Device for previously withdrawing bobbins of doffer

A technology of pre-drawing tubes and doffing machines, which is applied in the direction of textiles and papermaking, can solve the problems of high cost of use and inapplicability, and achieve the effects of high degree of automation, convenient replacement, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the specific drawings and embodiments.

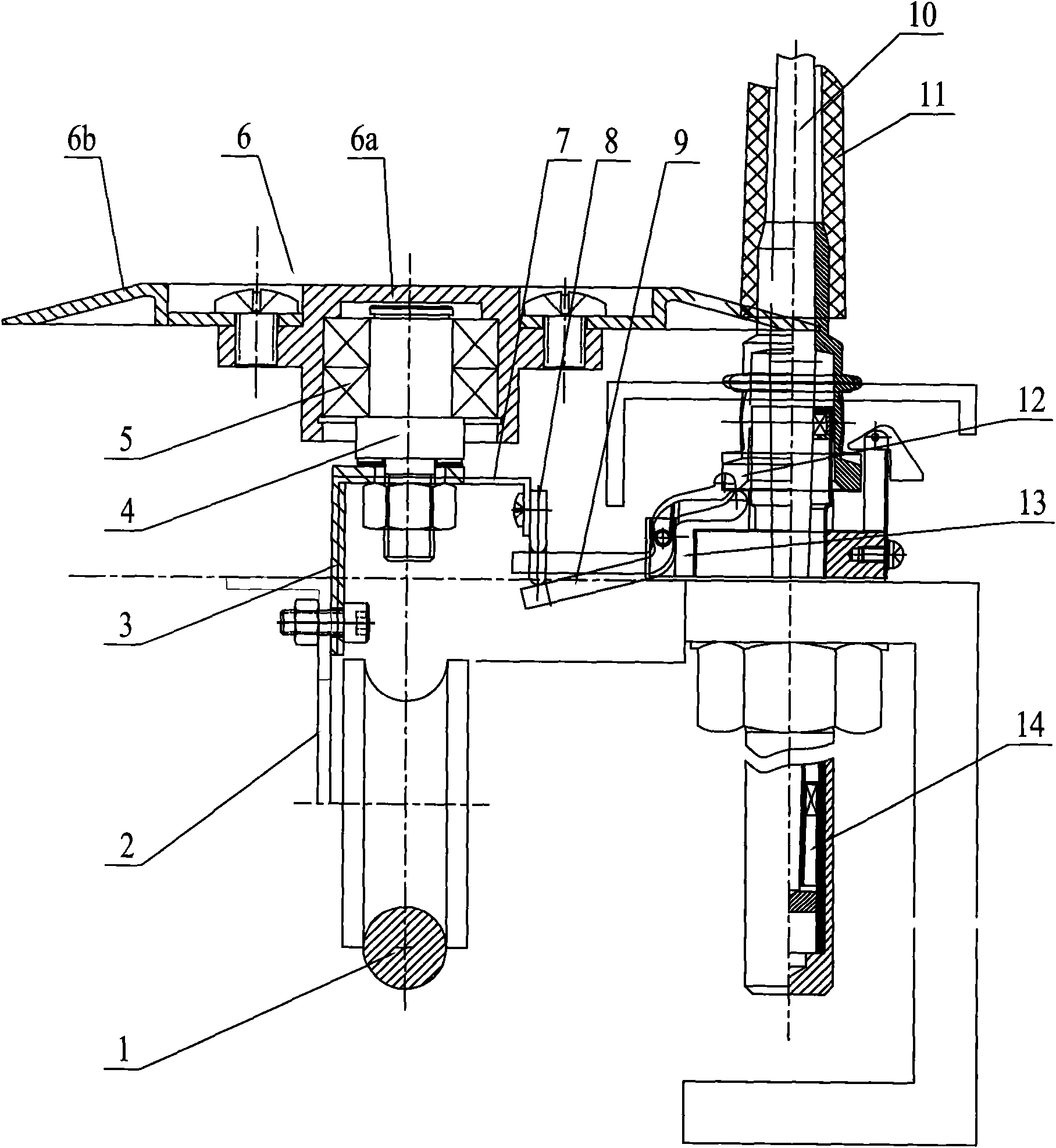

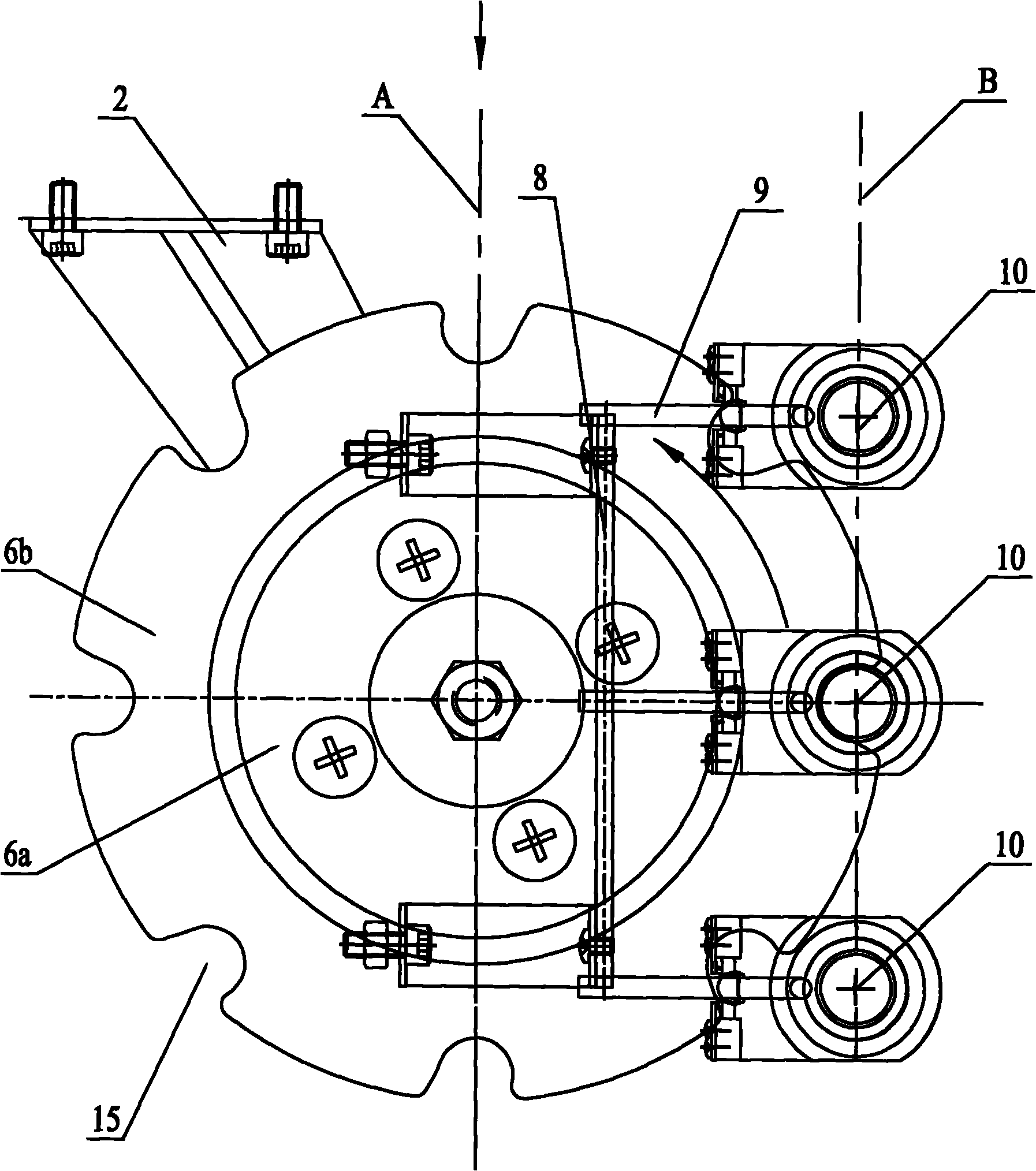

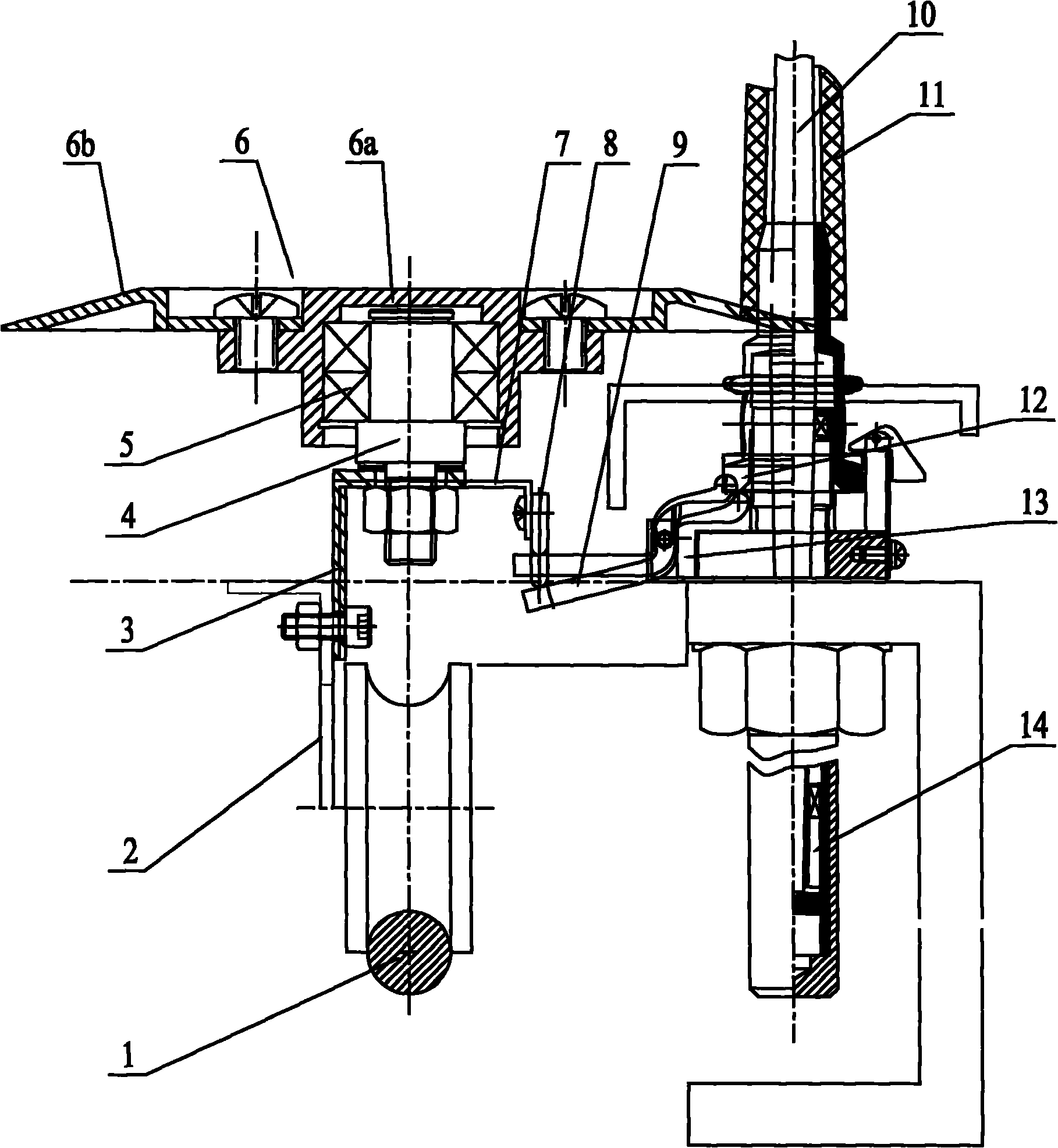

[0018] like figure 1 , figure 2 Shown: the present invention is mainly applied to the spinning frame in which the spindle 10 and the bobbin 11 are friction drive. The pre-extraction device is mainly composed of a doffing trolley 2 and a conical surface pre-loosening disc 6 installed on it; the doffing trolley 2 is placed on the guide rail 1 and can walk along the guide rail 1, and the doffing trolley 2 travels the route A Parallel to the center line B of the spinning frame spindle 10; the side of the doffing trolley 2 close to the spindle 10 is fixed with a mounting frame 3 by bolts, and a rotating shaft 4 is vertically fixed on the mounting frame 3, and the rotating shaft 4 passes through the The bolts are tightened and fixed; the conical surface pre-loosening disc 6 is installed on the rotating shaft 4 through the bearing 5, the disc plane of the conical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com