Patents

Literature

3075 results about "System pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

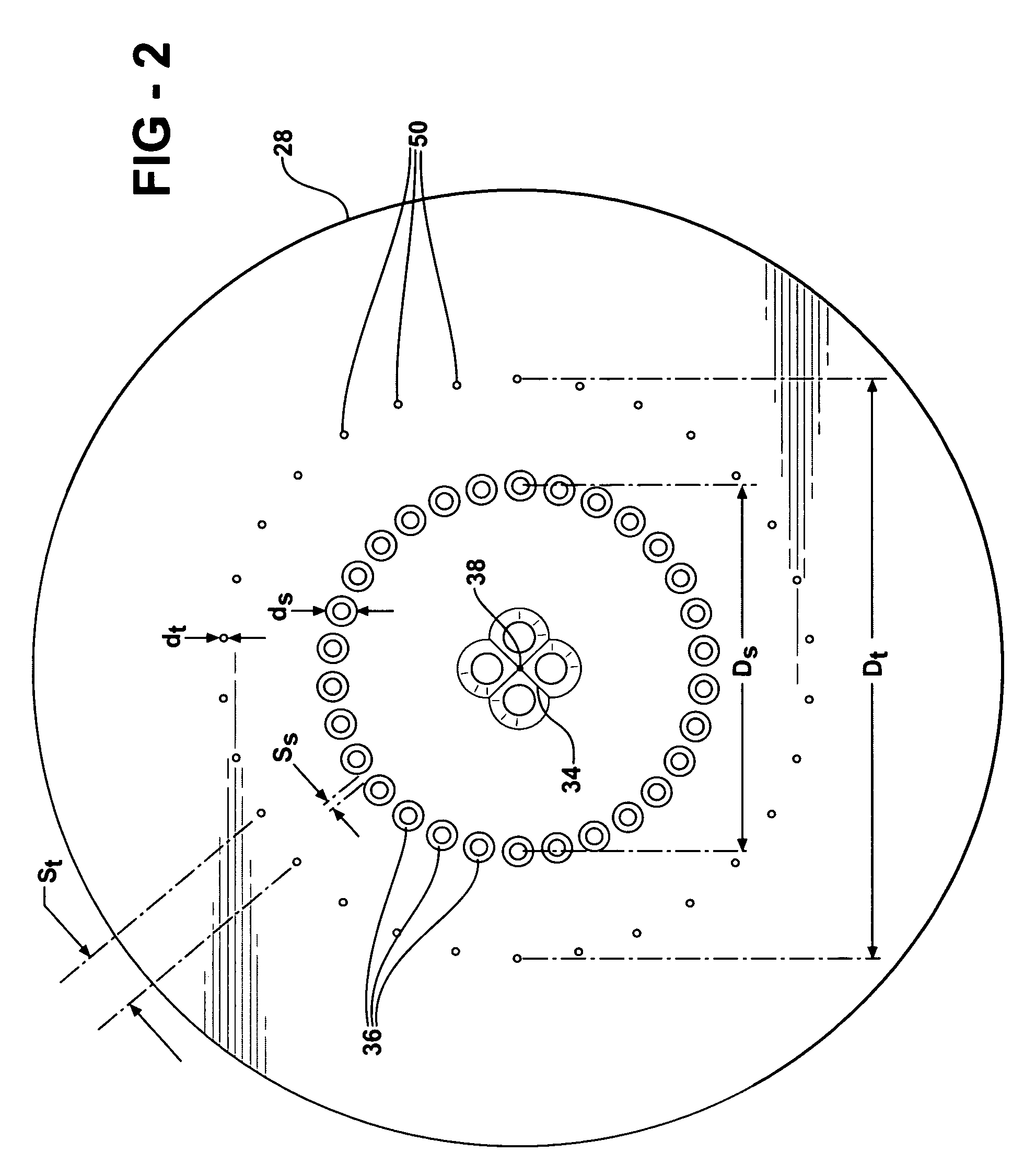

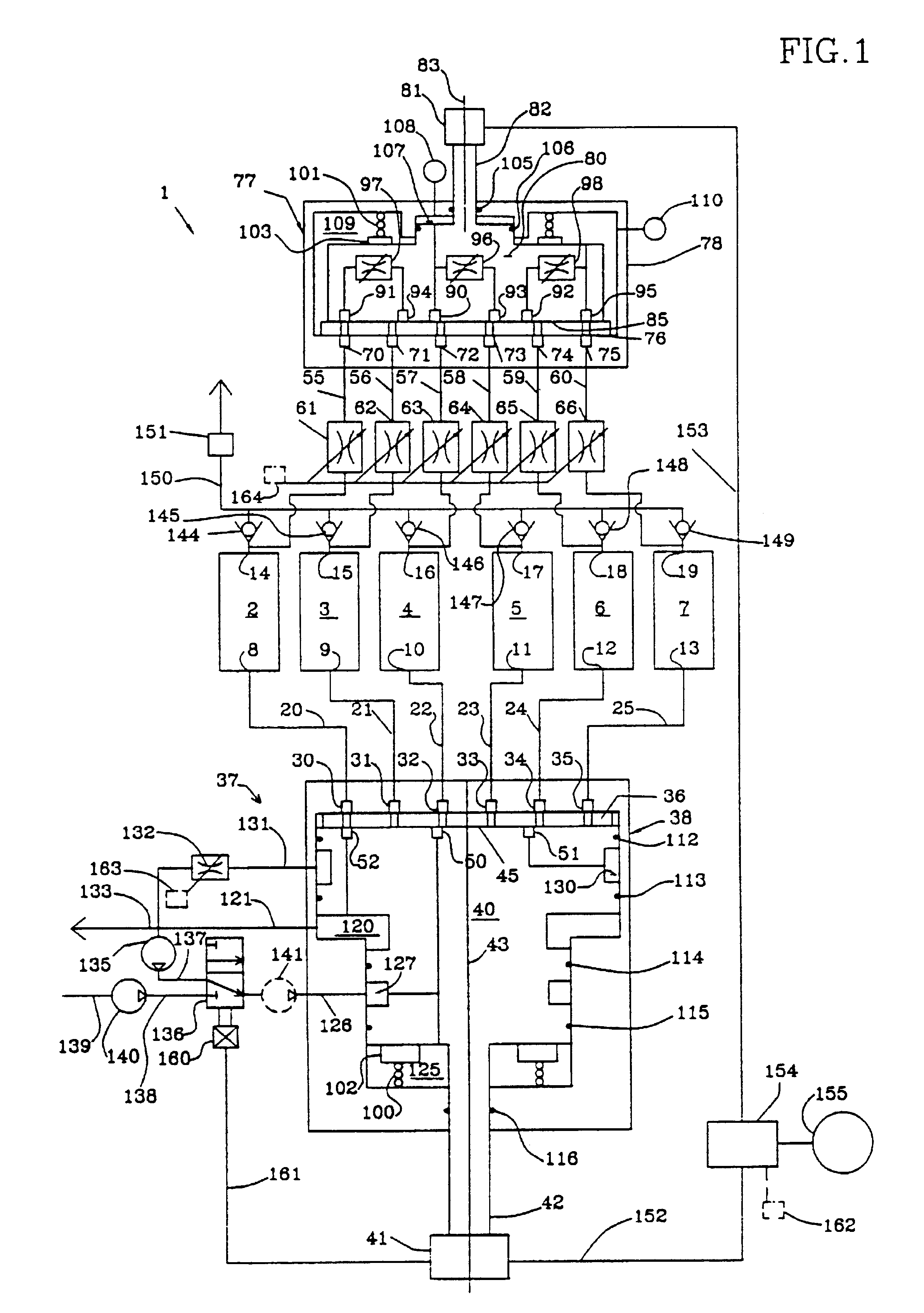

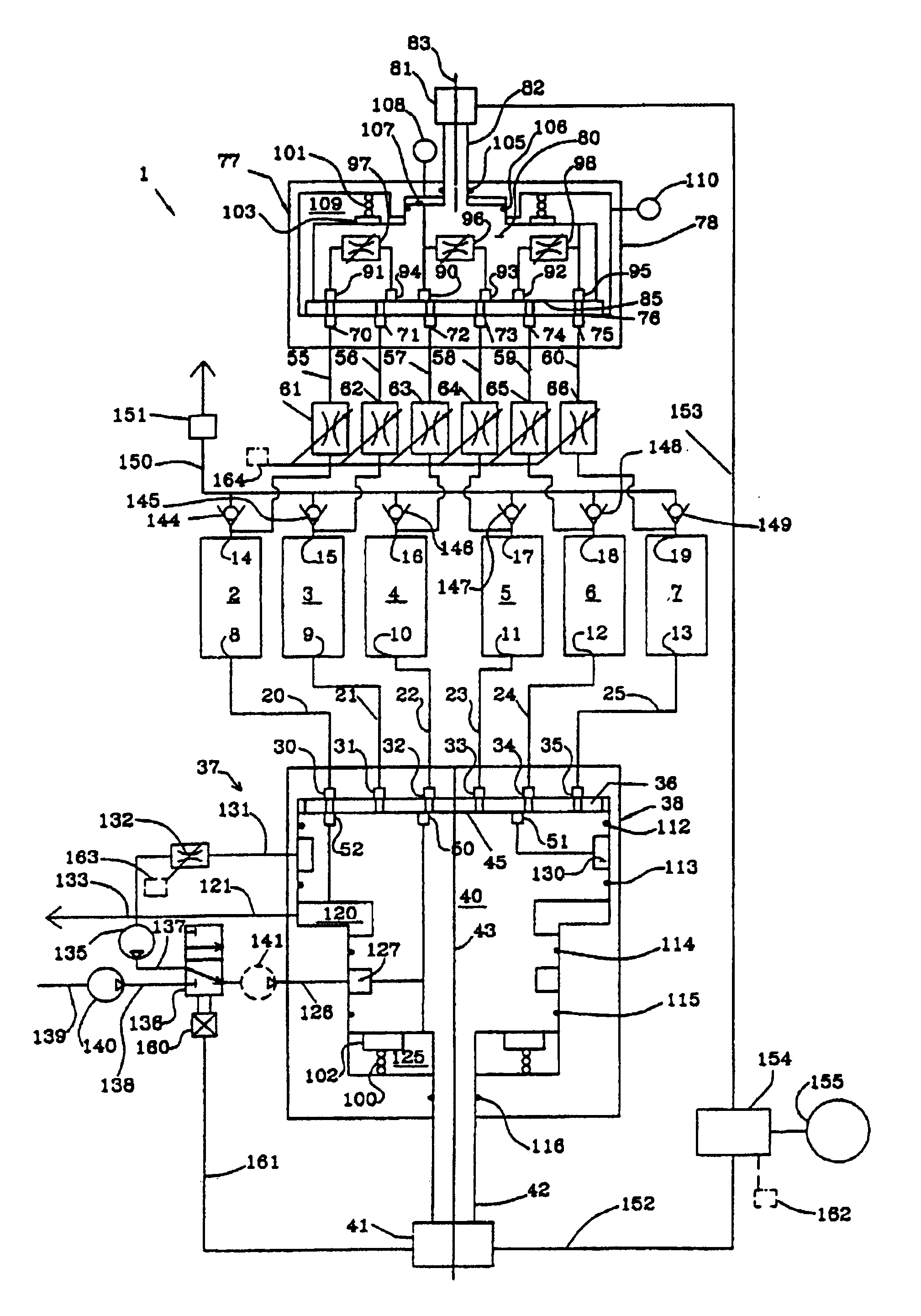

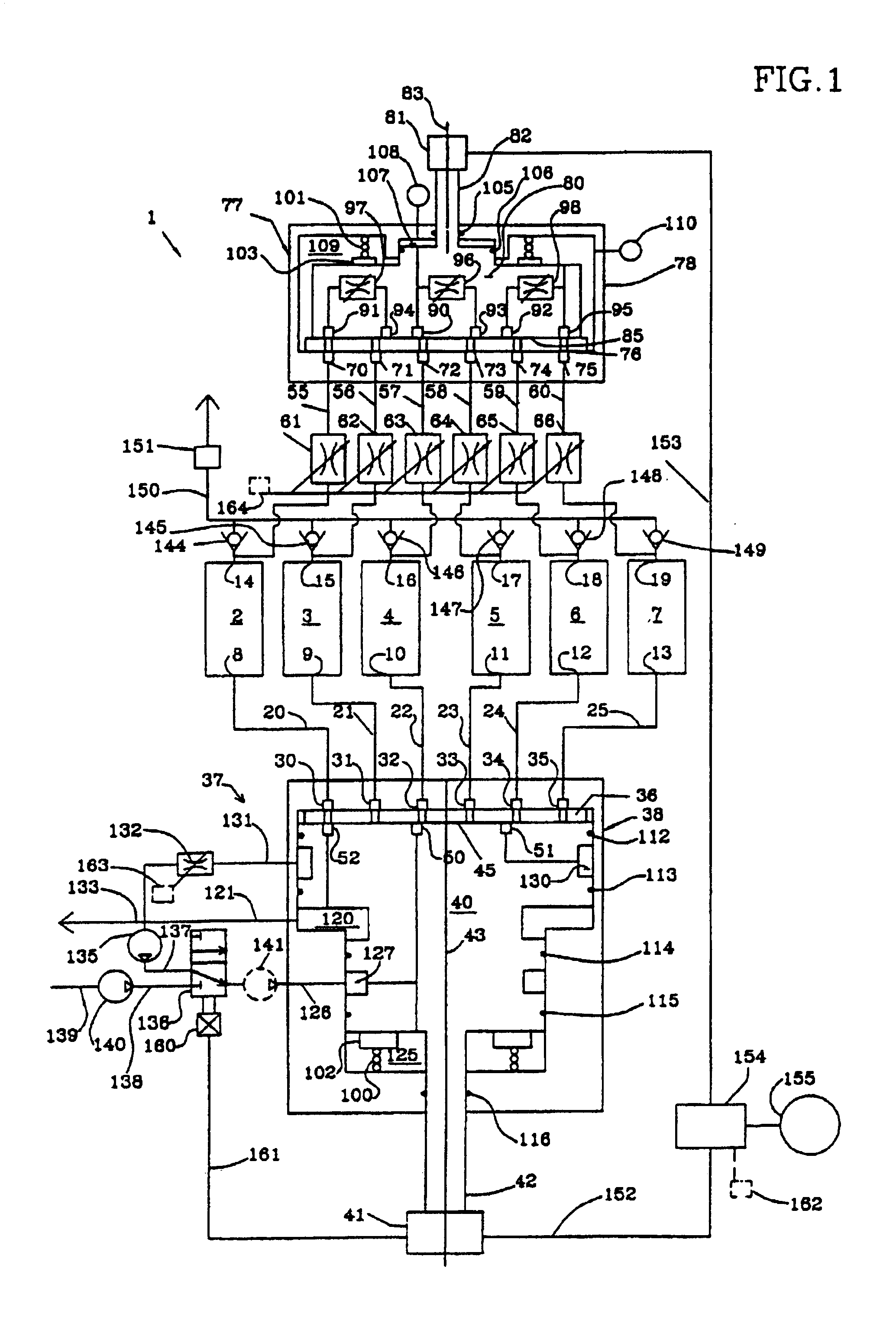

Flow regulated pressure swing adsorption system

InactiveUS6063161AAvoid damageGas treatmentHydrogen separation using solid contactSystem pressureProcess engineering

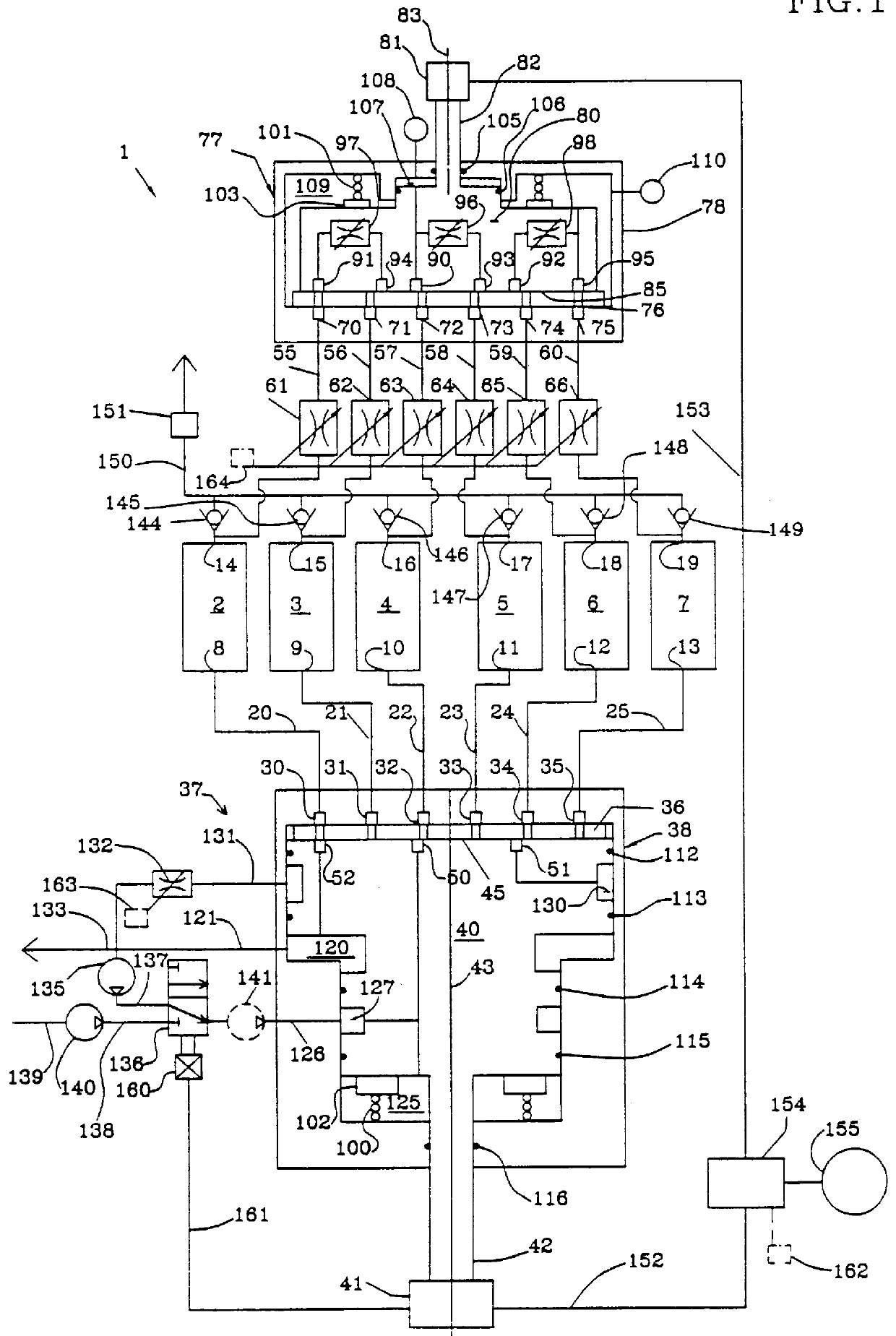

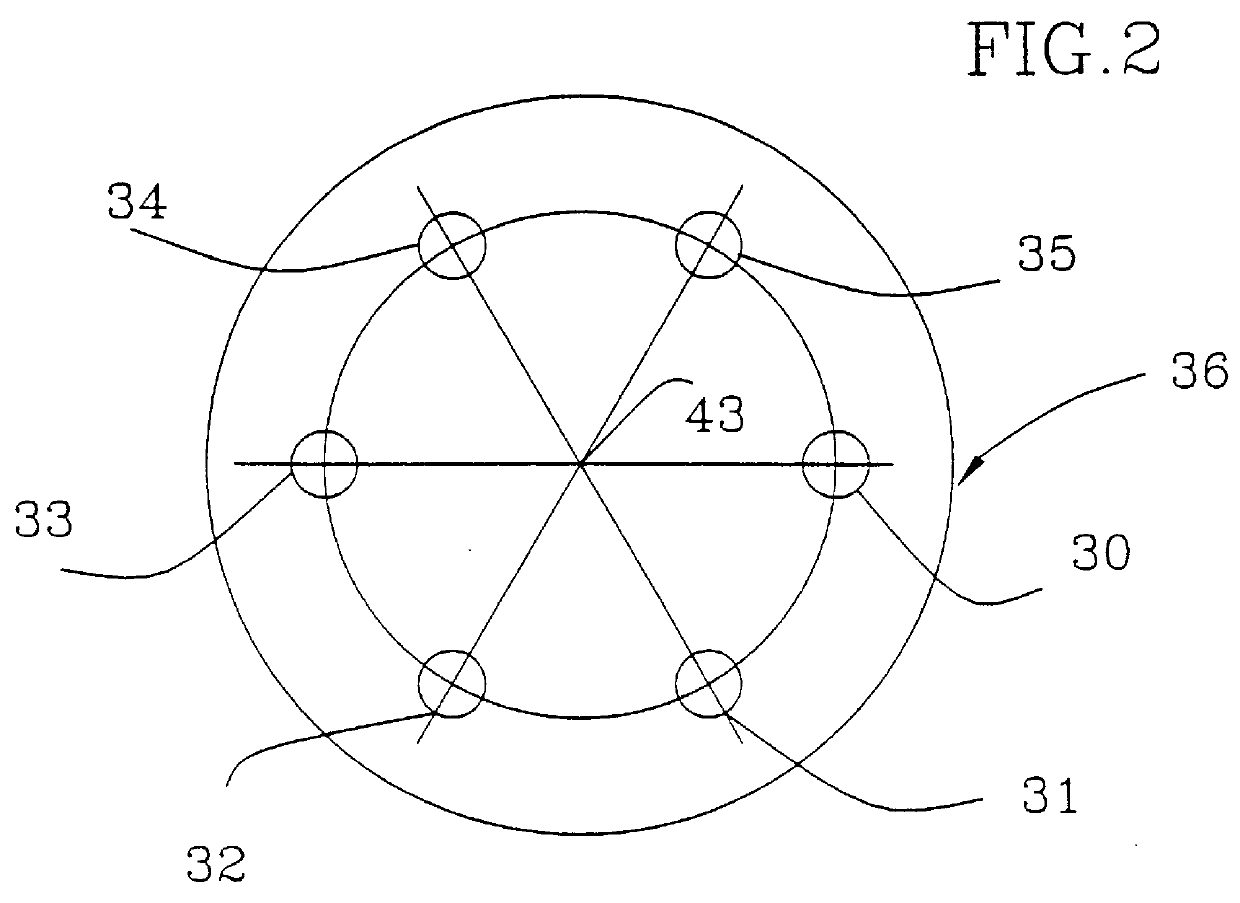

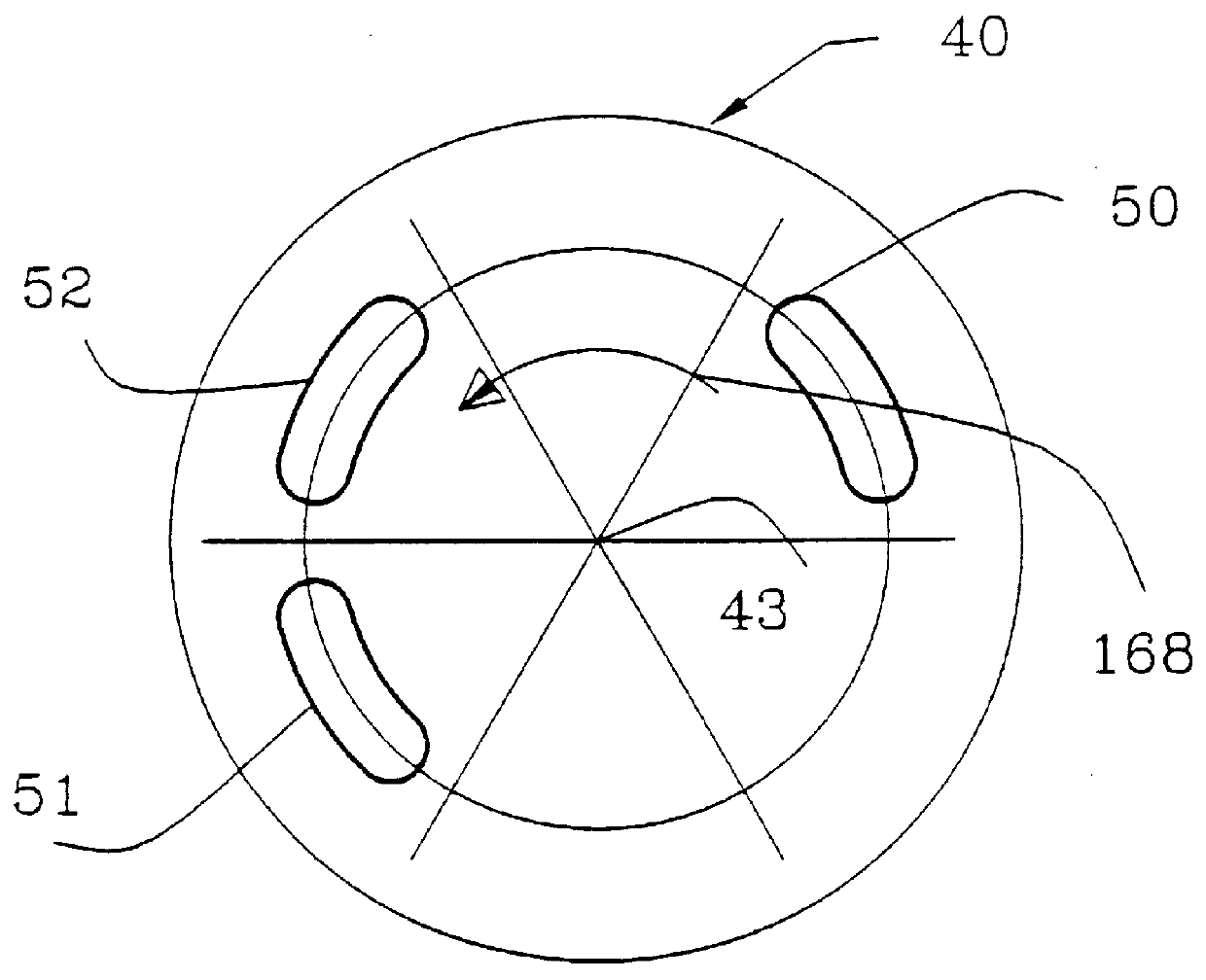

Pressure swing adsorption (PSA) separation of a gas mixture is performed in an apparatus with a plurality of adsorbent beds. The invention provides rotary multiport distributor valves to control the timing sequence of the PSA cycle steps between the beds, with flow controls cooperating with the rotary distributor valves to control the volume rates of gas flows to and from the adsorbent beds in blowdown, purge, equalization and repressurization steps.

Owner:QUSIR TECH +1

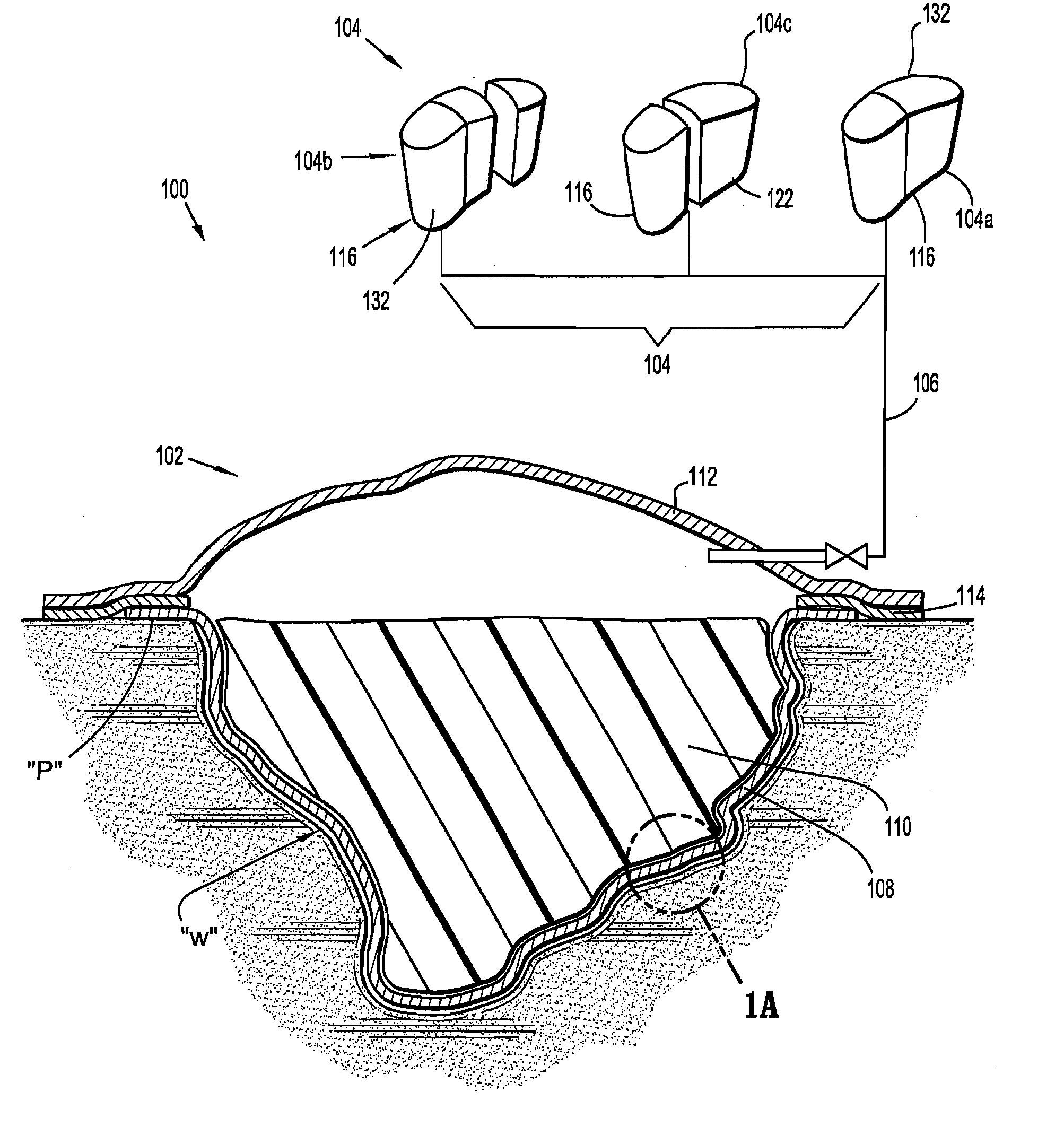

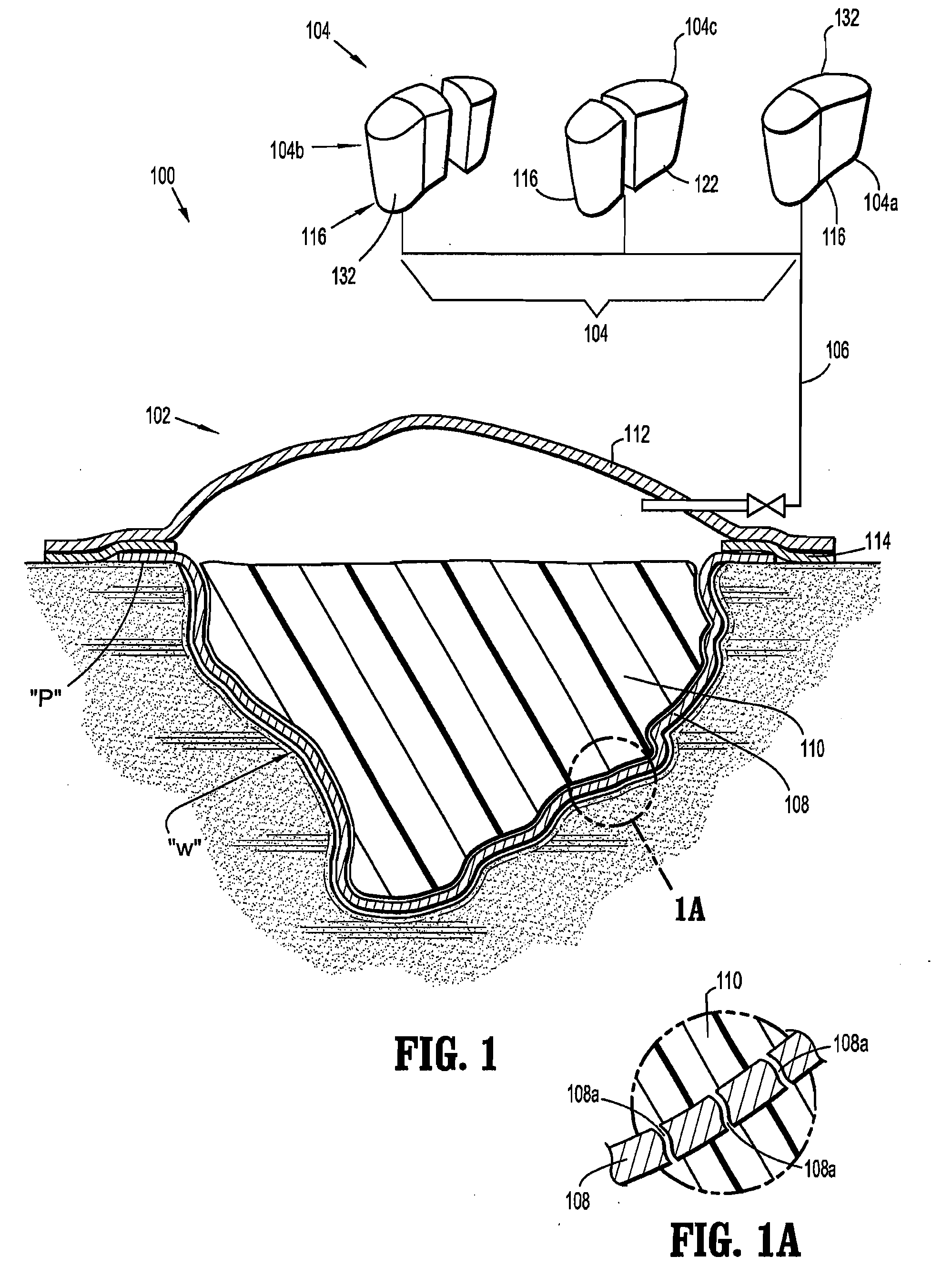

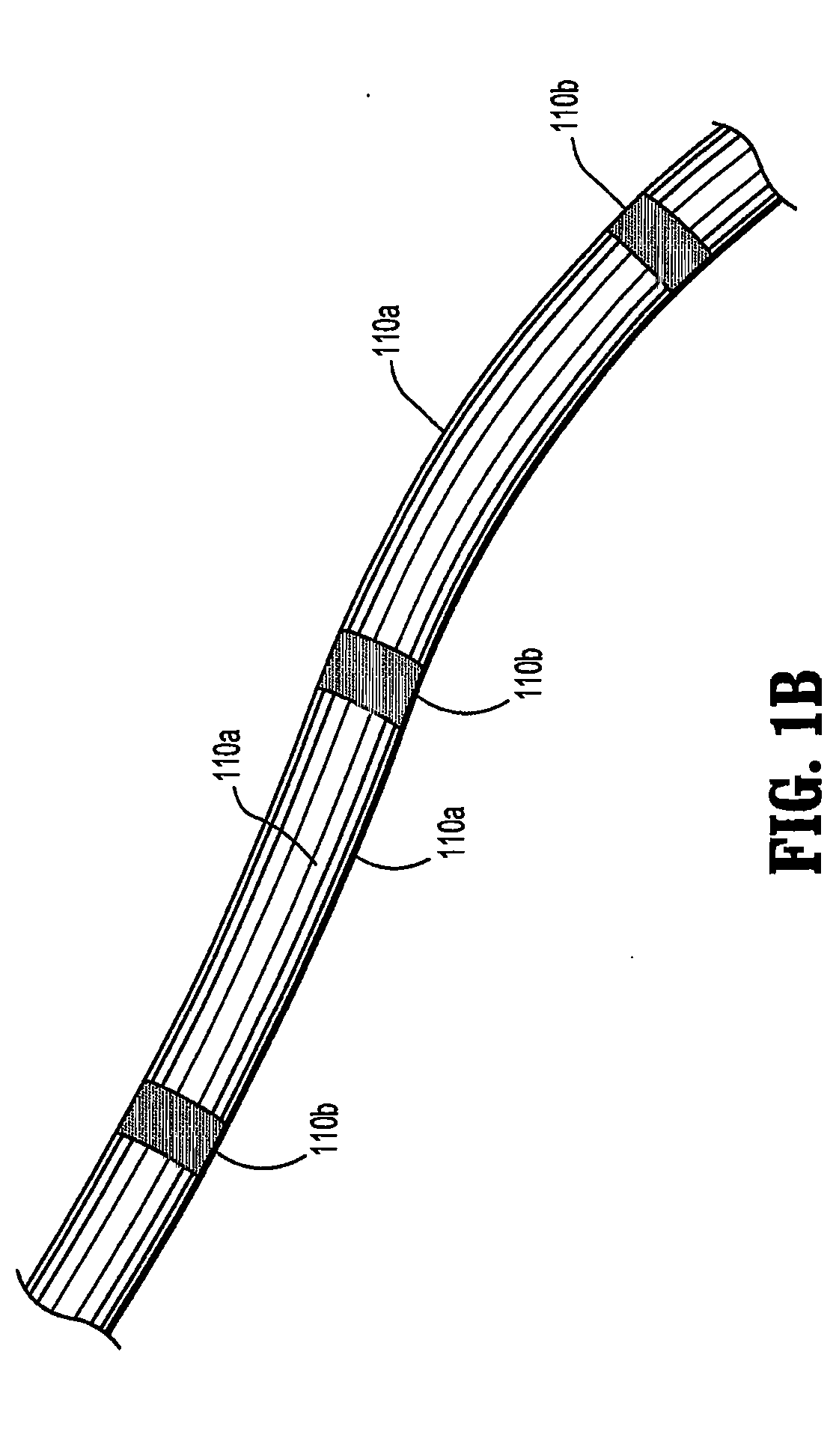

Portable wound therapy system

A portable system for subatmospheric pressure therapy in connection with healing a surgical wound, includes a wound dressing dimensioned for positioning relative to a wound bed of a subject, a portable subatmospheric pressure mechanism dimensioned to be carried or worn by the subject and a container for collecting exudates from the wound bed removed under the subatmospheric pressure supplied by the subatmospheric pressure mechanism. The portable subatmospheric pressure mechanism includes a housing, a subatmospheric pressure source disposed within the housing and in fluid communication with the wound dressing to supply subatmospheric pressure to the wound dressing and a power source mounted to or within the housing for supplying power to actuate the subatmospheric pressure source.

Owner:SMITH & NEPHEW INC

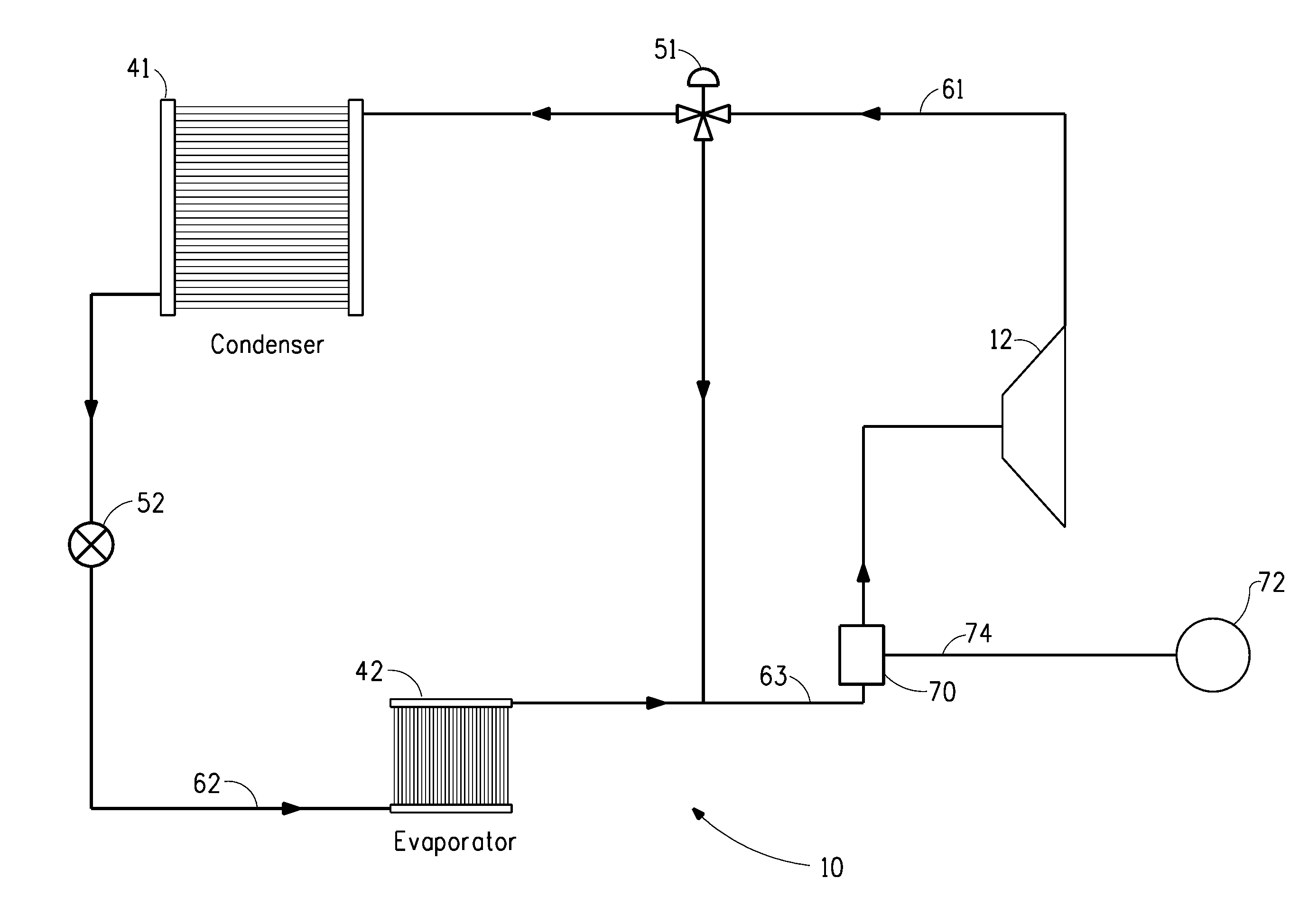

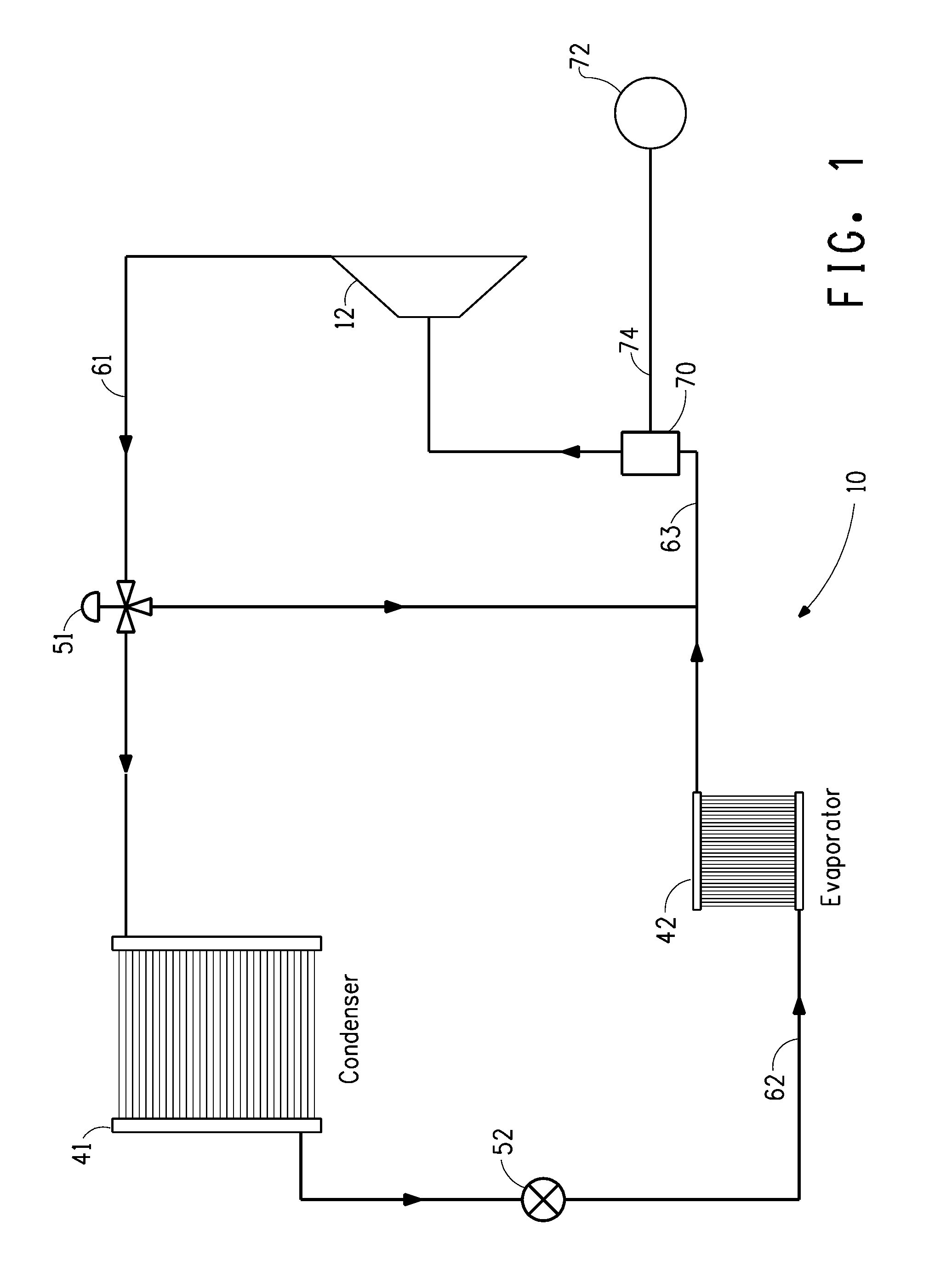

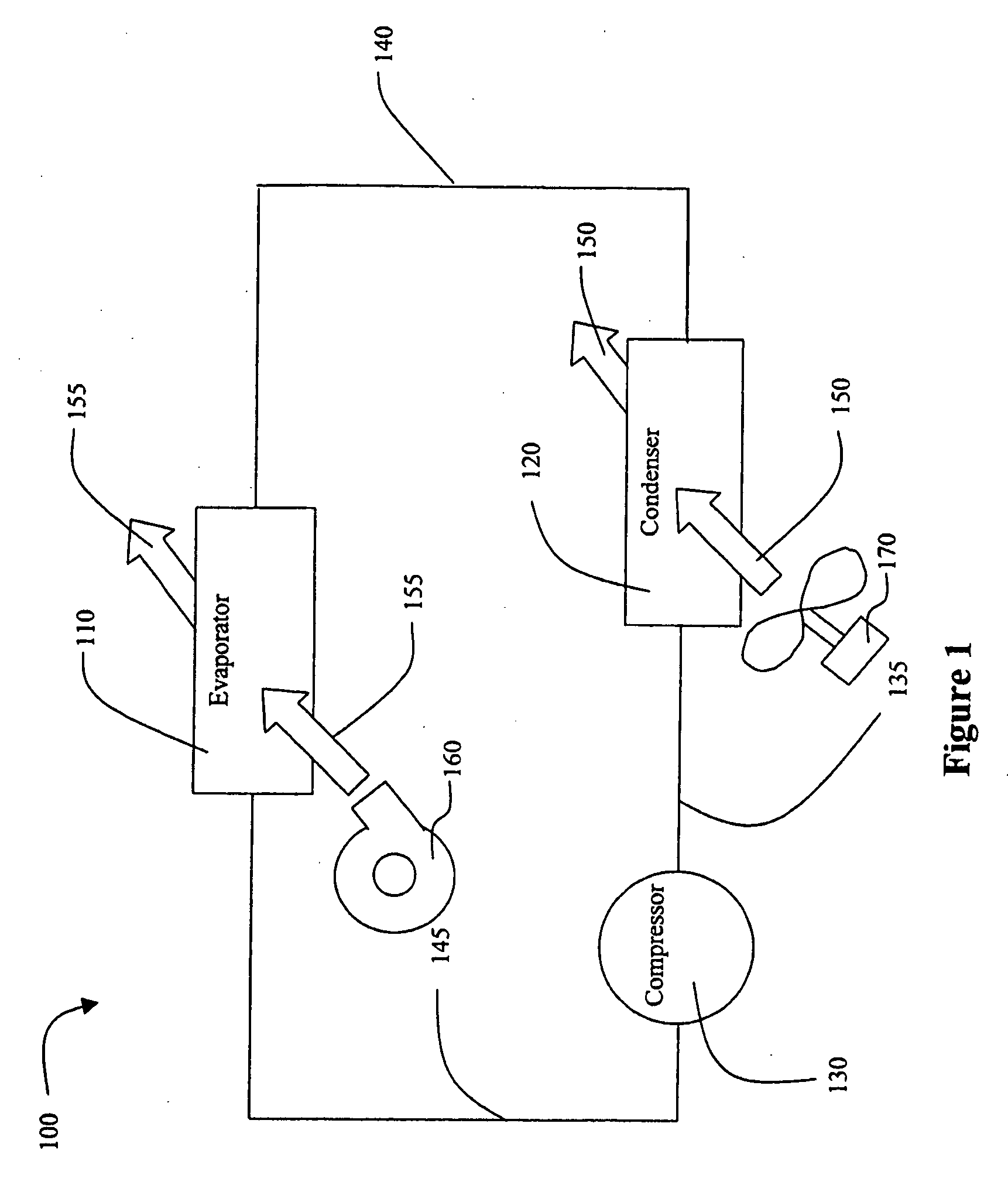

Method for leak detection in heat transfer systems

InactiveUS20080314073A1Low vapor pressureMeasurement of fluid loss/gain rateCompression machines with non-reversible cycleTransfer systemSystem pressure

Disclosed is a method for detecting a leak in a closed loop heat transfer system comprising monitoring the pressure of the heat transfer composition inside said heat transfer system, wherein a drop in pressure indicates a leak. Also disclosed is a heat transfer system comprising an evaporator, a compressor, a condenser, an expander and a device for measuring internal system pressure. The system pressure measuring device is disposed inside the closed loop heat system. The internal system pressure measuring means may be located either between the evaporator and the condenser, between the expander and the evaporator, between the compressor and the condenser, or between the condenser and the expander.

Owner:EI DU PONT DE NEMOURS & CO

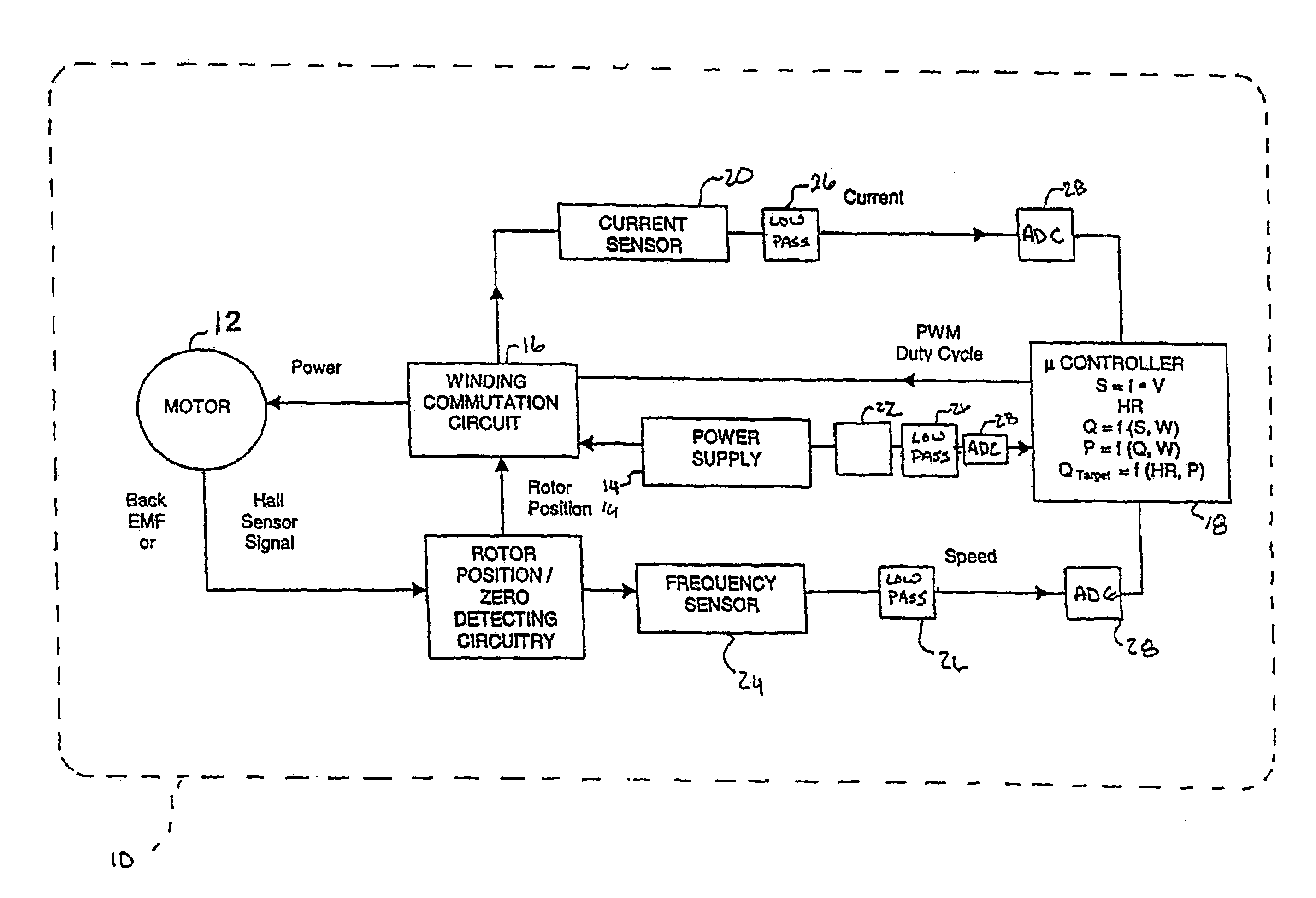

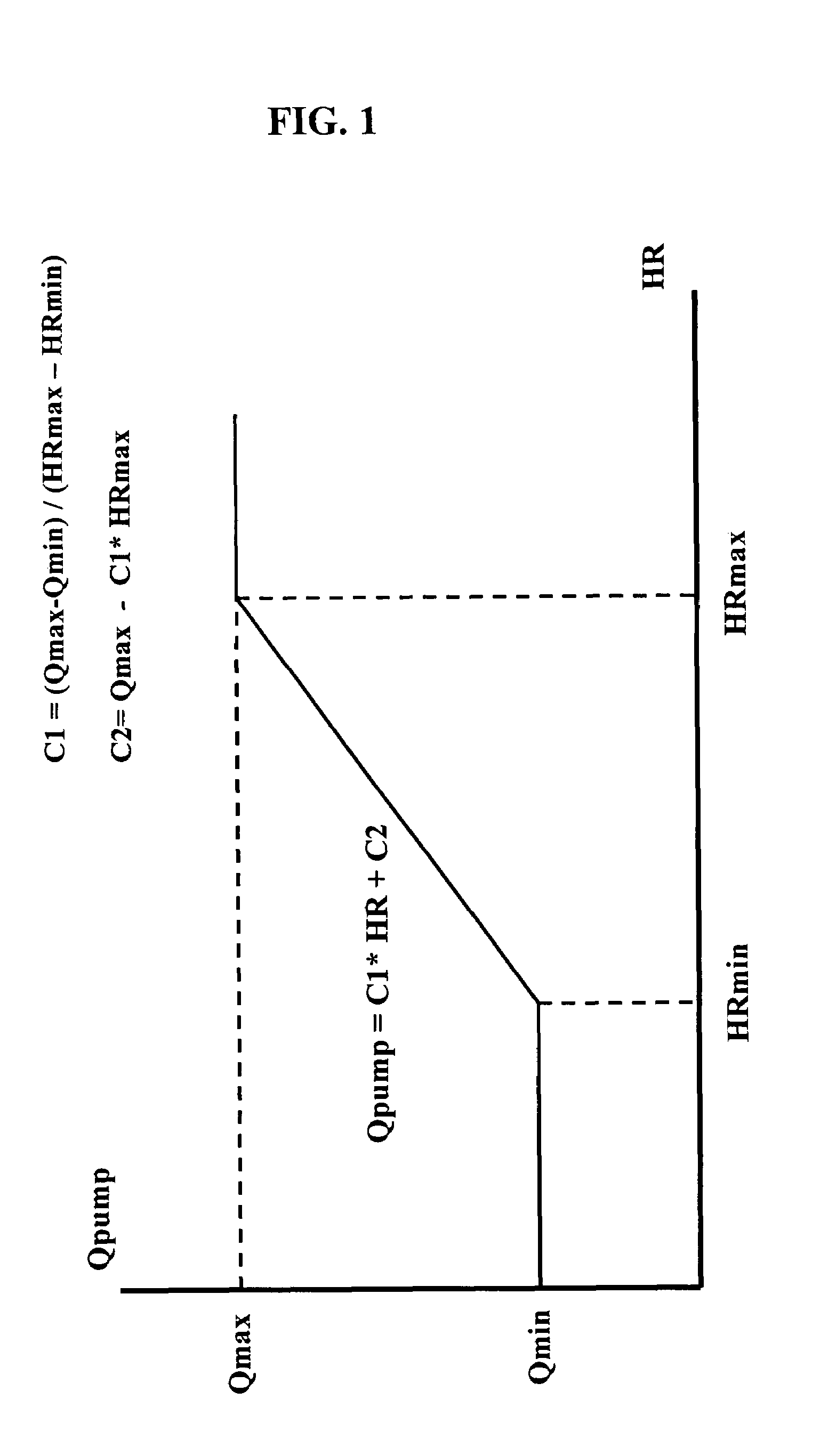

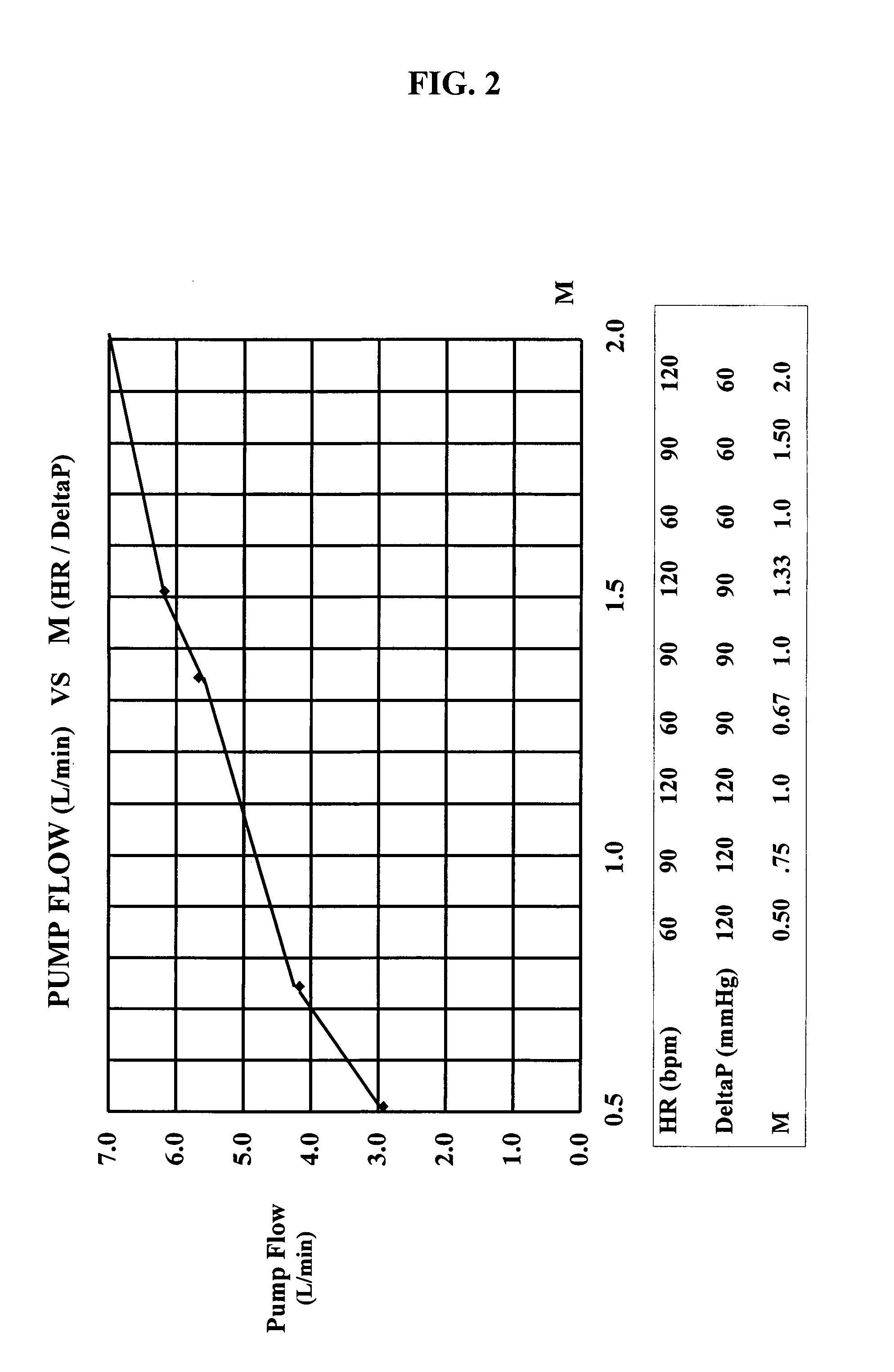

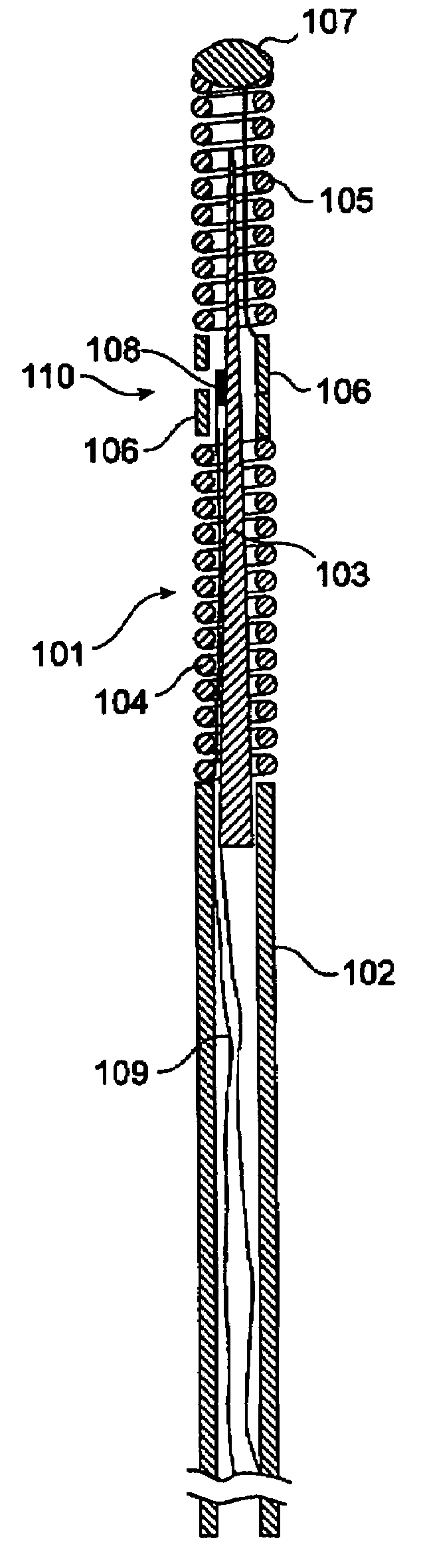

Chronic performance control system for rotodynamic blood pumps

InactiveUS7645225B2Simple control circuitIncrease control flexibilityDC motor speed/torque controlAC motor controlMicrocontrollerMotor speed

In a left ventricular assist device (LVAD) a rotodynamic blood pump (10) is powered by a brushless DC motor (12). A power supply (14) supplies power to the motor (12). Three feedback channels, one for each of voltage, current, and motor speed lead to a microcontroller or microprocessor (18). The three feedback waveforms are analyzed, and from these waveforms, motor input power, patient heart rate, current pump flow rate, and systemic pressure are determined. The microprocessor (18) then calculates a desired flow rate proportional to the patient heart rate. The microprocessor communicates a new power output to a commutation circuit (16), which regulates power to the motor (12). The pump (10) also includes safety checks that are prioritized over desired pump flow. These include prevention of ventricular suction, low pulsatility, minimum and maximum pump speed, minimum speed-relative pump flow, minimum absolute pump flow, minimum and maximum motor input power.

Owner:MEDVEDEV ALEXANDER +2

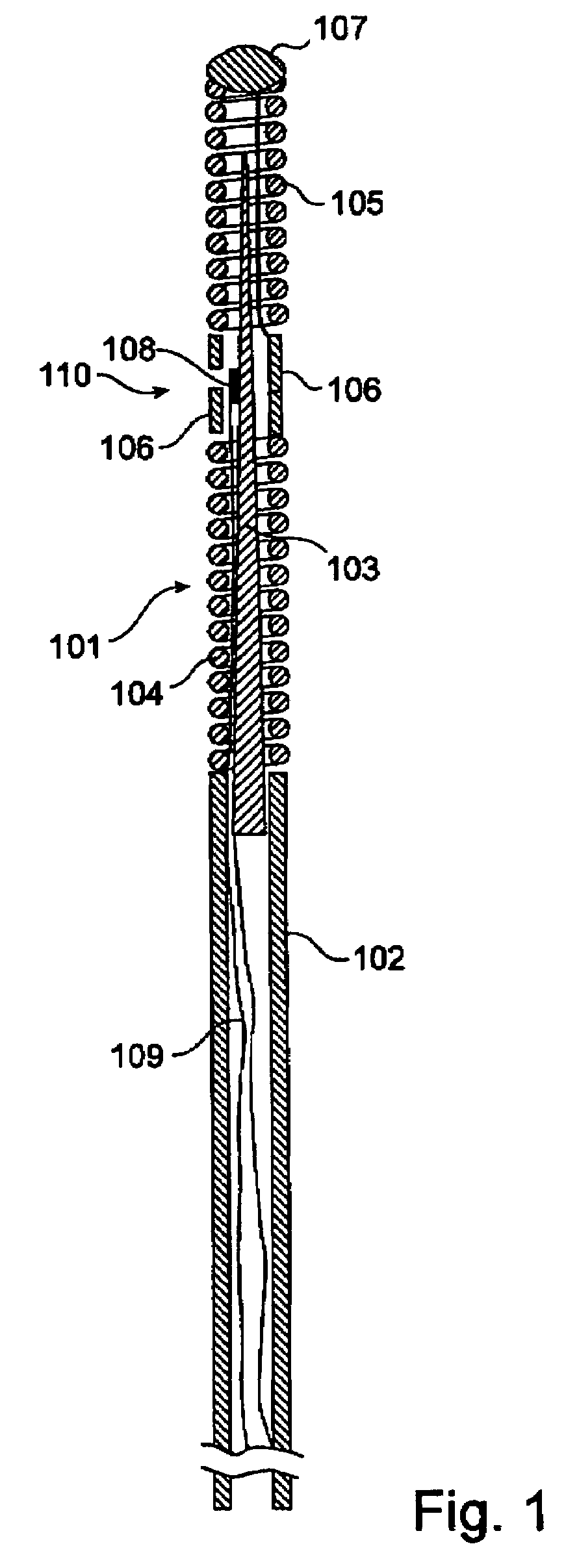

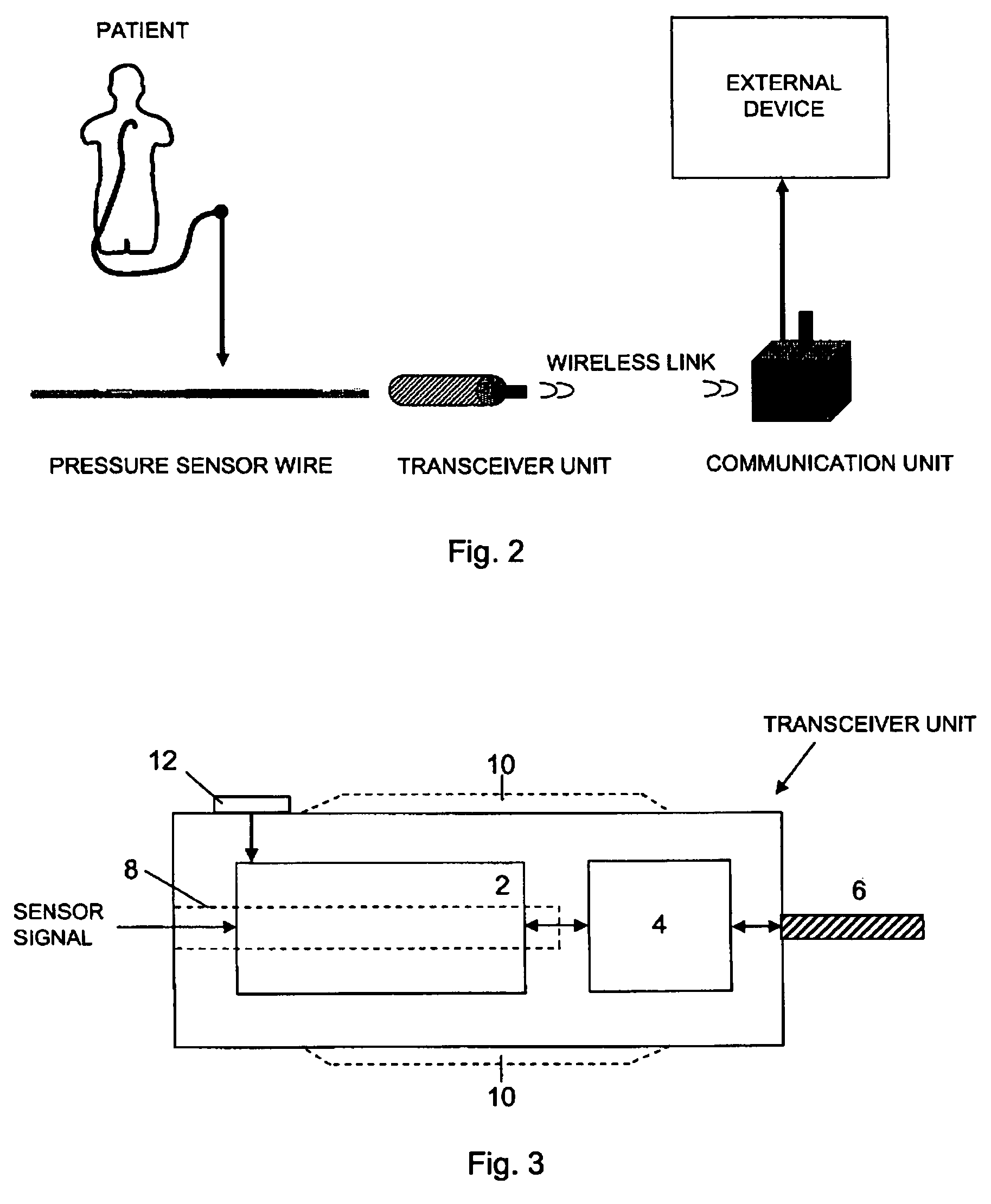

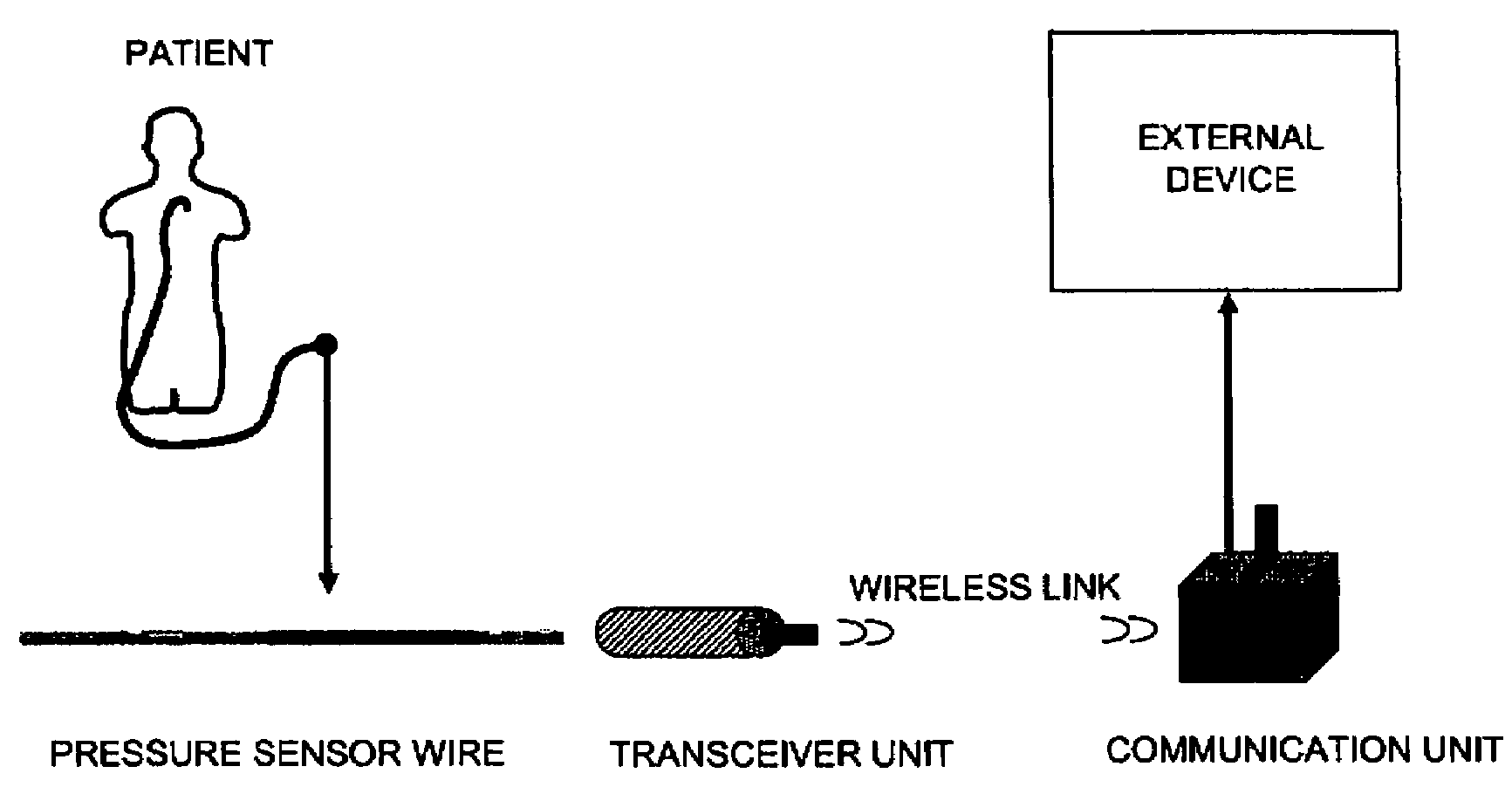

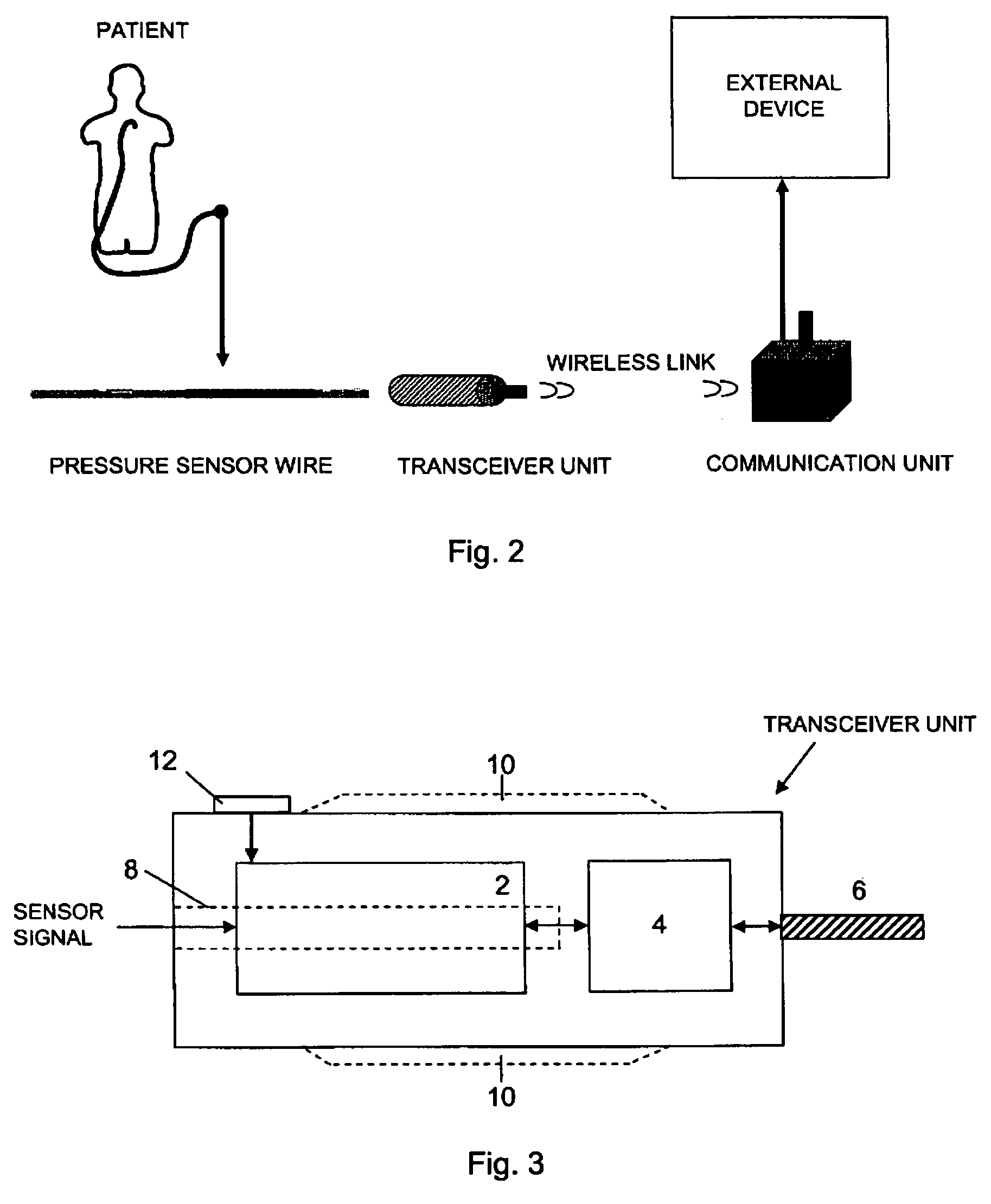

Transceiver unit in a pressure measurement system

Pressure measurement system comprising a pressure sensor wire with a pressure sensor to measure pressure inside a patient, and to provide measured pressure data to an external device. The pressure sensor wire is adapted to be connected, at its proximal end, to a transceiver unit that is adapted to wirelessly communicate via a communication signal with a communication unit arranged in connection with an external device, in order to transfer measured pressure data to the external device. The pressure data to be transferred is generated by the transceiver unit and transferred as a data stream. Preferably, the communication signal is a radio frequency signal.

Owner:ST JUDE MEDICAL COORDINATION CENT

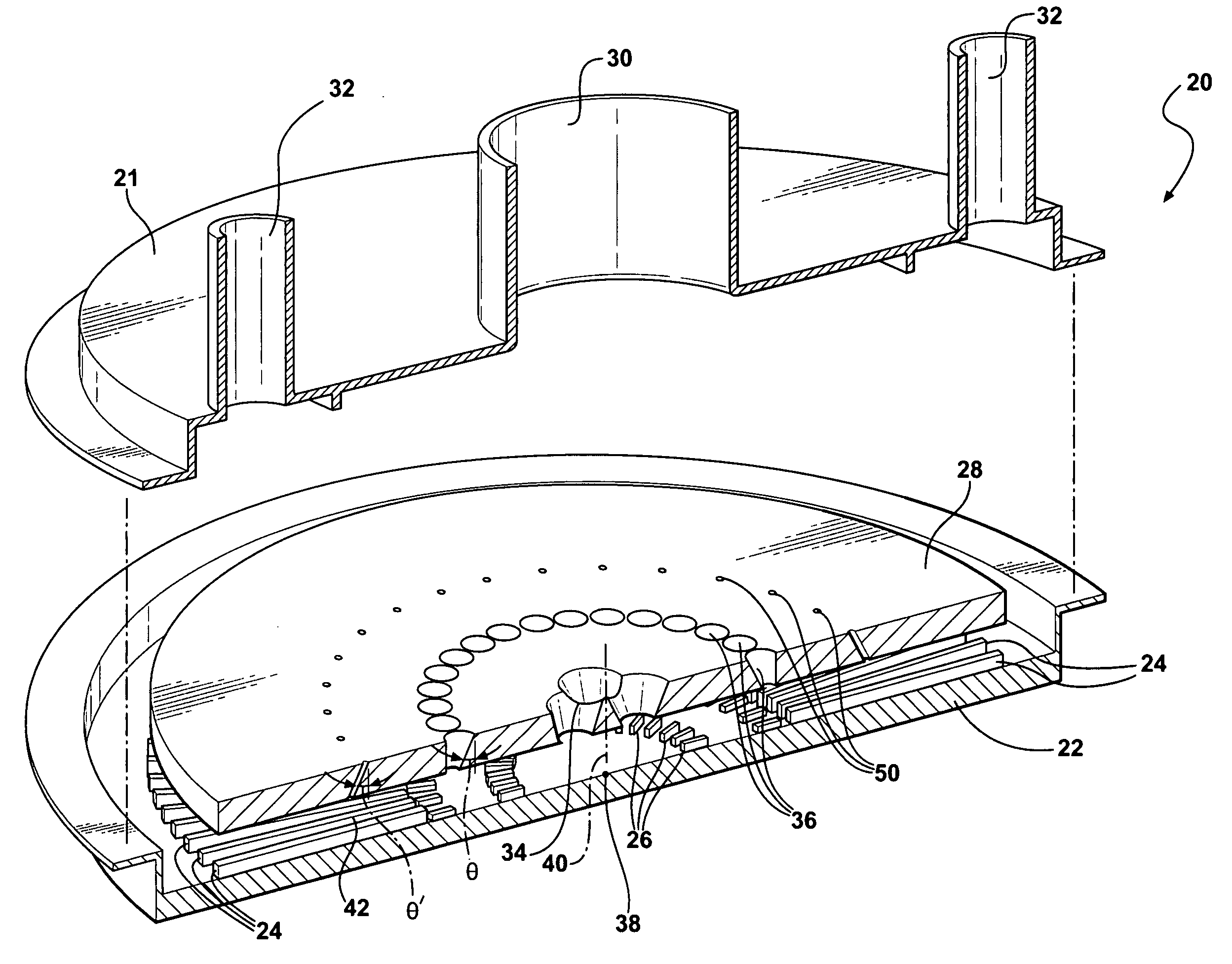

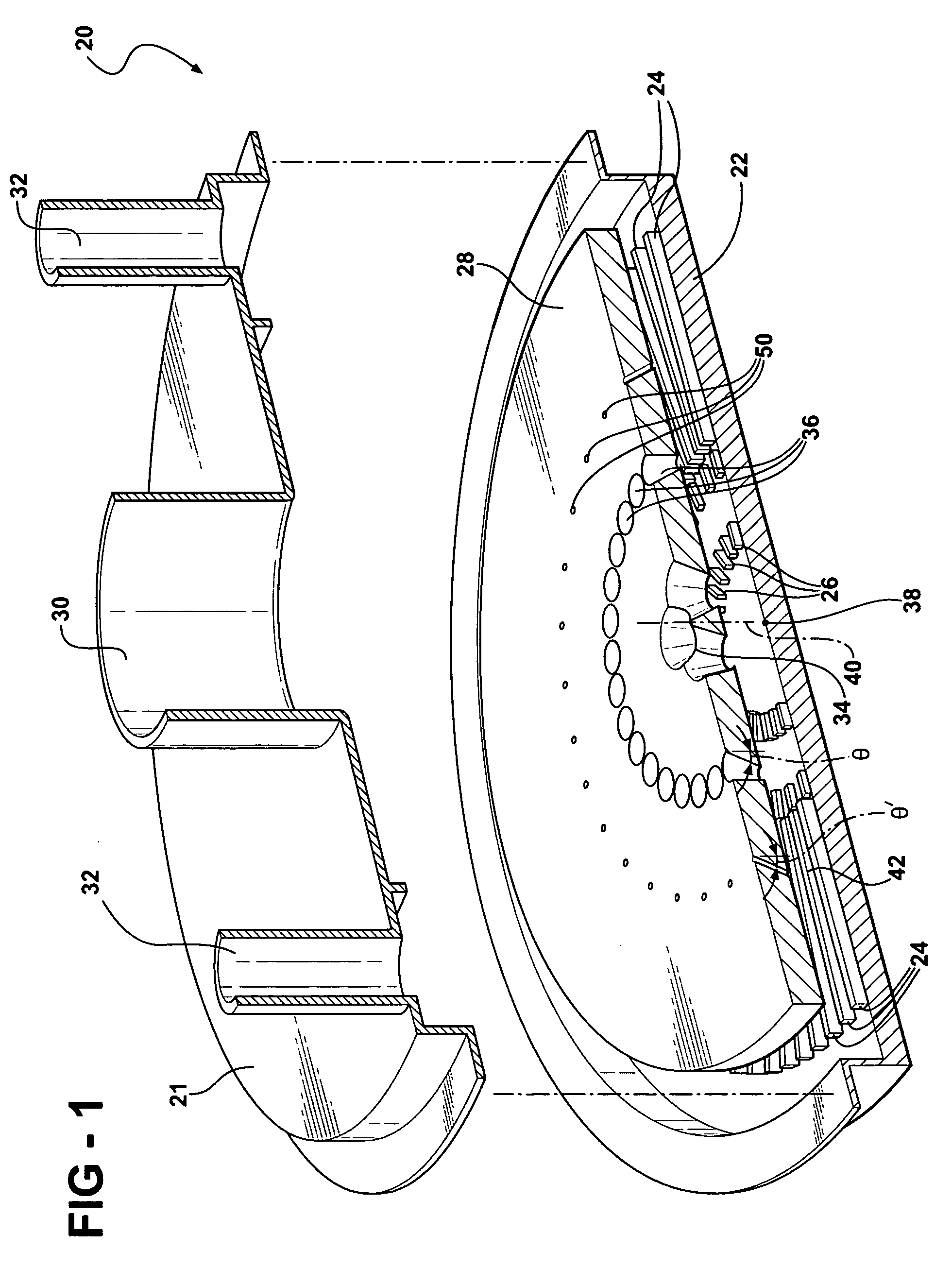

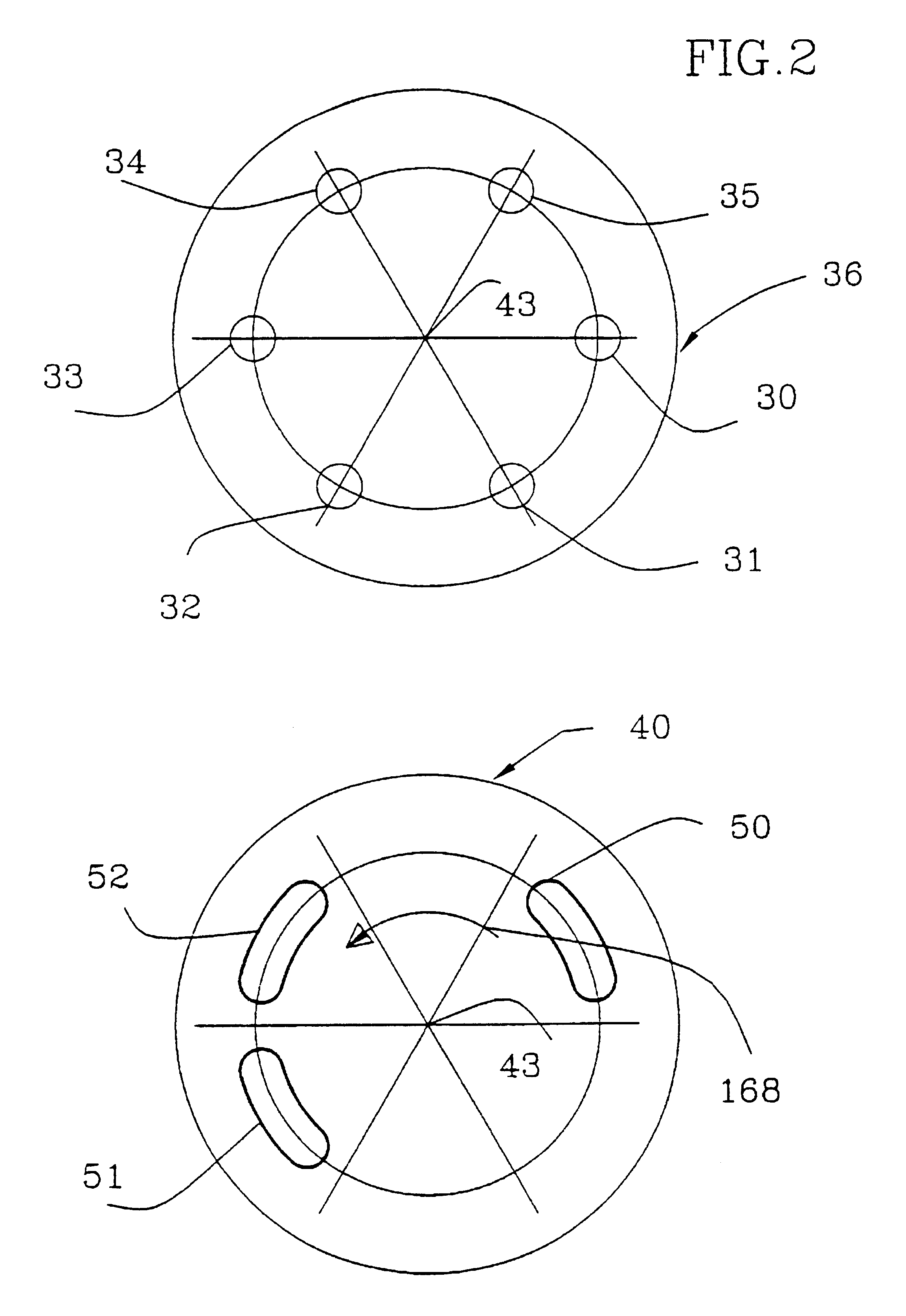

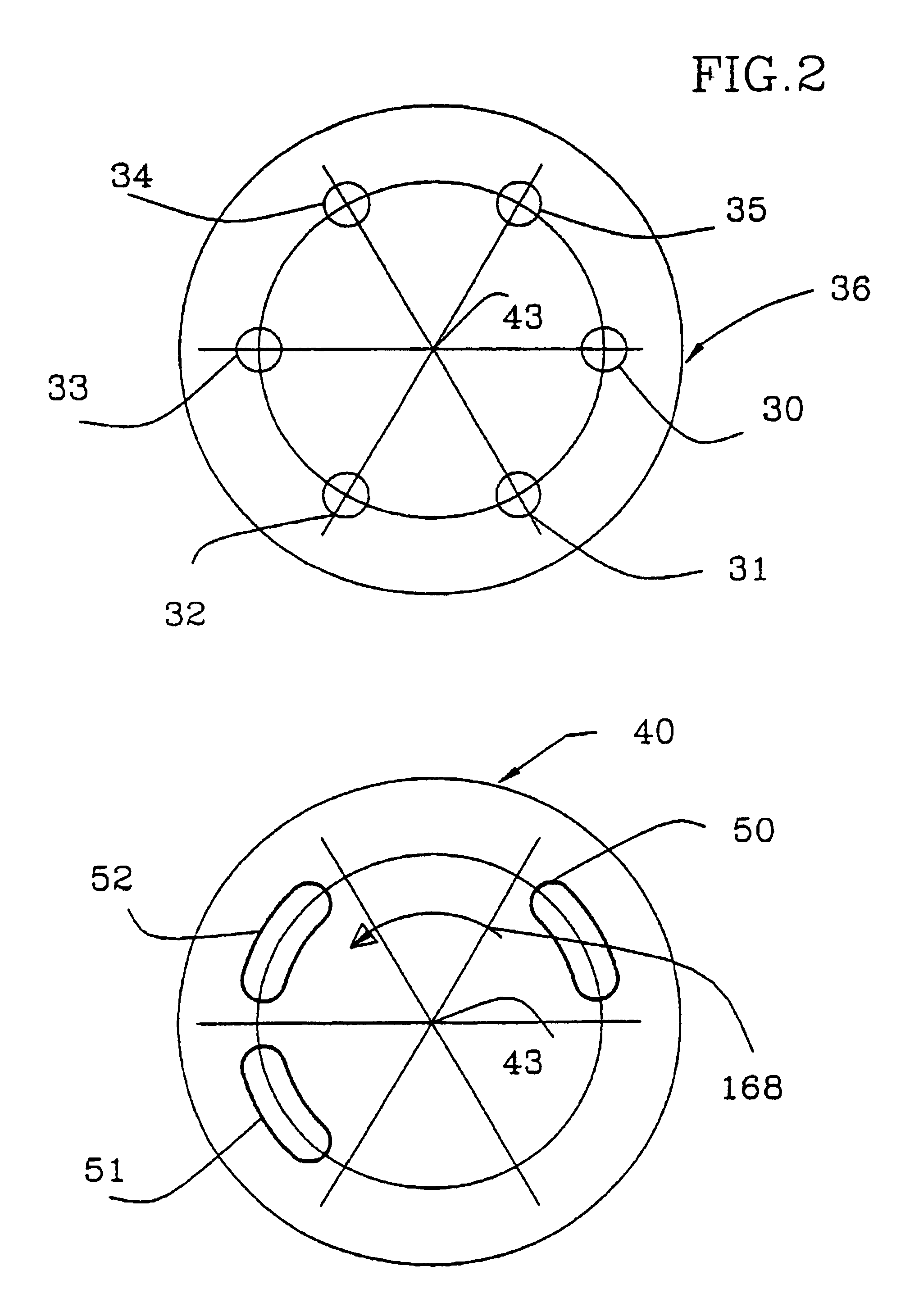

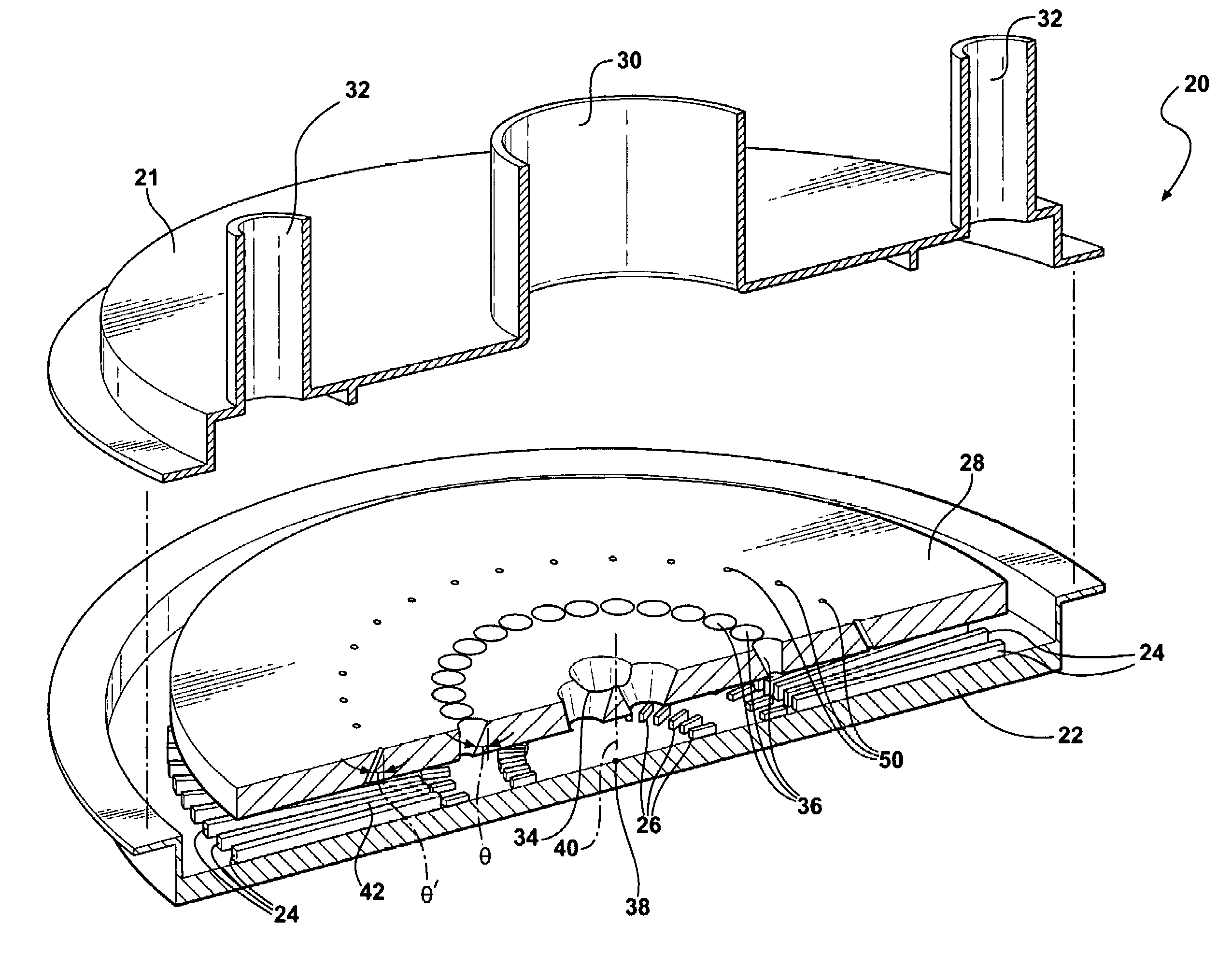

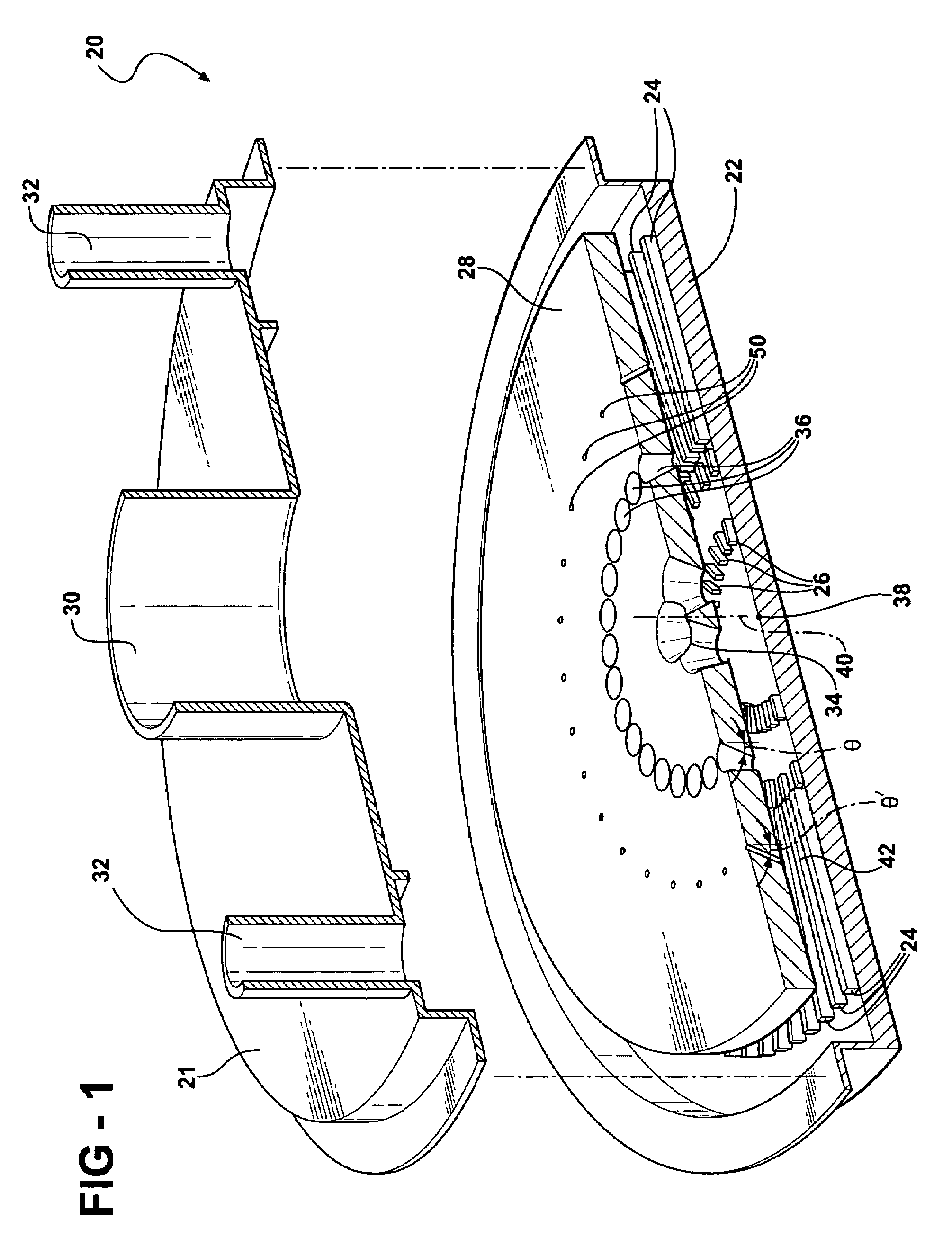

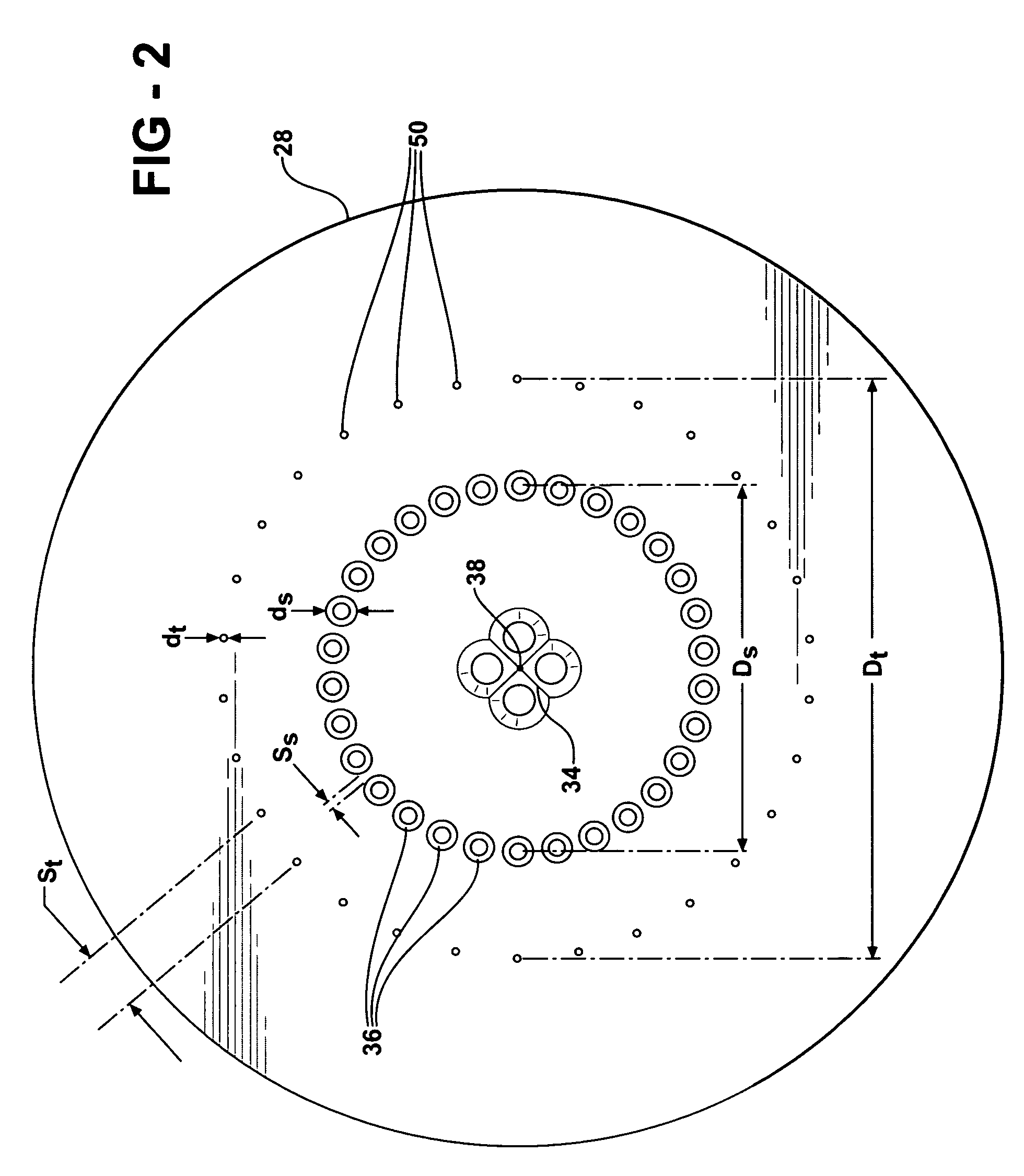

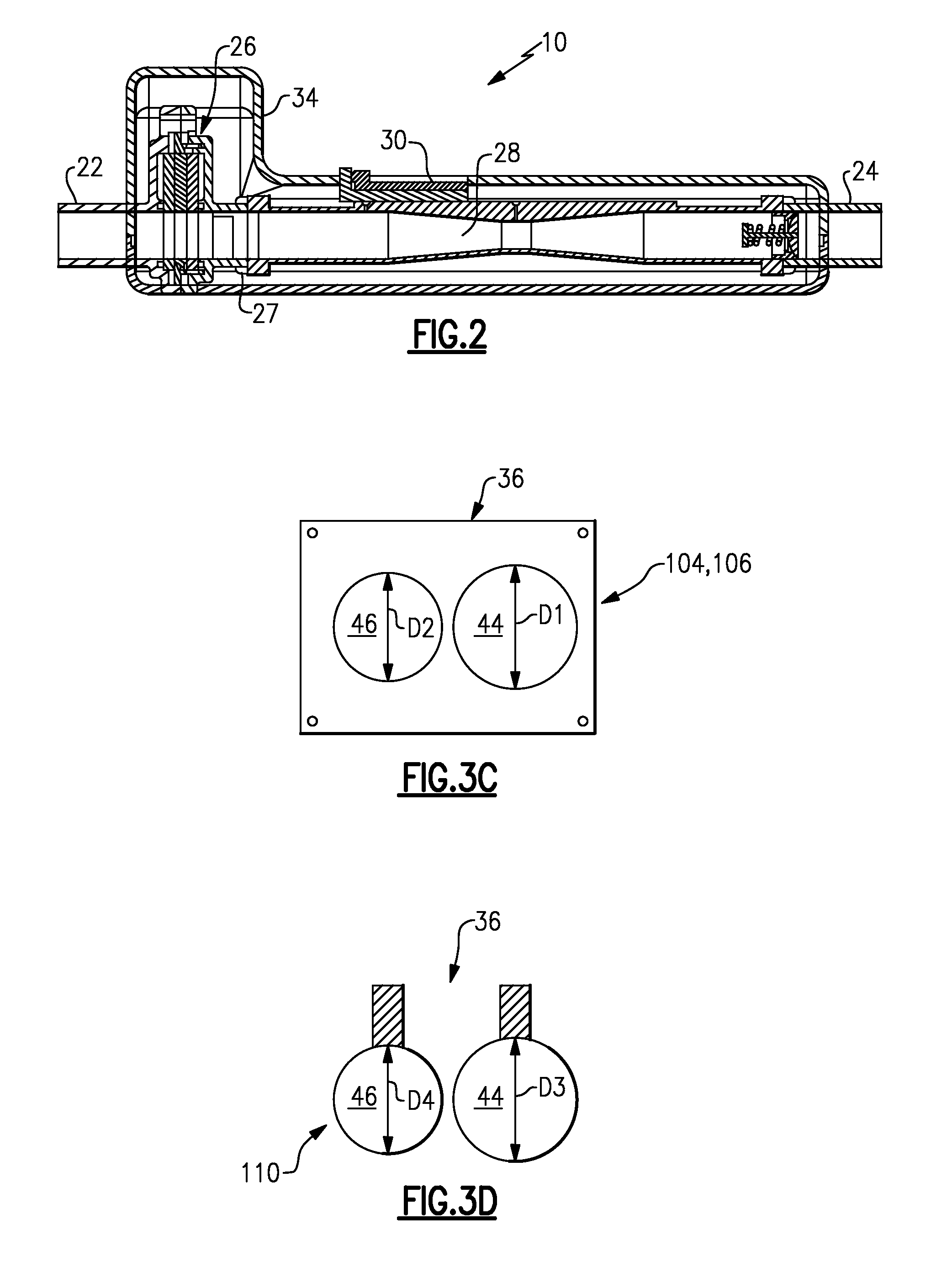

Impingement cooled heat sink with low pressure drop

InactiveUS20070272392A1Reduced life-timeIncrease pressureSemiconductor/solid-state device detailsSolid-state devicesSystem pressureEngineering

Two embodiments of a heat exchanger assembly for cooling an electronic device are shown respectively in FIGS. 1 and 3 and each comprises a housing, a plurality of high fins, a plurality of low fins, a nozzle plate, an inlet, at least one outlet, a primary nozzle, and a plurality of secondary nozzles. In the first embodiment shown in FIG. 1, the housing and the nozzle plate are circular in shape. In the second embodiment shown in FIG. 3, the housing and the nozzle plate are rectangular in shape. Both embodiments include a plurality of secondary nozzles that are aligned outwardly of the primary nozzle and the center axis of the nozzle plate. The secondary nozzles direct the flow of the cooling liquid outwardly of the primary nozzle from the center thus creating an overall system pressure drop lower than that of other assemblies without a plurality of secondary nozzles.

Owner:COOLIT SYSTEMS INC

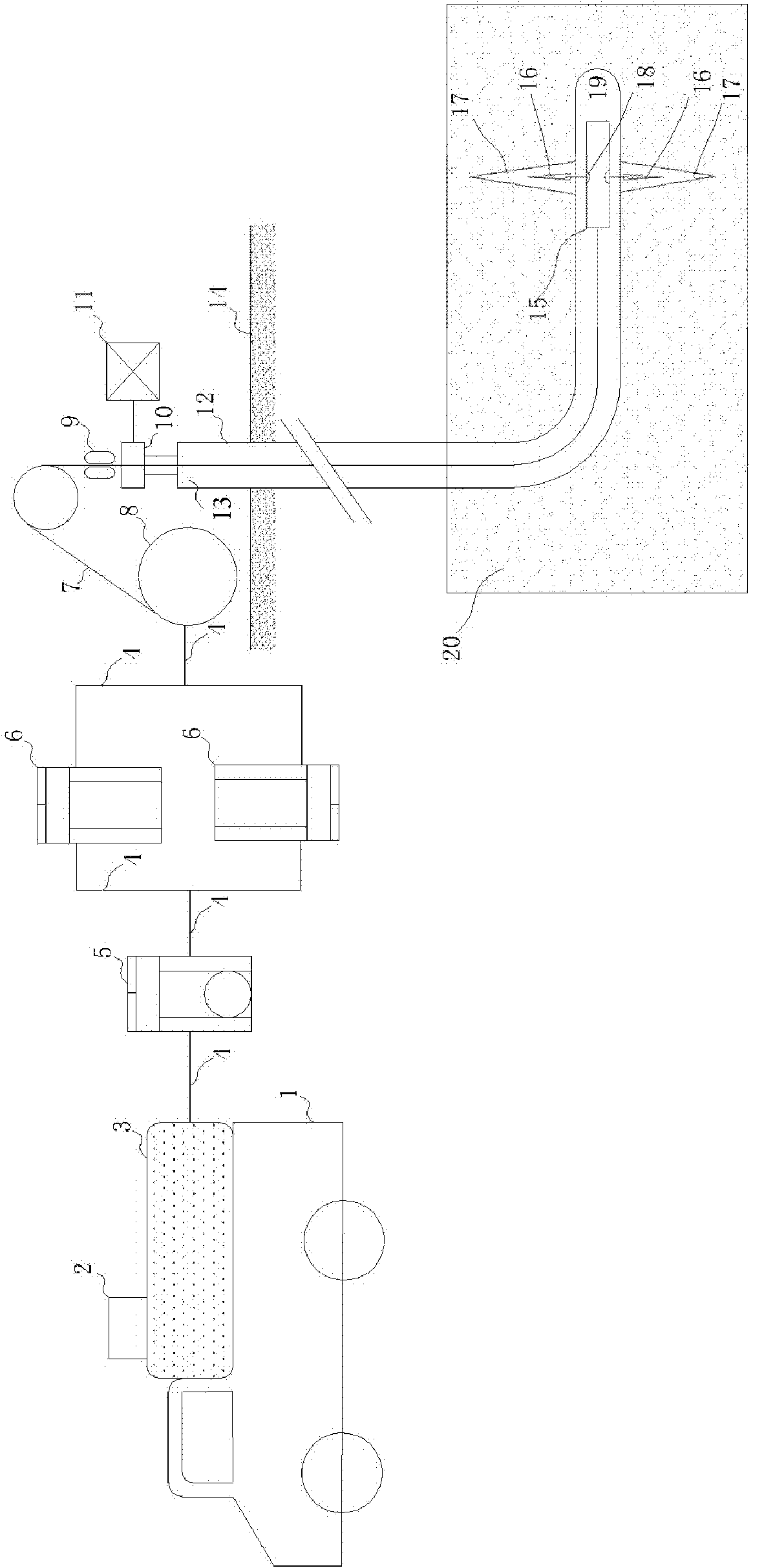

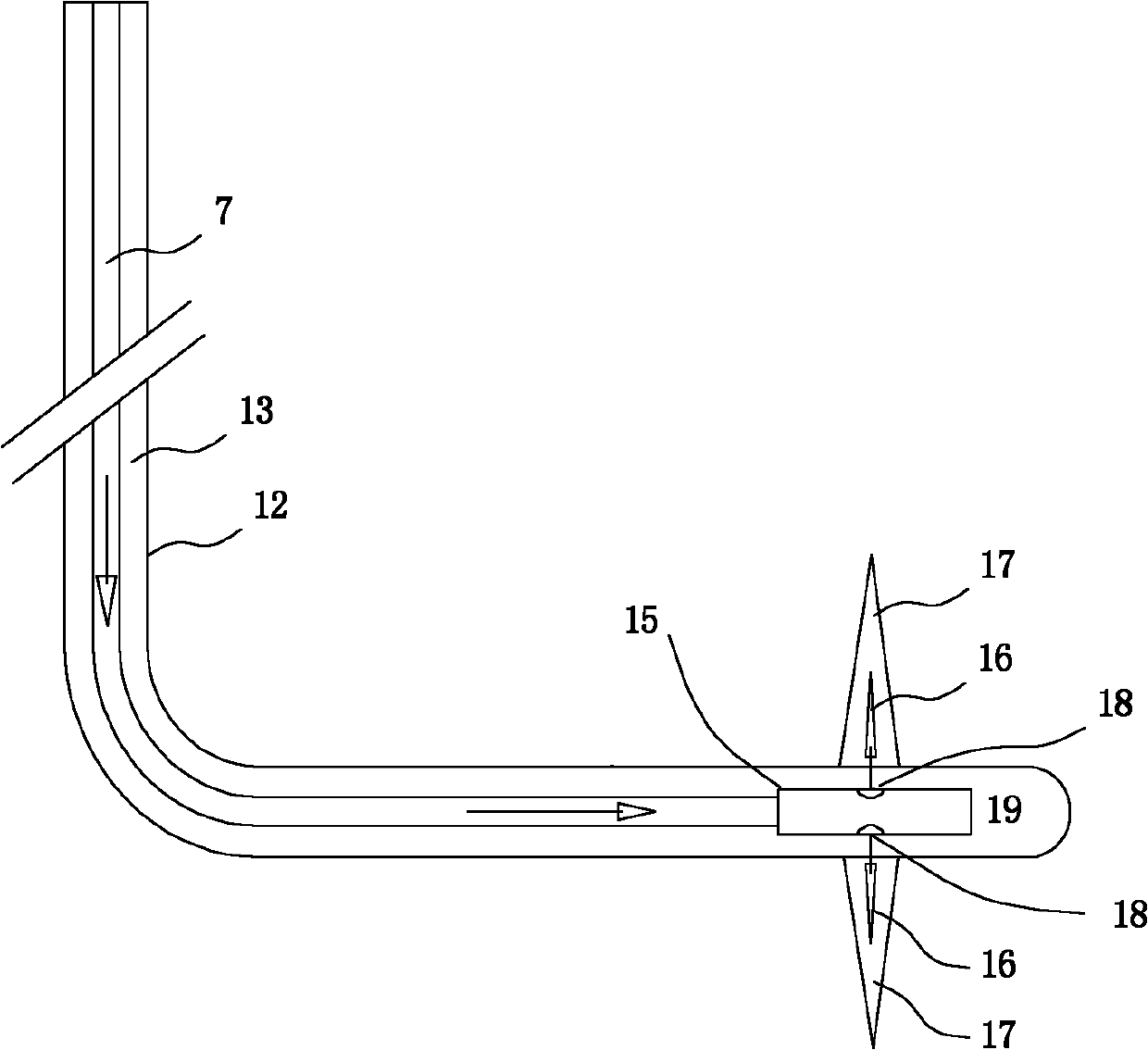

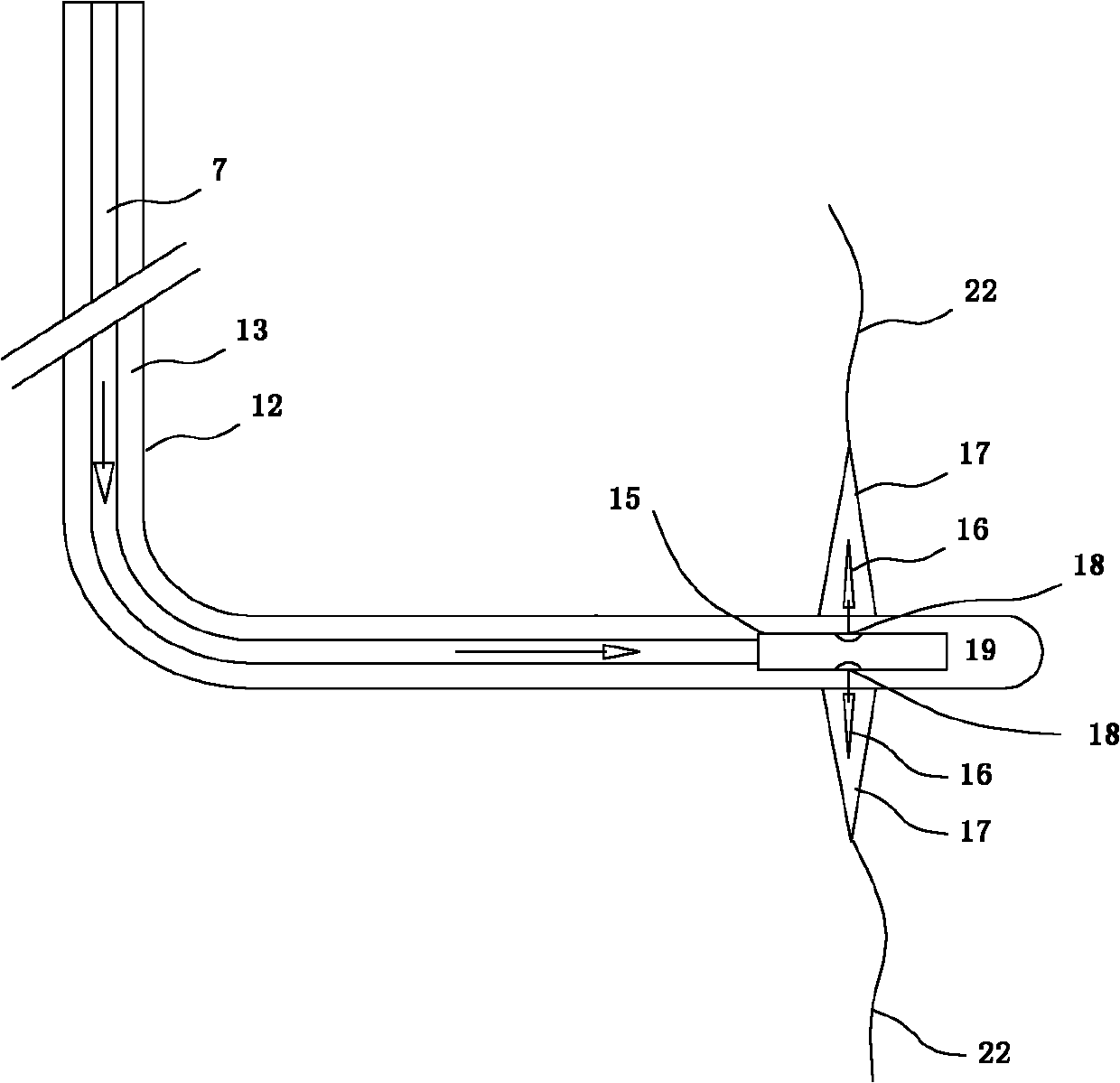

Coiled tubing supercritical CO2 jet fracturing method

ActiveCN102168545AJet rock breaking efficiency is highRock breaking threshold pressure is lowLiquid/gas jet drillingFluid removalWater basedFracturing fluid

The invention relates to a coiled tubing supercritical CO2 jet fracturing method. The method is used for performing jet fracturing on oil well reservoirs by taking supercritical CO2 as fracturing fluid. By the method, a supercritical CO2 fluid is used as the fracturing fluid to perform the jet fracturing; a supercritical CO2 sand jet perforating hole can reduce system pressure; the pressure needed by fissure extension can be further reduced by the characteristics of low viscosity and high dispersion performance of the supercritical CO2 fluid; most importantly, the supercritical CO2 jet fracturing does not pollute the reservoirs, but the supercritical CO2 can further improve the oil and gas recovery ratio after entering the reservoirs; the return discharge is not needed after the fracturing is completed; when the stage-by-stage jet fracturing is performed by using the coiled tubing, a tube pillar can be lifted or put down without mineshaft pressure relieving, the operation process is reduced and the operation cost is reduced, so that the method is extremely suitable for fracturing modification of unconventional oil-gas reservoirs such as thick oil reservoirs, low permeability and super-low permeability oil-gas reservoirs, shale gas reservoirs, coal bed methane reservoirs and the like of which the effects are low by using the conventional water-based fracturing fluid.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

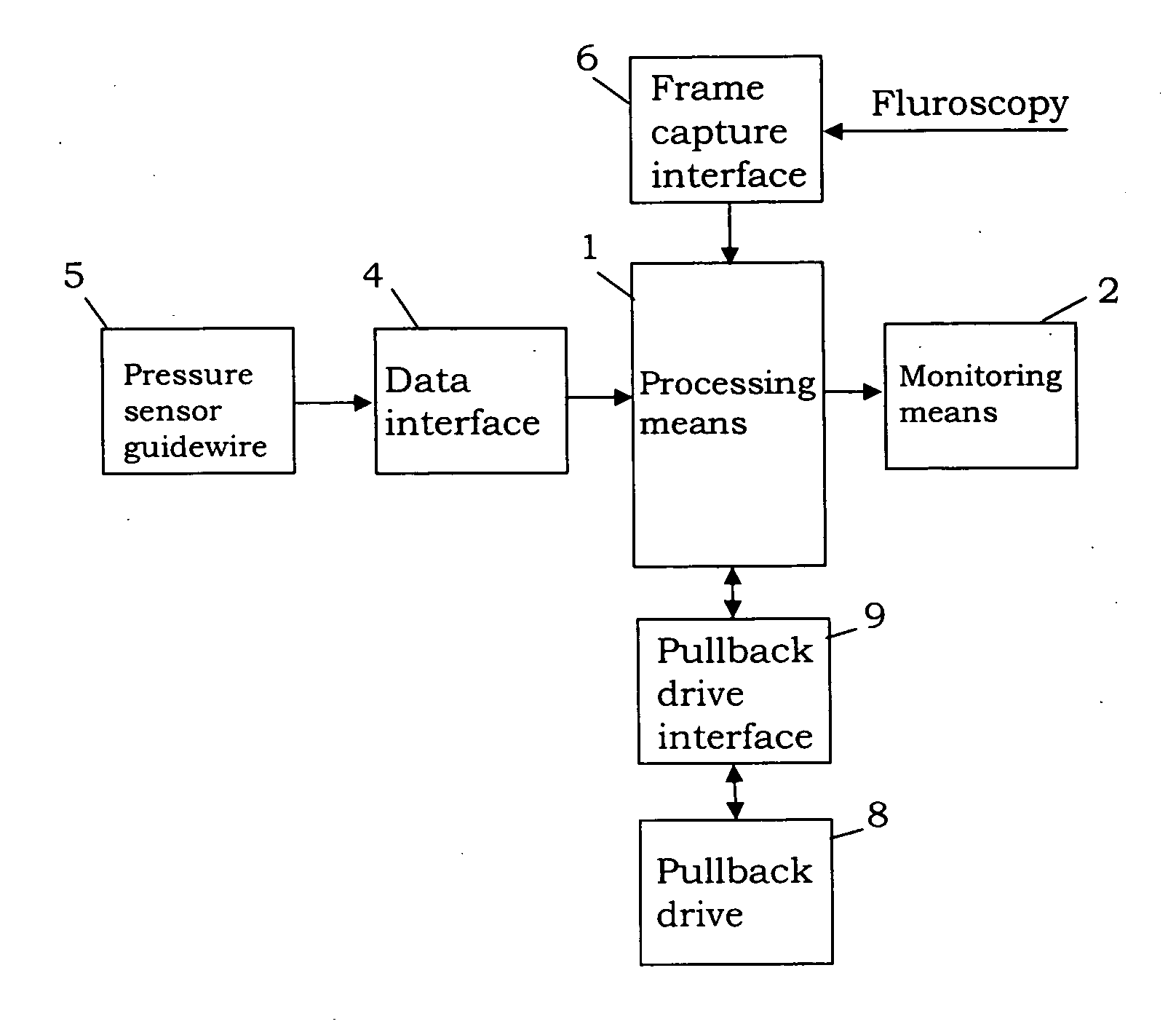

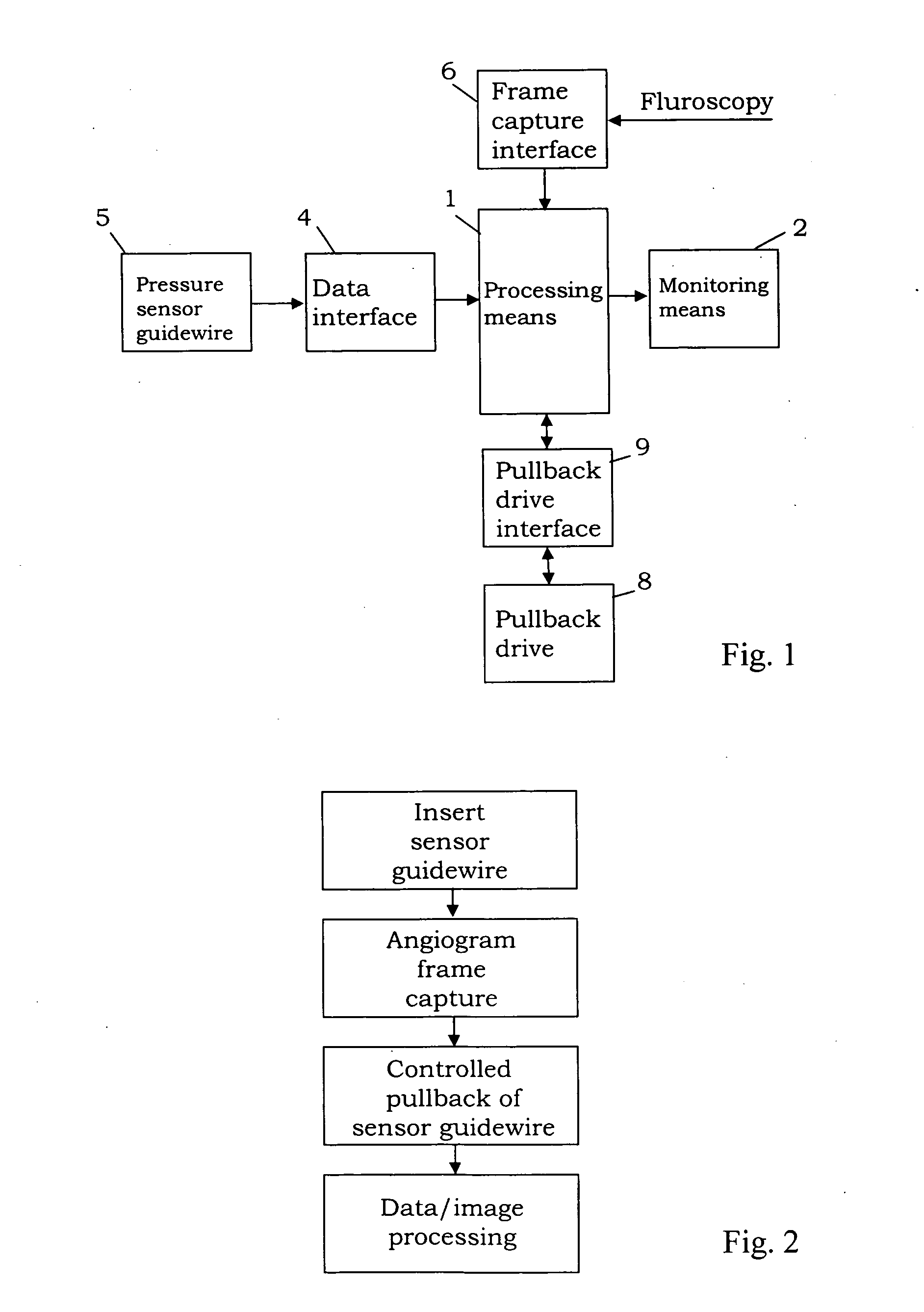

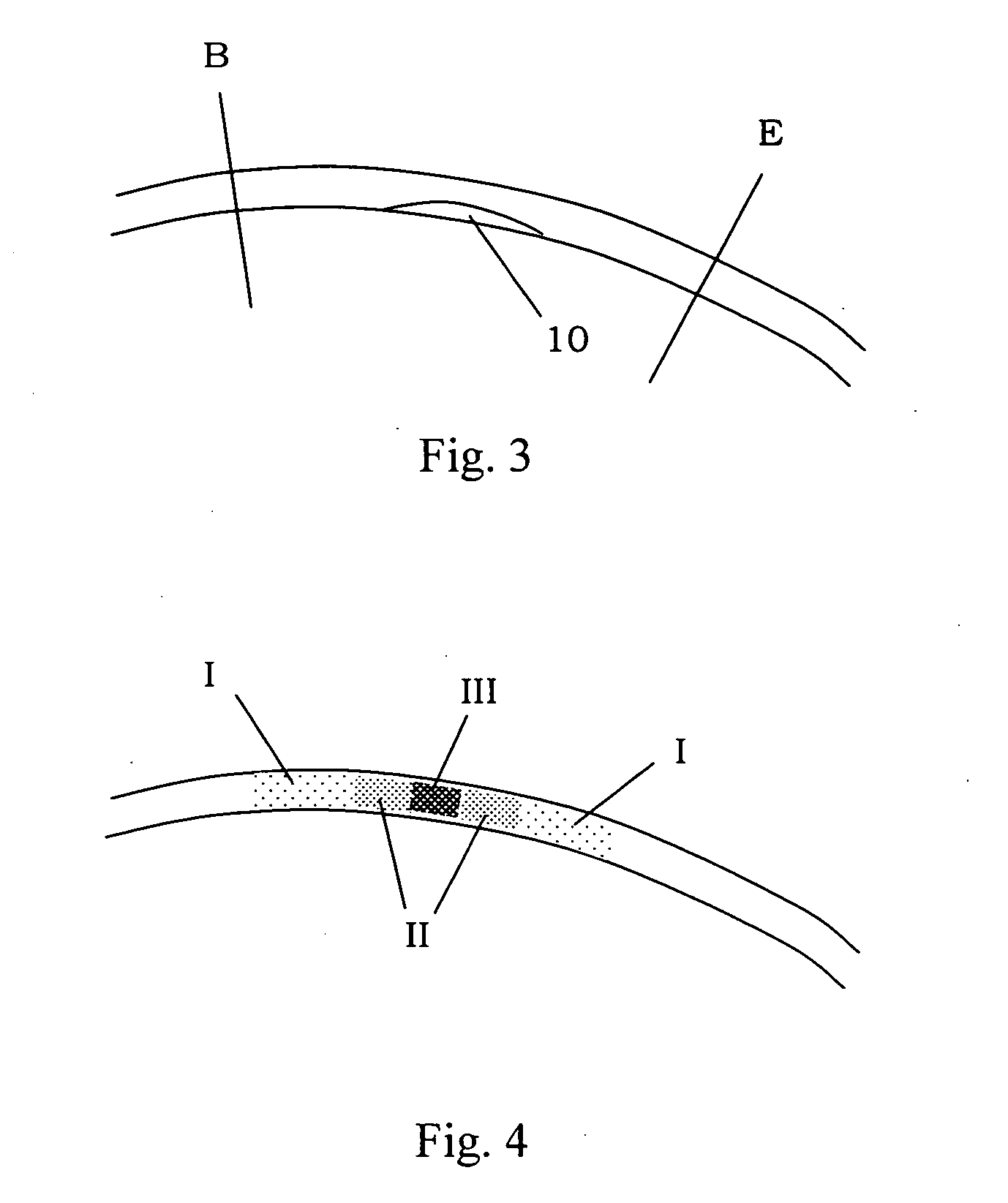

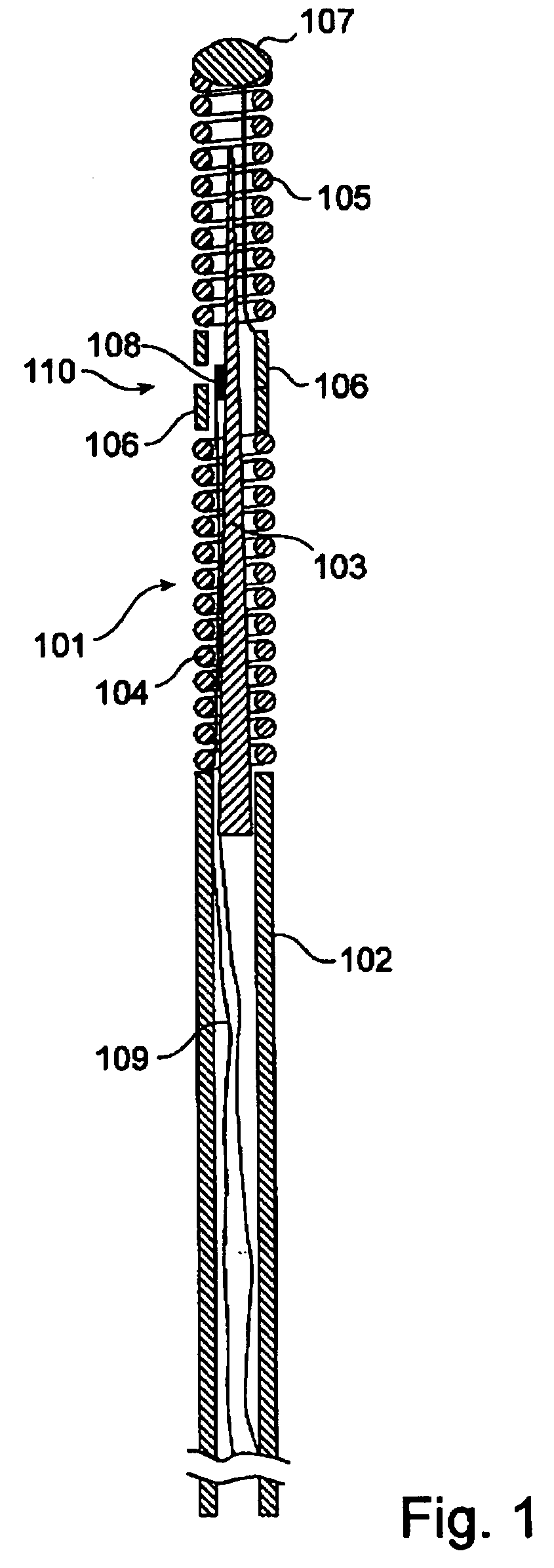

Pressure measurement system

Pressure measurement system, comprising a pressure detection device comprising a pressure sensor guidewire 5 provided with a pressure sensor connected to an electrical carrier for transmitting pressure data from the sensor to a processing means 1. The guidewire is adapted to be inserted into a vessel of a subject, and an image data capturing device for capturing image data representative of the vessel. The processing means 1 comprising a computer program product which comprises computer executable instructions for manipulating image data and pressure data to generate an output in which the pressure data is mapped onto a corresponding position on an image where that pressure data was detected to provide an integrated graphical image output on a monitoring means 2.

Owner:ST JUDE MEDICAL COORDINATION CENT

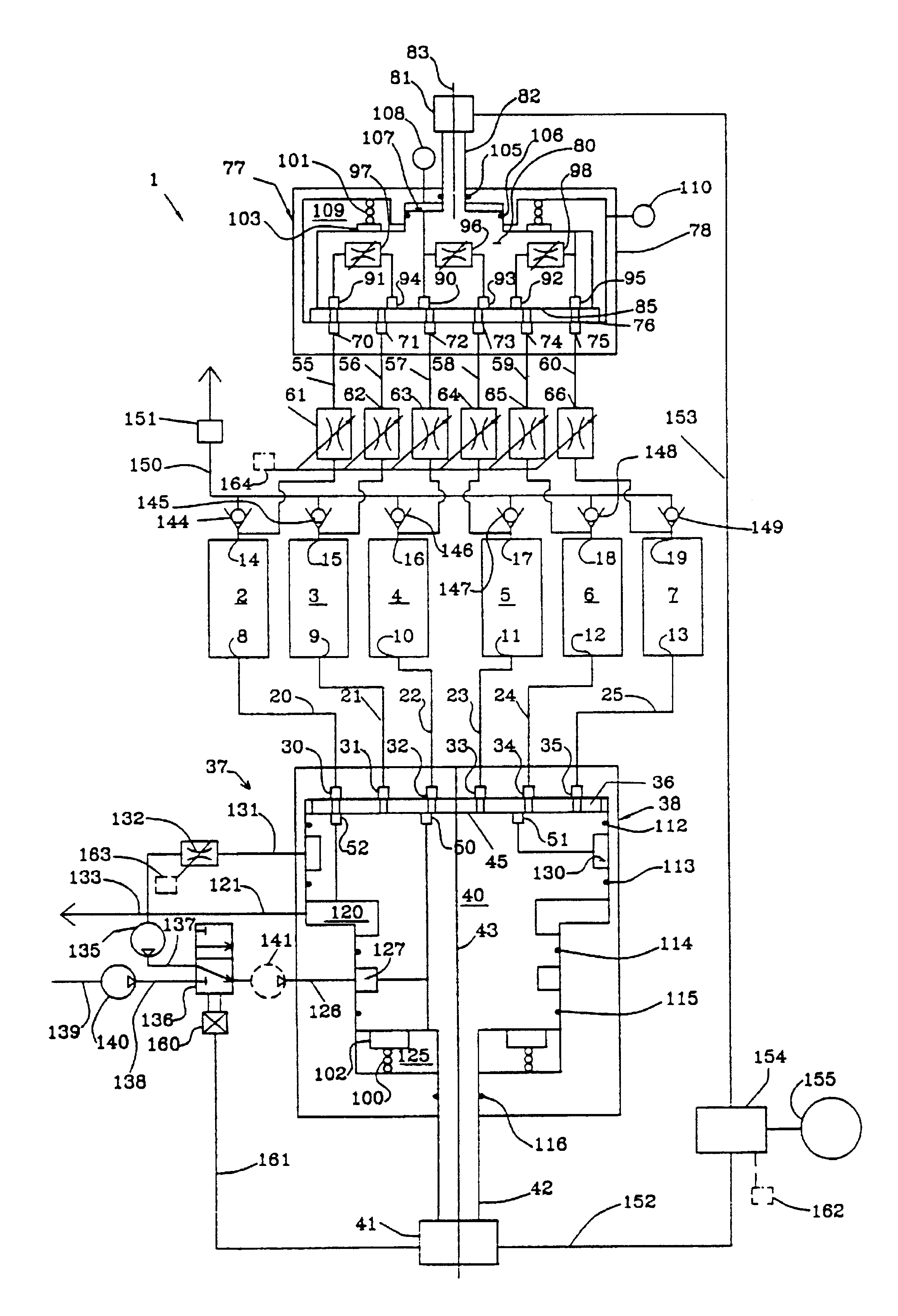

Flow regulated pressure swing adsorption system

InactiveUSRE38493E1Satisfactory operationGas treatmentIsotope separationSystem pressureProcess engineering

Pressure swing adsorption (PSA) separation of a gas mixture is performed in an apparatus with a plurality of adsorbent beds. The invention provides rotary multiport distributor valves to control the timing sequence of the PSA cycle steps between the beds, with flow controls cooperating with the rotary distributor valves to control the volume rates of gas flows to and from the adsorbent beds in blowdown, purge, equalization and repressurization steps.

Owner:AIR PROD & CHEM INC

Transceiver unit in a pressure measurement system

Pressure measurement system comprising a pressure sensor wire with a pressure sensor to measure pressure inside a patient, and to provide measured pressure data to an external device. The pressure sensor wire is adapted to be connected, at its proximal end, to a transceiver unit that is adapted to wirelessly communicate via a communication signal with a communication unit arranged in connection with an external device, in order to transfer measured pressure data to the external device. The pressure data to be transferred is generated by the transceiver unit and transferred as a data stream. Preferably, the communication signal is a radio frequency signal.

Owner:ST JUDE MEDICAL COORDINATION CENT

Flow regulated pressure swing adsorption system

Pressure swing adsorption (PSA) separation of a gas mixture is performed in an apparatus with a plurality of adsorbent beds. The invention provides rotary multiport distributor valves to control the timing sequence of the PSA cycle steps between the beds, with flow controls cooperating with the rotary distributor valves to control the volume rates of gas flows to and from the adsorbent beds in blowdown, purge, equalization and repressurization steps.

Owner:AIR PROD & CHEM INC

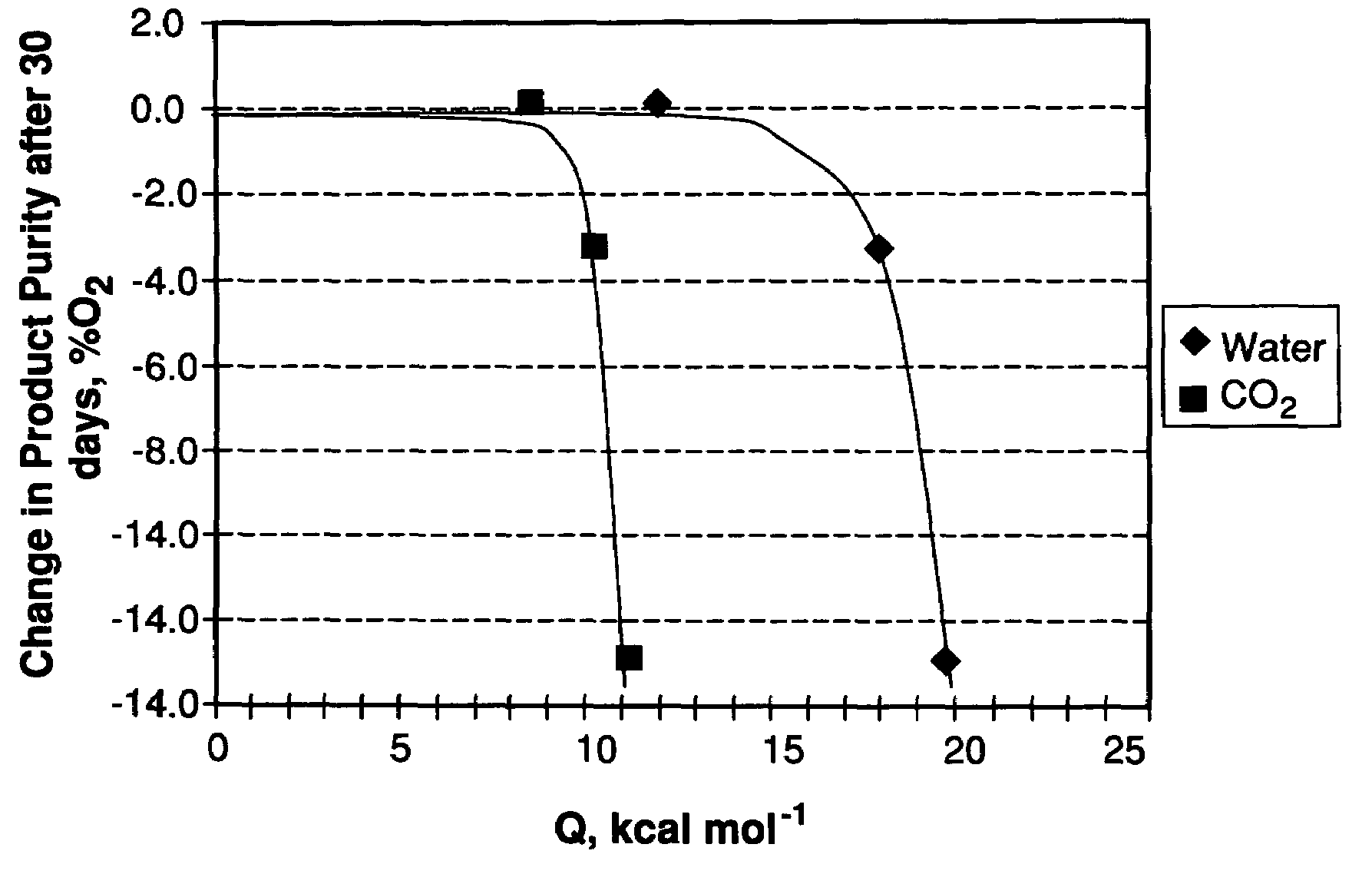

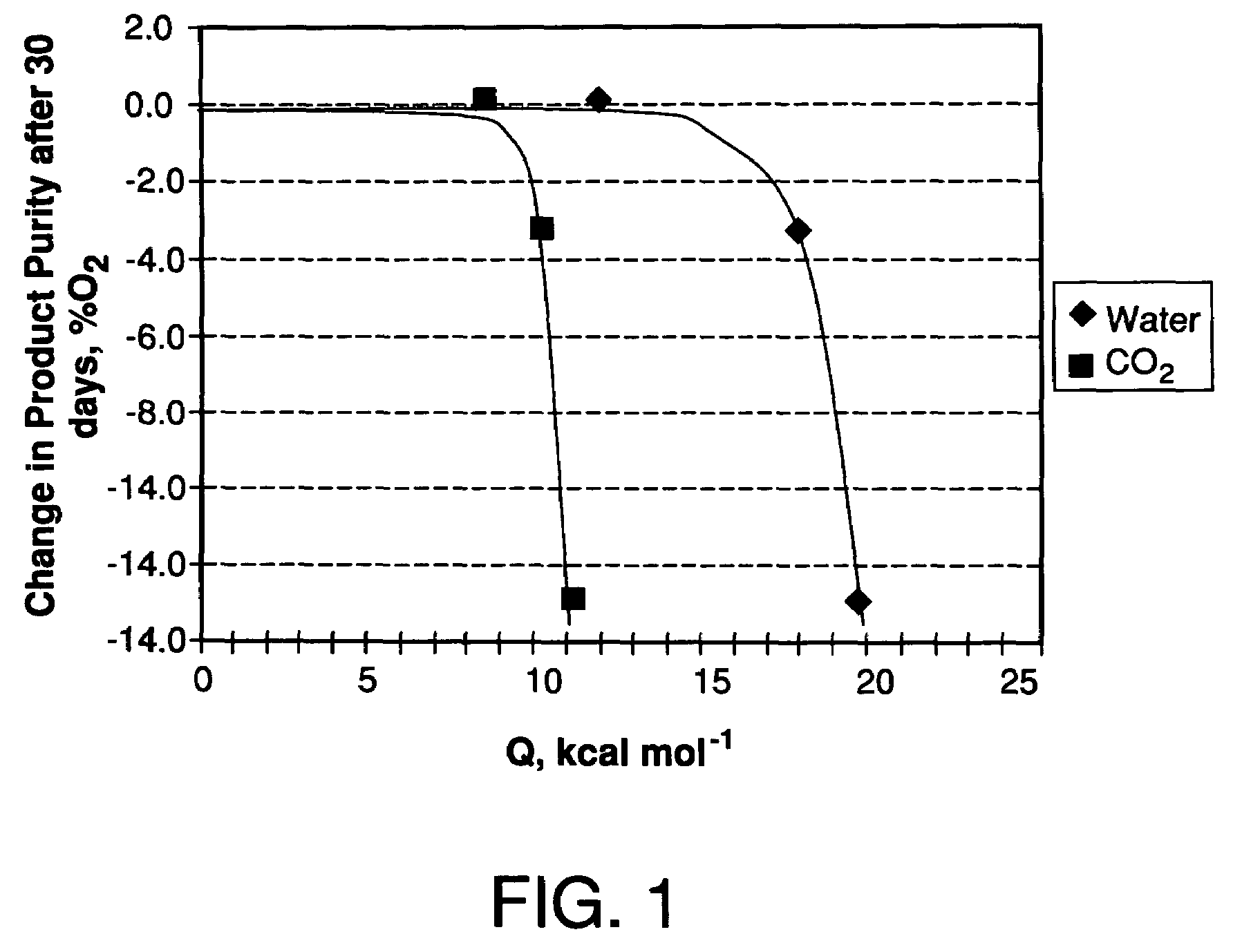

Performance stability in rapid cycle pressure swing adsorption systems

Pressure swing adsorption process for producing oxygen comprising (a) providing at least one adsorber vessel having a first layer of adsorbent adjacent the feed end of the vessel and a second layer of adsorbent adjacent the first layer, wherein the surface area to volume ratio of the first layer is in the range of about 0.75 to about 1.8 cm−1; (b) introducing a pressurized feed gas comprising at least oxygen, nitrogen, and water into the feed end, adsorbing at least a portion of the water in the adsorbent in the first layer, and adsorbing at least a portion of the nitrogen in the adsorbent in the second layer, wherein the superficial contact time of the pressurized feed gas in the first layer is between about 0.08 and about 0.50 sec; and (c) withdrawing a product gas enriched in oxygen from the product end of the adsorber vessel.

Owner:AIR PROD & CHEM INC

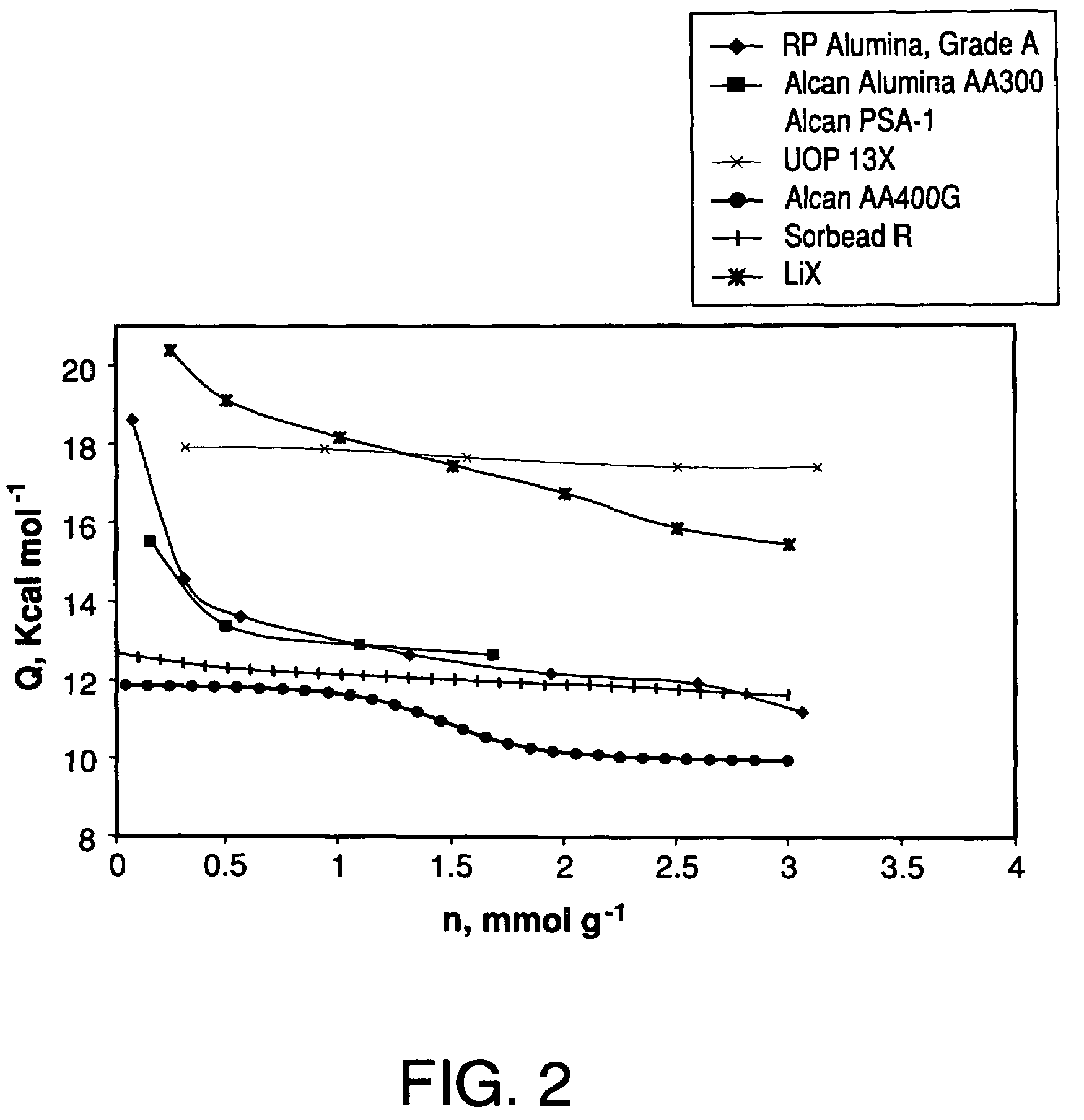

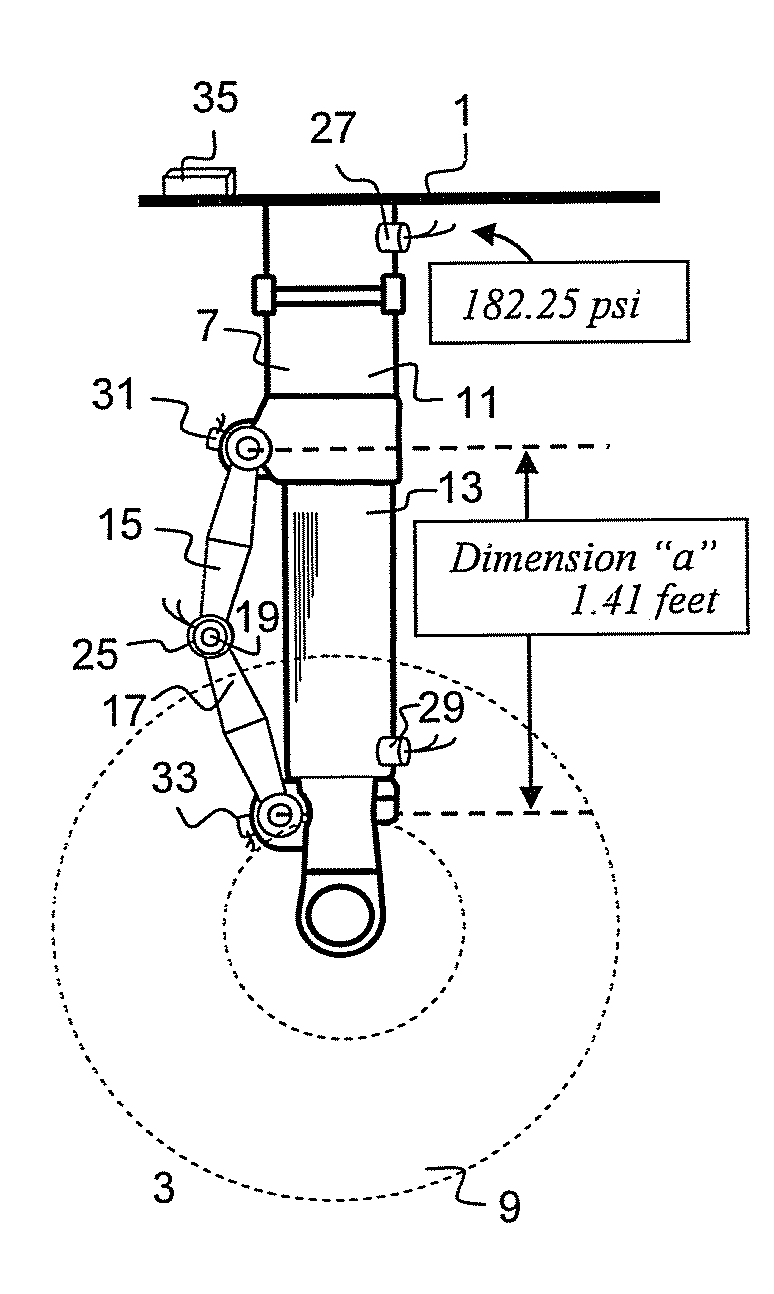

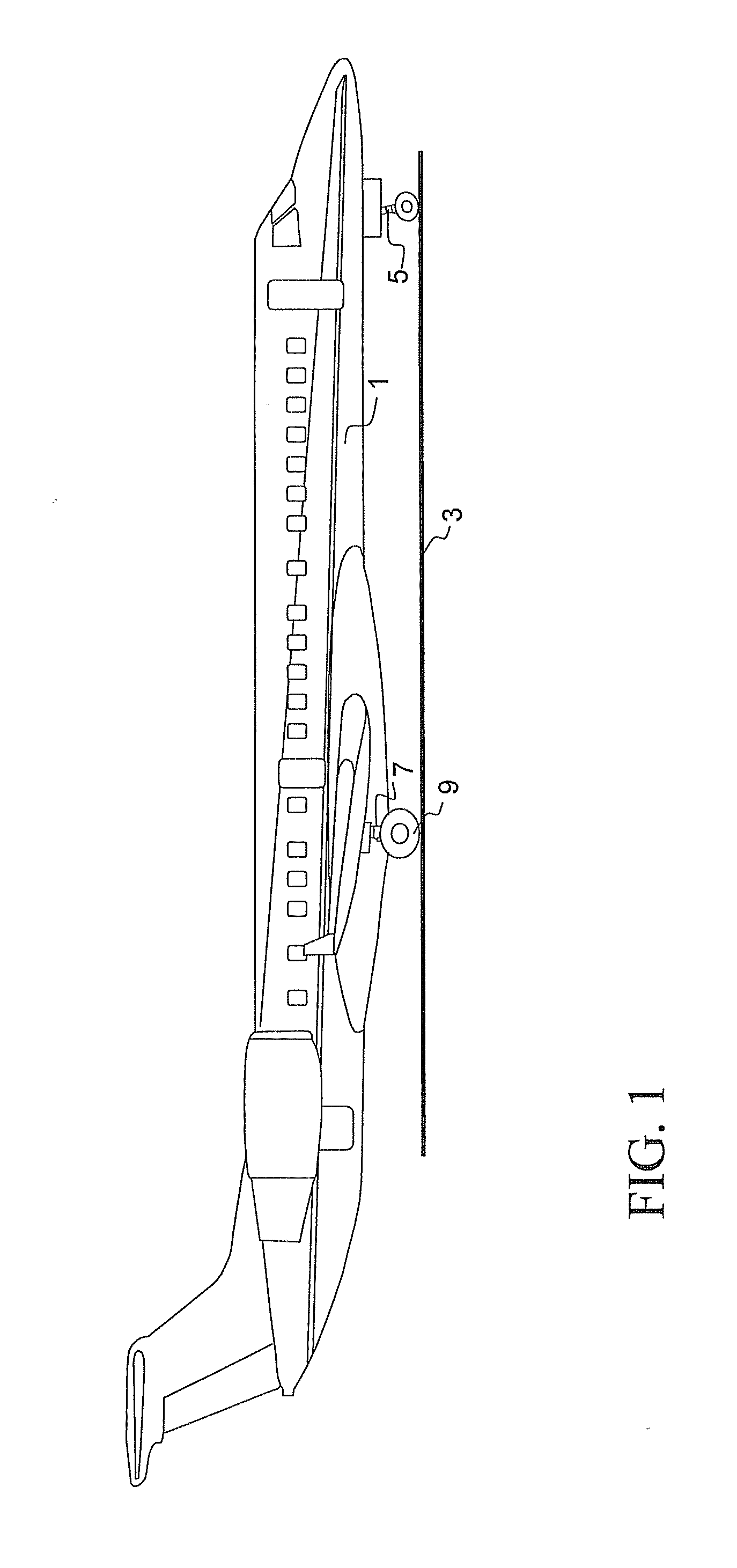

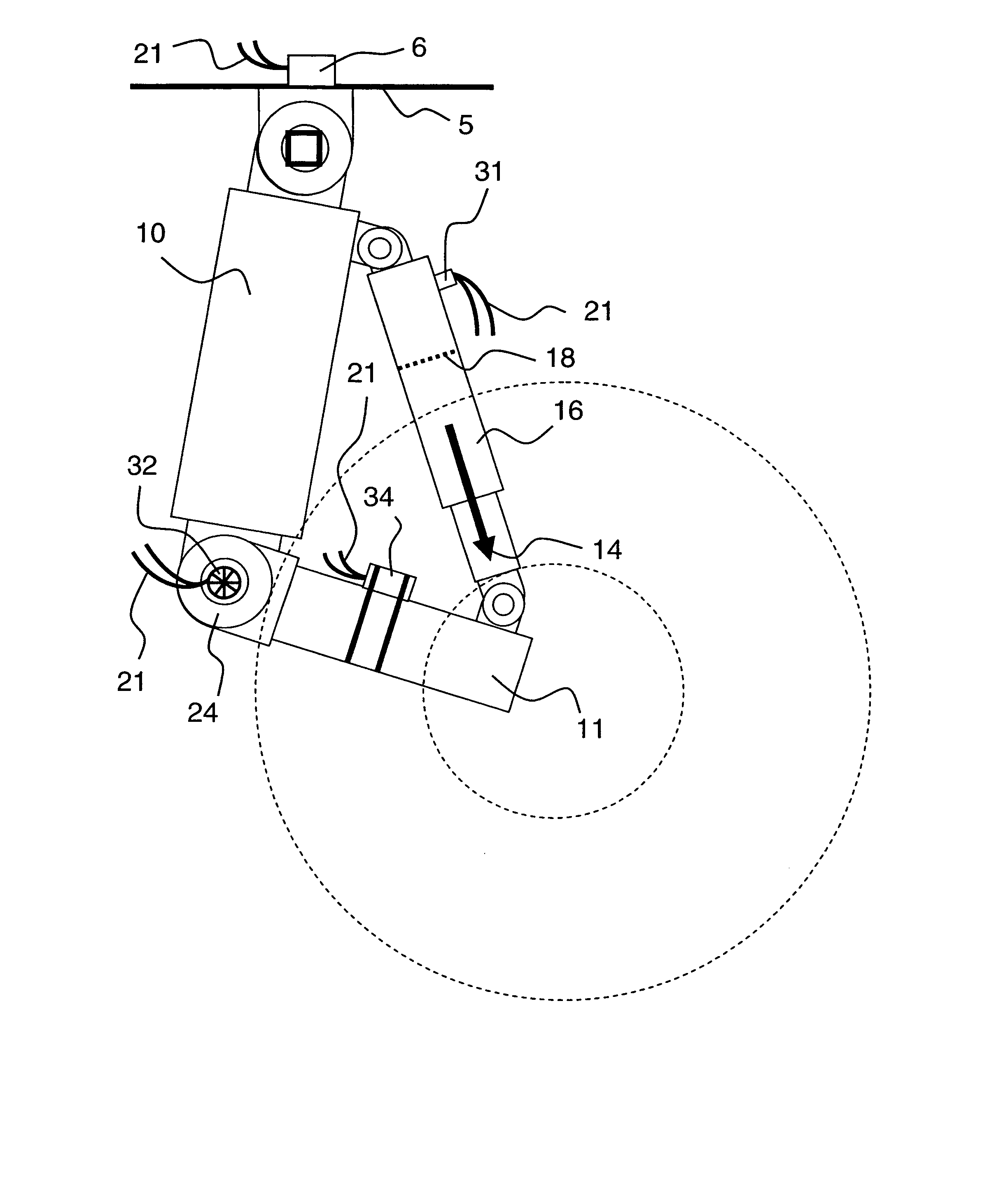

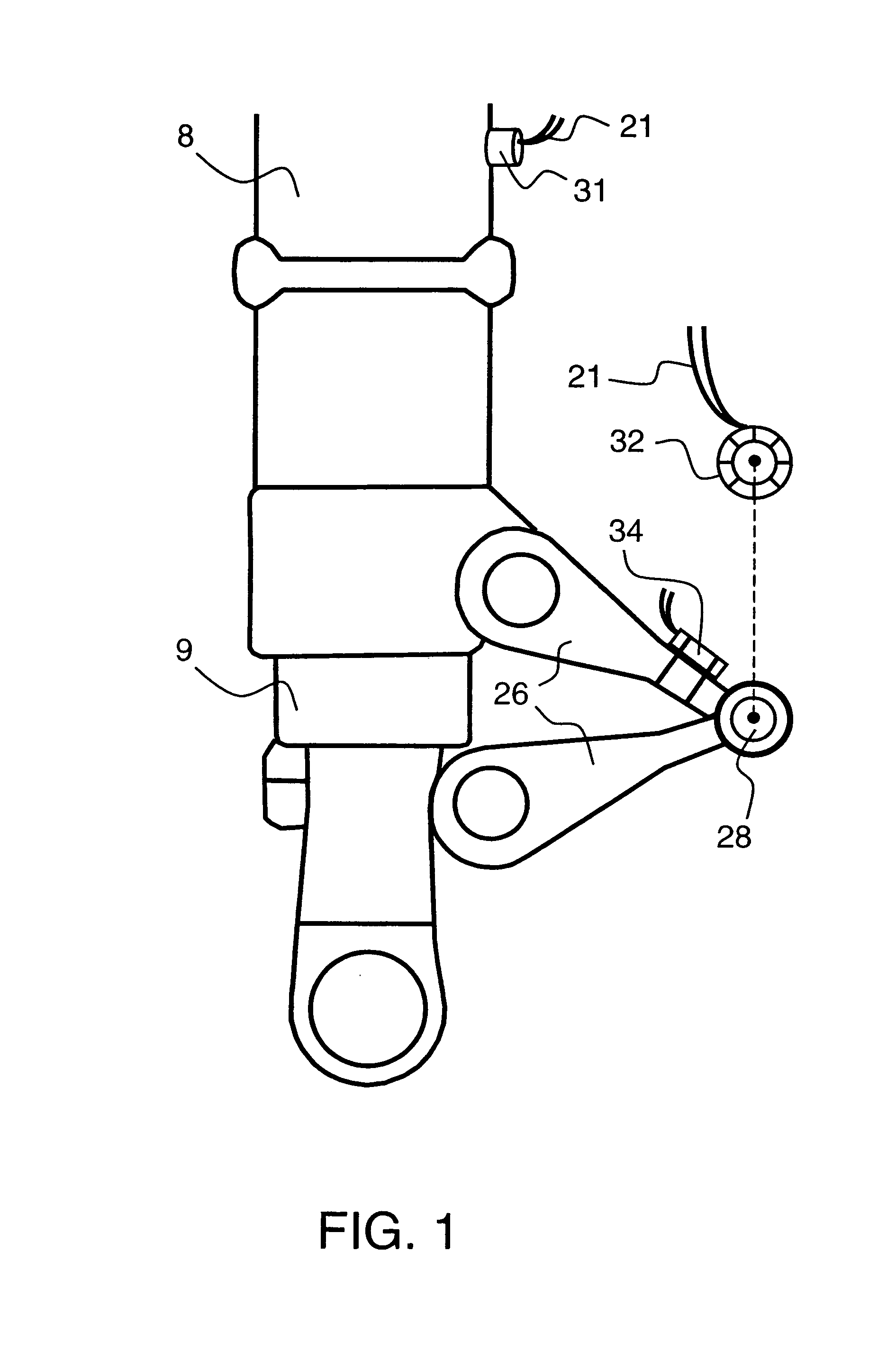

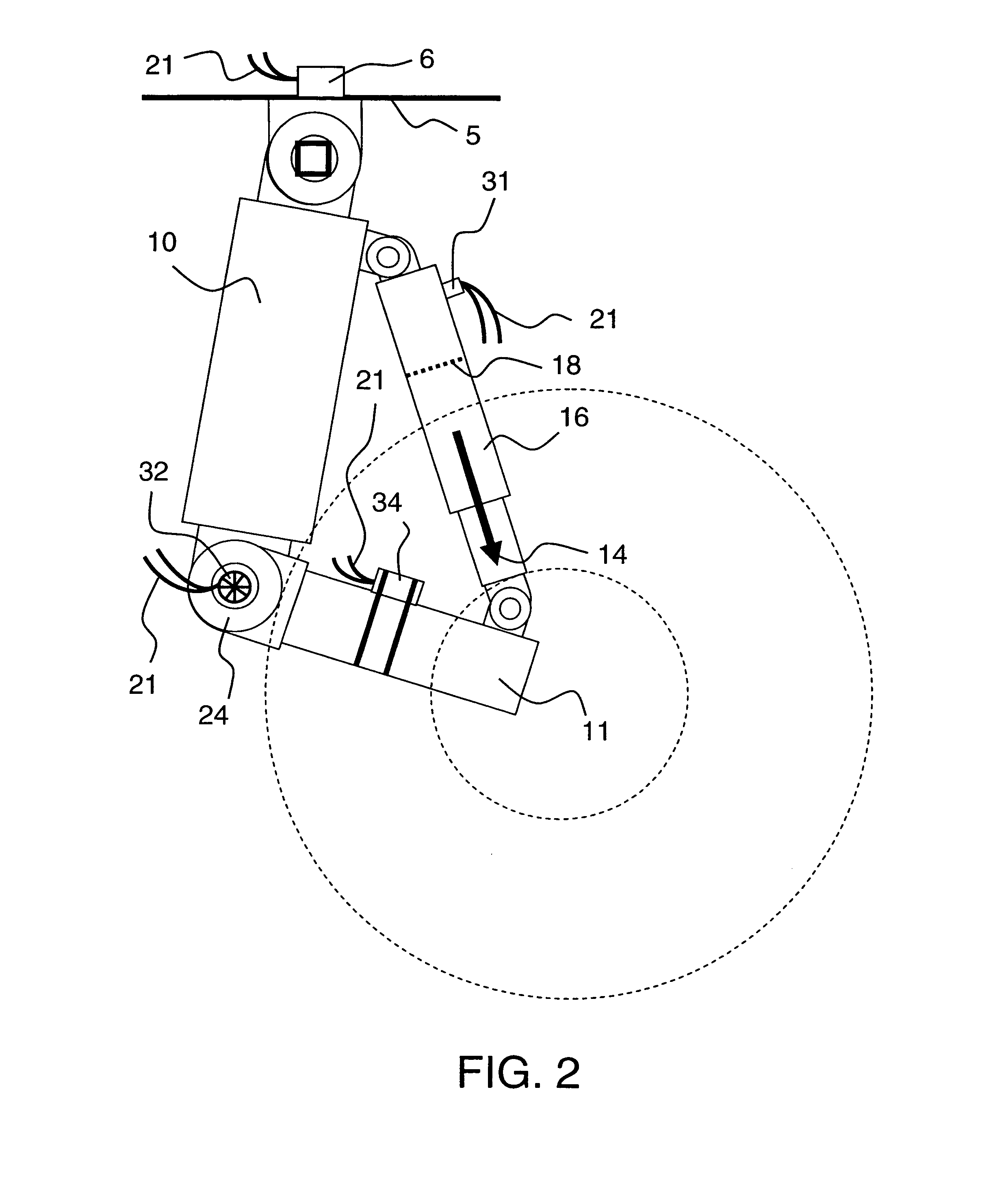

Automated inspection of aircraft landing gear internal fluid levels

ActiveUS20140046533A1Reduce system complexityRegistering/indicating working of vehiclesDigital data processing detailsJet aeroplaneAircraft landing

A system for use in monitoring, measuring, computing and displaying the volumes of internal gas within a telescopic aircraft landing gear strut. Pressure sensors and temperature sensors and motion sensors are mounted in relation to each of the landing gear struts to monitor, measure and record the impact movement and rates of internal landing gear strut fluids; experienced by landing gear struts, as the aircraft landing gear initially come into contact with the ground. The computer of this system measures the compression experienced by each landing gear strut and determines if the landing gear strut is improperly serviced with either excess or deficient volumes of nitrogen gas. Additional features include automating the inspections required to aircraft landing gear, prior to flight, during flight and during landing events.

Owner:NANCE C KIRK

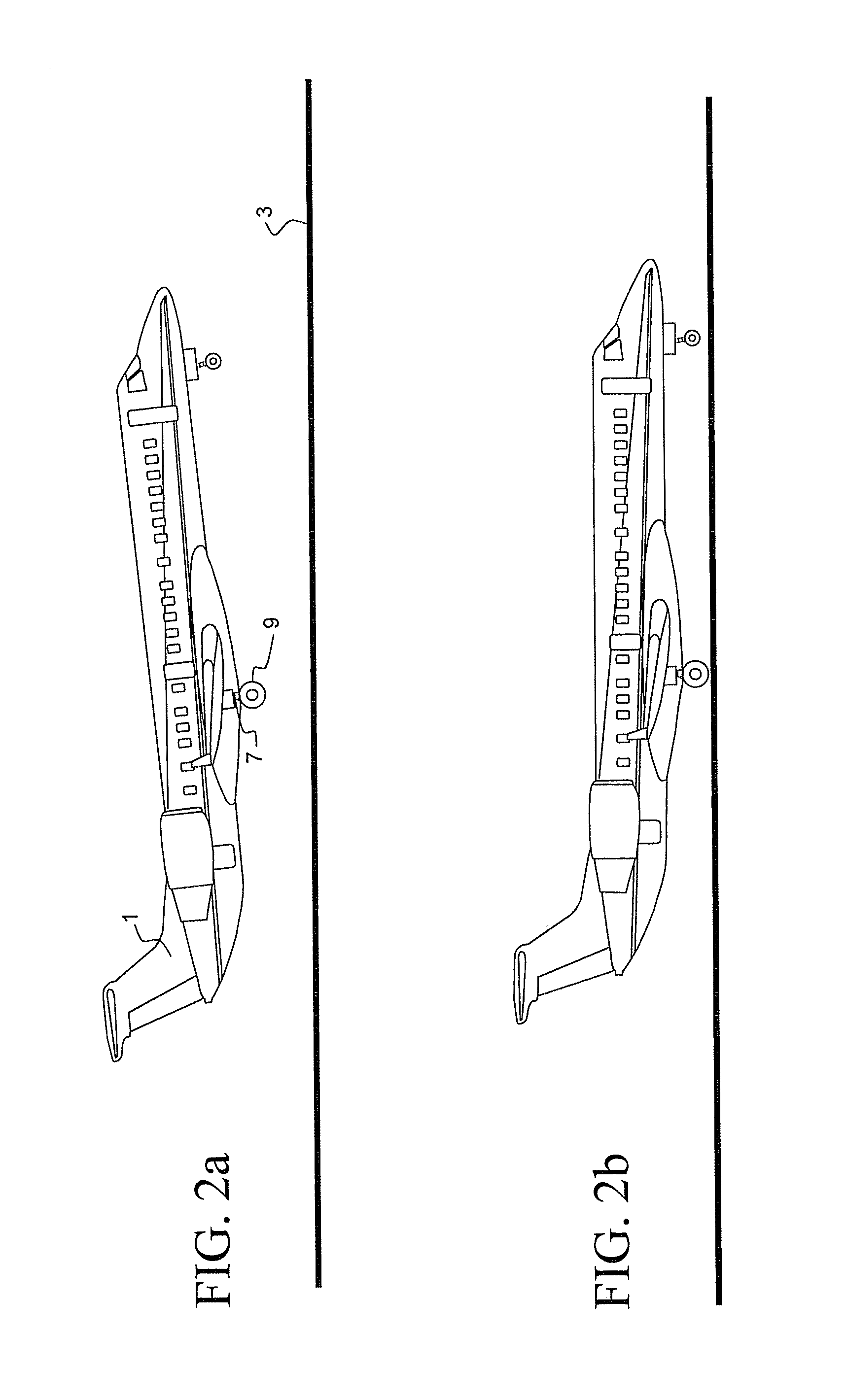

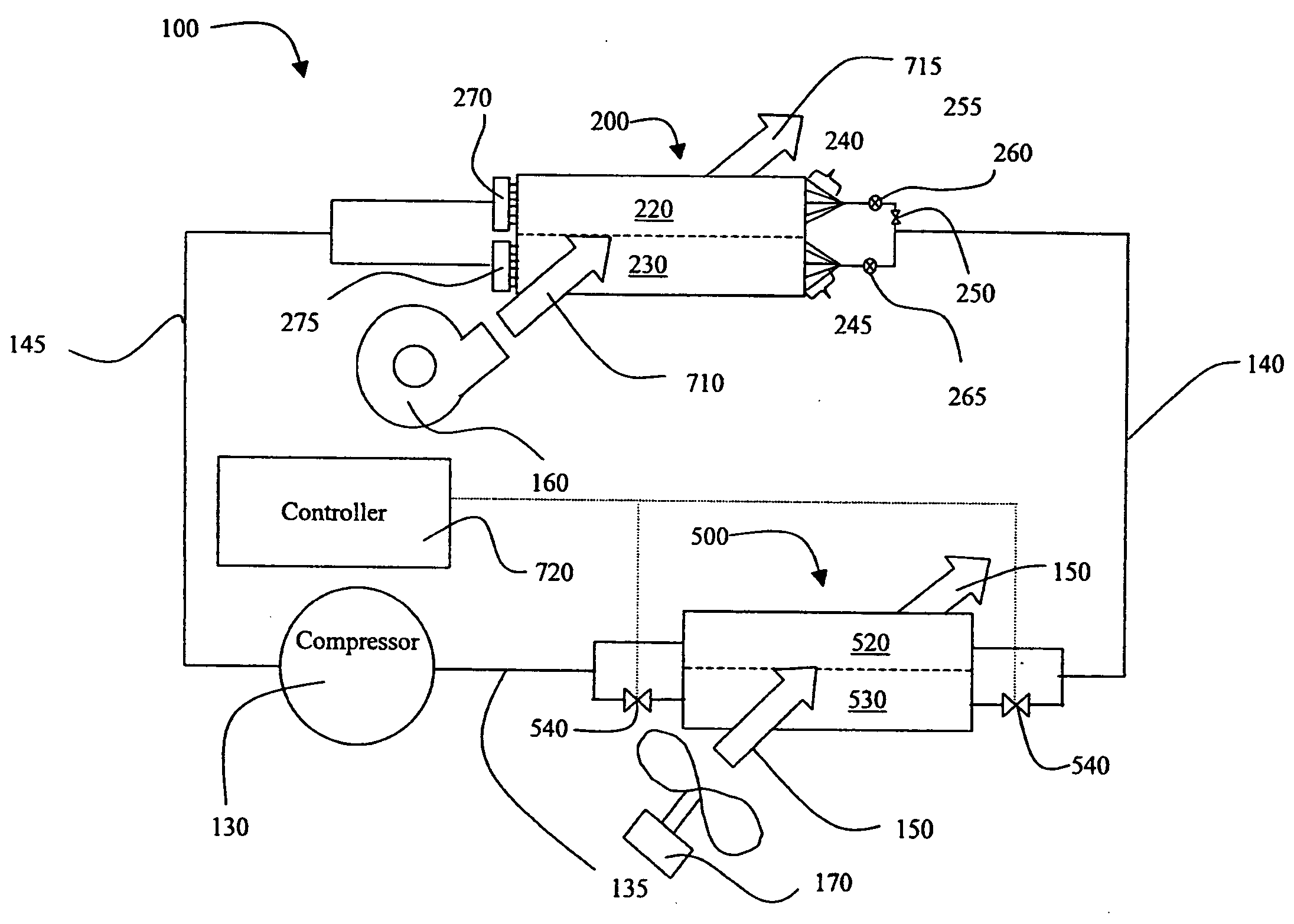

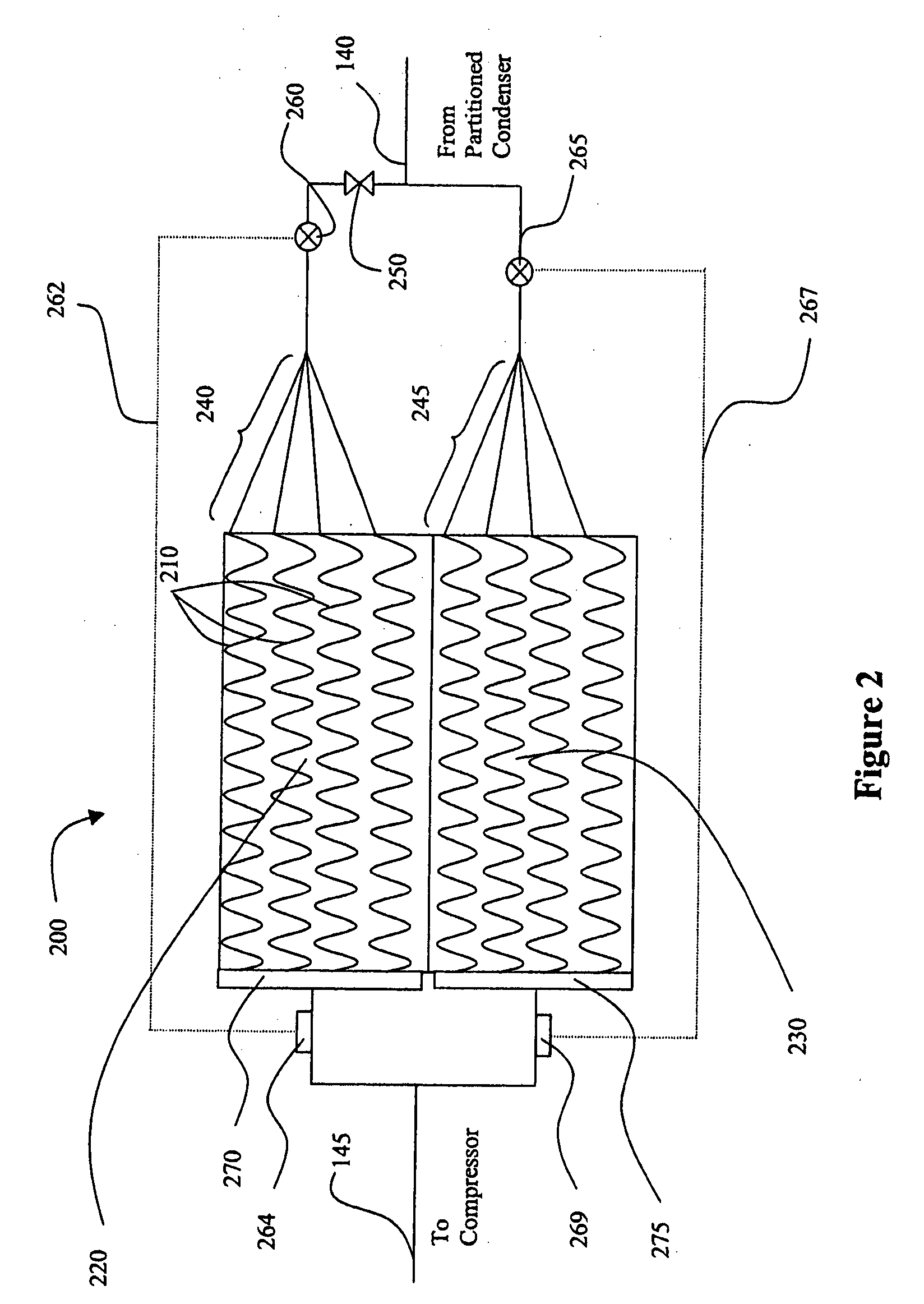

Method and system for dehumidification and refrigerant pressure control

InactiveUS20060288713A1Prevent freezingIncrease system pressureEvaporators/condensersCompression machines with several evaporatorsControl systemSystem pressure

A method for dehumidification and controlling system pressure in a refrigeration system includes providing a refrigeration system having a compressor, a condenser and an evaporator connected in a closed refrigerant loop. Each of the condenser and evaporator have a plurality of refrigerant circuits. A first heat transfer fluid is flowed over the condenser and a second heat transfer fluid is flowed over the evaporator. At least one of the refrigerant circuits of the condenser is isolated to provide a decreased amount of heat transfer area within the condenser and to increase the refrigerant pressure within the refrigeration system when the refrigerant pressure within the refrigeration system is at or below a predetermined pressure. At least one of the refrigerant circuits of the evaporator is isolated to dehumidify and maintain the temperature of the second heat transfer fluid at or above a predetermined temperature when dehumidification is required.

Owner:YORK INT CORP

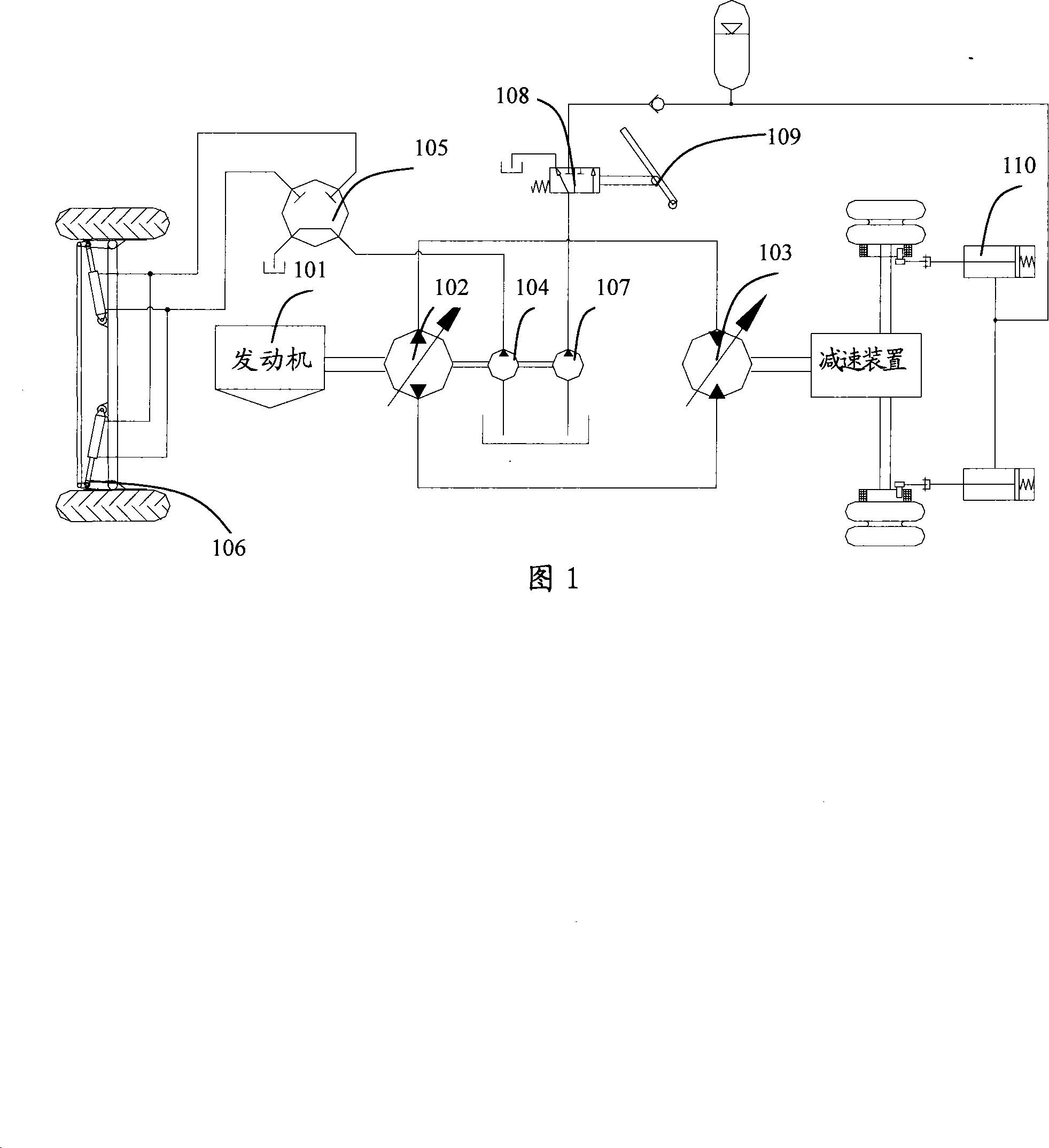

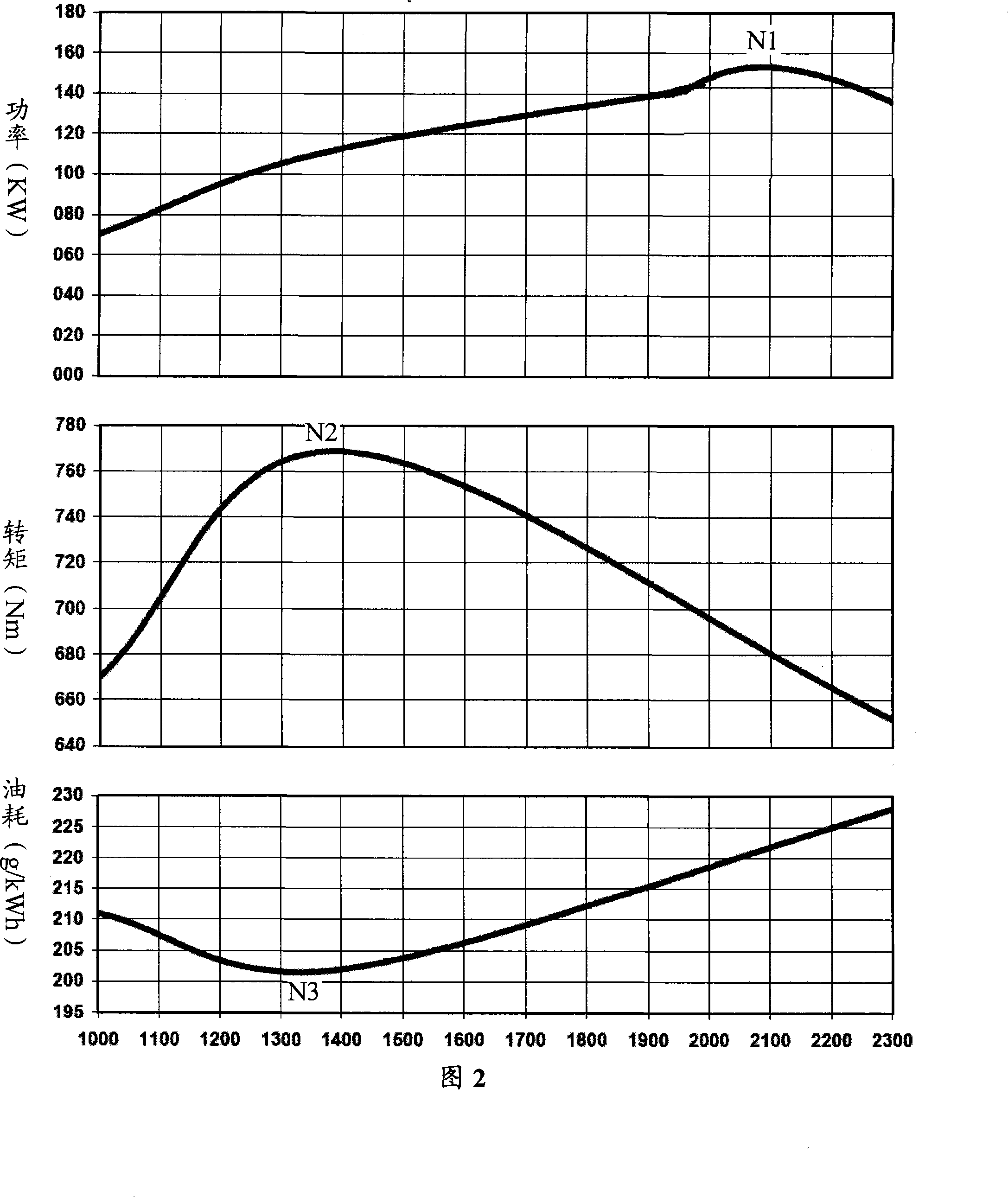

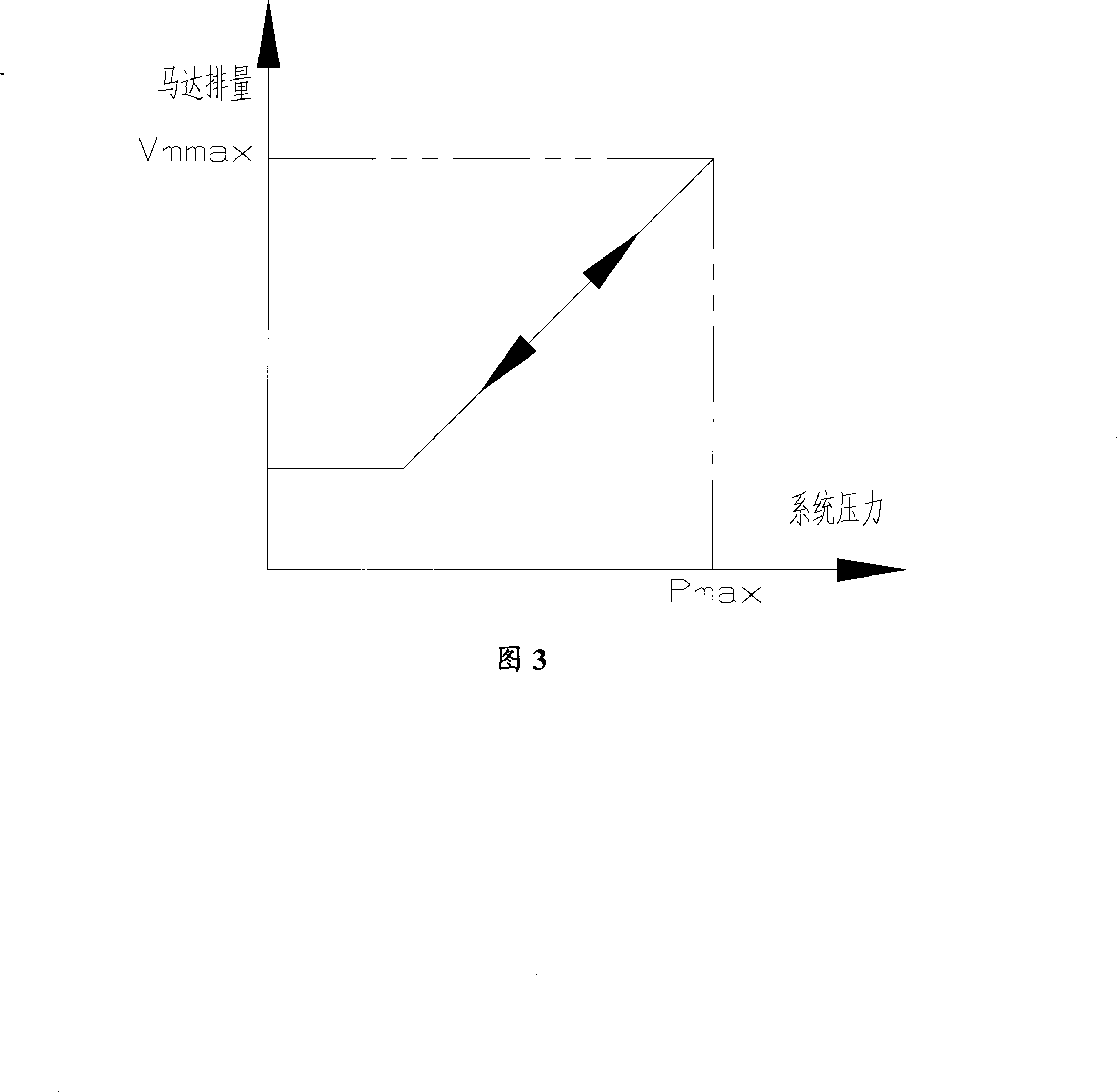

Hydraulic chassis engineering machinery walking control method and control system

InactiveCN101169078AAccurately implement control requirementsAvoid output powerEngine controllersPump controlHydraulic motorCurrent load

The invention provides a hydraulic chassis engineering machine step control method, which includes testing the current load state of the engineering machine, the opening degree of the throttle, and the actual run speed. The invention judges the current load state, when the load state is intermediate low, and the difference of the actual speed and the goal rotate speed exceeds the preset range, then corresponding current can be provided for the hydraulic motor for regulating the displacement; namely when the actual rotate speed is lower than the goal rotate speed, current for lowering the displacement can be provided to the hydraulic motor; when the actual rotate speed is higher than the goal rotate speed, the current for improving the displacement can be provided to the hydraulic motor; when the load state is in overload, the displacement of the hydraulic motor can be adjusted to the maximum. The required power of the system can be calculated according to the current displacement of the hydraulic motor, the demand of the rotate speed, and the current pressure of the system. Current, the displacement of which can meet the requirement of the controller, is provided for the hydraulic pump according to the required power of the system, and the needed displacement can ensure that the power absorbed by the hydraulic pump can meet the requirement of the hydraulic motor. Compared with the prior art, the invention can enable the engineering machine to realize the control requirement accurately.

Owner:SANY HEAVY IND CO LTD (CN)

Aircraft landing gear kinetic energy monitor

A system for use in monitoring, measuring, computing and displaying the Kinetic Energy generated and experienced while aircraft are executing either normal, overweight or hard landing events. Pressure sensors and motion sensors are mounted in relation to each of the landing gear struts to monitor, measure and record the impact loads and aircraft touch-down vertical velocities experienced by landing gear struts, as the aircraft landing gear initially comes into contact with the ground. Velocity adjustments are made to correct for errors caused by landing gear per-charge pressure and landing gear strut seal friction. The system also measures the landing loads experienced by each landing gear strut during the landing event and determines if aircraft limitations have been exceeded.

Owner:NANCE C KIRK

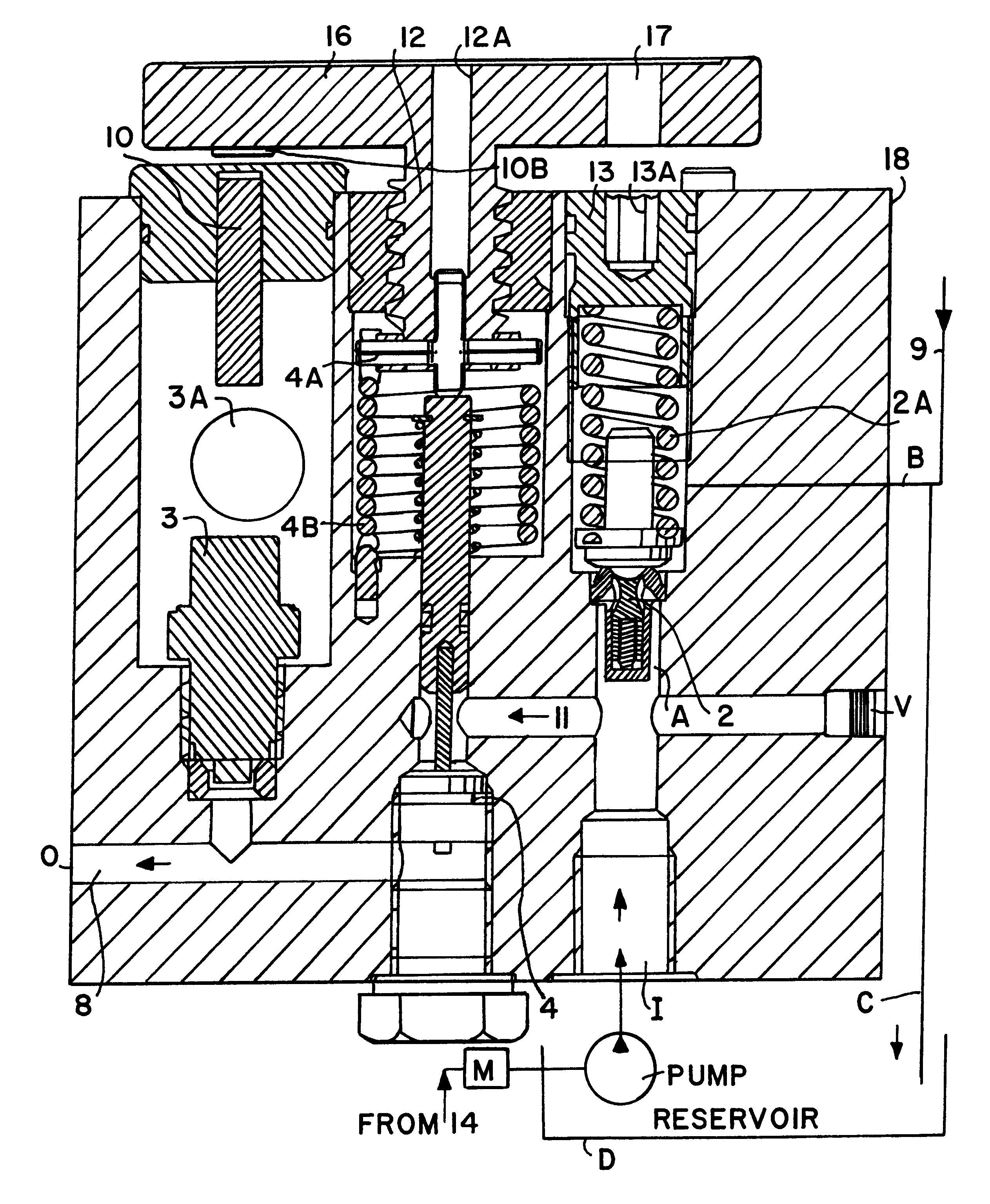

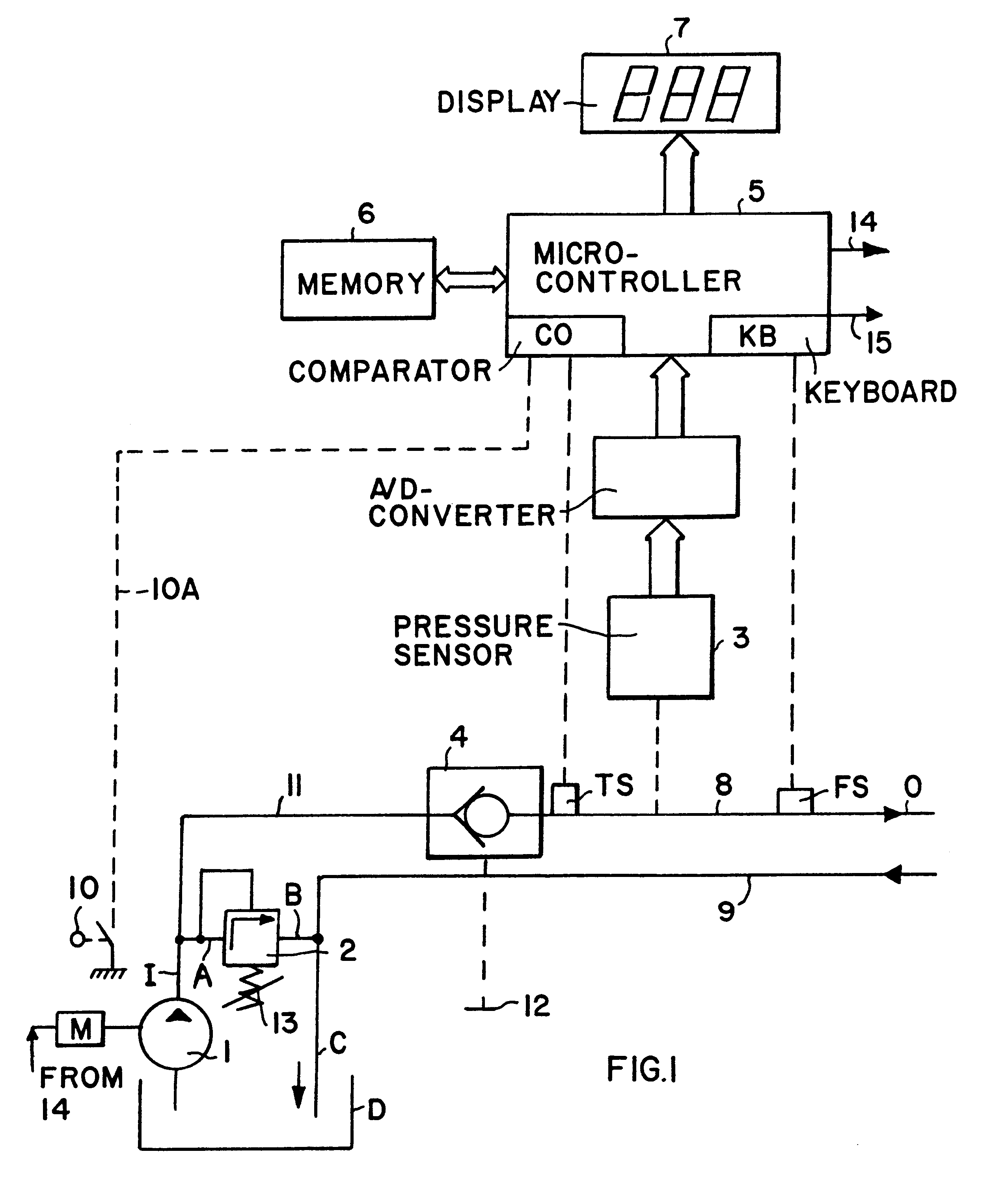

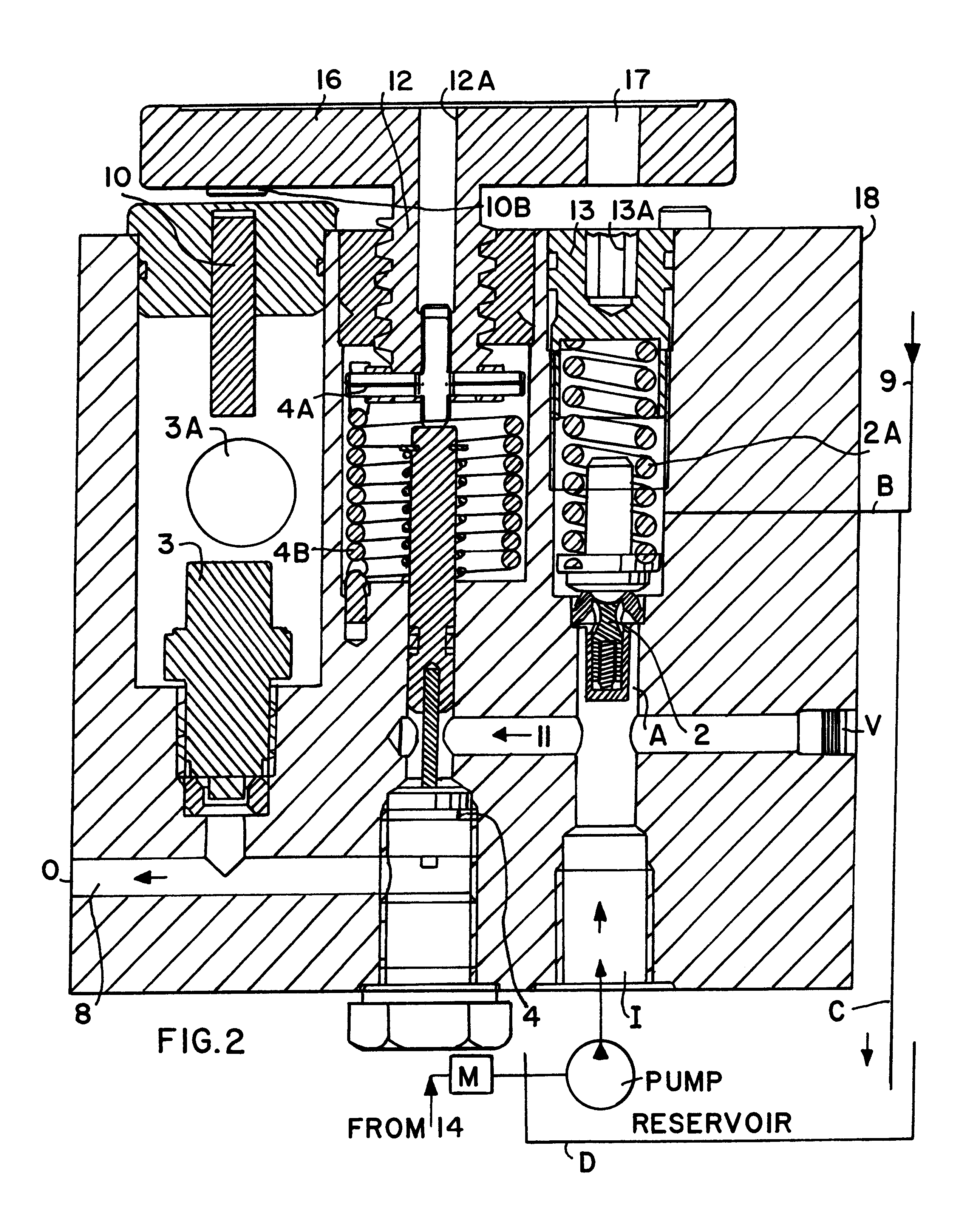

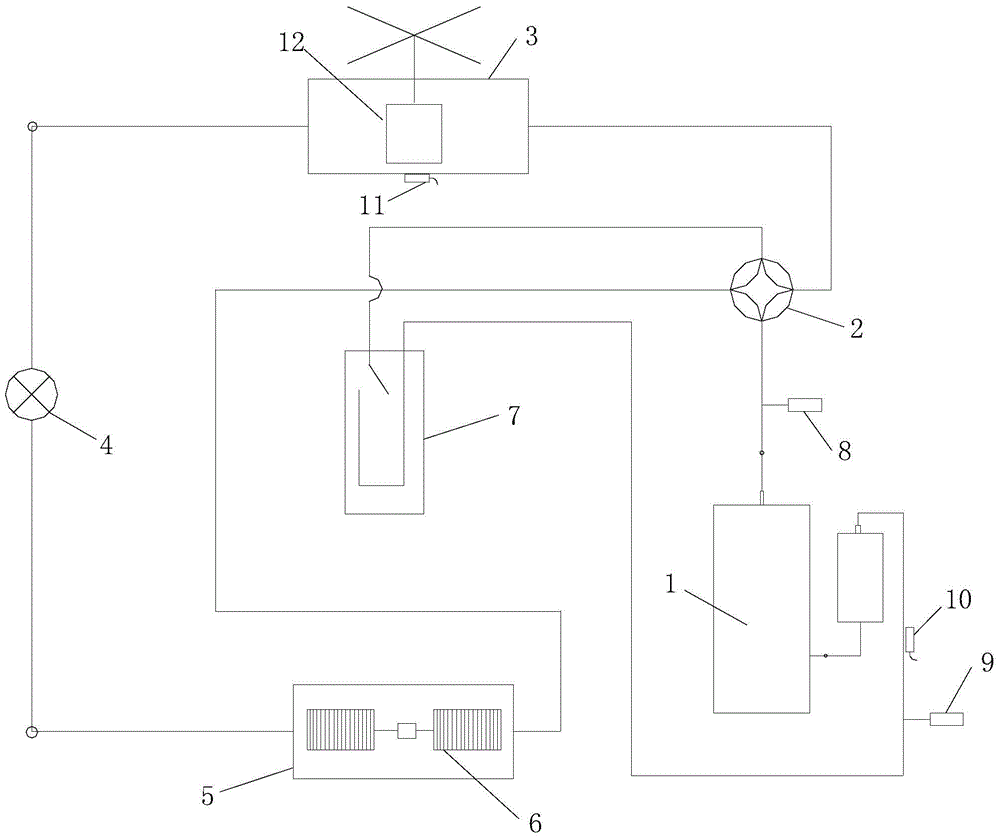

Apparatus and method for controlling a rated system pressure

The rated system pressure in a pressure control system is adjusted through a pressure relief valve (2). In addition to the pressure relief valve (2), the system includes a check valve (4), a pressure sensor (3), a position switch (10), a first pressure adjustment member (13) for the relief valve, a second pressure adjustment member (12) for the check valve (4), an actuator (16), and a microcontroller (15) with a memory (6) and a display (7). Faults caused by pressure adjustment interactions are prevented by permitting an adjustment of the pressure relief valve only if the check valve is fully open and a pump provides pressure. For this purpose the actuator (16) of the check valve in its normal position prevents an adjustment of the pressure relief valve. Opening the check valve by the actuator permits adjusting the pressure relief valve (2) and the switch (10) operated through the actuator sends a signal to the microcontroller to drive the pump. When the check valve is opened, the pressure is equalized throughout the system, so that adjusting the response pressure of the pressure relief valve automatically adjusts the system pressure to a desired rated pressure.

Owner:A ROMHELD

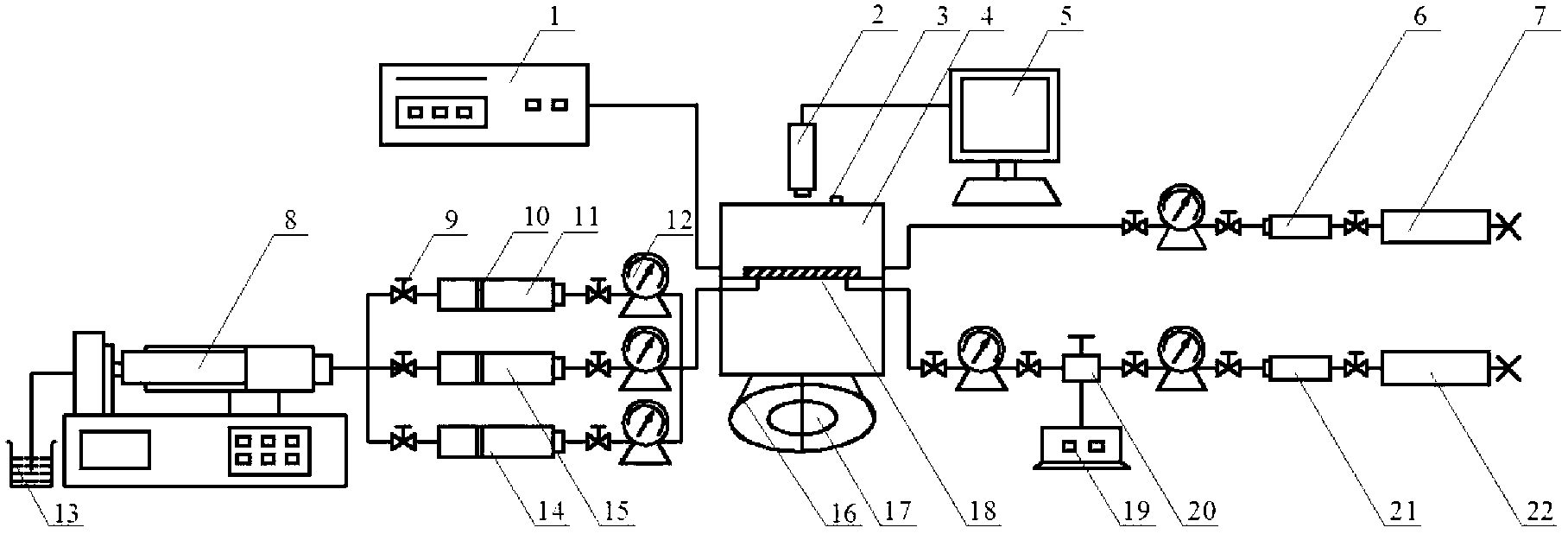

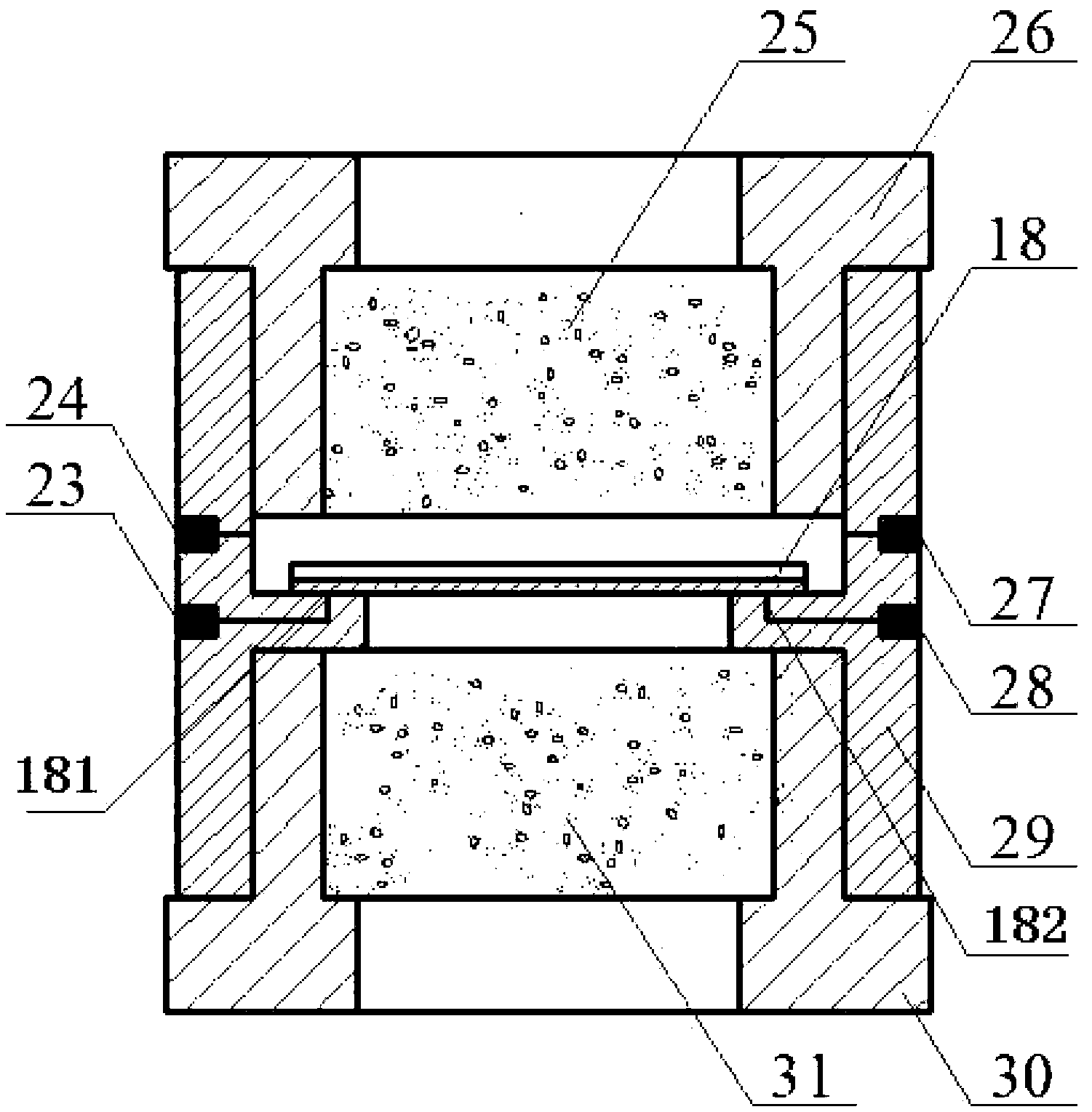

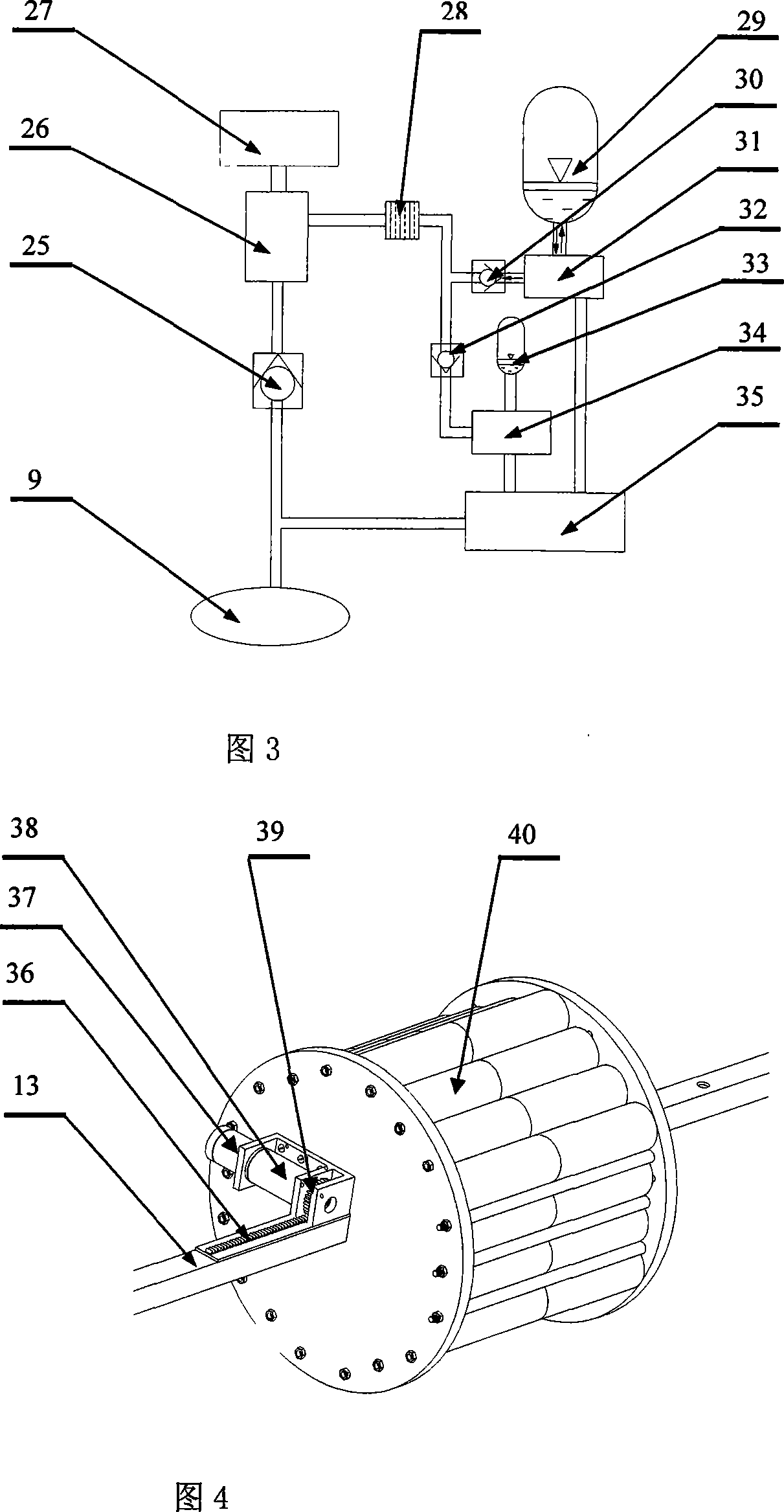

High temperature and high pressure visual device for simulating microorganism oil displacement and simulating method thereof

ActiveCN103216222AConvenient and effective temperatureConvenient and effective ring pressure sizeConstructionsFluid removalMicroorganismTemperature control

The invention relates to an experimental method and a device for simulating the process that microcosmic remaining oil is extracted in a microcosmic simulation model under the condition of oil deposit high temperature and high pressure, researching feasibility of microorganism oil displacement technology in improving enhanced oil recovery after water drive, and carrying out visualized microcosmic oil displacement experimental research under the high temperature and high pressure experimental conditions, in particular to a high temperature and high pressure visual device for simulating microorganism oil displacement and a simulating method thereof. The device comprises a model clamp clamping a microcosmic visual model, a displacement system, a back pressure system, an annular pressure system, a pressure monitoring system, a temperature control system and an image collecting system. According to the device, temperature and pressure can be controlled easily, used space is small, safety performance is excellent, operation is simple, action mechanism of microorganism and petroleum hydrocarbon and starting mechanism of the microorganism on the remaining oil can be conveniently observed in a visualized condition, and the device has important significance on wide application and popularization of microcosmic experiments in oil industries.

Owner:UNIV OF SCI & TECH BEIJING

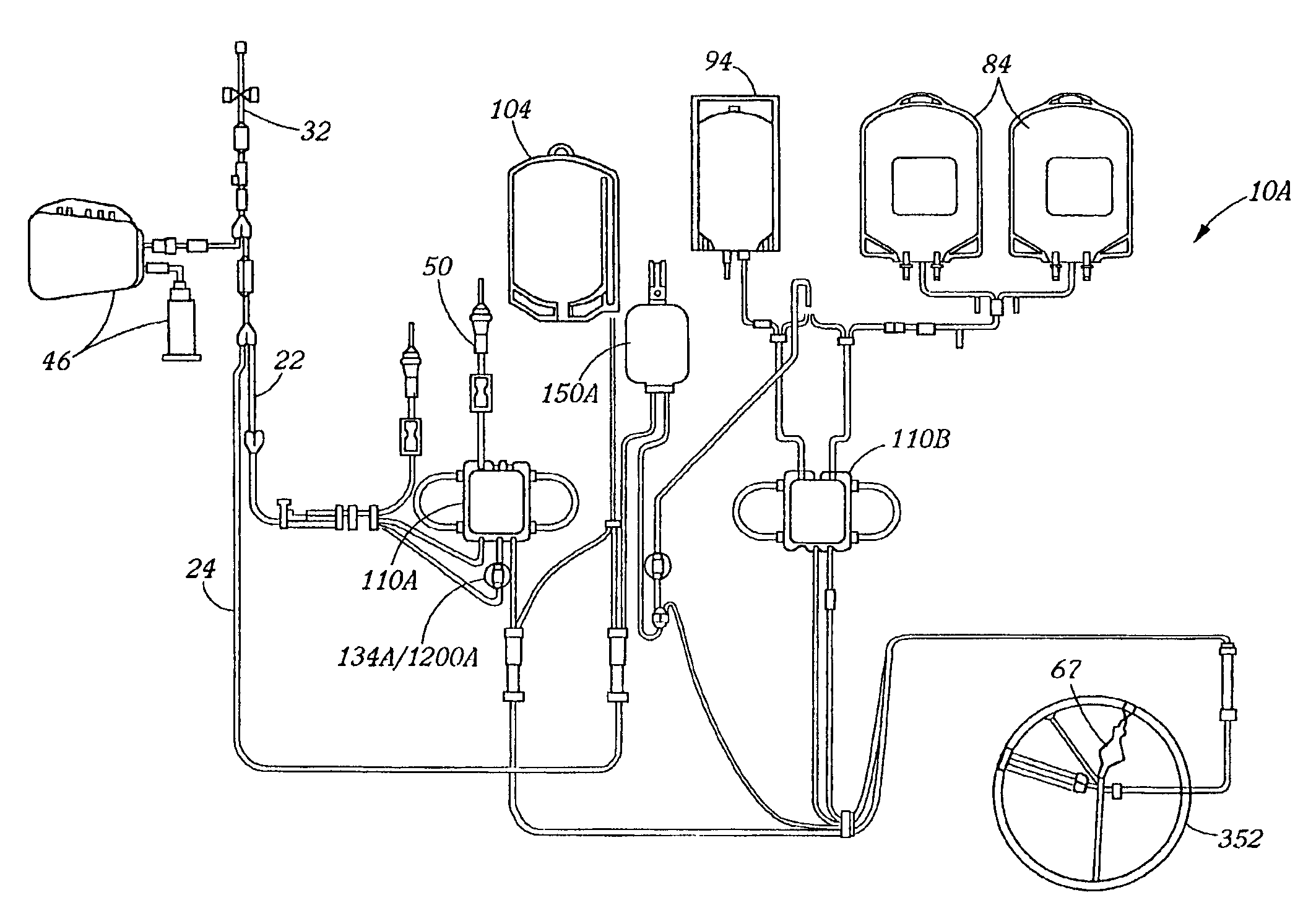

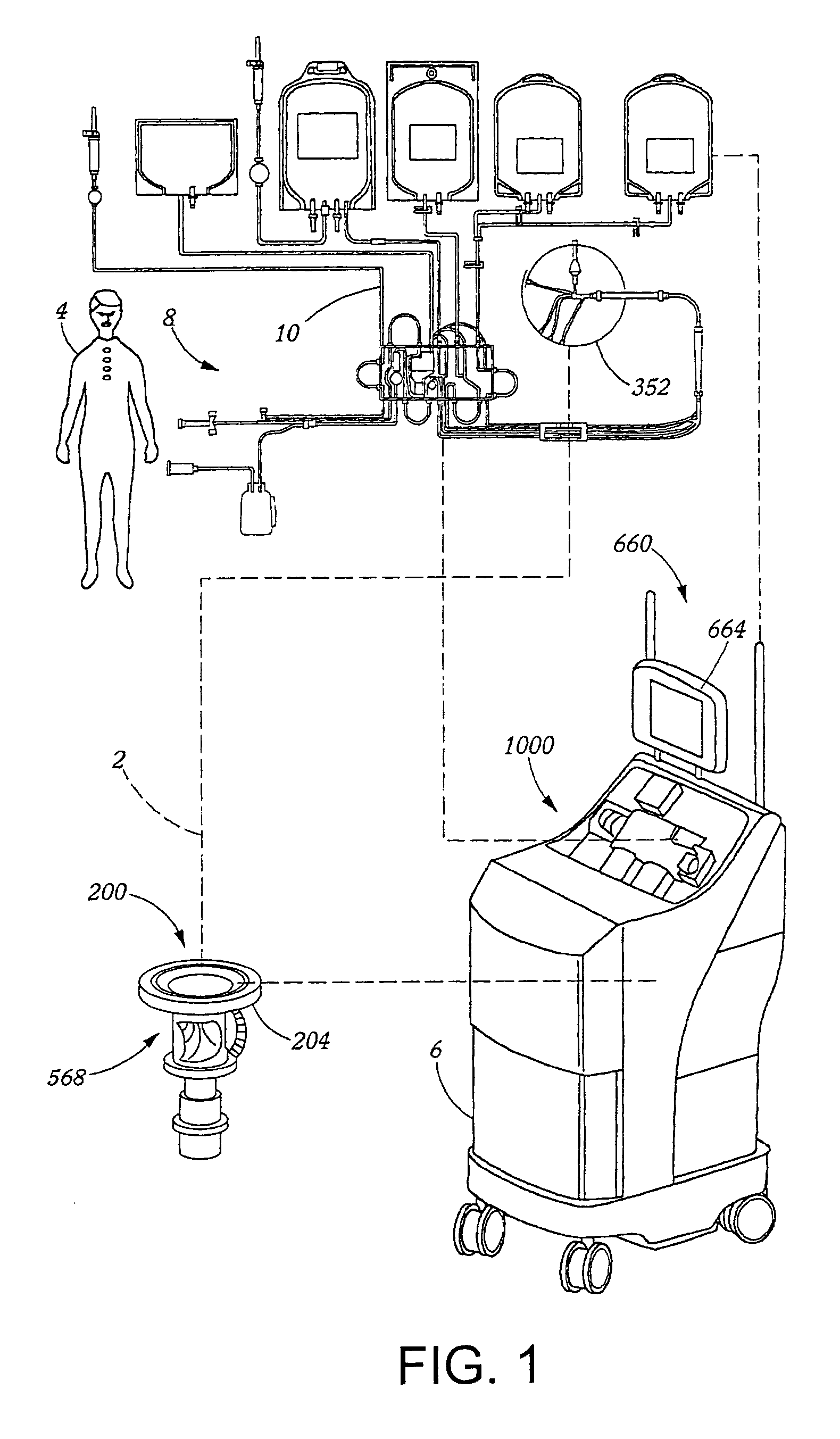

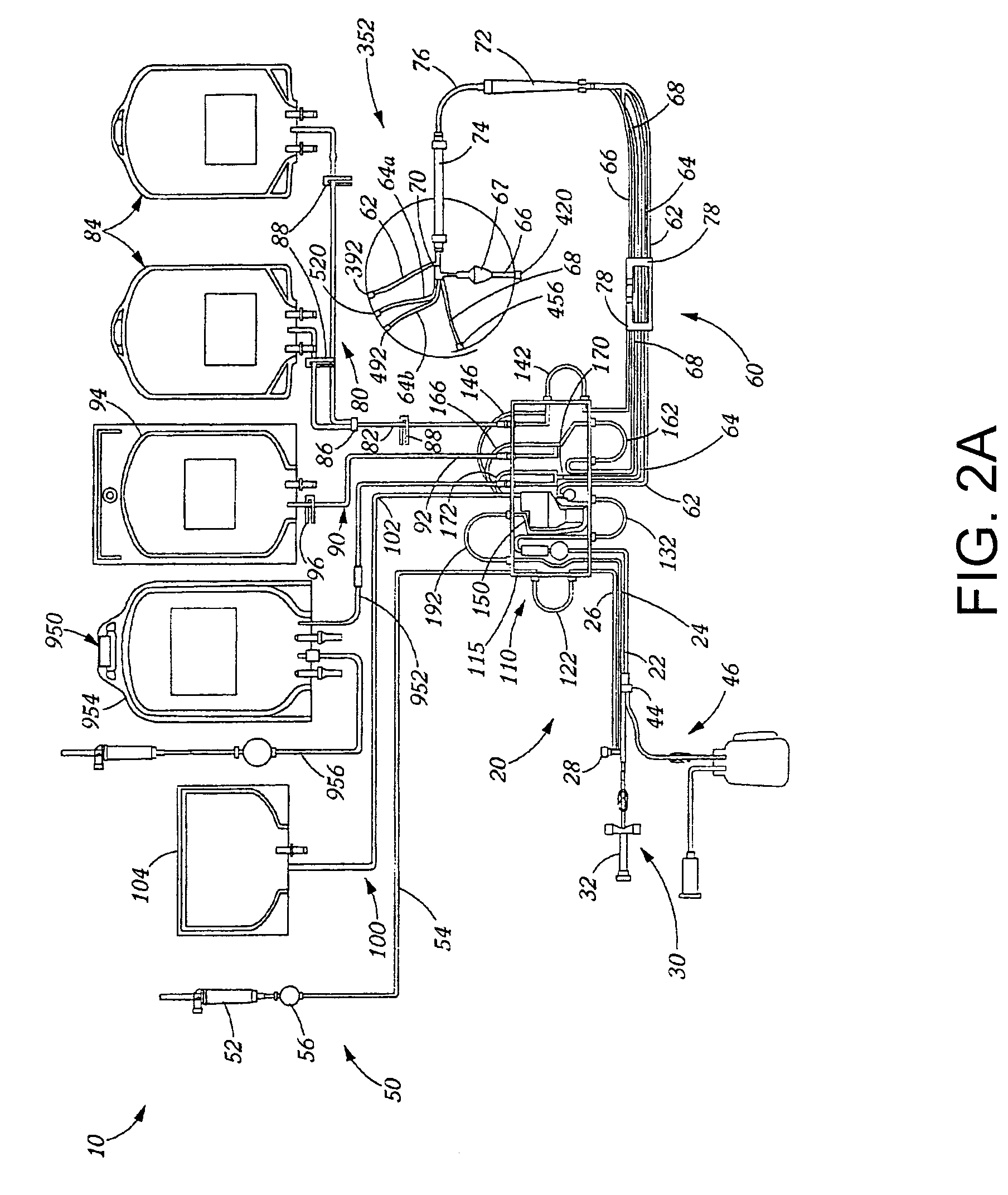

Extracorporeal blood processing methods and apparatus

InactiveUS7169352B1Improve responseSemi-permeable membranesSolvent extractionThree levelWhite blood cell

This invention provides a method for controlling a fluid separation system, preferably a blood apheresis system having a leukocyte reduction chamber. The method utilizes a three-level alarm system. A first-level alarm condition is triggered in response to a pressure drop in the system to less than or equal to a specified system pressure and pauses fluid flow in at least a portion of the system. A second-level alarm condition is triggered in response to a specified number of said pressure drops within a specified period and reduces the flow rate of the fluid in the system. The alarm conditions may also trigger a visible and / or audible alarm. These alarm levels permit flow through the leukocyte reduction chamber to continue when the pressure drop is caused by a non-serious, self-resolving or easily-correctable condition such as misalignment of system components.

Owner:TERUMO BCT

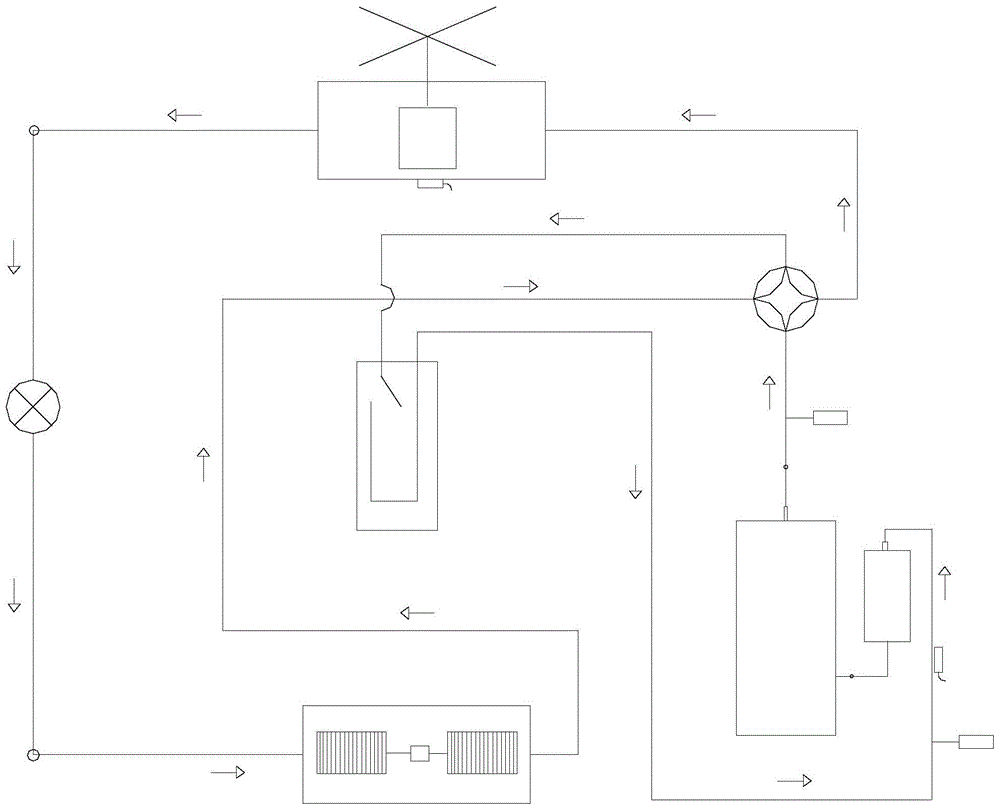

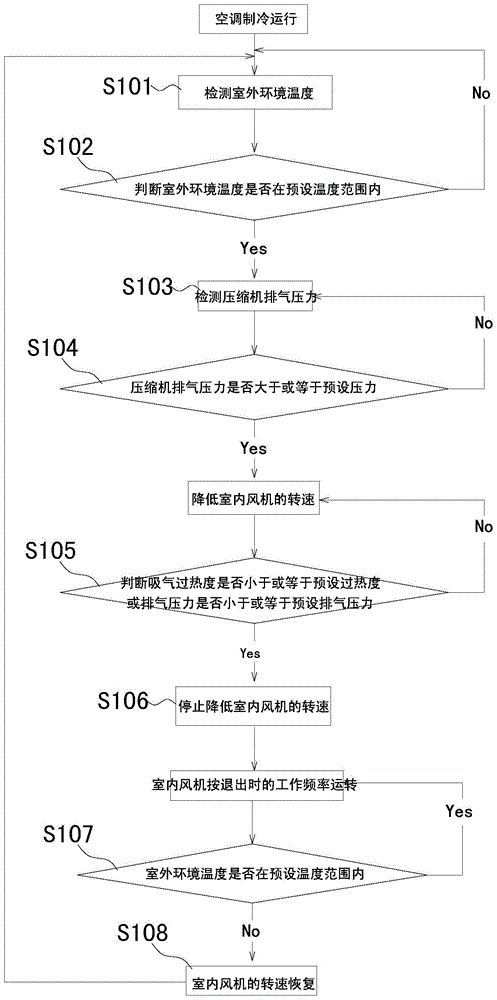

Pressure control method of air conditioning system

ActiveCN104697106AReduce exhaust pressureEffect of exhaust pressureMechanical apparatusSpace heating and ventilation safety systemsSystem pressureAir conditioning

Owner:GREE ELECTRIC APPLIANCES INC

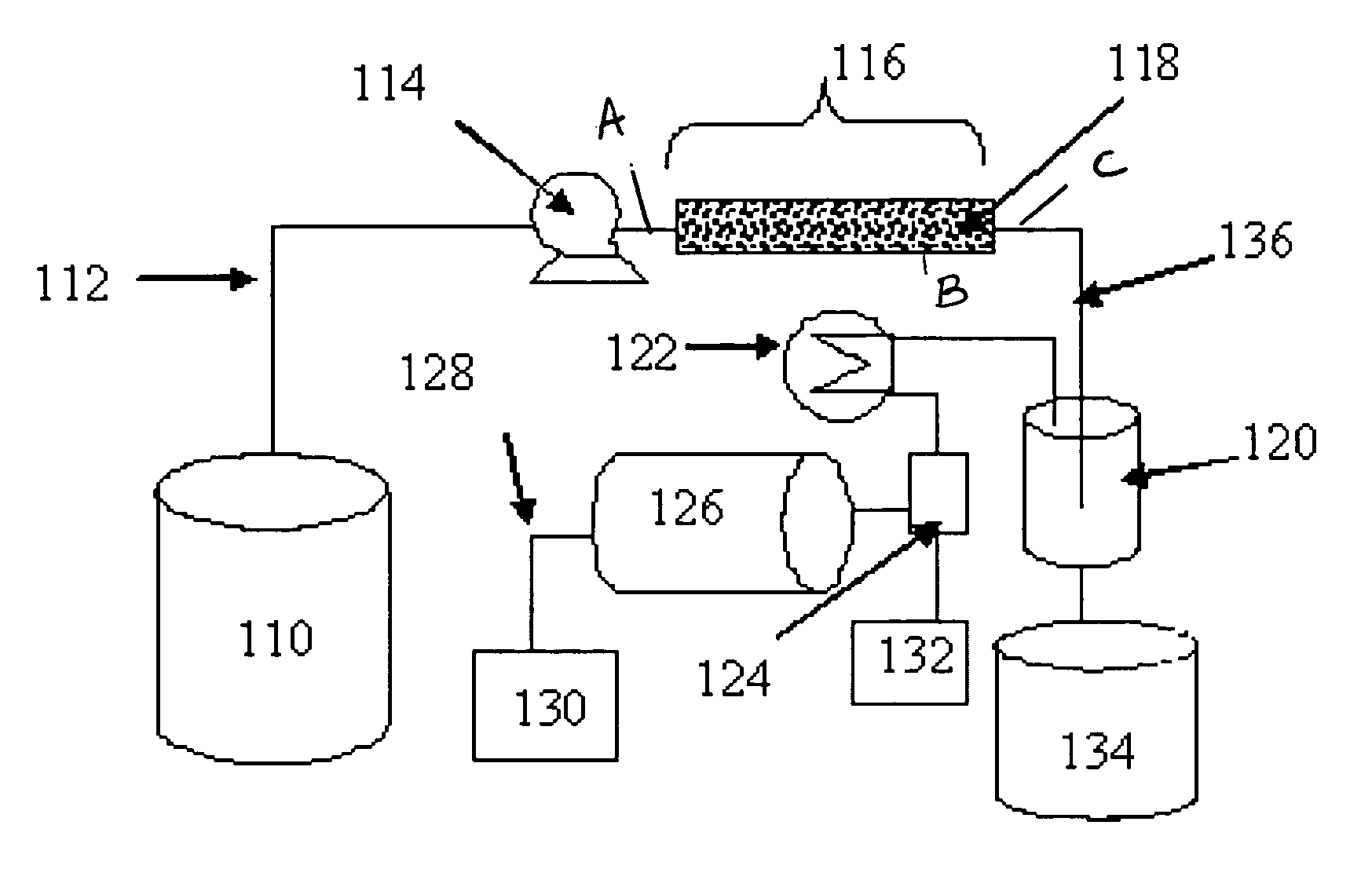

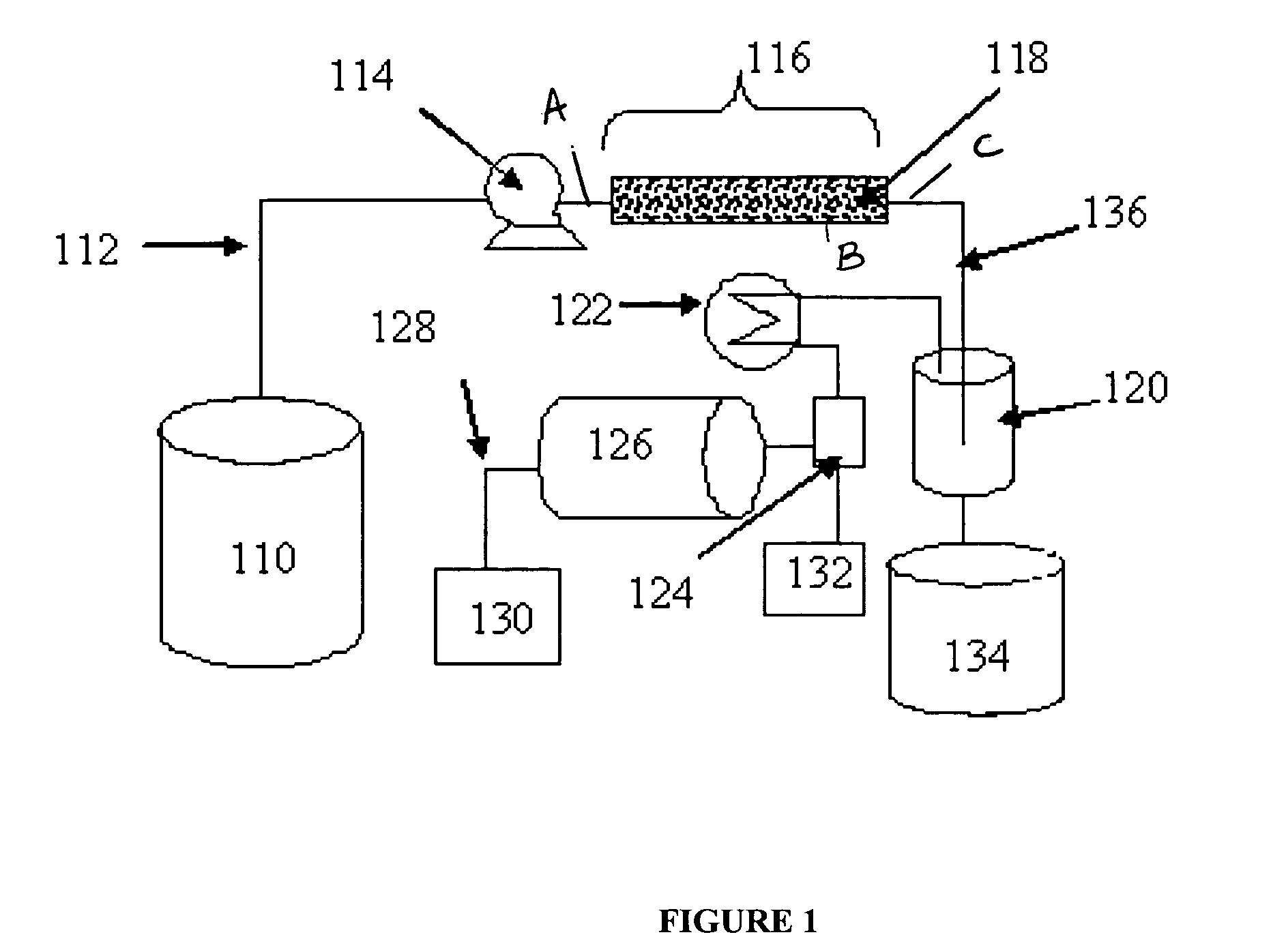

Systems and methods for controlling hydrogen generation

Systems and methods are disclosed for monitoring at least two system parameters (such as system temperature or pressure, or system pressure at two different locations) of a hydrogen generation system and controlling hydrogen generation from a fuel solution. The system comprises a hydrogen generator having a fuel chamber for a liquid fuel, a reactor chamber where the fuel undergoes a reaction to produce hydrogen, and at least two sensors in communication with the reactor chamber, the sensors measuring at least two system parameters of the hydrogen generator. The methods include control sequences for controlling the fuel flow rate to the reactor based on the sensed parameters.

Owner:MILLENNIUM CELL

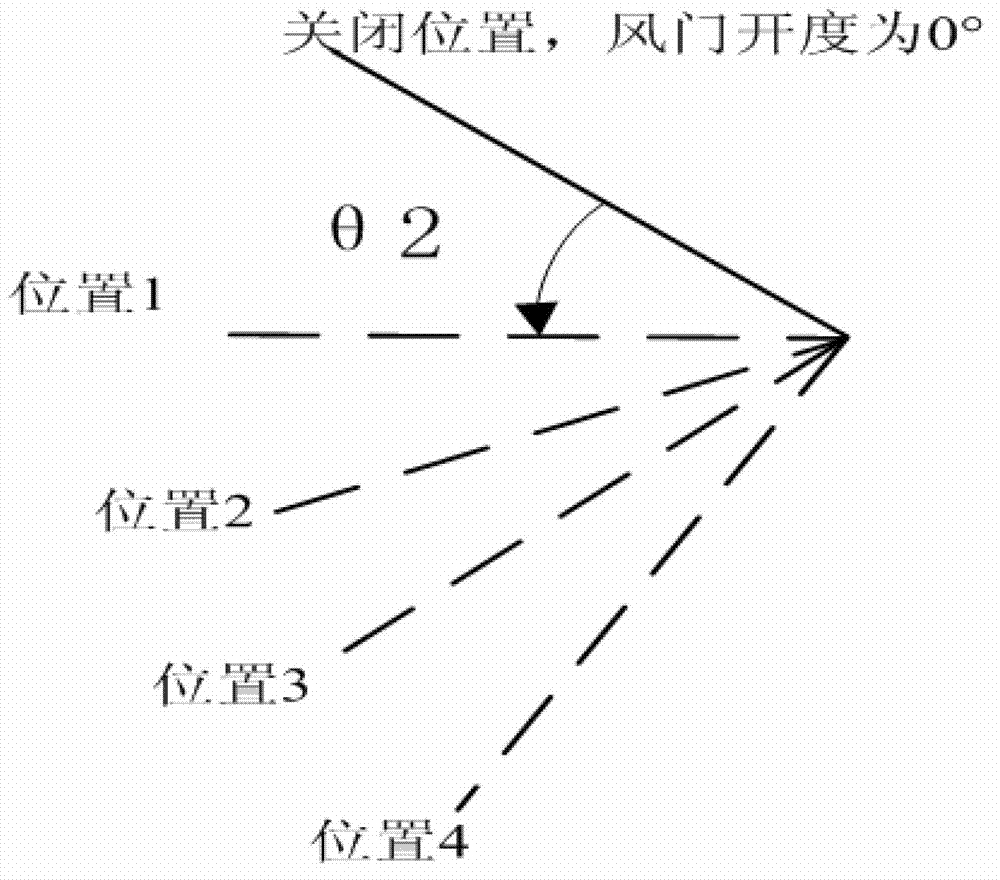

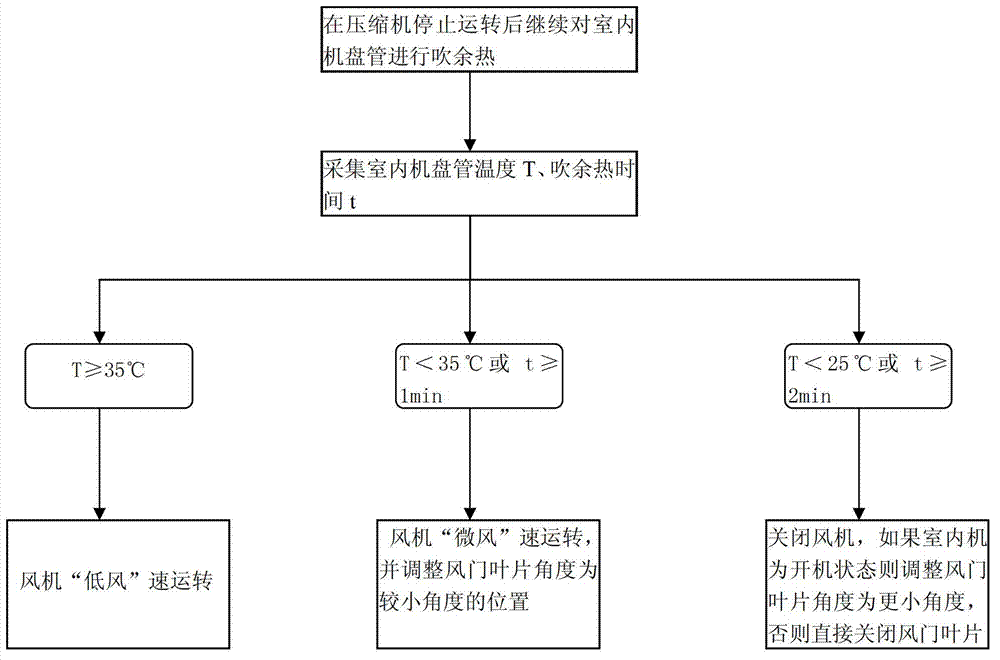

Air conditioner waste heat blowing control method

ActiveCN102927653AReduce noiseReduce the angleSpace heating and ventilation safety systemsLighting and heating apparatusSystem pressureEngineering

The invention relates to an air conditioner control technology and discloses an air conditioner waste heat blowing control method. Waste heat of a coiler of an indoor unit is blown out as quickly as possible after a compressor halts, so as to reduce the temperature of the coiler, and system pressure is in a balanced state to the greatest extent. The air conditioner waste heat blowing control method comprises the steps that: a fan of the indoor unit continuously operates to blow waste heat of the coiler of the indoor unit after the compressor stops in a heating state, and the temperature or waste heat blowing time of the coiler of the indoor unit is acquired and compared and judged with a preset threshold value, so as to realize corresponding regulation on the rotating speed of the fan of the indoor unit. The air conditioner waste heat blowing control method provided by the invention is applicable to waste heat blowing on indoor coilers of various air conditioners.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

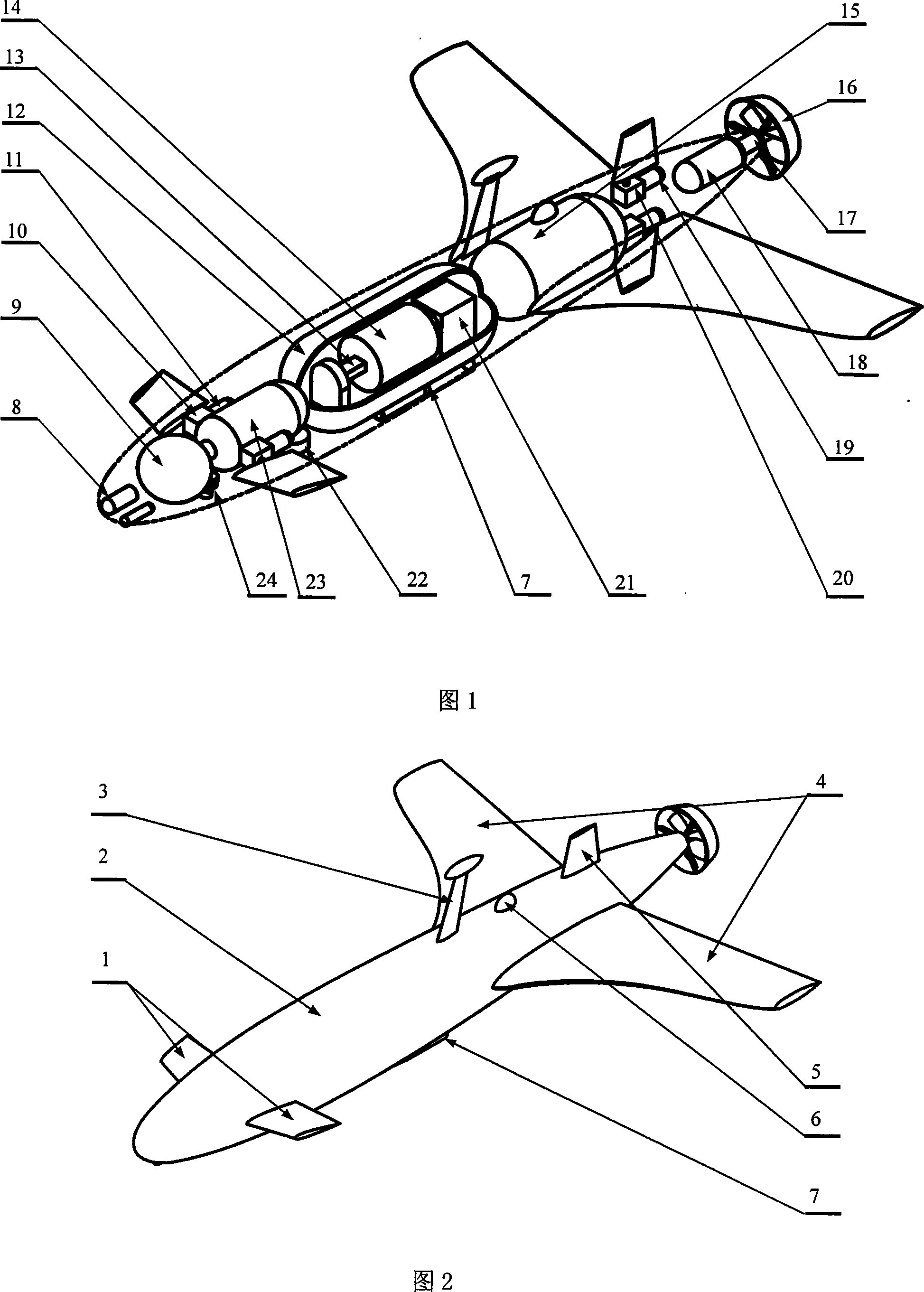

Hybrid driven under-water self-navigation device

InactiveCN101070092AAdd depthImprove gliding efficiencyPropulsion power plantsPropulsive elementsControl systemAttitude control

The invention discloses a self aircraft under water driven by the mixed power. It includes the main body, the fixed vane, the vertical tail vane, the horizontally fixed bow rudder and a canula screw thruster. In the dome, it is installed with the flotage driving out bladder, the flotage driving pressure capsule with the flotage driving system, the guise adjusting pressure capsule with the pitching adjusting system and the navigation system, the electric source and controlling system pressure capsule which are all connected with out water directly. By using the triangle vane, it is proper to improve the gliding effect when gliding; by using the horizontal bow rudder and the vertical tail rudder, the guise and the track can be controlled in the AUV mode to help the guise control in the gliding mode, the pitching guise adjusting system can reach the guise control in gliding mode. So it can monitor and detect the big field water for long time.

Owner:TIANJIN UNIV

Impingement cooled heat sink with low pressure drop

InactiveUS7597135B2Reduced life-timeIncrease pressureSemiconductor/solid-state device detailsSolid-state devicesSystem pressureHeat spreader

Owner:COOLIT SYSTEMS INC

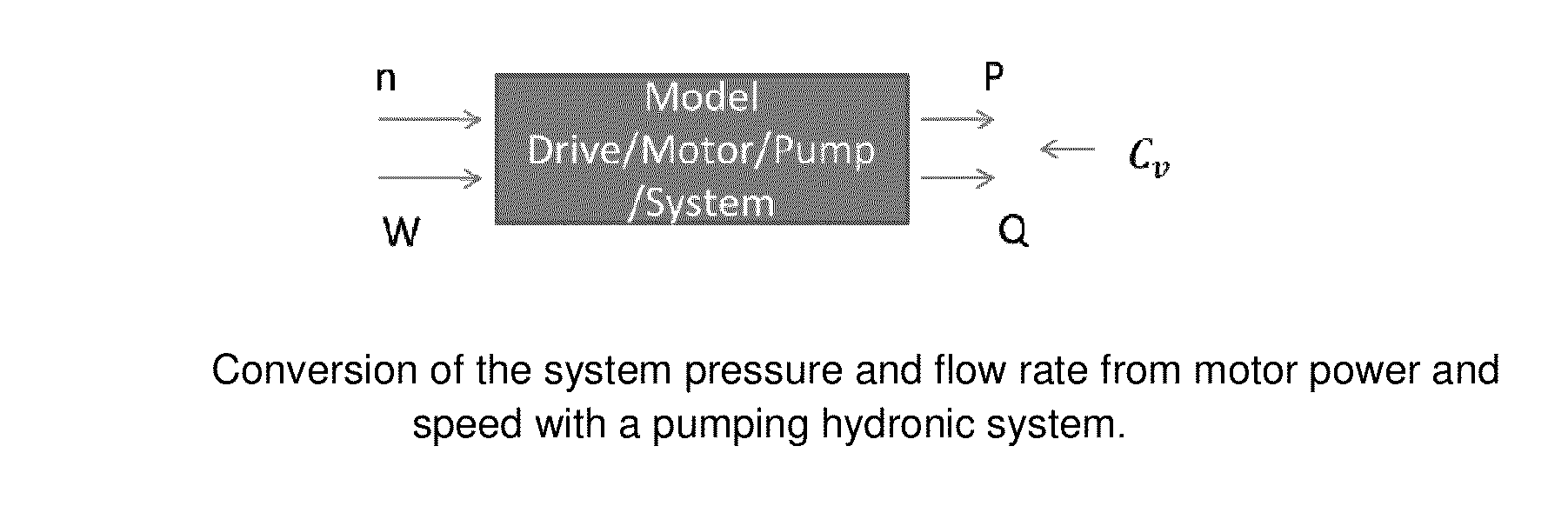

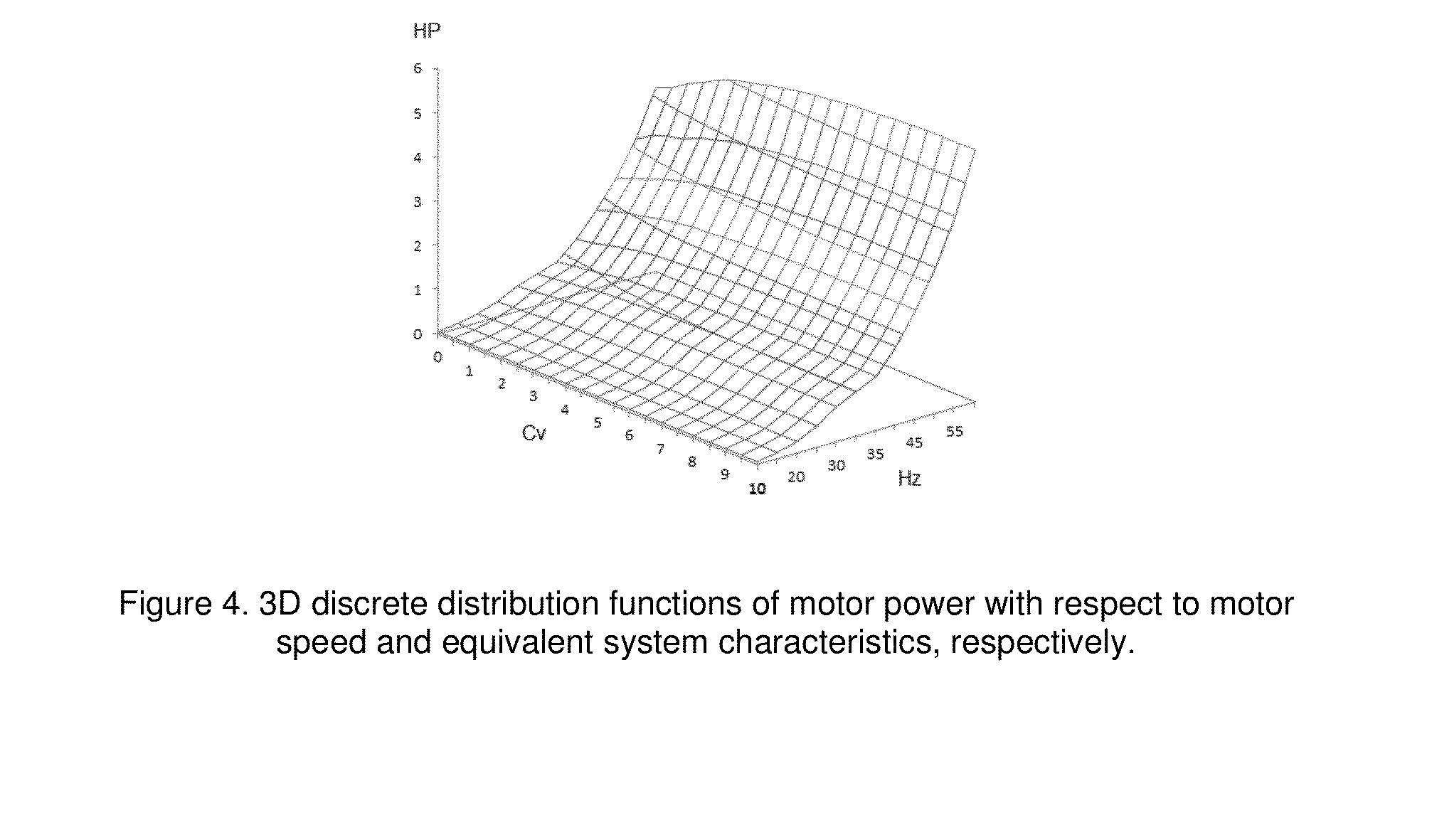

Mixed theoretical and discrete sensorless converter for pump differential pressure and flow monitoring

ActiveUS20140288716A1More accuracyFlow control using electric meansPump controlDifferential pressureComputer module

The present invention provides apparatus featuring a signal processor or processing module that may be configured at least to: process signaling containing information about an equilibrium point of pump differential pressure and system pressure formulated in a hydronic domain by utilizing pump and system characteristic curve equations so as to yield system pressure and flow rate at any particular load and time in a pump hydronic system, including using a multi-dimensional sensorless conversion technique; and determine equivalent hydronic system characteristics associated with the pump differential pressure and flow rate to their corresponding motor power and speed reconstructed and remapped by using a discrete numerical approach, based at least partly on the signaling received. The signal processor or processing module may provide corresponding signaling containing information about the system pumping flow rate and pressure determined.

Owner:FLUID HANDLING

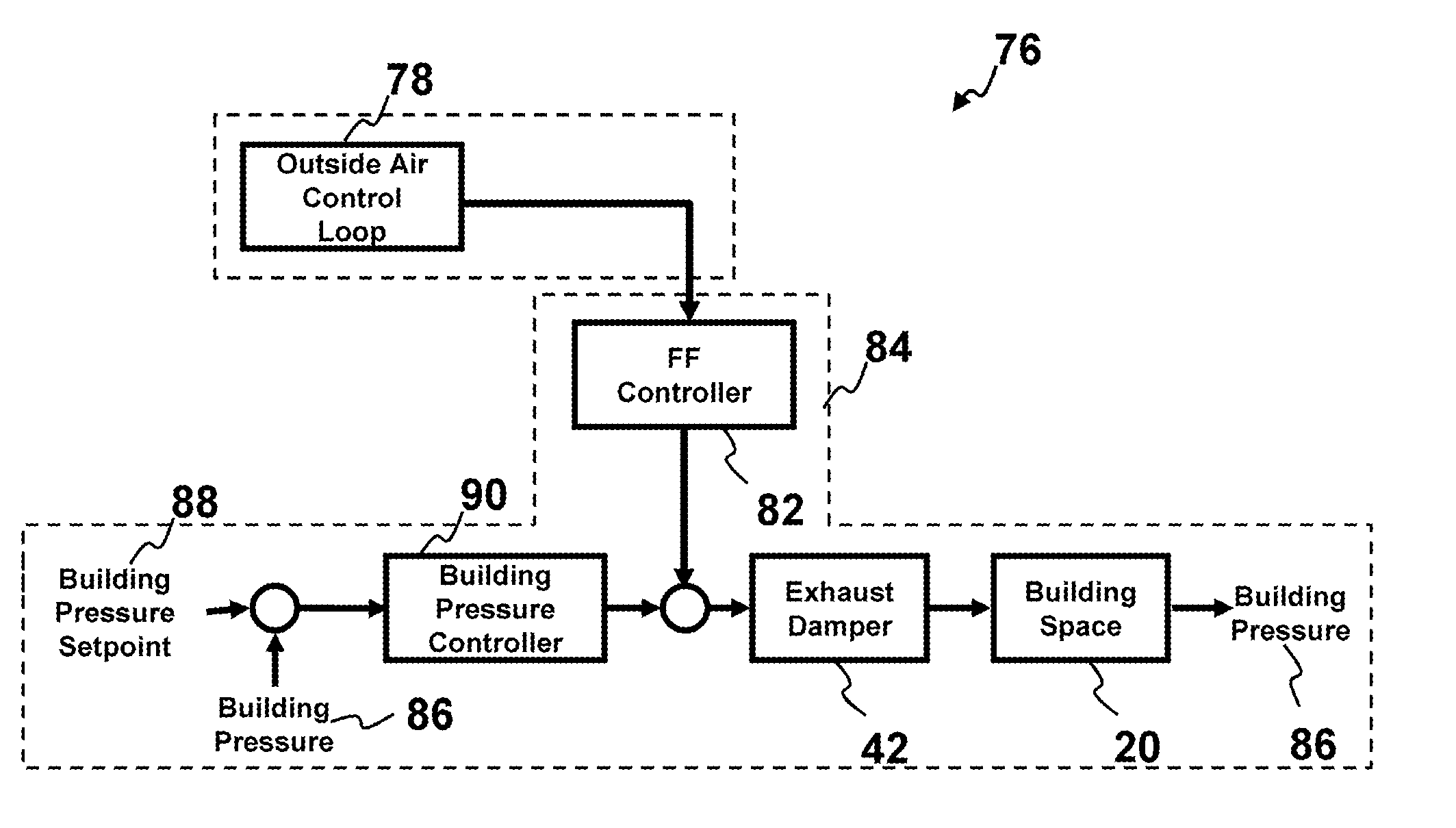

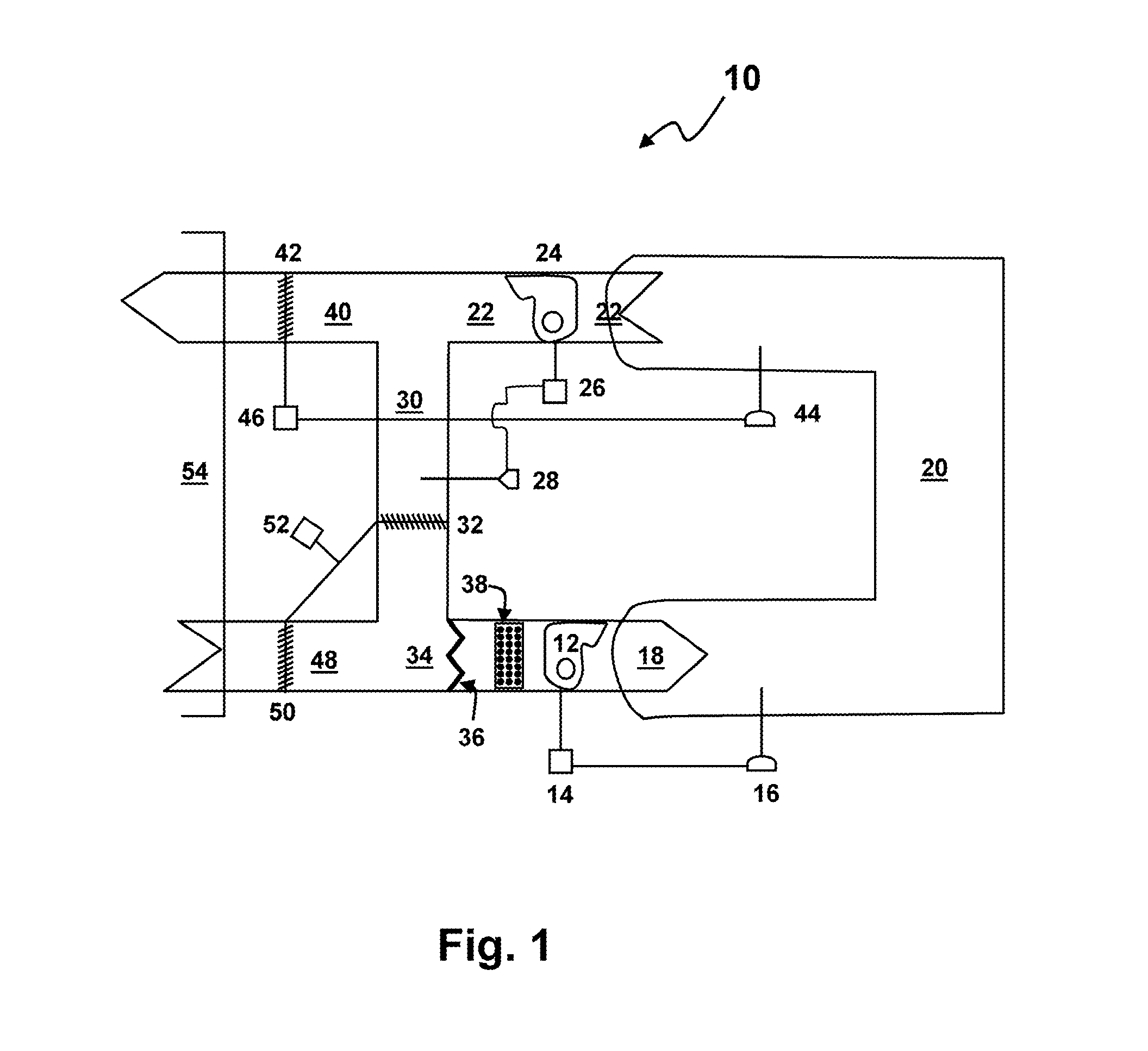

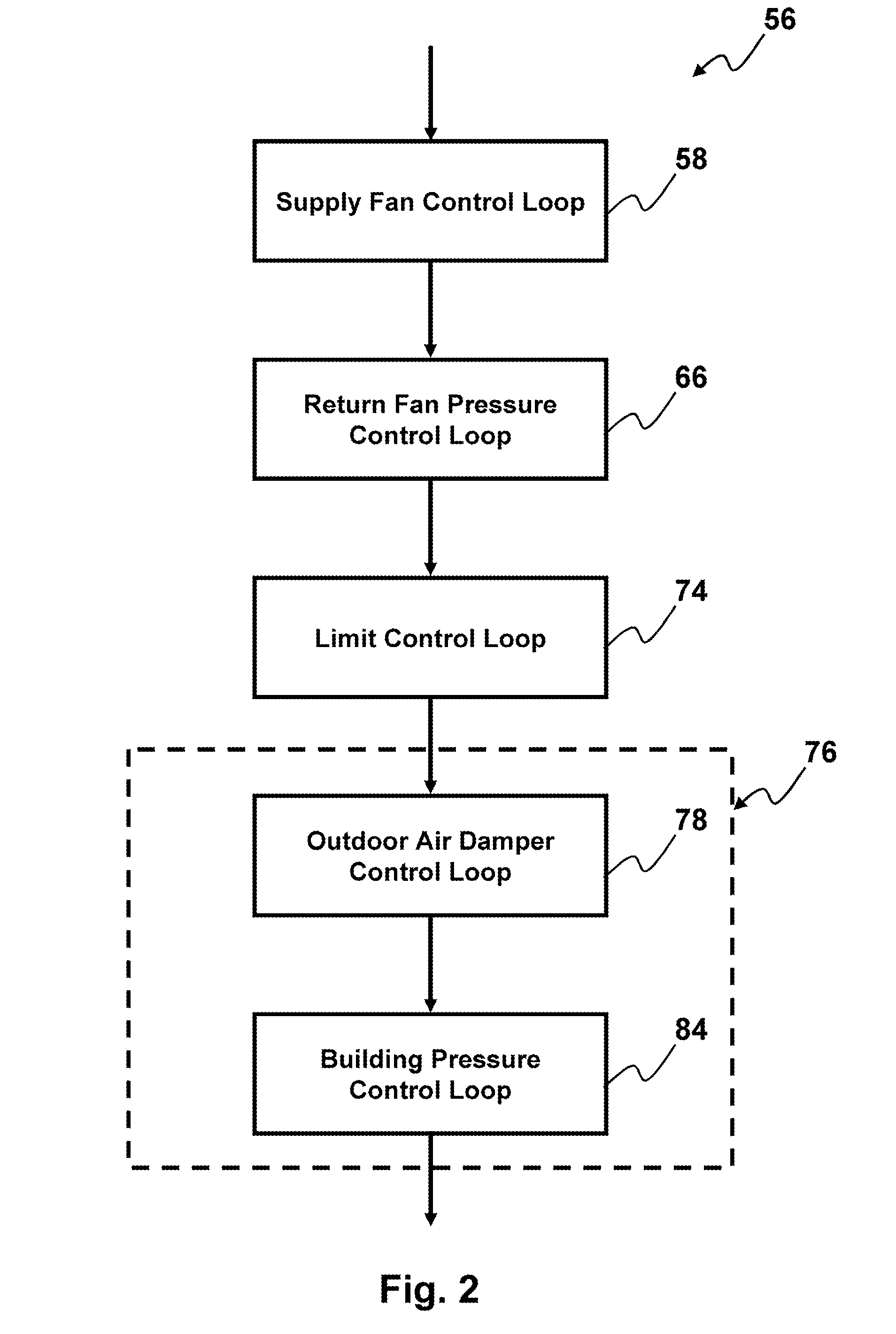

Return Fan Control System and Method

ActiveUS20100057258A1Sampled-variable control systemsMechanical apparatusControl systemSystem pressure

A return fan control system for an HVAC system comprises a supply fan control loop, a return fan control loop and a building pressure control system. The supply fan control loop comprises a duct pressure controller arranged to control a supply fan to a duct pressure setpoint. The return plenum pressure control loop comprises a return plenum pressure controller arranged to automatically control a return fan to a return plenum pressure setpoint determined by a setpoint reset function. The building pressure control system is operable to control a building pressure. The building pressure control system may comprise a building pressure control loop and an outside air control loop cooperatively arranged to control an exhaust damper in response to an outside air intake.

Owner:TRANE INT INC

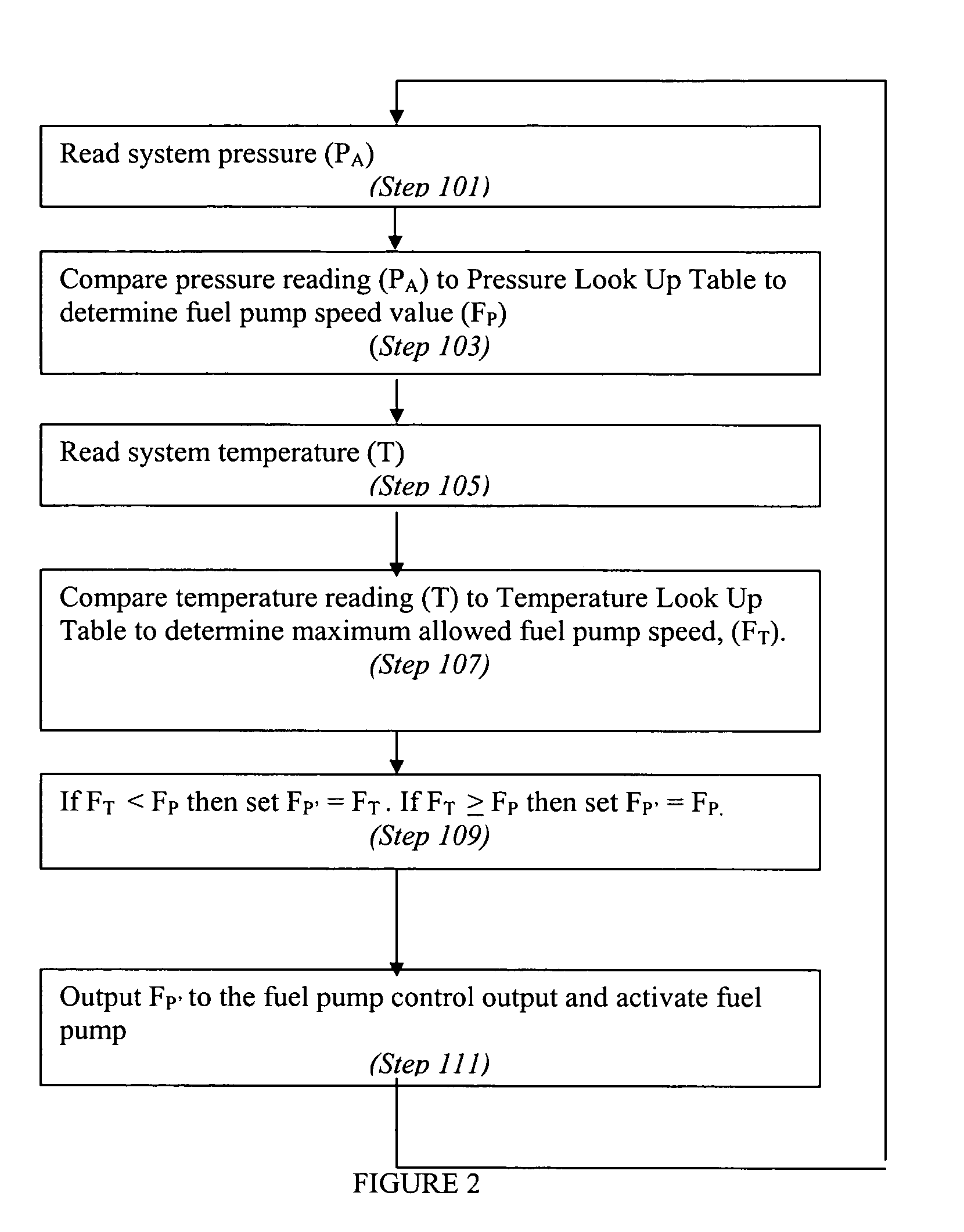

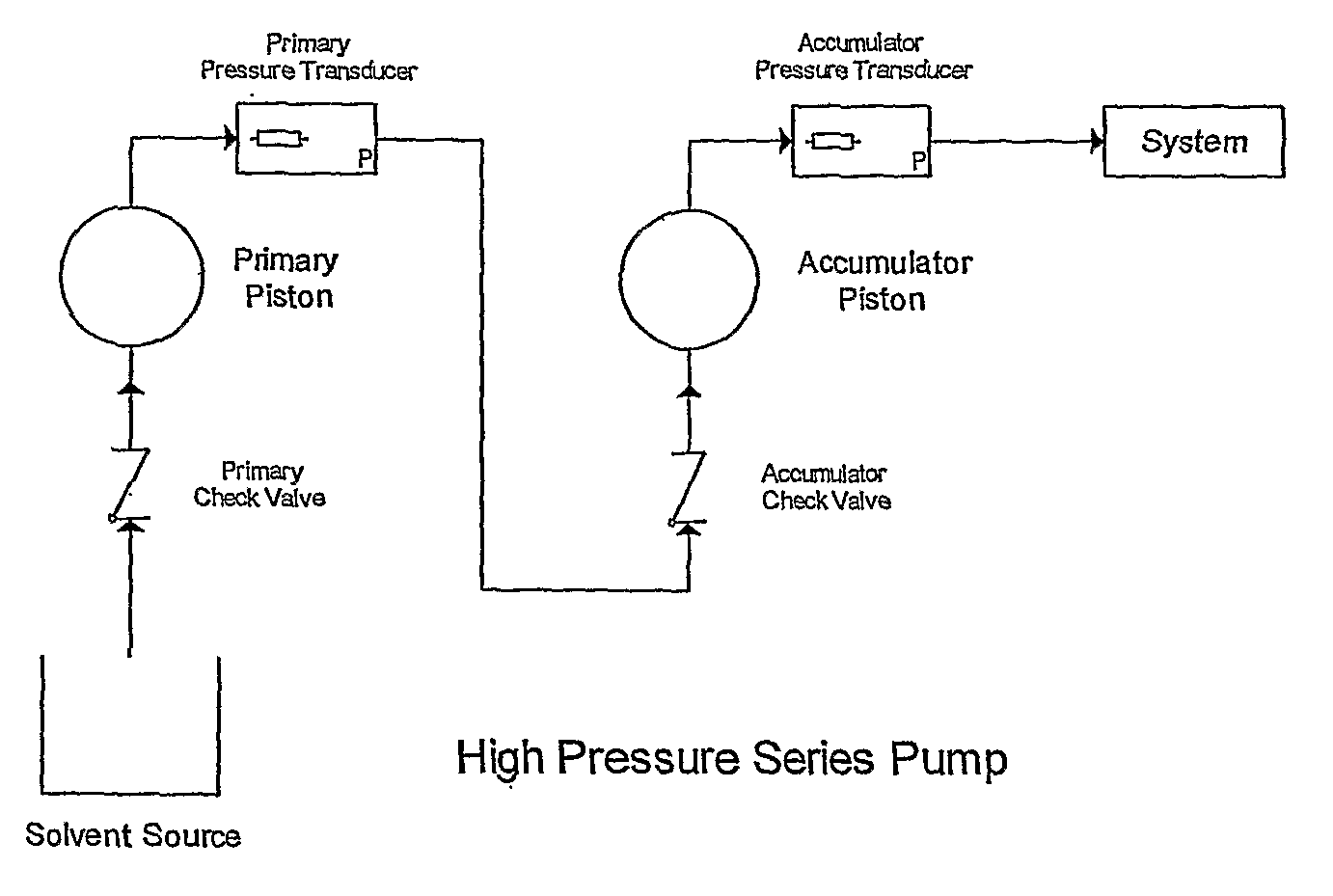

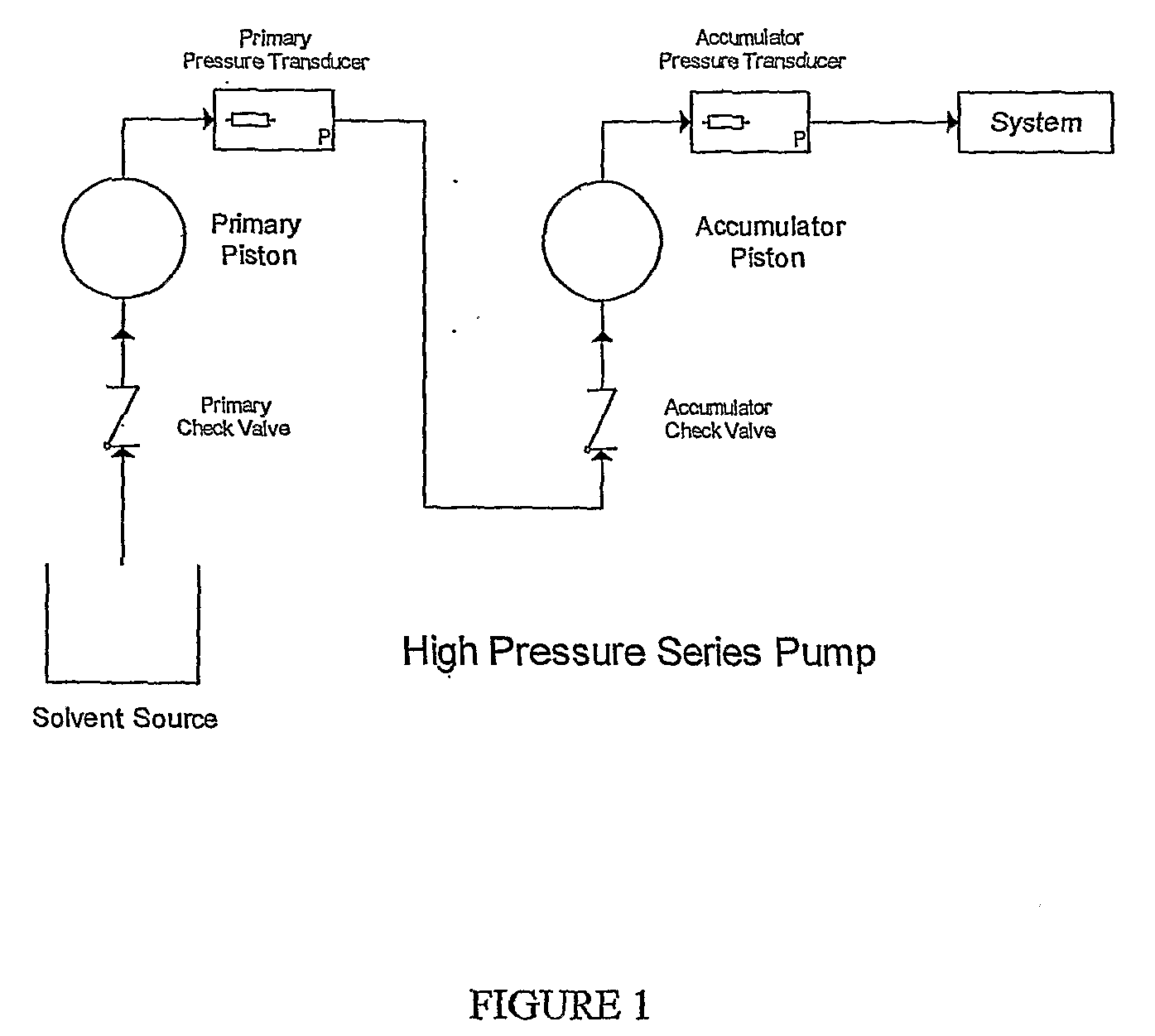

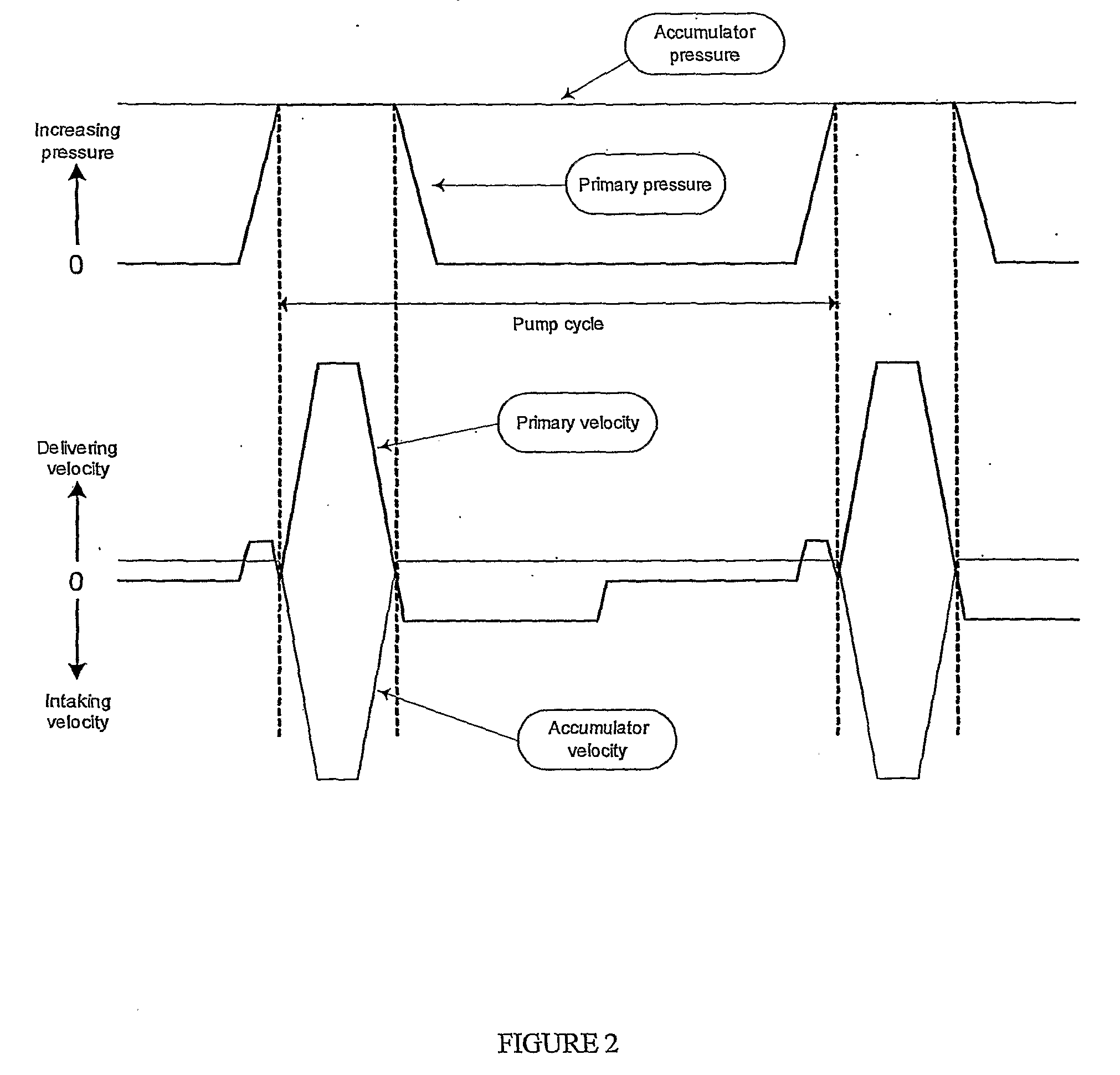

High Pressure Pump Control

ActiveUS20080206067A1Prevent composition errorReduce errorsFluid parameterComponent separationSystem pressureEngineering

A feedback control loop for a high pressure pump modifies the accumulator velocity and pressure during solvent transfer. The accumulator velocity is adjusted to maintain the system pressure equal to the expected pressure to thereby eliminate the effect of the flow deficit created by a thermal effect.

Owner:WATERS TECH CORP

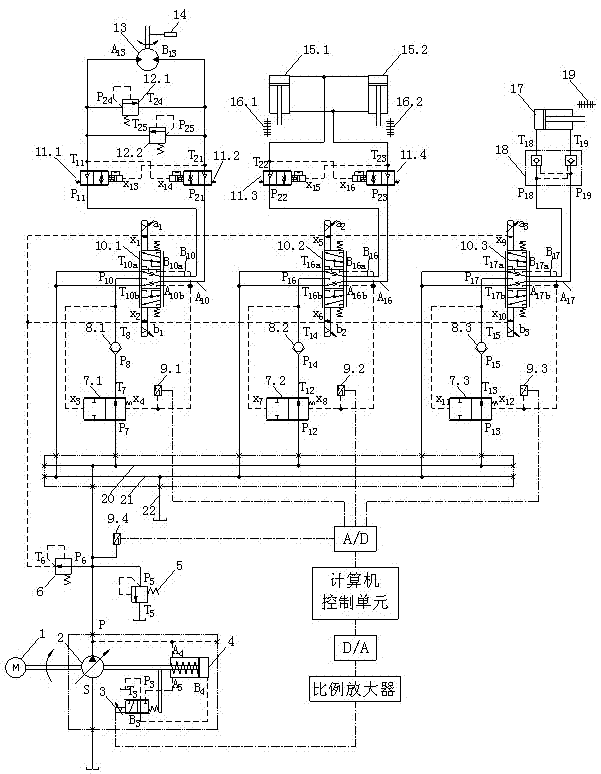

Energy-saving shield segment assembling and positioning electro-hydraulic control system adopting load-sensitive technology

InactiveCN103032396APrecise control of assembly positioningImprove construction qualityUnderground chambersServomotorsControl signalSystem pressure

The invention discloses an energy-saving shield segment assembling and positioning electro-hydraulic control system adopting a load-sensitive technology. The system comprises a motor, a variable pump, a two-position three-way proportional reversing valve, a variable cylinder, an overflow valve, a pressure reducing valve, a pressure compensating valve, a one-way valve, a multi-way valve, a balancing valve, a hydraulic lock, a hydraulic motor, a hydraulic cylinder, a moment rotation speed sensor, a displacement sensor and a pressure sensor. The multi-way valve with the pressure compensating valve in a segment assembling system is used for controlling the rotation speed of the hydraulic motor for driving the segment assembling machine to rotate and the moving speed of each hydraulic cylinder. The pressure sensor is used for detecting the pressure of a main oil passage of the system and the working pressure of each executer in real time; and a computer control unit is used for determining a variable pump control signal according to a system pressure signal, so that the displacement of the variable pump is changed with the load change so as to achieve load sensitive control. According to the invention, energy waste caused by continuous oil supply at the highest working pressure of the traditional system is avoided, the throttling loss and overflow loss are greatly reduced, and an obvious energy saving effect is obtained.

Owner:ZHEJIANG UNIV

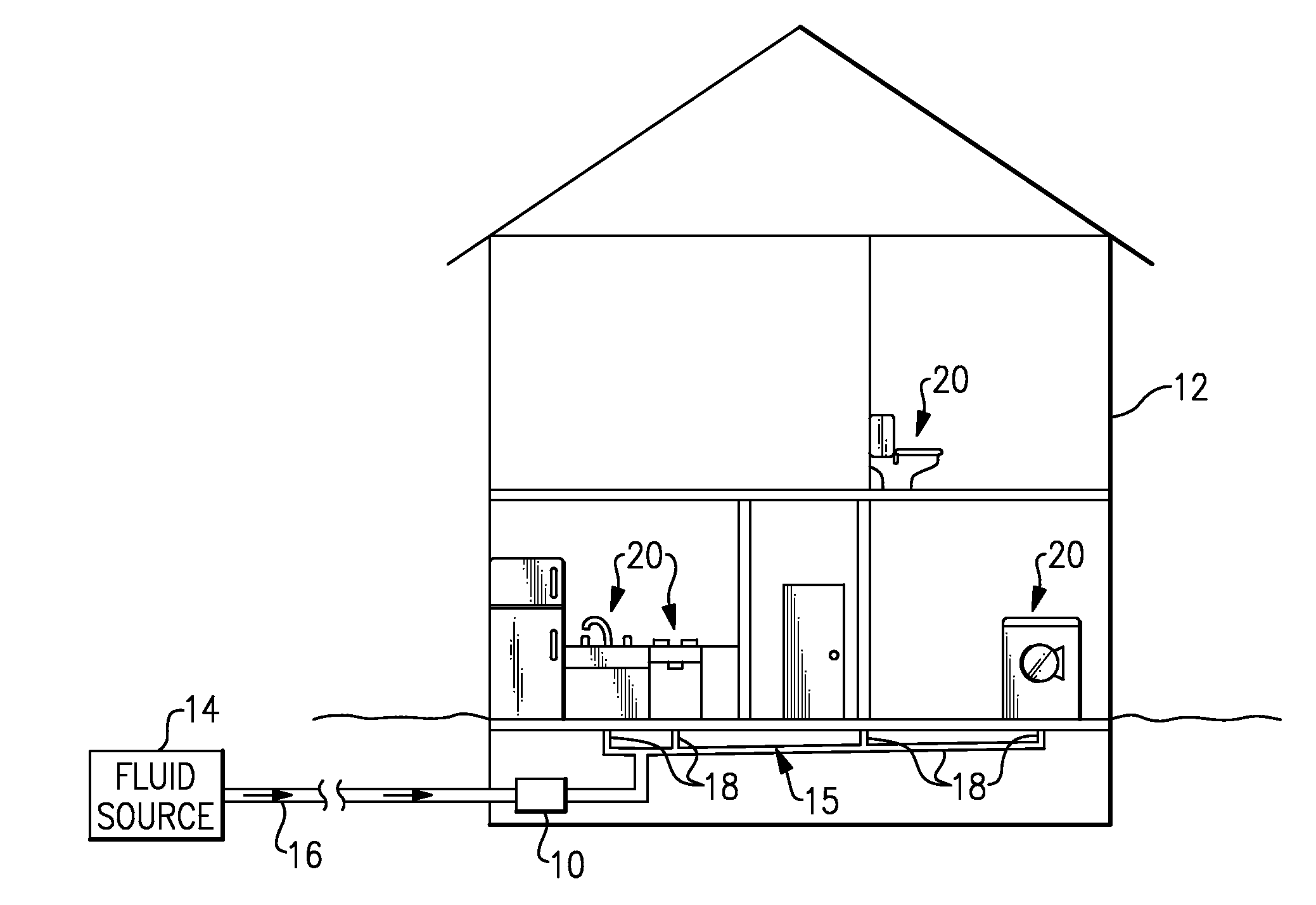

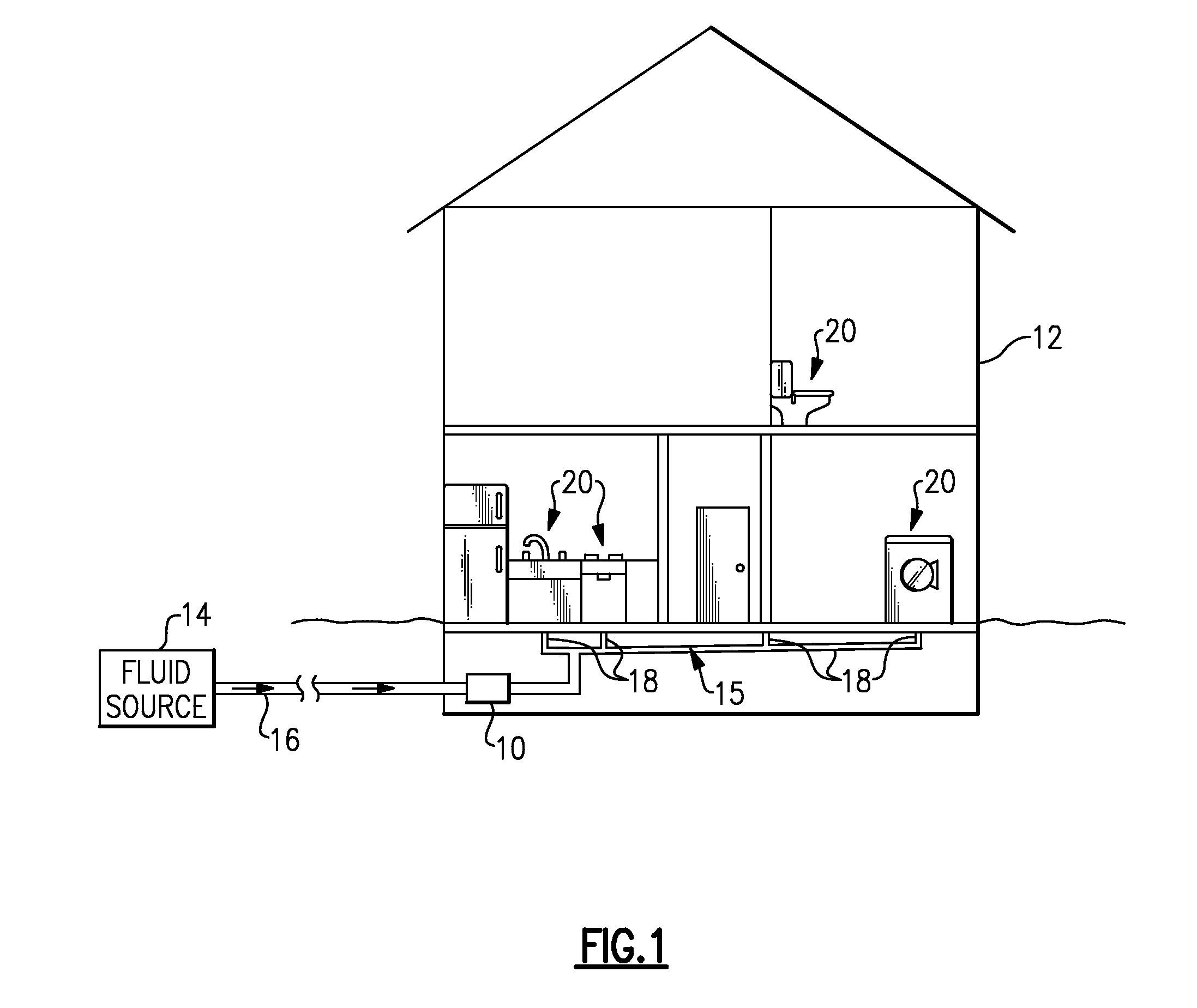

Fluid supply monitoring system

InactiveUS20080184781A1Measurement of fluid loss/gain ratePipeline systemsMonitoring systemSystem pressure

A method for testing a fluid supply system includes periodically preventing a fluid flow through the fluid supply system, and measuring a system pressure of the fluid flow subsequent to the step of preventing the fluid flow.

Owner:BRASSCRAFT MFG CO +1

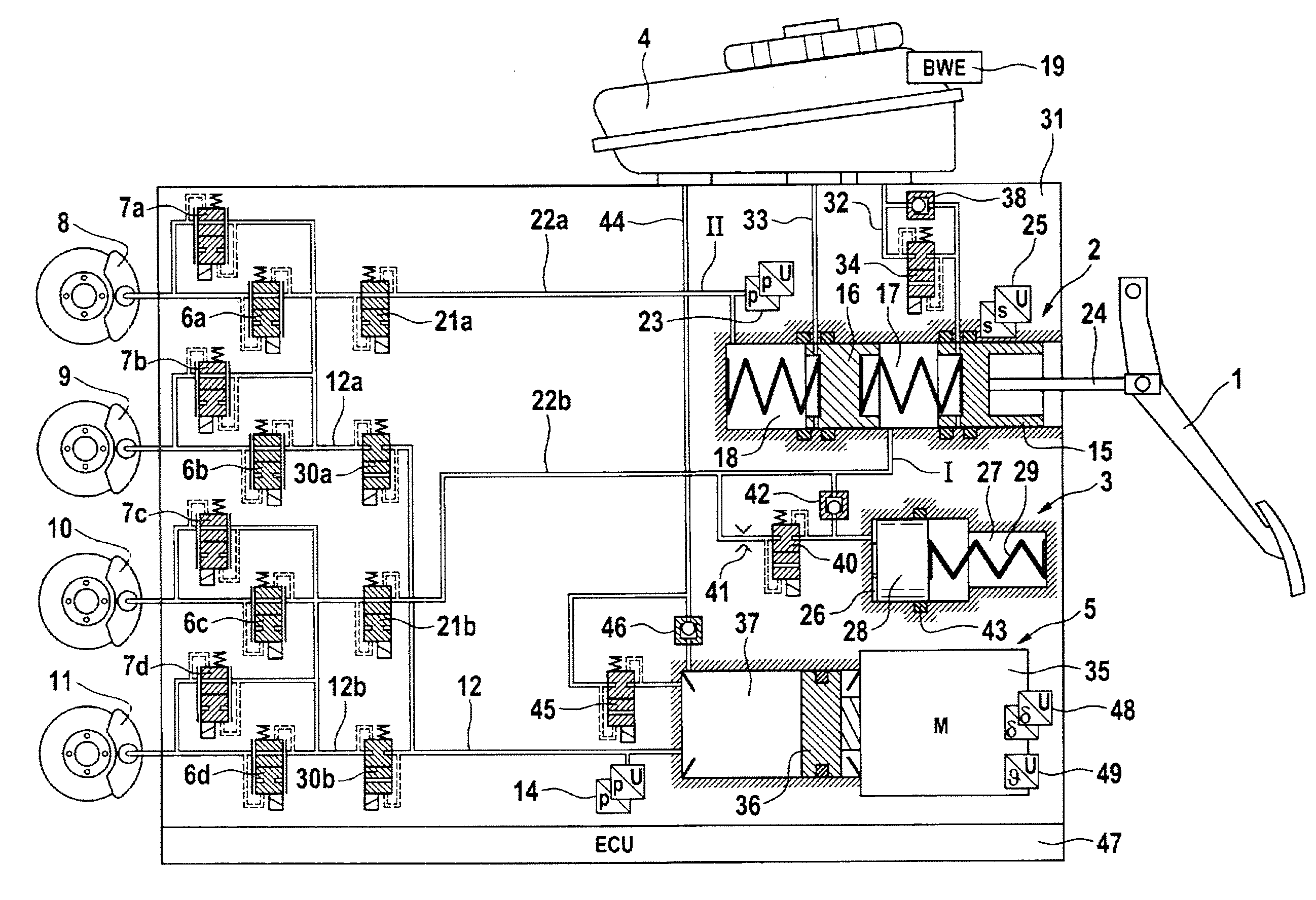

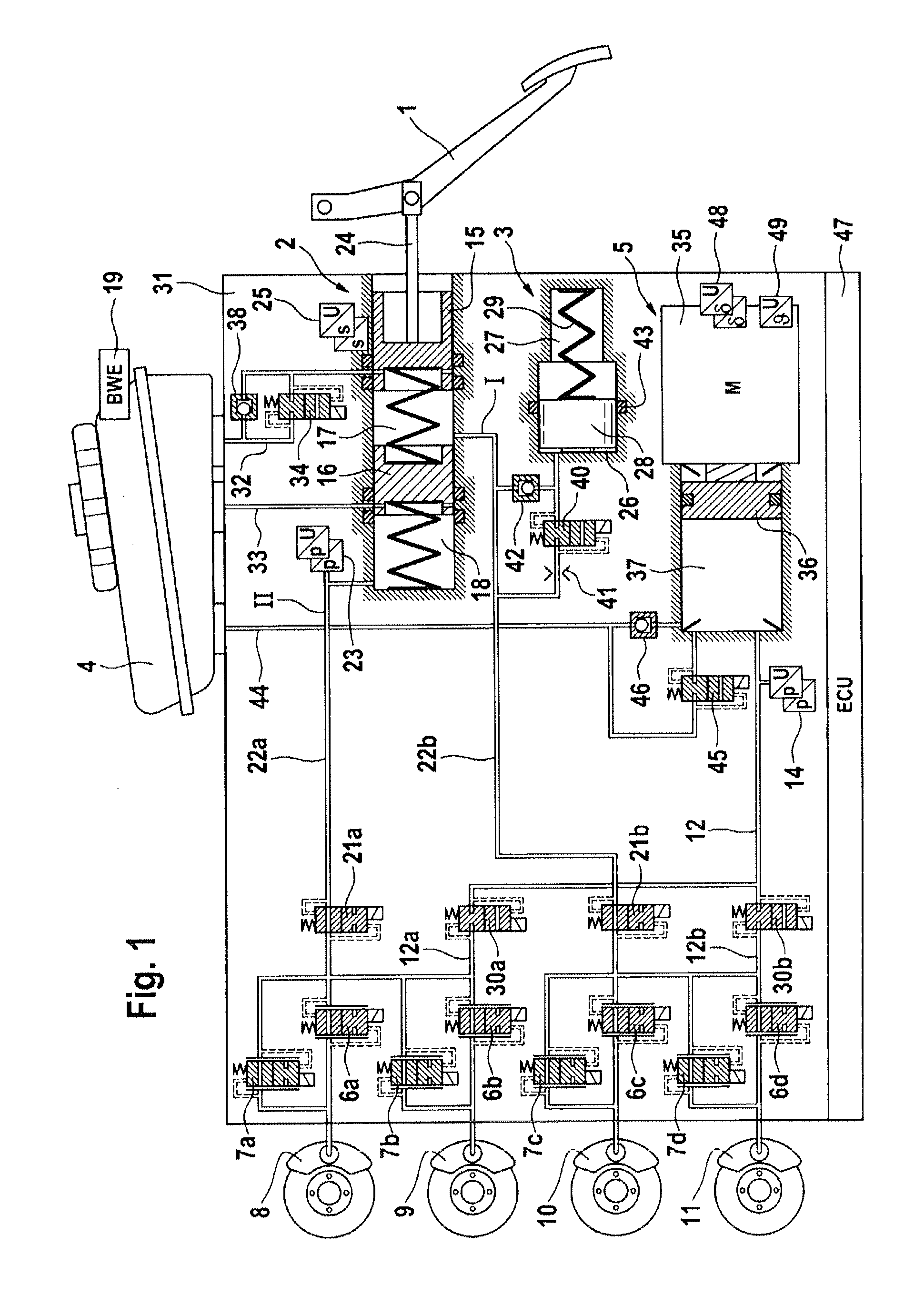

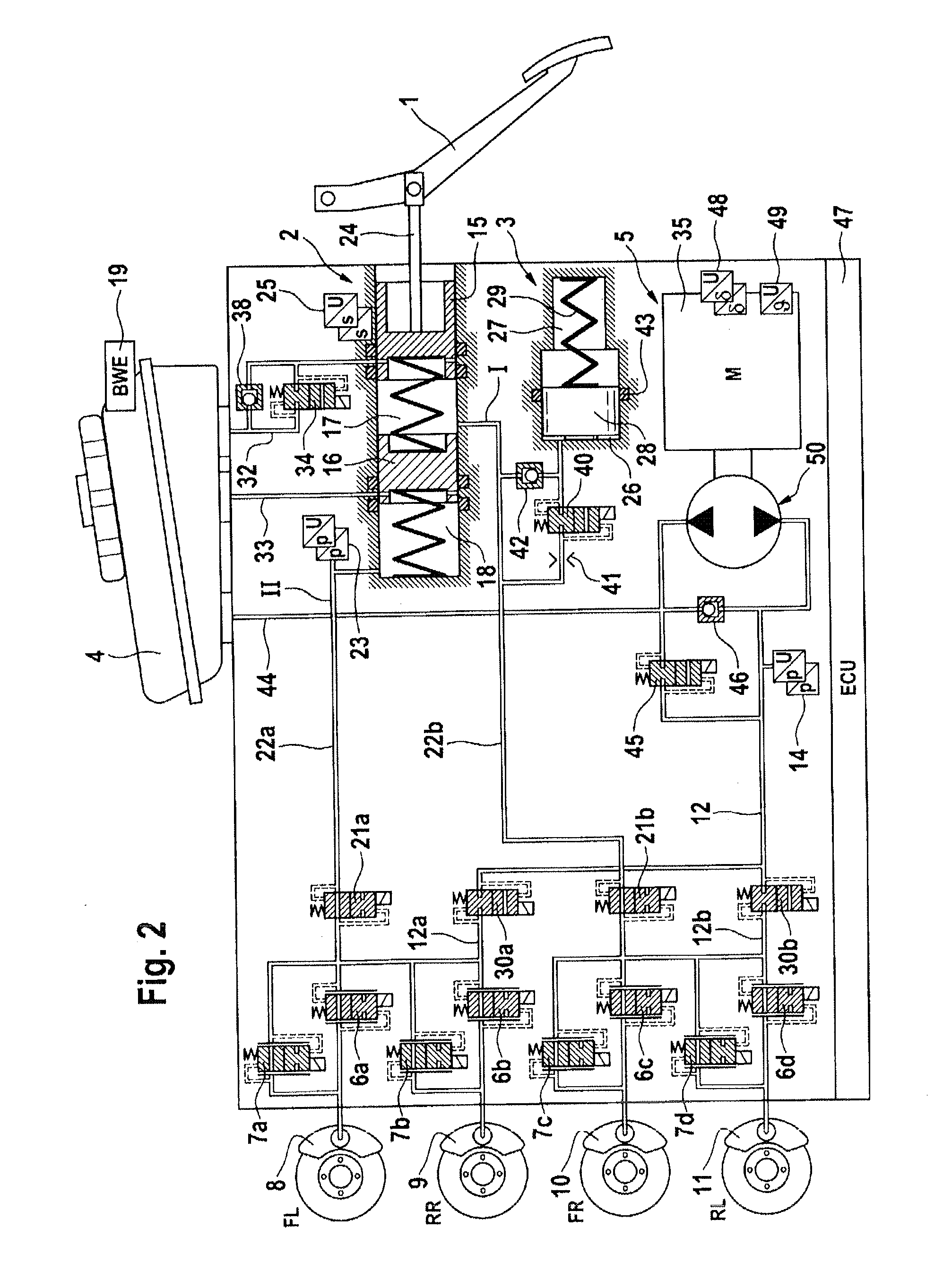

Method for operating a brake system and a brake system

ActiveUS20150035353A1Quality is easy to controlFoot actuated initiationsFluid braking transmissionMobile vehicleDriver/operator

Owner:CONTINENTAL TEVES AG & CO OHG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com