Patents

Literature

2634results about "Process control/regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

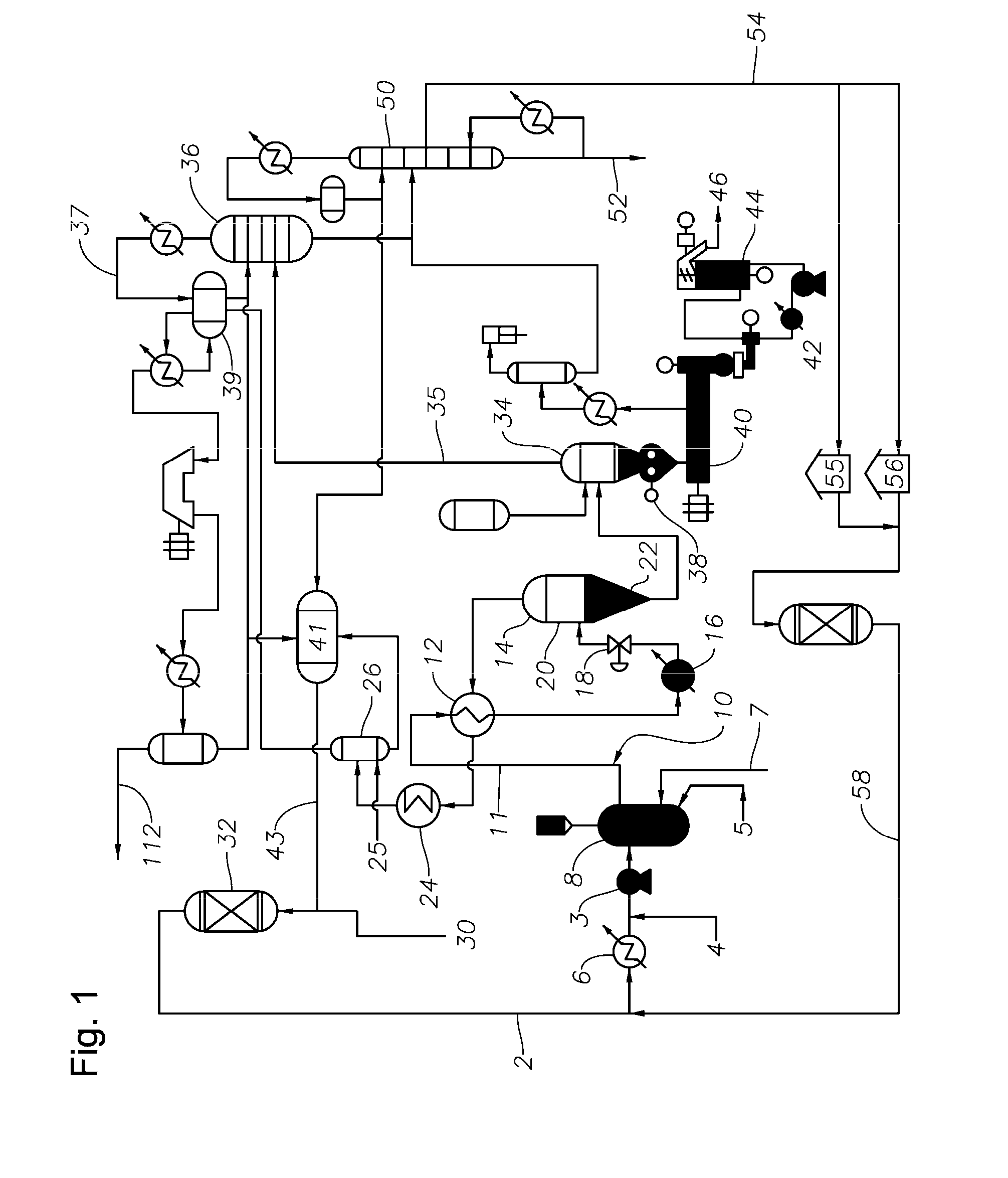

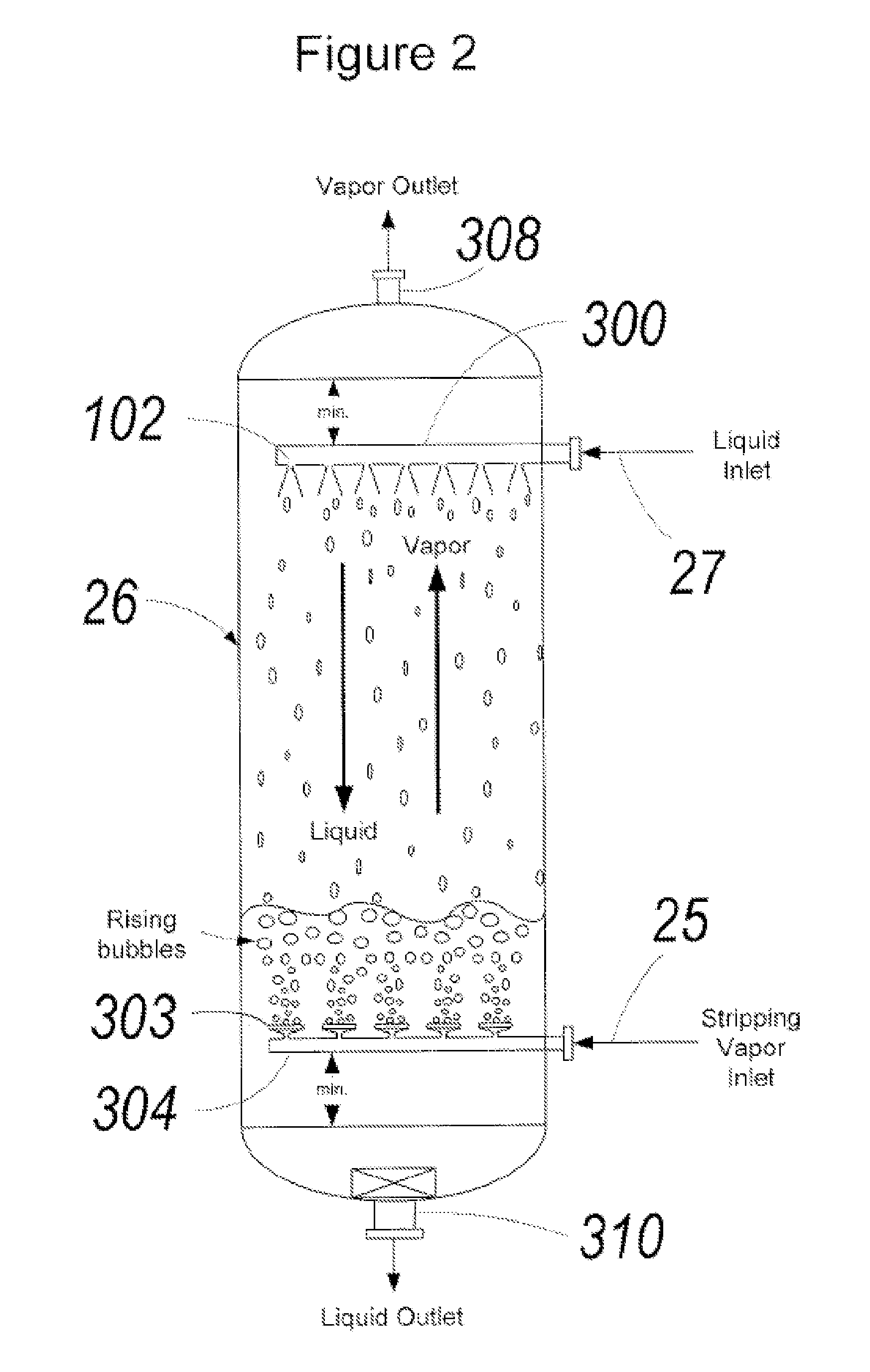

Processes and apparatus for continuous solution polymerization

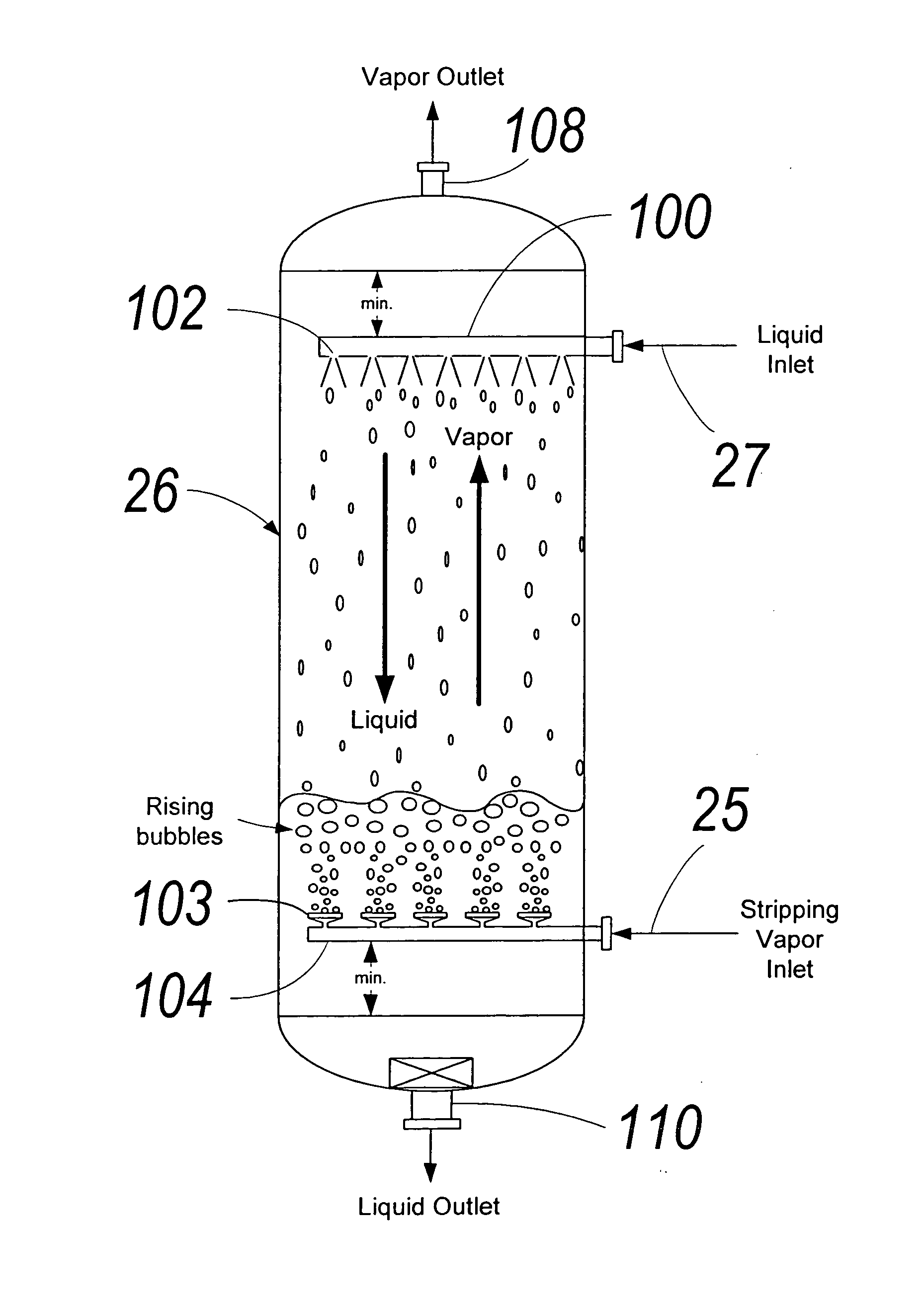

InactiveUS6881800B2Process control/regulationLiquid-gas reaction as foam/aerosol/bubblesSolution polymerizationProcess plant

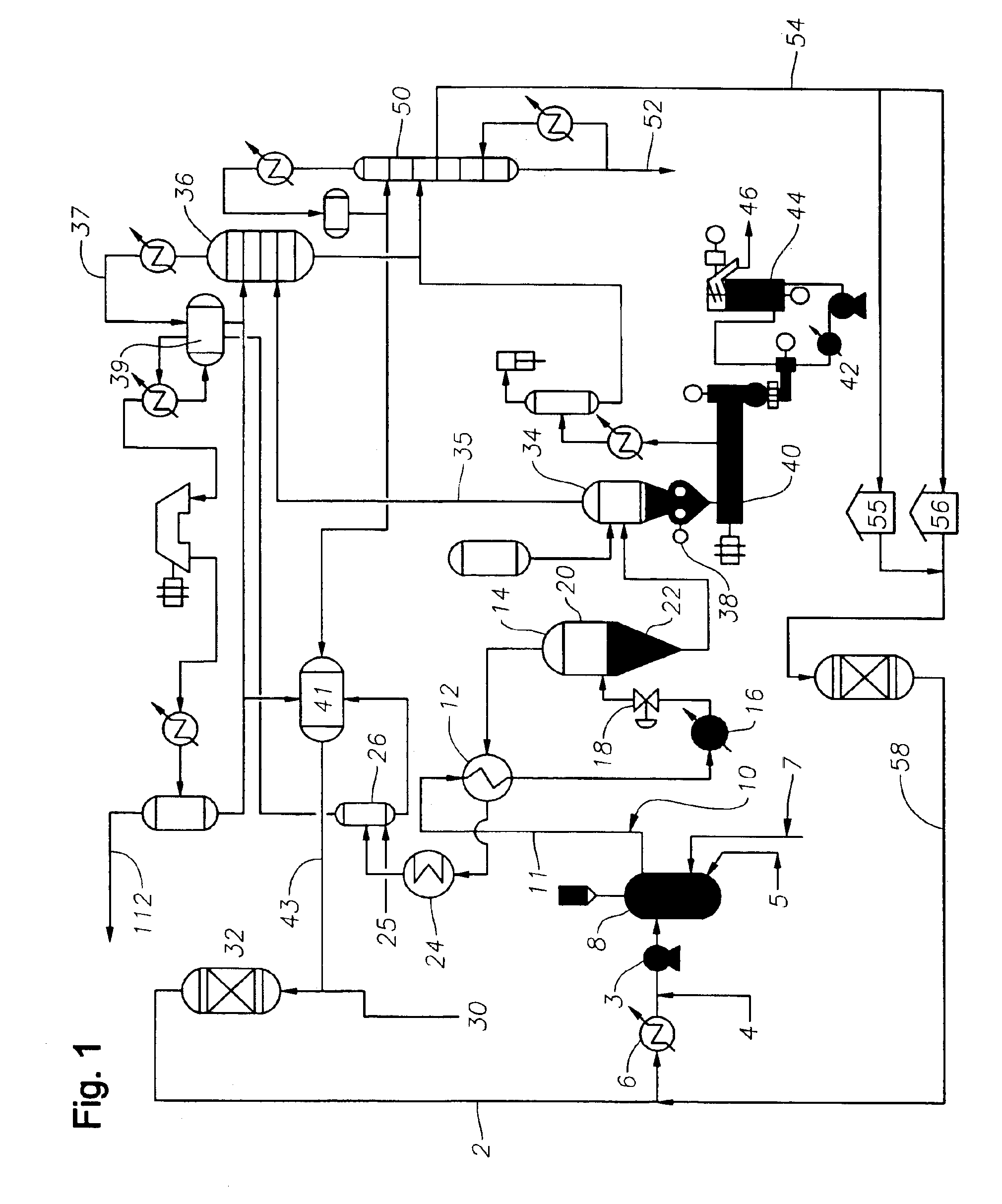

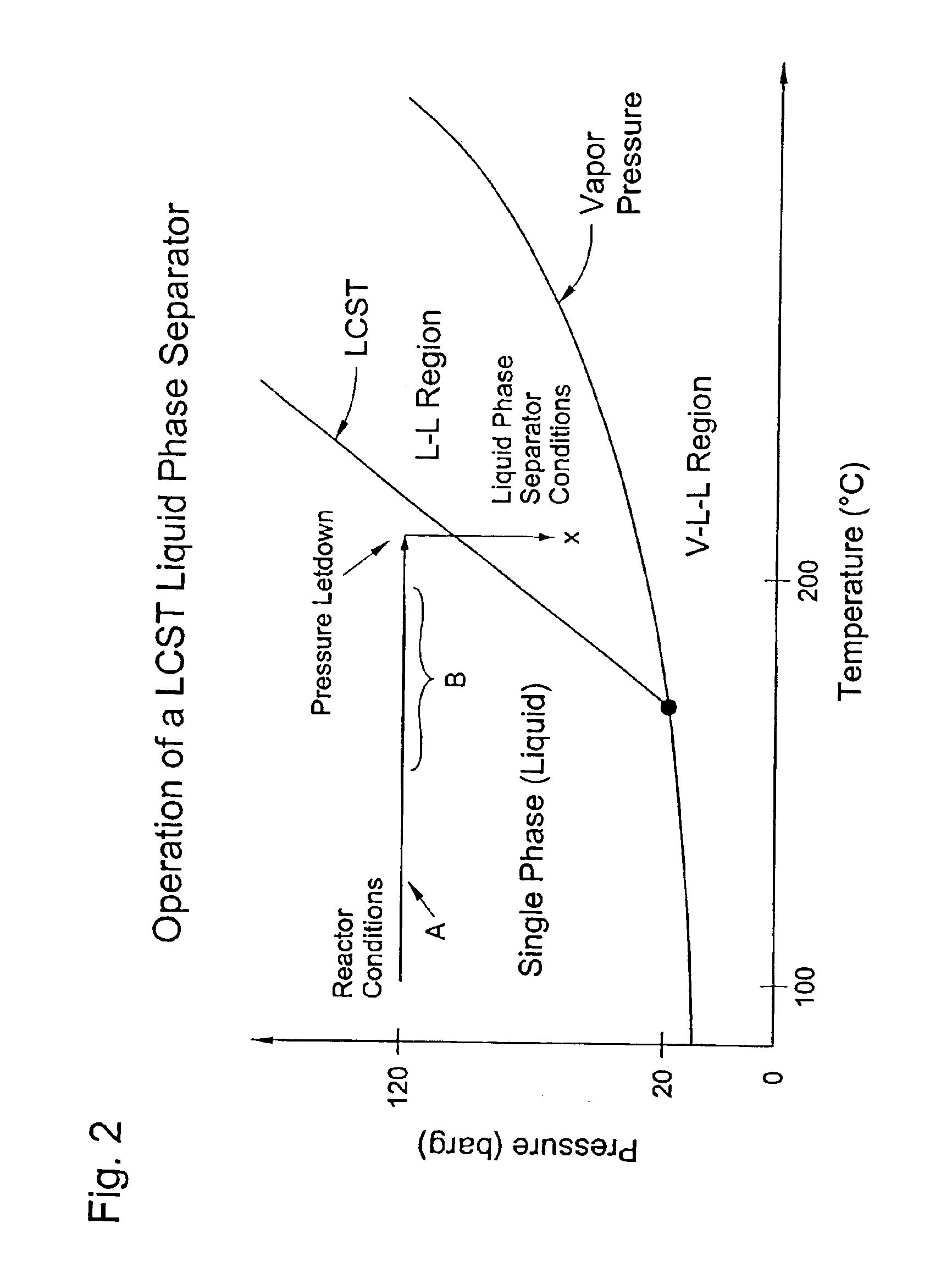

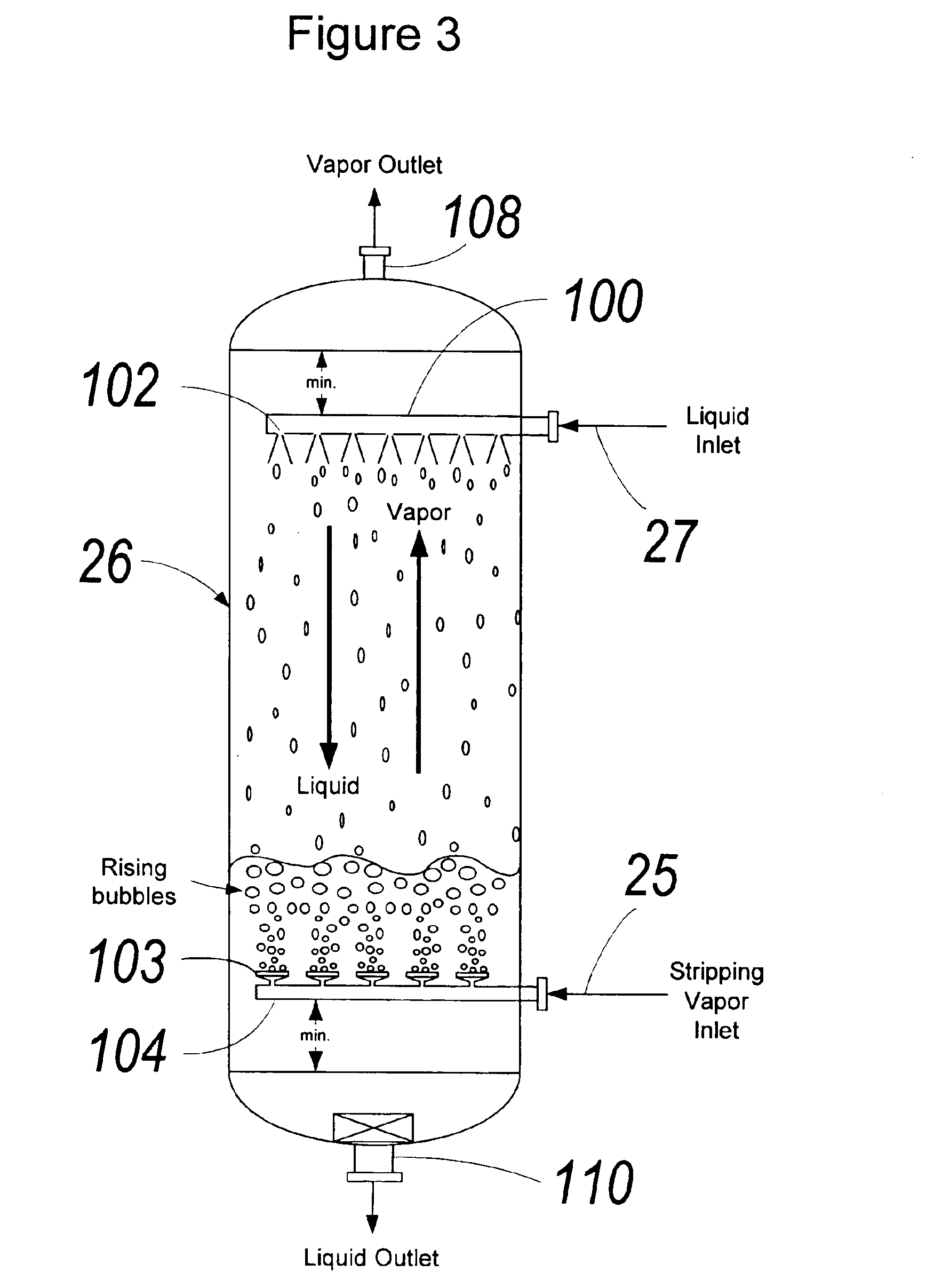

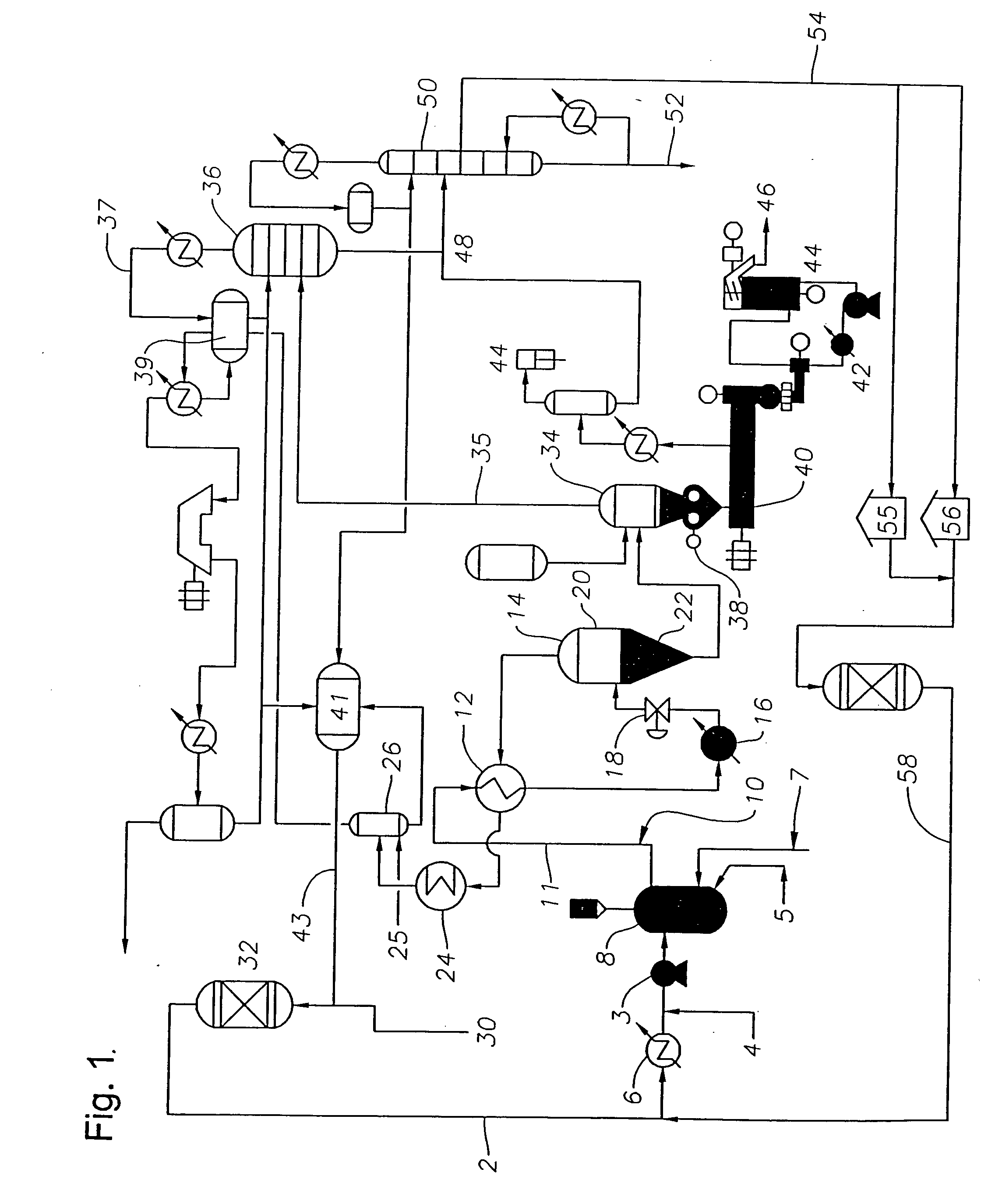

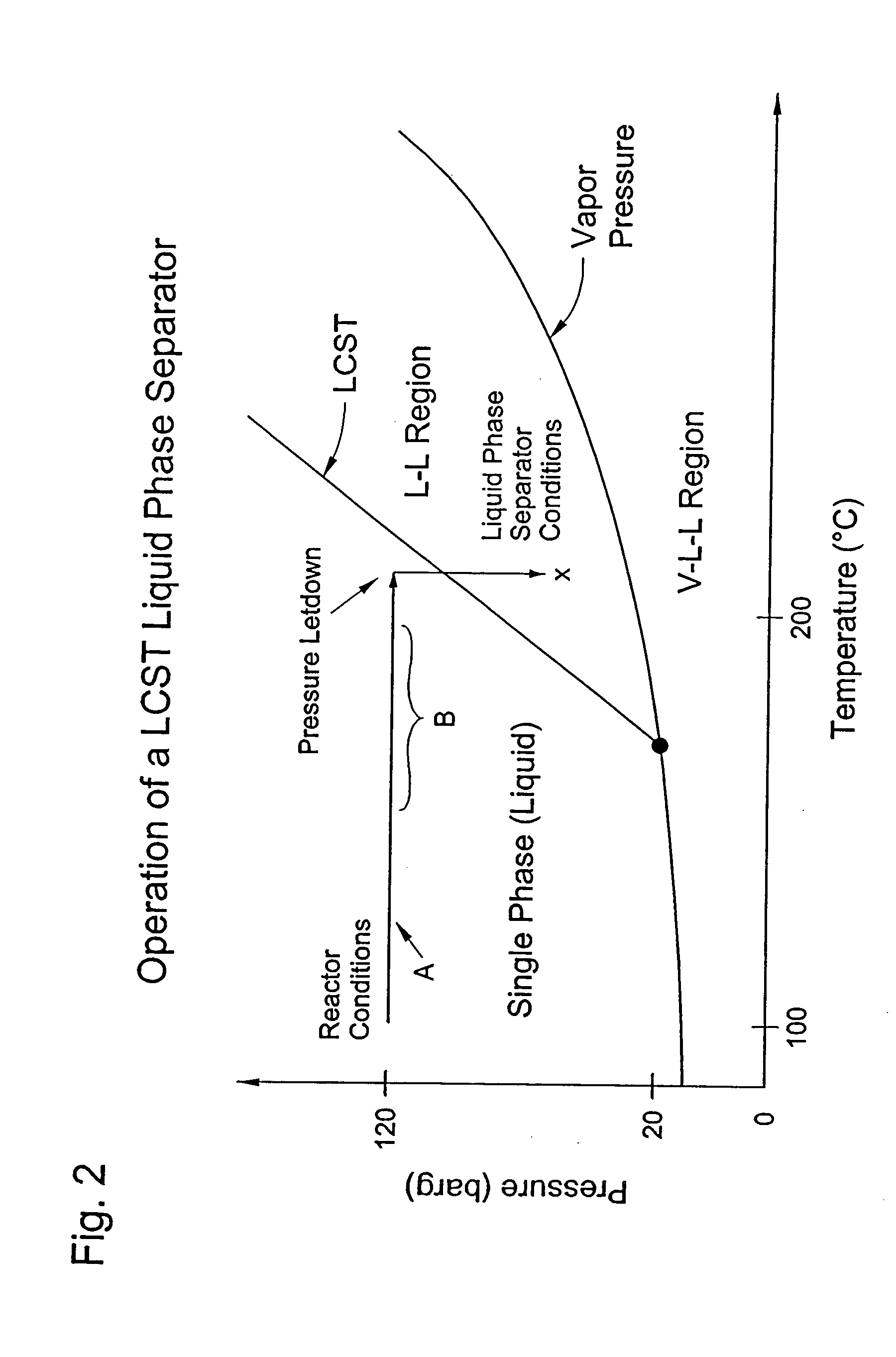

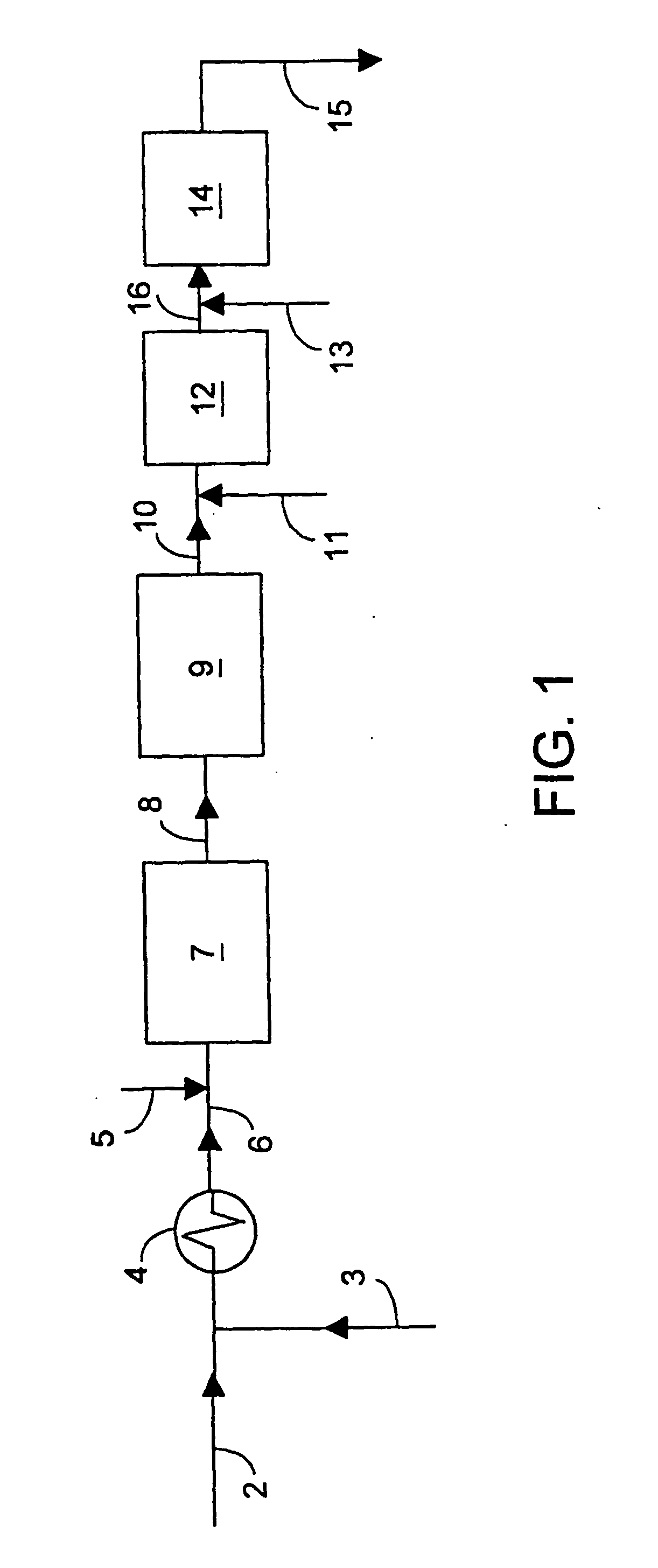

The invention relates to processes and plants for continuous solution polymerization. Such plant and processes include a pressure source, a polymerization reactor, downstream of said pressure source, pressure let-down device, downstream of said polymerization reactor, and a separator, downstream of said pressure let-down device, wherein said pressure source is sufficient to provide pressure to said reaction mixture during operation of said process plant to produce a single-phase liquid reaction mixture in said reactor and a two-phase liquid-liquid reaction mixture in said separator in the absence of an additional pressure source between said reactor and said separator.

Owner:EXXONMOBIL CHEM PAT INC

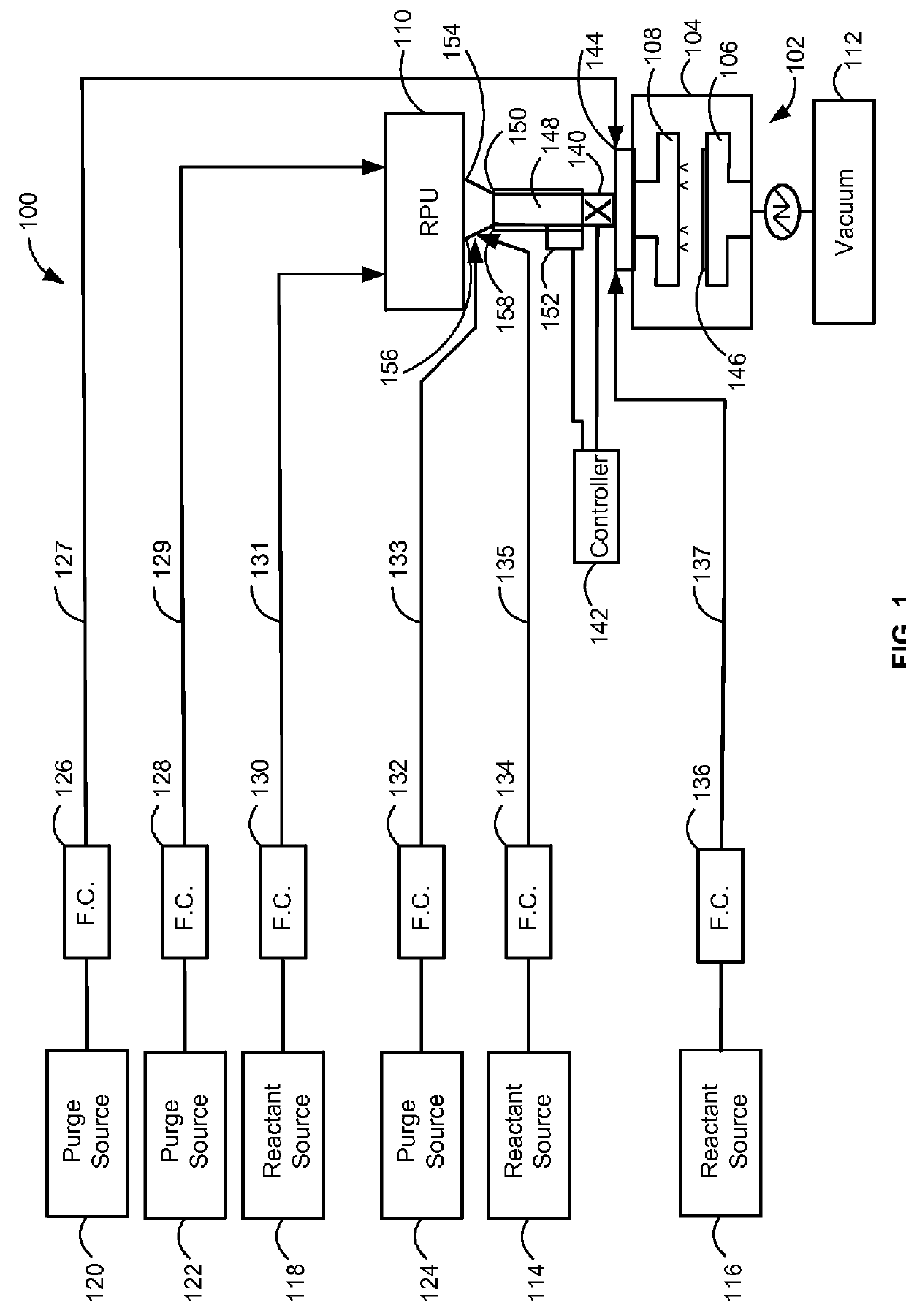

Method and system for in situ formation of gas-phase compounds

ActiveUS20160051964A1Process can be usedProcess control/regulationCell electrodesCompound aGas phase

A system and method for providing intermediate reactive species to a reaction chamber are disclosed. The system includes an intermediate reactive species formation chamber fluidly coupled to the reaction chamber to provide intermediate reactive species to the reaction chamber. A pressure control device can be used to control an operating pressure of the intermediate reactive species formation chamber, and a heater can be used to heat the intermediate reactive species formation chamber to a desired temperature.

Owner:ASM IP HLDG BV

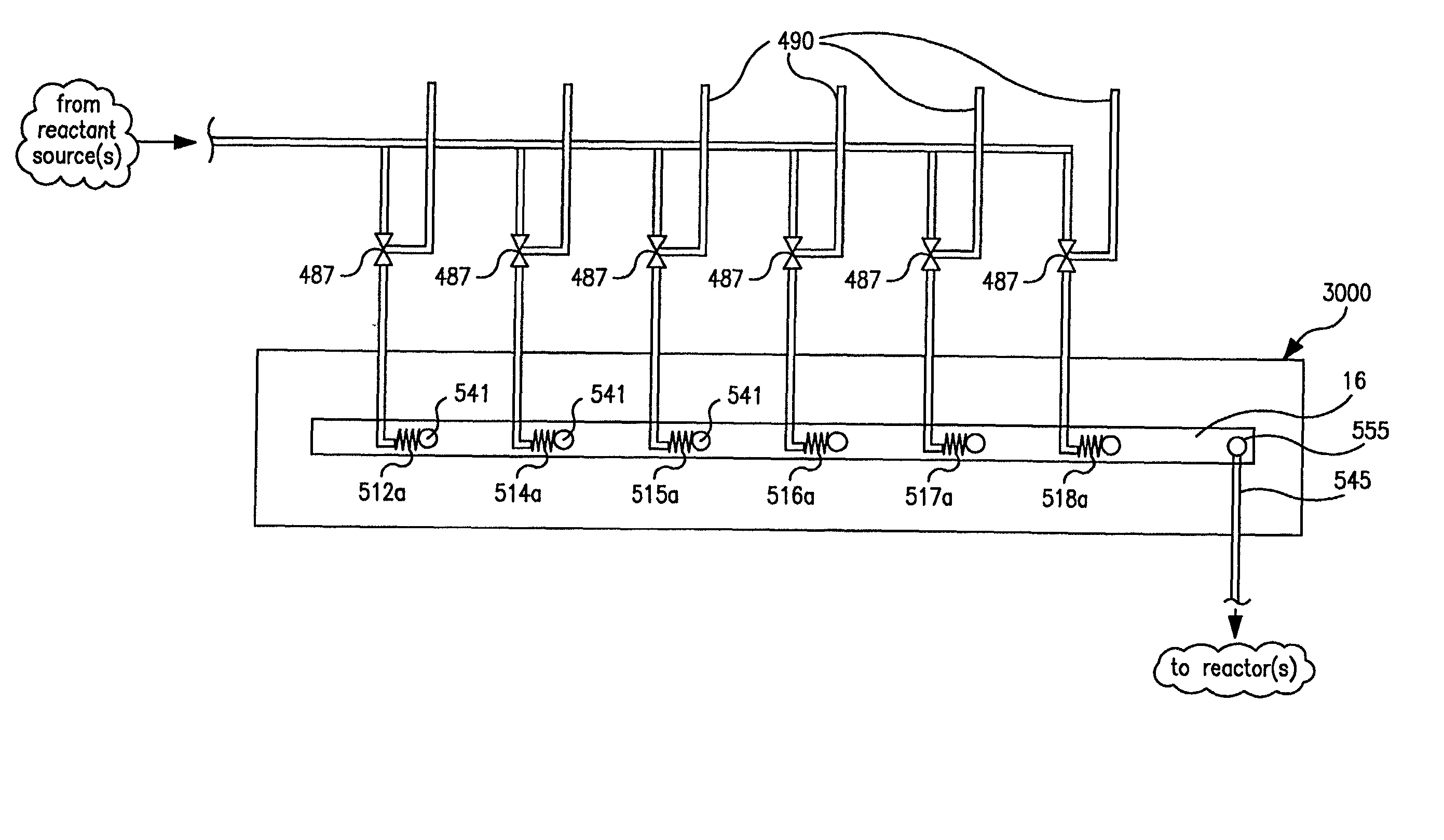

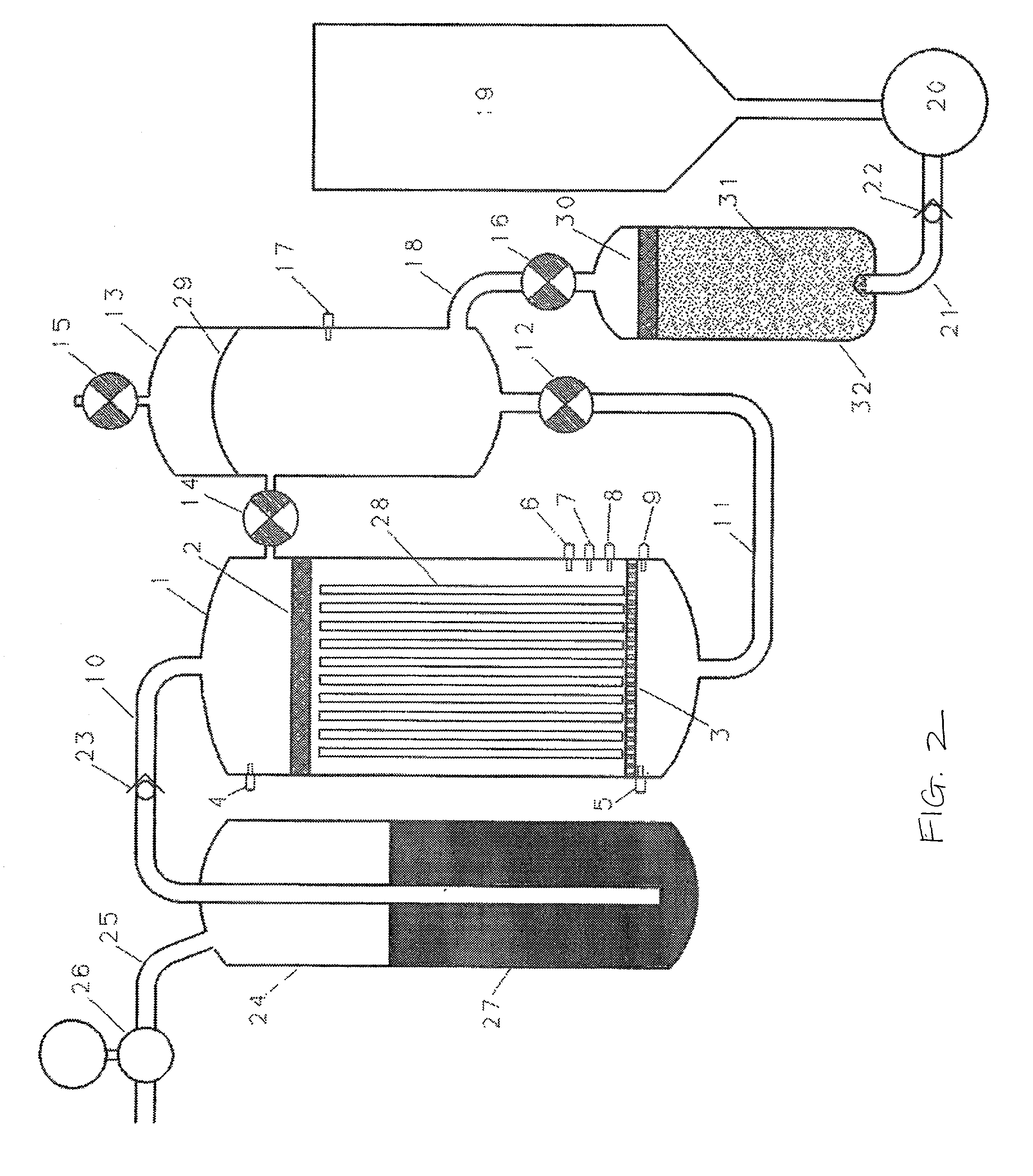

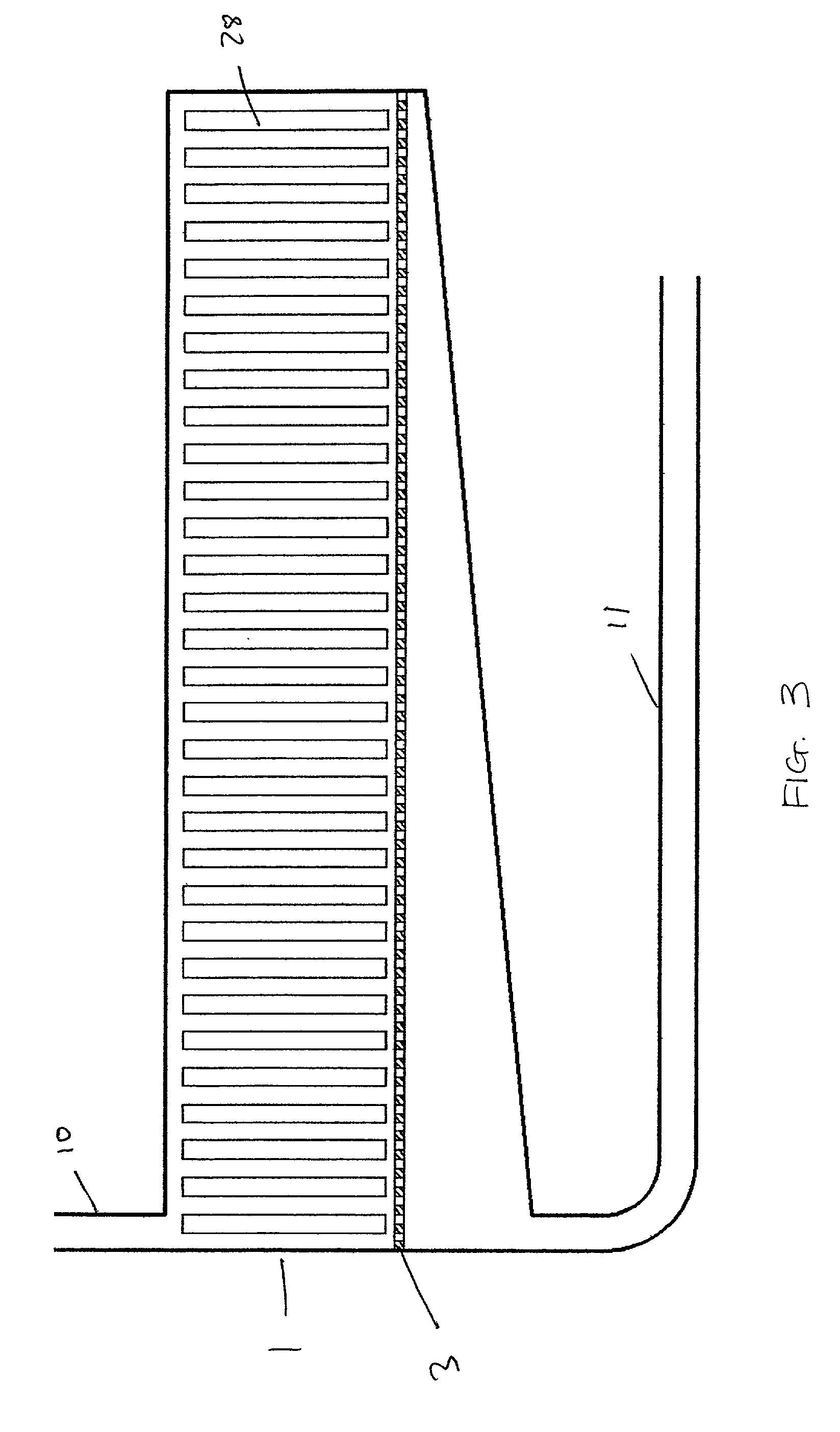

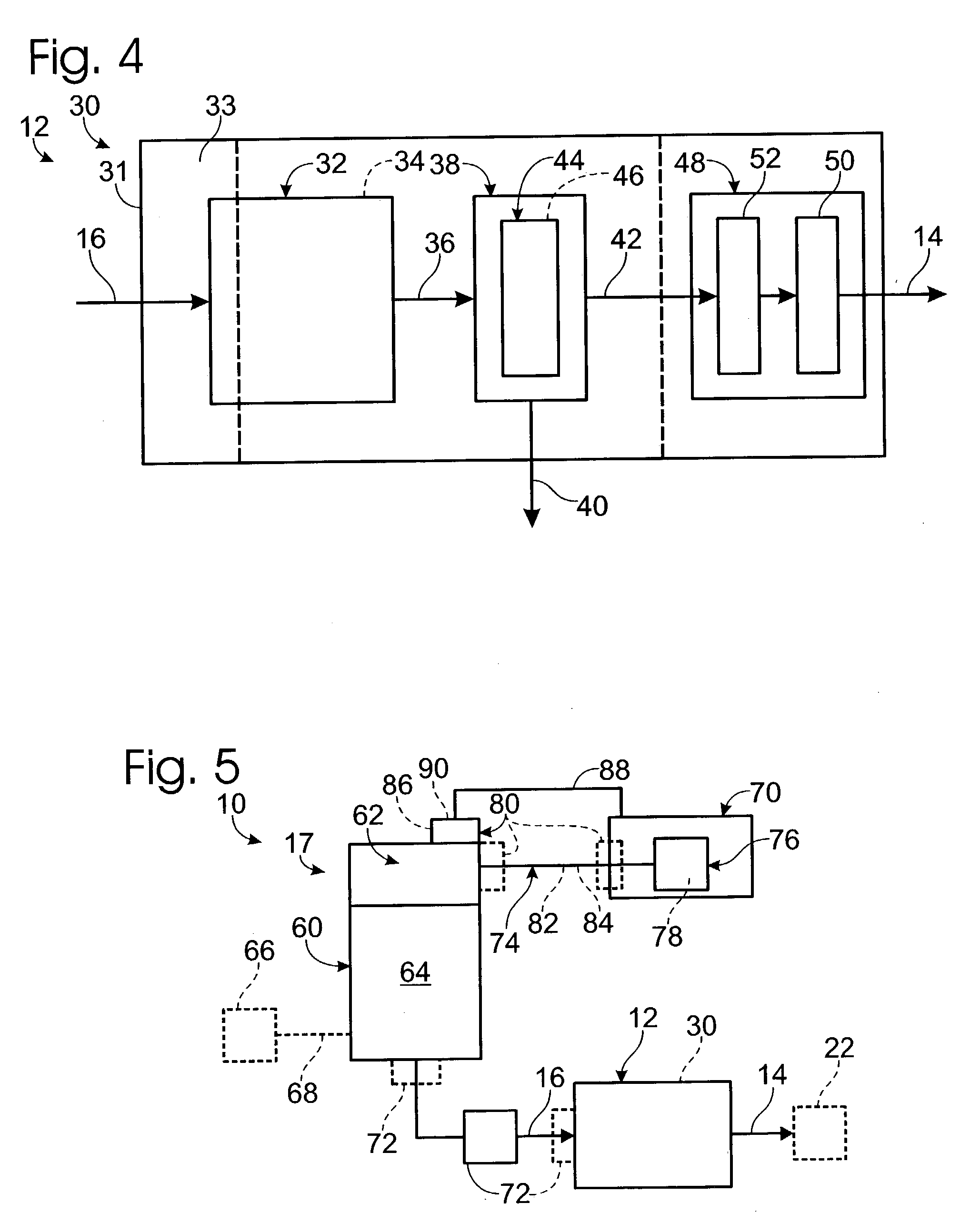

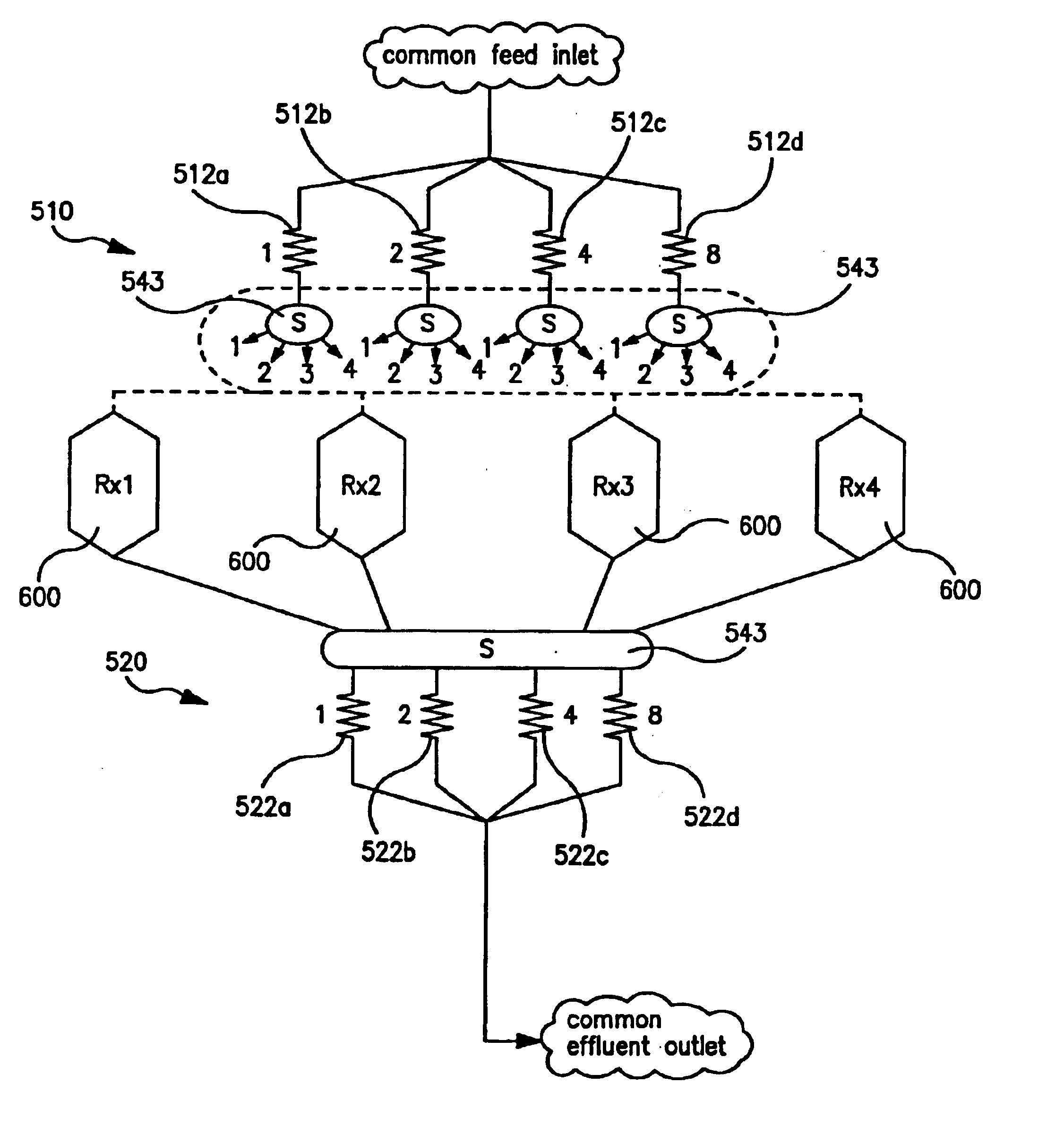

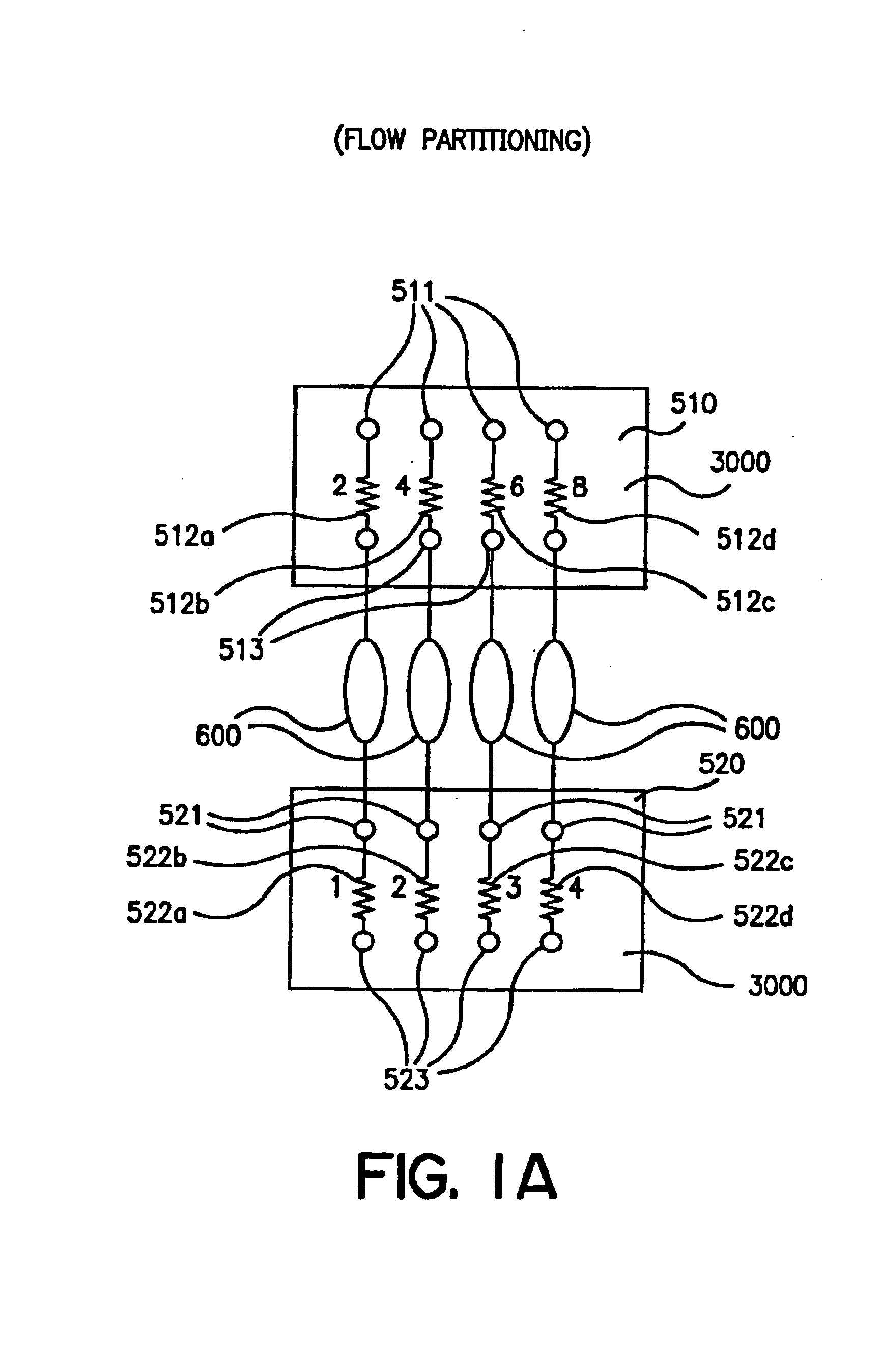

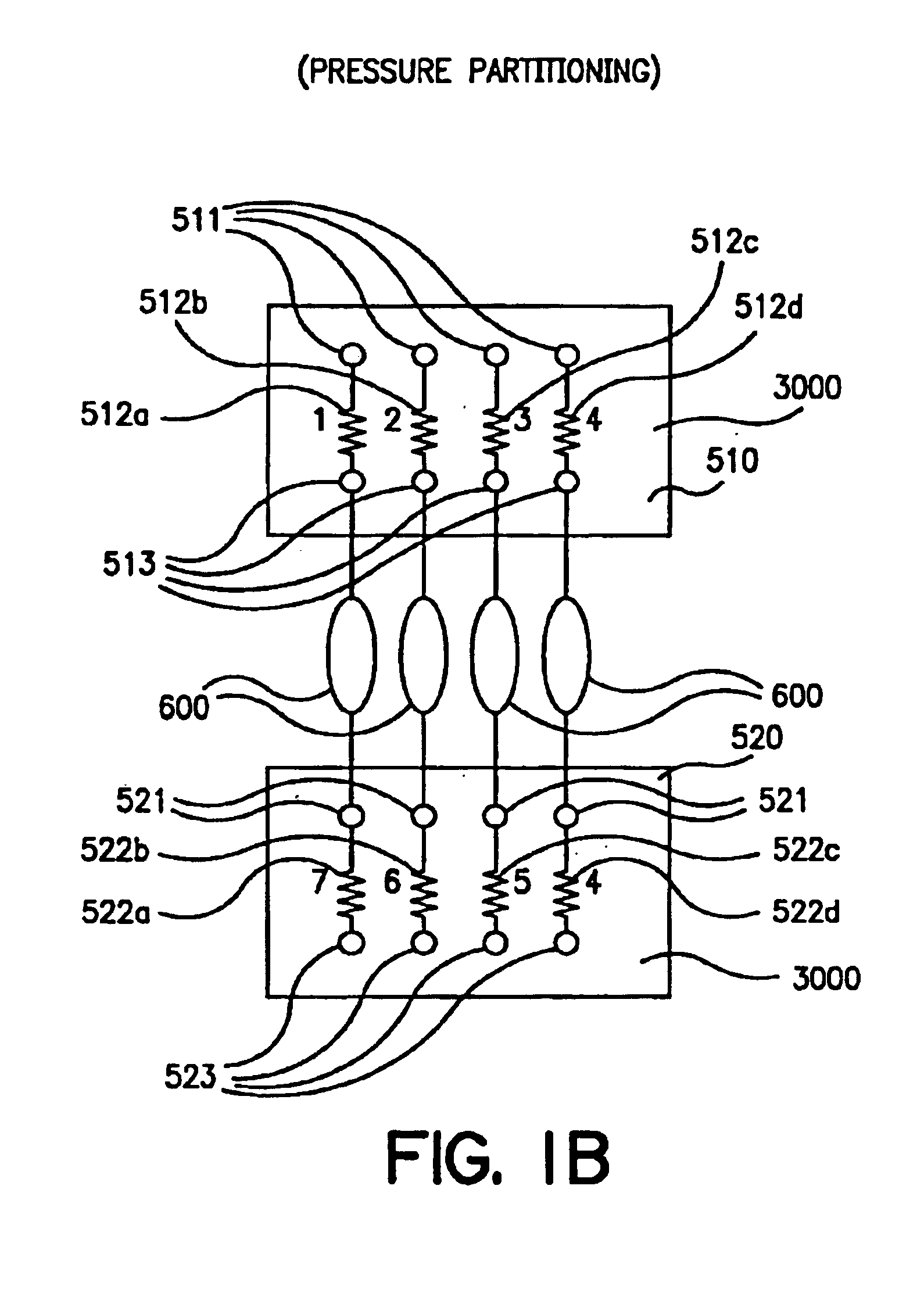

Parallel flow process optimization reactors

InactiveUS20020048536A1Extreme flexibilityAdvantageously and flexibly employedProcess control/regulationSequential/parallel process reactionsProcess optimizationDistribution system

Owner:FREESLATE

Parallel flow reactor having variable composition

InactiveUS20020045265A1Extreme flexibilityAdvantageously and flexibly employedProcess control/regulationSequential/parallel process reactionsDistribution systemEngineering

Owner:FREESLATE

Processes and apparatus for continuous solution polymerization

InactiveUS20040024146A1Suppress further polymerizationProcess control/regulationLiquid-gas reaction as foam/aerosol/bubblesSolution polymerizationProcess plant

The invention relates to processes and plants for continuous solution polymerization. Such plant and processes include a pressure source, a polymerization reactor, downstream of said pressure source, pressure let-down device, downstream of said polymerization reactor, and a separator, downstream of said pressure let-down device, wherein said pressure source is sufficient to provide pressure to said reaction mixture during operation of said process plant to produce a single-phase liquid reaction mixture in said reactor and a two-phase liquid-liquid reaction mixture in said separator in the absence of an additional pressure source between said reactor and said separator.

Owner:EXXONMOBIL CHEM PAT INC

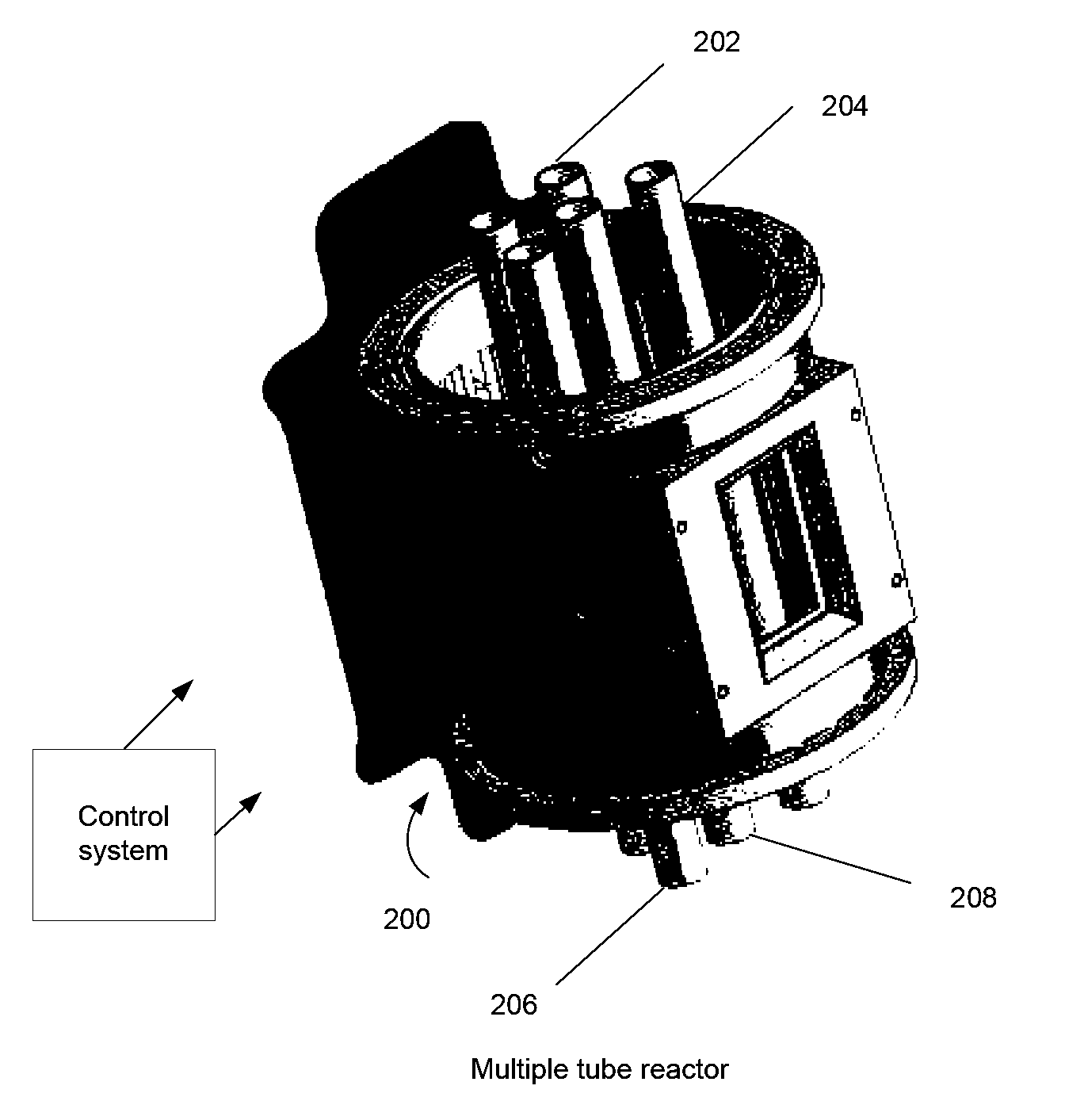

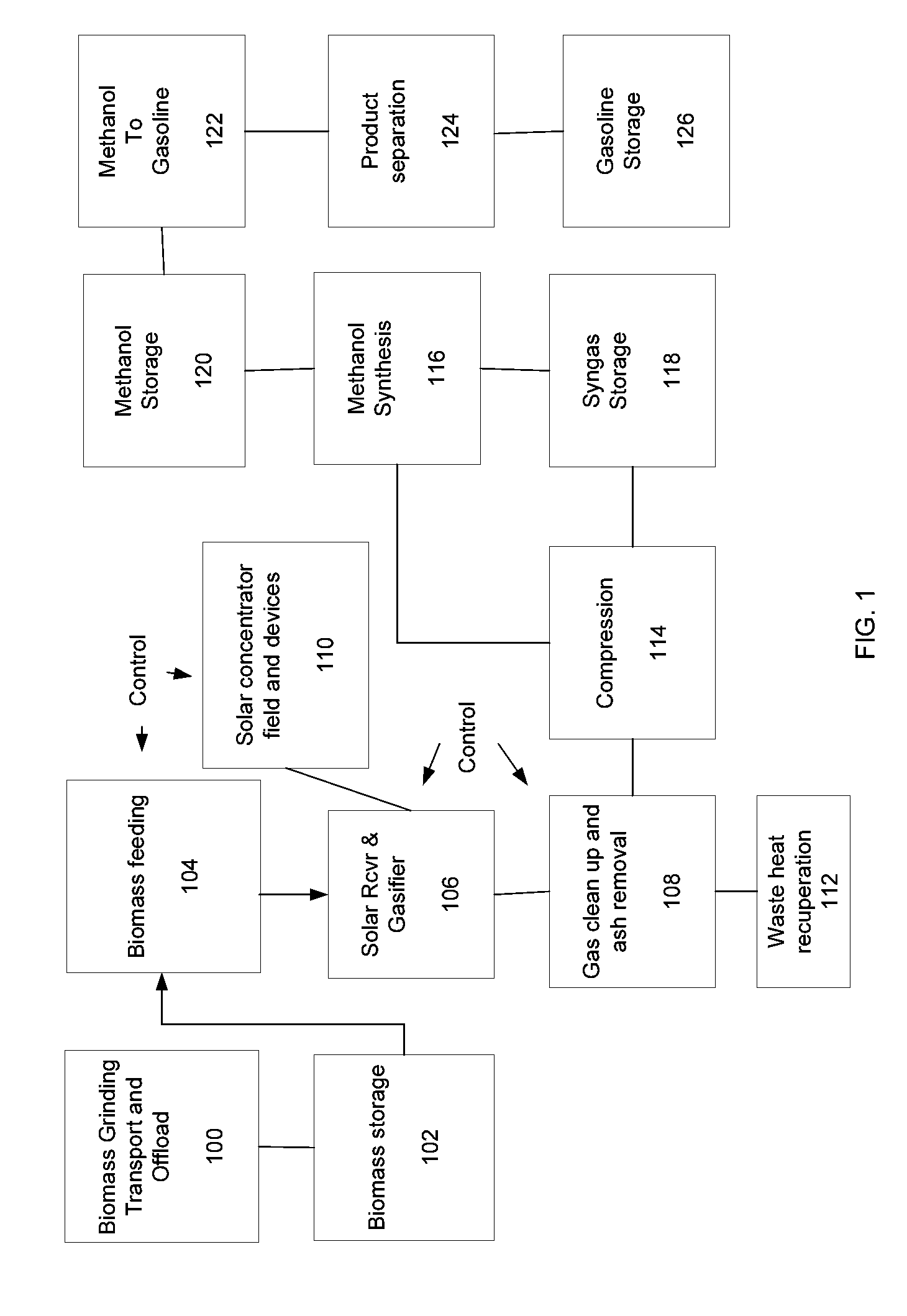

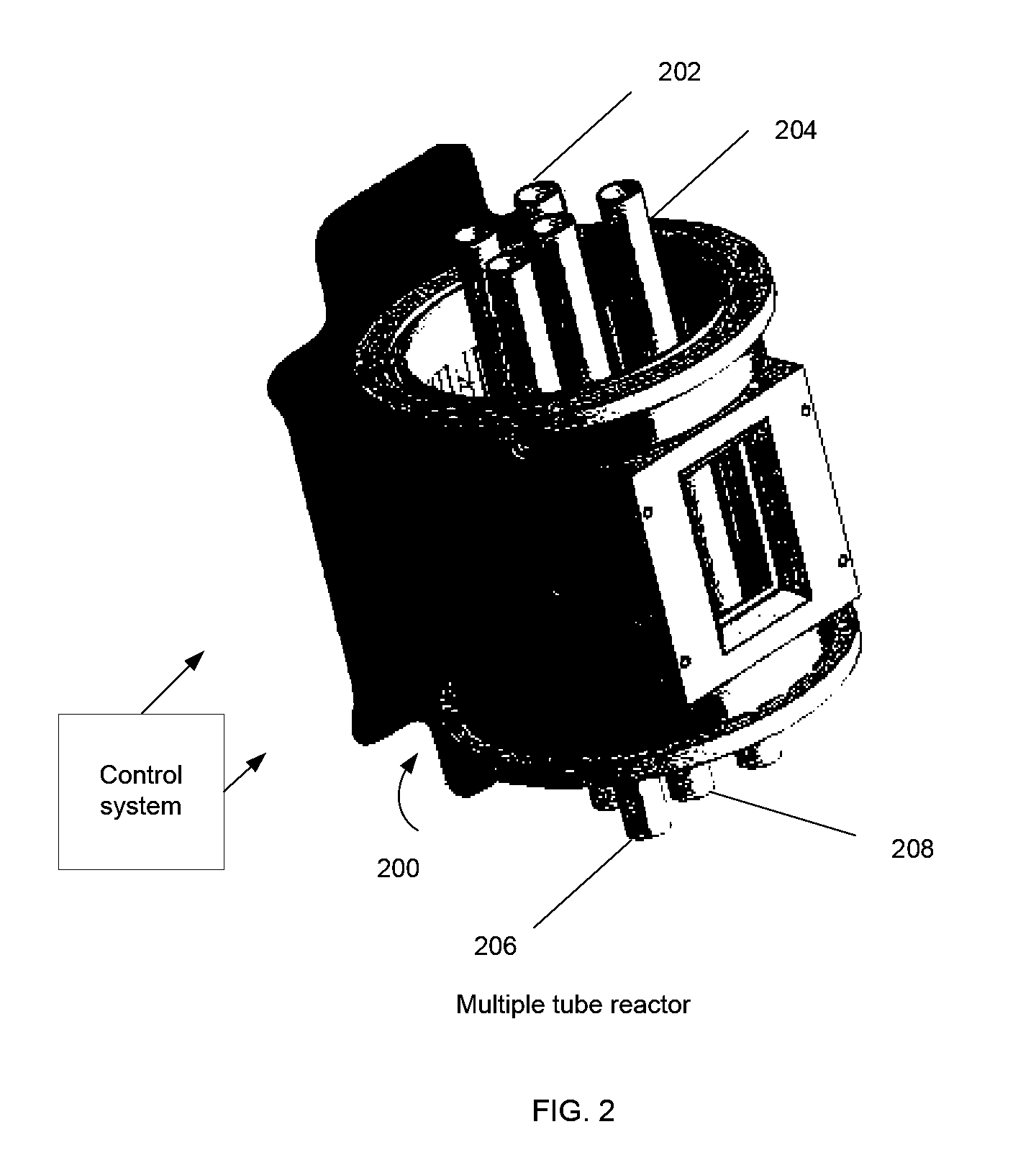

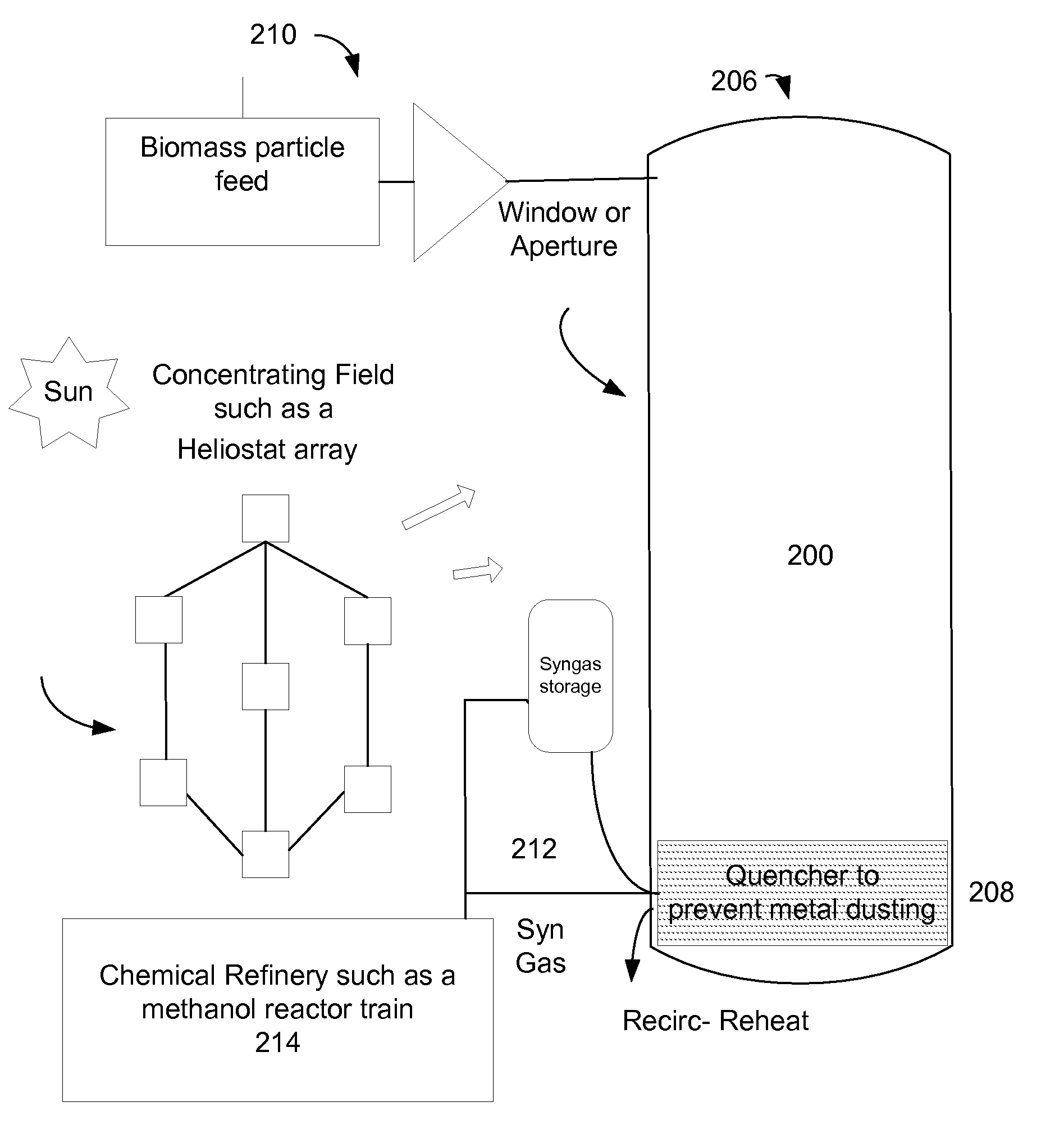

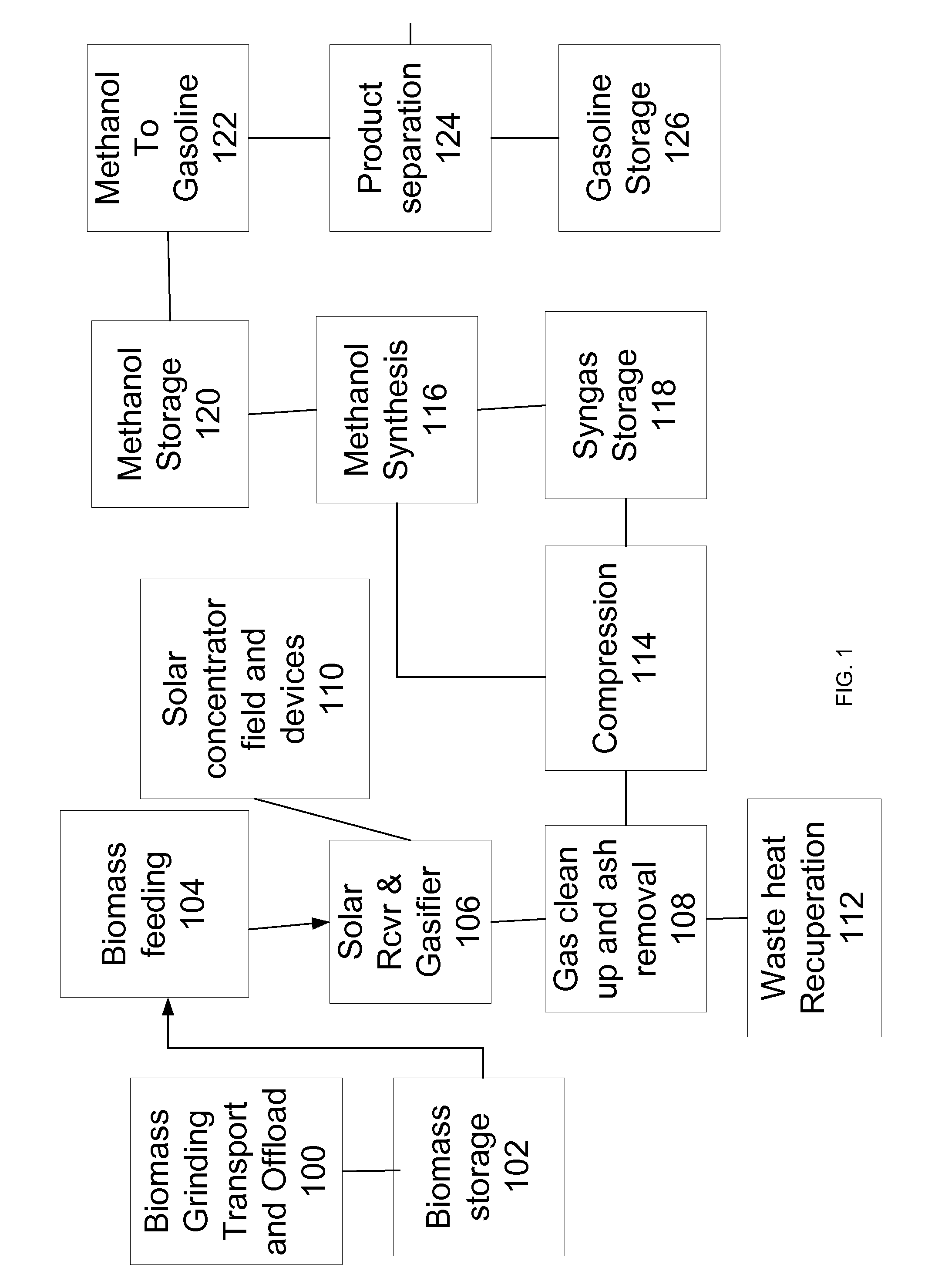

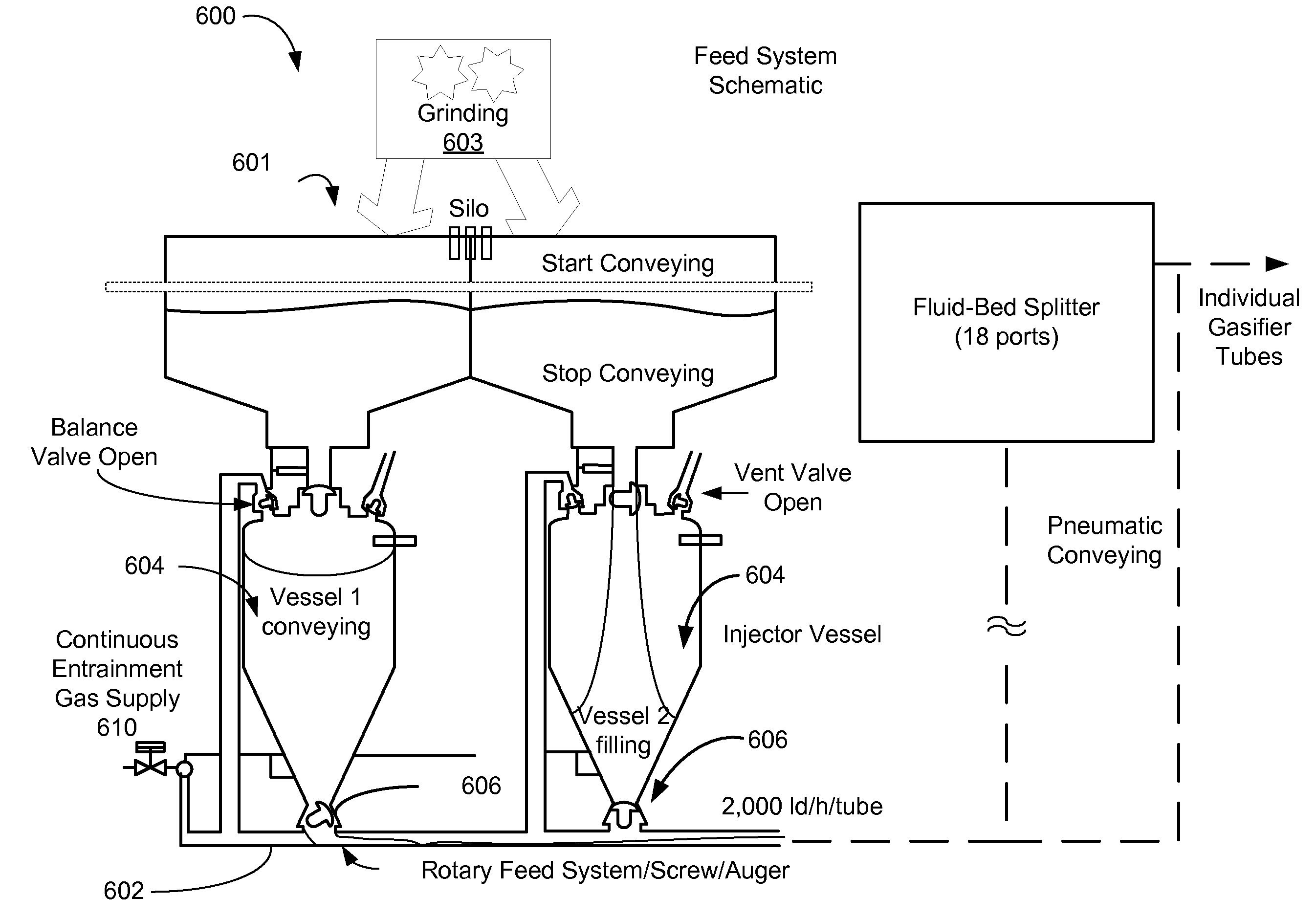

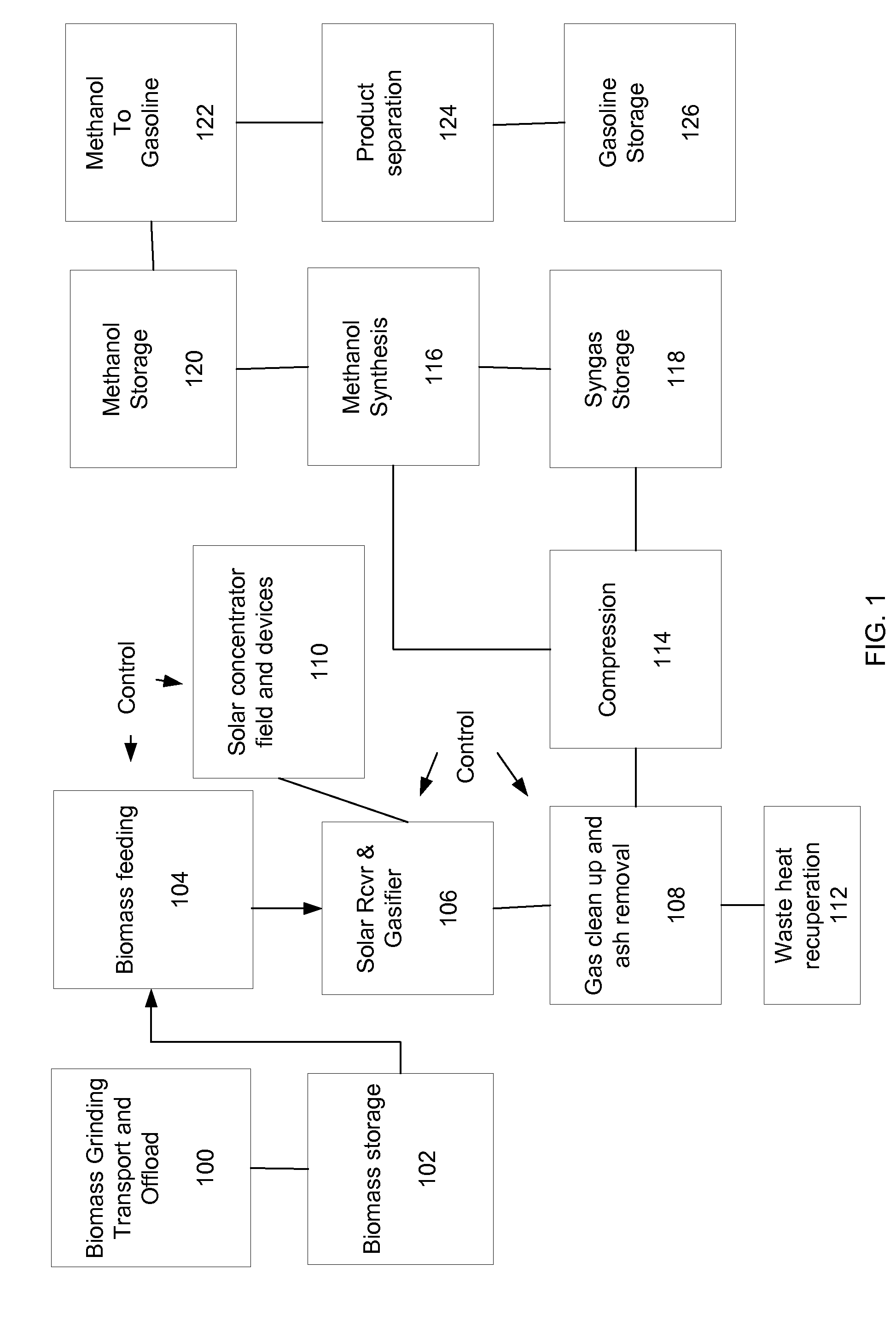

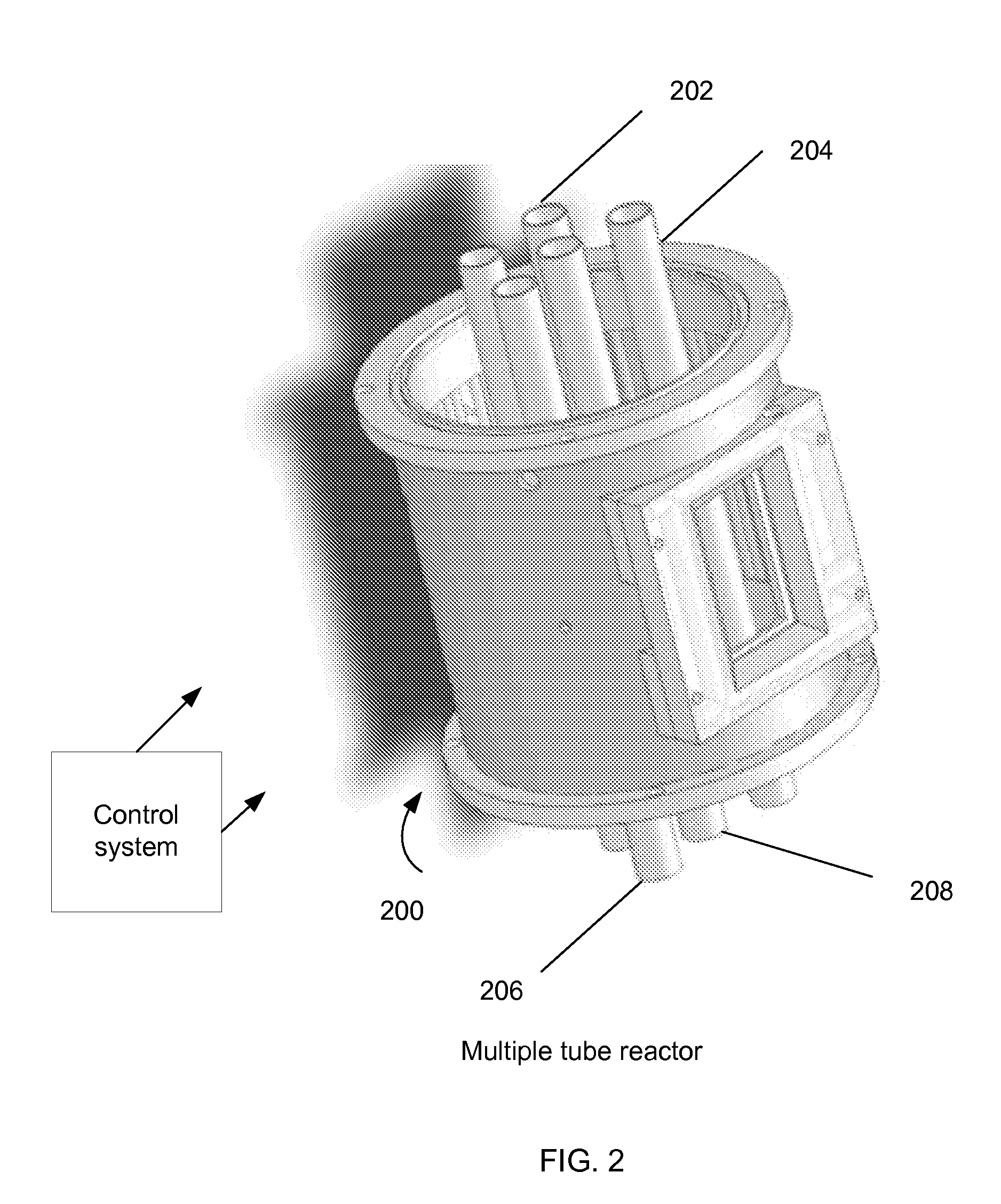

Systems and methods for solar-thermal gasification of biomass

InactiveUS20100237291A1Process control/regulationSolar heating energySteam reformingChemical reaction

A method, apparatus, and system for a solar-driven chemical plant that may include a solar thermal receiver having a cavity with an inner wall, where the solar thermal receiver is aligned to absorb concentrated solar energy from one or more of 1) an array of heliostats, 2) solar concentrating dishes, and 3) any combination of the two. Some embodiments may include a solar-driven chemical reactor having multiple reactor tubes located inside the cavity of solar thermal receiver, wherein a chemical reaction driven by radiant heat occurs in the multiple reactor tubes, and wherein particles of biomass are gasified in the presence of a steam (H2O) carrier gas and methane (CH4) in a simultaneous steam reformation and steam biomass gasification reaction to produce reaction products that include hydrogen and carbon monoxide gas using the solar thermal energy from the absorbed concentrated solar energy in the multiple reactor tubes.

Owner:SUNDROP IP HLDG LLC

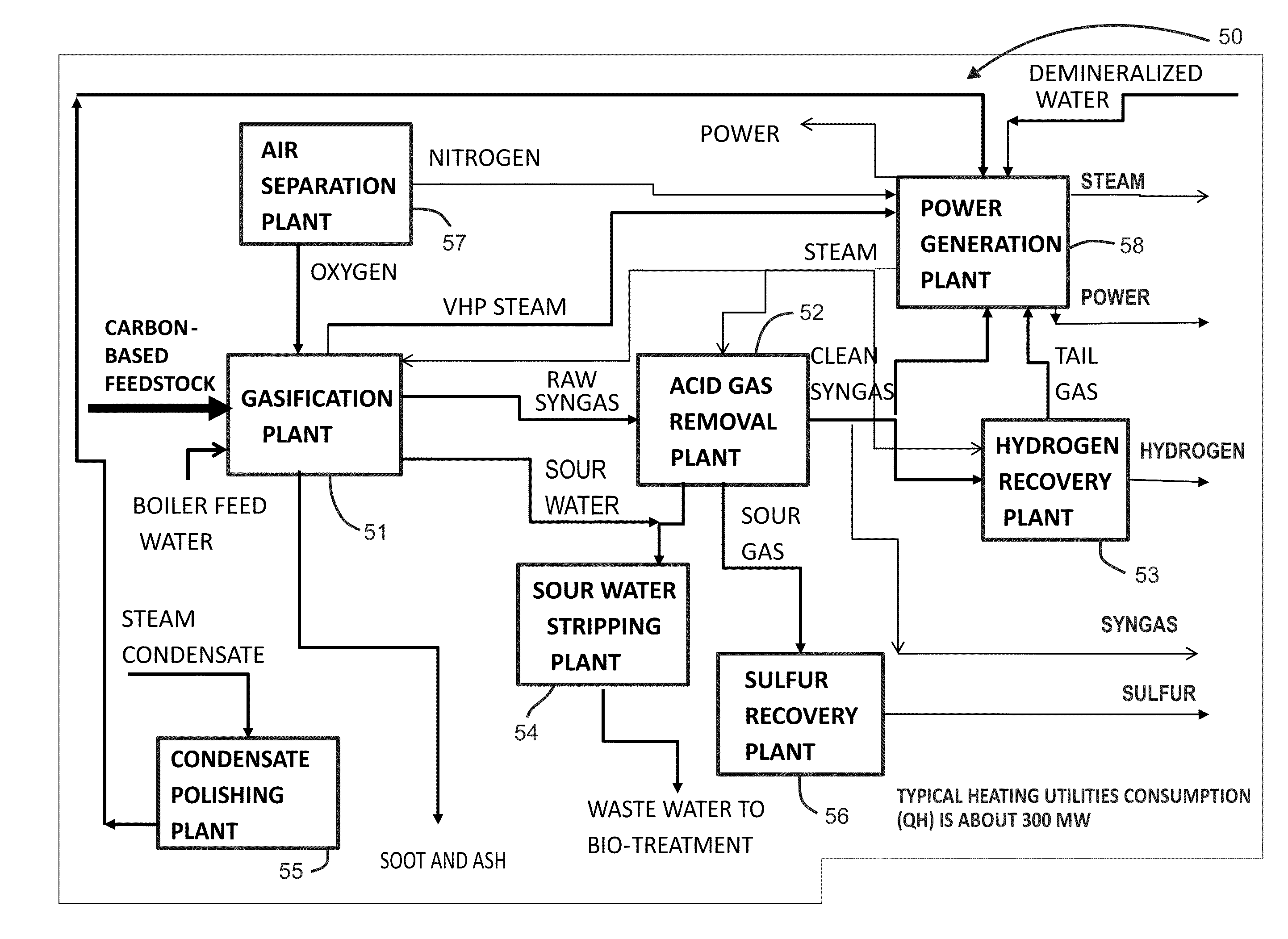

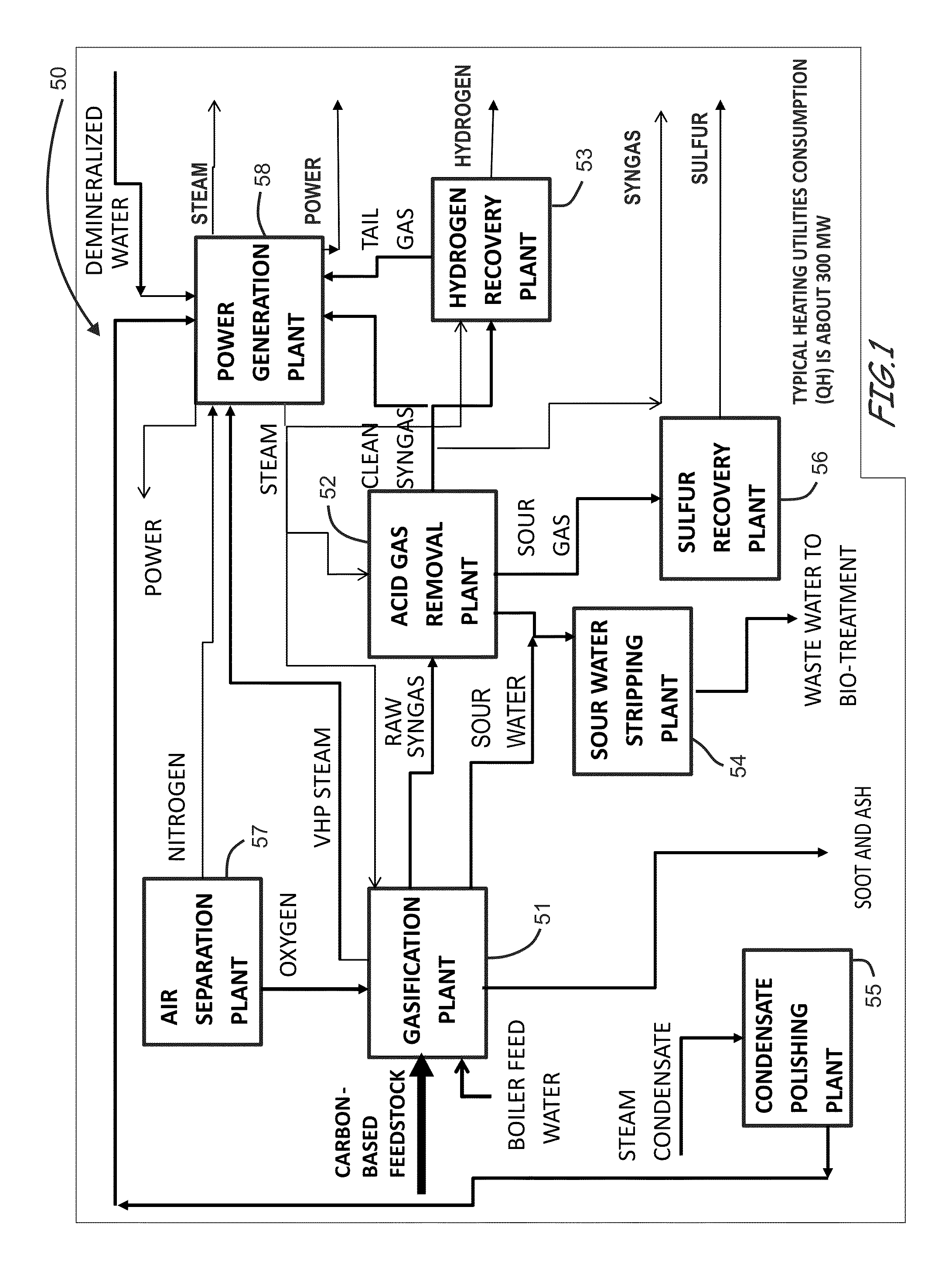

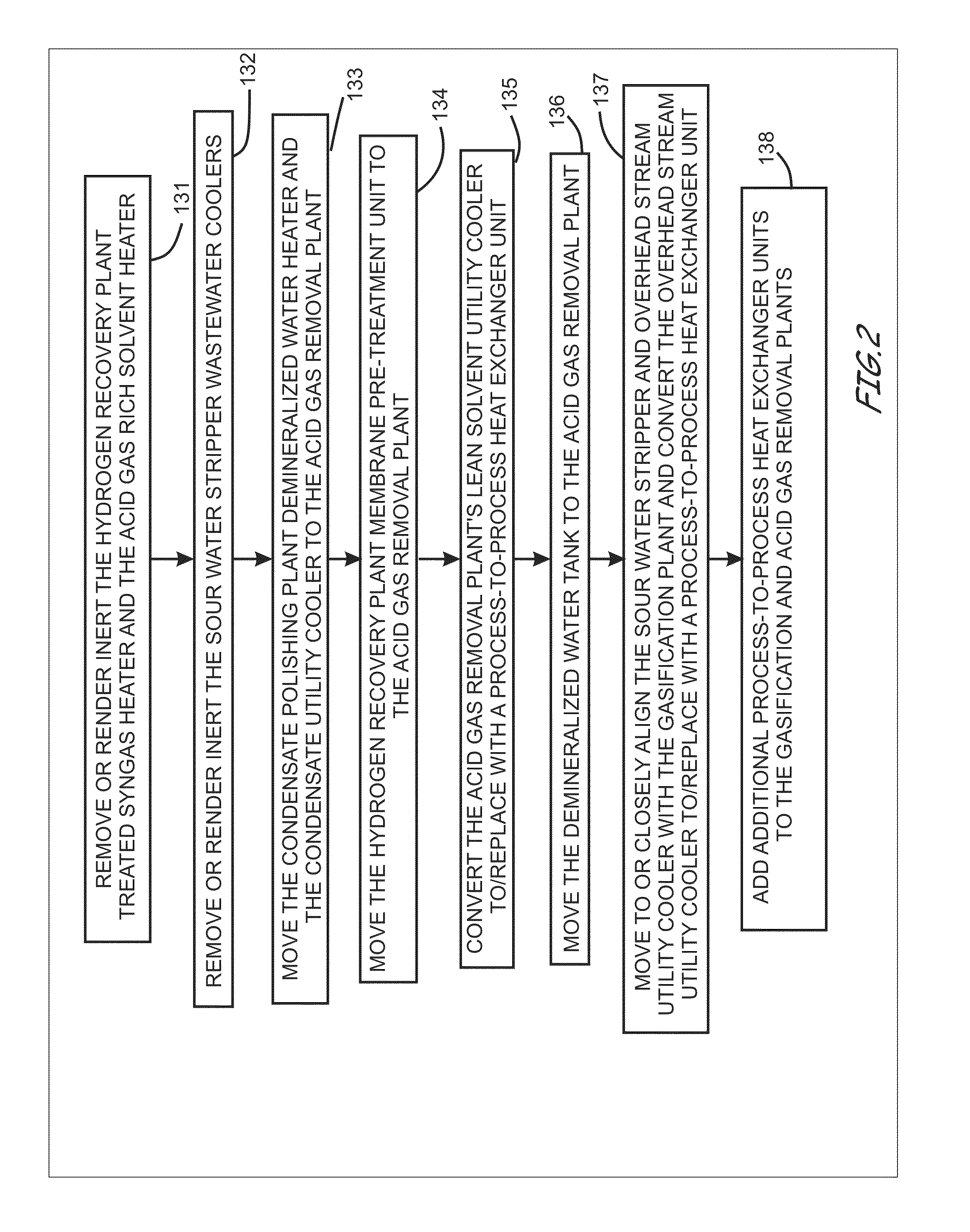

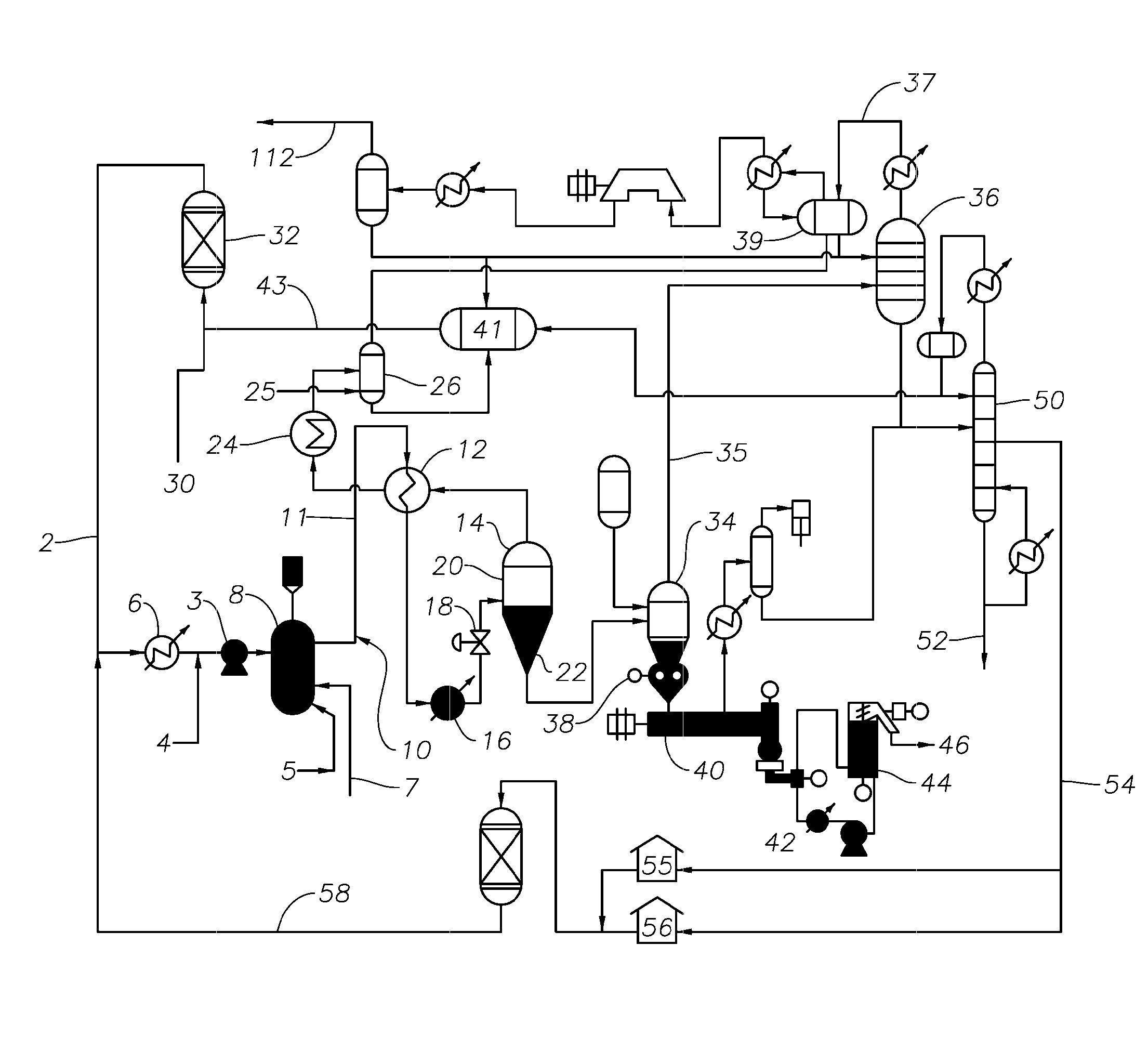

Energy efficient apparatus employing energy efficient process schemes providing enhanced integration of gasification-based multi-generation and hydrocarbon refining facilities and related methods

ActiveUS20150377079A1Less pollutionEasy to modifyProcess control/regulationGasifier mechanical detailsSolventMulti generation

Energy-efficient gasification-based multi-generation apparatus, facilities, or systems, and methods of modifying existing gasification-based multi-generation apparatus and the various conventional thermal coupling arrangements, are provided. Apparatus for managing waste heat recovery through integration of a gasification-based multi-generation facility or other multi-generation system with a hydrocarbon refining facility or other hydrocarbon refining system and methods of providing the respective integration are also provided. An exemplary apparatus includes an integrated site energy management system configured according to one or more process-based thermal coupling schemes comprising one or more thermal coupling arrangements between a gasification-based multi-generation system or facility and a hydrocarbon refining system or facility. The gasification-based multi-generation system or facility can include an acid gas removal system or plant configured to remove acidic contaminants from a raw syngas feed to thereby provide a treated syngas feed, the acid gas removal system or plant containing a separation section including a solvent regenerator, and a gasification system configured to generate the raw syngas feed from a carbon-based feedstock. The hydrocarbon refining system or facility can include an aromatics system or plant containing a xylene products separation section including one or more of the following: an Extract column and a Raffinate column. The integrated site energy management system can include a hot-water system extending between the separation section of the acid gas removal system or plant and the xylene products separation section of the aromatics system or plant, and a plurality of added heat exchanger units providing various advanced thermal coupling arrangements.

Owner:SAUDI ARABIAN OIL CO

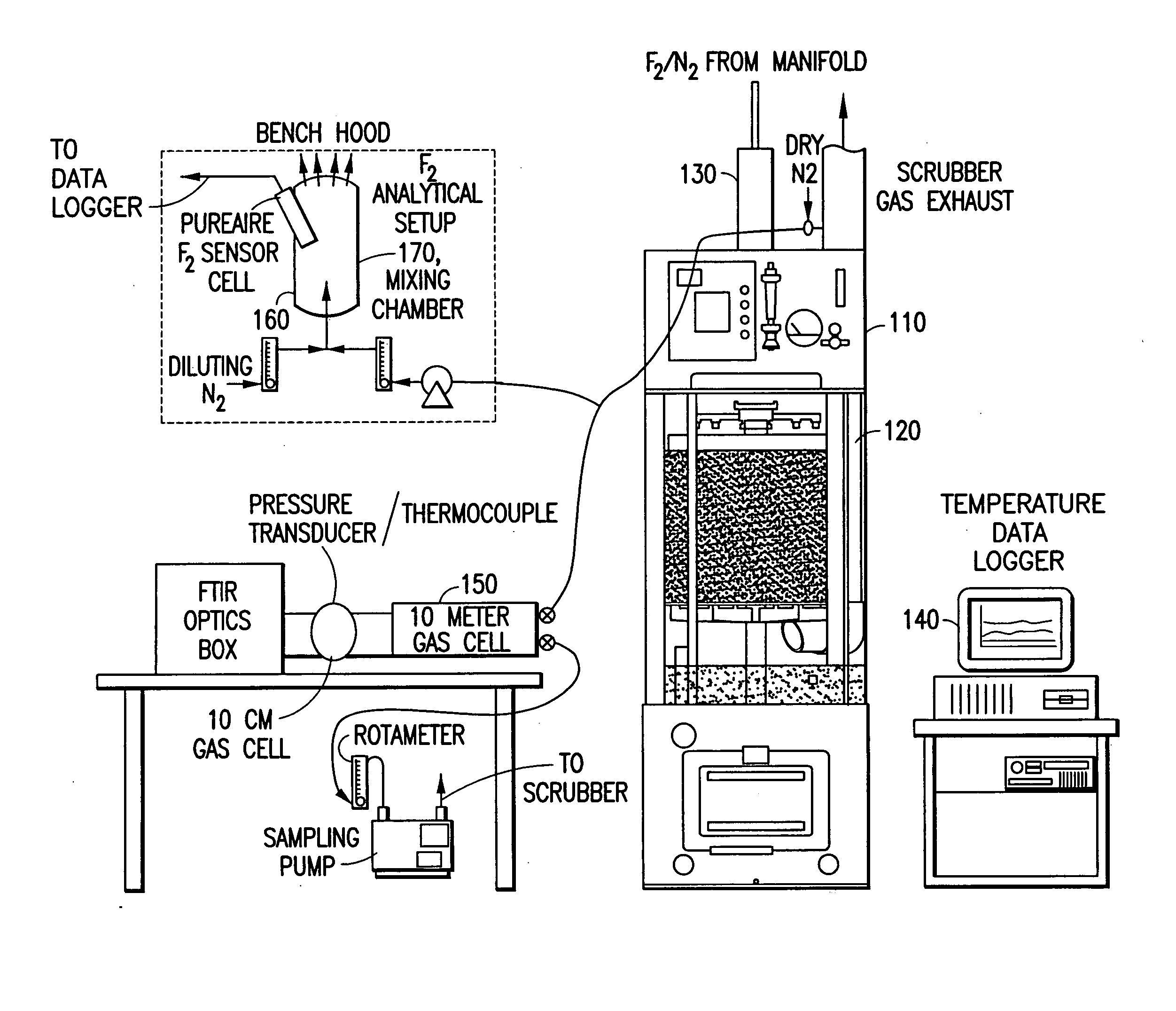

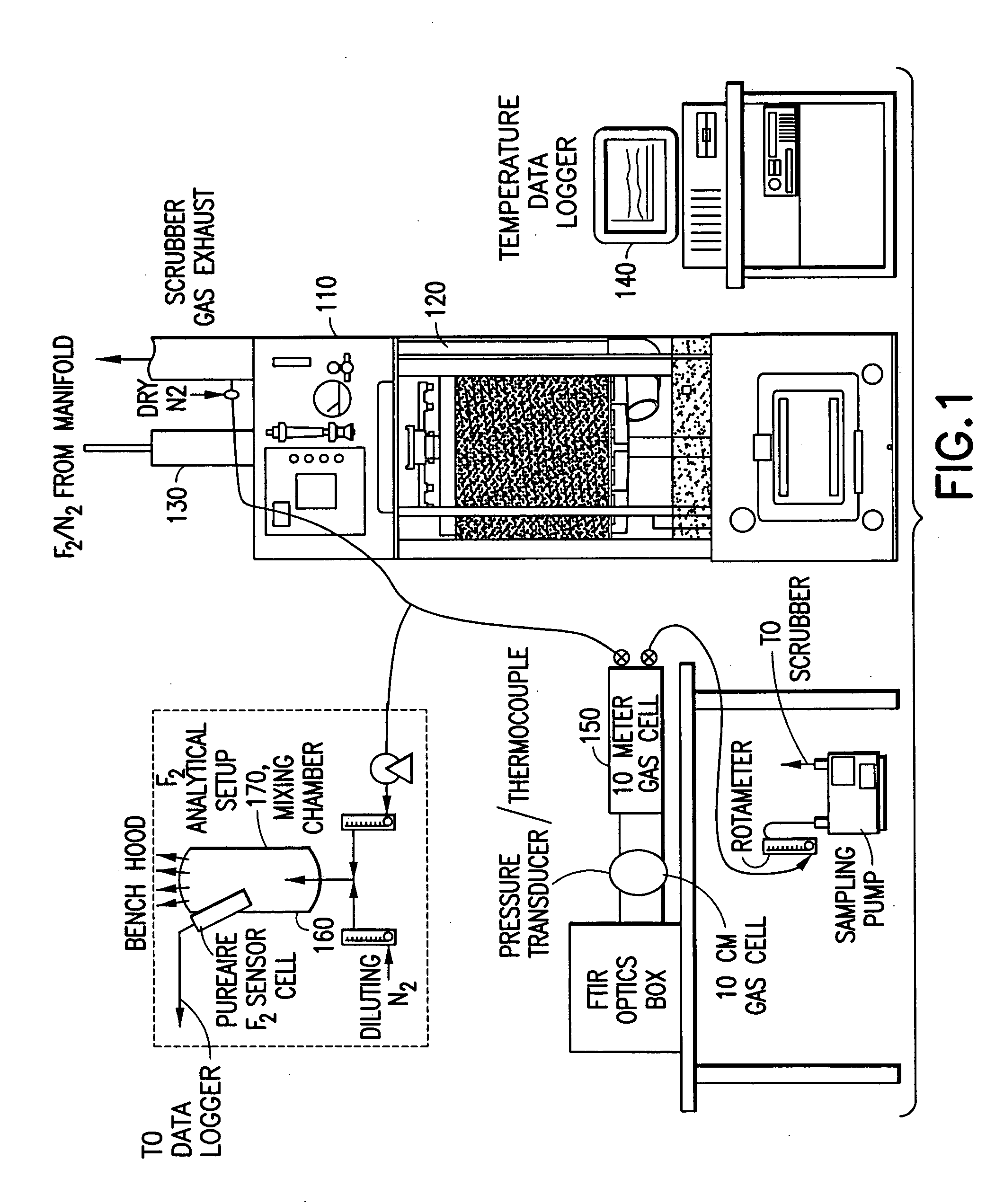

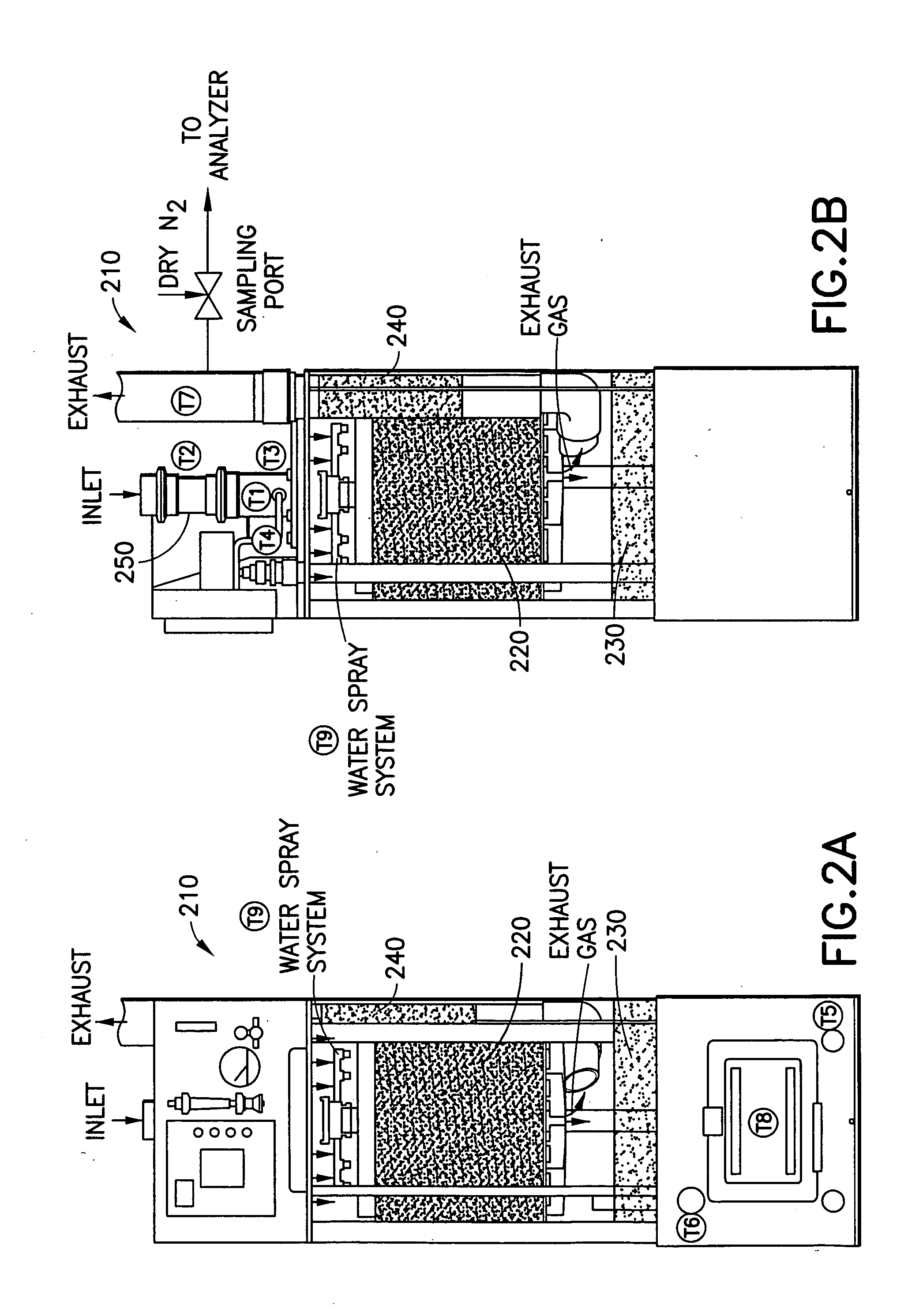

Apparatus and method for point-of-use treatment of effluent gas streams

InactiveUS20040213721A1Highly efficient mannerReduce foaming in the scrubbing systemProcess control/regulationHydrogenSilanesChlorofluorocarbon

A system for abating undesired component(s) from a gas stream containing same, such as halocompounds, acid gases, silanes, ammonia, etc., by scrubbing of the effluent gas stream with an aqueous scrubbing medium. Halocompounds, such as fluorine, fluorides, perfluorocarbons, and chlorofluorocarbons, may be scrubbed in the presence of a reducing agent, e.g., sodium thiosulfate, ammonium hydroxide, or potassium iodide. In one embodiment, the scrubbing system includes a first acid gas scrubbing unit operated in cocurrent gas / liquid flow, and a second "polishing" unit operated in countercurrent gas / liquid flow, to achieve high removal efficiency with low consumption of water. The scrubbing system may utilize removable insert beds of packing material, packaged in a foraminous containment structure. The abatement system of the invention has particular utility in the treatment of semiconductor manufacturing process effluents.

Owner:APPLIED MATERIALS INC

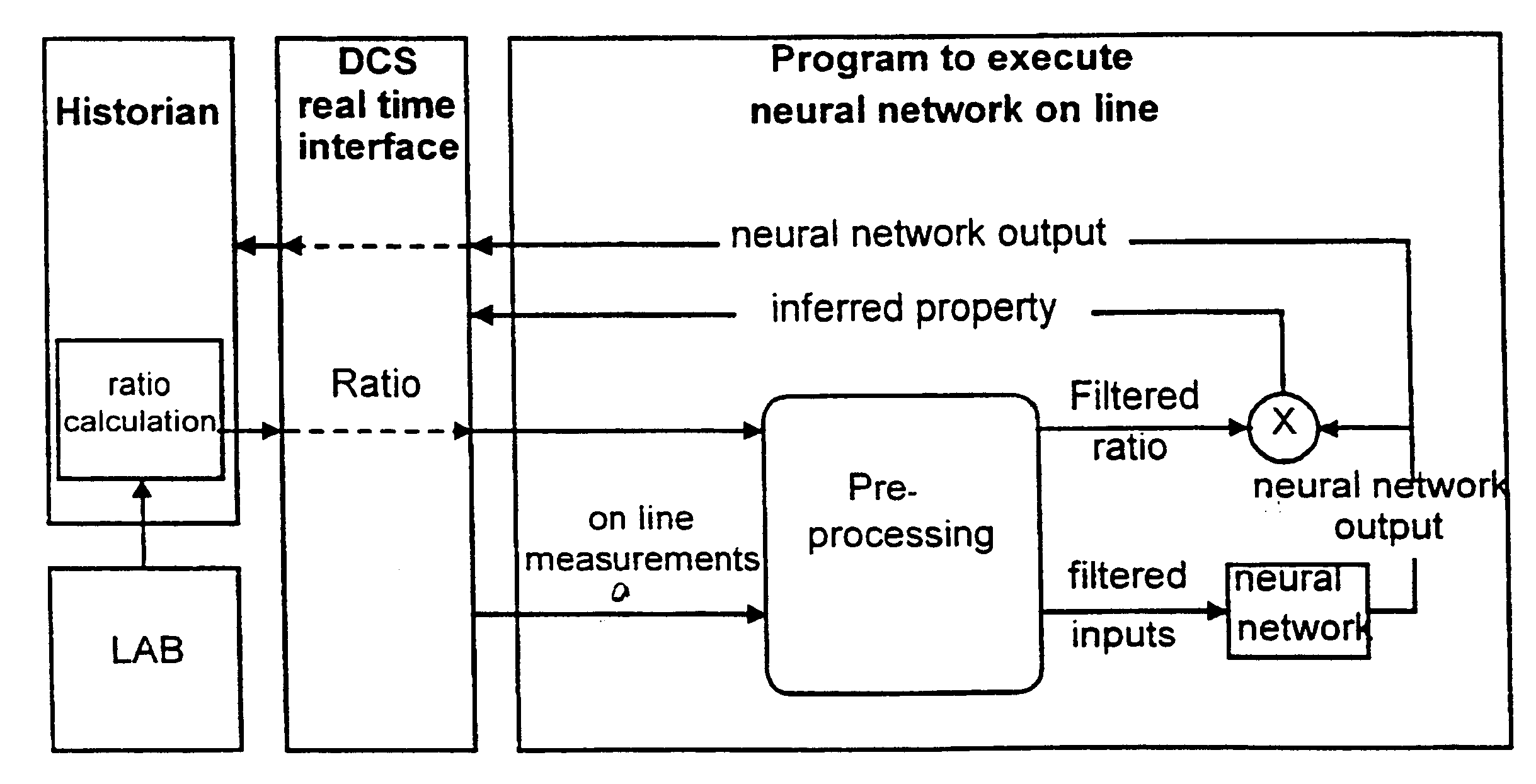

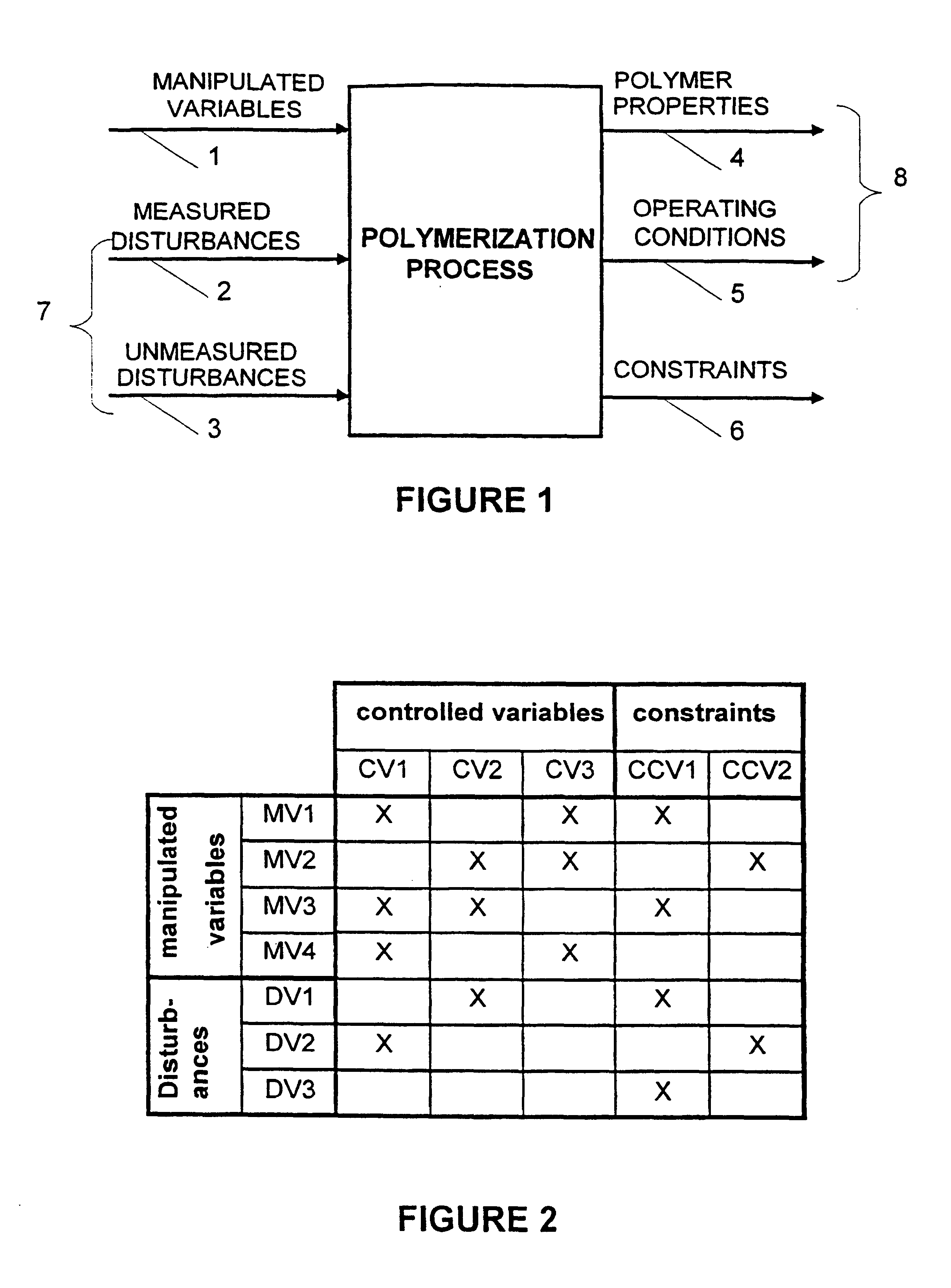

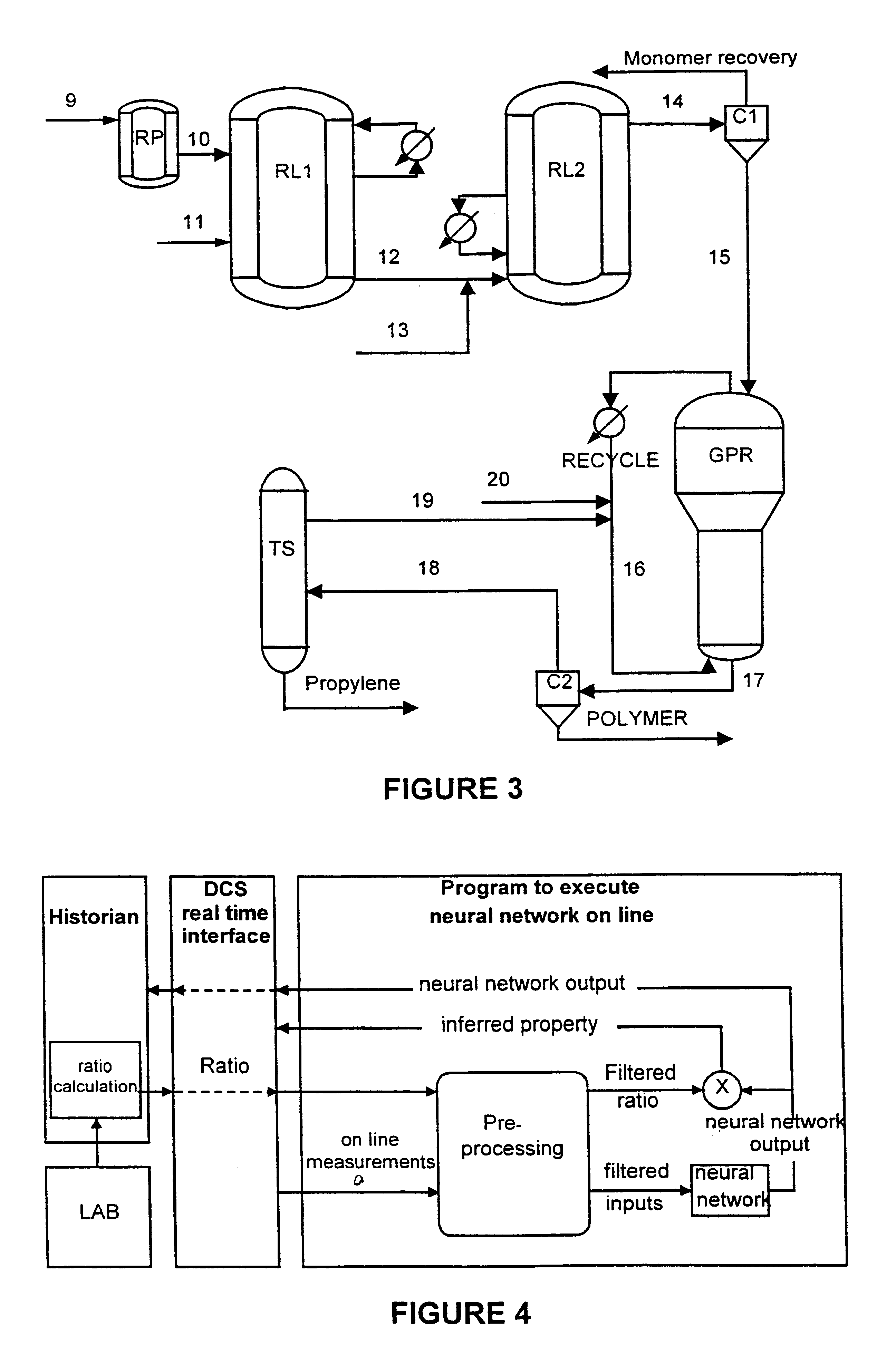

System for on line inference of physical and chemical system for on line control

InactiveUS6718234B1Speed maximizationProcess control/regulationSampled-variable control systemsContinuous measurementProduction rate

A system for on line inference and control of physical and chemical properties of polypropylene and its copolymers is described. The system comprises models for the inference of physical and chemical properties that are not continuously measured and relevant models to control these properties as well as production rate, density of the reaction medium and other process variables of interest. The described control system allows to maximize production rate as well as catalyst yield in the producing process.

Owner:BRASKEM SA

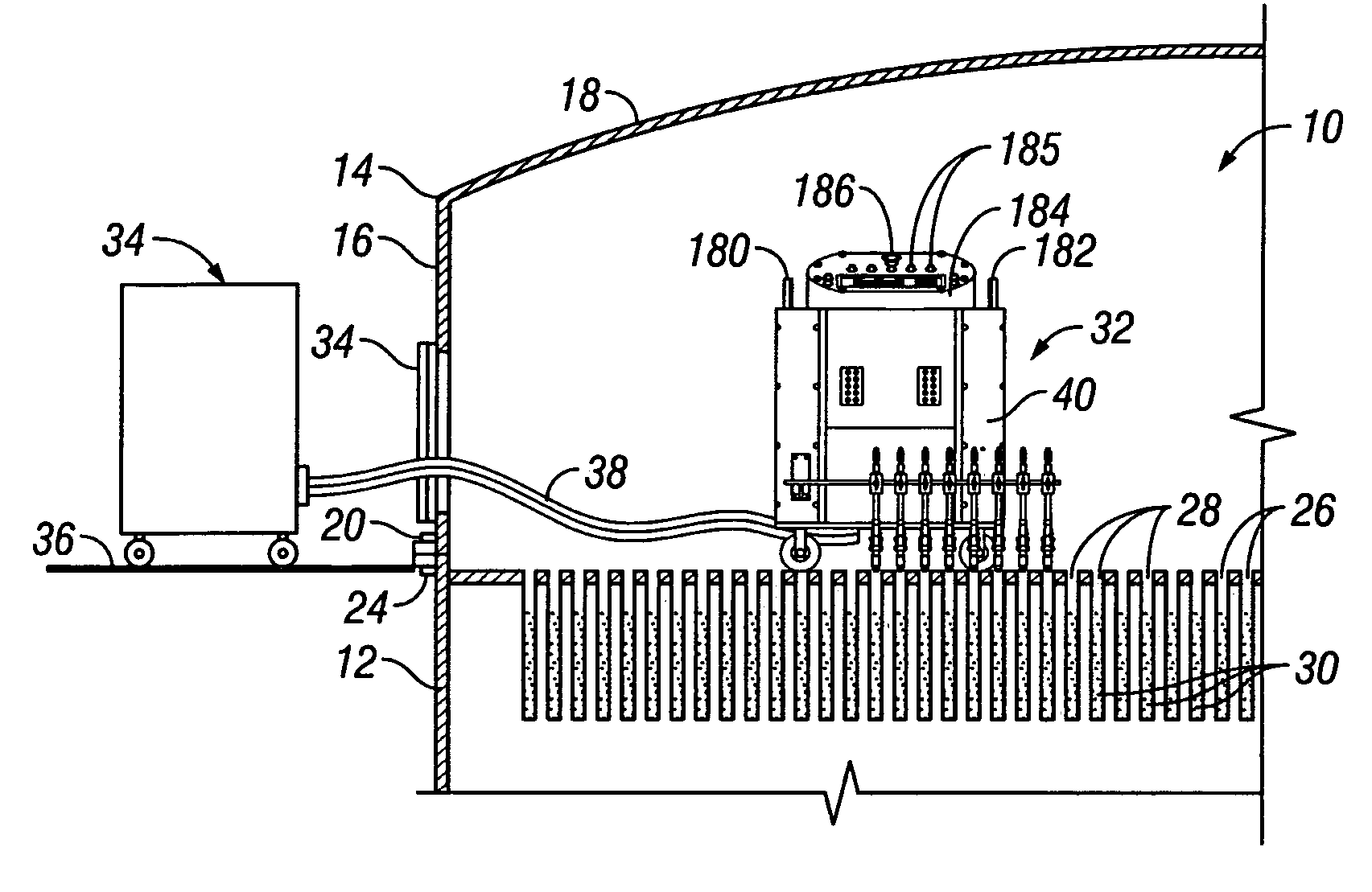

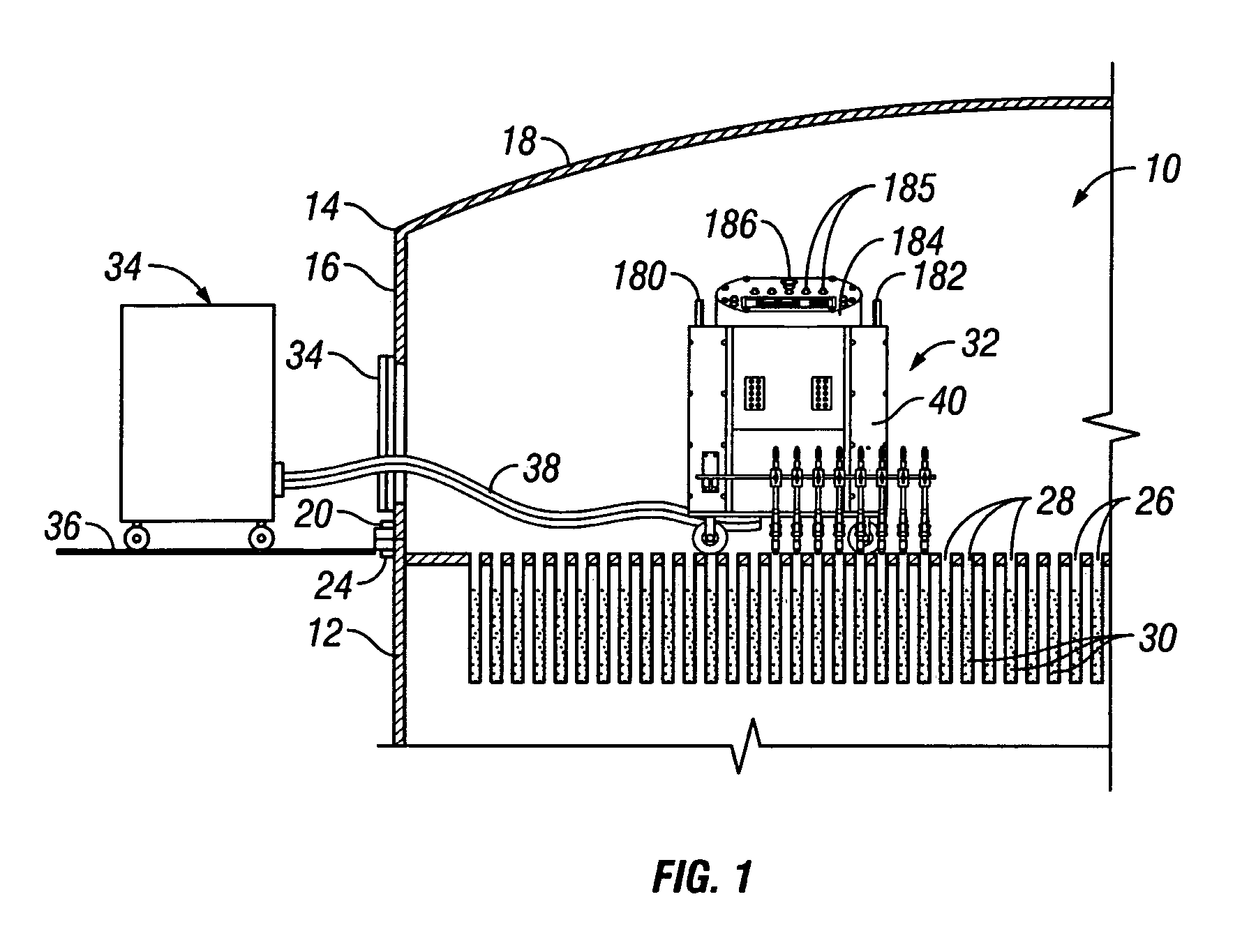

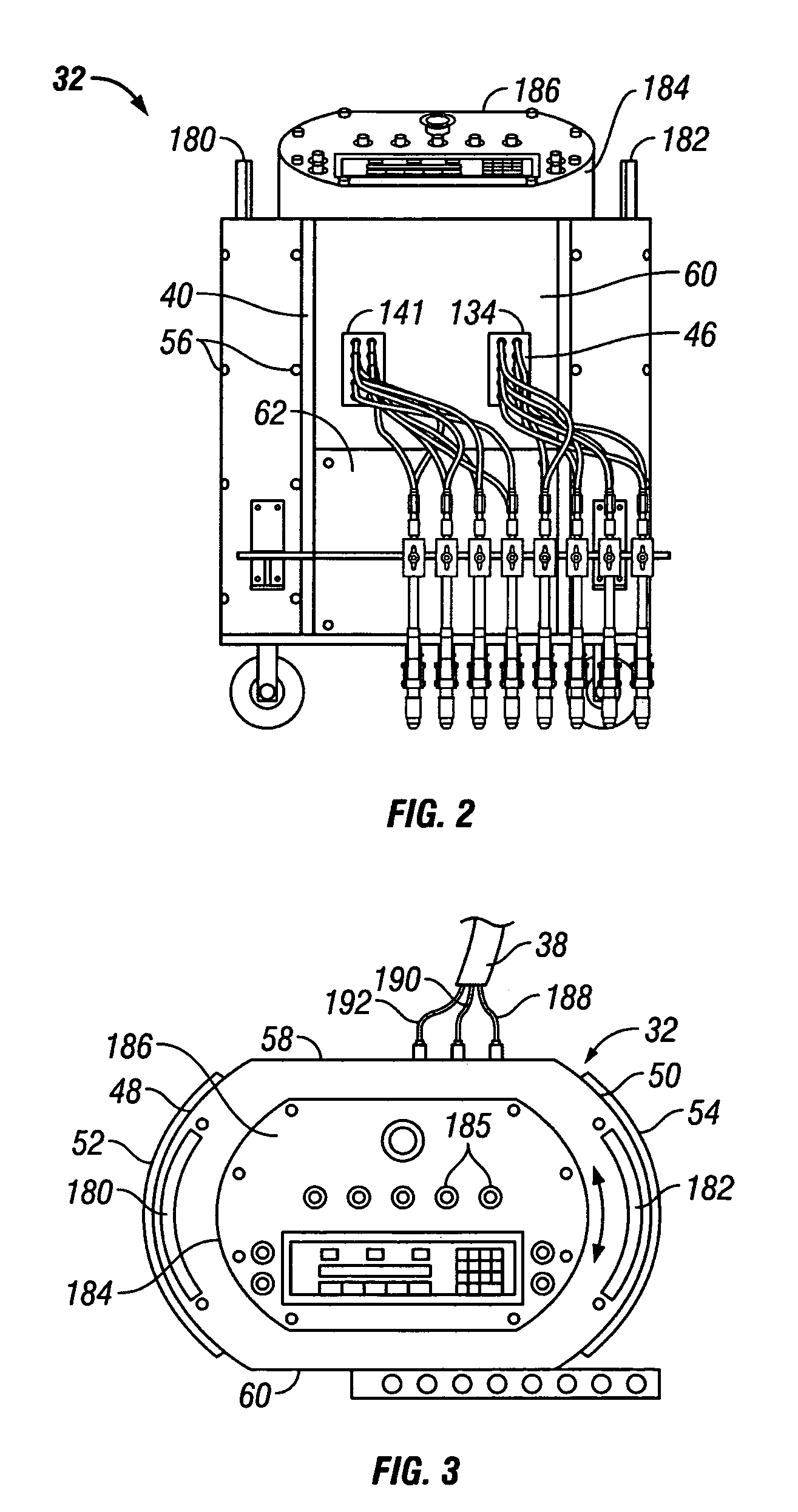

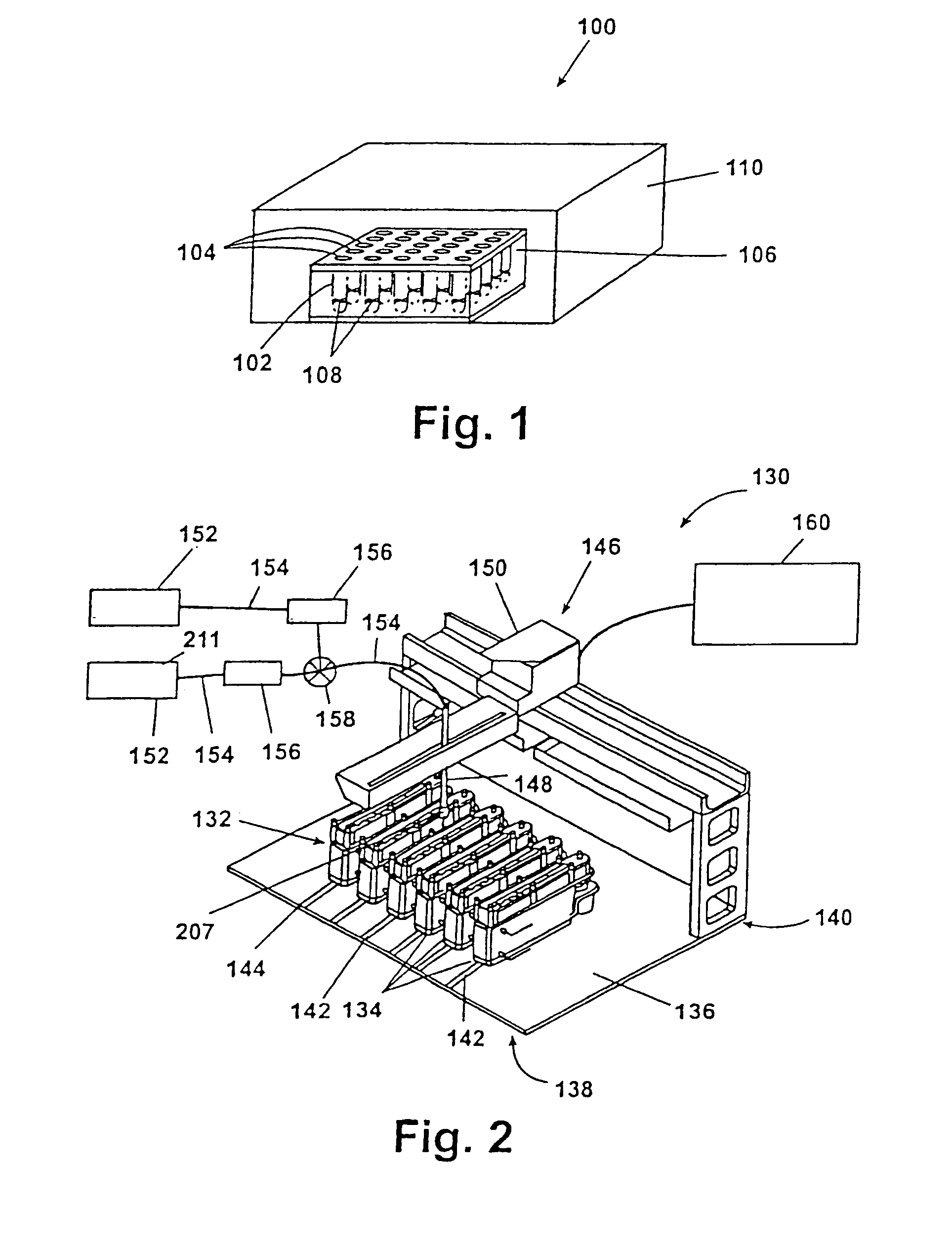

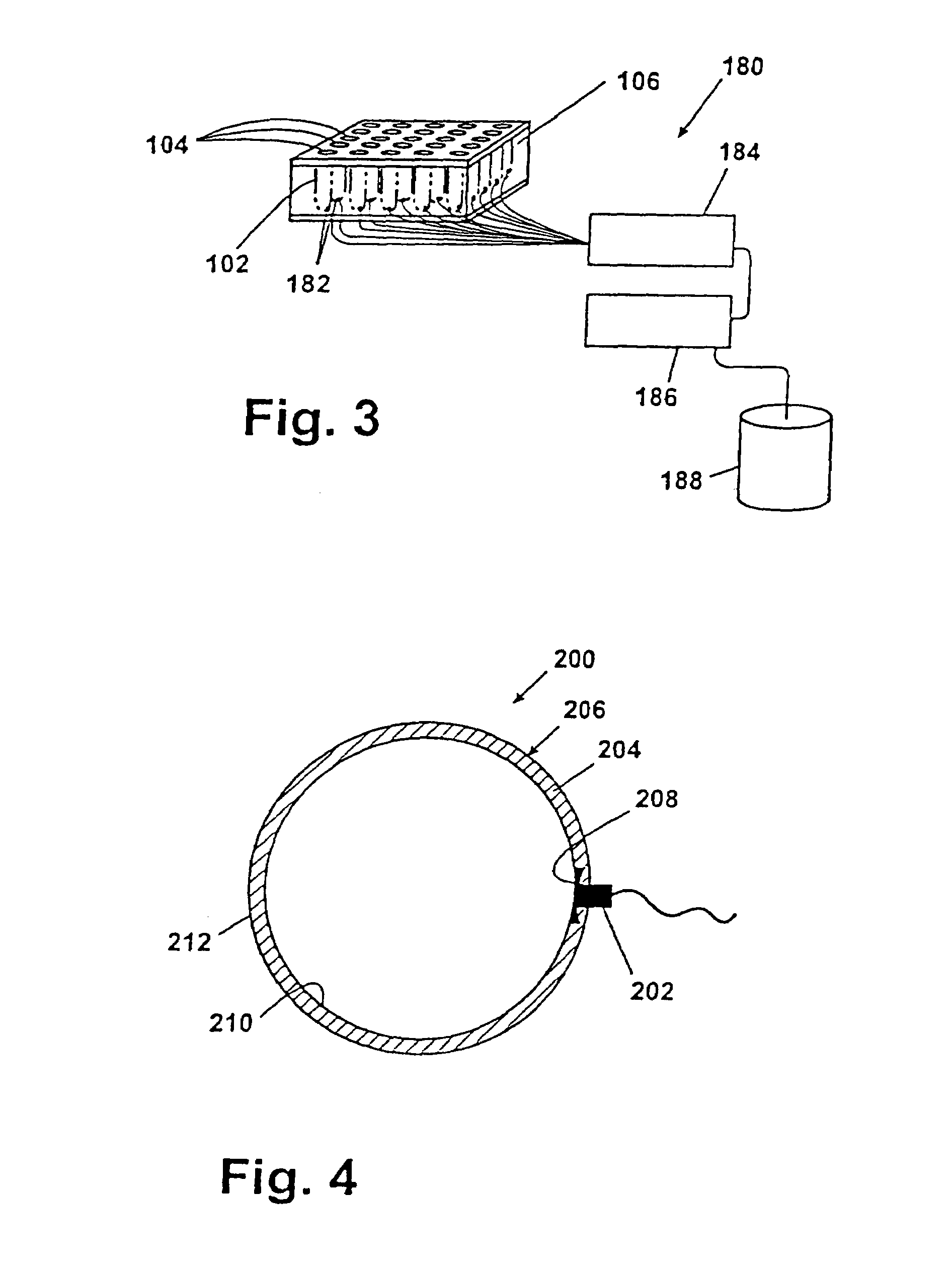

Method and apparatus for differential pressure testing of catalytic reactor tubes

ActiveUS6981422B1Efficient testingMinimizes servicing timeProcess control/regulationMaterial strength using tensile/compressive forcesDifferential pressureEngineering

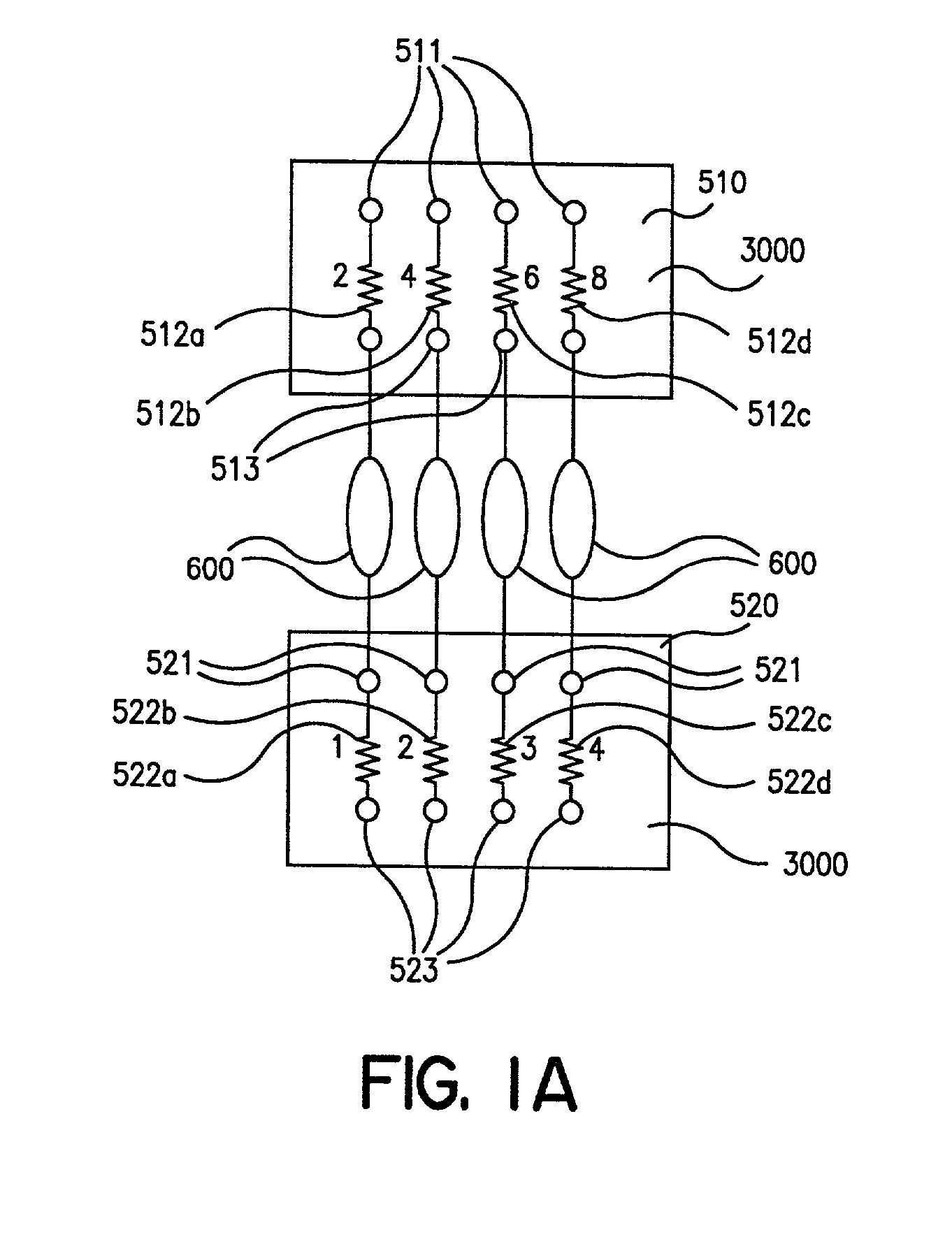

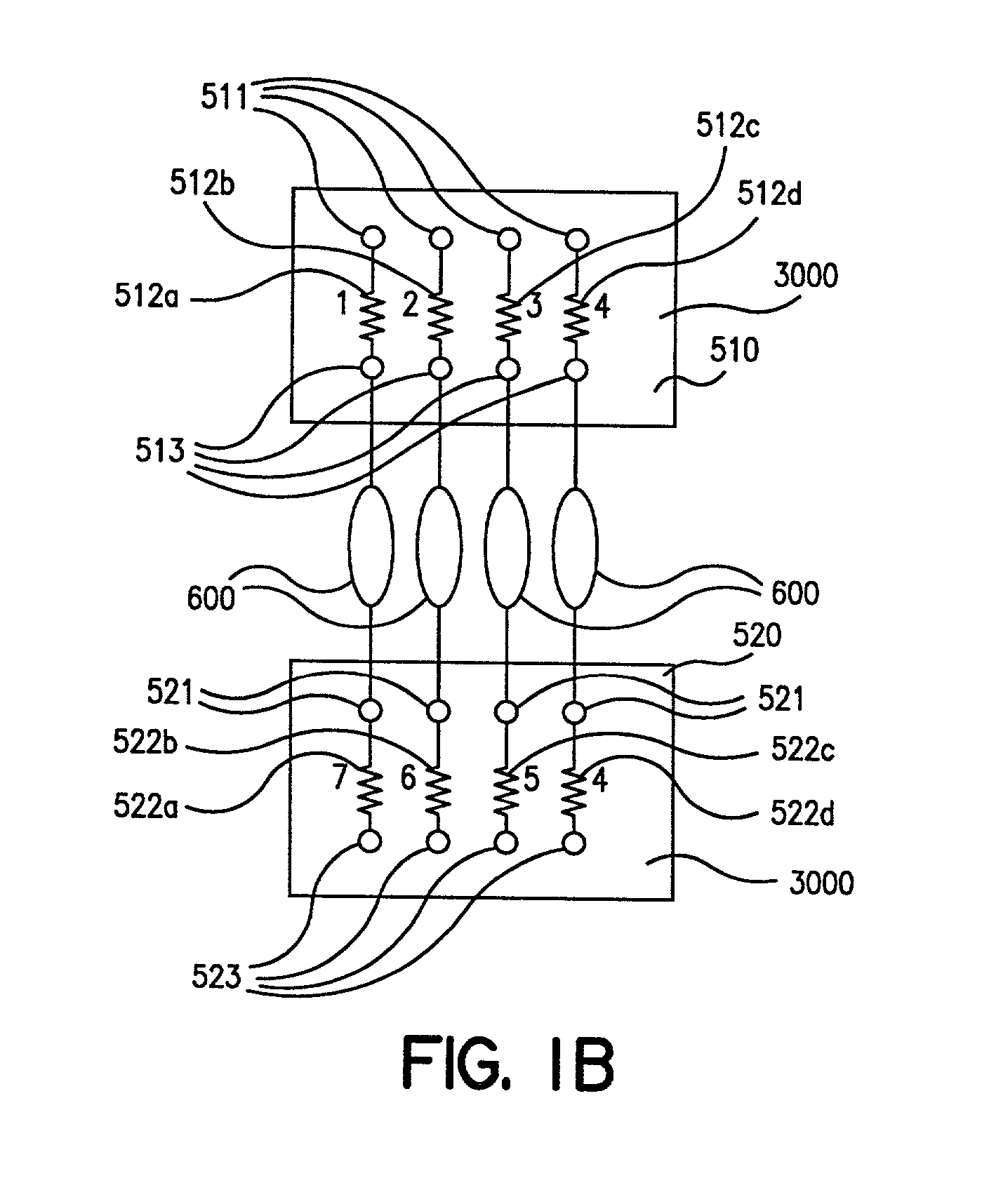

A multi-tube differential pressure (Delta P) testing system for testing catalyst filled tubes of tube and shell type catalytic reactors has at least one mobile test unit for movement on the upper tube sheet of a catalytic reactor. An array of test probes is mounted to the mobile test unit and is selectively positionable in sealed gas pressure communicating engagement within the upper ends of selected reactor tubes. A pressure testing gas delivery system is interconnected with the test probes and selectively communicates pressurized gas to the testing tubes at a blow-down pressure or selected test pressure determined by restricted orifices. A differential pressure measurement system measures the back-pressure resulting from application of test pressure to individual reactor tubes and having a computer receiving electronic back-pressure measurement data and producing an electronic and / or visual record correlated with a reactor tube numerical sequence and identifying the resulting back-pressure of each reactor tube of the multi-tube test. The testing system is capable of selectively electronically counting in normal sequence and in inverted sequence to accommodate test unit orientation and incorporates a separate manually positioned testing wand to accommodate tube positions of the reactor that cannot be readily accessed by one or more of the array of test probes.

Owner:WINDLASS METALWORKS

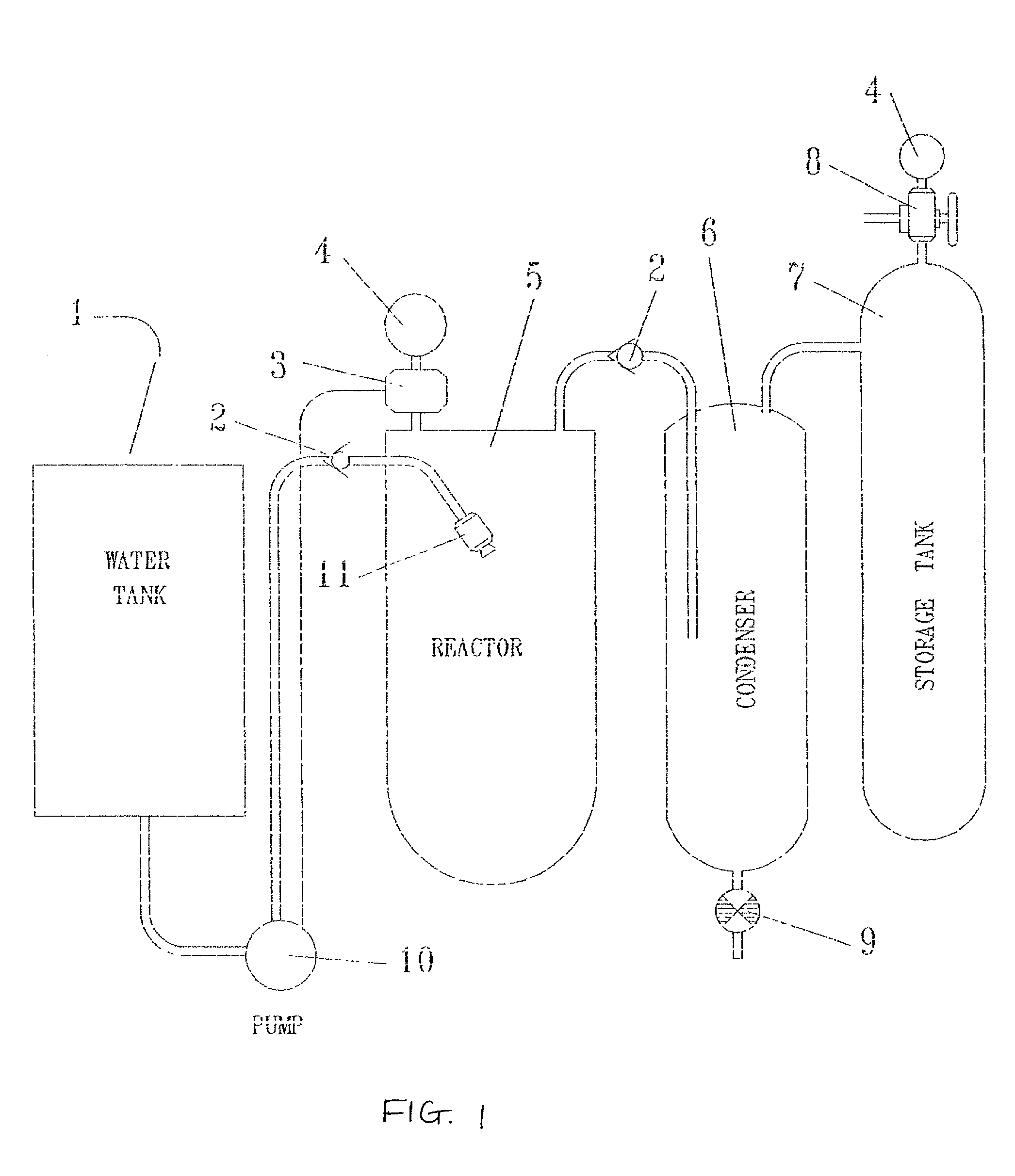

Method and apparatus for controlled generation of hydrogen by dissociation of water

The invention relates to a method and apparatus for controlling the dissociation of water into hydrogen and oxygen, the method including contacting a quantity of aqueous liquid with a quantity of dissociation initiating material in a reaction vessel; monitoring the temperature and / or pressure in the reaction vessel; monitoring the surface area of dissociation initiating material in contact with the aqueous liquid; and controlling the surface area of dissociation initiating material in contact with the aqueous liquid in response to the temperature, pressure, or both, or changes therein, or both, in the reaction vessel.

Owner:HYDROGEN ENERGY AMERICA

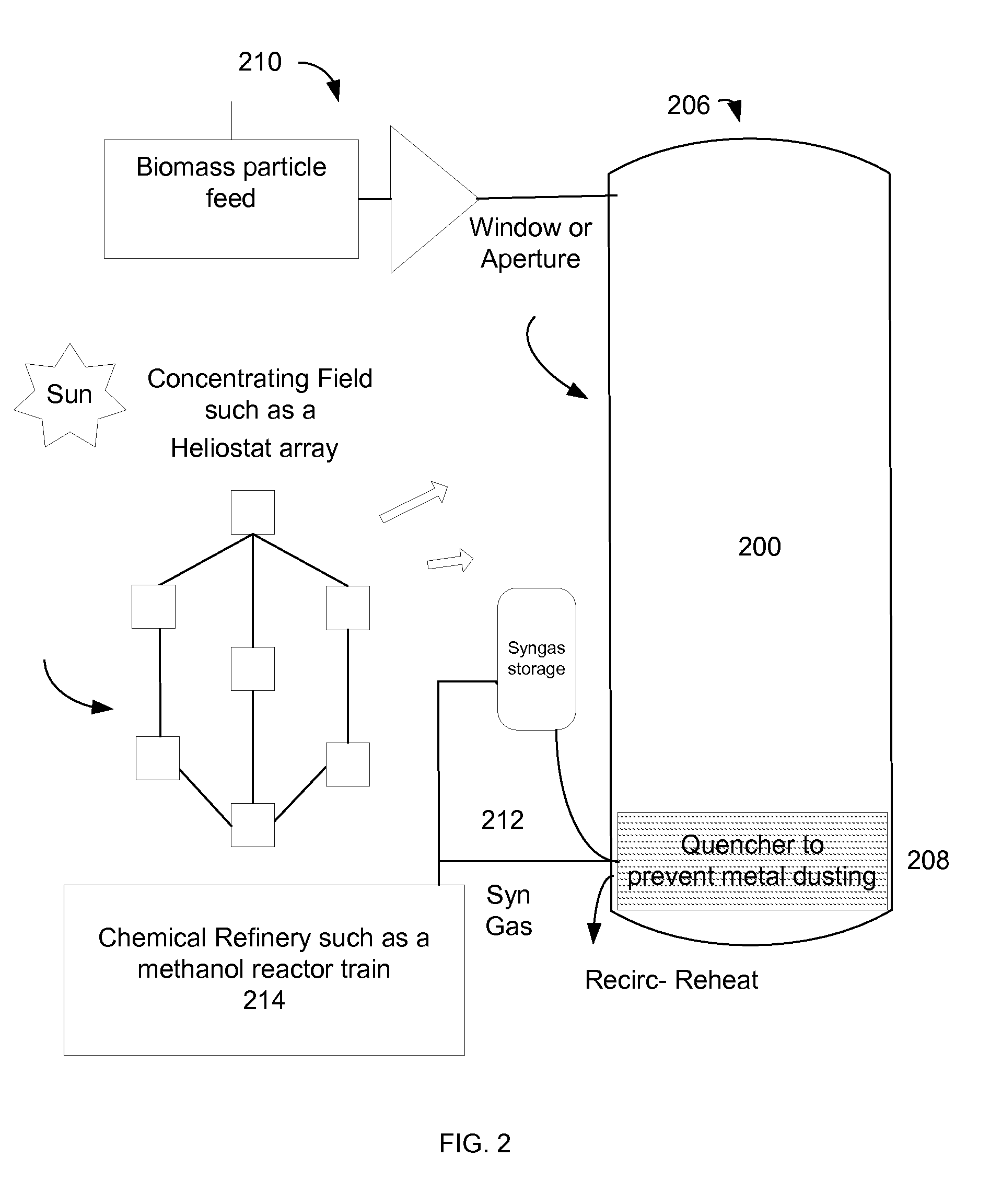

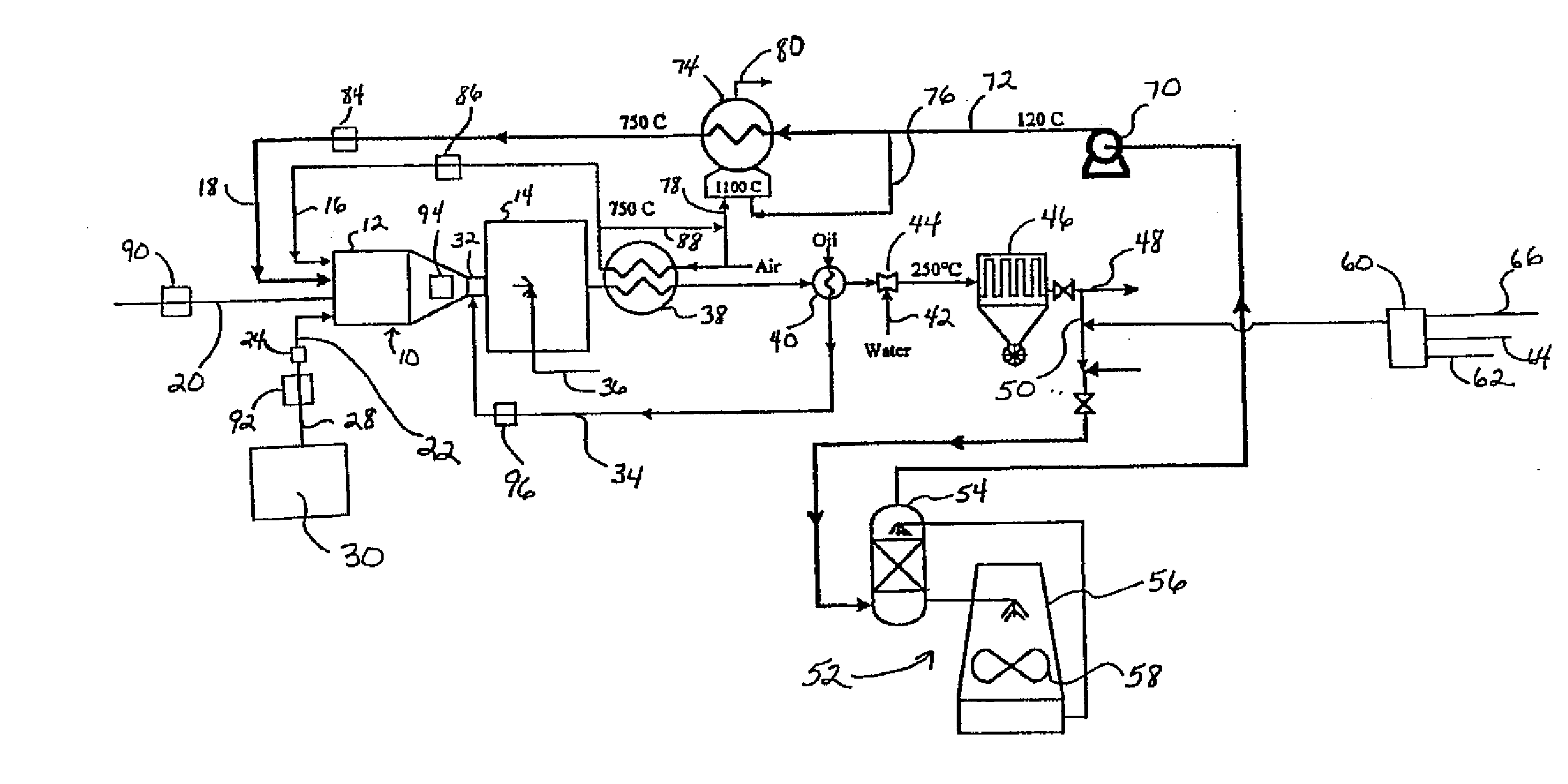

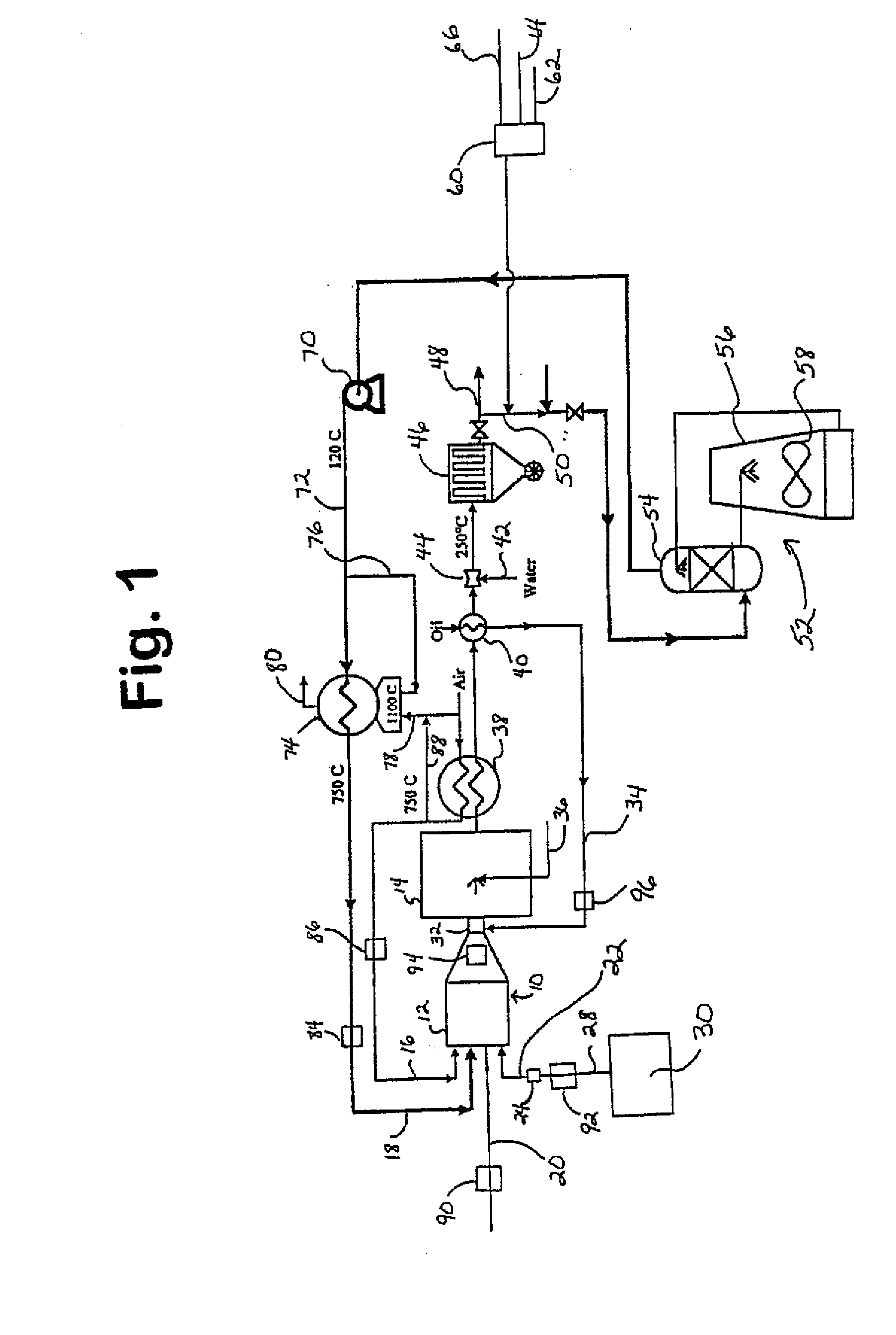

Systems and methods for quenching, gas clean up, and ash removal

A method, apparatus, and system for a solar-driven chemical plant are disclosed. An embodiment may include a solar thermal receiver aligned to absorb concentrated solar energy from one or more solar energy concentrating fields. A solar driven chemical reactor may include multiple reactor tubes located inside the solar thermal receiver. The multiple reactor tubes can be used to gasify particles of biomass in the presence of a carrier gas. The gasification reaction may produce reaction products that include hydrogen and carbon monoxide gas having an exit temperature from the tubes exceeding 1000 degrees C. An embodiment can include a quench zone immediately downstream of an exit of the chemical reactor. The quench zone may immediately quench via rapid cooling of at least the hydrogen and carbon monoxide reaction products within 0.1-10 seconds of exiting the chemical reactor to a temperature of 800 degrees C. or less.

Owner:SUNDROP IP HLDG LLC

Process for production of carbon black

InactiveUS7655209B2Increase flexibilityLow costProcess control/regulationPigmenting treatmentCombustorProcess engineering

Off-gas from a carbon black furnace is employed as a combustion gas feed stream to the burner or combustion zone of the same or a different carbon black furnace in accordance with certain embodiments, suitable conduit and valving is provided to pass off-gas, from which carbon black has been substantially removed, from any and all of multiple different carbon black furnaces to the burner. The off-gas is heated, preferably by plasma heating, and dewatered. Carbon dioxide stripping or rather stripping of gas components from the dewatered heated off-gas is found to be unnecessary to achieve economically favorable use of off-gas recirculation.

Owner:CABOT CORP

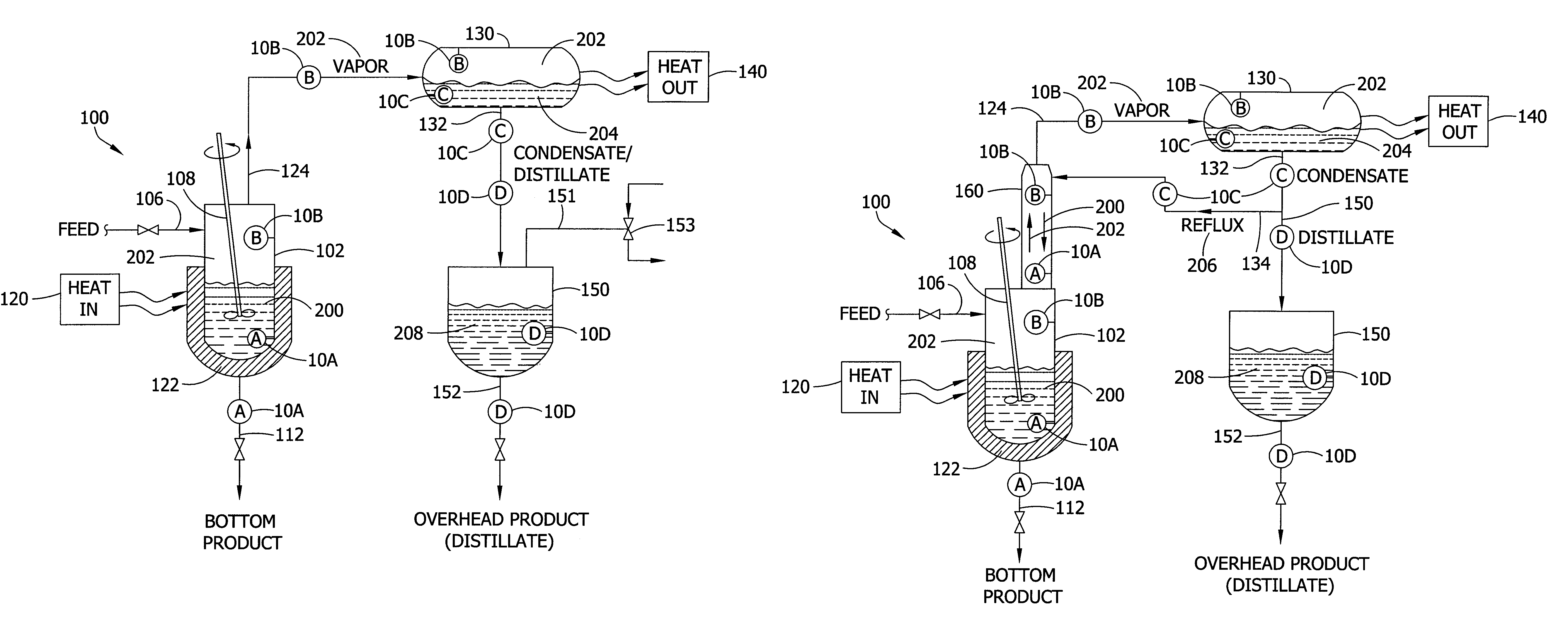

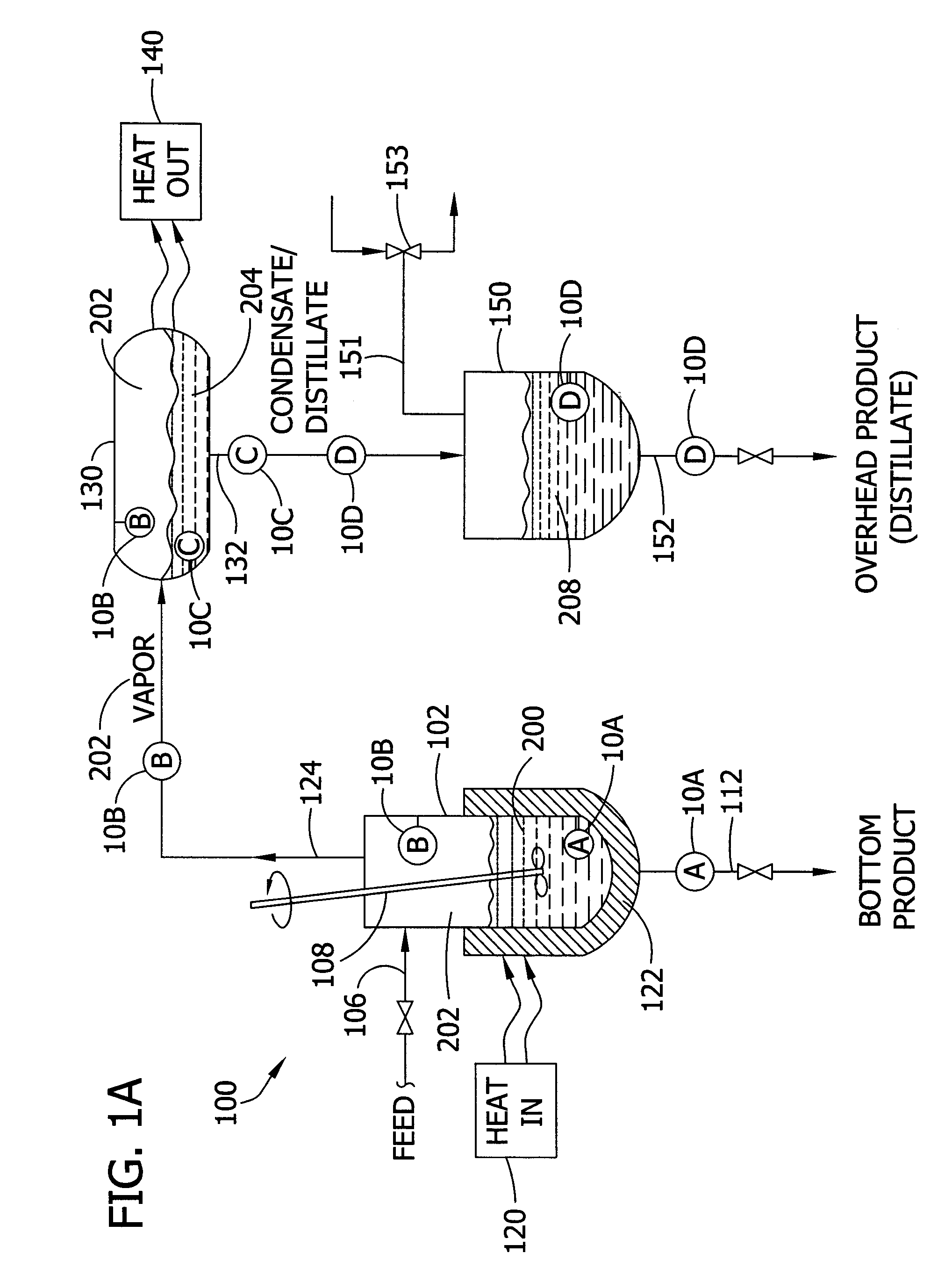

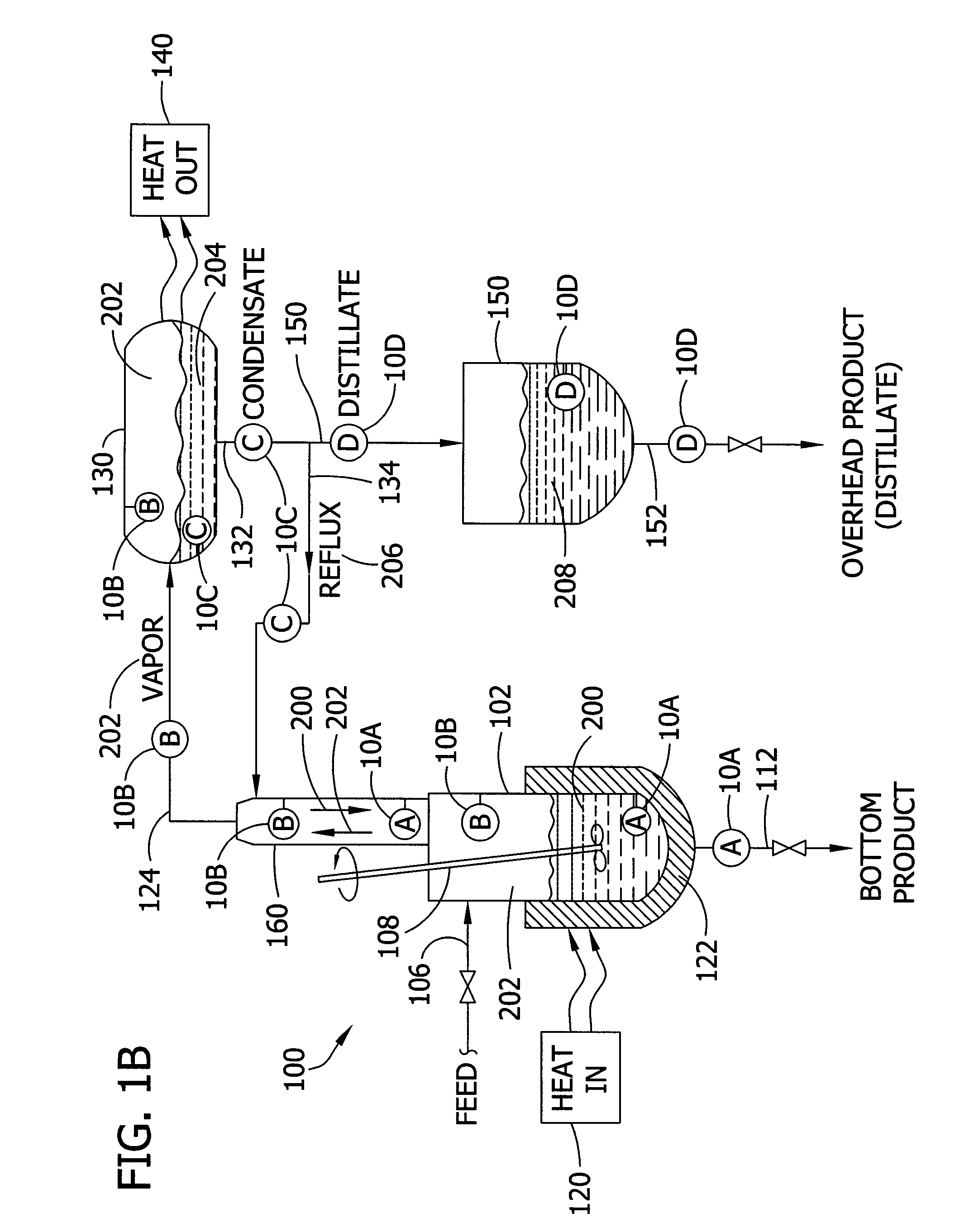

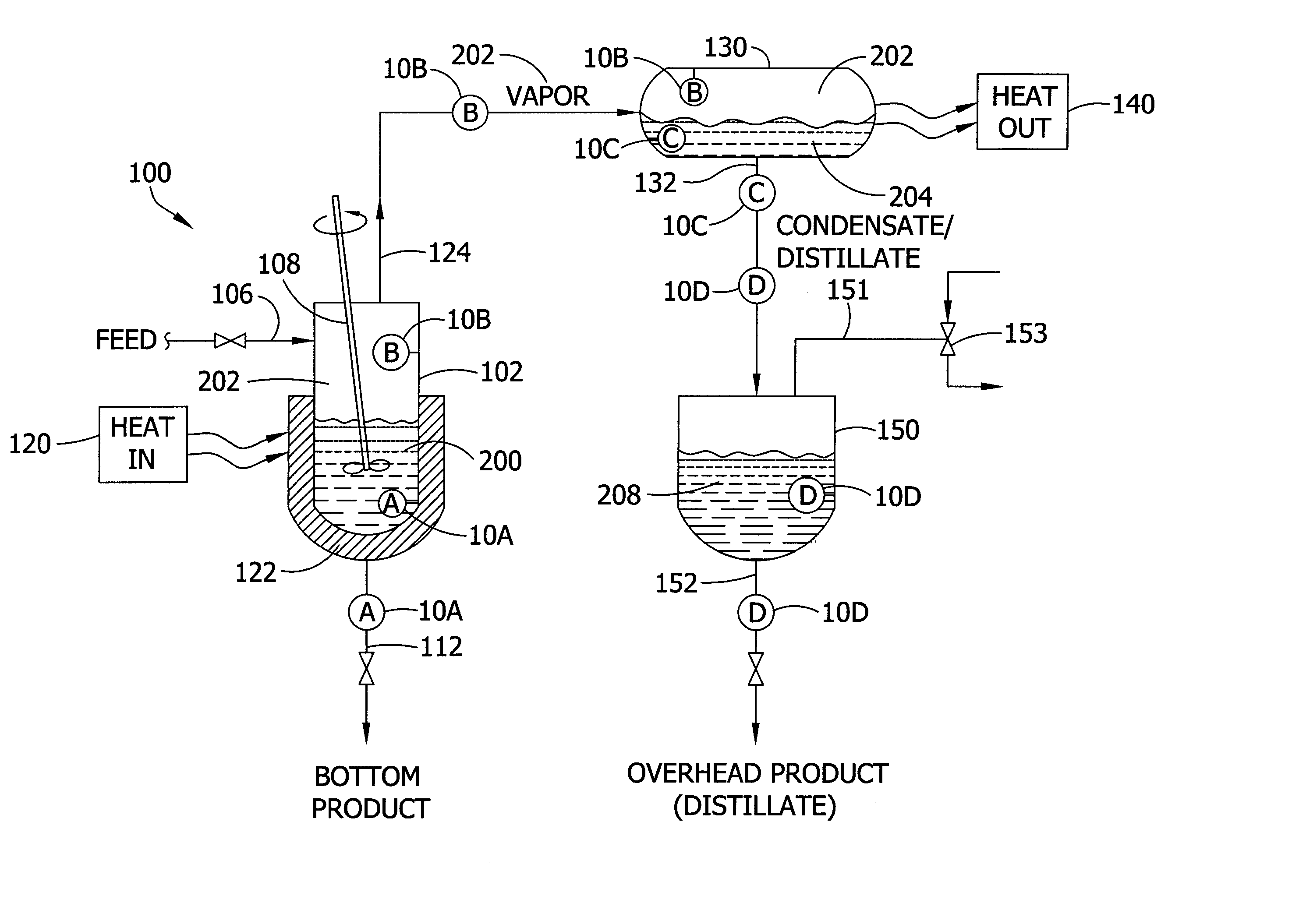

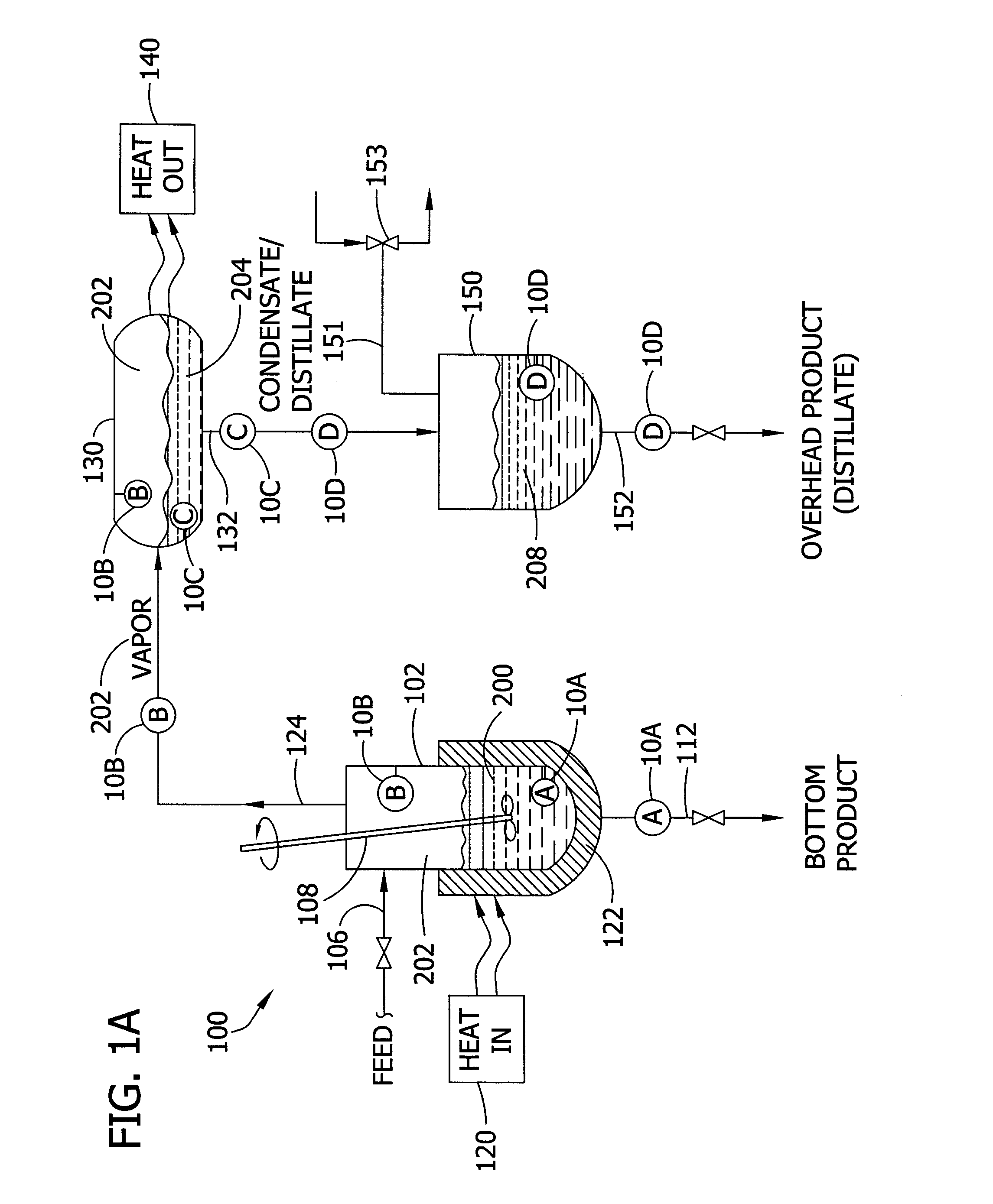

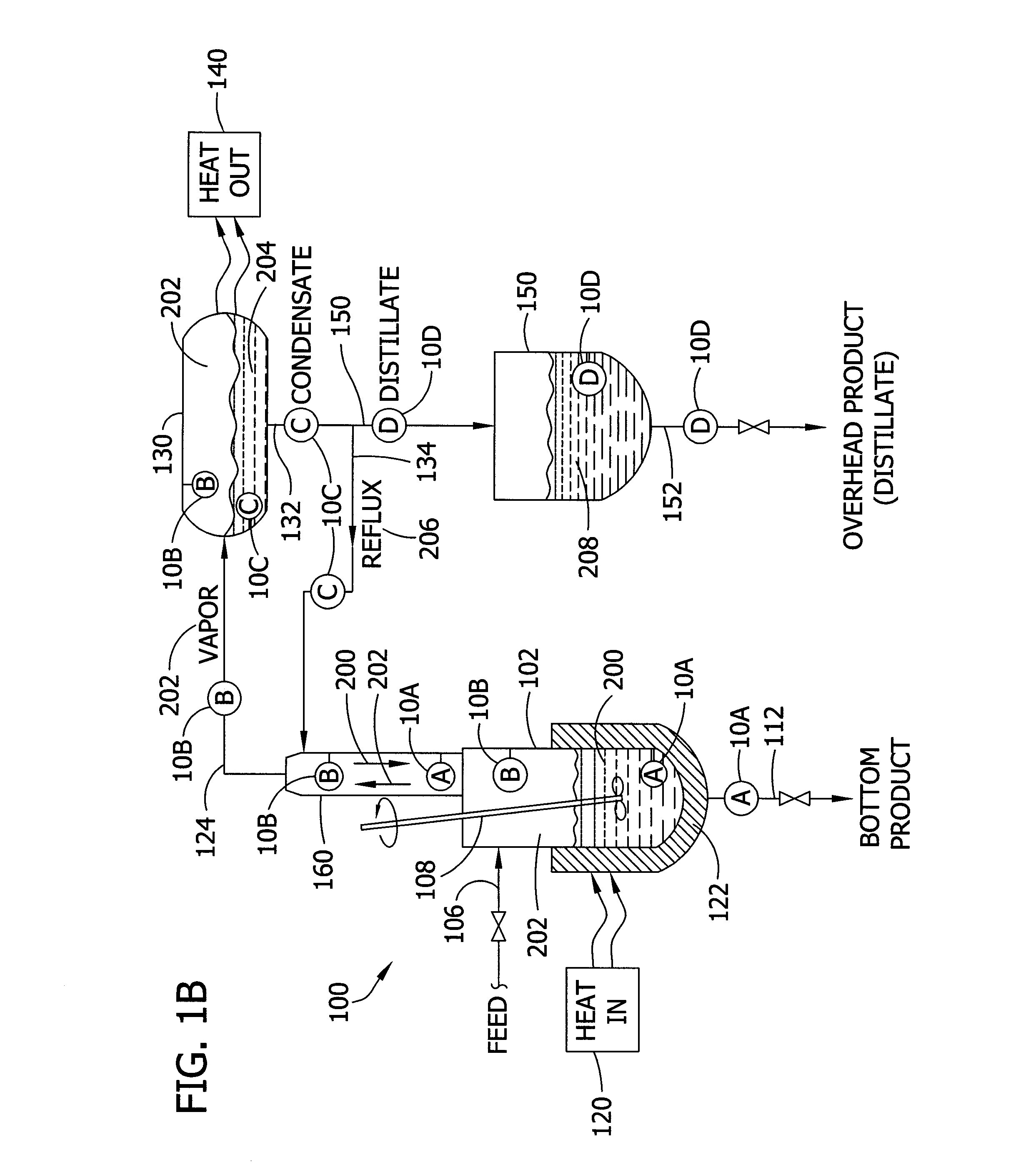

Systems for monitoring and controlling unit operations that include distillation

InactiveUS7603889B2High sensitivityHigh dielectric constantProcess control/regulationAnalysing solids using sonic/ultrasonic/infrasonic wavesDistillationUnit operation

Fluid sensor methods and systems adapted for monitoring and / or controlling distillation operations in fluidic systems, such as batch distillation operations or continuous distillation operations, are disclosed. Preferred embodiments are directed to process monitoring and / or process control for unit operations involving endpoint determination of a distillation, for example, as applied to a liquid-component-switching operation (e.g., a solvent switching operation), a liquid-liquid separation operation, a solute concentration operation, a dispersed-phase concentration operation, among others.

Owner:MEAS FRANCE

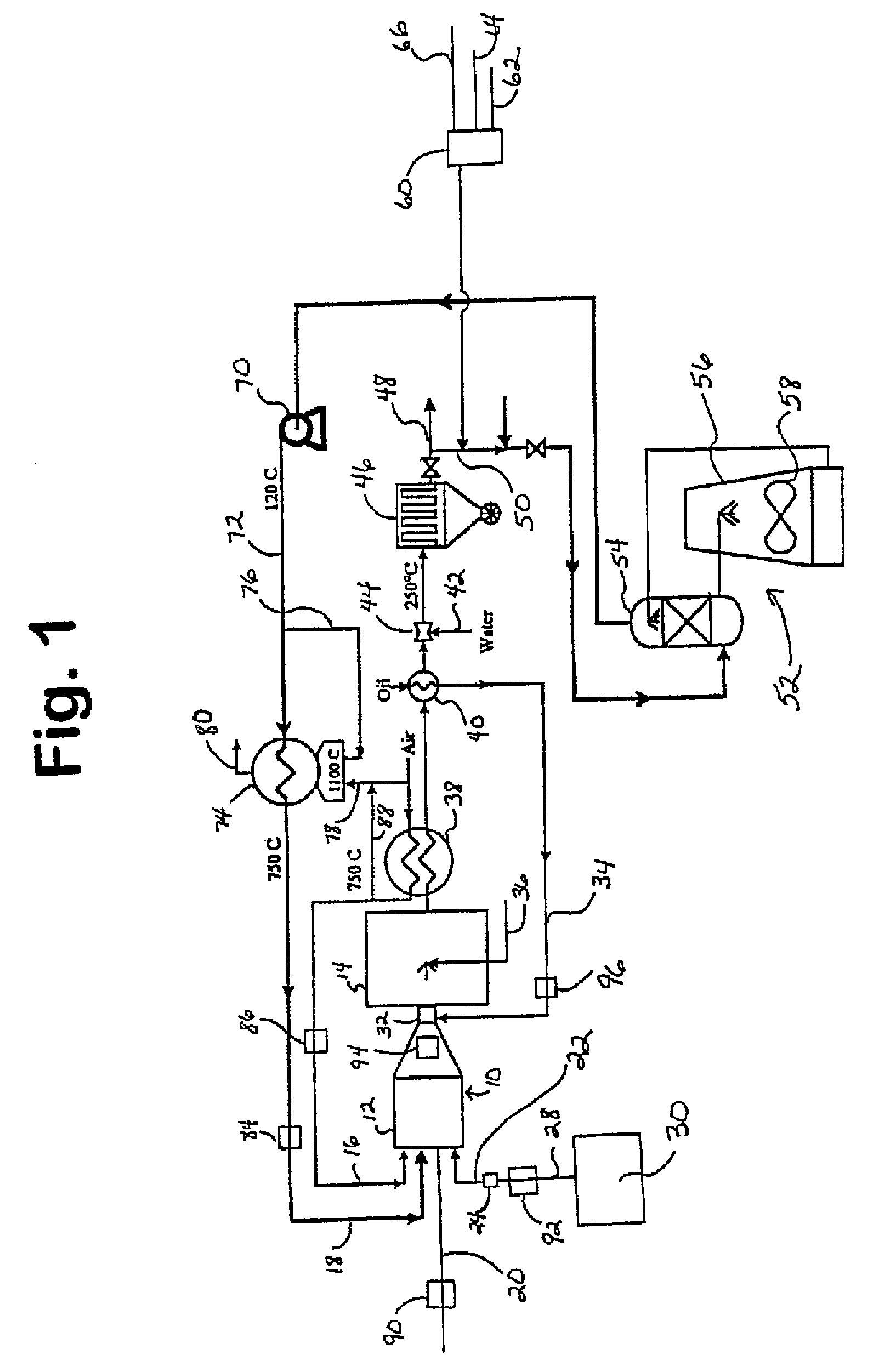

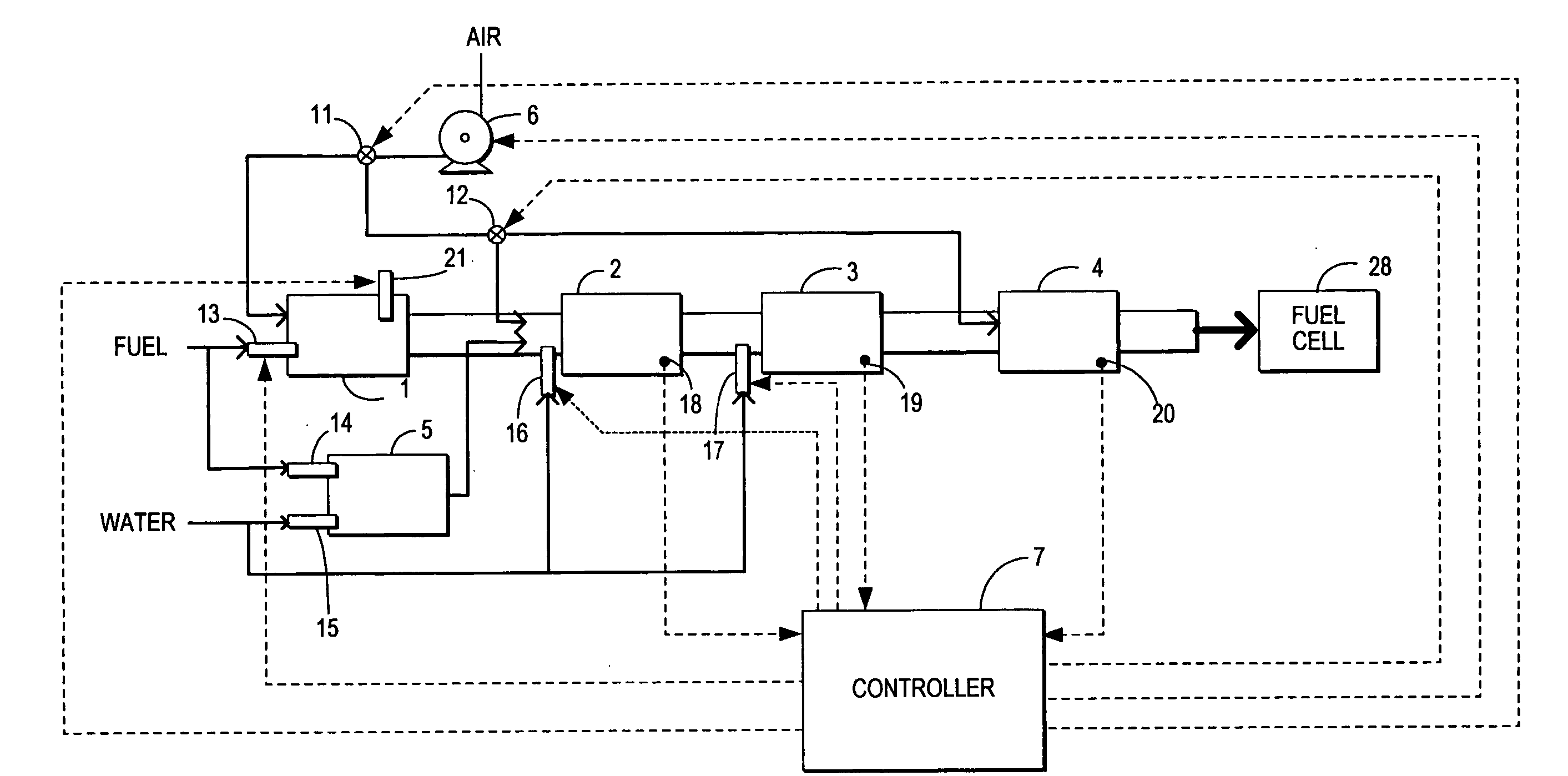

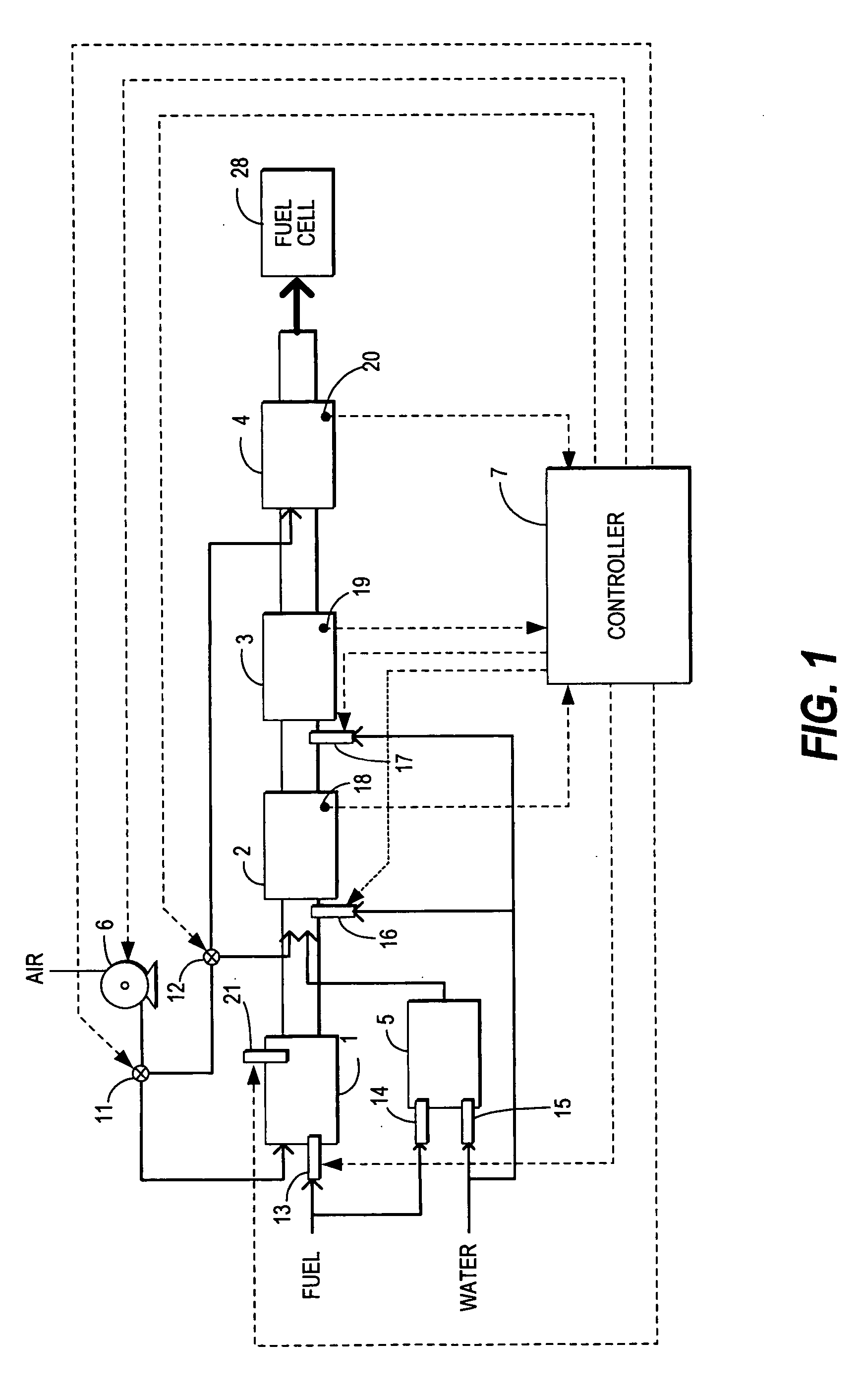

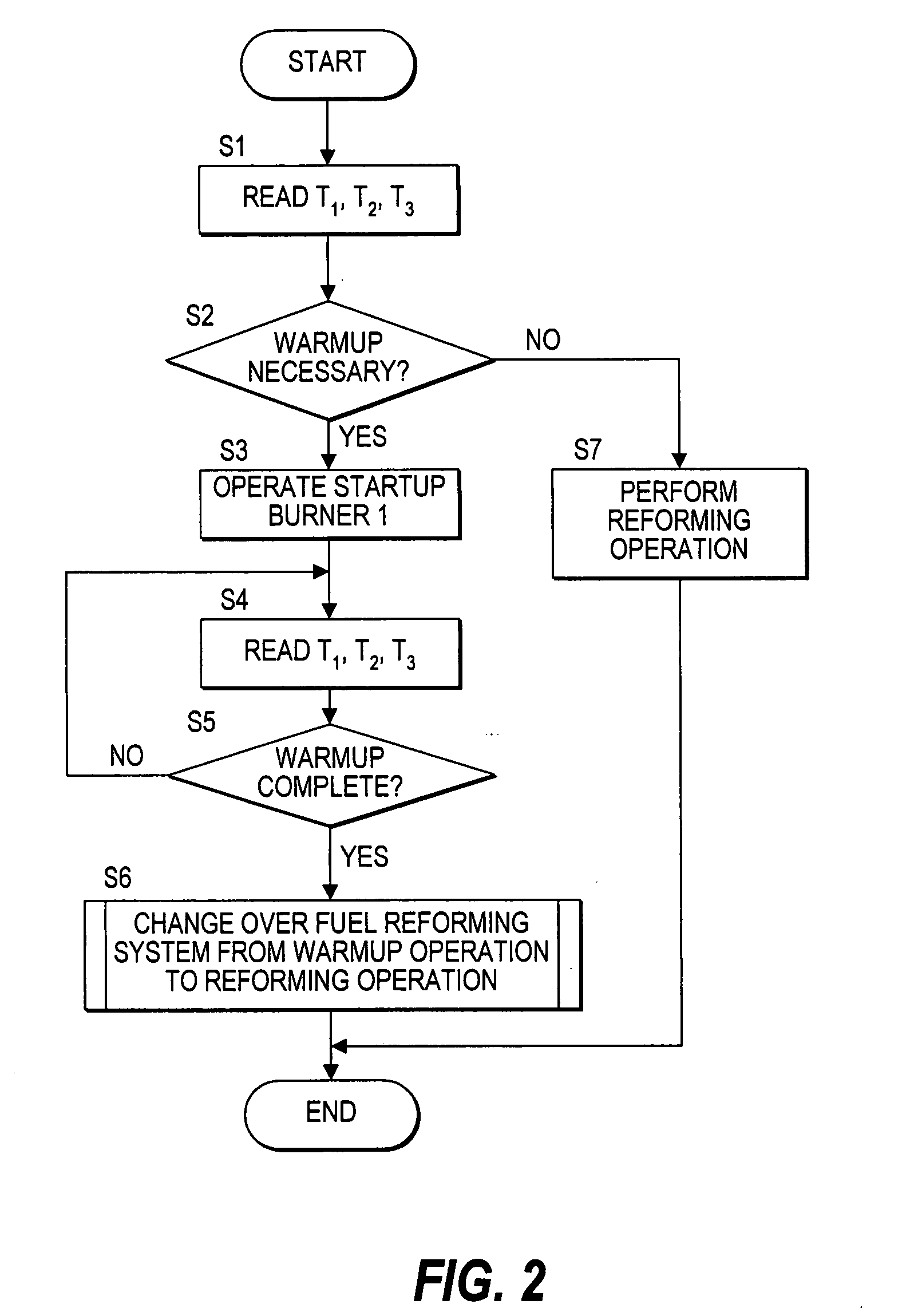

Fuel reforming system and fuel cell system having same

InactiveUS20050089732A1Process control/regulationFuel cell heat exchangeAutomotive engineeringLean combustion

A fuel reforming system, comprising a reformer (2, 3, 4) which produces reformate gas from rich raw fuel gas, and supplies the reformate gas to the fuel cell (28) during a reforming operation, a burner (1) which produces lean combustion gas, and supplies the lean combustion gas to the reformer (2, 3, 4) during a warmup operation of the reformer (2, 3, 4), and a nonflammable fluid supply apparatus which supplies a nonflammable fluid other than fuel and air to the reformer (2, 3, 4). During the warmup operation of the reformer (2, 3, 4), the lean combustion gas is supplied from the burner (1) to the reformer (2, 3, 4), and when warmup of the reformer (2, 3, 4) is complete, the nonflammable fluid is supplied from the nonflammable fluid supply apparatus to the reformer (2, 3, 4), and the reforming operation of the reformer (2, 3, 4) then starts.

Owner:NISSAN MOTOR CO LTD

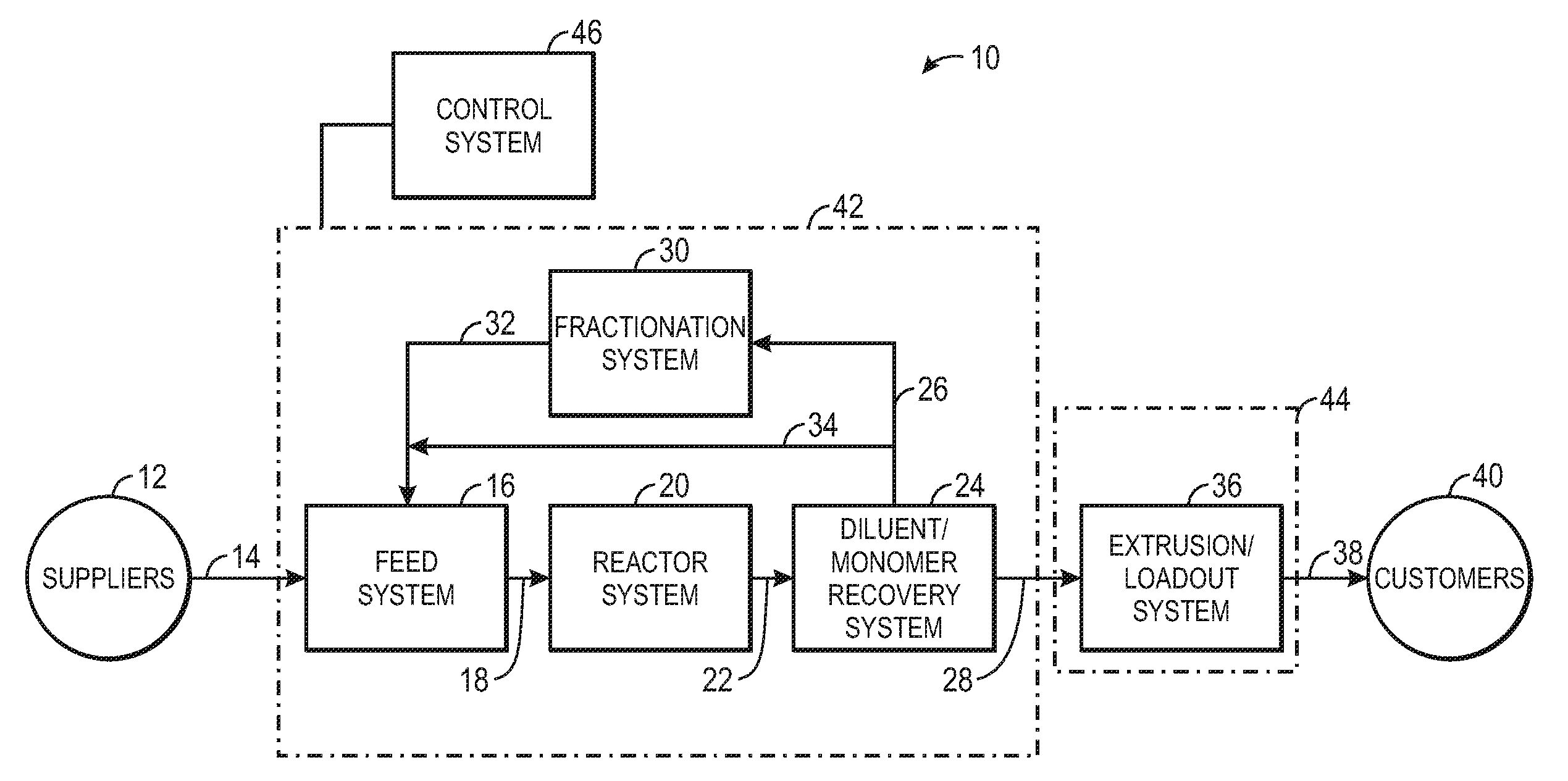

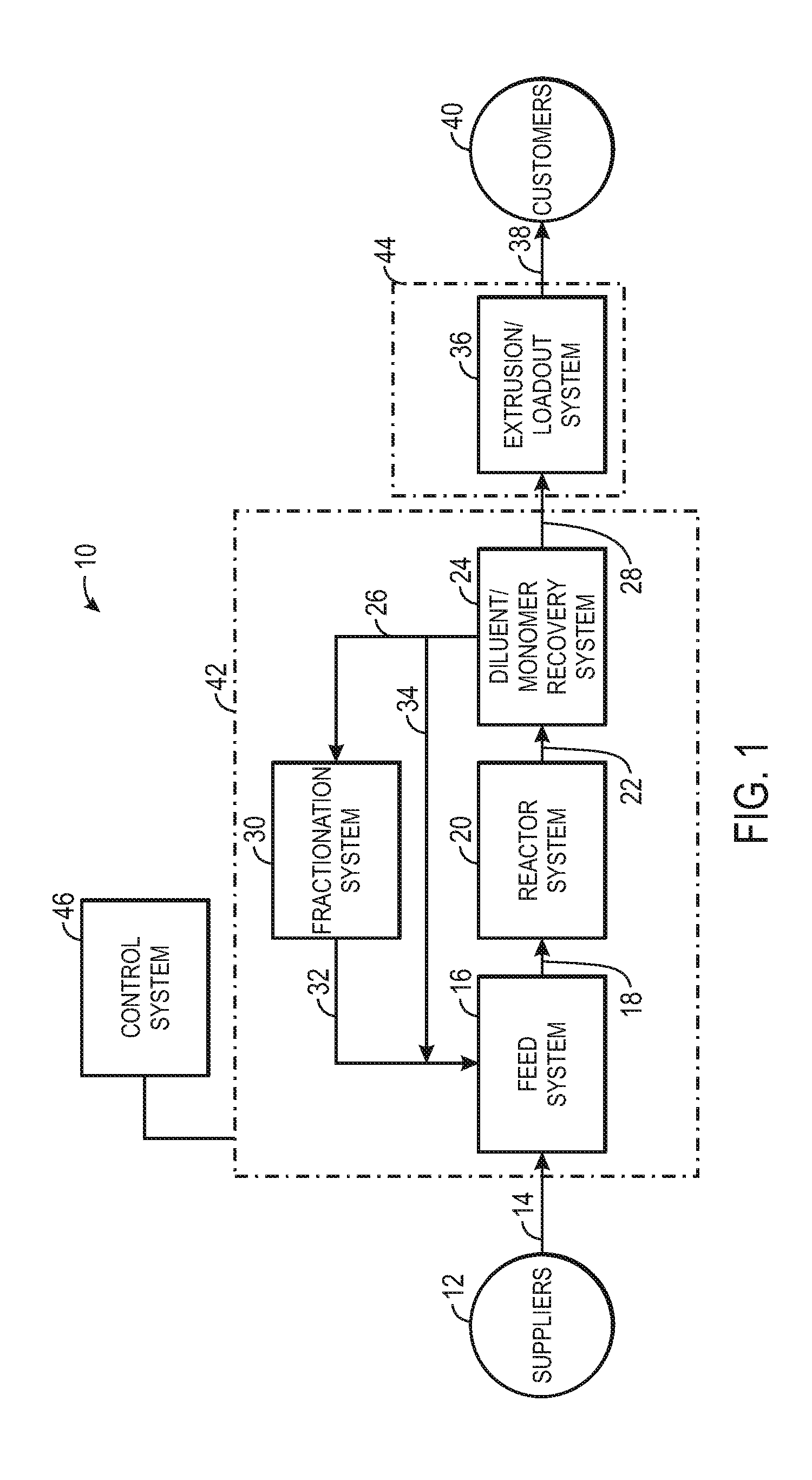

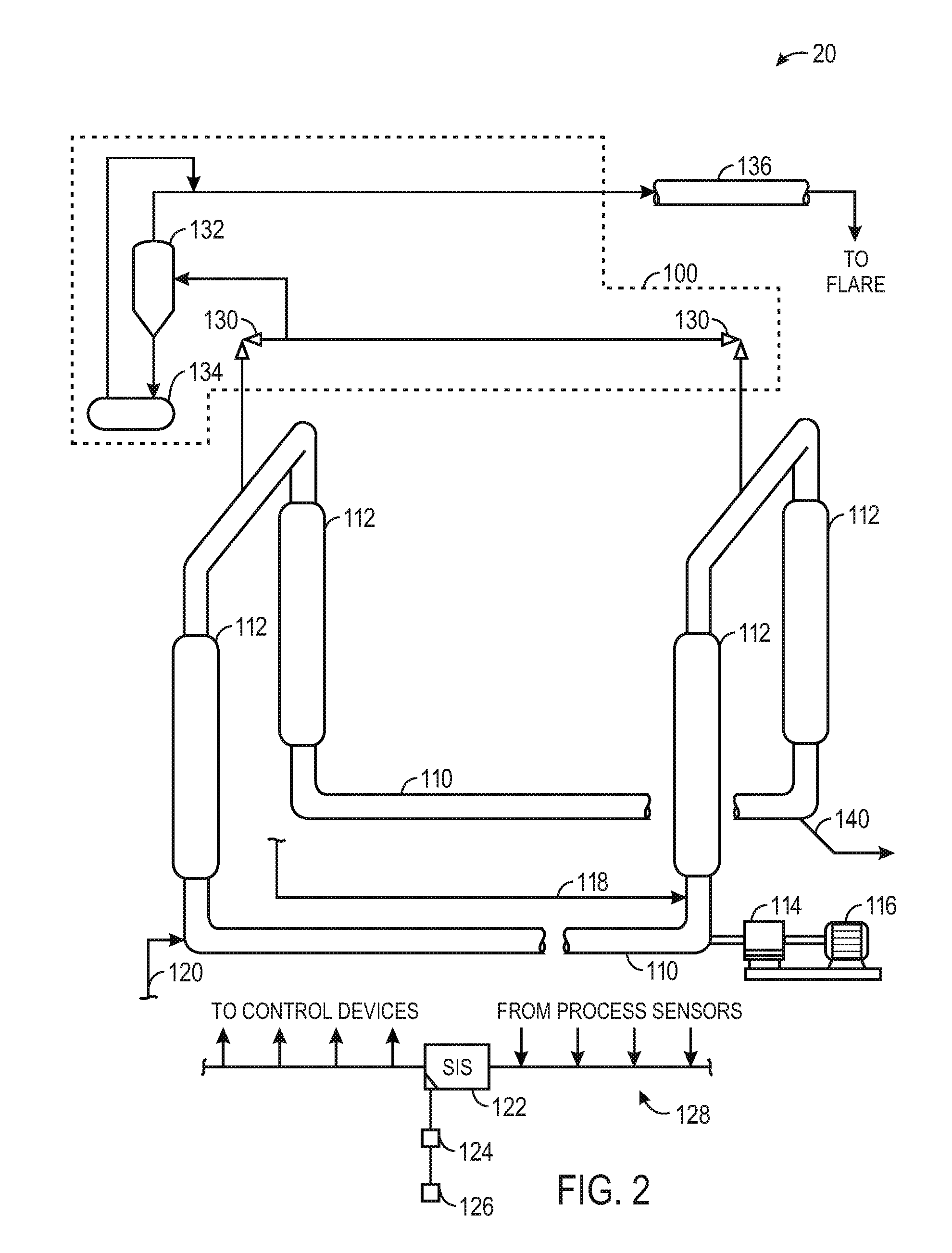

System and method for closed relief of a polyolefin loop reactor system

ActiveUS20110311014A1Process control/regulationEmergency protection arrangementsPolyolefinReactor system

A reactor system including an enclosed pressure relief system and / or a control system. The enclosed pressure relief system including a slurry separation system communicatively coupled with a pressure relief valve coupled to a loop reactor such that activation of the pressure relief valve results in discharge of a slurry from the loop reactor to the slurry separation system, wherein the slurry separation system is capable of separating solid and liquid components from gas components of the slurry and transmitting the gas components to a flare via a flare header.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

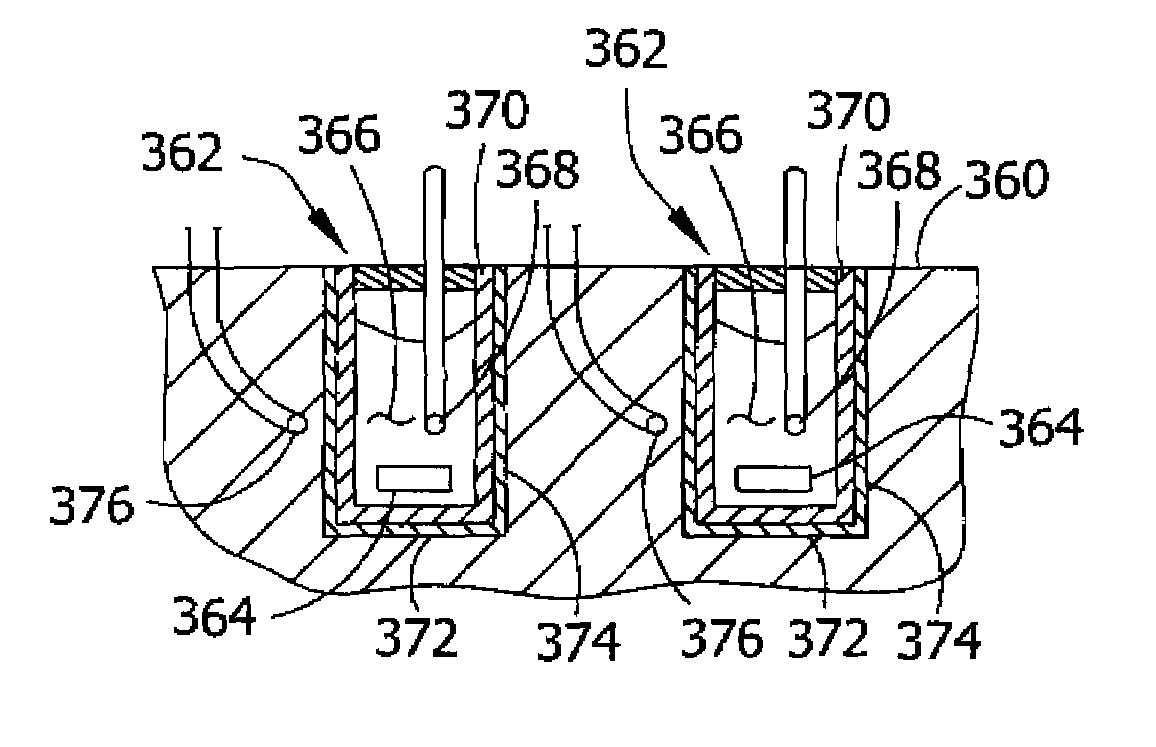

Parallel reactor with sensing of internal properties

InactiveUS7288229B2Minimize gas flowProcess control/regulationSequential/parallel process reactionsReaction rateAmbient pressure

An apparatus and method for carrying out and monitoring the progress and properties of multiple reactions is disclosed. The method and apparatus are especially useful for synthesizing, screening, and characterizing combinatorial libraries, but also offer significant advantages over conventional experimental reactors as well. The apparatus generally includes multiple vessels for containing reaction mixtures, and systems for controlling the stirring rate and temperature of individual reaction mixtures or groups of reaction mixtures. In addition, the apparatus may include provisions for independently controlling pressure in each vessel, and a system for injecting liquids into the vessels at a pressure different than ambient pressure. In situ monitoring of individual reaction mixtures provides feedback for process controllers, and also provides data for determining reaction rates, product yields, and various properties of the reaction products, including viscosity and molecular weight.

Owner:UNCHAINED LABS

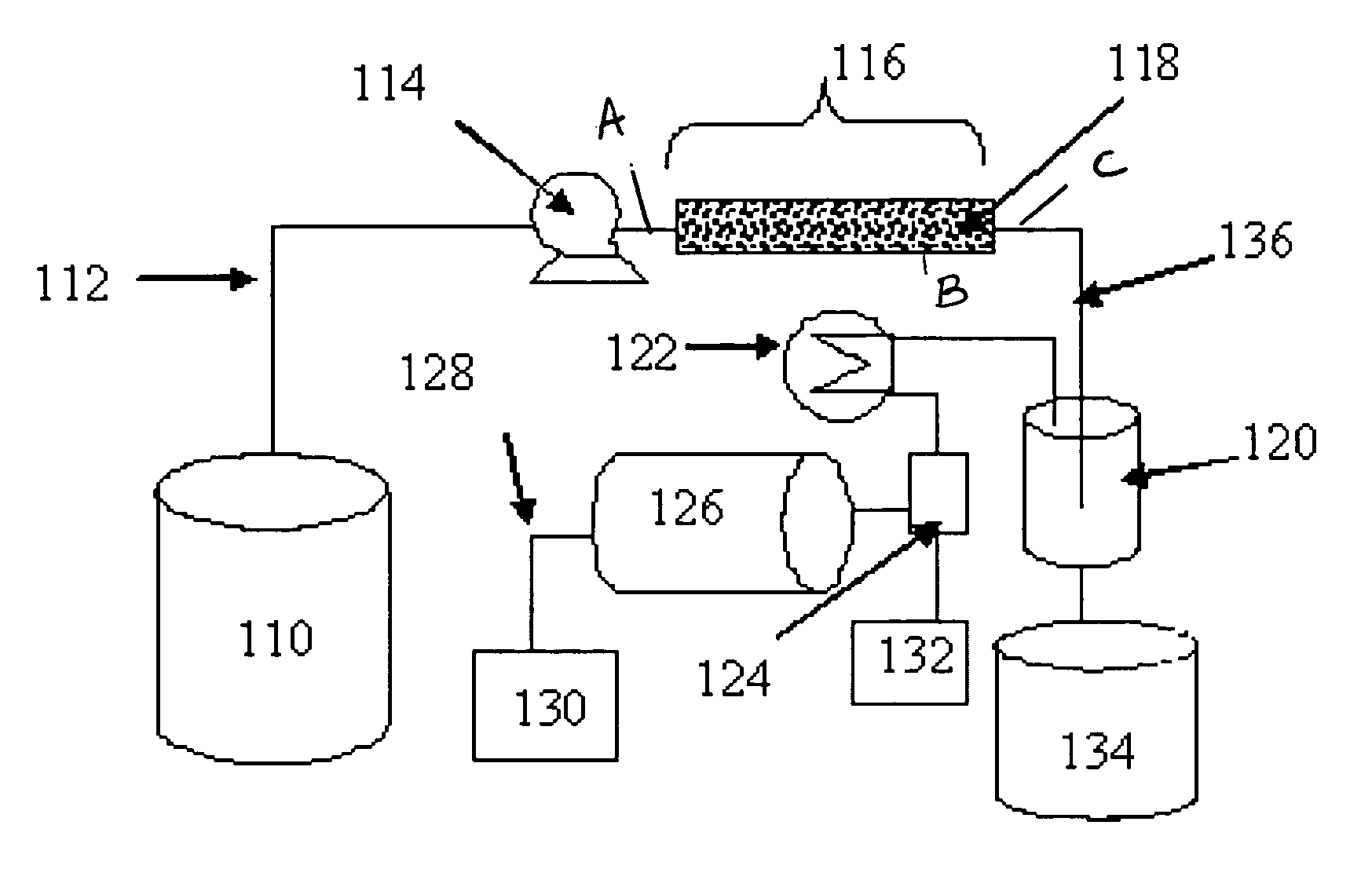

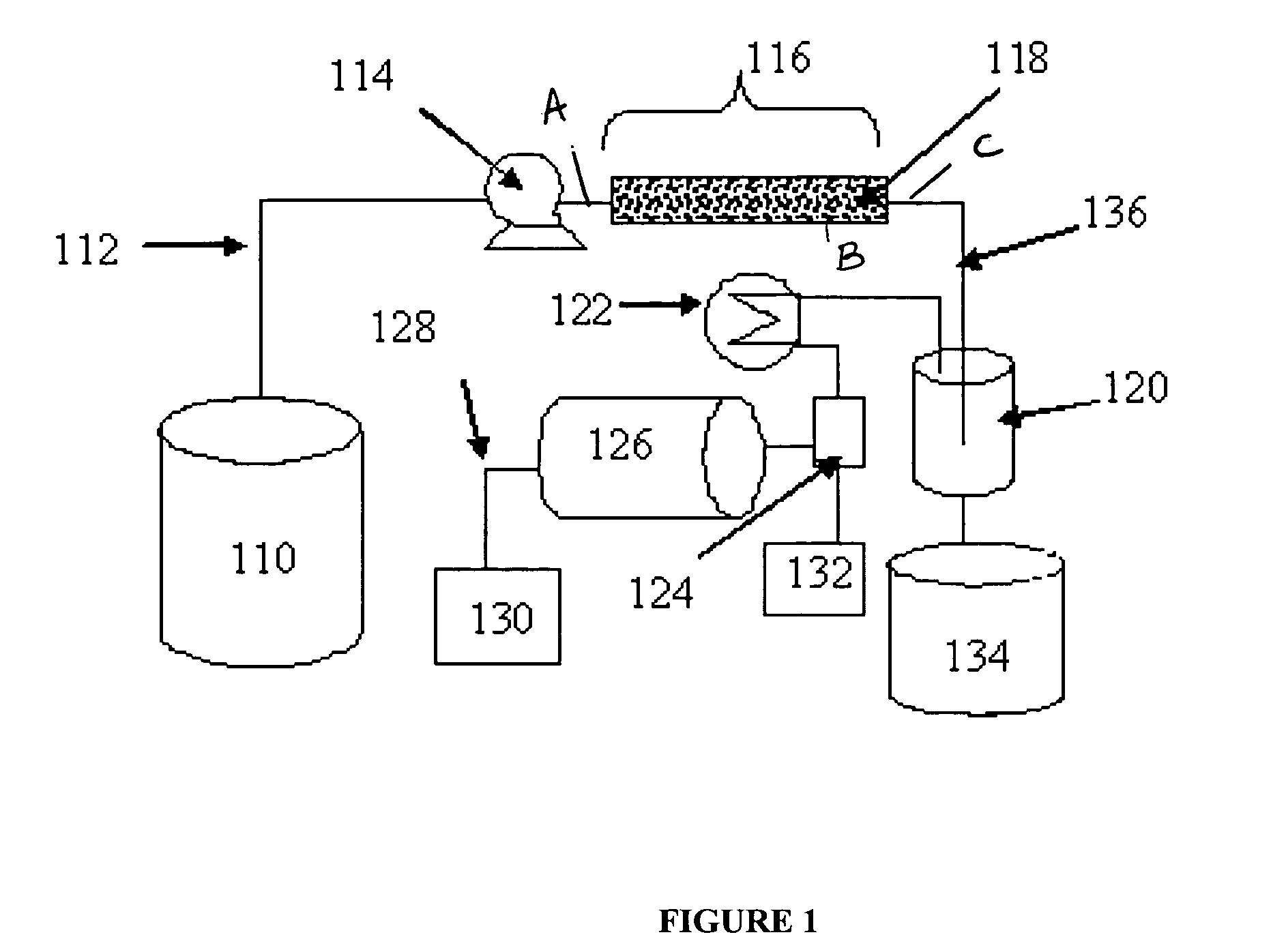

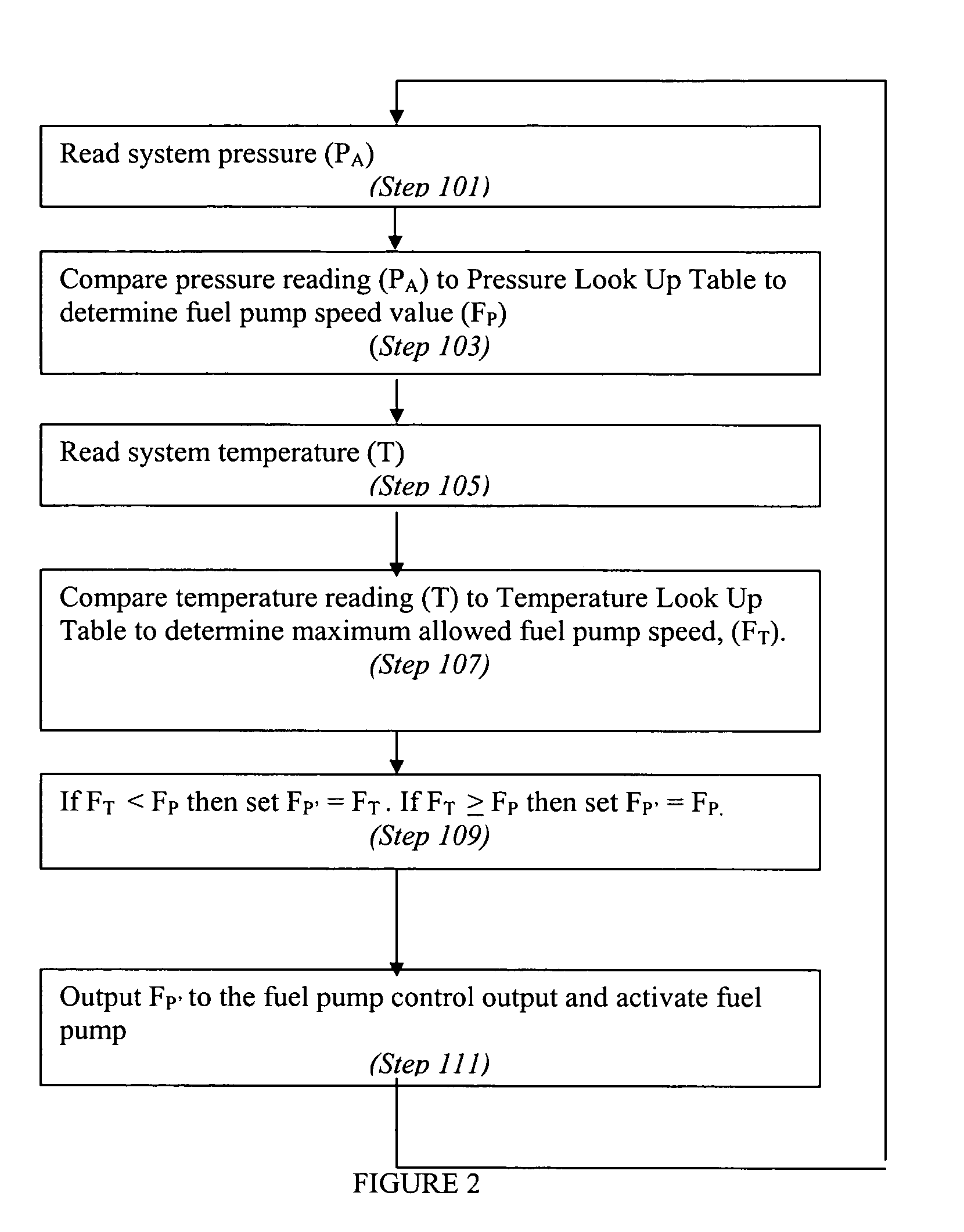

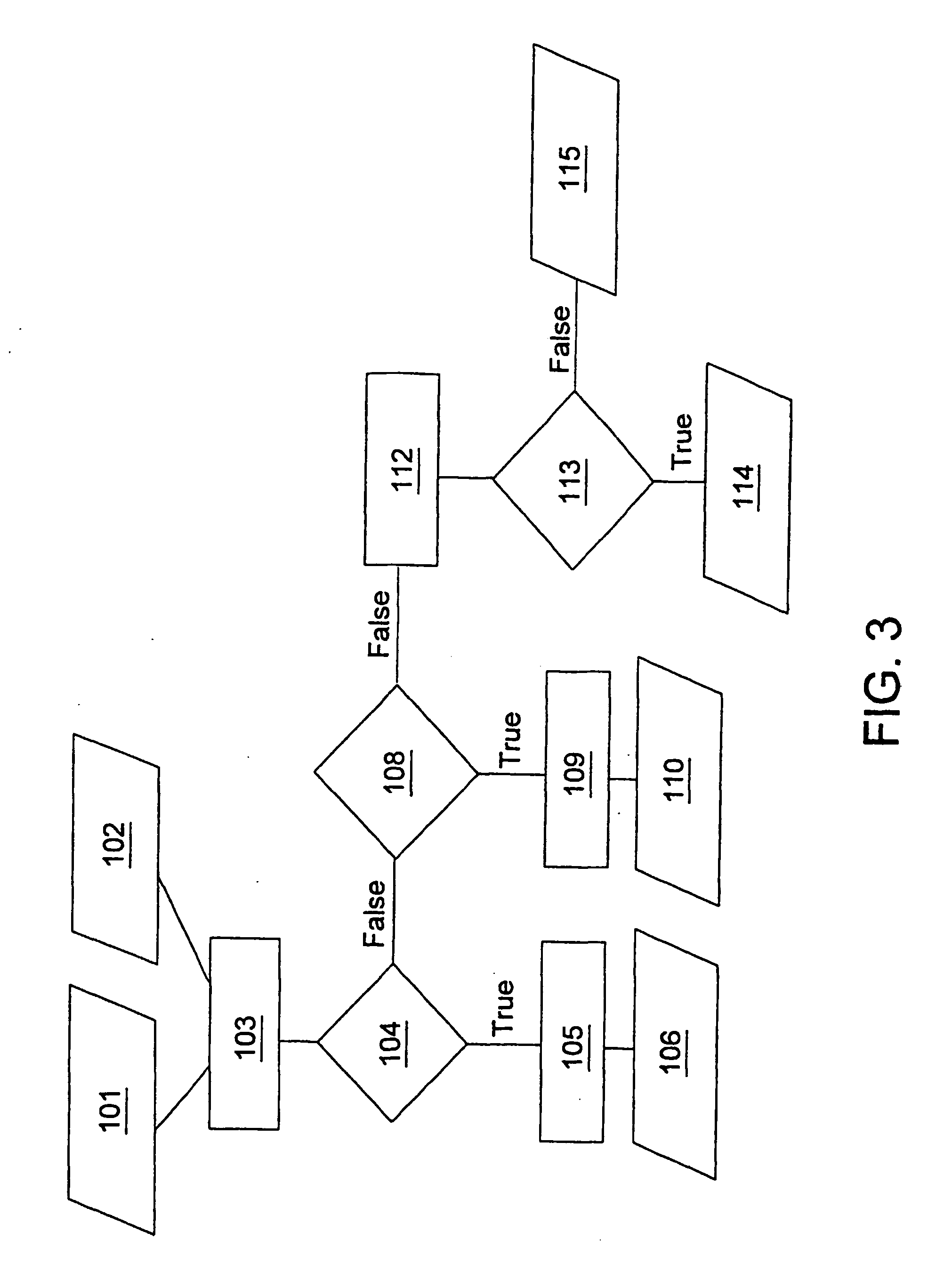

Systems and methods for controlling hydrogen generation

Systems and methods are disclosed for monitoring at least two system parameters (such as system temperature or pressure, or system pressure at two different locations) of a hydrogen generation system and controlling hydrogen generation from a fuel solution. The system comprises a hydrogen generator having a fuel chamber for a liquid fuel, a reactor chamber where the fuel undergoes a reaction to produce hydrogen, and at least two sensors in communication with the reactor chamber, the sensors measuring at least two system parameters of the hydrogen generator. The methods include control sequences for controlling the fuel flow rate to the reactor based on the sensed parameters.

Owner:MILLENNIUM CELL

Feedstock delivery system and fuel processing systems containing the same

Feedstock delivery systems for fuel processors, and fuel processing systems incorporating the same. In some embodiments, the feedstock delivery system includes at least one pressurized tank or other reservoir that is adapted to store in liquid form a feedstock for a fuel processor. The delivery system further includes a pressurization assembly that is adapted to pressurize the reservoir by delivering a stream of pressurized gas thereto. In some embodiments, the gas is at least substantially comprised of nitrogen or other inert gases. In some embodiments, the gas is a nitrogen-enriched or a reduced-oxygen air stream. In some embodiments, the delivery system includes a sensor assembly that is adapted to monitor the concentration of oxygen in, and / or being delivered to, the reservoir(s). In some embodiments, the delivery system includes a pumpless delivery system that regulates the delivery under pressure of the feedstock from the tank to the fuel processor.

Owner:IDATECH LLC

Monitoring and controlling unit operations

InactiveUS20070017291A1Efficiently sensingEffective monitoringProcess control/regulationAnalysing solids using sonic/ultrasonic/infrasonic wavesDistillationUnit operation

Fluid sensor methods and systems adapted for monitoring and / or controlling distillation operations in fluidic systems, such as batch distillation operations or continuous distillation operations, are disclosed. Preferred embodiments are directed to process monitoring and / or process control for unit operations involving endpoint determination of a distillation, for example, as applied to a liquid-component-switching operation (e.g., a solvent switching operation), a liquid-liquid separation operation, a solute concentration operation, a dispersed-phase concentration operation, among others.

Owner:MEAS FRANCE

Process For Production of Carbon Black

InactiveUS20080226538A1Increase flexibilityLow costProcess control/regulationPigmenting treatmentCombustorProcess engineering

Off-gas from a carbon black furnace is employed as a combustion gas feed stream to the burner or combustion zone of the same or a different carbon black furnace in accordance with certain embodiments, suitable conduit and valving is provided to pass off-gas, from which carbon black has been substantially removed, from any and all of multiple different carbon black furnaces to the burner. The off-gas is heated, preferably by plasma heating, and dewatered. Carbon dioxide stripping or rather stripping of gas components from the dewatered heated off-gas is found to be unnecessary to achieve economically favorable use of off-gas recirculation.

Owner:CABOT CORP

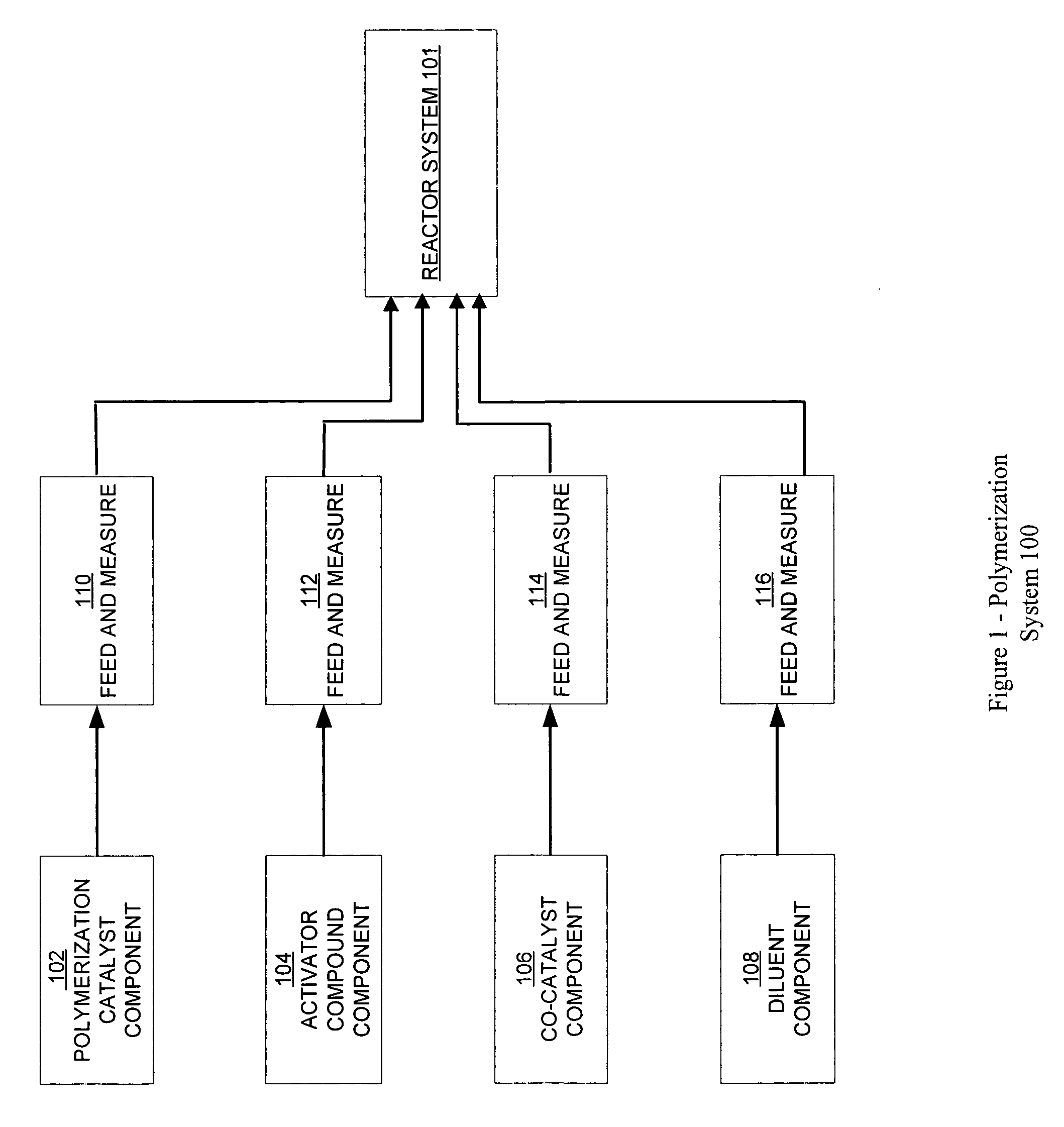

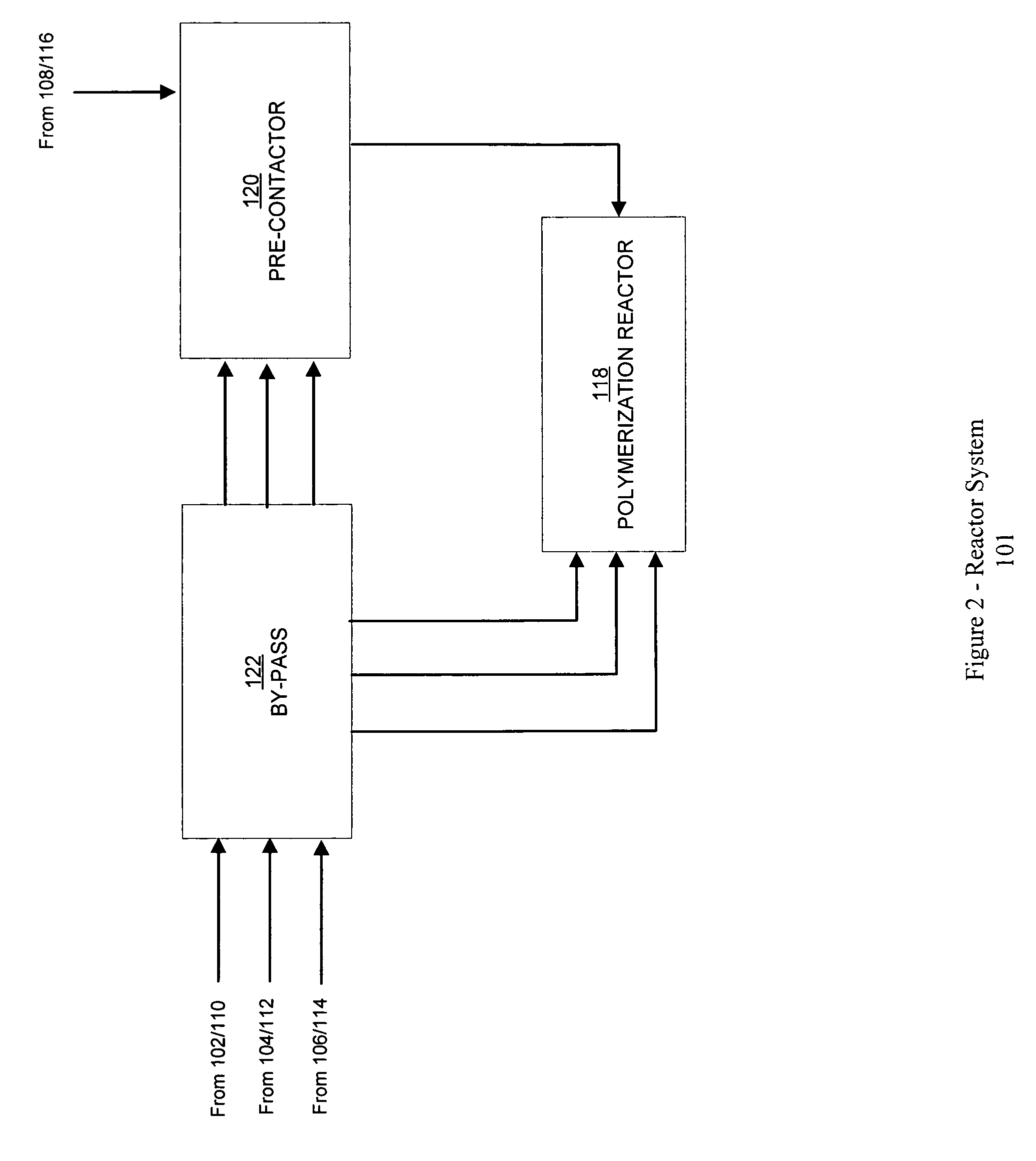

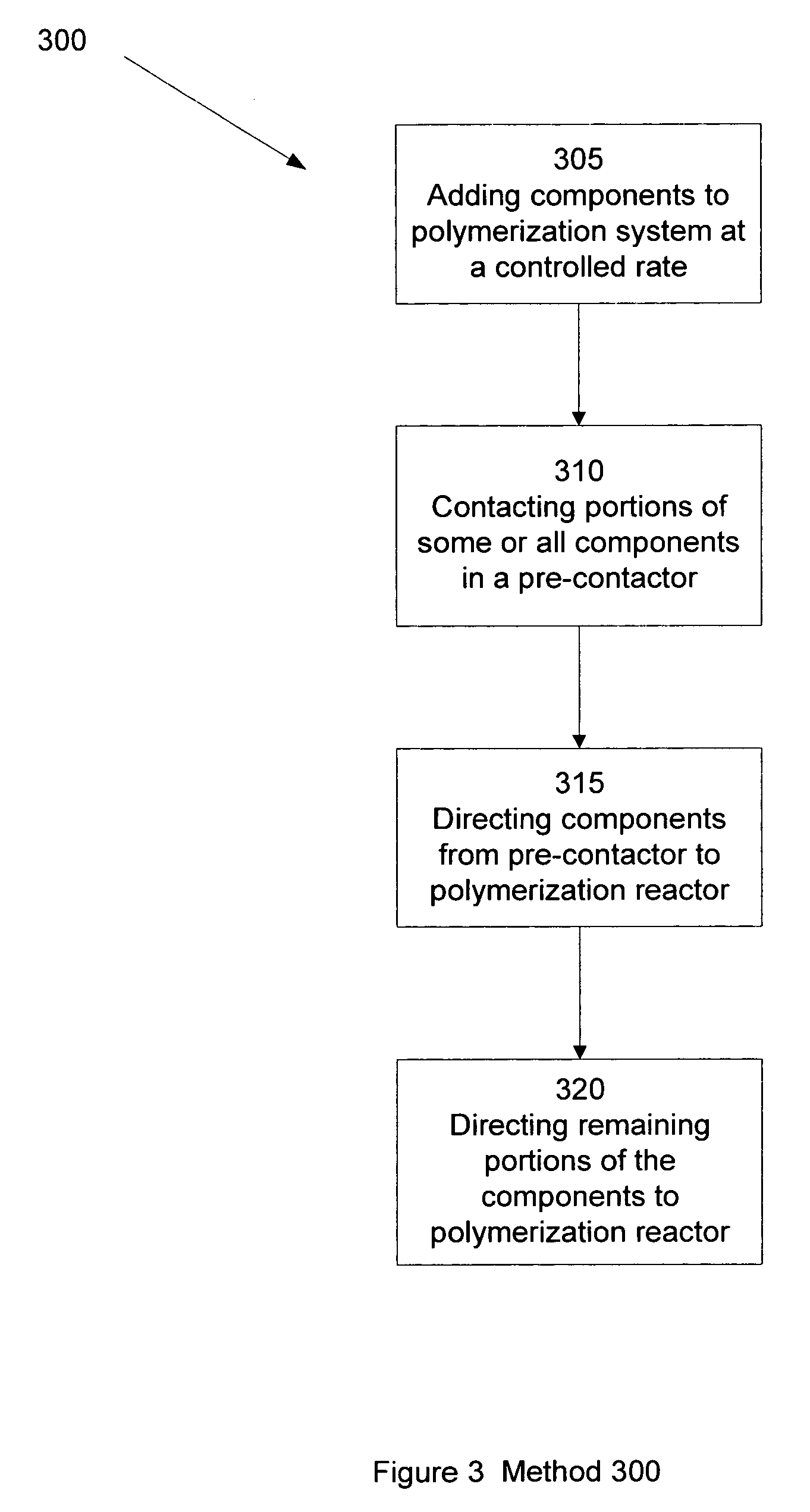

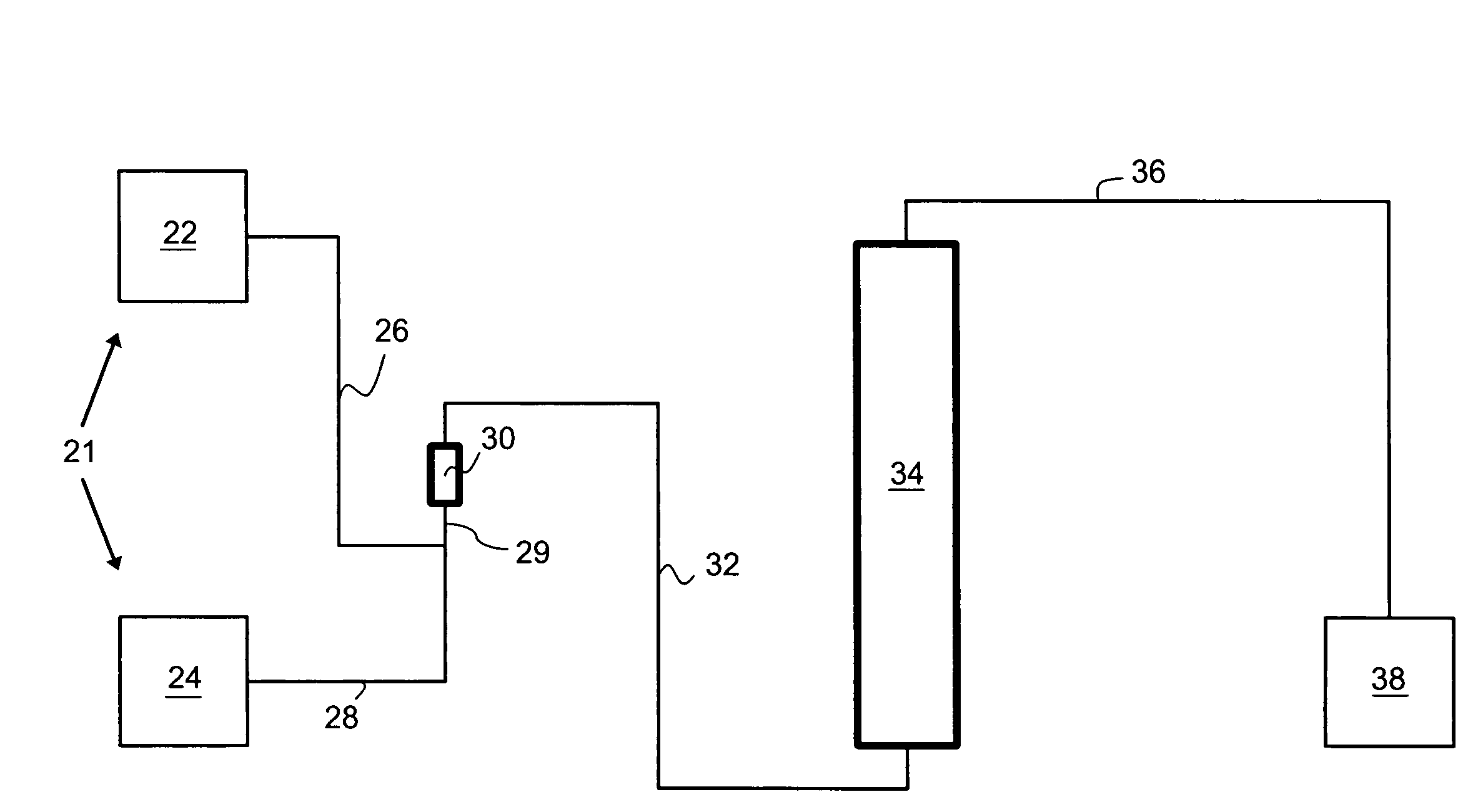

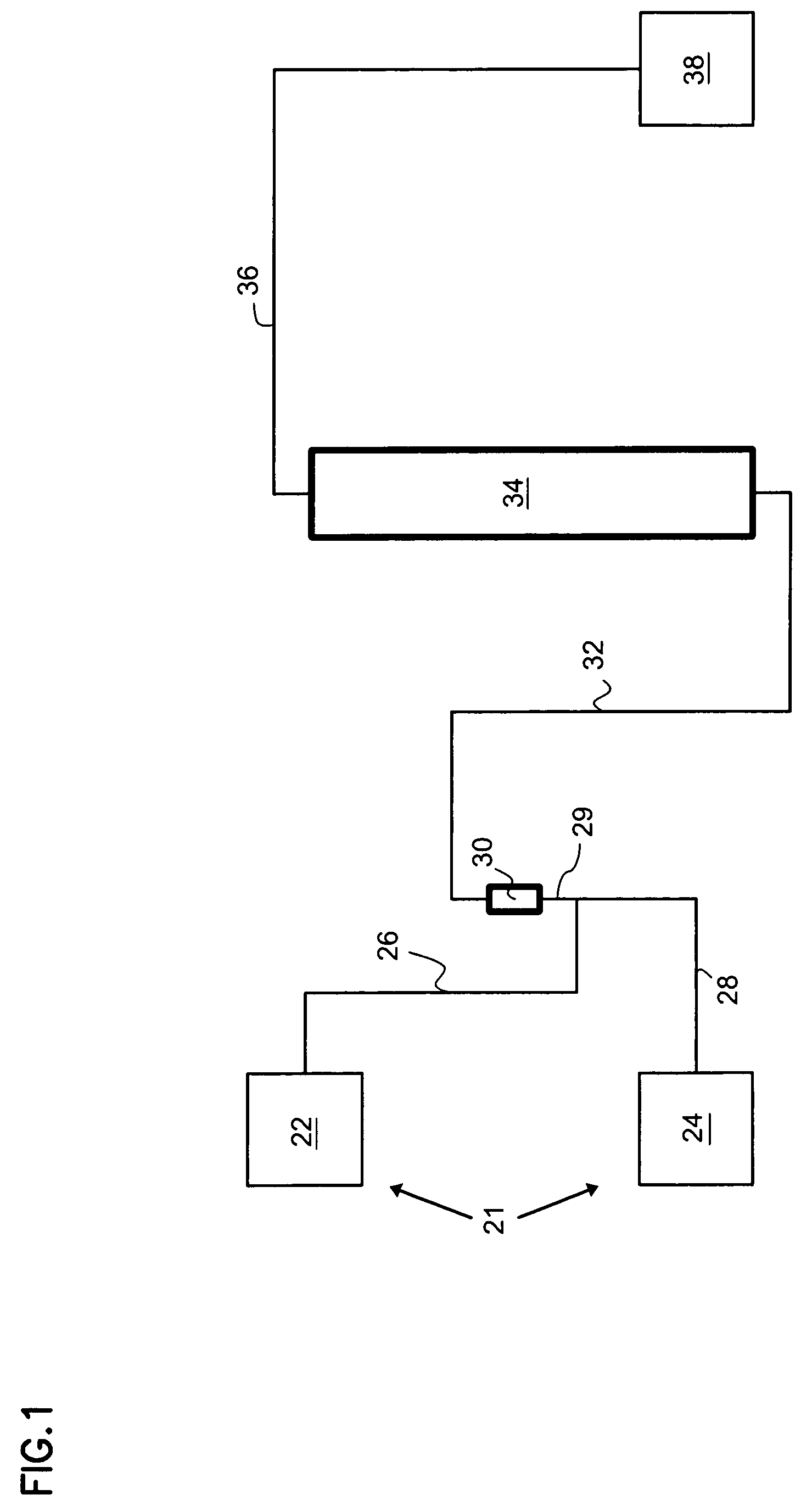

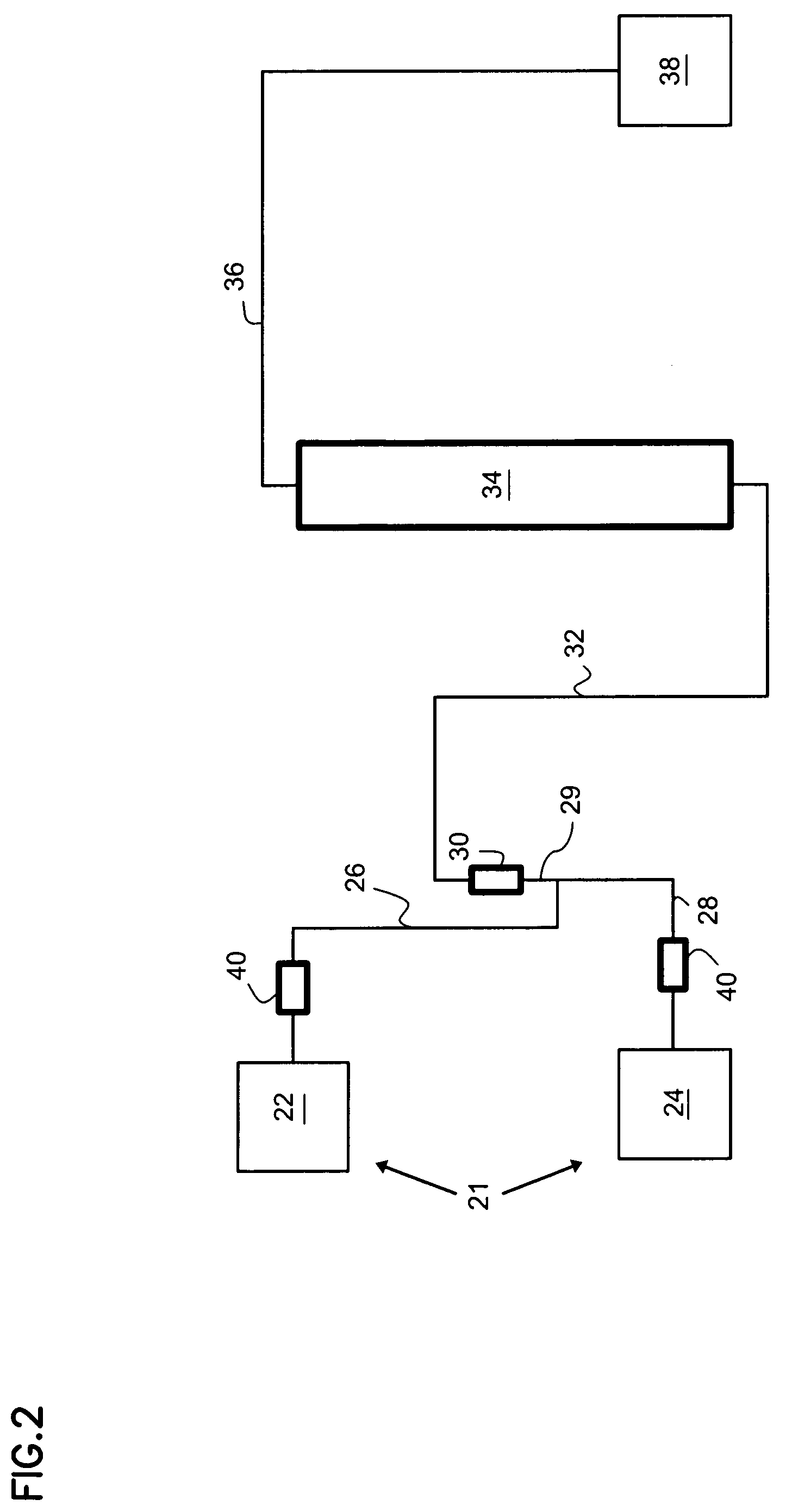

Multiple component feed methods and systems

Multiple components are selected, conveyed, and measured in a polymerization system. A control system adjusts the system variables to the desired values. Portions of the components can be fed to a pre-contactor before introduction into the polymerization reactor. The catalyst component concentrations and residence times are tightly controlled in the pre-contactor to affect product properties. The pre-contactor can be a single or multiple combinations of a CSTR or plug flow pre-contactors.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Apparatus and method for making a peroxycarboxylic acid

ActiveUS7547421B2Increase life and activity and safetyProcess control/regulationExhaust apparatusCarboxylic acidReagent

Owner:ECOLAB USA INC

Systems and methods for reactor and receiver control of flux profile

InactiveUS20100242352A1Improve availabilityProcess control/regulationSolar heating energyChemical reactionChemical reactor

A method, apparatus, and system for a solar-driven chemical reactor are disclosed, including a solar thermal receiver aligned to absorb concentrated solar energy. Some embodiments include a solar driven chemical reactor that has multiple reactor tubes. Some embodiments include one of 1) one or more apertures open to an atmosphere of the Earth or 2) one or more windows, to pass the concentrated solar energy into the solar thermal receiver. This energy impinges on the multiple reactor tubes and cavity walls of the receiver and transfer energy by solar radiation absorption and heat radiation, convection, and conduction. In this way, the energy causes reacting particles to drive the endothermic chemical reaction flowing in the reactor tubes. The design of the multiple reactor tubes and solar thermal receiver can be adapted per a solar flux profile to take advantage of variations in the concentrations of solar flux in the profile.

Owner:SUNDROP FUELS

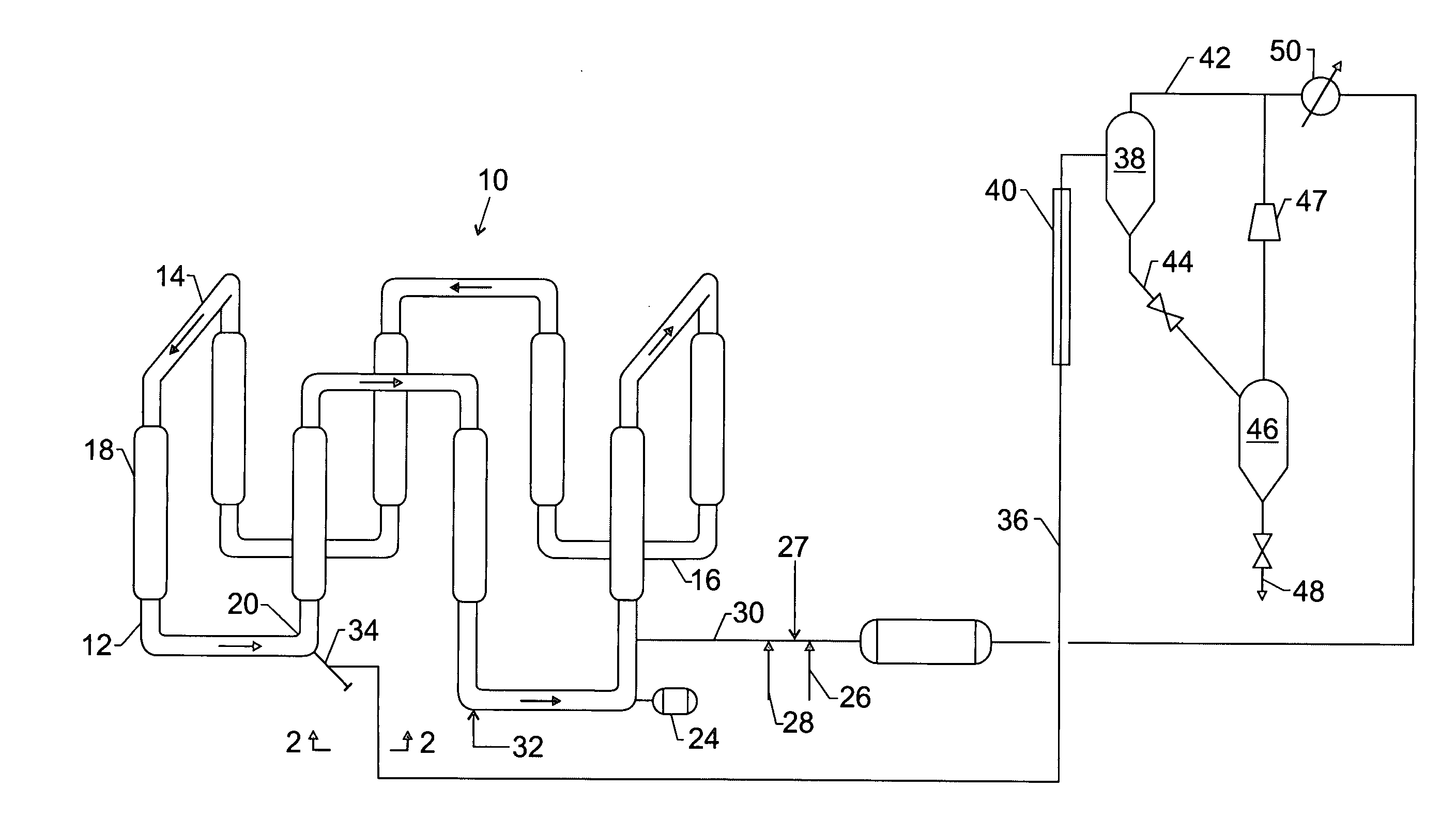

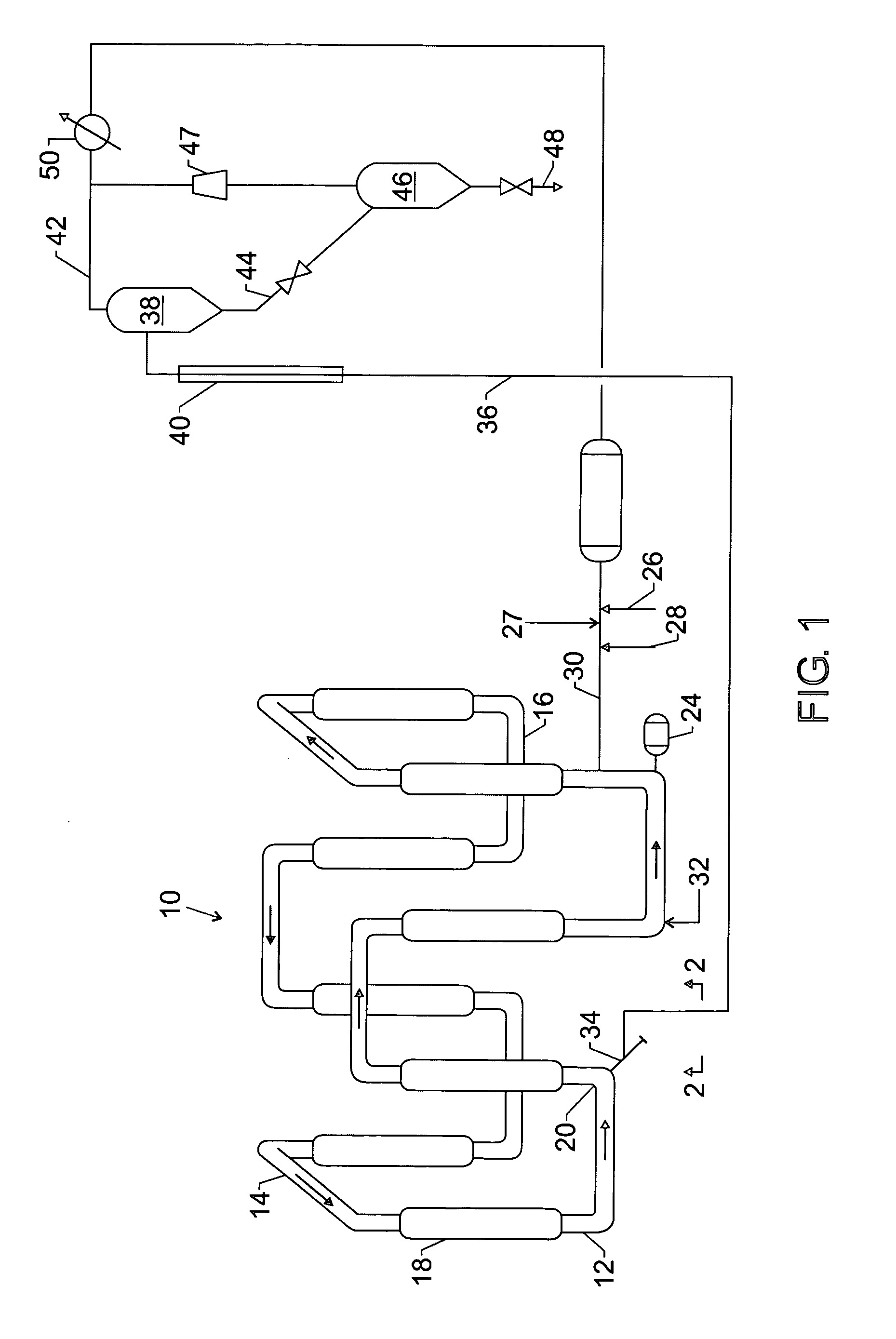

Processes And Apparatus For Continuous Solution Polymerization

InactiveUS20110172375A1Process control/regulationCleaning heat-transfer devicesHydrocarbon solventsThree stage

Described herein in one embodiment is a plant for the continuous solution polymerization of one or more monomers in a solvent, e.g., a hydrocarbon solvent. In one aspect, the plant comprises a high pressure pump and at least one heat exchanger downstream of the pump. In another aspect a feed is cooled by three heat exchangers which are refrigerated by means of a common three stage compressor. In another aspect, the plant comprises a primary reactor and a secondary reactor arranged to operate in parallel, in which the ratio of volume of the primary reactor to the secondary reactor is in the range of 60:40 to 95:5. In another aspect, a method of defouling a heat exchanger is provided in which the level of liquid refrigerant in the heat exchanger is temporarily lowered.

Owner:EXXONMOBIL CHEM PAT INC

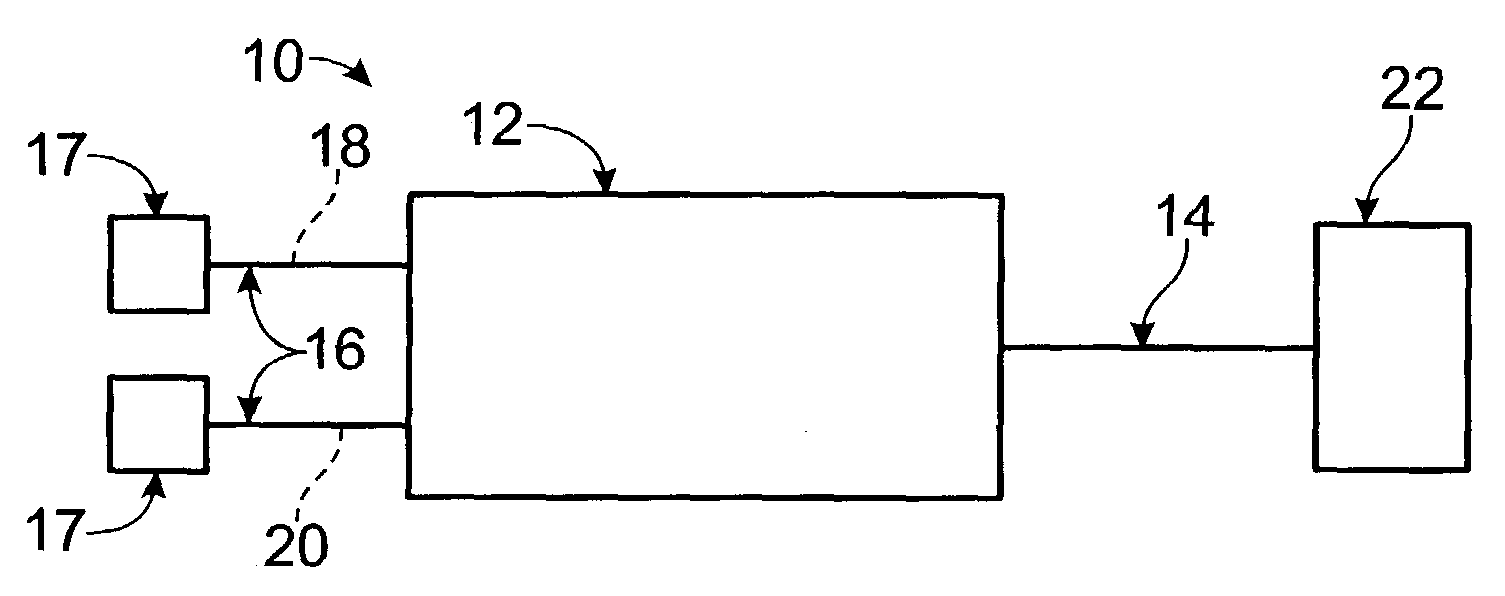

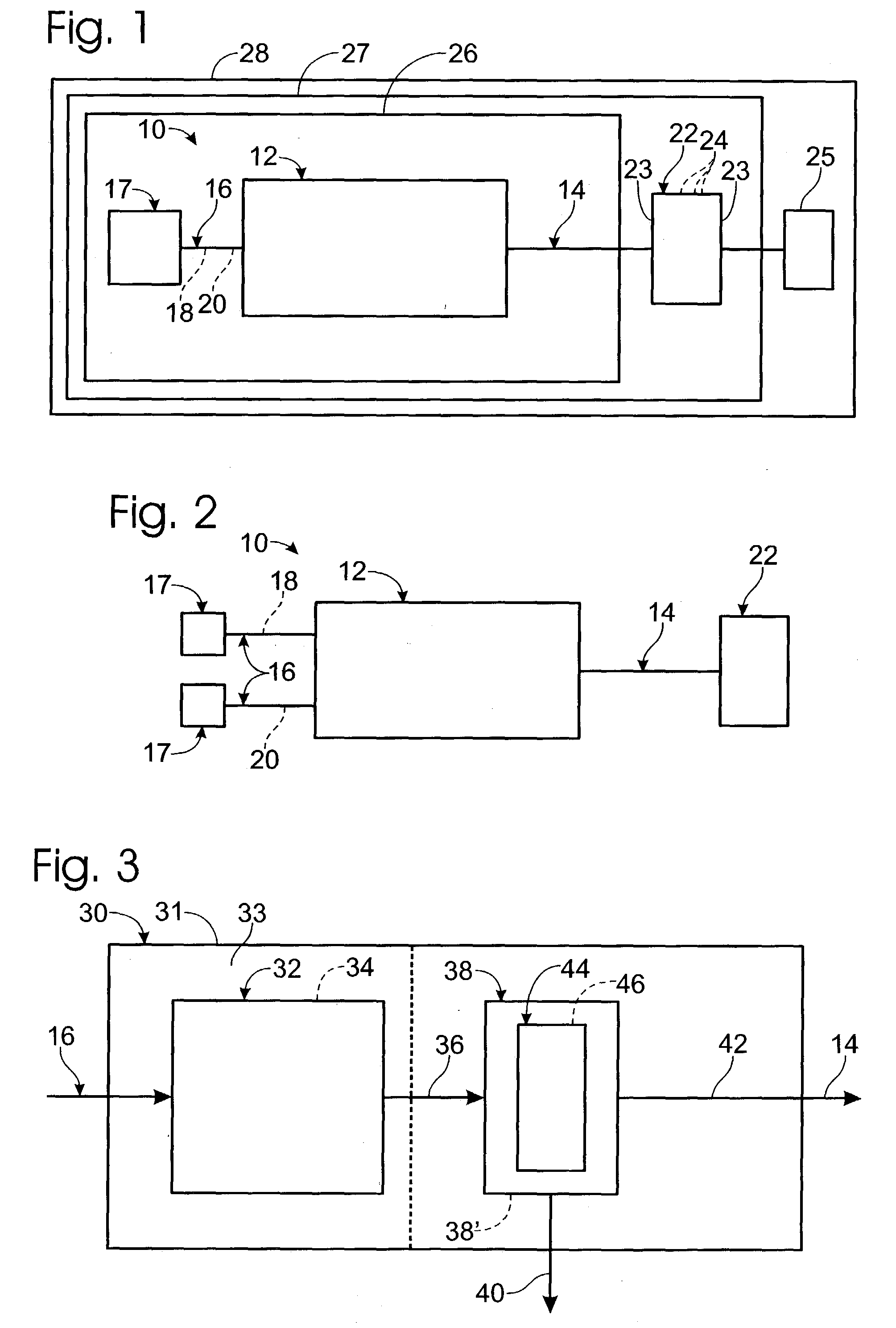

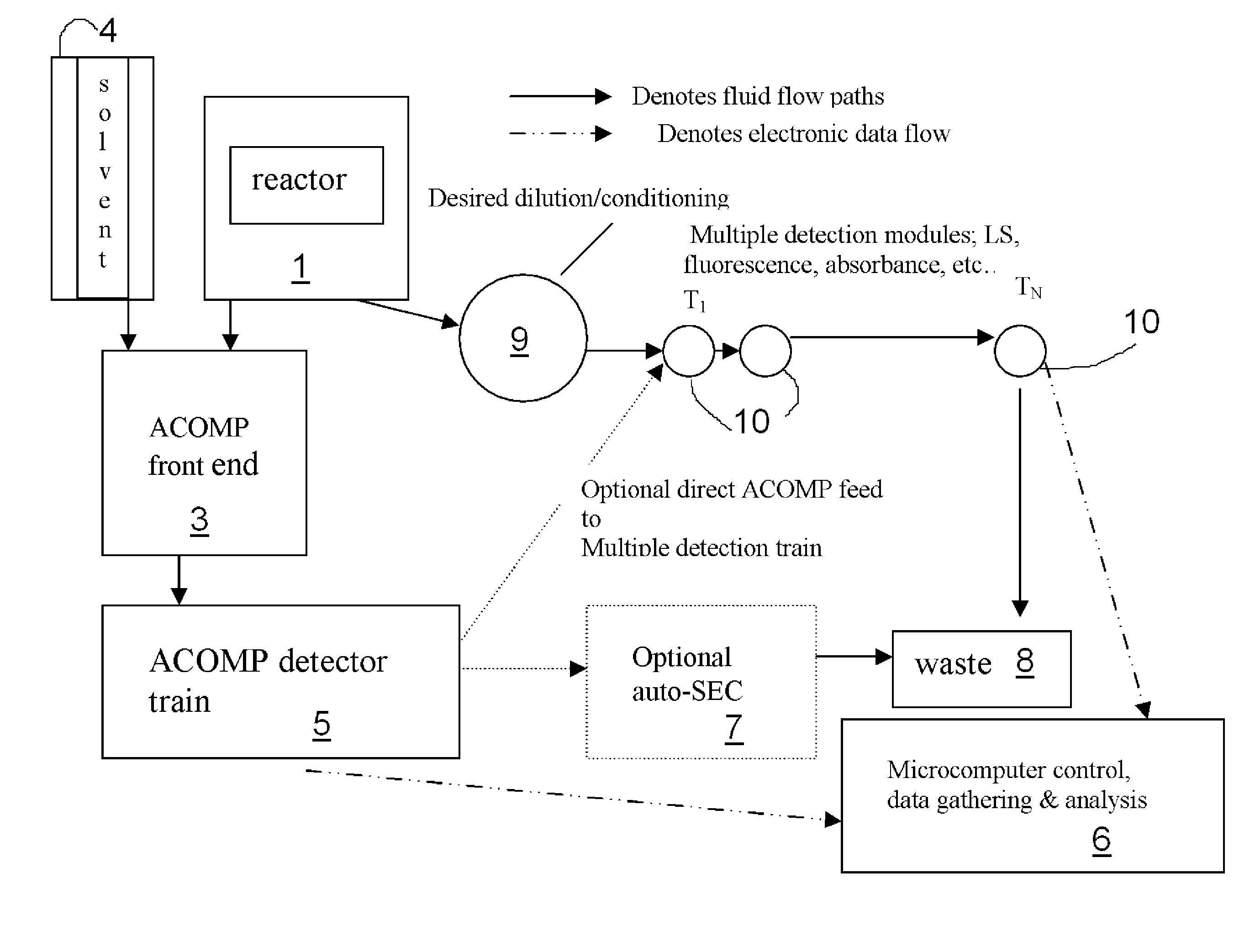

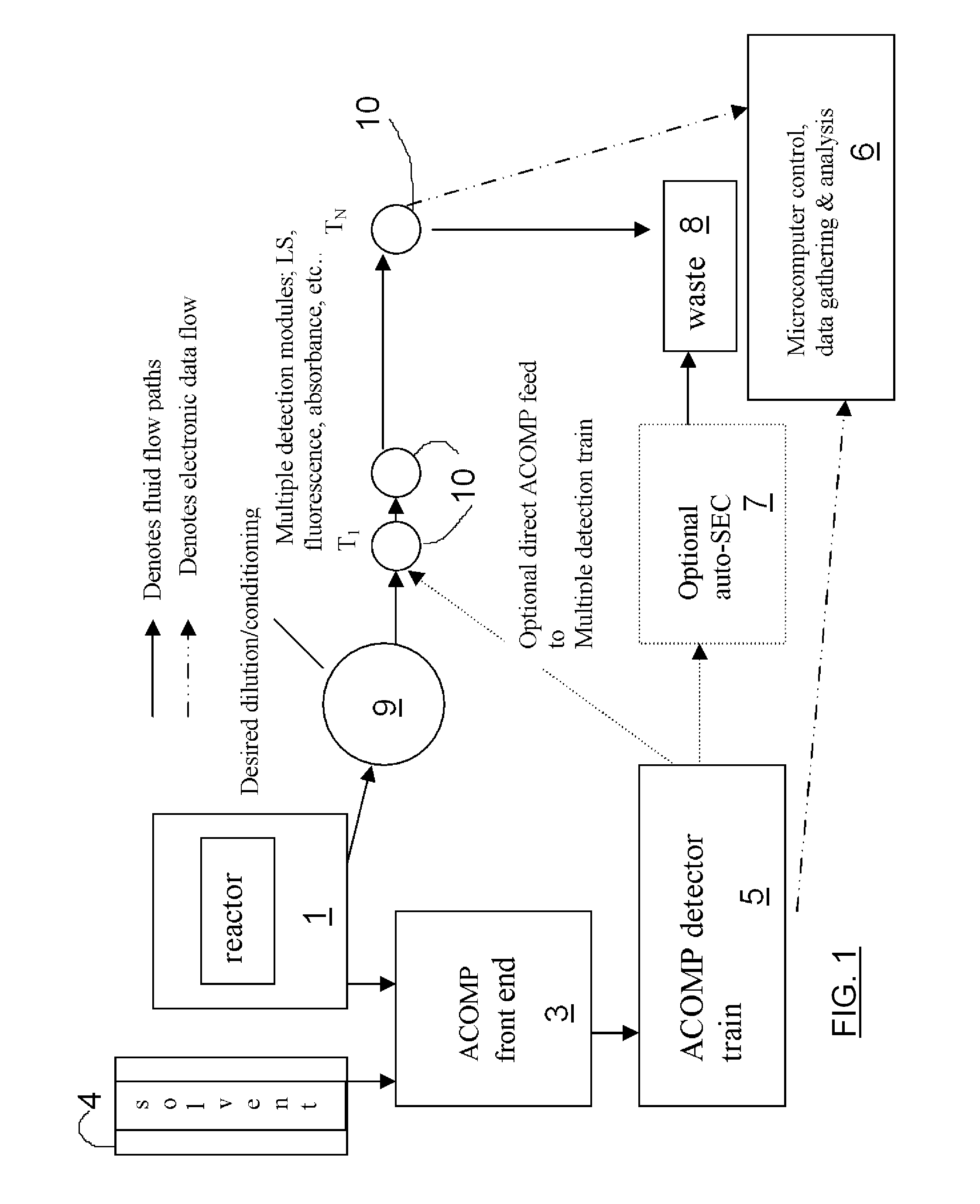

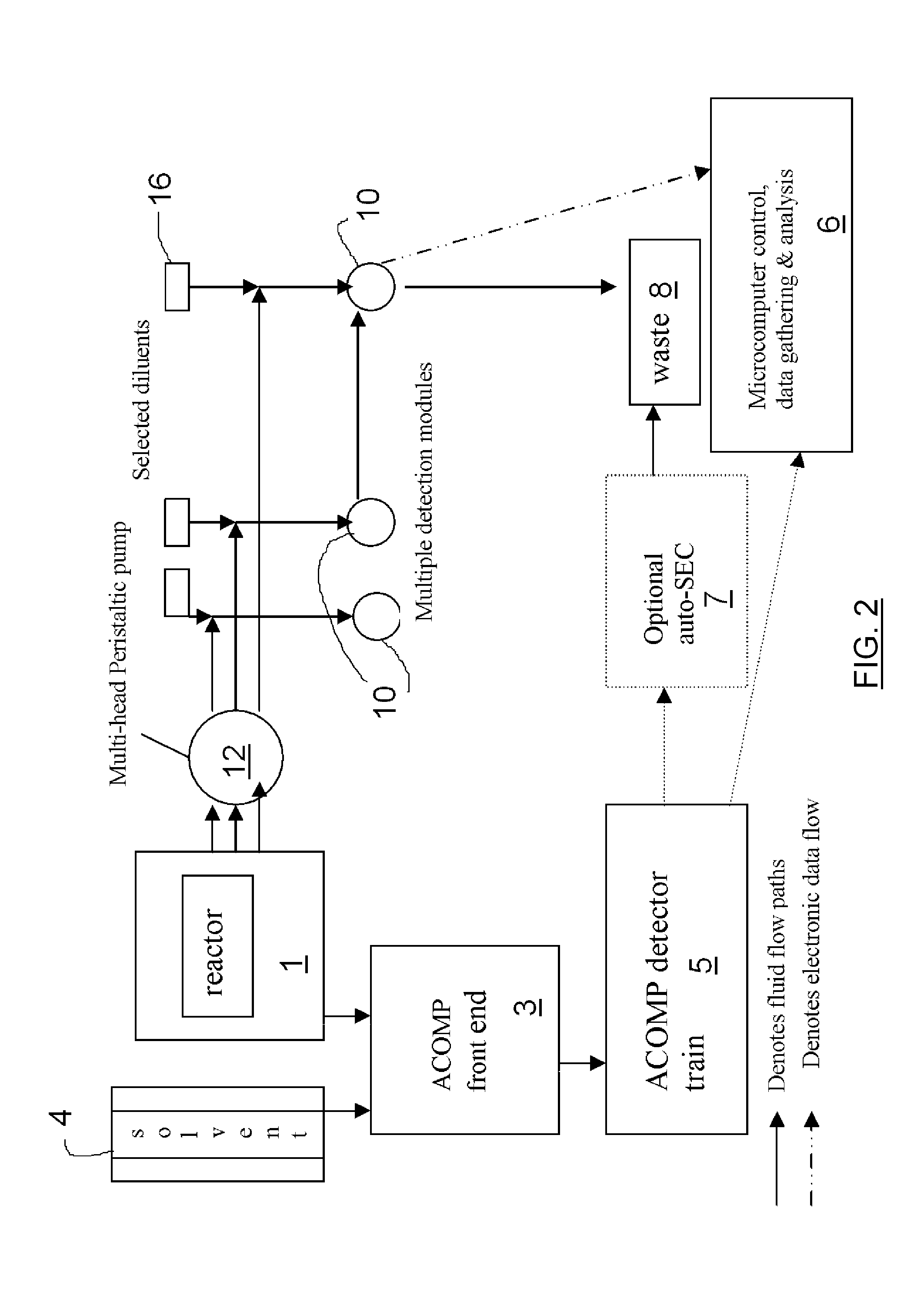

Methods and instrumentation for during-synthesis monitoring of polymer functional evolution

InactiveUS20090306311A1Improve throughputWide range of monitoringProcess control/regulationComponent separationFunctional evolutionColloid

A method of monitoring the evolution of polymer and / or colloid stimuli responsiveness during synthesis of polymers and / or colloids, including postpolymerization modifications on natural and synthetic polymers, includes providing a reactor in which the polymers and / or colloids are synthesized; and providing a means of monitoring the stimuli responsiveness of the polymers and / or colloids during said synthesis. Preferably, the method also includes monitoring the evolution of the characteristics of the polymers and / or colloids during said synthesis. Preferably, evolution of polymer and / or colloid stimuli responsiveness is correlated to the evolution of the properties of the polymers and / or colloids themselves. Also, preferably the conditions of the fluid in the reactor in which the synthesis occurs is determined. The determination can be by detection, choice of materials and temperature conditions, for example, and combinations thereof. The method and instrumentation disclosed can lead to optimization and control of processes and synthetic and modification strategies leading to polymers and colloids with desired stimuli responsiveness.

Owner:TULANE EDUCATIONAL FUND

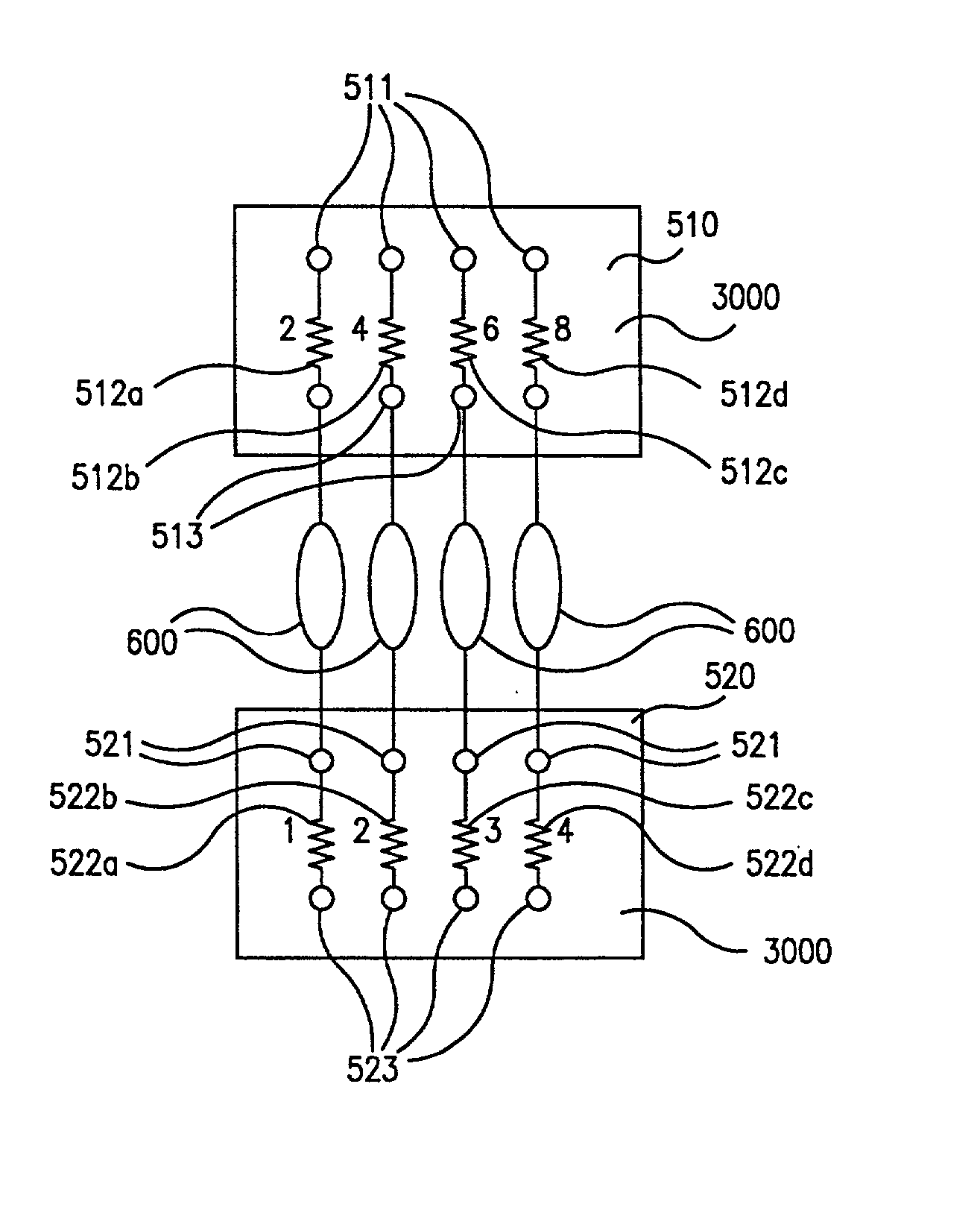

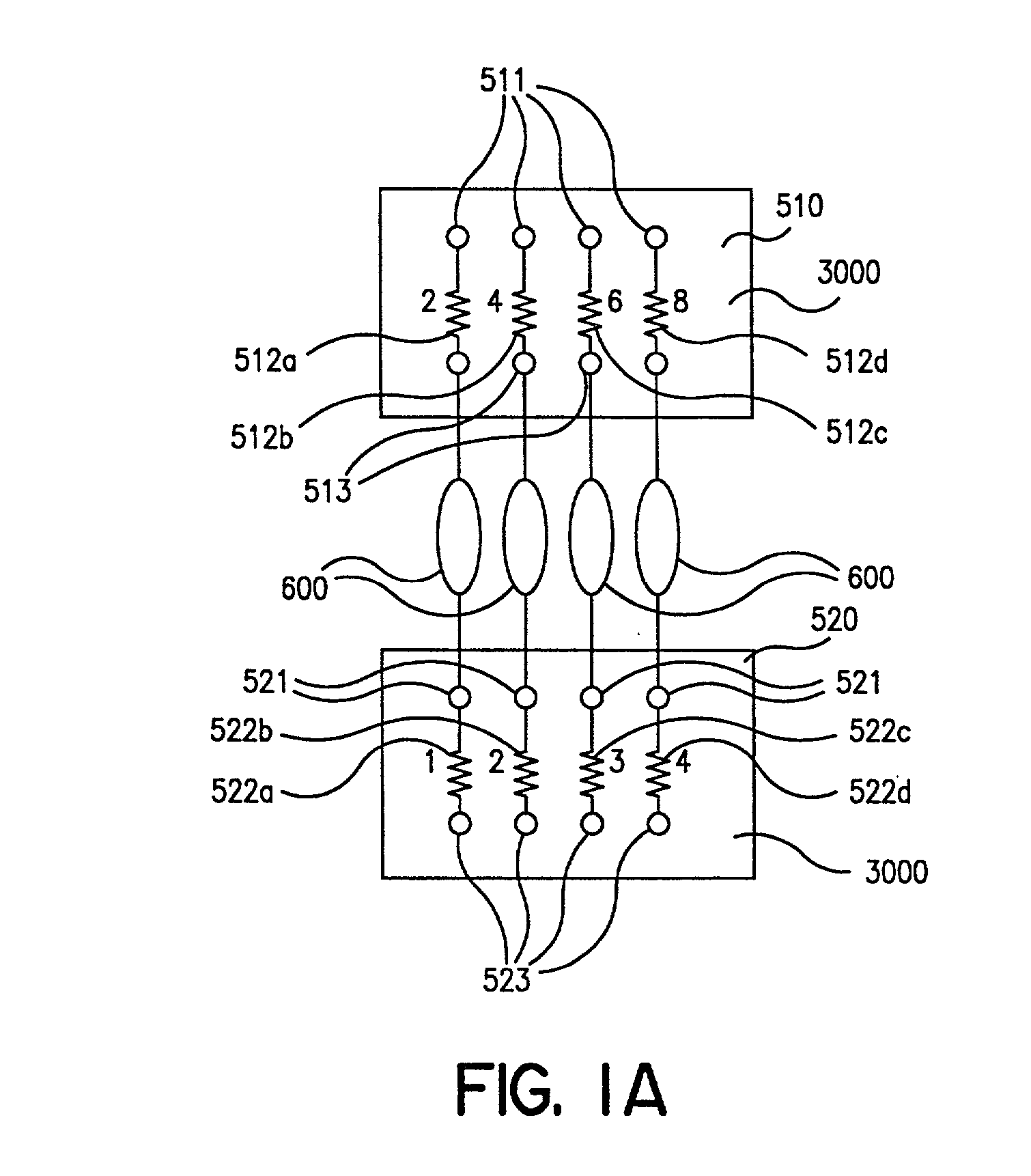

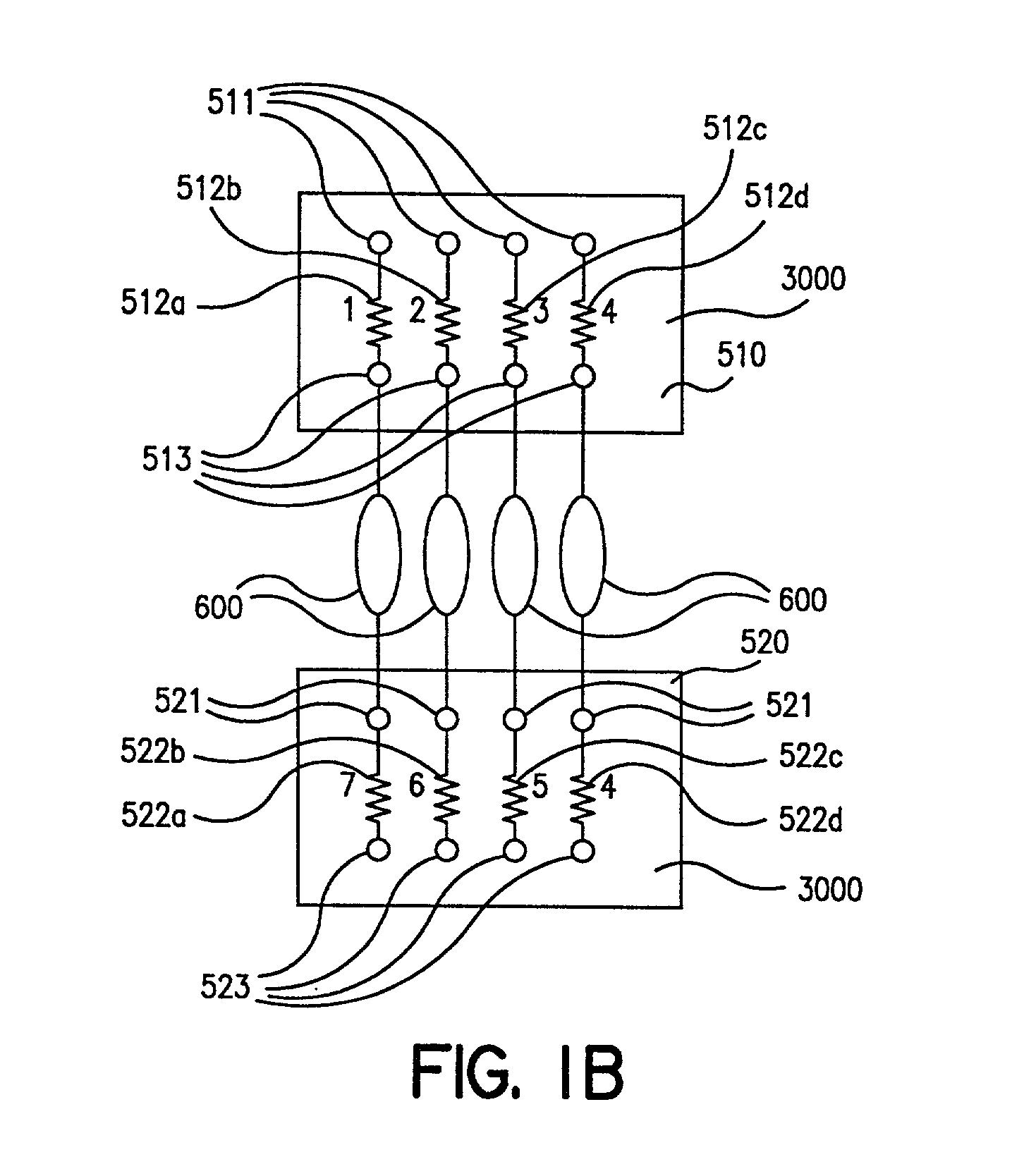

Parallel flow reactor having variable composition

InactiveUS7122156B2Efficient identification and optimizationExtreme flexibilityProcess control/regulationSequential/parallel process reactionsDistribution systemProcess engineering

Owner:FREESLATE

Feedforward control processes for variable output hydrogen generators

InactiveUS20060096175A1Improve efficiencyImprove stabilityProcess control/regulationExhaust apparatusFuel cellsProcess engineering

Hydrogen generators and integrated hydrogen generator / fuel cells systems are operated by determining the condition of the hydrogen generator and the condition of the fuel to the hydrogen generator for selection of predetermined flow rates for each of the externally-provided raw materials. The processes of the invention can provide rapid transitions between hydrogen production rates while enabling enhanced efficiency and stability during transient operations.

Owner:HYRADIX INC

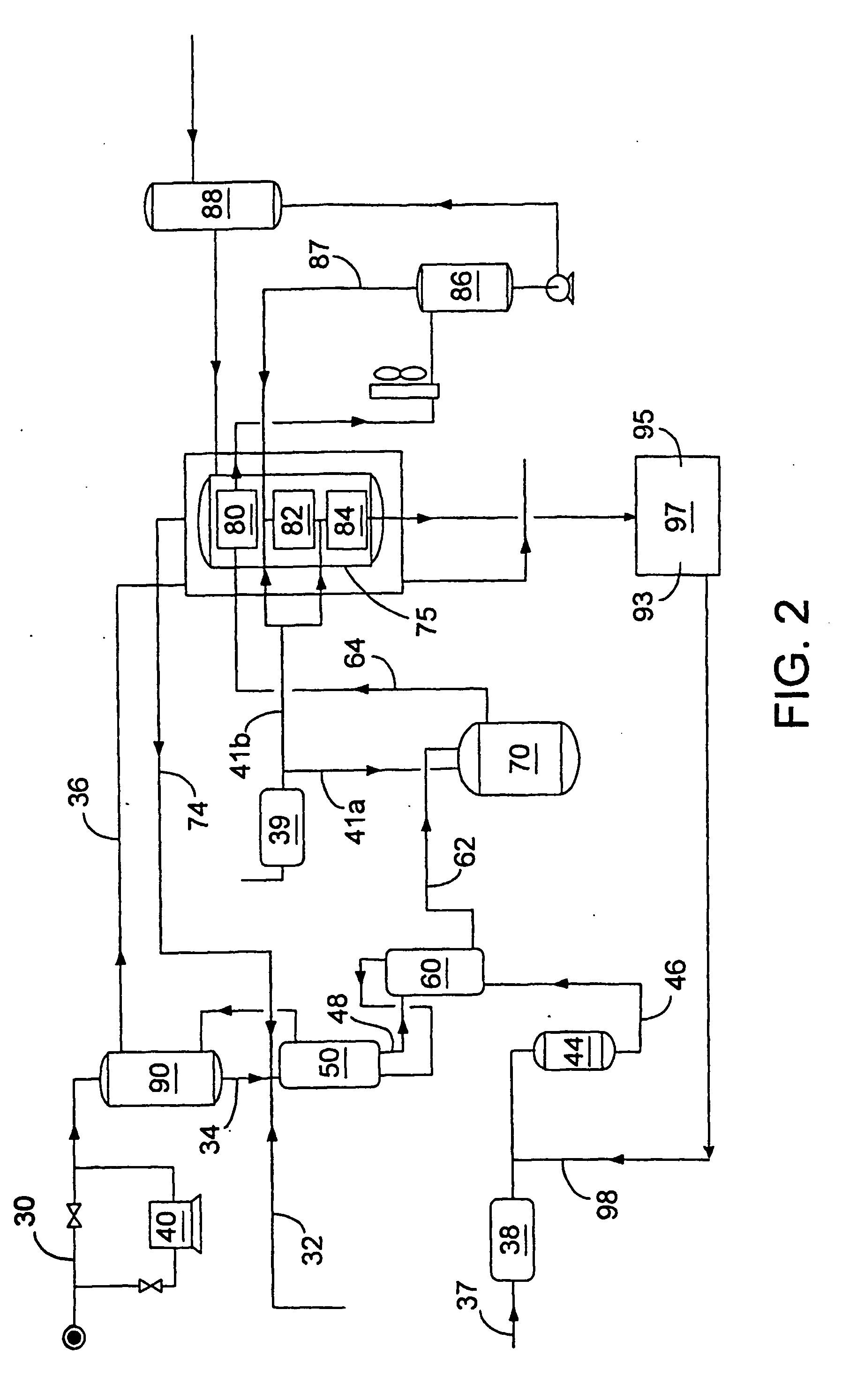

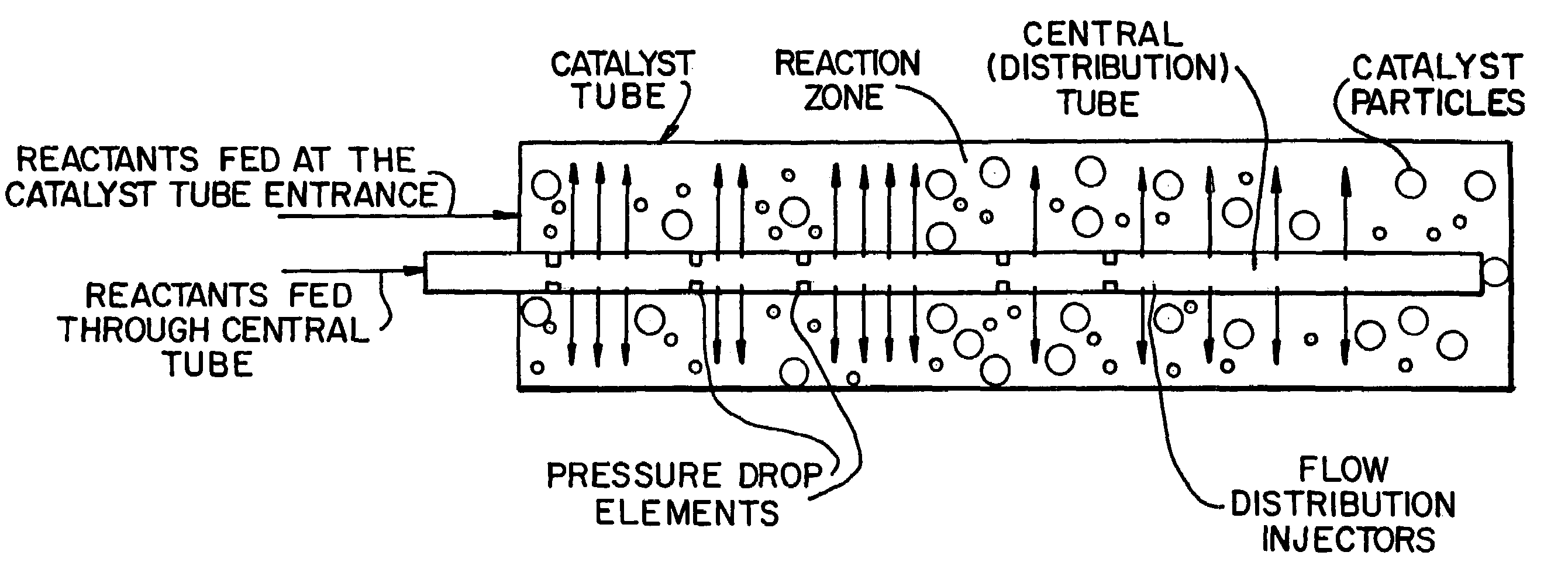

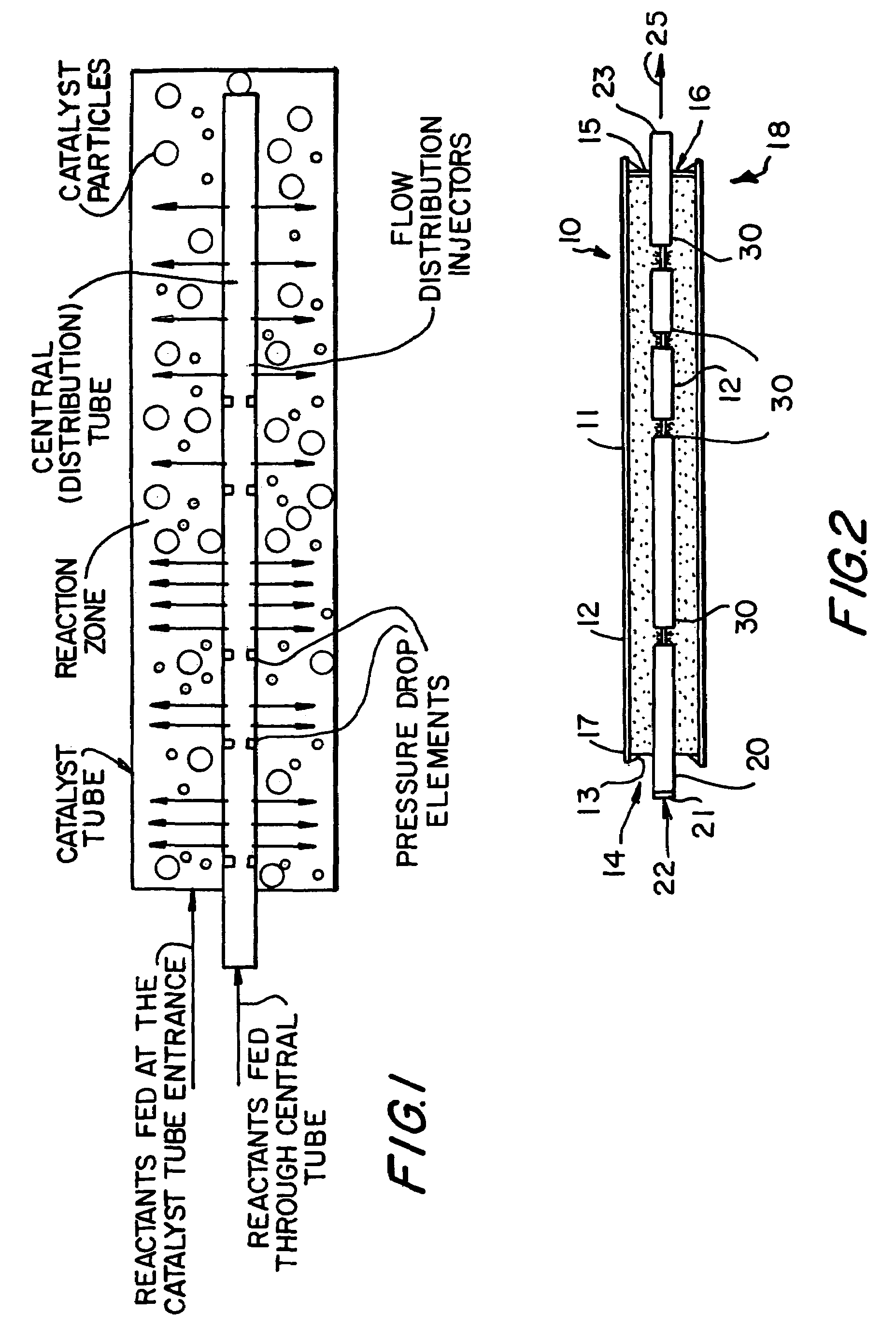

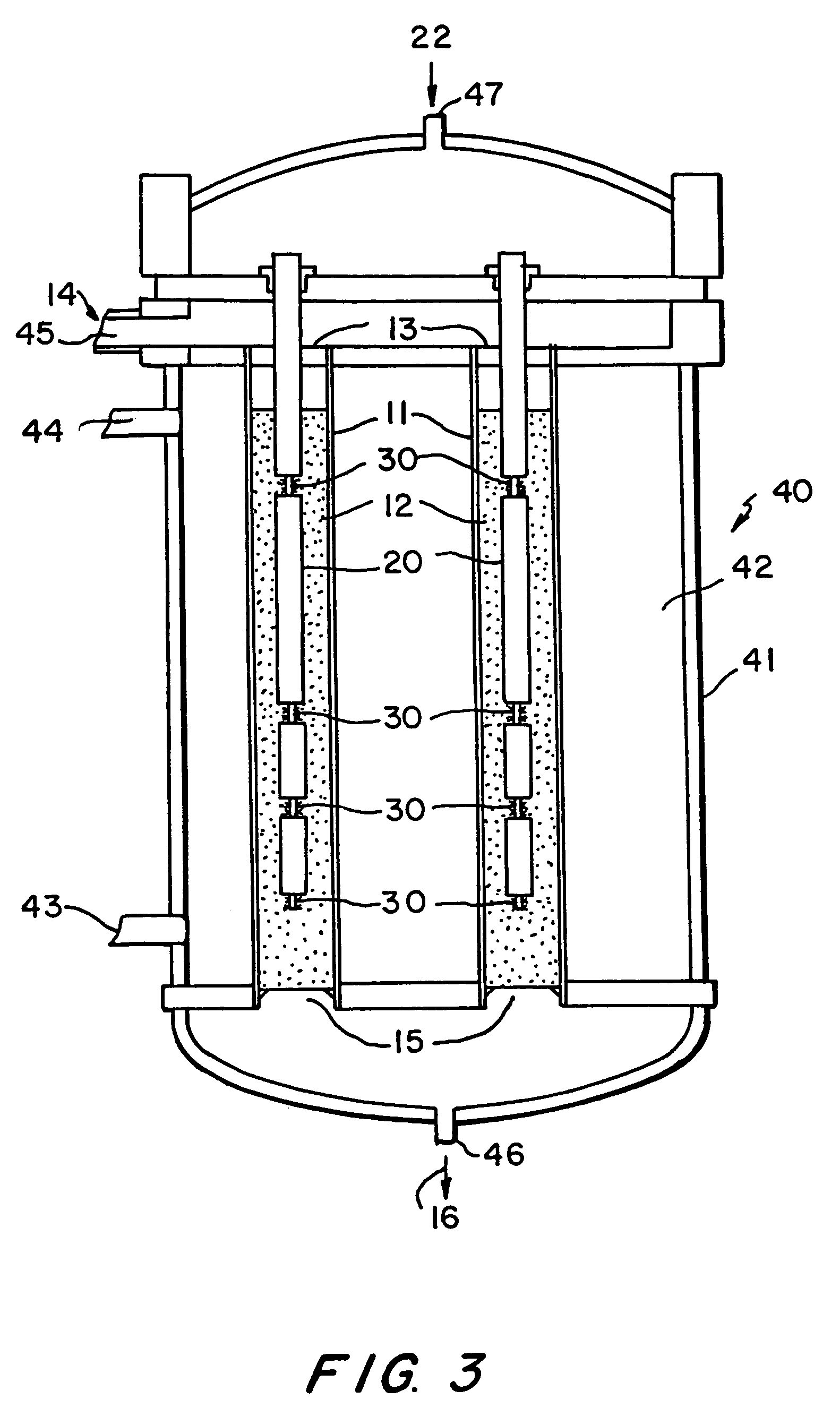

Apparatus for the controlled optimized addition of reactants in continuous flow reaction systems

InactiveUS6977064B1Improve catalytic performanceProcess control/regulationCombination devicesChemical reactionPartial oxidation

An apparatus for performing continuous flow chemical reactions such as oxidation, oxidative dehydrogenation and partial oxidation processes involving a reactor design characterized by controlled / optimized addition of a reactant with the objective of: (i) avoiding the explosion regime of the reactant mixture (e.g., hydrocarbon / oxidant mixture); (ii) maximizing the selectivity of the reaction to the desired product; (iii) limiting the reactor temperature gradient and therefore the threat of reaction runaway; and (iv) controlling the operating temperature of the reaction zone so that desirable temperature range is maintained over the entire zone.

Owner:SAUDI BASIC IND CORP SA

Method and apparatus for reducing reactor fines

InactiveUS20050095176A1Process control/regulationSynthetic resin layered productsPolymer scienceDiluent

A polymerization process and apparatus in which olefin monomer is polymerized in a liquid diluent in a loop reactor having a relatively smooth inner wall. Another aspect of the invention includes a first polymerization step in which at least one olefin monomer is polymerized in a liquid diluent in a loop reactor to produce a first product fluid slurry comprising liquid diluent and solid olefin polymer particles having a relatively low melt index. A second polymerization step is then provided in which at least one olefin monomer is polymerized in a liquid diluent in the same loop reactor to produce a fluid slurry comprising liquid diluent and solid olefin polymer particles having a relatively high melt index.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Popular searches

Chemical/physical/physico-chemical stationary reactors Chemical/physical/physico-chemical nozzle-type rreactors Decorative surface effects Semiconductor/solid-state device manufacturing Hydrazine Liquid chemical processes Liquid-liquid reaction processes Hydrogen peroxide Phosphorus oxides Gaseous chemical processes

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com