Automatic cloth single-layered separation and fetching method and mechanism of sewing machine

An automatic cloth and sewing machine technology, applied in the direction of cloth feeding mechanism, sewing machine components, sewing equipment, etc., can solve the problems that the cloth cannot maintain a fixed shape, it is difficult to automatically take and sew, and it cannot be fully automated, so as to achieve automatic operation , high degree of automation, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0028] The basic idea of the present invention is to use the stickiness of the rubber wheel to stick the cloth, and then use the suction cup to suck up the cloth, and the cloth is attached to the suction cup or clamped on the manipulator, so as to facilitate the movement of the cloth and provide a solution for the manipulator to pick up and move the cloth. Specific examples are as follows:

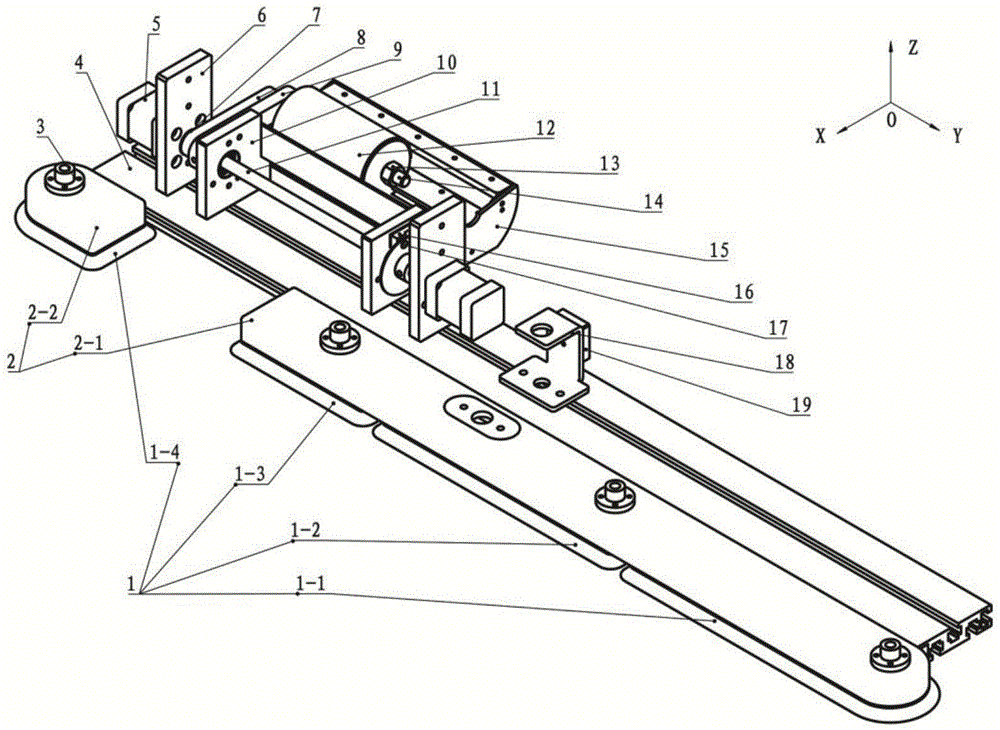

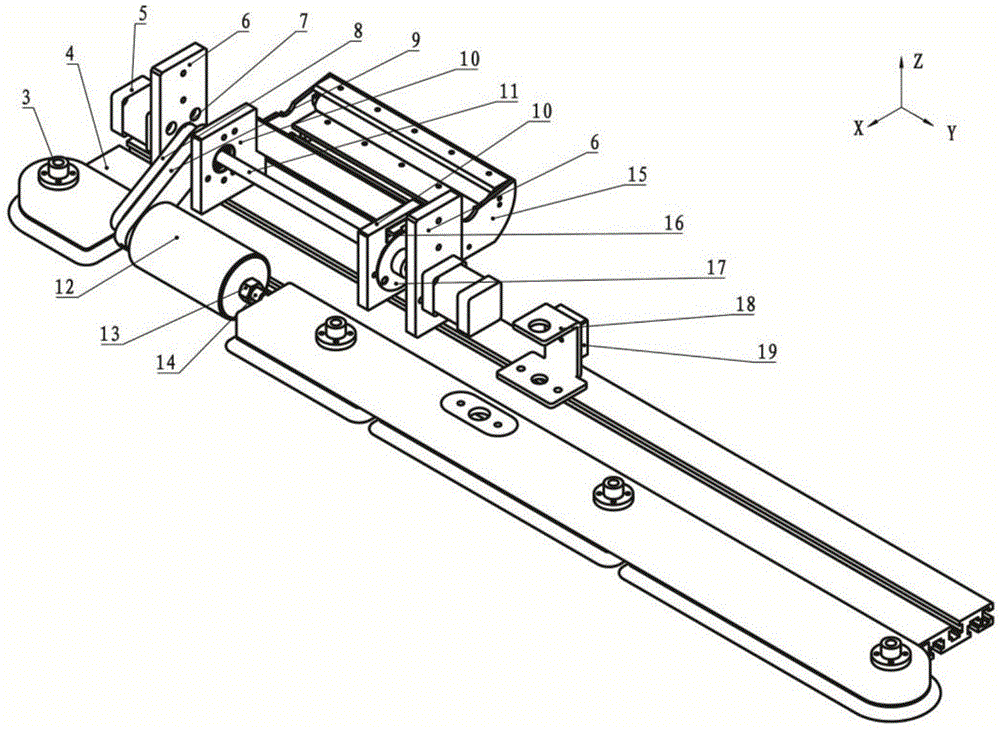

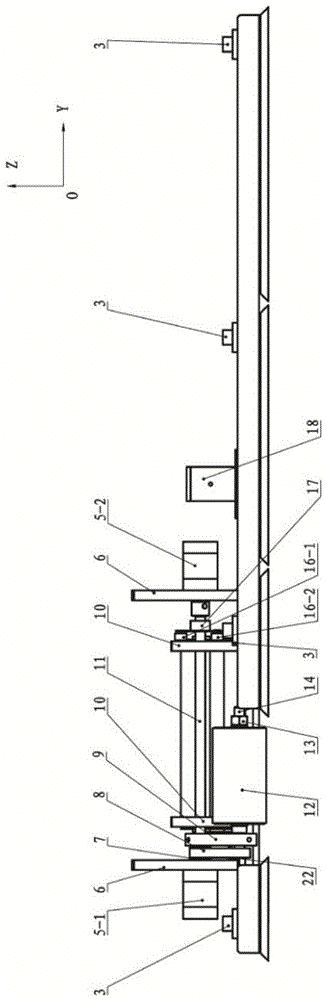

[0029] When the fabric is layered such as image 3 As shown, the swing motor 5-2 rotates, drives the swing frame shaft 11 to rotate, and drives the induction trigger 17 fixed on the swing frame shaft 11 to rotate together. The wheel stops at the set position figure 2 Shown is the layered state of sticking cloth. In the sticking state, the position of sticking wheel 12 is lower than that of suction cup 1 or clamping part. When the pressure sensor 19 detects the cloth, the retrieving mechanical arm (fixed substrate 4) stops the downward movement, At the same time, the cloth sticking whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com