Auger-type chestnut bud stripping machine

A technology of peeling machine and chestnut, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems such as the mixing of chestnut debris and the low efficiency of thorn buds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

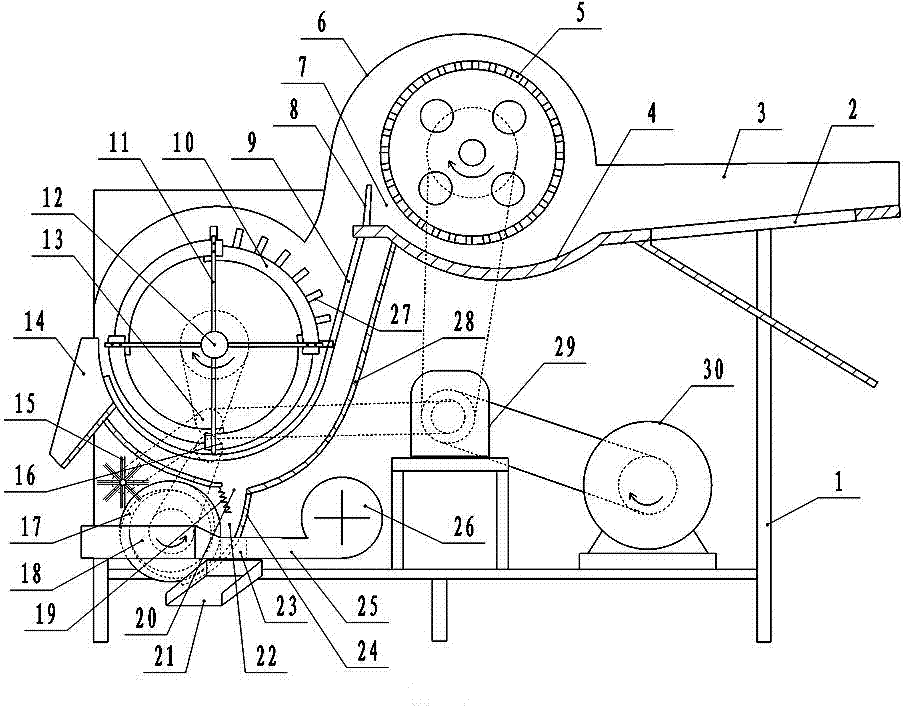

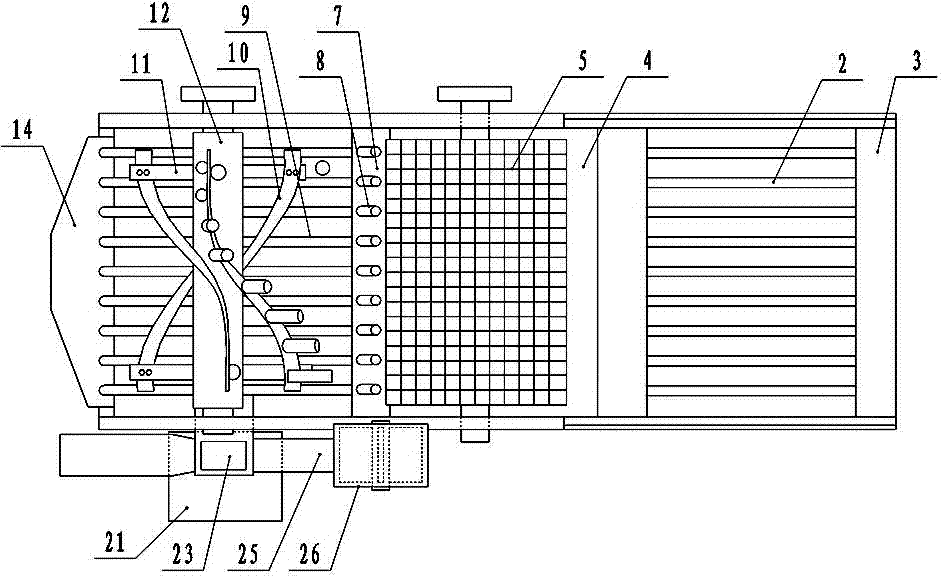

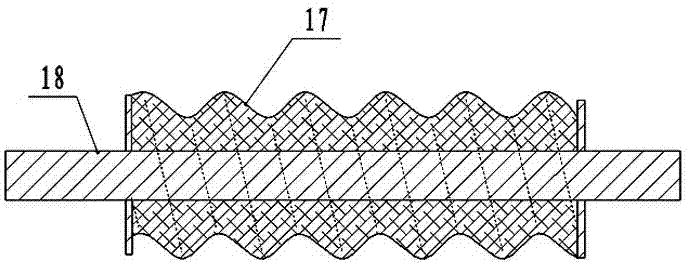

[0013] Example: such as figure 1 , figure 2 , image 3 and Figure 4 Shown, a kind of auger type chestnut thorn bud peeling machine is made up of frame 1, shell 6, rolling device, separating device, discharge device and power unit, and rolling device is made up of mesh-shaped pressure roller 5 and arc-shaped The two ends of the rotating shaft of the pressure roller 5 are installed in the upper middle of the frame 1, the backing plate 4 is installed under the pressure roller 5, the front end of the pressure roller 5 is equipped with a feed plate 3, and the rear end is designed with scraps Outlet 7, the gap between the backing plate 4 and the pressure roller 5 is larger at one end of the feed plate 3, and smaller at the end of the crushed material outlet 7; the separation device is installed below the crushed material outlet 7 of the rolling device; the rolling device and the separation device Installed in the shell 6; the discharge device is installed below the separation d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com