Patents

Literature

725results about How to "Ingenious and reasonable structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

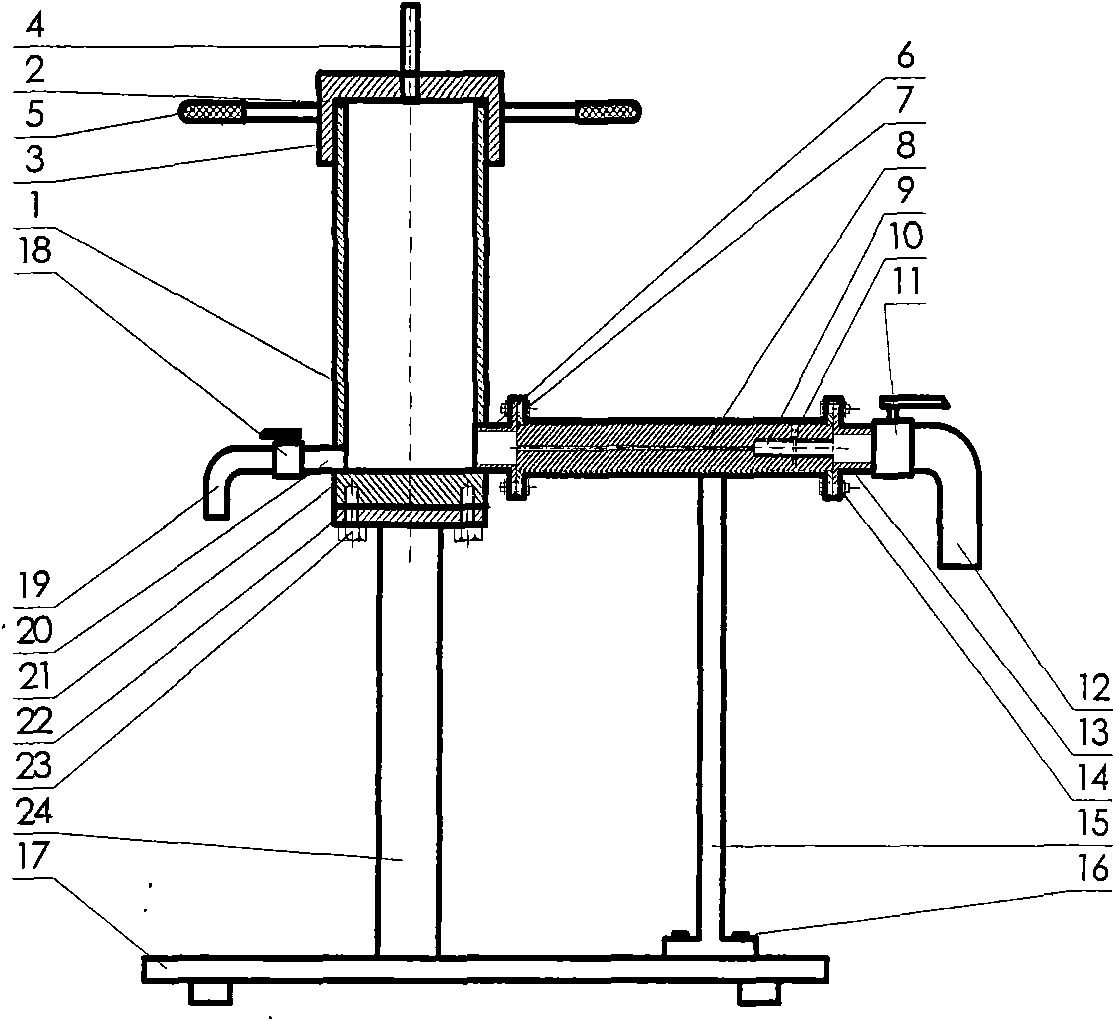

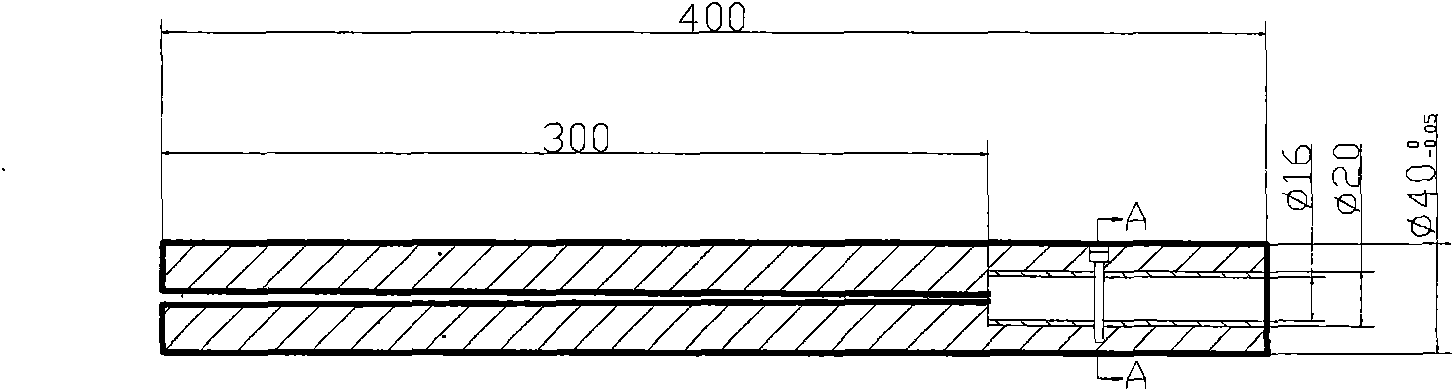

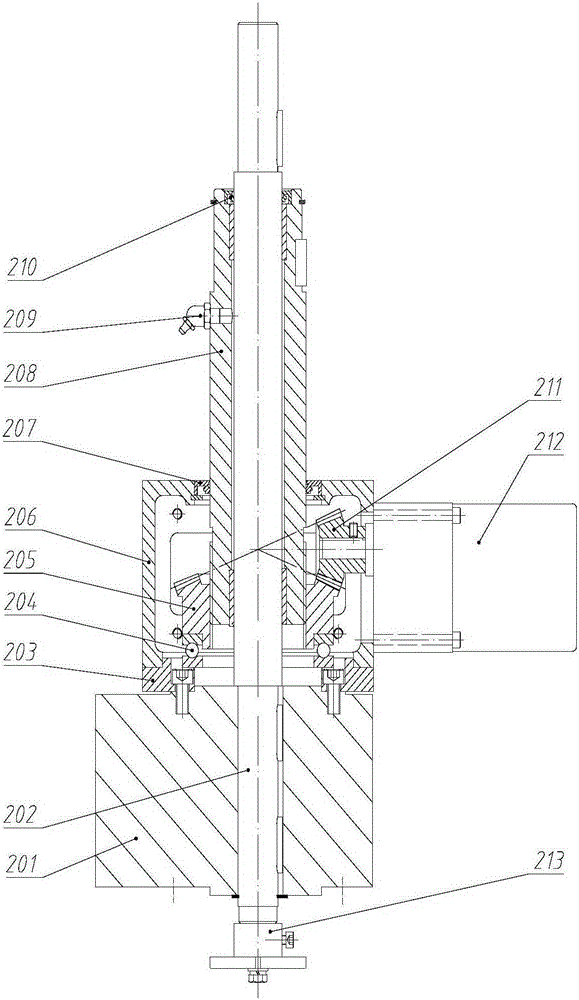

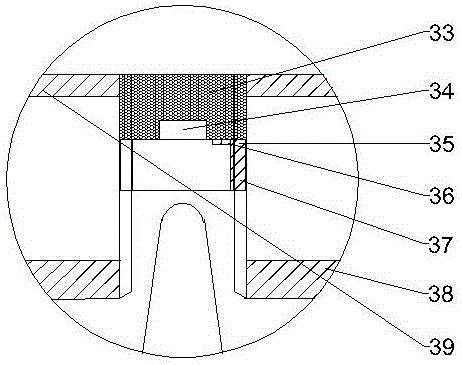

Simulation fracture plugging test device and test method

InactiveCN101672172APrevent critical leaksIngenious and reasonable structureSealing/packingStudy methodsHigh pressure

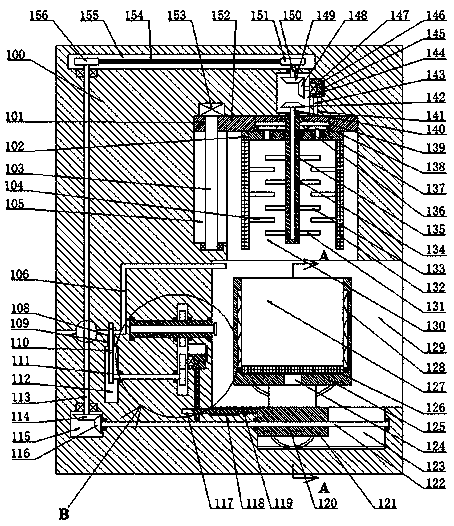

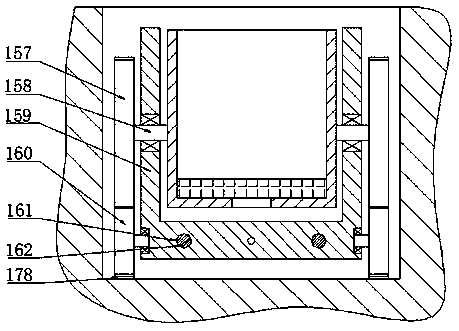

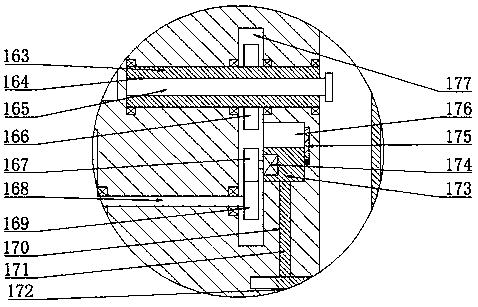

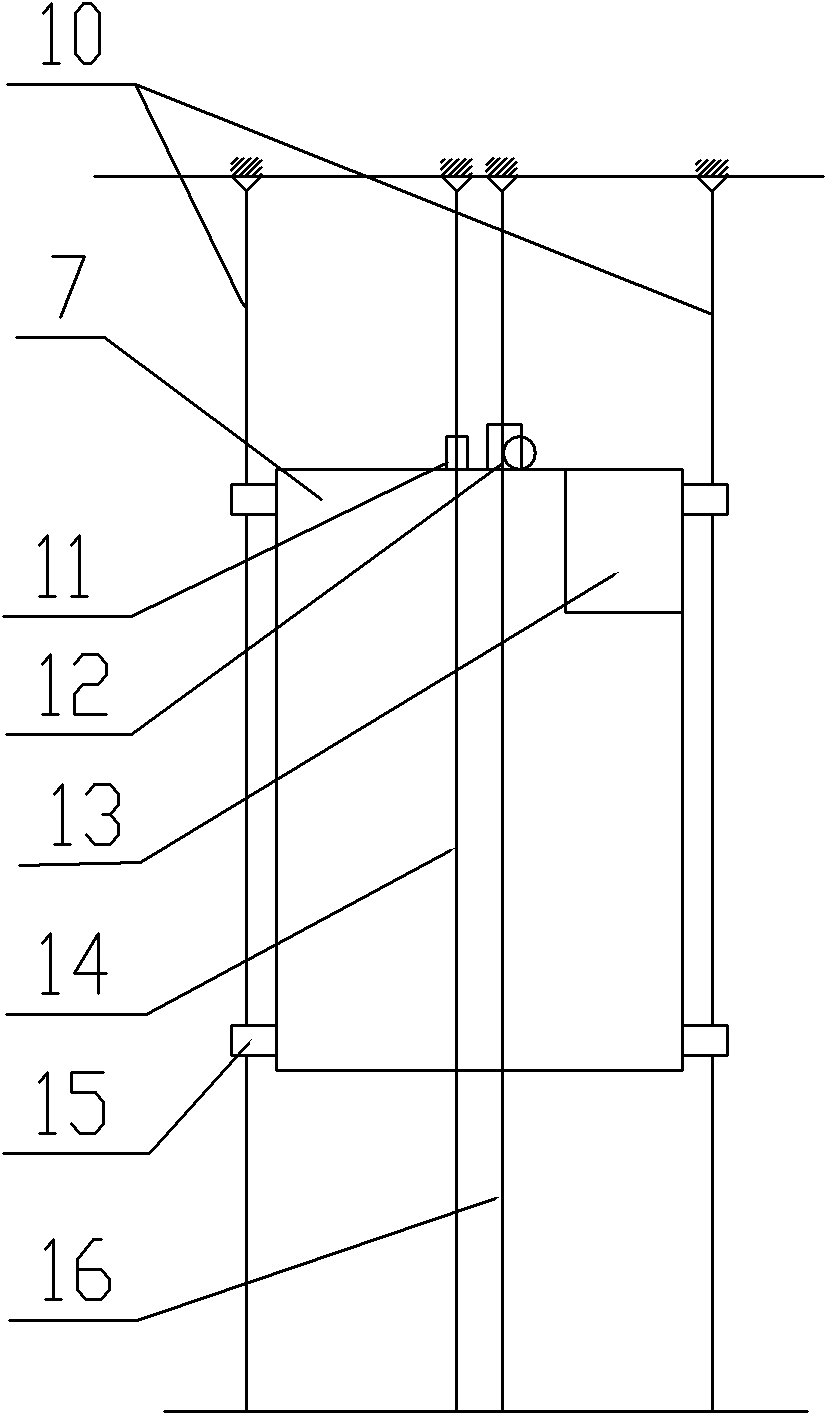

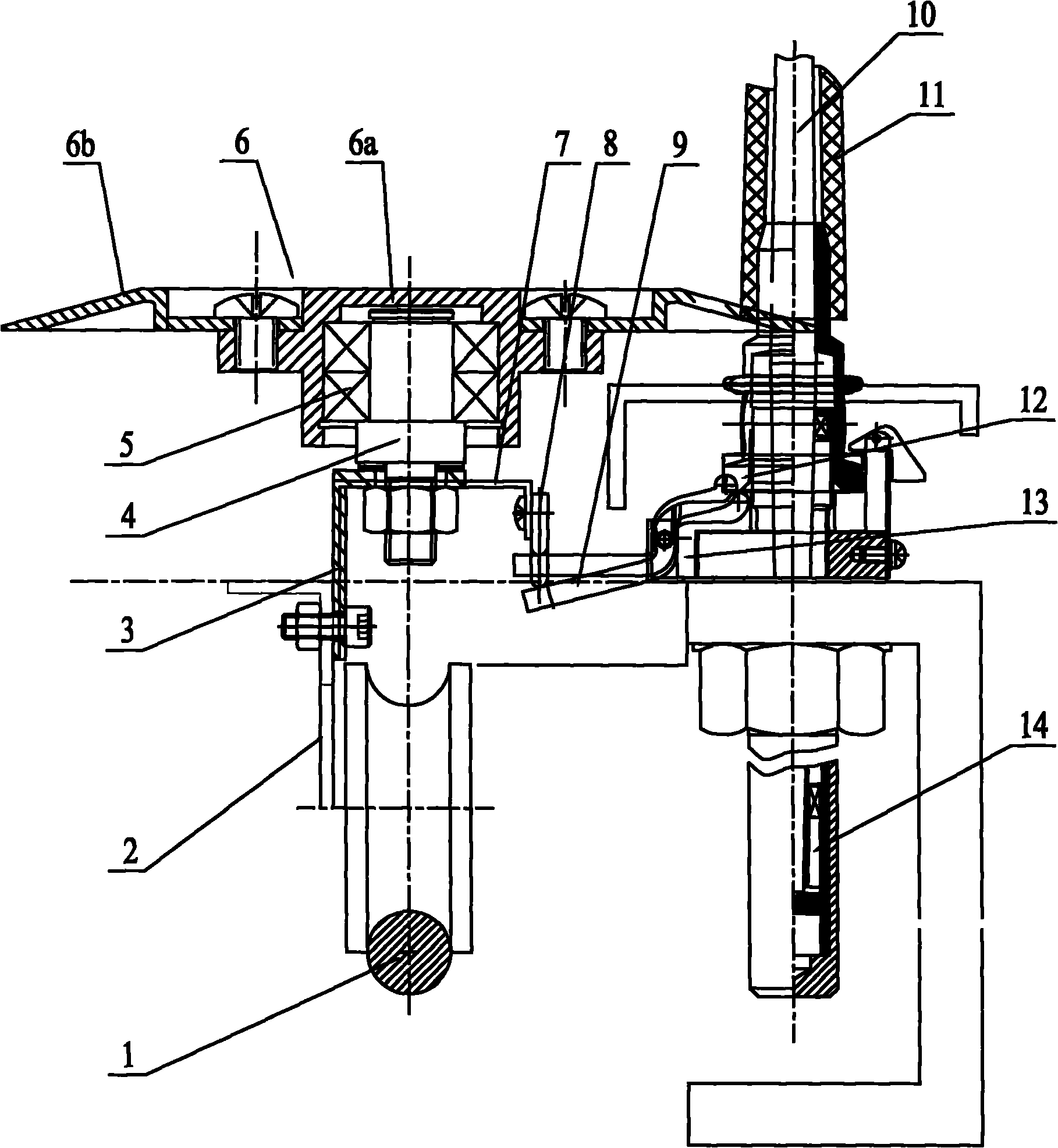

The invention relates to a simulation fracture plugging test device and a test method used in drilling operation in oil-gas fields, which can estimate fracture plugging materials with longer fracturedepth and a plugging drilling fluid or completion fluid system, and truly reflect the plugging effect of fracture leakage loss with depth. The test device consists of a fracture test module and a highpressure container. The technical scheme thereof is as follows: the upper end of the high pressure container is provided with an O-shaped seal ring of the high pressure container; the top part of anupper cover is provided with a needle check valve; the needle check valve is connected with the quick joint of the high pressure gas pipe of a nitrogen bottle; the high pressure container is connectedonto an upright post by a bottom cover and a bottom cover connecting flange; the fracture test module is located by a module locating sleeve, and is fixed by a module connecting fastening bolt; and aplugging fluid outlet pipeline is connected with a plugging fluid outlet connecting flange. The invention has the advantages of reasonable simulation fracture structure, stable and reliable high pressure sealing and working, convenient operation of test device, and the like, and can provide important test device and research method for customizing a production field plugging scheme.

Owner:SOUTHWEST PETROLEUM UNIV

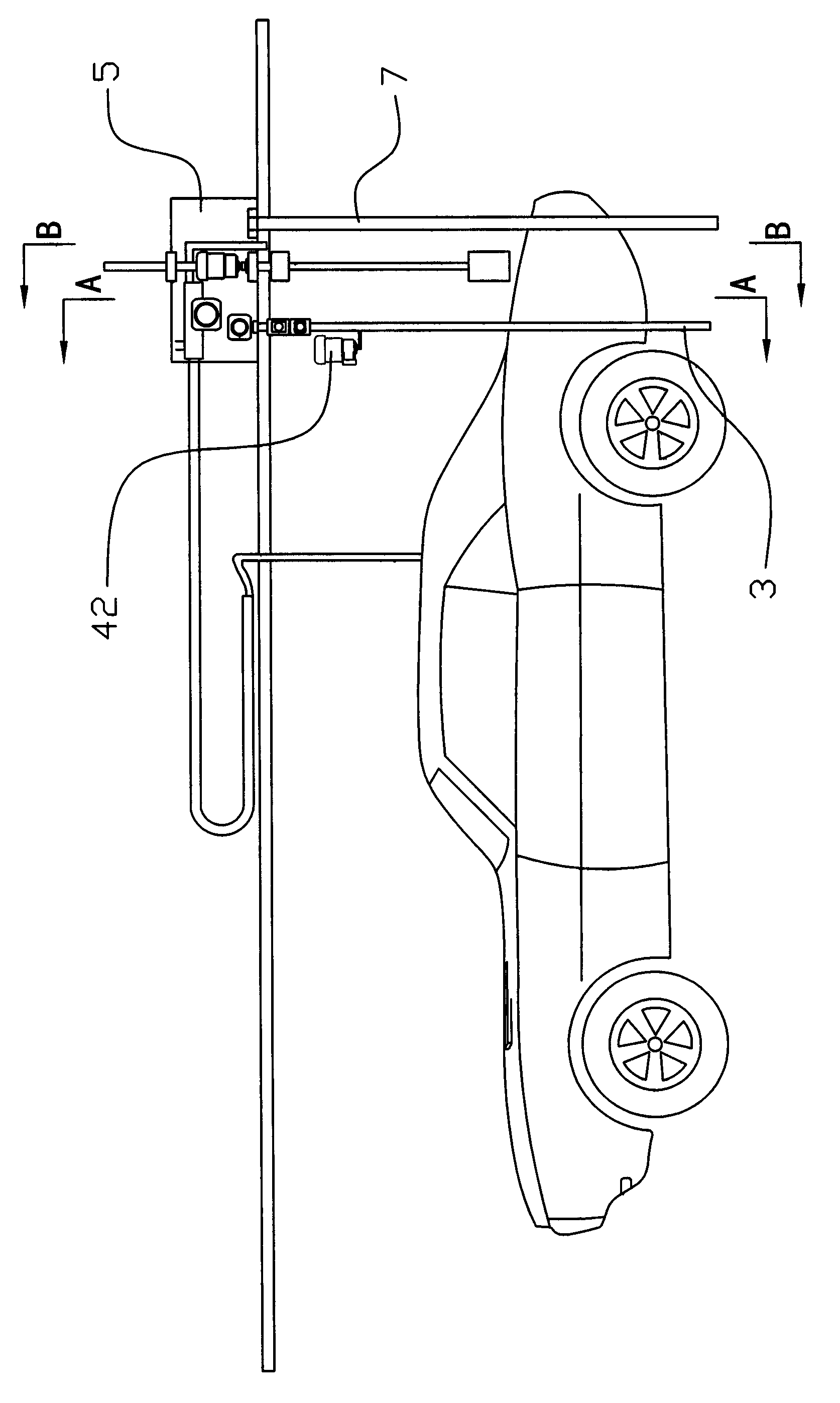

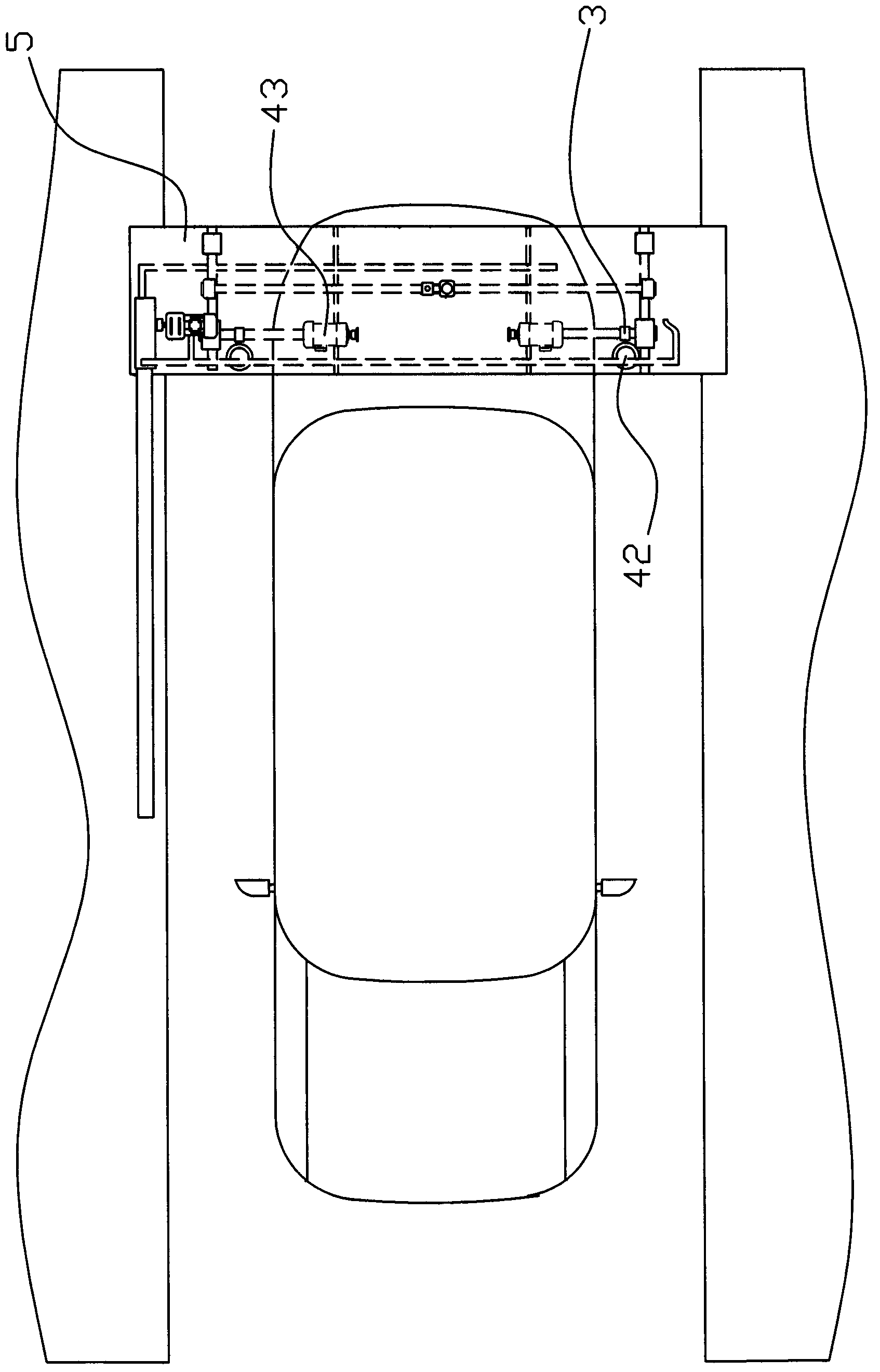

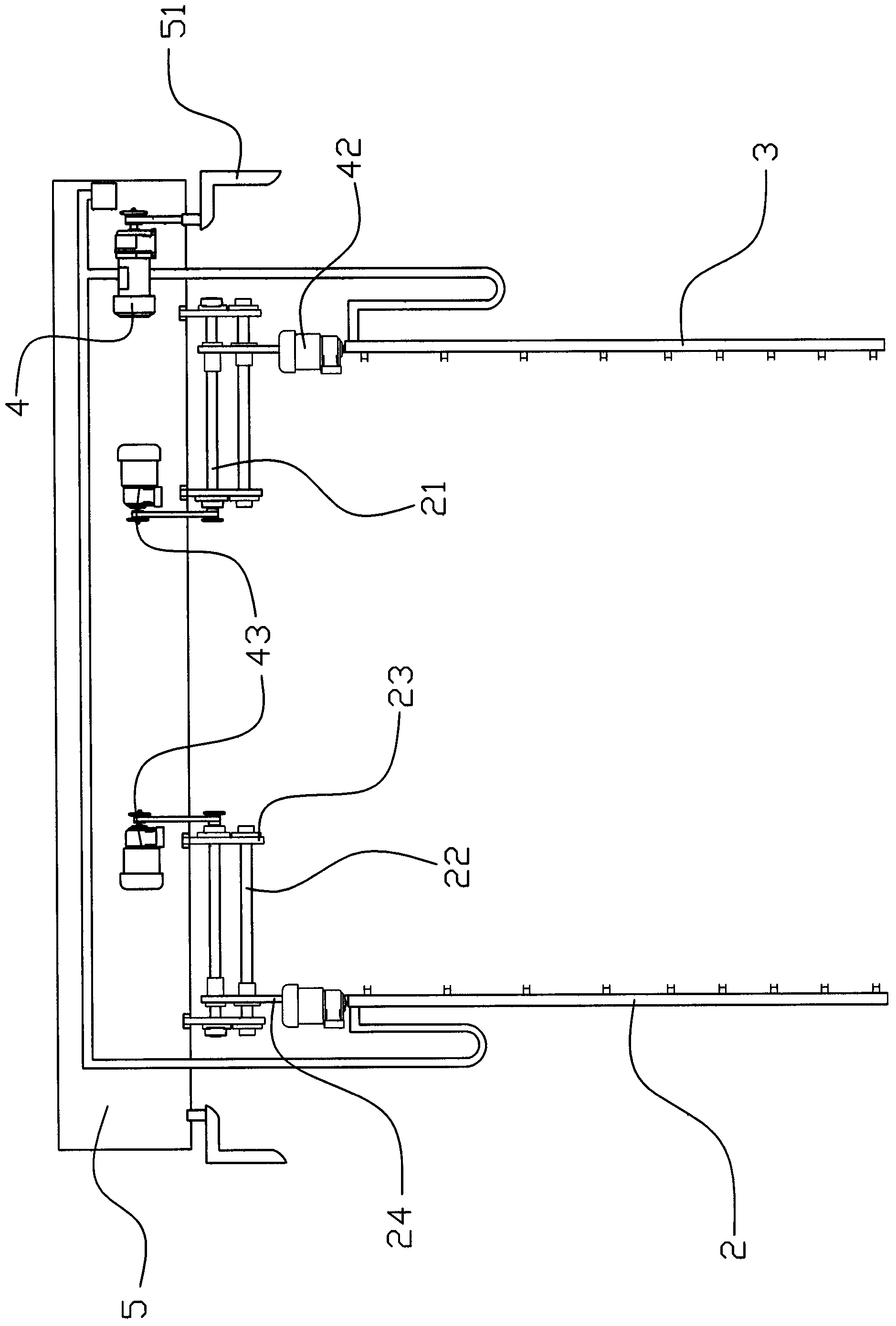

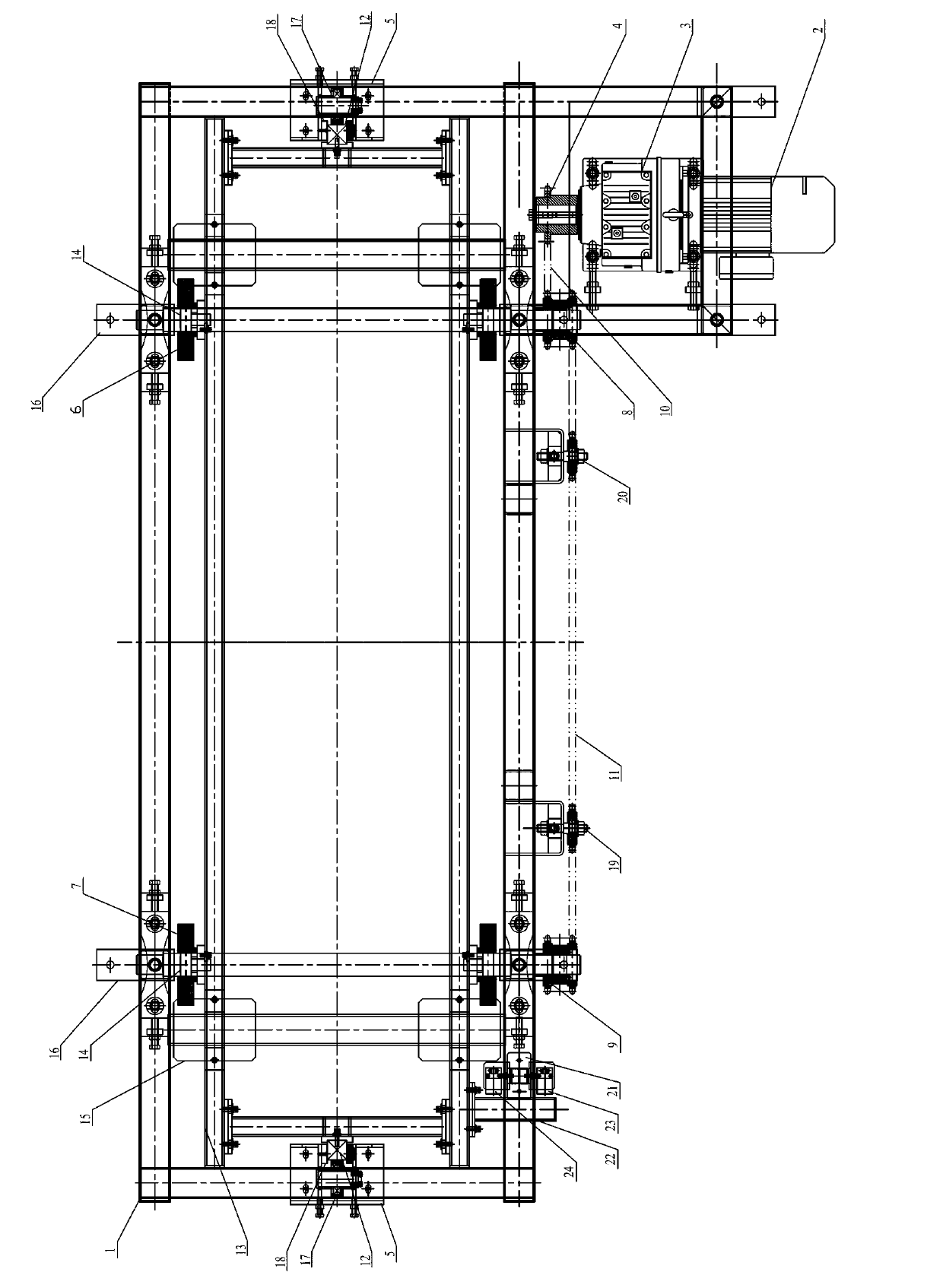

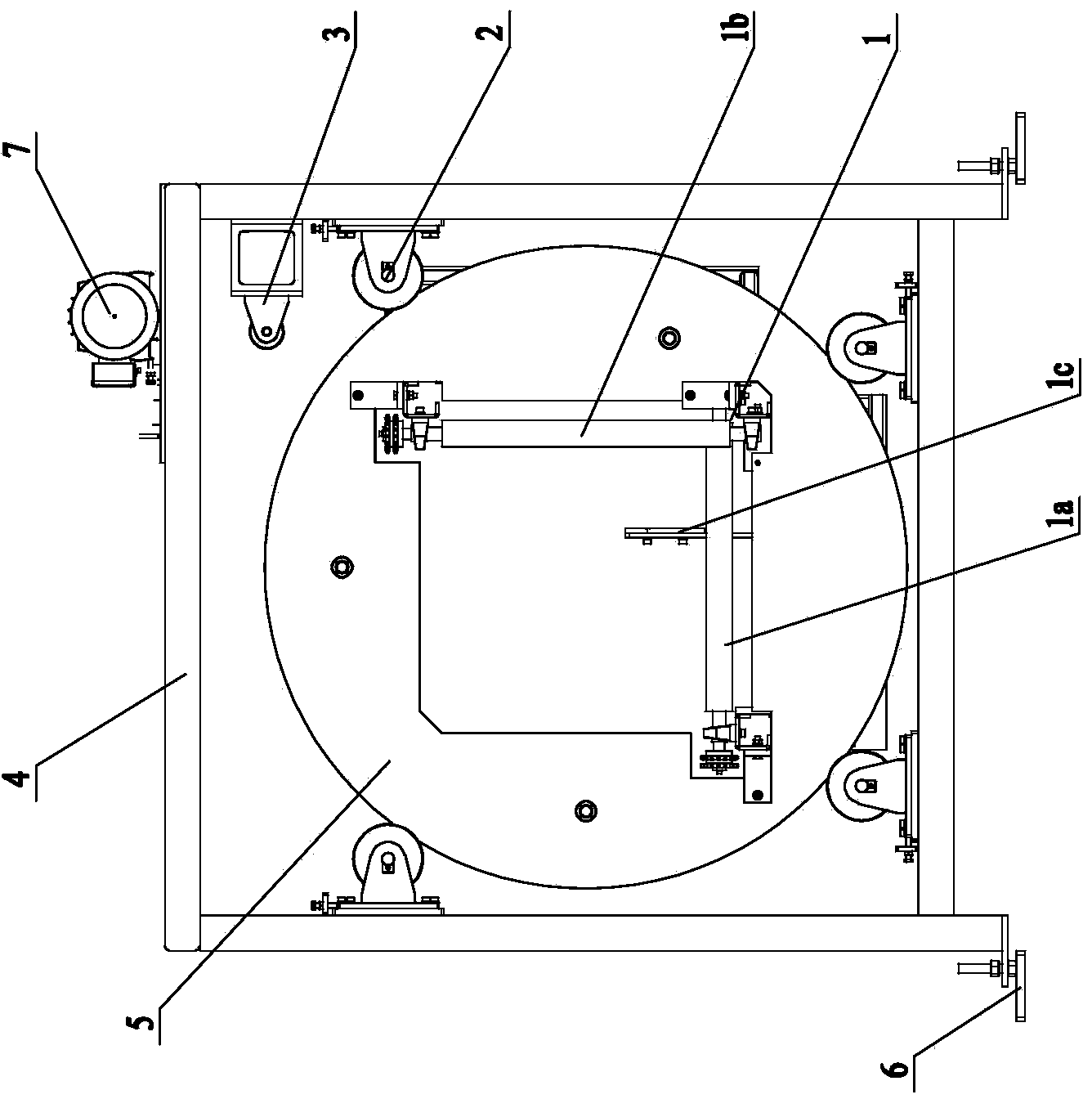

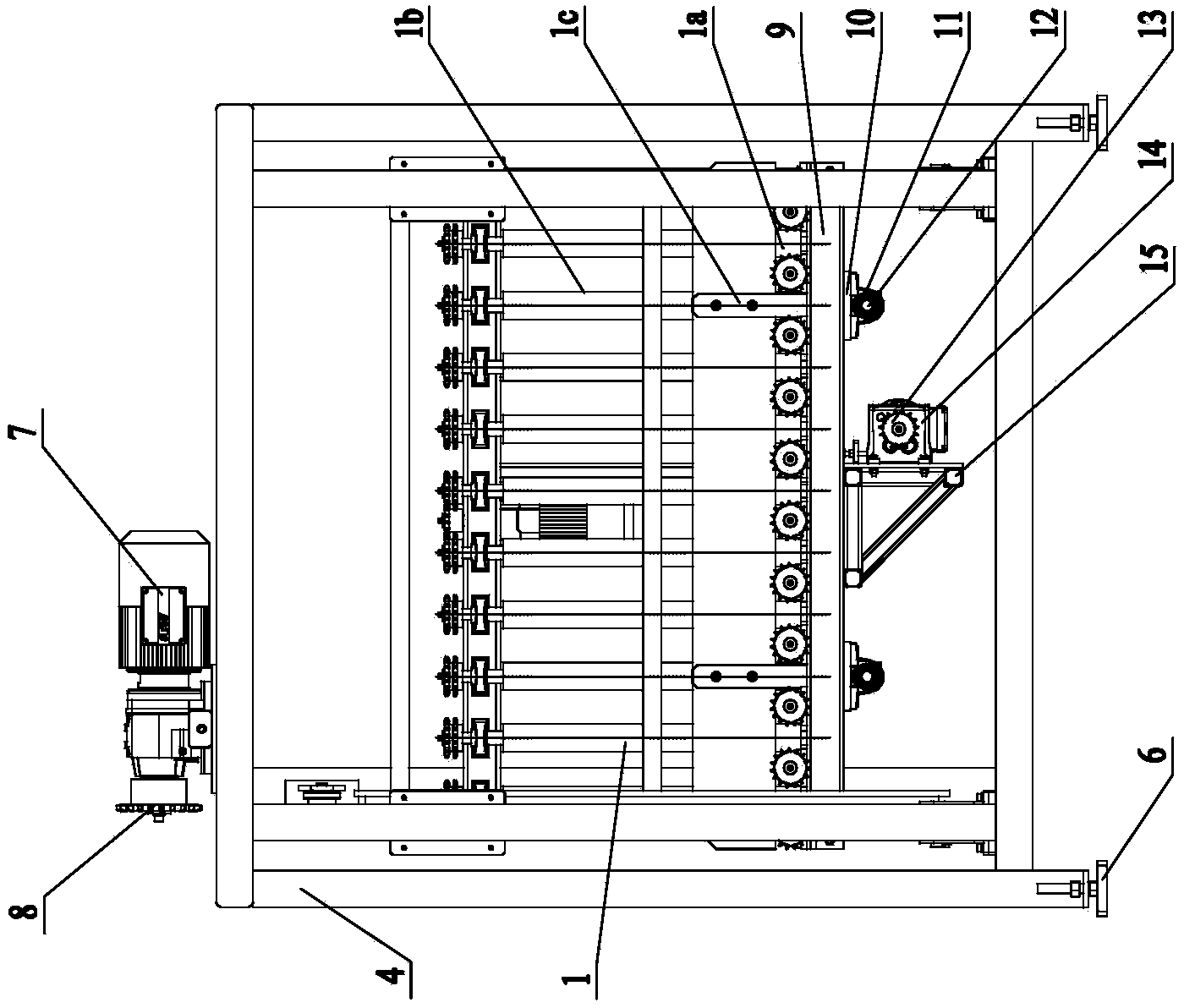

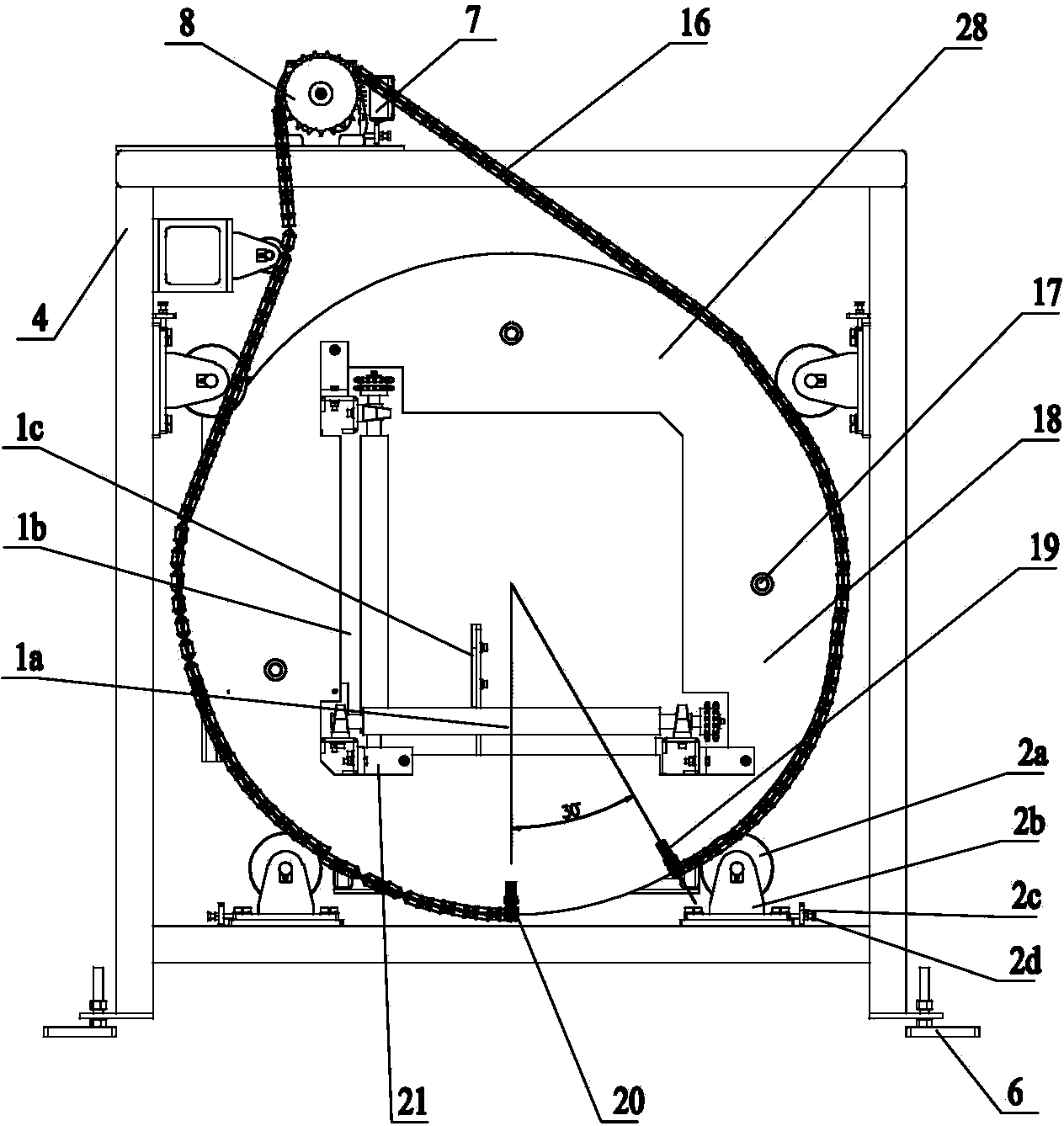

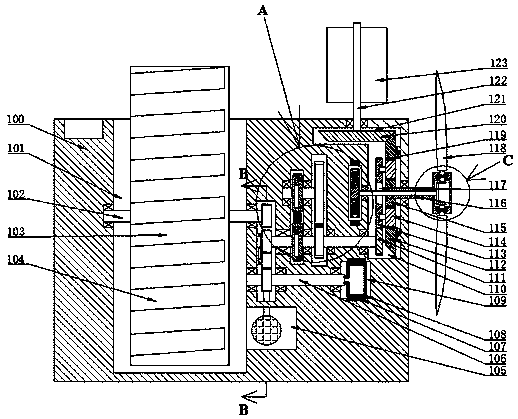

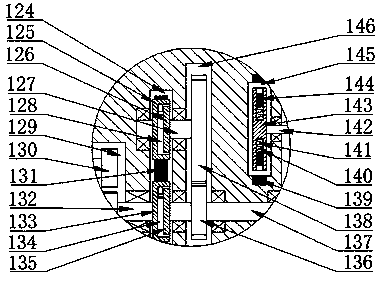

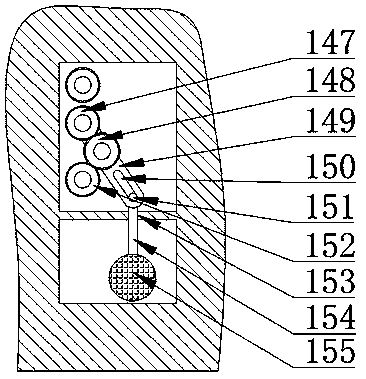

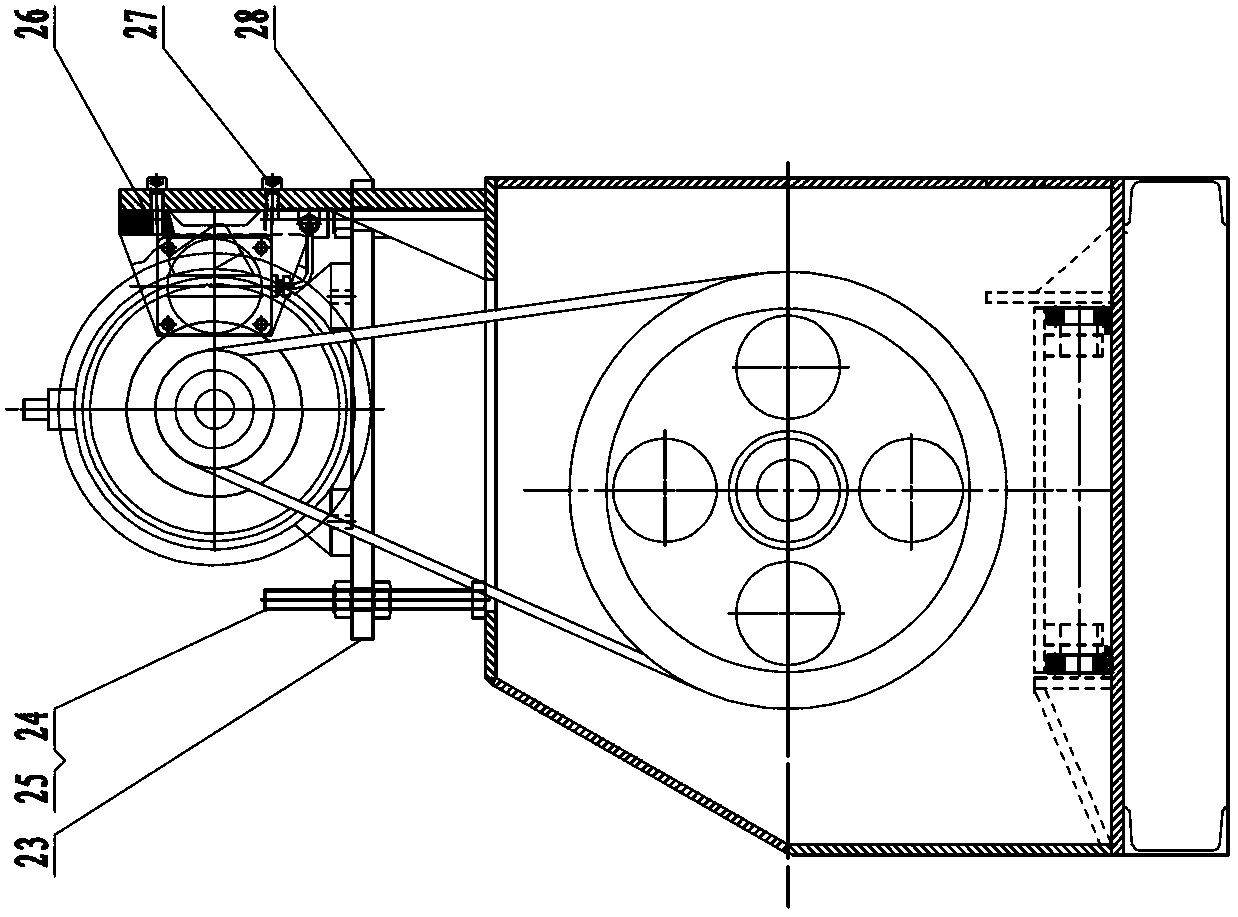

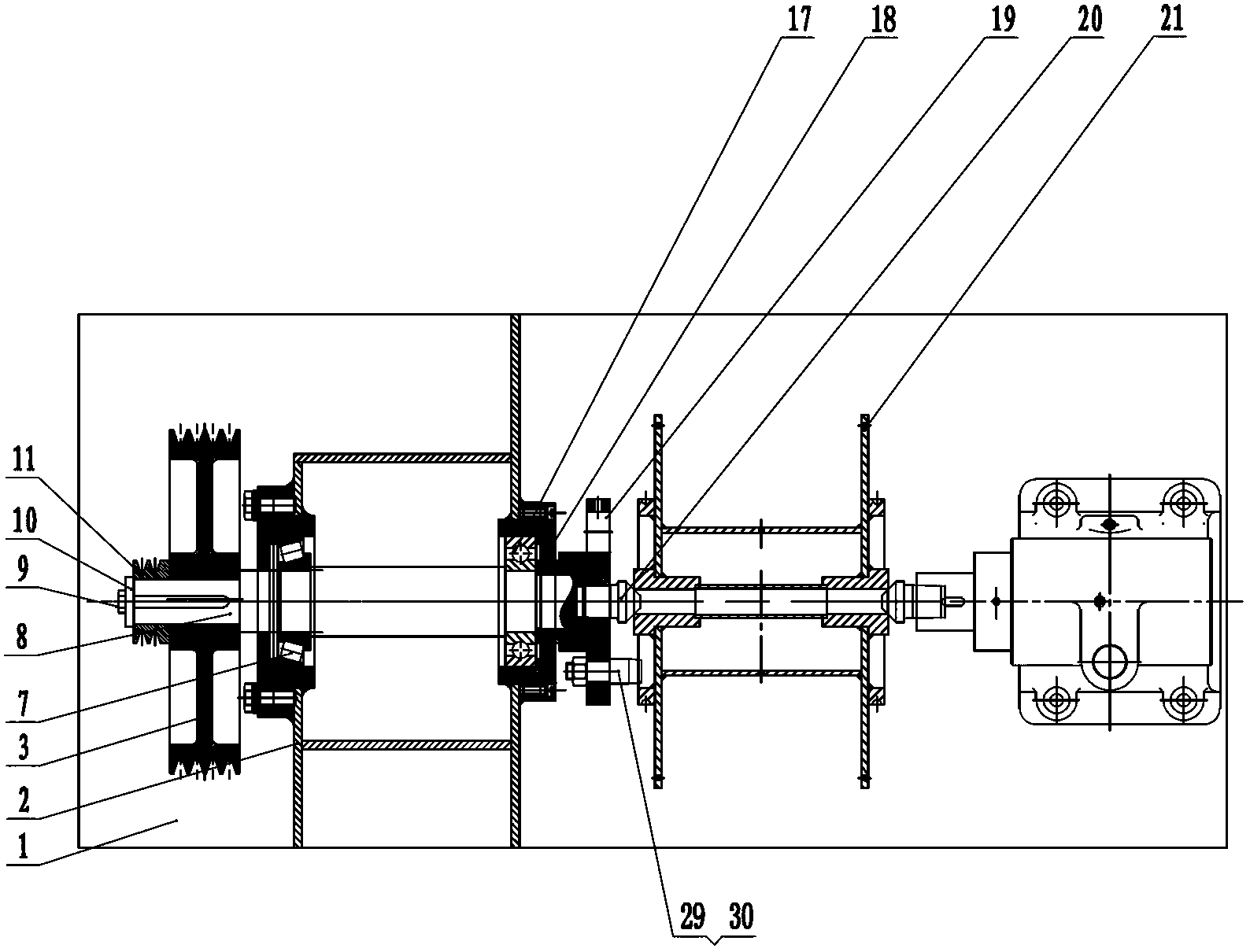

Full-automatic automobile washing device

ActiveCN104290718AShorten cleaning timeCar wash cleanCleaning apparatus for vehicle exteriorsElectric machineryDrive motor

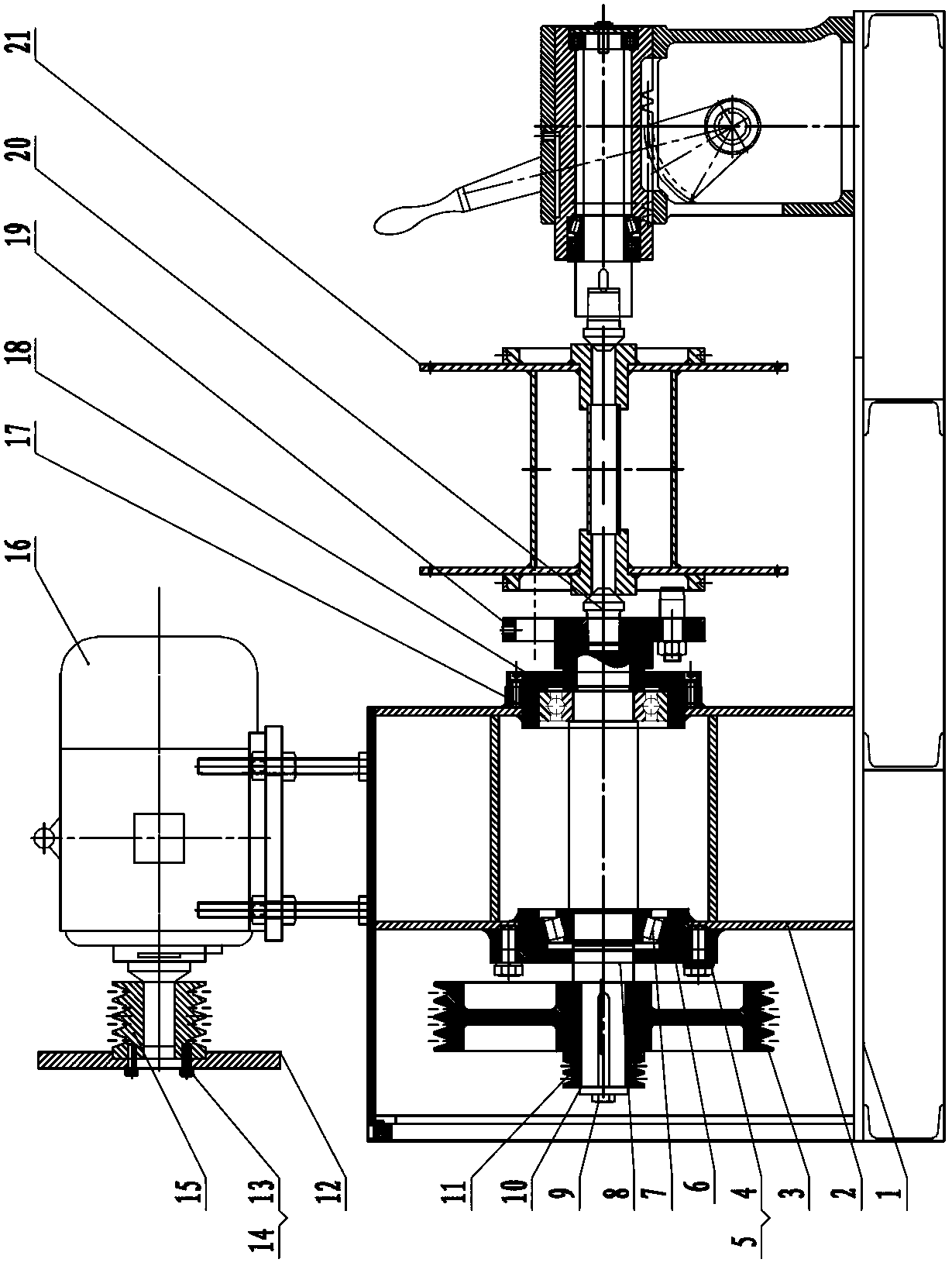

A full-automatic automobile washing device comprises a spraying device. The spraying device comprises a top spraying rod and vertical spraying rods. The left vertical spraying rod and the right vertical spraying rod are each provided with a plurality of shower nozzles in the vertical direction, and the nozzles of the left vertical spraying rod are opposite to the nozzles of the right vertical spraying rod. Shower nozzles with nozzles facing downwards are distributed on the top spraying rod. The spraying rods are each provided with a switching mechanism, and the shower nozzles can be connected with a high-pressure water source and a high-pressure air source. The switching mechanisms can be in linkage with an output shaft of a switching motor. The top spraying rod, the left vertical spraying rod and the right vertical spraying rod are connected with a beam which is arranged on a guide rail in the manner of sliding forwards and backwards through a driving motor, the top spraying rod can be arranged on the beam in an ascending and descending mode through a lifting motor, the left vertical spraying rod and the right vertical spraying rod can be connected with the beam in the manner of moving left and right through respective motors, and the beam is provided with a detecting device which can detect the size of an automobile body. The full-automatic automobile washing device is ingenious and reasonable in structure, high in automation degree and more complete in function, effectively solves the problems of an existing automobile washing machine, and is a very practical automobile washing device.

Owner:绍兴市中令汽车服务有限公司

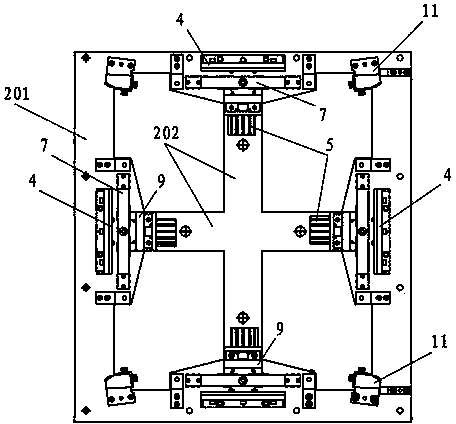

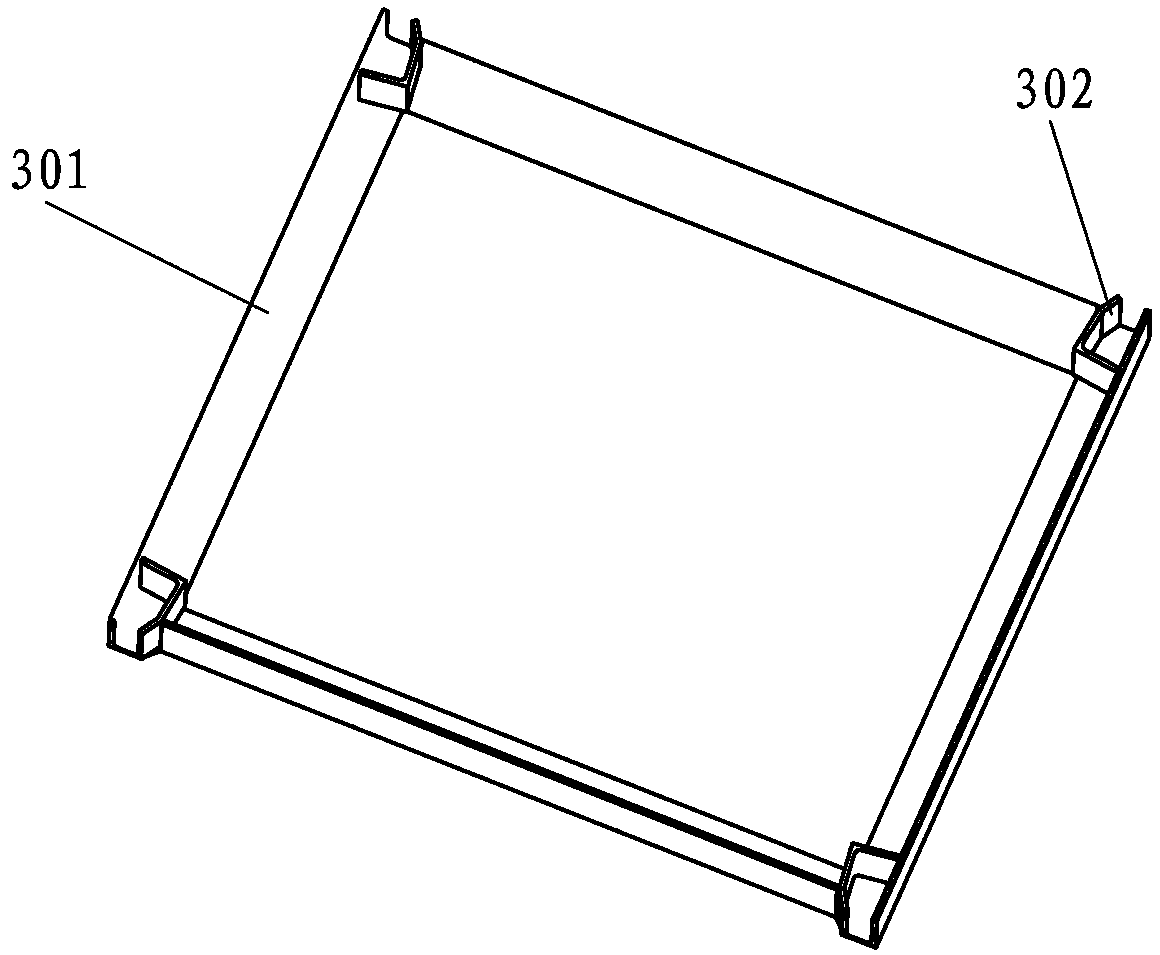

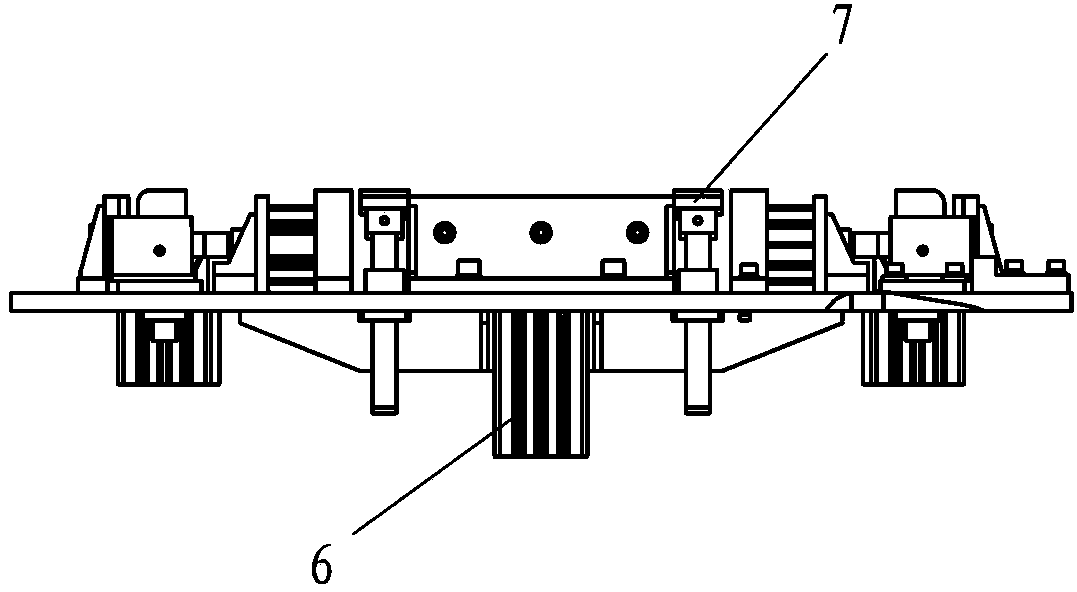

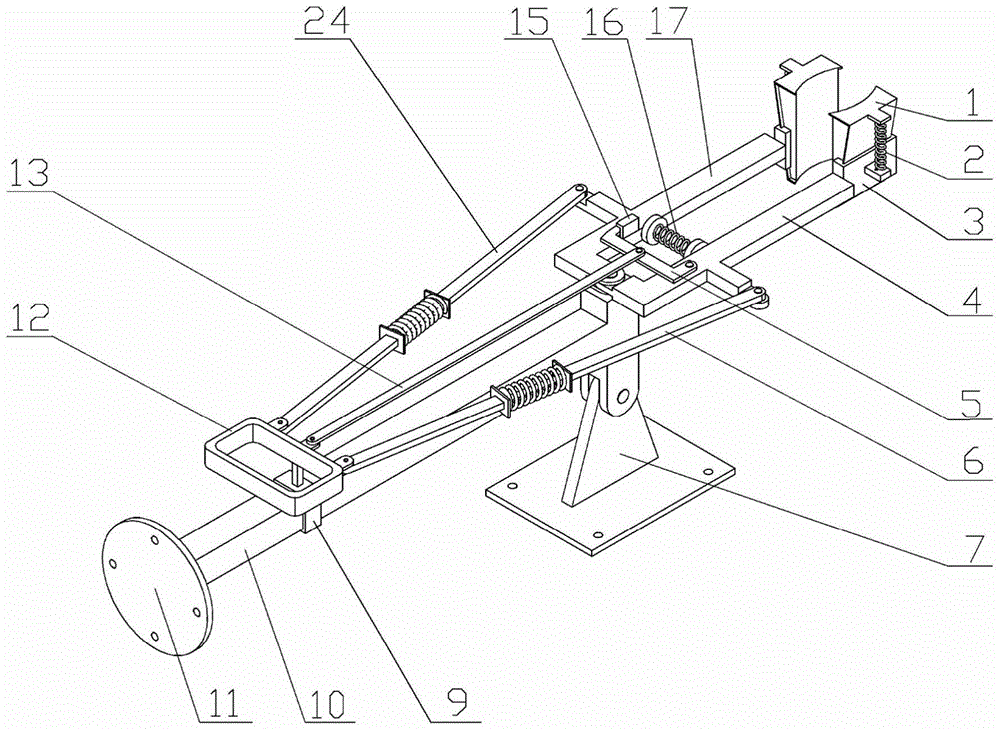

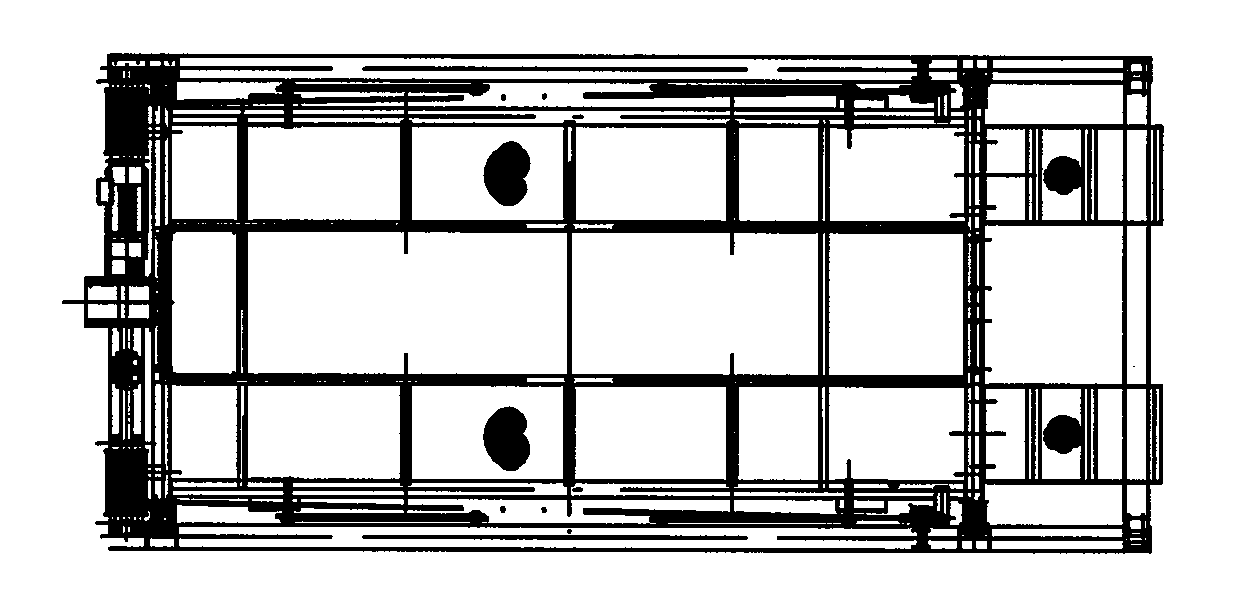

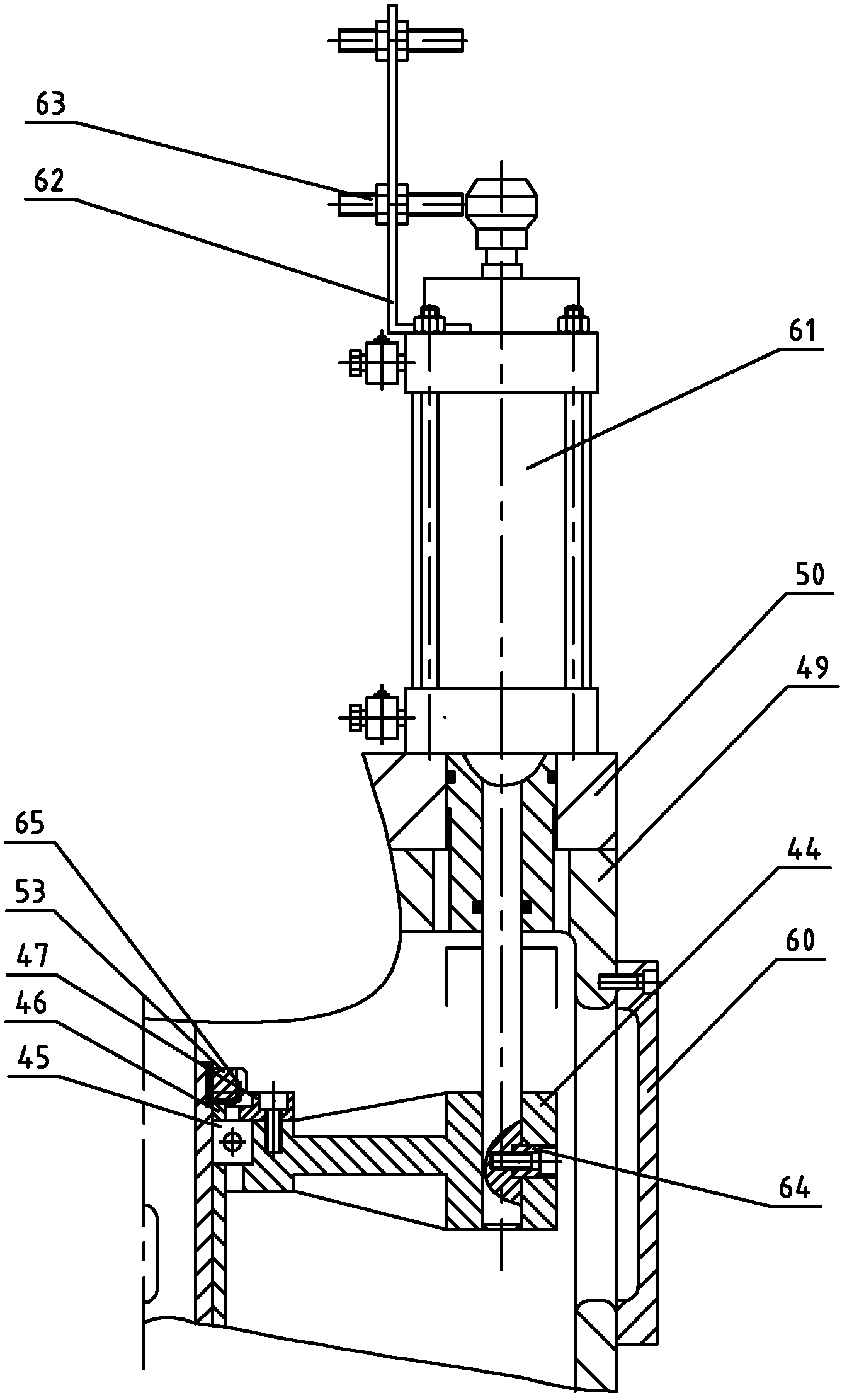

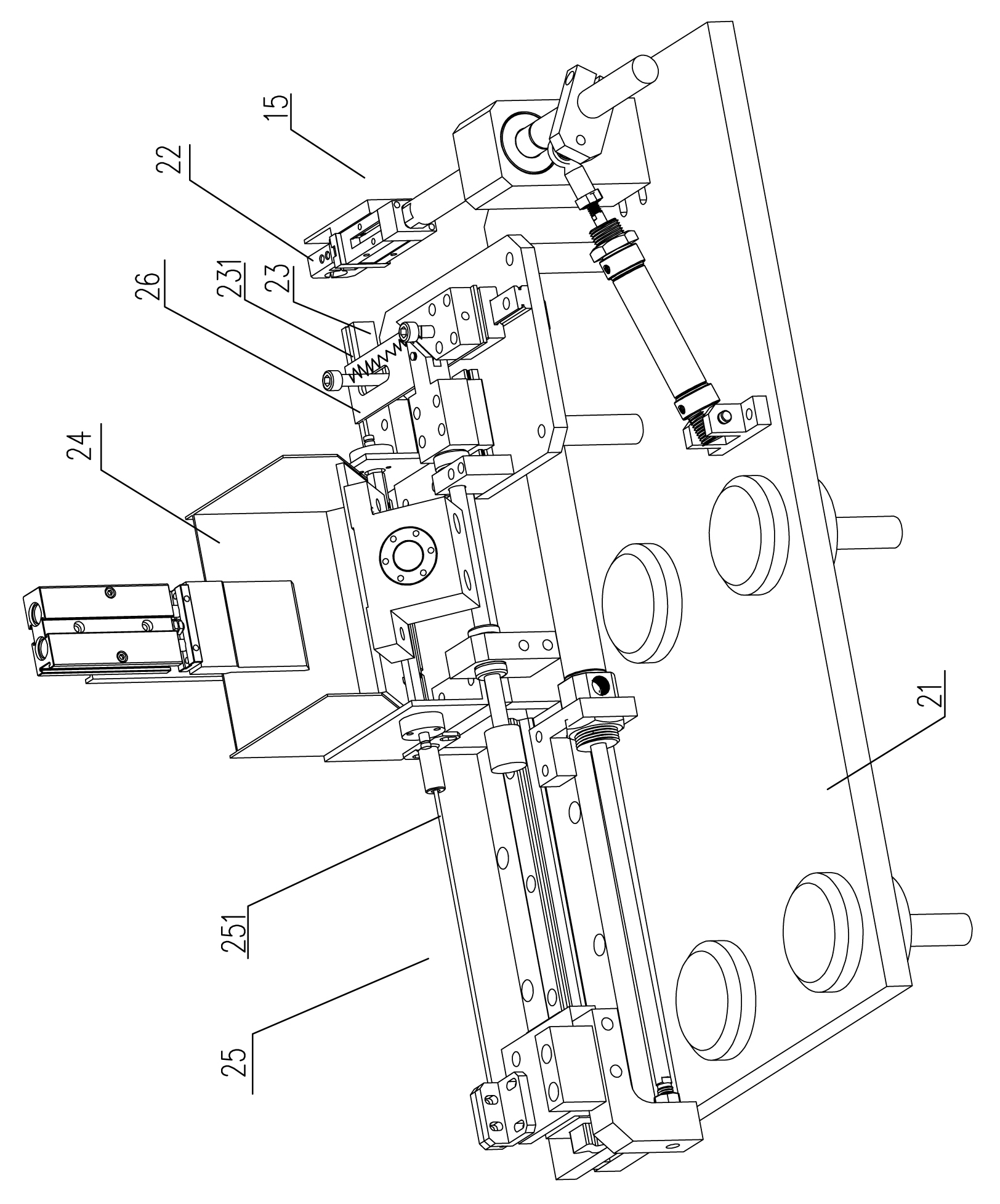

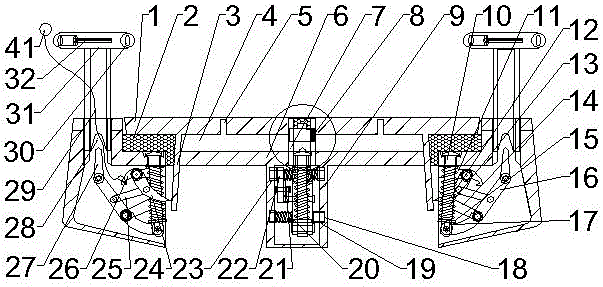

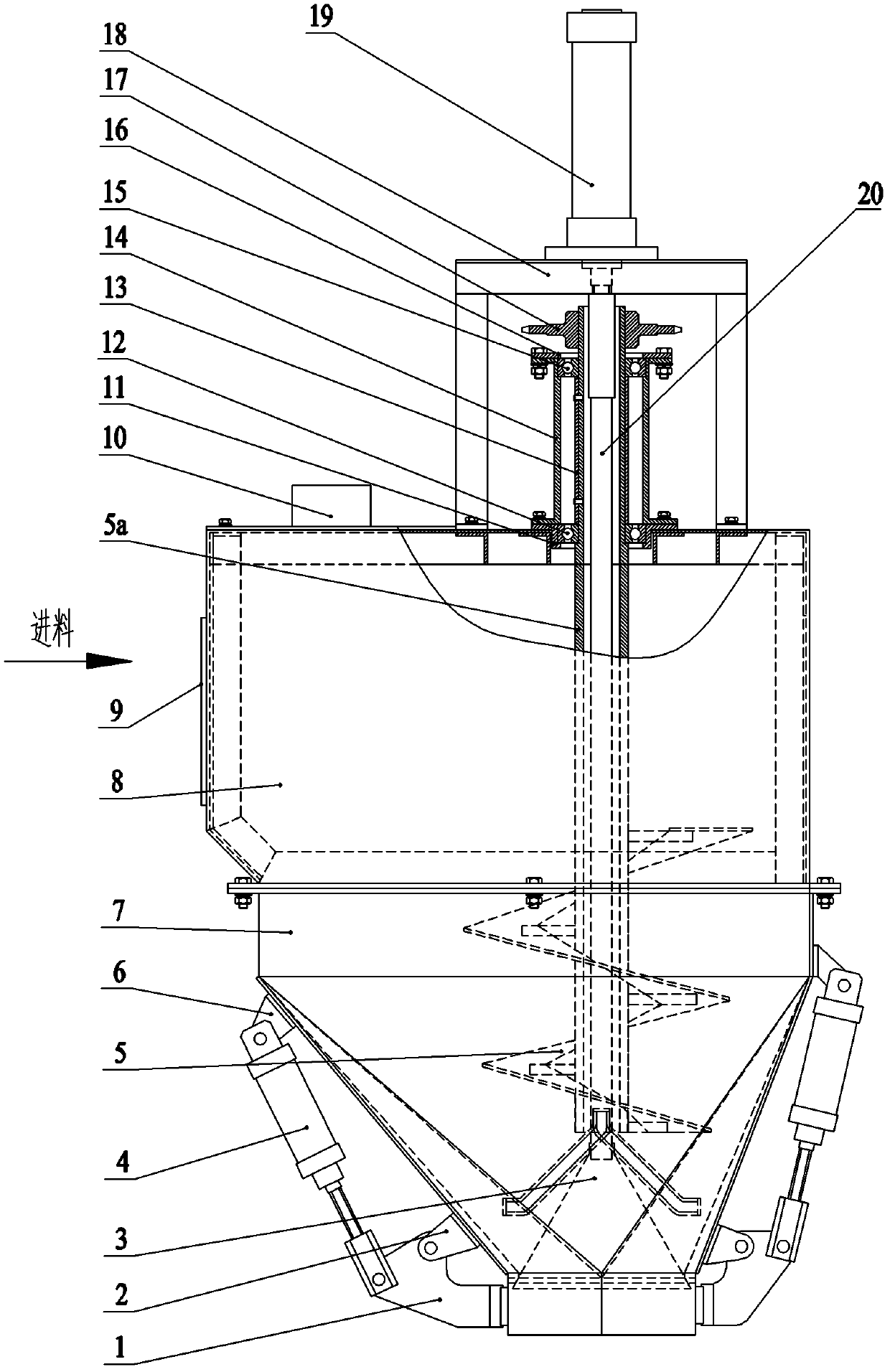

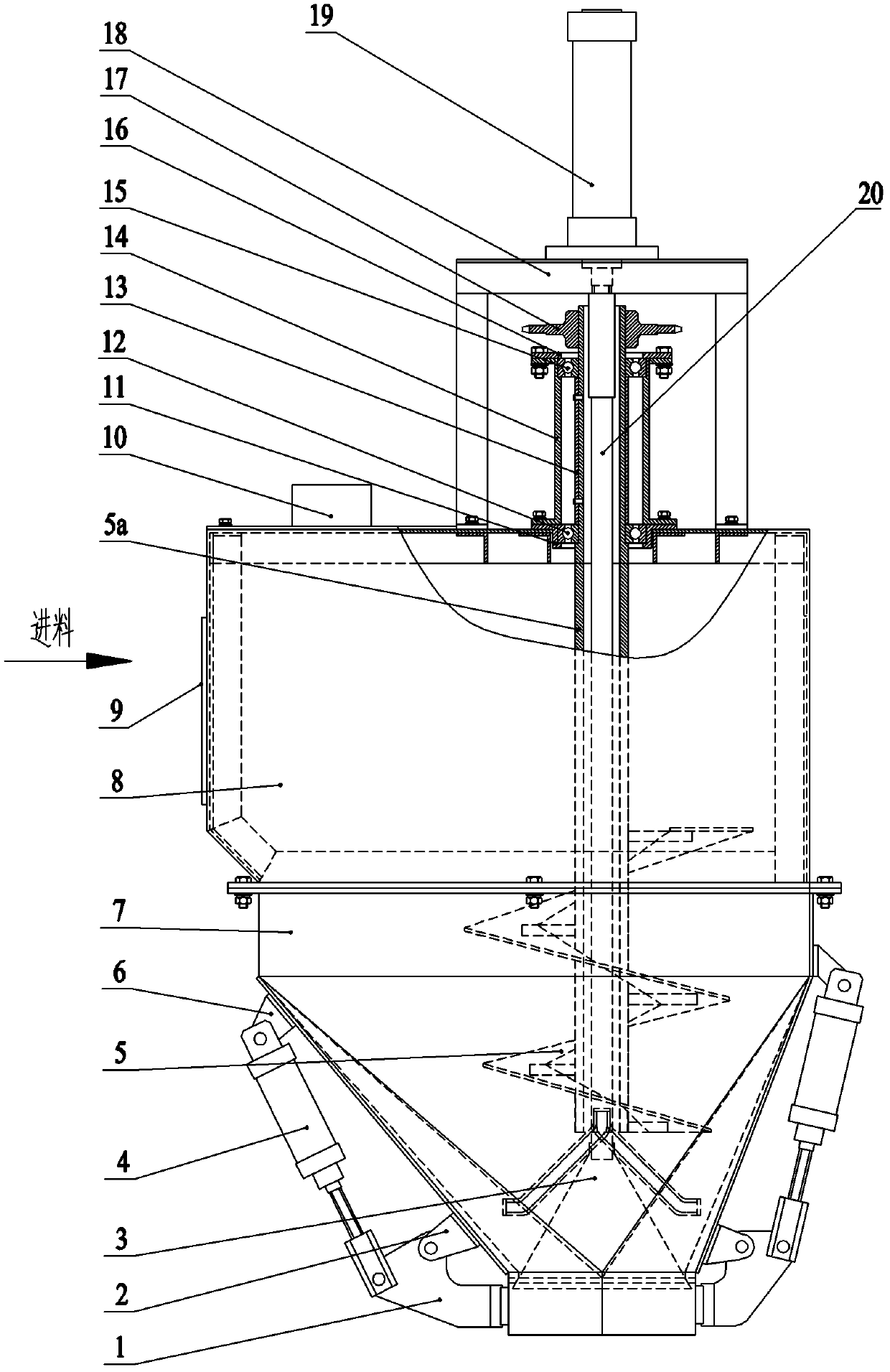

Tool mechanism for clamping frame workpiece of robot workstation

InactiveCN103350300AIngenious and reasonable structureImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesWorkstationBlock match

The invention discloses a tool mechanism for clamping a frame workpiece of a robot workstation. The mechanism comprises frame workpiece supports matched with the frame workpiece, wherein frame positioning blocks matched with workpiece frames are arranged on four frame supports; ejection air cylinders are arranged on inner sides of the frame positioning blocks; ejection rods of the ejection air cylinder are ejected, so that four frames of the frame workpiece are fixed and positioned stably in positions corresponding to the frame positioning blocks; and workpiece ejection mechanisms are arranged corresponding to the frames of the frame workpiece on the frame supports. The tool mechanism for clamping the frame workpiece of the robot workstation is ingenious and reasonable in structure; and the four scattered frames of the frame workpiece are directly positioned and fixed on the frame workpiece supports through arrangement of the ejection air cylinders and the frame positioning blocks, so that a complex underneath electric welding process in which positioning errors are prone to occur is not required, the workpice supports can be directly fixed and welded, the work efficiency is greatly improved, and the work errors are also greatly reduced.

Owner:上海气焊机厂有限公司

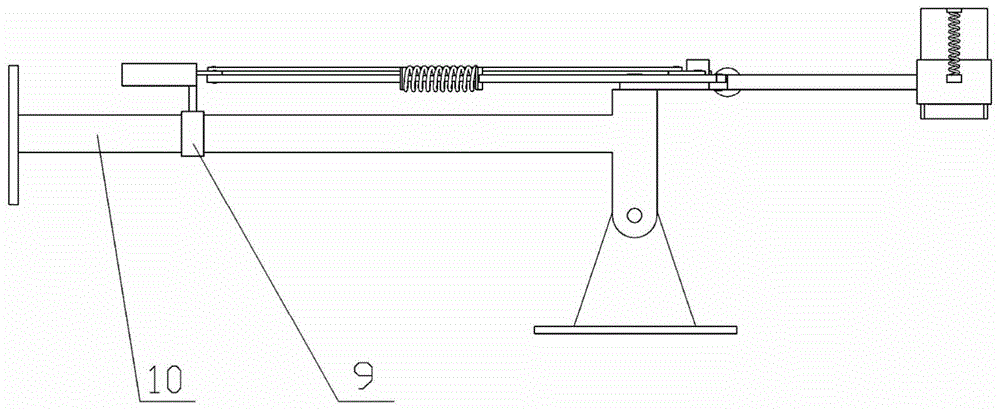

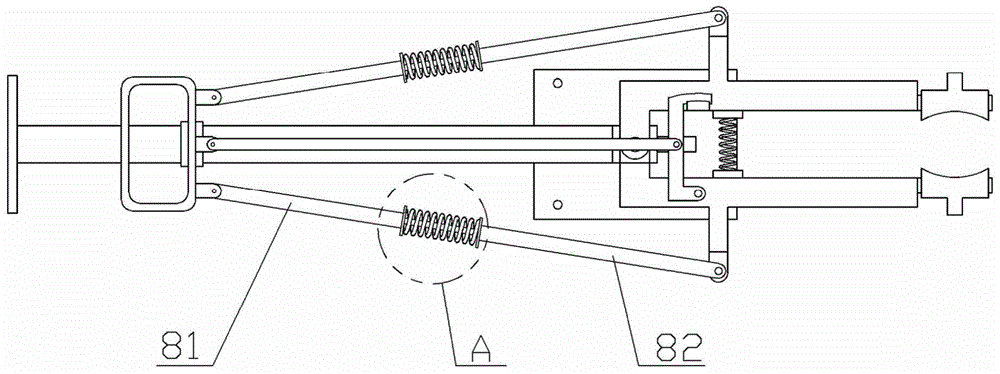

Cassava pulling up and holding mechanism

Owner:GUANGXI UNIV

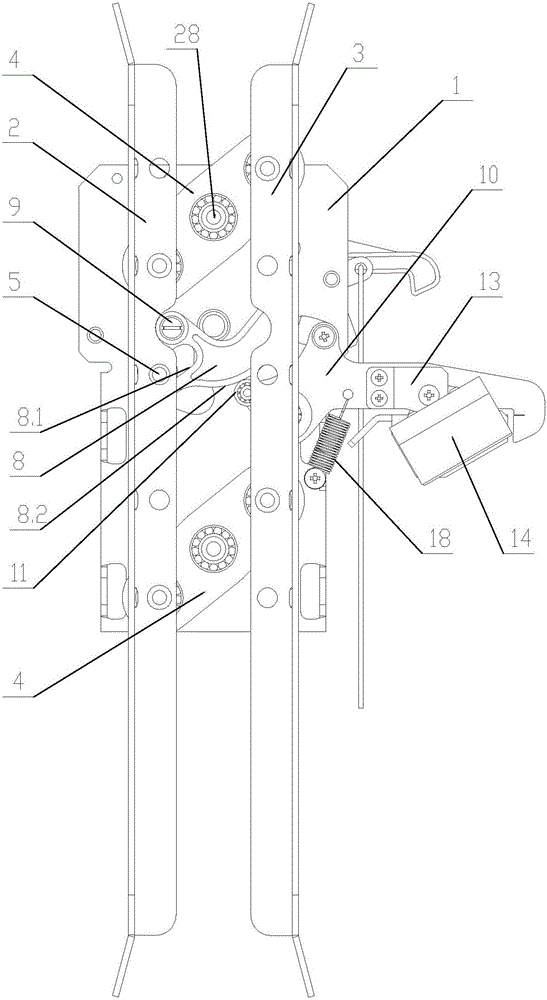

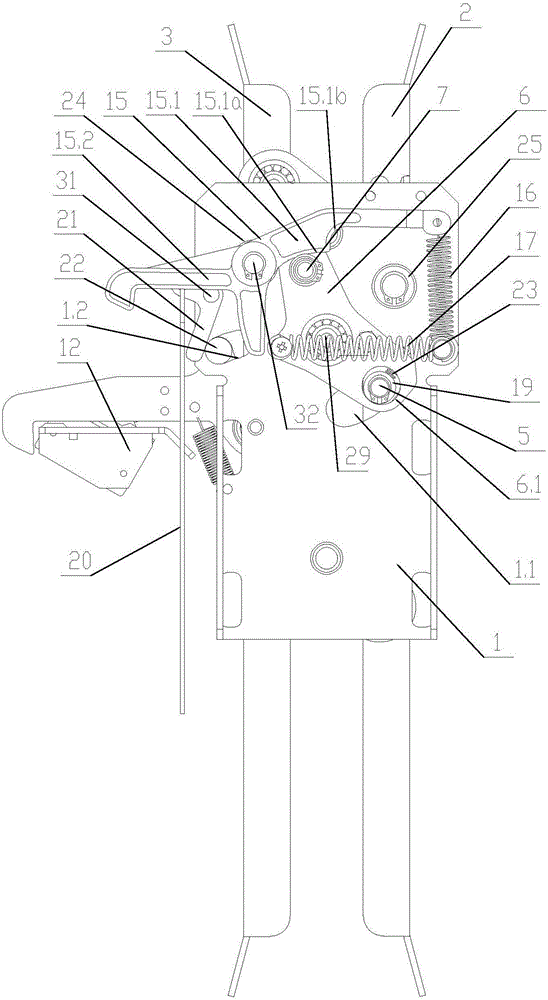

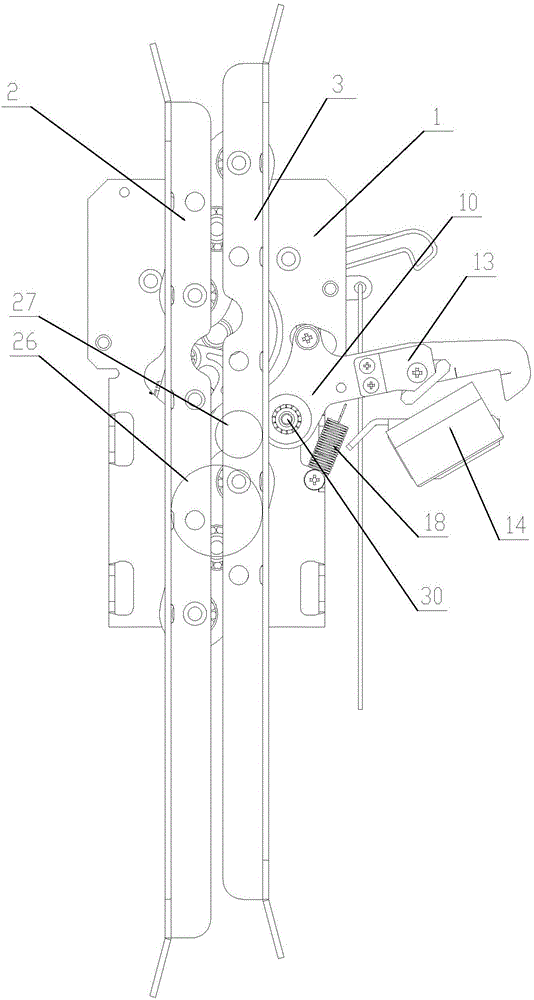

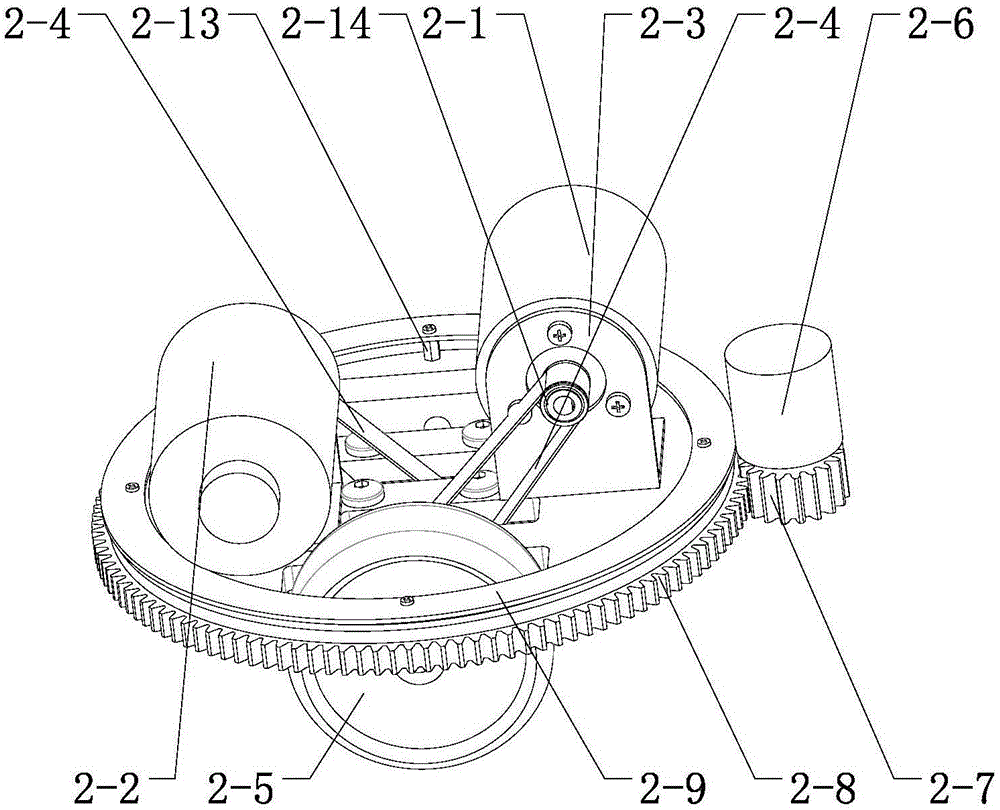

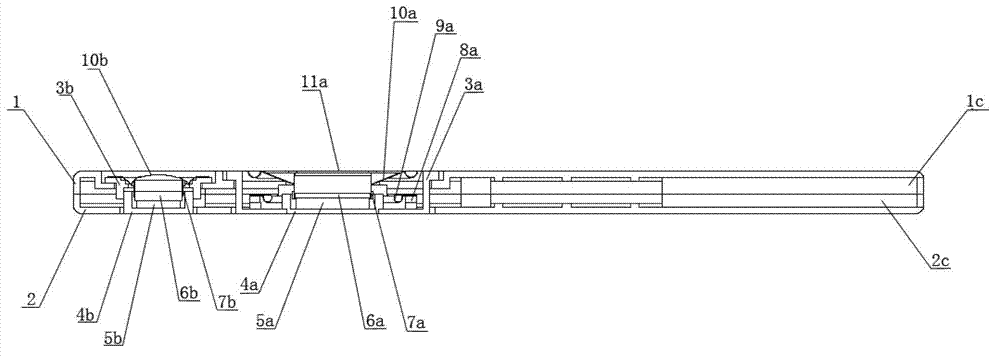

Integrated car door lock and door knife device

The invention relates to an integrated car door lock and door knife device. The integrated car door lock and door knife device comprises a door knife base plate, a knife arm assembly, a linkage assembly and a lock hook assembly, wherein the knife arm assembly, the linkage assembly and the lock hook assembly are installed on the door knife base plate, the knife arm assembly is used for opening or clamping a door ball, and the linkage assembly is used for matching with the knife arm assembly and the lock hook assembly, so as to lock or unlock. According to the integrated car door lock and door knife device, a car door lock and a door knife are integrated, the structure is smart and reasonable, the manufacturing cost is low, whether a door machine is in a flat unlocking area can be directly judged by utilizing the door ball of a landing door, the flat area can be judged without additionally installing other devices on the landing door, and a certain error of installing the landing door ball is permitted, so that the landing door is conveniently installed and debugged. In addition, in the flat area, the door can be opened inside and outside in any condition; in non-flat and rescue areas, the door opening spacing does not exceed 50 mm inside, and the car door opening requirements in a modification list of a new national standard I are fully satisfied.

Owner:展鹏科技股份有限公司

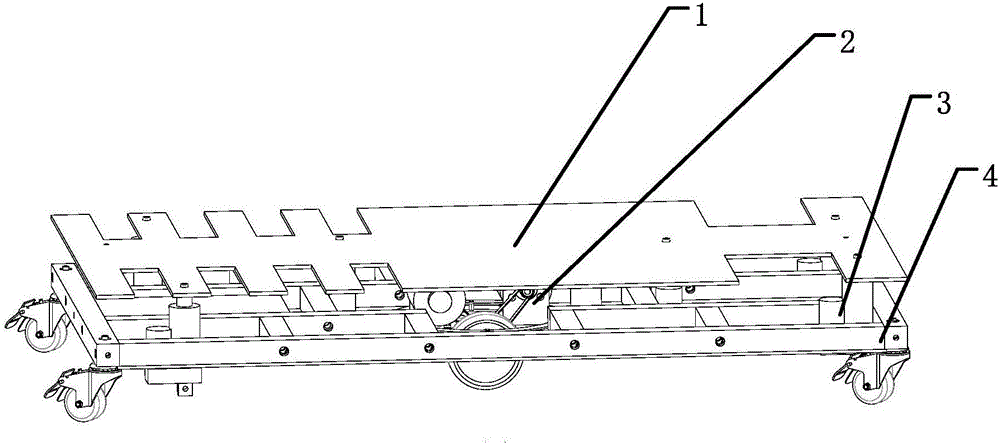

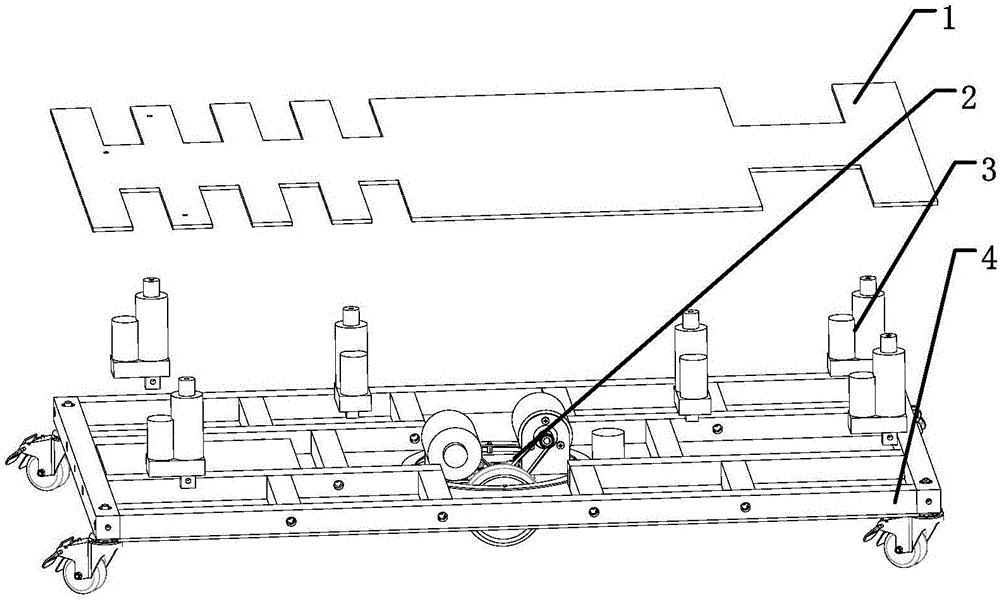

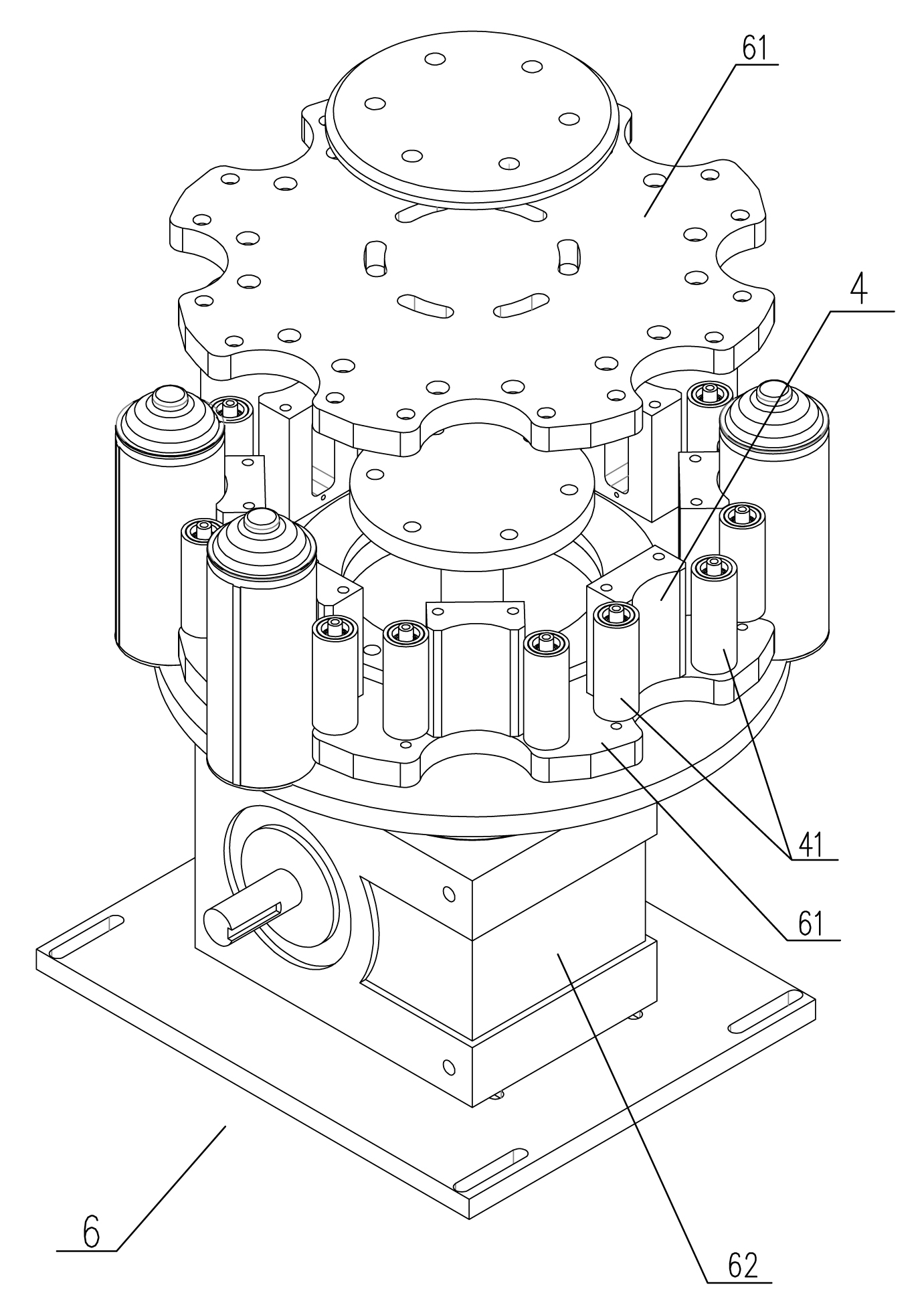

All-direction moving AGV with lifting comb teeth

The invention discloses an all-direction moving AGV with lifting comb teeth. The AGV comprises a servo machine frame provided with at least three universal wheels on the lower portion, a plurality of lifting supports are arranged on the upper plane of the servo machine frame, the upper ends of the lifting supports are connected with a comb tooth bearing plate through bolts, and a central universal drive disc is arranged in the geometric center of the servo machine frame. The central universal drive disc structure is ingeniously adopted, steering with a machine center as the rotation center is driven by two driving motors and two driving wheels on the central universal drive disc, and all-direction steering and moving of the vehicle are achieved. Besides, by means of the supporting mechanisms, the bearing plate can ascend and descend, and movement flexibility and work efficiency are improved. The AGV has the advantages of being scientific in design, ingenious and reasonable in structure, convenient to manufacture and low in cost.

Owner:海宁经开产业园区开发建设有限公司

Cam climbing mechanism

The invention relates to a cam climbing mechanism. A motor and a speed reducer are connected and are installed on a machine frame together, an output shaft of the speed reducer is provided with a driving sprocket, a first cam shaft is installed through a bearing in a bearing bracket which is located at one end of the top of the machine frame, a first sprocket is fixed arranged on the first cam shaft, and a short chain is sleeved on the driving sprocket and the first sprocket. A second cam shaft is arranged in a bearing bracket which is located at the other end of the top of the machine frame through a bearing, a second sprocket is fixedly arranged on the second cam shaft, and a long sprocket is sleeved on the first sprocket and the second sprocket. The lifting frame is placed on the machine frame, and a limit guide mechanism which enables the lifting frame to move in a lifting mode is arranged between the lifting frame and the machine frame. Work piece supporting plates are respectively arranged at two ends of the top of the lifting frame, support wheels are respectively arranged at two ends of the bottom of the lifting frame, and support wheels which are arranged at two ends of the bottom of the lifting frame are respectively arranged on an eccentric cam of the first cam shaft and an eccentric cam of the second cam shaft. The cam climbing mechanism has the advantages of being reasonable in structure, capable of achieving stable ejecting or descending of a tool support, constant in journey, safe and reliable.

Owner:MIRACLE AUTOMATION ENG CO LTD

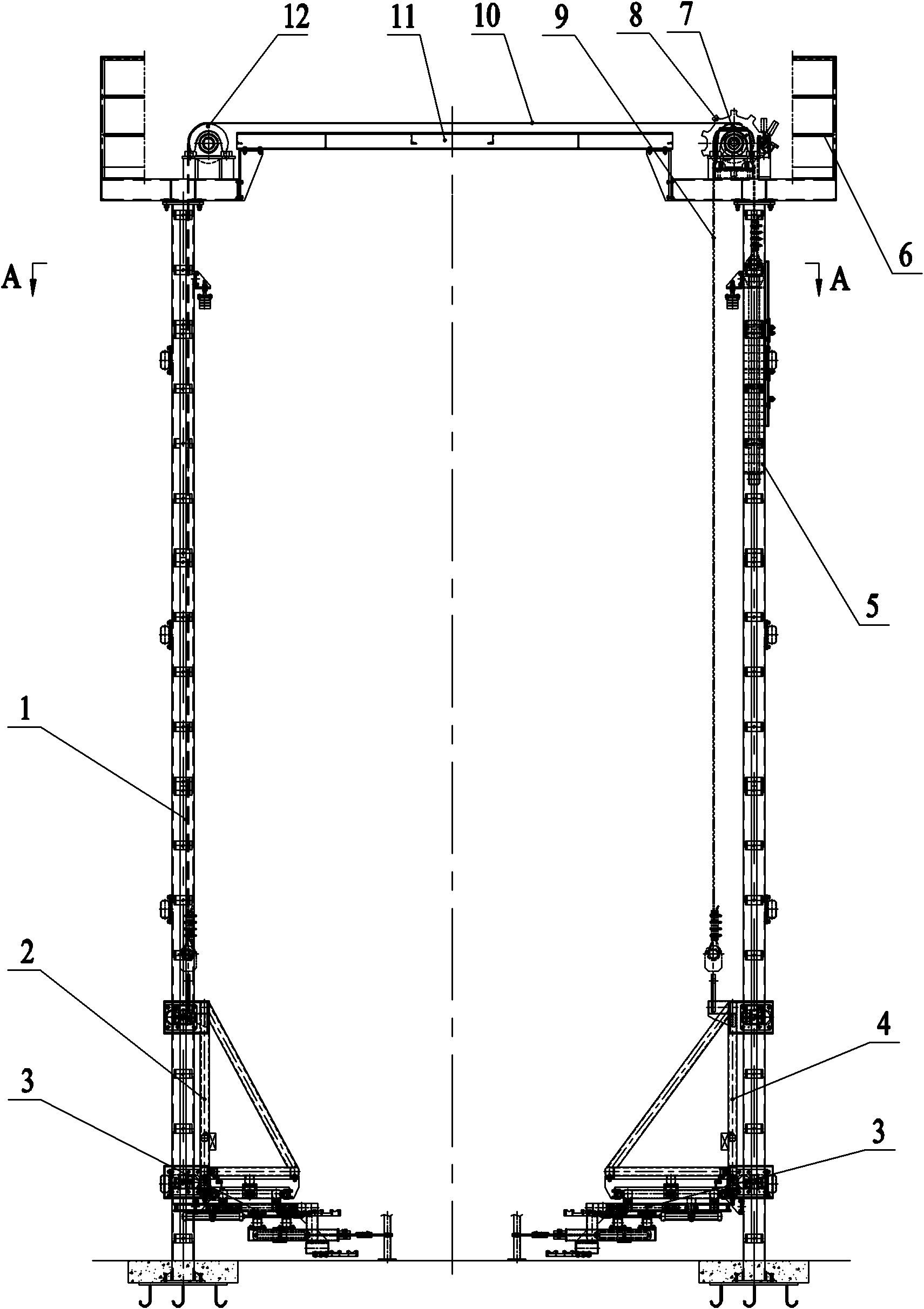

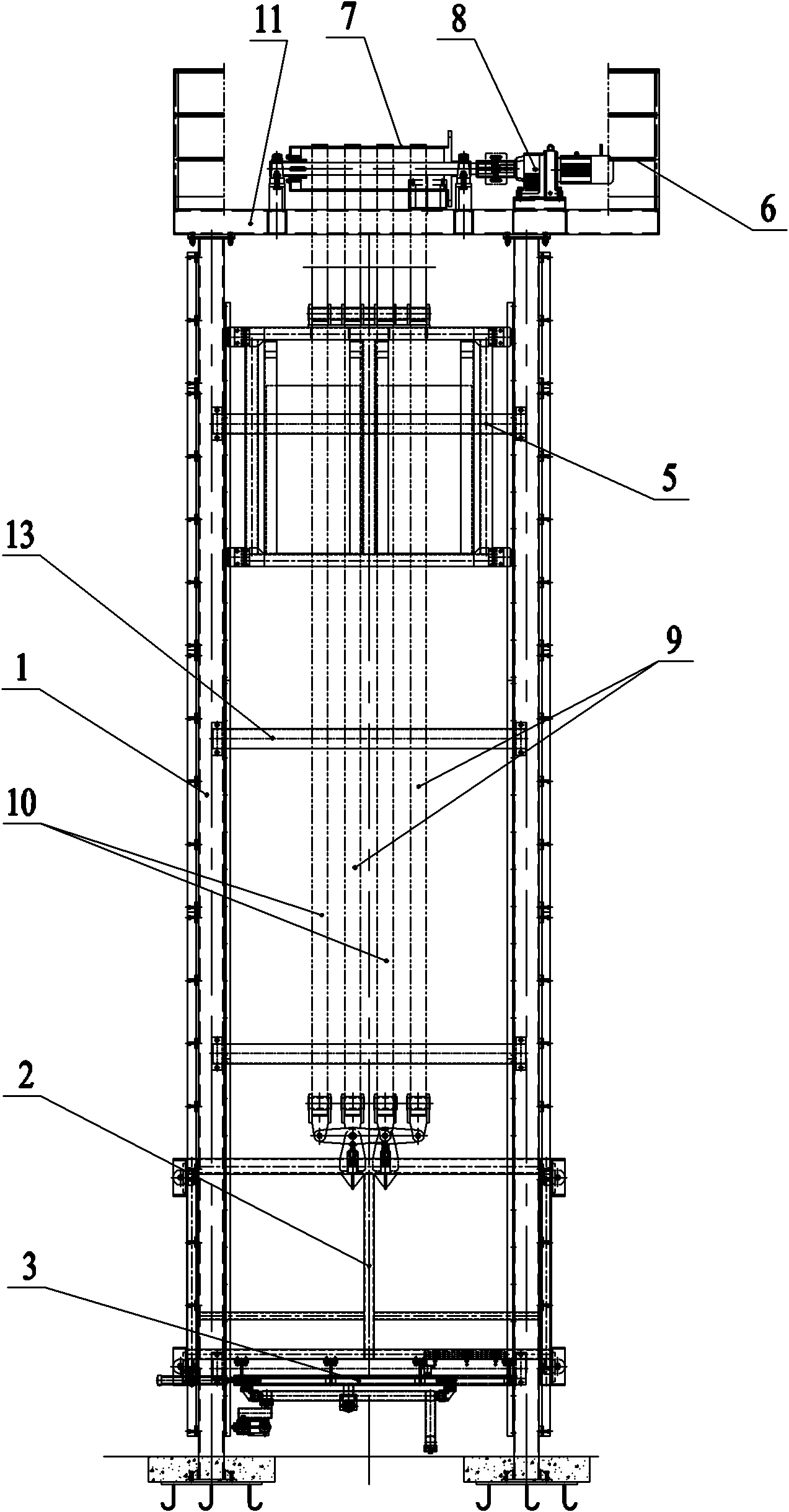

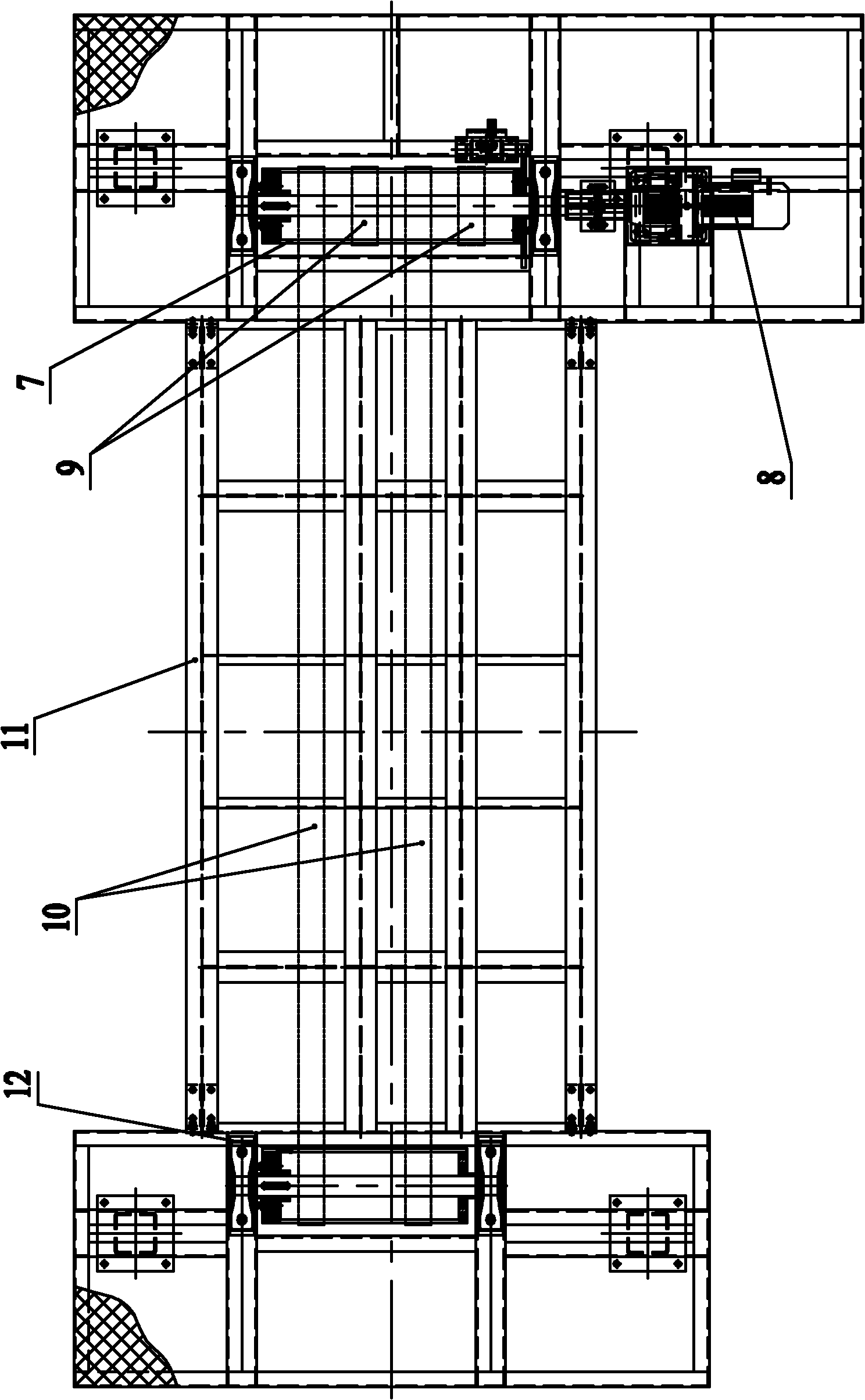

Motor traveling elevator

InactiveCN102060247AOvercome the defect that it cannot be placed accurately on the ground conveyorIngenious and reasonable structureLifting framesConveyor partsDrive motorEngineering

Owner:MIRACLE AUTOMATION ENG CO LTD

Squirrel-cage turnover device

InactiveCN104108589AIngenious and reasonable structureEasy to operateConveyor partsStructural engineeringMechanical engineering

Owner:WUXI SUNDA INTELLIGENT AUTOMATION & ENG COMPANY

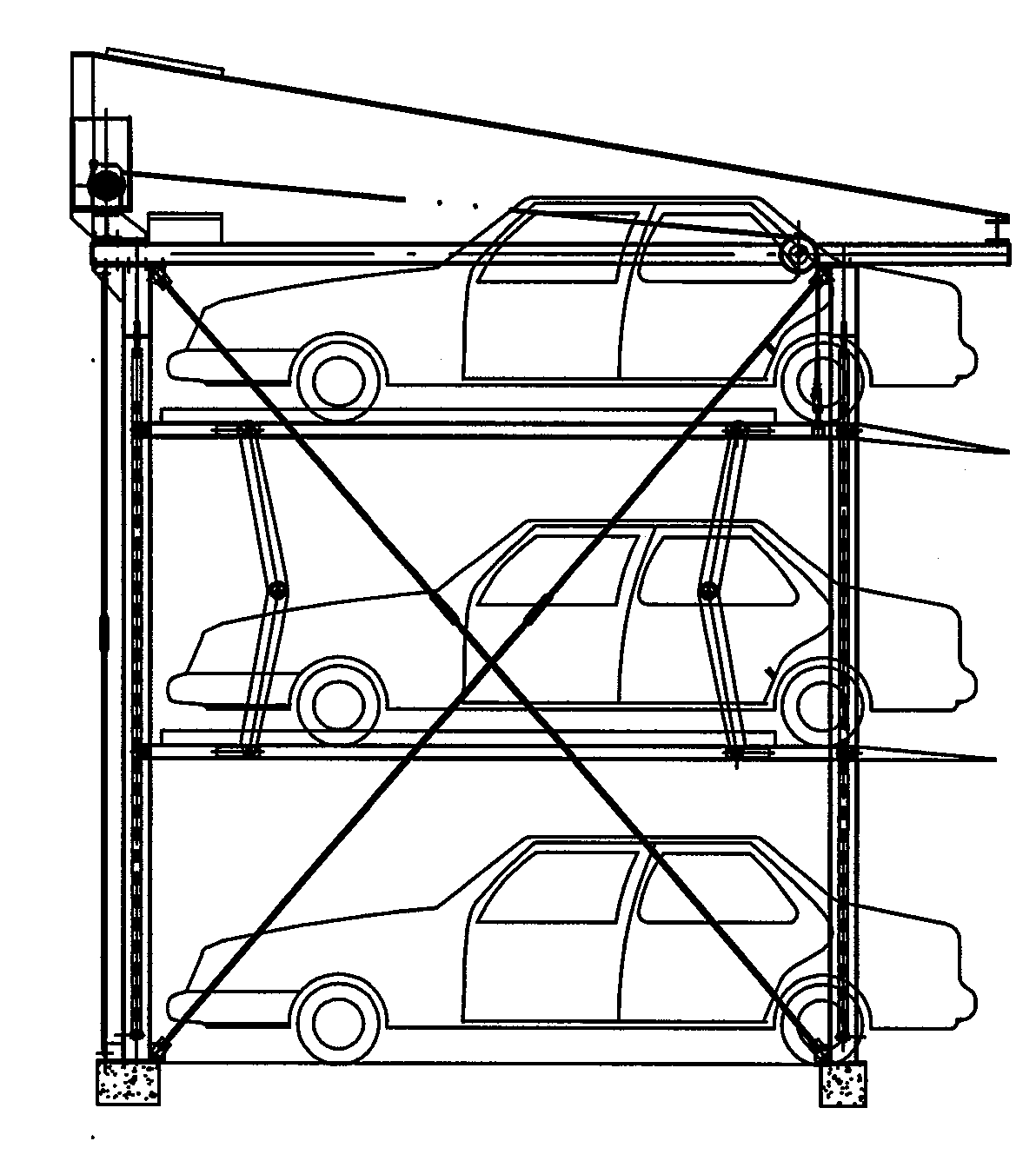

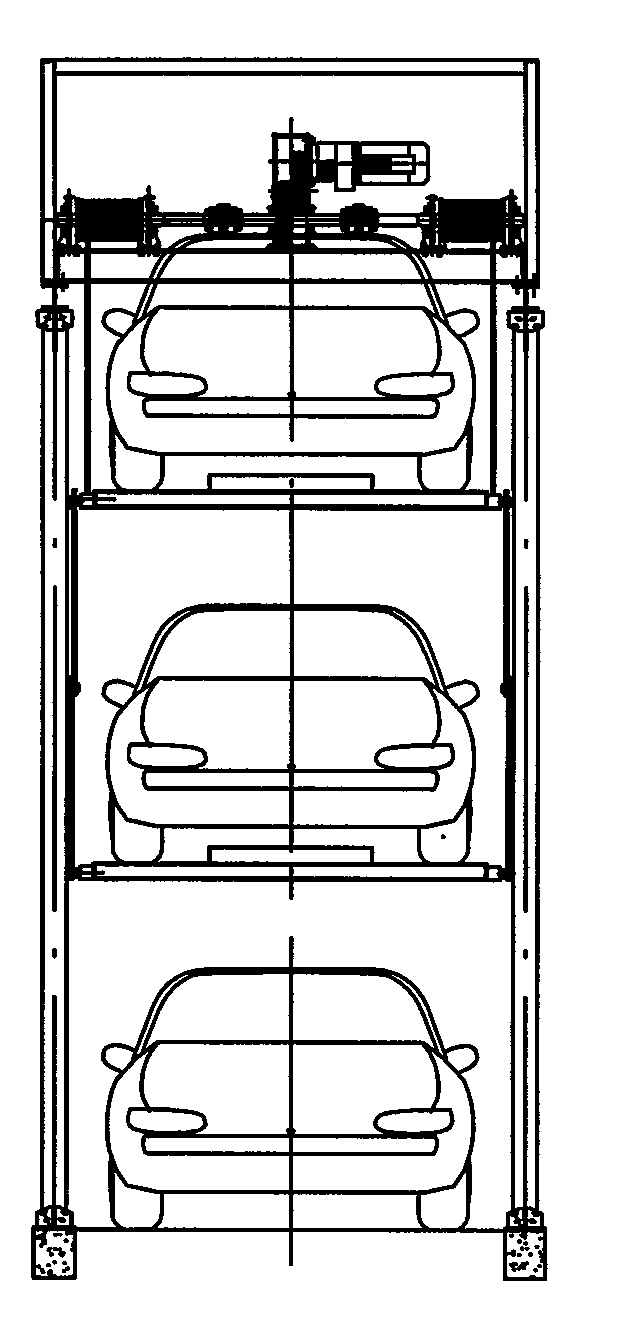

Mechanical ascending and descending parking device

The invention relates to a three-layer mechanical ascending and descending parking device which is driven by solar energy and adapts to the transformation of old residential areas. The device comprises a base and an ascending and descending vehicle table used for parking. The invention is characterized in that a steel frame is fixedly arranged on the base, the top of the steel frame is provided with a power source and a lifting mechanism connected with the power source, and the lifting mechanism provides power via the power source; and the ascending and descending vehicle table is connected on a cable wire of the lifting mechanism, and the ascending and descending vehicle table is driven to ascend and descend via the lifting mechanism. The invention occupies small area and has low manufacturing cost, and a single device or a plurality of side-by-side devices can be arranged on the corner floor of the old residential area. The device has ingenious and reasonable structure, and can be suitable for parking all vehicles. The lifting mechanism is a reel cable mechanism with low speed and large torque, and is driven by a small-power motor and a battery, a solar panel charges the battery all the day, and a power supply does not need to be switched on. An anti-falling mechanism is arranged in a steel frame column, so the safety is good; and the work noise is lower, and the device is suitable for the living environment of a housing estate.

Owner:上海明硕供应链管理股份有限公司

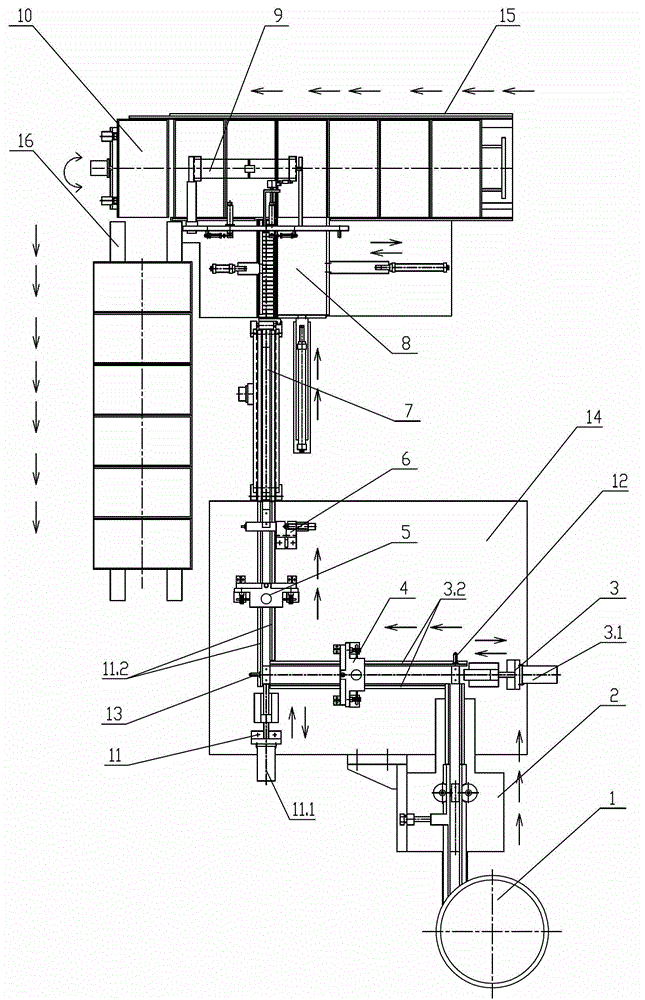

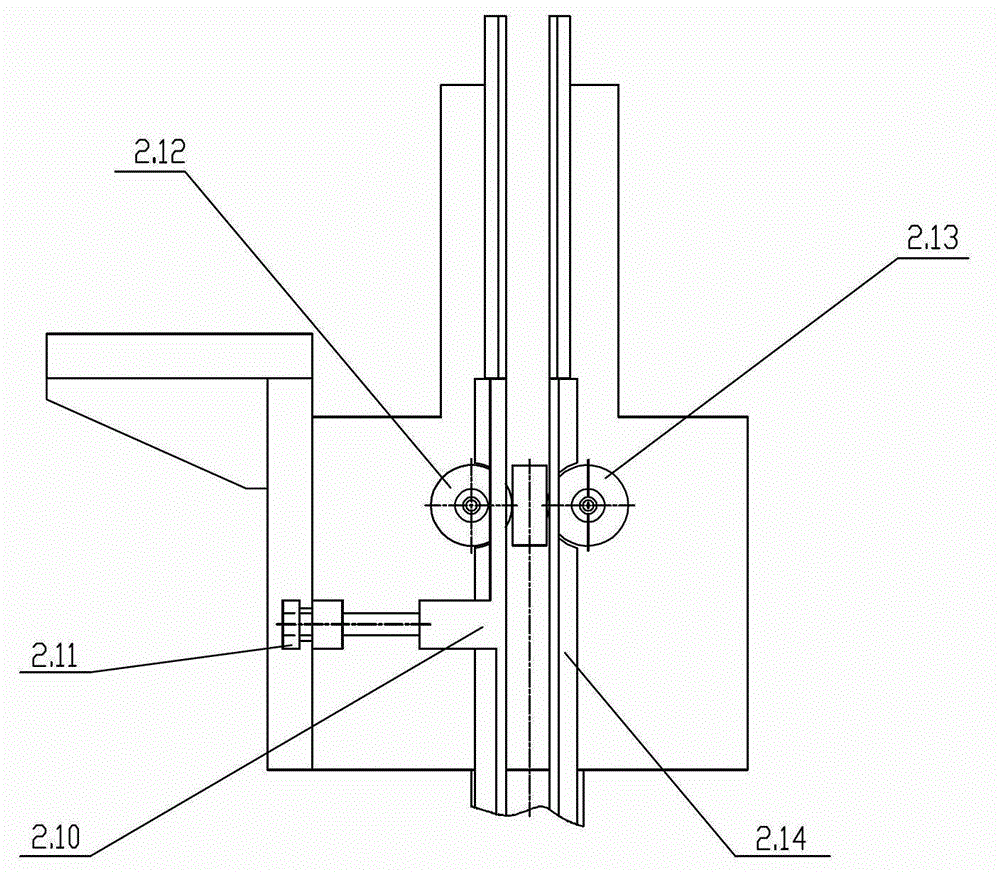

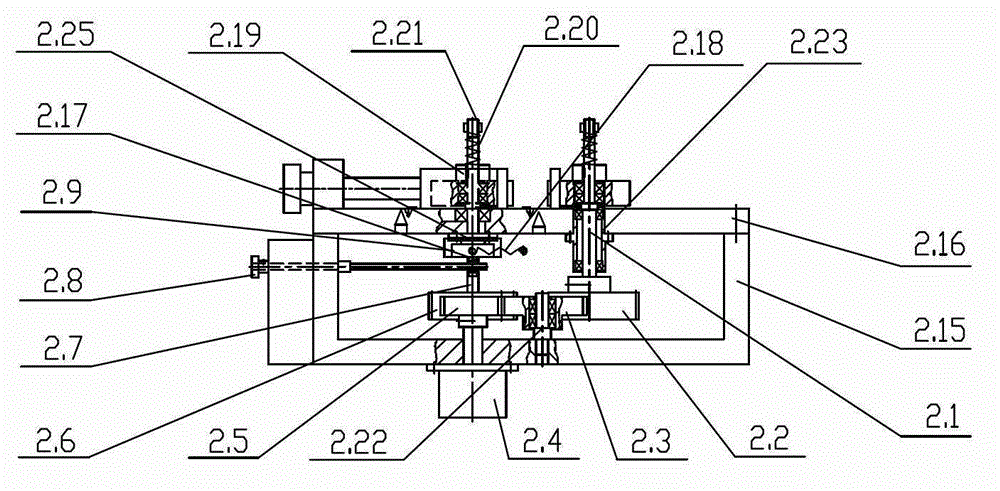

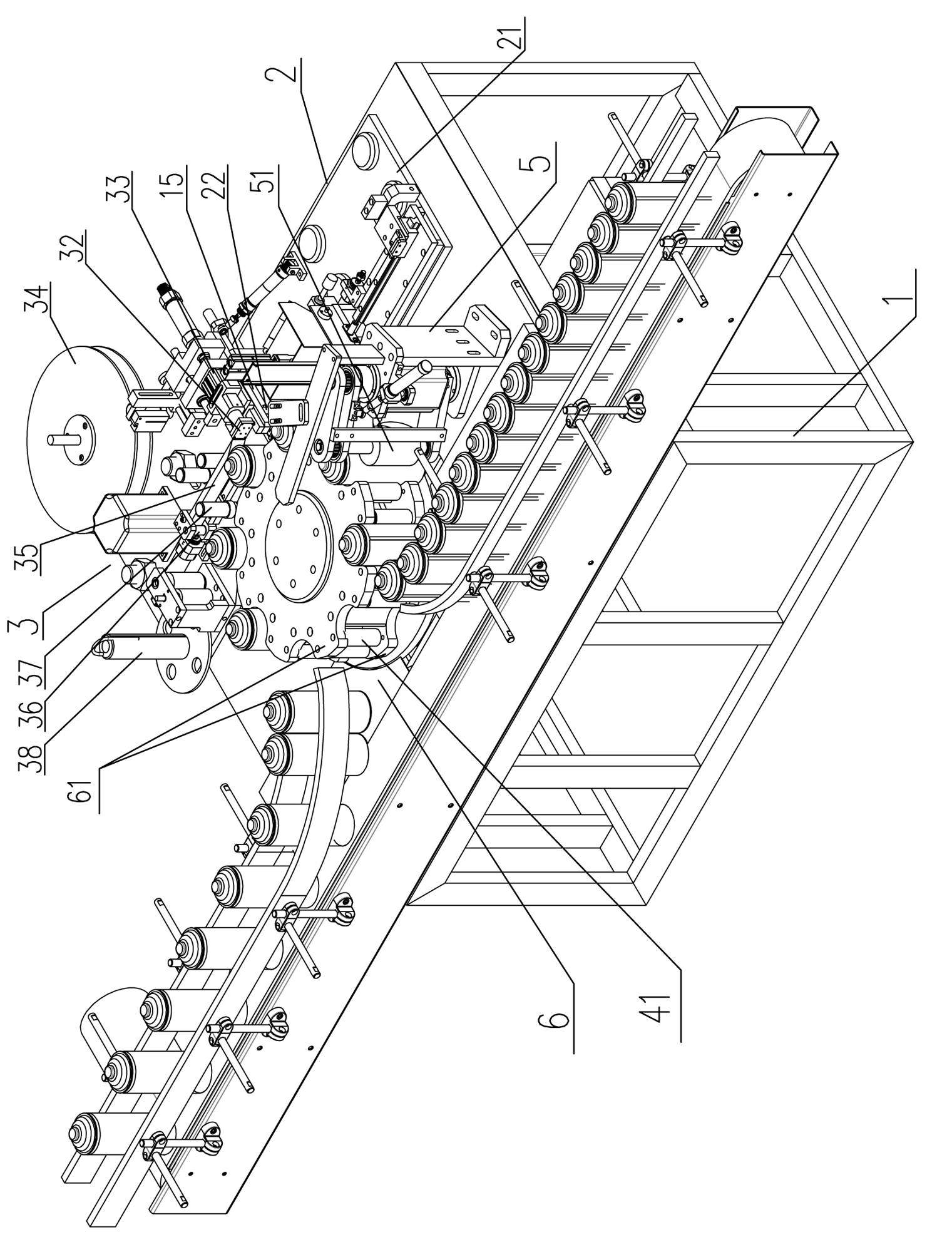

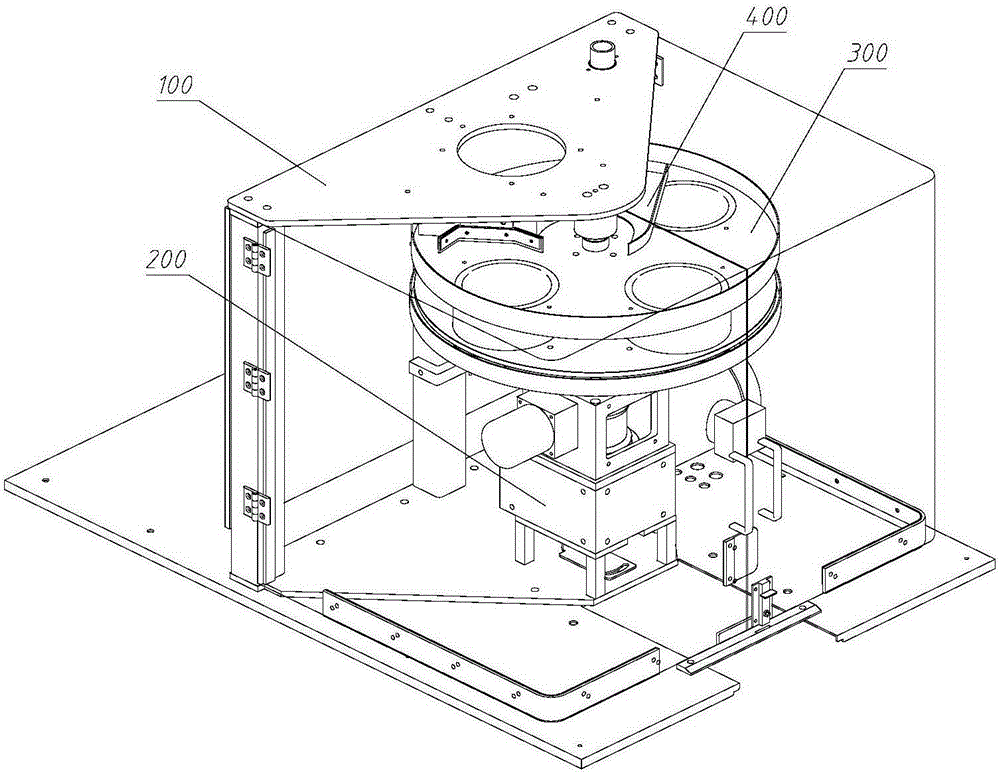

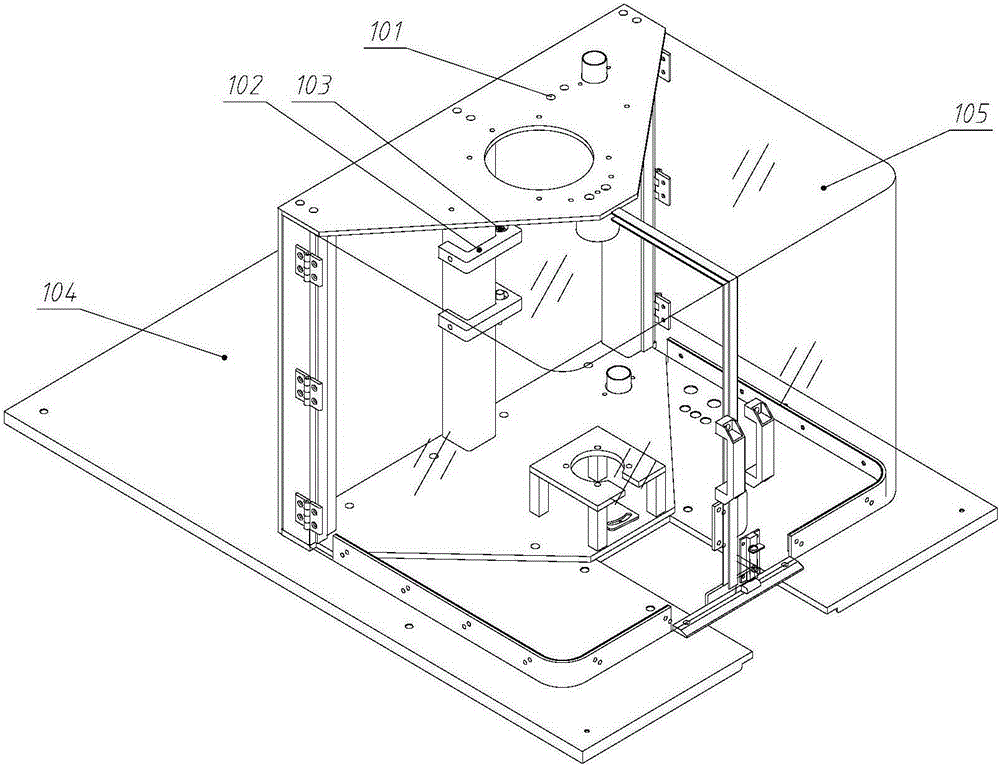

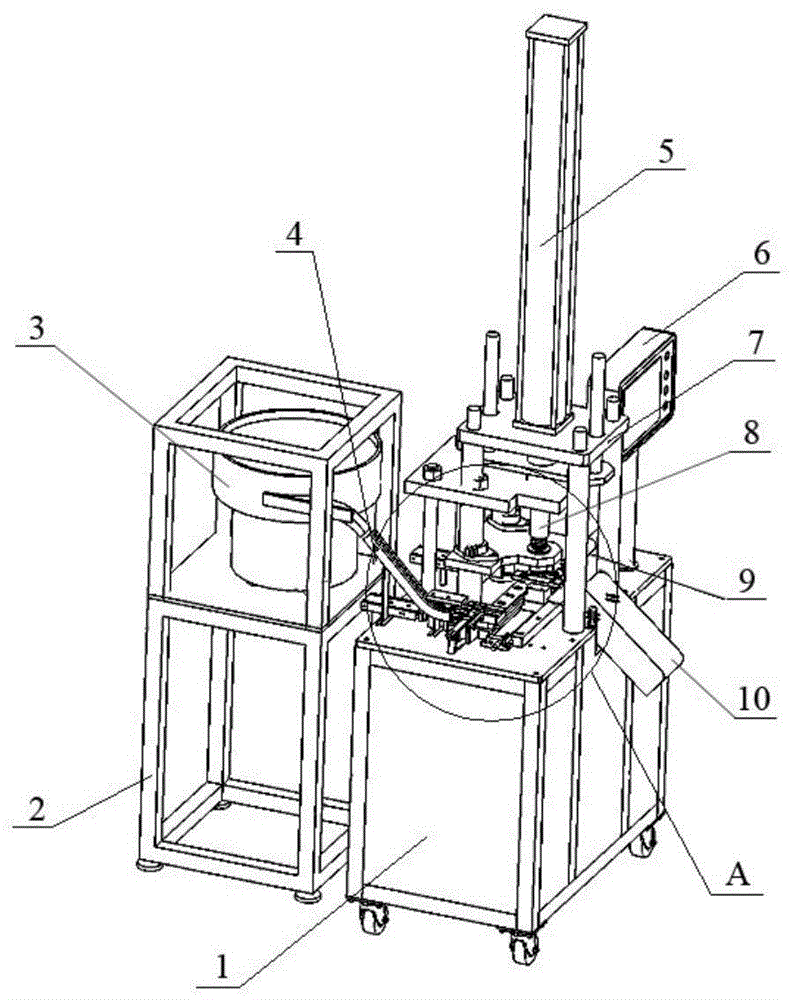

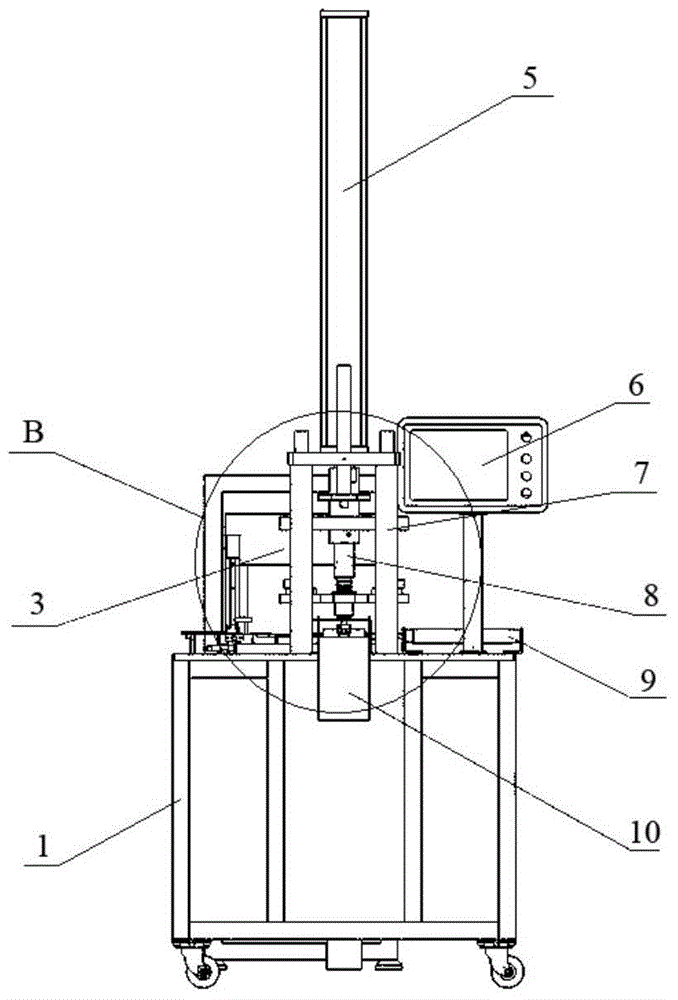

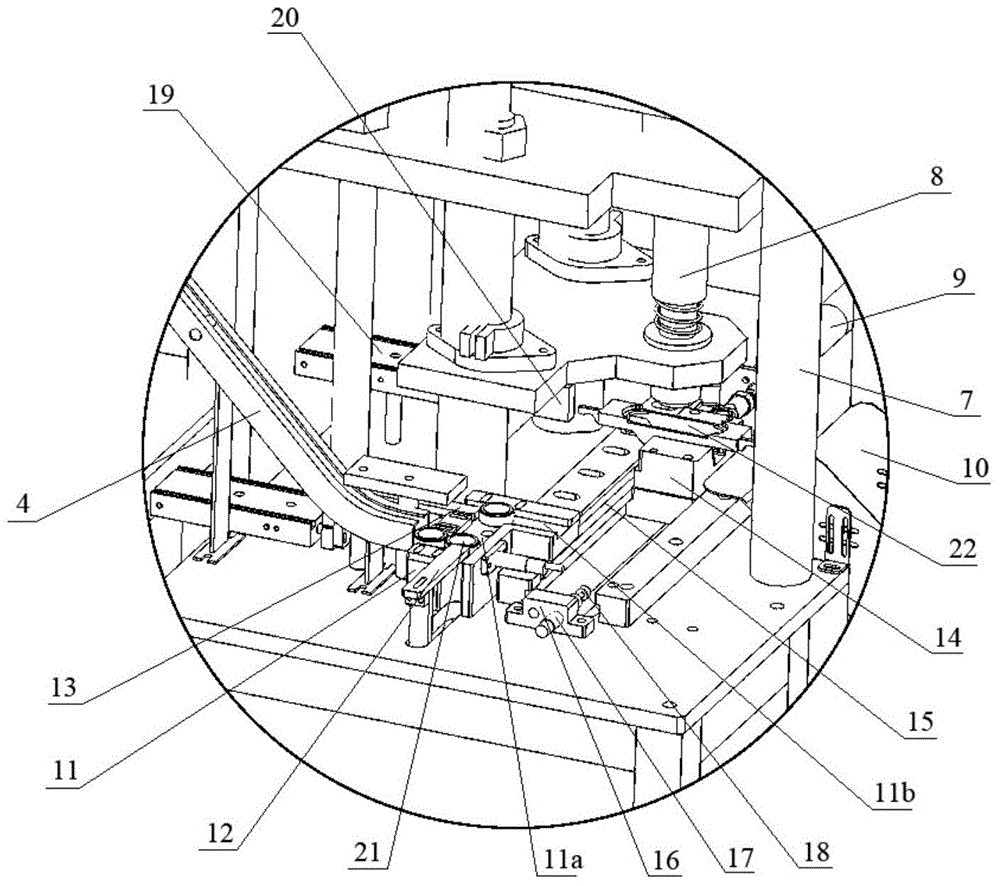

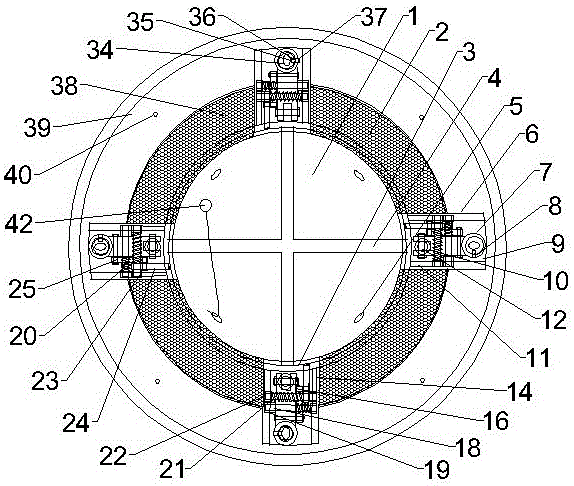

Capacitor shaping and packaging machine

ActiveCN102745365AIngenious and reasonable structureIncrease productivityEncapsulating capacitors apparatusIndividual articlesCapacitanceControl theory

The invention relates to a capacitor shaping and packaging machine. The capacitor shaping and packaging machine is characterized in that the capacitor shaping and packaging machine comprises a vibrating disk, a conveying mechanism, a longitudinal pushing mechanism, a longitudinal shaping mechanism, a horizontal pushing mechanism, a horizontal shaping mechanism, a cutting mechanism, a feeding mechanism, a capacitor-arranging mechanism, a capacitor box-pushing mechanism and a capacitor box-conveying mechanism. The capacitor shaping and packaging machine utilizes the vibrating disk to vibrationally feed capacitors, the longitudinal shaping mechanism and the horizontal shaping mechanism to longitudinally and horizontally shape capacitor leads, the cutting mechanism to cut capacitor leads, the capacitor-arranging mechanism to arrange capacitors and push arranged capacitors into empty capacitor boxes on the capacitor box-conveying mechanism and then the capacitor box-conveying mechanism to convey out loaded capacitor boxes. The capacitor shaping and packaging machine can integrate the acts of shaping, cutting and packaging capacitors, thus increasing the production efficiency.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

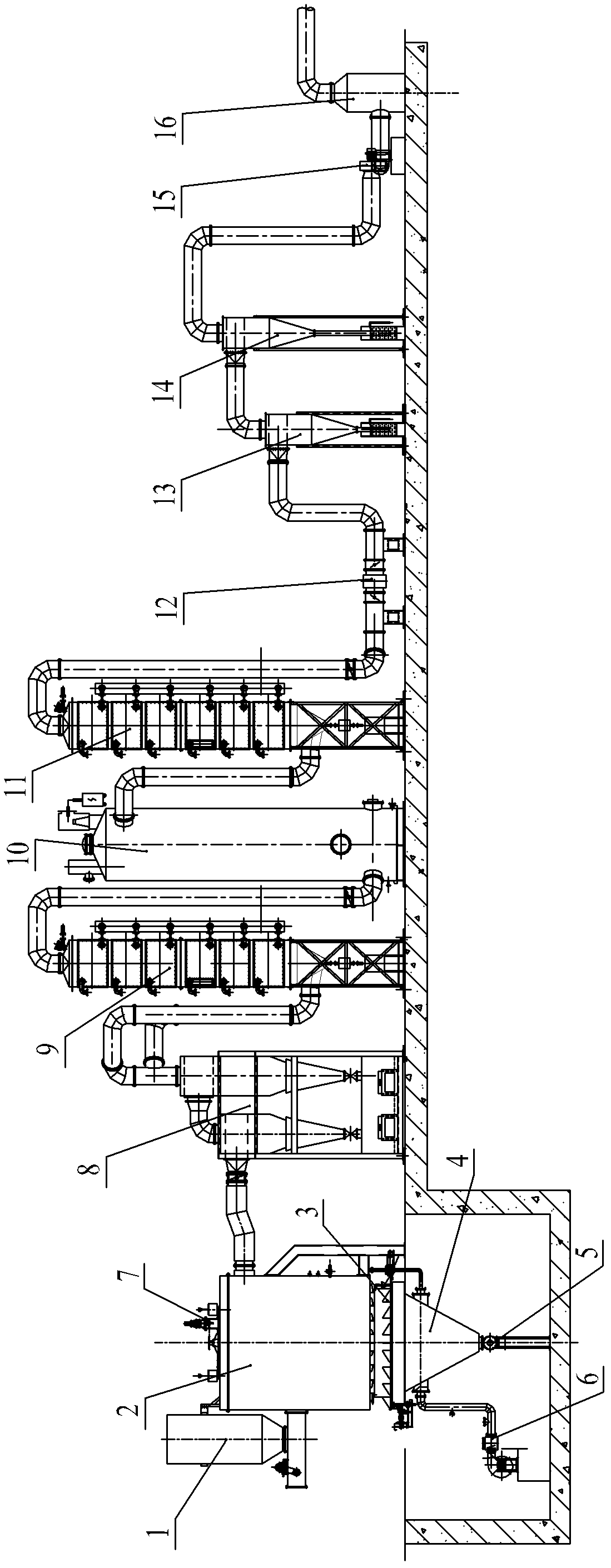

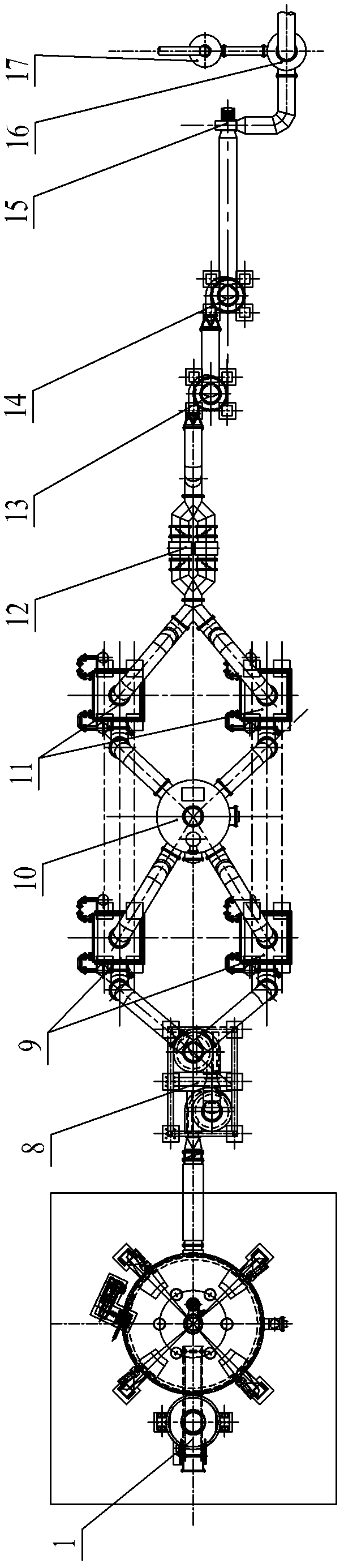

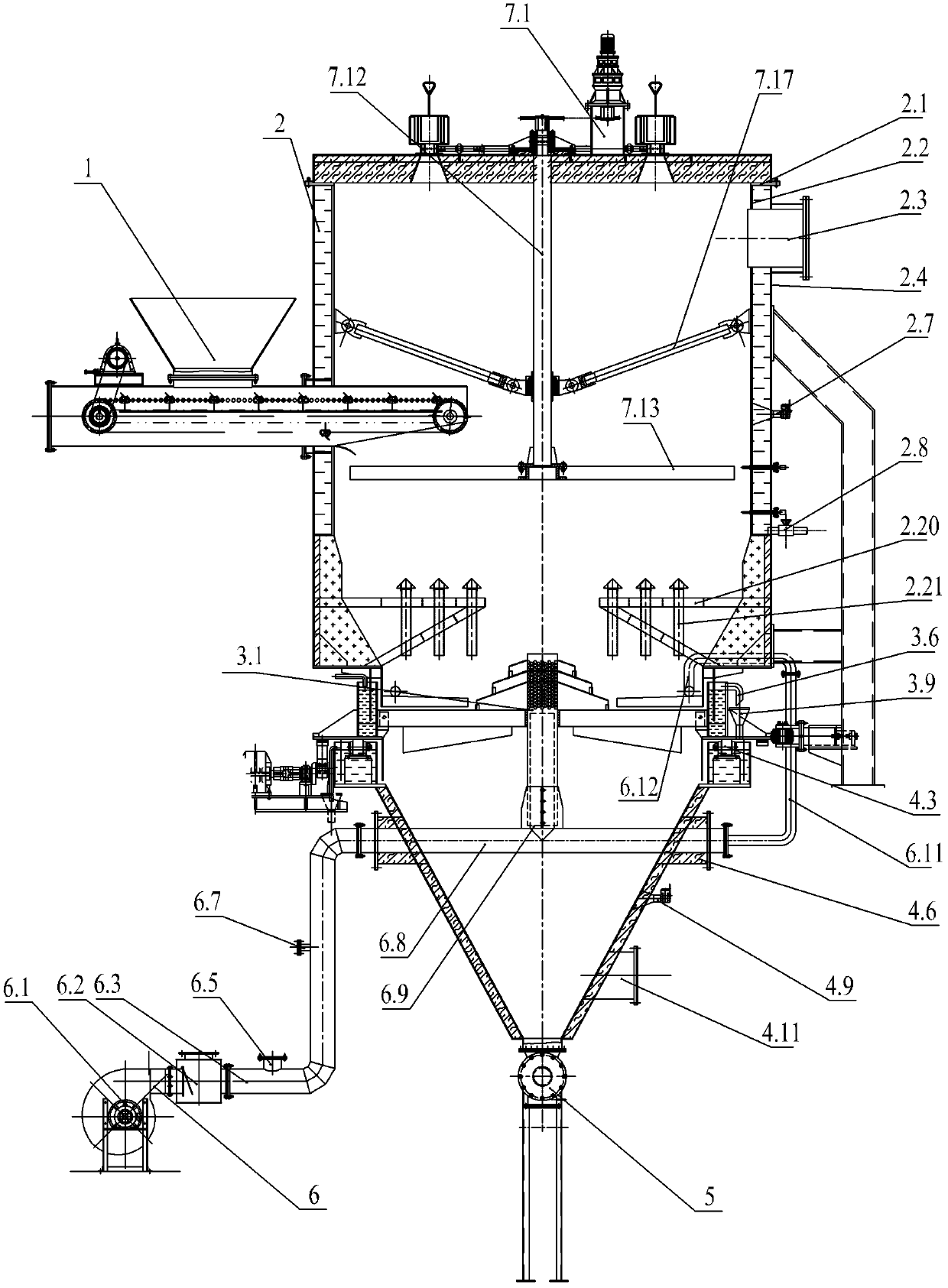

Biomass gas generation system

ActiveCN102703121AProduce secondary pollutionIngenious and reasonable structureProductsReagentsIntercoolerBiomass gasifier

The invention relates to a biomass gas generation system. The system comprises a feed device, a biomass gasification furnace, a post-treatment system and a gas transmission and storage pipeline system which are connected in a sequence of gas generation and treatment, wherein the biomass gasification furnace is provided with a fuel inlet and a gas outlet, the fuel inlet is connected with the feed device, and the gas outlet is communicated with the post-treatment system through a connecting pipe fitting; and the post-treatment system comprises a cyclone dust collector, a primary pipe-type intercooler, an electrical tar precipitator, a secondary pipe-type intercooler, a filter and purification device, a primary water-steam separator and a secondary water-steam separator. The biomass gas generation system has a smart and reasonable structure, cannot cause secondary pollution to the surrounding environment while biomass energy is reasonably utilized; and prepared gas can be applied to civil use instead of the conventional stove or liquefied gas, and can be applied to the industrial field, such as directly being used as industrial gas or being used for supplying power generation for power generation equipment.

Owner:无锡湖光工业炉有限公司

Main spindle box for milling and drilling machine

InactiveCN102328098AMeet the needs of milling and drilling combined processingMeet the needs of compound processingOther manufacturing equipments/toolsMaintainance and safety accessoriesDrive shaftGear wheel

The invention relates to a main transmission box for a milling and drilling machine. The main transmission box comprises a sealed cavity composed of a box body and a box cover, and an input shaft component, a transmission shaft component and an output shaft component are mounted in the sealed cavity. The main transmission box is characterized in that a gear shaft is rotatably mounted in the sealed cavity, a main shaft motor is mounted on the sealed cavity, an output shaft of the main shaft motor is connected with the gear shaft; the transmission shaft can be rotatably mounted in the sealed cavity, and a high-low-drive gear set is assembled on the transmission shaft in a sliding manner; a large transmission gear in the high-low-drive gear set is always engaged with a gear shaft in the input shaft component; the main shaft can be rotatably mounted in the sealed cavity, a large output gear and a small output gear are mounted on the main shaft; a main shaft broaching-loosening cutter is arranged in the main shaft for firmly grasping a cutter. The transmission shaft box has rational and clever structure, and can meet a high output torque demand of the main shaft milling processing and a high output rotation speed demand of the drilling processing, can effectively meet the milling-drilling composite processing demands of parts. By the adoption of the transmission shaft box, the working efficiency can be obviously improved and the processing precision can be ensured.

Owner:无锡桥联数控机床有限公司

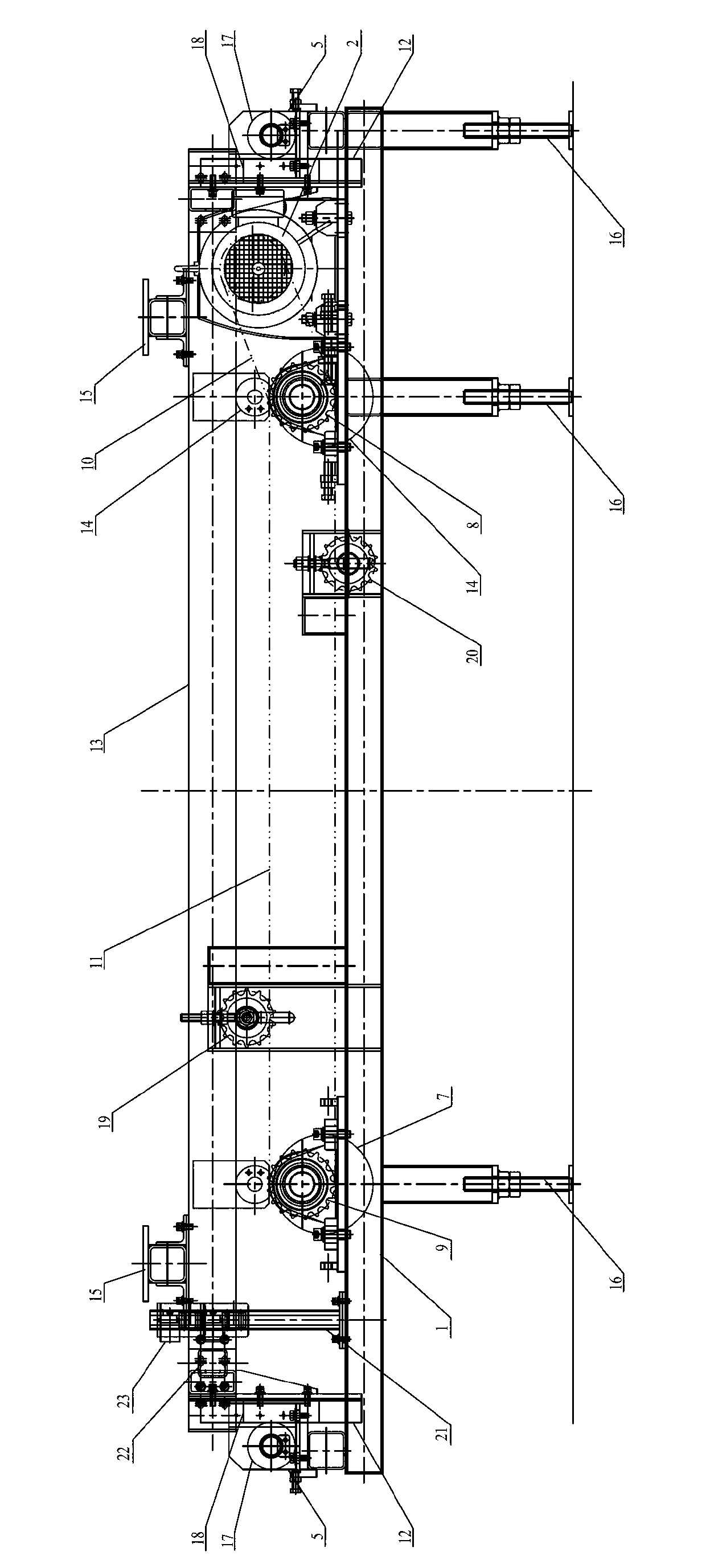

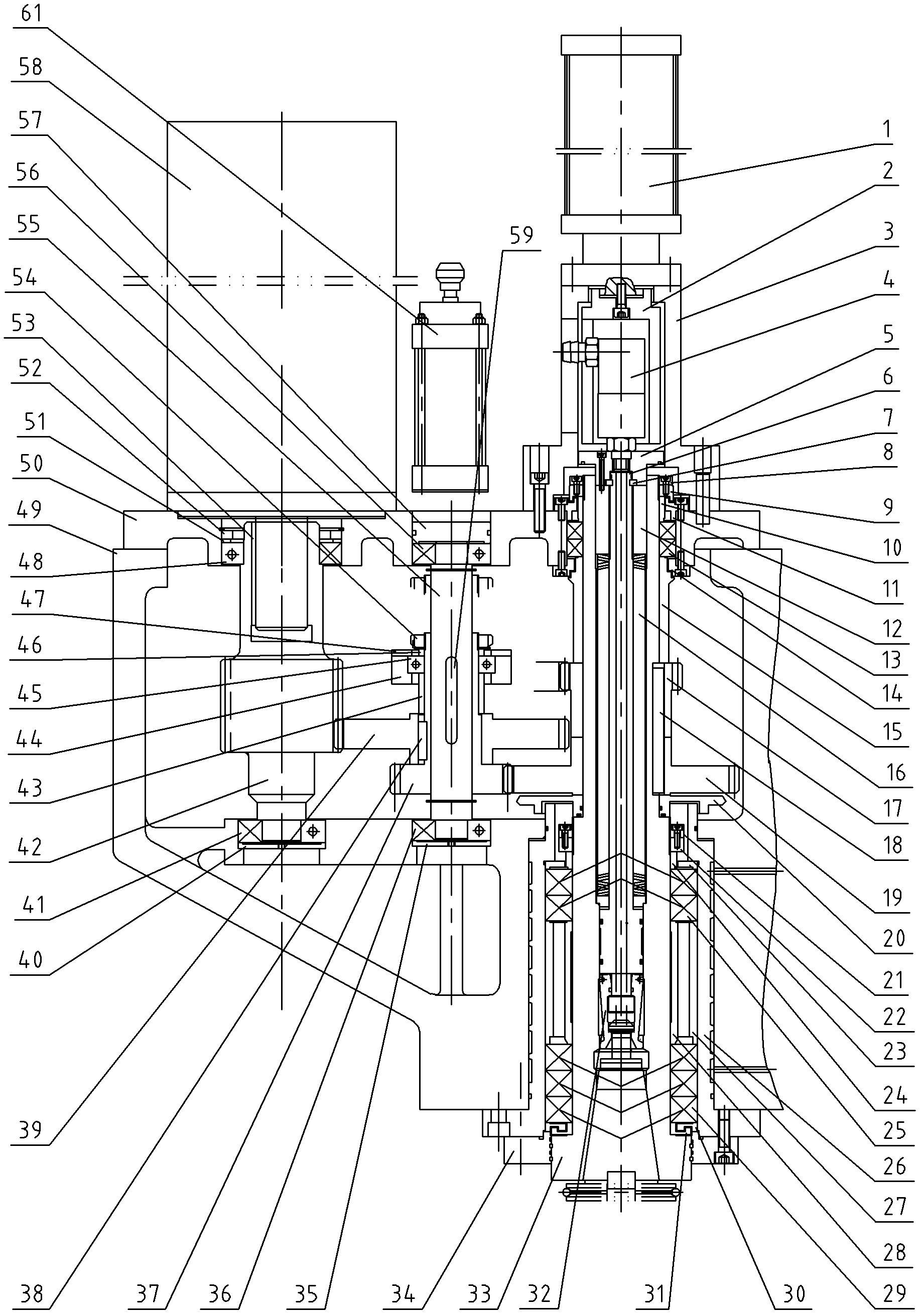

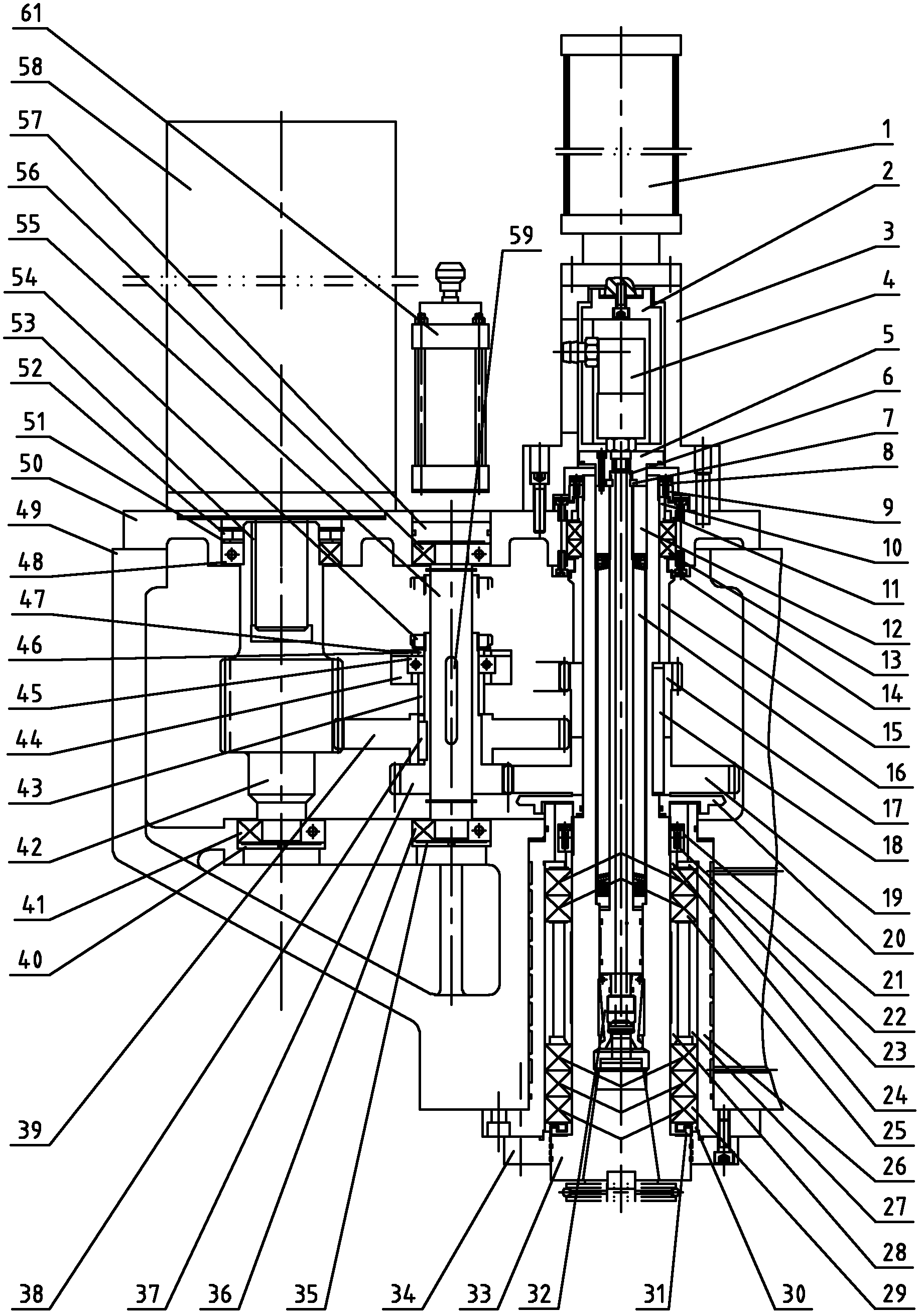

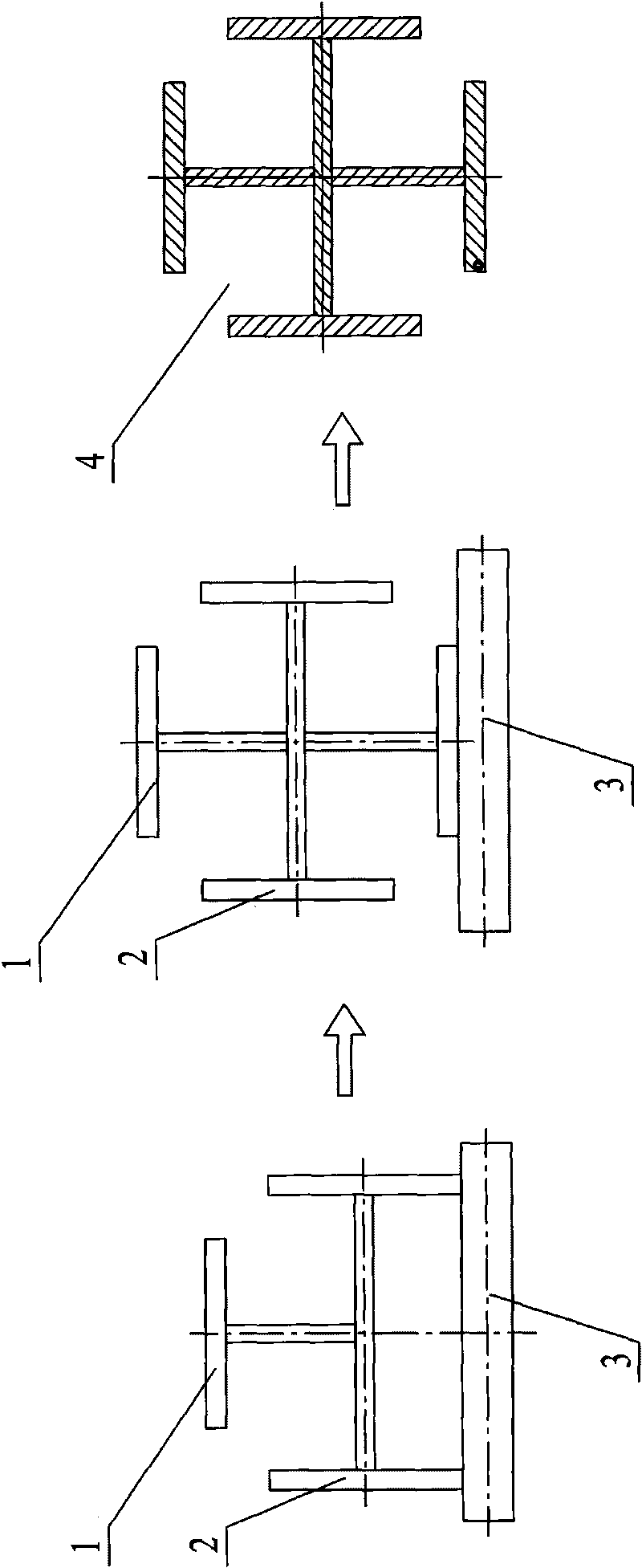

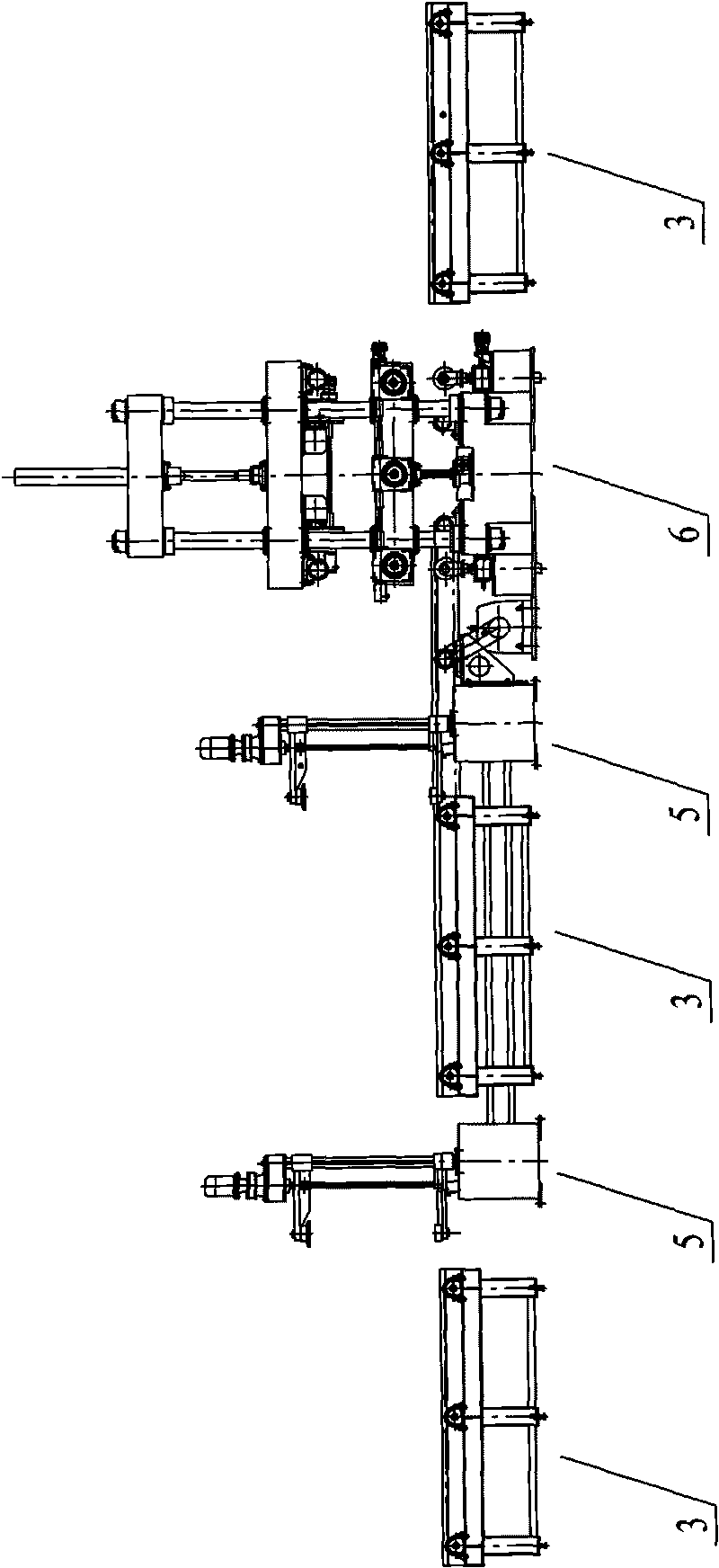

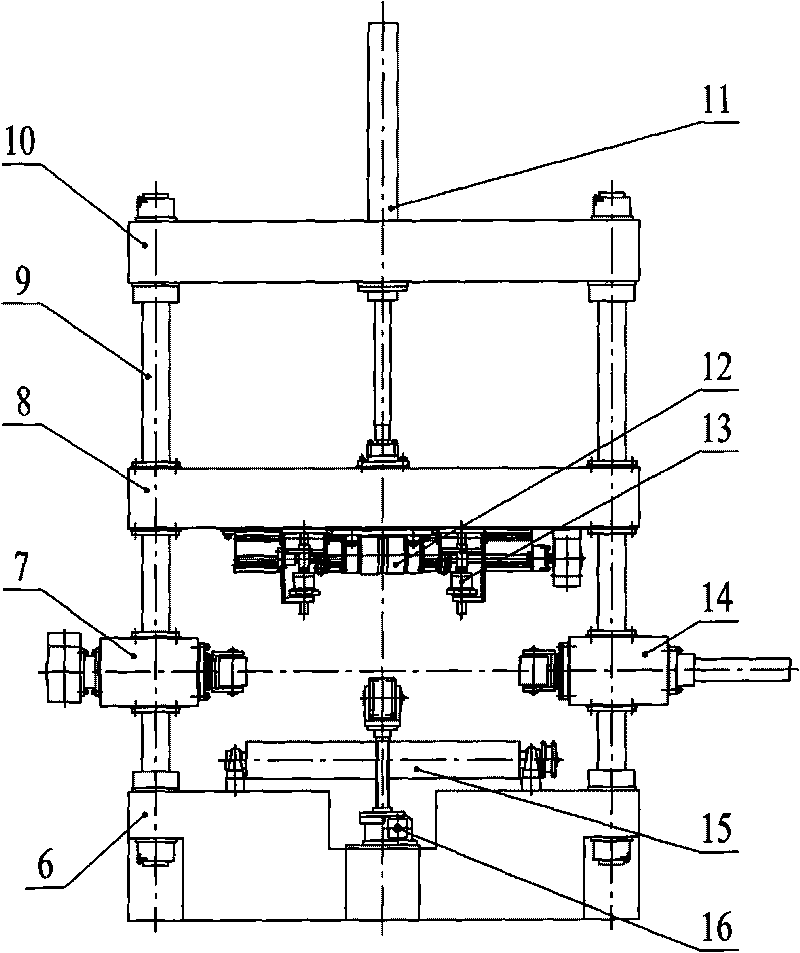

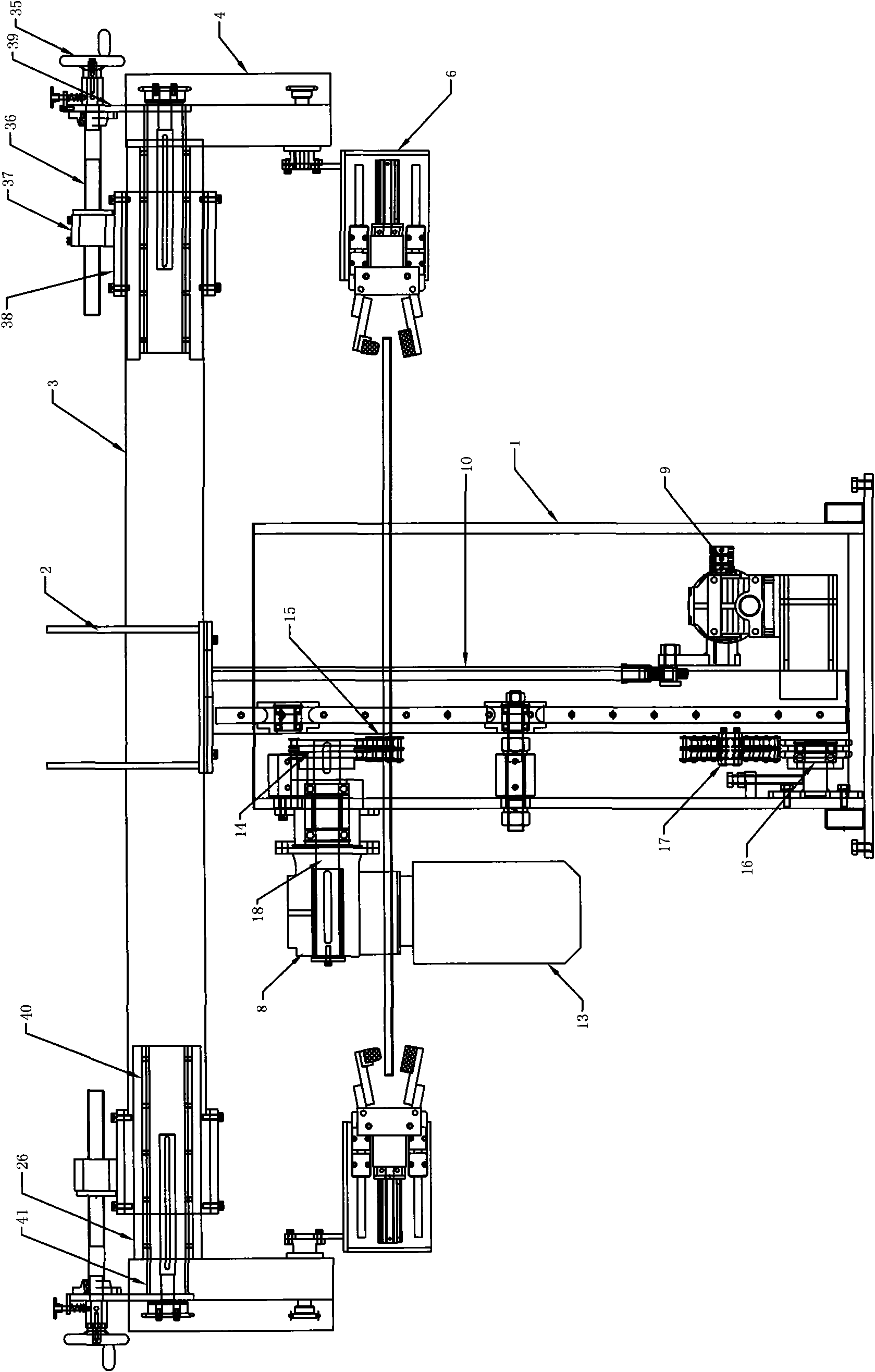

Crossed column assembling machine

ActiveCN101695787AImprove quality and efficiencyImprove production efficiencyResistance welding apparatusElectrical controlEngineering

The invention relates to a crossed column assembling machine which comprises a drive device, a pre-centring device, a host machine, a hydraulic system and an electrical control system. The crossed column assembling machine is characterized in that a base in the host machine is fixed on the ground, and four vertical columns are vertically installed at four corners of the base; four corners of an upper cross beam and a lifting beam are respectively provided with holes corresponding to the vertical columns; the vertical columns penetrate through the holes; the upper cross beam is fixed on the vertical columns, and the lifting beam can be freely lifted up and down on the vertical columns; a cylinder body of an upper press oil cylinder is fixed on the upper cross beam, and the piston rod end of the upper press oil cylinder is connected with the lifting beam; an upper press wheel and an upper positioning and clamping mechanism are installed on the lower surface of the lifting beam; a lower positioning mechanism and a lower clamping mechanism are respectively connected with a lifting mechanism installed on the base and lifted by the control of the lifting mechanism; and a drive roller is installed on the base by a bearing assembly and used for carrying H-shaped steel. The invention has skillful and reasonable structure, realizes the assembling mechanization of a crossed column, improves the manufacture quality and the manufacture efficiency of the crossed column and lowers the labor intensity.

Owner:无锡洲翔成套焊接设备有限公司

Automatic pipe-sticking machine

InactiveCN102069930AReduce labor intensityIngenious and reasonable structurePackagingPulp and paper industryFully automatic

The invention discloses an automatic pipe-sticking machine, which comprises a stand on which a pipe outlet mechanism and a gummed paper sticking mechanism are arranged. An external guide pipe is output from the pipe outlet mechanism, and can be stuck and adhered to a product to be stuck with a pipe by gummed paper output from the gummed paper sticking mechanism. By arranging the pipe outlet mechanism and the gummed paper sticking mechanism, after the guide pipe is discharged by the pipe outlet mechanism, the gummed paper sticking mechanism can automatically strip off the gummed paper and stick the guide pipe onto the product by the gummed paper. The automatic pipe-sticking machine has an ingenious and rational structure, the fully automatic pipe sticking is realized, the labor intensity of workers is relieved, the production efficiency of pipe sticking is improved, and products subjected to pipe sticking are attractive and uniform; moreover, the automatic pipe-sticking machine is widely applied to working procedures for external packing of pipe sticking on the products in a production line.

Owner:广州市冠浩机械设备有限公司

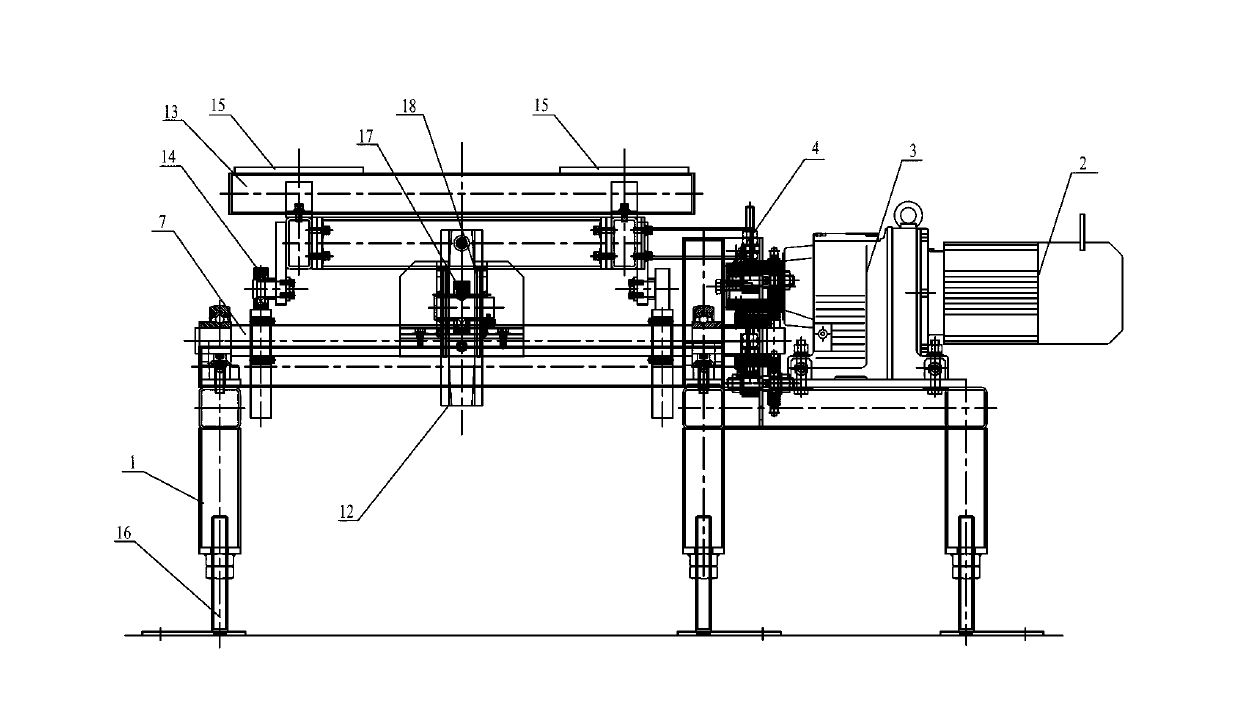

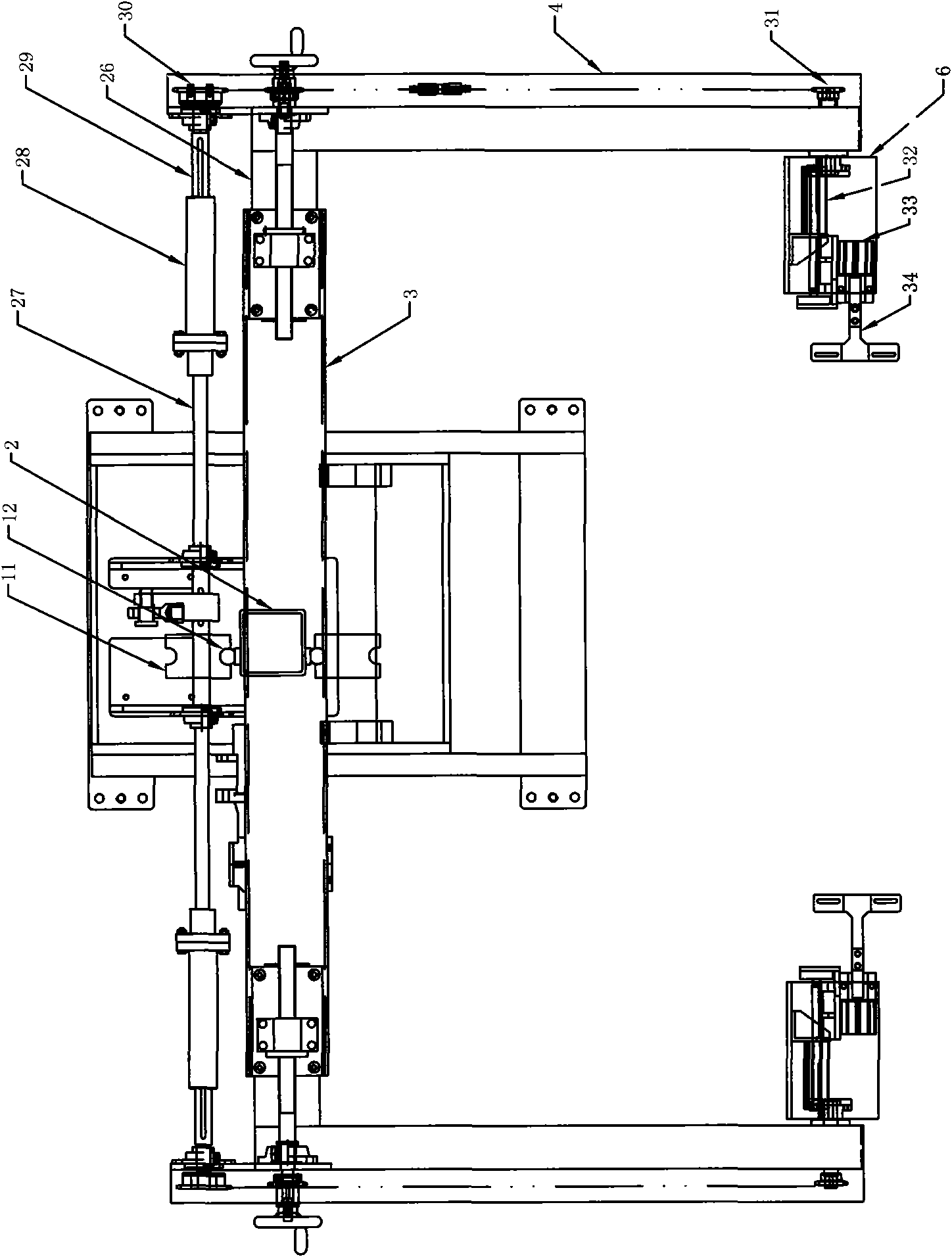

Double-cutter head assembly mechanical hand of four-wheeled grass cutter

ActiveCN101890709APneumatic implementationFully automatedGripping headsAssembly machinesElectric controlManipulator

The invention relates to a double-cutter head assembly mechanical hand of a four-wheeled grass cutter, which comprises a base, lifting columns, a movable arm and a driving device, wherein the movable arm comprises a beam, mechanical arms, clamping and turning mechanisms and a pressing device; the pressing device is arranged at the top ends of the lifting columns; the mechanical arms are arranged at the two ends of the beam; the beam is arranged at the top ends of the lifting columns and is positioned below the pressing device; the driving device comprises a lifting driving device and a rotation driving device; the lifting driving device is arranged at the bottoms of the lifting columns; the rotation driving device is arranged in a base frame and is connected with the pressing device and the beam through a pull rod; and the clamping and turning mechanisms which clamp parts to be assembled are arranged at the front ends of the mechanical arms. In the scheme, the taking and putting of cutter heads from a conveyor line, and the turning of the cutter heads are completely automatically controlled by the mechanical hand, the actions of clamping, lifting, turning, backing-pressure and the like are realized by the combination of pneumatic driving and motor driving, and the complete automation is realized by the effective combination of mechanical control, pneumatic control and electric control.

Owner:怡锋工业设备(深圳)有限公司

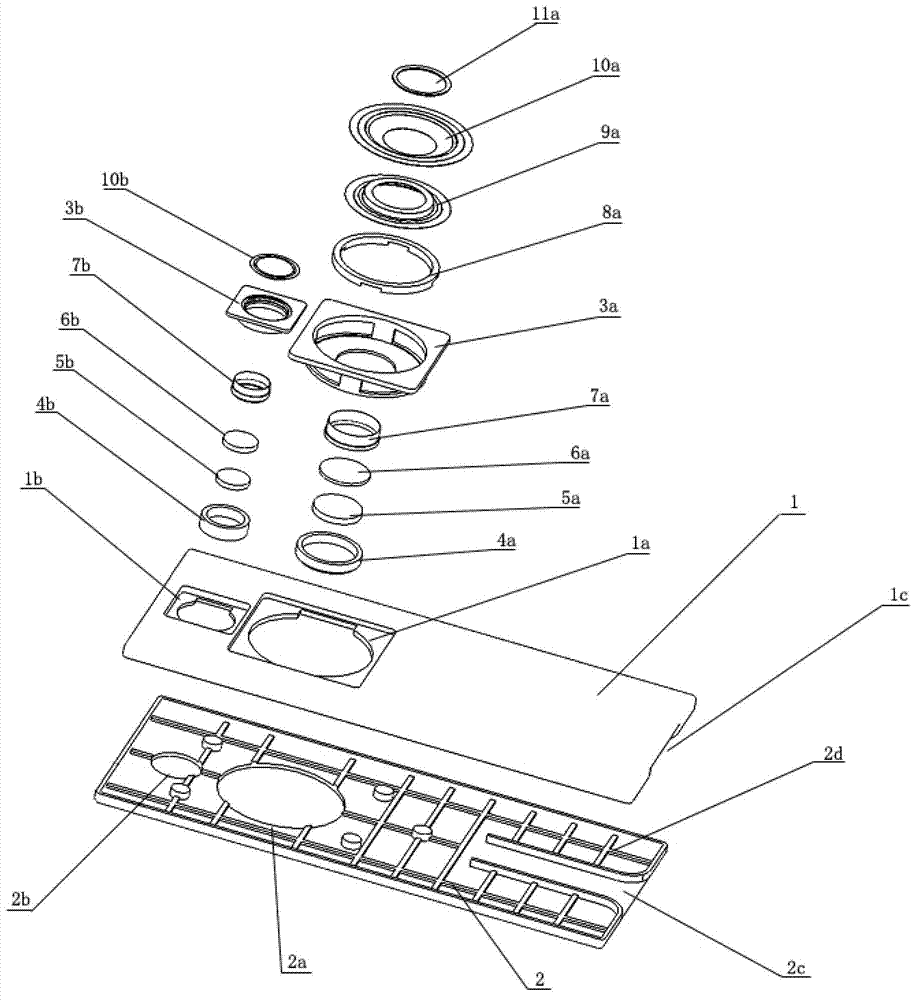

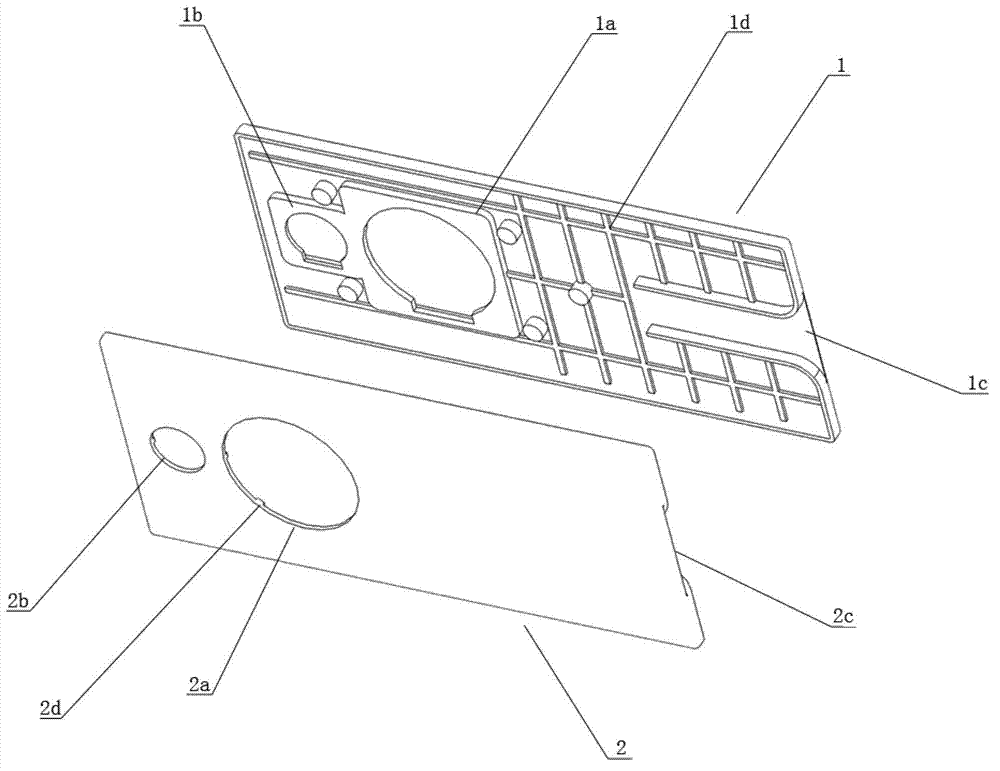

Thin double-cone phase inversion type loudspeaker box

ActiveCN103037283AAvoid \"acoustic short circuit\"Avoid interferenceFrequency/directions obtaining arrangementsInverterSound quality

The invention relates to a thin double-cone phase inversion type loudspeaker box. A box body is mainly composed of a lower shell and an upper shell, wherein a high pitch unit installing hole, a low pitch unit installing hole and a lower shell phase inversion hole are formed in the lower shell, the high pitch unit installing hole and the low pitch unit installing hole are distributed along the long axis direction and are located in the left half portion of the lower shell, the high pitch unit installing hole is close to the left end of the lower shell, the lower shell phase inversion hole is arranged along the long axis direction and is located in the right half portion of the lower shell, and an opening of the lower shell phase inversion hole is located in the right end of the lower shell. A high pitch unit positioning groove, a low pitch unit positioning groove and an upper shell phase inversion hole are formed in the upper shell, wherein the lower shell and the upper shell constitute the box body. A high pitch loudspeaker unit is arranged in the high pitch unit installing hole and the high pitch unit positioning groove, and a subwoofer unit is arranged in the low pitch unit installing hole and the low pitch unit positioning groove. An inverter tube is formed by corresponding combination of the lower shell phase inversion hole and the upper shell phase inversion hole. The thin double-cone phase inversion type loudspeaker box is ingenious and reasonable in structure, and pretty good low frequency tone quality is achieved under the condition that the thin structure of the loudspeaker box is guaranteed.

Owner:WUXI JIEFU ELECTROACOUSTIC

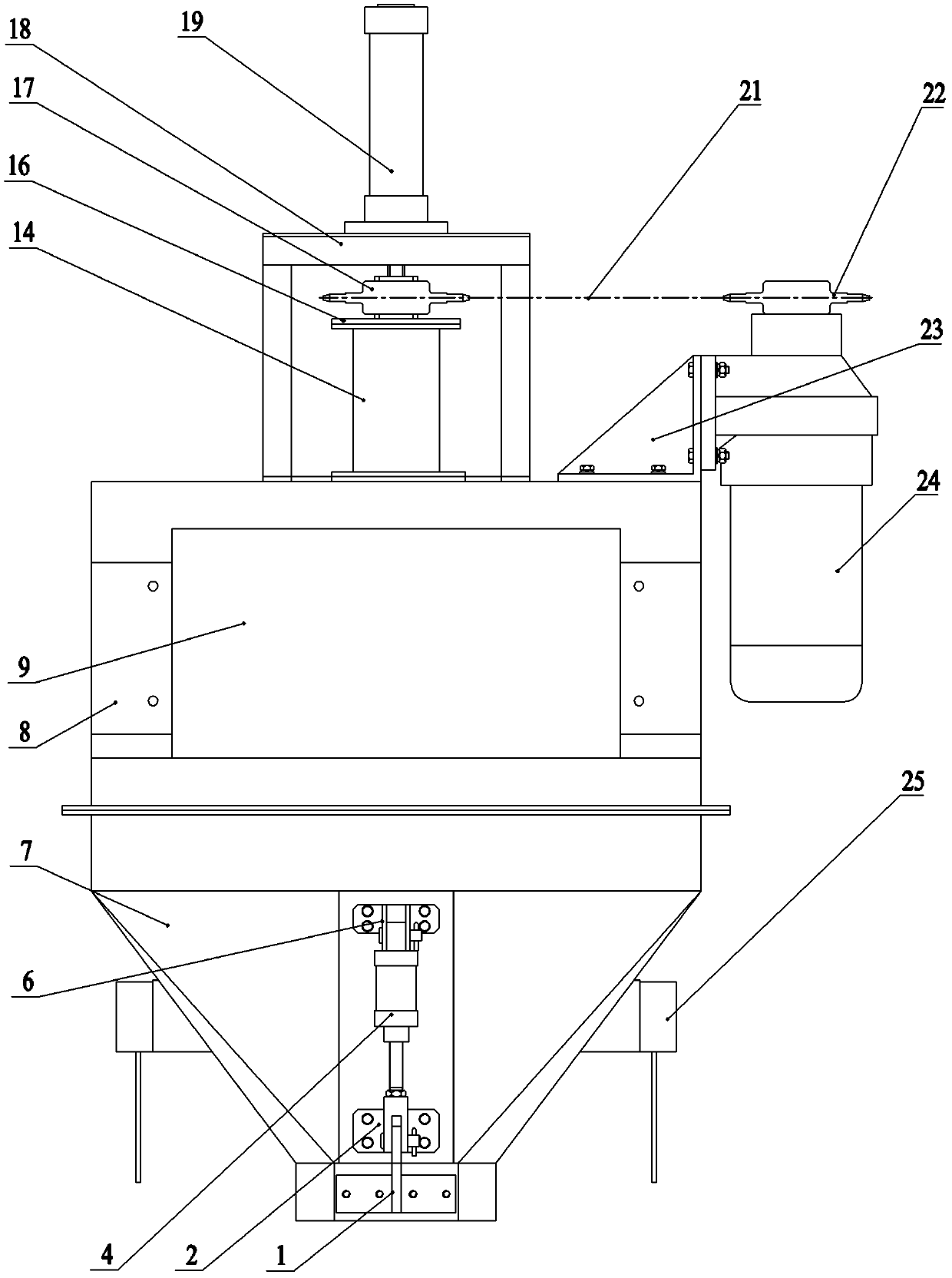

Volume-automatically-adjusted metering device

ActiveCN105173145AIngenious and reasonable structureImprove performanceSolid materialEngineeringFlange

The invention relates to a volume-automatically-adjusted metering device. The device is mainly composed of a supporting component, an adjusting component, a metering component and a material bucket component and is characterized in that the material bucket component is fixed to the supporting frame of the supporting component, and a material bucket directly faces a feeding opening formed in the supporting frame; a discharging motor of the adjusting component is mounted on a tray of the supporting component; and a movable disc flange of the metering component is fixed to a main shaft of the adjusting component, and a fixed disc flange is mounted on a shaft sleeve of the adjusting component and located between two limiting plates of the supporting component. The metering device can accurately meter packaging materials well, and a full-automatic packaging machine is reasonable in structure, reliable in performance, easy and convenient to operate, and capable of accurately and efficiently carrying out packaging.

Owner:WUHAN RENTIAN PACKAGING TECH

Application method of wind motor

InactiveCN109209773AIngenious and reasonable structureEasy to useWind motor controlWind energy with electric storageEngineeringWind force

The invention provides an application method of a wind motor. The wind motor comprises a motor body and a water storage cavity with an upward opening, and the water storage cavity is formed in the left side of the motor body; a water drawing device is arranged in the water storage cavity, and the motor body is internally provided with a first cavity and a first transmission cavity; a vertical axiswind power device is arranged in the first cavity and comprises a first rotating shaft rotatably arranged in the top wall of the first cavity, the downwardly-extending tail end of the first rotatingshaft extends into the tail end of the first cavity, and a first bevel gear is fixedly mounted at the tail end of the first rotating shaft. The application method has the advantages that the wind motor is more reasonable and ingenious in overall structure, and quite convenient to use; equipment blades are prevented from being damaged by wind power through a protection device; the rotating direction of an output shaft of equipment can be kept constantly consistent through a direction adjusting device; the equipment can be switched to power generation or work, practicability and convenience of the equipment are improved, and accordingly, high application and promotion value is achieved.

Owner:XIANJU YUNLI ELECTRONICS TECH CO LTD

Mixing equipment for clay or cement material

ActiveCN109834821AIngenious and reasonable structureEasy to useDischarging apparatusClay mixing apparatusEngineeringAutomation

The invention provides mixing equipment for a clay or cement material. The mixing equipment comprises a machine body and a first cavity provided with an opening facing right and formed in the right side end wall of the machine body. A first sliding cavity with an opening upward is formed in the bottom wall of the first cavity, and the first sliding cavity is internally and slidably provided with afirst sliding block. First sliding holes penetrating left and right are formed in the first sliding block in a front and back symmetry mode. The mixing equipment is more reasonable and ingenious in overall structure and very convenient to use, a same power source can be used for driving the equipment to stir and automatically discharge, and the automation degree is high and stirring is more sufficient; and meanwhile, the mixing equipment uses the same power source to realize the water inlet control and material discharge, and the amount of liquid injected can be automatically controlled according to the amount of the material, so that a mixture is more effective, and the mixing equipment can completely discharge the mixture in a mixing tank to avoid equipment damage caused by the drying of the mixture, and has high use and popularization value.

Owner:禹城市金德建材有限公司

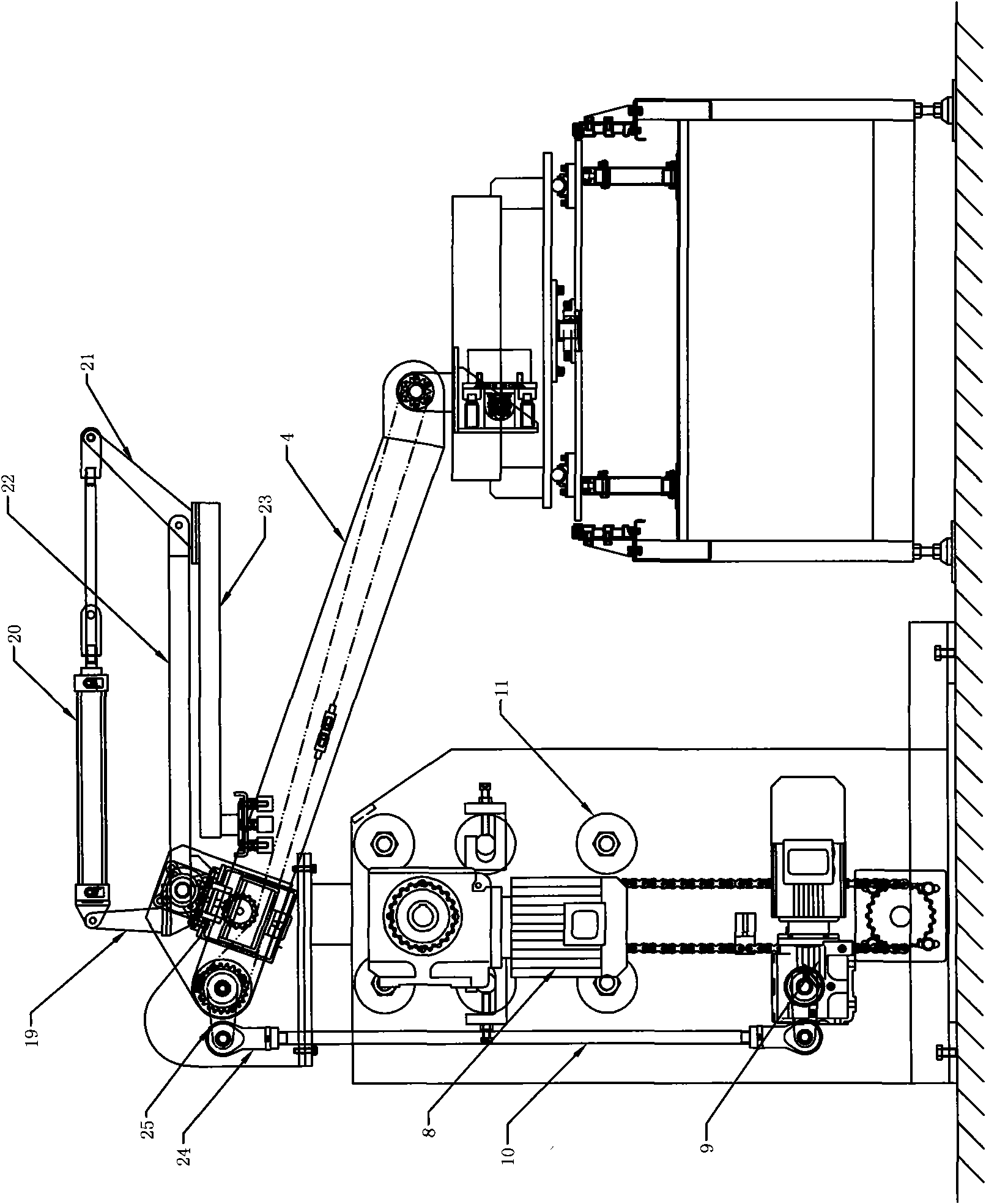

Winding machine

InactiveCN102699133AIngenious and reasonable structureImprove work efficiencyFilament handlingWinding machineControl theory

The invention relates to a winding machine. The winding machine comprises a rack, and is characterized in that a center actively fixing device is mounted at one end of the rack, a center passively moving device is mounted at the other end of the rack, and the center actively fixing device is matched with the center passively moving device so as to support and drive a H-shaped wheel. The winding machine is ingenious and reasonable in structure. The H-shaped wheel is supported and driven by matching the center actively fixing device with the center passively moving device and is time-saving and labor-saving to replace. The working efficiency can be greatly improved and the operation is safe.

Owner:WUXI PINGSHENG SCI & TECH

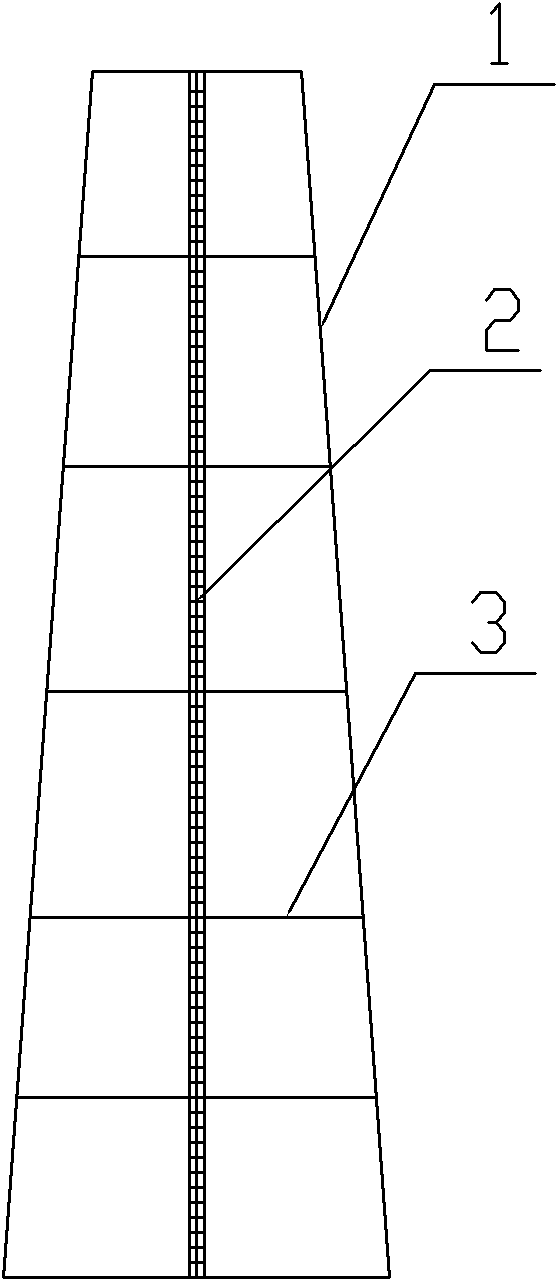

Lifting maintenance platform for wind power generator set

InactiveCN102134030AIngenious and reasonable structureEnsure safe lifting operationsElevatorsBuilding liftsAutomatic controlAutomotive engineering

The invention relates to a lifting maintenance platform for a wind power generator set. A plurality of work platforms with different heights are arranged in a tower post of the wind power generator set. The lifting maintenance platform is characterized in that: a guide rail is arranged on the inner wall of the tower post; the lifting maintenance platform can be lifted up and down along the guide rail; the top of the tower post is fixed with a speed limit safety wire rope and a traction wire rope which are drooped to the bottom; the speed limit safety wire rope is in fit connection with a safety speed limit system arranged on the top of the lifting maintenance platform; the traction wire rope is in fit connection with a traction mechanism arranged on the top of the lifting maintenance platform; the traction mechanism is provided with an overweight limit system; the safety speed limit system and the overweight limit system are controlled by an intelligent automatic control system; and the lifting maintenance platform is operated to ascend and descend under the traction effect of the traction mechanism. The lifting maintenance platform has a reasonable and ingenious structure and can provide convenience and safety insurance for installation, maintenance and repair of the tower post and power generation equipment.

Owner:博宇(无锡)科技有限公司

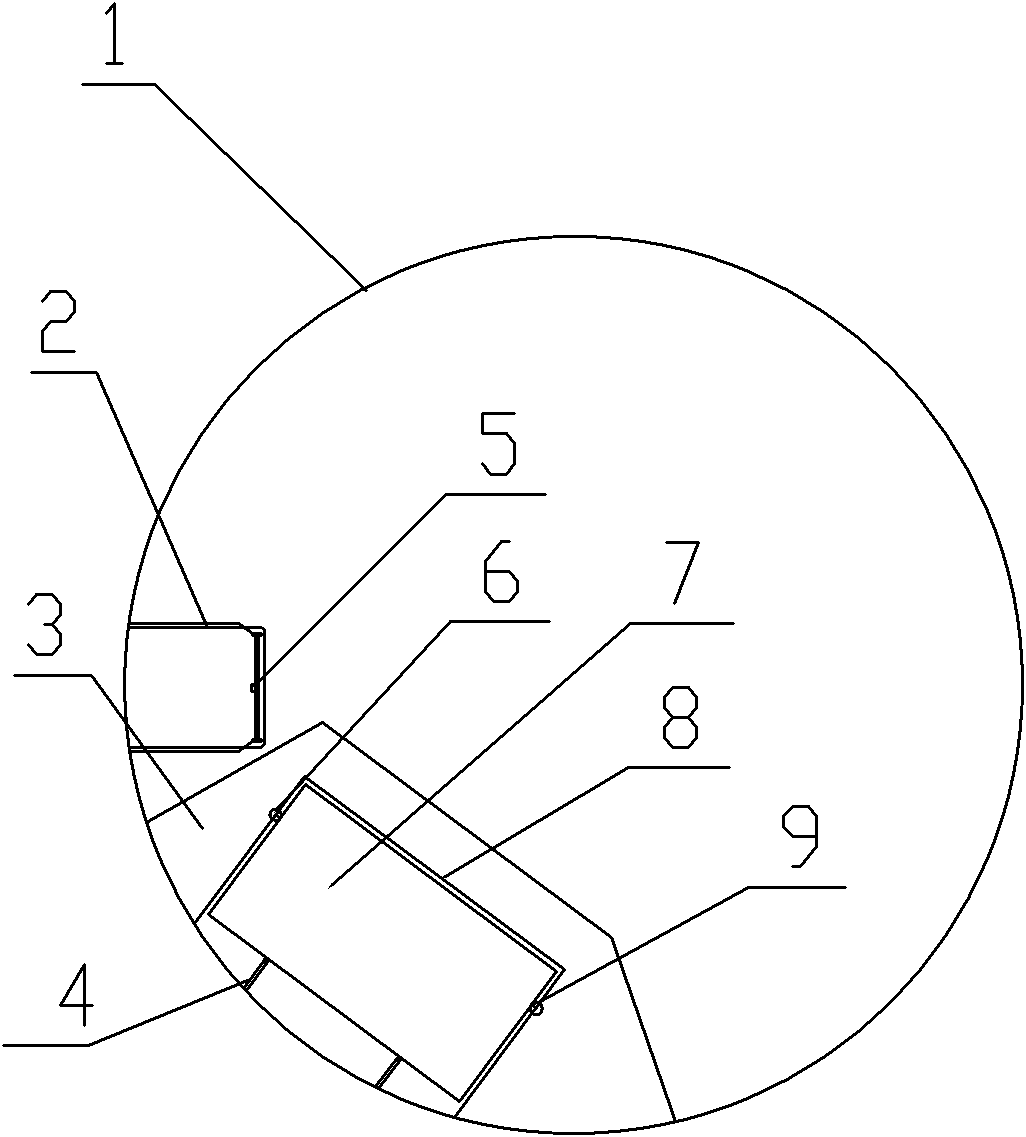

Vertical axis wind wheel connecting rod combination variable pitch wind power generation device

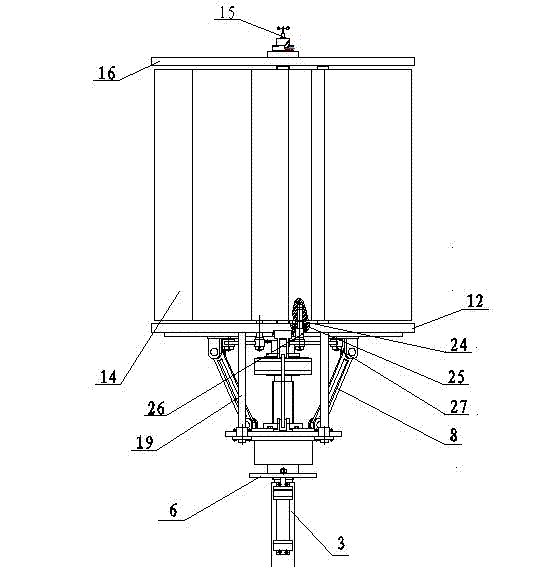

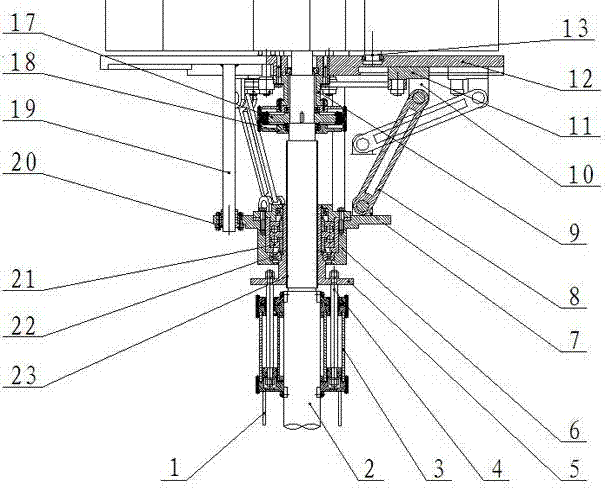

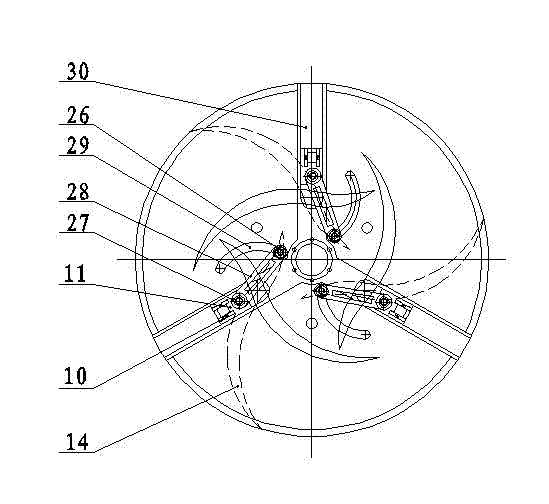

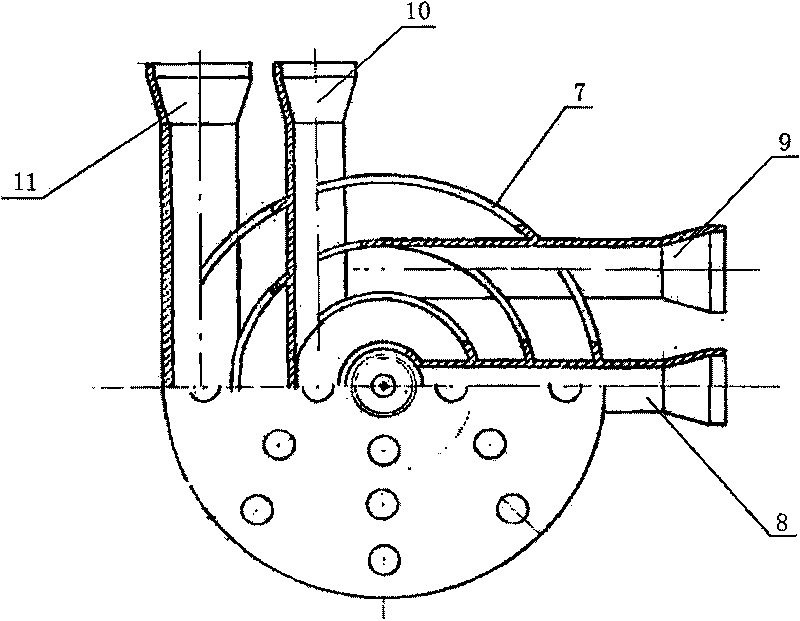

InactiveCN103089548AAdjustability of sweeping areaAdjust the sweeping areaWind motor controlWind motor combinationsBlade plateVertical axis wind turbine

The invention relates to an adjustable wind power generation device, namely a vertical axis wind wheel connecting rod combination variable pitch wind power generation device. The vertical axis wind wheel connecting rod combination variable pitch wind power generation device includes a lower support plate, an upper support plate which are sleeved on the central shaft of the wind wheel, and a wind wheel blade plate which arranged between the upper support plate and the lower support plate. A power generation rotor is fixedly connected with the lower supporting plate, and the stator is fixed on the central shaft of the wind wheel. A blade plate support shaft is arranged between the upper support plate and the lower support plate, and the wind wheel blade plate is arranged on the blade plate support shaft and rotates around the blade plate support shaft. A variable pitch system capable of adjusting the working position of the wind wheel blade plate is arranged on the central shaft of the wind wheel. The vertical axis wind wheel connecting rod combination variable pitch wind power generation device can effectively lower the rotating speed of the wind wheel, reduced the wind energy conversion rate of the vertical axis wind wheel, and achieves the overload protection for a permanent magnet generator.

Owner:HENAN UNIV OF SCI & TECH

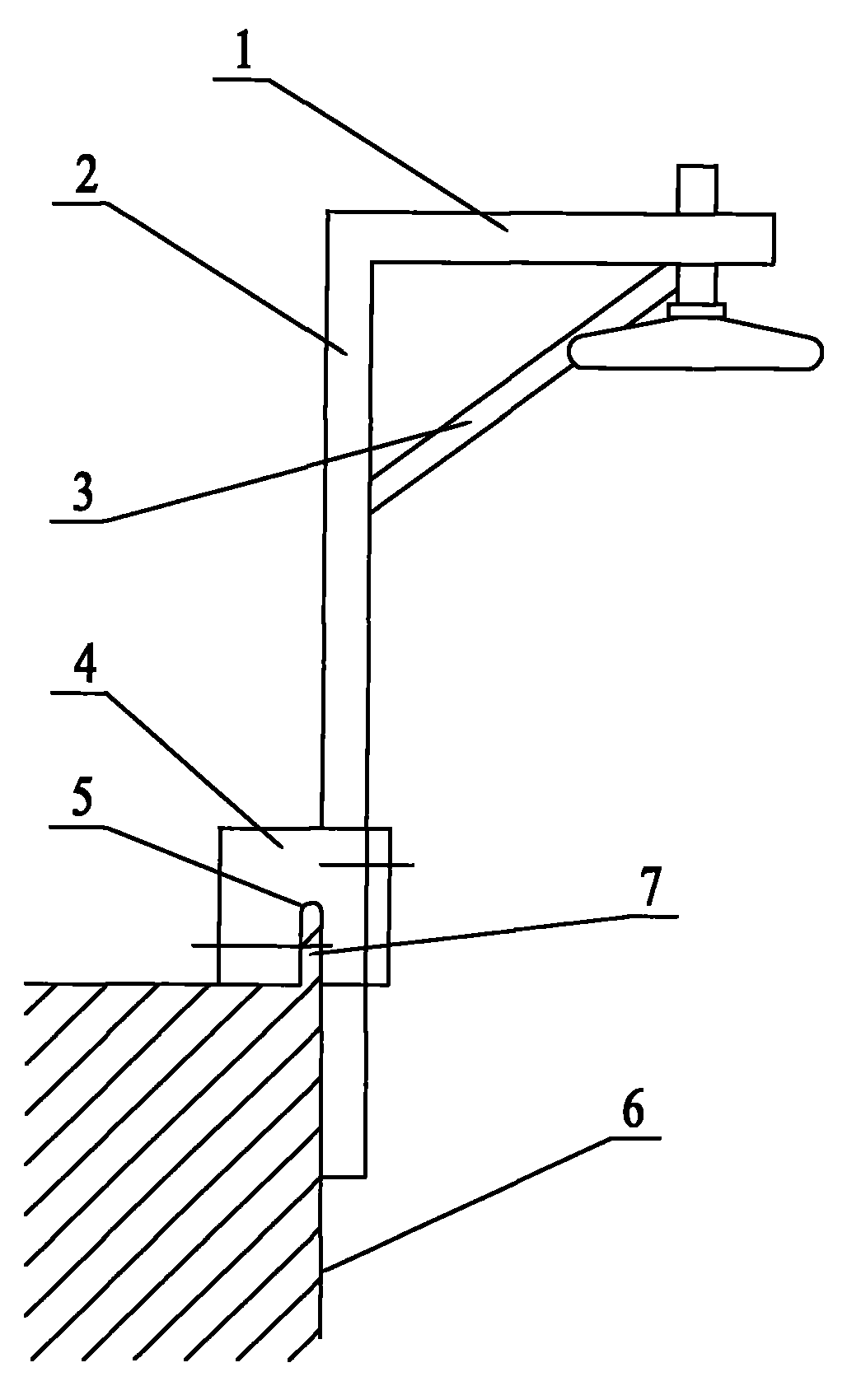

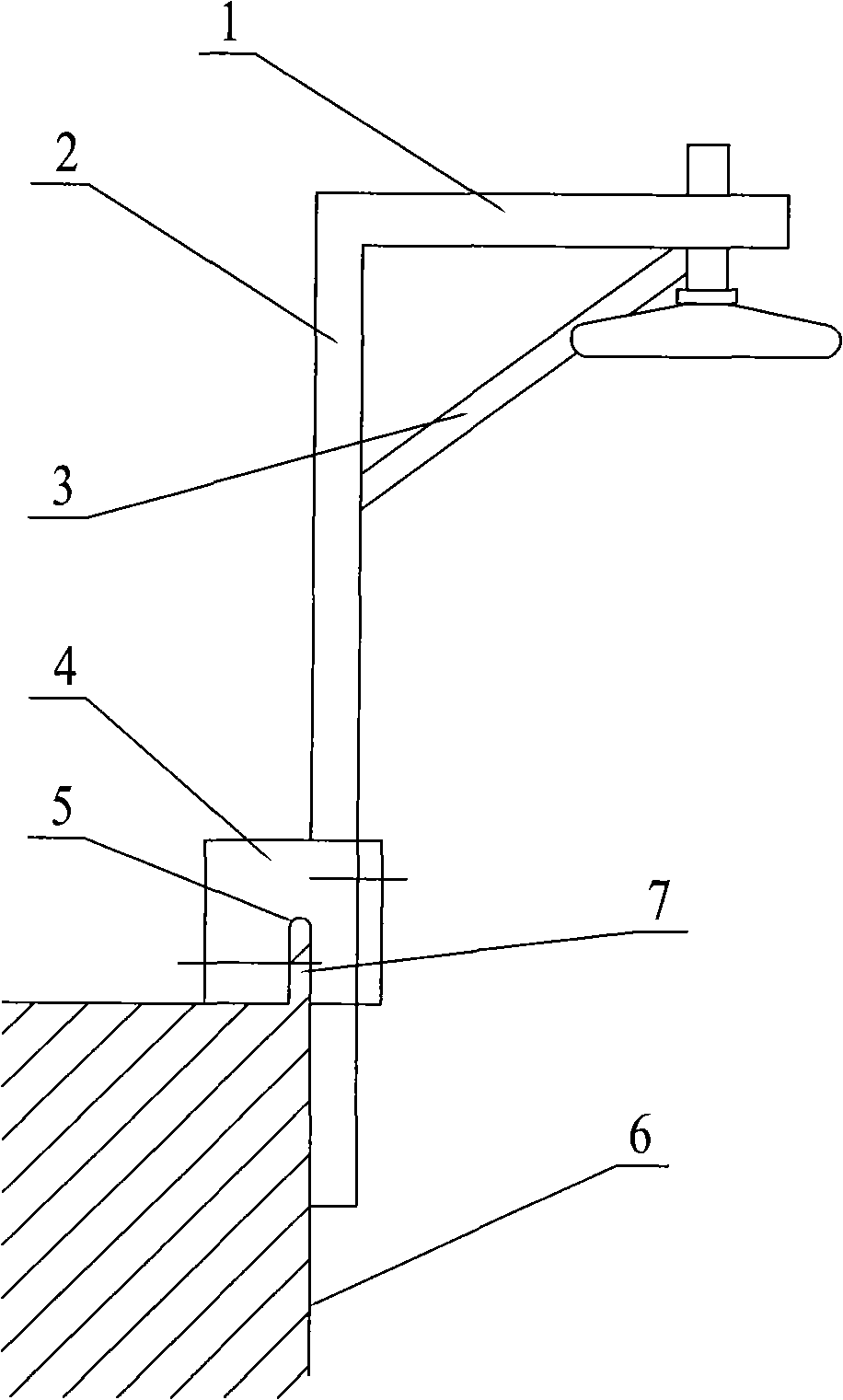

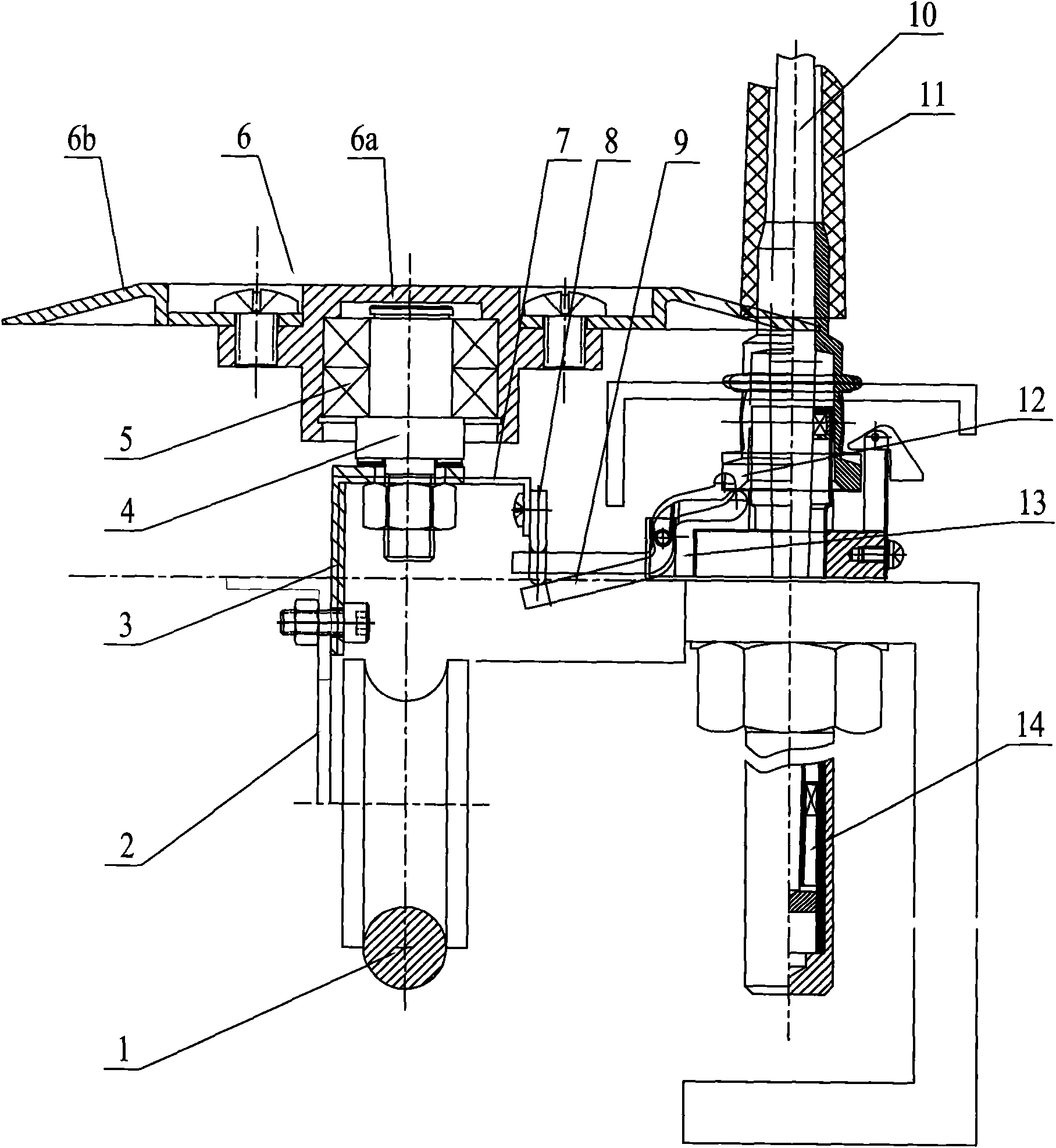

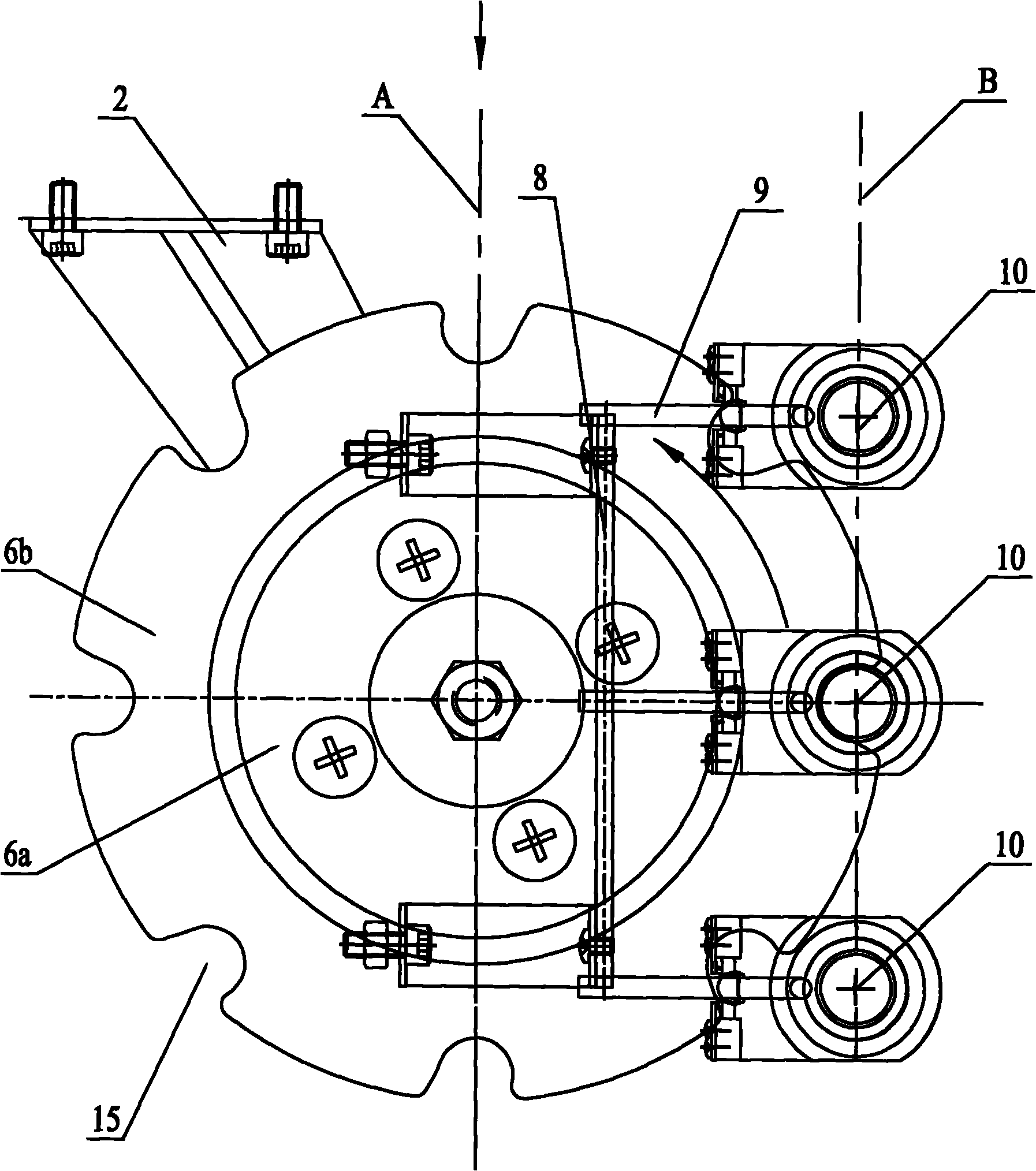

Clamp type hanging basket suspension frame

InactiveCN101812920AWon't breakIngenious and reasonable structureScaffold accessoriesBuilding support scaffoldsHull structureArchitectural engineering

The invention relates to a clamp type hanging basket suspension frame. The clamp type hanging basket suspension frame comprises a suspension frame body and a clamp; wherein the suspension frame body comprises traverse suspension frame and a vertical brace rod, the middle part of the brace rod is fixedly connected with the front end of the clamp, the lower end of the brace rod is retained on the outer wall of construction or the side plate of ship, the rear end of the clamp is provided with a bayonet, and the bayonet is used for being bulked on the guard rail of construction or ship board. The invention is reasonable and smart in structure, the suspension frame is directly clamped and fixed on the guard rail of construction or ship board by virtue of the clamp, use is convenient and flexible, lateral steel wire rope is not required for fixing, thus no lug is required to be welded and structure of construction or ship can not be destroyed. The clamp can be flexibly replaced according to condition of construction or ship, applicability is strong, and working performance is greatly improved.

Owner:WUXI COSMO SUSPENDED PLATFORM

Device for previously withdrawing bobbins of doffer

InactiveCN101818393AIngenious and reasonable structureHigh degree of automationTextiles and paperYarnBobbin

The invention relates to a device for previously withdrawing bobbins of a doffer, which is applied to a spinning machine with friction drive type spindles and friction drive type bobbins. The device comprises a doffing dolly; the doffing dolly is arranged on a guide way and can walk along the guide way; the walking route of the doffing dolly is parallel with the center connecting wires of the spindles of the spinning machine; one side of the doffing dolly, which is near to the spindle, is provided with a conical surface pre-loosing disc which can rotate around a rotating shaft through the rotating shaft; the disc plane of the conical surface pre-loosing disc is perpendicular to the length direction of the spindle; the edge of the conical surface pre-loosing disc is designed to be a conical surface; the periphery of the edge of the conical surface pre-loosing disc is evenly provided with at least three of arc gaps; the distance among the adjoining arc gaps is equal to that among the spindles; and the radiuses of the arc gaps are larger than those of the spindles and less than the those of the bottom surfaces of the bobbins. The device has ingenious and reasonable structure, has high automation degree, can withdraw the bobbins on the premise that the yarn is not damaged, and leads the spinning machine which uses a large number of the common spindles to be capable of realizing the automatic doffing.

Owner:WUXI JIJU TEXTILE TOOLS

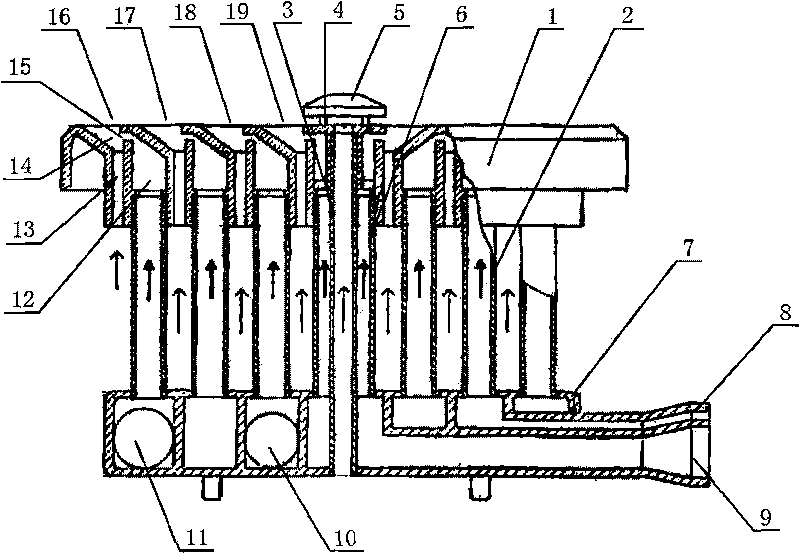

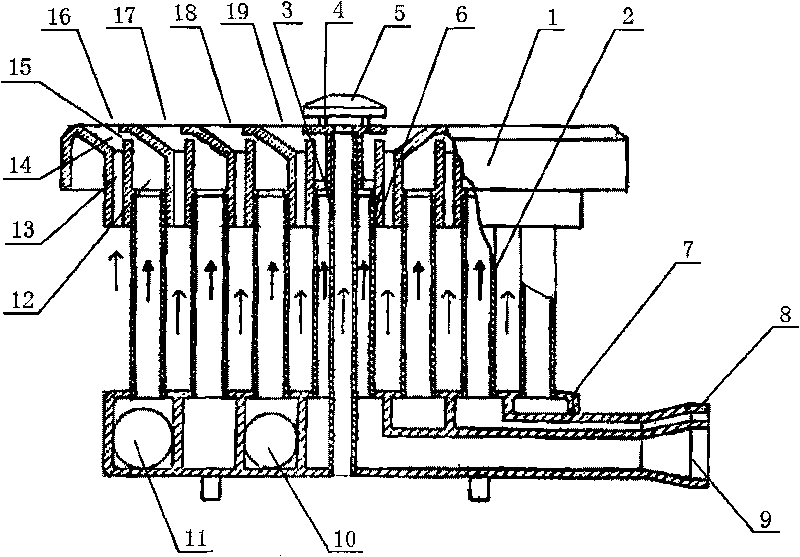

No-fan flame multilayer oxygen supply energy saving burner

The invention relates to a no-fan flame multilayer oxygen supply energy saving burner, comprising a combustion tray and a shunt, wherein the upper part of the combustion tray is successively provided with a central combustion chamber and at least one stage of external combustion chamber from center to periphery, and the lower part of the combustion tray is provided with connecting holes which are respectively and correspondingly communicated with the central combustion chamber and at least one stage of external combustion chamber; the shunt is successively provided with a central air inlet and at least one stage of external air inlet from center to periphery, the central air inlet corresponds to the connecting hole of the central combustion chamber and is connected with the connecting hole of the central combustion chamber by an air inlet sleeving; the external air inlet corresponds to the connecting holes of each stage of external combustion chamber on the combustion tray one by one and is connected with the connecting holes of each stage of external combustion chamber by a gas pipe; gas is respectively led into the central air inlet and the external air inlet by a central inlet pipe and an external inlet pipe; the center of the combustion tray is provided with a midstream ring in which an oxygen supply pipe is spliced; and the oxygen supply pipe is installed in the air inlet sleeving and downwards passes through the shunt. The invention has reasonable and artful structure, energy saving, no noise pollution, sufficient combustion and wide application range.

Owner:施央君 +1

Automatic riveting apparatus of loudspeaker U iron and basin stand

ActiveCN104967959AReduce labor difficultyReduce labor intensityElectrical transducersEngineeringMachine

The invention relates to an automatic riveting apparatus of loudspeaker U iron and a basin stand. A U iron feeding sorting mechanism is used for sequentially conveying the U iron to a positioning clamp in a U iron basin stand translation mechanism. The U iron basin stand translation mechanism is used for sending the U iron and the basin stand to a stamping position below a stamping mechanism. The stamping mechanism is used for riveting the U iron and the basin stand together, wherein the U iron and the basin stand are sent to the stamping position. A finished product charging conduit is installed on a machine stand. A feed inlet of the finished product charging conduit is located in front of the stamping position of the stamping mechanism. A finished product material pushing mechanism is arranged right behind the stamping position of the stamping mechanism. The finished product material pushing mechanism is used for pushing the U iron and the basin stand which form interference riveting into the feed inlet of the finished product charging conduit. The structure is ingenious and reasonable. The basin stand and the U iron can be automatically stamped and riveted according to a program. Labor difficulty and intensity of operation personnel are effectively reduced. An assembling qualified rate and production efficiency are increased. An injury risk of operator hands below a stamping head is avoided.

Owner:WUXI JIEFU ELECTROACOUSTIC

Manhole cover which is resistant to theft, noise, sedimentation and reverse gushing and opened in hidden mode

InactiveCN106065632AImprove the anti-theft effectImprove concealmentArtificial islandsUnderwater structuresRubber ringArchitectural engineering

The invention relates to the technical field of construction engineering pipelines. A manhole cover is composed of a manhole cover body, a base, pawls, cover opening ejector rods, elliptical reverse thread locking heads, unlocking opening reverse thread rods and the like. A trapezoid stopping ring on the bottom surface of the manhole cover body is sleeved with a pressure-proof rubber ring for preventing noise. When the manhole cover body is installed and placed on the base, the pawls are pressed down by the trapezoid stopping ring, and elastic force of ejector rod springs is transmitted to the pawls through levers and pawl connection rods to abut against and lock the trapezoid stopping ring so that an antitheft effect can be achieved. When the manhole cover body is opened, reverse thread pressure proof rubber plugs, gib headed keys and the elliptical reverse thread locking heads are taken out, the unlocking opening reverse thread rods are screwed into elliptical reverse thread locking holes, conical funnels and conical ejector rods are sleeved and connected, the levers are pushed, and the pawls are receded and unlocked through the pawl connection rods; and at the moment, the levers are just jacked to the upper ends of long-strip-shaped opening unlocking holes, and the manhole cover body is opened in a hidden mode by the pushing force of the unlocking opening reverse thread rods through the levers and the cover opening ejector rods. The contact surface between the manhole cover and a road is increased in a multilayer mode through a pawl mechanism box, a pressure-proof rubber ring flange face and a pavement flange face so that sedimentation can be prevented.

Owner:温兴亮

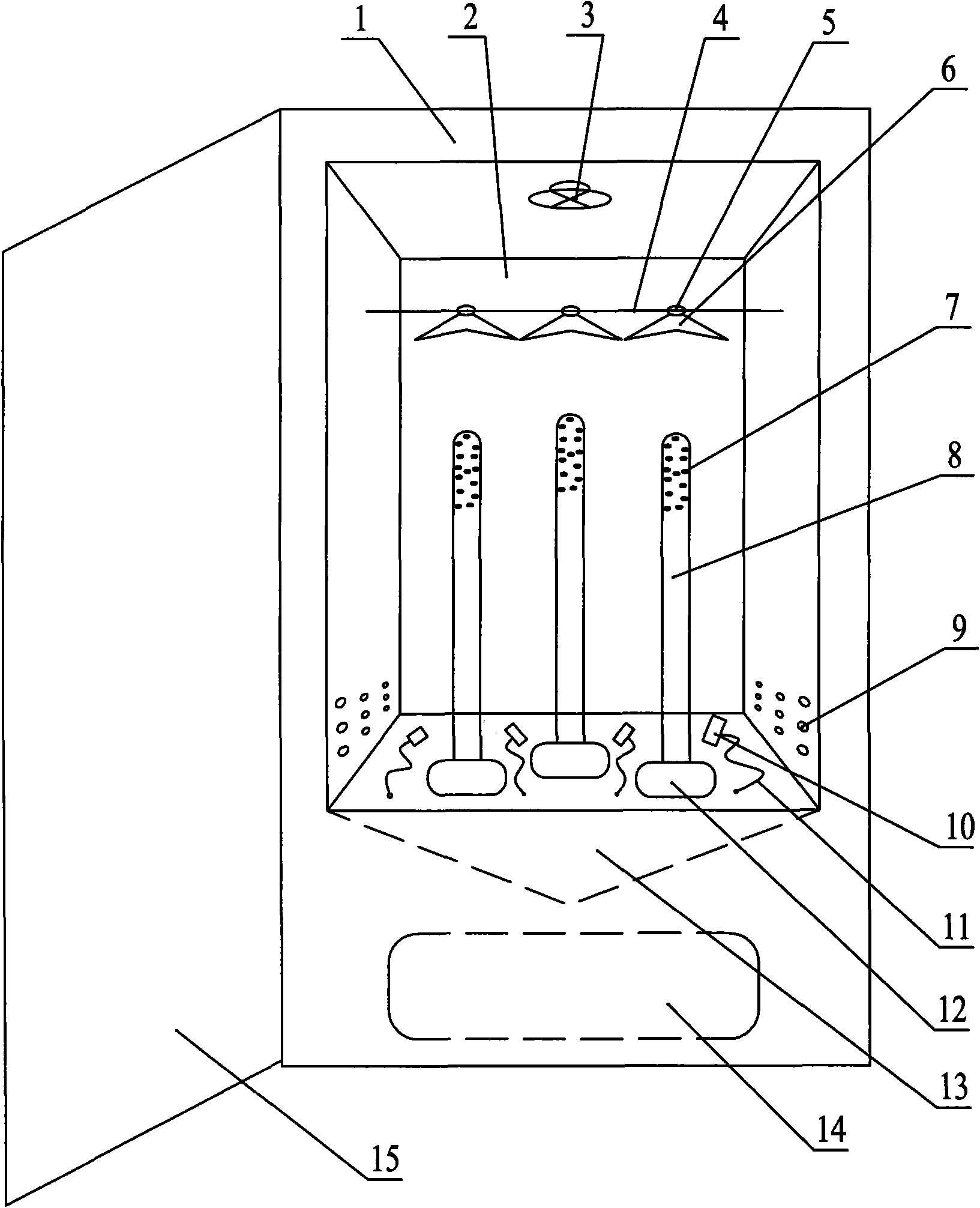

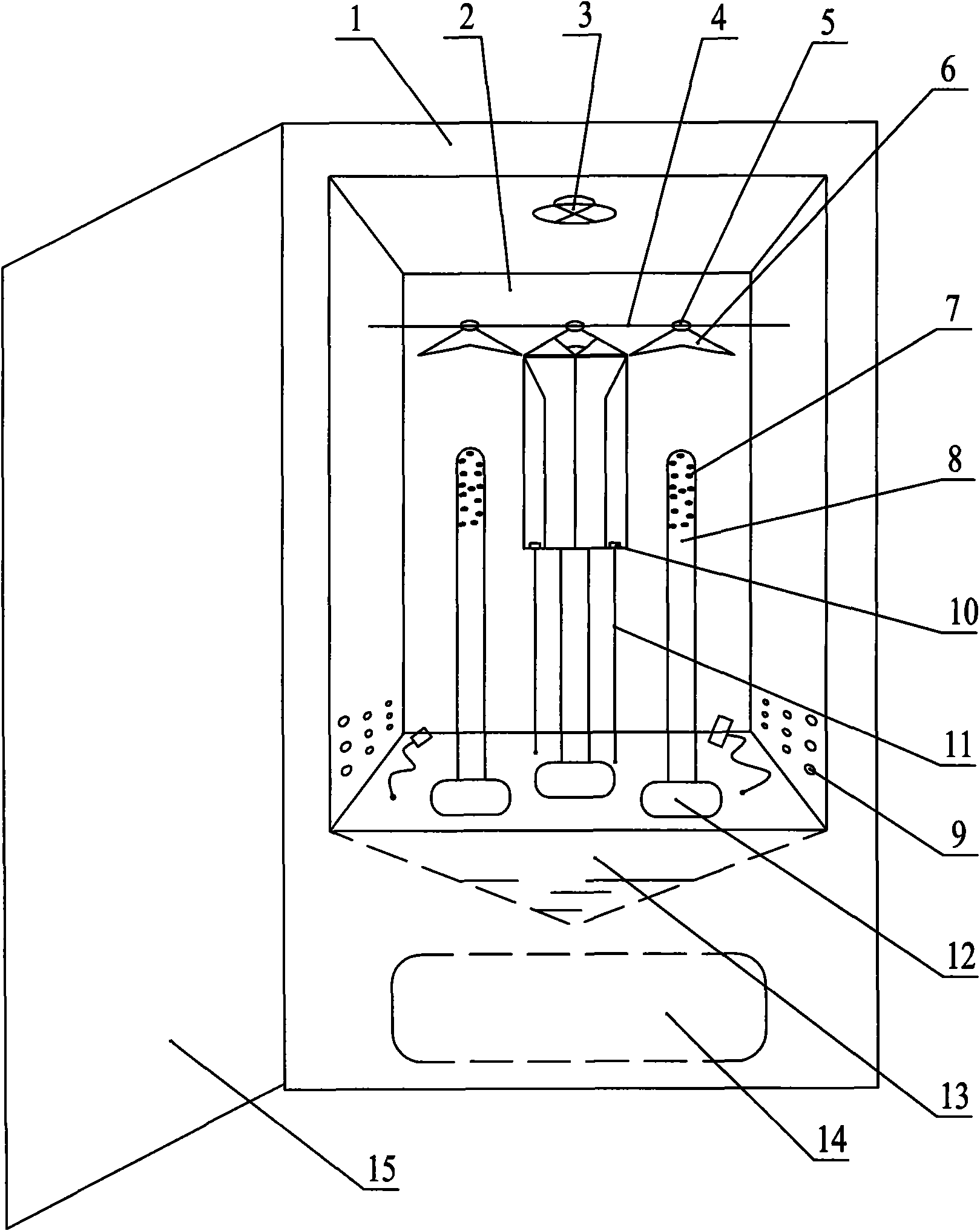

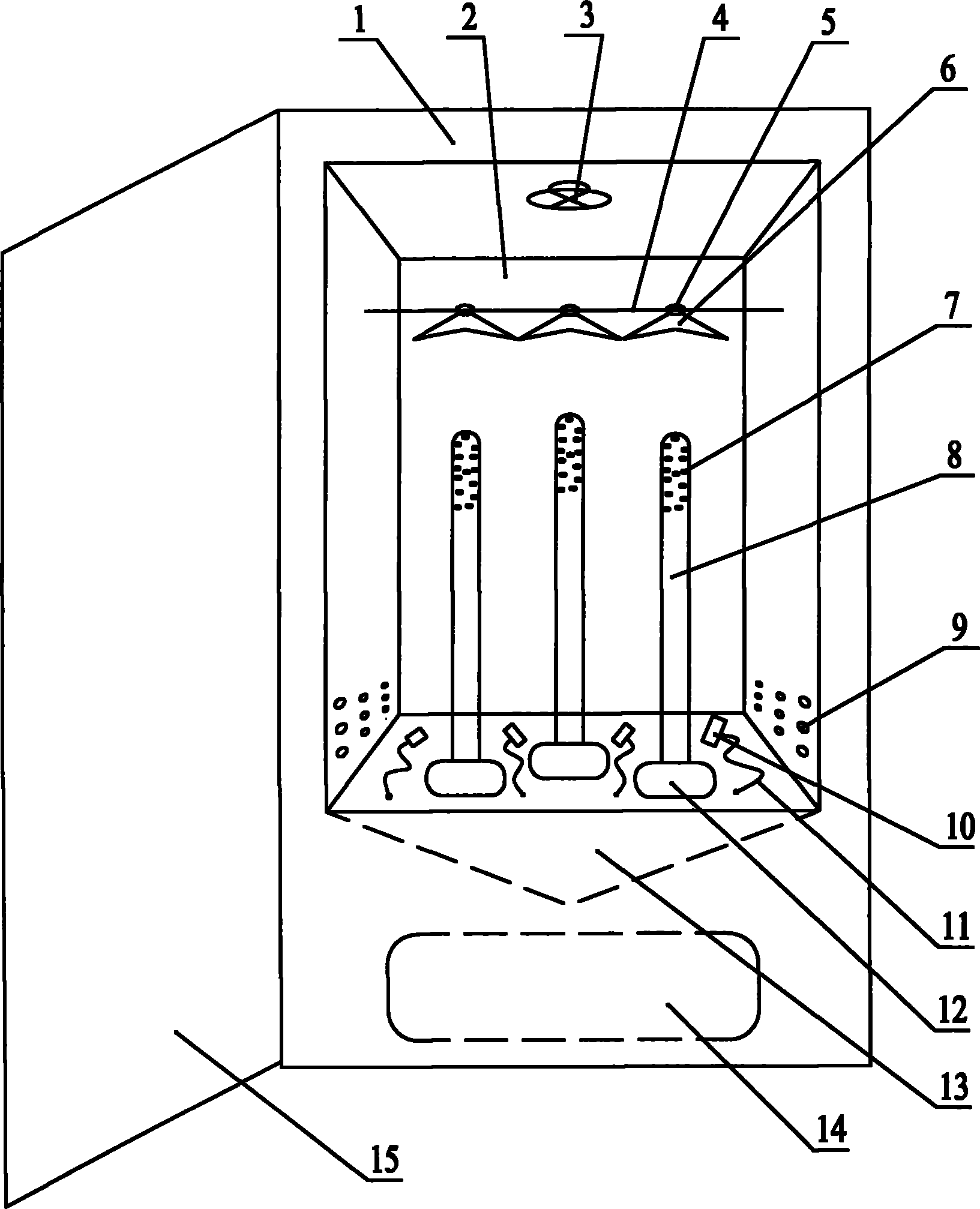

Steam washing machine with hanging-type clothes hanger

InactiveCN101838899AIngenious and reasonable structureImprove washabilityOther washing machinesWashing machine with receptaclesClothes hangerAutomation

The invention relates to a steam washing machine with a hanging-type clothes hanger. According to the technical scheme provided by the invention, the steam washing machine with the hanging-type clothes hanger comprises a box body, wherein a steam generator is arranged in the bottom of the box body, a washing room used for accommodating clothes is arranged in the box body, and outer jet holes are arranged on the wall of the washing room, communicated with the steam generator and used for spraying steam into the box body. The steam washing machine is characterized in that a hanging rod is arranged at the upper part of the washing room, and at least one clothes hanger is arranged on the hanging rod; at least one jet cylinder with hollow interior is vertically arranged at the bottom of the washing room, the jet cylinders are arranged under the clothes hangers and are in one-to-one correspondence with the clothes hangers, the lower ends of the jet cylinders are communicated with the steam generator, and inner jet holes are densely distributed all over the body of the upper part of the steam spray cylinder. The invention has smart and reasonable structure, high automation degree and favorable washing effect and can realize soft washing and reduce the wear damage to clothes by a large extent.

Owner:丁晔

Material bagging apparatus provided with stirring mechanism

InactiveCN102633001AIngenious and reasonable structureWell mixedSolid materialAgricultural engineeringProcess engineering

The invention relates to a material bagging apparatus provided with a stirring mechanism, which comprises a feeding box body, a bag clamping box body, the stirring mechanism, a box body opening and closing mechanism and a bag clamping mechanism, wherein a feed hole is arranged at one side of the feeding box body; and a cover plate is arranged on the top of the feeding box body; the bag clamping box body is connected and fixed under the feeding box body; the bag clamping box body is communicated with the interior of the feeding box body; a discharge hole is arranged at the lower end of the bag clamping box body; the stirring mechanism is used for stirring materials in the feeding box body and the bag clamping box body; the bag clamping mechanism is used for clamping a packaging bag sheathed at a discharge hole of the bag clamping box body, so that the material can be conveniently bagged; and the box body opening and closing mechanism is used for blocking the discharge hole of the bag clamping box body when the material is stirred and opening the discharge hole of the bag clamping box body when the material is bagged. The material bagging apparatus integrates the two functions of stirring and bagging the material, and an automatic quantitative fertilizer preparation device is more compact in structure, so that the height of the fertilizer preparation device is greatly reduced, the material is evenly mixed, and the production cost is greatly lowered.

Owner:WUXI NAITE ELECTROMECHANICAL INTEGRATING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com