Patents

Literature

7540 results about "Cotton material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of making a part of large dimensions out of composite material

InactiveUS6264877B1Avoid disadvantagesRisk of pollutionFinal product manufactureLaminationGlass fiberFiber

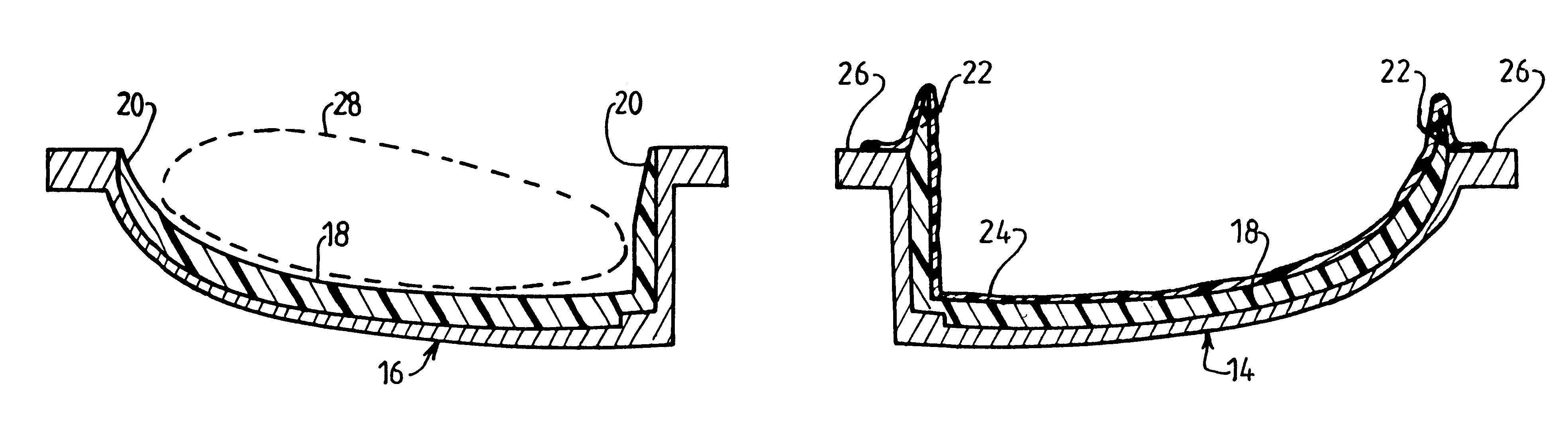

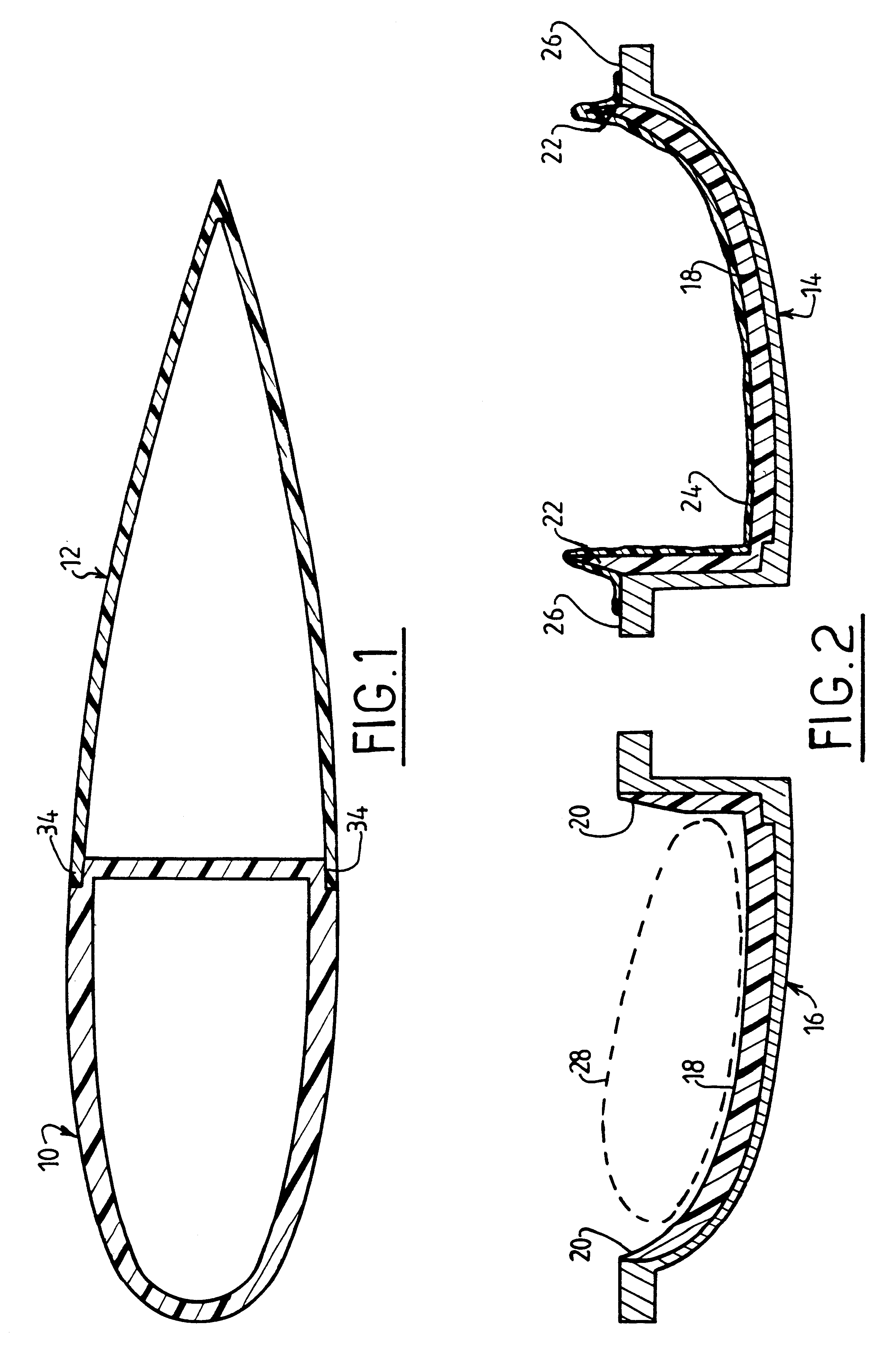

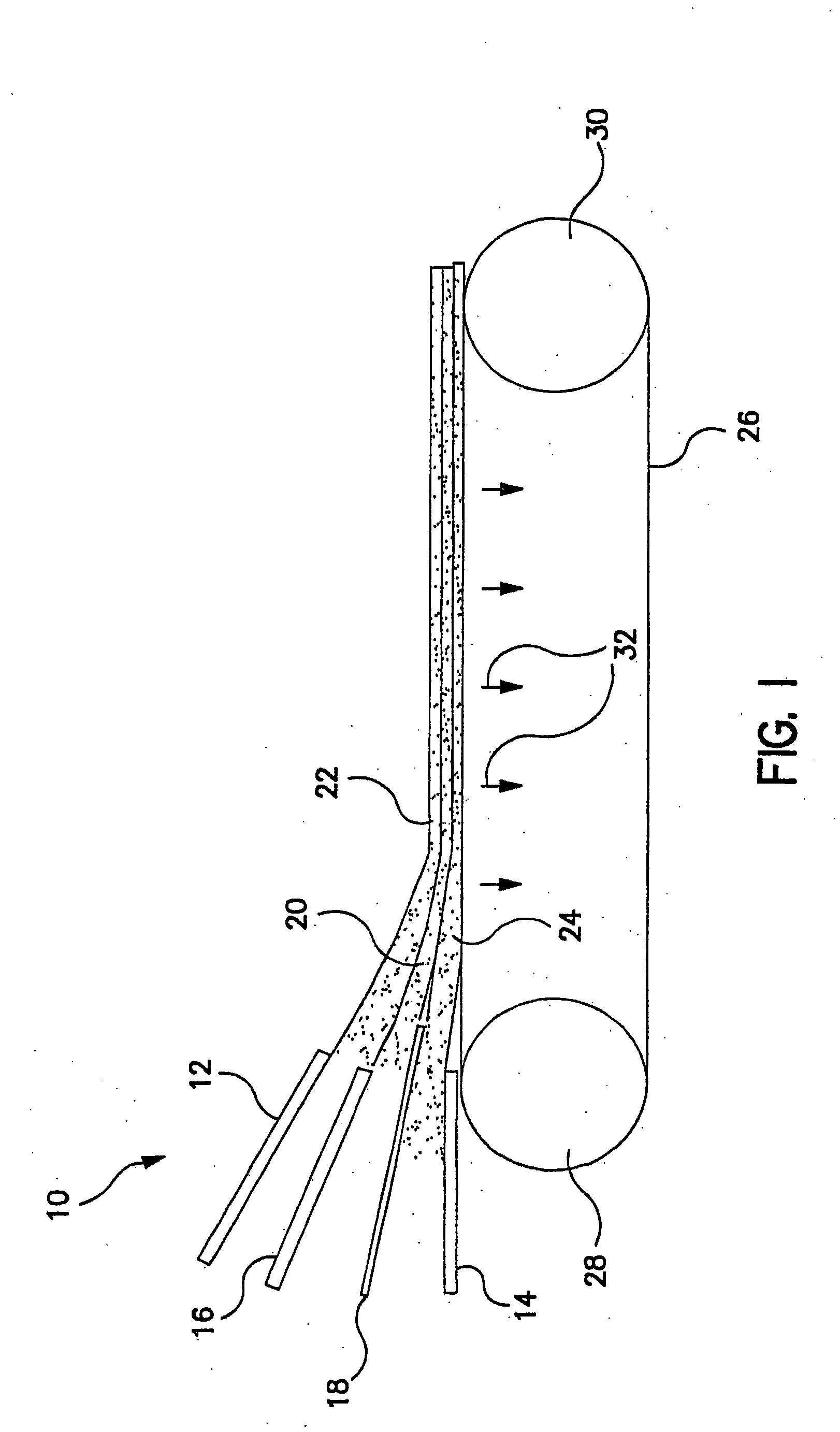

A method of making a composite material part, in particular a wind turbine blade of great length, consists in placing a thickness of a cloth made up of threads comprising a mixture of polypropylene threads or fibers and of glass fibers or threads in two mold portions having the shape of the part that is to be made, placing an inflatable envelope on the cloth inside one of the mold portions, in closing the mold, in placing it in an enclosure fed with hot gas under pressure to melt the polypropylene of the cloth, thereby embedding the glass fibers or threads, then in allowing it to cool, and in unmolding.

Owner:ALTERNATIVES ENERGIES

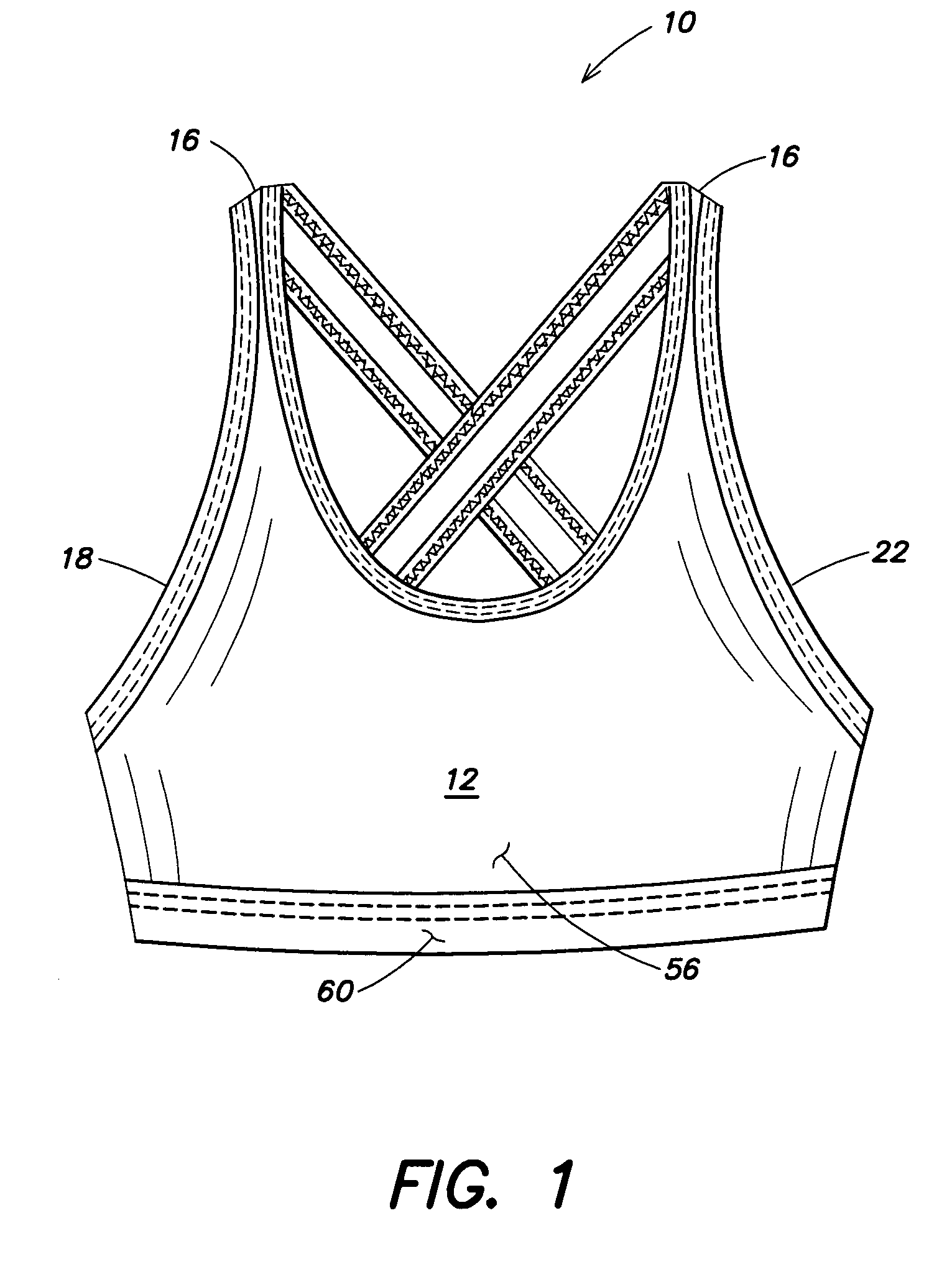

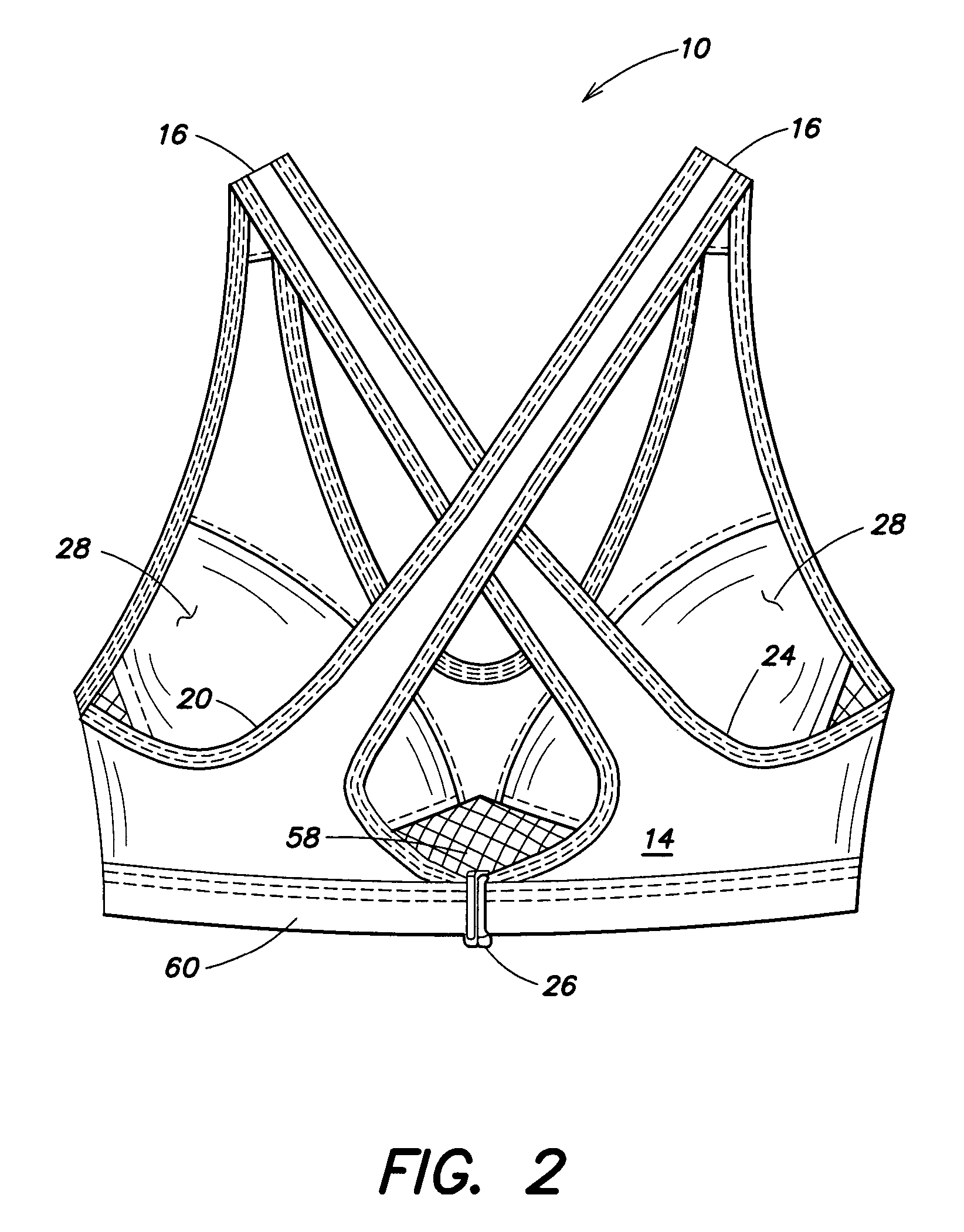

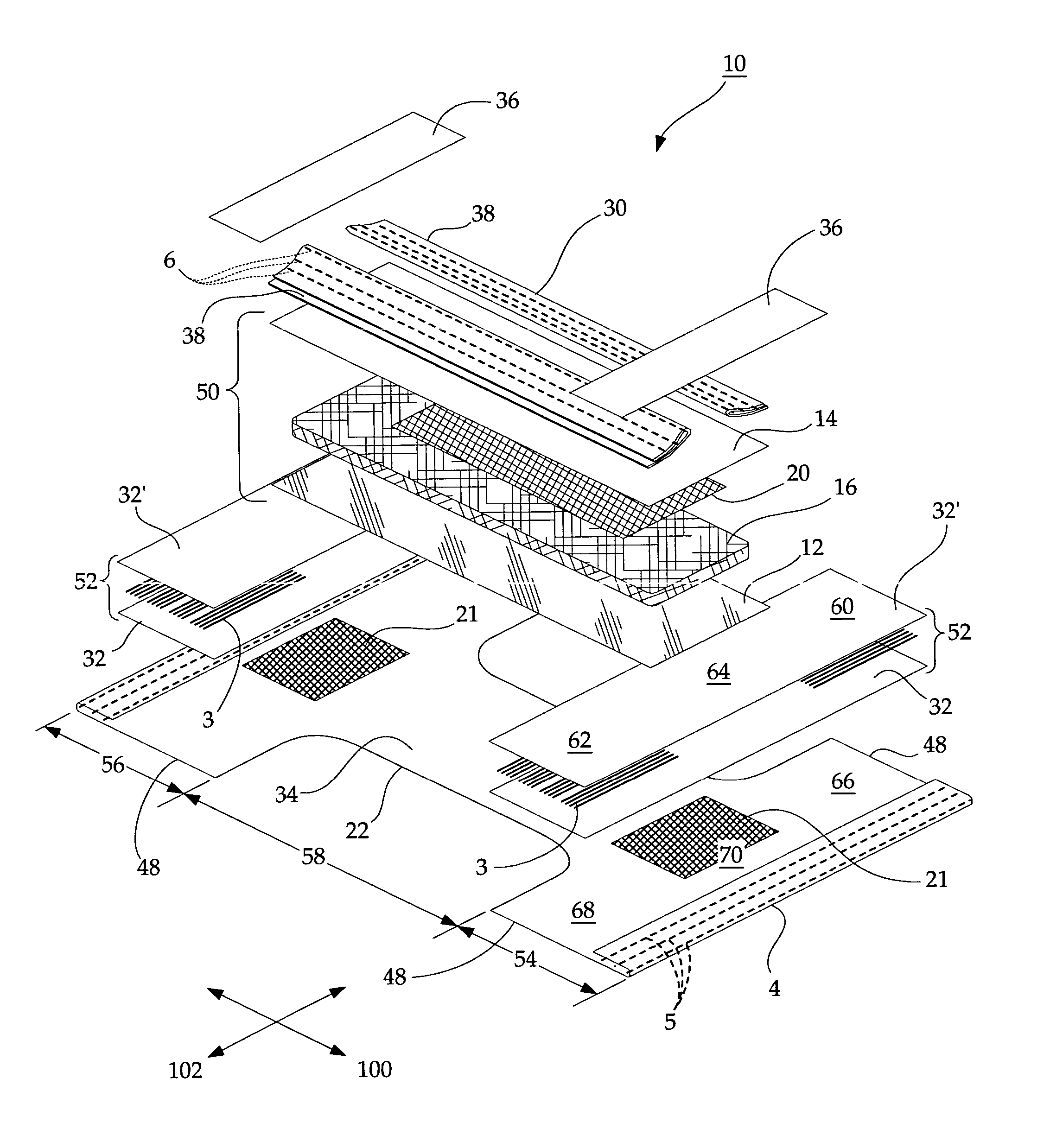

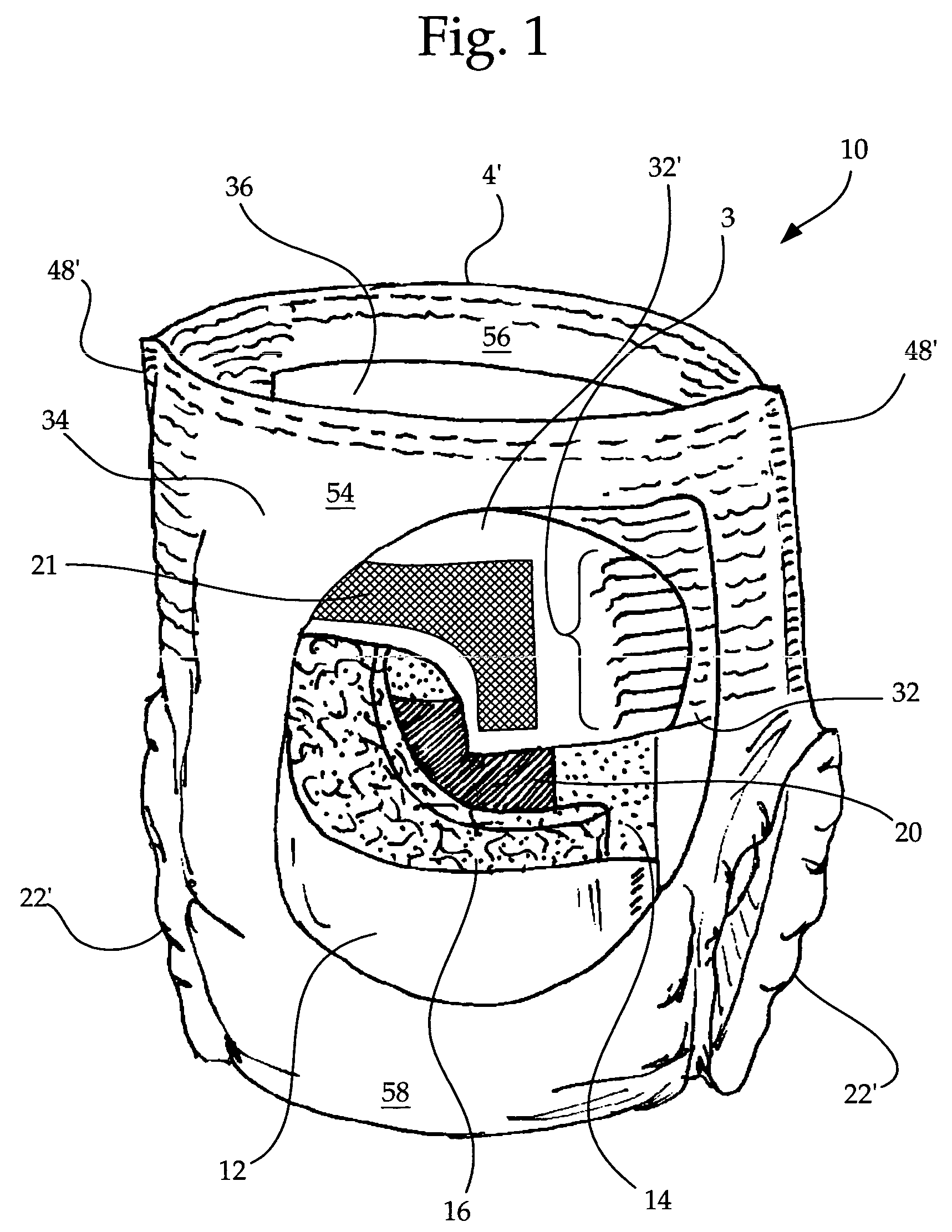

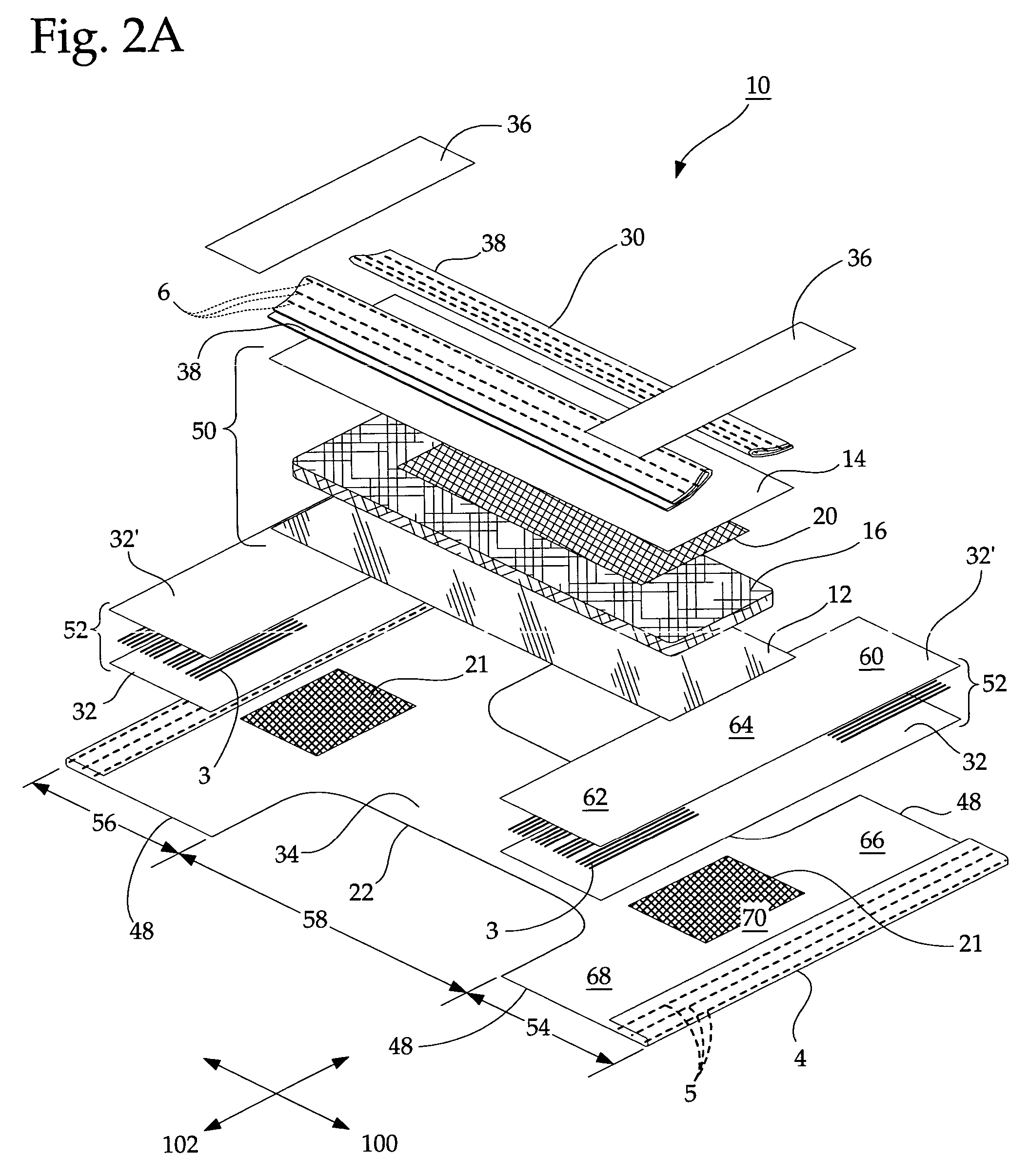

Brassiere, brassiere components, and materials for use thereof

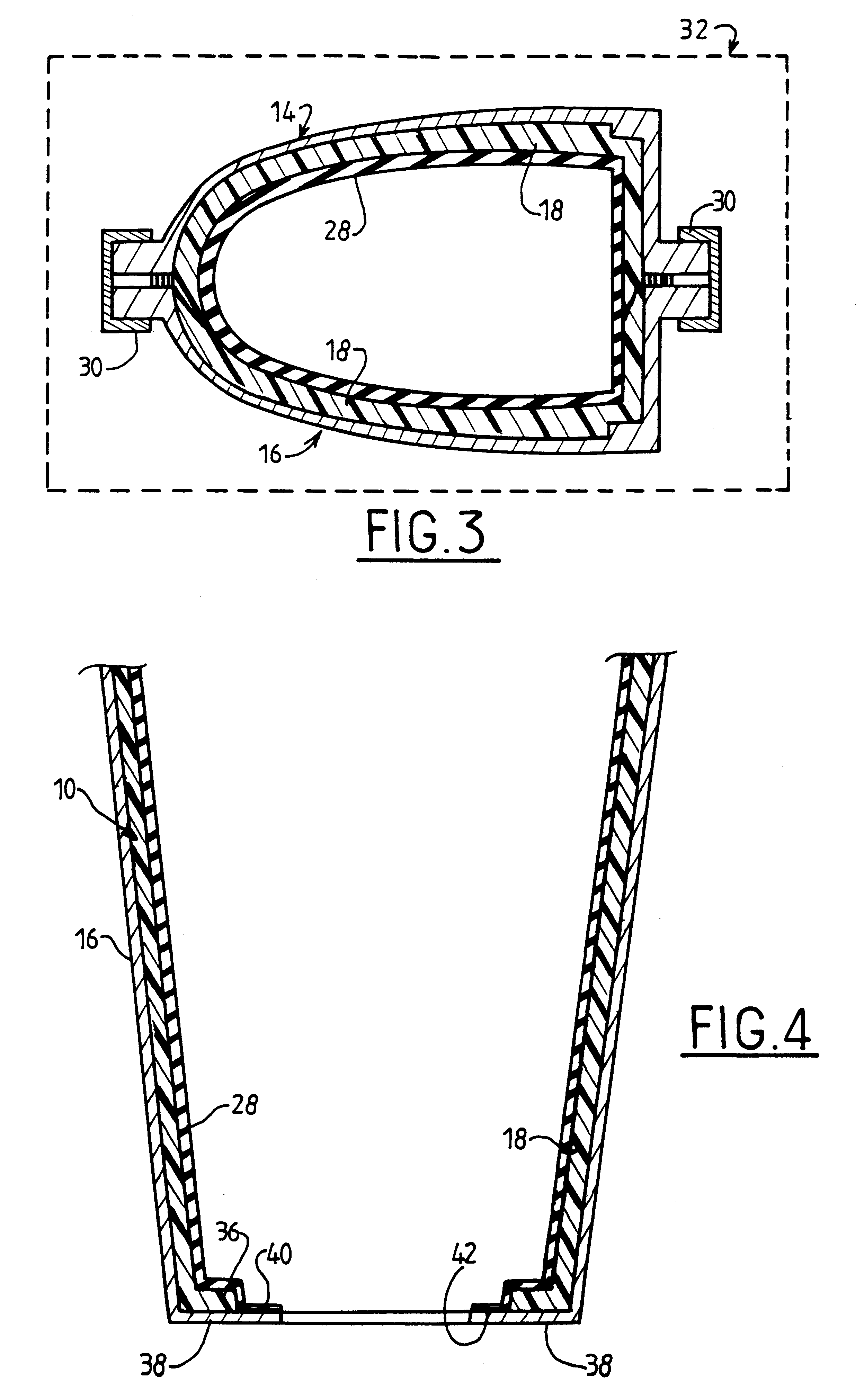

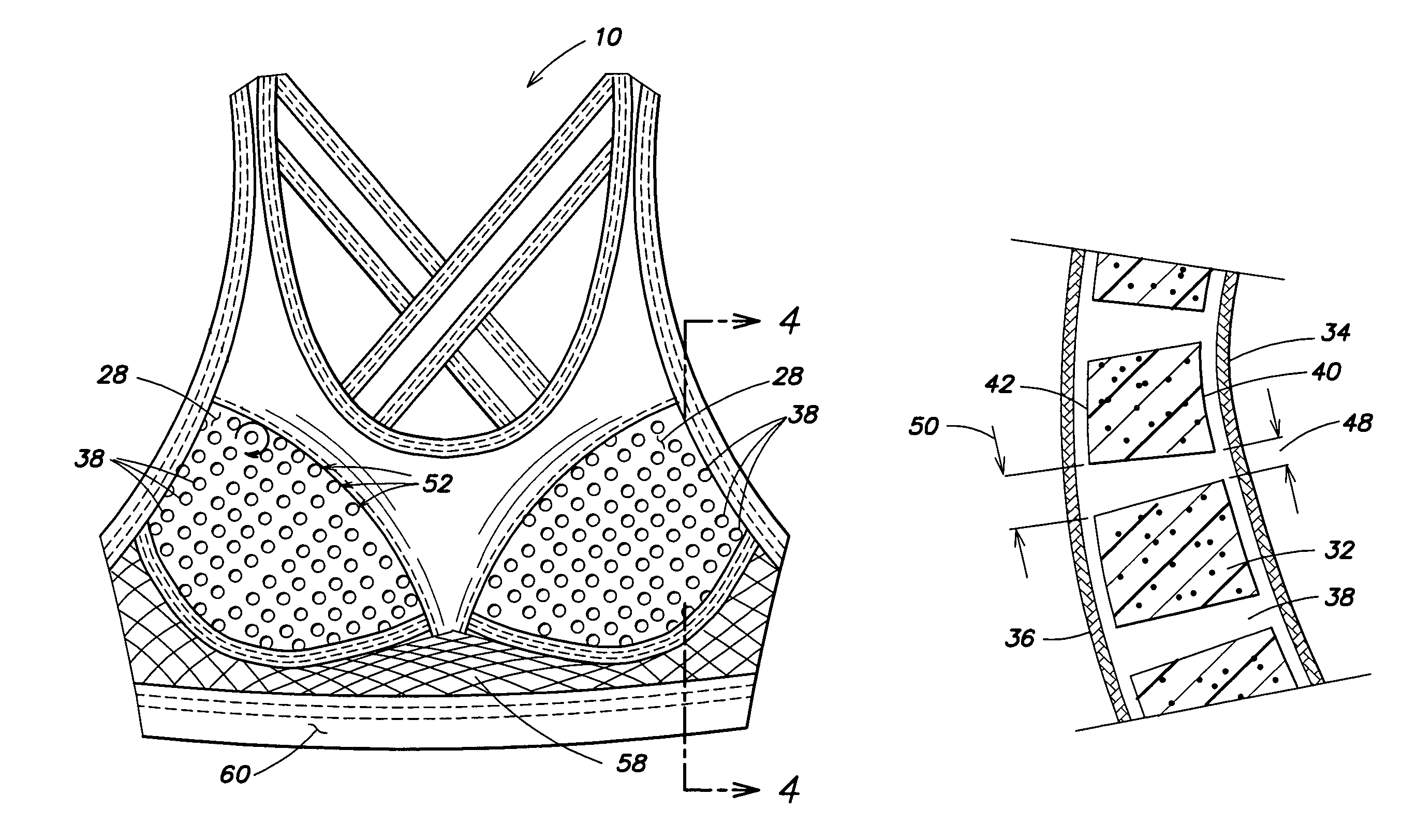

A breathable and moisture permeable bra that is stylish, provides adequate support and is comfortable to wear is provided. Materials, such as wicking materials, for use in the bra, as well as other active wear, are also provided. The brassiere may include breast-supporting pads having a pad component including a perforated, molded foam cup encased by an inner and a first outer cloth layers and a second outer cloth attached to the outside of the pad component. The cloths may include materials that are breathable and may have wicking properties. In addition to the pad, the brassiere may include a wicking layer adapted to lie adjacent a wearer's skin to pull moisture away from the skin. The brassiere may also include an outer layer adapted to lie most distal the user's skin, that may provide an aesthetically pleasing exterior of the brassiere.

Owner:WELLS FARGO RETAIL FINANCE LLC AS AGENT

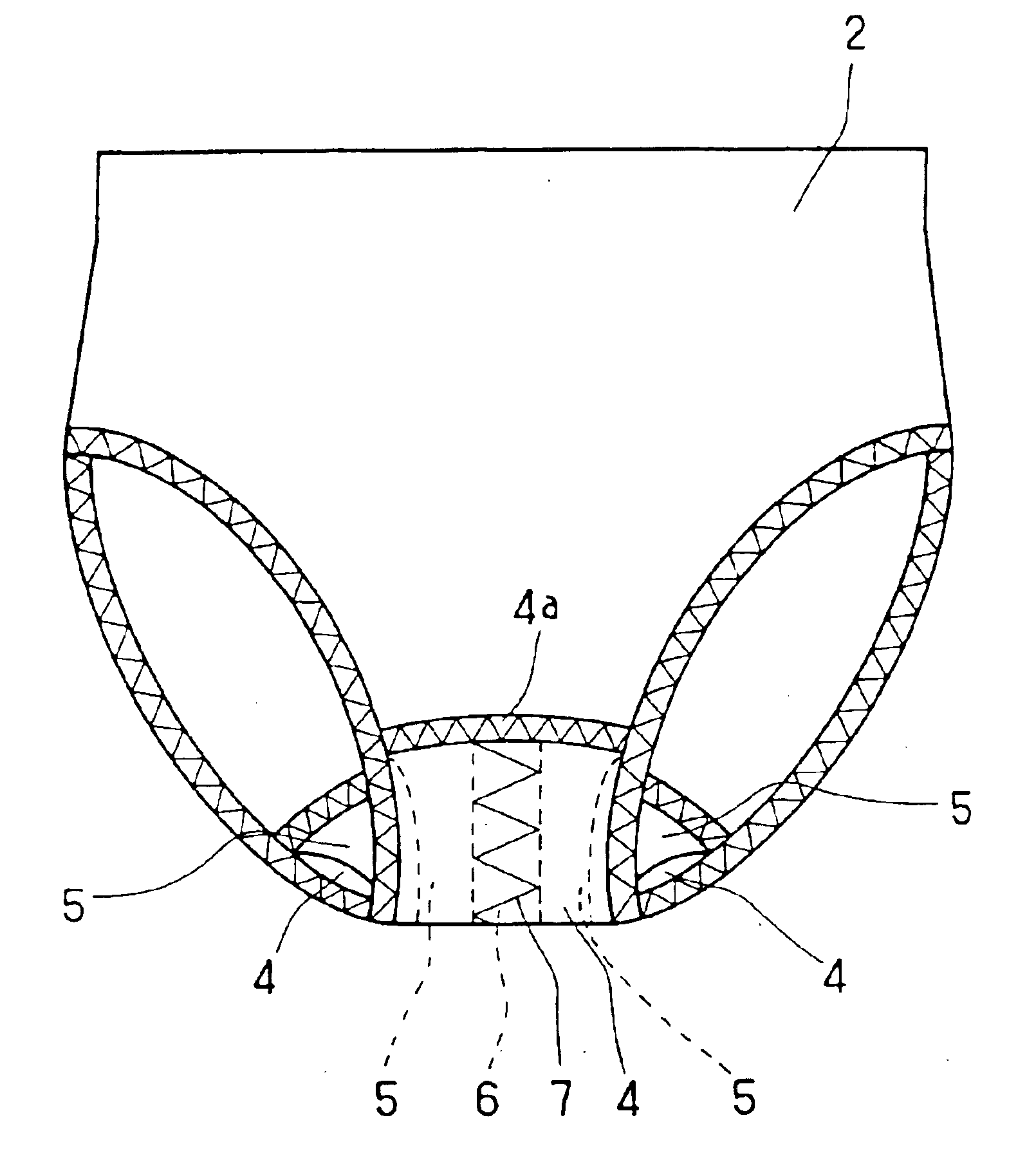

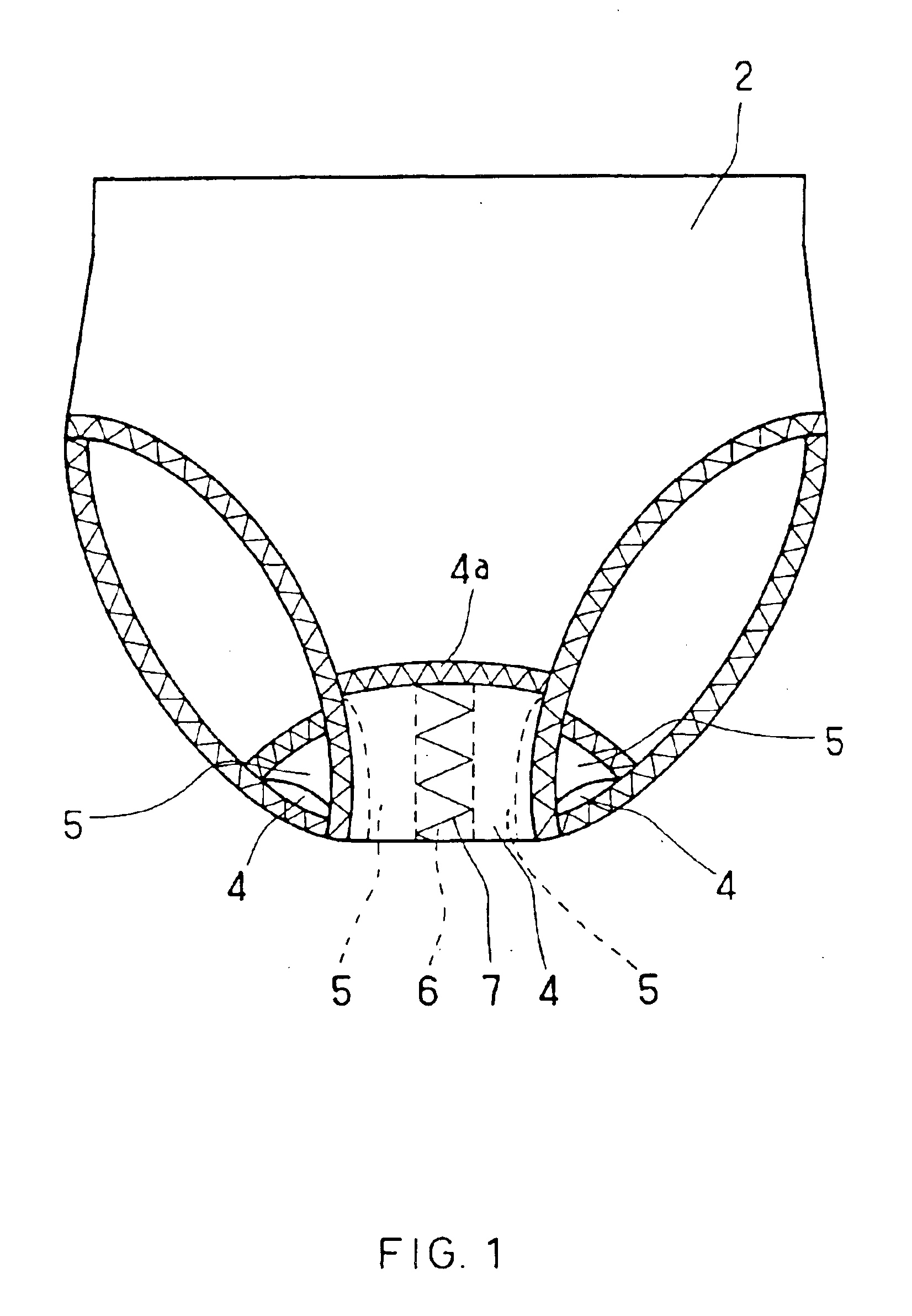

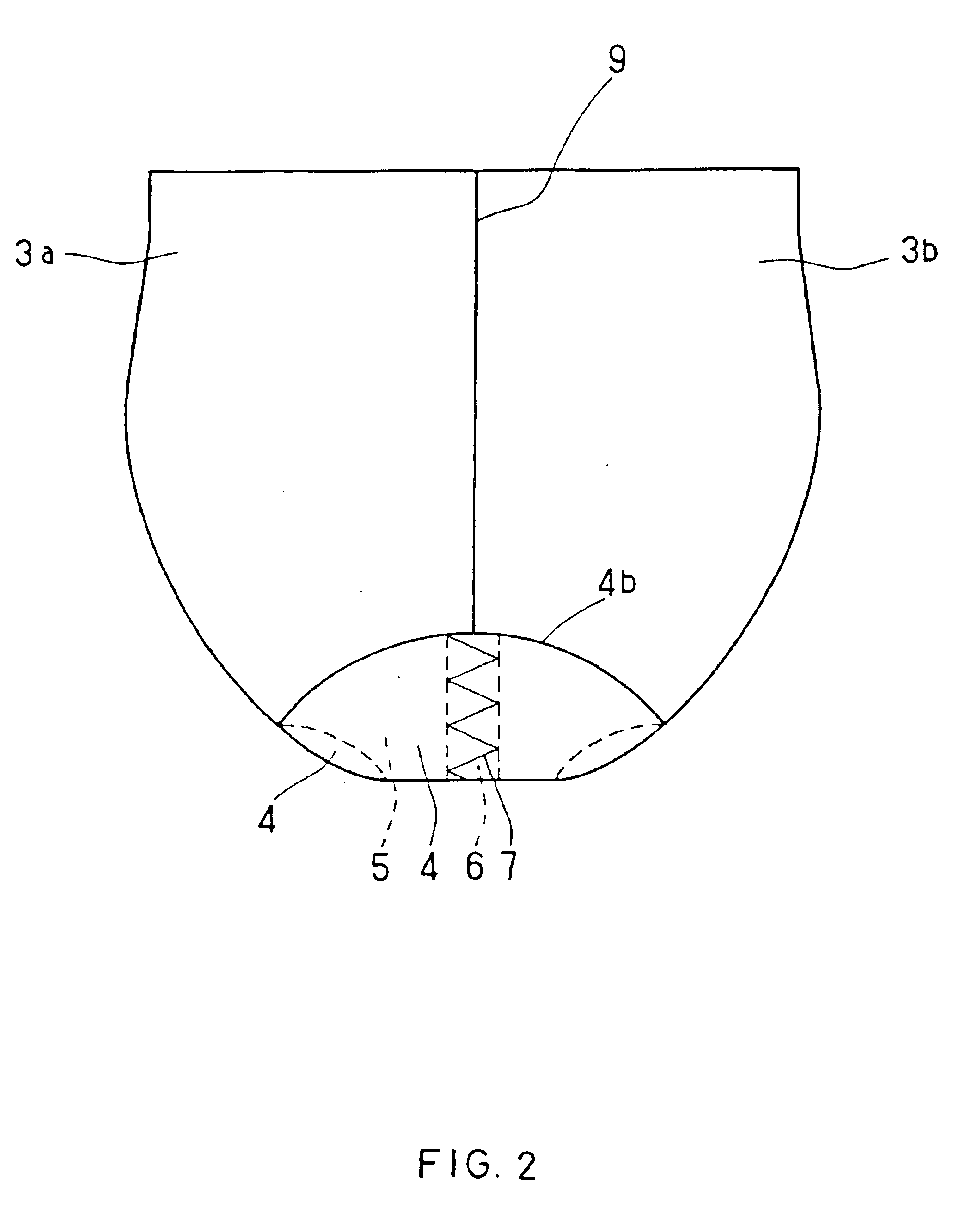

Garment with crotch part

This invention relates to a garment with a crotch part used in contact with skin, including: a garment main body including a stretchable crotch cloth piece; and a second crotch cloth piece on which an absorbent article is to be applied and held, provided on the inner side of the crotch cloth piece of the garment main body, wherein the second crotch cloth piece is mounted to the garment main body at its front and rear edges and is mounted to the crotch cloth piece of the garment main body at least in one portion of its center line, and right and left edges of the second crotch cloth piece are not bonded to the garment main body and are in free state. An absorbent article can be held at a determined position on the crotch part of the garment with stability and security. The garment also is excellent in close contact to the pudendal cleft region, is difficult to be steamed in use, and has fine appearance and good wearing comfort after mounting an absorbent article.

Owner:WACOAL

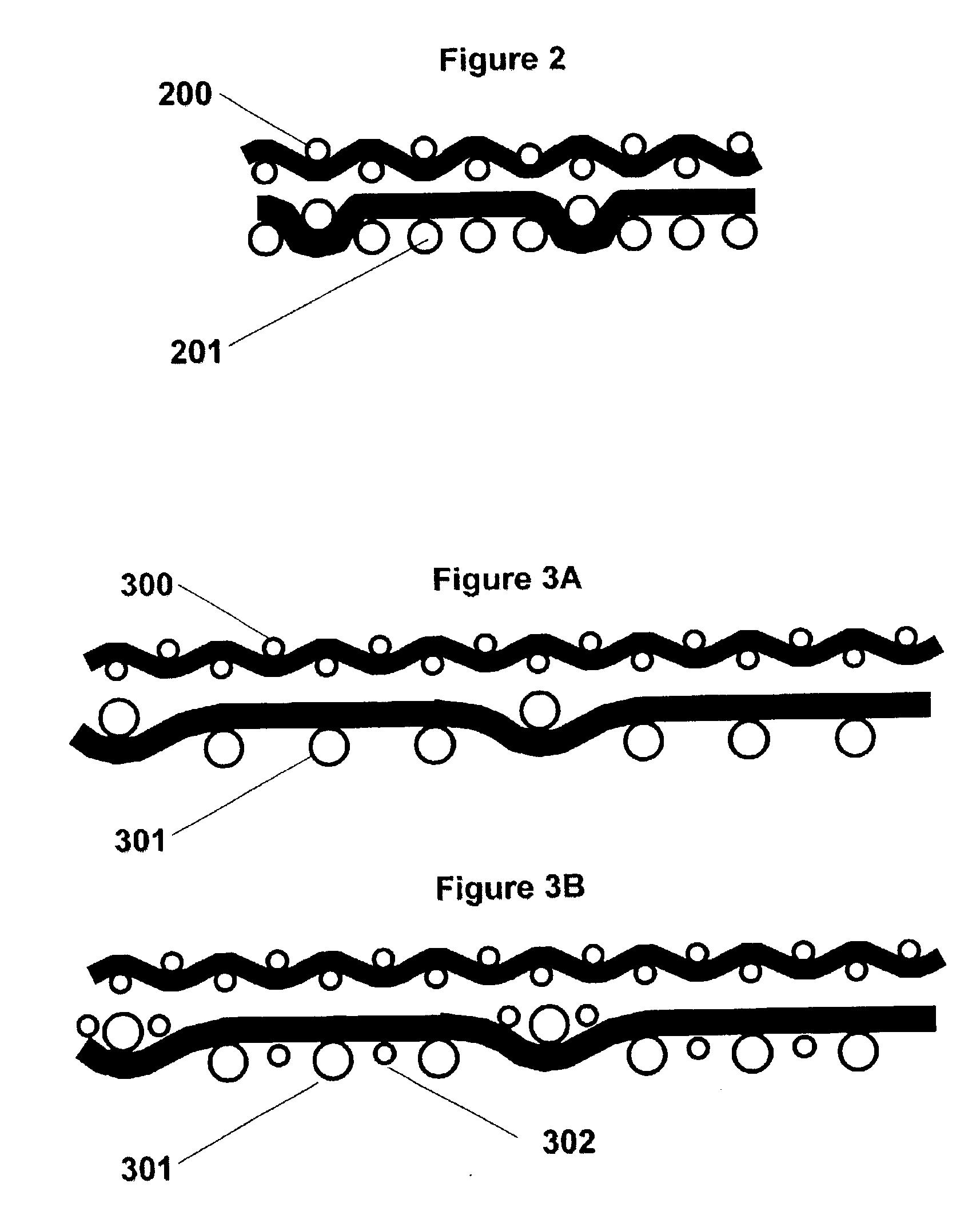

Cloth-like laminate and absorbent garment

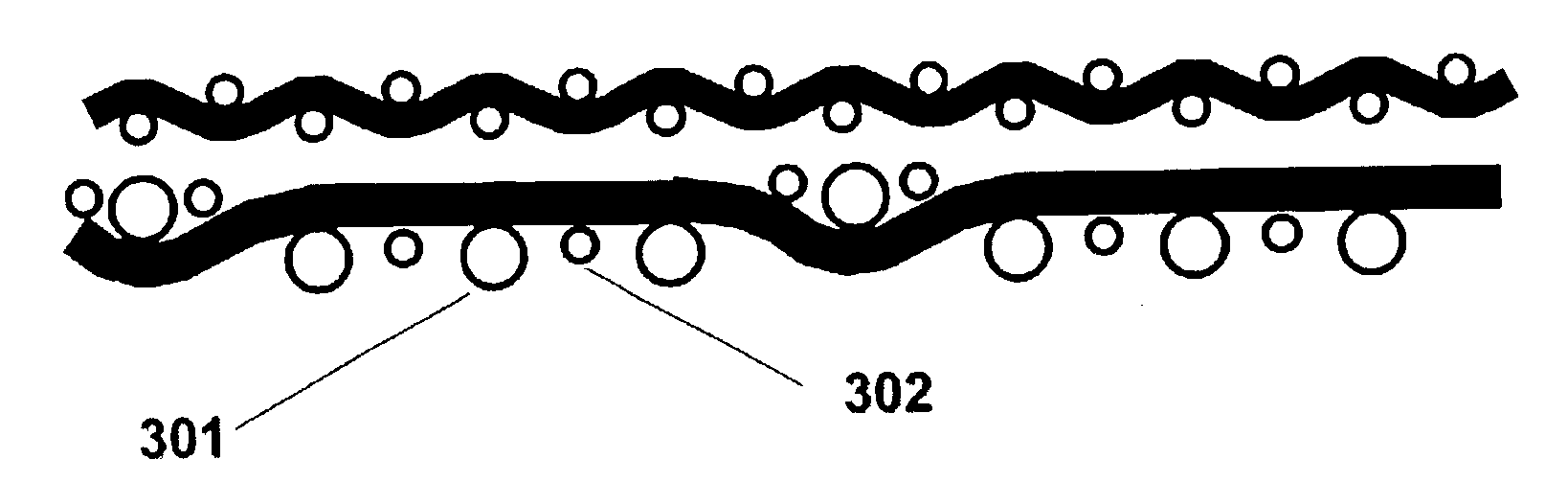

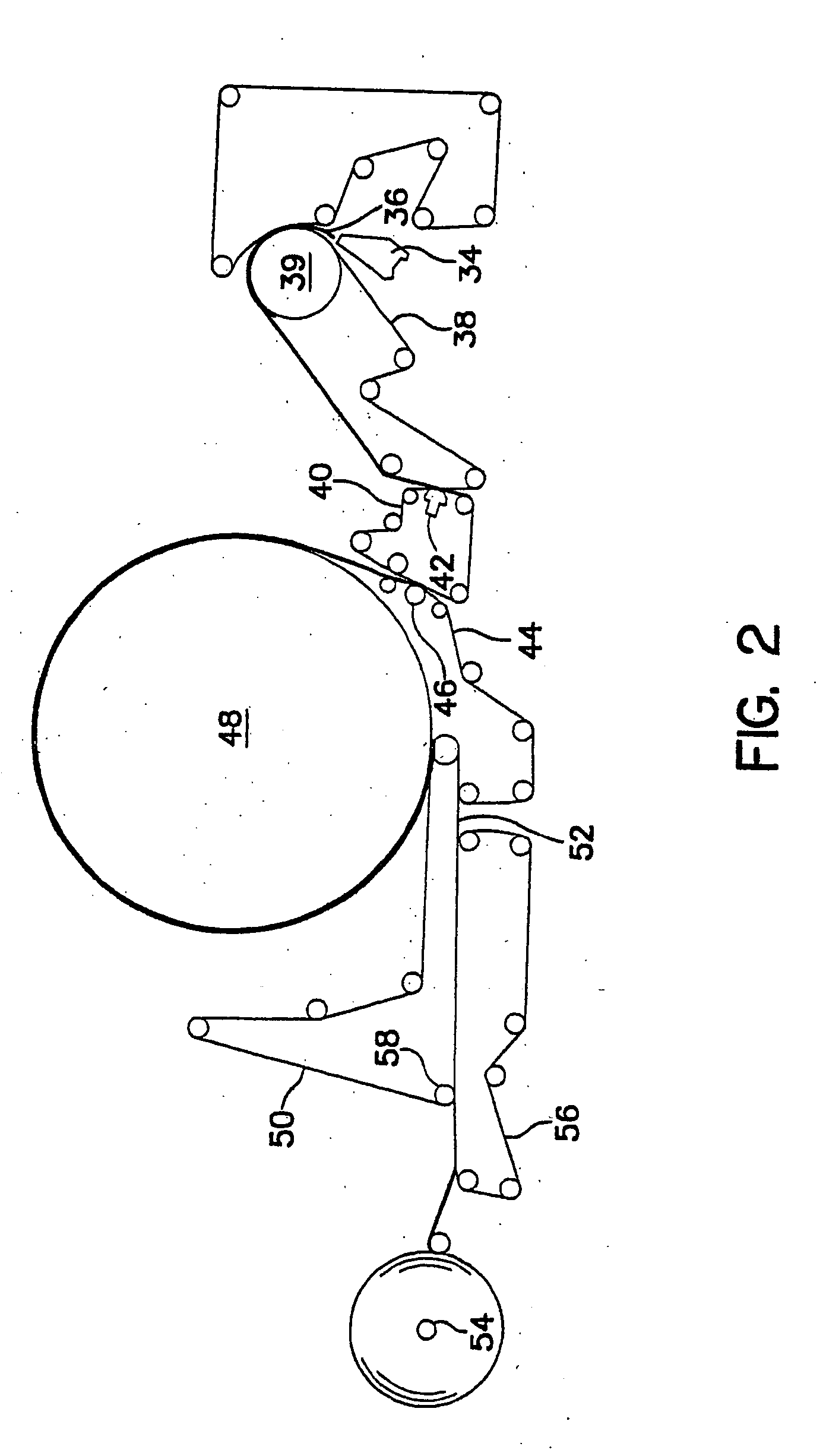

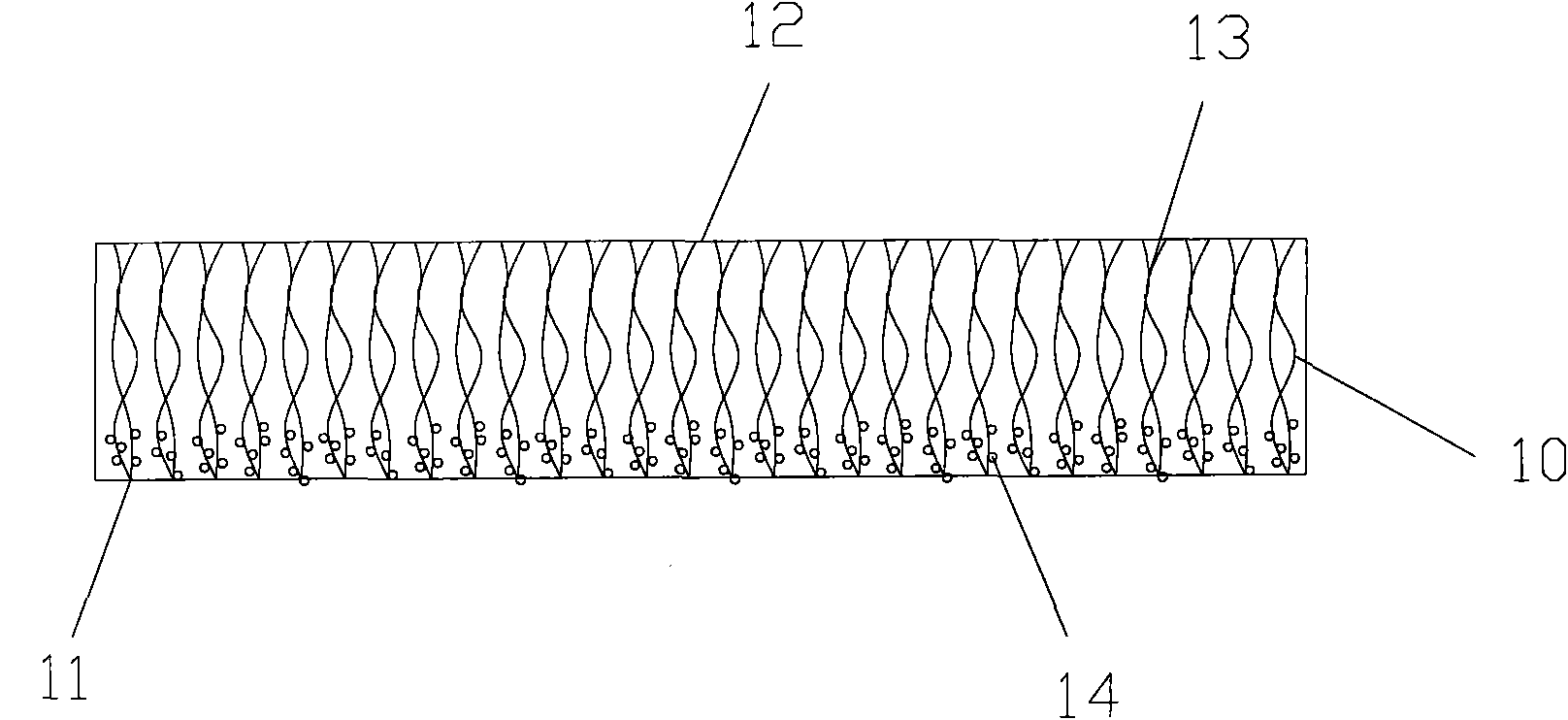

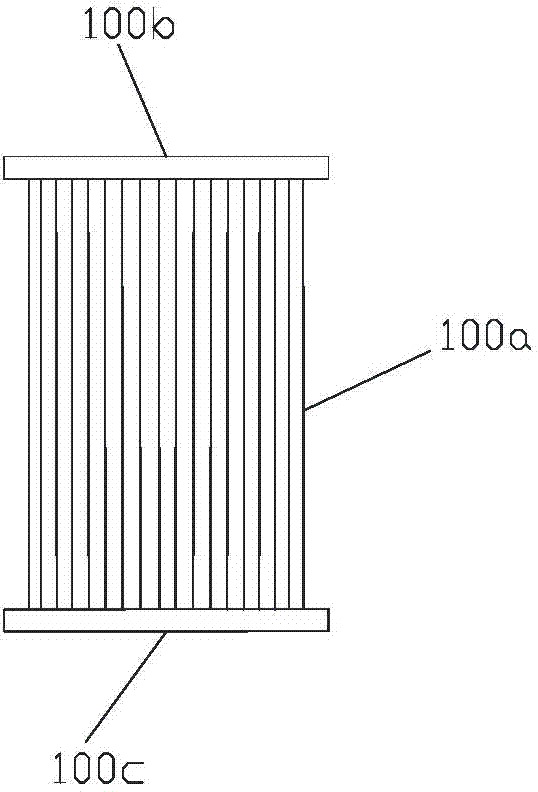

An elastic assembly for absorbent garments having a first carrier layer, a second carrier layer, and an elastic layer attached between the first and second carrier layers to impart elasticity to an elasticized portion of the elastic assembly. The elastic layer is made of elastic strands having a decitex of about 600 or less. The elastic strands are arranged generally in parallel with one another and with a spacing of about 1 to about 10 elastic strands per centimeter. The elasticized portion of the elastic assembly has a thickness of about 2.6 mm or less at a pressure of 0.05 p.s.i. and about 8 or more corrugations per centimeter when in an elastically relaxed state. The first and second carrier layers are attached to one another in the elasticized portion substantially only by a coating of adhesive on the elastic strands. Absorbent garments incorporating the elastic assembly and a method of making the elastic assembly are also provided.

Owner:FIRST QUALITY RETAIL SERVICES

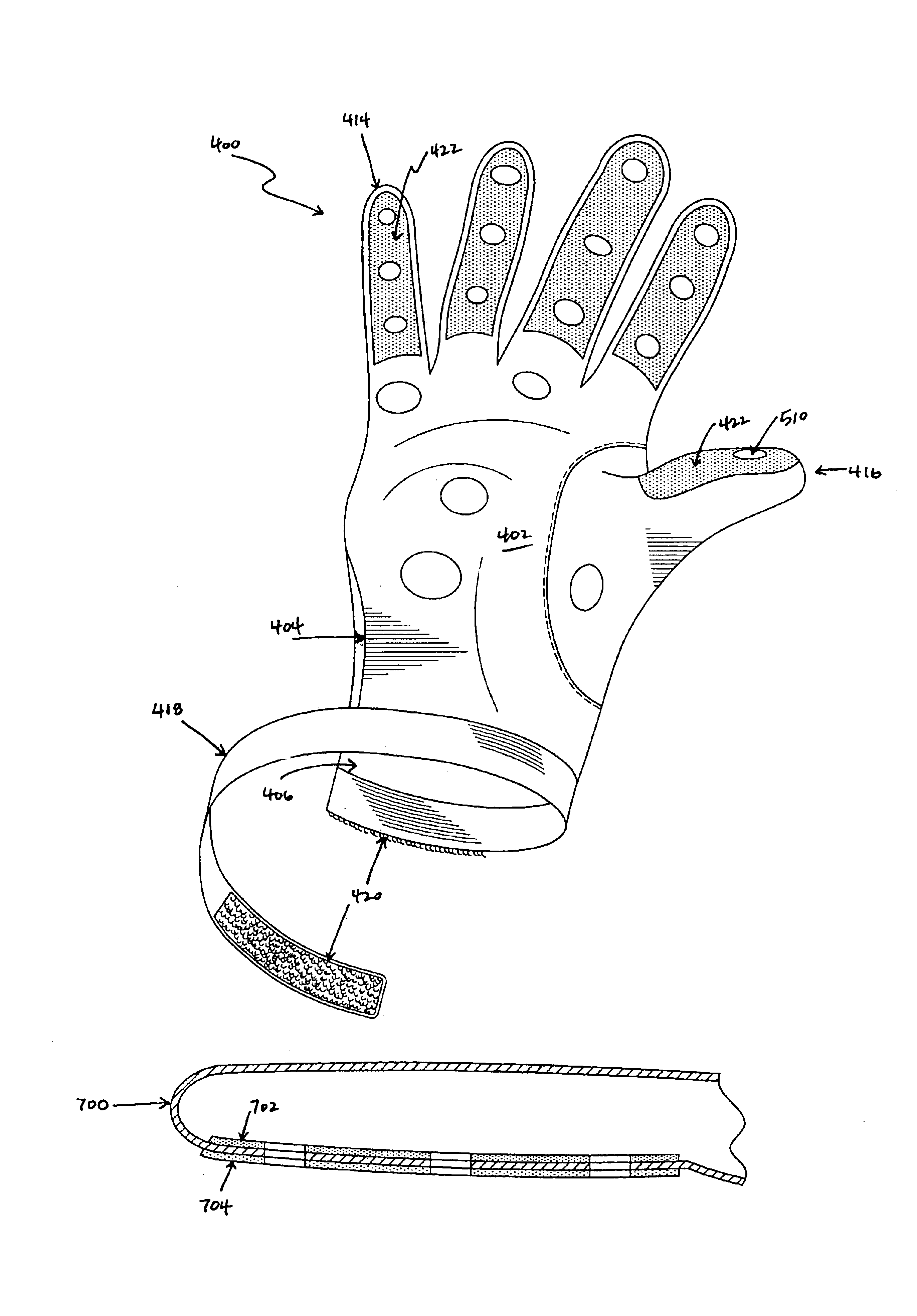

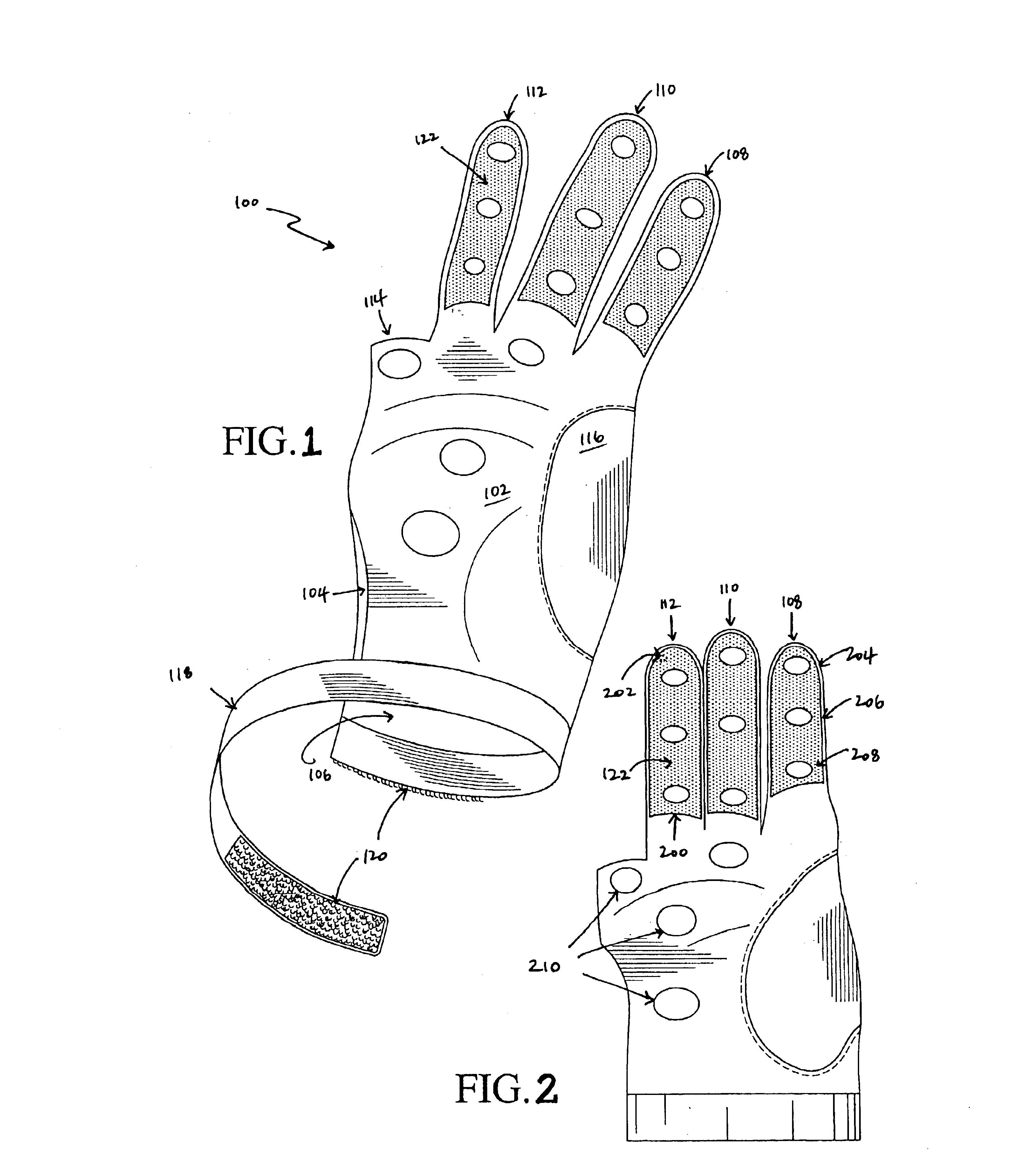

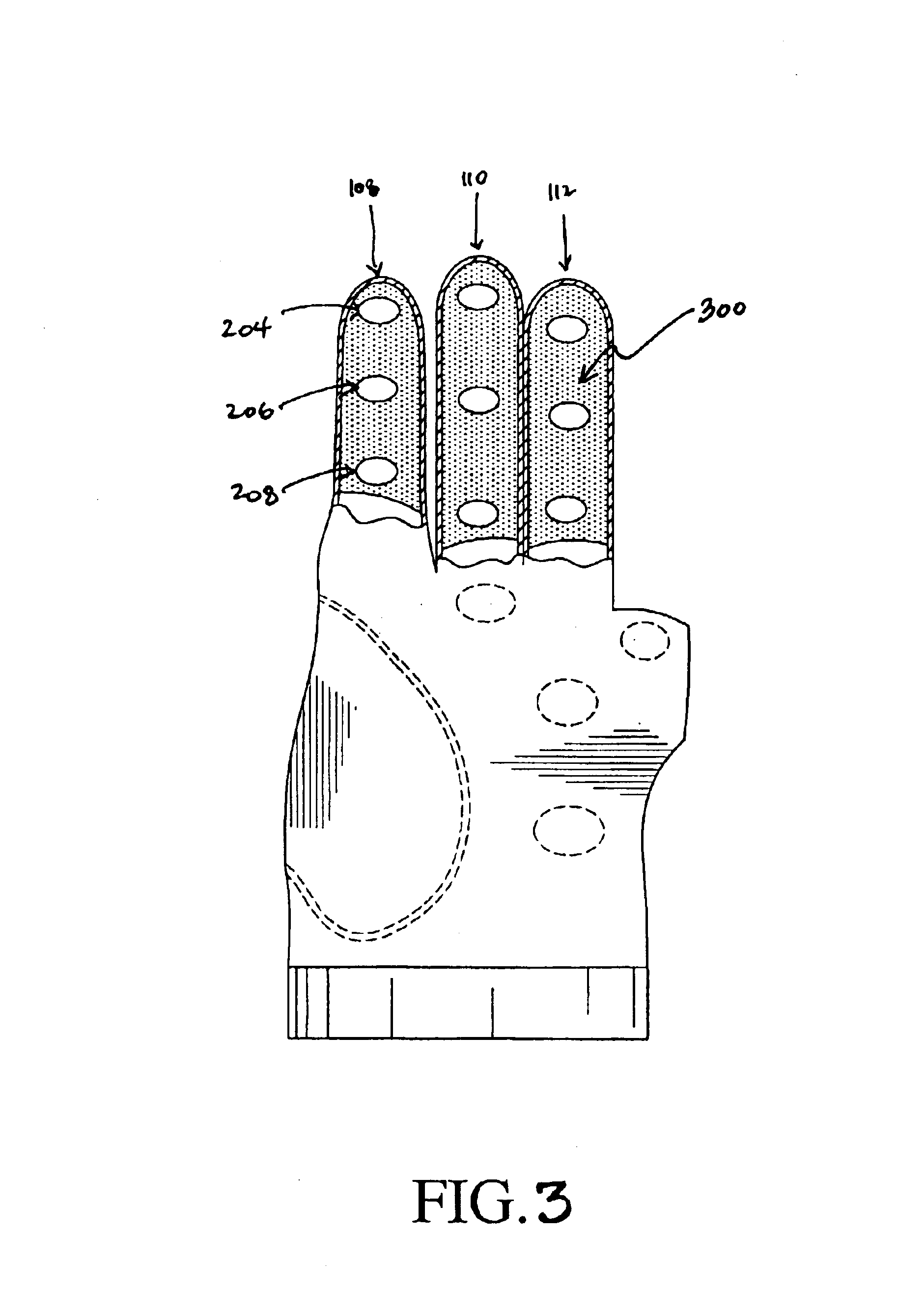

Non-slip glove

A non-slip glove for all types of weather is disclosed where emory cloth is employed as an exterior friction material to prevent and substantially eliminate slipping from the surface of a moving object as well as handles of golf clubs and baseball bats. The glove has applications to other environments such as construction workers using high-speed drills, drum hammers and the like. Further a finer grit emory cloth has been employed in the interior surface of the glove so as to not irritate the skin but maintain friction contact with the hand so that moisture that may enter inside the glove will not cause the glove to slip on the hand.

Owner:CASS NORMAN ALVIN

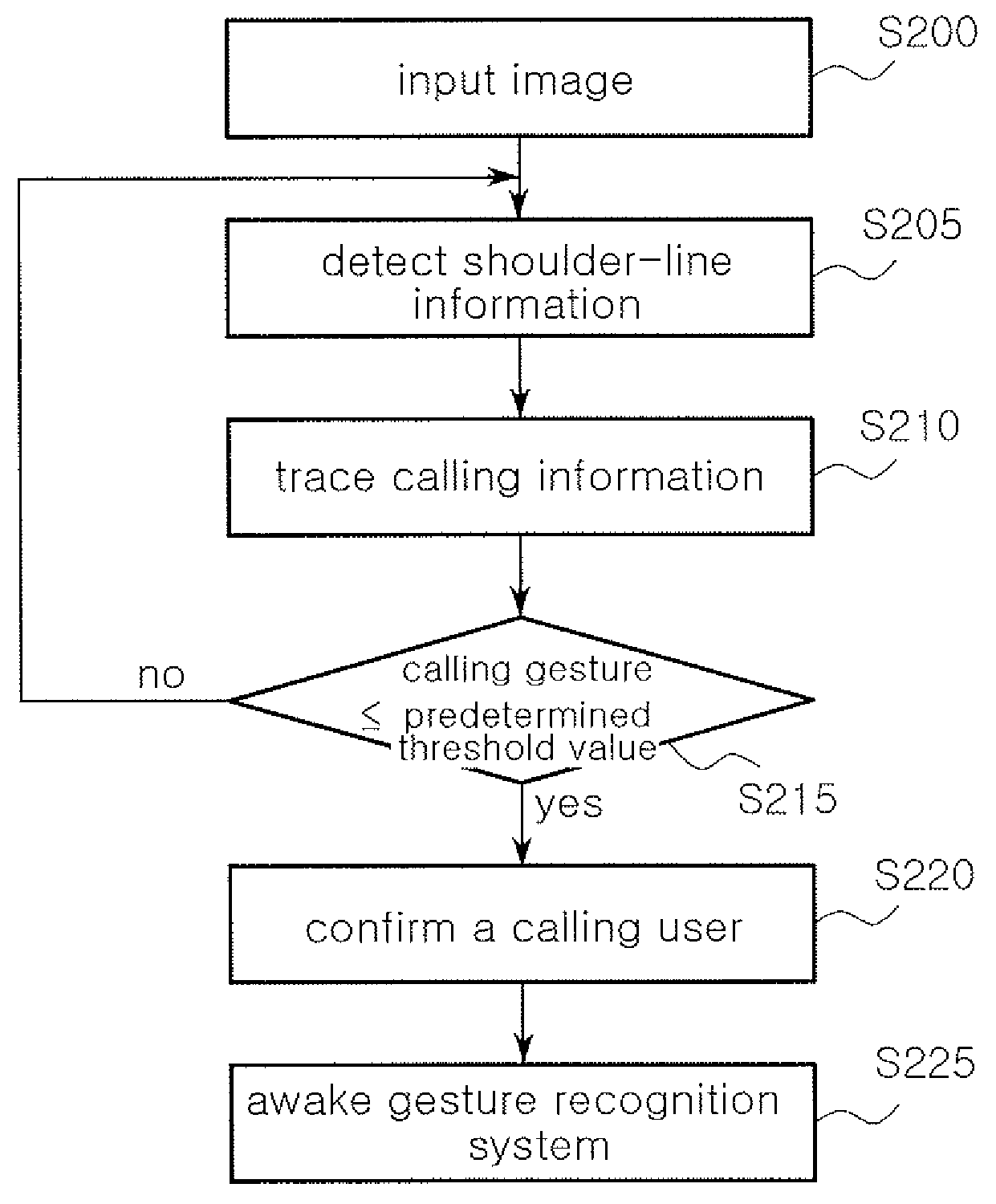

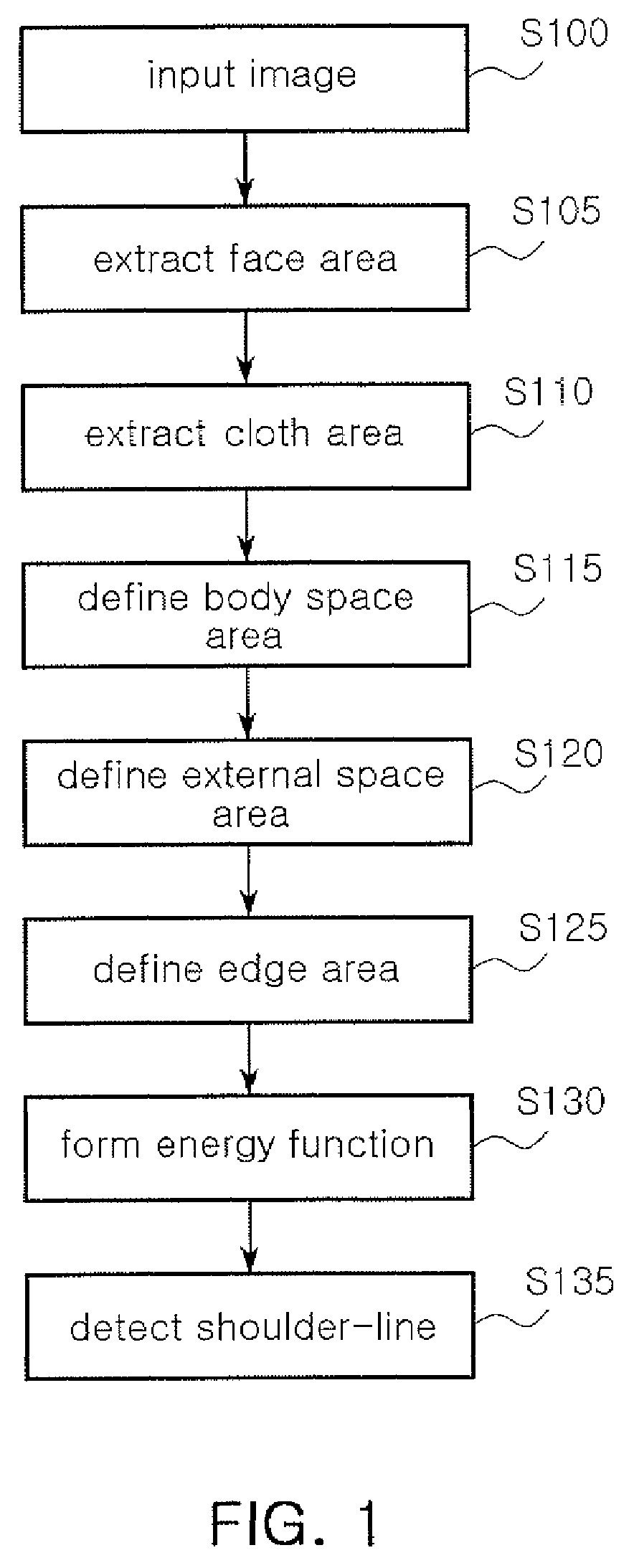

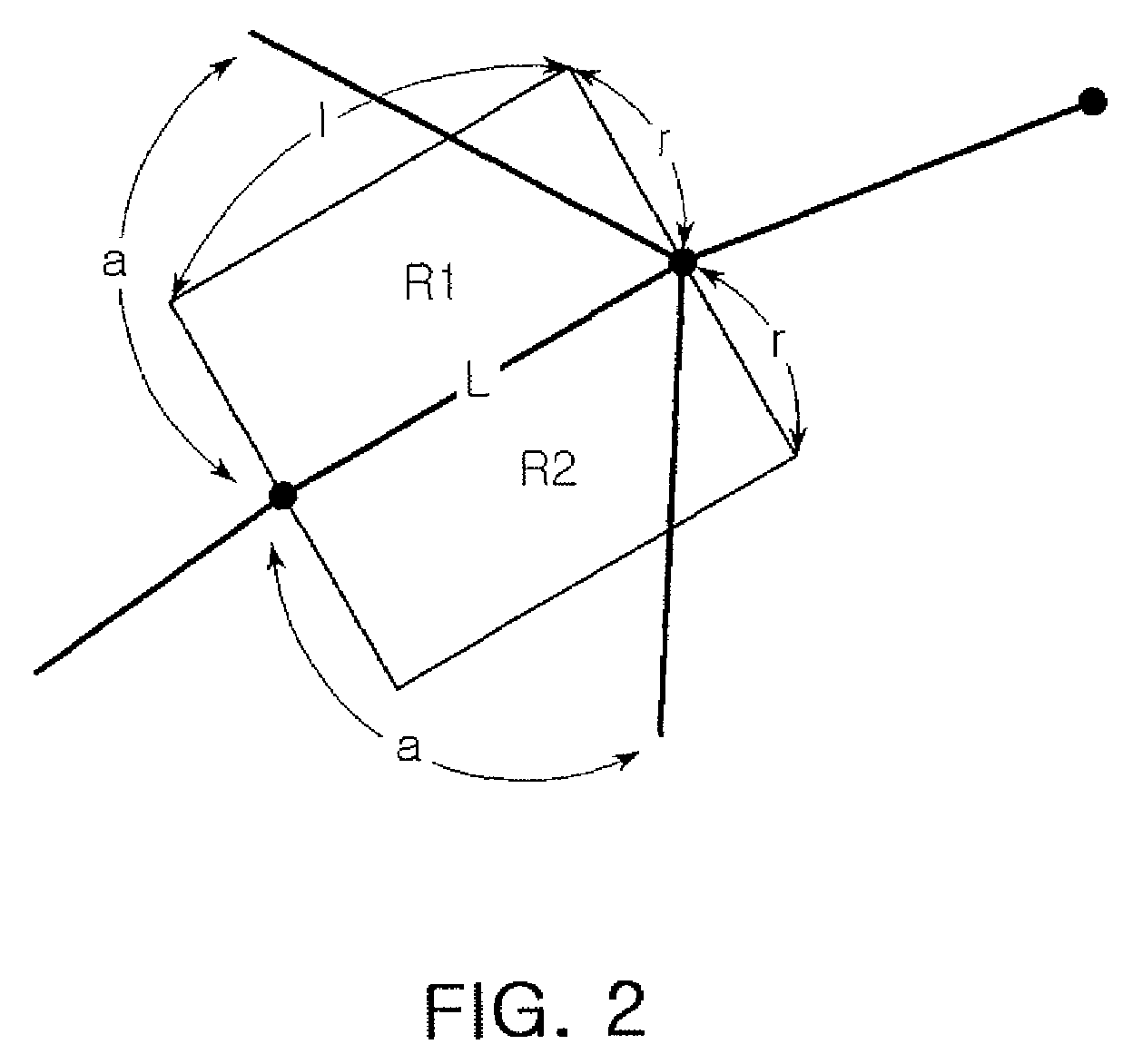

Method and apparatus for shoulder-line detection and gesture spotting detection

InactiveUS20080037875A1Image analysisCharacter and pattern recognitionShortest distanceExterior space

Owner:ELECTRONICS & TELECOMM RES INST

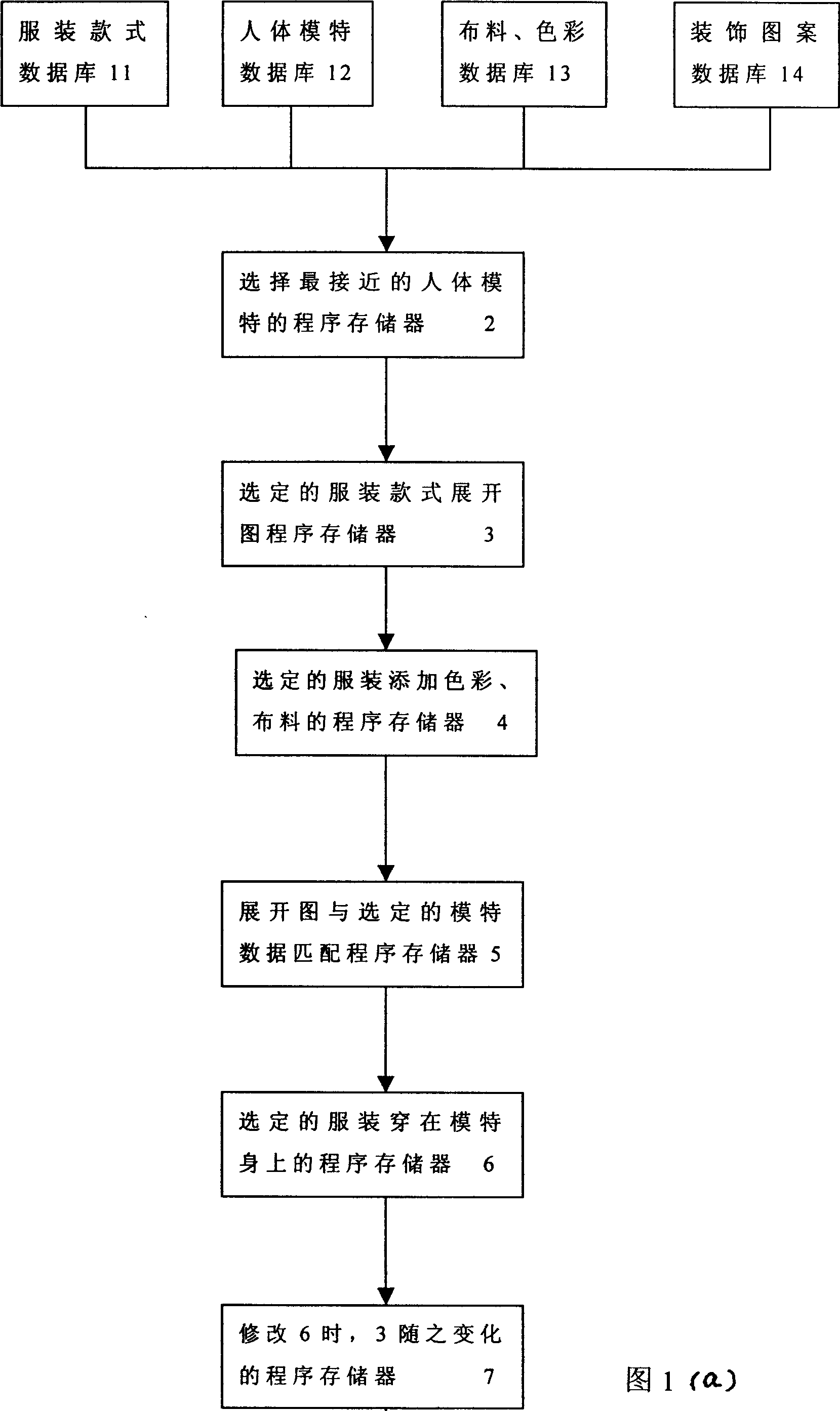

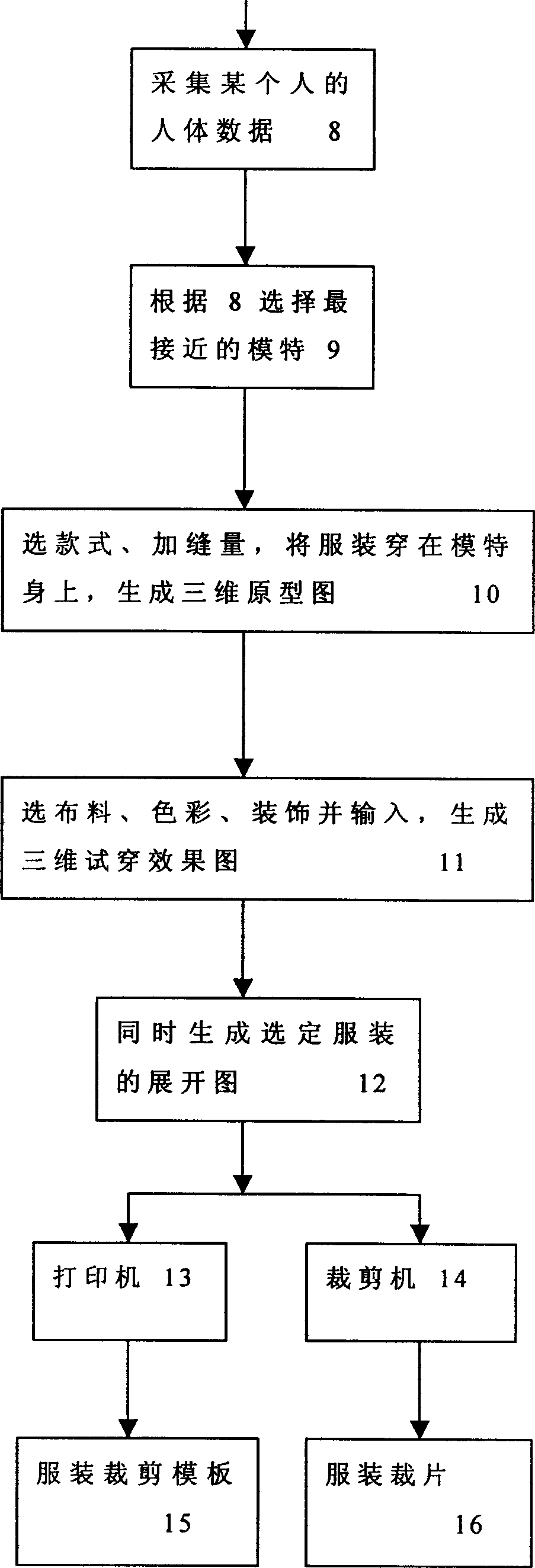

Three-dimensional garment designing and cutting method

InactiveCN1779687ASimple designSpeed upSpecial data processing applicationsClothes making applicancesGraphicsEngineering

A 3D designing method of garment includes setting up databank of 3D dress form data, garment fashion databank, databank of cloth and color as well as decoration, garment developed drawing databank and databank of test dressing drawing; storing said data into storage; collecting body data of client and inputting it in computer; selecting suitable fashion and sewing amount from said databank then putting on garment on model to form original drawing of 3D garment; selecting color, cloth and decoration for garment to form test dressing result drawing and developed drawing of 3D garment.

Owner:叶武月

Energy-conserving textile fabric washing device

InactiveCN107326567AWash thoroughlySolve incomplete cleaningLiquid/gas/vapor removalTextile treatment machine arrangementsAgricultural engineeringWater pipe

The invention discloses an energy-conserving textile fabric washing device. The washing device comprises a case. A cleaning room, a drying room and a disinfection room are formed in an inner cavity of the case in sequence from left to right. A fixed support on the left side face of the case is fixedly connected with a feeding roller through a fixed shaft. A fixed support on the right side face of the case is fixedly connected with a discharge roller through a fixed shaft. A feeding opening is formed in the upper portion of the left side face of the case. A discharge opening is formed in the upper portion of the right side face of the case. The upper surface of the case is fixedly connected with a water storage tank, and the bottom of the left side face of the water storage tank is fixedly connected with a water pipe fixedly connected with a booster pump. The energy-conserving textile fabric washing device has the advantages of thoroughly cleaning and disinfecting cloth, effectively recycling cleaning fluid to avoid water body pollution and effectively utilizing heat in the drying room. The problems are solved that existing textile fabric wastes energy and cannot be cleaned thoroughly.

Owner:秦泽坤

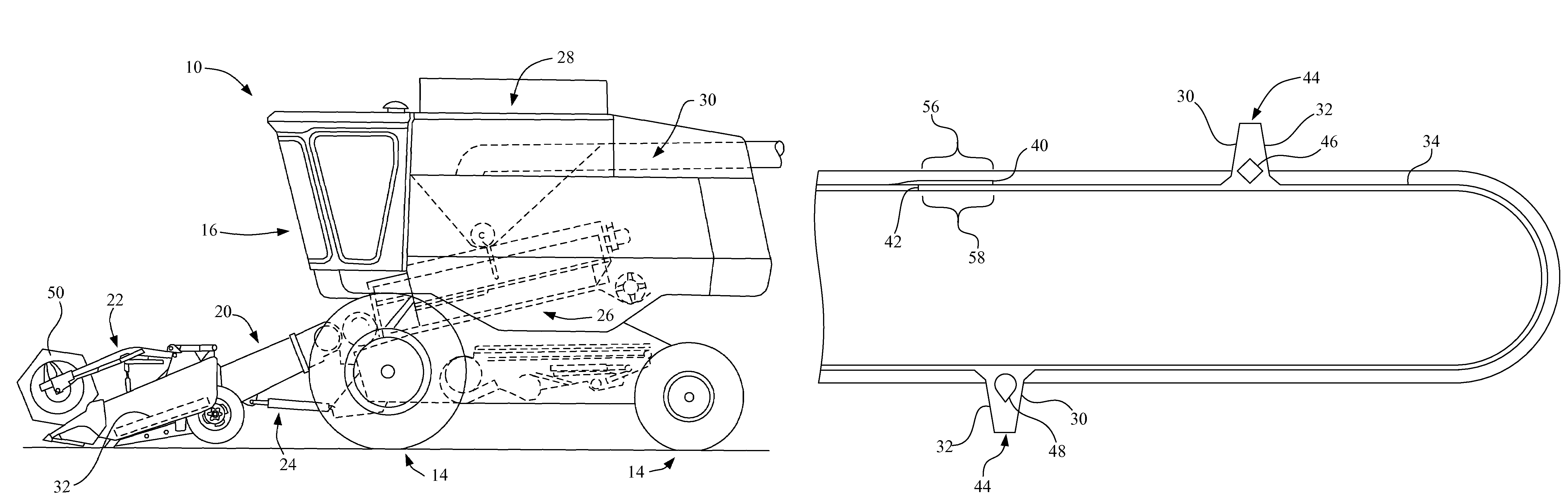

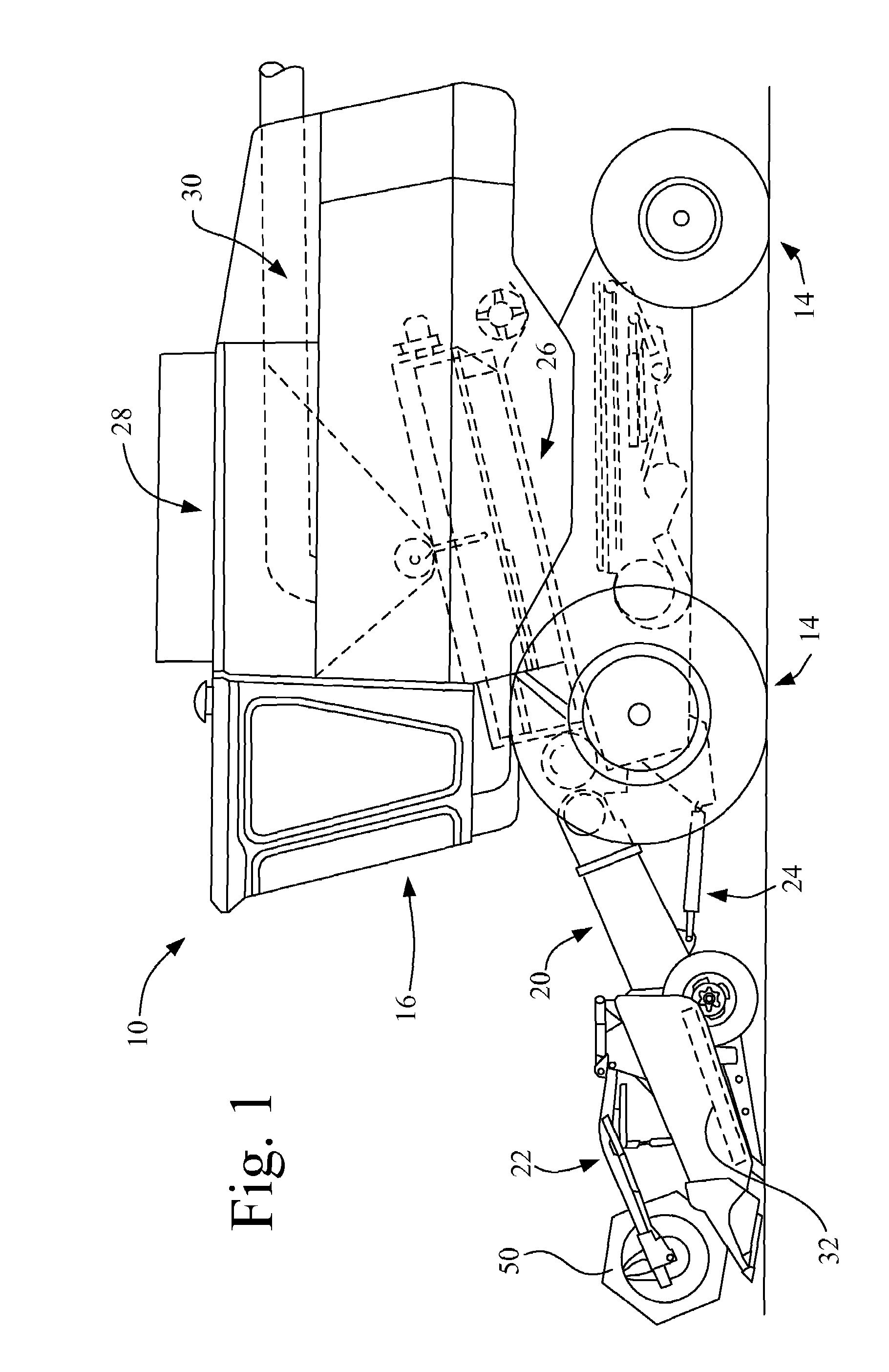

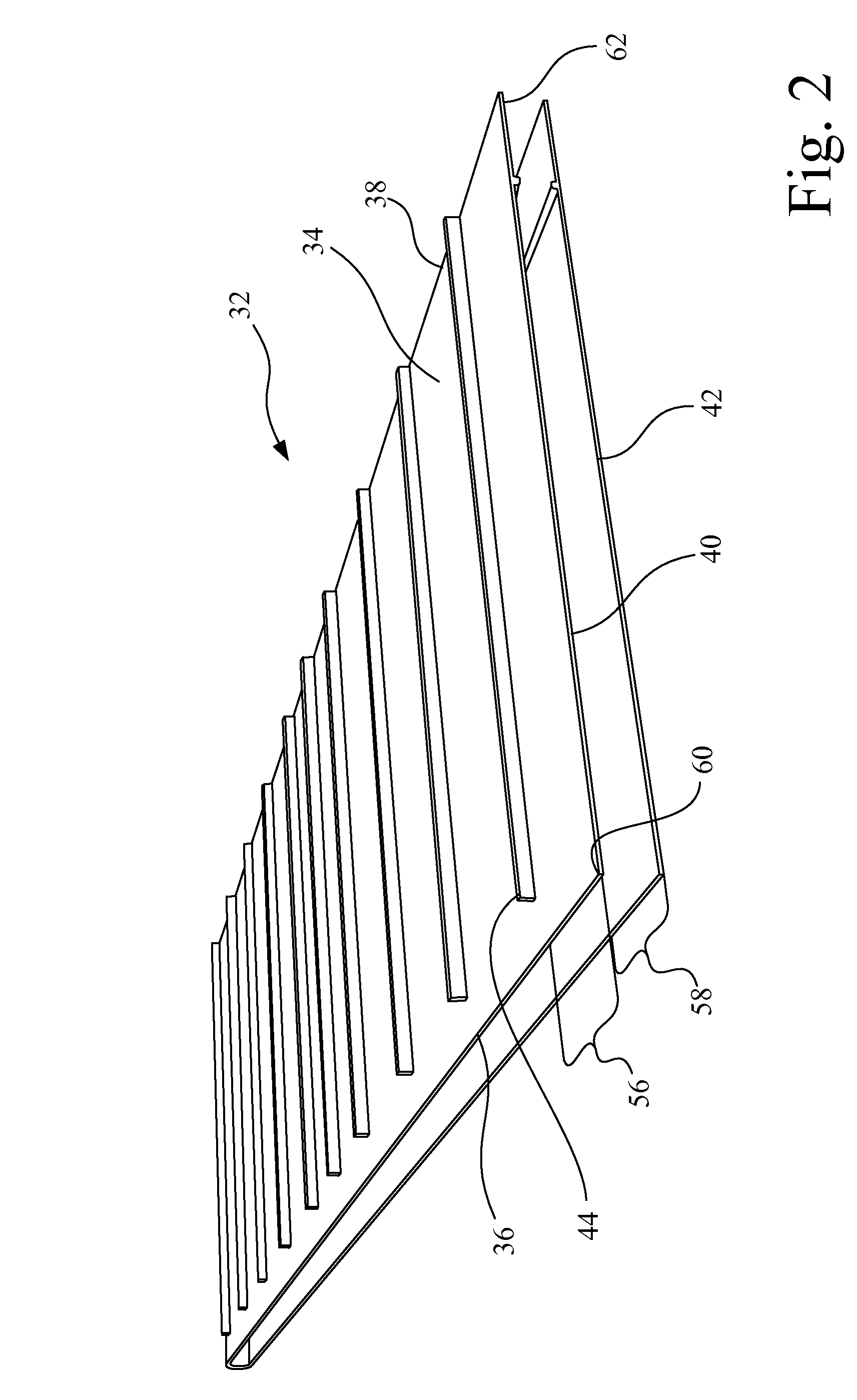

Seamless draper belt

Owner:DEERE & CO

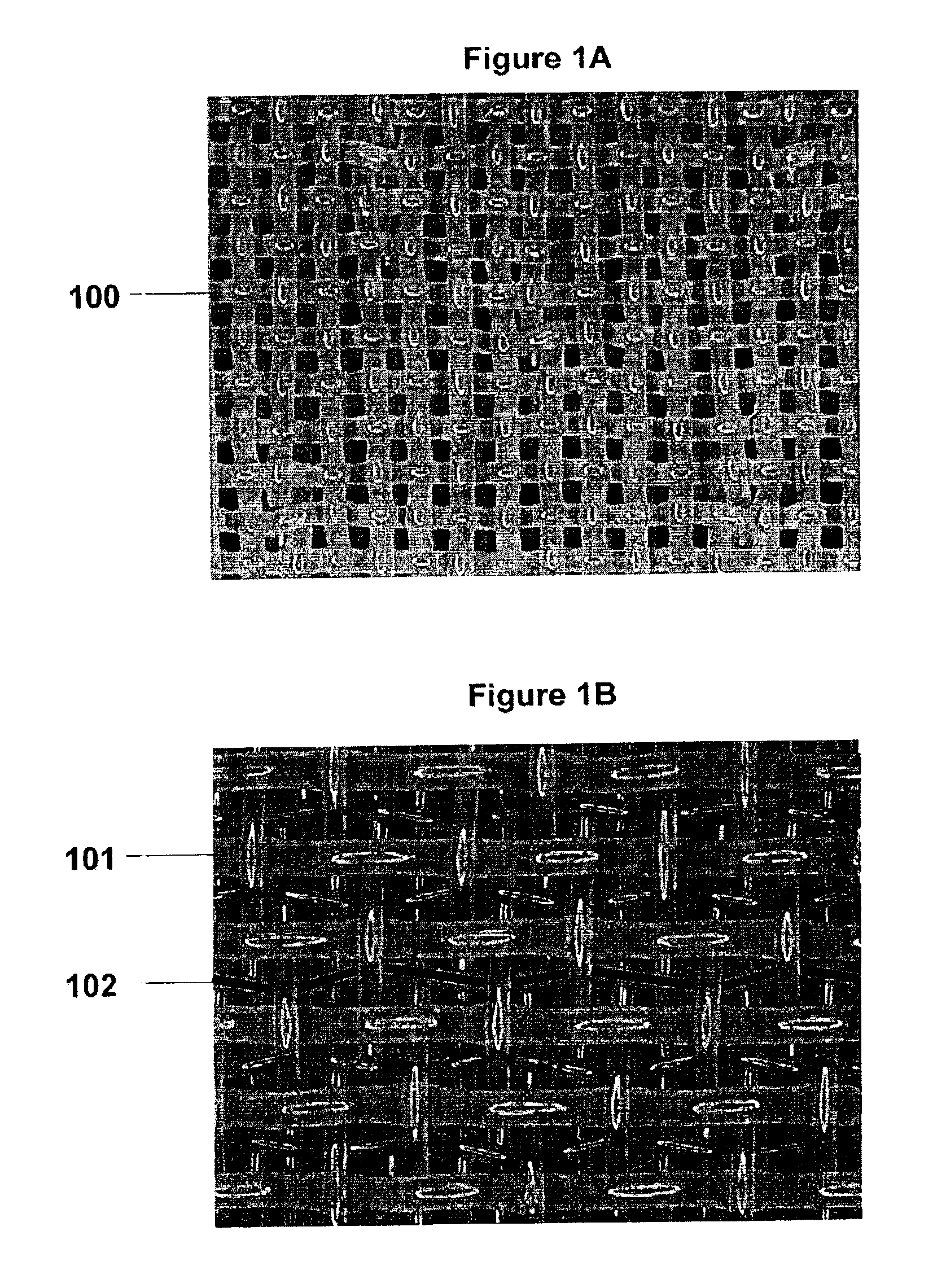

Multi-layer papermaker's fabrics with packing yarns

InactiveUS6902652B2Increasing caliperImproved seam strengthMachine wet endPaper/cardboardCotton materialLateral movement

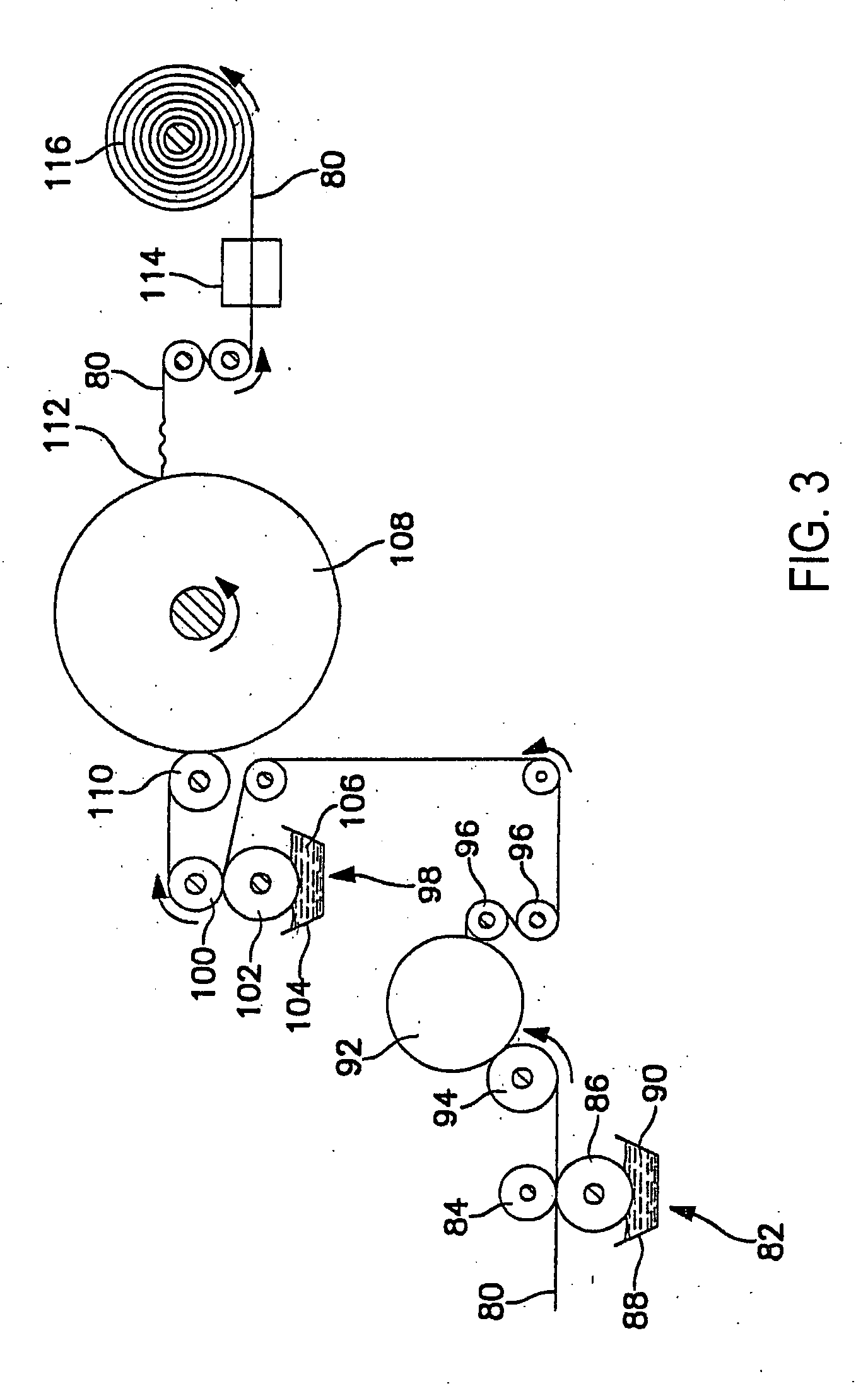

A papermaker's fabric, usable in the forming section of a paper machine, having a top layer and a bottom layer of cross-machine direction (CD) wefts. The top (forming) layer and bottom (wear side) layer are woven together to form a multi-layer fabric. CD packing yarns are inserted between adjacent wear side weft yarns. The packing yarns reduce the void volume on the wear side of the cloth without significantly disrupting the air permeability or increasing the caliper of the fabric. The placement of the packing yarns also adds to the CD stability and seam strength of the fabric and reduces the lateral movement of the wear side weft yarns.

Owner:ALBANY INT CORP

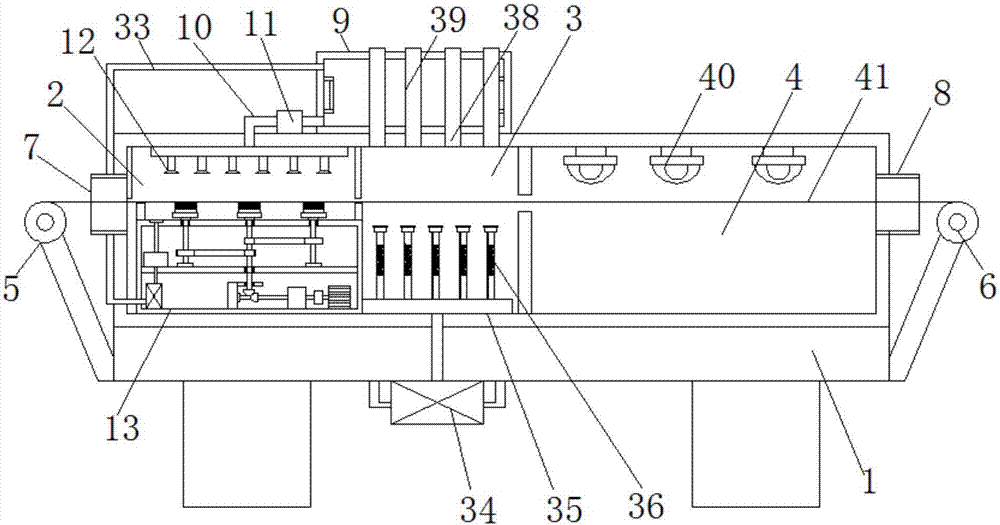

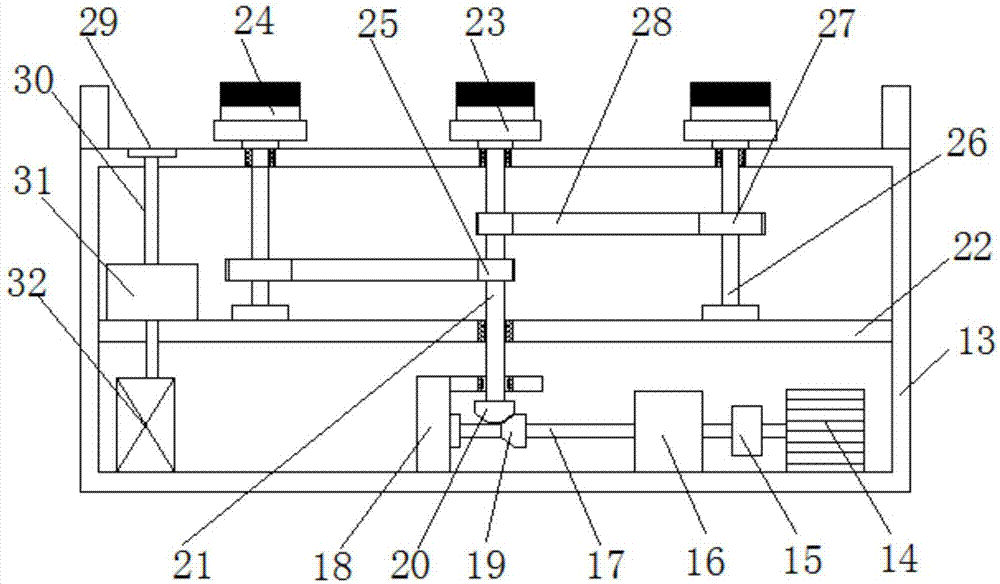

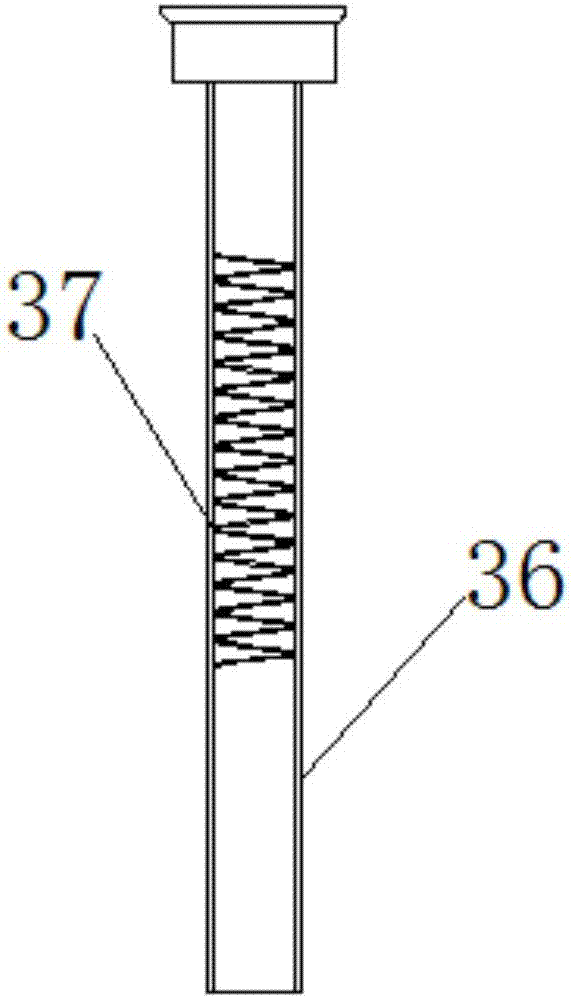

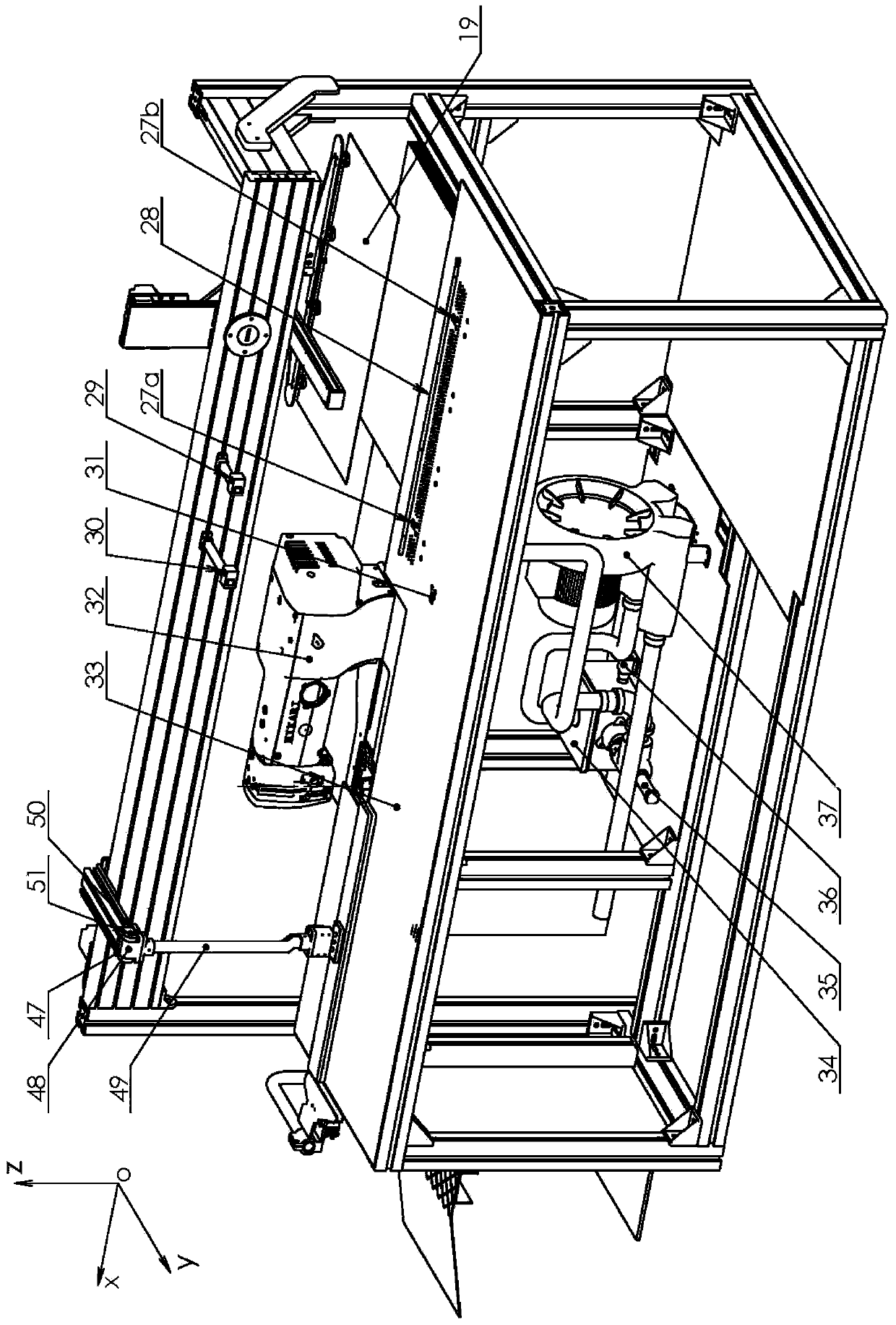

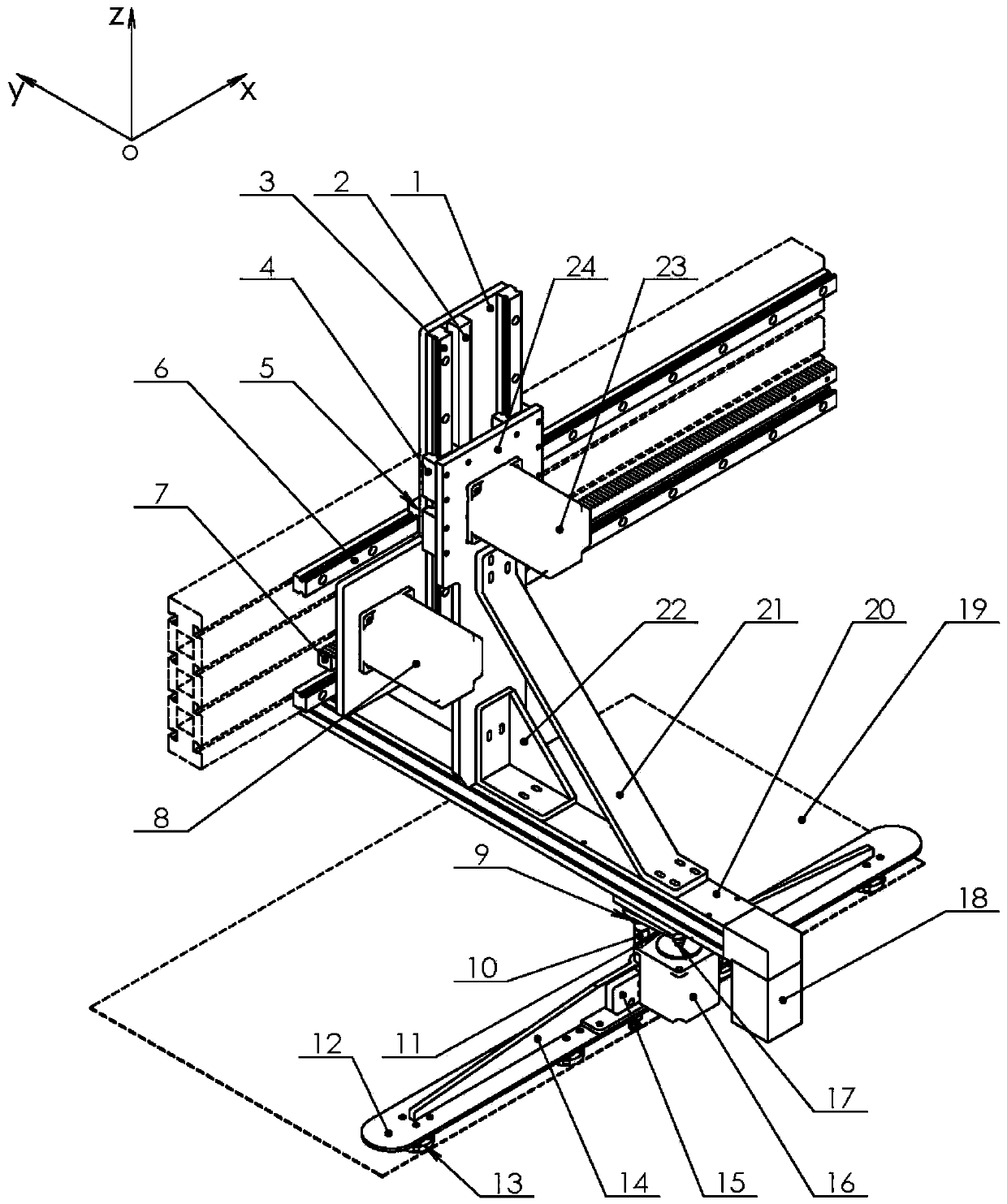

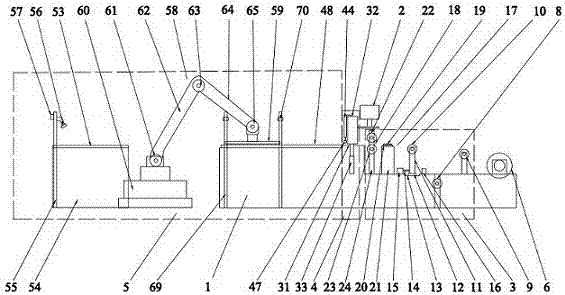

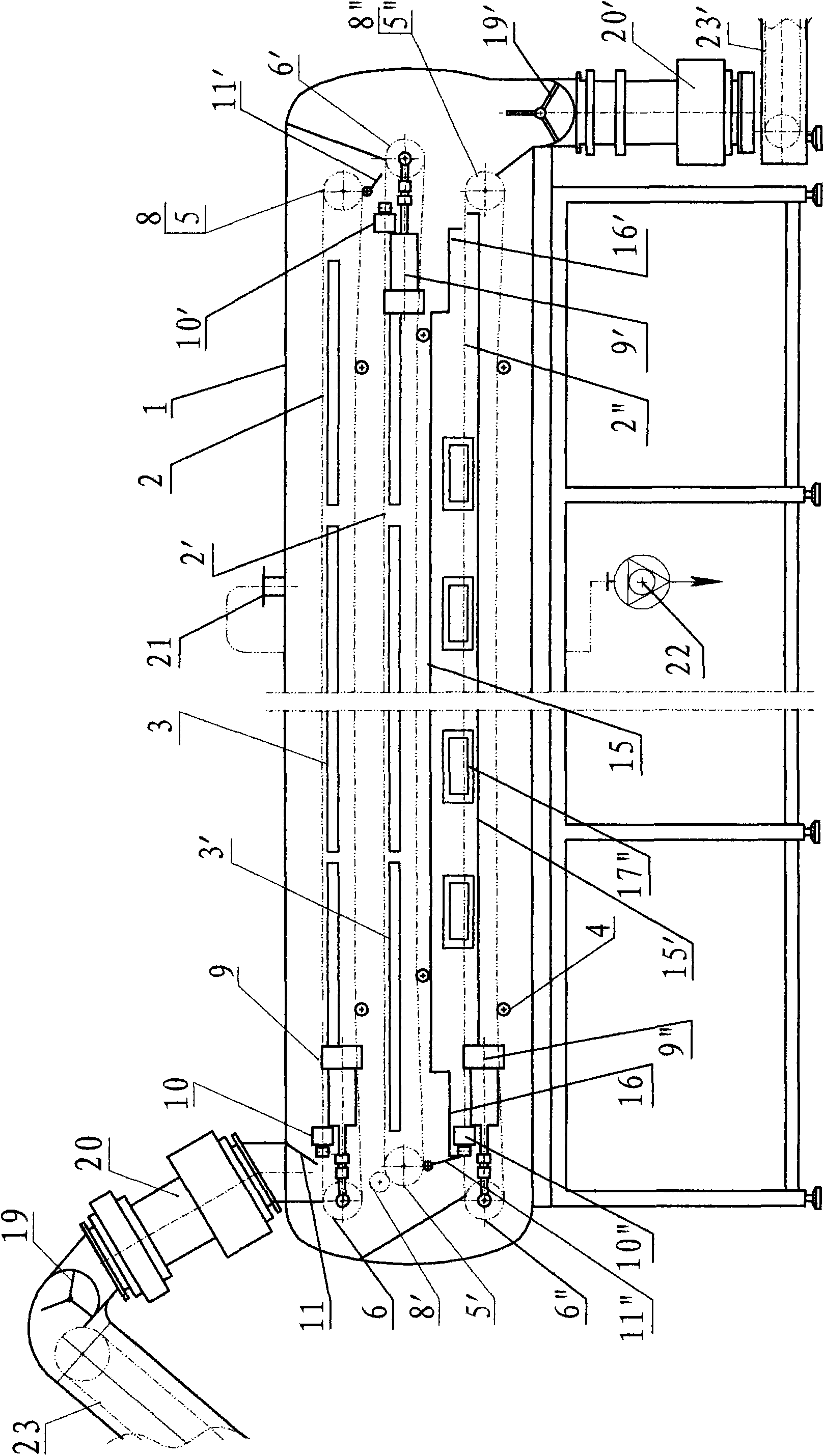

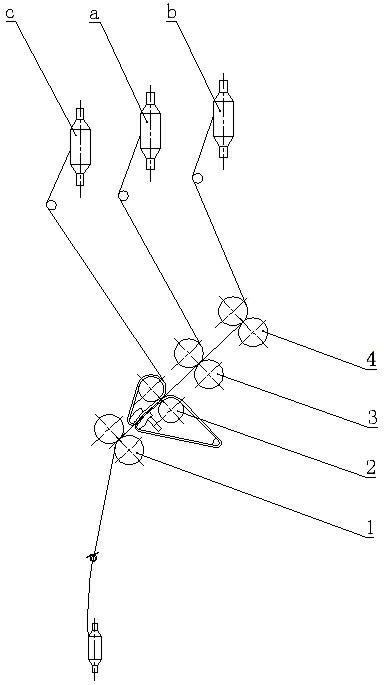

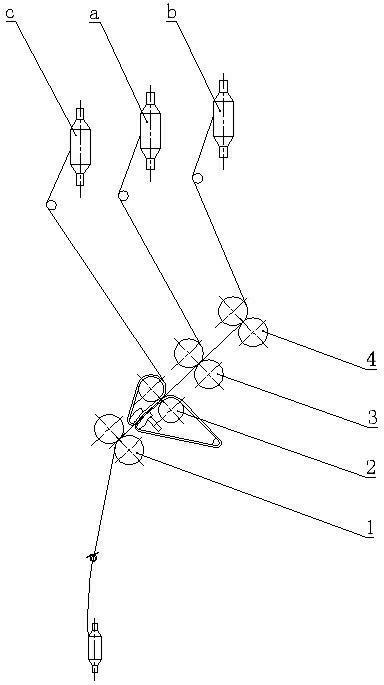

Full-automatic material taking and material feeding sewing machine

The invention relates to a full-automatic material taking and material feeding sewing machine. The full-automatic material taking and material feeding sewing machine comprises a fabric taking device, a fabric position correction system, an air pump system and a sewing material pressing and feeding device, wherein a horizontal guide rail is arranged in the X direction above a machine frame; the entire fabric taking device can conduct movement in X direction along the horizontal guide rail and can further conduct movement in Z direction on the horizontal guide rail; a linear module in a Y direction is arranged at the lower part of the fabric taking device; a rotating and regulating mechanism is arranged at the lower part of the linear module in the Y direction; a sucking disc fixing plate is arranged at the lower part of the rotating and regulating mechanism; the fabric position correction system comprises a fabric position sensing device; the fabric position sensing device comprises at least three sensors and a driving system that monitors the position of the fabric and transmits the signals of the fabric position deviation to the fabric taking device; the driving system corrects the placing position of the fabric through adjusting the global movement of the fabric taking device in the X direction, the Y-direction movement of the linear module in the Y direction and the rotating angles of the rotating and regulating mechanism.

Owner:上海富山精密机械科技有限公司

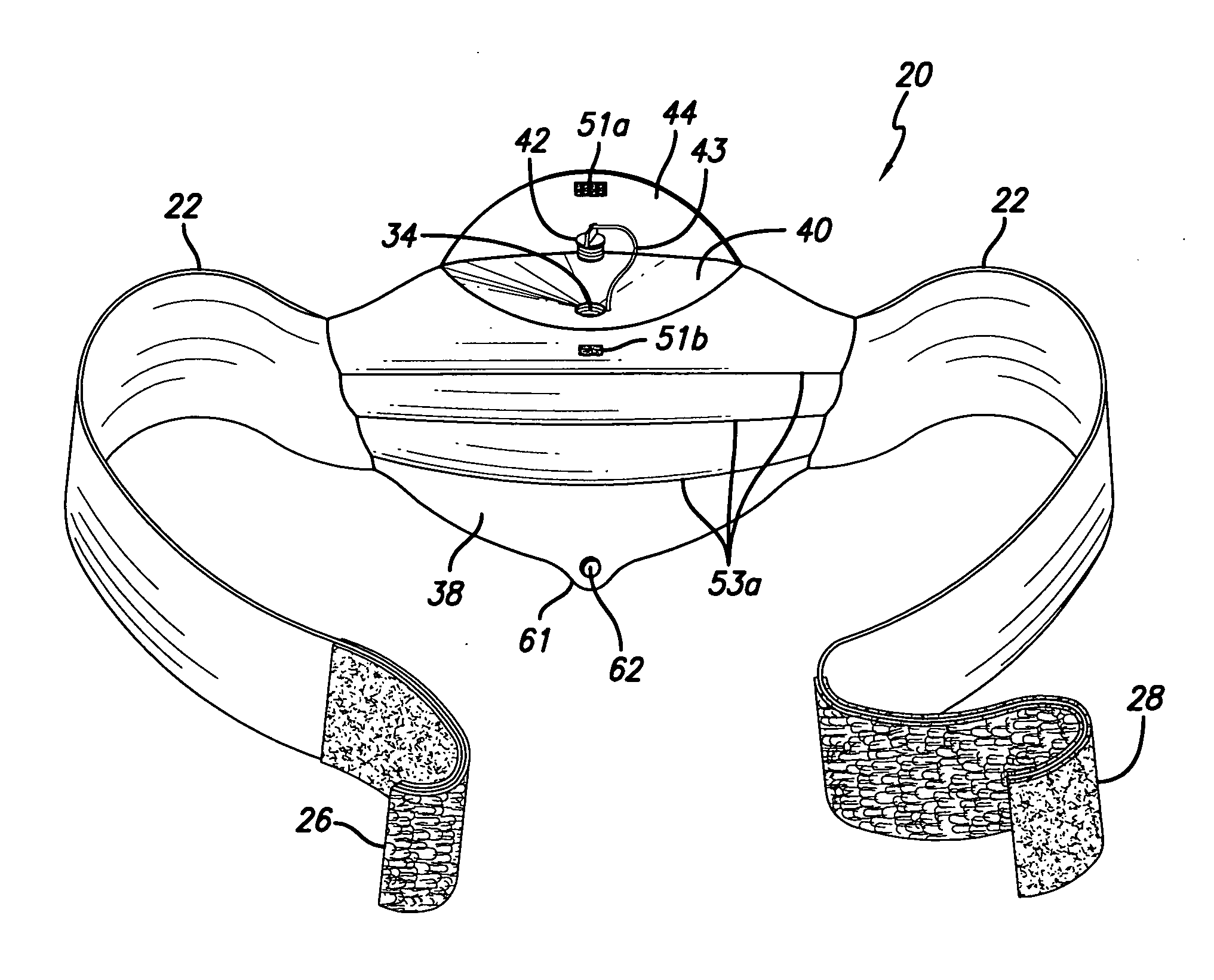

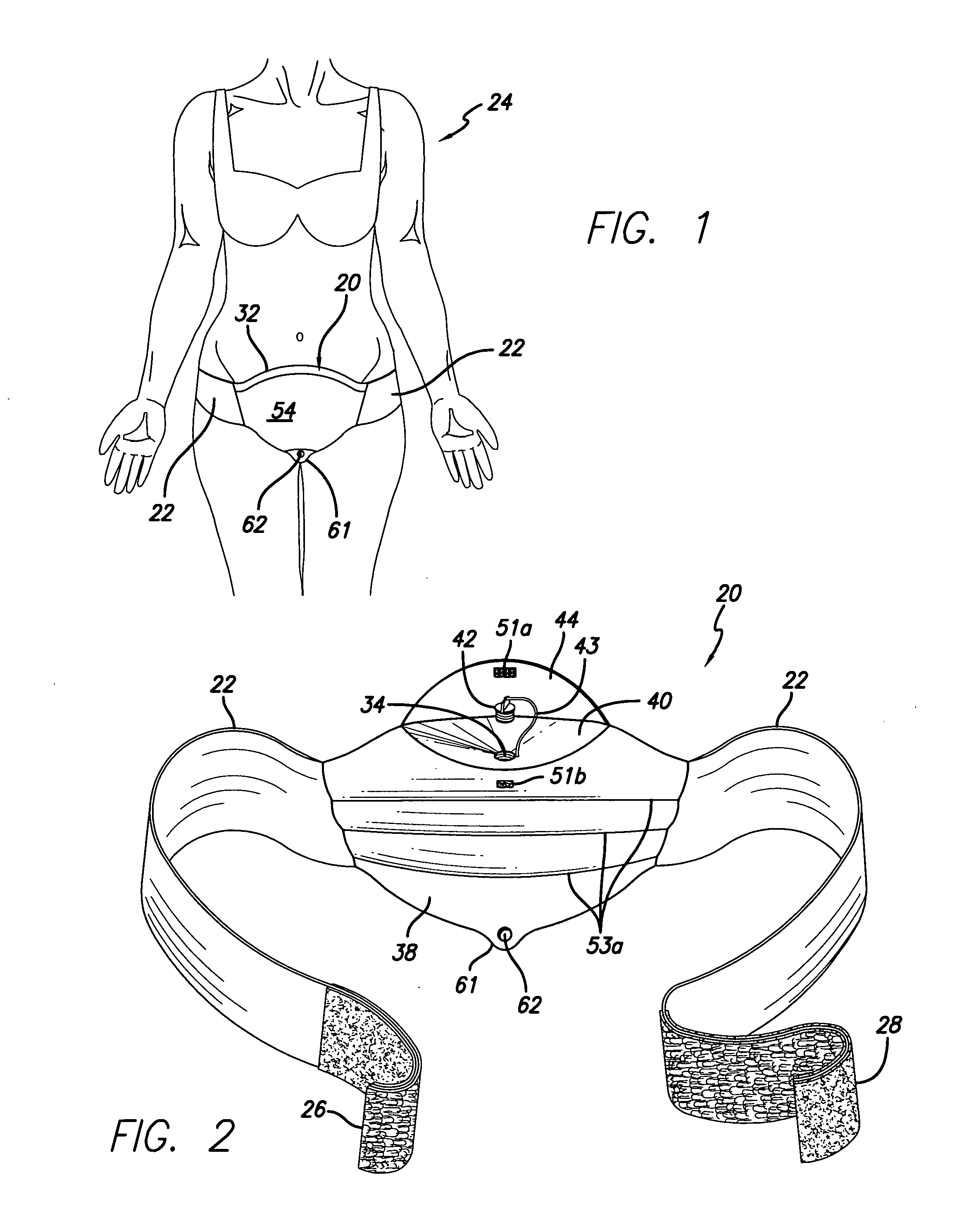

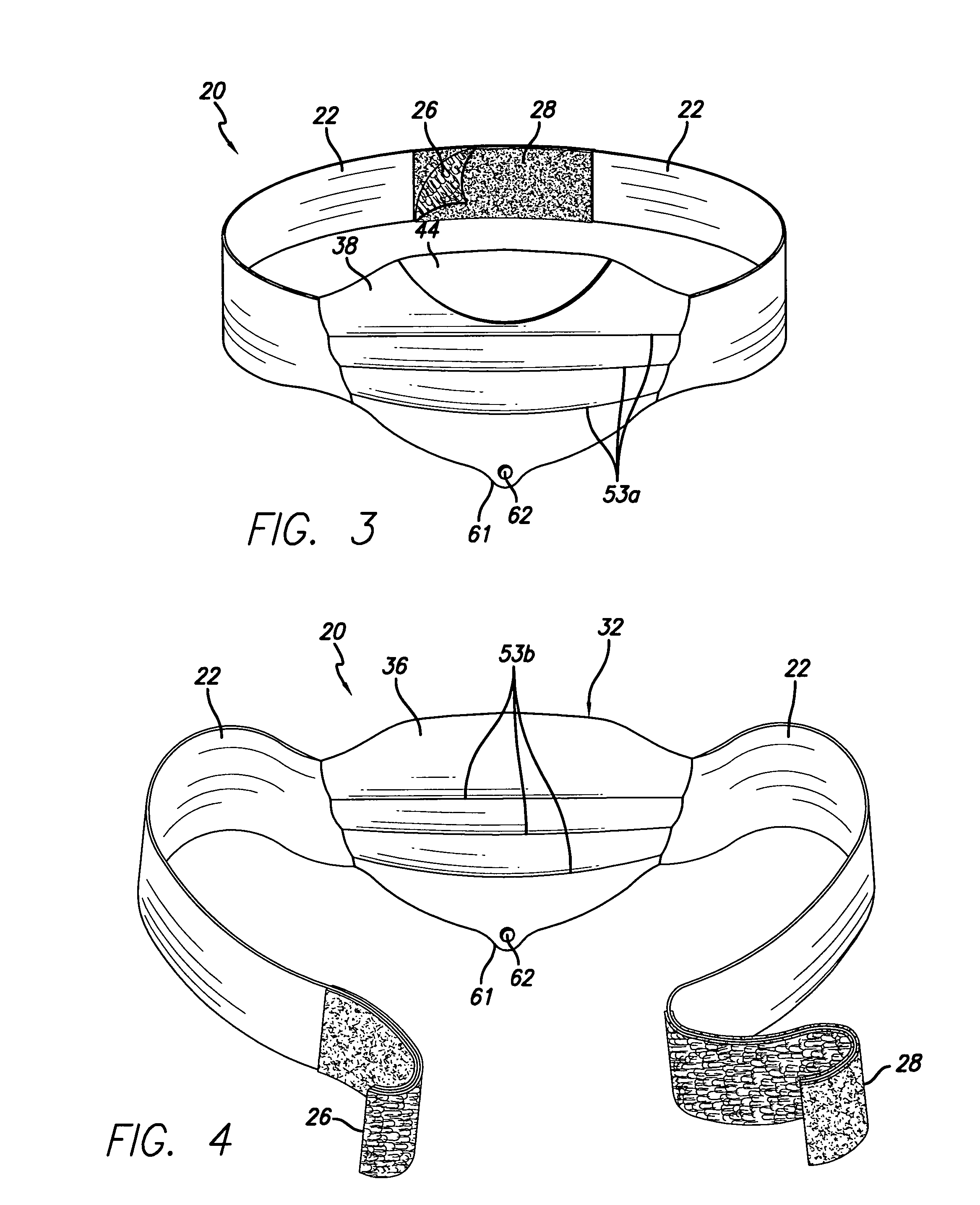

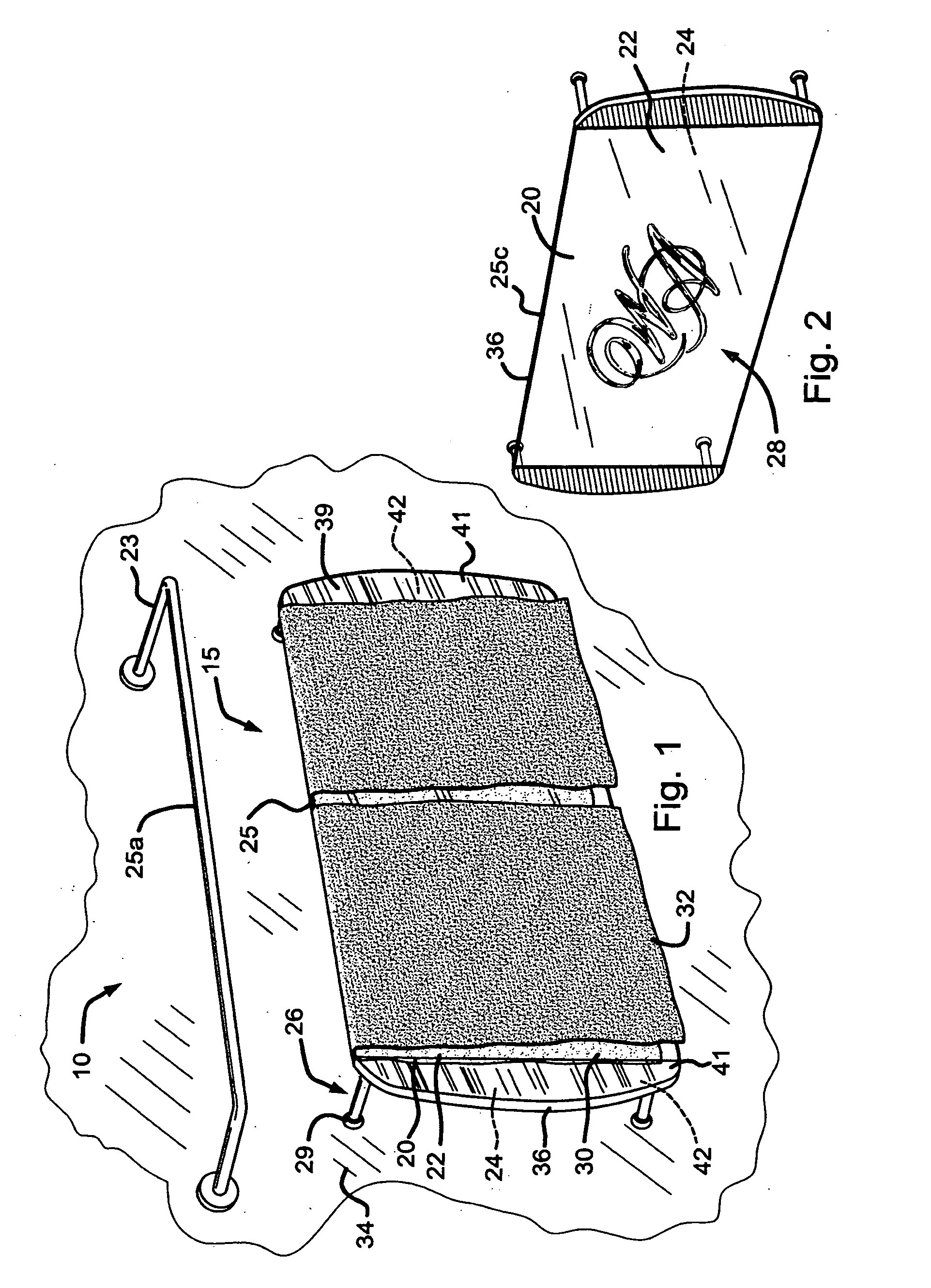

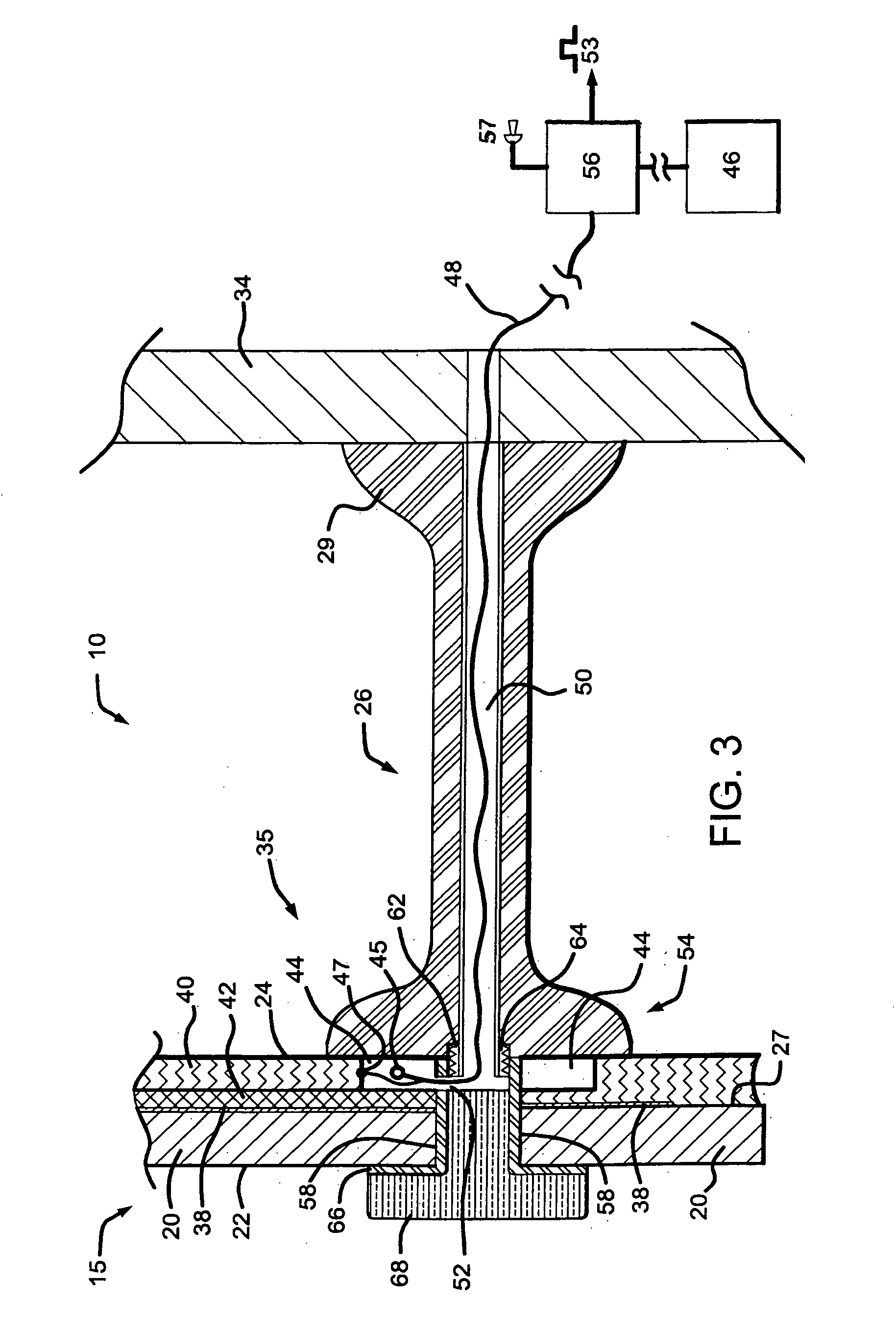

Therapeutic hot and cold water belt

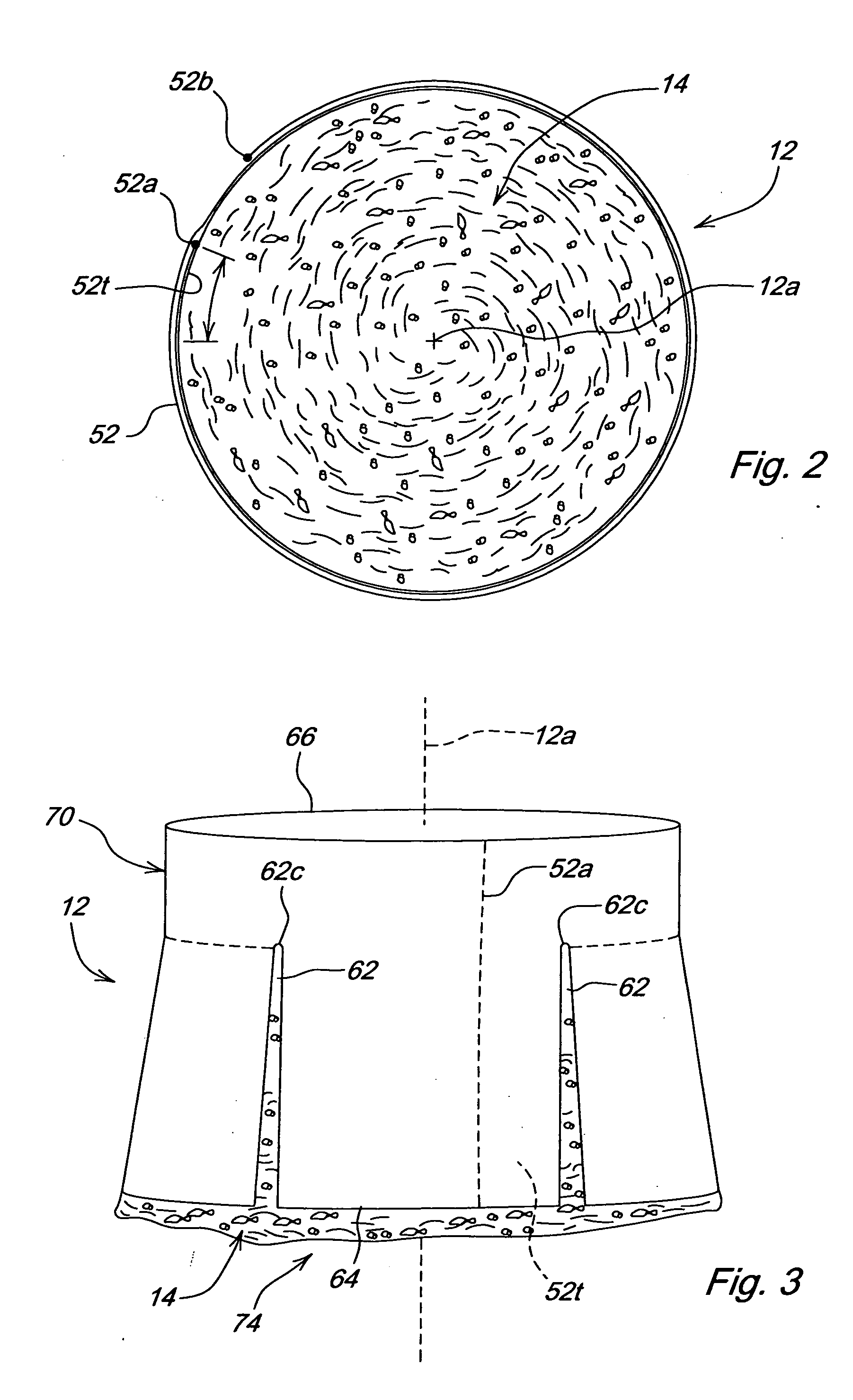

InactiveUS20090306749A1Avoid contactFreedom of movementLarge containersLinings/internal coatingsWater flowEngineering

The therapeutic hot and cold water belt (20), which offers comfortable relief from pain, is placed about the waist, lower abdomen, back or any other part of the body, and then secured in place by an elasticized belt terminating in a hook-and-loop fastener system. The belt includes a water pouch (32) to receive and contain water. Ribs (46, 48, 50) are secured to the inside of the pouch, which divide it into compartments (46a, 46b, 46c, 46d), and maintain the shape of the pouch so that it will not balloon out when the water is inserted therein. The ribs also limit and thereby conserve the amount of water placed in the pouch. For comfort against the body, the pouch may be covered with a combed cotton material (54), which is secured also by a hook-and-loop fastener system. A funnel opening (34) to the pouch allows easy filling of the pouch with water. The funnel opening is secured with a screw (42) to prevent any pressure on the pouch from forcing the water flow out. Another cover (44) folds back from the top of the plastic pouch container to prevent the screw plug from having contact with the wearer. The user determines the temperature of water poured inside, whether hot, cold or warm. The system is placed on the body, and positioned and secured in place as desired.

Owner:MULINDWA DAMALIE

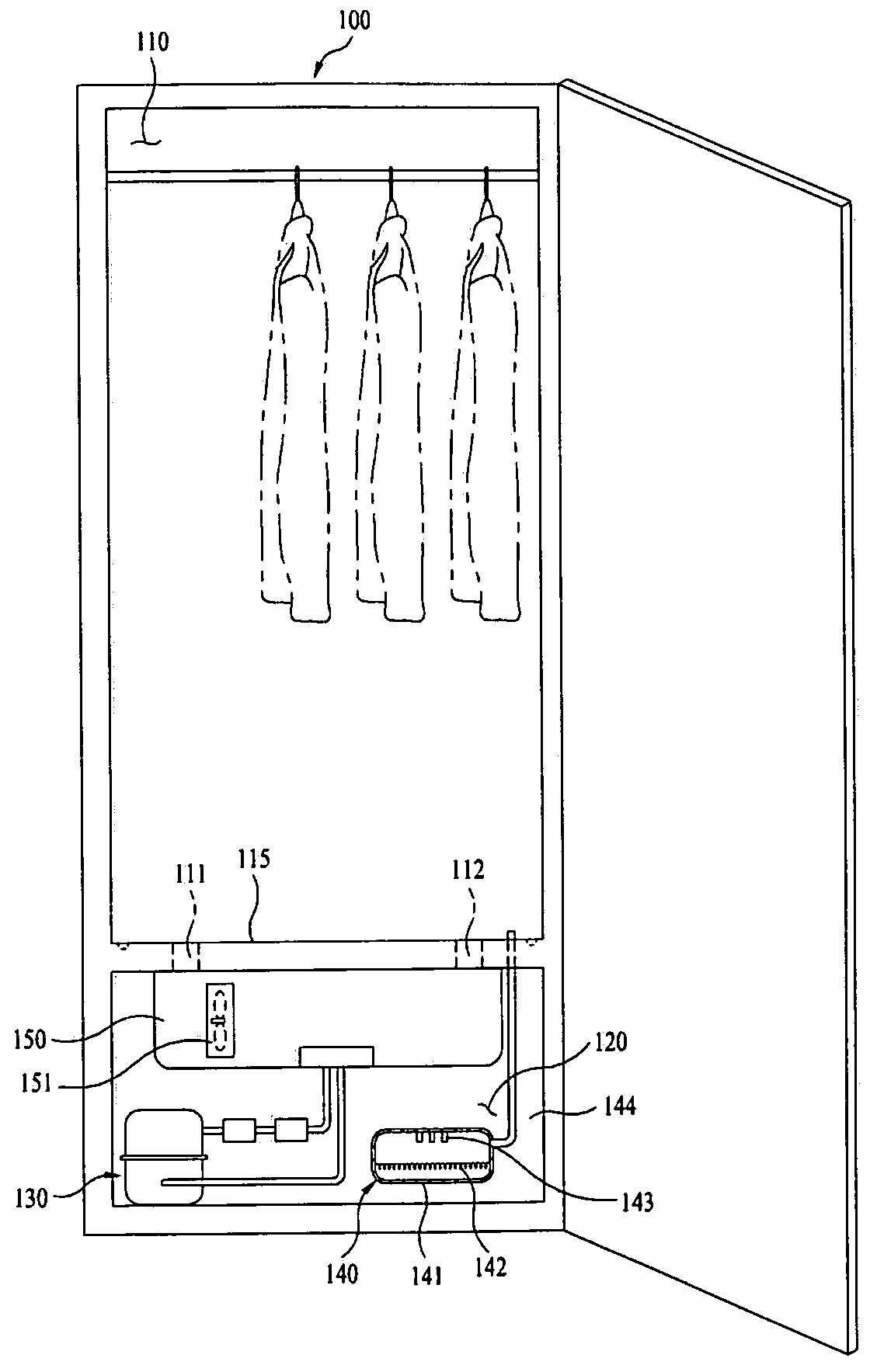

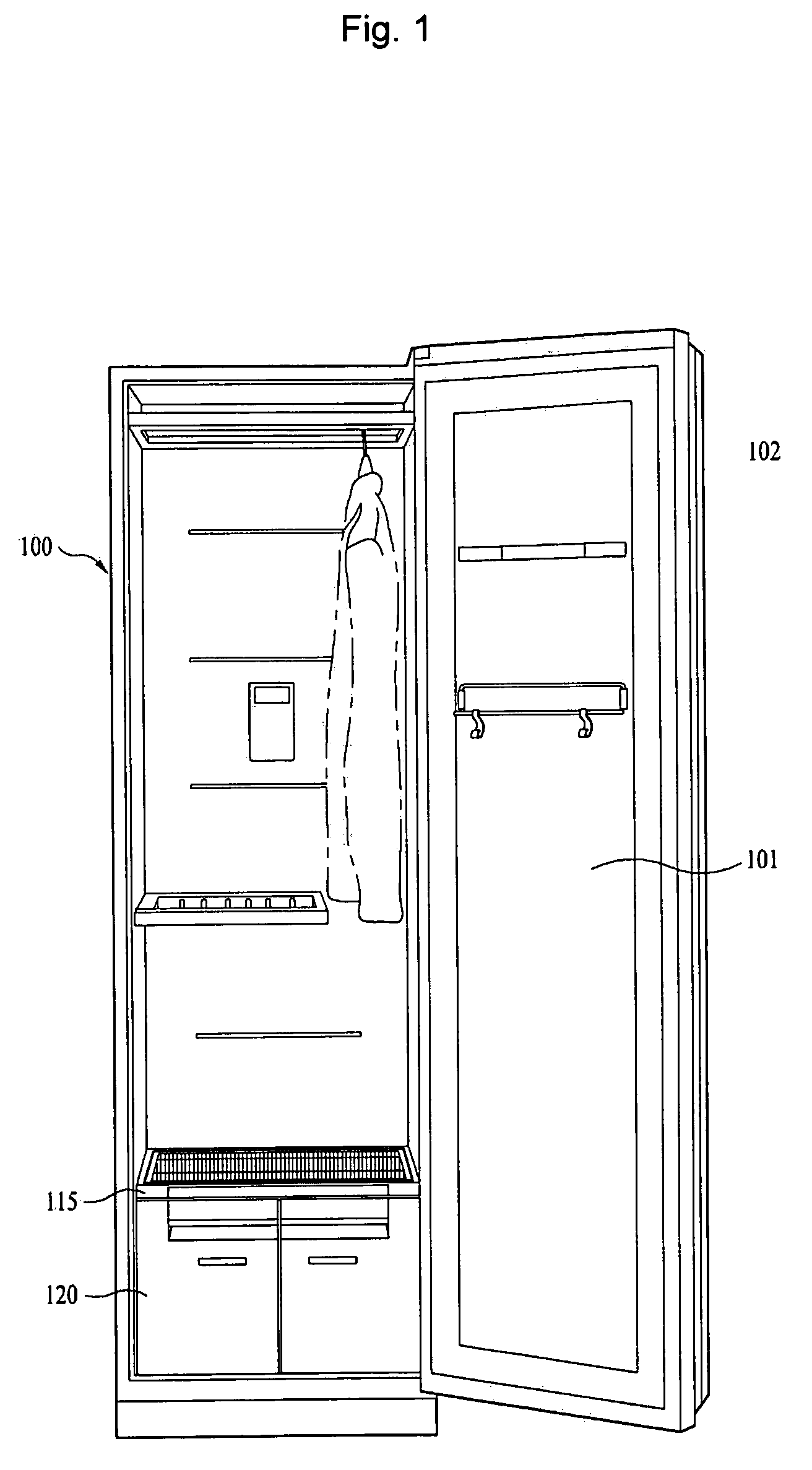

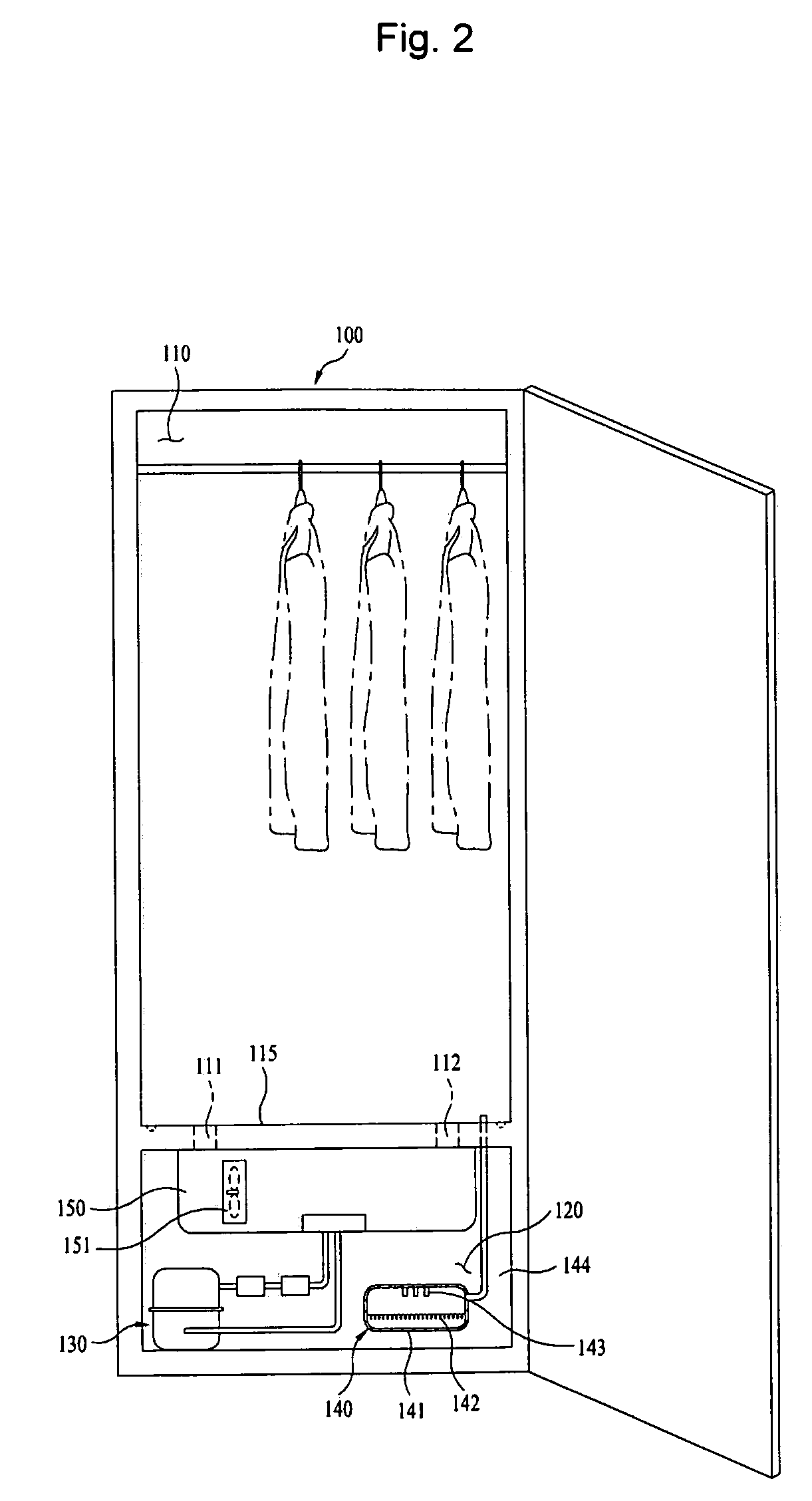

Cloth treating apparatus

Disclosed is a cloth treating apparatus, which supplies hot air to a accommodating space receiving clothes to dry the clothes. The cloth treating apparatus includes a cabinet including a accommodating space to receive clothes, and an electric component chamber, in which a moisture supply device to spray steam to the accommodating space and a air supply device to supply hot air are installed; and a condensed water treating unit to treat condensed water, generated by condensing the steam sprayed to the accommodating space or the hot air supplied from the air supply device. Therefore, the cloth treating apparatus treats the condensed water generated in the accommodating space, and thus prevents the generation of substances harmful to the human body, such as mold, in the accommodating space.

Owner:LG ELECTRONICS INC

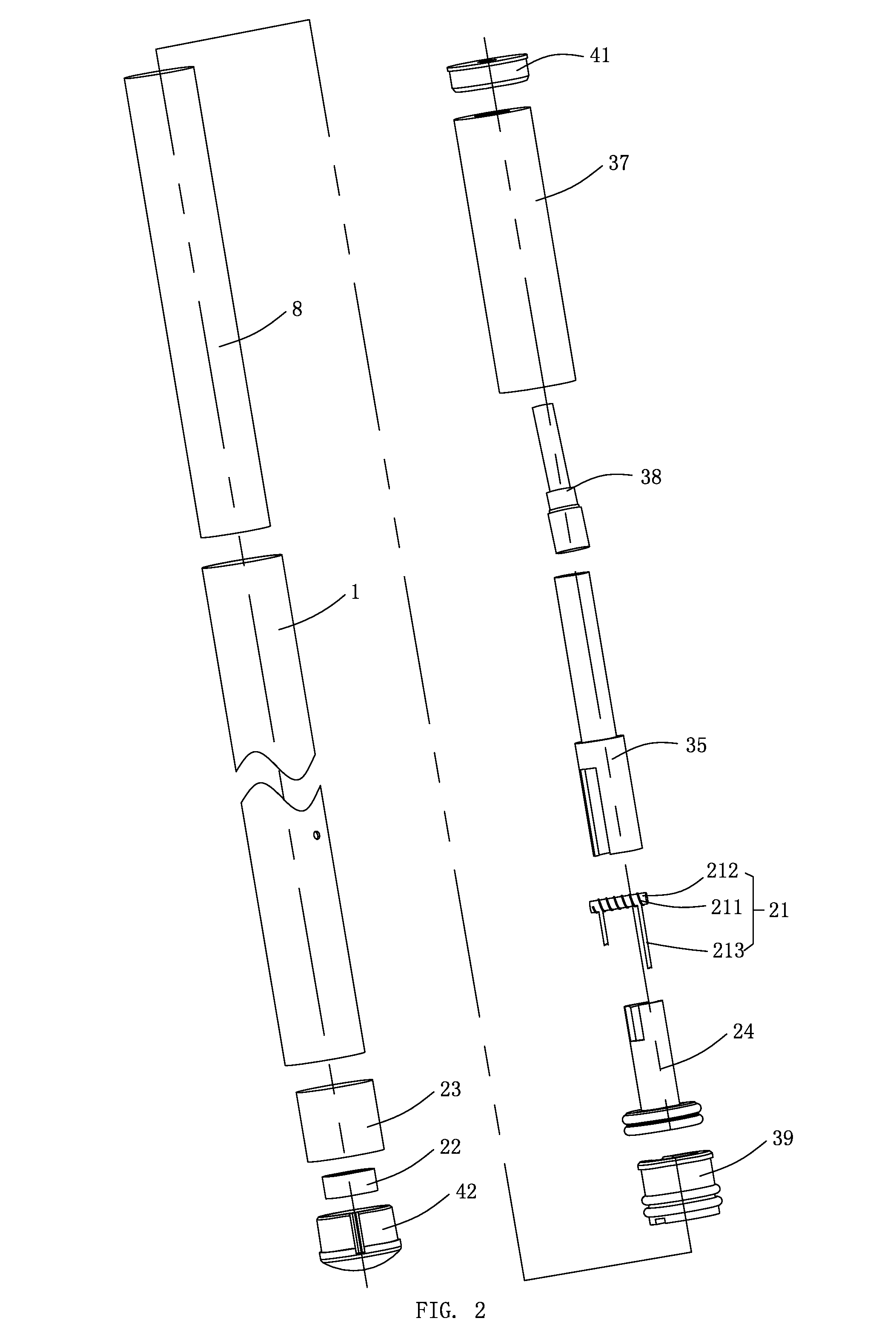

Electronic cigarette adopting organic cotton

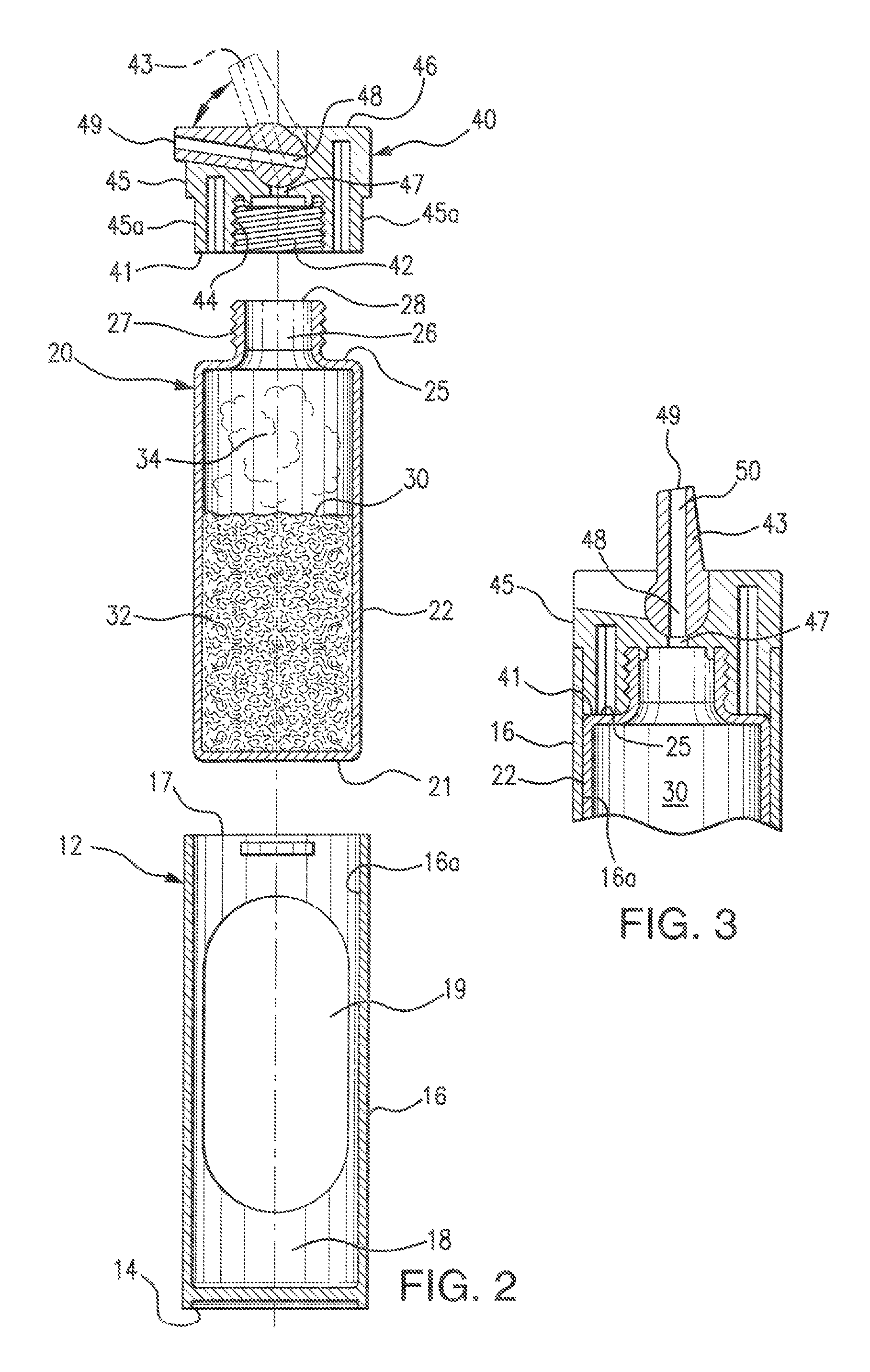

InactiveUS9532601B2The internal structure is firm and reliableAvoid damageTobacco pipesTobacco devicesGlass fiberEngineering

An electronic cigarette adopting organic cotton includes a liquid storage component and an atomizing device, the atomizing device includes a hollow spiral heating wire, a liquid guiding member inserted in the heating wire, the liquid guiding member is made of non-fiberglass organic cotton materials; the atomizing device further includes a smog conduit inserted in the liquid storage component for supporting the liquid storage component and serving as a channel for the smog, the smog conduit comprises an outer sleeve and an inner sleeve, one inserted into another to position the liquid guiding member therebetween, and the liquid guiding member has its opposite ends respectively to be protruded out of an outer sidewall of the smog conduit and firmly abut against an inner sidewall of the liquid storage component. This kind of electronic cigarettes is harmless to the human body and has stable and reliable inner structure.

Owner:HUIZHOU KIMREE TECH

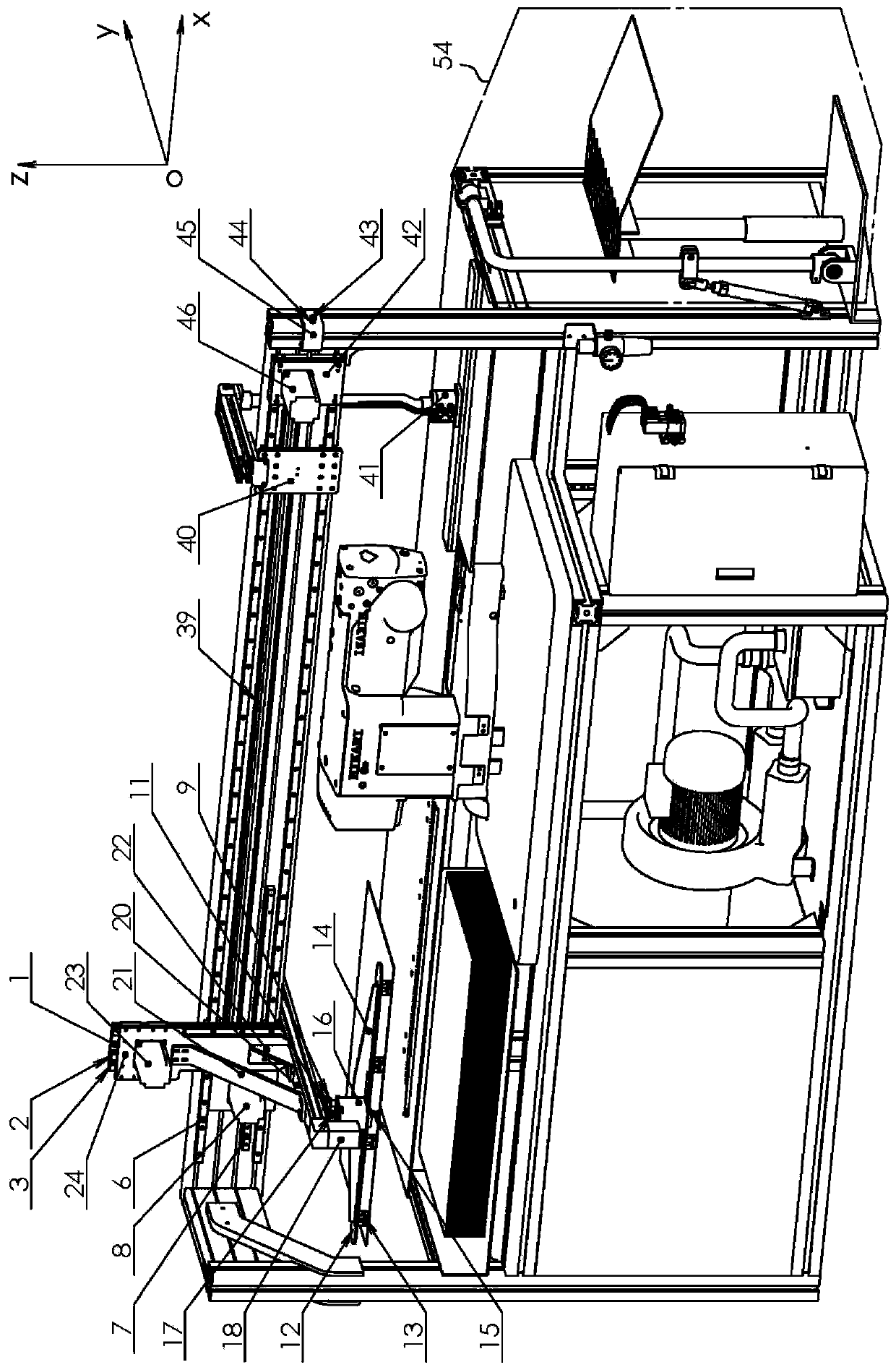

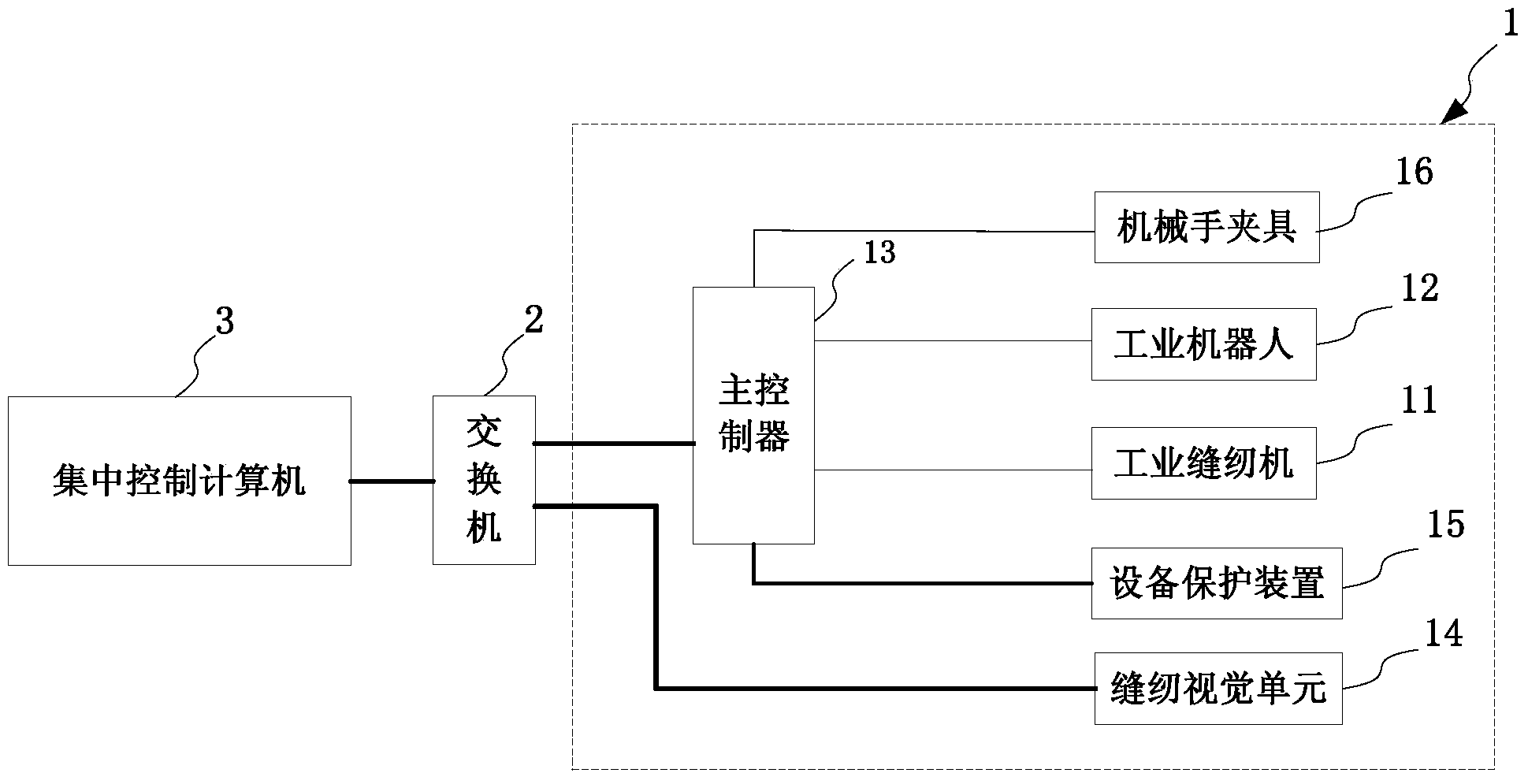

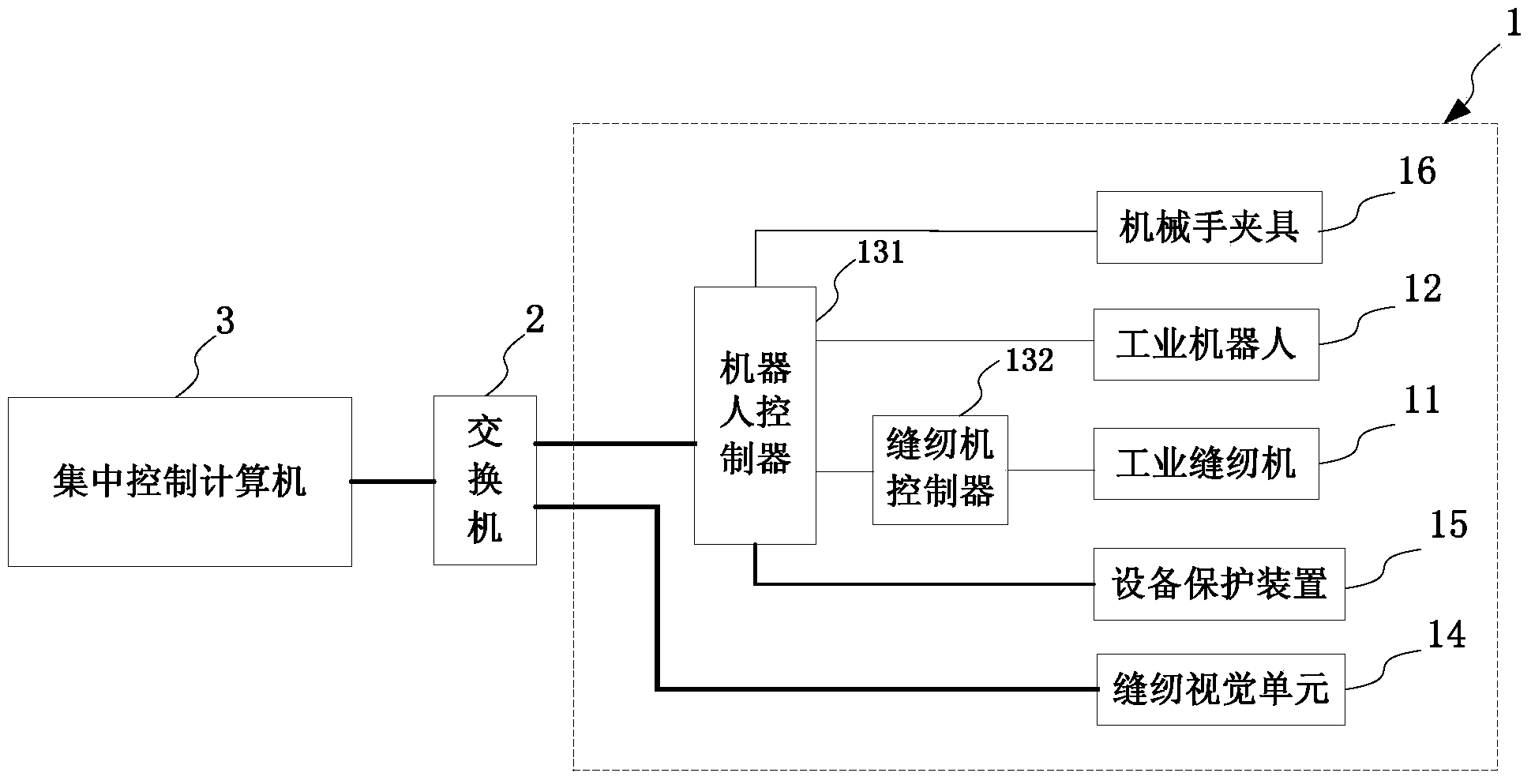

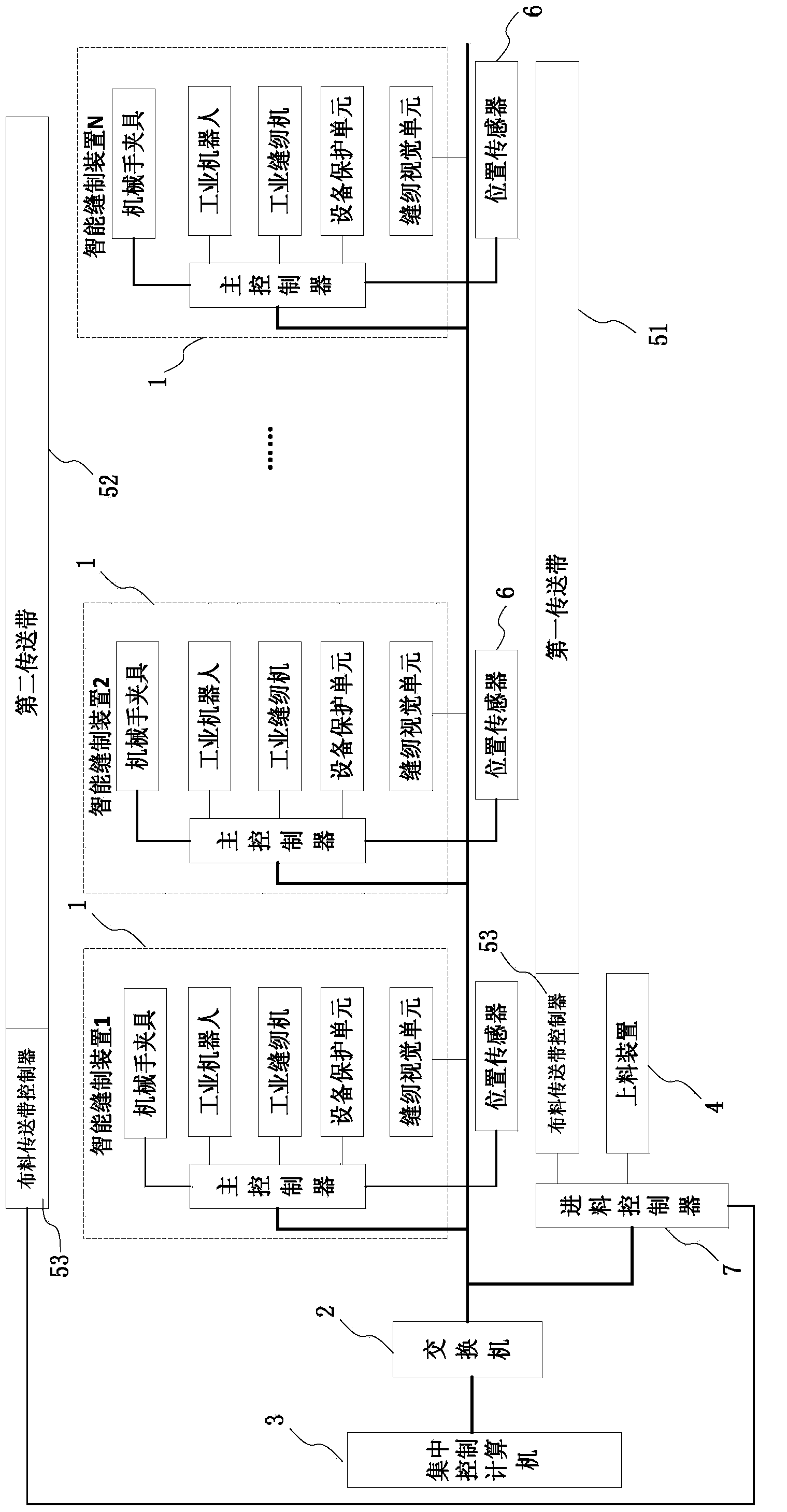

Intelligent sewing device and system

ActiveCN104018297ASewing precisionImprove work efficiencyProgramme-controlled sewing machinesSewing-machine control devicesHuman–computer interactionManipulator

The invention provides an intelligent sewing device and system. The device comprises an industrial sewing machine for sewing cloth, a mechanical arm clamp, an industrial robot, a main controller and a sewing vision unit. The industrial robot operates the mechanical arm clamp for sewing matching. The industrial sewing machine, the mechanical arm clamp, an equipment protecting device and the industrial robot are connected through the main controller which then carries out control. The sewing vision unit is used for shooting sewing workbench images and obtaining cloth images. The system comprises a plurality of intelligent sewing devices, main controllers, exchangers, feeding controllers, loading devices, feeding devices and centralized control computers. The main controllers and the exchangers are in communication connection with the intelligent sewing devices. The feeding controllers are in communication connection to the exchangers. The loading devices are connected with the feeding controllers. The feeding devices are used for placing of cloth by the loading devices and conveying the cloth to the intelligent sewing devices. The centralized control computers are in communication connection with operation man-machine interaction platforms of the exchangers. Through the system, automatic loading, feeding and sewing are achieved, during a sewing process, the cloth can be used for locating or correcting an algorithm, sewing is accurate, and working efficiency and product yield are greatly improved.

Owner:JACK SEWING MASCH CO LTD

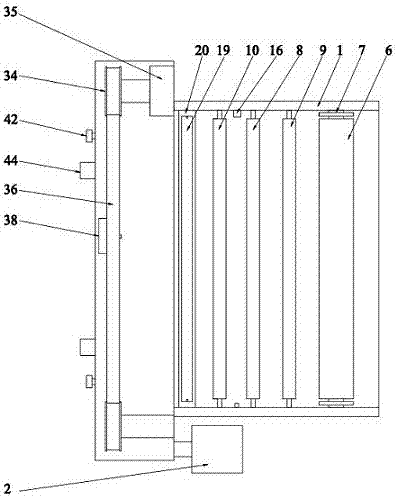

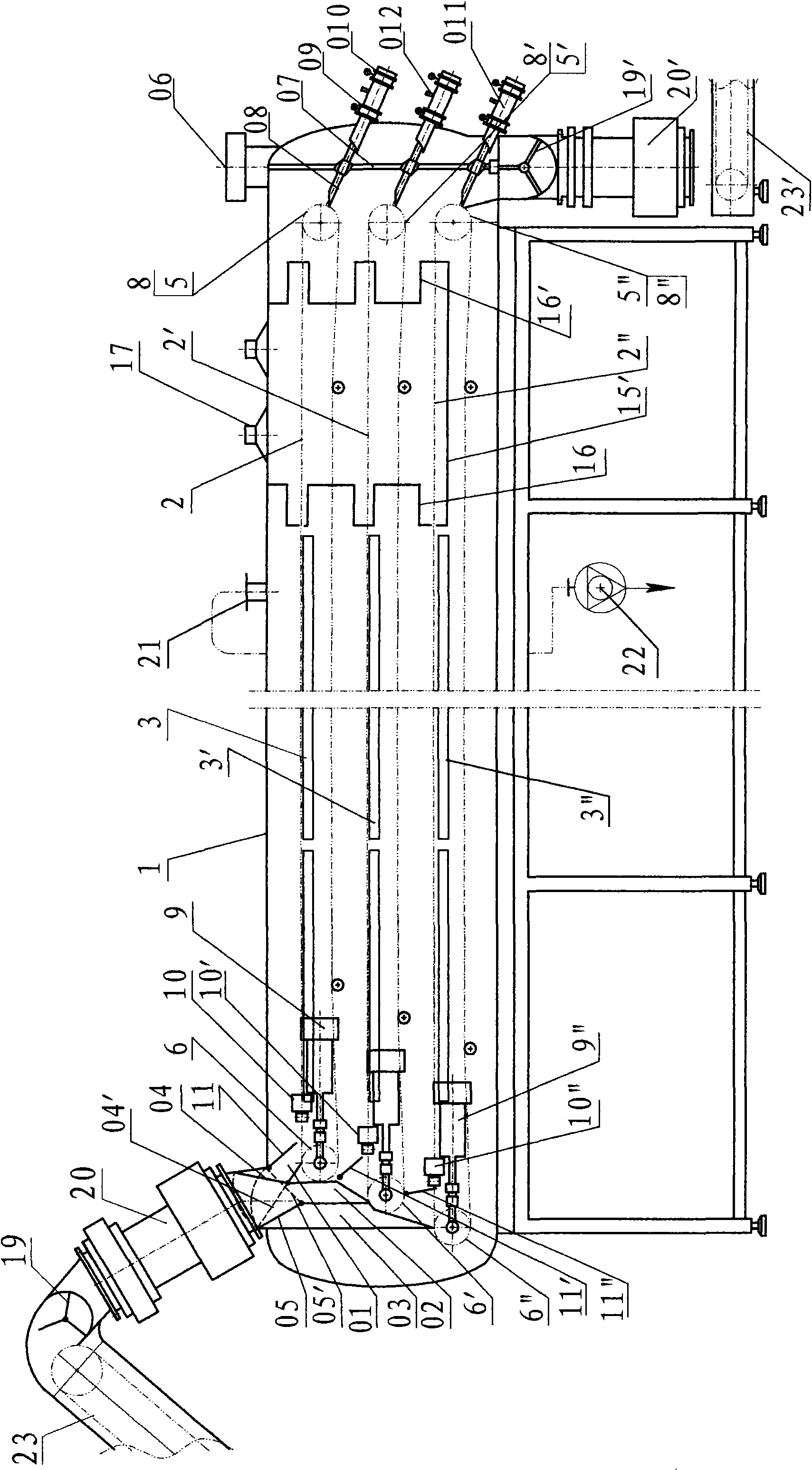

Full-automatic cloth cutting device

ActiveCN107354708AImprove cutting yieldReduce intensitySevering textilesMetal working apparatusHydraulic cylinderControl system

The invention relates to the field of cloth processing equipment, in particular to a full-automatic cloth cutting device which comprises a machine frame and a power distribution console. The machine frame is provided with a cloth feeding device, a cloth cutting device and a cloth collecting device. The front end of the cloth feeding device is provided with a raw material roller. The full-automatic cloth cutting device is characterized in that the cloth feeding device comprises a first cloth supporting roller, a tension roller, a second mop roller, a cloth pressing mechanism and a driving mechanism. The cloth cutting device comprises a cutting platform and a cutting lifting table which are connected through a cutting hydraulic cylinder. The cutting lifting table is provided with a linear guideway, a synchronizing wheel, a synchronous belt, a cutting knife, a limiting switch and a cloth pressing roller. The cloth collecting device comprises a belt conveying platform, an image collector, an automatic cloth detection platform, an industrial camera and a robot cloth collecting mechanism. The robot cloth collecting mechanism comprises a mechanical hand, a sucker mechanism and a control system. The sucker mechanism comprises a sucker support and a vacuum sucker. The full-automatic cloth cutting device can implement automatic calibration, automatic cloth cutting, automatic cloth collection and cloth detection, and the cutting yield and working efficiency are greatly improved.

Owner:WEIHAI BAOWEI NEW MATERIAL TECH CO LTD

Splittable cloth like tissue webs

ActiveUS20050145352A1Similar basisBasis weightNon-fibrous pulp additionNatural cellulose pulp/paperPulp and paper industryUltimate tensile strength

Owner:KIMBERLY-CLARK WORLDWIDE INC

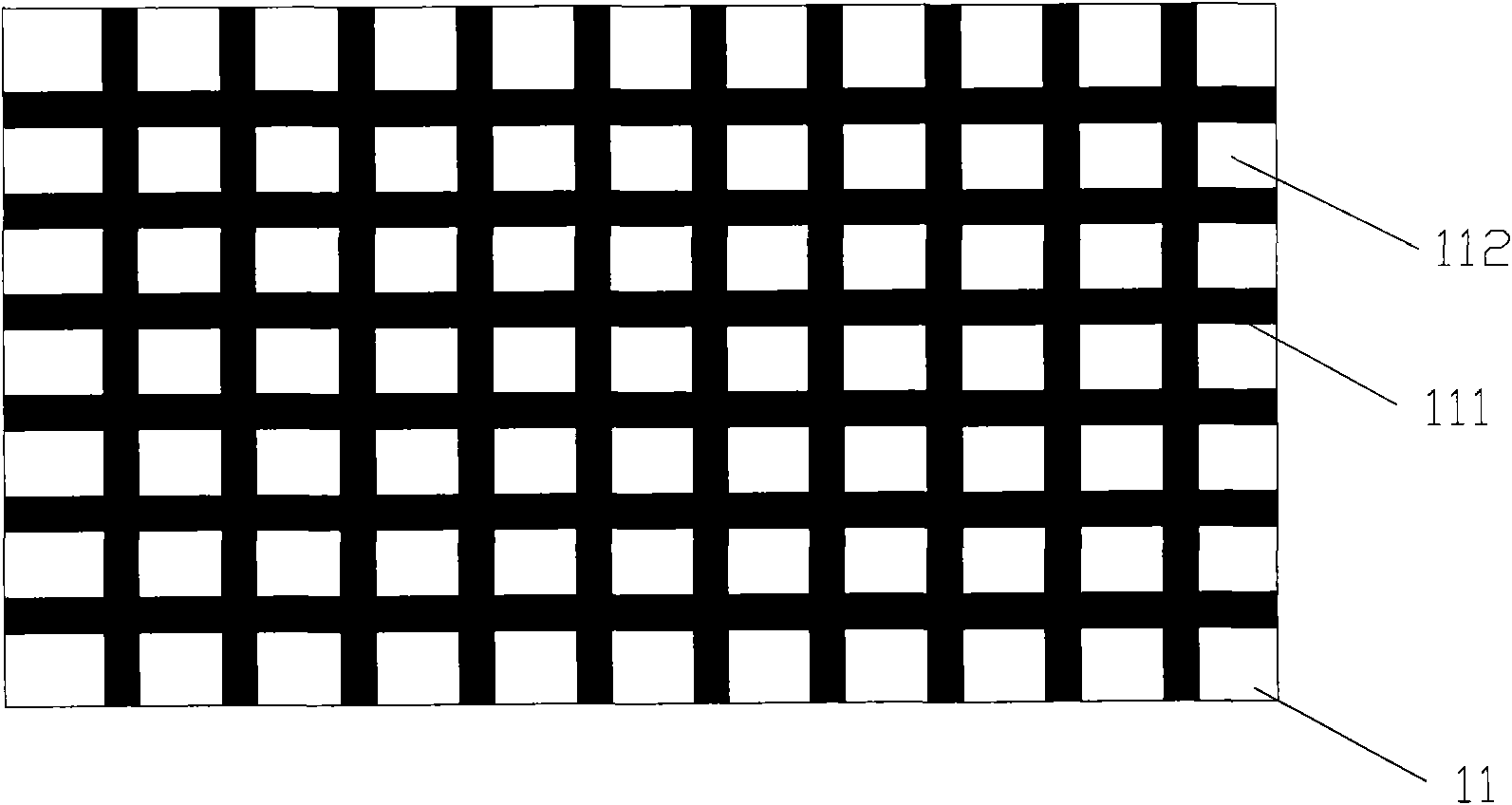

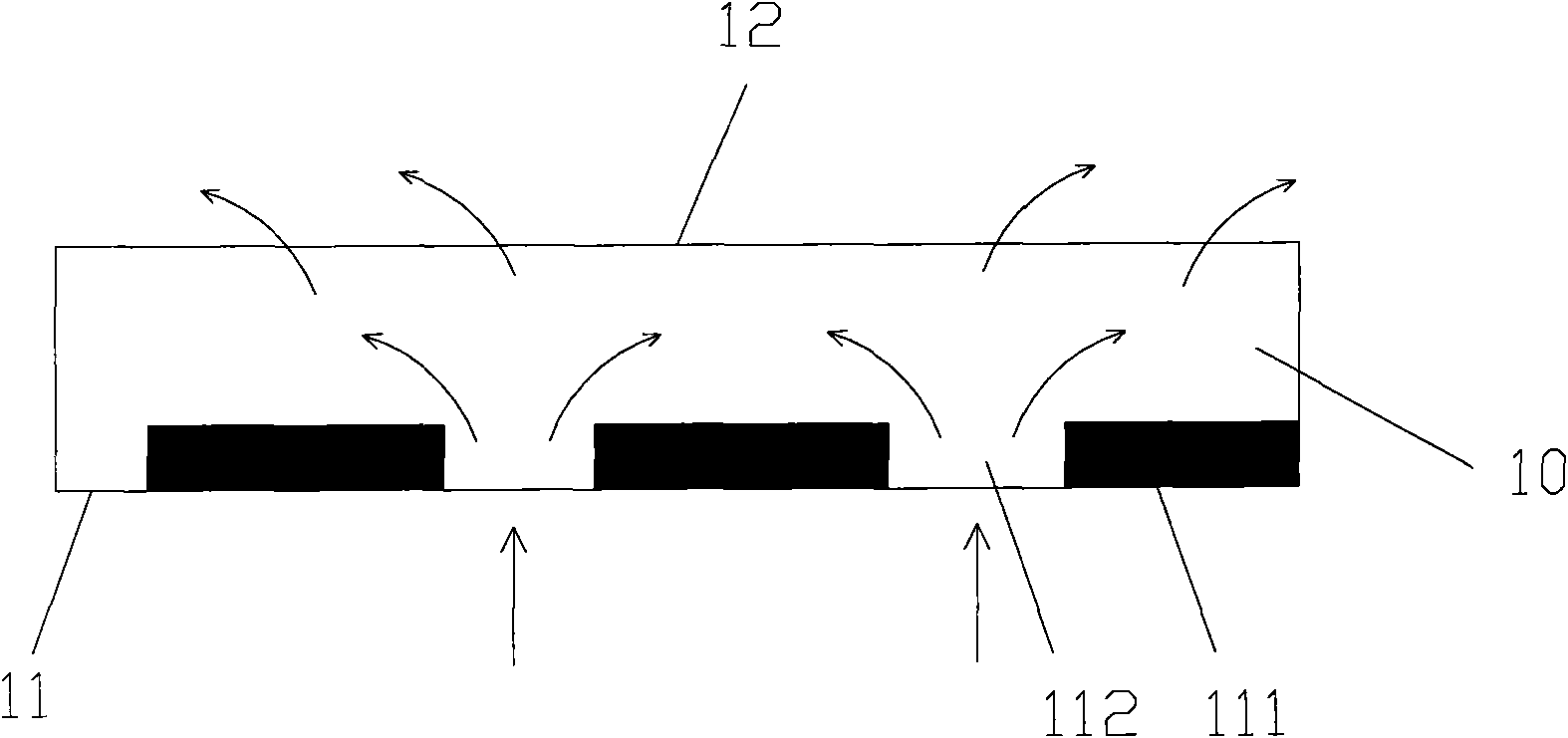

One-way moisture-transfer all-cotton spunlaced nonwoven as well as product and preparation method thereof

ActiveCN101775701AExcellent unidirectional moisture transfer performanceEffective absorptionNon-woven fabricsVegetal fibresSubstance useNonwoven fabric

The invention discloses a one-way moisture-transfer all-cotton spunlaced nonwoven and as well as a product and a preparation method thereof. The all-cotton spunlaced nonwoven comprises an all-cotton spunlaced nonwoven matrix, the all-cotton spunlaced nonwoven matrix comprises a hydrophobic surface and a hydrophilic surface, wherein the hydrophobic surface contains hydrophobic substances used for transferring moisture from the hydrophobic surface to the hydrophilic surface. The one-way moisture-transfer all-cotton spunlaced nonwoven selects an all-cotton material, has light and soft texture and good one-way moisture-transfer effect and can effectively absorb and permeate the moisture and prevent the moisture from reversely flowing, thereby enabling the hydrophobic surface directly contacting with the skin of a human body to keep dry and bringing about more comfortable feeling for a user of a one-way moisture-transfer product.

Owner:WINNER MEDICAL (HUANGGANG) CO LTD

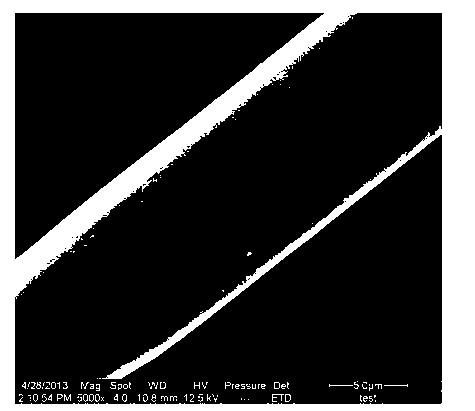

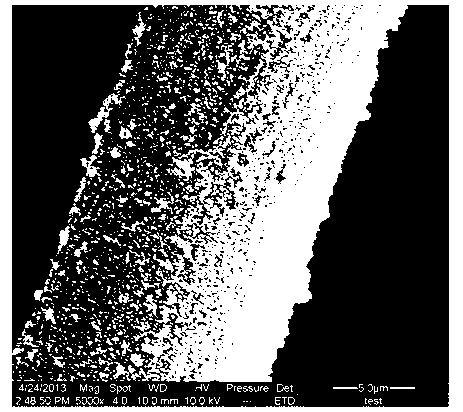

Method for preparing super-hydrophobic super-oleophylic cotton

ActiveCN103276590ASimple methodRaw materials are easy to getLiquid separationVegetal fibresProcess engineeringOrganic chemistry

The invention discloses a method for preparing super-hydrophobic super-oleophylic cotton, and belongs to the field of functional materials, in order to solve the technical problems that an existing oil-water separation absorption object is high in preparation technique requirement, is high in cost and the like. The method provided by the invention comprises the following steps of: 1, preparing a SiO2 precursor solution; 2, preparing an OTS (octadecyltrichlorosilane) modified liquid; 3, immersing cotton in a NaOH water solution, capping, boiling, cooking on low heat, and cooling; 4, then immersing into the SiO2 precursor solution, flushing with absolute ethyl alcohol clearly, and drying at room temperature, thereby obtaining the super-hydrophobic / super-oleophylic cotton. Each gram of super-hydrophobic / super-oleophylic cotton material can absorb 10-40grams of organics, and can be recycled. The method provided by the invention is simple in technology, is low in cost, is short in cycle, is low in energy consumption, and does not need a complex special device.

Owner:NORTHEAST FORESTRY UNIVERSITY

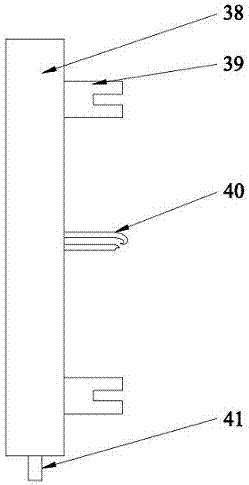

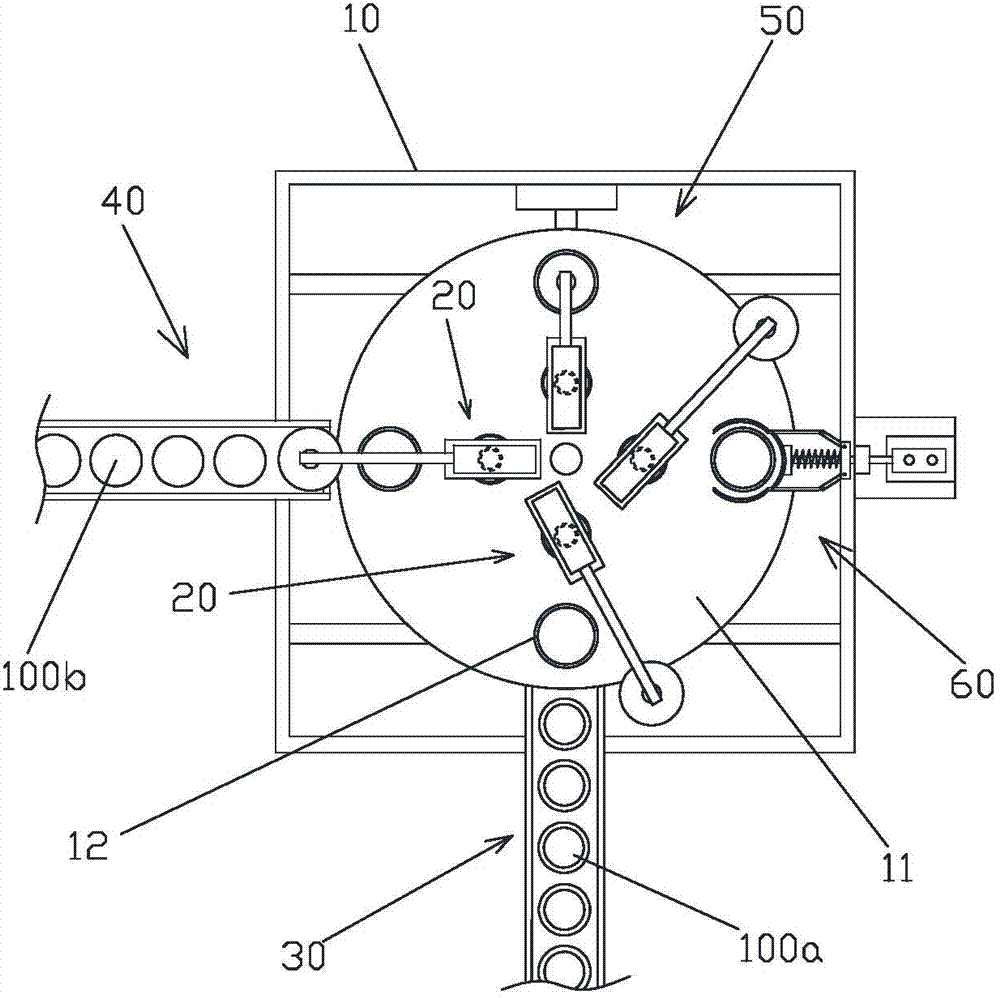

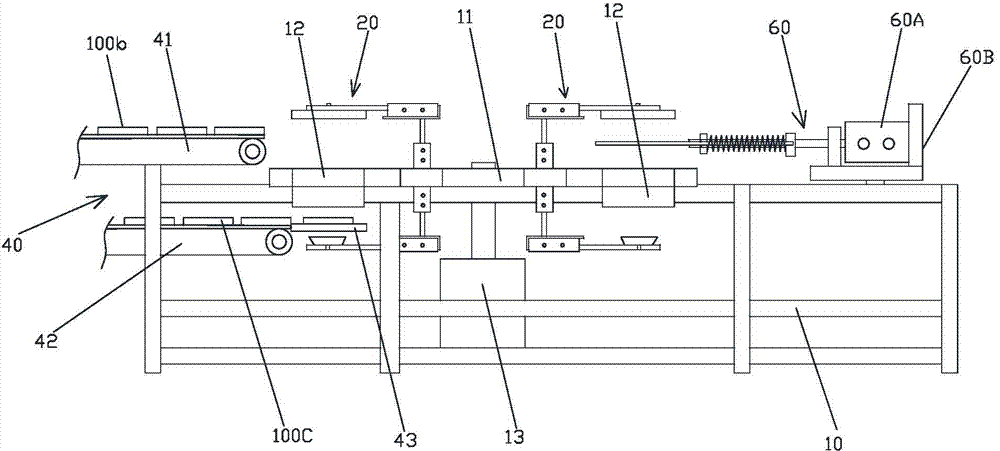

Air purifying filter element rapid assembling equipment

InactiveCN104741917AIncrease productivityRealize the assemblyWelding/cutting auxillary devicesAssembly machinesAir filterMechanical engineering

The invention relates to air purifying filter element rapid assembling equipment. The air purifying filter element rapid assembling equipment comprises a rotating disk which is rotatably fixed on a rack and is arranged horizontally and a first driving mechanism connected with the rotating disk. The circumference of the rotating disk is provided with clamping devices at intervals, wherein the clamping device are used for clamping air filter element assemblies. The positions, in the rotating direction of the rotating disk, of the periphery of the rotating disk is sequentially provided with a feeding device, a distributing device, an assembling device and an unloading device at intervals, wherein the feeding device is used for conveying filter element bodies to the clamping devices, the distributing device is used for conveying upper end covers and lower end covers to the clamping devices, the assembling device is used for carrying out connecting among the air filter element assemblies, and the unloading device is used for carrying out unloading on assembled air filter elements. According to the technical scheme, assembling and fixed connecting between the upper and lower end covers and the filter element bodies can be rapidly achieved, and the production efficiency of the air filter elements is improved.

Owner:朱玉兵

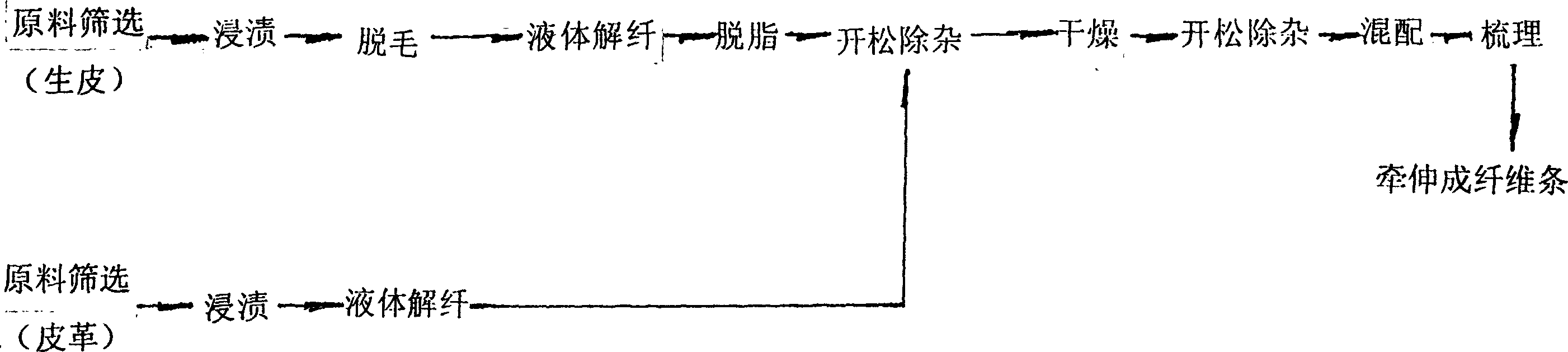

Fabric strip for spinning and its processing method

The invnetion relates to a spinning fiber rod comprised of 5-100% collagen fiber and residual textile fiber. Wherein, the process method comprises: screening material, dipping, defibering, degreasing, cleaning, dewatering, drying, opening to remove impurity, mixing, carding, and drafting. This invention can obtain material from wide source, has well applicability, high tensile strength, well moisture / oil absorption properties, and fit to spread in textile industry.

Owner:张立文

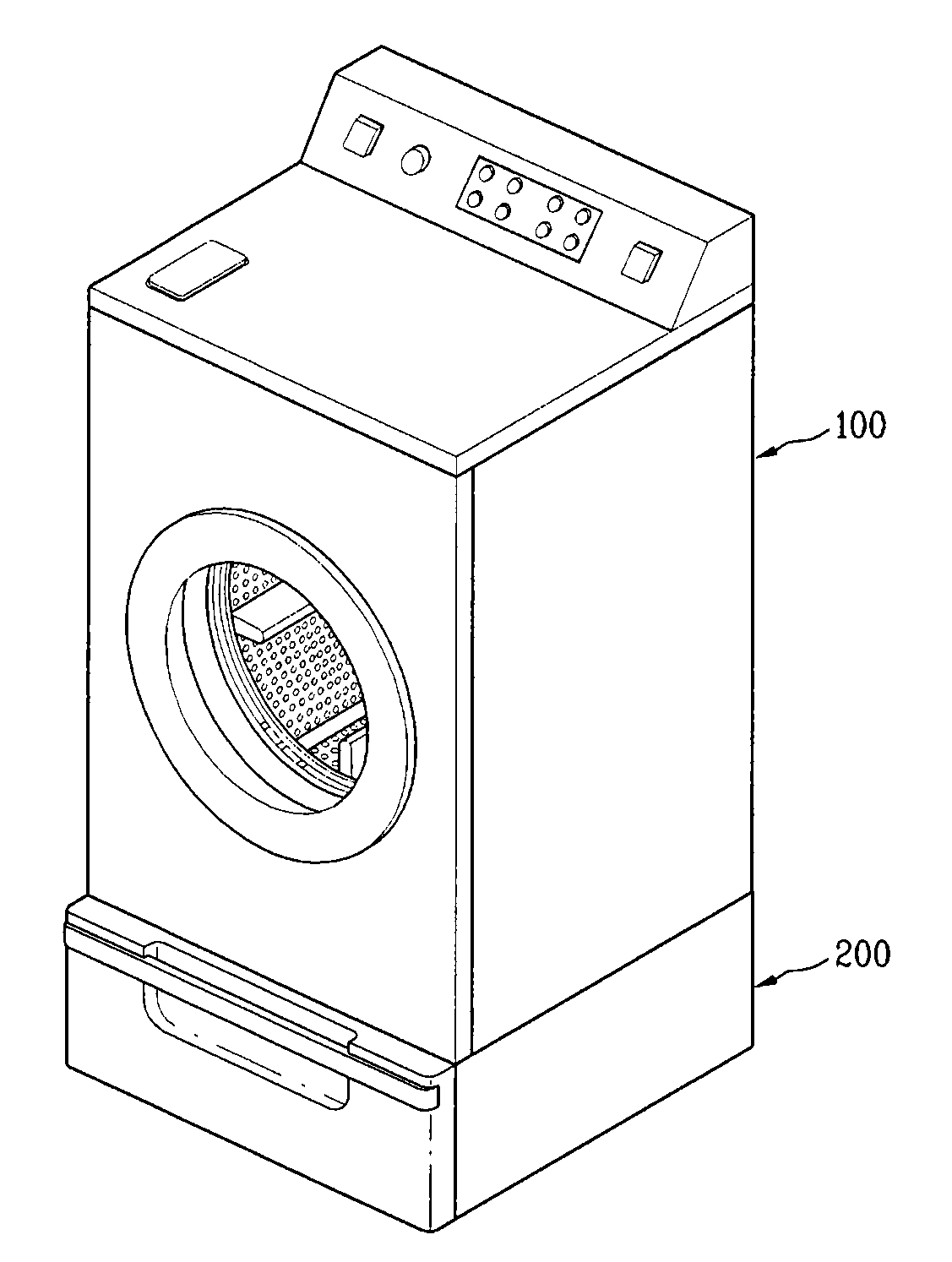

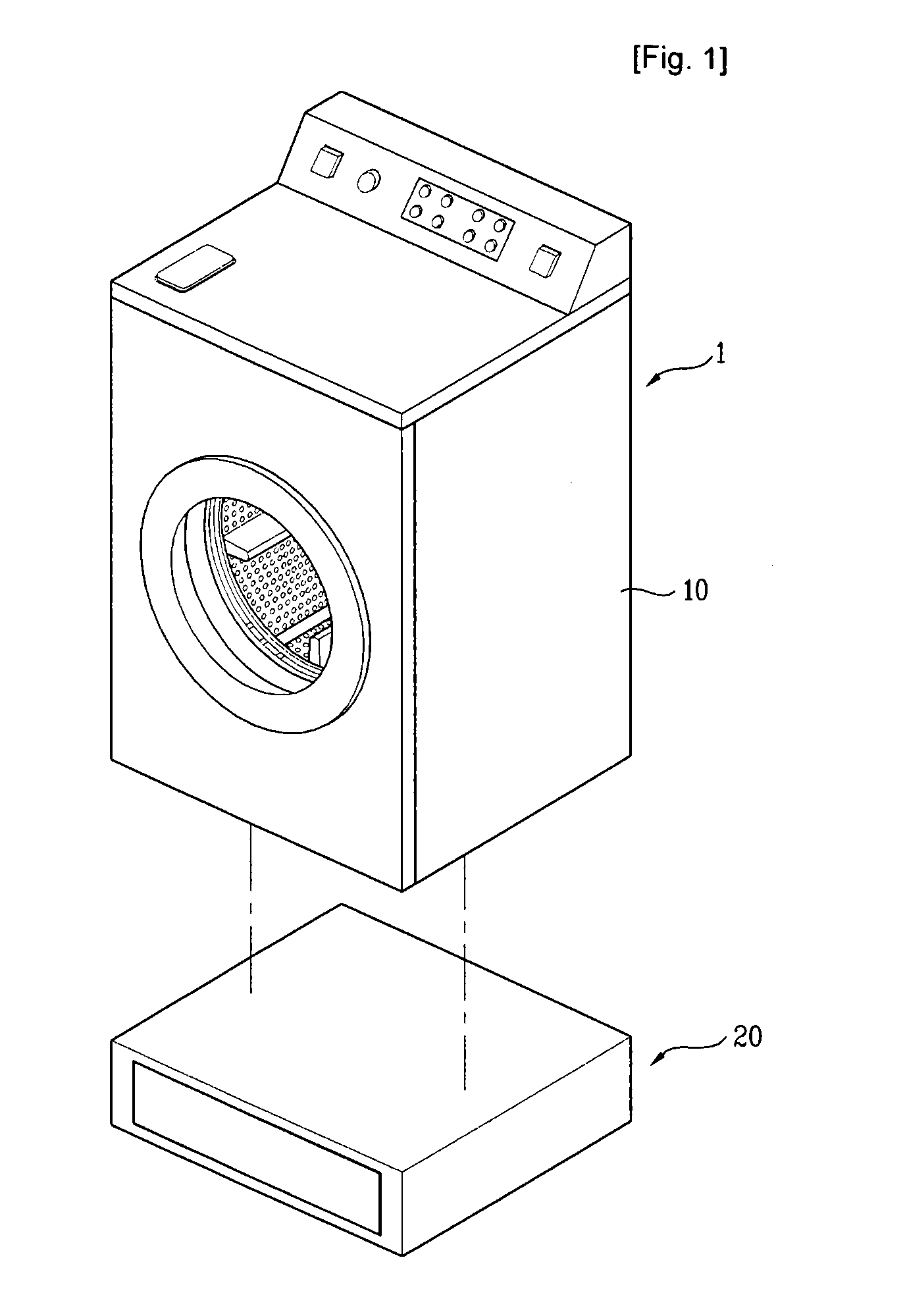

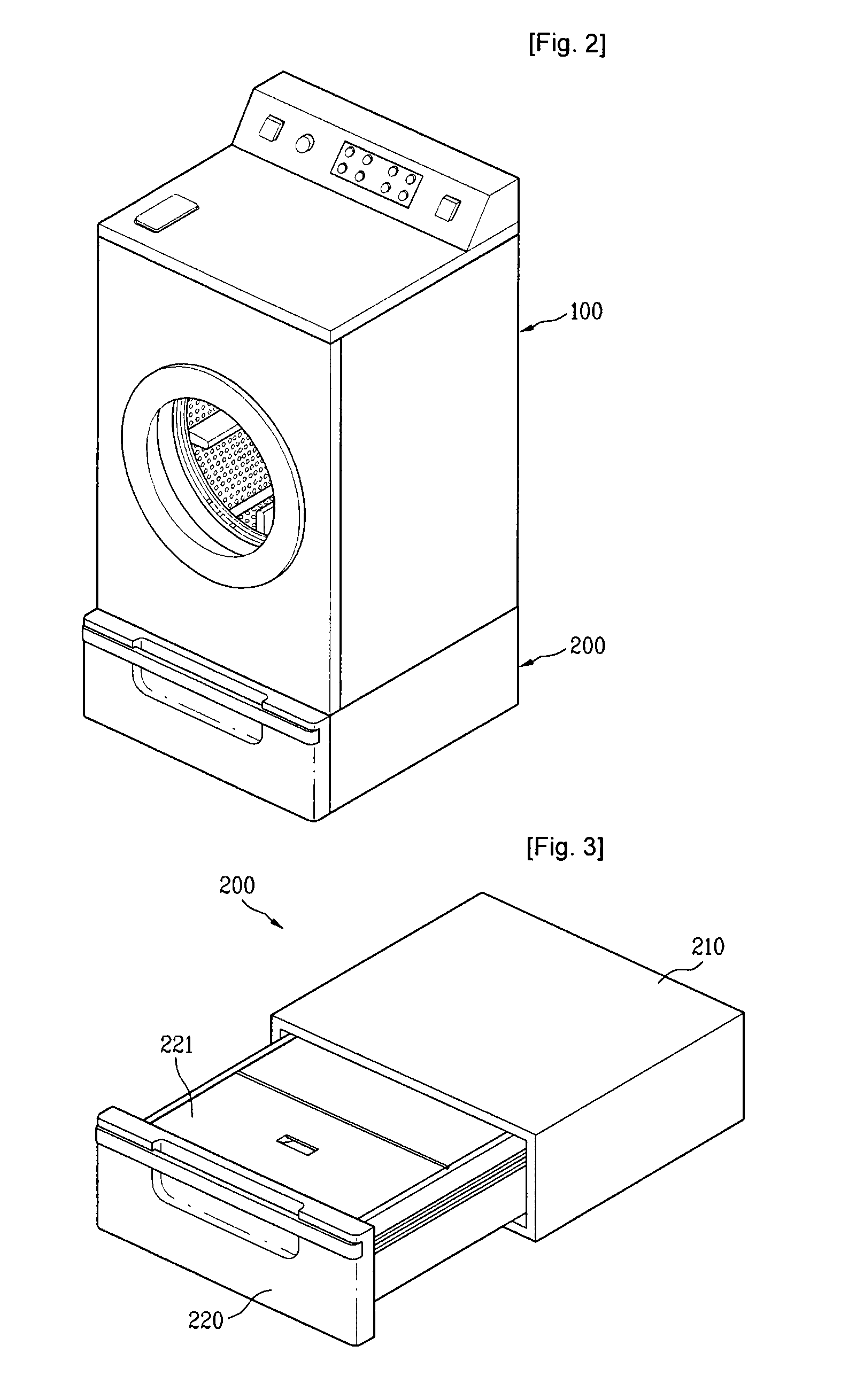

Cloth treating apparatus

ActiveUS20110030428A1Large capacityImprove energy savingOther washing machinesTextiles and paperCotton materialWaste management

A cloth treating apparatus is disclosed. The cloth treating apparatus comprises a main body washing or drying clothes, and an auxiliary treating apparatus including a cabinet provided at one side of the main body; and a drawer slidably provided in the cabinet to form a accommodating space, having a hot air supply device, wherein the hot air supply device supplies a hot air to the accommodating space and is provided on an external rear surface of the drawer.

Owner:LG ELECTRONICS INC

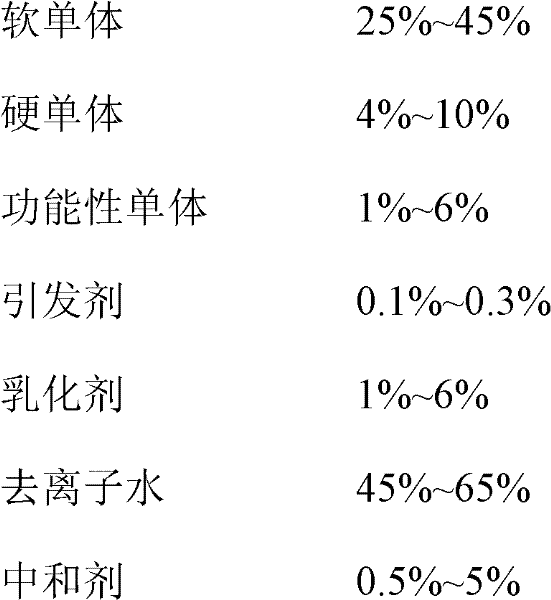

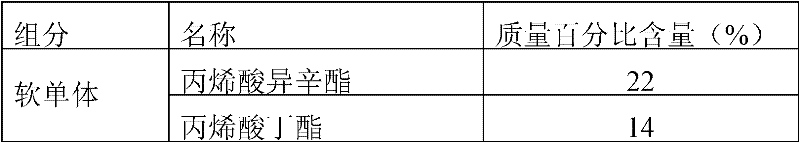

Environment-friendly printing platen adhesive emulsion and preparation method thereof

InactiveCN102344522ANot easy to slideNot easy to break awayEster polymer adhesivesDyeing processTextile printerPolymer science

The invention discloses an environment-friendly printing platen adhesive emulsion and a preparation method thereof, and the emulsion comprises the following components by weight: 25%-45% of soft monomers, 4%-10% of hard monomers, 1%-6% of functional monomers, 0.1%-0.3% of initiators, 1%-6% of emulsifiers, 45%-65% of deionized water, and 0.5%-5% of neutralizers. The adhesive of the invention is anaqueous environment-friendly product, adopts water as a solvent, does not contain any volatile solvent, is environment-friendly, does not discharge toxic substances such as formaldehyde and the like,does not contain alkylphenol additives; the adhesive has good adhesive force to various textile fabrics; fabrics are not easy to slide on the platen or be separated from the platen; printing color register is accurate; the preparation method of the invention adopts a new crosslinking monomer, and increases the water resistance and cohesive adhesion lasting force of the adhesive; the adhesive can be used repeatedly; because of the good cohesive adhesion lasting force of the adhesive, no adhesive is left at the fabric bottom during fabric removal; meanwhile the adhesive of the invention has moderate and adjustable viscosity, is convenient for using, and is easy to adhesive application by a scraper plate.

Owner:连云港百利合新材料发展有限公司

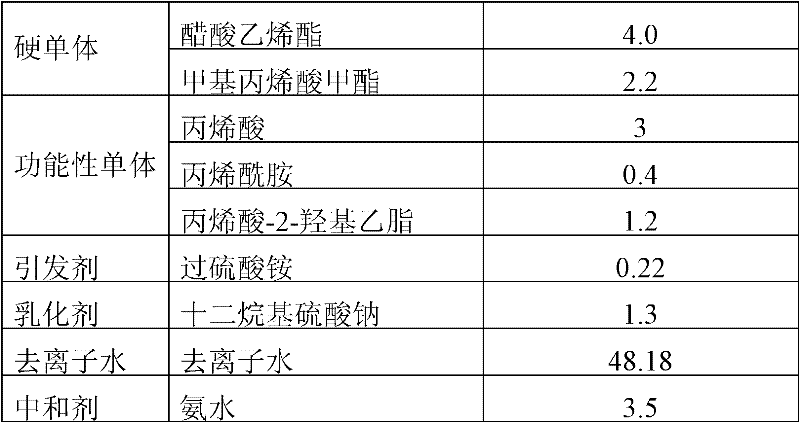

Method and apparatus for a cloth heater

A cloth heater and method for using the heater are provided. The heater utilizes a horizontally disposed surface, a heated glass panel, and support members. The horizontally disposed surface may comprise the top edge or surface of the heated glass panel, or a surface on a separate rack that is above and vertically inline with the top edge of the heated glass panel. The heated glass panel also has two opposing major surfaces. The support members physically support the heated glass panel and have electrical leads that communicate electrical power to the heated glass panel, thus heating the heated glass panel. When a cloth is placed across the horizontally disposed surface, the horizontally disposed surface supports the cloth, and the cloth makes contact with the two opposing major surfaces of the heated glass panel, thus heating the cloth at both opposing major surfaces.

Owner:ENGINEERED GLASS PRODS

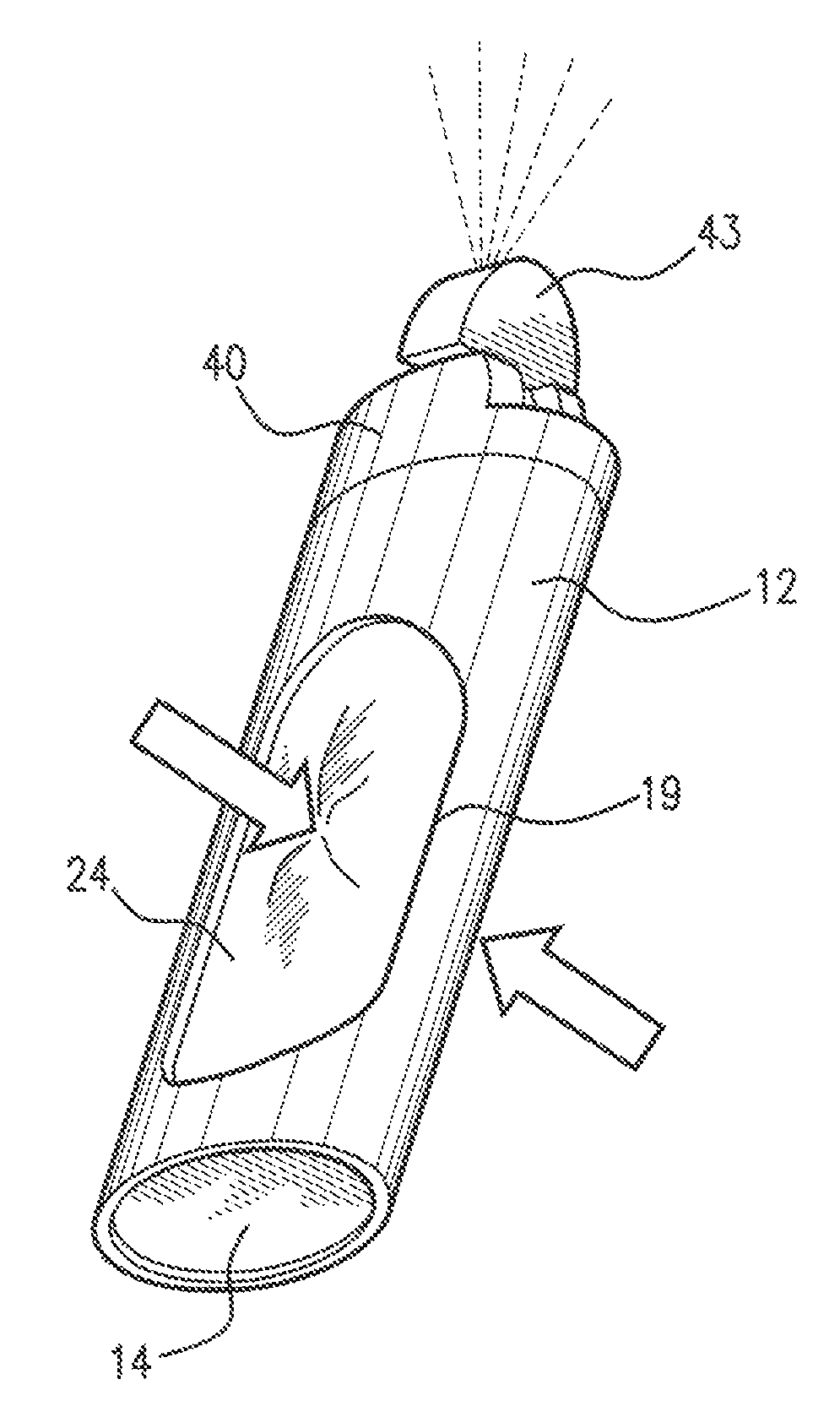

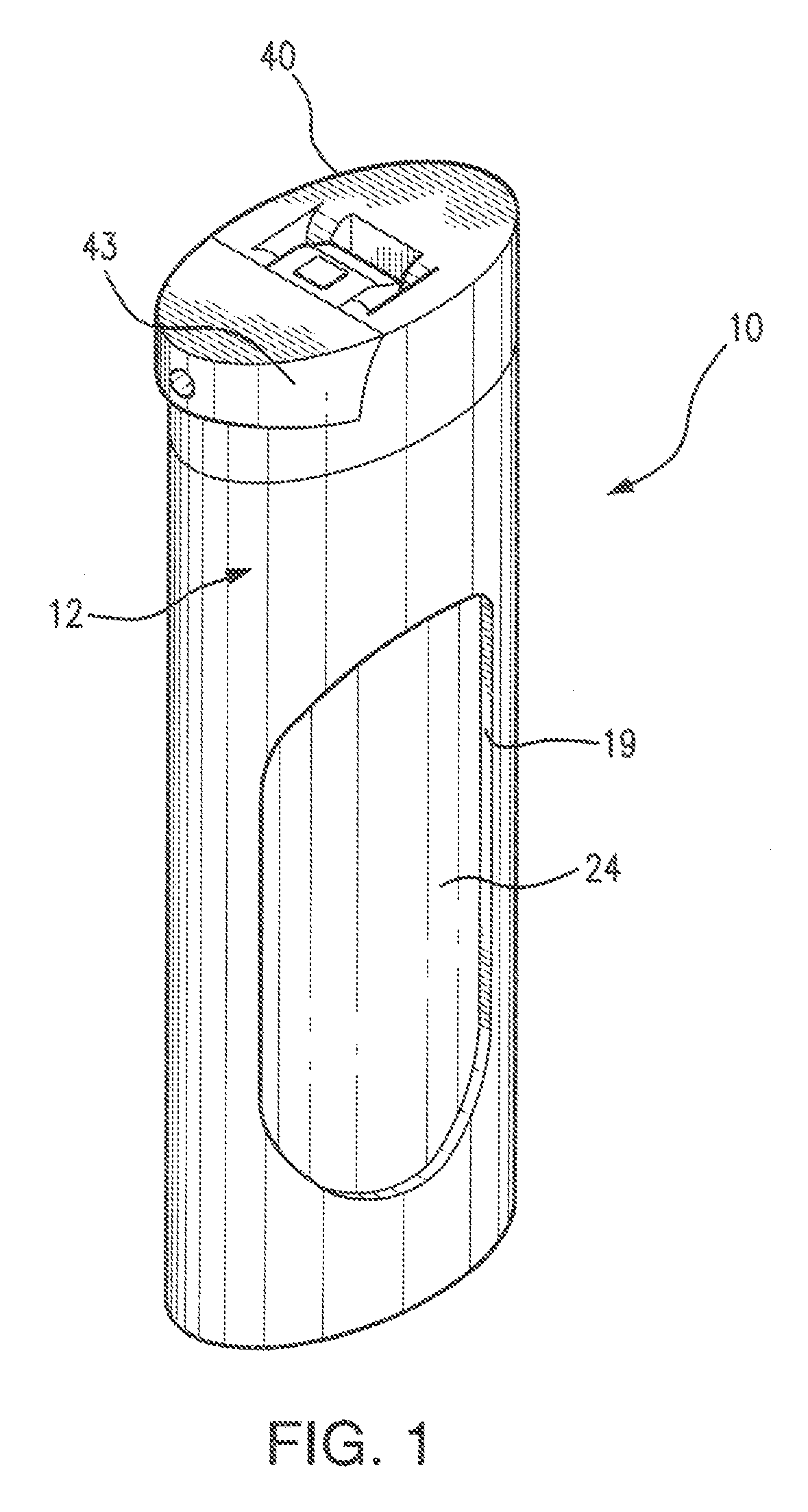

Personal aromatherapy device

A personal device for releasing the aroma of an essential oil includes an inner flexible container received within a rigid outer shell that is open on opposite sides to expose side portions of the inner flexible container. An interior chamber of the flexible container is partially filled with cotton or other fibrous material and a charge of an essential oil that saturates the cotton material. A cap fitted to an open top end of the flexible container includes a flip nozzle with a ball valve. The flip nozzle is operable between a lowered position to close the ball valve and seal the open top of the flexible container closed, and a raised straight up position to open the ball valve and permit release of beneficial aromas of the essential oil from an open end of the nozzle upon squeezing the exposed sides of the flexible container while holding the nozzle below the user's nostrils so that the aromas are released for direct inhalation through the user's nostrils.

Owner:KOLINS MARIA C

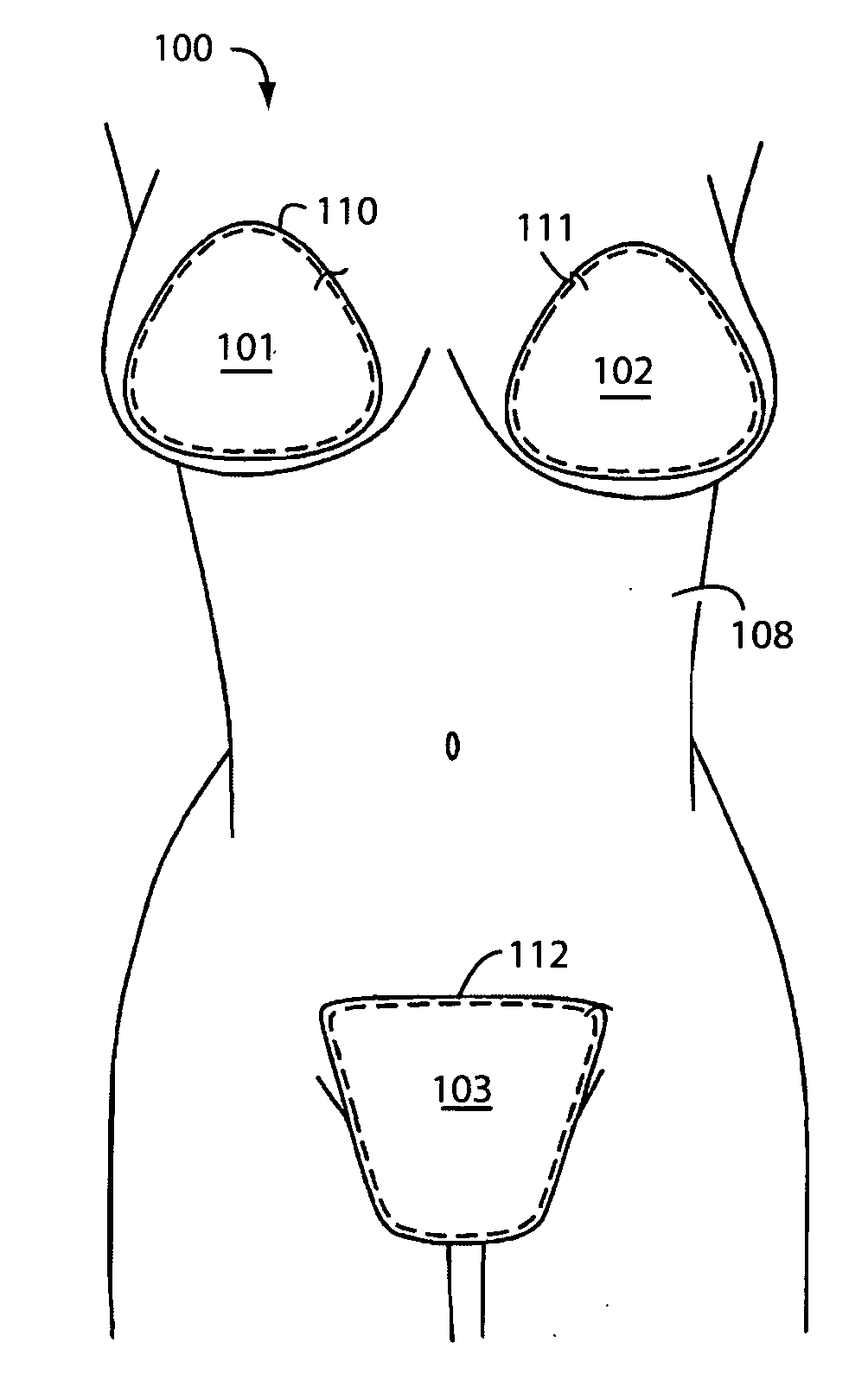

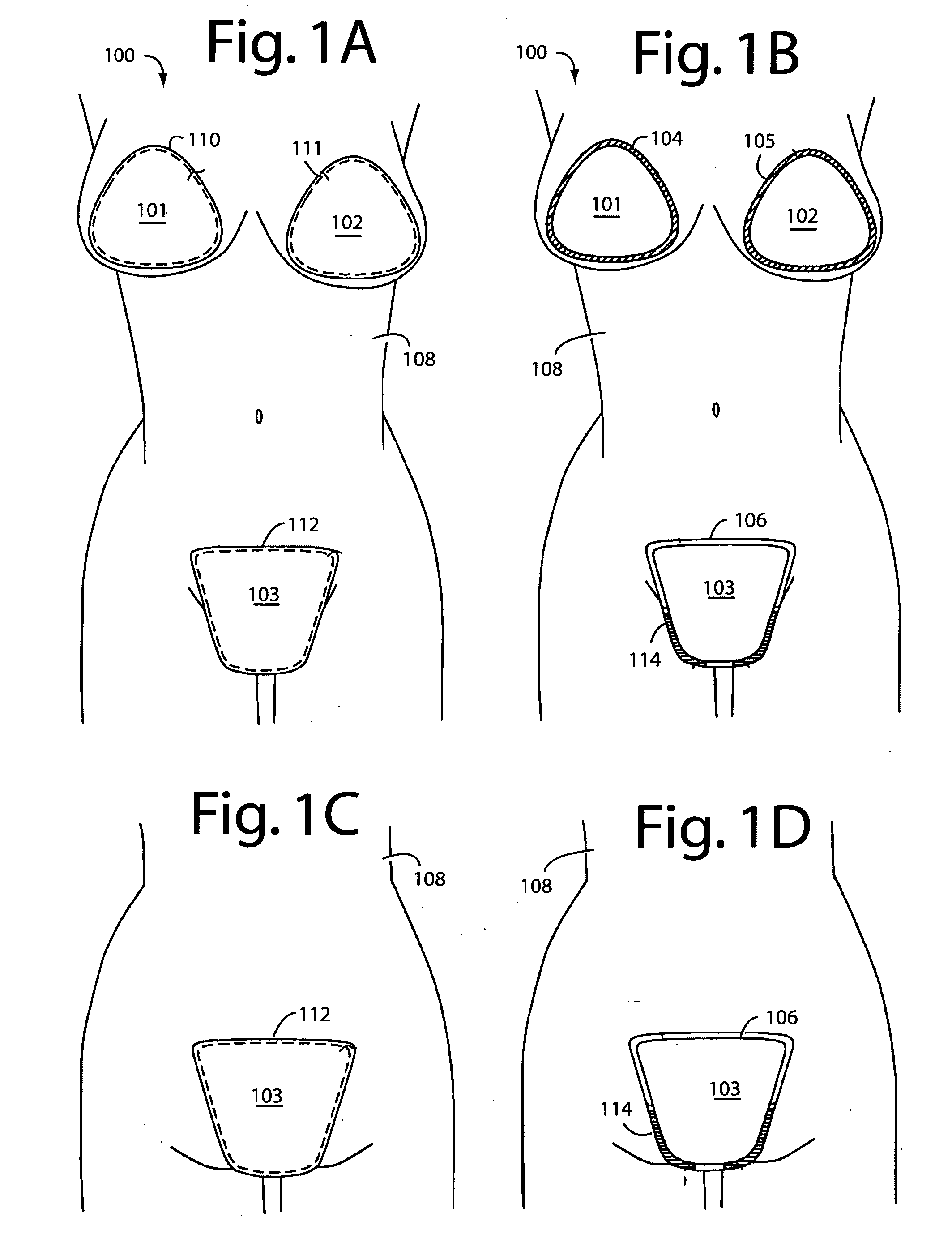

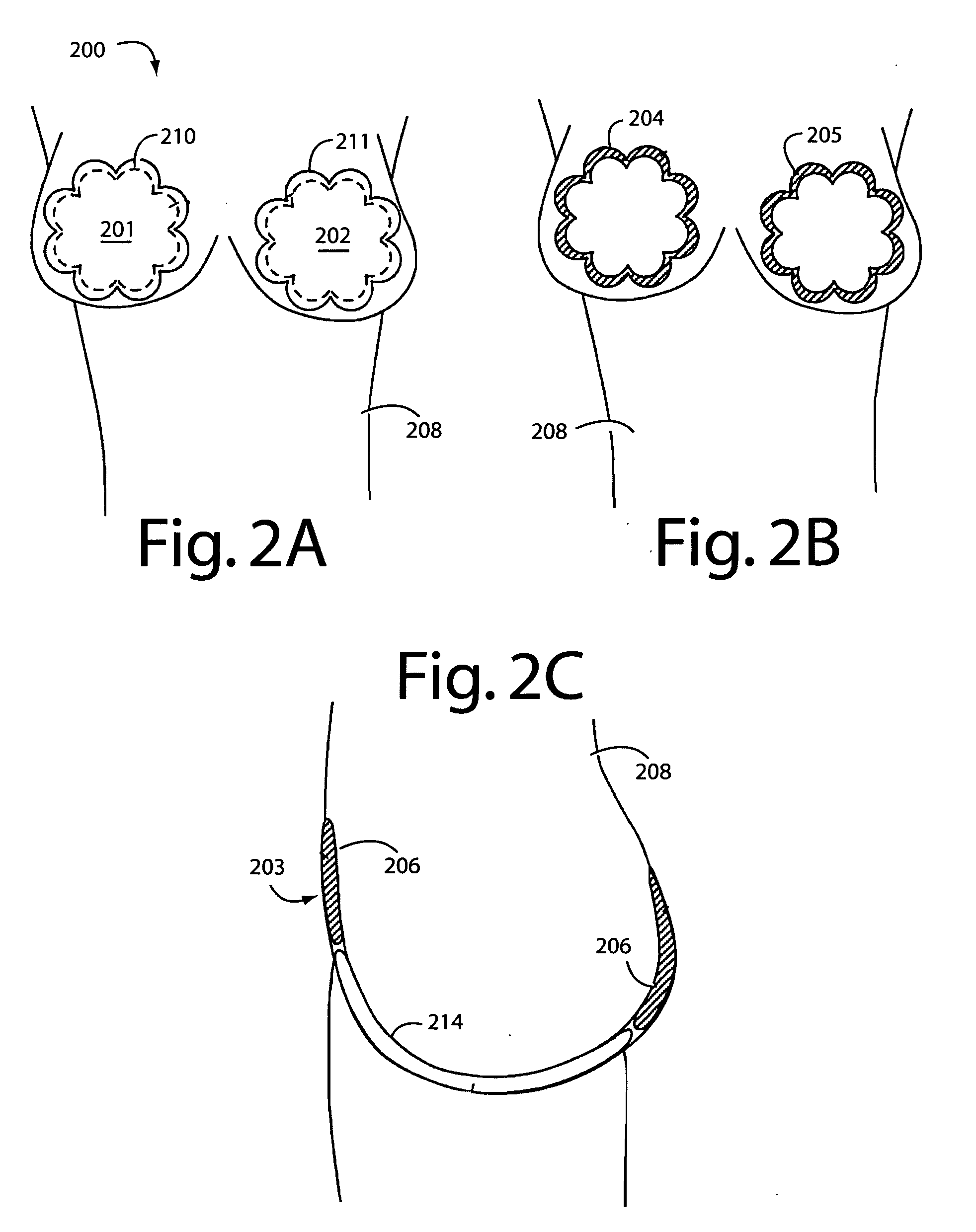

Minimum clothing for spas and clinics

A spa or clinic clothing comprises biodegradable, hypoallergenic, non-transparent patches to cover the breasts of females and the genitals of males and females. Each patch is equipped with fashion tape along its edges to secure them to the skin a user for a single use. After one use lasting no more than a few hours, the patches are discarded. Fabric versions of the cloth patches have stitched edges, darts, and liners. Paper, Lyocell versions have multiple layers and finished edges.

Owner:ANDREWS ELAINE

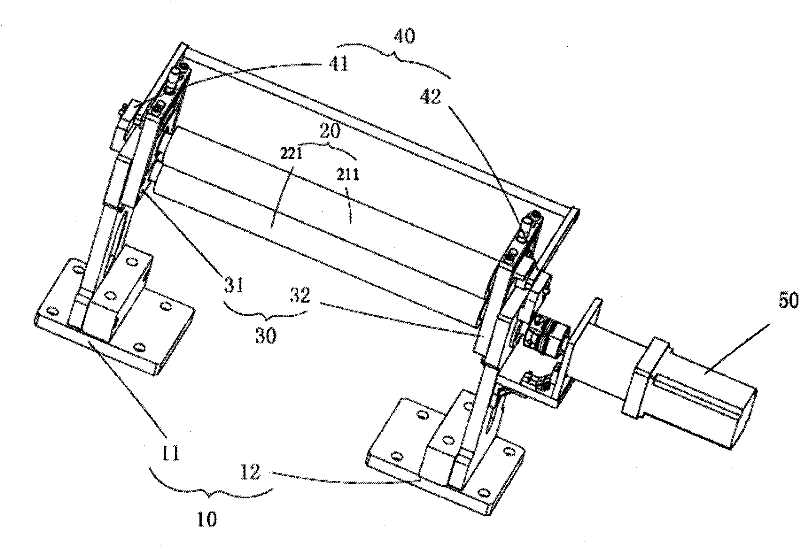

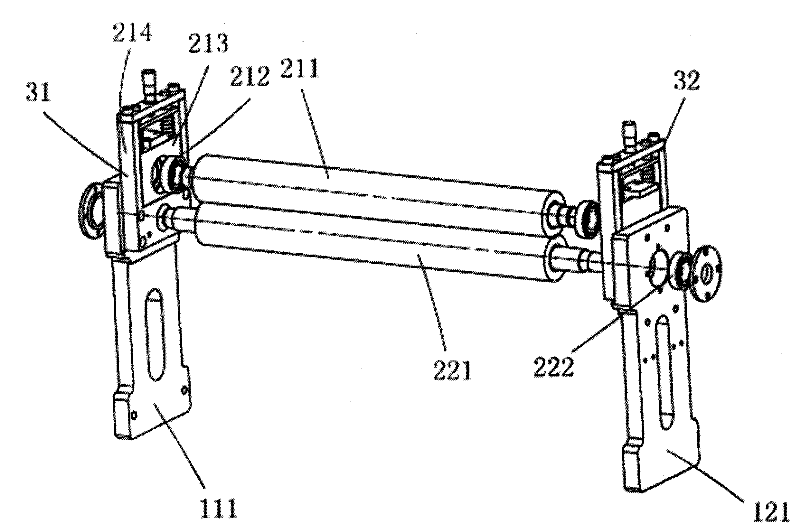

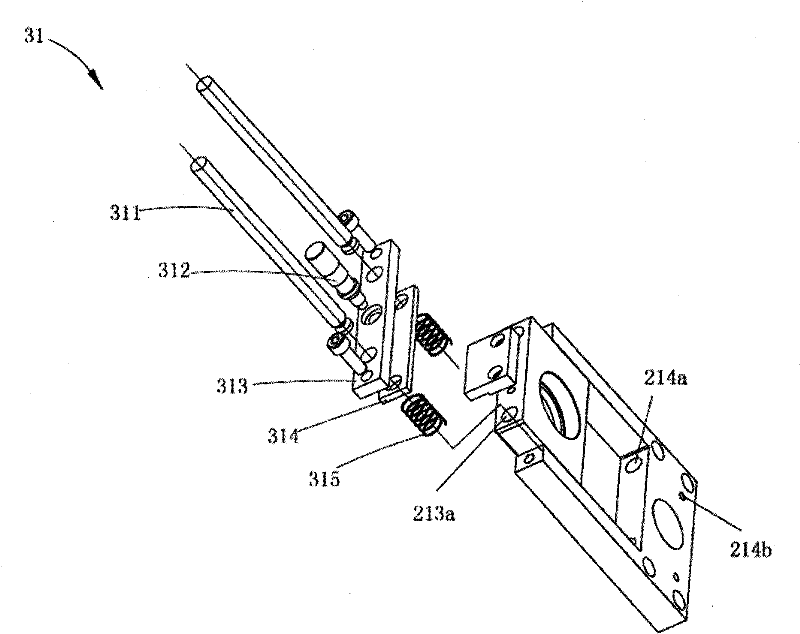

Pressure-adjusting conveying friction double roll device

ActiveCN101746632AAchieve the purpose of separationEasy to adjustWebs handlingEngineeringMechanical engineering

The invention provides a pressure-adjusting conveying friction double roll device which is suitable for conveying thin film substrates. The pressure-adjusting conveying friction double roll device comprises a support assembly, a friction double roll assembly, a friction double roll pressure adjusting assembly, a friction double roll separating assembly and a friction double roll driving assembly. The support assembly is used for providing support and interface connected with equipment for the pressure-adjusting conveying friction double roll device; the friction double roll pressure driving assembly is used for providing rotating power for the friction double roll assembly so as to drive the feed of the thin film substrates; the friction double roll pressure adjusting assembly is used for evenly adjusting the pressure between a driving roll and a floating roll of the friction double roll assembly so as to adapt to the conveying force used for the feed of different thin film substrate; and the friction double roll separating assembly is used for assisting in rapidly separating the driving roll from the floating roll so as to be convenient for changing new thin film substrates and rearranging materials. The pressure between the two axes of the double rolls can be adjusted, and the two axes of the double rolls can be separated from each other flexibly. The thin film substrate conveying system is easy and convenient to operate and is practical.

Owner:HUAZHONG UNIV OF SCI & TECH

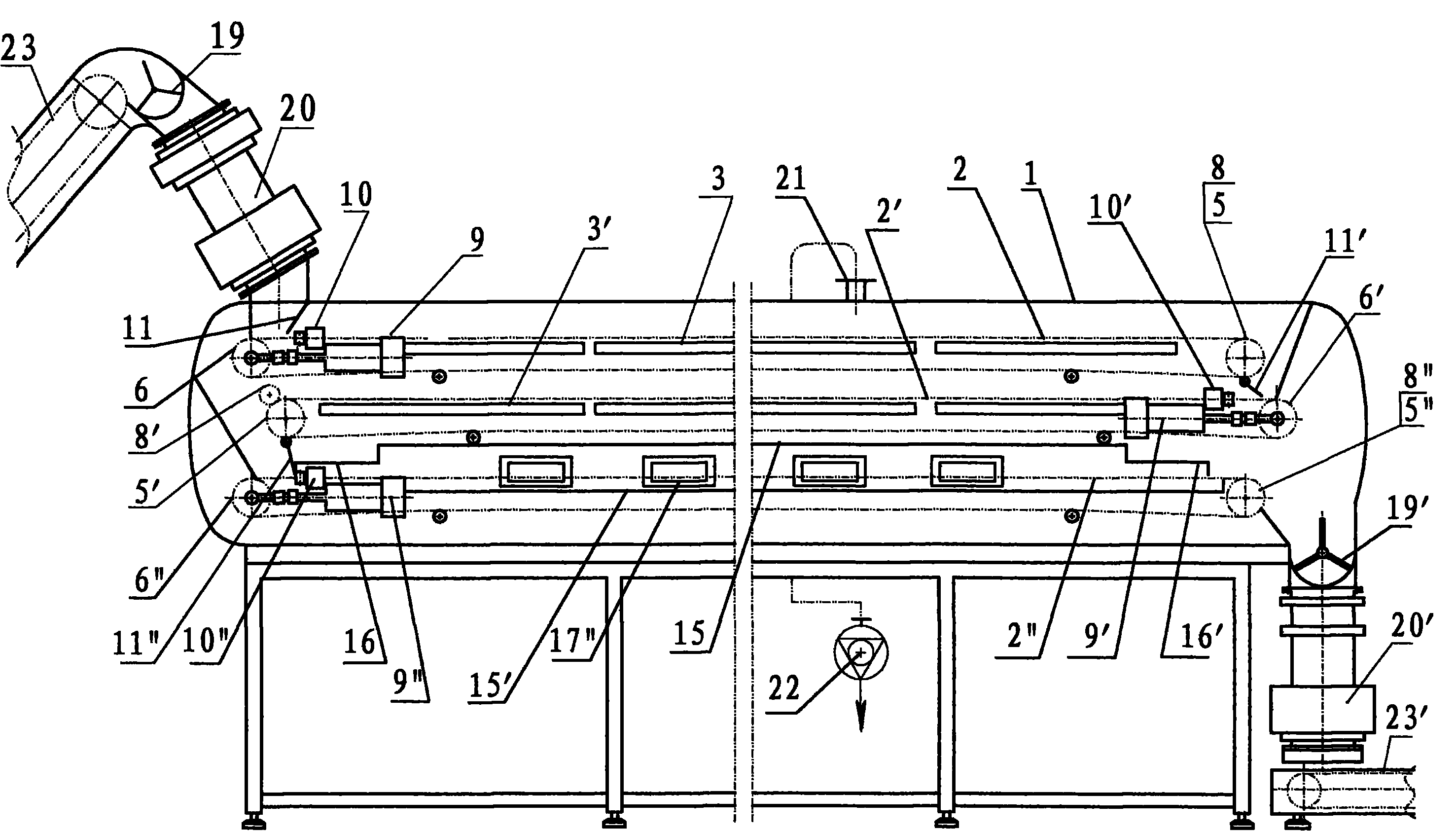

Continuous microwave vacuum drying and sterilizing processing device

InactiveCN101813408ASimple structureVacuum tightDrying using combination processesDrying solid materials with heatMicrowaveHigh energy

The invention belongs to the drying or sterilization processing machinofacture field in which solid or semi-liquid materials and the like of food, traditional Chinese medicinal materials, chemical engineering products and agricultural and sideline products can keep vacuum degree under the conditions of material feeding and discharging. The continuous microwave vacuum drying processing device is mainly formed by the combination of a feeding conveyer belt, a feeding / discharging sealing device, a vacuum chamber, a material bucket, a material fixing pump, a material distributing device, a heater, a microwave magnetic control device, a fetching device, a microwave choke device, a conveyer belt, a vacuum system, a feeding / discharging fixed supply device, a material conveyer belt and a storage tank. The equipment not only lowers drying temperature, but also quickens drying speed, has the characteristics of rapidness, high efficiency, low temperature and the like, can better retain original color, aroma and taste of processed materials of food, medicine and the like, the loss of vitamin and other thermal sensitive nutrition or active ingredients, thus obtaining better drying quality, ensuring the processed products to reach the requirement of high quality, high benefit, high energy conservation and time saving, being favorable for environmental protection and social comprehensive benefit, and having wide variety applicability.

Owner:陈长清

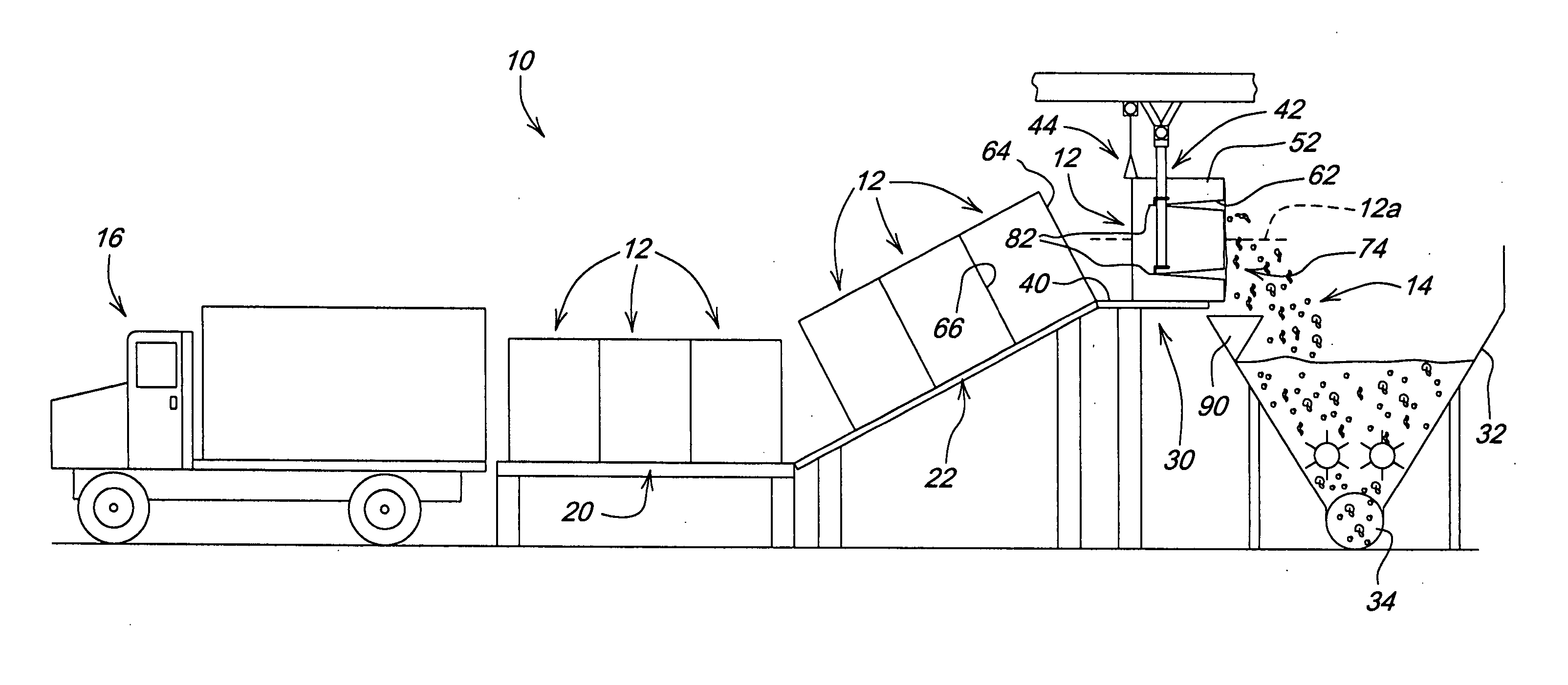

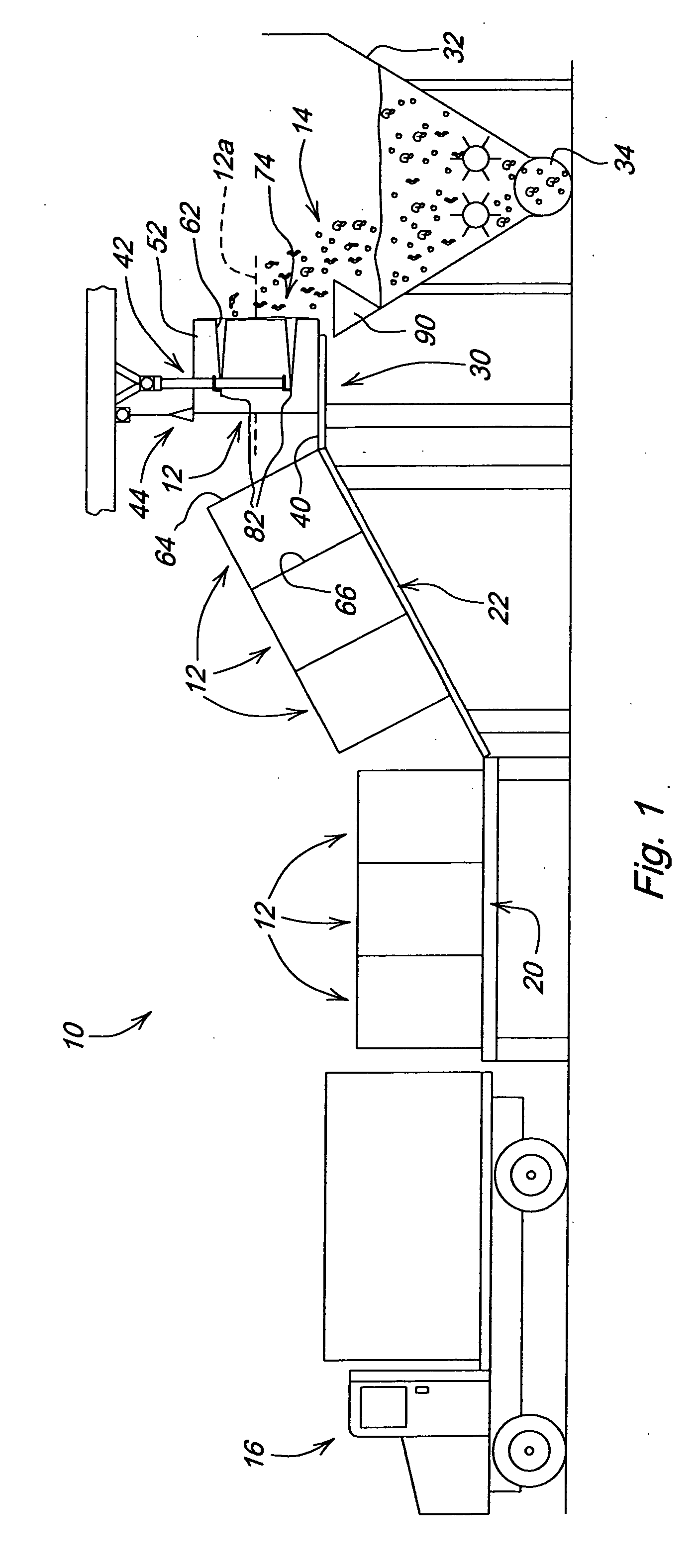

Module wrap removal

InactiveUS20060191241A1Eliminates wrap material contaminationEasy to disassembleOpening closed containersBottle/container closureControl mannerEngineering

A system wherein plastic wrap on round bales of cotton is partially slit starting at one end of the bale and continuing to a location offset from the opposite end of the bale. One or more partial lengthwise slits allow the cotton to fall into a gin input hopper in a controlled manner and maintain the entire wrap, including any non-adhered inner tail remnants, attached to an intact circumferential wrapper portion at the end of the bale opposite the slit end. The non-slit wrapper end portion is pulled from end of the bale, and the remaining cotton material drops into the receptacle free of contamination by any wrap material.

Owner:DEERE & CO

Method for producing multicolor composite slub or satin color yarn series, shell fabric and yarn

The invention discloses a method for producing a multicolor composite yarn. The method includes that a roller device is added to a spinning frame, the process is adjusted, and a clearance motion is formed between the added roller and a prior middle roller, so that a prior two colored yarn of a component of a yarn is changed, and the multicolor composite yarn is obtained. The yarn and the shell fabric which is produced by the yarn have the advantages that the yarn and the shell fabric are multicoloured and extremely suitable for the current market of diversified demands, and the cloth has various colors.

Owner:RUGAO CITY DINGYAN TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com