Hydraulic chassis engineering machinery walking control method and control system

A technology for construction machinery and travel control, applied in engine control, liquid variable displacement machinery, pump control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

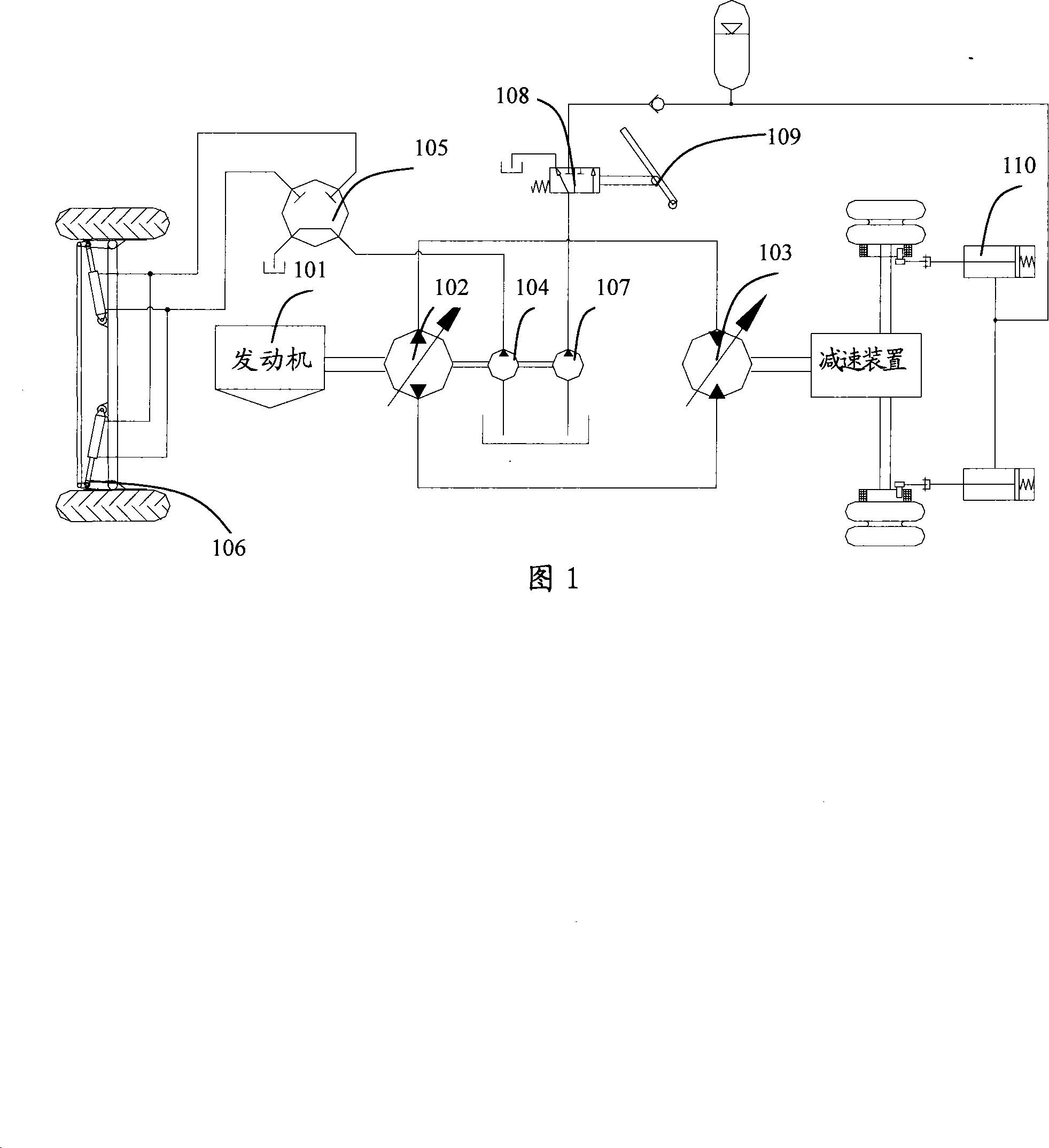

[0038] Please refer to Fig. 1, which is a schematic diagram of a power transmission system of a hydraulic chassis construction machine with a single pump and a single motor.

[0039] It can be seen from the figure that in the hydraulic chassis of the construction machine, its traveling mechanism includes an engine 101 , a hydraulic pump 102 , and a hydraulic motor 103 .

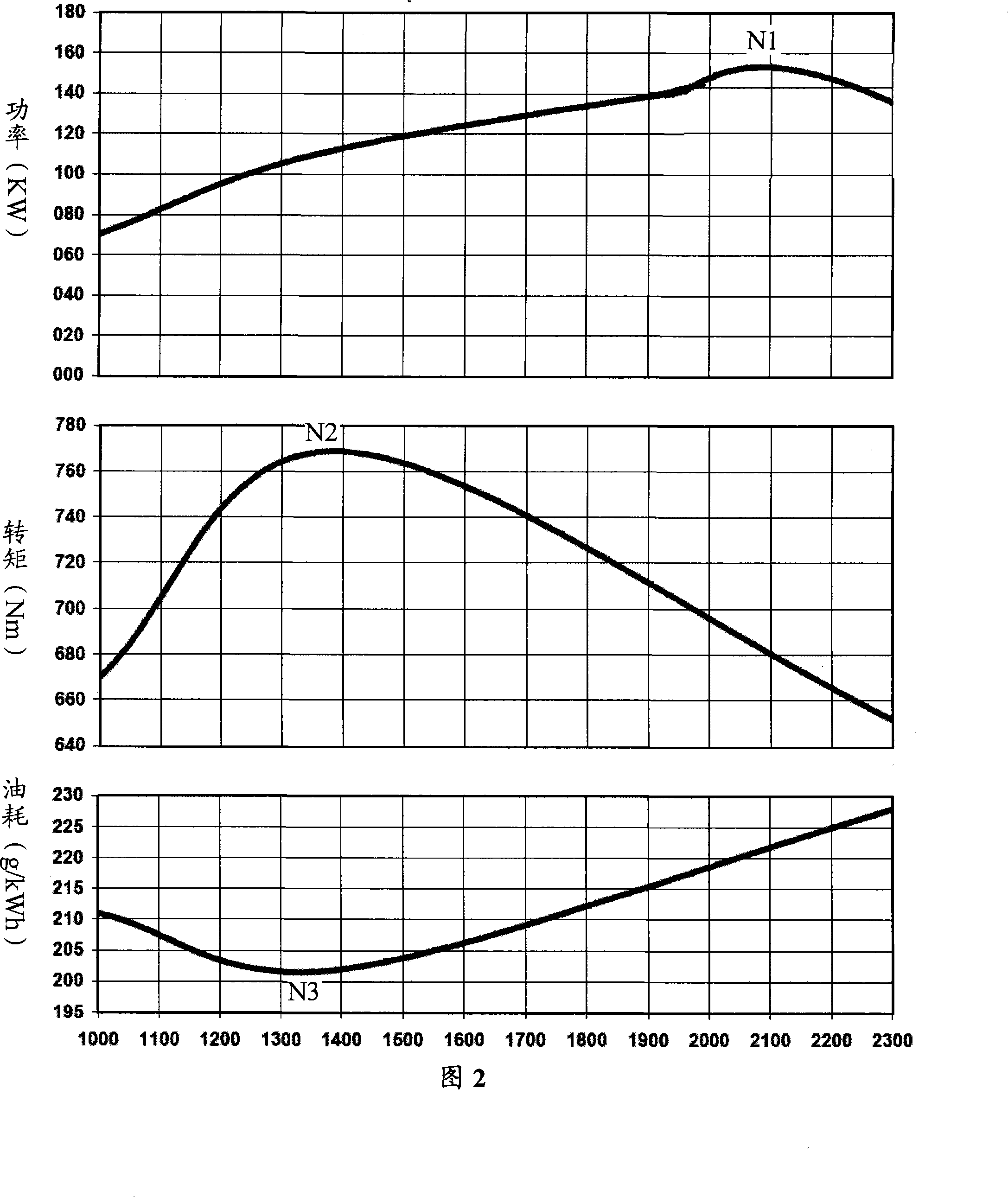

[0040] The engine 101 serves as a prime mover to provide power to the engineering machine. The throttle opening of the engine 101 can be adjusted, and different throttle openings correspond to different engine output characteristic curves. At each throttle opening, the output characteristic curve of the engine includes torque-speed curve, power-speed curve, fuel consumption-speed curve, these curves can provide the relationship between engine torque, power and fuel consumption and speed, the engine can be adjusted The parameter is the throttle opening of the engine. Corresponding to the same throttle opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com