Patents

Literature

71results about How to "Reduce labor difficulty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

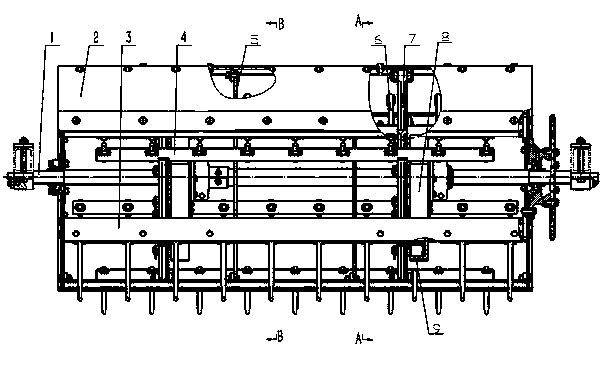

Automatic adhesive sticking machine of flexible packaged lithium battery

ActiveCN102593521ARealize automatic feedingIncrease productivityFinal product manufactureElectrolyte accumulators manufactureAdhesiveEngineering

The invention relates to an automatic adhesive sticking machine of a flexible packaged lithium battery. The automatic adhesive sticking machine comprises a workbench arranged on a frame, wherein a conveyer chain is arranged on the workbench, a clamp for clamping the battery to be adhesive-stuck is arranged on the conveyer chain, and a driving mechanism for driving the clamp to open and close is arranged on the workbench; and a conveying mechanism for conveying the battery to be adhesive-stuck to the clamp, a cutting mechanism for cutting aluminum-plastic film surplus edge on the adhesive sticking side of the battery to be adhesive-stuck, a rubber belt conveying mechanism, an adhesive sticking mechanism for sticking an adhesive tape to the aluminum plastic film of the battery, an adhesive bending mechanism for bending the adhesive tape stuck on the battery, a base material tearing mechanism for tearing off the base material of double-sided glue of the adhesive tape, a folding mechanism for folding the adhesive tape and a product discharging mechanism are sequentially arranged on the workbench, and the mechanisms are respectively connected with a master control circuit. The adhesive sticking machine realizes automatic conveying, cutting, adhesive sticking, adhesive bending, folding and discharge of the battery, greatly improves the production efficiency and the adhesive-stuck battery quality, and reduces the labor difficulty and intensity.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

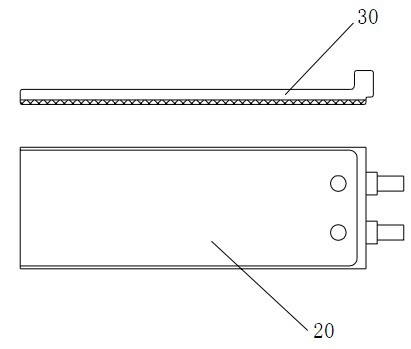

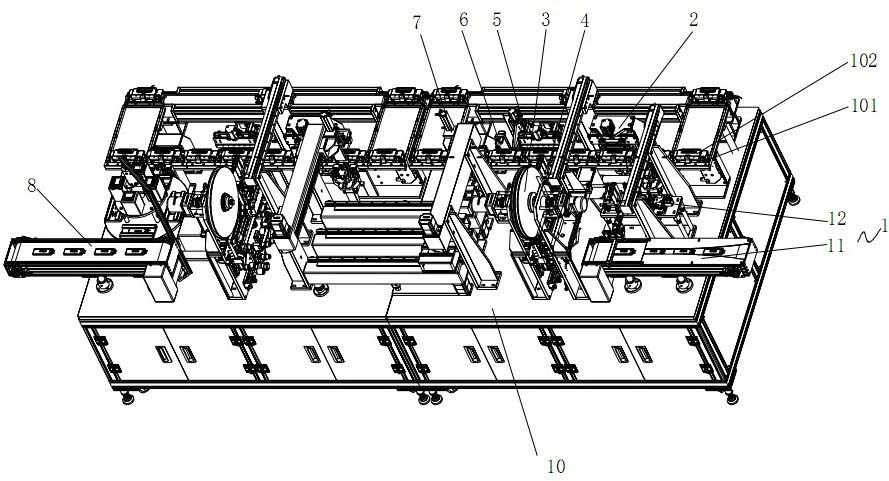

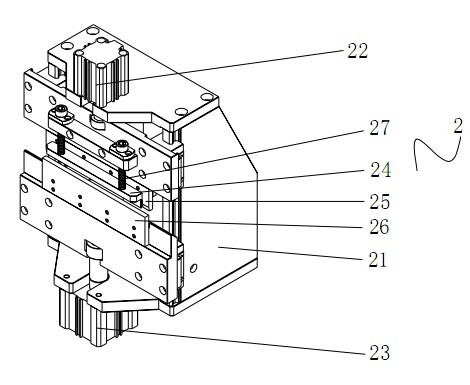

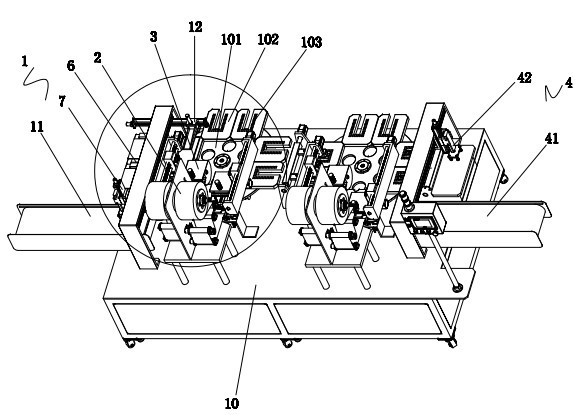

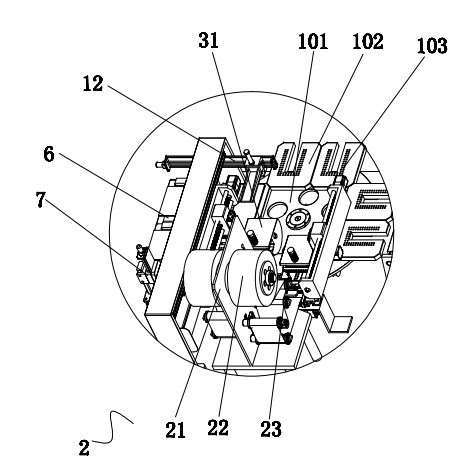

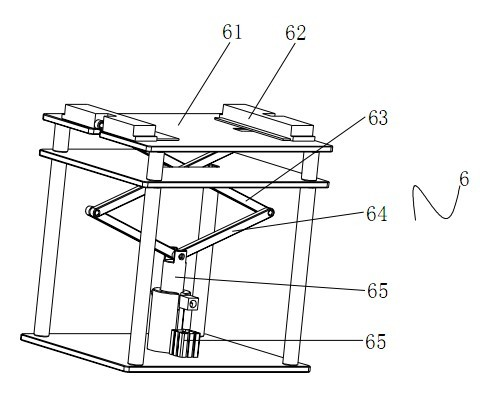

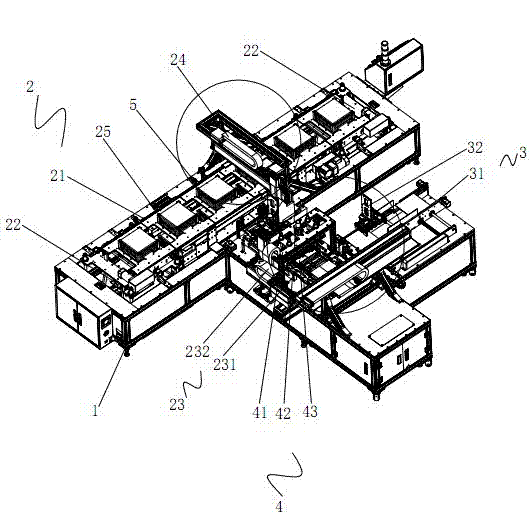

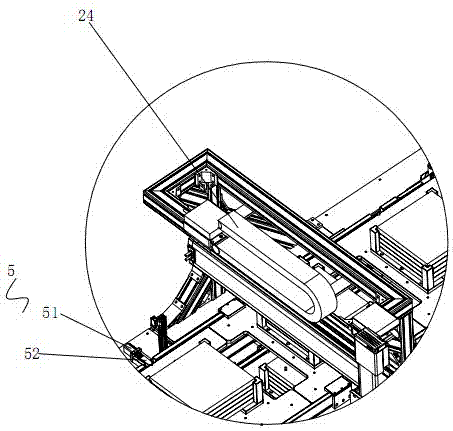

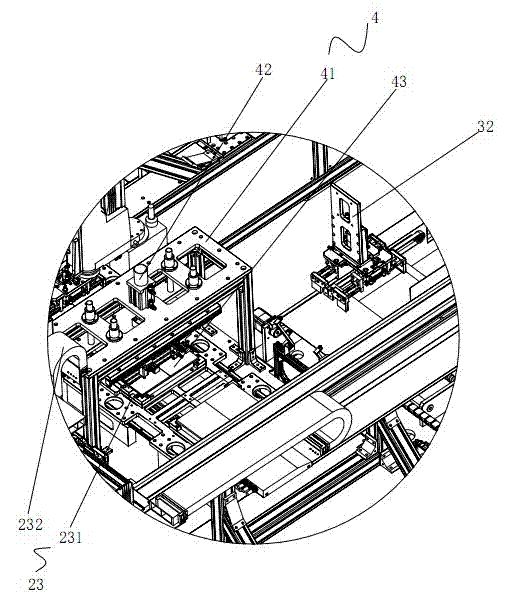

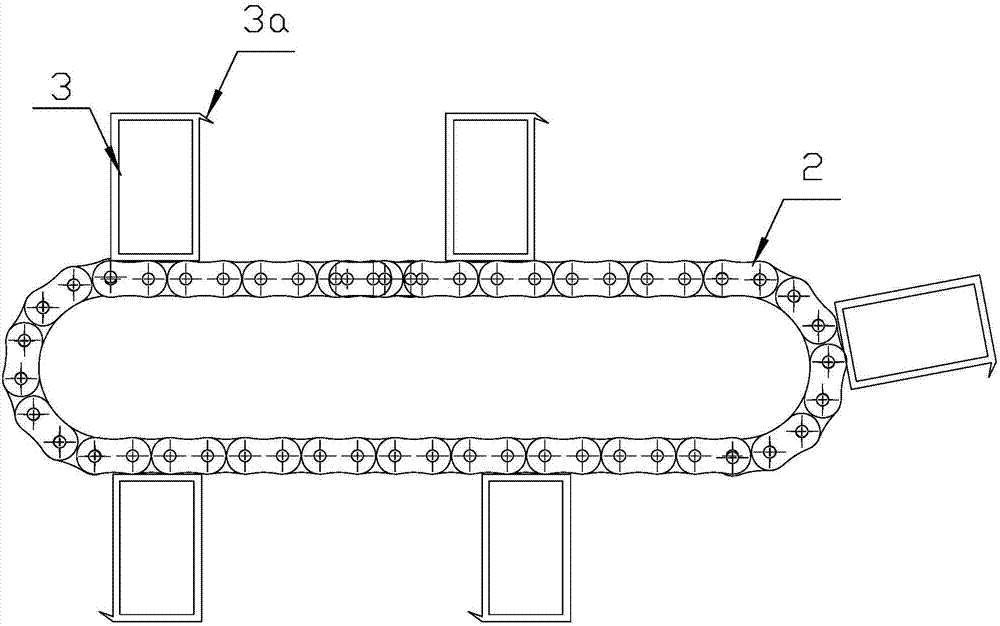

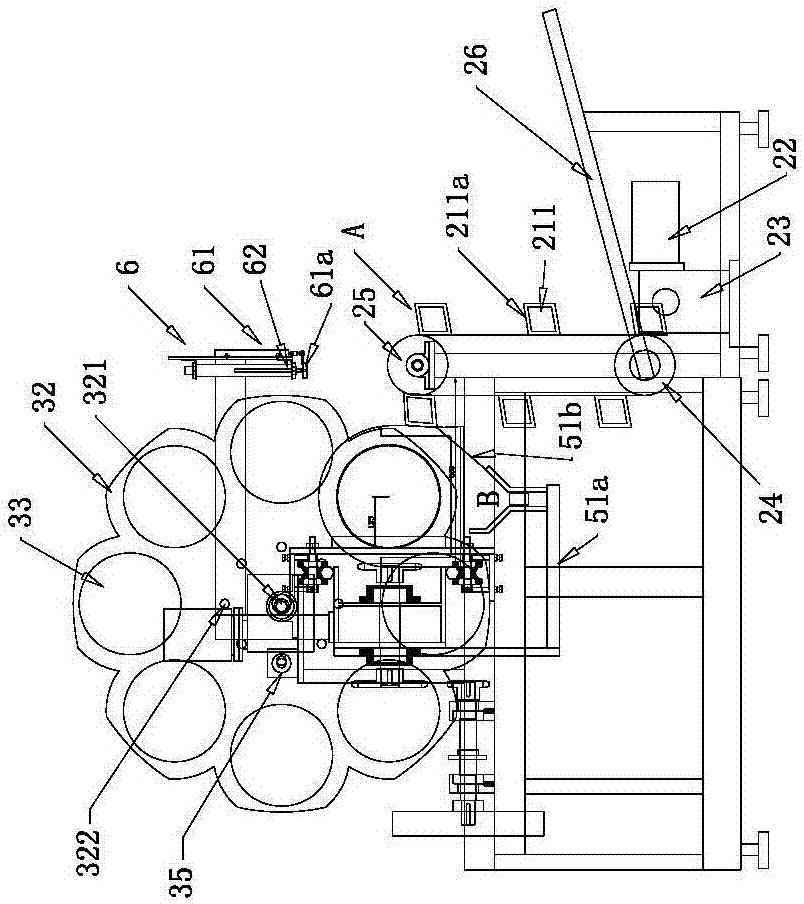

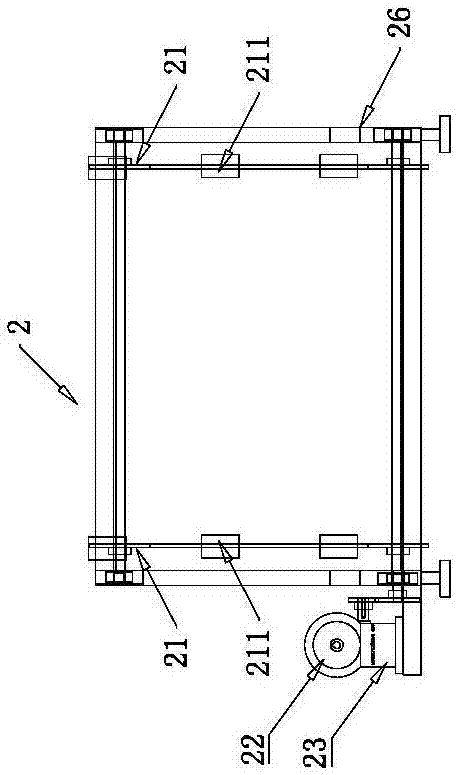

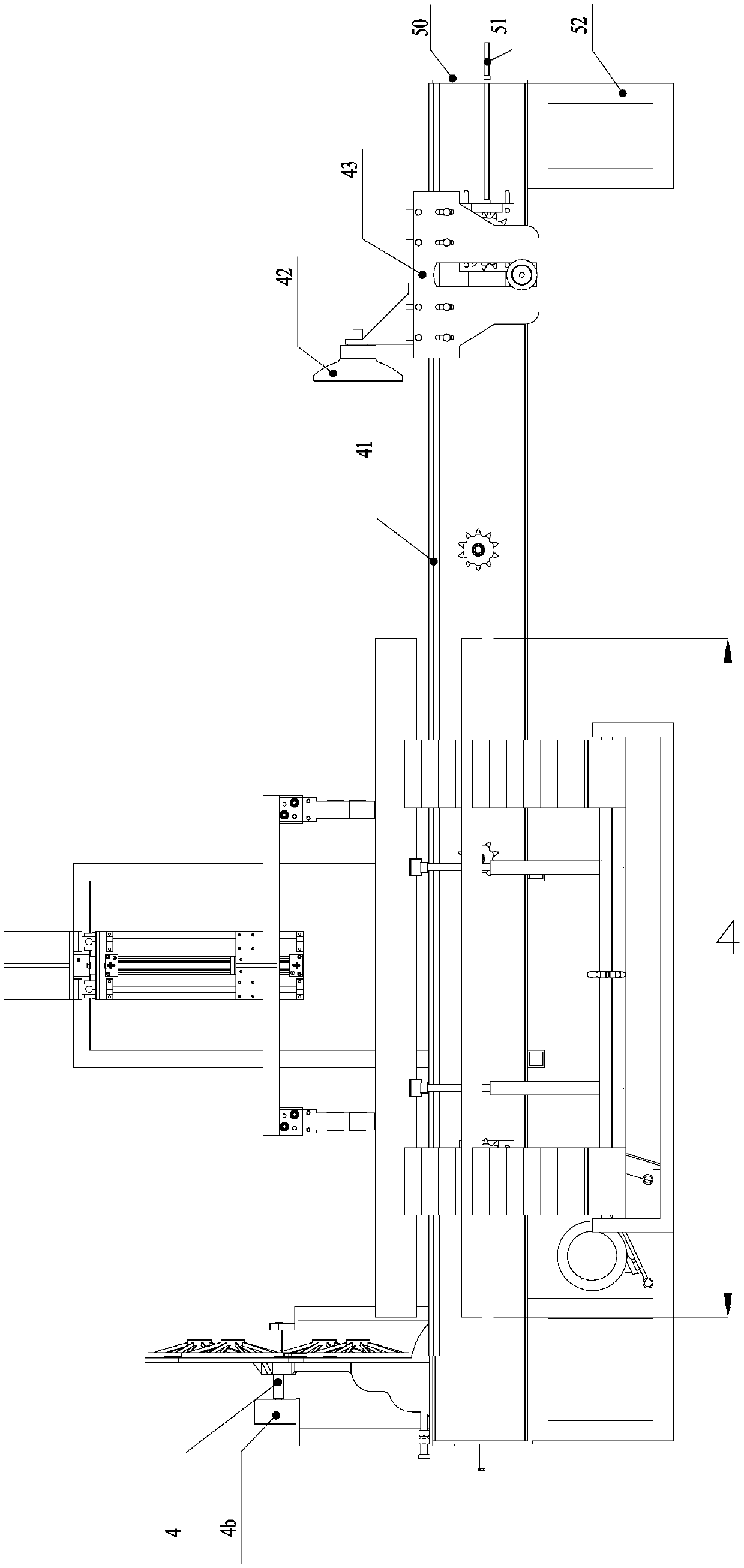

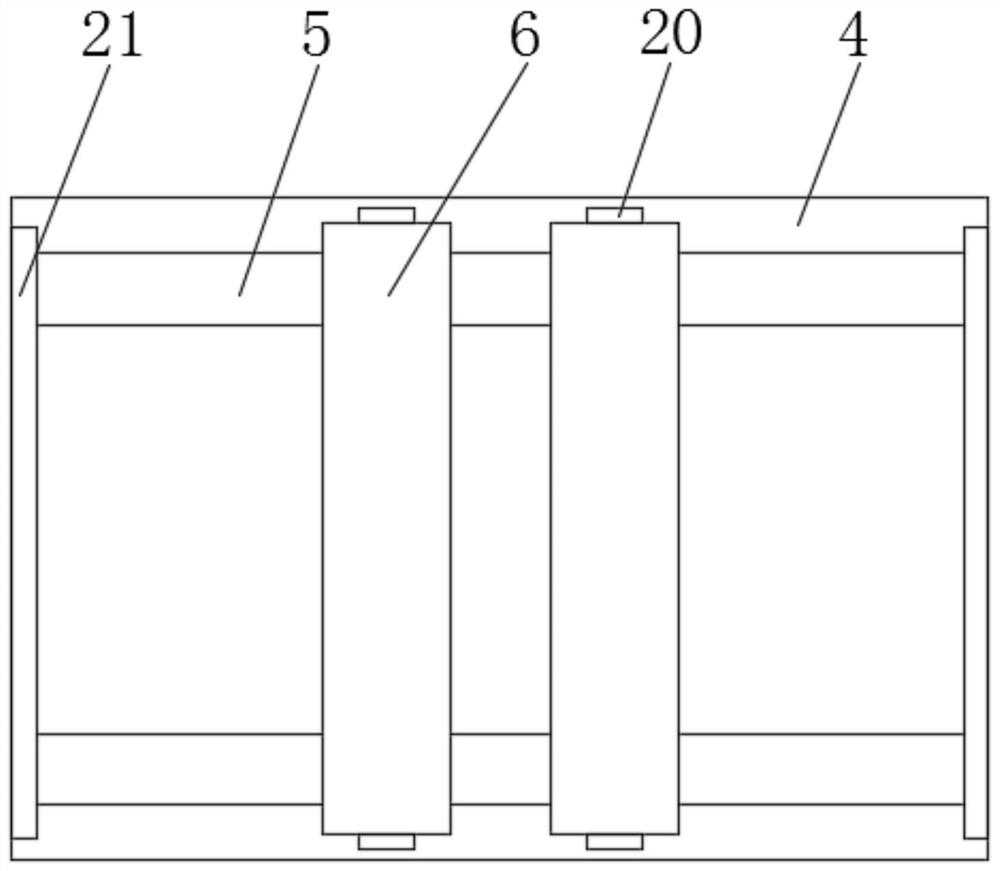

Automatic laminator for flexible-package lithium battery

ActiveCN102582193ARealize automatic feedingQuality improvementLamination ancillary operationsFinal product manufactureElectrical batteryEngineering

The invention relates to an automatic laminator for a flexible-package lithium battery. The automatic laminator comprises a working table and a rotary plate arranged on the working table. A clamp for sucking a battery is arranged on the rotary plate; a battery feeding mechanism for conveying batteries to be laminated to the clamp, a membrane belt feeding mechanism for conveying membrane belts, a lamination mechanism for adhering the membrane belts to the surface of the battery and a battery discharging mechanism are arranged on the working table in sequence. And the mechanisms are respectively connected with a main control circuit. According to the laminator provided by the invention, the battery feeding mechanism, the membrane belt feeding mechanism, the lamination mechanism and the battery discharging mechanism are arranged on the working table in sequence, and are respectively connected with the main control circuit, so that the batteries are automatically fed, laminated and discharged, the production efficiency and the laminated battery quality can be greatly improved, and the labor difficulty and the labor intensity can be reduced.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

Automatic assembly machine of bottom shell of LED (light-emitting diode) module

InactiveCN102371481ARealize the assemblyConveying many productsMetal working apparatusEngineeringUltimate tensile strength

The invention relates to an automatic assembly machine of a bottom shell of an LED (light-emitting diode) module. The machine comprises a frame and an assembly mechanism, wherein the assembly mechanism is arranged on the frame and used for pressing a PCB (printed circuit board) into the bottom shell, a bottom shell feeding mechanism for conveying the bottom shell to an assembly working position is arranged on one side of the assembly mechanism on the frame, a PCB feeding mechanism for conveying the PCB to the assembly working position is arranged on the other side of the assembly mechanism onthe frame, and each mechanism is respectively connected with a master control circuit. The automatic assembly machine of the bottom shell of the LED module can realize automatic feeding and assembly of the bottom shell and the PCB products, greatly improve the production efficiency and the quality of the assembled products and reduce the labor difficulty and the intensity.

Owner:周俊雄

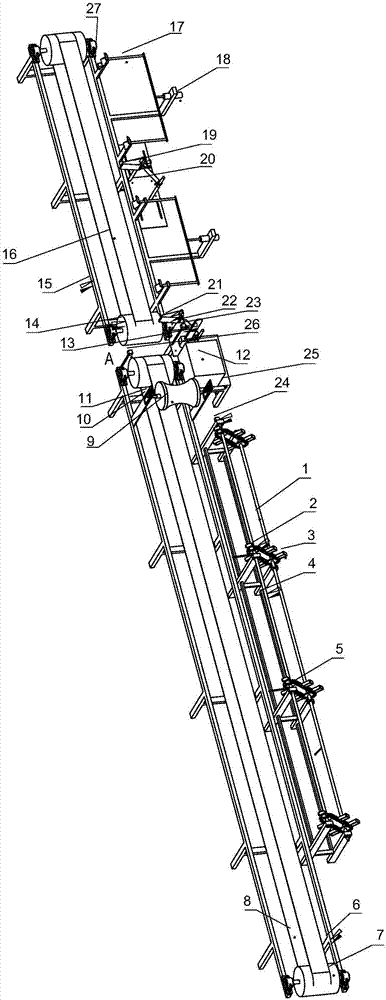

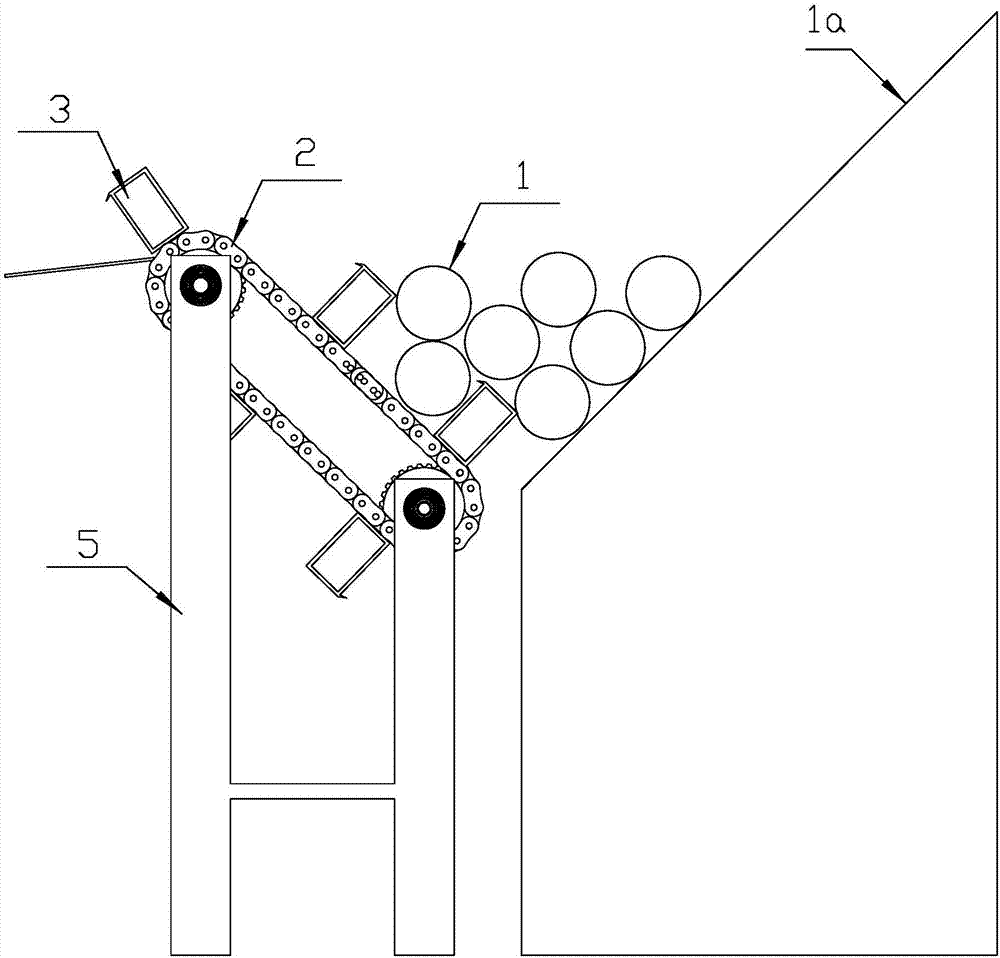

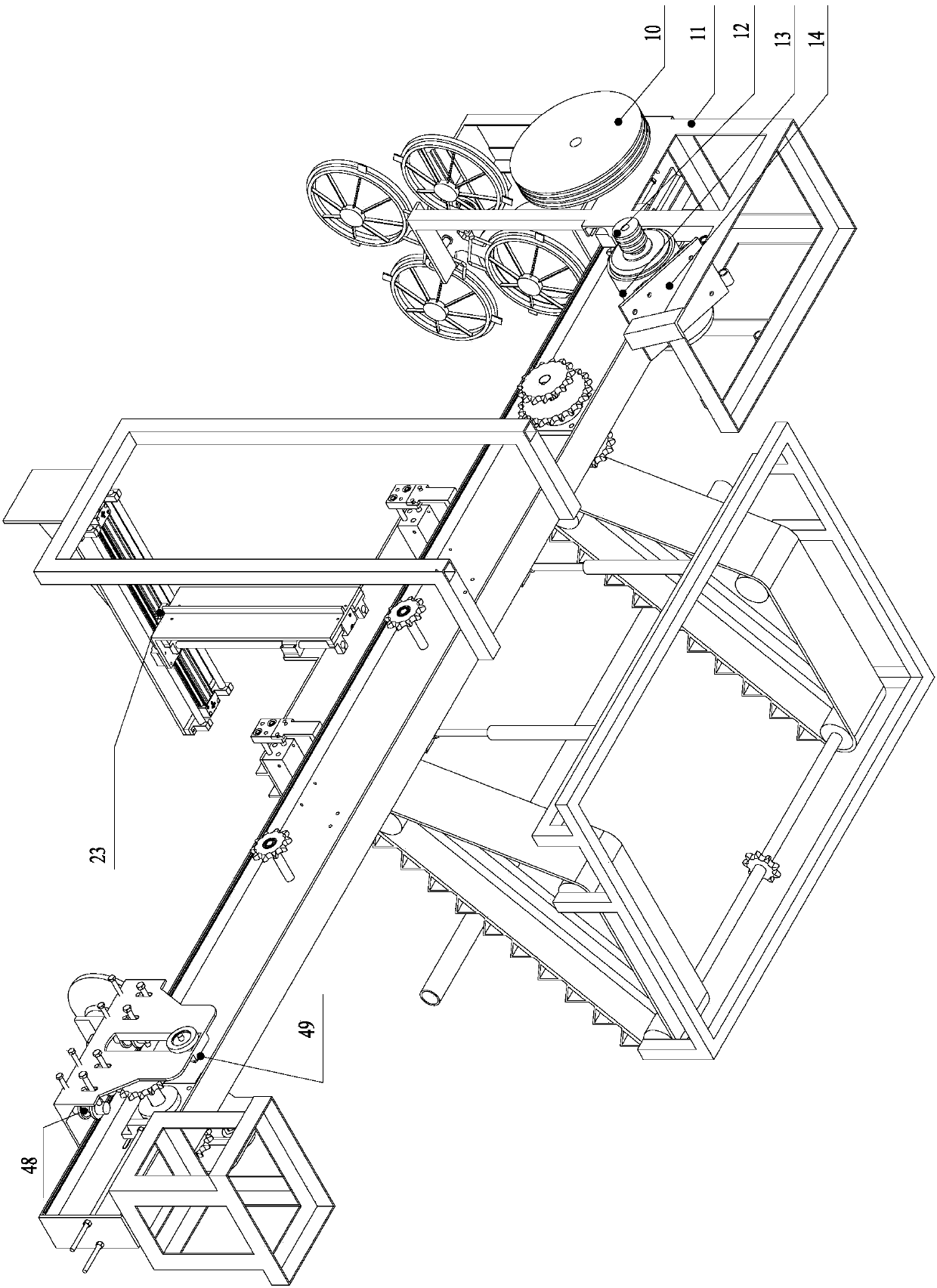

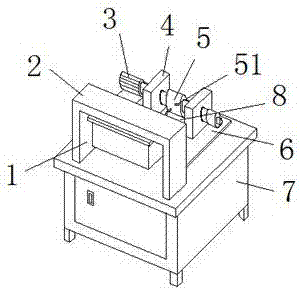

Automatic feeding segmentation equipment for bamboo wood

PendingCN107443508ARealize automatic feedingReduce labor intensityFeeding devicesCane mechanical workingWood cuttingConveyor belt

The invention provides bamboo wood cutting equipment used for processing crude bamboo into bamboo segments. The equipment comprises a crude bamboo loading mechanism, a crude bamboo feeding mechanism, a crude bamboo cutting mechanism and a discharging mechanism which are arranged on a machine frame. The crude bamboo loading mechanism comprises a conveying chain, and the moving direction of the conveying chain is perpendicular to the axial direction of the conveyed crude bamboo. The crude bamboo feeding mechanism comprises a feeding conveyor belt and a roller clamp. One section of the feeding conveyor belt is parallel to the conveying chain, and the moving direction of the feeding conveyor belt is perpendicular to that of the conveying chain. The roller clamp is elastically fixed to the gap between the machine frame and the feeding conveyor belt up and down, so that a height-adjustable channel allowing the crude bamboo to pass through is reserved. The crude bamboo cutting mechanism comprises an electric saw used for sawing the crude bamboo. The discharging mechanism comprises a discharging conveyor belt. The discharging conveyor belt is arranged behind the crude bamboo cutting mechanism so that the bamboo segments cut off by the crude bamboo cutting mechanism can drop onto the discharging conveyor belt and further be conveyed to leave the conveyor belt. By means of the bamboo wood cutting equipment, automatic feeding, segmented cutting and discharging of the crude bamboo can be realized through machines.

Owner:BEIJING FORESTRY MACHINERY RES INST OF STATE FORESTRY ADMINISTRATION

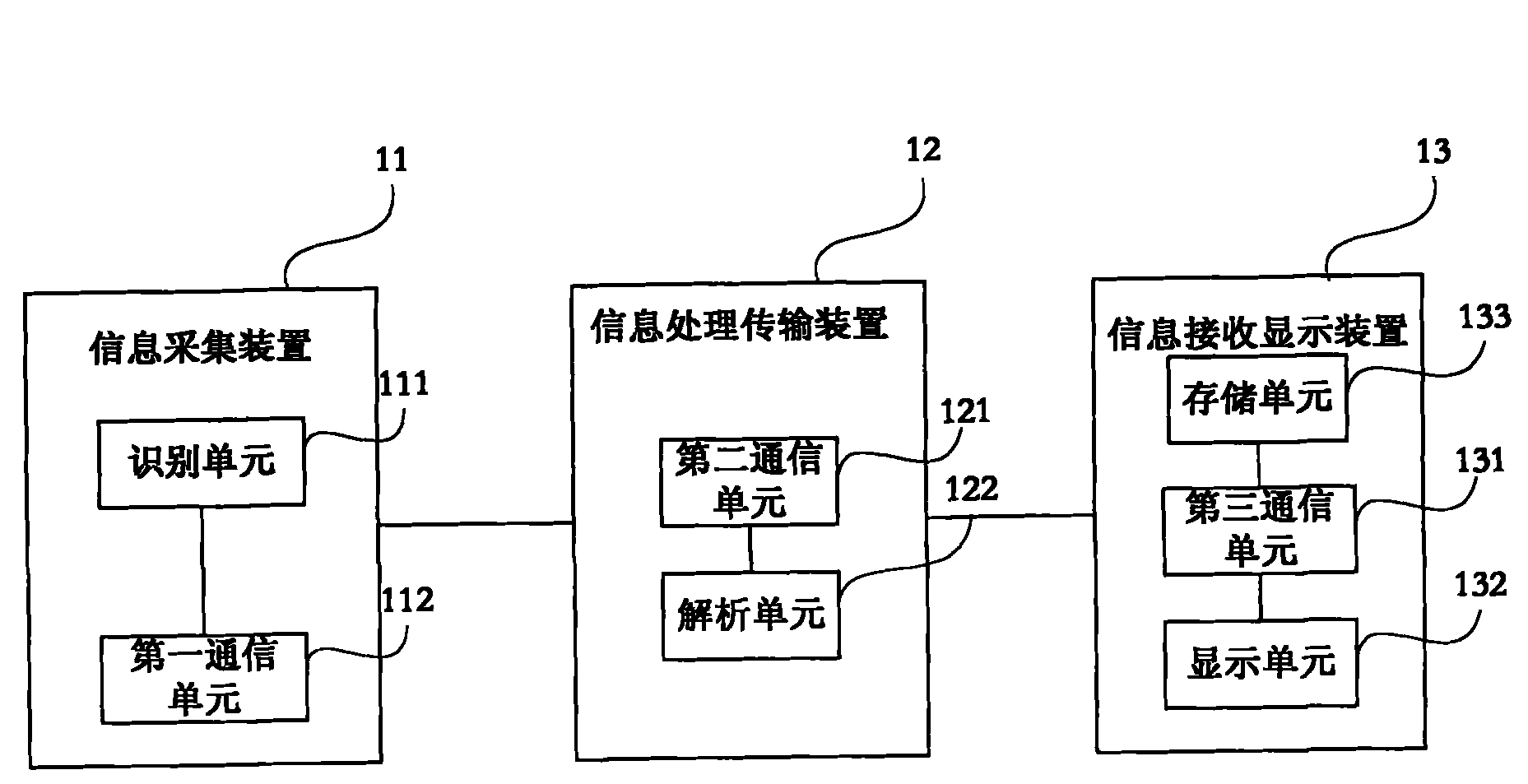

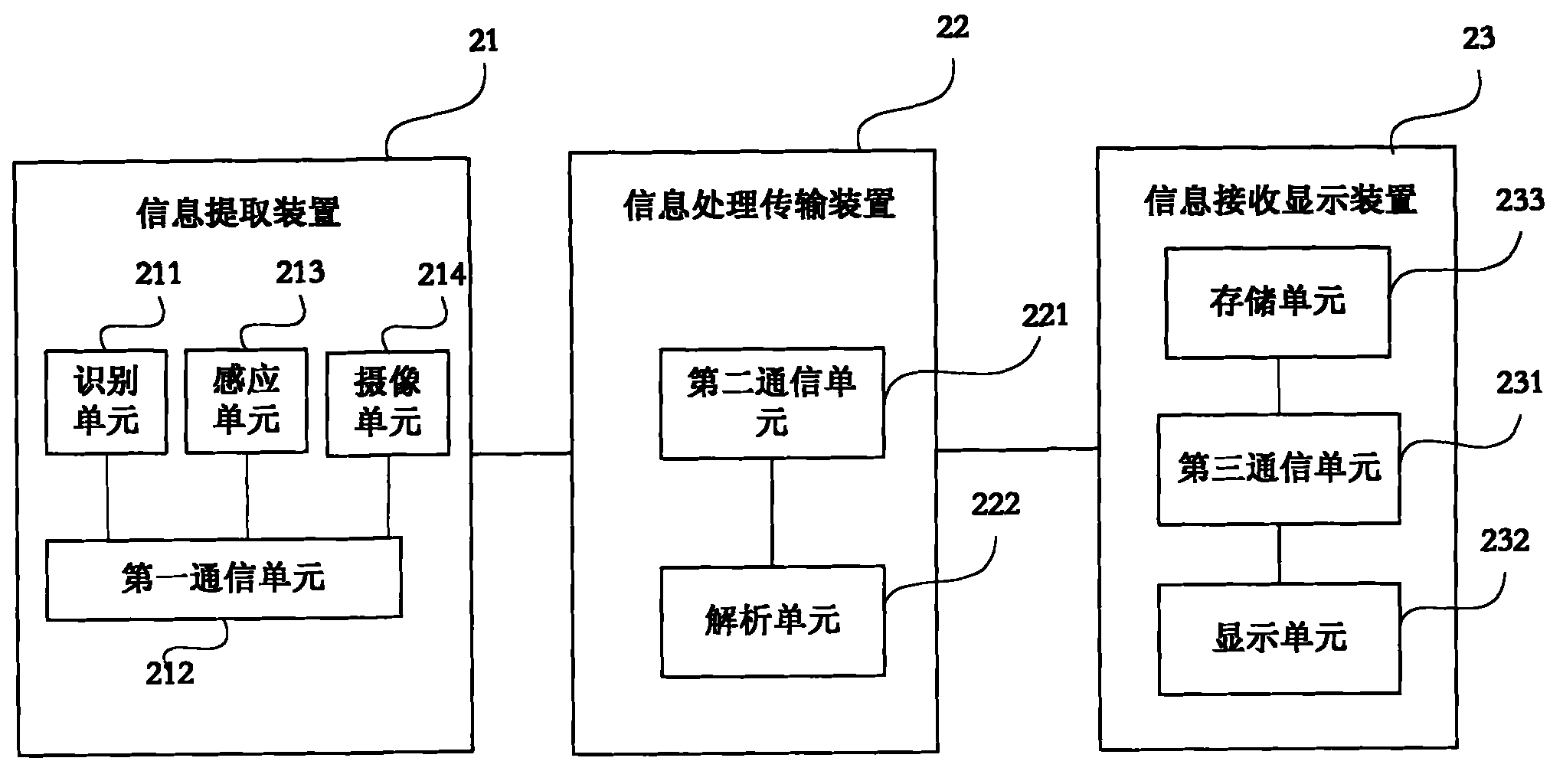

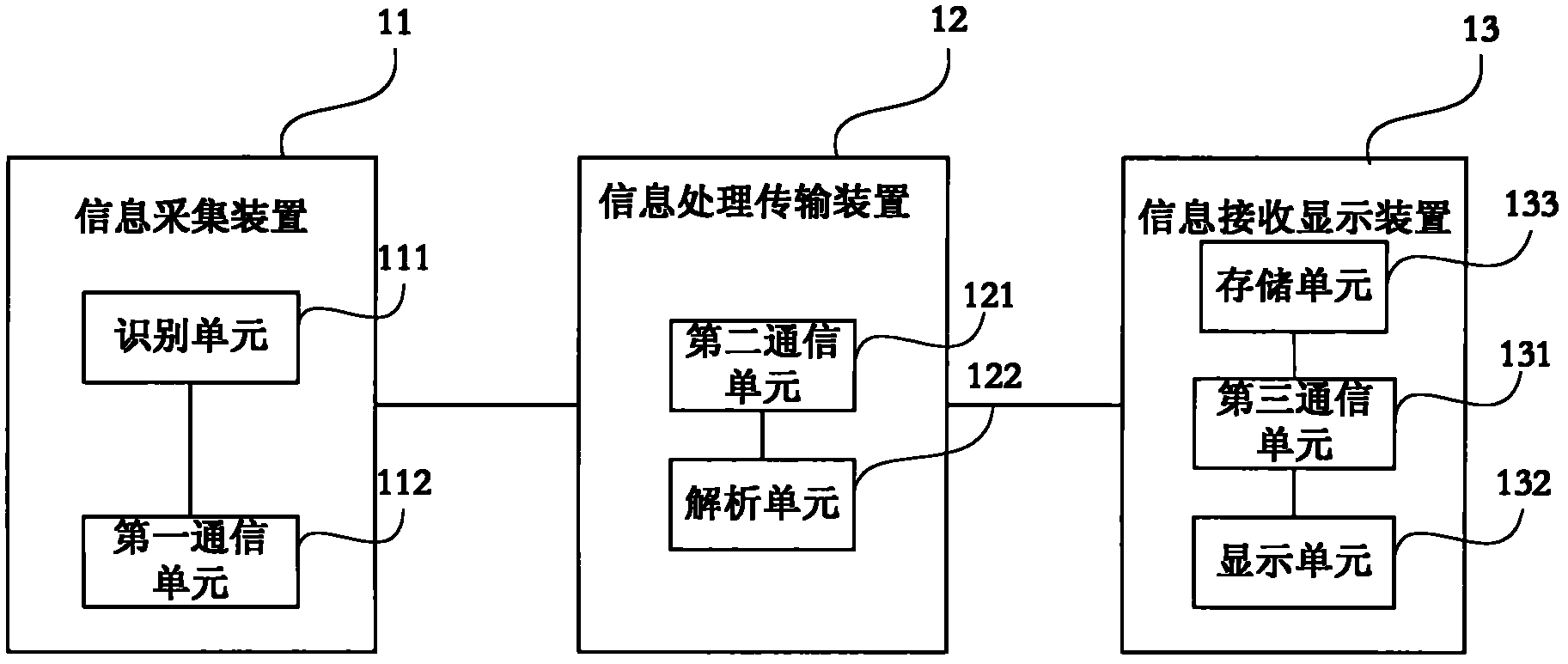

Agricultural production activity information tracing system

ActiveCN102496071ARealize automatic identificationShorten the timeData processing applicationsSensing record carriersInformation processingGuidance system

The invention discloses an agricultural production activity information tracing system comprising an information acquisition device, an information processing and transmitting device and an information receiving and display device. The information acquisition device is a portable device, and is used for acquiring information of body movements, operating tool and operating object of an operator in the agricultural operations, and transmitting the information to the information processing and transmitting device. The information processing and transmitting device is used for parsing the received information, and transmitting the parsing result to the information receiving and displaying device. The information receiving and displaying device is used for receiving and storing the parsed figure and image information used for being consulted and read in deep data mining analysis. With the information tracing system of the invention, the activity information of the operator in the agricultural production process can be recorded and acquired accurately and quickly, in combination with an Internet of things crop information monitoring system, a soil and atmospheric environment information monitoring system and the like, the system provided by the invention can be taken as the basis for building an agricultural product information tracing system, an agricultural production expert guidance system and the like.

Owner:JIUZHOU HAIYUAN TECH BEIJING

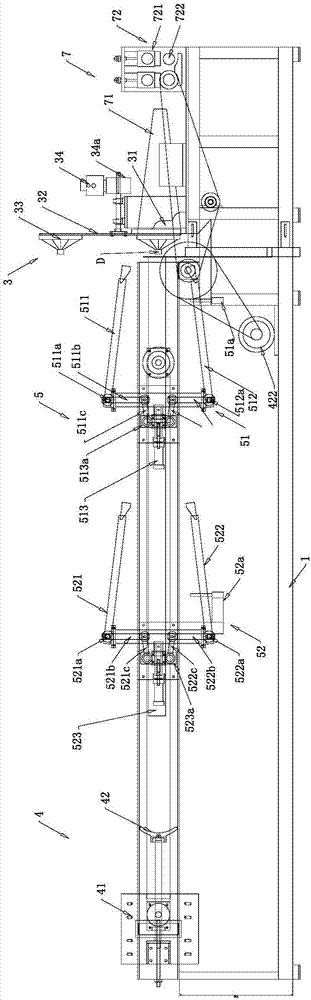

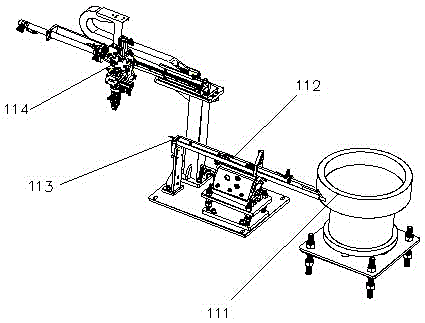

Automatic feeding fast centering continuous bamboo breaking equipment and bamboo breaking method

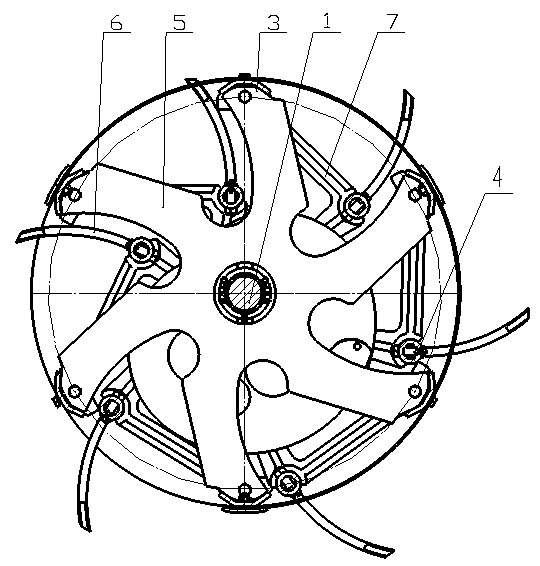

ActiveCN107414986AHigh precisionRealize the purpose of breaking bambooCane mechanical workingReciprocating motionEngineering

The invention relates to automatic feeding fast centering continuous bamboo breaking equipment, which comprises a bamboo section feeding mechanism, a bamboo breaking cutter head mechanism, a bamboo pushing mechanism, a bamboo section grasping mechanism and a bamboo section diameter detection mechanism, wherein the bamboo section feeding mechanism, the bamboo breaking cutter head mechanism, the bamboo pushing mechanism, the bamboo section grasping mechanism and the bamboo section diameter detection mechanism are arranged on a machine frame; particularly, the bamboo section grasping mechanism comprises two clamps; each clamp comprises two material clamping arms in vertical arrangement; the two material clamp arms are connected with a slide block connected with an air cylinder through a connecting rod mechanism; the air cylinder does reciprocating movement; and the upper and lower material clamping arms are gathered and separated for conveying the bamboo sections onto a bamboo breaking path. By combining a control device, the automatic feeding fast centering continuous bamboo breaking equipment can realize the automatic feeding and fast centering on the bamboo sections. The invention also provides a bamboo breaking method using the equipment.

Owner:BEIJING FORESTRY MACHINERY RES INST OF STATE FORESTRY ADMINISTRATION +1

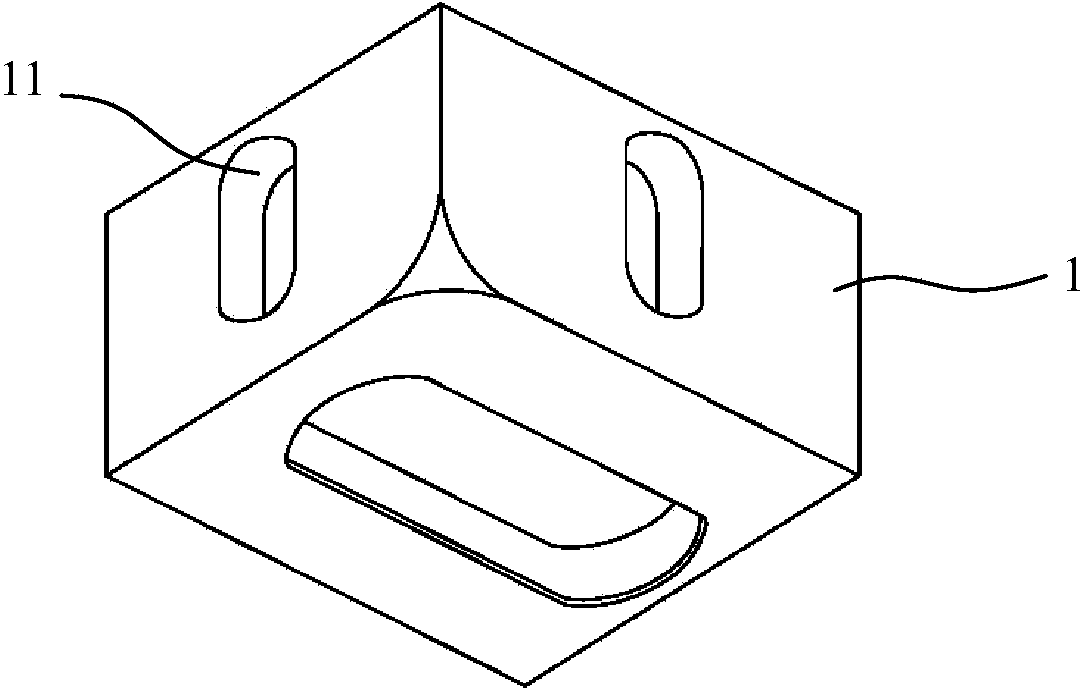

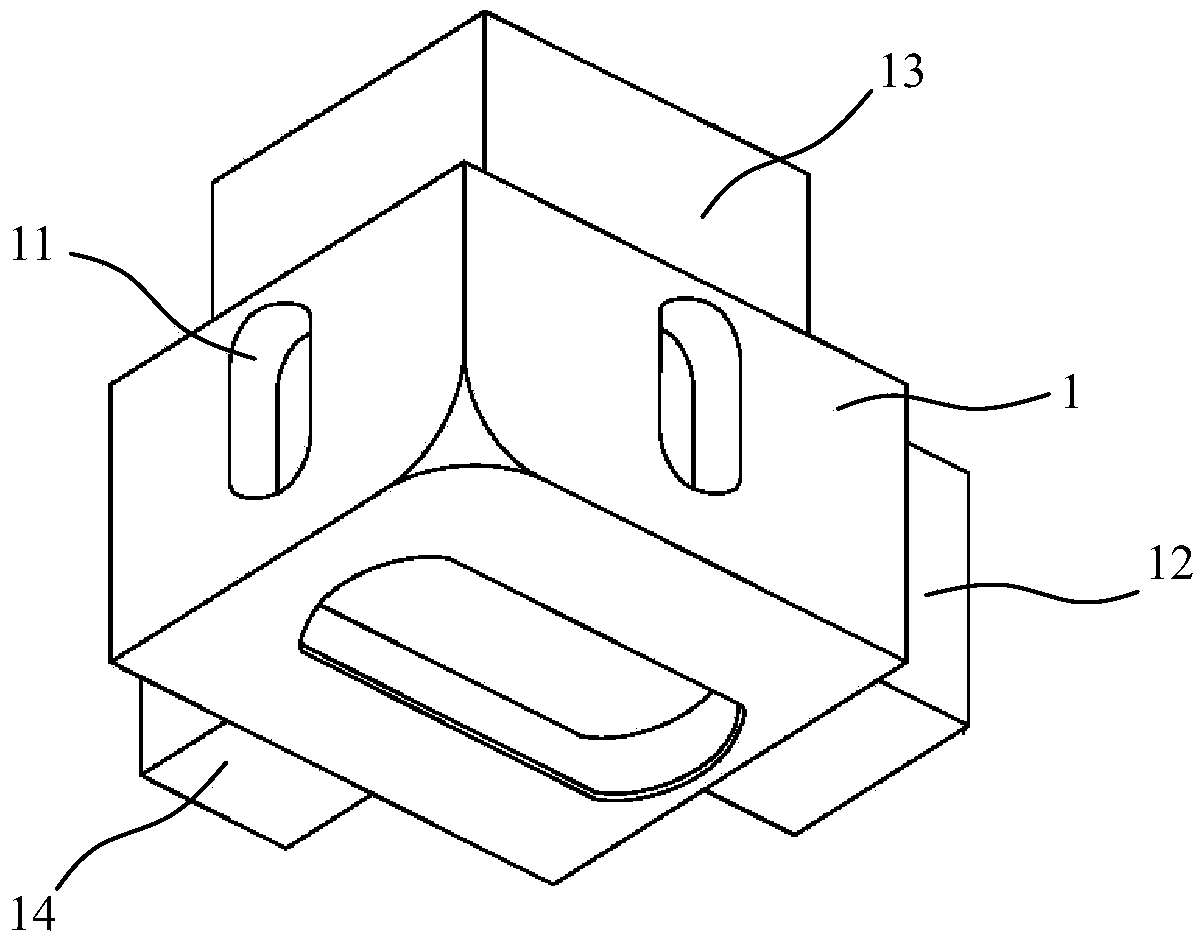

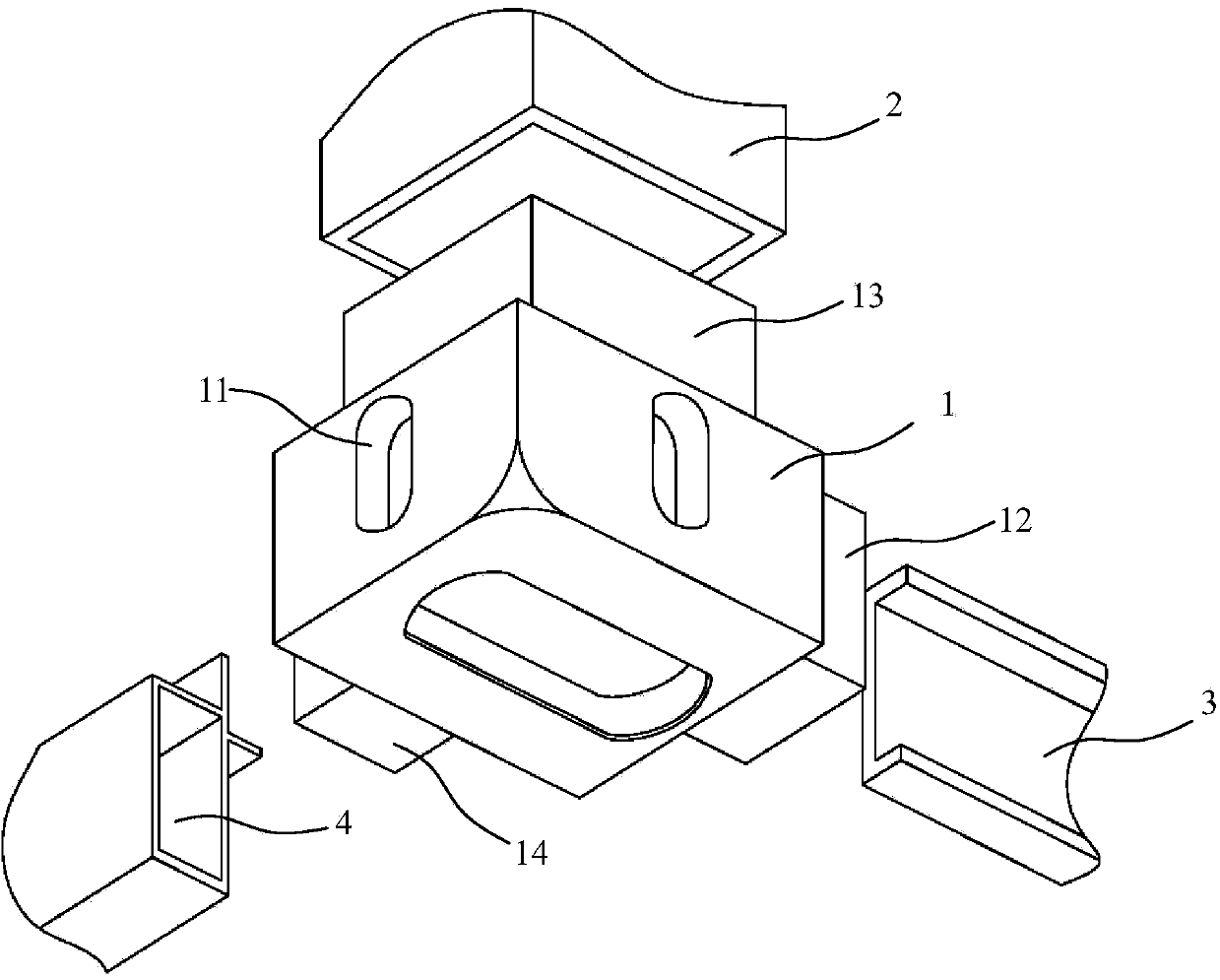

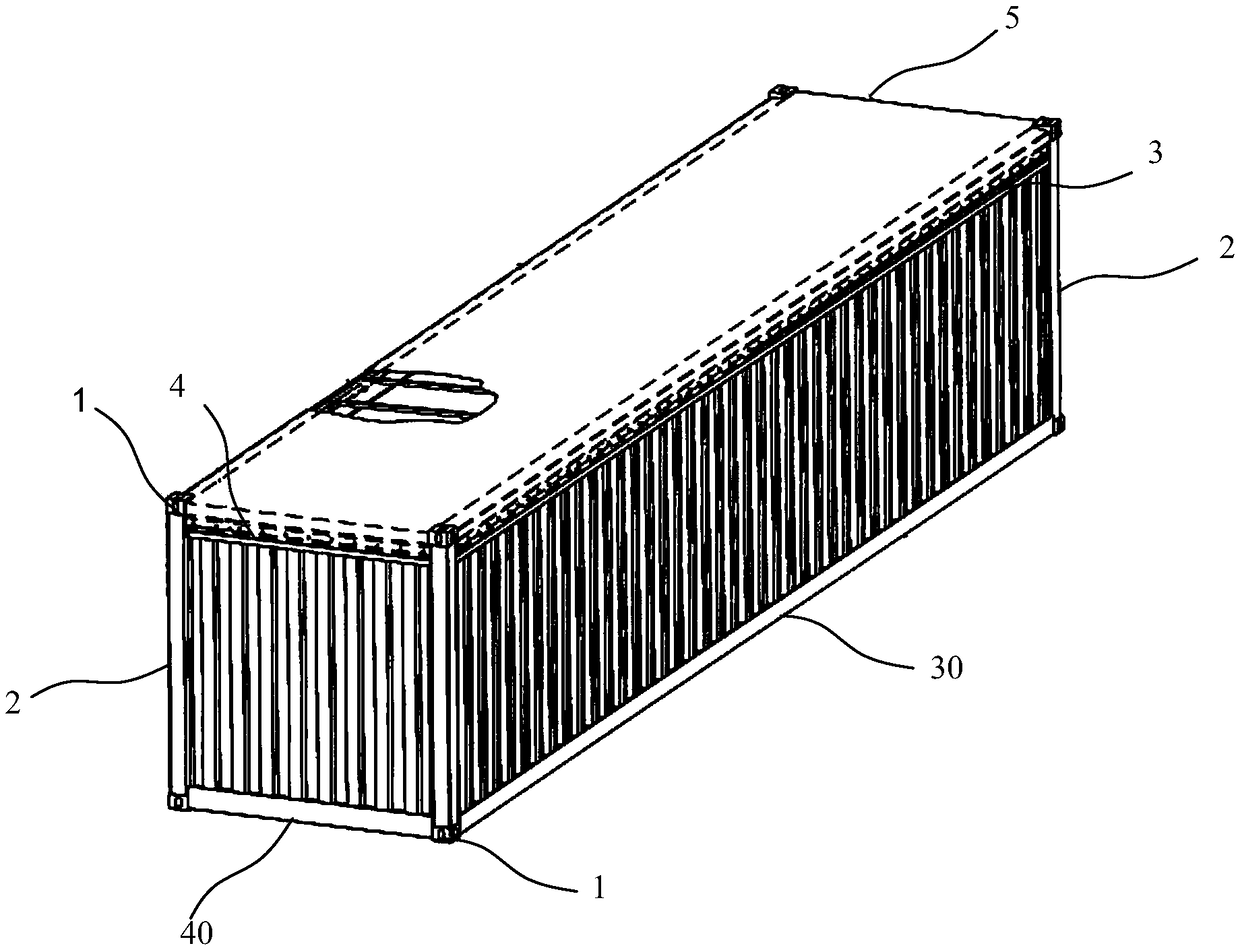

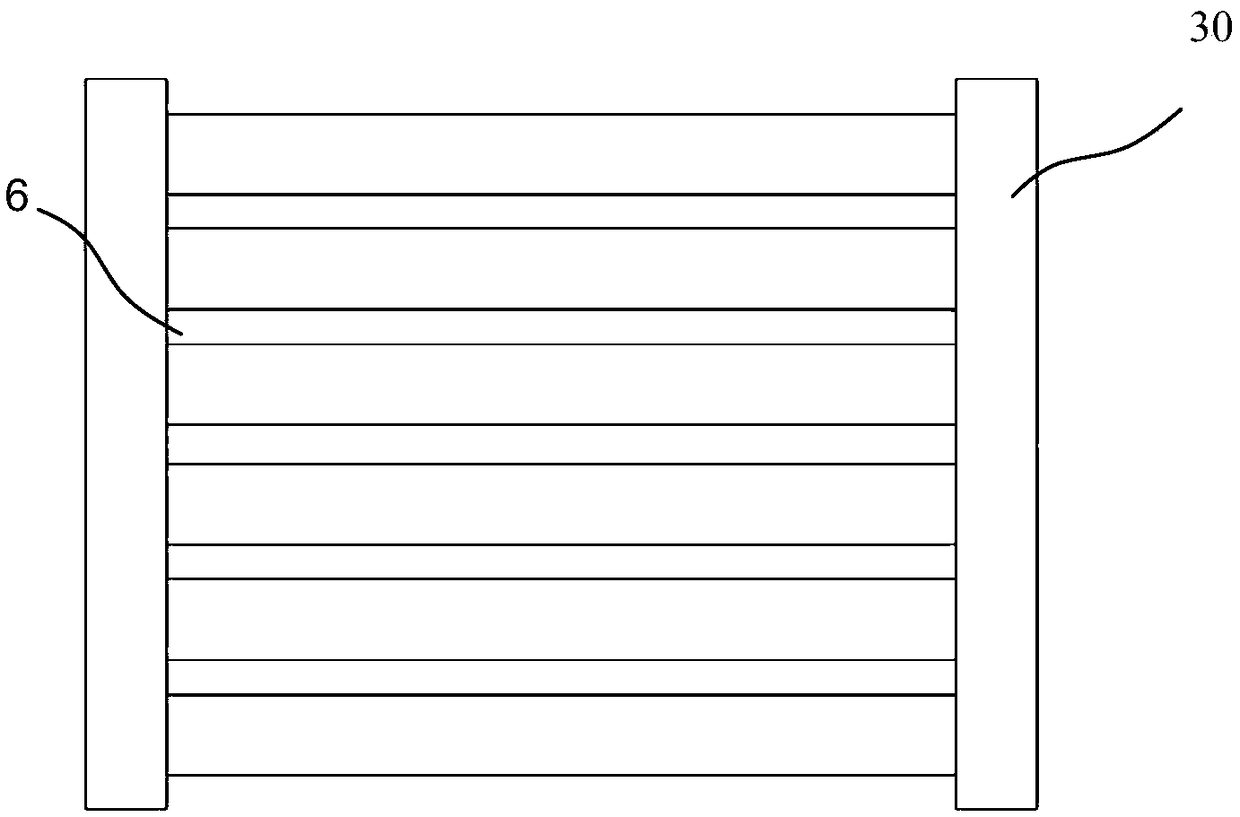

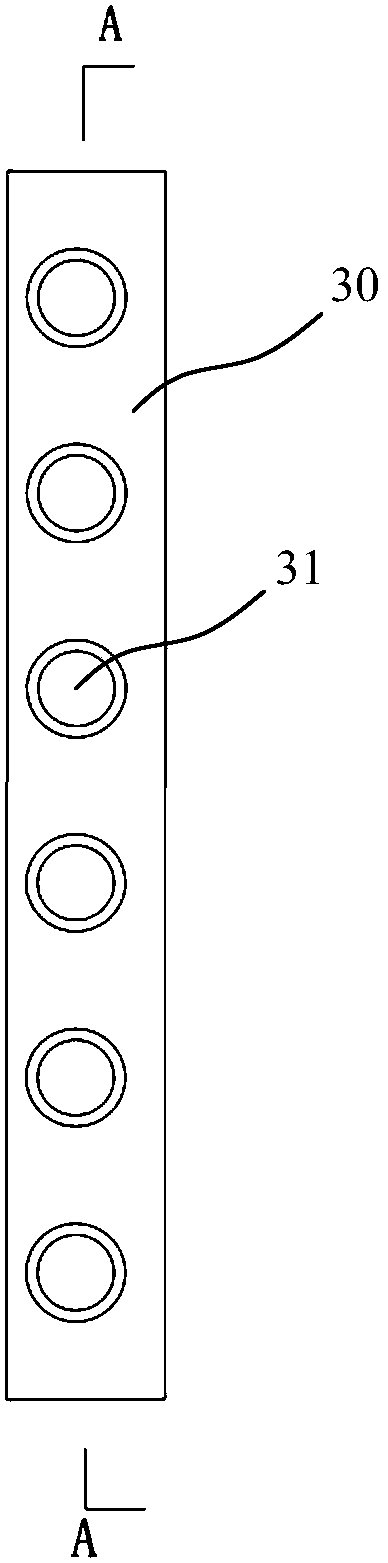

Corner fitting for container, container and container-type movable house

InactiveCN104176396ARapid productionReduce consumptionLarge containersBuilding constructionsTransportation energyAlloy

The invention discloses a corner fitting for a container, the container and a container-type movable house. A main body of the corner fitting for the container is cuboid-shaped; mounting through holes are formed in three outer end surfaces of the main body facing the outer side of the container, and the other three end surfaces of the main body can be fixedly connected with a side beam, an upright column and an end beam of the container respectively; a connecting boss is arranged on at least one end surface in the three end surfaces connected with the side beam, the upright column and the end beam of the container, can be connected with a matched beam column of the container in an insertion manner, and can be fixedly connected with the beam column of the container. According to the container and the container-type movable house with the corner fitting structure, a conventional welded structural part connecting mode can be replaced with a bond-riveted mode, the labor difficulty of a connecting process is reduced, the work efficiency is improved, and industrial pollution and energy consumption are reduced; meanwhile, a light aluminum alloy can be adopted as a base material of the container, and therefore the transportation energy consumption and the transportation cost are greatly reduced.

Owner:邵妮

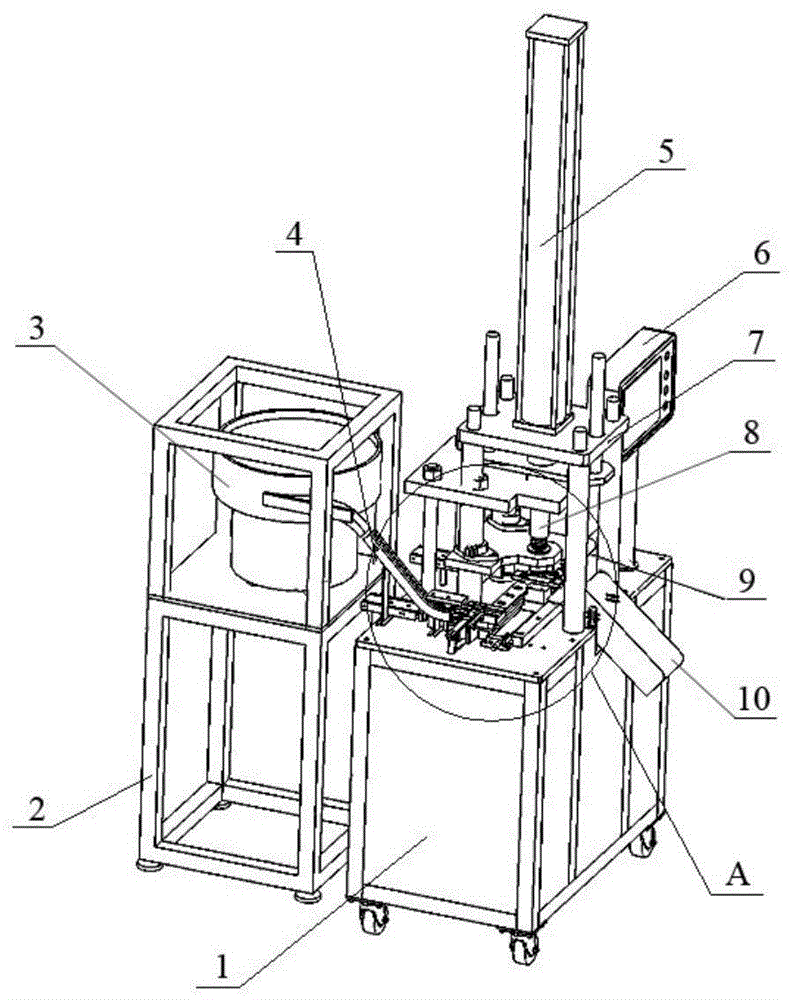

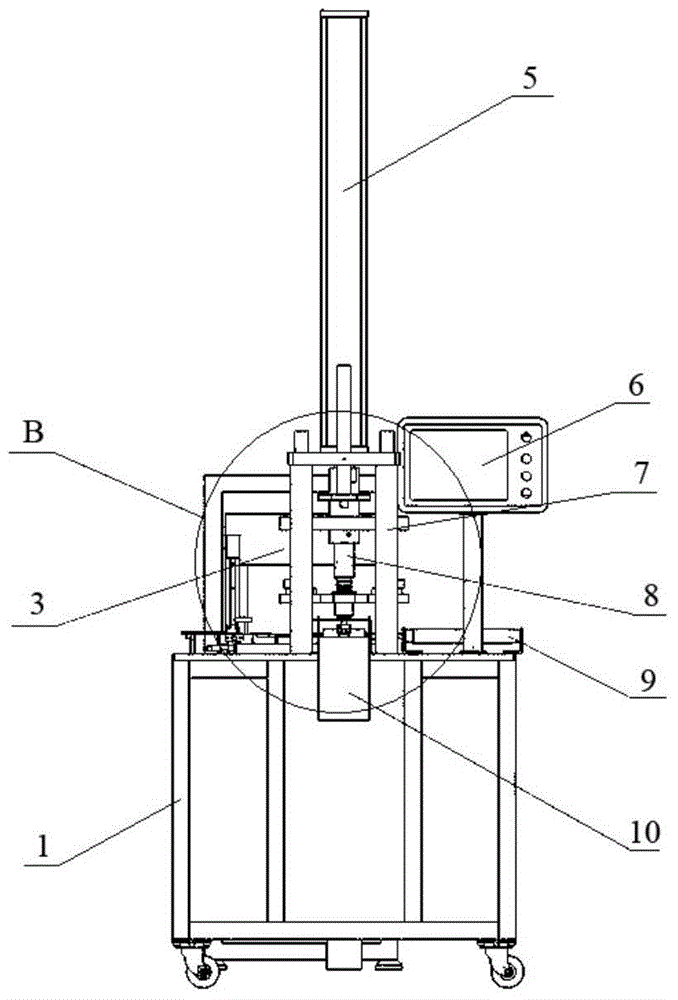

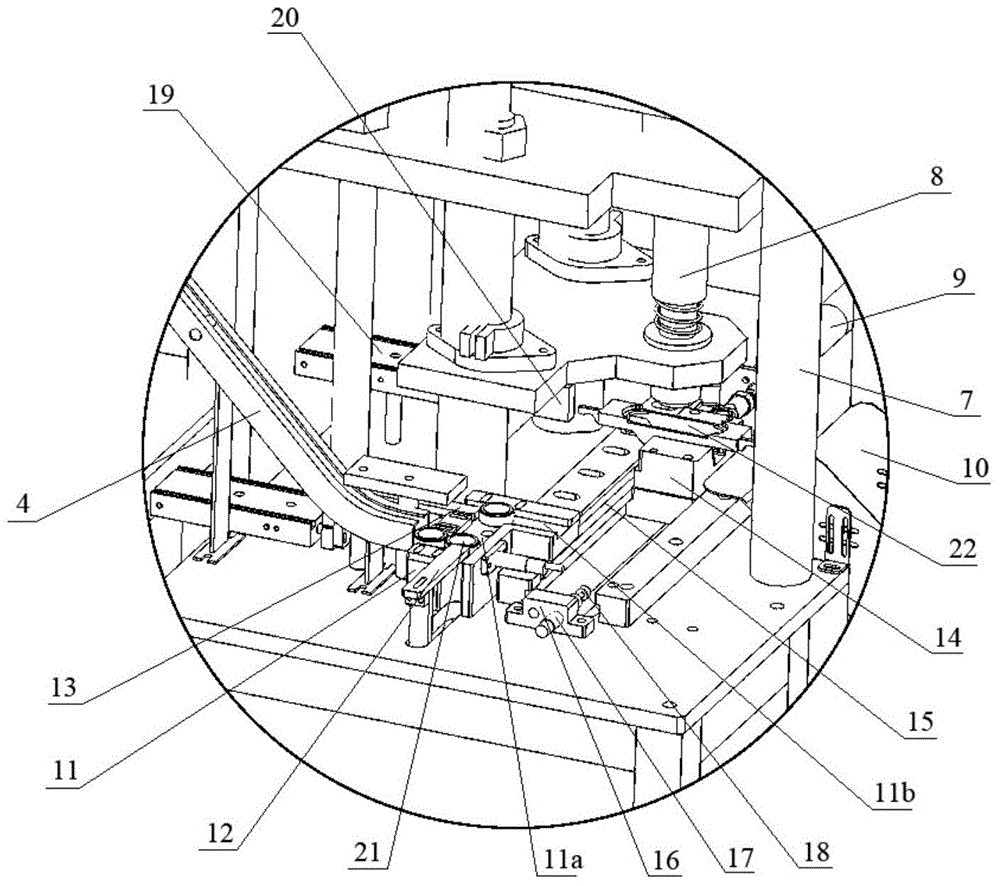

Automatic riveting apparatus of loudspeaker U iron and basin stand

ActiveCN104967959AReduce labor difficultyReduce labor intensityElectrical transducersEngineeringMachine

The invention relates to an automatic riveting apparatus of loudspeaker U iron and a basin stand. A U iron feeding sorting mechanism is used for sequentially conveying the U iron to a positioning clamp in a U iron basin stand translation mechanism. The U iron basin stand translation mechanism is used for sending the U iron and the basin stand to a stamping position below a stamping mechanism. The stamping mechanism is used for riveting the U iron and the basin stand together, wherein the U iron and the basin stand are sent to the stamping position. A finished product charging conduit is installed on a machine stand. A feed inlet of the finished product charging conduit is located in front of the stamping position of the stamping mechanism. A finished product material pushing mechanism is arranged right behind the stamping position of the stamping mechanism. The finished product material pushing mechanism is used for pushing the U iron and the basin stand which form interference riveting into the feed inlet of the finished product charging conduit. The structure is ingenious and reasonable. The basin stand and the U iron can be automatically stamped and riveted according to a program. Labor difficulty and intensity of operation personnel are effectively reduced. An assembling qualified rate and production efficiency are increased. An injury risk of operator hands below a stamping head is avoided.

Owner:WUXI JIEFU ELECTROACOUSTIC

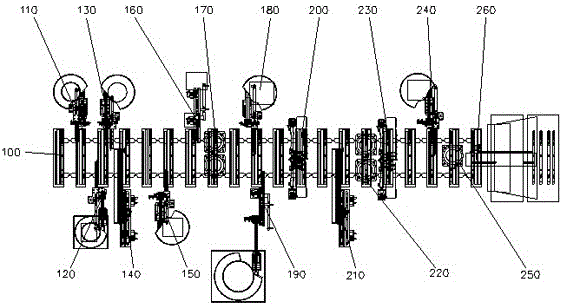

Automatic bamboo breaking equipment and bamboo breaking method thereof

The invention provides automatic bamboo breaking equipment which comprises a rack. The rack is provided with a bamboo section feeding mechanism, a bamboo breaking cutter disc mechanism, a bamboo pushing mechanism, a bamboo section grabbing mechanism and a bamboo section feeding mechanism. The bamboo breaking cutter disc mechanism comprises a cutter base. The cutter base is provided with a bamboo breaking cutter disc. The bamboo section feeding mechanism comprises a conveyor belt connected with a feeding drive device. The bamboo pushing mechanism comprises a supporting sliding rail. The supporting sliding rail is provided with a bamboo pushing base in a sliding manner. The bamboo pushing base is connected with the bamboo pushing drive device. The bamboo section grabbing mechanism comprisestwo clamps arranged on a clamp fixing base. Each clamp comprises two V-shaped clamping bases with openings opposite to each other horizontally. The V-shaped clamping bases are arranged on the clamp fixing base in a sliding manner. The V-shaped clamping bases are connected with a linear drive device in a clamped manner. The bamboo section feeding mechanism comprises a support. The support is provided with a guide rail. The clamp fixing base is arranged on the guide rail in a sliding manner and connected with a moving drive device. The automatic bamboo breaking equipment can break bamboo breaking automatically. The invention further provides a bamboo breaking method.

Owner:BEIJING FORESTRY MACHINERY RES INST OF STATE FORESTRY ADMINISTRATION

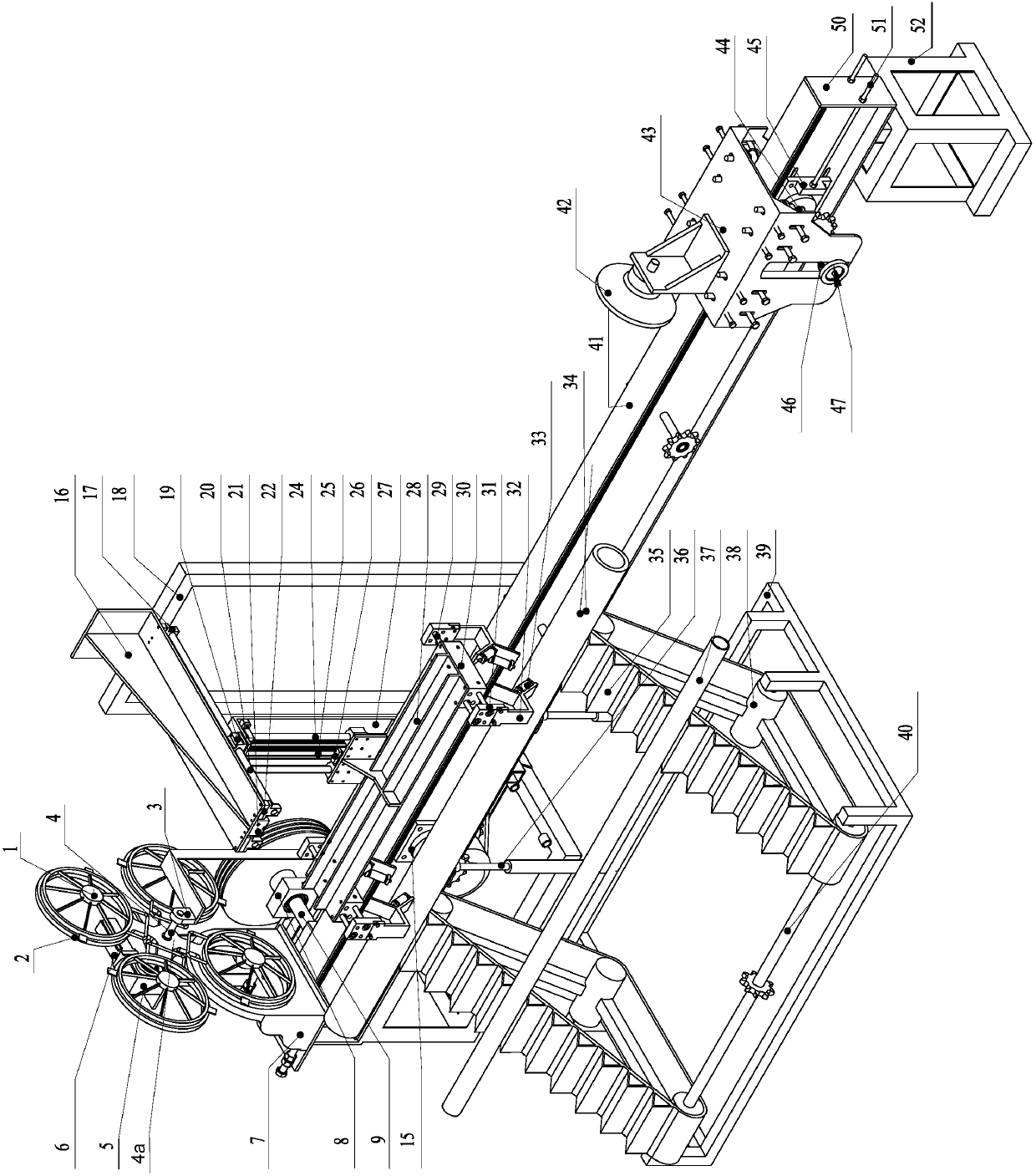

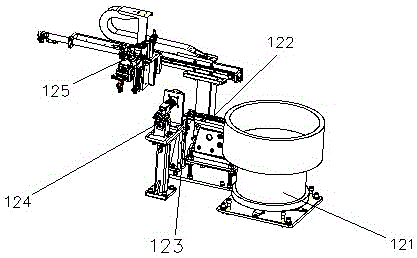

Automatic assembly equipment for guide rod and assembly method of automatic assembly equipment

The invention discloses automatic assembly equipment for a guide rod. The automatic assembly equipment for the guide rod comprises a circular rivet feeding device, an eccentric rivet feeding device, an L-shaped piece feeding device, a long steel bar feeding device, a gasket feeding device, an oval piece feeding device, a first spin riveting detection device, a square rivet feeding device, a stopping piece feeding device, a first overturning device, a rack feeding device, a second spin riveting detection device, a second overturning device, a plastic piece feeding device, a third spin riveting detection device and a finished product taking-out device. All the devices form an integrated assembly system, a chain stay wire jig is adopted for achieving operation among all the devices, production efficiency and quality of assembled products are improved, and the labor difficulty and labor intensity are lowered. A linear transfer manner is adopted for operation of the automatic assembly equipment, a vibrating disk discharging mechanism, a clip discharging mechanism, an air cylinder mechanical hand mechanism, a dual-grasping mechanical hand mechanism and other mechanisms are adopted for the equipment, full-automatic work is achieved, and production efficiency is improved. The invention further discloses an assembly method of the automatic assembly equipment for the guide rod.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

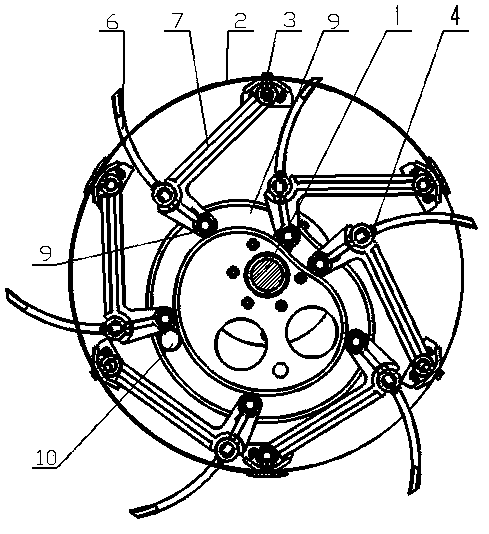

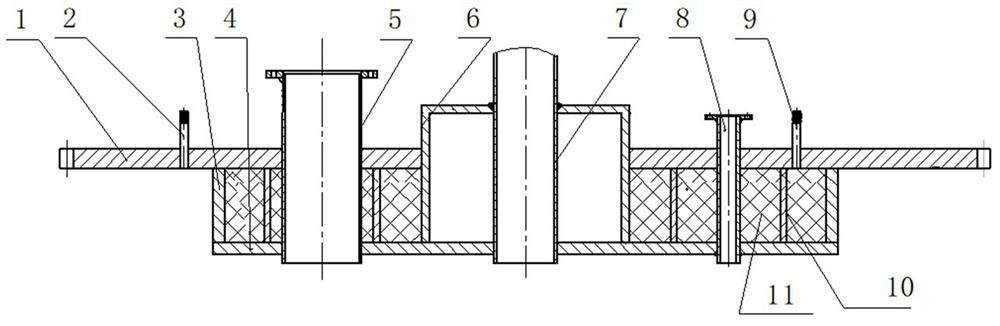

Residual film picking roller with film picking teeth

The invention discloses a residual film picking roller with film picking teeth. The residual film picking roller comprises a cam disc fixedly installed on a roller shaft, film picking tooth beams parallel to the roller shaft are evenly distributed on the periphery of the cam disc, the film picking teeth on the film picking tooth beams are matched with through holes in the wall of the roller, the film picking tooth beams are fixedly connected with inflection points of crank throw arms, rolling rings arranged on the end portions of short arms of the crank throw arms are matched with grooves in the cam disc, the end portions of long arms of the crank throw arms are hinged to an axial framework of the roller, roller wall radial supporting frames are evenly distributed in the roller, a rolling ring replacement window is formed in the bottom face of the cam disc, connecting lugs are arranged on the upper portions of threads of tooth handles of the film picking teeth, connecting holes are formed in the connecting lugs, locknuts are installed on the tooth handles, extending out of installation holes in the film picking tooth beams, of the film picking teeth of the film picking tooth beams, and the film picking teeth are fixedly connected to the film picking tooth beams by the connecting lugs through screws. The residual film picking roller is reasonable in structure, safe and reliable in performance, good in stability of operation, high in recycling rate of residual films and convenient to maintain, and the use cost can be reduced.

Owner:INST OF AGRI MECHANIZATION XINJIANG AGRI INST

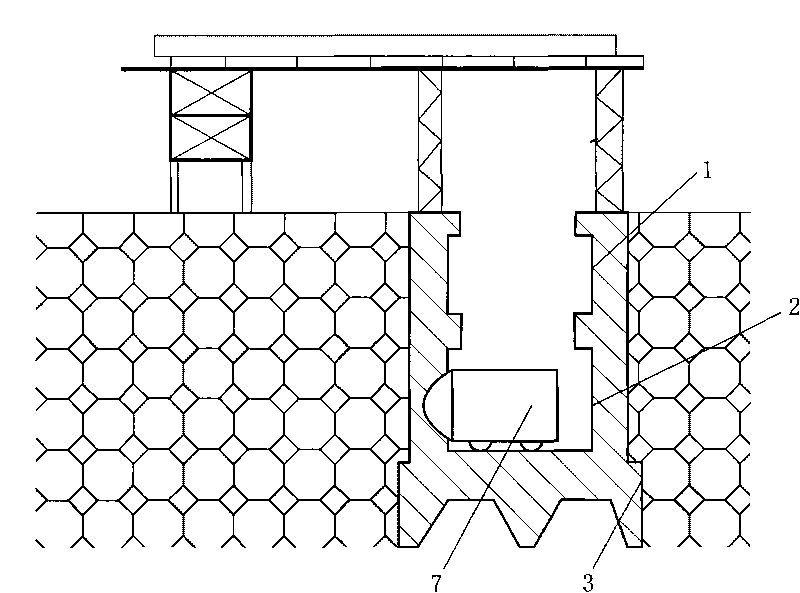

Palisade structure for underground architectural shaft and shield machine cutting construction method thereof

The invention discloses a palisade structure for an underground architectural shaft, which has a reinforcement structure formed by connecting an upper reinforcing cage, a middle FRP reinforcing cage and a lower reinforcing cage. The invention also discloses a shield machine cutting construction method of the underground architectural shaft palisade structure, which comprises the following steps: after hoisting, overlapping and binding the lower reinforcing cage, the middle FRP reinforcing cage and the upper reinforcing cage, concreting to form the underground architectural shaft palisade structure; and when the shield machine advances to a position of the FRP reinforcing cage of the underground architectural shaft, replacing the cutter of the shield machine by a hob, a serrated knife or a scraper blade, and then cutting the palisade structure for the underground architectural shaft. The palisade structure and construction method of the invention can accelerate the construction progress of the underground buildings, and reduce the wear of the blade of the shield machine to a certain extent, thus, the method is suitable to be popularized in the palisade structure of the underground architectural shaft passed in and out by the shield machine.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +3

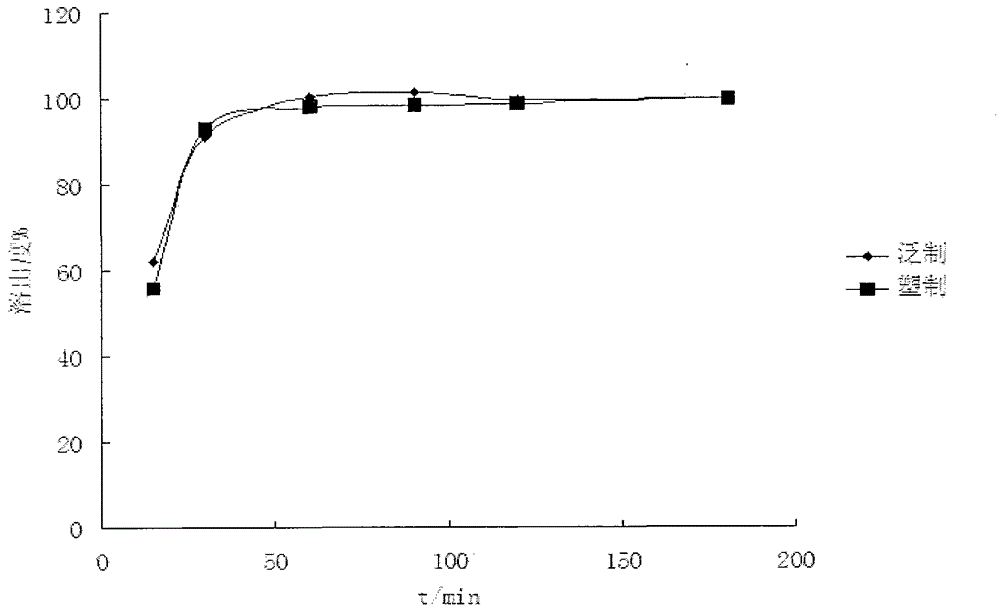

Method for preparing cardiovascular disease drug micropills

ActiveCN104435114AAchieve productionReduce volatilityAmphibian material medical ingredientsHydroxy compound active ingredientsGINSENG EXTRACTSlurry

The invention provides a method for preparing cardiovascular disease drug micropills. The method comprises the following steps: adding 6-13 weight parts of storax into ethanol aqueous solution, and uniformly mixing; grinding the following components into fine powder of 80-100mesh in parts by weight: 1-5 parts of musk, 1-5 parts of ginseng extract, 1-5 parts of calculus bovis, 3-11 parts of cinnamon, 1-6 parts of venenum bufonis and 6-14 parts of borneol, uniformly mixing the fine powder with the ethanol aqueous solution of storax, and adding water to prepare a soft material; extruding the prepared soft material to prepare pills; grinding 1-5 parts of musk, 10-20 parts of ginseng extract, 1-5 parts of calculus bovis, 7-15 parts of cinnamon and 1-6 parts of venenum bufonis into fine powdr of 80-100mesh; and rolling the prepared pills, spraying 40-60 percent of ethanol aqueous solution, and adding the prepared fine powder, so that the fine powder is adhered to the pills by slurry. According to the preparation method, a plastic molding method and a pill processing method are combined, so that the production efficiency of heart-protecting musk pills can be improved, the yield is improved, the influence of human factors on the product is reduced in the production process, and the labor intensity is reduced. Therefore, the drug powder is constant in ratio, and the product quality is stable.

Owner:HEHUANG PHARMA SHANGHAI

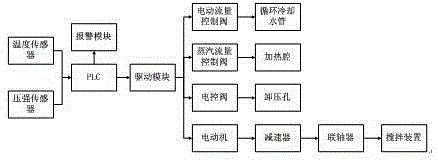

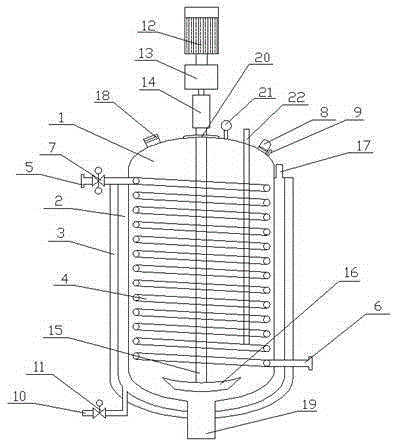

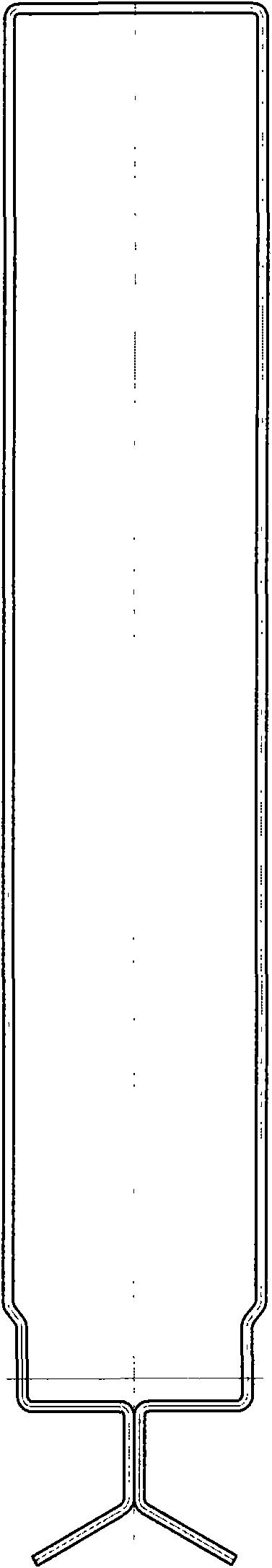

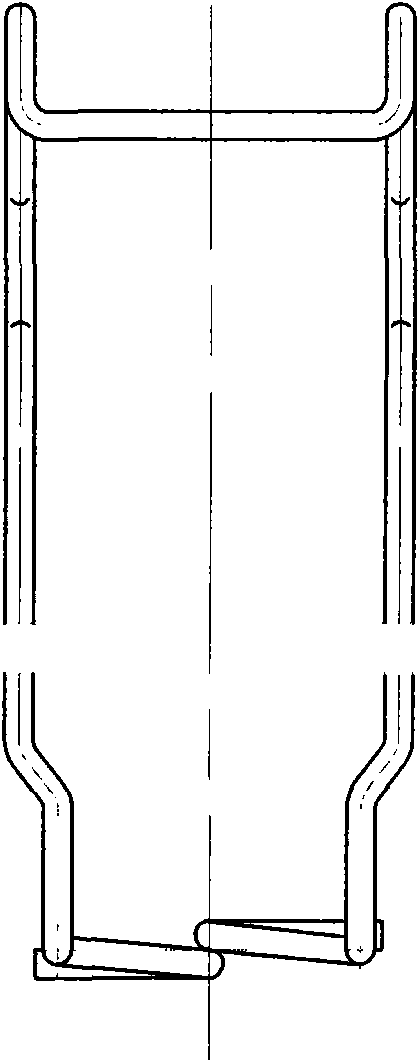

Reaction vessel having automatic control function

InactiveCN106732243AAvoid explosionReduce churnChemical/physical/physico-chemical stationary reactorsAutomatic controlEngineering

The invention discloses a reaction vessel having automatic control function. The reaction vessel comprises a vessel body, a stirring device, a power apparatus, a detection apparatus and a control apparatus, a heating chamber is arranged outside the vessel body, a vacuum insulation chamber is arranged outside the heating chamber, a recirculated cooling water pipe is arranged in the vessel body, two ends of the recirculated cooling water pipe respectively pass through the vessel body as a water inlet and a water outlet, an electric flow control valve is arranged on the water inlet, a discharged hole is arranged on the vessel body, an electric control valve is arranged on the discharged hole, a steam inlet is arranged at the lower end of the heating chamber, and a steam flow control valve is arranged on the steam inlet. According to the invention, heating or cooling can be automatically adjusted, reaction correctness and completeness can be ensured, labor is saved, time is saved, cost is reduced, and security is increased.

Owner:JIANGSU HUAYUE SPECIAL EQUIP

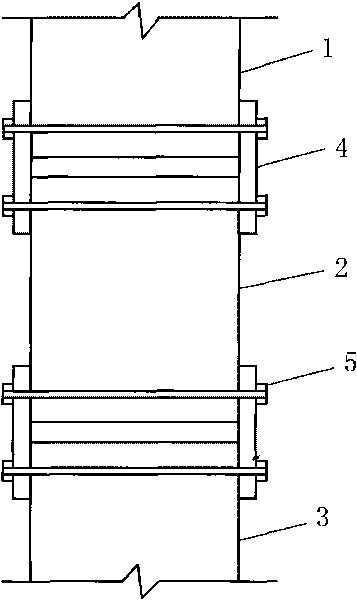

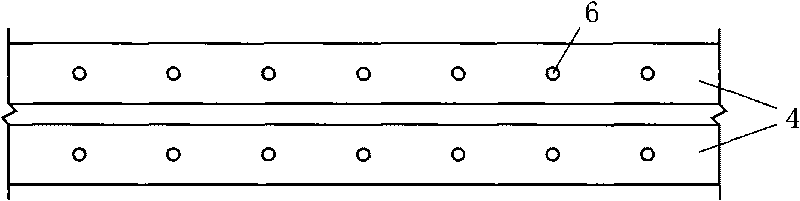

Production process for concave-convex type folding dust-catching cloth bag framework

InactiveCN101927115ARealize automated productionShorten production timeDispersed particle filtrationResistance welding apparatusEngineeringUltimate tensile strength

The invention relates to a production process for a concave-convex type folding dust-catching cloth bag framework, which comprises the following steps of: (1) straightening and cutting steel wires; (2) carrying out a door pressing type process step, a two-end pressing process step and welding for the steel wires to form a steel wire frame; (3) forming the steel wire frame to be with a concave angle contour and a 90-degree bend angle to form a lower framework section unit; (4) carrying out the forming welding for a set of the lower framework sections to form a cage-shaped lower framework section; (5) carrying out outward pressing and claw turning, a groove pressing process step and a 90-degree bend angle formation for the steel wire frame to form an upper framework section unit; (6) carrying out the forming welding for a set of the upper framework section units to form a cage-shaped upper framework section; (7) inserting one upper framework section into a set of the lower framework sections in sequence, so as to finish the production of the concave-convex type folding dust-catching cloth bag framework. The production process has high automation, and framework parts produced by the process are normative and standard and are convenient to assemble, the production efficiency is greatly improved, and the labor strength of workers is reduced.

Owner:TIANJIN MAIRUI ENVIRONMENTAL PROTECTION TECH CO LTD

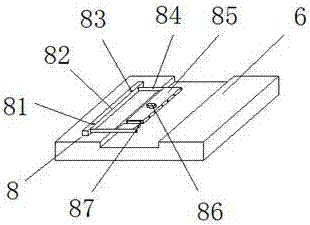

Rapid pulling device for voice coil gauges of loudspeaker

ActiveCN104954967AReduce labor difficultyReduce labor intensityElectrical transducersLoudspeakerBrake lining

The invention relates to a rapid pulling device for voice coil gauges of a loudspeaker. A device frame is arranged above a belt conveying line in a crossing manner; a displacement cylinder in a displacement mechanism is mounted at the top of the device frame, and a horizontal slider is connected with a piston rod of the displacement cylinder; a longitudinal cylinder in a pulling mechanism is connected to the horizontal slider, a longitudinal slider is connected with a piston rod of the longitudinal cylinder, a pneumatic gripper cylinder is connected to the longitudinal slider, and a pneumatic gripper is mounted at the piston rod end of the pneumatic gripper cylinder; a horizontal cylinder in an ejection mechanism is mounted on one side of the bottom of the device frame, and the piston rod end of the horizontal cylinder faces the belt conveying line and is connected with an ejection groove; a locating plate is mounted on the other side of the bottom of the device frame and is opposite to the front surface of the ejection groove; a longitudinal blocking cylinder in a blocking mechanism is mounted on one side of the bottom of the device frame, and the piston rod end of the longitudinal blocking cylinder is connected with a brake lining; a blanking groove is formed beside the pulling mechanism. The device can rapidly and accurately pull the voice coil gauges, the working difficulty and the labor intensity are reduced, the assembling qualification rate is increased, and the production efficiency is improved.

Owner:WUXI JIEFU ELECTROACOUSTIC

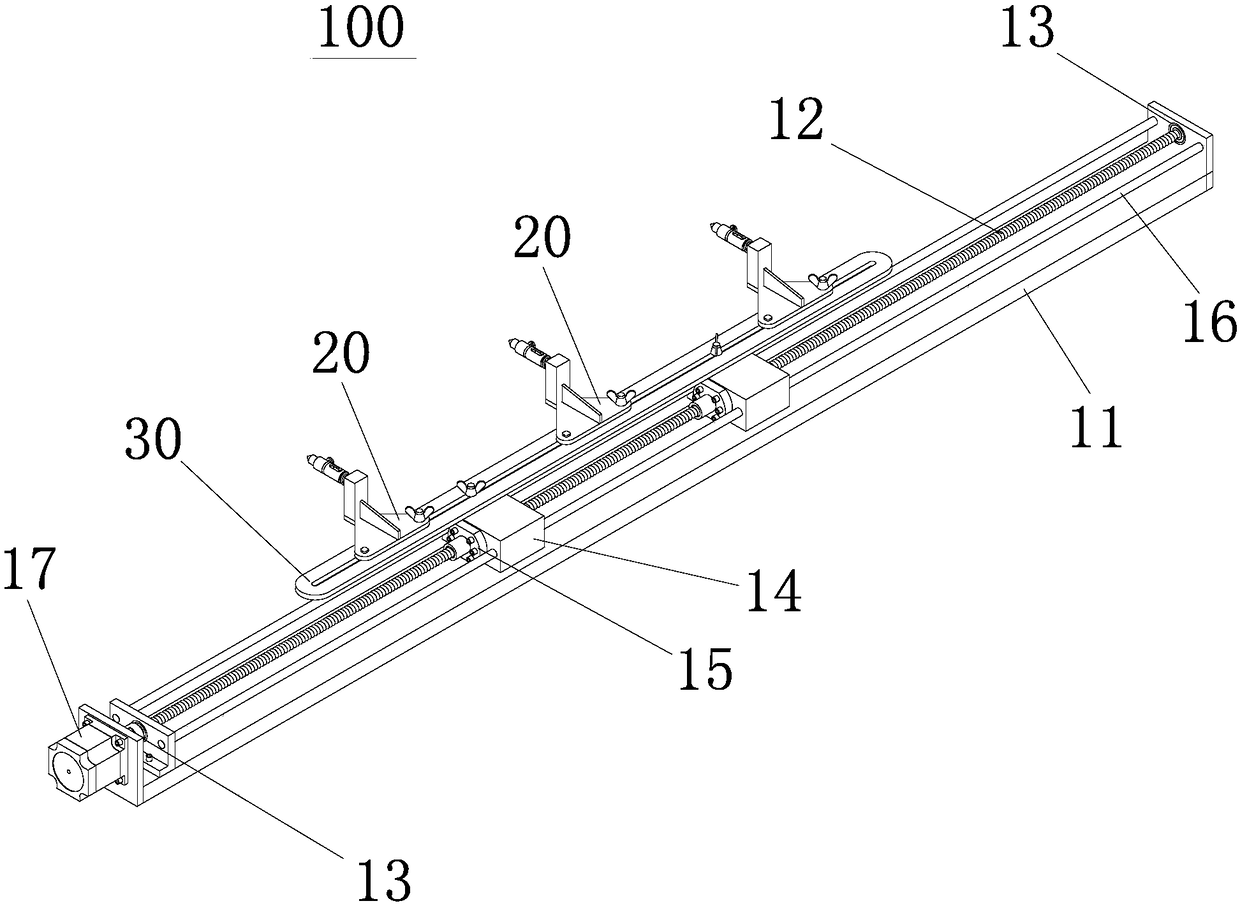

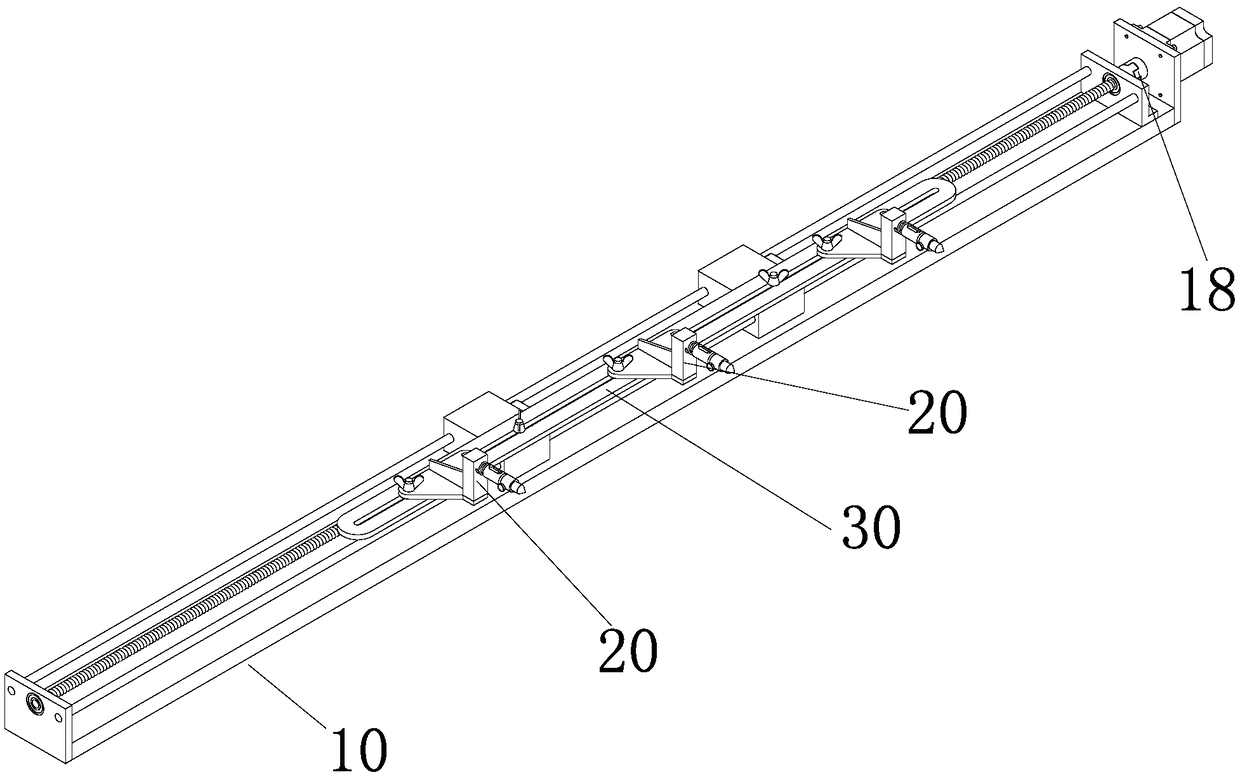

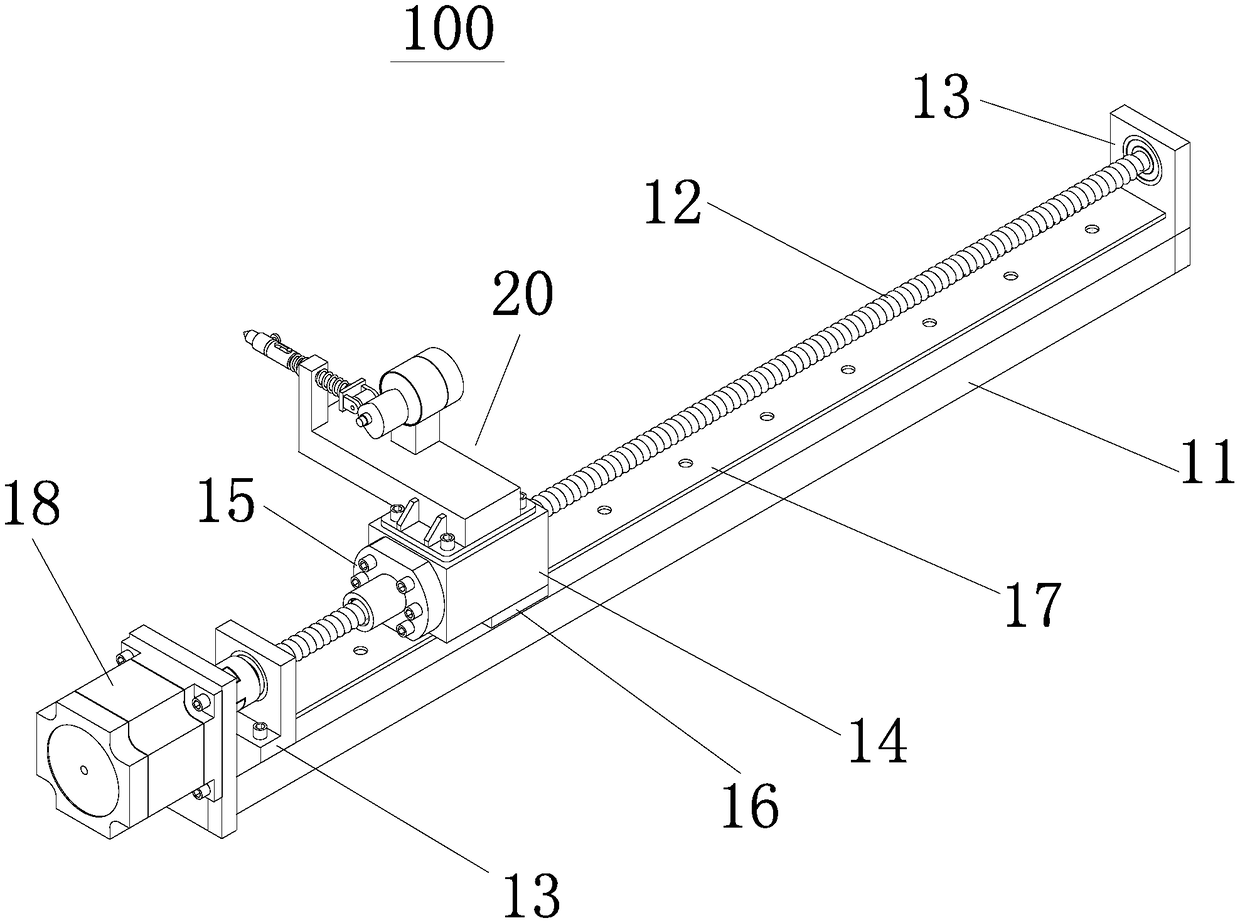

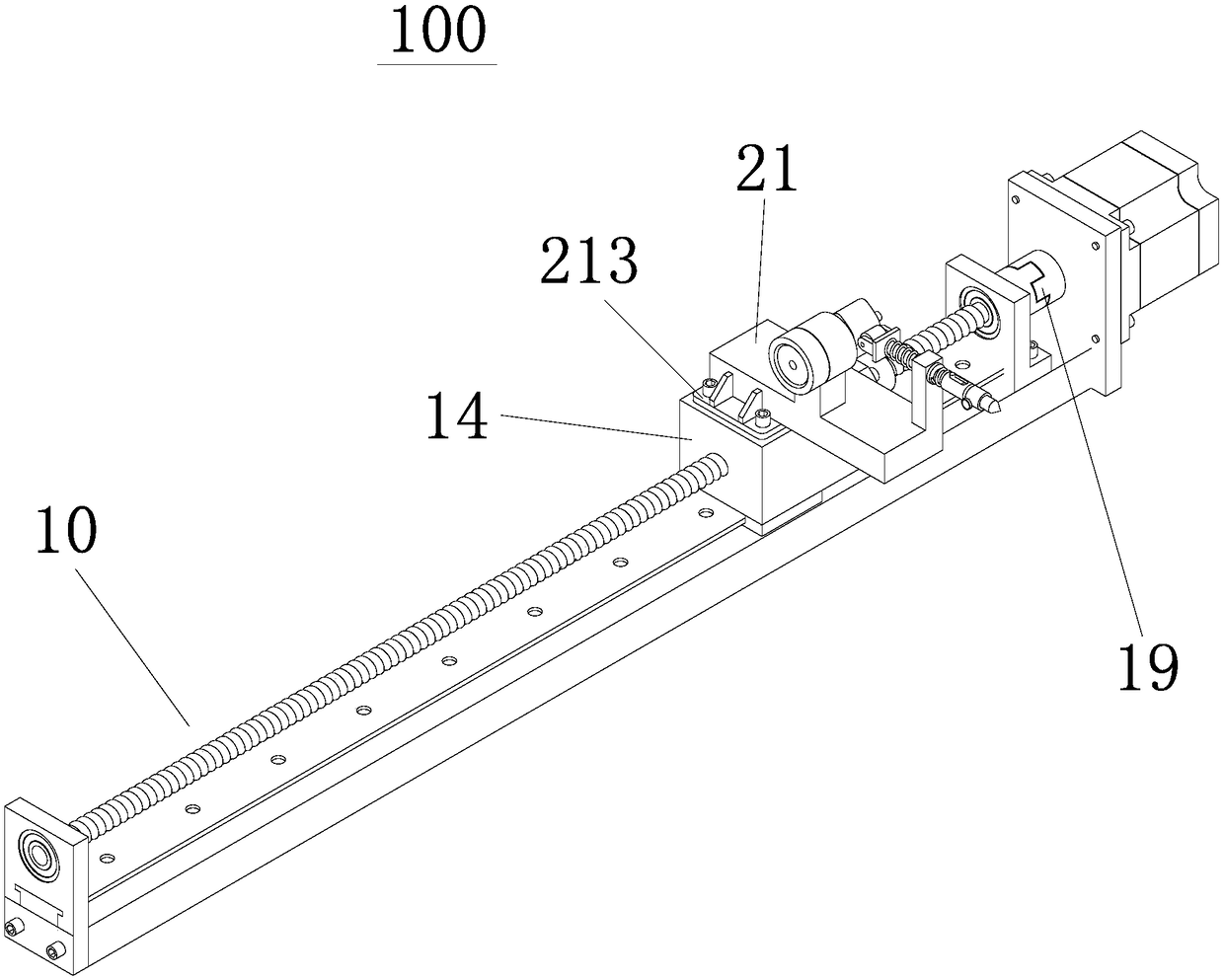

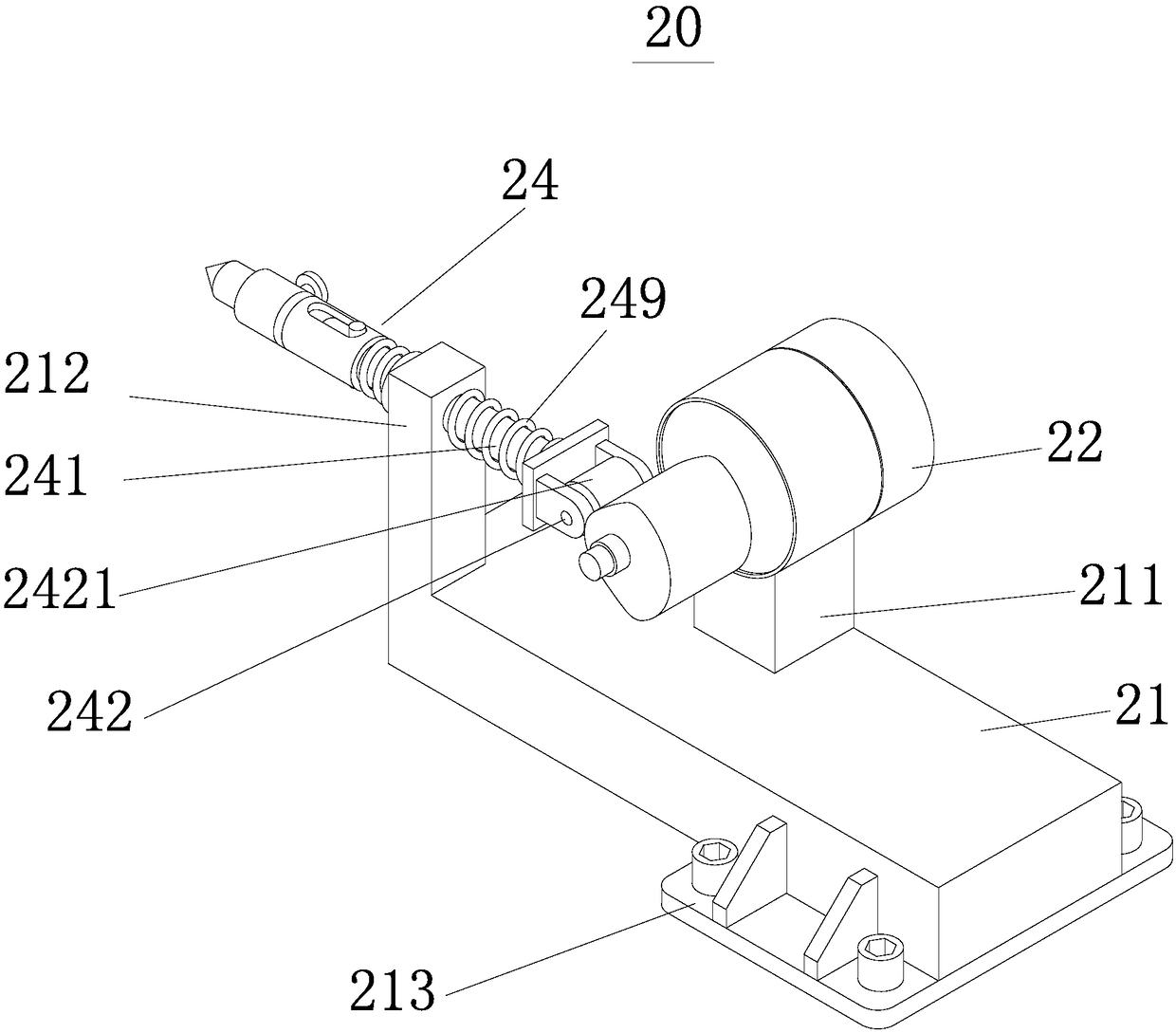

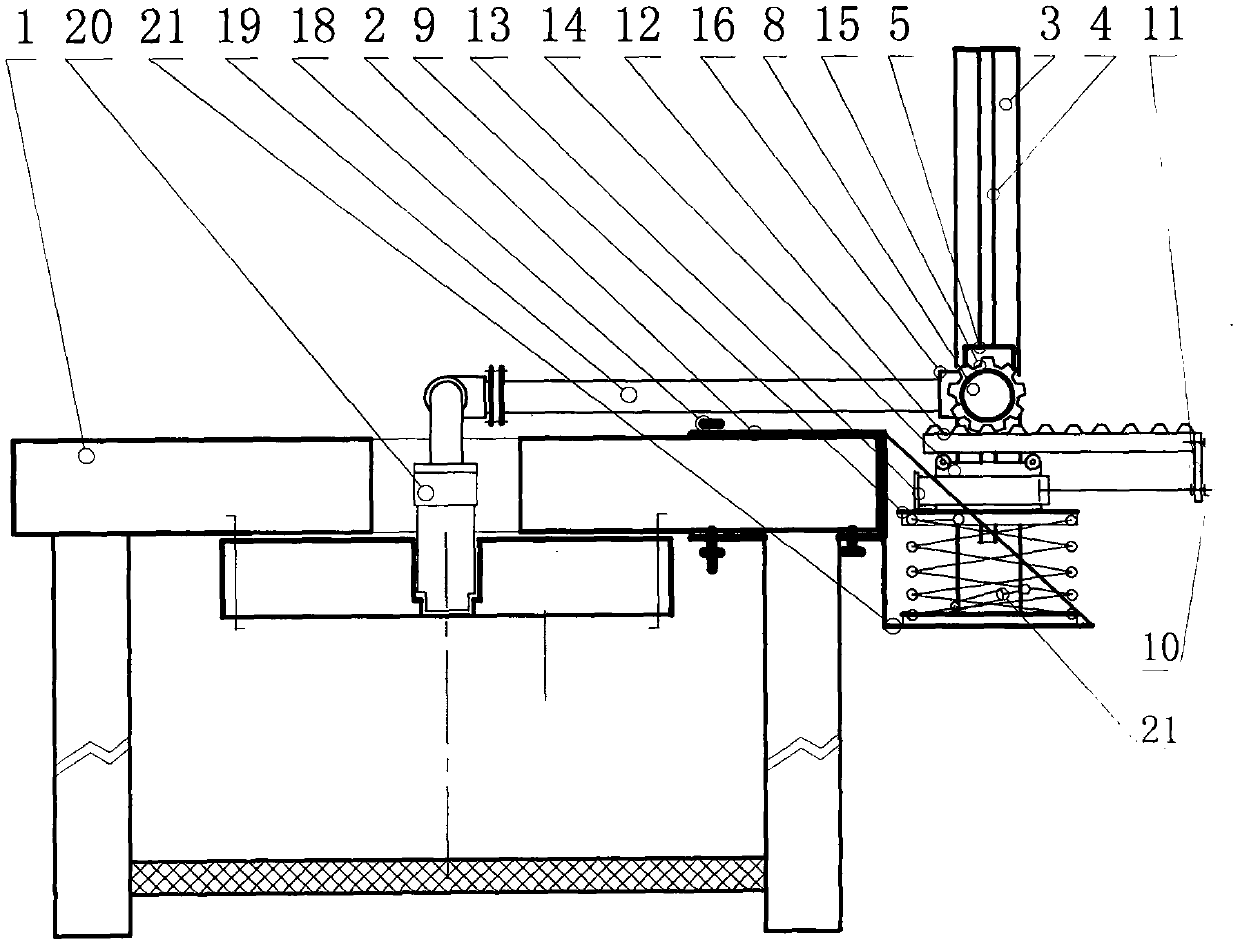

Electric displacement setting-out device and lofting method of heteromorphic spiral body intersecting line

ActiveCN109366446AQuick drawGuaranteed stakeout accuracyOther workshop equipmentReading levelEngineering

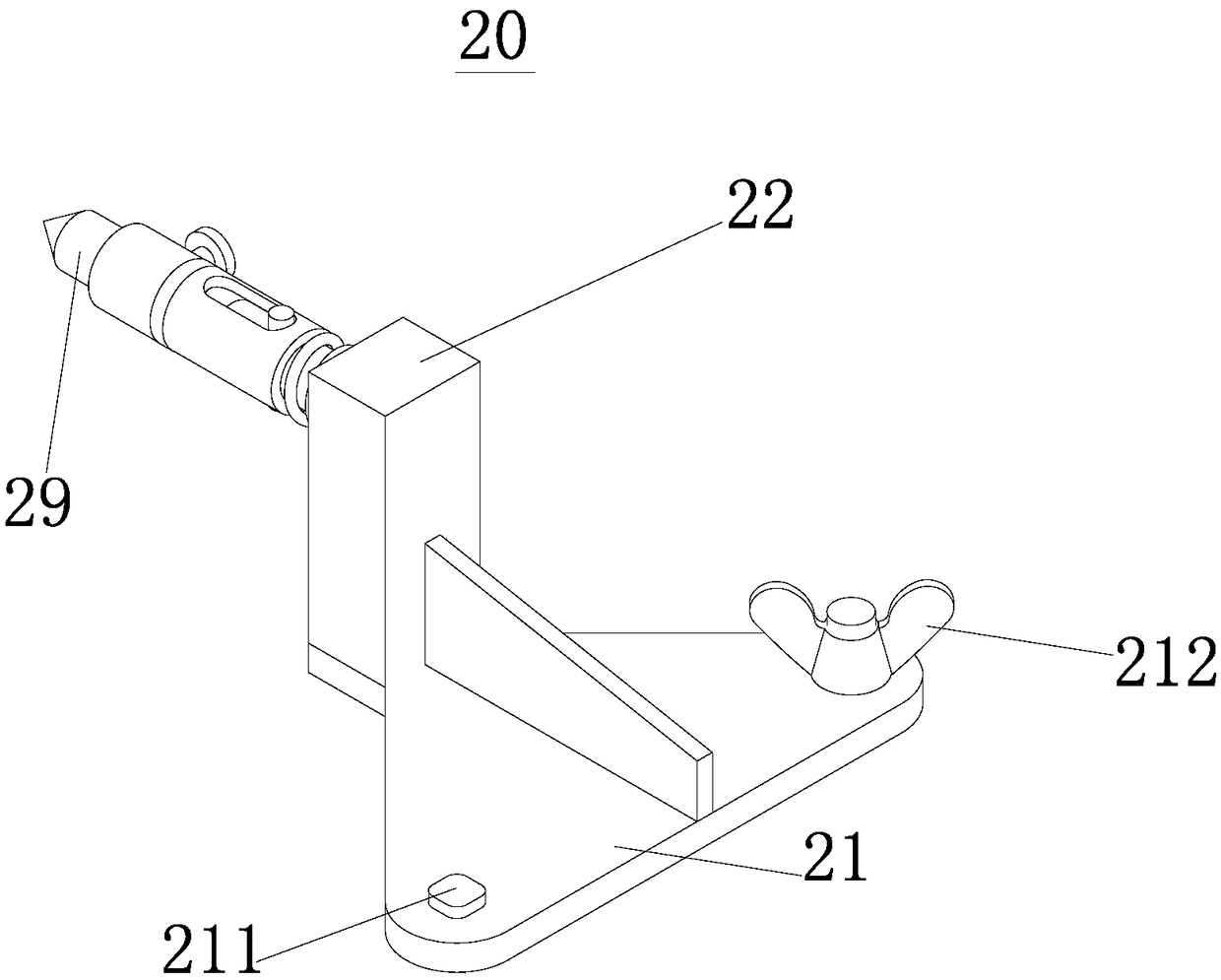

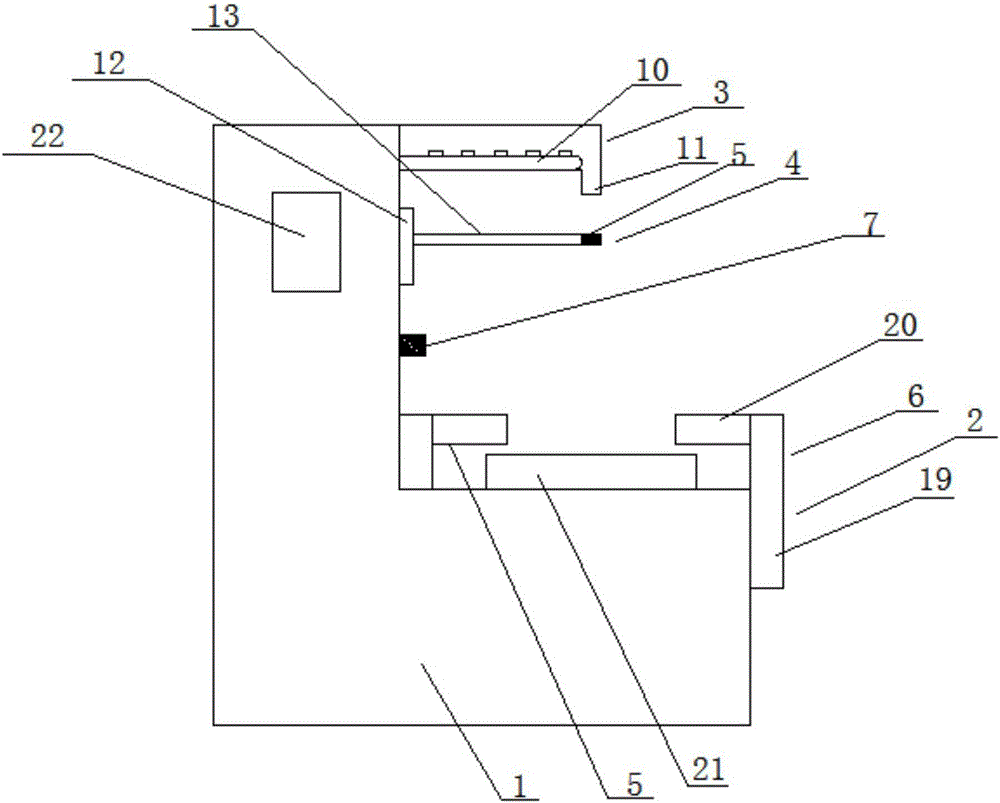

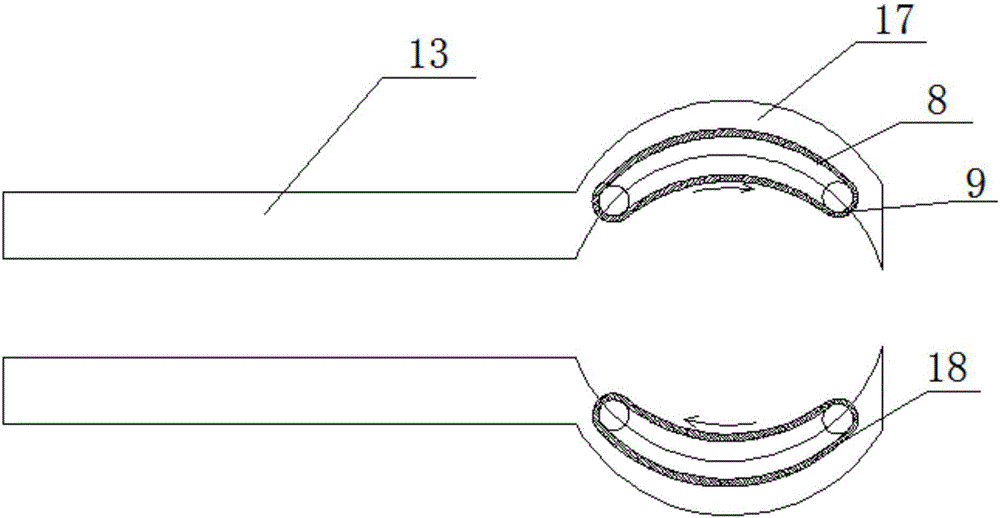

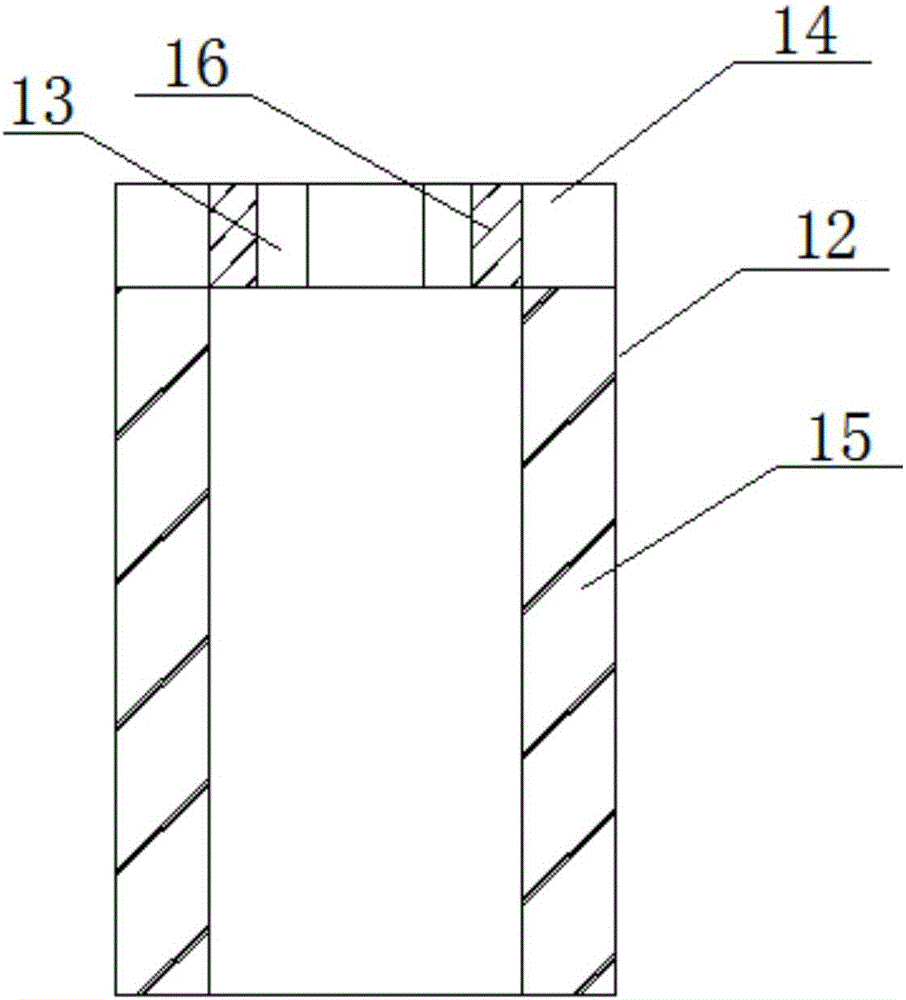

The invention relates to an electric displacement setting-out device and a lofting method of a heteromorphic spiral body intersecting line. The electric displacement scoring device comprises a screw rod sliding platform and one or more setting-out mechanisms mounted on the screw rod sliding platform, wherein the screw rod slipway is used for driving the setting-out mechanism to move and score according to displacement information; each setting-out mechanism adopts a self-adapting control structure, and comprises a bottom plate, a bracket, a fixing rod, a rod sleeve, a spring and a pen head; each bracket is vertically mounted at one end of the corresponding bottom plate; each fixing rod is horizontally mounted at the upper end of the corresponding bracket; each rod sleeve is arranged on thecorresponding fixing rod in a sleeving manner; each pen head is mounted at the front end of the corresponding rod sleeve; and each spring is arranged between the corresponding rod sleeve and the corresponding bracket, and is arranged on the corresponding fixing rod in a sleeving manner. The method disclosed by the invention adopts the setting-out device for lofting, so that the problems of a conventional two-dimensional three-view setting-out method is tedious in steps, and requirements for space imagination capacity and orthographic view reading level of constructors are high, are avoided, and the problems that when an intersecting line of a large-diameter circular pipe placed on a positioner is lofted, avoiding the positioner is needed, and during section relay lofting on the surface ofthe circular pipe, positioning is easy to be inaccurate, and the construction and the mounting accuracy are influenced, are solved.

Owner:CHINA FIRST METALLURGICAL GROUP

High-efficiency low-cost industrial full-automatic capping machine

InactiveCN105731327AAppropriate tightnessWide range of applicationsCapsThreaded caps applicationLarge applicationsPressure sensor

The invention discloses a high-efficiency low-cost industrial full-automatic capping machine which comprises a machine frame, a conveying device, a control device, a support device, a cap feeding device and a tightening device, wherein the cap feeding device, the tightening device, the support device and the conveying device are arranged on the machine frame from top to bottom in sequence; the support device comprises an inner support device and an outer support device; an ultrasonic detector is arranged above the inner support device; one side end part of the tightening device is arranged in a sliding way; rotary chains are arranged on the inner side of the other side end part of the tightening device; and pressure sensors are arranged on the rotary chains. The high-efficiency low-cost industrial full-automatic capping machine can realize automation of a capping process, can well control the cap tightening degree, reduces the production cost and the working difficult, increases the working efficiency and has good practicability and a large application range.

Owner:台州绿创包装容器股份有限公司

Net-shaped supporting type large cover for titanium sponge reduction distillation production

PendingCN112375922AGuarantee product qualityPrevent bump deformationStructural engineeringMaterials science

The invention relates to a net-shaped supporting type large cover for titanium sponge reduction distillation production. The net-shaped supporting type large cover comprises a large flange and furthercomprises a pressurizing pipe, a cylinder body, a large cover bottom plate, an evacuation pipe sleeve, a heater shell, a vacuum channel pipe, a feeding pipe sleeve and a large cover evacuation pipe which are arranged on the large flange. The large flange is connected with the large cover bottom plate through the cylinder body to form a closed cavity, and a heat preservation layer is arranged in the closed cavity. A net-shaped supporting structure is arranged between the large flange and the large cover bottom plate and is formed in a casting manner. The net-shaped supporting structure is composed of arc plates A, B and C and rib plates A and B; the rib plates B are arranged at the two sides of the feeding pipe sleeve to form triangular arrangement; under the action of the net-shaped supporting structure, concave-convex deformation and weld joint tension fracture of the large cover bottom plate are avoided, the air inlet rate of a titanium sponge product is reduced, and the productionquality of titanium sponge is guaranteed; and deformation of the feeding pipe sleeve, the evacuation pipe sleeve and the vacuum channel pipe is avoided, and the labor difficulty of assembling a feeding pipe and a vacuum evacuation pipe by an operator is reduced.

Owner:ZUNYI TITANIUM

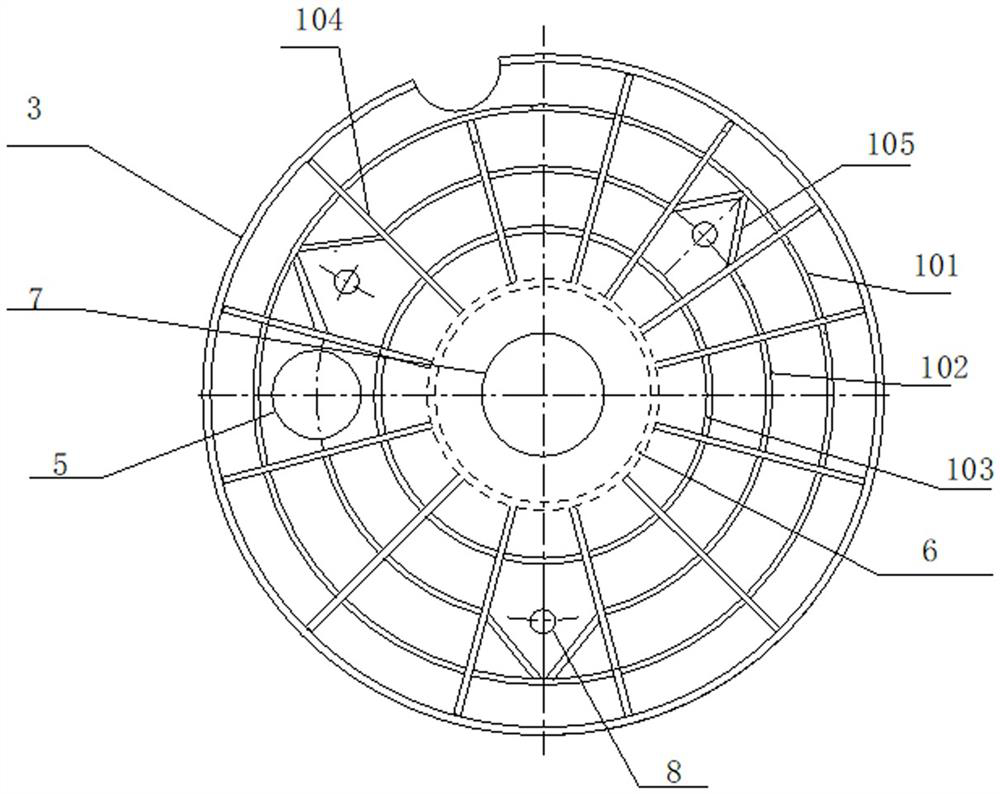

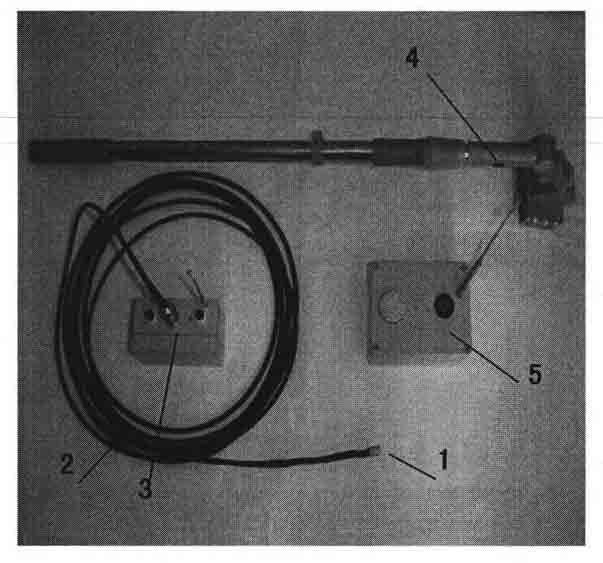

Blocking site detection locator of electric wire protective sleeve

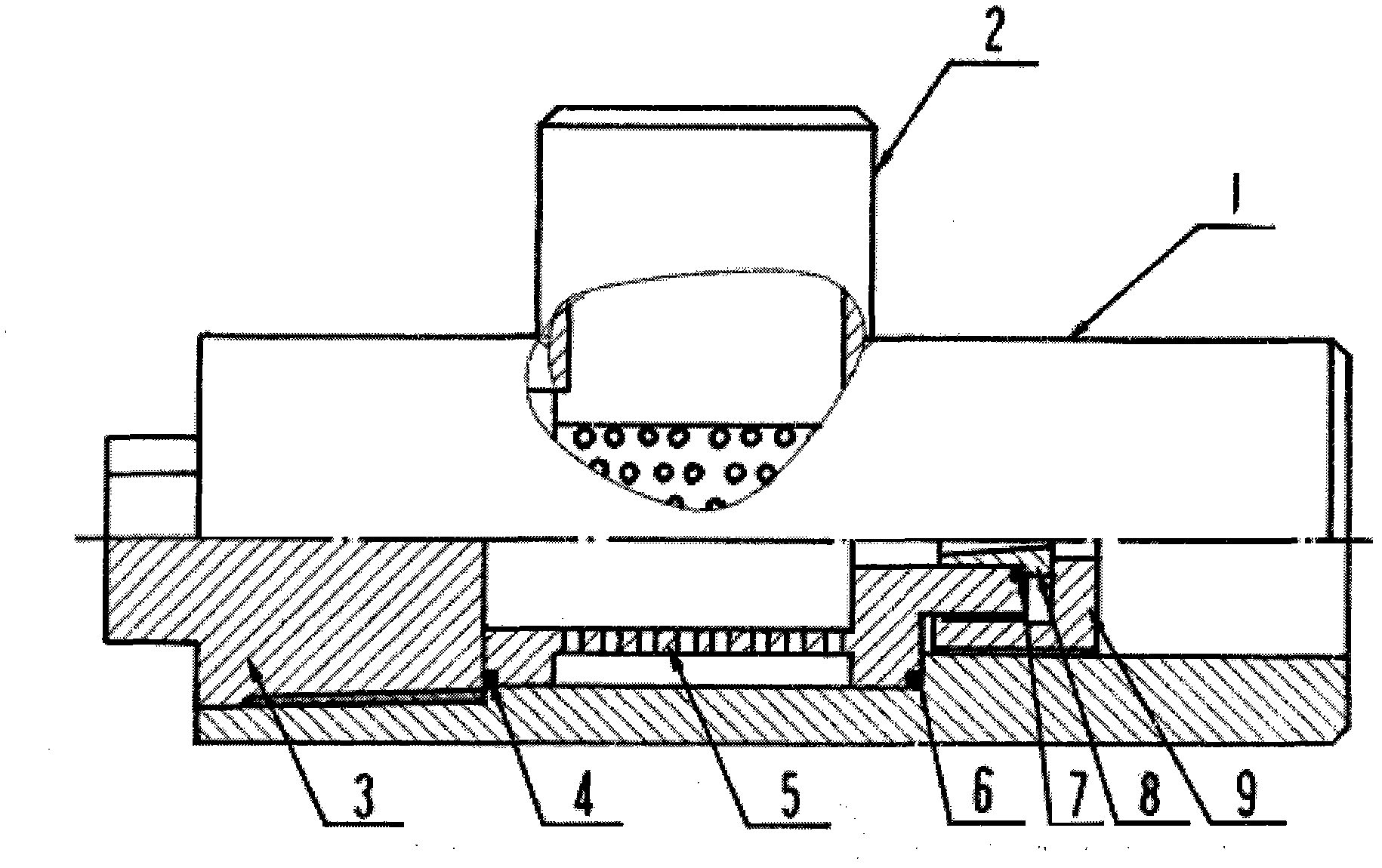

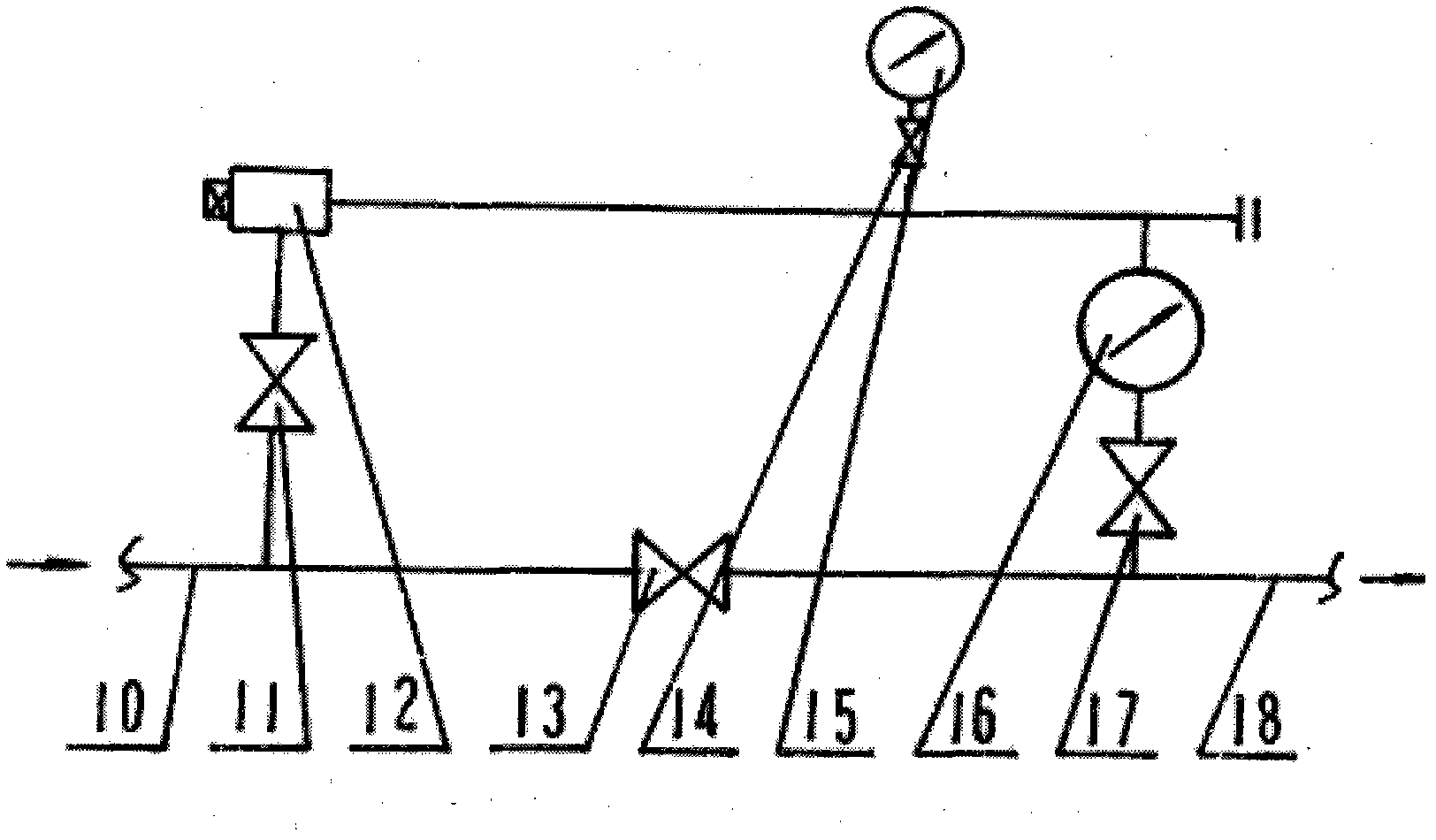

InactiveCN101988970AHigh sensitivityImprove accuracyElectric/magnetic detectionAcoustic wave reradiationEngineeringElectric wire

A blocking site detection locator of the electric wire protective sleeve relates to a detection locating device of the blocking site of the electric wire protective sleeve. The detection locator is especially suitable for the detection and location of the blocking site of the electric wire protective sleeve in the building electrical construction which is laid in the concrete or wall. The detection locator comprises a magnetic induction device (1) and a detection cable which are inserted in the electric wire protective sleeve, a trigger device (3), a detection locating device (4) moving above the electric wire protective sleeve and a portable sound-and-light alarm (5); and the detection locator is convenient to operate, is economical and reasonable, and can realize accurate positioning.

Owner:山东省建设集团有限公司 +1

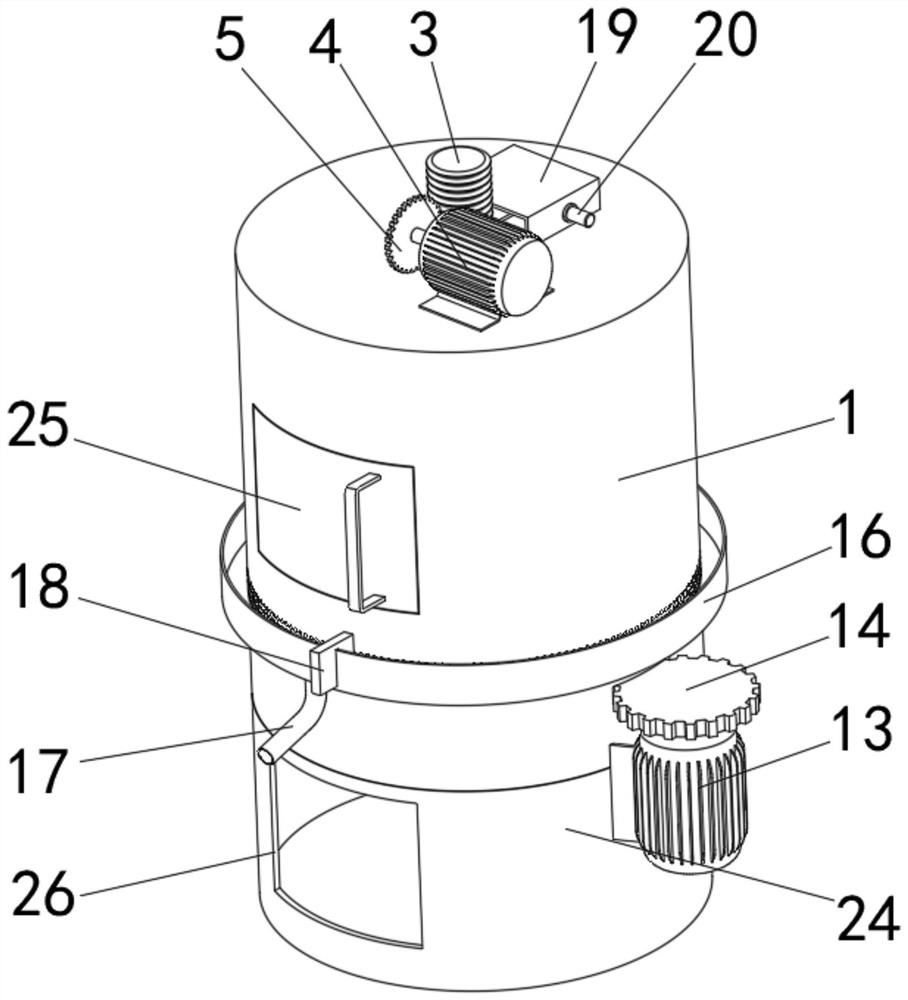

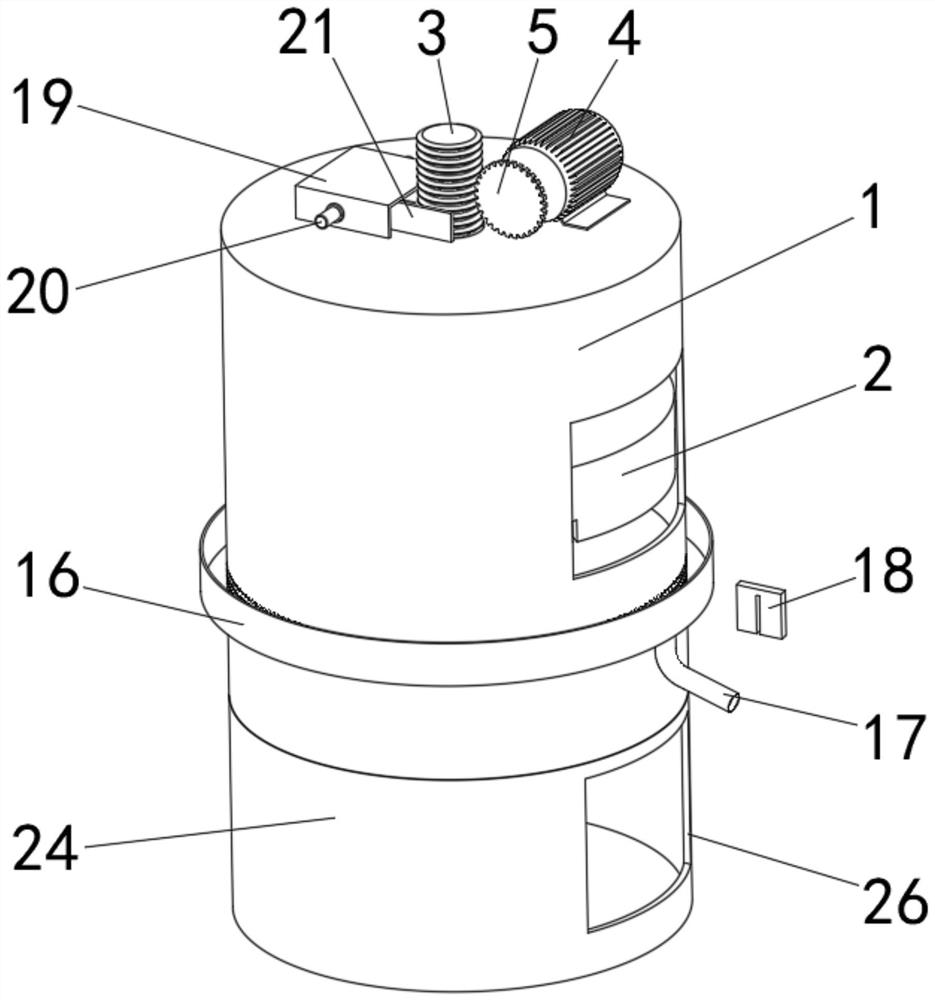

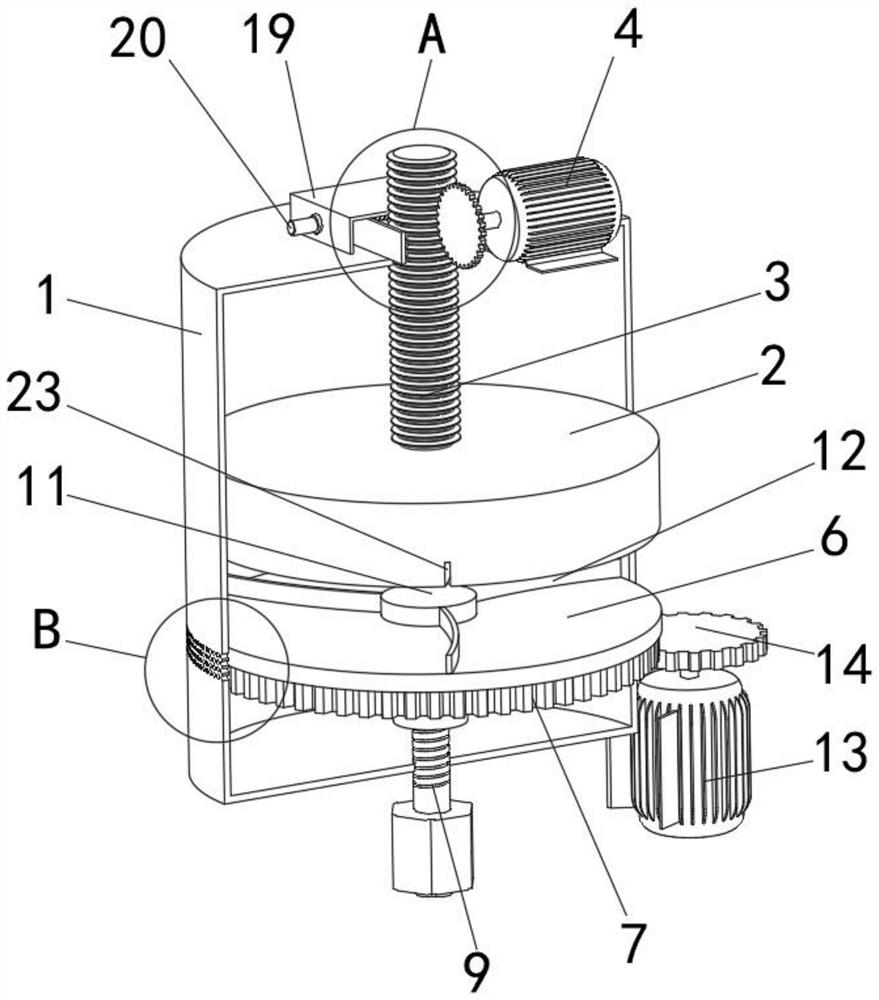

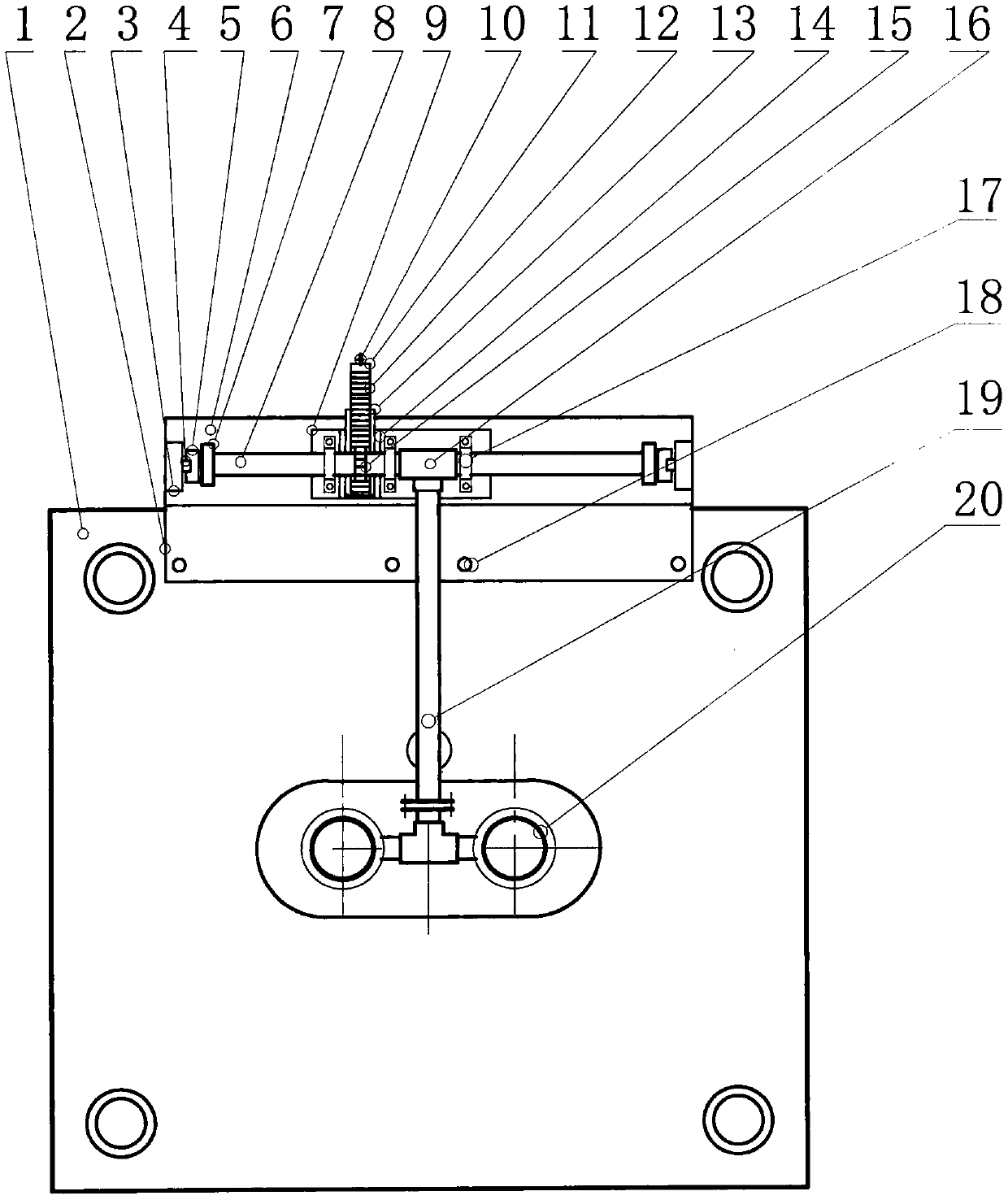

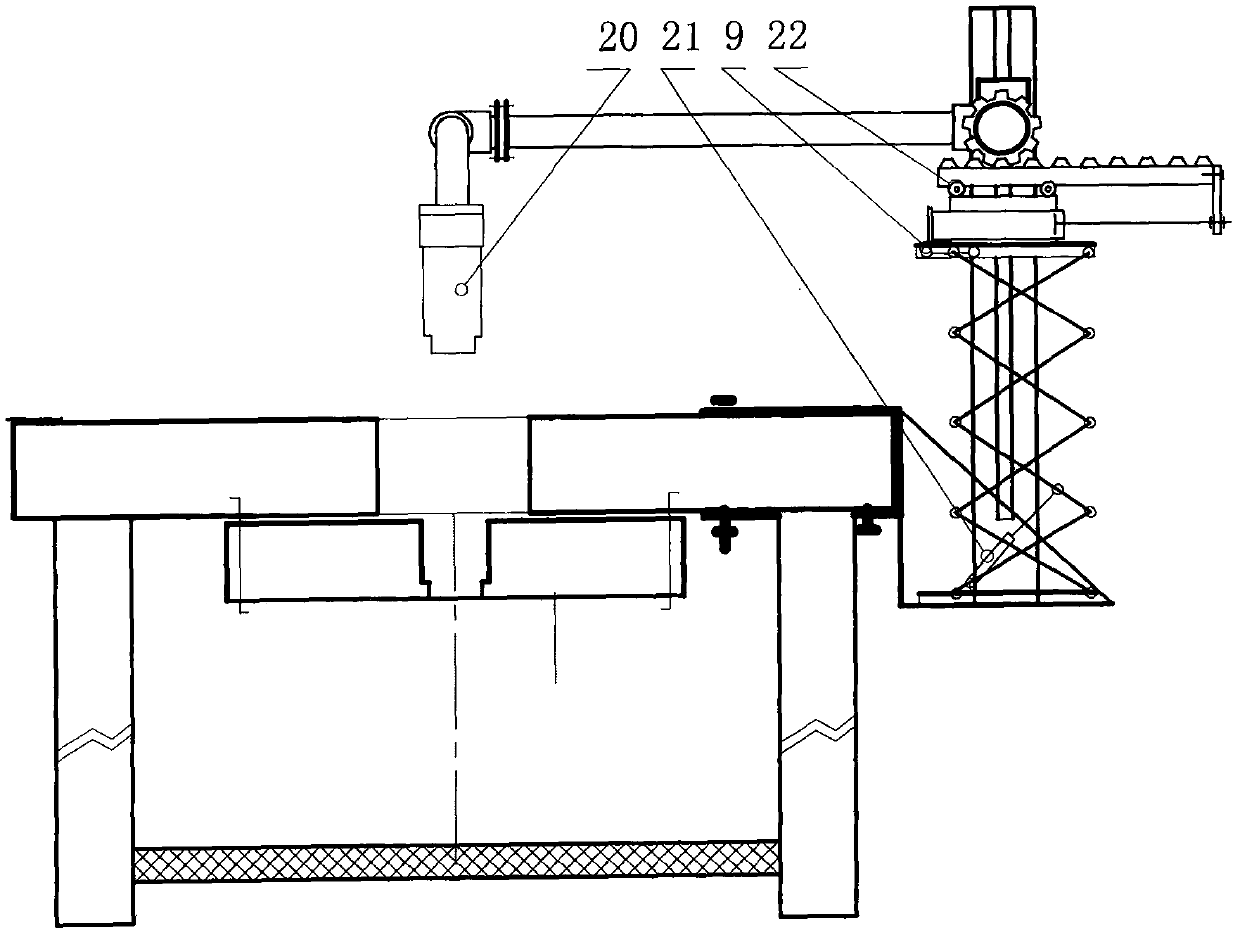

Preparation method and preparation equipment of biomimetic mineralized collagen scaffolds

InactiveCN113713936AReduce labor difficultyEasy to operateGrain treatmentsCompression moldingGear wheel

The invention belongs to the technical field of mineralized collagen scaffolds, and discloses preparation equipment of biomimetic mineralized collagen scaffolds. The preparation equipment comprises a pressing chamber, a pressing plate is movably connected to an inner cavity of the pressing chamber, an annular rack is fixedly mounted on the top surface of the pressing plate, a pressing motor is fixedly mounted on the top surface of the pressing chamber, the output end of the pressing motor is fixedly sleeved with a first gear, and the inner cavity of the pressing chamber is movably connected with a grinding plate. According to the preparation equipment, a third gear is driven by a grinding motor to rotate, the grinding plate is driven to rotate when the third gear rotates, the pressing plate can be driven to rotate in the opposite direction when the grinding plate rotates through meshing of a driving gear, a planetary gear and a gear ring, during rotation, after compression molding, through downward movement of the pressing plate and the grinding plate, a biomimetic collagen block can be directly ground, the biomimetic collagen block does not need to be taken out through a special tool, operation is easy, and the labor difficulty of operators is lowered.

Owner:成都市天使之翼健康管理咨询有限责任公司

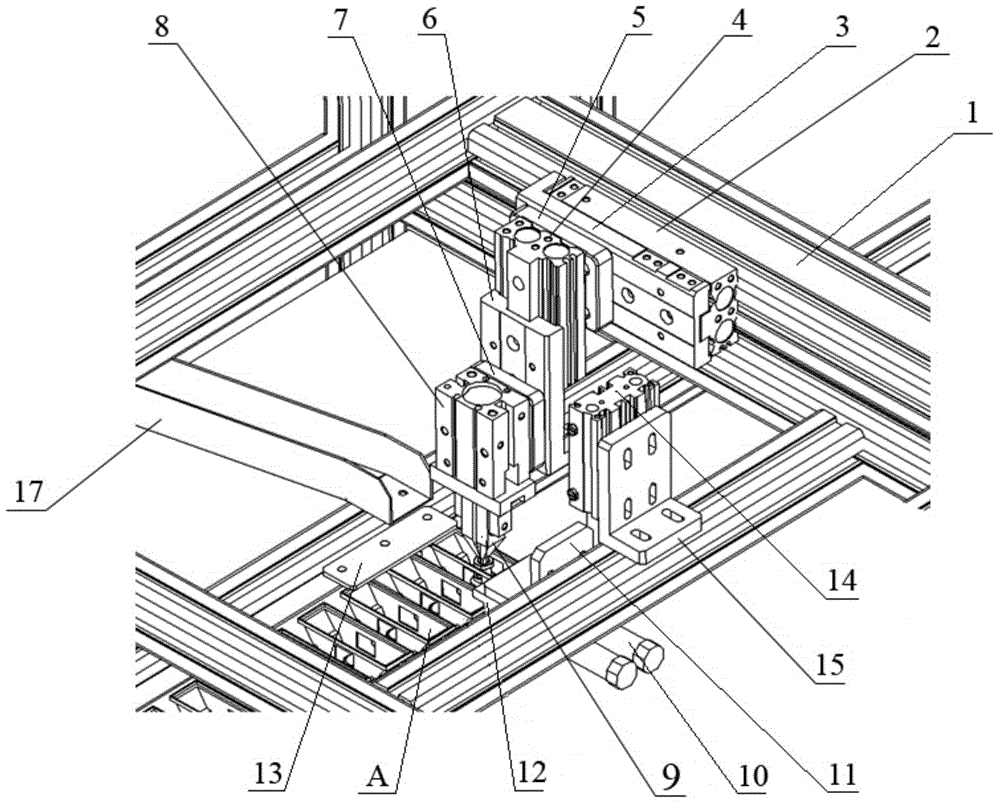

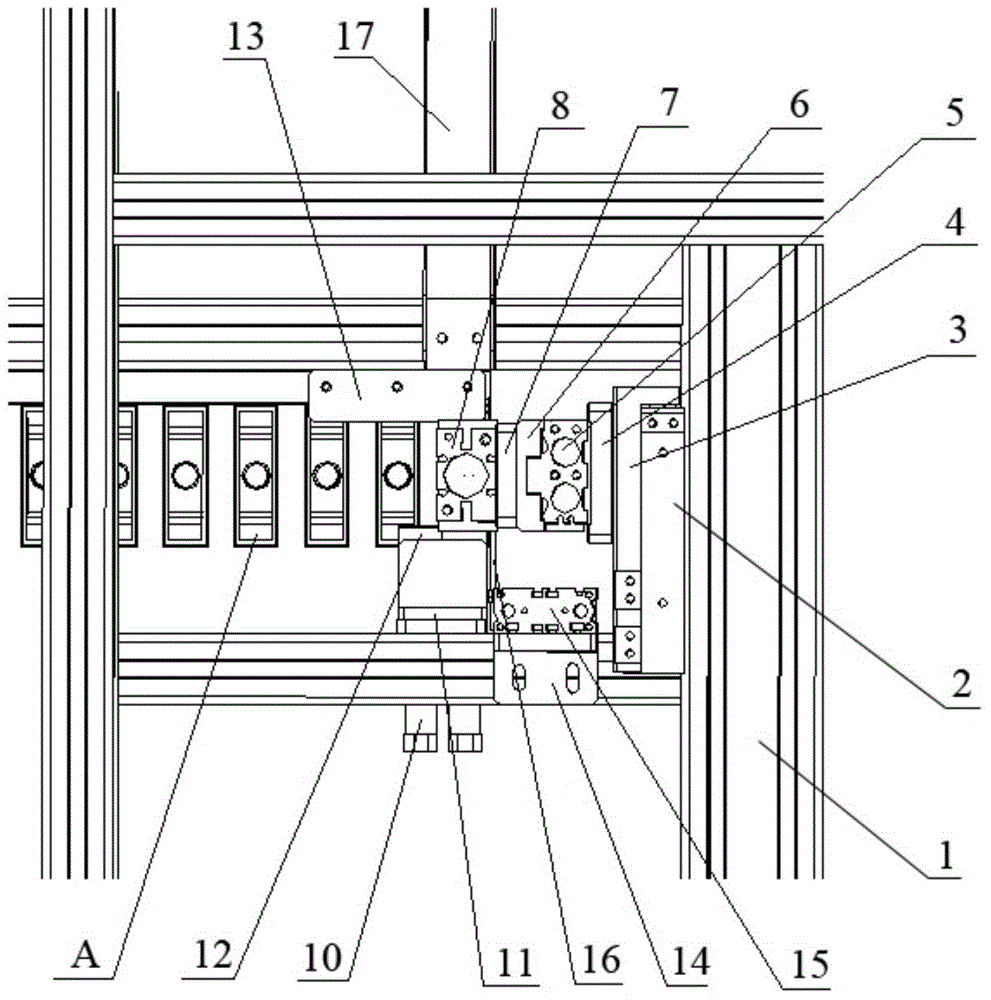

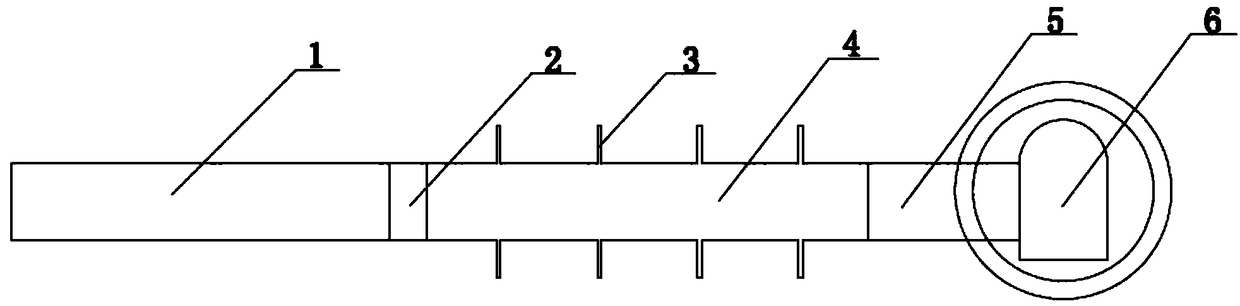

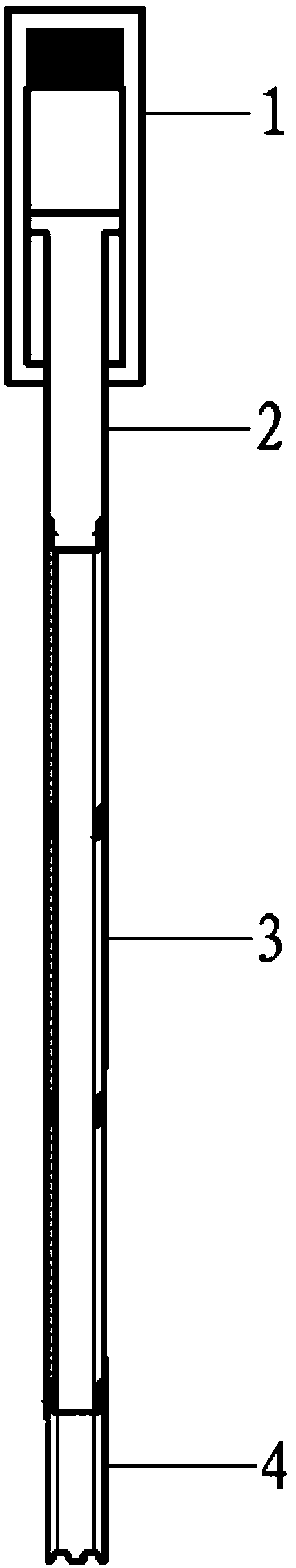

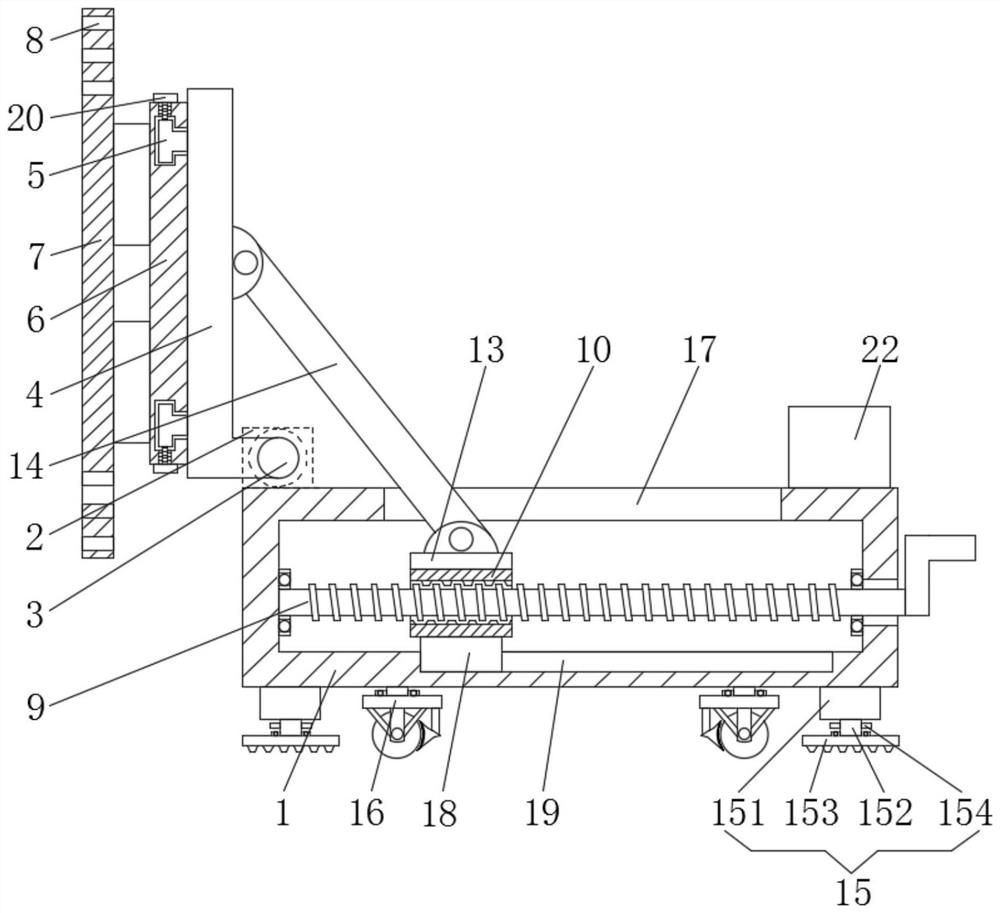

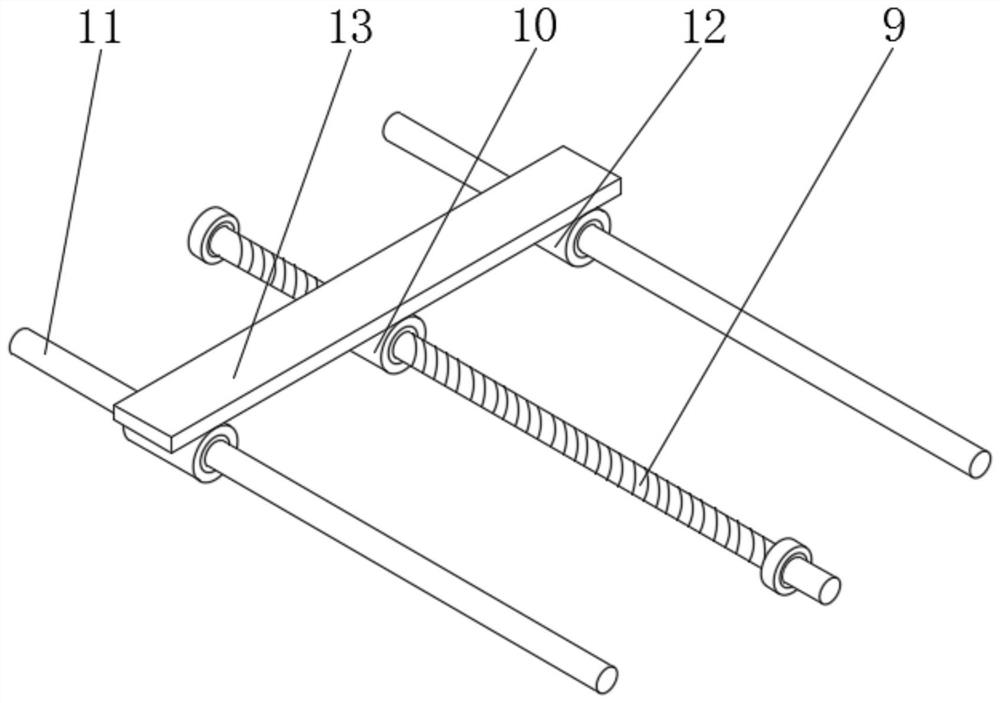

Electric displacement scriber and setting-out method of pipeline intersecting lines

ActiveCN109366445AGuaranteed stakeout accuracyReduce labor difficultyOther workshop equipmentCamMechanical engineering

The invention relates to an electric displacement scriber and a setting-out method of pipeline intersecting lines. The electric displacement scriber comprises a screw rod sliding table and a scribingdevice installed on the screw rod sliding table, and the screw rod sliding table drives the scribing device to move and scribe according to displacement information; the scribing device comprises a support, a driving mechanism and a scribing mechanism; the driving mechanism and the scribing mechanism are installed on the support, and a cam is installed at the output end of the driving mechanism; and the scribing mechanism comprises a connecting rod, a driven base and a scribing end, the driven base and the scribing end are installed at the two ends of the connecting rod, the driven base alwaysmakes contact with the cam, and the scribing end is used for scribing on a round pipe. The electric displacement scriber is adopted for the setting-out method, the tedious steps of a conventional two-dimensional three-view drawing method and the requirements for high spatial imagination ability and high graph identification level of constructors are avoided, the setting-out requirement of the intersecting lines can be met when large pipelines are connected, meanwhile the setting-out requirement of intersecting lines of a special-shaped spiral steel structure can be satisfied, the setting-outprecision is guaranteed, the operation and labor difficulty is reduced, and the construction cost is reduced.

Owner:CHINA FIRST METALLURGICAL GROUP

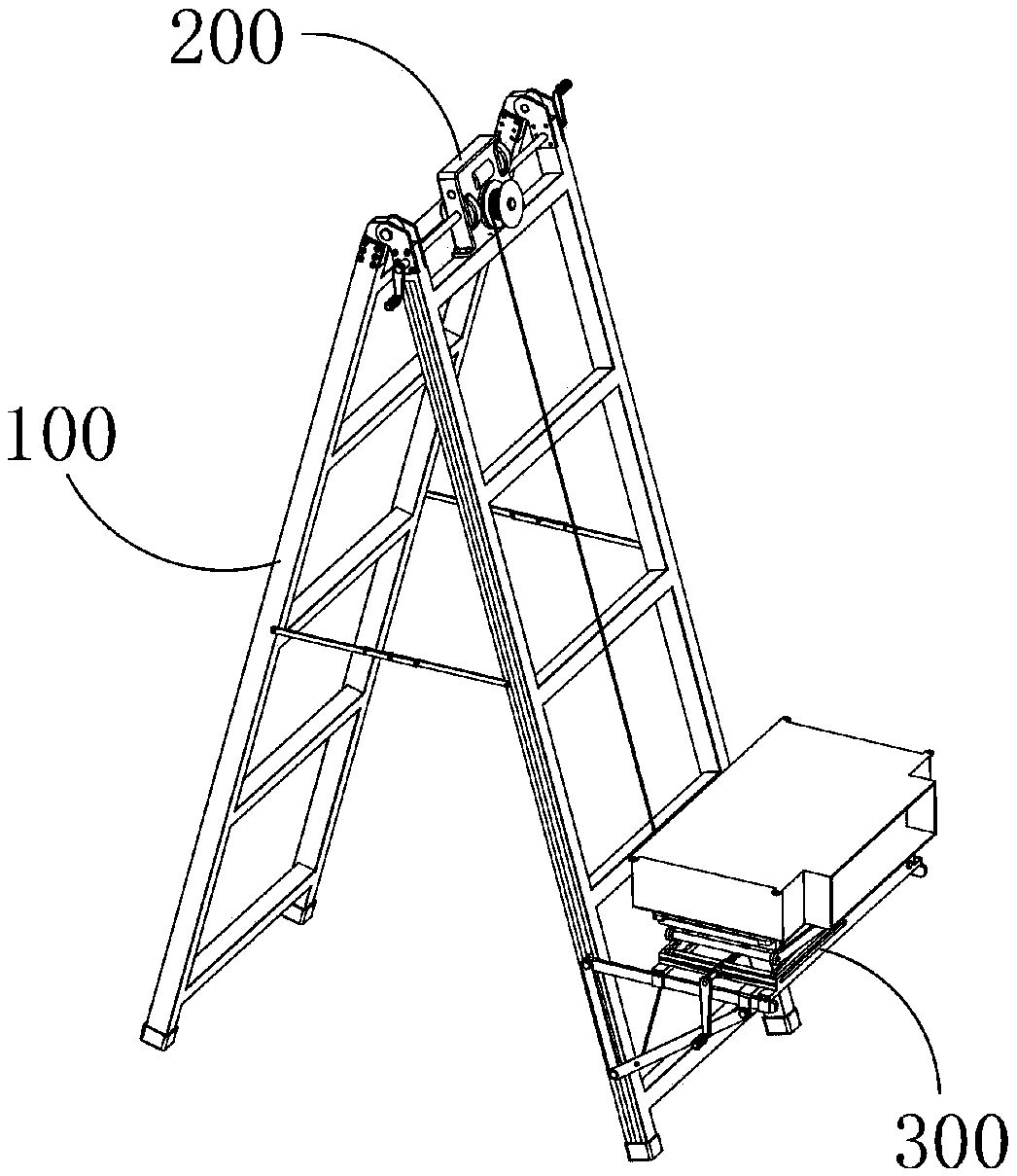

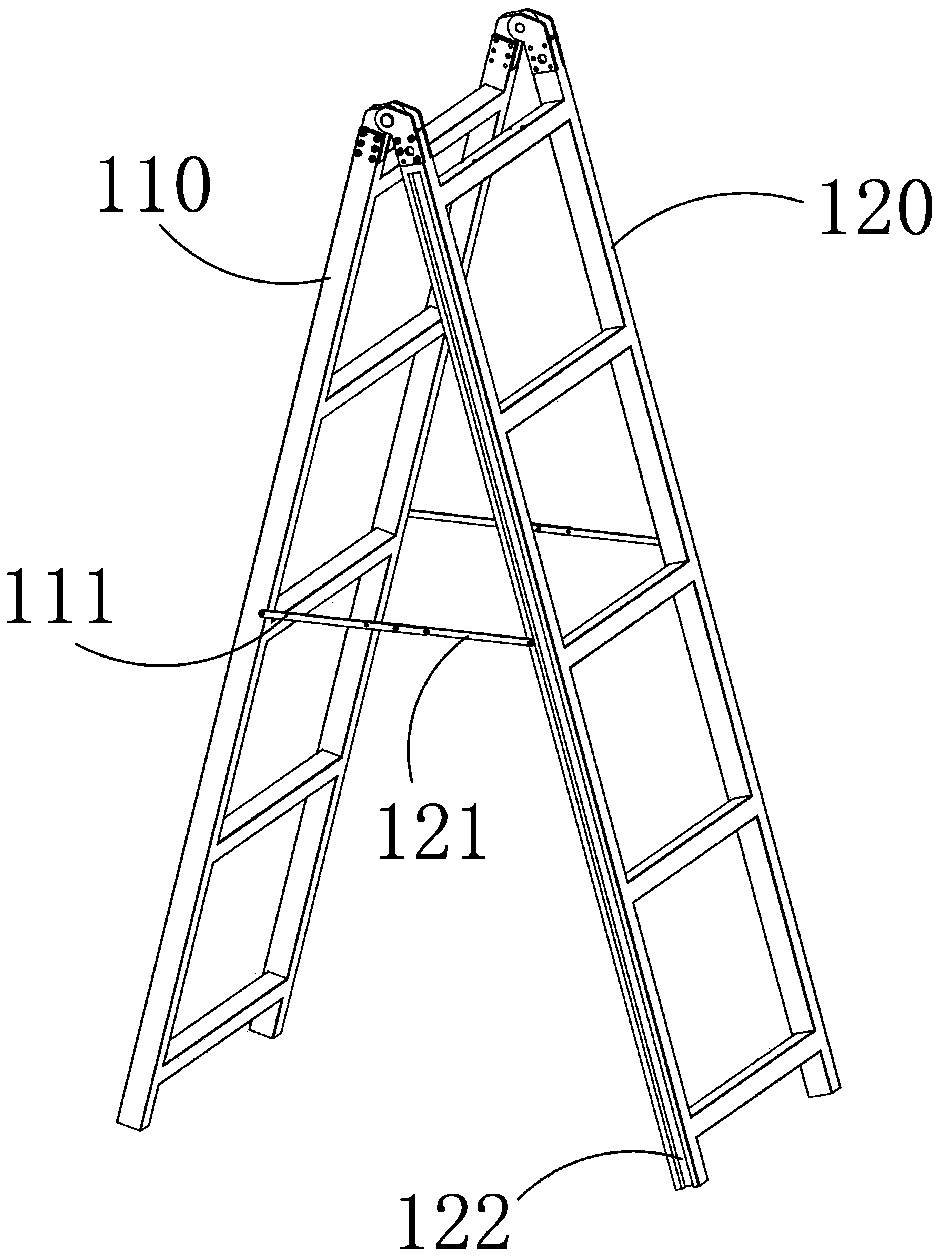

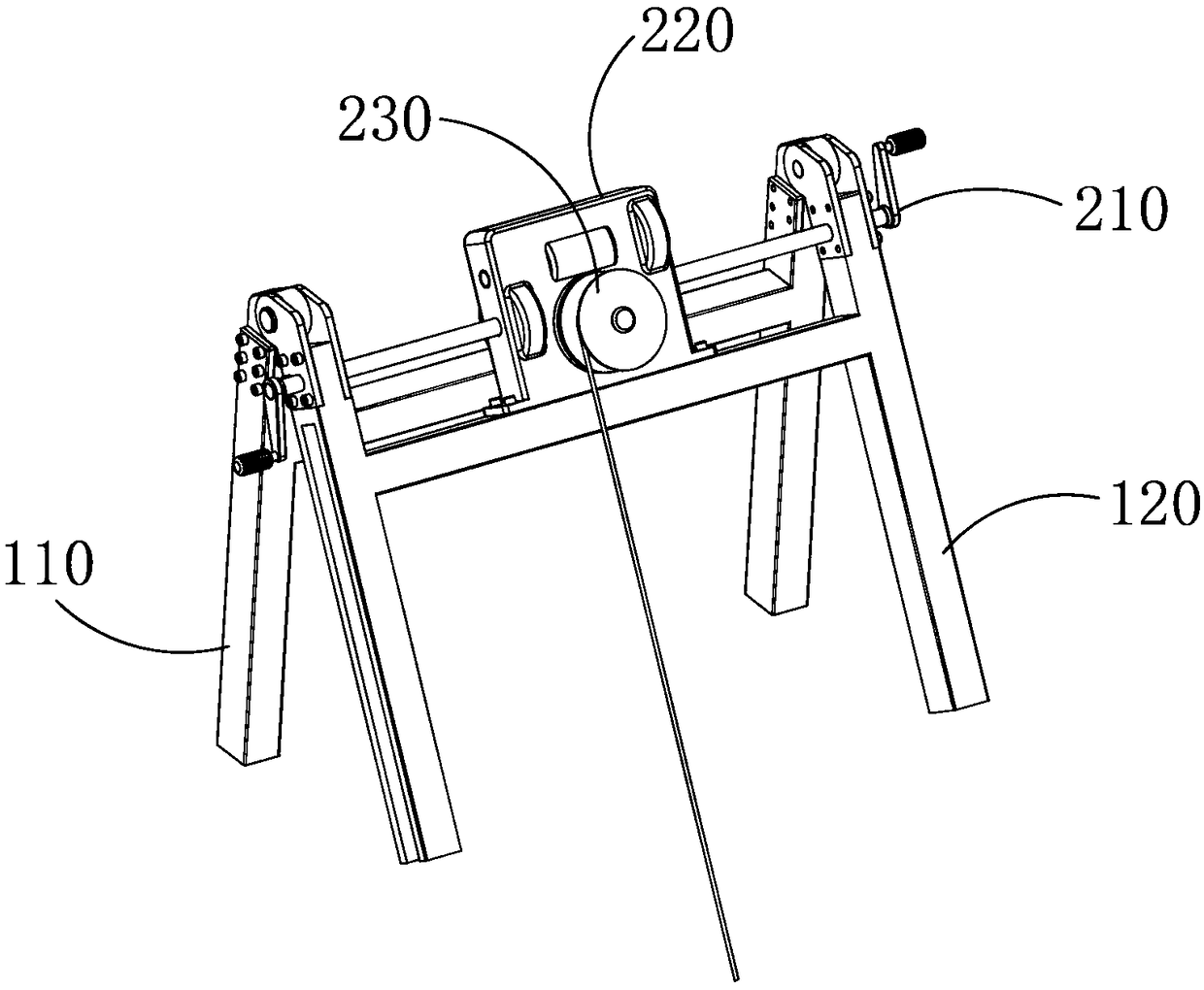

Manual lifting type trestle ladder for mounting air conditioners, ceiling lamps and other electric appliances

ActiveCN109162630AReduce labor intensity and riskReduce labor intensityLaddersEngineeringIndustrial engineering

Owner:嘉兴市康立德构件股份有限公司

Overturning equipment for simple gravity casting machine

InactiveCN110369695ARaise the gradeFacilitate automatic castingMould handling equipmentsMarine engineeringAlloy

Overturning equipment for a simple gravity casting machine comprises a positioning mechanism, a lifting mechanism, overturning mechanisms and a control mechanism. A positioning frame is arranged on anupper die table. A positioning platform is arranged at the lower end of the positioning frame. Guide columns, guide rails and overturning shafts are correspondingly arranged on the two sides of the positioning platform. A lifting platform is arranged on the positioning platform. A lifting oil cylinder is arranged in the lifting platform. Bearing seats are arranged on the lifting platform. Rack frames are arranged in the two bearing seats. The overturning mechanisms are arranged on the rack frames. According to the overturning equipment for the simple gravity casting machine, the positioning frame is arranged on the upper die table, the overturning equipment is suitable for an original lower movable die gravity casting machine, also suitable for a modern upper movable die gravity casting machine, automatic casting of a spoon machine is facilitated, and direct installation is facilitated; the automation equipment which repetitively uses gates is more popular and intelligent; and the equipment has low investment and also increases the process yield of aluminum alloy metal die gravity casting products.

Owner:WUXI XIYANGKANG SCI & TECH

Bottom frame for container and container and container type mobile house thereof

InactiveCN108951871ARapid productionEfficient productionLarge containersBuilding constructionsEngineeringScrew thread

The invention discloses a bottom frame for a container and the container and a container type mobile house thereof. The bottom frame for the container includes a lower end beam, a lower door beam, twobottom side beams and multiple bottom cross beams. The lower end beam, the lower door beam, and the two bottom side beams are connected to form an outer frame of the bottom frame, the bottom cross beams are connected between the bottom side beams in a crossing mode. The bottom frame for the container is characterized in that the bottom cross beams are spirally connected with the bottom side beams, multiple first grooves or first protrusions are formed in the bottom side beams, internal threads are formed in the first grooves, and external threads are formed on the outer sides of the first protrusions; and external threads matched with the first grooves are formed on the end portions of the bottom cross beams, or cavities are formed in the end portions of the bottom cross beams, internal threads matched with the first protrusions are formed in the cavities. The bottom frame for the container improves the working efficiency of the container, greatly reduces industrial pollution, and reduces energy consumption.

Owner:邵妮

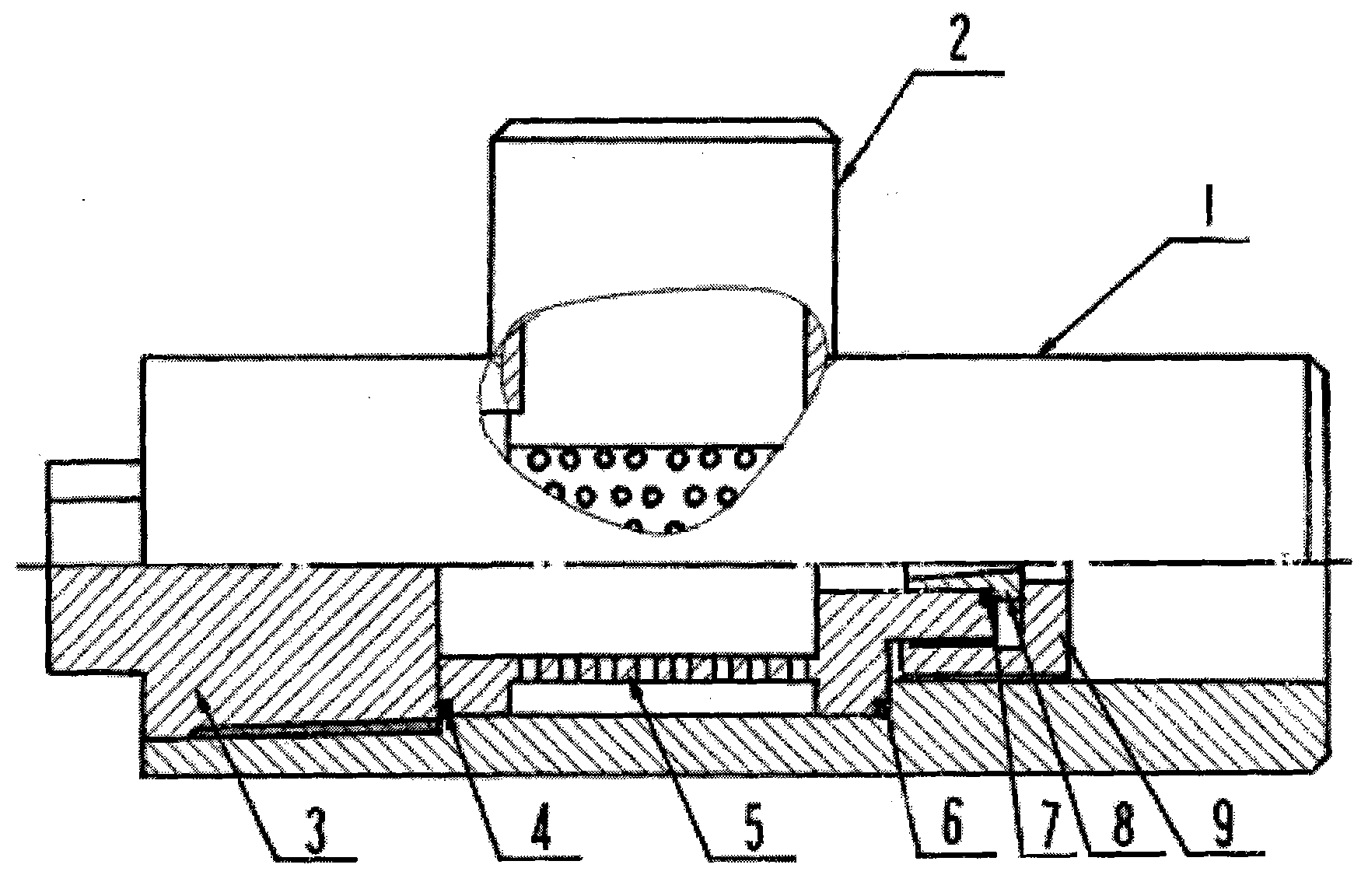

Thickened oil watering regulation-free device

InactiveCN102022102AReduce labor difficultyImprove the accuracy of water meteringFluid removalOil fieldEngineering

A thickened oil watering regulation-free device used in oil field comprises a shell, an inlet, a screwed plug, a sealing ring, a filter screen, a nozzle and a pressing cap, wherein the device has a T-shaped cylinder structure; the left end of the shell is provided with internal threads while the interior of the right end is provided with internal threads; the external threads on the right end of the filter screen are connected to the internal threads of the pressing cap; the filter screen and the pressing cap tightly press the nozzle; the sealing ring is arranged between the filter screen and the nozzle; the external threads on the pressing cap are connected to the internal threads inside the right end of the shell; the sealing ring is respectively arranged between the left and right ends of the filter screen and the shell; the screwed plug is connected to the internal threads of the left end of the shell; and the inlet is arranged in the middle part of the shell and is opposite to the filter screen. The device of the invention is simple in structure and convenient in assembling, can relieve the working difficulty of staff, can increase the accuracy of measuring oil well watering and efficiently avoid the inaccurate watering measurement caused by watering fluctuation, at the same time, the device can increase the crude oil measuring accuracy and is significant to completely and accurately take the primary data and draw up the extracting allocation and development program in the oil-field development process.

Owner:CHINA PETROLEUM & CHEM CORP +1

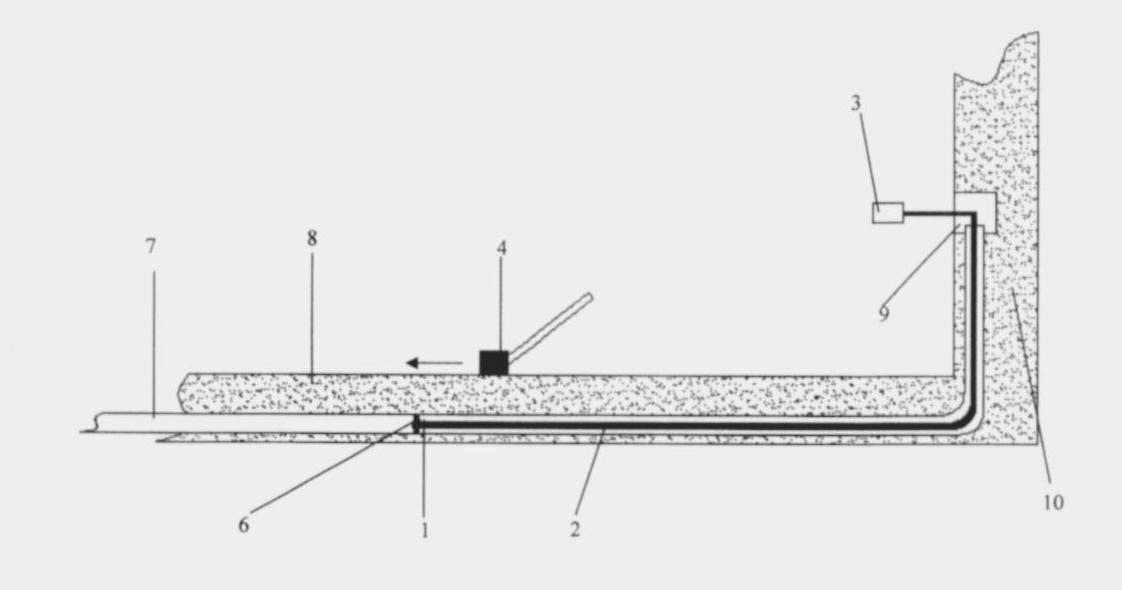

Safe blocking method for excavation disturbed area of roadway of high-level radioactive waste disposal repository

The invention discloses a safe blocking method for an excavation disturbed area of a roadway of a high-level radioactive waste disposal repository and relates to the technical field of high-level radioactive waste disposal. According to the safe blocking method, multiple sets of sealing sections are excavated in the roadway wall of the original high-level radioactive waste disposal repository andfilled with buffer material blocks, under the effect of underground water, the buffer material blocks expand, and thus the sealing sections are sealed. According to the safe blocking method for the excavation disturbed area of the roadway of the high-level radioactive waste disposal repository, when nuclides leak, flow into the roadway and flow through the excavation disturbed area, leakage of thenuclides from rock stratum gaps is effectively blocked through the sealing sections, so that the safety of the high-level radioactive waste disposal repository is guaranteed, and potential safety hazards of nuclide leakage is eliminated.

Owner:CHINA UNIV OF MINING & TECH

Automatic glue brushing machine

InactiveCN107983579AReduce labor intensityIncrease productivityLiquid surface applicatorsCoatingsEngineeringFully automatic

The invention discloses an automatic glue brushing machine, which comprises a glue aligning mechanism, a machine frame and a residue glue clearing mechanism, wherein a first support frame is arrangedat one side of the machine frame; a work table is arranged at the other side of the machine frame; the glue aligning mechanism is arranged under the first support frame; second support frames are symmetrically arranged at the left side and the right side above the work table; a rotating shaft is arranged at one side of the second support frame; the residue glue clearing mechanism is arranged at the other side of the second support frame; a glue brushing round wheel is arranged at the outer part of the rotating shaft. The glue is brushed onto a workpiece to be processed through a glue brushinground wheel structure; a glue water thickness detection sensor structure monitors the thickness of glue water on the surface of the glue brushing round wheel in real time, so that the glue dischargingfrom a glue discharging pipe can be timely controlled; the fully automatic glue brushing production is realized; the work intensity of workers is reduced; the production efficiency is greatly improved; the structure is simple; the design is reasonable; the manufacturing cost is low; the automatic glue brushing machine is applicable to medium-small-sized enterprise and factory production.

Owner:常州晗业智能科技有限公司

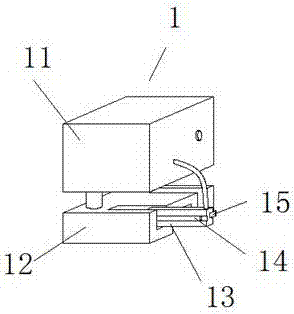

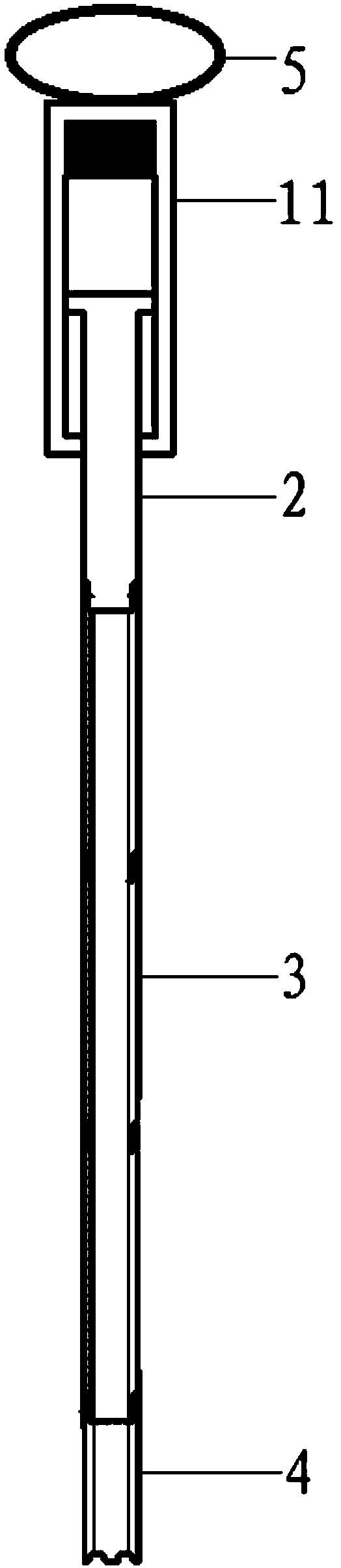

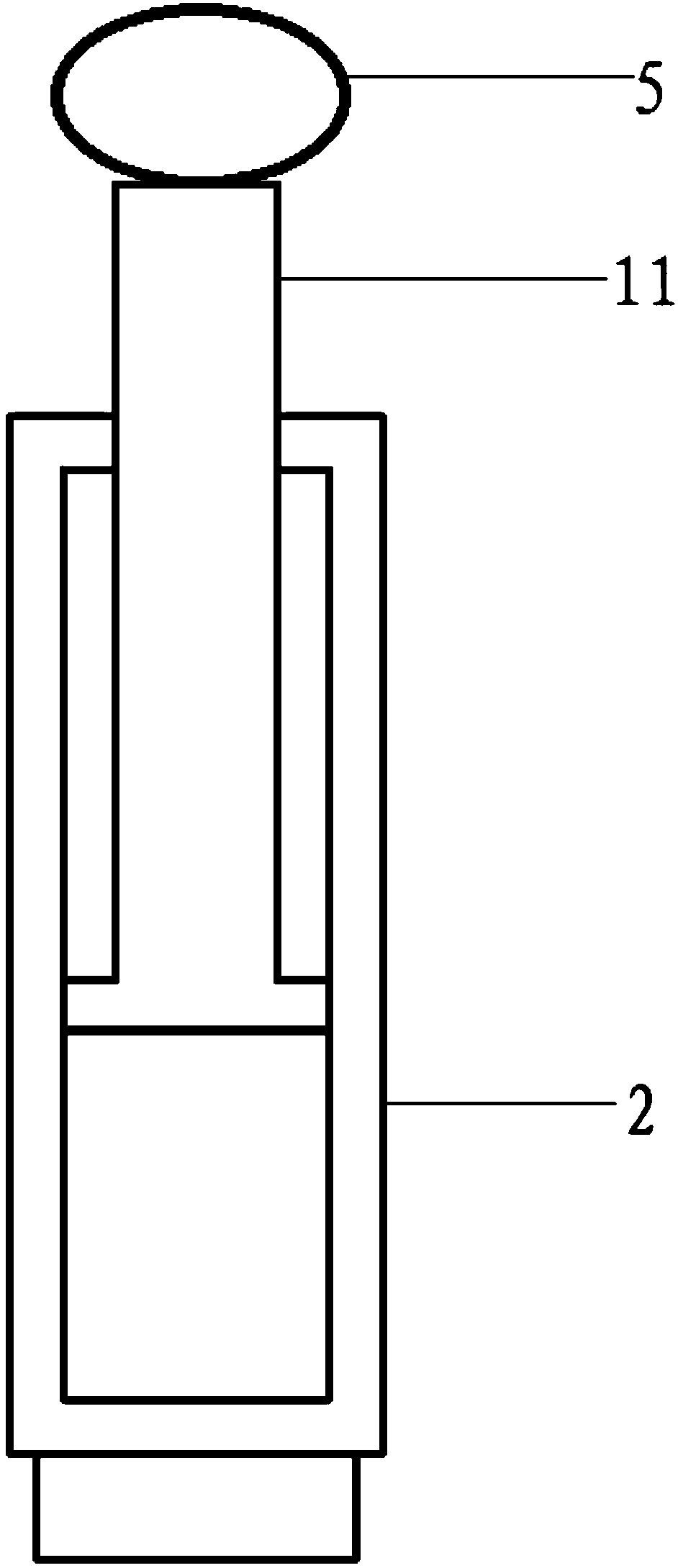

Soil sampling device and method

PendingCN109612772ARealize the sampling operationRaise to achieveWithdrawing sample devicesEngineeringDrill bit

The invention discloses a soil sampling device and method, and belongs to the field of soil environment. The device comprises an impact unit, a power transmitting component, one or more memory units and a drill bit unit. The impact unit comprises an impact component and a weighting component used for weighting the impact component. The weighting component is located on the impact component. The impact component can slide with respect to the power transmitting component. The power transmitting component, the memory units and the drill bit unit are sequentially connected. The weighting componentincreases load of the impact component, and downward gravity of the impact component is adopted to apply force to the drill bit unit. The device can be lifted by removing the weighting component fromthe impact component. Labor cost is reduced, and working efficiency is improved.

Owner:中水新科(北京)环保科技有限公司

Prefabricated wallboard supporting device for house building

InactiveCN112780073ASolve the problem of not being able to adjust the support positionSolve the problem of not being able to adjust the support angleBuilding material handlingArchitectural engineeringEngineering

The invention discloses a prefabricated wallboard supporting device for housing construction. The device comprises a moving box, positioning plates are fixedly connected to the front position and the rear position of the left side of the top of the moving box correspondingly, a rotating shaft is rotationally connected to the opposite sides of the two positioning plates through bearings, and an L-shaped plate is fixedly connected to the left side of the rotating shaft. By arranging the L-shaped plate, the sliding rail, the sliding plate and the limiting bolt, the supporting plate can move, by arranging the structure, the supporting device has the advantage that the supporting position can be adjusted when the supporting device is used, the problem that the supporting position cannot be adjusted when an original supporting device is used is solved, and therefore the supporting effect is prevented from being affected. Through the arrangement of the positioning plate, the rotating shaft, the screw rod, the sleeve, the sliding column, the sliding cylinder, the bearing plate and the push plate, the L-shaped plate can rotate conveniently, through the arrangement of the structure, the supporting device has the advantage that the supporting angle can be adjusted when the supporting device is used, and therefore the supporting effect is further prevented from being influenced.

Owner:山西建筑职业技术学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com