Method for mechanically harvesting winter rape efficiently with low power consumption

A technology of winter rapeseed and rapeseed, applied in the field of mechanized harvesting of winter rapeseed, achieves the effects of intuitive judgment method, increased yield, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

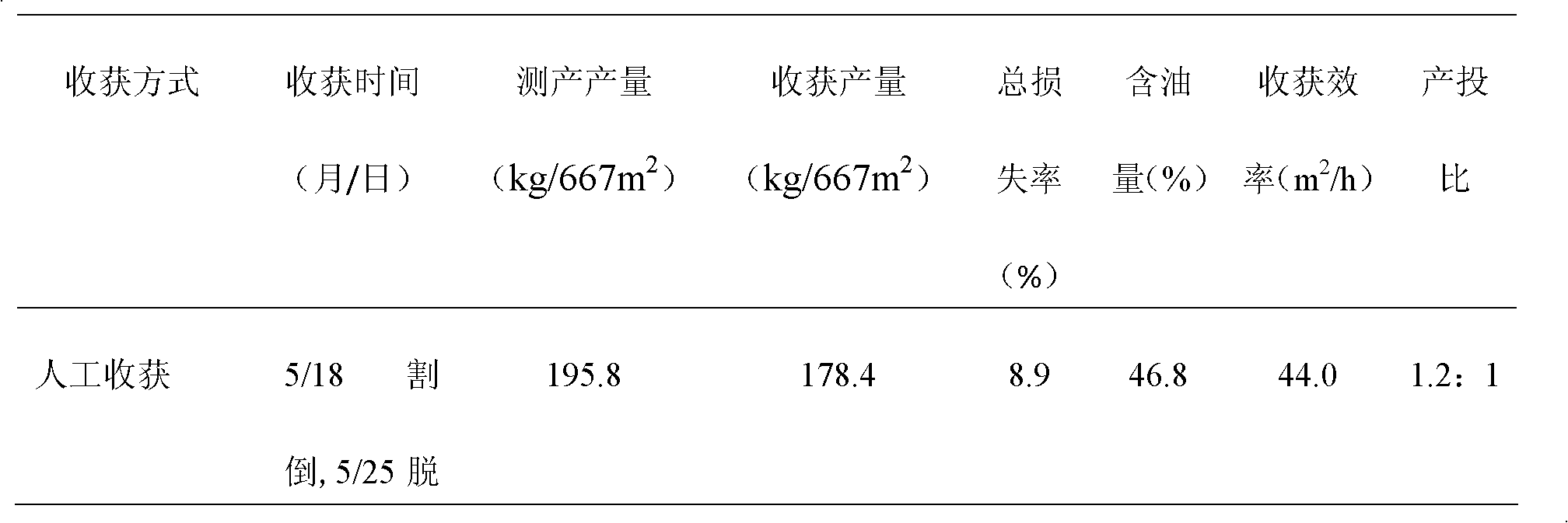

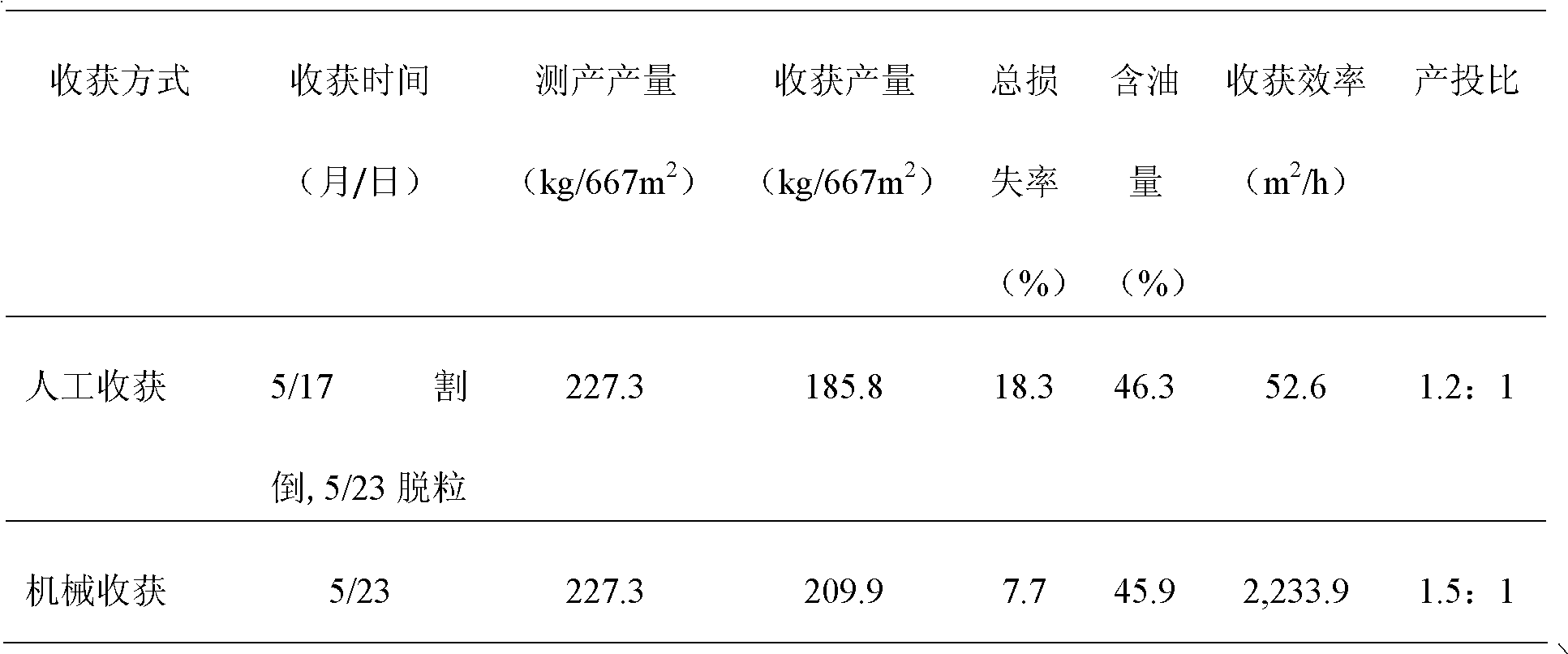

[0027] In order to better understand the present invention, the patent of the present invention will be further described by taking Zhongshuang 11 and Zhongyouza 11 rape varieties as examples below. Since the varieties suitable for mechanized production have similar agronomic characters, the method provided by the invention is also effective for other Brassica napus varieties suitable for mechanized production (such as Dadi 55, Zheyou 18 and other varieties).

[0028] A method for mechanized harvesting winter rapeseed with high efficiency and low consumption, the steps are:

[0029] (1) Establishment of winter rape populations suitable for mechanized harvesting:

[0030] A: Preparations before sowing rape mechanically: choose a paddy field with a higher terrain and a lower groundwater level, drain and dry the field 10 days before the rice harvest, and two days before sowing, every 667m 2 Use 250ml of Kewuzong to spray 50kg of water for weeding. When the soil moisture content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com