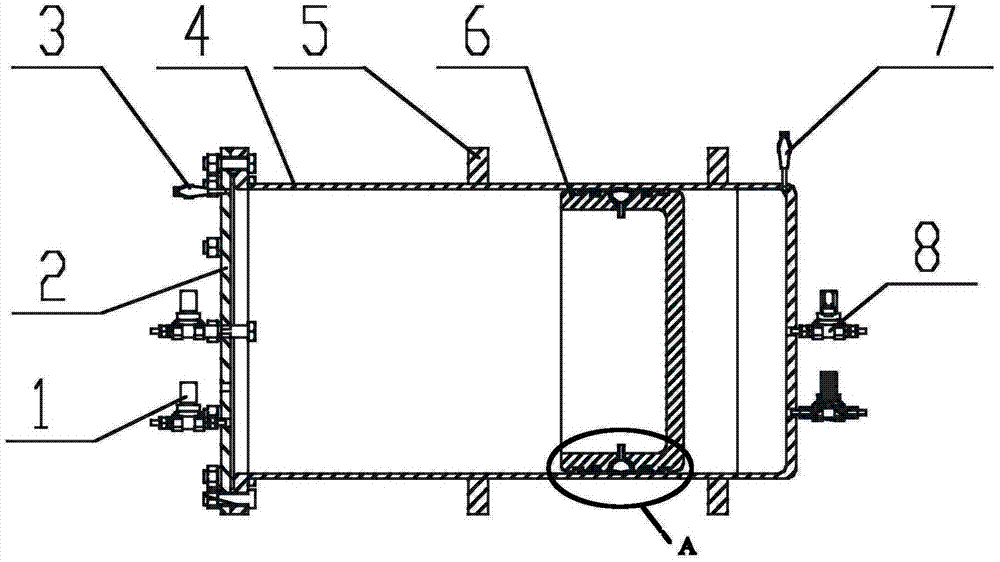

High-speed spindle on-line automatic balancing experiment system

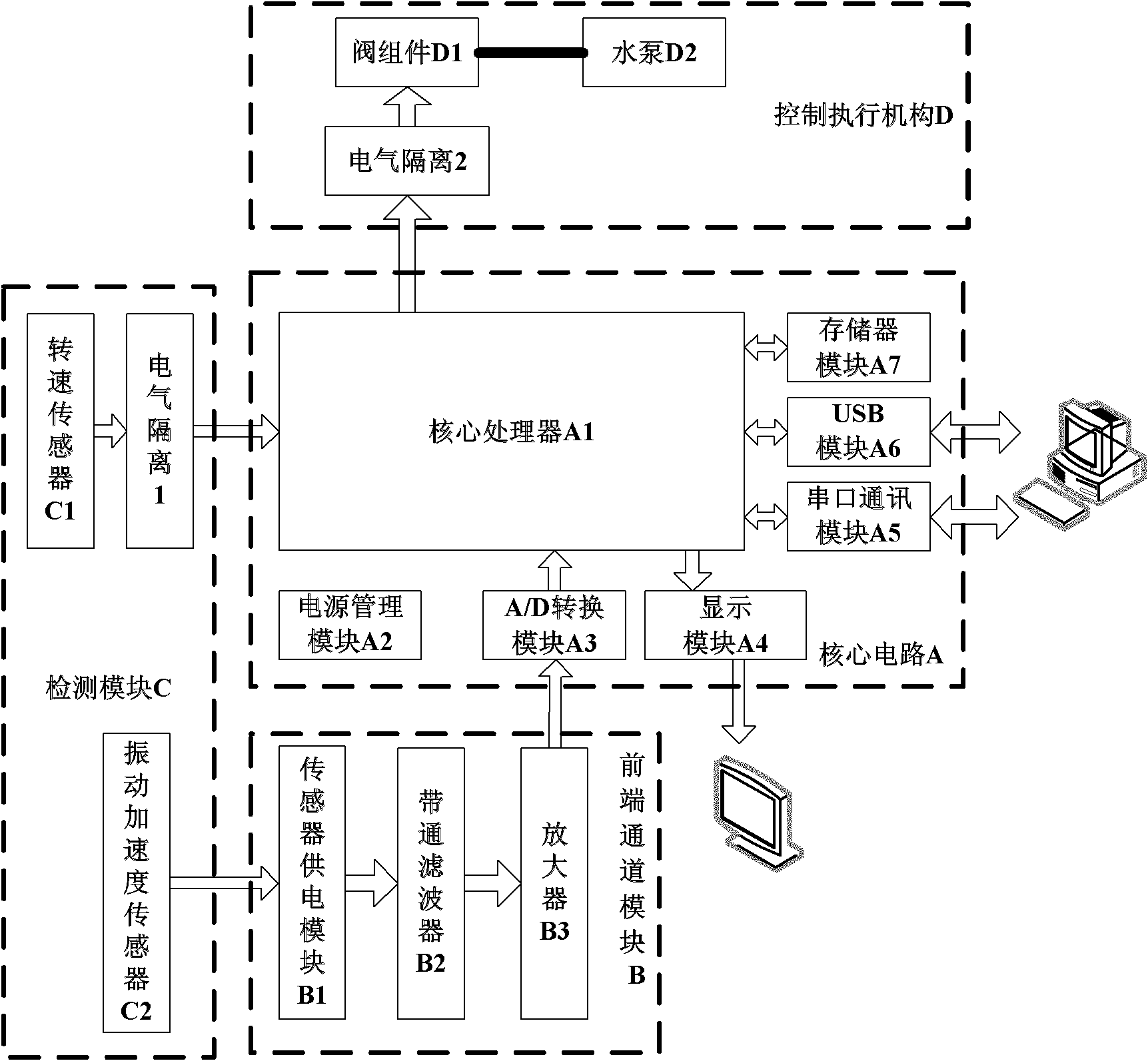

ActiveCN102095555AMeet the needs of high-speed dynamic balanceHigh balance precisionStatic/dynamic balance measurementElectricityAudio power amplifier

The invention discloses a high-speed spindle on-line automatic balancing experiment system. A spindle is arranged on a spindle positioning seat; a magnetic grid encoder is arranged on a bearing on the inner side of the spindle; displacement sensors are arranged the outer sides of two ends of the spindle; on-line dynamic balance devices are arranged at two ends of the spindle; balance water ponds in the on-line dynamic balance devices are arranged on a spindle rotor; a water gun is fixed on an experiment shock absorption platform; a spindle unbalance simulation devices is fixed on end faces of two sides of the spindle rotor through threads; the displacement sensors are connected with a high-speed synchronous data acquisition instrument through a charge amplifier; a photoelectric sensor is connected with the high-speed synchronous data acquisition instrument; and the magnetic grid encoder is connected with a high-speed synchronous counting card through a 1Vpp signal conditioning module. An industrial control computer is connected with an on-line automatic balancing device controller through a universal serial bus. Through the high-speed spindle on-line automatic balancing experiment system, high-speed spindle on-line automatic balancing experiment can be realized, and the system has the characteristics of high speed, accuracy and integrated level and the like.

Owner:XI AN JIAOTONG UNIV

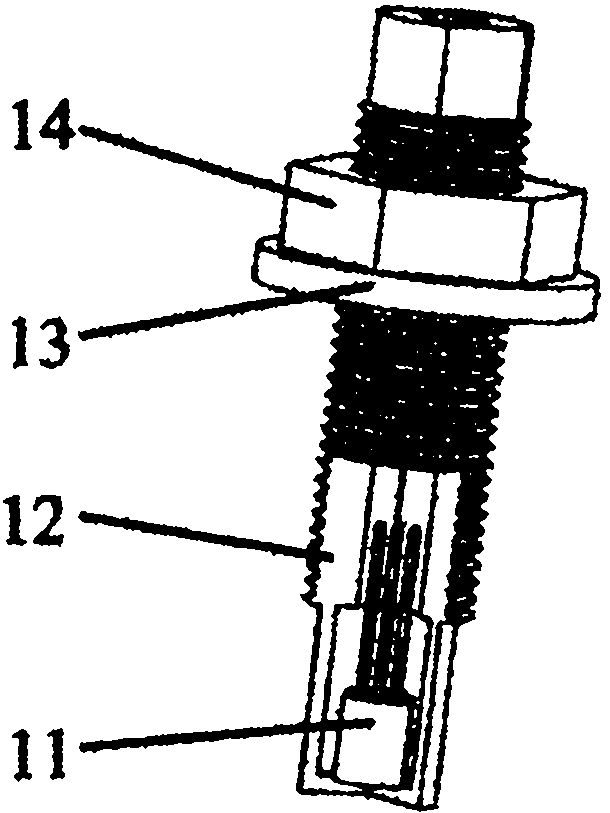

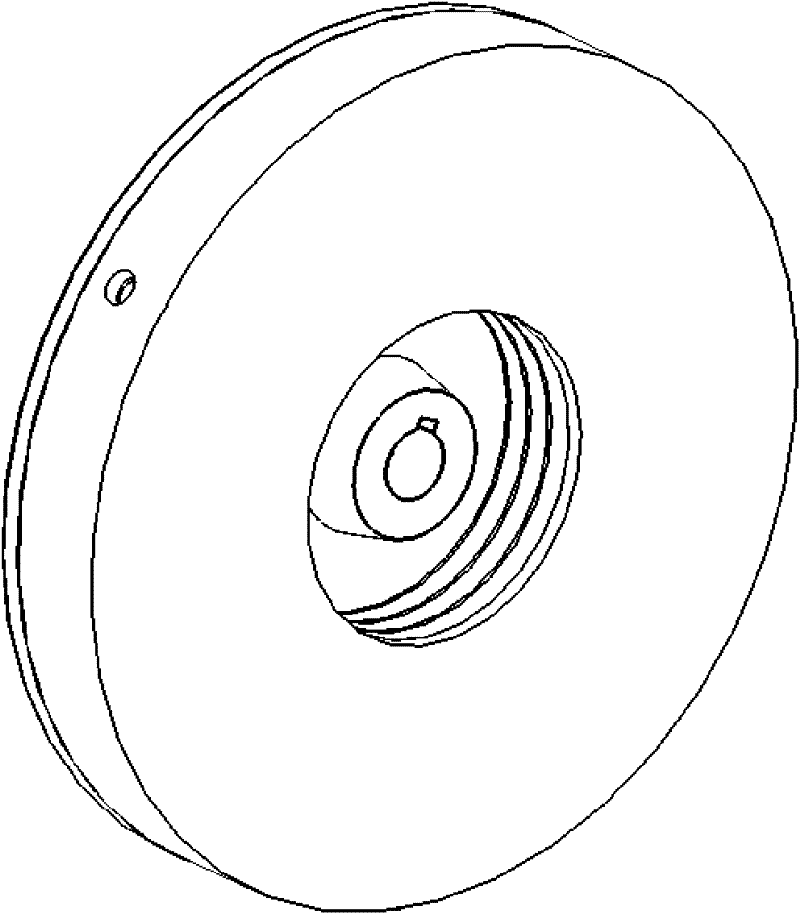

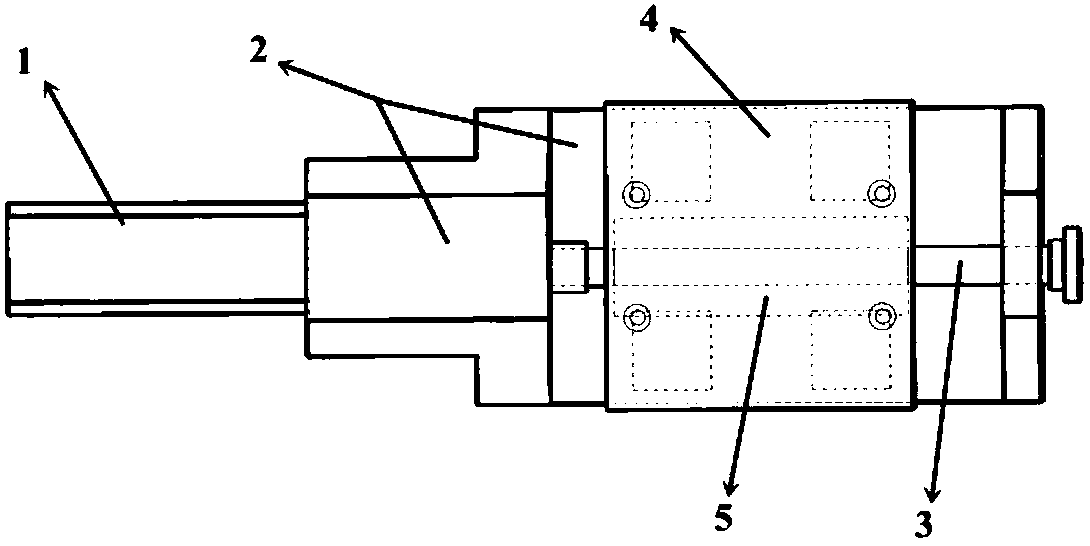

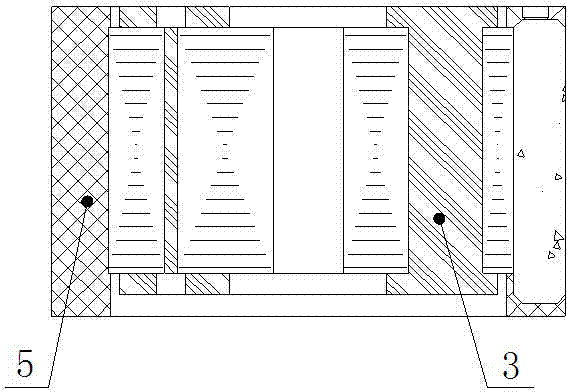

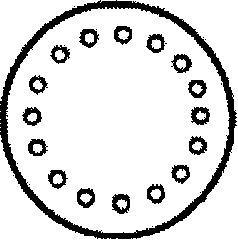

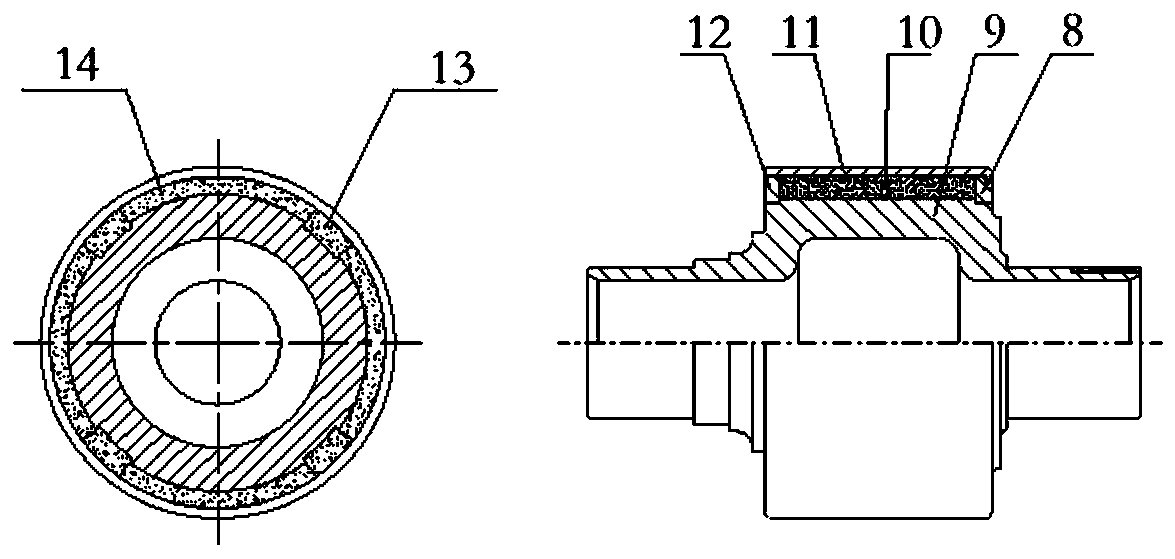

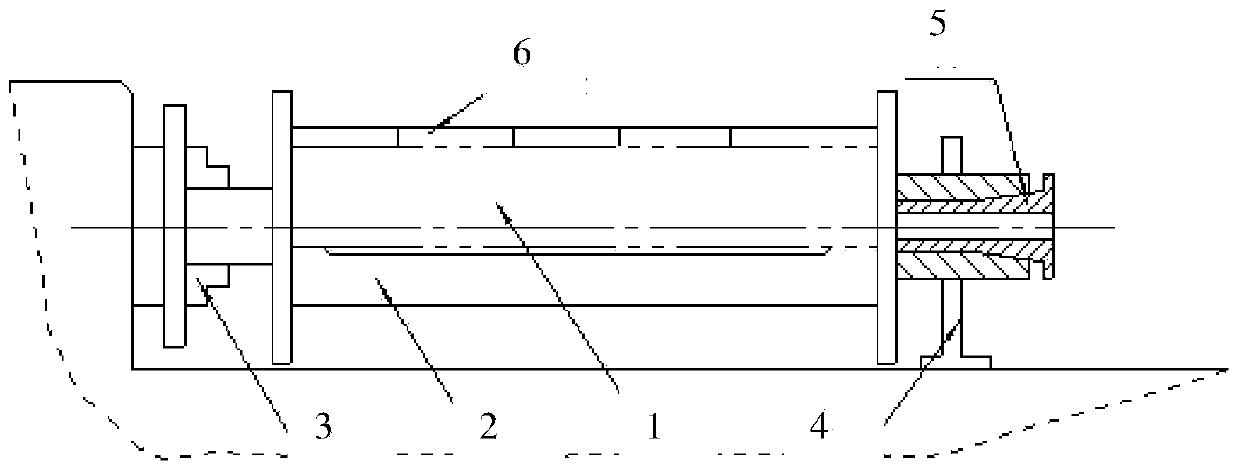

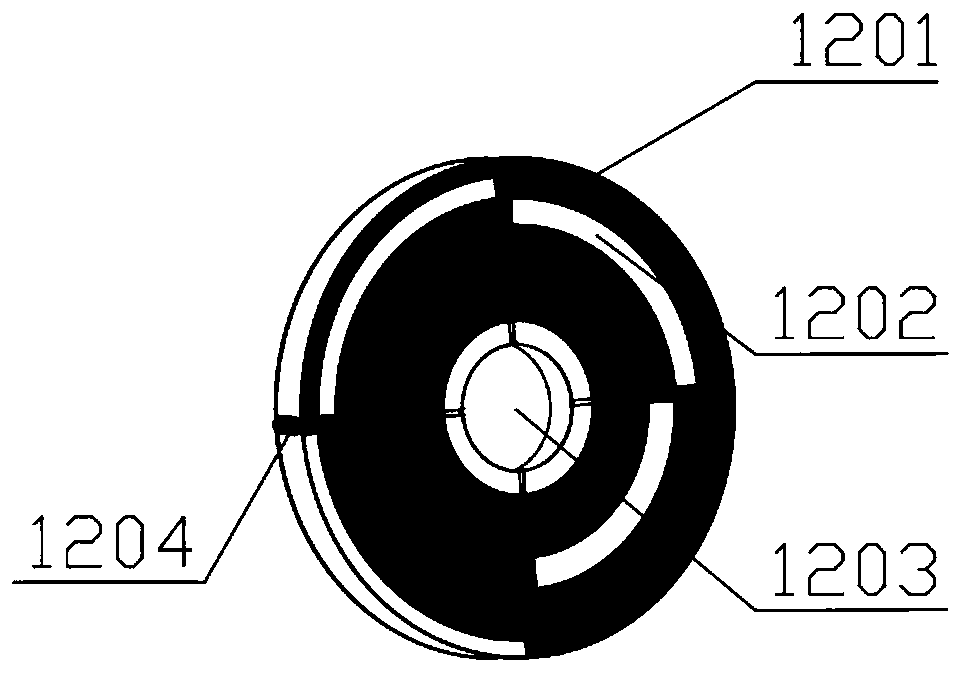

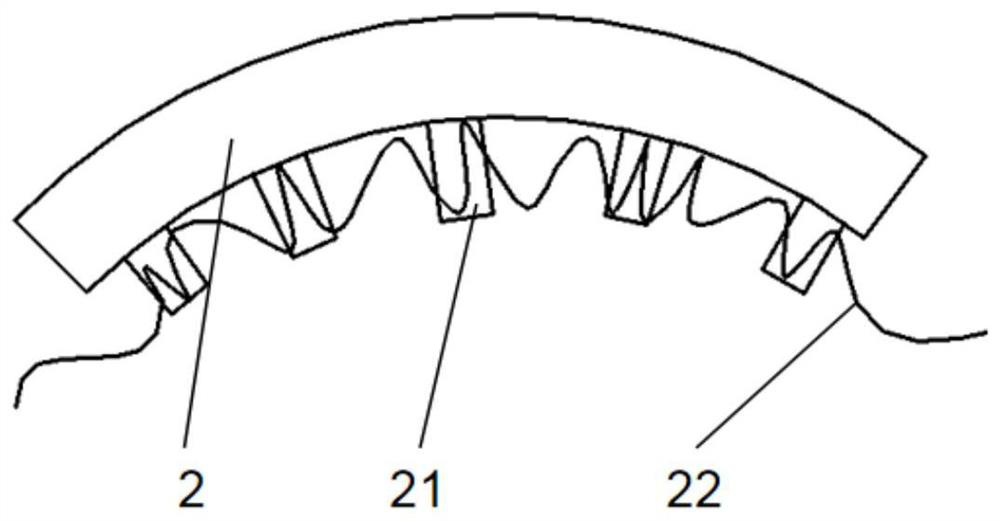

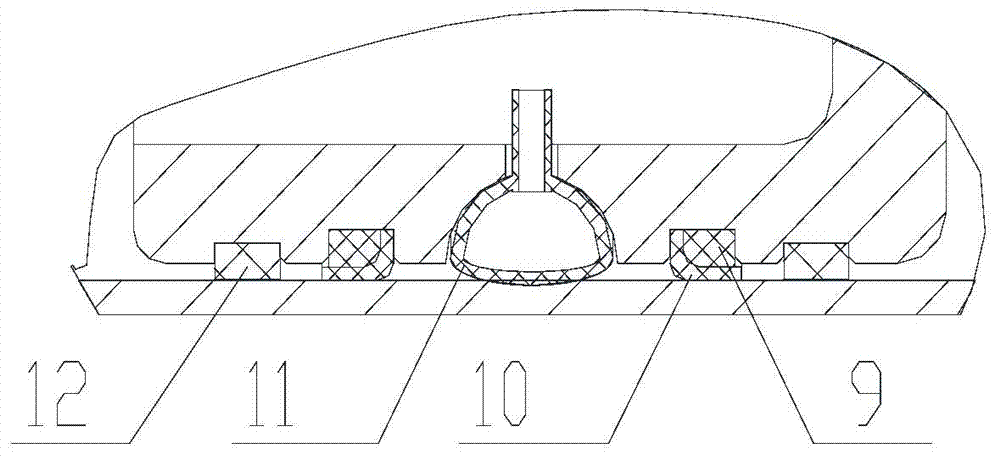

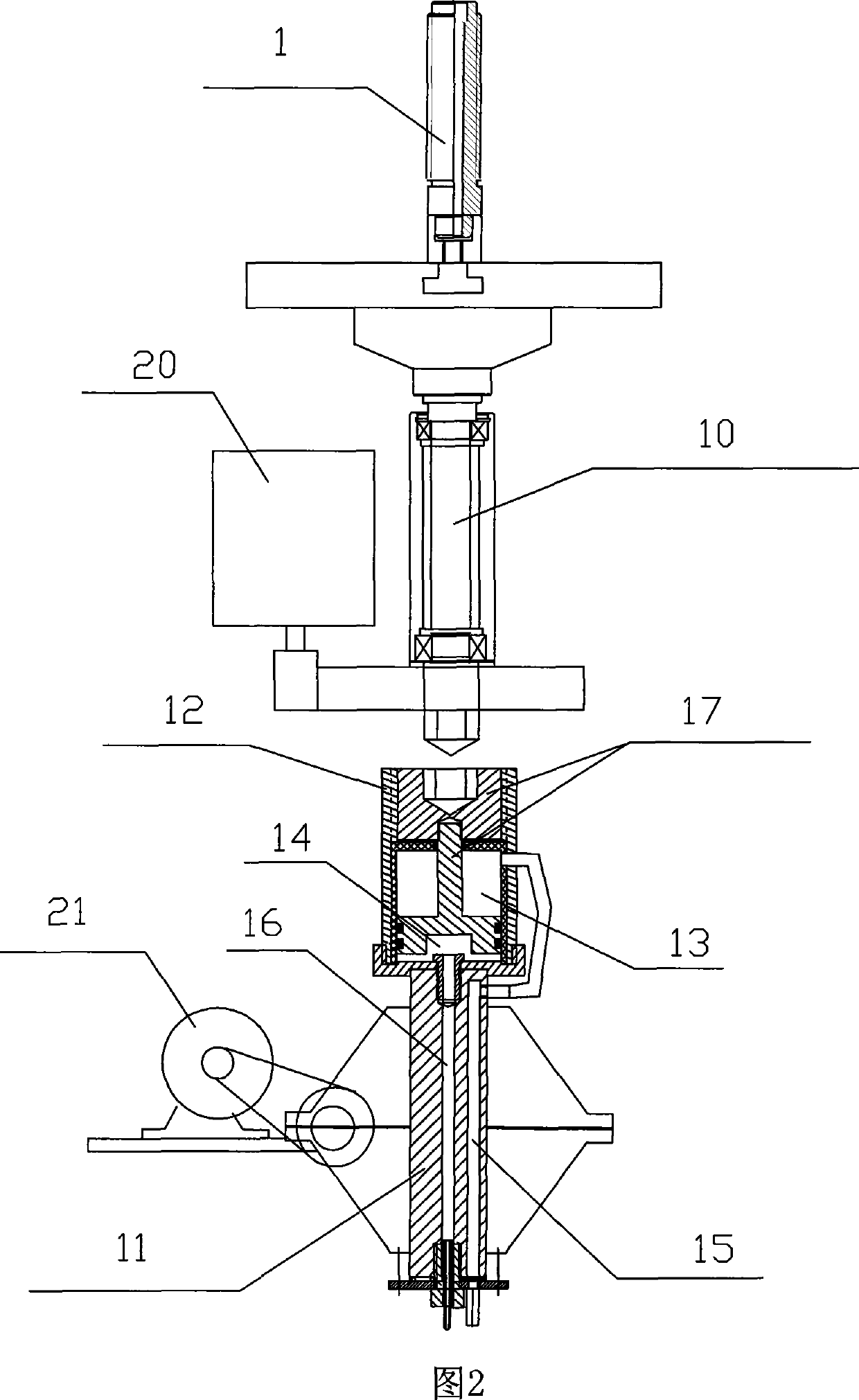

Liquid-injection type online dynamic balance head structure for high rotating speed

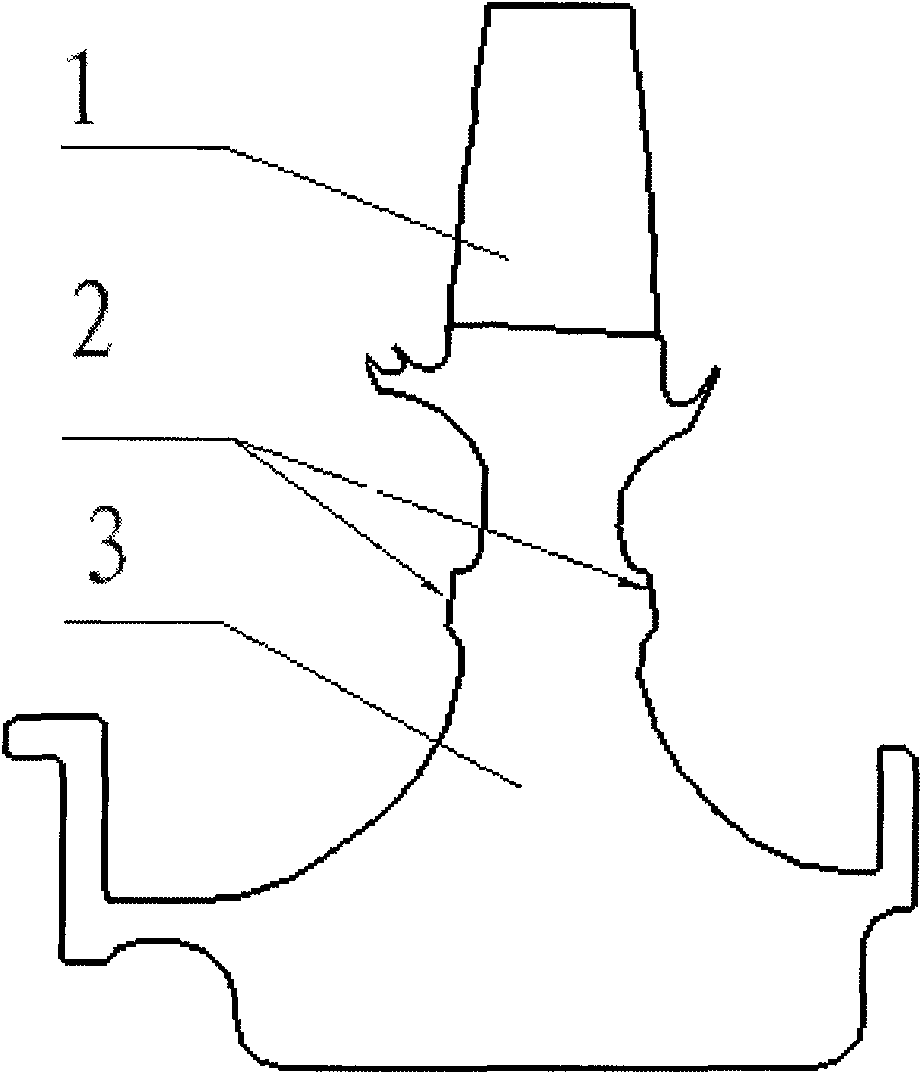

InactiveCN102183338AReduce rotary speedRealize online liquid injection dynamic balanceRotating bodies balancingStatic/dynamic balance measurementDynamic balanceEngineering

The invention discloses a liquid-injection type online dynamic balance head structure for high rotating speed, comprising a chassis and a water tank disc connected with the chassis, wherein a liquid injection hole is saliently arranged in the center of the chassis; the water tank disc is provided with a center hole which is sleeved with the liquid injection hole of the chassis; the inner side of the wall of the center hole of the water tank disc is provided with three parallel annular grooves which are circumferentially distributed; the outer side of the center hole of the water tank disc is provided with three sector-shaped liquid storage cavities which are evenly distributed; liquid outlet holes which are communicated with the liquid storage cavities and correspond to the liquid storage cavities are respectively arranged on the annular grooves of the center hole of the water tank disc; and liquid discharge holes are arranged on the outer side walls of the liquid storage cavies. The three liquid storage cavities are respectively of a design structure that the inner side is opened along the radial direction so as to enlarge and balance a liquid injection time window and realize 360-degree continuous liquid injection. The balance head structure is simple, has a low cost, can improve the balancing precision and efficiency through a low-flow continuous liquid injection mode, rectify the unbalance amount of a rotary machine and reduce the mechanical vibration. The invention is suitable for online dynamic balance of a rotor under a high rotating speed condition.

Owner:XI AN JIAOTONG UNIV

Method for adjusting mass center of three-axis air bearing table based on non-orthogonal structure

ActiveCN103869833AHigh balance precisionMeet the use requirementsControl using feedbackAir bearingCentre of rotation

The invention relates to and is applicable to the field of full ground physical simulation, in particular to a method for adjusting the mass center of a three-axis air bearing table based on a non-orthogonal structure. The method aims to solve the problems that in the prior art, adjustment of the mass center of the three-axis air bearing table requires manual leveling, time is wasted, and the adjustment accuracy of the mass center of the three-axis air bearing table is low. By means of the method, the mass center of the three-axis air bearing table can be adjusted to the position where the mass center of the three-axis air bearing table and the rotation center of the three-axis air bearing table coincide, so that the experiment table has high balance precision, the positioning accuracy of a three-dimensional mass center adjustment system of the experiment table is higher than 10 microns, and the using requirement existing when the experiment table conducts posture simulation on the ground is met; time for adjustment of the mass center is greatly shortened, manual operation is not needed, and adjustment time is shortened by over one time compared with the prior art.

Owner:HARBIN INST OF TECH

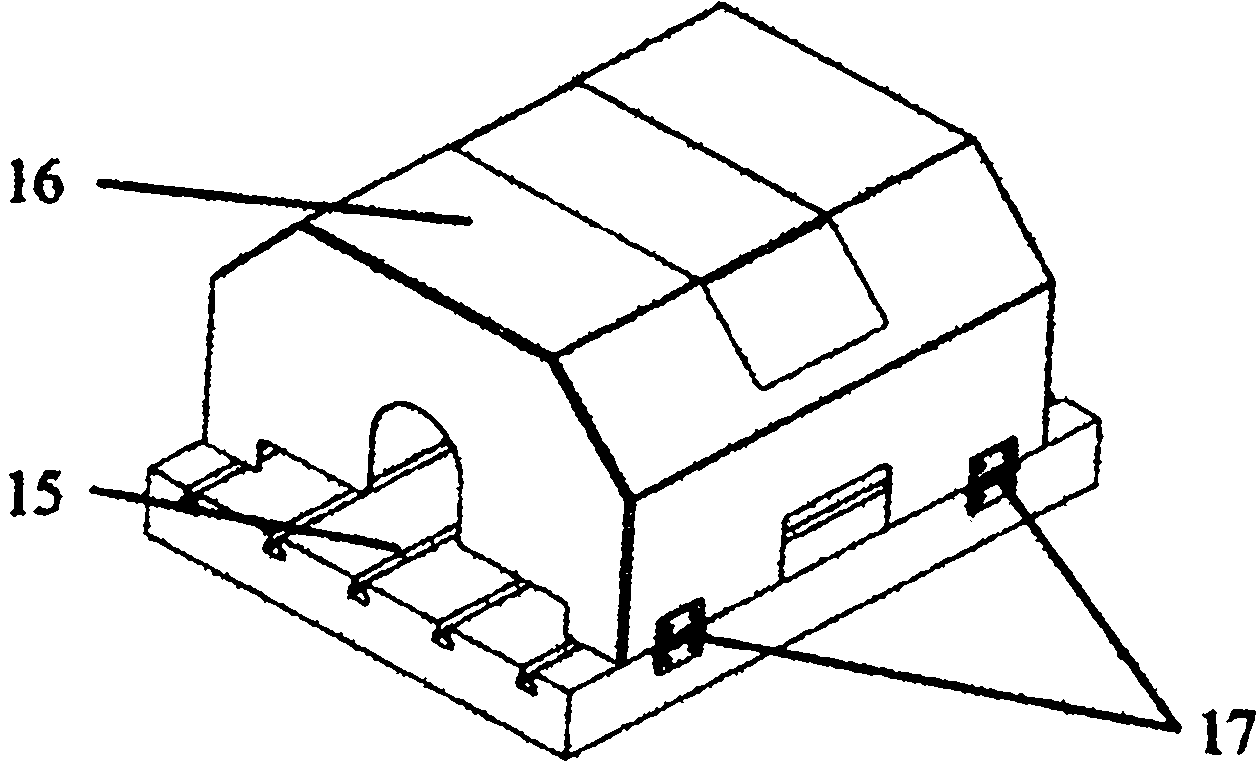

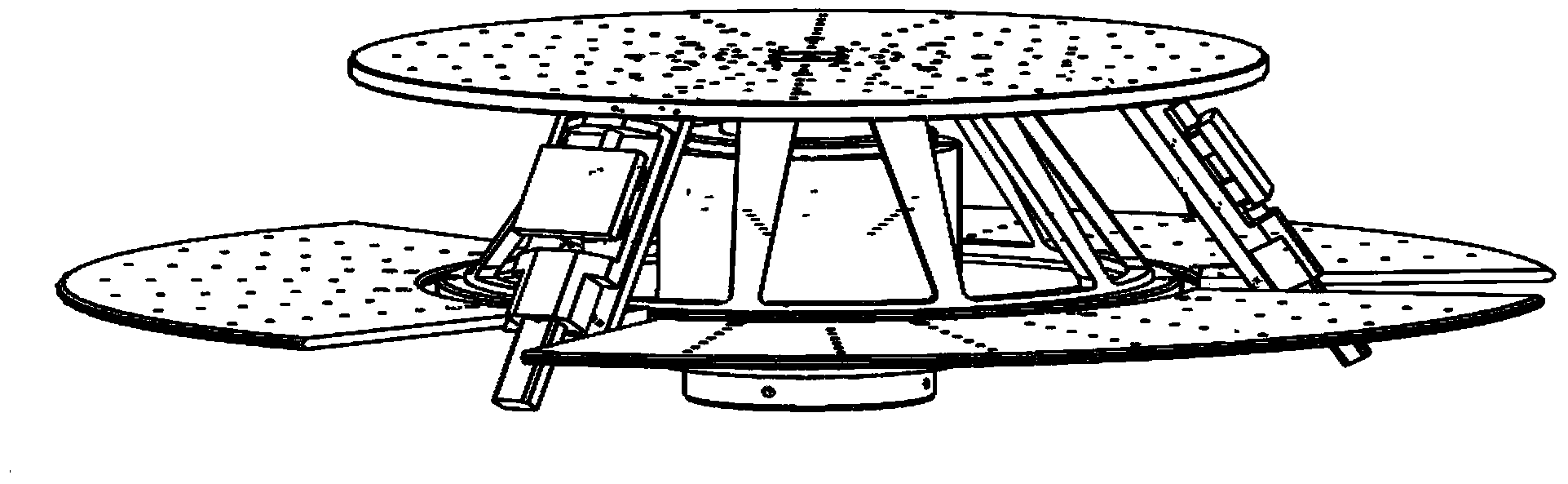

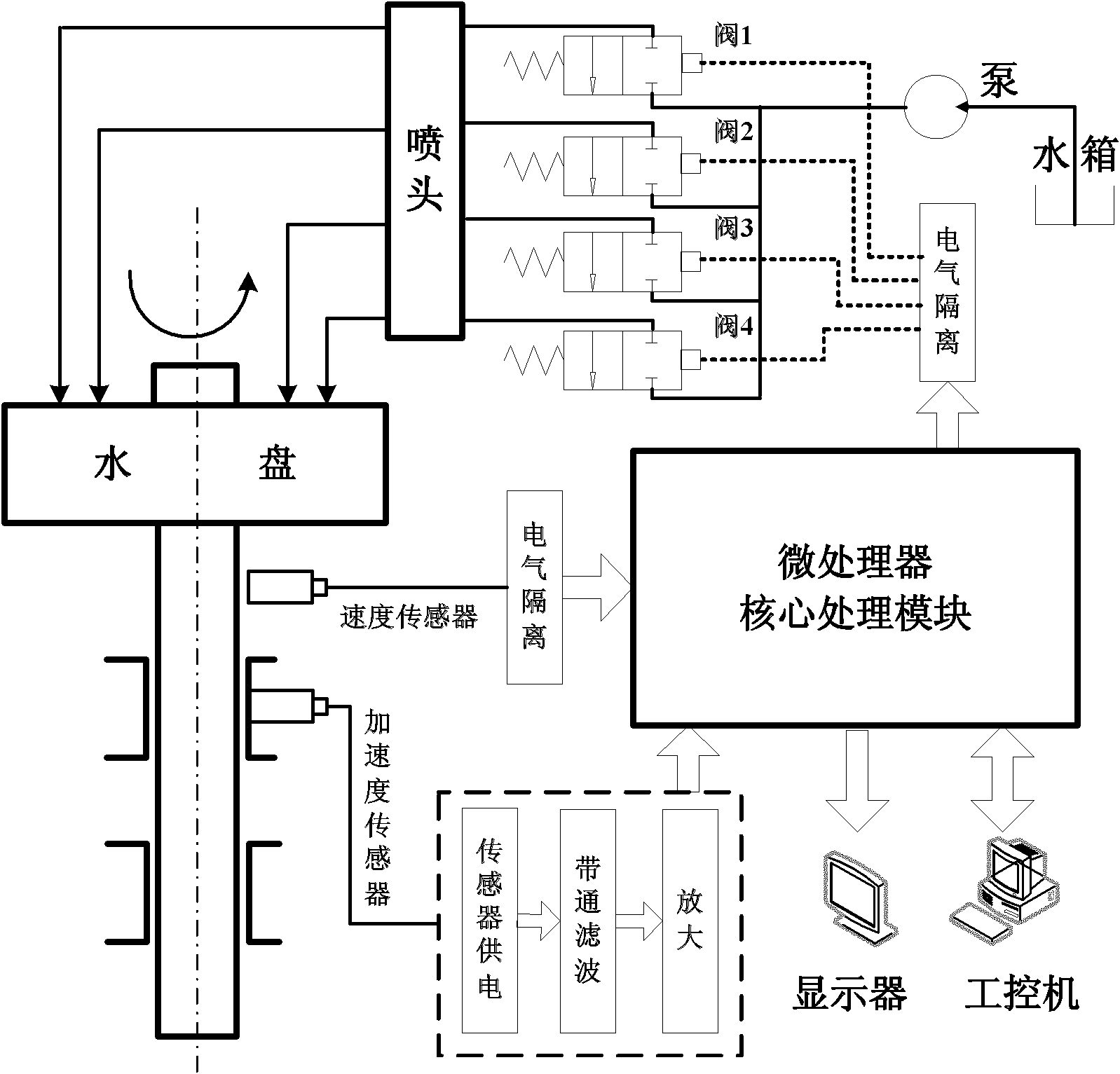

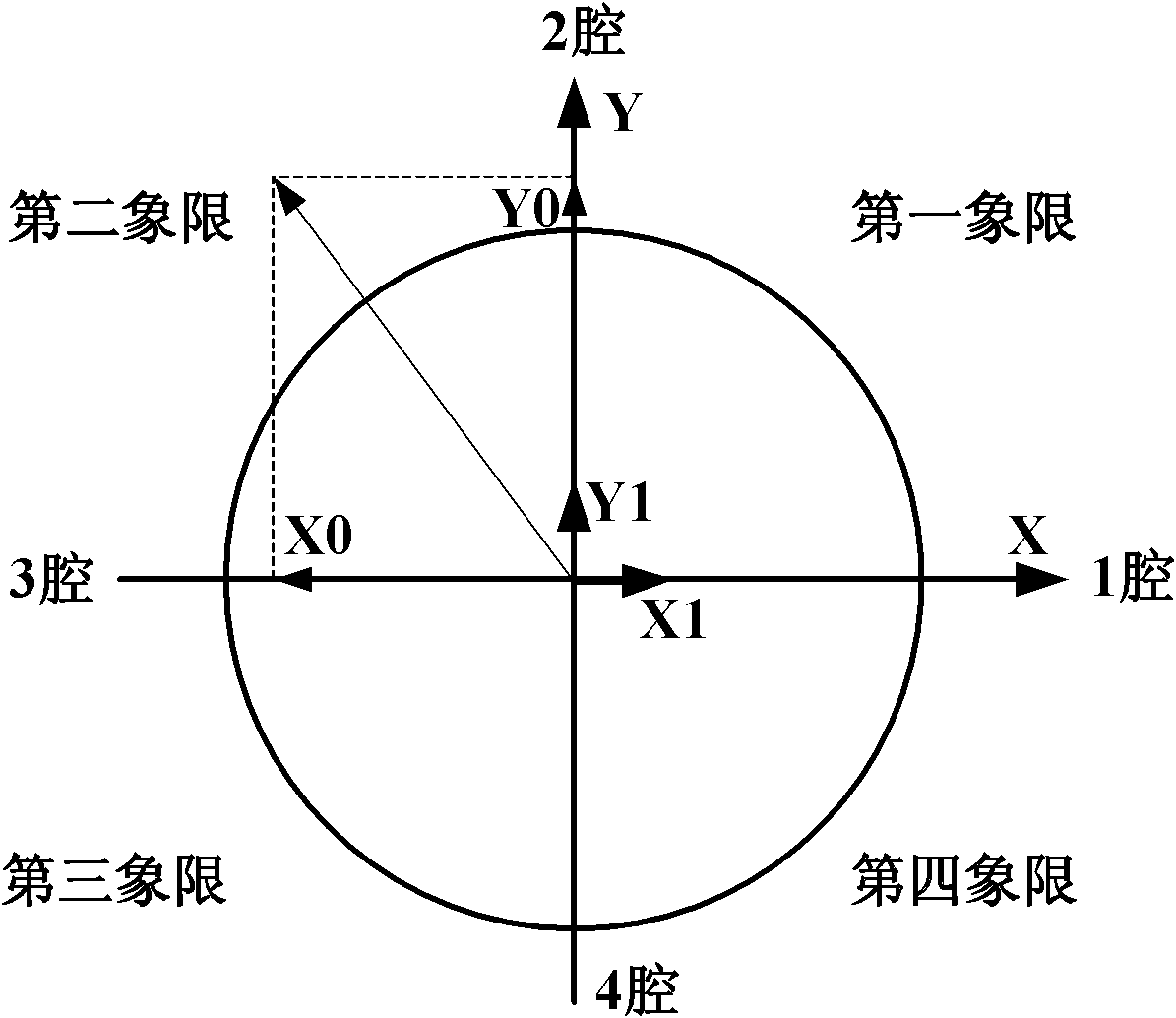

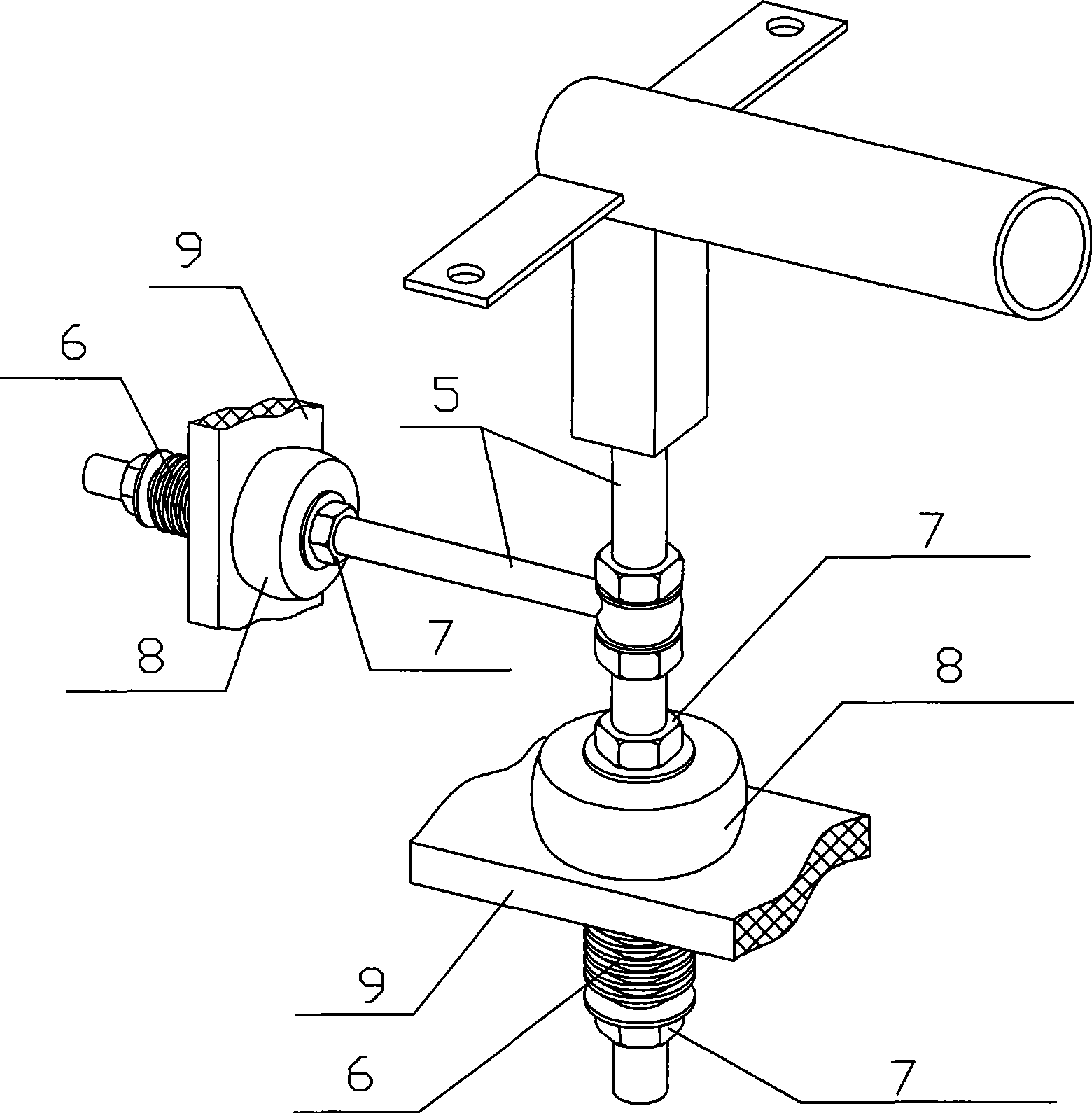

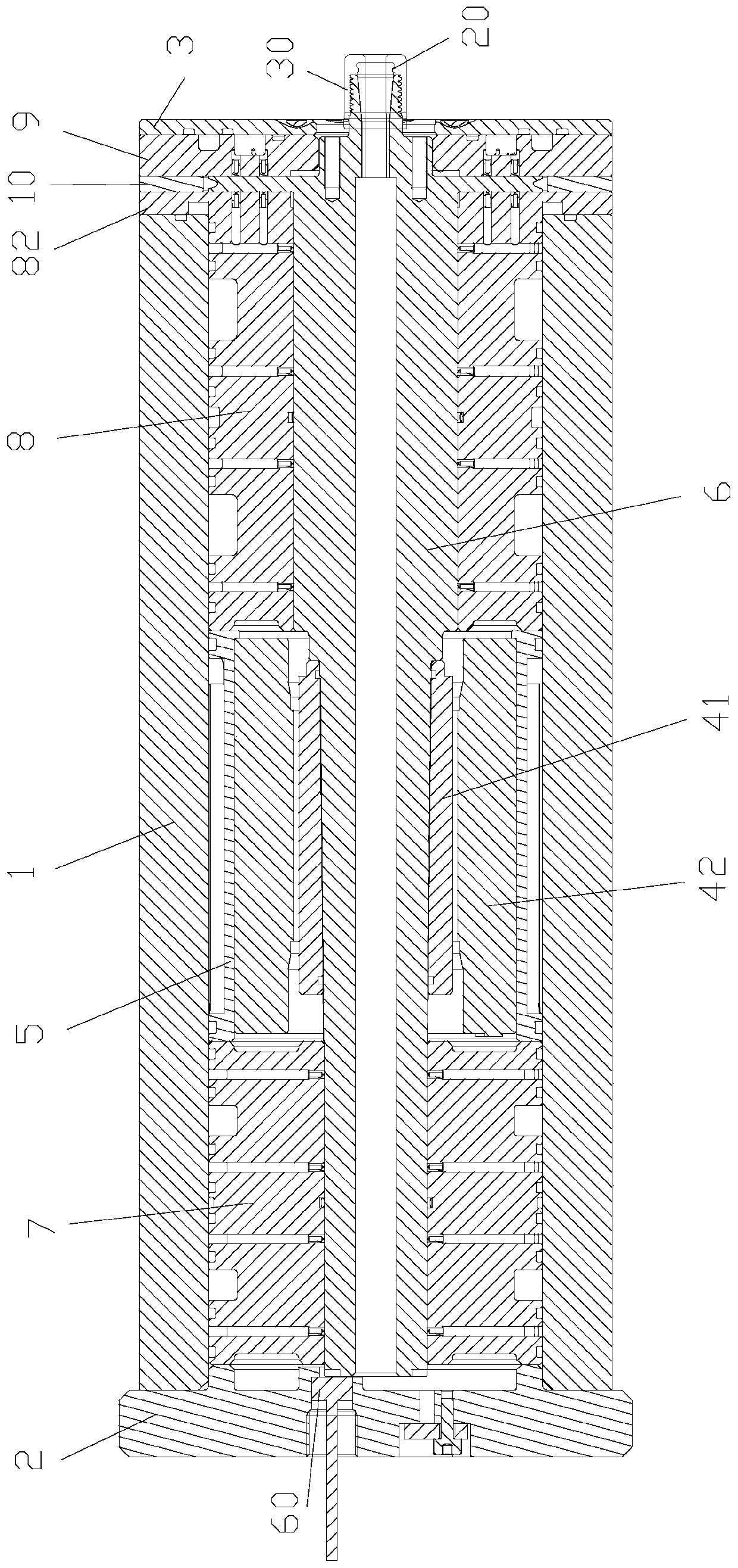

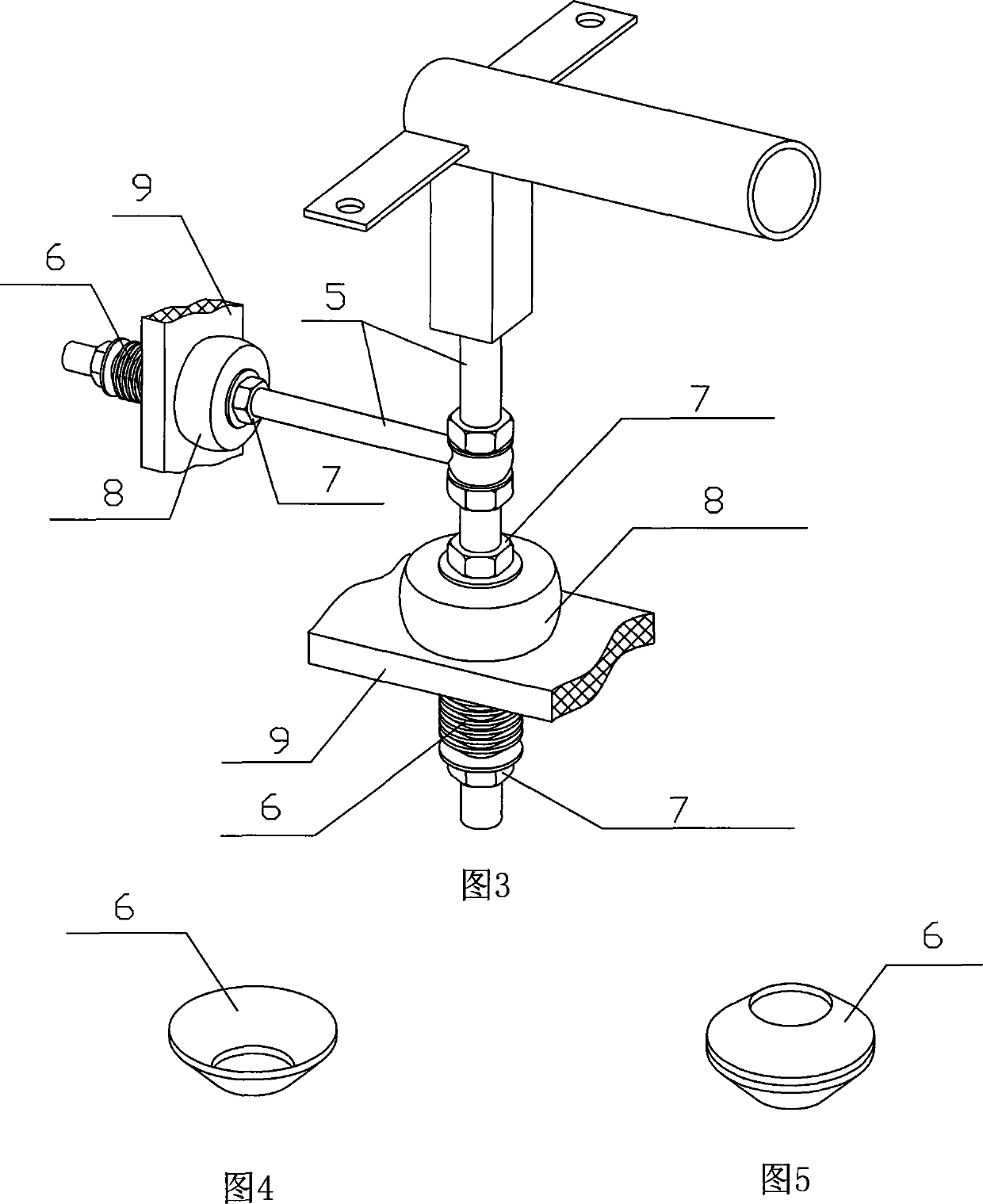

Automatic on-line balancing system of liquid-injection high-speed main shaft

ActiveCN102095554AEase of field applicationImprove balance efficiencyStatic/dynamic balance measurementWater channelSpray nozzle

The invention discloses an automatic on-line balancing system of a liquid-injection high-speed main shaft, which is mainly composed of a mechanical structure part and an electric control part, wherein the mechanical structure part comprises a water pan structure and a spray nozzle part; the water pan is directly installed on one end of the main shaft; a water channel in the water pan can ensure that liquid can be stably and accurately distributed in an appointed water cavity after the liquid is injected into the water pan via a spray nozzle; the spray nozzle is connected with a workbench, and the position and the angle of the spray nozzle can be adjusted; the electric control part obtains the vibration signal of the main shaft in real time; according to the vibration change situation of the main shaft, a valve assembly is controlled to precisely inject water; and vibration information collected before and after water is injected each time is used as a judgement basis for system control. The automatic on-line balancing system of a liquid-injection high-speed main shaft is characterized in that centrifugal force generated by the liquid offsets with the initial amount of the unbalance of the main shaft after repeated liquid injection, and the main shaft system is balanced.

Owner:XI AN JIAOTONG UNIV

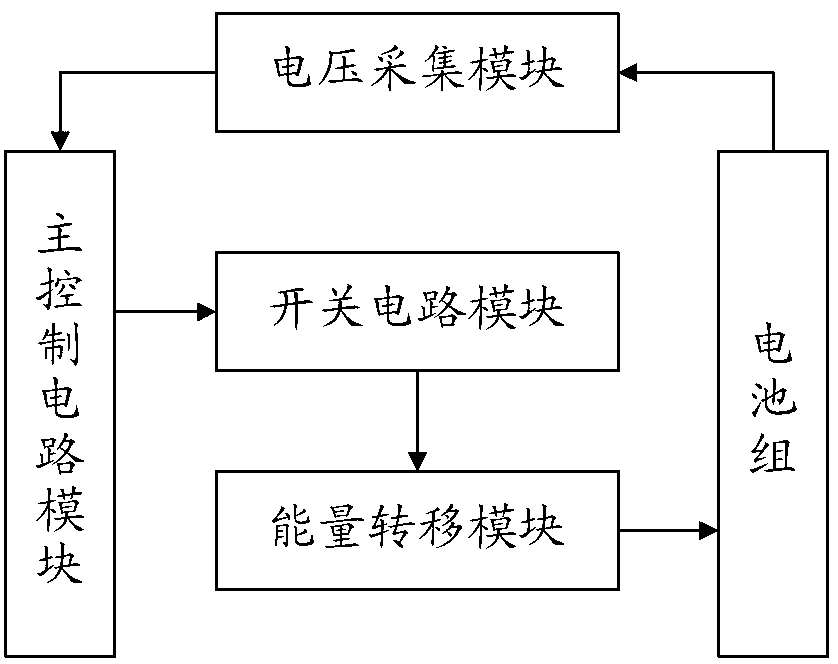

Battery power equalization circuit

ActiveCN103269108ACell balanceThe power balance circuit can adopt top-down one-way power balanceBatteries circuit arrangementsElectric powerDriver circuitEnergy transfer

The invention provides a battery power equalization circuit which comprises battery packs, a voltage acquisition module, a switching circuit module, power transferring modules and a main control circuit module, wherein the switching circuit module comprises a plurality of group-inner switches and a plurality of driving circuit used for respectively driving the corresponding group-inner switches; the main control circuit module is used for judging whether powers among batteries are equalized according to voltage signals at two ends of each battery; and if not, sending control signals are to the corresponding driving circuits in the switching circuit module, so that the driving circuits can control the corresponding group-inner switches to be conducted / cut off. Therefore, the power equalization among all the battery packs is realized firstly via the two groups of power transferring modules arranged in parallel; and then the power equalization among the batteries in each battery pack is realized respectively via the two groups of power transferring modules arranged in parallel. As a result, the power equalization among all the batteries is realized. The battery power equalization circuit is simple to control, high in equalization precision and rapid in speed.

Owner:CHERY AUTOMOBILE CO LTD

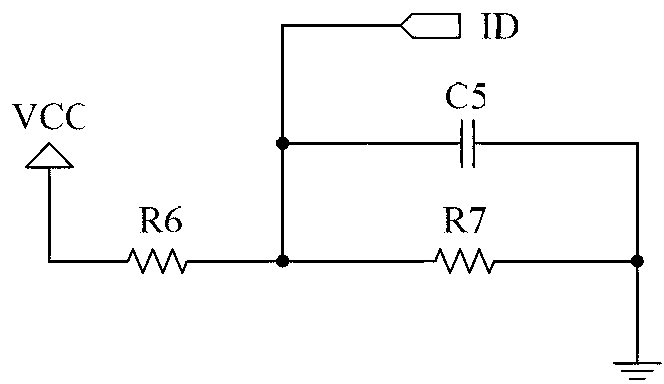

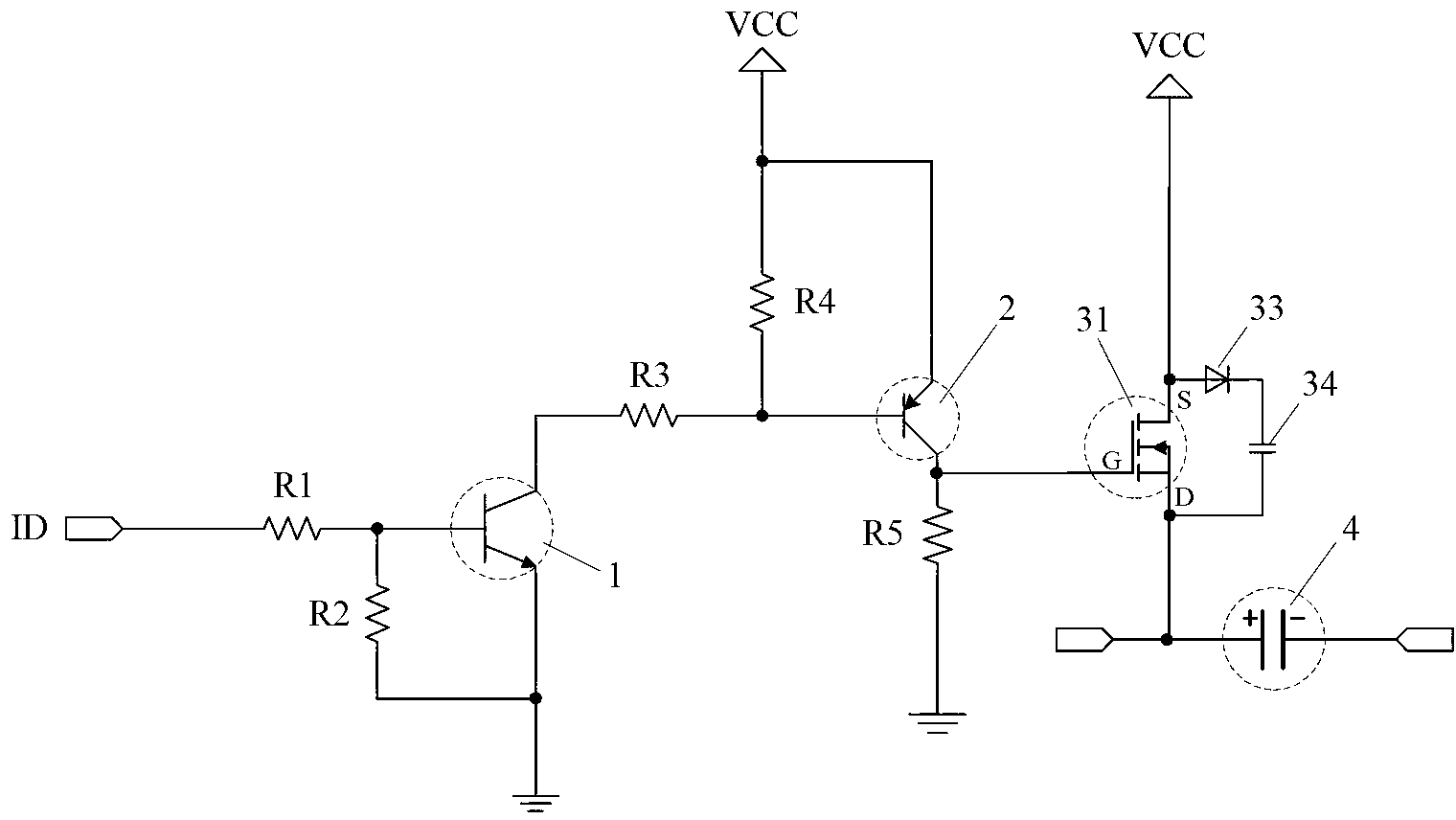

Lossless equalization controller and control method

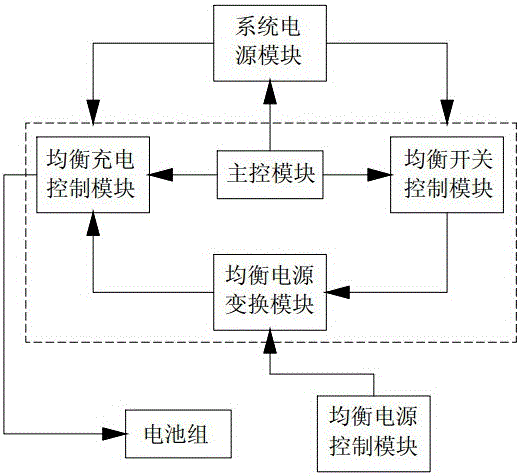

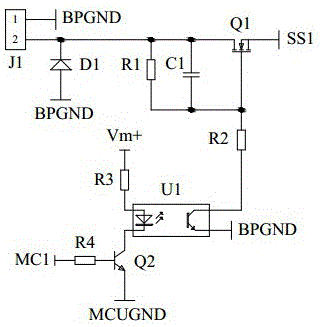

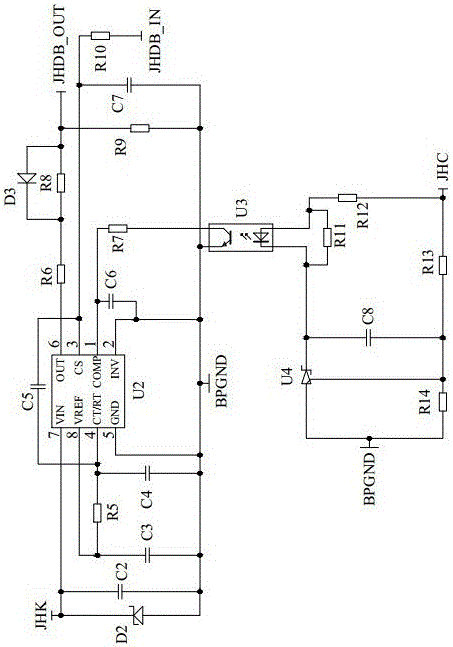

ActiveCN106100078ALow costImprove securityCharge equalisation circuitElectric powerCharge controlComputer module

A lossless equalization controller and a control method belong to the technical field of battery equalization control. The controller comprises a battery pack formed by a plurality of cells, an equalization switch control module, an equalization power control module, an equalization power transformation module, an equalization charging control module, a system power supply module and a master control module, wherein the system power supply module supplies power to the equalization switch control module, the equalization charging control module and the master control module. The controller has the advantages of rapid equalization speed, safe and reliable equalization process, low cost and easy promotion and application. The control method includes detecting battery equalization degree, equalizing laggard cells in the battery pack when the battery equalization degree is equal to or greater than 0.3%, detecting system fault, clearing system fault and other detection steps. The equalization precision is high, and the equalization process is safe and reliable.

Owner:SHANDONG DEPUDA ELECTRIC MOTOR CO LTD

Static balancing adjusting method for cast type blisk

ActiveCN101832840AHigh balance precisionSimple structureBlade accessoriesStatic/dynamic balance measurementGravitationCasting types

The invention discloses a static balancing adjusting method for a cast type blisk. The static balancing adjusting method for the cast type blisk comprises the following steps of: firstly, machining a basic hole at the center of the disk during the primary pretreatment to the blisk; then measuring the primary unbalance of the bilsk by the basic hole and calculating the eccentric distance of the blisk according to the primary unbalance and weight of the bilsk; after that, fixing the blisk then adjusting rotation center of the disk by performing hole expansion to the basic hole according to the eccentric distance to make the rotation center of the basic hole coincide with the center of gravity thereof; then performing fine machining to the bilsk taking the adjusted basic hole as benchmark; and finally, grinding a balancing discharging belt to fulfill the requirement of static balancing. The static balancing adjusting method for the cast type blisk can get rid of relatively serious unbalance caused by uneven distribution of blade weight during casting. The method is simple and easy to implement and the precision requirement to casting is low. Characteristics such as simple structure and high reliability of blisk are reserved.

Owner:CHINA GAS TURBINE ESTAB

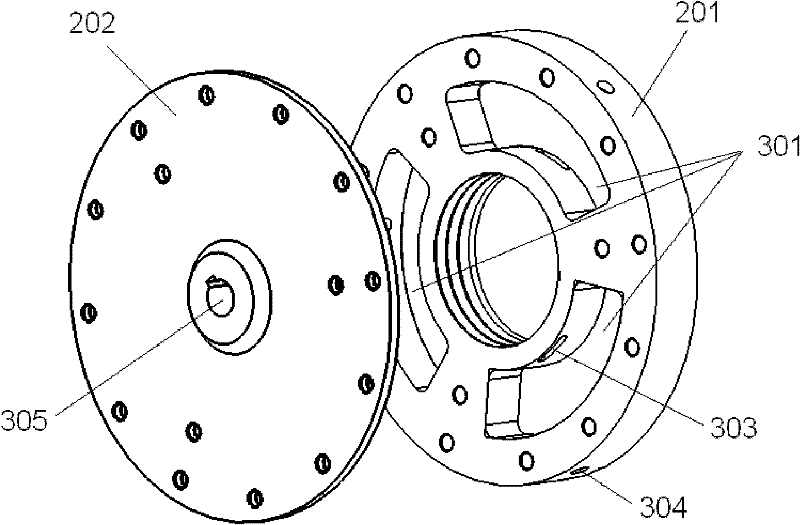

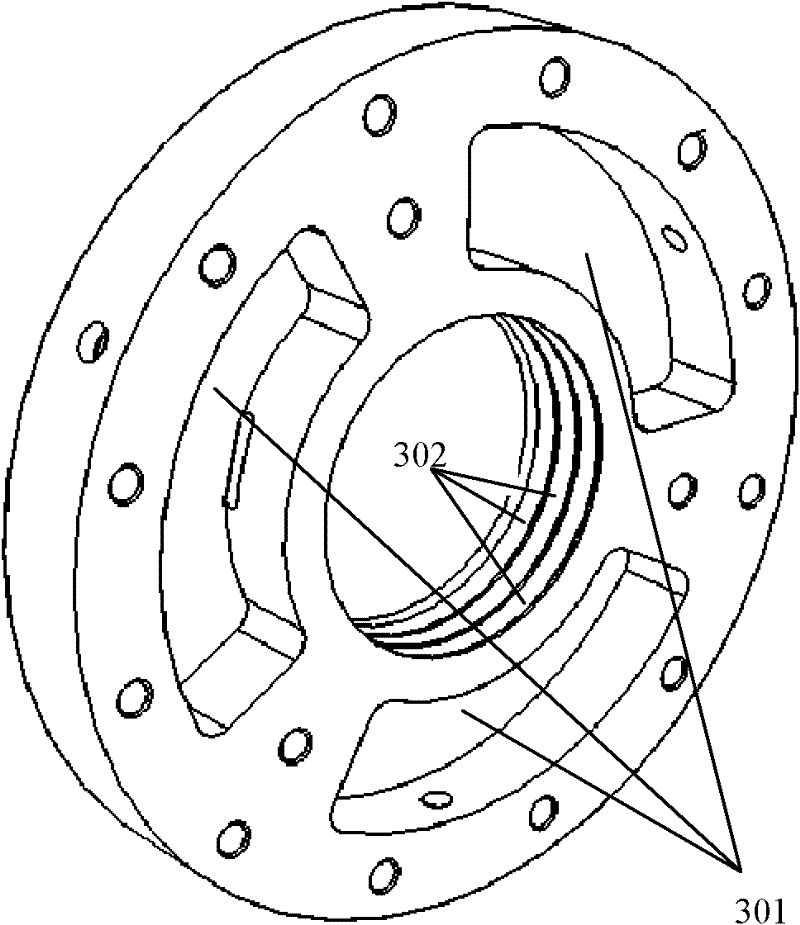

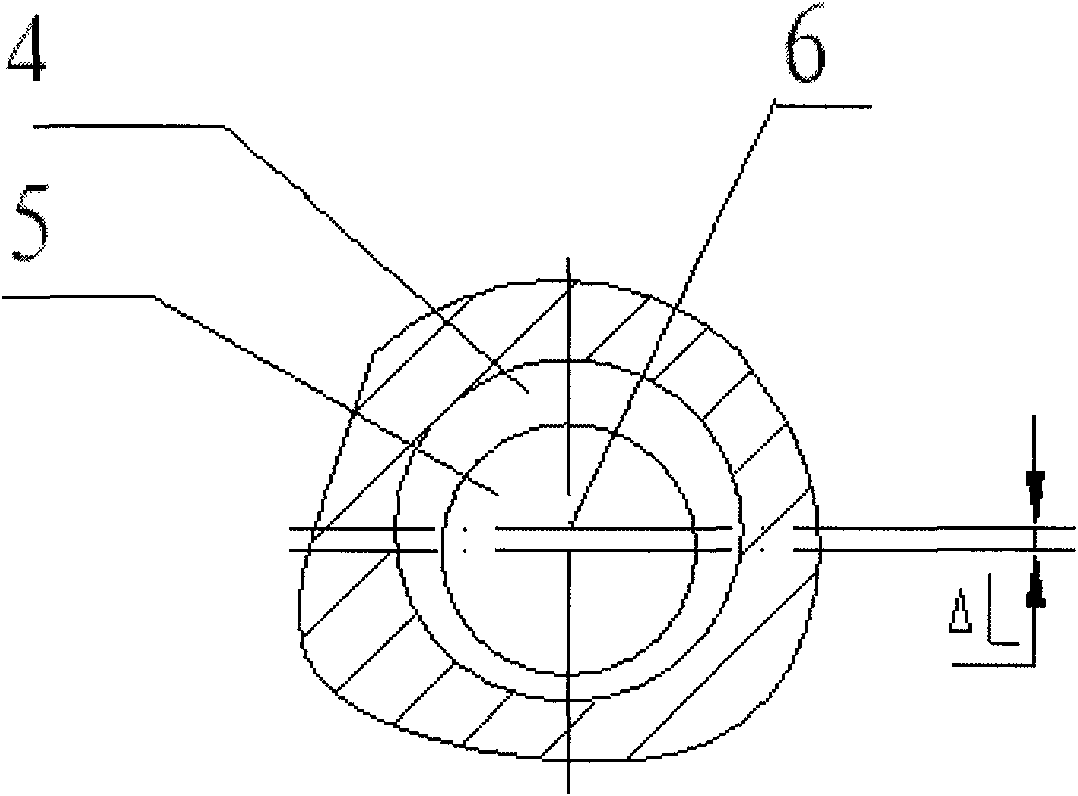

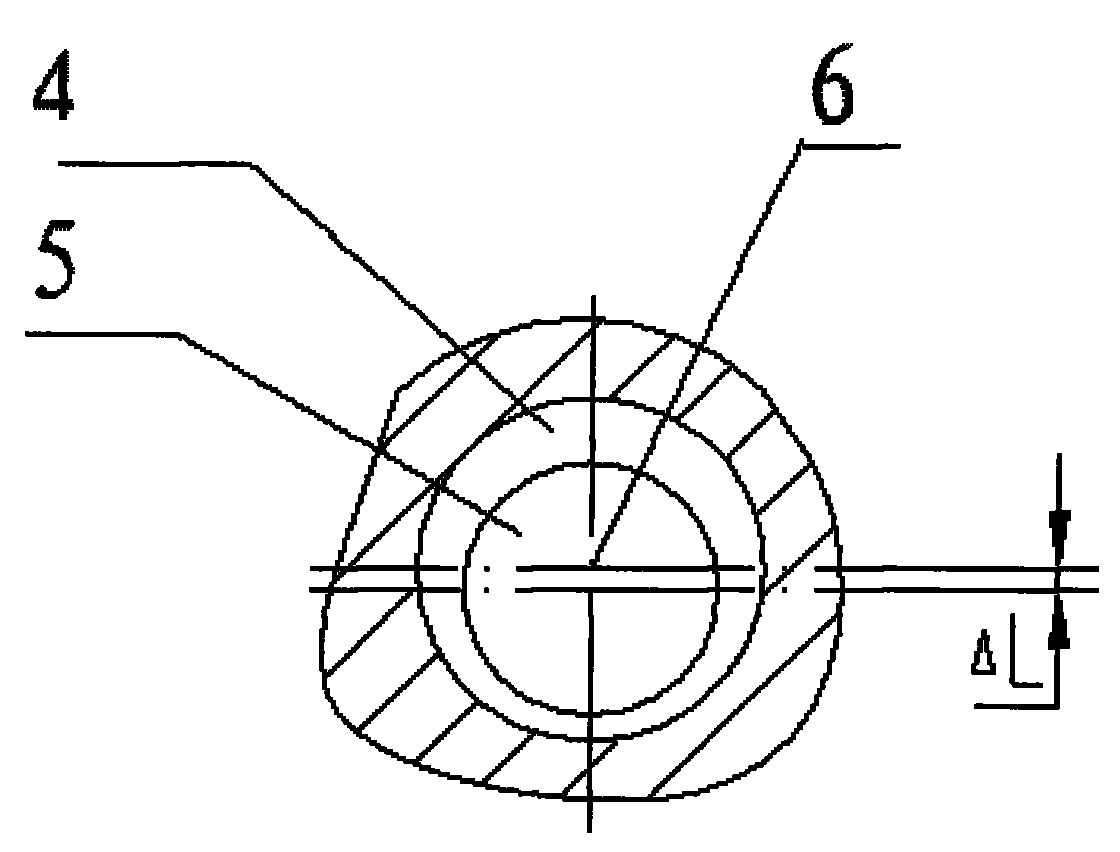

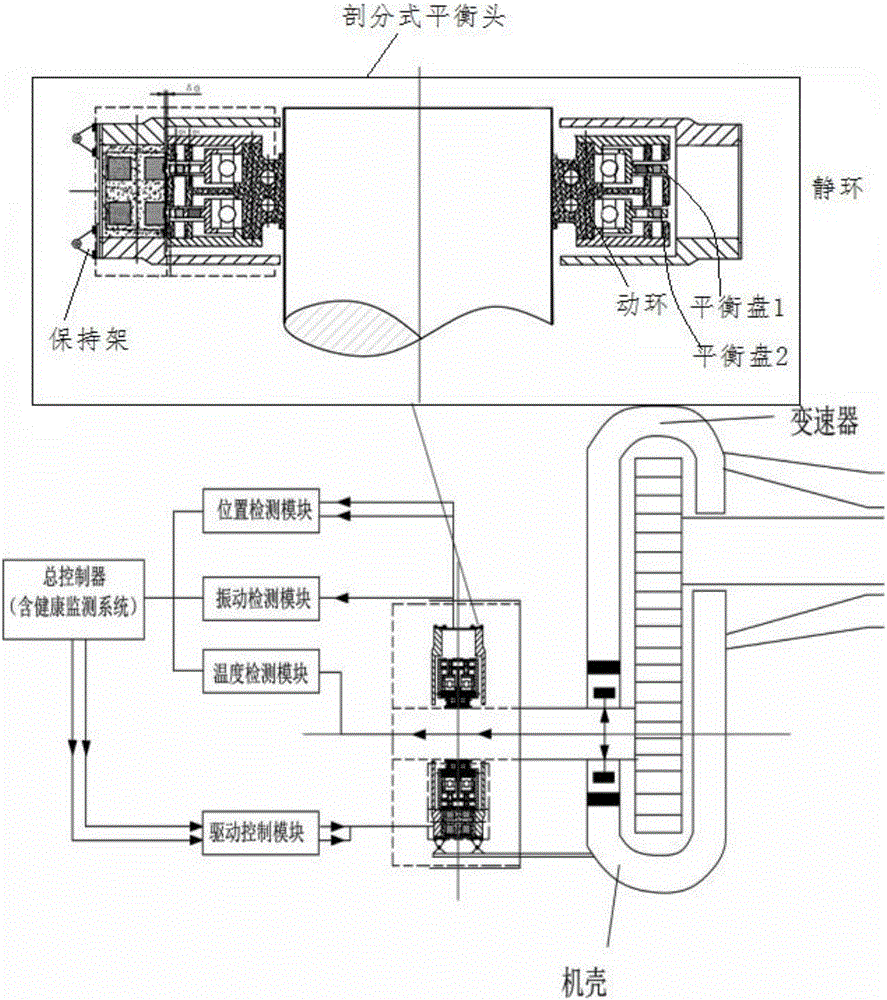

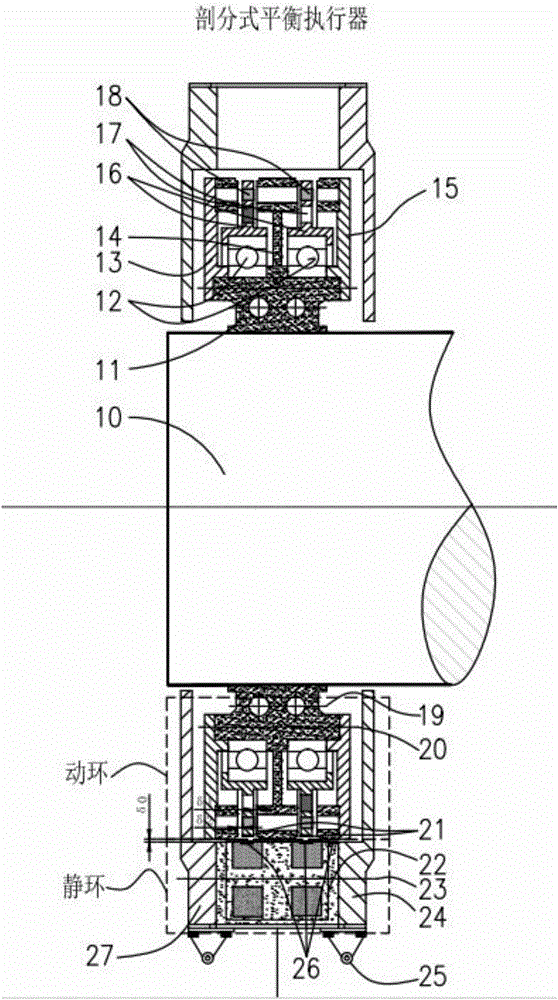

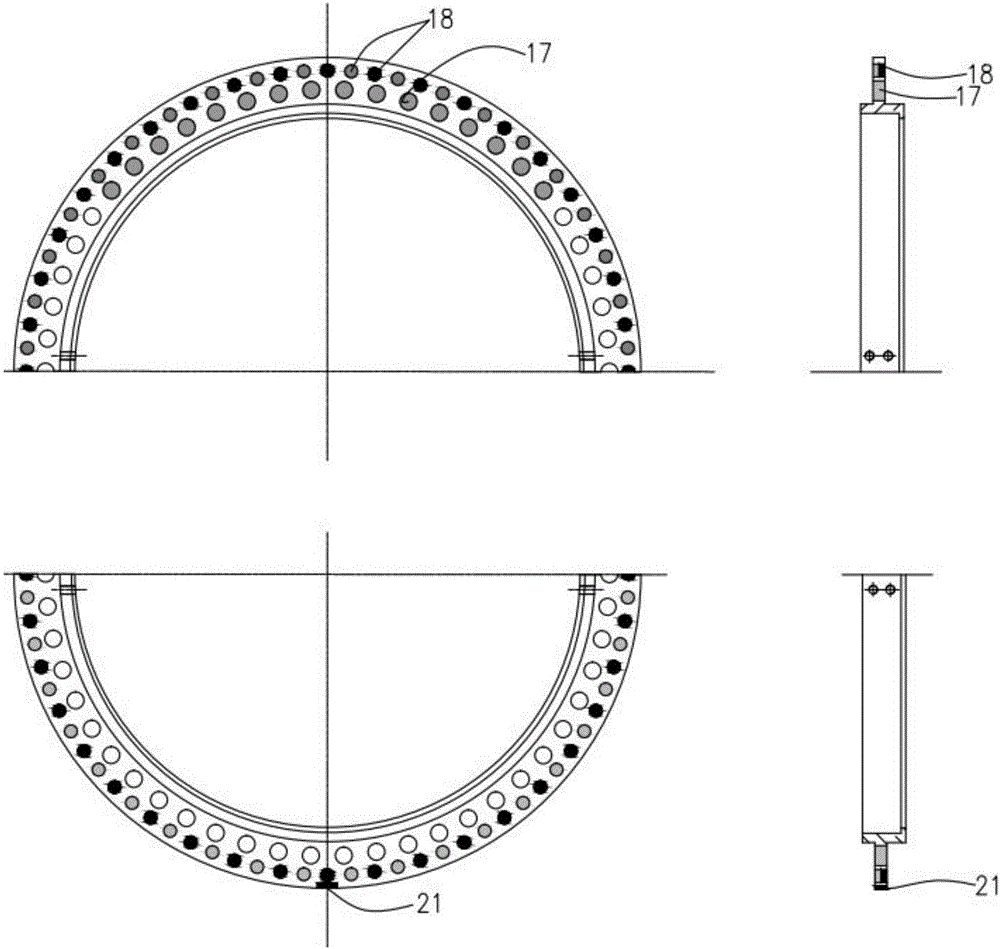

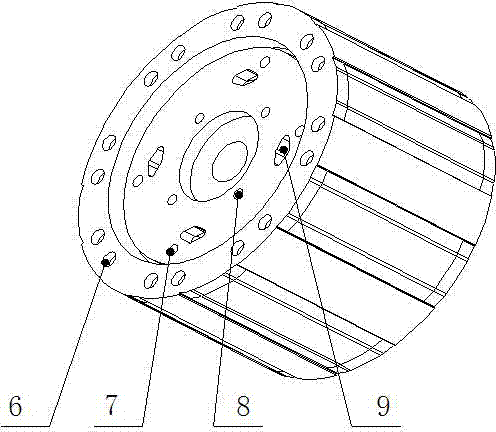

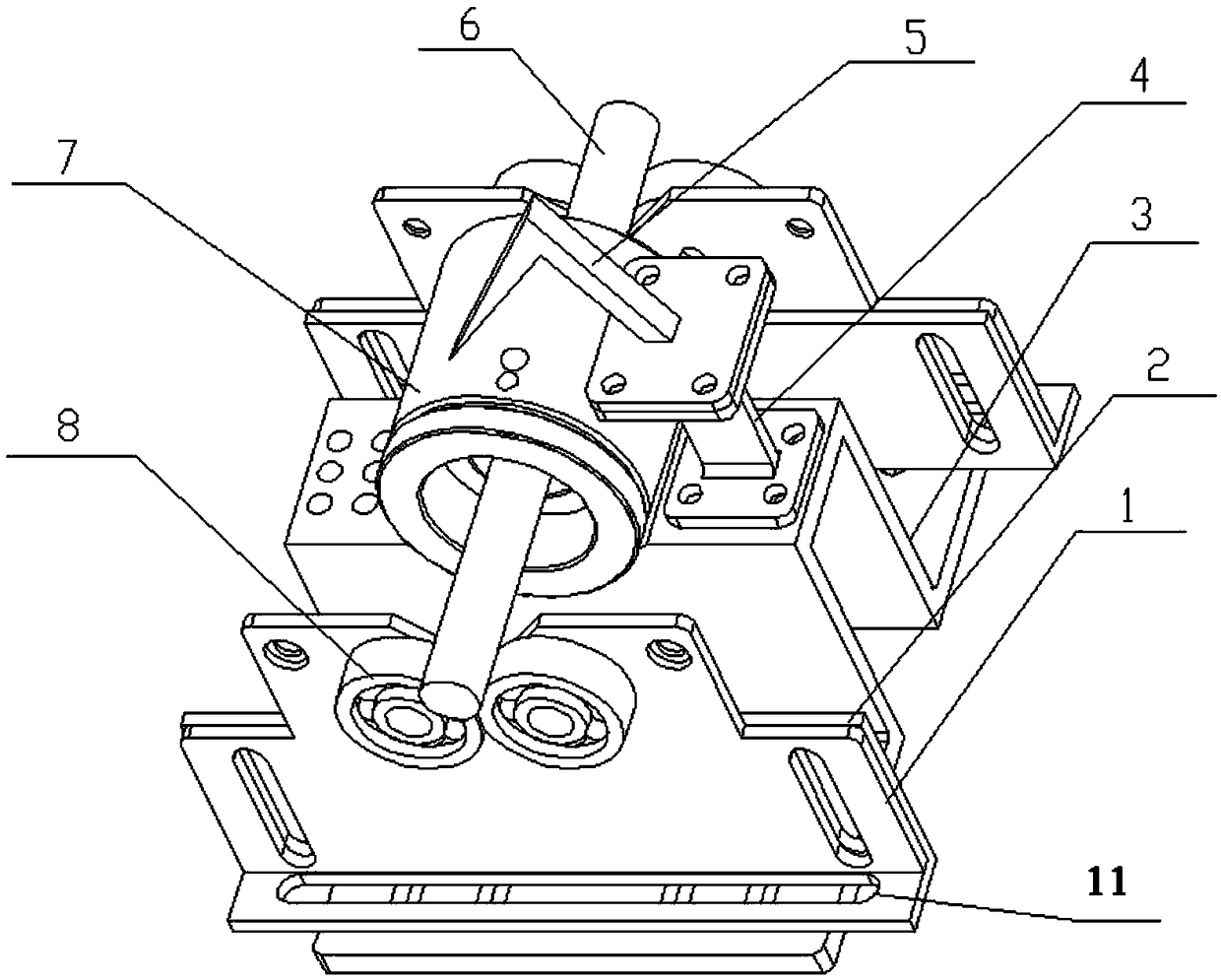

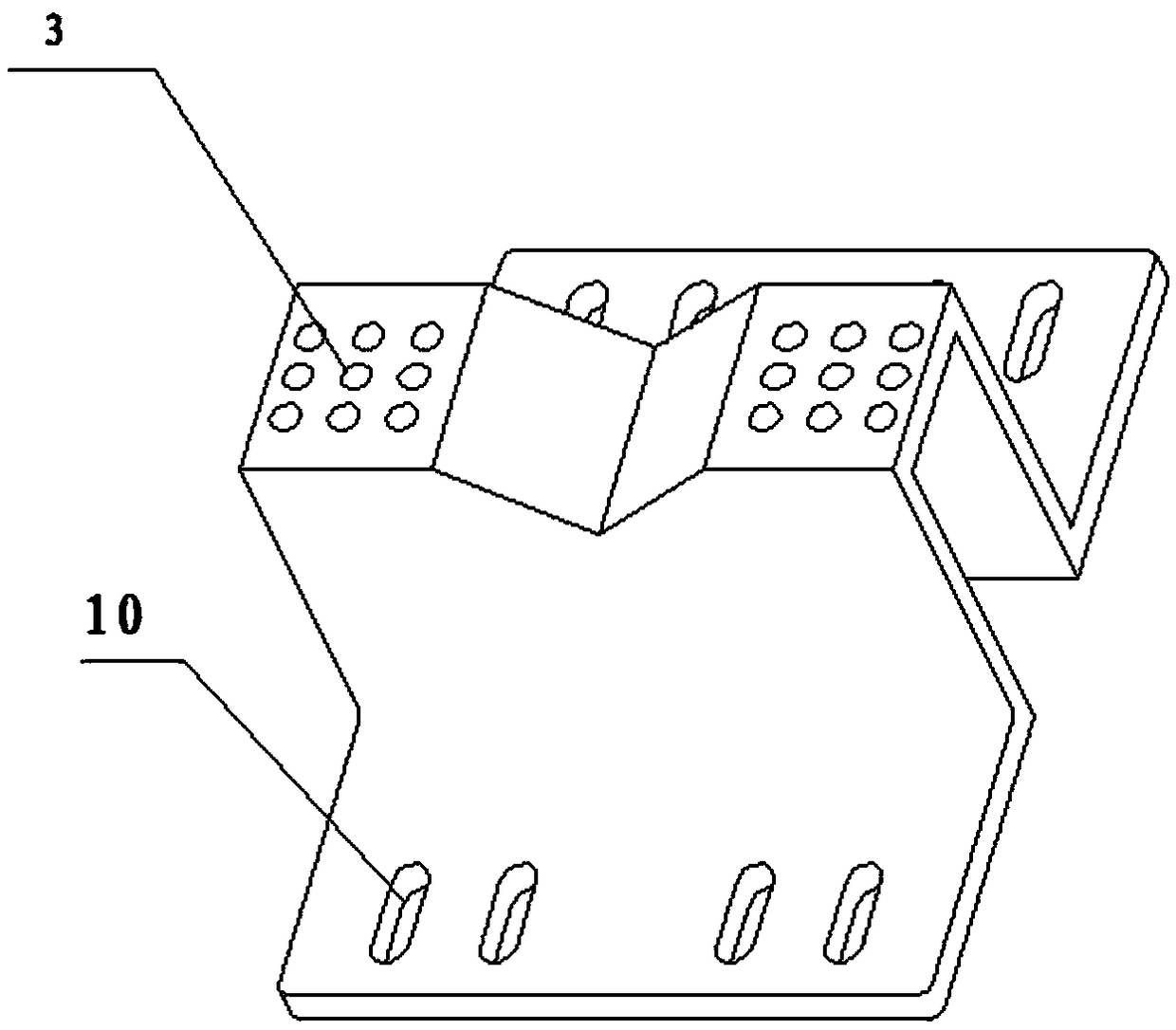

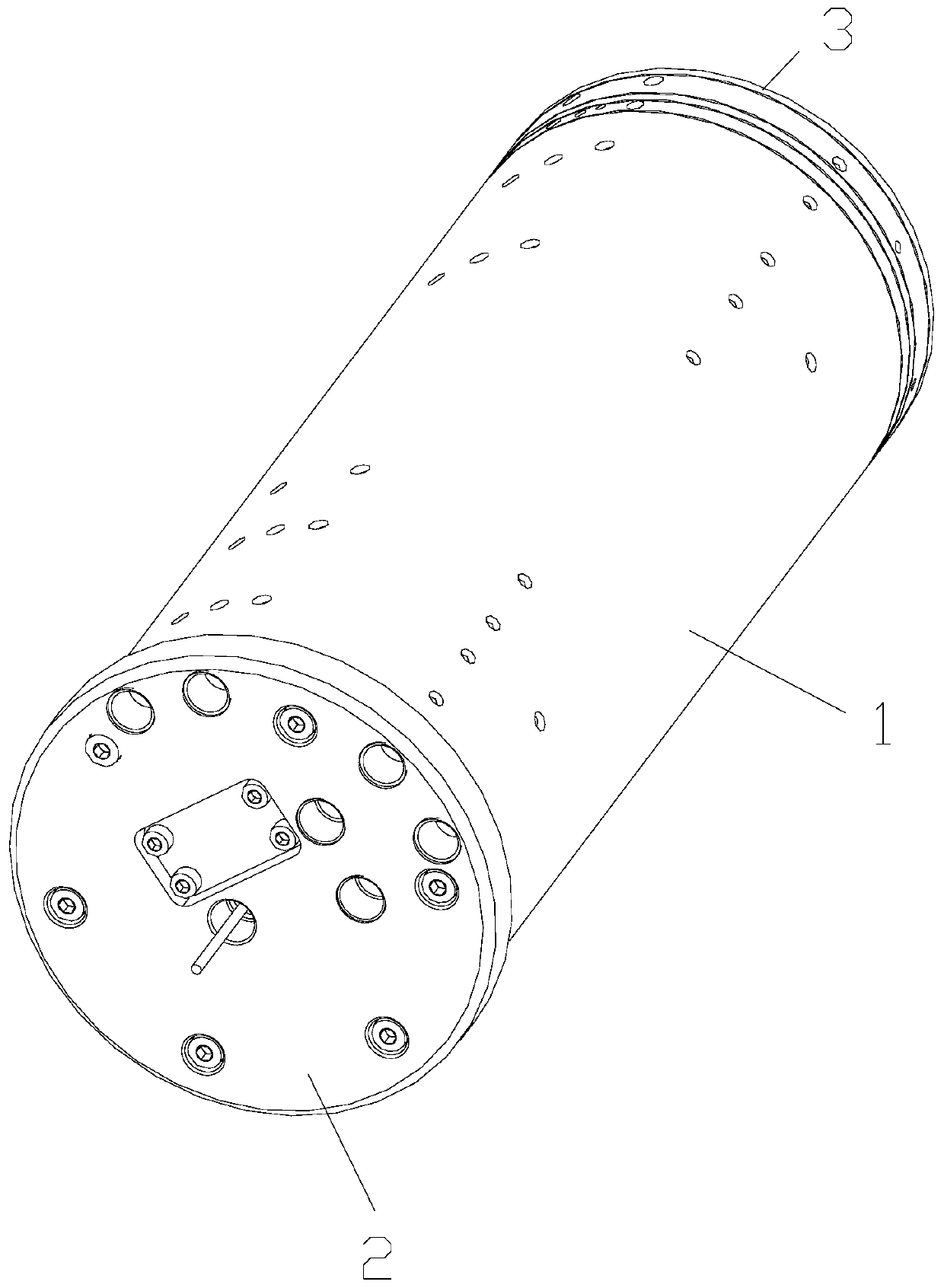

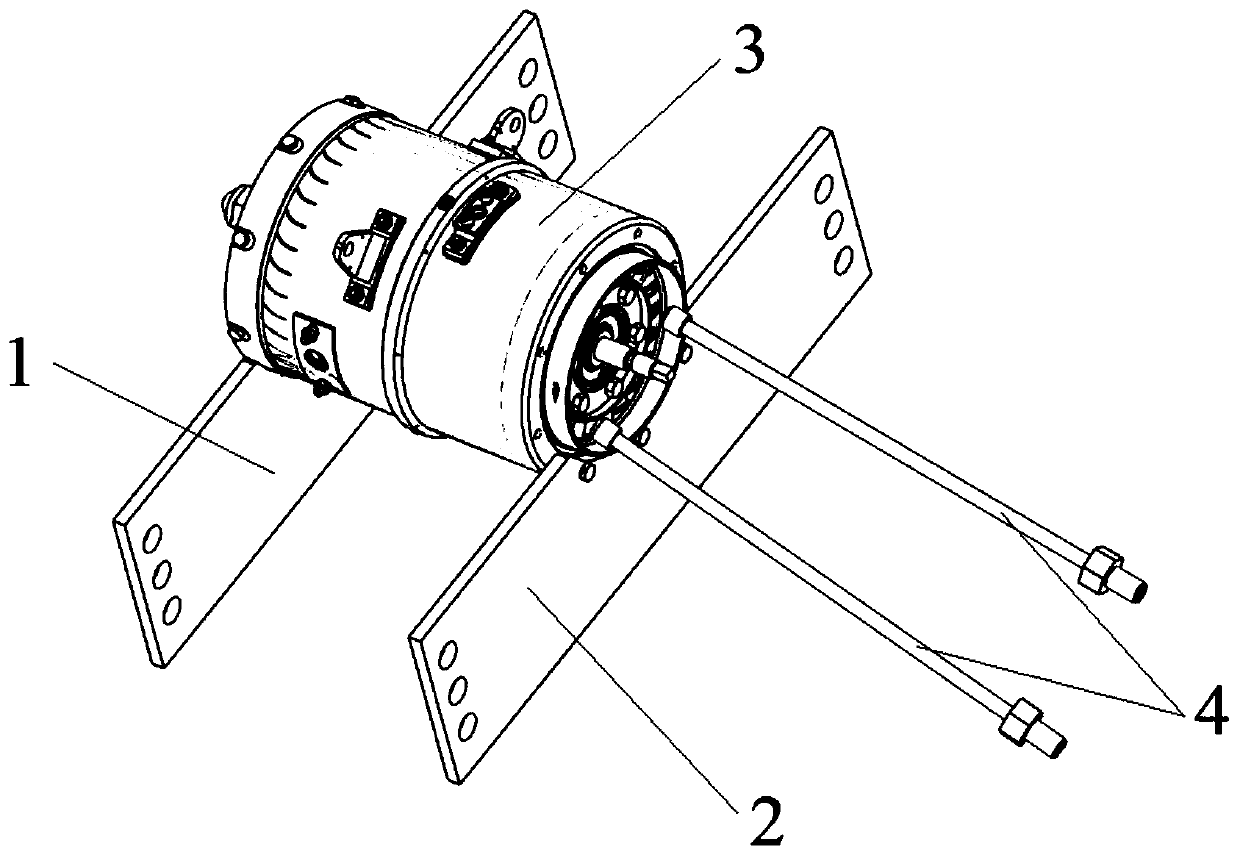

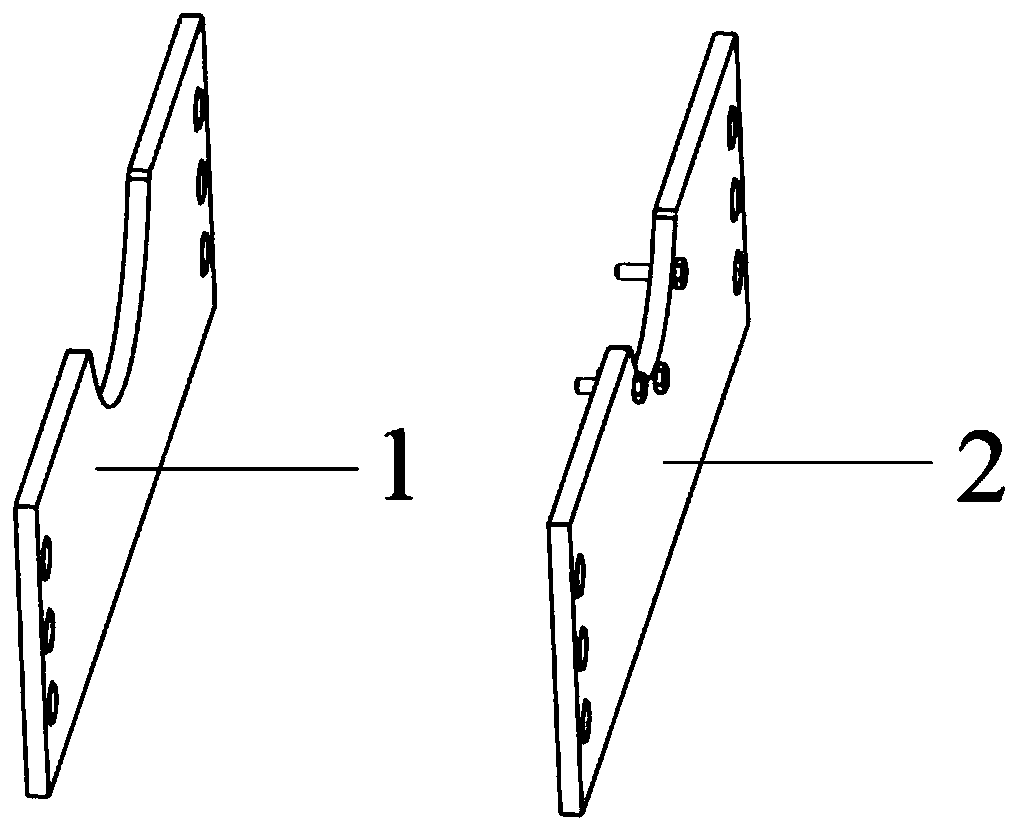

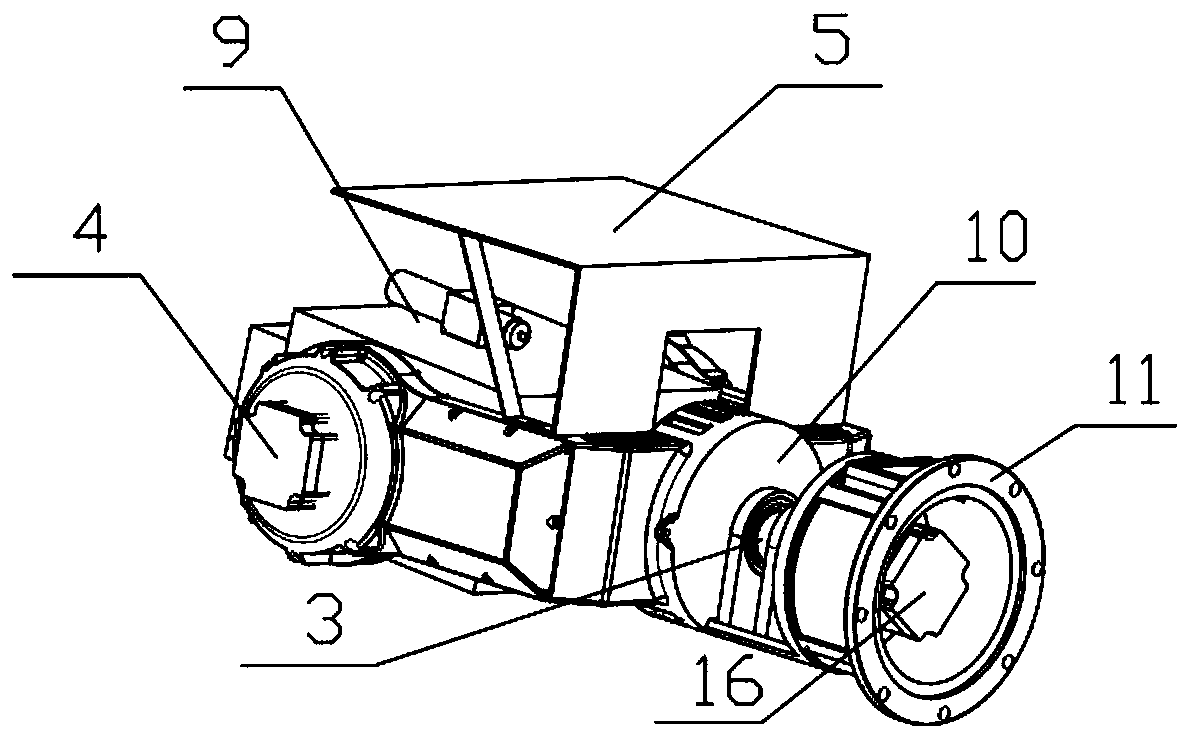

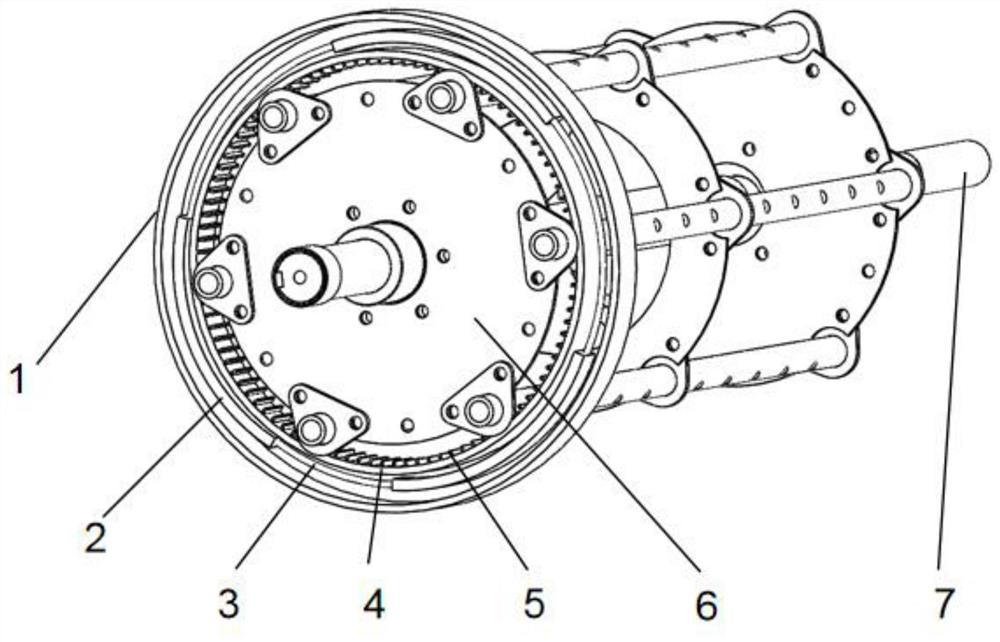

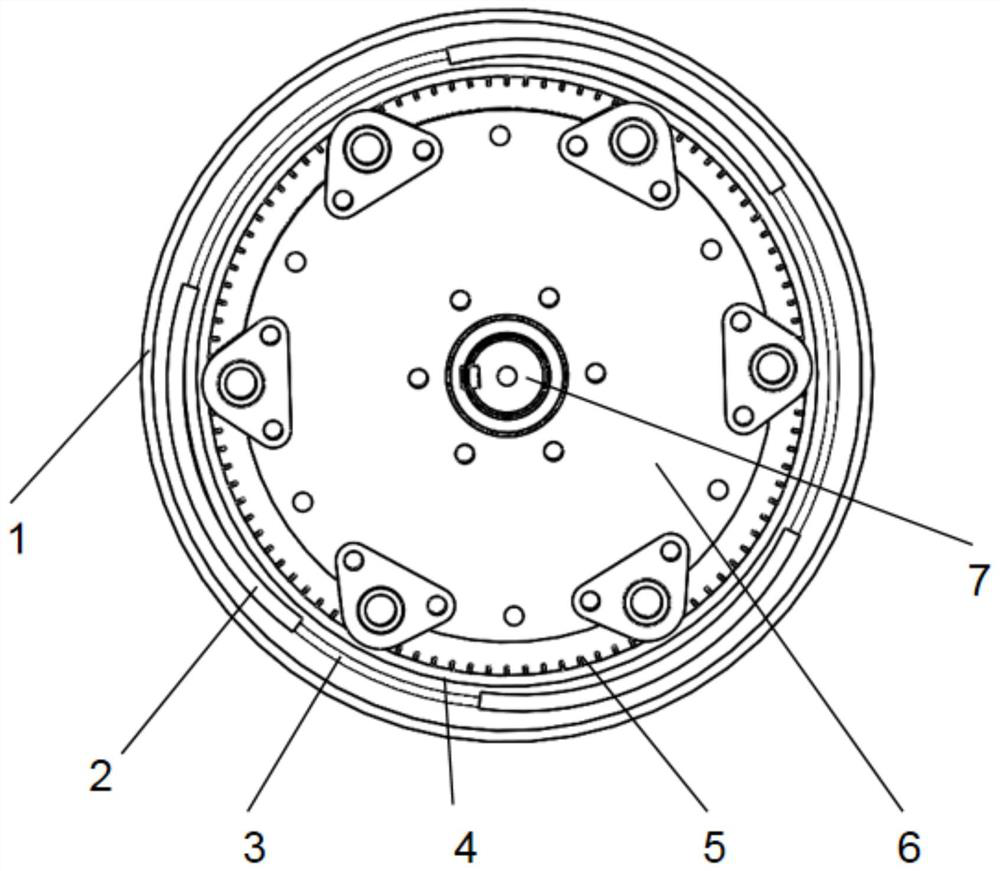

Split type automatic balancing device for realizing on-line automatic balance of rotating machine

ActiveCN106768642AImprove the installation effectSave assembly timeStatic/dynamic balance measurementEngineeringOriginal Device

The invention discloses a mechanical device for realizing the on-line automatic balance of a rotating machine. The device is of a split type structure, and comprises two parts of a split type moving ring and a split type stationary ring, wherein a split type transitional sleeve is connected with a rotating main shaft and the moving ring, and plays a role of supporting the moving ring; the series mounting and fixation are realized for all split components of the stationary ring in the axial direction through stationary ring set bolts; a split structure is adopted by the stationary ring; the stationary ring enwraps the moving ring in the circumferential direction; the split surfaces of all the split components of the moving ring are connected respectively by adopting ways of a bolt, a plug-in type, a connecting piece and the like; all the split components of the moving ring are subjected to the series mounting and fixation in the axial direction through moving ring set bolts. By using the split type structure of the mechanical device, an automatic balancing device is enabled to not only be applicable to the development of a novel product but also be applicable to an in-service rotating appliance; the simplification and the convenience of an automatic balancing head in mounting and disassembly processes are promoted greatly; the assembly and the disassembly of the automatic balancing device can be completed without needing to disassemble an original device; the application and popularization of the automatic balancing device are facilitated.

Owner:BEIJING UNIV OF CHEM TECH

Injection-molding shock absorption rotor

InactiveCN104505963AIngenious and reasonable structureEasy to processMagnetic circuit rotating partsManufacturing dynamo-electric machinesMotor resonanceAbsorption effect

The invention discloses an injection-molding shock absorption rotor which comprises a supporting iron core and magnetic steel, wherein shock absorption rubber is arranged at the periphery of the supporting iron core; a magnetic yoke is arranged at the periphery of the shock absorption rubber; a plurality of pieces of magnetic steel are uniformly distributed at the periphery of the magnetic yoke; engineering plastic is injected into clearances between a dovetail groove in the magnetic yoke and the magnetic steel and clearances formed between the outer circles of the adjacent magnetic steel. The injection-molding shock absorption rotor is ingenious and reasonable in structure and convenient to process; the shock absorption effect is enhanced, the equipment noise generated by motor resonance is avoided, the rotor balance precision is improved, and the mechanical strength of the rotor is improved; the magnetism can be improved by over 30 percent in comparison with a common rotor; the service life is prolonged; the injection-molding shock absorption rotor has extremely high use value and economical benefits.

Owner:FGLS ELECTRIC CO LTD

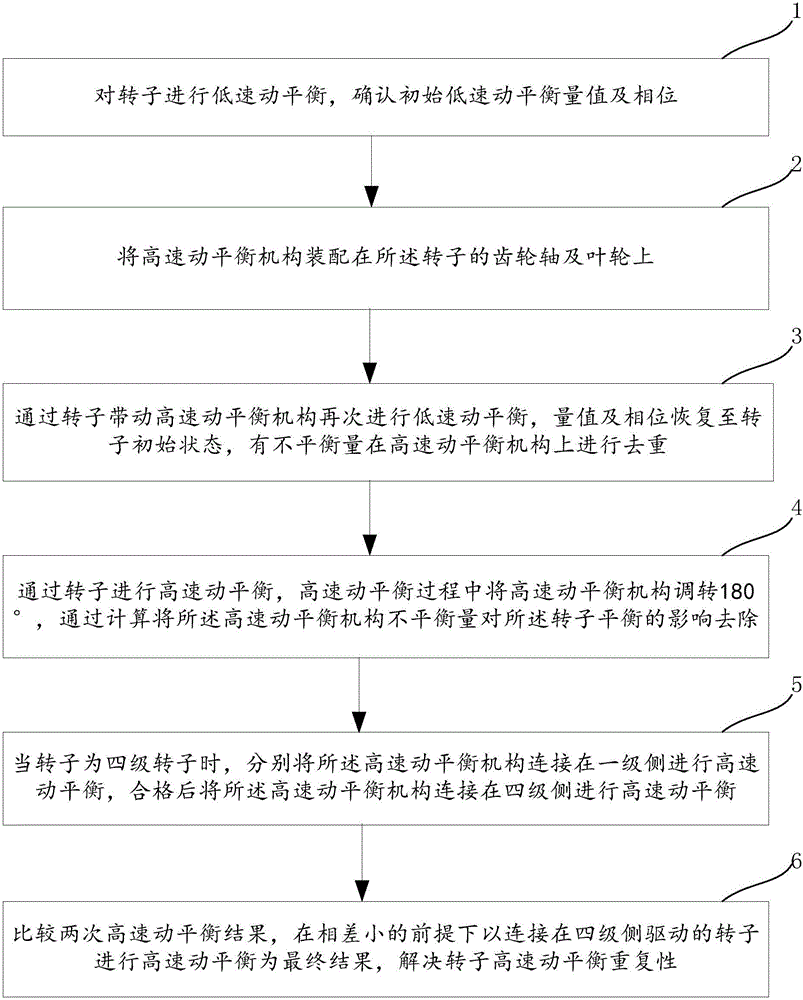

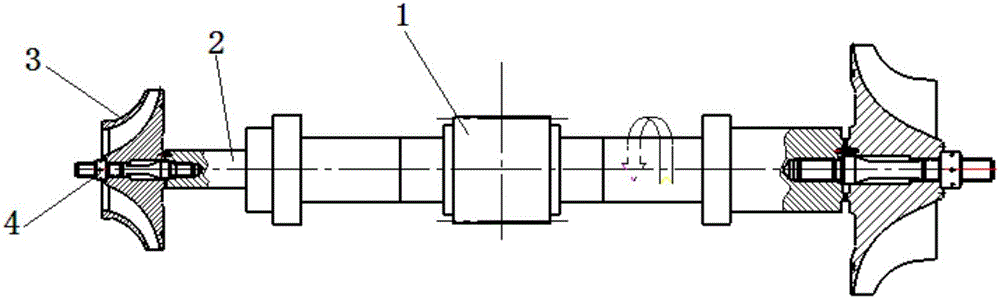

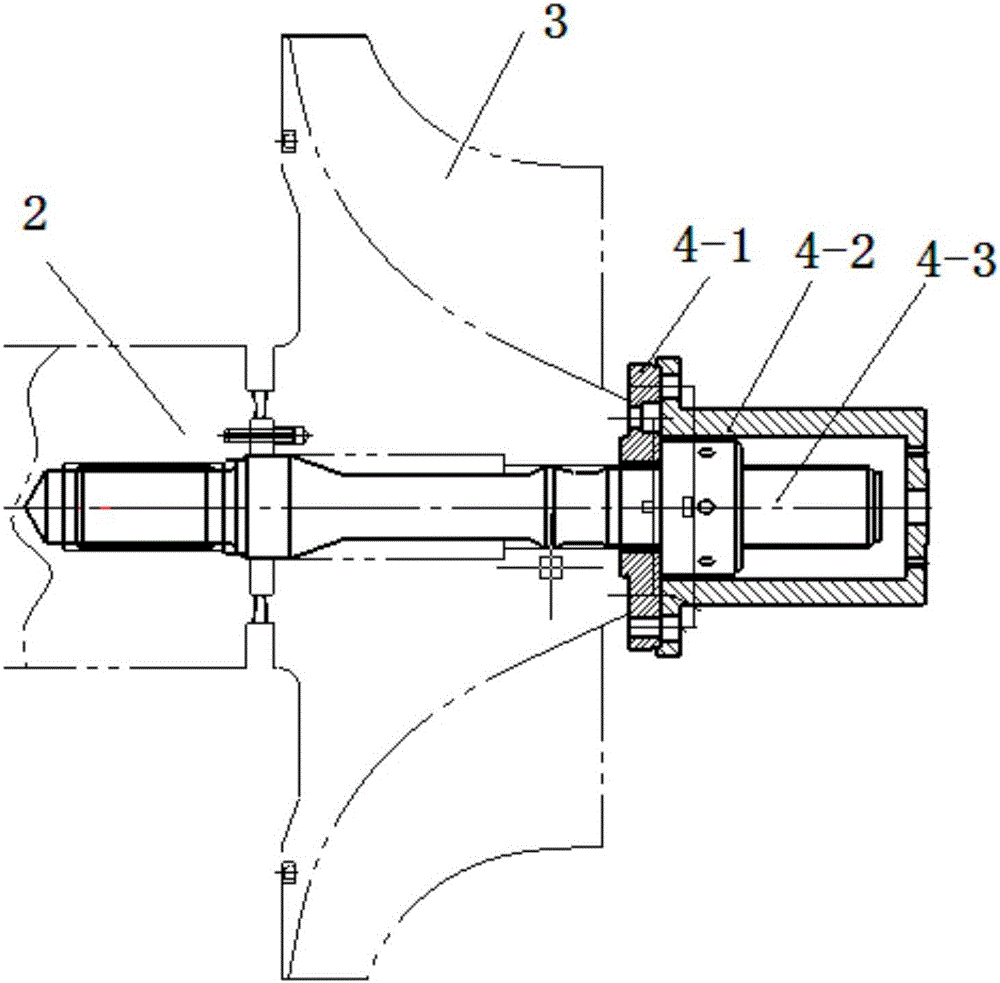

High-speed dynamic balancing method and apparatus of assembly type compressor rotor

ActiveCN105928658ASolve high-speed dynamic balance repeatabilityHigh balance precisionStatic/dynamic balance measurementImpellerEngineering

The invention discloses a high-speed dynamic balancing method and apparatus of an assembly type compressor rotor, and belongs to the technical field of rotor dynamic balancing. The high-speed dynamic balancing apparatus of the assembly type compressor rotor comprises a high-speed bearing and a high-speed dynamic balancing mechanism. The high-speed dynamic balancing mechanism comprises a stretching bolt, a taper reduction sleeve and a joint, the taper reduction sleeve is connected with a gearshaft and impellers, the stretching bolt passes through the taper reduction sleeve to be connected with the gearshaft, and the joint is connected with the taper reduction sleeve. The high-speed dynamic balancing method and apparatus of the assembly type compressor rotor effectively improve the rotor balance precision, the first-order critical rotation speed of the rotor is simple, and high-speed balancing can be carried out.

Owner:SHENYANG BLOWER WORKS GROUP CORP

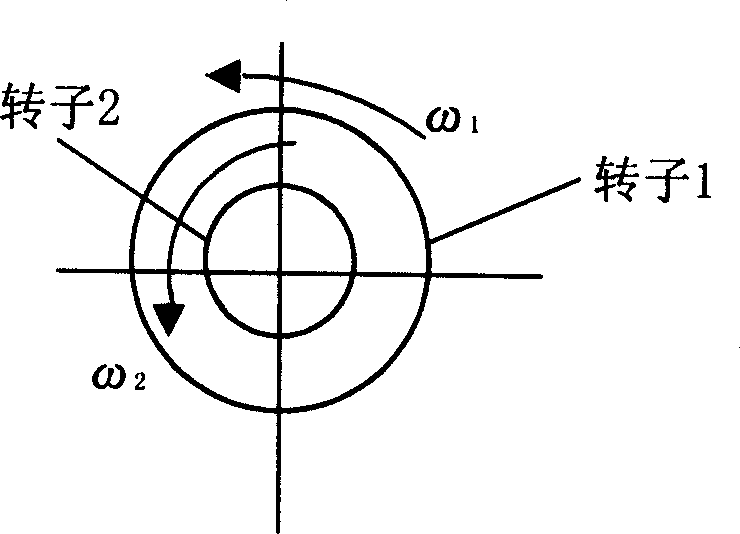

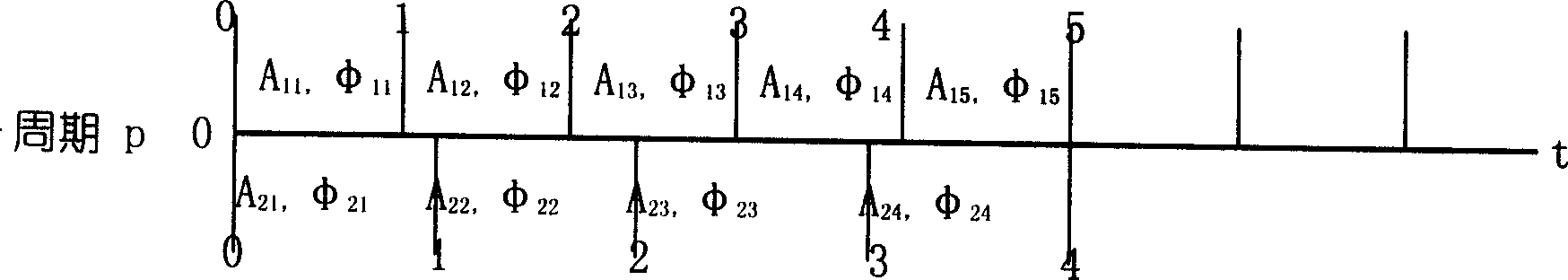

Multiple shaft multiple rotor dynamic balancing test method

InactiveCN1587944AAchieve dynamic balanceAchieving one-by-one balanceStatic/dynamic balance measurementCentering/balancing rotorsExperimental methodsDynamic balance

The invention relates to an experimental method for multi axis series and multi rotor dynamic balance, includes the following steps(1) before assembly, do assembly experiment to each fiducial respectively, making balanced error within standard specialized range; (2) each fiducial is assembled; (3) choose willingly one rotor to be the measuring basis and make complete machine revolve according to working condition, then extract inbalanced signal of P vibration periods in the system (P is the smallest common multiple or its integral multiple of vibration periods of all rotor in the system ) and do dynamic balance to the fiducial rotor; (4) choose willingly another rotor as measuring basis choose willingly one rotor to be the measuring basis and make the complete machine revolve according to working condition, then extract inbalanced signal of P in the system (P is the smallest common multiple or its integral multiple of vibration periods of all rotor in the system ) and do dynamic balance to the fiducial rotor; (5) repeate step(4) until all the rotors have been dynamic balanced, the complete machine experiment is finished.

Owner:HENAN UNIV OF SCI & TECH

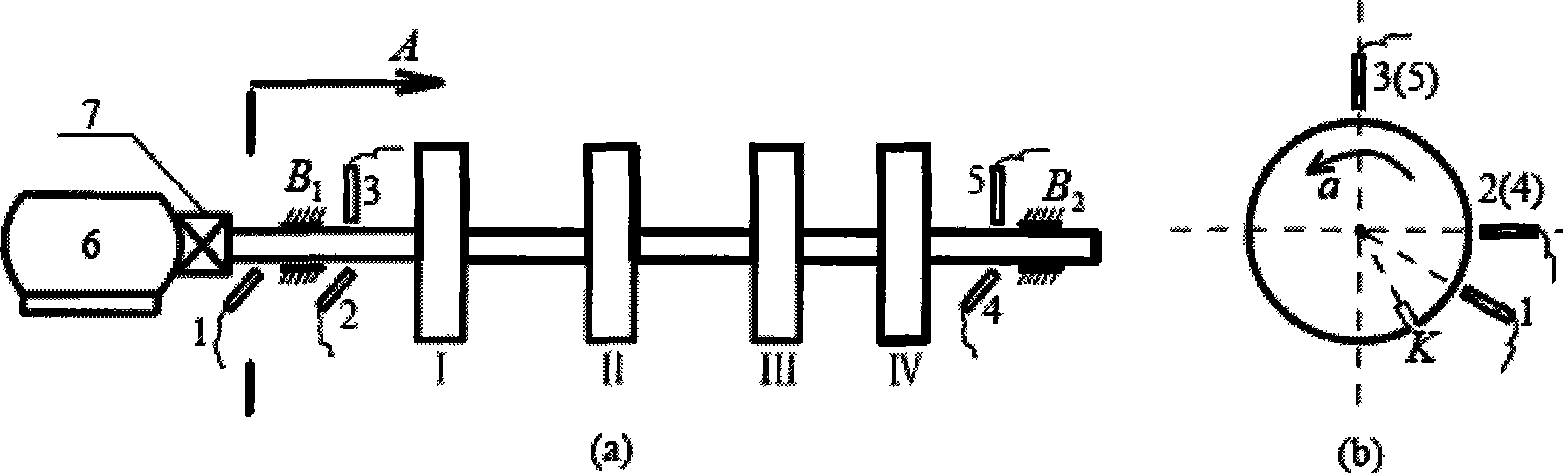

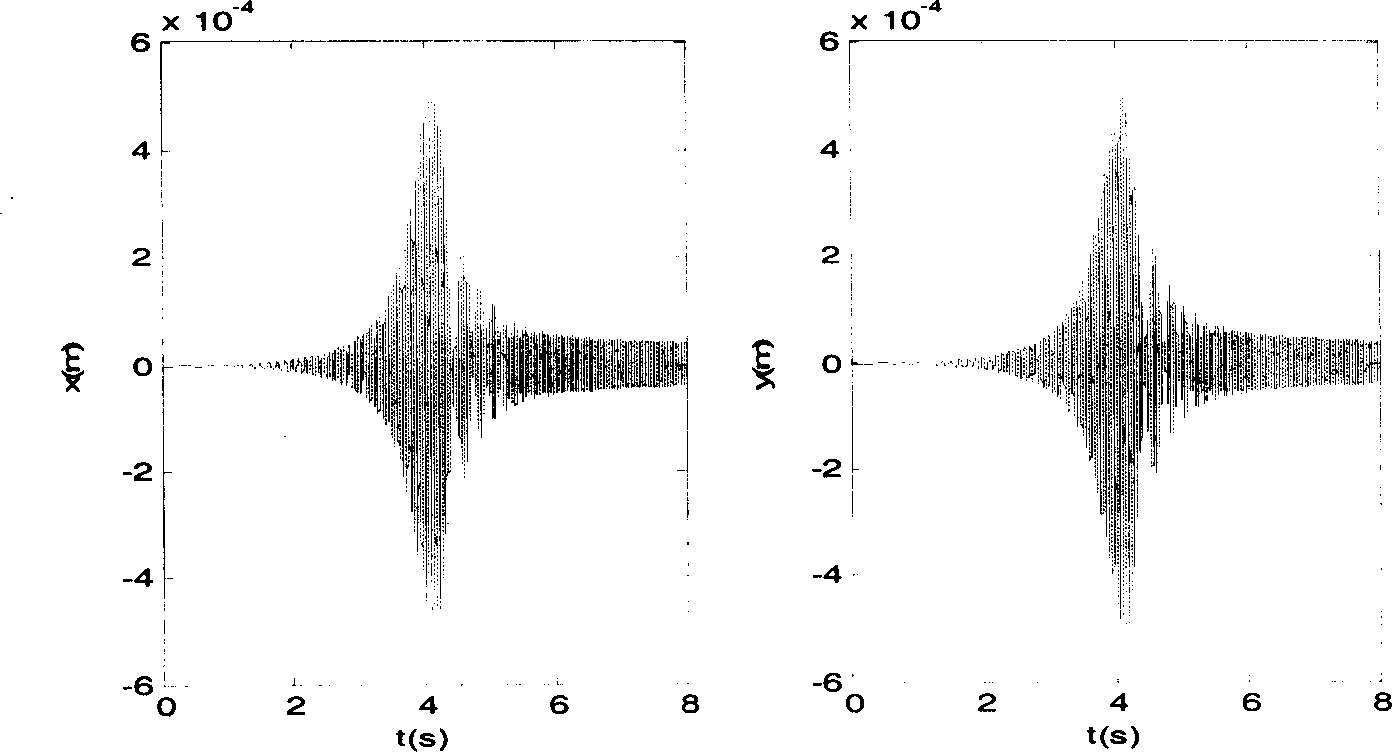

Double surface transient equilibration method for flexible rotor

InactiveCN101387567ABalanced and reliableHigh balance precisionStatic/dynamic balance measurementStart timePosition angle

The invention relates to a dynamic balance method for flexible rotors, which can balance and damp rotary machines. The dynamic balance method is characterized in that based on the instant imbalance response in the accelerated start of a flexible rotor, in the first two critical regions, the dynamic balance method collects the instant imbalance response data adjacent to the bearings at two ends to quickly recognize the position angles of the first order and second order mode imbalances of the rotor; combines the mode state of the rotor and utilizes one-time added test start to synchronously balance the first two order modes of the rotor. The balance method can utilize imbalance acceleration instant response information to effectively and reliably balance flexible rotors, having less start times and high balance accuracy in the balance process. Compared with the prior balance method, the balance method has the advantages of high speed and efficiency.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

One disc flexible rotor transient equilibration process

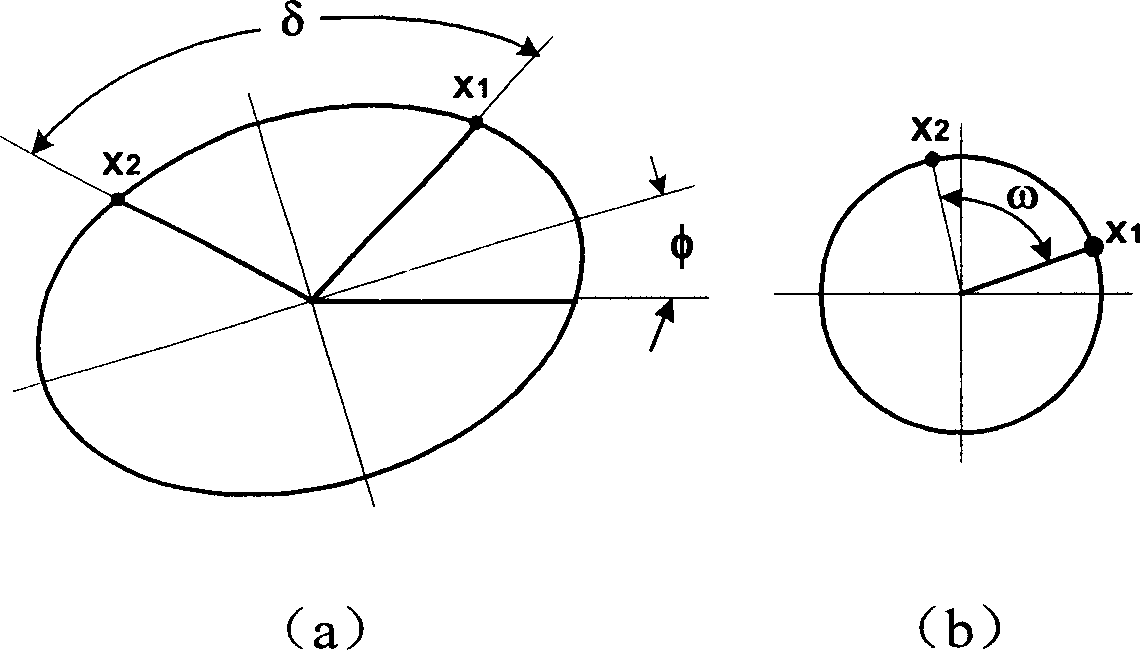

InactiveCN101191753AImprove balanceFew boot timesStatic/dynamic balance measurementSpeed/accelaration controlClassical mechanicsPrecession angle

The invention relates to a transient balance method for one-disc flexible rotors. The invention is characterized in that: the vibration displacement signals along X direction and Y direction and the corresponding key-phase signals during the acceleration of the rotor are collected; the collected vibration displacement signals are processed, the deflection response, the speed signals along X direction and Y direction, the self-rotation angle acceleration of the rotor, the precession angle of the rotor as well as the speed of the precession angle are obtained, the speed of the precession angle of the rotor is partitioned, and the azimuth angle where the rotor is unbalanced is confirmed according to the result of the partitioning; the magnitude of the unbalanced quantity of the rotor is confirmed by adding one time trial weight; the balance weight is adjusted according to the confirmed azimuth angle and magtitude of the unbalanced quantity of the rotor, to finish the balancing work of the one-disc flexible rotor. With the method provided by the invention, the balancing of the one-disc flexible rotor can be conveniently and quickly realized by transient response; the needed startup times during the balancing is less and the balancing accuracy is high.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

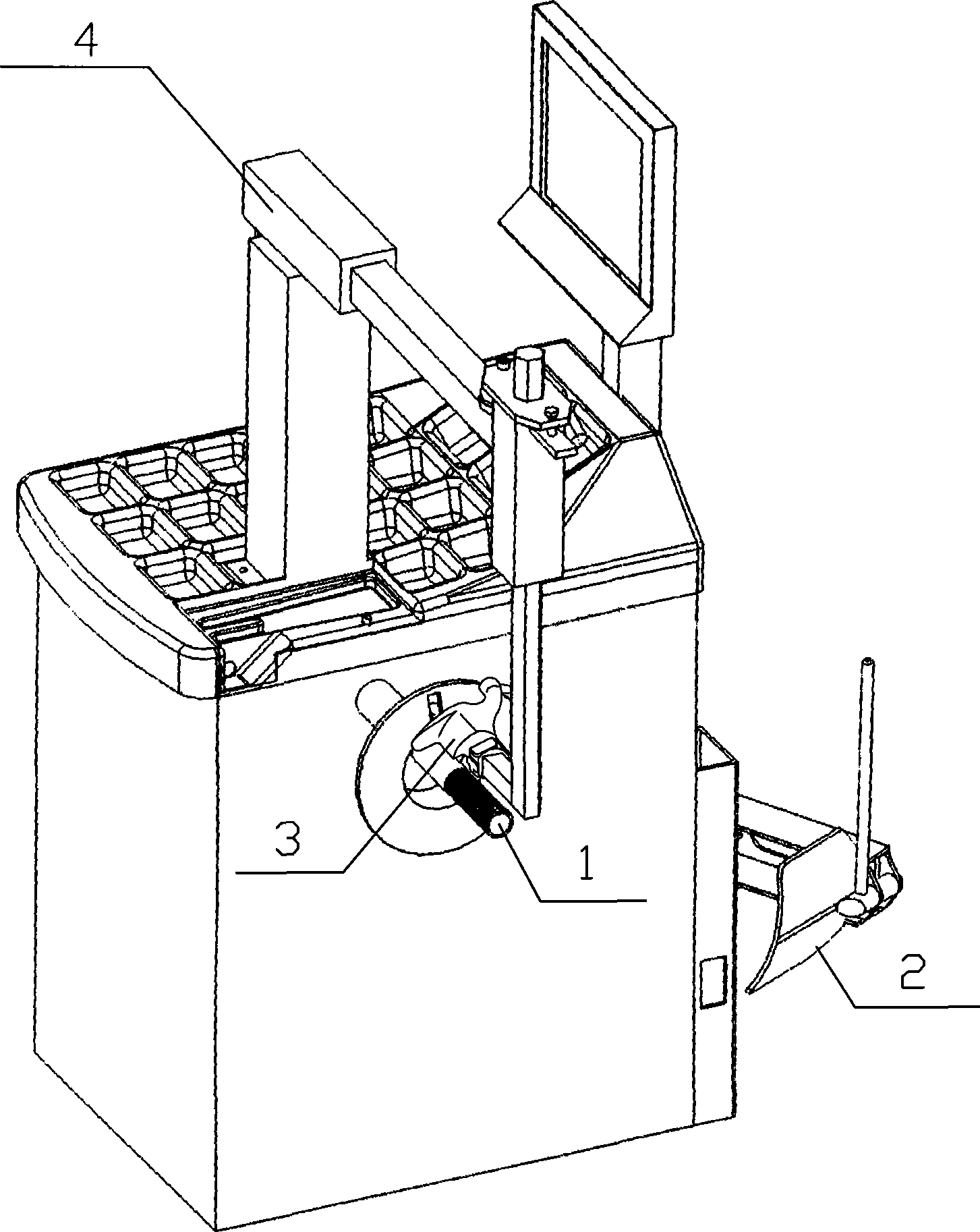

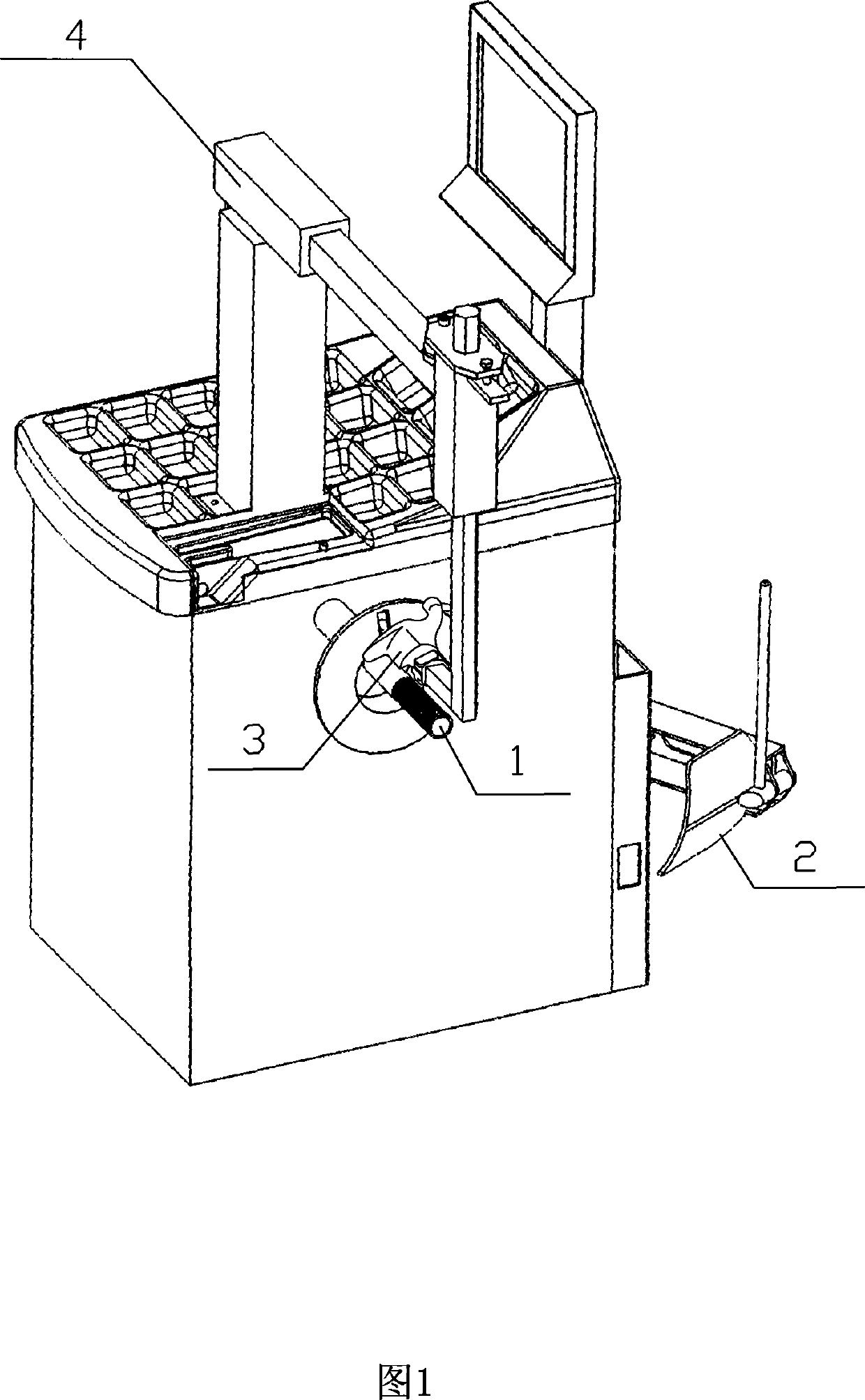

Tyre-disassembling and balancing integrated machin

InactiveCN101474948ABalance operation has no effectHigh balance precisionStatic/dynamic balance measurementTyre repairingEngineeringAutomotive engineering

The invention relates to a tire disassembly balancing all-in-one machine, which aims to solve the technical problem that how to fill in the blank of the prior art and provides the tire disassembly balancing all-in-one machine. The tire disassembly balancing all-in-one machine comprises a tire assembling shaft, a balance driving mechanism, a balance detecting system, a beak and a tire disassembly / assembly driving mechanism. The beak is arranged on a telescopic frame which at least comprises two mutually perpendicular telescopic arms, wherein one telescopic arm is in parallel to the tire assembling shaft, and the axial lead of the beak is in parallel to that of the tire assembling shaft; and an on-off device is arranged between the tire disassembly / assembly driving mechanism and the tire assembling shaft, and the tire assembling shaft can be switched between two driving mechanisms and under the control of the on-off device. The machine can be used for double purposes, and the processes of disassembling and assembling tires are completed on the same equipment. Therefore, the machine has the advantages of simple structure, convenience and labor conversation, and can be widely used forvarious garages, automobile maintenance stations and tire shops.

Owner:焦建飞

Ferromagnetic motor rotor dynamic balance test device

ActiveCN108801551ALow thermal conductivityImprove wear resistanceStatic/dynamic balance measurementBall bearingDynamic balance

A ferromagnetic motor rotor dynamic balance test device relates to the field of motor dynamic balance without a magnetic armature. The ferromagnetic motor rotor dynamic balance test device comprises two movable support plates, two fixed support plates, a main support plate, a pressure plate column, a pressure plate, a ferromagnetic motor rotor, a rotor support tool and two ball bearings; the two fixed support plates are placed symmetrically on both sides of the main support plate; the two movable support plates are fixedly mounted on the outer side walls of the two fixed support plates; the rotor support tool is fixedly installed at the middle of the top end of the main support plate; the ferromagnetic motor rotor passes through the rotor support tool in the axial direction; the pressure plate column is fixedly mounted on the top end of the main support plate, and the pressure plate column is disposed on one side of the rotor support tool; the pressure plate is fixedly mounted on the top end of the pressure plate column and the supporting tool; and the two ball bearings are respectively fixedly mounted on the top ends of the outer side walls of the two movable support plates, and the top ends of the two ball bearings are in contact with the ferromagnetic motor rotor. The ferromagnetic motor rotor dynamic balance test device improves the balance precision of the rotor to a higher level of G0.4, and the dynamic balance performance is consistent.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

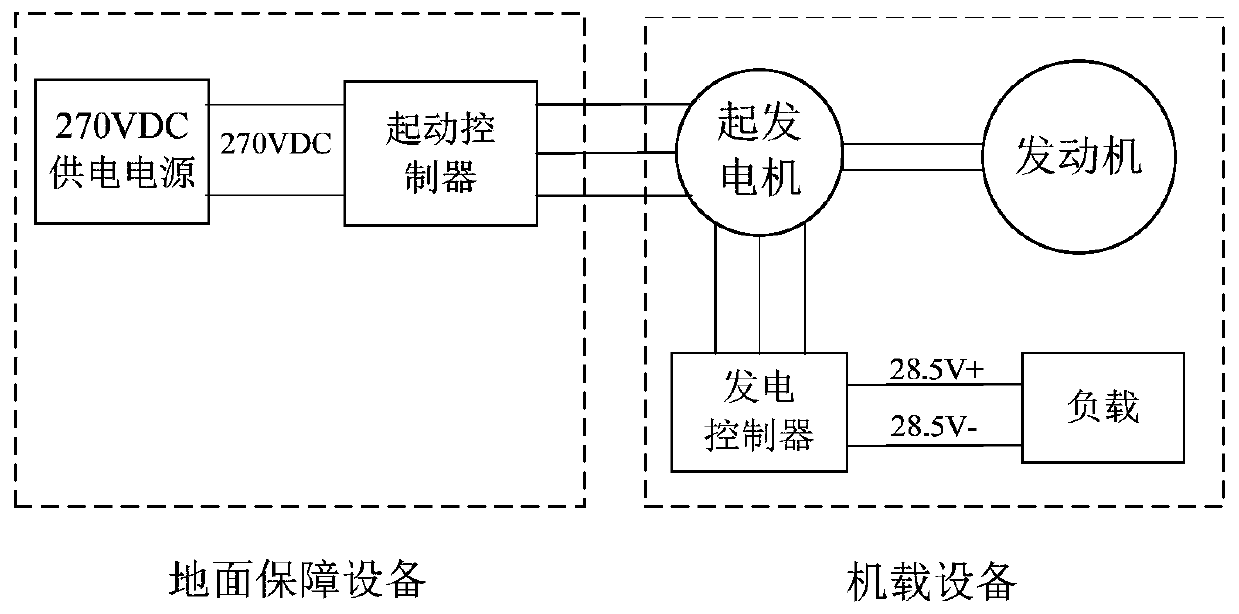

High-voltage and low-voltage compatible built-in brushless direct-current power generation system

ActiveCN111009992AReduce volumeEasy to operateElectronic commutation motor controlWindings insulation shape/form/constructionDC - Direct currentElectric machine

The invention discloses a high-voltage and low-voltage compatible built-in brushless direct-current power generation system, which belong to the technical field of aerospace electrical design and manufacturing. The power generation system comprises a brushless power generator, a starting controller and a power generation controller; the brushless power generator is arranged in an engine and is directly connected with an engine rotating mechanism; the brushless generator is used as a starter in an engine starting state and works in an electric state, drags the engine to an ignition rotating speed and assists power after ignition, and is used as a generator after ignition of the engine and works in a power generation state; the starting controller is used for driving and controlling the electric operation of the generator, and in the starting stage of the engine, the starting controller drives and controls the motor to drag the engine from a static state to a rotating speed meeting the ignition requirement of the engine and assists the engine to operate to reach the required rotating speed to automatically stop the electric driving control of the motor; and the power generation controller rectifies the three-phase alternating current output by the generator into 28.5 V direct current to supply power to a load on an unmanned aerial vehicle.

Owner:BEIJING POWER MACHINERY INST

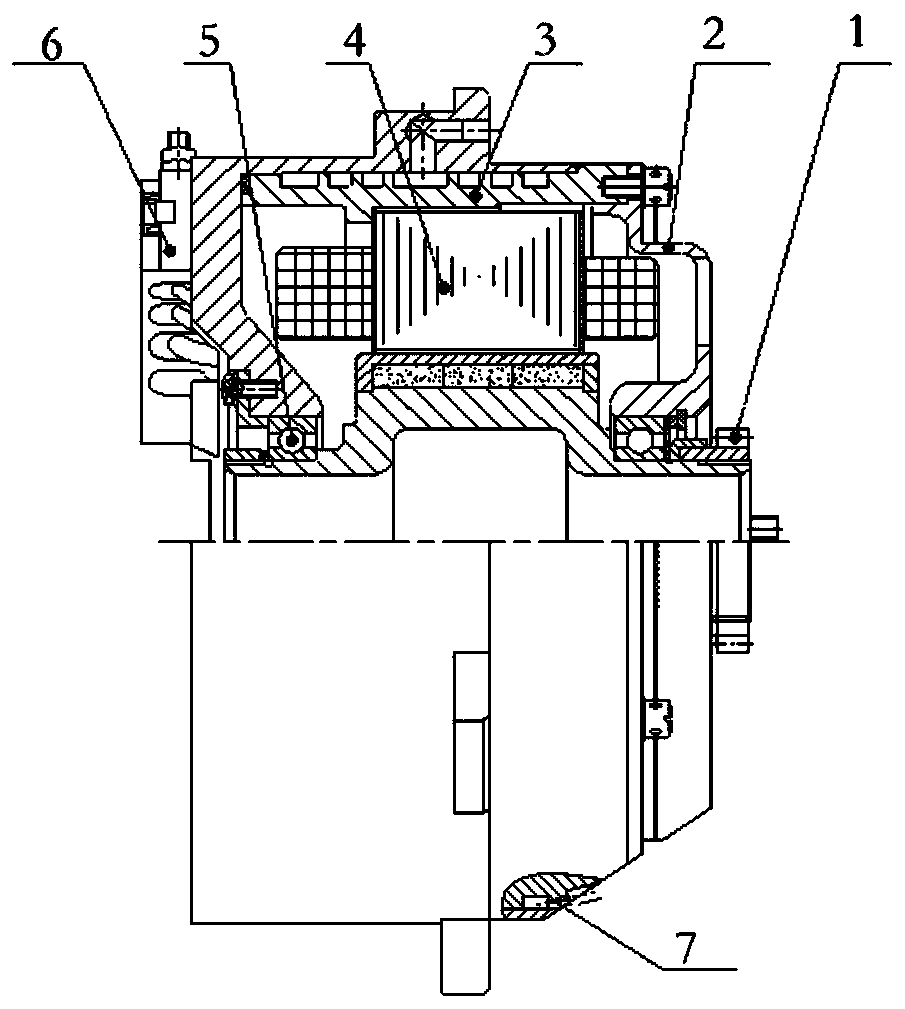

High-speed air bearing motorized spindle

PendingCN110369736AImprove cooling effectSimple structureLarge fixed membersMaintainance and safety accessoriesAir bearingThrust bearing

The invention discloses a high-speed air bearing motorized spindle. The high-speed air bearing motorized spindle comprises a machine body assembly, a rotation assembly, a motor assembly and an air bearing support assembly. The rotation assembly comprises a mandrel arranged in a cavity of an outer casing. The air bearing support assembly comprises a left radial bearing, a radial thrust bearing, a right thrust bearing and a pneumatic structure. The left radial bearing, the motor assembly, the radial thrust bearing and the right thrust bearing are arranged side by side in the cavity of the outercasing from left to right. The position, close to the right end, of the mandrel is provided with a thrust disc. The radial thrust bearing and the right thrust bearing are arranged on the left side andthe right side of the thrust disc. A gap adjusting ring is arranged on the outer periphery of the thrust disc in a sleeving mode. High-pressure gas is introduced into gaps between the mandrel and bearings through a gas path structure, thus, a gas film is formed in the gaps between the mandrel and all the bearings, and the mandrel is suspended. The high-speed air bearing motorized spindle has theadvantages of high load bearing, rigidity, precision and heat dissipation capability and simple machining and assembly process.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

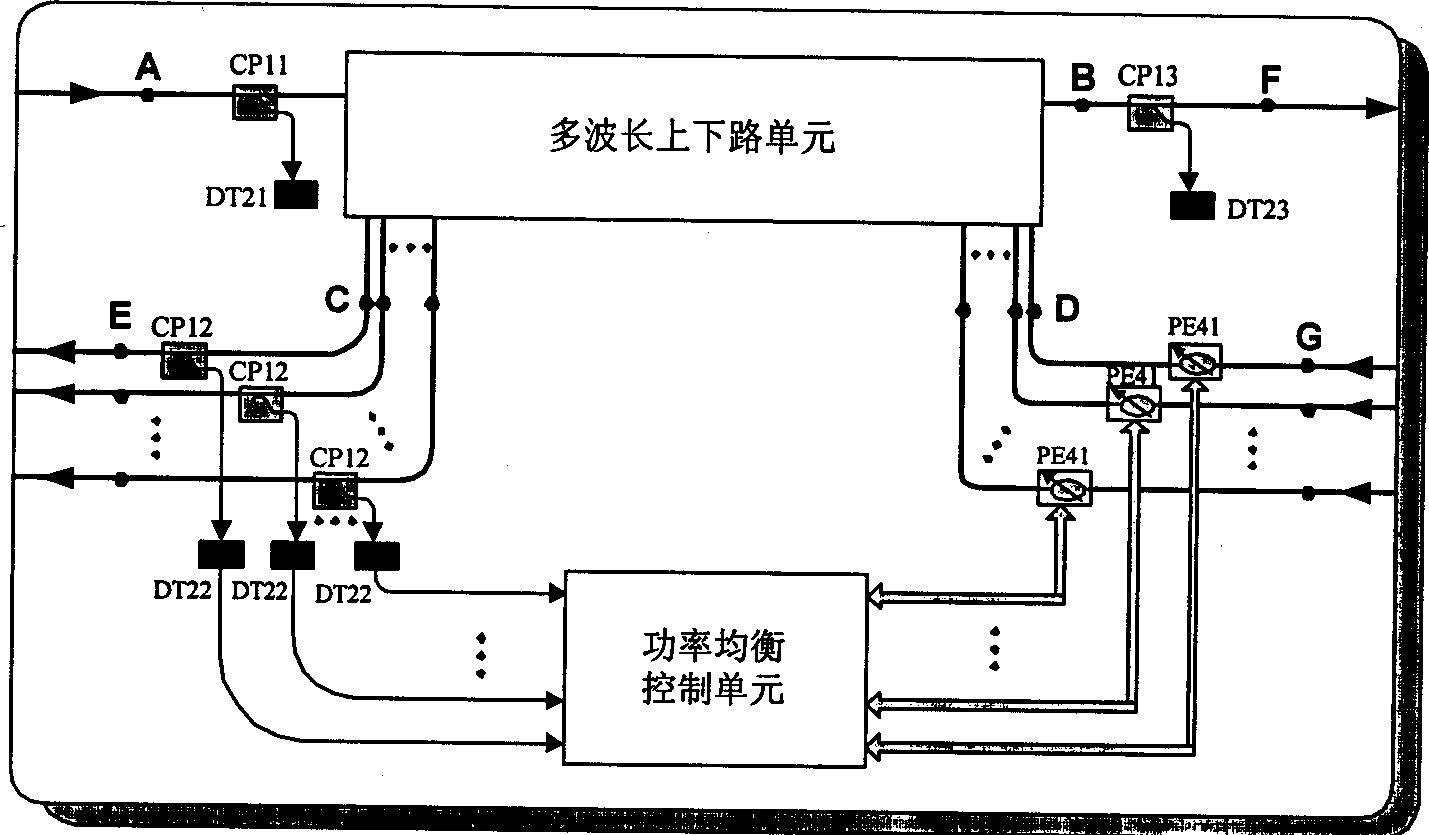

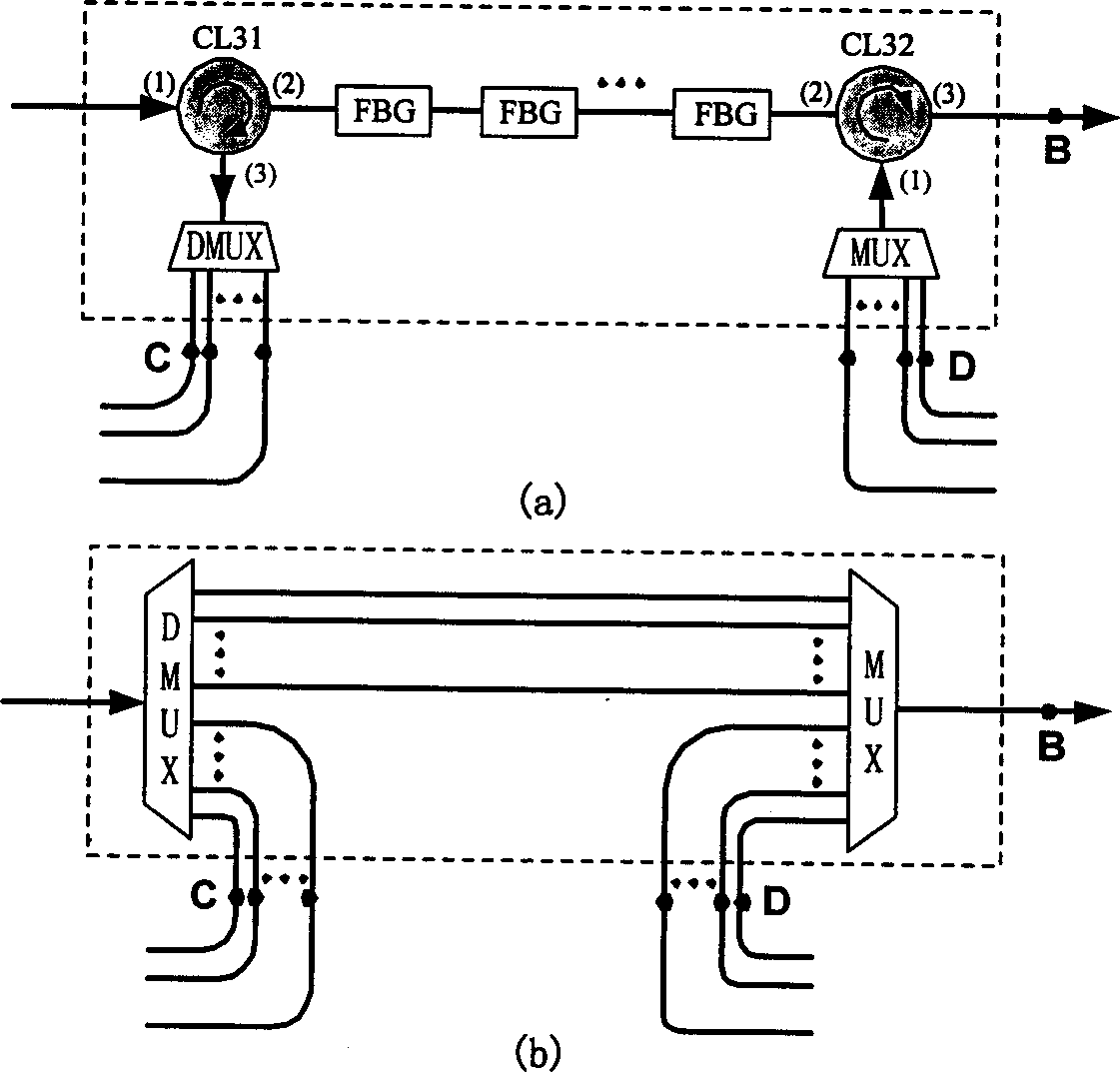

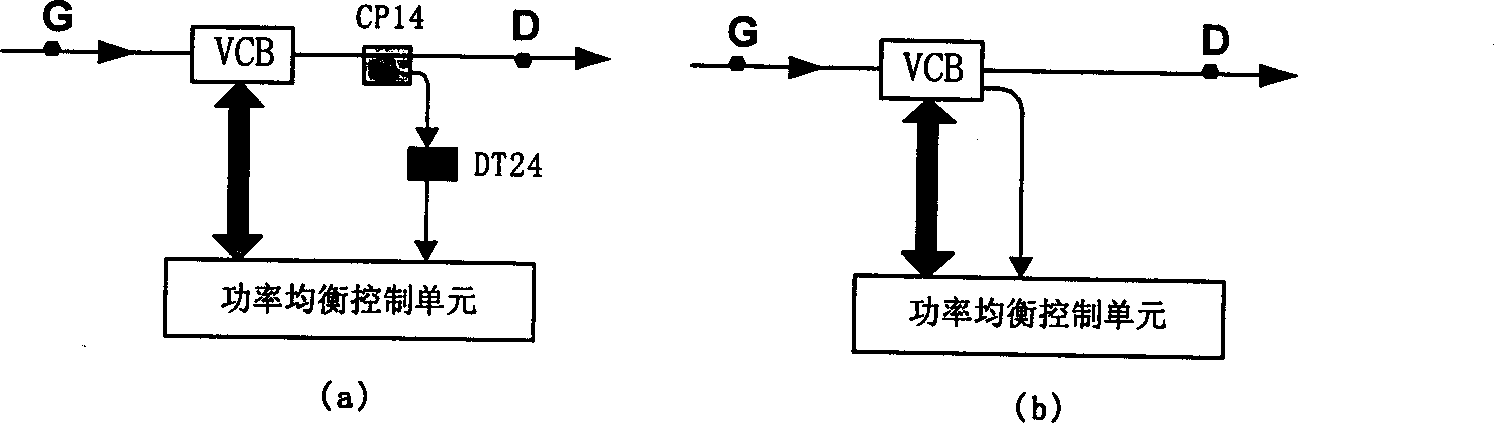

Light add and drop multiplexer for multi-wave length adaptive light power equalization

InactiveCN1339891ADoes not add additional disequilibriumReduce complexityWavelength-division multiplex systemsCoupling light guidesElectricityMultiplexer

The present invention belongs to the field of light communication network technology. The multiplexer includes: multiple wavelength entrance and exit unit, real-time light power monitoring unit comprising light coupler, light detector and drive circuit, power equalizing unit with electrically tunable light attenuator and power equalizing control unit connected successively. The optical add and drop multiplexer (OADM) of the present invention has high stability, low leakge, low cross talk, low loss, being modular and intelligent and high equalizing precision and has excellent application prospect.

Owner:TSINGHUA UNIV

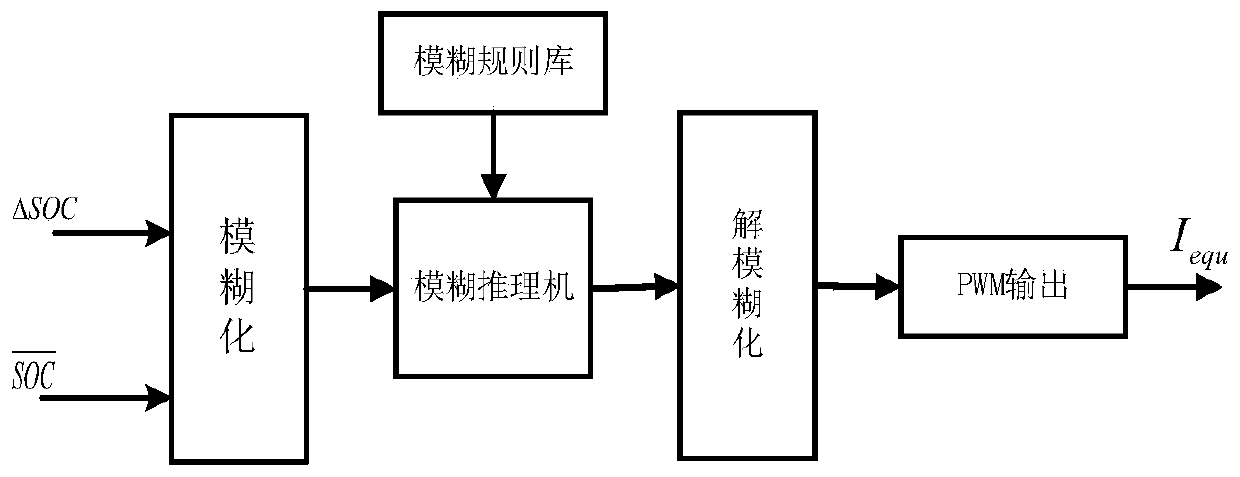

Electric vehicle power battery active equalization device and method

PendingCN111301226AAchieve transferUniform speedBatteries circuit arrangementsSecondary cells servicing/maintenancePower batteryDefuzzification

Owner:XIAN TECH UNIV

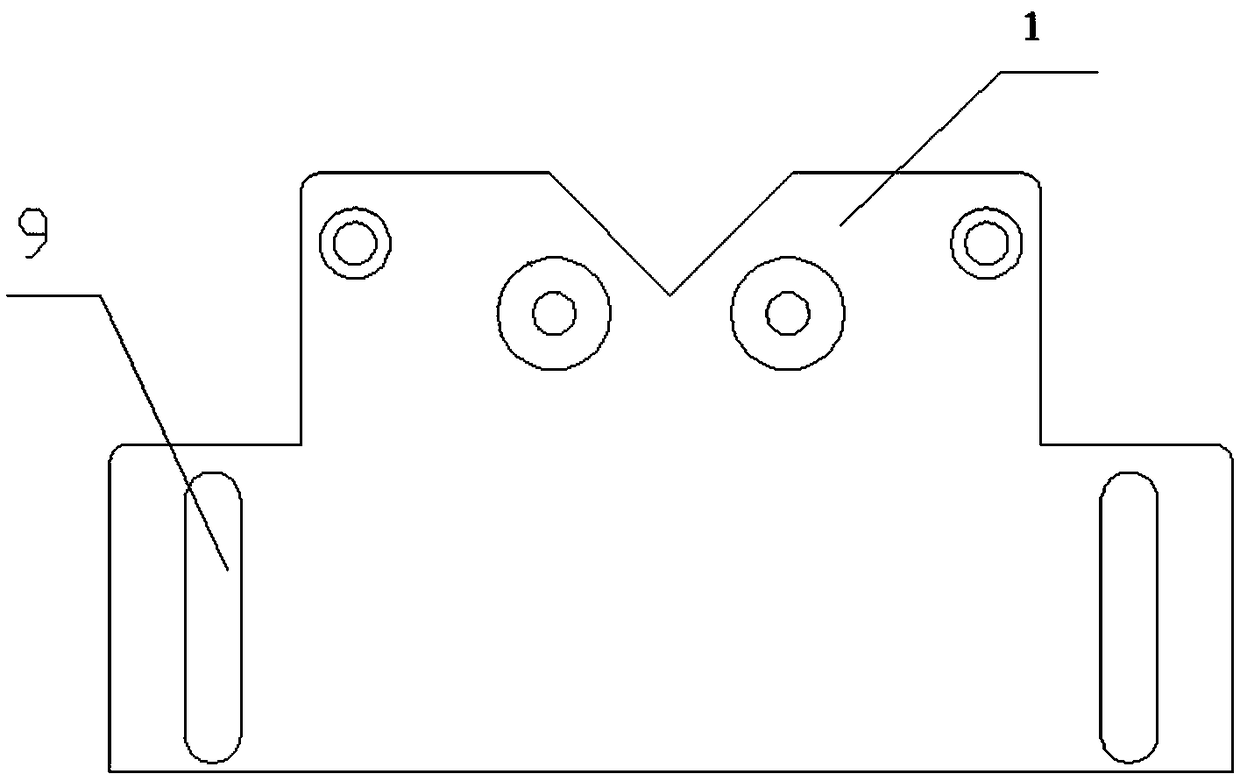

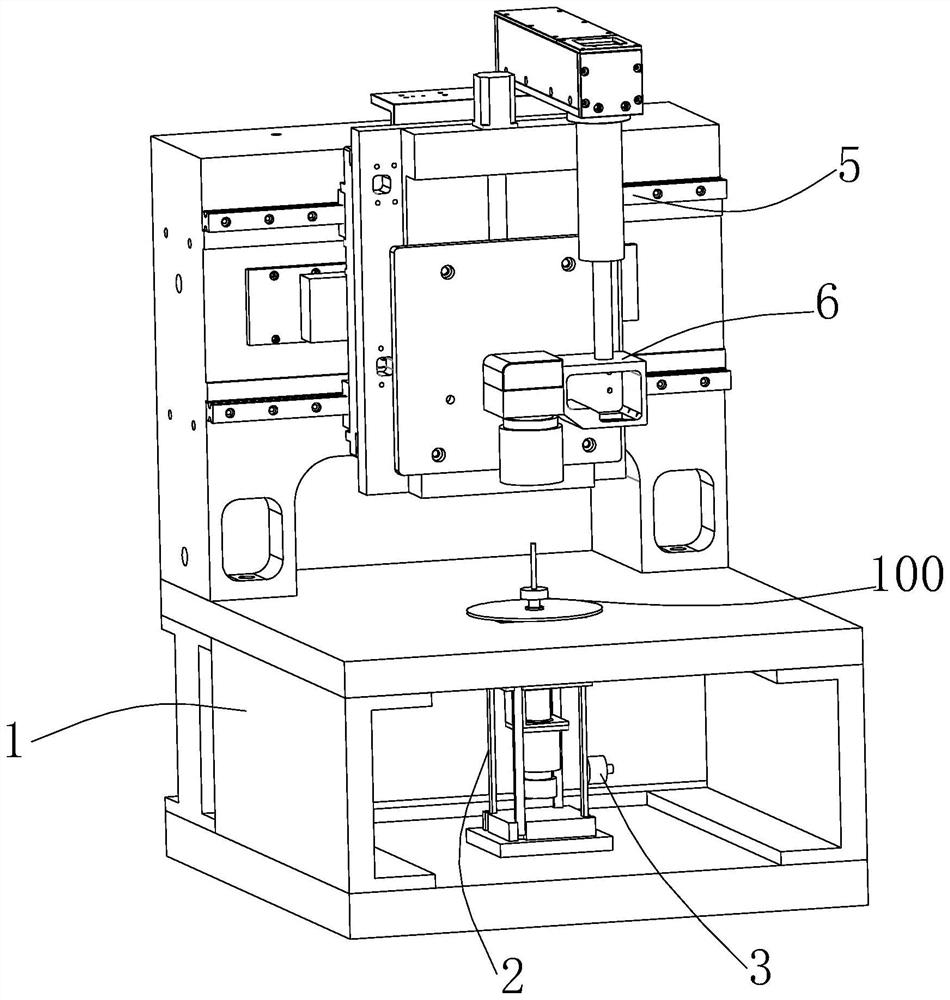

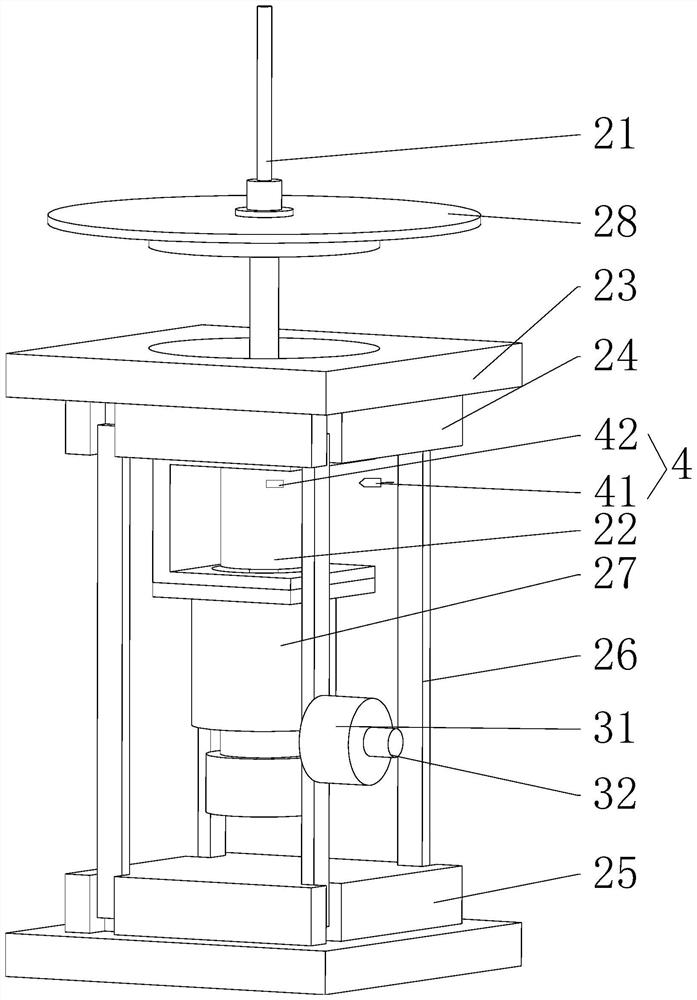

Whole-machine dynamic balancing device and method for micro turbojet engine

InactiveCN111044222AAvoid errorsHigh balance precisionEngine testingStatic/dynamic balance measurementBalancing machineDynamic balance

The invention, which belongs to the field of engineering machinery, relates to a whole-machine dynamic balancing device and method for a micro turbojet engine. Under the condition that all rotor pieces and stator pieces of the micro turbojet engine are assembled together, an engine is fixed to a supporting swing frame of a horizontal dynamic balancing machine through a connecting plate. A pneumatic nozzle is designed to be connected with a pneumatic device arranged on the dynamic balancing machine, then a turbine rotor arranged on the engine is blown to rotate through a pneumatic device and apneumatic nozzle, the engine is blown to rotate at a balanced speed, and then dynamic balance testing and correction are carried out. And after completion, the engine does not need to be disassembled,subsequent final engine assembly can be directly carried out, so that repeated assembly errors after dynamic balance of the traditional combined rotor are avoided, the balance precision is high, andthe production efficiency is high.

Owner:BEIJING POWER MACHINERY INST

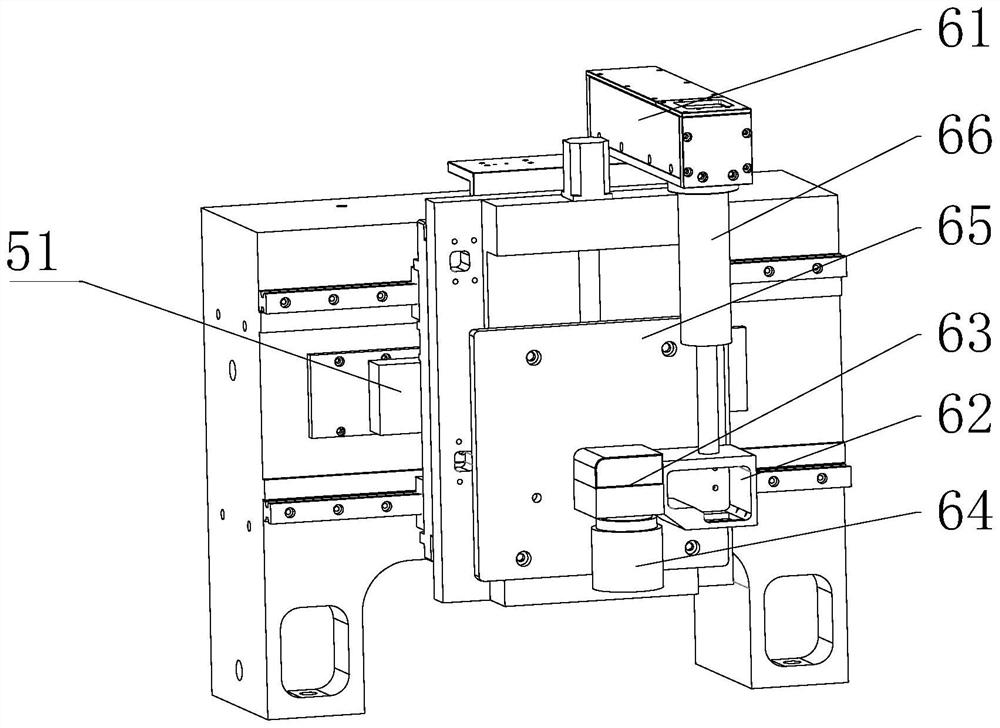

High-precision integrated laser de-weight automatic balancing device and method

PendingCN114264413AShorten working lifeWork lessStatic/dynamic balance measurementDynamic balanceVibration transmission

The invention belongs to the field of dynamic balance de-weight devices and methods, and particularly relates to a high-precision integrated laser de-weight automatic balancing device and method. The device is provided with an equipment supporting mechanism, a vibration transmission mechanism, a vibration detection mechanism, a reference phase detection mechanism, an automatic alignment mechanism and a laser de-weight mechanism, a vibration transmission mechanism used for transmitting vibration generated when a rotor rotates is arranged in the equipment supporting mechanism, a vibration detection mechanism used for detecting vibration and a reference phase detection mechanism are fixed to the vibration transmission mechanism, and an automatic alignment mechanism used for automatic alignment is arranged above the vibration transmission mechanism. And a laser de-weight mechanism is arranged on the automatic alignment mechanism. The laser de-weighting mode adopted by the invention belongs to non-contact de-weighting, internal stress does not occur in the rotor after correction, and the working performance and the service life of the rotor can be effectively improved and prolonged.

Owner:无锡超通智能制造技术研究院有限公司

Balancing apparatus for rotating bodies, in particular tool-carriers with tools rotating at high speed

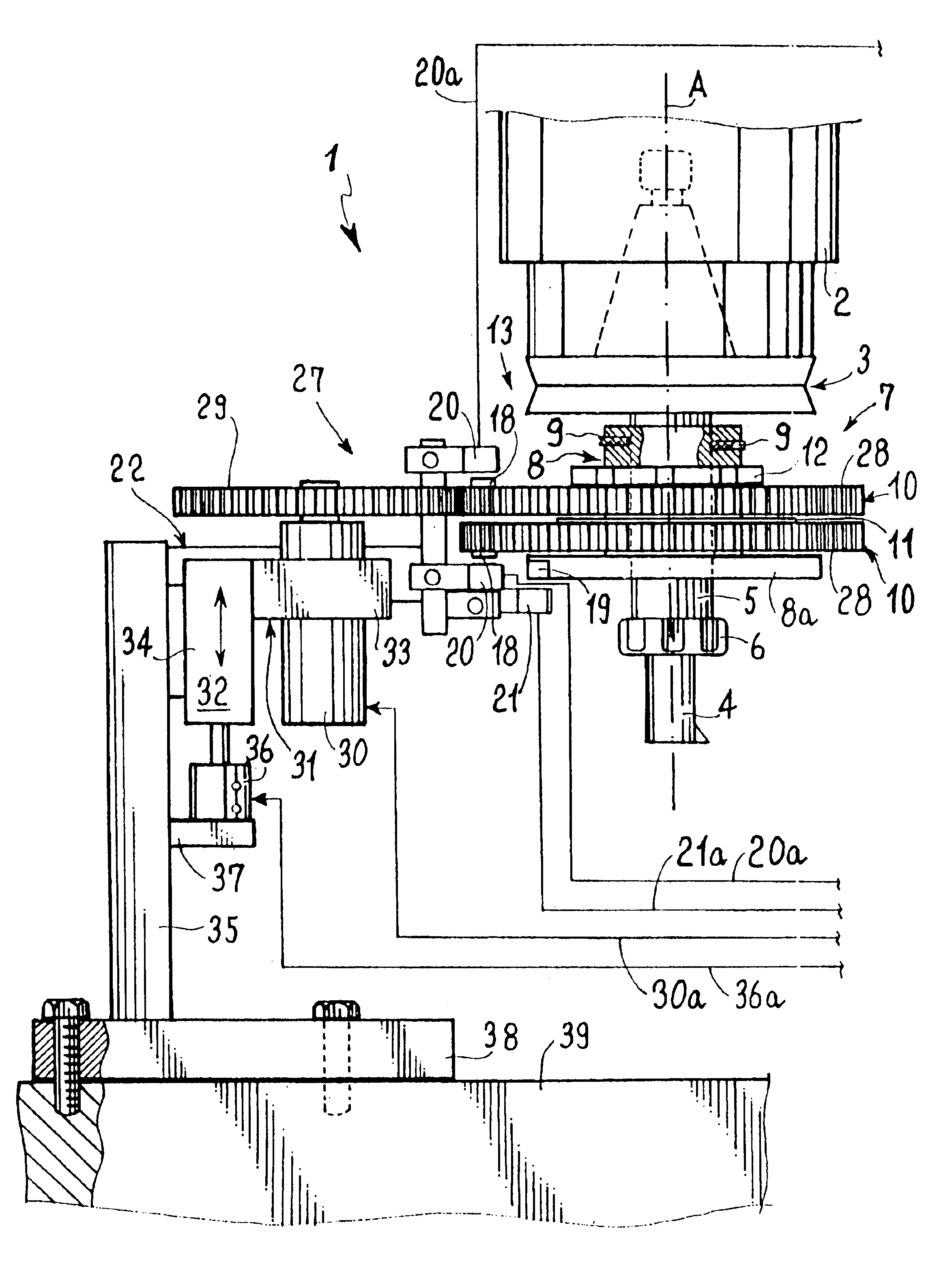

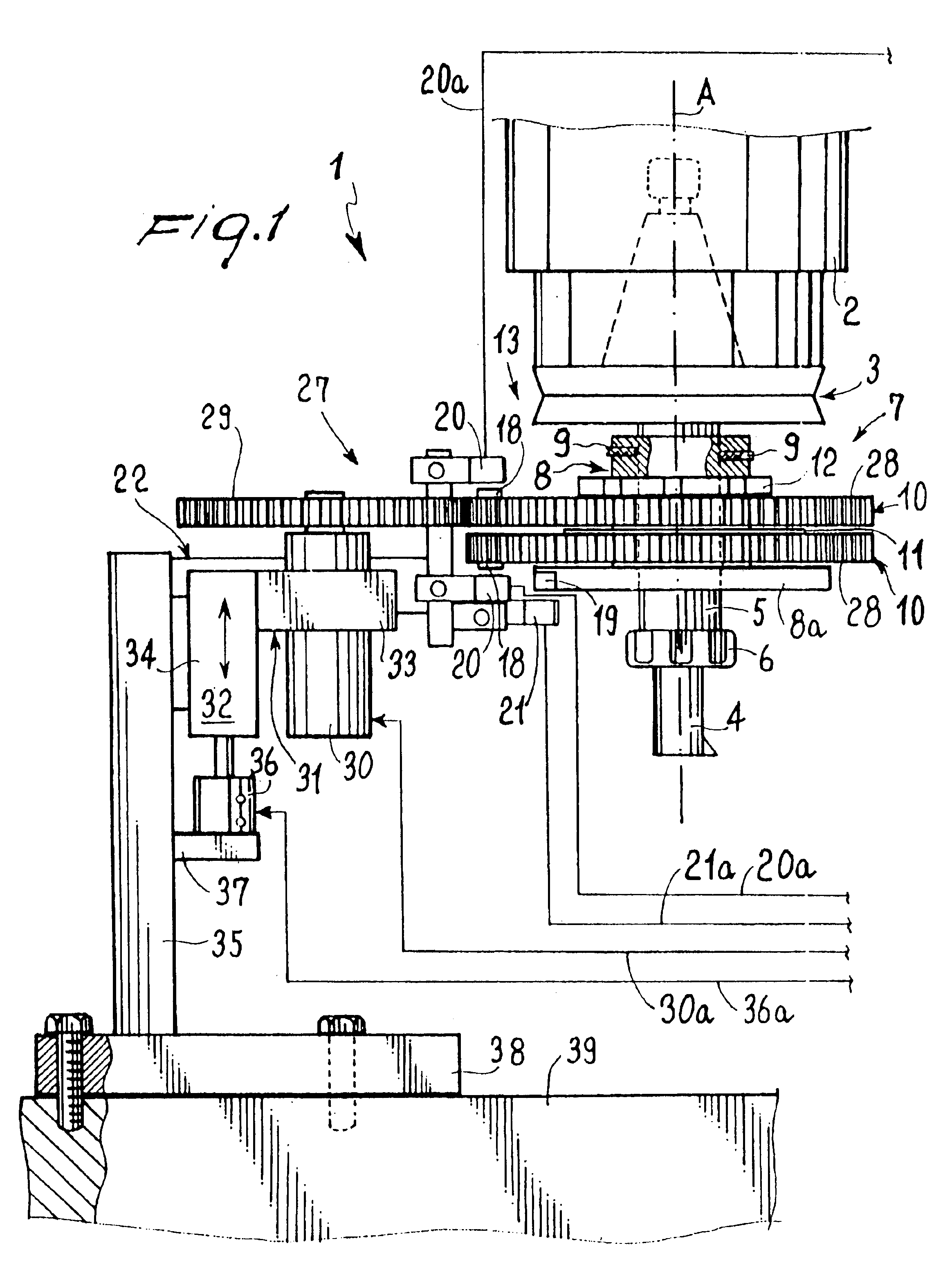

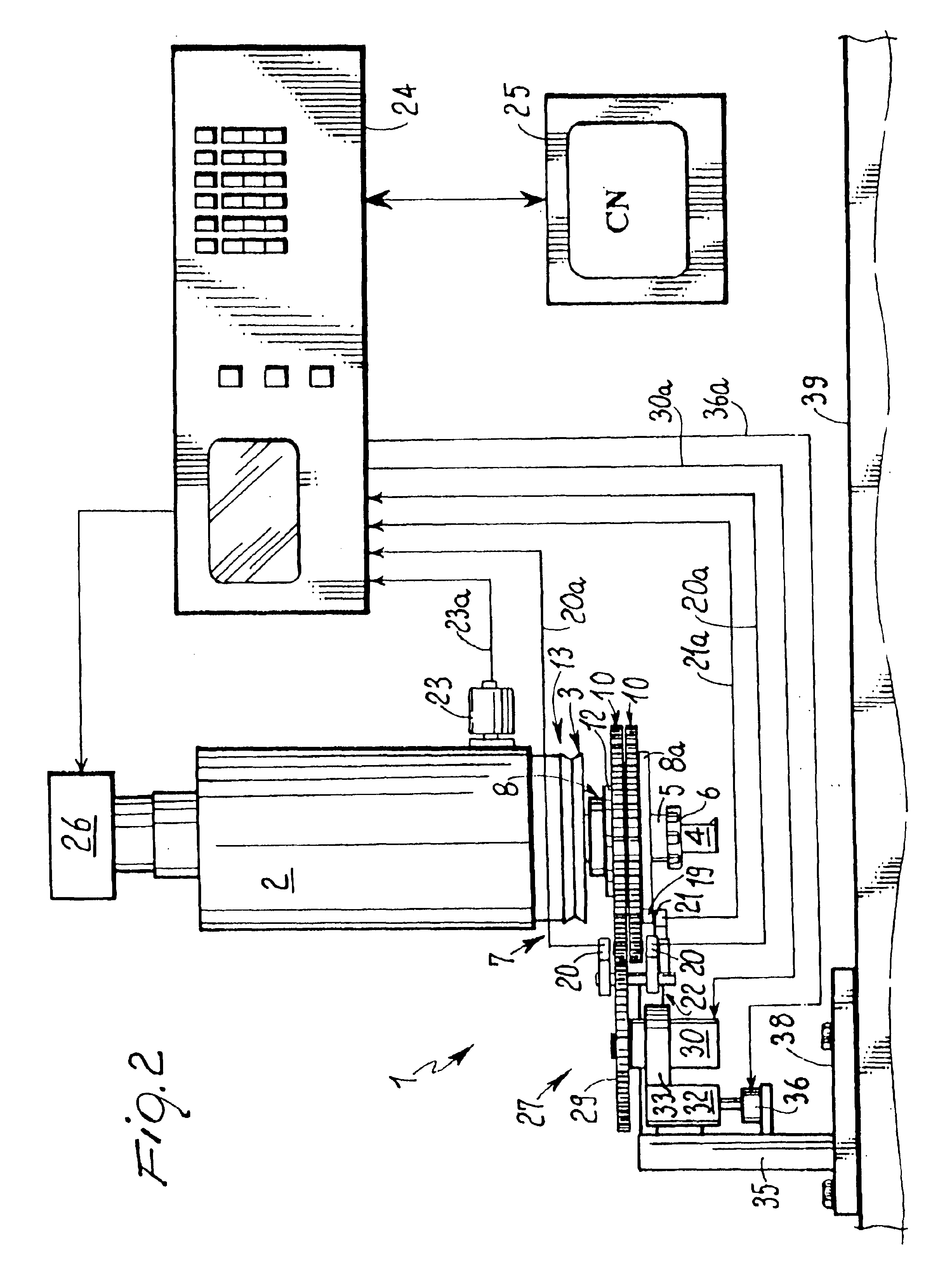

InactiveUS6901798B2Reduce volumeLow costRotating vibration suppressionStatic/dynamic balance measurementGear wheelEngineering

The apparatus (1) comprises at least two balancing rings (10) disposed in axial side by side relationship and coaxial with each other on the rotating body (13) to be balanced. The rings (10) are each unbalanced and rotatable with the rotating body (13), but can each be angularly rotated relative to the latter through positioning members. These members may comprise either a gear (29) that can be selectively engaged in rotation with peripheral toothings (28) of the rings (10) when the rotating body (13) is stopped, to bring the rings (10) to a relative angular position to which the situation of balance of the rotating body (13) corresponds, or locking elements to be selectively engaged with peripheral notches in the rings (10) to retain the rings (10) one by one while the rotating body (13) is rotated relative to the rings (10) through such an angle that the angular balance position is achieved.

Owner:BALANCE SYST

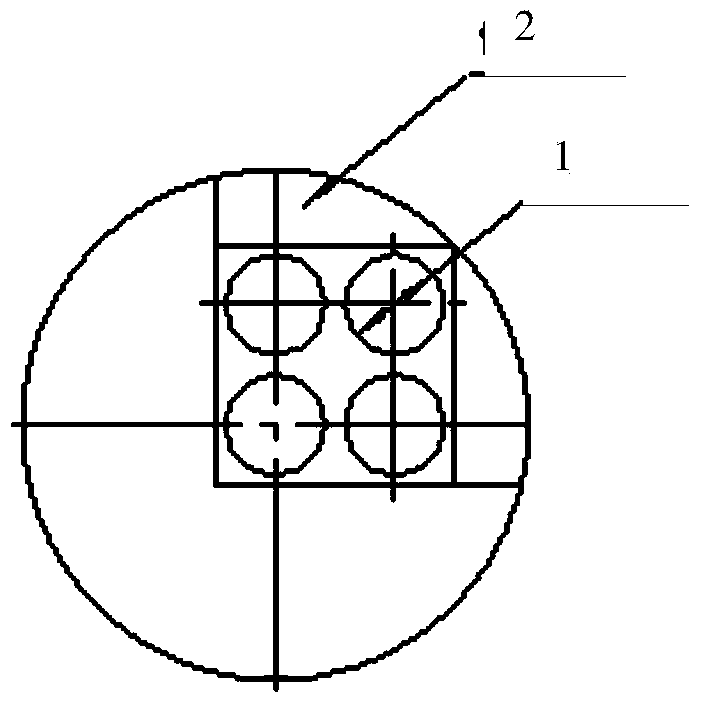

Porous metallic beryllium deep-hole machining method

InactiveCN103722203AReduce cutting forceAvoid cutting forcePositioning apparatusMetal-working holdersSurface finishBrick

The invention relates to a porous metallic beryllium deep-hole machining method. The porous metallic beryllium deep-hole machining method includes: adopting an eccentric fixture to mount a workpiece on a deep-hole drilling machine; performing primary drilling on a first hole and stopping upon drilling through prior to removing the workpiece; adopting a method by using a gasket to remove positioning deviation and filling equal-weighing objects into the drilling position prior to loading the workpiece into the eccentric fixture once again for primary drilling on a second hole; after four holes are primarily drilled according to above processes, performing multistage broaching and reaming according to the above processing steps. The multiple deep holes of a four-hole square brick are subjected to machining by adopting the deep-hole drilling processes including drilling (phi 20mm), multistage broaching (phi 24mm, phi 26mm, phi 28mm, phi 30mm and phi 32mm) and reaming, so that deep-hole machining of large diameter (> / =32mm) and large length diameter (50-150) upon metallic beryllium materials can be realized, machining precision of the hole after reaming can reach the level of IT7, and surface smoothness can reach Ra 0.4.

Owner:西北稀有金属材料研究院宁夏有限公司

Double-sided online de-weighting dynamic balancing system for ultra-precise flexible rotor

ActiveCN111168244ASolve the problem of difficult balance at working speedHigh balance precisionLaser beam welding apparatusUltra high speedControl system

The invention discloses a double-sided online de-weighting dynamic balancing system for an ultra-precise flexible rotor. The system comprises an ultra-high-speed flexible main shaft, the ultra-high-speed flexible main shaft is supported on a main shaft clamp, unbalanced de-weighting discs are installed at the two ends of the ultra-high-speed flexible main shaft, and a laser online de-weighting system is arranged beside each unbalanced de-weighting disc in a matched mode. The two laser on-line de-weighting systems are connected with a measurement and control system, and the laser on-line de-weighting systems achieve position adjustment in the up-down direction and the left-right direction and rotary motion posture adjustment of a de-weighting laser in the two directions. The measurement andcontrol system realizes functions of vibration signal acquisition and accurate extraction under complex working conditions, laser de-weight system position and de-weight laser posture adjustment control, laser pulse emission control and man-machine interaction. According to the system, through combining the laser rapid removal technology, the unbalance test and automatic de-weighting functions ofthe ultra-high-speed flexible rotor in a rotating state are realized, the labor cost is saved, and the balance efficiency is greatly improved.

Owner:XI AN JIAOTONG UNIV

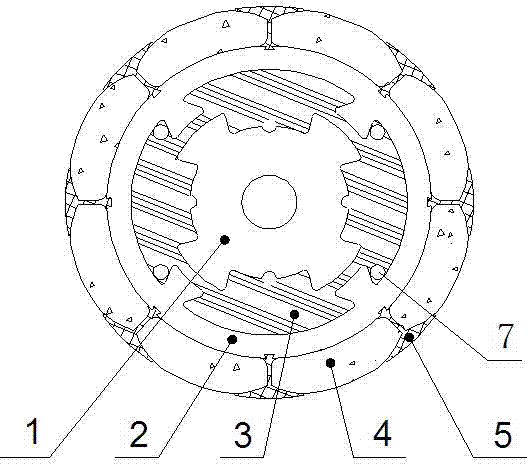

Automatic balancing device for threshing cylinder of combine harvester and control method

ActiveCN113366968AEasy to install and adjustEasy to operateMowersThreshersDynamic balanceControl engineering

The invention provides an automatic balancing device for a threshing cylinder of a combine harvester and a control method. The automatic balancing device comprises an annular outer shell, a plurality of balance weight sliding blocks, an annular guide rail, an annular inner shell, permanent magnets and a dynamic balance detection system, wherein the annular inner shell is located in the annular outer shell, the annular guide rail is installed between the annular outer shell and the annular inner shell, the balance weight sliding blocks are distributed in the circumferential direction of the annular guide rail, and each balance weight sliding block is provided with an electromagnetic solenoid; the permanent magnets are circumferentially and uniformly arranged on the inner wall of the inner shell; the dynamic balance detection system comprises a detection mechanism and a controller; the detection mechanism is used for measuring vibration signals of a threshing cylinder shaft and the rotating speed of the threshing cylinder; and the controller calculates the unbalance amount of the threshing cylinder, the unbalance amount comprises the phase and the needed balance weight, the current of the electromagnetic solenoids is controlled through wires according to the phase and the result of the needed balance weight, and therefore the balance weight sliding blocks are controlled to move on the annular guide rail, online active dynamic balance adjustment of the threshing cylinder of the combine harvester is achieved, and the threshing effect and the working efficiency are improved.

Owner:JIANGSU UNIV

High-speed flexible rotor dynamic balance method

InactiveCN101949753BOmit solvingDrive lessStatic/dynamic balance measurementVertical vibrationElement model

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Piston type self-balancing oil-water substitution oil storage tank

ActiveCN104229062ASimple structureCompact structureHull interior subdivisionVessel movement reduction by mass displacementFuel oilOil water

The invention discloses a piston type self-balancing oil-water substitution oil storage tank. The piston type self-balancing oil-water substitution oil storage tank comprises a tank body of a tubular structure and a valve group arranged on the tank body. The piston type self-balancing oil-water substitution oil storage tank is characterized in that a movable piston type isolating device is arranged inside the tank body and divides the oil storage tank into two mutually-independent size-variable spaces used for storing fuel oil and substitution water respectively; the isolating device comprises a body and a mechanical seal assembly, wherein the body is matched with an inner cavity structure of the tank body, and the seal assembly is used for isolating the fuel oil and the substitution water on the two sides of the isolating device. The piston type self-balancing oil-water substitution oil storage tank has the advantages that the system structure is simple and compact, the self-balancing property is good, contamination to the fuel oil is low in the oil-water substitution process, economy is good, and reliability is high, and is quite suitable for a ship which needs to carry a large amount of fuel oil but has limited overall space.

Owner:SHANGHAI MICROPOWERS

Tyre-disassembling and balancing integrated machin

InactiveCN101474948BBalance operation has no effectHigh balance precisionStatic/dynamic balance measurementTyre repairingAutomotive engineering

The invention relates to a tire disassembly balancing all-in-one machine, which aims to solve the technical problem that how to fill in the blank of the prior art and provides the tire disassembly balancing all-in-one machine. The tire disassembly balancing all-in-one machine comprises a tire assembling shaft, a balance driving mechanism, a balance detecting system, a beak and a tire disassembly / assembly driving mechanism. The beak is arranged on a telescopic frame which at least comprises two mutually perpendicular telescopic arms, wherein one telescopic arm is in parallel to the tire assembling shaft, and the axial lead of the beak is in parallel to that of the tire assembling shaft; and an on-off device is arranged between the tire disassembly / assembly driving mechanism and the tire assembling shaft, and the tire assembling shaft can be switched between two driving mechanisms and under the control of the on-off device. The machine can be used for double purposes, and the processes of disassembling and assembling tires are completed on the same equipment. Therefore, the machine has the advantages of simple structure, convenience and labor conversation, and can be widely used for various garages, automobile maintenance stations and tire shops.

Owner:焦建飞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com