Injection-molding shock absorption rotor

A technology of rotor and shock-absorbing rubber, which is applied in the direction of magnetic circuit rotating parts, manufacturing motor generators, electrical components, etc., can solve the problems of motor power and efficiency that are difficult to meet the requirements, waste of human resources, abnormal motor noise, etc., to achieve Improve the use value and economic benefits, improve the shock absorption effect, and improve the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

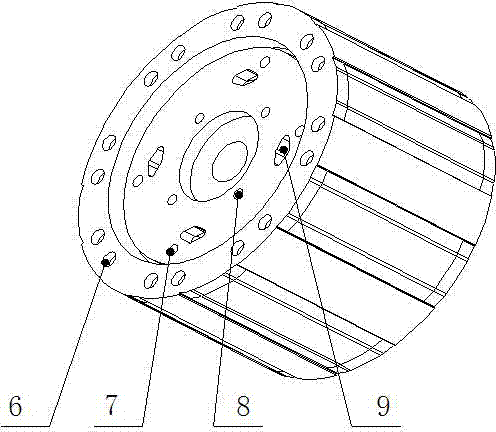

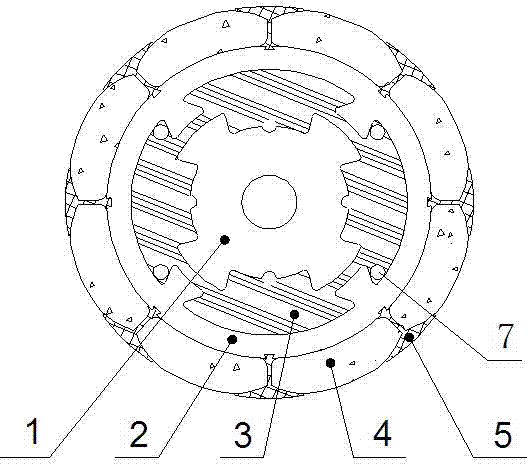

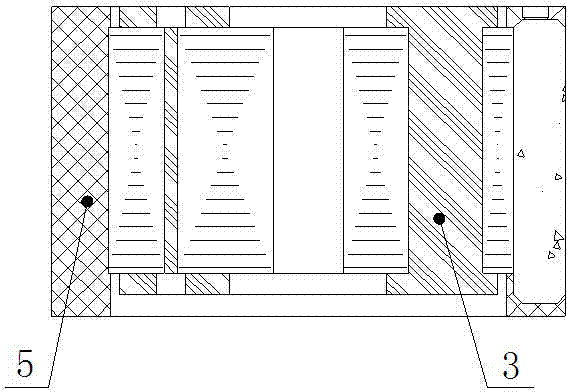

[0018] Referring to the accompanying drawings, an injection-molded shock-absorbing rotor includes a supporting iron core 1 and a magnetic steel 4, and is characterized in that: the outer periphery of the supporting iron core 1 is provided with a shock-absorbing rubber 3, and the outer periphery of the shock-absorbing rubber 3 is provided with a yoke 2 A plurality of magnetic steels 4 are evenly distributed on the periphery of the magnetic yoke 2, and engineering plastics 5 are injected in the gap between the dovetail groove on the magnetic yoke and the magnetic steel and the gap formed between the outer circles of adjacent magnetic steels. A plurality of dovetail grooves 21 are evenly arranged on the outer circle of the magnetic yoke 2, and a plurality of dovetail bosses B22 are evenly arranged on the inner circle of the magnetic yoke 2. Several dovetail bosses A12 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com