Automatic riveting apparatus of loudspeaker U iron and basin stand

An automatic riveting and speaker technology, applied in the direction of sensors, electrical components, etc., can solve the problems of speaker products unqualified, operator injury, difficult operation, etc., to avoid the risk of injury, reduce labor difficulty and strength, and the structure is ingenious and reasonable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific drawings and embodiments.

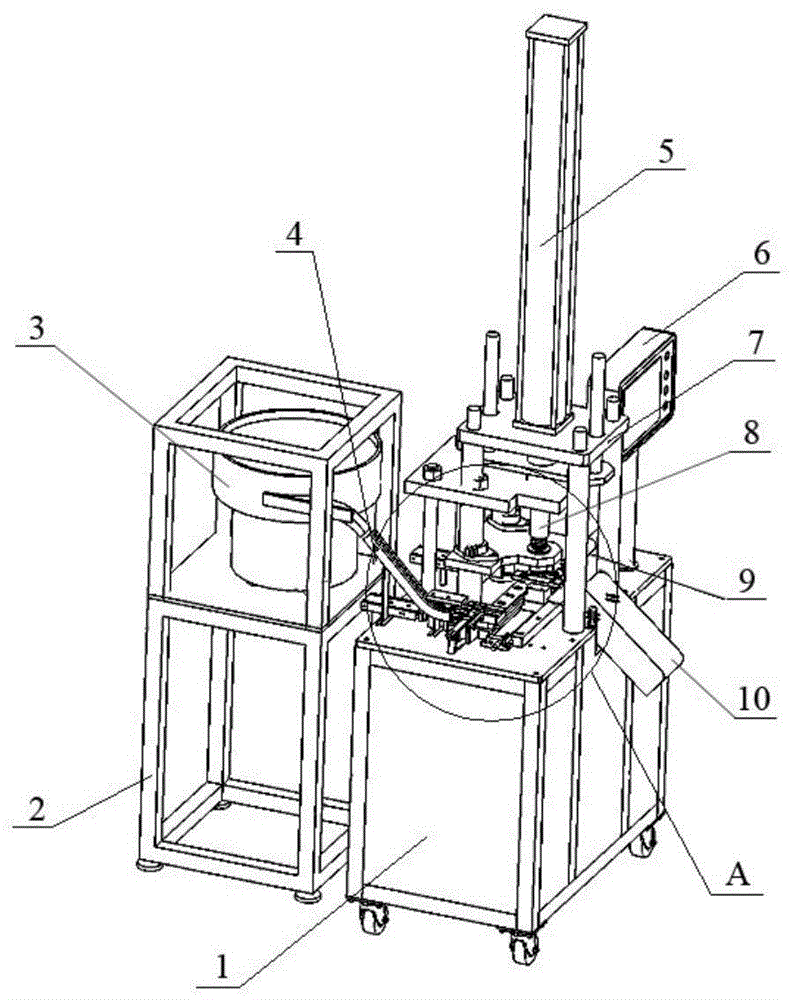

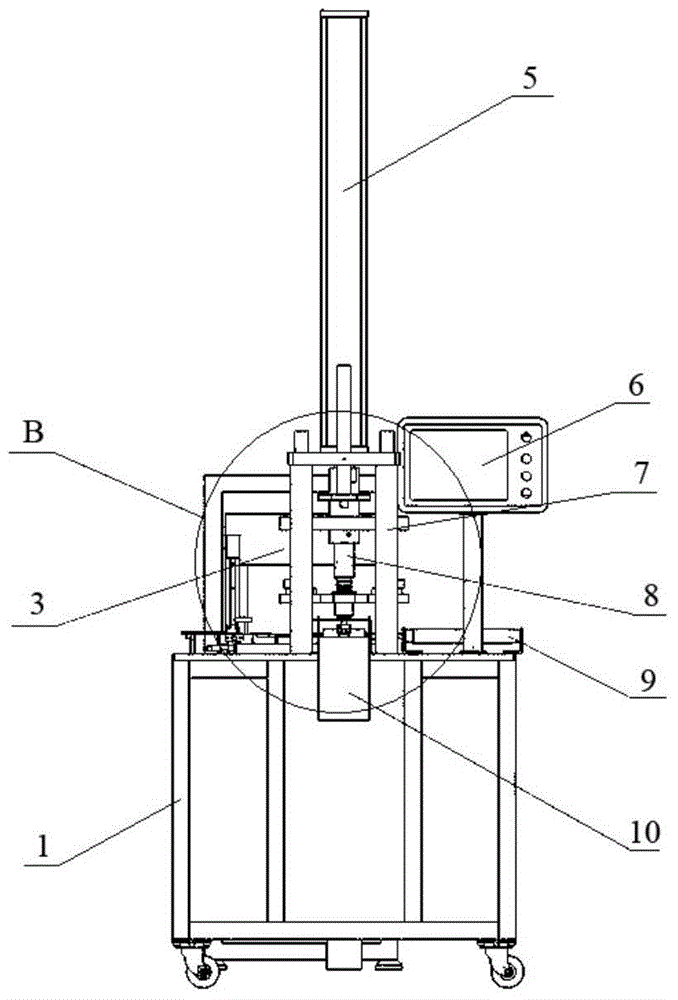

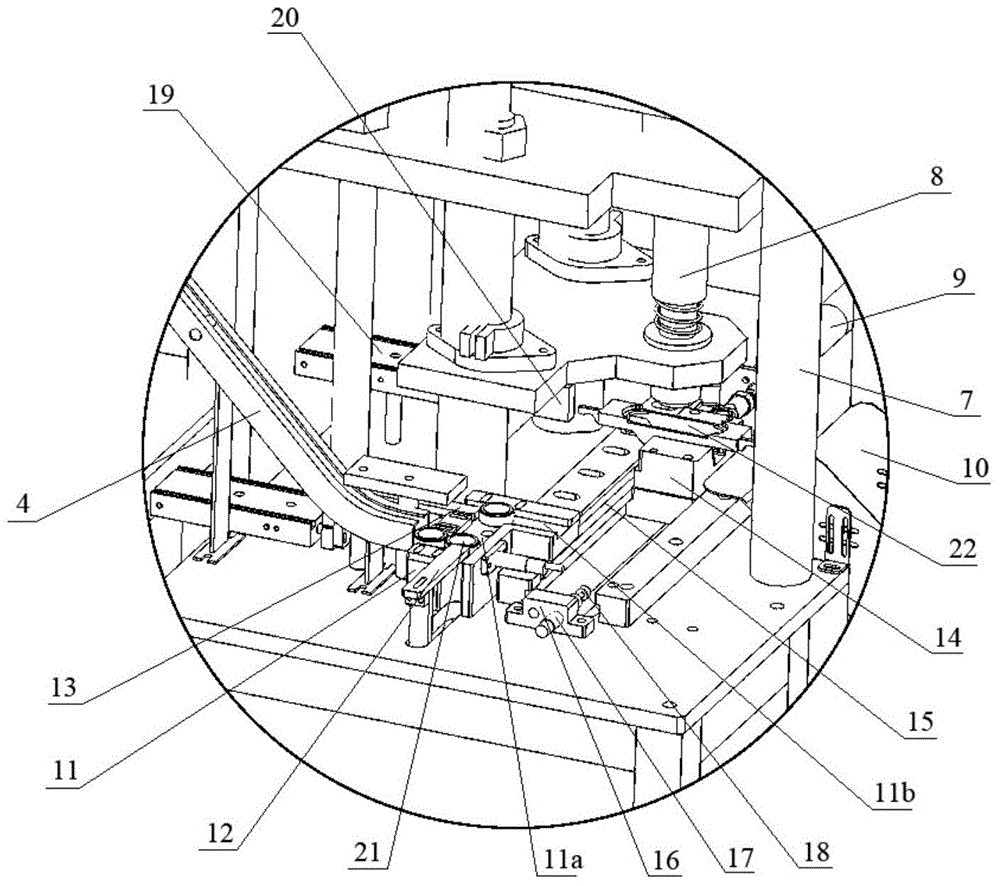

[0017] Such as Figure 1~Figure 4 As shown: the automatic riveting device of the speaker U iron and the basin frame in the embodiment is mainly composed of the machine platform 1, the U iron feeding and sorting mechanism, the U iron basin frame translation mechanism, the stamping mechanism, the finished product blanking chute 10, and the finished product pushing mechanism And form a complete set of electrical control box 6.

[0018] Such as Figure 1~Figure 4 As shown, the U-iron feeding and sorting mechanism is used to transport the U-iron 21 to the positioning fixture 14 in the U-iron basin frame translation mechanism in sequence; The iron material channel 4, the sorting guide block 11, the first pushing plate 12 and the second pushing plate 13 are composed, the vibrating material frame 2 is arranged on the side of the machine platform 1, and the vibrating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com