Automatic feeding segmentation equipment for bamboo wood

An automatic feeding and bamboo technology, which is applied in mechanical equipment, sawing equipment, wood processing equipment, etc., can solve the problems of high cost, large proportion of manual operation, and high labor intensity of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] specific implementation plan

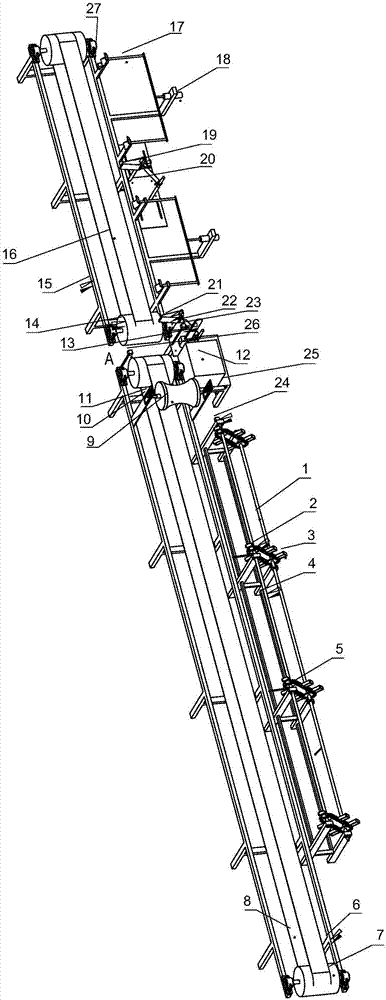

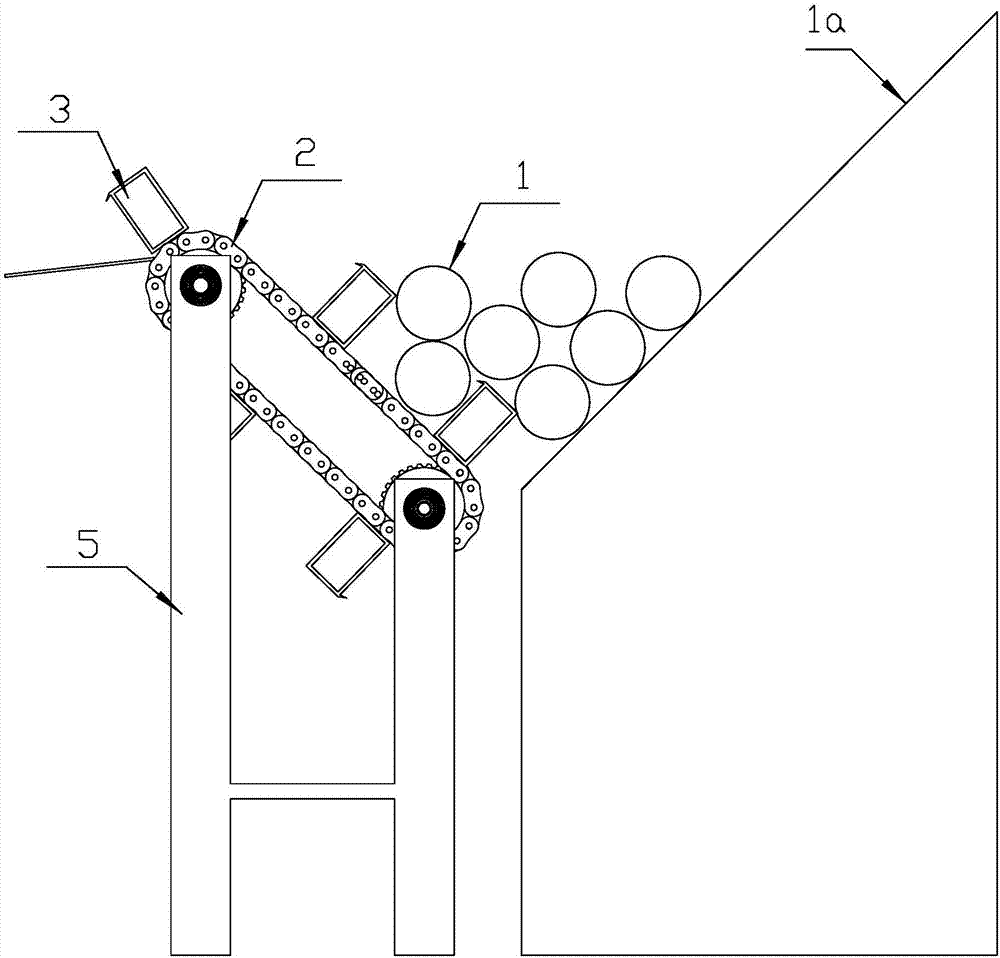

[0062] The bamboo material automatic feeding fixed section equipment as shown in Fig. 1, comprises a frame, is provided with raw bamboo feeding mechanism, raw bamboo feeding mechanism, raw bamboo cutting mechanism, bamboo in the bamboo joint identification mechanism on this frame Section baffle mechanism, discharge mechanism, discharge screening mechanism. Specifically, the frame includes a feeding frame 5, a feeding frame 6, a discharging frame 15 and a cutting frame 25, and the feeding mechanism is arranged on the feeding frame 5; On the frame 6; the discharging mechanism is arranged on the discharging frame 15; the cutting electric saw 12 is arranged on the cutting frame 25.

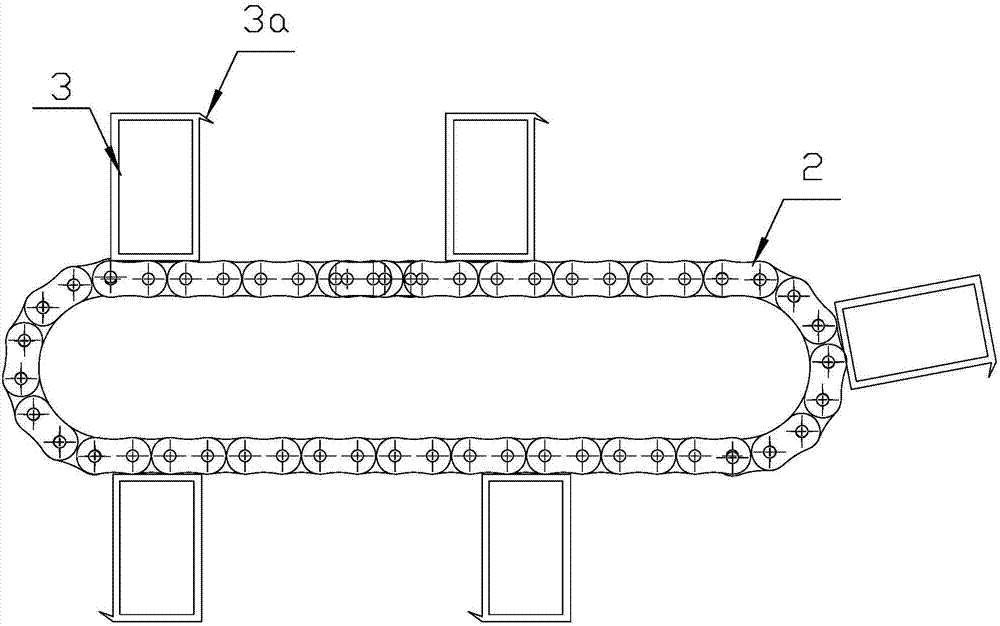

[0063] The raw bamboo feeding mechanism includes a transport chain 2, which is arranged on the long axis 4 through a sprocket wheel, and the long shaft 4 is connected with the feeding frame 5 through a bearing, and is connected with a hook 3 on the transport chai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com