Refrigerant recovery control method and air conditioning system

A control method and refrigerant recovery technology, applied in heating and ventilation control systems, heating and ventilation safety systems, refrigerators, etc., can solve problems affecting production efficiency, customer complaints, pollution of the surface of the unit, etc., to achieve no refrigerated oil residue, It is easy to achieve the effect of promotion and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

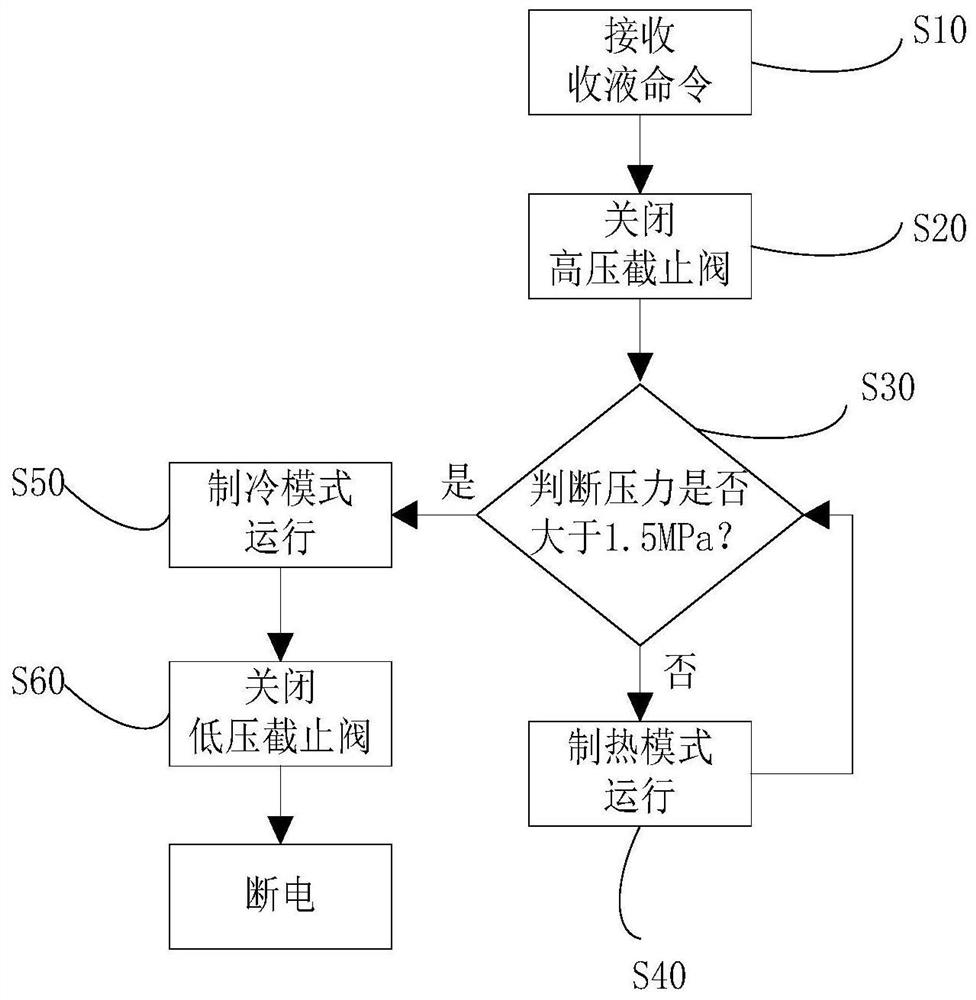

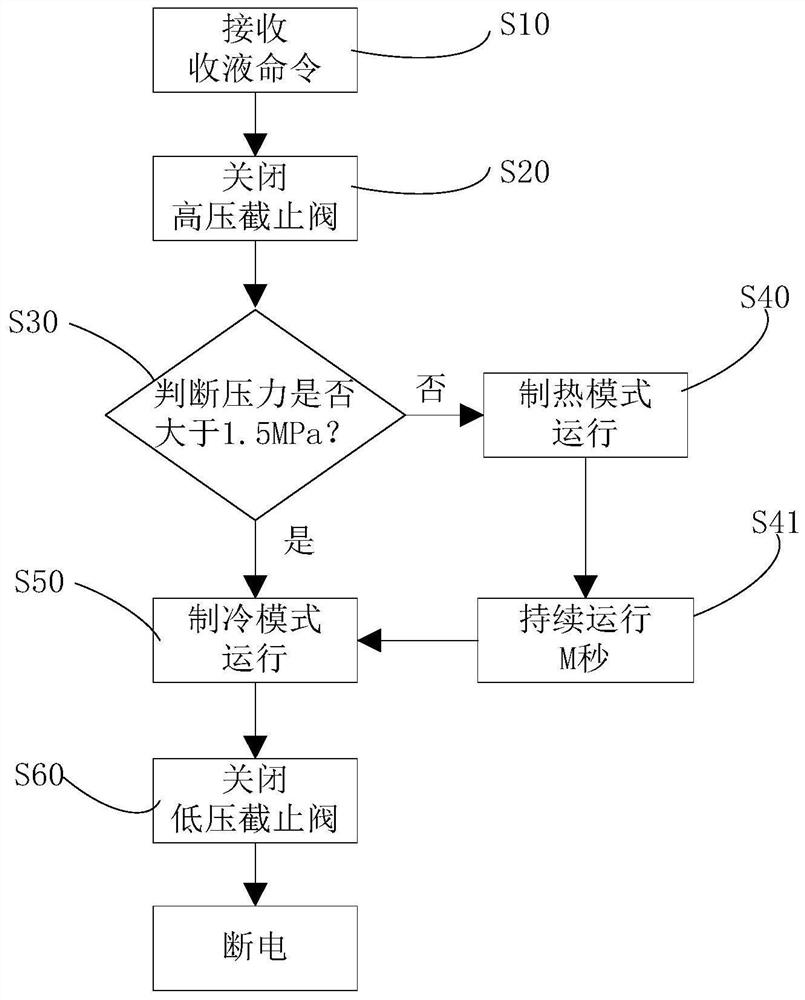

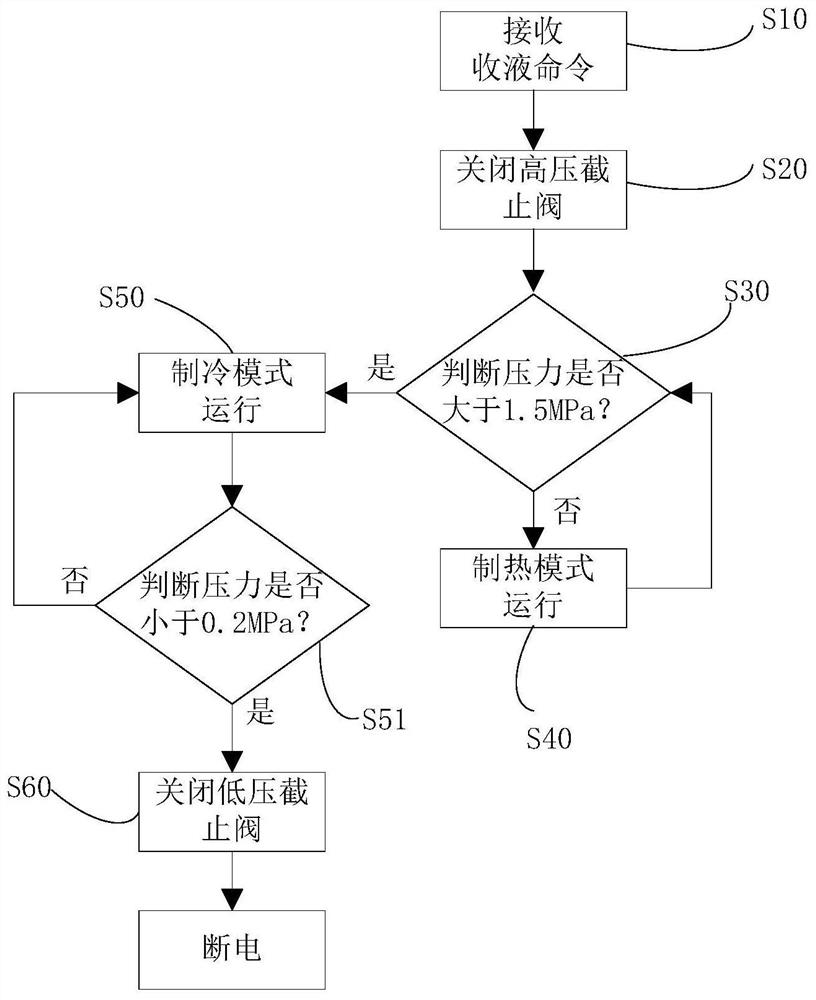

[0033] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] During the commercial inspection and test, the air conditioner is generally tested for heating mode operation and cooling mode operation, and then the liquid collection operation (recovering the refrigerant in the pipeline to the compressor of the outdoor unit) is performed so that the subsequent indoor and outdoor units can be disconnected. When the connection is opened, there will be no residual refrigerant in the indoor unit, and the amount of refrigerant in the compressor can also be guaranteed.

[0035] The two ends of the pipeline of the indoor heat exchanger of the air conditioner communicate with the outdoor heat exchanger and the compressor respectively through a high-pressure cut-off valve and a low-pressure cut-off valve, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com