Device and method for total straw returning, layered plowing, fertilizing, sowing and pressing compound operation

An operation device and a straw technology, which are applied in the field of straw returning to the field, fertilization and seeding operation device, can solve the problems of low efficiency of rotary tiller, large power consumption of rotary tiller, increased resistance, etc., so as to reduce the intensity of agricultural labor, the method is simple and reasonable, and the improvement of The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

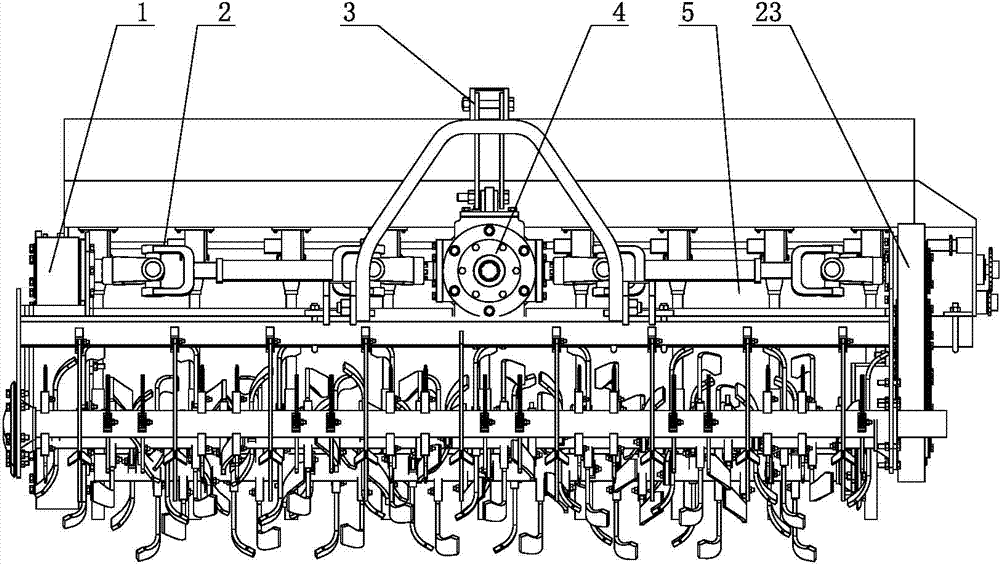

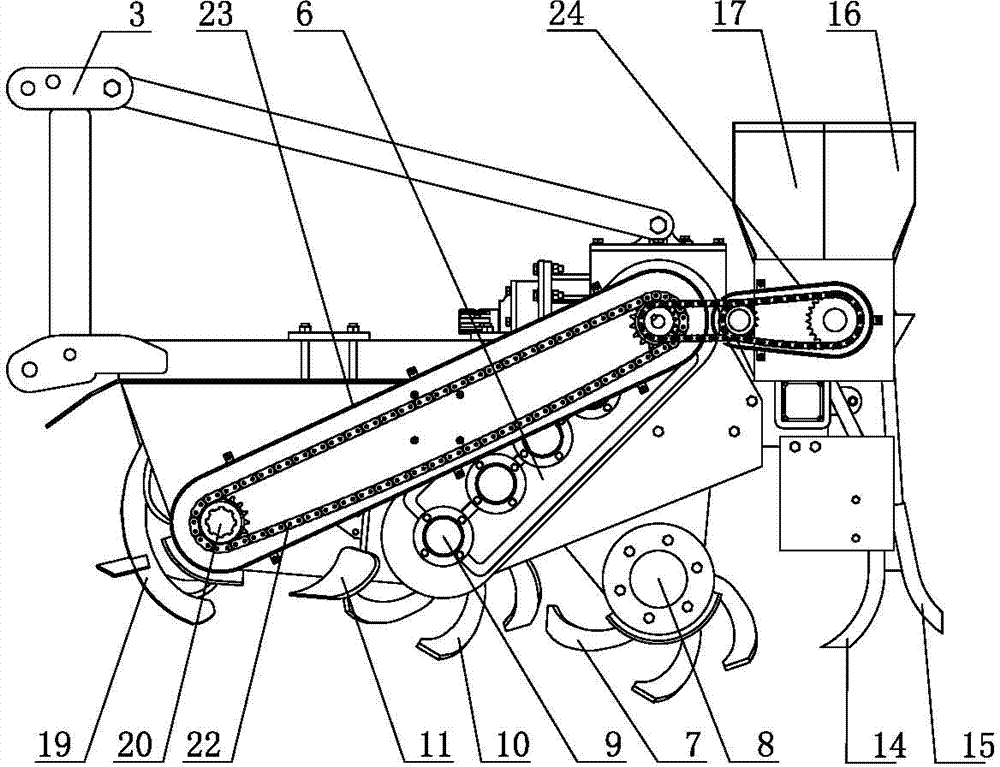

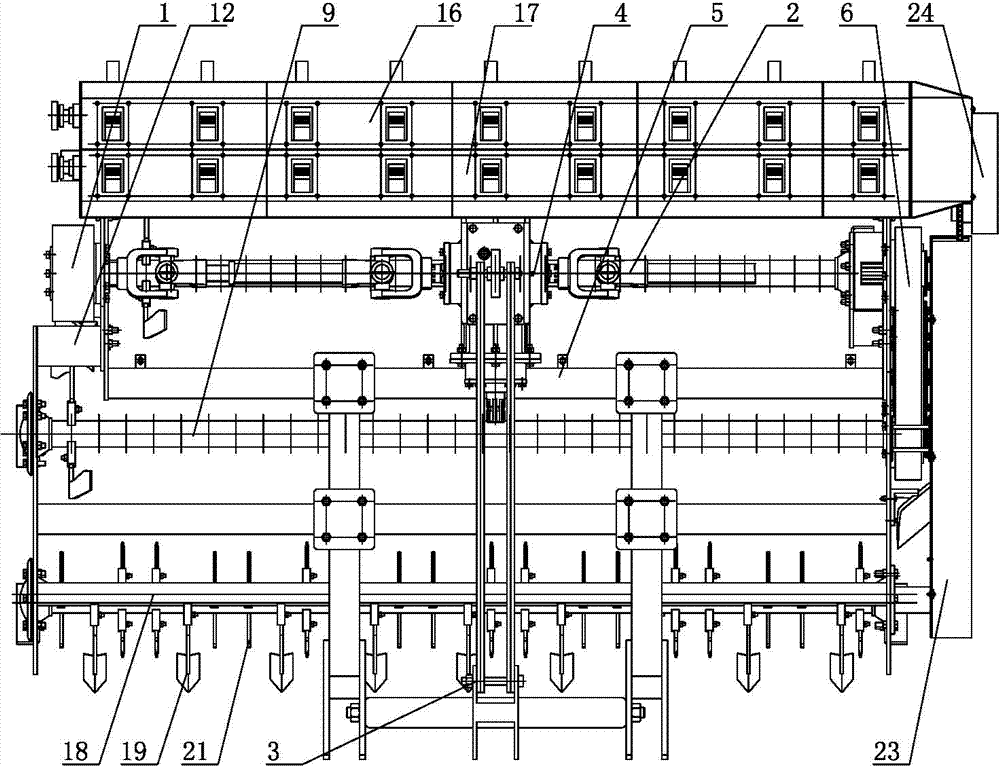

[0035] Such as Figure 1-Figure 7As shown, it includes a suspension frame 3, the suspension frame 3 is movably connected with the frame 5, and the frame 5 is provided with an intermediate transmission box 4, a first shaft side transmission box 6 and a second shaft side transmission box 1, and the first shaft The side transmission box 6 and the second shaft side transmission box 1 are respectively arranged on the left and right sides of the frame 5, and the middle transmission box 4 is connected to the first shaft side transmission box 6 and the second shaft side transmission box 1 via a universal joint 2 The left side plate 12 and the right side plate 13 are respectively fixed on both sides of the frame 5, and the first rotary tiller shaft 9 and the second rotary tiller shaft 8 are parallel and rotatably arranged on the left side plate 12 and the right side plate 13 Between, on the first rotary blade shaft 9, the first shaft rotary blade 10 is installed, on the second rotary b...

Embodiment 2

[0042] A method of using the full amount of straw returning to the field in layered tillage, fertilization, seeding and suppression compound operation device of embodiment 1 to carry out operations, the steps of which are as follows:

[0043] (1) Spread the stubble stalks on the field;

[0044] (2) Using the compound operation device for returning full amount of straw to the field for layered tillage, fertilization, seeding and suppression to carry out layered tillage compound planting operation, which is continuously carried out according to the following steps:

[0045] a. The fixed knife presses the straw, and the straw crushing knife rotates to chop the straw;

[0046] b. The first shaft rotary tiller rotates in the forward direction and the depth of the rotary tillage is 5-15cm; the chopped straw is mixed into the soil;

[0047] c. The second-axis rotary tiller rotates in reverse and plows down to a depth of 5-15cm on the basis of the first-axis rotary tiller; the chopp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com