Stalk crushing returning and residual plastic film recovery combined machine

A technology of combined working machine and residual film recovery, applied in collectors, harvesters, crop processors, etc., can solve the problems of difficult recovery of residual film, high energy consumption for crushing straw, and mismatching speed, so as to meet the requirements of crushing straw. And the requirements of recycling residual film, not easy to wind up the working parts, the effect of high working speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

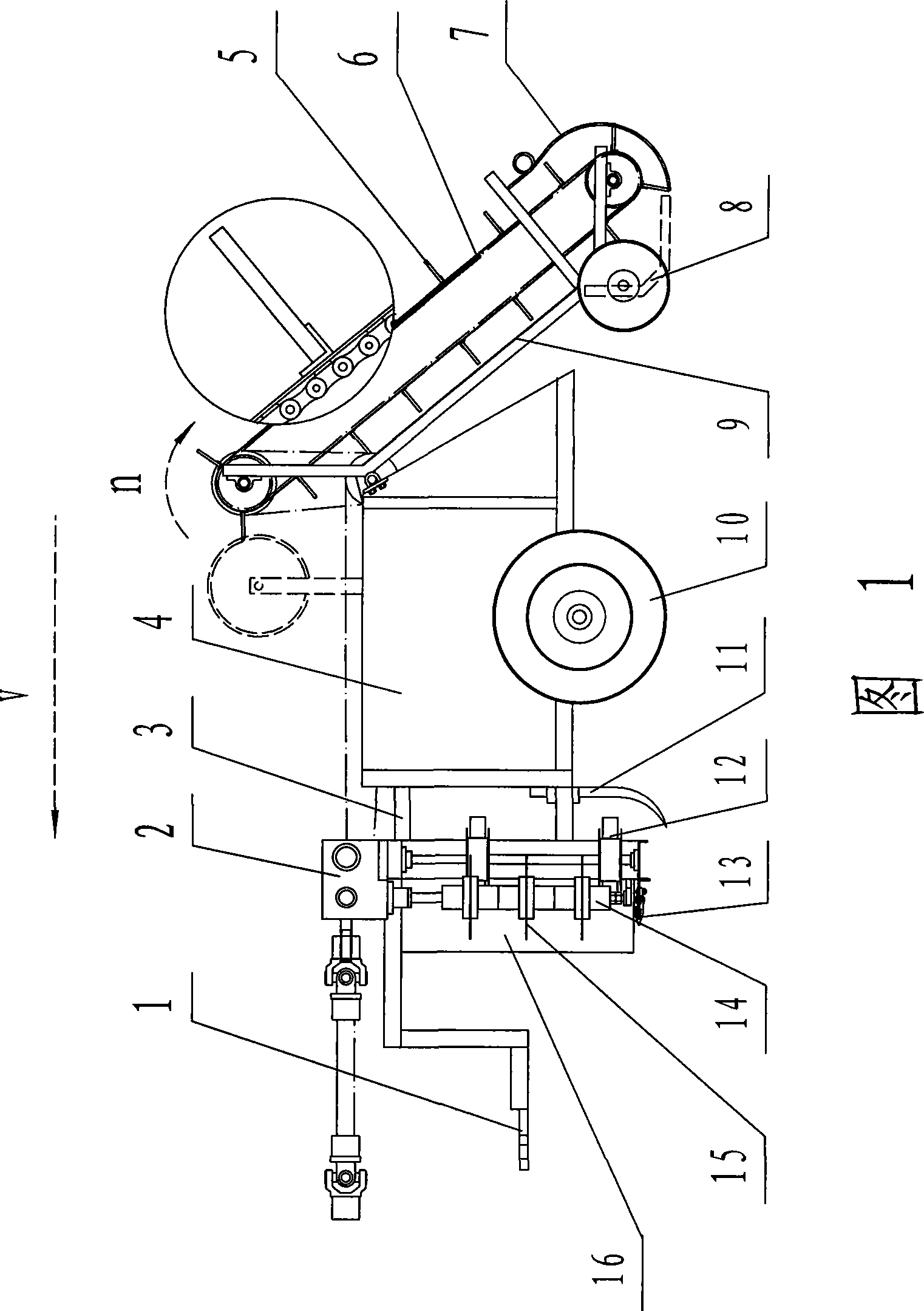

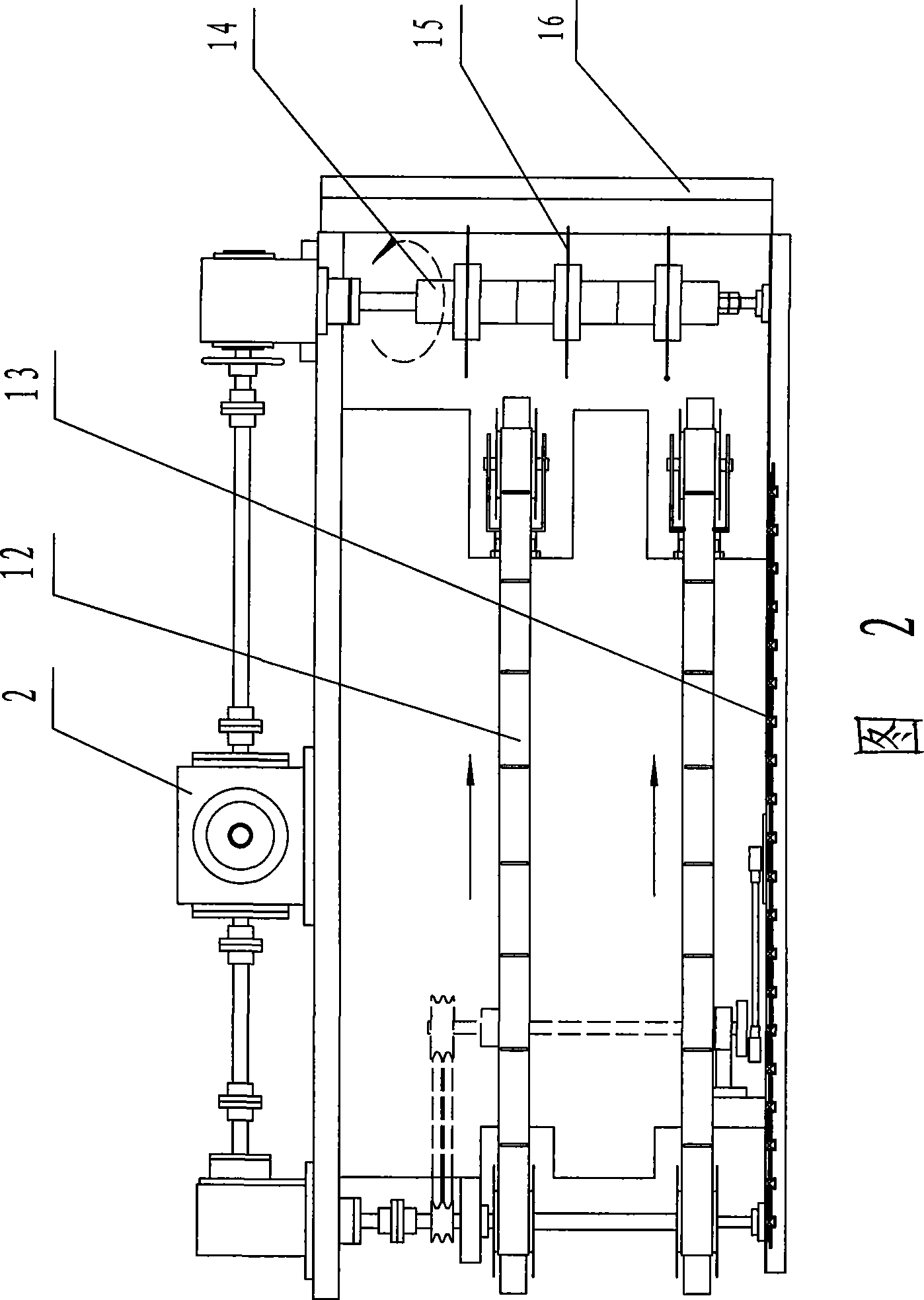

[0014] Referring to Figure 1 and Figure 2, it is an embodiment of a combined operation machine for straw crushing and returning to the field and residual film recovery, including traction device (1), transmission system (2), frame (3), residual film box (4), Ground wheel (10), soil loosening rod teeth (11), straw crushing device and residual film recovery device, the straw crushing device is arranged in front of the residual film box, and the straw crushing device consists of a reciprocating cutter (13), a transverse conveyor belt ( 12), a disc cutter (14), a shield (16) and a transmission device, the reciprocating cutter (13) is below the straw crushing device, and the horizontal conveyor belt (12) is in the Above the reciprocating cutter (13), a disc cutter (14) is provided on one side of the transverse conveyor belt (12), and the disc cutter is provided with a cutter head (15). Guard cover (16) is arranged on the outside of above-mentioned disc type chopper (14), and descri...

Embodiment 2

[0016] The difference between this embodiment and embodiment 1 is that the profiling wheel (8) is a supporting plate.

Embodiment 3

[0018] The difference between this embodiment and embodiment 1 is that there is a film stripping device on the front side of the upper end of the residual film recovery device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com