Patents

Literature

1271results about "Crop conditioners" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

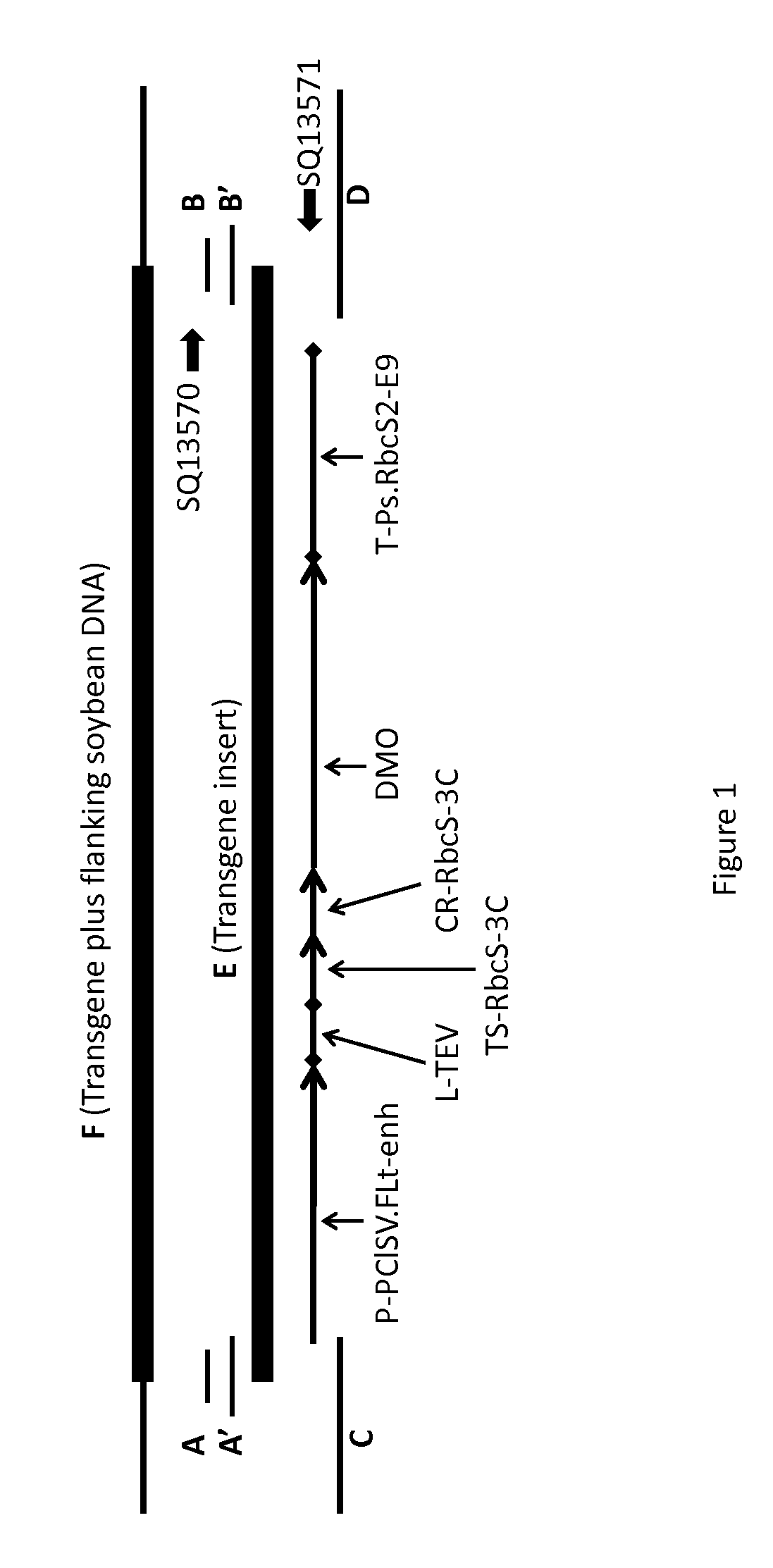

Soybean transgenic event mon 87708 and methods of use thereof

The invention provides a transgenic soybean event MON 87708 plant and plants, plant cells, seeds, plant parts, and commodity products derived from event MON 87708. The invention also provides polynucleotides specific for event MON 87708 and plants, plant cells, seeds, plant parts, and commodity products comprising polynucleotides specific for event MON 87708. The invention also provides methods related to event MON 87708.

Owner:MONSANTO TECH LLC

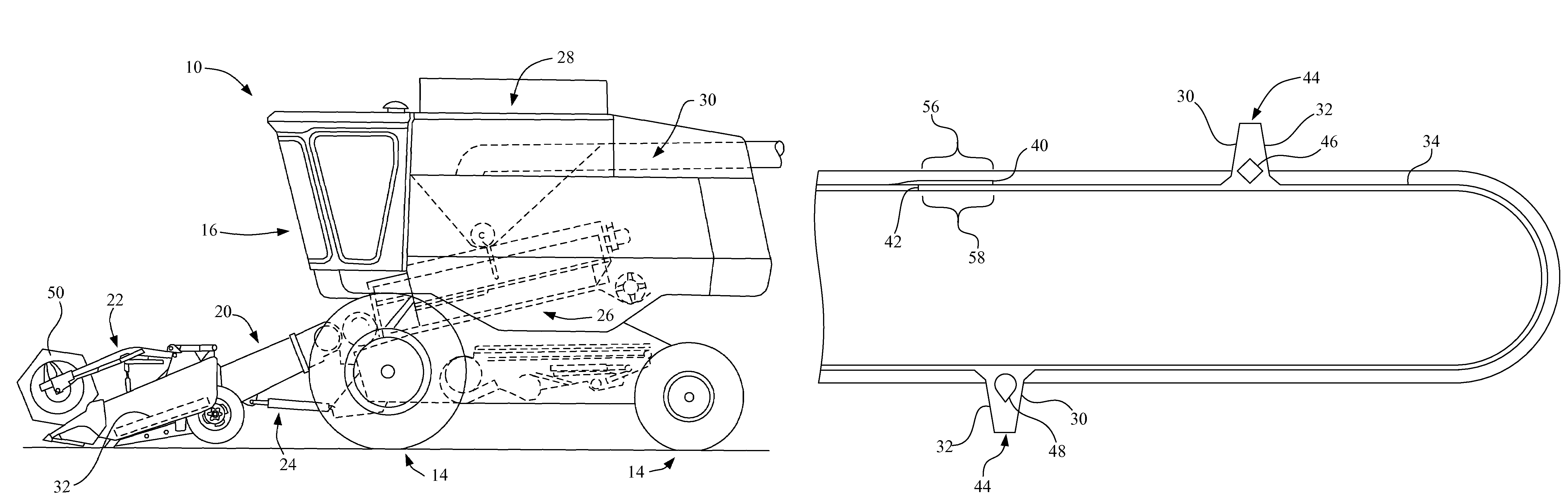

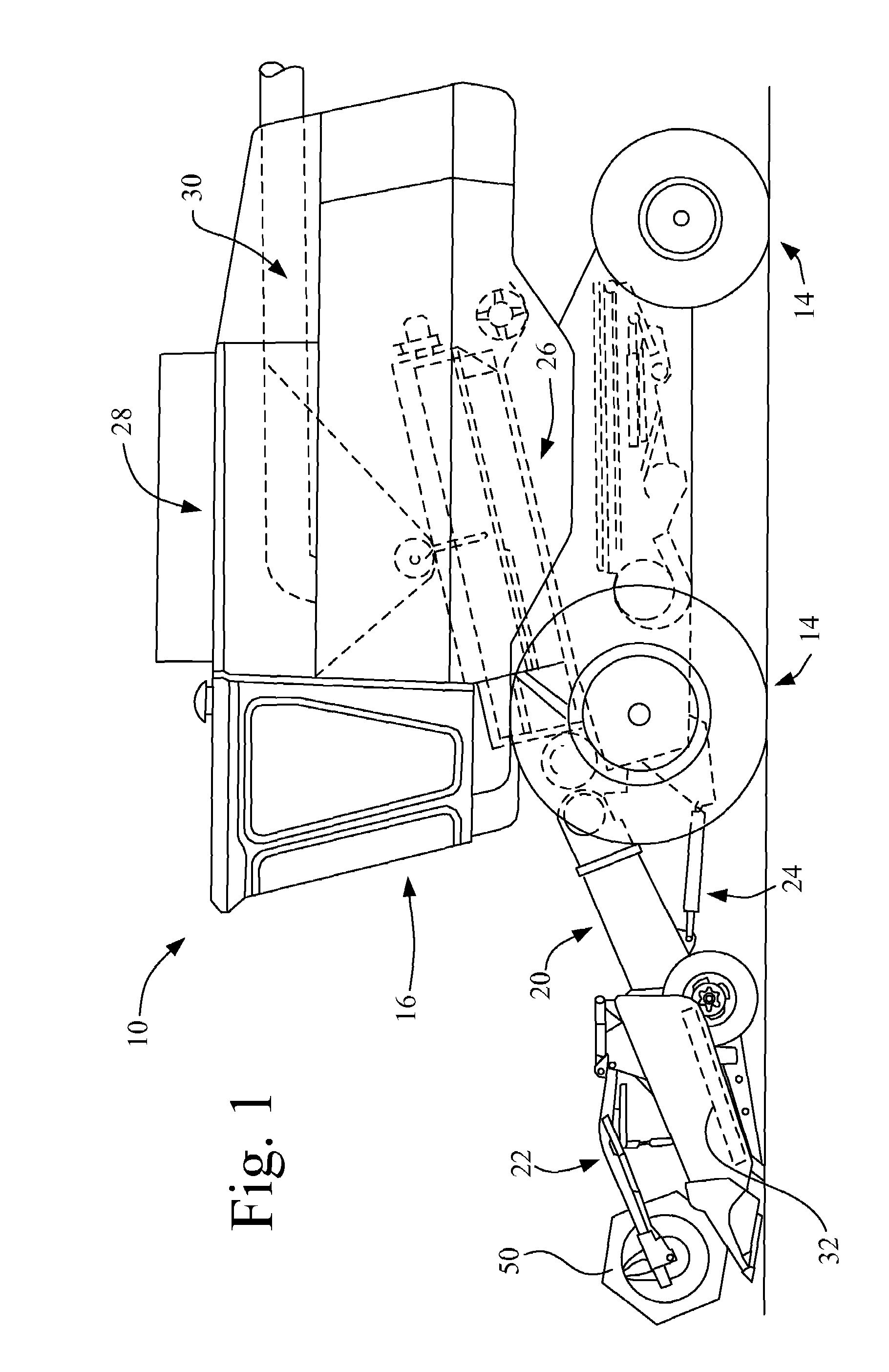

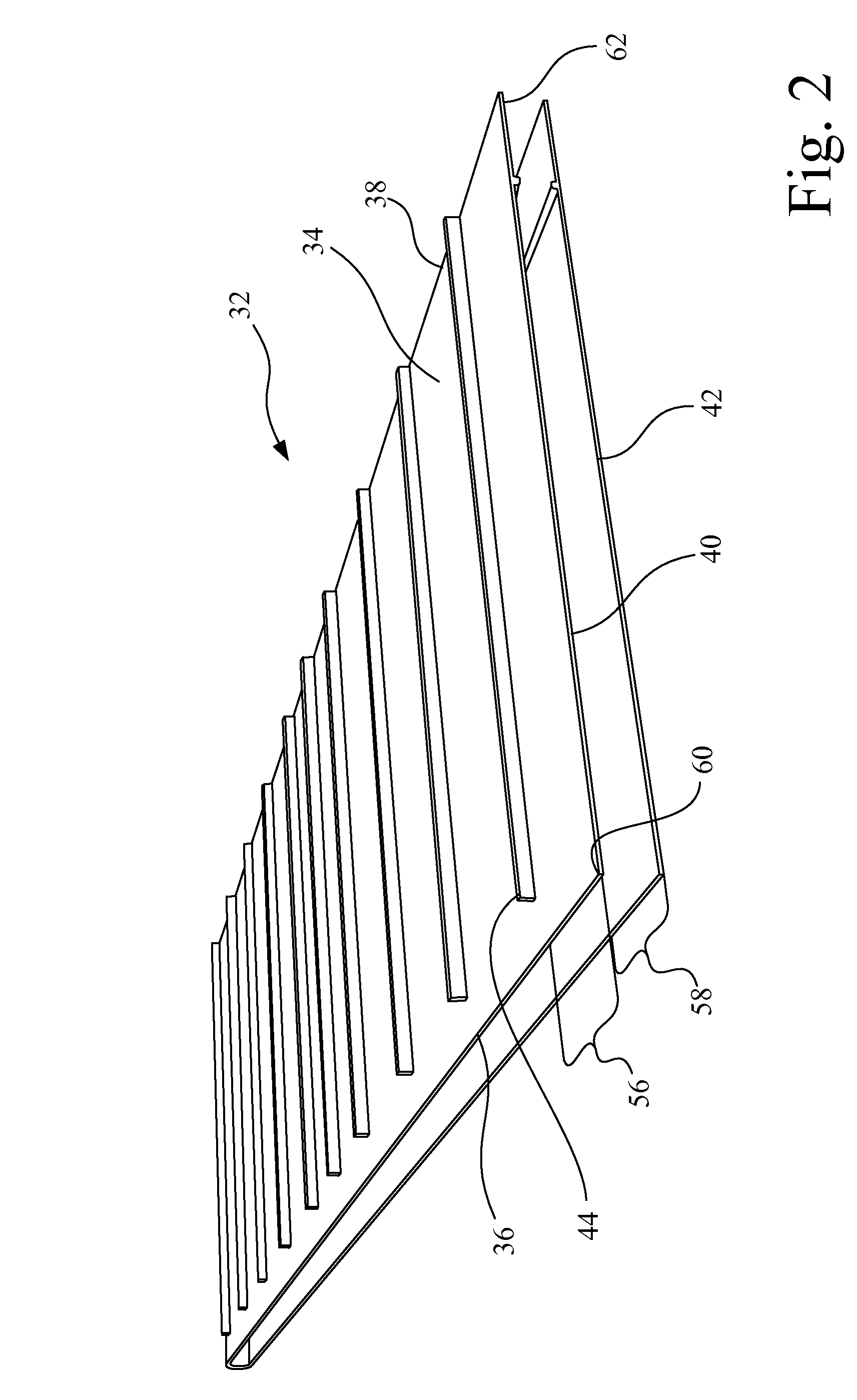

Seamless draper belt

Owner:DEERE & CO

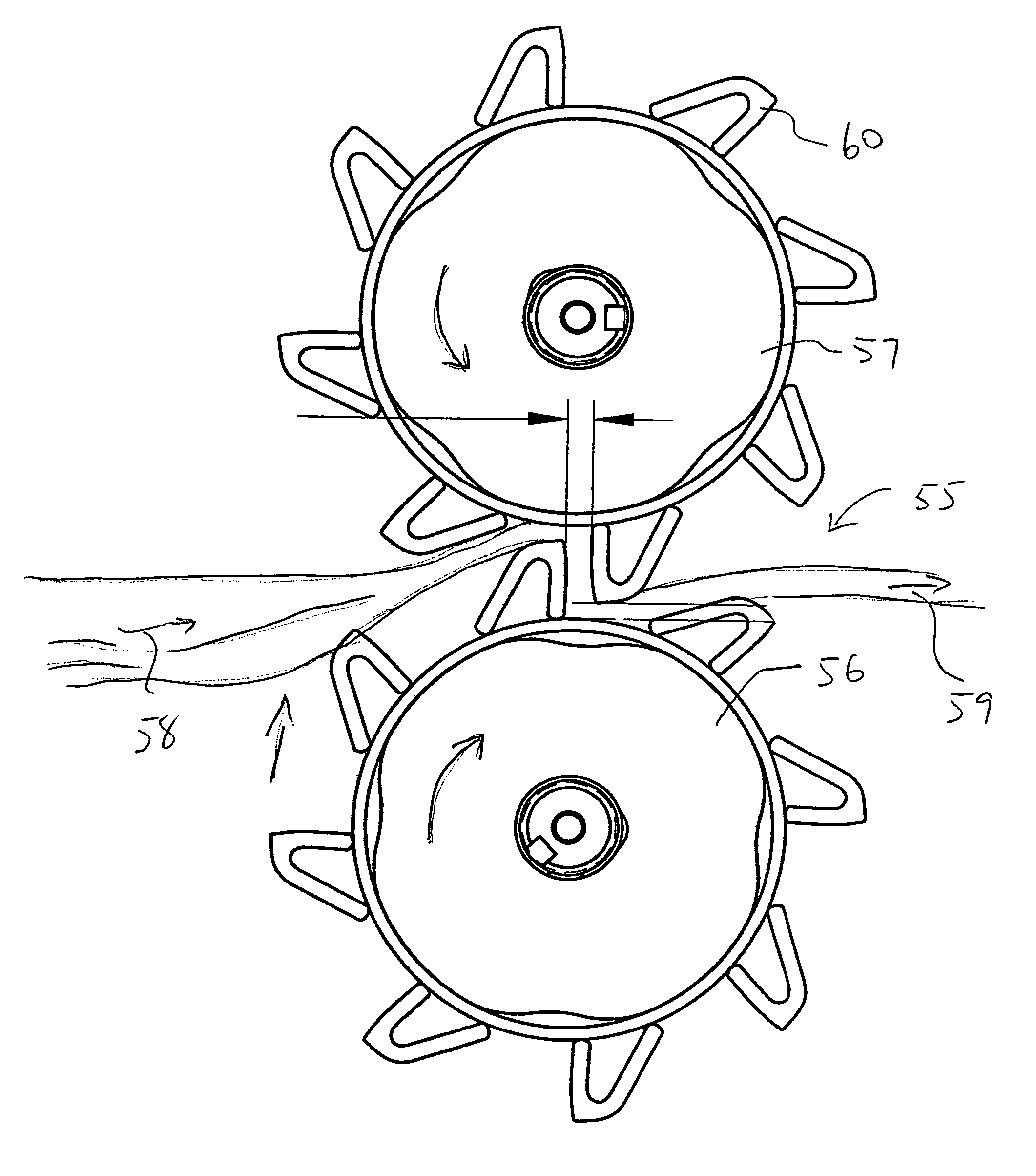

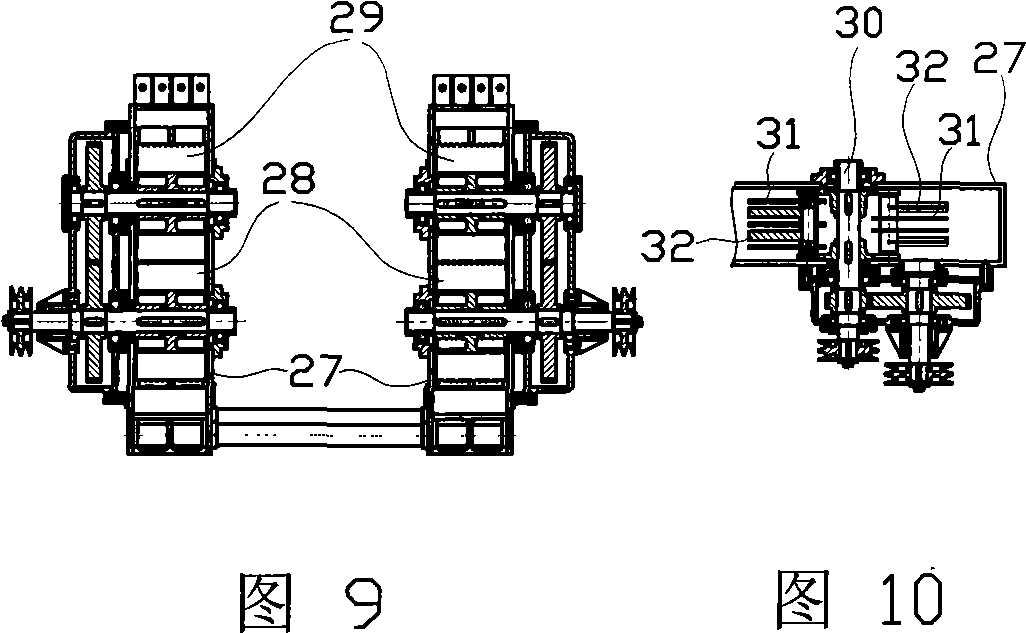

Crop processor roll arrangement for a forage harvester

A forage harvester and a method of operating the same which comprises a crop processor unit located in a crop flow between a cutterhead and a blower rotor, the crop processor unit being for handling crop material including kernels, the crop processor comprising a pair of counter-rotating processor rolls arranged to crack kernels between the rolls when the rolls are in a first position, both processor rolls being movable away from each other to move each roll substantially out of the crop flow into a second position. A cover plate is preferably arranged to move and cover the lower roll when the rolls are in a second position and to isolate the lower roll from the crop flow. The processor rolls are preferably driven by independent drives. One of the drives can be a hydraulic motor supplied with pressure from a hydraulic pump which can also work as a motor. When used as a motor the cutterhead may be driven in the reverse direction for maintenance purposes.

Owner:BLUE LEAF I P INC +1

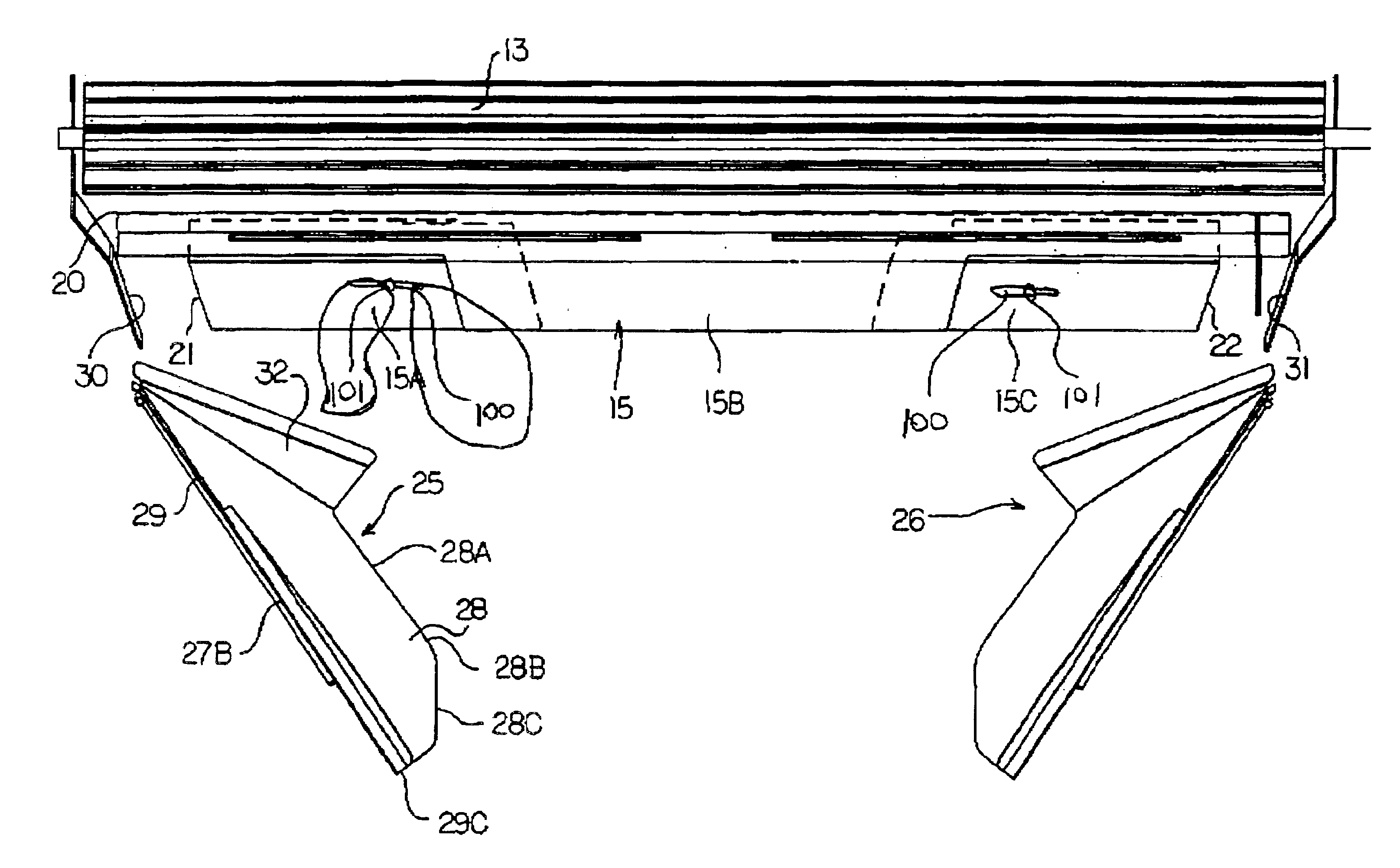

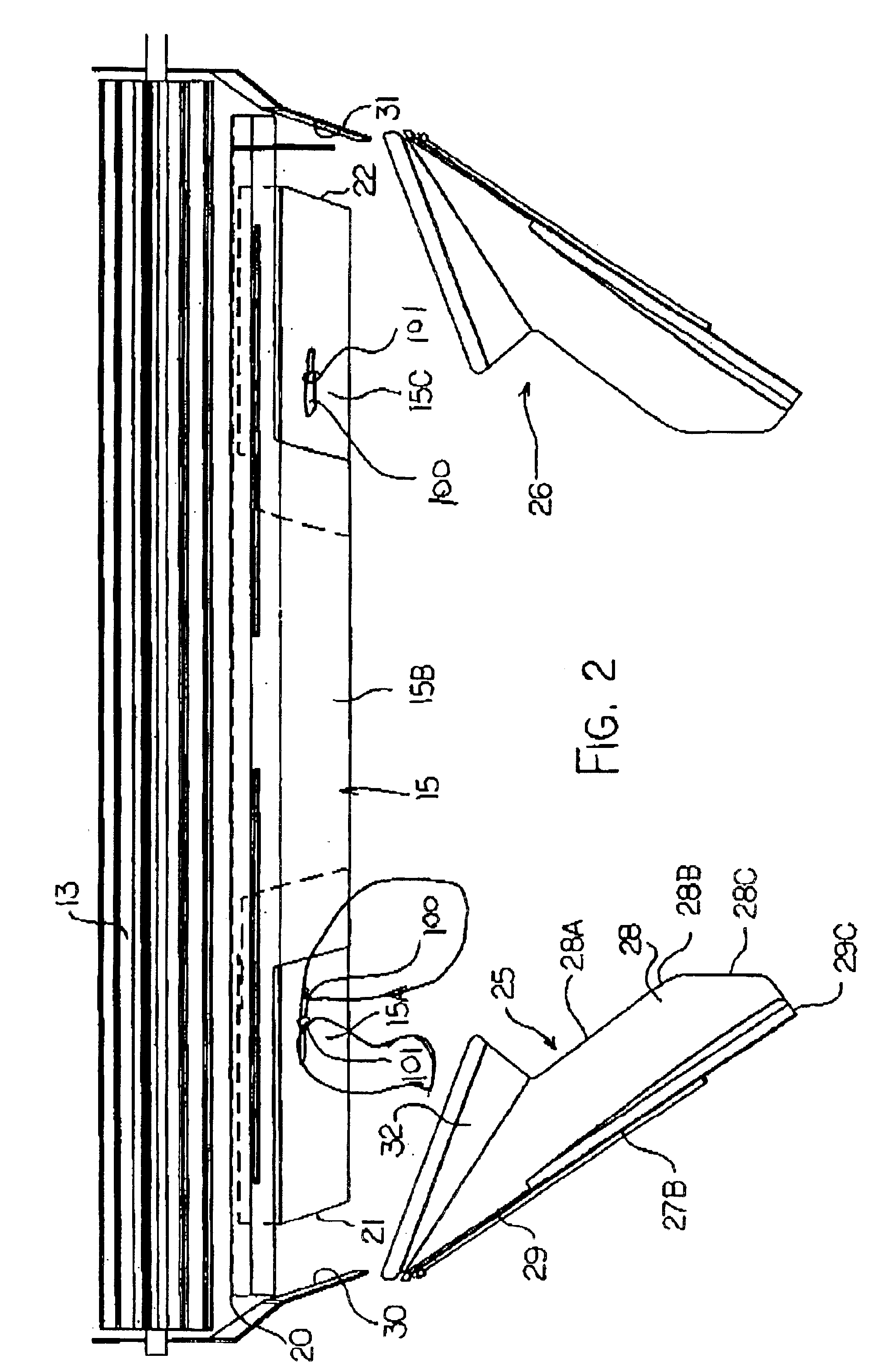

Windrow forming system for a crop harvesting header

A windrow is formed by discharging the crop rearwardly from a crop conditioner, engaging a center part of the web with a center deflector panel which is adjustable in width so as to direct that portion of the web, selected to match the intended width of the windrow, in contact with the center deflector panel downwardly toward the ground leaving two side portions which are not deflected and thus move to a height above the center portion, and engaging each of the side portions with a side deflector panel so that the side portion is redirected from a position at one side of the center portion and above the center portion to a position on top of the center portion.

Owner:MACDON INDS

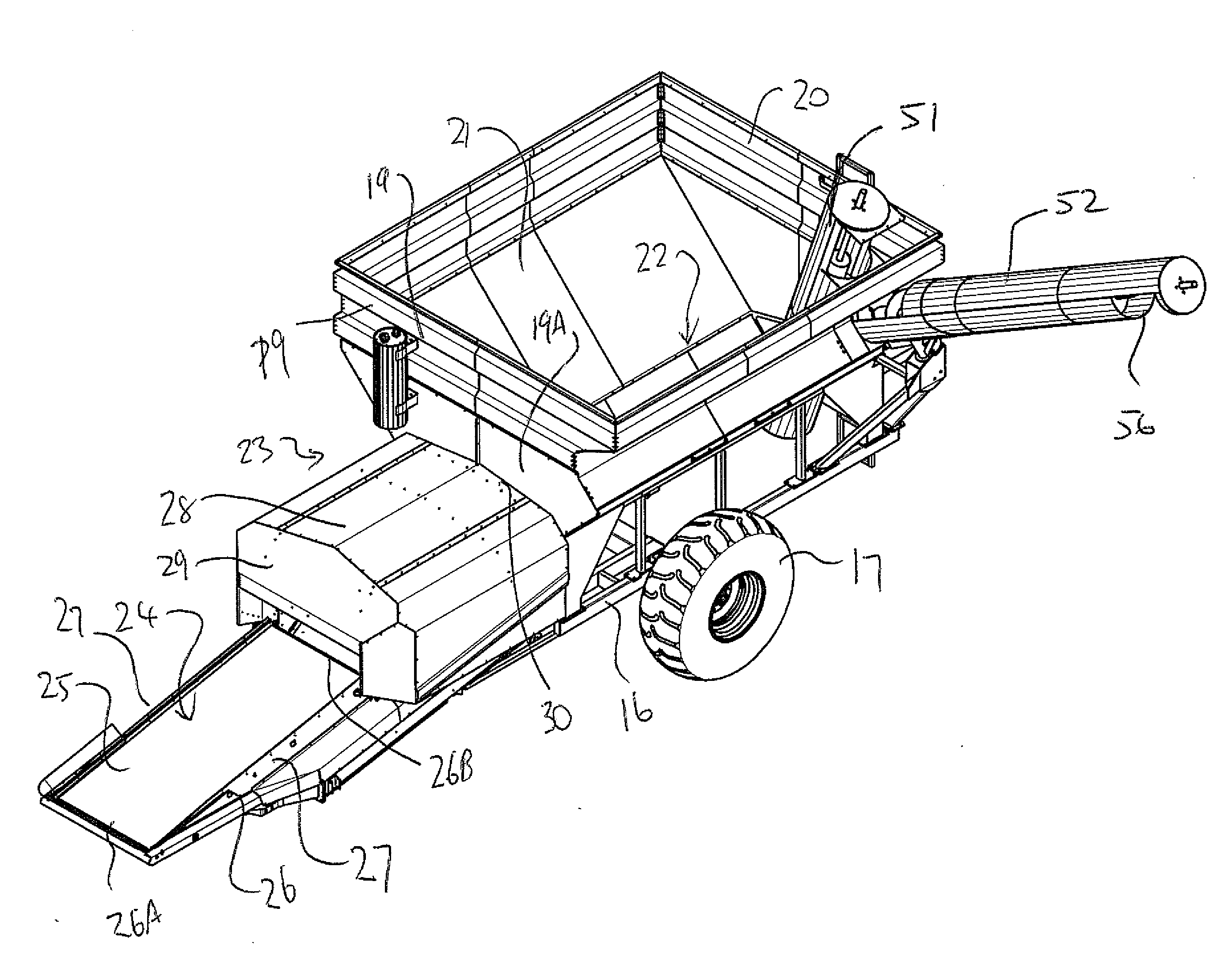

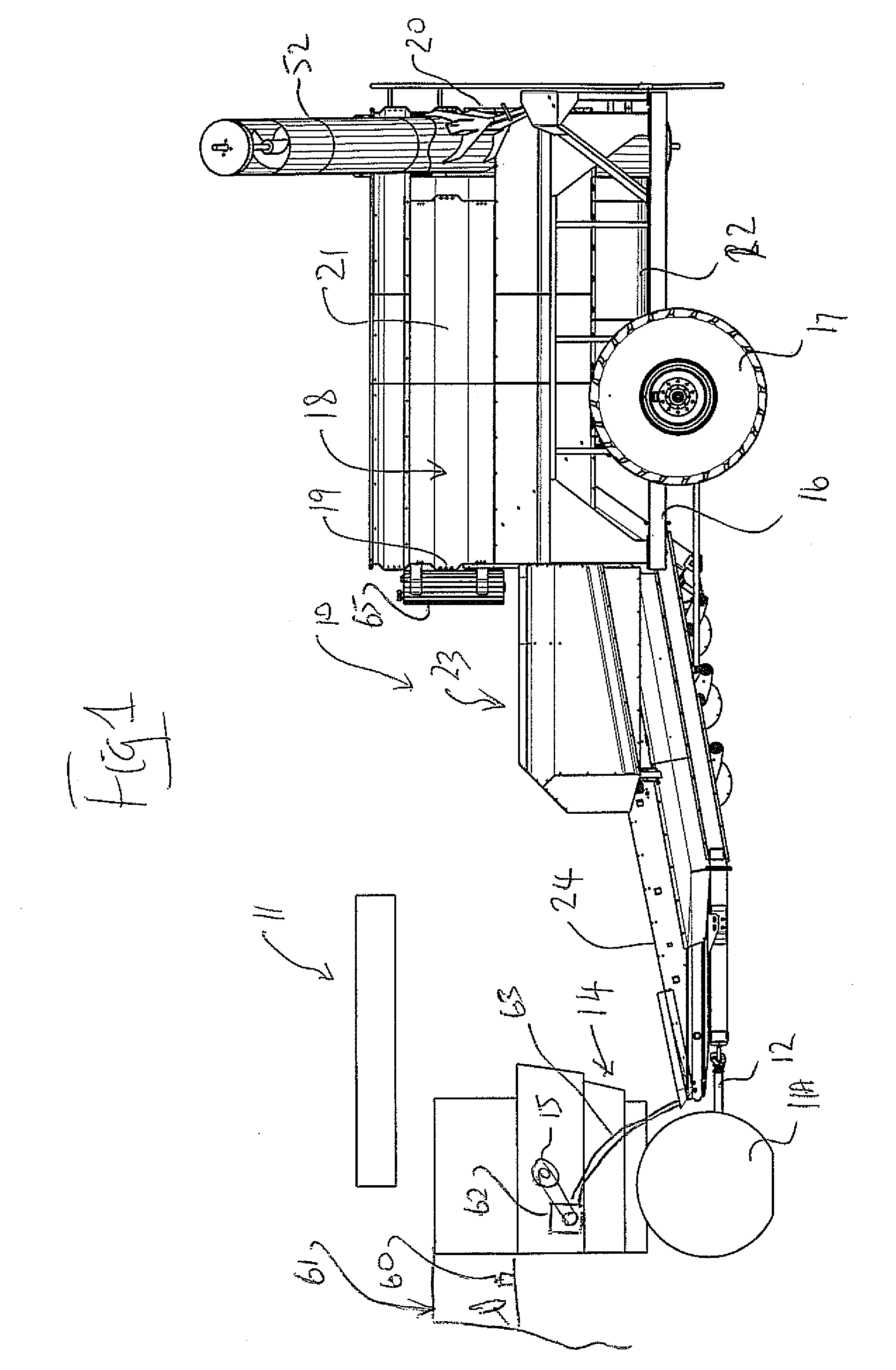

Harvesting corn cobs

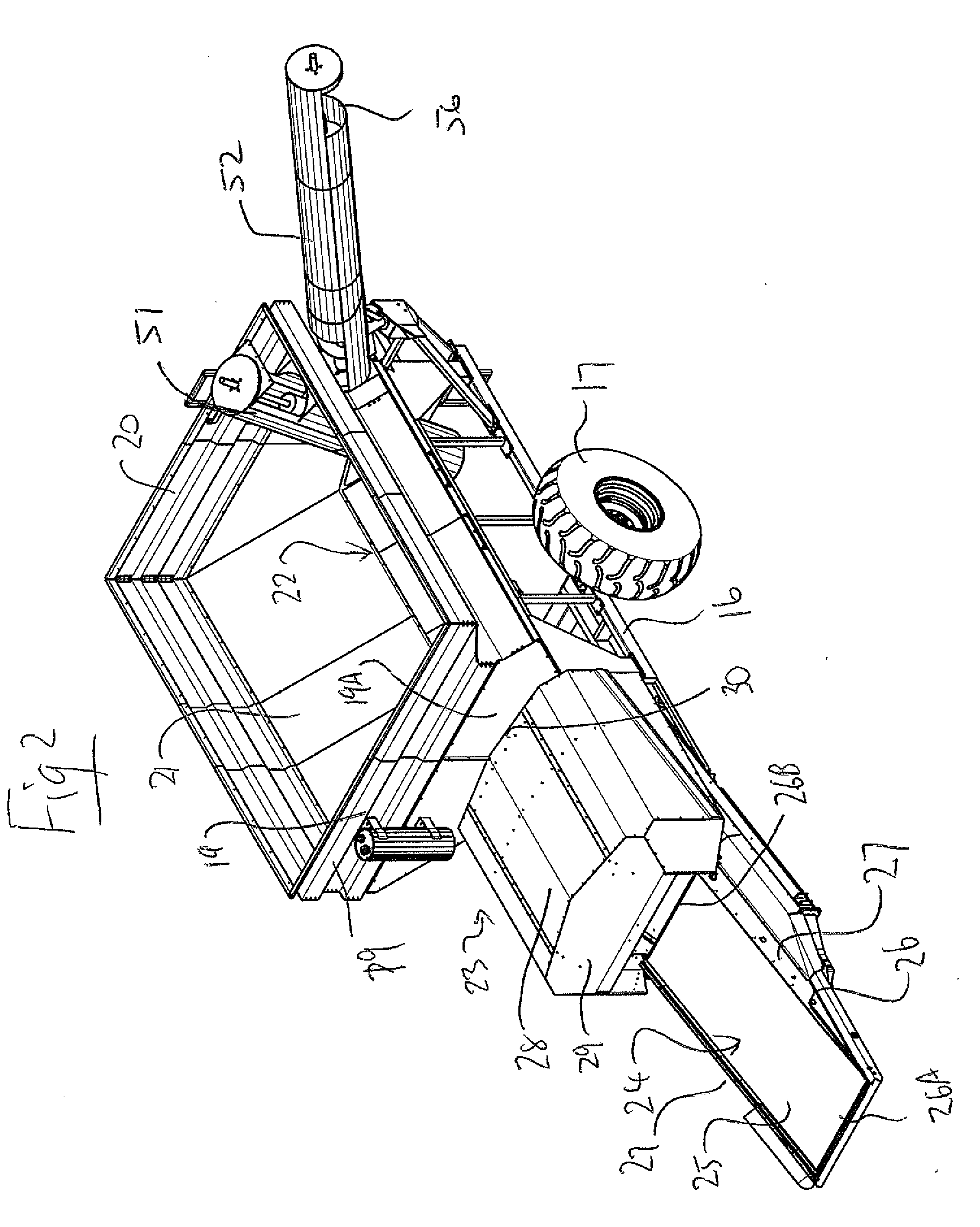

A cart is towed behind a combine harvester for collecting corn cobs and includes a conveyer belt feeding into a system for separating cobs from residue to be discharged and a tank for receiving and transporting the cobs. An unload auger is provided from the tank to one side of the cart while the cart moves forward. Power for driving the cart is obtained from a chopper drive of the combine harvester. The separating arrangement includes a series of sequential blower fans for blowing air through the discharged material as it is discharged from a conveyor and into a spreading guide disperses the residue. The cobs are conveyed using a series of augers where the auger to flight distance is at least 2 inches and particularly a pair of augers feed the cobs through a front wall of the tank so as to push cobs upwardly into the tank.

Owner:REDEKOP ENTERPRISES

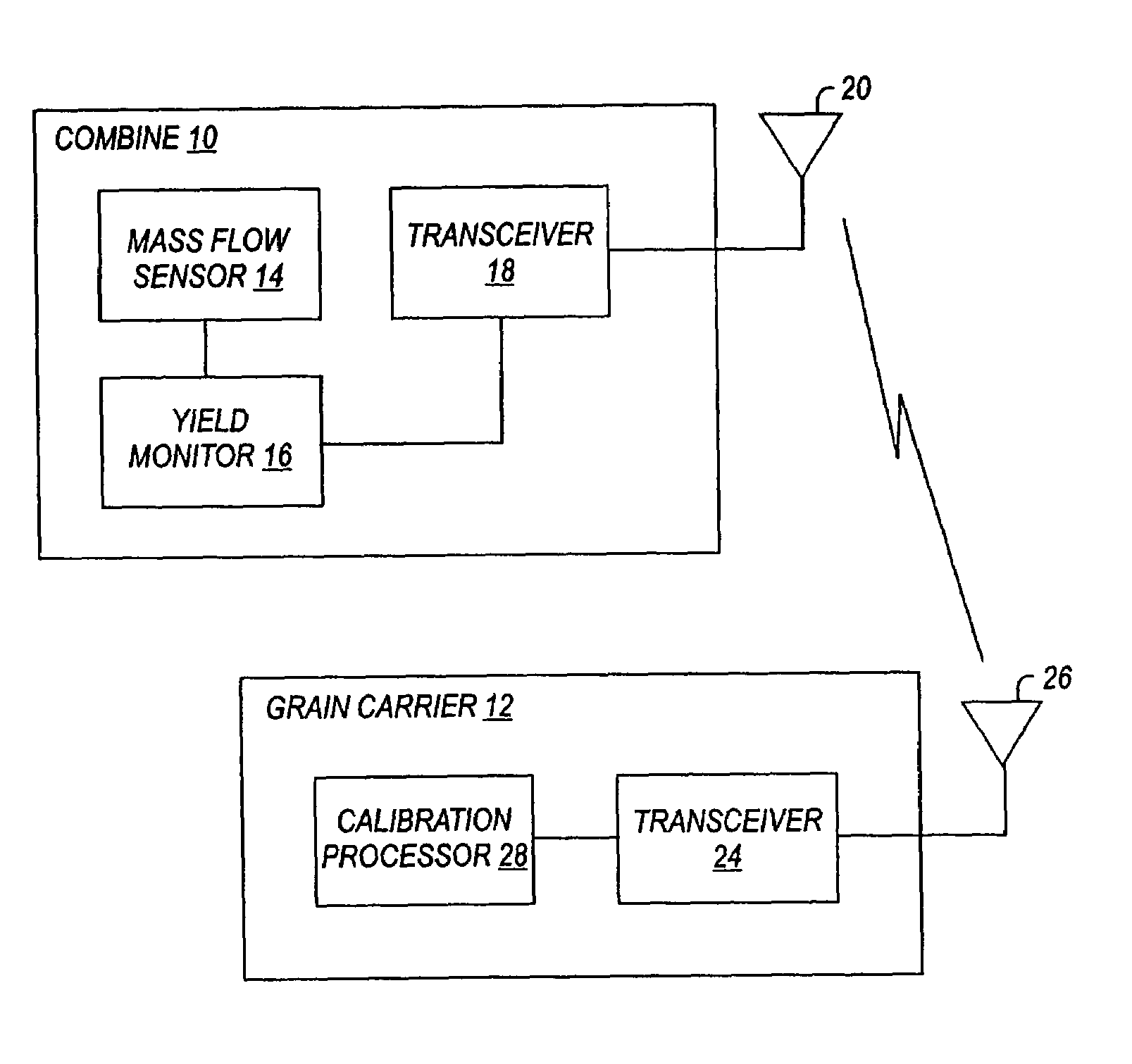

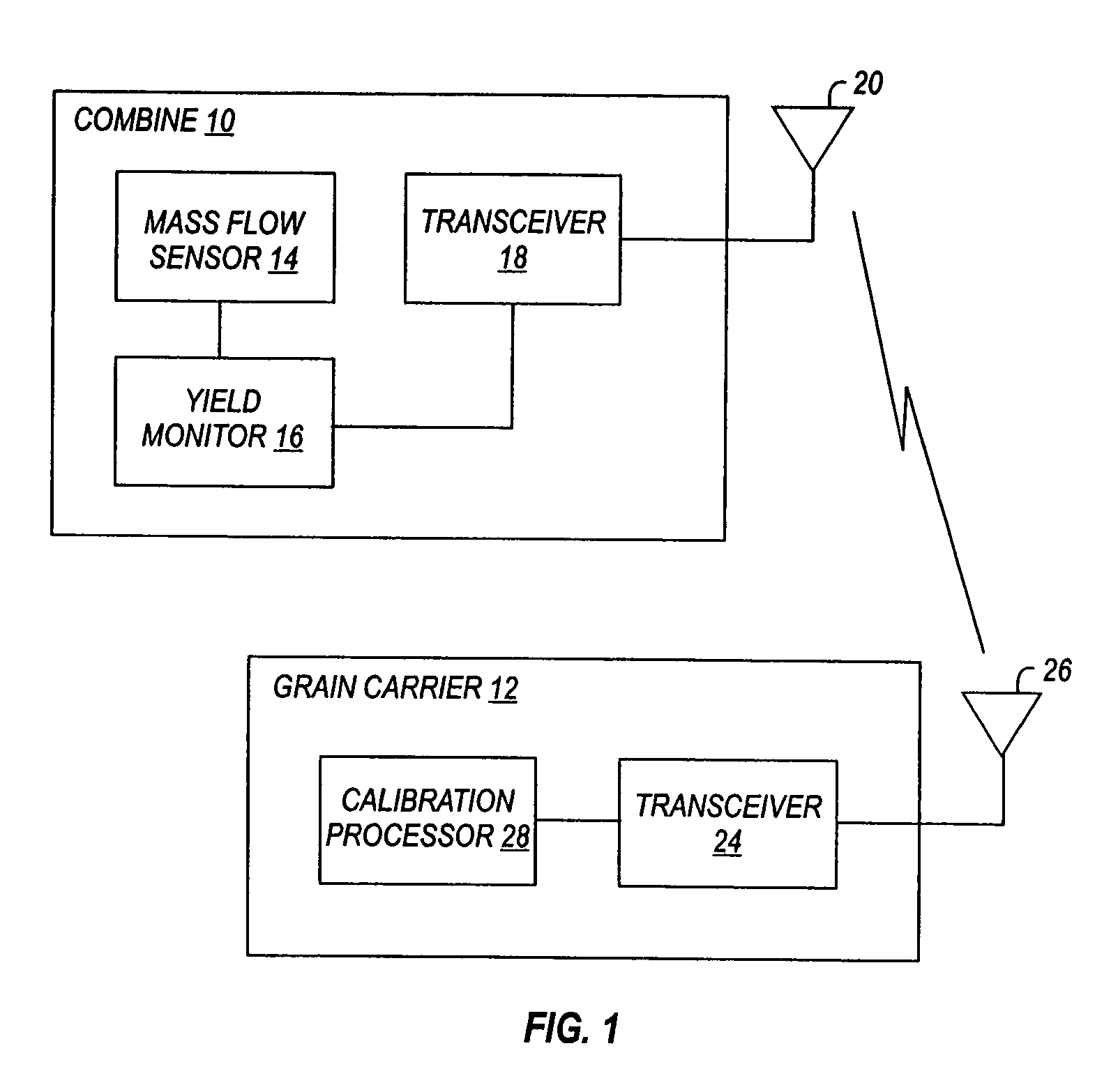

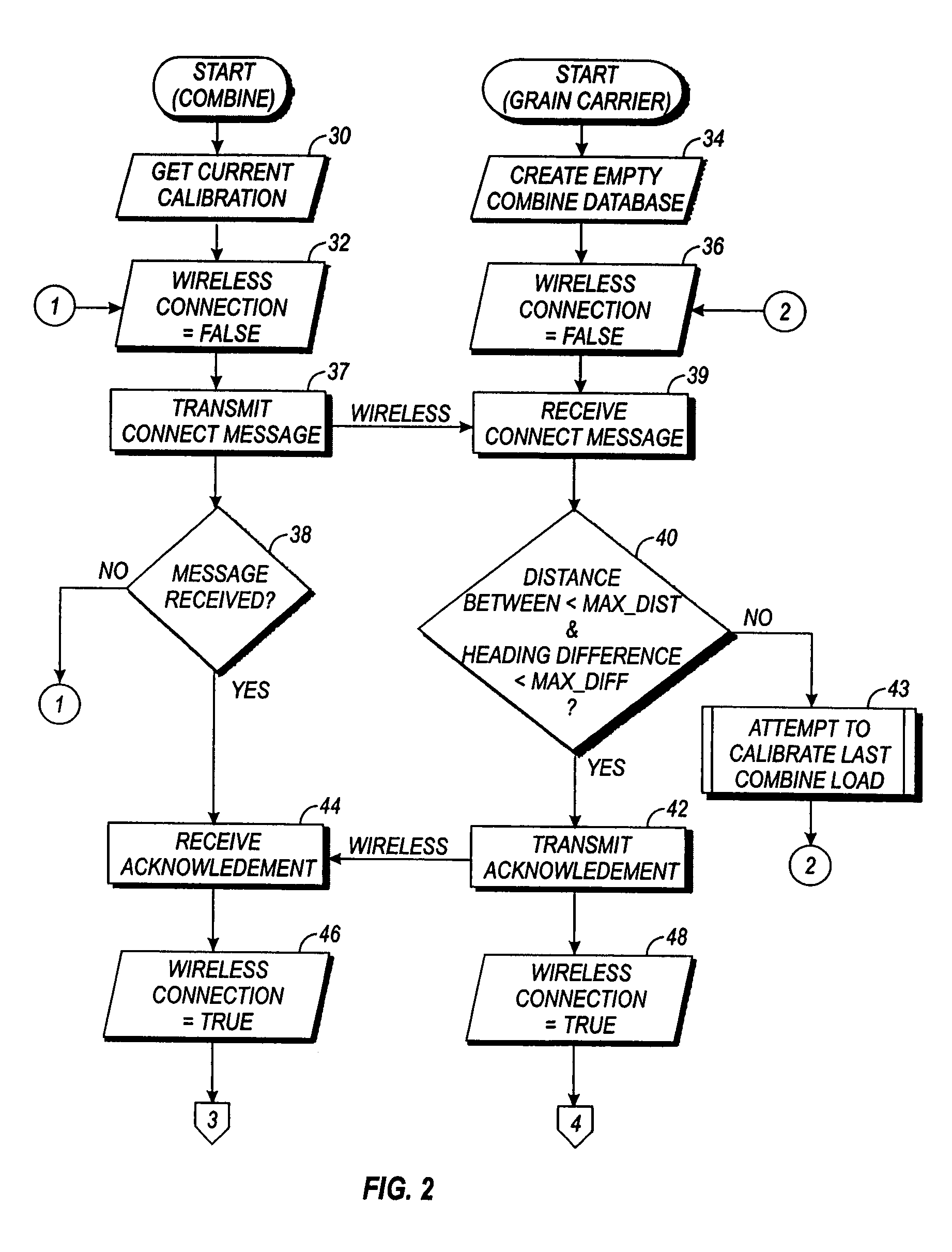

Automatic mass-flow sensor calibration for a yield monitor

A system and method is provided for remotely and automatically calibrating a mass-flow sensor in a yield monitor of a combine. The invention uses a wireless communication device installed on a combine and a remote wireless communication device installed on a grain carrier or truck carrier. Once an actual weight is obtained, calibration information is sent to the combine to calibrate the mass-flow sensor.

Owner:DEERE & CO

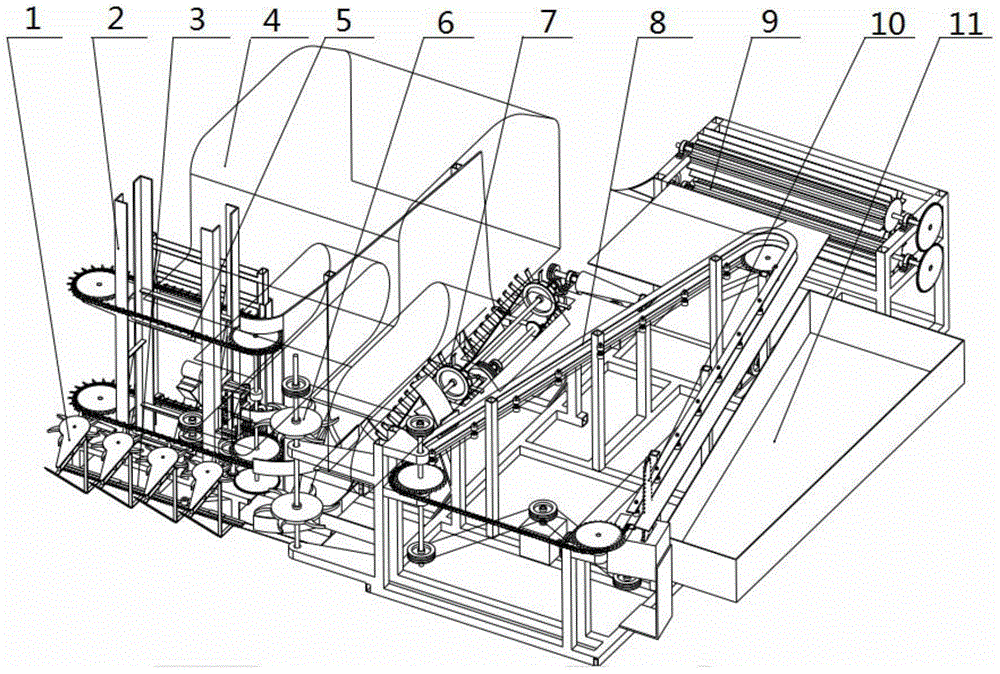

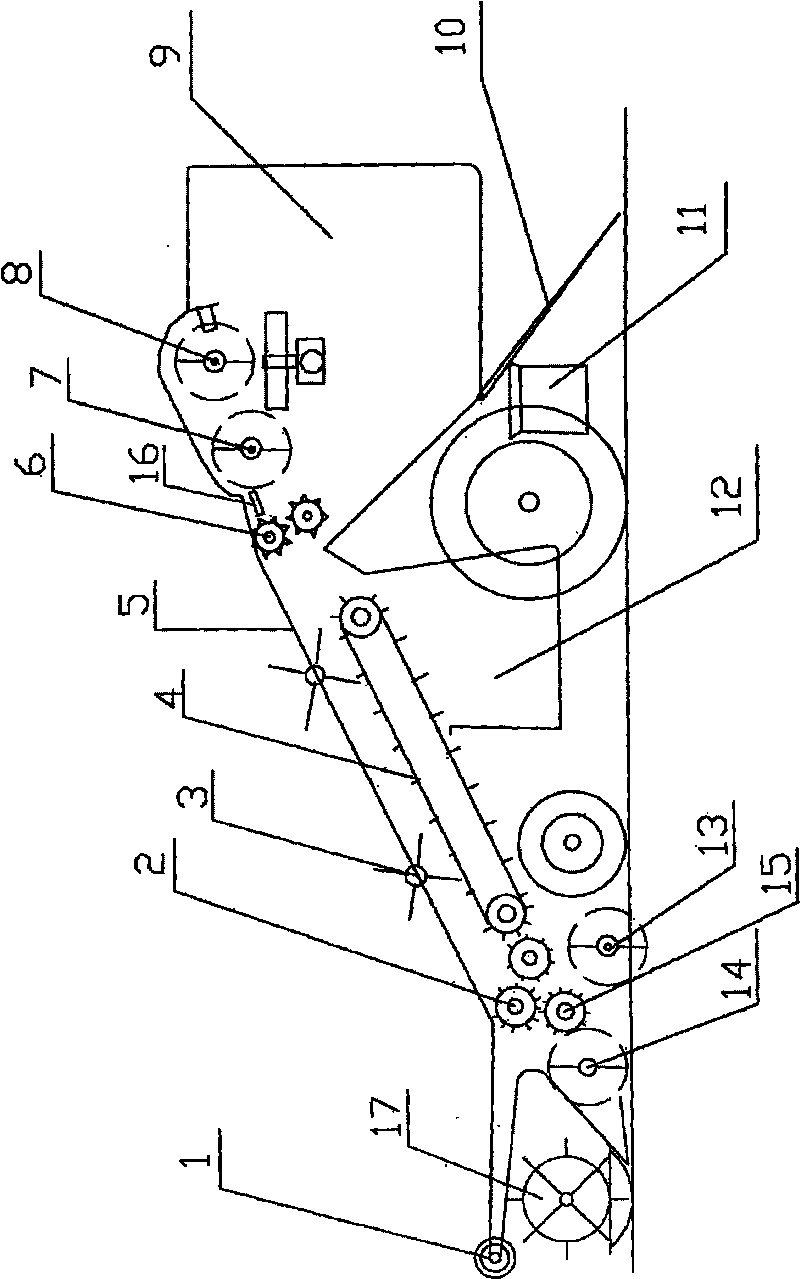

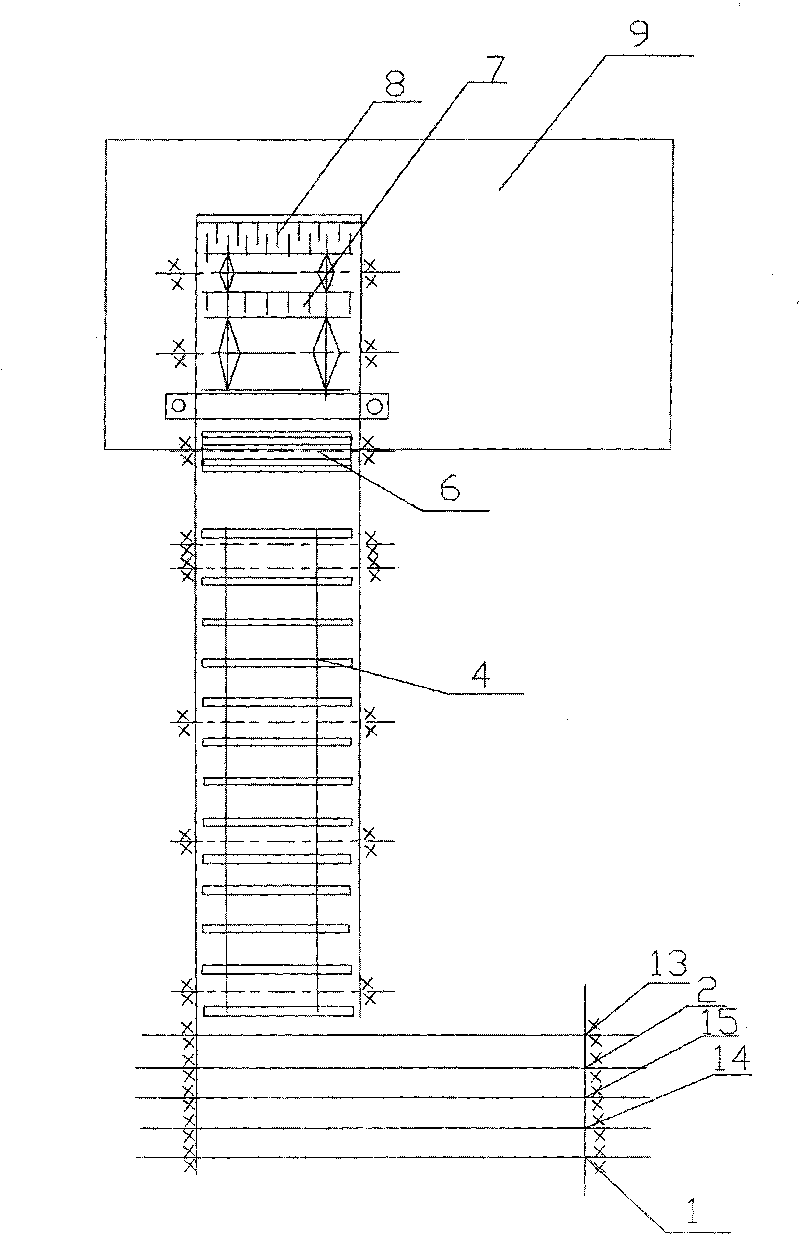

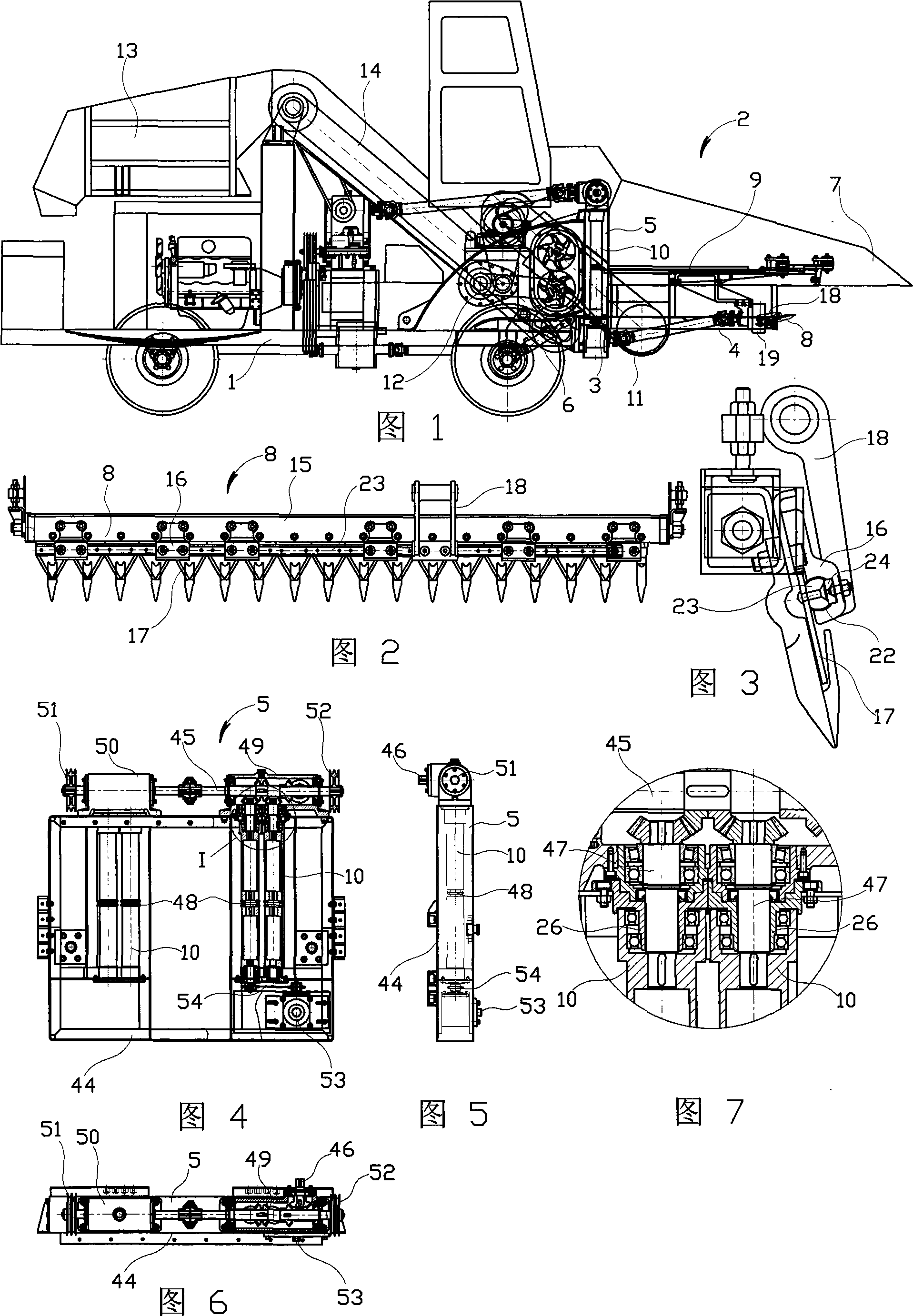

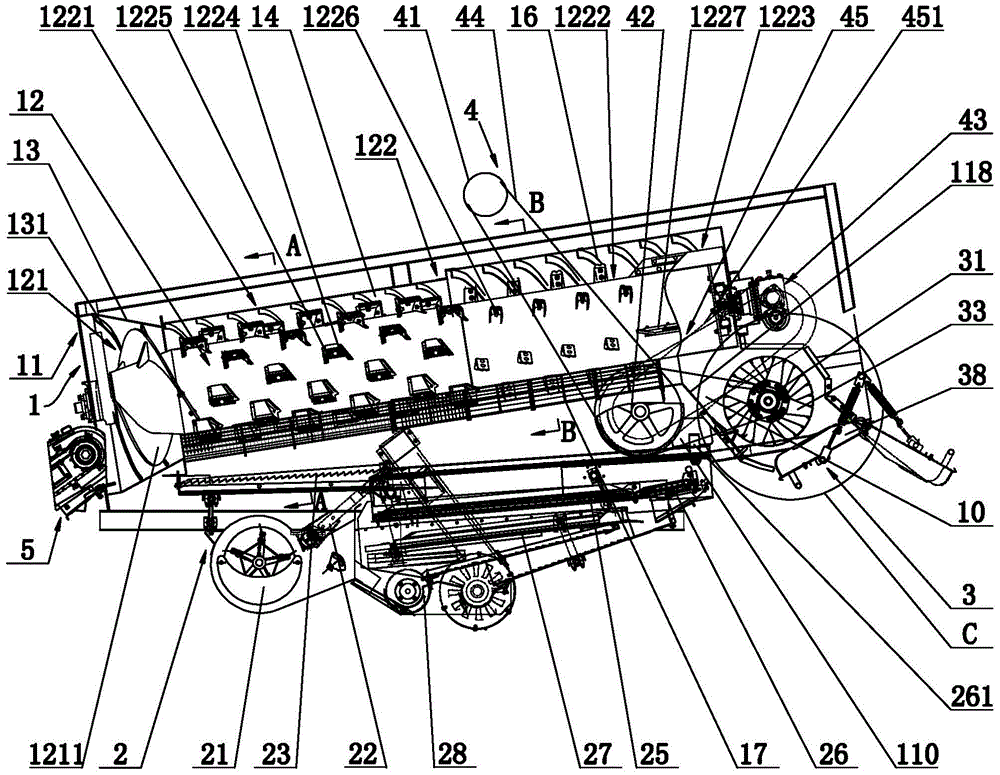

Ramie combine harvester

InactiveCN103597951AReduce heavy pollutionHigh organic contentCrop conditionersMowersFiberCombine harvester

The invention discloses a ramie combine harvester which comprises a ramie pulling device, a ramie cutting mechanism, a travel mechanism, a horizontal transportation device, a ramie pulling turning device, a ramie distribution conveying device, a double-cylinder ramie decorticating mechanism, a cutting device, a clamping device and a finished product collection box which are sequentially arranged. The ramie pulling device, the ramie cutting mechanism, the horizontal transportation device and the ramie pulling turning device are fixed on the same support to form a header, the header and the travel mechanism are combined to finish harvesting, the ramie distribution conveying device, the clamping device and the cutting device are fixed on another support, and the ramie distribution conveying device, the clamping device, the cutting device, the double-cylinder ramie decorticating mechanism and the finished product collection box jointly finish decorticating ramie. By the aid of the ramie combine harvester, ramie stalks can be cut, ramie fibers and sticks can be separated once, harvesting efficiency is high, all procedures such as scraping and machining are automatically finished, the separation rate of the ramie fibers, ramie peels and the sticks reaches more than 94%, and subsequent ramie decorticating mechanical separation and high-quality ramie yield are facilitated.

Owner:WUHAN TEXTILE UNIV

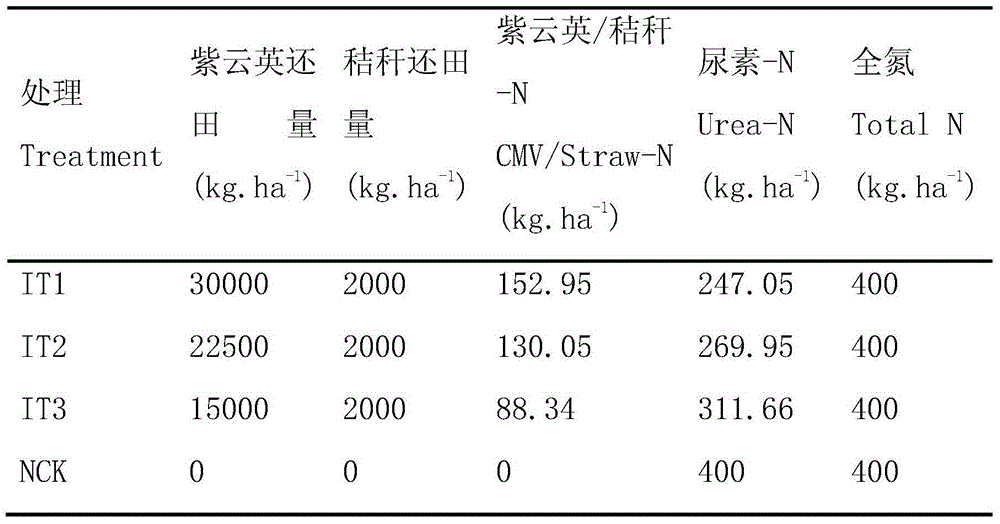

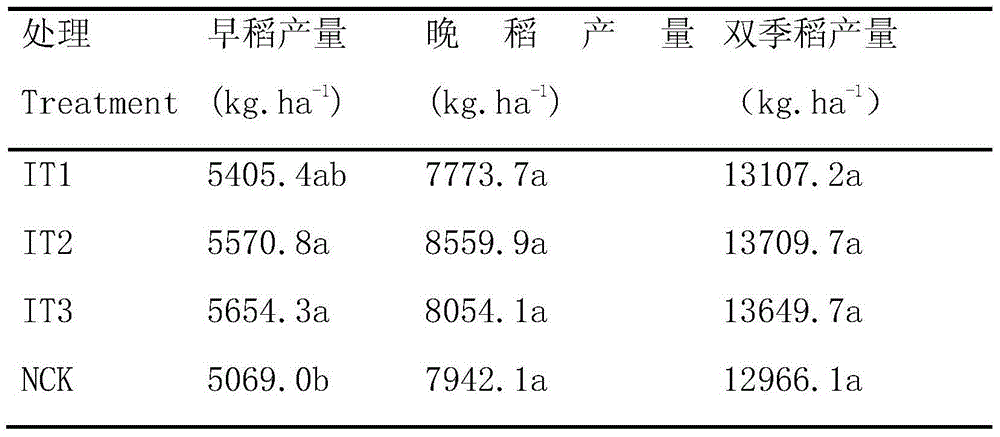

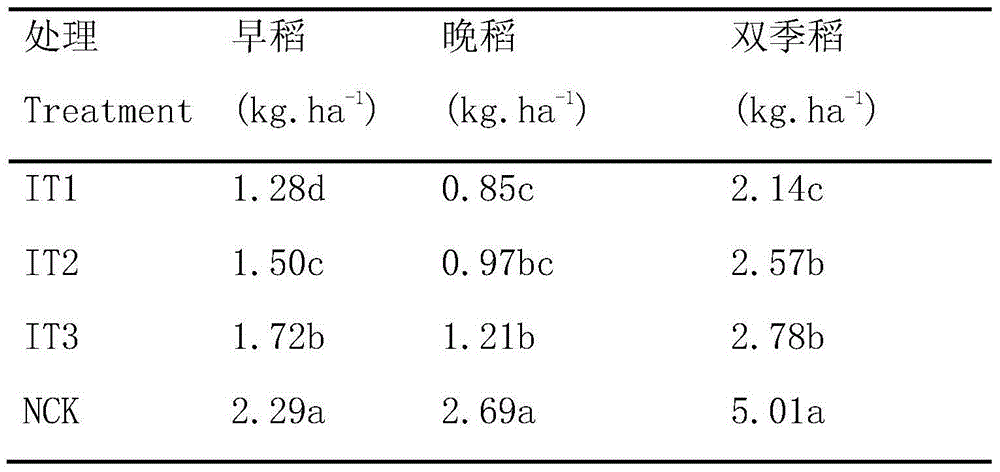

Method for increasing yield of double cropping rice by turnover and fertilizer saving of Astragalus sinicus L. and straw in rice field

InactiveCN104145618AAvoid quality problemsAvoid quality lossCrop conditionersMowersCropping systemAgricultural science

The invention belongs to the technical field of fertilizer-saving high-yield culture in agricultural production and relates to a method for increasing yield of double cropping rice by turnover and fertilizer saving of Astragalus sinicus L. and straw in a rice field. Specifically, the method includes that during growth of early rice, green Astragalus sinicus L. is overturned and pressed to return to the field so as to replace part of nitrogenous fertilizer, and during growth of late rice, straw of the early rice is returned to the field to replace part of nitrogenous fertilizer, and purposes for nitrogenous fertilizer conservation and high yield are achieved in the integral production cycle of double cropping rice. The method solves the problems that areas of vacant fields in winter are enlarged, the rice field is deteriorated, ecological cost for rice production is increased, and fertilizer utilization rate is seen low and the like in a rice cropping system of southern China. The method is a cultivating technology high in yield, nitrogenous fertilizer saving and lower in N2O emission and provided for increasing yield of the double cropping rice, reducing fertilizer investment and increasing fertilizer utilization rate.

Owner:CHINA AGRI UNIV

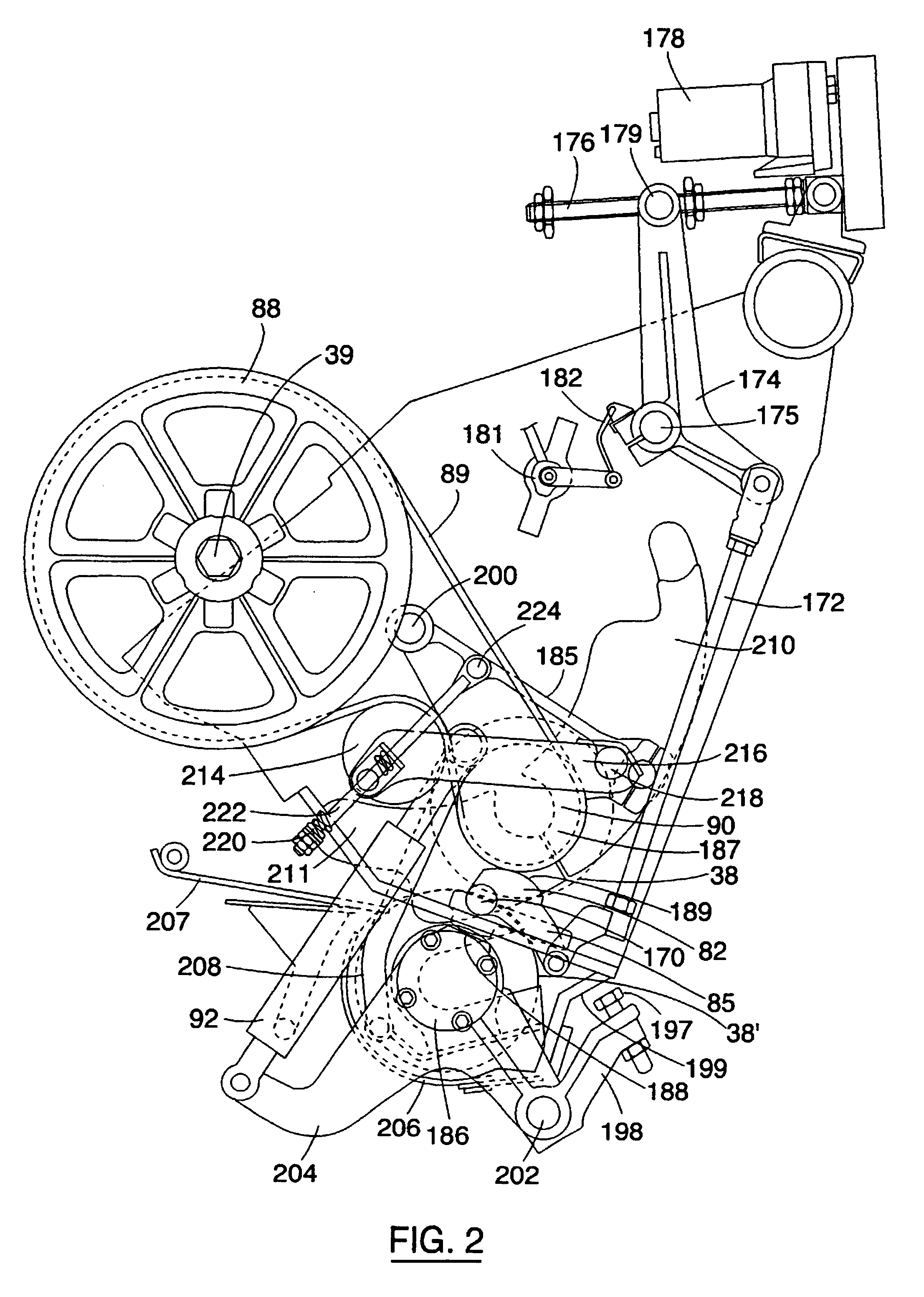

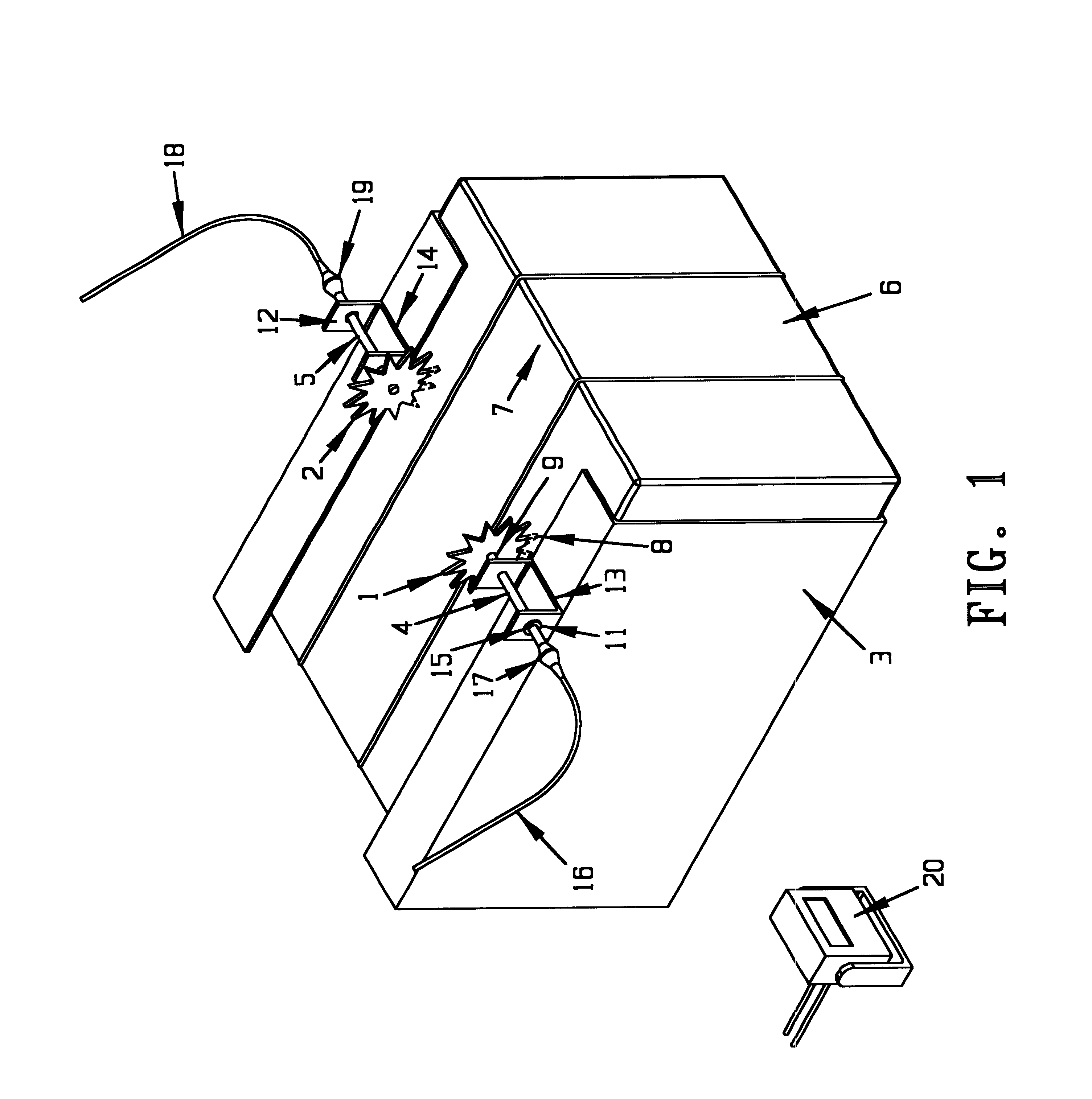

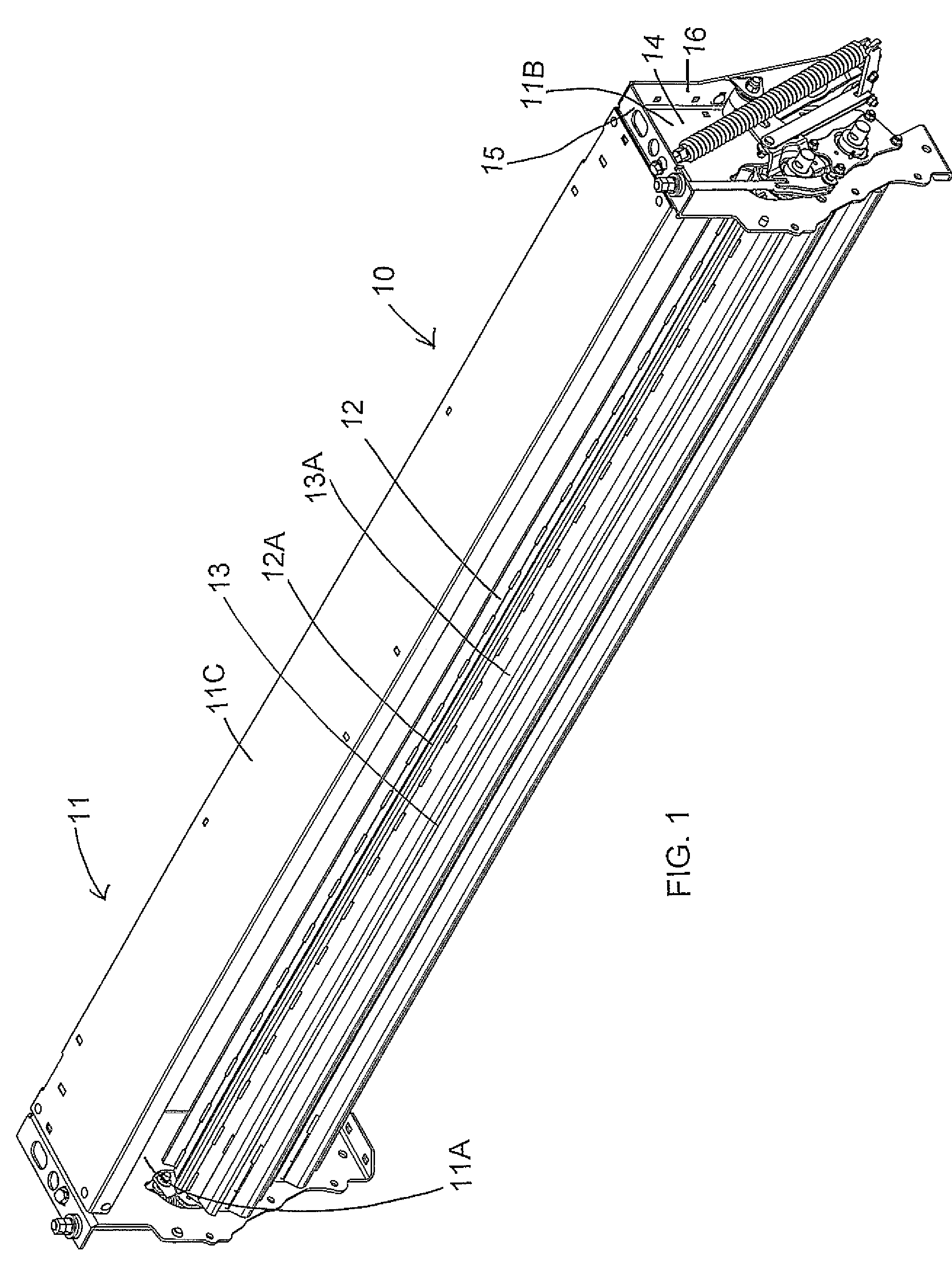

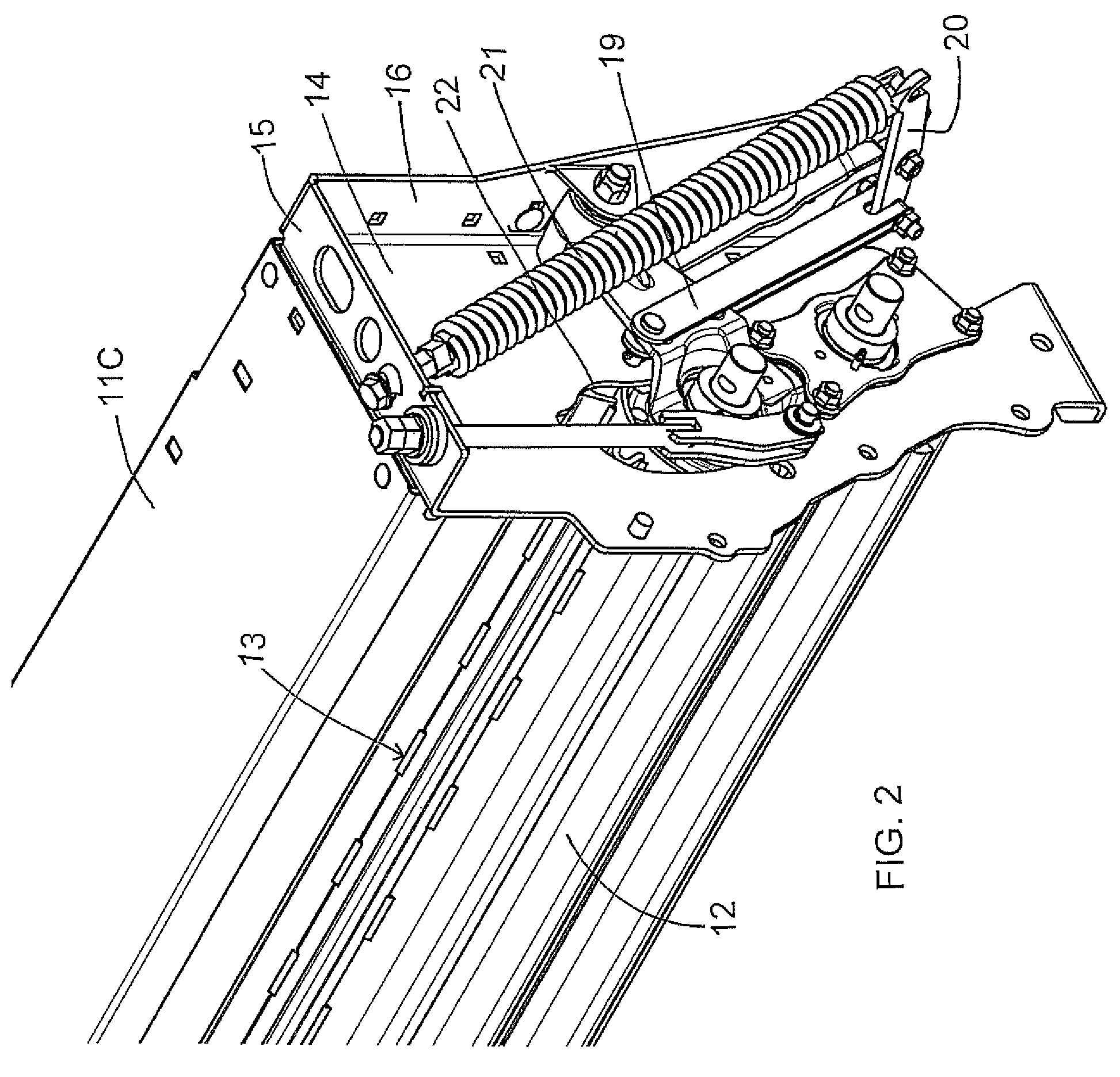

Crop conditioning roller flute shape

ActiveUS7322175B2Improved shape and arrangementImprove actionCrop conditionersHarvestersFluteForage harvester

A forage conditioner for conditioning cut crop material from a forage harvester includes a fixed bottom fluted roller carried in end housings and a top fluted roller which is pivotally mounted on the housings by a linkage pivotal relative to the housing about an axis lying in a plane at right angles to the roller axes so that the top roller is liftable from crushing position against the bias of a spring extending along the top roller. Flutes on the rollers are arranged with a first surface on one side which extends substantially radially outwardly to an apex and a second surface which has a first portion parallel to a tangent of the roller and a second portion inclined inwardly to the roller surface at an angle significantly less than 90 degrees. The bottom roller is arranged with the first surfaces leading to carry the crop into the area between the rollers and the top roller is arranged with the first surface trailing. Thus the first surface of intermeshing flutes pass through a condition in which the first surfaces are substantially parallel and on opposite sides of a line joining the centers of the rollers to provide an effecting conditioning action on the crop.

Owner:MACDON INDS

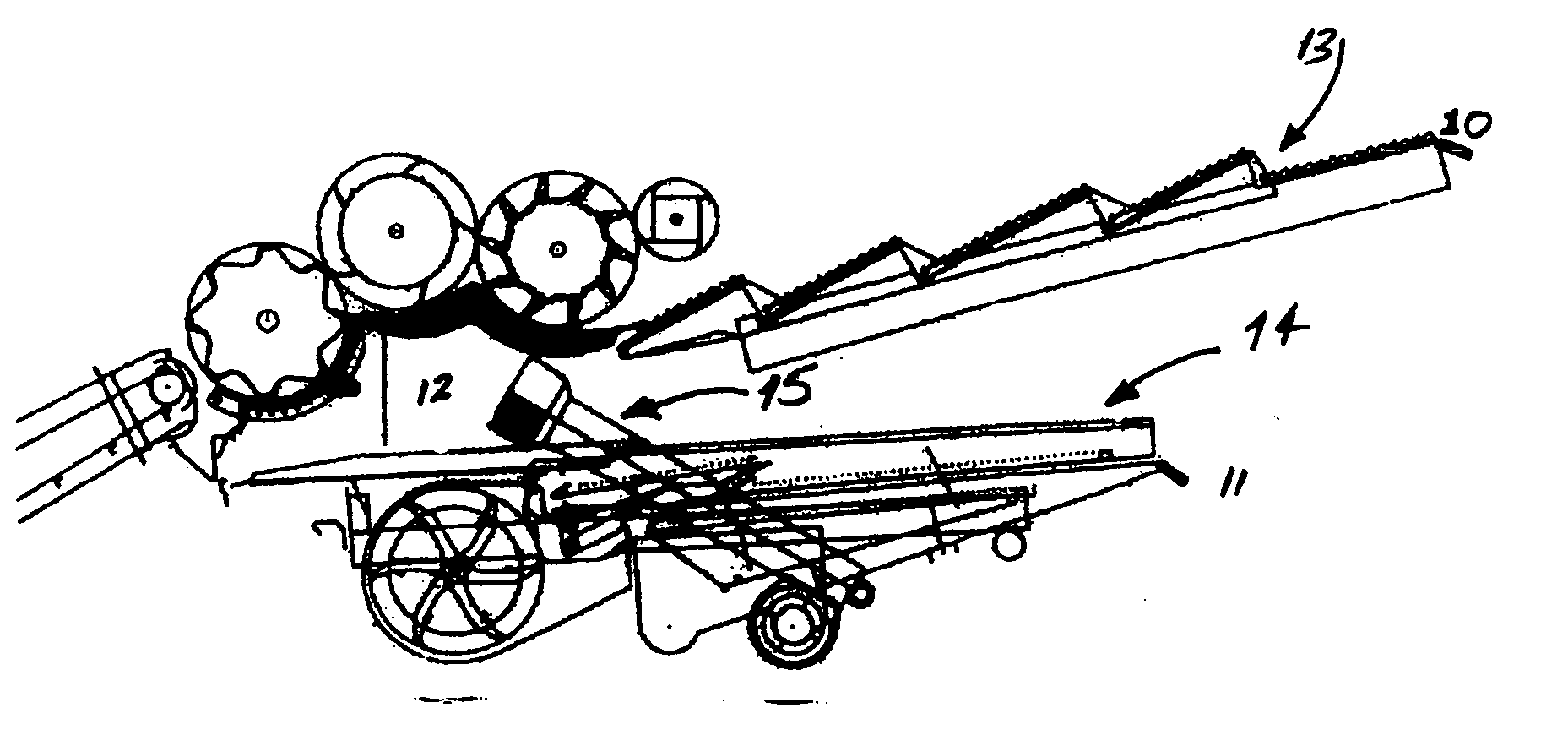

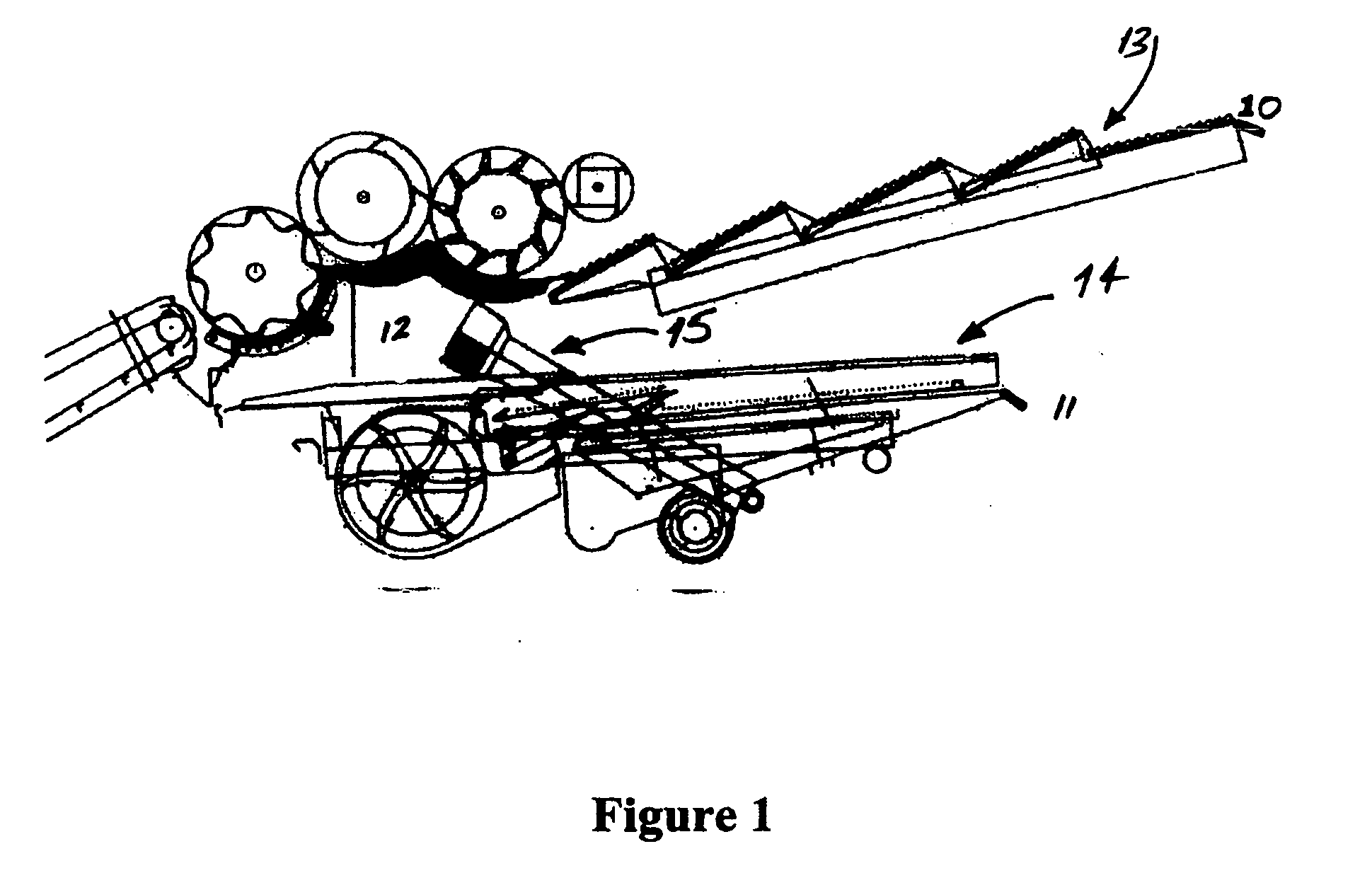

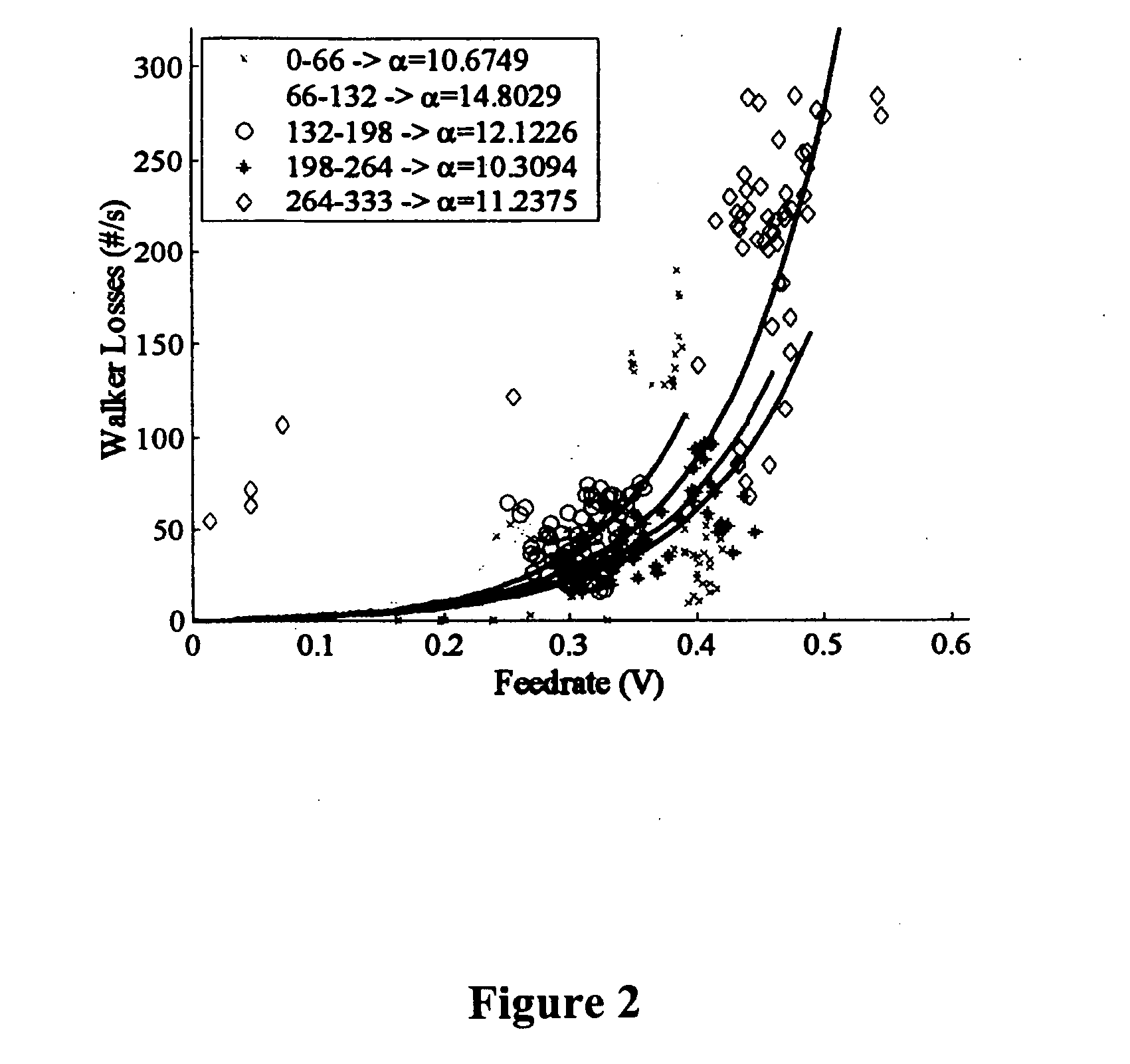

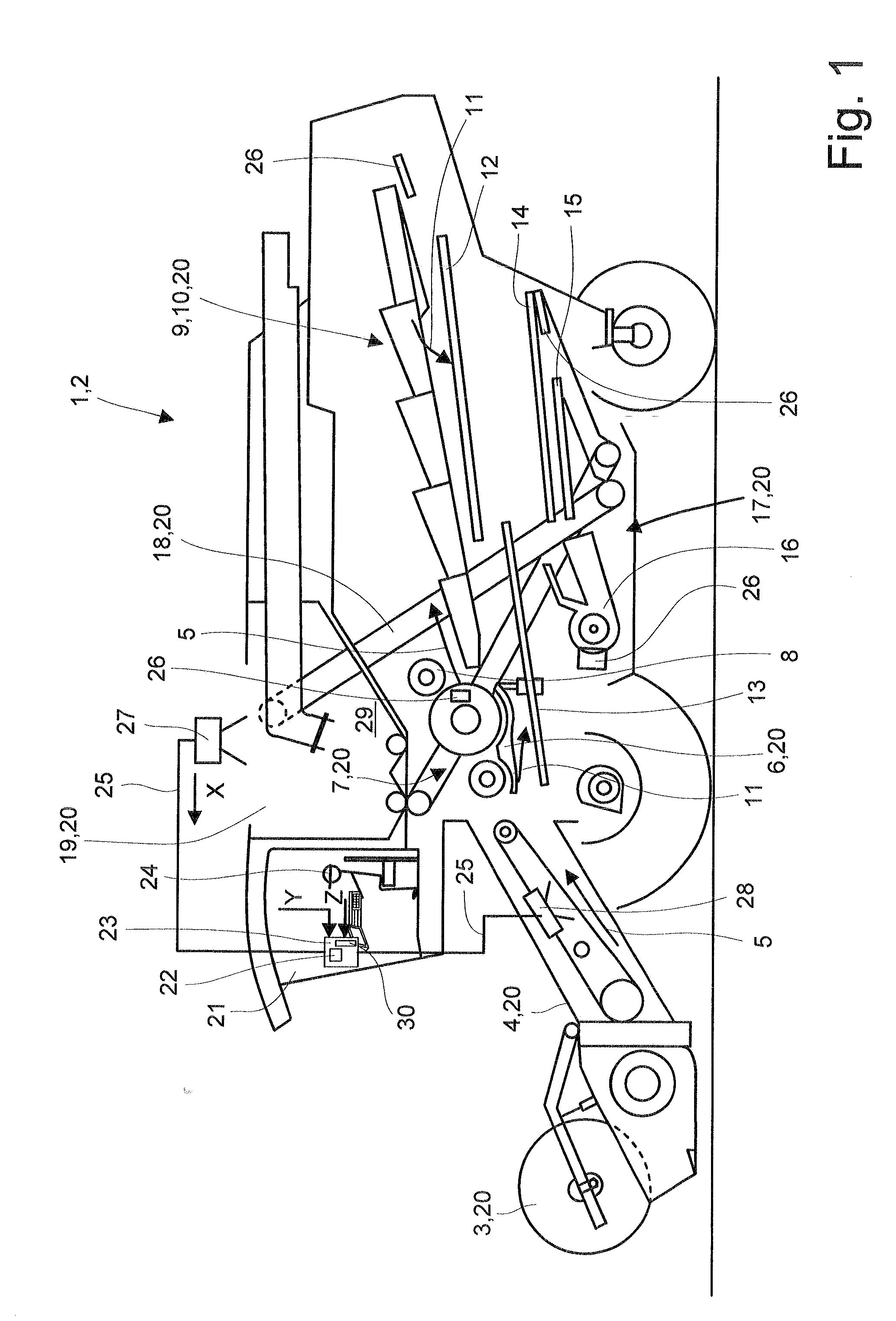

Methods of optimising stochastic processing parameters in crop harvesting machines

ActiveUS20050241285A1Analogue computers for trafficCrop conditionersCombine harvesterIndustrial engineering

The flow of crop material through a harvesting machine, such as a combine, can be described using a wide range of models, providing a relationship between the harvester load u(t), e.g. the mass flow at the inlet, and an effectiveness value y(t), e.g. the grain loss at the outlet. However, prior art models are not applicable to a wide range of harvesting conditions or are very complicated, requiring a multitude of inputs. The invention proposes to use a simple model, comprising a stochastic parameter , which is continuously optimized to adjust the model to the latest prevailing working conditions. Such parameter may be considered to constitute a variable which characterizes the instantaneously prevailing readiness of the harvesting process. Such variable can be used for establishing field maps showing the evolution of the harvesting operation itself. It can also be used in automatic routines which adjust the harvester speed in order to limit the grain losses.

Owner:BLUE LEAF I P INC

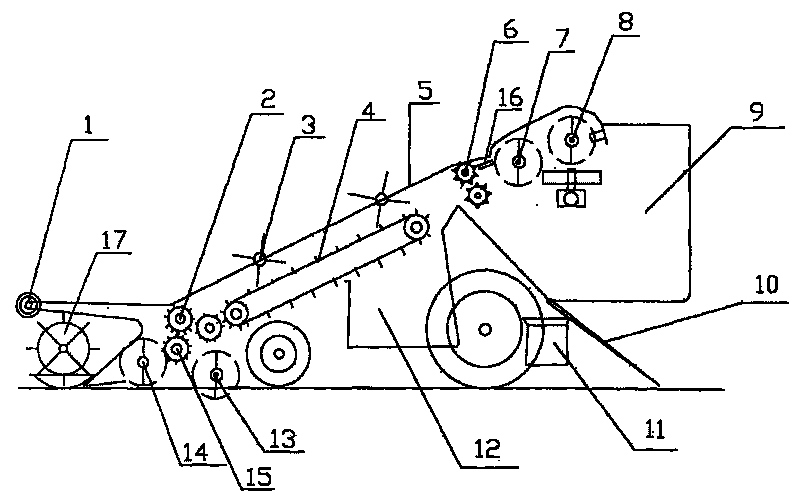

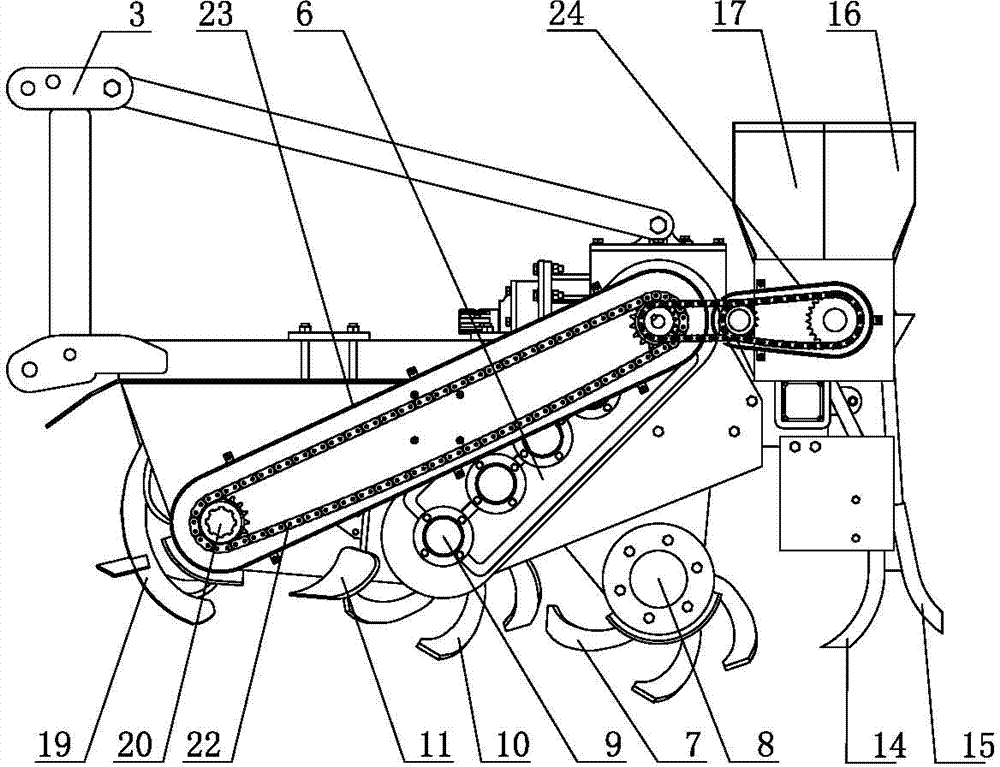

Multifunction straw chopping ensilage machine

InactiveCN101720600ASmall loadReduce energy consumptionCrop conditionersMowersEngineeringForage harvester

The invention discloses agricultural machinery and in particular discloses a multifunction straw chopping ensilage machine. The ensilage machine comprises a support frame which is provided with a feed device and a crushing device. The ensilage machine is characterized in that the front end of the support frame is provided with a straw cutting rotary blade for cutting the straws; the feed device comprises an upper feed roll and a lower feed roll which have opposite rotation directions; a certain gap is arranged between the upper feed roll and the lower feed roll; a conveyer chain is arranged on the right upper part of the gap between the two feed rolls; a certain distance exists between the conveyer chain and the upper end of the support frame; the crushing device is arranged at the tail end of the conveyer chain and a collection device is arranged at the lower end of the crushing device. The invention has the beneficial effects of realizing one-off completion of corn straw cutting, straw feeding, straw conveying, straw chopping, secondary straw crushing, stubble ploughing and soil moisture preserving, straw collection and ensilage and aftercrop of residual corn ears, and having light load, low energy consumption and high efficiency.

Owner:袁东明

Device and method for measuring hay bale moisture

Owner:HARVEST TEC

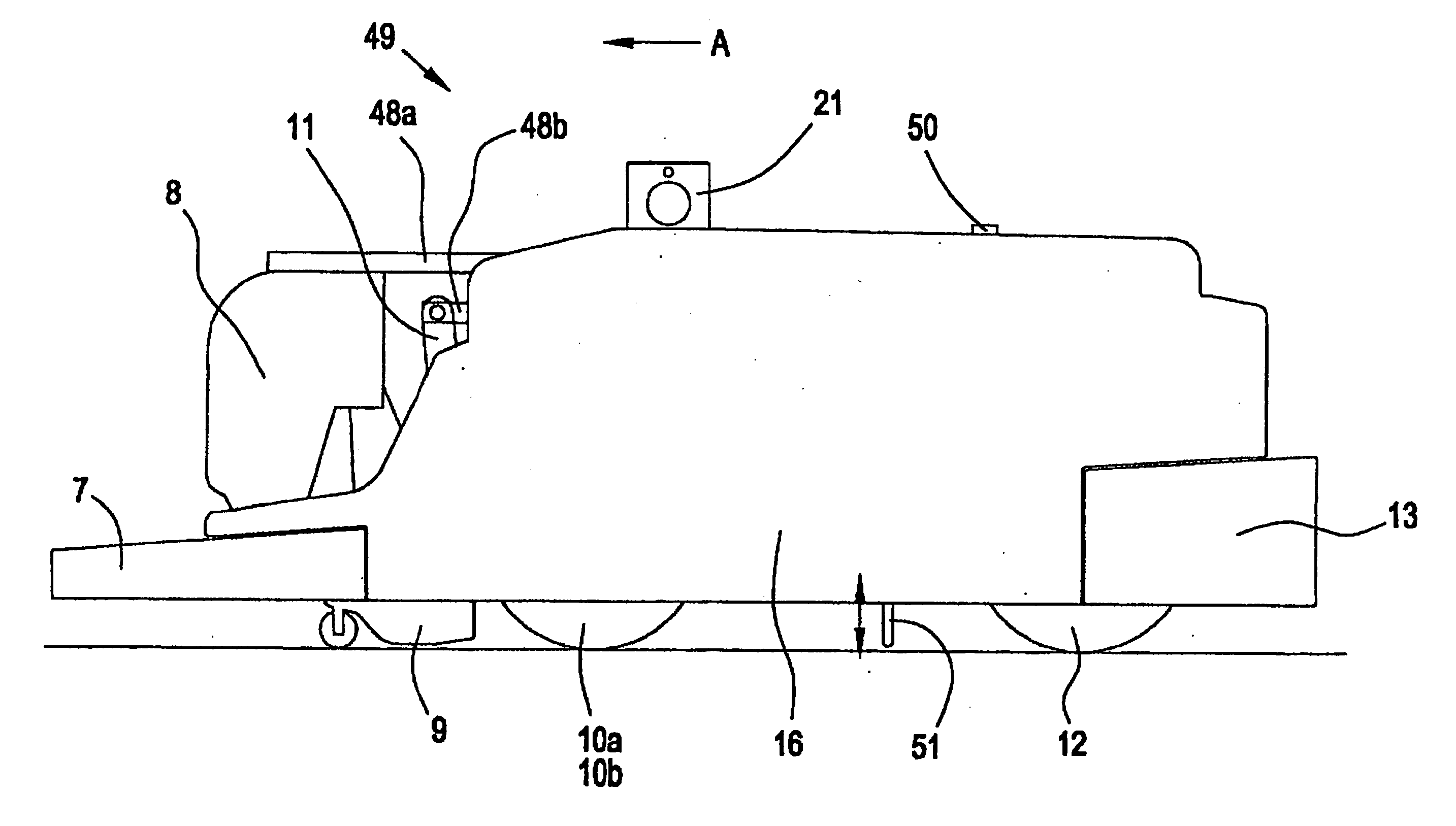

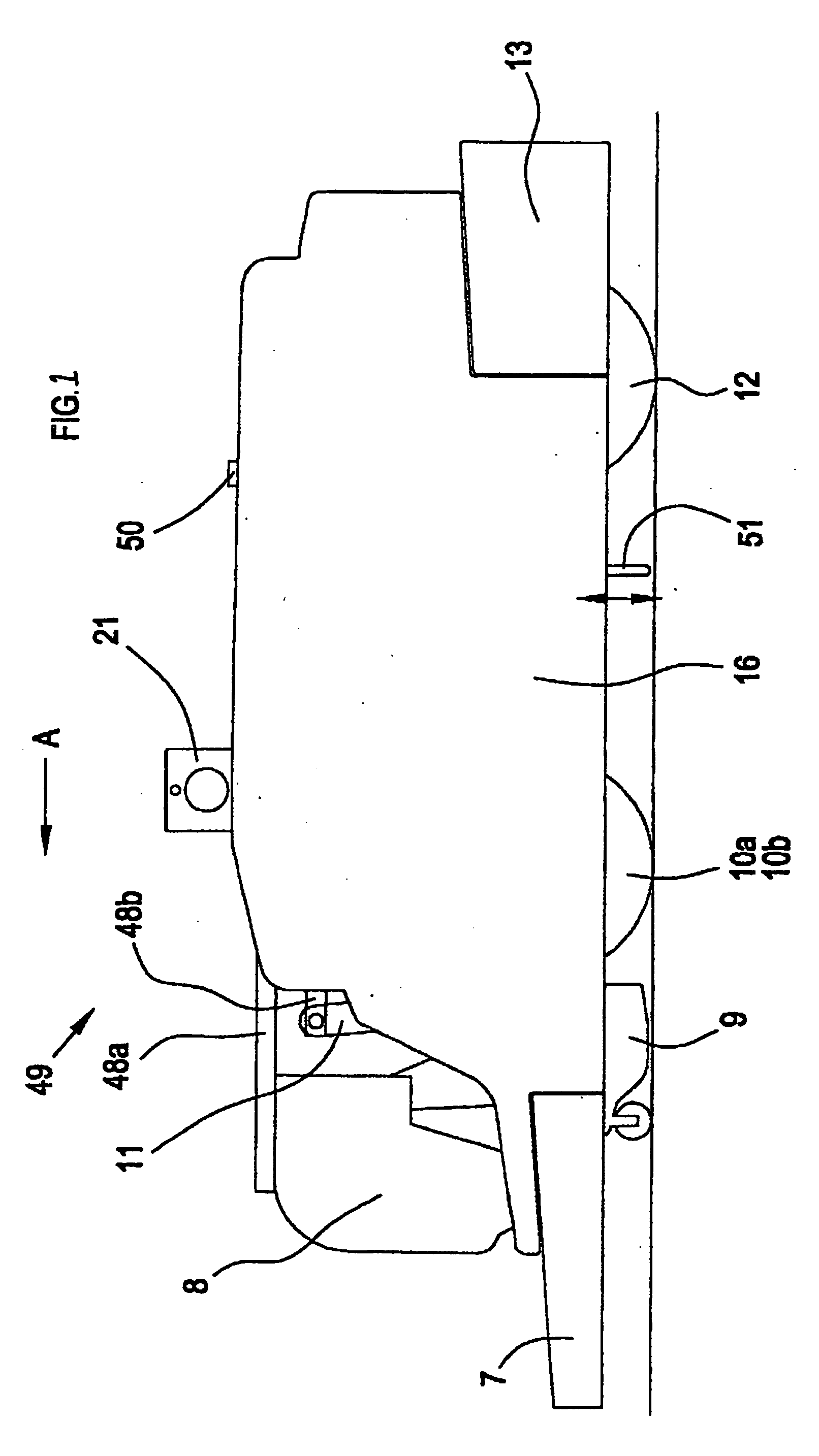

Environmentally responsive autonomous ground maintenance equipment

InactiveUS20050034437A1Minimizing turf damageIncrease stroke lengthVehicle fittingsCrop conditionersPath lengthEngineering

An autonomous ground maintenance vehicle is capable of varying its operating parameters in response to environmental conditions. These operating parameters include maximum permitted acceleration, deceleration, velocity, rate of change of direction and rate of change of steering values. A rain sensor 50 and moisture sensor 51 may be mounted to the vehicle or be positioned on the ground. An inclinometer may also be provided such that the operating parameters may be varied according to the inclination of the ground to be maintained. If guidance means is provided to guide the vehicle along a specified path a variable operating parameter may be a minimum allowable specified path length.

Owner:MCMURTRY

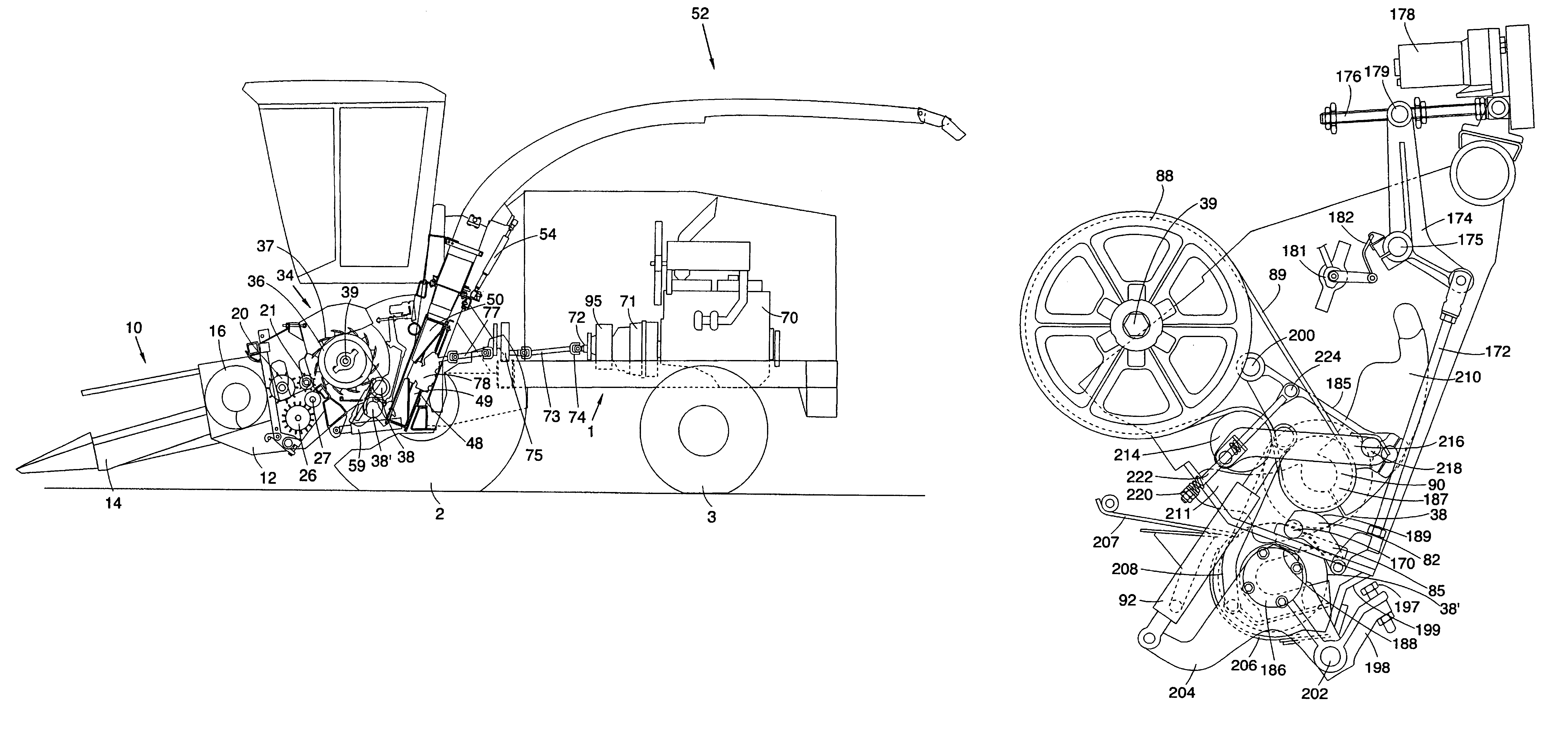

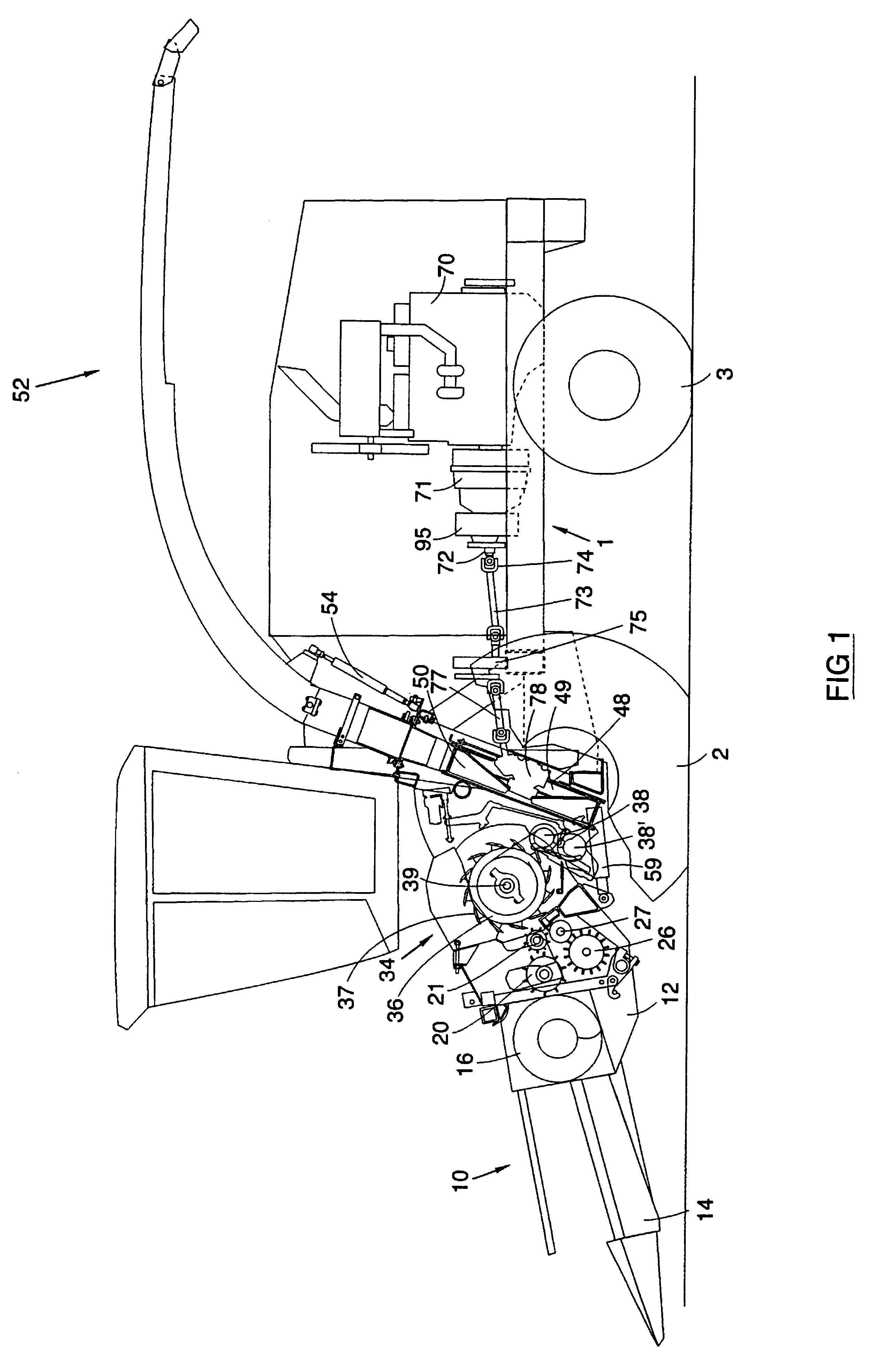

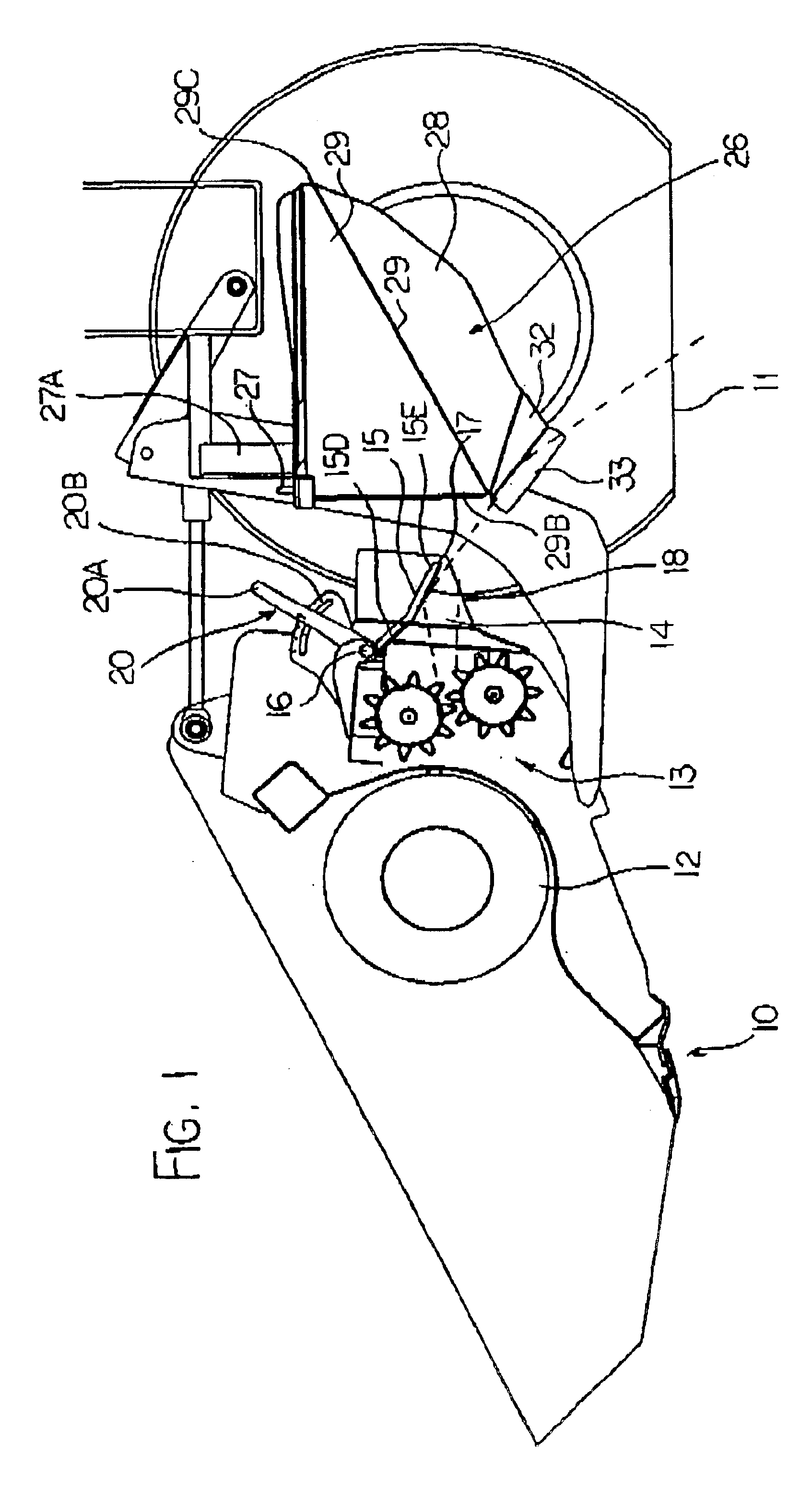

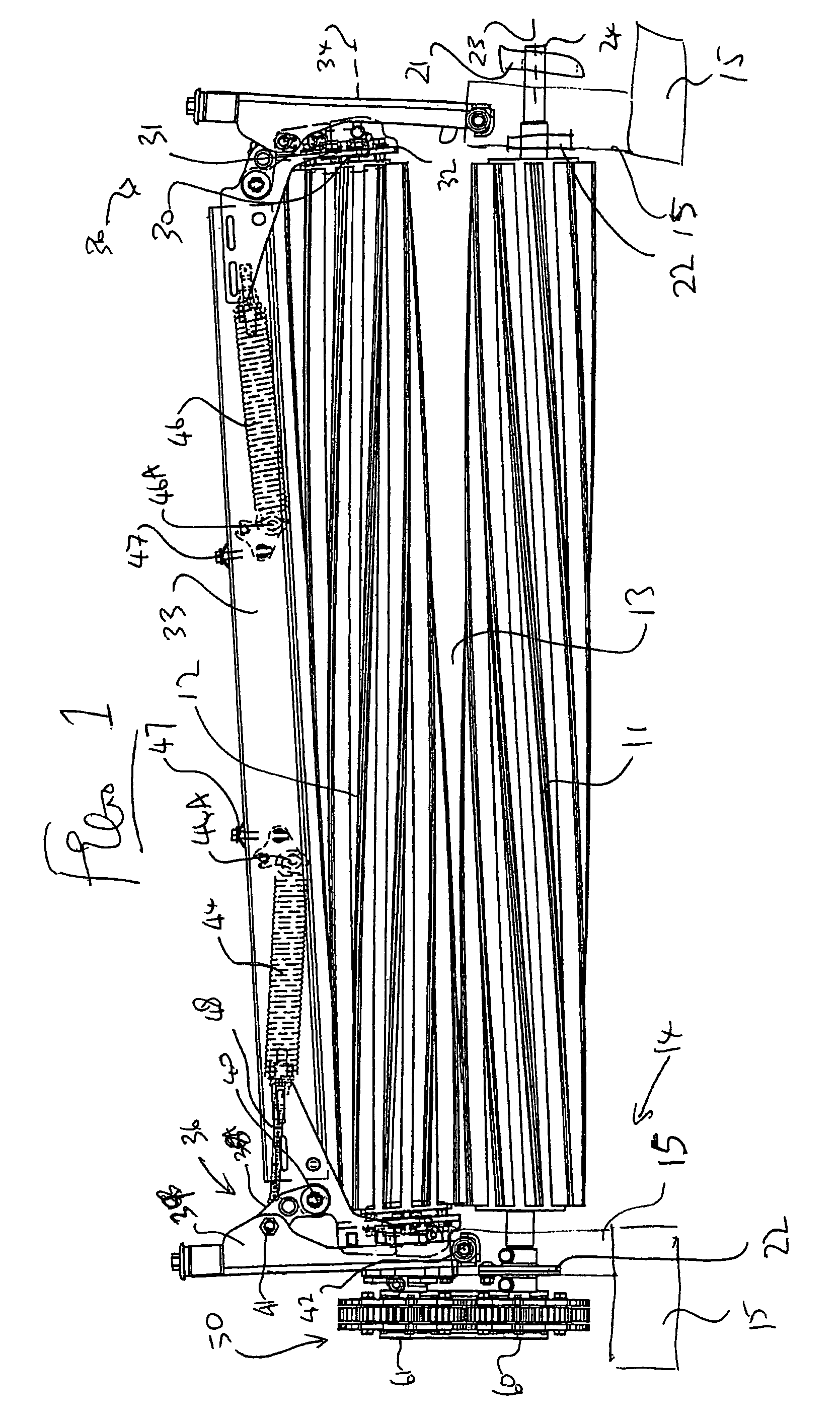

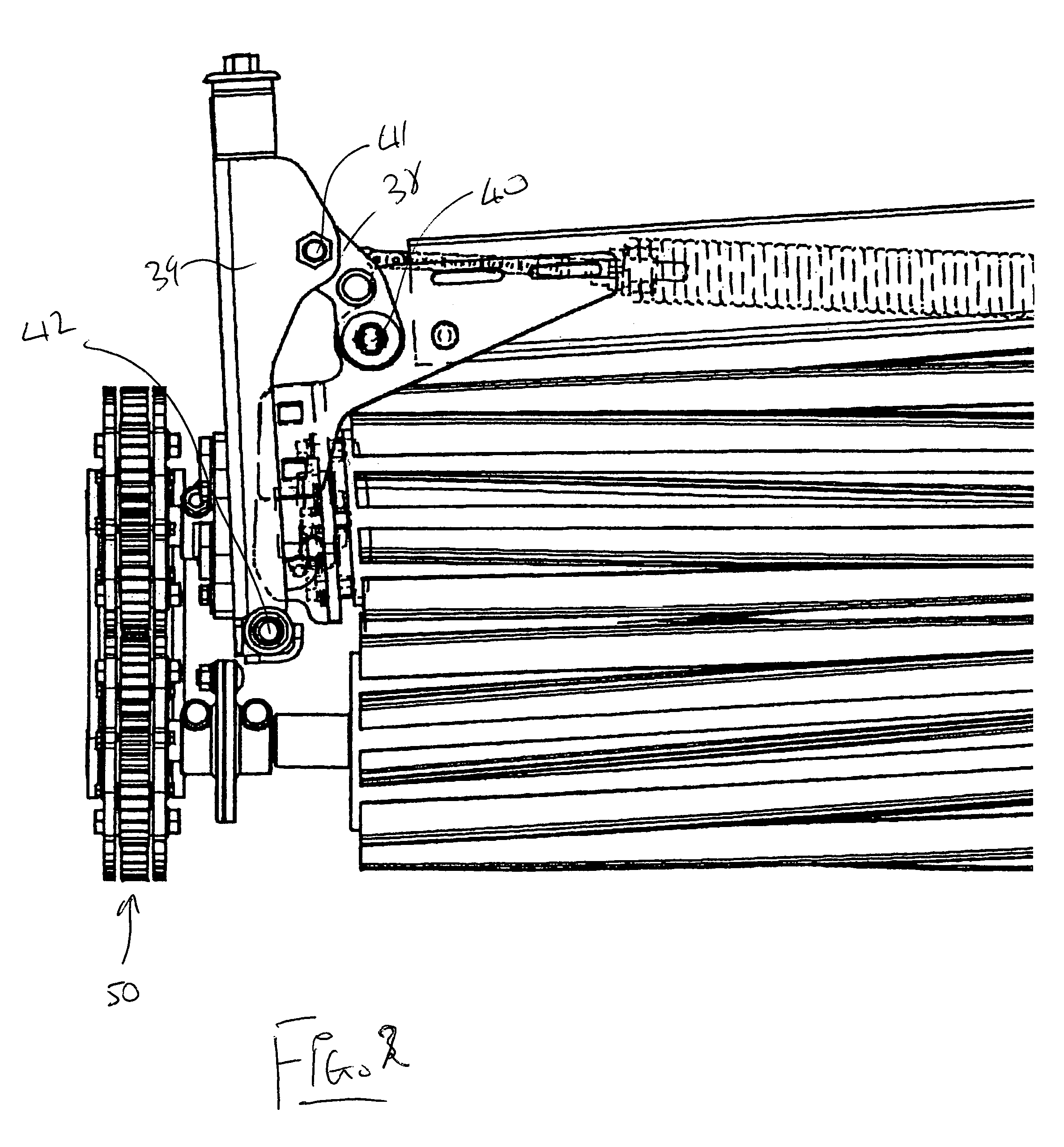

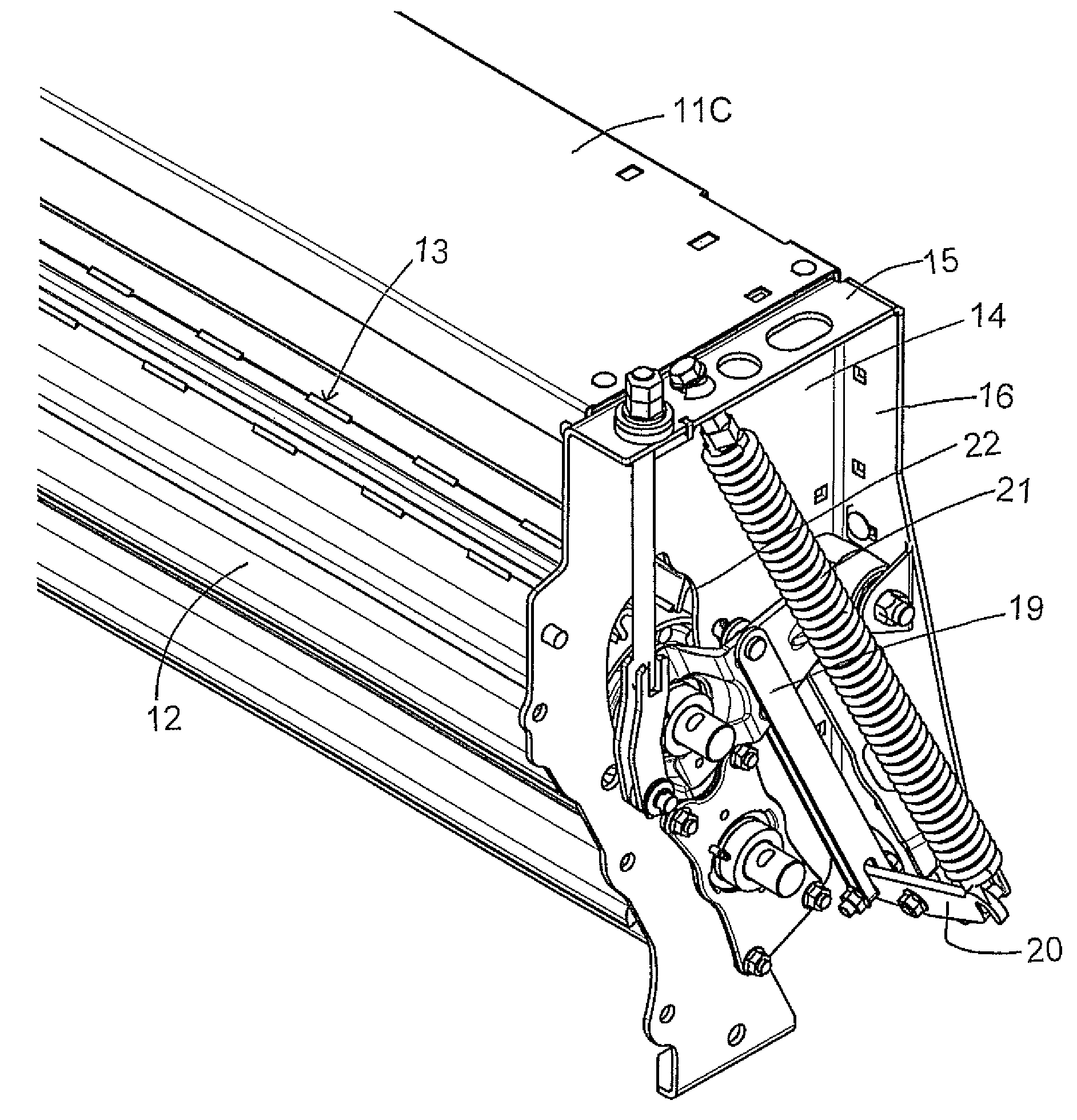

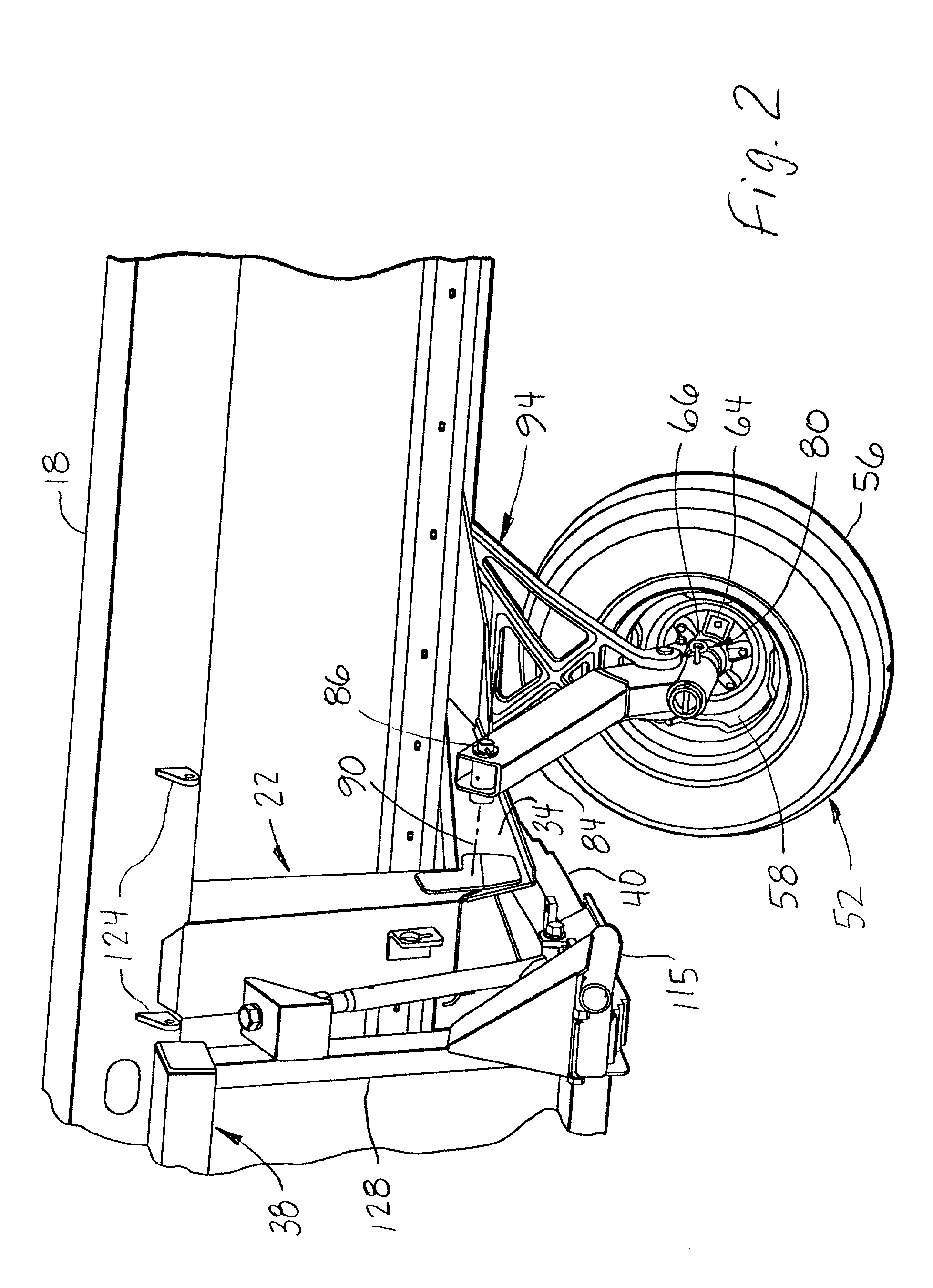

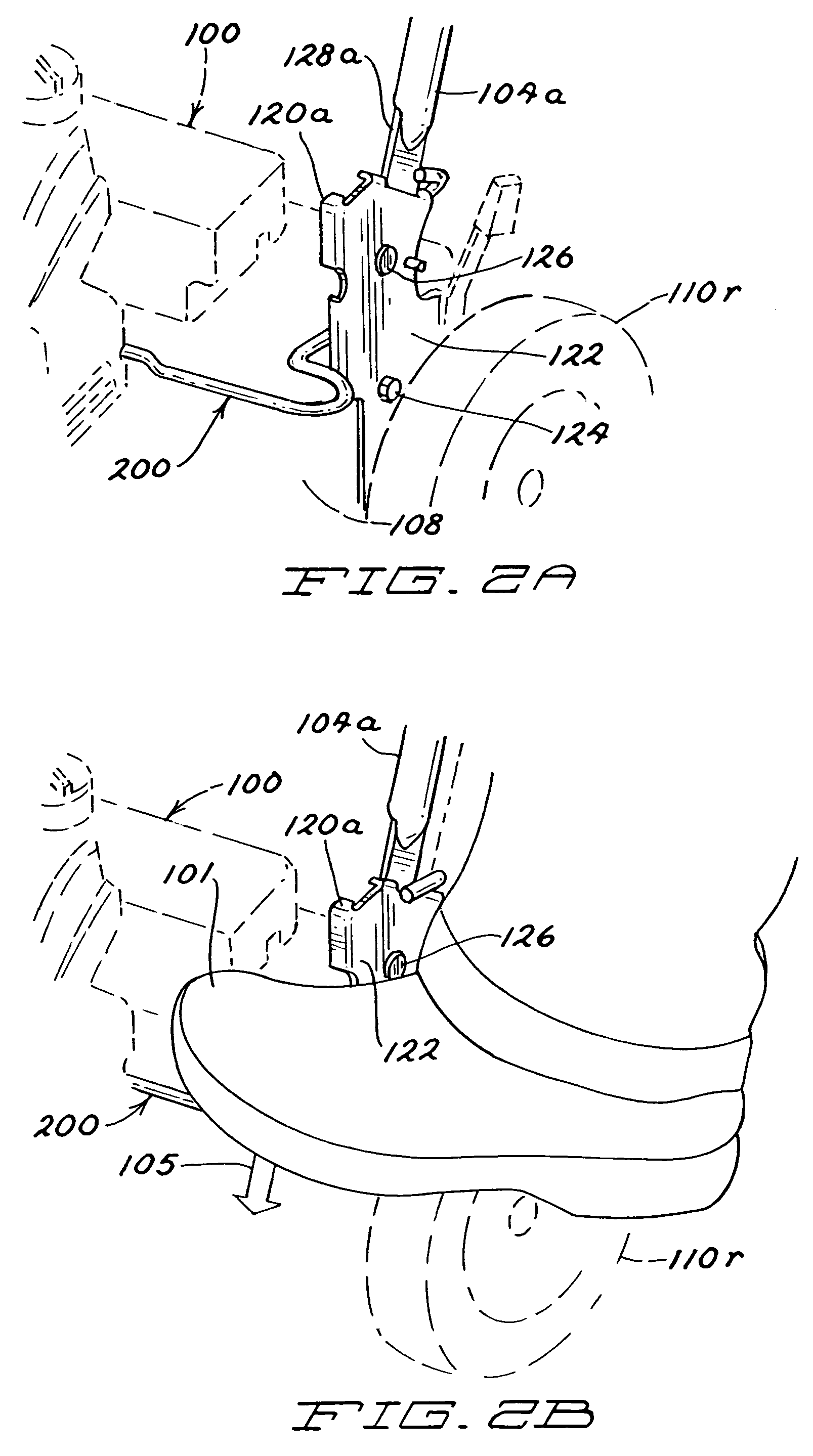

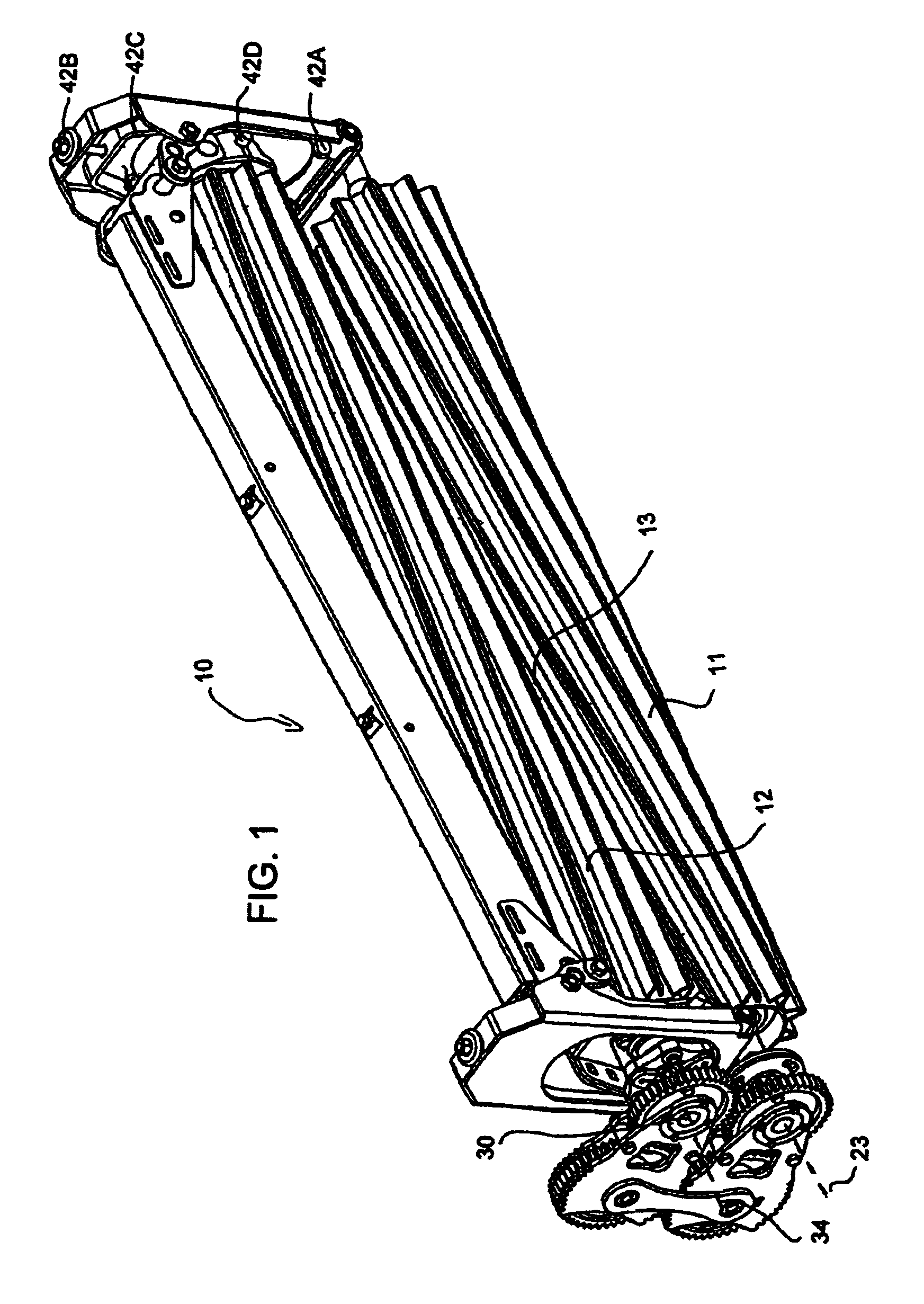

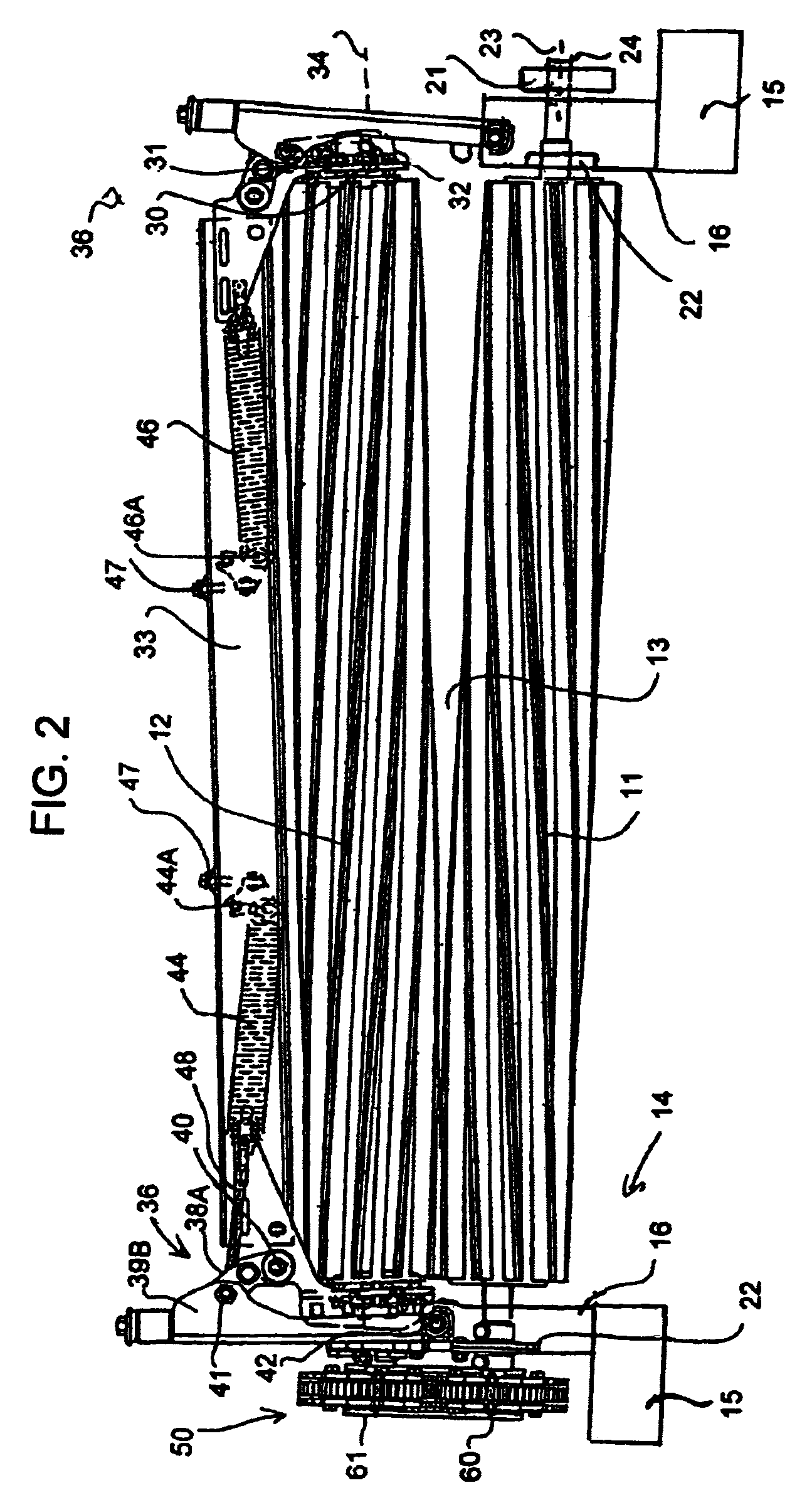

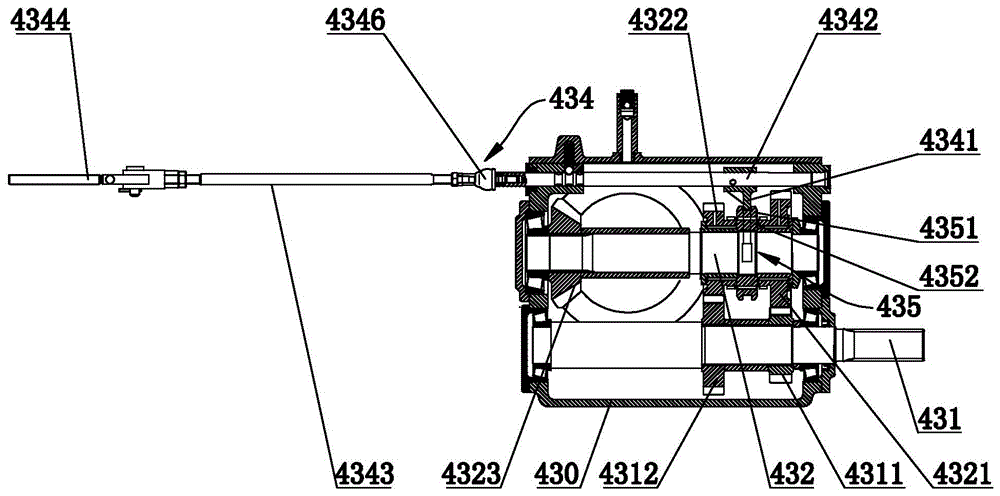

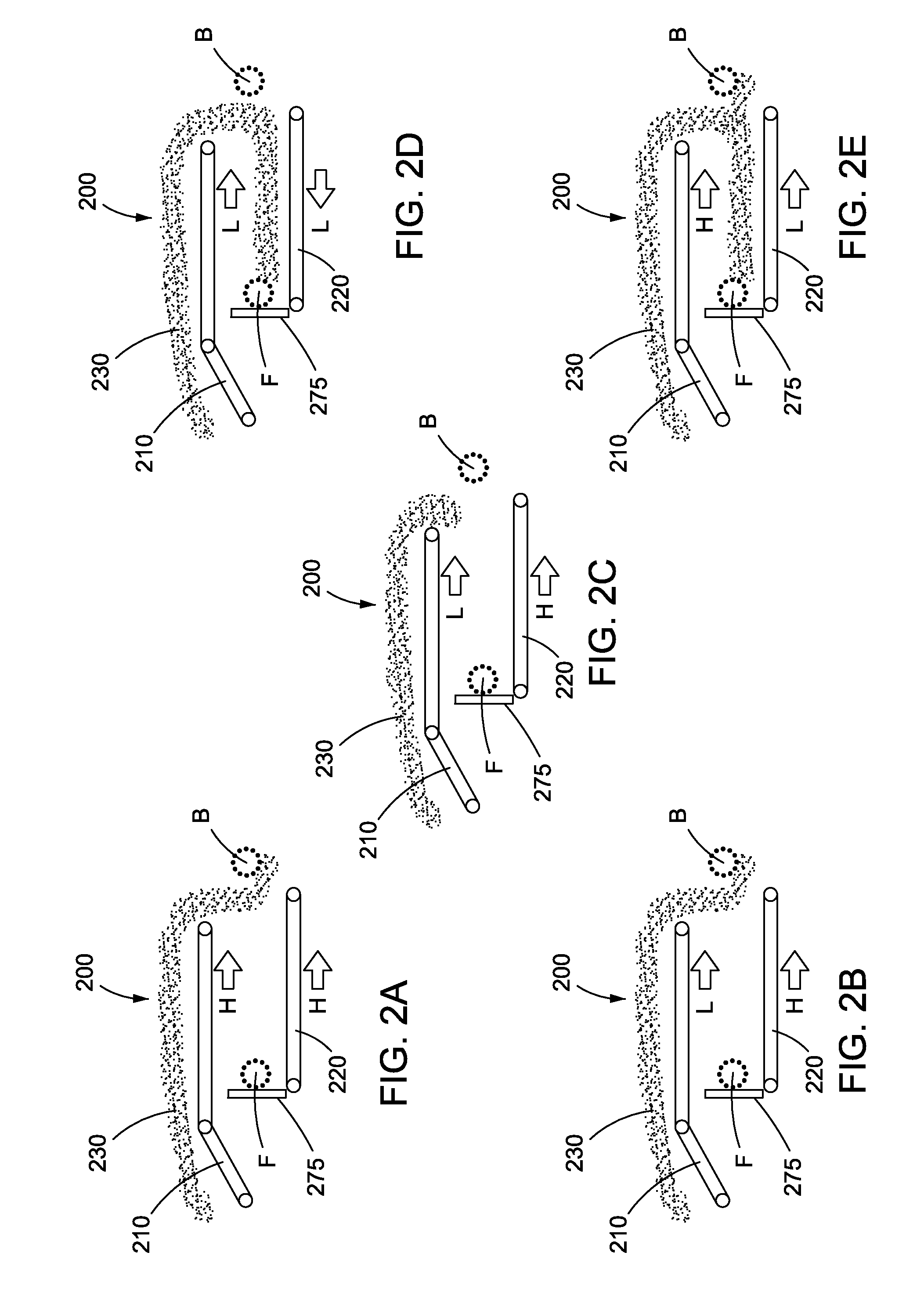

Tensioning of the top roll of a crop conditioner

ActiveUS8056311B1Easy tension adjustmentEasy to controlCrop conditionersHarvestersRadial planeEngineering

A crop conditioner includes a frame mounting a bottom fixed roller and a top liftable roller. The top roller is liftable at each end on a pivot member tensioned by a tension link, a tension spring and a bell crank connected between the tension link and the spring. The bell crank is mounted on the conditioner frame for pivotal movement about a pivot axis which lies transversely to a line parallel to the pivot axis of the second roller so that the bell crank extends from the tension link to the tension spring in a direction outwardly of the radial plane of the roller pivot axis. The spring extends upwardly and forwardly from the bell crank pivot at a rear flange of the frame to an adjustment screw of the spring at a top flange of the frame immediately adjacent an adjustment of a bottom stop of the top roller.

Owner:MACDON INDS

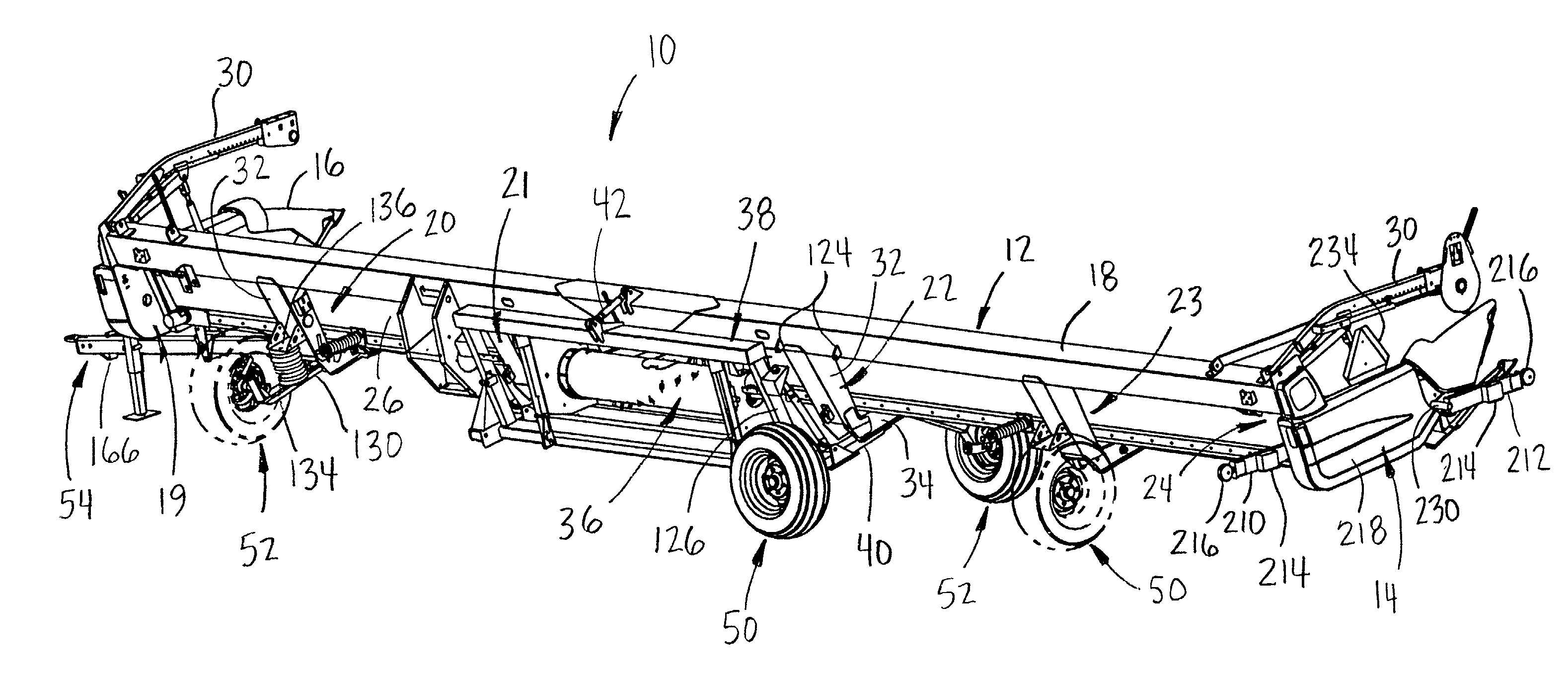

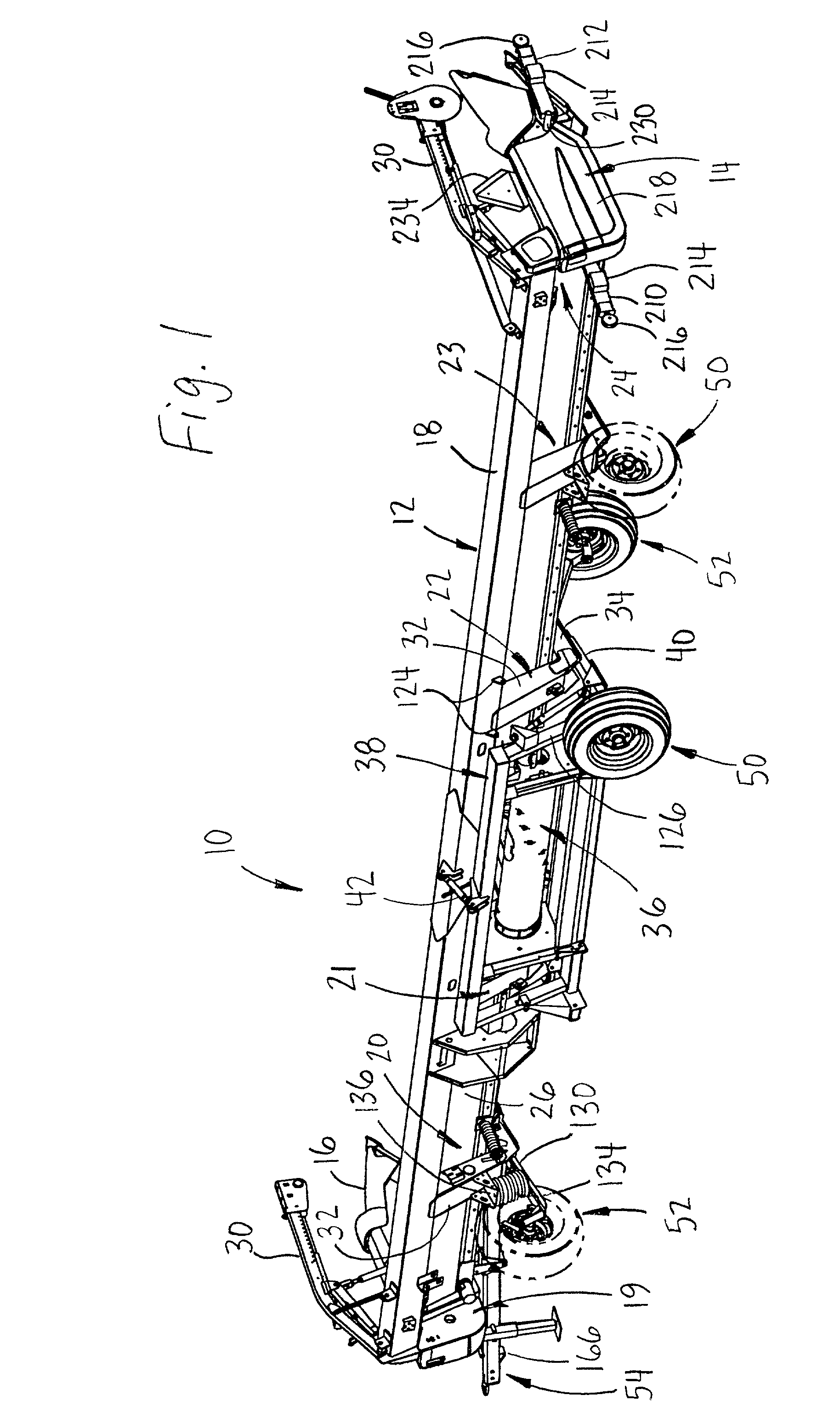

Header for a harvester having an integral transport system

An implement, such as a header for a combine, having an integral transport system with a pair of ground engaging wheels that are moved between transport positions used in transporting the implement and stowed positions on the implement during use of the implement. The wheels may be used as gauge wheels during use to support the ends of the implement. A trailer tongue is retractable and stowed onboard the implement during use, as is a tongue jack. Lights are provided at the end of the implement for visibility during transport. The lights are stowed beneath a cover on the end of the implement to protect the lights from damage during use. All components of the transport system are carried on the implement during use to ensure that they are with the implement when needed to transport the implement. All components are mounted with pins, enabling the implement to be converted between transport and use configurations without the use of hand tools.

Owner:DEERE & CO

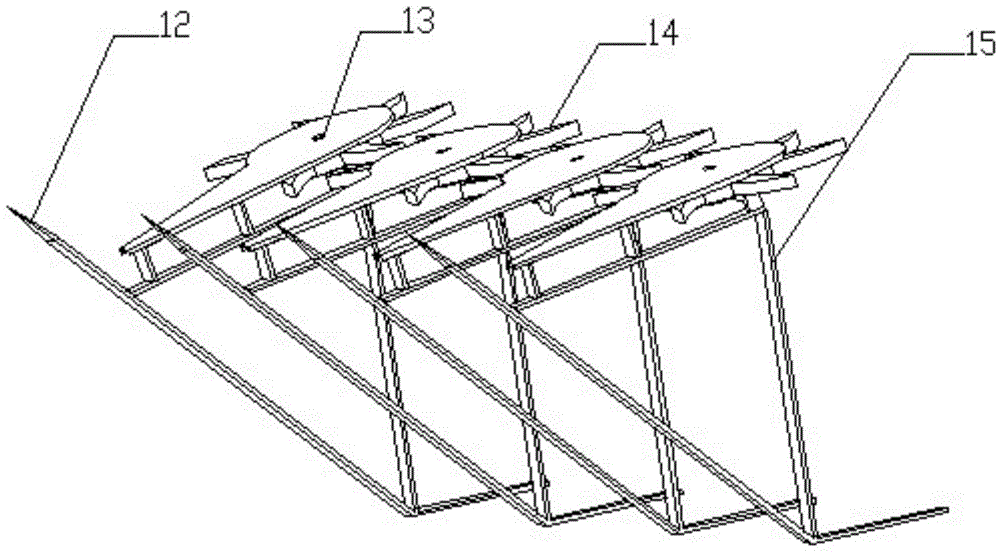

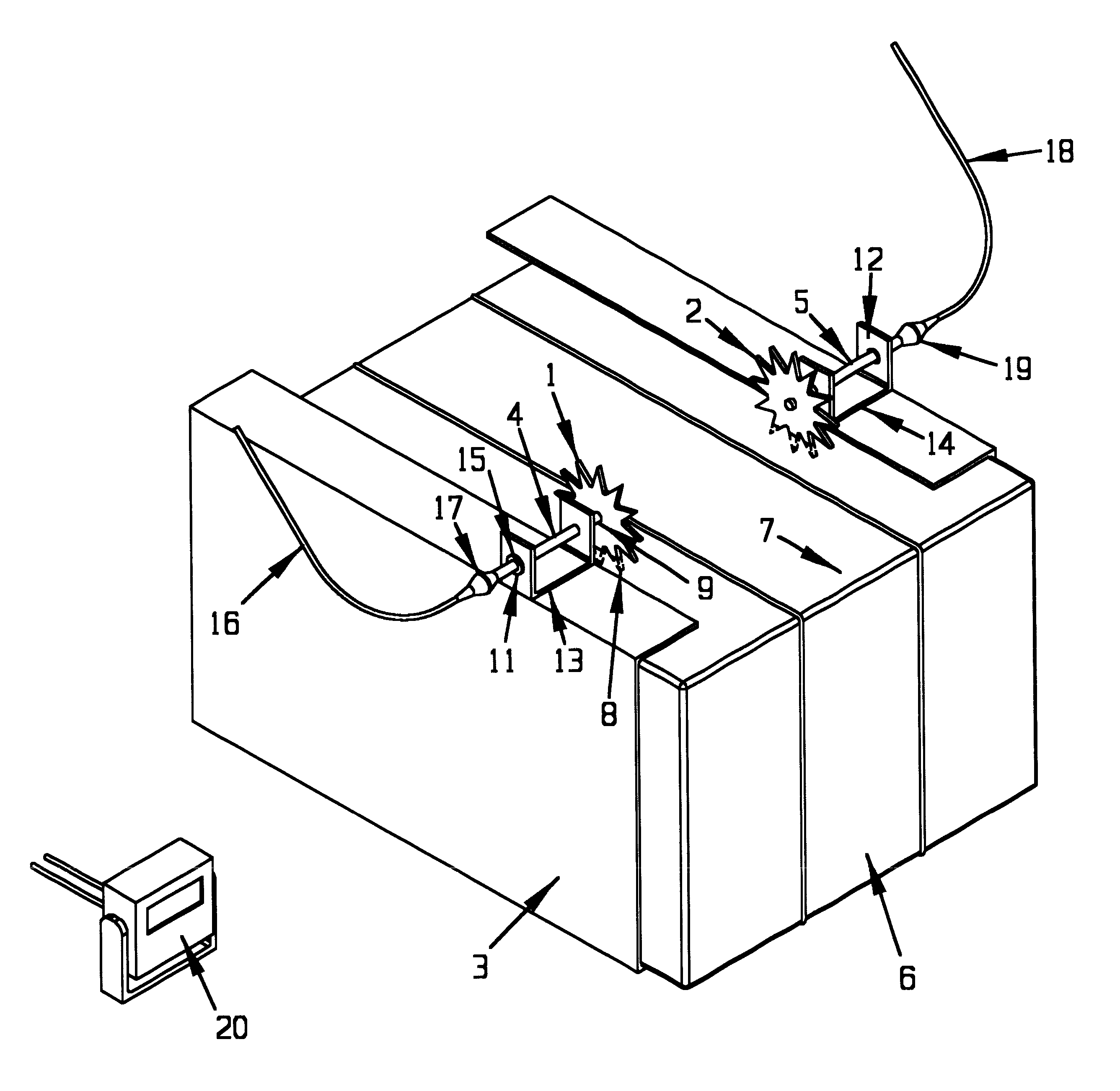

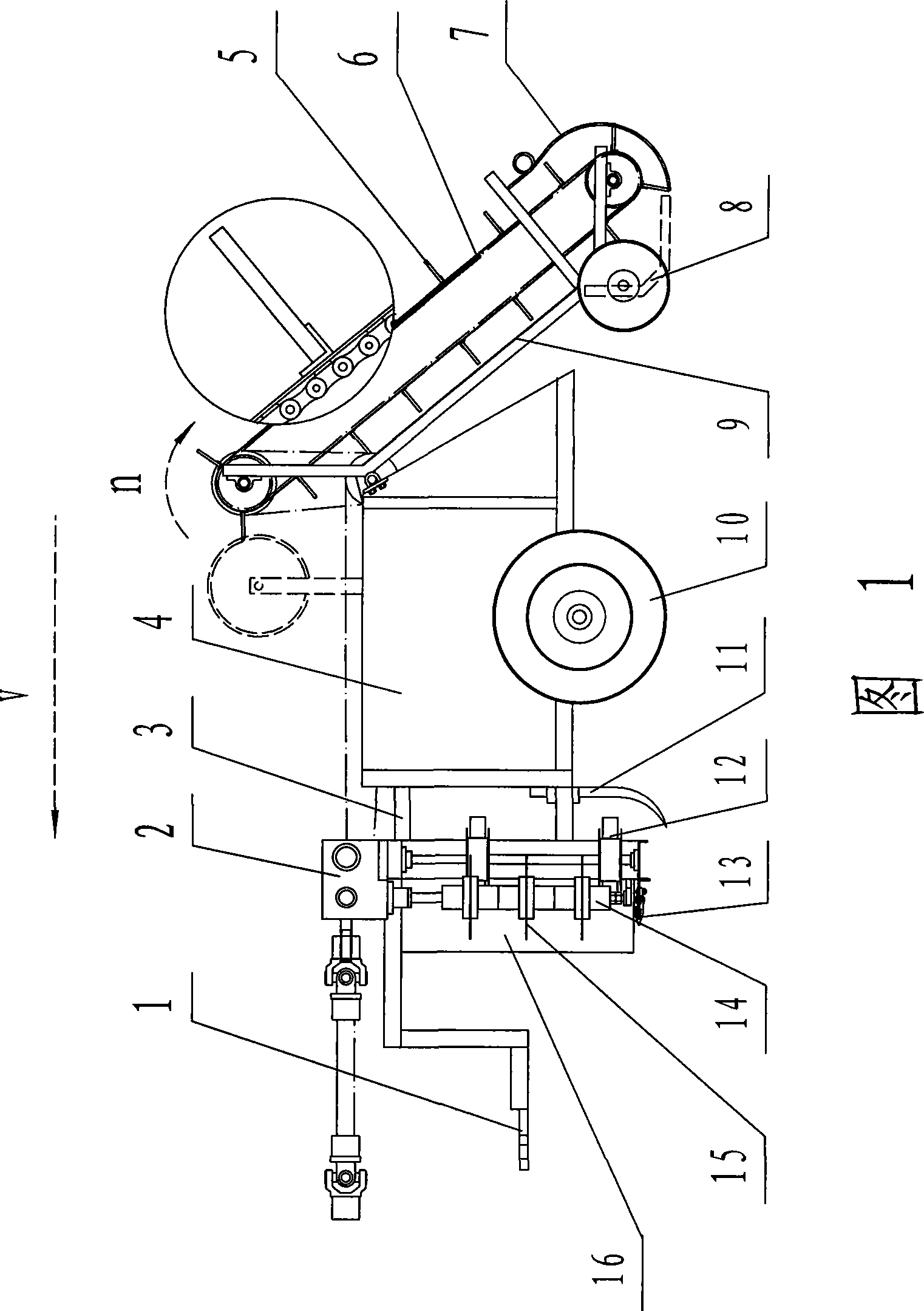

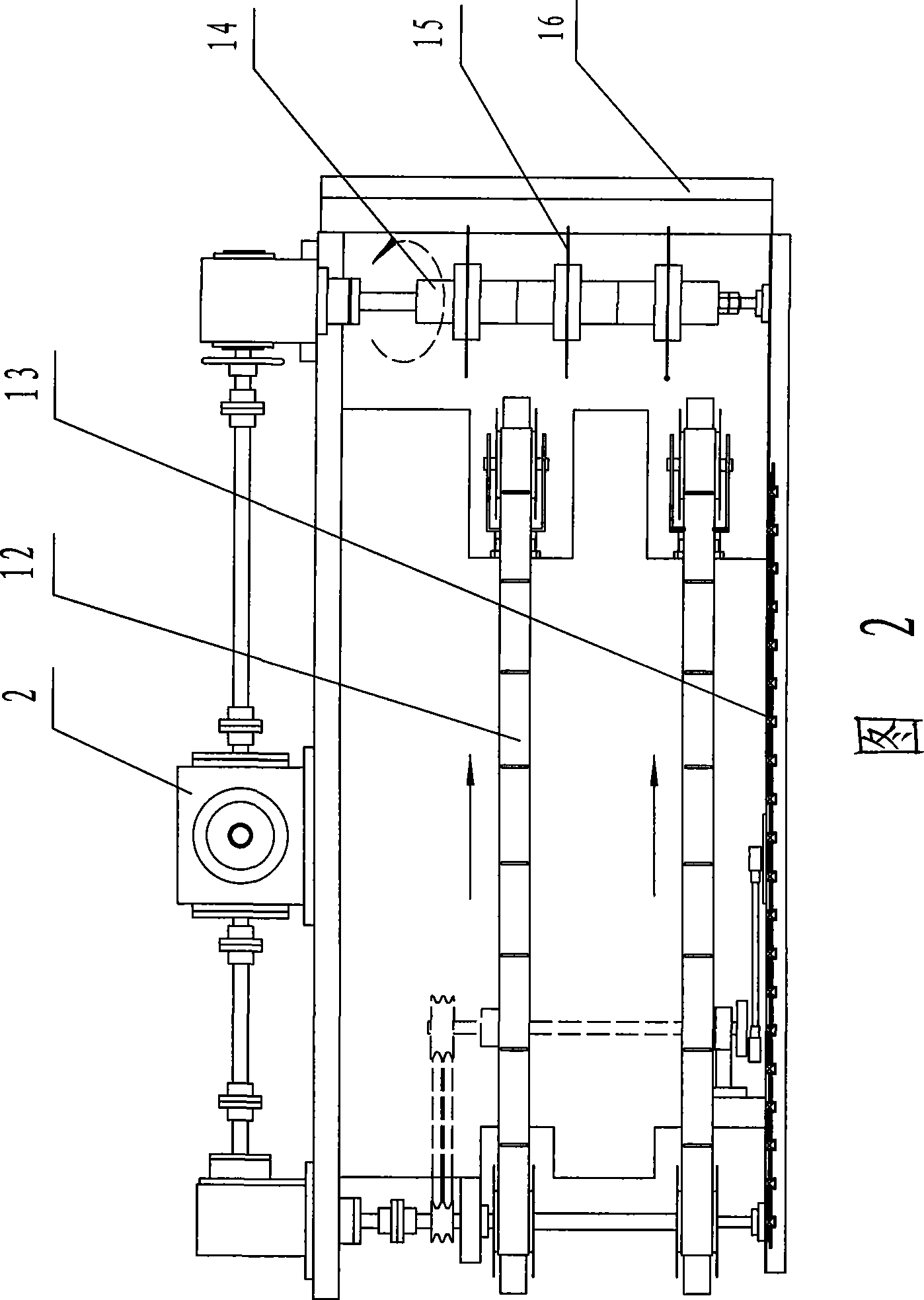

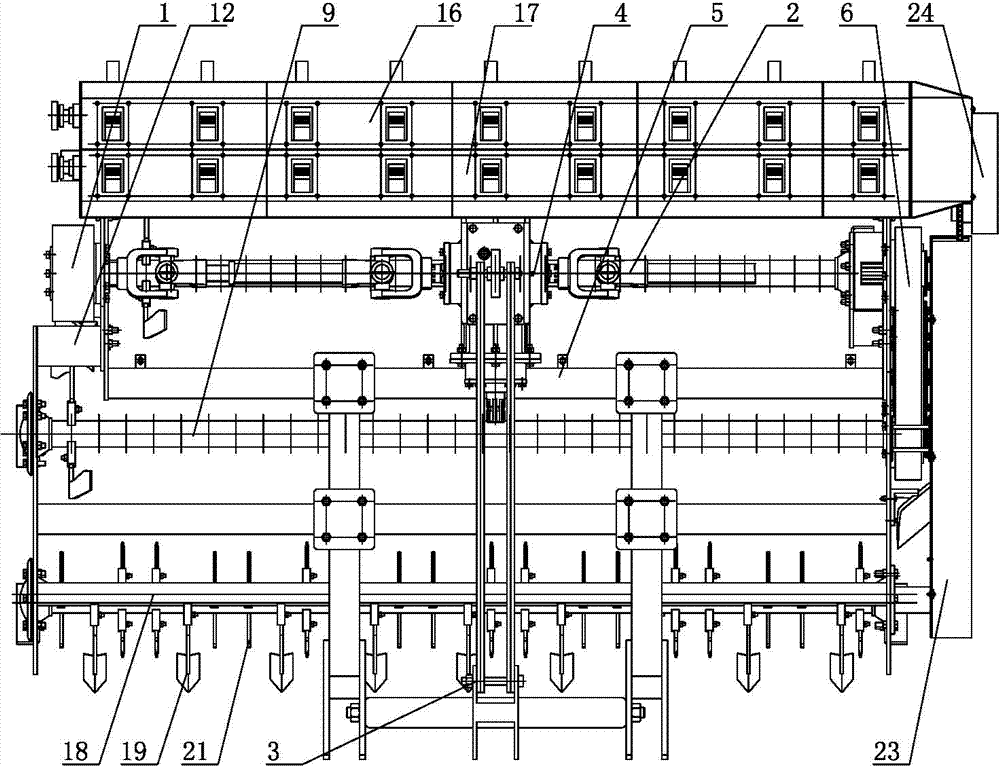

Stalk crushing returning and residual plastic film recovery combined machine

The invention relates to a machine used for the combined operation of chopping crop straws and returning farmland and recycling residual films on the ground surface. The machine comprises a traction unit (1), a transmission system (2), a frame (3), a residual film box (4), a land wheel (10), a scarifier tyne (11), a straw chopping device and a residual film recycling device; the straw chopping device consists of a reciprocating cutterbar (13), a transverse conveying belt (12), a disc type chopper (14), a protection hood (16) and a transmission device; wherein, the residual film recycling device is arranged at the back of the residual film box and consists of a chain harrow (6), an elastic gear (7) for raking the film, a bottom board (9) and a feeler wheel (8); a gear rod (5) is arranged on the chain harrow, and the elastic gear (7) for raking the film is arranged at the back side of the residual film recycling device. The machine can finish the two operations of returning the straws to the farmland and recycling the residual films, has the advantages of high operation speed, clean residual film recycling, small energy consumption and film-rod separation; moreover, the residual films are hard to twist working parts; therefore, the demands of chopping the straws and recycling the residual films can be met.

Owner:SHIHEZI UNIVERSITY

System and method for identifying bales of hay

A system and method for tagging individual bales of hay as they are baled and recording information regarding the moisture, weight, preservative applied. Field position, quality and other information available at the time of baling;, all sequenced to the formation of the bale by a timing and positioning device.

Owner:HARVEST TEC

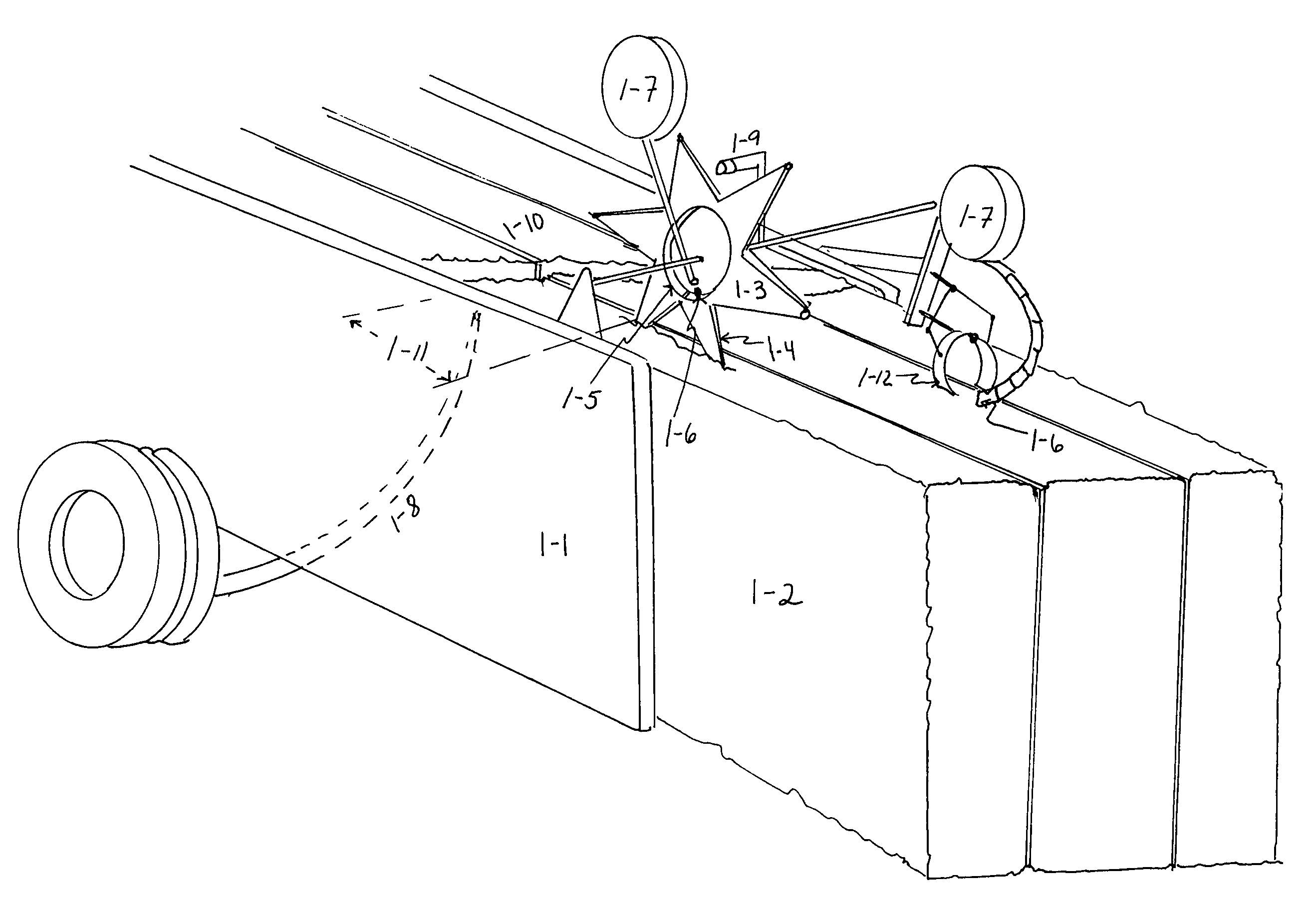

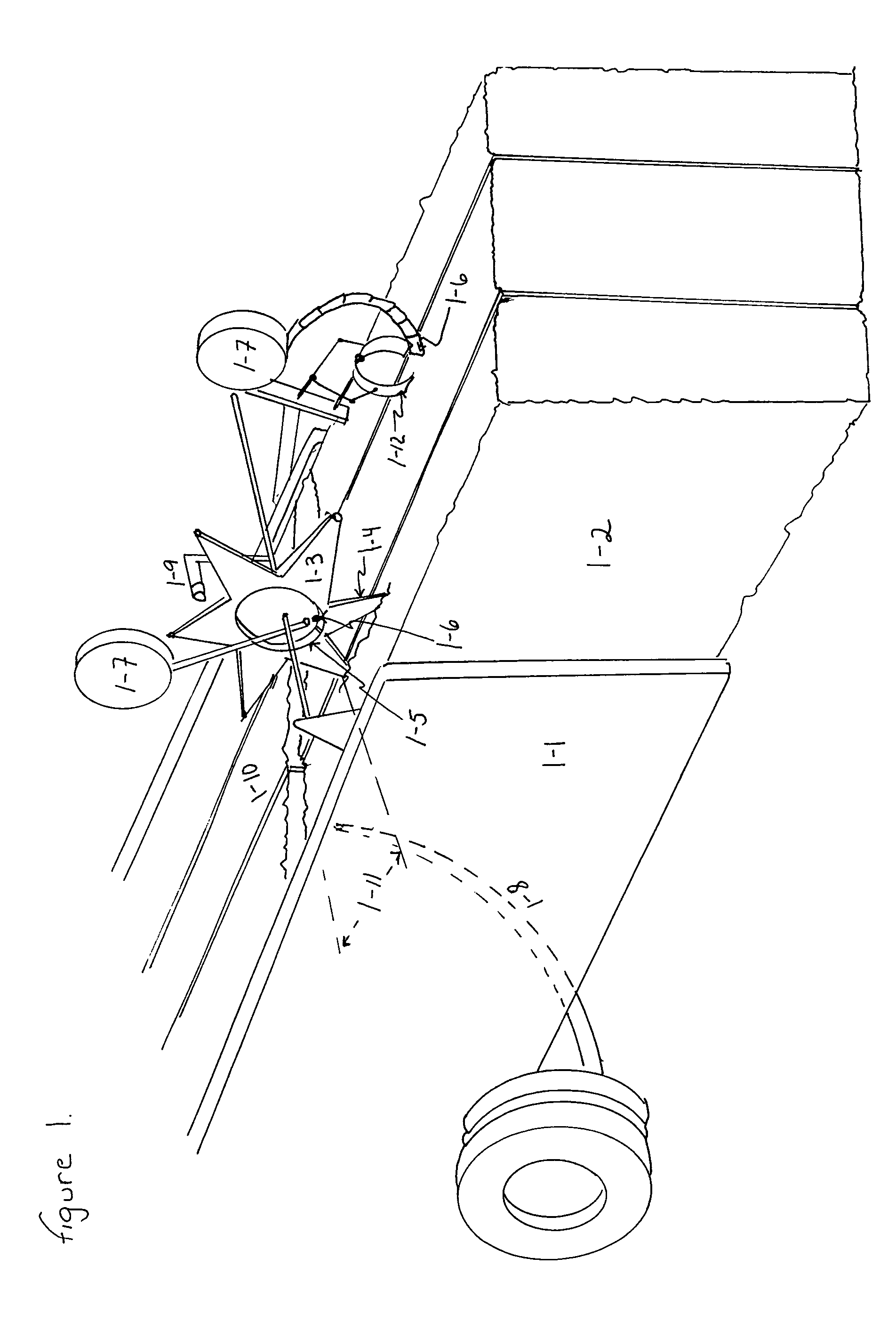

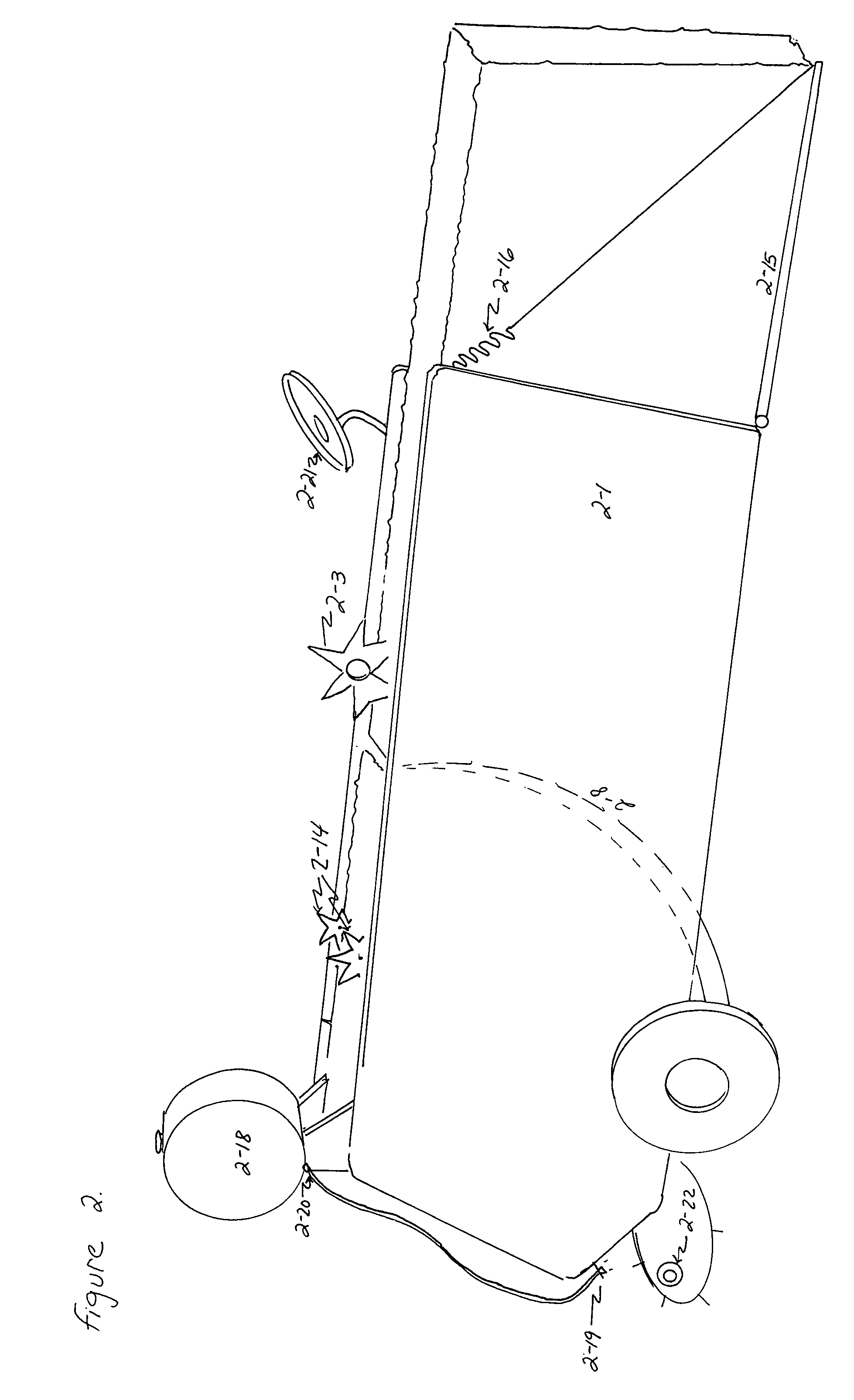

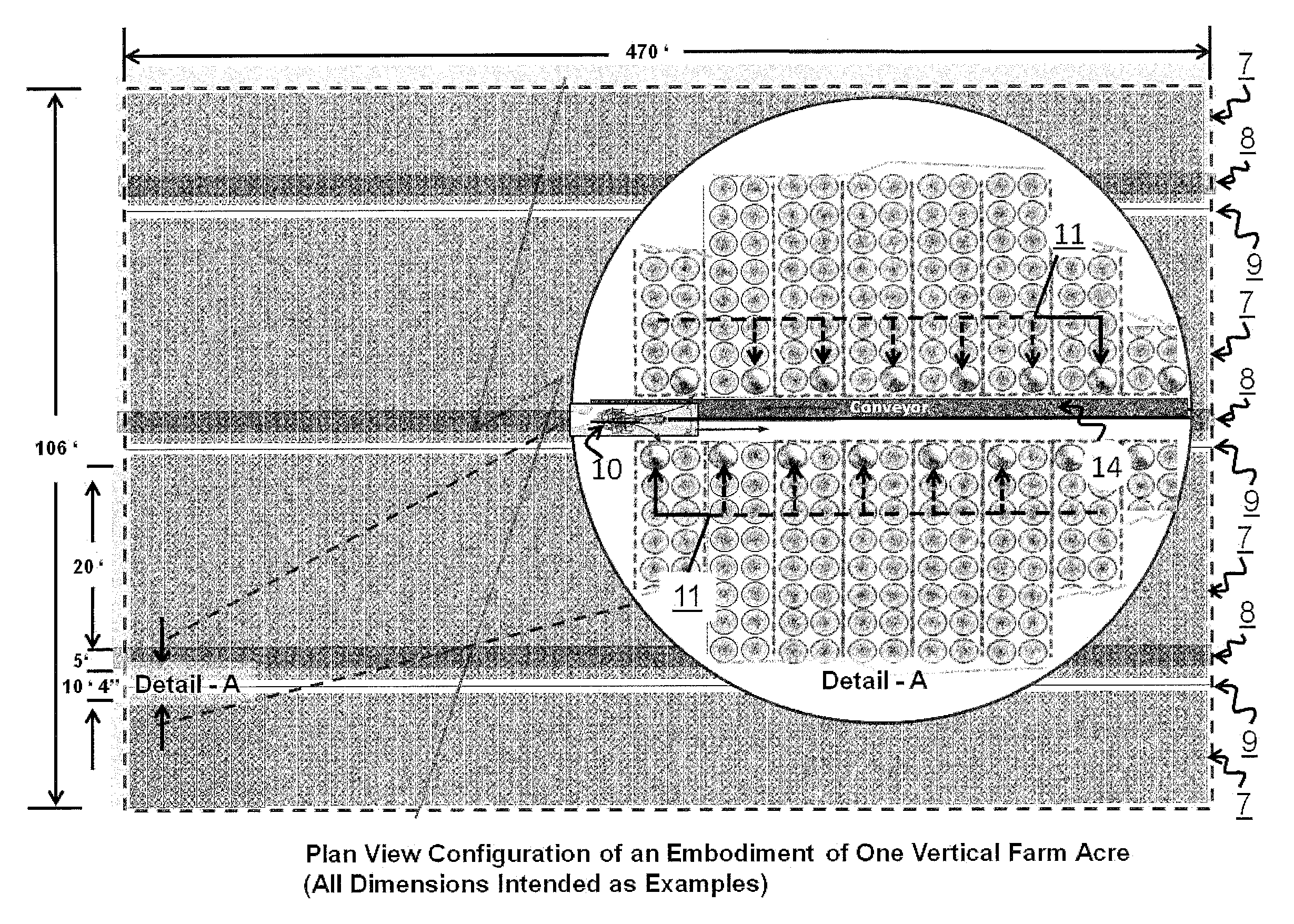

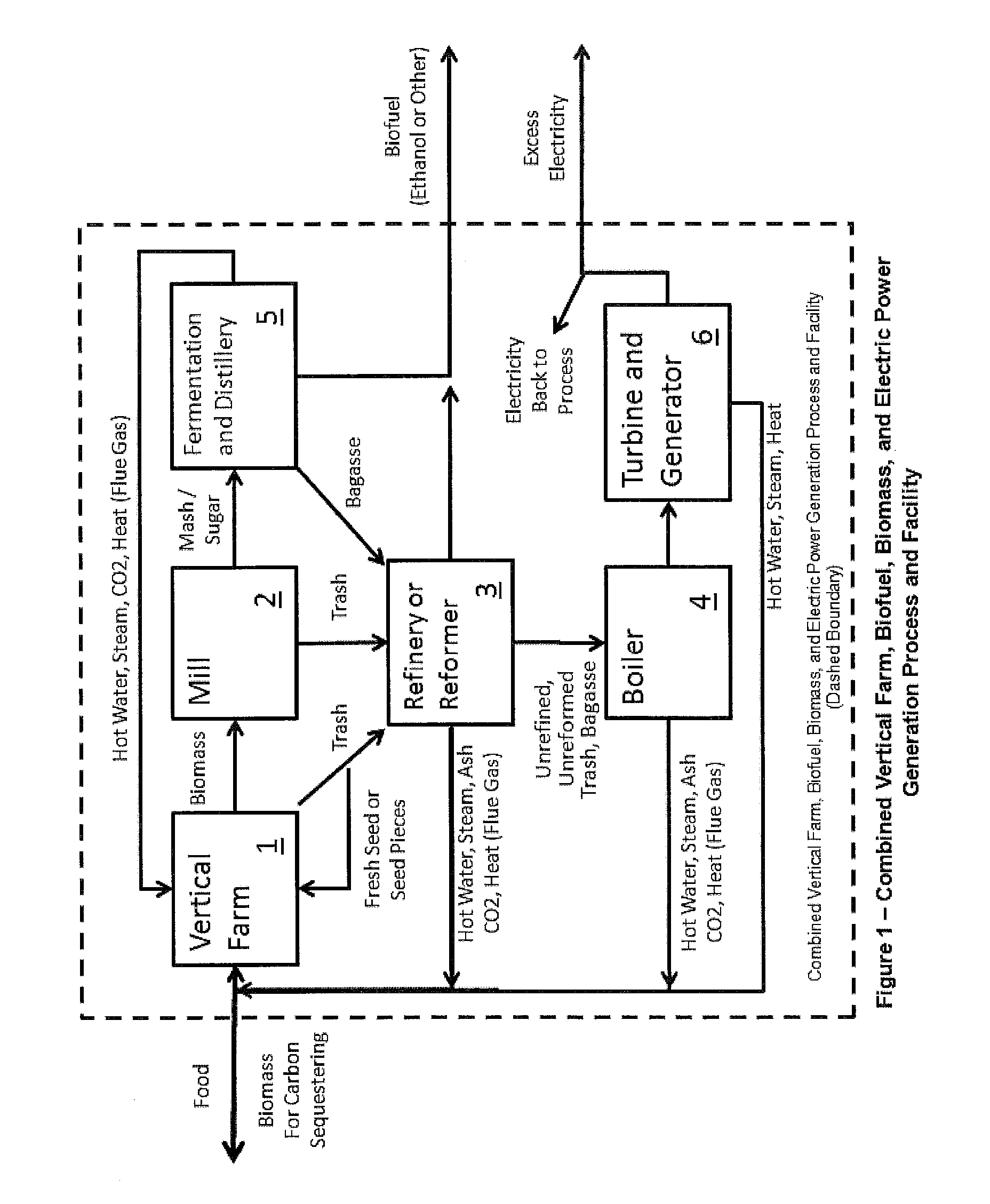

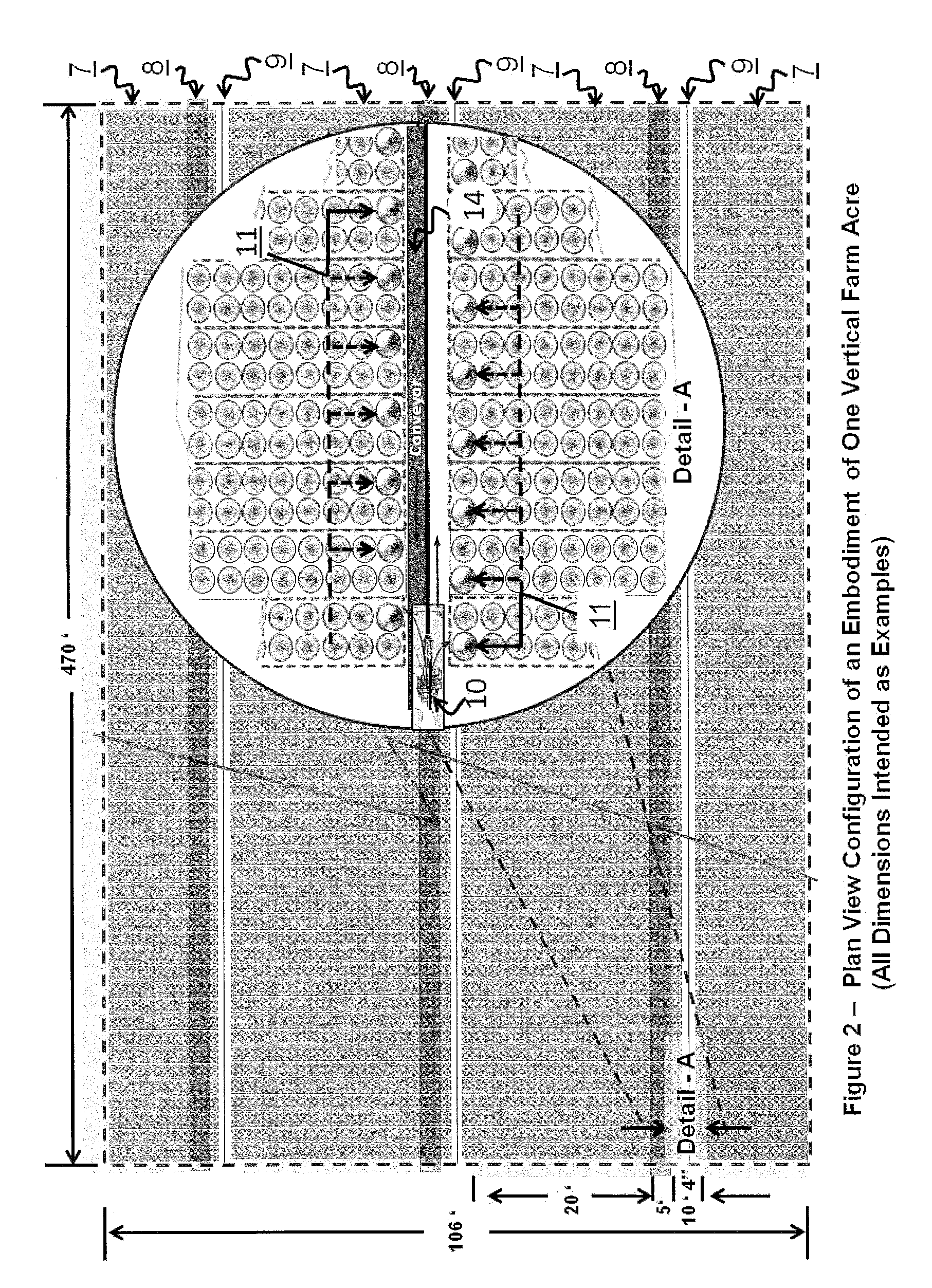

Combined Vertical Farm, Biofuel, Biomass, and Electric Power Generation Process and Facility

InactiveUS20110131876A1Minimal lossEqually distributedRoot feedersCrop conditionersGeneration processBiofuel

Methods and associated apparatus for automatically growing agricultural crops vertically and / or in a continuous fashion throughout each year (Vertical Farm) in combination with contiguous and co-located production of biofuel, food, biomass for the purpose of carbon sequestering (carbon credits), and biomass electric power generation. A process that incorporates vast arrays of continuous-loop conveyors, towering upon vertical framework, which allow potted plants to be transported throughout all stages of maturity in a manner which substantially multiplies yield per acre, allows production to proceed in both natural and artificial light, allows production and harvesting to be automated, and allows production to proceed in conditions which are highly favorable to plants but unfavorable to humans. The entire apparatus can be constructed of lightweight, cost-effective materials which afford mass-production and mass-array into vast automatic growing operations.

Owner:PETTIBONE GLEN JAMES +1

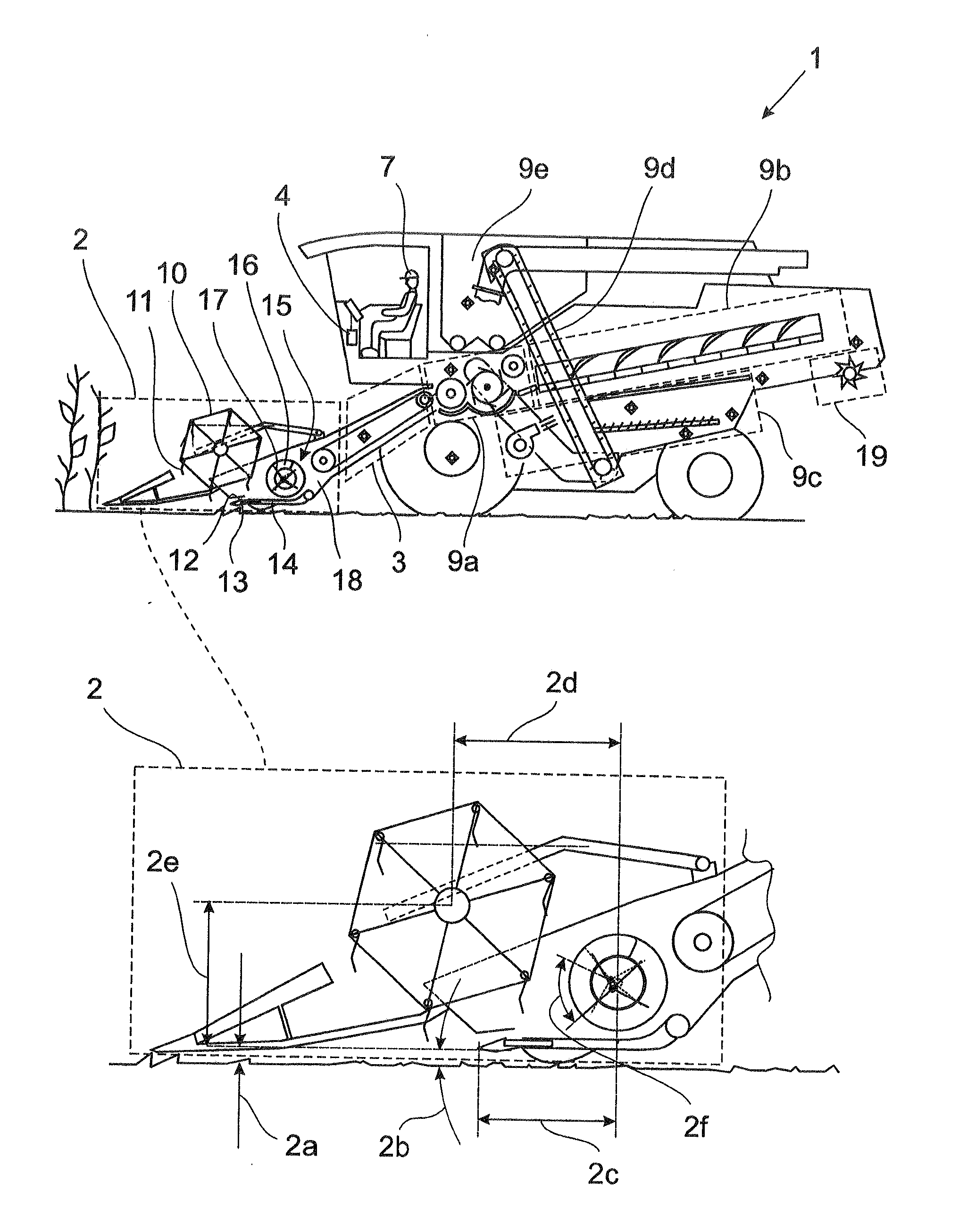

Agricultural harvesting machine

An agricultural harvesting machine has a header designed as a front attachment for cutting and picking up crop and a driver assistance system for controlling the header. The driver assistance system has a memory for storing data and a computing unit for processing the data stored in the memory. The header together with the driver assistance system forms an automated header, in that a plurality of selectable harvesting-process strategies is stored in the memory and in order to implement a selected harvesting-process strategy or the selected harvesting-process strategies, the computing device autonomously determines at least one machine parameter, a header parameter and specifies this to the header.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

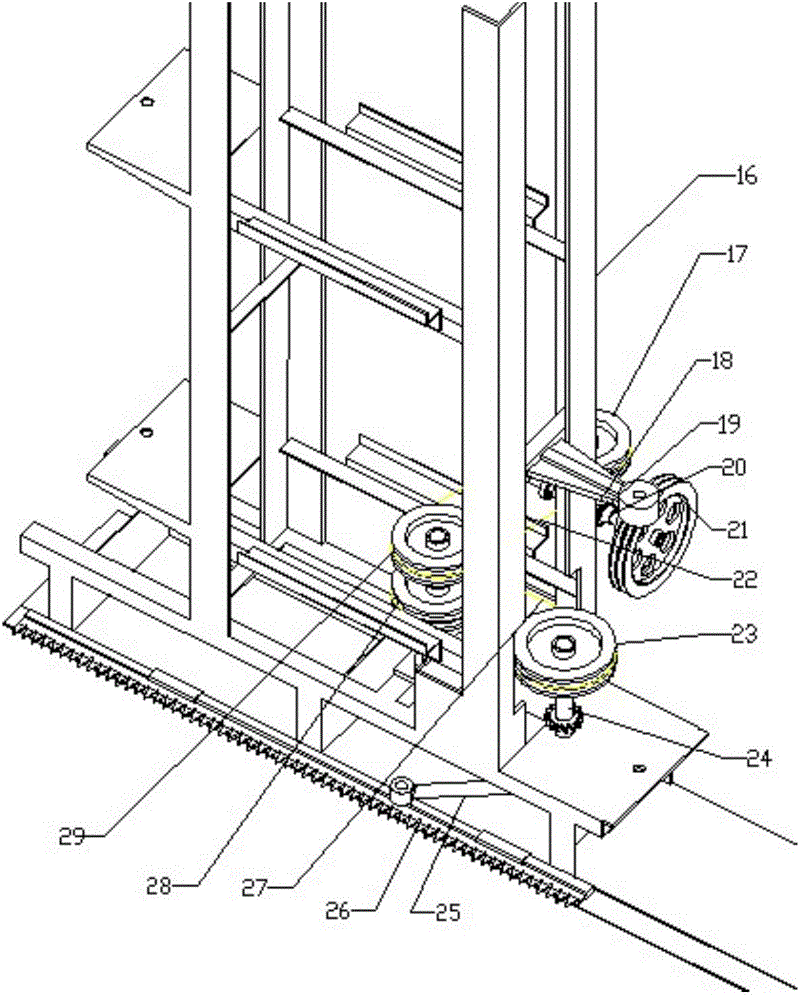

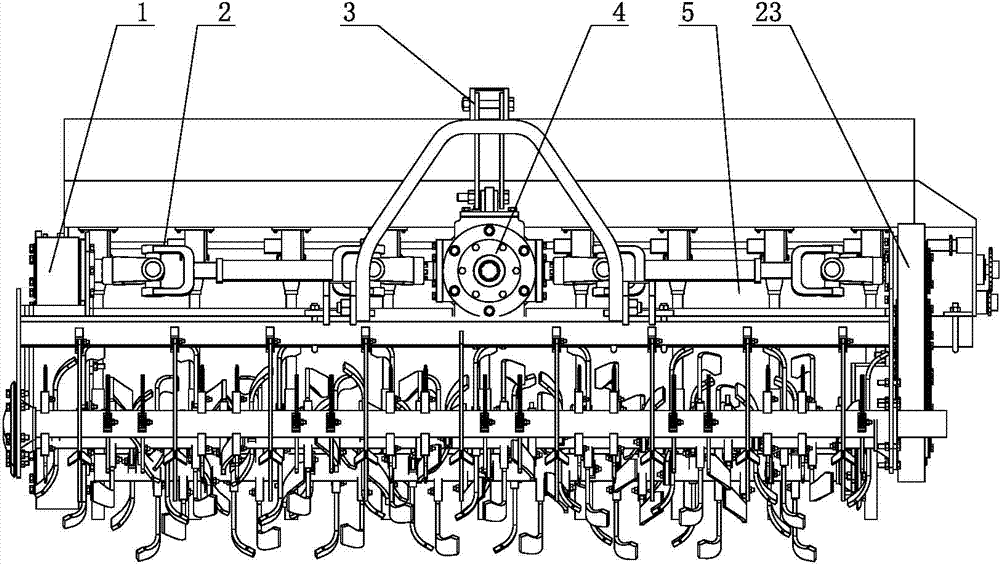

Device and method for total straw returning, layered plowing, fertilizing, sowing and pressing compound operation

ActiveCN103609217AImprove work efficiencyThe compound operation method is simple and reasonableSpadesCrop conditionersAgricultural engineeringAgriculture

The invention discloses a device and a method for total straw returning, layered plowing, fertilizing, sowing and pressing compound operation. The device comprises a first shaft-side transmission case and a second shaft-side transmission case. The first shaft-side transmission case and the second shaft-side transmission case are respectively arranged on the left side and the right side of a framework, a left side plate and a right side plate are respectively fixed to the two sides of the framework, a first rotary blade shaft and a second rotary blade shaft are arranged between the left side plate and the right side plate, and the first rotary blade shaft is positioned above the front of the second rotary blade shaft; the lowermost portion of the first shaft-side transmission case is higher than the lowermost portion of the second shaft-side transmission case; plowing areas of first-shaft rotary blades simultaneously cover plowing areas of second-shaft rotary blades and an area corresponding to the second shaft-side transmission case; fertilizing cases and sowing cases are arranged at the rear of the second rotary blade shaft, and a straw cutting device is further arranged at the fronts of the first-shaft rotary blades. The method includes steps for one-step straw cutting, rotary plowing, fertilizing, sowing and pressing compound operation. The device and the method have the advantages that total straw can be returned to fields, the plowing depth can be increased, and the plowing efficiency can be improved.

Owner:YANGZHOU UNIV

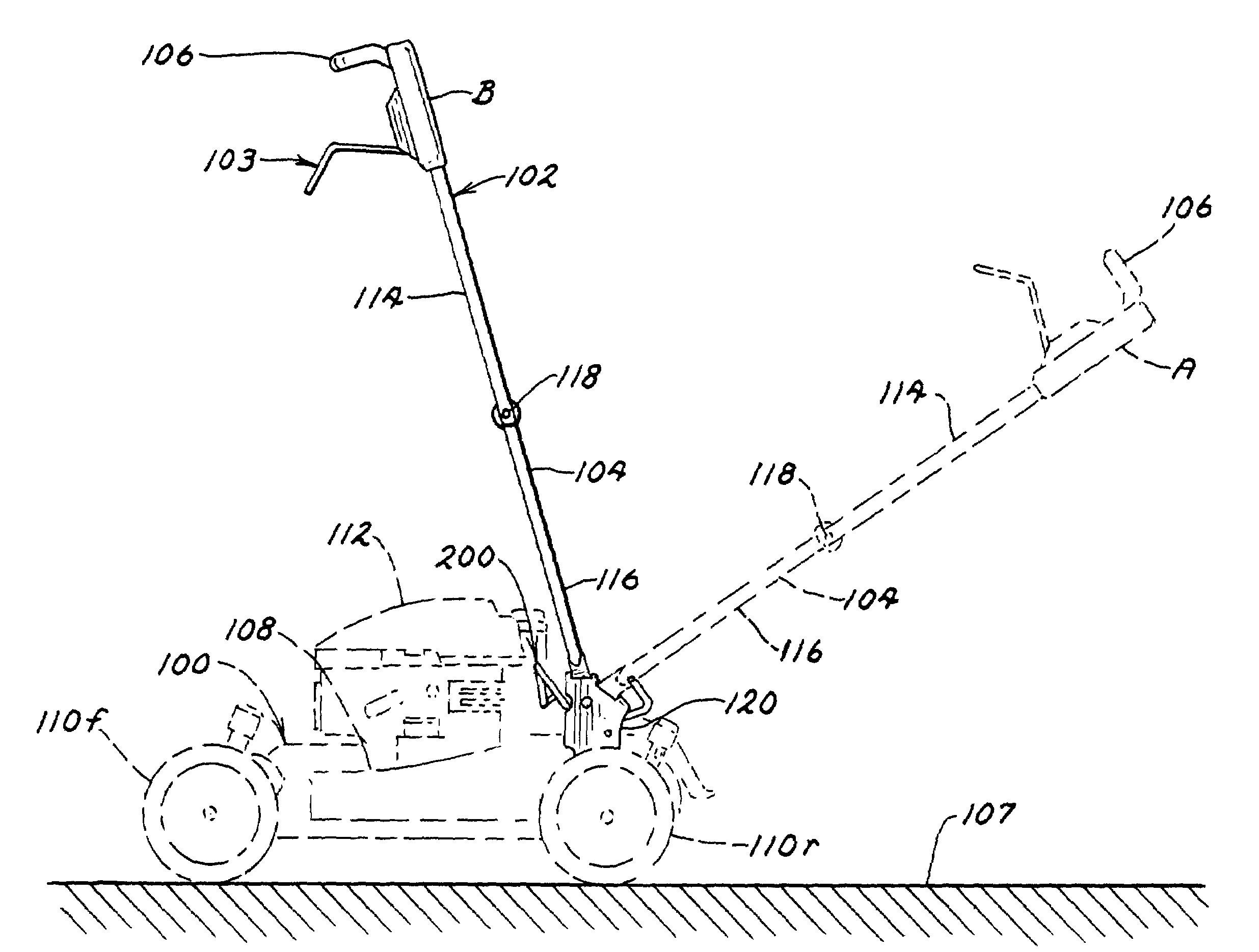

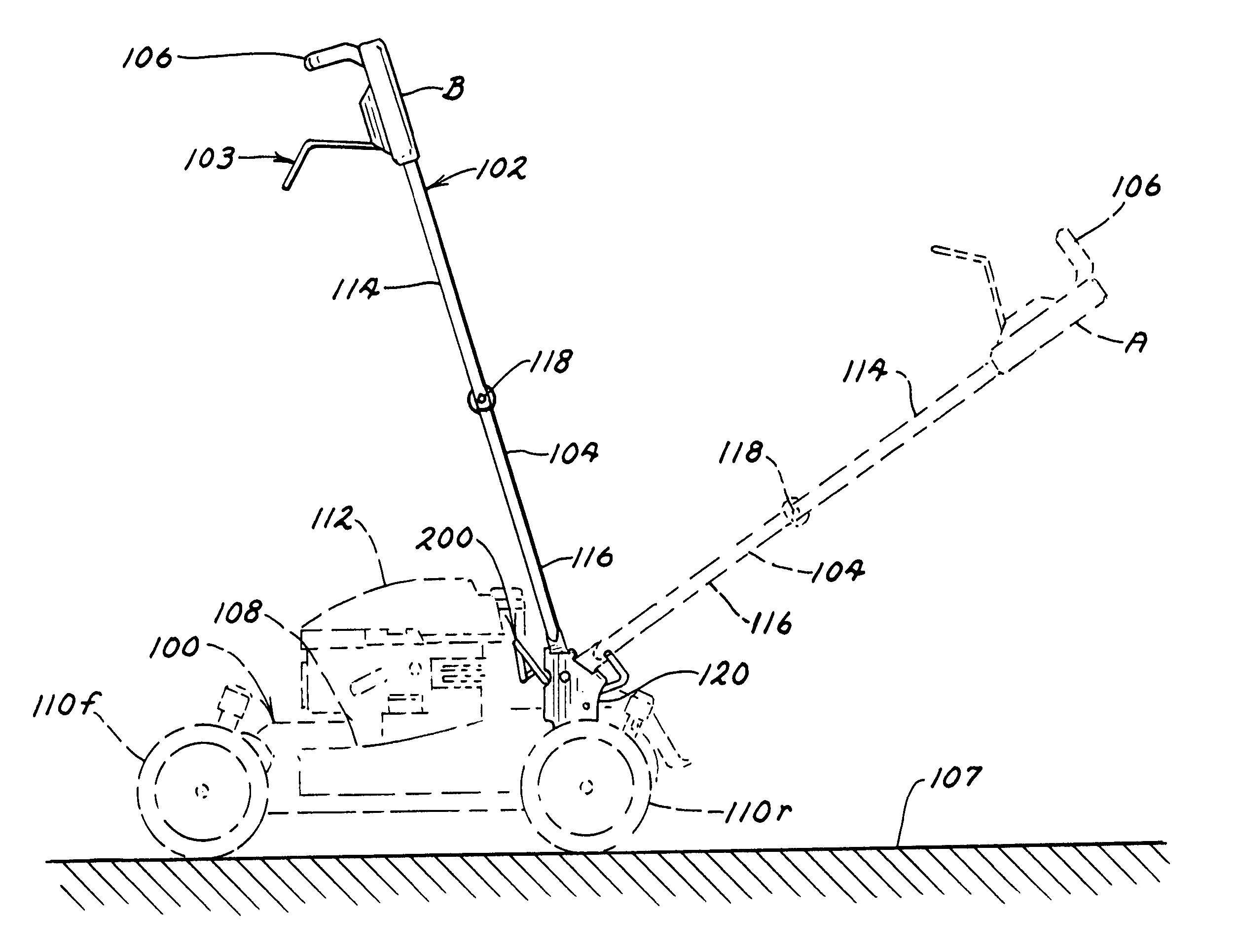

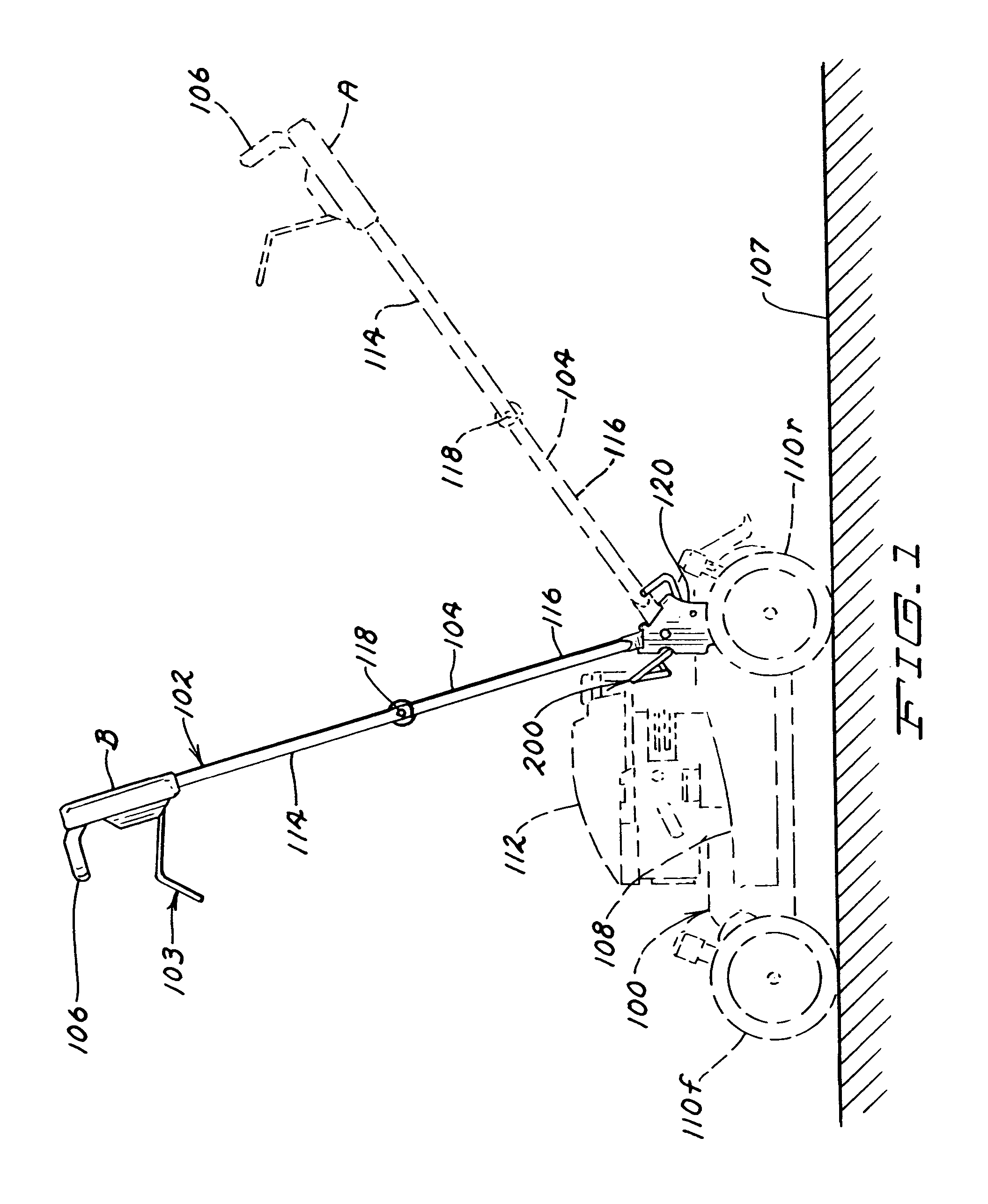

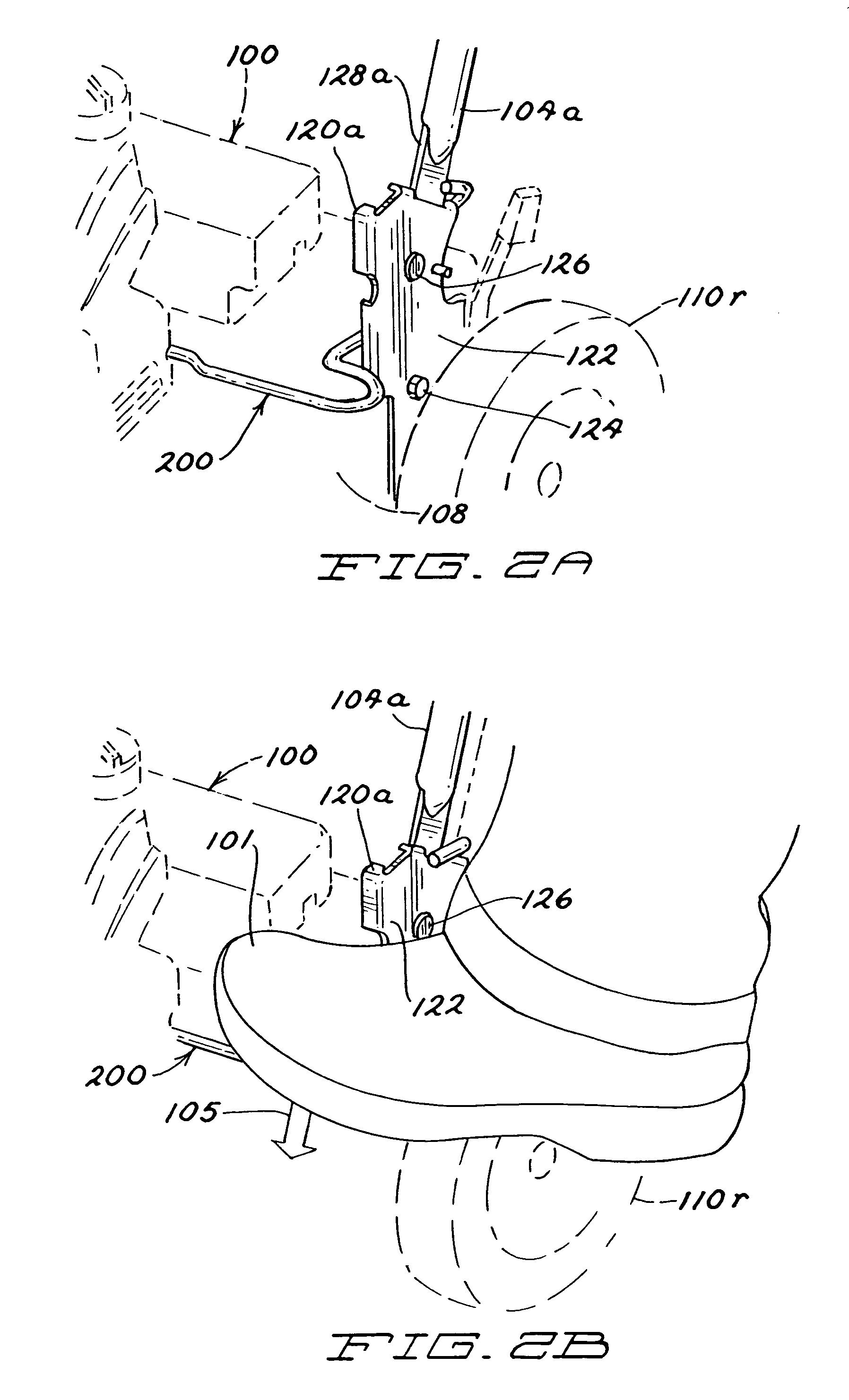

Walk-behind implement and handle assembly release apparatus for use with same

A walk-behind implement, e.g., lawn mower, having a handle assembly, and a handle assembly release apparatus for use with such an implement. The release apparatus, in one embodiment, may permit unlocking of the handle assembly from a first operating position relative to a housing of the implement. Once unlocked, the handle assembly may be moved, e.g., pivoted, to a second storage position. In one embodiment, the release apparatus may include a lever member that may be actuated by the application of a force applied by an operator's foot.

Owner:TORO CO THE

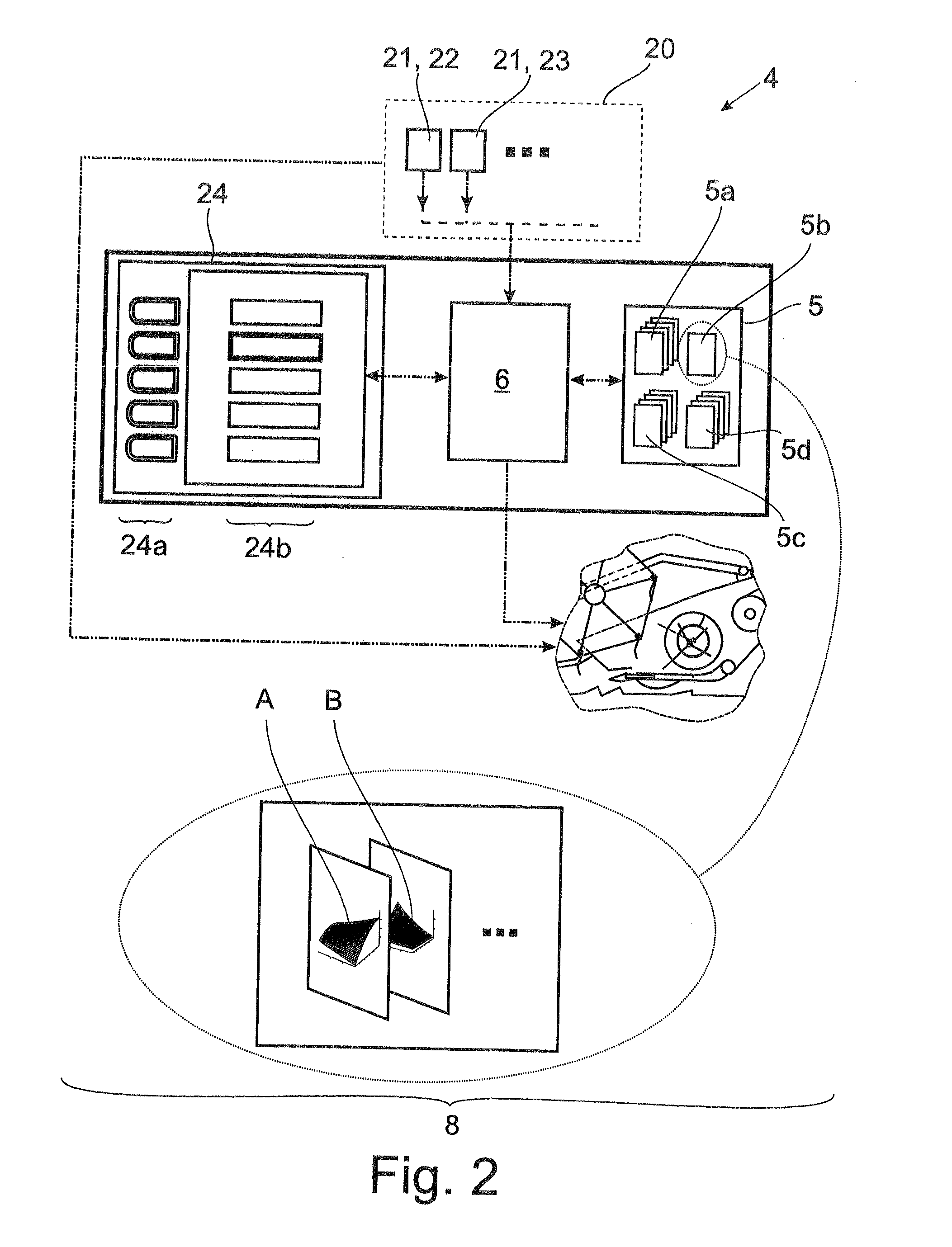

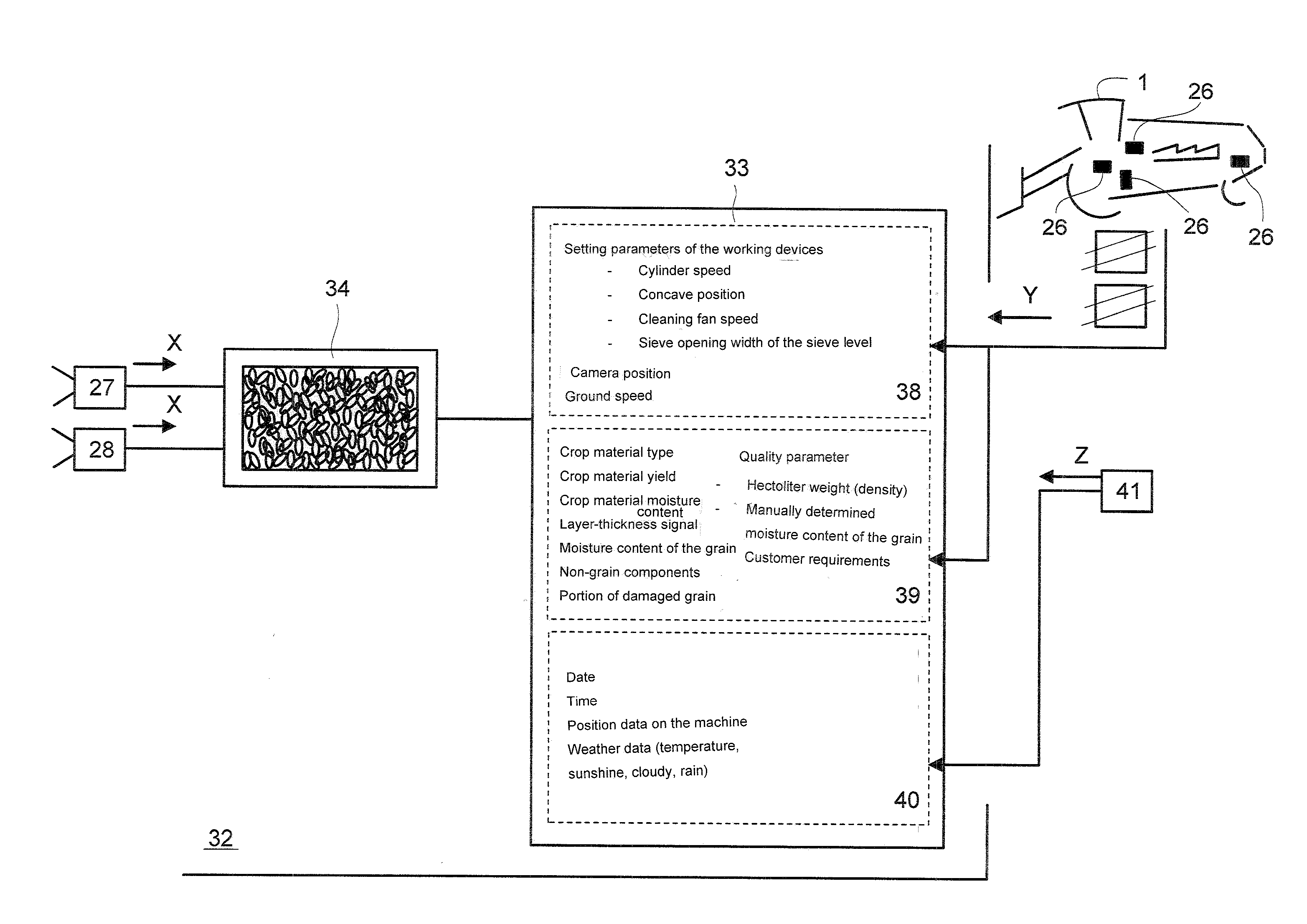

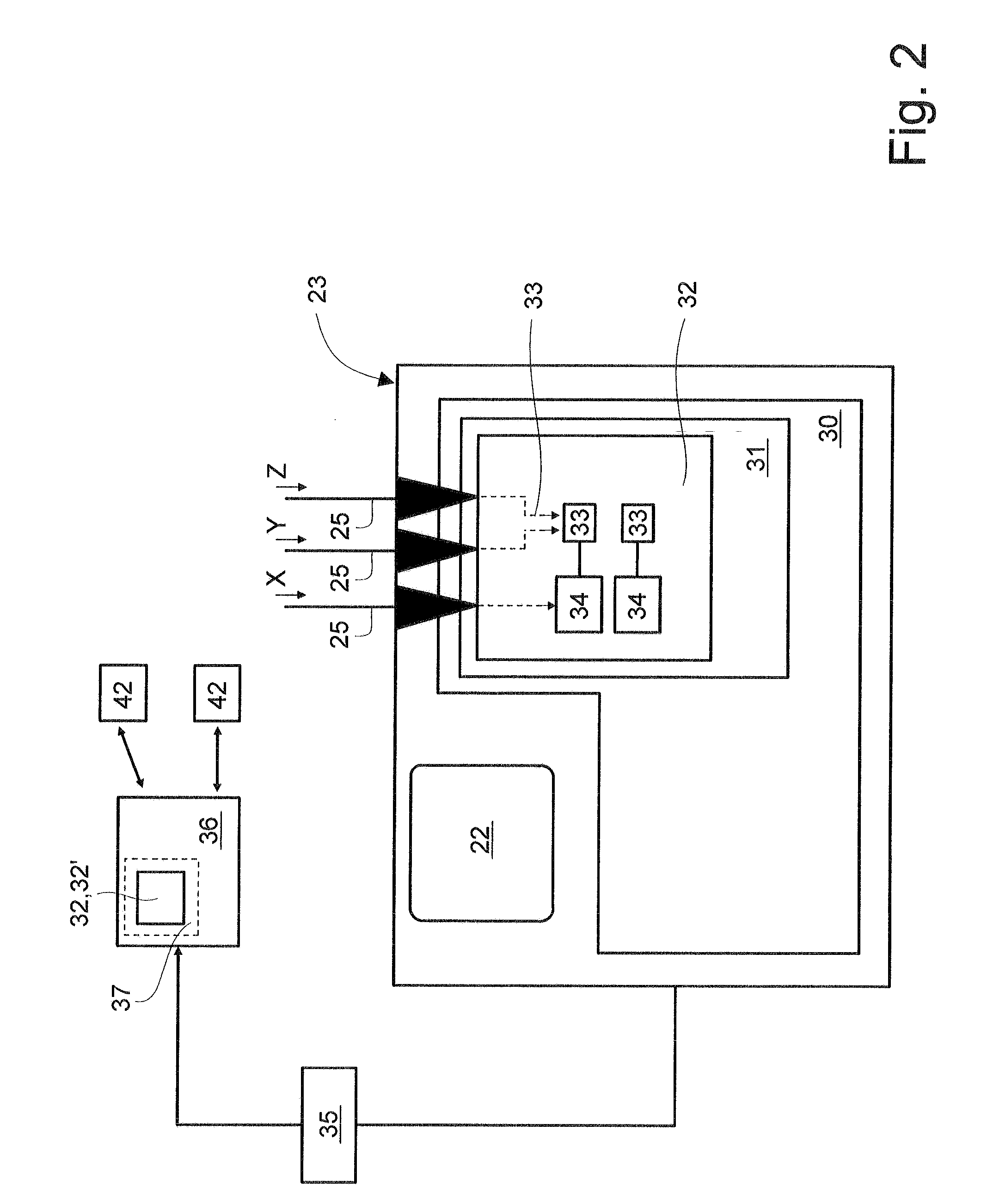

Creation of image databases for image evaluation

InactiveUS20100121541A1Avoid disadvantagesAnalogue computers for trafficCrop conditionersImage evaluationComputer science

For creating an image database for an image evaluation procedure, preferably within an agricultural content, the individual images in the image database are generated during the working process of an agricultural working machine by at least one camera system assigned to the agricultural working machine, and the individual images generated by the at least one camera system are linked to specific data on the working process of the agricultural working machine, and every individual image, which is linked to specific data, is stored in the image database in a manner such that it may be repeatedly called up and edited.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

Walk-behind implement and handle assembly release apparatus for use with same

A walk-behind implement, e.g., lawn mower, having a handle assembly, and a handle assembly release apparatus for use with such an implement. The release apparatus, in one embodiment, may permit unlocking of the handle assembly from a first operating position relative to a housing of the implement. Once unlocked, the handle assembly may be moved, e.g., pivoted, to a second storage position. In one embodiment, the release apparatus may include a lever member that may be actuated by the application of a force applied by an operator's foot.

Owner:TORO CO THE

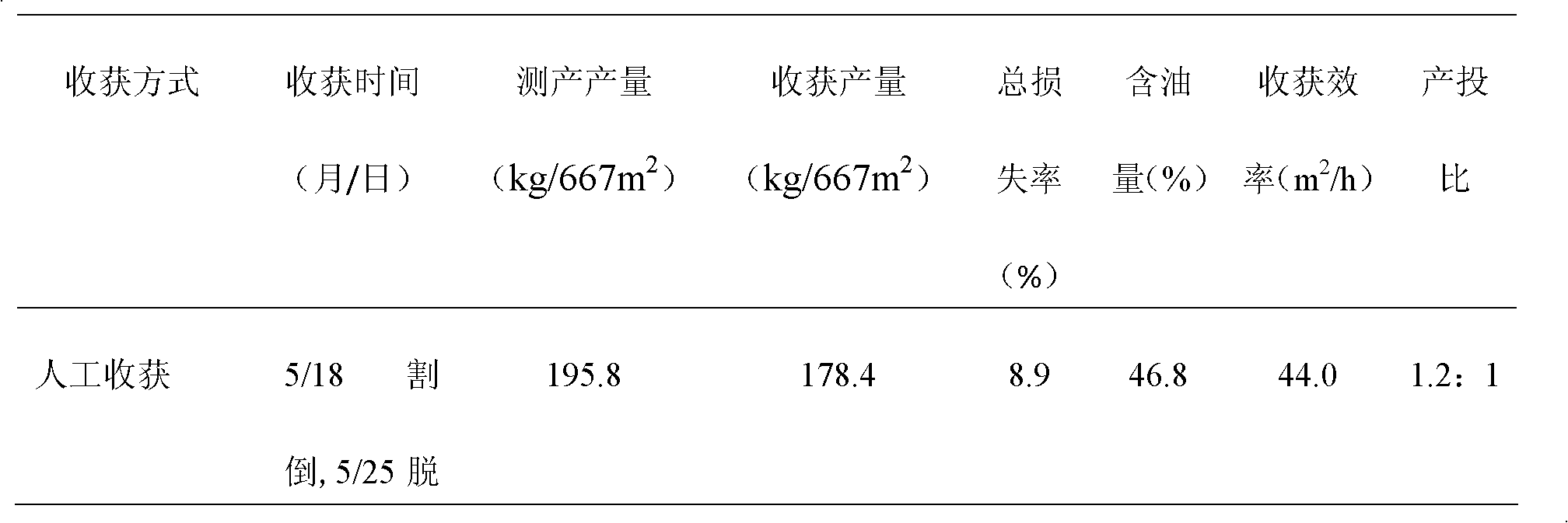

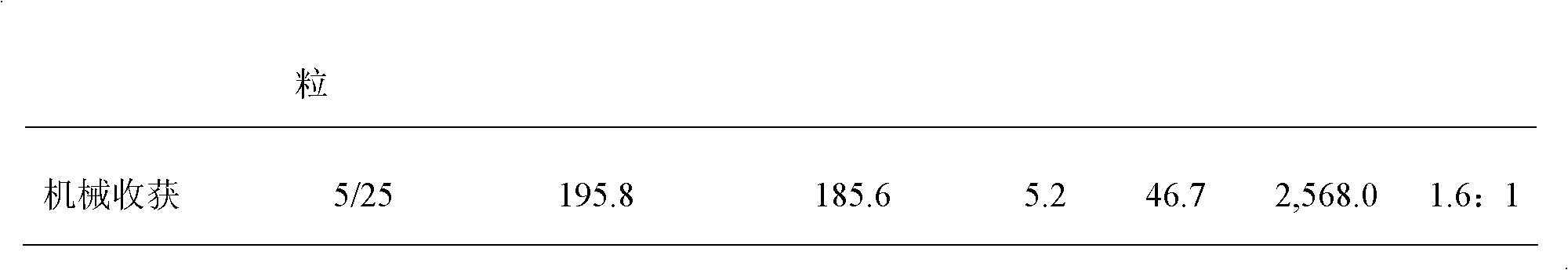

Method for mechanically harvesting winter rape efficiently with low power consumption

InactiveCN102124898AIncrease harvest yieldAvoid pollutionSeed and root treatmentCrop conditionersDiseaseLoss rate

The invention discloses a method for mechanically harvesting winter rape efficiently with low power consumption. The method comprises the following steps of: A, constructing a rape group suitable for mechanical harvest: selecting the variety suitable for mechanical production, performing mechanical precise-quantity direct seeding when the soil water content is 30 to 40 percent, and constructing an ideal group and a plant type by fertilizer and water application and disease inset pest and weed control; B, adjusting a mature period: spraying a ripener two to three days before the harvest of rape seed ripening stage in the regions of contradictory seasons; C, harvesting at right time: observing and measuring the morphological physiological index of the plant before the harvest of the rape, wherein more than 95 percent of siliques, namely yellow loquat fruits in the cropland are suitable for mechanical harvest; D, mechanically harvesting and measuring loss rate: harvesting by a special rape harvesting mechanism in a combining way in the period suitable for harvest; E, smashing and returning rape straw to the cropland: flooding the straw in water immediately after the harvest of rape, decaying and returning to the cropland. The method is easy and convenient to operate, improves a one-time efficient branch height, reduces the branch number, reduces the thickness of the pod layer, solves the problems of high harvest loss rate, and improves the yield.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

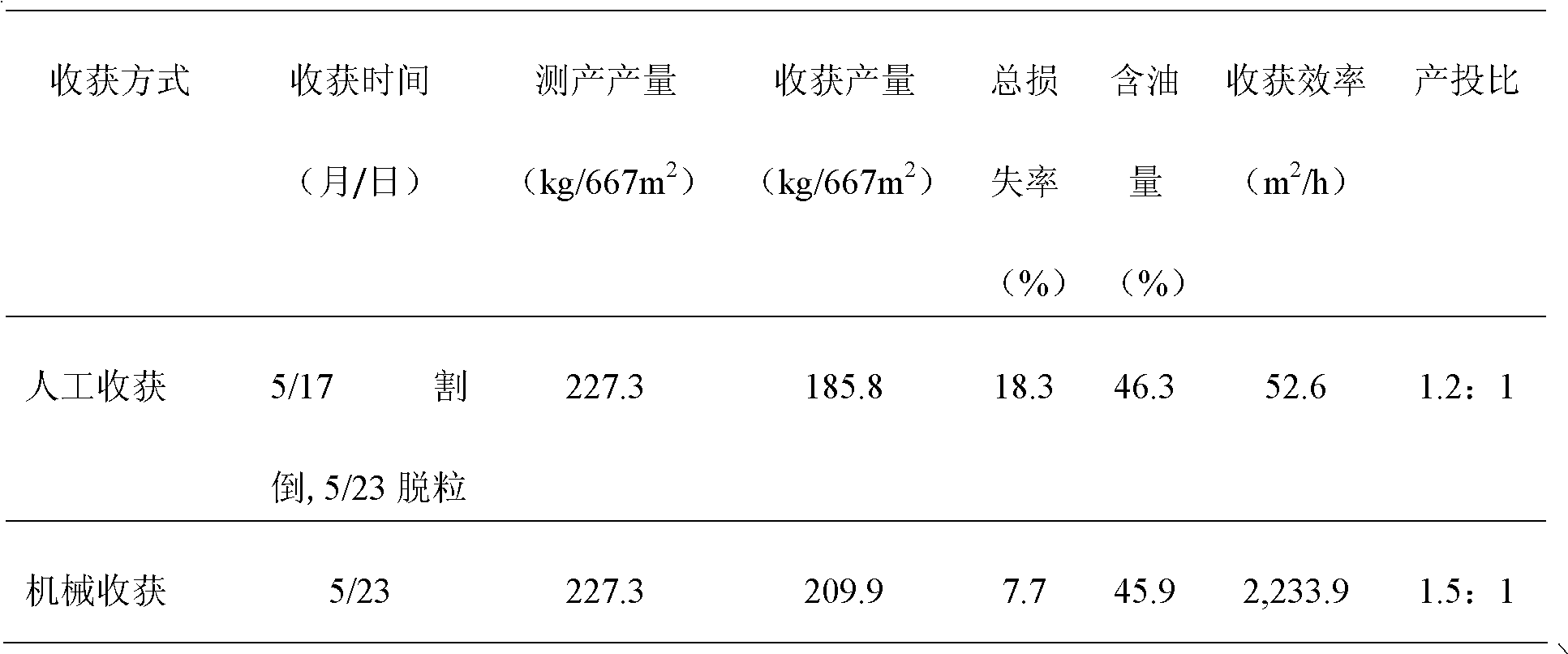

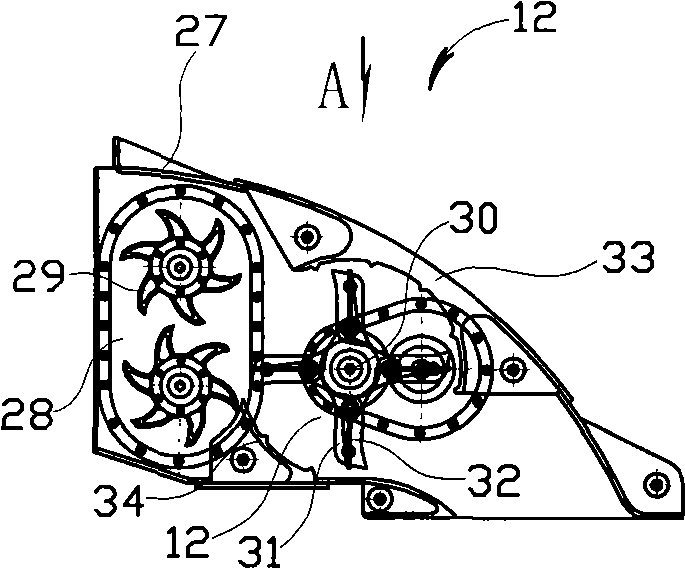

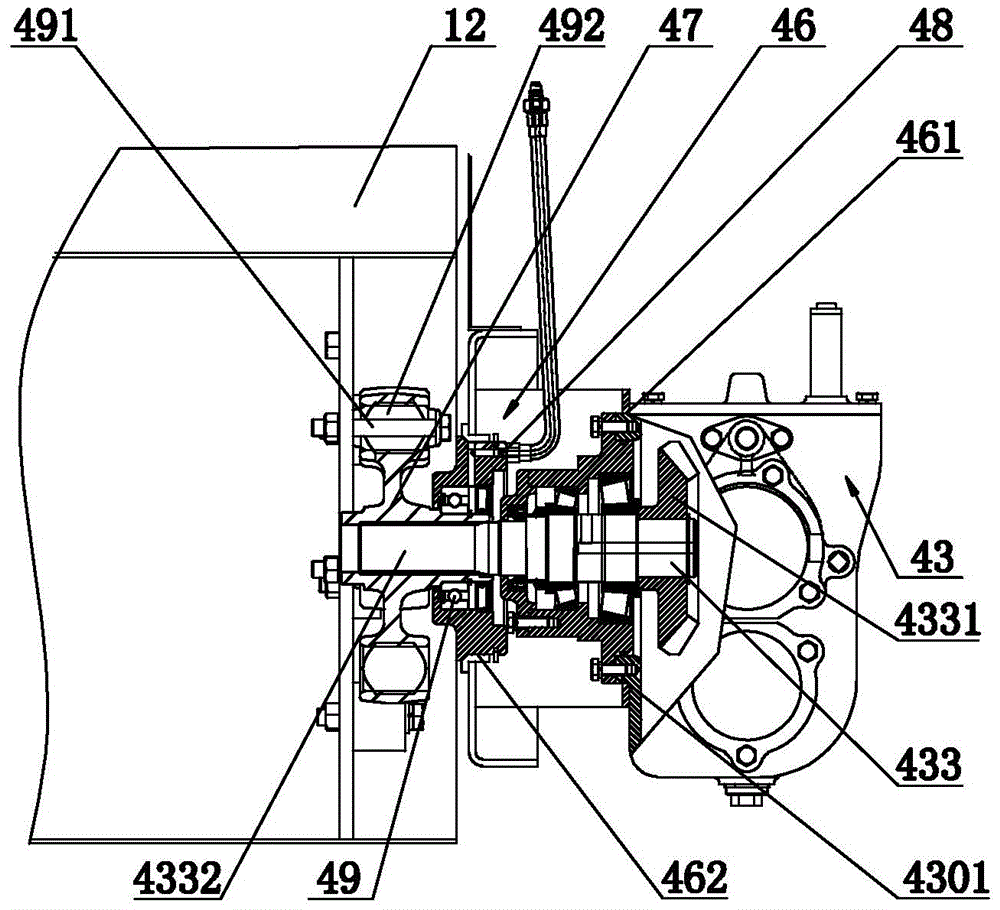

Conditioning roller drive

ActiveUS7188461B2Accurate angular timingAccurate timingCrop conditionersHarvestersGear wheelEngineering

A forage conditioner for conditioning cut crop material from a forage harvester includes a fixed bottom fluted roller carried in end housings and a top fluted roller which is pivotally mounted on the housings by a linkage pivotal relative to the housing about an axis lying in a plane at right angles to the roller axes so that the top roller is liftable from crushing position against the bias of a spring extending along the top roller. Rotation of the bottom roller is transferred to the top roller through a gear train which includes two idler gears each mounted on a respective arm with the arms constrained to move symmetrically relative to the rollers by intermeshing teeth on the arms so as to control the angular timing of the rollers to ensure accurate intermeshing of the flutes.

Owner:MACDON INDS

Self-propelled corn harvester

InactiveCN101530036AFirmly restrainedNot easy to jumpCrop conditionersMowersVehicle frameEngineering

The invention relates to a self-propelled corn harvester. A cutting platform is hinged at the front part of an automotive vehicle frame and is provided with a grain lifter, a cutting knife, a gripping conveyor chain, a snapping roll and a stalk crusher, wherein the middle part of the frame is provided with a corn ear conveyor, while and the rear part is provided with a fruit ear box, the cross sections of a chute below pressing plates evenly distributed on a cross beam of the cutting knife and a sliding rod in the chute are mutually matched drum shapes, an anti-attrition lining plate is arranged between the pressing plates and the sliding rod, the snapping roll is arranged on the frame through an unloading sleeve, a crankshaft in a shell of the straw grinder is hinged with hammer leaves, a radial material-throwing plate is arranged between the hammer leaves on the crankshaft, the inner wall of the shell is provided with an upper screw plate and a lower screw plate, and a full rubber corrugated flange conveying belt is arranged between a driving roller and a driven roller of the core ear conveyor. The sliding rod of the cutting knife is not easy to beat and is advantageous for cutting operations, and the bearing load of an input bearing of the snapping roll is small so that the snapping roll is not easy to be damaged; corn stalk grains after crushing are small and does not influence farming after being applied to fields; and the full rubber corrugated flange conveying belt conveys corn ears with small power consumption in the process of conveying the core ears, and is not easy to go wrong.

Owner:程辉 +1

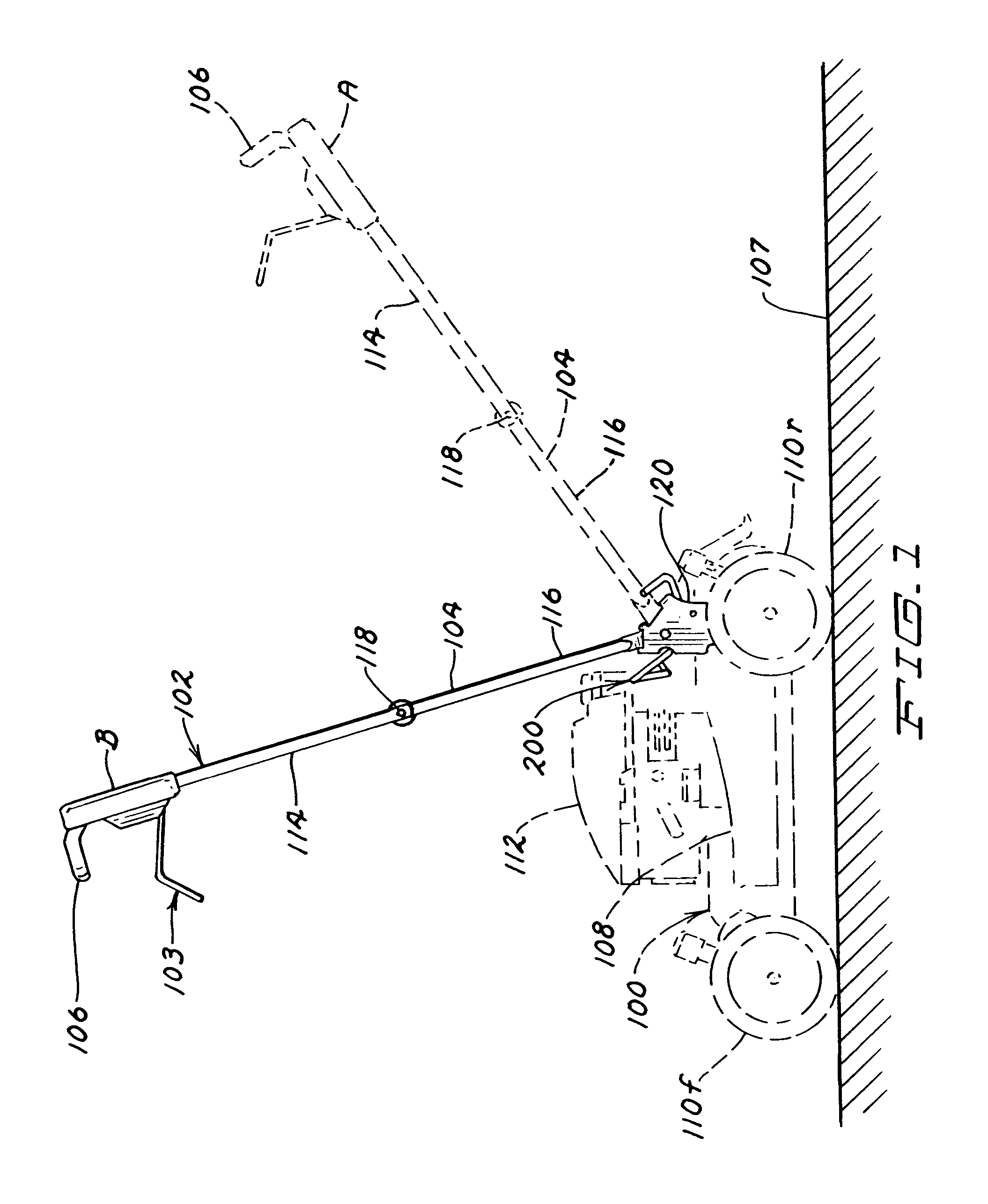

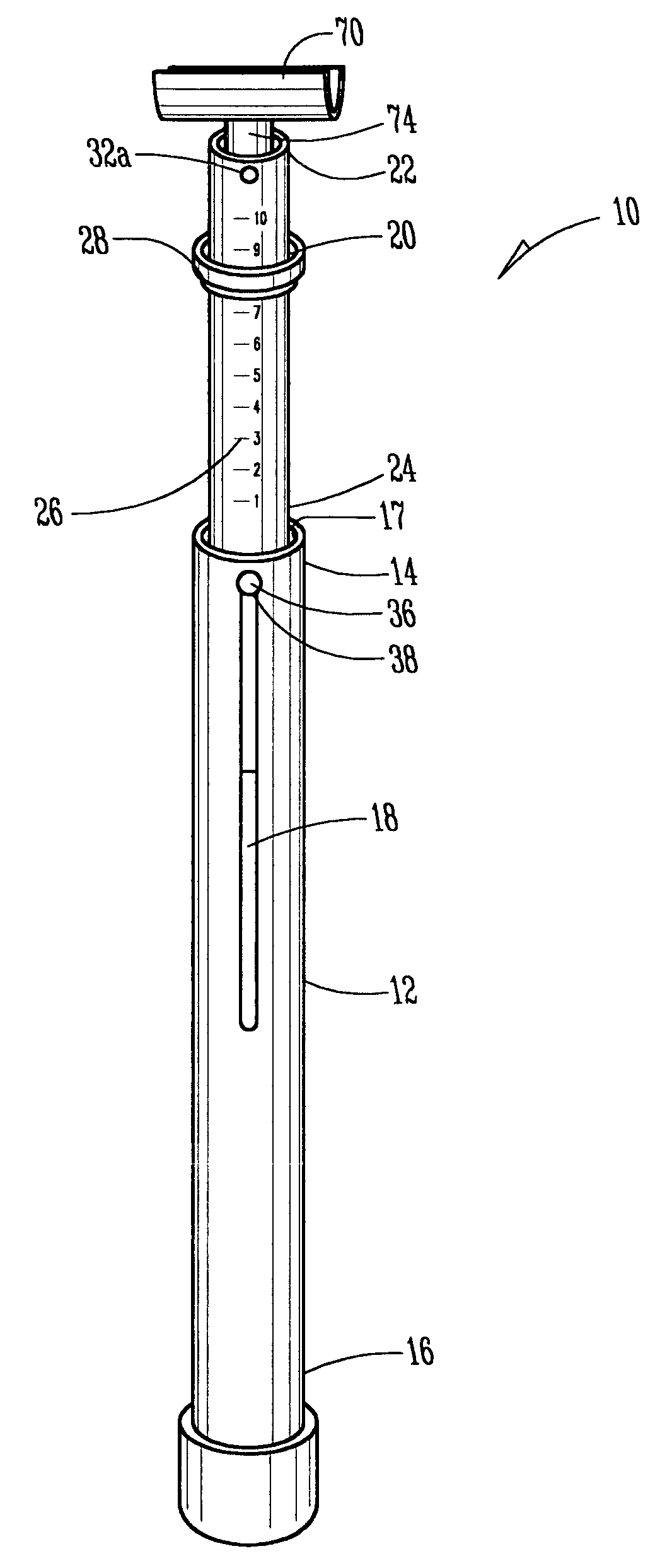

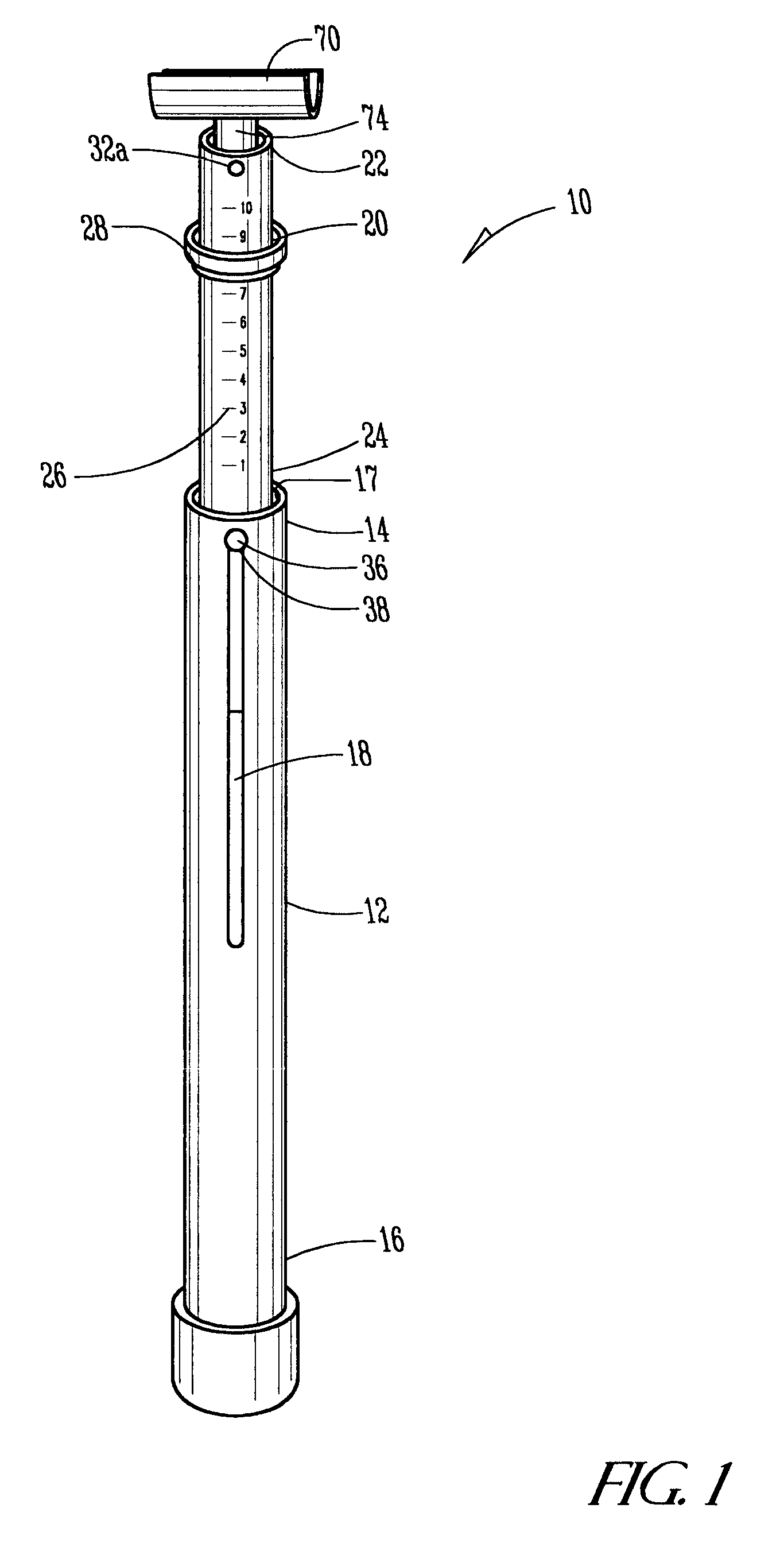

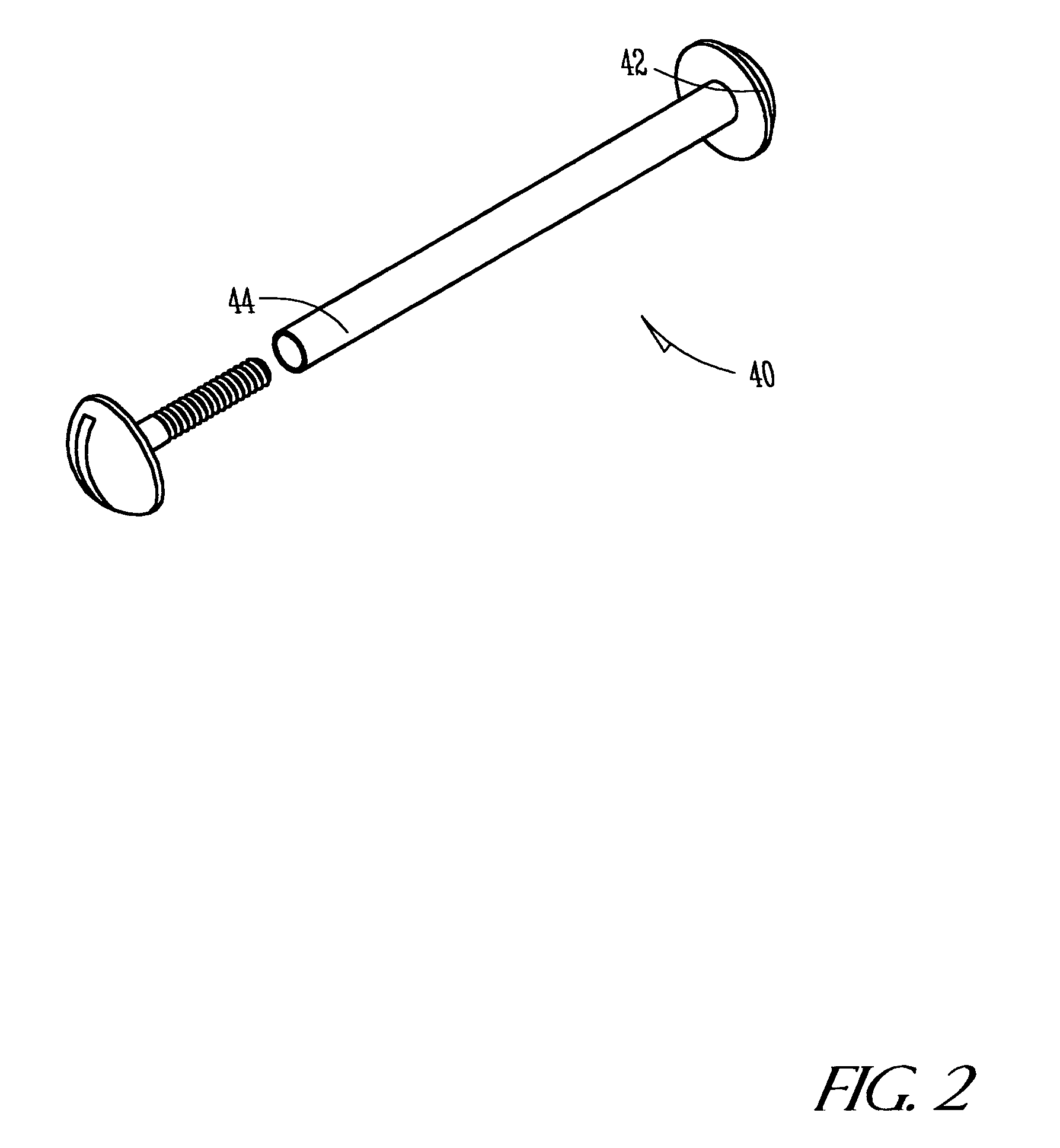

Stalk strength tester

The stalk strength tester of the present invention includes an internal shaft and an external shaft in telescopic relationship. Pivotally associated with the upper end of the internal shaft is a trough-like stalk cradle. A set of measurement markers are on the upper end of the internal shaft and a rubber ring is around the internal shaft and abuts the external shaft. Associated with the other end of the internal shaft is a tension member. A tension adjustment structure is provided for adjusting the tension in the tension member. In operation, a stalk is positioned into the cradle and the tester is pushed against it. The internal shaft telescopically slides against the tension member and into the external shaft until the cradle pivots at which time the rubber ring remains in a position relative to one of the markers as an indicator of the tension measured.

Owner:MUCKLER GREGORY A

Threshing cleaning device of longitudinal-axial-flow combine harvester

ActiveCN105123147ALarge field return functionAchieve bothCrop conditionersMowersPulp and paper industryCombine harvester

The invention discloses a threshing cleaning device of a longitudinal-axial-flow combine harvester, and belongs to the technical field of combine harvesters. The threshing cleaning device comprises a threshing separating device, a cleaning device body and a stalk chopper. The threshing separating device comprises a threshing machine body and a longitudinal-axial-flow roller driven by a power device. The longitudinal-axial-flow roller comprises a feeding-in part and a roller body part, and the roller body part sequentially comprises a threshing section, a separating section and a weed-discharging section. A feeding-in shell is fixed to the portion, corresponding to the feeding-in part, of the threshing machine body, a threshing section roller cover is arranged on the upper portion, corresponding to the threshing section, of the threshing machine body, and a threshing section concave plate is arranged on the lower portion, corresponding to the threshing section, of the threshing machine body. A separating section roller cover is arranged on the upper portion, corresponding to the separating section, of the threshing machine body, a separating section concave plate is arranged on the lower portion, corresponding to the separating section, of the threshing machine body, and the diameter of the separating section roller cover is larger than that of the threshing section roller cover. The feed quantity is large in harvesting, the function of returning stalks to the field is achieved, working efficiency is improved, kinds of crops are harvested, and the requirements for earnings of a user are met.

Owner:LOVOL HEAVY IND

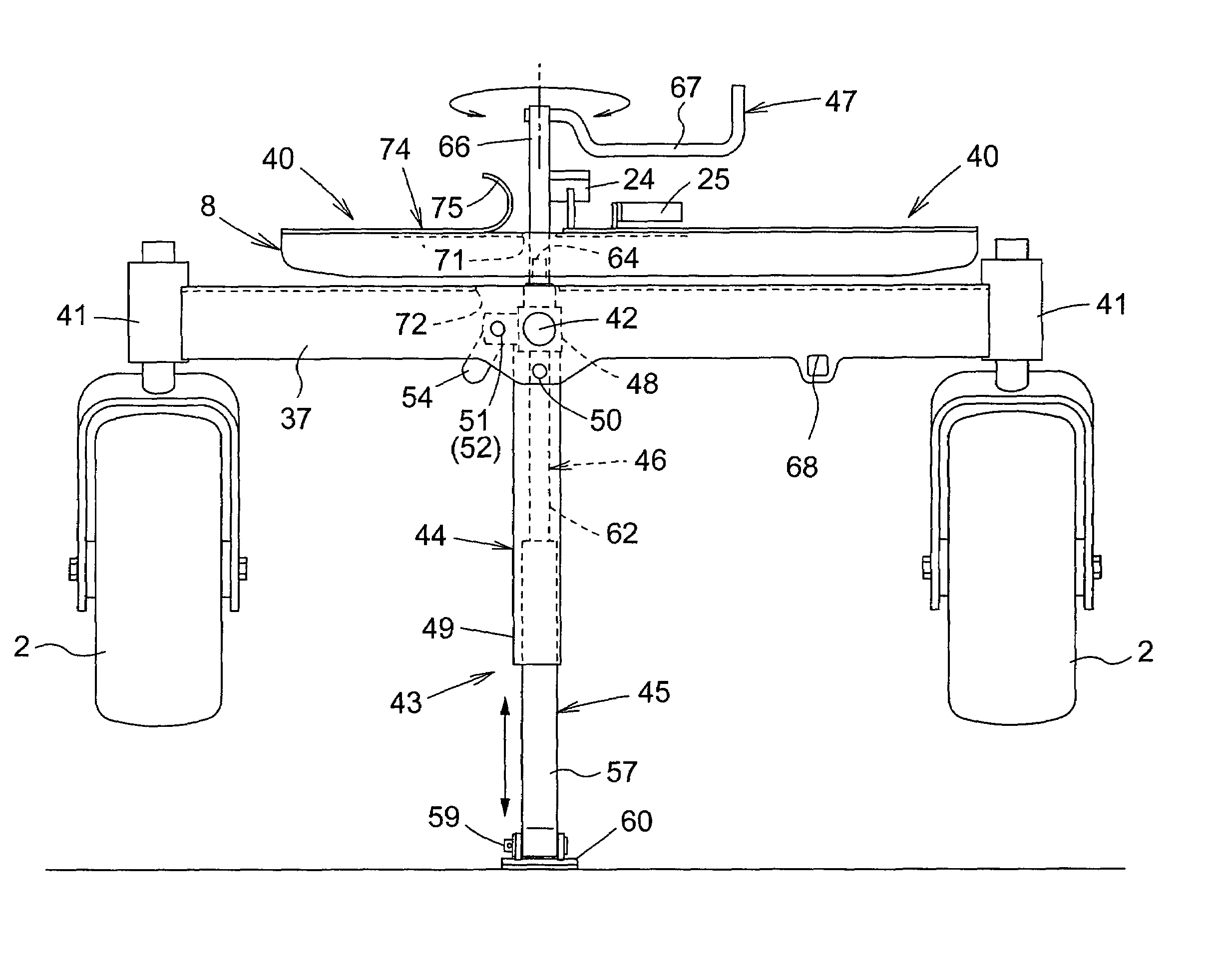

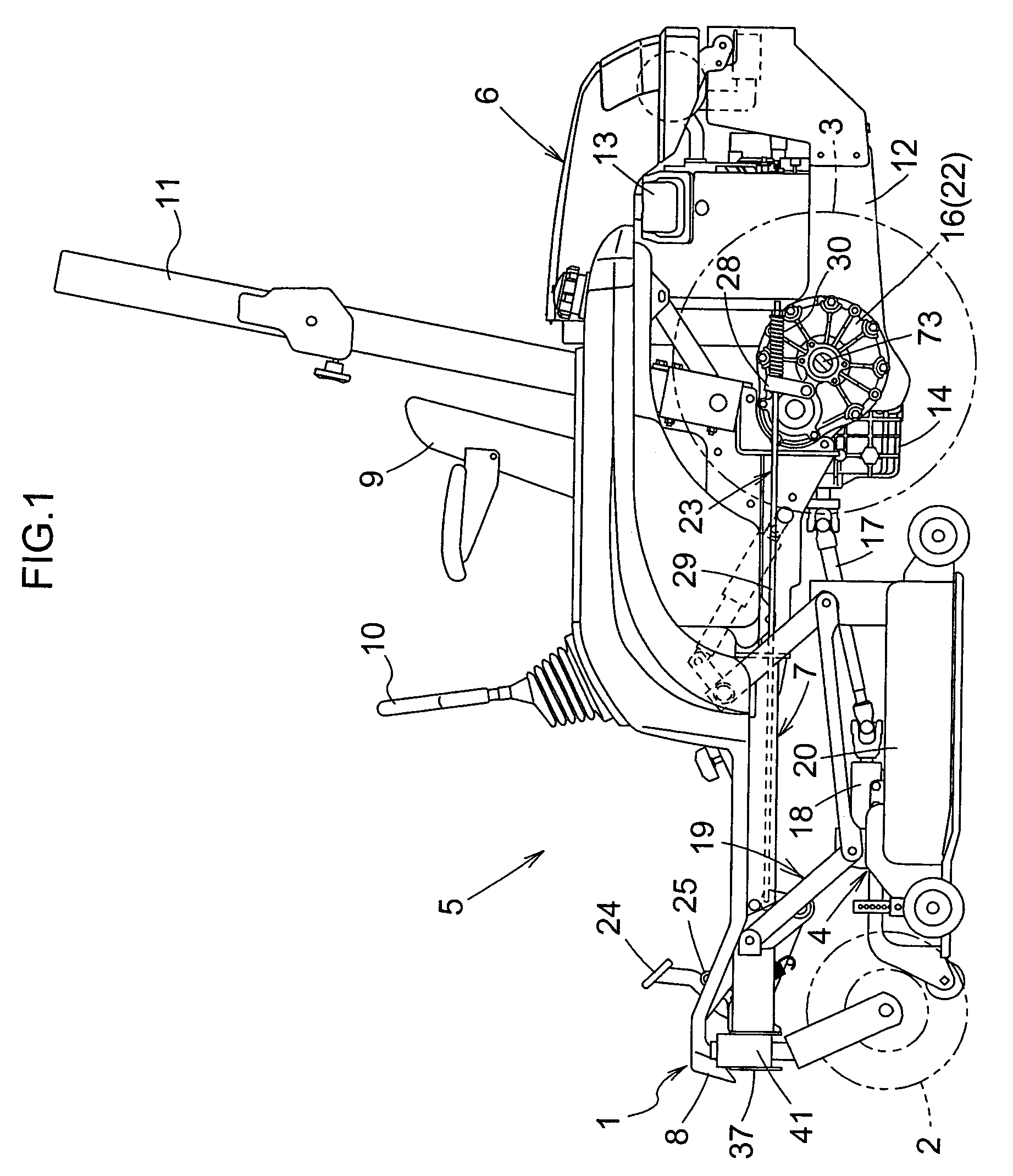

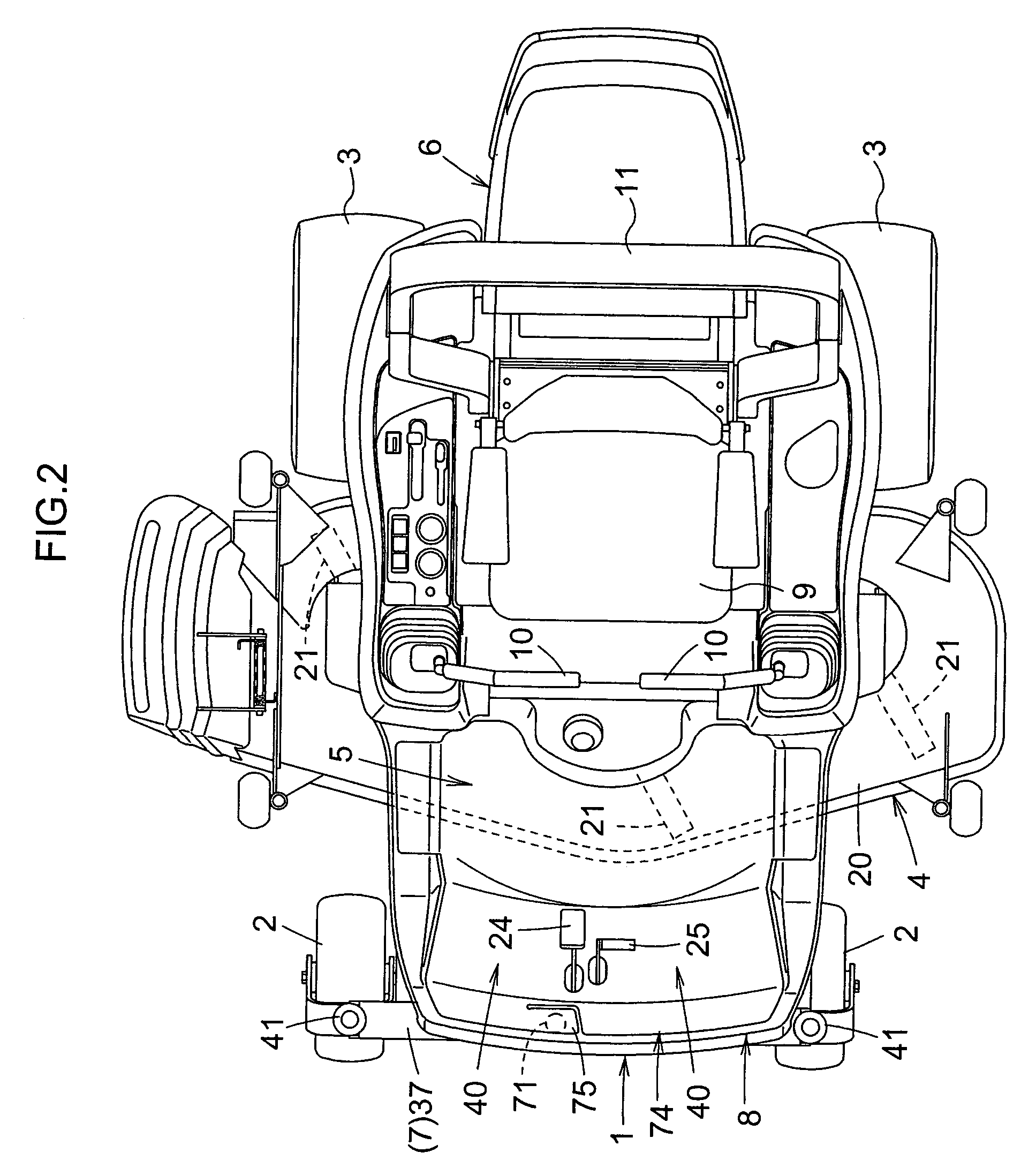

Mid-mount mower having a mower unit disposed between front and rear wheels

InactiveUS6973768B2Suppressing cost increaseSuppressing structural complicationCrop conditionersMowersMowerBody frame

A mid-mount mower having a body frame supported above the ground by front wheels and rear wheels, the body frame having a front cross frame in a forward portion thereof with respect to a longitudinal direction of a vehicle body, and a mower unit disposed between the front wheels and rear wheels. A main jack body is mounted on the front cross frame to be pivotable about a pivot shaft extending longitudinally of the vehicle body. The main jack body is in a storage position extending along the front cross frame when pivoted to a first pivot position about the pivot shaft, and in a substantially vertical position relative to the ground when pivoted to a second pivot position about the pivot shaft. The main jack body has a controlled portion exposed upward when the main jack body is in the vertical position. The main jack body is extendible and contractible, in the vertical position relative to the ground, to raise and lower the front cross frame when an operating force is applied through a control device engaged with the controlled portion of the main jack body.

Owner:KUBOTA LTD

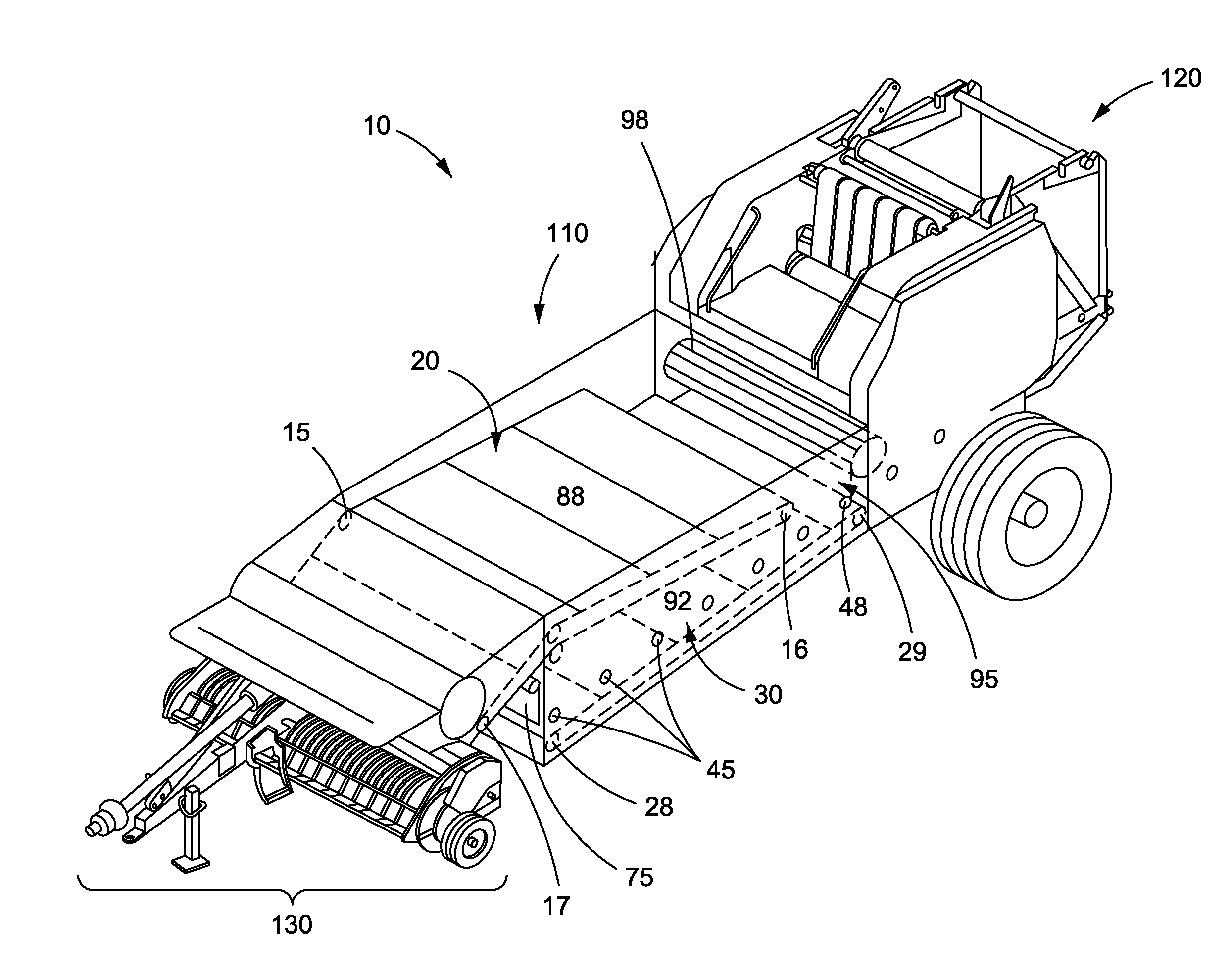

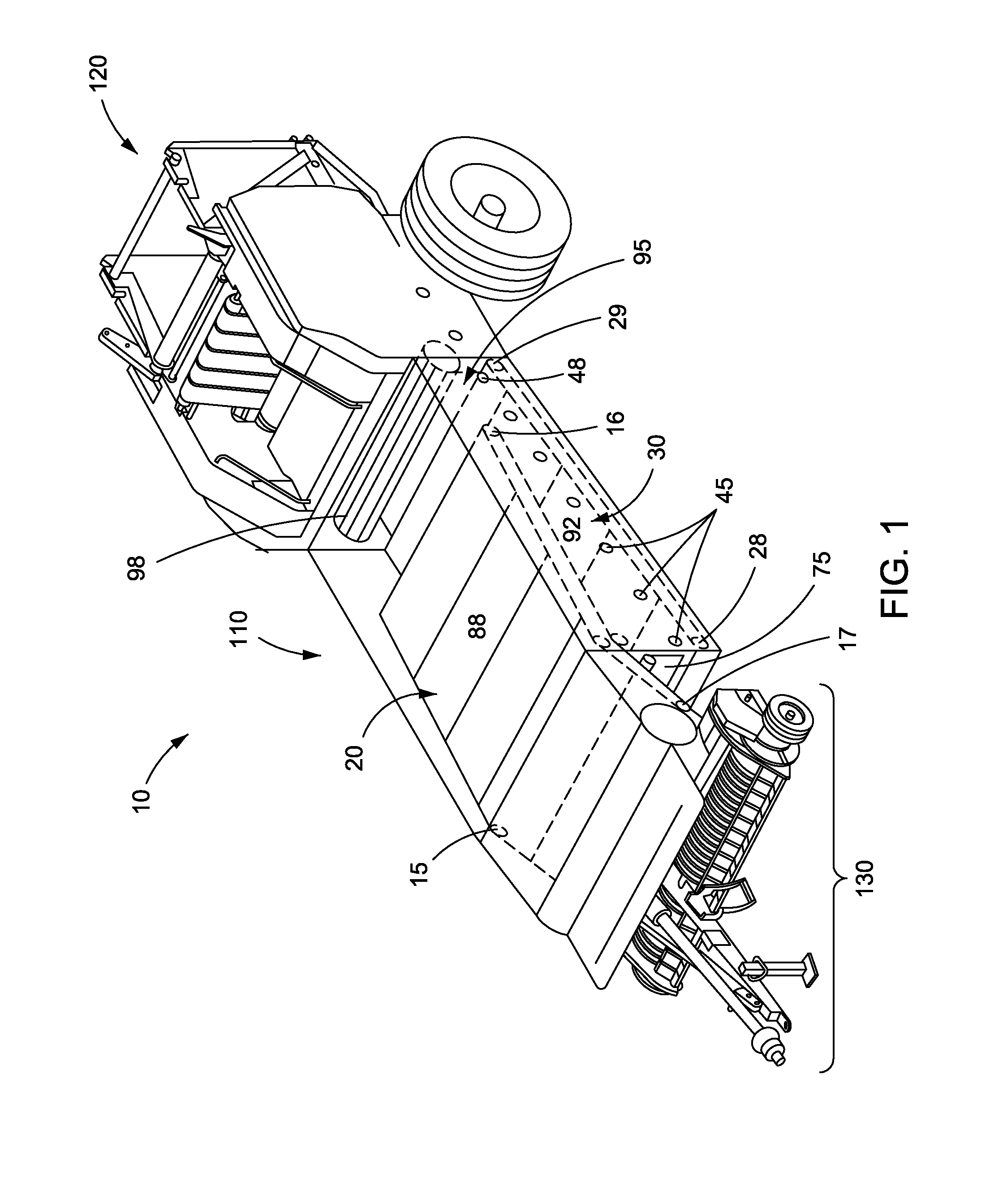

Continuous crop accumulator for agricultural harvesters

The present invention relates to a conveyor system that may be used with an agricultural harvester, such as a round baler, waste baler, combine, sugarcane harvester or cotton harvester. More particularly, the conveyor system utilizes at least a first and a second conveyor belt of which at least one of the conveyor belts is independently movable in the forward and backward directions. The speed and direction of the conveyor belts can be controlled to optimize continuous baling of harvested crop in the agricultural baler.

Owner:CNH IND CANADA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com